Patents

Literature

1074results about How to "Water resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

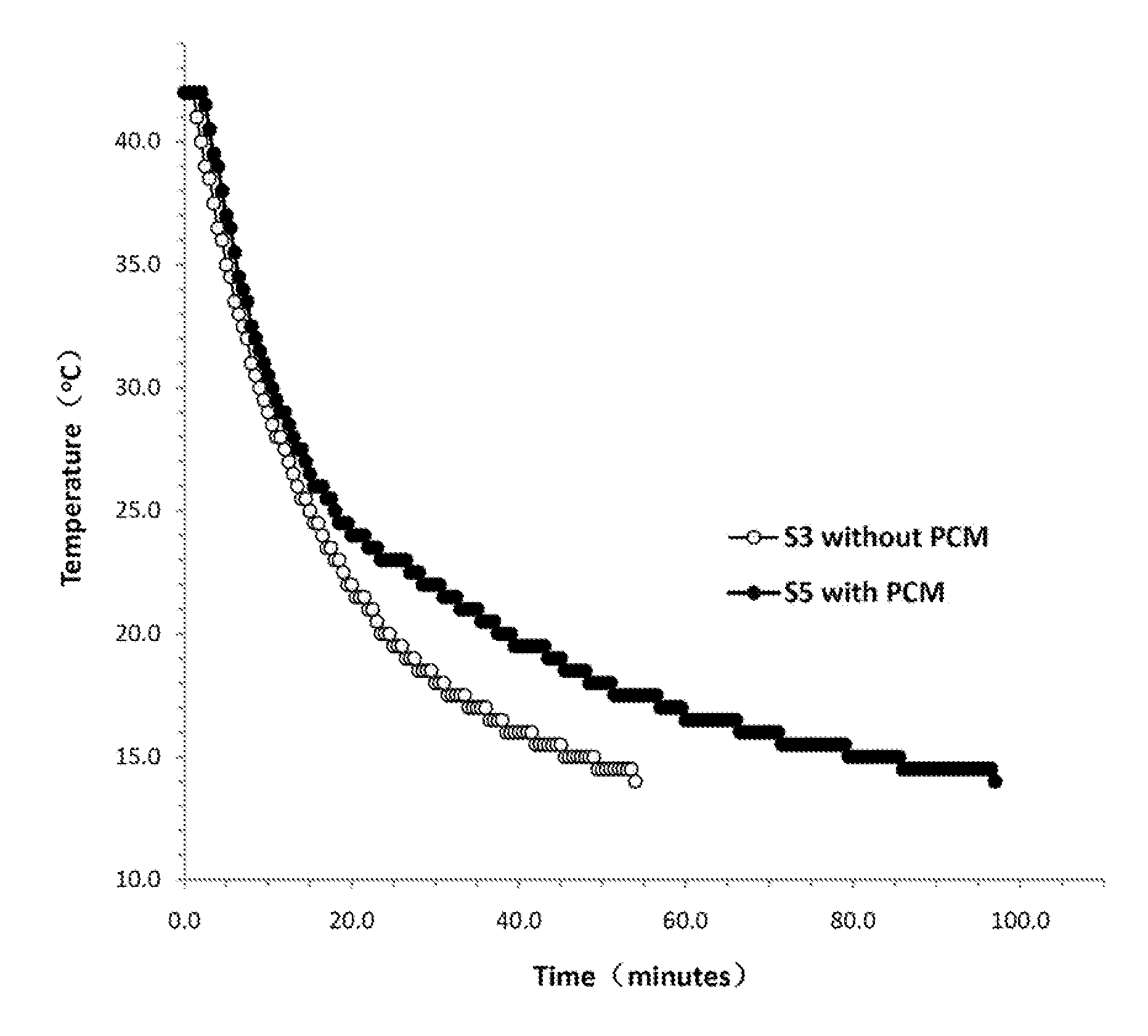

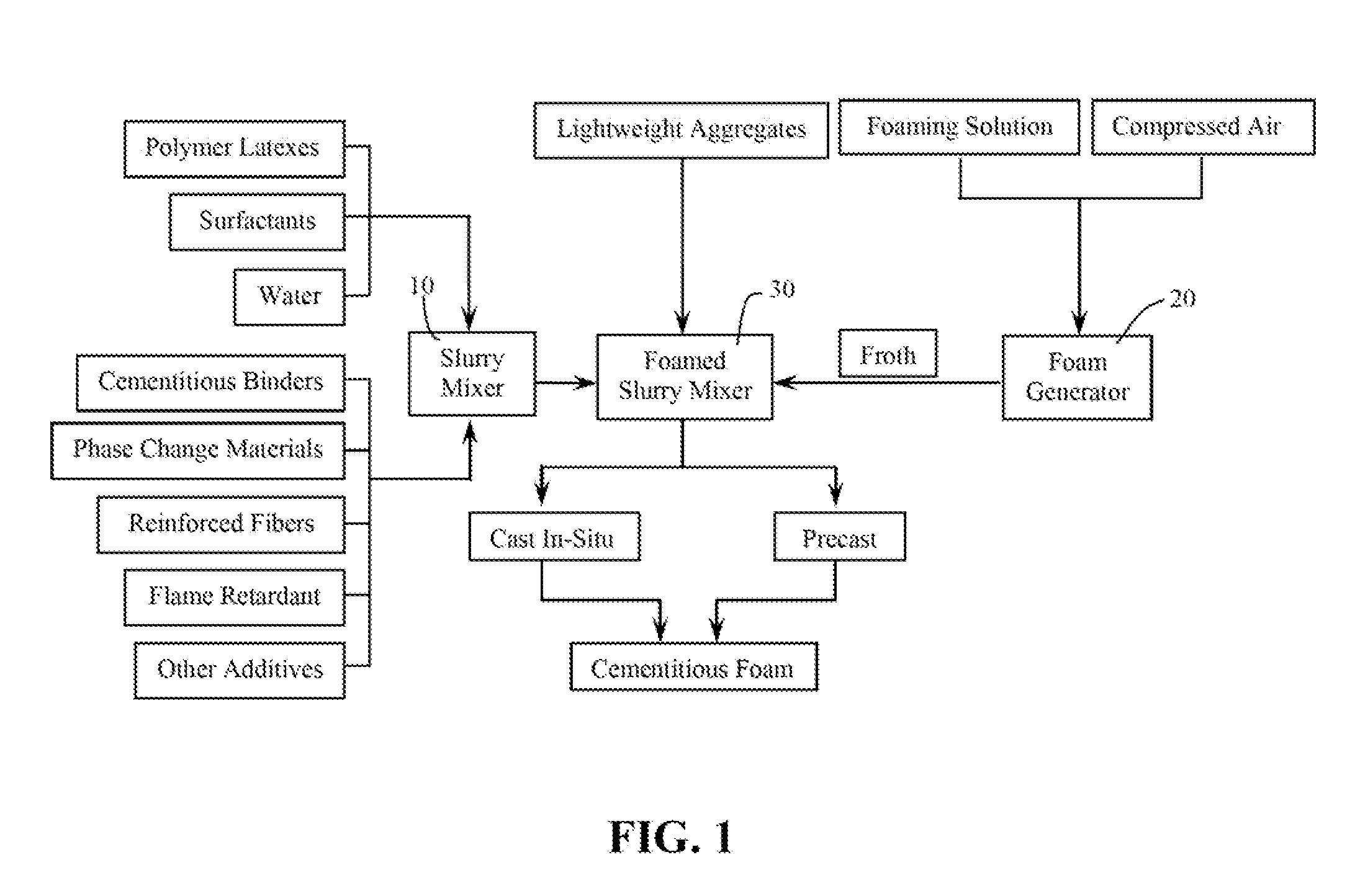

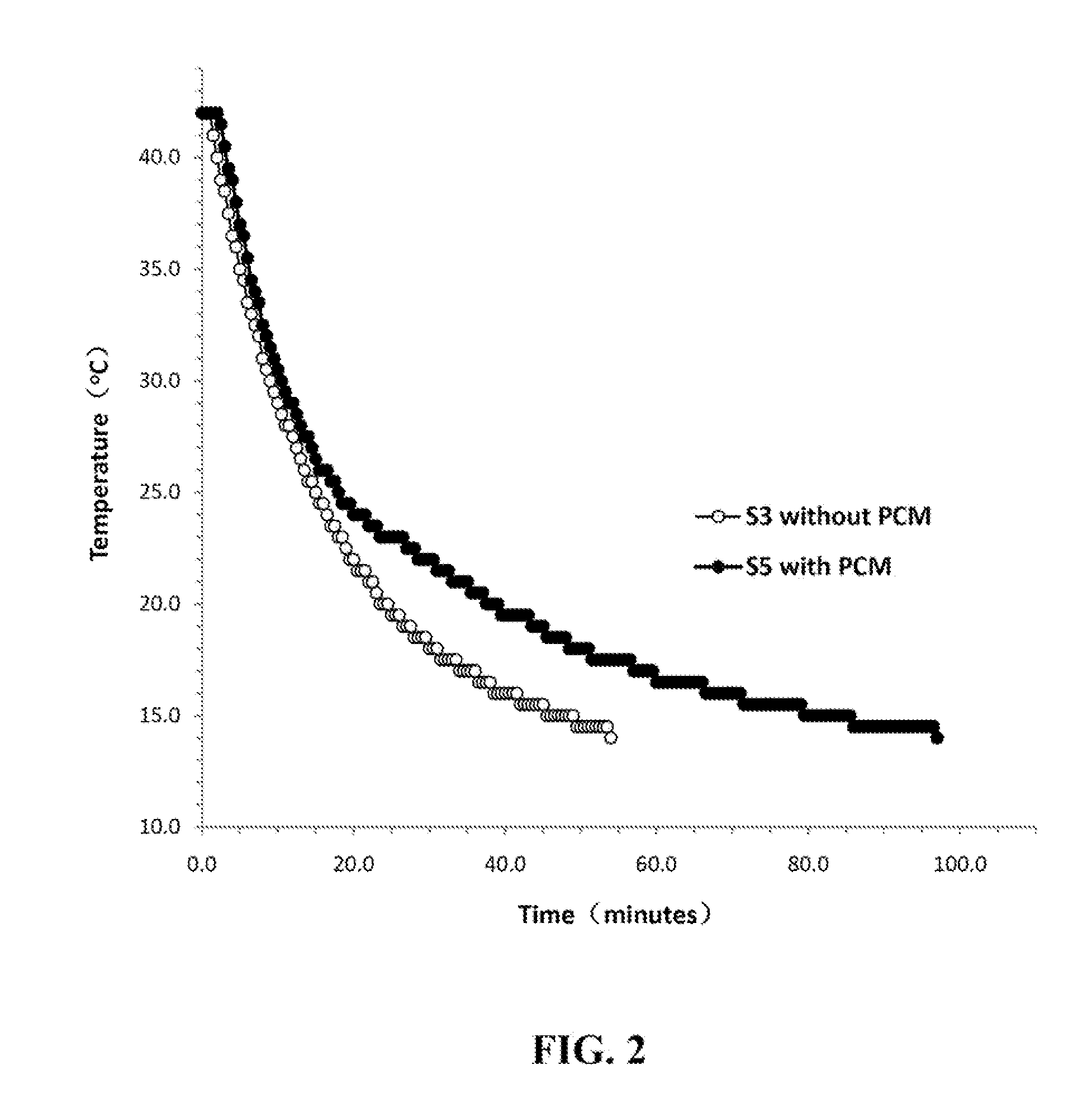

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

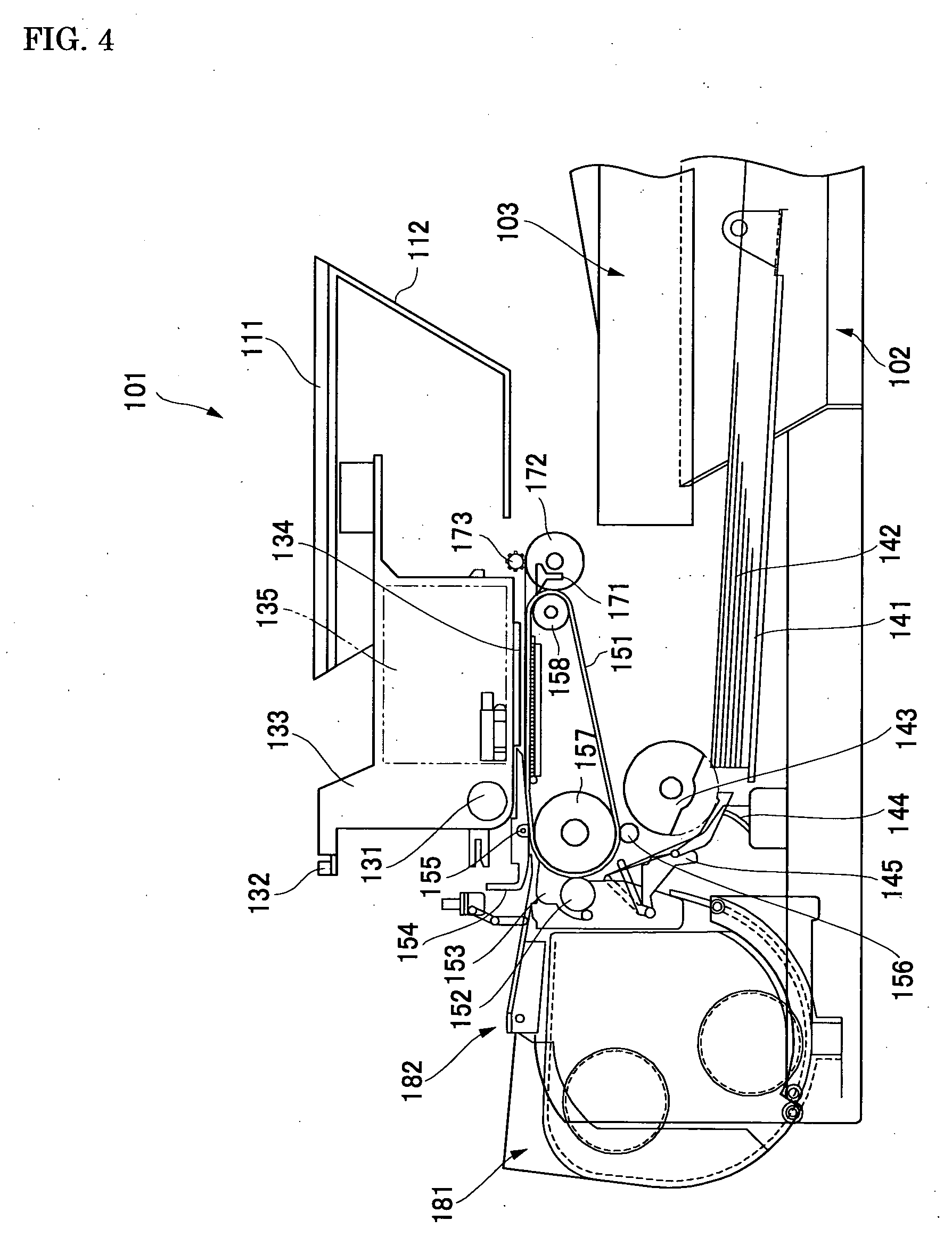

Recording Ink, Ink/Media Set, Ink Cartridge, Inkjet Recording Method and Inkjet Recording Apparatus

ActiveUS20080233363A1Avoid it happening againHigh image densityDecorative surface effectsLayered productsParticulatesWater dispersible

To provide a recording ink which contains at least a water-dispersible colorant, a water-dispersible resin, a wetting agent, a surfactant and water, wherein the content of the wetting agent in the recording ink is in the range of from 20% by mass to 35% by mass, the total solid content of the water-dispersible colorant and the water-dispersible resin in the recording ink is in the range of from 12% by mass to 40% by mass, the water-dispersible resin contains fluorine resin particulates, and the ratio A:B, where A is the solid content of the water-dispersible resin in the recording ink and B is the solid content of a pigment contained in the water-dispersible colorant in the recording ink, is in the range of 0.5 to 8.

