Integrated NOx and PM reduction devices for the treatment of emissions from internal combustion engines

a technology of internal combustion engine and reduction device, which is applied in the direction of machines/engines, separation processes, transportation and packaging, etc., can solve the problems of excessive meeting effort, exhaust is too oxygen-rich for three-way catalysts to be effective, and the exhaust system is too large and expensive to achieve the effect of reducing the volume and cost of an exhaust system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

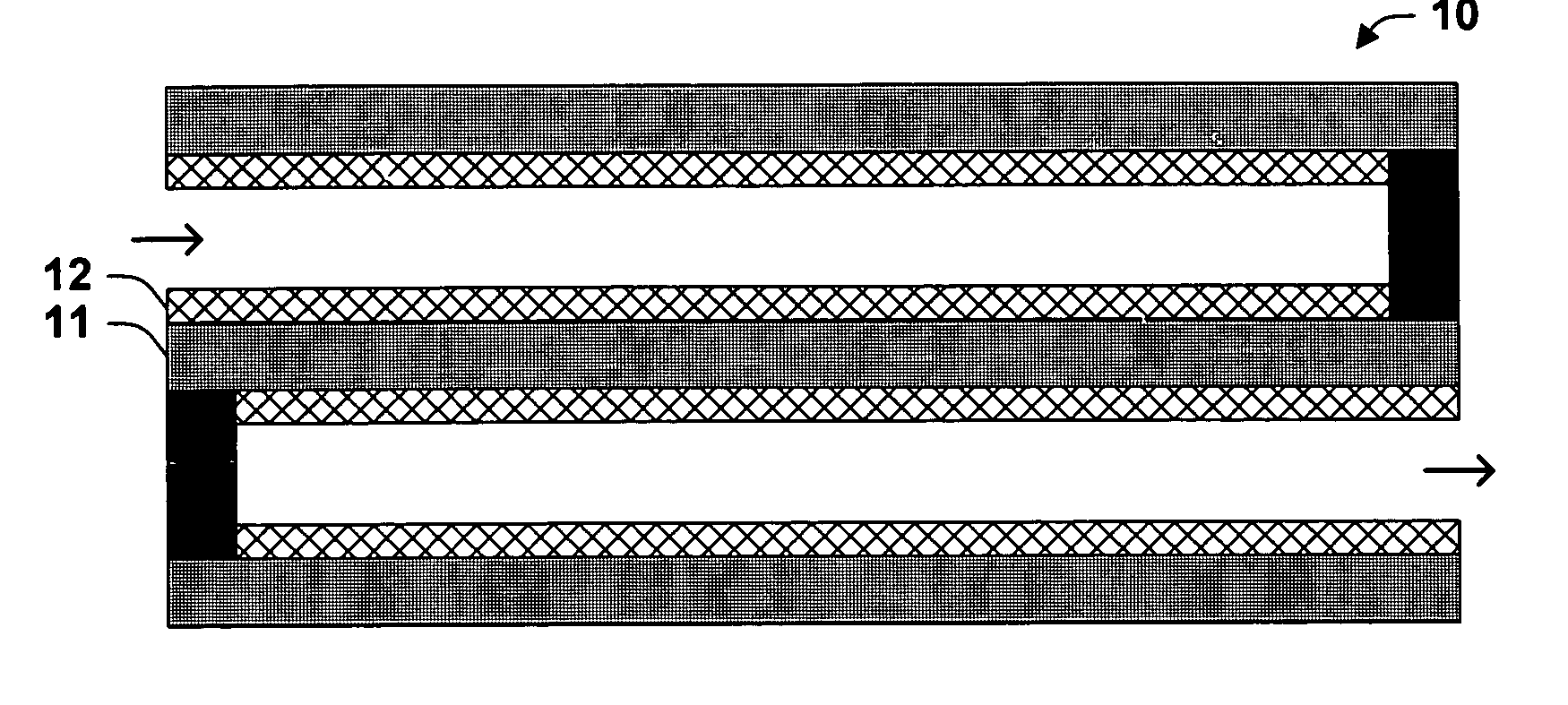

[0021] A particulate filter is a relatively large device and is only one of several devices that may be required in a diesel exhaust system to meet emissions control regulations. Incidental to its main function, which is to physically screen particulate matter from exhaust gases, a typical particulate filter occupies a large volume and presents a large contact area to the exhaust gases. The space taken up by a particulate filter and / or the filter's large contact area can be used to facilitate a second function. In one aspect of the invention, that function is that of an SCR catalyst bed.

[0022]FIG. 1 is a schematic illustration of an exemplary particulate filter / SCR catalyst 10. The device 10 comprises filter elements 11 and catalyst elements 12. The filter elements 11 are porous and the structure of the device 10 generally causes exhaust gases to pass through the filter elements 11. The catalyst elements 12 comprise an ammonia SCR catalyst. In FIG. 1, the ammonia SCR catalyst is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com