Patents

Literature

102 results about "Flagellar basal body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A basal body (synonymous with basal granule, kinetosome, and in older cytological literature with blepharoplast) is a protein structure found at the base of a eukaryotic undulipodium (cilium or flagellum). It is formed from a centriole and several additional protein structures, and is, essentially, a modified centriole.

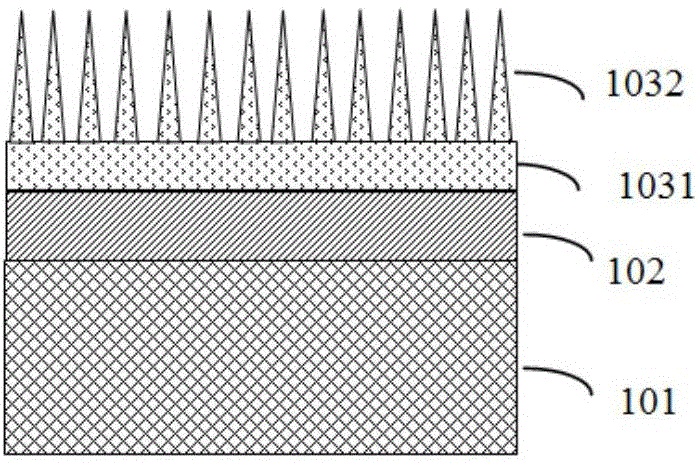

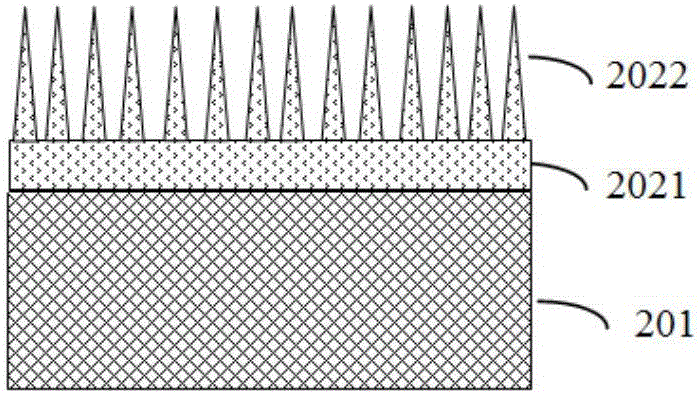

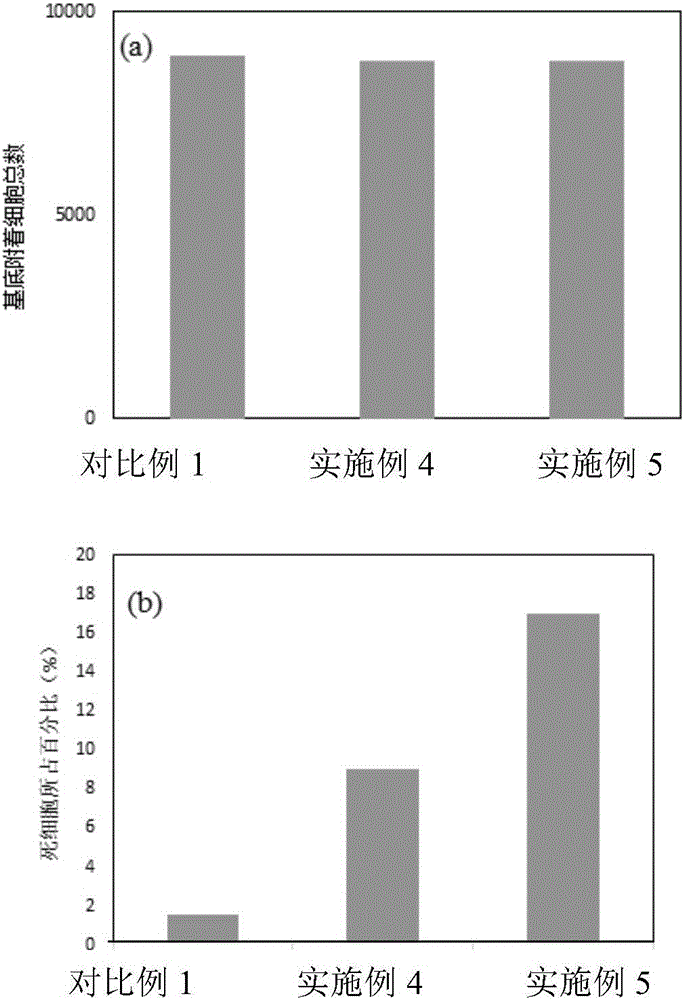

Structural part with like diamond array and preparation method thereof

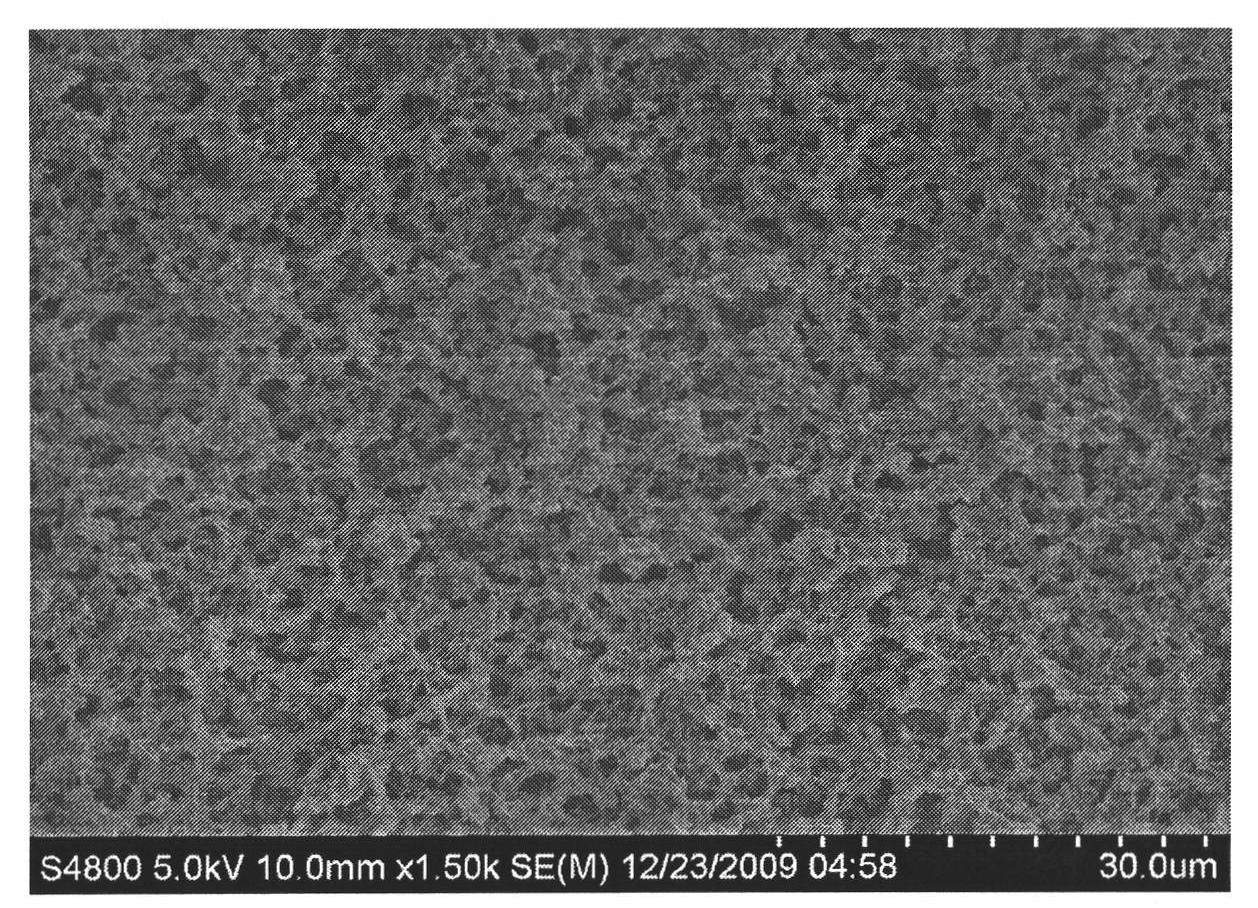

The invention provides a structural part with a like diamond array. The structural part comprises a basal body, and a like diamond nanometer needle array arranged on the basal body and with a tip structure; and the like diamond nanometer needle array is obtained by etching a like diamond coating layer formed on the basal body. The structural part with the like diamond array can generate pressure on cell walls of bacteria, punctures the cell walls of the bacteria to enable the bacteria to extend and finally dissolve to cause death, effectively damages formation of biofilms, and is prominent in antibacterial property. The invention further provides a preparation method of the structural part with the like diamond array.

