Patents

Literature

64results about How to "High accuracy consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

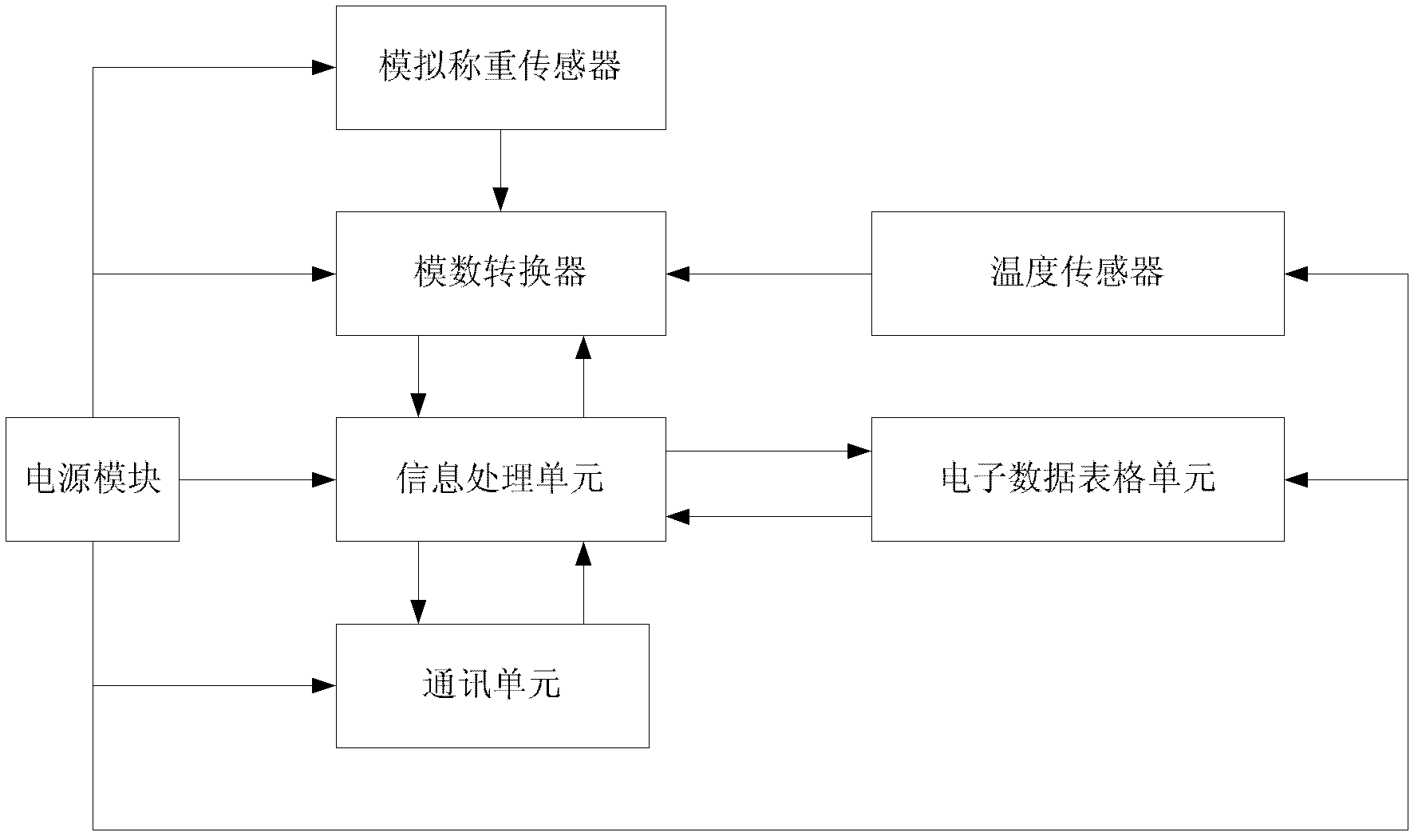

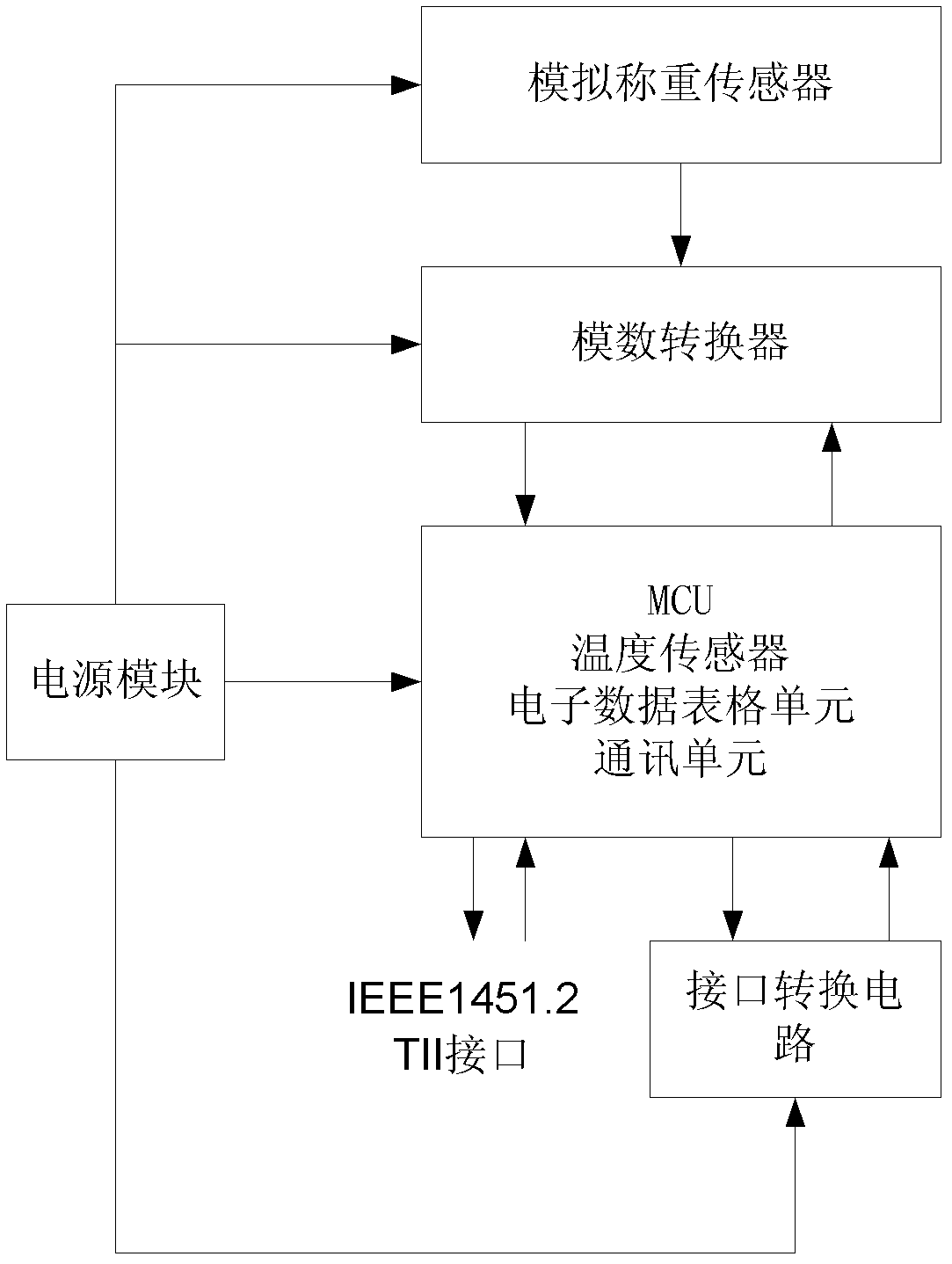

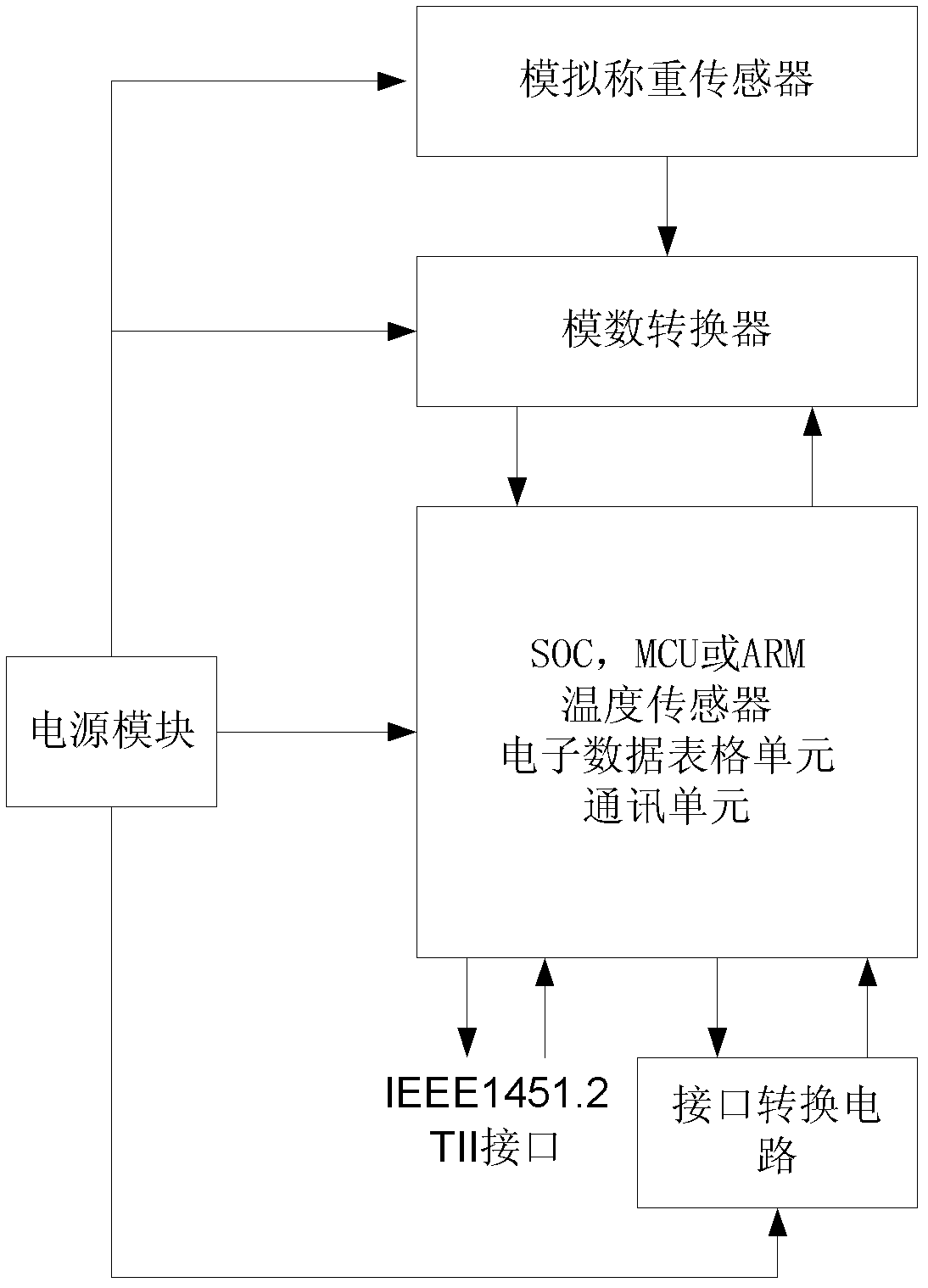

Networking intelligent digital weighing sensor

InactiveCN102538918AMeets the requirements of the Independent Interface (TII)Easy to addWeighing apparatus using elastically-deformable membersWeighing auxillary devicesSmart transducerImage resolution

The invention discloses a networking intelligent digital weighing sensor, which comprises a simulation weighing sensor, a temperature sensor, an analog-to-digital converter, an electronic data table unit, an information processing unit, a communication unit and a power supply module, wherein the electronic data table unit conforms to IEEE1415.2 standards, the simulation weighing sensor is used for collecting weight data, the temperature sensor is used for collecting real-time temperature data, the analog-to-digital converter is used for converting the weight data and the real-time temperature data into corresponding digital signals, the information processing unit is used for outputting weight data after compensation calibration, and the communication unit is provided with a universal serial interface and a communication interface compatible with IEEE1415.2. The technical scheme conforms to requirements of the IEEE1415.2 standards on an independent interface of the intelligent sensor and simultaneously solves the problems that in the sensor manufacture process, the precision is difficult to improve, the production efficiency is low, the finished product rate is low and the like, and in addition, the digital weighing sensors with the same resolution ratio can be produced in batches.