Owner:RICOH KK

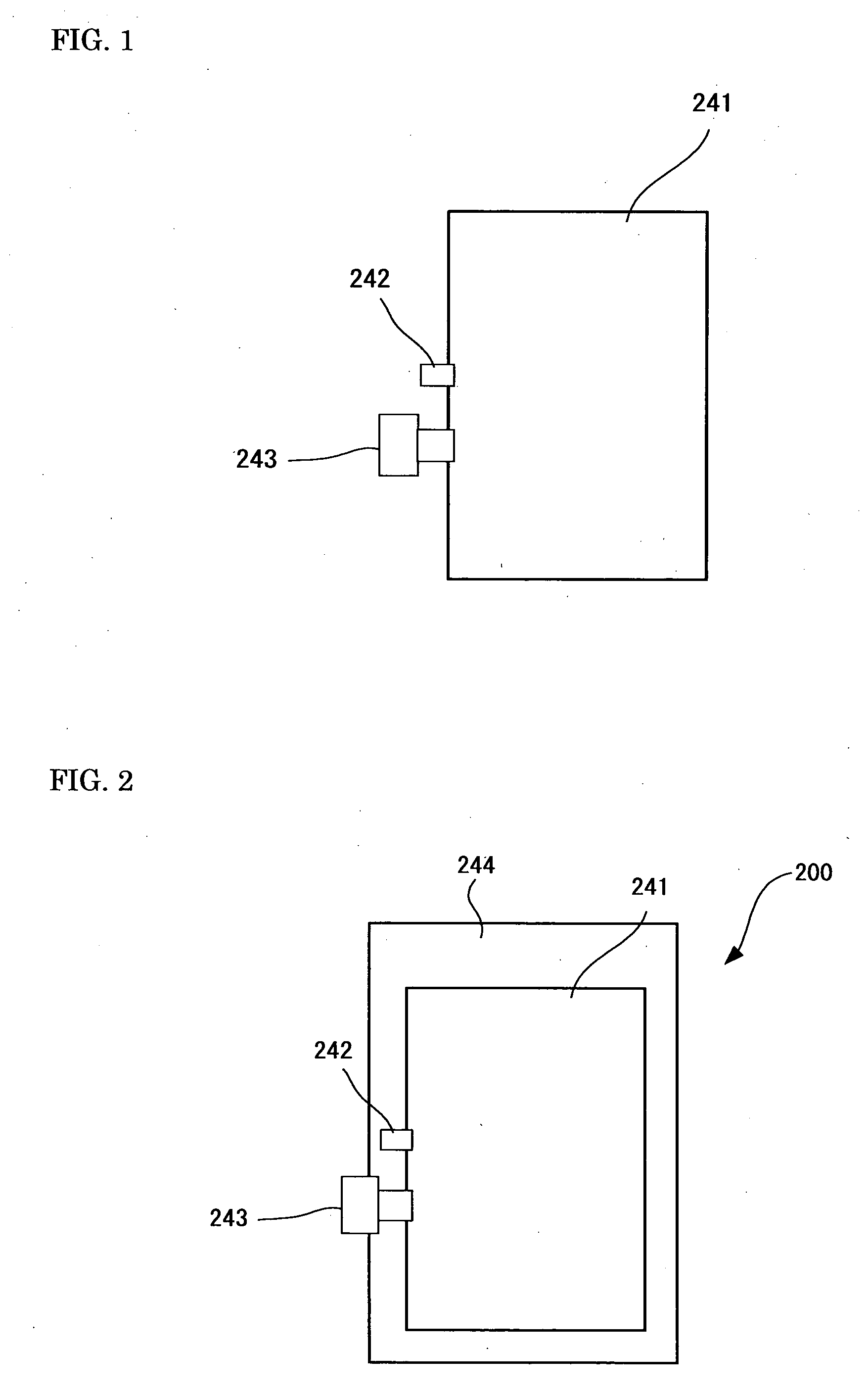

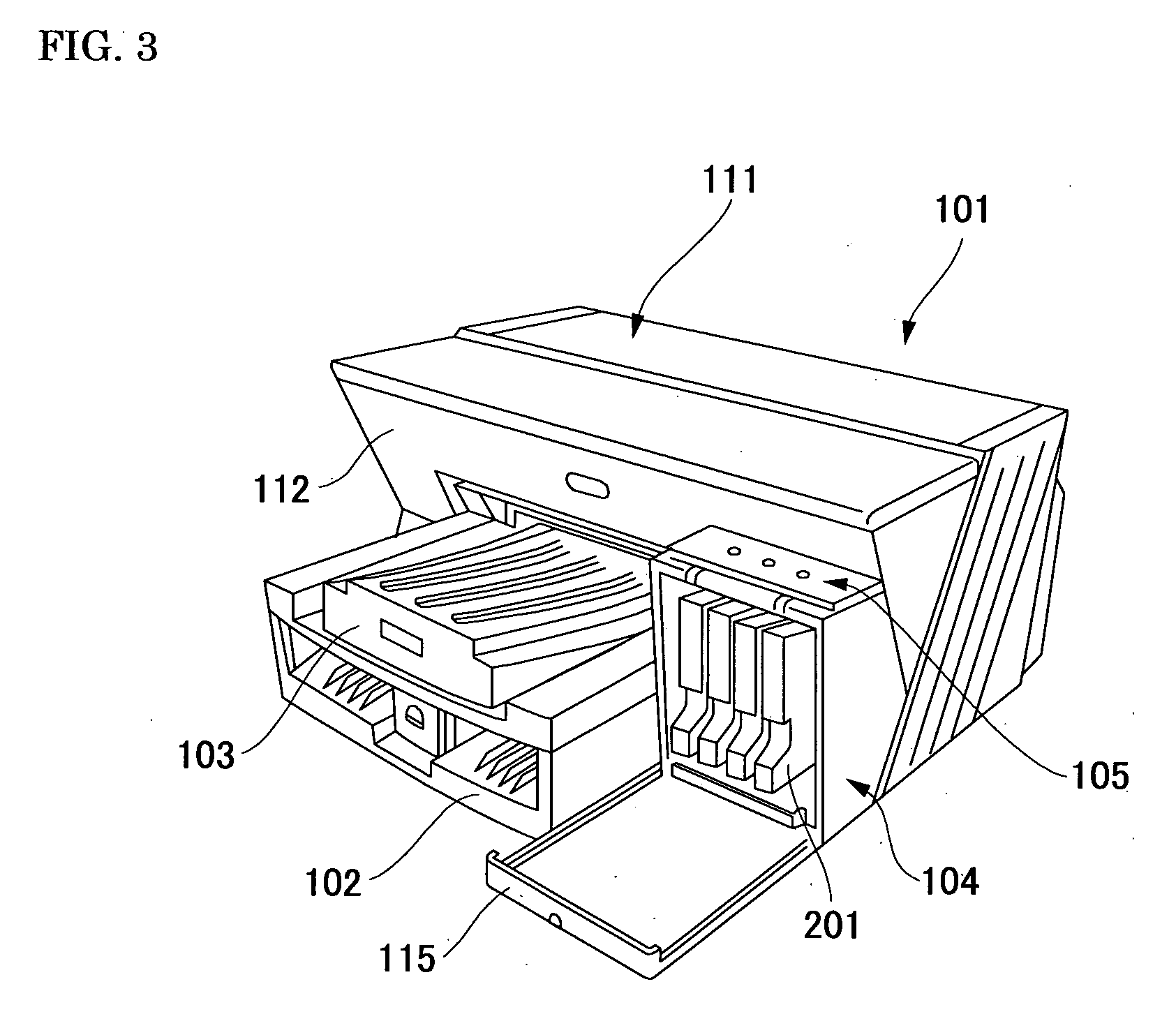

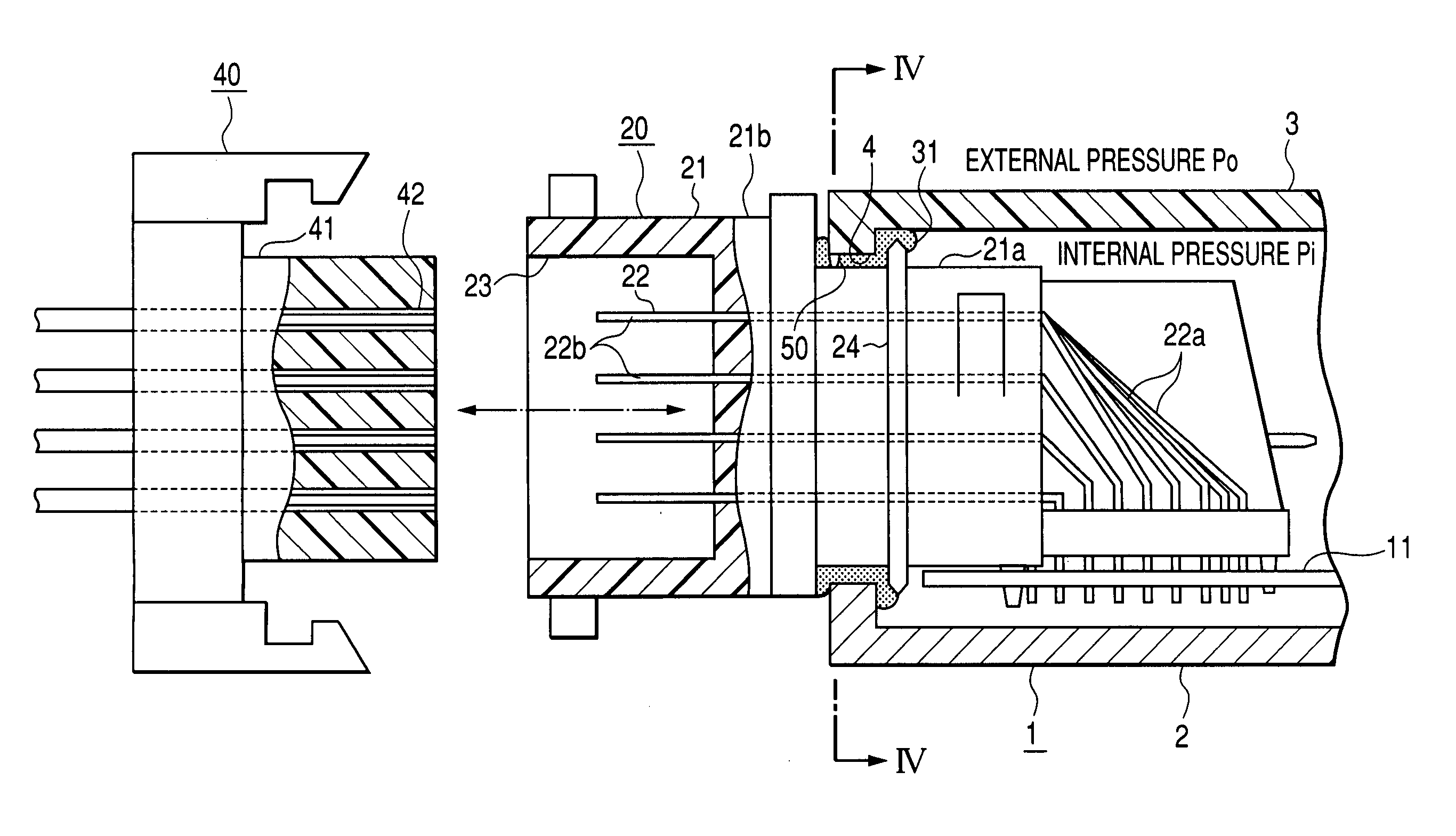

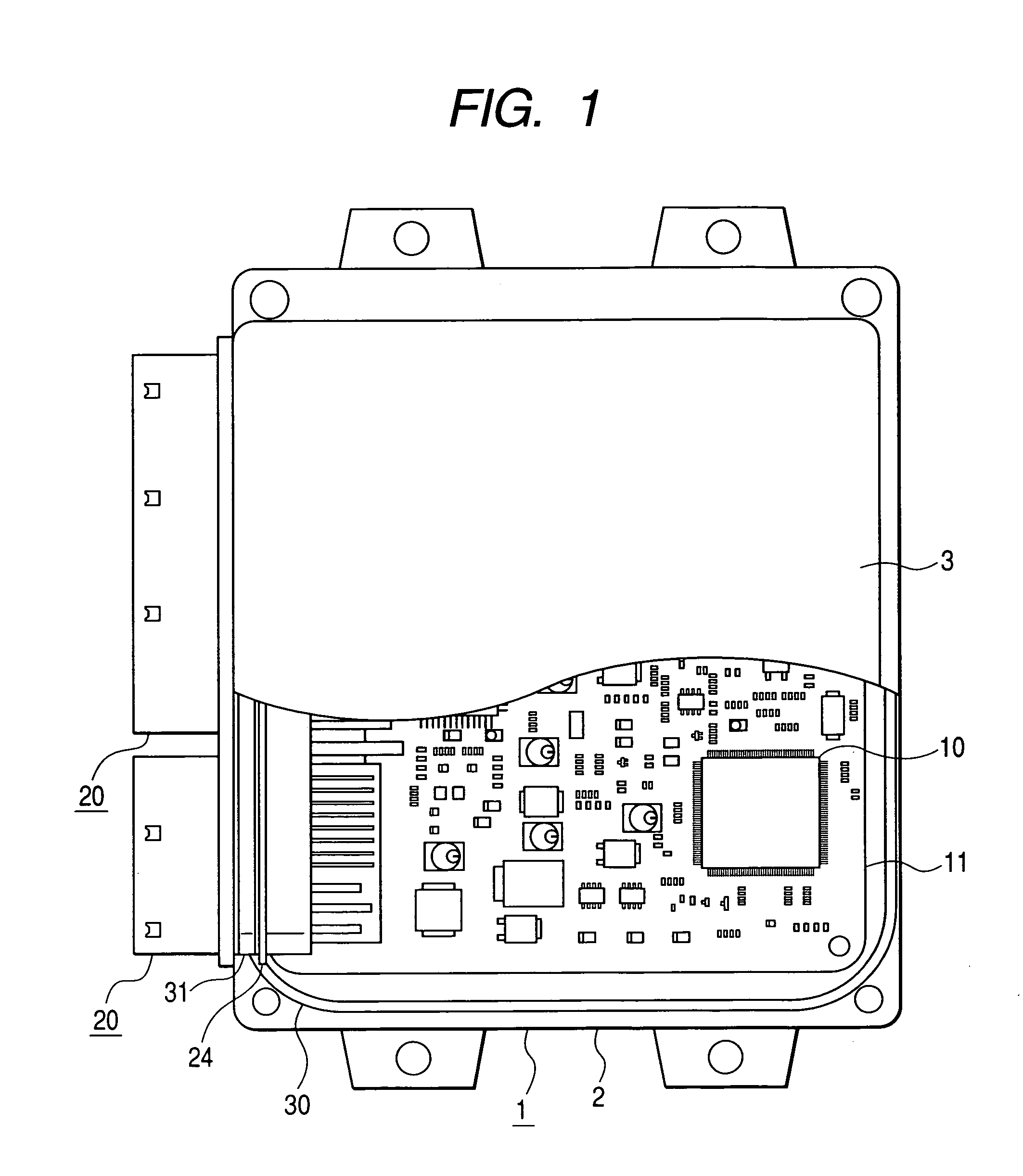

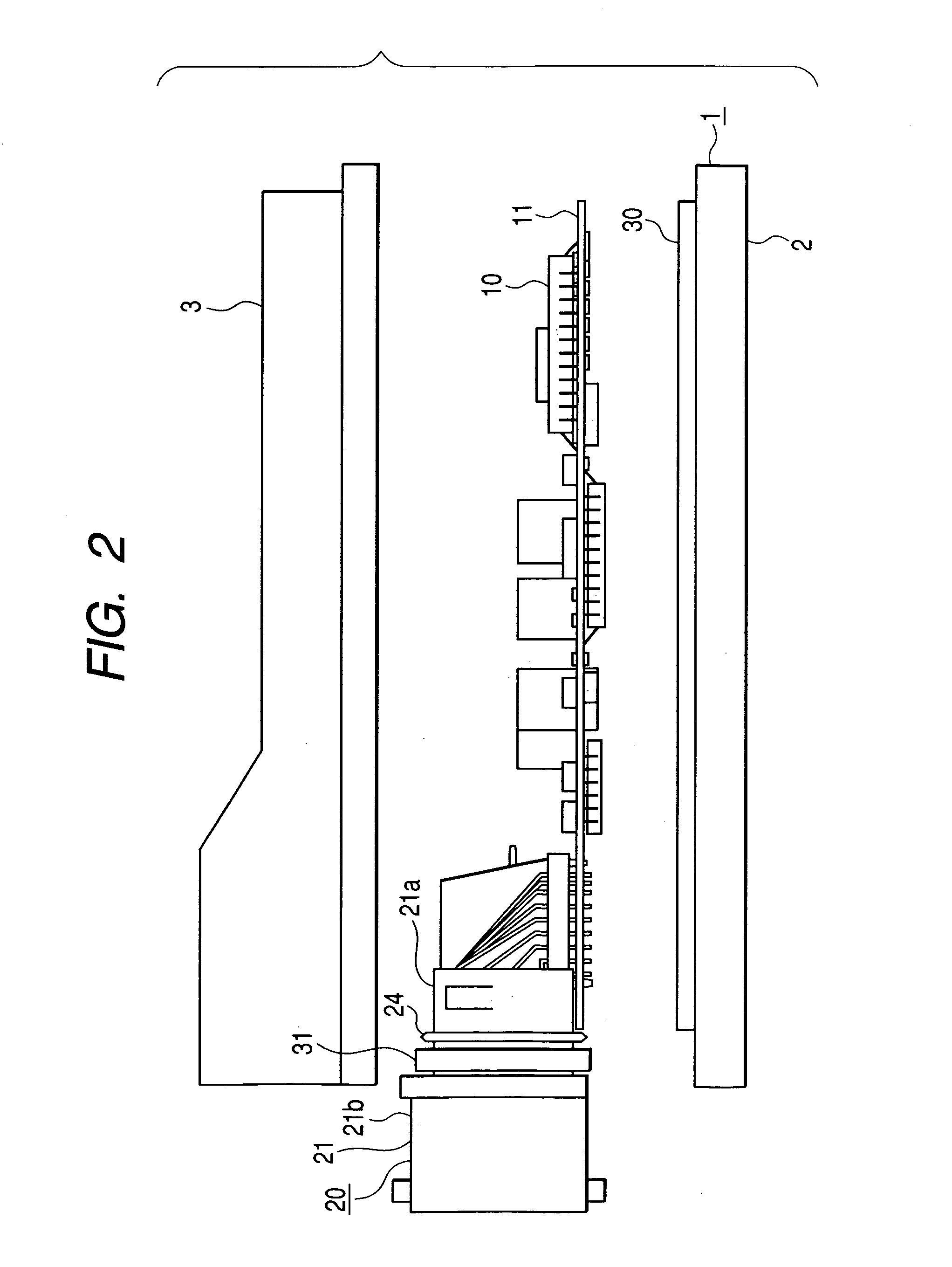

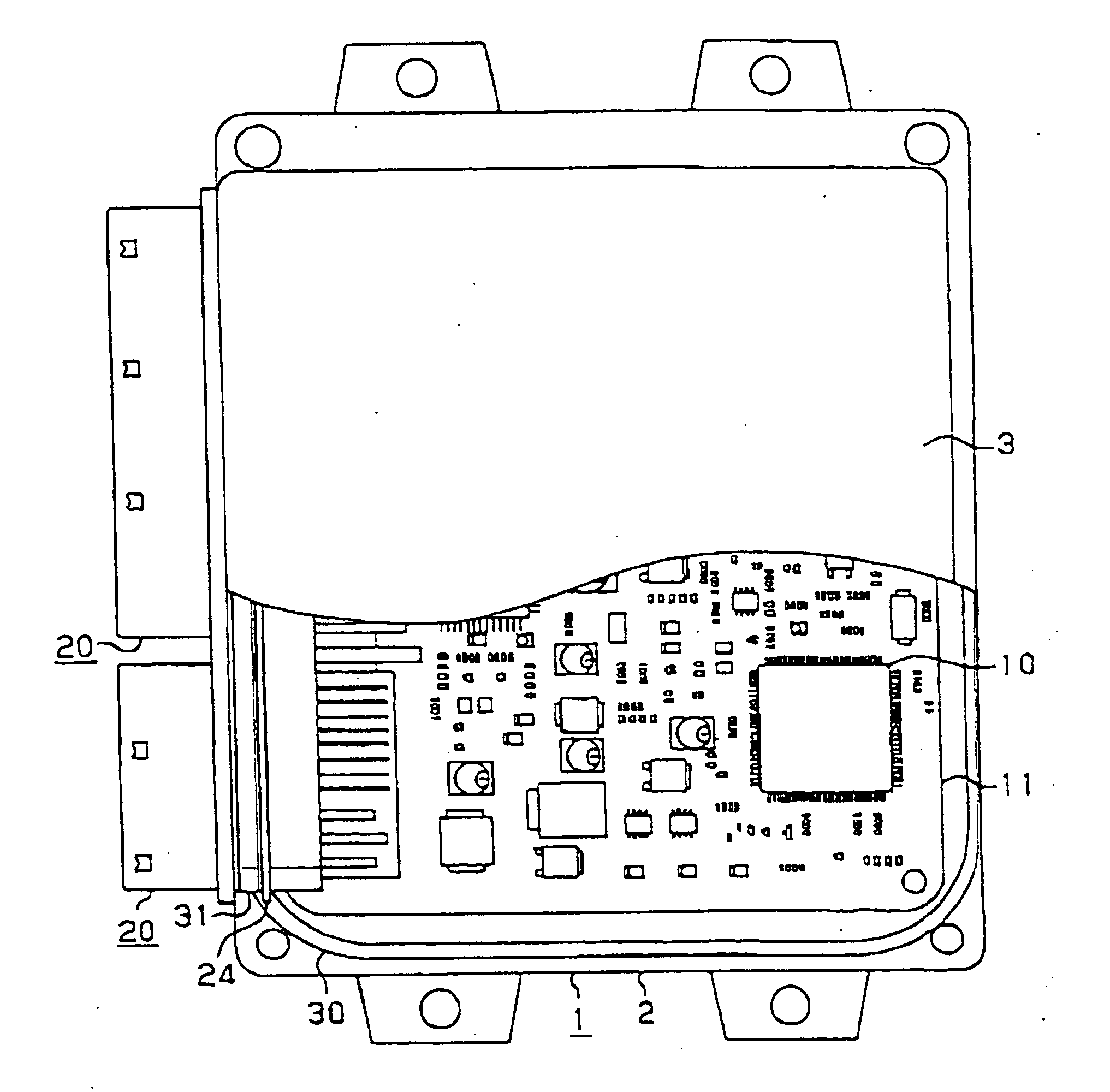

