Connecting piece for auxiliary frame and installation method thereof

An installation method and a technology of connectors, which are applied in the direction of frame fixing, etc., can solve the problems of long installation time, inability to fully realize standardized operation, fracture and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

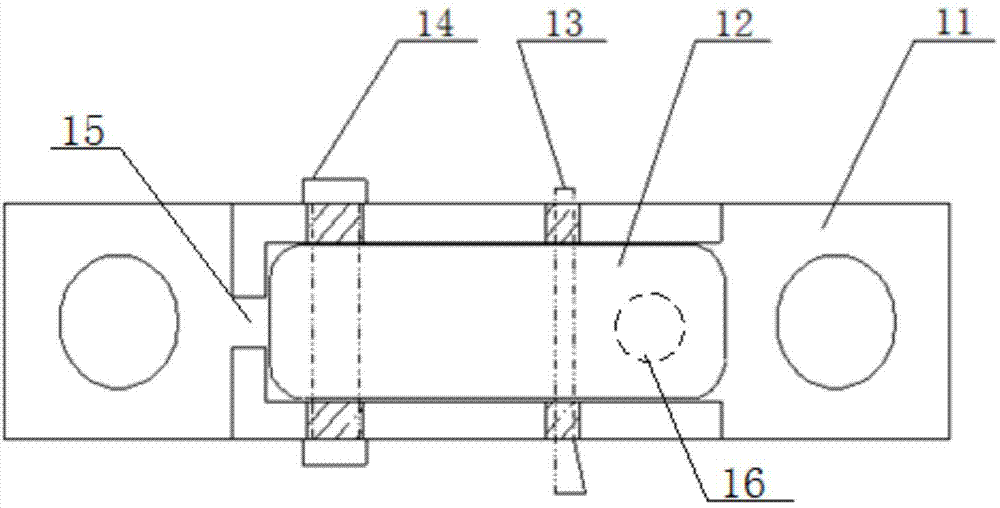

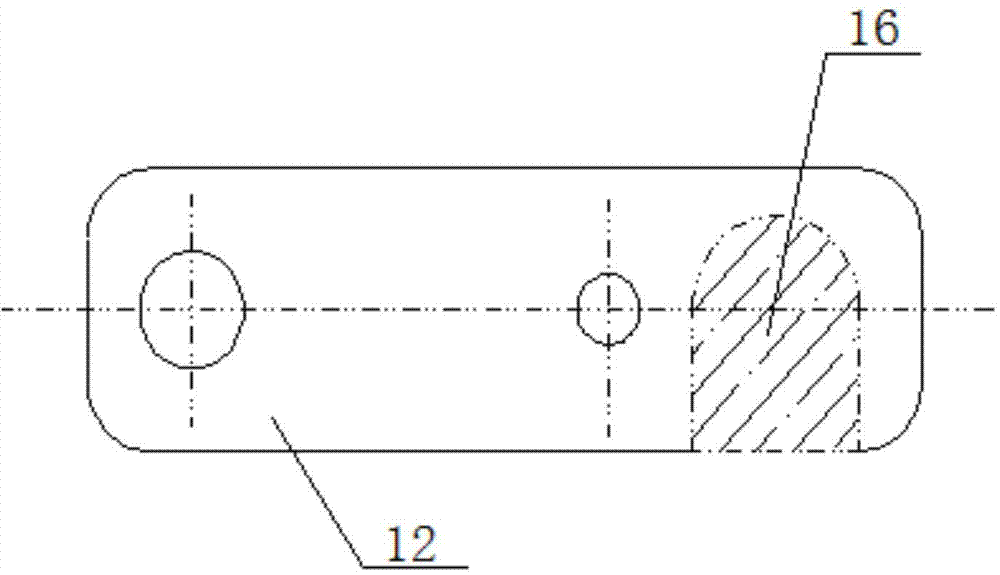

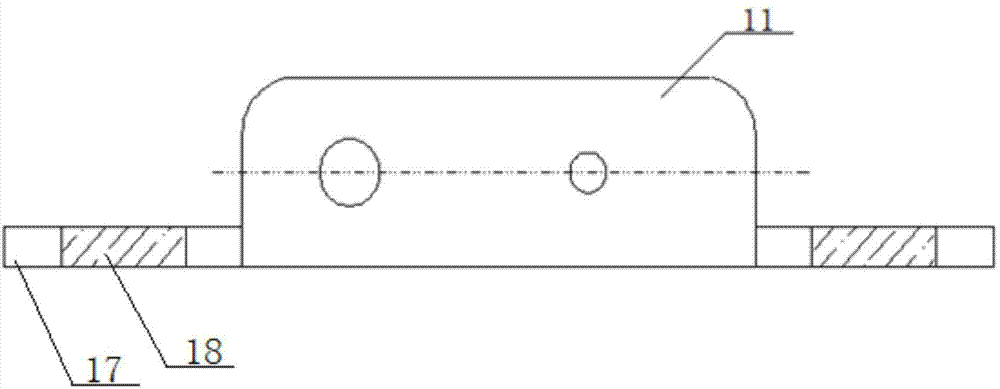

[0034] Such as Figure 1~5 , 7 is a schematic diagram of the installation structure of the frame connector and the outer frame of the present invention, and a schematic diagram of a setting method for the reserved hole, including a connector 10, an outer shell 11, an inner shaft 12, a fixed pin 13, a positioning pin 14, and a limiter. Position device 15, cavity 16, mounting plate 17, mounting hole 18, outer frame 20, attached frame 21, window sill flashing layer 22, waterproof structure 23, filler layer 24, expansion bolt 25 and reserved hole 27.

[0035] The housing 11 of the connecting piece 10 is a rectangular structure. Inside the housing 11, an inner shaft 12 is arranged along the long axis direction, and a fixed pin 13 and a positioning pin 14 are arranged in a position perpendicular to the inner shaft 12 and connected to the housing 11. The positioning pin 14 is arranged at one end of the inner shaft 12 , and the fixing pin 13 is arranged near the middle of the inner sh...

Embodiment 2

[0039] Such as Figure 1~4 , 6 and 8 are schematic diagrams of the installation structure of the frame-attached connector and the outer frame of the present invention, and a schematic diagram of another arrangement of reserved holes, including a connector 10, an outer shell 11, an inner shaft 12, a fixing pin 13, and a positioning pin 14. Limiting device 15, cavity 16, mounting plate 17, mounting hole 18, outer frame 20, attached frame 21, waterproof structure 23, filler layer 24, expansion bolt 25, adhesive layer 26 and reserved hole 27.

[0040]The housing 11 of the connecting piece 10 is a rectangular structure. Inside the housing 11, an inner shaft 12 is arranged along the long axis direction, and a fixed pin 13 and a positioning pin 14 are arranged in a position perpendicular to the inner shaft 12 and connected to the housing 11. The positioning pin 14 is arranged at one end of the inner shaft 12 , and the fixing pin 13 is arranged near the middle of the inner shaft 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com