Patents

Literature

398results about How to "Shorten the installation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

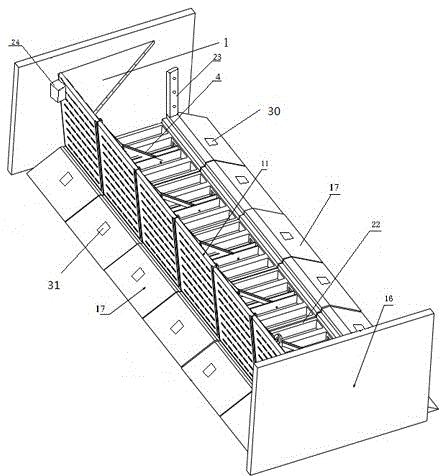

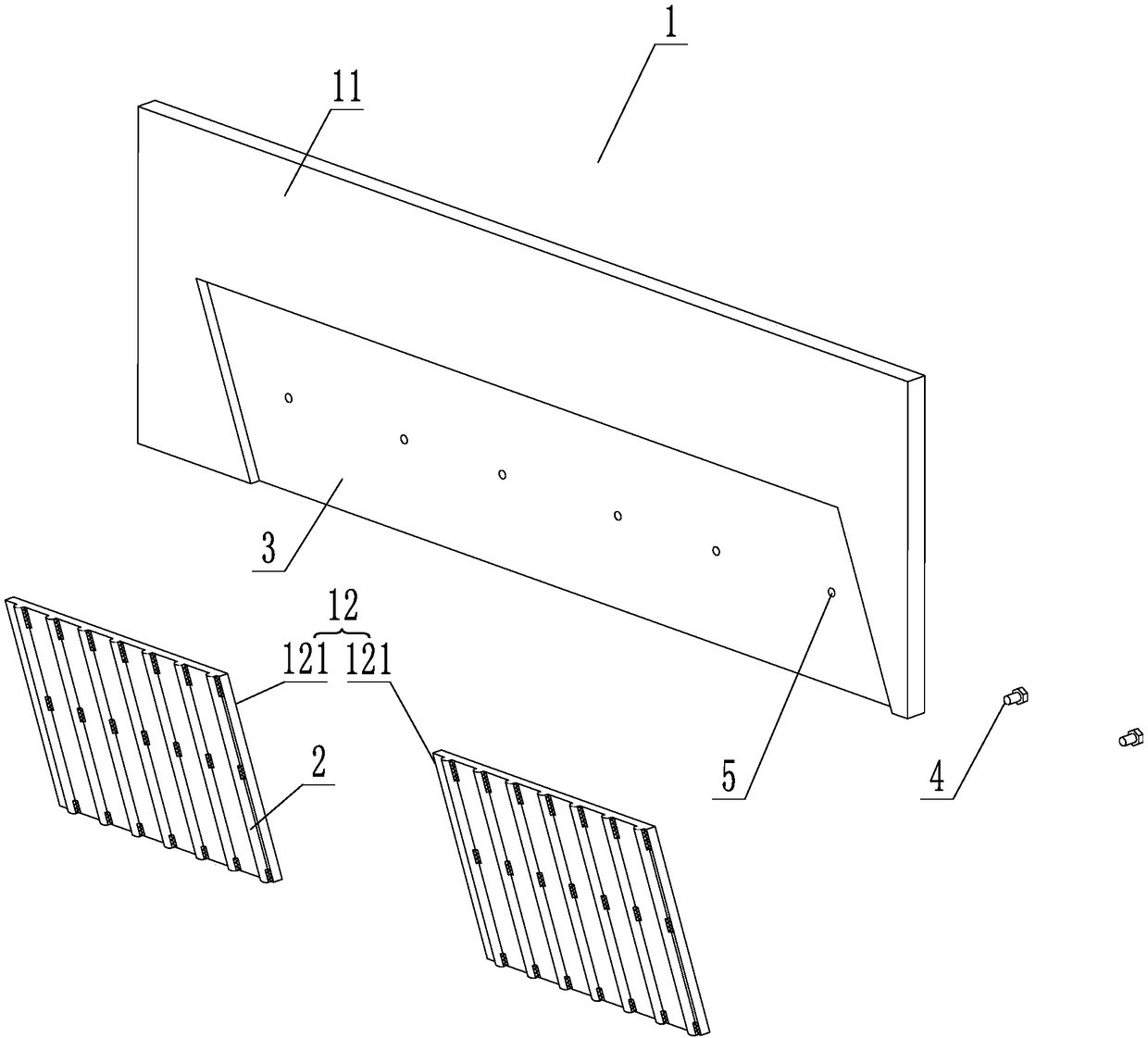

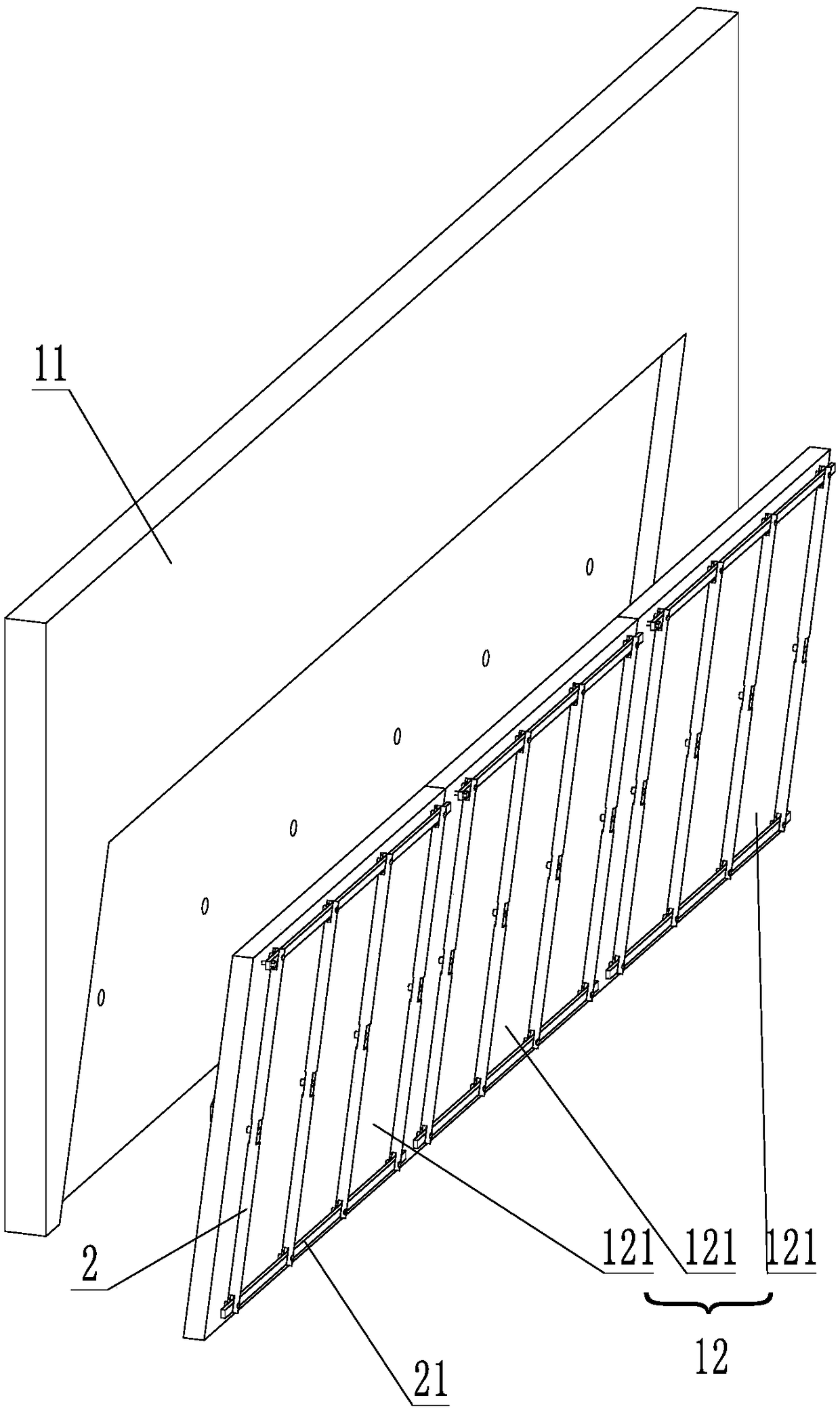

Modular automatic water stop device

The invention discloses a modular automatic water stop device. The modular automatic water stop device comprises two or more automatic water stop units which are arranged in parallel in a line. Each automatic water stop unit comprises a panel and a base detachably installed on the ground, wherein a water storage cavity penetrating through the base vertically is formed in the base, one end of the panel is arranged on the base in a rotating mode, the water storage cavity is opened or closed when the panel rotates, a floating plate is arranged on the face, used for covering the base, of the panel, and a water inlet communicated with the water storage cavity is formed in the end, not connected with the panel, of the base. Every two adjacent bases are detachably connected. The modular automatic water stop device has the advantages that the automatic water stop device is simple in structure, convenient to machine and suitable for most water stop sites, the transport difficulty of the automatic water stop device is lowered, the use range of the automatic water stop device is widened, the installation construction cost and the machining cost of the automatic water stop device are reduced, the installation cycle is shortened, and the purpose of water stop for fixed buildings is rapidly and efficiently achieved.

Owner:NANJING JUNLI TECH

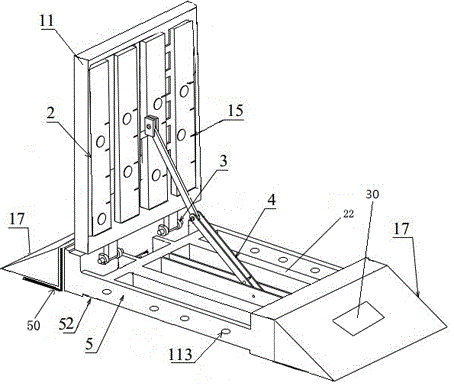

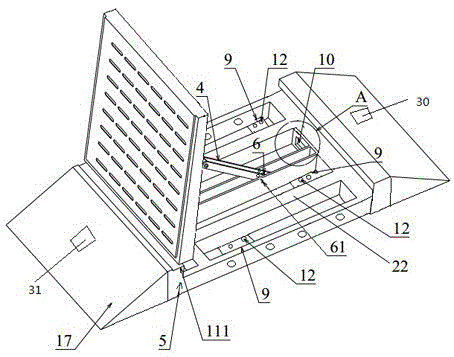

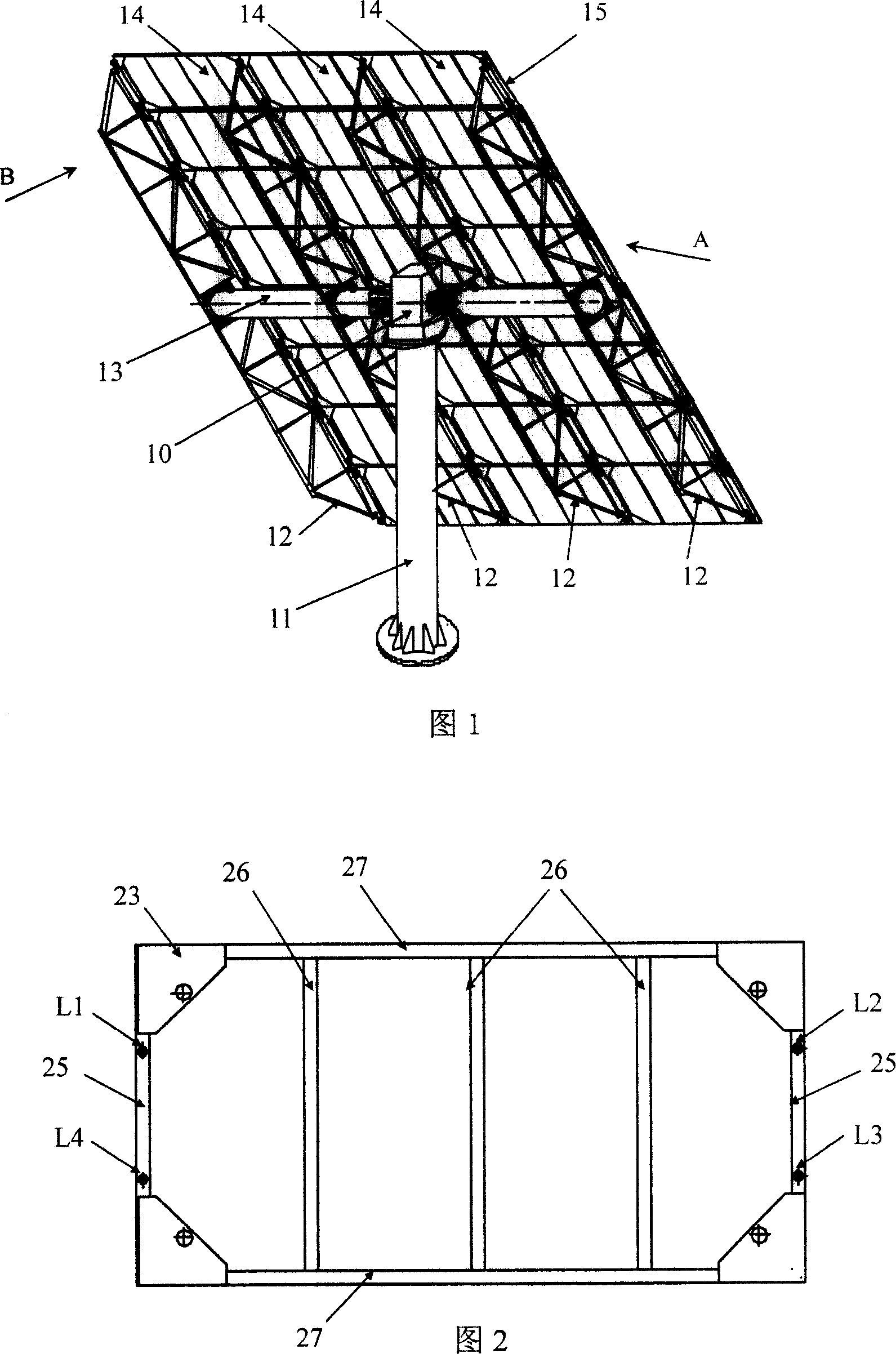

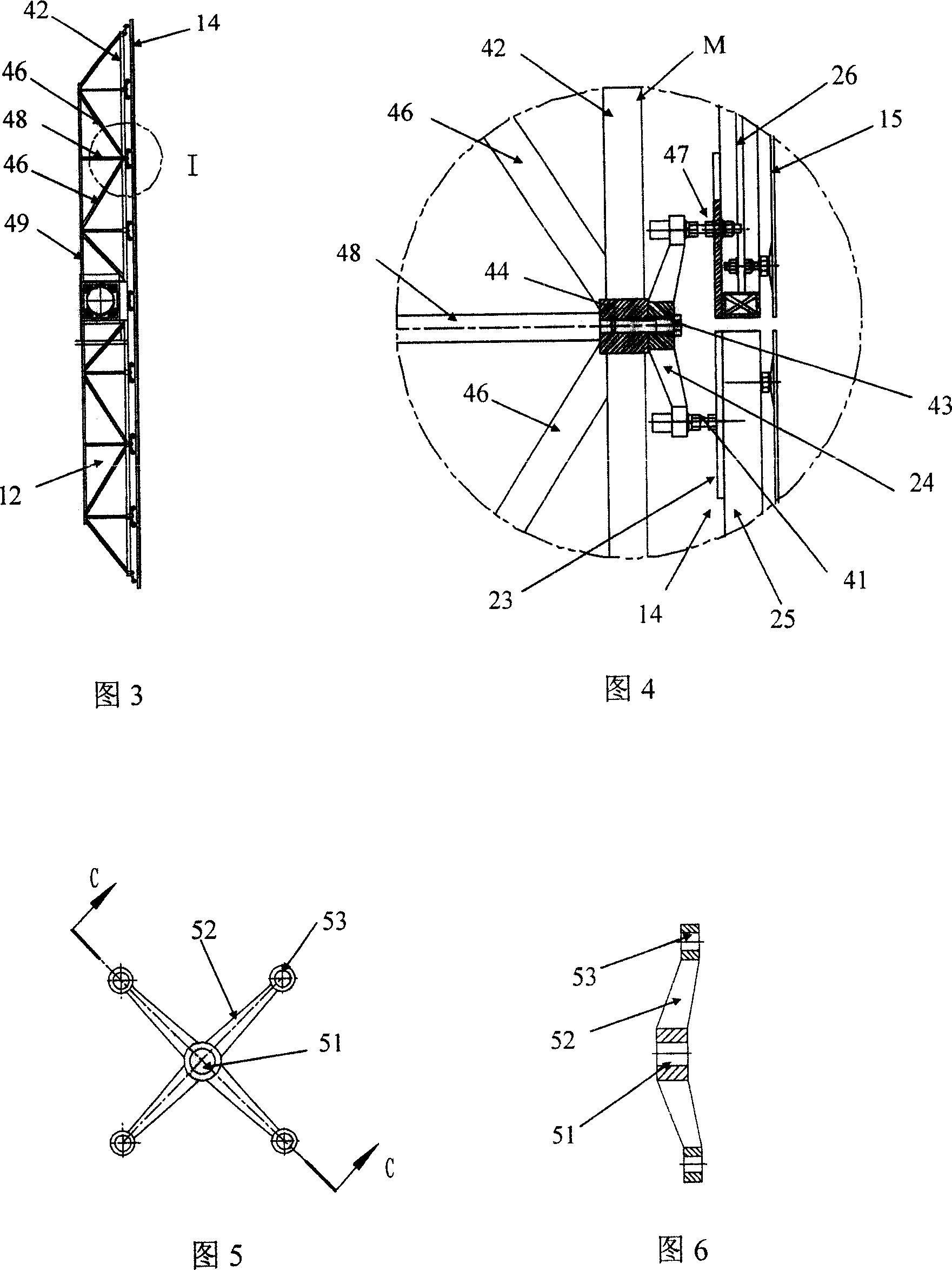

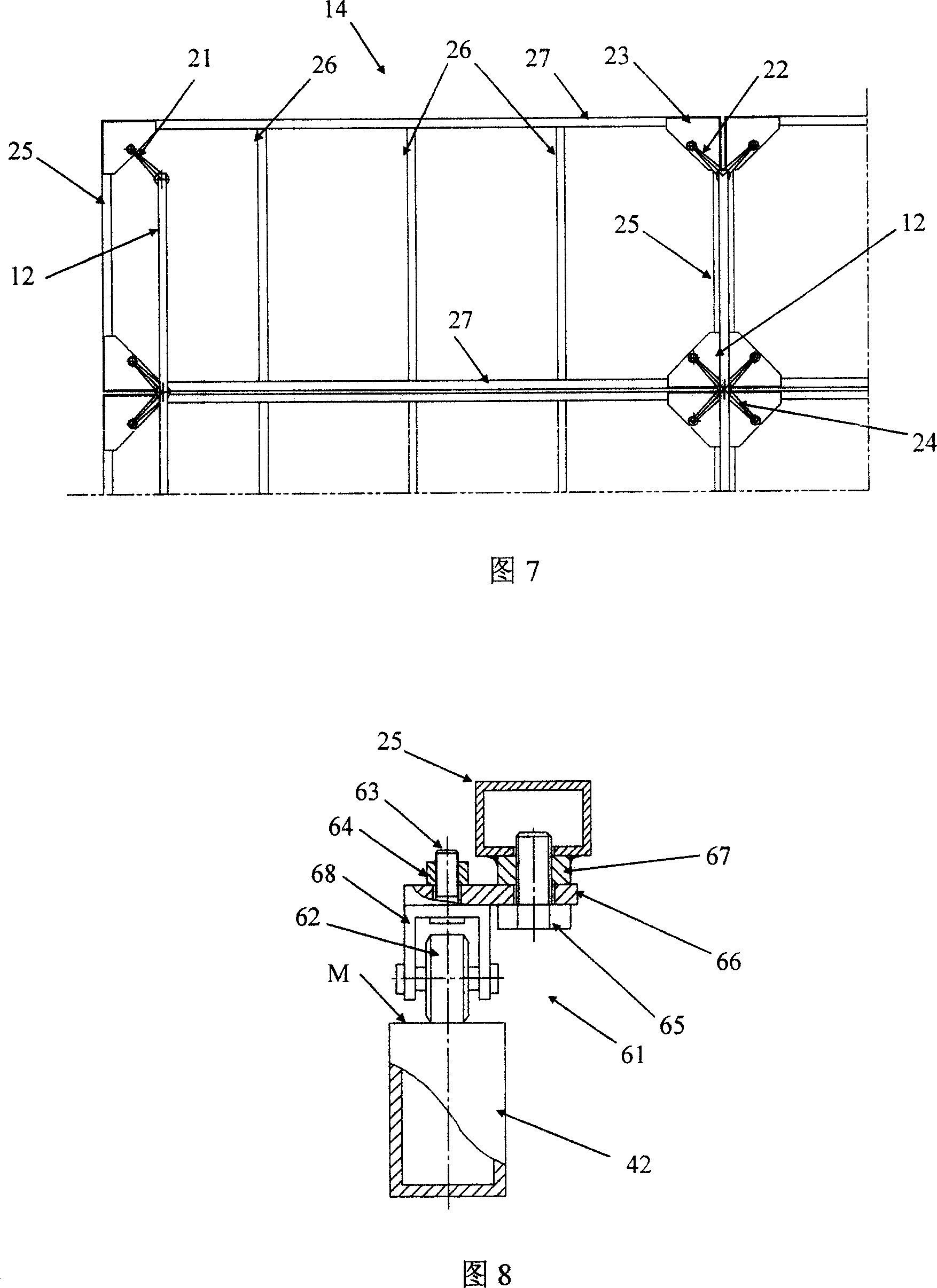

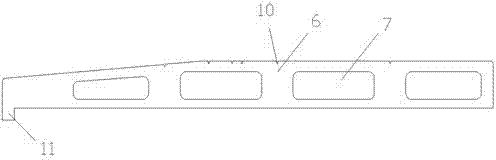

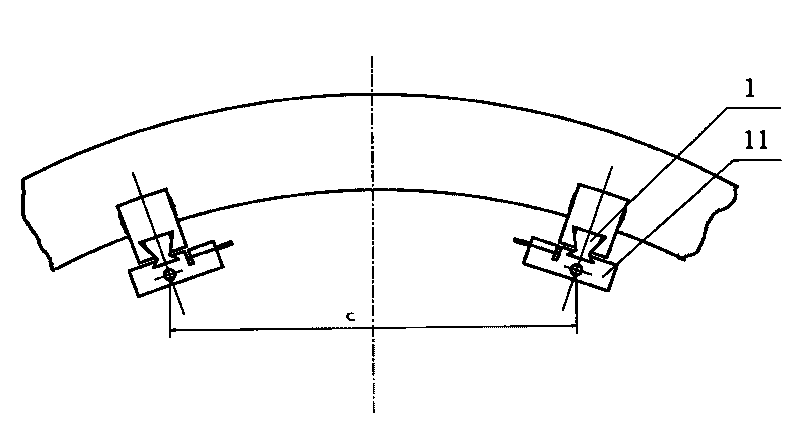

Supporter device of heliostat

InactiveCN101017033ALower heat transfer coefficientGood weather resistanceSolar heating energySolar heat collector controllersHeliostatBraced frame

