Patents

Literature

2541results about "Catalyst support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

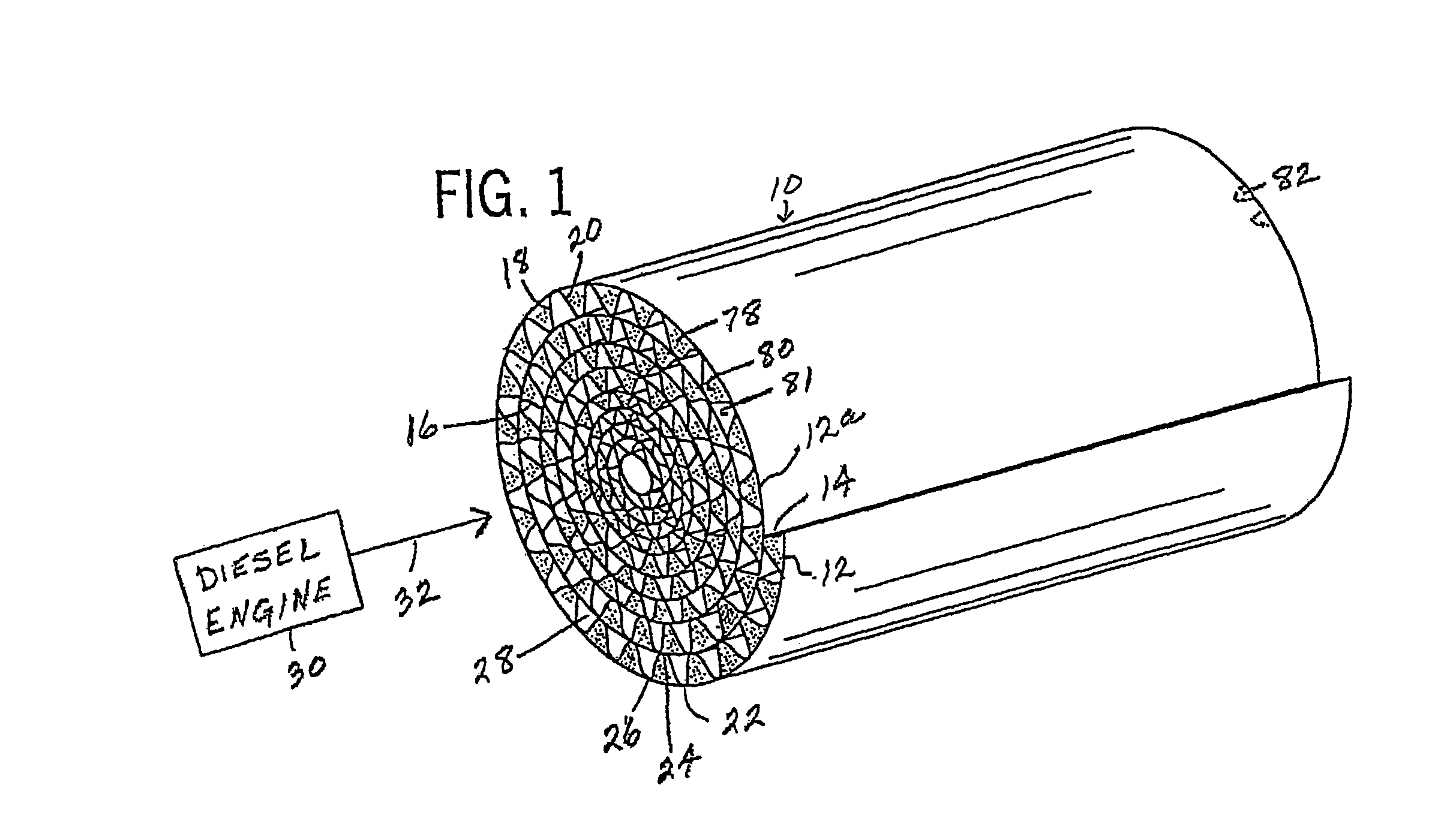

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

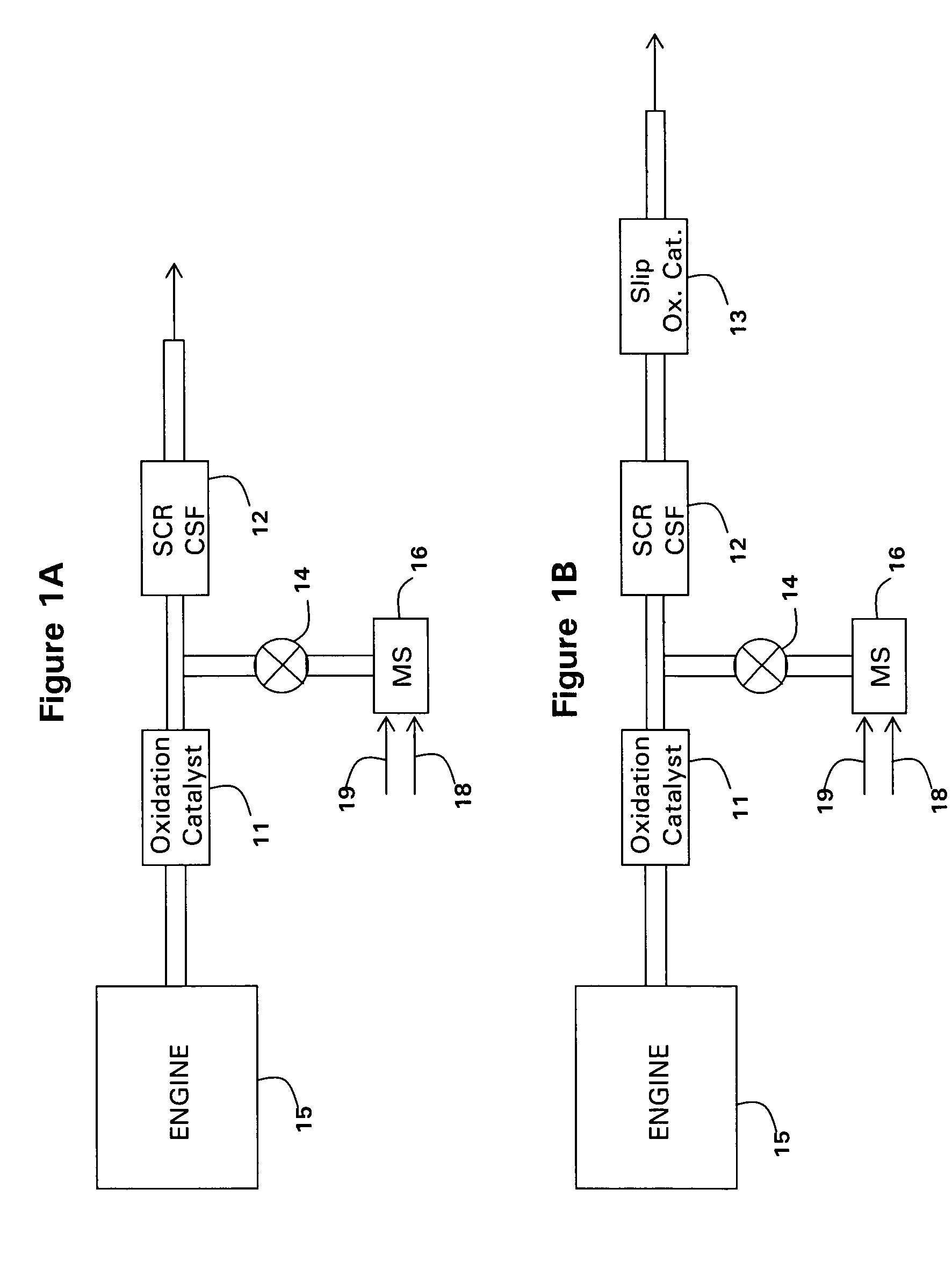

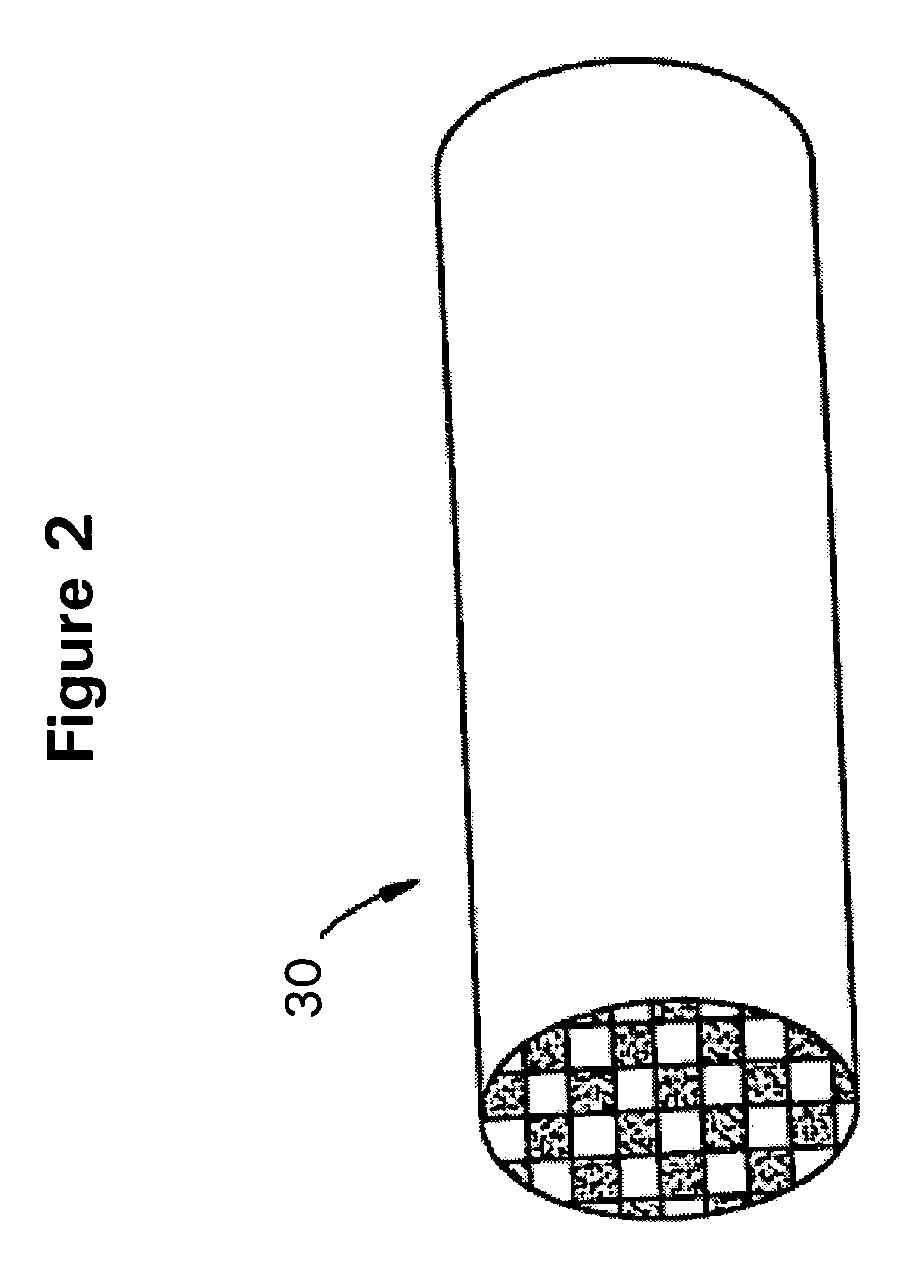

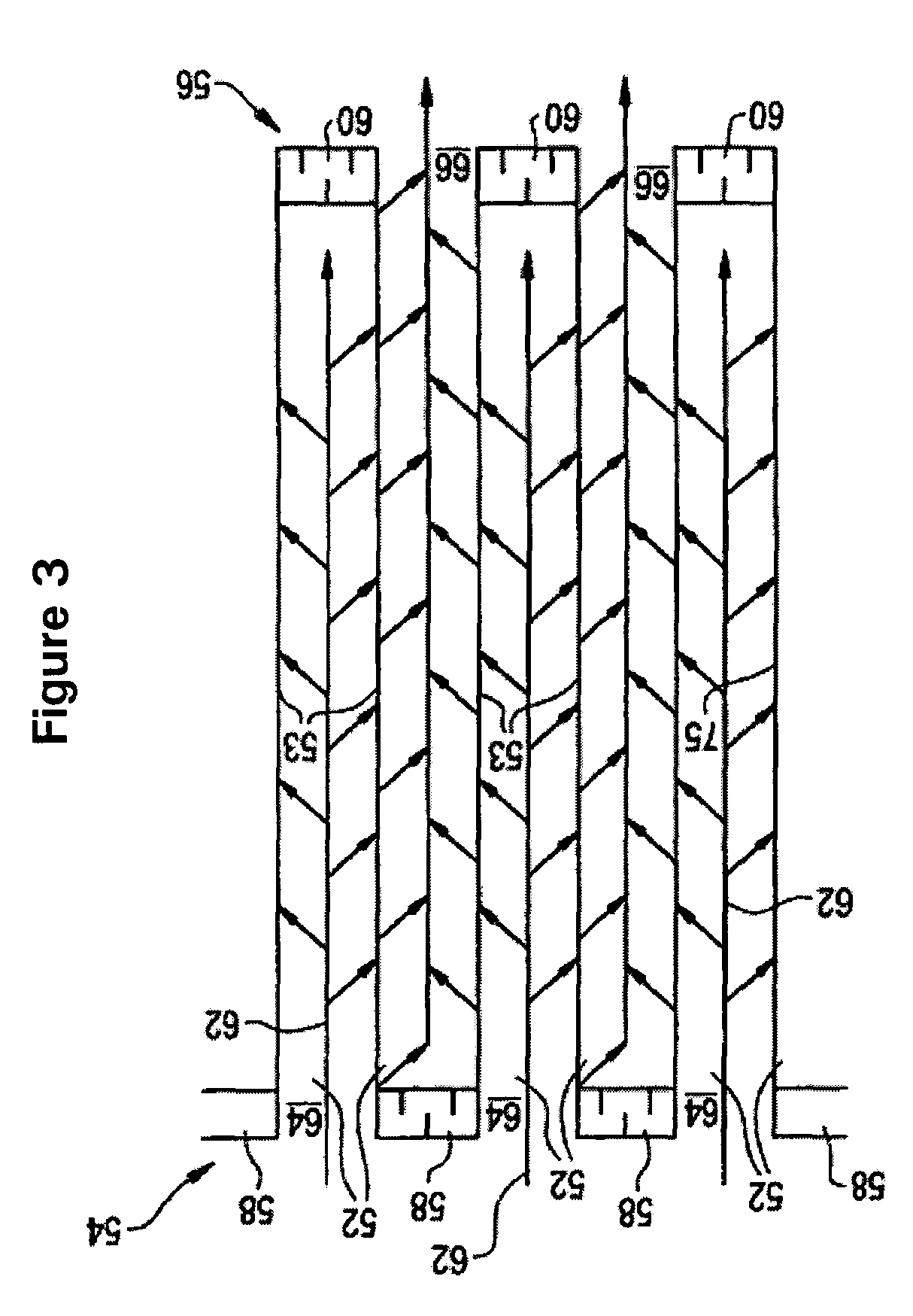

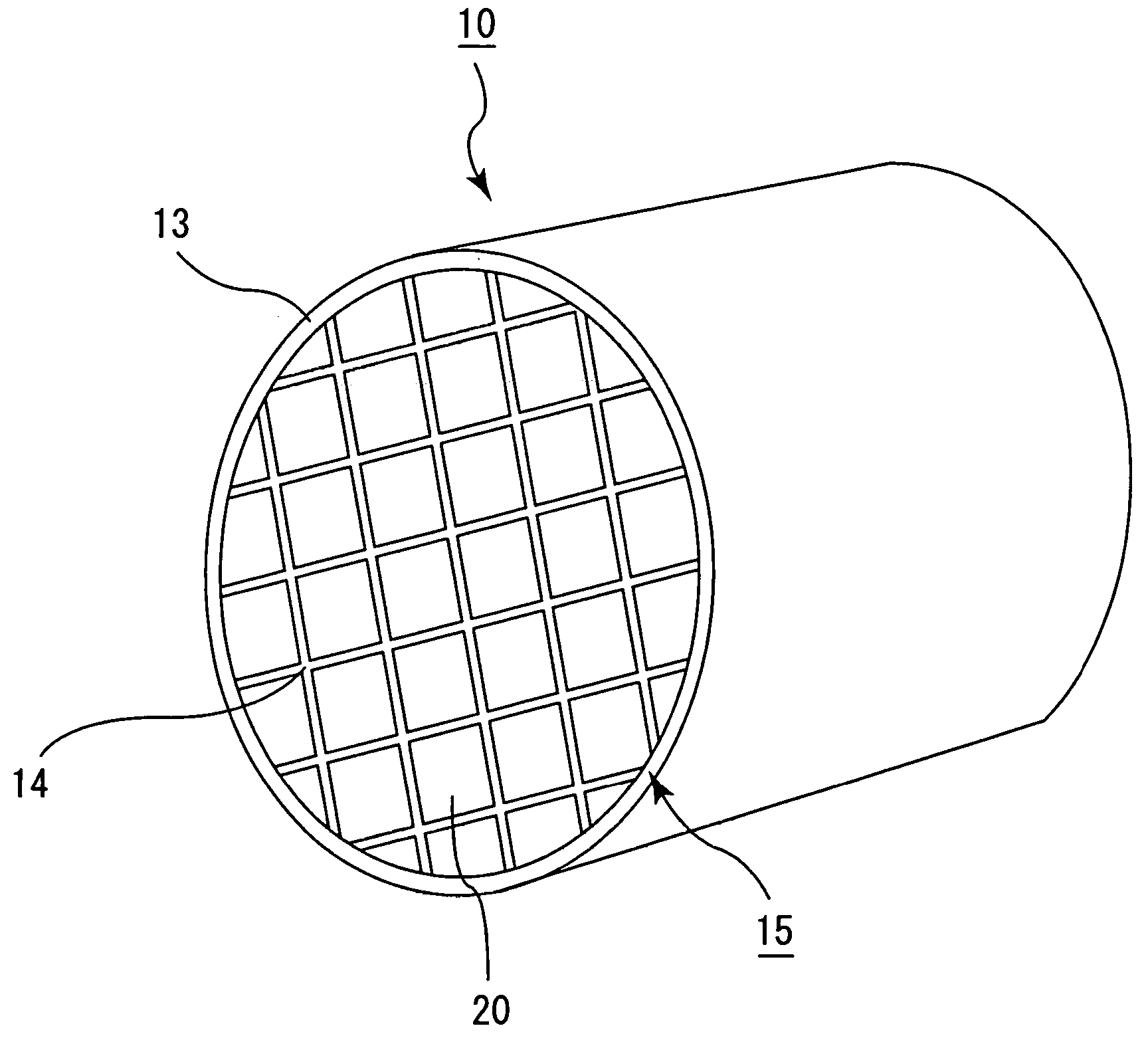

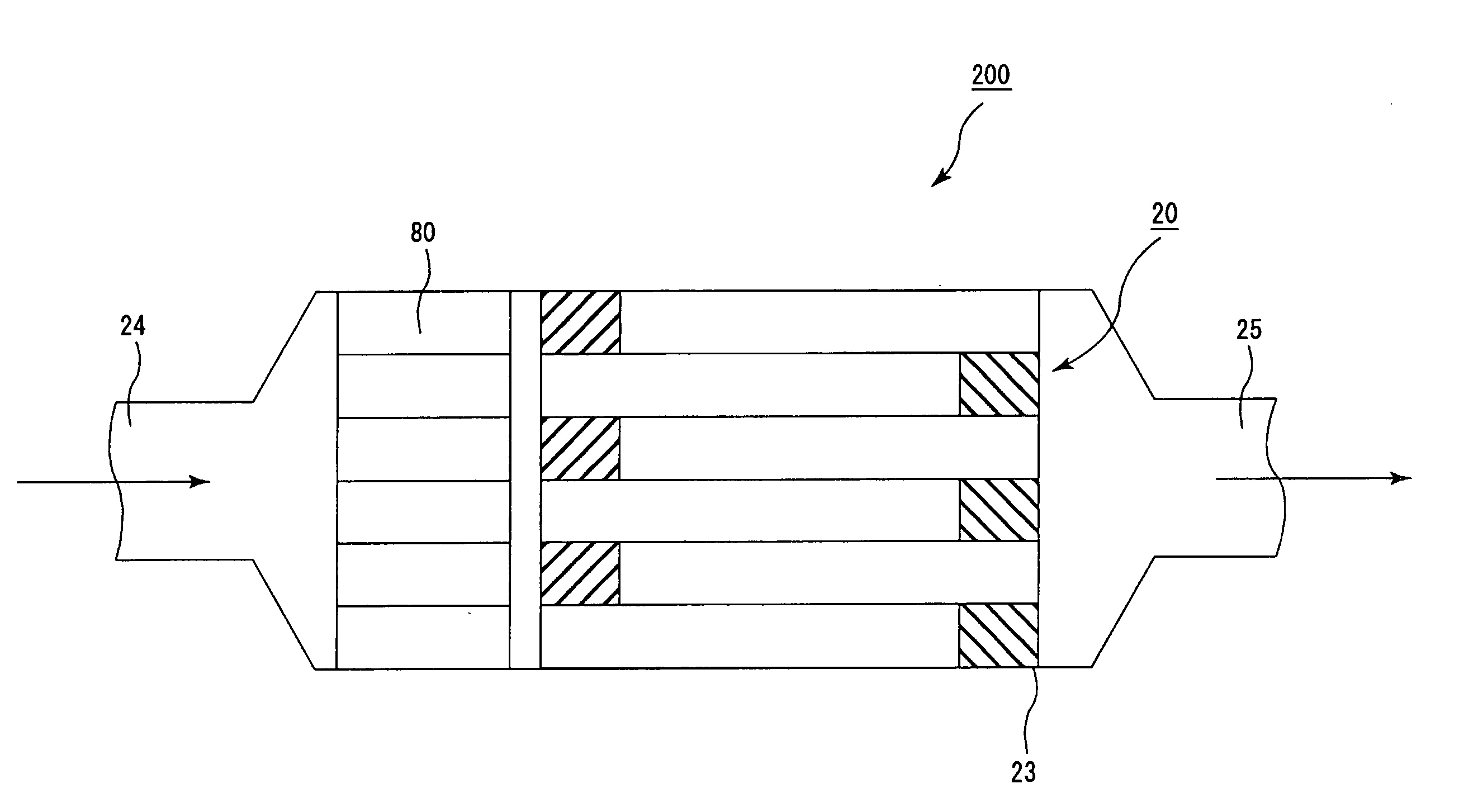

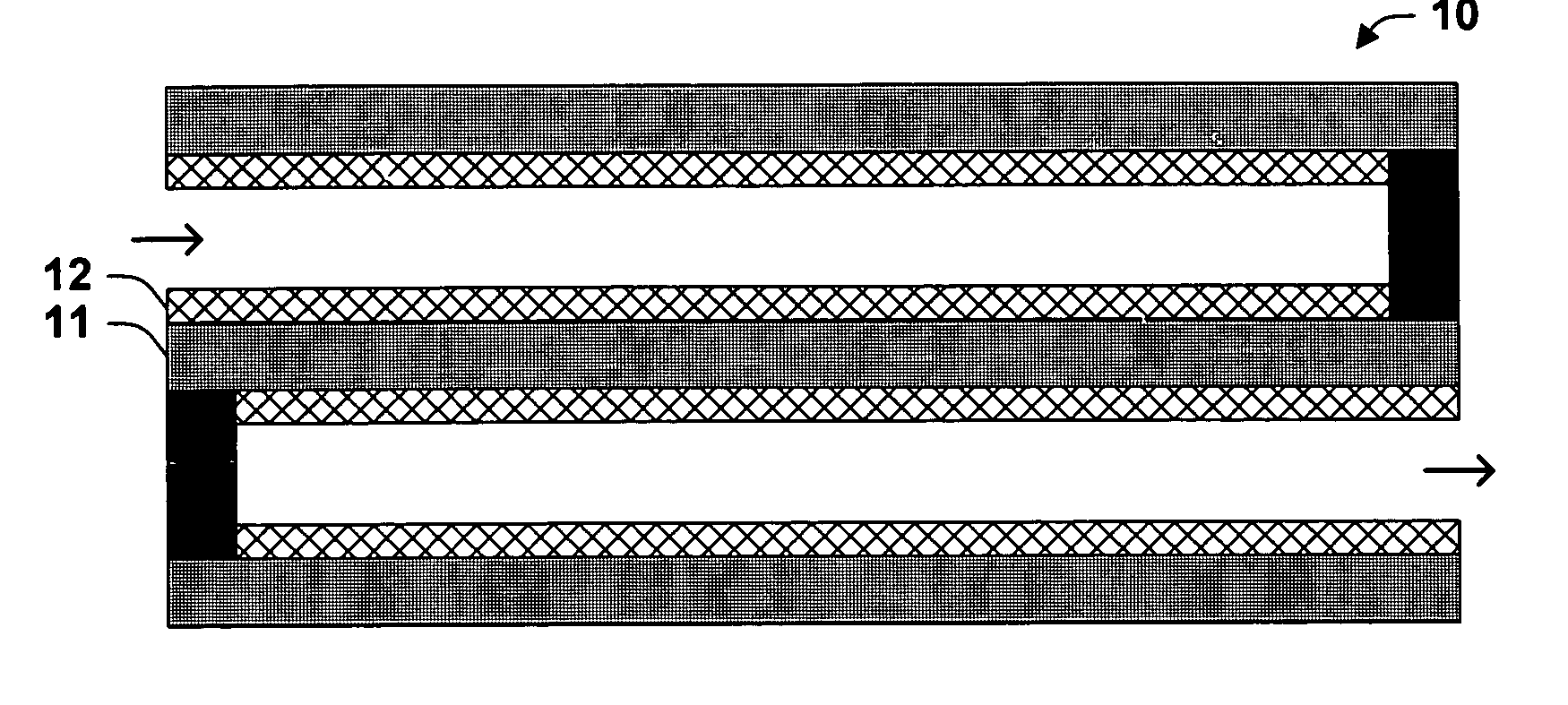

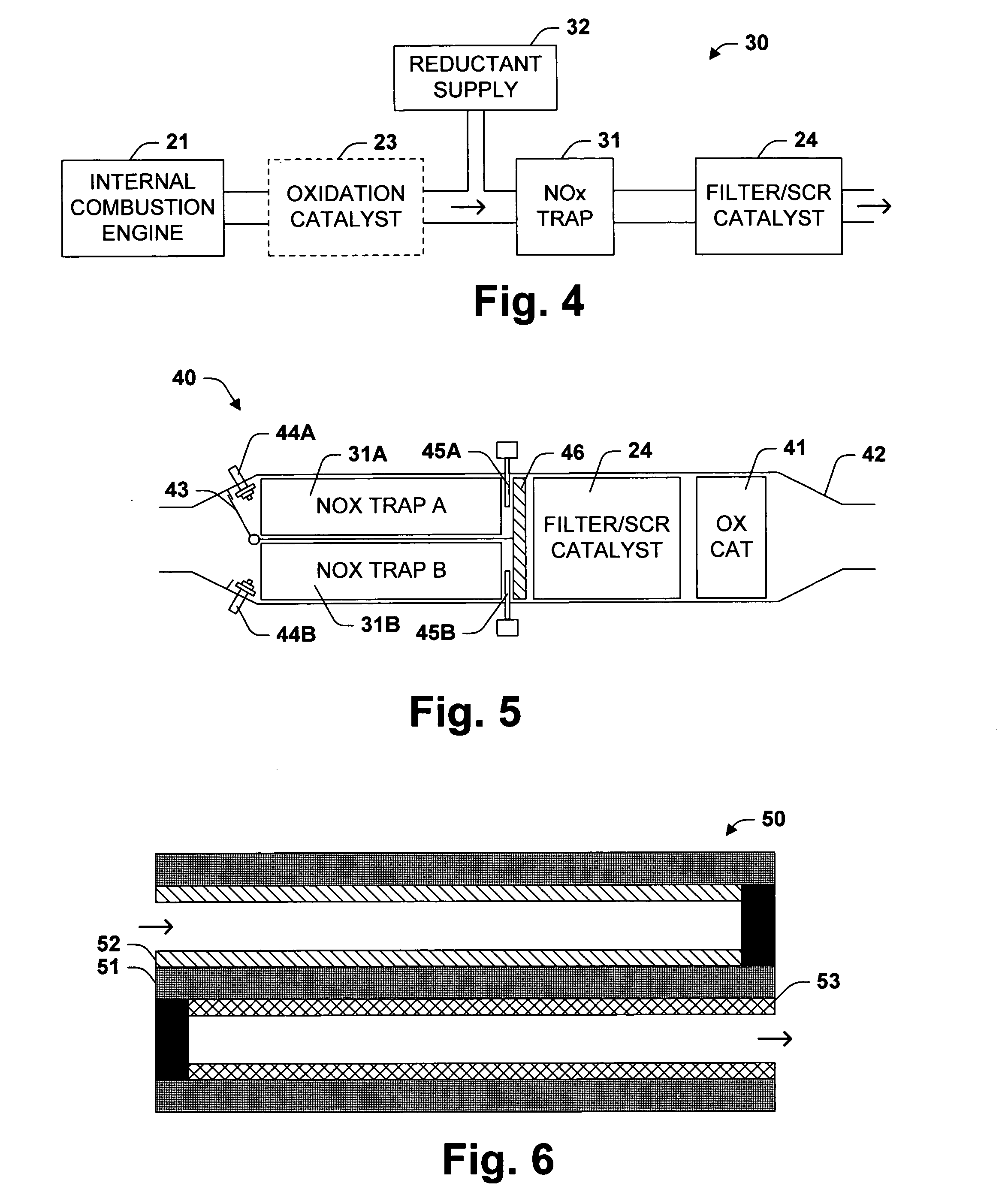

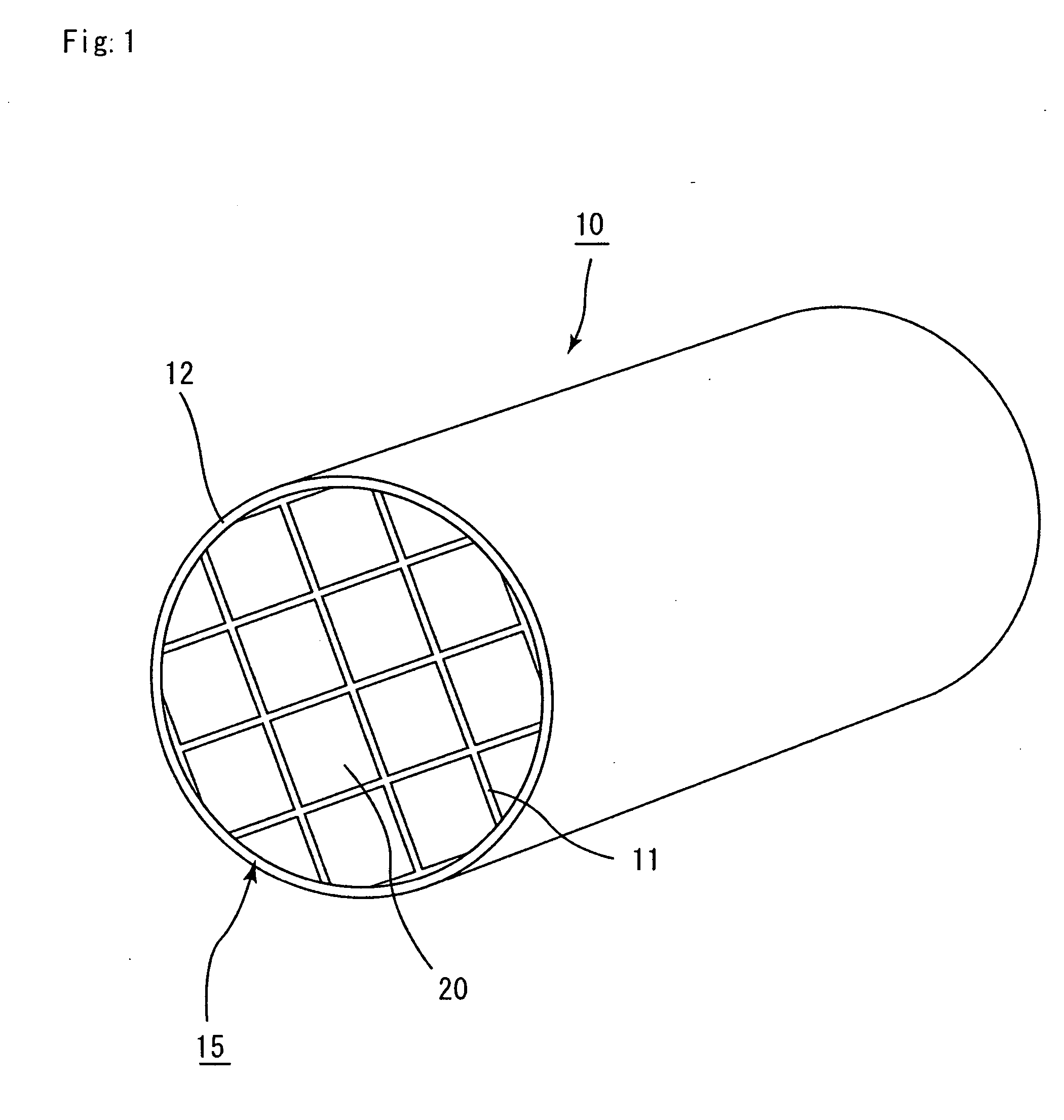

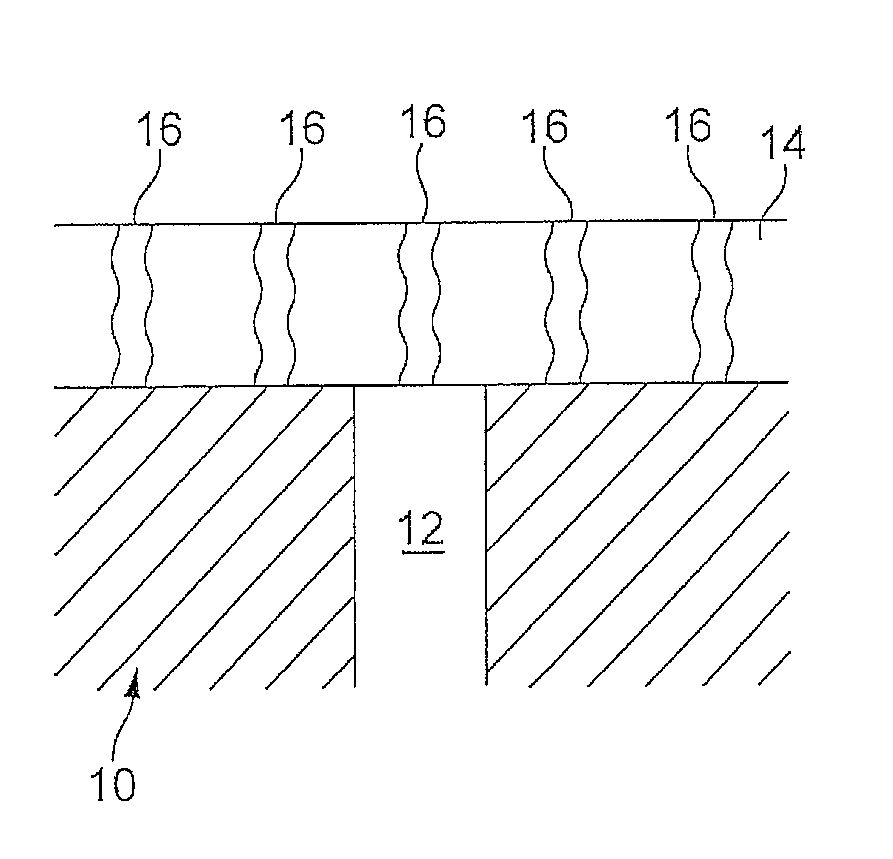

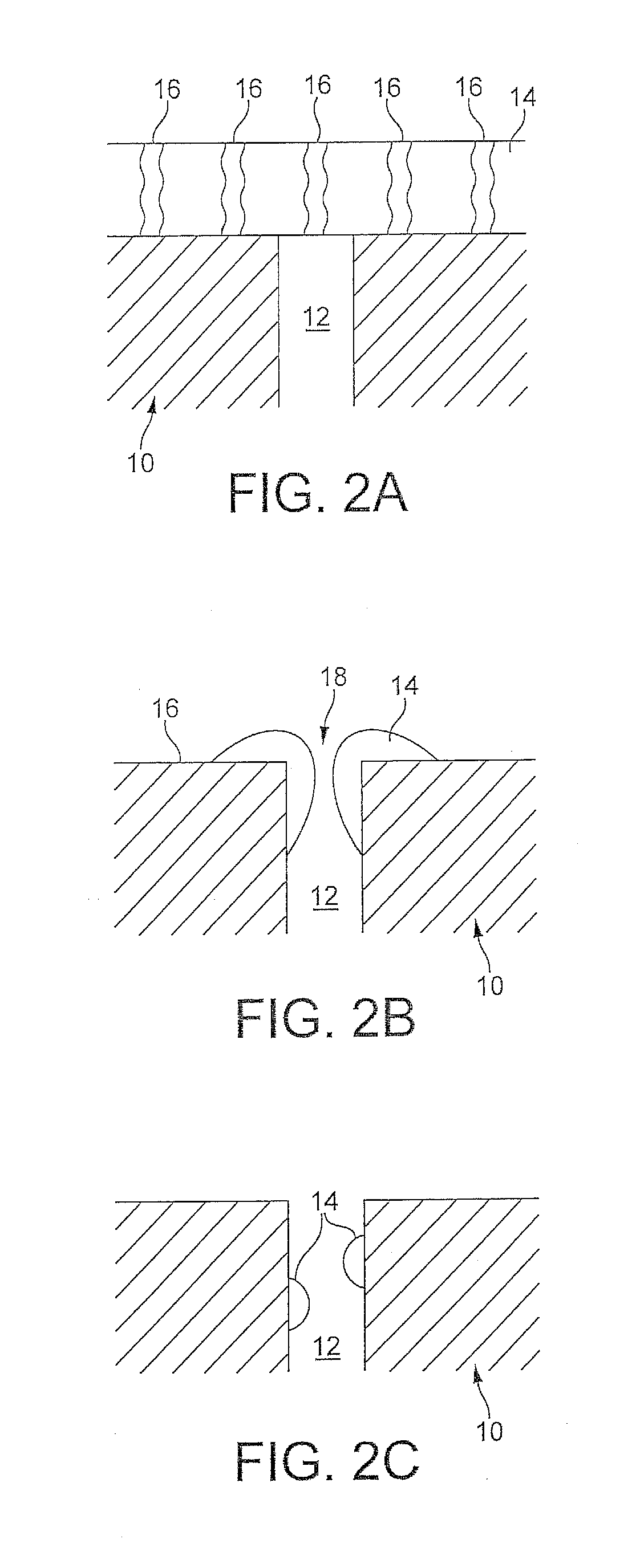

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

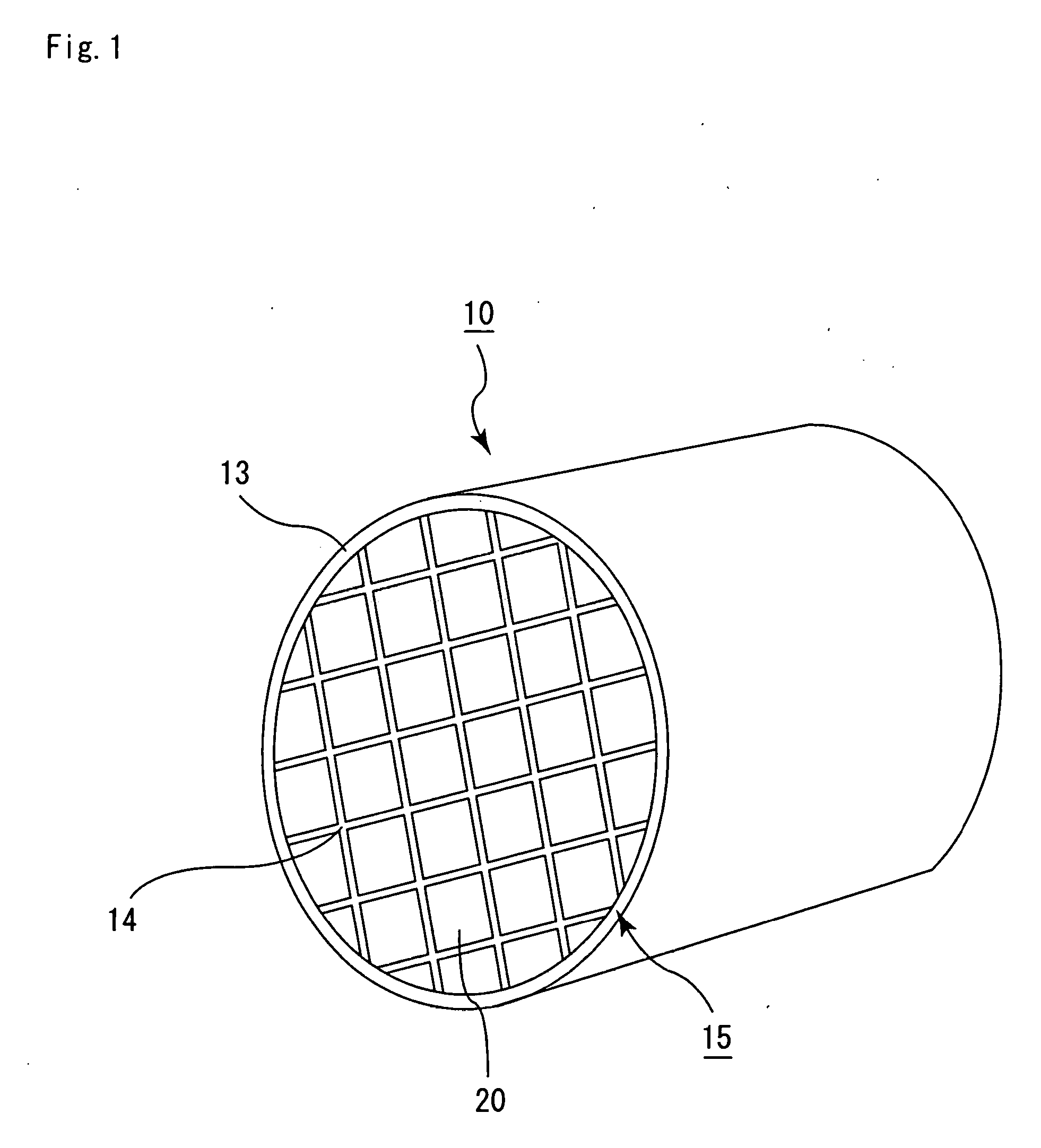

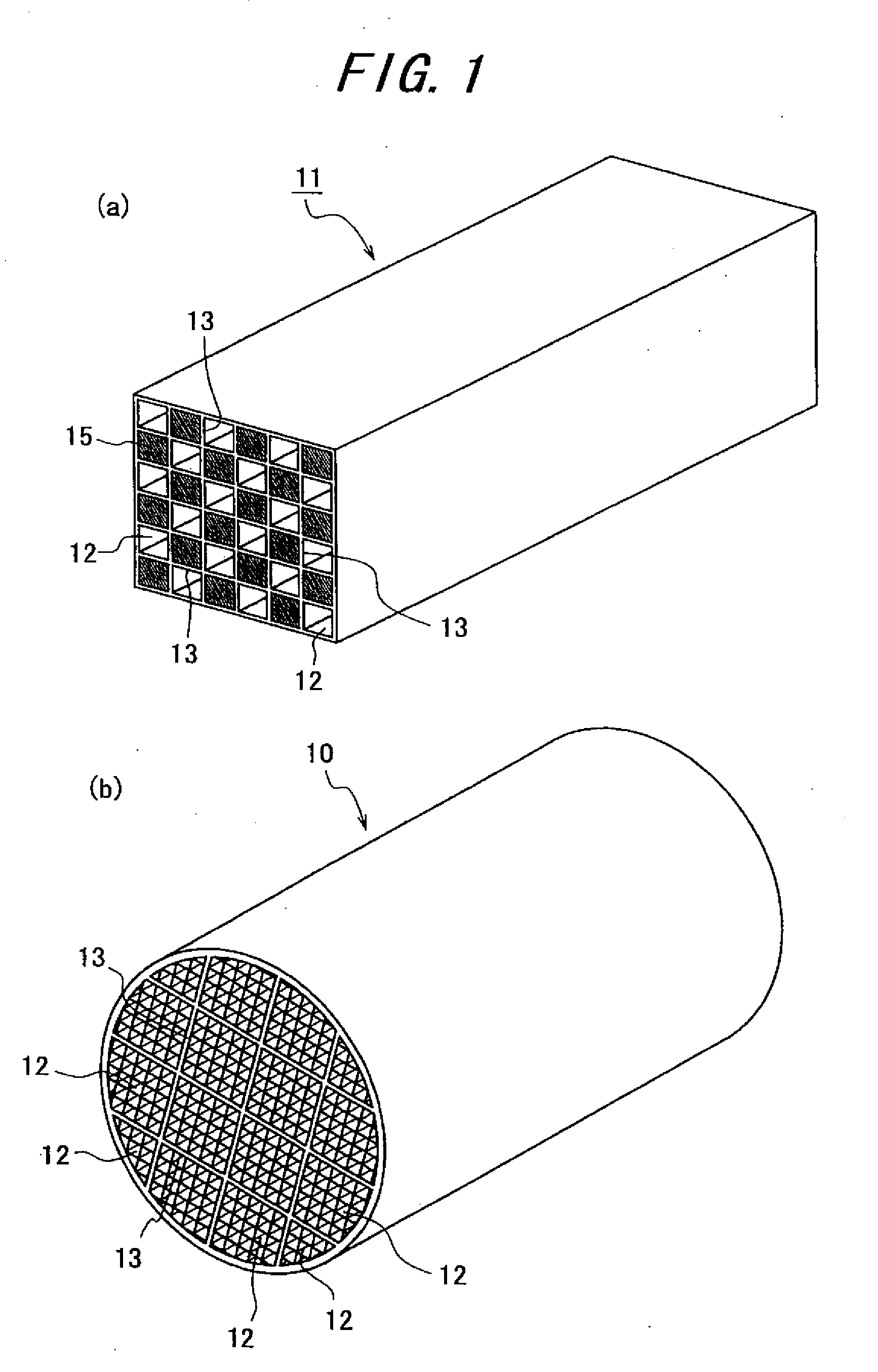

