Ceramic honeycomb filter, exhaust gas-purifying device, and exhaust gas-purifying method

A ceramic honeycomb and filter technology, which is applied in the field of exhaust purification, can solve problems such as the temperature rise of the exhaust gas and the damage of the inflow side plugging part, so as to prevent the increase of pressure loss, eliminate clogging, and avoid damage or melting loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

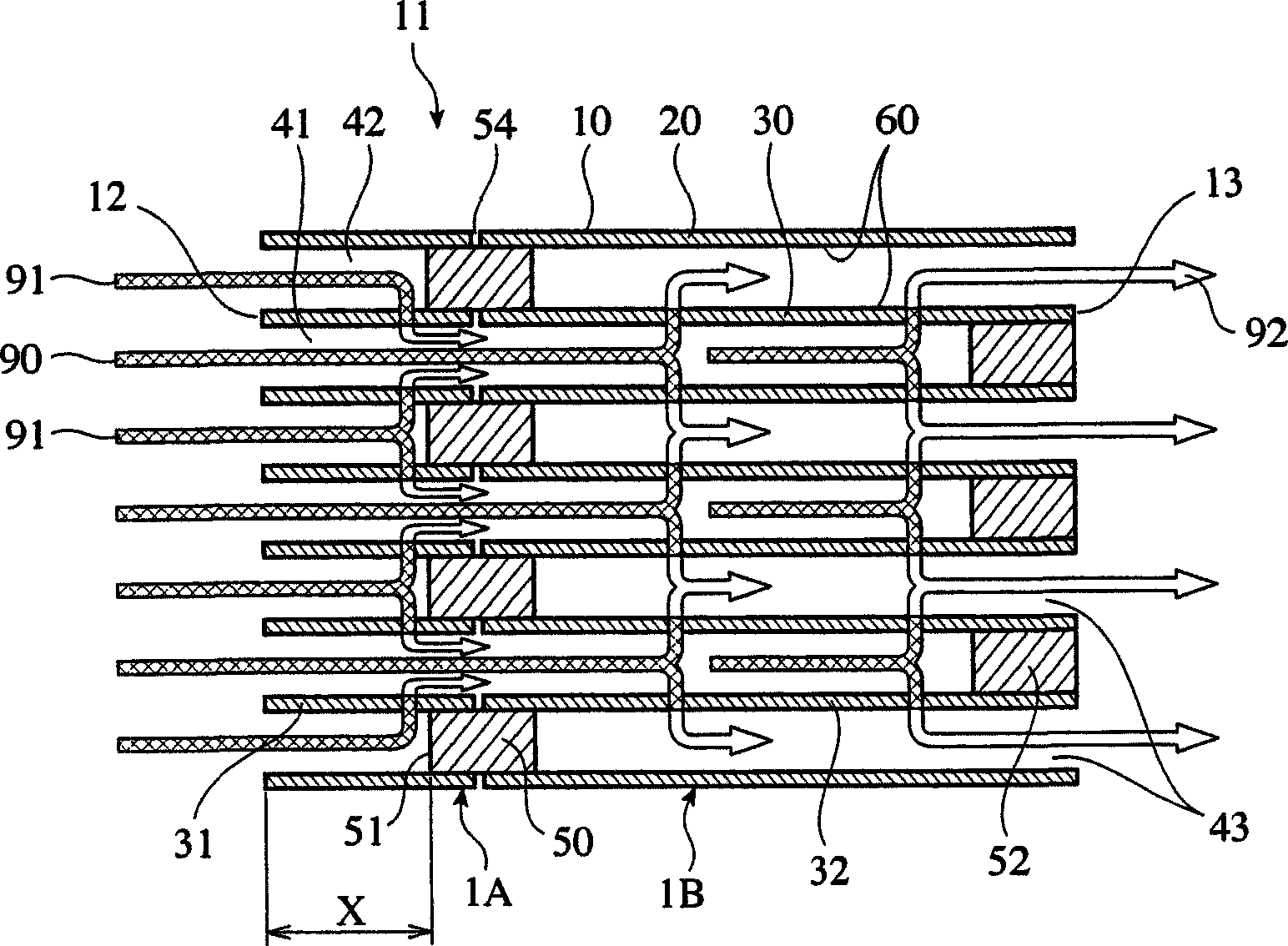

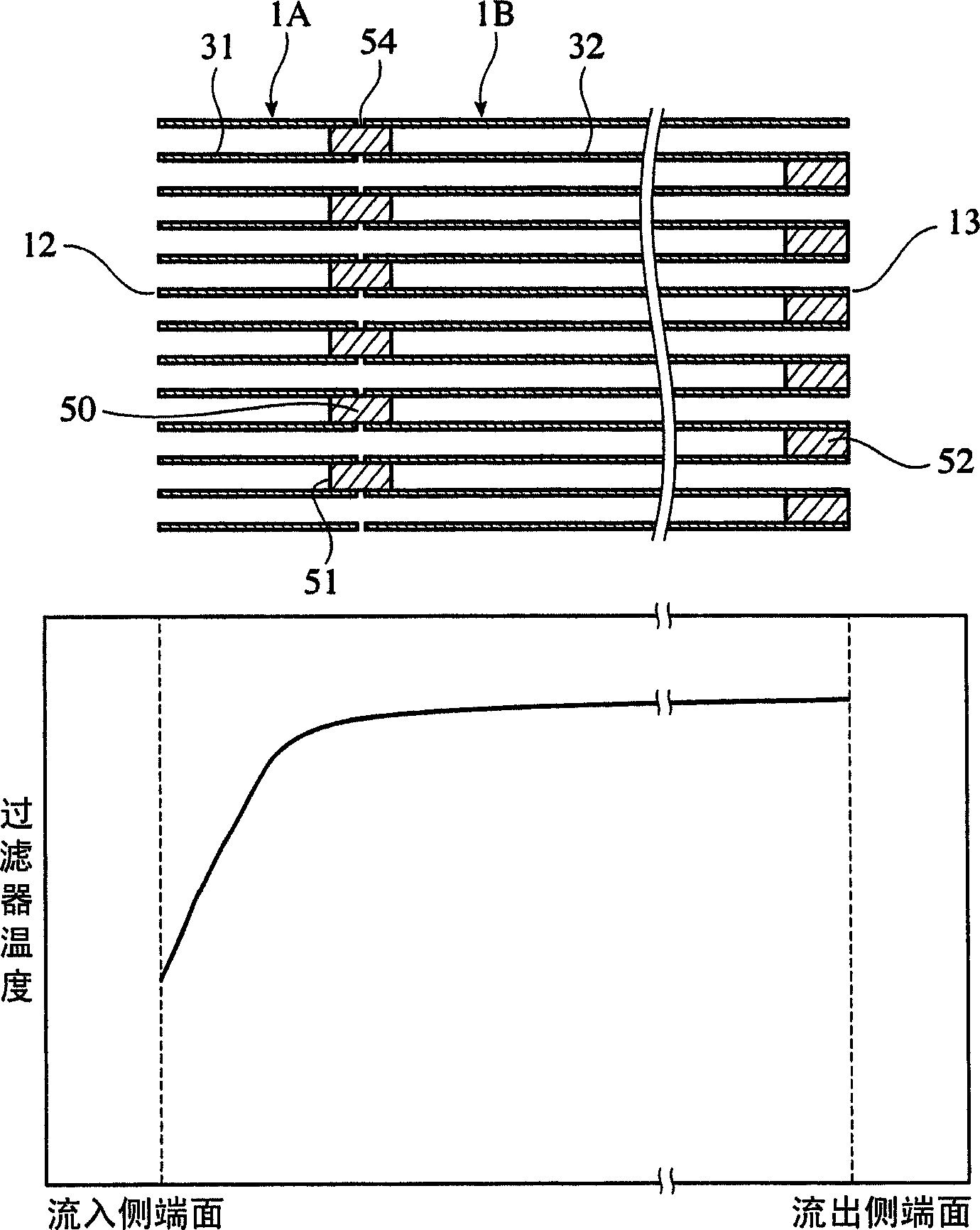

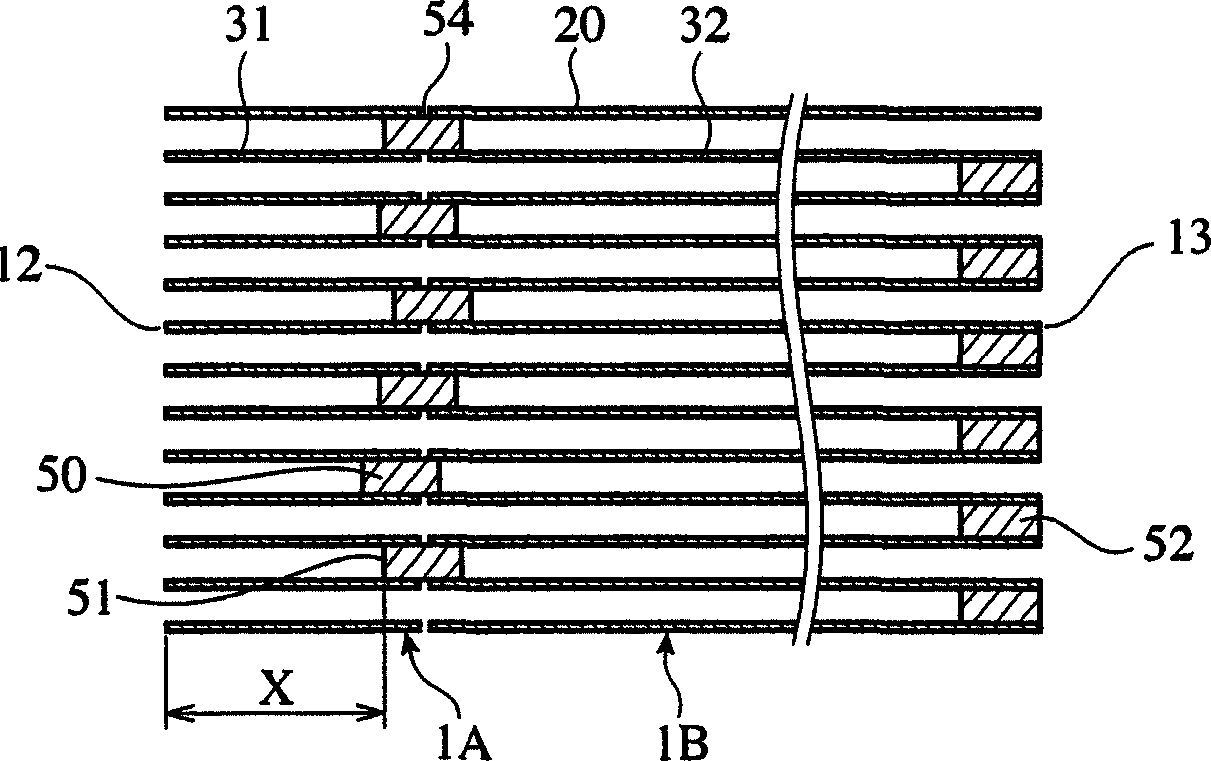

[0084] Prepare kaolin, talc, silica, aluminum hydroxide, alumina and other powders to obtain SiO 2 : 47~53%, Al 2 o 3 : 32-38%, MgO: 12-16%, and CaO, Na 2 O, K 2 O, TiO 2 , Fe 2 o 3 , PbO, P 2 o 5Inevitably mixed ingredients: 2.5% (accounting for the mass ratio of the whole) cordierite raw material powder below 2.5%, add forming aids and pore-forming agents, inject a specified amount of water, further fully mix, and prepare to be extruded into Clay with honeycomb structure. Next, extrusion molding is performed using a known extrusion molding die to manufacture a molded body having a honeycomb structure having an outer