Owner:SHENZHEN INST OF ADVANCED TECH

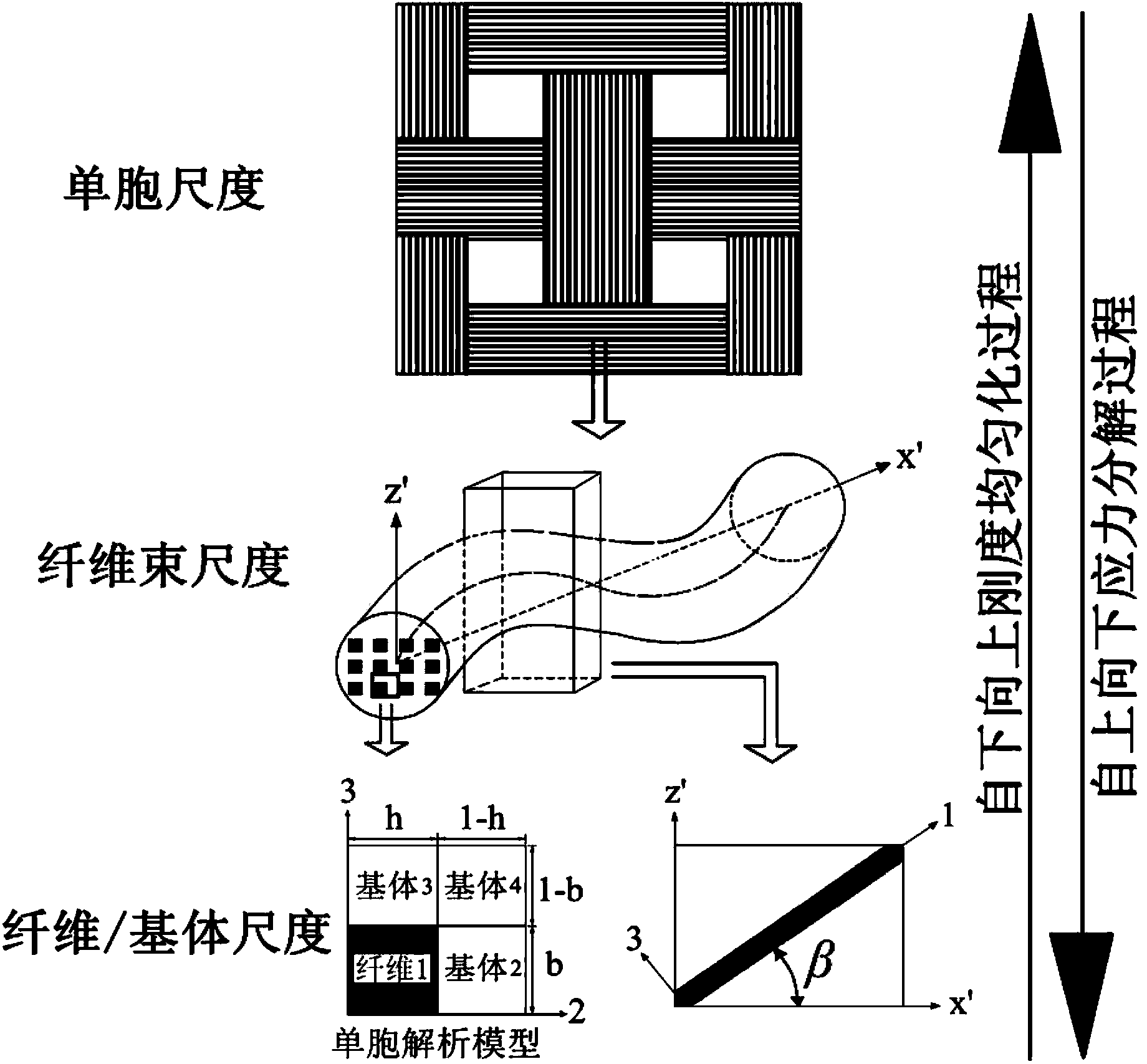

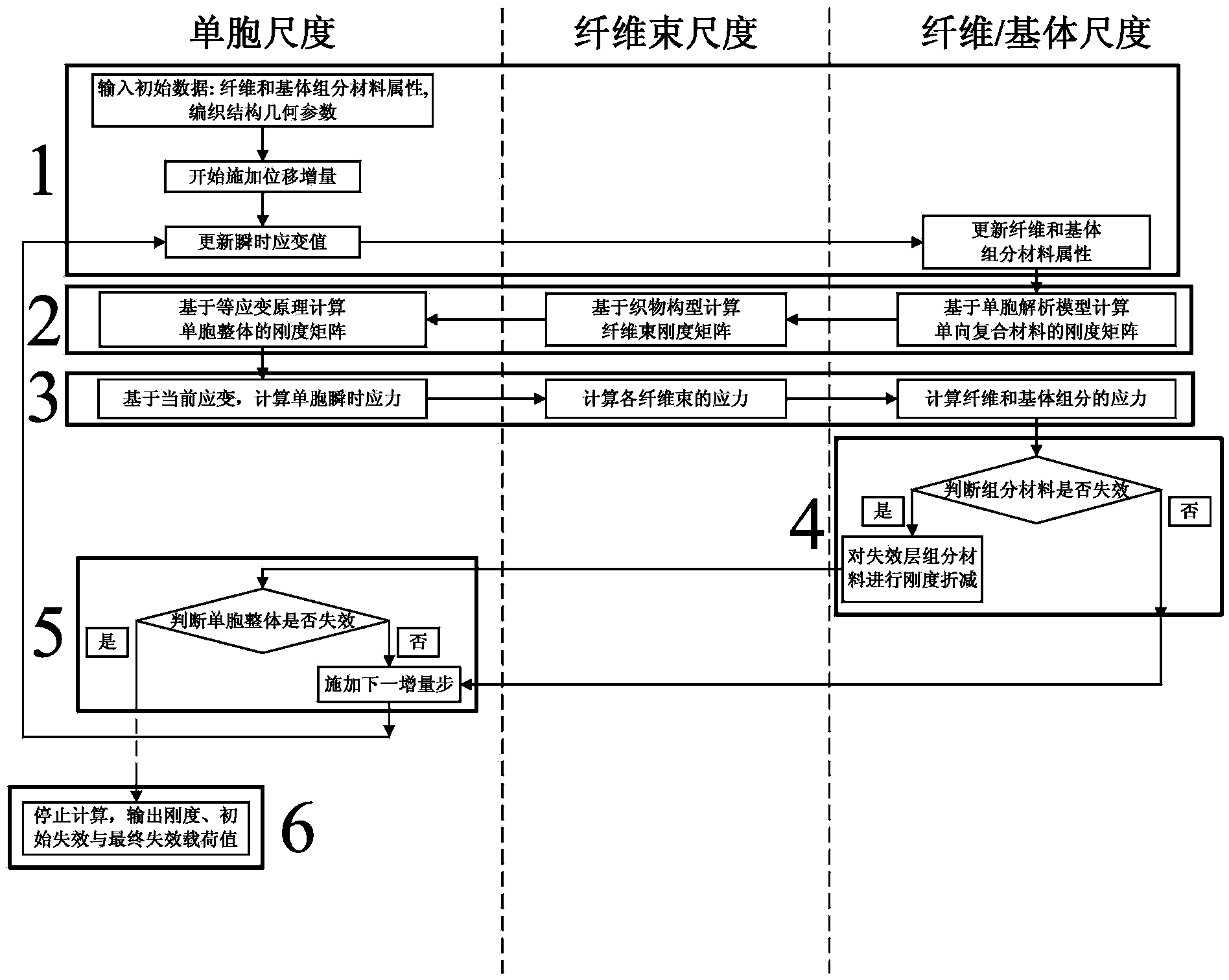

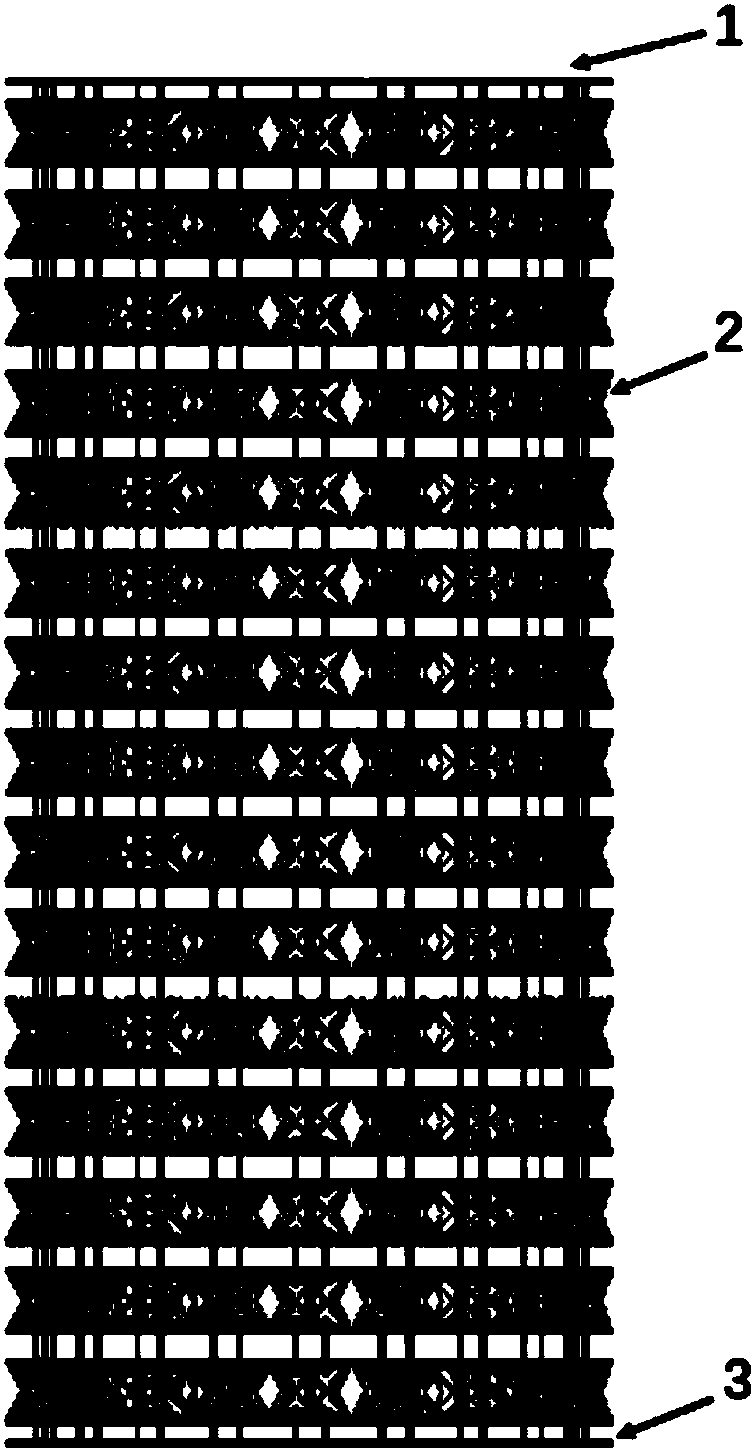

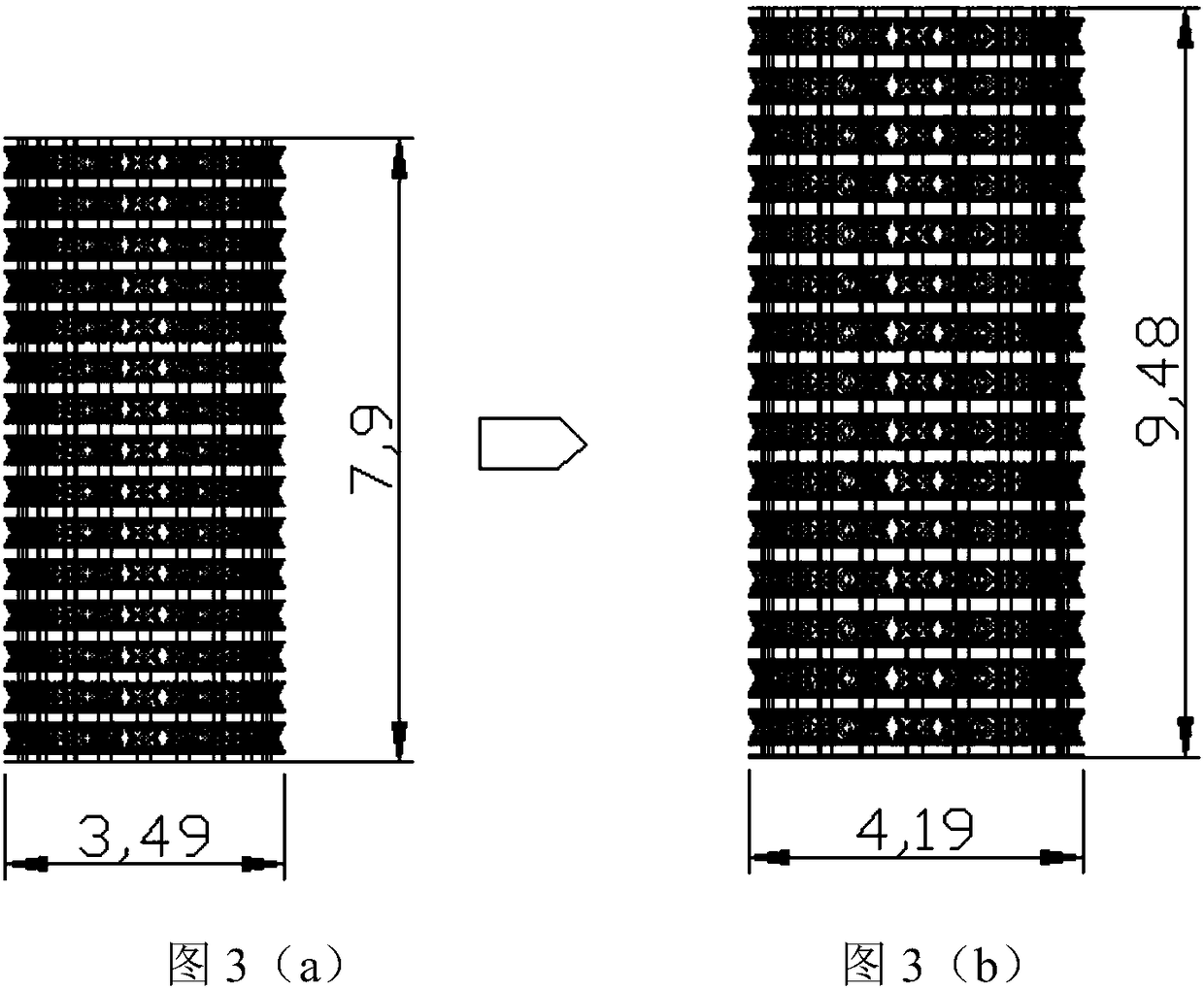

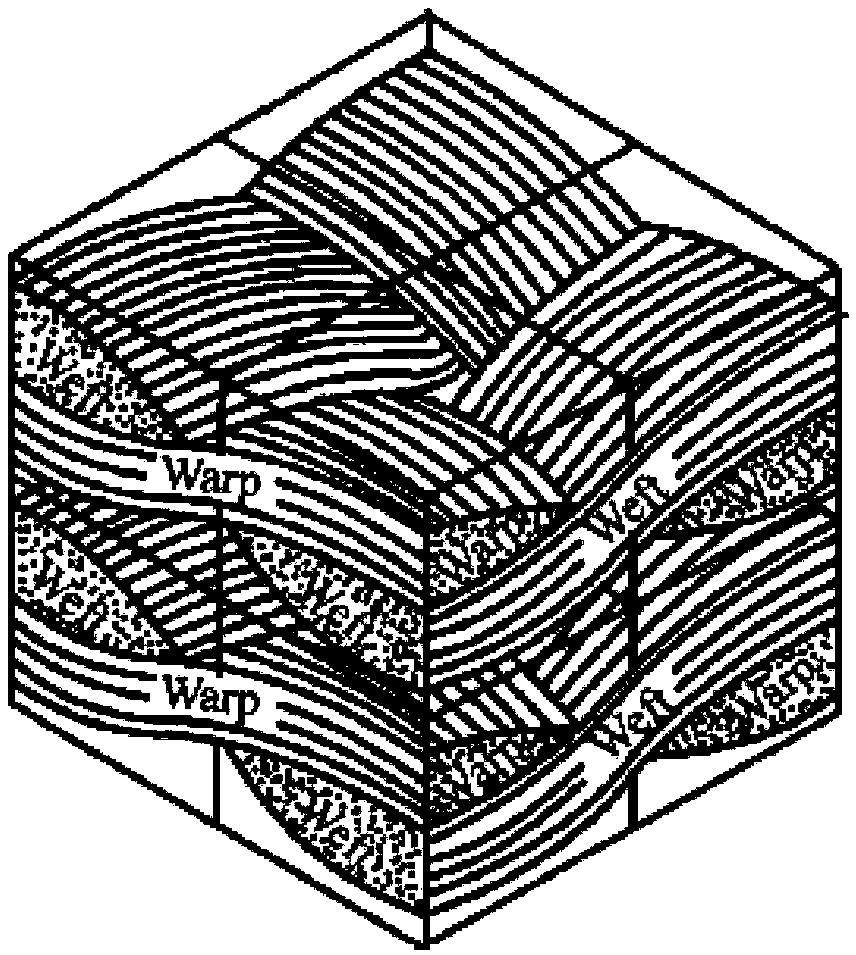

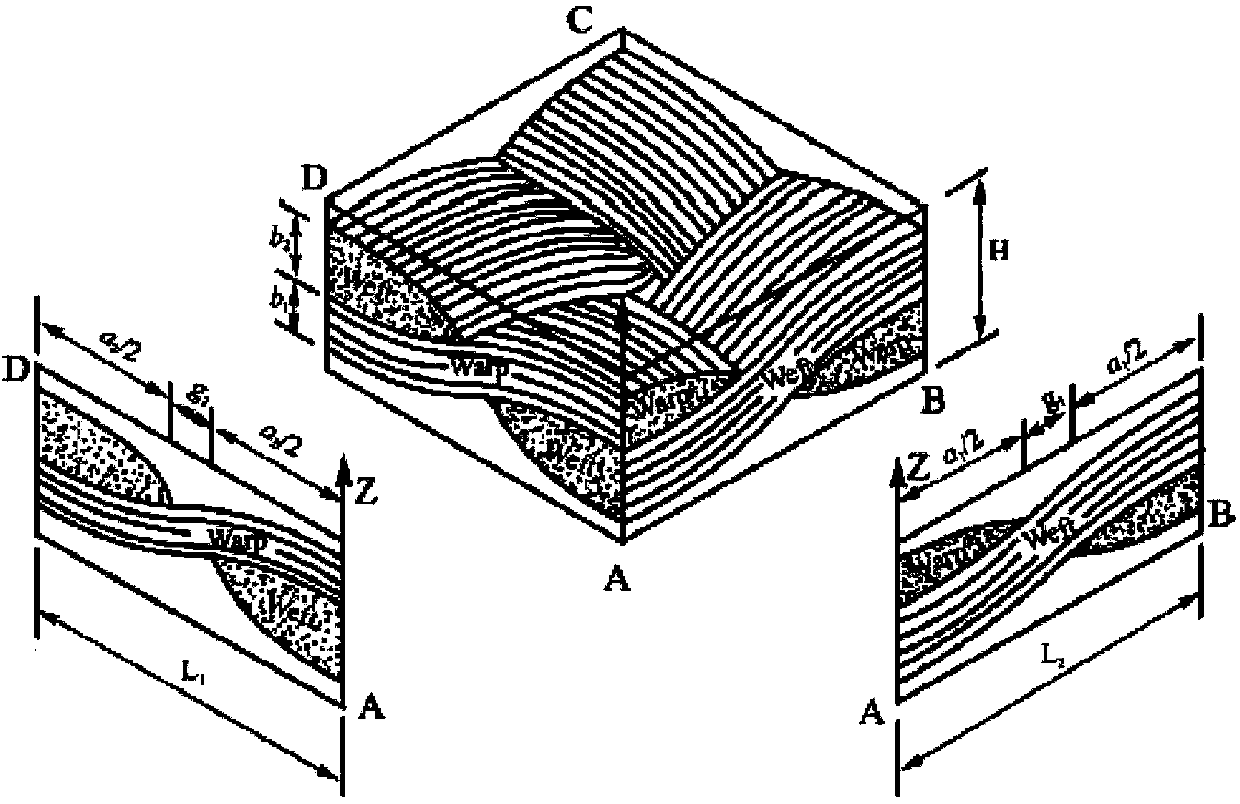

Multiscale prediction method for mechanical property of woven composite material

InactiveCN103366085ASufficient computational precisionReveal the failure mechanismSpecial data processing applicationsFlagellar basal bodyState of art

The invention relates to a multiscale prediction method for the mechanical property of a woven composite material. The method comprises the following steps that 1), an initial parameter is input; 2), elastic stiffness matrixes of a fiber / basal body scale, a fiber bundle scale and a unit cell scale are computed sequentially according to a bottom-to-top homogenization process; 3), a multiscale incidence matrix is constructed; 4), stress-strain analysis is performed on unit cell entirety, stress is decomposed by the multiscale incidence matrix from top to bottom, and stress-strain fields under all the scales are obtained synchronously; 5), whether an ingredient material is in a failure is judged according to respective failure criteria of a fiber and a basal body; if so, the corresponding ingredient material is subjected to stiffness reduction; 6), whether the unit cell entirety is in a failure is judged, and if so, Step 7) is executed, or else, a next displacement increment is added and Step 2) is returned; and 7), stiffness and strength computation results of the woven composite material are output. Compared with the prior art, the method has the advantages of high computation efficiency, high precision, high universality and the like.

Owner:SHANGHAI JIAO TONG UNIV

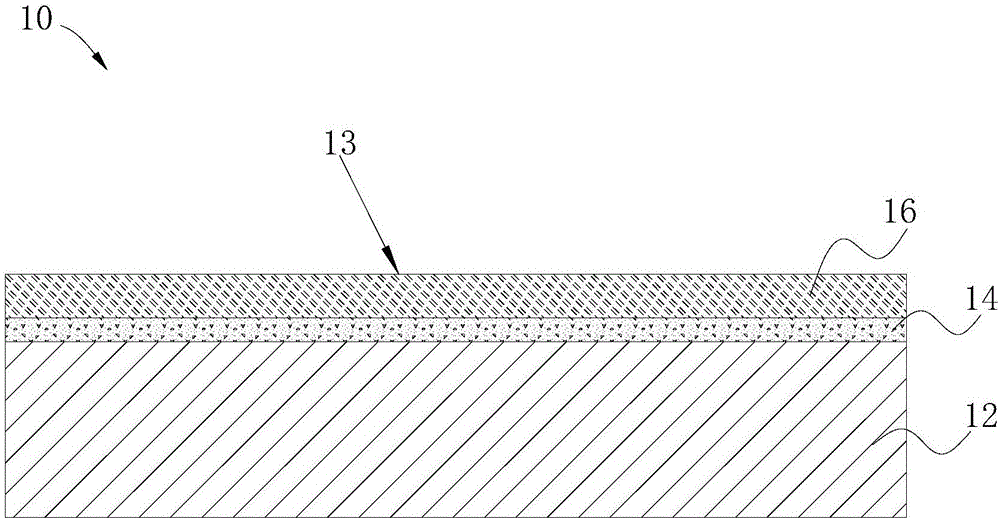

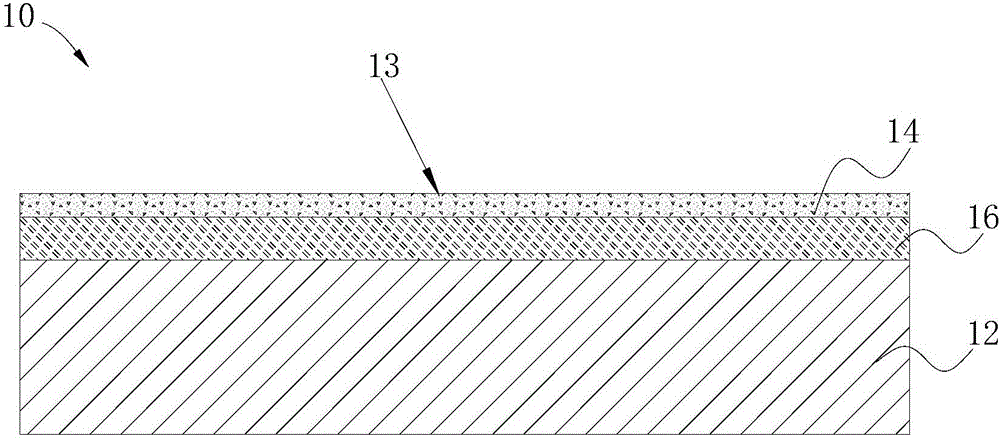

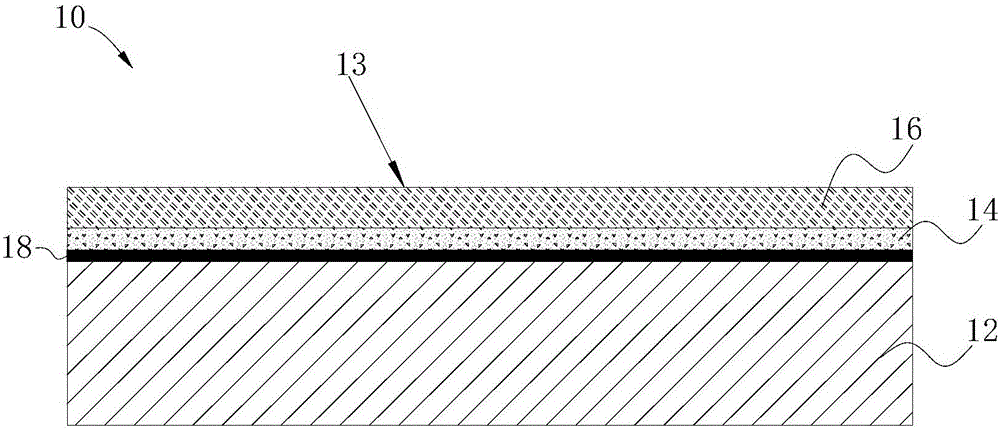

Shell, manufacturing method and mobile terminal

InactiveCN106534418ANot easy to fall offAvoid uneven colorVacuum evaporation coatingSputtering coatingFlagellar basal bodyMaterials science

The invention discloses a shell, a manufacturing method and a mobile terminal. The shell comprises a basal body and an optical film formed on the basal body; and the optical film is sintered on the basal body, so that the appearance expression colour of the basal body is adjusted. According to the shell in the embodiment of the invention, after being formed on the basal body, the optical film is attached onto the basal body in an enhanced manner through a sintering process; therefore, the optical film is difficult to fall off from the basal body; and the problem that the perceptive colour is non-uniform due to falling off of the optical film can be avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Alumina supporter for silver catalyst and silver catalyst

InactiveCN102688784AHigh activityHigh selectivityCatalyst carriersOrganic chemistryPorosityFlagellar basal body

The invention discloses an alumina supporter for a silver catalyst. The alumina supporter comprises a cylindrical basal body with a central passage, and at least three partially cylindrical valve leaflets separated at equal intervals, wherein the valve leaflets are integrally connected on the periphery of the basal body. The alumina supporter with a new shape has high surface area and porosity between the supporters, can effectively reduce the pressure drop of a catalyst bed of the reactor, optimize the flow condition in the catalyst layer, achieve better mass and heat transferring effect and improve the performance of the silver catalyst. The silver catalyst prepared by utilizing the alumina supporter has stable performance and higher activity and selectivity, and is particularly suitable for the reaction for producing ethylene oxide by ethylene oxidization.

Owner:CHINA PETROLEUM & CHEM CORP +1

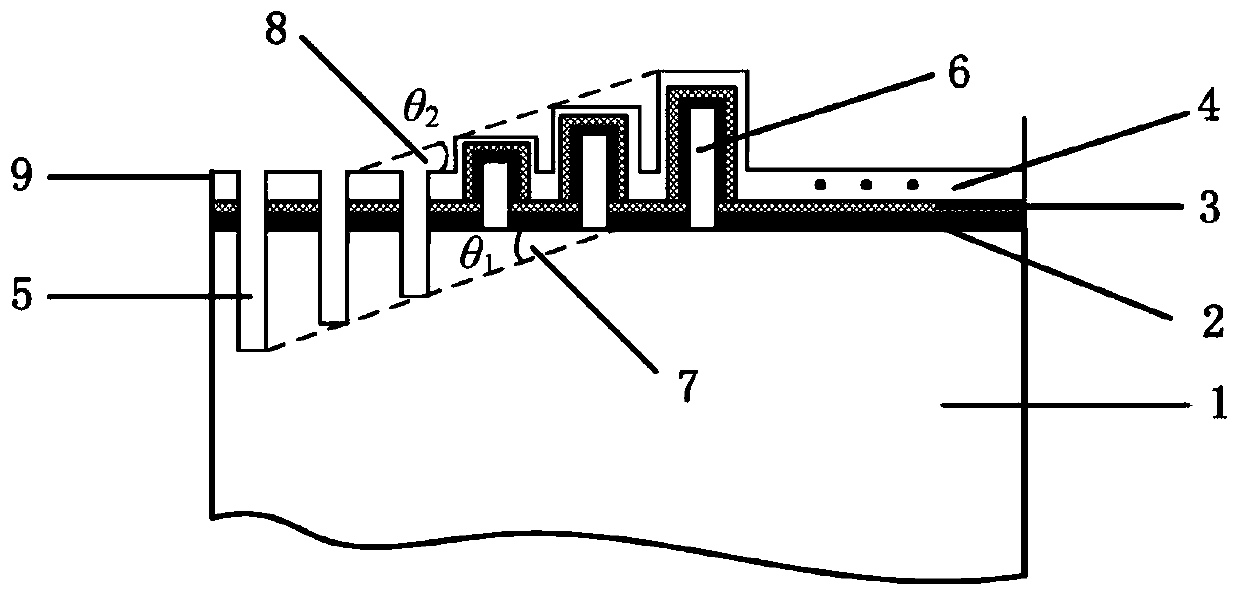

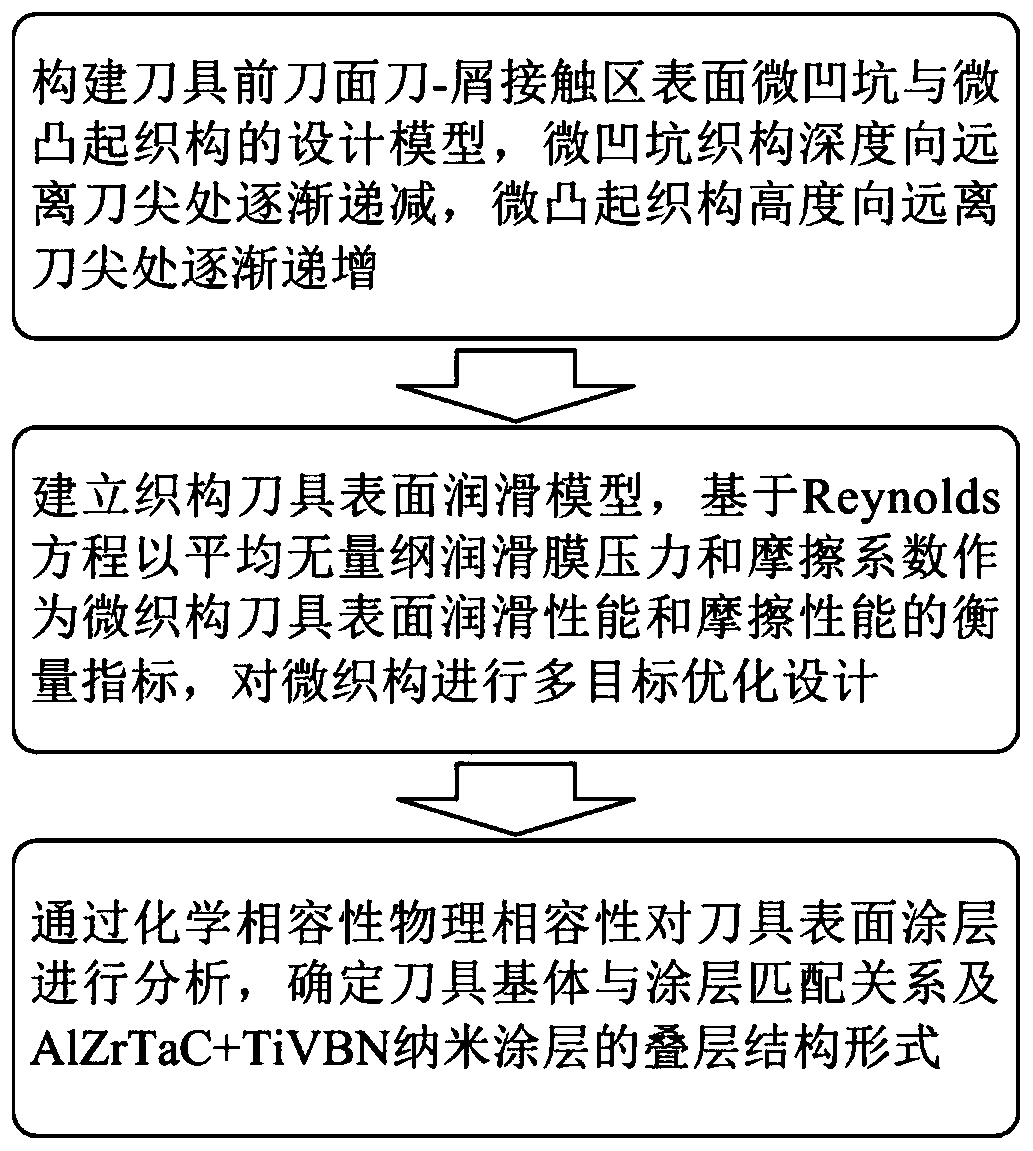

Bionic texture and coating layer cooperated anti-friction cutter and design method thereof

The invention discloses a bionic texture and coating layer cooperated anti-friction cutter and a design method thereof. The cutter adopts a basal body material of high-speed steel, hard alloys or ceramic; a bionic micro pit and micro projection composite texture is arranged in a cutter-chip contact area on the front cutter surface of the basal body material of the cutter; AlZrTaC+TiVBN alternate-distributed nanometer laminate coating layers are arranged on the surfaces of the texture and a basal body; the alternate laminate coating layers at least comprise single layers of 10 AlZrTaC layers and 10 TiVBN layers; and the thickness of the single layers of AlZrTaC and TiVBN is not bigger than100 nm. The design method of the cutter comprises the following steps: a design model of a micro texture on the surface of the cutter-chip contact area on the front cutter surface of the cutter is built; the oil film pressure and the friction coefficients of the cutter-chip contact interface are analyzed based on a Reynolds equation to optimize the geometric size of the micro texture and the depth or height gradual change dip angles theta 1 and theta 2; and through physical compatibility and chemical compatibility analysis, a laminate structural form of AlZrTaC+TiVBN coating layers is built. The cutter synthesizes the characteristics of the micro texture and the nanometer laminate coating layers, can reduce the friction and the wear of the cutter in the lubricating liquid cutting process, and can be widely applied to the cutting in the cutting liquid mode.