Owner:CHIPSEA TECH SHENZHEN CO LTD

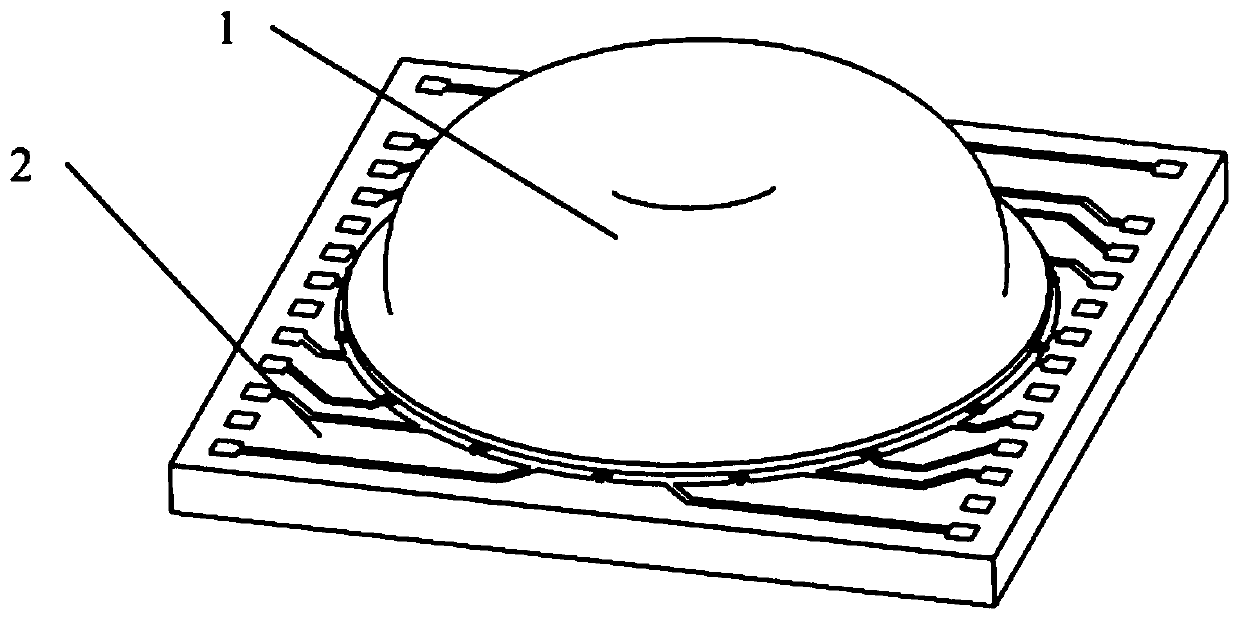

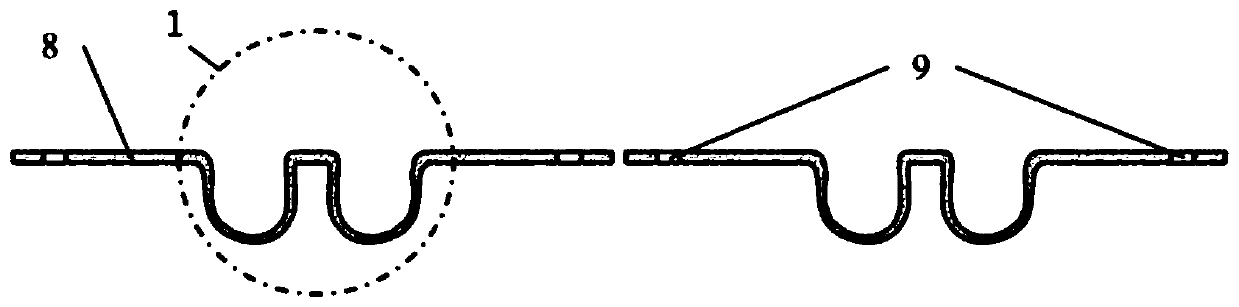

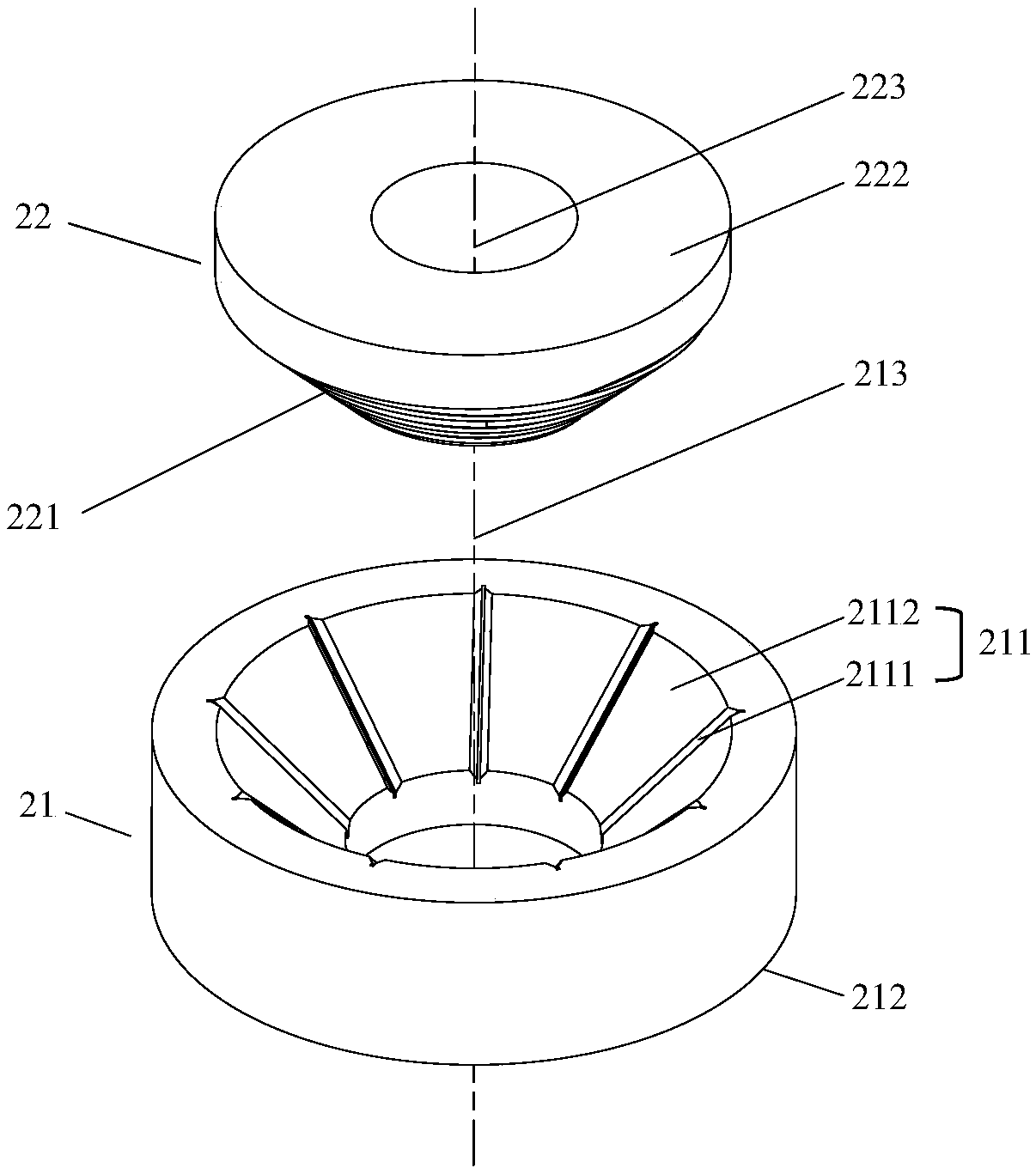

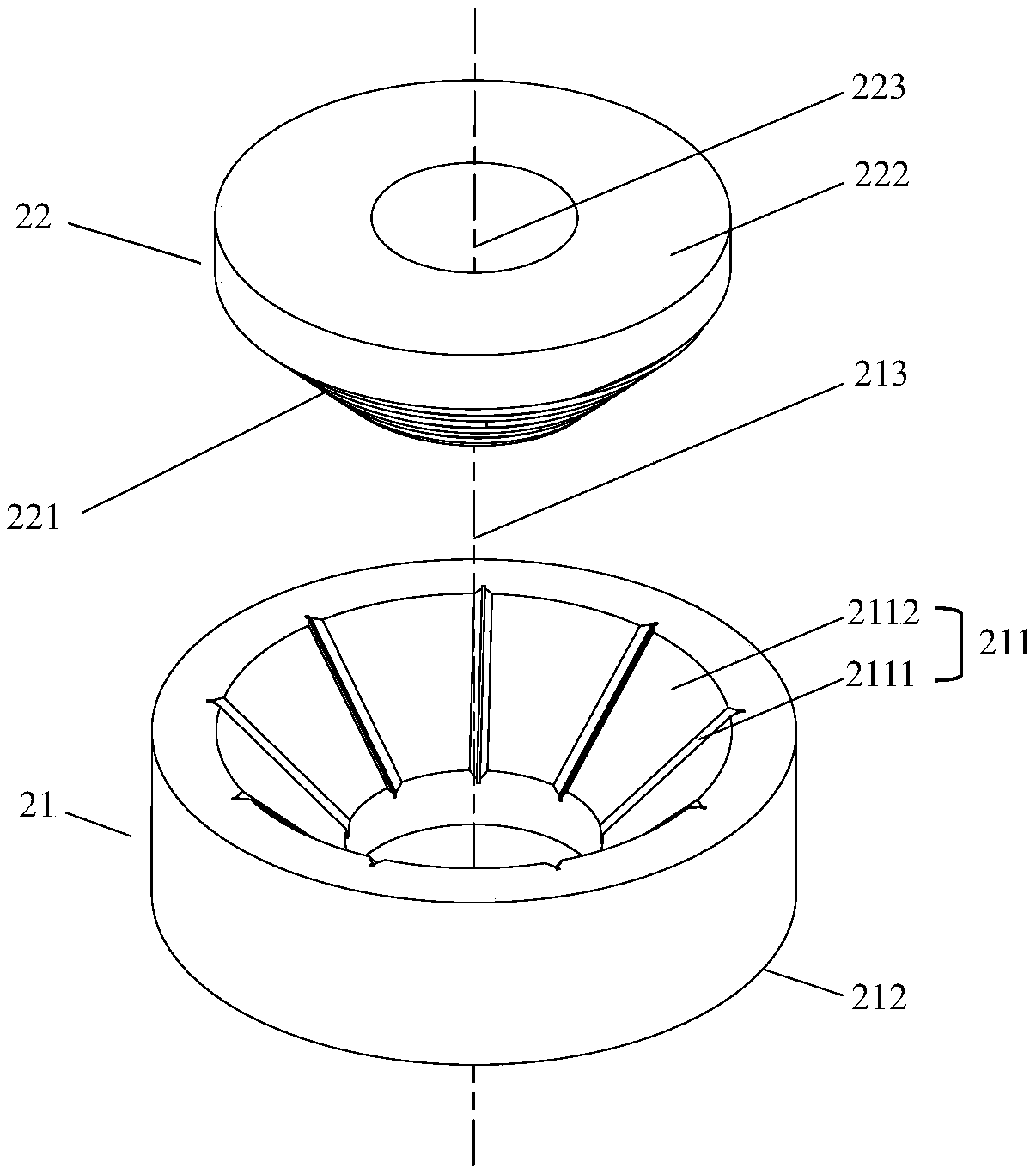

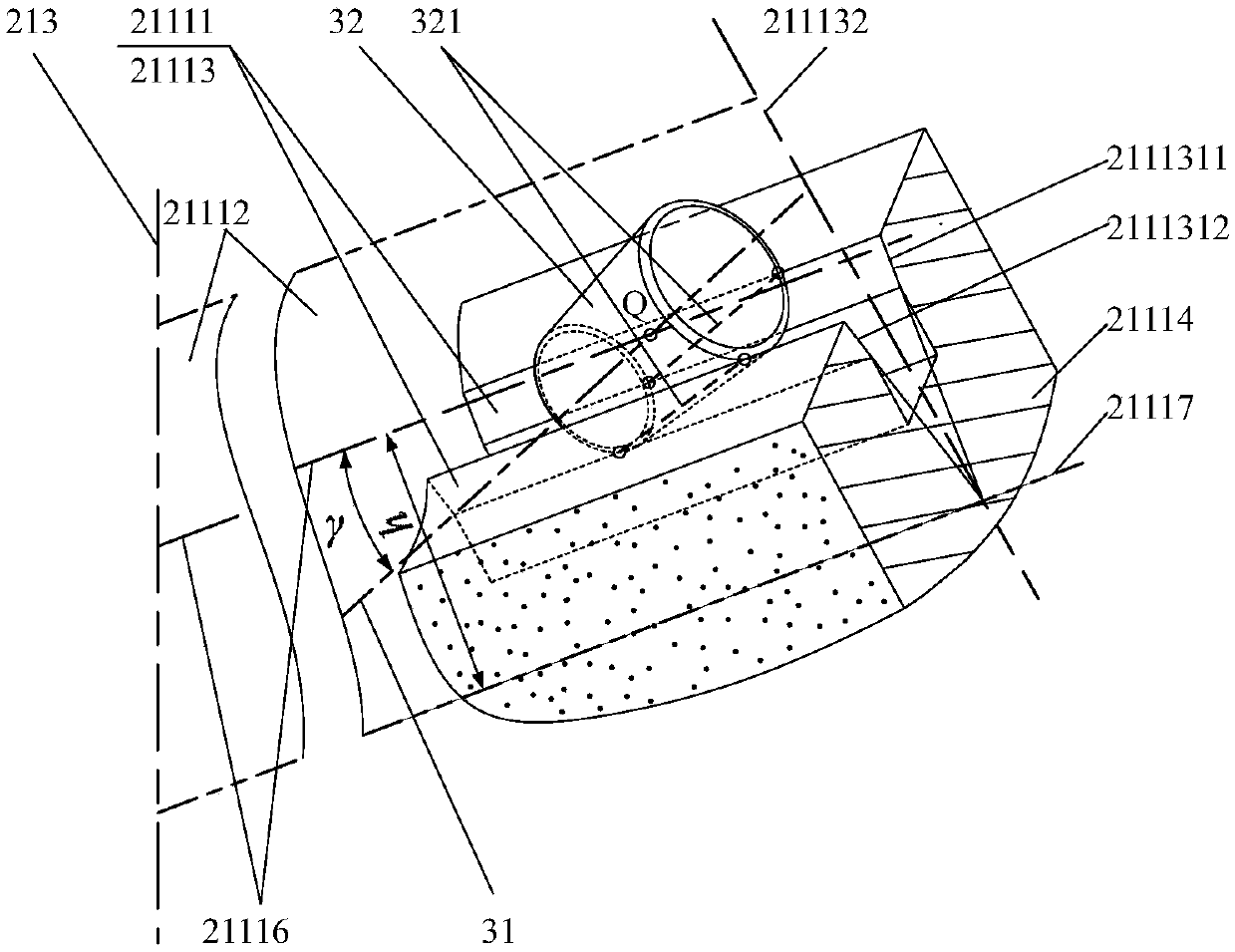

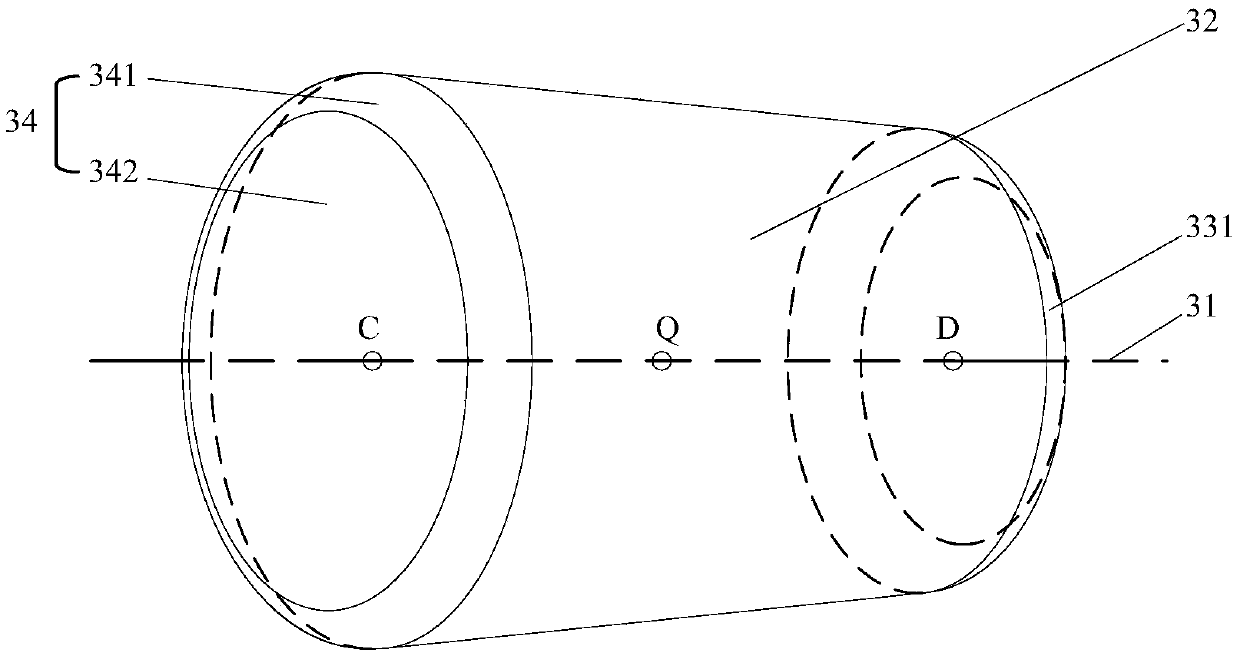

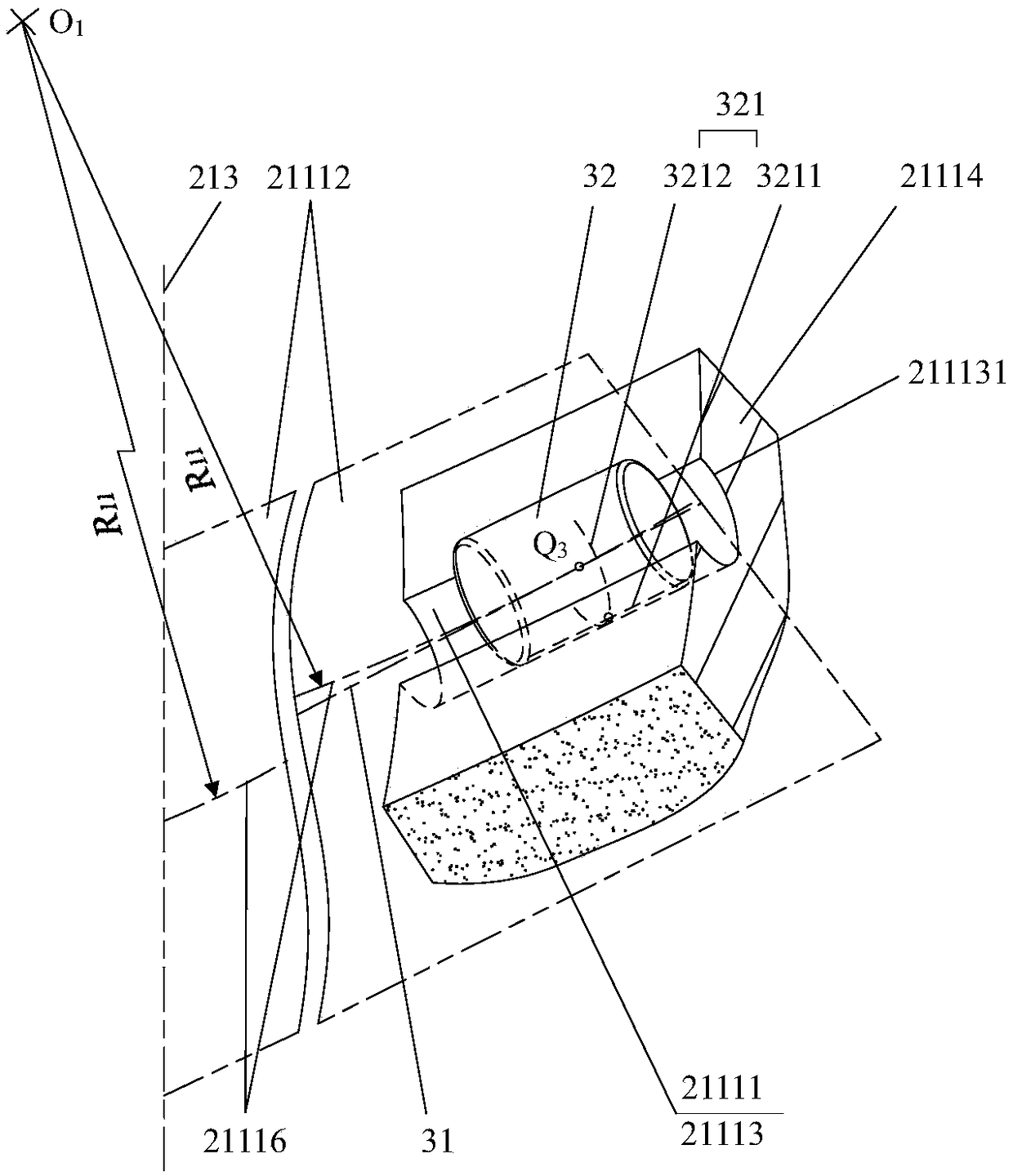

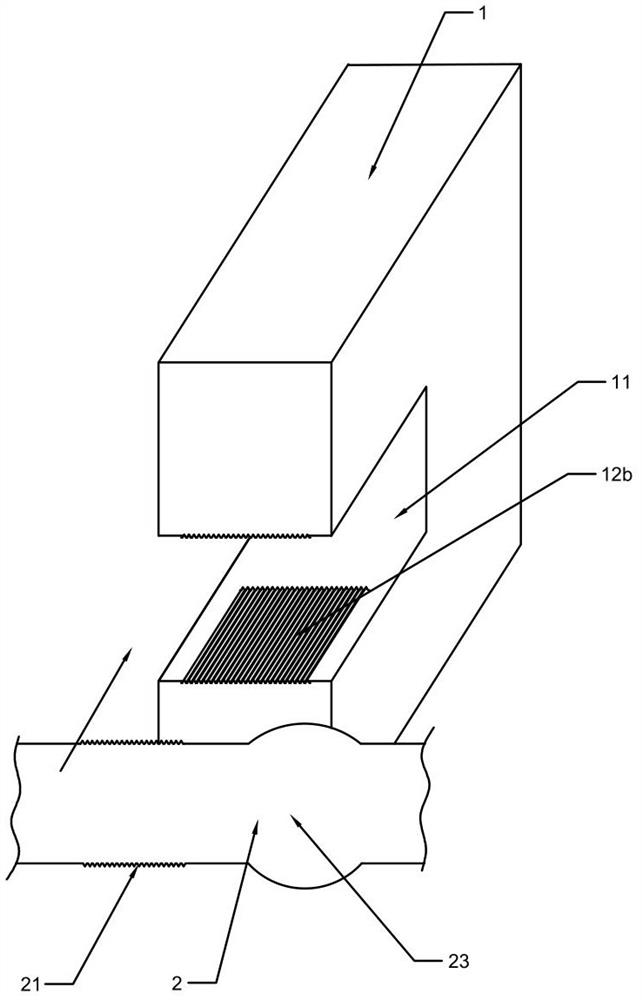

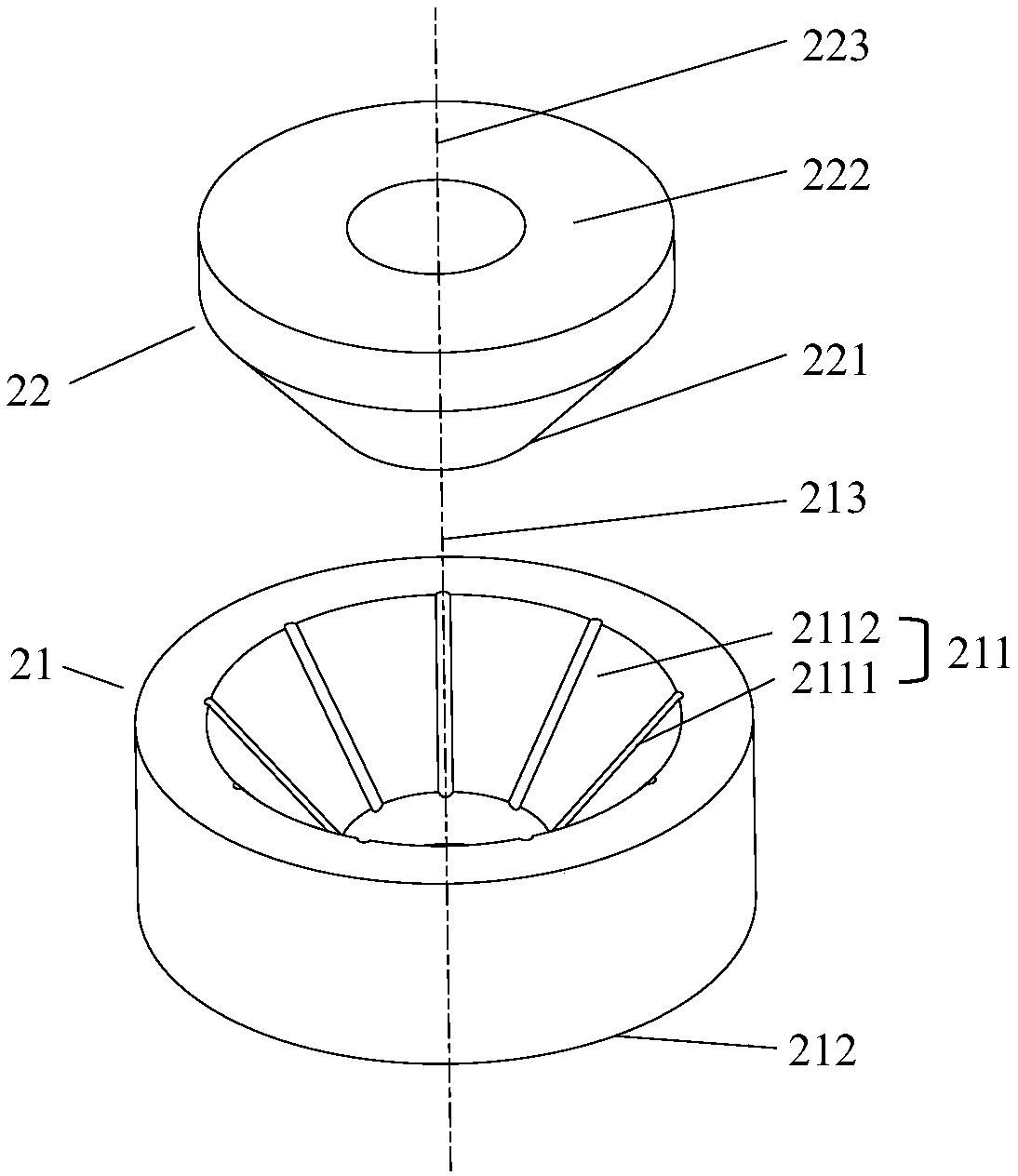

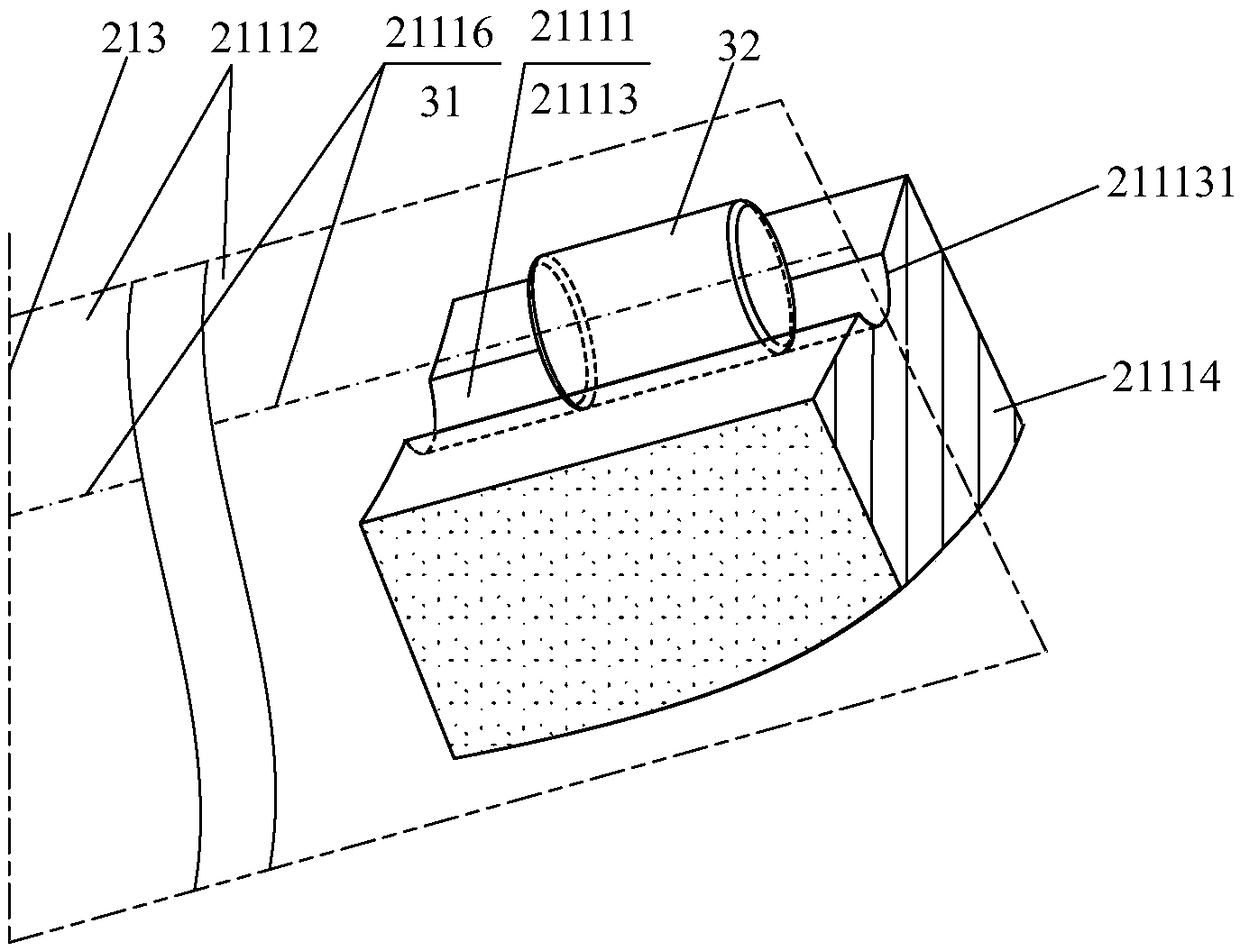

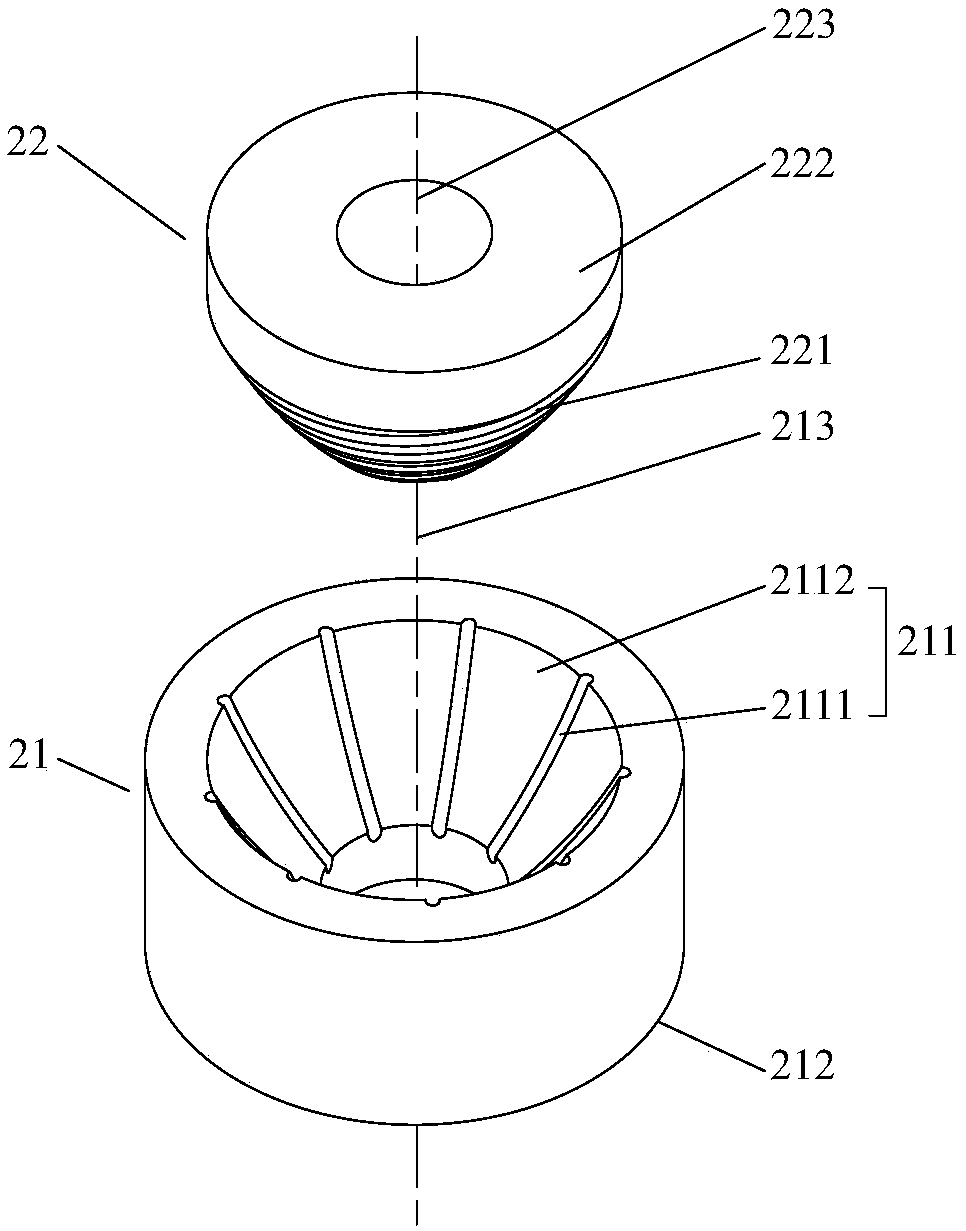

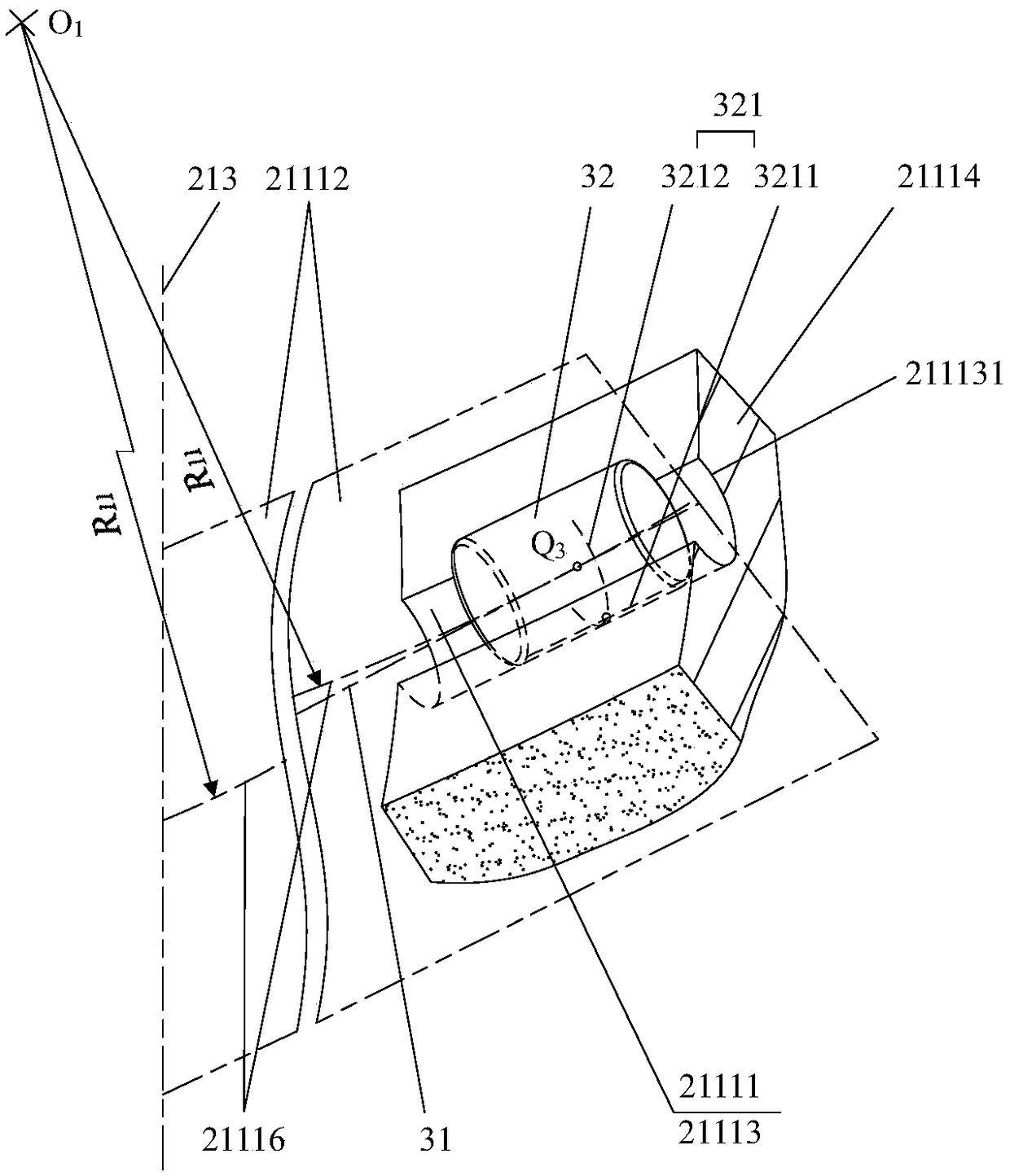

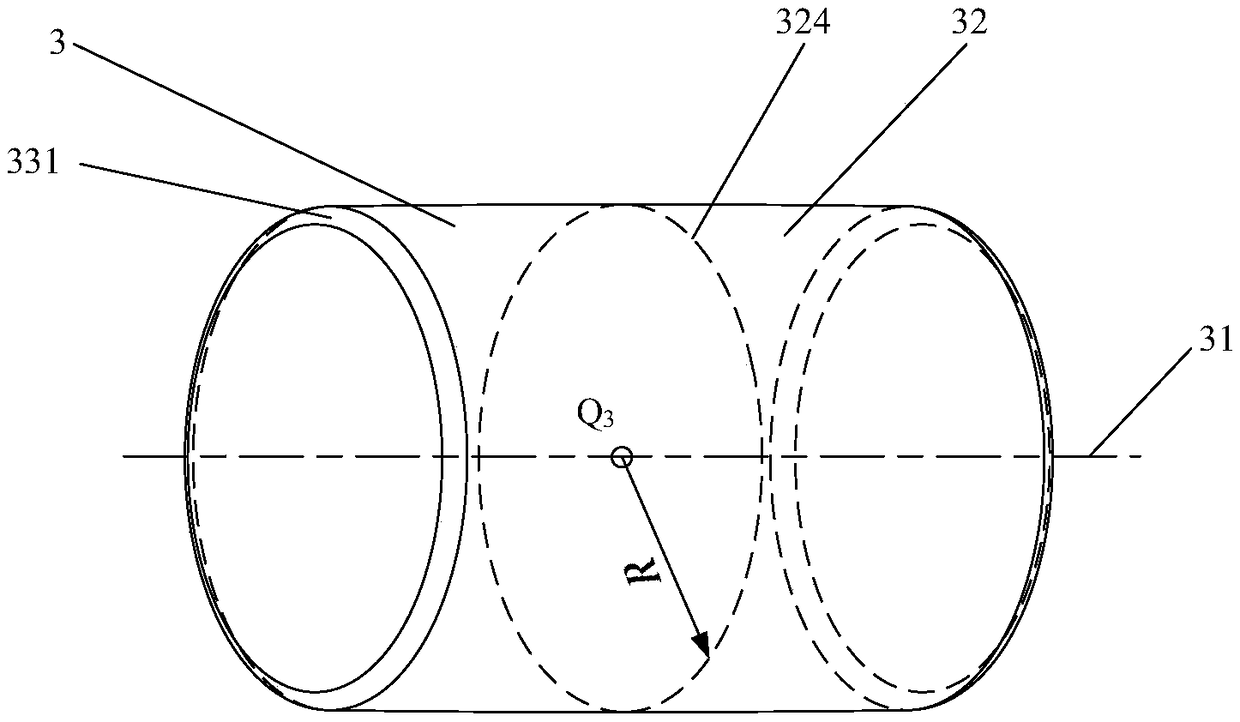

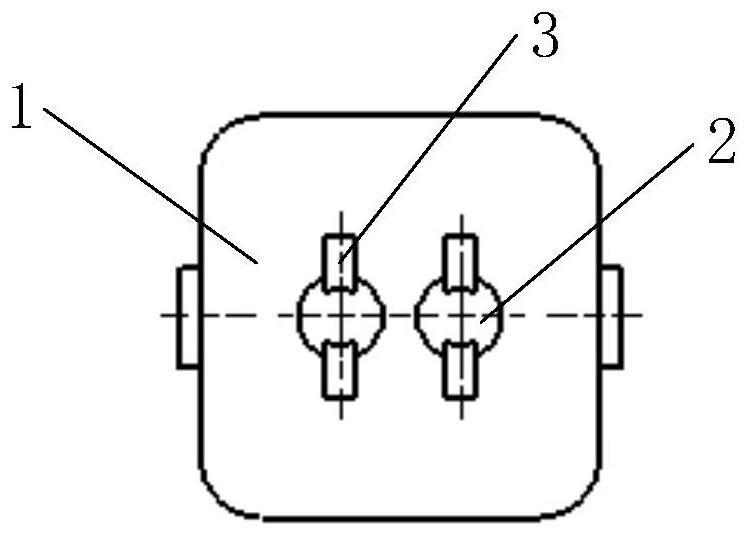

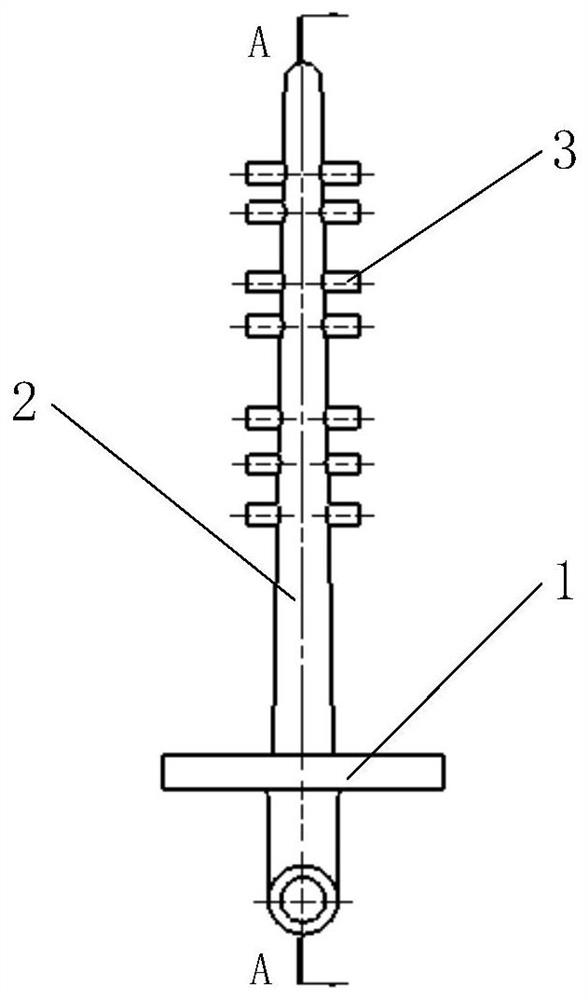

Micro-hemispherical resonator gyro structure, assembly method and wafer fixture

InactiveCN110749315AReduce assembly errorsImprove stabilitySpeed measurement using gyroscopic effectsMicrostructural device assemblyPhysicsResonator

The invention relates to a micro-hemispherical resonator gyro structure, an assembly method and a wafer fixture. The invention discloses a micro-hemispherical resonator gyro structure wafer level assembly method, comprising the following steps: performing high temperature softening deformation machining and forming on independently manufactured glass sheets, then forming a micro-hemispherical resonant structures in the middle of each glass sheet, cutting glass sheet locating holes at the two ends of each glass sheet by adopting laser cutting, and by taking the locating holes as a benchmark, aligning multiple micro-hemispherical resonant structures which are the same and fixing the same micro-hemispherical resonant structures on the wafer fixture; and then performing operations by taking the wafer fixture as a unit, and completing subsequent processes, namely micro-hemispherical resonant structure releasing, surface metallization, fixation with a planar electrode, separation from the wafer fixture as well as cleaning, thus the micro-hemispherical resonator gyro structure driven by the planar electrode at the bottom is obtained. The micro-hemispherical resonator gyro structure waferlevel assembly method disclosed by the invention fixes and mounts multiple independently manufactured micro-hemispherical resonant structures on the same wafer fixture, a wafer level mounting operation is realized, an assembly error of the micro-hemispherical resonator gyro structure can be obviously reduced, stability and consistency of the processes as well as assembly efficiency are improved.