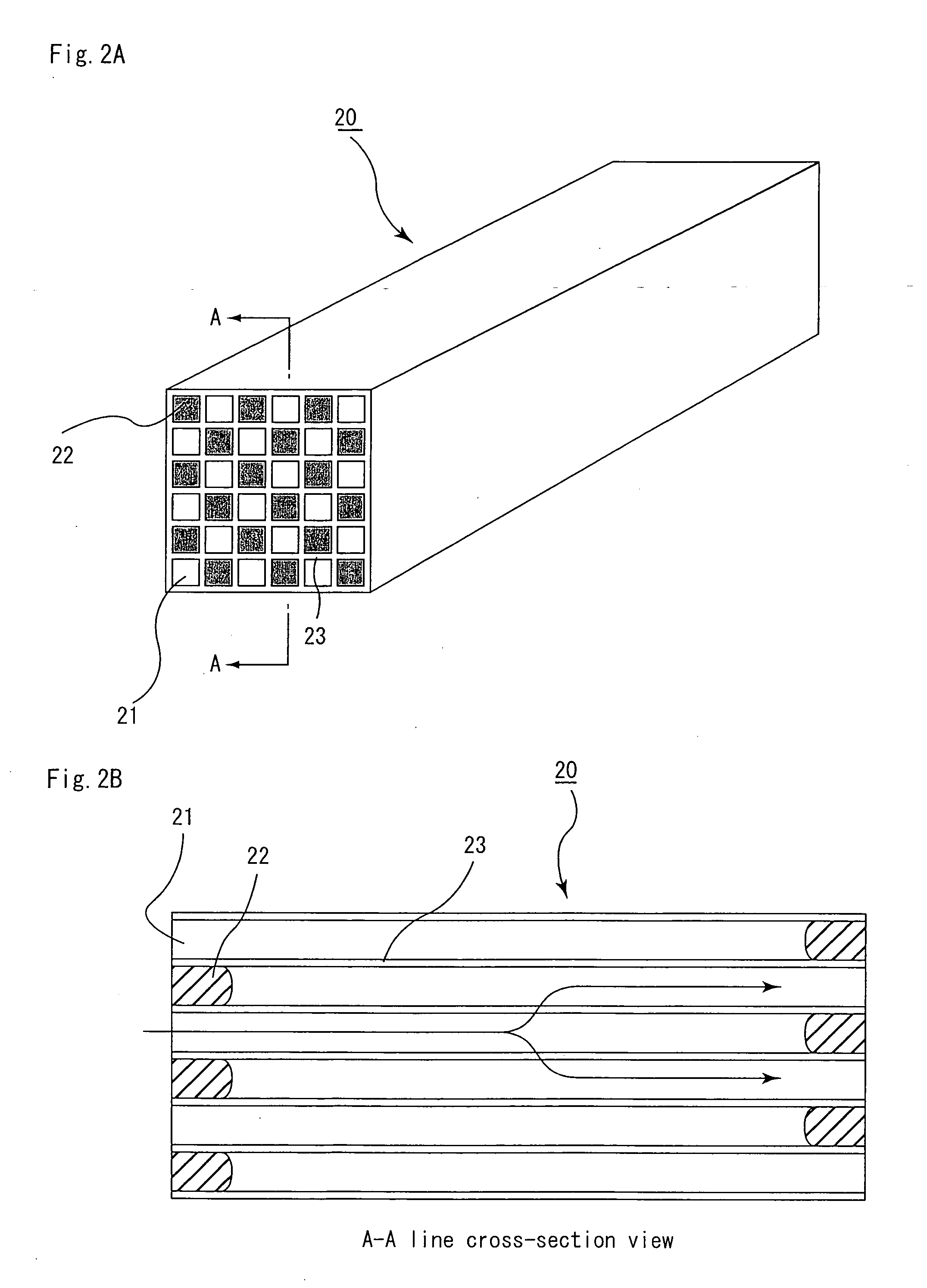

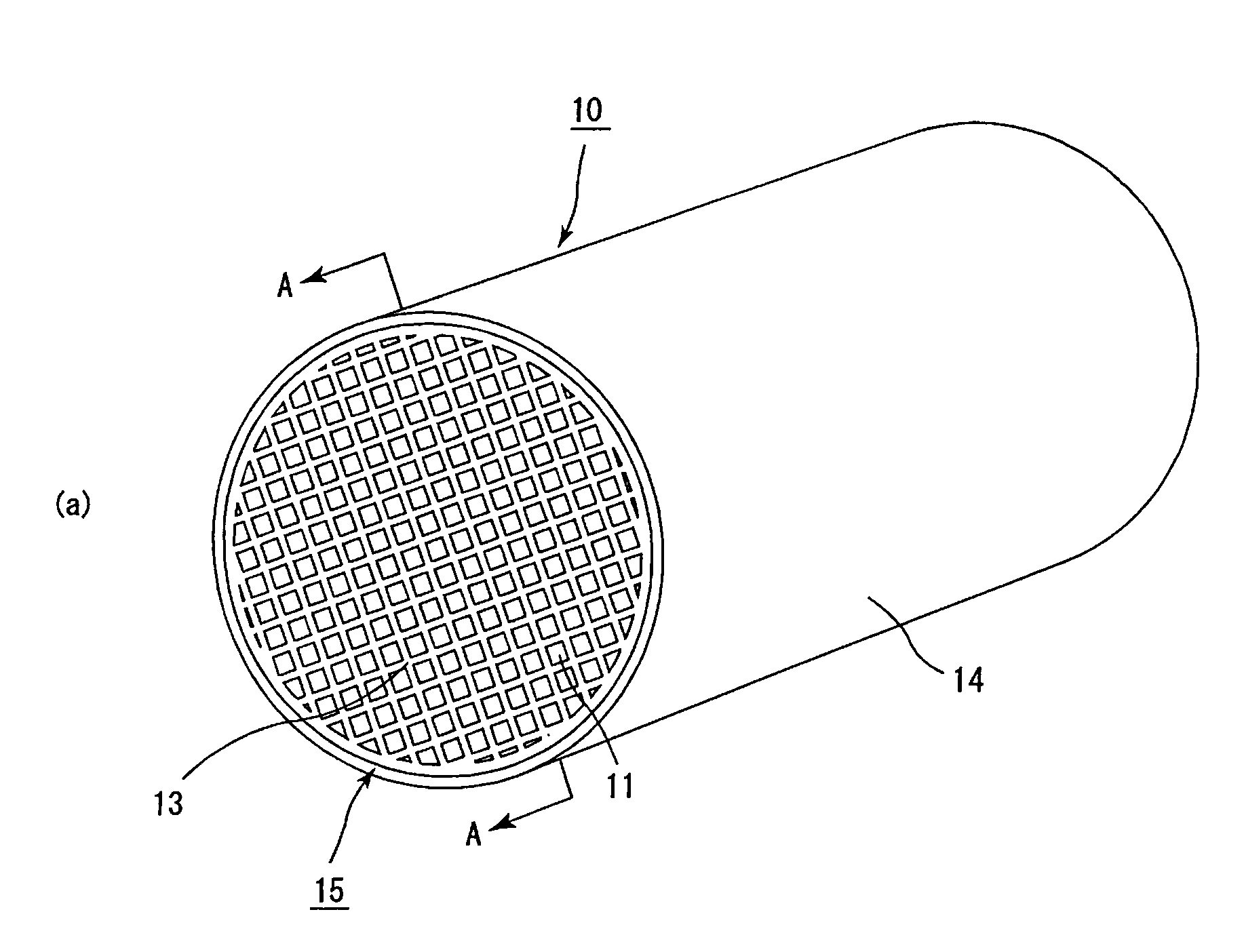

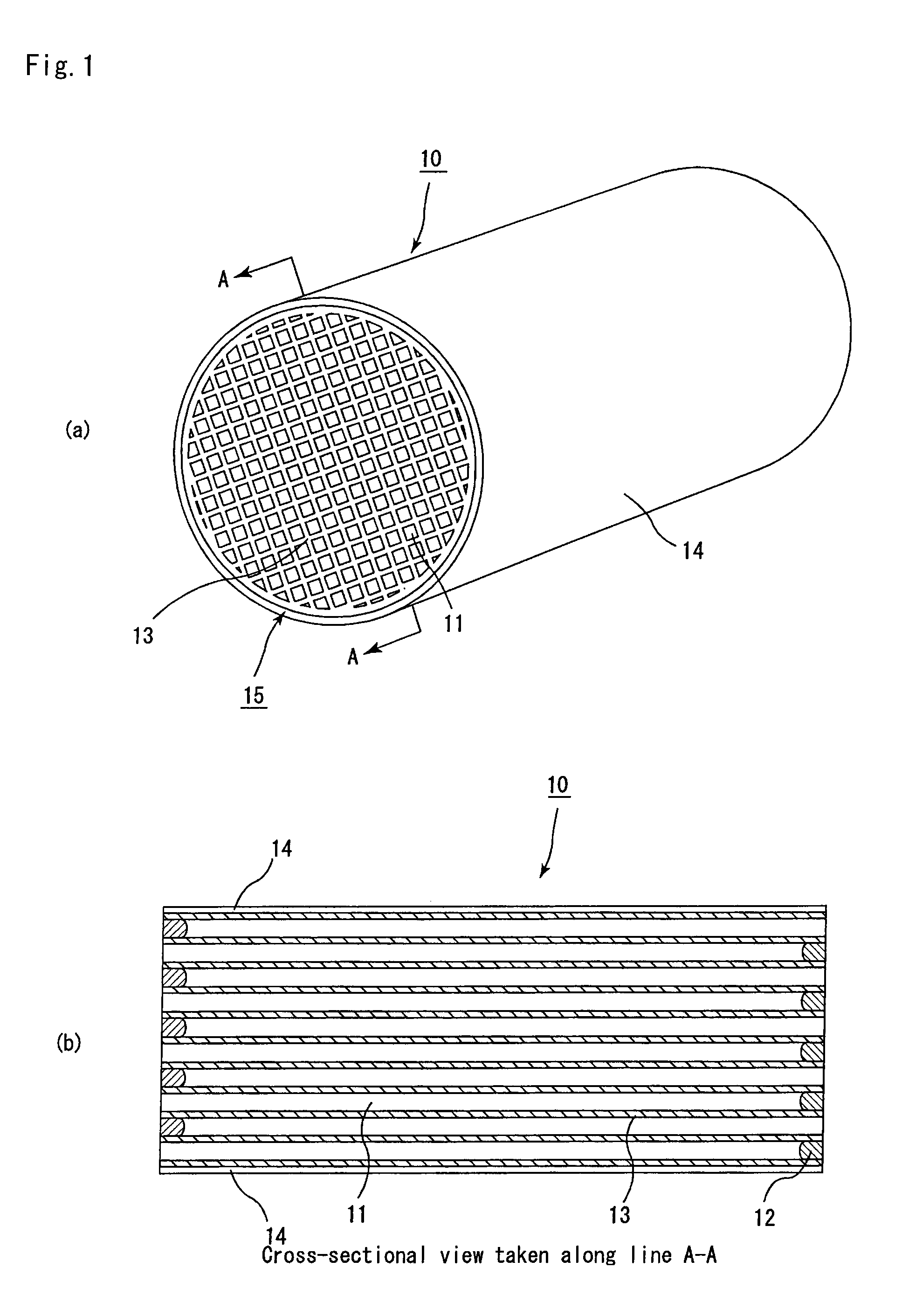

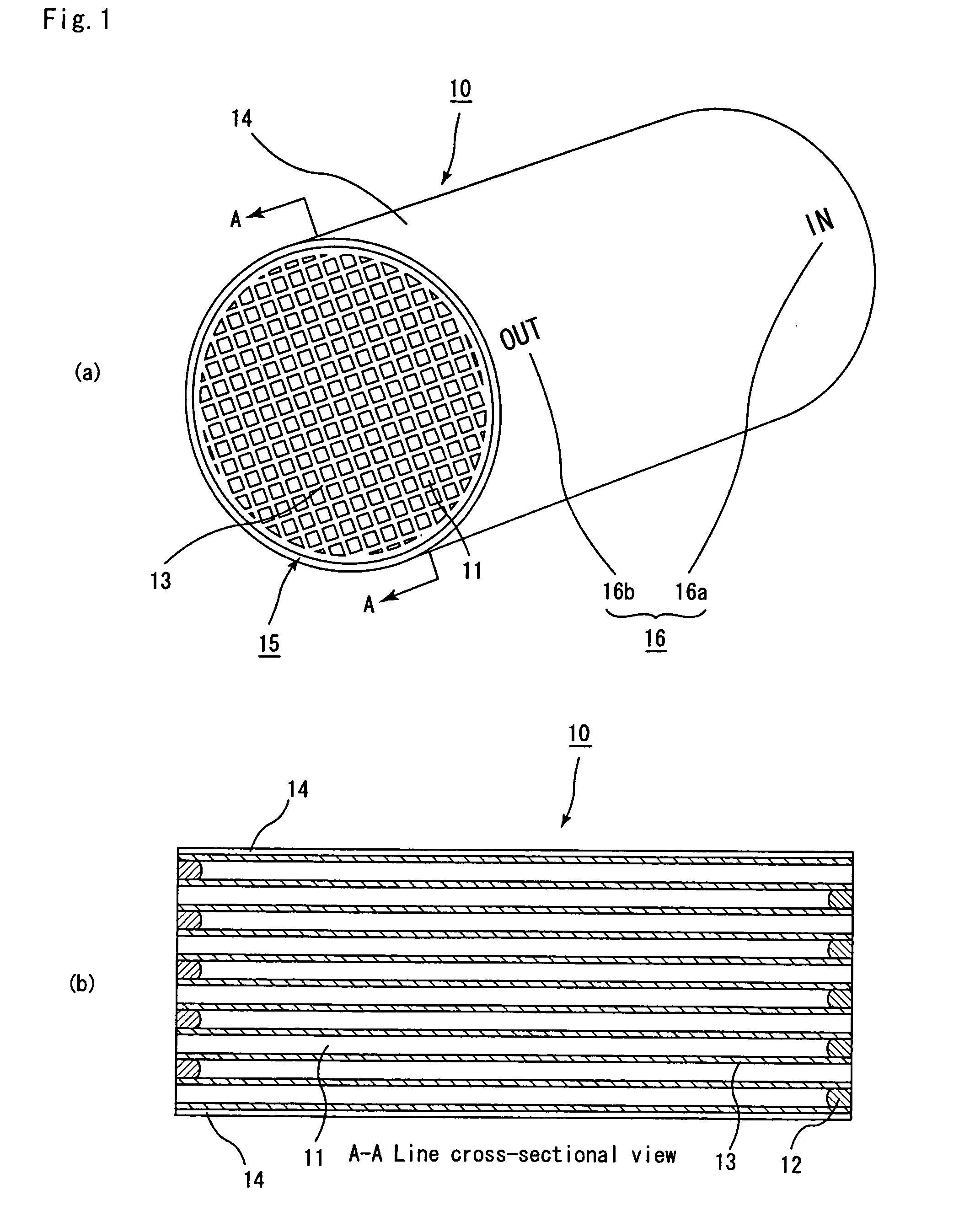

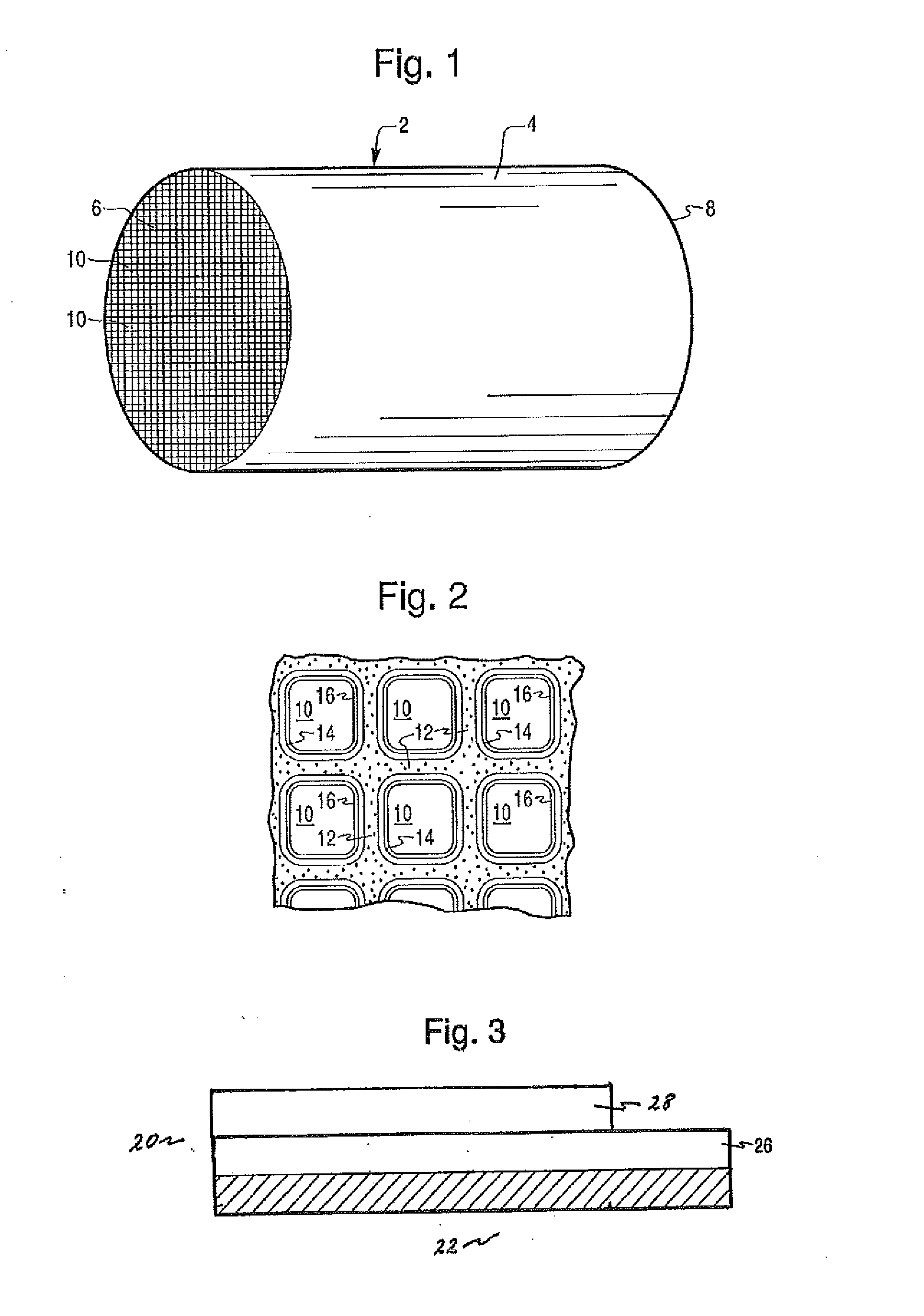

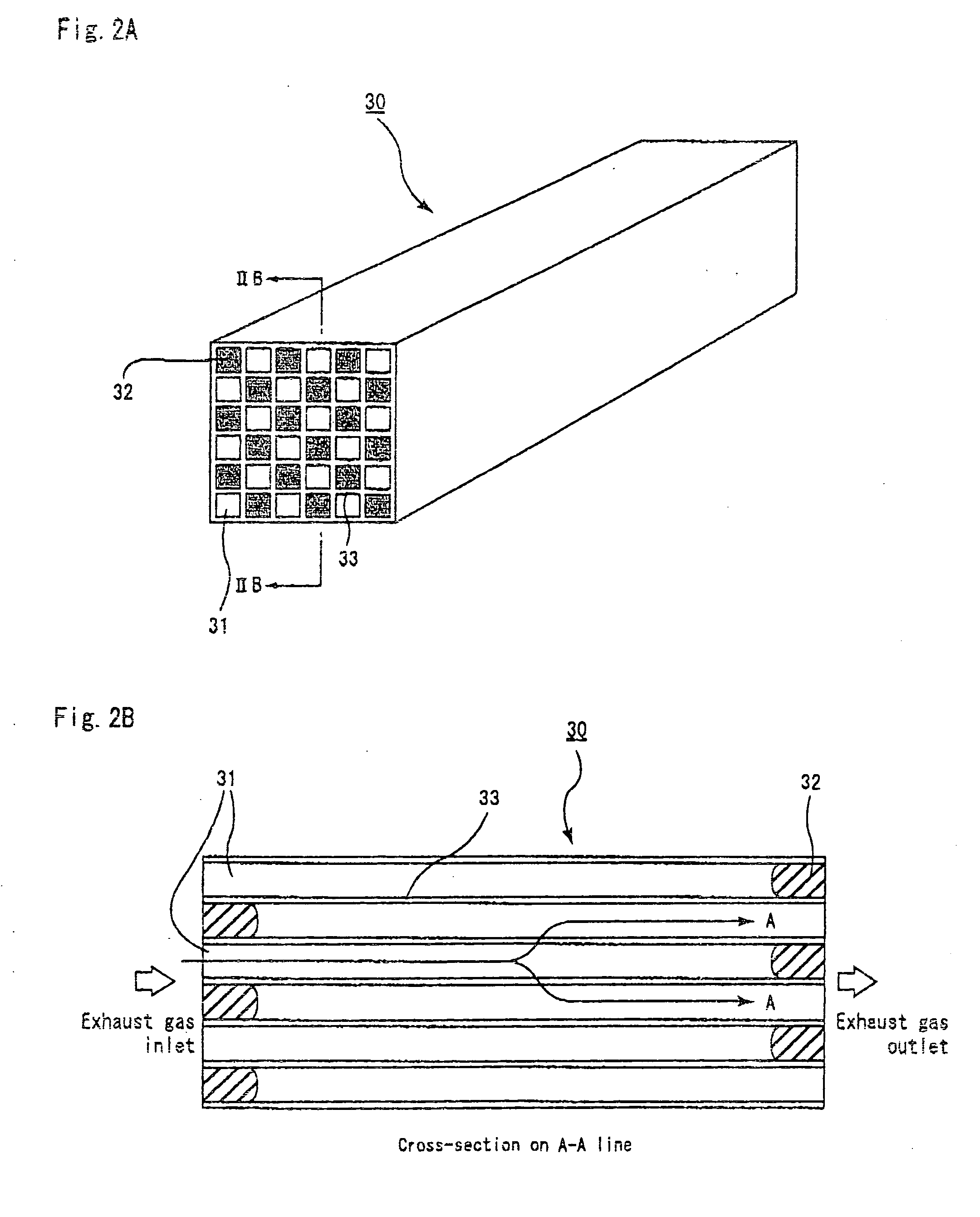

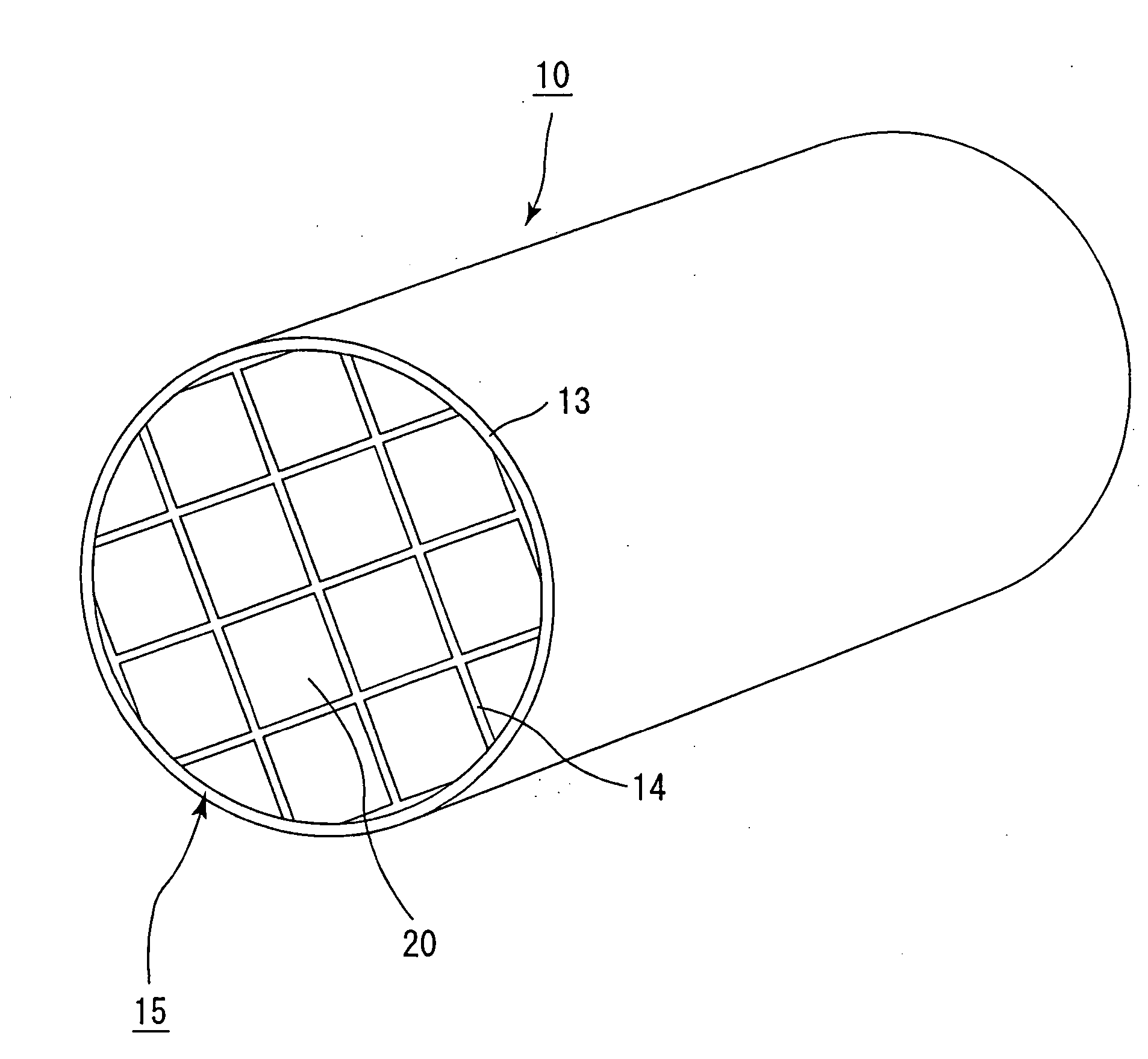

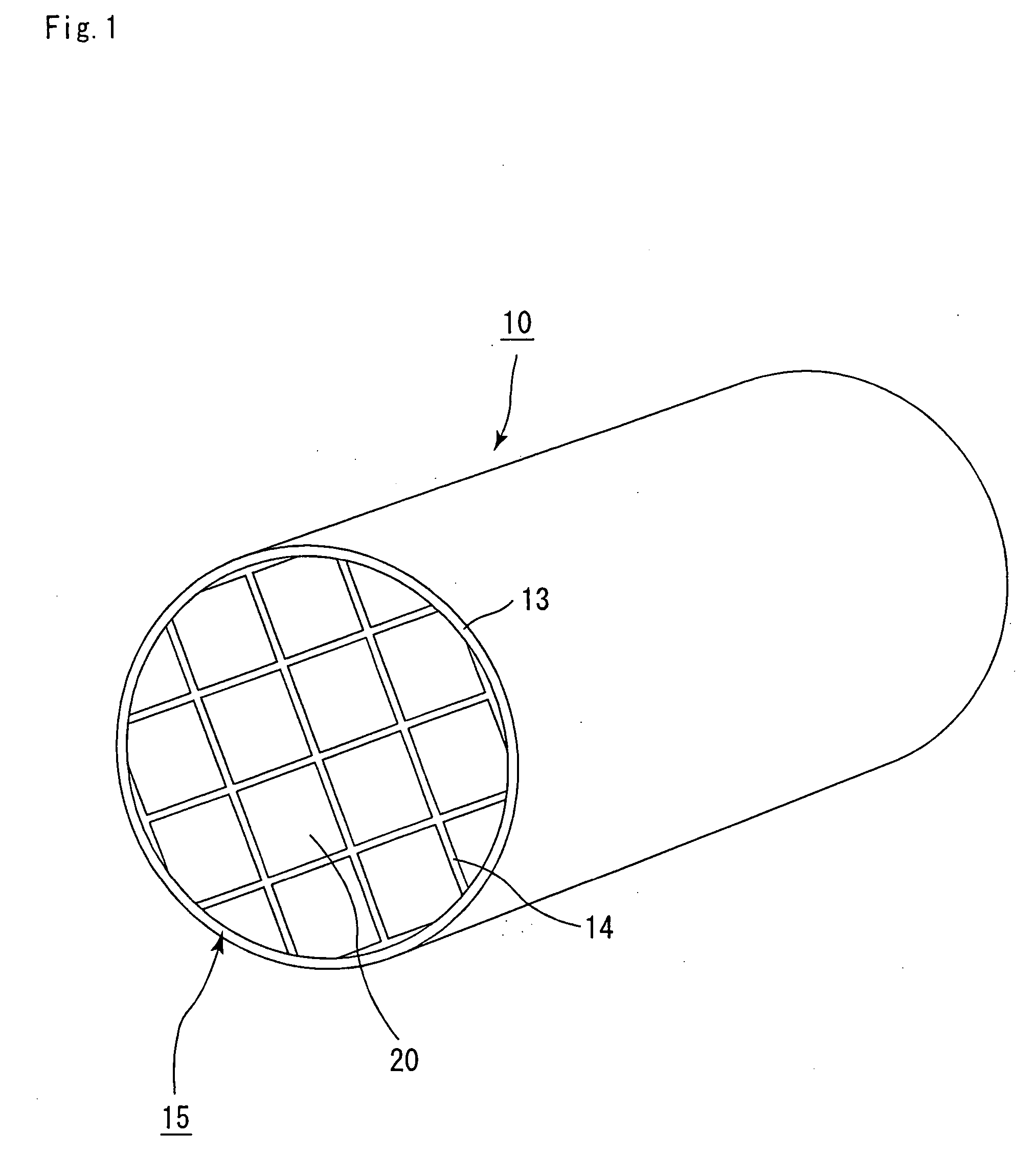

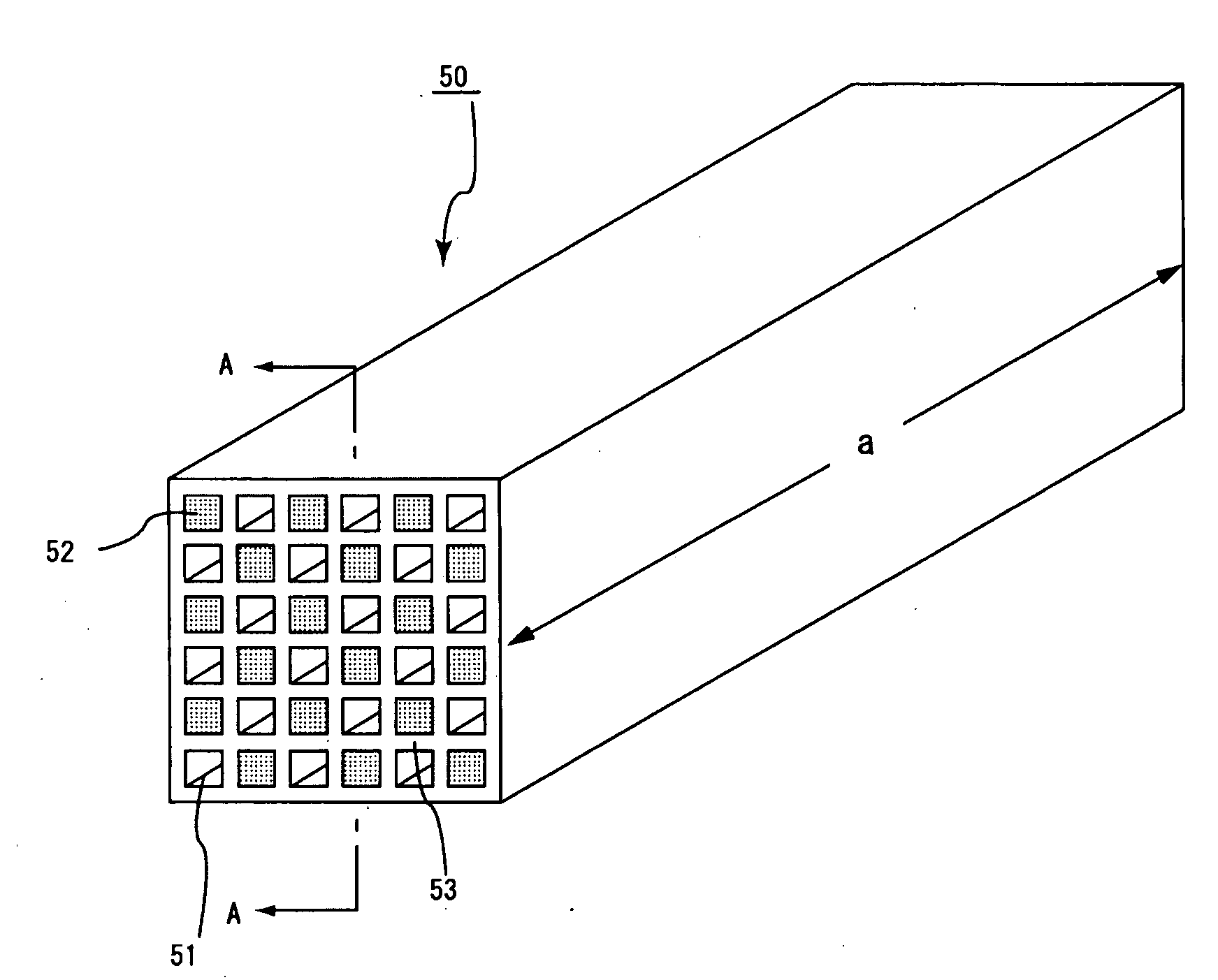

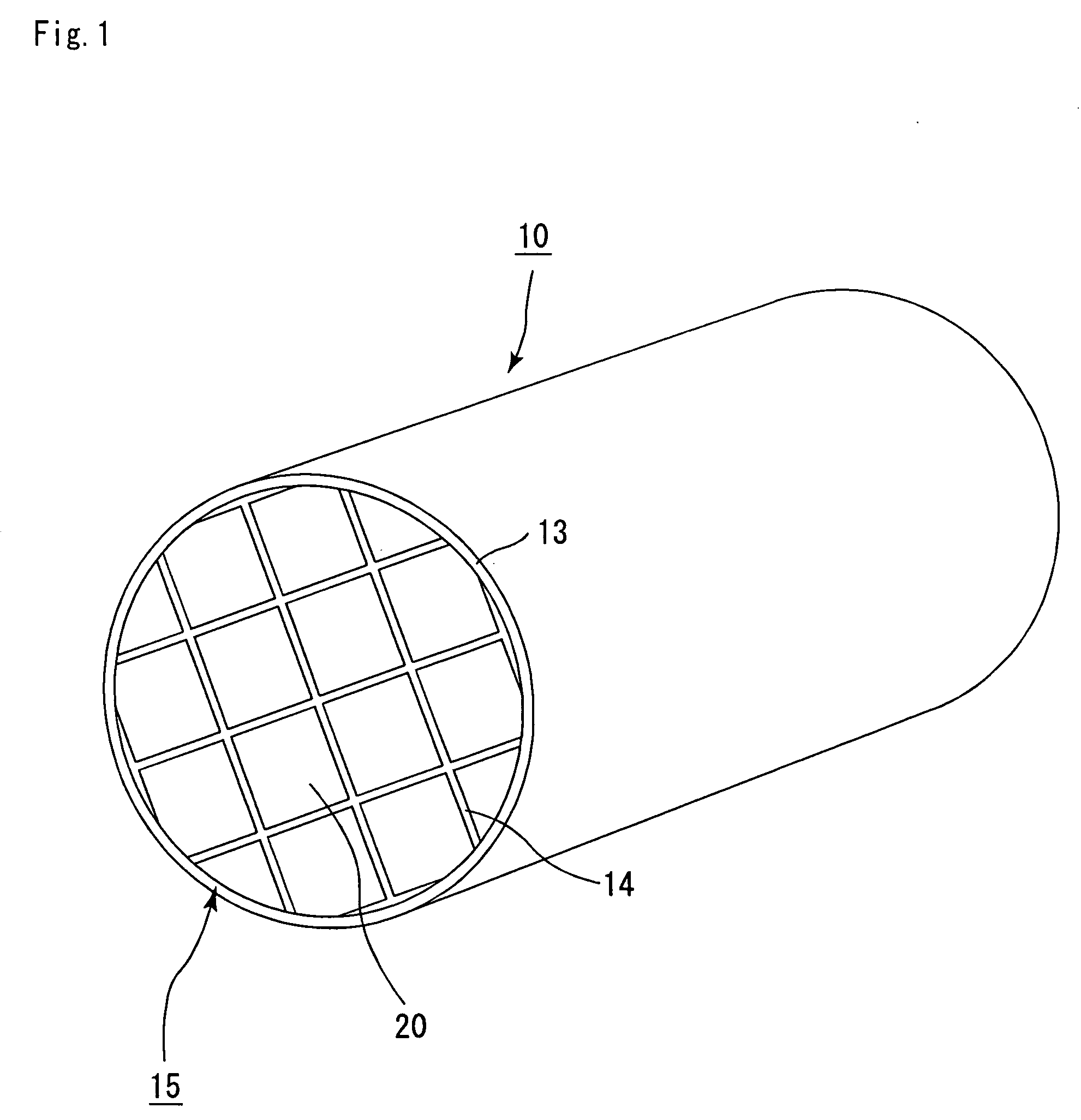

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

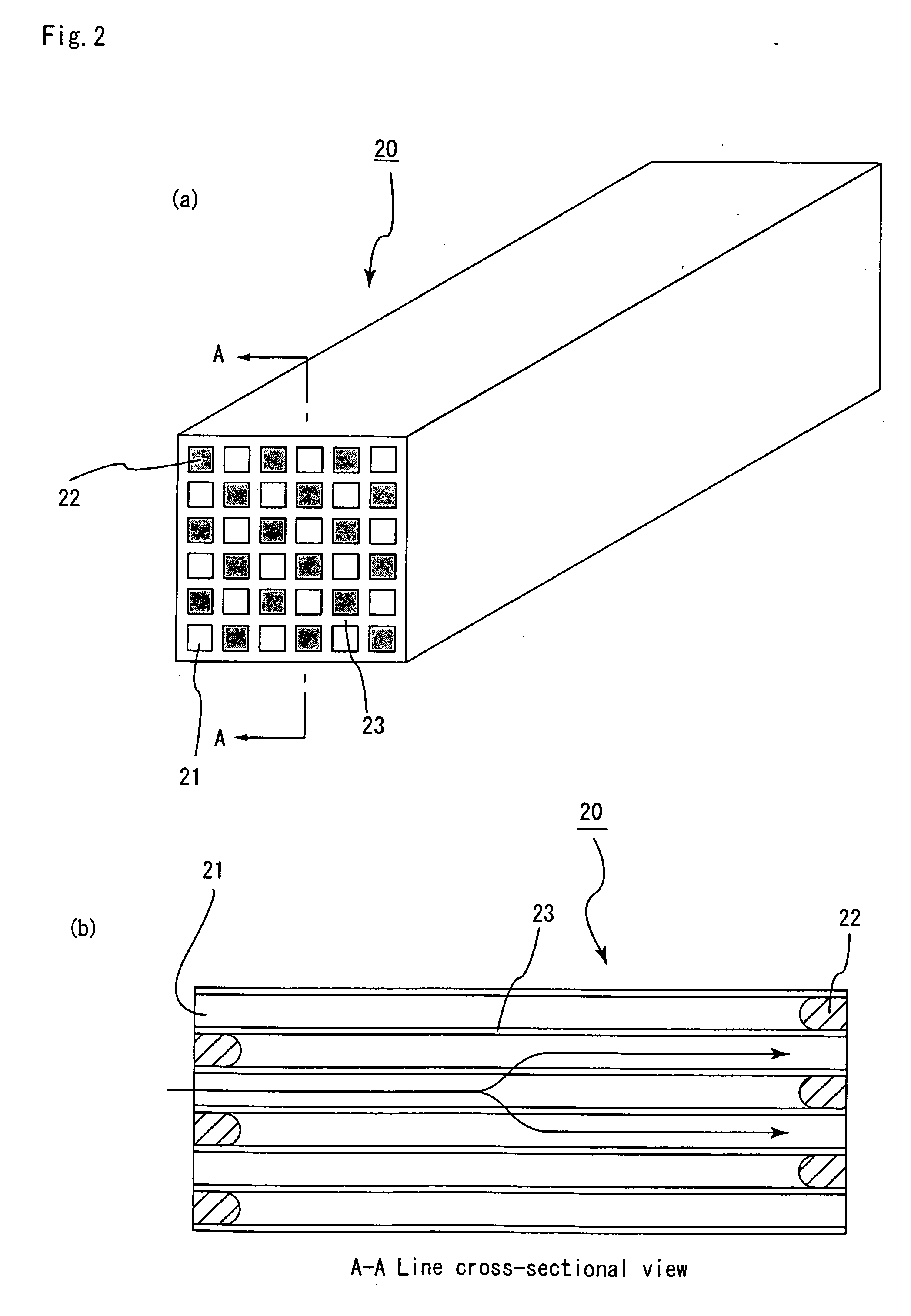

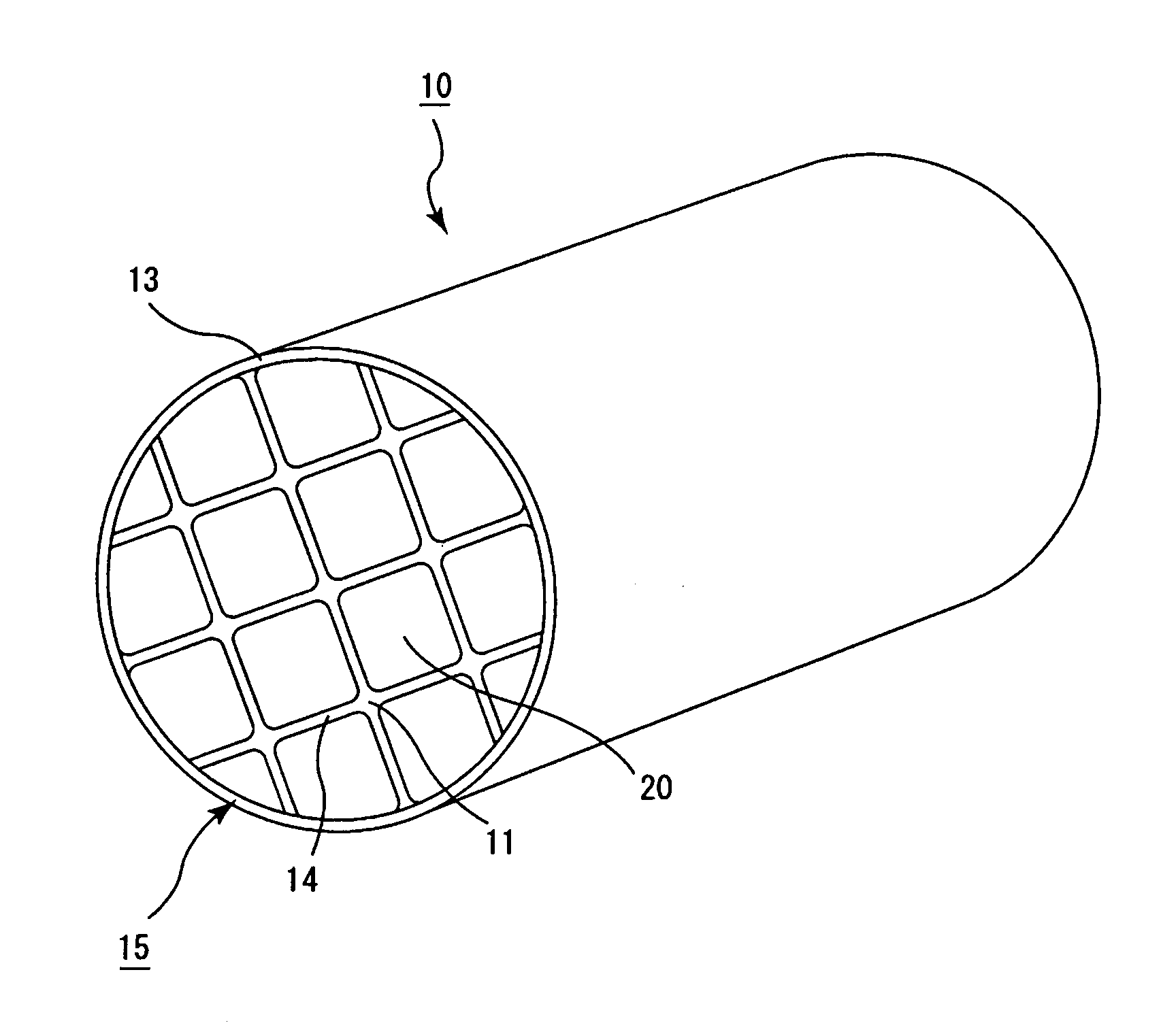

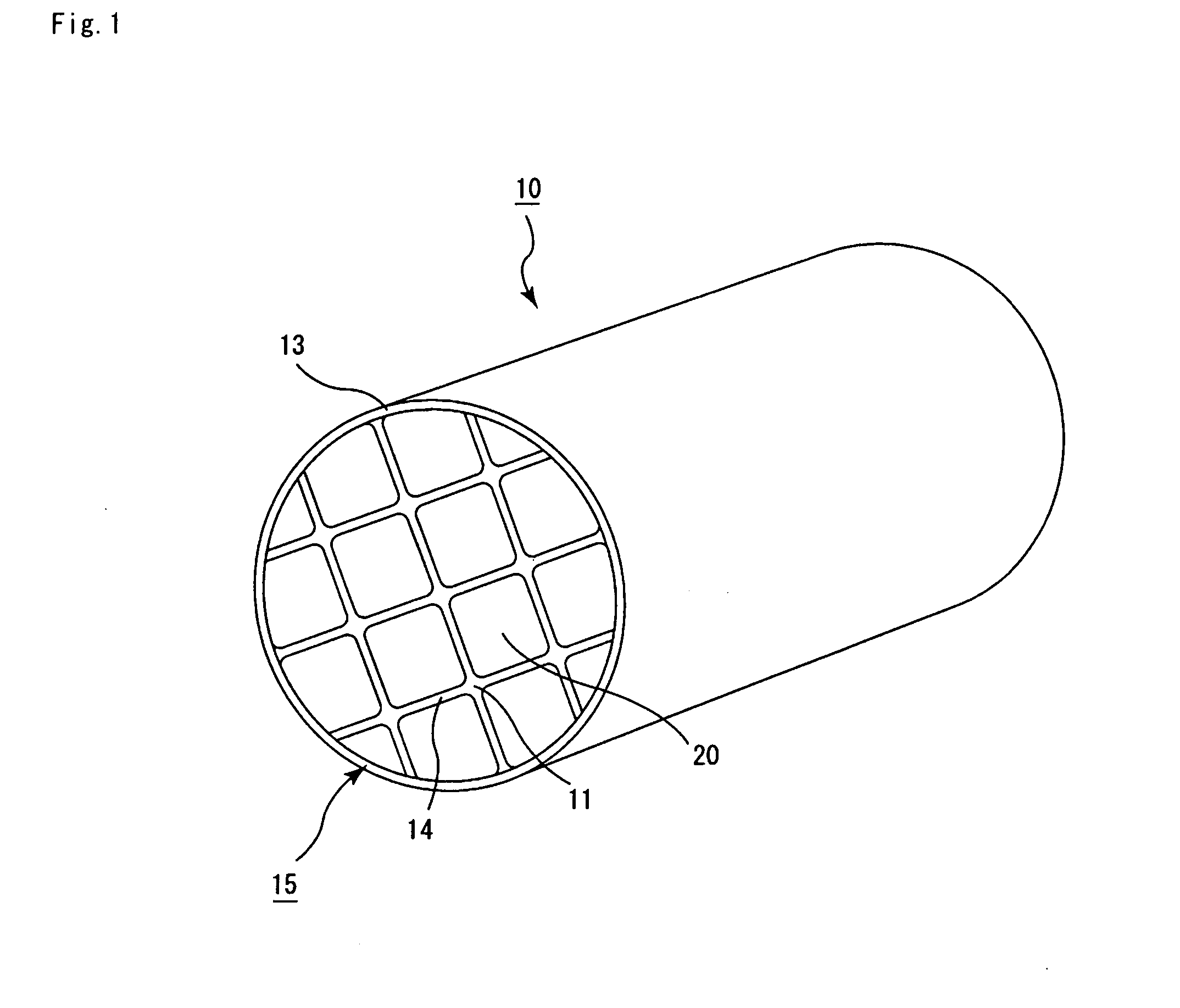

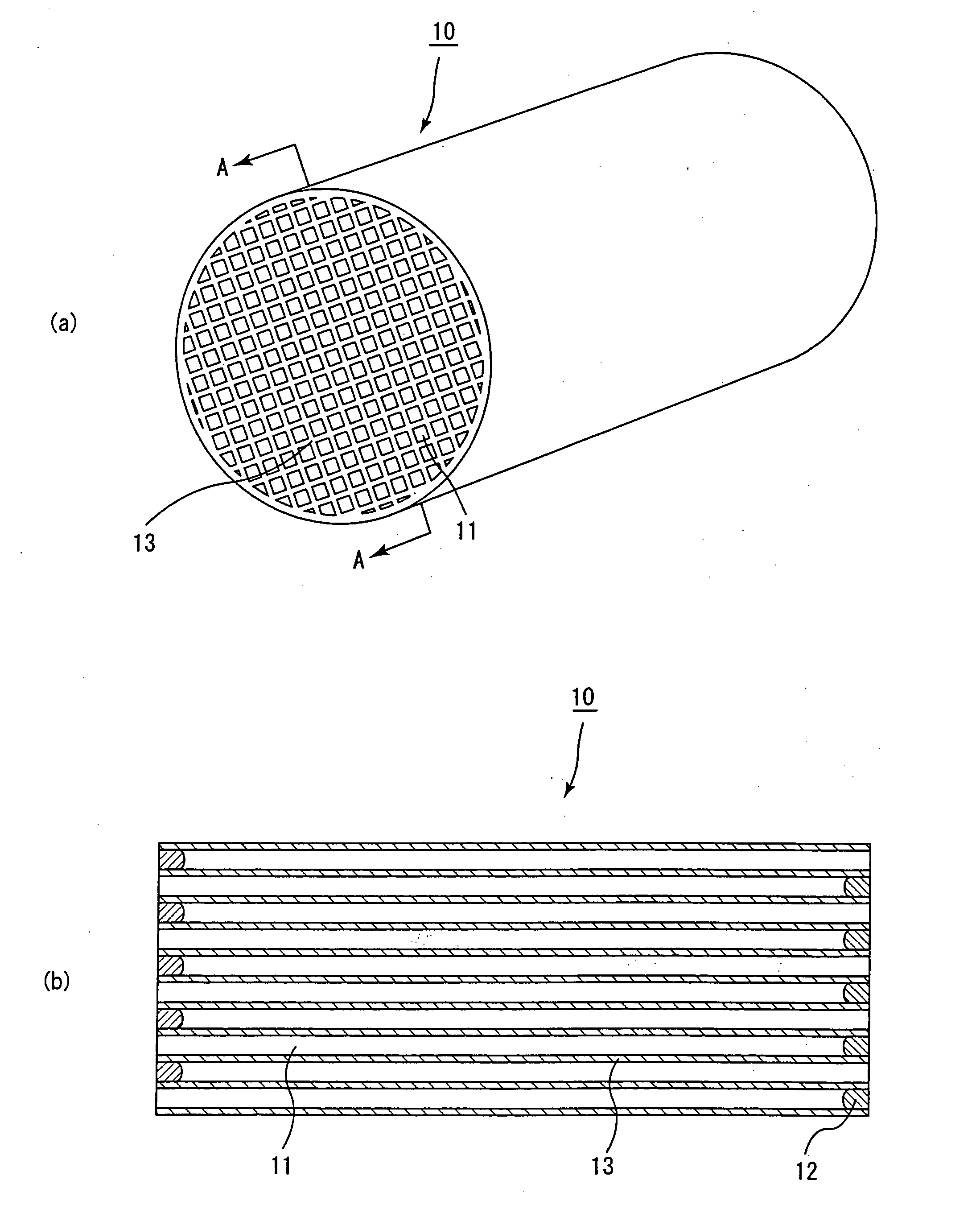

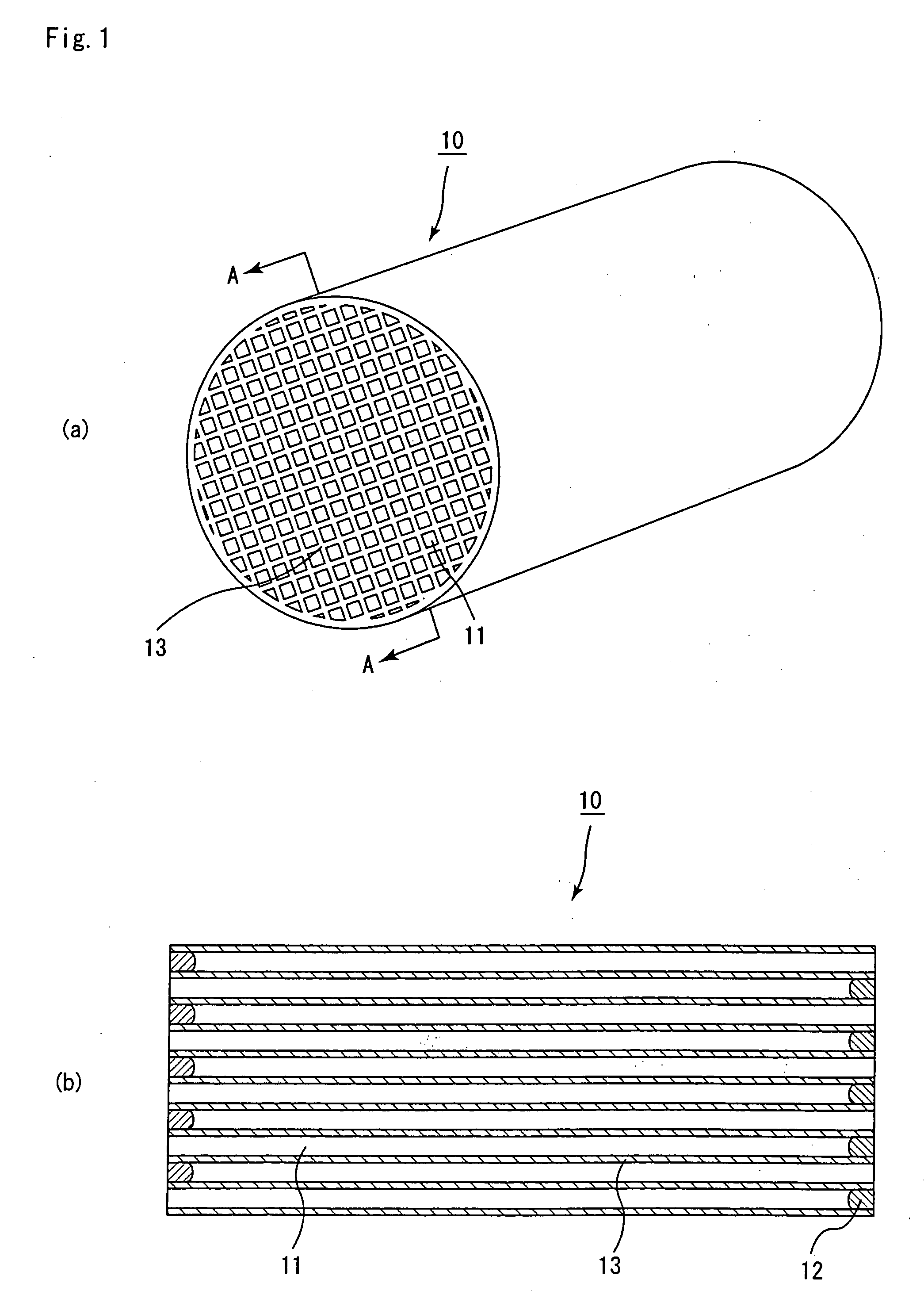

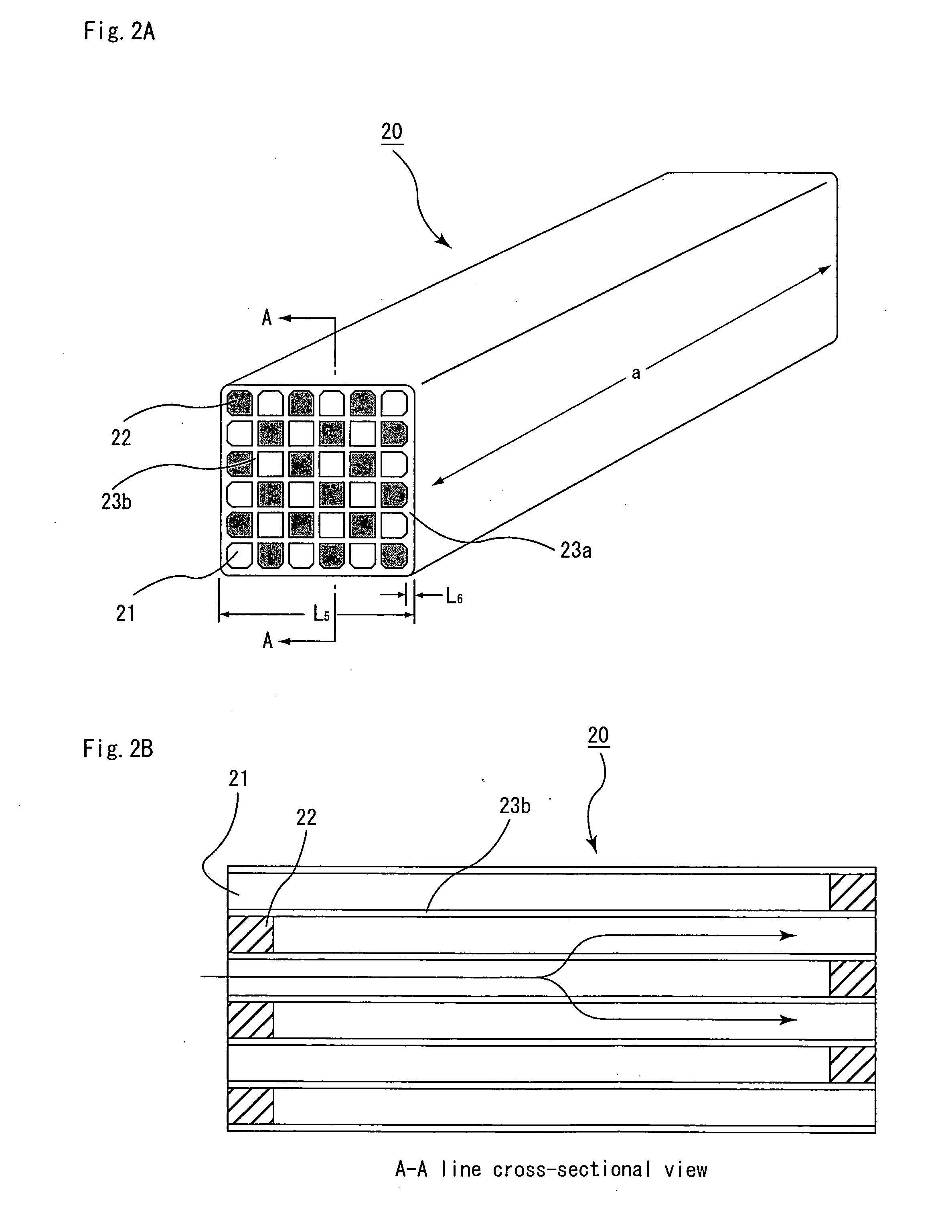

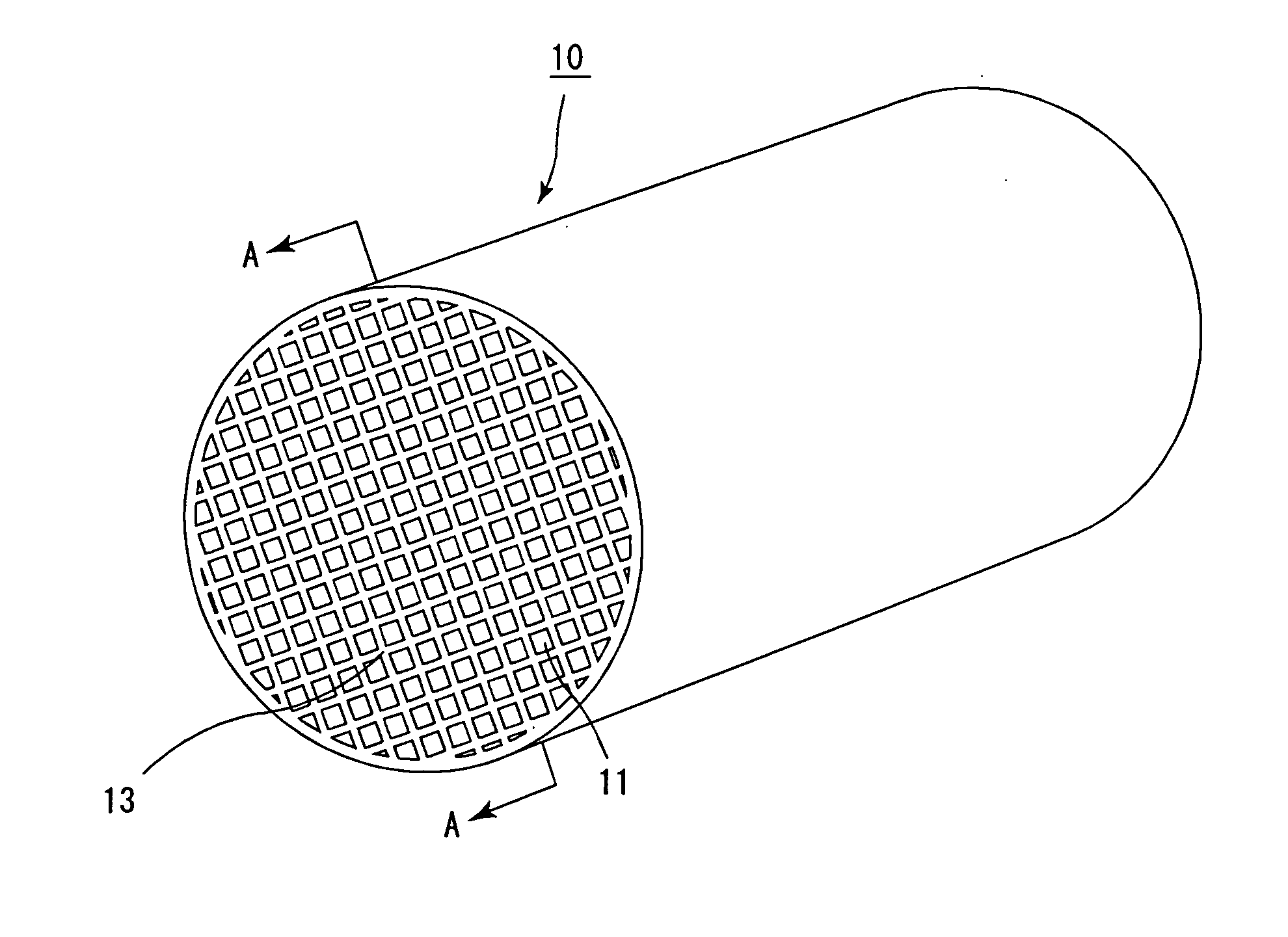

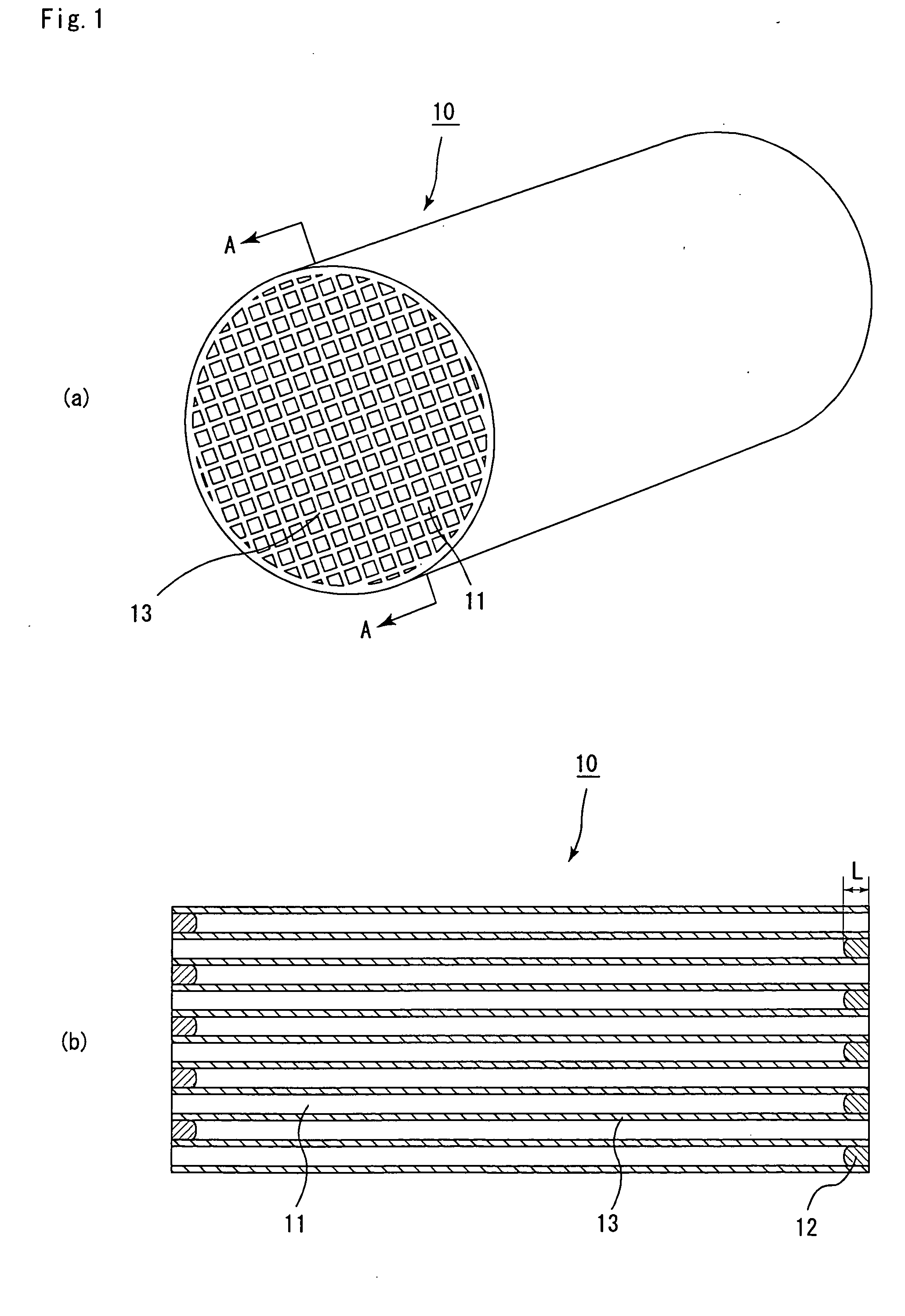