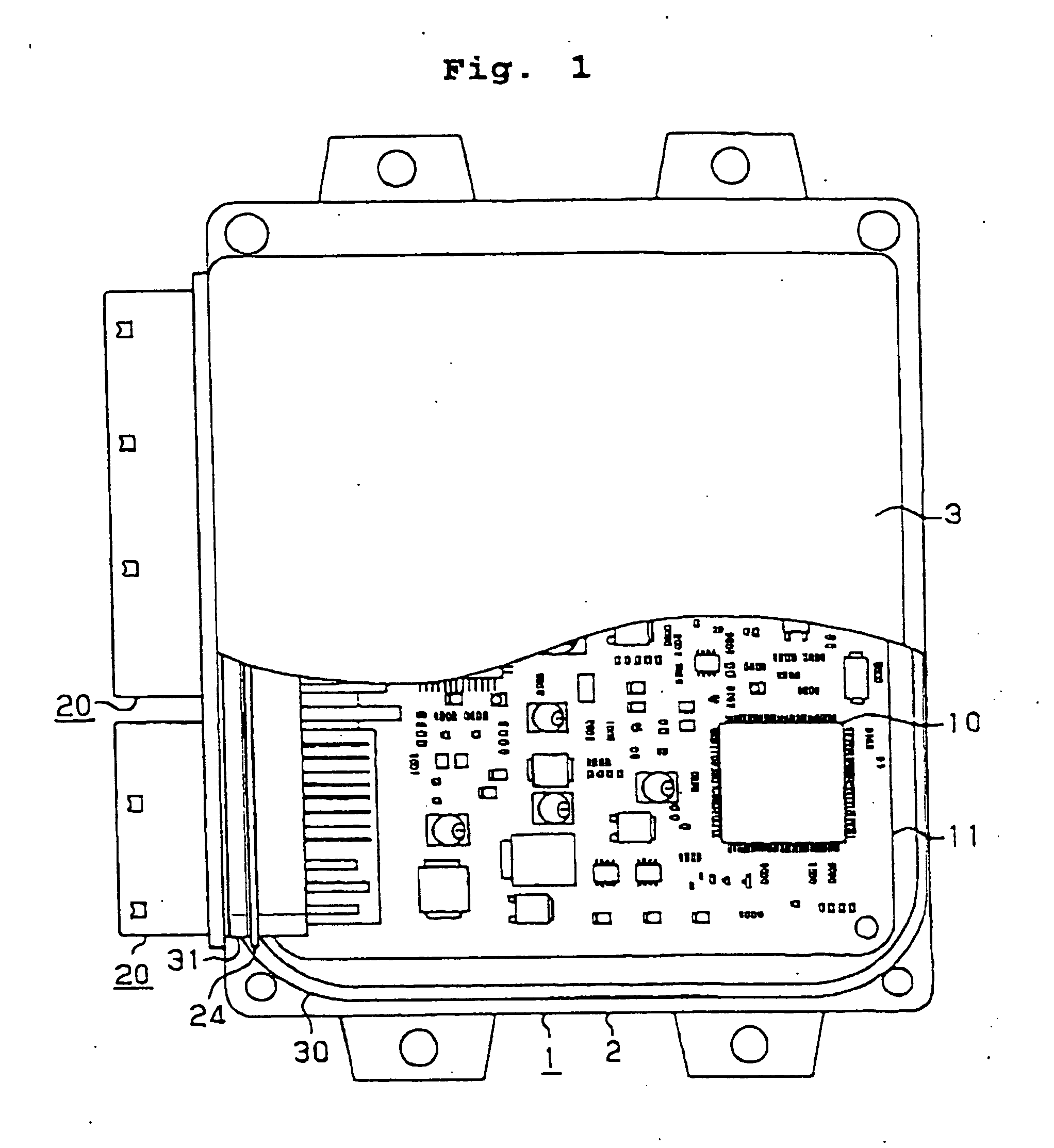

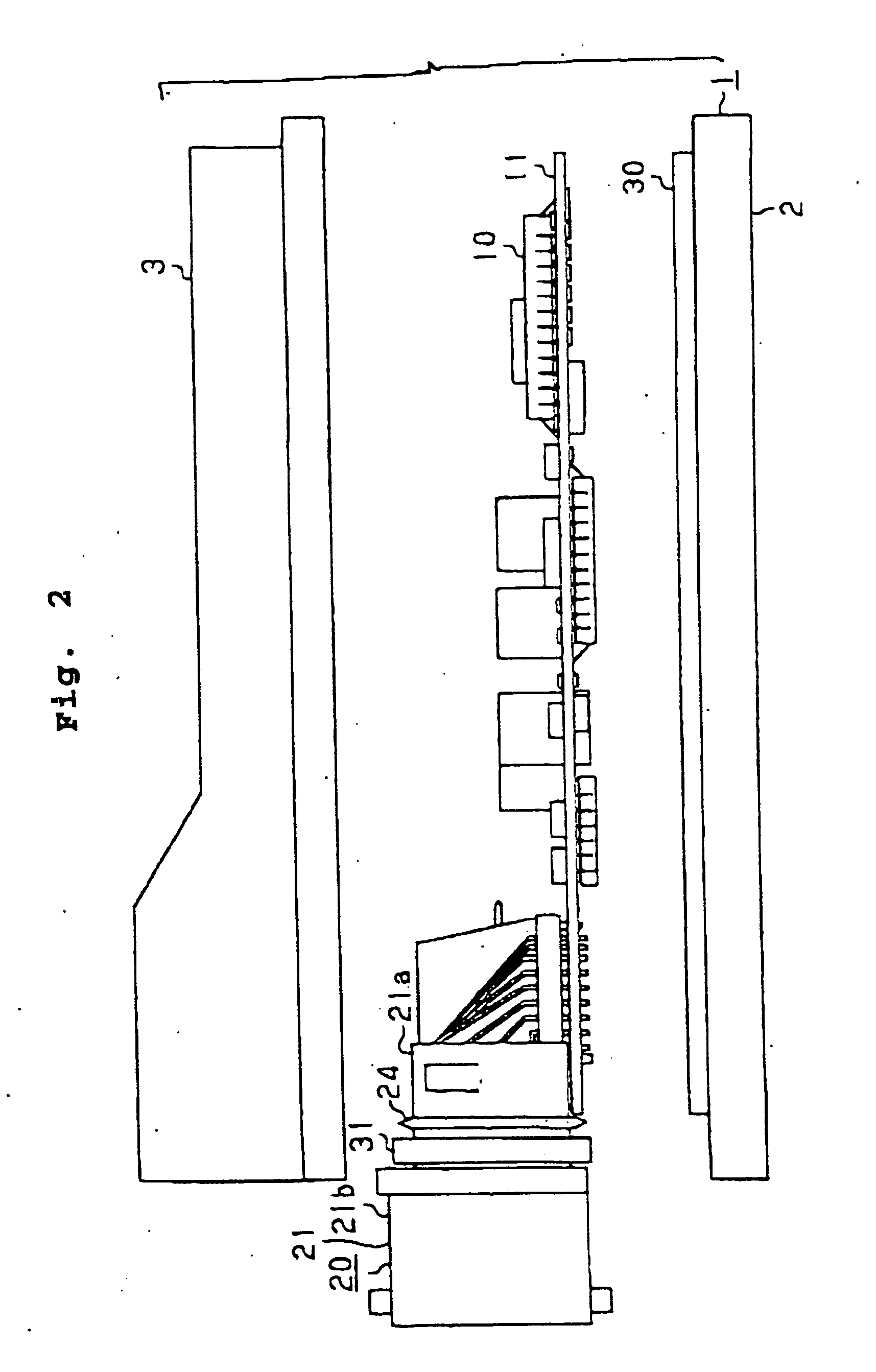

Water-resistant casing structure for electronic control device

ActiveUS7144275B2Minimize stressWater-resistant seal effectiveSecuring/insulating coupling contact membersPrinted circuitsElectronic componentWater resistant