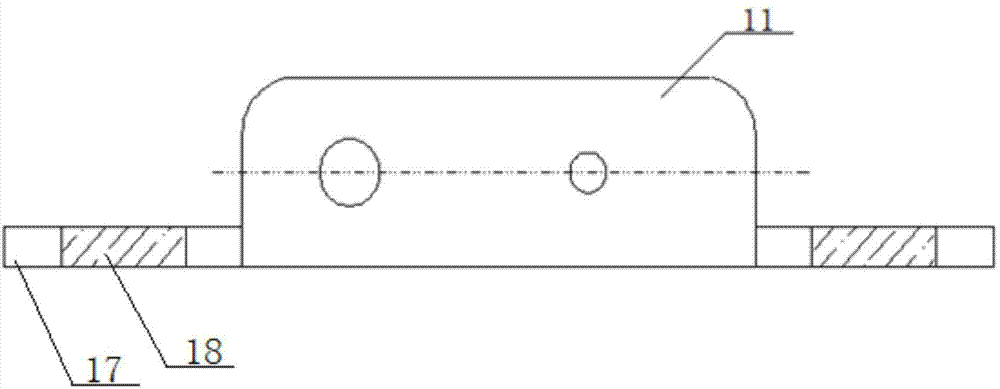

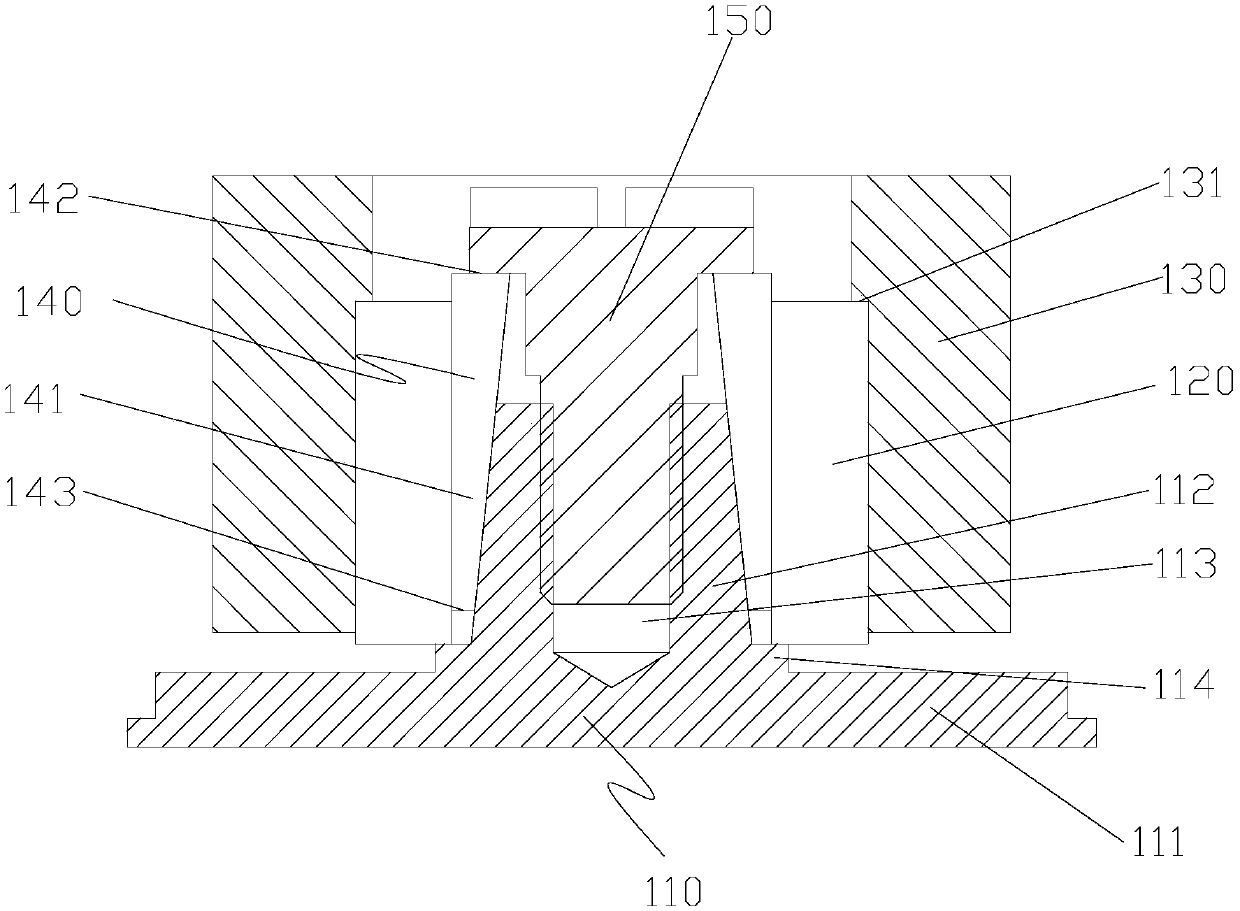

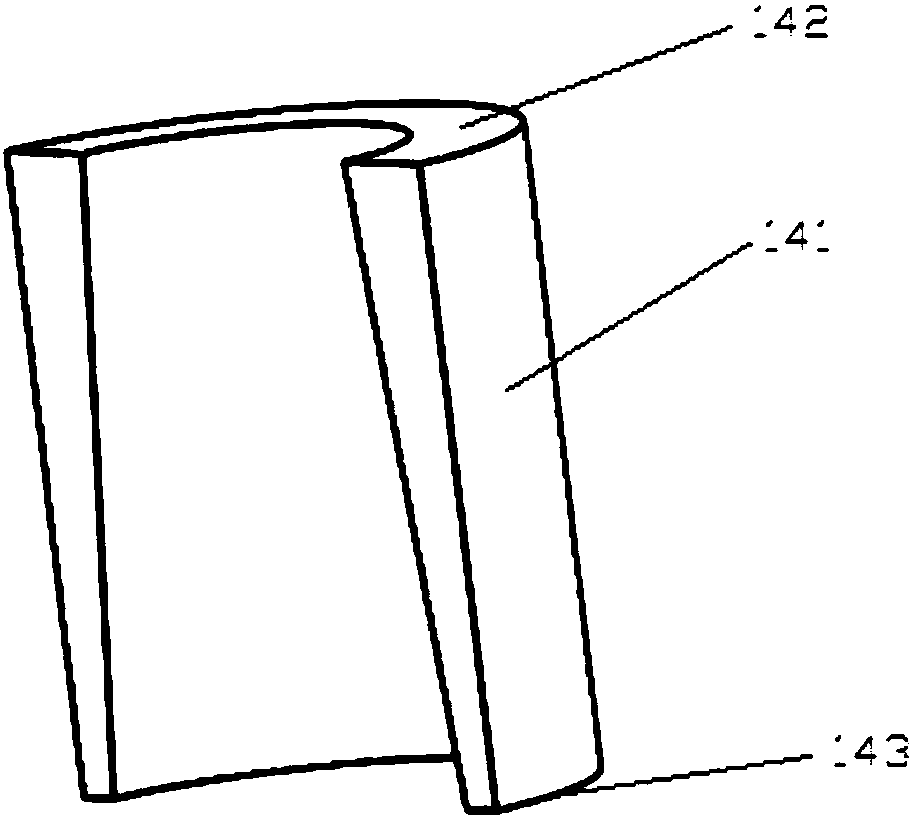

The invention relates to a heliostat support structure, formed by a post (11), a transverse axle (13), a support arm (12) and a mirror support frame (14), wherein the support arm (12) and the mirror support frame (14) have all elements made from non metal section bar, to reduce weight and the load of transmitter, thereby using small power motor to reduce system cost. The chamber of the non-metal section bar is arranged with rib plates inside, to obtain wind resistant ability. The support arm (12) and the mirror support frame (14) are connected via a porous connector, to support easy installment and adjust the installed height of the mirror support frame (14). The invention can mount a roller element (61) on the mirror support frame (14) to reduce installment time and cost.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Energy-saving door and window attached frame and door and window installation method

ActiveCN102777103AAvoid installationSolve the connection waterproof problemFrame fasteningWindow/door framesBuilding energyConstruction engineering

Owner:JIANGSU HONGSHA DOOR & WINDOW +1

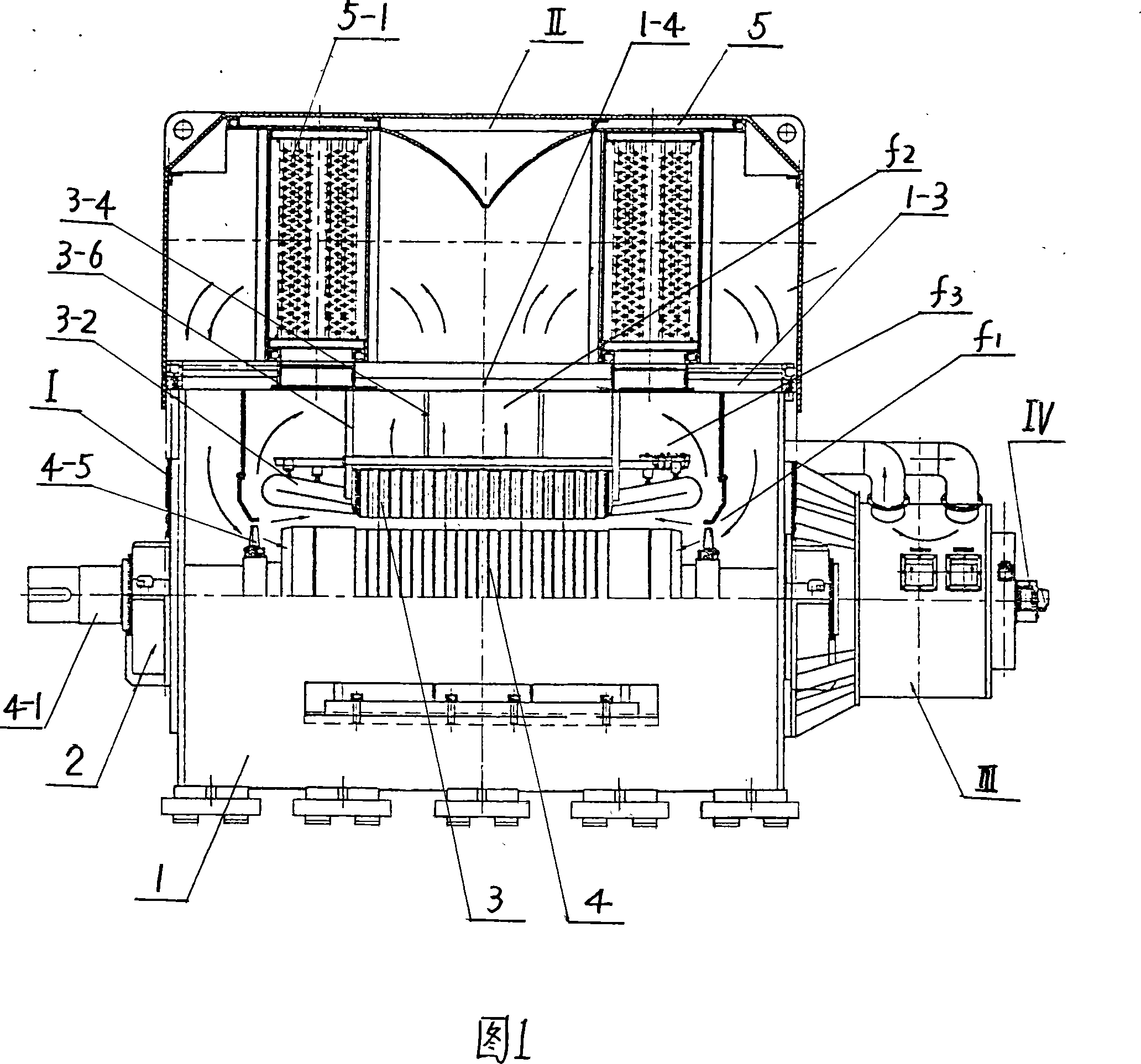

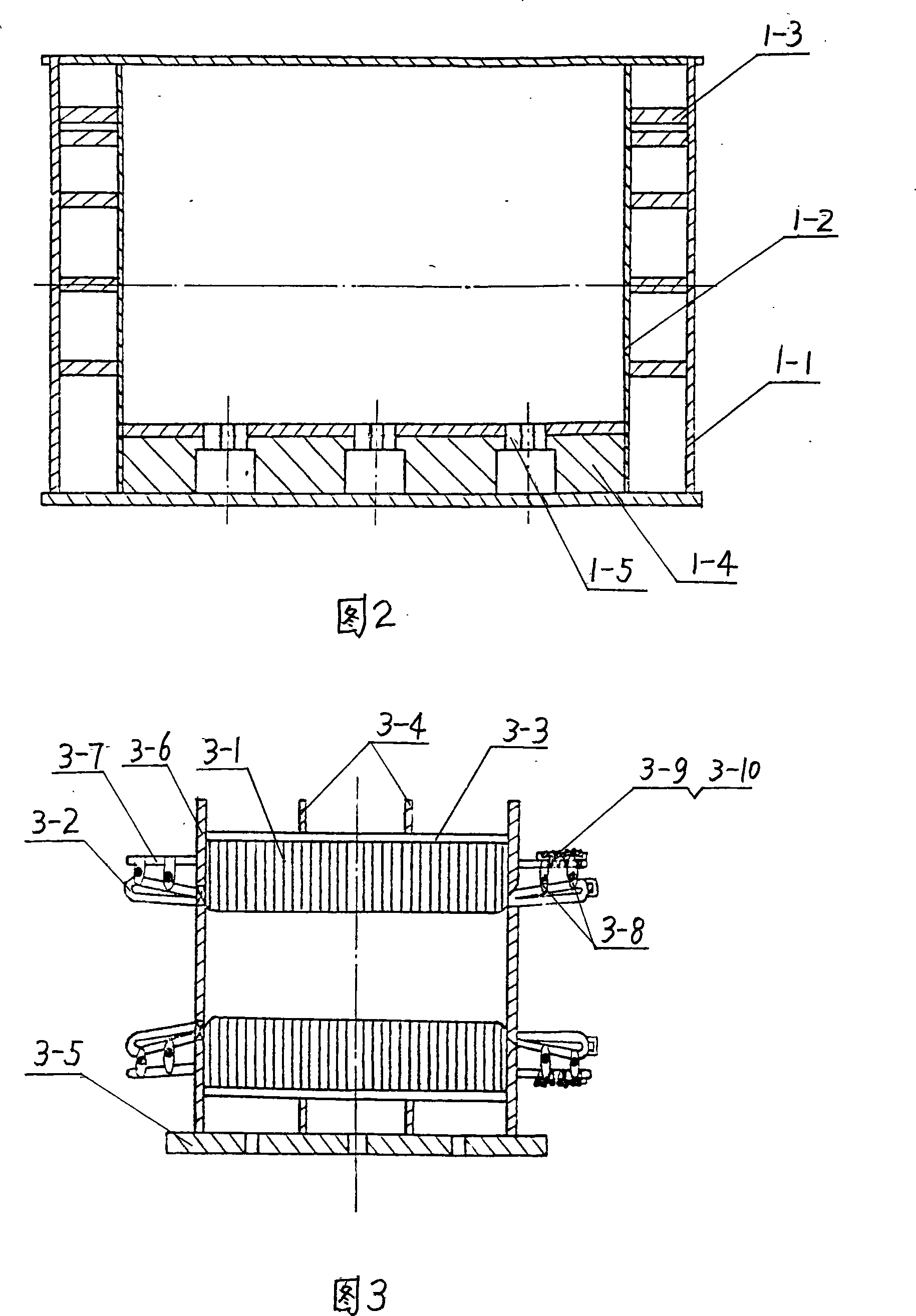

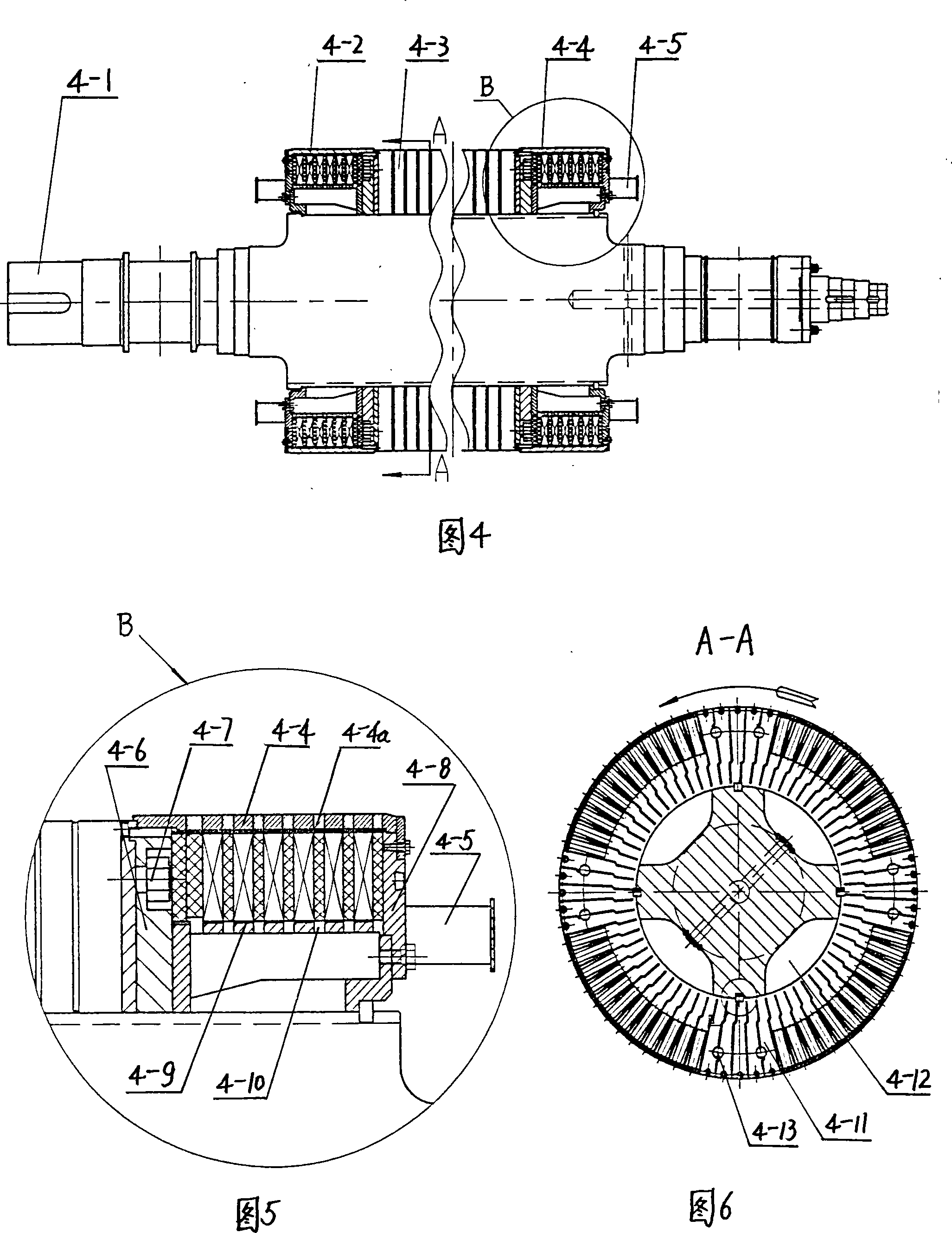

High-capacity non-salient pole nest plate type synchronous generator

ActiveCN101227129AEasy offlineGuaranteed accuracySynchronous generatorsMagnetic circuit rotating partsEngineeringDynamo

The invention relates to a large capacity non-salient pole plate fine type synchronous generator, which is characterized in that a main generator is provides with a stator which is sleeved with a motor base split unit and a rotor which is connected with a motor base through an end cover bearing, an exciting end of a rotor rotating shaft is provided with a brushless excitation system with a high pole number, the tail end of the system is provided with a grounding detecting device, and a cooling system comprises a cooling device which is positioned on the main generator, four ducted cooling paths which circulates in multiply return circuits and is formed by a stator ventilating circuit, a rotor ventilating circuit, an air gas ventilating circuit and an exciting dynamo ventilating circuit of the main generator. The generator has the advantages of reasonable design of the whole system, compact structure, complete function of each portion, convenient installation and maintenance, reliable operating property, high quality of voltage and electric current which are produced and the like, which saves manufacturing cost.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

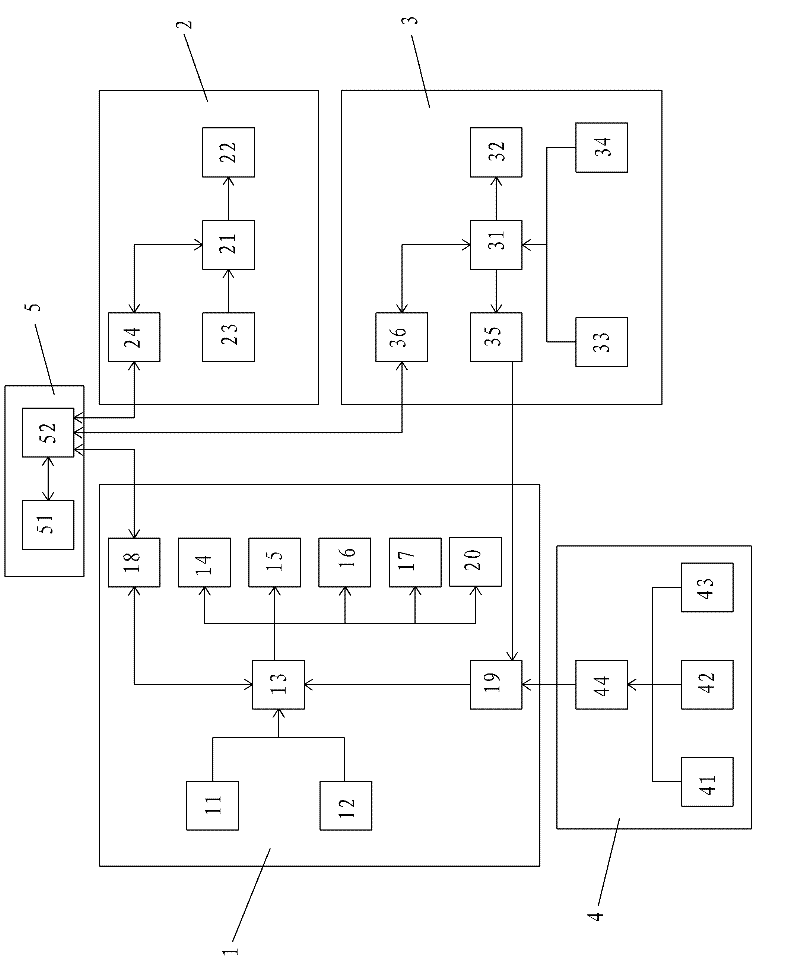

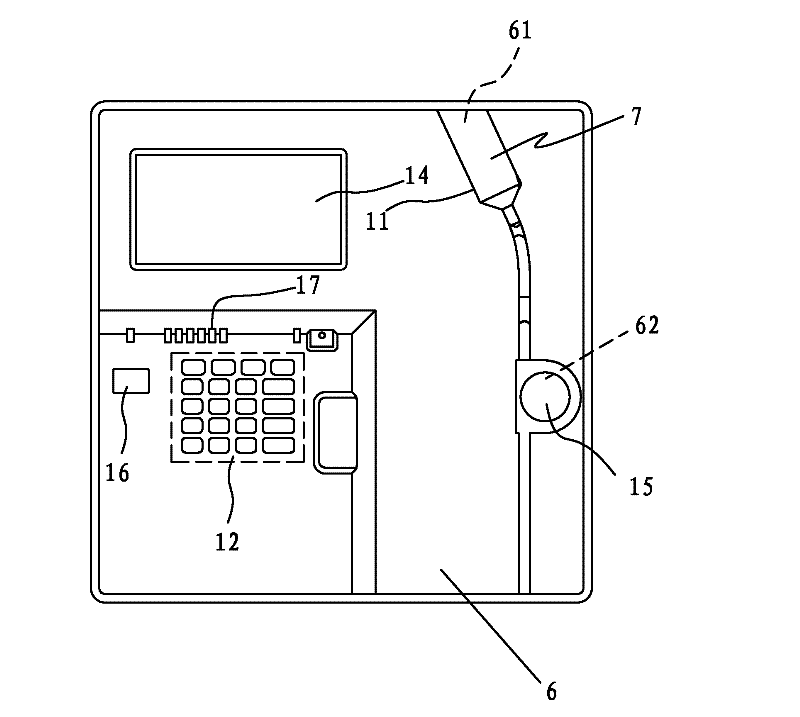

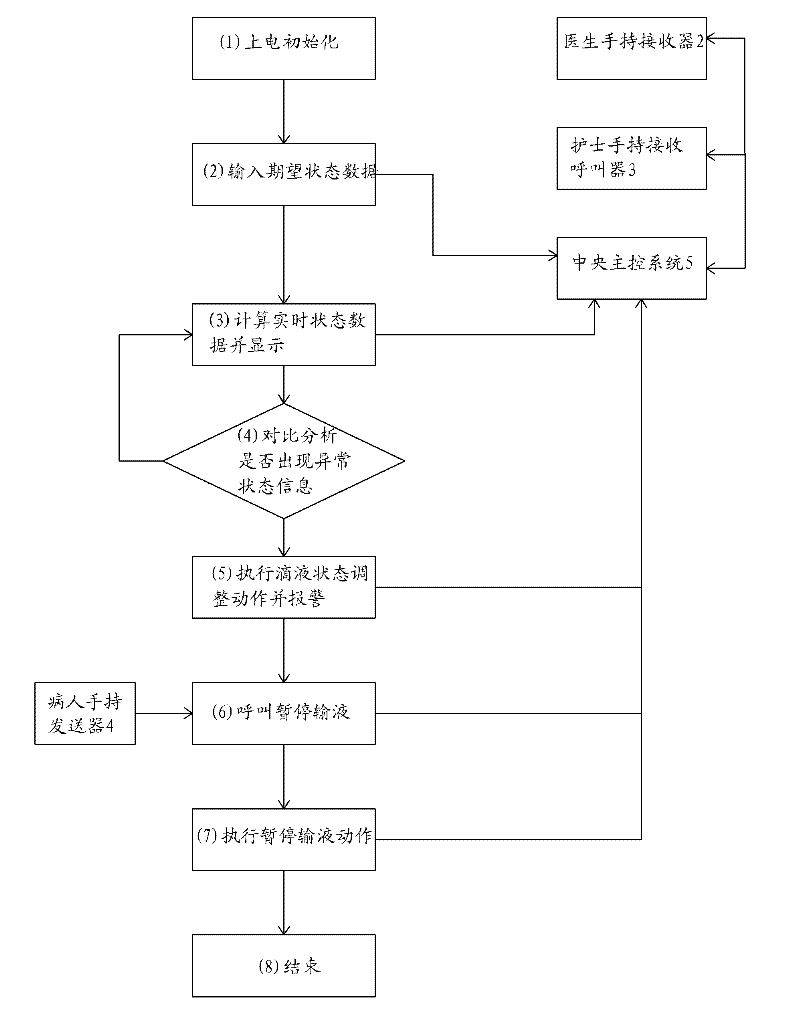

Infusion calling automatic control and medical care management system

InactiveCN102218170AAccurate detectionEasy to controlAlarmsFlow monitorsAutomatic controlControl system

The invention provides an infusion calling automatic control and medical care management system. The system comprises hospital bed intelligent terminals, a doctor handheld terminal, a nurse handheld terminal, a central master control system for patient handheld terminals and a nurse station, wherein the hospital bed intelligent terminals are arranged on hospital beds and can accurately detect abnormal status information and give the alarm in the infusion process and simultaneously carry out the adjustment on the dropping speed automatically; in the non-infusion process, the hospital bed intelligent terminals can remind nurses of carrying out a nursing procedure on patients at regular time; the patient handheld terminals are used for sending the information to the hospital bed intelligent terminals; and the wireless communication among the doctor handheld terminal, the nurse handheld terminals and the hospital bed intelligent terminals is completed by the central master control system.The system is capable of accurately detecting the abnormal status information and giving the alarm in the infusion process and simultaneously adjusting the dropping speed automatically; the system iscapable of reminding the nurses of carrying out the nursing procedure on patients at regular time in the non-infusion process; the central master control system is used for managing the information of the patients and the information of medical care personnel and carrying out the real-time control and management on the plurality of hospital bed intelligent terminals.

