Preparation method of silver catalyst carrier for production of ethylene oxide and application thereof

A silver catalyst, alumina carrier technology, applied in catalyst carriers, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Large and other problems, to achieve the effect of high activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

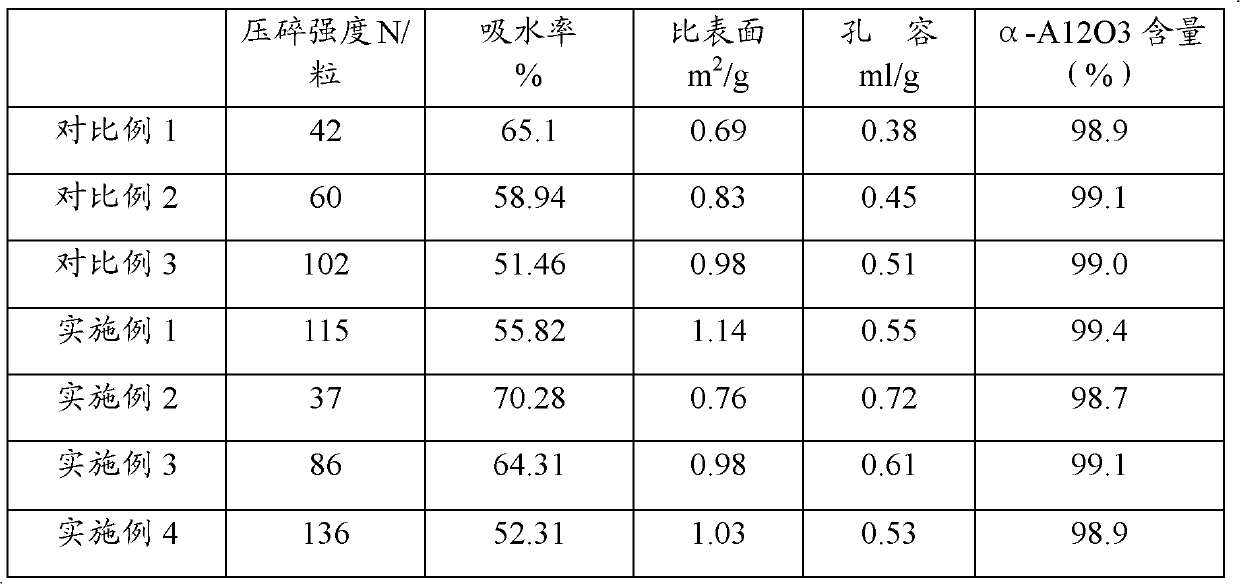

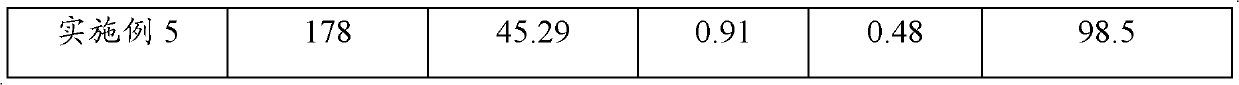

Embodiment 1

[0050] Preparation of vector

[0051] 250~500 mesh trihydrate α-Al 2 o 3 3587g, fake monohydrate Al greater than 200 mesh 2 o 3 1196g, NH 4 Put 150g of F and 25g of barium nitrate into a mixer and mix evenly, transfer to a kneader, add 42g of Vaseline and 2100ml of dilute nitric acid (concentrated nitric acid: water = 1:3, weight ratio), and knead into a paste that can be extruded shape. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry it at 80-120°C for more than 2 hours to reduce the free water content to below 10%. Put the above kneaded carrier into a bell kiln, raise it from room temperature to 1280°C over 33 hours, and calcinate at 1280°C for 10 hours to obtain white α-Al 2 o 3 carrier. The measured carrier physical property data and pore structure distribution data are shown in Tables 1 and 2 below, respectively.

[0052] Catalyst preparation

[0053] Dissolve 980g of ethylenediamine a...

Embodiment 2

[0057] The preparation of the carrier is the same as in Example 1, except that the trihydrate α-Al 2 o 3 3986g and fake Al monohydrate 2 o 3 797g. The obtained carrier physical property data and pore structure distribution data are shown in Tables 1 and 2 below, respectively.

Embodiment 3

[0059] The preparation of the carrier is the same as in Example 1, except that the trihydrate α-Al 2 o 3 3826g and fake Al monohydrate 2 o 3 957g. The obtained carrier physical property data and pore structure distribution data are shown in Tables 1 and 2 below, respectively. The preparation of the catalyst is the same as in Example 1, and the test results of the catalyst are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com