Carrier of ethylene oxide silver catalyst, and its preparation method and application

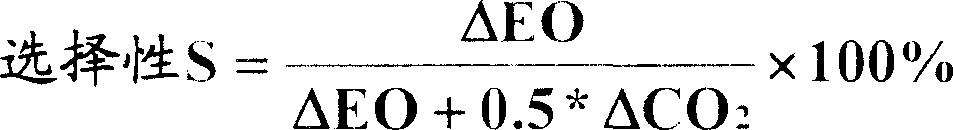

A technology of silver catalyst and ethylene oxide, which is applied in the direction of catalyst carrier, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of low water absorption of the carrier, unfavorable deposition of active components and additives, etc., and achieve selectivity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In the preparation of the silver catalyst of the present invention, firstly, the aqueous solution of silver nitrate is reacted with ammonium oxalate or oxalic acid aqueous solution, and the silver oxalate precipitate is precipitated. Add additives to the aqueous solution of amines such as pyridine, butylamine, ethylenediamine, 1,3-propylenediamine, ethanolamine or their mixtures to form an impregnation solution. Then use the obtained impregnating solution to impregnate the above-mentioned alumina carrier for 30 minutes under the condition that the vacuum degree is less than 10mmHg, drain it, and place it in an air stream or a nitrogen-oxygen mixture with an oxygen content of not more than 21% (such as 8.0% oxygen) at 180 ~ The temperature range of 700°C, preferably 200-500°C, is maintained for 1 minute to 120 minutes, preferably 2 minutes to 60 minutes, for thermal decomposition. Silver oxide can also be used instead of silver nitrate, and silver oxalate can also be dir...

Embodiment

[0065] The present invention will be further described below in conjunction with examples, but the scope of the present invention is not limited to these examples.

[0066] Preparation of Carrier Comparative Examples 1 and 2

[0067] 50~500 mesh trihydrate α-Al 2 o 3 312g, fake monohydrate Al greater than 200 mesh 2 o 3 92g, petroleum coke 0 and 81g, NH 4 F 7g and Mg(NO 3 ) 2 8.5 g was put into a mixer and mixed uniformly, transferred to a kneader, added 0.12 liters of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry it at 80-120°C for more than 2 hours to reduce the free water content to below 10%.

[0068] The preparation of carrier embodiment 1-3

[0069] 50~500 mesh trihydrate α-Al 2 o 3 312g, fake monohydrate Al greater than 200 mesh 2 o 3 92g, 5, 11 and 21g of petroleum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com