Owner:吴迪熙

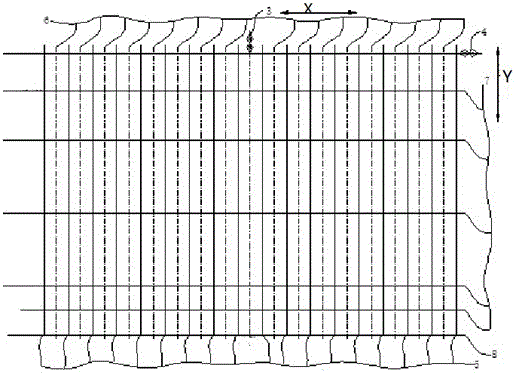

Installation method of double-faced guide rail used for ultra-large type container ship transverse bulkhead block

ActiveCN106080964AShorten the installation cycleReduced installation accuracyDry-dockingSlipwaysMechanical engineeringWaterline

The invention discloses an installation method of a double-faced guide rail used for an ultra-large type container ship transverse bulkhead block. The block comprises a first section, a second section, a third section and a fourth section. The installation method comprises the following steps that the transverse bulkhead block central line and the hatch coaming top plate line are surveyed and marked on an overall assembly platform; a set of docking block positioning central lines and a set of guide rail rack positioning central lines are surveyed and marked in the ship width direction; a set of first waterlines and a block lower edge line are marked in the ship height direction; a plurality of cement docking blocks are arranged according to the hatch coaming top plate line, the first waterlines and the docking block positioning central lines, and a guide rail rack embedded jig frame is installed in a forklift groove between every two adjacent cement docking blocks; a guide rail rack is hoisted into the guide rail rack embedded jig frames; the first section, the second section, the third section and the fourth section are hoisted onto the multiple cement docking blocks and welded; and the guide rail rack is positioned and installed. By the adoption of the installation method, deformation caused by turning-over of the block can be reduced, and the installation accuracy is high.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

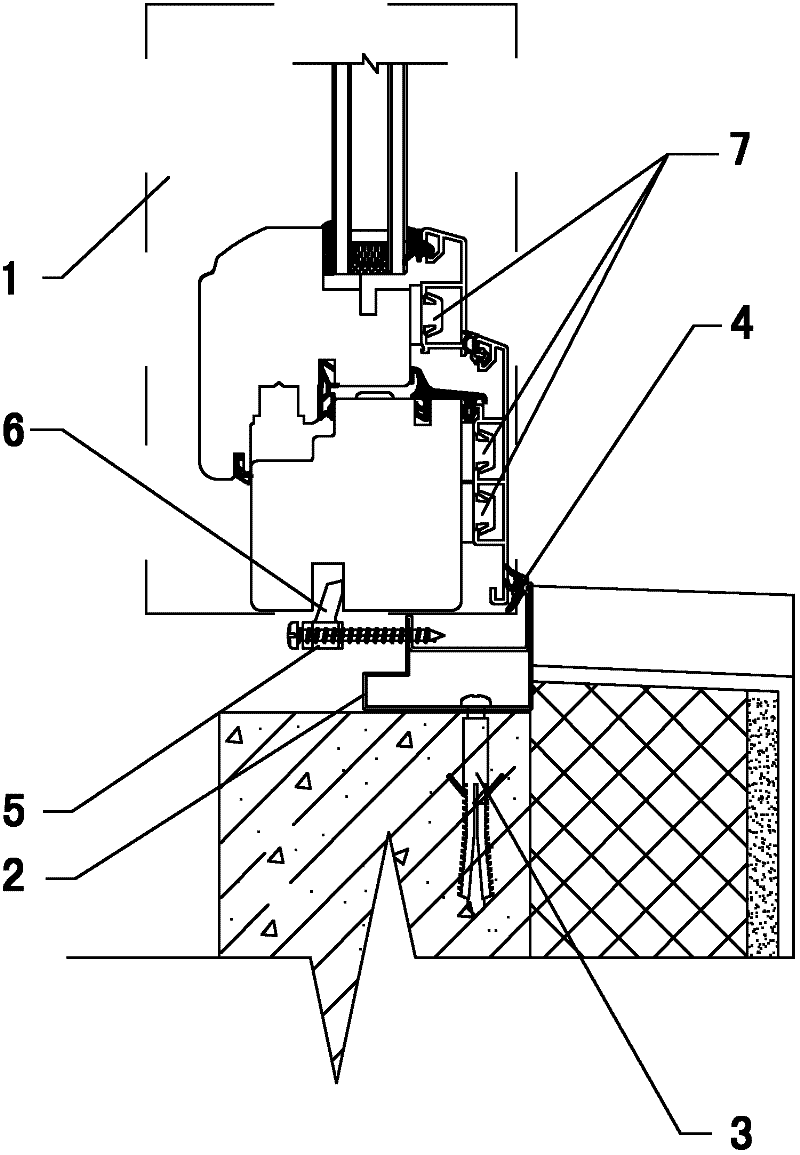

Installation method for energy-saving steel-plastic auxiliary frames and doors/windows

InactiveCN104179417AAchieve standardizationRealize the insulation effectFrame fasteningStandardizationUtilization rate

The invention relates to the field of door / window installation methods, in particular to a conveniently-operated installation method for energy-saving steel-plastic auxiliary frames and doors / windows. The installation method for the energy-saving steel-plastic auxiliary frames and the doors / windows comprises the steps of connection of auxiliary frames and fixing steel sheets, splicing of the auxiliary frames, connection of the auxiliary frames and a wall, and connection of the auxiliary frames and the doors / windows. The method is reasonable in design and convenient to operate, and standardization of installation holes of the doors / windows and integration of heat insulation and heat preservation are realized; after the auxiliary frames are installed, the holes do not need to be painted, so that the labor cost for civil construction is reduced; moreover, the problem of leakage caused by non-tight seam filling at a joint between the peripheries of outer frames of the doors / windows and the wall is solved; after the doors / windows are installed in place at one time, finished door / window products are delivered to users for use without any damage; the installation period of the doors / windows is greatly shortened, the utilization rate of door / window engineering occupied fund is improved, resources are effectively saved, and the cost is effectively reduced.

Owner:JIANGSU GOLDEN LILY DOORS & WINDOWS TECH

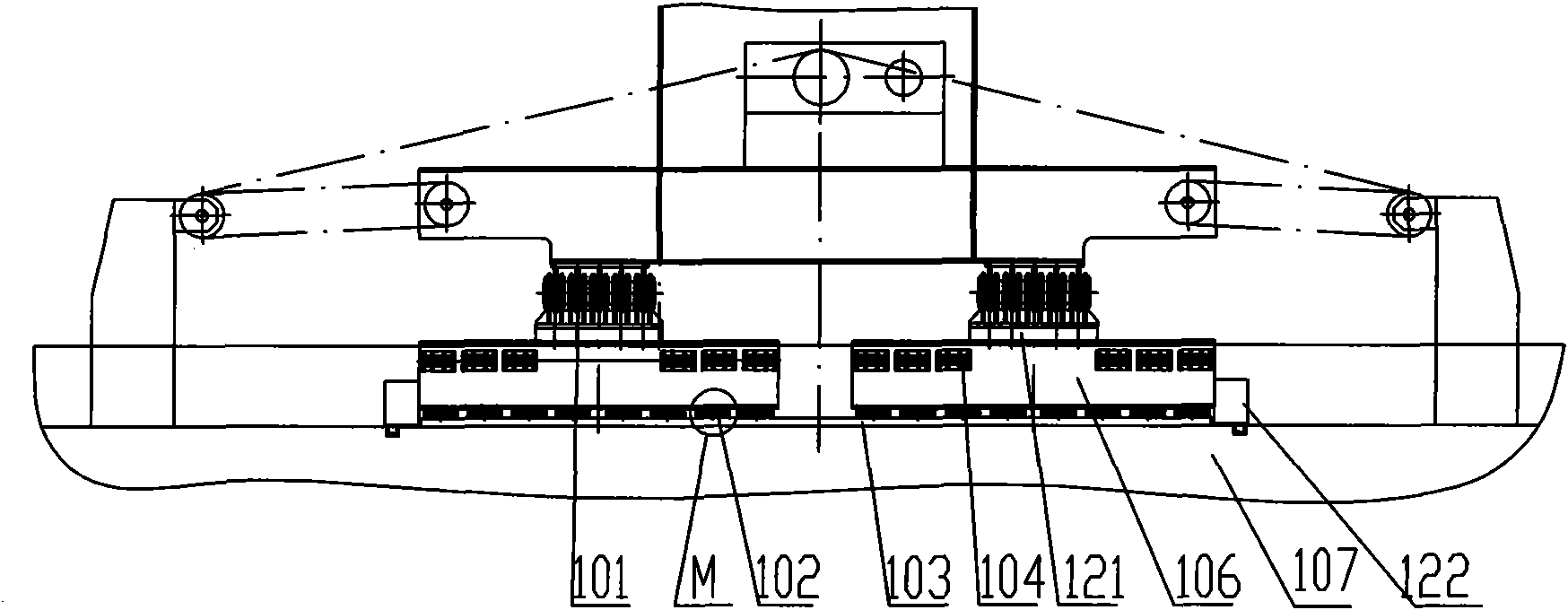

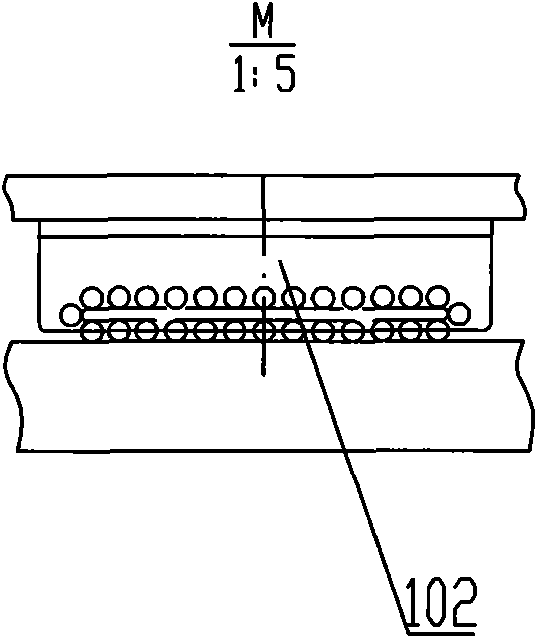

Method for mounting main unit with resilient support

ActiveCN101376431AImprove environmental comfortImprove ride comfort performancePropulsion power plantsPropulsive elementsEngineeringLiving environment

The invention discloses an installation method of a main engine with an elastic support, the main engine comprises a main engine carrier block and a main engine base, the main engine carrier block is connected with the main engine base through the elastic support, and the elastic support comprises a vertical shock absorbing block, a side shock absorbing block and a longitudinal shock absorbing block. The elastic support is arranged between the main engine carrier block and the base, and the vibration generated during the operation of the main engine is absorbed by a rubber damping device of the rubber shock absorbing block, so that the vibration and the noise are weakened. The use of the installation method can shorten the overall installation period of the ship main engine and greatly enhance the progress. The method is applicable to ships with higher requirements on the ship noise and the vibration indicators, so as to obtain good working and living environment of the ships and the comfort of passengers.

Owner:JIANGNAN SHIPYARD GRP CO LTD

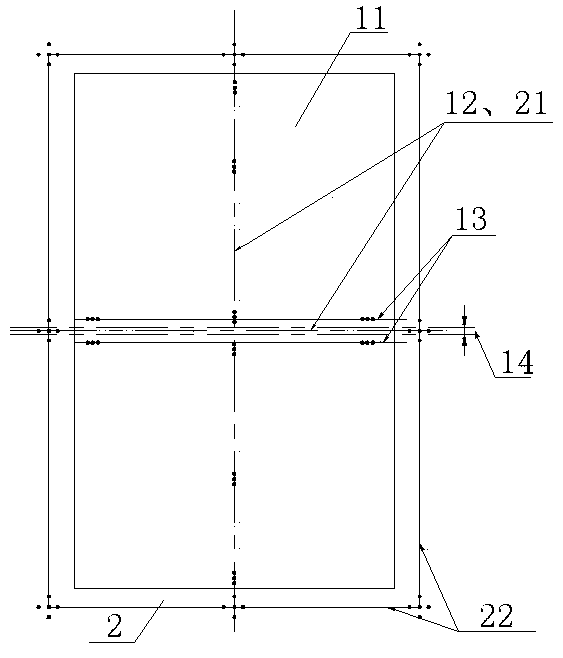

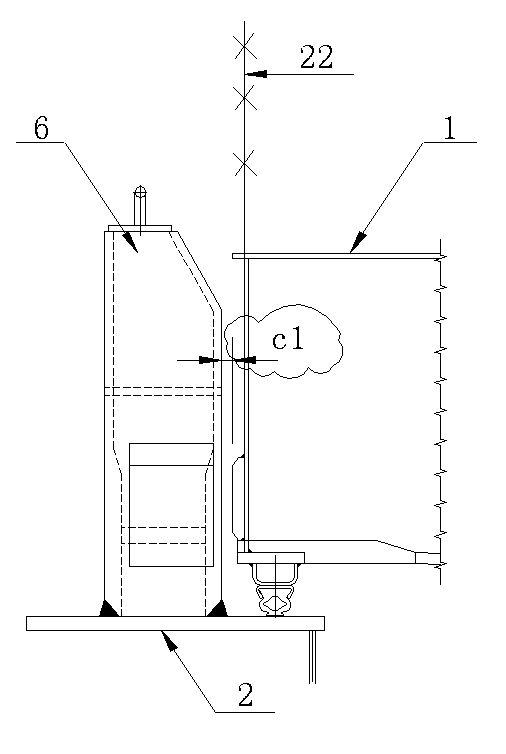

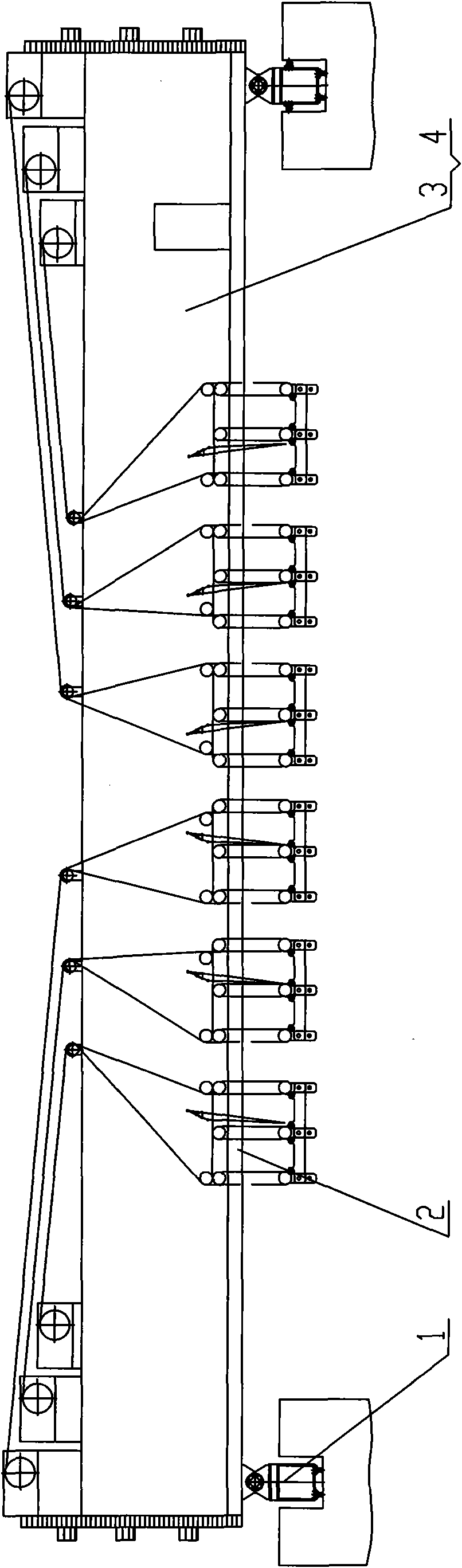

Deck face hatch cover system installing method

ActiveCN104192265AResolve flatness damageReduce repeated liftingVessel hatches/hatchwaysMarine engineeringCovering system

The invention provides a deck face hatch cover system installing method. The method comprises the steps that firstly, hatch covers are manufactured, concretely, longitudinal and transverse center lines and involution lines of the hatch covers are marked; secondly, an outfitting piece is installed on a ship in advance, concretely, longitudinal and transverse center lines and hatch cover theoretical lines of hatch coamings are marked, the positioning size of the outfitting piece is measured, and the outfitting piece is directly assembled and welded before the hatch covers are installed to the ship; thirdly, the hatch covers are installed on the ship, concretely, the hatch covers are hoisted to the ship to correspond to the hatch cover theoretical lines at the front end and the rear end of the upper hatch coaming, separating seams of the port and starboard hatch covers are adjusted to correspond to the longitudinal center line on a hatch coaming panel, and the contact gap between supporting blocks and press depths of rubber strips are adjusted to meet tolerance requirements. By the adoption of the deck face hatch cover system installing method, it can be ensured that the measurement standard needed when the outfitting piece is manufactured and the standard needed when the outfitting piece is preinstalled on the ship are consistent, the period of installing the outfitting piece on the ship is shortened, the percent of pass of installation precision and quality is improved, and hatch cover repeated hoisting and conveying frequency can be reduced.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Multi-suspension-centres crane

ActiveCN101607676AImprove the forceEven by forceTravelling cranesWinding mechanismsWinding machineReduction drive

The invention discloses a multi-suspension-centres crane which comprises main beams, an operating mechanism, a lifting mechanism and an electric control system, wherein the operating mechanism comprises a bearing mechanism composed of an idle wheel device and an elastic body, and a drive mechanism composed of a motor, a reducer, a winding drum group, two groups of steel ropes, a pulley block and a pulley bracket, wherein the lifting mechanism comprises more than 2 sets of winding machines on each main beam, adopts a multilayer winding and symmetrical rope mode of duplex winding drums and steel ropes, and adopts a mode that a hook connecting piece is respectively hinged or fixedly connected with a corresponding hook group through a pin roll. The multi-suspension-centres crane has the characteristics of safety and reliability, strong practicability and the like through the self-set corresponding control method, is suitable to a crane with ultra-high lifting load, especially the multi-suspension-centres crane for lifting by sections on an offshore drilling platform.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Dual-dovetail type unmovable key bar assembling and welding process for water turbine generator

InactiveCN101758323AReduce radial bending welding distortionGuaranteed Radius ToleranceArc welding apparatusWater turbineSkew angle

The invention provides a dual-dovetail type unmovable key bars assembling and welding process for a water turbine generator, which adopts a large-span equal division method to install key bars and welds the other key bars by lap welding the template within each large span. The key bar radius, radial skew angle, radius difference of adjacent bars and chord length difference of adjacent bars are adjusted up to standards by a support block C-shaped clip and other tools. The support block is welded by CO2 arc welding, the welding direction is from inner side to outer side, in order to whole controlling the welding deformation direction of the key bar chord length. The support block among each base ring plate are welded by skip welding, the radial bending welding deformation of the key bar is reduced. The invention has the advantages of simple and concise welding process, convenient assembly operation, high precision of key bar welding, high production efficiency and short assembly circle.

Owner:HARBIN ELECTRIC MASCH CO LTD

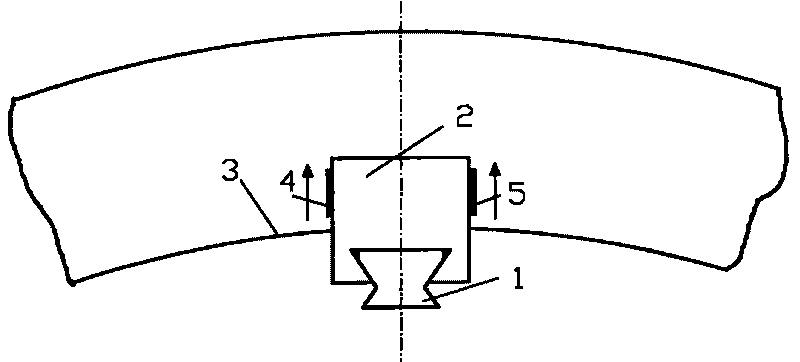

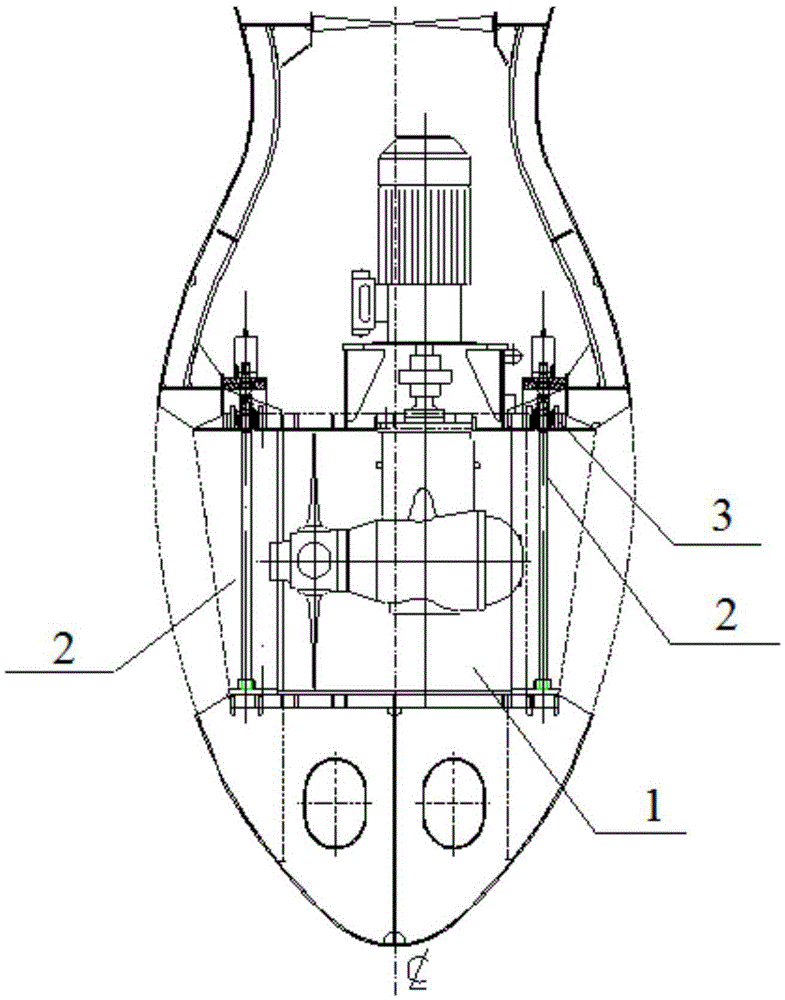

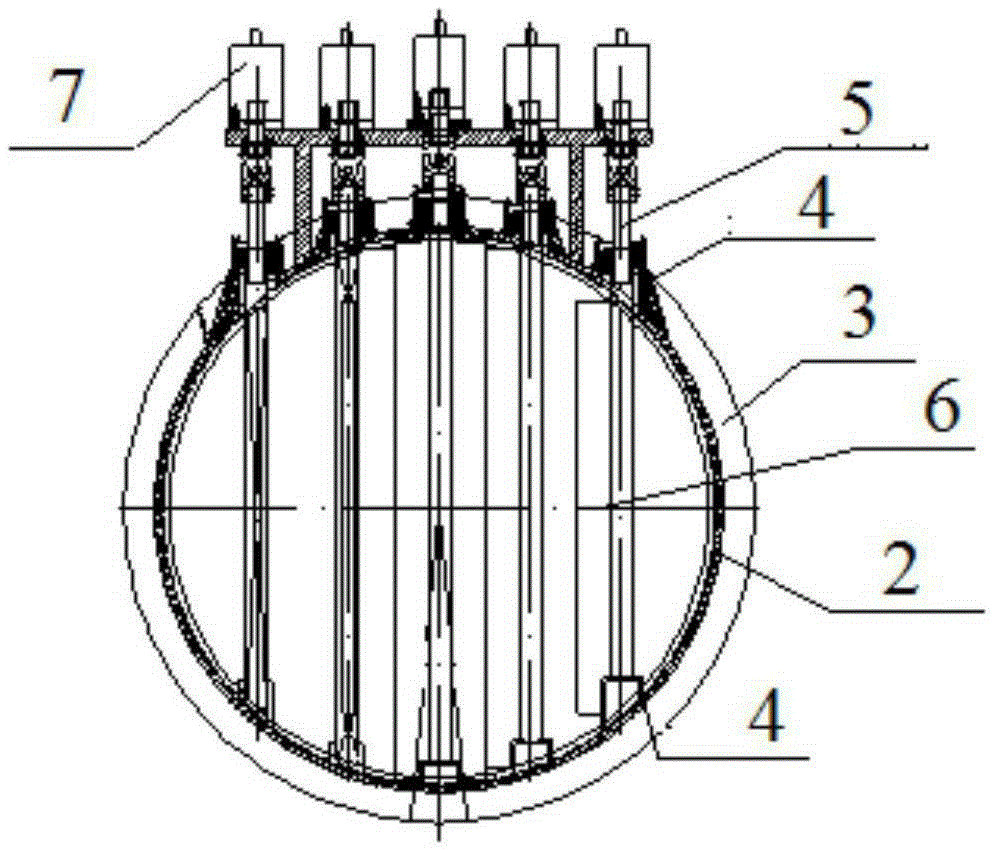

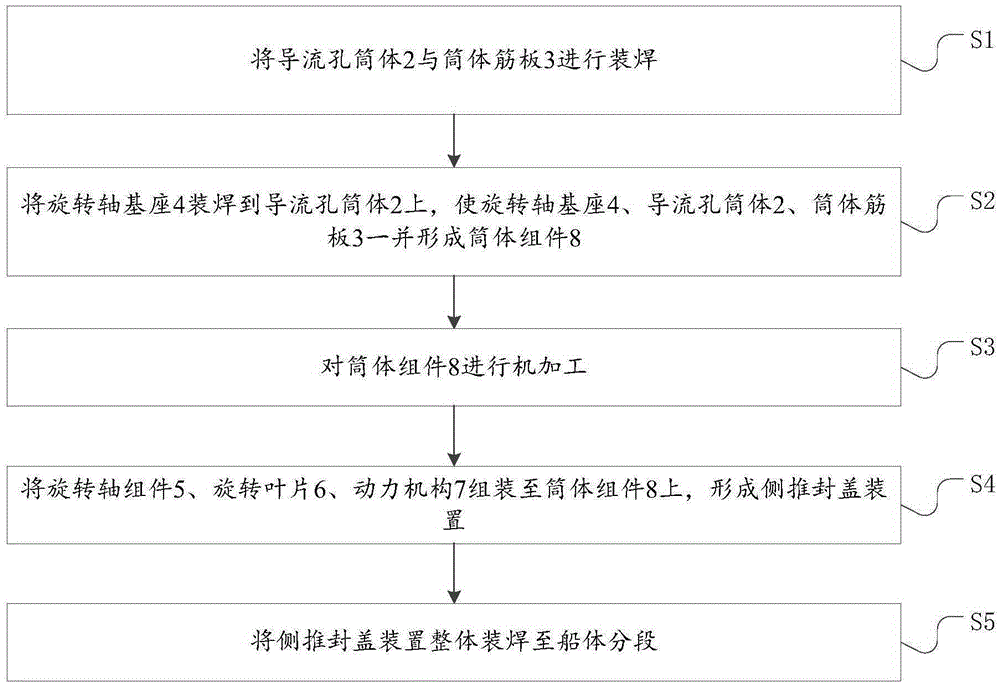

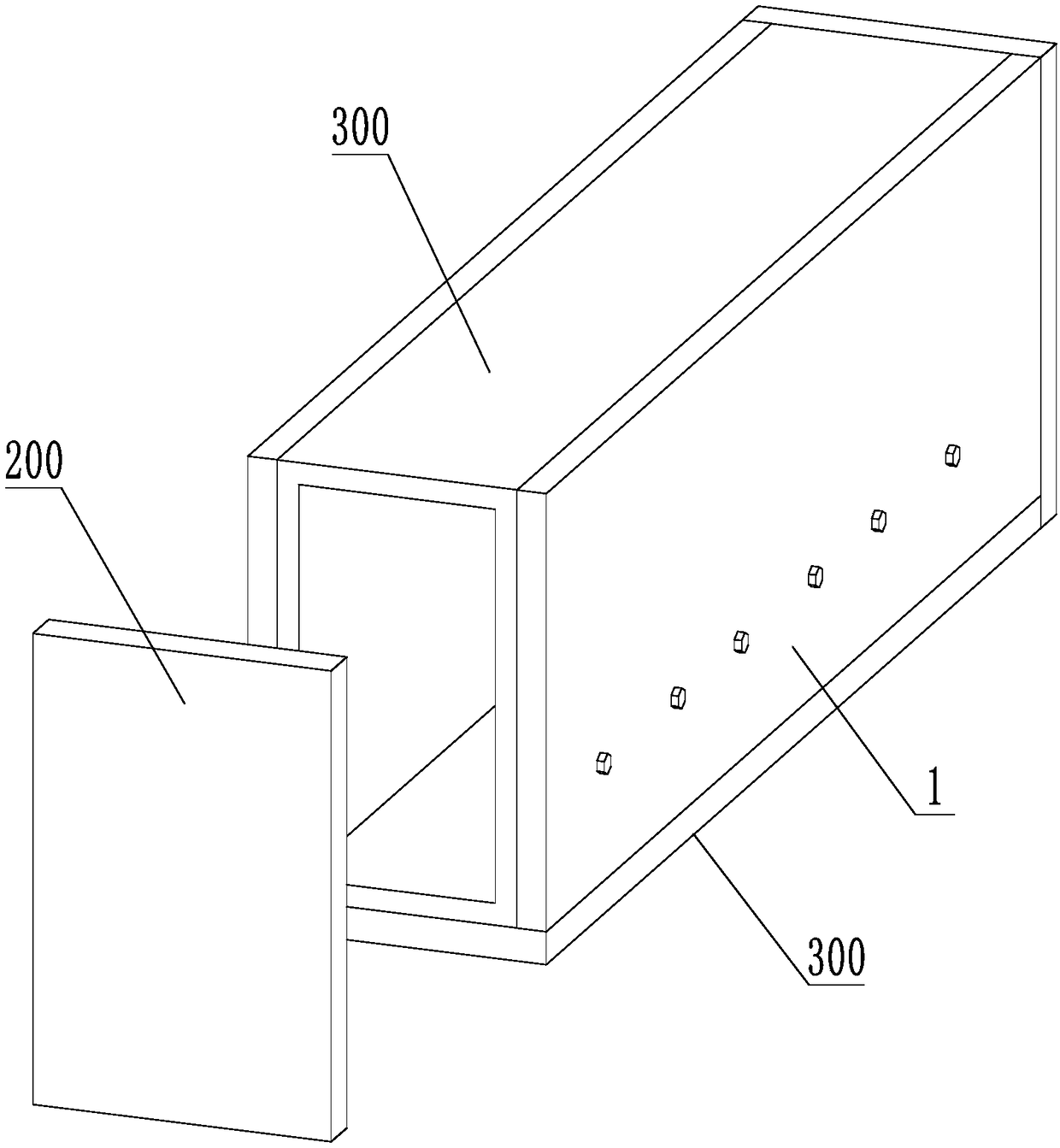

Assembling method of side-push seal cover device

The invention discloses an assembling method of a side-push seal cover device. The assembling method of the side-push seal cover device comprises the steps of firstly assembling and welding a flow guide hole cylinder with a cylinder rib plate, then assembling and welding a rotating shaft base to the flow guide hole cylinder to enable the rotating shaft base, the flow guide hole cylinder and the cylinder rib plate to jointly form a cylinder assembly; machining the cylinder assembly; then assembling a rotating shaft assembly, rotating blades and a power mechanism to the cylinder assembly to form the side-push seal cover device; finally integrally assembling and welding the side-push seal cover device to a ship body section. By adopting the assembling method, since a rotating shaft, the rotating shaft assembly, the rotating blades and the power mechanism are assembled first and then the side-push seal cover device is integrally installed to the ship body section, the assembling of the components of the side-push seal cover device in the ship body section can be avoided, an installation period is shortened, the machining in the ship body section can be avoided and the machining difficulty can be reduced.

