Patents

Literature

546 results about "Silver catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

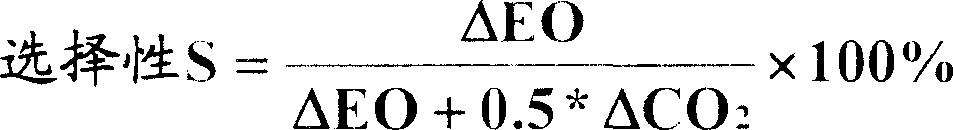

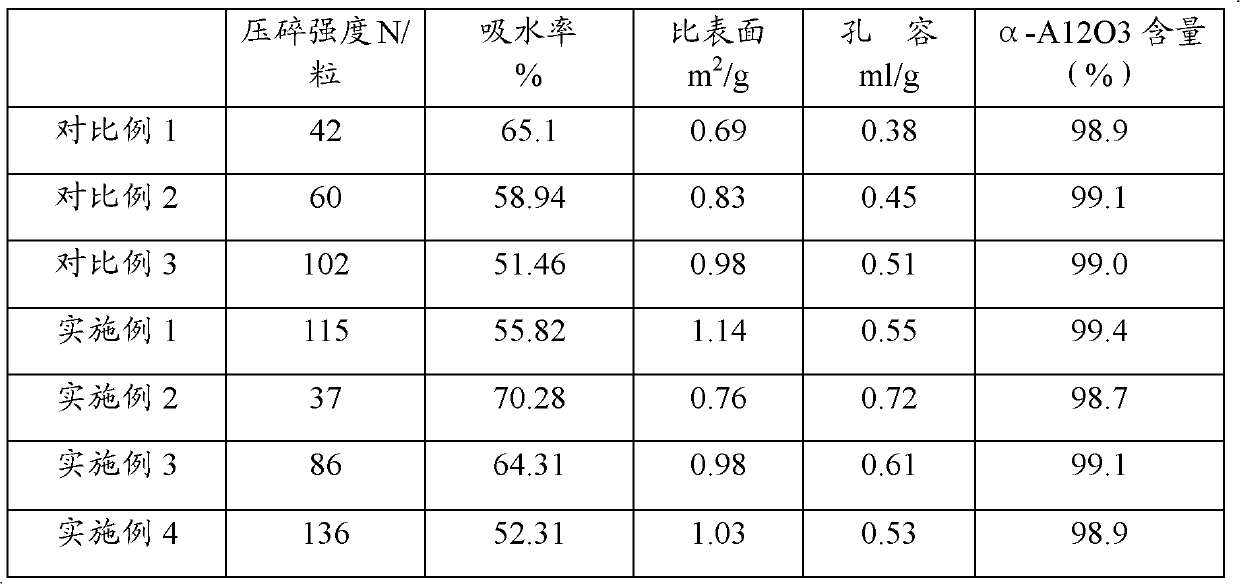

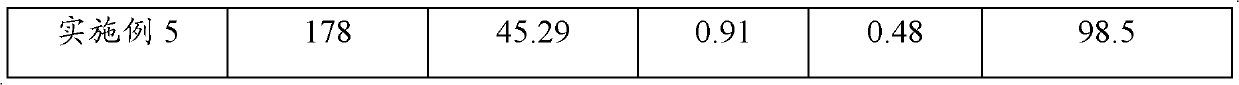

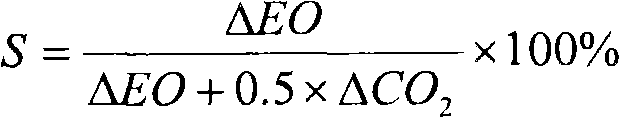

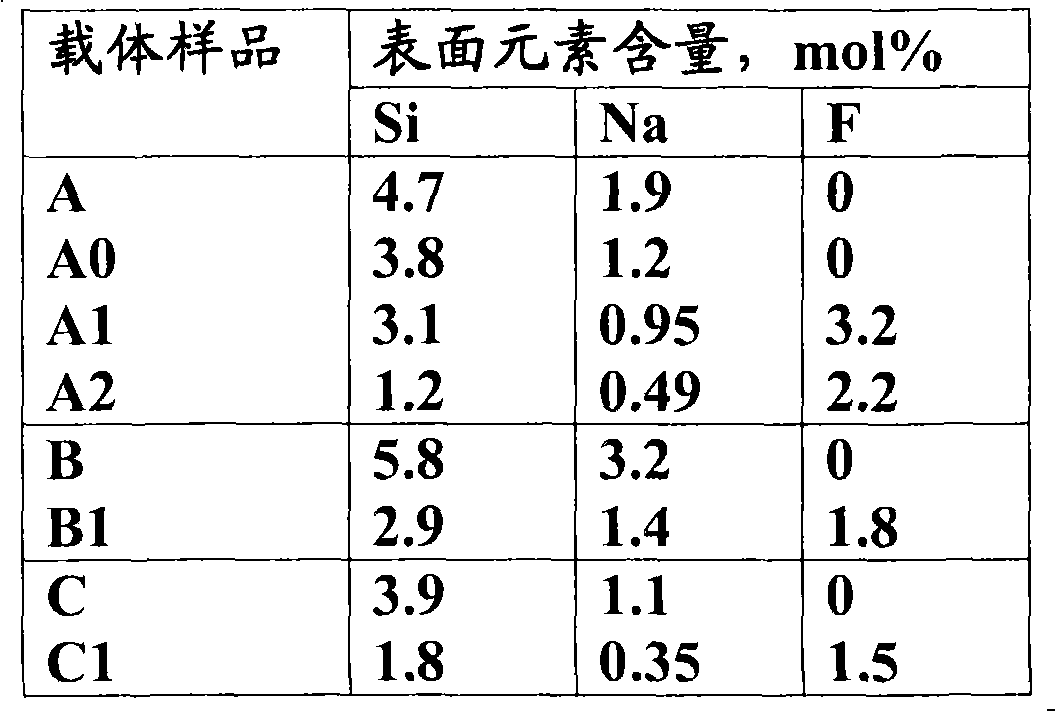

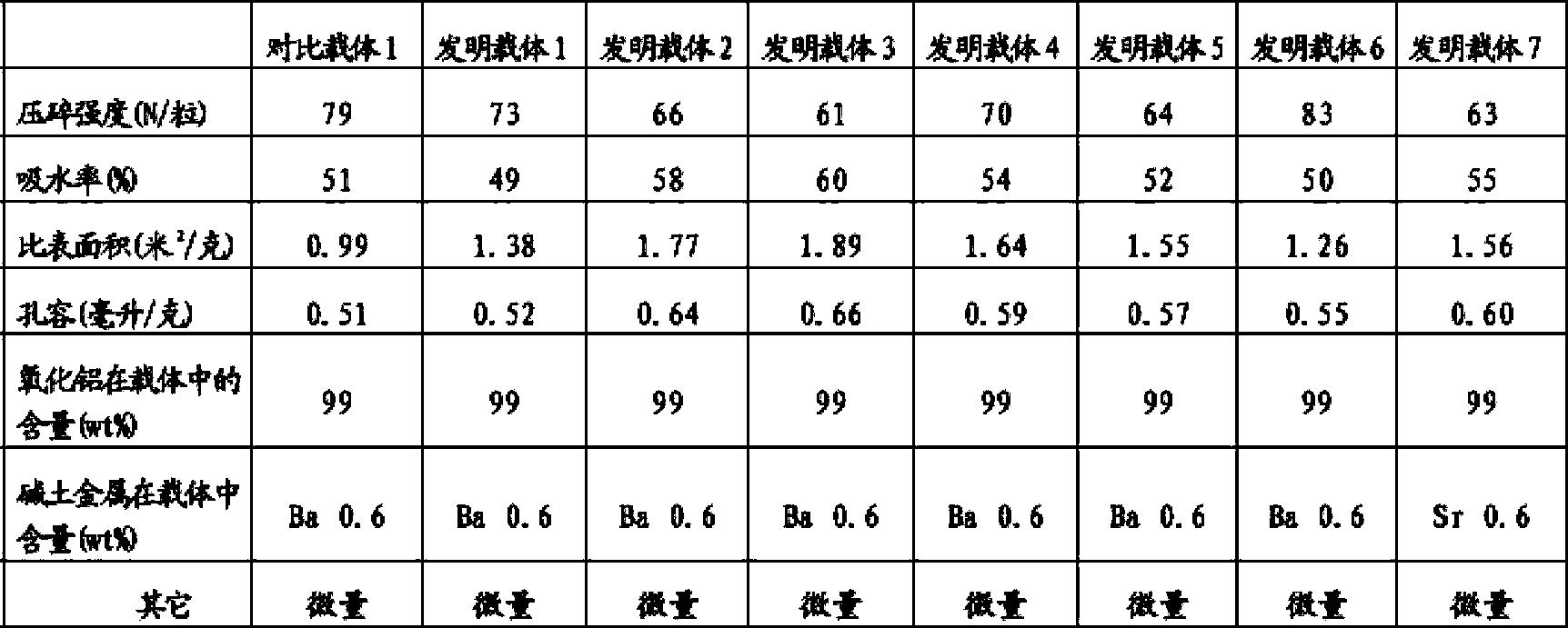

Carrier of ethylene oxide silver catalyst, and its preparation method and application

ActiveCN101007287AHigh activityGood choiceCatalyst carriersOrganic chemistryAlkaline earth metalPtru catalyst

The invention involves alumina carrier used for Ag catalyst which is used for produce epoxyethane with oxygenizing ethane and its preparation method the Ag catalyst prepared by the carrier, and relates to the usage of the catalyst in ethane oxygenizes epoxyethane. The preparation method mixes three-hydratedalpha-aluminum oxide with certain particle size, hydratedalpha-aluminum oxide, certain amount of inflammable carbonaceous material, fluxing agent, fluoride and optional heavy alkaline earth metal compounds, adds admixture and water after mixing uniformly, kneading uniformly, squeezing and shaping, then preparingalpha-alumina carrier after drying and roasting. The specific surfaceof the invention is 0.2- 2.0m2 / g, the hole volume is 0.35-0.85ml / g, water absorption ratio>=30%, crushing strength is 30-120N / particle. The carrier is dipped by the solution of silver ammine complex, alkaline metal compound and alkaline earth metal compound, and prepares the Ag catalyst for epoxyethane with oxygenizing ethane after drying and activating.

