Preparation method of thermosensitive microgel asymmetric supported nano silver catalyst

An asymmetric, microgel technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., which can solve the problems of limited nature, cumbersome, and difficult to control , to improve the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

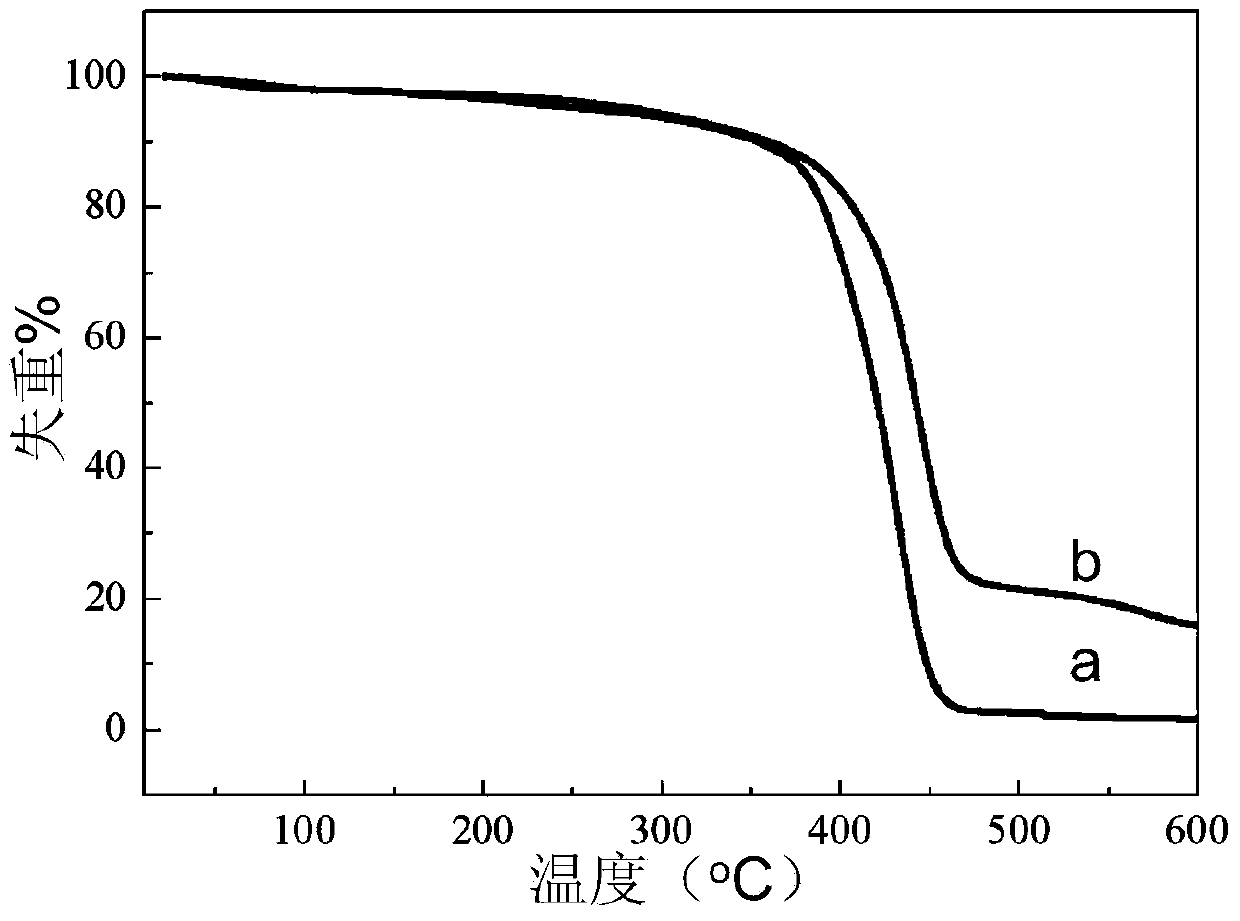

[0025] 1. Preparation of poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide copolymethacrylic acid) core-shell microgel

[0026] Under nitrogen protection, fully dissolve 0.20g of N-isopropylacrylamide and 1.80g of styrene in 90mL of twice distilled water, transfer to a 150mL three-necked reaction flask, mechanically stir at 400 rpm, and heat to 70°C in a water bath. Add 10 mL of an aqueous potassium persulfate solution with a mass-volume concentration of 16 g / L, and react at a constant temperature for 8 hours to obtain a milky white N-isopropylacrylamide copolymer polystyrene microsphere dispersion.

[0027] Add 0.23g of methacrylic acid and 5.96g of N-isopropylacrylamide aqueous solution with a mass fraction of 16% to 1.085g of an 8% NaOH aqueous solution, mix well, and then add 0.069g of N,N'-methylene Bisacrylamide, 0.5mL0.95mol / L ammonium persulfate aqueous solution, mixed evenly, the resulting mixture was transferred into the N-isopropylacrylamide copolymer p...

Embodiment 2

[0032] The preparation method of the poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) core-shell composite microgel in this example is the same as that in Example 1. In step 2 of preparing thermosensitive microgel asymmetrically loaded nano-silver catalyst, 0.016g poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) Add core-shell type composite microgel and 15mL double-distilled water into a 150mL three-necked reaction flask, disperse evenly, and swell with magnetic stirring at room temperature for 12 hours, adjust the pH value to 8 with 0.03mol / L aqueous sodium hydroxide solution, and add 5mL .01mol / L silver nitrate aqueous solution, the quality of poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) core-shell composite microgel and silver nitrate The ratio is 1:0.5. After mixing evenly, ventilate nitrogen and continue to stir for 4 hours to obtain a microgel dispersion liquid swollen wi...

Embodiment 3

[0034] The preparation method of the poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) core-shell composite microgel in this example is the same as that in Example 1. In step 2 of preparing thermosensitive microgel asymmetrically loaded nano-silver catalyst, 0.016g poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) Add core-shell type composite microgel and 15mL double-distilled water into a 150mL three-necked reaction flask, disperse evenly, and swell with magnetic stirring at room temperature for 12 hours, adjust the pH value to 8 with 0.03mol / L aqueous sodium hydroxide solution, and add 5mL .015mol / L silver nitrate aqueous solution, the quality of poly(N-isopropylacrylamide-styrene) / poly(N-isopropylacrylamide-methacrylic acid) core-shell composite microgel and silver nitrate The ratio is 1:0.75. After mixing evenly, ventilate nitrogen and continue to stir for 4 hours to obtain a microgel dispersion liquid swollen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com