Catalyst for preparing alcohol through hydrogenation of acetic acid and preparation method

A catalyst, a technology for producing ethanol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of large hydrogen-acid ratio, high reaction temperature and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

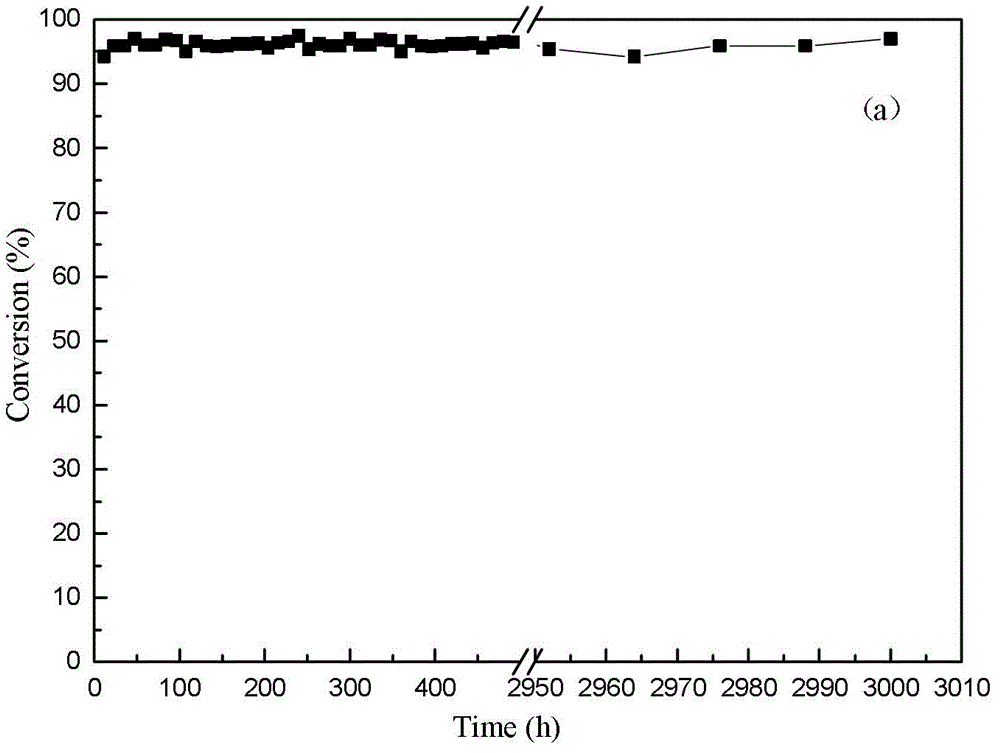

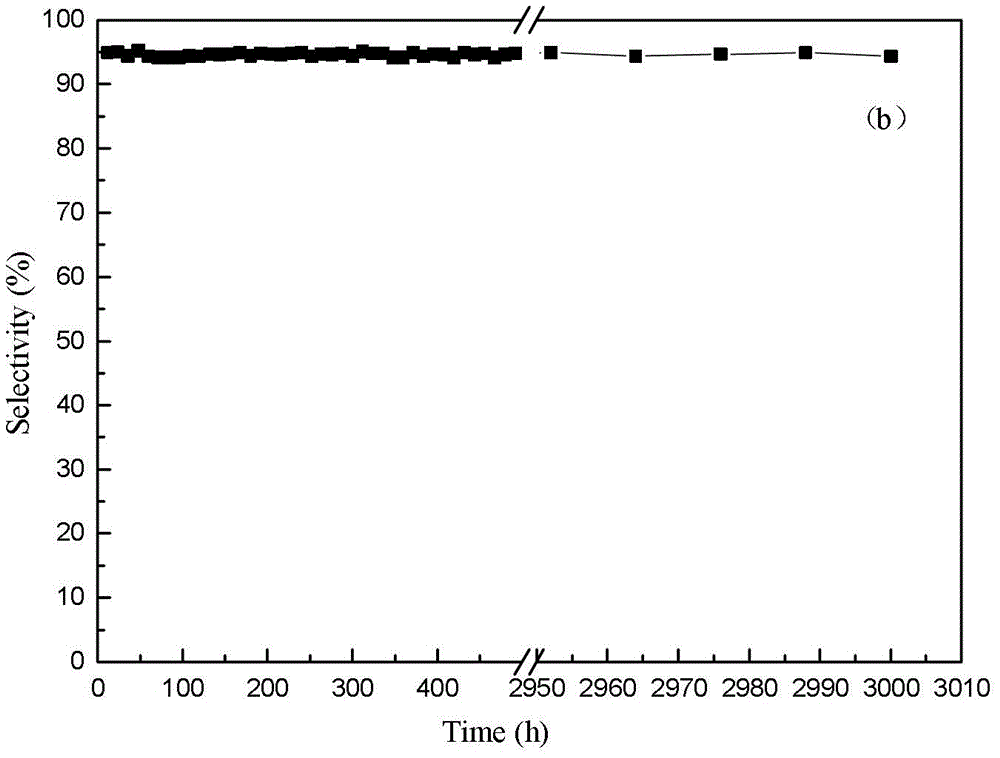

Image

Examples

Embodiment 1

[0027] 1) Add 1.0g SiO 2 With Ca(NO 3 ) 2 The solution (0.67ml, 3.0M) was soaked overnight, baked at 100°C for 12h, and roasted at 400°C for 2h.

[0028] 2) The sample obtained in 1) was treated with SnCl 2 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

[0029] 3) The sample obtained in 2) was treated with H 2 PtCl 6 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

Embodiment 2

[0031] 1) Add 1.0g SiO 2 With Ca(NO 3 ) 2 The solution (2.0ml, 1.0M) was impregnated overnight, baked at 100°C for 12h, and baked at 400°C for 2h.

[0032] 2) The sample obtained in 1) was treated with SnCl 2 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

[0033] 3) The sample obtained in 2) was treated with H 2 PtCl 6 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

Embodiment 3

[0035] 1) Add 1.0g SiO 2 With Ca(CH 3 COO) 2 The solution (0.67ml, 3.0M) was soaked overnight, baked at 100°C for 12h, and roasted at 400°C for 2h.

[0036] 2) The sample obtained in 1) was treated with SnCl 2 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

[0037] 3) The sample obtained in 2) was treated with H 2 PtCl 6 The solution (1.0ml, 0.05M) was impregnated overnight, baked at 100°C for 12h, and calcined at 400°C for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com