Owner:CHINA PETROLEUM & CHEM CORP

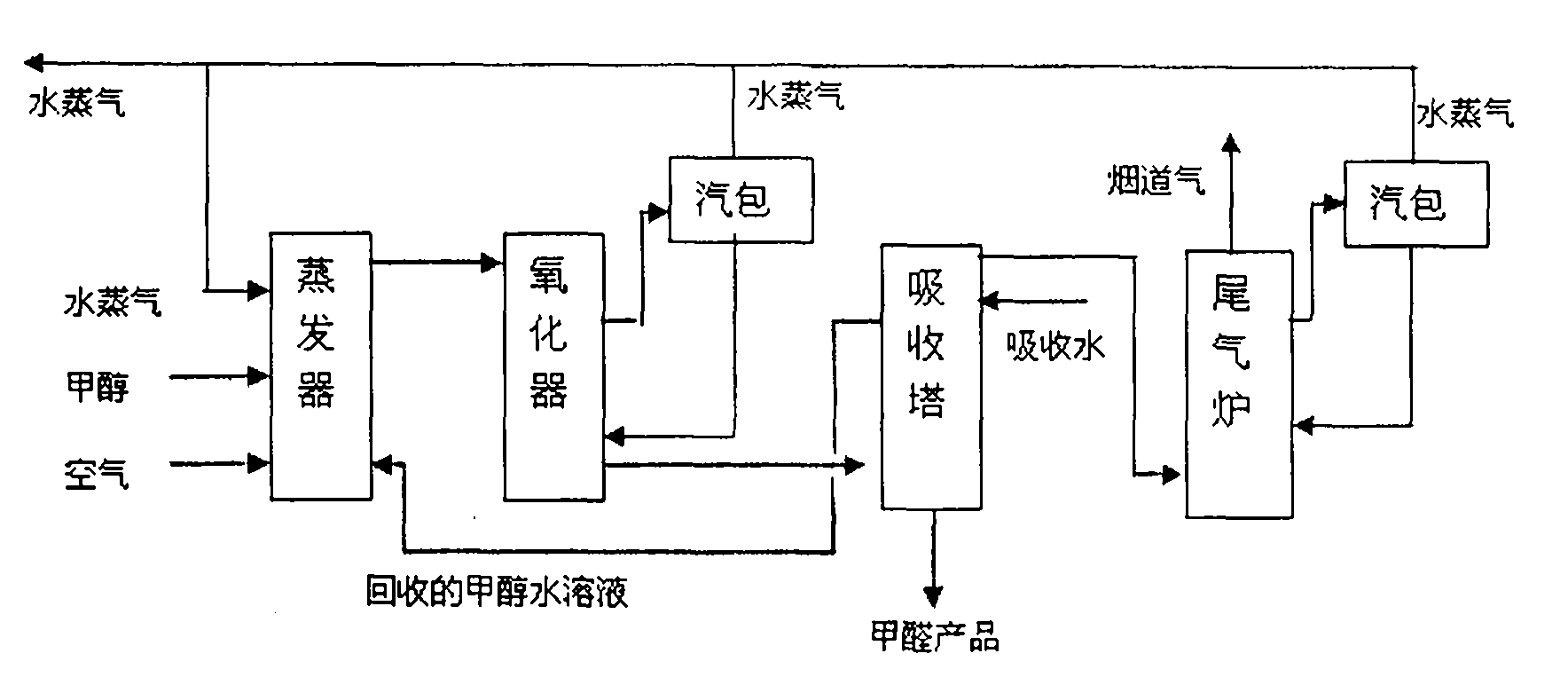

Alkylene oxide catalyst and use thereof

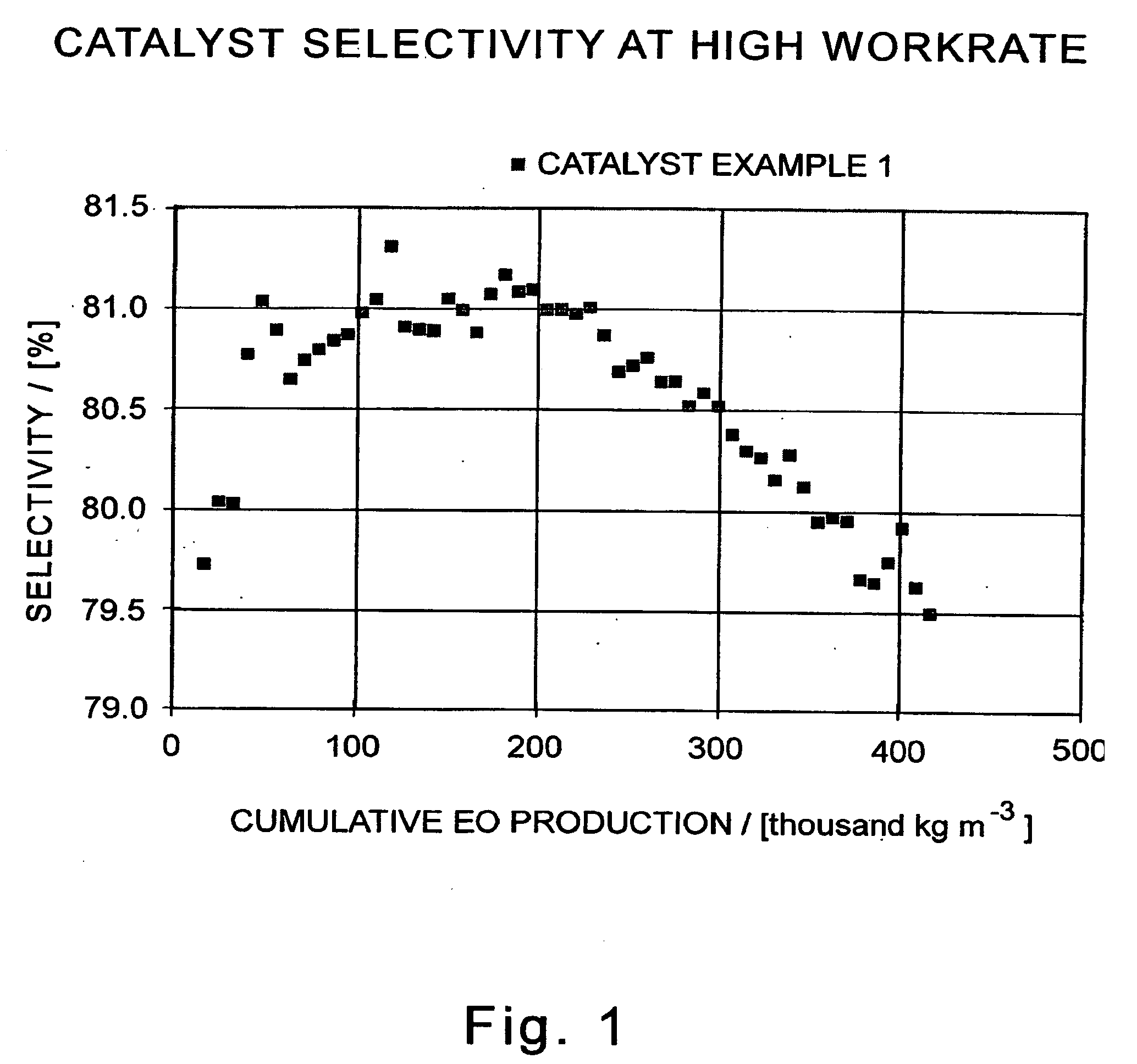

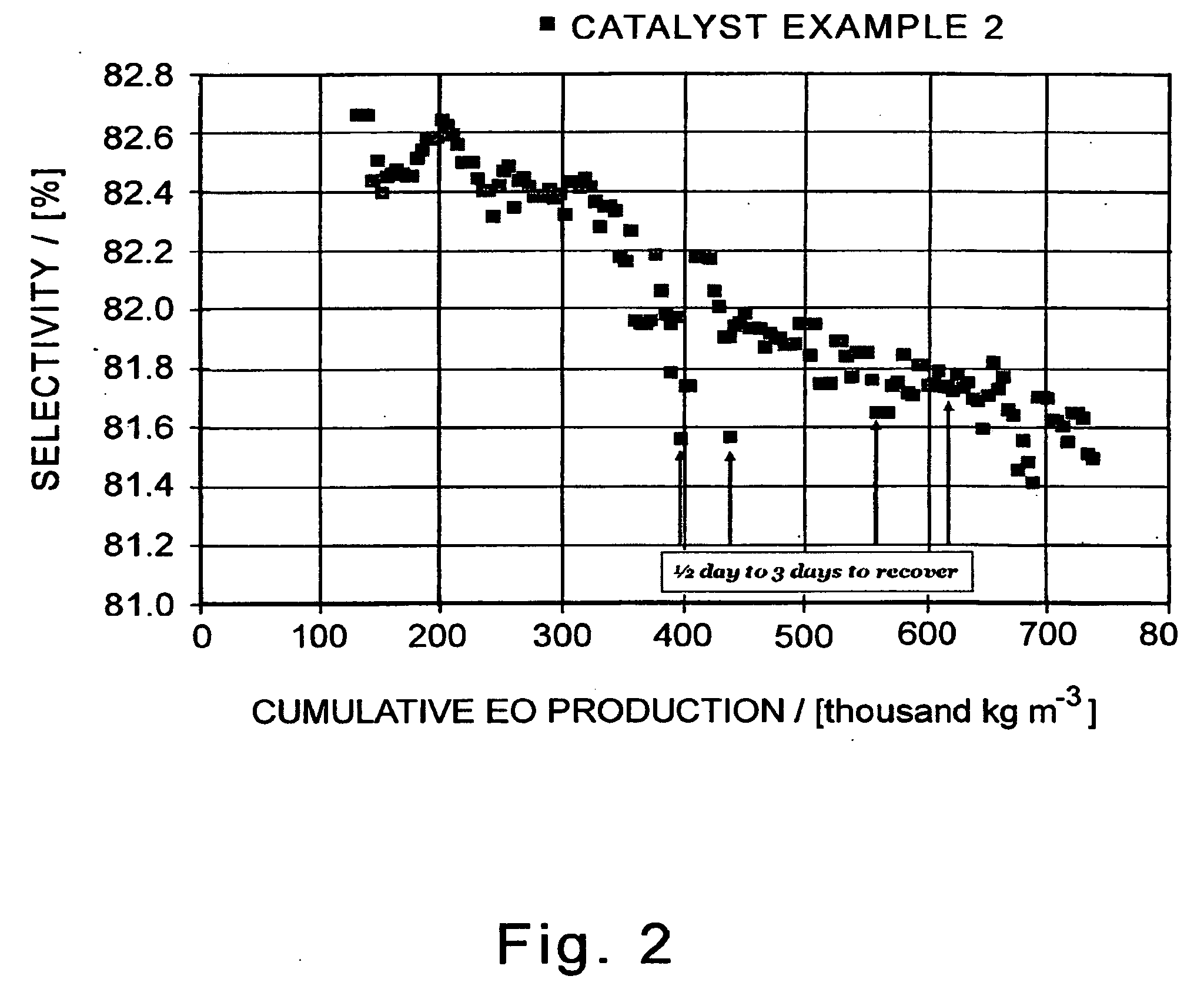

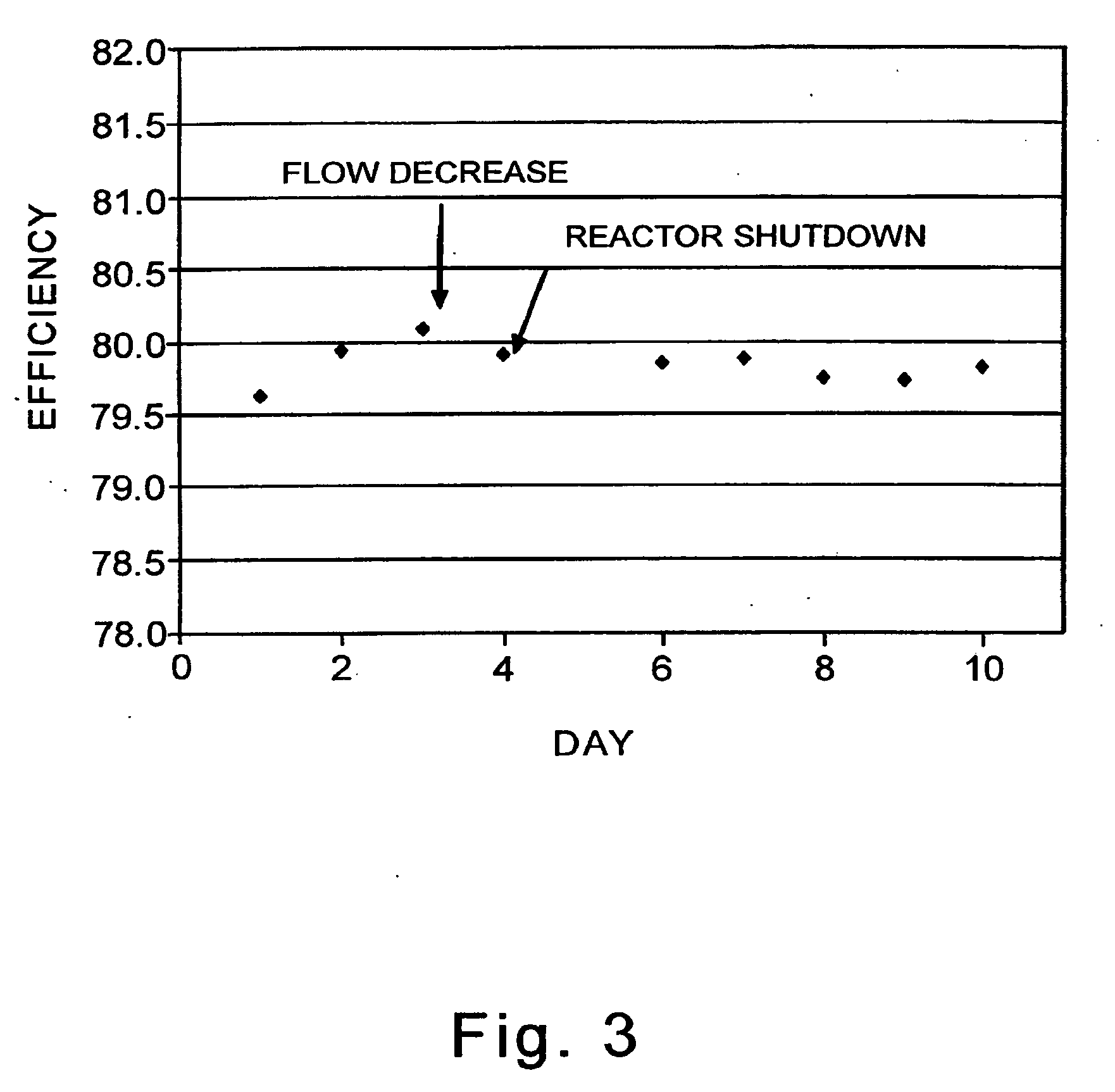

InactiveUS20090177000A1Selectivity towards ethylene oxide formation is optimalGood choiceOrganic chemistryCatalyst activation/preparationOxygenEthylene

A supported silver catalyst and use thereof in a process for producing an alkylene oxide, such as ethylene oxide, by the direct oxidation of an alkylene with oxygen or an oxygen-containing gas, wherein the catalyst provides improved stability and improved resilience to reactor upsets and timely recovery to substantially pre-upset levels of catalyst activity and / or efficiency. In some embodiments, the catalyst also exhibits improved activity. A catalyst capable of producing ethylene oxide at a selectivity of at least 87 percent while achieving a work rate of at least 184 kg / h / m3 at a temperature of no greater than 235° C. when operated in a process where the inlet feed to a reactor containing the catalyst comprises ethylene, oxygen, and carbon dioxide, wherein the concentration of carbon dioxide in the inlet feed is greater than or equal to 2 mole percent.

Owner:DOW GLOBAL TECH LLC

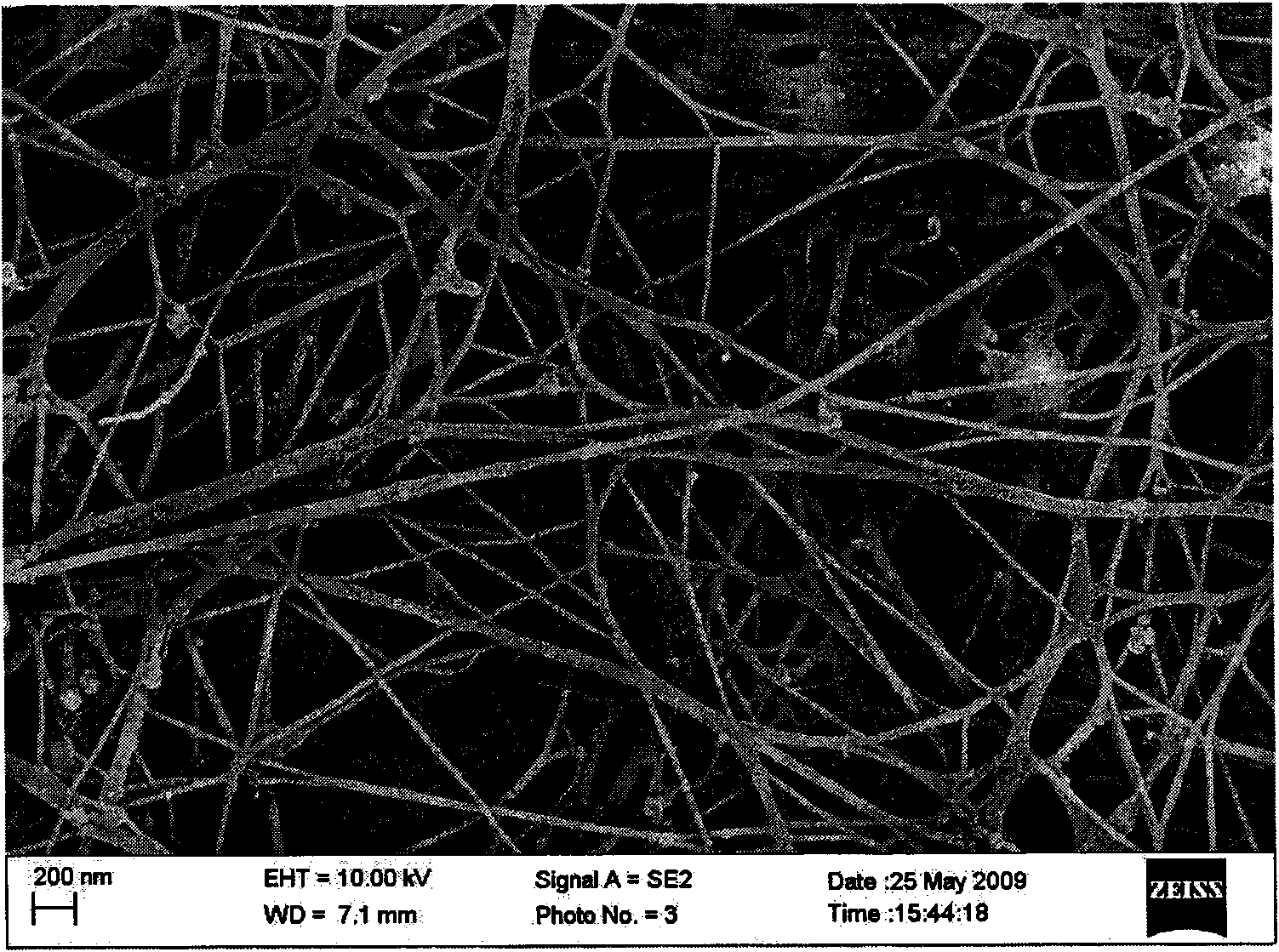

Preparation for in-situ compounding simple-substance nano silvery bacteria cellulose membrane

