Composite rubberized fabric of rubber and thermoplasticity polyamine formic ether and manufacturing method thereof

A polyurethane and composite tape technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve the effect of improving mechanical strength, wide hardness range, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

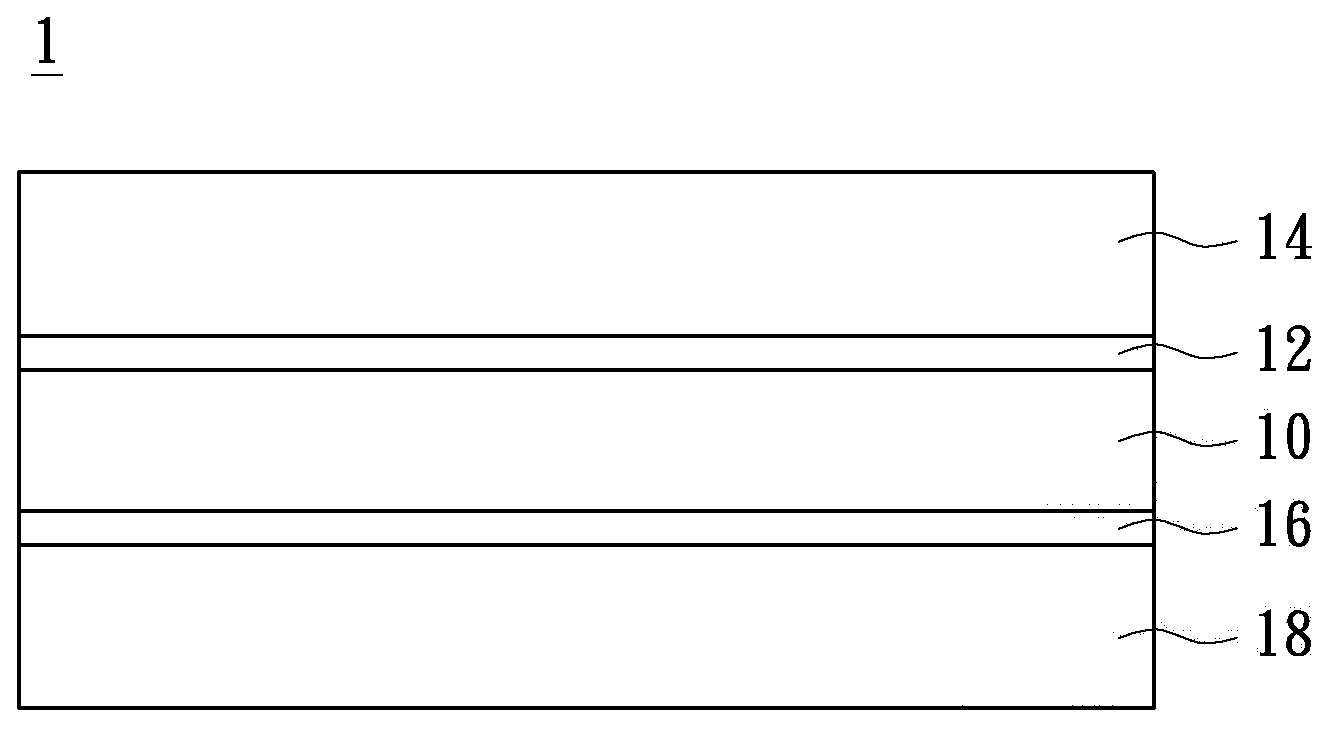

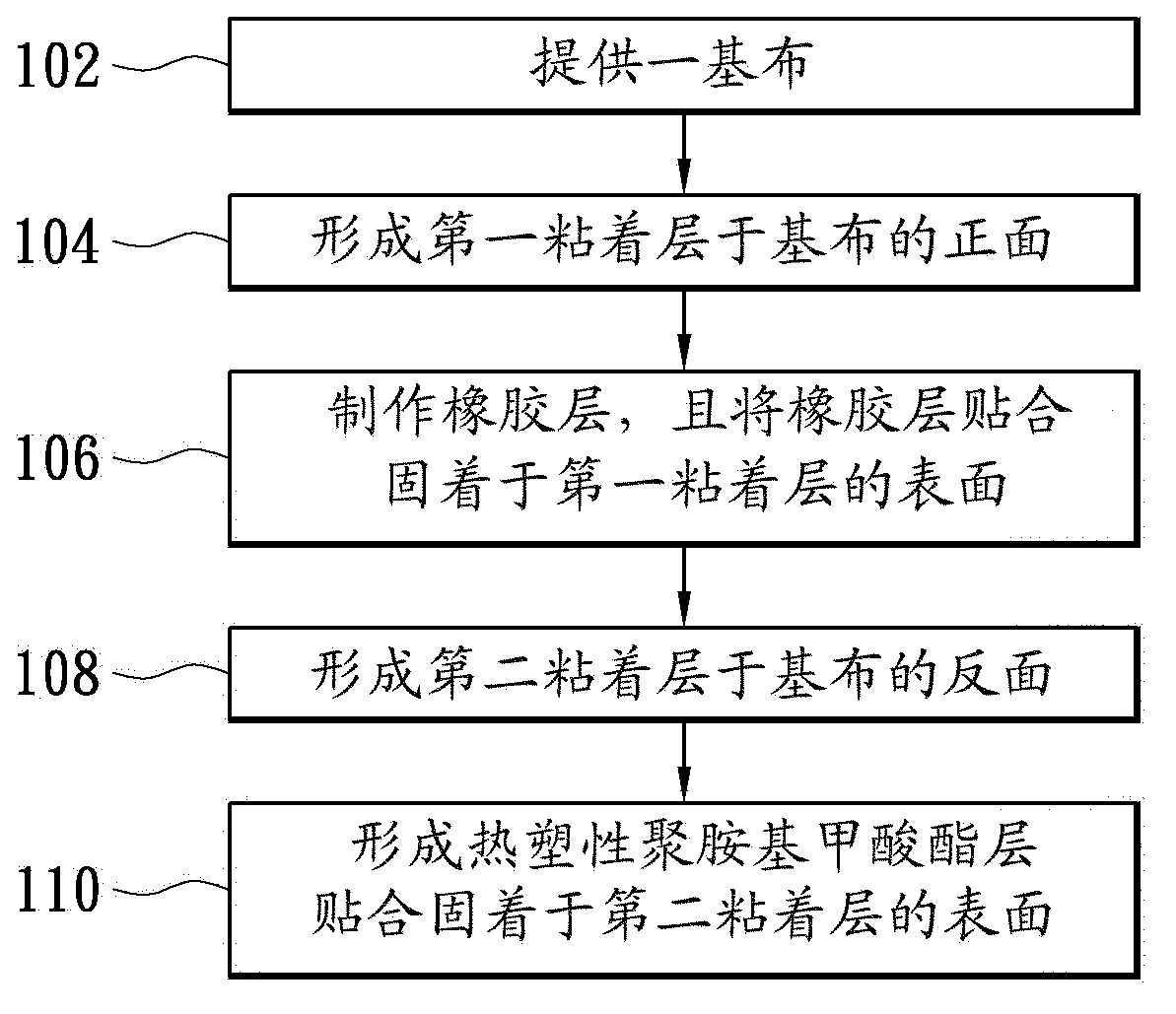

[0017] Please refer to figure 1 and figure 2 As shown, the present invention provides a method for manufacturing a rubber and thermoplastic polyurethane composite tape 1, which includes the following steps:

[0018] First, as described in step S102, a base fabric 10 is provided. The base fabric 10 is one of nylon fiber fabric and polyester fiber fabric, but the material of the base fabric 10 is not limited to the above.

[0019] As described in step S104, a first adhesive layer 12 is formed on the front surface of the base fabric 10, and the first adhesive layer 12 may be formed of an adhesive, that is, the first adhesive layer 12 functions to connect the base fabric 10 and the rubber layer 14.

[0020] As described in step S106, a rubber layer 14 is fabricated, and the rubber layer 14 is adhered and fixed to the surface of the first adhesive layer 12. In more detail, the method of making the rubber layer 14 is to put the formula of the rubber layer 14 in a 10,000-horsepower mixer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com