Owner:NAT UNIV OF DEFENSE TECH

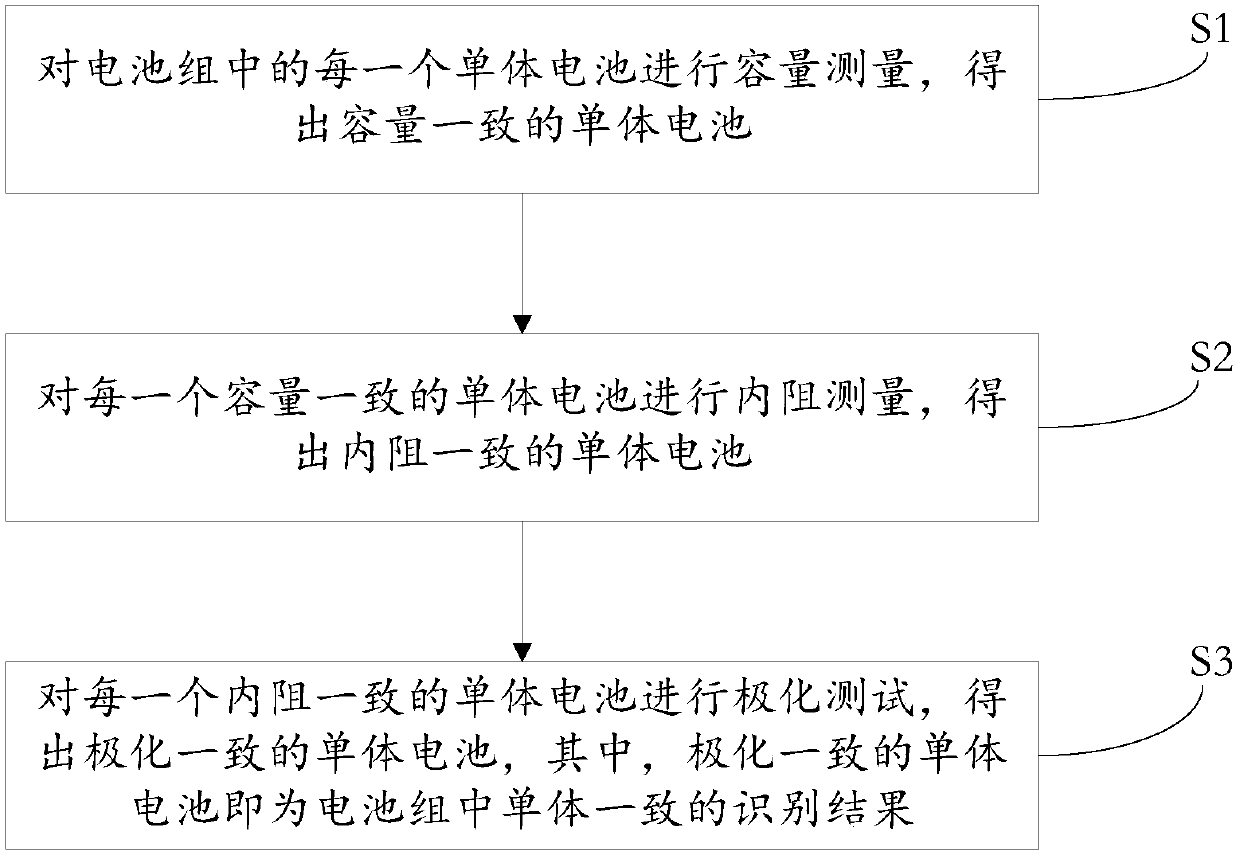

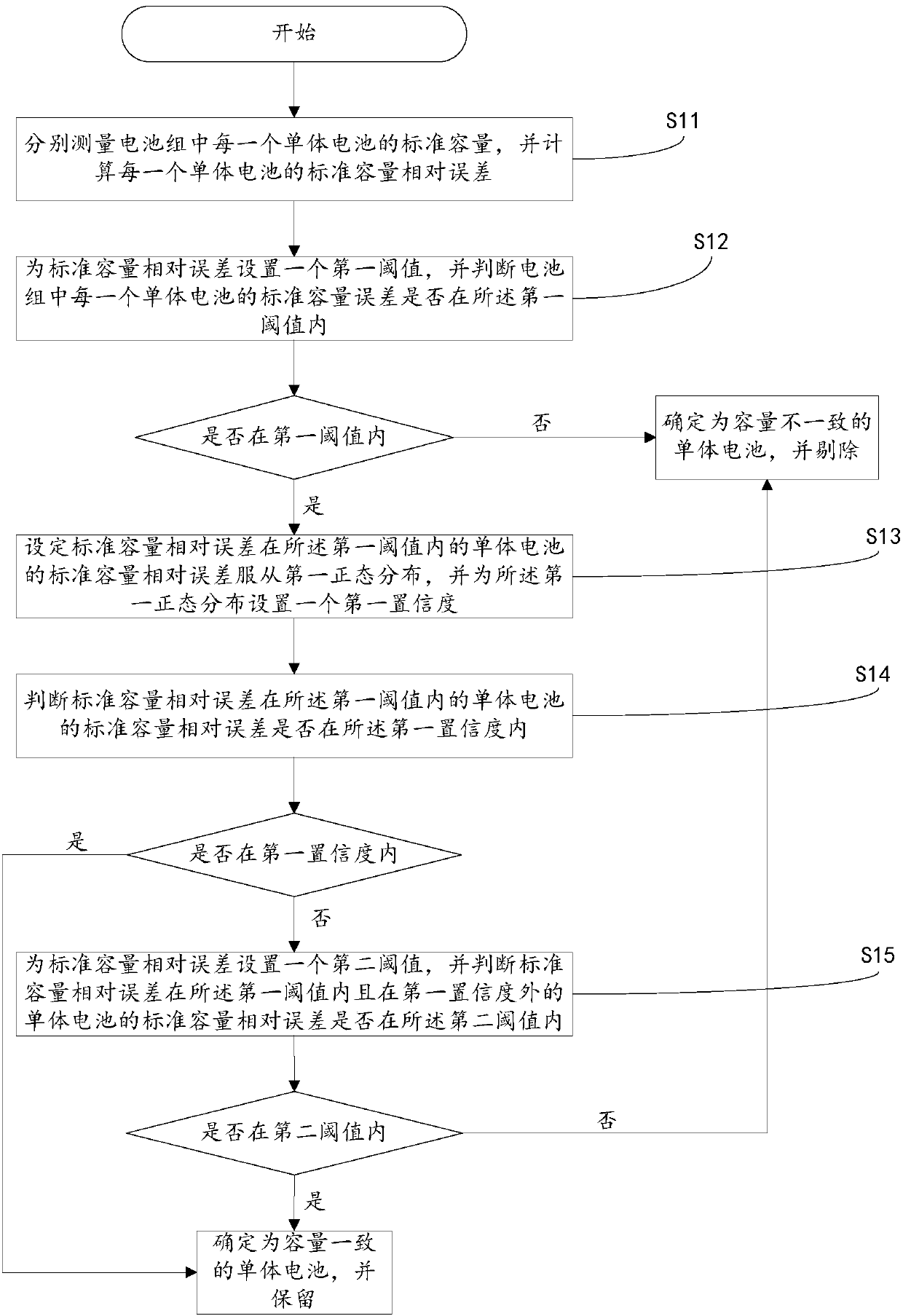

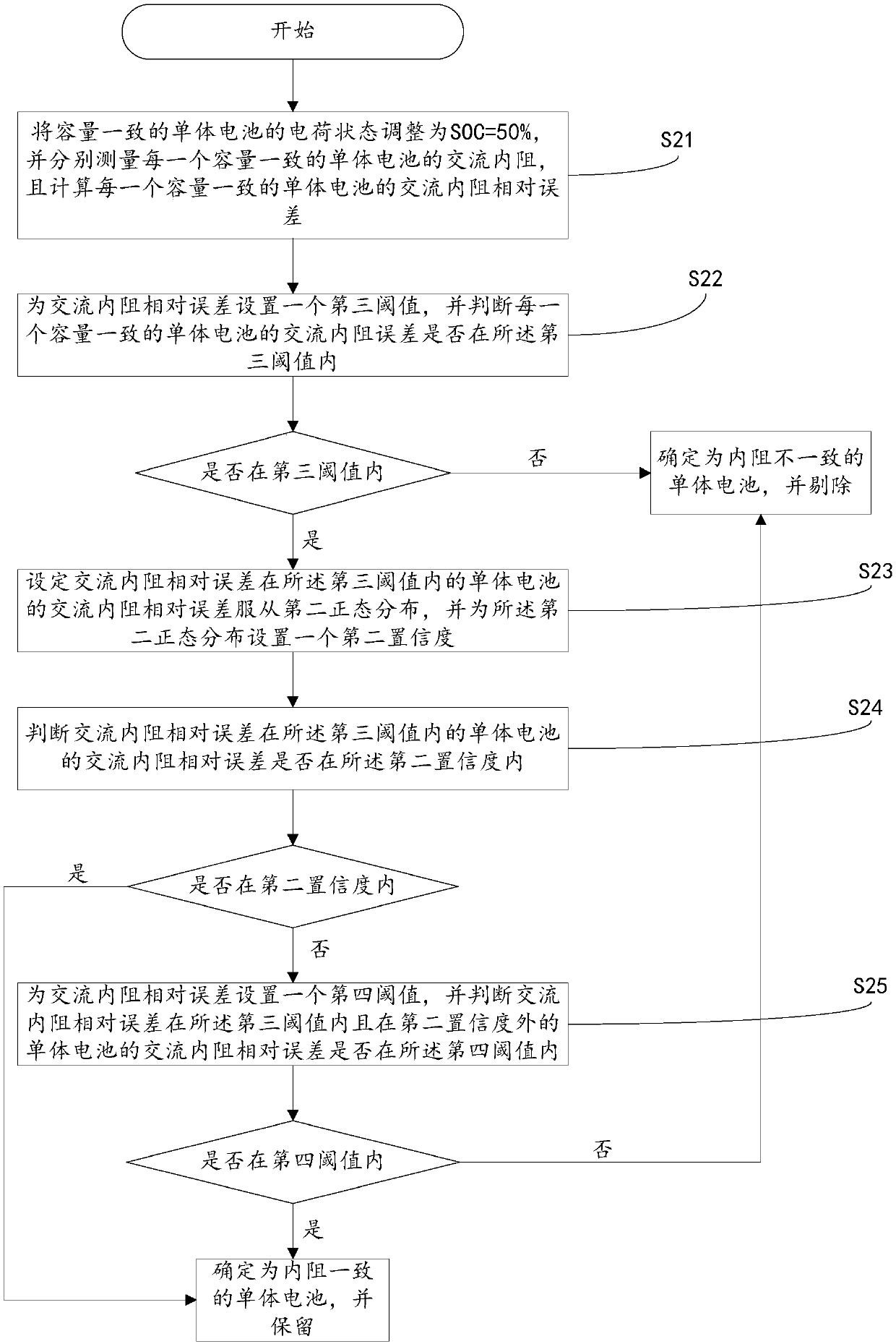

Battery pack single battery consistency identification method and system

ActiveCN107132481AHigh-precision identificationIdentify and quantifyElectrical testingElectrical batteryInternal resistance

The invention relates to a battery pack single battery consistency identification method and system. The method comprises the following steps that S1, capacity measurement is performed on each single battery in a battery pack so as to obtain the single batteries of consistent capacity; S2, internal resistance measurement is performed on each single battery of consistent capacity so as to obtain the single batteries of consistent internal resistance; and S3, polarization testing is performed on each single battery of consistent internal resistance so as to obtain the single batteries of consistent polarization, wherein the single batteries of consistent polarization are the single battery consistency identification result of the battery pack. The beneficial effects of the battery pack single battery consistency identification method and system are that the consistency of the battery pack is divided into the capacity consistency, the internal resistance consistency and the polarization consistency by the battery pack single battery consistency identification method, and the single batteries simultaneously meeting the three consistencies are the batteries of the qualified consistency so that the battery pack single battery consistency can be accurately and quantitatively identified.

Owner:广东硅岳能源科技有限公司

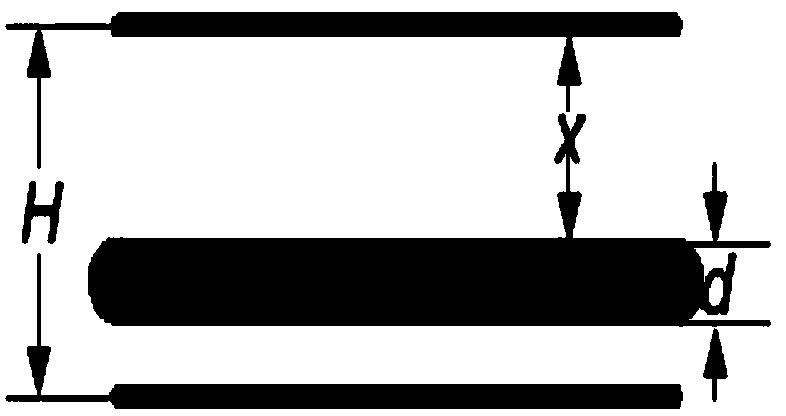

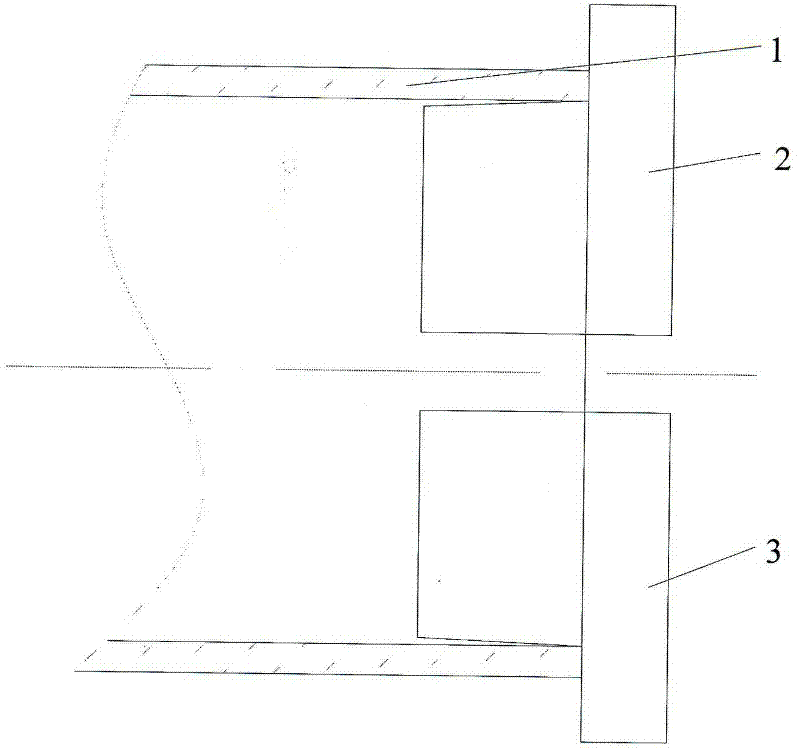

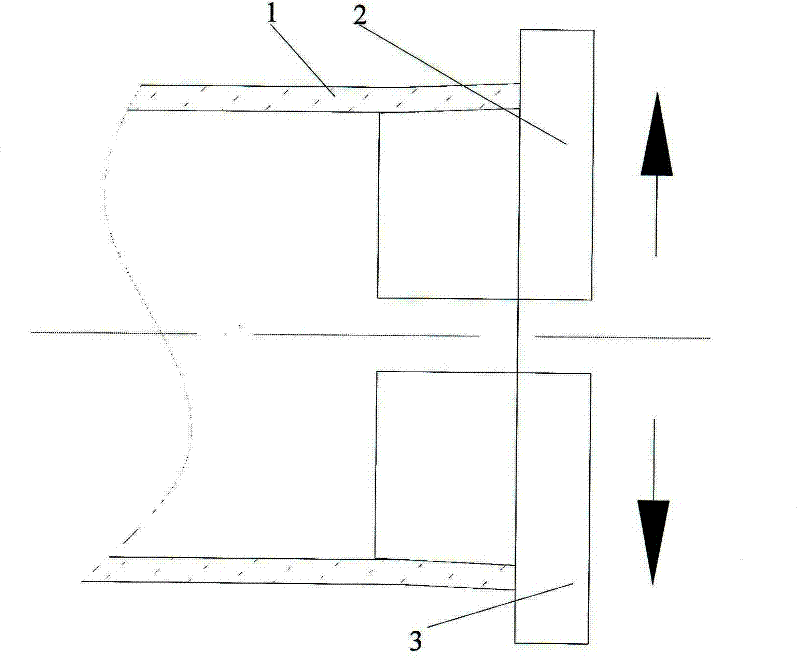

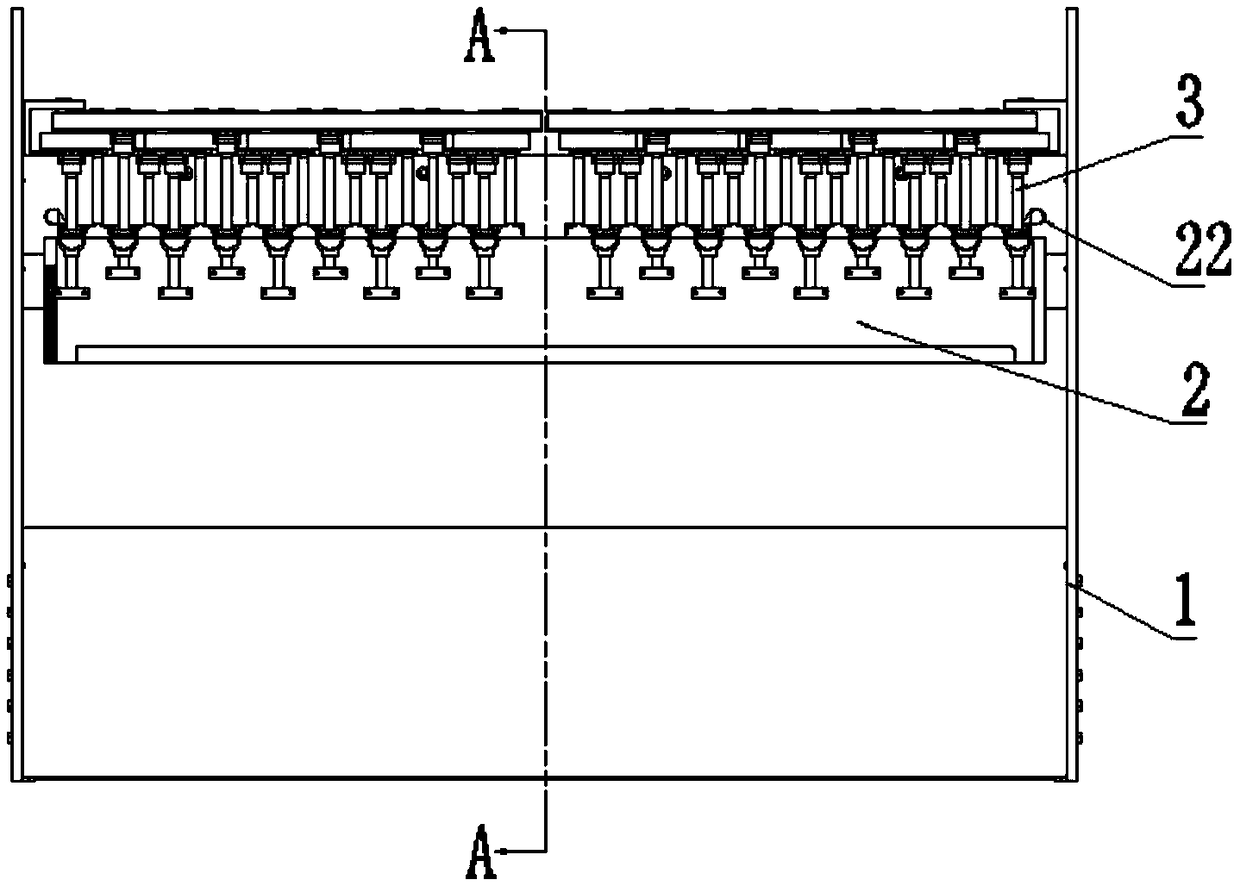

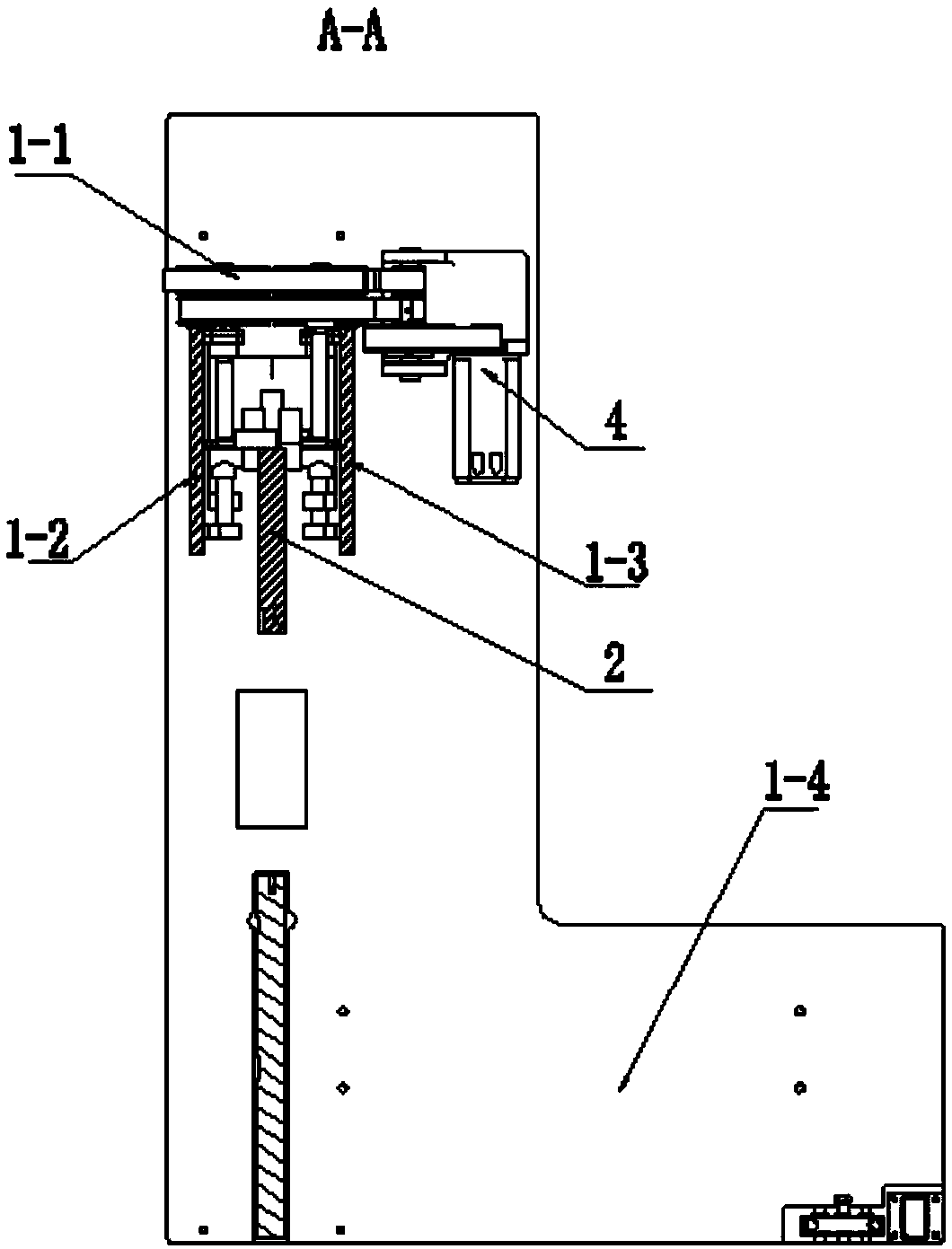

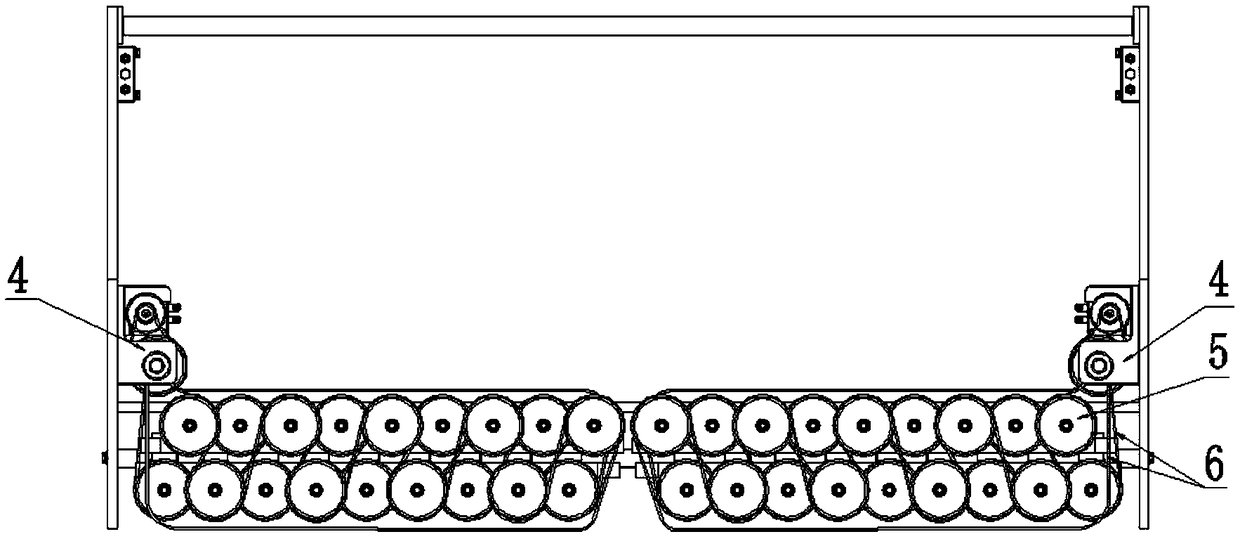

Method and system for measuring battery plate surface density based on capacitive transducer

InactiveCN103447201AIncrease productivityHigh accuracy consistencyLiquid surface applicatorsElectrical/magnetic thickness measurementsProgrammable logic controllerAccuracy and precision

The invention discloses a method and a system for measuring the battery plate surface density based on a capacitive transducer. The measuring system comprises a surface density measuring device, wherein the surface density measuring device is connected with a data processing circuit connected with a PLC (Programmable Logic Controller), and comprises a scanning frame which is a 'C' type scanning frame, and a reciprocating device which is used for driving the scanning frame; a probe of the capacitive transducer and a bottom smooth metal plate are respectively mounted on the upper and lower scanning arms of the scanning frame. According to the invention, the traditional off-line measurement mode is changed, so that the production efficiency is improved greatly, the survey accuracy and the consistency of product quality are improved, materials are saved, the cost is saved, and uniform control over the surface density of a battery plate is realized.

Owner:UNIV OF JINAN

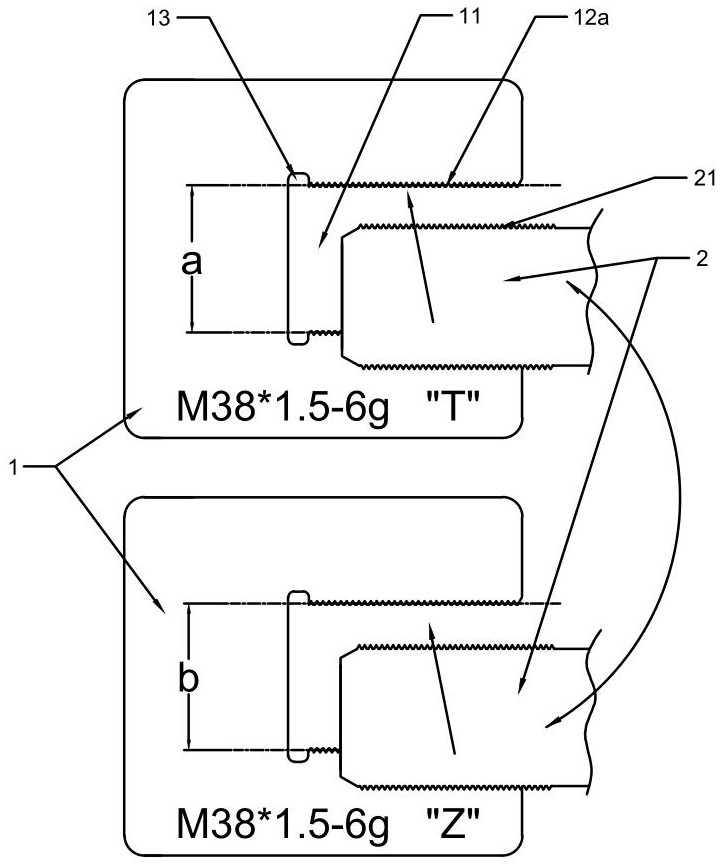

Cold precision forging technique for Z type contacts

ActiveCN102319851ASave raw materialsIncrease profitMetal-working apparatusFurnace typesForgingCopper

The invention discloses a cold precision forging technique for Z type contacts, which relates to the technical field of cold precision forging and solves the problem that the conventional machining technique of post-forging bending can hardly guarantee the designed shapes and application requirements of Z type contacts. The technique includes the steps that: a copper bar directly enters a die, and is blanked and preformed; the preformed blank is annealed to be softened; after the blank receives intermediate treatment, cold precision forging is carried out; another unformed flat-bottomed hole of the cold precision forged blank is reamed; and subsequent treatment is carried out. The technique can guarantee the consistency of the shapes of finished products, and can ensure that the metal fibers of the Z type contacts can be continuously distributed according to the shape of the Z type contacts.