peripheral wall 20 and a flow path with a square cross section surrounded by a partition 30 on the inner peripheral side of the outer peripheral wall 20. , fired after drying, and manufactured a honeycomb structure 1A with an exhaust gas inflow side partition 31 and a honeycomb structure 1B with an exhaust gas outflow side partition 32, the exhaust gas i...

Embodiment 6

[0098] By the same method as in Example 2, a honeycomb having a separator structure with a separator pitch of 1.5 mm and a separator thickness of 0.3 mm, a separator with a porosity of 65%, a diameter of 267 mm, and a total length of 96.4 mm was fabricated. A honeycomb structure 1A, and a honeycomb structure 1B having a spacer of 1.5 mm, a thickness of 0.3 mm, a porosity of 65%, a diameter of 267 mm, and a total length of 208.3 mm. . To the end of the flow path of the honeycomb structure 1A and the honeycomb structure 1B, a raw material containing a plasticizing plugging material is inserted to form a checkered pattern, and then the honeycomb structure 1A The honeycomb structures 1A and 1B are integrated by forming a gap 54 of 0.1 mm between them and the separator of 1B.

[0099] On the other end surface 13 of the honeycomb structure 1B, a resin film is pasted, the film is perforated alternately with the inflow-side plugging parts 50, a raw material-like plugging material is ...

Embodiment 7

[0103] By the same method as in Example 2, a honeycomb having a separator structure with a separator pitch of 1.5 mm and a separator thickness of 0.3 mm, a separator with a porosity of 65%, a diameter of 267 mm, and a total length of 96.9 mm was fabricated. Honeycomb structure 1A, and a honeycomb structure 1B having a separator structure with a separator pitch of 1.5 mm and a separator thickness of 0.3 mm, a separator with a porosity of 65%, a diameter of 267 mm, and a total length of 206.9 mm . In addition, plugging portions 50 were used to integrate them, and the gap 54 was set to 1 mm, and plugging portions 52 were formed alternately with plugging portions 50 on the other end surface 13 of the honeycomb structure 1B.

[0104] On the honeycomb structure 1A and the plugging portion 50, Pt, cerium oxide, and activated alumina (catalyst B) are loaded so that the loading amount of cerium oxide and activated alumina is the same as that of catalyst A, and the loading amount of Pt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com