Owner:SOUTHEAST UNIV

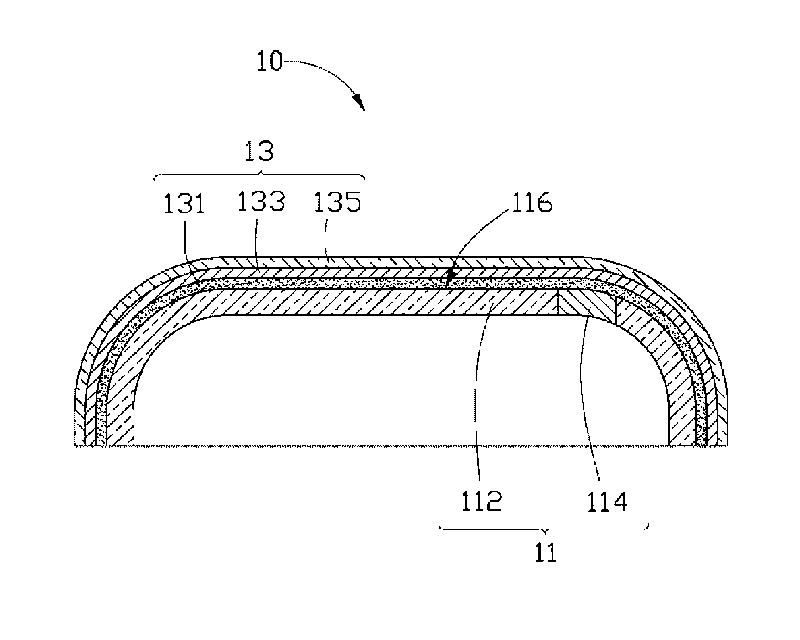

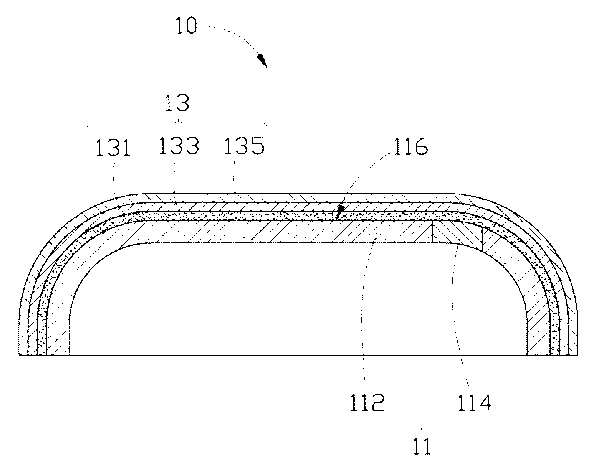

Shell and manufacture method thereof

InactiveCN101730410AHigh mechanical strengthSkip the assembly processMagnetic/electric field screeningDecorative surface effectsFlagellar basal bodyLacquer

The invention provides a shell, comprising a basal body and a decorative film formed on the surface of the basal body. The basal body is integrally formed by a metal component and a plastic component; one surface of the basal body is formed by the metal component and the plastic component together; the decorative film is formed on the surface of the basal body and comprises a priming layer directly formed on the surface of the basal body, a non-conductive vacuum film coating layer formed on the surface of the priming layer and a transparent protective lacquer layer formed on the non-conductive vacuum film coating layer. The shell not only has higher mechanical strength, but also can satisfy the radio frequency requirement of an electronic device and has uniform metal appearance effect. The invention further provides a method for manufacturing the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

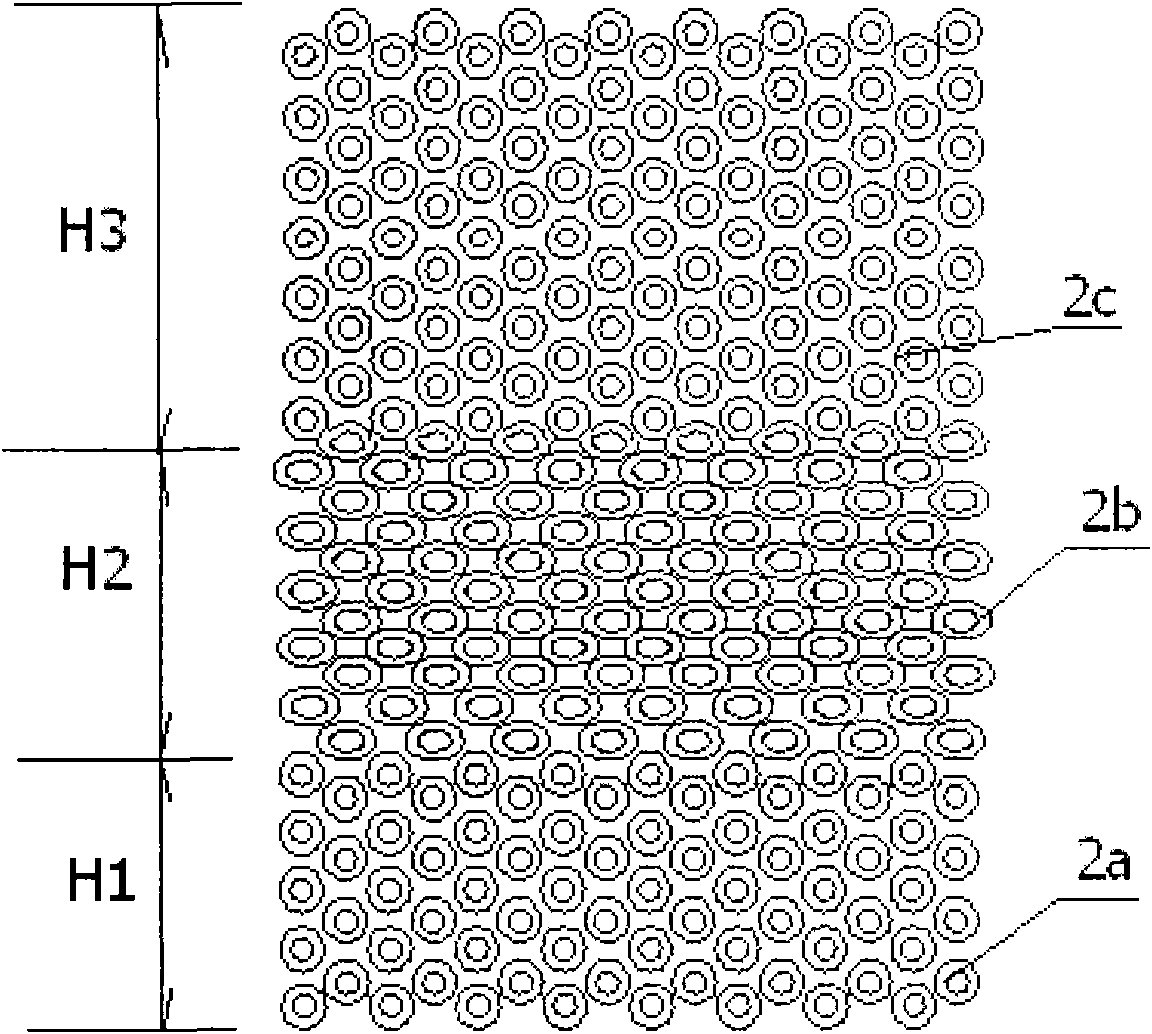

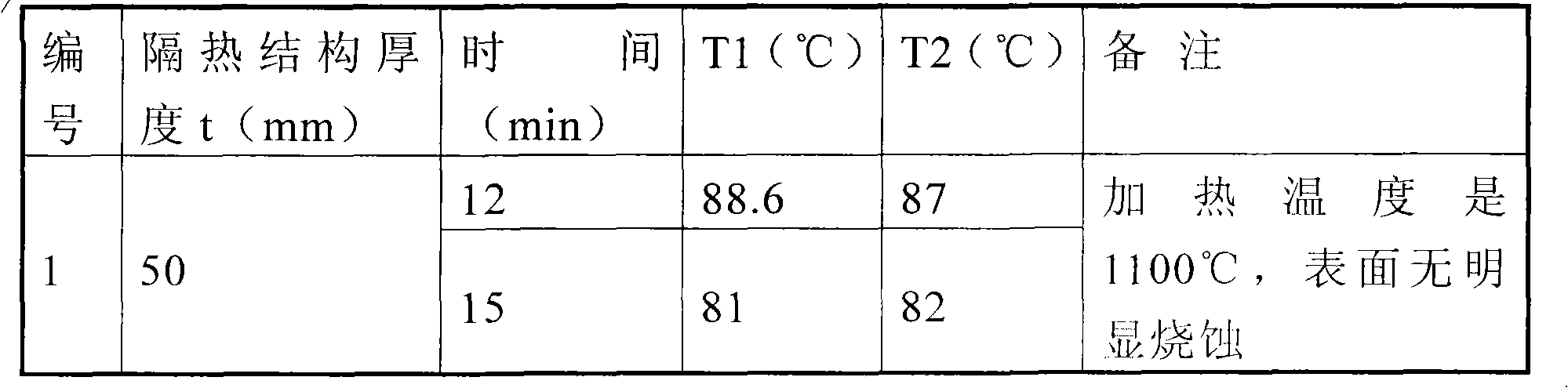

Novel inorganic thermal protection structure and manufacturing method thereof

InactiveCN101648598ALow densityLow ablation resistanceLaminationLamination apparatusFlagellar basal bodyFiber

The invention discloses a novel inorganic thermal protection structure and a manufacturing method thereof. The novel inorganic thermal protection structure comprises an aluminum alloy basal body, a heat insulation layer and a heat-protection layer, wherein the heat insulation layer is a space reticular structure with a plurality of staggered hole gaps, the staggered hole gaps comprise a hollow sleeve pipe braided by a plurality of layers of quartz fibre wound on the aluminum alloy basal body, and the heat-protection layer is a model body which is formed by pressing a silicon nitride powder body and is matched with the heat insulation layer. The internal diameter of the quartz fibre sleeve pipe is 0.5-1.0 mm. The quartz fibre sleeve pipe is wound by a wet method, and the distance of the sleeve pipe is 1-4 mm; the quartz fibre sleeve pipe comprises the following parameters from the inside to the outside: the internal ring direction winding layer thickness H 1 is 1-4 mm, the spiral winding layer thickness H2 is 20-35 mm, and the external ring direction winding layer thickness H3 is 5-20 mm; the winding parameter of the spiral winding layer thickness is 75-85 degrees, and the winding direction between layers is formed by opposite superposition. The thickness of the silicon nitride heat-protection layer is 2-4 mm.

Owner:国营江北机械厂

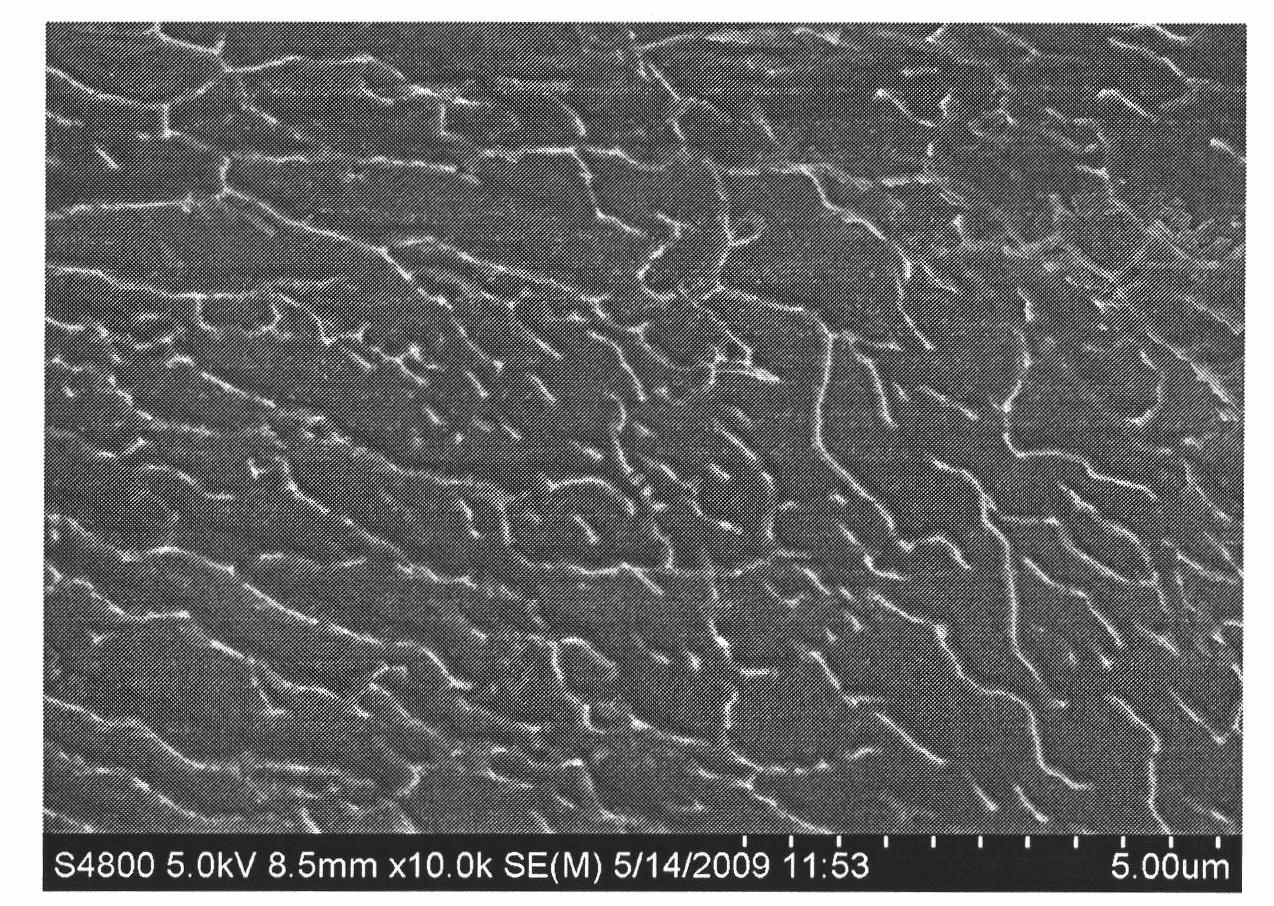

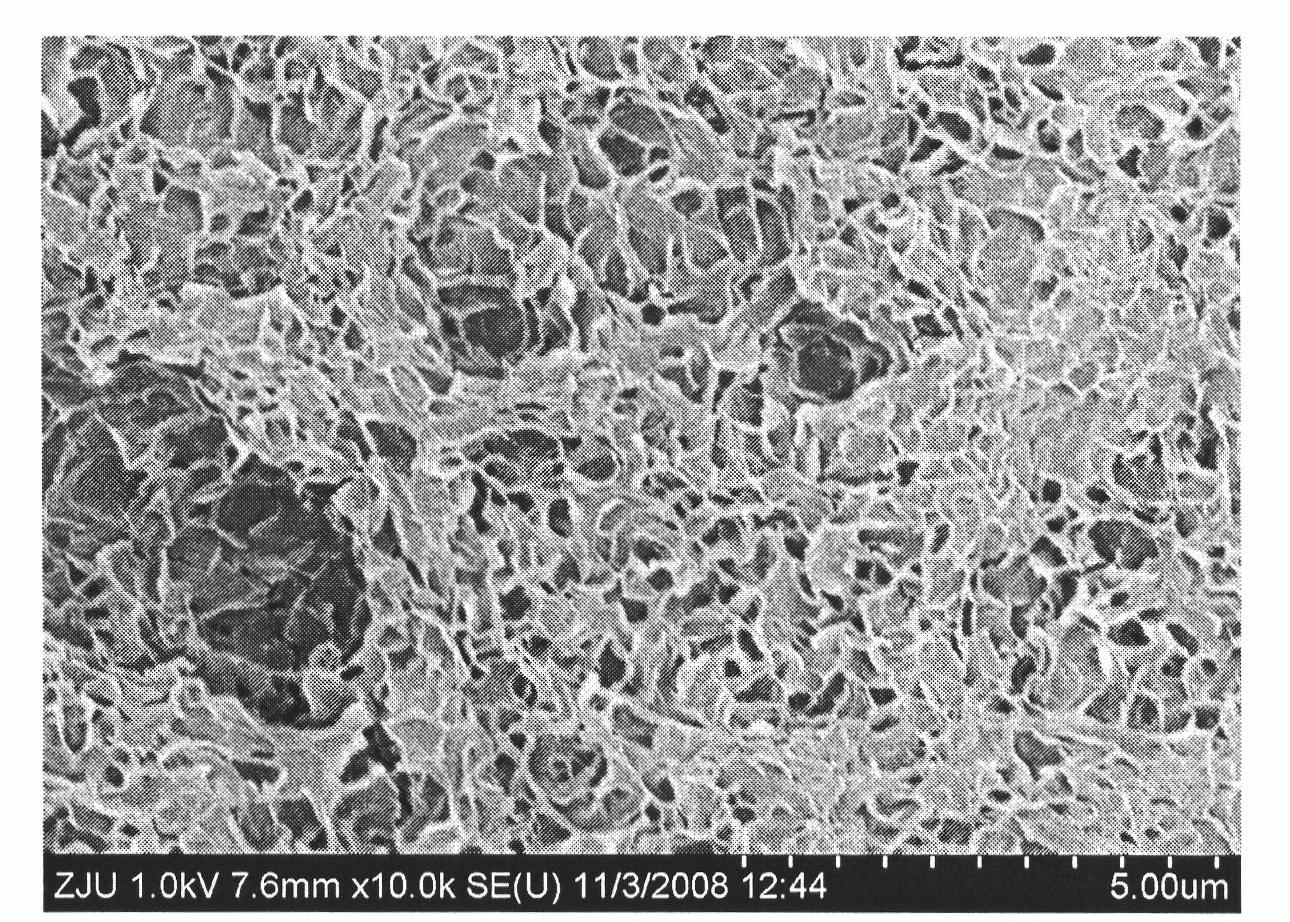

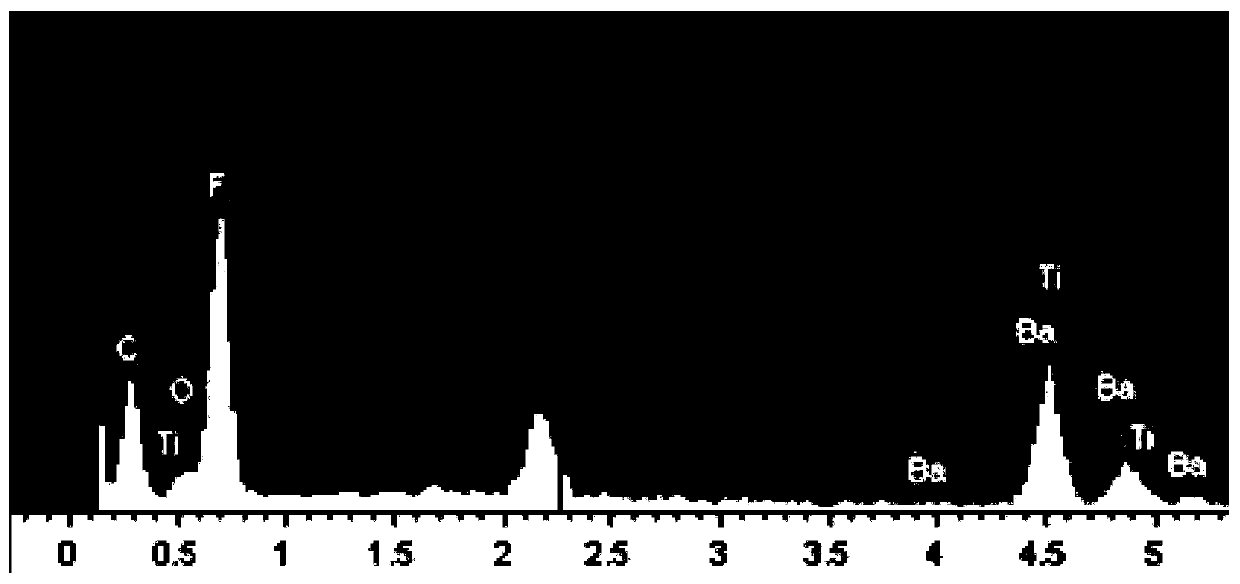

Heterogeneous layered mineralized coating on surface of medical implant and preparation method thereof

InactiveCN102028969ASimple and fast operationProsthesisElectrolytic organic material coatingCross-linkElectrochemical response

The invention discloses a heterogeneous layered mineralized coating on the surface of a medical implant. The surface of the medical implant is sequentially provided with a dense chitosan layer, a porous mineralized chitosan layer and a mineralized collagen / chitosan cross-linking layer from bottom to top. With Collagen, chitosan, a calcium-containing compound and a phosphorus-containing compound as raw materials, the heterogeneous layered mineralized coating is assembled once on the surface of a medical metal basal body through electrochemical reaction in a water solution, and the deposition state of each phase can be adjusted by adjusting the electrolytic deposition parameter, therefore, the heterogeneous layered mineralized coating is prepared. The method provided by the invention is simple and feasible and high in controllability; the medical material coating prepared with the method can promote the attachment and the propagation of cells on the surface of the coating and has a function of carrying drugs and enhanced bioactivity; and the bonding strength of the coating and a metal base plate is high, and the stability is favorable.