Owner:QINHAN PRECISION IND CO LTD

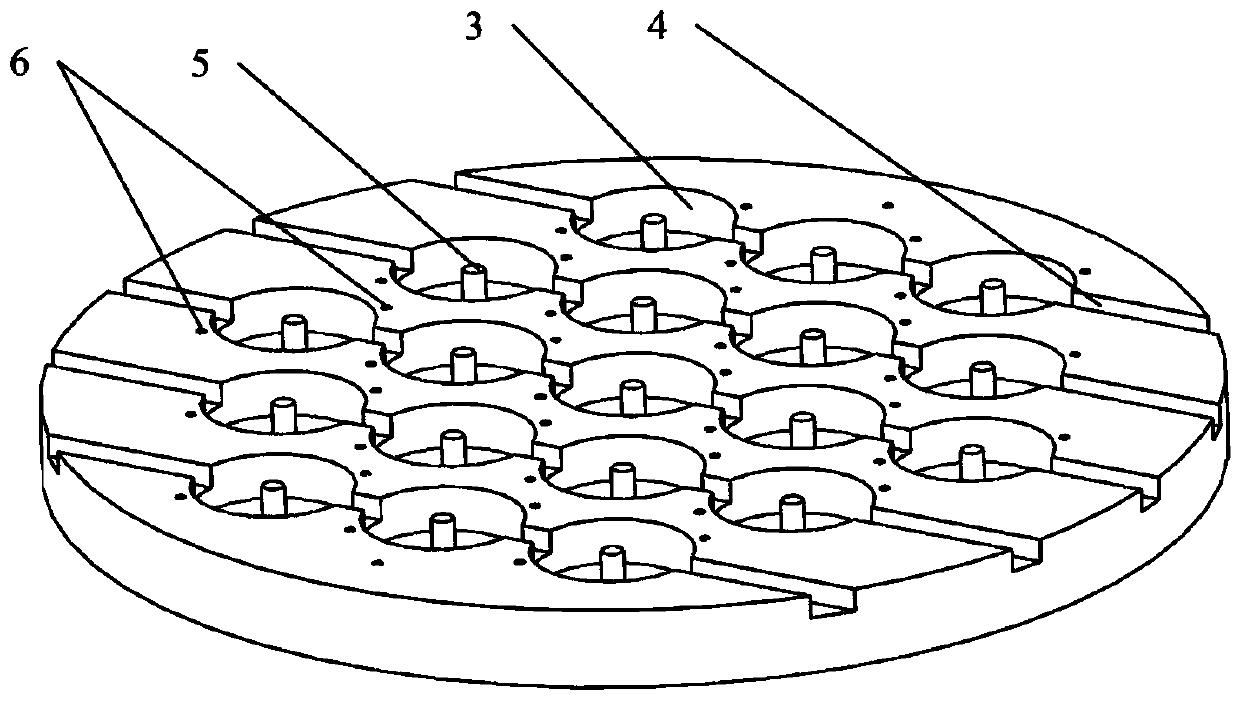

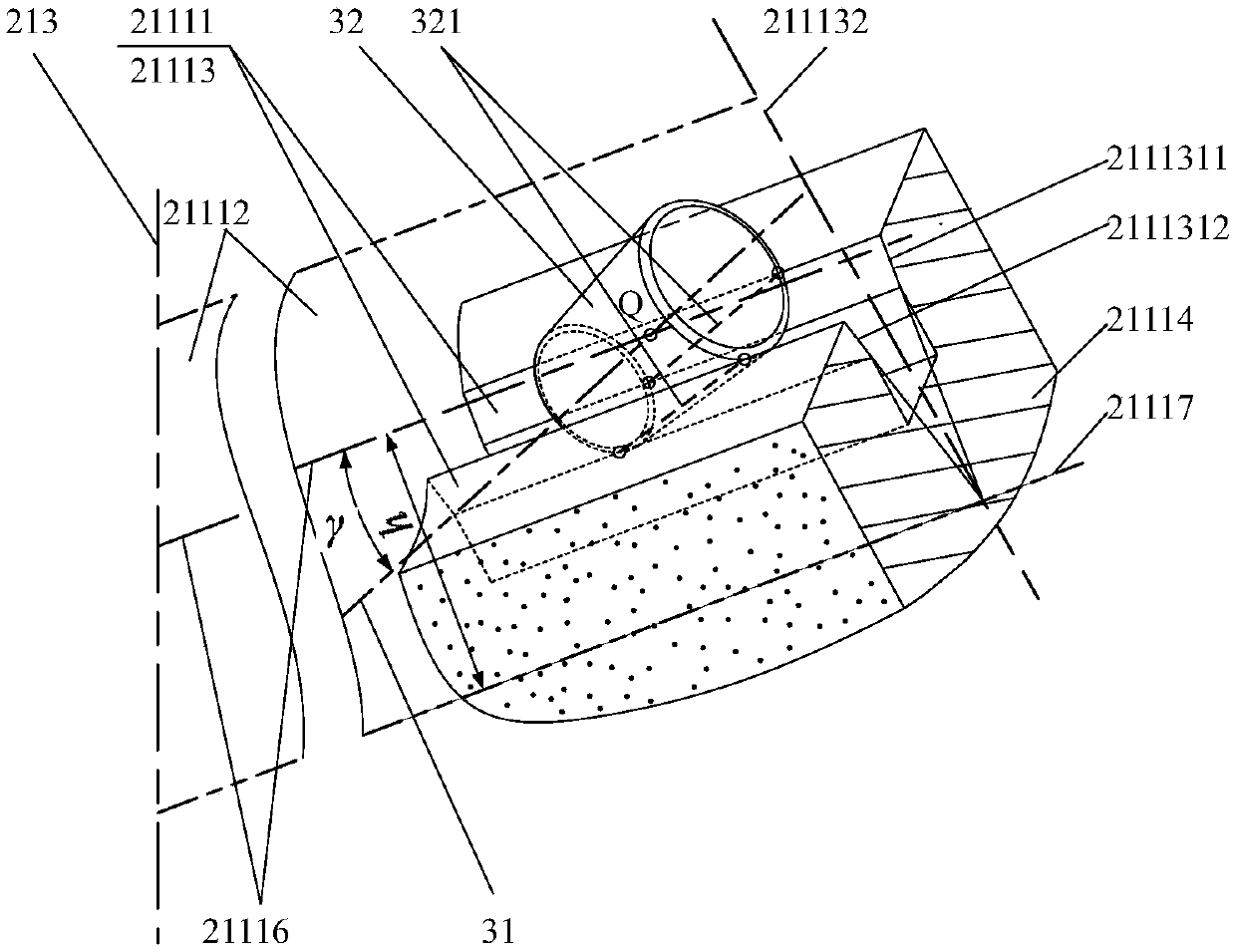

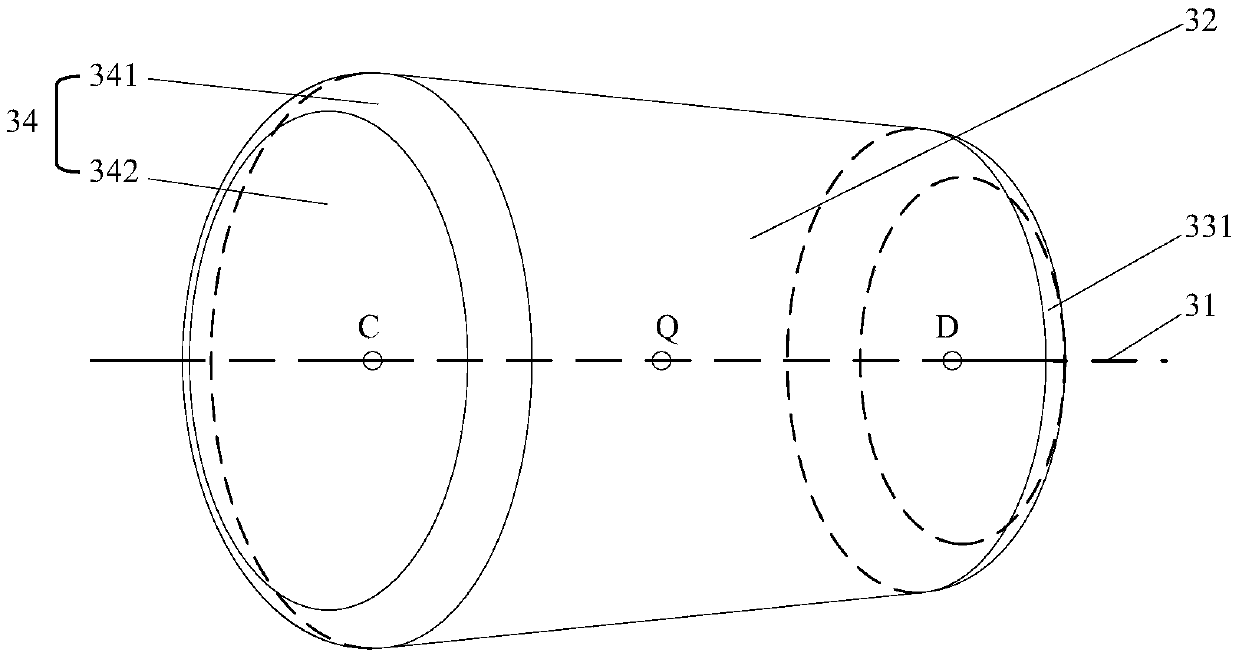

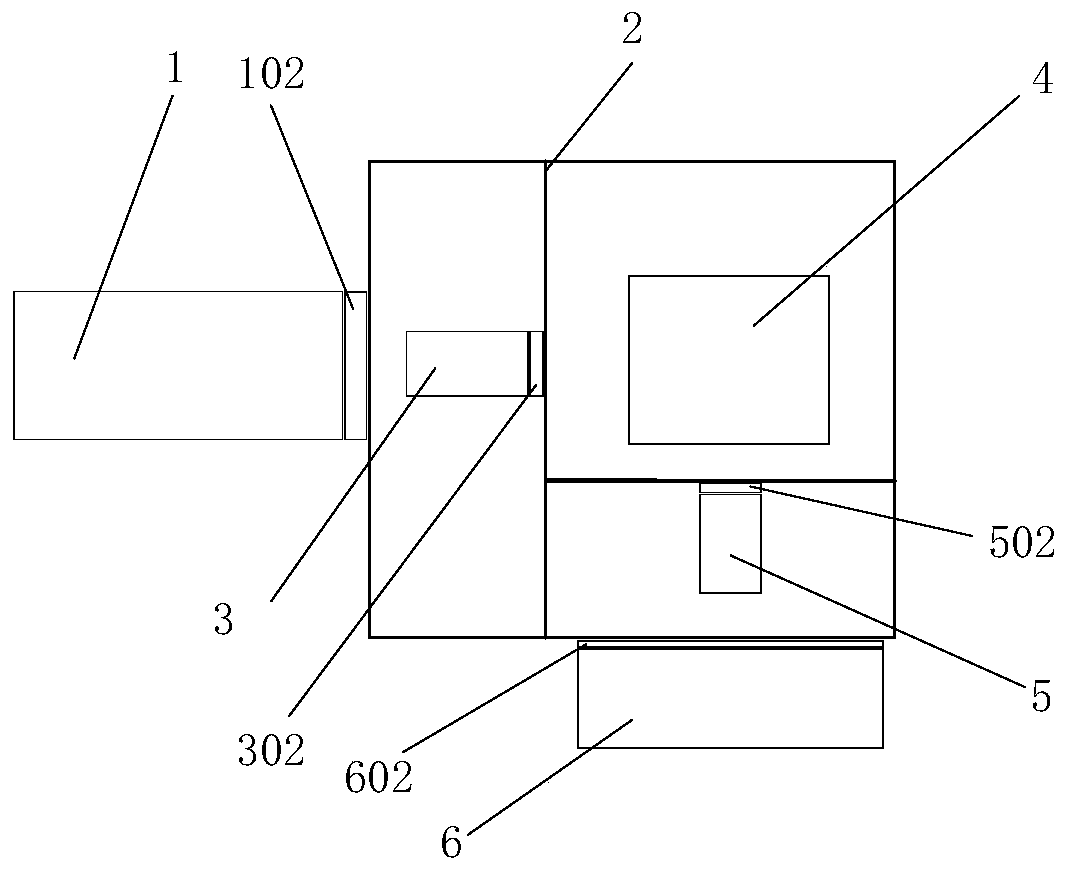

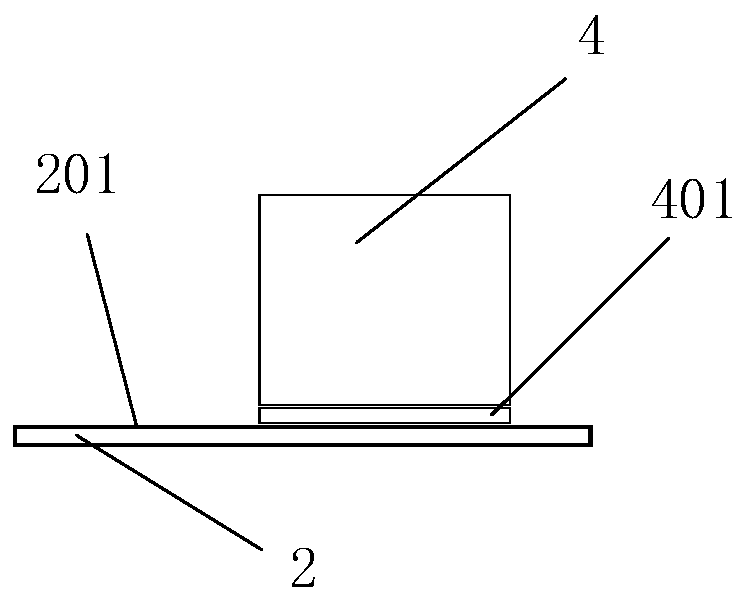

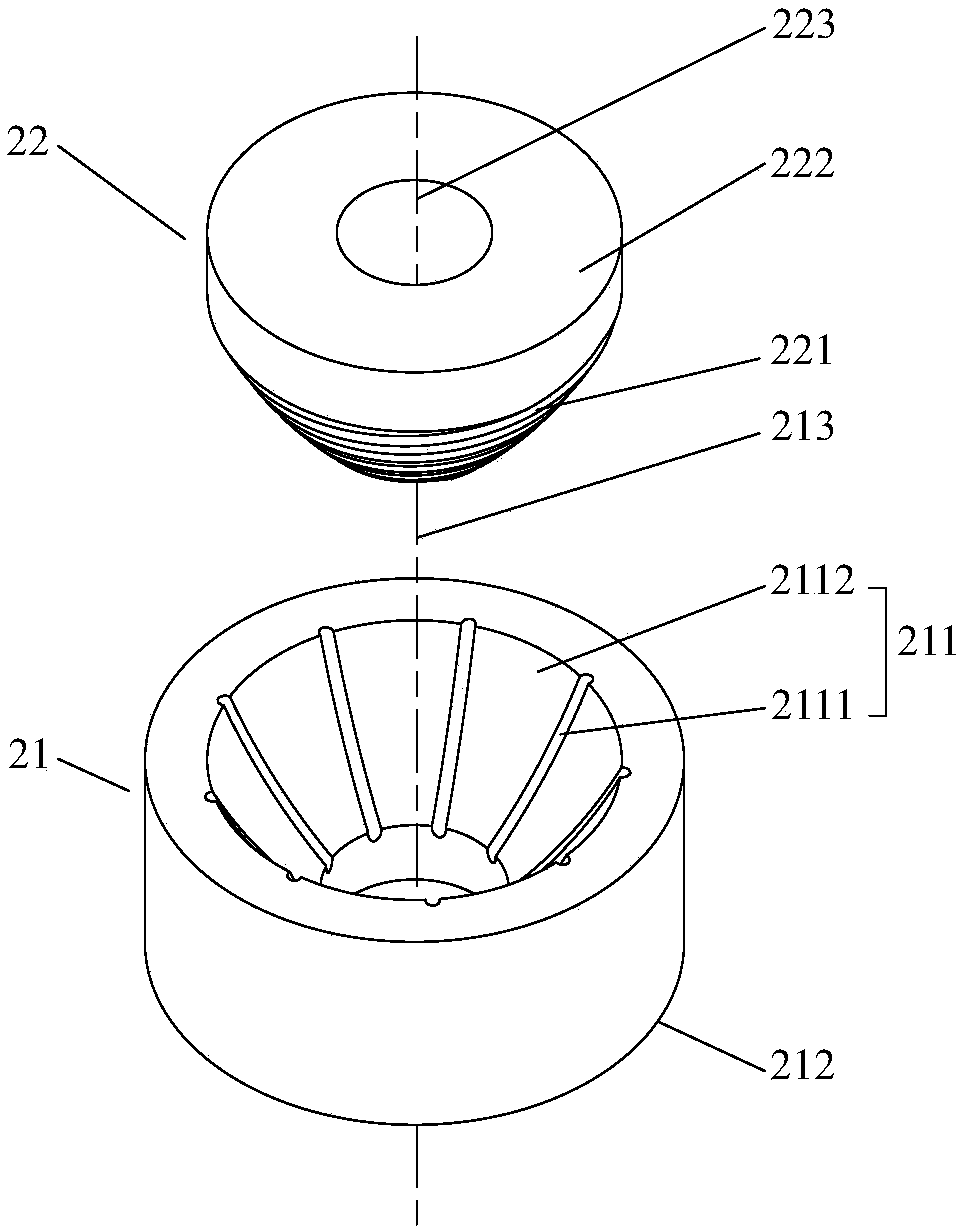

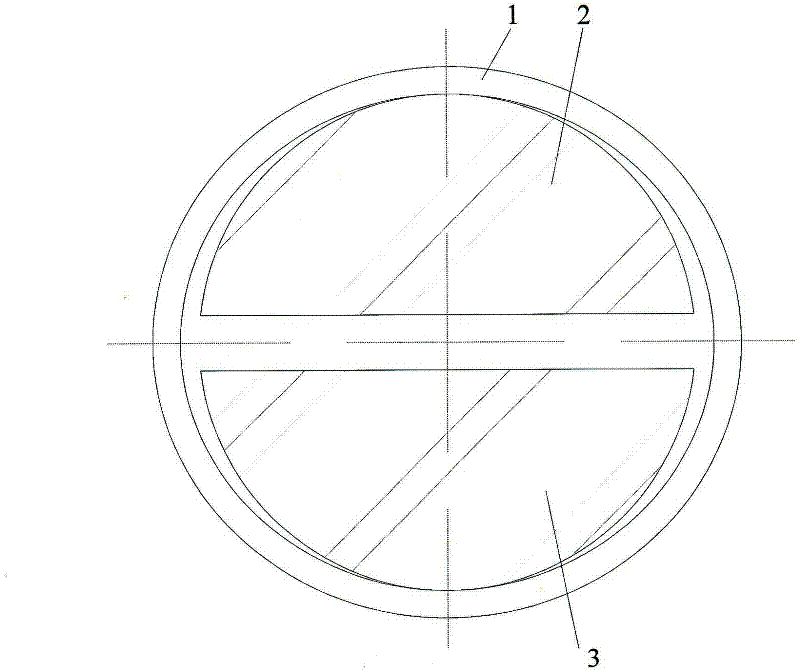

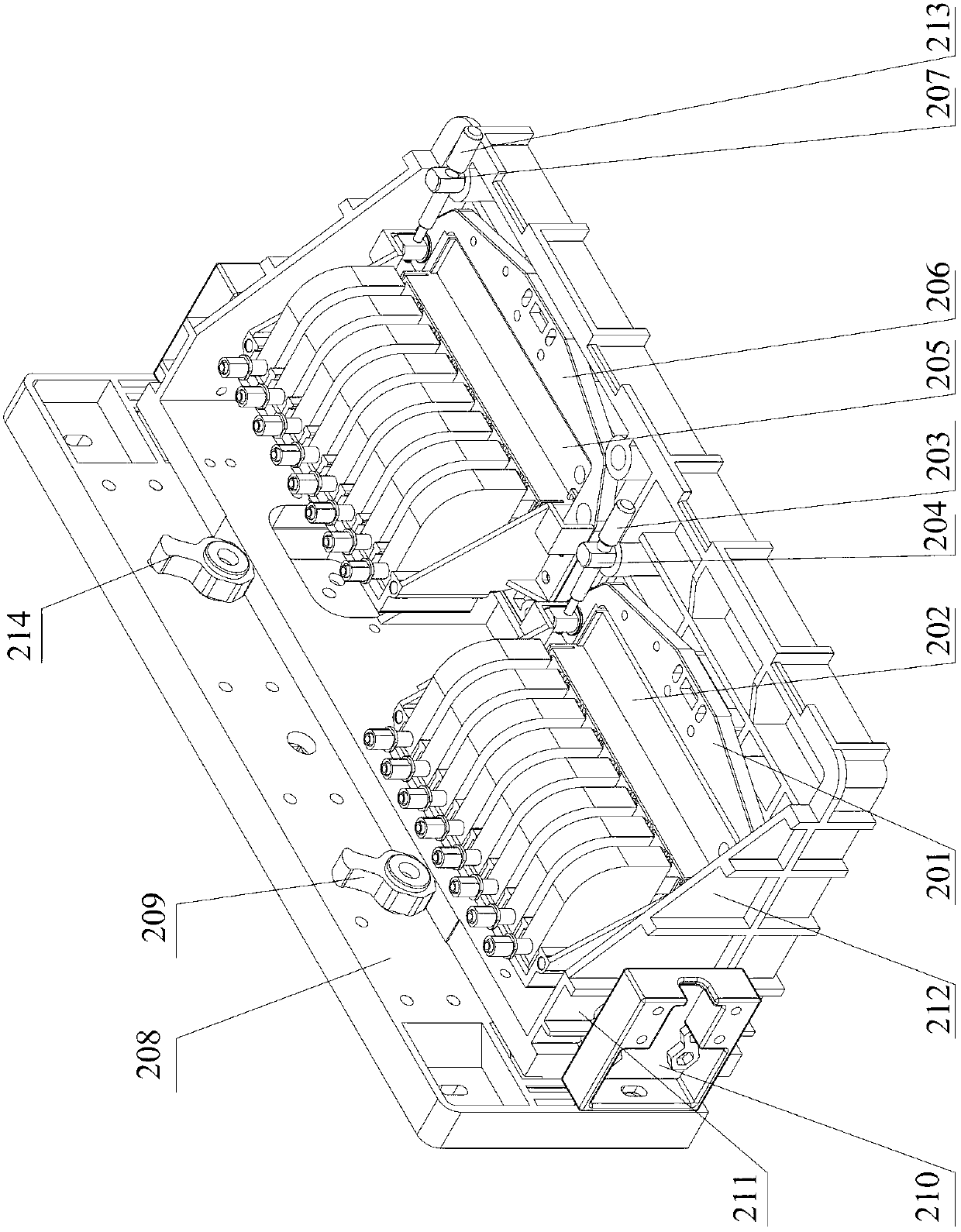

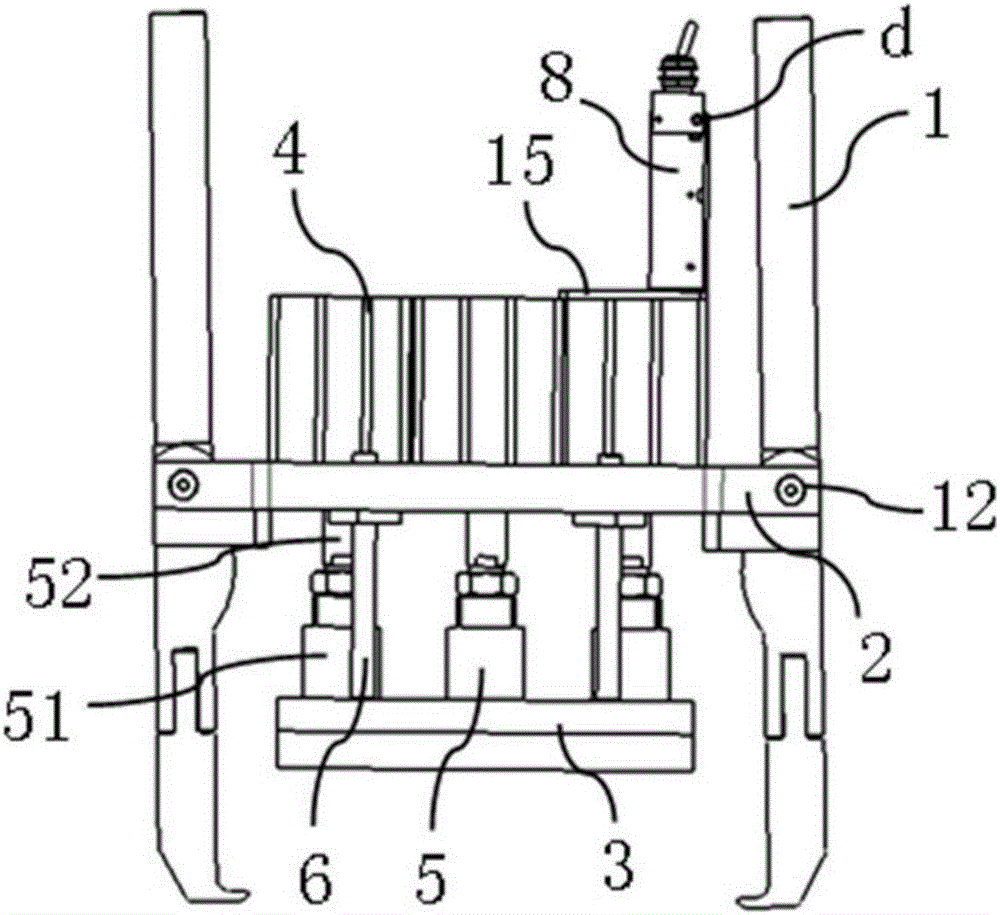

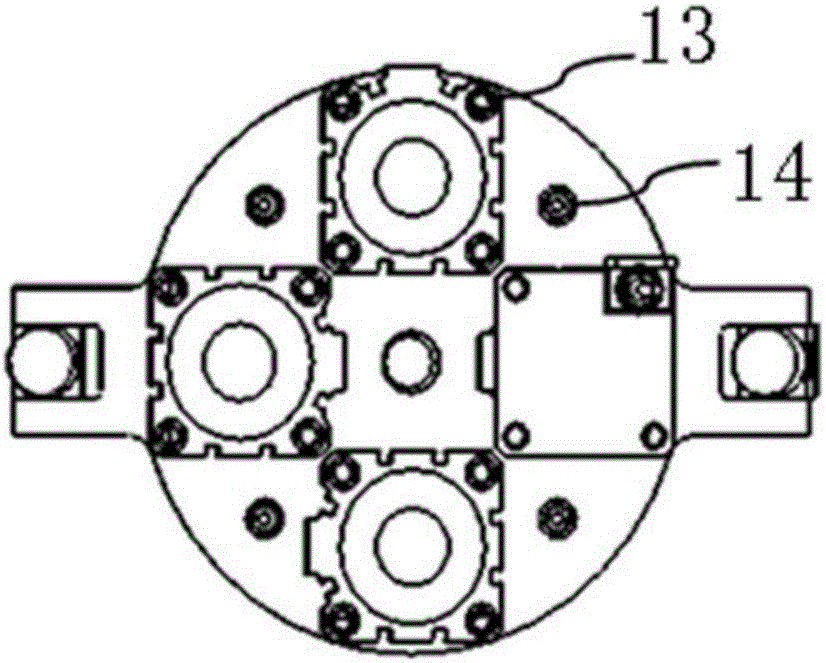

Grinding disc used for precise processing of rolling surface of tapered roller and equipment method

PendingCN108723979AReduce removalRemove comprehensivelyLapping machinesLapping toolsCircular discEngineering

The invention discloses grinding equipment used for precise processing of the rolling surface of a tapered roller and a grinding disc sleeving piece. The grinding equipment comprises main equipment, the grinding disc sleeving piece and a roller circular disc external system, the main equipment comprises a base, an upright column, a beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device, and the roller circular disc external system comprises a roller collecting device, a roller transporting system, a roller arrangement system and a roller feed-in mechanism; the grinding disc sleeving piece comprises a pair of coaxially arranged first and second grinding discs of which the front surfaces are opposite to each other, the front surface of the first grinding disc comprises a set of linear grooves distributed on the base surface (right circular conical surface) of the first grinding disc in a radial form, the front surface of the second grinding disc comprises one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding disc, and the sum of the cone apex angles of the base surfaces of the first and second grinding discs is 360 degrees. The grinding equipment has the precise processing capacity to process the rolling surfaces of mass tapered rollers.