Owner:DENSO CORP

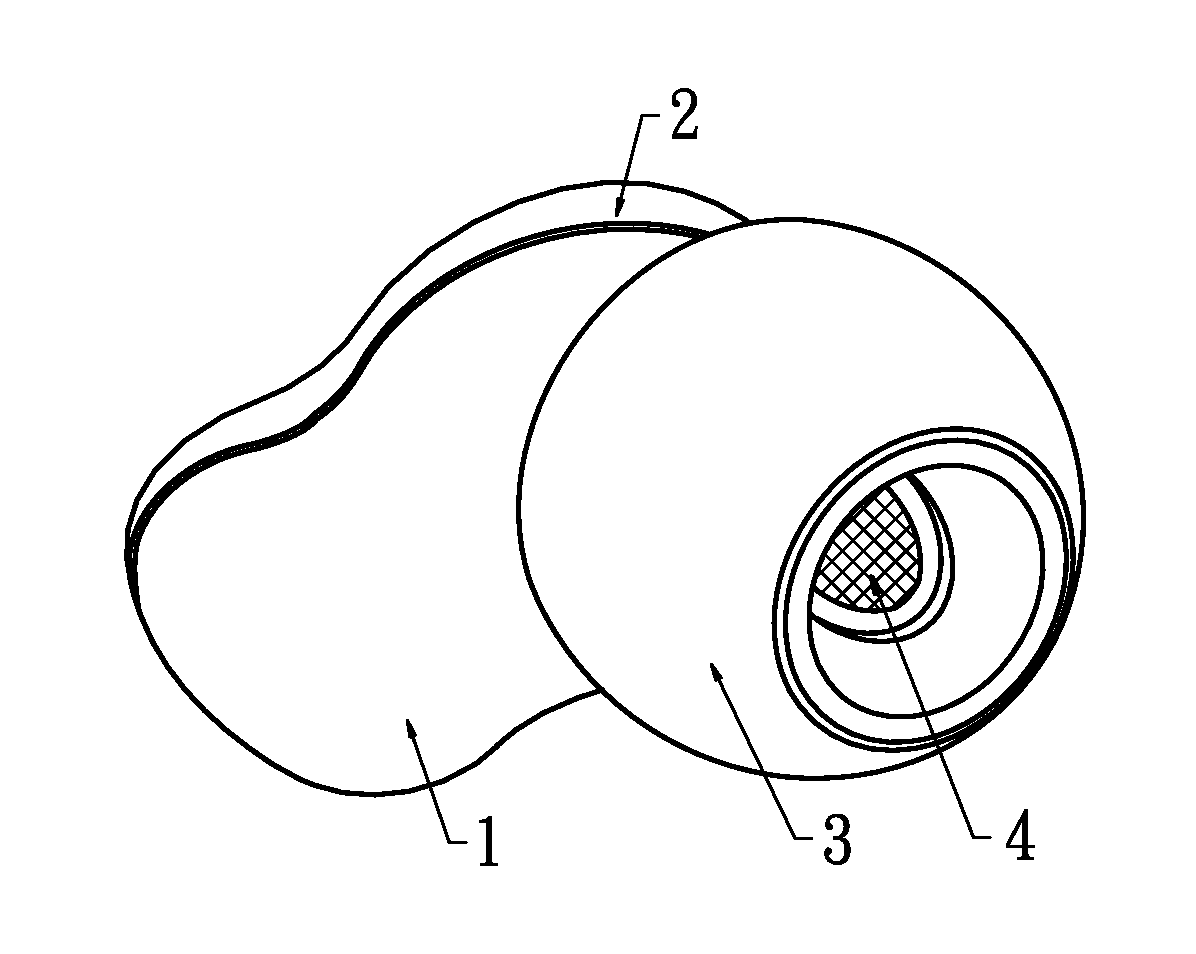

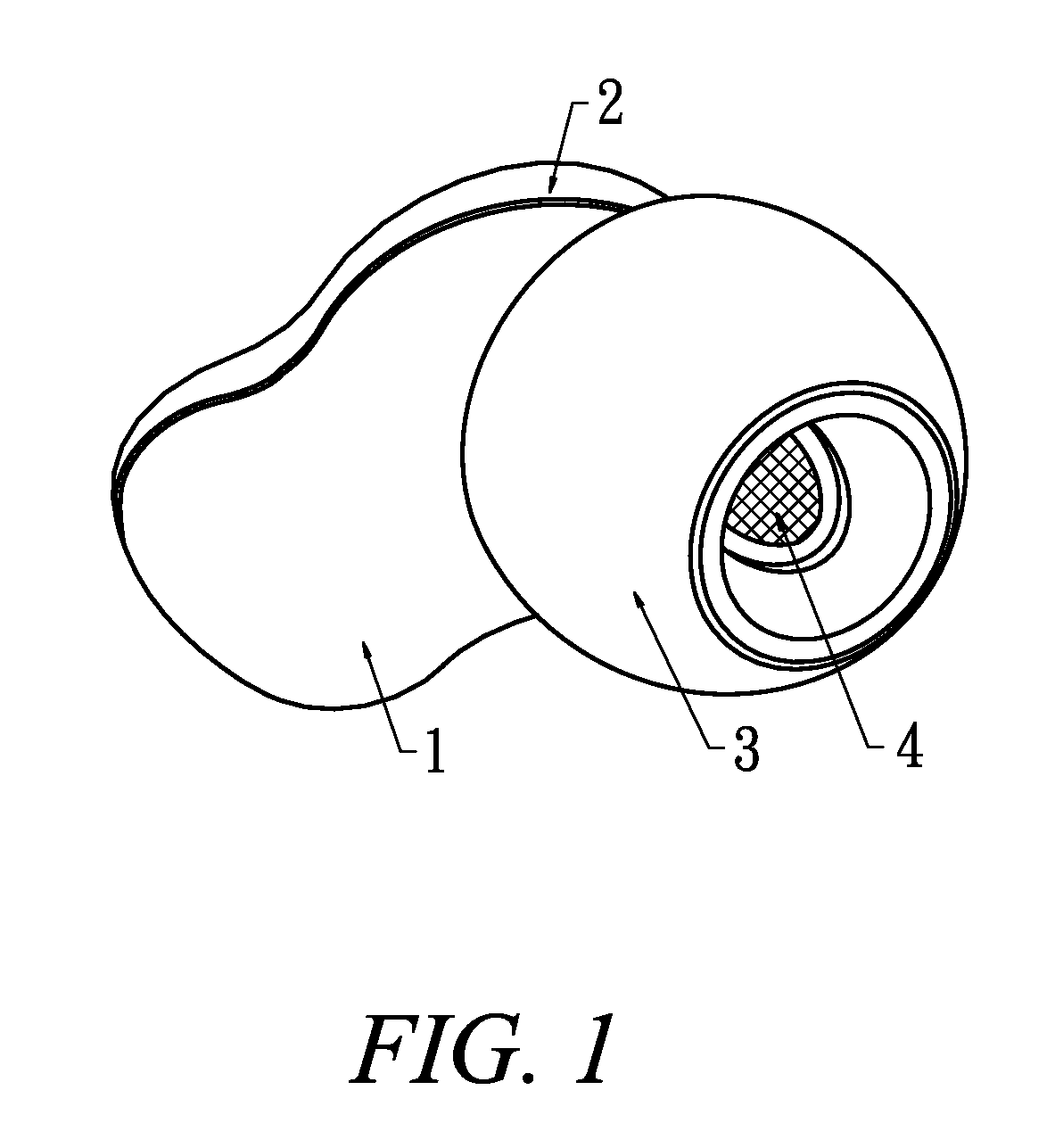

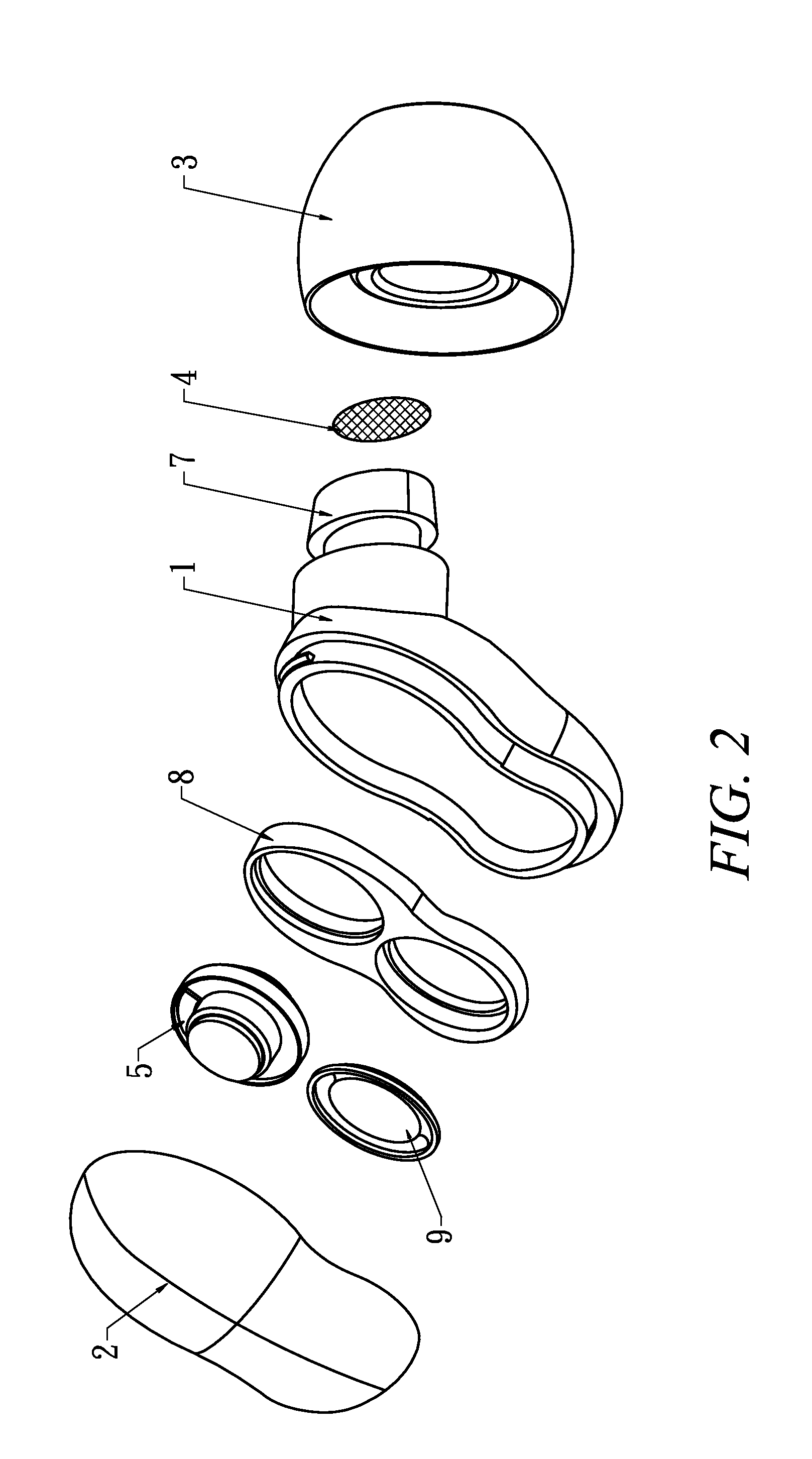

Negative pressure earphone

ActiveUS20130259286A1Negative pressure earphoneSimple structureIntra aural earpiecesTransducers for subaqueous useEngineeringHeadphones

A negative pressure earphone includes a main body, a cover portion, a silica gel earplug, a filtering net and a moving coil sound unit. The silica gel earplug is fitted to the protruding end of the main body. The filtering net is provided on the opening of the protruding end and the moving coil sound unit is disposed inside the main body. The cover portion is fitted to the other end of the main body. A sealing framework portion is disposed inside the main body and the moving coil sound unit is fitted to the sealing framework portion. A negative pressure portion is disposed on the sealing framework portion. The negative pressure earphone of the present invention is structurally simple and water resistant and does not have to have an opening in its cover portion.

Owner:EASTERN TECH HLDG

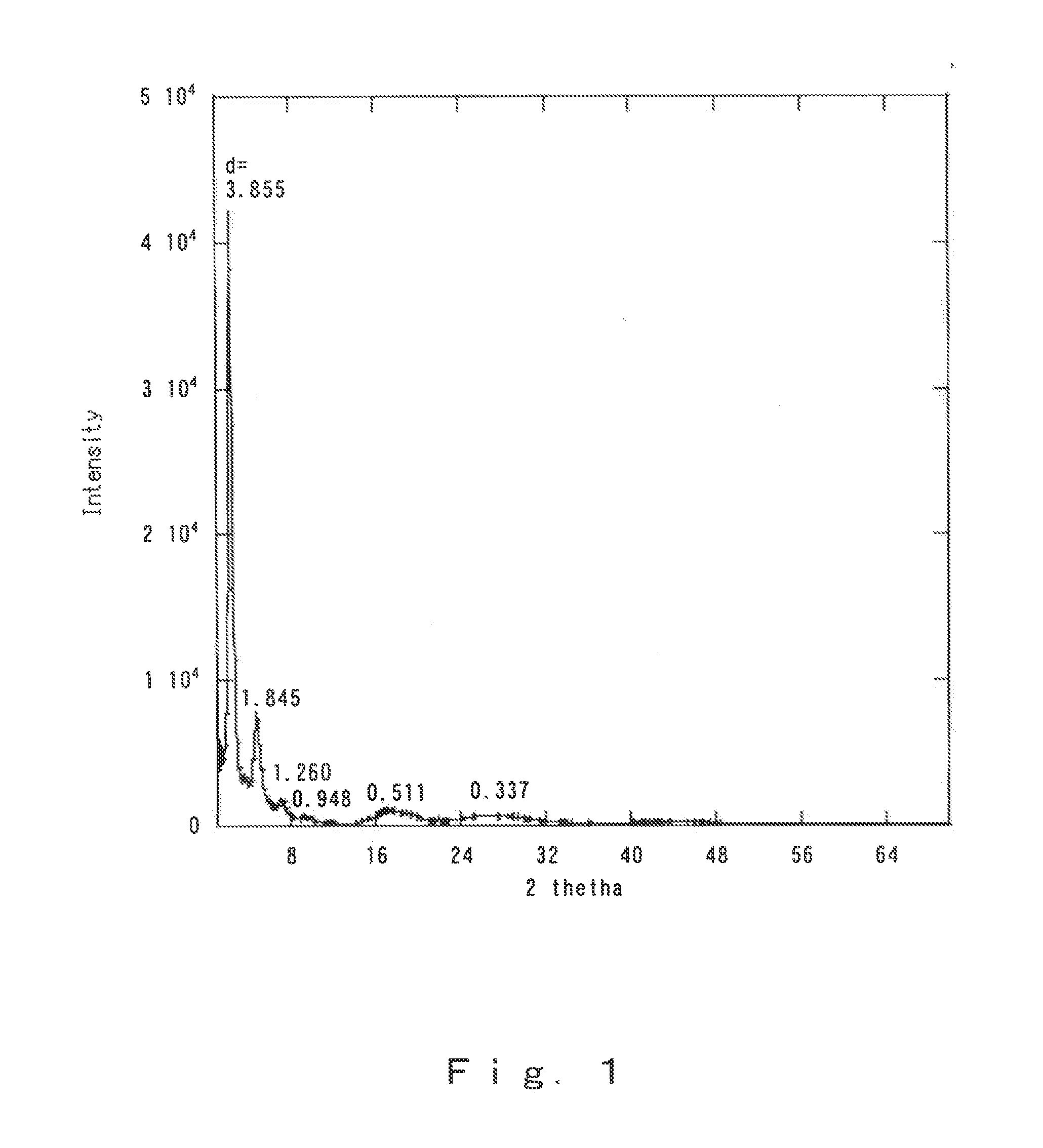

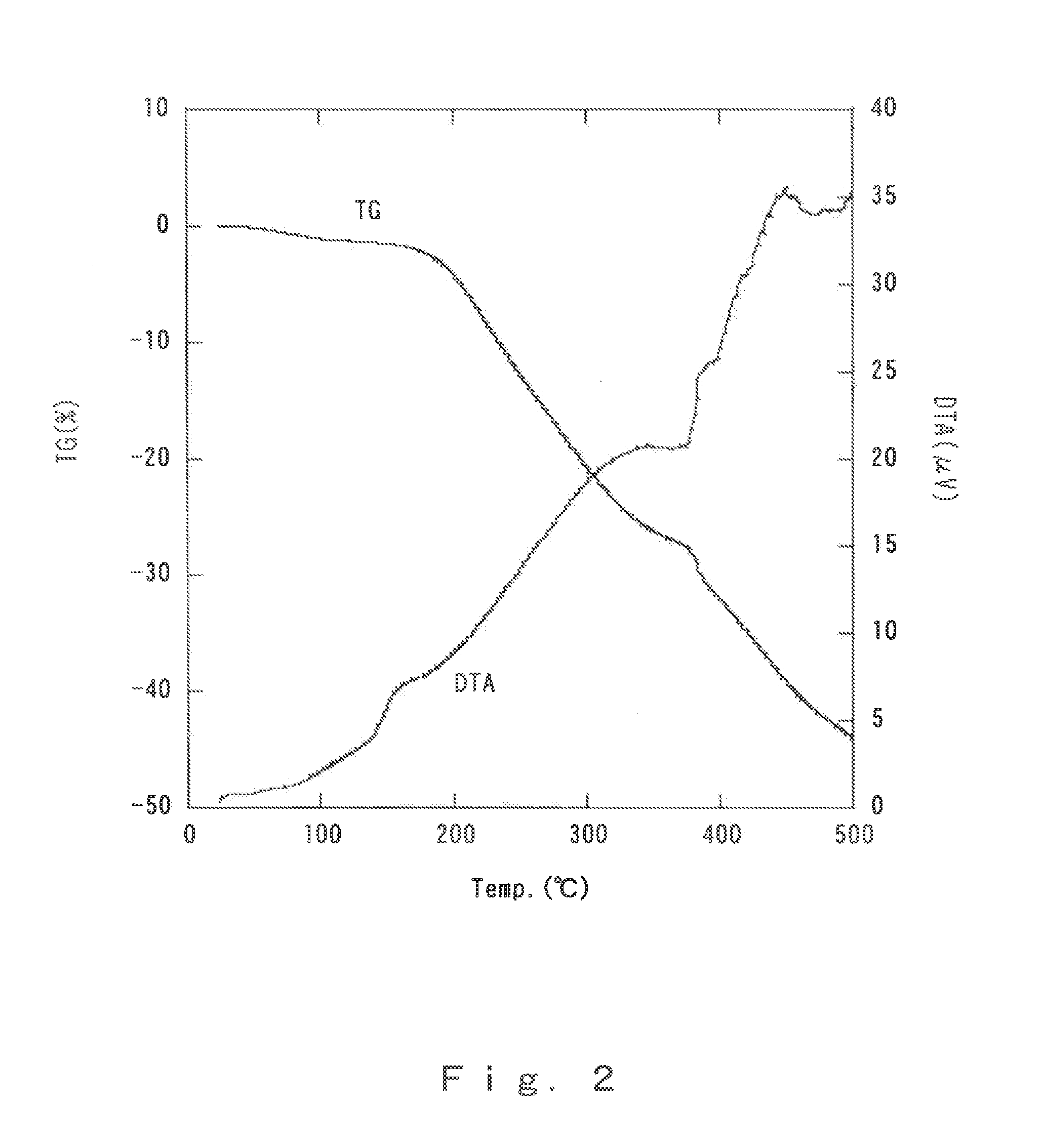

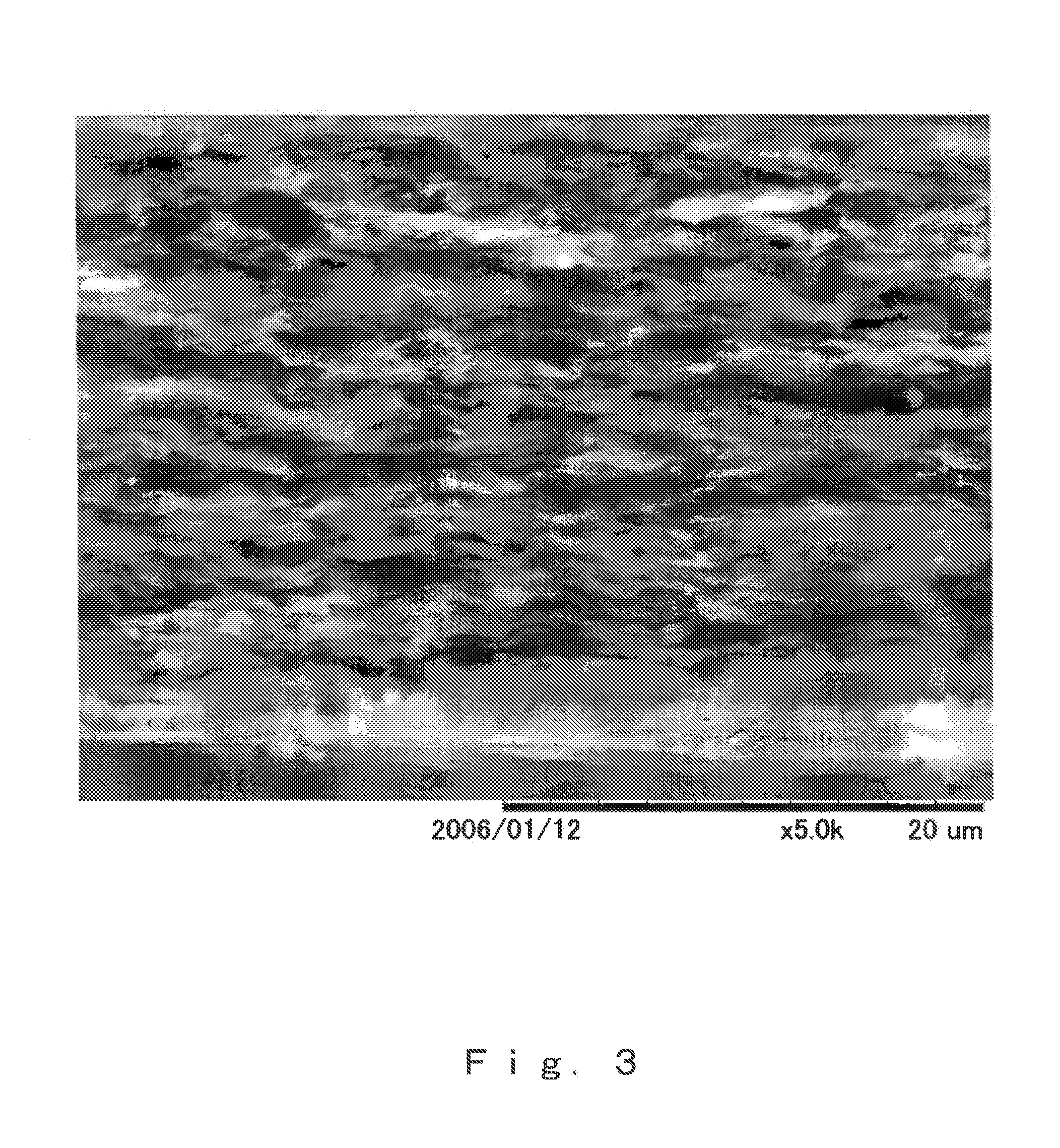

Film made from denatured clay

ActiveUS20090202806A1High mechanical strengthGood flexibilityAlkali metal silicate coatingsCellulose coatingsHeat resistanceWater vapor