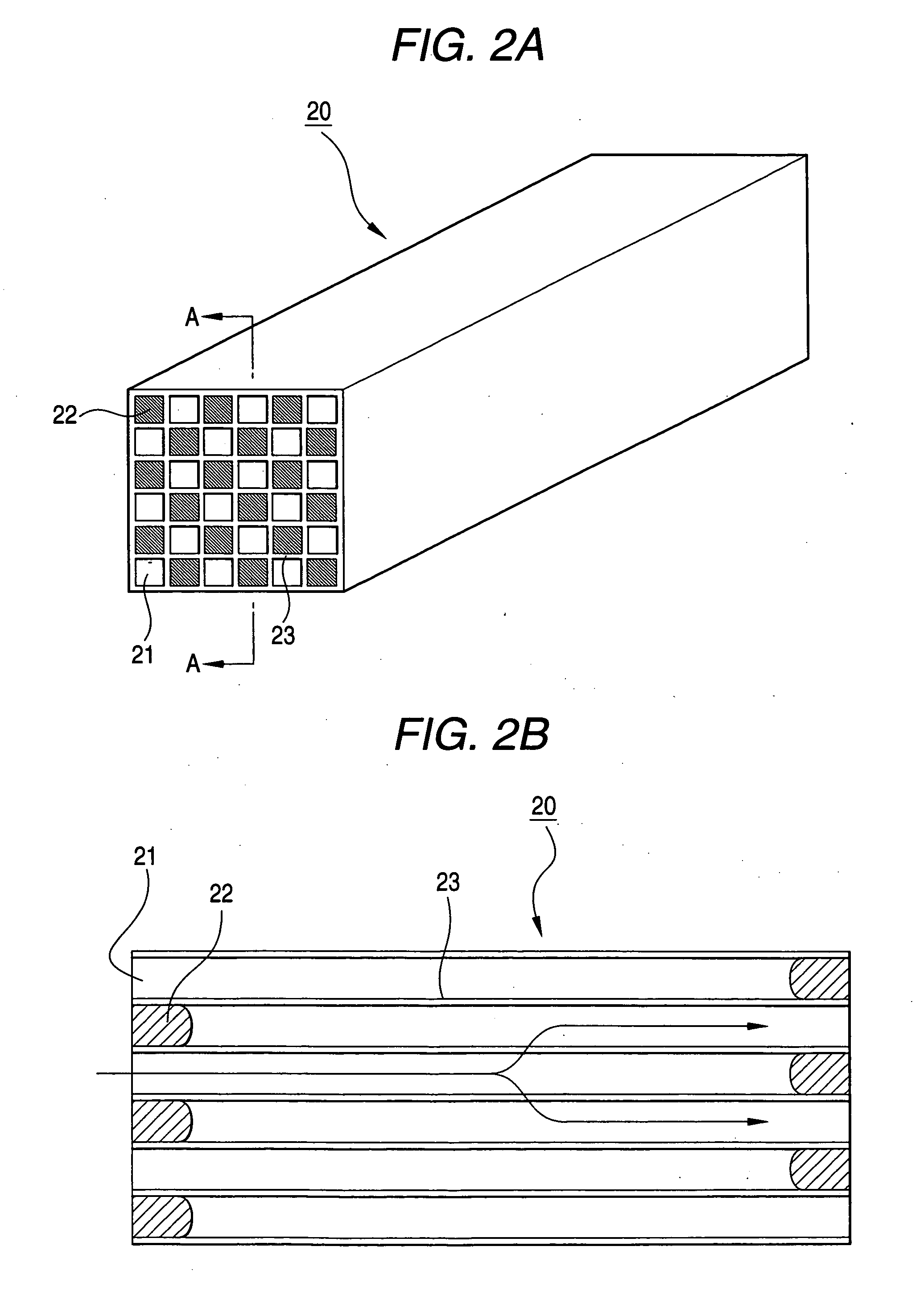

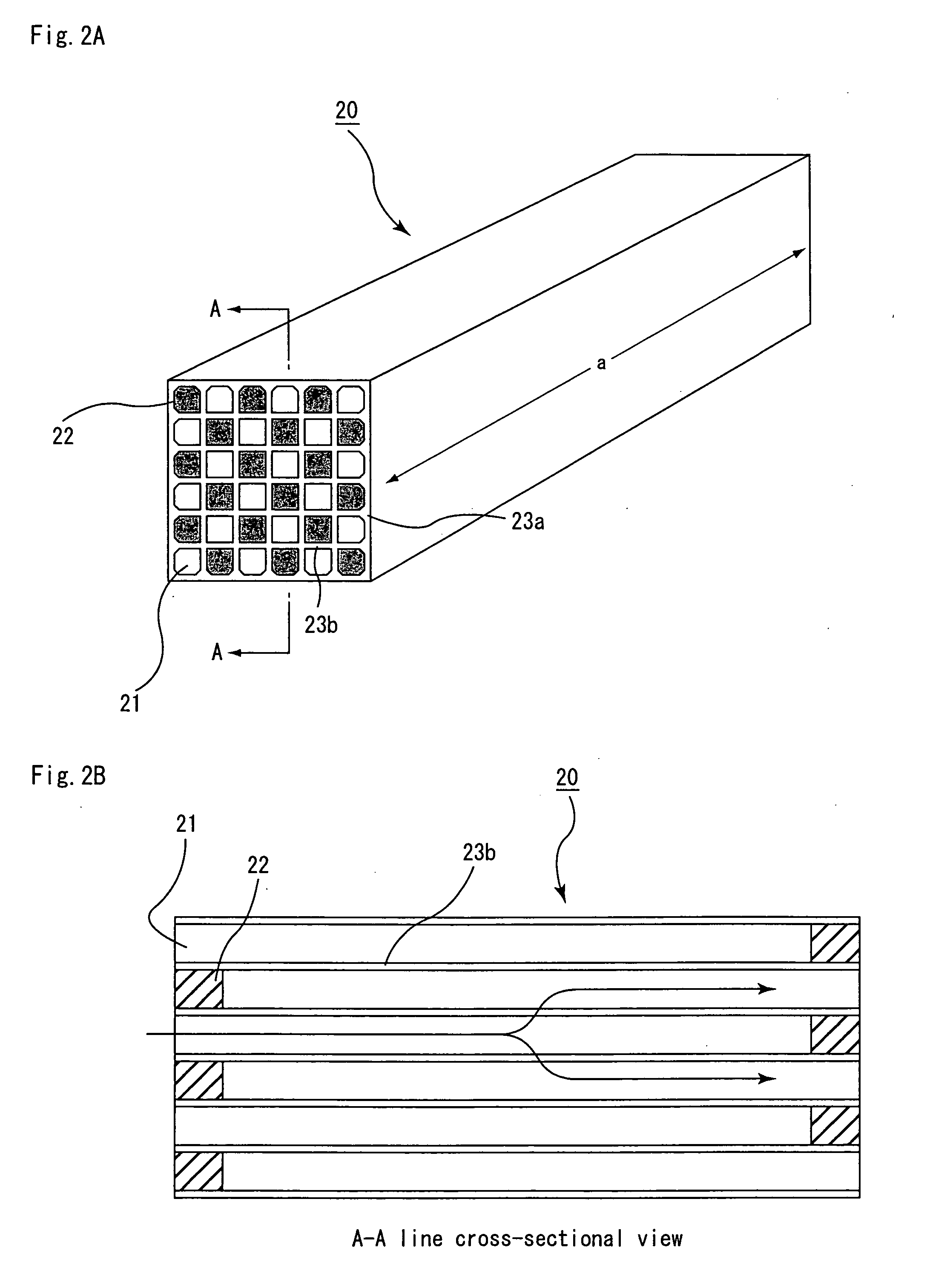

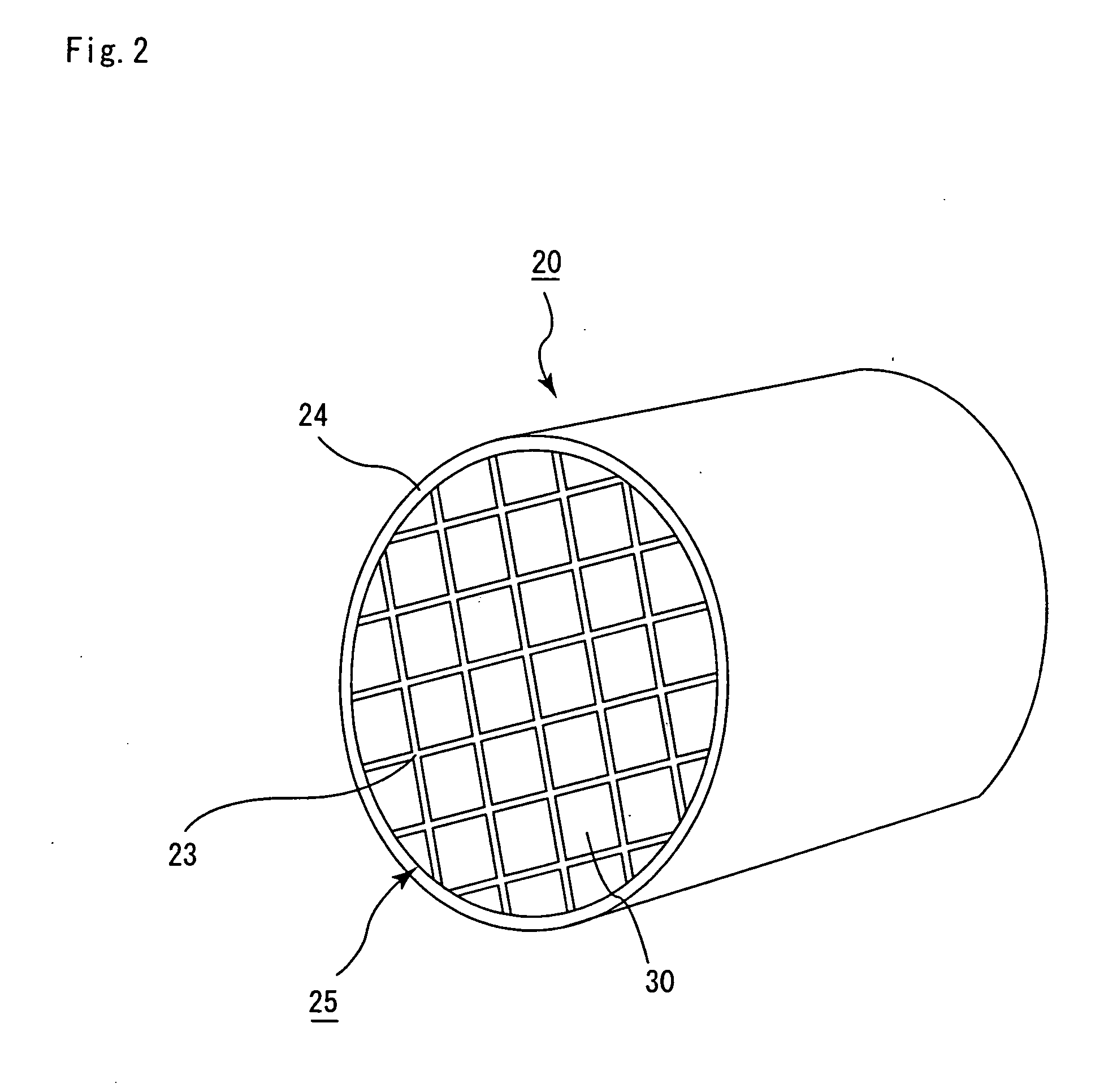

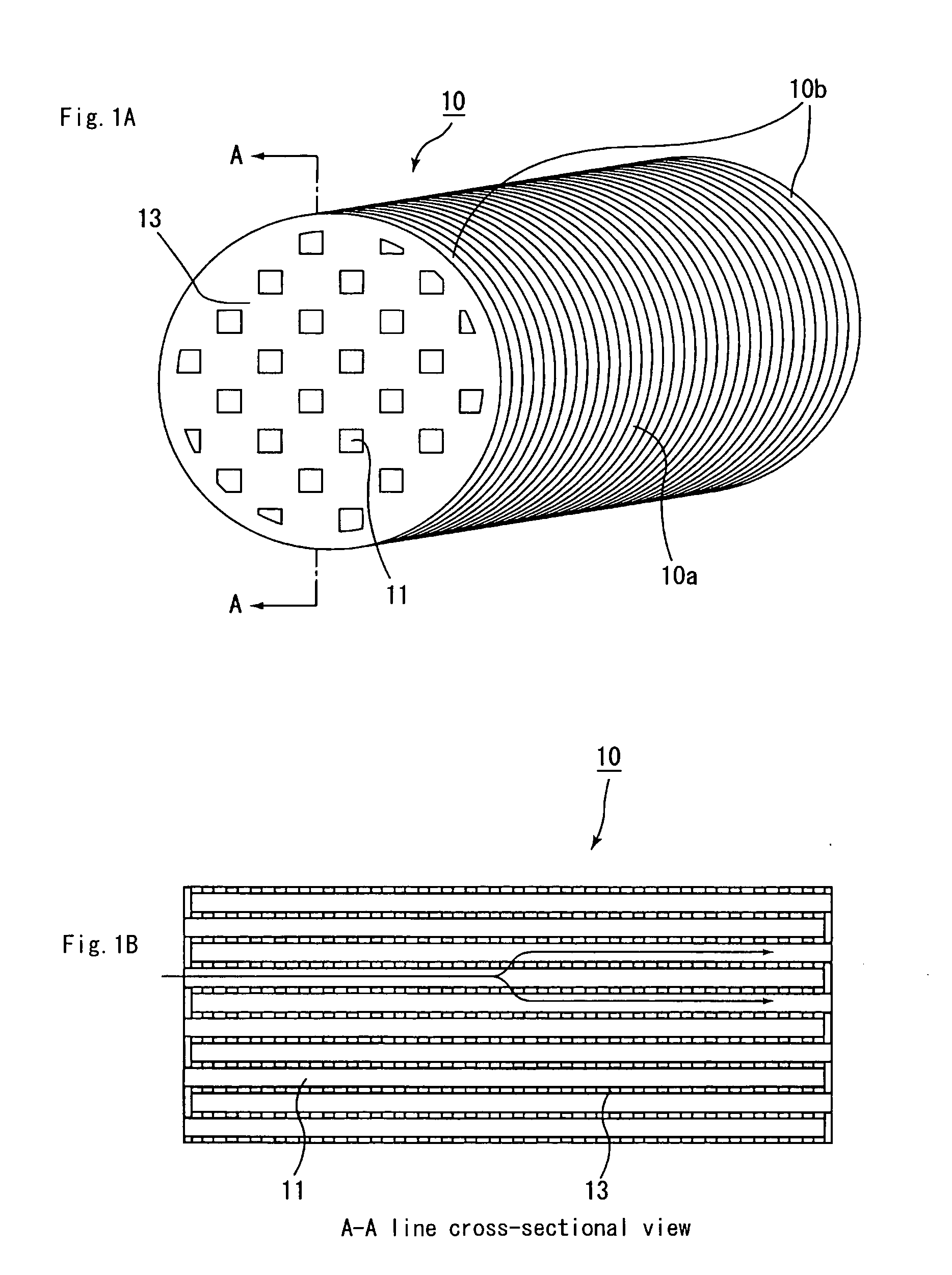

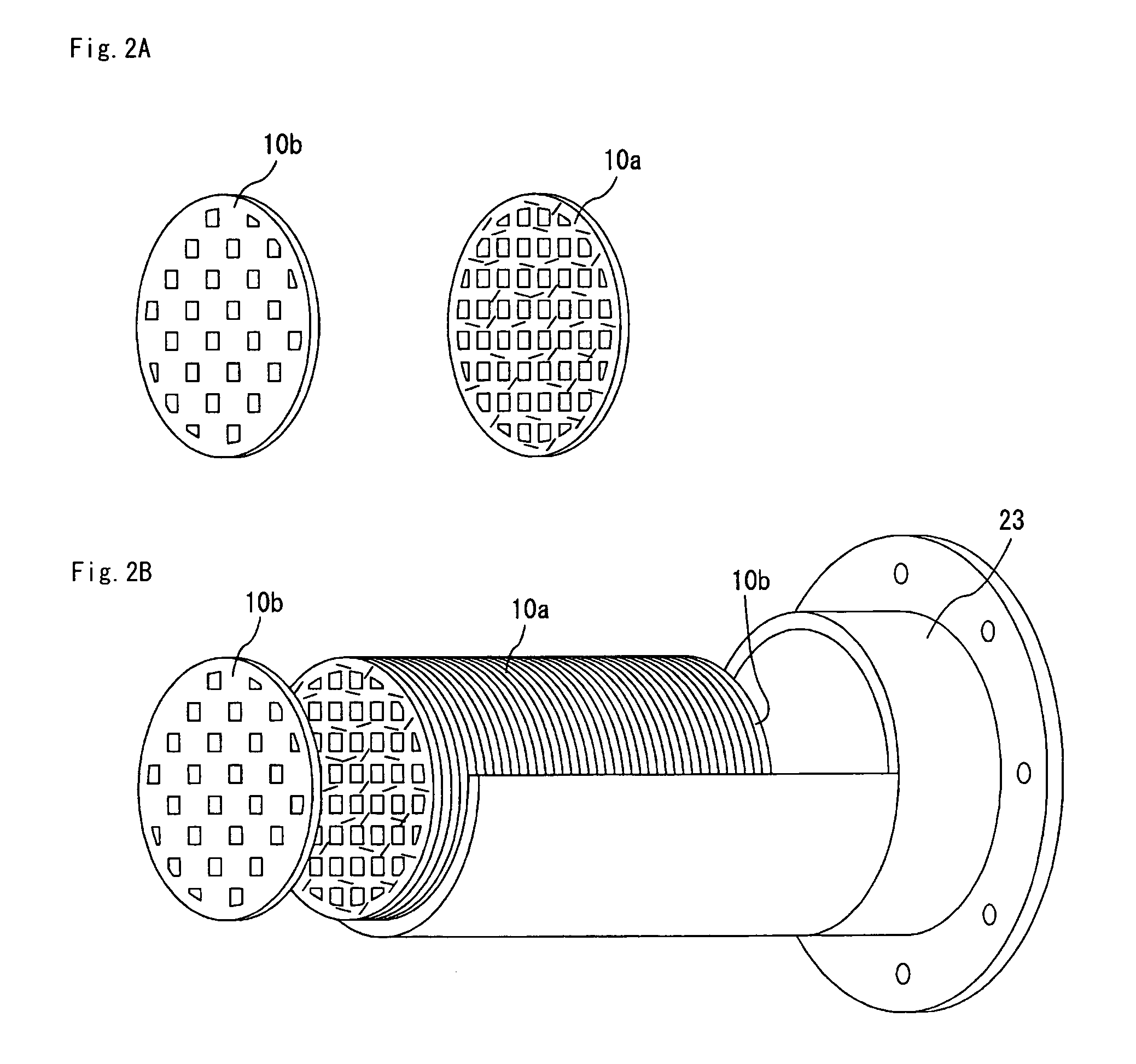

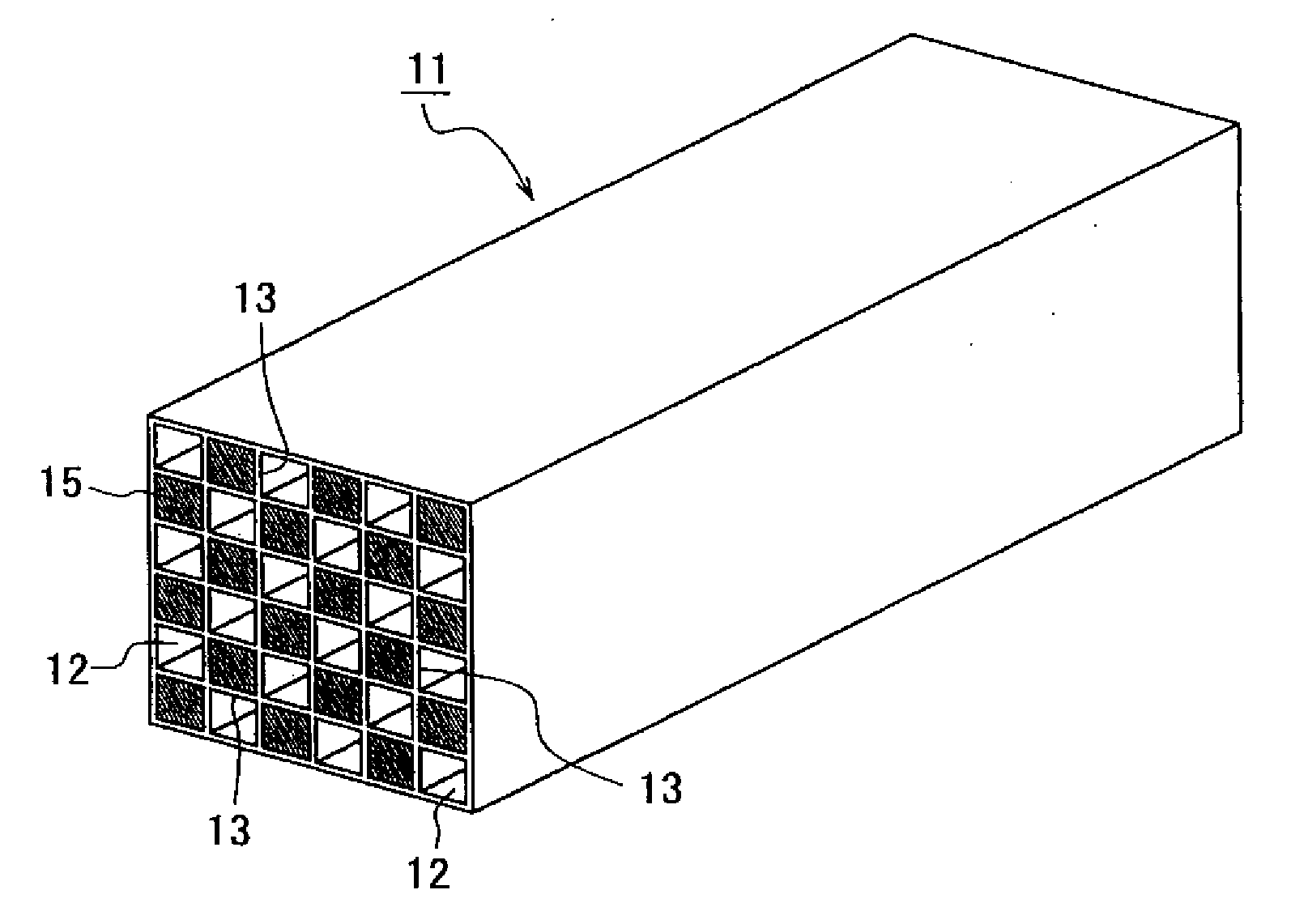

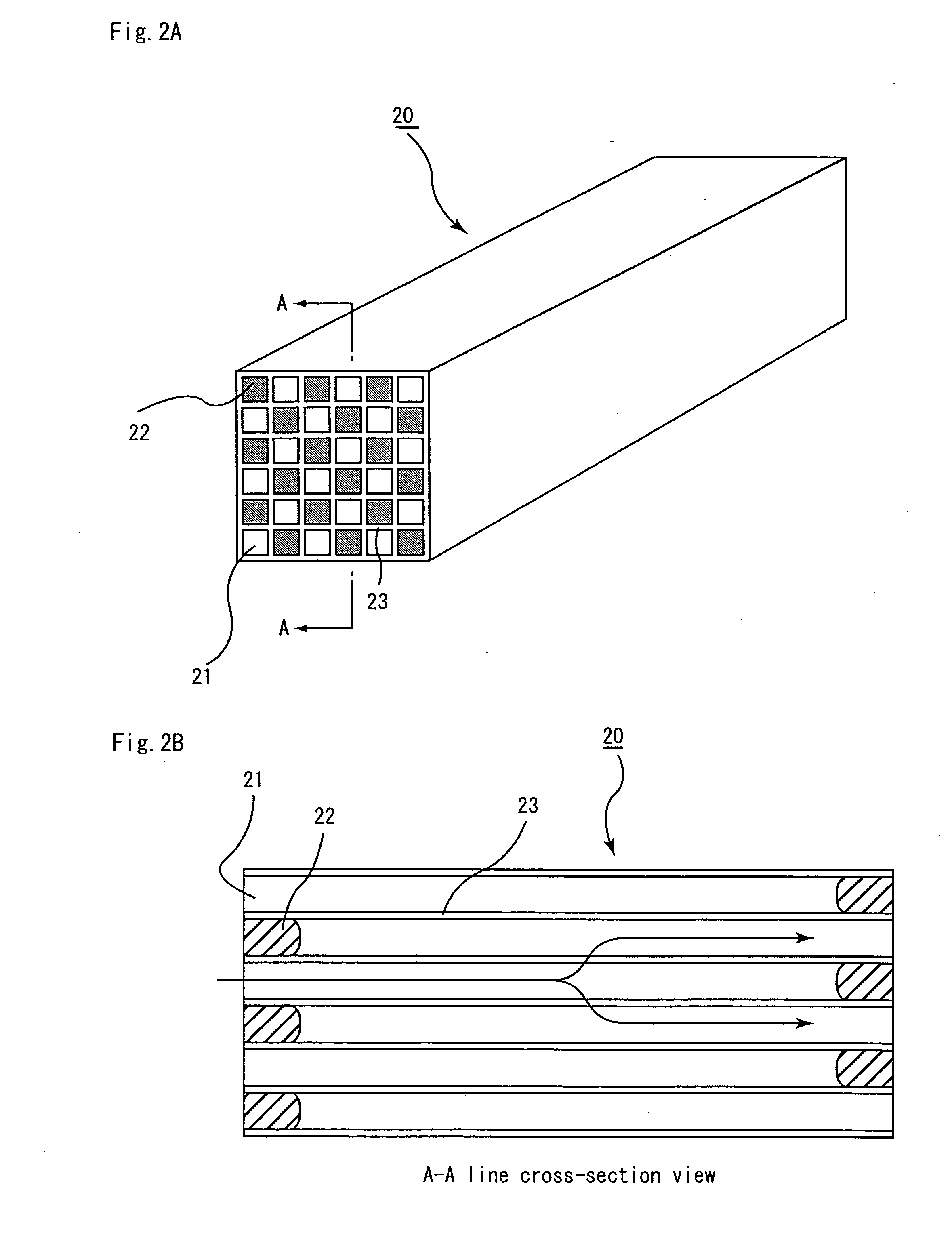

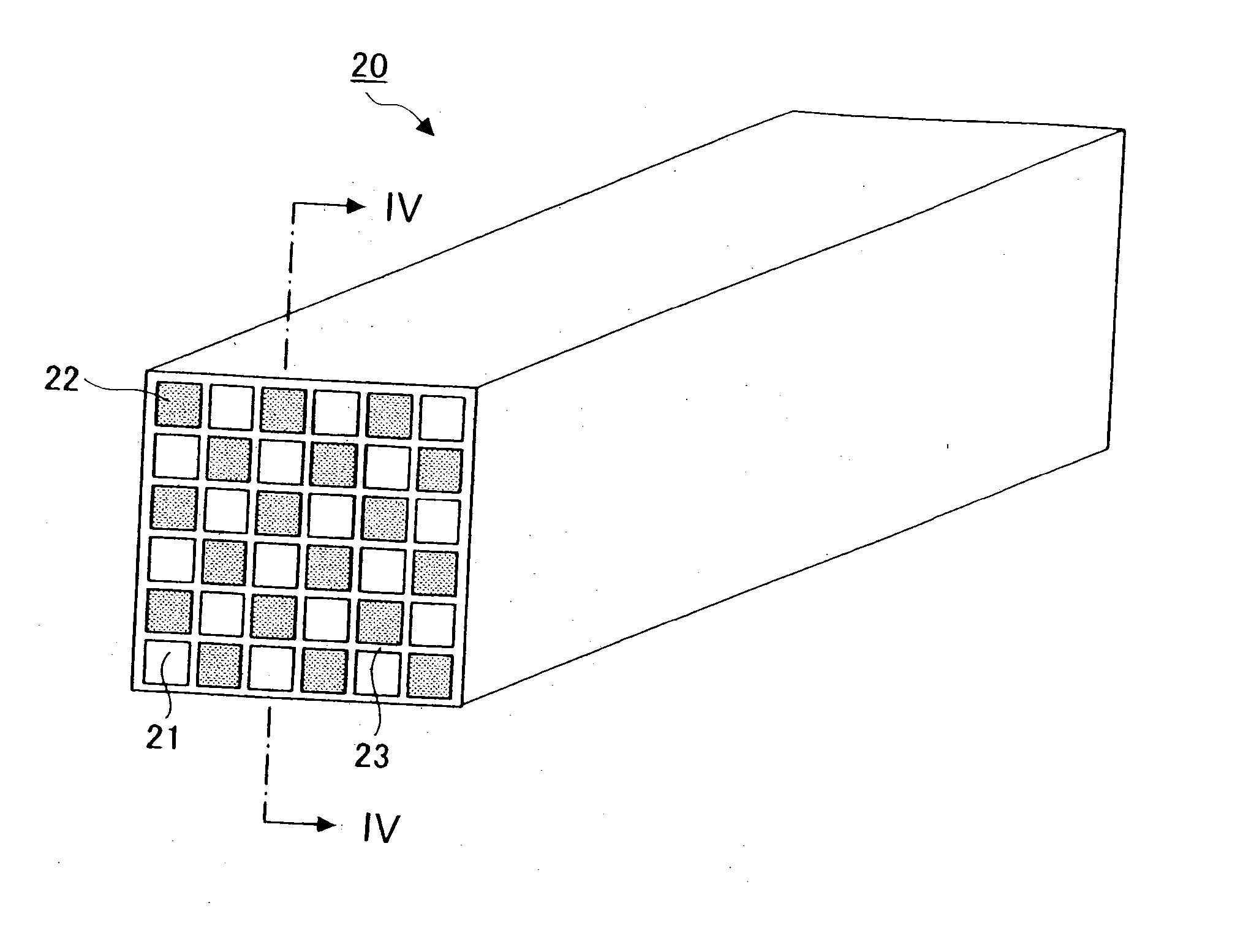

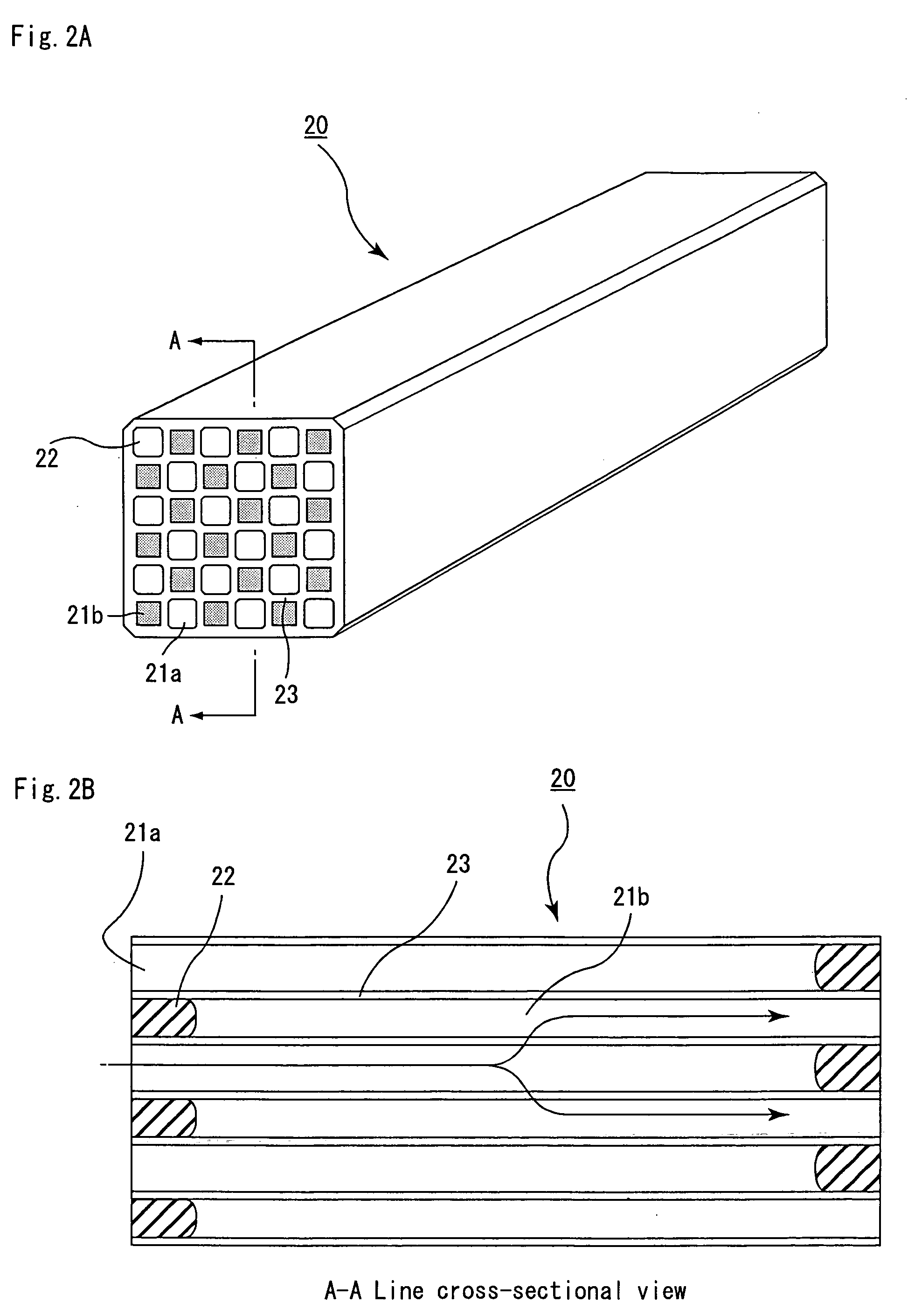

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

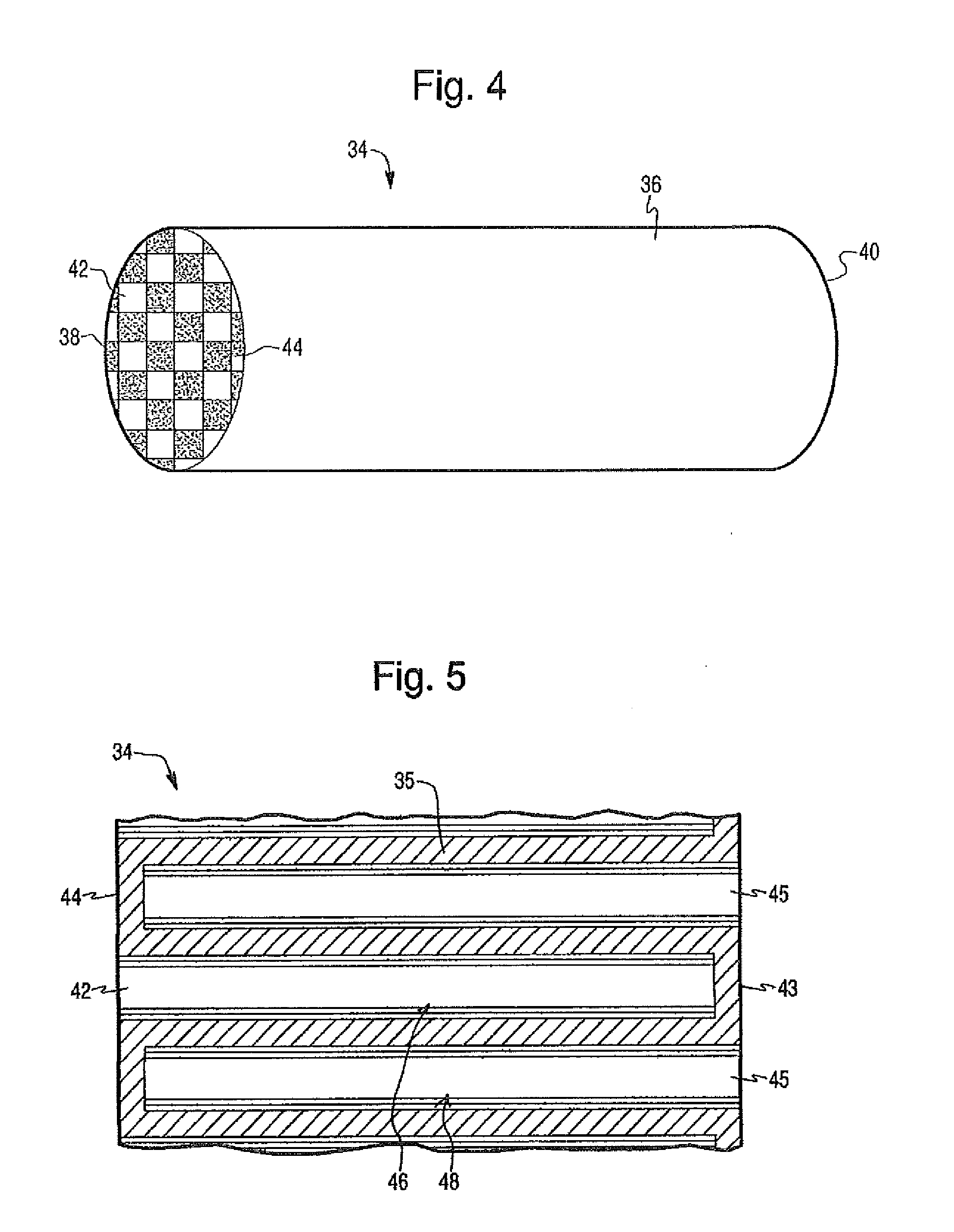

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

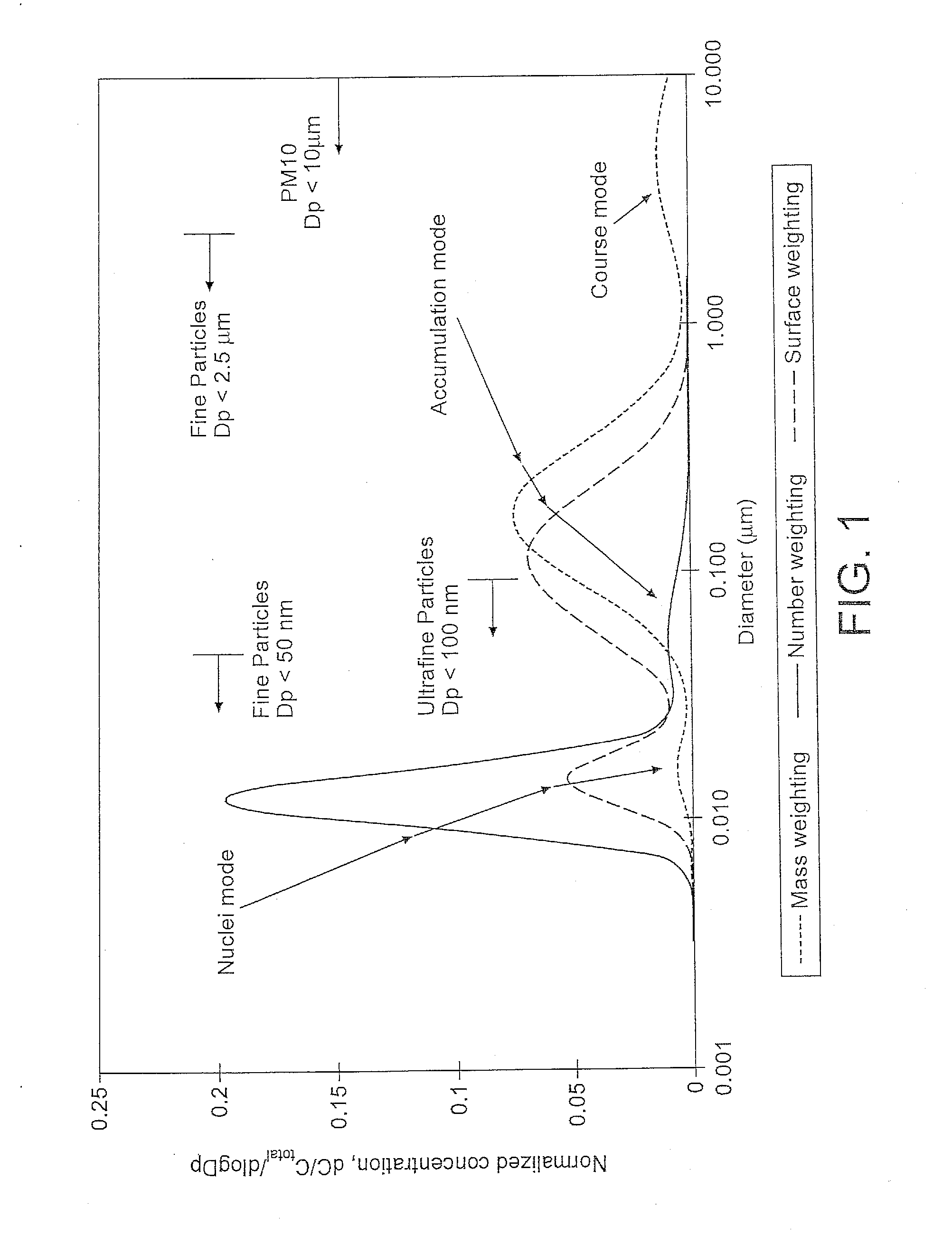

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

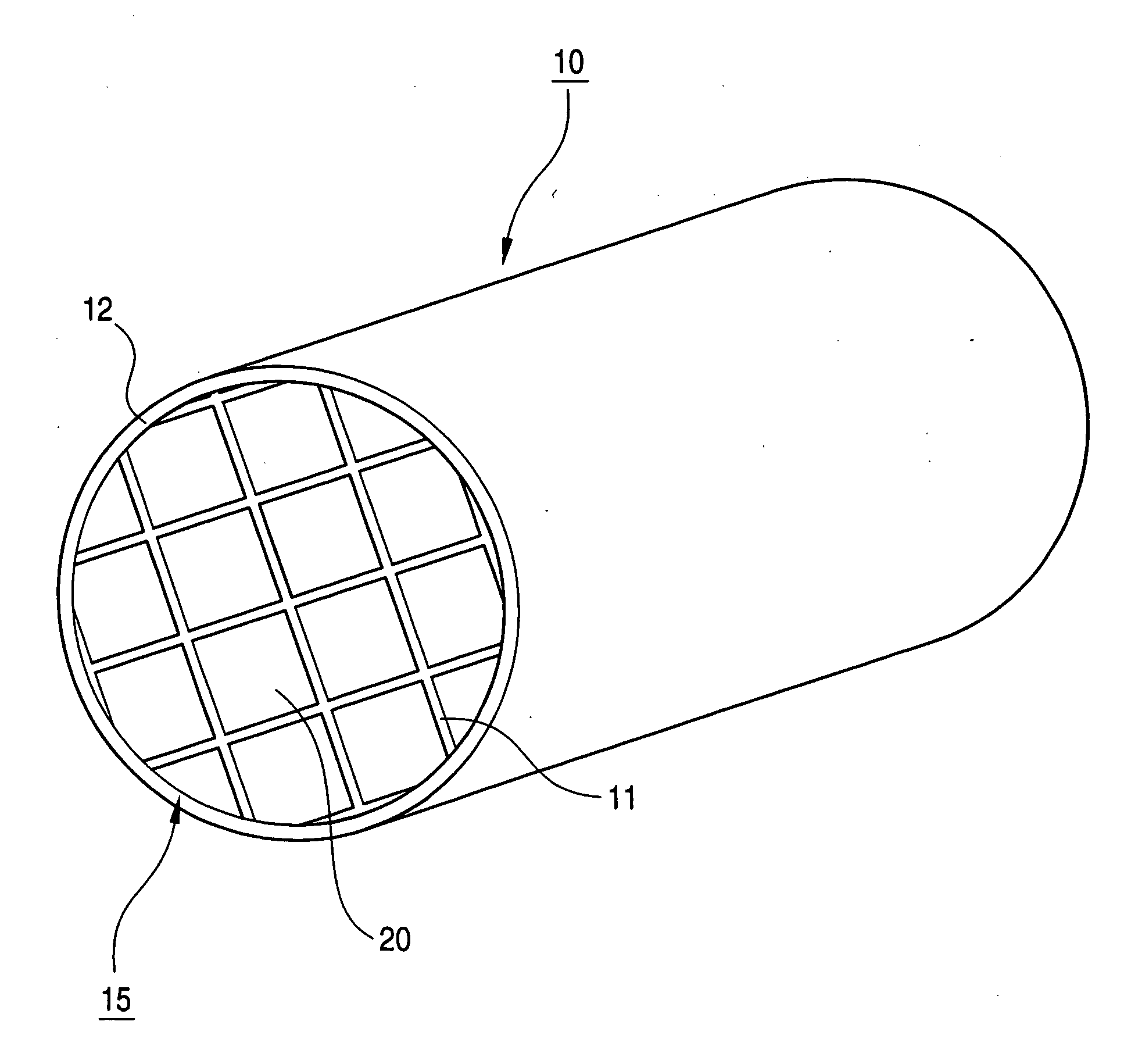

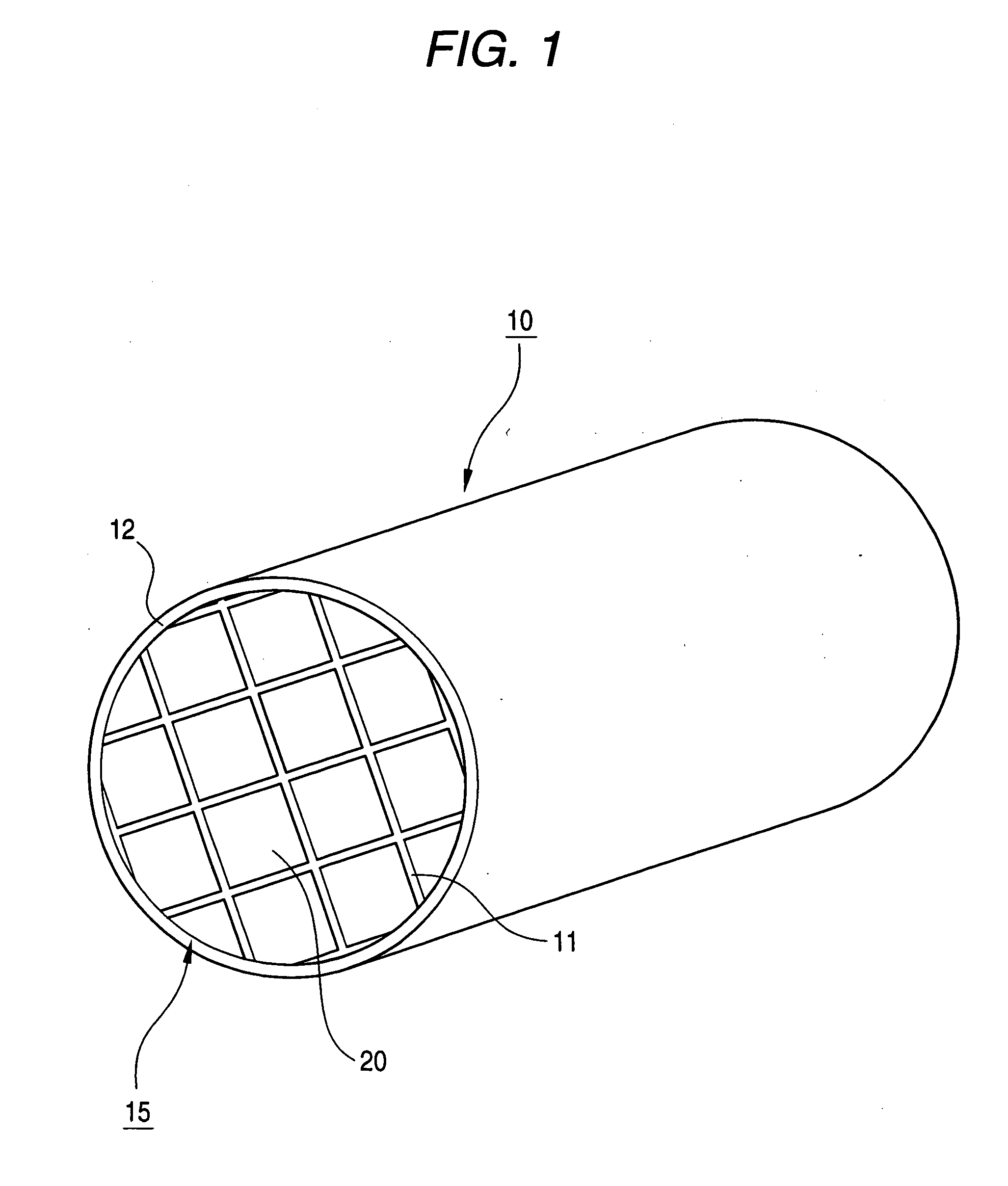

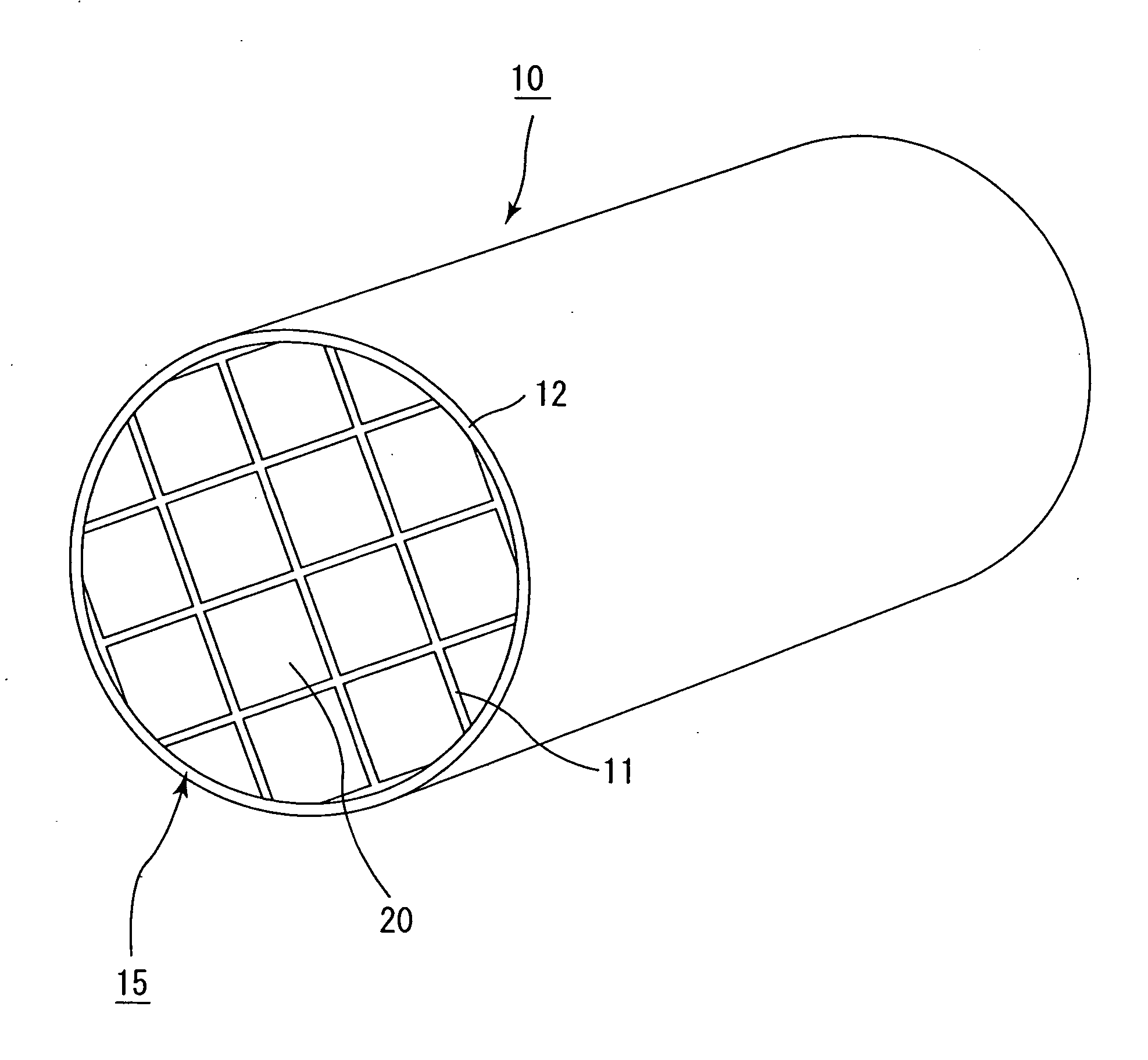