ActiveCN101586309AHigh antibacterial activityImprove antibacterial propertiesFibre treatmentMicroorganism based processesWound dressingFragility

The invention provides a preparation for the in-situ compounding simple-substance nano silvery bacteria cellulose membrane, and relates to the biological medical material field, characterized in that the bacteria cellulose membrane has special three-dimensional nano network structure, the silver-ammonia solution reacts with the chemical agent containing aldehyde group to generate silver simple-substance nano particle in situ in the network structure. In addition, in the invention, the special drying method is adopted to improve the defect of big fragility of the prepared silver-contained nano bacteria cellulose dry membrane. The bacteria cellulose membrane containing simple-substance nano silver particle provided by the invention has excellent antibacterial performance and simple preparation technique, and can be widely used in the biological medical field such as large-area wound dressing, bundling belt and the like, also can be used in the industry field such as the preparation of nano silver particle and silver catalyst, and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Supported nano-silver catalyst capable of eliminating formaldehyde at room temperature and preparation method thereof

InactiveCN103127952AReduce contentLow costMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention discloses a supported nano-silver catalyst capable of eliminating formaldehyde at room temperature. The catalyst uses ZSM-5 molecular sieves as carrier, and is prepared by supported nano-silver active components through metallic oxide modifying. The catalyst is composed of, by weight, 1% to 5% of nano-silver active components, 1% to 20% of metallic oxide, and 75% to 98% of ZSM-5 molecular sieves. The invention discloses a preparation method of the supported nano-silver catalyst capable of eliminating the formaldehyde at room temperature. The preparation method is characterized by comprising the following steps: the ZSM-5 molecular sieve carrier is modified, and drying and roasting are carried out to obtain the finished catalyst after the modified carrier is put into a solution to carry out equivalent-volume impregnation at 10 DEG C to 60 DEG C. The airspeed of the catalyst at room temperature is 10000 h-1 hour, the formaldehyde removal rate of the catalyst is up to more than 93.7%, the formaldehyde is catalyzed to be oxidated into harmless water and carbon dioxide to achieve green elimination, and a preparation process is simple, easy to operate, low in cost, and free of secondary pollution.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of silver catalyst carrier for production of ethylene oxide and application thereof

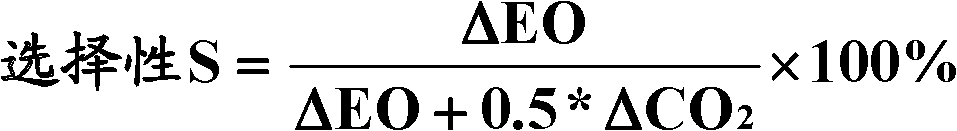

ActiveCN103372466AHigh activityHigh selectivityCatalyst carriersOrganic chemistryAlkaline earth metalGranularity

The invention provides an alpha alumina carrier of a medium-selectivity silver catalyst. The preparation method of the carrier comprising the following steps of: preparing a solid mixture comprising the following components: 45-85% of trihydrate alpha-Al2O3 with the granularity of 250-500 mesh, 10-55% of pseudo monohydrate Al2O3 with the granularity being more than 200 mesh, 0.01-5.0% of combustible lubricating material, 0.05-8.0% of fluoride mineralizer, and 0.01-5.0% of heavy alkaline-earth metal compound; kneading and forming the solid mixture, binder and water, wherein the use amount of the binder is 25-60wt% of the total weight of the solid mixture; and drying the product obtained in the previous step, and roasting at 1200-1400 DEG C to form the carrier, wherein in the carrier, in terms of the total pore volume, holes with the pore diameter of 0.5-2.5mu m are 60-90%. The medium-selectivity silver catalyst prepared from the carrier provided by the invention is applied to epoxidation reaction in which the inlet CO2 concentration of a reaction device is 1-3mol%, and is particularly applied to production of ethylene oxide through ethylene oxidization; and the activity and the selectivity are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the production of an olefin oxide

InactiveUS7348444B2Other chemical processesOrganic compound preparationPolymer scienceReaction temperature

A process for the production of an olefin oxide, which process comprises reacting a feed comprising an olefin and oxygen in the presence of a silver-containing catalyst, wherein before the catalyst has reached an advanced stage of ageing the reaction temperature is above 255° C. and the olefin content of the feed is above 25 mole-%, relative to the total feed.

Owner:SHELL OIL CO

Hydrogenation catalyst

InactiveUS20060178262A1High selectivityImprove stabilityHydrocarbon purification/separationHydrocarbonsIridiumCopper

The present development relates to a catalyst composition for the selective hydrogenation of acetylene and to a method for preparing the catalyst. The catalyst comprises iridium, palladium and, optionally, at least one of the elements selected from the group consisting of silver, gold, copper, zinc and tin. In a preferred embodiment, the catalyst is prepared such that the palladium is located within the first 250 micrometers of the surface of the catalyst carrier. In contrast to the catalysts of the prior art, including for example, palladium / silver catalysts, the catalyst of the present invention exhibits high selectivity and an improved stability of the catalytic performance over an extended period of time.

Owner:SUD CHEM AG

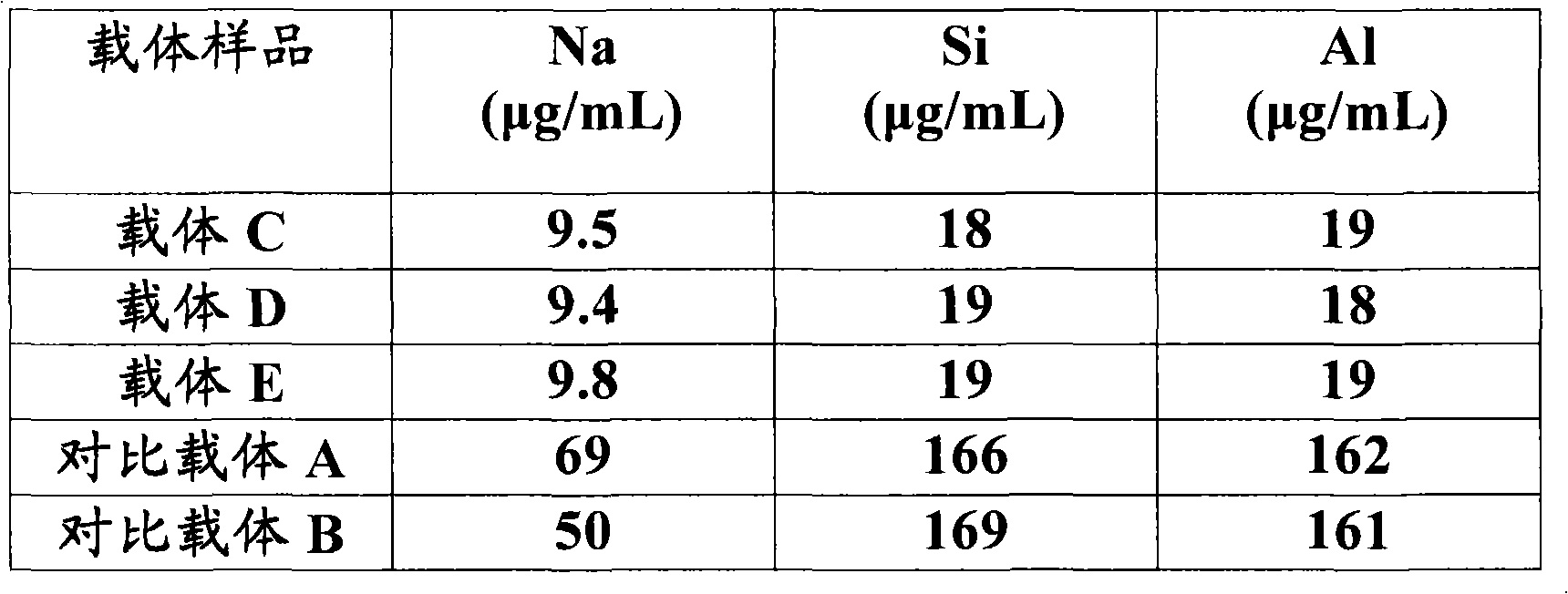

Carrier of silver catalyst for producing ethylene oxide, preparation method thereof, silver catalyst prepared by using same and application thereof in producing ethylene oxide

ActiveCN101850243AOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRheniumHydrofluoric acid

The invention relates to an aluminum oxide carrier for catalyzing ethylene to have epoxidation in gas and solid phases to produce ethylene oxide (EO), a preparation method thereof, a silver catalyst prepared by using the preparation method and application thereof in producing the EO. The silver catalyst contains an effective catalytic quantity of silver, one or more optional alkali metal mixtures, optional alkaline-earth metals or a mixture thereof, an optional rhenium aid and an alpha-aluminum oxide carrier treated through hydrofluoric acid. When the carrier and the obtained silver catalyst are used for the epoxidation of the ethylene for preparing the EO, the carrier and the obtained silver catalyst have higher activity and selectivity and long-term stability.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing vinyl epoxide argentum catalyst

InactiveCN1467028AHigh activityHigh selectivityOrganic chemistryCatalyst activation/preparationAlkaline earth metalReaction temperature

A process for preparing silver catalyst used for epoxidizing ethylene includes such steps as treating alpha-alumina as carrier by the solution or gas of alkaline substance, washnig with water until it becomes neutral, drying to obtain carrier, and carrying silver and assistant chosen from S, Re, Mo, W, Ni, alkali metal, and alkali-earth metal. Its advantages are low reaction temp and high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