Owner:TIANJIN UNIV

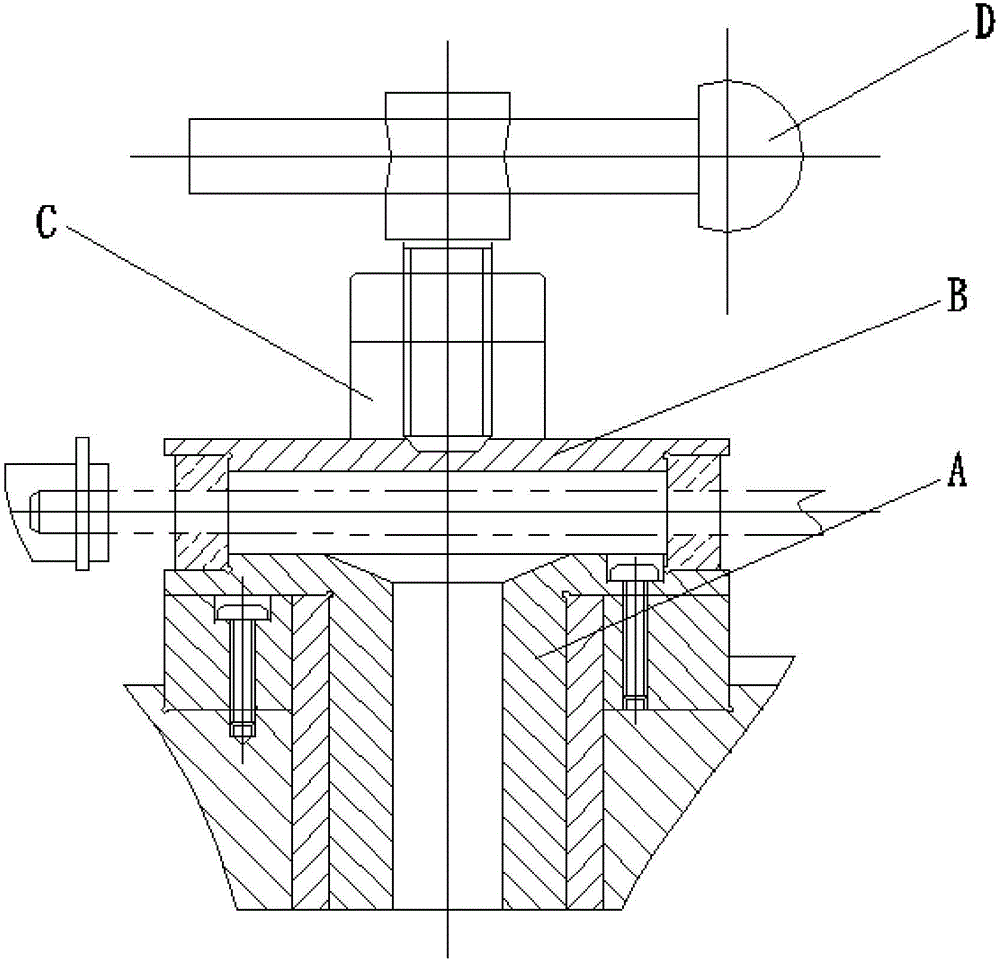

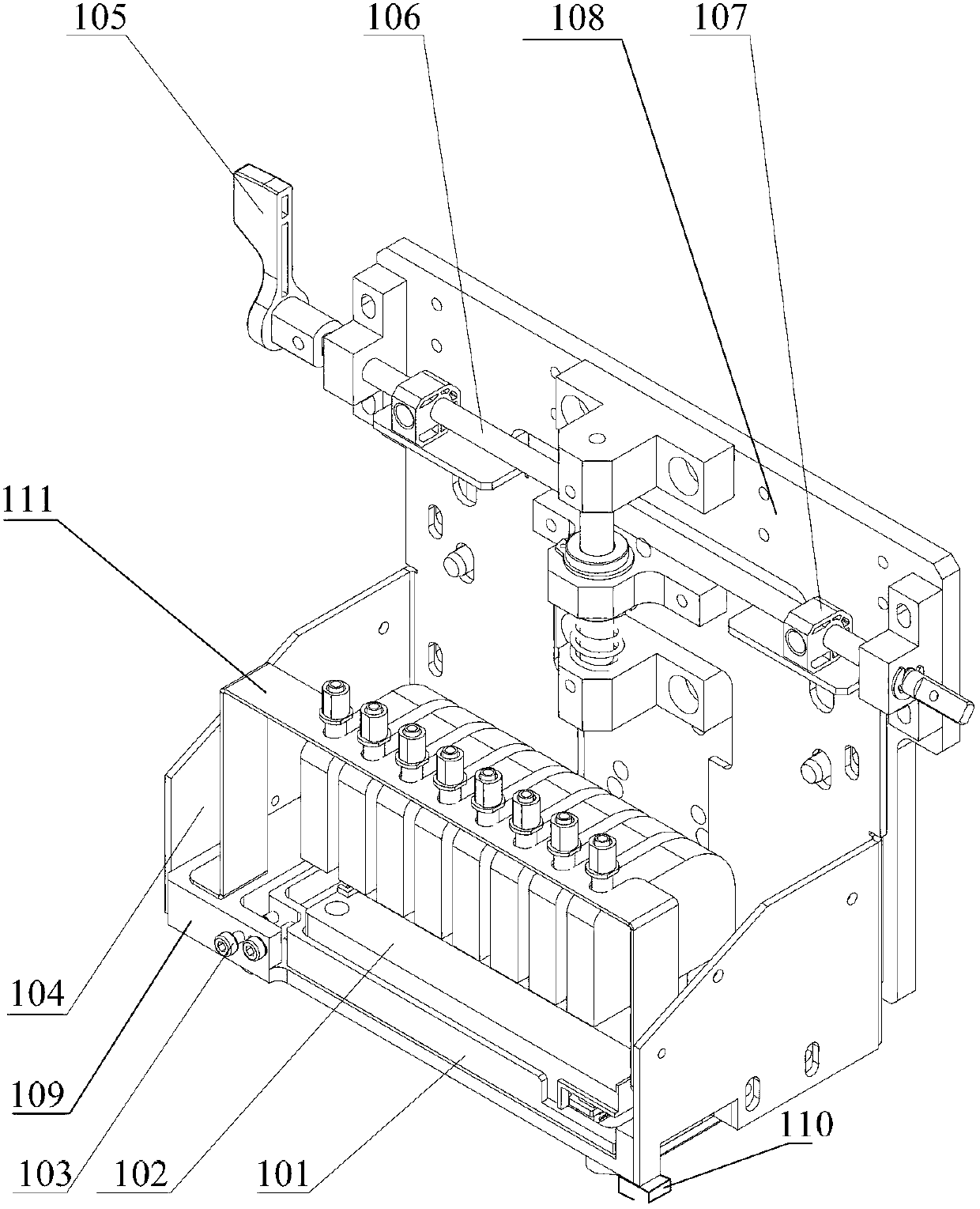

Tool for pocket hole of short cylindrical roller bearing retainer and pocket hole method thereof

The invention provides a tool for a pocket hole of a short cylindrical roller bearing retainer and a pocket hole method of the tool, relates to a tool for the pocket hole and the pocket hole method of the tool, and aims to solve the problem that due to the inconsistency between the axial position degree and the circumferential position degree of the pocket hole, the processing quality of the retainer is affected. According to the tool, a locating shaft is installed on a workbench in a rotatable mode, a locating rotating shaft is installed in a center hole formed in the locating shaft in a sleeved mode, and the retainer is installed on the locating shaft; a cover plate is installed on the retainer in a press mode, a stepped hole is formed in the middle of the cover plate, and a press block is installed in the stepped hole of the cover plate in a rotatable mode; and a press rod is vertically screwed into the press block, a screwing rod is horizontally arranged at the upper end of the press rod in a penetrating mode, and a locating pin is detachably inserted into the pocket hole of the retainer. The method comprises the steps that the tool for the pocket hole of the retainer is installed; the retainer is fixed; the position of the pocket hole to be broached is determined; the work of preparation before broaching is conducted; after a broaching machine is started, broaching of the pocket hole is accomplished; and broaching is conducted repeatedly until broaching of the pocket hole of the retainer is accomplished. The tool for the pocket hole and the pocket hole method of the tool are used for production of the bearing retainer.

Owner:AVIC HARBIN BEARING

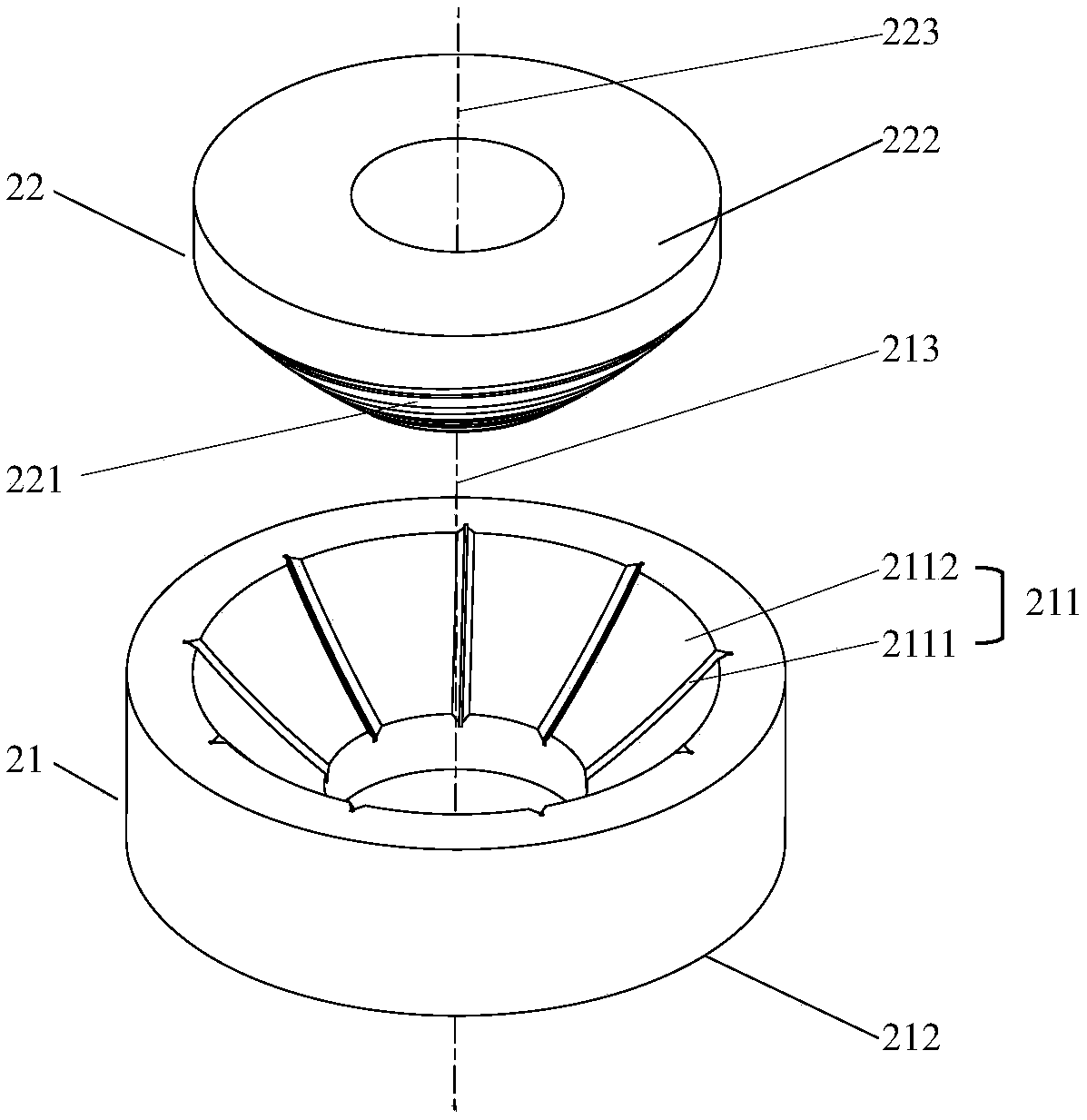

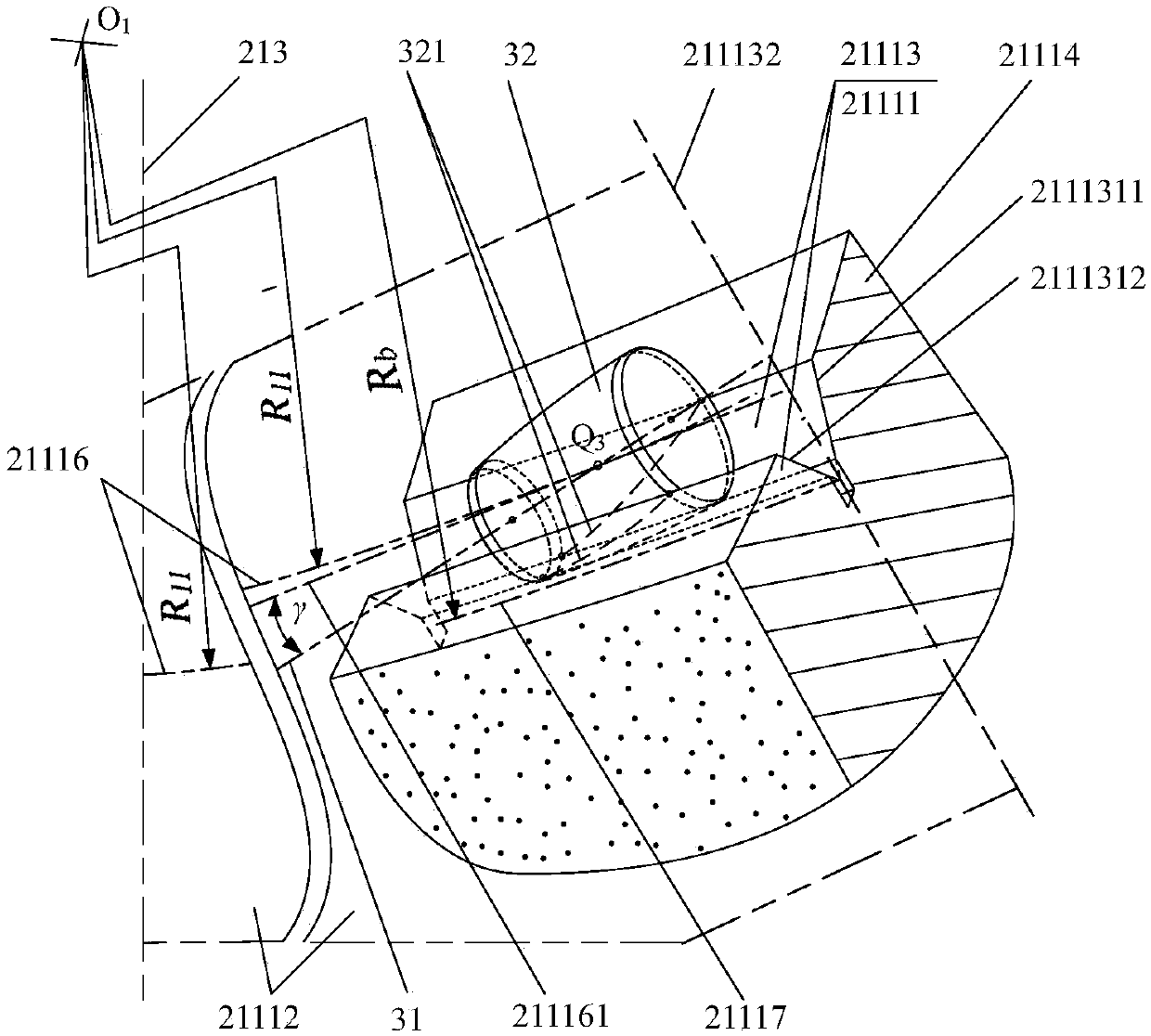

Magnetic grinding disc, equipment and method for tapered roller rolling surface finishing

PendingCN108723982AReduce removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceSurface finish

The invention discloses grinding equipment and a magnetic grinding disc kit for tapered roller rolling surface finishing of ferromagnetic materials. The grinding equipment comprises a main body, the magnetic grinding disc kit and a roller circulation disc outer system. The main body includes a base, a column, a beam, a slide table, an upper tray, a lower tray, an axial loading device and a spindledevice. The roller circulation disc outer system includes a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The magnetic grinding disc kit includes a pair of coaxial first and second grinding discs of which the front surfaces are disposed opposite to each other. The front surface of the first grindingdisc includes a set of linear grooves radially distributed on a base surface (positive conical surface) of the first grinding disc, the front surface of the second grinding disc includes one or morespiral grooves distributed in the base surface (positive conical surface) of the second grinding disc, and a ring-shaped magnetic structure is embedded inside a base body. The grinding equipment has the finishing ability of multitudinous ferromagnetic material tapered roller rolling surfaces.

Owner:TIANJIN UNIV

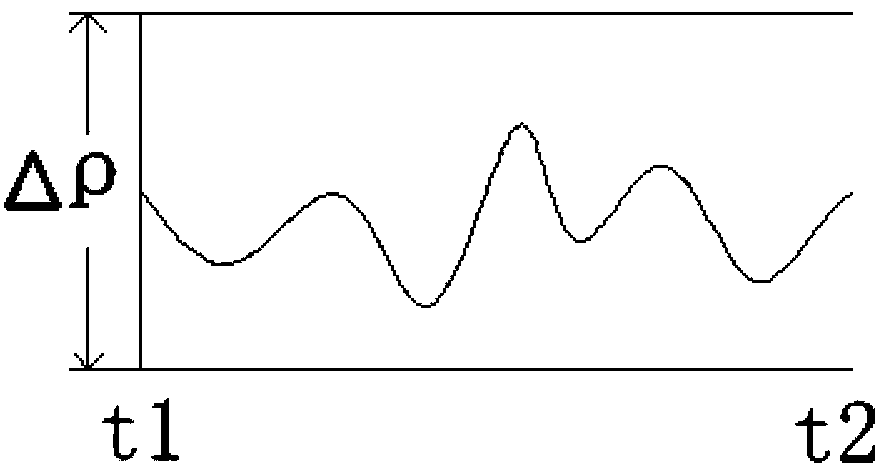

Alignment method of unfocused interference spectrometer

ActiveCN110470398AReduce the difficulty of ground installationHigh accuracy consistencyRadiation pyrometryInterferometric spectrometrySpace environmentEngineering

In order to solve the technical field of high ground alignment difficulty of an unfocused interference spectrometer, the invention provides an alignment method of an unfocused interference spectrometer. The method comprises the following steps of (1) designing and processing trimming pads between components; (2) performing single alignment on each component; (3) in ground air environment, performing integration alignment on each component and the corresponding trimming pads; (4) performing vacuum image surface presetting; (5) curing the assembly precision; and (6) verifying the performance. Byusing a block alignment and unified integration alignment method, the ground alignment difficulty of the unfocused interference spectrometer is greatly reduced; the precision consistency of the unfocused interference spectrometer in a space environment and a ground air environment is improved; meanwhile, the alignment period is shortened; after the alignment in the ground air environment is completed, a vacuum image surface presetting method and mechanics simulation tests are combined; and optical indexes of the unfocused interference spectrometer are enabled to meet the design requirements after the launching phase and orbit insertion.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

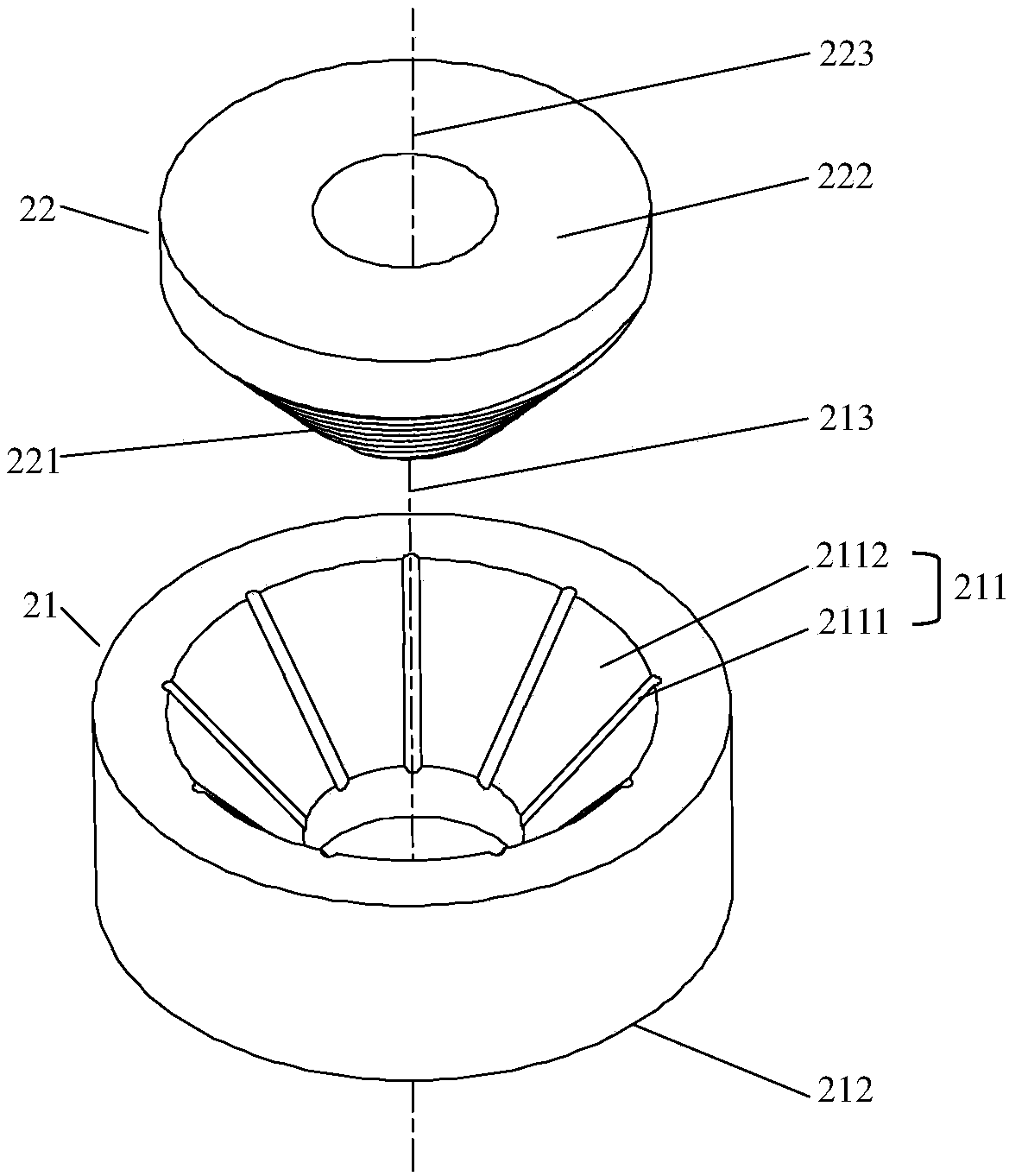

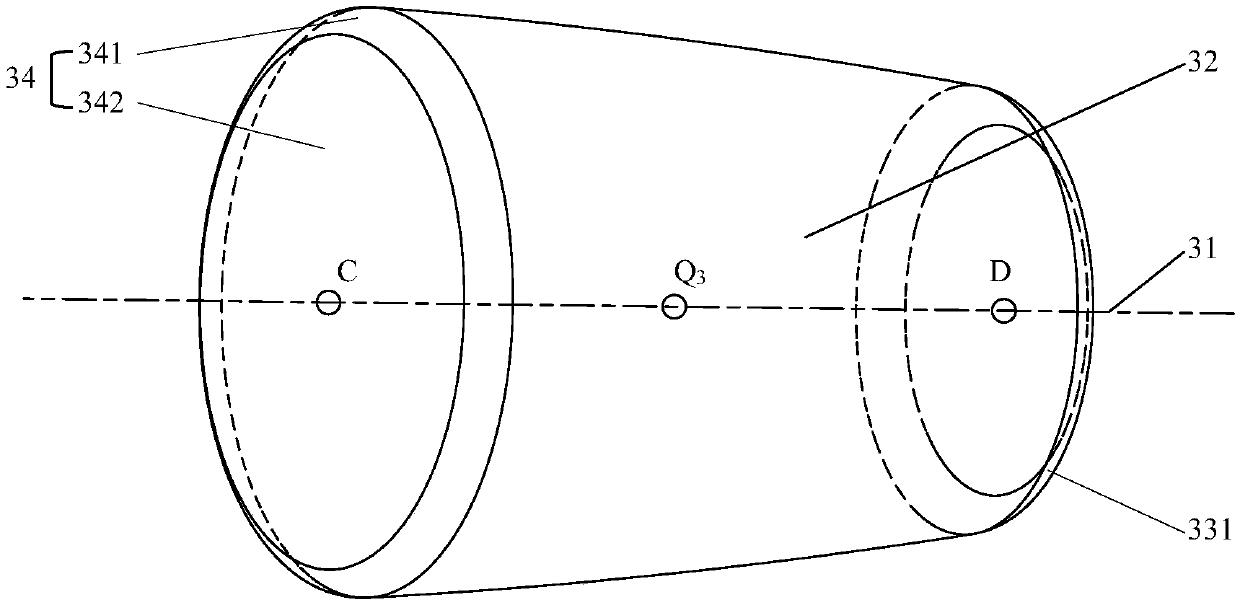

Grinding disk, apparatus and method for finishing rolling surface of convex cylindrical roller

ActiveCN108890516AAchieve removalRemove comprehensivelyLapping machinesLapping toolsMechanical engineeringEngineering

A lapping apparatus and a lapping disk kit for finis a rolling surface of a convex cylindrical roller are disclose. That lapping apparatus includes a main body, a lapping disk kit and a roller circulation disk out system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. The outer system of the roller circulating disk comprises a roller collecting device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism. The abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. A front surface of the first abrasive disk includes a set of concave arc grooves radially distributed on a base surface of the first abrasive disk (concave circular arc rotating surface), The front surface of the second abrasive disk includes one or more spiral grooves distributed on the base surface of the second abrasive disk (convex circular arc rotating surface),and the radii of curvature of the base circle and the radii of curvature of the cross-section of the base surface of the first and second abrasive disks are equal to each other. A lapping apparatus ofthat present invention has the finis machining capability of a rolling surface of a large numb of convexity cylindrical rollers.

Owner:TIANJIN UNIV

Magnetic grinding plates, equipment and method for finish machining of rolling surface of cylindrical roller

The invention discloses grinding equipment and a magnetic grinding plate suite for finish machining of the rolling surface of a cylindrical roller made of a ferromagnetic material. The grinding equipment comprises a main unit, the magnetic grinding plate suite and a roller circulating plate external system, wherein the main unit comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device; the roller circulating plate external system comprises a roller collecting device, a roller demagnetizer, a roller conveyor, a roller finishing mechanism and a roller feed-in mechanism. The magnetic grinding plate suite comprises a first grinding plate and a second grinding plate which are coaxial, and the front sides of the pair of grinding plates are opposite; a group of linear grooves radially distributed on the base surface (right circular conical surface) of the first grinding plate are arranged on the front side of the first grinding plate, one or more spiral grooves distributed on the base surface (right circular conical surface) of the second grinding plate are formed on the front side of the second grinding plate, and an annular magnetic structure is inlaid in a substrate of the second grinding plate. The grinding equipment has the finish machining capacity for the rolling surfaces of a large scale of cylindrical rollers made of the ferromagnetic material.

Owner:TIANJIN UNIV

Grinding disc, equipment and method for finish machining of rolling surface of convex circular cone roller

PendingCN108673331AReduce removalIncrease contact stressLapping machinesLapping toolsEngineeringCircular cone

The invention discloses grinding equipment and grinding disc external member for finish machining of the rolling surface of a convexity circular cone roller. The grinding equipment comprises a main machine, the grinding disc external member and a roller circulating disc external system. The main machine comprises a base, a stand column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller circulating disc external system comprises a roller collecting device, a roller conveying system, a roller cleaning mechanism and a roller feeding mechanism. The grinding disc external member comprises a pair of first and second grinding discs, wherein the front surfaces of the first and second grinding discs are coaxially arranged are arranged in an opposite mode. The front surface of the first grinding disc comprises a group of concave arc grooves radially distributed on the first grinding disc base surface (concave arc rotating surface), the front surface of the second grinding disc comprises one or more spiral grooves distributed on the second grinding disc base surface ( convex arc rotating surface ), and the radius of curvature of the base circle and the radius of curvature of the base surface cutting line of the first and second grinding discs are equal. The grinding equipment and grinding disc external member for finishmachining of the rolling surface of the convexity circular cone roller has the finish machining capability of rolling surfaces of large-scale convexity circular cone rollers.