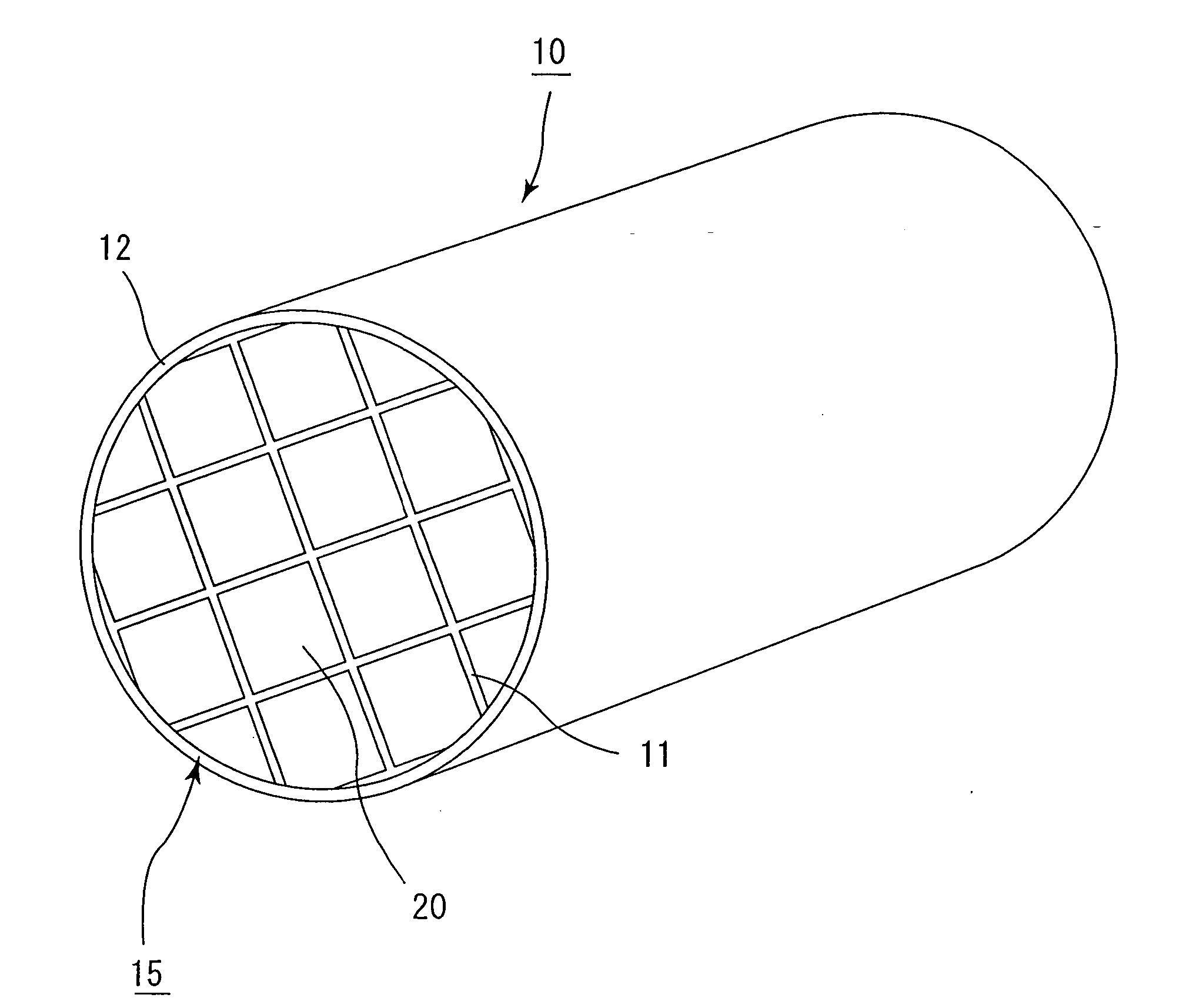

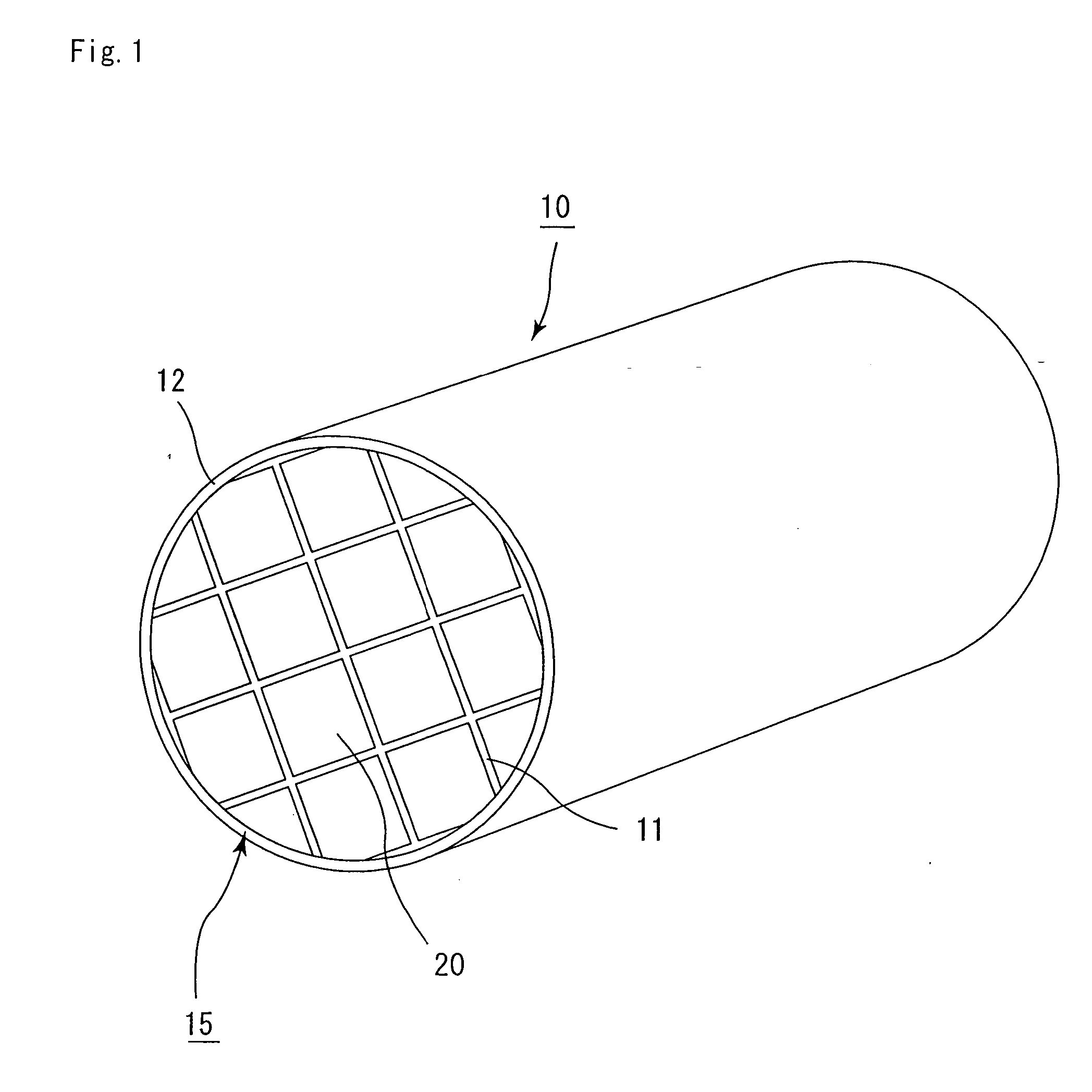

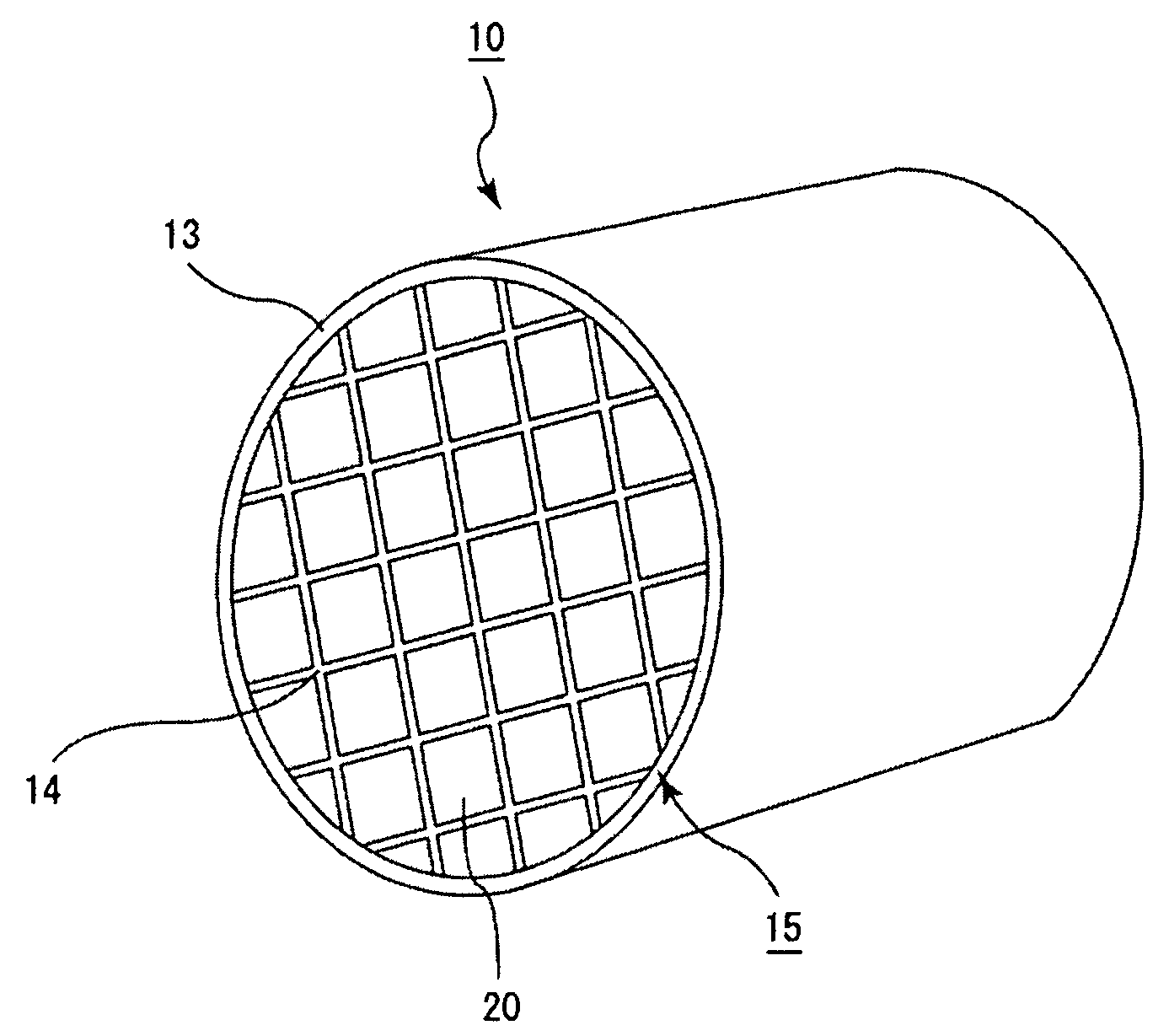

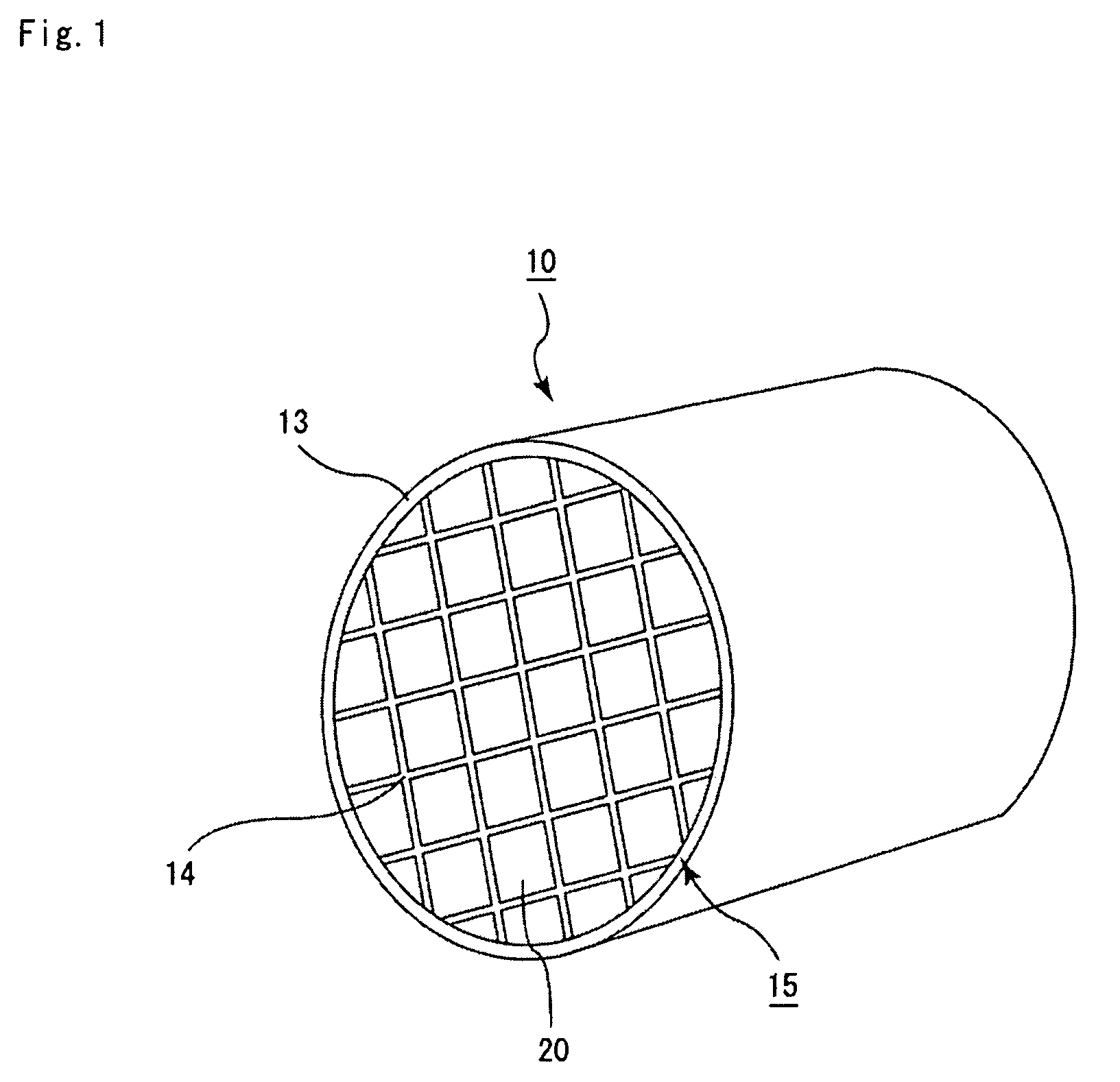

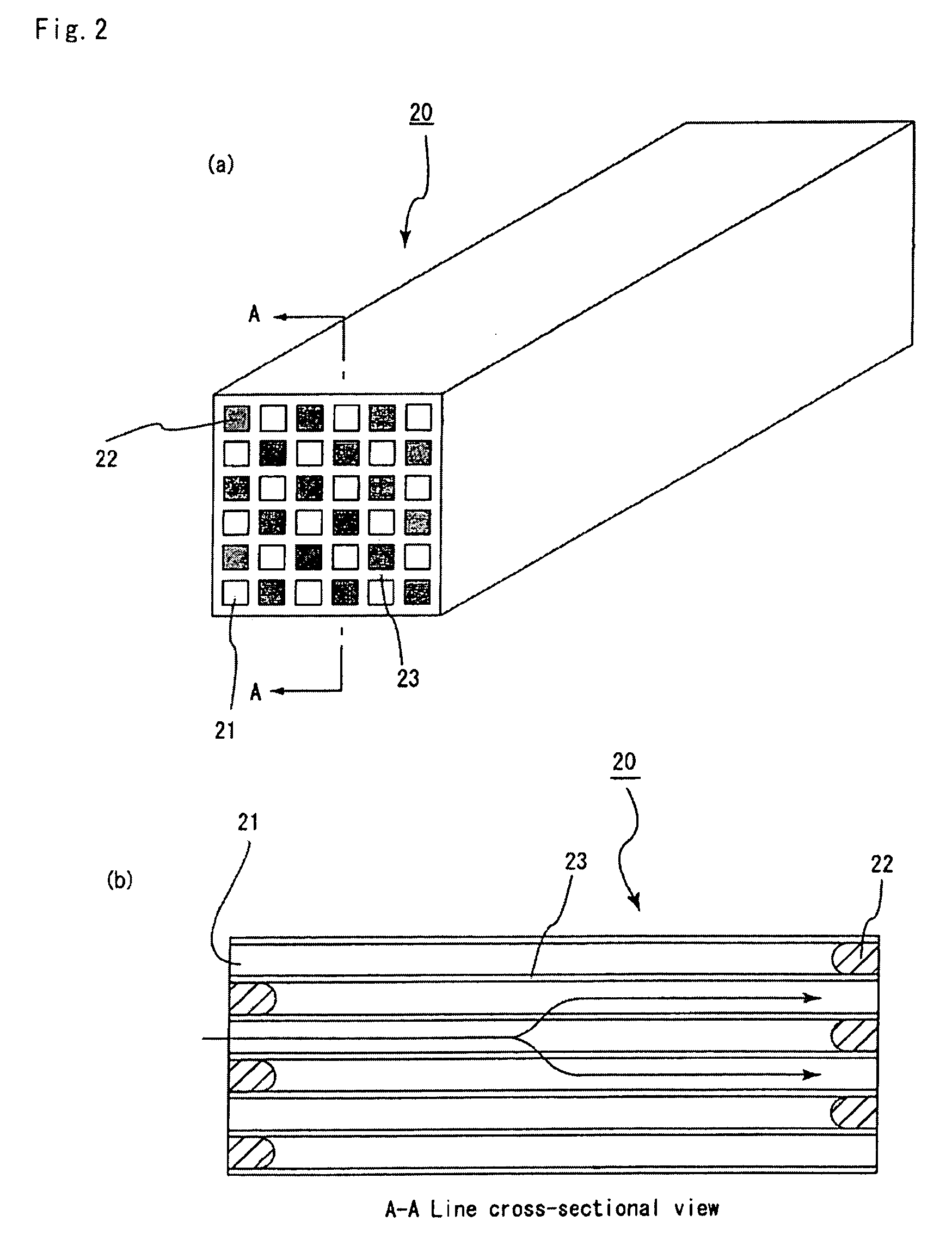

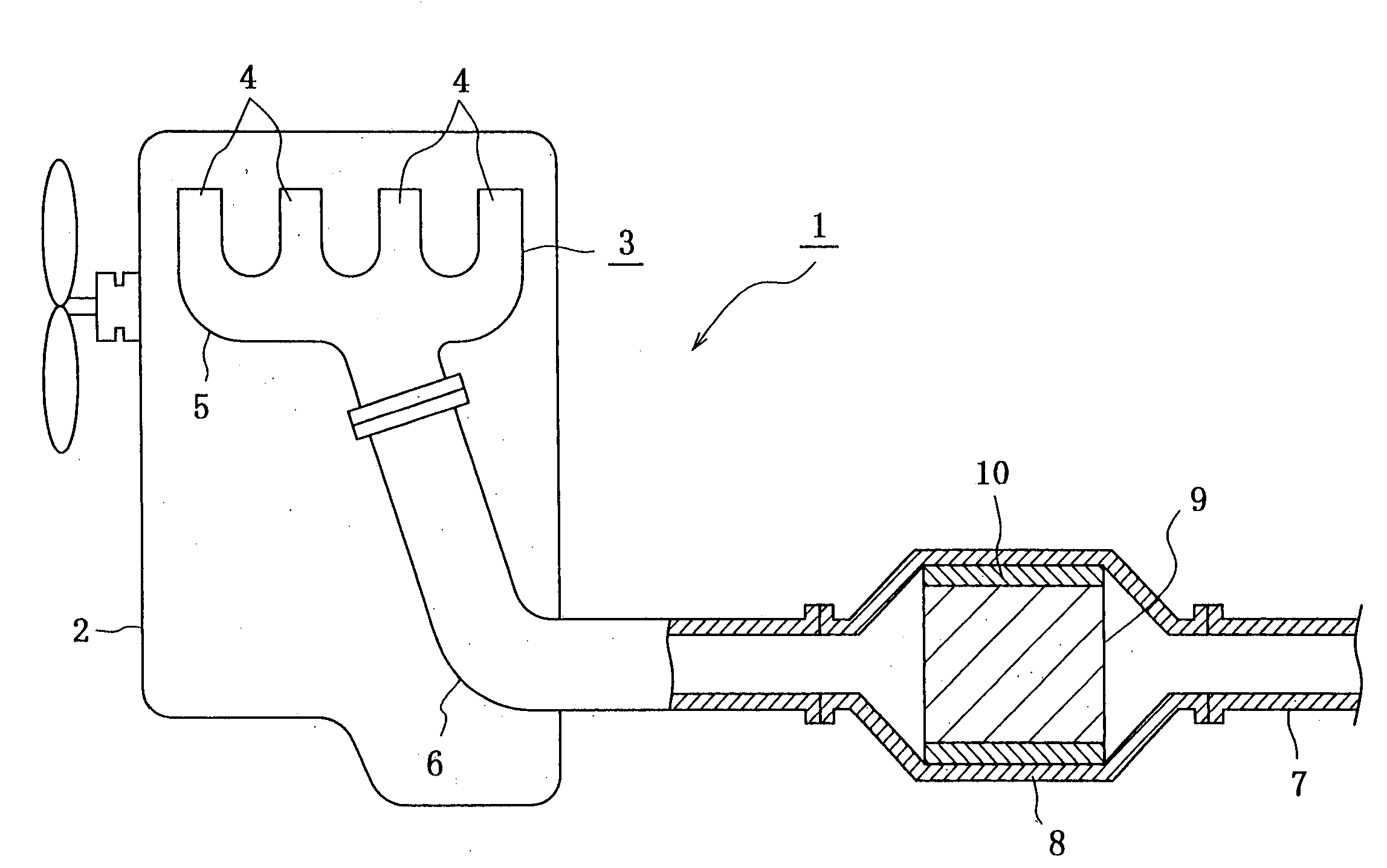

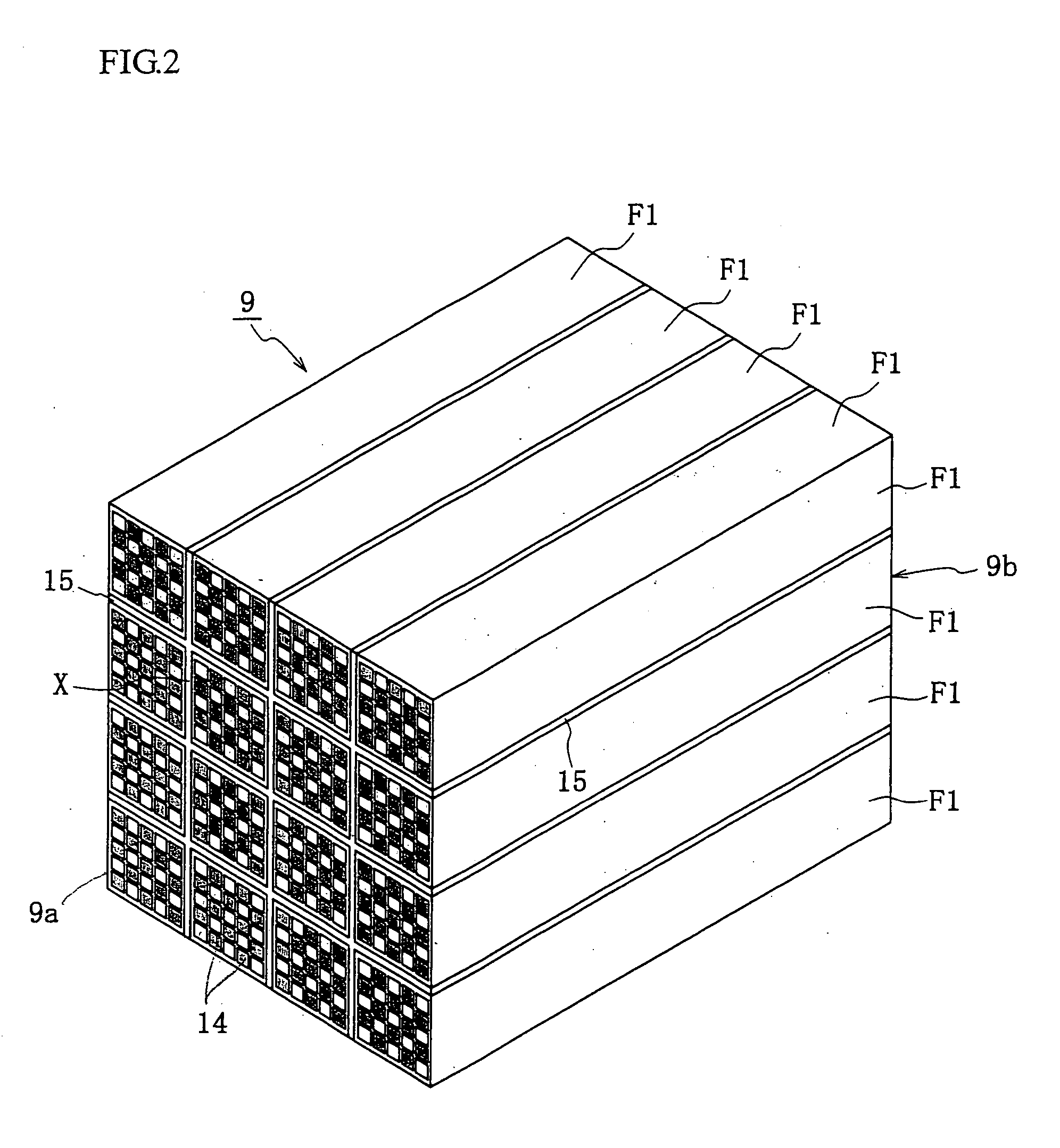

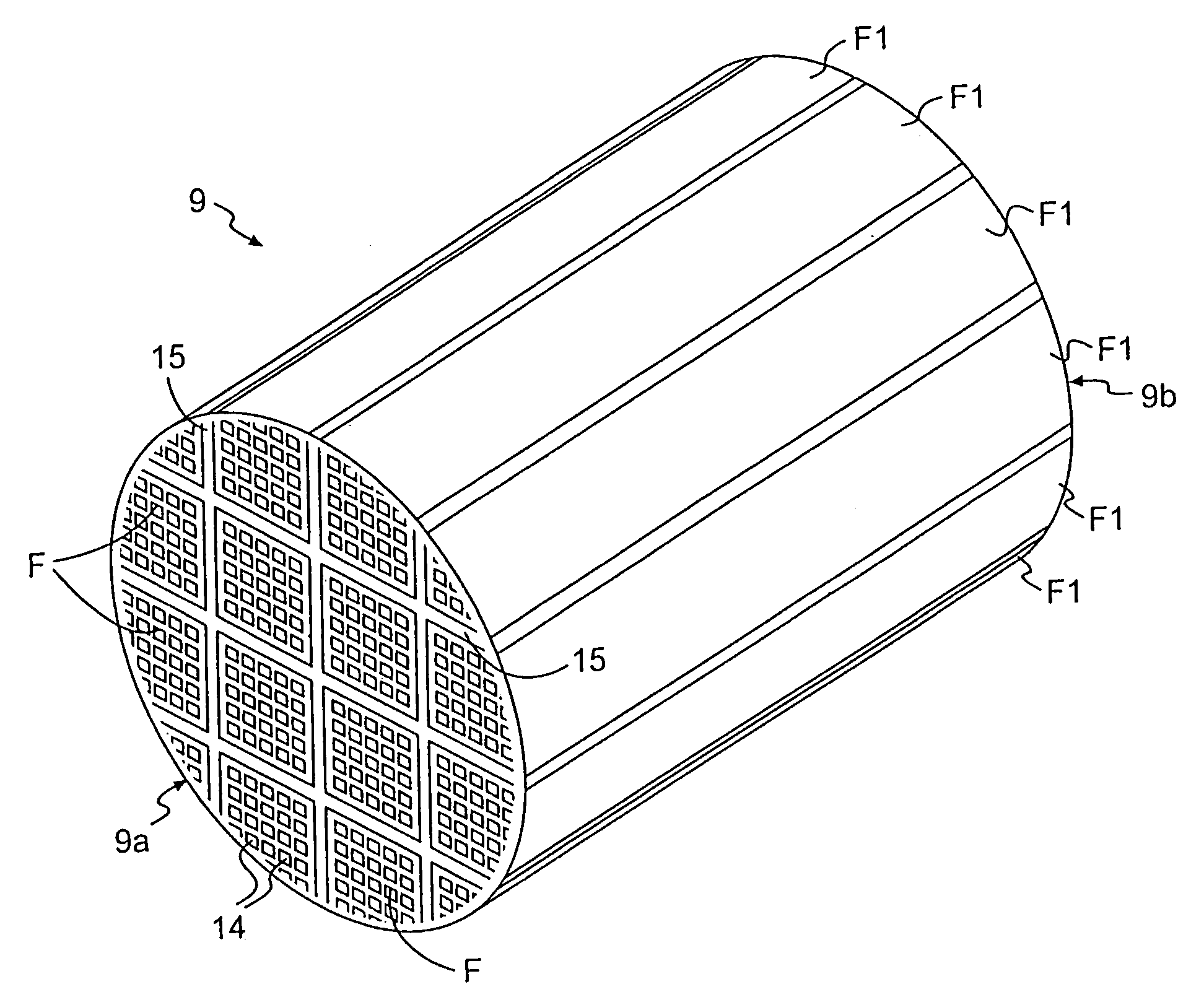

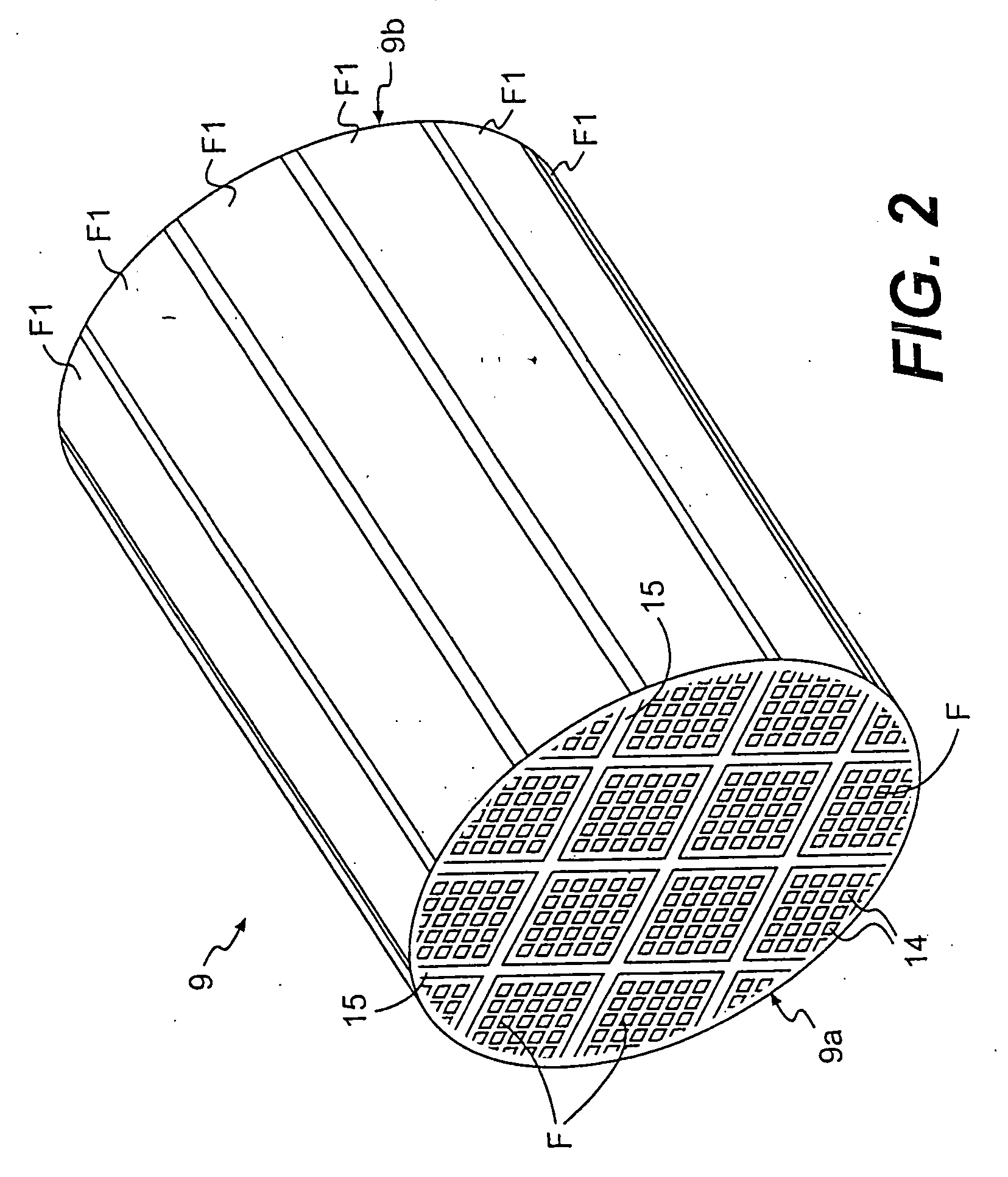

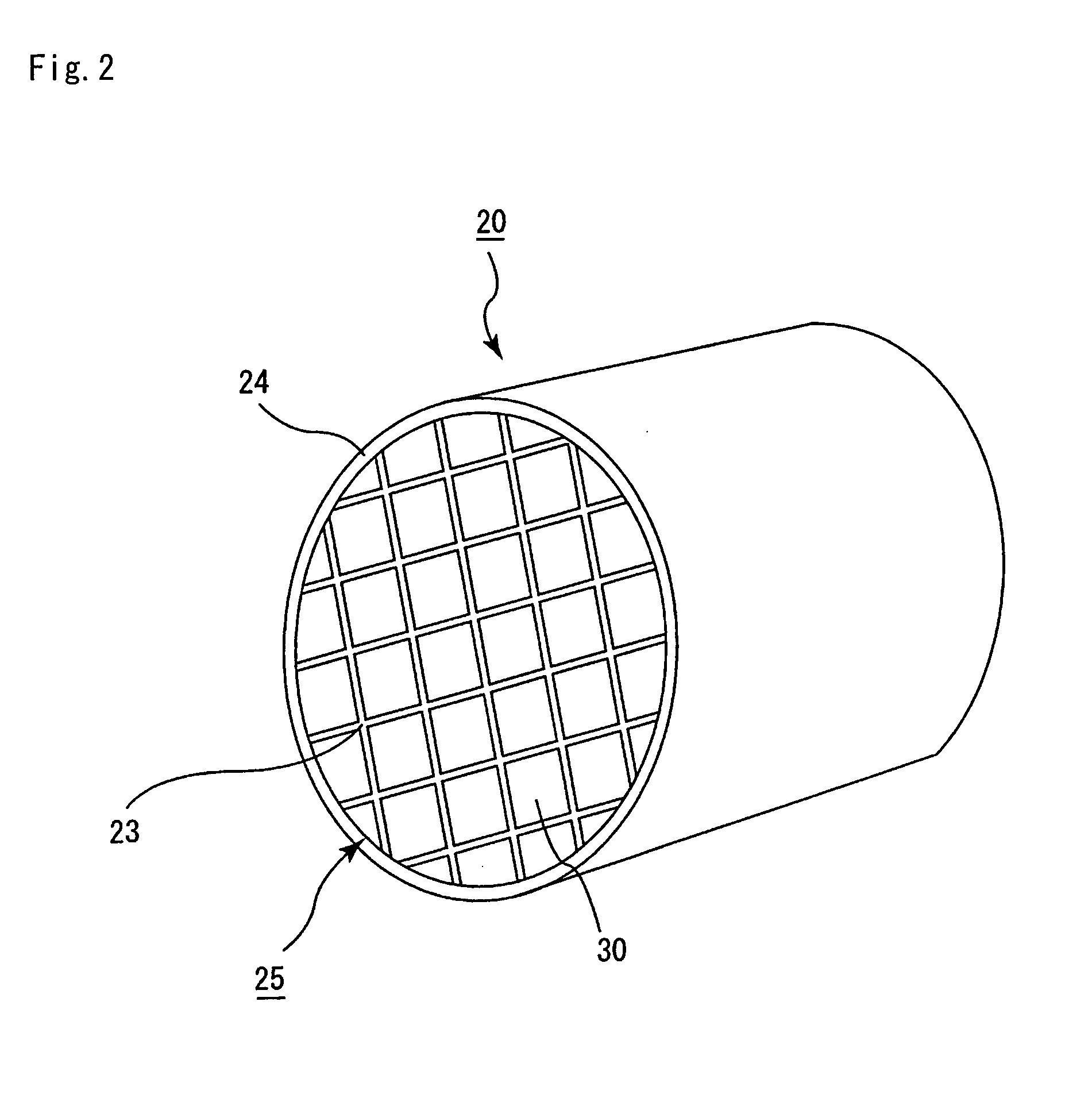

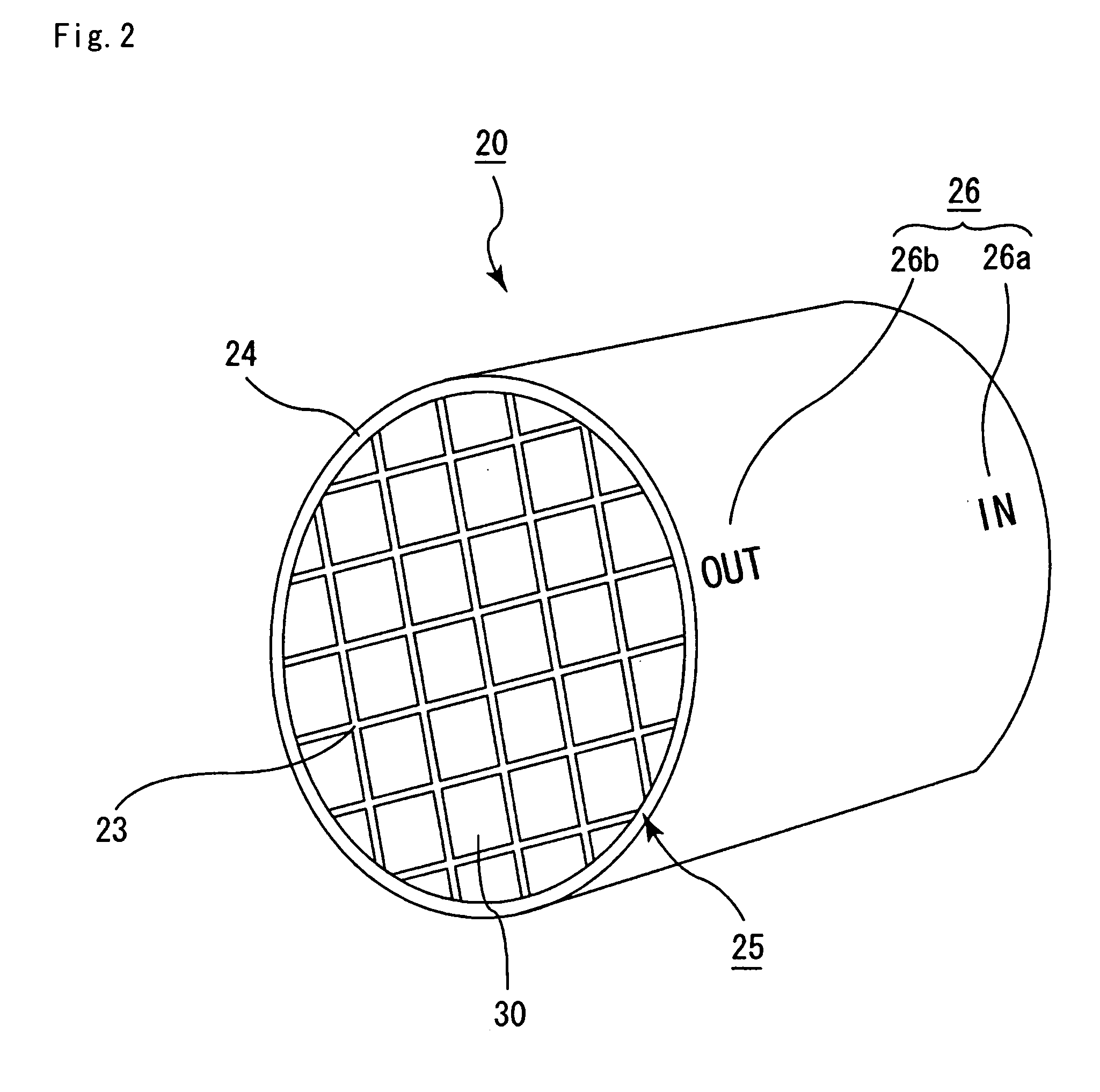

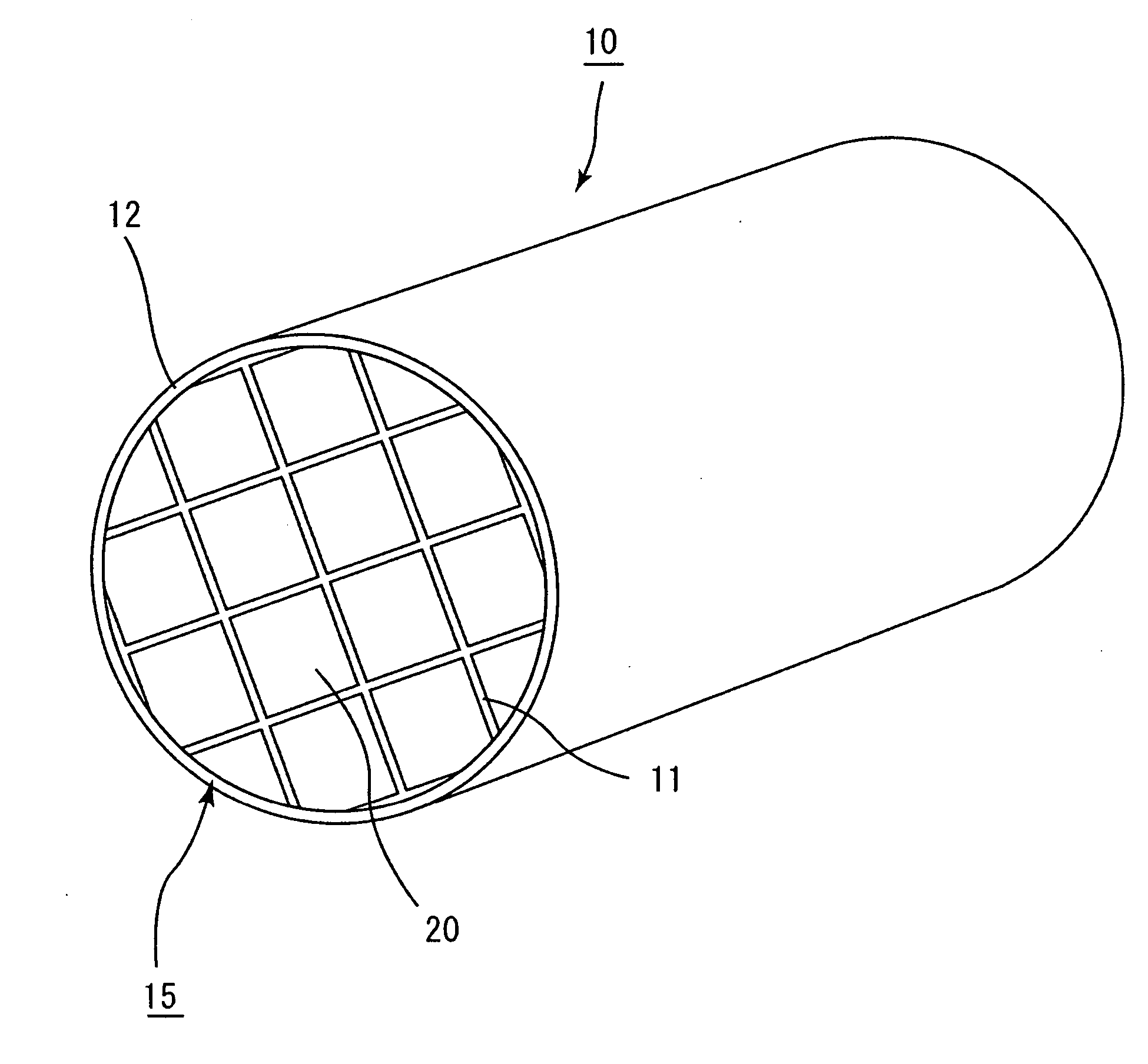

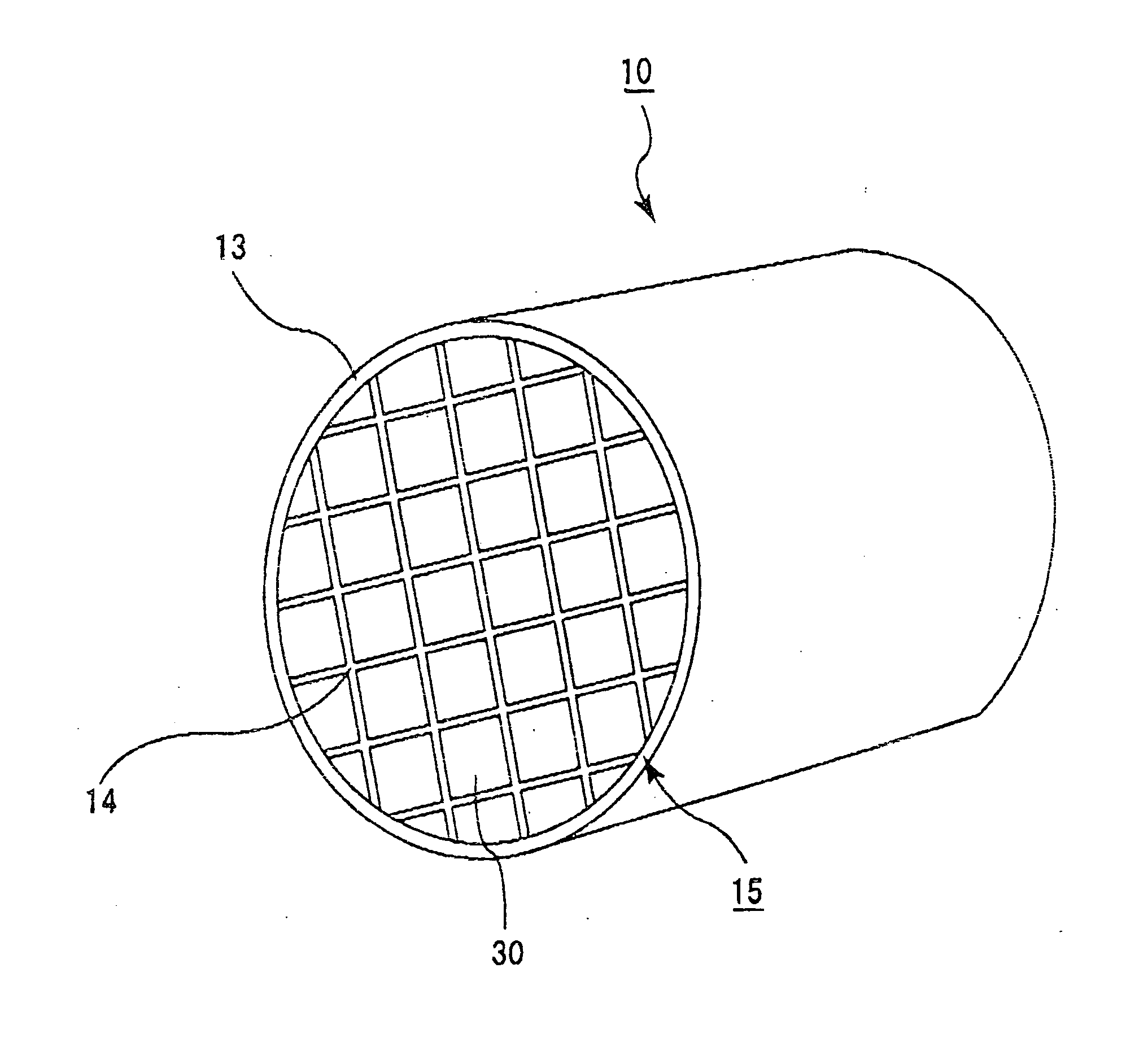

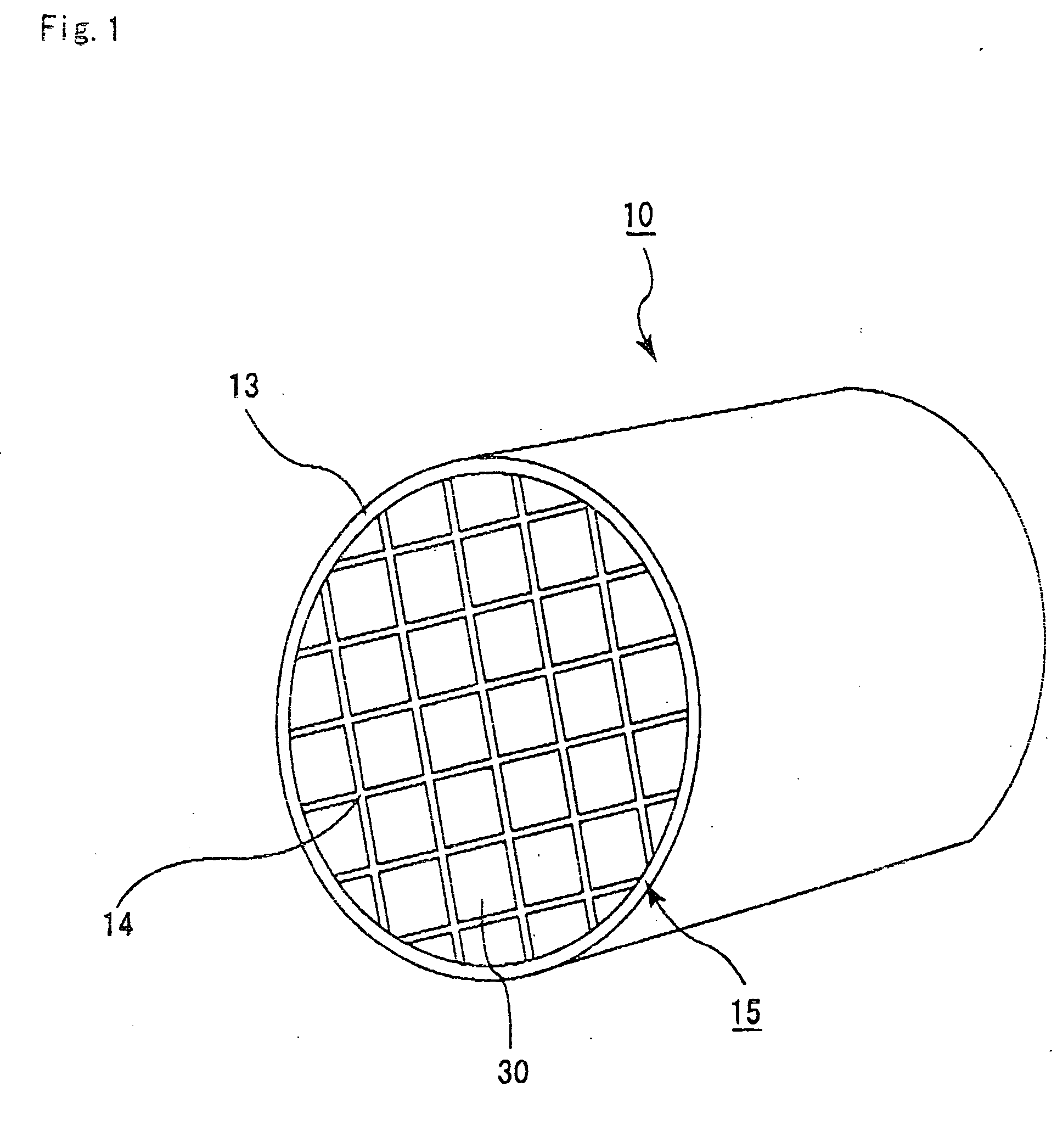

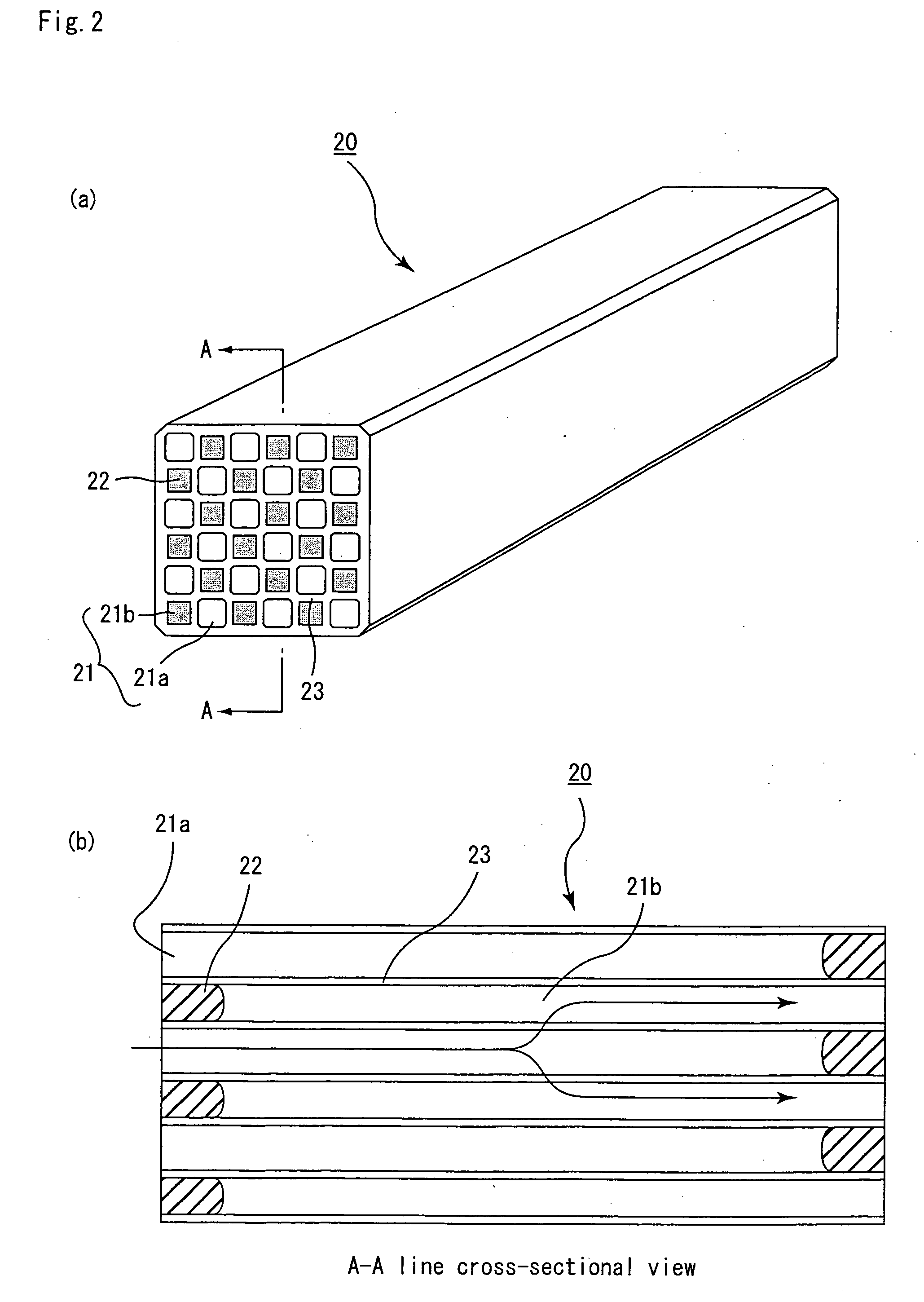

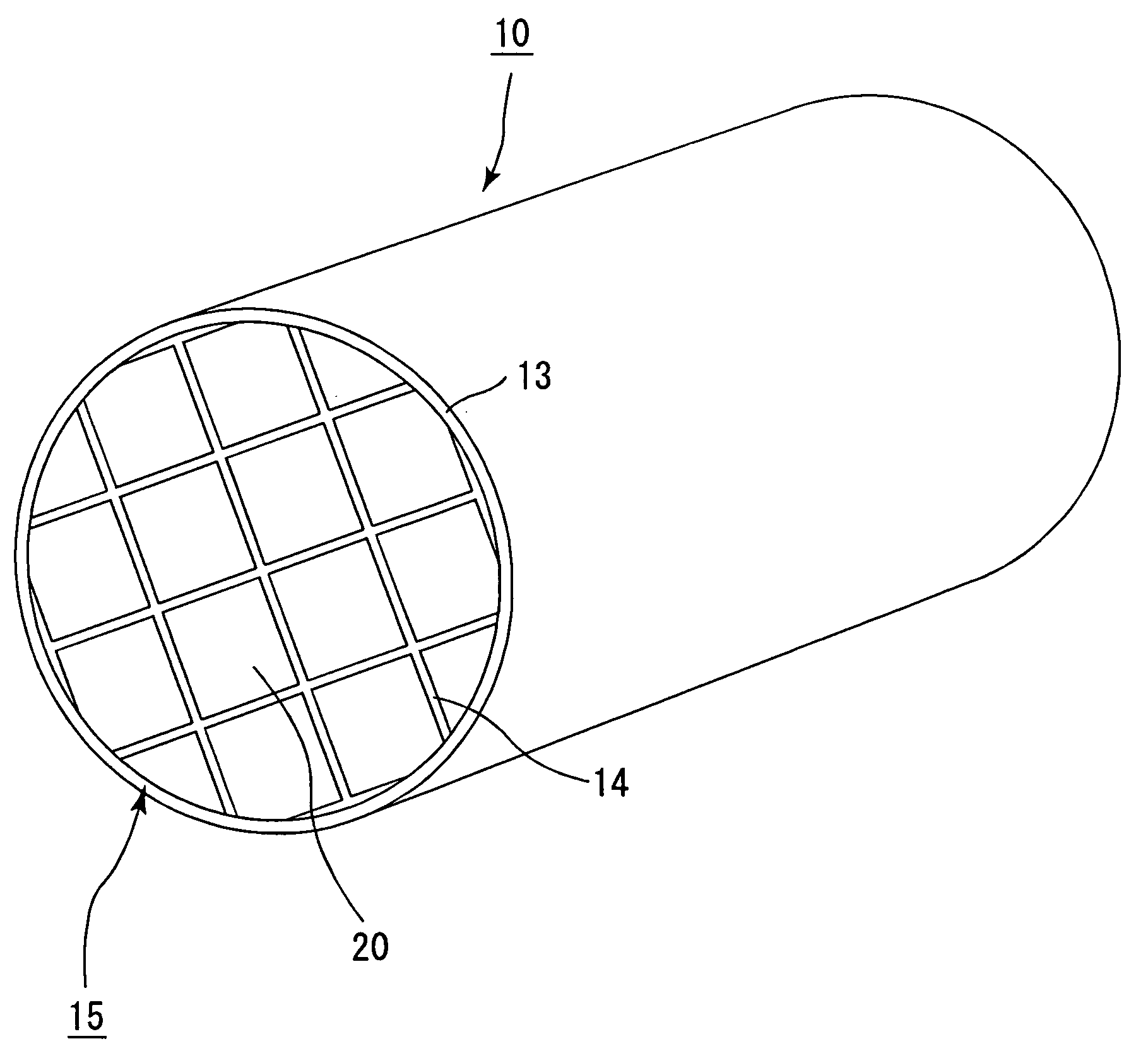

Honeycomb filter and ceramic filter assembly

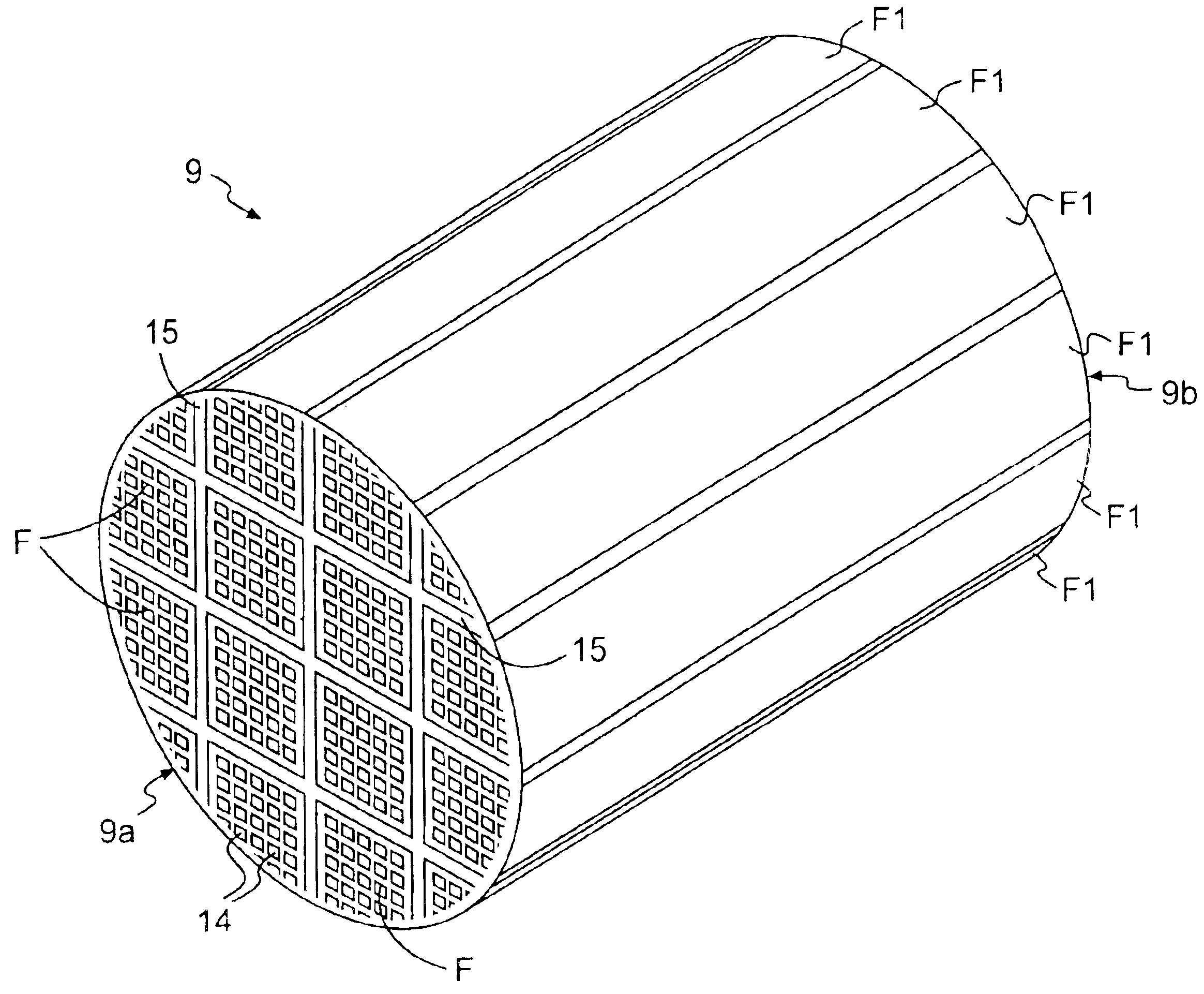

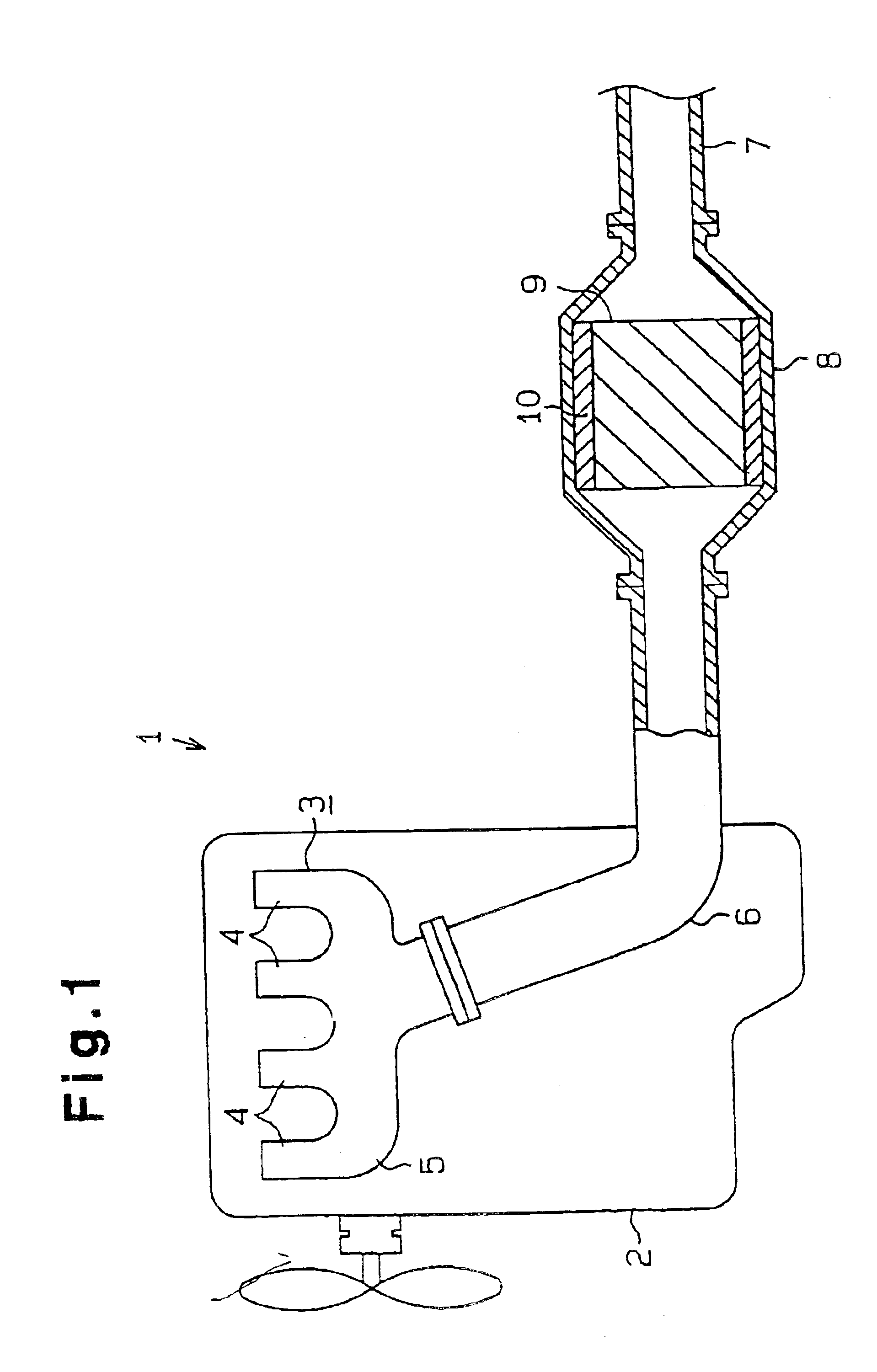