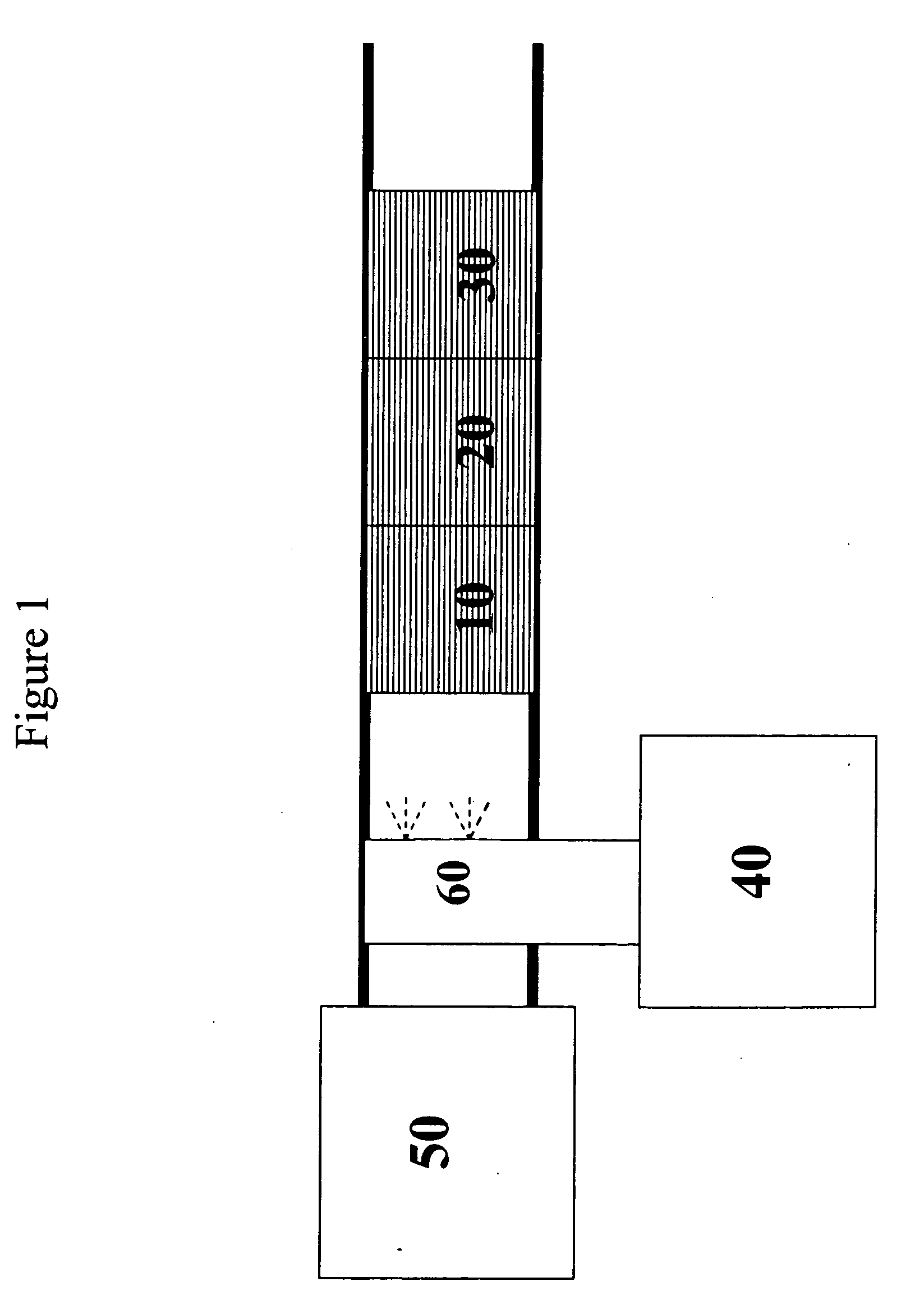

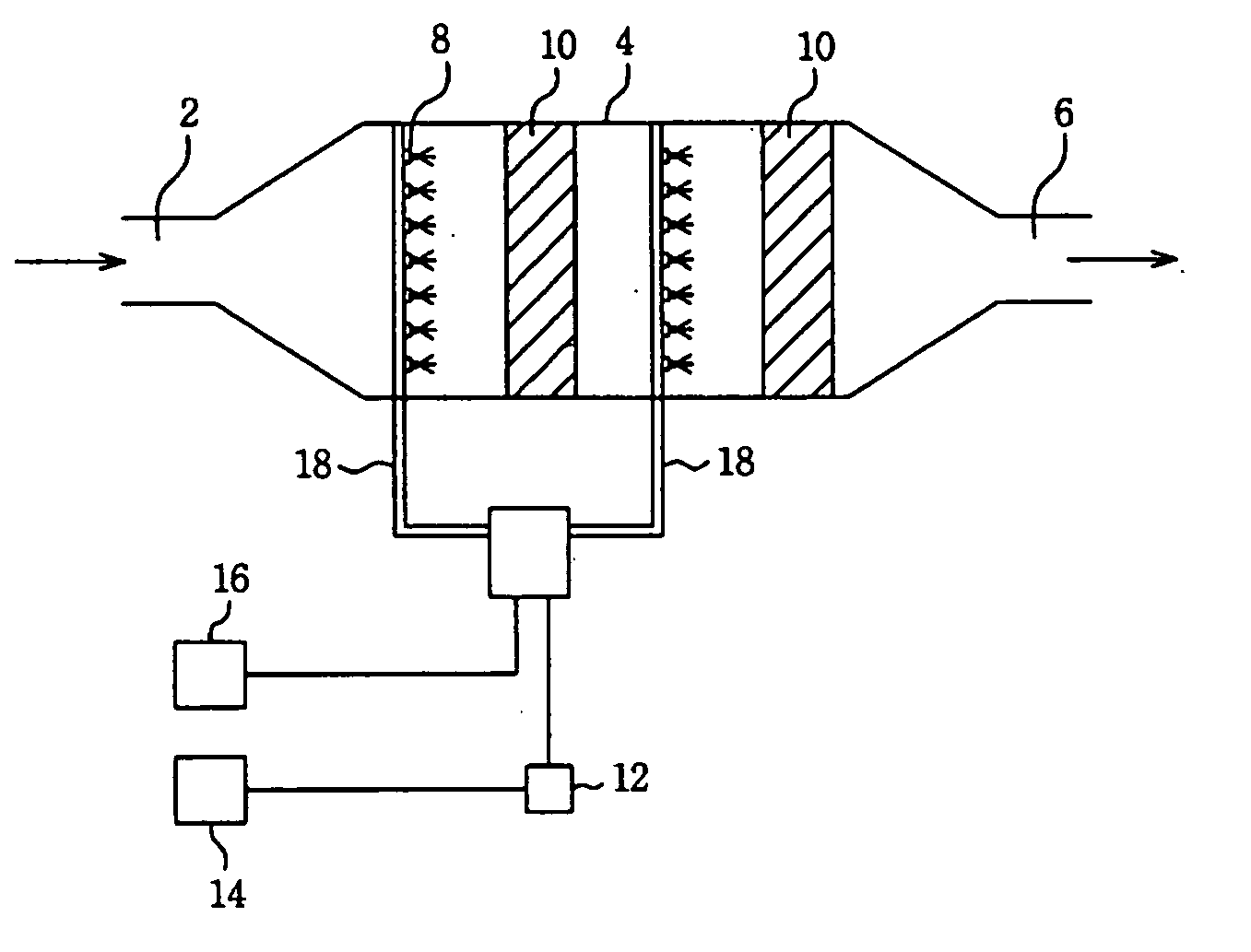

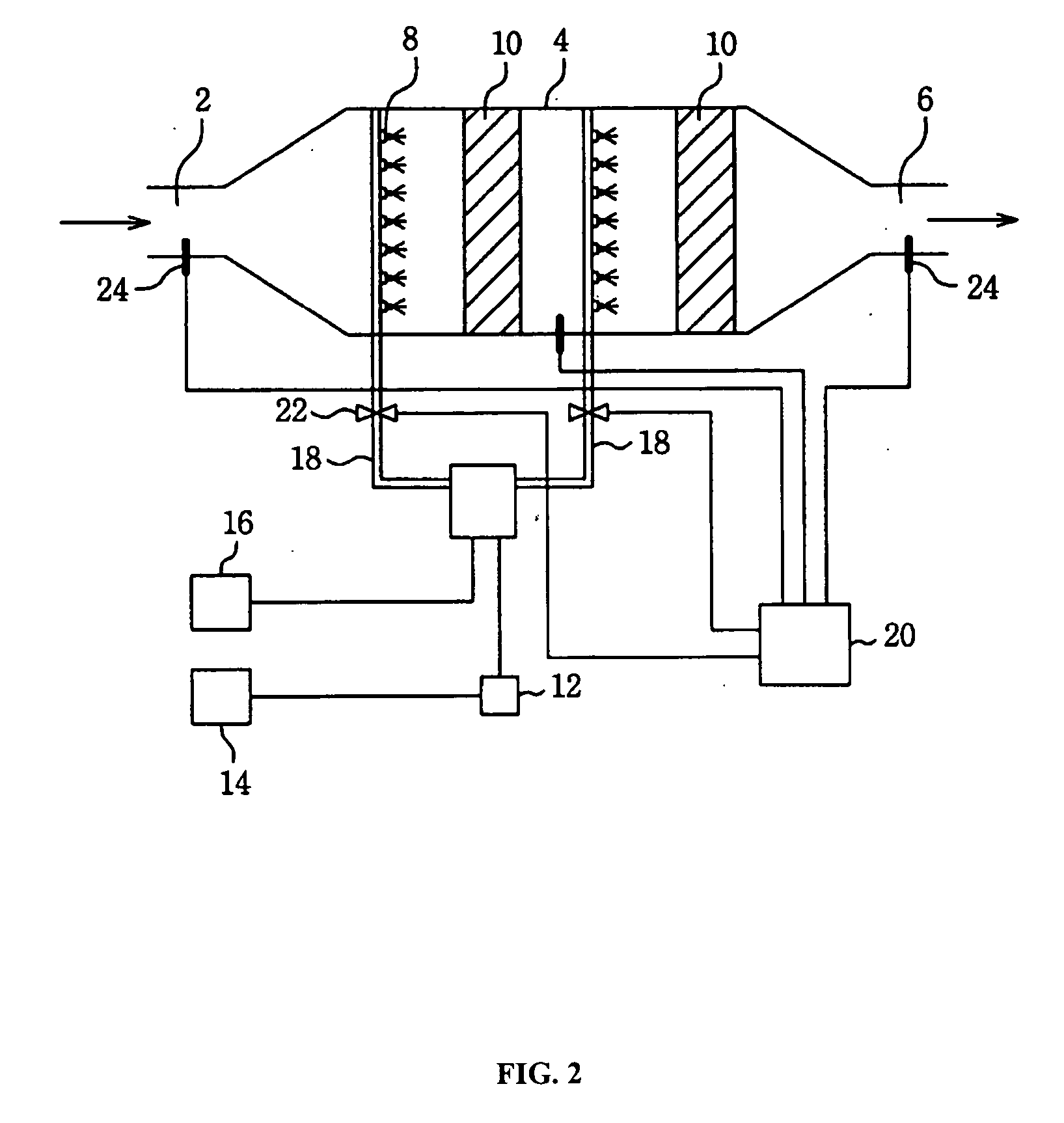

Catalytic process for nitrogen oxides reduction by multi-injection and use thereof

Disclosed is a method of effectively removing nitrogen oxides contained in an exhaust gas from a combustion process with a stationary source and / or a mobile source using gases or liquid oils as a fuel, such as gasoline, kerosene and bio-diesel oil. More particularly, provided are an apparatus and a method of removing nitrogen oxides, in which a reducing agent is sprayed into the exhaust gas passing through an alumina-promoted silver catalyst installed at the flow path of the exhaust gas.

Owner:KOCAT

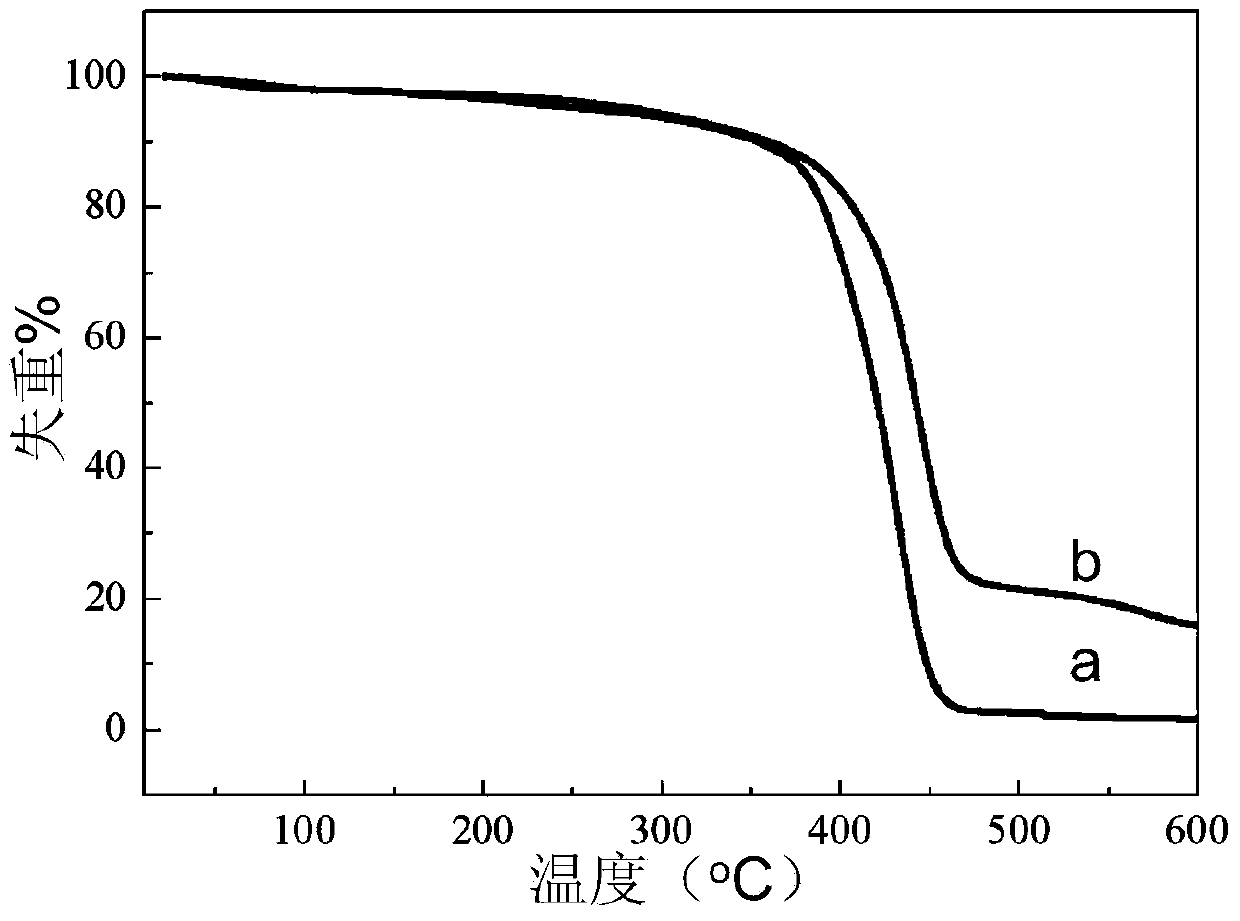

Preparation method of thermosensitive microgel asymmetric supported nano silver catalyst

InactiveCN103464203AHigh catalytic activityImprove adsorption capacityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsEmulsion polymerizationPickering emulsion

A preparation method of a thermosensitive microgel asymmetric supported nano silver catalyst comprises the steps of preparing poly-(N-isopropylacrylamide-styrene) / poly-(N-isopropylacrylamide-methacrylic acid) core-shell microgel by a soap-free emulsion polymerization method and a seed emulsion polymerization method, and then synthesizing the asymmetric supported nano silver catalyst taking the microgel as a template by a pickering emulsion template method. The thermosensitive microgel asymmetric supported nano silver catalyst prepared by the method shows good thermosensitivity, and good catalytic activity as the catalytic reaction efficiency is regulated and controlled by temperature and the thermosensitivity of the microgel simultaneously during catalytic reduction of p-nitrophenol.

Owner:SHAANXI NORMAL UNIV

Alumina carrier, preparation method, silver catalyst prepared by alumina carrier, and application thereof

The present invention relates to a preparation method for an alumina carrier. The method comprises: (a) mixing alpha-aluminum trihydroxide, pseudo aluminum monohydrate, an alkaline earth metal salt, an optionally burnout carbon-containing material, an optionally fluoride, a binder and water; (b) carrying out extruding and forming; (c) carrying out drying at a temperature of 60-200 DEG C; (d) carrying out baking at the temperature of 1200-1600 DEG C, such that alpha-aluminum oxide is prepared by transformation to obtain a semi-finished carrier;; (e) adopting an organic acid aqueous solution to treat the resulting semi-finished carrier from the step (d), wherein the organic acid can be subjected to thermal decomposition, and the pH value of the organic acid aqueous solution is not more than 2.5; (f) carrying out water washing for the resulting treated carrier from the step (e) until the pH value of the leaching solution is more than 5; and (g) carrying out a further heat treatment at the temperature of 80-1200 DEG C. The present invention further relates to the aluminum oxide carrier prepared by the method, a silver catalyst containing the carrier, and an application of the silver catalyst. With adopting the silver catalyst in preparation of ethylene oxide by the ethylene epoxidation reaction, the improved selectivity is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

