Patents

Literature

30results about How to "Skip the assembly process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

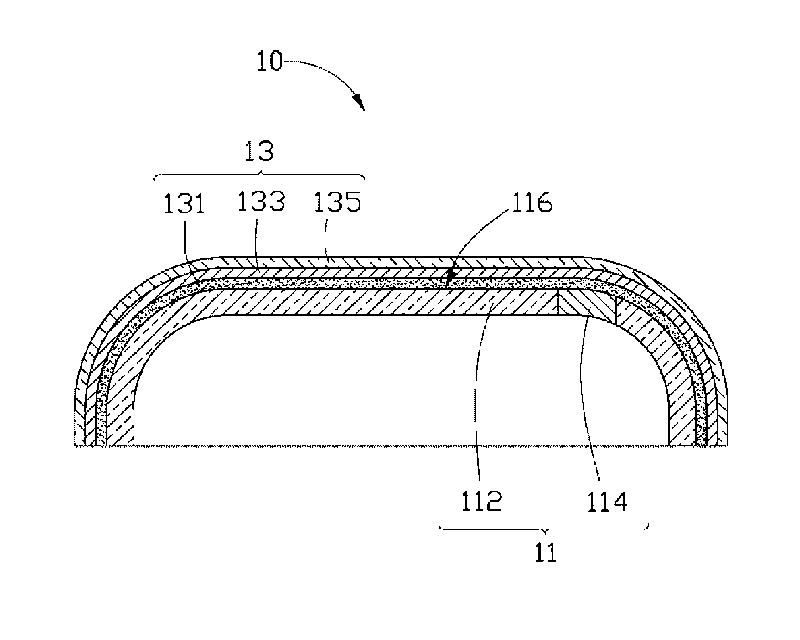

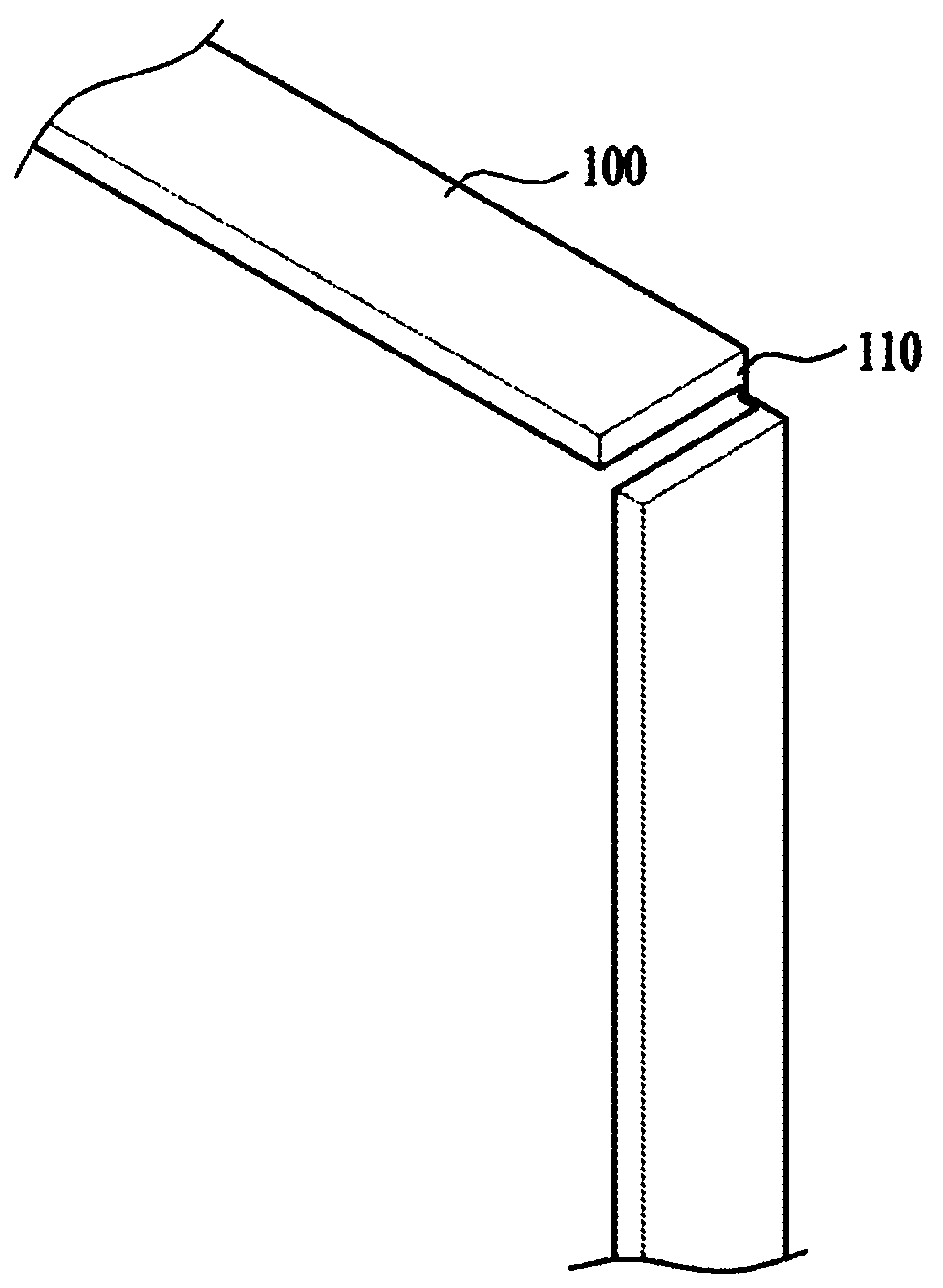

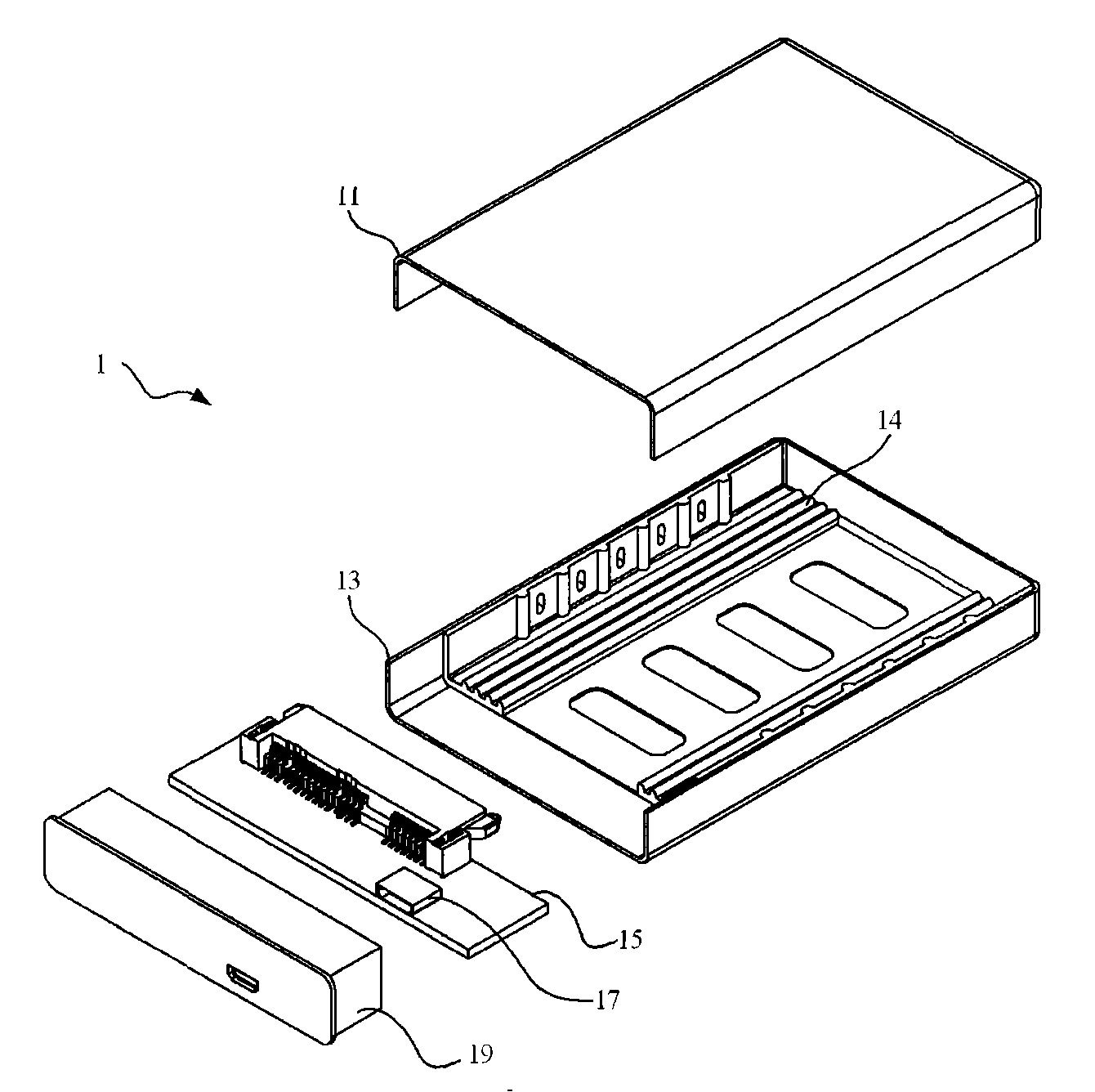

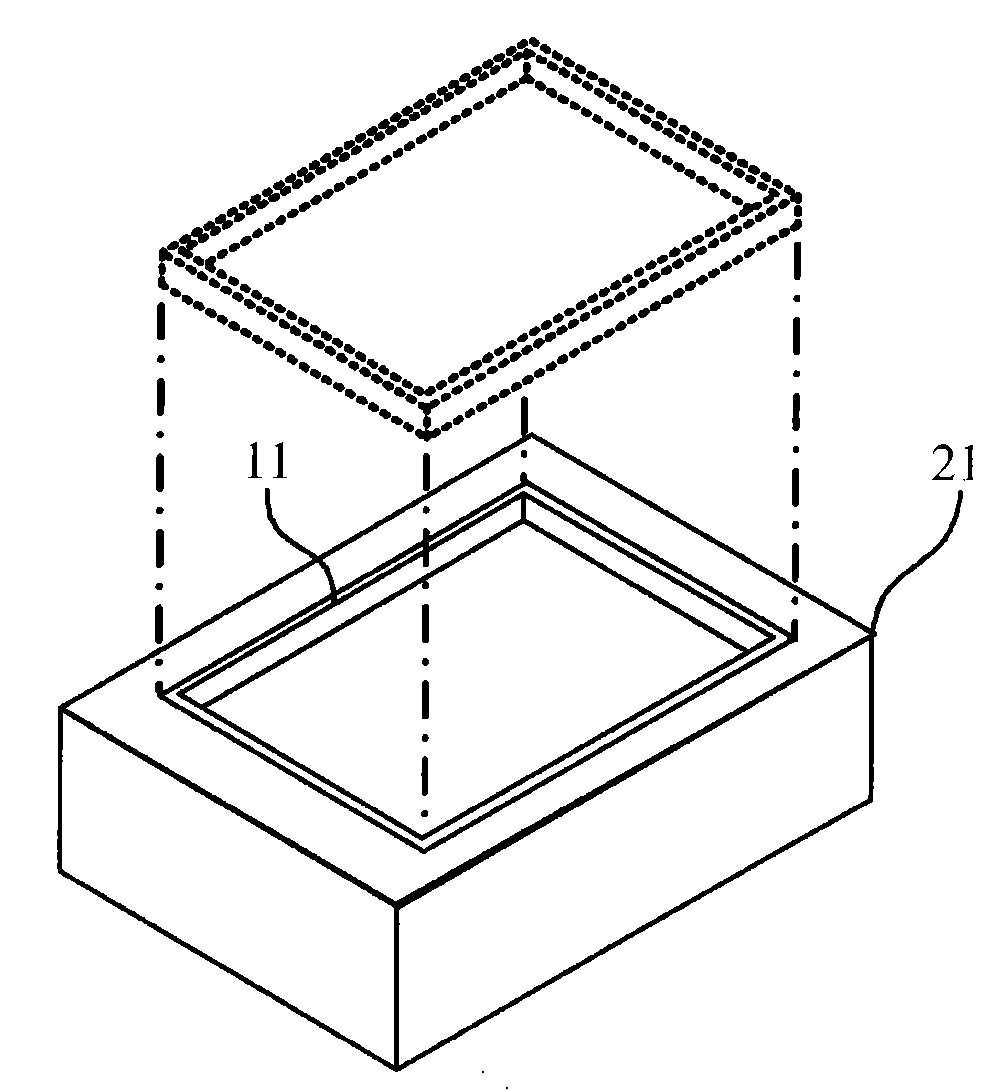

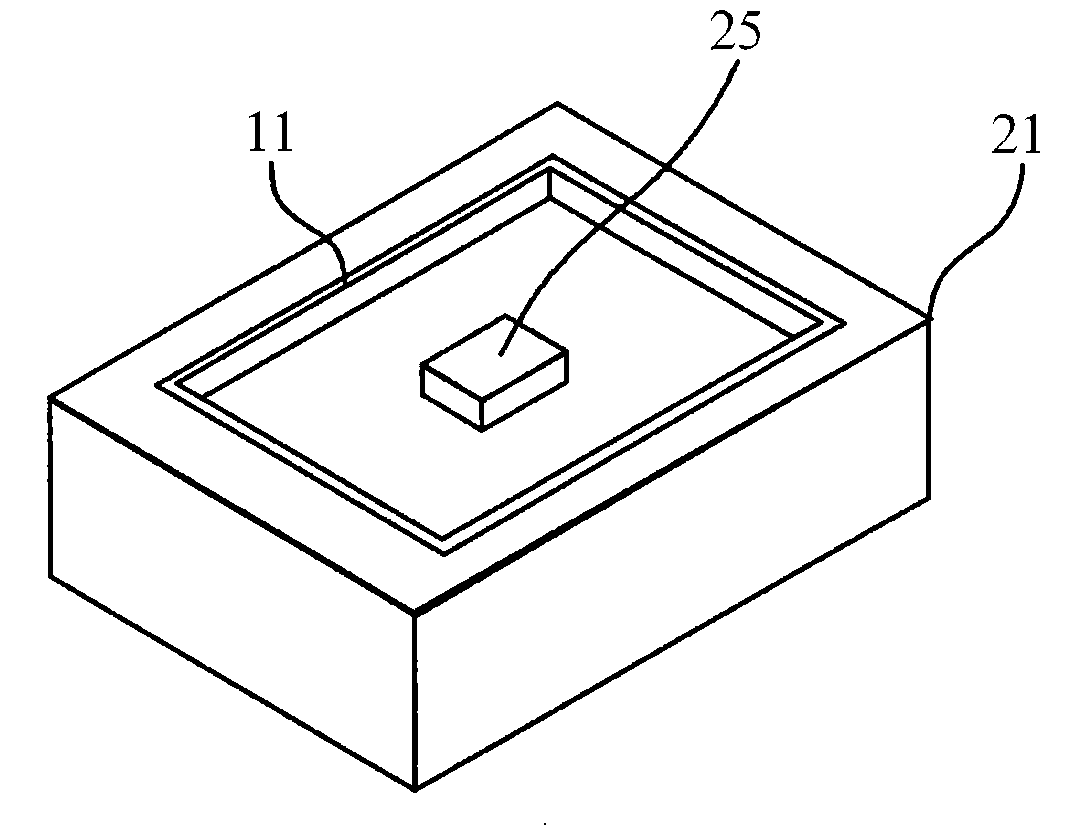

Shell and manufacture method thereof

InactiveCN101730410AHigh mechanical strengthSkip the assembly processMagnetic/electric field screeningDecorative surface effectsFlagellar basal bodyLacquer

The invention provides a shell, comprising a basal body and a decorative film formed on the surface of the basal body. The basal body is integrally formed by a metal component and a plastic component; one surface of the basal body is formed by the metal component and the plastic component together; the decorative film is formed on the surface of the basal body and comprises a priming layer directly formed on the surface of the basal body, a non-conductive vacuum film coating layer formed on the surface of the priming layer and a transparent protective lacquer layer formed on the non-conductive vacuum film coating layer. The shell not only has higher mechanical strength, but also can satisfy the radio frequency requirement of an electronic device and has uniform metal appearance effect. The invention further provides a method for manufacturing the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

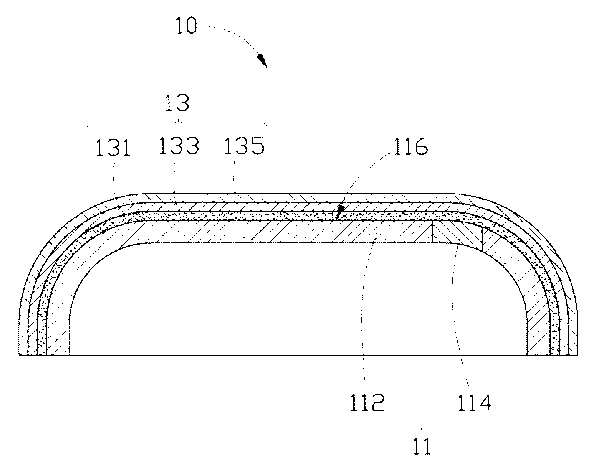

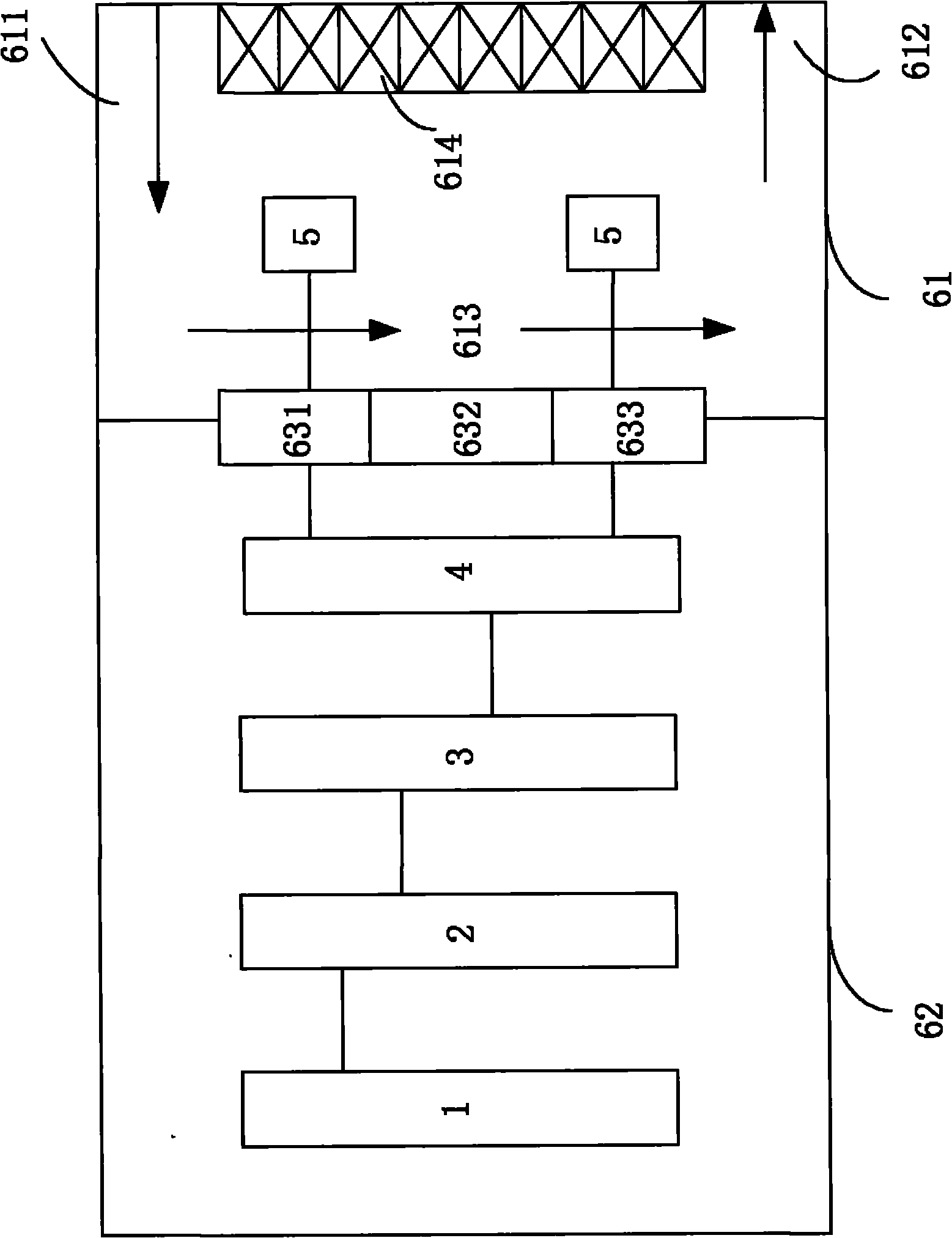

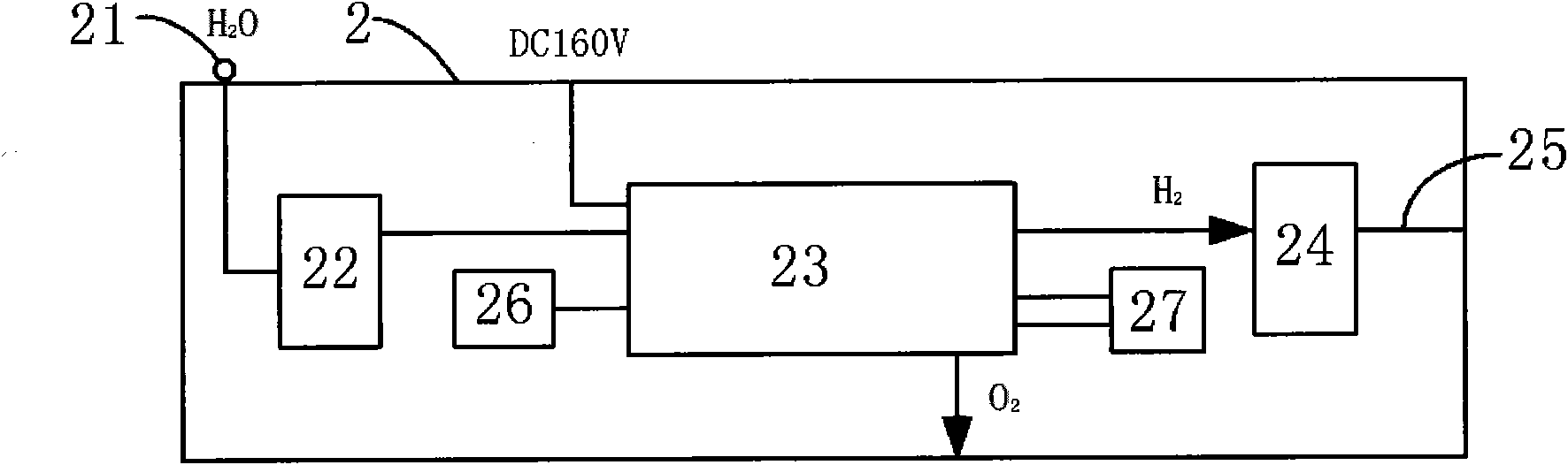

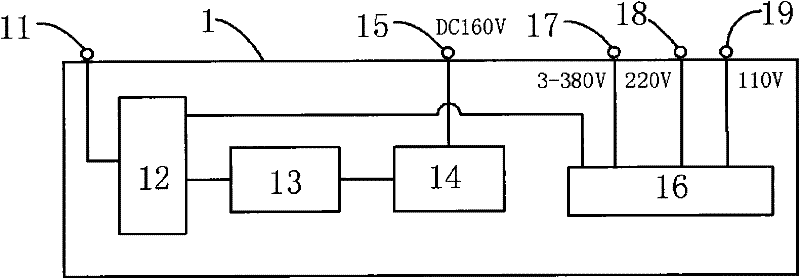

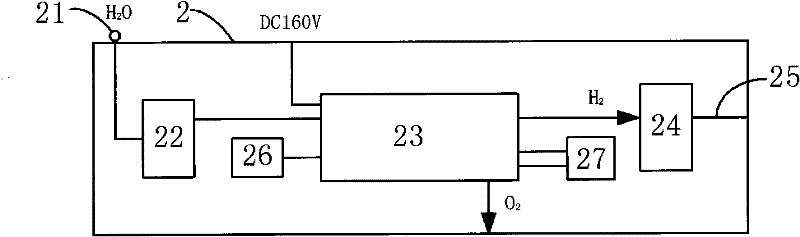

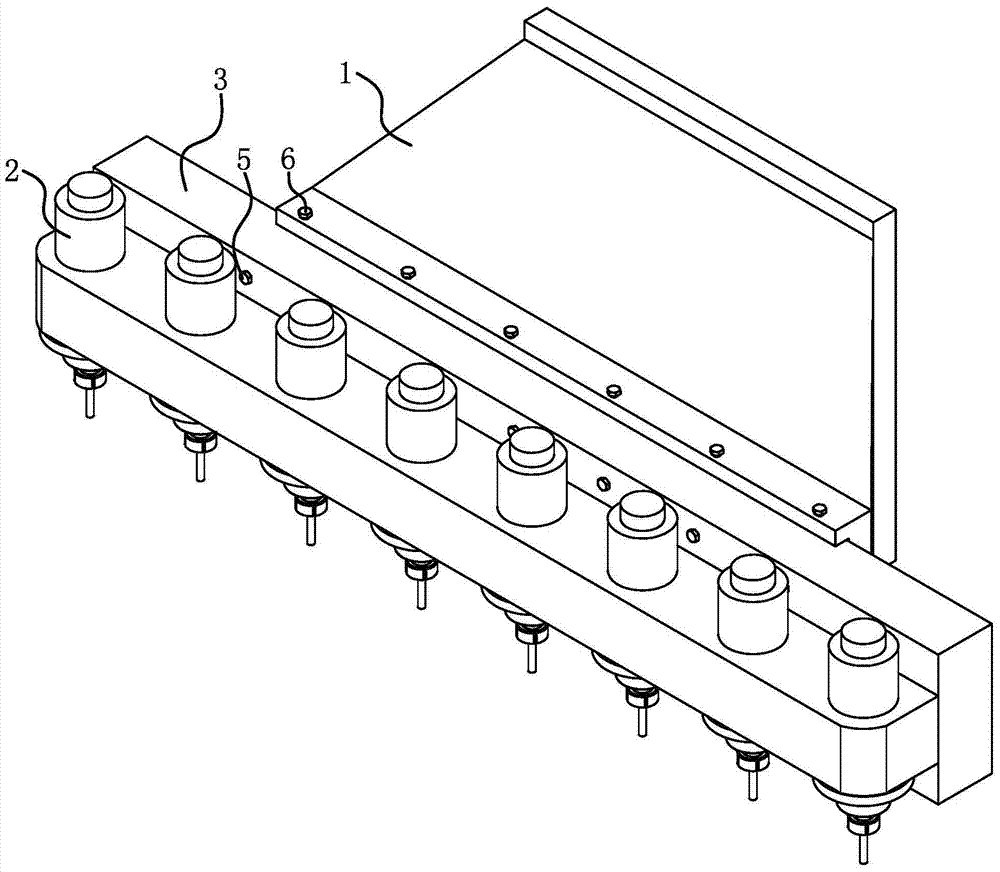

Van-type movable hydrogen manufacturing and hydrogen refueling station

InactiveCN101941418ASkip the assembly processReduce commissioning costsVehicle servicing/repairingHydrogenLow voltage

The invention discloses a van-type movable hydrogen manufacturing and hydrogen refueling station, comprising a power source compartment, a hydrogen manufacturing compartment, a compression compartment, a hydrogen storing compartment and a gas selling machine, wherein the power source compartment and the compression compartment and the hydrogen storing compartment are respectively formed by changing a shipping container; the power source compartment converts the local high-voltage power source into low-voltage direct current, dynamic voltage and lighting voltage which are suitable for being used in the invention; the hydrogen manufacturing compartment is provided with a tap water interface, a water treatment facility, an electrolytic cell and a hydrogen purifying device which are connected in sequence; the compression compartment is provided with a low-voltage buffer tank connected with the hydrogen purifying device, and a compressor connected with the low-voltage buffer tank; the hydrogen storing compartment is provided with at least a high-voltage hydrogen storing tank which is connected with the compressor through a check valve; and the gas selling machine is connected with the high-voltage hydrogen storing tank through a reducing valve. The van-type movable hydrogen manufacturing hydrogen and refueling station of the invention is convenient for transoceanic transportation by changing the shipping containers, thus lowering the installation difficulty and the debugging cost.