The present invention provides a novel technology and a novel material having excellent pliability, gas barrier properties and water resistance, for the technical fields of packaging materials, sealing materials, electric insulating materials and the like, the present invention relates to a film of a material having a denatured clay as a main constituent thereof, wherein (1) the film comprises a denatured clay and an additive, (2) the weight ratio of the denatured clay is not less than 70% relative to total solids, (3) the film has gas barrier properties and water-vapor barrier properties, (4) the film has heat resistance, (5) the film has water resistance, (6) the film has sufficient mechanical strength to be used as a self-supporting film, and (7) the film can be formed on the surface of metals, plastics, rubber, paper and the like, and the present invention can provide a material comprising the denatured clay film in which denatured clay particles are highly oriented and which has excellent heat resistance, excellent pliability, excellent gas barrier properties, excellent water-vapor barrier properties, and high water resistance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Water-resistant casing structure for electronic control device

ActiveUS20060046535A1Stress minimizationGuaranteed uptimeSecuring/insulating coupling contact membersPrinted circuitsEngineeringElectronic component

Owner:DENSO CORP

Fire retardant composition

InactiveUS20100069488A1Improve flame retardant performanceEfficient and reasonably safe to manufactureFireproof paintsOrganic active ingredientsCross-linkActive agent

A composition can embrace a fire retardant can be combined with a fluoropolymer, which can be a coating, for example, a paint, especially a latex paint, or which can be an organic solvent based coating, for example, a paint. The fire retardant can be an ammonium phosphate containing fire retardant, which can be combined with a fluoropolymer, a penetrating barrier, borate-containing formulation having resistance to water damage with protective properties coming from materials used in food packaging and cosmetics, and / or a medium-to-long chain polar carboxyl substance to make a composition. Also, a composition can embrace a fire retardant formulation having a cross-linked component, which composition may be a coating, for example, a paint or stain, especially a latex paint. The cross-linked component may be a base of the paint or stain, say, a vinyl acetate base of the fire retardant latex paint. At least one other active agent, for example, a mold inhibitor and / or an insecticide, may be included. The composition can be used by contacting it with a substrate, which beneficially is otherwise flammable. The composition or its residue may be found in combination with the substrate.

Owner:NO BURN INVESTMENTS

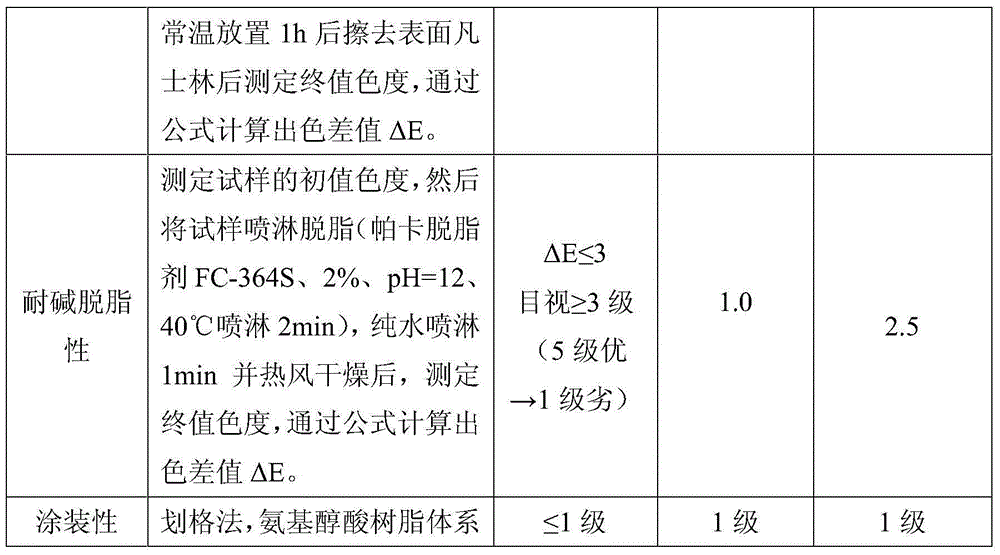

Water-based environment-friendly finishing paint and preparation method thereof

InactiveCN101712833AGood anti-corrosion decoration effectHigh hardnessEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based environment-friendly finishing paint, which is prepared from the following compositions in part by weight: 20 to 70 parts of water borne acrylic resin solution of which the solid content is 30 to 80 percent and / or 20 to 70 parts of water borne epoxy resin solution of which the solid content is 30 to 80 percent, 4 to 10 parts of water borne amino resin solution of which the solid content is 60 to 98 percent; 1 to 5 parts of organic amine, 0.2 to 2 parts of wetting and leveling agent, 0.2 to 2 parts of thickener, 0.1 to 0.8 part of defoaming agent, 1 to 5 parts of adhesion promoter, 0.2 to 5 parts of catalyst, 10 to 30 parts of alcohol diluting solvent and / or 1 to 5 parts of nontoxic ether diluting solvent, and 20 to 50 parts of deionized water, wherein the catalyst is one or more of ammonias, alcohols and benzenesulfonic acids. The water-based environment-friendly finishing paint has the advantages of wide applicable range, high hardness, good flexibility, strong adhesion, good scratchproof performance, and environmental protection. Simultaneously, the invention also discloses a method for preparing the water-based environment-friendly finishing paint.

Owner:重庆亢石新材料科技有限公司

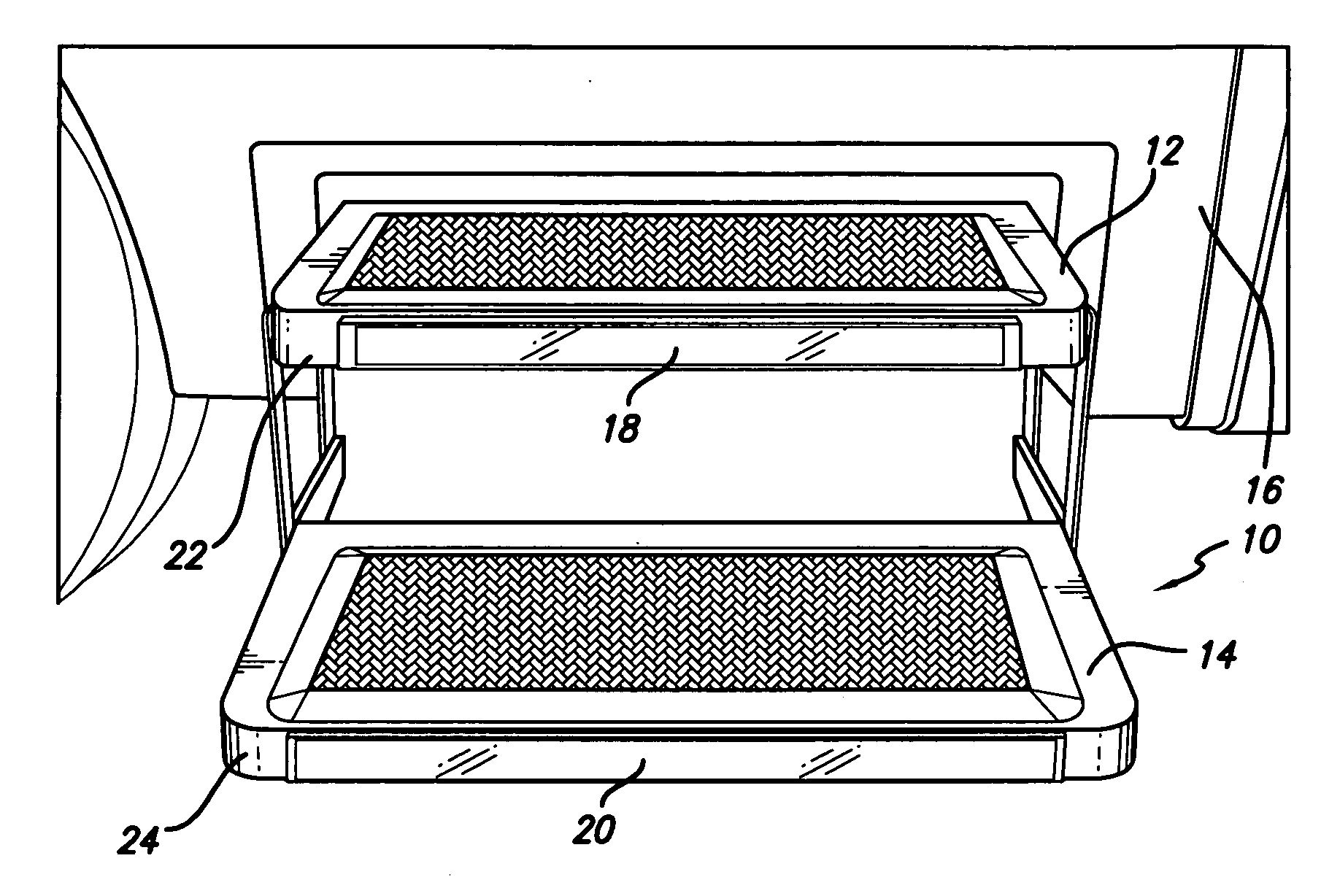

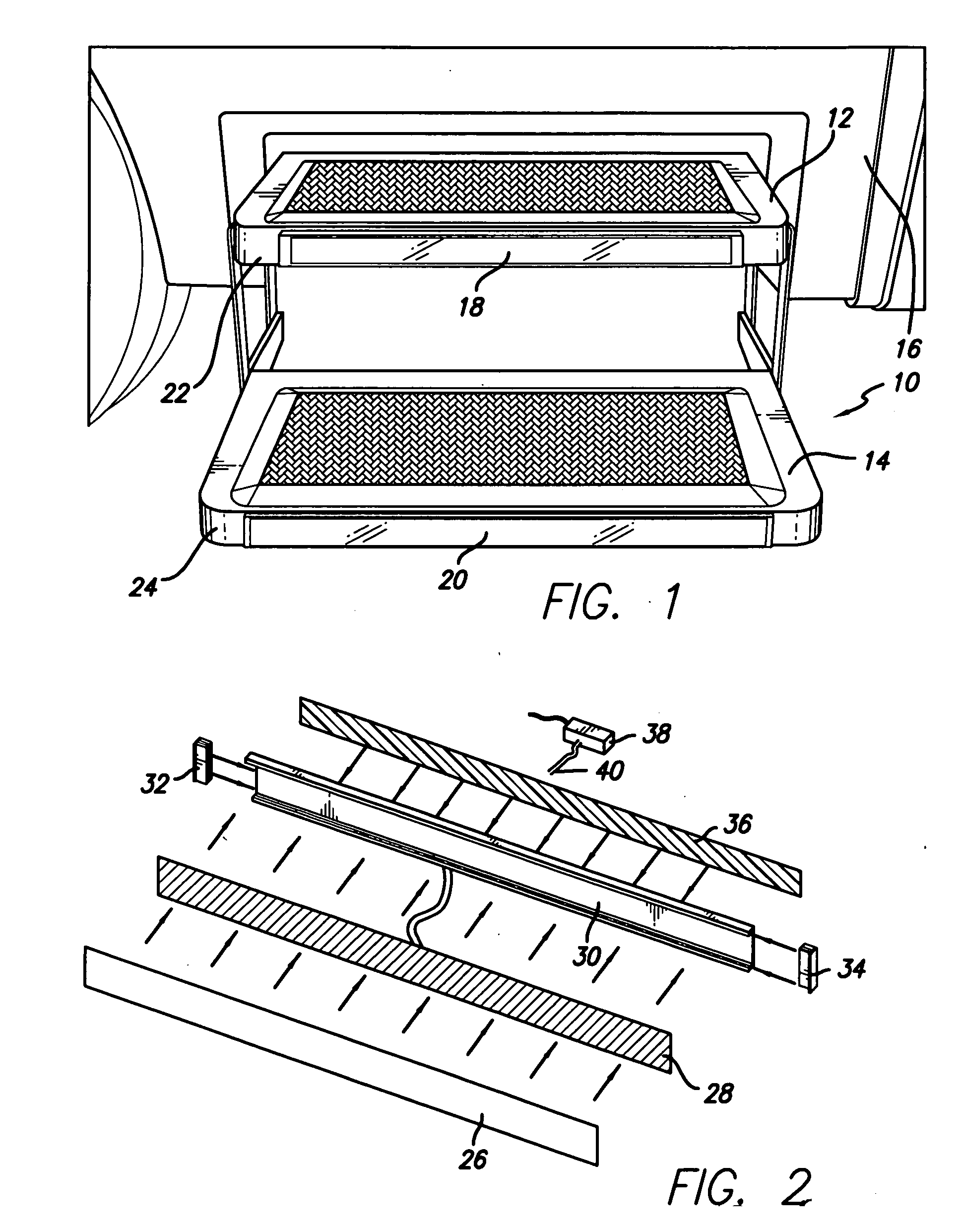

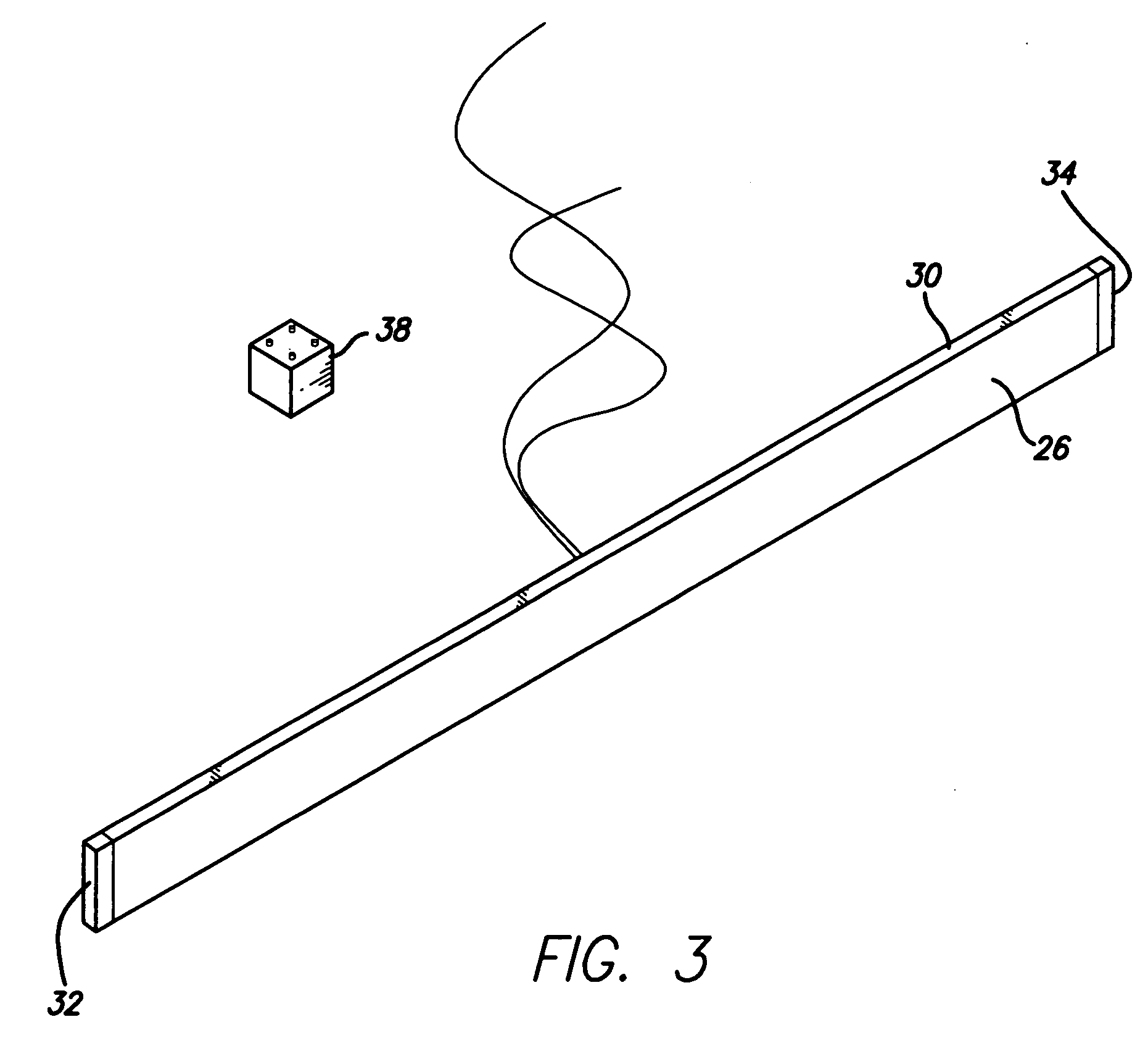

Step light

InactiveUS20070290475A1Water resistantLow profileOptical signallingSteps arrangementEngineeringElectroluminescence

Owner:CAMCO MFG

Corrosion-resisting wear-resisting powder coating for metal

The present invention provides a new type anti-corrosion wear-resisting coating material for metal. Said coating material is made of petroleum fermentation nylon-1212 as base material and adding epoxy resin, solidifying agent, wear-resisting agent, lubricating agent, leveling agent, chemical inhibitor, optical stabilizing agent and pigment. Said coating material has excellent elasticity and flexibility, and has the good water-proofing property, impact resistance and can raise service life of machines, so that it has extensive application.