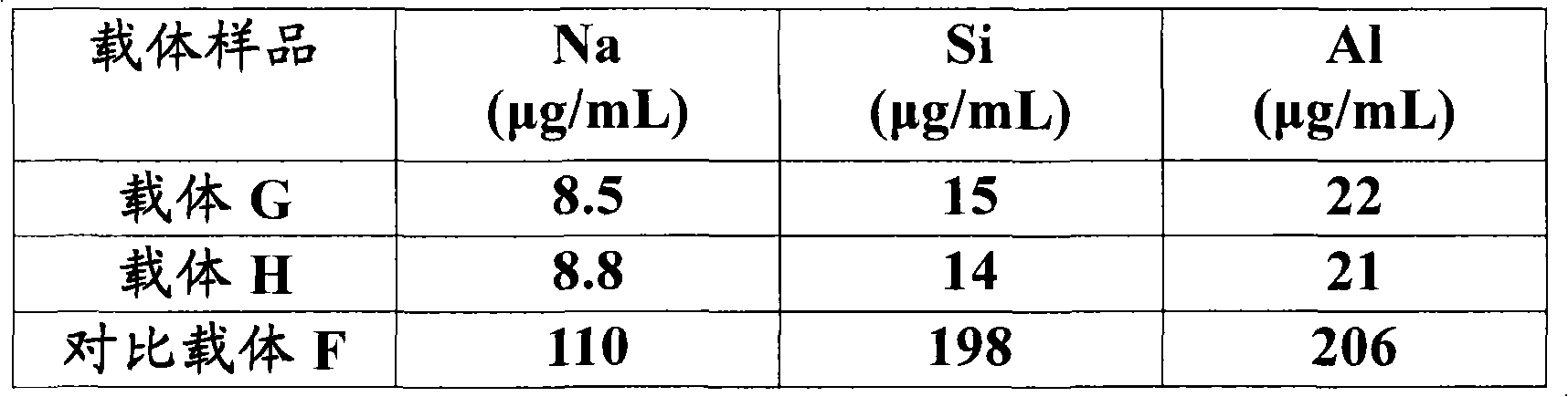

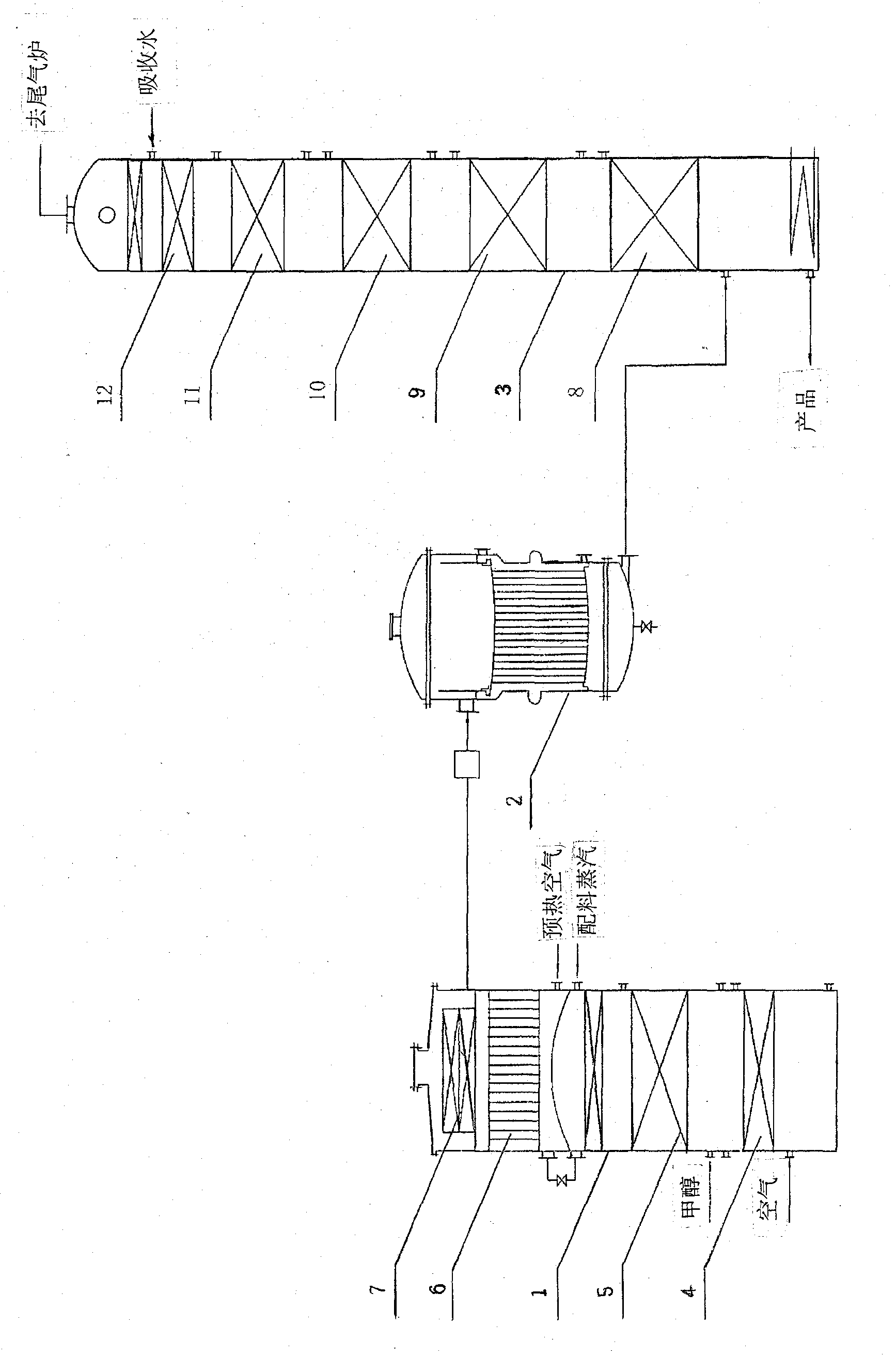

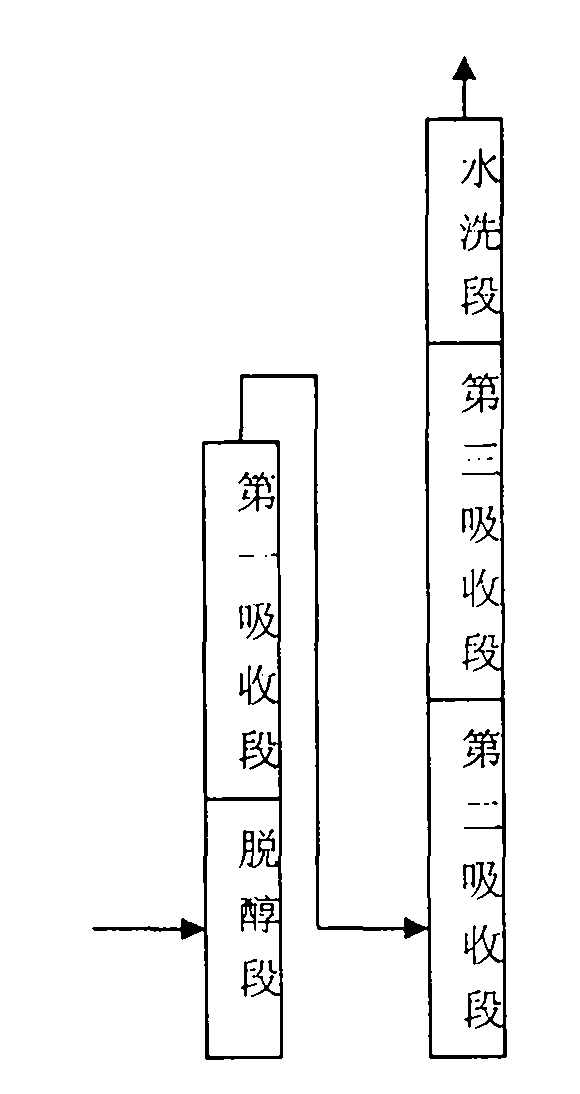

Production process and device of formaldehyde

InactiveCN102320942AExtend your lifeShort processOrganic compound preparationCarbonyl compound separation/purificationMaterial consumptionSaturated water vapor

The invention relates to a production process and device of formaldehyde, in particular to a production process and device of the formaldehyde, which can realize circulated recycling of unreacted methanol. The process comprises the following steps of: defogging after heated methanol and recycled diluting methanol form a mixed gas with air in an evaporator; then adding a small amount of saturated steam or not adding the saturated steam; and heating and filtering; introducing the mixed gas to a reactor filled with a silver catalyst for reacting to generate a formaldehyde gas; recycling the waste heat of the generated gas to produce steam; then introducing the steam to an absorbing tower for absorbing; carrying out dealcholization on the extracted finished product by utilizing a high-temperature generated gas; and extracting diluting methanol from the upper part of the absorbing tower back to the evaporator for recycling. The device comprises three kinds of main equipment, such as the evaporator, the reactor and the absorbing tower as well as auxiliary equipment, such as a fan, a pump, a heat exchanger, and the like. The invention has the advantages of simple process, low unit product energy consumption and material consumption, high product concentration methanol content close to zero.

Owner:田宝峰

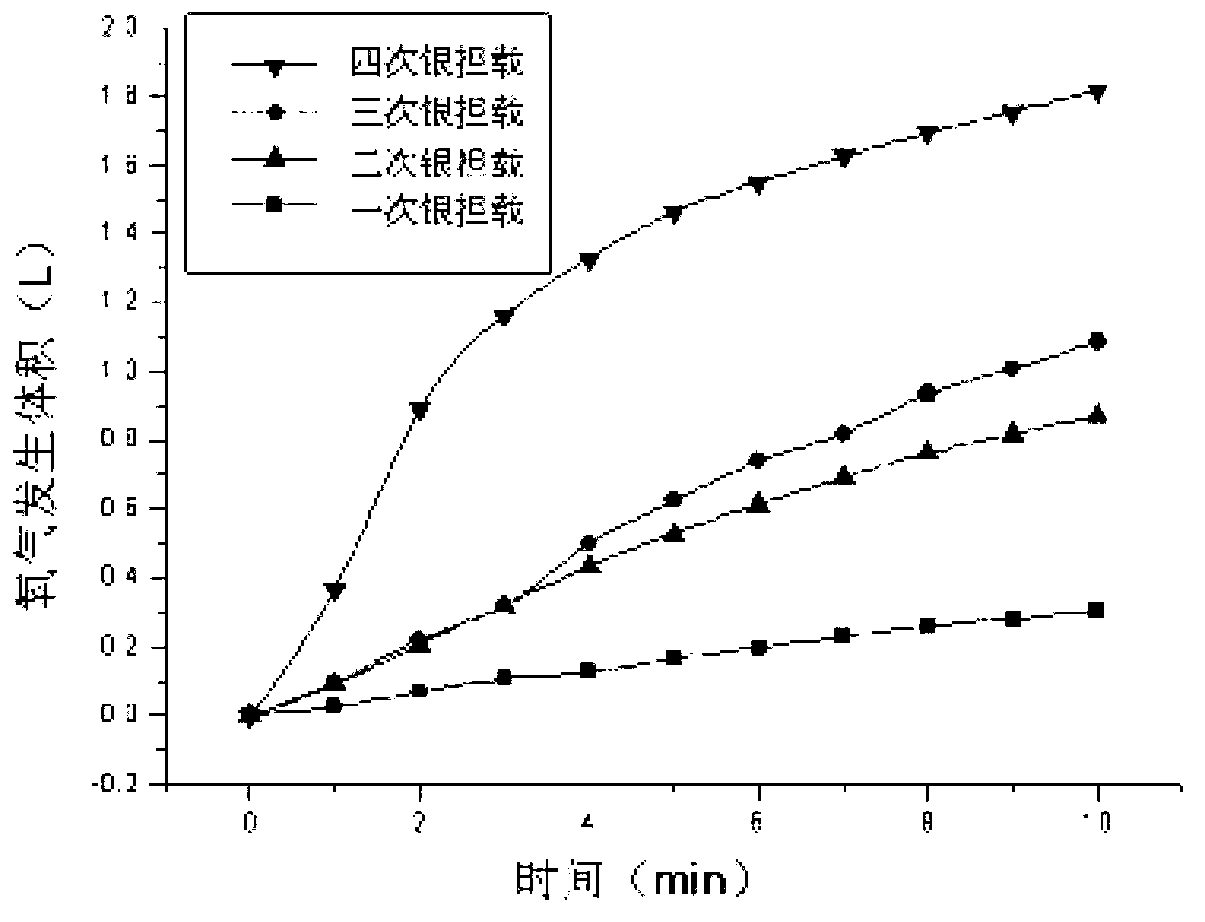

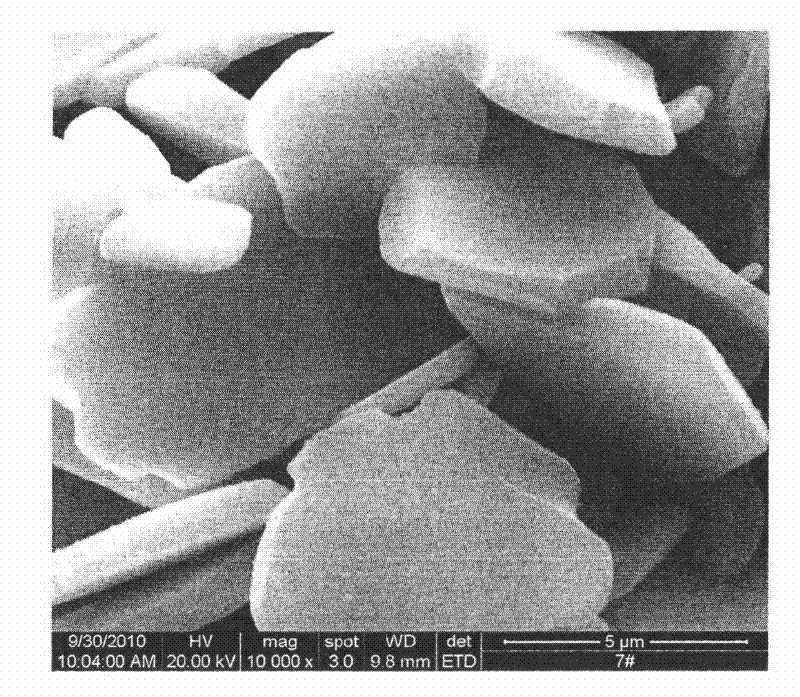

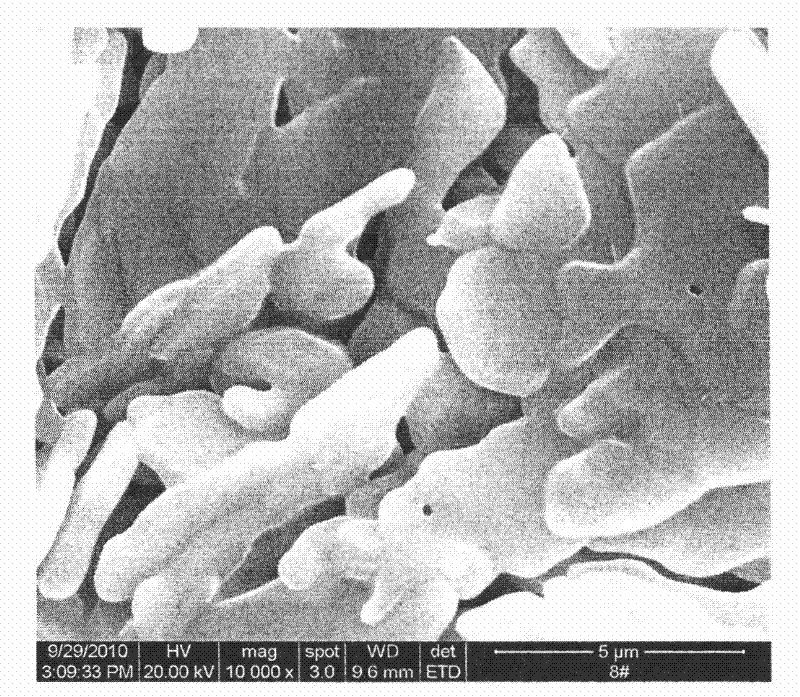

Preparation method of catalysts for oxygen production implemented through decomposition of hydrogen peroxide

InactiveCN103272615AHigh mechanical strengthGood material compatibilityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsShock waveDecomposition

The invention relates to catalyst preparation, and aims to provide a preparation method of catalysts for oxygen production implemented through the decomposition of hydrogen peroxide. The method comprises the following steps of: immersing a nickel-foam solid sample into a silver nitrate solution, heating the obtained object, carrying out a replacement reaction, and cooling the obtained product to room temperature; taking an alkaline sodium borohydride solution, reducing nickel ions in the previous solution to metal nickel and depositing the metal nickel to the solid sample; and taking out the solid sample, calcinating the solid sample for 2-5 hours under nitrogen so as to obtain a silver catalyst taking nickel foam as a carrier. According to the invention, micropores of nickel foam are used as oxygen transport channels, so that the service life of the catalyst is greatly prolonged. Meanwhile, because the structure compatibility of nickel and silver is excellent, and silver atoms are dissolved in the crystal structure of nickel so as to form a solid solution, so that the mechanical strength of nickel foam can be enhanced, and the capability of a carrier to resist shock waves produced by the generation of oxygen is increased, thereby greatly improving the stability and reliability of catalysts.