Owner:袁家祯

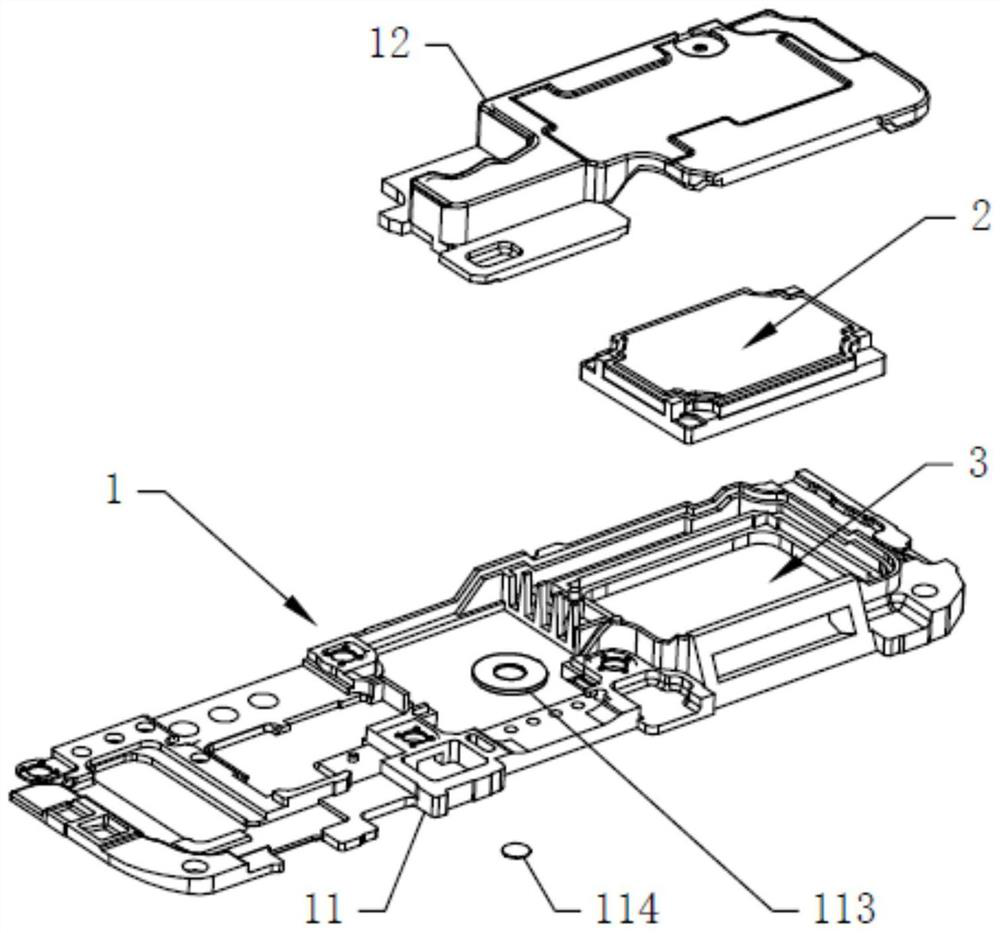

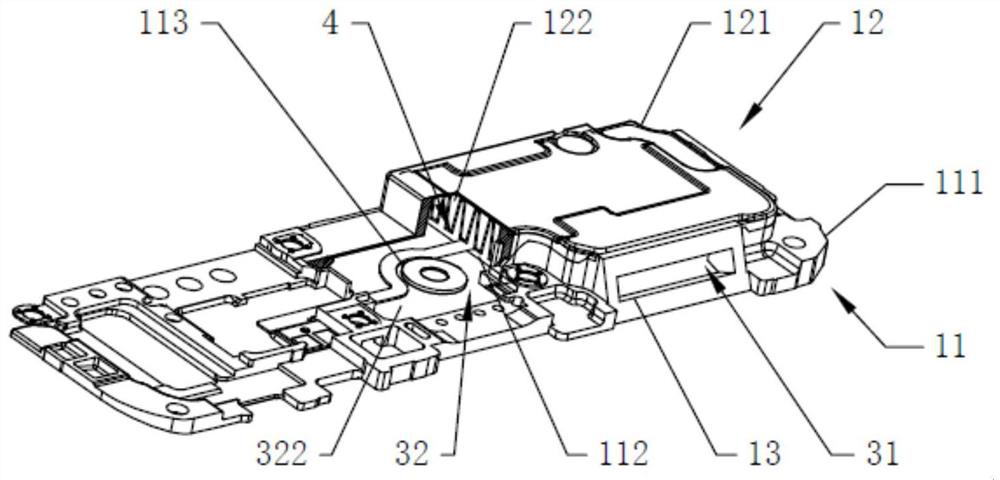

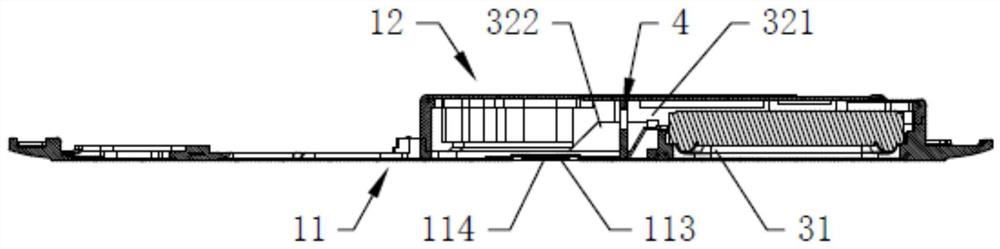

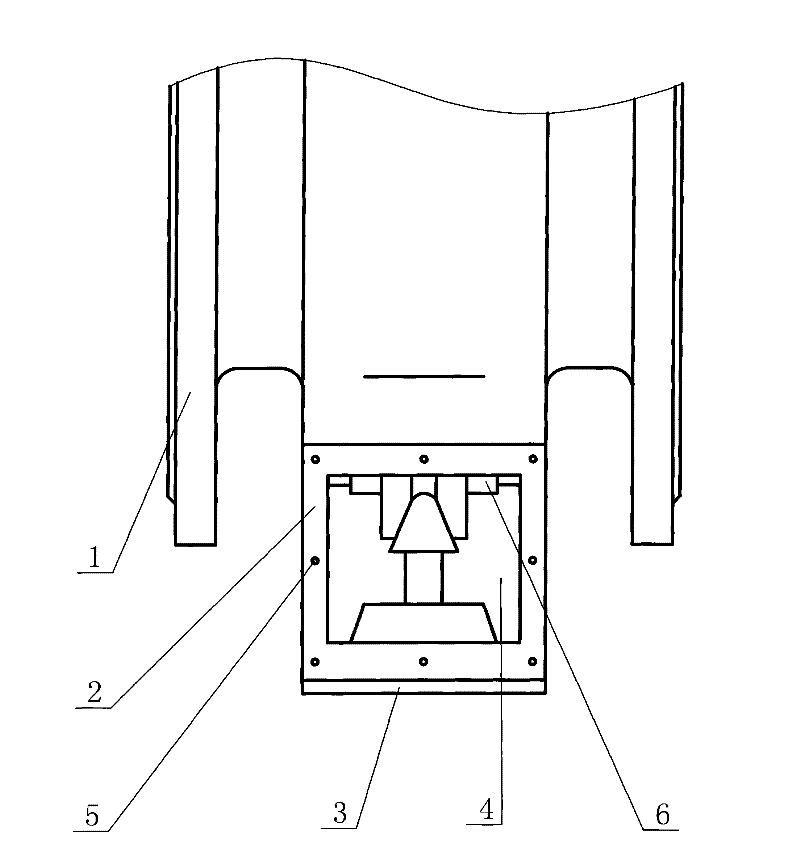

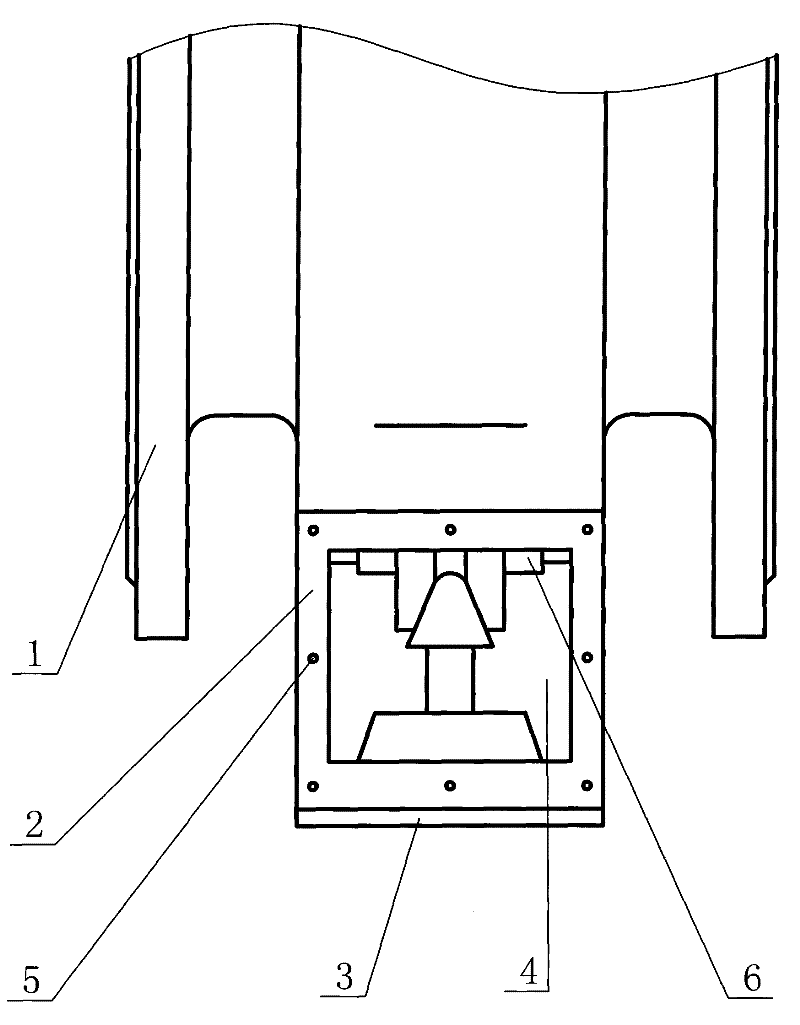

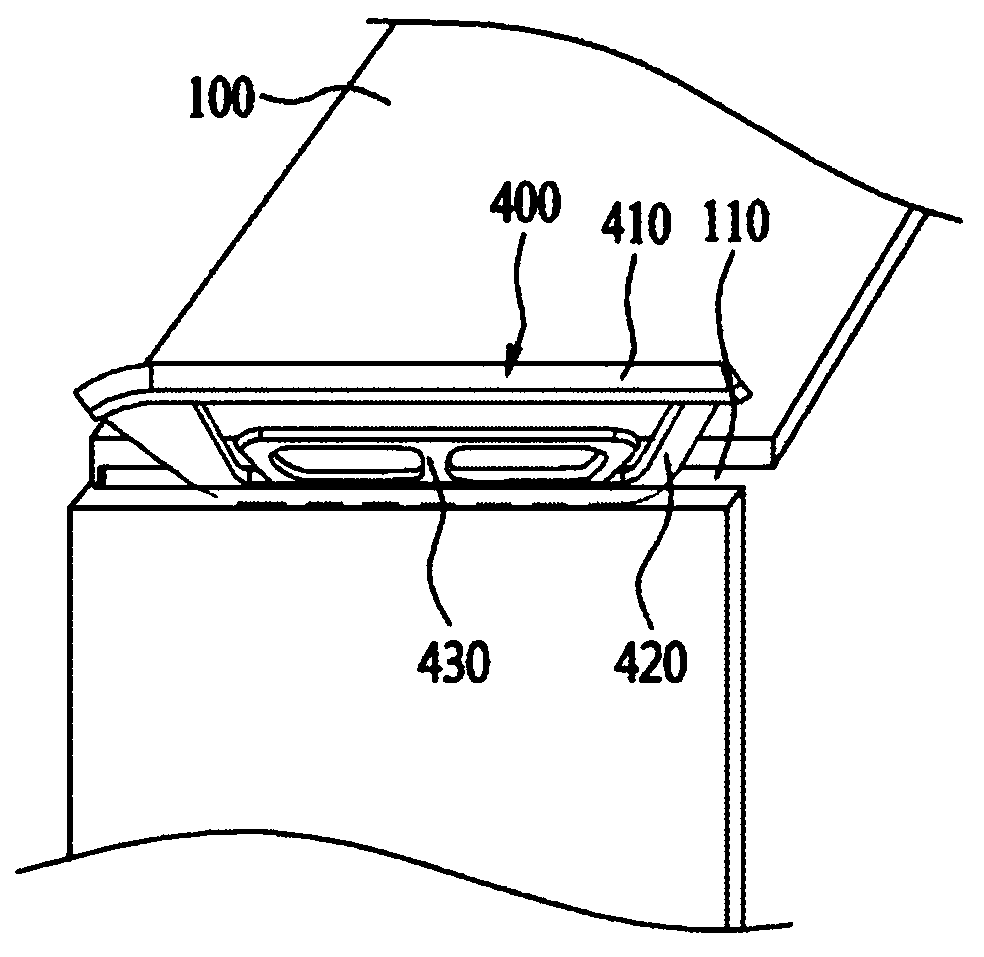

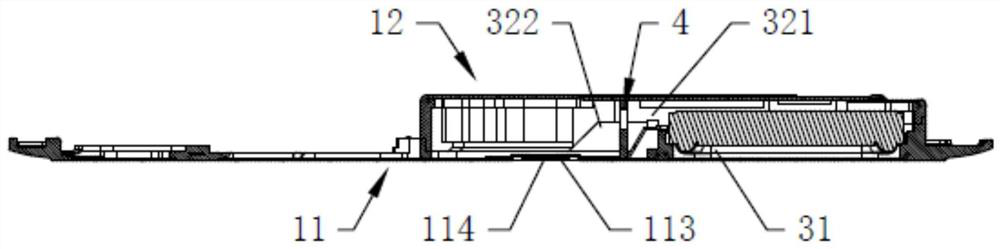

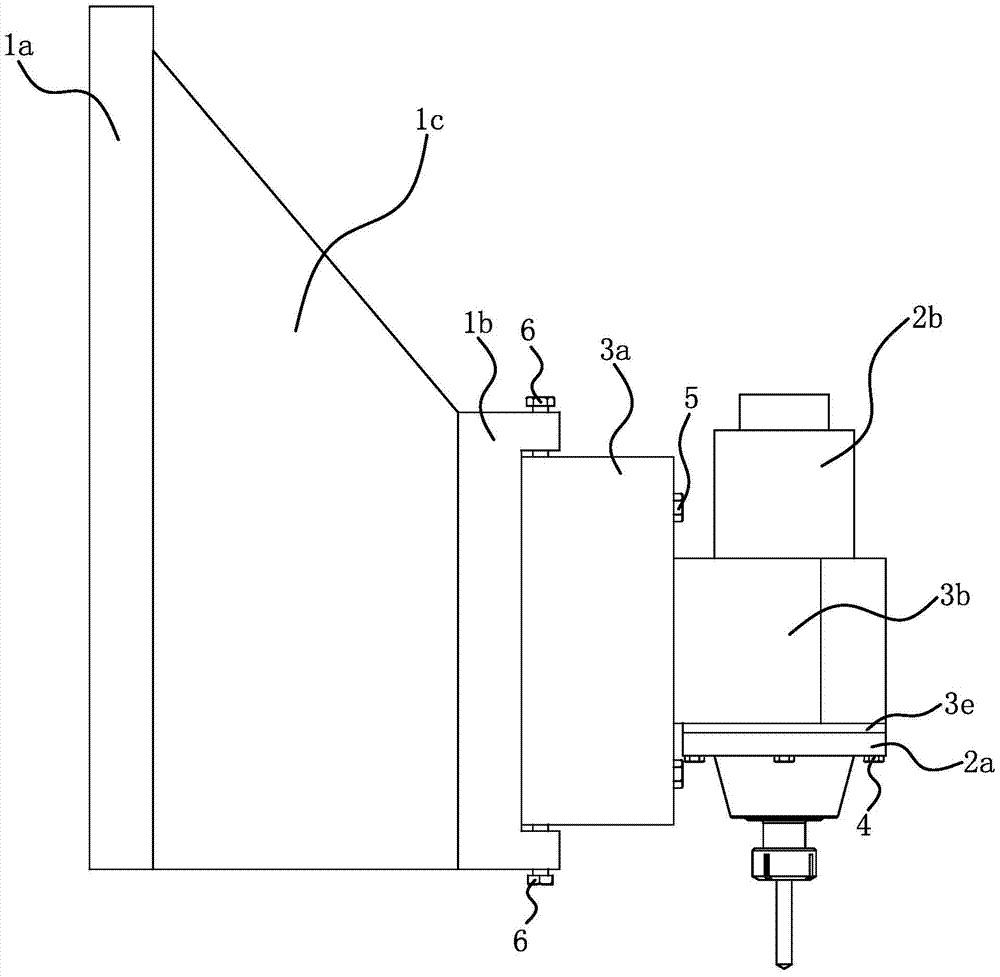

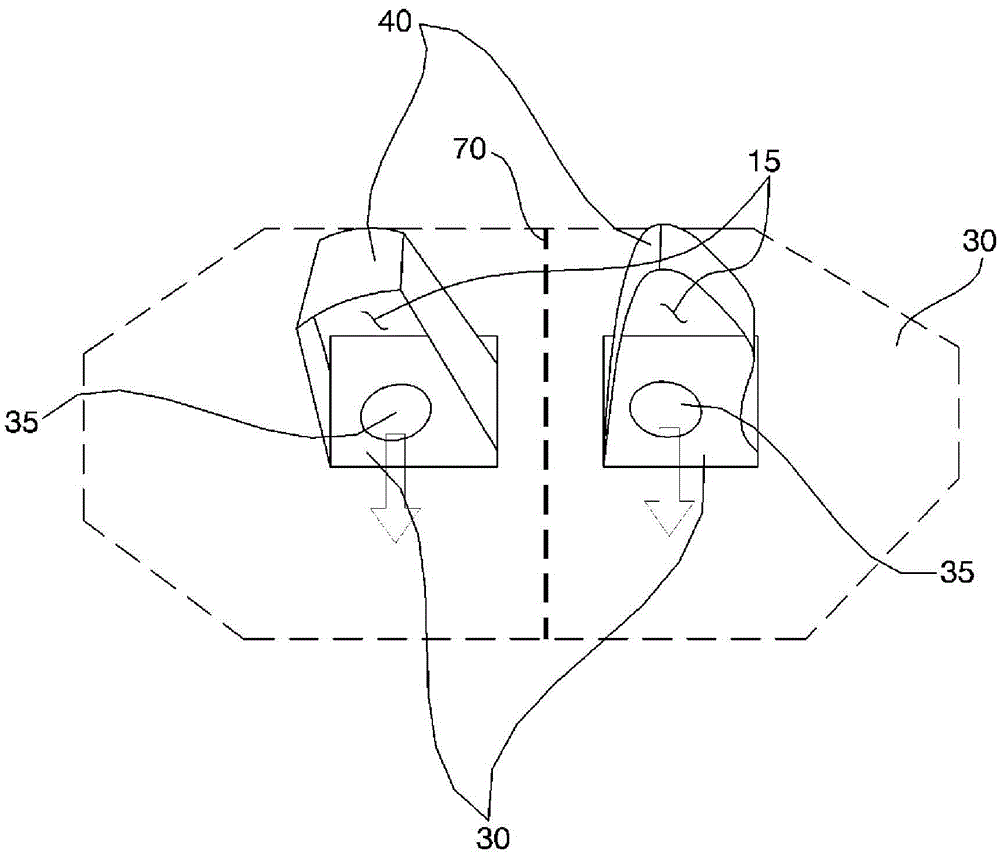

Loudspeaker module and electronic equipment

ActiveCN111954128AAchieve isolationAchieve circulationElectrical transducersEngineeringSound production

The invention discloses a loudspeaker module, which comprises a shell with an accommodating cavity and a sound production unit accommodated in the accommodating cavity, and is characterized in that the accommodating cavity is divided into a front cavity and a rear cavity by the sound production unit; the shell comprises a lower shell body and an upper shell body, the upper shell body comprises a first body part and a first isolation wall arranged on the first body part in a protruding mode, the lower shell body comprises a second body part and a second isolation wall arranged on the second body part in a protruding mode, and the first isolation wall and the second isolation wall are inserted in a butt joint mode. The rear cavity is divided into a first rear cavity and a second rear cavity,and the second rear cavity is filled with sound absorption particles; a breathable isolation channel is formed between the end faces of the first isolation wall and the second isolation wall, and thewidth of the breathable isolation channel is smaller than the diameter of the sound absorption particles. Processing and assembling of an isolation assembly in traditional design are omitted, the manufacturing process is simple, and the processing cost is reduced; the assembling procedures are reduced, the difficulty is reduced, and the assembling efficiency and the yield are remarkably improved.

Owner:GOERTEK INC

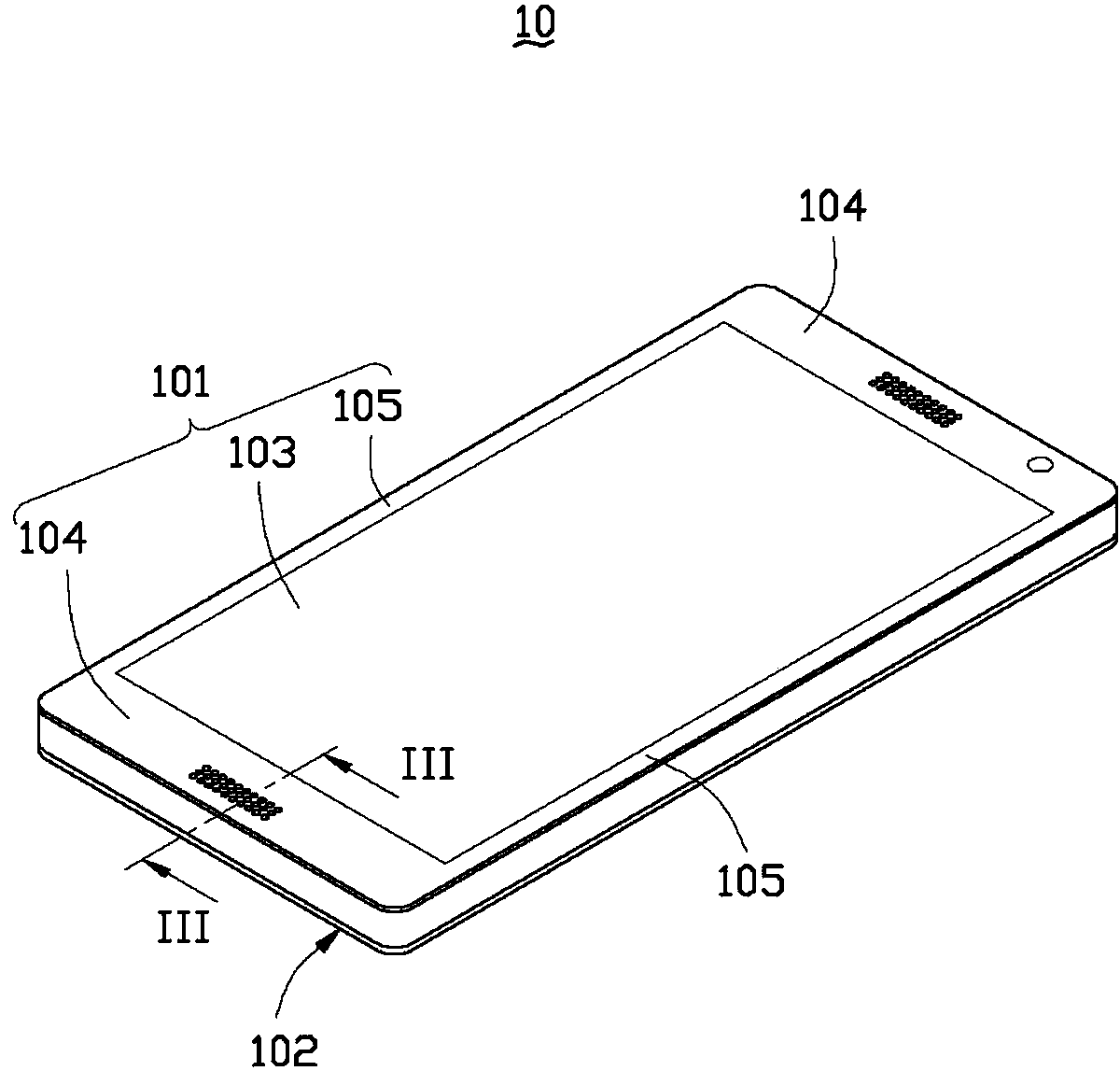

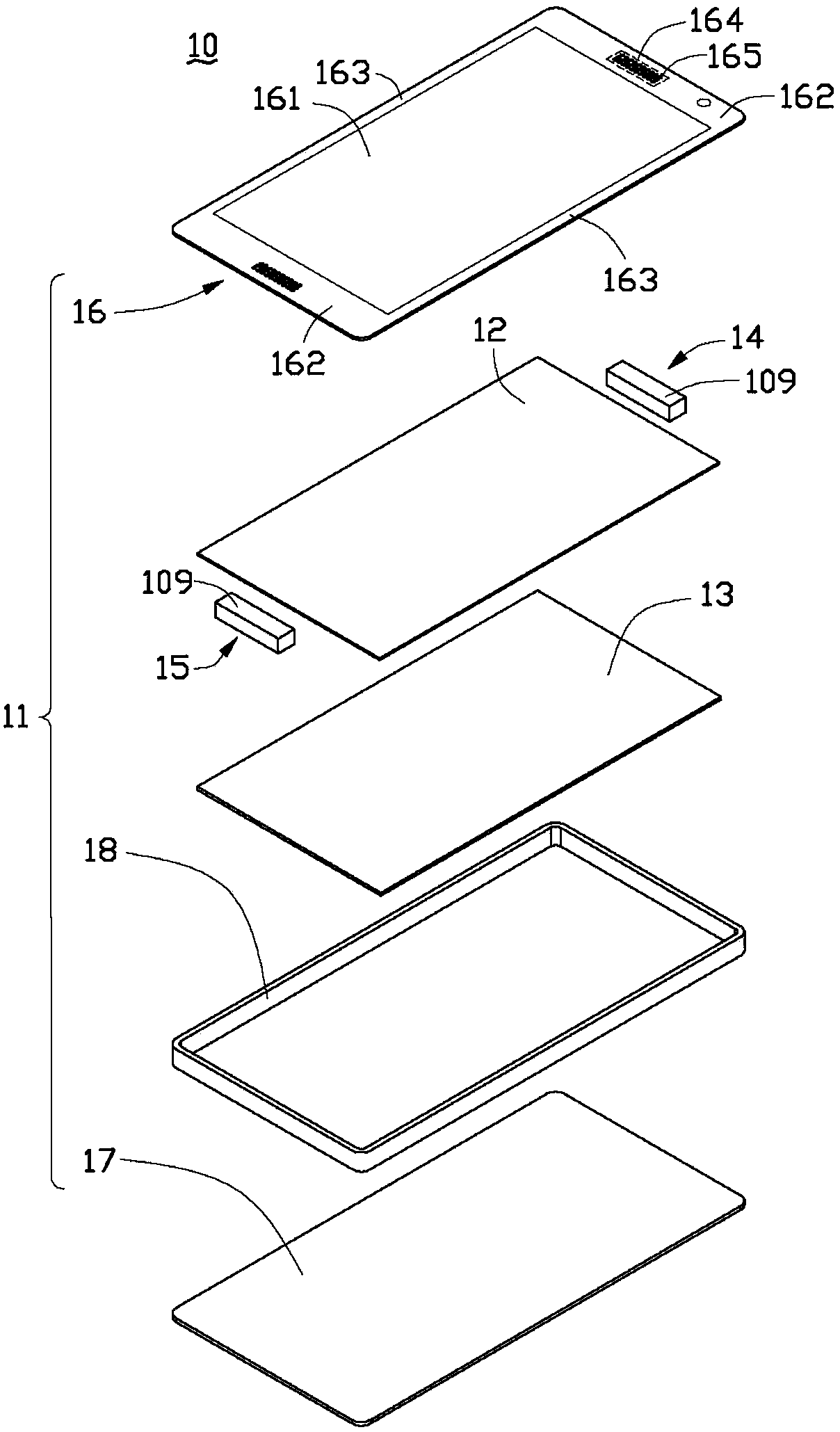

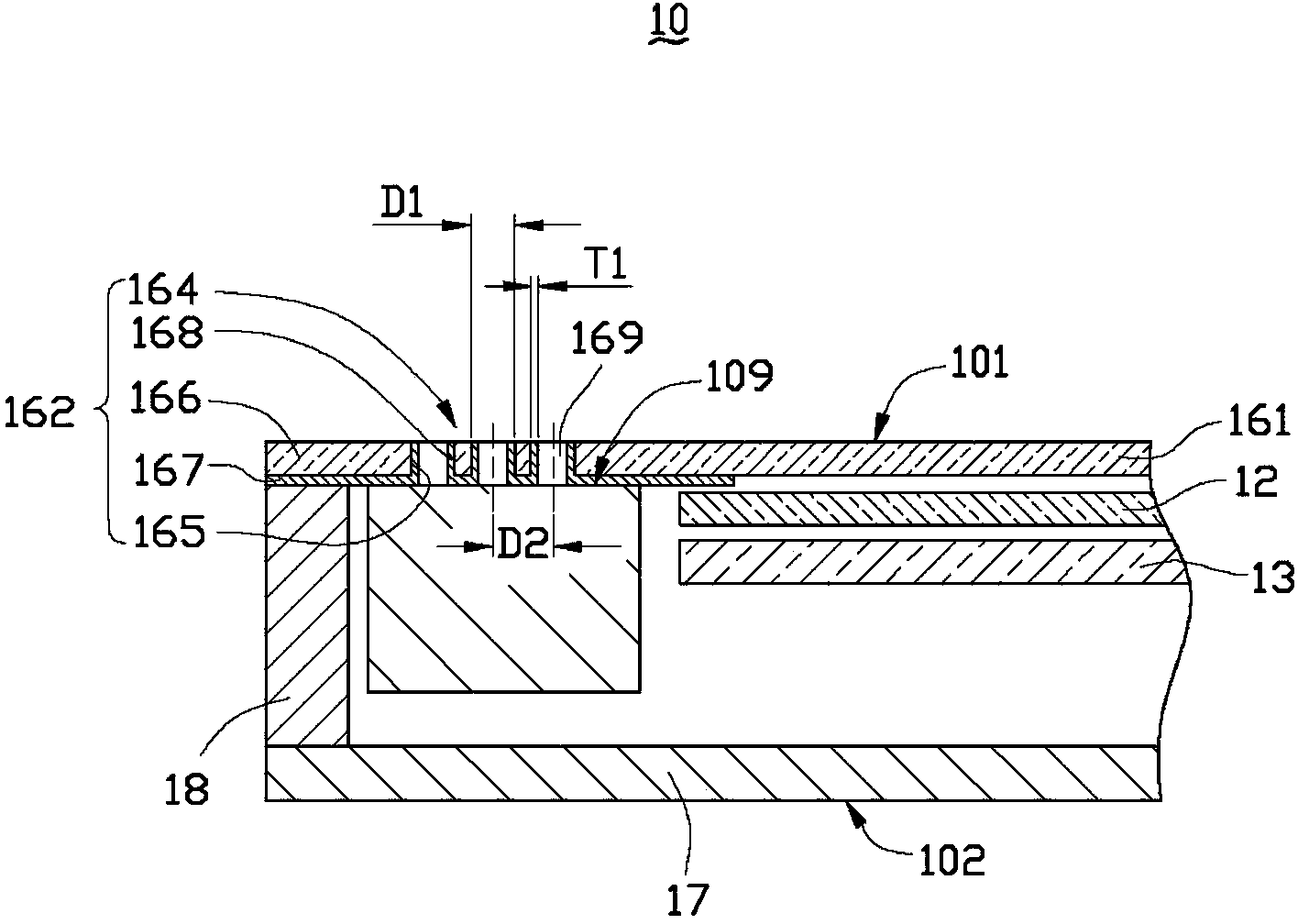

Shell of electronic device and electronic device

InactiveCN103442532AHigh strengthImprove reliabilityMicrophonesLoudspeaker screensBiomedical engineering