Owner:ZHEJIANG UNIV

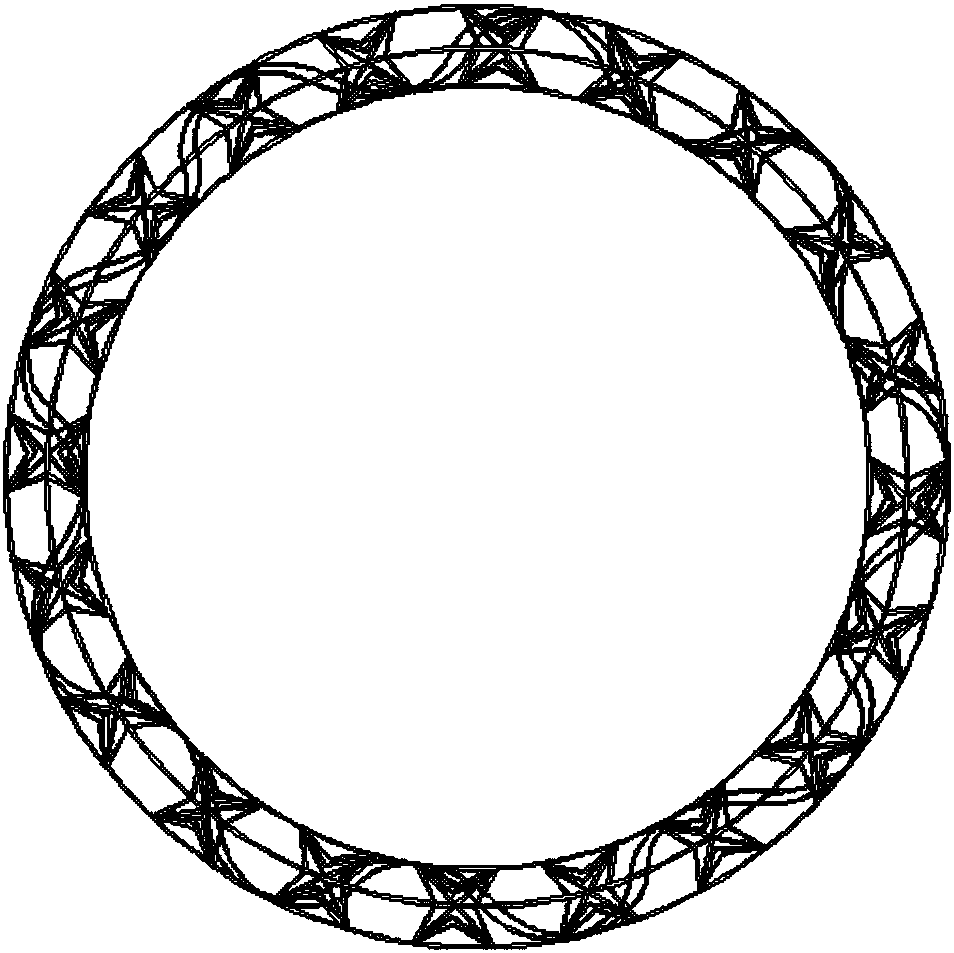

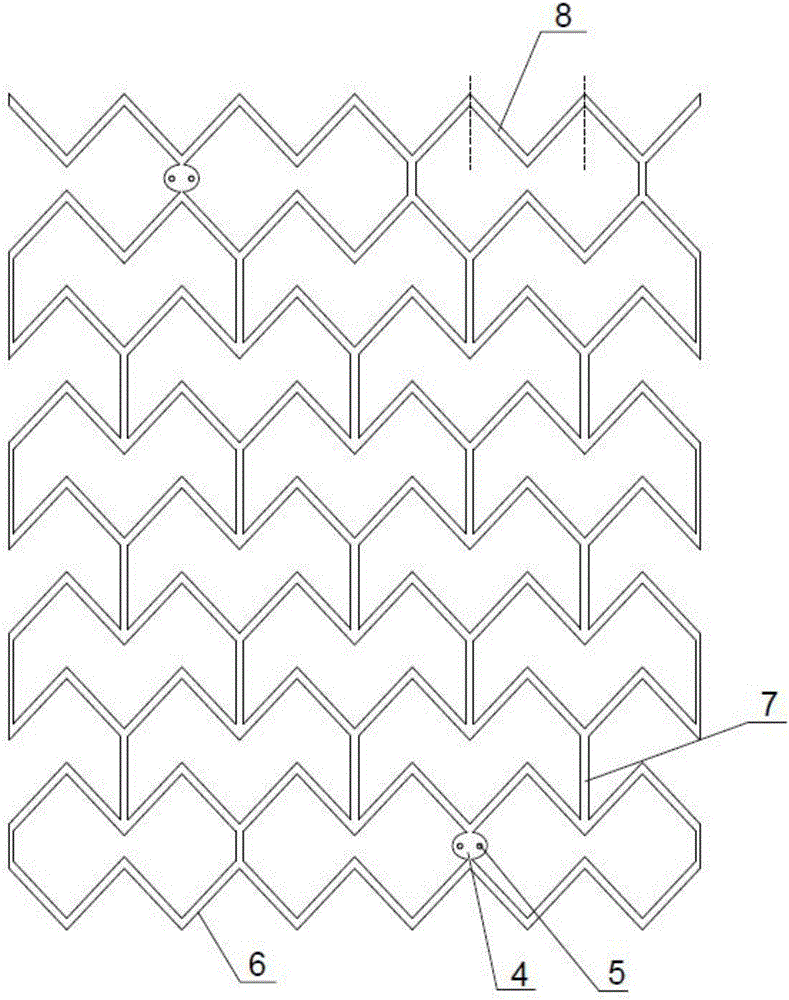

Three-dimensional vector expansion cardiovascular stent with memory effect based on 4D printing and manufacturing method

ActiveCN108403256ASufficient expansion forceReduce harmStentsAdditive manufacturing apparatusFlagellar basal bodyCardiovascular stent

The invention discloses a three-dimensional vector expansion cardiovascular stent with a memory effect based on a 4D printing and manufacturing method. The stent is made by metalprinting a metal material with a vector expansion effect and comprises multiple net annular wires uniformly arranged in the axial direction and composed of inwards concave hexahedral grid basic units, multiple layers of the net annular wires are arranged in an array to constitute a stent main body, and an upper supporting ring and a lower supporting ring are connected to the net annular wires at the two ends of the stent main body respectively and fix the stent main body. The manufacturing method of the three-dimensional vector expansion cardiovascular stent comprises the steps of controlling the energy density oflaser area selecting melting, adjusting austenite-martensite phase change temperature, using different energy densities to form different parts of a basal body structure and achieving deformation adjustability of a formed cardiovascular stent based on temperature dependence change. Thus different parts of the stent have different expansion coefficients based on temperatures, so that the stent better adapts to the specificity and the thermal expansion of the shape of the blood vessel.

Owner:SOUTH CHINA UNIV OF TECH

Bionic electrical activity moldable titanium reinforced composite film material and preparation method thereof

ActiveCN110433343AImprove piezoelectric performanceGood flexibilityTissue regenerationProsthesisFlagellar basal bodyComposite film

The invention discloses a bionic electrical activity moldable titanium reinforced composite film material and a preparation method thereof. The bionic electrical activity moldable titanium reinforcedcomposite film material mainly consists of an electrical activity film material and a titanium mesh, wherein the electrical activity film material is a piezoelectric polymer film or a nanometer composite film consisting of a nanometer level piezoelectric ceramic particle filling and a piezoelectric polymer basal body; and the volume by percentage of the piezoelectric ceramic particle filling is 0-20%. Through adjustment of parameters of a preparation technology, bionic electrical properties and molding of a titanium mesh composite reinforced film can be controllably adjusted. The prepared electrical activity titanium mesh reinforced composite film material has favorable effects on performing bone implantation molding, maintaining bone mass and accelerating bone repair, is high in clinicalmaneuverability, is particularly suitable for clinical indications of extensive bone defect molding repair of bone stuffing implantation, oral cavity implant repair bone increment, tooth extraction socket site preservation and the like. The preparation method which is adopted is simple, and high in controllability, and can be applied to industrial production.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

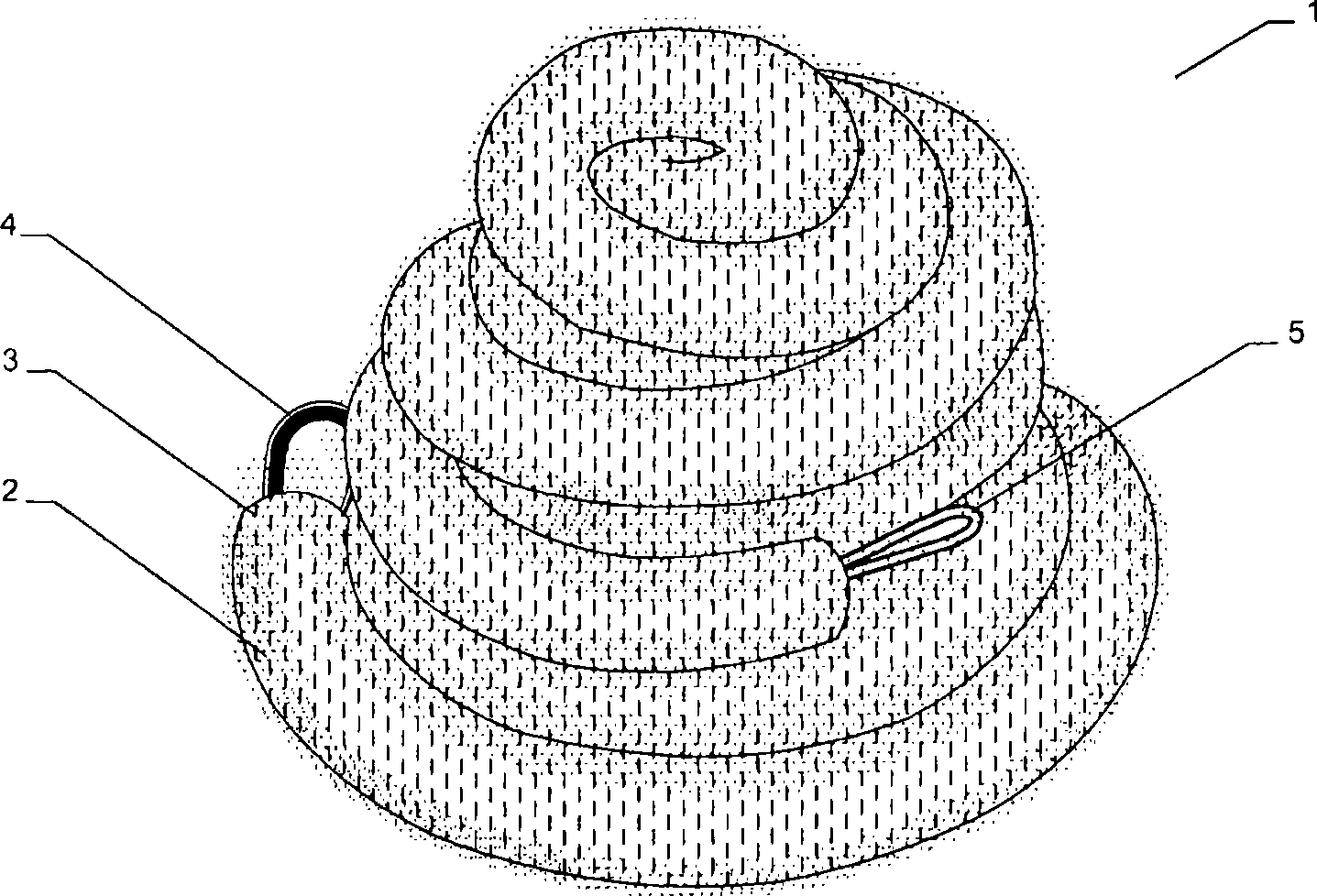

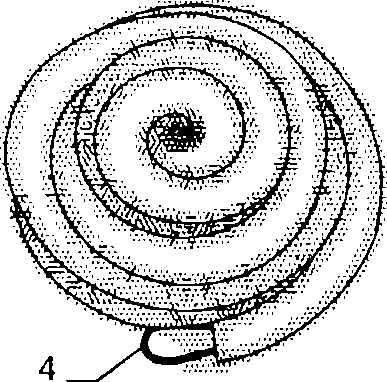

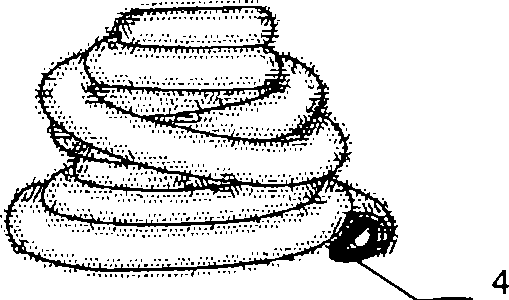

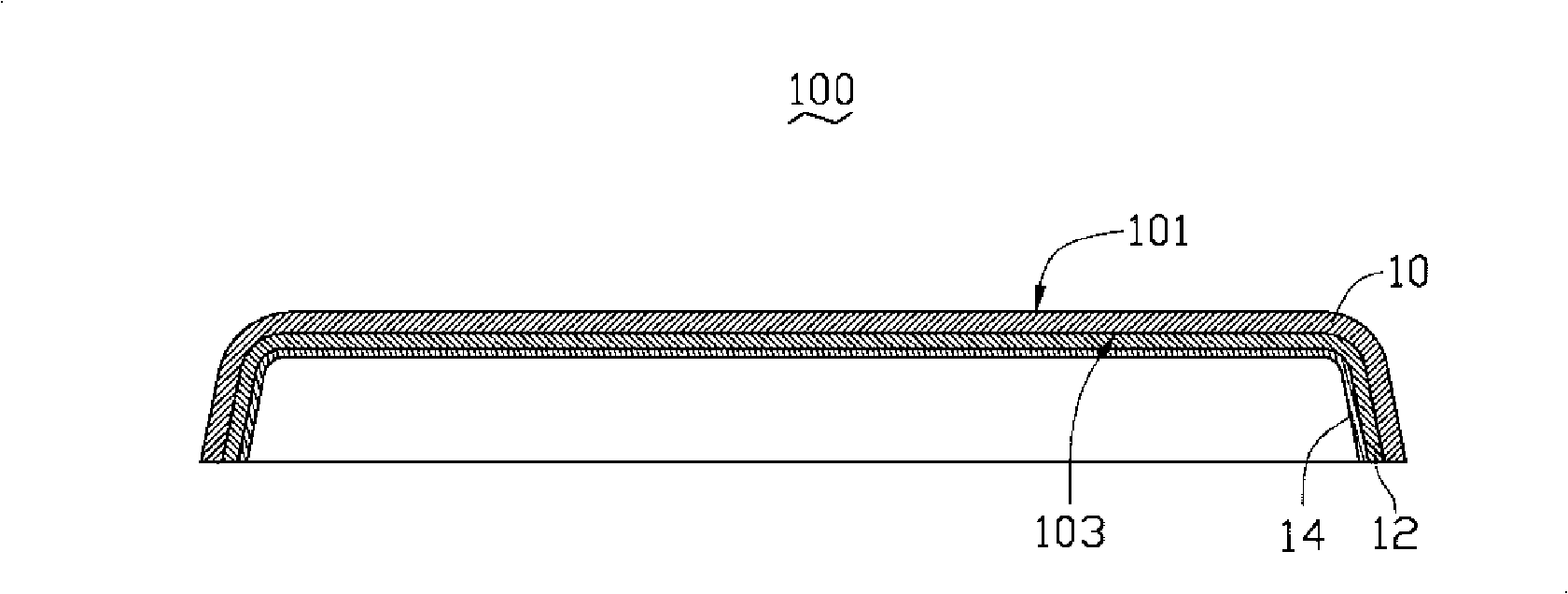

Embolization device

The invention relates to an embolization device (1) comprising a basal body (3) and at least one thrombogenic fibre (2) forming thrombus, wherein the basal body can be converted from an elongate primary shape to a secondary shape, the at least one thrombogenic fibre is arranged in a configuration wound around the basal body. In a method for producing an embolization coil of this kind, a primary coil (30) forming a basal body (3) of the embolization coil (1) has at least one thrombogenic fibre (2) wound around it, and the primary coil (30) is converted in shape to a secondary coil.

Owner:PFM医疗制品股份公司

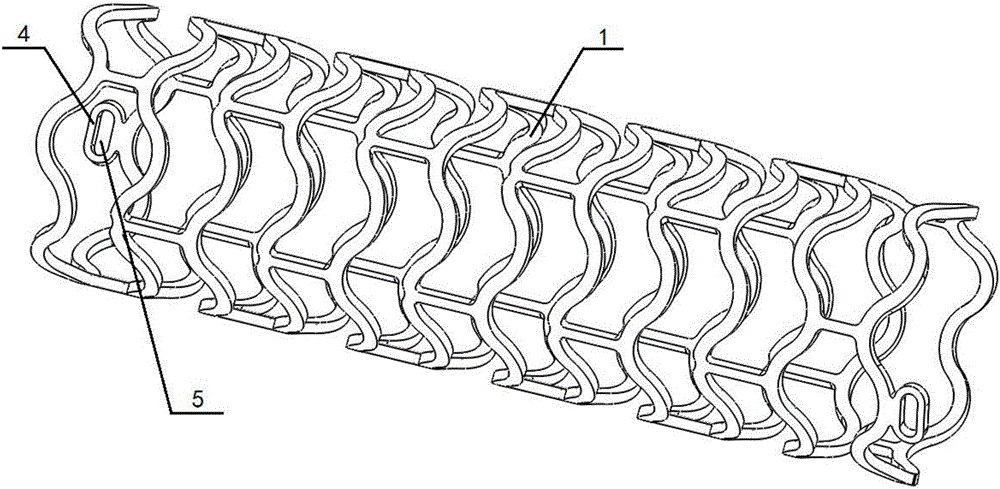

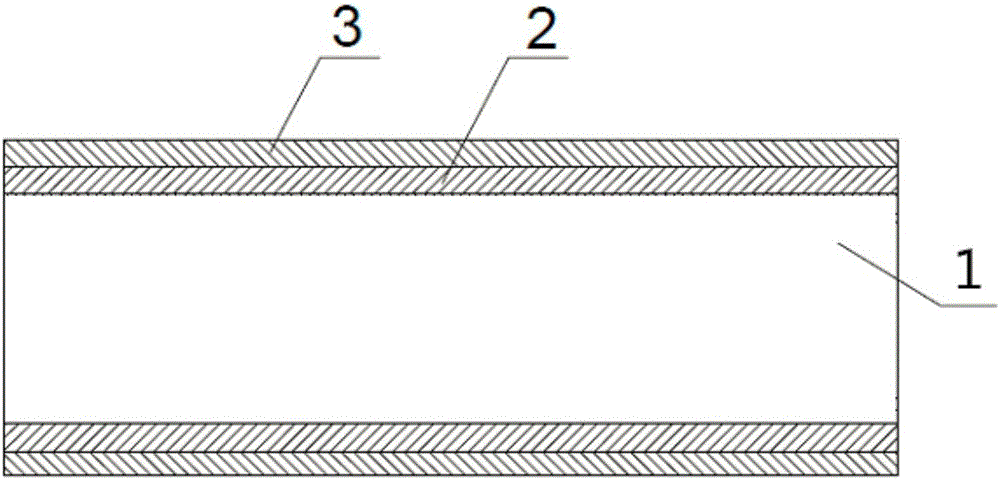

Full-degradable vascular stent for vascular disease treatment and production method of full-degradable vascular stent

ActiveCN106039425AAvoid long-term medication problemsImprove performanceSurgeryCoatingsFlagellar basal bodyVascular disease

The invention provides a full-degradable vascular stent for vascular disease treatment. The full-degradable vascular stent is consisted of a stent body which is shaped like a circular tube and coating covering the stent body; the surface of the stent body is of a hollow-out reticulate structure engraved by laser; image marking pieces are respectively arranged at two ends of the stent body, image marking holes are arranged in the image marking pieces, and imaging objects are arranged in the image marking holes. The production method of the full-degradable vascular stent includes the steps of 1), preparing raw materials; 2), processing the raw materials into tubular products; 3), strengthening and toughing the tubular products; 4), preparing the stent body; 5), pressing the imaging objects into the image marking holes; 6), producing the drug coating and top controlled-releasing layers. The stent body is produced by adopting full-degradable material, so that the stent body can be gradually and fully absorbed by a basal body after implantation, and the problem about long-term medication of patients is solved; the imaging objects are arranged at two ends of the stent body, so that tracing role of the imaging objects can be well played during interventional operation; 3), the production method is simple in production, low in production cost, and the vascular stent produced is stable in performance.