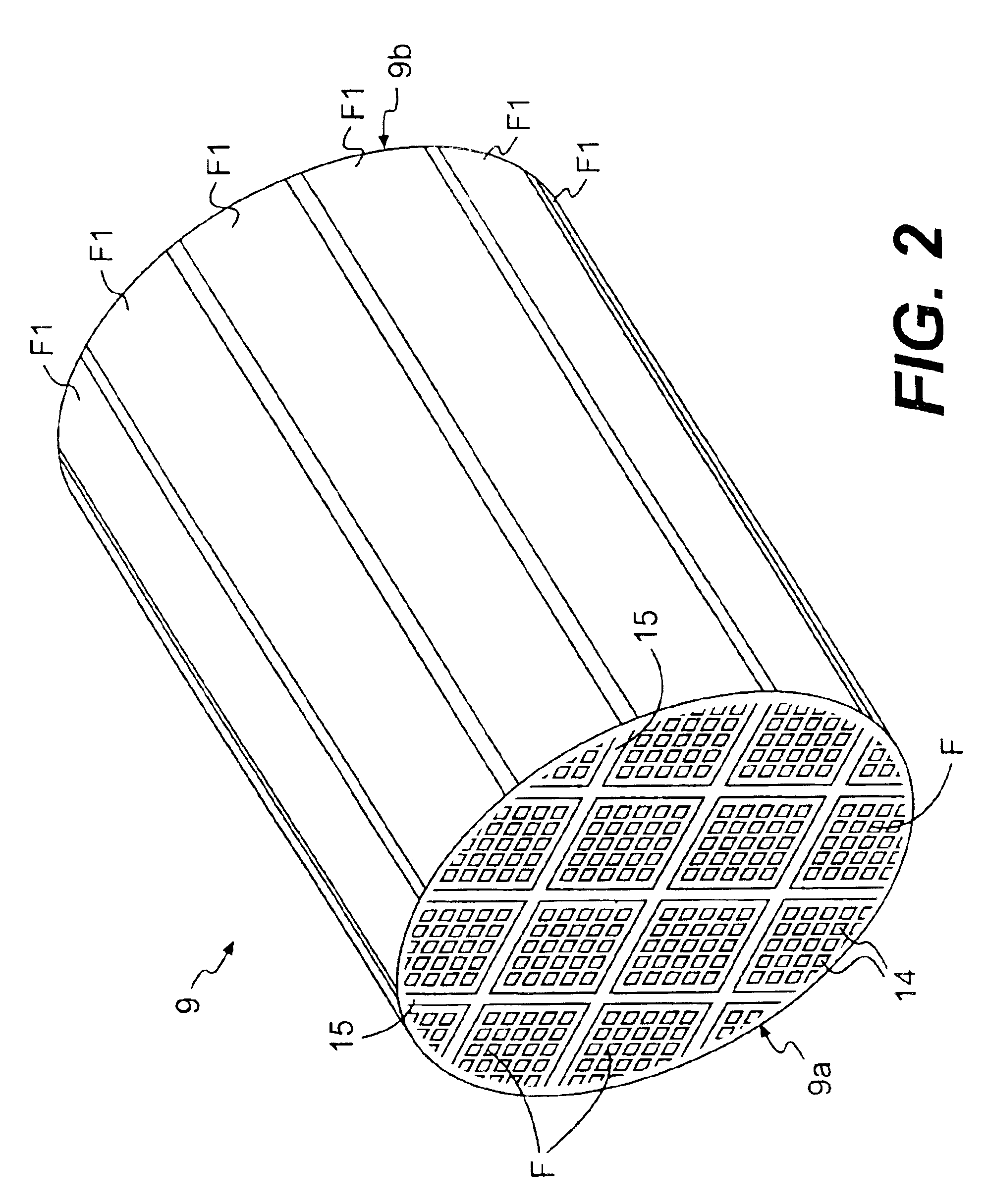

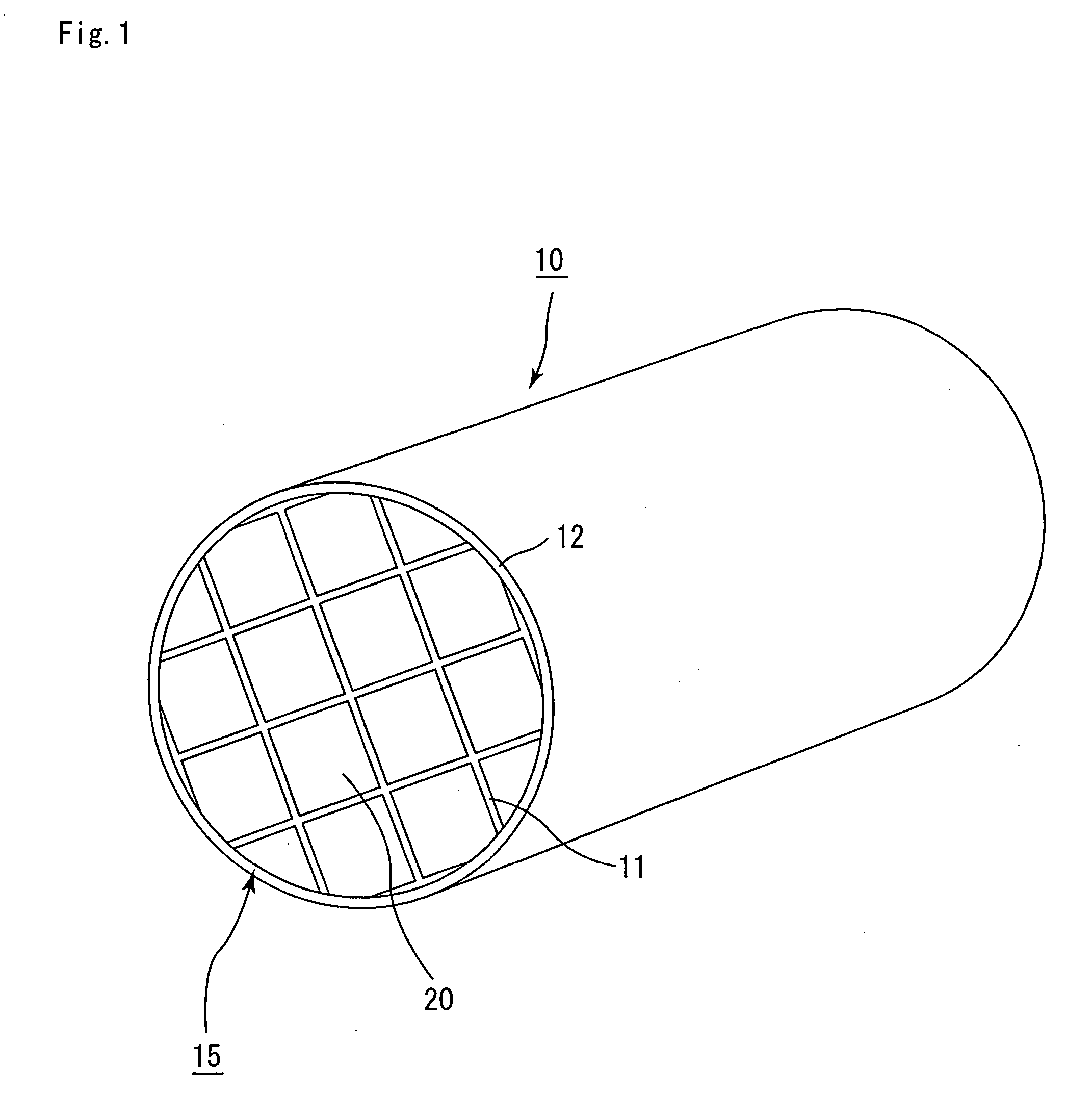

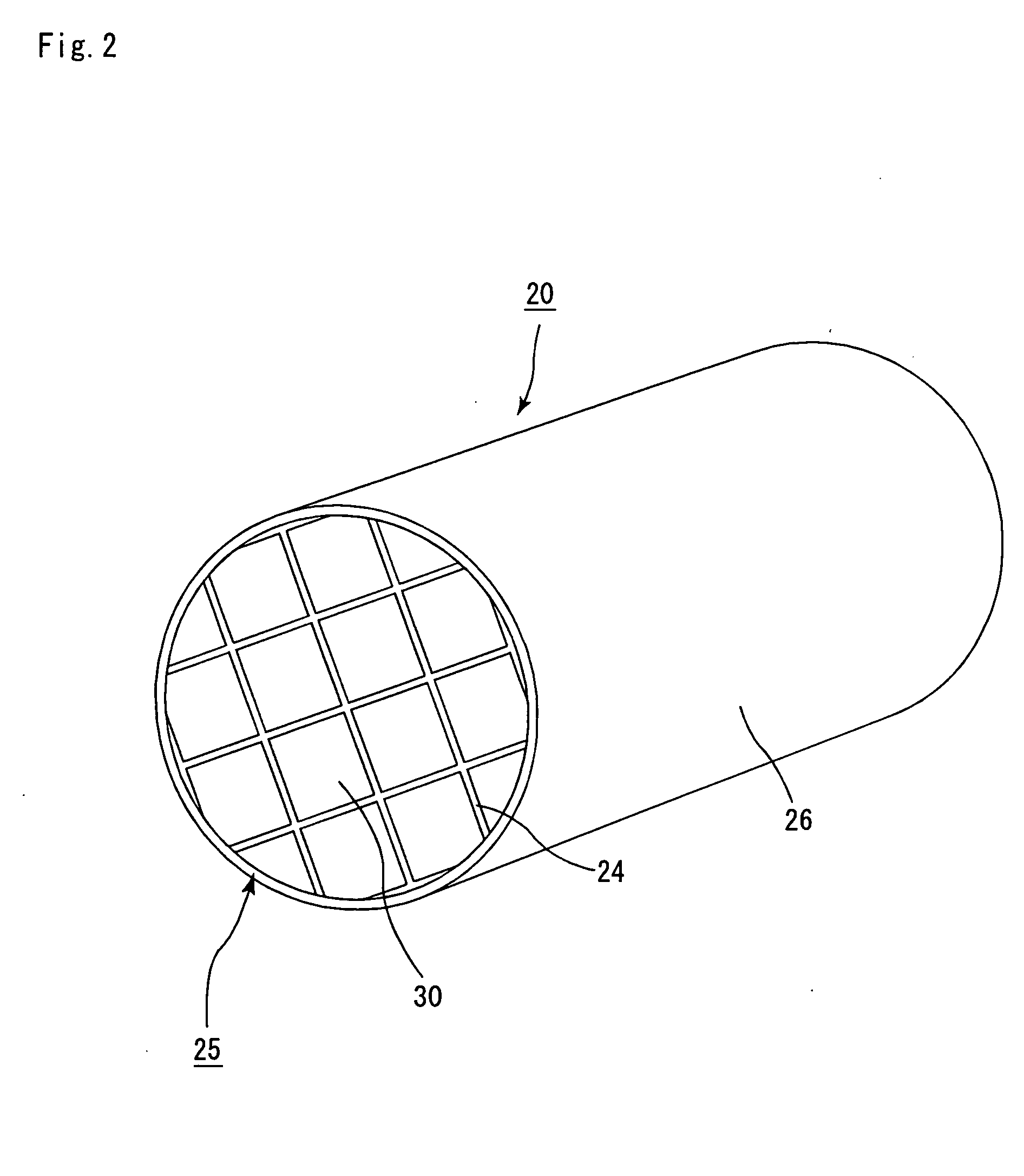

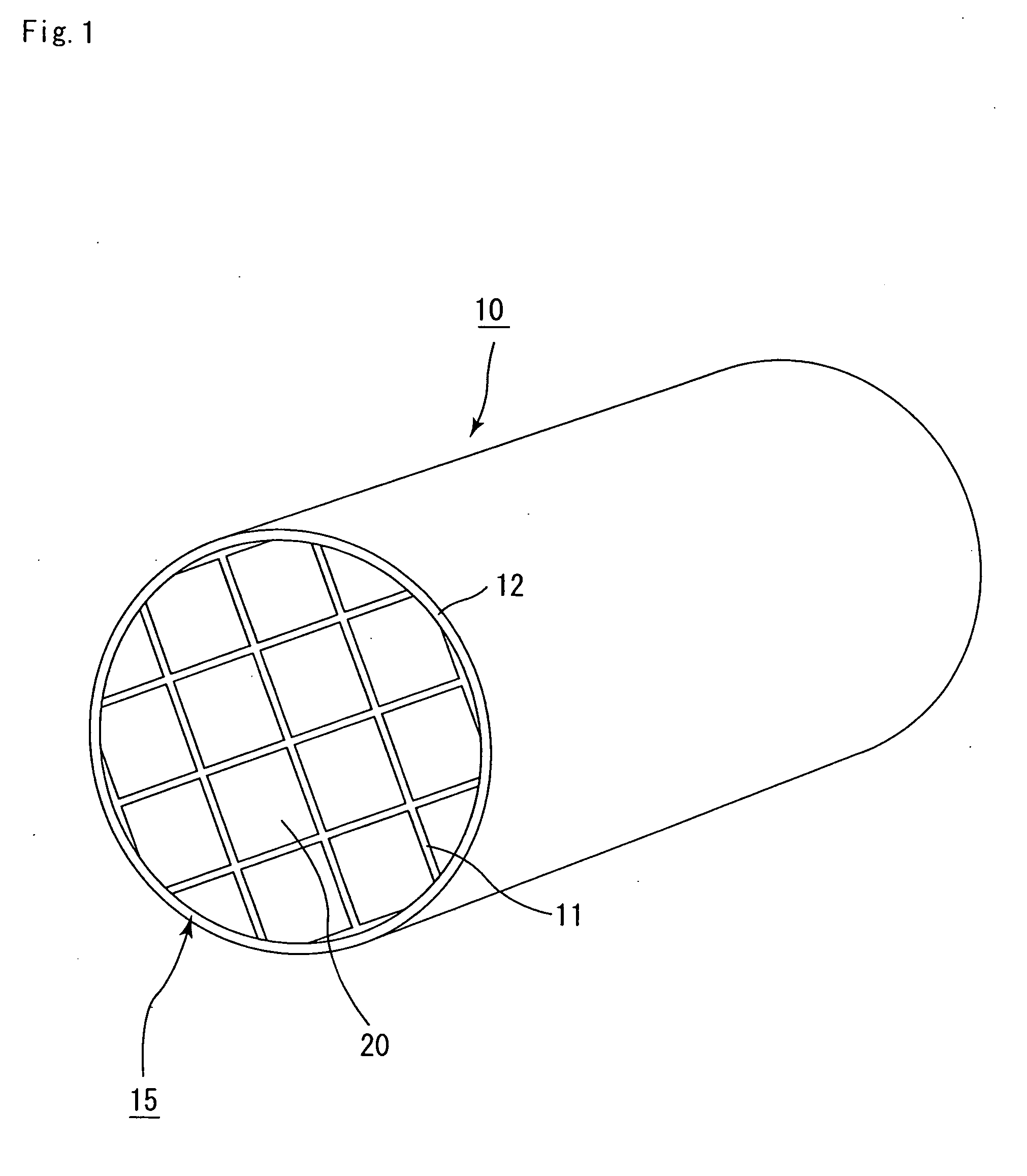

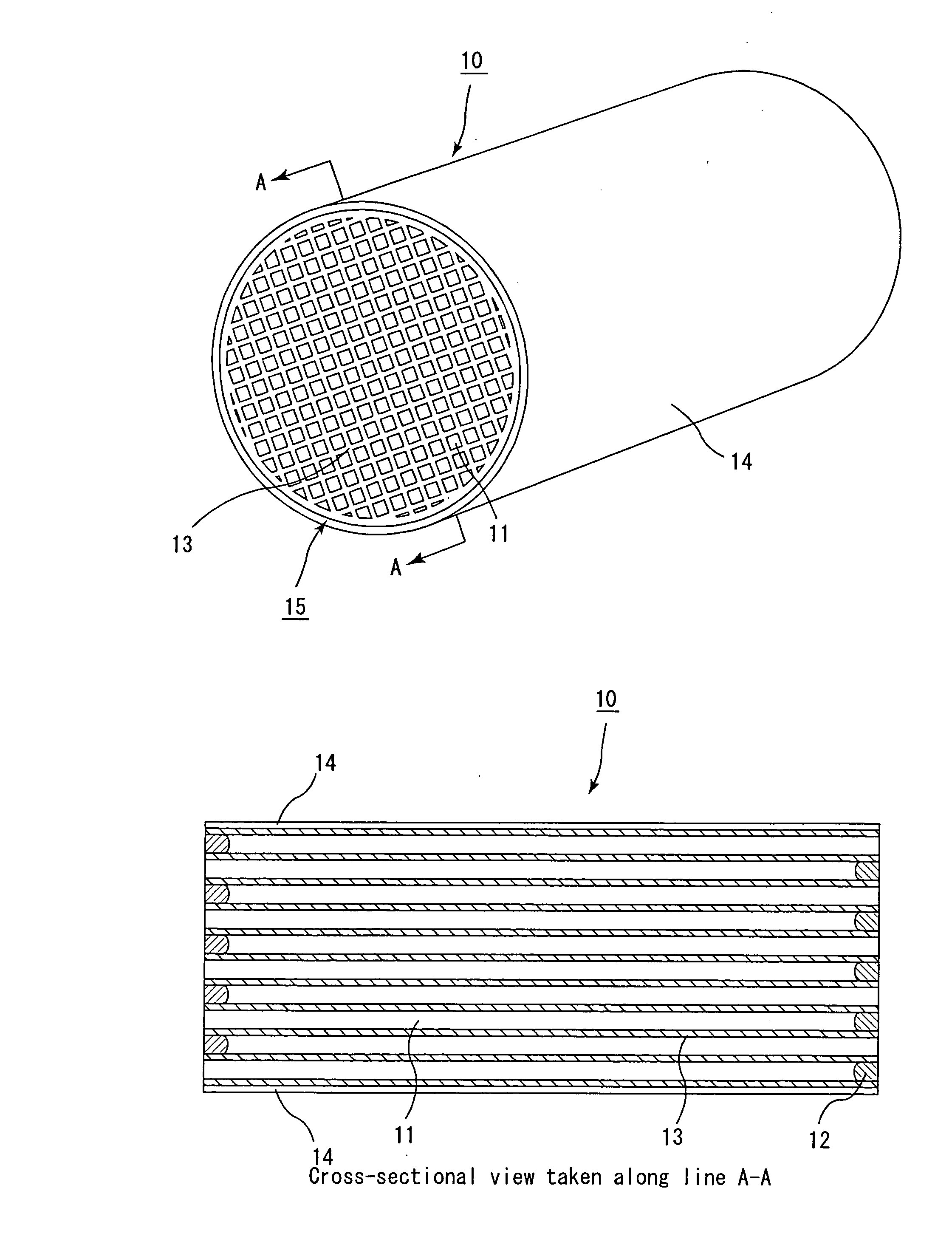

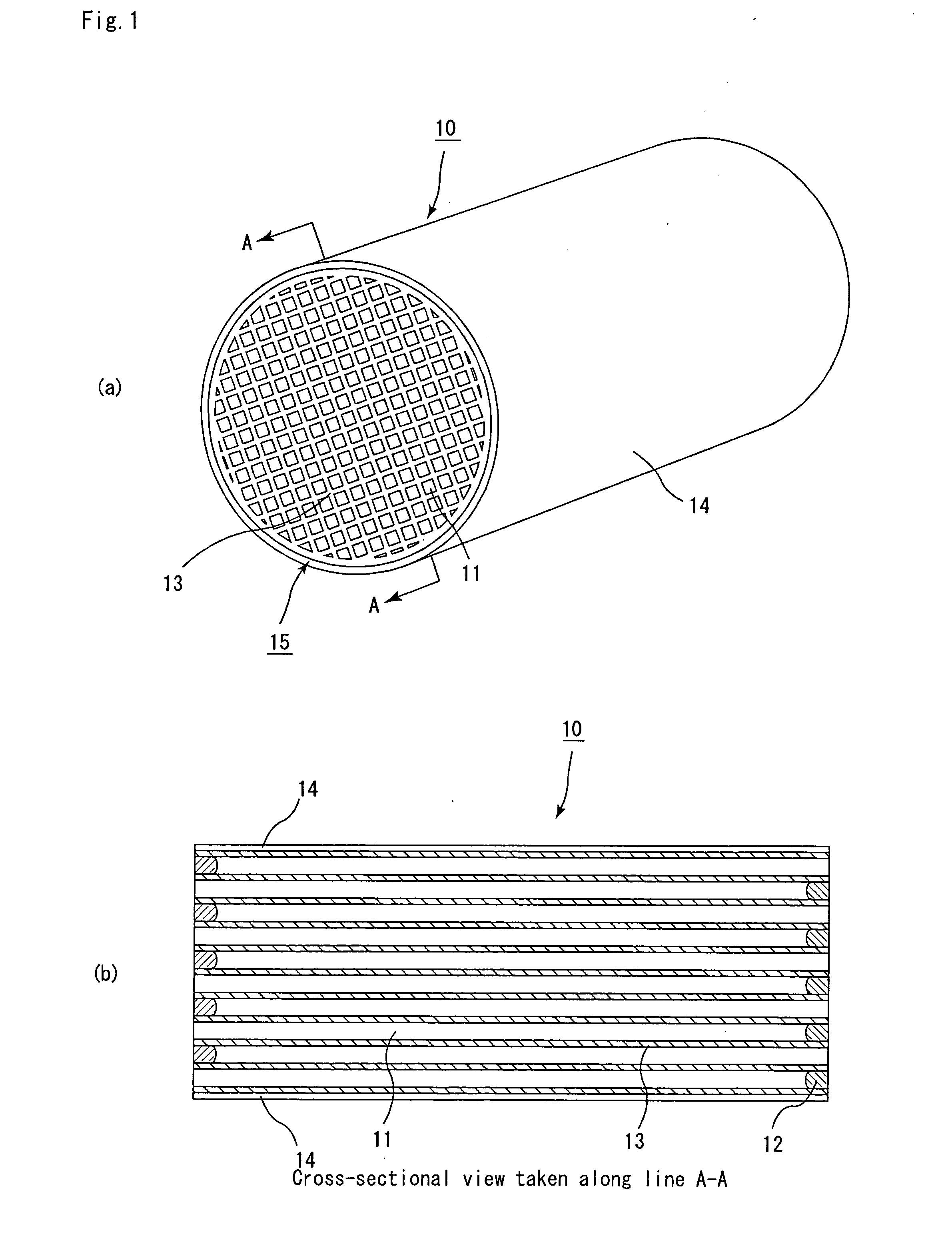

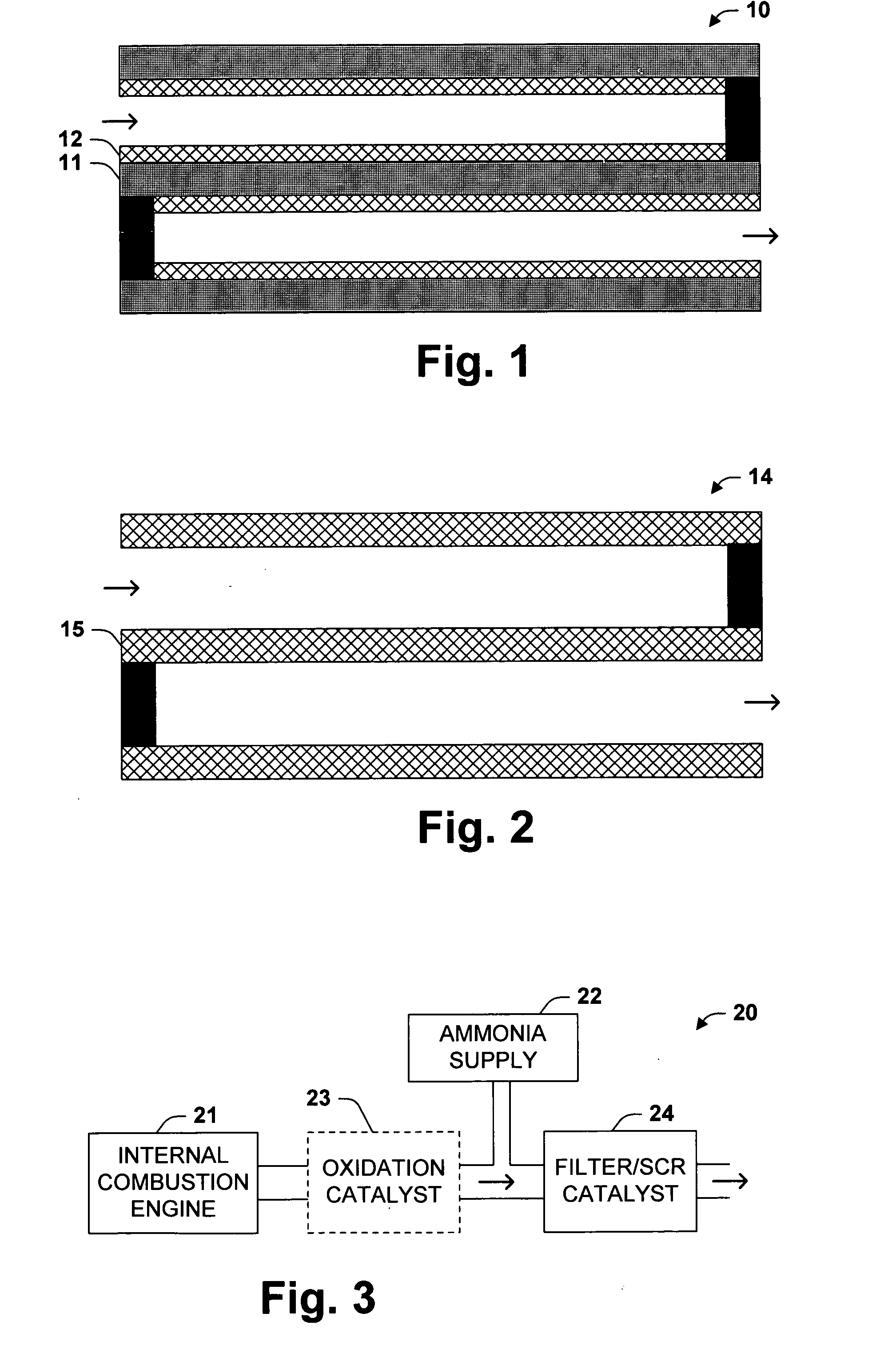

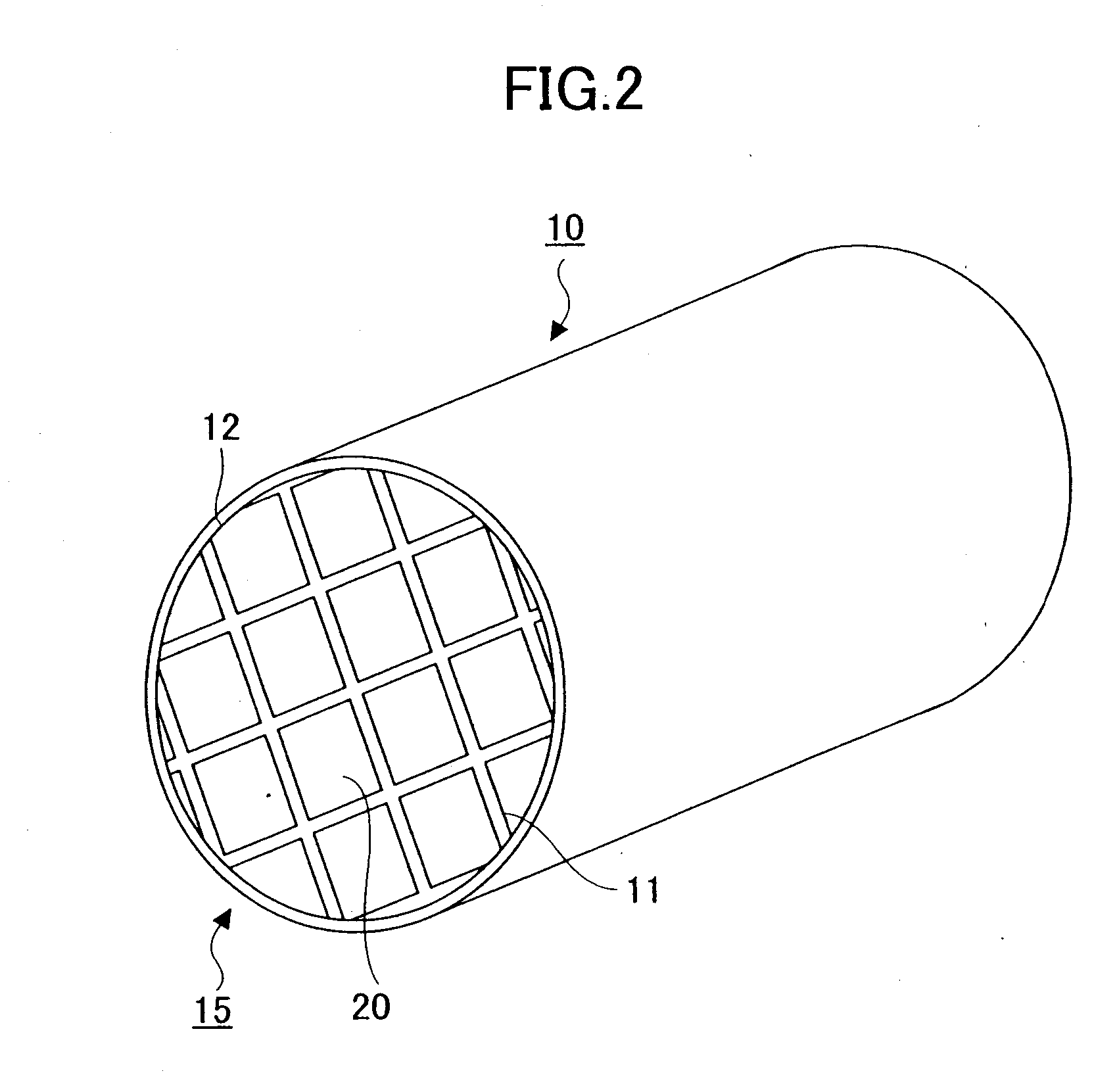

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

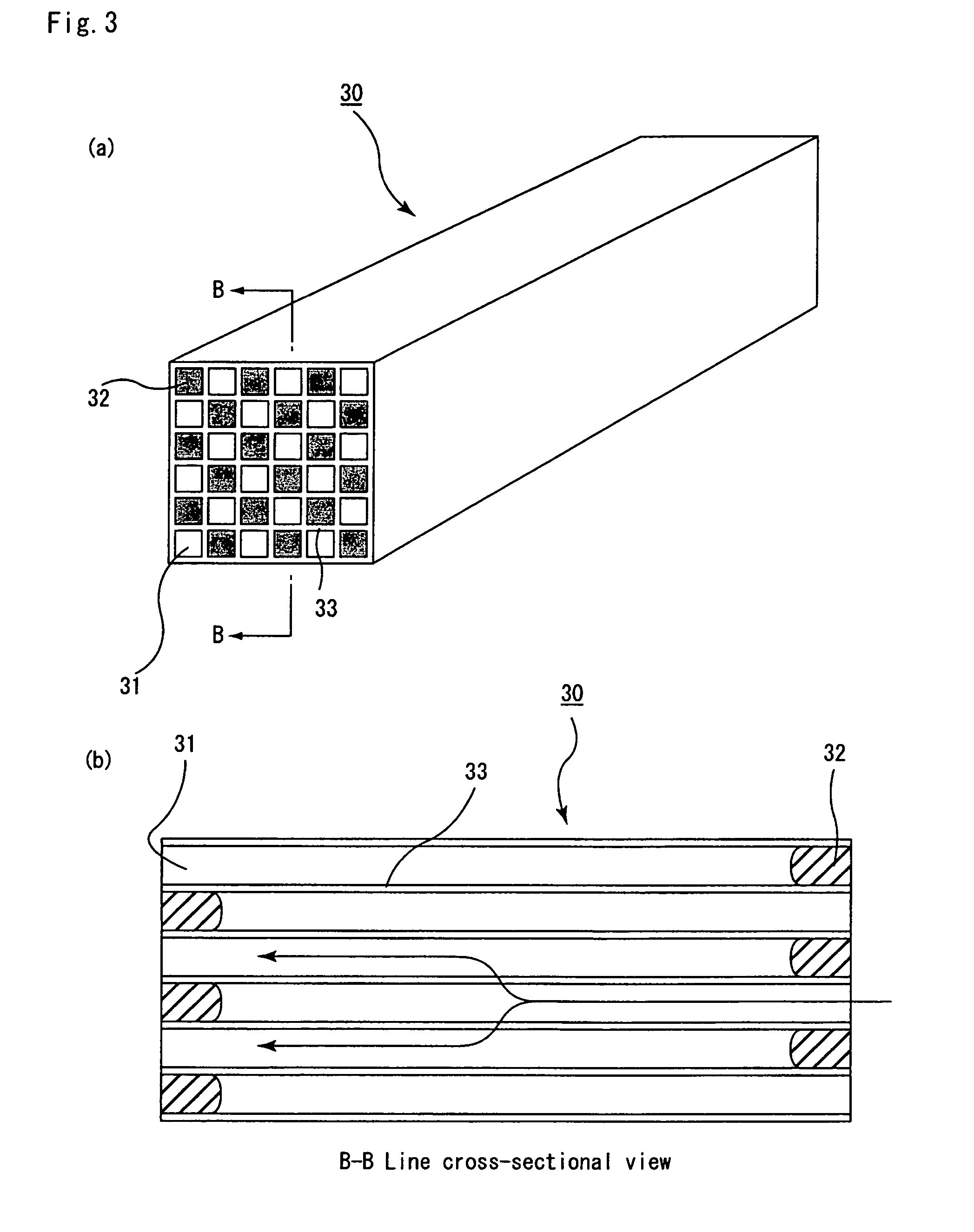

Honeycomb filter for clarification of exhaust gas

InactiveUS20050180898A1Increased durabilityReduce crackingCombination devicesInternal combustion piston enginesParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases. A plurality of rectangular columnar porous ceramic members are combined with one another through a sealing material layer to constitute a ceramic block, each of the rectangular columnar porous ceramic member including a number of through holes that are placed in parallel with one another in the length direction with a partition wall interposed therebetween. A sealing material layer is also formed on a circumference portion of the ceramic block, and the partition wall that separates the through holes functions as a filter for collecting particulates. On a cross section perpendicular to the length direction of the porous ceramic member of the ceramic block, the maximum width L (mm) of the crisscross portion of the sealing material layer is 1.5 to 3 times greater than the minimum width I (mm) of the sealing material layer.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