Owner:TIANJIN UNIV

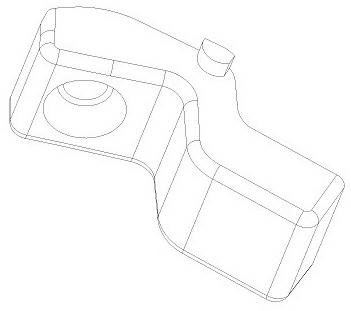

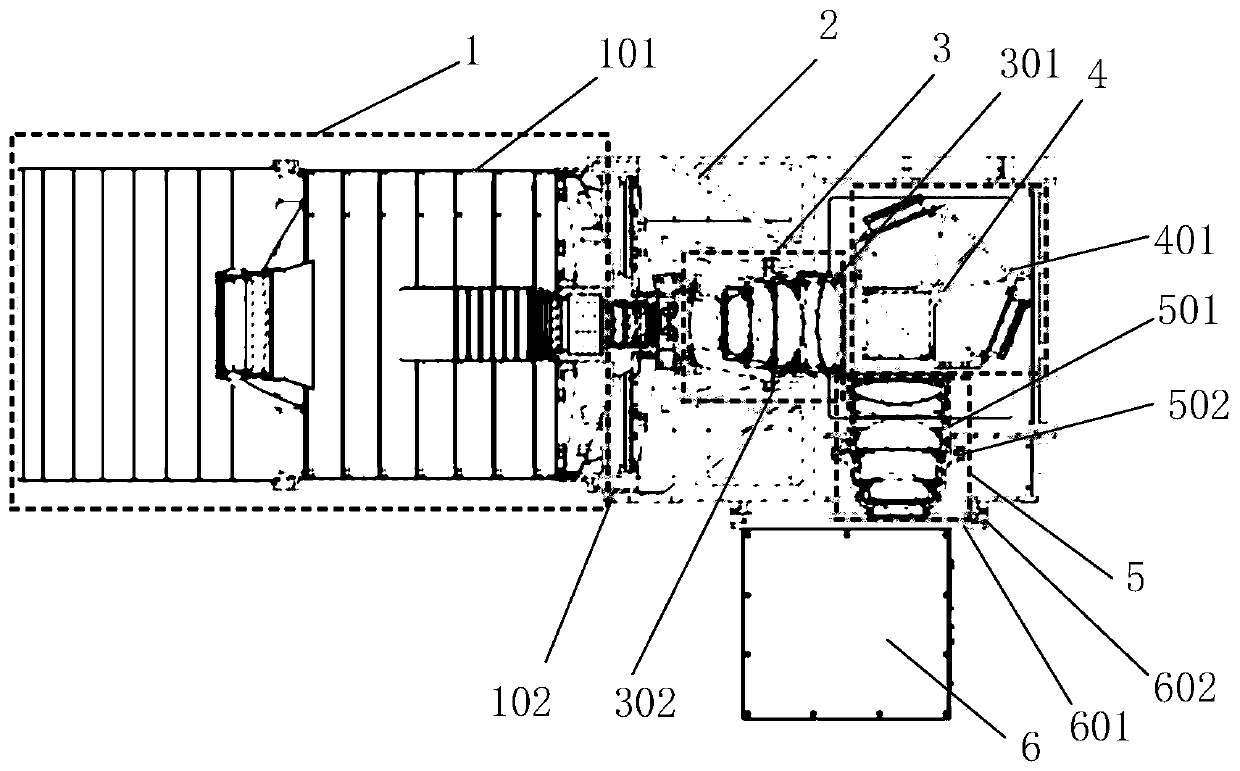

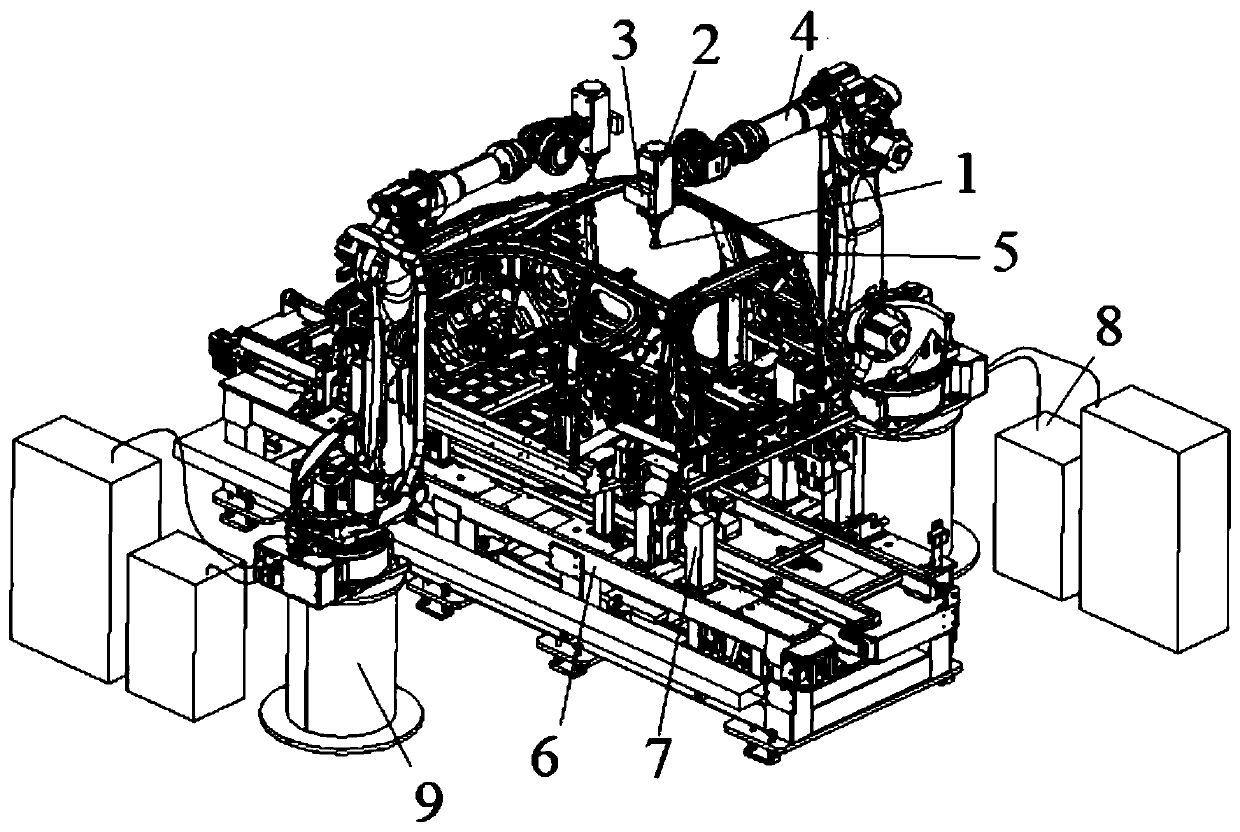

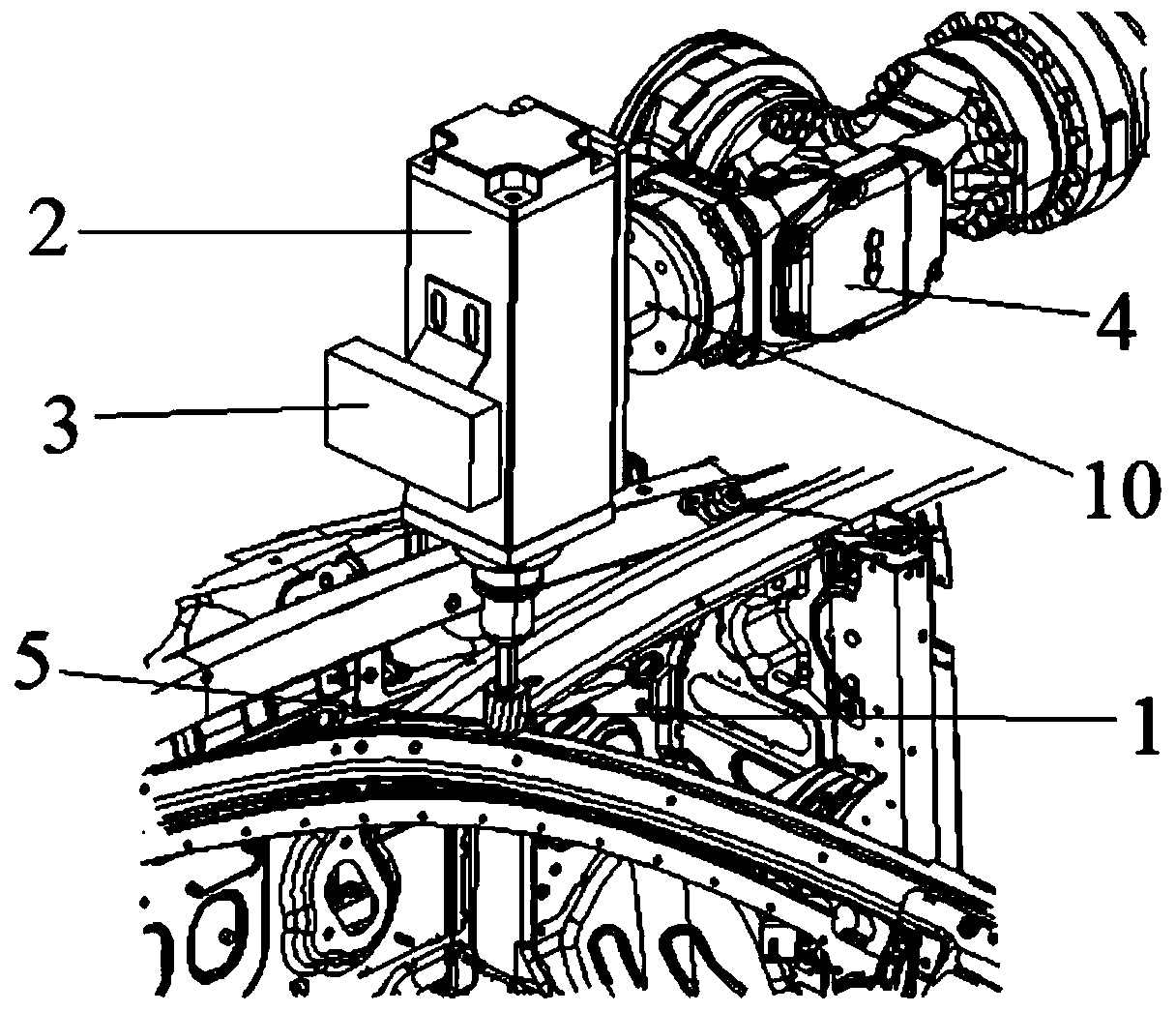

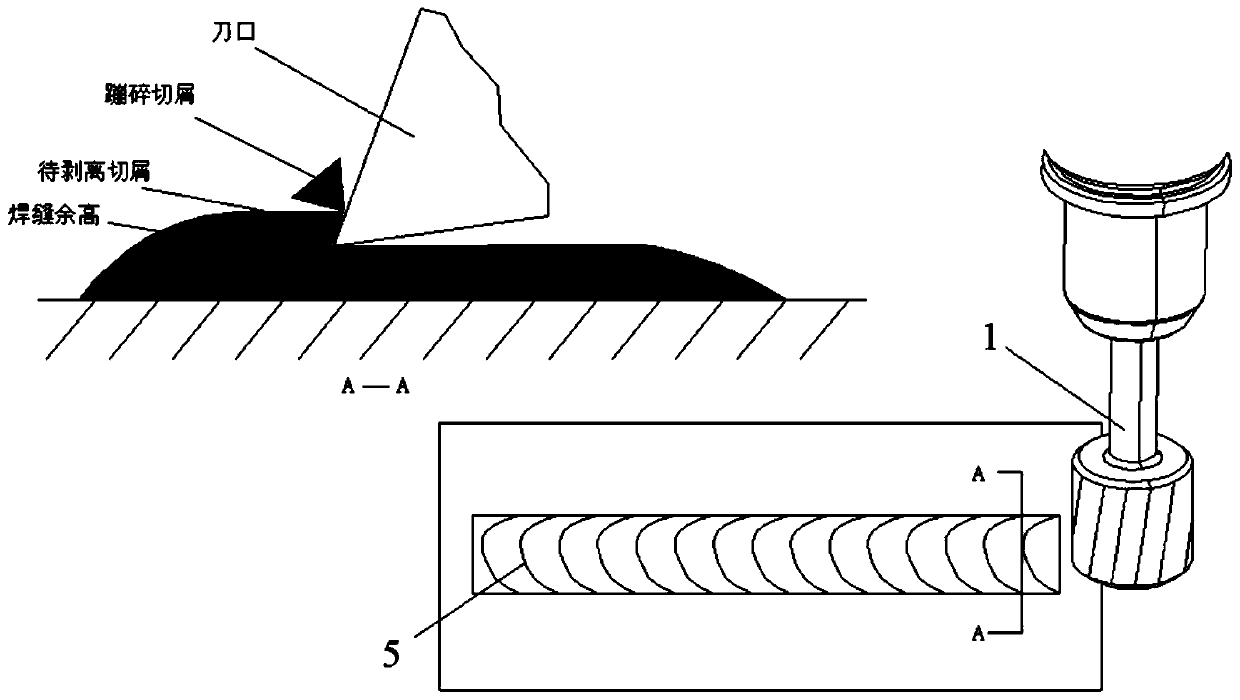

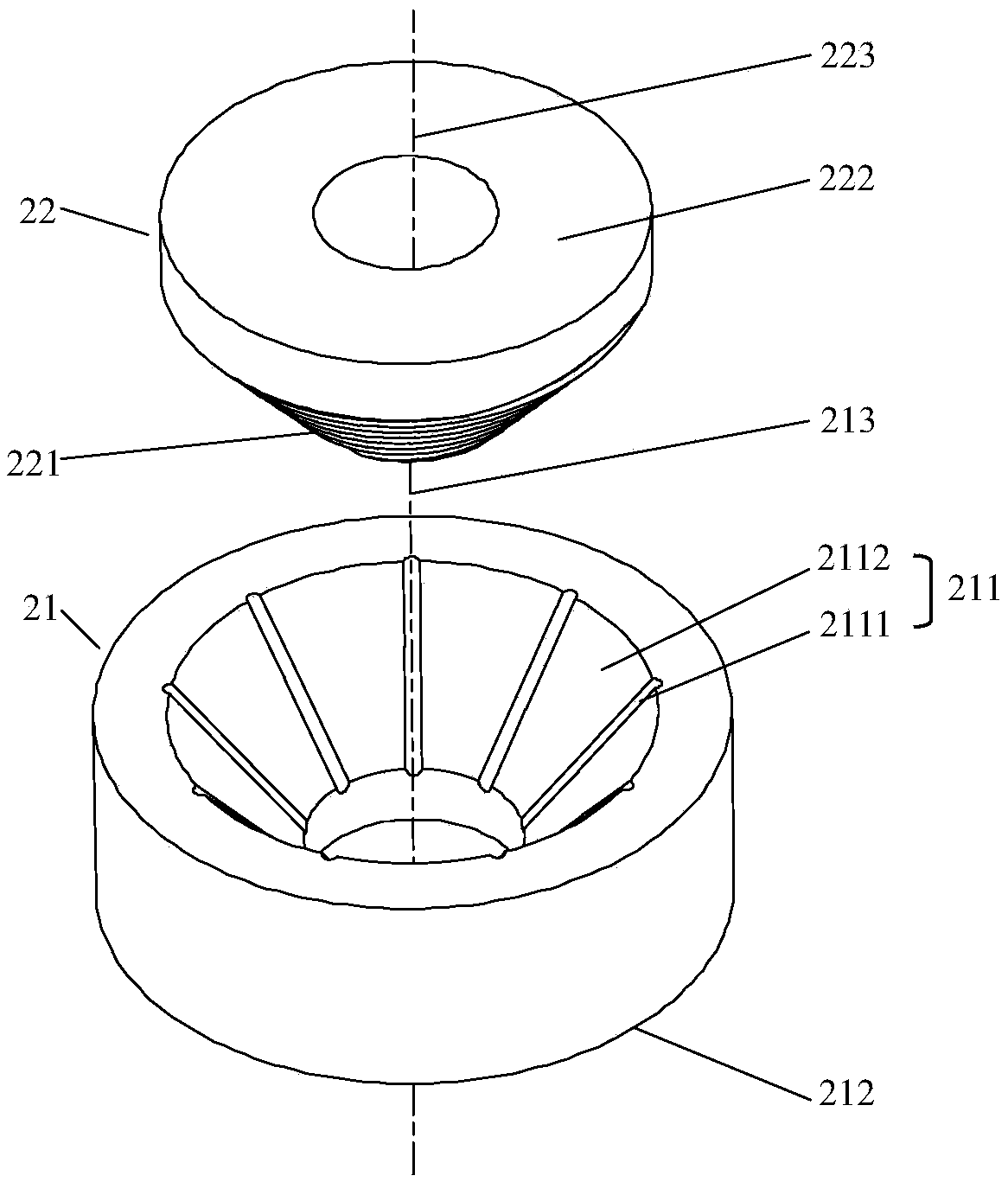

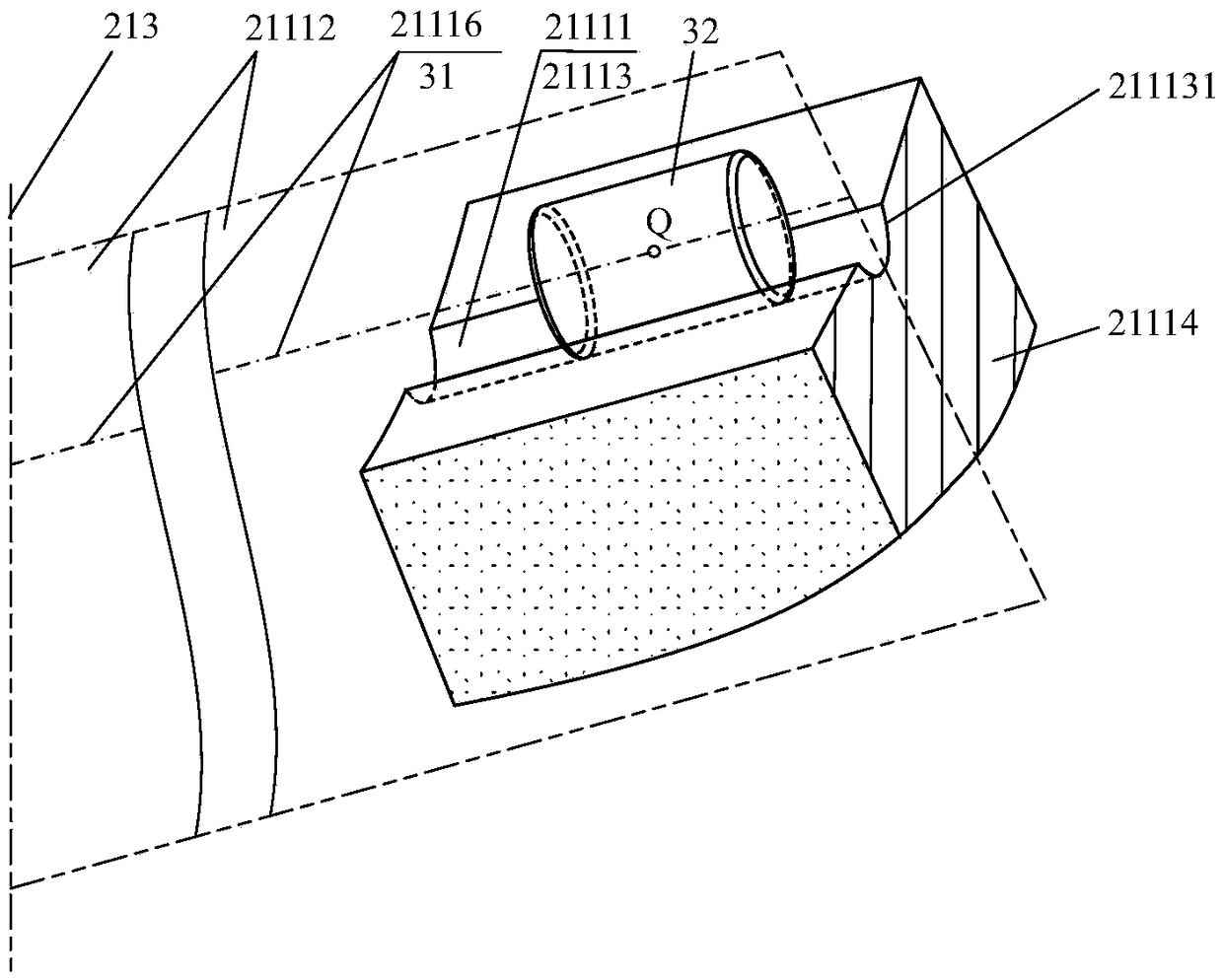

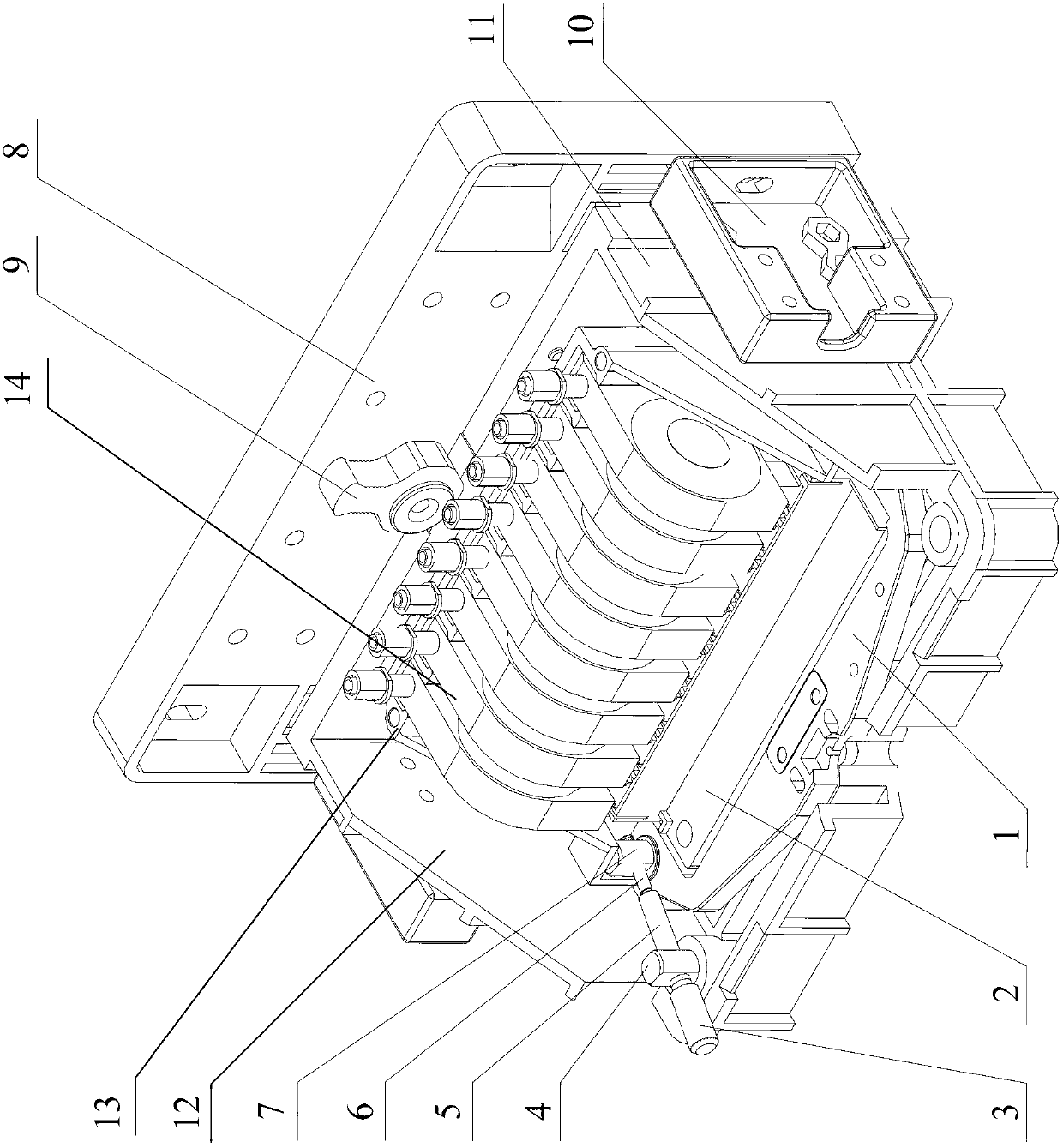

Self-adaption machining system and control method thereof and car body machining equipment

ActiveCN110560754AMeet assembly requirementsHigh accuracy consistencyMilling machinesMilling equipment detailsData controlControl engineering

The invention discloses a self-adaption machining system and a control method thereof and car body machining equipment. The self-adaption machining system is used for machining a workpiece and comprises an executing system, a motorized spindle, a milling tool head, a visual detecting device and a control device. The executing mechanism is in transmission connection with the motorized spindle and drives the motorized spindle to move. The motorized spindle drives the milling tool head to move. The executing mechanism and the motorized spindle are in communication connection with the control device, and the control device comprises a memorizer storing preliminary machining data and waste parameters of the workpiece. The control device carries out operation to obtain intermediate parameters, machining data is further obtained, the control device adjusts a first work parameter and a second work parameter according to post machining data and the waste parameters to control the motion of theexecuting mechanism and the motorized spindle correspondingly, and therefore it is guaranteed that the milling parameters of the milling tool head meet the requirement of the waste parameters. The self-adaption machining system and the control method thereof and the car body machining equipment have the advantages that the automation degree is high, production is safe and environment-friendly, theproduction and labor cost is greatly reduced, and the precision consistency is high.

Owner:奇瑞新能源汽车股份有限公司

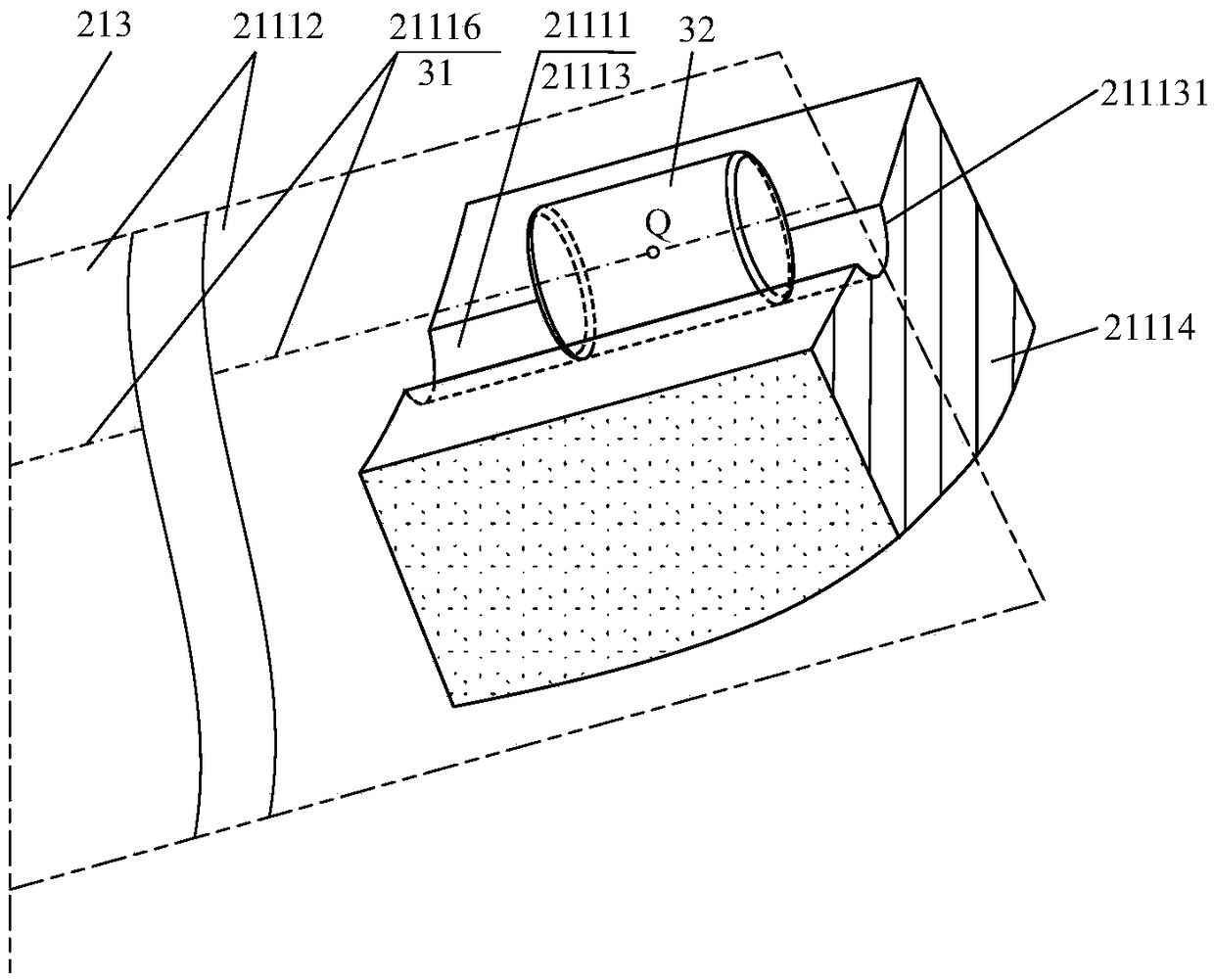

Grinding disc and equipment and method for accurate machining of rolling surface of cylindrical roller

PendingCN108908094ARemove comprehensivelyRemove lessLapping machinesLapping toolsEngineeringBase plane

The invention discloses grinding equipment for accurate machining of the rolling surface of a cylindrical roller and a grinding disc kit. The grinding equipment comprises a main machine, the grindingdisc kit and a roller circulation disc external system, wherein the main machine comprises a substrate, a vertical column, a transverse beam, a sliding table, an upper tray, a lower tray, an axial loading device and a main shaft device; the roller circulation disc external system comprises a roller collecting device, a roller conveying system, a roller arrangement mechanism and a roller feeding mechanism; the grinding disc kit comprises a first grinding disc and a second grinding disc which are coaxial, and the fronts of the first grinding disc and the second grinding disc are arranged oppositely; the front of the first grinding disc comprises a group of linear grooves which are radially distributed on the base plane (right circular conical surface) of the first grinding disc; the front ofthe first grinding disc comprises one or multiple spiral grooves which are distributed on the base plane (right circular conical surface) of the second grinding disc; and the sum of the flaring angles of the base planes of the first grinding disc and the second grinding disc are 360 degrees. The grinding equipment has the capability of accurately machining the rolling surfaces of large quantitiesof cylindrical rollers.