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

Van-type movable hydrogen manufacturing and hydrogen refueling station

InactiveCN101941418BSkip the assembly processReduce commissioning costsVehicle servicing/repairingHydrogenLow voltage

Owner:袁家祯

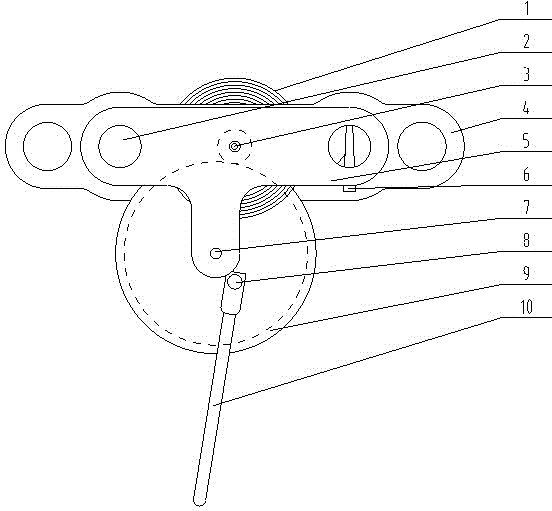

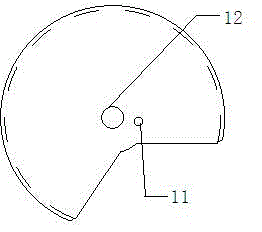

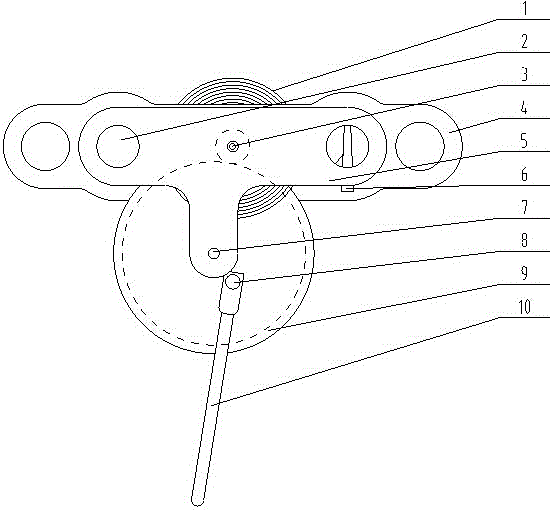

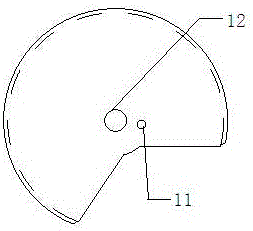

Movement of mechanical sphygmomanometer for self-calibration production technology

ActiveCN104783770AThe overall structure is ingeniously designedCompact structureEvaluation of blood vesselsAngiographyPhysicsCrank

The invention relates to a movement of a mechanical sphygmomanometer for a self-calibration production technology. The movement of the mechanical sphygmomanometer for the self-calibration production technology is characterized in that the movement is composed of an upper clamping plate, a lower clamping plate, movement columns arranged between the upper clamping plate and the lower clamping plate, a pointer shaft, a hairspring providing elastic recovery, a hairspring pin for fixing the hairspring and a crank connecting rod, the upper clamping plate is fixedly connected with the lower clamping plate through the movement columns, the pointer shaft is installed in holes of the upper clamping plate and the lower clamping plate and can rotate, one end of the hairspring is fixed on the pointer shaft, the other end of the hairspring is fixed on one movement columns through the hairspring pin, and a gear is arranged on the pointer shaft.

Owner:HONSUN NANTONG

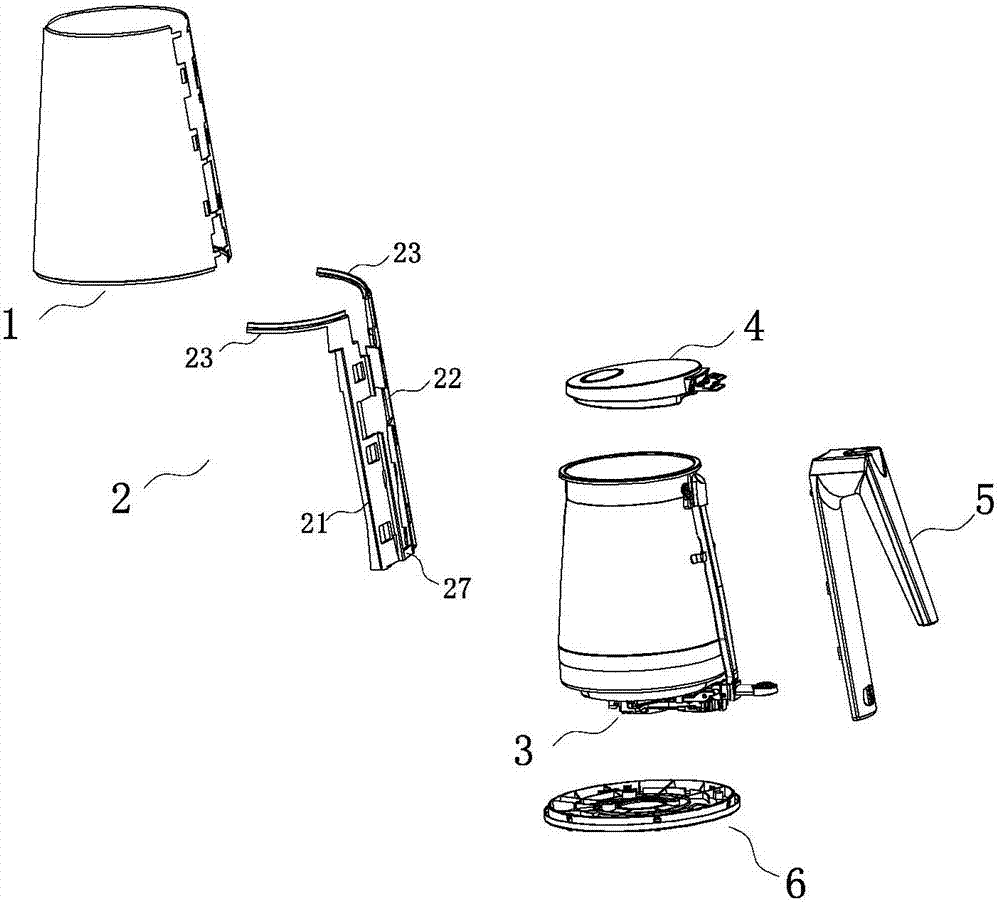

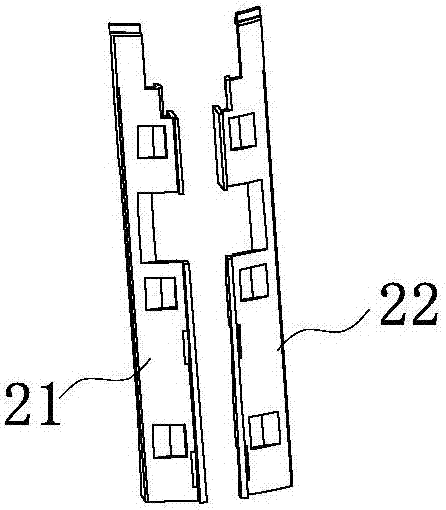

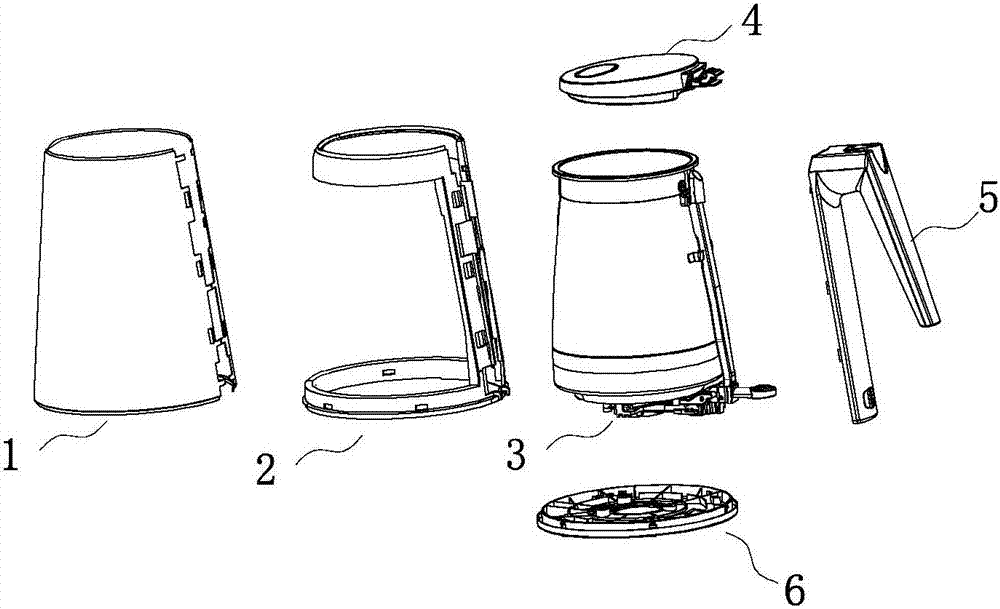

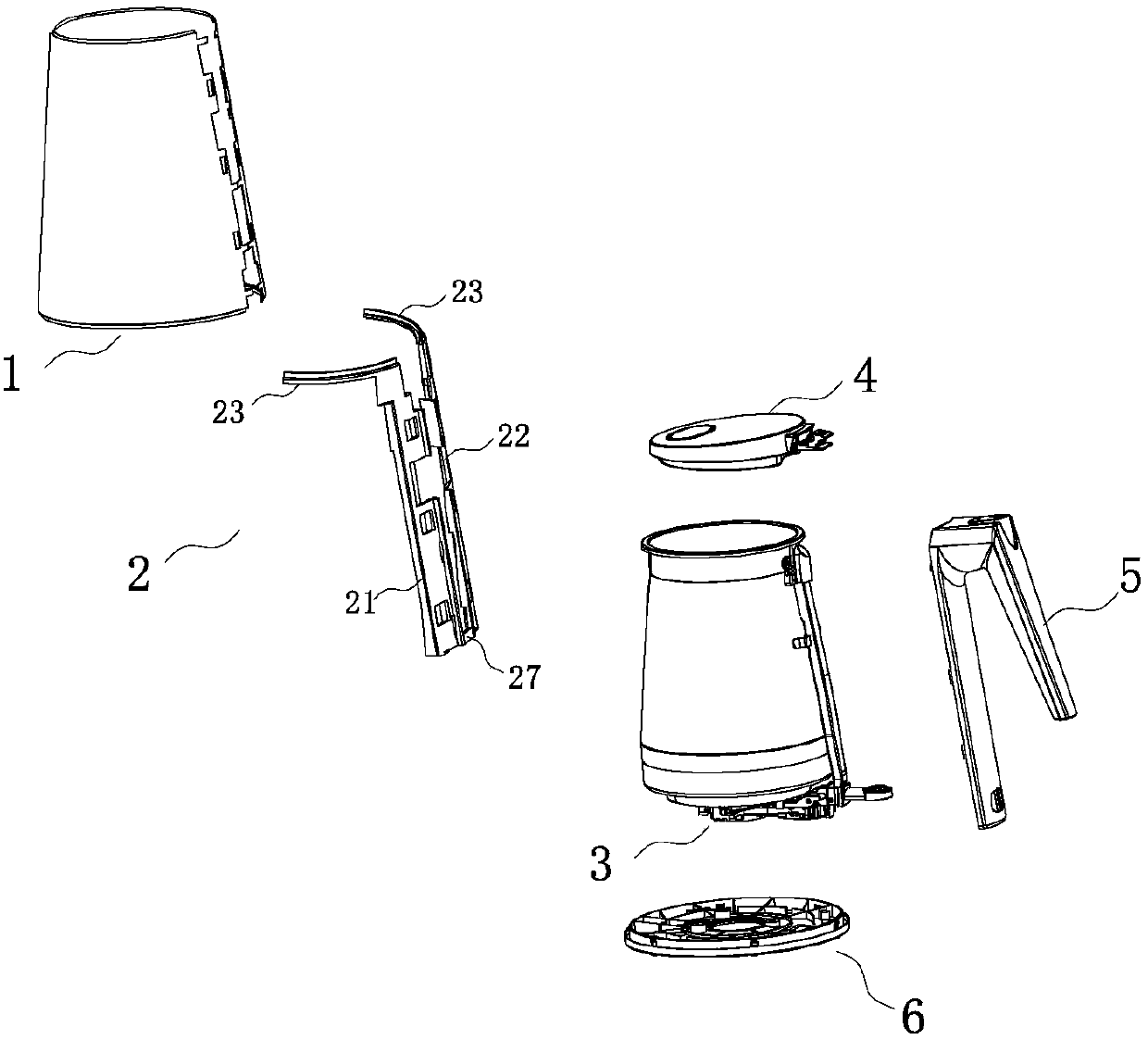

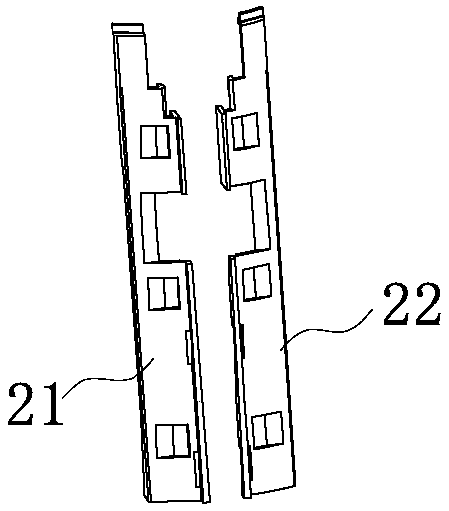

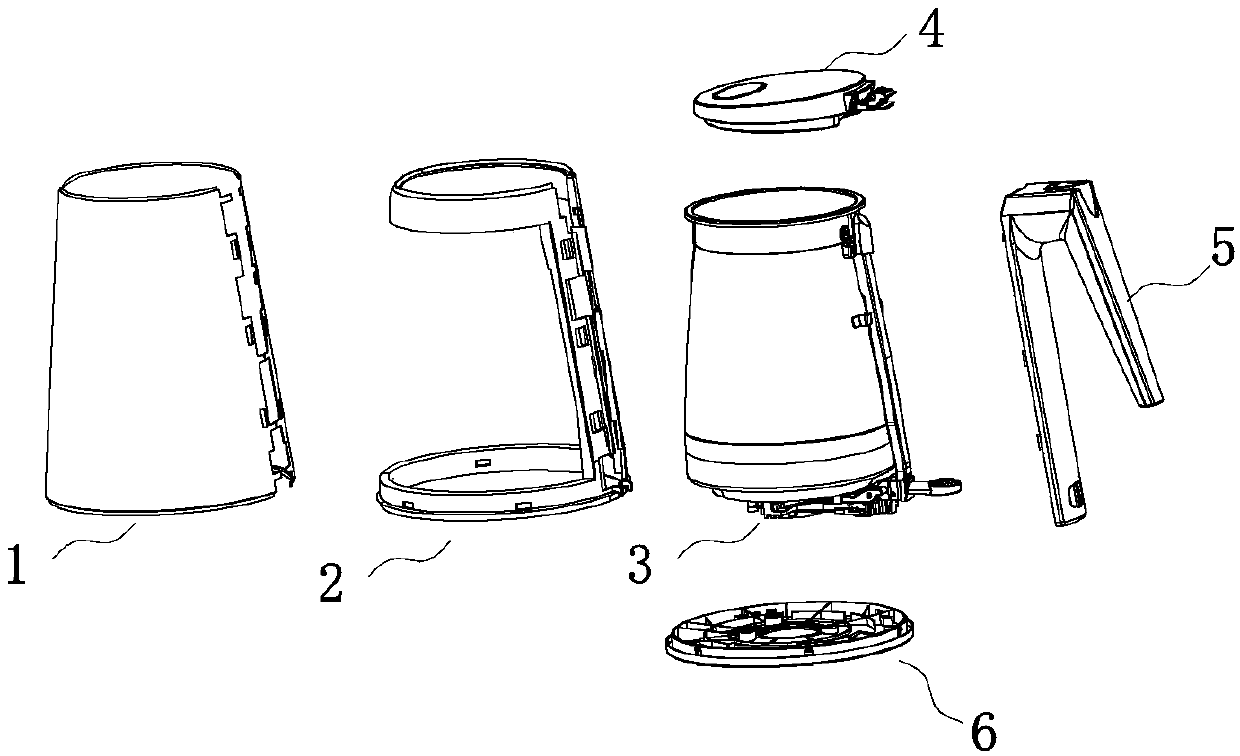

Kettle body structure

The invention relates to a household appliance, in particular to a kettle body structure. A kettle body comprises a container, a casing and a handle, wherein an opening is formed in one side of the casing, the container is sleeved with the casing, and the casing is metal; the kettle body structure further comprises a plastic support arranged between the metal casing and the container, the plastic support is used for supporting the metal casing and comprises a first support and a second support which are arranged at the opening and axially arranged along the outer wall of the container, and the handle covers the opening. By use of plasticity and strength of plastics, the strength of the metal casing can be enhanced, plastic supports in different structural forms can be formed to adapt to different casing shapes, and the cost of the plastics is lower than that of metal.