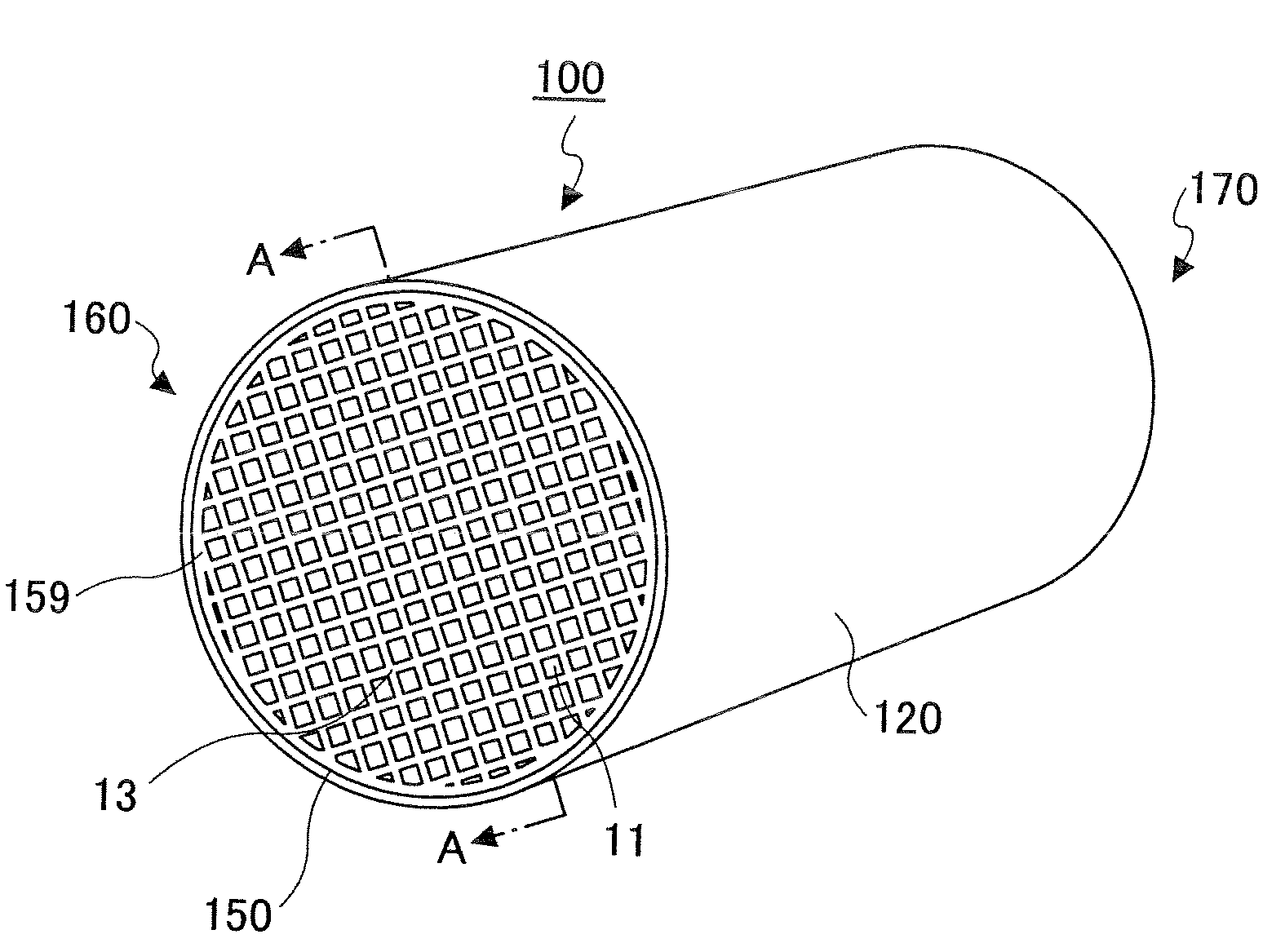

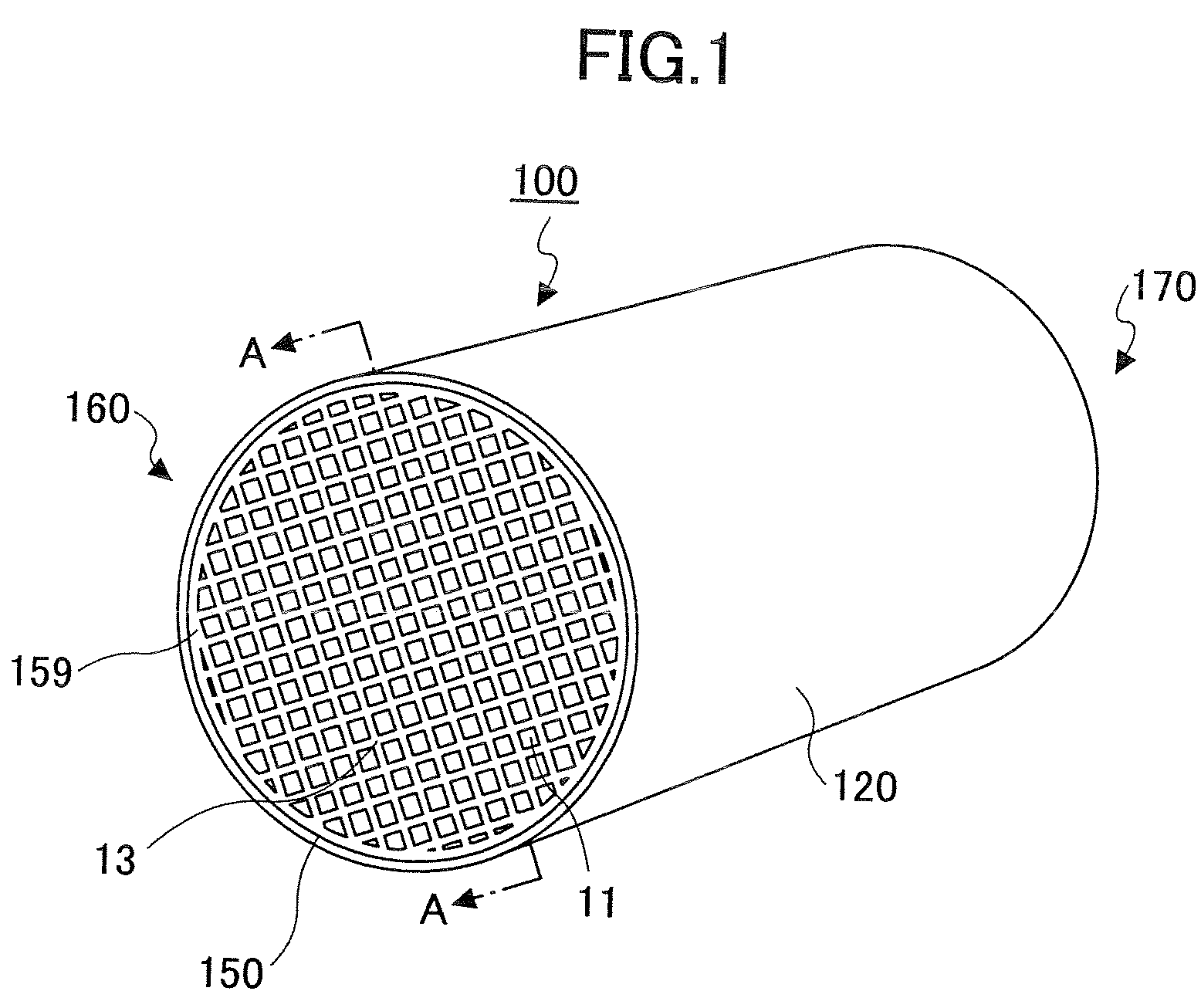

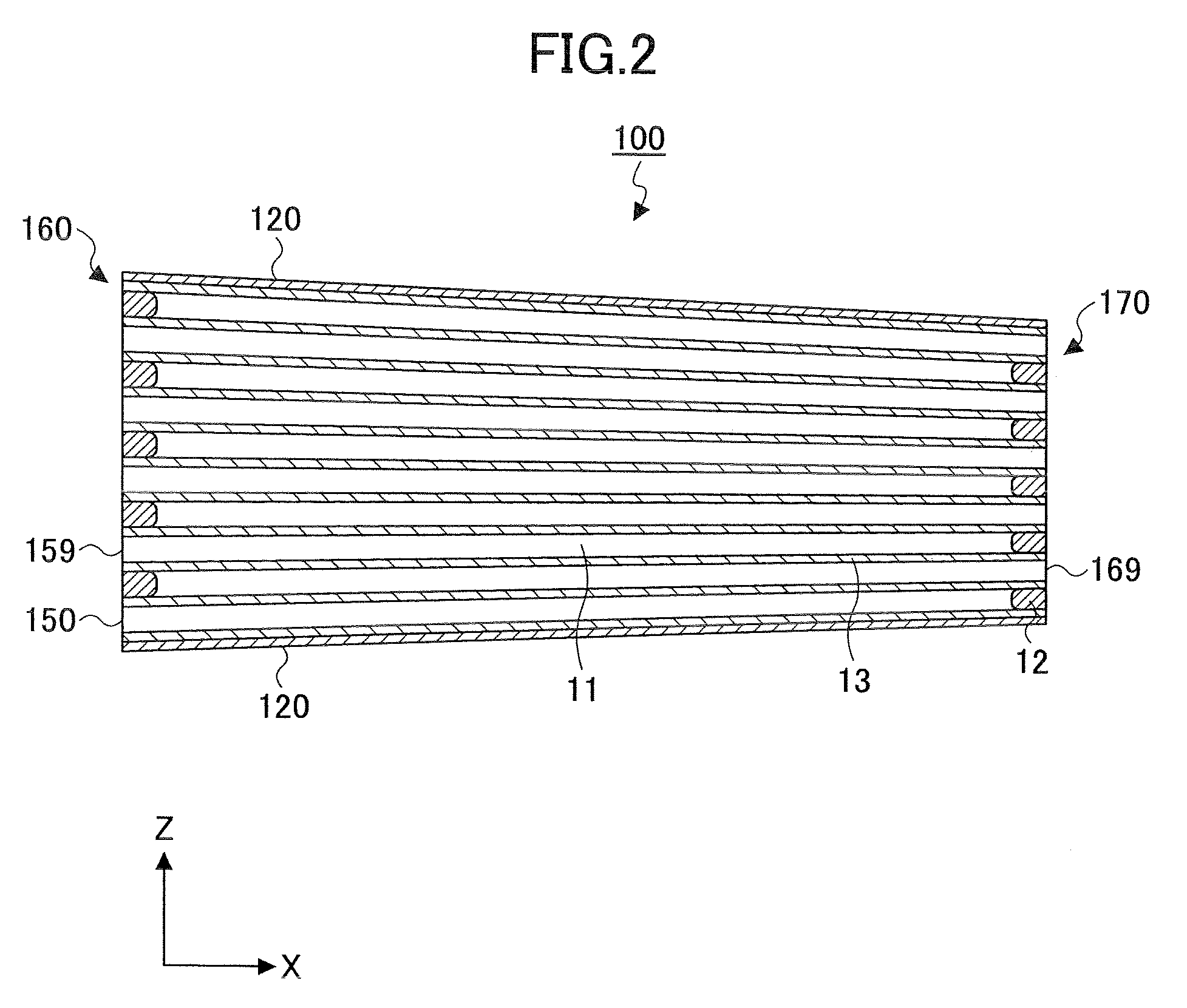

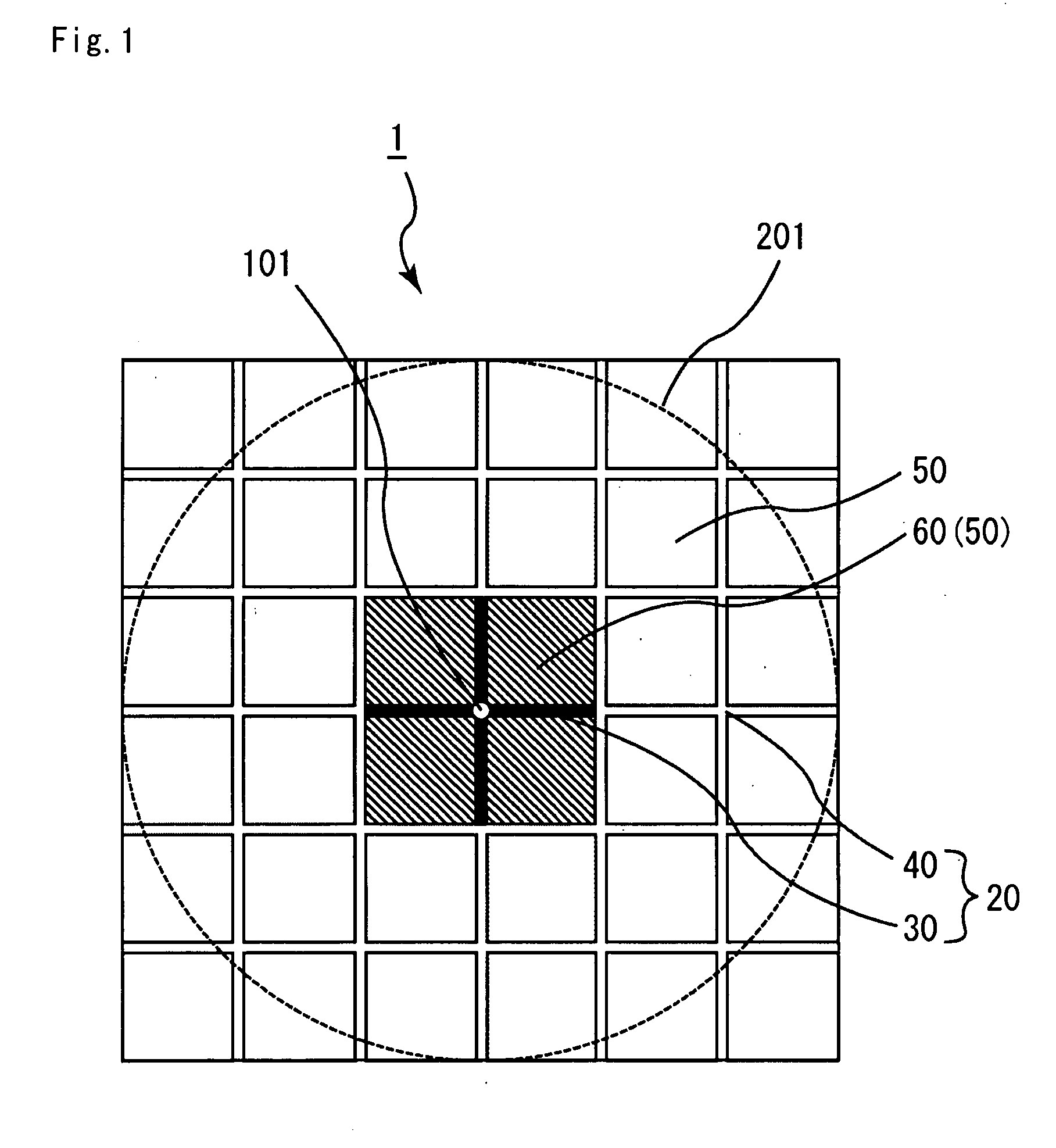

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

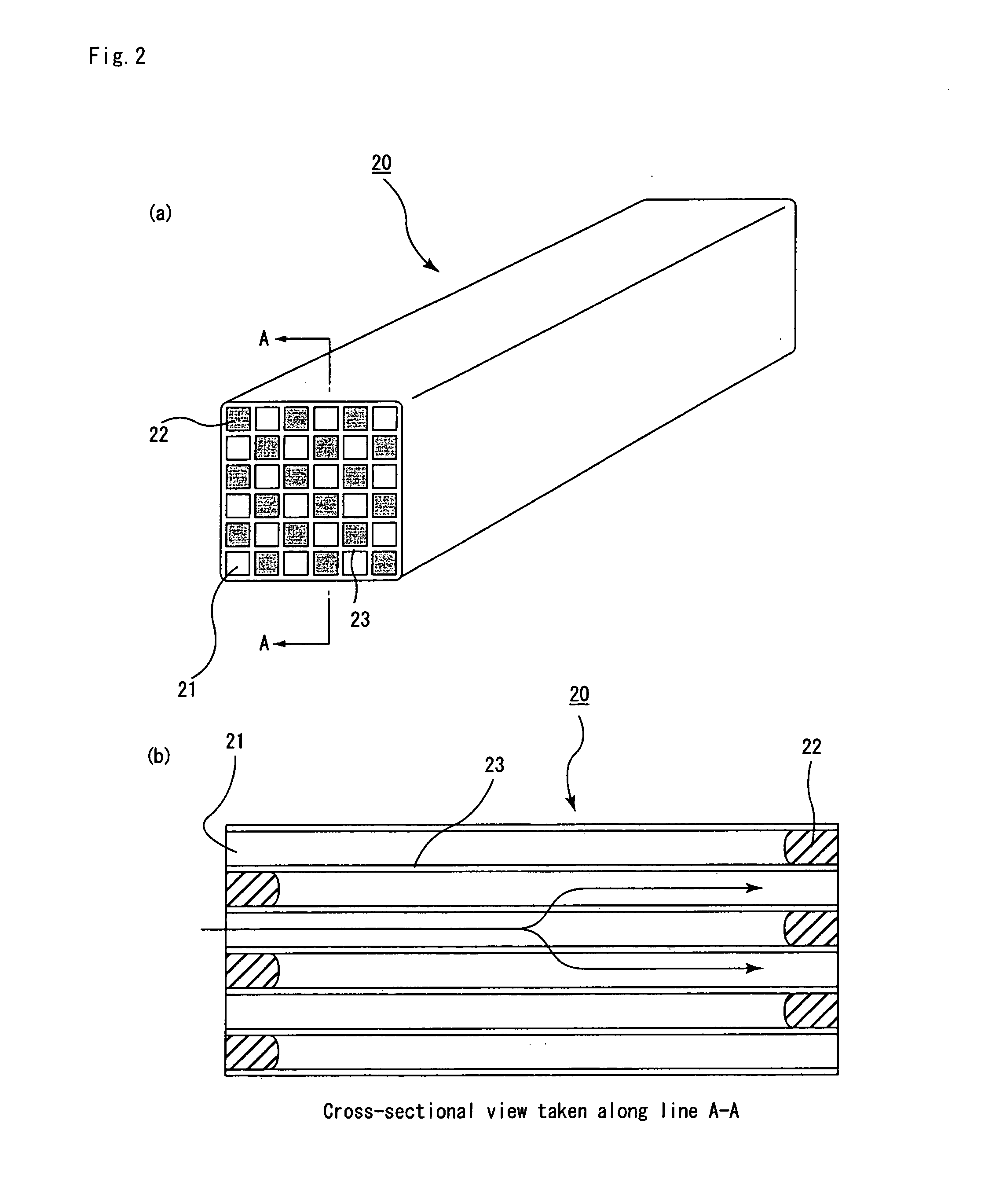

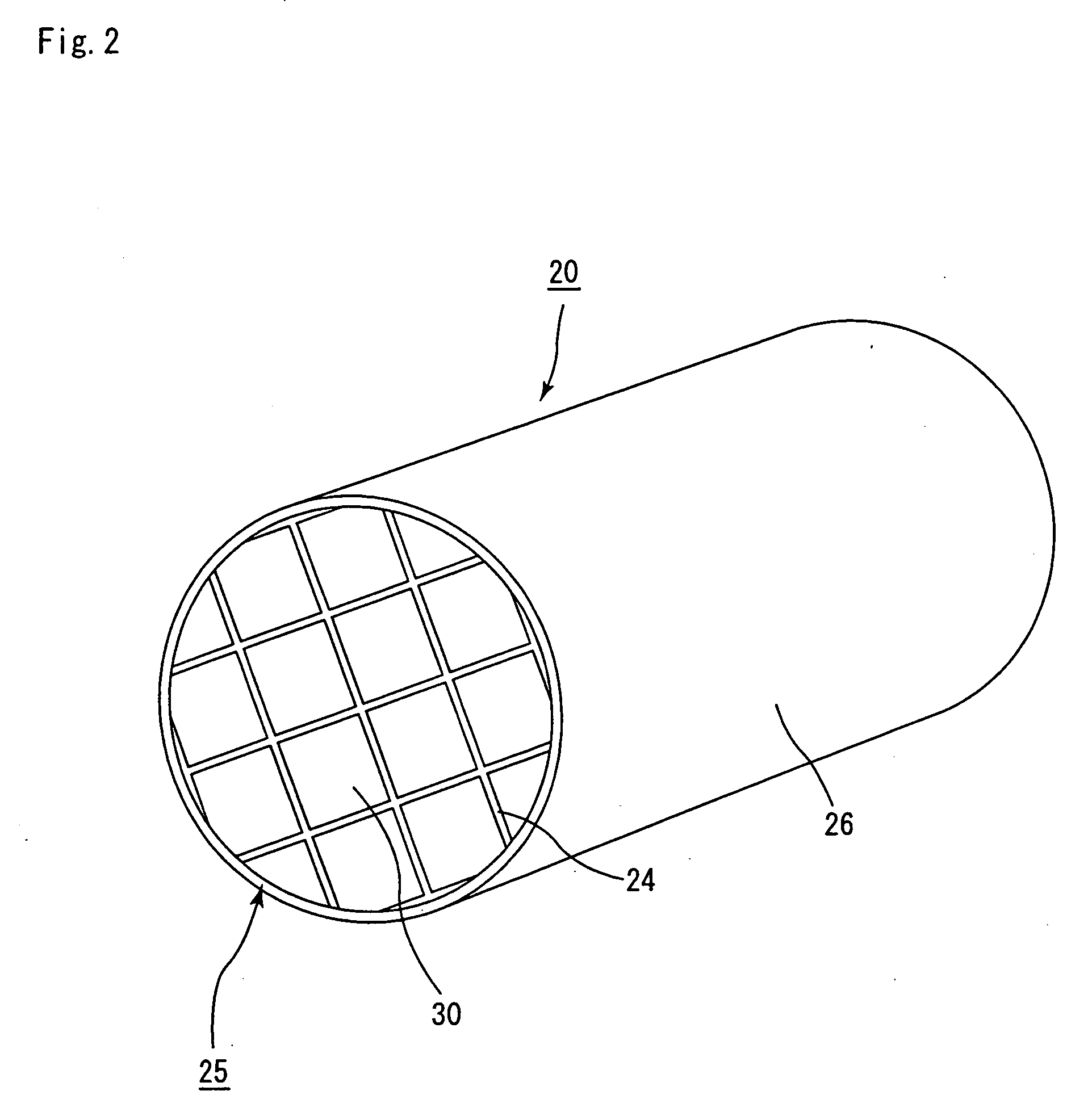

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

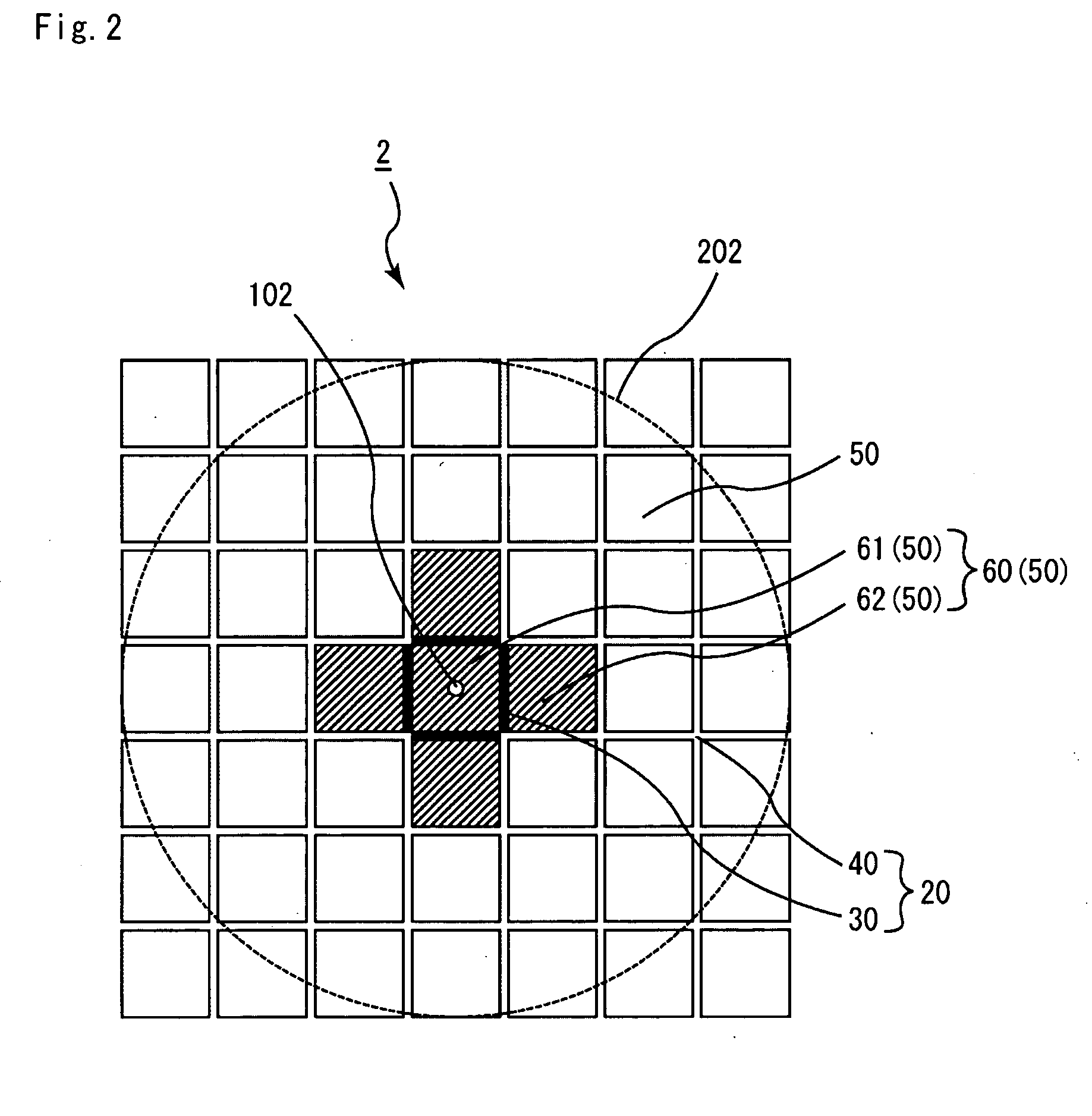

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

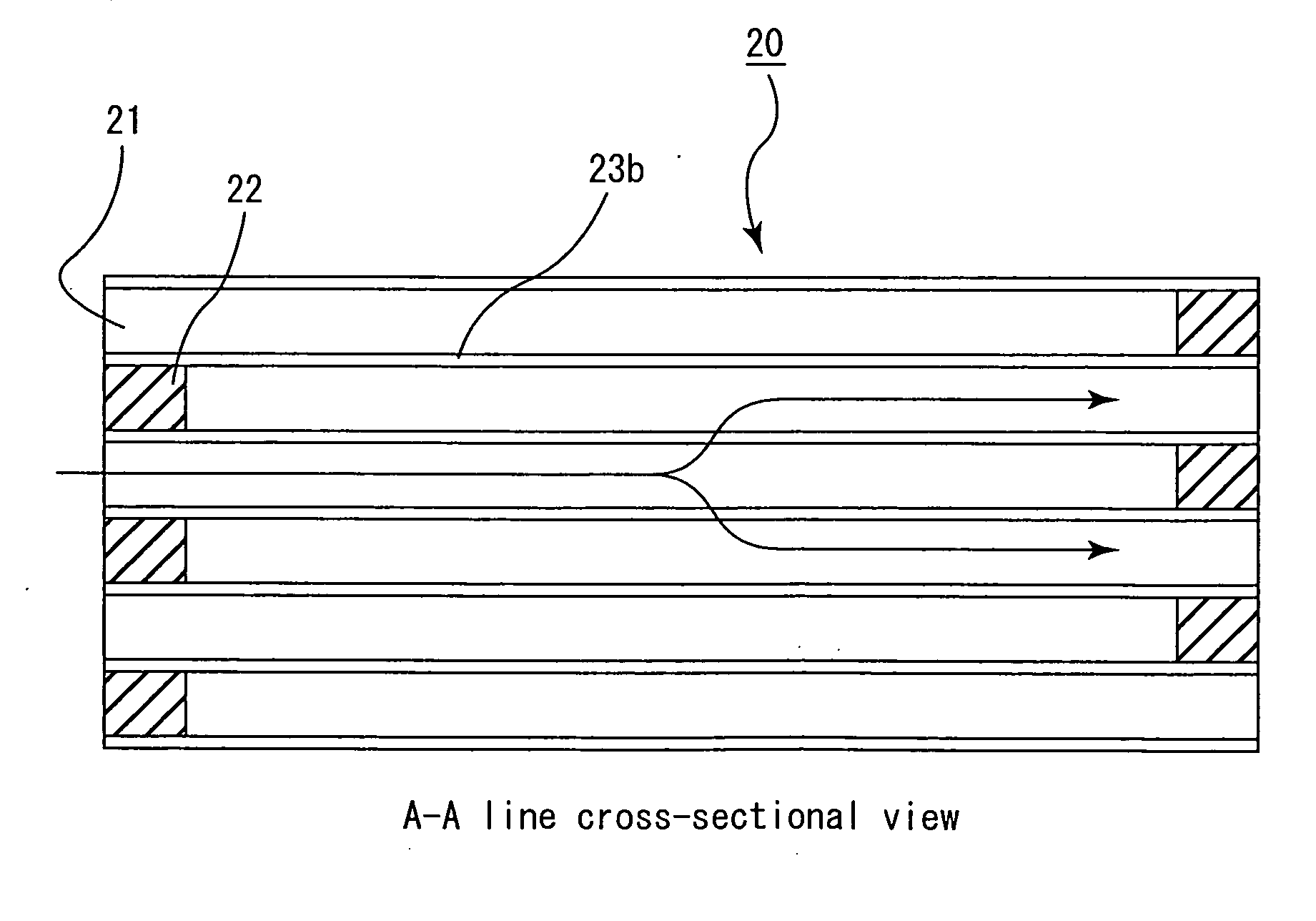

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

Honeycomb filter for purifying exhaust gas

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases having a structure in that, even when comparatively large sealing material layer is included therein, there is hardly any increase in the amount of organic components contained in exhaust gases to be discharged. The present invention provides a honeycomb filter for purifying exhaust gases, having a structure in that a sealing material layer is formed on a circumference of a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, and the wall portion which separate the through holes from each other functions as a filter for collecting particulates, wherein the rate Sα of an area occupied by the sealing material layers to the total area of a cross-section including the through holes in the direction perpendicular to the through holes is set to 0.5% or more, and the rate Vα of organic components to the honeycomb filter for purifying exhaust gases is set to 0.5% by weight or less.

Owner:IBIDEN CO LTD

Honeycomb structured body and exhaust gas purifying device

InactiveUS20070020155A1Simple processReduce the temperatureCombination devicesGas treatmentApparent densityEngineering

A honeycomb structured body of the present invention comprises a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween, wherein an oxide catalyst is supported on at least one portion of the cell wall, and the honeycomb structured body has an apparent density of about 0.7 g / cm3 or less.

Owner:IBIDEN CO LTD

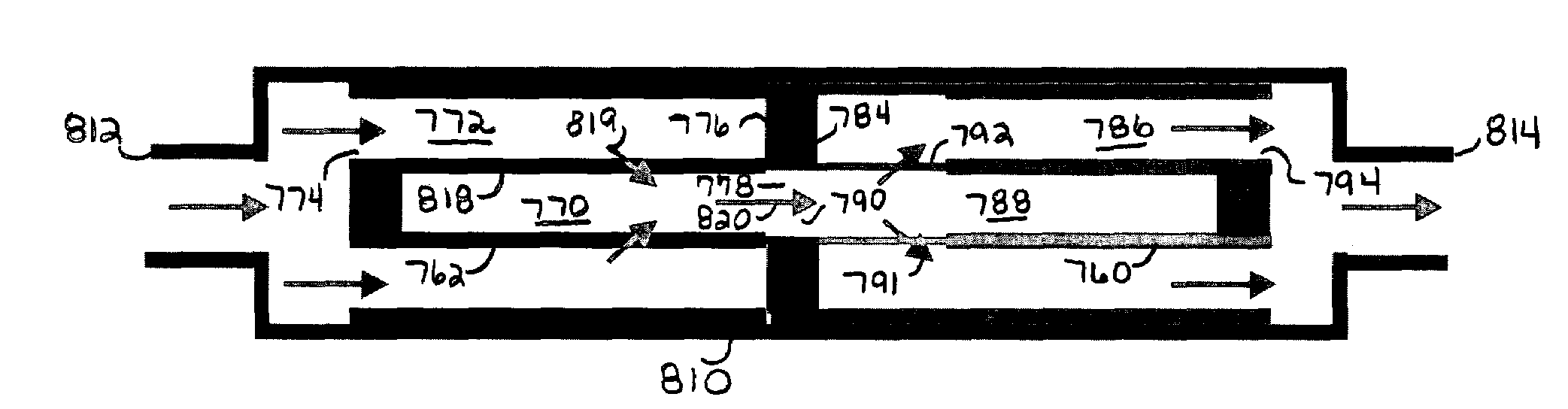

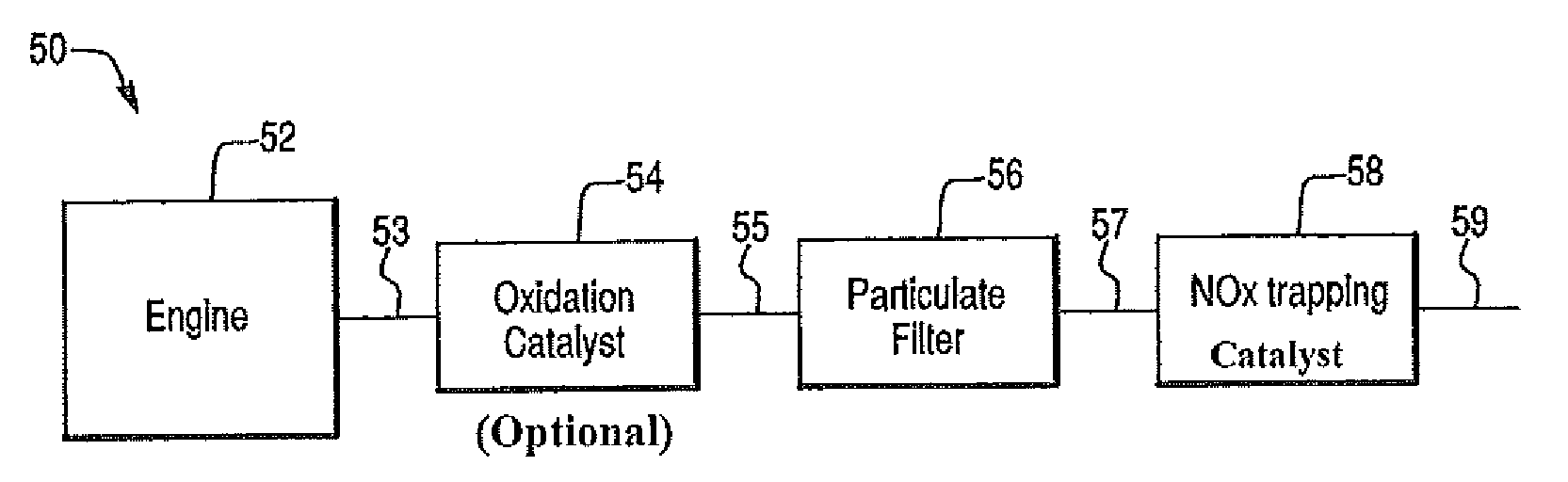

Integrated NOx and PM reduction devices for the treatment of emissions from internal combustion engines

InactiveUS20060179825A1Reduce volumeReduce expensesNitrous oxide captureGas treatmentEnvironmental engineeringDiesel particulate filter

One concept of the inventors relates to a system and method in which a particulate filter comprises at least about 40% by weight of an NOx adsorbant. The filter can be used as both an NOx trap and a particulate filter. By constructing the filter elements using a substantial amount of NOx adsorbant, a large volume of NOx adsorbant can be incorporated into the particulate filter, which substantially reduces the volume and expense of an exhaust system that includes both a catalytic diesel particulate filter and an NOx trap having a large quantity of NOx adsorbant. In a preferred embodiment, the filter also oxidizes NO to NO2. In another preferred embodiment, an SCR catalyst is position downstream of the filter elements.

Owner:EATON CORP

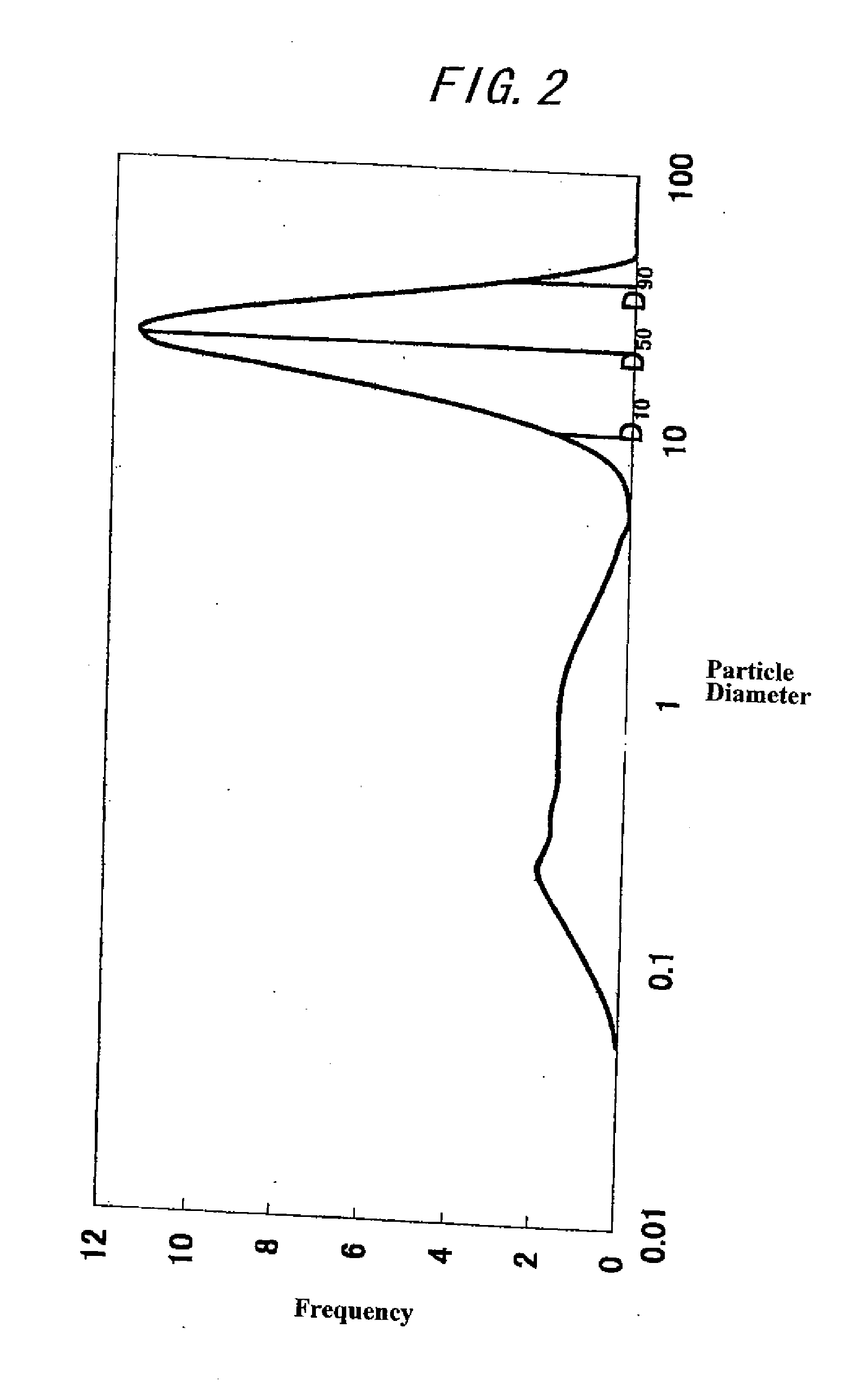

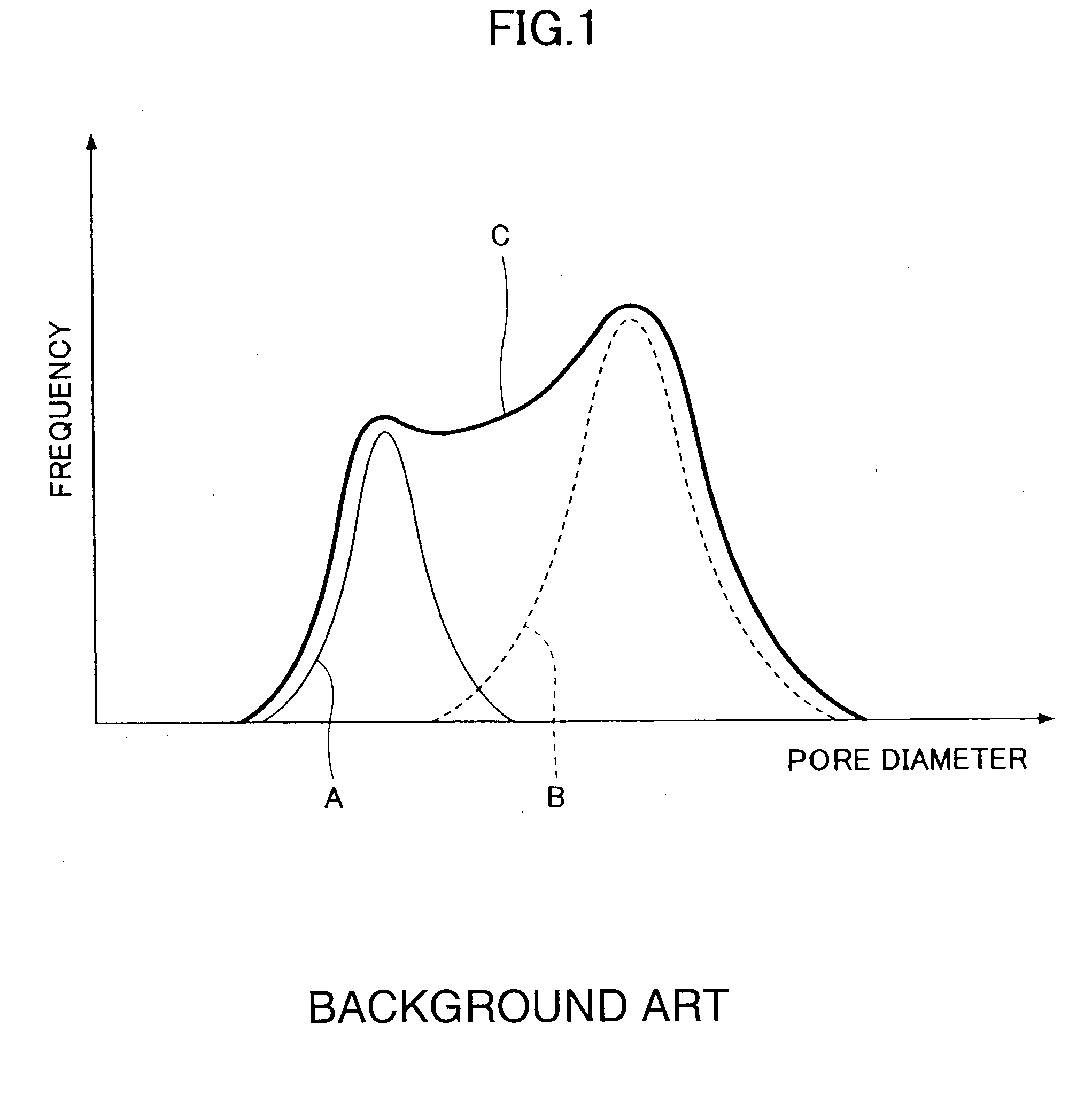

Ceramic Honeycomb Structural Body and Method of Manufacturing the Same

A ceramic honeycomb structural body is manufactured by molding silicon carbide raw powders into a honeycomb pillar shape and then firing it to form a sintered body. The silicon carbide raw powders are comprised of about 60 to about 80% by mass of particles of first particle group having one frequency peak in the particle size distribution and a particle size of 1.0 μm to about 100 μm, and about 20 to about 40% by mass of particles of a second particle group having a particle size of about 0.1 μm or more and less than 1.0 μm.

Owner:IBIDEN CO LTD

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

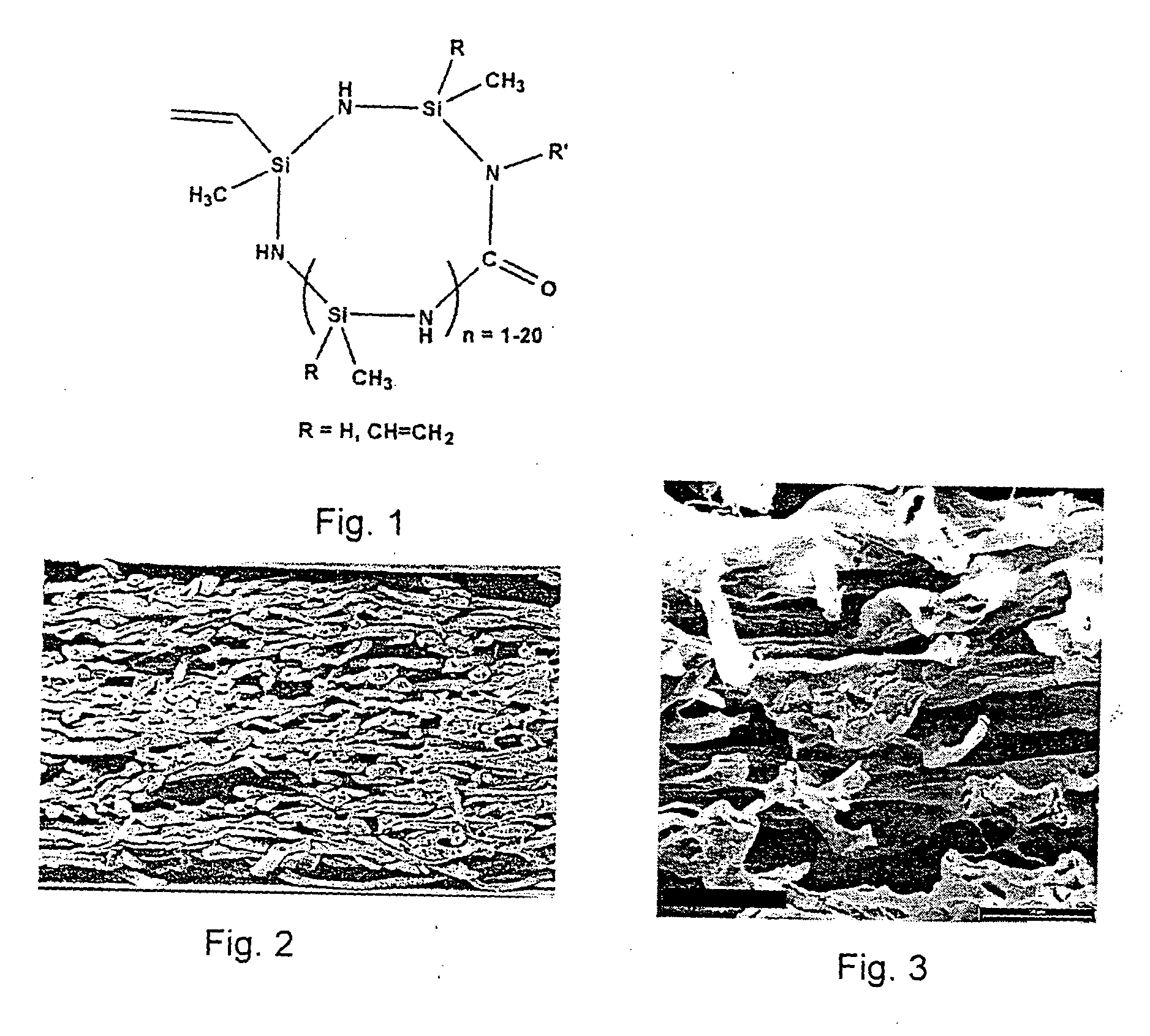

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

Honeycomb filter for purifying exhaust gases, adhesive, coating material, and manufacturing method of honeycomb filter for purifying exhaust gases

InactiveUS20080241015A1Increased durabilityHigh strengthCombination devicesPhysical/chemical process catalystsParticulatesAdhesive

Owner:IBIDEN CO LTD

Ceramic filter and exhaust gas decontamination unit

ActiveUS20050102987A1Improve filtering efficiencyExtended service lifeCombination devicesInternal combustion piston enginesMetallurgyActive component

It is to provide a filter for an exhaust gas having a high thermal conductivity irrespective of a relatively high porosity or showing characteristics that the whole of the filter containing a high refractive index substance or pigment is easily warmed but hardly cooled while making low the thermal conductivity of the filter as a whole. This filter is provided with a catalyst coat layer formed by carrying a catalyst active component on a surface of a porous ceramic carrier, in which a porosity of the porous ceramic carrier is 40-80% and a substance or a pigment indicating a thermal conductivity as the filter of 3-60 W / mk or having a large refractive index at a thermal conductivity of 0.3-3 W / mk.

Owner:IBIDEN CO LTD

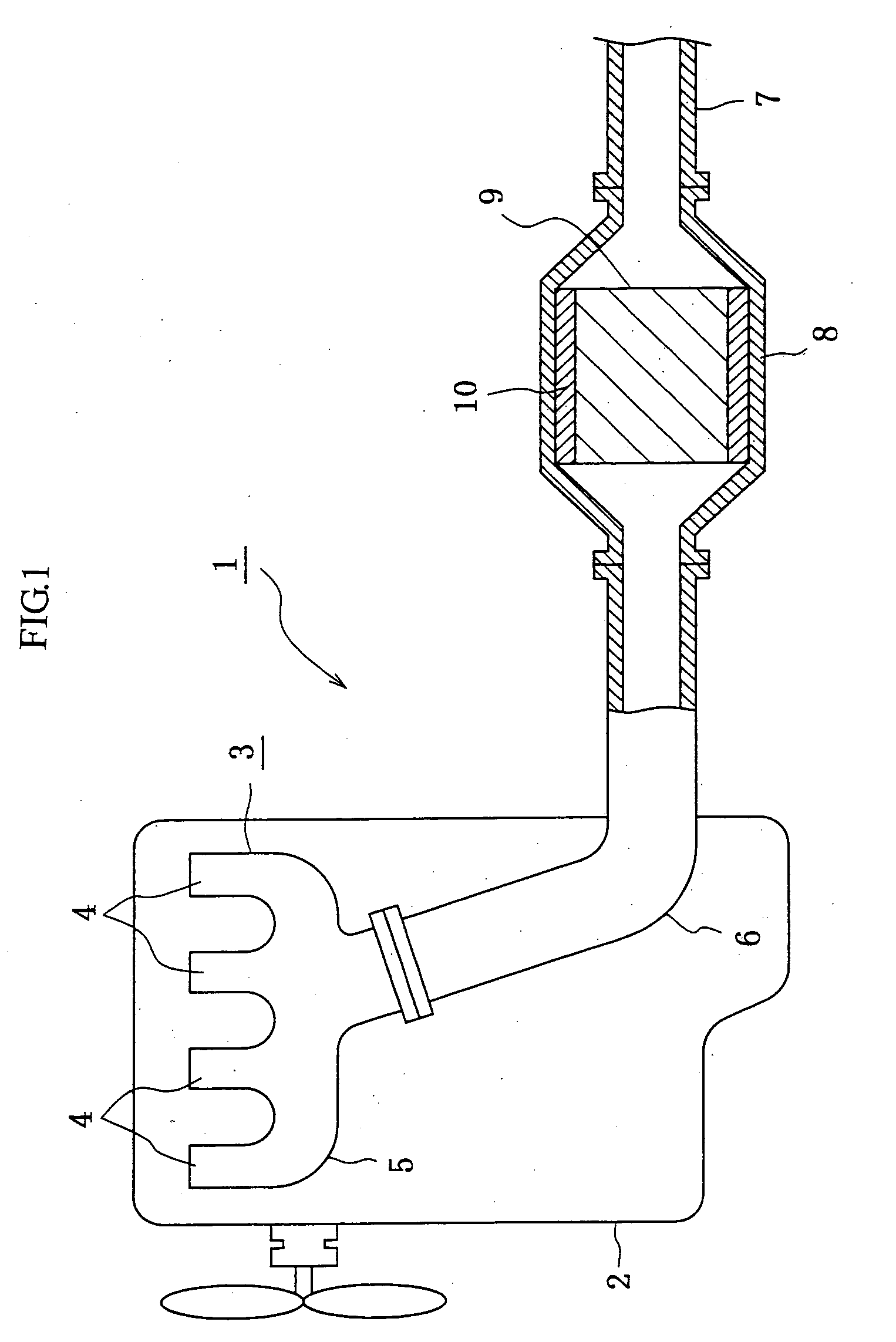

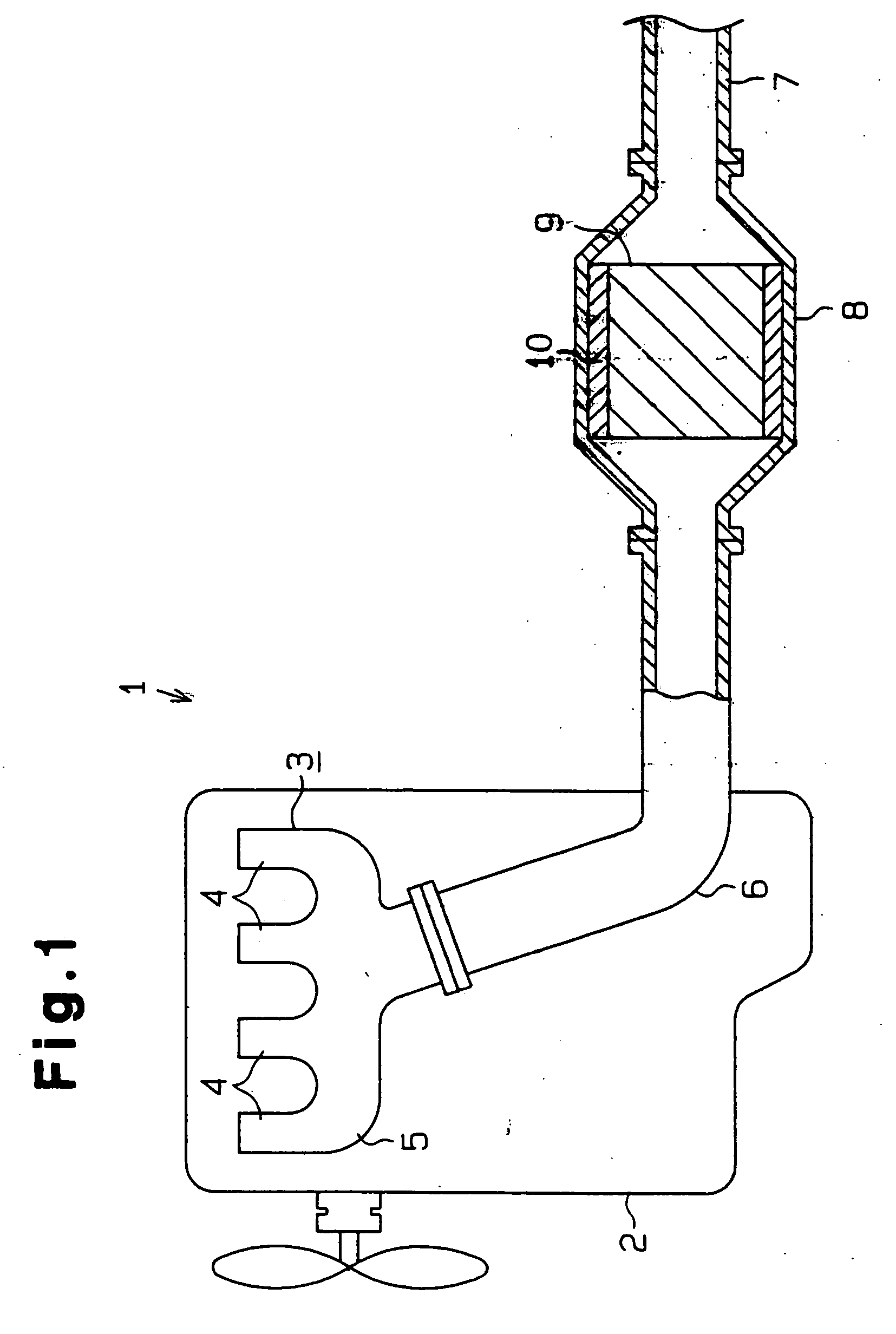

Honeycomb filter and ceramic filter assembly

InactiveUS20060021310A1Internal combustion piston enginesDispersed particle filtrationMetallurgyHoneycomb

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

Method for manufacturing honeycomb filter for purifying exhaust gases

InactiveUS20080213485A1Dispersed particle filtrationTransportation and packagingExhaust fumesHoneycomb

A method for manufacturing a honeycomb filter for purifying exhaust gas, including: providing a columnar body including porous ceramic and having a wall portion and through holes partitioned by the wall portion, the through holes extending in a length direction of the columnar body, coating a sealing material including one or more organic components over a circumferential surface of the columnar body to form a sealing material layer; and heating the columnar body having the sealing material layer on the circumferential surface of the columnar body at a temperature sufficient to lower a total weight of the organic component with respect to a total weight of the honeycomb filter, Vα.

Owner:IBIDEN CO LTD

Honeycomb structure body

InactiveUS20060073970A1Distinguish clearlyInternal combustion piston enginesDispersed particle filtrationExternal combustion engineEngineering