Owner:TIANJIN UNIV

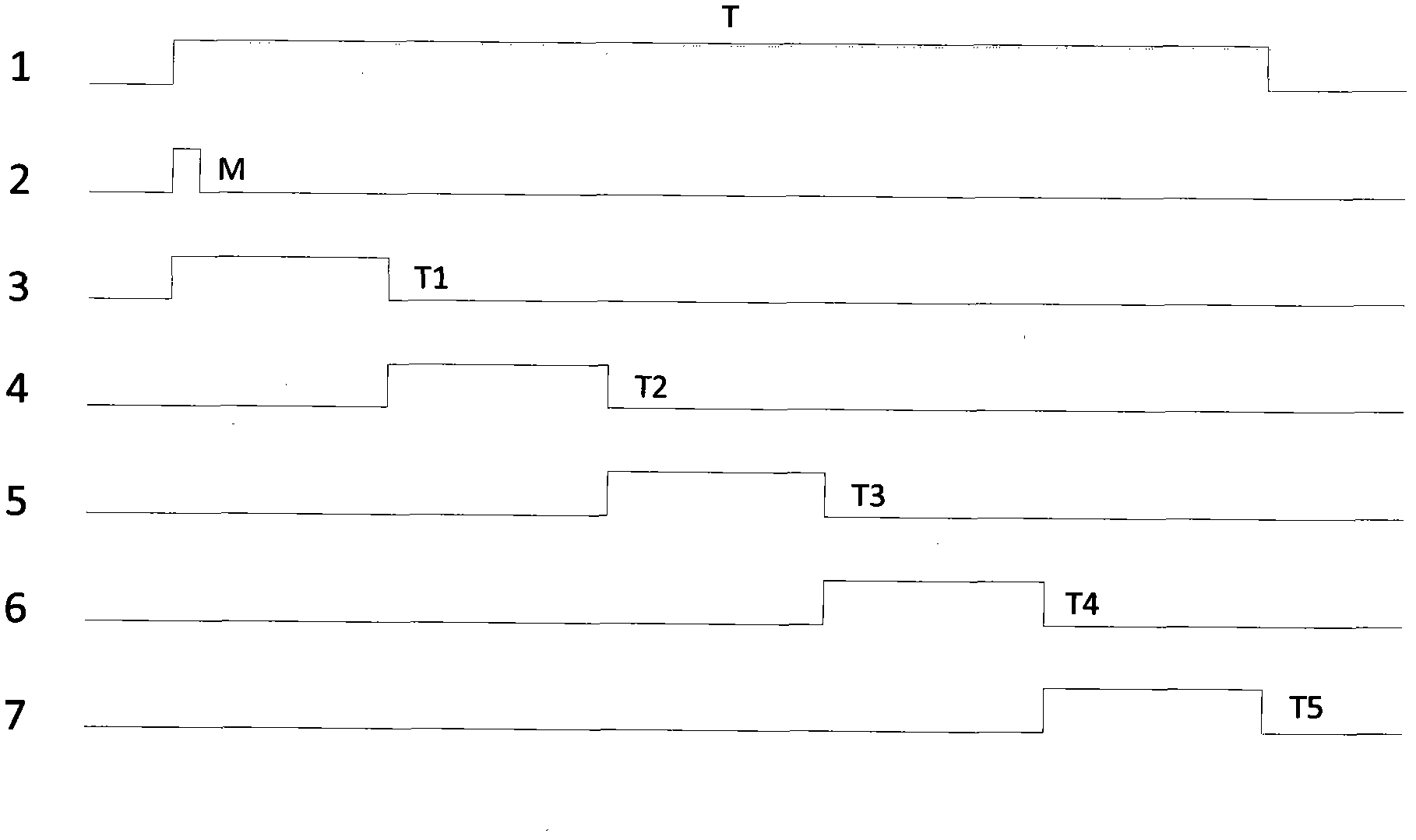

Electromagnetic multi-pen electronic whiteboard

InactiveCN102736818AReduce difficultyFM Difficult Problem SolvingInput/output processes for data processingWhiteboardTime-sharing

The invention is applicable to an electronic whiteboard of an electronic induction technology. Technically, a mode that a pen is provided with an operation frequency is abandoned; multi-pen same-frequency time-sharing operation is adopted; specific working time is distributed to each pen; electronic pens are only allowed to work in the own specific time; and a system can determine a certain working pen according to data obtained at different time, so that multi-pen multi-color operation is implemented.

Owner:BEIJING REALLY SUN

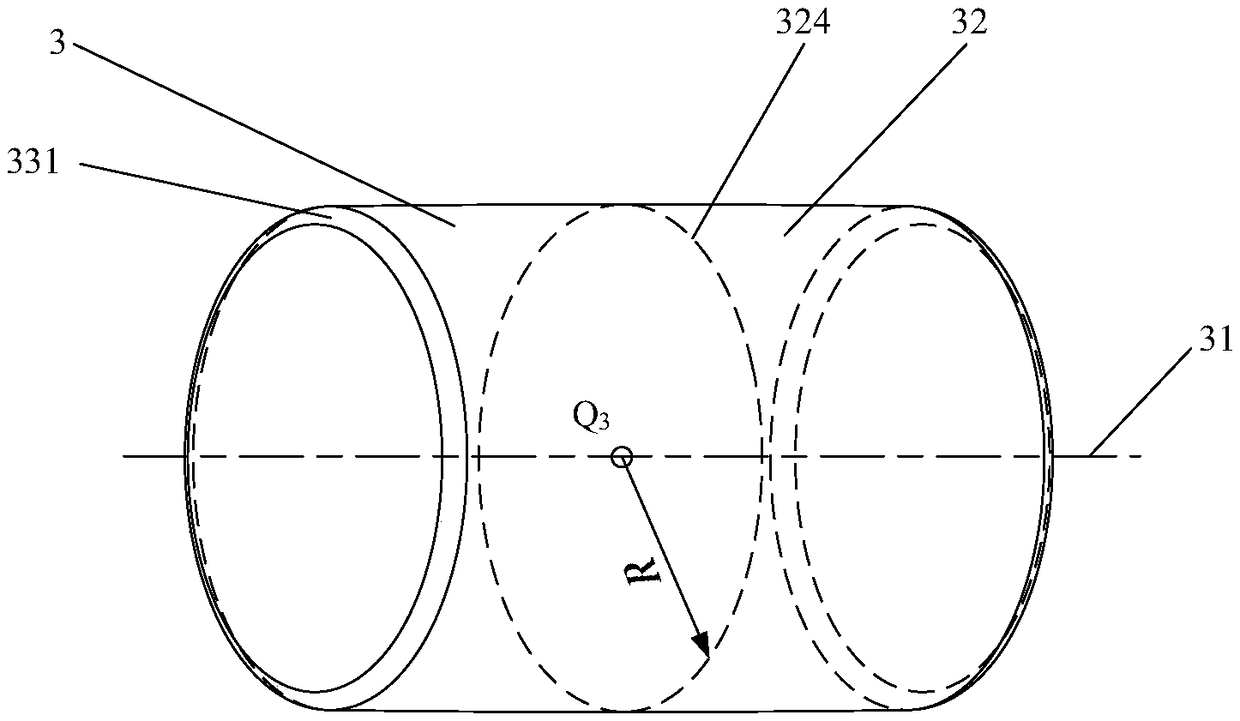

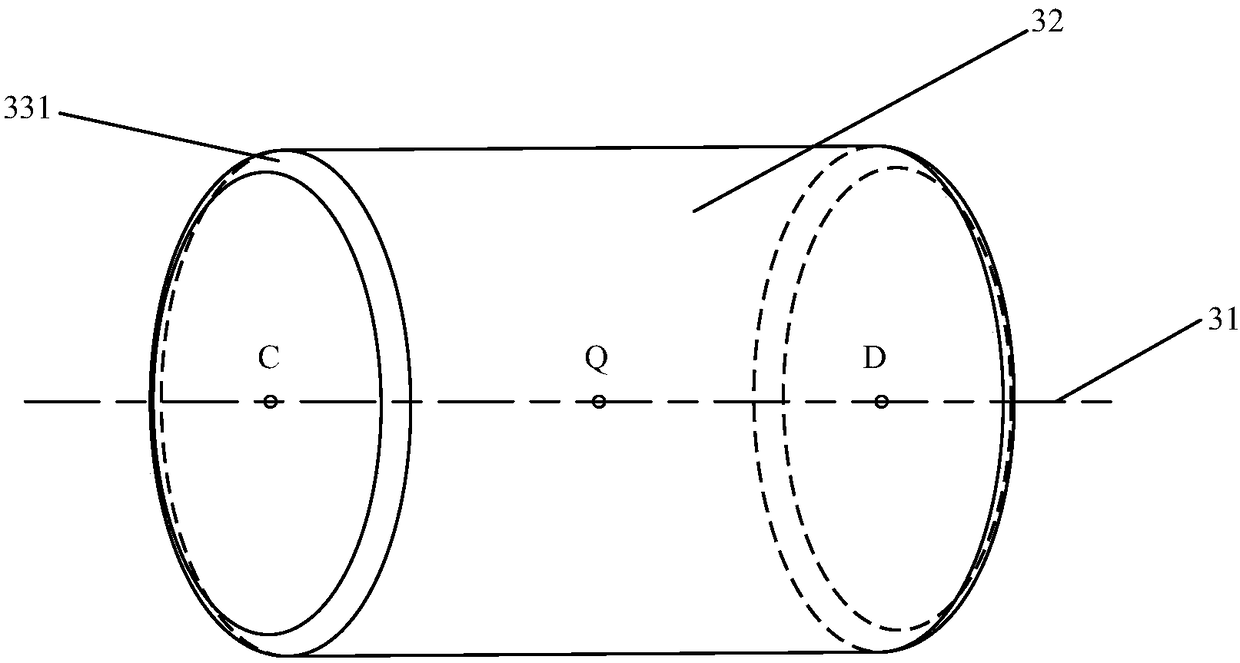

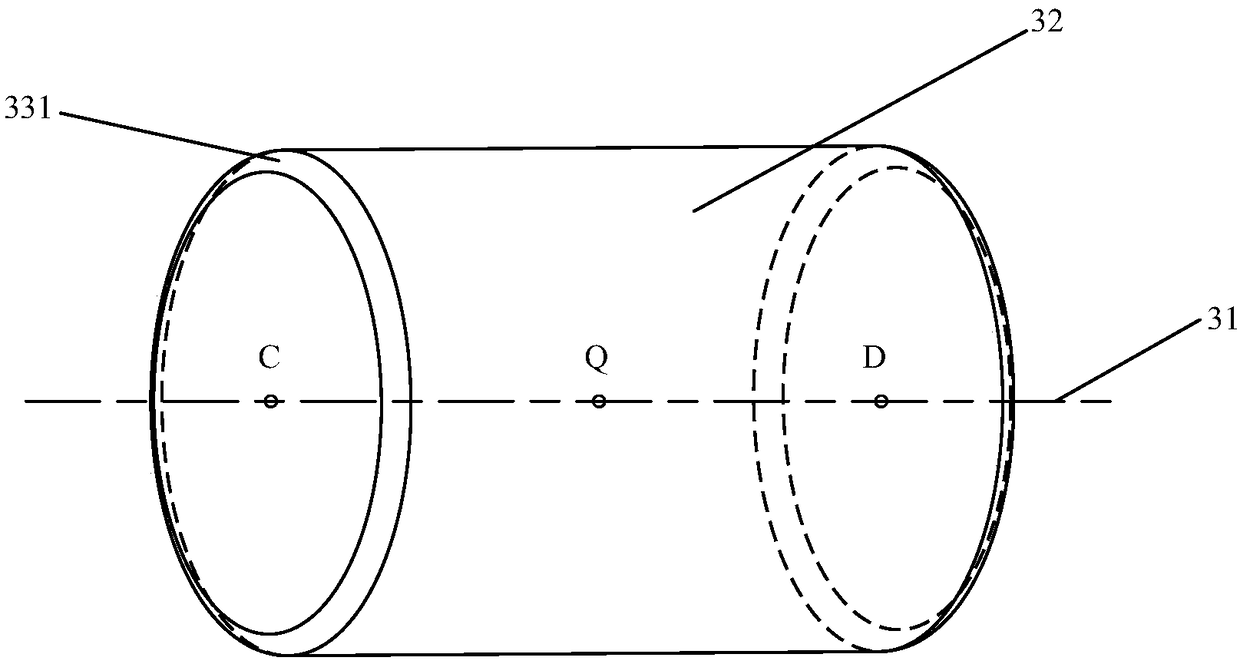

Round setting technique for pipe end of large-size pipe fitting

The invention relates to a round setting technique for a pipe end of a large-size pipe fitting. The round setting technique is characterized by comprising the following steps: firstly, preparing an end face of a pipe blank by swelling an inner swelling petal mould so as to cause the uniform peripheral stretching plastic deformation on the end face of the pipe blank, thereby increasing the perimeter of a geometrical neutral layer of the cross section of the pipe end; pressing the end face of the pipe blank by two semicircular petal moulds along the radial direction so as to cause the uniform compressing deformation on the end face of the pipe blank, thereby controlling the last ovality and cross-section perimeter size of the pipe end of the pipe blank; and controlling the molding precision of the pipe end within a tolerance allowed scope. The round setting technique has the advantages that the consistency of shape and size of the pipe end of the pipe blank is increased, the pipeline connection is conveniently performed and the production efficiency is increased at the same time.

Owner:YANSHAN UNIV

Numerical control bending machine transmission system and numerical control bending machine

ActiveCN108817143ARealize bending processingIncrease deflectionFluid gearingsStress distributionNumerical control

The invention discloses a numerical control bending machine transmission system and a numerical control bending machine. The numerical control bending machine transmission system comprises a sliding block body and a ball screw driving mechanism, wherein stress parts are uniformly distributed on the sliding block body, the plurality of ball screw driving mechanisms are arranged, and the ball screwdriving mechanism is used for applying downward acting force on the sliding block body through the stress pieces on the sliding block body. According to the numerical control bending machine transmission system and the numerical control bending machine, the sliding block body is provided with the plurality of stress pieces, the ball screw driving mechanism directly applies force to the stress pieces, the stress pieces applies force to the sliding block body, due to the fact that the stress pieces are uniformly distributed on the sliding block body, the stress distribution on the whole slidingblock body is more uniform, the sliding block body moves downwards so as to realize bending machining of parts, moreover, the bending force applied to the parts by the sliding block body is uniformlydistributed in the range of a whole working table, so that the relatively large deflection generated during bending machining especially bending machining of long-size medium-thickness plate parts isovercome, and the machining precision and the consistency of the precision can be improved.

Owner:王勇

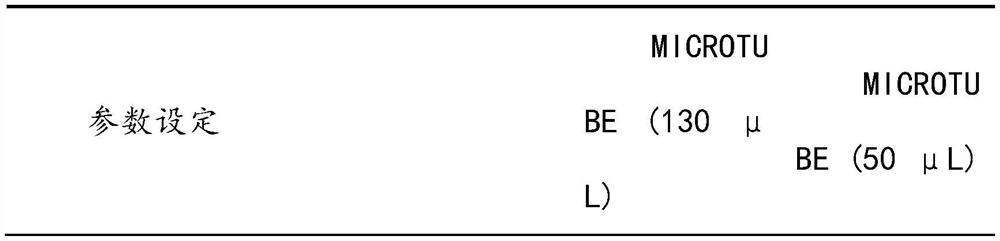

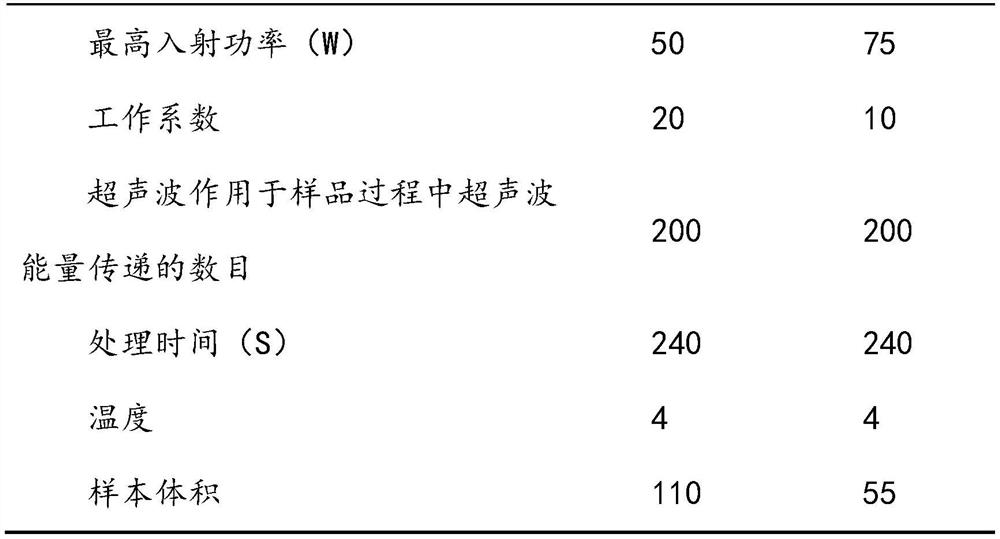

Tumor microsatellite instability detection kit based on second-generation sequencing probe capture technology

PendingCN111926075AAccurate interpretationMany detection pointsMicrobiological testing/measurementGeneticsEndometrial cancer

The invention provides a tumor microsatellite instability detection kit based on a second-generation sequencing probe capture technology. The detection kit adopts the second-generation sequencing probe capture technology, and reagents of the detection kit comprise a quality control product, a library building reagent and an RNA probe; the quality control products comprise a negative quality control product and a positive quality control product; the negative quality control product is a negative sample dissolved in TE, and the positive quality control product is a plasmid containing an MSI site dissolved in TE; an NGS technology is selected on the basis of an MSI experimental method; the kit has the advantages that detection sites are many, up to 40 microsatellite sites are covered after screening, the microsatellite coverage area is wide, the uniformity is good after RNA probe adjustment, good medication guidance can be provided for patients, and the kit is suitable for multiple tumors such as colorectal cancer, endometrial cancer and gastrointestinal tumor.

Owner:俊兮生物科技(上海)有限公司

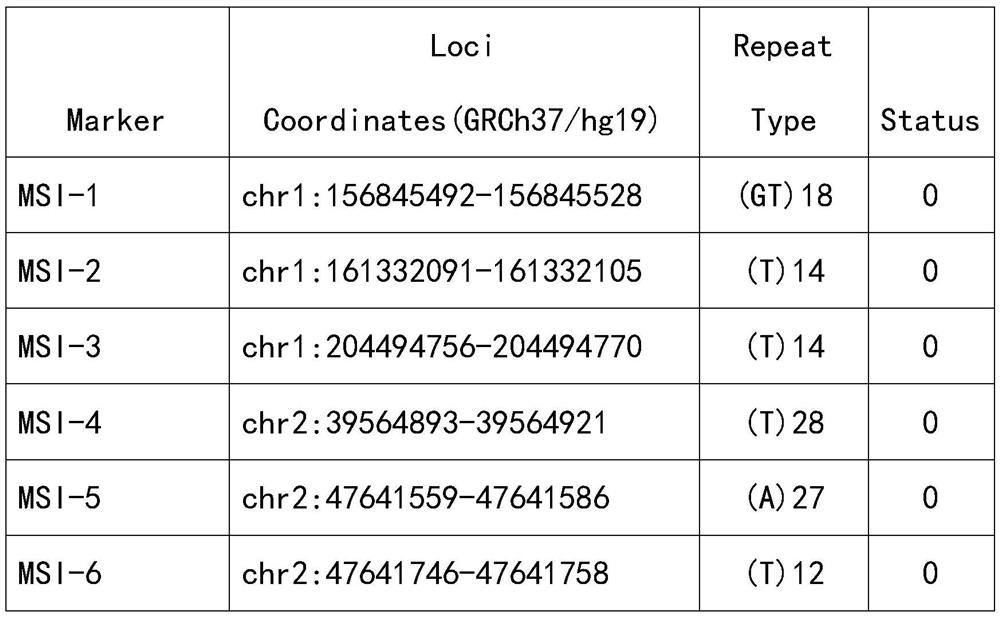

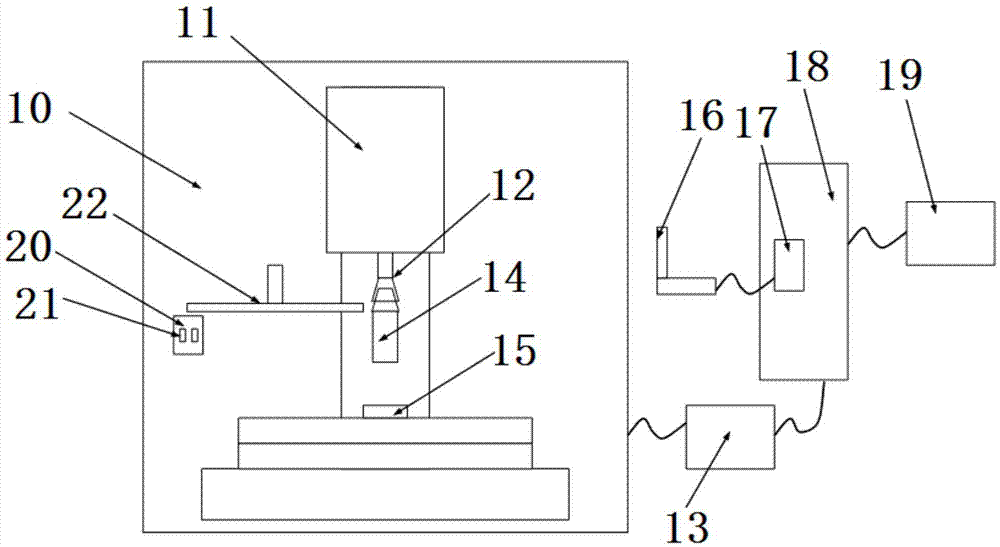

Image measuring head and image measuring system used for numerical control milling machine

InactiveCN105436996ASimple structural designLow costMeasurement/indication equipmentsMetal working apparatusNumerical controlEngineering

The invention discloses an image measuring head and an image measuring system used for a numerical control milling machine, and the image measuring head and the image measuring system are simple in structural design and are relatively low in cost. The image measuring head can be conveniently and quickly fixed to a main shaft like a tool used for the numerical control milling machine, so that on-position measuring is realized. Moreover, the tool and the measuring head are convenient and quick to replace. Meanwhile, the image measuring head and the image measuring system are high in measuring speed and are beneficial to improving the production efficiency. The measured data can be used as compensation basis of a next workpiece, so that precision consistency of different processed workpieces is improved. More importantly, the image measuring head and the image measuring system can be matched with each shaft of the numerical control milling machine to move, so that geometric quantity measuring for a plurality of processing surfaces of a complex processing part can be realized.

Owner:TZTEK TECH

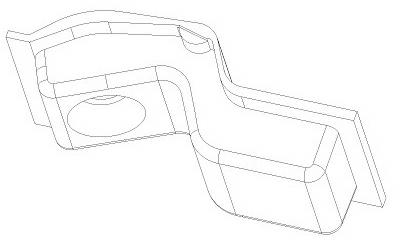

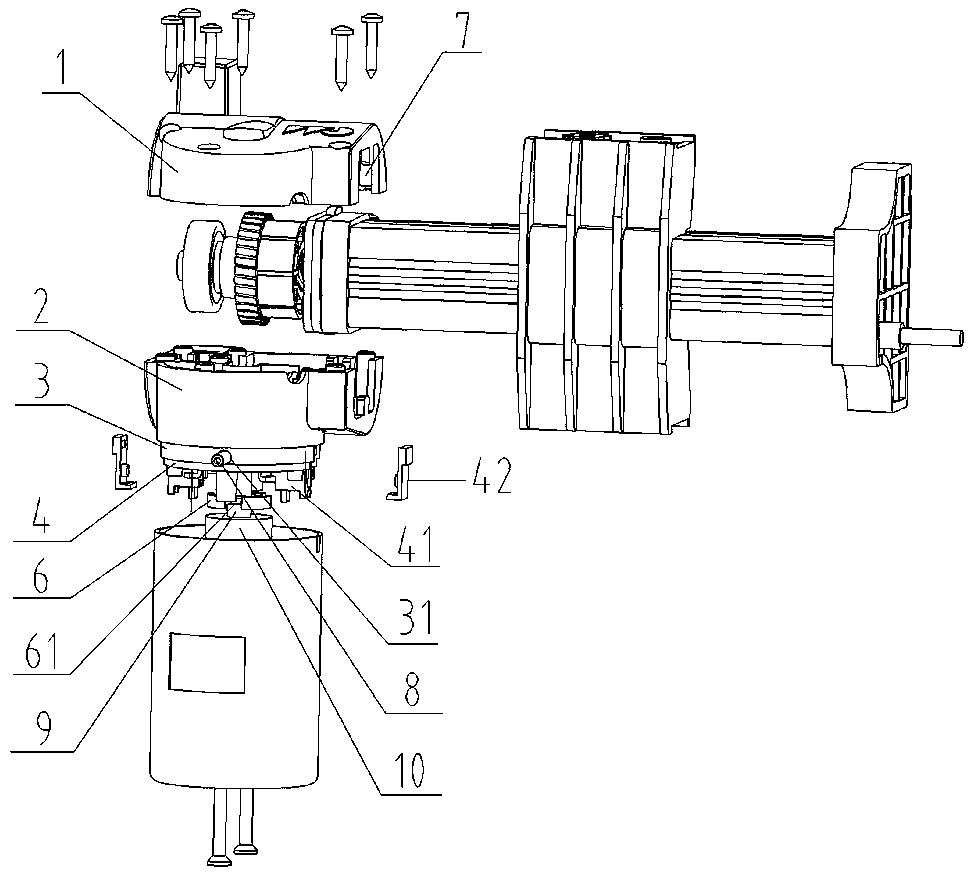

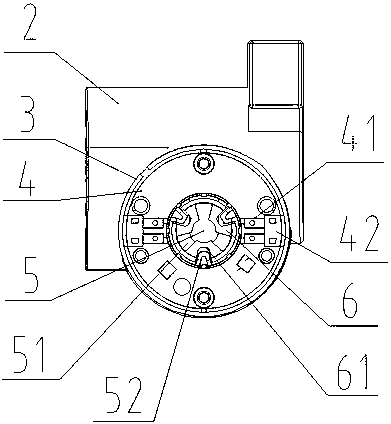

Spray head frame of printer

ActiveCN103101336AImprove assembly accuracyHigh accuracy consistencyPower drive mechanismsDie castingEngineering

The invention discloses a spray head frame of a printer. The spray head frame comprises a spray head sliding plate, a spray head frame body, a spray head frame height adjusting device, an ink bag pressing piece, a spray head adjusting plate and a spray head adjusting plate horizontal adjusting device, wherein the spray head frame body is arranged on the spray head sliding plate in a vertical sliding mode, the spray head frame height adjusting device is used for adjusting the height of the spray head frame body, the spray head adjusting plate is used for driving a spray head of the spray head frame of the printer to be parallel to the spray head sliding plate, the spray head adjusting plate is arranged on the spray head frame body in a horizontal sliding mode, the spray head adjusting plate horizontal adjusting device is used for adjusting the horizontal position of the spray head adjusting plate, the ink bag pressing piece is used for fixing an ink bag of the spray head frame of the printer, and the spray head sliding plate, the spray head frame body, the spray head frame height adjusting device, the ink bag pressing piece, the spray head adjusting plate and the spray head adjusting plate horizontal adjusting device are molded in an injection mode or a die-casting mode. The parts of the spray head frame of the printer are molded in the injection mode or the die-casting mode so that dimensional accuracy and dimensional consistency of the parts are improved, and therefore assembly accuracy of the parts is improved.