Owner:ZHEJIANG UNIV

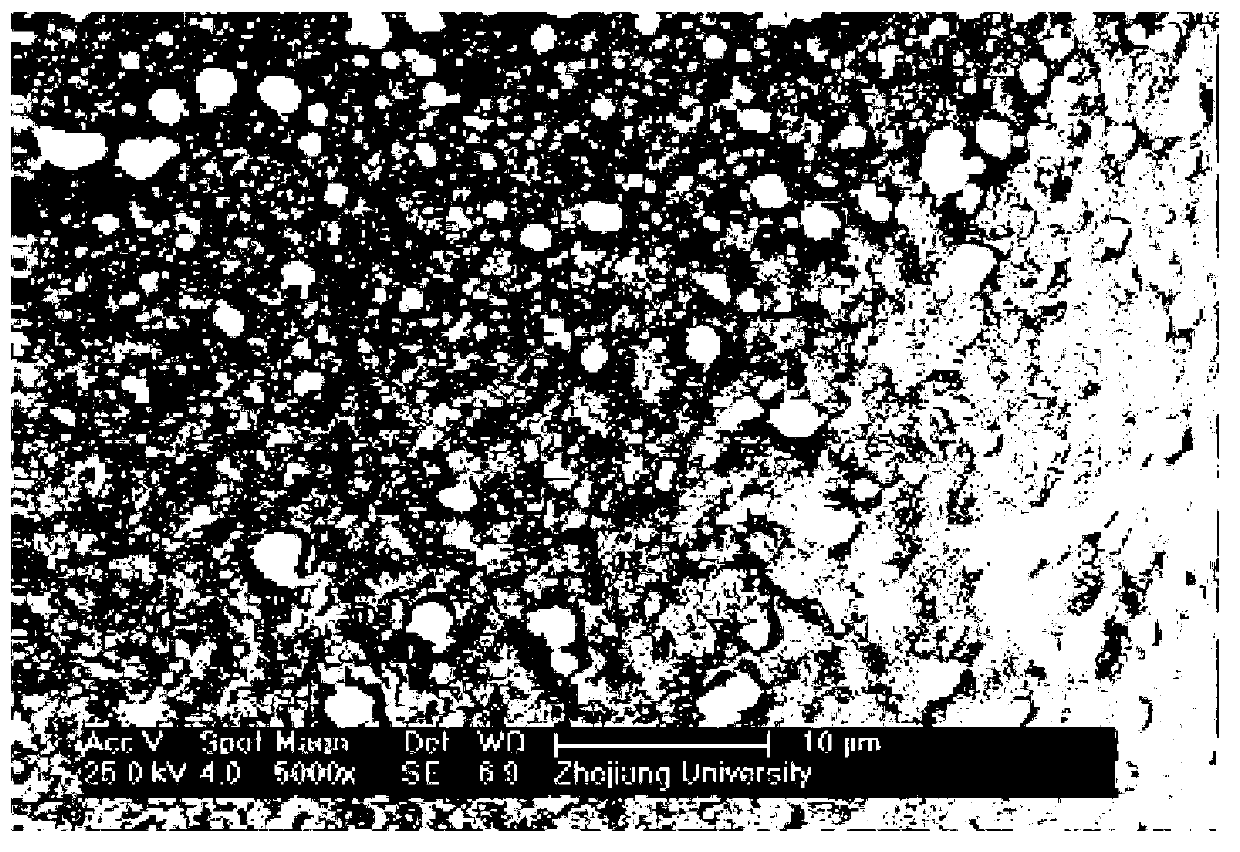

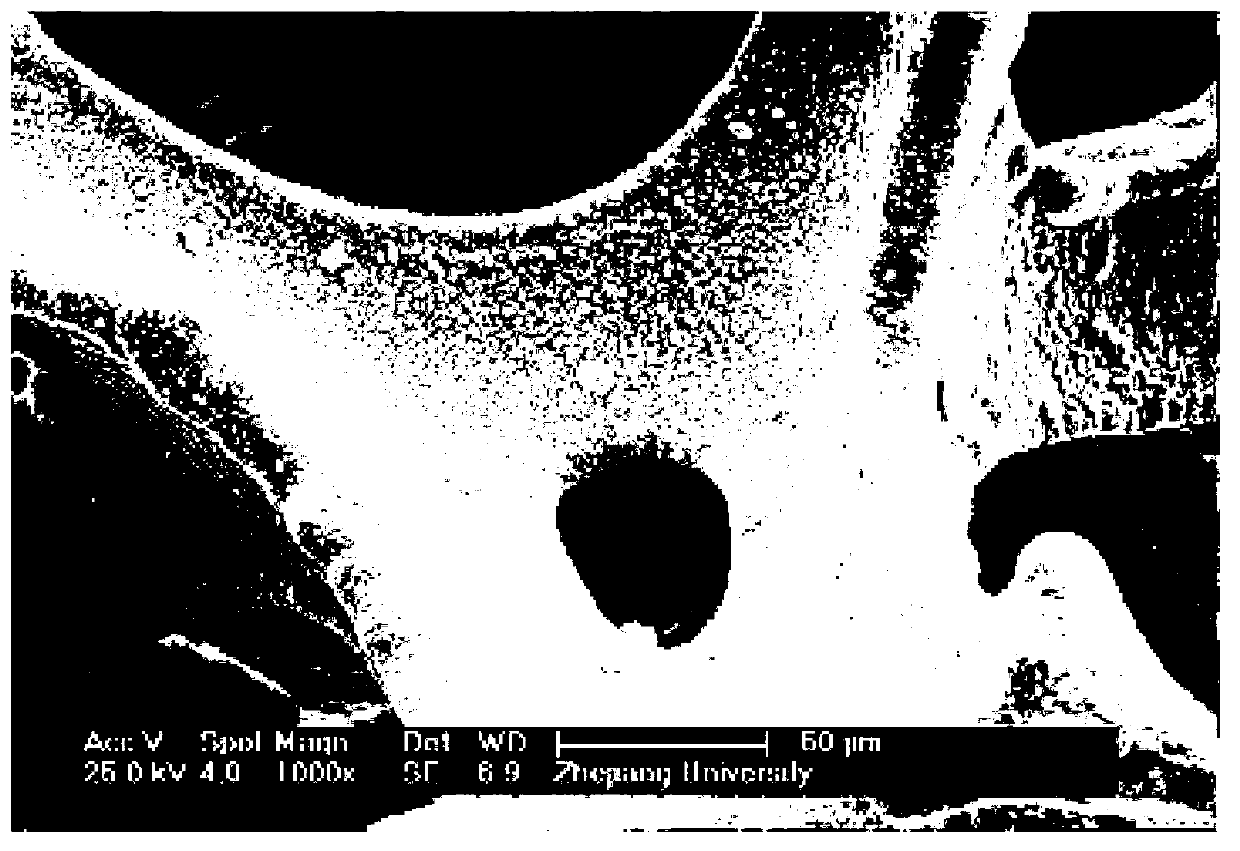

Preparation method of silver catalyst carrier, carrier prepared by preparation method, silver catalyst prepared by carrier and application thereof

ActiveCN102527430AEasy to getThe preparation method is simple and easyCatalyst carriersOrganic chemistryPolymer scienceEthylene

The invention relates to a preparation method of a porous alpha-alumina carrier of a silver catalyst used for ethylene oxide production by virtue of ethylene oxidation. The method is characterized in that before a formed body is formed, and a titanium silicalite is added into a formed body raw material. The silver catalyst prepared by the carrier which is prepared by the method shows excellent epoxidation capability and activity in the process of preparing ethylene oxide by virtue of ethylene oxidation. The invention also relates to the carrier prepared by the method, the silver catalyst prepared by the carrier, and application of the silver catalyst in ethylene oxide production by virtue of ethylene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

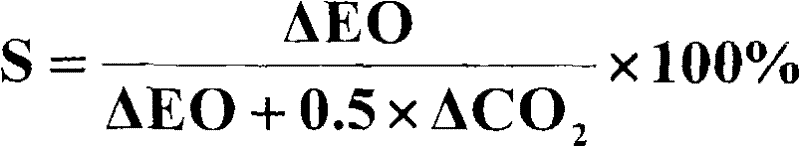

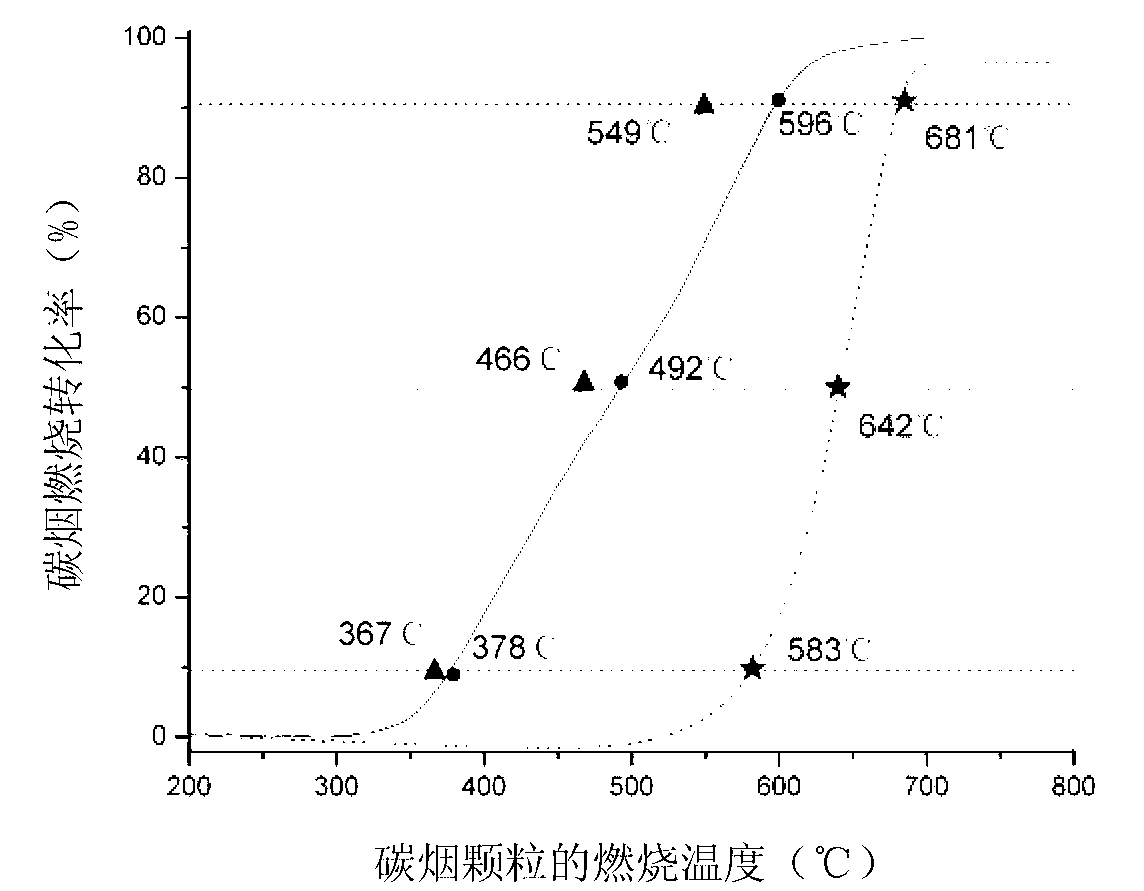

Supported silver catalyst for reducing soot particle burning temperature and preparation method

InactiveCN103212414AStrong oxidation activityGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater basedCerium(IV) oxide

The invention discloses a supported silver catalyst for reducing soot particle burning temperature and a preparation method, relating to catalysts. The catalyst comprises an active component and a carrier, wherein the active component is silver; the carrier is cerium dioxide or cerium-based composite oxide; the supported amount of silver is 1-20% of the weight of the carrier; and the cerium-based composite oxide has the general formula of Ce1-xMxOy, and M is rare-earth metal. The carrier is prepared by adding a surfactant as a template into a cerium-based solution through a hydrothermal precipitation method. The catalyst is prepared by introducing a complexing auxiliary agent into a water-based silver nitrate solution, evaporating to dryness and baking. The prepared catalyst has excellent oxidative activity in the process of soot burning, is capable of reducing the temperature of soot T50 from 642 DEG C to about 400 DEG C to reach the operating temperature range of a diesel engine, and reaches and exceeds various types of reported soot particle burning catalysts under the same evaluation conditions.