Owner:JOYOUNG CO LTD

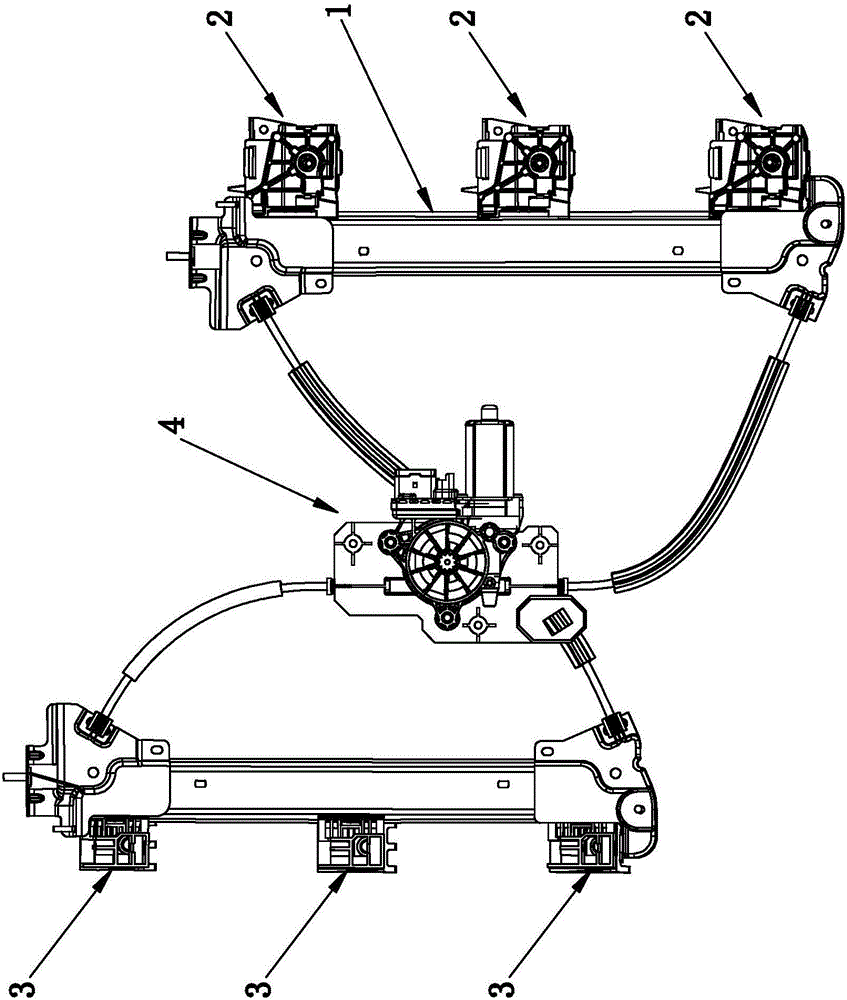

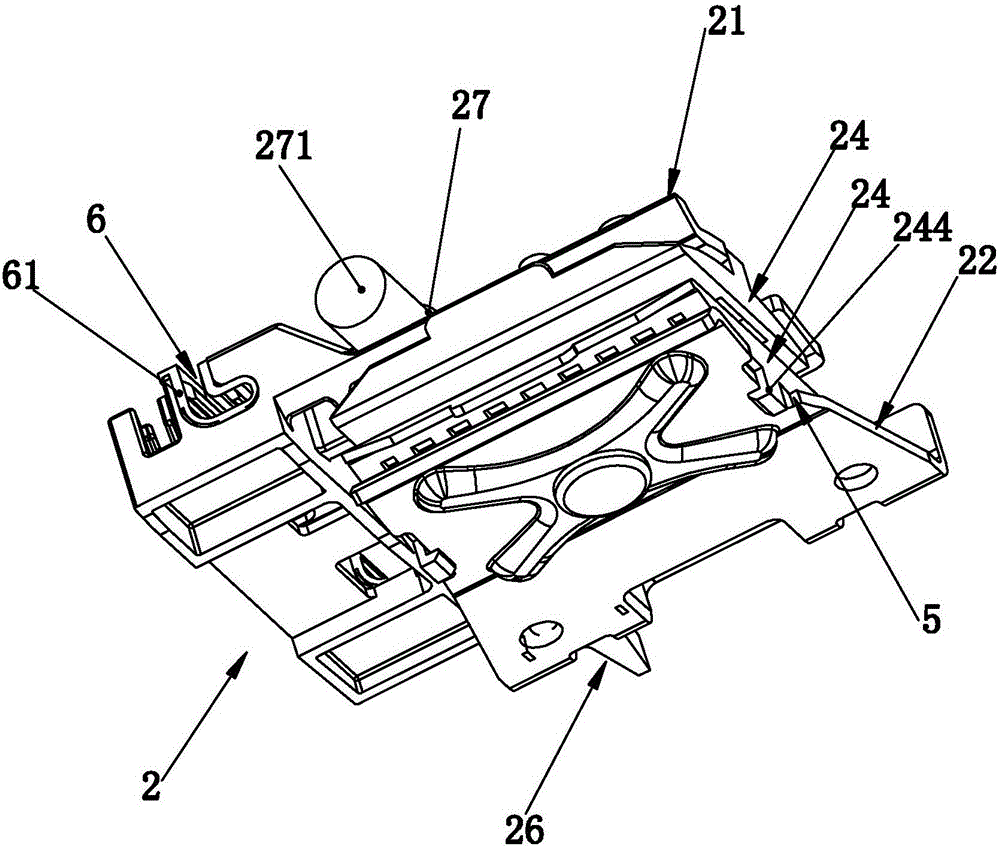

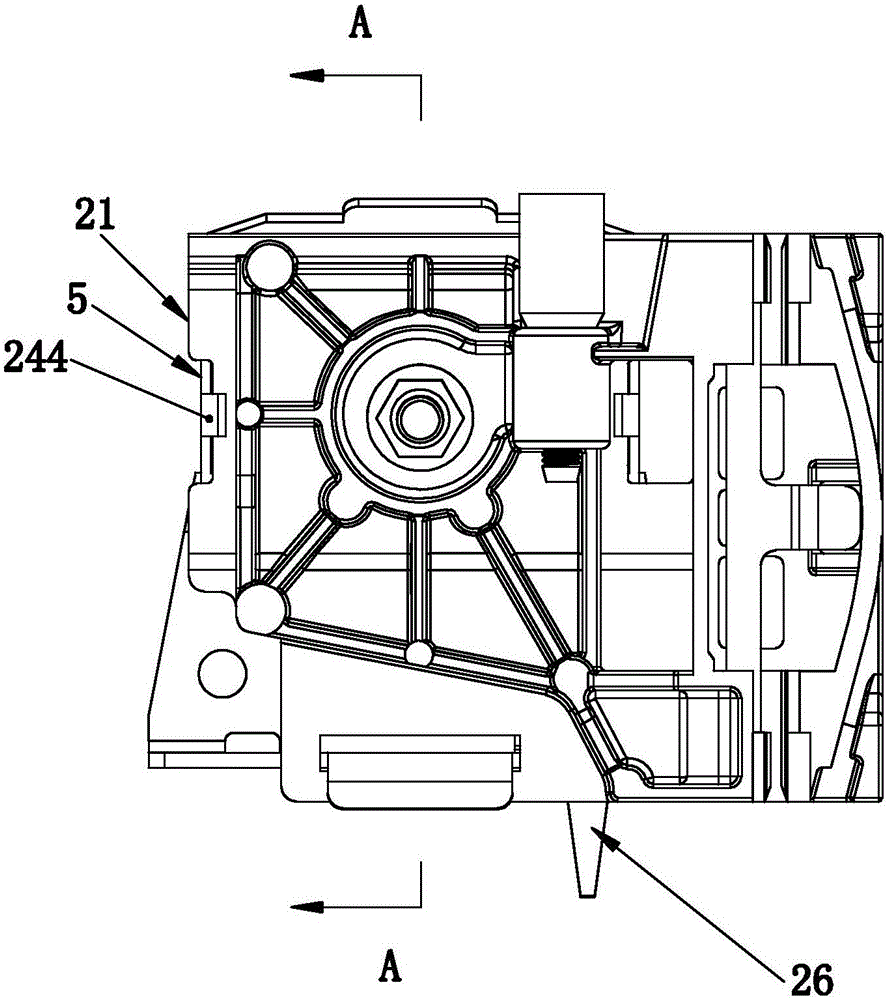

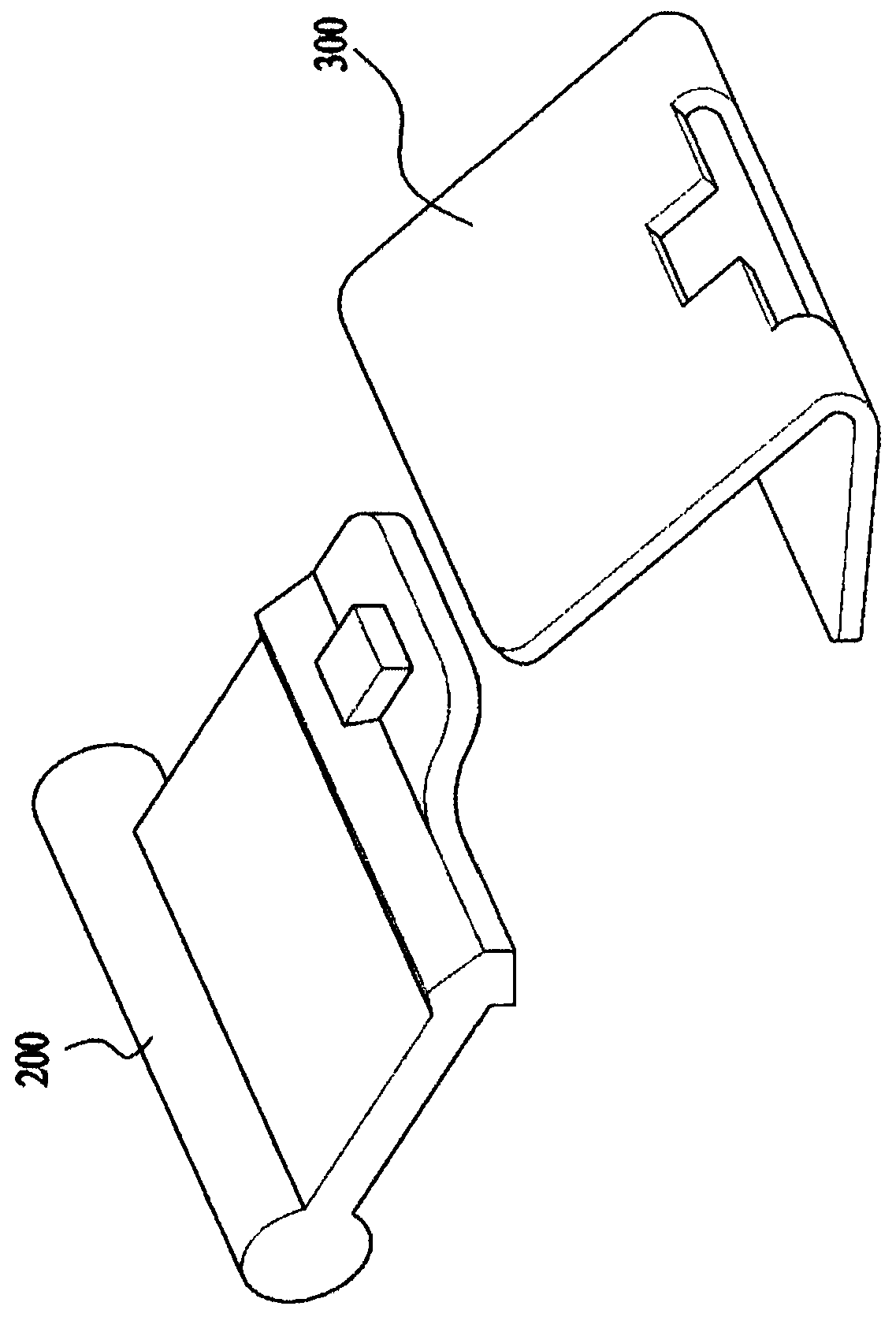

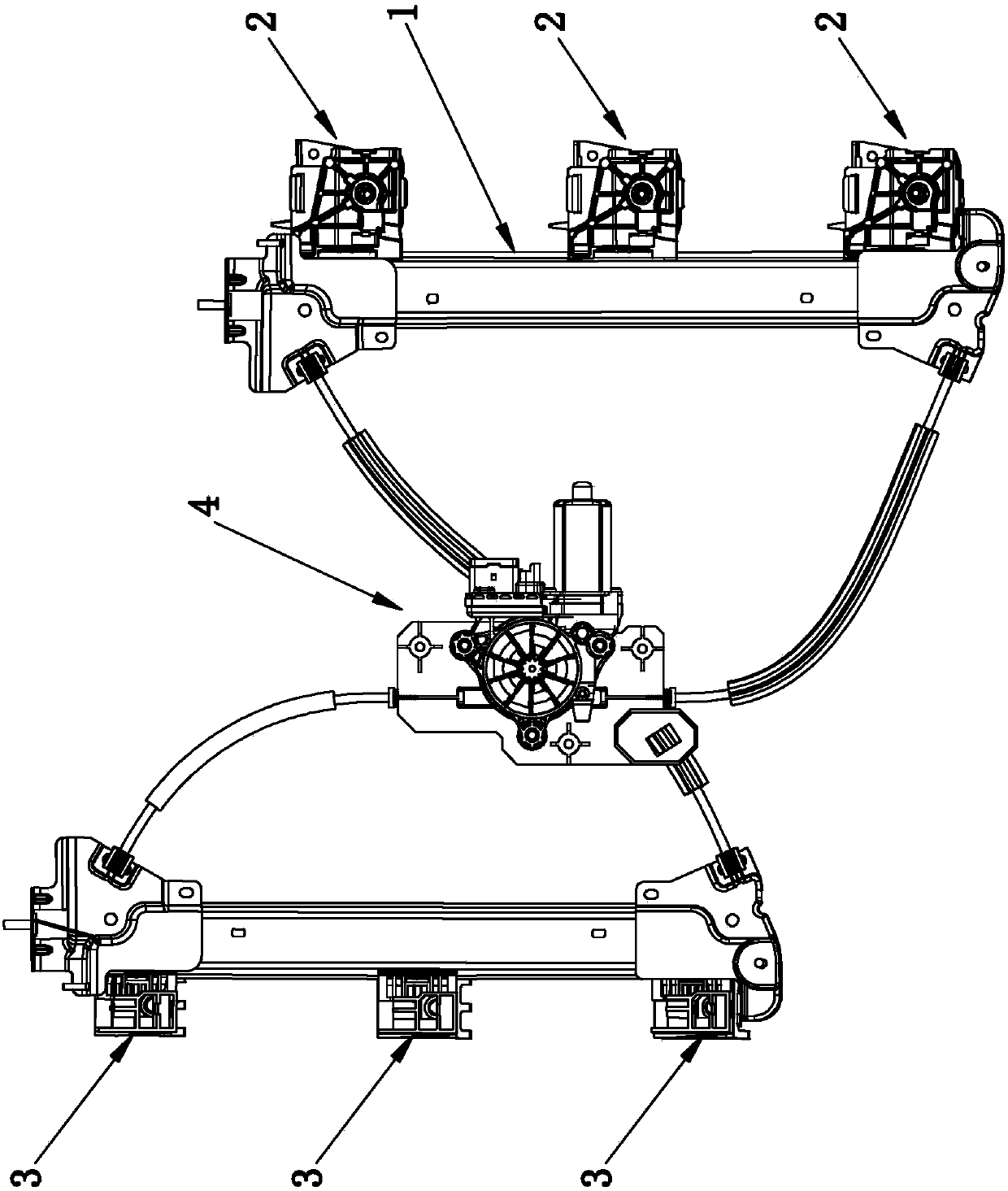

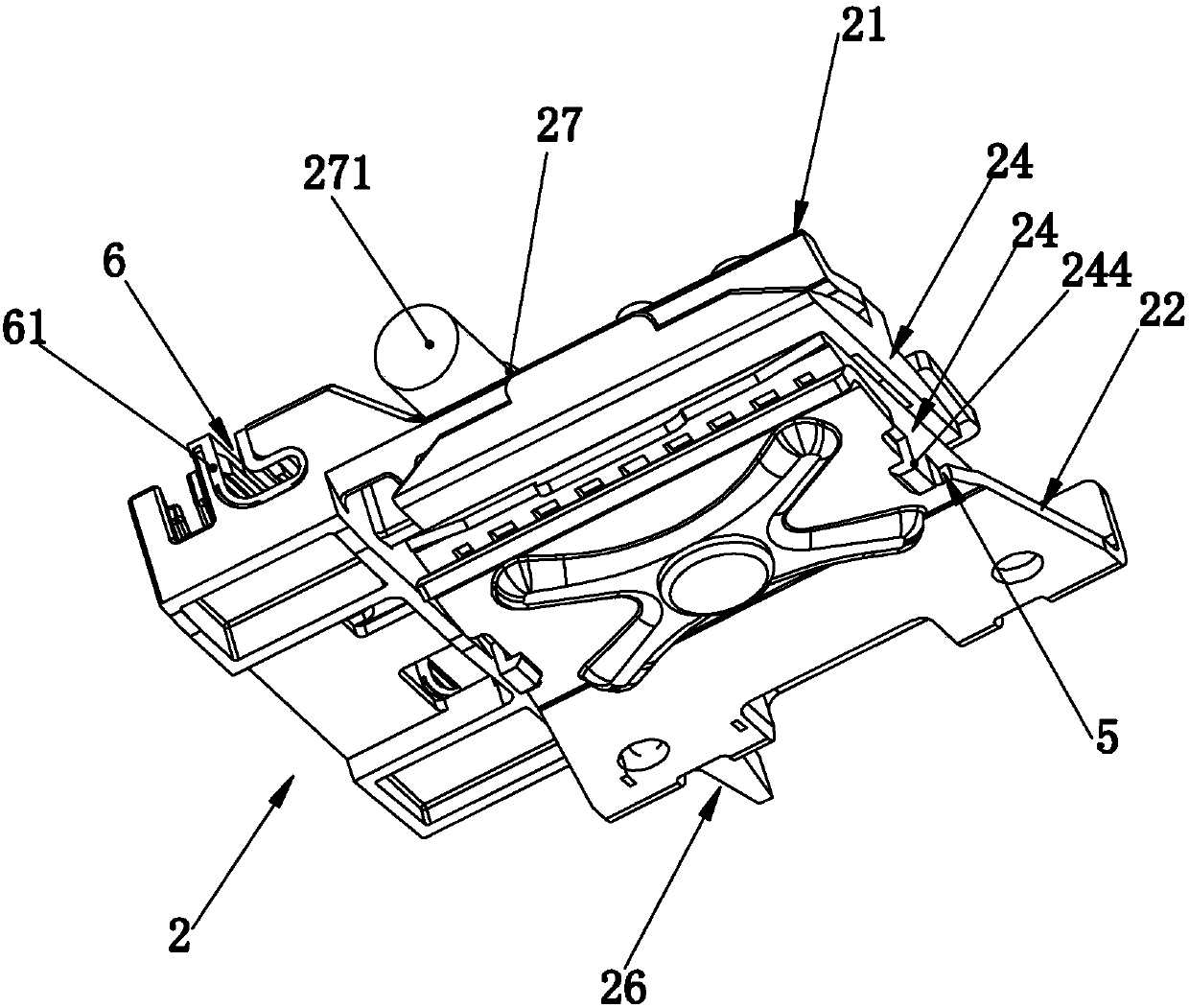

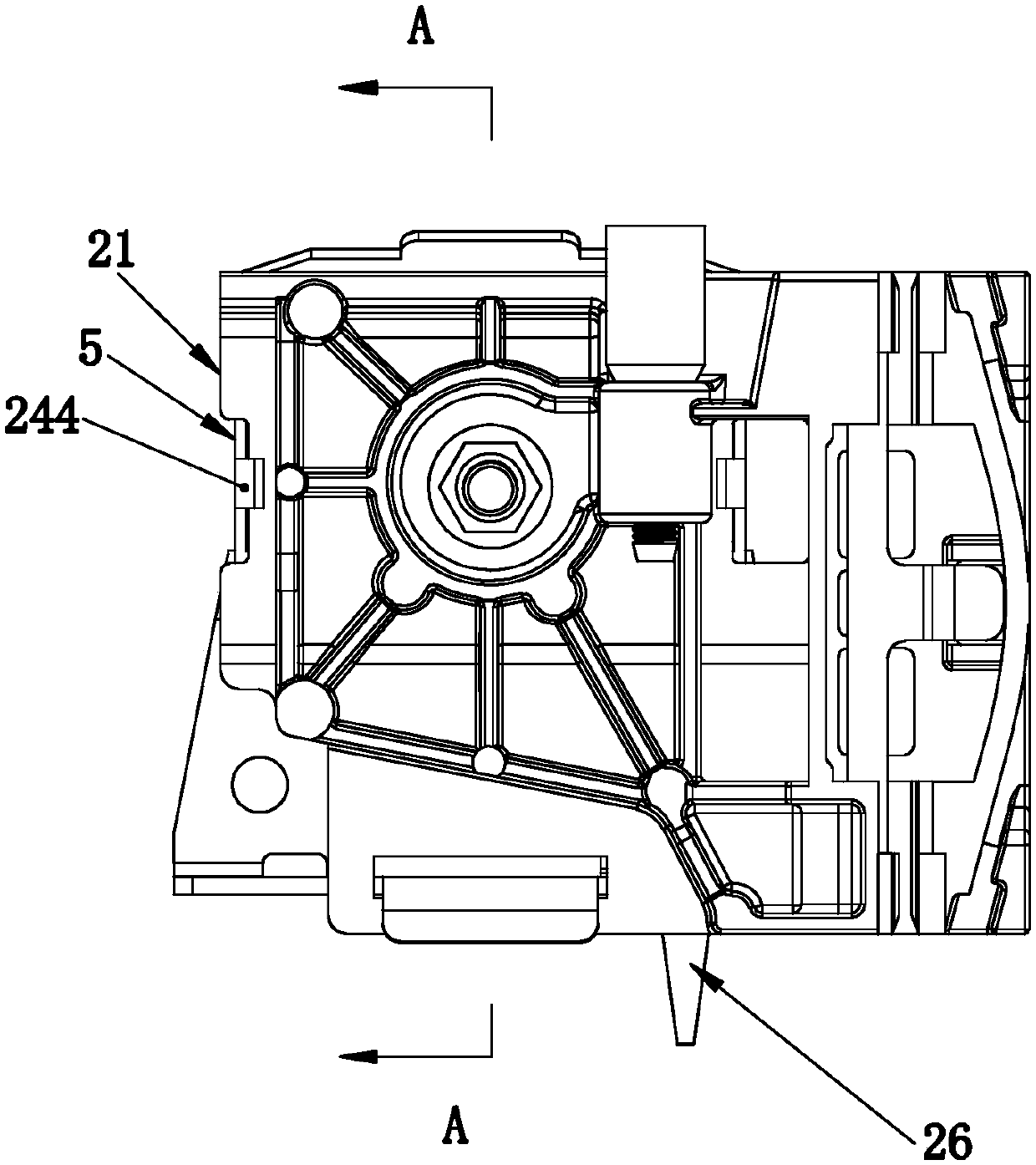

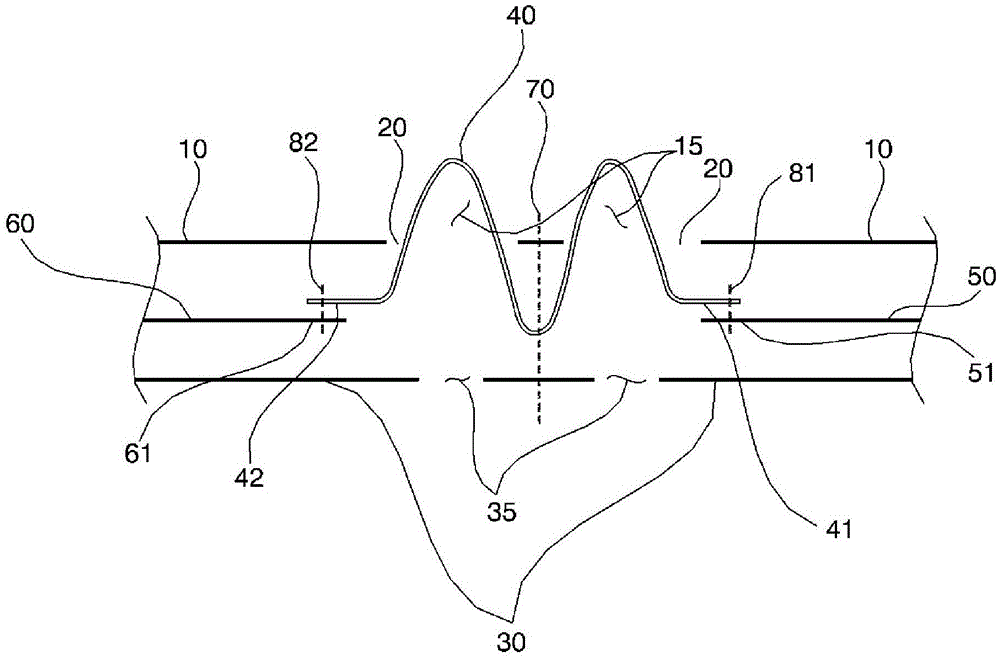

Double-guide-rail window glass lifter

ActiveCN106837050AAccurate installation angleEasy to install anglePower-operated mechanismSpare part

The invention relates to automobile spare parts, in particular to a double-guide-rail window glass lifter. According to the technical scheme, the double-guide-rail window glass lifter comprises guide rails, main guide rail glass clamping assemblies, auxiliary guide rail glass clamping assemblies and a driving assembly, wherein the main guide rail glass clamping assemblies and the auxiliary guide rail glass clamping assemblies are erected on the guide rails. Each main guide rail glass clamping assembly comprises a main clamping body and a main clamping block. Each auxiliary guide rail glass clamping assembly comprises an auxiliary clamping body and an auxiliary clamping piece. Movable clamping pieces are arranged in each main clamping space. The opposite end faces, located inside each main clamping space, of the corresponding main clamping body and the main clamping block are cambered surfaces, and the outer surface of each movable clamping piece is provided with a regulating cambered surface. The auxiliary clamping pieces are flexible hooks integrally formed with the auxiliary clamping bodies and are located in corresponding auxiliary clamping spaces, and the end faces, opposite to the auxiliary clamping bodies, of the auxiliary clamping pieces are provided with clamping lugs. The auxiliary clamping bodies are provided with dismounting openings corresponding to the clamping lugs. By the adoption of the technical scheme, the double-guide-rail window glass lifter which is convenient to dismount and mount, wide in universality and capable of achieving angle adjustment conveniently is provided.