Owner:乐普(深圳)国际发展中心有限公司

Biological medical material with biological responding coating and preparing method

InactiveCN1743014AHigh crystal contentHigh phase purityCoatingsFlagellar basal bodyBiomedical engineering

The present invention discloses a biological medical material with biological resposibility coating layer and its preparation method. It is formed from medical basal body and metal-iron-doped fluorine-contained hydroxy apatite nano coating layer coated on the surface of medical basal body. Said biological medical material can stimulate osteoblast differentiation and proliferation in early stage of implatation, can promote growth of bone and can accelerate cure process. Said invention also provides the concrete steps of its preparation method.

Owner:ZHEJIANG UNIV

Liquid crystal hydroxyl apatite/polymer compound aeolotropy bone substitute material and preparing method thereof

InactiveCN101199869AHigh tensile strengthImprove bending strengthProsthesisFlagellar basal bodyApatite

Disclosed is a liquid crystal hydroxyapatite / polymer compounded anisotropic bone-substituted material and the preparation method, including the following steps: (1) dissolve hydrophilic macromolecule polymer with polarity into organic solvent; (2) mix together with proper n-HA liquid crystal to have liquid crystal n-HA particles arranged evenly in the polymer; (3) heat the mixing liquid to volatilize organic liquid; (4) freeze the condensate of the mixing liquid under a super-low temperature to fix the orderly arrangement of n-HA in the polymer; (5) dry for 24 hours; (6) after hot briquetting, get n-HA / polymer biological composites. The n-HA is stick-shaped liquid crystal particles with the diameter of 12-20nm and the length of 200-300nm and distributes evenly in polymer basal body along certain direction, so that the mechanical property along the n-HA arranging direction is optimized greatly, that is, the bionical simulation of the natural bone is achieved from the aspects of component, texture and performance. Thereby, the using requirement for clinic load-bearing bone material can be satisfied.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Conducting powder by using laminar soilicate mineral as basal body, and preparation method

InactiveCN1728287AWidely distributedLow priceConductive materialClaywaresFlagellar basal bodyCarbon film

The current conducting powder is mineral of layer silicate clad by carbon film. Method includes steps: (1) mixing one portion of mineral of layer silicate (weight) with 3-8 portions of water; adding 0.01-0.05 portions of dispersant into the admixture; mixing round to make the admixture even by dispersion emulsion machine with high shear to obtain suspension ore pulp; (2) carrying out spray drying the ore pulp to obtain powder of mineral of layer silicate; (3) under 300-500 deg.C, inducting nitrogen into powder of mineral of layer silicate so as to obtain their admixture; under 500-900 deg.C, inducting gas from carbon source into the said admixture to produce powder with mineral of layer silicate as basal body. Cost of raw material is low, since mineral of layer silicate is wide distributed. Comparing with conducting powder in carbon or metal series, the disclosed powder possesses advantages of easy of purification and decentralization, stable and high ration of performance.

Owner:ZHEJIANG UNIV

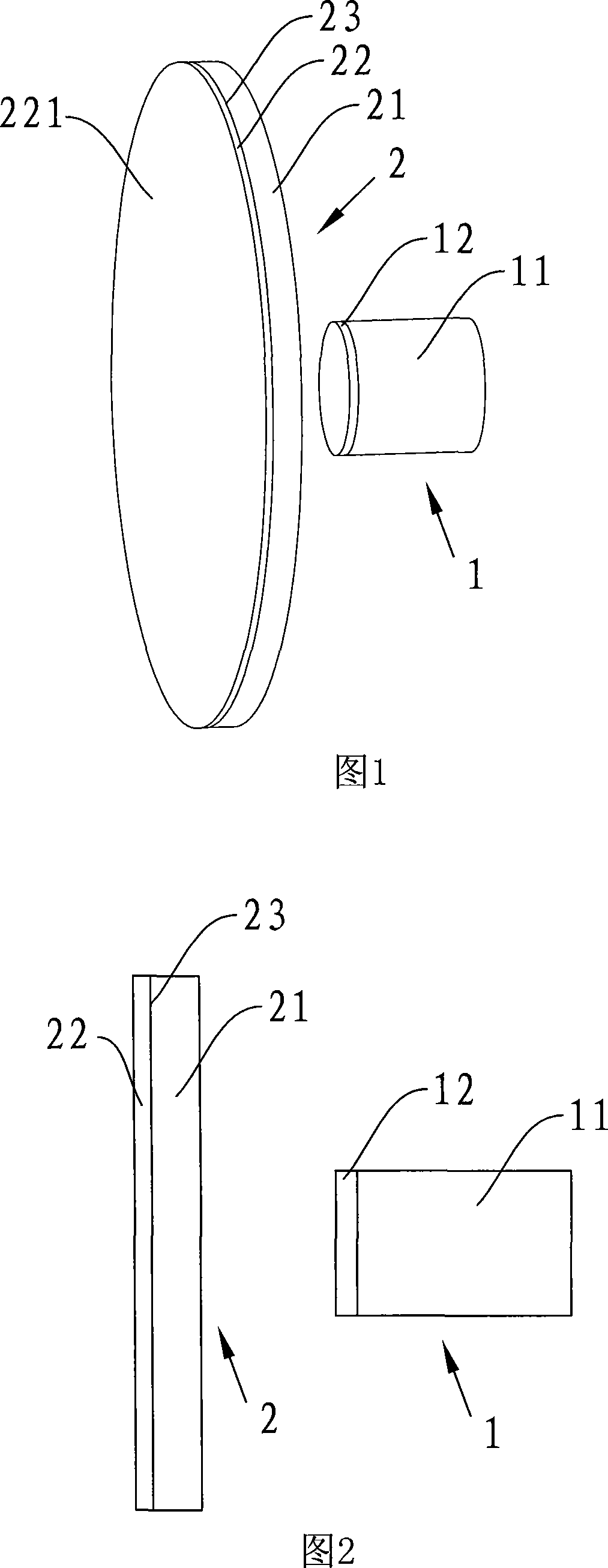

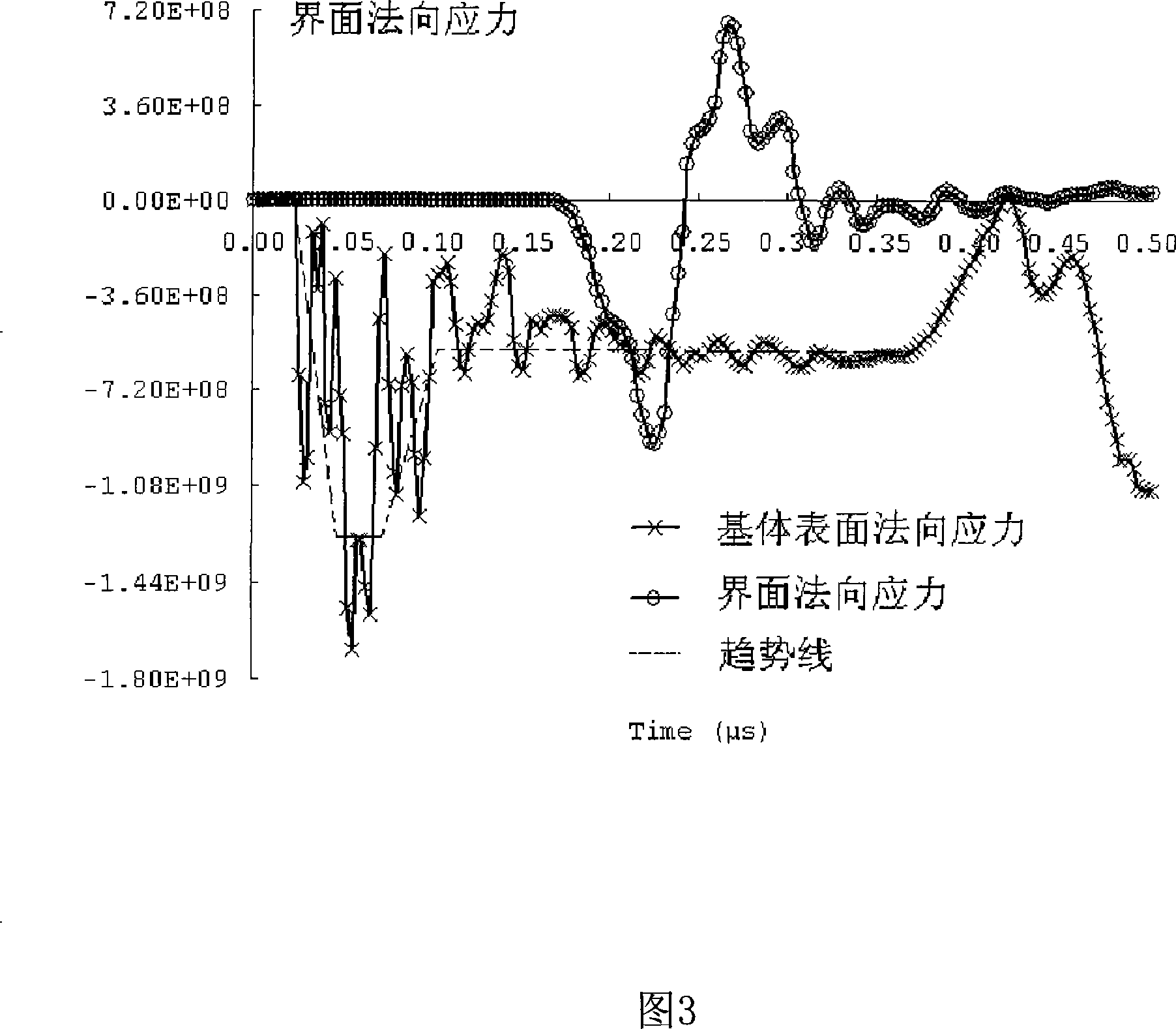

Bullet impact method for testing coating/ thin film basal body interface bond strength

InactiveCN101236152AEasy to operateThe principle is simpleUsing mechanical meansMaterial analysisFlagellar basal bodyInterface bond

The invention discloses a bullet impact method for measuring coating / film-basal body interface bonding strength, which comprises the following steps of preparing a flat plate sampling covered by the coating to be measured; preparing a bullet with coating, wherein the basal body of the bullet being made of material with lower acoustic impedance; firing out the bullet with a launching device to enable the bullet to impact the basal body surface of the sample with the coating part of the bullet being perpendicular to the basal body surface; measuring the initial speed of the bullet when touching the sample, and obtaining the sample coating / film-basal body interface stress history according to the known numerical calculation and theoretical analysis; measuring the coating / film-basal body interface stripping characteristic size of the sample, and establishing the relationship between the coating / film-basal body interface stress history and the coating / film-basal body interface stripping characteristic size to evaluate the coating / film-basal body interface bonding performance. The invention which has a simple principle and a clear model is capable of measuring the coating / film-basal body interface bonding performance of a tight bonding coating and the coating / film-basal body interface dynamic performance with high operationability.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Hard coating hardness measuring method

InactiveCN1423115ASolve the technical problems of hardness measurementAccurate measurementInvestigating material hardnessFlagellar basal bodyHardness

First, the technique of the tiny mechanics probe is adopted to carry out the first step of the indentation detecting of the composite body of the coating layer / basal body. In the indentation detecting, the load is applied to the indenter, making the deformation zone in front of the indenter expand to the basal body. The varying relation between the indentation load and the indentation depth is recorded. Based on the change of the indentation depth, the hardness of the compoiste body of the coating layer / basal body under the loaded condition is calculated out. Further, the varying curve between the hardness and the indentation load is made. The second step of the indentation detecting is carried out under the coating layer without the influence of the deformation of the basal body. The invention possesses the features of the accuracy and reliable.

Owner:SHANGHAI JIAO TONG UNIV

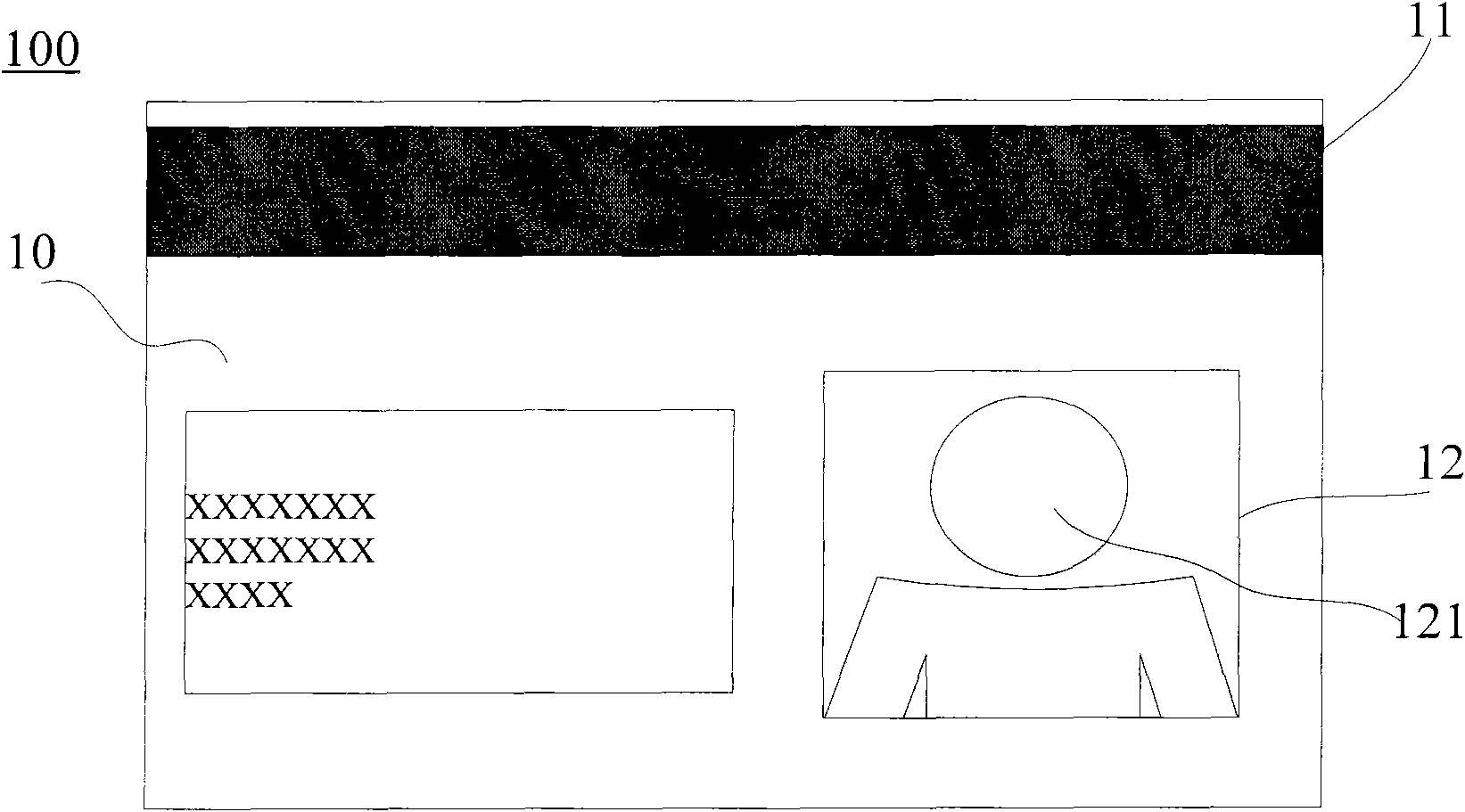

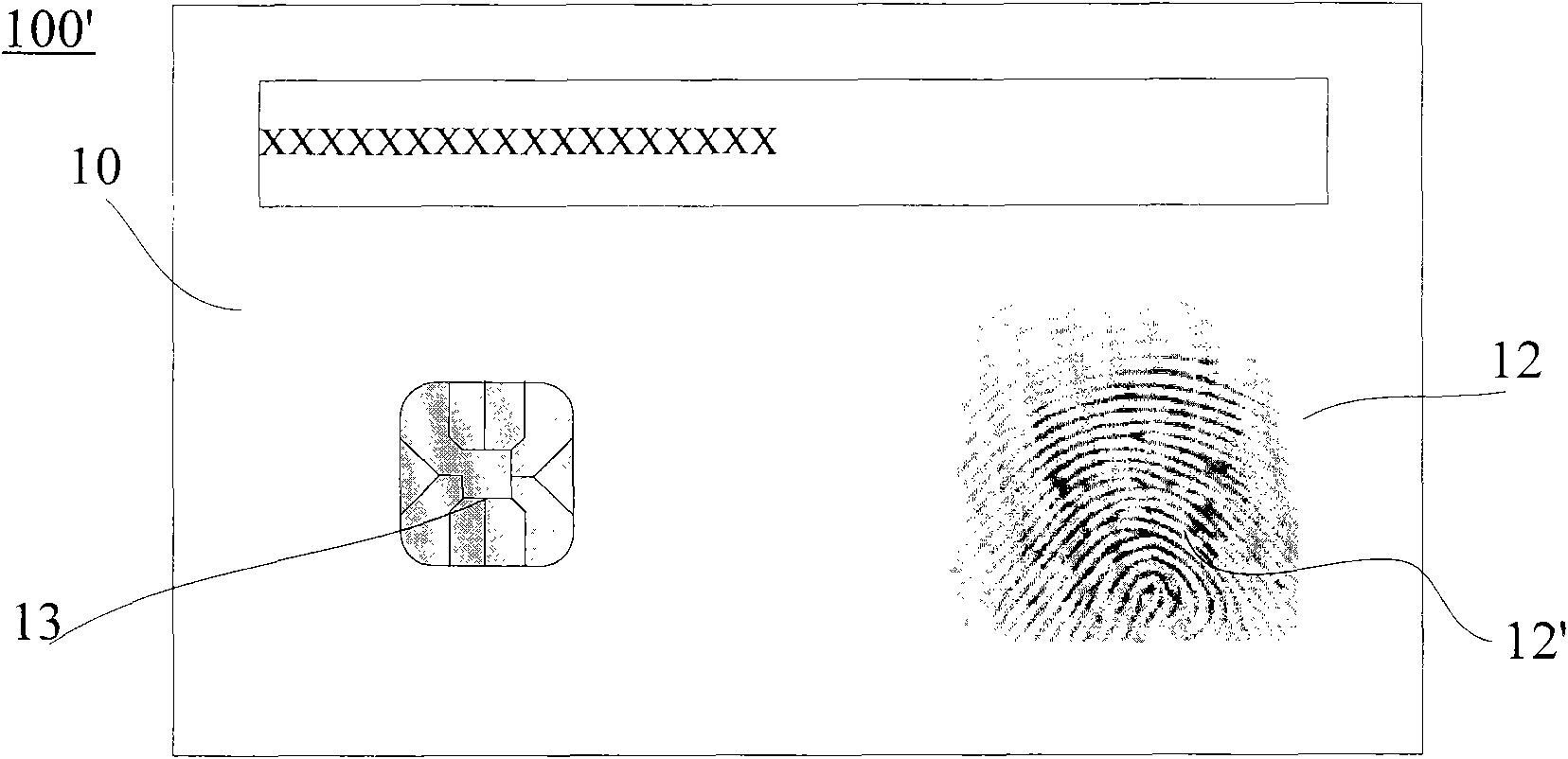

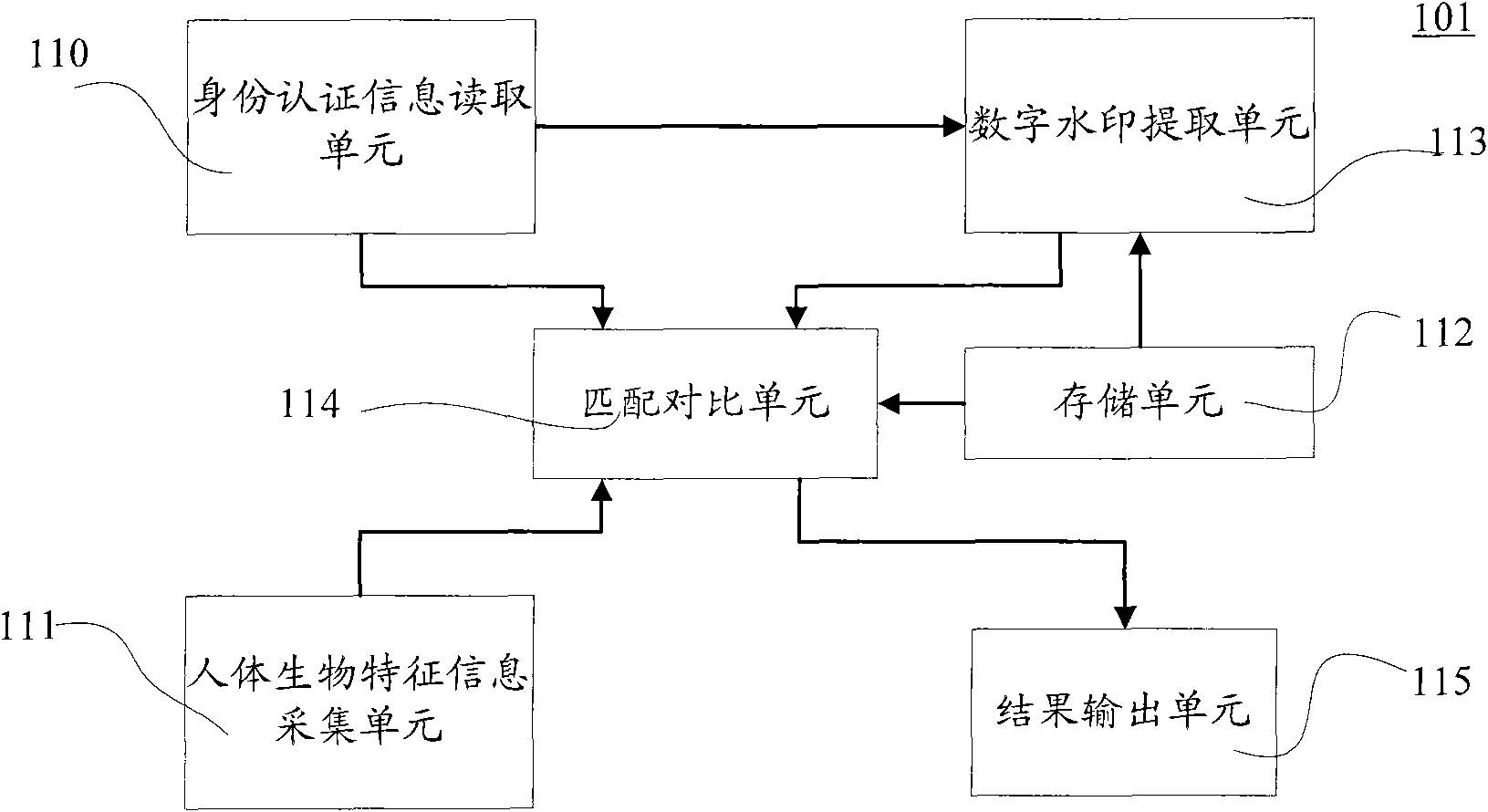

Security card, card authentication system, financial equipment with the same and authentication method