Owner:XIAMEN UNIV

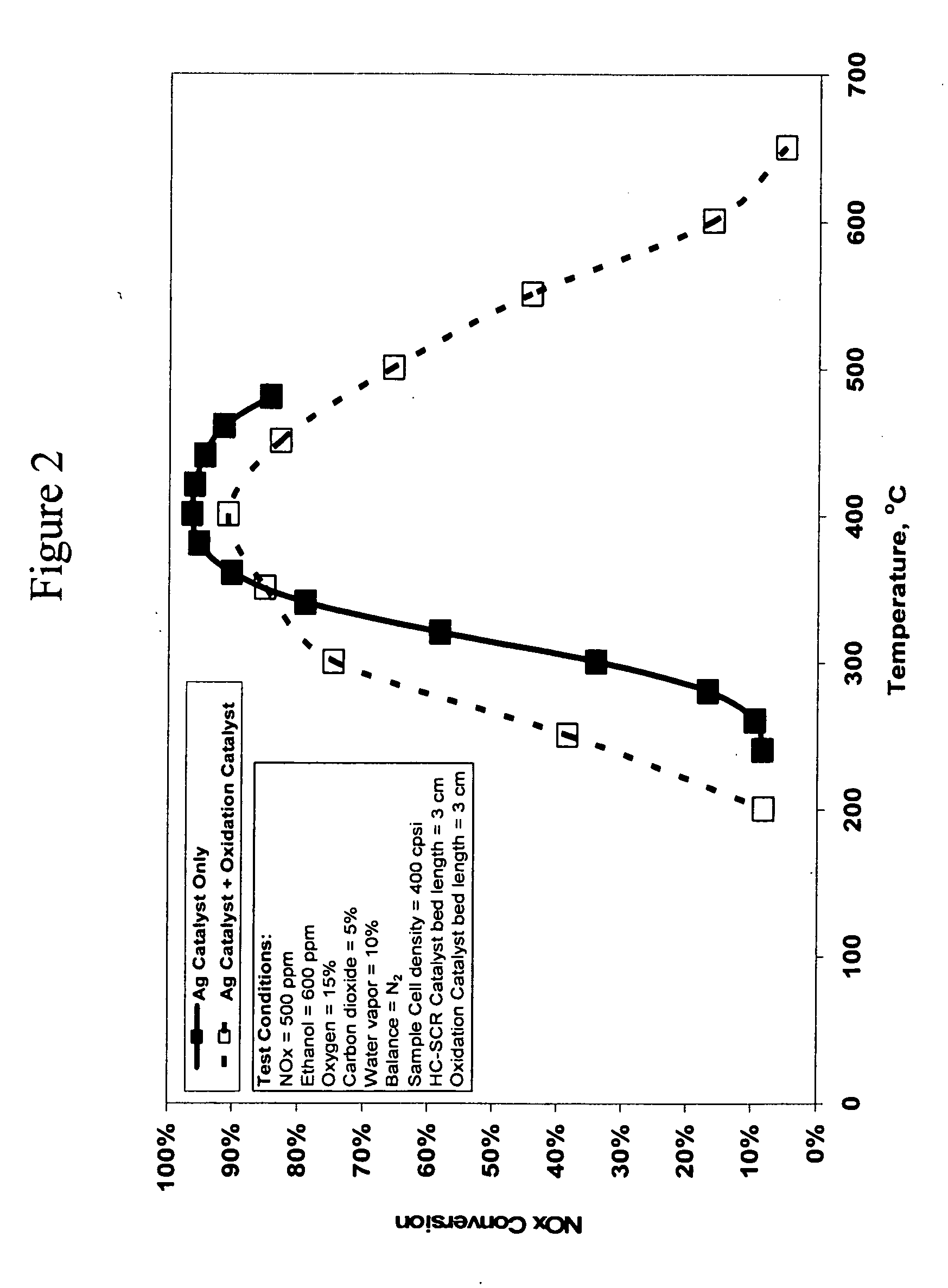

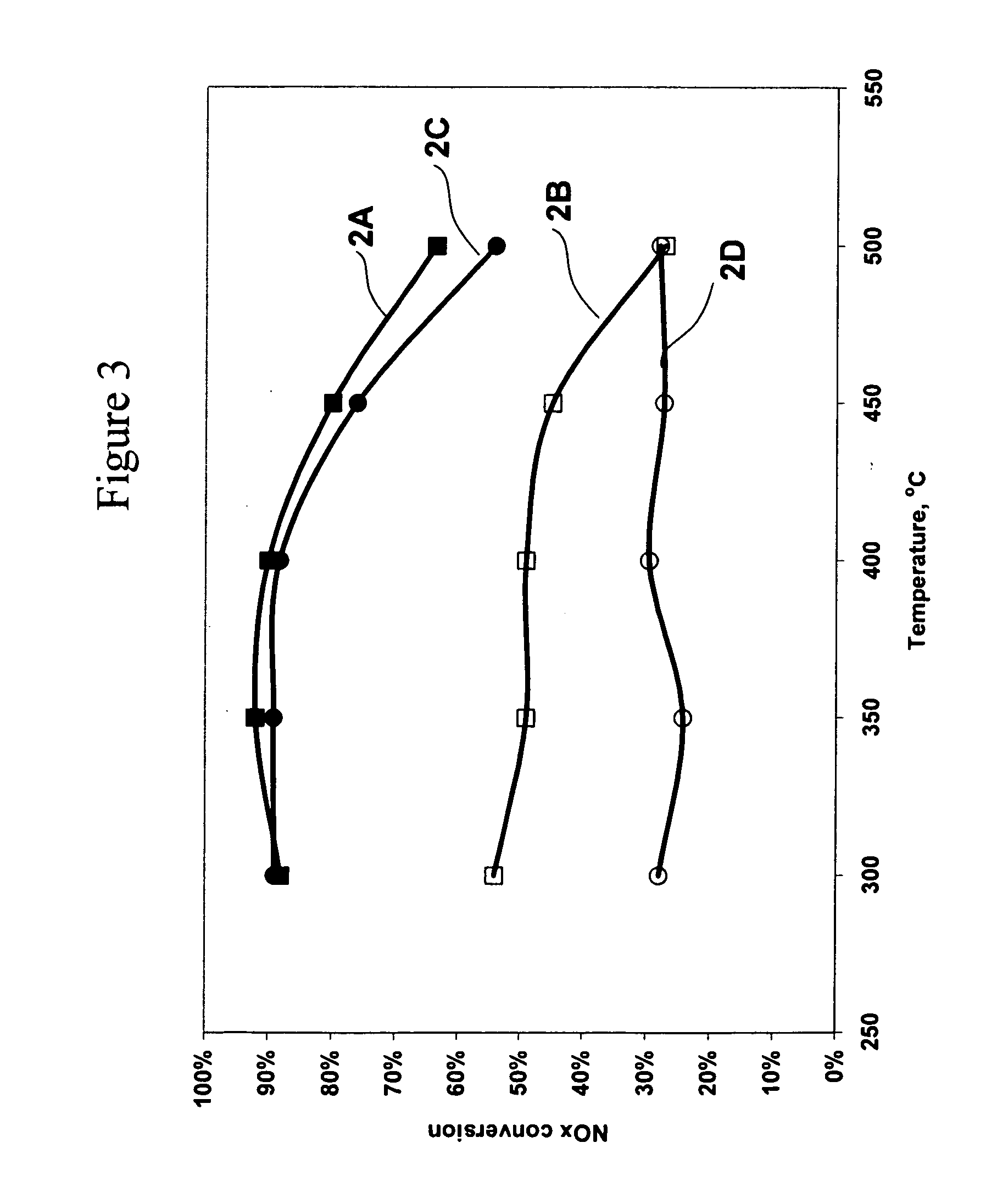

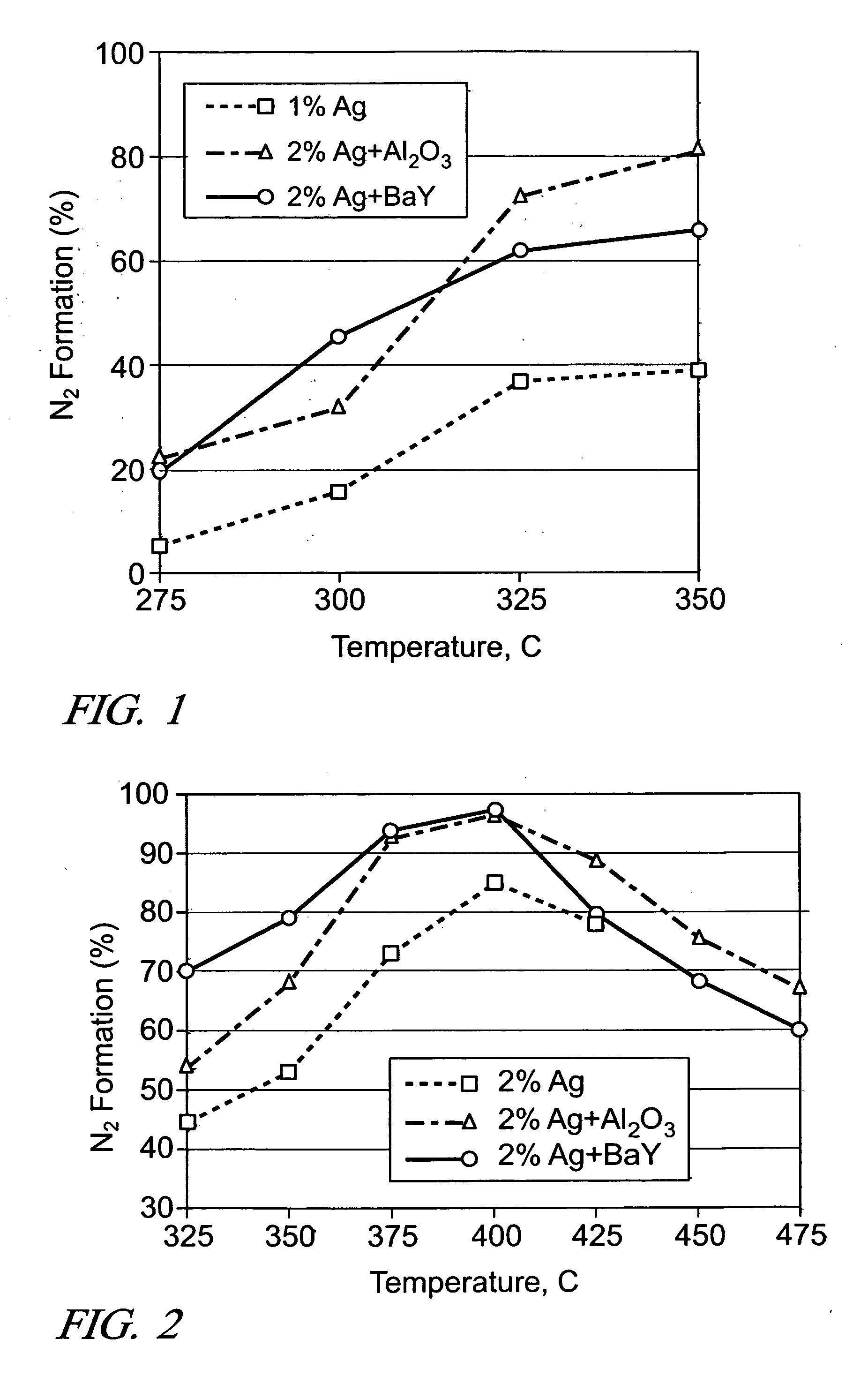

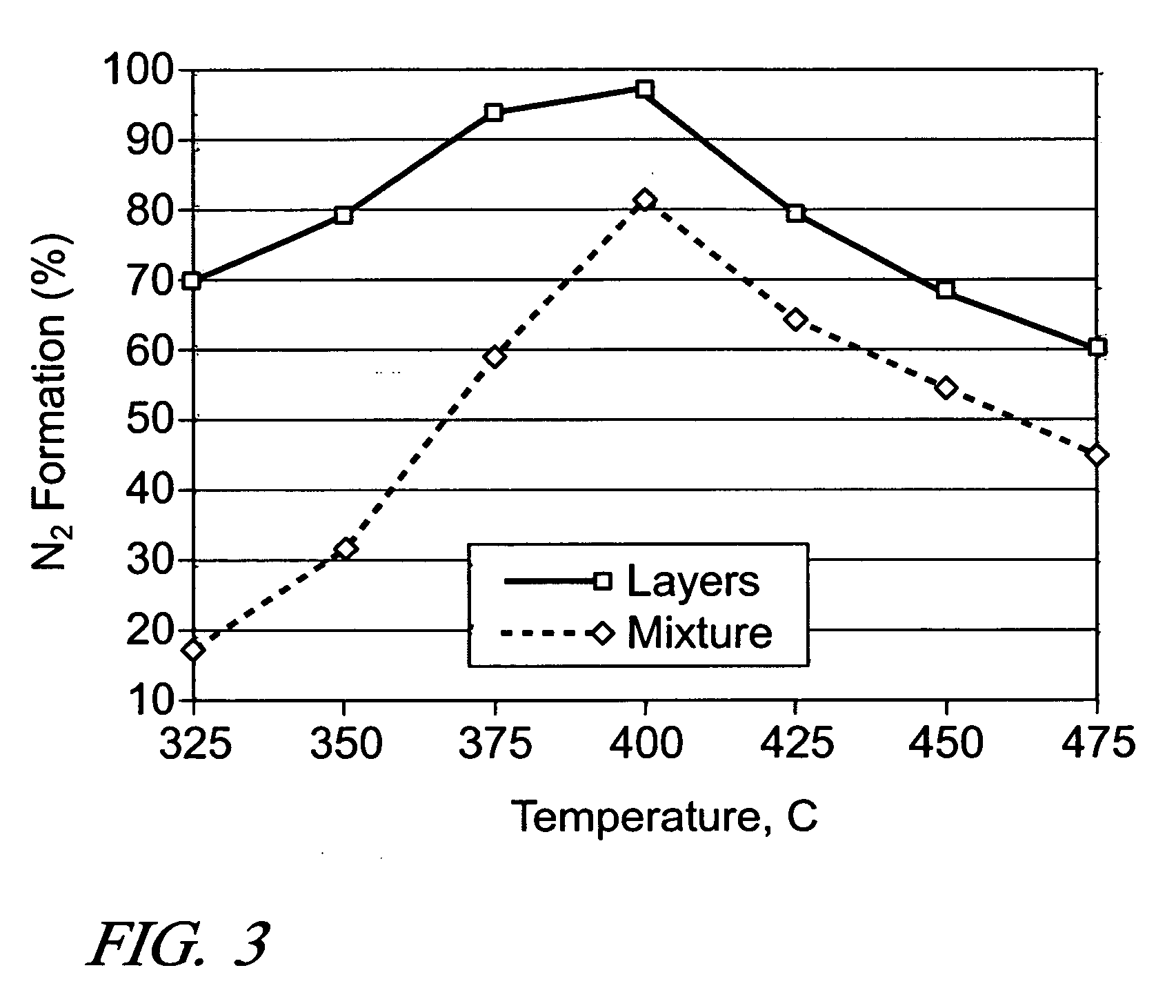

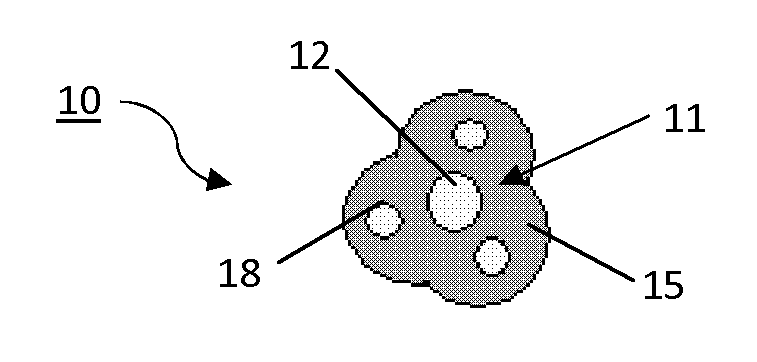

Reduction of NOx emissions using a staged silver/alumina catalyst system

ActiveUS20070031310A1Low costSpeed up the conversion processNitrogen compoundsMolecular sieve catalystsPartial oxidationHydrocotyle bowlesioides

The hydrocarbon-assisted, selective catalytic reduction of NOx constituents in lean-bum engine exhaust is benefited by passage of the exhaust over a staged catalyst bed comprising a first stage of an alumina-supported silver catalyst for oxidation of NO to NO2 and partial oxidation of added hydrocarbon to an aldehyde. Downstream of the silver catalyst is a second catalyst selected for the reaction of hydrocarbon and aldehyde species with NO2 to reduce it to nitrogen. Gamma-alumina and BaY zeolite are examples of suitable second stage catalysts.

Owner:GM GLOBAL TECH OPERATIONS LLC

Synthetic method for supported silver phosphate/silver catalyst

InactiveCN102614902APromote absorptionImprove utilization efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationO-Phosphoric AcidPtru catalyst

The invention discloses a synthetic method for a supported silver phosphate / silver catalyst. The synthetic method includes steps of weighing 1-1.2mmol of silver nitrate to prepare 10-15mmol / L of solution at first and dripping weak aqua ammonia into the solution to obtain Tollens' reagent; then weighing 20g of bentonite; adding 80-100mL of distilled water into the bentonite to immerse the bentonite for 10 hours to 12 hours so as to obtain bentonite suspension; dripping the Tollens's reagent into the bentonite suspension, stirring, ageing in water bath at the temperature ranging from 80 DEG C to 85 DEG C for 24 hours, washing by four times to five times, and adding 30-50mL of distilled water; dripping 0.01-0.1mol / L of phosphoric acid in a product, stirring for 4 hours, leading the mole ratio of the adding quantity of the phosphoric acid to the used quantity of the silver nitrate to be 1:3, ageing in water bath at the temperature ranging from 60 DEG C to 65 DEG C for 24 hours after stirring is finished, and repeatedly washing until supernate is neutral; and finally drying at the temperature of 105 DEG C, grinding, and irradiating under an xenon lamp with the power of 400-500w for 50-80 minutes so as to obtain the supported silver phosphate / silver catalyst. Utilization efficiency to natural light is increased, stability of a system is guaranteed, a nanometer laminated structure of the bentonite is utilized, accordingly, absorption ability of the catalyst and a carrier is improved, and degradation efficiency is increased.