Owner:浙江益华汽车配件有限公司

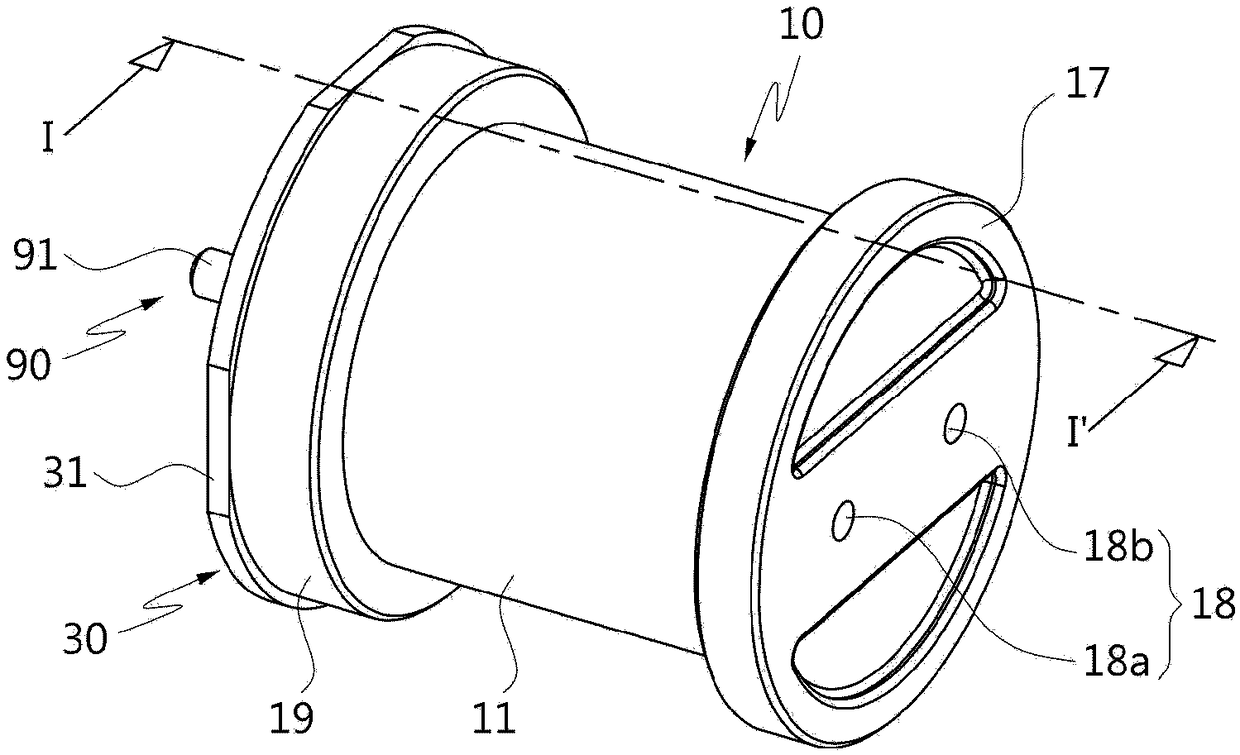

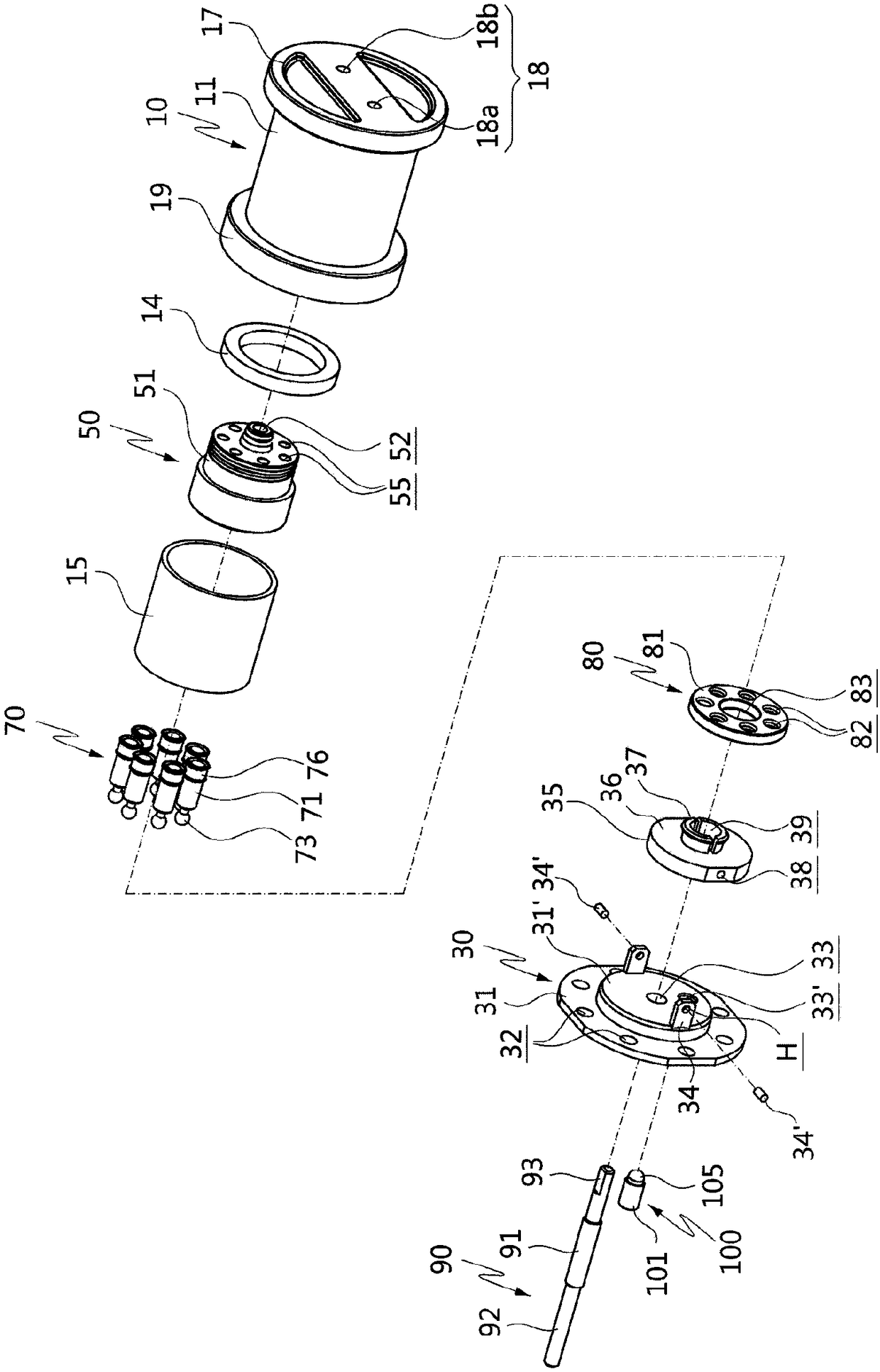

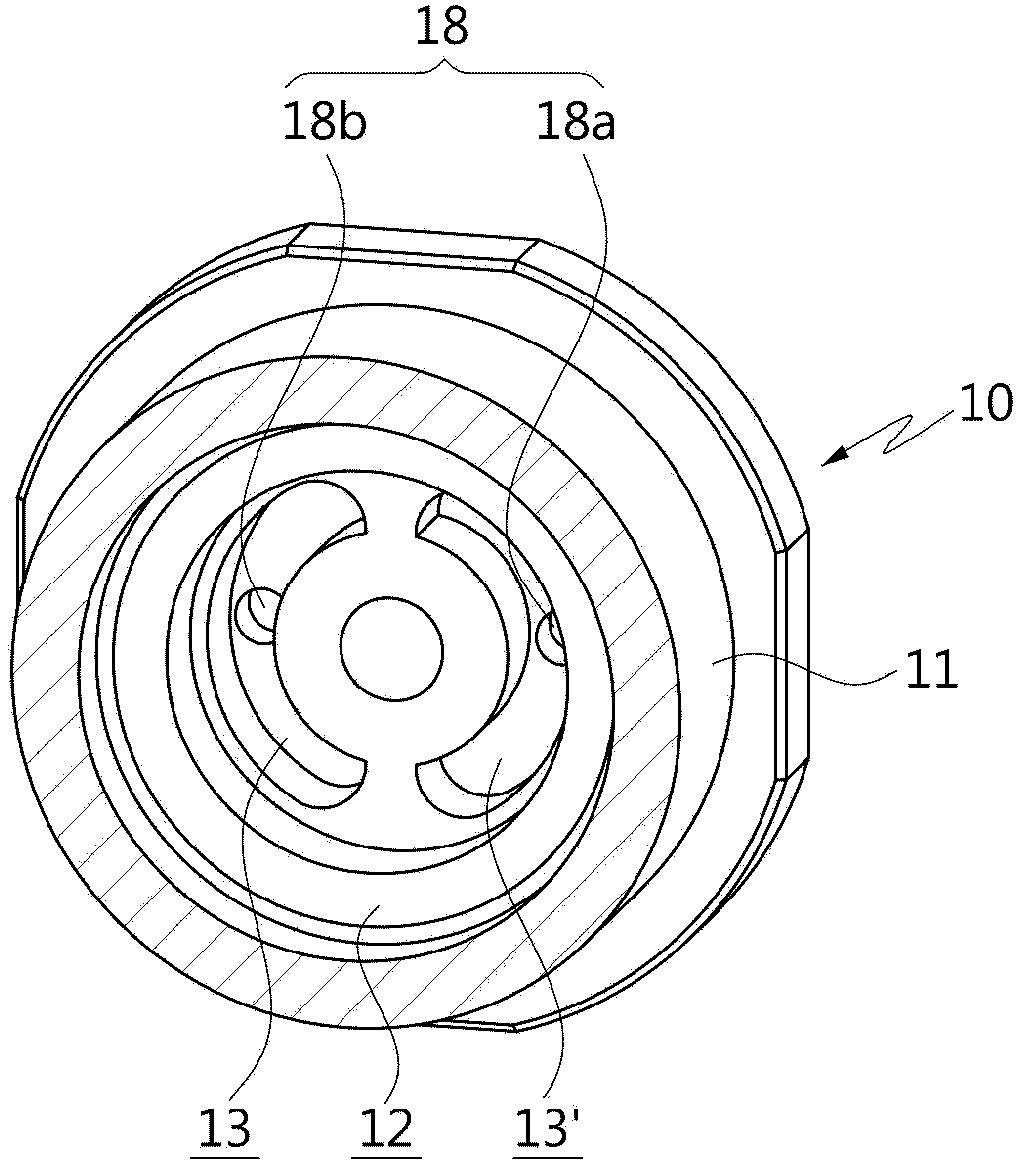

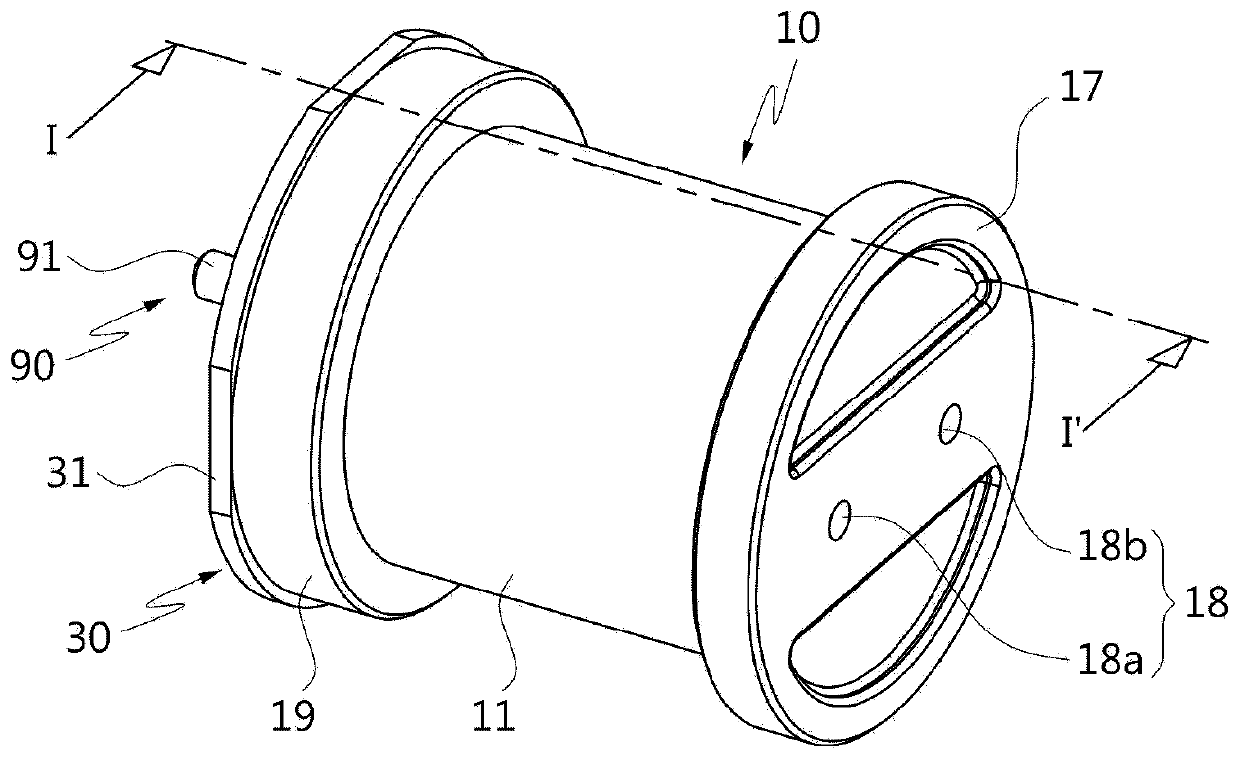

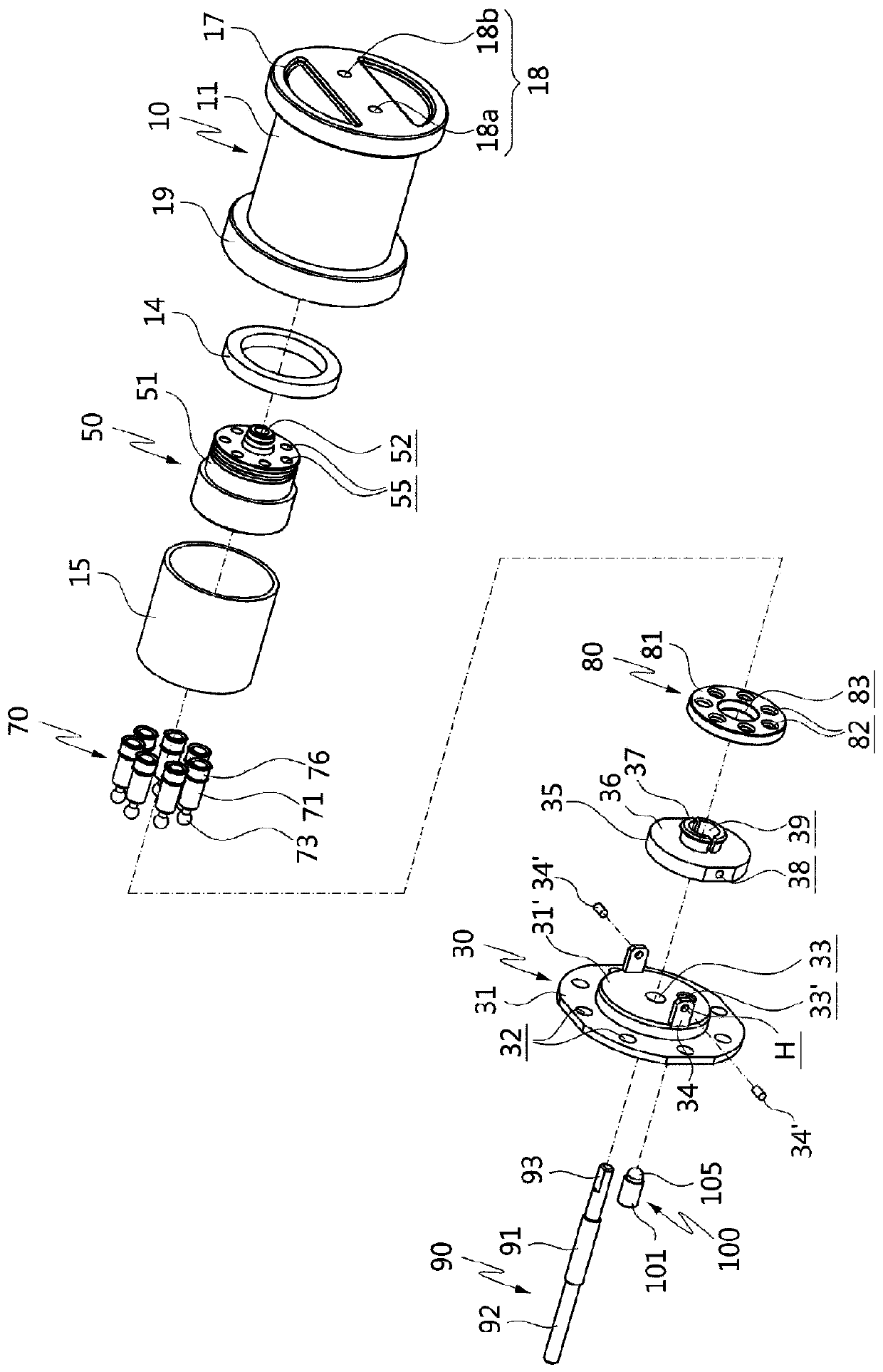

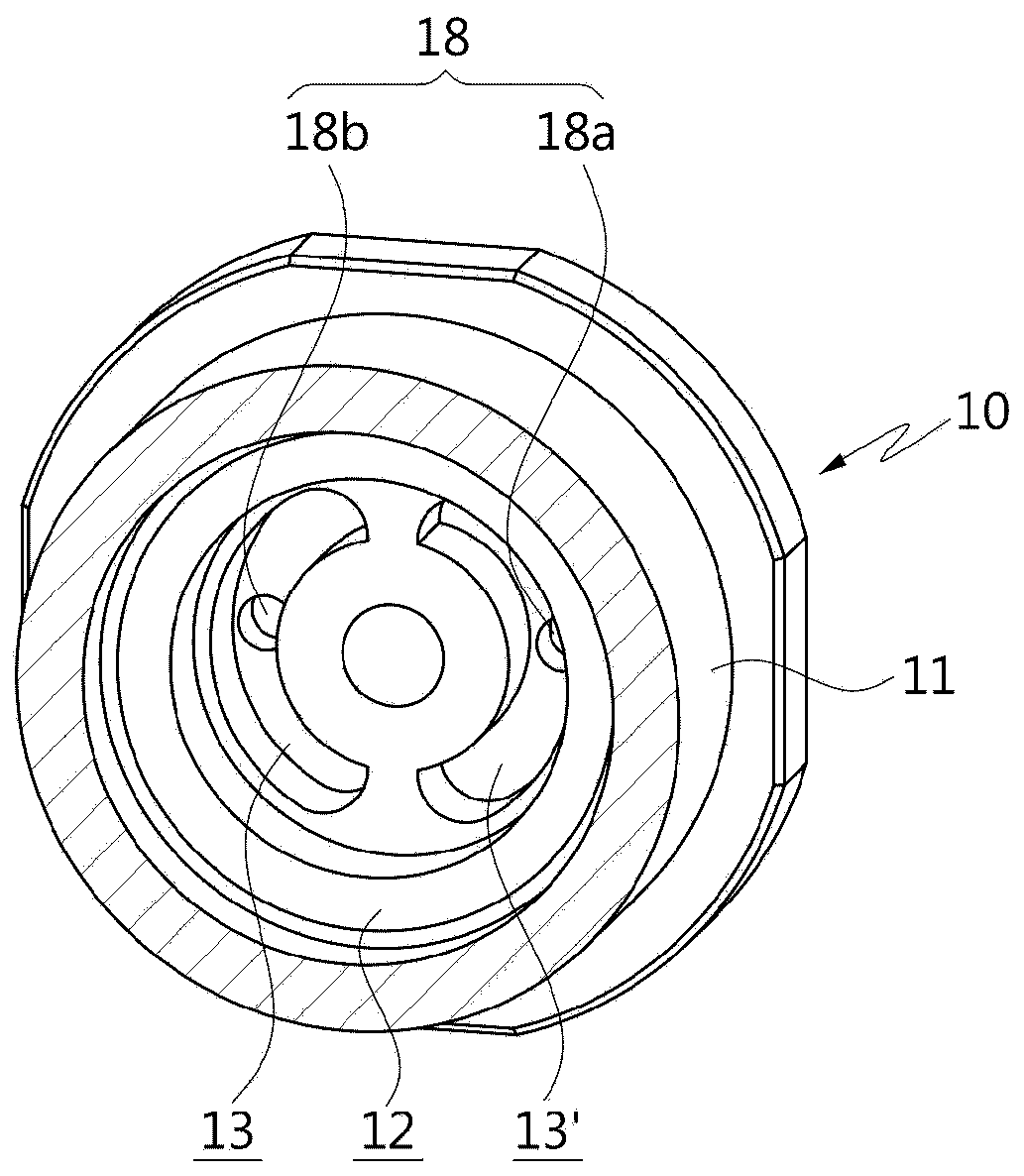

Variable capacity type fluid pump

ActiveCN108361165AReduce in quantityReduce the number of assembly processesPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

The invention discloses a variable capacity type fluid pump. The fluid pump comprises shells, a swash plate, a cylinder column, a piston assembly, a check ring and an inclination adjusting part; a driving space is formed inside the shells; the swash plate is arranged in the driving space, can be installed in a rotating mode by taking supports as the center, and can adjust the inclination angle ofan inclination surface; the cylinder column is installed in the driving space and can rotate under the action of a driving shaft, and multiple air cylinder holes are formed in the inner part of the cylinder column along the direction parallel to the driving shaft; at least a part of the piston assembly is inserted into the interiors of the air cylinder holes of the cylinder column, and the pistonassembly is subjected to linear movement in the air cylinder holes while rotating along the cylinder column; the check ring is connected to the piston assembly, and rotates along with the piston assembly in the state that the piston assembly is attached to the inclination surface of the swash plate; and the inclination adjusting part enters and exits from the driving space through the shells, andin the process that the inclination adjusting part is inserted into the driving space, the inclination angle of the swash plate is adjusted by utilizing the tail end of one side of the inclination adjusting part to push the bottom surface of the swash plate.

Owner:SHANGHAI HYACT TECH LTD

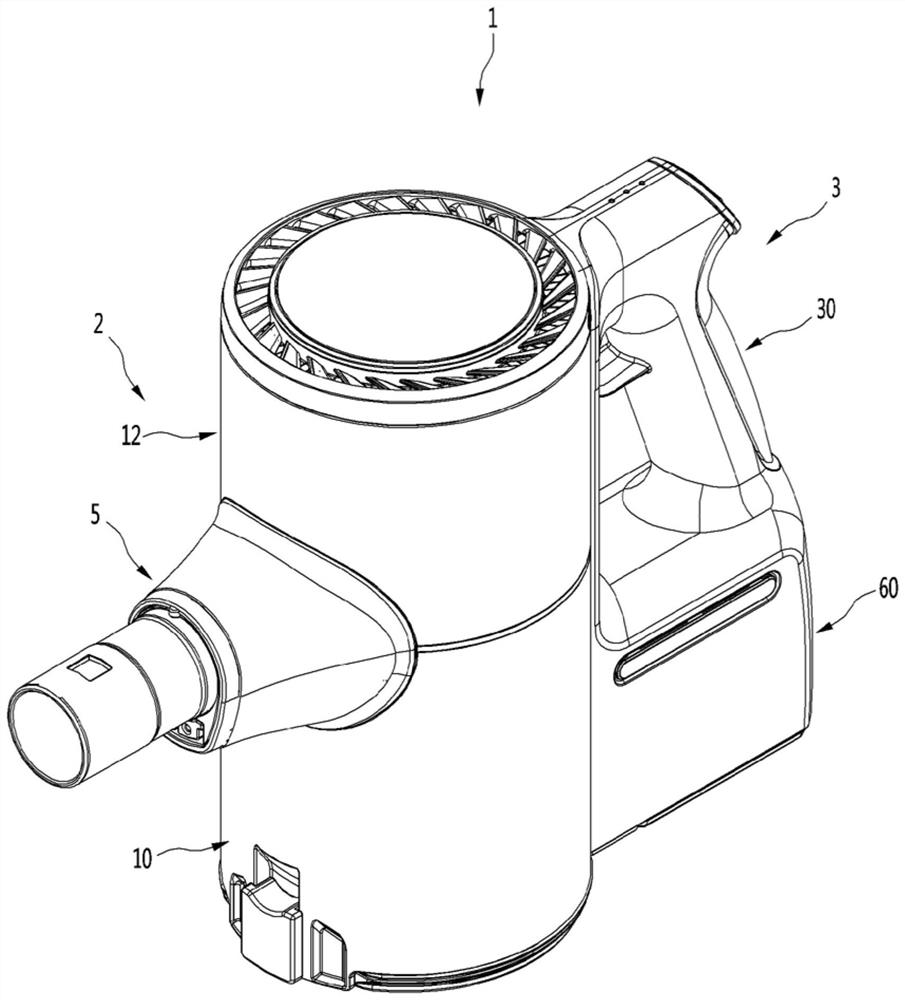

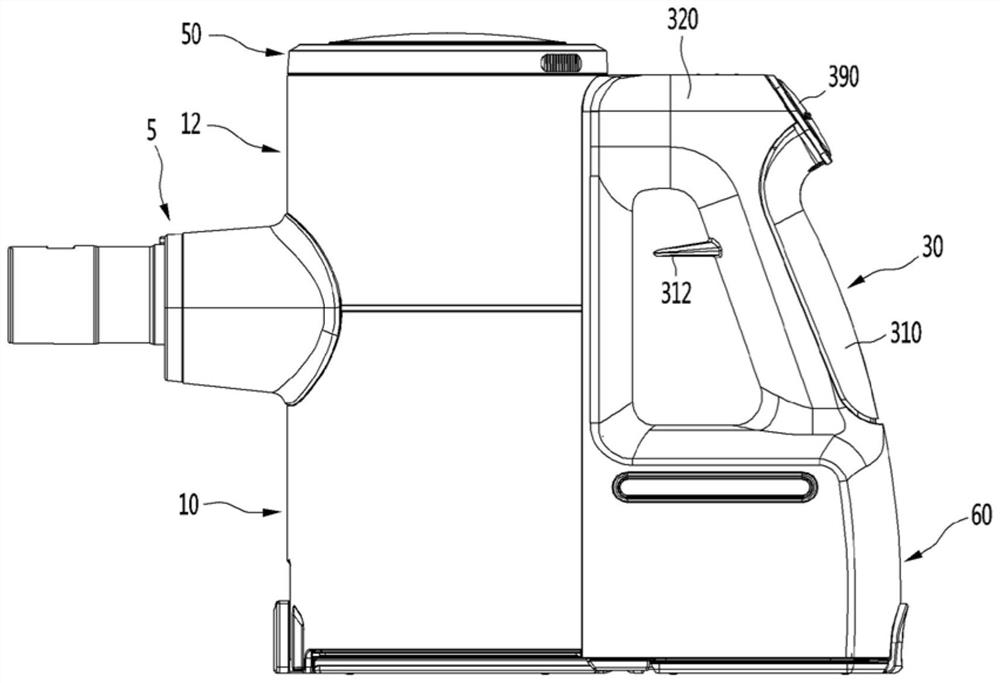

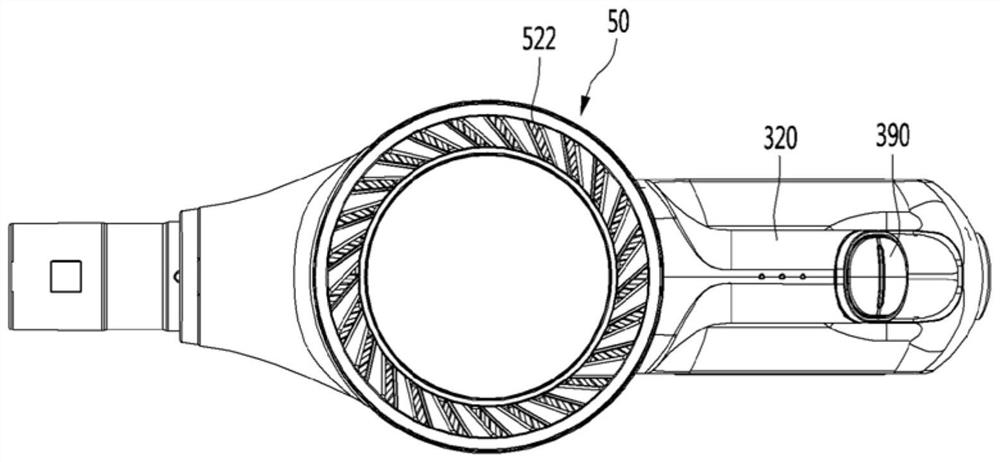

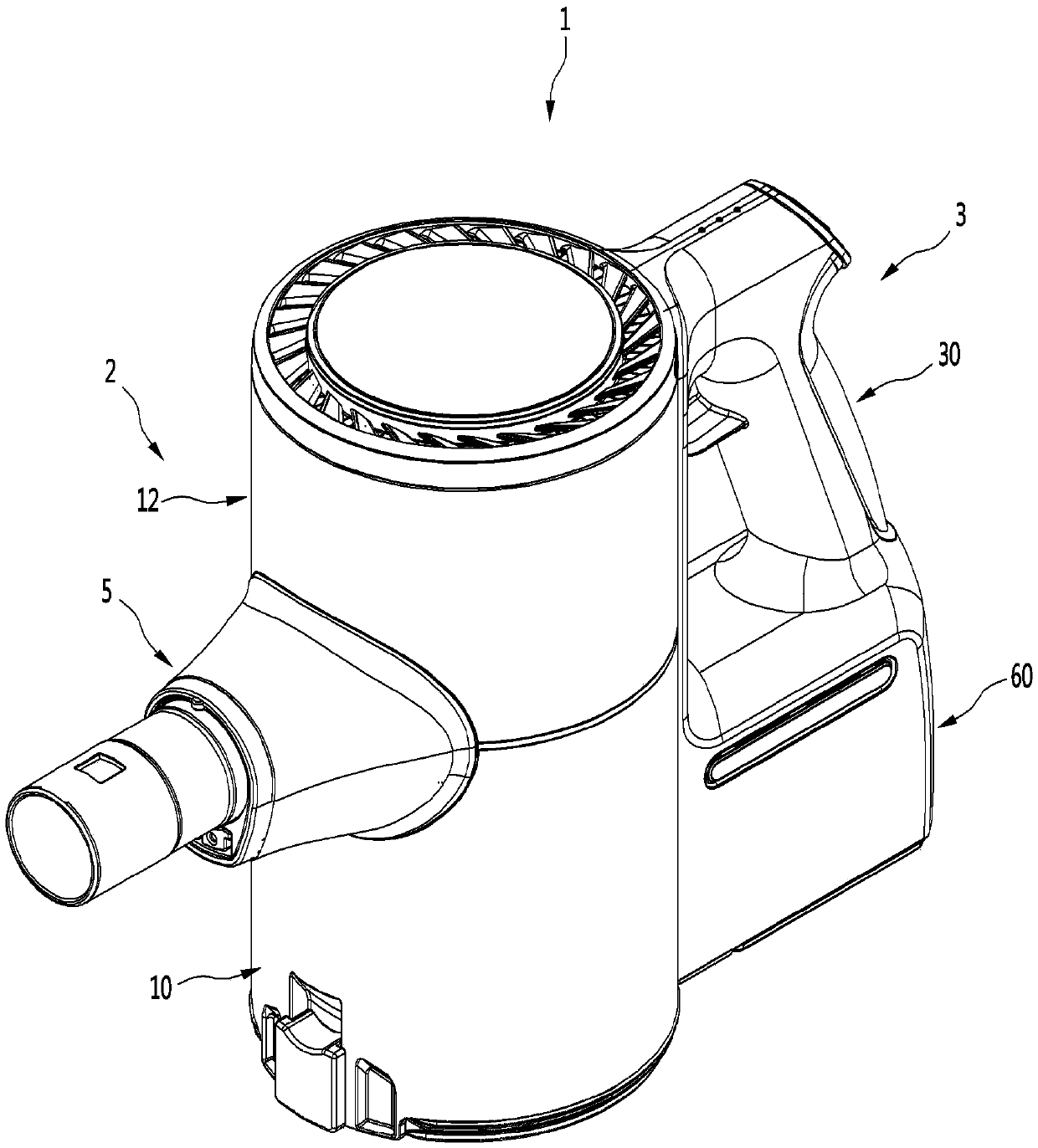

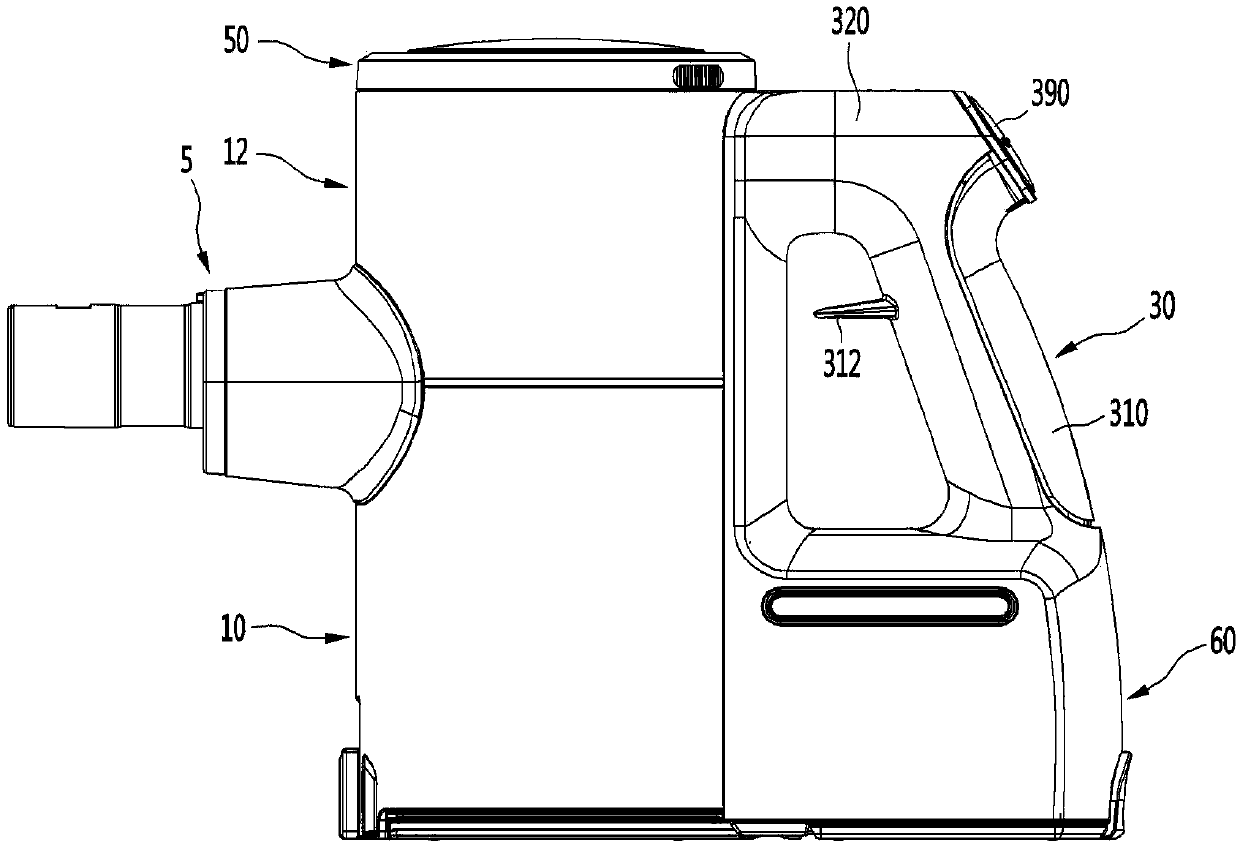

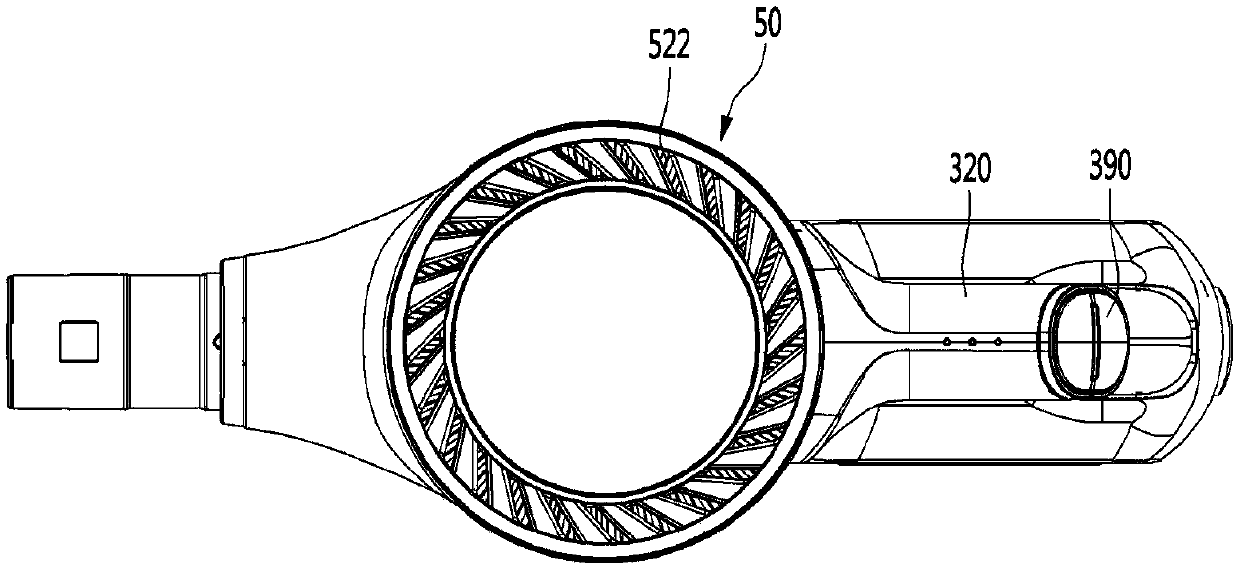

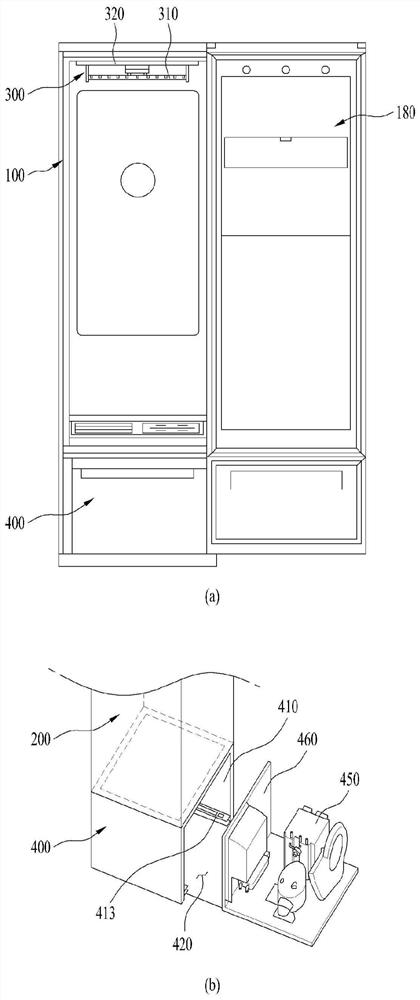

Vacuum

ActiveCN111904328ASkip the assembly processEasy to assembleSuction filtersMotor fan assembly mountingMechanical engineeringVacuum cleaner

A vacuum according to one aspect comprises: a suction unit for guiding dust and air; a main body provided with a dust separation unit for separating dust from the air guided by the suction unit; a main body terminal installed on the main body; a handle which can be attached to the main body by sliding; and a handle terminal provided on the handle and connecting to the main body terminal in the process of the handle being attached to the main body by sliding.