InactiveCN101777212AImprove post-processing efficiencyUniqueness guaranteedPayment architectureImage data processing detailsFlagellar basal bodyComputer hardware

The invention provides a security card and a card authentication system, in particular relating to a bank card with security authentication and a bank card authentication system. The security card adopts the means that after digital watermarks are embedded in the human body biological characteristic information of a legal owner, the human body biological characteristic information is bound with a card to solve the problem that the security card is copied or distorted to result in the embezzlement of the bank card. The security card comprise a slice-shaped basal body, at least one storage medium for storing the information of the card, and a load bearing medium of the identity authentication information of the legal owner of the security card, wherein the identity authentication information of the legal owner is the human body biological characteristic information encrypted through the digital watermarks. The image information of the human body biological characteristic information is preferably printed on the surface of the card, wherein the image information of the human body biological characteristic information comprises faces, fingerprints, veins, irises and the like.

Owner:GRG BAKING EQUIP CO LTD

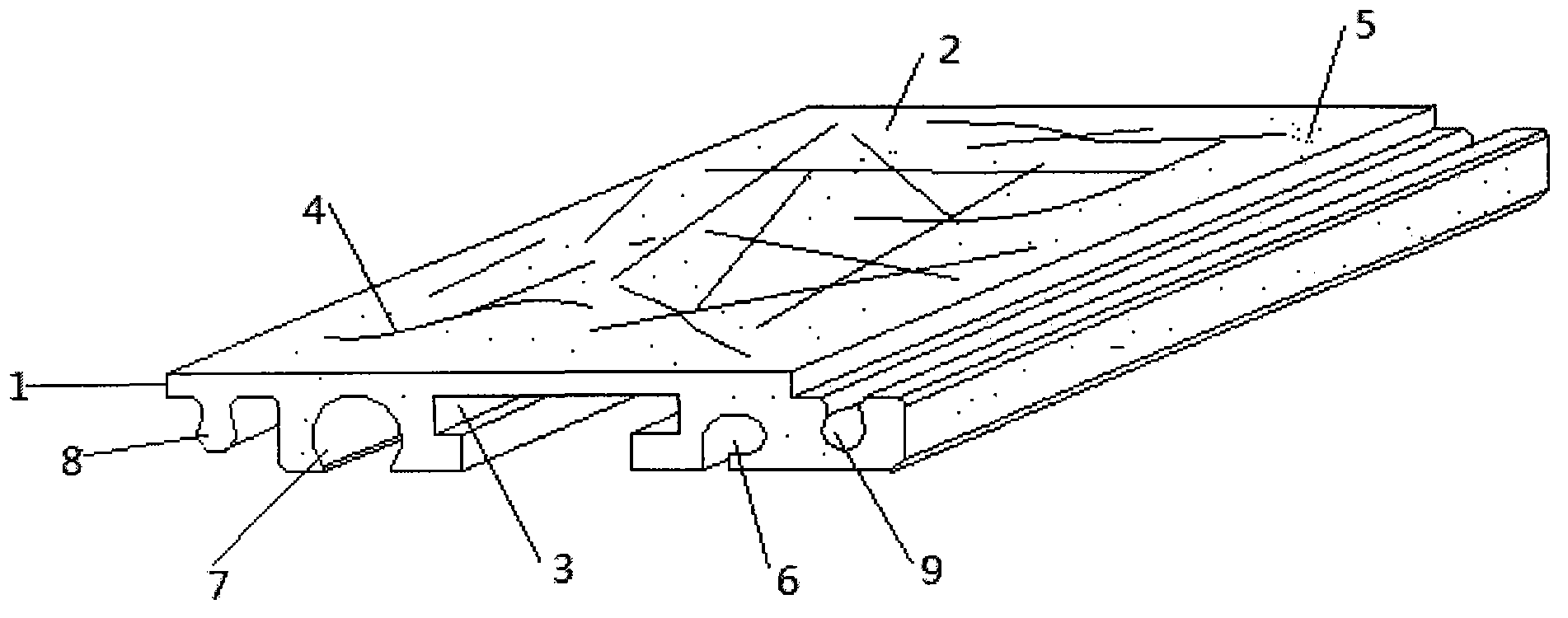

High thermal conductivity glass reinforced plastic ground heating floor

ActiveCN103225384AWith mechanical propertiesImprove thermal conductivityFlooringFiberFlagellar basal body

The invention discloses a high thermal conductivity glass reinforced plastic ground heating floor which comprises a floor basal body, wherein concave patterns are formed on one side of the floor basal body, the floor basal body is made of high thermal conductivity glass reinforced plastic, the high thermal conductivity glass reinforced plastic is prepared through the following raw materials according to weight ratio: 25 to 30 parts of resin, 30 to 40 parts of heat conducting carbon fiber, and 20 to 40 parts of heat conducting metal powder. The floor has an excellent mechanical property and a heat-conducting property, is convenient to mount and construct, and is beautiful and elegant.

Owner:李建生

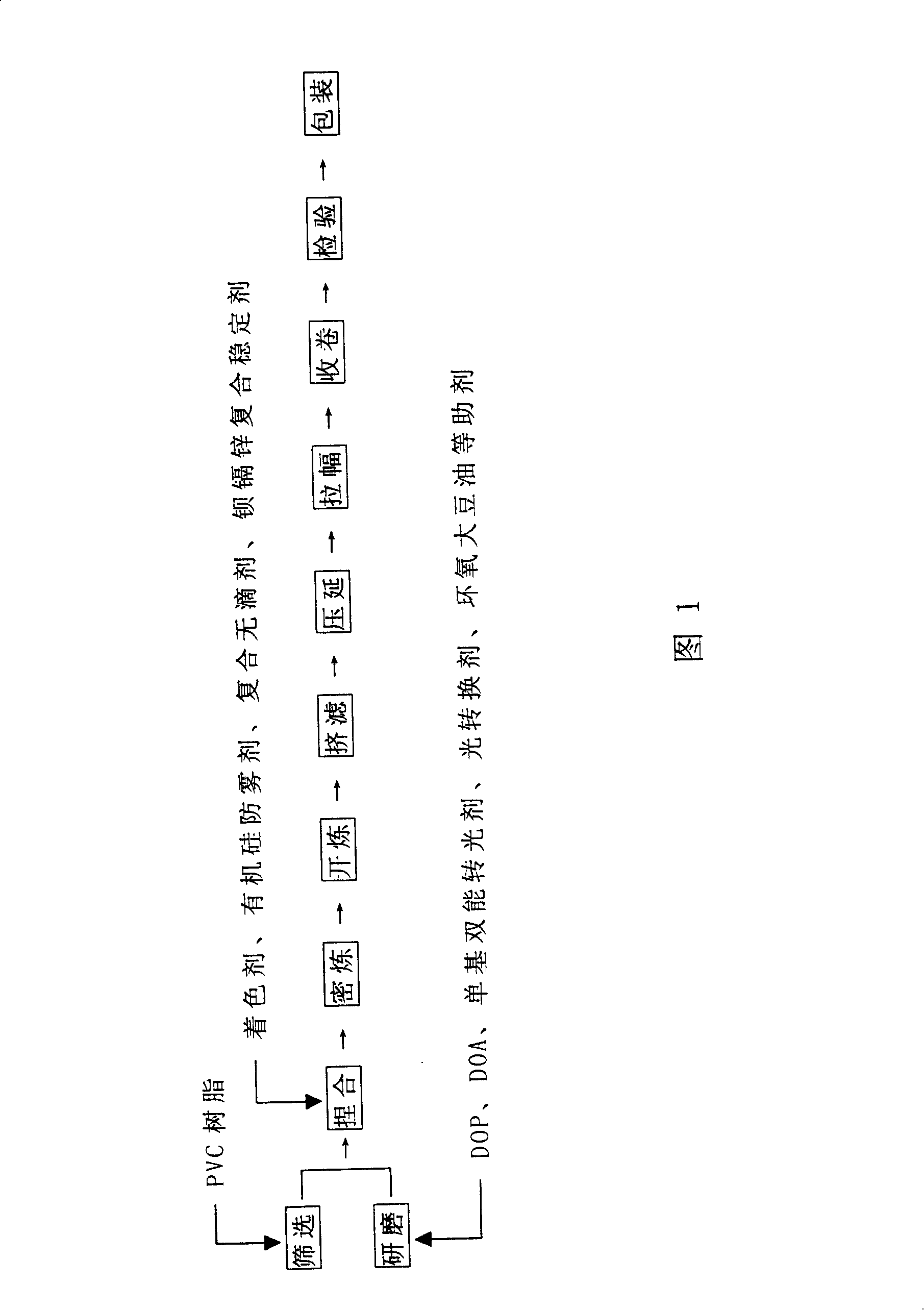

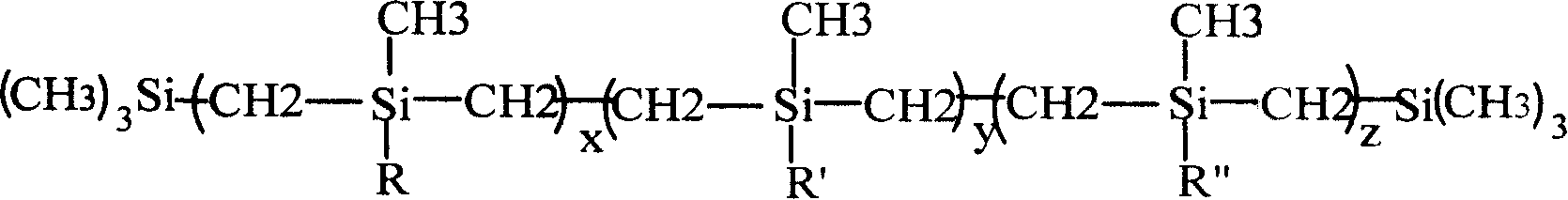

Polychloroethylene fruit tree special-purpose membrane

InactiveCN101230147AGood yieldImprove qualityClimate change adaptationGreenhouse cultivationFlagellar basal bodyPolyvinyl chloride

The invention relates to agricultural polyvinyl chloride shed film exclusively used for the fruit trees, which can adjust the transmitted spectrum of the sunlight in the greenhouse, promote the photosynthesis of the fruit trees, and improve the fruit quality and output. Polyvinyl chloride resin is taken as the basal body of the agricultural polyvinyl chloride shed film exclusively used for the fruit trees, plasticizer, heat stabilizer, ultraviolet absorber, compound dripless agent, organosilicon antifogging agent, hindered amine light stabilizer and light conversion agent, etc. are added in the basal body, and then the agricultural polyvinyl chloride shed film exclusively used for the fruit trees is prepared through the production process steps of reducing and tentering, etc. The invention can overcome the deficiency that the polyvinyl chloride film is produced by utilizing the ultraviolet absorber as the light stabilizer, during the novel polyvinyl chloride function film production, a method that the hindered amine light stabilizer and the light conversion agent with reasonable compounding ratio are added is adopted, to ensure that the light transmittance of the film is improved in a certain wavelength range, to play the effect on promoting the fruit coloring of the fruit tree in the shed.

Owner:白山市喜丰塑业有限公司

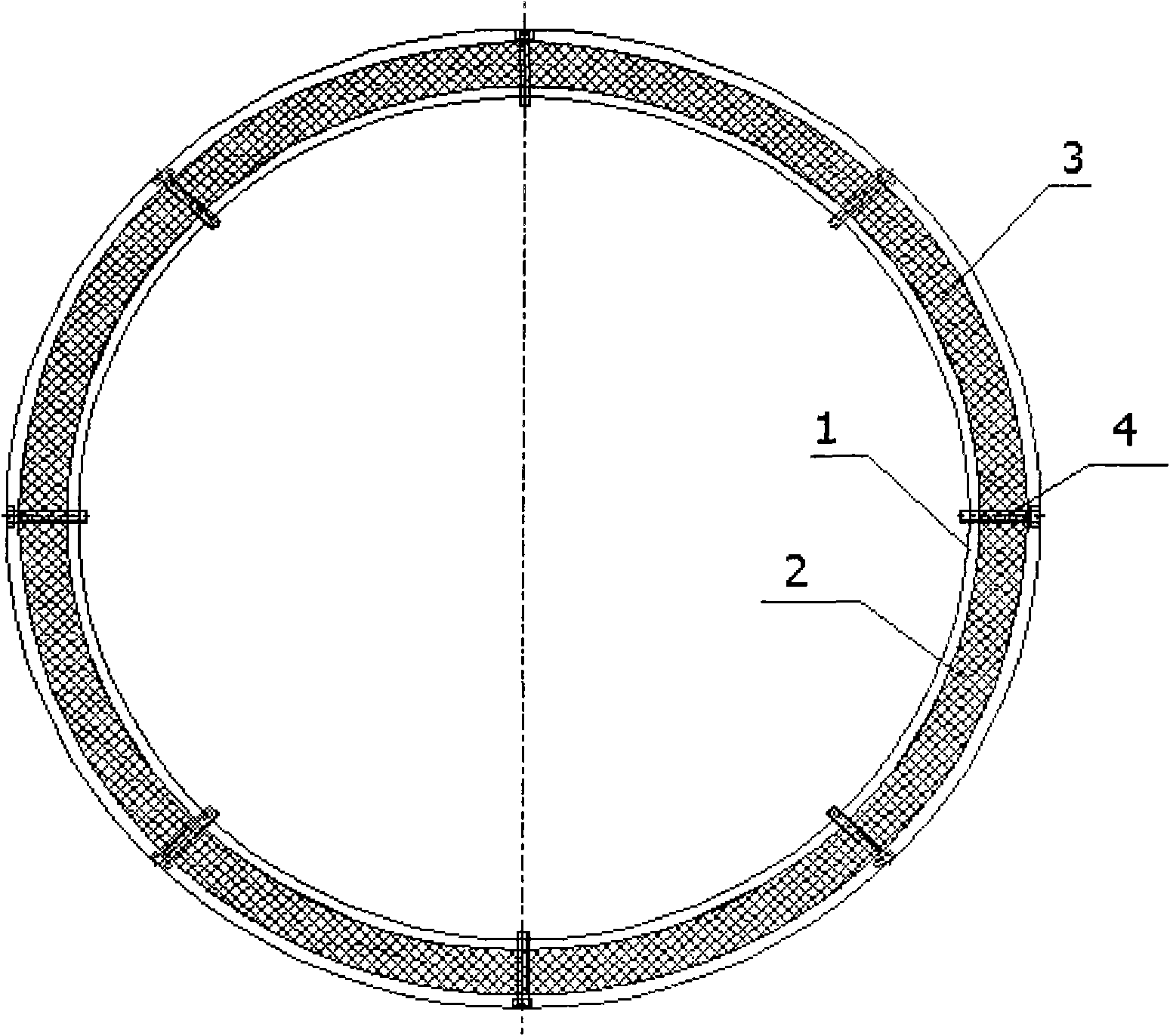

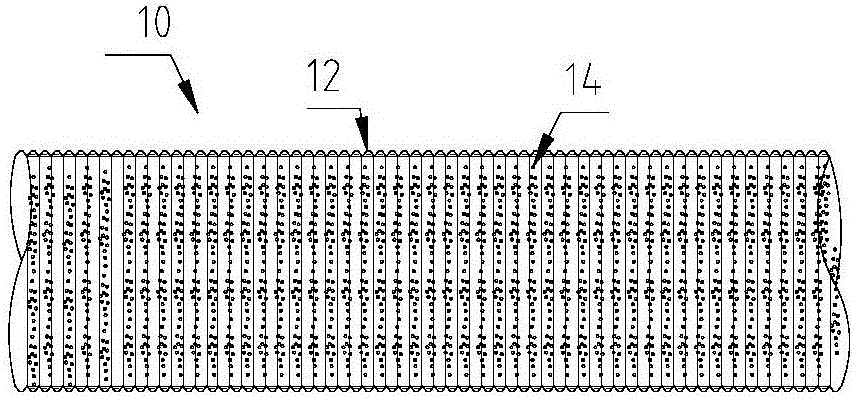

Composite artificial blood vessel

The invention discloses a composite artificial blood vessel, which can be implanted in a human body, and belongs to the field of processing of bio-medical materials. The composite artificial blood vessel comprises a reinforcing body and a basal body, wherein the reinforcing body is of a textile structure which constitutes a skeleton of the artificial blood vessel; and the basal body is made from a bio-compatible material; and according to a combining method, a basal body solution is uniformly spread in the surfaces and pores of the reinforcing body and is dried. The composite artificial blood vessel disclosed by the invention is good in penetration resistance and biocompatibility, so that a pre-operative preliminary coagulation operation is avoided, and the success rate of a surgery and the convenience of surgical operations are improved.