Owner:WUCHANG SHIPBUILDING IND

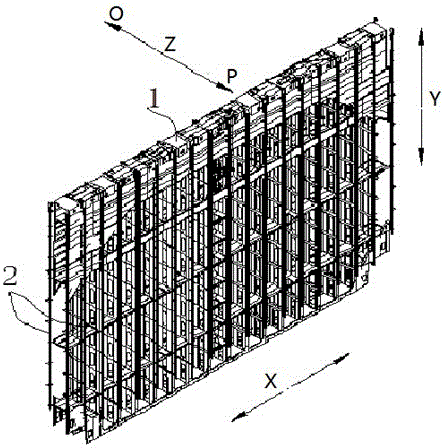

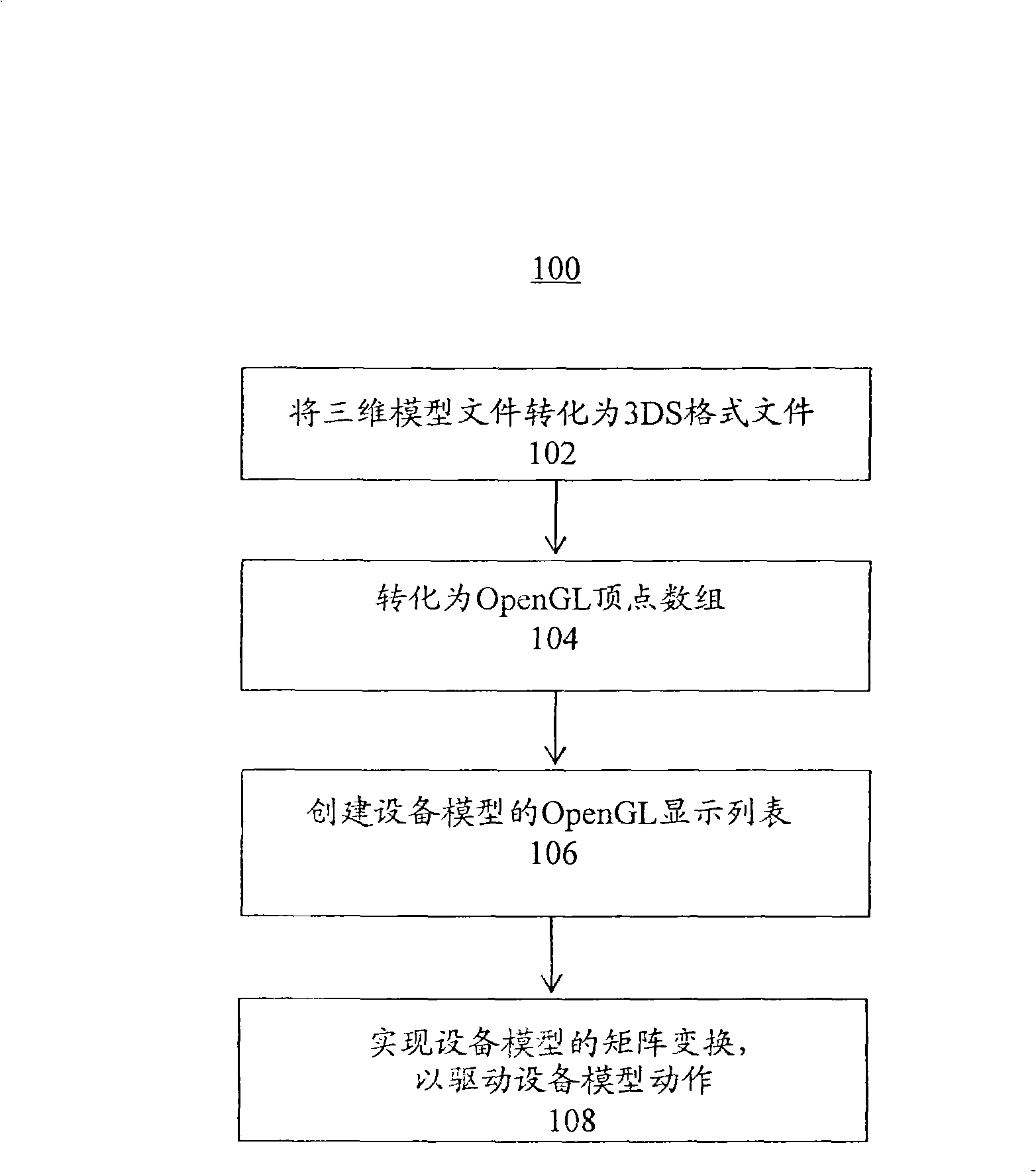

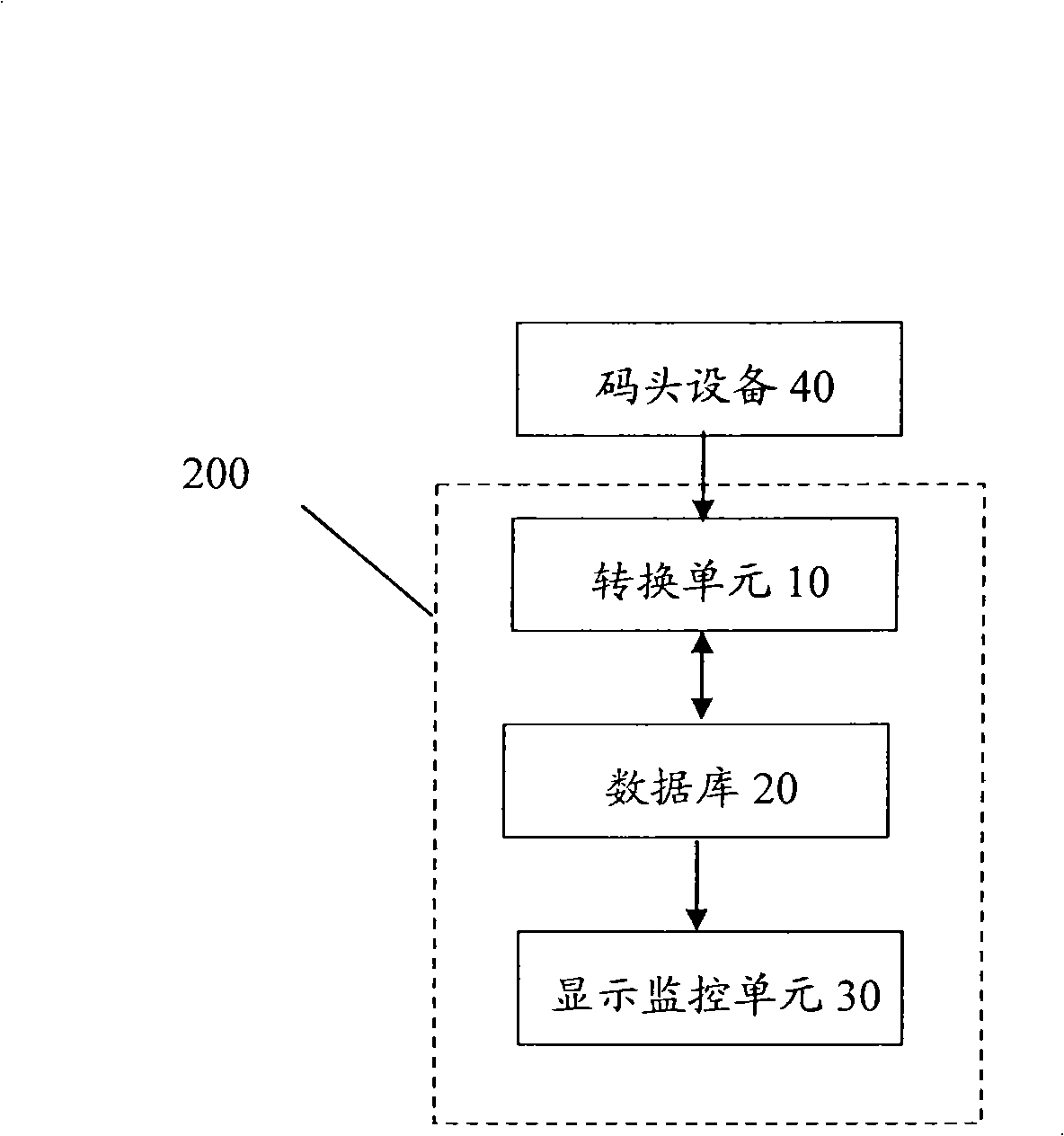

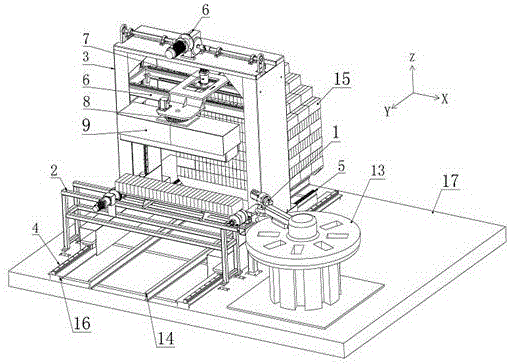

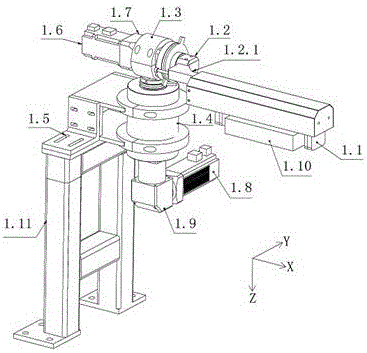

Three-dimensional display monitoring system and method for wharf equipment

InactiveCN101312525AImprove display and show progressShorten the installation cycleClosed circuit television systemsAnimationThree dimensional displayPoint data

The invention discloses a three-dimension display monitoring system of dock device and a method. The method comprises: converting a device model document into a 3DS format device model document to be converted into an OpenGL top point data array and an OpenGL display list of relative devices, adopting an OpenGL matrix conversion function to process matrix conversion of the device model to drive the device model. The invention adopts three-dimension modeling technique and OpenGL display technique, to display the working condition of the dock device via the three-dimension model, thereby effectively improving display effect and display process, to realize real-time monitoring display on the whole dock yard, working area panoramic field and each device. The on-site user only needs a display, a mouser and a net wire to display and monitor all devices real-timely in the dock stack yard, to improve operation simplicity and flexibility.

Owner:SHANGHAI ZHENHUA HEAVY IND

Adobe stacking machine and adobe stacking method

InactiveCN105836481AThe stacking method is criss-crossThe stacking method is criss-cross, without reducing the output of a single brick car.Stacking articlesDe-stacking articlesBrickControl system

The invention discloses an adobe stacking machine and an adobe stacking method. The adobe stacking machine comprises a small mechanical arm, a conveying line, a large mechanical arm with a movable portal frame as a frame and a control system. The portal frame serves as the frame of the large mechanical arm. The large mechanical arm comprises a lifting mechanism, an X axial movement mechanism, a rotating mechanism and a clamping mechanism. The lifting mechanism is located in the portal frame to slide vertically, and therefore the height of the whole equipment is controllable. The X axial movement mechanism slides left and right in the portal frame, and the requirement for stacking adobes clamped by the clamping mechanism to the two sides of a brick vehicle after the adobes are rotated is met to the maximum degree. The rotating mechanism and the clamping mechanism are arranged so that a rotating function can be increased for the large mechanical arm, the stacking direction of the adobes is changed by changing the rotating angle of the clamping mechanism, and therefore the adobes are sacked in a criss-cross manner, and the brick collapsing accident is avoided on the basis of not reducing the yield of a single brick vehicle.

Owner:CHANGDE GUIXIANG HYDRAULIC EQUIP CO LTD

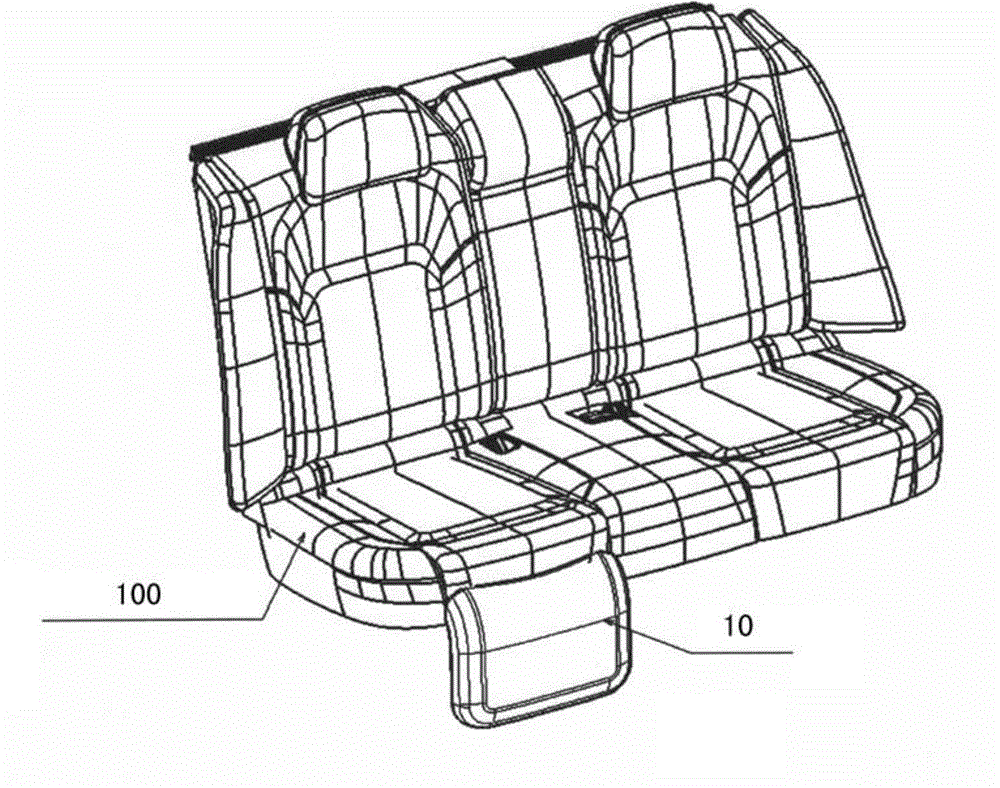

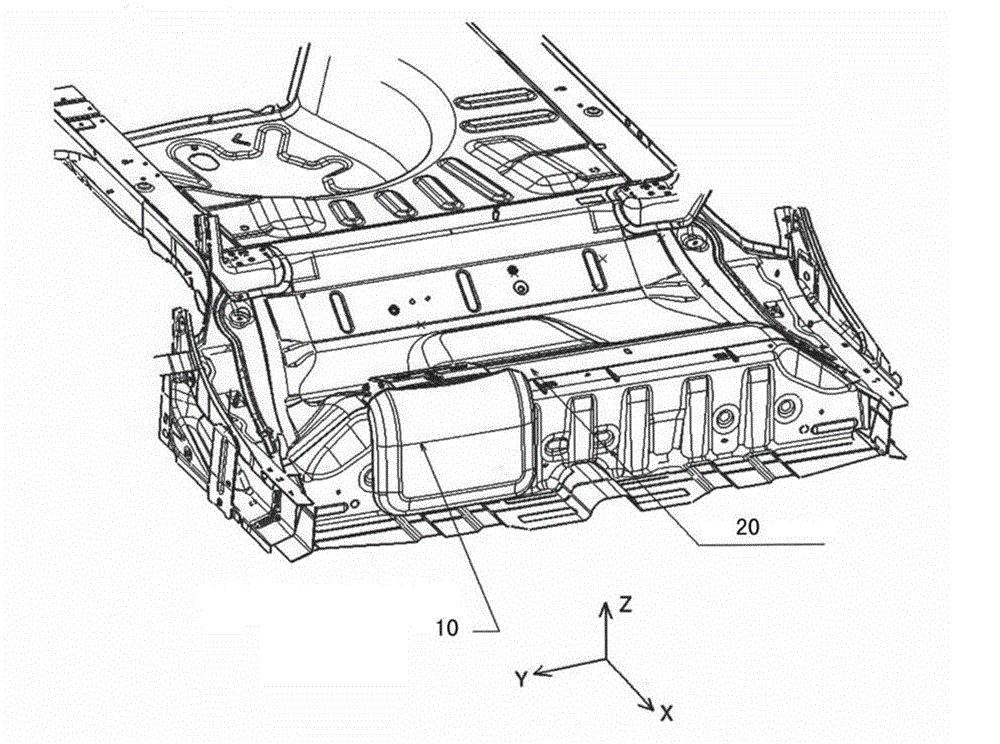

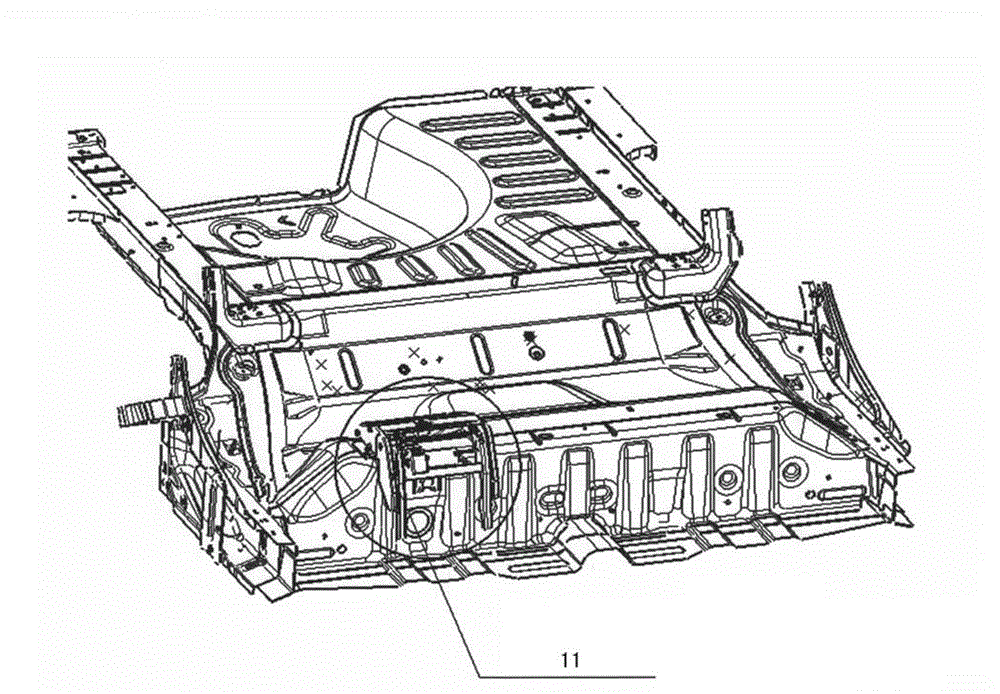

Leg supporting device used for seat of vehicle

The invention provides a leg supporting device used for a seat of a vehicle. The leg supporting device comprises a leg support face mask and a frame mechanism, wherein the frame mechanism is wrapped by the leg support face mask, the frame mechanism comprises a shell body fixed to the floor of a vehicle body, the leg supporting stand installed on the shell body in a pivotal mode and the drive mechanism which drives the leg supporting stand to rotate. Fixed plates arranged on two sides of the shell body are fixed to the top face of a seat beam in the rear row of the floor of the vehicle body through a threaded fastener, and a clamping component arranged on the bottom of the shell body is meshed with a fixed pin arranged on the side face of the seat beam in the rear row of the vehicle body floor.