Owner:LG ELECTRONICS INC

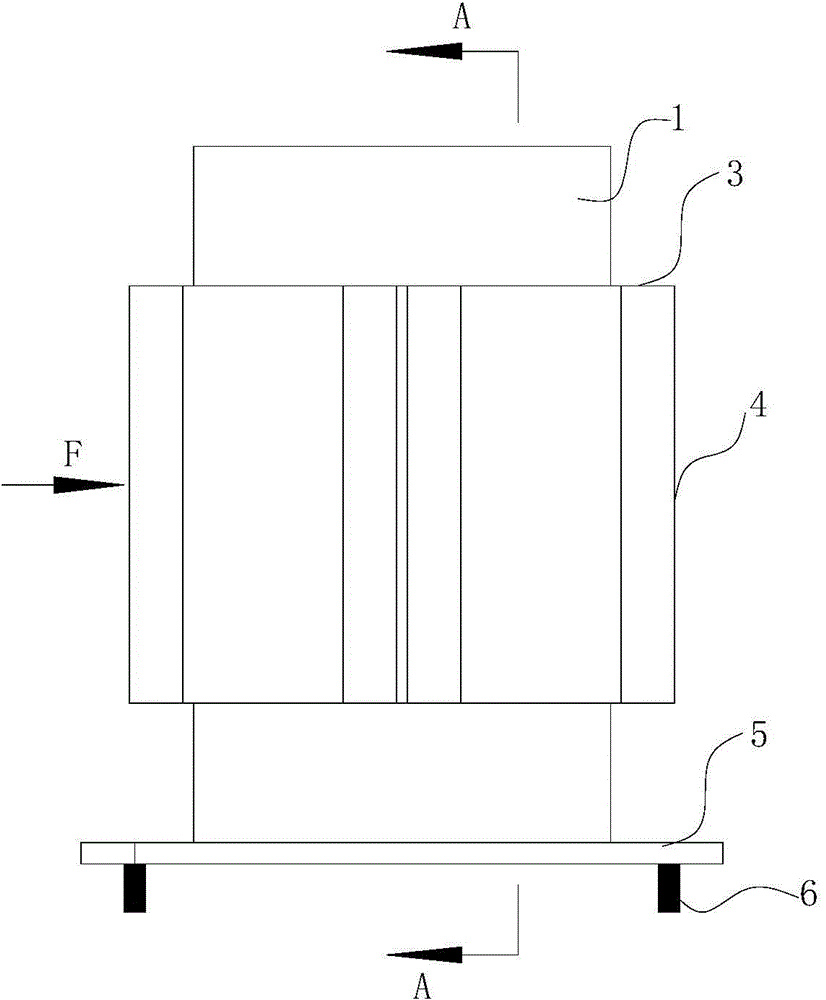

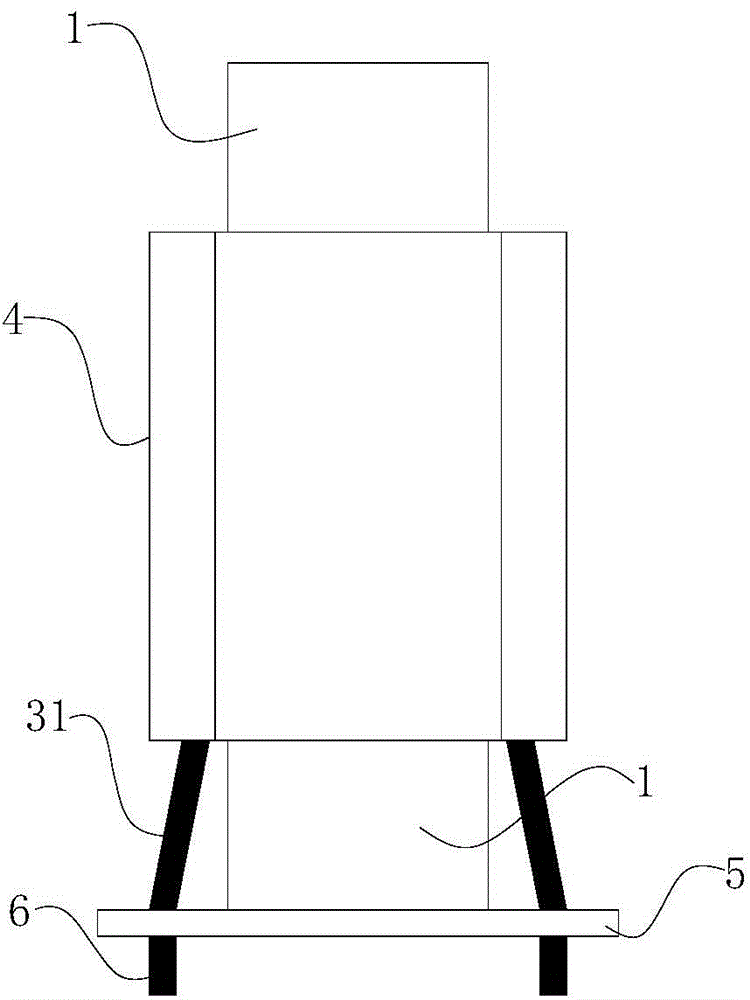

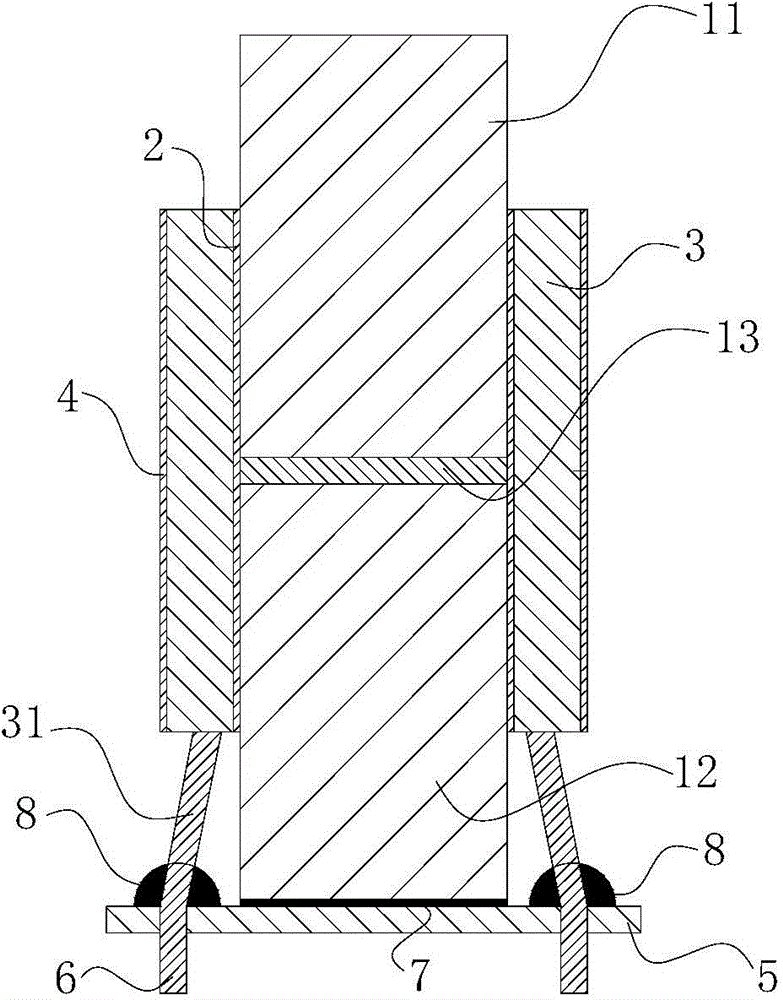

Stitch electric reactor and method for manufacturing same

InactiveCN104392829AAvoid the possibility of entanglementAvoid unreachable phenomenaTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsEngineeringConductor Coil

The invention relates to a stitch electric reactor and a method for manufacturing the same. The stitch electric reactor comprises an iron core, an insulating framework, a coil winding, an insulating protective layer and an insulating bottom plate. Openings are formed in two ends of the hollow insulating framework, and the insulating framework fixedly sleeves the periphery of the iron core; the coil winding comprises a conducting wire, an insulating layer is arranged on the outer surface of the conducting wire, the conducting wire is fixedly wound on the periphery of the insulating framework, and two ends of the conducting wire extend out of the lower surface of the insulating framework; the insulating protective layer covers the periphery of the coil winding; the insulating bottom plate is fixed to the lower end of the iron core, and via holes for the two ends of the conducting wire are formed in the insulating bottom plate; the two ends of the conducting wire penetrate the via holes, stitches are formed by portions, which are positioned at the lower end of the insulating bottom plate, of the conducting wire, and the peripheries of the stitches are free of insulating layers; the stitches are used for being connected with other electronic elements. The stitch electric reactor and the method have the advantages that the stitch electric reactor is low in production cost and simple in production process.

Owner:苏州正意电材股份有限公司

Dust collector

PendingCN109561799ASkip the assembly processEasy to assembleSuction filtersMotor fan assembly mountingDust collectorElectrical and Electronics engineering

One embodiment of the invention discloses a dust collector, and the dust collector comprises a suction unit that guides dust and air; a main body that includes a dust separation unit for separating dust from air guided through the suction unit; a main body terminal mounted on the main body; a handle unit that is slide-coupled to the main body; and a handle terminal mounted on the handle unit and connected to the main body terminal when the handle unit is slide-coupled to the main body.

Owner:LG ELECTRONICS INC

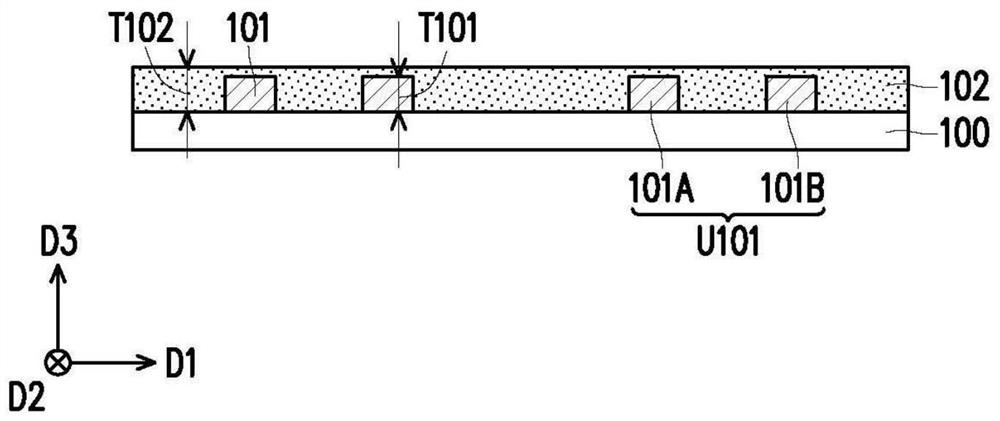

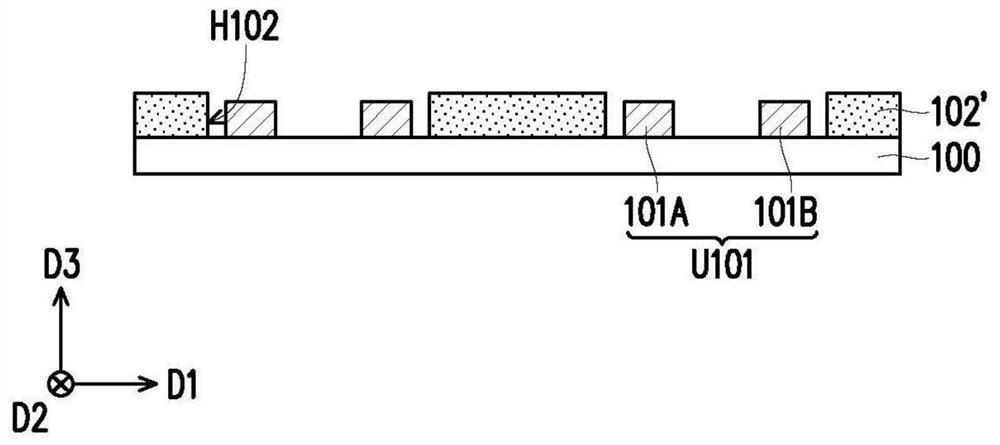

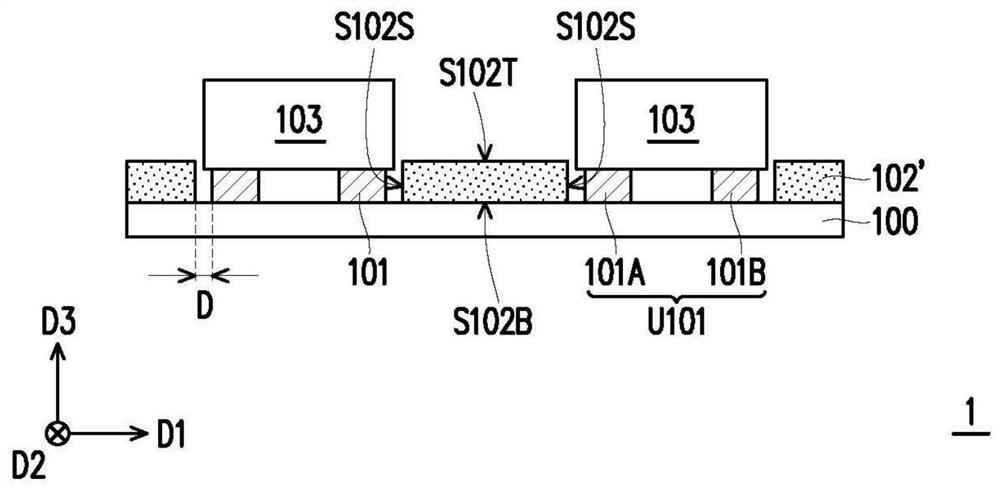

Light emitting device and manufacturing method thereof

PendingCN112582524AGood reliabilityReduce the difficulty of assemblySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectrical and Electronics engineering

The invention provides a manufacturing method of a light emitting device. The manufacturing method comprises the following steps: providing a driving substrate; disposing a plurality of light emittingunits on the driving substrate; forming a reflective layer on the driving substrate, wherein forming the reflective layer on the driving substrate includes coating the reflective layer on the drivingsubstrate.

Owner:INNOLUX CORP

Cleaning structure of gas gate valve

InactiveCN101713476BSkip the assembly processOmit the processing technologyValve arrangementsEngineeringValve seat

Owner:江苏鑫通环保科技有限公司

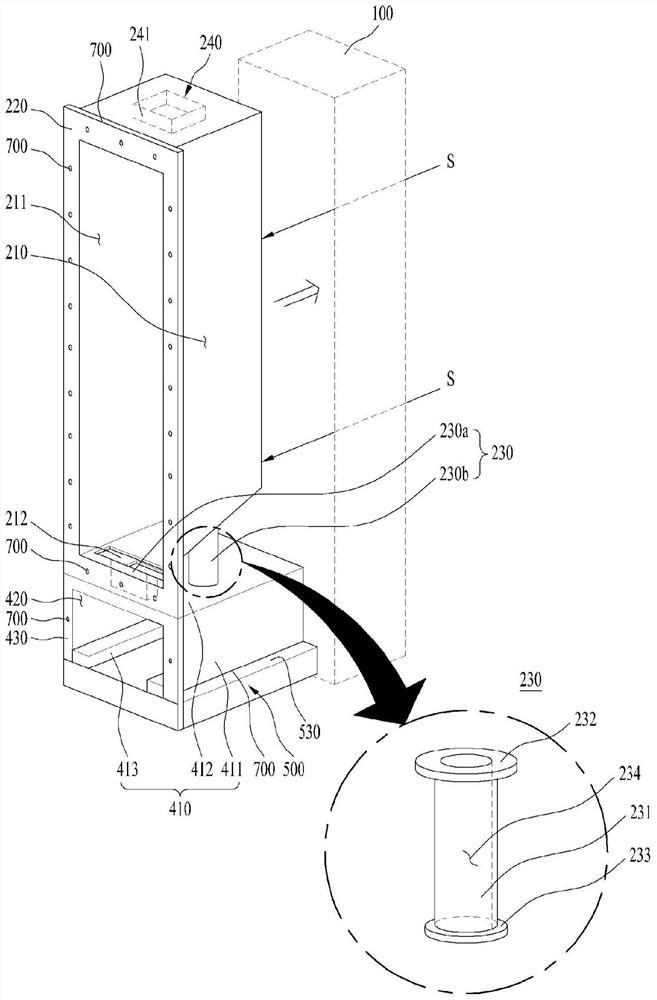

Insert components for trimming gap areas

ActiveCN106538084BEasy to trimSimplify the assembly processFurniture joining partsDomestic stoves or rangesBiomedical engineering

Disclosed is an insertion assembly which is inserted into a gap area provided in a panel to fill the gap area, the insertion assembly including: a body unit covering the gap area so that the gap area is not exposed to the outside; an insertion unit extending from the body unit and inserted into the gap region; and a hook unit extending from the insertion unit to the body unit at a preset distance, the hook unit including one end connected to the insertion unit and set free The other end of the end, wherein the body unit, the insertion unit and the hook unit are integrally formed with each other.

Owner:LG ELECTRONICS INC

A speaker module and electronic equipment

Owner:GOERTEK INC

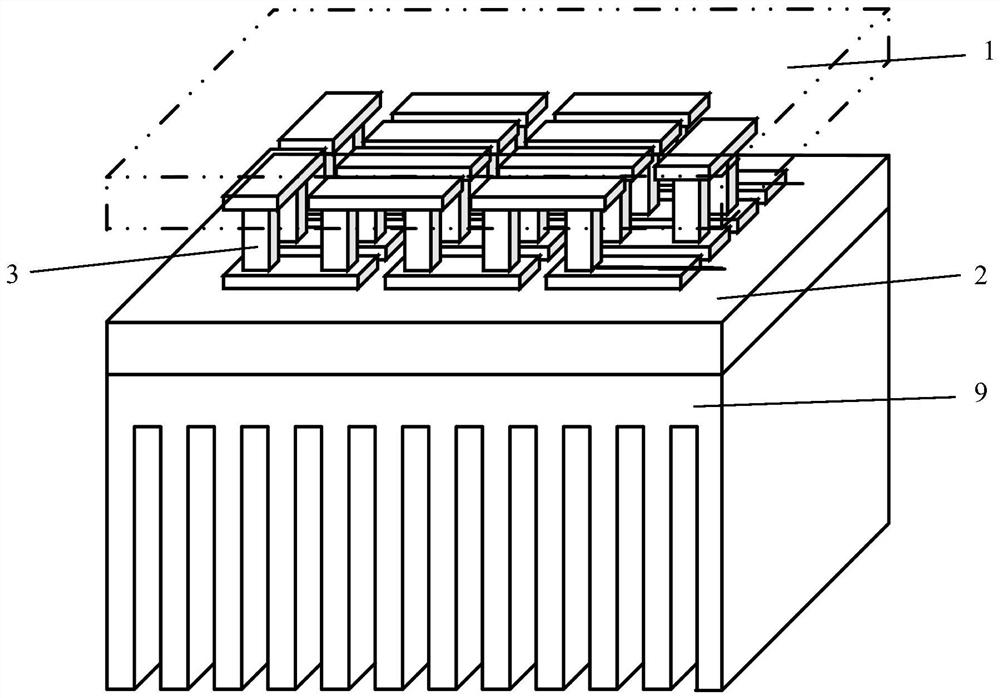

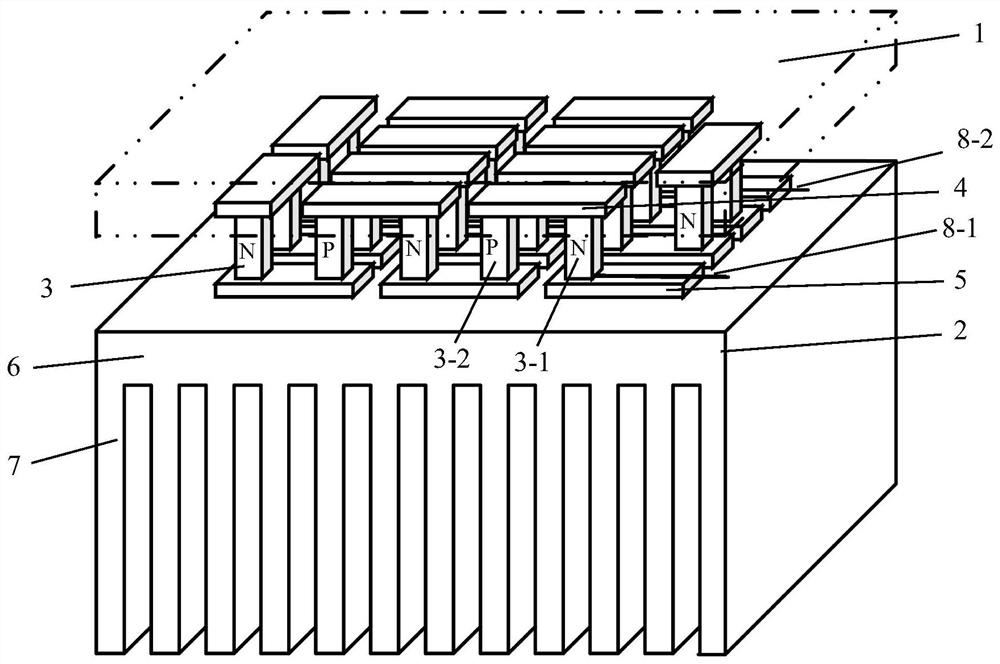

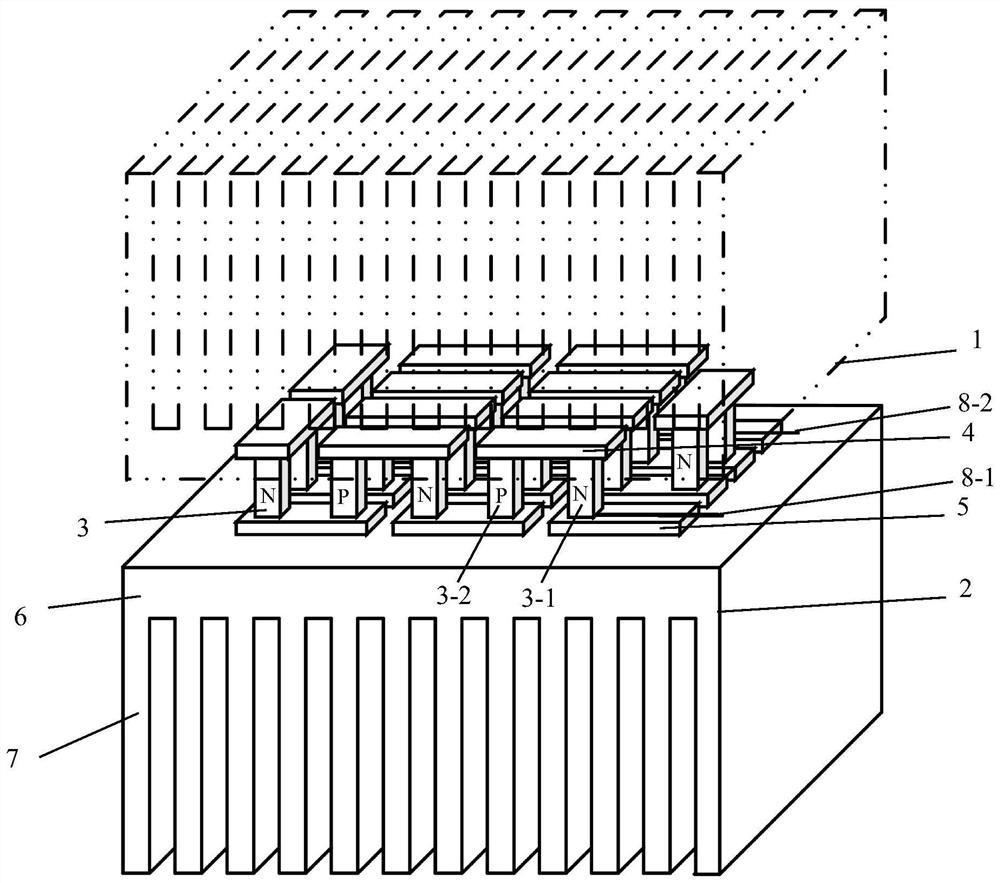

Thermoelectric device and cooling fin integrated thermoelectric assembly

PendingCN114156244ARealize integrationImprove conversion efficiencyThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermoelectric materialsHeat sink

The invention relates to the technical field of thermoelectric assemblies, and provides a thermoelectric device and cooling fin integrated thermoelectric assembly, which comprises a first ceramic substrate, a second ceramic substrate and thermoelectric material crystal grains, a first flow deflector is welded on the first ceramic substrate, a second flow deflector is welded on the second ceramic substrate, one end of the thermoelectric material crystal grain is welded on the first flow deflector, and the other end of the thermoelectric material crystal grain is welded on the second flow deflector; at least one of the first ceramic substrate and the second ceramic substrate is a ceramic substrate with fins, and the ceramic substrate with the fins comprises a ceramic base and radiating fins which are integrally formed. The conversion efficiency of the thermoelectric assembly can be improved, the production cost of the thermoelectric assembly is reduced, and the production efficiency of the thermoelectric assembly is improved.