Owner:苏州拓丰市政工程有限公司 +1

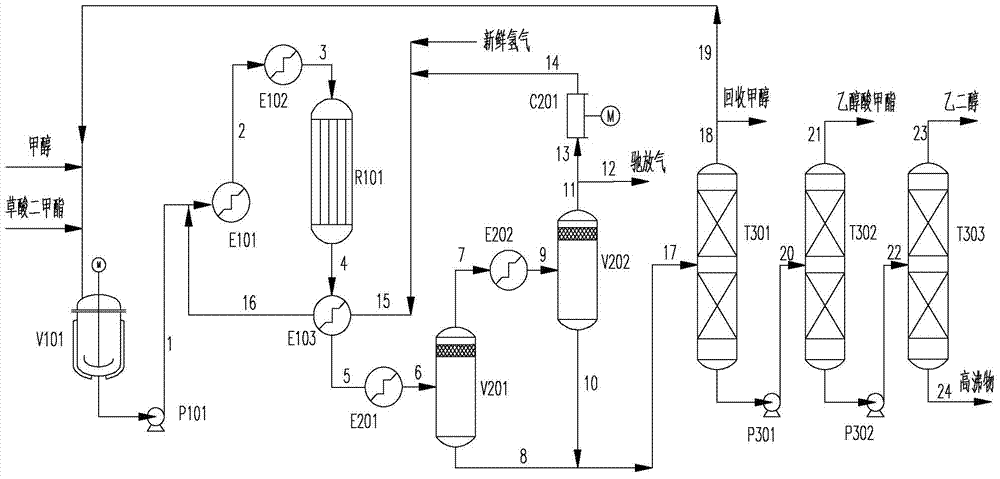

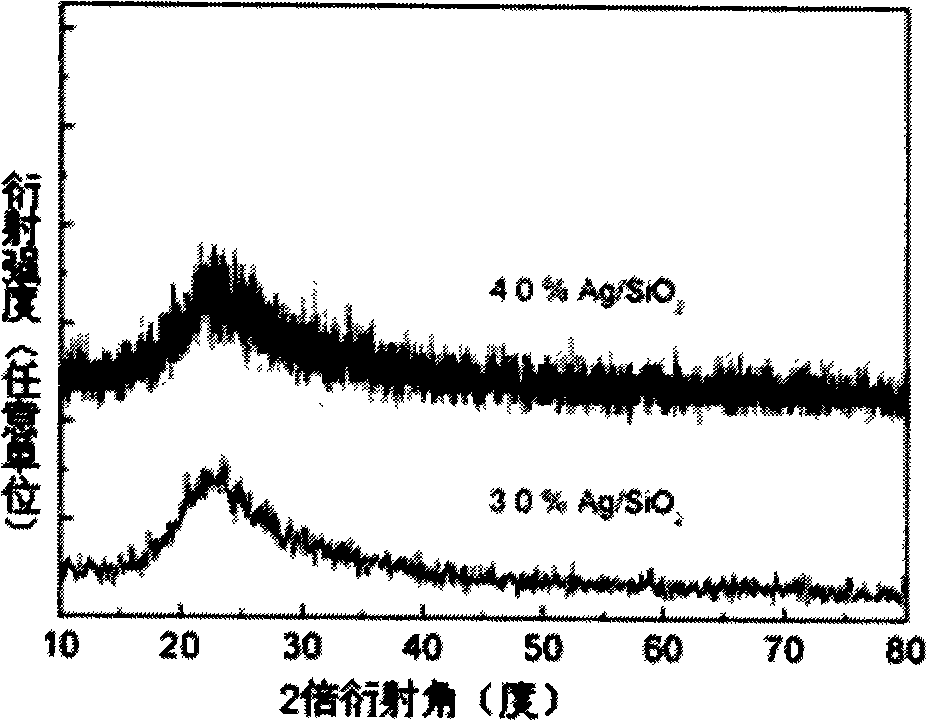

SiO2 supported nanometer silver catalyst, preparing method and applications thereof

InactiveCN101224422ALow costHigh yieldOrganic compound preparationAmino compound preparationNitro compoundPolyamide

The invention discloses a catalyst for loading silver on SiO2, a preparation method and application in a selective catalytic hydrogenation of chloro-aromatic compounds, nitryl-aromatic ene, nitryl-aromatic aldehydes, nitryl-aromatic ketone, and nitryl-aromatic polyamide. The synthetic method is that tetraethoxysilane and aminopropyl-triethoxysilane are added by weight proportion of 1: 0.1-1: 25 into an ammonia solution containing definite AgNO3, then the solution is stirred to form gelatinate under room temperature and dried under 100-200 DEG C for about 4-12 hours, thus obtaining the catalyst. The synthetic catalyst of the invention solves two problems of current catalytic hydrogenation of aromatic nitro-compounds: (1) a secondary reaction of dechlorination is generated during the hydrogenation of chloronitrobenzenes of aromatic nitro-compounds; (2) the selectivity of reaction is poor when alkene, aldehydes, ketone, nitrile and amide groups coexist.

Owner:NANJING UNIV

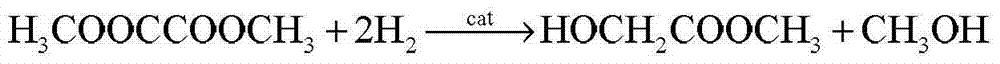

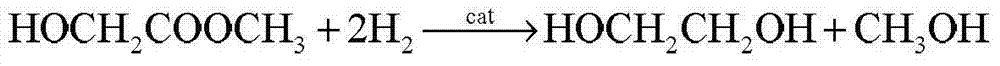

Production method of methyl glycolate

InactiveCN104262152AHigh selectivityReduce partial pressureOrganic compound preparationCarboxylic acid esters preparationDistillationMixed materials

The invention relates to a production method of methyl glycolate, aiming to mainly solve the problems of low conversion rate of dimethyl oxalate and low selectivity of methyl glycolate in the prior art. The production method of methyl glycolate comprises the following steps of (1) enabling a mixed material composed of a methanol solution of dimethyl oxalate and feed gas containing hydrogen to be in contact with a silver-containing catalyst in a reactor to react to obtain a mixture flow containing methyl glycolate, carrying out heat exchange, and then, enabling the mixture flow to enter a gas-liquid separation system; (2) sequentially carrying out condensation, primary gas-liquid separation, condensation and secondary low-temperature gas-liquid separation on the mixture flow subjected to heat exchange to obtain crude methyl glycolate; and (3) carrying out reduced-pressure distillation separation on crude methyl glycolate to obtain the methyl glycolate product. According to the technical scheme, the conversion rate of dimethyl oxalate can be higher than 99%, the selectivity of methyl glycolate can be higher than 80%, and the production method can be applied to industrial production of methyl glycolate.

Owner:SHANGHAI HUAYI GRP CO

Support for silver catalyst in ethylene oxide production, methods for preparing the same, silver catalyst prepared therefrom, and use thereof

ActiveUS20120065055A1High catalytic activityLow selectivityOrganic chemistryCatalyst activation/preparationEthyleneSilver catalyst

The present invention relates to a support for silver catalyst used in the ethylene oxide production, a preparation method for the same, a silver catalyst prepared from the same, and its use in the ethylene oxide production. The silver catalyst produced from the silver catalyst support has an improved activity, stability and / or selectivity in the production of ethylene oxide by epoxidation of ethylene.

Owner:CHINA PETROCHEMICAL CORP +1

Catalyst carrier and preparation method as well as catalyst prepared by carrier and application of catalyst

The invention provides a catalyst carrier and a preparation method as well as a catalyst prepared by the carrier and an application of the catalyst. According to the preparation method, activated aluminum oxide with various crystalline phases and of various types is employed, including one or more mixtures of gamma-A12O3, rho-A12O3, alpha-A12O3, kappa-A12O3, theta-A12O3 and the like, preferably one, two or three mixtures of gamma-A12O3, rho-A12O3 and alpha-A12O3, to replace or partially replace hydrate (namely aluminum hydroxide) of aluminum oxide as one of raw materials for preparing the carrier to prepare the carrier of a silver catalyst. The performances of the carrier prepared with the method are improved obviously. The carrier shows good activity and selectivity in an ethylene oxidation to oxirane process after loading silver and various active components to prepare the silver catalyst, and particularly, the selectivity is improved obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

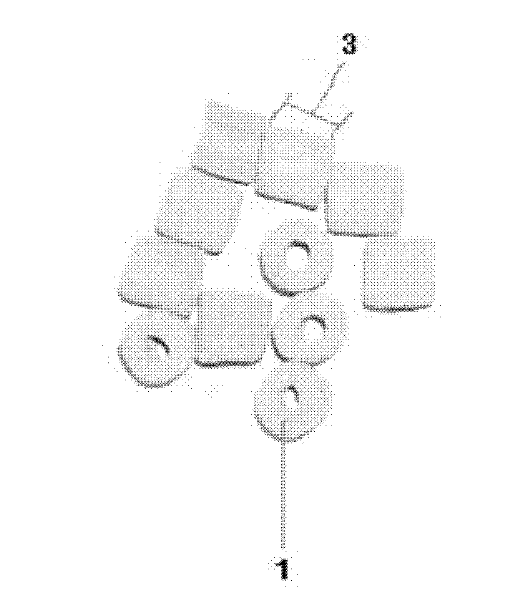

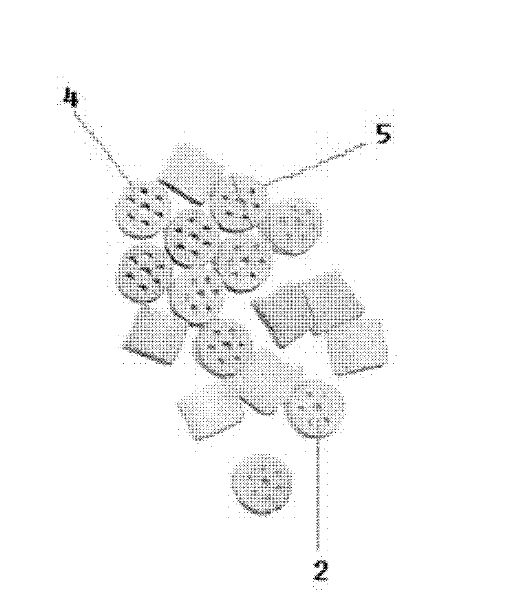

Alumina supporter for silver catalyst and silver catalyst

InactiveCN102688784AHigh activityHigh selectivityCatalyst carriersOrganic chemistryPorosityFlagellar basal body

The invention discloses an alumina supporter for a silver catalyst. The alumina supporter comprises a cylindrical basal body with a central passage, and at least three partially cylindrical valve leaflets separated at equal intervals, wherein the valve leaflets are integrally connected on the periphery of the basal body. The alumina supporter with a new shape has high surface area and porosity between the supporters, can effectively reduce the pressure drop of a catalyst bed of the reactor, optimize the flow condition in the catalyst layer, achieve better mass and heat transferring effect and improve the performance of the silver catalyst. The silver catalyst prepared by utilizing the alumina supporter has stable performance and higher activity and selectivity, and is particularly suitable for the reaction for producing ethylene oxide by ethylene oxidization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loading silver catalyst for preparing anhydrous formaldehyde by direct dehydrogenation of methanol and its manufacturing method

InactiveCN1537673AHigh catalytic activityIdeal stoichiometric reaction resultCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsAlcoholMagnesium salt

A Ag-carried catalyst for preparing the anhyrous formaldehyde by derect dehydrogenation of methanol is prepared by sol-gel method, which includes such steps as mixing ethyl silicate with the solution of soluble Mg salt and Al salt in water or alcohol, dropping their mixture in the aqueous solution of inorganic Ag salt, gelatinizing while adding the solution of soluble Al salt for increasing the activity and selectivity of product, ageing, drying and calcining. Its advantages are high transform rate of methanol and selectivity of formaldehyde (up to 100%) and low cost.

Owner:FUDAN UNIV

Ag catalyst for producing epoxyethane, its preparation method and uses

The invention discloses a silver catalyst making method and appliance of epoxyethane, which comprises the following steps: soaking the compound with silver, organic amine, alkali metal adjuvant, cerium adjuvant, random alkali earth metal adjuvant, rhenium adjuvant and theses adjuvant solutions to sinter into porous alpha-alumina carrier; filtering; drying; activating through compound gas with oxygen to produce silver catalyst. The method possesses higher flexibility and selectivity.

Owner:BEIJING YANHUA PETRO CHEM

Olefin epoxidation process

ActiveUS8546592B2Reduce probabilityIncrease ratingsOxygen-containing compound preparationOrganic compound preparationAlkenePartial pressure

Owner:SHELL USA INC

Supported silver catalyst and an epoxidation process using the catalyst

Owner:SHELL INT RES MAATSCHAPPIJ BV

Silicon dioxide supported nano-silver catalyst, preparation and use thereof

InactiveCN101301608ALow costHigh yieldOrganic compound preparationAmino compound preparationNitro compoundPtru catalyst

The invention discloses a silicon dioxide load nanometer silver catalyst, preparation method and application in nitro compound catalytic hydrogenation reaction thereof. The preparing method comprises adding 1.0g of silicon dioxide in 20-50ml aqueous solution with 0.016g-0.064g of silver nitrate dissolved therein; stirring for 8-12 hours at 40 DEG C; adding 10-50ml of alcohol; heating up to 110 DEG C solvent thermal reaction for 8-12 hours; filtrating pale yellow solid; drying the solid at 100-120 DEG C for 8-12 hours to obtain the silicon dioxide load nanometer silver catalyst. The catalyst prepared by the invention is used for nitryl aromatic compound selective hydrogenation to prepare amido aromatic compound, and can realize complete transformation under optimization condition.

Owner:NANJING UNIV

Silver supported catalyst for preparing anhydrous formaldehyde by direct dehydrogenation of methanol and manufacturing method thereof

InactiveCN1544147AImprove catalytic performanceEasy to manufactureOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlcoholDehydrogenation

The invention is a novel supported silver catalyst for preparing anhydrous formaldehyde by direct methanol dyhydrogenation. It is prepared by a sol-gel method (SOL-GEL method), i.e. mixing a certain amount of TEOS (tetraethoxysilane) with the water or alcohol solution containging soluble Zn and Al salts, then dripping to an inorganic silver salt water solution and preparing it through gelling, ageing, drying, baking, etc. During the gelling course, the Zn and Al salt solution added make acid-alkali neutralization to some extent, which largely enhances its activity and selectivity. It not only has high catalytic activity and longer service life but also simple and convenient to prepare, having lower price and suitable for industrial application.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com