Tobacco leaf boxing density deviation pressure detection method and detection device thereof

A technology of density deviation and detection device is applied in the direction of determining the specific gravity by measuring the pressure difference, which can solve the problems of high cost and human harm, and achieve the effect of low cost and good safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

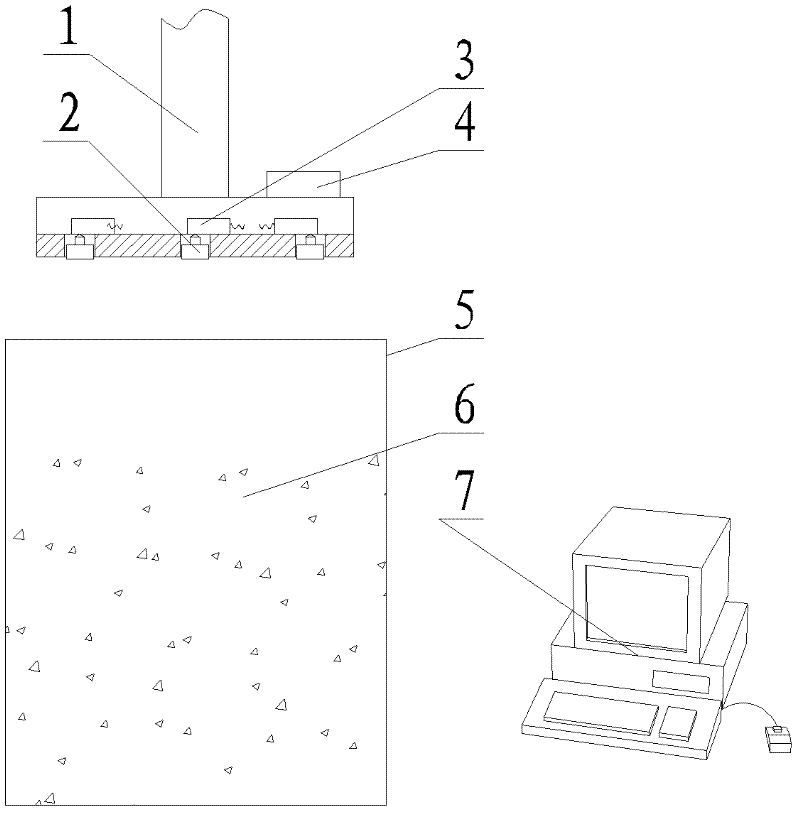

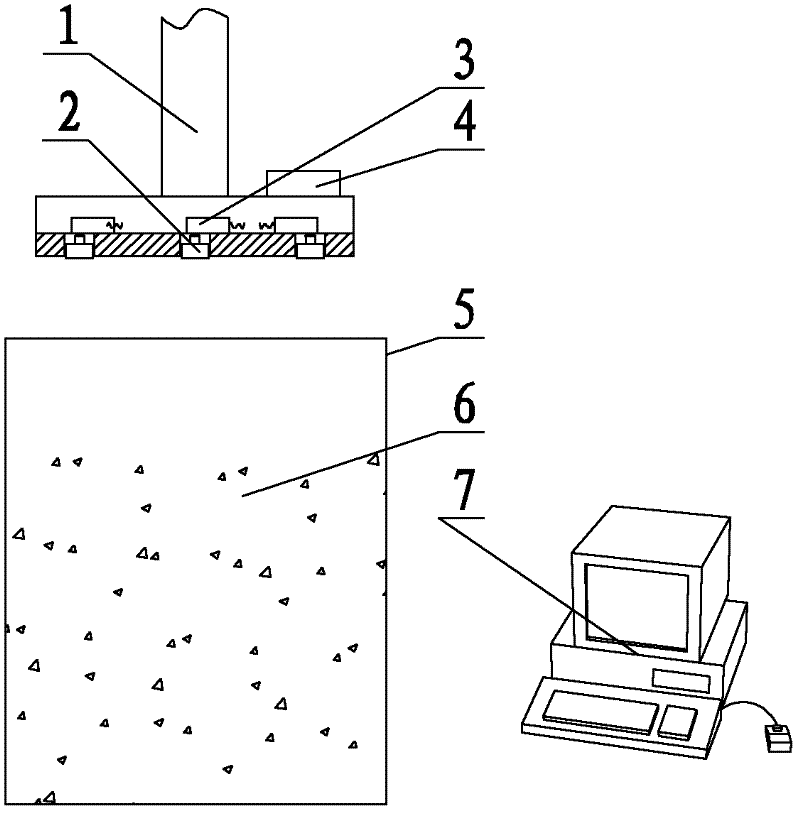

[0026] See figure 1 , The embodiment of the tobacco leaf packing density deviation pressure detection device is provided with at least one set of data acquisition device and data processing system, and the data acquisition device is connected with the data processing system; the data acquisition device consists of the pressure head 1, the sampler 2 , Pressure sensor 3 and data acquisition card 4, sampler 2 is fixed on pressure sensor 3 with bolts, pressure sensor 3 is fixed on pressure head 1 with bolts, sampler 2 is embedded in pressure head 1, and the end surface is higher than the pressure The head 5~10mm, the pressure sensor 3 and the data acquisition card 4 are connected with a cable, and fixed on the upper surface of the pressure head 1. The data processing system is the industrial computer 7, and the input port of the industrial computer 7 is connected to the data acquisition card 4. The signal output terminal is connected.

[0027] Based on the size limitation of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com