Owner:ZHENGZHOU UNIV

Aqueous environment-friendly packaging steel drum paint and preparation method thereof

InactiveCN101735703AGood anti-corrosion decoration effectHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an aqueous environment-friendly packaging steel drum paint, which is prepared by mixing the following compositions in part by weight: 20 to 70 parts of aqueous solution of acrylic resin with a solid content of 30 to 80 percent and / or aqueous solution of epoxy resin with the solid content of 30 to 80 percent, 4 to 10 parts of aqueous solution of amino resin with the solid content of 60 to 98 percent, 1 to 5 parts of organic amine, 1 to 50 parts of filling materials with the granularity of more than 2,000 meshes, 0.5 to 10 parts of color paste, 0.2 to 2 parts of wetting levelling agent, 0.2 to 2 parts of thickening agent, 0.1 to 0.8 part of antifoaming agent, 1 to 5 parts of adhesive force accelerant, 0.2 to 5 parts of catalyst, 0 to 30 parts of alcohol diluting solvent and / or 0 to 5 parts of non-toxic ether diluting solvent, and 20 to 50 parts of deionized water. The aqueous environment-friendly packaging steel drum paint has the advantages of wide application range, high rigidity, good flexibility, strong adhesive force and good anti-scraping and anti-collision properties and environmental protection; and meanwhile, the invention discloses a preparation method for the aqueous environment-friendly packaging steel drum paint.

Owner:重庆亢石新材料科技有限公司

Water-based transparent anticorrosive paint, preparation method and application method thereof

InactiveCN101899256AKeep the appearanceWater resistantAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based transparent anticorrosive paint, a preparation method and an application method thereof. The preparation method thereof comprises the following steps: firstly, utilizing an emulsifier to emulsify epoxy resin into an epoxy resin micro-fine emulsion; then adding various auxiliaries, rust-proofing pigments and water, and utilizing a high-speed disperser to evenly disperse the mixture; and finally grinding the dispersed mixture into the water-based transparent anticorrosive paint with the fineness less than 30 mu m by utilizing a sand mill. The application method thereof comprises: adding a water-based epoxy hardener into the water-based transparent anticorrosive paint in the mass ratio of 2:1. The water-based transparent anticorrosive paint is matched with the water-based epoxy hardener for use; and after being covered on ferrous metal, being subjected to chemical reaction and being crosslinked to form a film, the water-based transparent anticorrosive paint has strong adhesive force, good rust prevention, water resistance, oil resistance and other performances, and can maintain the primary color of metal.

Owner:资阳赛特化工有限公司

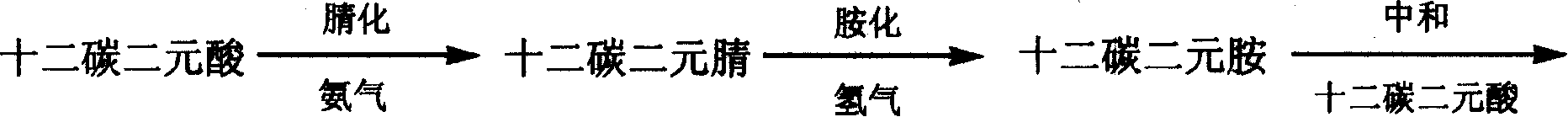

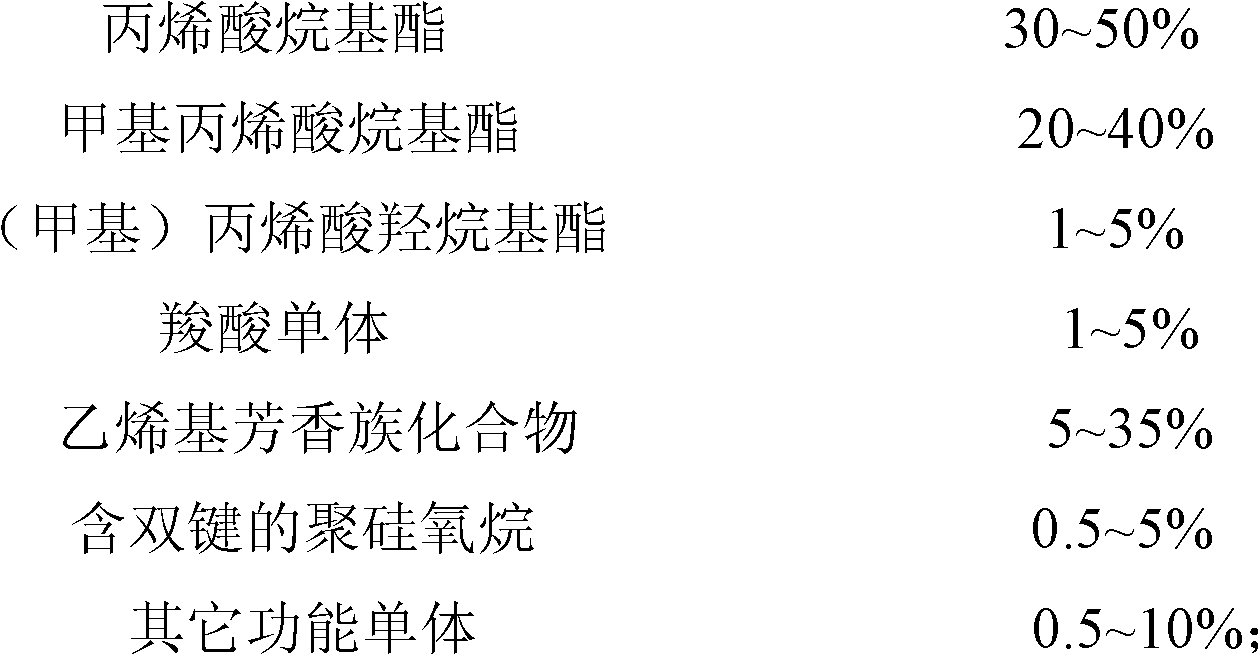

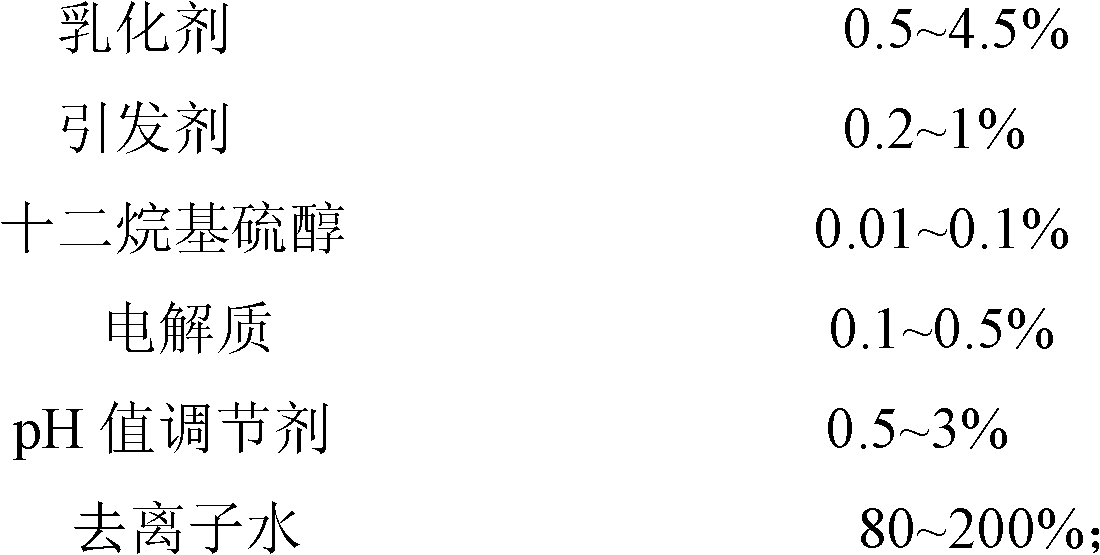

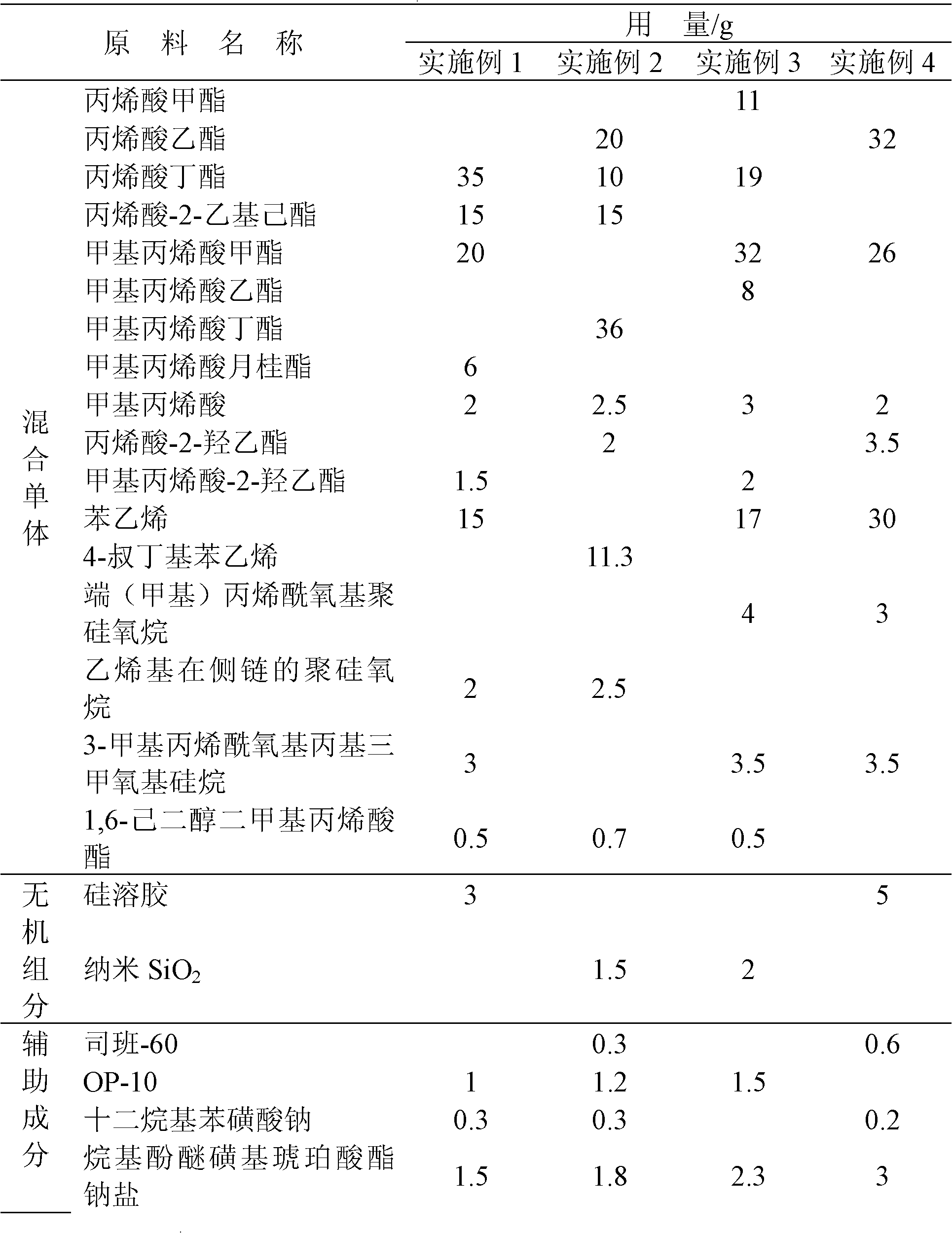

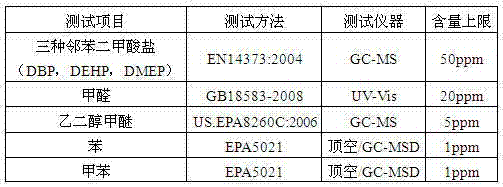

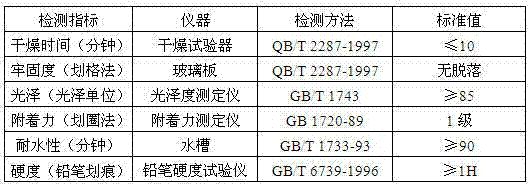

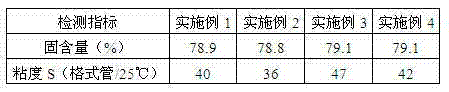

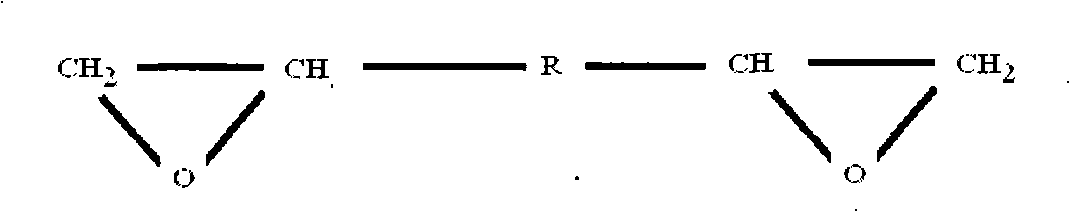

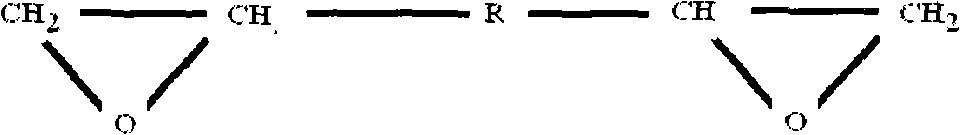

Self-layering organic-inorganic nano composite emulsion and method for preparing same

The invention relates to self-layering organic-inorganic nano composite emulsion and a method for preparing the same. The emulsion is made of mixed monomers, inorganic components and auxiliary components. The self-layering organic-inorganic nano composite emulsion is obtained by generating (or precipitating) organic nano particles inside (or on the surface) of latex particles in situ while introducing double-bond polysiloxane, and the emulsion is high in solid content, low in viscosity and high in storage stability. Due to differences of surface energy and compatibility (solubility parameters) between polysiloxane and other components in filming of emulsion, the polysiloxane molecules migrate to be enriched to a coating surface to form a self-layering structure.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Non-methanal environment-friendly type plant protein modified adhesion agent

InactiveCN101319131AMeet emission testing standardsSolve the hazardProtein adhesivesGlue/gelatin preparationFiberRapeseed

The invention relates to a formaldehyde-free environment-friendly vegetable protein modified adhesive, which aims to solve the problem that the prior urea-formaldehyde adhesive, phenolic aldehyde adhesive and melamine aldehyde adhesive release formaldehyde and cause environmental hazard and pollution, etc. The compositions in portion by weight of the modified adhesive are: 30 to 50 portions of natural plant dregs, 5 to 12 portions of basic material, 5 to 10 portions of calcium hydroxide emulsion, 6 to 15 portions of urea, 4 to 10 portions of alkyl sodium sulfate, 2 to 5 portions of 10 to 20 percent of inorganic acid and 90 to 120 portions of deionized water. The invention takes macromolecular proteins in natural plant soybean dregs, peanut dregs, rapeseed dregs, cottonseed dregs, linseed dregs and sunflower seed dregs as raw materials so as to synthesize a new-generation formaldehyde-free environment-friendly vegetable protein modified adhesive through chemical modification. The formaldehyde-free environment-friendly vegetable protein modified adhesive has the characteristics of uniform and stable product, high adhesion strength, hydrolysis resistance and nontoxicity, etc.; moreover, the performance and the price of the modified adhesive are suitable for wood adhesion and for making artificial fiber boards such as plywood, shaving board and fiber board.