Owner:金川集团铜业有限公司 +2

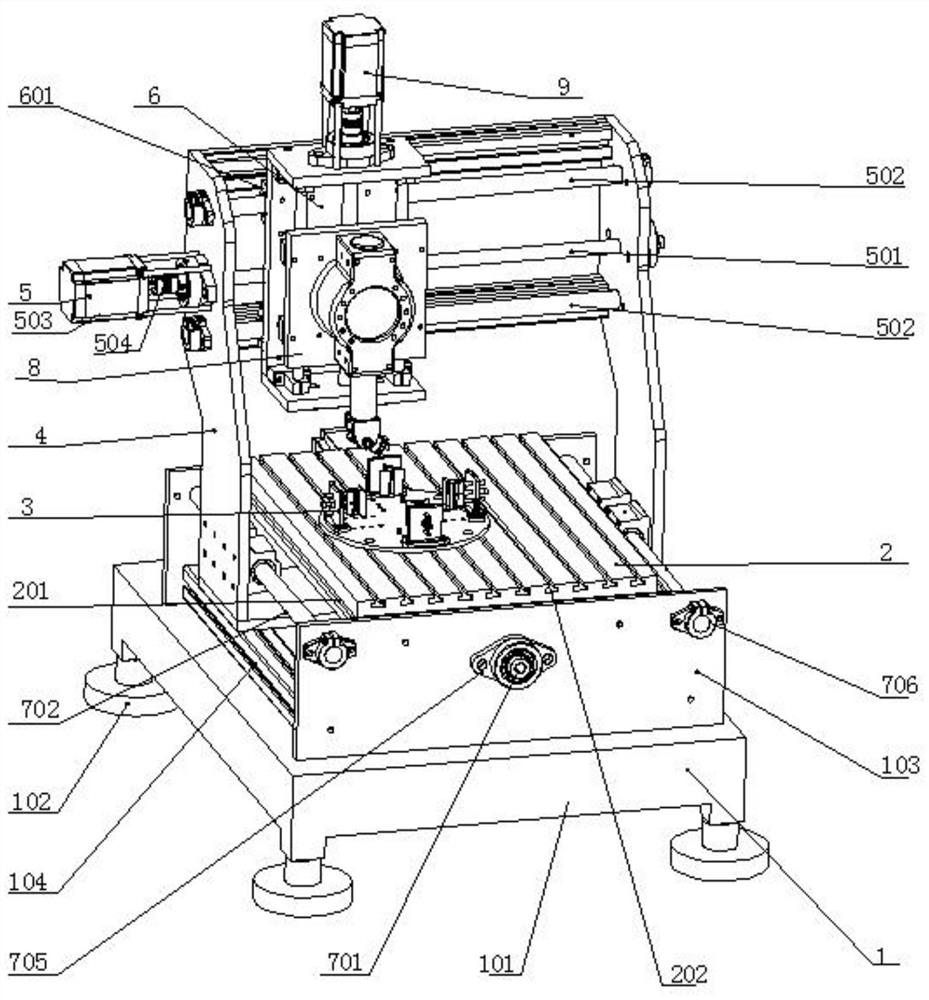

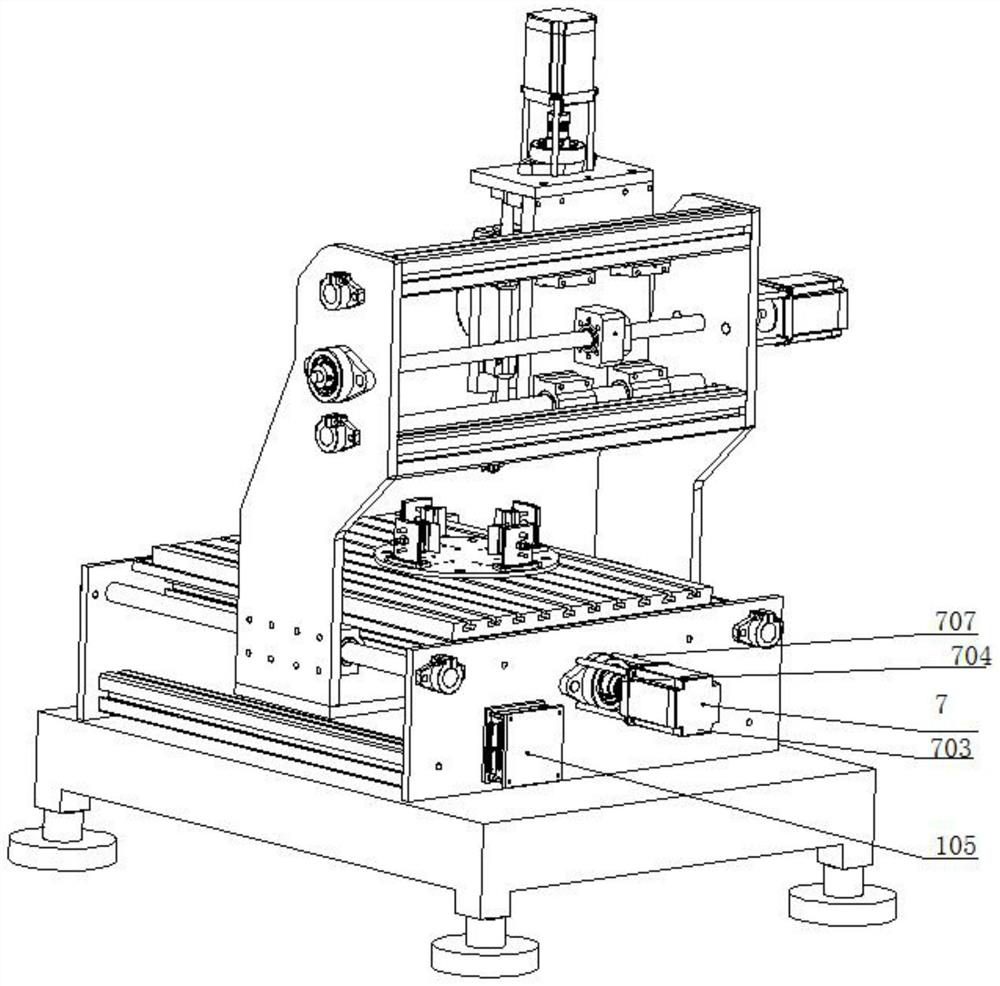

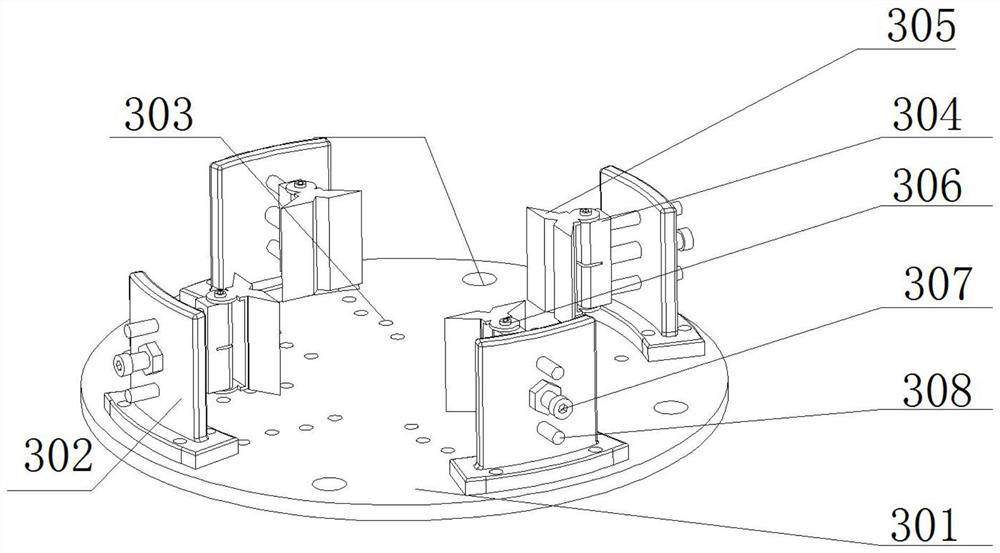

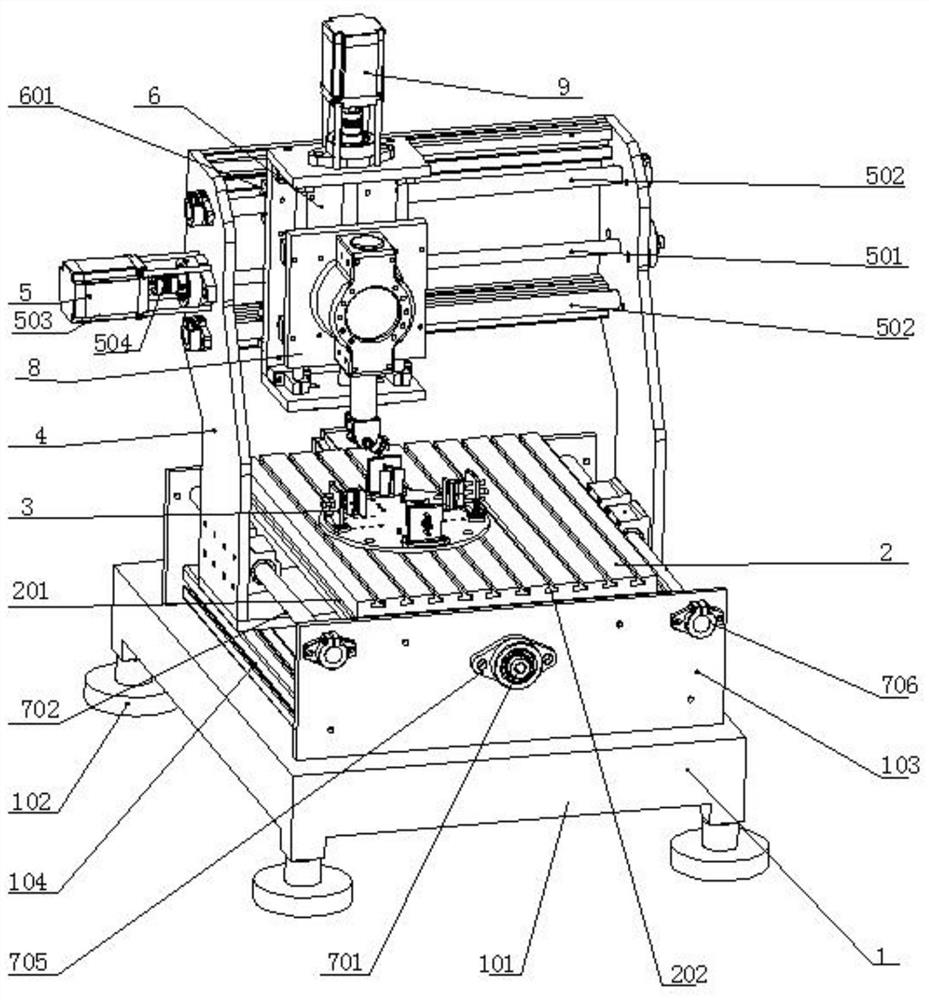

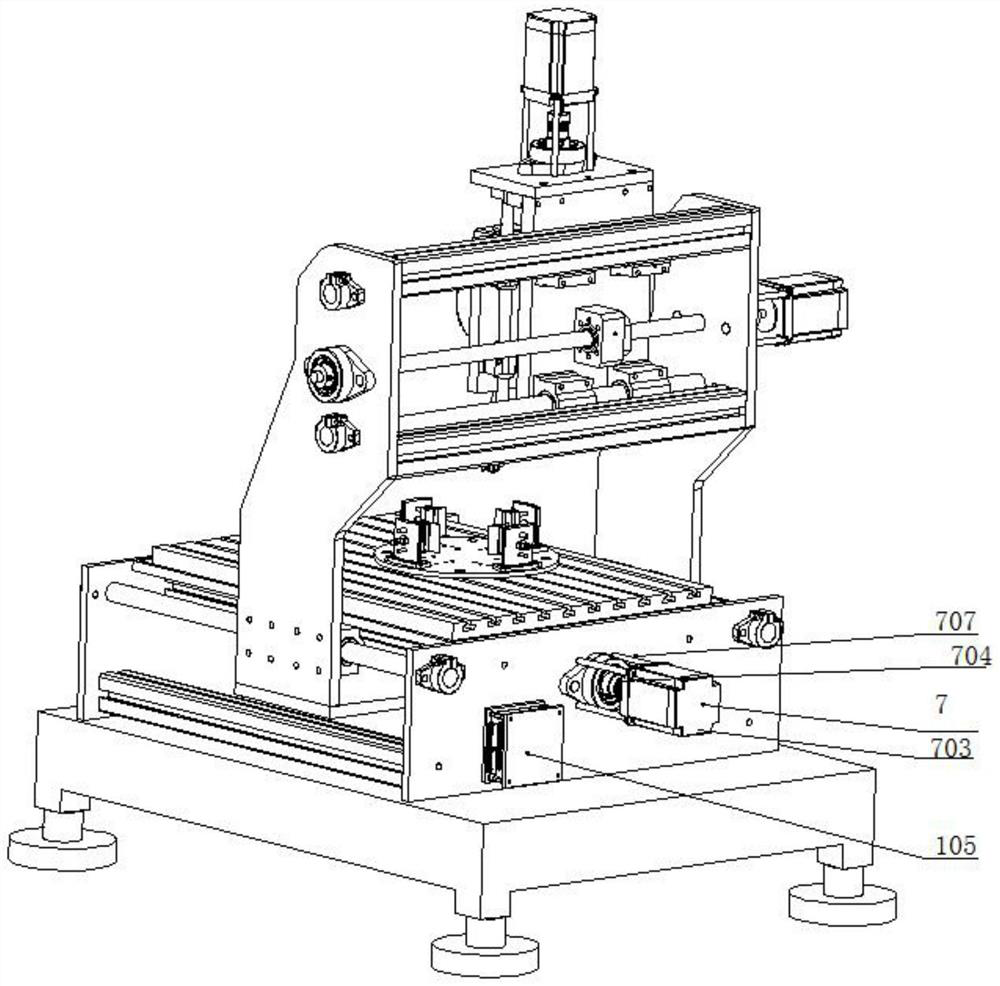

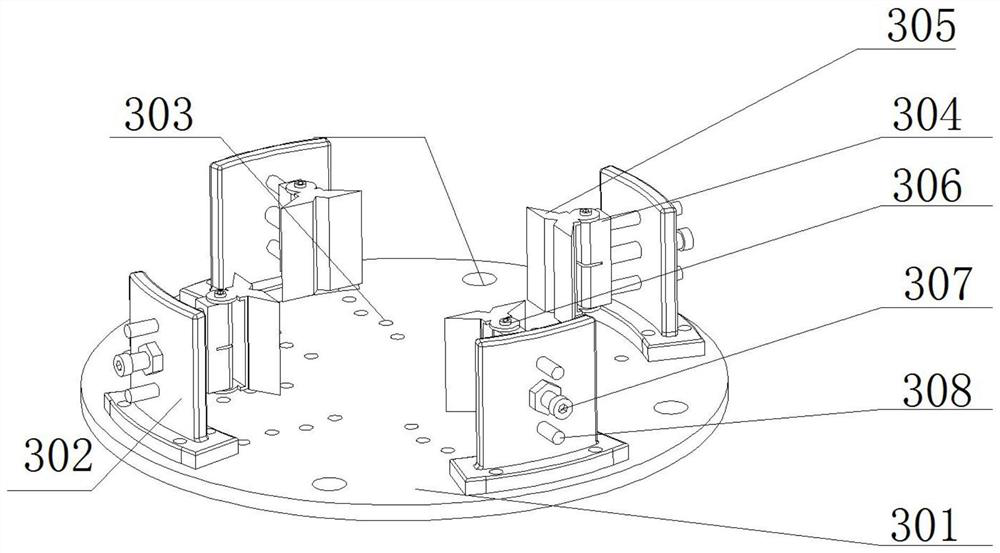

Machining device used for machining off-axis multi-reflector imaging system

ActiveCN112077615AAvoid tuningSkip the assembly processLarge fixed membersPositioning apparatusElectric machineryMachine tool

The invention discloses a machining device used for machining an off-axis multi-reflector imaging system. The machining device used for machining the off-axis multi-reflector imaging system comprisesa machine tool base, wherein a workbench is installed on the machine tool base, a special clamp used for clamping the off-axis multi-reflector imaging system is installed on the workbench, a moving frame is installed on the machine tool base, a lifting frame is installed in the moving frame, a lifting board is installed in the lifting frame, a rotating shaft is arranged on the lifting board, a small ultrasonic motorized spindle and a swing motor are connected with the bottom of the rotating shaft through a U-shaped board, and the small ultrasonic motorized spindle can conduct X-axis movement,Y-axis movement and Z-axis movement, and can conduct rotational movement and swing movement. During complex surface machining, complex curved surfaces can be machined by the small ultrasonic motorizedspindle which can conduct movement at multiple degrees of freedom, and the machining precision is high.

Owner:NORTHEASTERN UNIV

External enclosure, external electronic device and manufacturing method thereof

InactiveCN101770796BFast preparationLow costCarrier constructional parts dispositionUndesired vibrations/sounds insulation/absorptionFiberElastomer

The invention discloses an external enclosure, an external electronic device and a manufacturing method thereof. The external enclosure comprises a carbon fiber shell and an elastic body directly molded on at least one inner side surface of the carbon fiber shell. The external enclosure and the external electronic device are jointed with a rubber elastic body through the carbon fiber shell at a time, so an additional assembling or bonding step can be saved. Therefore, the external enclosure has the advantages of rapid manufacturing and cost saving.

Owner:PEGATRON

Double rail glass lifter

ActiveCN106837050BAccurate installation angleEasy to install anglePower-operated mechanismSpare partEngineering

The invention relates to automobile spare parts, in particular to a double-guide-rail window glass lifter. According to the technical scheme, the double-guide-rail window glass lifter comprises guide rails, main guide rail glass clamping assemblies, auxiliary guide rail glass clamping assemblies and a driving assembly, wherein the main guide rail glass clamping assemblies and the auxiliary guide rail glass clamping assemblies are erected on the guide rails. Each main guide rail glass clamping assembly comprises a main clamping body and a main clamping block. Each auxiliary guide rail glass clamping assembly comprises an auxiliary clamping body and an auxiliary clamping piece. Movable clamping pieces are arranged in each main clamping space. The opposite end faces, located inside each main clamping space, of the corresponding main clamping body and the main clamping block are cambered surfaces, and the outer surface of each movable clamping piece is provided with a regulating cambered surface. The auxiliary clamping pieces are flexible hooks integrally formed with the auxiliary clamping bodies and are located in corresponding auxiliary clamping spaces, and the end faces, opposite to the auxiliary clamping bodies, of the auxiliary clamping pieces are provided with clamping lugs. The auxiliary clamping bodies are provided with dismounting openings corresponding to the clamping lugs. By the adoption of the technical scheme, the double-guide-rail window glass lifter which is convenient to dismount and mount, wide in universality and capable of achieving angle adjustment conveniently is provided.

Owner:浙江益华汽车配件有限公司

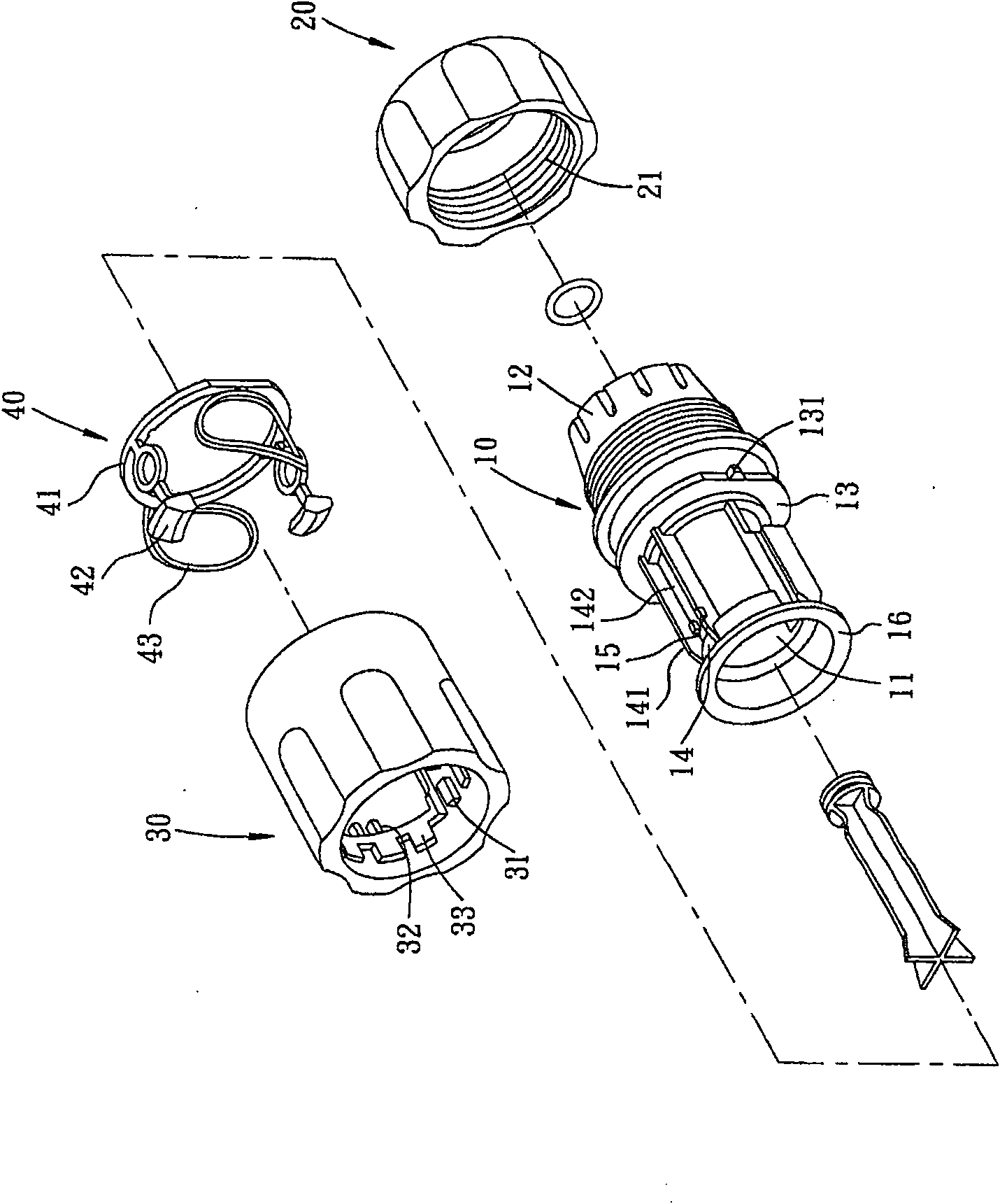

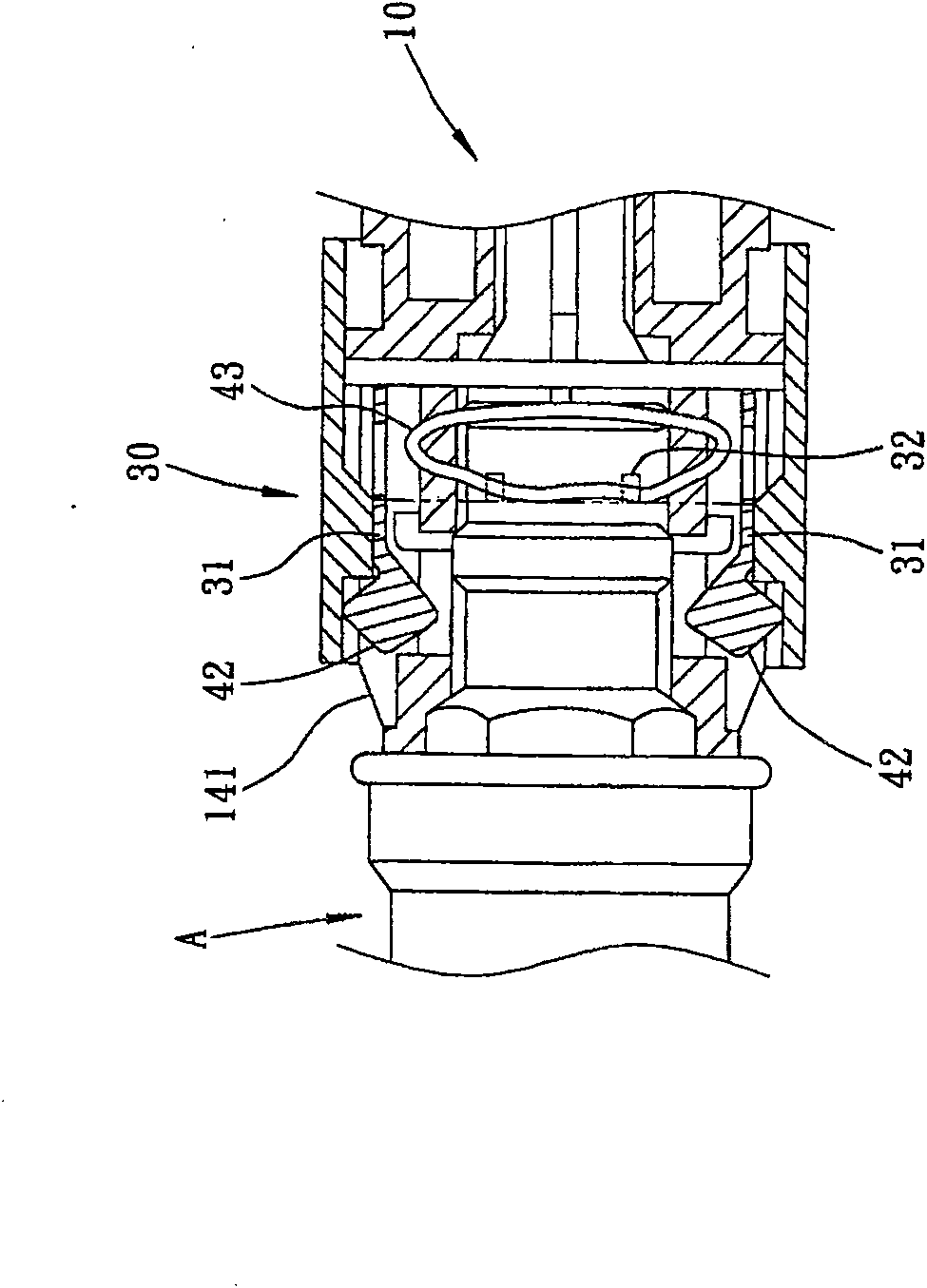

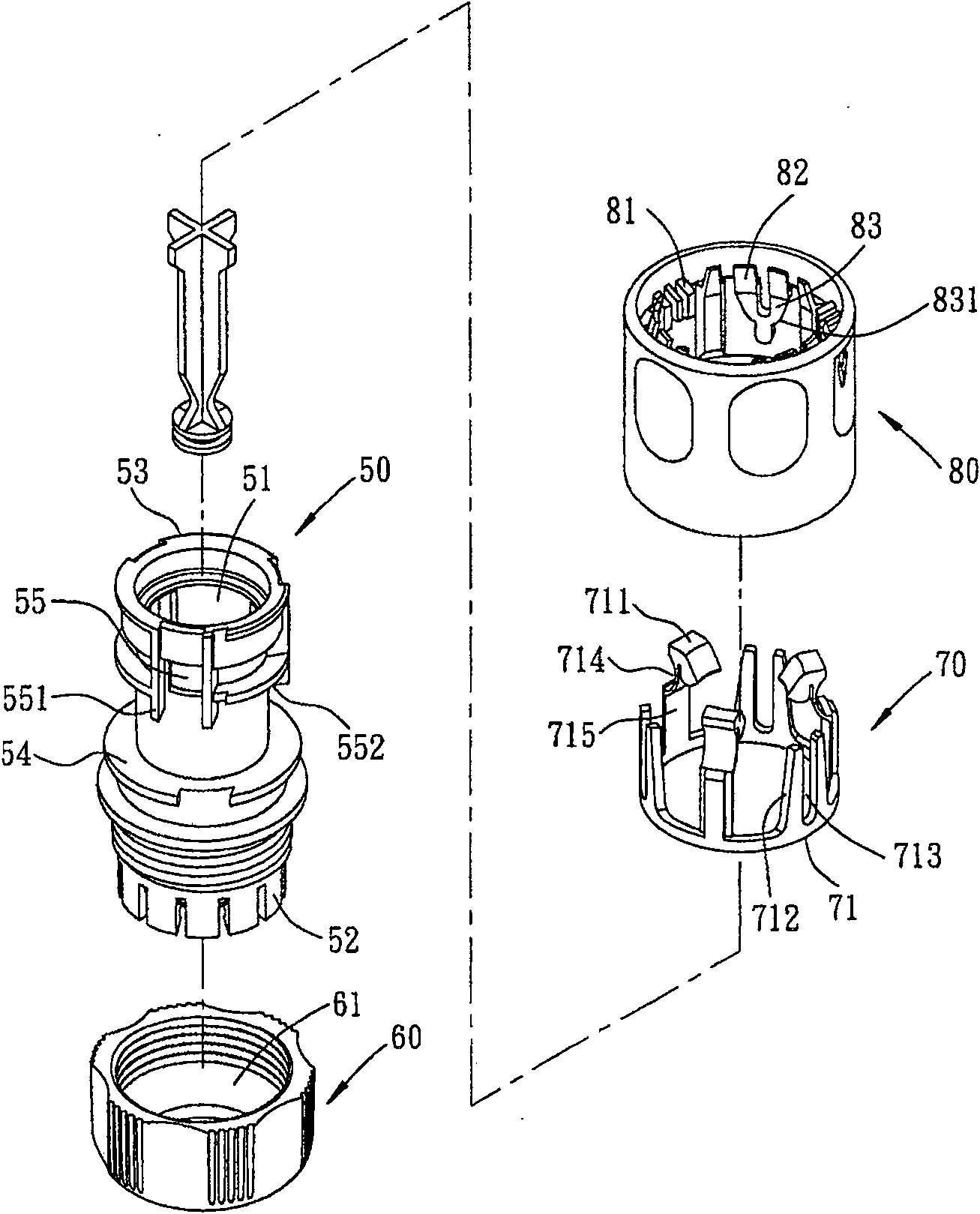

Gardening current connector structure

The invention relates to a current connector structure used for gardening. The current connector structure is formed by assembling a body, elastic clamping pieces and a sleeve, wherein, the body is provided with a plurality of slotted holes which are respectively used for clamping of a clamping piece; the elastic clamping pieces are annularly provided with a plurality of pairwise elastic feet to respectively form an elastic space; the inner wall of the sleeve is annularly provided with a plurality of pushing blocks which are just opposite to the two elastic feet; when the pushing blocks of the sleeve are pressed down, the elastic feet can relatively form a clamping elastic force, and then the sleeve can be quickly lifted elastically and reset, thereby the phenomena of distortion and clamping of an elastic body of the prior connector when the sleeve is pressed down and elastic fatigue can be avoided in the aspect of operation which is made to be smooth and easy.

Owner:YUAN MEI CORP

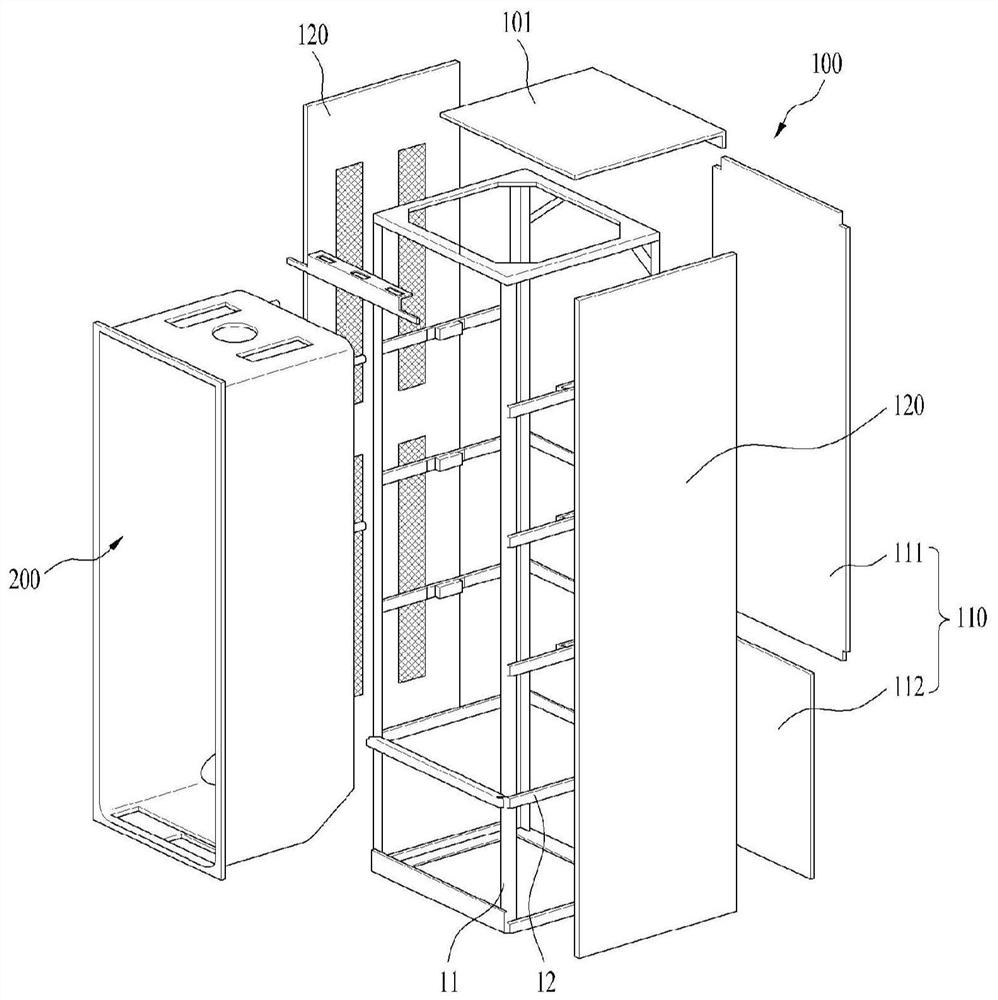

Clothing treatment device

ActiveCN112119186ASkip the assembly processAvoid deformationOther washing machinesIroning apparatusFoaming agentMechanical engineering

The present invention relates to a clothing treatment device capable of omitting a frame for structurally connecting an inner case and a cabinet by filling a foaming agent between the inner case and the cabinet forming an appearance. The clothing treatment device comprises: a cabinet having an opening at the front thereof; a door which is rotatably provided in front of the opening to open and close the opening; an inner case which is provided in the cabinet to form an accommodation space in which clothes are accommodated; and a hot air supply unit which is provided at the lower portion of theinner case to supply at least one of hot air and moisture to the accommodation space, wherein the inner case is formed of a styrene resin that maintains adhesion to the foaming agent injected into theinner portion of the cabinet.

Owner:LG ELECTRONICS INC

Volume adjustable fluid pump

ActiveCN108361165BReduce in quantityReduce the number of assembly processesPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

A variable displacement pump comprising an outer housing (10, 30), a drive space (12) being formed in the interior thereof. A swash plate (35) is positioned in the drive space (12) and mounted in such a way as to allow rocking centered on brackets (34), and adjustment of the angle of inclination of an inclined surface (36). A cylinder block (50) is mounted in the drive space (12) and rotates under the action of a drive shaft (90), multiple cylinder holes (55) being formed in the interior of the block and extending in a direction parallel to the drive shaft (90). A piston assembly (70), at least a portion whereof is inserted into the cylinder holes (55) of the cylinder block (50), moves rectilinearly therein while rotating along with the cylinder block (50). A retainer plate (80), being connected to the piston assembly (70) and holding same close to the inclined surface (36) of the swash plate (35), rotates along with the piston assembly (70). An incline adjustment part (100) passes through the outer housing (10, 30) and is extendable and retractable within the drive space (12), and one side thereof, when inserted into the interior of the drive space (12), is used to push the bottom surface of the swash plate (35) and thereby adjust the angle of inclination of same.