Owner:PEUGEOT CITROEN CHINA AUTOMOTIVE TRADE +1

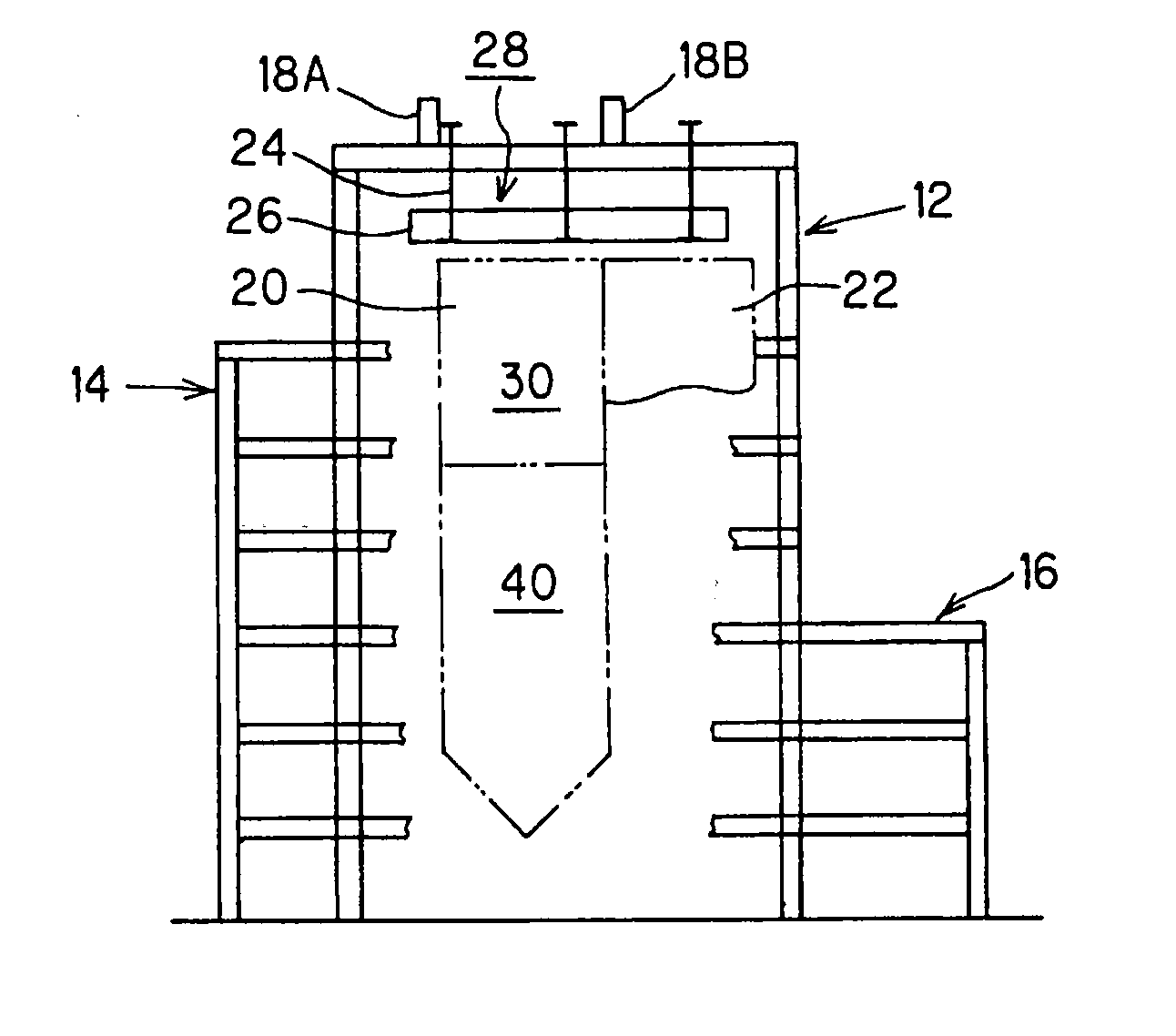

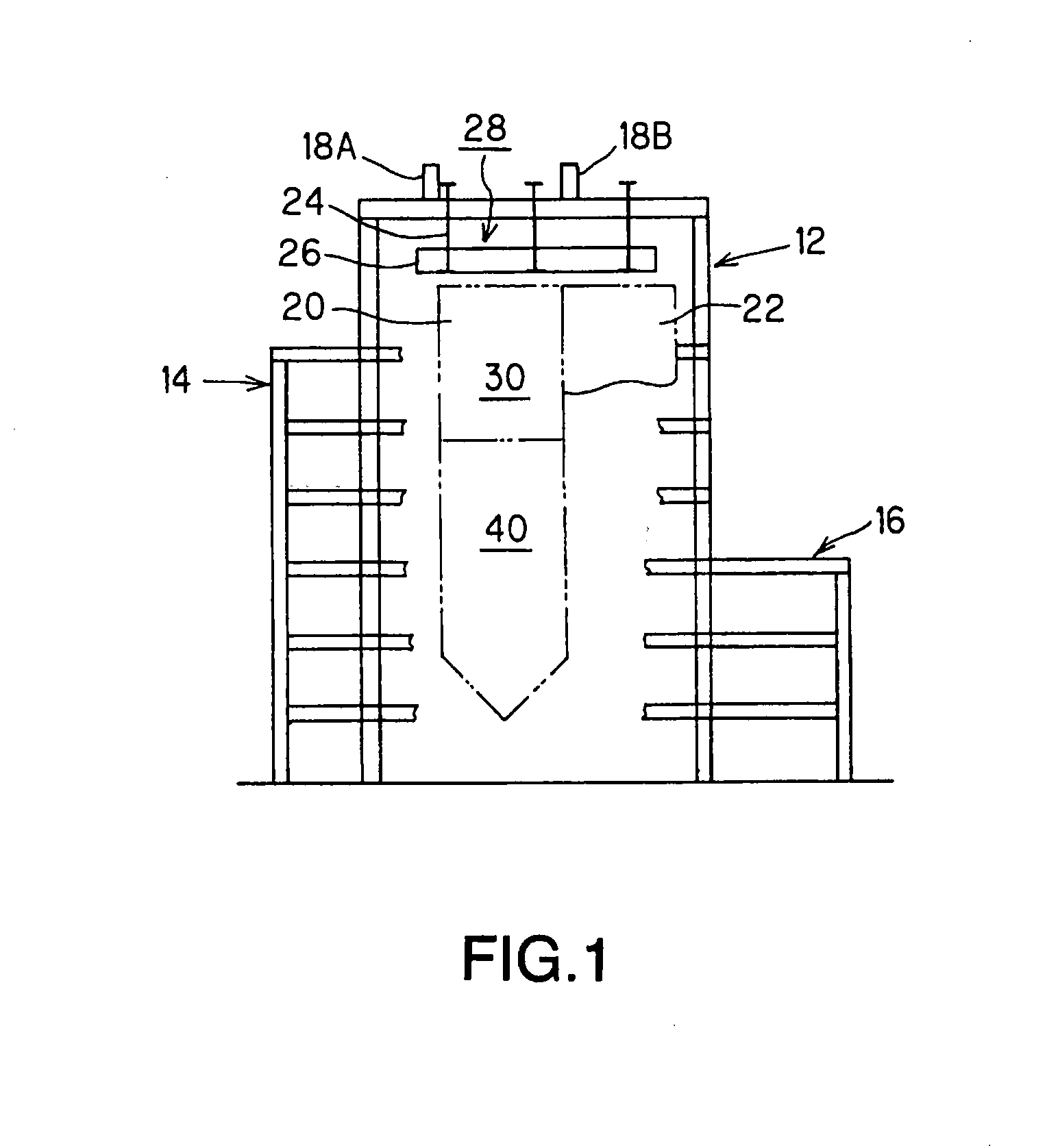

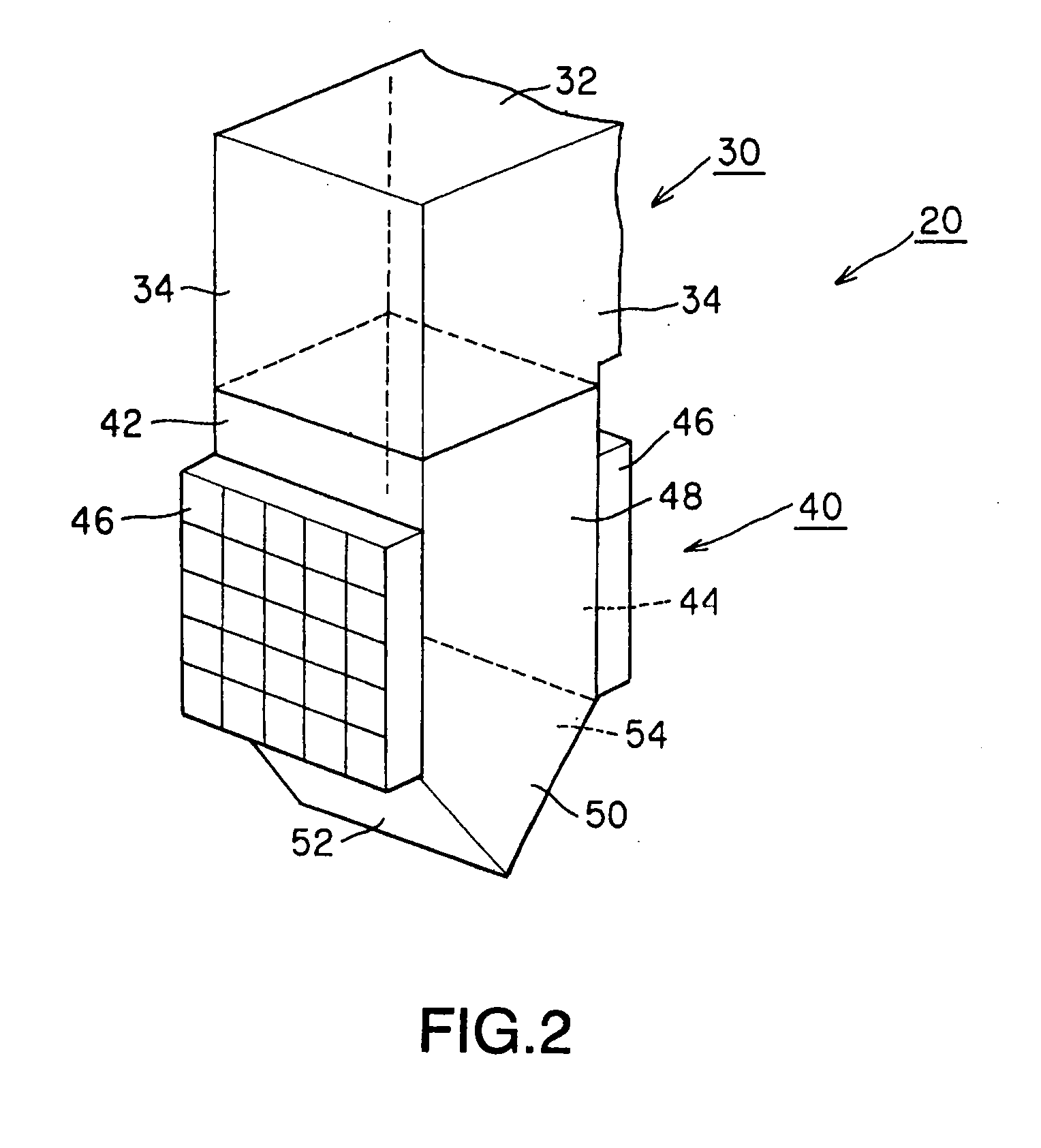

Method of installing furnace walls of a boiler

InactiveUS20070272172A1Guaranteed safe operationOptimize locationBoiler supporting/setting arrangementsFuel injection apparatusWork periodEngineering

New and useful method of installing furnace walls for a boiler that does not require dedicated temporary lifting mechanism and reduces the installation work period significantly is disclosed. The method of installing furnace walls for a boiler configured with an upper portion of boiler proper 30 and a lower portion of boiler proper 40, temporally suspending two left and right face furnace water wall panels 48 among four furnace water wall panels, the upper portion of boiler proper is assembled while it is hanged from a top girder module 28 positioned on the top portion of a center portion in a boiler frame, a furnace rear wall 44 and a furnace front wall 42 among the furnace water wall panels are hanged sequentially, the temporally suspended two left and right face furnace water wall panels 48 are moved to designated positions, and the upper ends of the furnace water wall panels 48, 44 and 42 are connected with the lower end of the upper portion of boiler proper 30.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

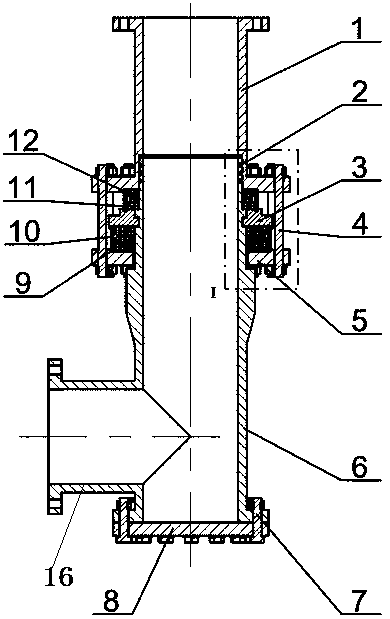

Radial azimuth stepless angle adjustment mechanism for gas drilling manifold

The invention discloses a radial azimuth stepless adjustment for a gas drilling manifold, comprising a fixing sub, a fastener, a hanging flange and a rotating sub; the upper end of the rotating sub is in insertion connection and hermetic fit with the fixing sub, the lower end of the rotating sub is provided with an outlet connection end having predetermined fixing angle, the hanging flange sleeves the rotating sub, the fastener is positioned between the lower end of the fixing sub and the hanging flange, the rotating sub is hung to the fastener, the hanging flange is fixedly connected to the lower end of the fixing sub through a screw set, a roller bearing is disposed in an annular space between the fastener and the hanging flange, and a roller bearing is disposed between the fastener and the lower end of the fixing sub. The radial azimuth stepless adjustment enables the direction of a sand discharge line to be adjusted and enables the sand discharge line to be quickly connected out of a well site, repeated mounting and demounting is avoided, workload and work intensity are greatly reduced for workers, mounting period is shortened, worker cost and crane application expenditure are reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

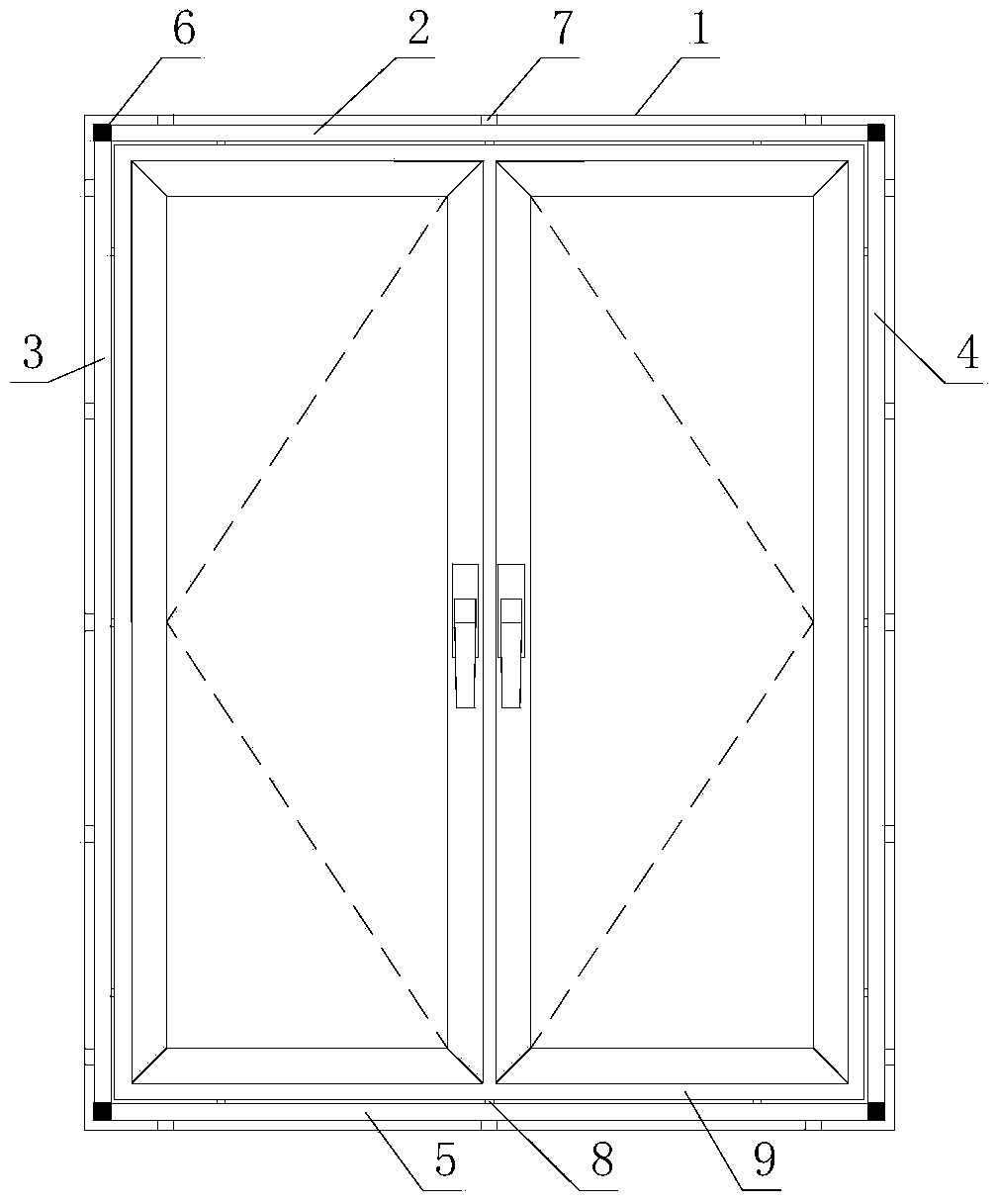

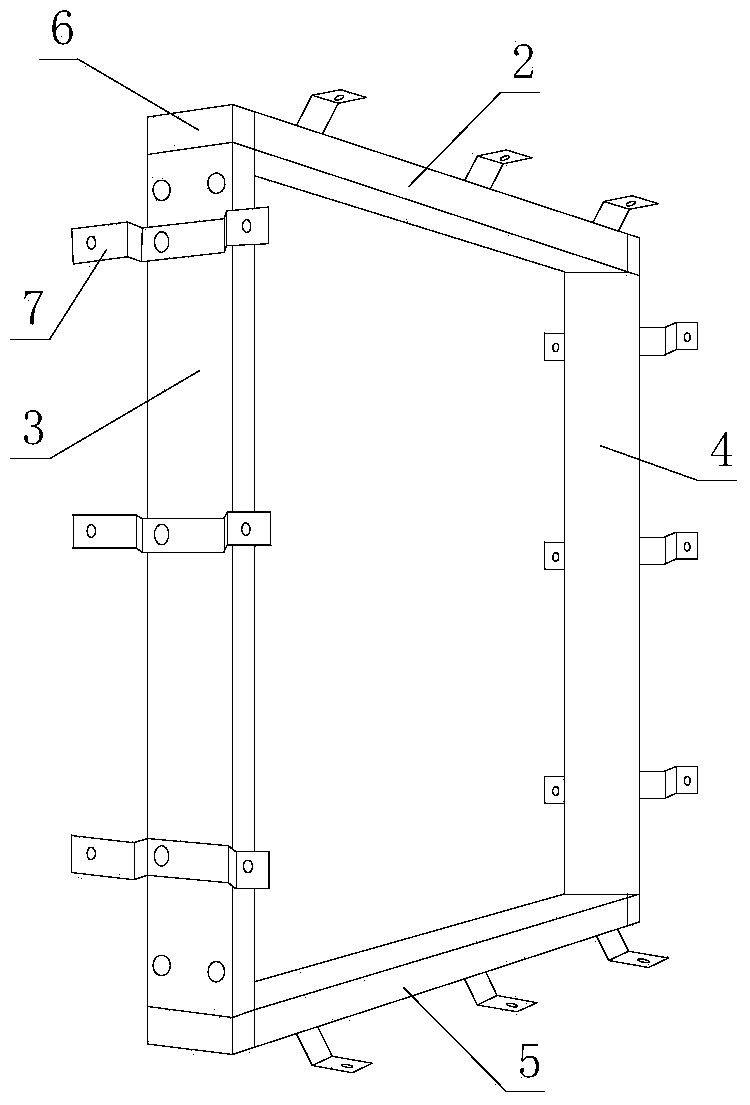

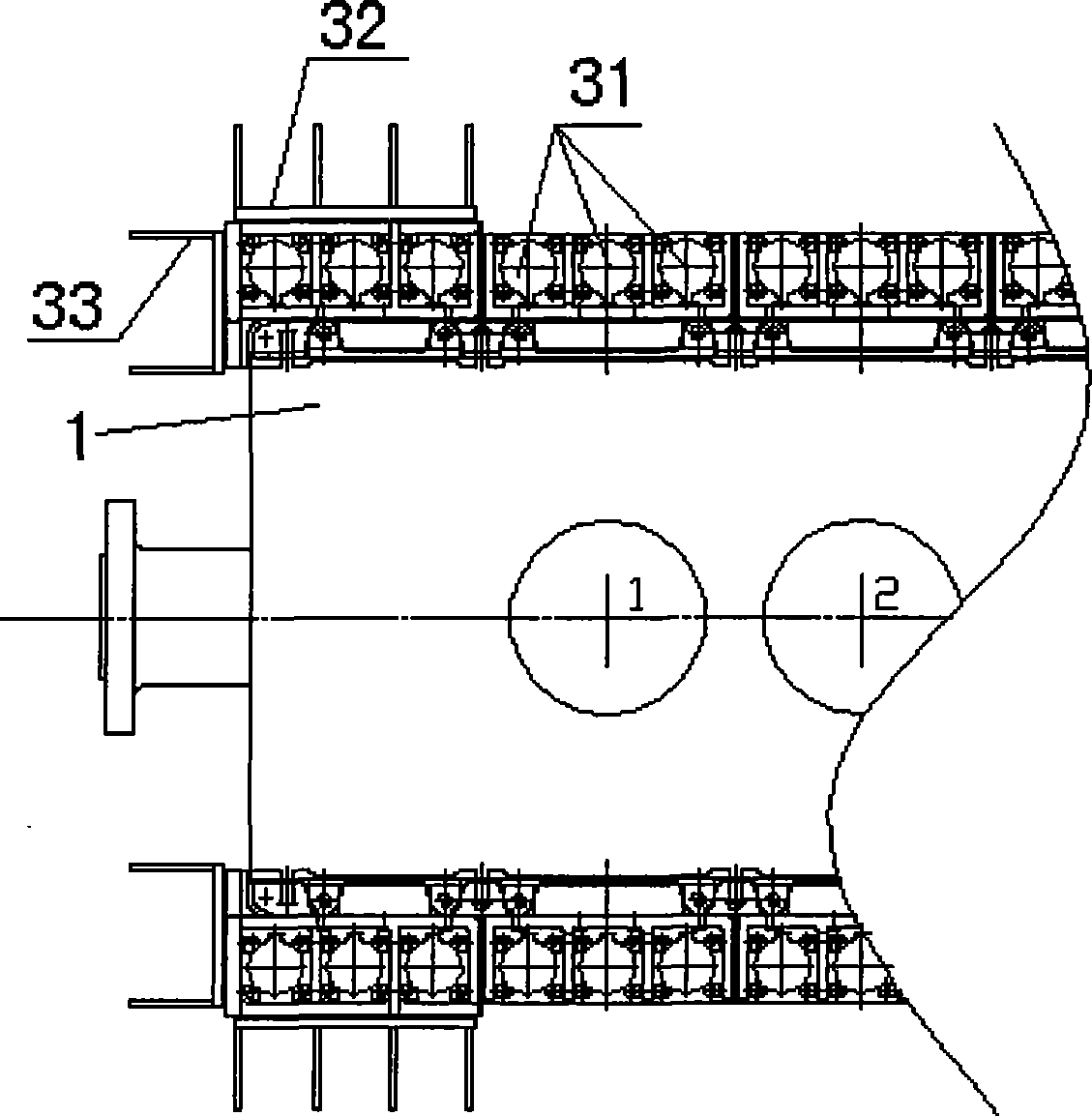

Connecting piece for auxiliary frame and installation method thereof

ActiveCN104712220ANot easy to cause damageShorten the installation cycleFrame fasteningGlass fiberAlloy

The invention discloses a connecting piece for an auxiliary frame and an installation method of the connecting piece for the auxiliary frame. An inner shaft is arranged in a shell, a fixing pin and a positioning pin are arranged in the direction perpendicular to the principle axis of the inner shaft, the positioning pin is arranged at one end of the inner shaft, and the fixing pin is arranged in the middle of the inner shaft. A limiting device is arranged in the shell and is located at the end fixed to the positioning pin through the inner shaft. A cavity is formed in the portion, opposite to the shell, of the surface of the inner shaft, and a spring is arranged in the cavity. According to the connecting piece for the auxiliary frame and the installation method of the connecting piece for the auxiliary frame, the connecting piece serving as a universal connecting piece can be applied to aluminum alloy doors / windows or plastic steel doors / windows or aluminum wood doors / windows or glass fiber reinforced plastic doors / windows, and standard installation is achieved; meanwhile, the connecting piece is arranged between an outer frame and the auxiliary frame, the displacement and deformation performance is effectively improved, connection of the auxiliary frame and the outer frame is not affected, the problem that doors / windows deform due to deformation of a building is solved, and the service life is greatly prolonged; meanwhile, the connecting piece is convenient to dismantle, and installation efficiency is improved.