Owner:上海世鹏聚氨酯科技发展有限公司

White finishing mortar composition

The invention provides a white surface mortar compound which comprises the following components of parts by weight: 400 to 600pbw of white cement, 50 to 100pbw of semi-water gypsum, 50 to 100pbw of calcium hydroxide, 200 to 400pbw of modified fiber light calcium, 30 to 50pbw of latex powder which can be dispersed again, 2 to 4pbw of cellulose ether, 1 to 3pbw calcium chloride, 1 to 3pbw of calcium formate, 1 to 3pbw of aluminum potassium sulfate, 1 to 5pbw of polypropylene fiber and 250pbw of water. The surface mortar compound of the invention can be hydrated with cement and other components to form fine, dense and good finish surface to be applied for painting a wall body with different color surfaces, and the cost is reduced while the construction efficiency is enhanced. The compound is particularly applicable to an insulation system of the external wall of a civil building and an office building, which is economic and can be used as the surface mortar and internal dope of other wall bodies.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Lightweight ceramic material and process for manufacturing same

The present invention is one kind of light ceramic material and its production process, and belongs to building material technology. The ceramic material is produced with waste slag from polishing ceramic product, ceramic clay, high temperature sand and low temperature sand and through material compounding, crushing, forming, drying, sintering in kiln and packing. The produced ceramic material has the features of light weight, high strength, heat insulation, sound insulation, fireproofing, waterproofing and long service life. The present invention raises the utilization of ceramic raw material, reduces environmental pollution, and the produced ceramic material may be used in decorating outer and inner walls of building, as tunnel sound insulating material, house ceiling decoration, etc.

Owner:聂曼云

High comprehensive performance composite grinding piece and manufacturing method thereof

ActiveCN105500225AImprove polishing efficiencyReduce internal stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWeather resistanceCerium

The invention discloses a high comprehensive performance composite grinding piece which comprises a base material, grinding particles and an adhesion agent, wherein the surface of the base material is divided into a plurality of areas; the grinding particles attached to the identical areas have identical sizes; the grinding particles attached to the different areas have different sizes; the sizes of the grinding particles attached to the various areas of the base material increase gradually from the center of the base material to the edge of the base material; the grinding particles are composite grinding particles formed by compositing nano cerium dioxide particles and silicon dioxide particles; and the adhesion agent consists of a component A and a component B. The invention also provides a manufacturing method of the high comprehensive performance composite grinding piece. The manufacturing method comprises the following steps of a gluing procedure, a sand planting procedure, a post curing procedure, a flexing water carrying procedure, a laser cutting procedure, a base material deformation prevention treatment procedure and a storage procedure. The manufacturing method is simple and convenient, and is low in manufacturing cost, and the manufactured composite grinding piece has weather resistance, fatigue resistance, high temperature resistance and abrasion resistance, and is long in service life and high in polishing efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

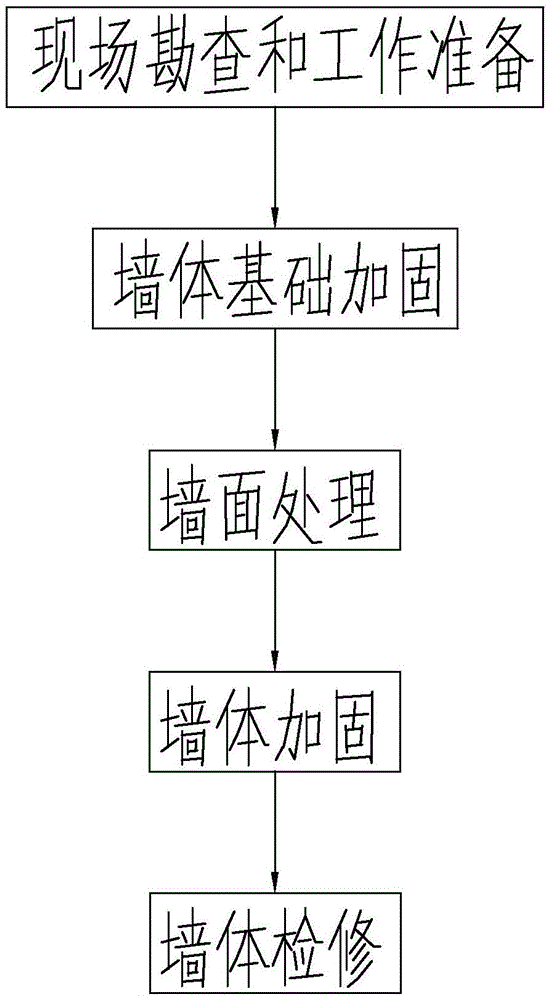

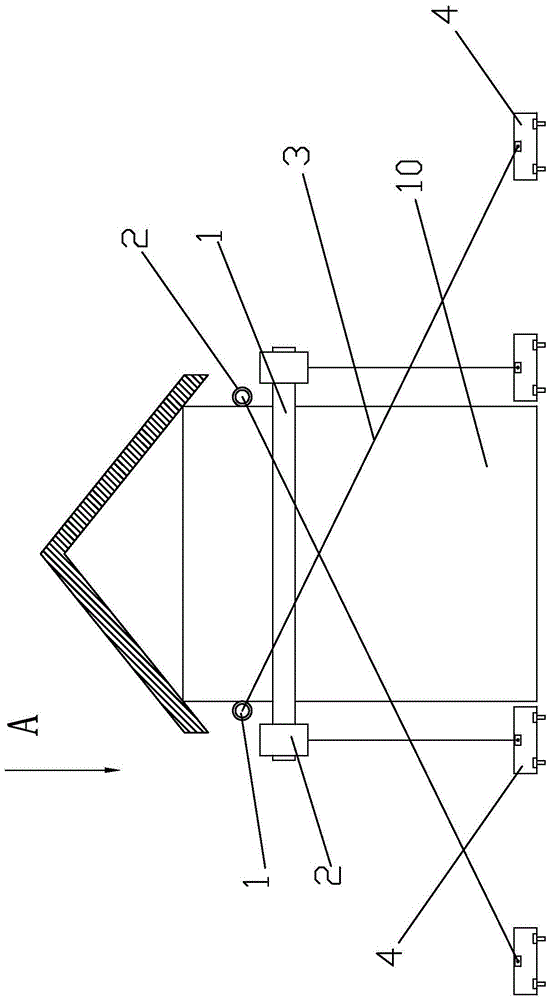

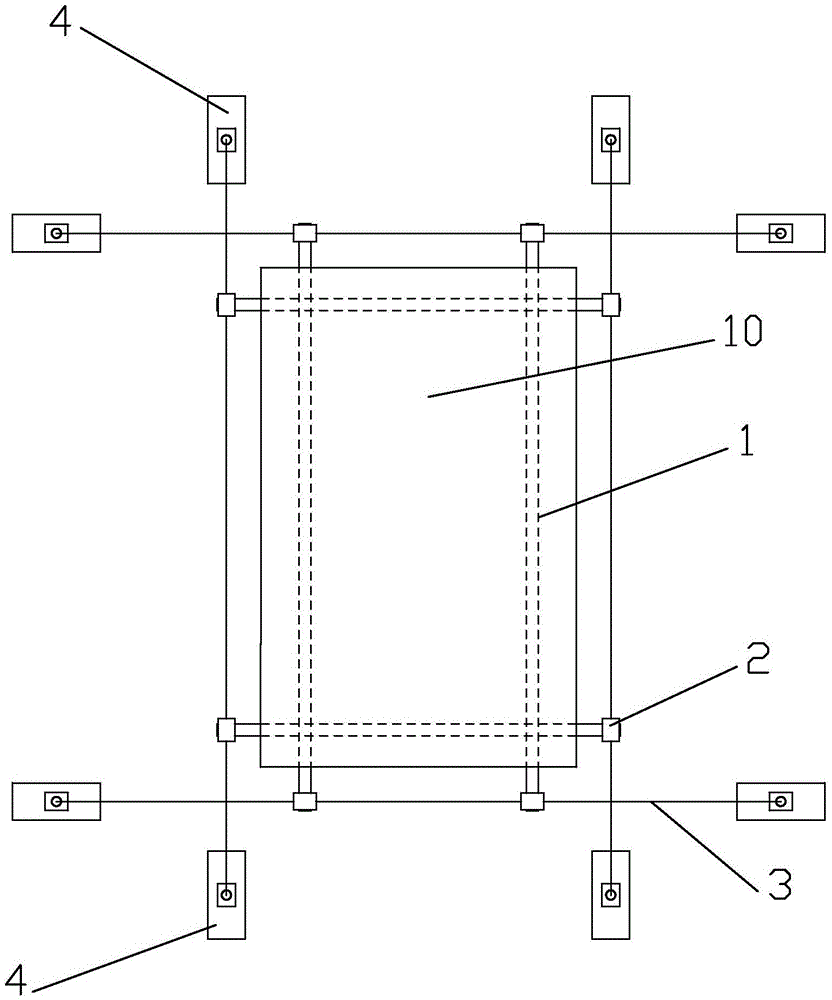

Construction method for reinforcing and repairing integral wall of ancient architecture

InactiveCN105604343ASimple construction methodEasy to implementBuilding repairsBearing capacityBuilding construction

The invention discloses a construction method for reinforcing and repairing an integral wall of ancient architecture. The construction method comprises the steps of site survey and work preparation, wall foundation reinforcement, wall surface treatment, wall reinforcement and wall maintenance. The construction method is simple and easy to implement, scientific and convenient, and has the advantages of fast construction progress, low construction cost, high working efficiency and wide application range. According to the principle of 'repairing the old as the old', the cultural relic value of ancient architectural elements is kept, only damaged parts are repaired and reinforced, and the whole wall does not need to be replaced. The ancient architecture wall is priceless in cultural relic value. By using the method, original parts can be kept when the ancient architecture wall is damaged and loses bearing capacity, and a bearing function is recovered; the method conforms to the principle of 'repairing the old as the old', and is of great significance to the protection of the national cultural relics.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