Owner:SHANGHAI HYACT TECH LTD

a pot structure

ActiveCN106955018BPlay a supporting roleHigh strengthWater-boiling vesselsEngineeringUltimate tensile strength

Owner:JOYOUNG CO LTD

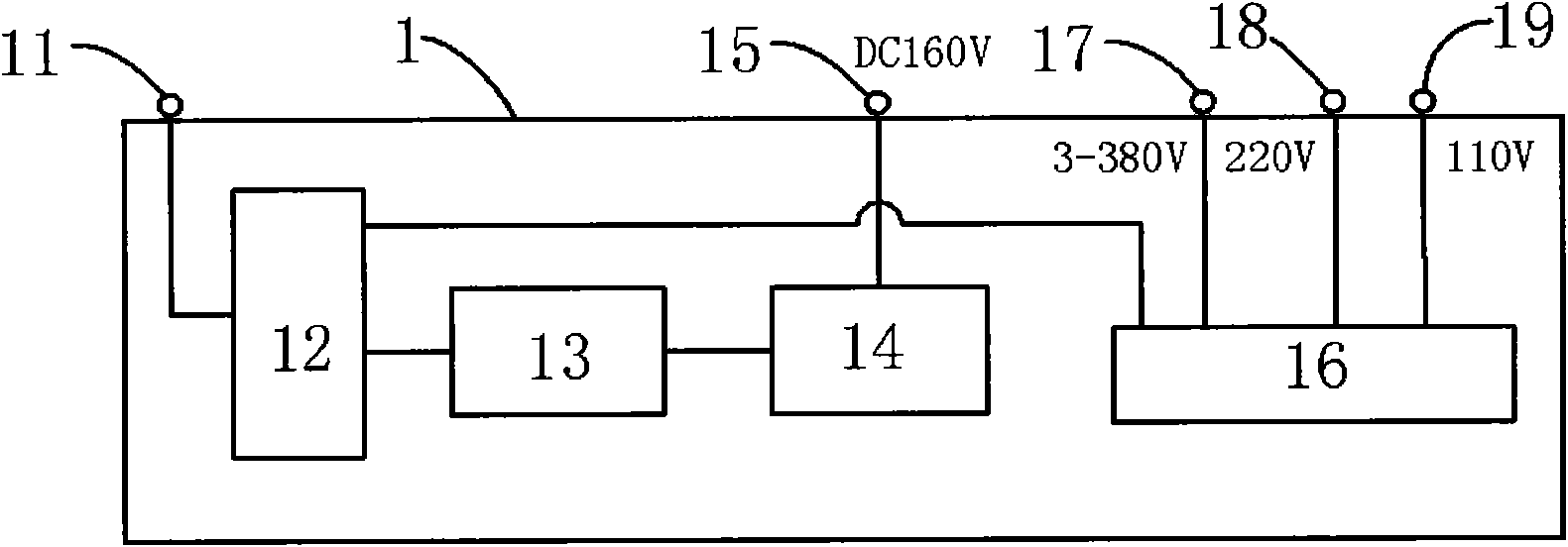

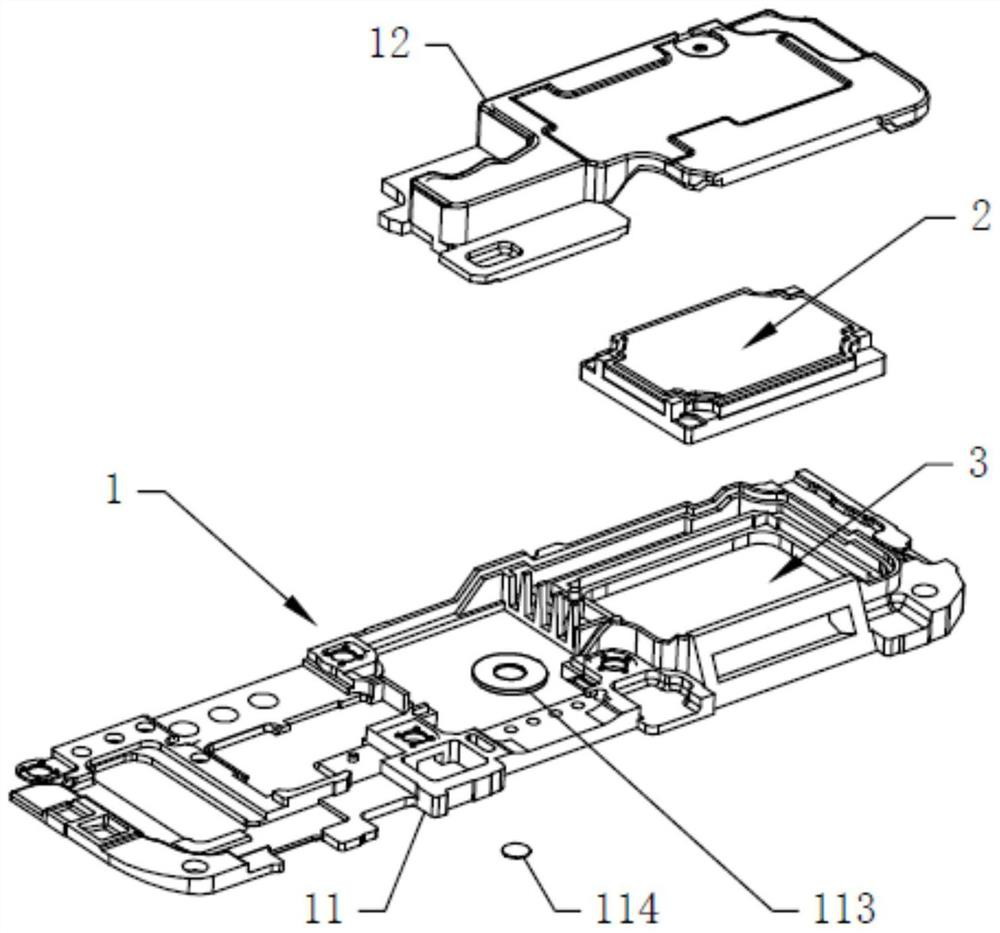

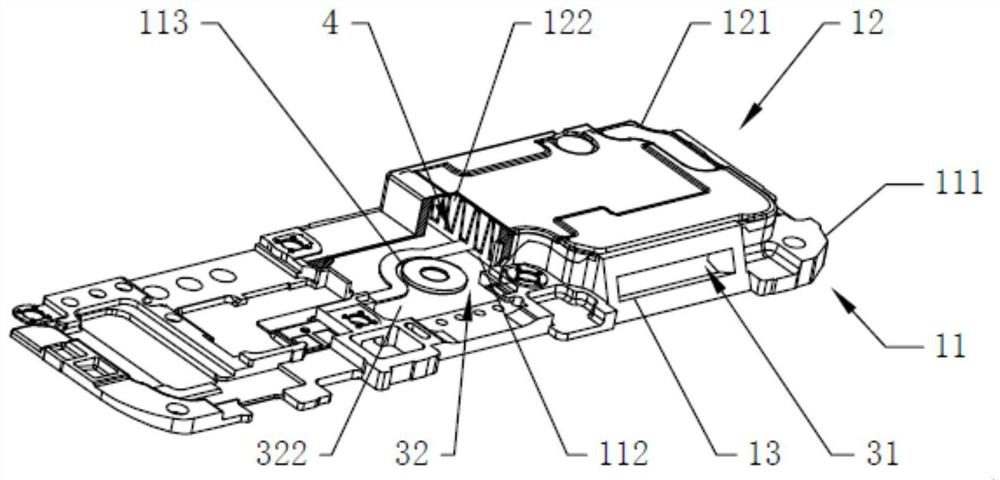

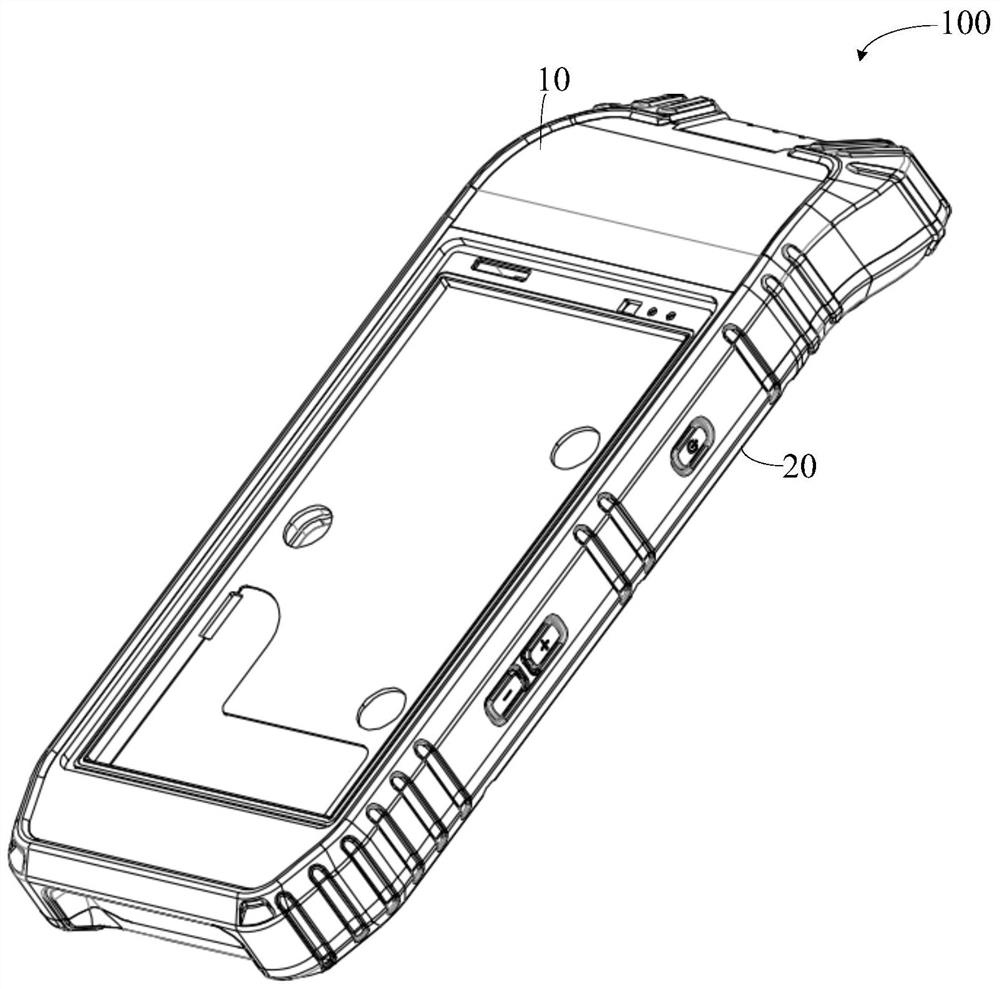

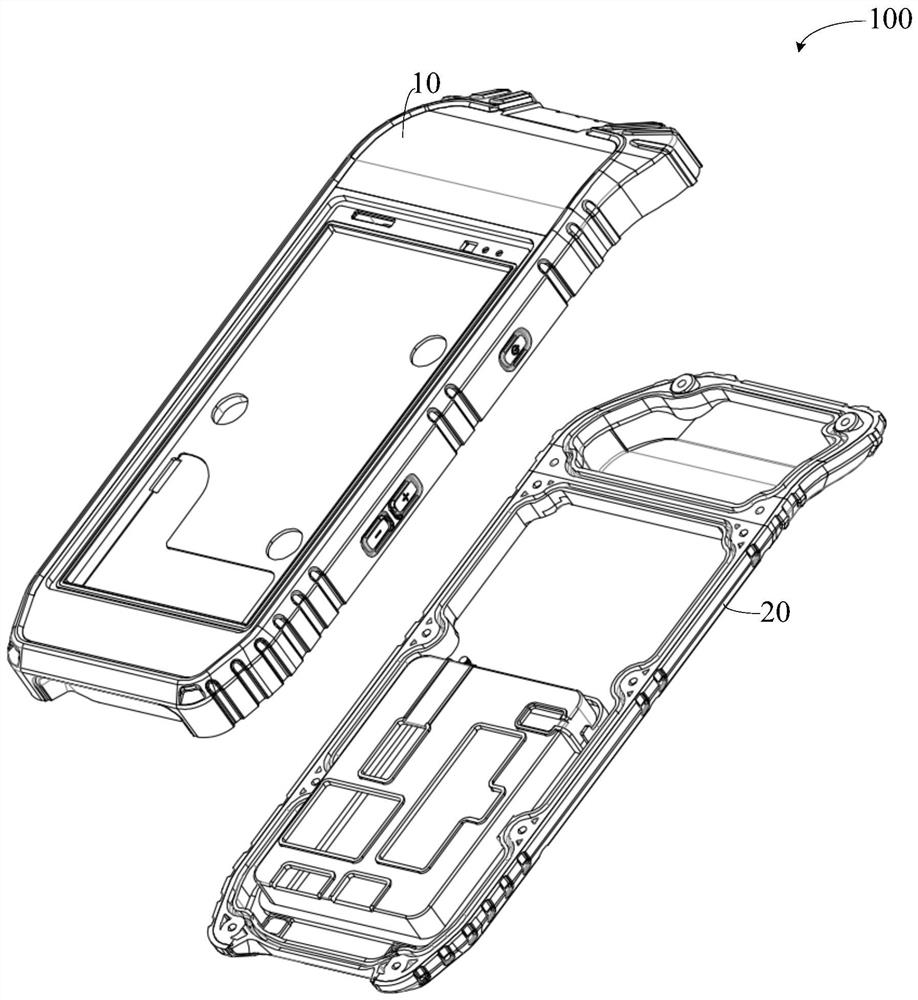

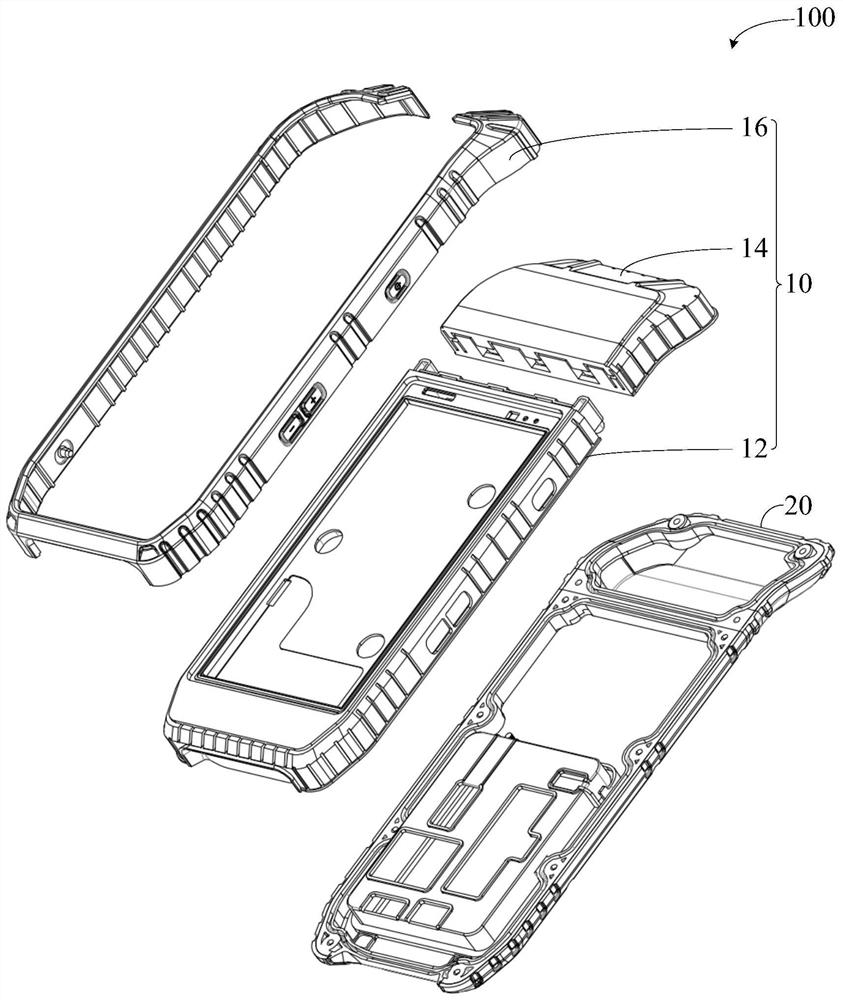

Shell, reinforced handheld terminal and preparation method of shell

ActiveCN113194649ASkip the assembly processWith electromagnetic shielding functionCasings/cabinets/drawers detailsMetal casingsEngineeringMechanical engineering

The invention relates to the technical field of handheld terminals, and discloses a shell, a reinforced handheld terminal and a preparation method of the shell, and the shell comprises a first shell, a second shell and a waterproof interlayer. A first accommodating cavity is formed in the first shell, and the first shell is made of a metal material; the second shell is integrally formed on the first shell, a second accommodating cavity is formed in the second shell, the first accommodating cavity is formed in one side of the second accommodating cavity, and the second shell is made of a non-metal material; and the waterproof interlayer is integrally formed on the first shell and the second shell, and the waterproof interlayer at least partially covers the first shell and the second shell. The first shell, the second shell and the waterproof glue layer are integrally formed, the assembling process of the first shell, the second shell and the waterproof glue layer is omitted, and the technical problem that in the prior art, the assembling process is tedious due to the fact that the shell for reinforcing the handheld terminal is formed by assembling multiple parts is solved.

Owner:SHENZHEN CHUANGZHICHENG TECH CO LTD

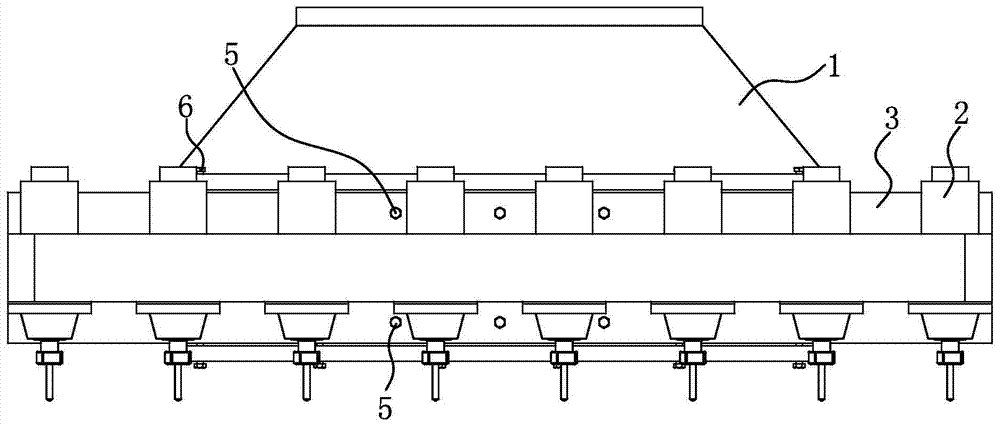

Vertical engraving and milling machine spindle motor installation structure

ActiveCN105127763BImprove machining accuracyHigh accuracy consistencyLarge fixed membersDriving apparatusMachining processControl theory

The invention provides a spindle motor installation structure of a vertical type carves-milling machine, belonging to the technical field of machine tools, for solving the problem that in the existing spindle motor mounting structures, the precision of all spindle motors can not be guaranteed easily. The spindle motor installation structure of the vertical type carves-milling machine comprises a strip-shaped cross beam, wherein motor mounting holes with the quantity equal to that of the spindle motors are formed in the cross beam, the spindle motors and the motor mounting holes are arranged in a one-to-one correspondence manner, the spindle motors are fixed in the motor mounting holes in the cross beam, the cross beam is fixed on the front side surface of a machine head through first fastening bolts, and adjusting bolts and a bolt horizontal adjustment mechanism capable of adjusting the horizontal state of the cross beam by rotating and screwing the adjusting bolts are arranged between the machine head and the cross beam. In the spindle motor installation structure, during the machining process of the cross beam, by controlling the machining precision, the requirements on parameters including the perpendicularity of the motor mounting holes, the center-to-center distances among the motor mounting holes, the parallelism among the motor mounting holes, and the like, are guaranteed, therefore, the consistency of the precision of all the spindle motors is significantly improved, and further, the machining precision of the carves-milling machine is greatly improved.

Owner:陈美青

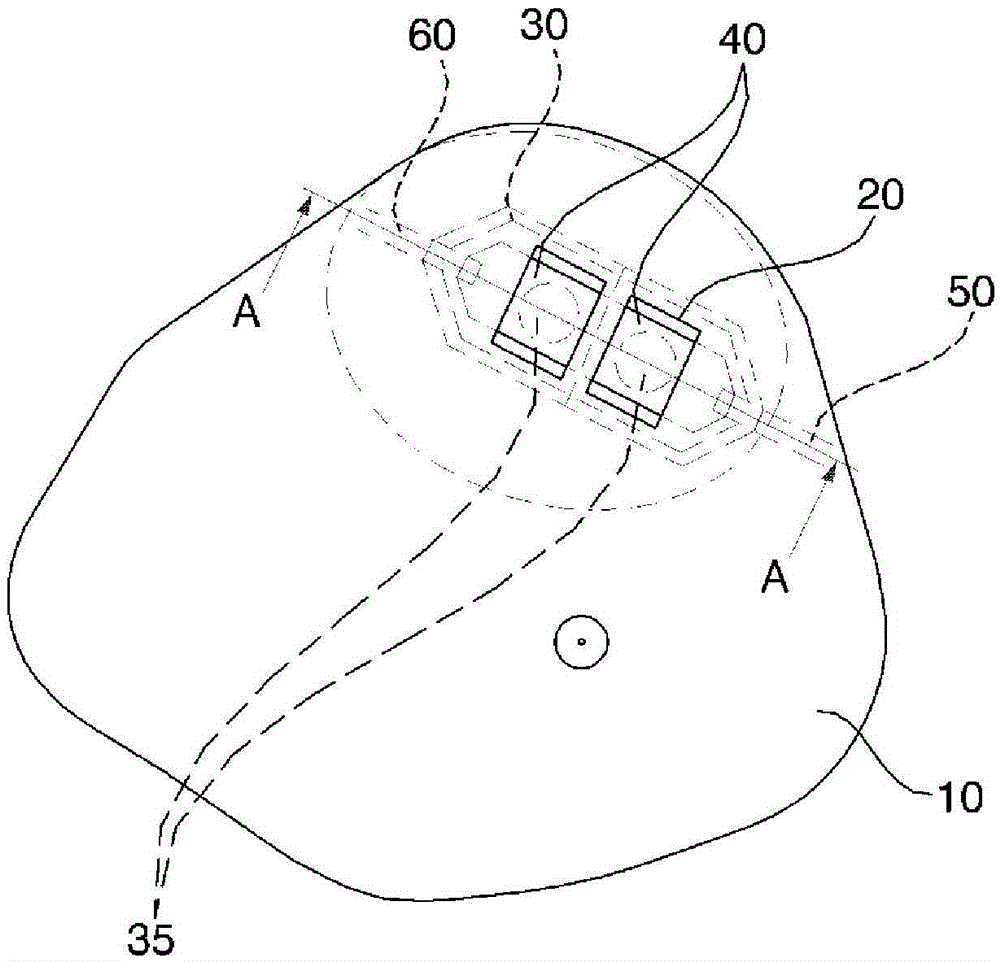

vehicle airbag

The invention discloses a vehicle airbag, which is characterized in that it comprises: an airbag cushion, which is formed with an exhaust hole for discharging inflowing gas to the outside; an exhaust guide member, which is arranged inside the airbag cushion, and is formed in a The exhaust hole guides the gas that has flowed into the interior of the airbag cushion; and an exhaust cover provided between the exhaust guide member and the airbag cushion at the initial stage of deployment of the airbag cushion The guide hole and the vent hole are opened at the end of deployment, and at least one of the guide hole and the vent hole is closed at the middle stage of deployment of the airbag cushion. According to the present invention, even if children aged 3 to 6 or elderly and infirm passengers are seated, it is possible to reduce the neck and / or head injuries of passengers in this out-of-position (Out Of Position) state. , can reduce the weight of components, reduce the weight of the airbag, and save costs.

Owner:HYUNDAI MOBIS CO LTD

A movement of a mechanical sphygmomanometer for a self-calibrating production process

ActiveCN104783770BSimplify the movementIncrease productivityEvaluation of blood vesselsAngiographySphygmomanometerIndustrial engineering

The invention relates to a movement of a mechanical sphygmomanometer for a self-calibration production technology. The movement of the mechanical sphygmomanometer for the self-calibration production technology is characterized in that the movement is composed of an upper clamping plate, a lower clamping plate, movement columns arranged between the upper clamping plate and the lower clamping plate, a pointer shaft, a hairspring providing elastic recovery, a hairspring pin for fixing the hairspring and a crank connecting rod, the upper clamping plate is fixedly connected with the lower clamping plate through the movement columns, the pointer shaft is installed in holes of the upper clamping plate and the lower clamping plate and can rotate, one end of the hairspring is fixed on the pointer shaft, the other end of the hairspring is fixed on one movement columns through the hairspring pin, and a gear is arranged on the pointer shaft.

Owner:HONSUN NANTONG

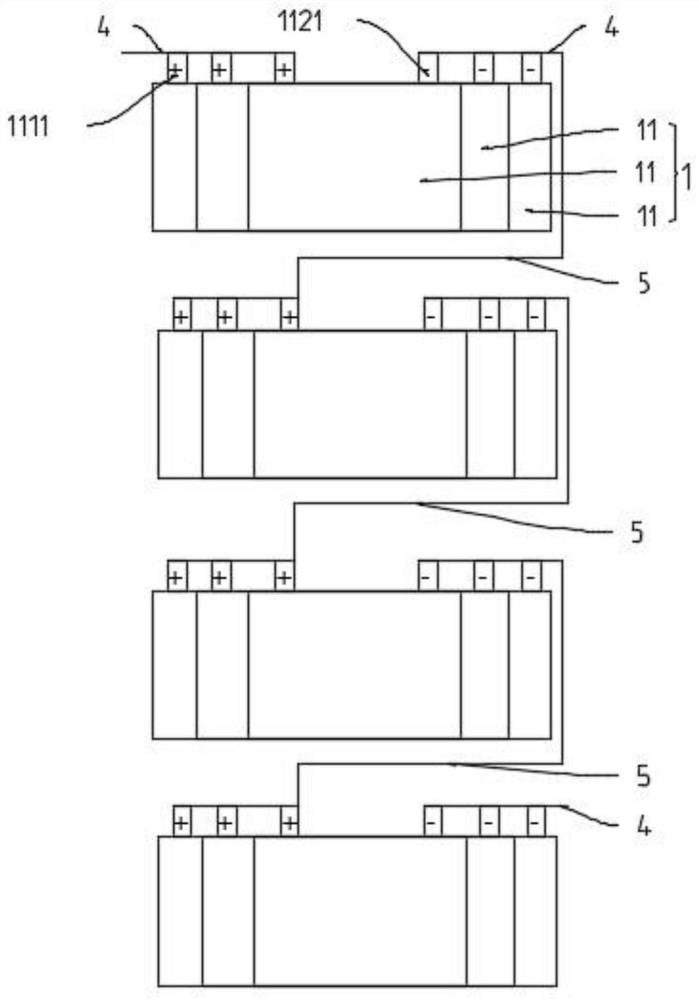

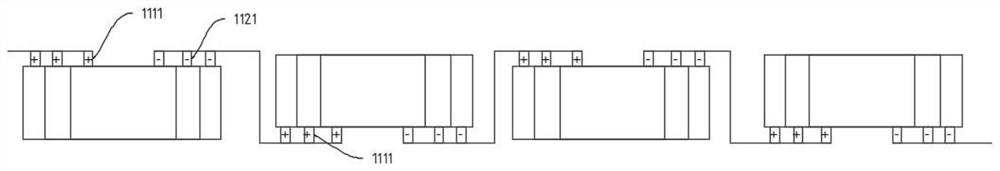

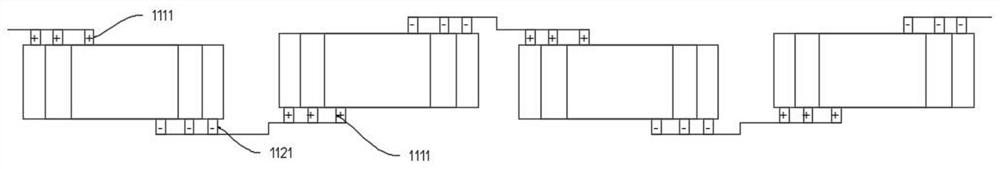

Battery

PendingCN114300796ASkip the assembly processReduce usageCell component detailsElectric current flowBattery cell

The invention provides a battery, and relates to the technical field of energy equipment, the battery comprises a shell and a plurality of battery units arranged in the shell, and each battery unit comprises a plurality of battery cell units; the plurality of battery units are sequentially connected in series, and the plurality of battery cell units in each battery unit are connected in parallel; or the plurality of battery units are connected in parallel, and the plurality of battery cell units in each battery unit are sequentially connected in series. According to the battery, the battery cell units can be connected in parallel to enable the battery to have high current, then a plurality of battery units are connected in series to enable the battery to have high voltage, and a single battery has high current and high power at the same time, so that the use requirement of the single battery can be met in some occasions with high-power requirements; the single battery can be directly used as a PACK structure, and a plurality of batteries are not required to be assembled into a battery module, so that the assembling process of the battery module is omitted, and the cost is saved.

Owner:三一技术装备有限公司

A processing device for processing an off-axis multi-reflection imaging system

ActiveCN112077615BAvoid tuningSkip the assembly processLarge fixed membersPositioning apparatusElectric machineryEngineering

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com