Owner:WENZHOU ACPASS DISPLAY EQUIP

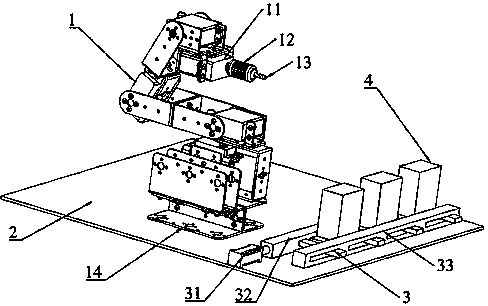

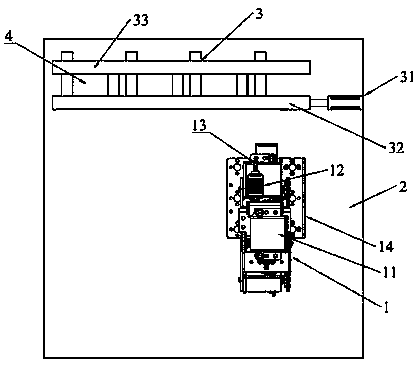

A plastic window hole milling process based on a hole milling manipulator, and equipment

ActiveCN104162703AProcessing automationReduce human involvementMilling equipment detailsManipulatorMachining process

A plastic window hole milling process based on a hole milling manipulator and equipment are disclosed. The equipment comprises the manipulator, a servo motor, an electric spindle, a milling cutter, a support, a pedestal, section bar clamps, an air cylinder, a sliding clamping plate and a fixed clamping plate. The manipulator is driven by the servo motor. The tail end of the manipulator is provided with the electric spindle. The electric spindle drives the milling cutter to rotate. The sliding clamping plate and the fixed clamping plate are installed on the pedestal. Sides of the sliding clamping plate and the fixed sliding plate are provided with transversal bar mechanisms. The fixed clamping plate is provided with a square groove along the length direction. The transversal bar mechanisms at a side of the sliding clamping plate pass through the square groove of the fixed clamping plate. The air cylinder is disposed at the top of the sliding clamping plate. A piston rod of the air cylinder is connected to the top end of the sliding clamping plate by welding. Section bars are disposed among the transversal bar mechanisms of the sliding clamping plate and the fixed sliding plate. According to the process and the equipment, the automatic manipulator is utilized to drive the milling cutter to achieve the hole machining step of the section bars, thus achieving automatic machining, reducing the degree of participation of manual work, and improving the machining precision and machining consistency.

Owner:UNIV OF JINAN

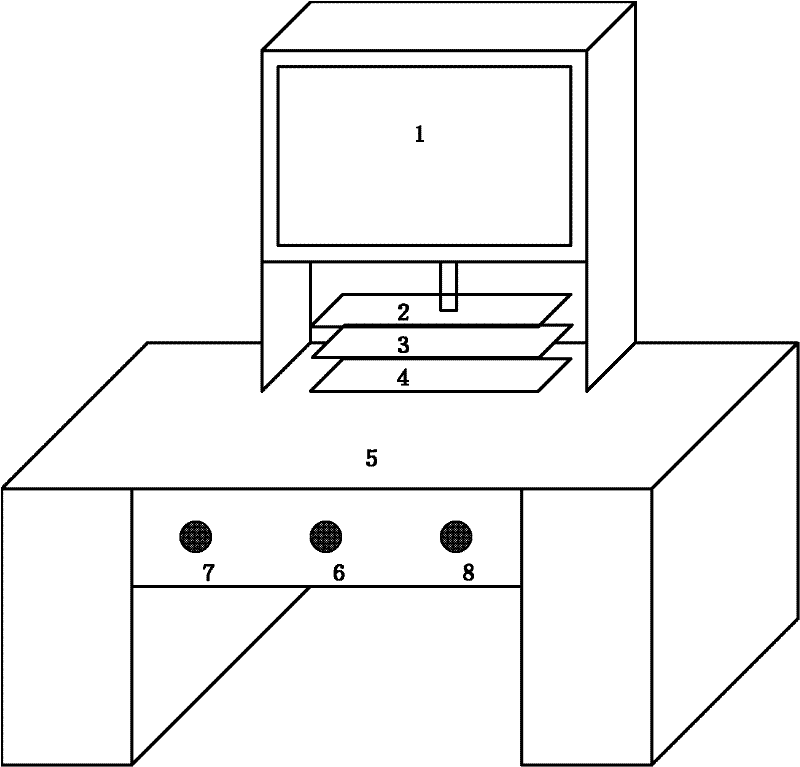

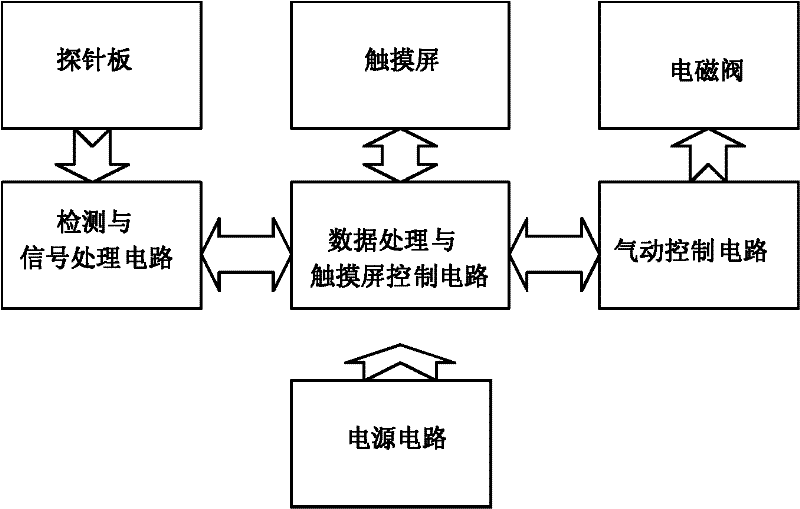

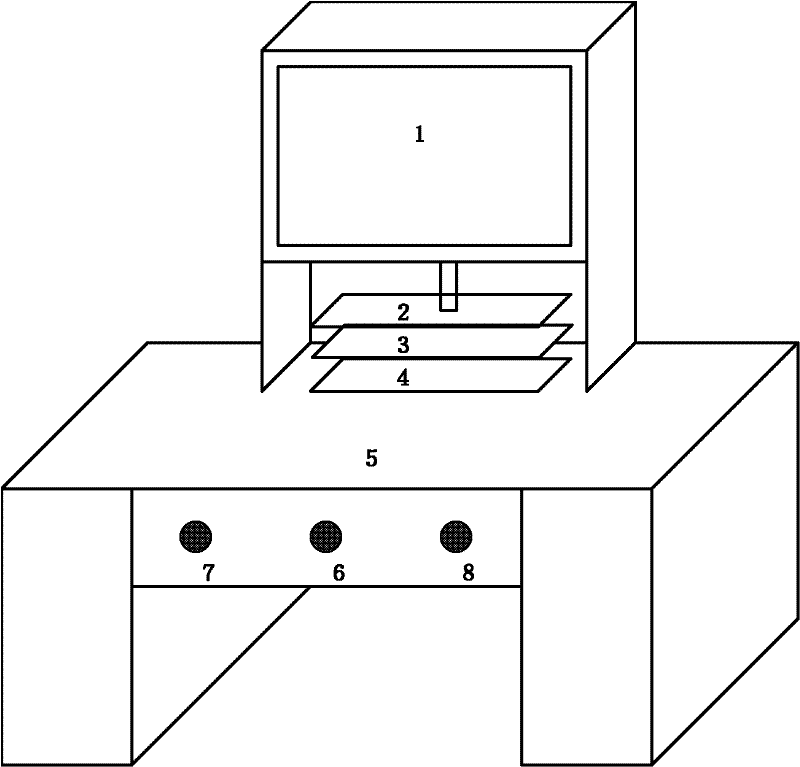

Visual precision detection device for potentiometer carbon diaphragm array plate

InactiveCN102253294ARealize visual operationImprove efficiencyElectrical testingMicrocomputerSignal processing circuits

The invention relates to a visual precision detection device for a potentiometer carbon diaphragm array plate, comprising an operating floor, wherein the surface of the operating floor is sequentially provided with a probe plate, a detected carbon diaphragm plate and a pneumatic laminated plate from bottom to top; the pneumatic laminated plate is connected with a pneumatic control circuit; the pneumatic control circuit is connected with a touch screen by a data processing and touch screen controlling circuit; the touch screen is used for visualized operation; the pneumatic laminated plate moves vertically to cause the detected carbon diaphragm and the probe plate to reliably contact; and the probe plate detects the data processing and touch screen controlling circuit connected with a signal processing circuit for detection. The visualized operation can be carried out by the touch screen, pneumatic control is adopted for mechanics, and microcomputer controlling and data processing are adopted for electrics. The visual precision detection device can be used for replacing two to three labor forces.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

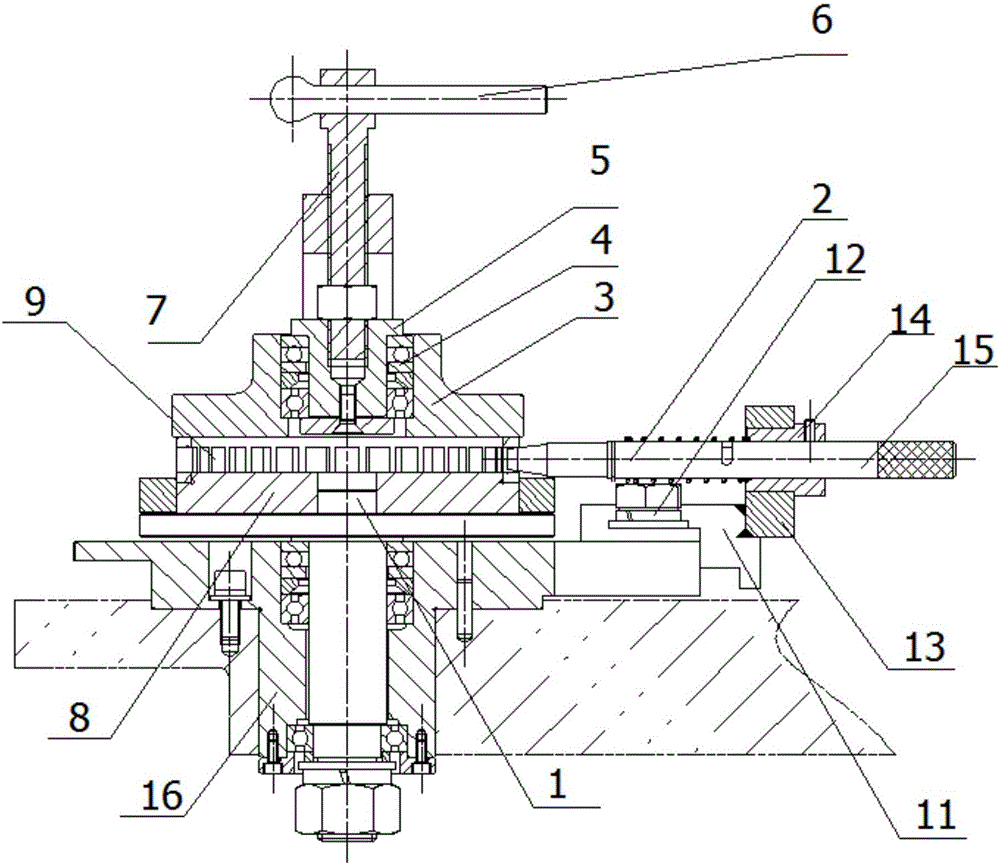

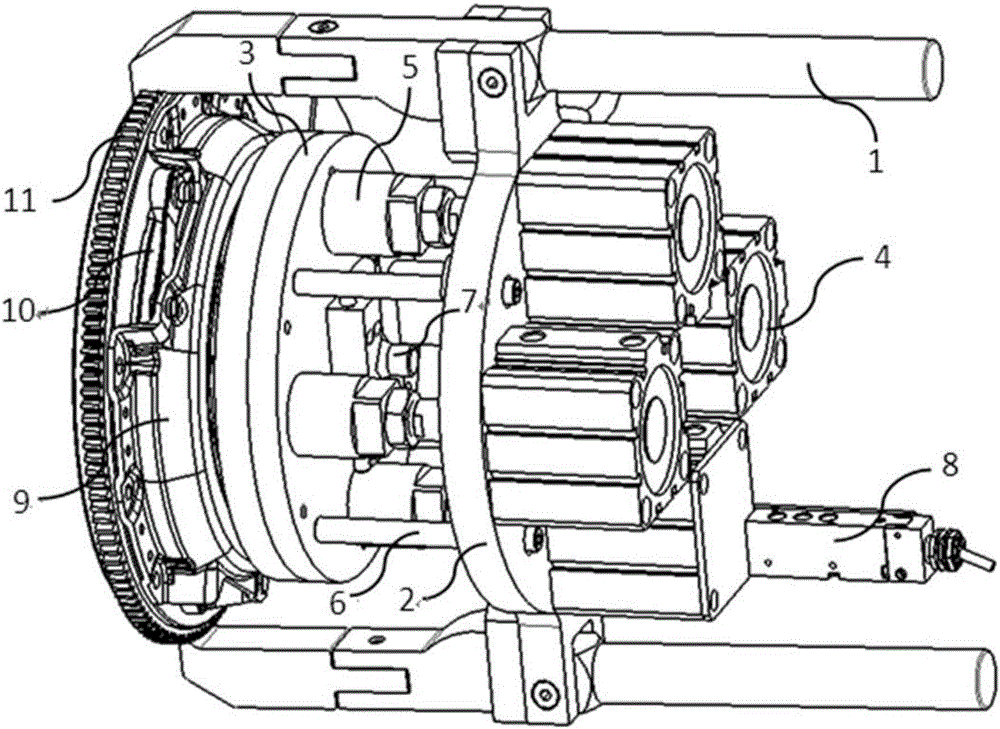

Clutch assembling tool

ActiveCN106312521AShorten the installation cycleHigh accuracy consistencyMetal working apparatusClutchCycle time

The invention relates to a clutch assembling tool which comprises a clamping jaw, a fixed disc, a working disc, a cylinder, a cylinder push rod assembly, a limiting polished rod and a regulating valve. The fixed disc is rotatably connected with the clamping jaw, the cylinder is fixed to the fixed disc, one end of the cylinder push rod assembly movably penetrates the fixed disc and then is connected with the cylinder, and the other end of the cylinder push rod assembly is fixedly connected with the working disc. The regulating valve is arranged on the cylinder. The periphery of the fixed disc is provided with a limiting polished rod through hole, one end of the limiting polished rod is fixedly connected with the working disc, and the other end of the limiting polished rod penetrates the limiting polished rod through hole. According to the technical scheme, the clutch assembling tool is high in adaptability and can be suitable for most of clutch assembly, clutch installation cycle time is shortened, clutch assembly precision and assembly consistency are greatly improved, and the problem of shaking caused by poor clutch assembly accuracy is effectively solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

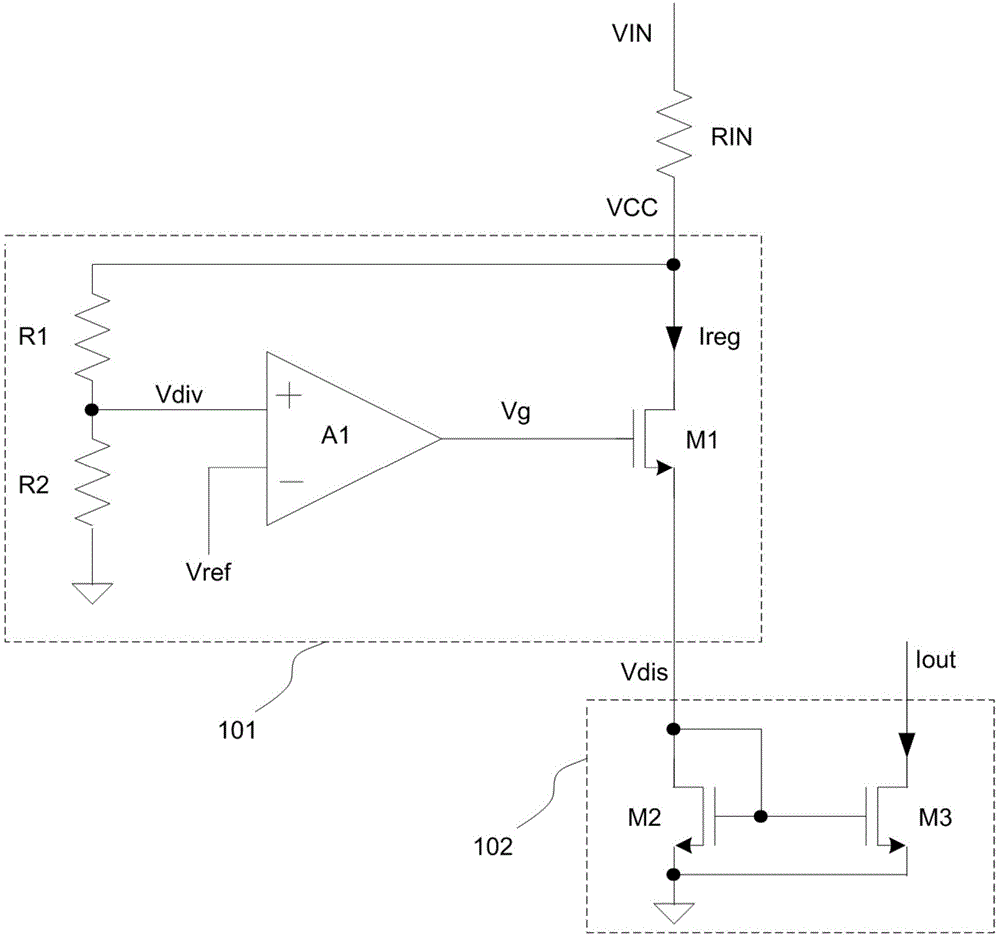

Line voltage detection circuit for switching power supply

ActiveCN104569548ASuit one's needsHigh accuracy consistencyCurrent/voltage measurementElectrical resistance and conductanceVoltage regulator module

A line voltage detection circuit for a switching power supply comprises a line voltage input end used for inputting a line voltage, an input resistor, a voltage regulator module and a current sampling module, wherein the input resistor, the voltage regulator module and the current sampling module are connected in sequence; one end of the input resistor is connected with the line voltage input end, and the other end of the input resistor is connected with the voltage regulator module; the voltage regulator module comprises a first output end used for outputting a regulating voltage, a second output end used for outputting a regulating current, and an input end used for outputting a reference voltage, and the voltage regulator module controls the regulating voltage and outputs the regulating current to the current sampling module; an input end of the current sampling module is connected with the second output end of the voltage regulator module and used for receiving the regulating voltage, and an output end of the voltage regulator module is used for outputting a detection current proportional to the regulating current. By means of the line voltage detection circuit for the switching power supply, the ratio of a detection output value and a line voltage input value can be set according to a resistance value inputted to the resistor.

Owner:SHANGHAI BEILING

Driver box body structure

PendingCN108616186AHigh matching precisionHigh accuracy consistencySupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses a driver box body structure. The driver box body structure comprises a driver upper box body, a driver lower box body, a motor front end cover and a motor brush rack plate, wherein the motor front end cover is arranged on the driver lower box body, the motor brush rack is arranged on the motor front end cover, a screw hole is formed in a side surface, a brush handle is arranged on the motor brush rack plate, a through hole is formed in the center, openings are formed in a front end and a rear end of the brush handle and communicate with each other, a limitation step isarranged in the through hole, a boss is arranged on the limitation step, and the driver lower box body, the motor front end cover, the motor brush rack plate and the brush handle are integratedly formed. By the driver box body structure, the matching accuracy of the driver box body and the product consistency are improved, the assembly process is reduced, and the cost is reduced; the openings areformed in the two ends of the brush handle, a rotor is pressed during assembly, a carbon brush is arranged, and the carbon brush is prevented from being damaged; a rotor bearing is reinforced by the formed screw hold matched with a screw, and the bearing is prevented from axially moving; and the automatic locking function of a driver is improved by a damping piece, and the problems that a large-range driver having the automatic locking function is high in cost and is easy to damage are solved.

Owner:DEWERTOKIN TECHNOLOGY GROUP CO LTD

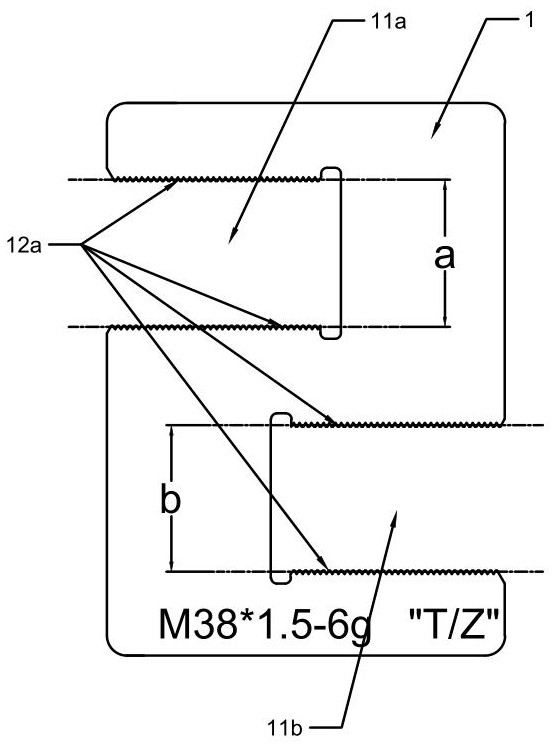

External thread rapid detection tool, manufacturing method and using method thereof

PendingCN113028933AImprove machining accuracySolve the tediousness of detection operationsPlug gaugesMechanical measuring arrangementsRigid blockMachining

The invention discloses an external thread rapid detection tool, a manufacturing method and a using method thereof, wherein the rapid detection tool is manufactured by forming a straight edge notch in a rigid block body and further machining and forming a linear tooth groove matched and meshed with external threads. According to the detection tool, the situation that the axial length of the whole external threads needs to be traversed in a threaded connection mode in the traditional external thread detection process is changed, and the detection of the specification precision of the external thread can be rapidly completed only by intermittently adjusting the axial angle of a detected object and horizontally sliding the detected object and the detection tool. By applying the scheme of the quick detection tool, the problem that the detection operation is tedious due to the fact that the axial lengths of a round hole and an external thread of a traditional go-no go gauge are greatly different is solved, the machining difficulty is reduced, and the precision consistency of detection tools of the same specification can be improved; and in the actual use of the testing fixture, the abrasion rate of multiple meshing sliding can be greatly reduced, and the detection efficiency can be multiplied.

Owner:苏州鑫凯达精密机械有限公司

Magnetic abrasive disk for finishing rolling surface of cylindrical roller, apparatus and method

The invention discloses an abrasive device and a magnetic abrasive disk kit for finishing a rolling surface of a cylindrical roller made of ferromagnetic material. The grinding equipment includes a main machine, a magnetic grinding disc set and a roller circulating disc external system. The main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axialloading device and a spindle device, wherein the main engine comprises a base, a column, a cross beam, a sliding table, an upper tray, a lower tray, an axial loading device and a spindle device. Theouter system of the roller circulating disk comprises a roller collecting device, a roller demagnetizing device, a roller conveying system, a roller finishing mechanism and a roller feeding mechanism.The magnetic abrasive disk kit includes a pair of first and second abrasive disks coaxially and oppositely disposed facing each other. The front surface of the first abrasive disk includes a set of linear grooves radially distributed on the base surface (right conical surface) of the first abrasive disk, the front surface of the second abrasive disk is the working surface (right conical surface)of the second abrasive disk, and an annular magnetic structure is embedded in the base body of the second abrasive disk. A lapping device of that invention has the finis machining capability of a large numb of cylindrical roller rolling surfaces made of ferromagnetic material.

Owner:TIANJIN UNIV

Magnetic grinding disc, device and method for crowned tapered roller rolling surface finish machining

PendingCN108723981AReduce removalIncrease contact stressLapping machinesLapping toolsSurface finishEngineering

The invention discloses a grinding device and magnetic grinding disc suite for ferromagnetic material crowned tapered roller rolling surface finish machining. The grinding device includes a main machine, the magnetic grinding disc suite and a roller recirculating disc external system. The main machine includes a base, upright columns, a beam, a sliding platform, an upper tray, a lower tray, an axial loading device and a main shaft device. The roller recirculating disc external system includes a roller collection device, a demagnetization device, a conveying device, a tidying mechanism and a feed-in mechanism. The magnetic grinding disc suite includes a pair of grinding discs including a first grinding disc and a second grinding disc, wherein the first grinding disc and the second grindingdisc are coaxially arranged, and the front faces of the first and second grinding discs are opposite. The front face of the first grinding disc includes a group of concave arc grooves which are radially formed in the base face (concave arc rotation face) of the first grinding disc; the front face of the second grinding disc includes one or more spiral grooves formed in the base face (convex arc rotation face) of the second grinding disc, and an annular magnetic structure is embedded in the base body of the second grinding disc. The grinding device for ferromagnetic material crowned tapered roller rolling surface finish machining has the capability of conducting finish machining on crowned tapered roller rolling surfaces of large-batch ferromagnetic materials.

Owner:TIANJIN UNIV

Magnetic grinding disks, device and method for finish machining of rolling surfaces of convex cylindrical rollers

ActiveCN108705444AAchieve removalRemove comprehensivelyLapping machinesLapping toolsDemagnetizing deviceEngineering

The invention discloses a grinding device and a magnetic grinding disk kit for finish machining of the rolling surfaces of ferromagnetic-material convexity cylindrical rollers. The grinding device comprises a main machine, the magnetic grinding disk kit and a roller circulating disk external system. The main machine comprises a base, stand columns, a cross beam, a sliding table, an upper tray, a lower tray, axial loading devices and a main shaft device. The roller circulating disk external system comprises a roller collecting device, a demagnetizing device, a conveying system, a sorting mechanism and a feed-in mechanism. The magnetic grinding disk kit comprises a pair of coaxial first and second grinding disks, and the front sides of the first grinding disk and the second grinding disk areoppositely arranged. The front side of the first grinding disk comprises a group of inside-sunken arc line grooves radially distributed on a first grinding disk base face (inside-sunken arc rotatingface); and the front side of the second grinding disk comprises one or more spiral grooves distributed on a second grinding disk base face (outside-protruding arc rotating face), and an annular magnetic structure is embedded in a base body of the second grinding disk. The grinding device has the capacity for finish machining of the rolling surfaces of the ferromagnetic-material convexity cylindrical rollers on a large scale.

Owner:TIANJIN UNIV

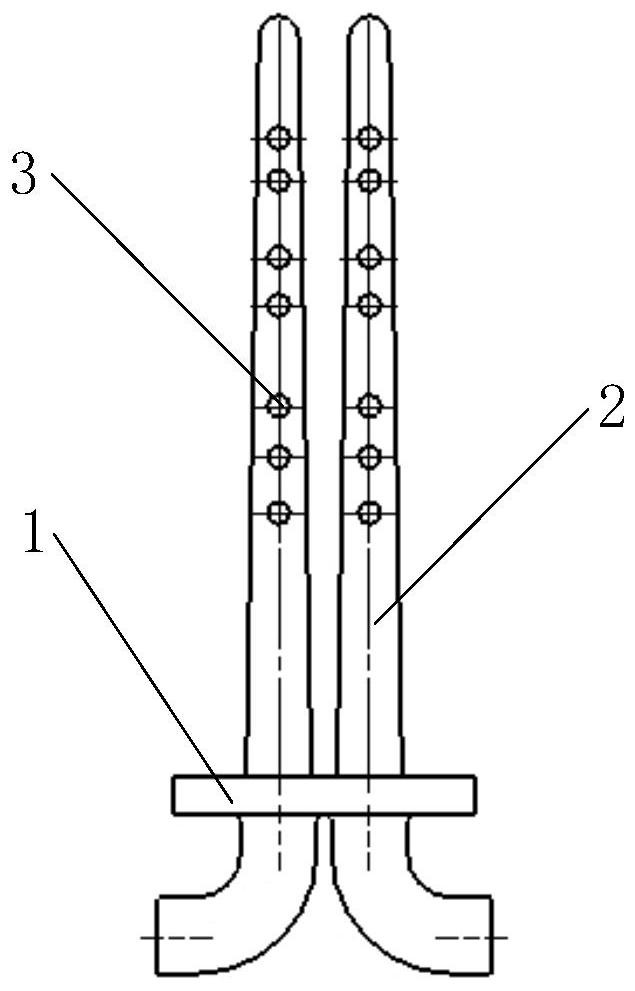

Process for forming equal-wall-thickness reducing fuel spray rod through selective laser melting

ActiveCN112045187AImprove manufacturing precisionImprove complianceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHeat shield

The invention discloses a process for forming an equal-wall-thickness reducing fuel spray rod through selective laser melting, and belongs to the technical field of additive manufacturing. The processfor forming the equal-wall-thickness reducing fuel spray rod through selective laser melting comprises the following steps of: S1, establishing a three-dimensional model of an equal-wall-thickness reducing fuel spray rod; S2, determining the forming direction of the equal-wall-thickness reducing fuel spray rod; S3, adding supports; S4, setting selective laser melting forming process parameters; S5, forming the equal-wall-thickness reducing fuel spray rod through selective laser melting; and S6, carrying out post-processing. According to the process for forming the equal-wall-thickness reducing fuel spray rod through selective laser melting, the number of processing procedures of the equal-wall-thickness reducing fuel spray rod is greatly reduced, the turnover time is greatly shortened, tools and clamps are not needed, the manufacturing period is shortened, the manufacturing cost is reduced, and the technical problems of large welding deformation of the fuel spray rod, a long repair period of a heat shield, large assembly residual stress, repeated correction and the like are solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com