Owner:常州玖洲联横建材有限公司

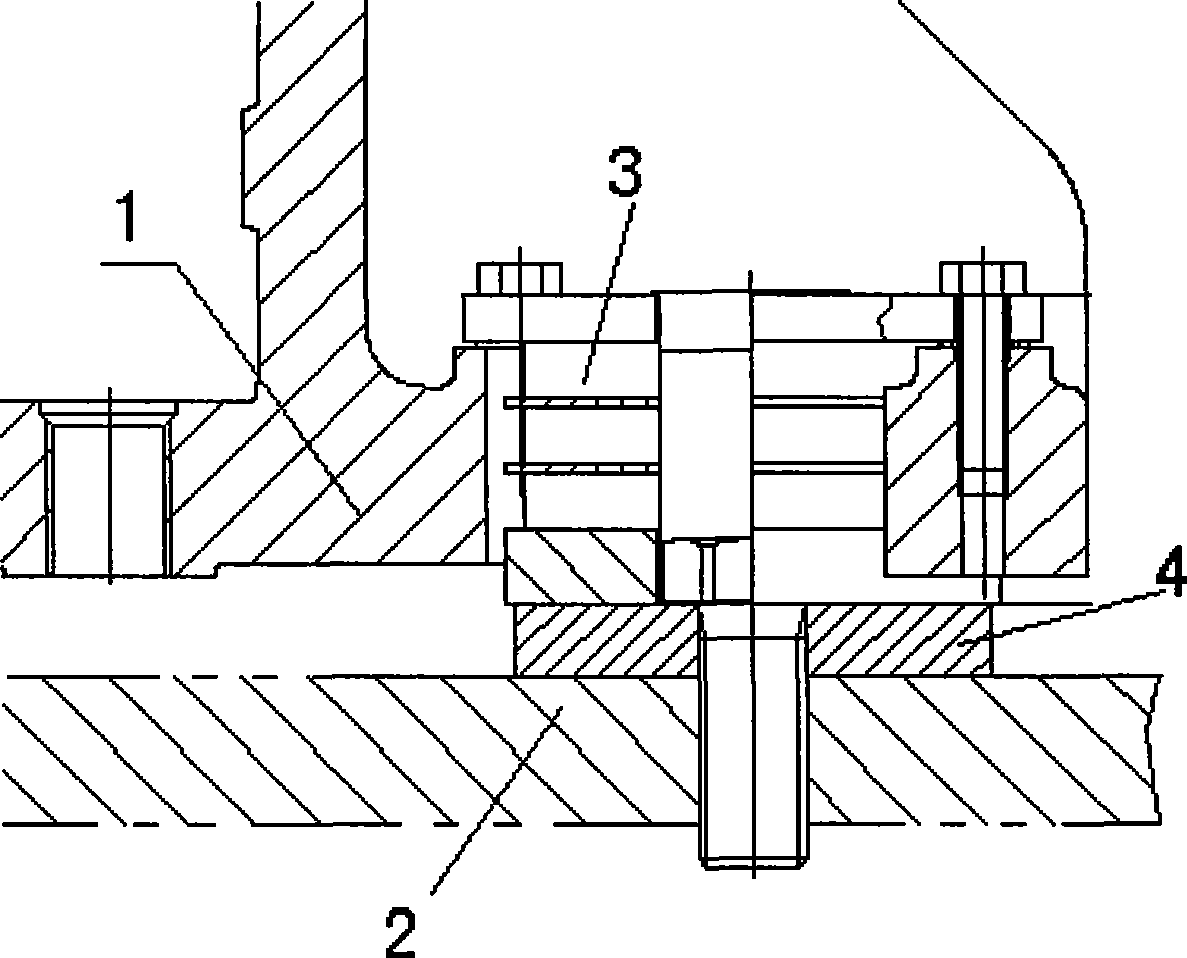

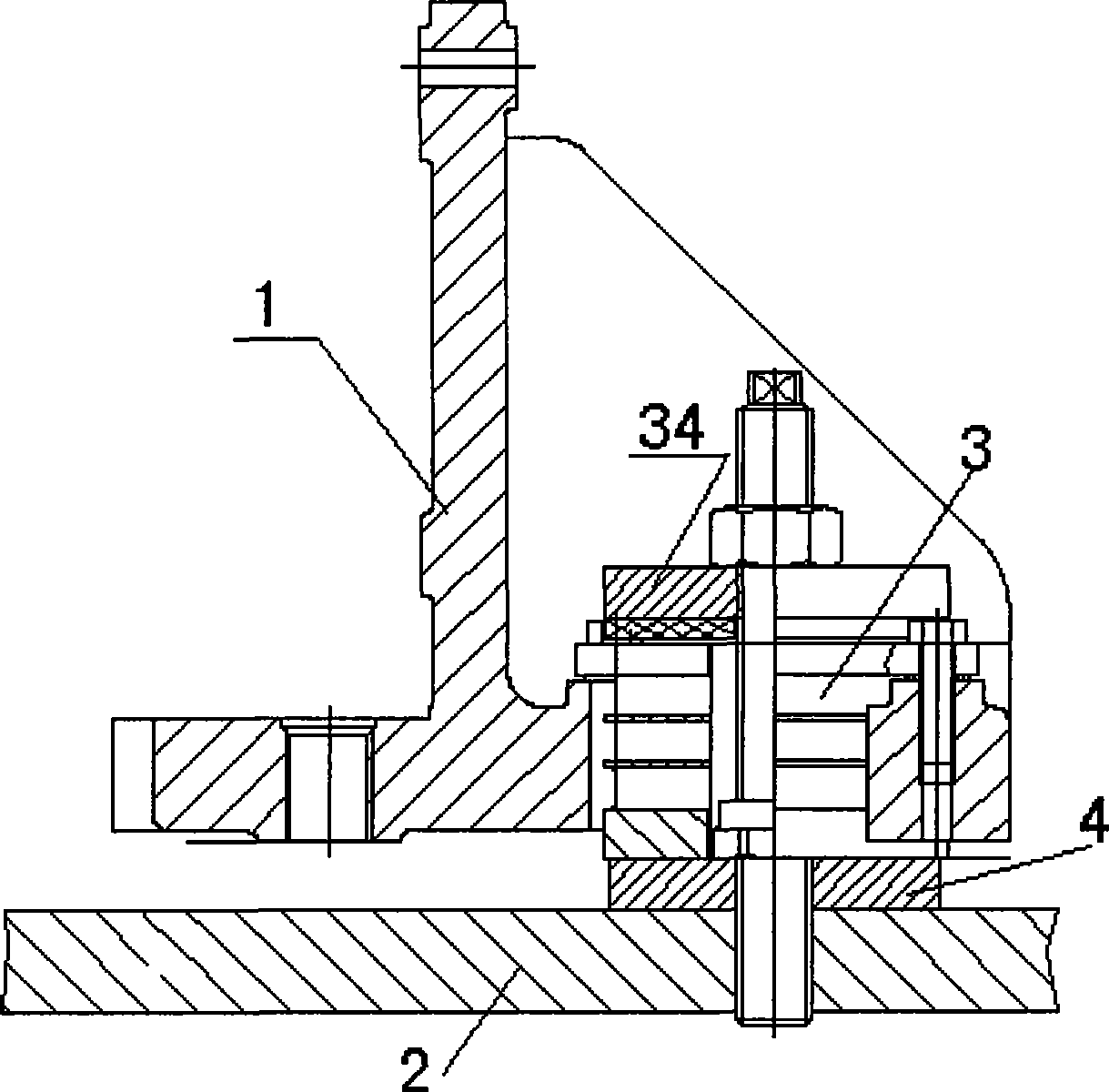

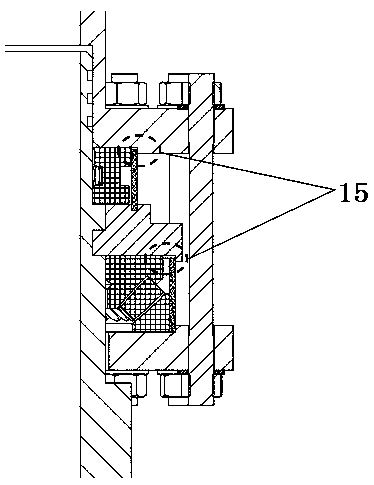

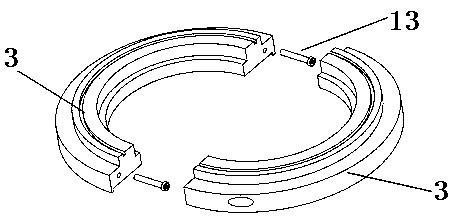

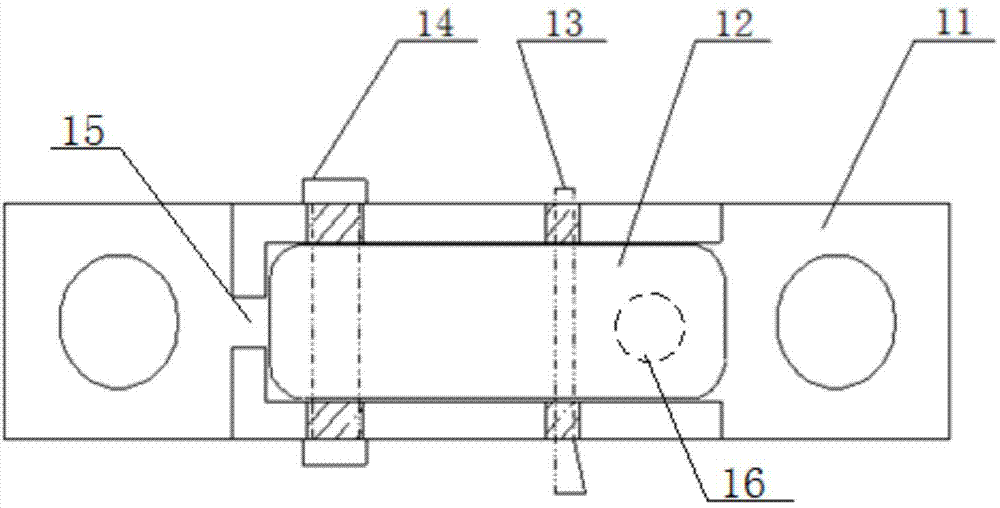

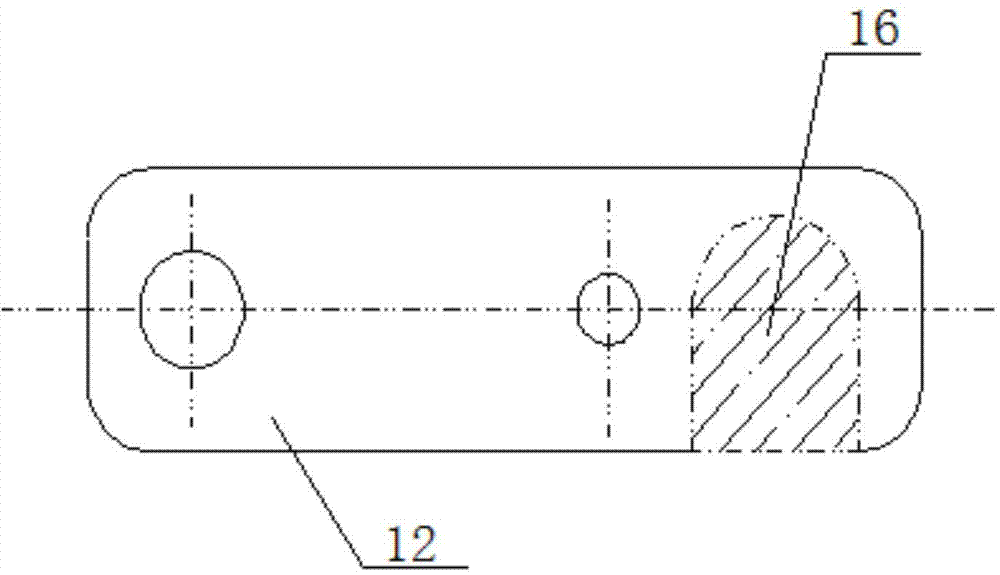

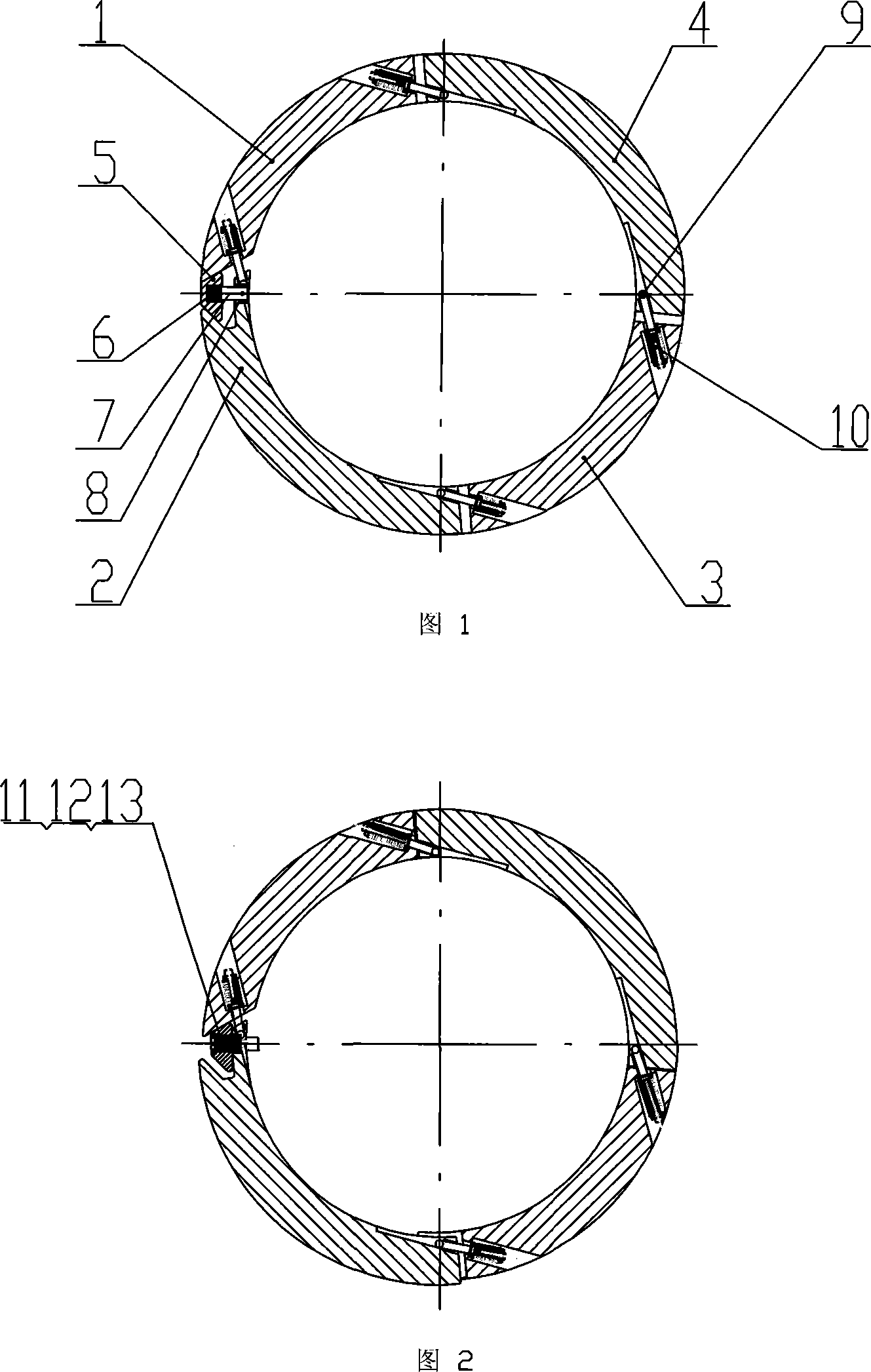

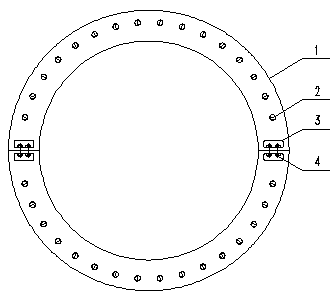

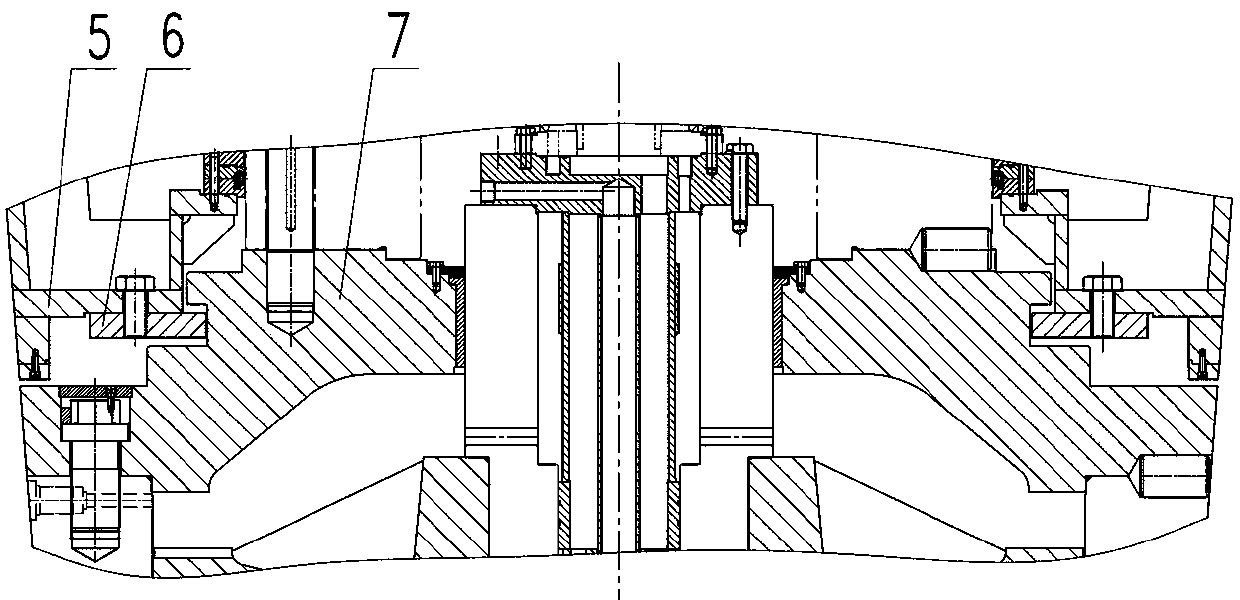

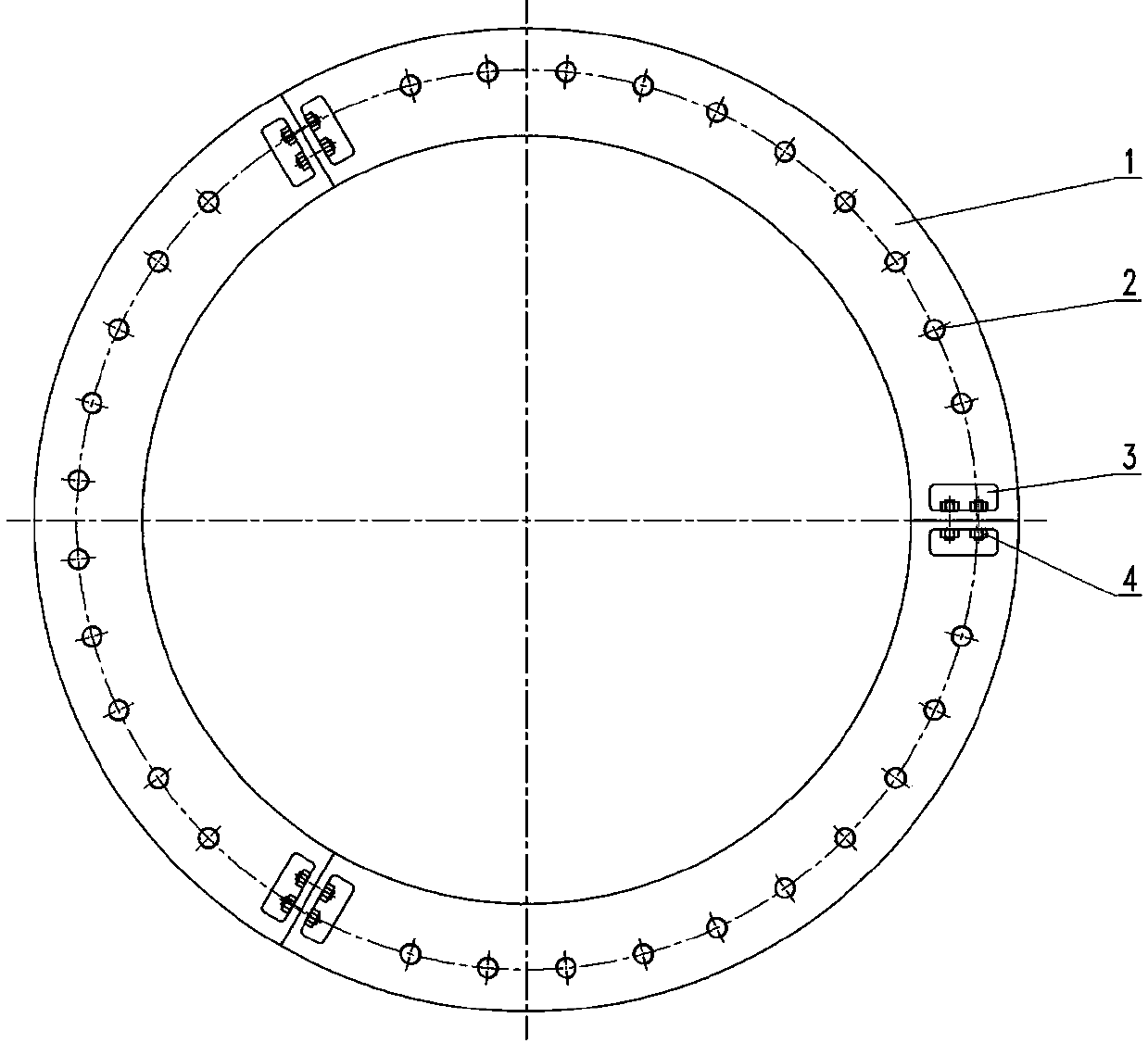

Charge output element and ring-shaped shearing type piezoelectric acceleration sensor

PendingCN107688102AAvoid expansionShorten the installation cycleAcceleration measurement using interia forcesElectricityEngineering

The embodiment of the invention provides a charge output element and a ring-shaped shearing type piezoelectric acceleration sensor which comprises a base, a piezoelectric element, a mass block, a pre-tightening part and a locking part, wherein the base comprises a supporting part, a connecting part and an installing hole; the piezoelectric element is sheathed outside the connecting part, and a ring-shaped gap is formed between the piezoelectric element and the connecting part; the mass block is sheathed outside the piezoelectric element; the pre-tightening part is inserted into the ring-shapedgap; the locking part is provided with a columnar part and a blocking part which are connected; all the elements are locked by matching of the columnar part and the installing hole; and the blockingpart abuts against a first end so as to lead the pre-tightening part to provide a radial pre-tightening force for fastening the piezoelectric element, the mass block and the base. The charge output element and the ring-shaped shearing type piezoelectric acceleration sensor provided by the embodiment of the invention have the advantages that due to rigid contact between the charge output elements,the contact rigidity of the whole structure can be greatly improved, and adhesion is not needed, so that the installation period of the charge output elements is effectively shortened.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

Coiling machine sleeve barrel with wrench jaw

The invention relates to a recoiler sleeve provided with a gate, comprising more than 3 sector-shaped boards. By being connected with bolts, the sector-shaped boards are connected into a whole with disk springs on the joint position. The invention is characterized in that a gate is arranged between two boards of the sector-shaped boards; the gate position also comprises a gate slide block, a gate slide block jack system and a gate slide block resetting device. The clamp slide block is matched with the gate and as the diameter expanding and shrinking of the recoiler sleeve is pushed out and back to and fro through the gate under the action of the gate slide block resetting device, the tightening and opening of the gate is realized. The invention realizes rolling up belt coils with different internal diameters on one recoiler, which enhances the utilization rate and production efficiency of the equipment and has dramatic economic benefit.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

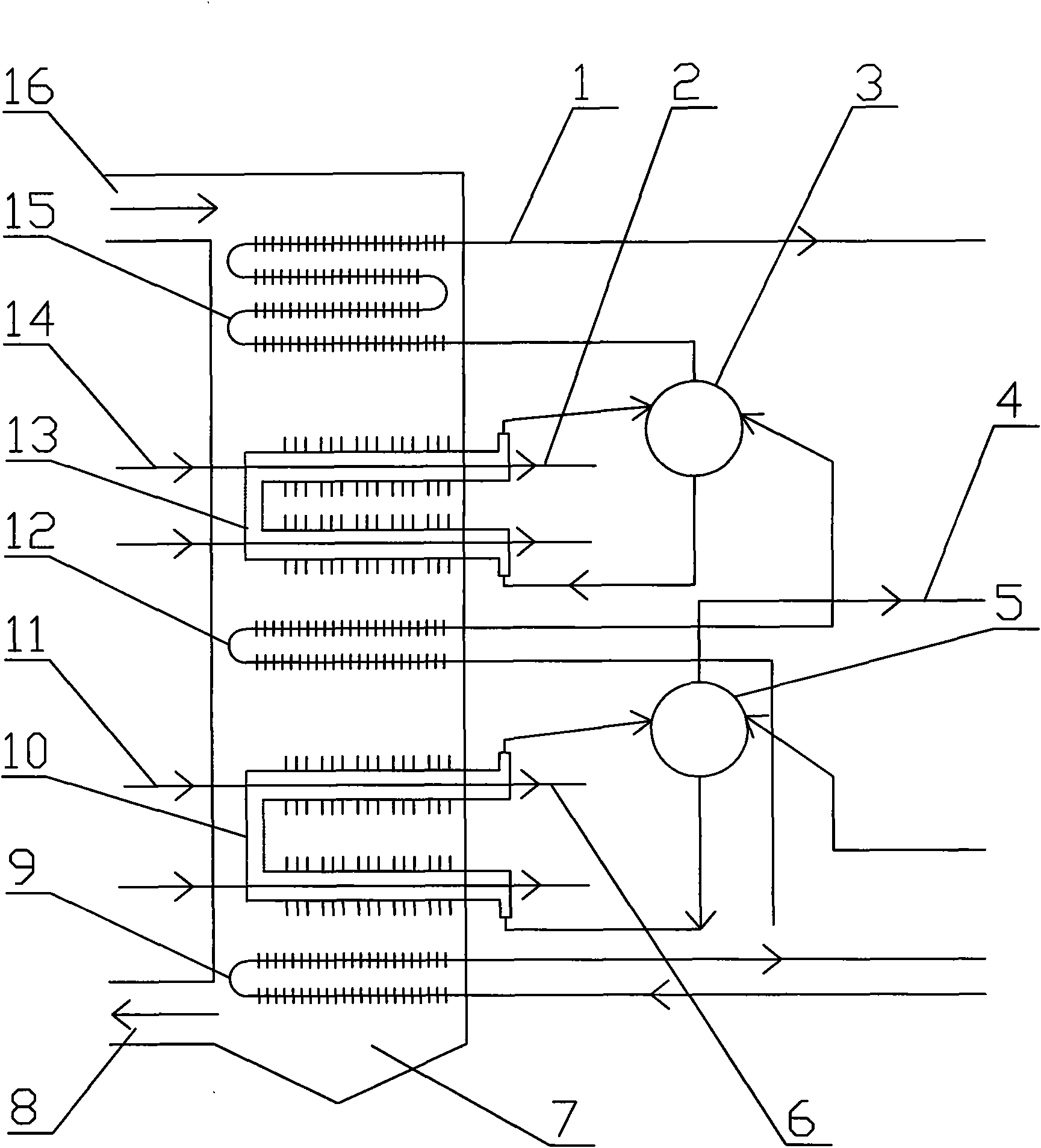

Double-working substance heat source sintering cogeneration-type boiler system

ActiveCN101832718ALarge self-generated electricityImprove heat transfer effectEnergy industryIncreasing energy efficiencyElectricityFlue gas

The invention relates to an afterheat boiler system, in particular to a double-working substance heat source sintering cogeneration-type boiler system. The system comprises a vertical cooling machine, a sintering machine, a cogeneration-type boiler, a steam condensing and compensating turbine and a generator, wherein hot air produced by the vertical cooling machine is introduced into the upper part of the cogeneration-type boiler through a pipeline; warm flue gas in the sintering machine is introduced into a sleeve-type medium-pressure evaporator on the upper-middle part of the cogeneration-type boiler through the pipeline; low-temperature flue gas of the sintering machine is introduced into a sleeve-type low-pressure evaporator on the lower-middle part of the cogeneration-type boiler through the pipeline; medium-pressure over-heat steam produced by the cogeneration-type boiler is introduced into a main steam port of the steam condensing and compensating turbine through the pipeline; and low-temperature saturated steam produced by the cogeneration-type boiler is introduced into the steam compensating port of the steam condensing and compensating turbine through the pipeline so that the steam condensing and compensating turbine drives the generator to generate electricity. By taking energy cascade utilization as a theoretical basis and taking heat exchange equipment of the vertical cooling machine as source equipment, the system integrates and recoveries the afterheat of sintering flue gas efficiently and realizes the maximum generated electricity converted from heat power.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