An object of the present invention is to provide a honeycomb structural body which is inserted, for use, into a pipe forming an exhaust passage of an internal combustion engine, and makes it possible to clearly distinguish an exhaust gas flow-in side and an exhaust gas flow-out side. The present invention is directed to a columnar honeycomb structural body comprising porous ceramics each including a number of through holes that are placed in parallel with one another in the length direction with a wall portion interposed therebetween, wherein information regarding the honeycomb structural body is displayed on a circumferential surface and / or an end face thereof.

Owner:IBIDEN CO LTD

Honeycomb structured body

Owner:IBIDEN CO LTD

Porous sintered body, method of manufacturing porous sintered body, and method of manufacturing exhaust gas purifying apparatus

A method of manufacturing a porous sintered body includes mixing at least two groups of silicon carbide particles and a pore forming material having an average particle diameter Y μm to obtain a molding material. The at least two groups of silicon carbide particles have different average particle diameters and have a first group of silicon carbide particles whose blending quantity by weight in the molding material is greatest among the at least two groups of silicon carbide particles. The first group have an average particle diameter X μm. The relationships 15≦X, 0.5·X≦Z≦0.9·X, and 0.8·Z≦Y≦1.8·Z are satisfied, wherein Z μm is an average pore diameter of the porous sintered body no less than 10 μm and no greater than 20 μm.

Owner:IBIDEN CO LTD

Exhaust system for a vehicular positive ignition internal combustion engine

ActiveUS20110158871A1Reduce frequencyImprove filtering effectCombination devicesCation exchanger materialsParticulatesPorous substrate

Owner:JOHNSON MATTHEY PLC

NOx Adsorber Catalyst with Superior Low Temperature Performance

The lean NOx trap catalyst composition of the present invention comprises distinct layers, or zone configuration or multi-brick arrangement. The top layer, front zone or front brick is free of any alkali or alkaline earth NOx trapping components. The under layer, rear zone or rear brick may contain any desirable NOx trapping component in contact with a precious metals group catalyst (e.g., Pt). Catalysts of this invention show wide temperature operation window with superior low temperature performance.

Owner:BASF CORP

Ceramic structure, method of manufacturing ceramic structure, and device for manufacturing ceramic structure

ActiveUS20050178098A1Hardening the bonding materialCombination devicesAuxillary pretreatmentMetallurgyAdhesive

A ceramic structure includes a plurality of porous ceramic members each being warped, each of the plurality of porous ceramic members having a bonding portion and end portions at both ends of each of the plurality of porous ceramic members in a longitudinal direction of each of the plurality of porous ceramic members, and an adhesive provided only on the bonding portion between the plurality of porous ceramic members to connect the plurality of porous ceramic members except for the end portions of the plurality of ceramic members.

Owner:IBIDEN CO LTD

Honeycomb structural body and exhaust gas treating apparatus

ActiveUS20080190083A1Combination devicesEnvelopes/bags making machineryEngineeringHoneycomb structure

A pillar-shaped honeycomb structural body includes a first end face and a second end face substantially parallel to each other; and a peripheral surface connecting the first end face and the second end face. The first end face and the second end face have similar peripheral shapes. A taper rate P satisfies 0<P≦ approximately 4%, the taper rate P being expressed by the formula (1), taper rate P(%)=(D1−D2) / (2L)×100, wherein the maximum width of the first end face is D1, the maximum width of the second end face is D2, and the distance between the first end face and the second end face is L.

Owner:IBIDEN CO LTD

Honeycomb structure

ActiveUS20050011174A1Increasing limiting collection amountReduce total pressure lossCombination devicesAuxillary pretreatmentParticulatesEngineering

A honeycomb structural body which is capable of increasing the limiting collection amount of particulate, reducing the pressure loss in use, and reducing fluctuations in the pressure loss even if the flow rate from an internal combustion engine of exhaust gases fluctuates. The honeycomb structural body is a columnar honeycomb structural body in which a large number of through holes are arranged side by side in the length direction with a partition wall interposed therebetween. The large number of through holes are constituted by a group of large-capacity through holes, with one end thereof sealed to make the total cross-sectional areas perpendicular to the length direction relatively greater, and a group of small-capacity through holes, with the other end thereof sealed to make the total cross-sectional areas relatively smaller. The honeycomb structural body includes a plurality of columnar porous ceramic members.

Owner:IBIDEN CO LTD

Honeycomb structure and method for manufacturing the same

ActiveUS20090130378A1High bonding strengthGas treatmentDispersed particle filtrationHoneycomb structureMaterials science

A honeycomb structure includes a ceramic block including a plurality of honeycomb fired bodies, a first adhesive layer, and a second adhesive layer. The plurality of honeycomb fired bodies includes center-portion honeycomb fired bodies located at a center portion in a cross-section perpendicular to the longitudinal direction and peripheral honeycomb fired bodies surrounding the center-portion honeycomb fired bodies. The first adhesive layer is interposed between the center-portion honeycomb fired bodies to connect the center-portion honeycomb fired bodies. The second adhesive layer is interposed between each of the center-portion honeycomb fired bodies and each of the peripheral honeycomb fired bodies and between the peripheral honeycomb fired bodies. An adhesive strength α between the center-portion honeycomb fired bodies bonded via the first adhesive layer is higher than an adhesive strength β between honeycomb fired bodies bonded via the second adhesive layer.

Owner:IBIDEN CO LTD

Honeycomb structured body and exhaust gas purifying device

ActiveUS20060019061A1Improve heat resistanceCombination devicesGas treatmentExhaust fumesEngineering

The honeycomb structured body of the present invention is a pillar-shaped honeycomb structured body having a honeycomb structure that a number of through holes are placed in parallel with one another in the length direction with a wall portion interposed therebetween and one of ends of each through hole is sealed, wherein a relation between a volume Y (L) of said honeycomb structured body and an aperture ratio X (%) on an inlet side satisfies the following inequality (1):Y≦−1.1X+68.5 (wherein Y≦19, 35≦X≦56) (1).

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com