Owner:JIANGSU BIODA LIFE SCI CO LTD

Mo-Mo+Si+Al functionally graded material and preparation method thereof

InactiveCN101704310AImproved microcrack self-healing abilityImprove self-healing abilityLayered productsSolid state diffusion coatingSelf-healingFlagellar basal body

The invention relates to an Mo-Mo+Si+Al functionally graded material and a preparation method thereof, belonging to the technical field of metallurgical materials and used for solving the problems of thin gradient layer and poor microcrack self-healing property of the functionally graded material. The Mo-Mo+Si+Al functionally graded material is characterized in that metal Mo is used as a basal body, a gradient distribution layer is arranged outside the basal body, wherein the contents of Si and Al in the gradient distribution layer gradually increase. The material has the change law of the components form inner phase to outer phase as follows: Mo-Mo5Si3+Mo3Si+Al4Mo+Mo-Mo5Si3+MoSi2+Al4Mo-MoSi2+Al4Mo+Si. The preparation method of the material comprises the steps of preparing a Si-Al alloy penetrating source, diffusing Si and Al in a molybdenum basal body, cooling the material and the like. The material has thick gradient layer and strong microcrack self-healing property; and the method has the characteristics of high forming speed of the gradient layer, short preparation time of the gradient layer, easy process control and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

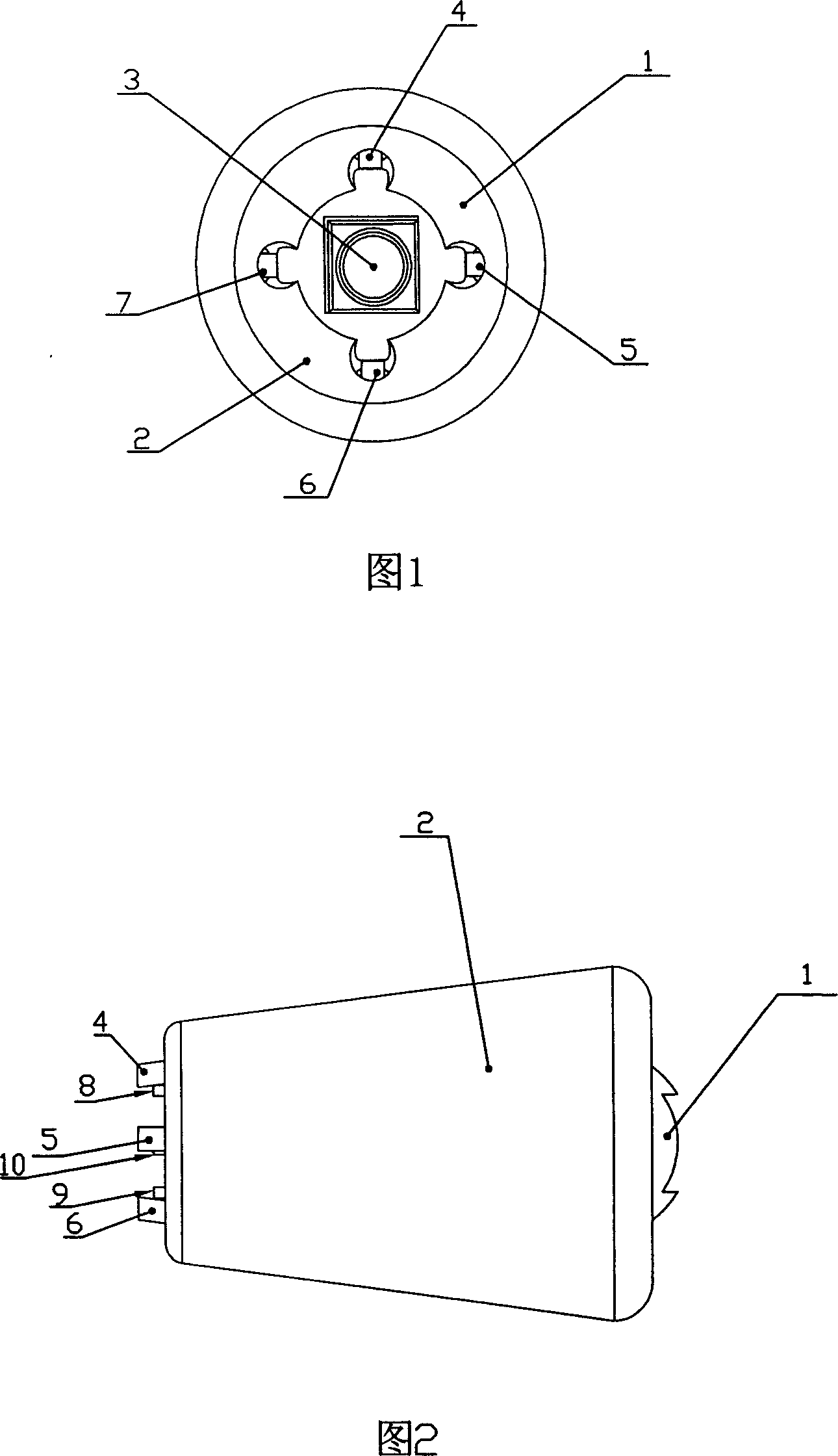

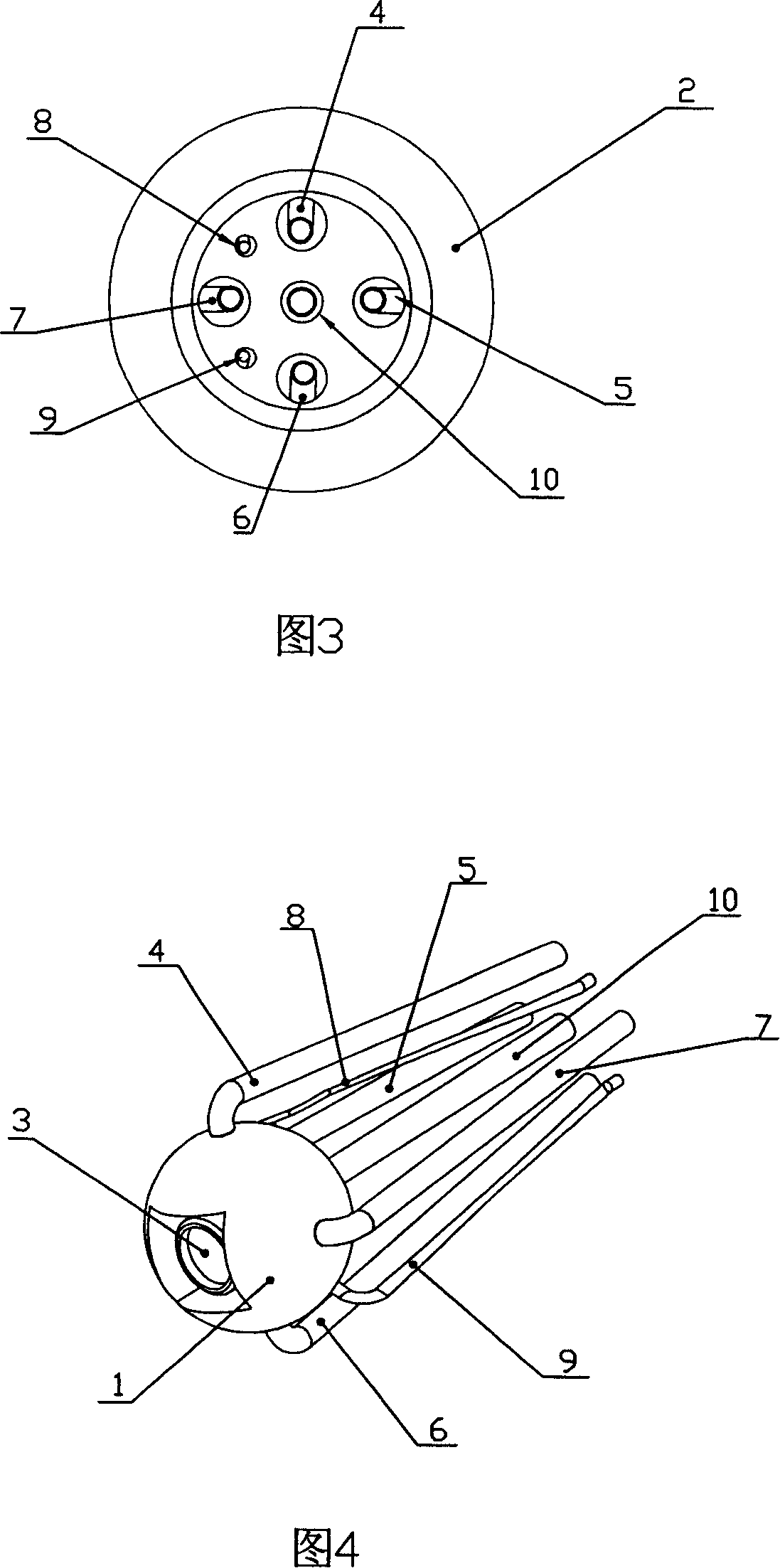

Ball-supporting porous pneumatic artificial-muscle parallel-connection-drive bionic eye

The invention discloses a sphere support multi-orifice pneumatic muscle paralleling driving bionic ocular. Spherical bionic eyeball is arranged in the basal body and can rotate freely. CCD pick-up camera capable of rotating with the spherical bionic eyeball is fixed in the eyeball. the CCD pick-up camera is connected to the signal processing part through data line. One end of six artificial pneumatic muscles connects with the spherical bionic eyeball by penetrating the basal body with channel. four muscles is quartered according to the same circle and connected to the eyeball, and respectively simulates superior rectus, musculus rectus medialis, musculus rectus inferior, and musculus rectus lateralis of human eyes. The other two muscles are respectively located at behind the above muscles and above and below the eyeball to simulate musculus obliquus dorsalis and musculus obliquus ventralis. The pneumatic muscles completely simulate muscle drives Structure of human eyes and make the bionic eyeball roll flexibly like human eyes.

Owner:ZHEJIANG UNIV

Method for producing large bimetal regulating nut

InactiveCN1900540AImprove reliabilityHigh bonding strengthNutsBoratesFlagellar basal bodyRoom temperature

The method includes following steps: casting and roughening inner cylindrical face from carbon steel to prepare basal body of nut in carbon steel; carrying out rust removing, degreasing, and drying processes for the basal body; putting the basal body into borax liquation, and heating to 850-900 deg.C; taking the basal body out from the borax liquation, removing redundant borax liquation from outer and inner surface of basal body of nut; then fixing nut in carbon steel on centrifuge rapidly, centrifugal casting brass alloy onto surface of inner cylindrical face of basal body of nut in carbon steel, materials and proportioning by weight of brass alloy are as following: Cu 60-65%, Zn 25-30%, Sn 1.5-5%, Mn 2.5-4%, Fe 1.5-3%, Ni 1-3%; taking bi metallic nut rough out from centrifuge, water cooling it to room temperature; process of removing stress, and shaping. Advantages are: low cost, reliable quality of product, and high production efficiency.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

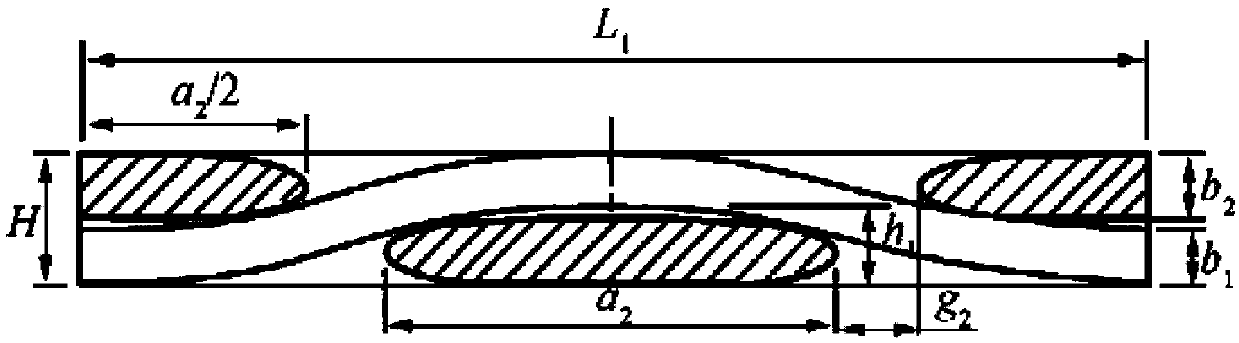

New method for predicting residual thermal stress of planar-knitted composite material

InactiveCN103473440APredict macroscopic residual thermal stressesSpecial data processing applicationsFlagellar basal bodyAnalytic model

The invention relates to a new method for predicting the residual thermal stress of a planar-knitted composite material, which comprises the following three steps of 1. selecting a minimum repetitive unit as a representative volume element according to the planar-knitting mode of a fiber bundle so as to determine the cell-body unit of the fiber bundle, and obtaining a simplified cell-body unit model according to the contraction deformation and stress conditions of component materials, i.e. a basal body and fibers, in the processes of cooling and solidification on the basis; 2. analyzing the stress of the basal body and the fibers in the cell-body unit according to the contraction-deformation compatibility conditions of the component materials i.e. the basal body and the fibers in the processes of cooling and solidification, and obtaining the constitutive relation between the thermal deformation of the component materials and the internal force of the cell-body unit so as to establish the thermal-stress analytic model of a planar-knitted composite-material single-layer plate; 3. establishing the thermal-stress equation of the planar-knitted composite-material single-layer plate according to the thermal-deformation compatibility conditions of the planar-knitted composite-material single-layer plate and a pure basal-body layer, and predicting the macroscopic residual thermal stress of a planar-knitted composite-material laminated plate through the performance of the component materials.

Owner:BEIHANG UNIV

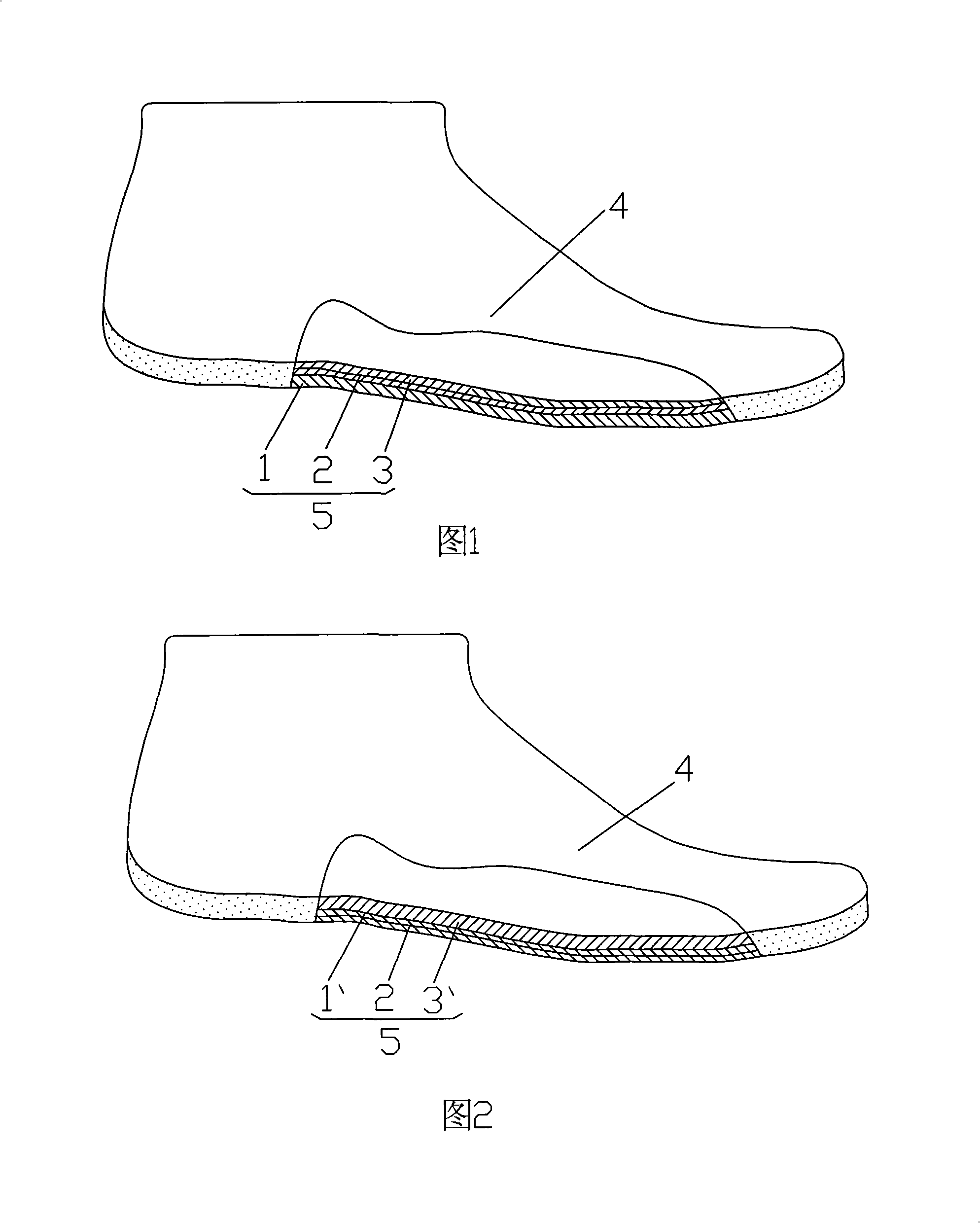

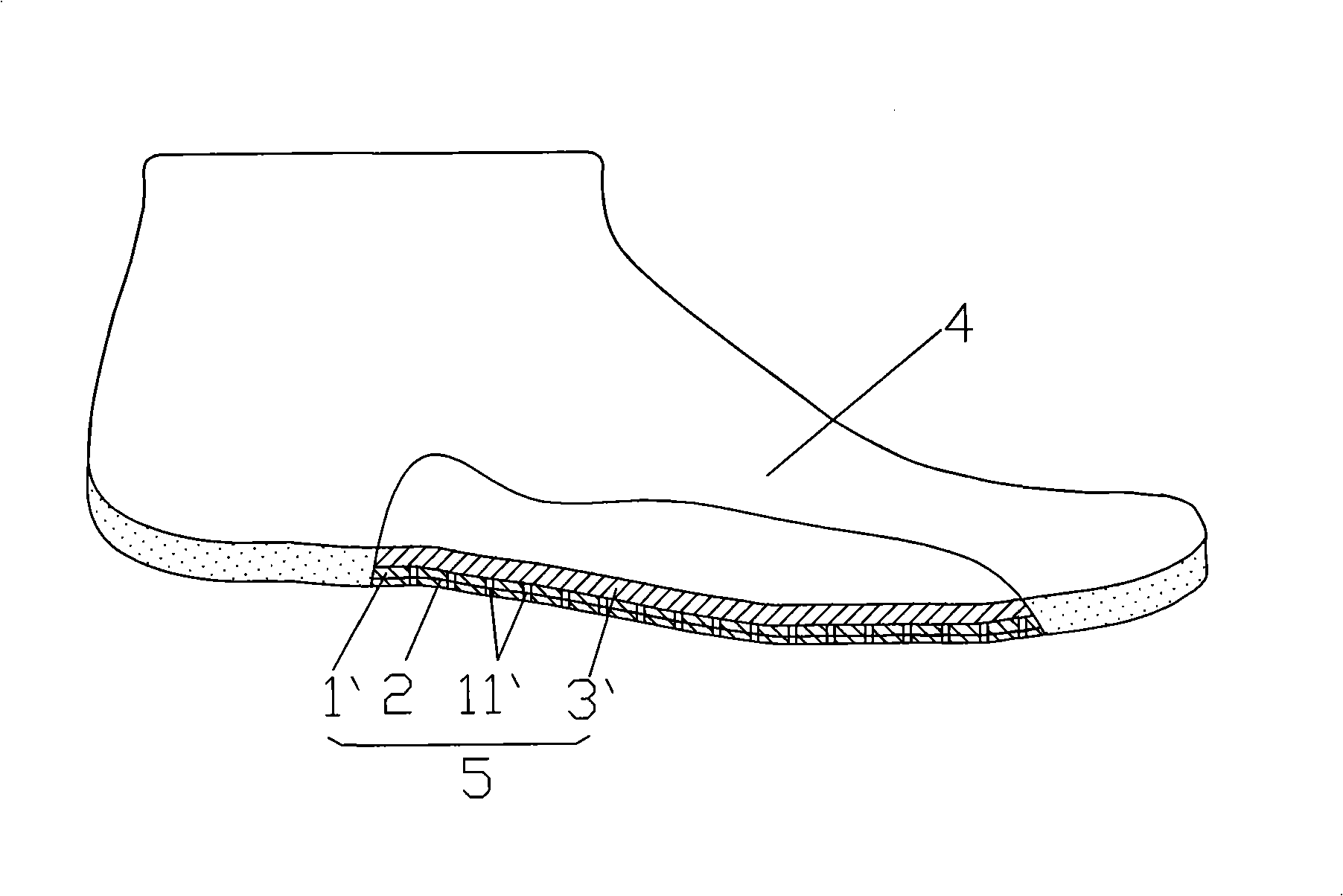

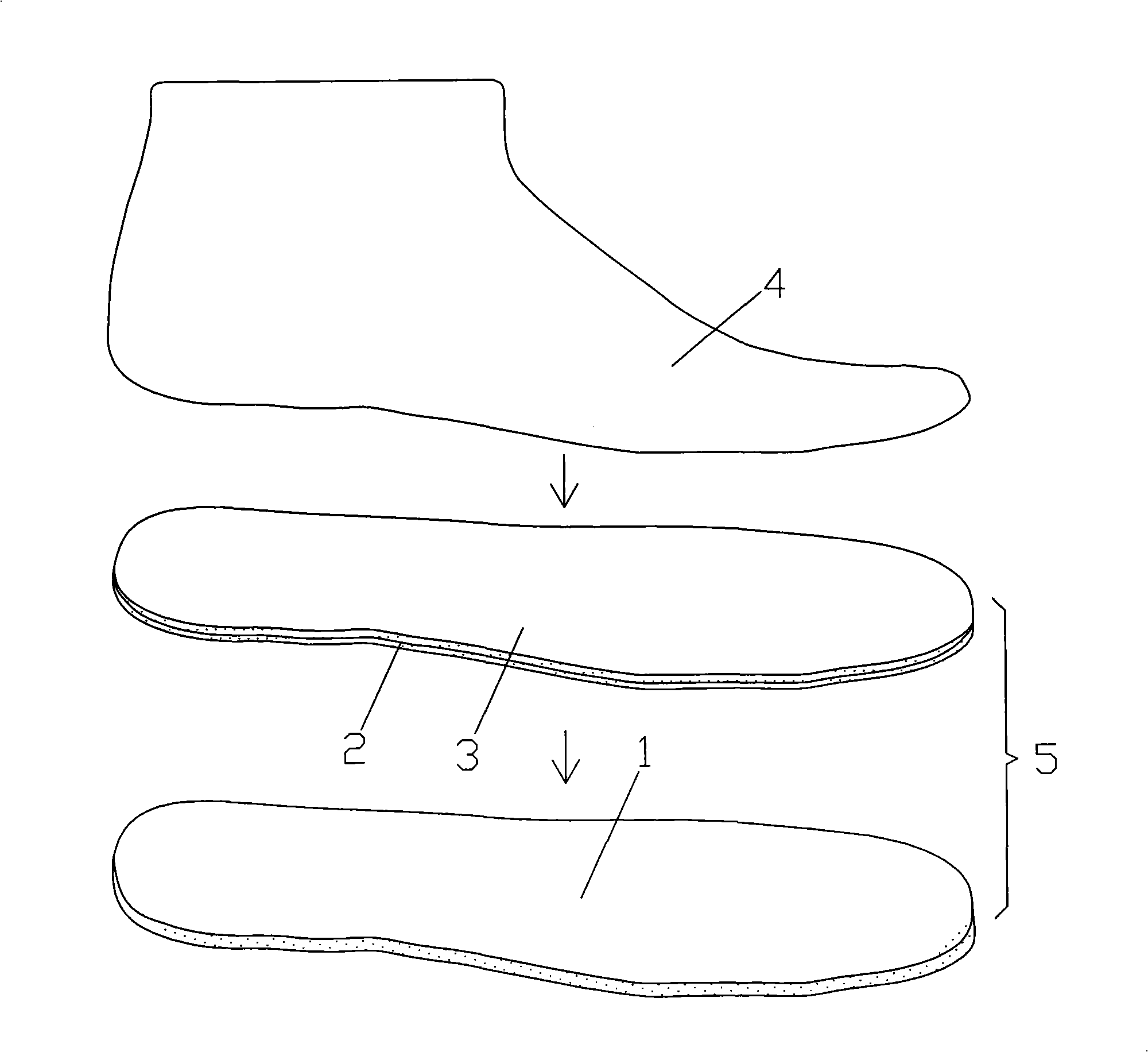

Environmental-protecting shoes for preventing prick and fungus

The invention relates to an anti-thrust, rot resistance and environment-friendly shoe, comprising a vamp and a sole; the vamp is fixed on the sole, wherein, the sole comprises a basal body and a metal lamella; the metal lamella is embedded in the basal body and molded with the basal body in one; the basal body is a thermoplastic elastomer. The sole of the invention is molded in one by embedding the basal body in the metal lamella, and the basal body is a thermoplastic elastomer; on one hand, the metal lamella strengthens the firmness of the shoe so that the whole shoe is not deformed easily, on the other hand, the metal lamella has the functions of anti-thrust and rot resistance. In addition, the basal body formed by the thermoplastic elastomer has excellent processing performance and simple production technique, requires no vulcanization, can be recycled and is nontoxic if the basal body is burned, thus producing good environment-friendly shoes. The invention discloses a manufacturing method of an outsole and a midsole of the anti-thrust, rot resistance and environment-friendly shoe.