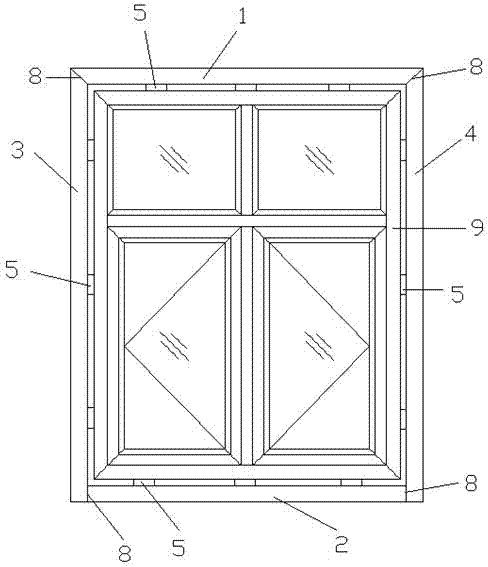

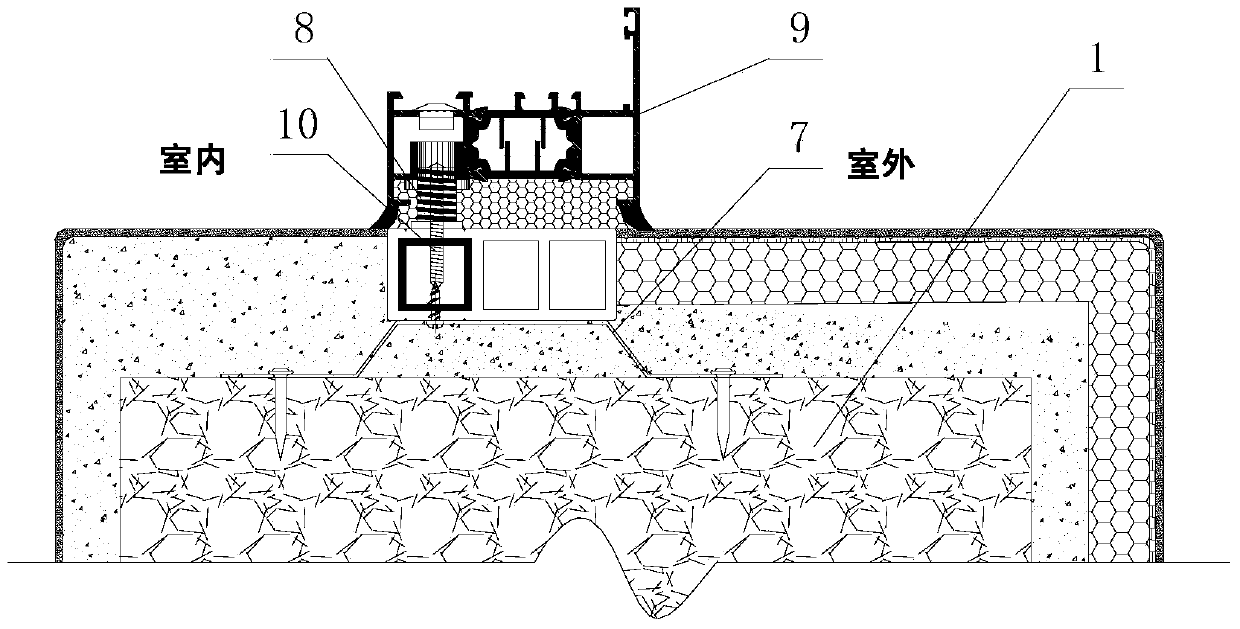

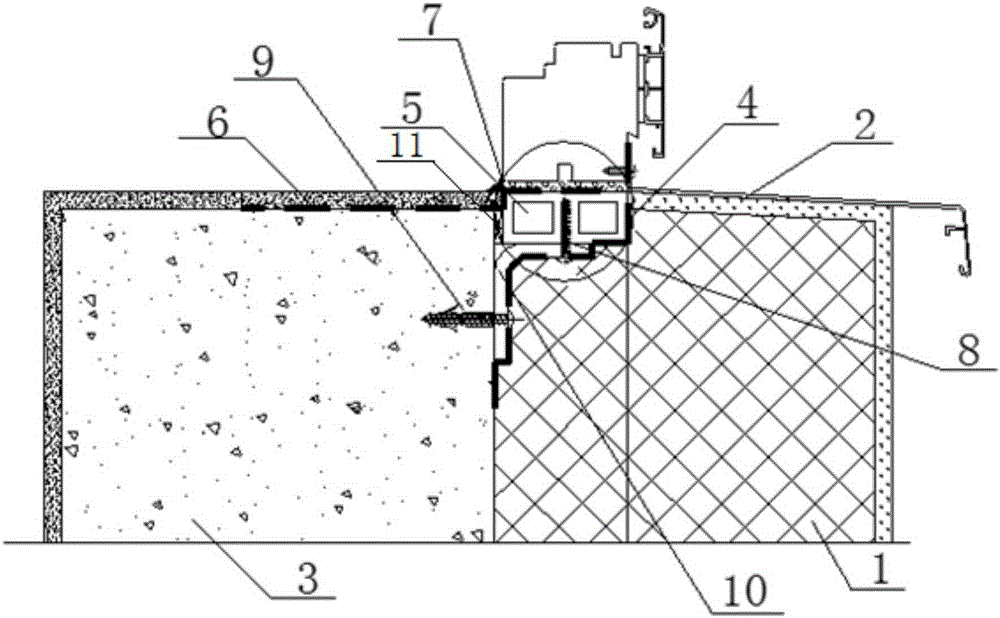

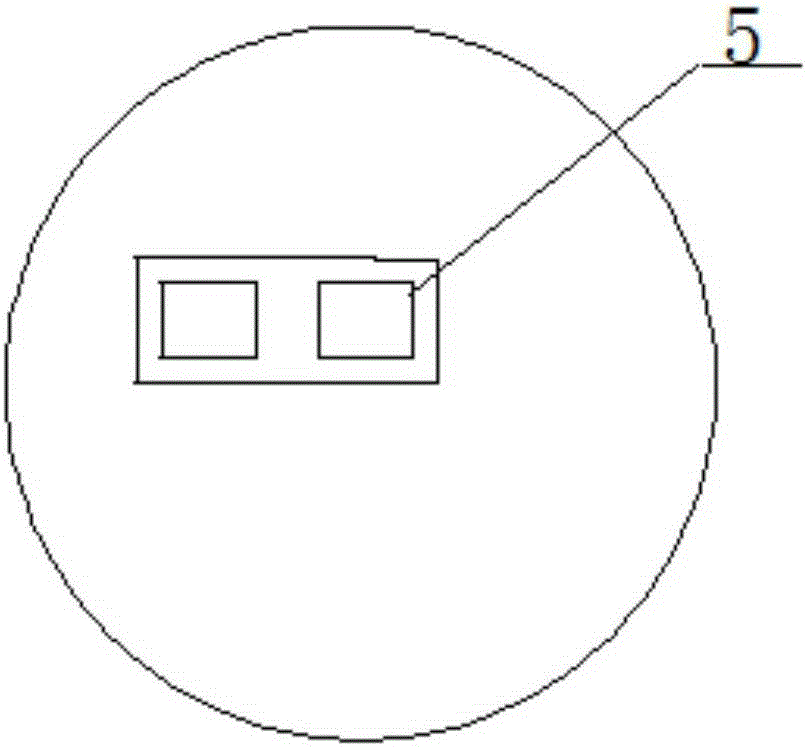

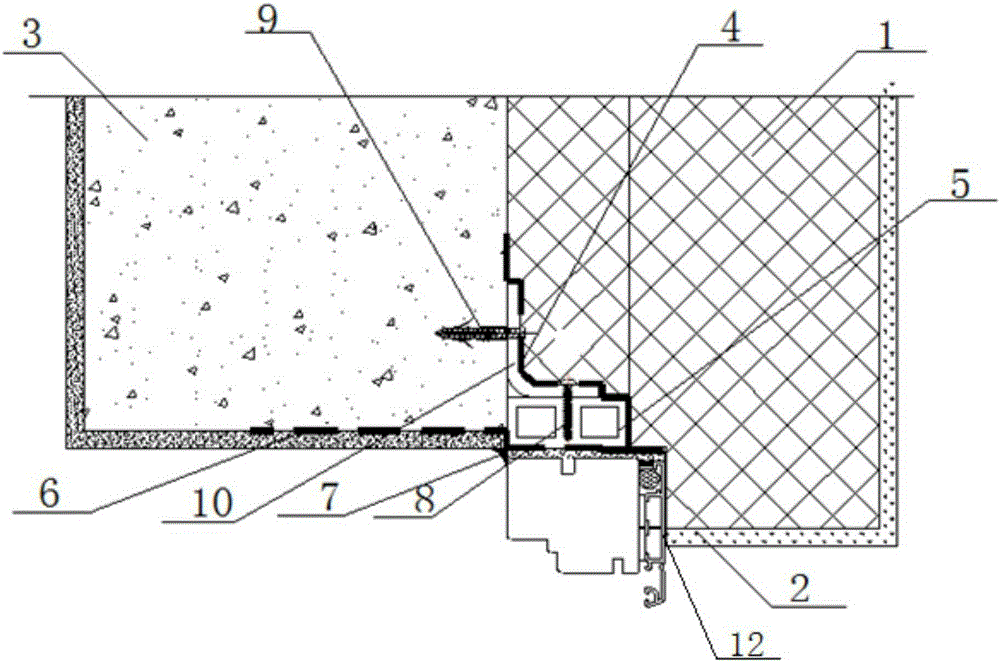

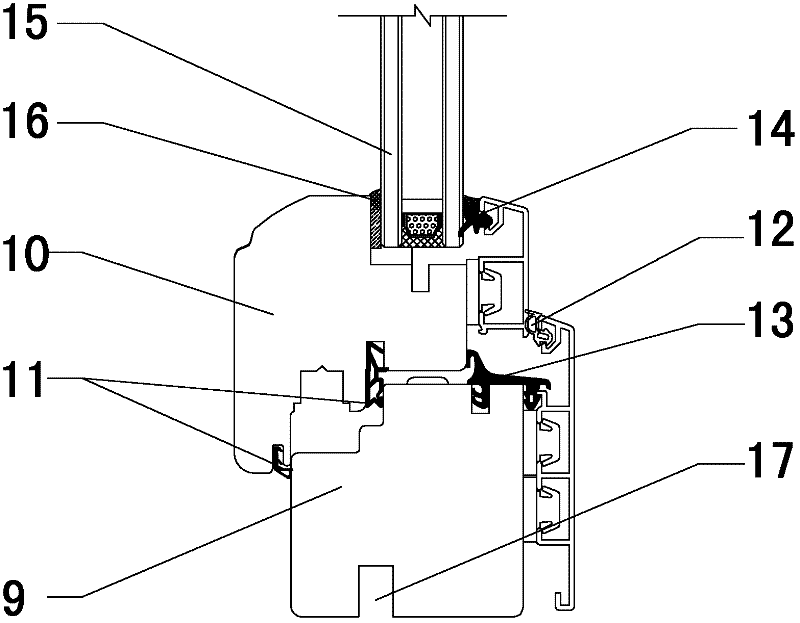

Passive window with auxiliary frame and installation method thereof

InactiveCN105201335ATo overcome the defect that the maintenance needs to remove the wallGuaranteed air tightnessFrame fasteningBase framesWindow openingEngineering

The invention discloses a passive window structure with an auxiliary frame and an installation method thereof. The installation method comprises the following steps: (1) installing the auxiliary frame on a wall at the outer side of a window opening, embedding in an outer insulating layer, and enabling four sides of the auxiliary frame to be respectively consistent with the window opening in verticality and levelness; (2) after the auxiliary frame is installed, sticking a waterproof and breathable membrane on the outer surface of the auxiliary frame, sticking a waterproof and gas-isolated membrane on the front of the auxiliary frame, and installing positioning lines on the outside top surface and two side surfaces of the auxiliary frame; and (3) connecting the auxiliary frame with the passive window to finish installation. After the auxiliary frame of the passive window is adopted, the passive window disclosed by the invention is simpler in structure, can completely meet the energy-saving requirement, is more reasonable in design, is energy-saving and environment-friendly, is reduced in cost, convenient in installation and standardized in installation, thoroughly solves the connection problem of passive window installation and external insulation construction, and is increased in installation yield.

Owner:常州玖洲联横建材有限公司

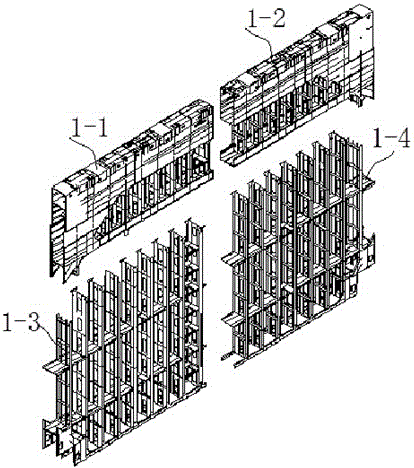

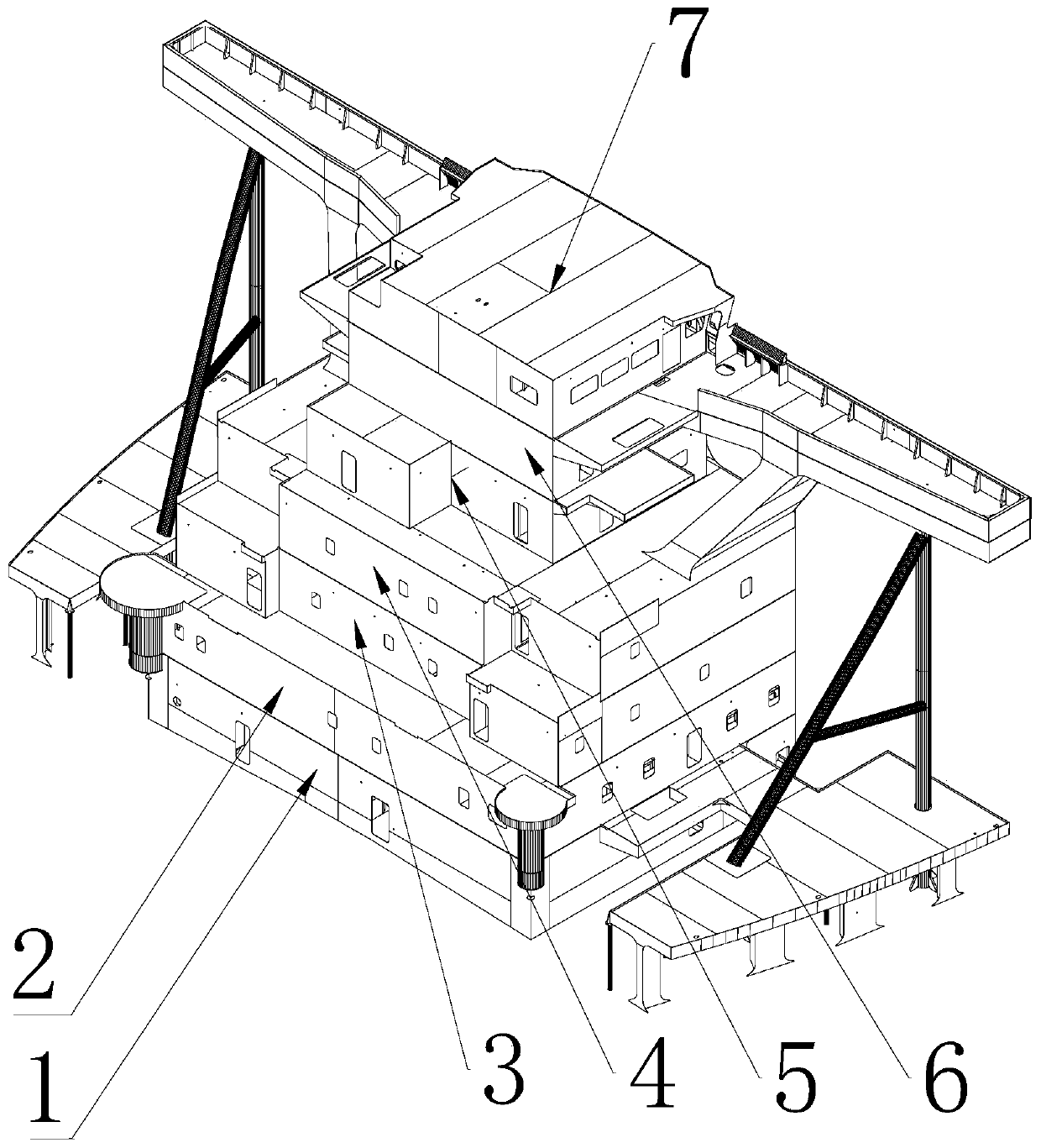

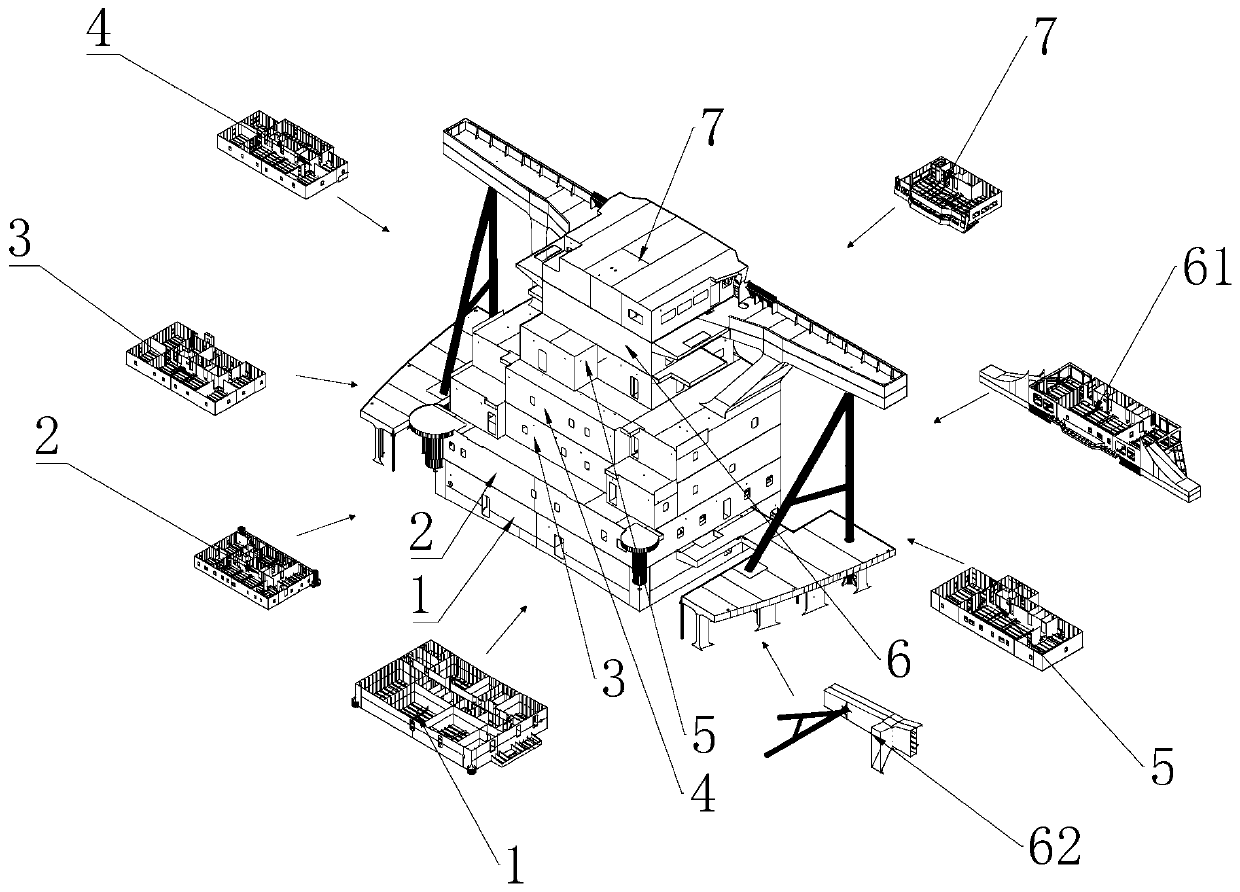

Pre-assembling method of large-sized ship superstructure

InactiveCN110562386AShorten the installation cycleReduce labor costsVessel partsMarine engineeringEconomic benefits

The invention discloses a pre-assembling method of a large-sized ship superstructure. The large-sized ship superstructure comprises a first deck section, a second deck section, a third deck section, afourth deck section, a fifth deck section, a navigation bridge deck section and a compass deck section, wherein the navigation bridge deck section comprises a first sub section and a second sub section; the pre-assembling method of the large-sized ship superstructure comprises the following steps of (1) hoisting the first deck section as a positioning section to perform position an upper tire; and (2) hoisting the second deck section, the third deck section, the fourth deck section, the fifth deck section, the first sub section, the second sub section and the compass deck section in sequenceto be positioned and mounted. According to the pre-assembling method of the large-sized ship superstructure, through pre-assembling construction method, the large-sized ship superstructure and a mainhull are constructed in a concurrent manner so that the mounting period in a dock is greatly shortened and the labor cost is greatly reduced; and through procedure advancing, a production node can besatisfied, and the construction period in the dock can be greatly shortened. The awkward situation of the construction progress is prevented from being affected due to limitation on a site; and the safety, quality, environment and economic benefit aspects are all greatly improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

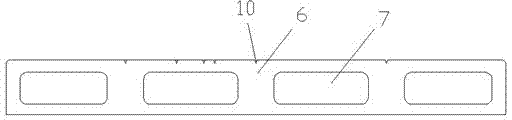

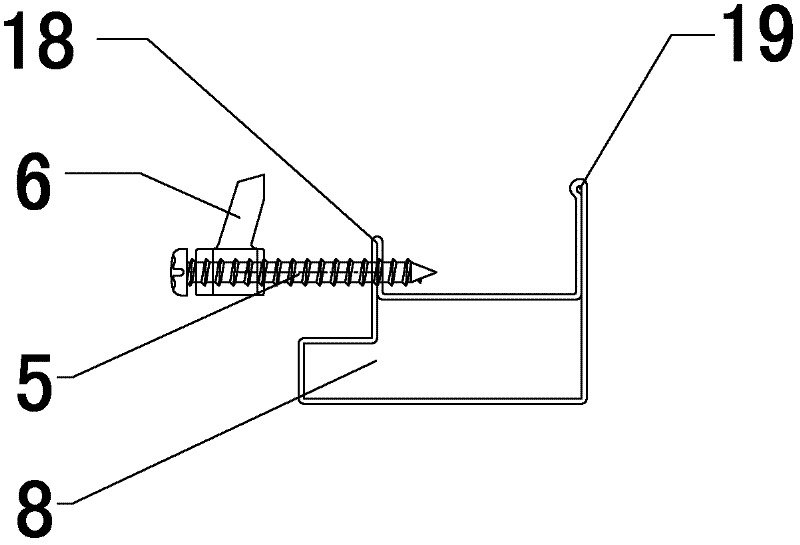

Heat preservation doors and windows with conveniently-dismounted attached frames of doors and windows

ActiveCN102409926AEasy to processReasonable structureFrame fasteningSealing arrangementsEngineeringMaterials processing

The invention relates to heat preservation doors and windows with conveniently-dismounted attached frames of the doors and windows. The heat preservation doors and windows comprise heat preservation doors and windows as well as attached frames of the doors and windows, wherein the attached frames of the doors and windows are connected with a building structure with openings to be mounted with the doors and windows through expansion bolts; the attached frames are provided with pitch-adjustable T-shaped pieces; the heat preservation doors and windows are clamped with the attached frames through processed mounting clamping grooves which are arranged outside window frames and the pitch-adjustable T-shaped pieces having adjustable screws; and sealing strips are additionally arranged on the outer edges of the attached frames and used for ensuring the sealing between the doors and windows and the attached frames after the installation. The heat preservation doors and windows provided by the invention have the advantages of simple structure, convenience for material processing, simplicity for installation and strong adjustability, besides, the attached frames of the doors and windows are mounted outside the doors and windows through elastic, weather-resistant, formed and heat-insulating sealing strips, the conventional gluing sealing technology is discarded, so that the installation is simpler and more convenient, the sealing effect and service life of the doors and windows are largely improved and prolonged respectively, meanwhile the energy saving and heat preservation effects of the doors and windows are also improved; moreover, mounting holes are unnecessary to punch on the doors and windows, therefore the air tightness and water tightness of the doors and windows are improved, and the processing steps are reduced.

Owner:BEIJING MELOOK DOOR & WINDOWS COP

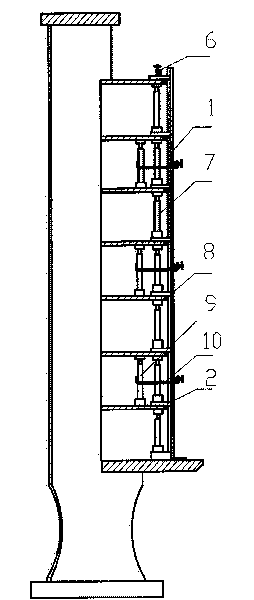

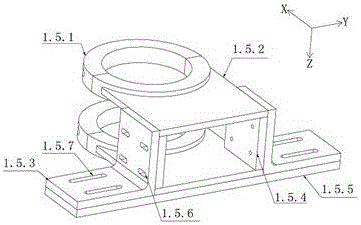

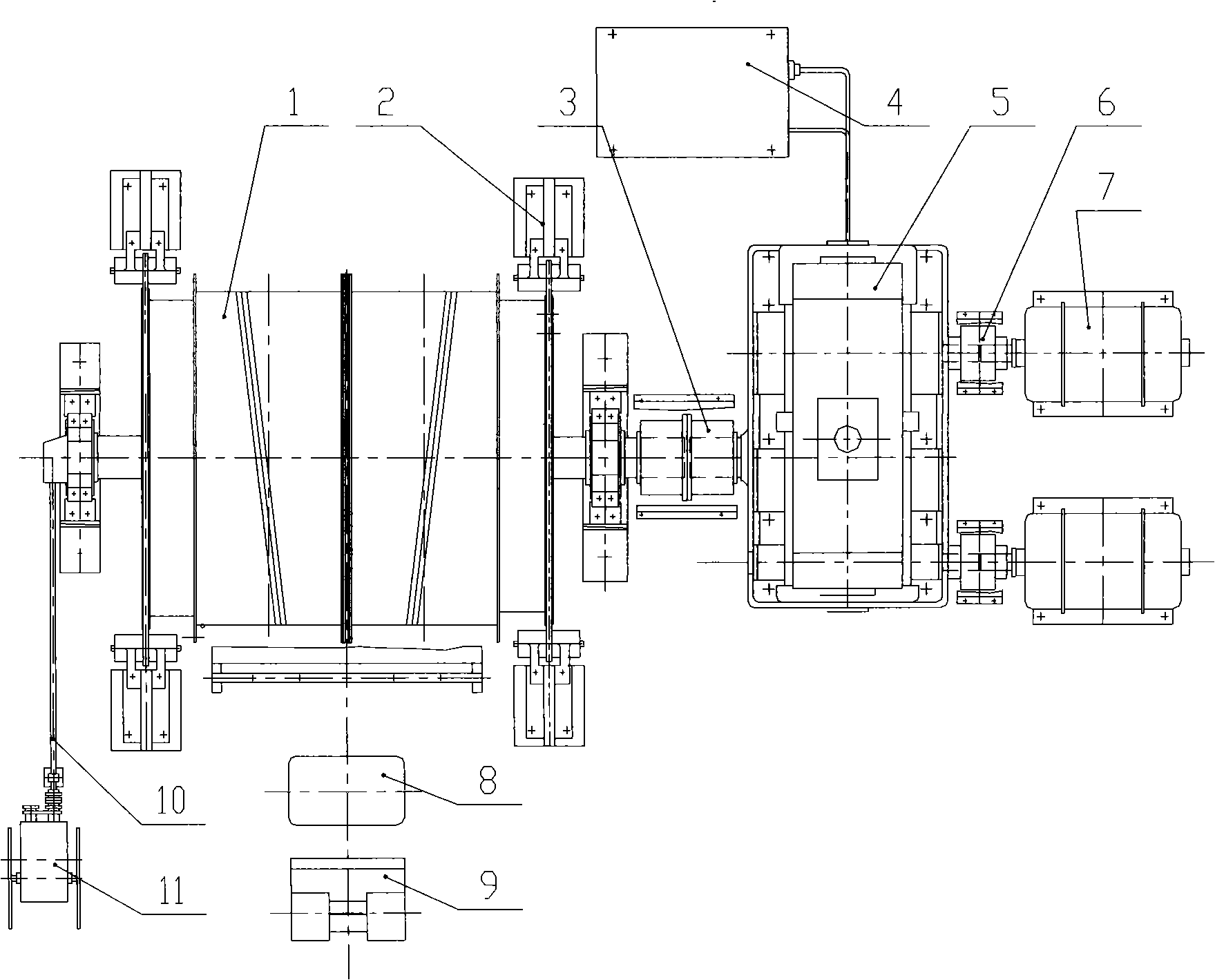

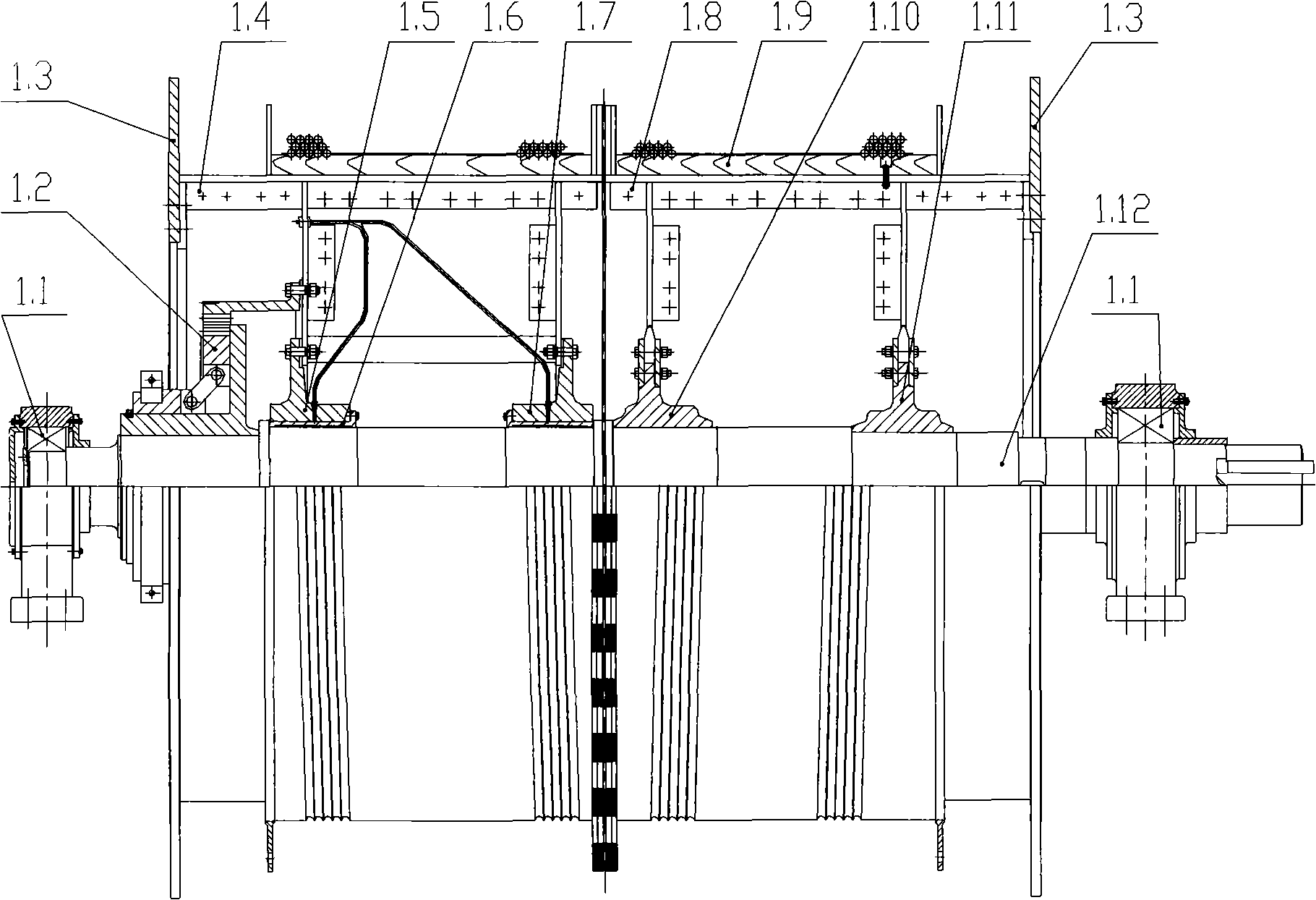

Novel sinking hoist

InactiveCN101279699AImprove product qualityShorten the installation cycleWinding mechanismsClutchLubrication