Owner:东莞市兴隆鞋材有限公司

Shell

The invention relates to a shell which comprises a transparent basal body, a first decoration layer arranged on the transparent basal body and a second decoration layer arranged on the first decoration layer, wherein the first decoration layer is a semitransparent ink layer and contains matters with metal luster; and the second decoration layer is a color ink layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

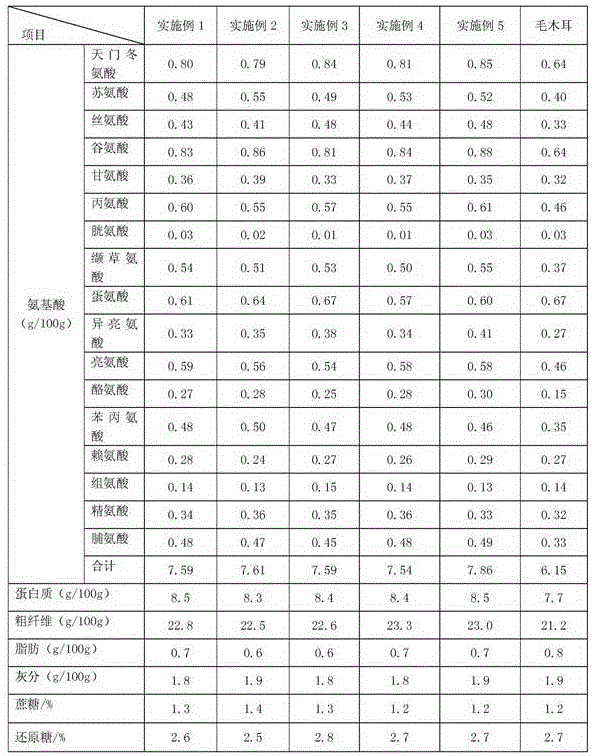

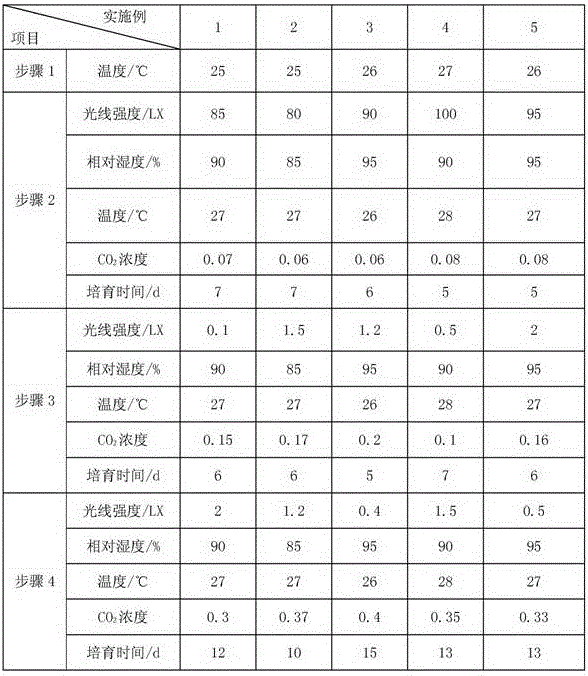

Club fungus cultivating method and product thereof

ActiveCN106489540ASmooth textureTender tasteCultivating equipmentsMushroom cultivationHigh concentrationFlagellar basal body

The invention discloses a club fungus cultivating method and a product thereof. The club fungus cultivating method comprises the steps that basal cell division is promoted while auricularia polytricha sporocarp development is interrupted by adjusting and controlling temperature and light intensity and cooperating with proper high-concentration CO2, top end cells of auricularia polytricha bases are simulated to continue to divide and growth upwards when normal cell division in auricularia polytricha basal bodies is up to a certain degree, so that the auricularia polytricha bases undergo the expanding, growing and proliferating process and bifurcate from the base portions, the middle-upper portions bifurcate for multiple times to form clusters, the top ends form finger-shaped cluster sets, finally coral grape vine shapes are formed, and the appearance, taste and nutritive value of club fungi are superior to those of club fungi of auricularia polytricha.

Owner:FUJIAN NANPING AGRI SCI INST

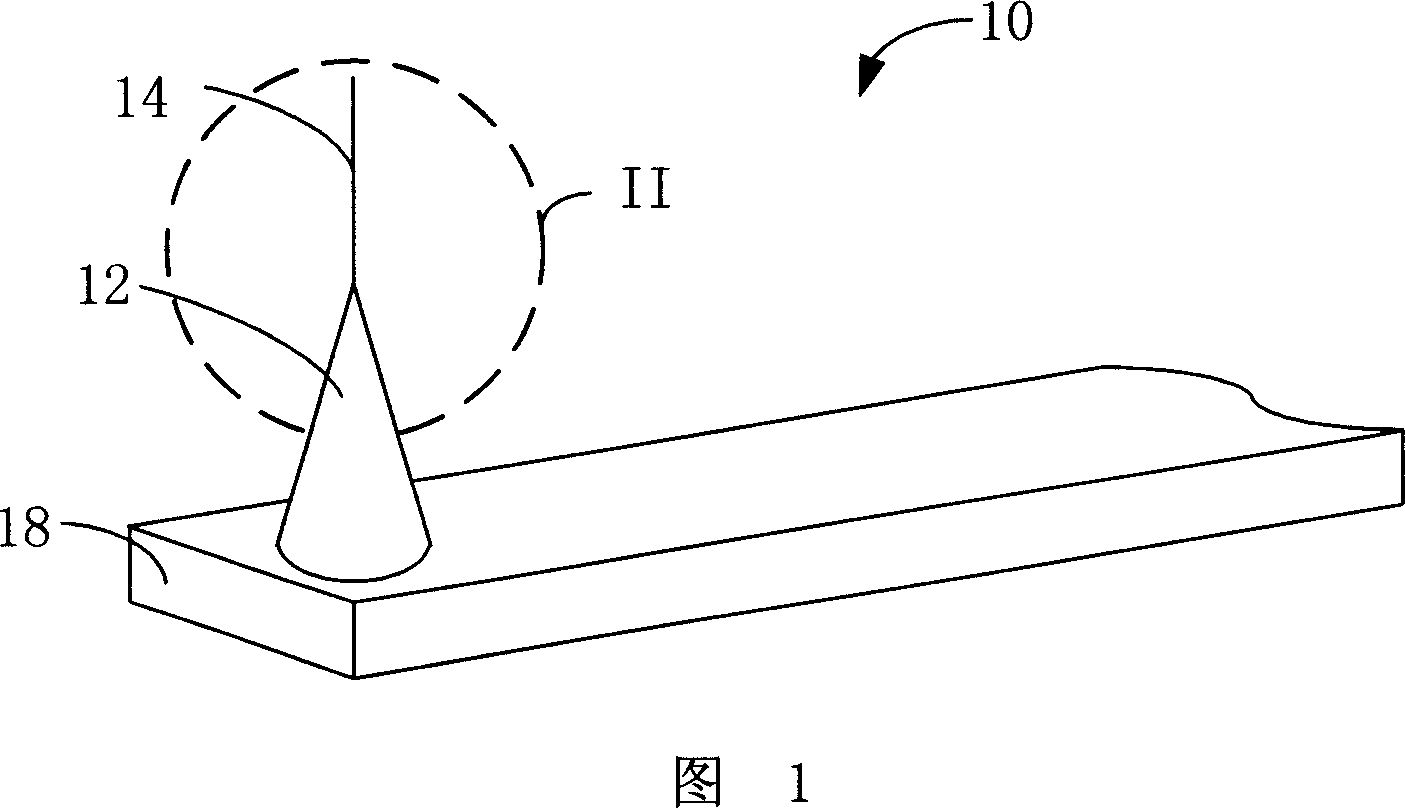

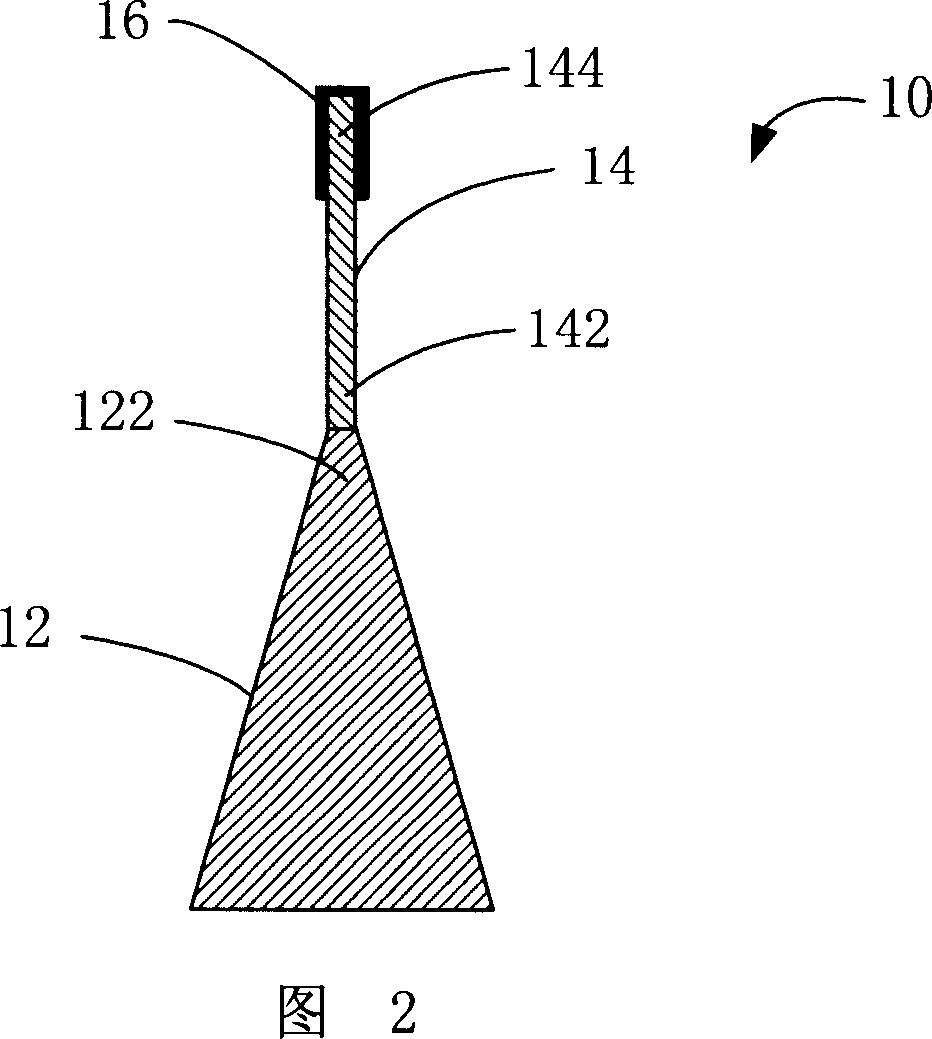

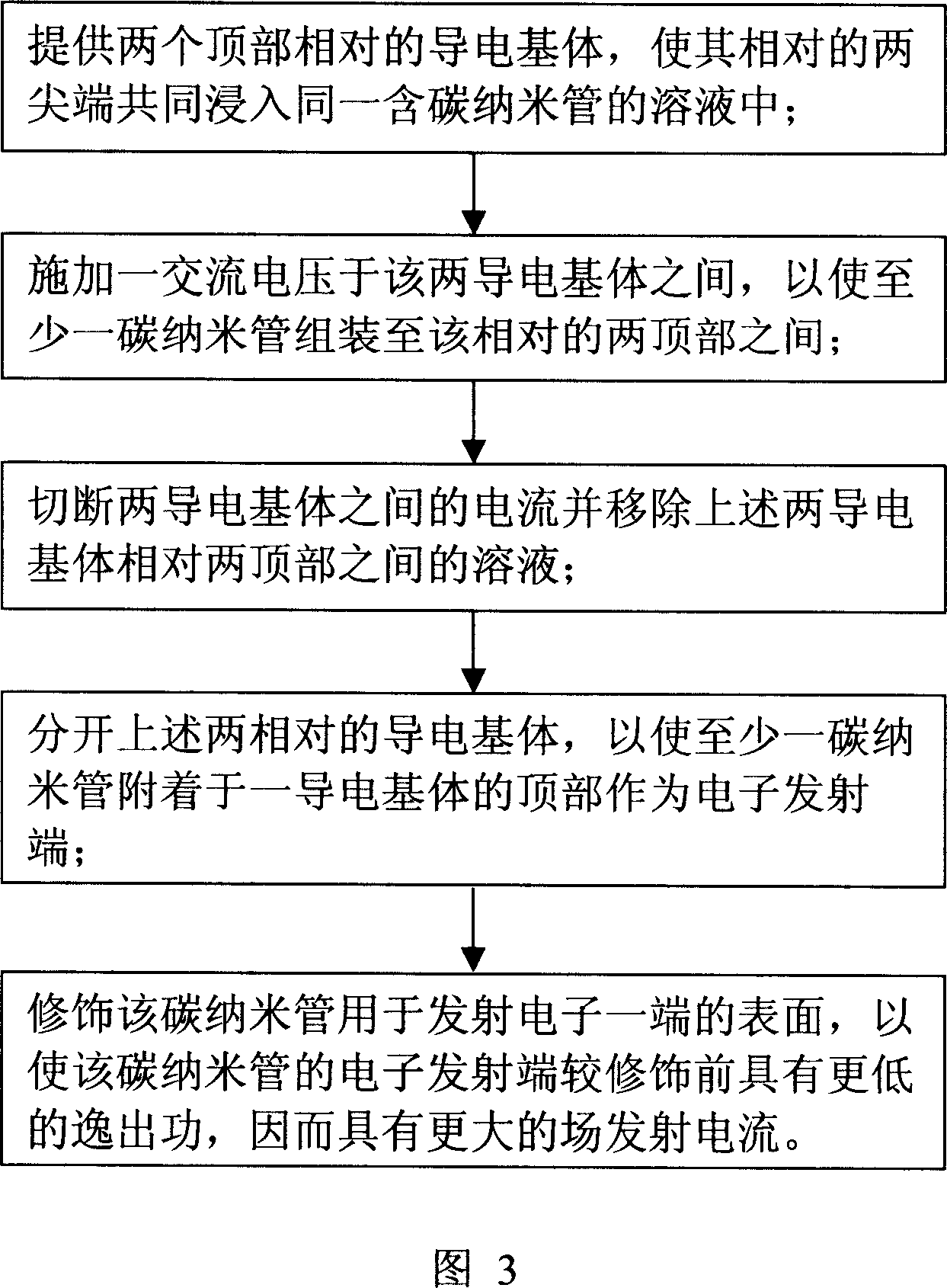

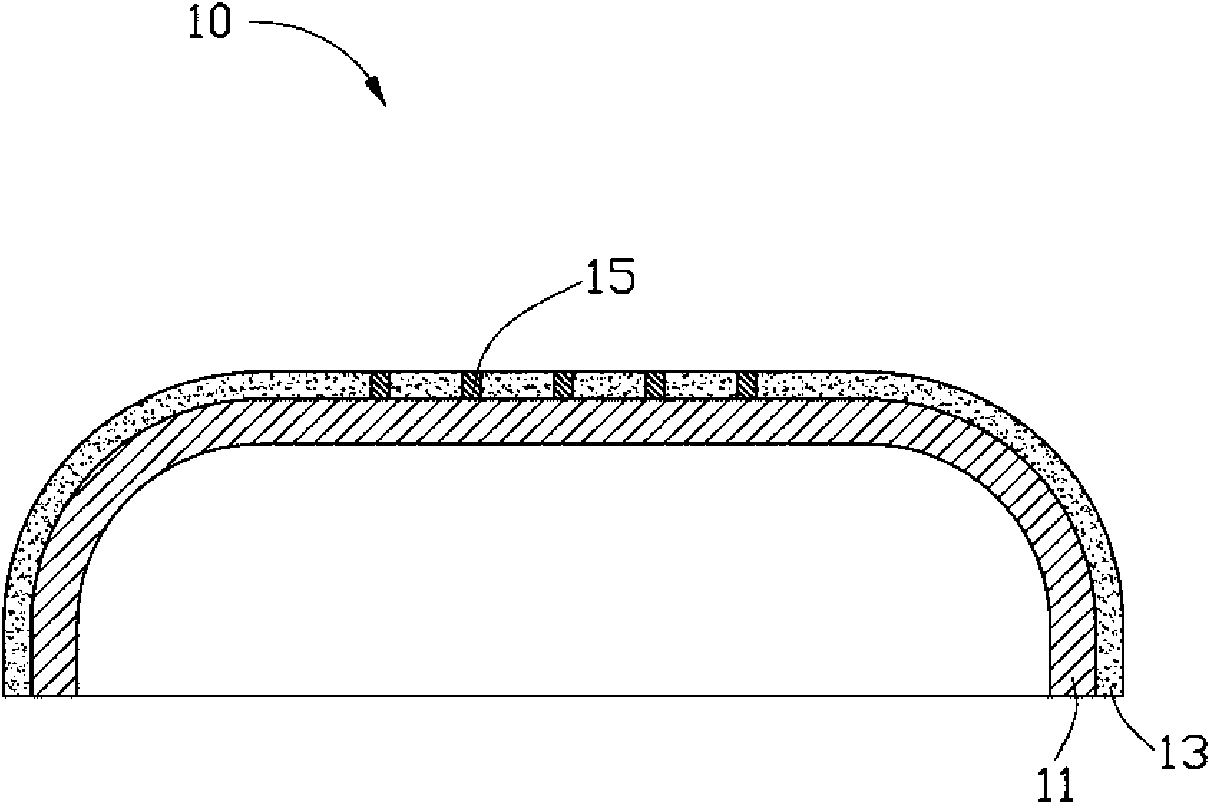

Carbon nano tube field transmitting electronic source

ActiveCN101051595AHigh densityIncrease emission currentElectric discharge tubesIndividual molecule manipulationFlagellar basal bodyElectron source

The electron source of field emission of Nano carbon tube includes a current conducting basal body, at least a Nano carbon tube, and a finishing coat. The current conducting basal body possesses a top portion. One end of the Nano carbon tube is connected to the top portion electrically; and the other end is extended out along the top portion. Being distributed and infiltrated on surface of Nano carbon tubes evenly, the finishing coat covers the said extended end. Work function of the finishing coat is lower than work function of the Nano carbon tube.

Owner:TSINGHUA UNIV +1

Shell and manufacturing method thereof

InactiveCN101662902AStrong three-dimensional senseQuick modificationDecorative surface effectsMetal casingsFlagellar basal bodyMetallurgy

The invention relates to a shell which comprises a basal body, a powder coating and a pattern layer, wherein the powder coating is formed on the basal body, the pattern layer is formed in the powder coating, a groove is formed on the coating, and the pattern layer is sol filled in the groove. A manufacturing method of the shell comprises the following steps: providing the basal body; spraying thepowder coating on the surface of the basal body; etching the groove on the powder coating; and filling sol in the groove.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com