The invention relates to a novel sinking hoist; a speed reducer (5) is connected with a motor (7) and a main shaft device (1) through an elastic pin coupling (6) and a gear coupling (3); a disc-shaped brake device (2) is allocated; an idle end is connected with a driving device (12) of a depth indicator; the indicator monitors the depth of sinking and is controlled by a control box (9), a lubrication station (4) and a hydraulic station (8) provide lubrication and brake oil pressure. A main shaft (1.12) is fixed by a rolling element bearing house (1.1); a motile reel (1.4) and a fixed reel (1.8) are arrayed; the two ends fix a fabricated brake disc (1.3); the reel is embedded with a plastic liner (1.9); the motile reel is fixedly connected with a left and a right wheel hubs (1.5 and 1.7) and is internally provided with two semi-copper tiles (1.6); the motile reel does not rotate along with the main shaft and is connected with a rope adjusting clutch (1.2); the fixed reel is fixedly connected with a left and a right wheel hubs (1.10 and 1.11) and rotates along with the main shaft. The sinking hoist has unique structure.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Axial-flow kaplan turbine rotating-wheel hoisting and suspension method

ActiveCN104176619AConvenience guaranteedGuaranteed accuracyLoad-engaging elementsHydraulic turbinesKaplan turbine

The invention discloses an axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring solves the problem that the existing axial-flow kaplan turbine rotating-wheel hoisting and suspension method has complex processes and is inconvenient for operation. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring comprises at least two arc-shaped snap ring bodies and the snap ring bodies are uniformly provided with screw holes for combining the snap ring bodies and a kaplan turbine diversion cone. The axial-flow kaplan turbine rotating-wheel hoisting and suspension snap ring has a simple structure, is free of tooling holes of a base ring and blade main bodies, is free of a concave ring groove or a raised ring belt of a main shaft, can be simply and conveniently operated, saves many processes, and greatly improves set installation and unkeep work efficiency.

Owner:DONGFANG ELECTRIC MACHINERY

Roughening-free construction method and mould for precast hollow slab girder

ActiveCN108908662AReduce construction difficultyClosely connectedDischarging arrangementMouldsPlate girderBuilding construction

The invention relates to a roughening-free construction method and mould for a precast hollow slab girder, relates to the field of bridge building construction, and solves the problem that the surfaceof the precast hollow slab girder is difficultly roughened. The roughening-free construction mould comprises a bottom formwork of a rectangular groove structure with an opening in the upper end, an end formwork and a lateral formwork, wherein the lateral formwork comprises an external plate and a plurality of inner lining plates which are detachably connected to the inner side of the external plate, a plurality of paralleled protruding ribs which make contact with the surface of the precast hollow slab girder are arranged on the inner surfaces of the inner lining plates, grooves are formed inthe inner side face of the external plate, the inner lining plates are inserted into the grooves and are flush with the surface of the external plate, and locking bolts penetrate through the externalplate from the outer side face to the inner side face and are in threaded connection with the inner lining plates. In the slab girder precasting stage, roughening is conducted, grooved rough surfaceswhich are uniformly distributed are formed, and construction is simple.

Owner:北京中兴恒工程咨询有限公司

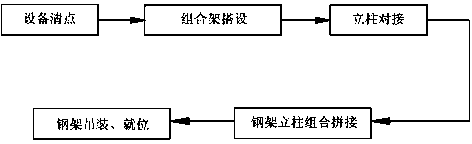

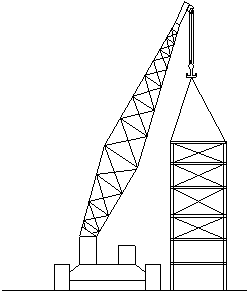

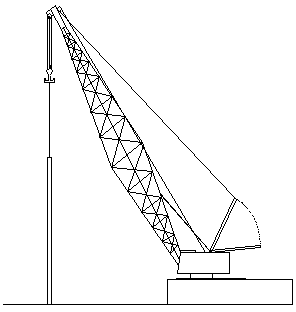

Boiler steel frame combination and installation process of sintering machine circular cooler

ActiveCN104033878AImprove installation stabilityShorten the installation cycleBoiler supporting/setting arrangementsTruckMotherboard

The invention discloses a boiler steel frame combination and installation process of a sintering machine circular cooler. According to the process, a left central line and a right central line are marked on the upper section and the lower section of each stand column; the two sides of connectors are padded firmly and leveled respectively in the butting process; the left central lines and the right central lines are led to bottom plates and top plates; the stand columns are aligned and leveled, and limiting pieces are welded; when stand column single pieces are combined, the top planes of the columns serve as the same datum point, a 25-ton truck crane is adopted to hoist assemblies, and marker lines on the periphery of column foot bottom plates coincide with in-position lines on a foundation when the assemblies are in position; a front framework is hoisted before the top plates are hoisted, and a rear framework is hoisted before air preheater tube boxes are hoisted; after front columns, front beams, rear columns and rear beams are installed in position, and the column feet and the foundation are fixed, single-piece hoisting and assembly hoisting are combined, action lines of loading of main slab beams pass through the centers of the stand columns in the installation process, and secondary grouting is carried out after hoisting of all large components of the boiler is completed. Through the process, the tightness of installation can be guaranteed in the installation process, the installation stability is high, and the installation cycle of the steel frame is short.

Owner:CHINA MCC5 GROUP CORP

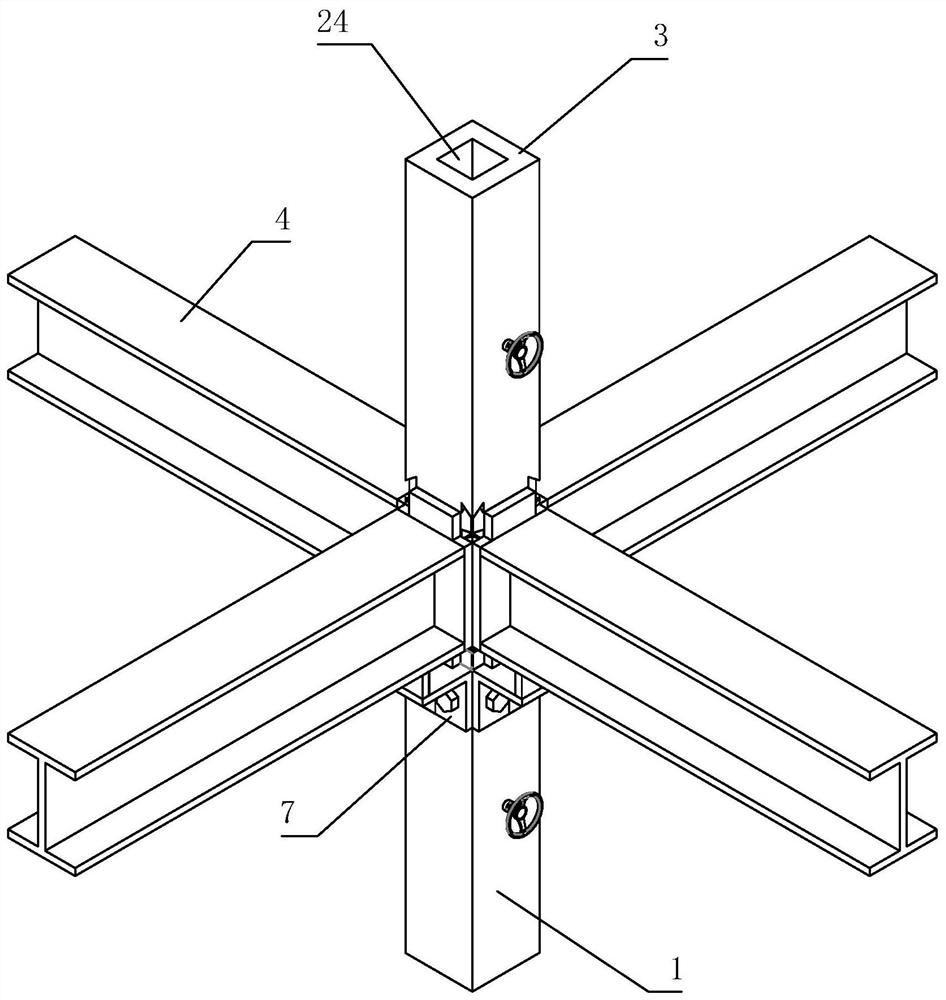

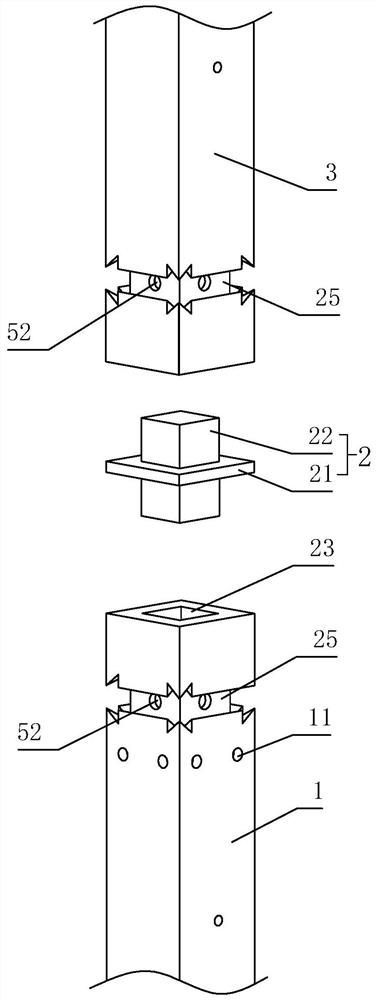

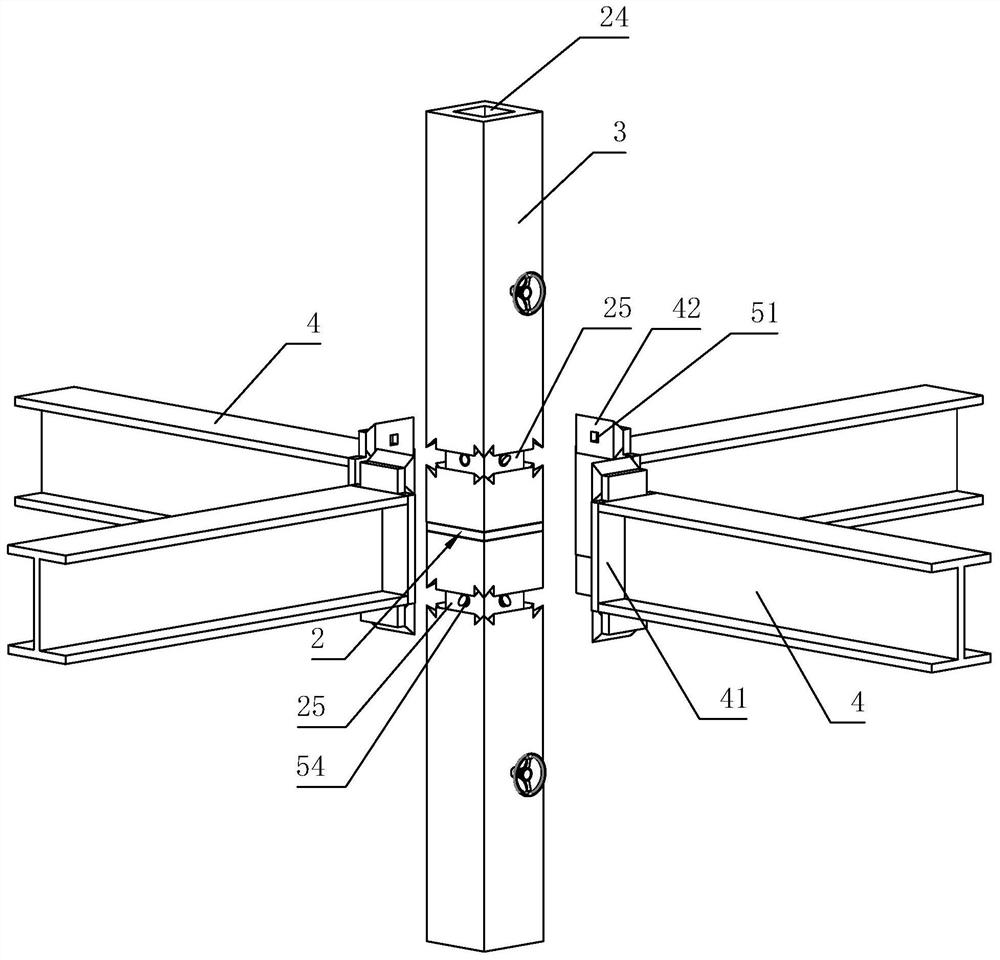

Fabricated building frame hollow column joint structure and construction method thereof

ActiveCN111894128ARealize fixed installationImprove installation efficiencyStrutsBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to a fabricated building frame hollow column joint structure. The fabricated building frame hollow column joint structure comprises lower-layer prefabricated stand columns, connecting column bodies inserted into the upper portions of the lower-layer prefabricated stand columns, upper-layer prefabricated stand columns arranged on the upper portions of the connecting column bodies in a sleeving mode and cross beams with the ends installed on the lower side walls of the upper-layer prefabricated stand columns and the upper side walls of the lower-layer prefabricated stand columns; mounting cavities are formed in the upper end faces of the upper-layer prefabricated stand columns and the lower end faces of the lower-layer prefabricated stand columns in the vertical direction, dovetail grooves extending in the horizontal direction are formed in the outer side walls, located in the mounting cavities, of the upper-layer prefabricated stand columns and the outer side walls, located in the mounting cavities, of the lower-layer prefabricated stand columns, mounting plates are fixedly connected to the ends of the cross beams, dovetail blocks embedded in the dovetail grooves in a sliding mode are arranged on the side wall of the mounting plates in a protruding mode, and the mounting cavities are provided with limiting mechanisms for limiting the sliding positions of the dovetail blocks. The fabricated building frame hollow column joint structure has the effect of facilitating installation of the beam column joint.

Owner:广东中博建设工程有限公司

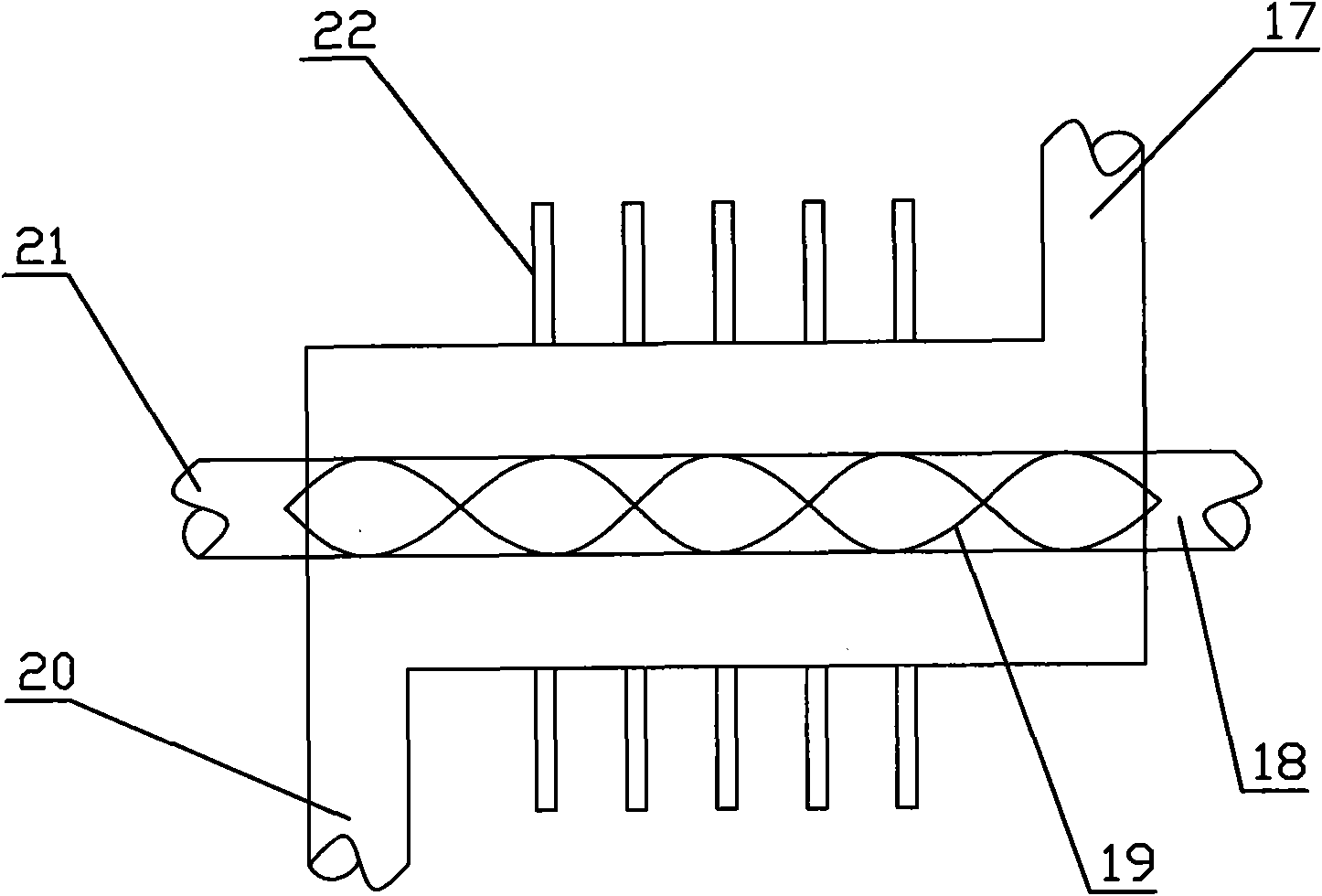

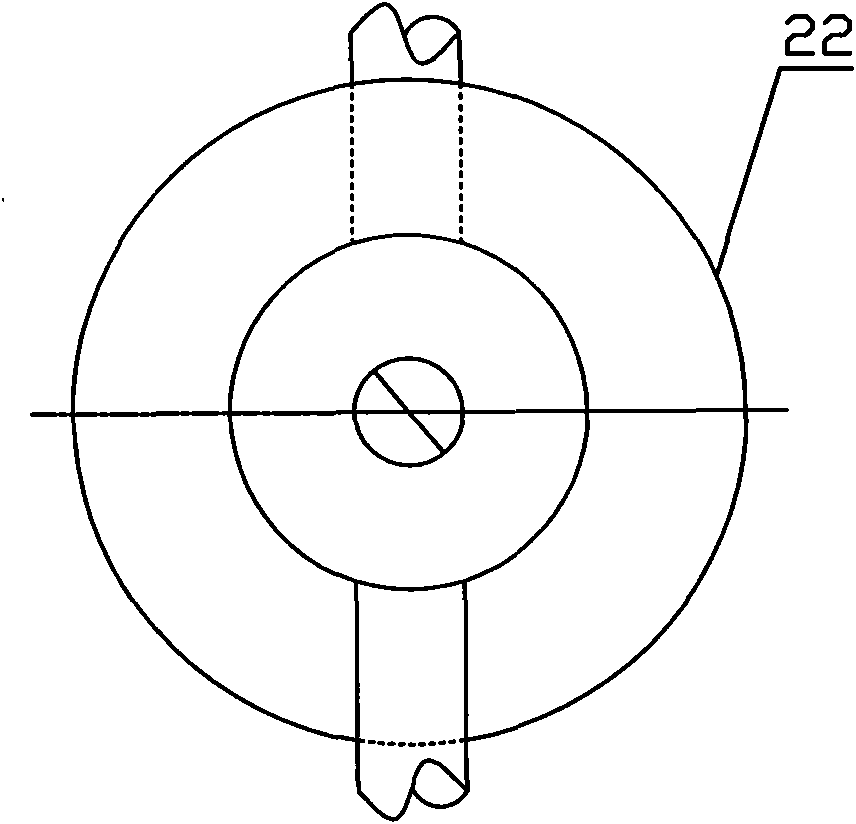

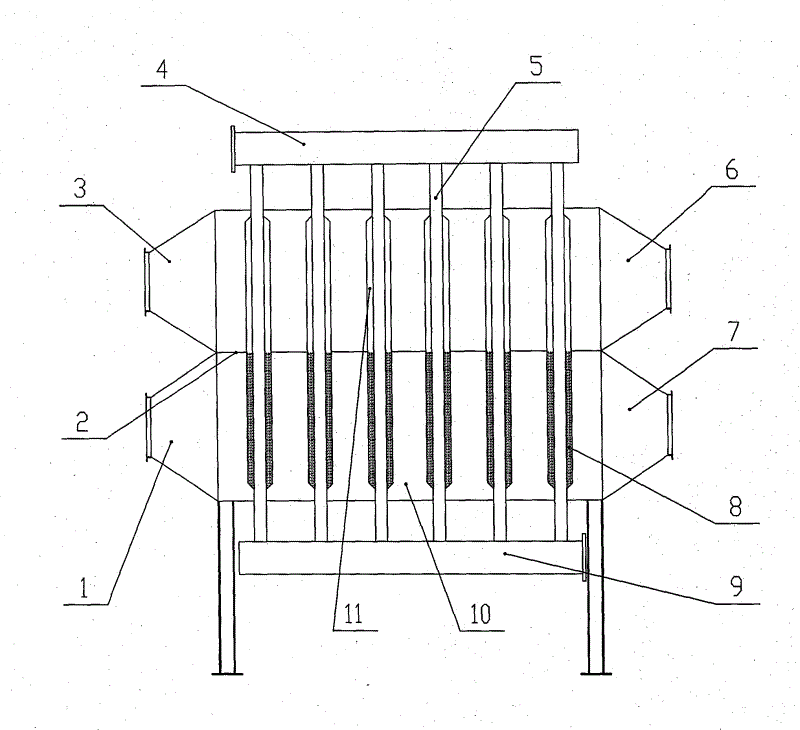

Novel flue gas waste heat recycling device

ActiveCN102620578AReduce productionReduce steel consumptionStationary tubular conduit assembliesCold airFlue gas

The invention discloses a novel flue gas waste heat recycling device, which comprises a flue inlet, a flue outlet, a cold air inlet, a hot air outlet, a shell pass, a partition, a water inlet header, a water outlet header and heat exchange tube components. The water inlet header and the water outlet header are located at the top and bottom of the shell pass respectively, and are connected by the heat exchange tube components which are located in the shell pass. The outside of the shell pass is connected with the flue inlet, the flue outlet, the hot air outlet and the cold air inlet. The shell pass is divided into a flue gas passage and an air passage by the partition, so that the manufacturing of the outside shell of the traditional heater is omitted, the steel consumption is lowered, and the manufacturing cost is reduced. Airtight chambers are arranged outside the heat exchange tube components, and each of the airtight chambers is half full of superconductive liquid and half vacuum, so that the air and the water can absorb heat at the same time, the heat exchange effect is good, and the whole efficiency is improved. By the novel flue gas waste heat recycling device, cost of manufacturing, transportation, installation and management is reduced, and resources are saved greatly for the society.

Owner:代树明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com