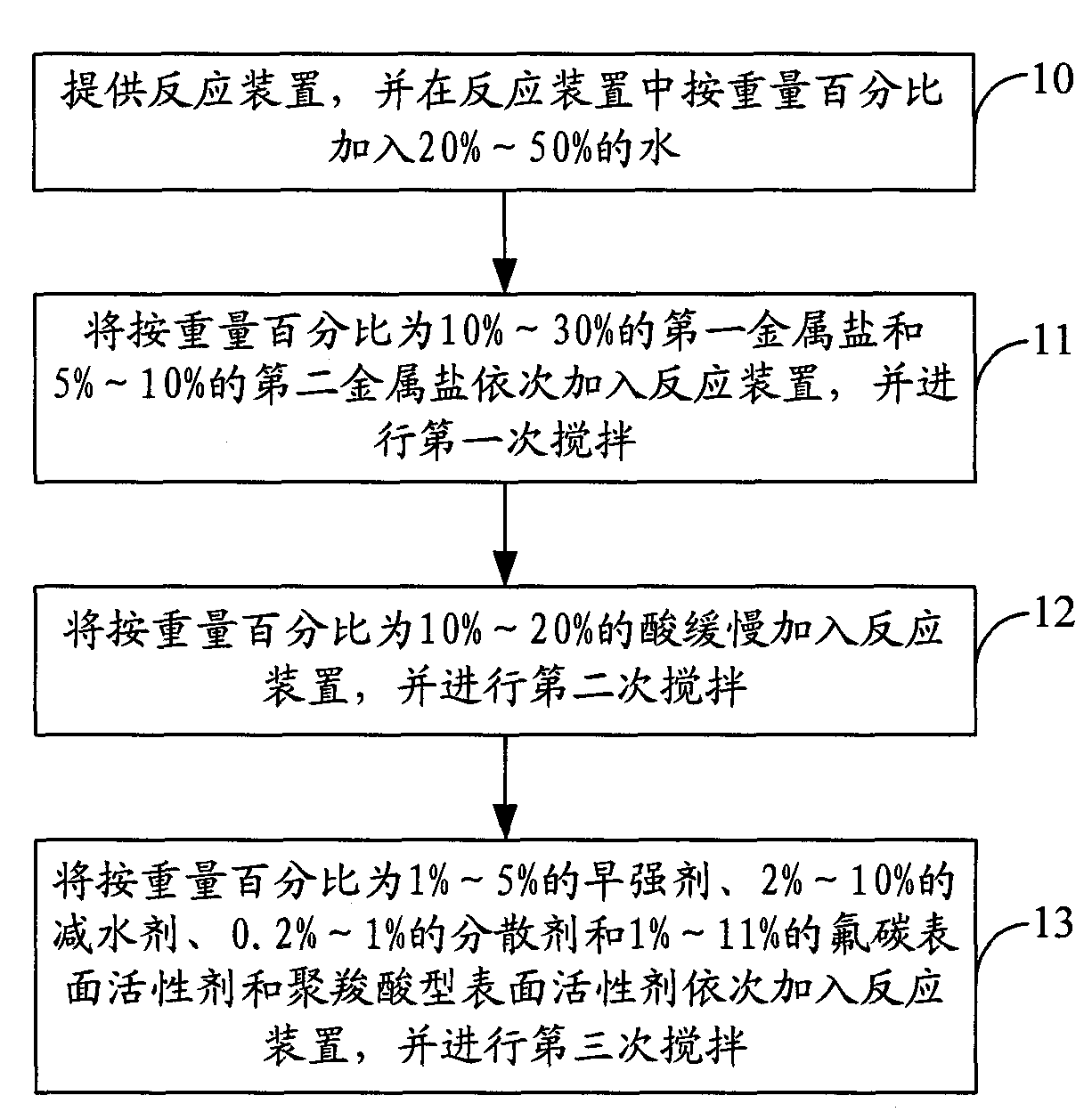

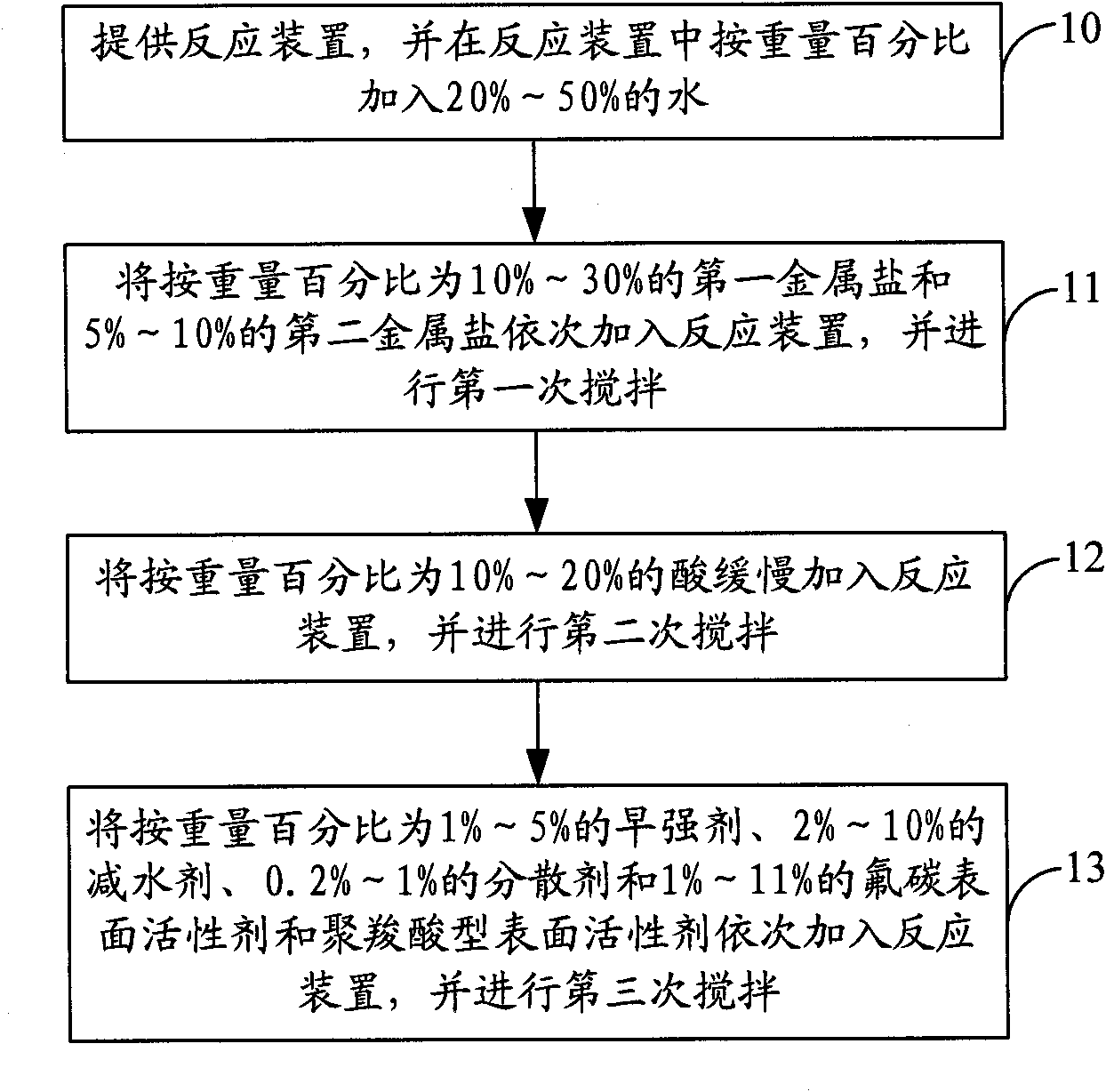

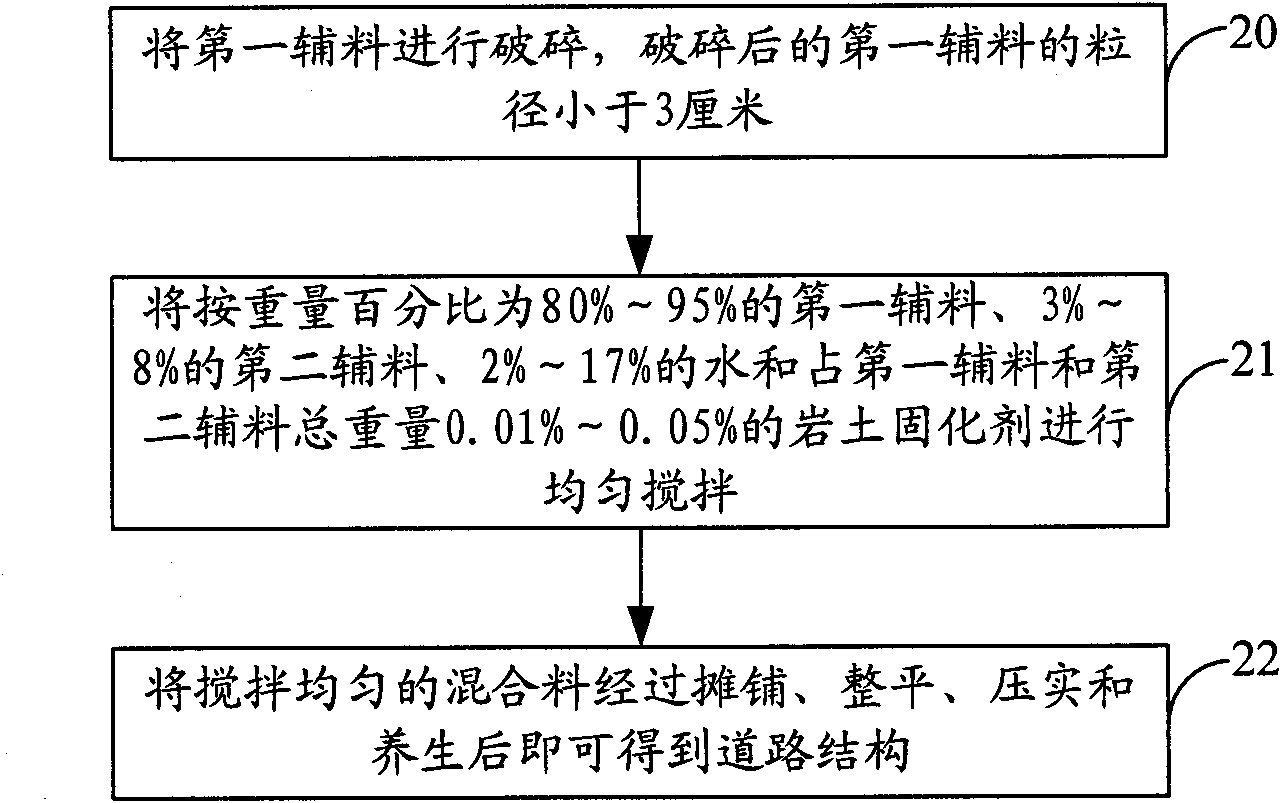

Soil and rock curing agent and manufacturing method thereof and road structure and manufacturing method thereof

InactiveCN101812300AReduced strength requirementsMeet strength requirementsIn situ pavingsRoads maintainenceWater resourcesCompressive strength

The invention relates to a soil and rock curing agent and a manufacturing method thereof and a road structure and a manufacturing method thereof. The soil and rock curing agent comprises a first metal salt, a second metal salt, water, acid, an early strength agent, a water reducing agent, a dispering agent, a fluorocarbon surfactant and a polycarboxylate surfactant. Widely distributed soil, decayed rock, building rubbish and tailing resource are main materials and the soil and rock curing agent is added, thereby being capable of reducing road cost; road roadbed, airport foundation, port foundation and water resource facilities built with the soil and rock curing agent have the advantages of short curing period, water resistance, cold resistance and hairline crack prevention, thereby improving compression strength and bending strength and greatly reducing construction cost.

Owner:田文利

Preparation of Foam Concrete by a Chemical Foaming Method

The invention discloses a chemical foaming method for preparing foamed concrete, which belongs to the technical field of building thermal insulation materials. The raw material composition and weight percentage of foam concrete are: cement 20-80wt%, ore powder 1-5wt%, fly ash 5-30wt%, foaming agent 1-6wt%, water 10-70wt%, modifier 0.2- 1.5wt%, fiber 0.2-1wt%, auxiliary material 1-8wt%. Its preparation method is to pour water into the container first, then put a certain amount of cement, ore powder, fly ash, and additives into the water, stir evenly with a stirrer, pour in foaming agent to mix and stir, and then quickly transfer After leaving the mixer, the foaming is completed within 30 minutes, and the strength is reached after 24 hours, and the formed foam concrete is obtained after 28 days of curing. The foamed concrete obtained by the invention has good water resistance, low thermal conductivity, low dry density, high strength, strong durability, simple formula and convenient construction; it can partially replace polystyrene board, extruded plastic board and rubber powder in the external wall insulation system Polystyrene particles and other organic insulation materials.

Owner:北京翰高兄弟科技发展有限公司

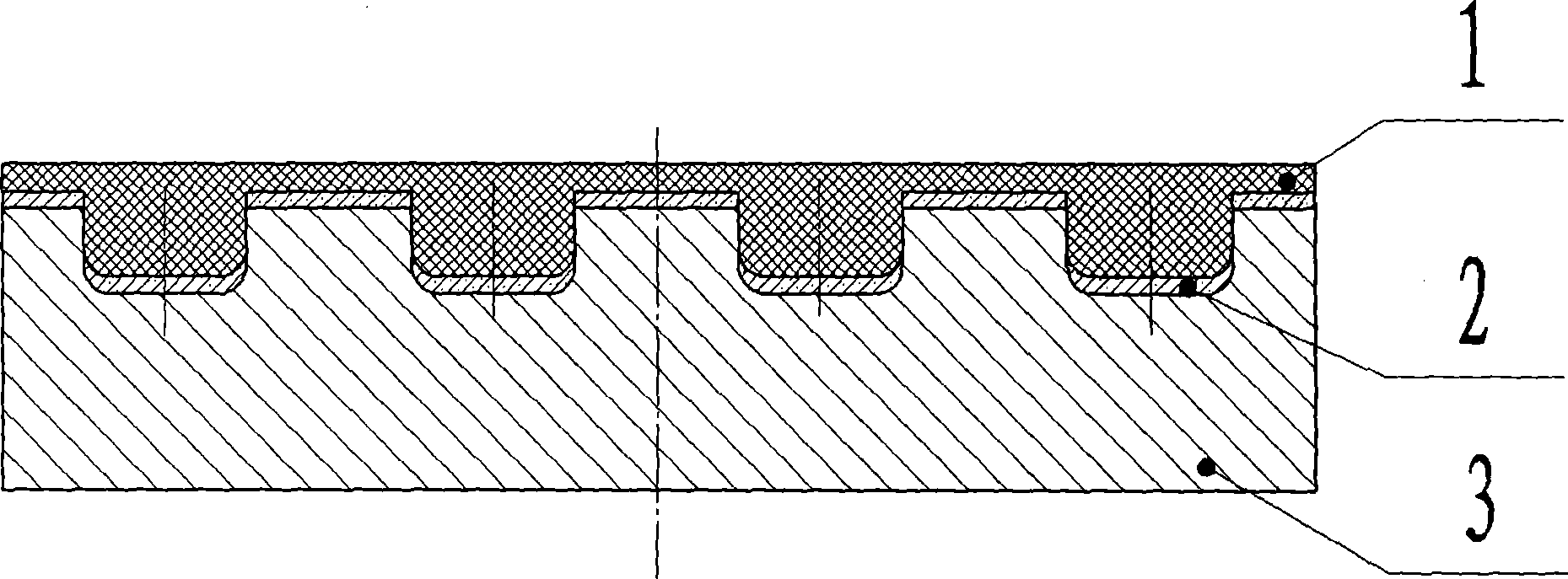

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

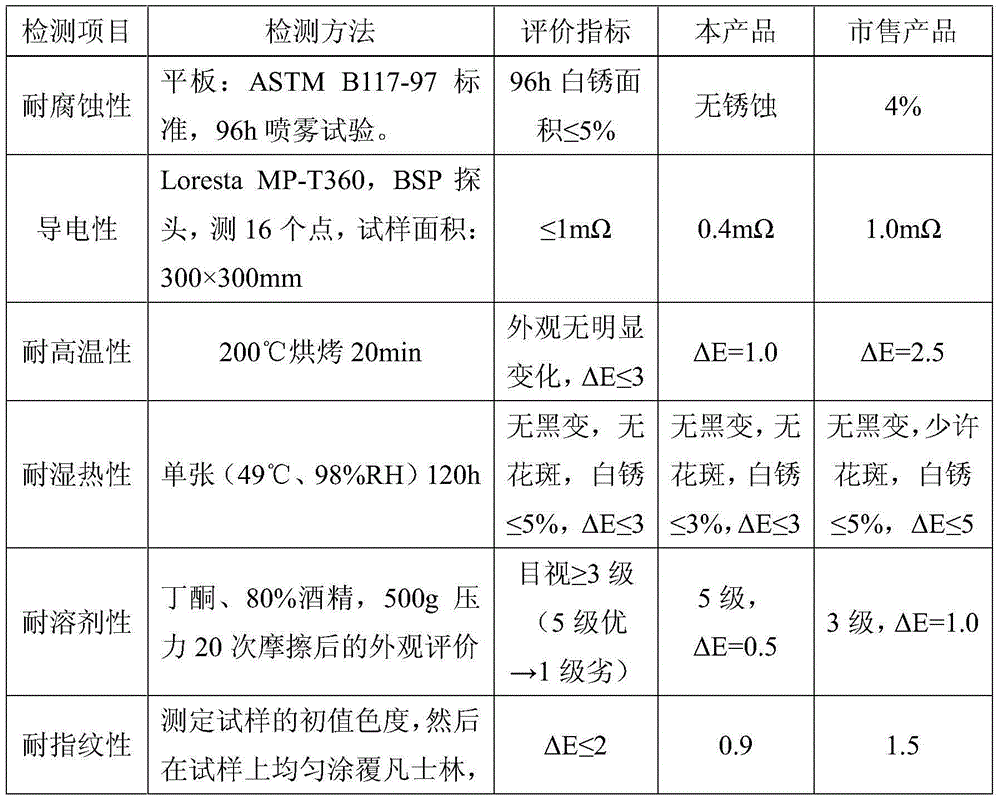

Water-based chromium-free fingerprint-resistant paint for galvanized steel plate

InactiveCN104449154AReduce consumptionWeather resistantAntifouling/underwater paintsPaints with biocidesWater basedPhosphate

The invention discloses water-based chromium-free fingerprint-resistant paint for a galvanized steel plate. The paint comprises raw materials in parts by weight as follows: 30.0-55.0 parts of a fluorine-modified water-based self-crosslinking acrylate emulsion, 0.1-1.5 parts of a neutralizer, 0.5-1.0 part of a silane coupling agent, 0.1-0.2 parts of laurocapram, 0.6-1.0 part of chlorinated paraffin, 4.0-8.0 parts of inorganic sol, 1.5-3.5 parts of metal salt, 0.1-0.3 parts of glycerin, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.1-0.2 parts of polydimethylsiloxane, 1.5-5.5 parts of a cosolvent, 1.0-2.5 parts of aluminium dihydrogen phosphate and 40-50 parts of water; the curing temperature is as low as 40-60 DEG C, and energy consumption is reduced. The fluorine-modified water-based self-crosslinking acrylate emulsion is adopted to enable a film to have weather-resistant, waterproof and self-cleaning performance and the like, the film has a self-repairing function when damaged, and the forming processability is greatly improved. Low VOC (volatile organic compounds) emission is realized, and the problem of chromium passivation pollution is solved.

Owner:HEFEI UNIV OF TECH

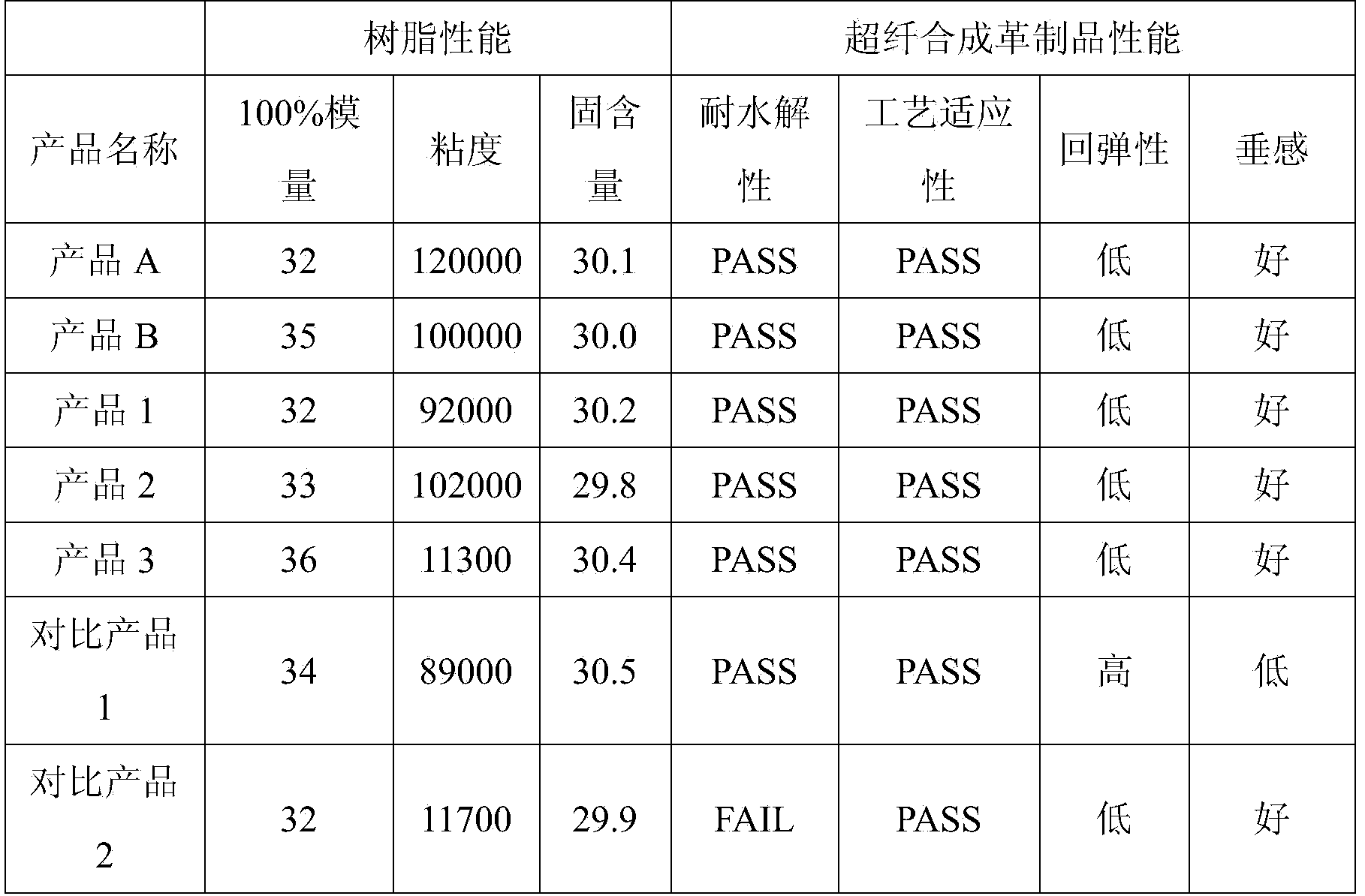

Polyurethane resin, and preparation method and application thereof

InactiveCN103450436AWith softWith slow reboundSynthetic resin layered productsTextiles and paperFiberSolvent

The invention discloses a polyurethane resin which is prepared from the following components in percentage by mass: 20-24% of polyalcohol composition, 1.1-1.5% of small molecule chain extender, 6.6-8.7% of isocyanate, 66-70% of solvent, 0.04-0.05% of blocking agent and 0.07-0.16% of assistant. The invention also discloses a preparation method and application of the polyurethane resin. The polyurethane resin disclosed by the invention has the characteristics of high softness, slow rebound, hydrolysis resistance, hot toluene resistance and the like; and the ultrafine fiber synthetic leather produced from the soft slow-rebound polyurethane resin has favorable sense of weeping, and is used for clothing leather.

Owner:XUCHUAN CHEM SUZHOU

Adhesive for compounding marble veneer with base material and preparation method thereof

ActiveCN101948667AEasy to useFast curing at room temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a bi-component modified epoxy adhesive for compounding a marble veneer with base materials such as a marble slab, a granite slab, a porcelain slab and a preparation method thereof. The adhesive comprises a component A and a component B, wherein the component A is prepared from epoxy resin, polyether, torispherical silicon micro-powder, heavy calcium carbonate and an auxiliary agent; and the component B is prepared from homemade modified amine, polyether amine, the torispherical silicon micro-powder, the heavy calcium carbonate and the auxiliary agent. The product has the characteristics of room temperature curing, high bond strength, water, heat and freeze-thaw resistance, low cost, convenient construction and the like.

Owner:HUNAN MAGPOW ADHESIVE INDS

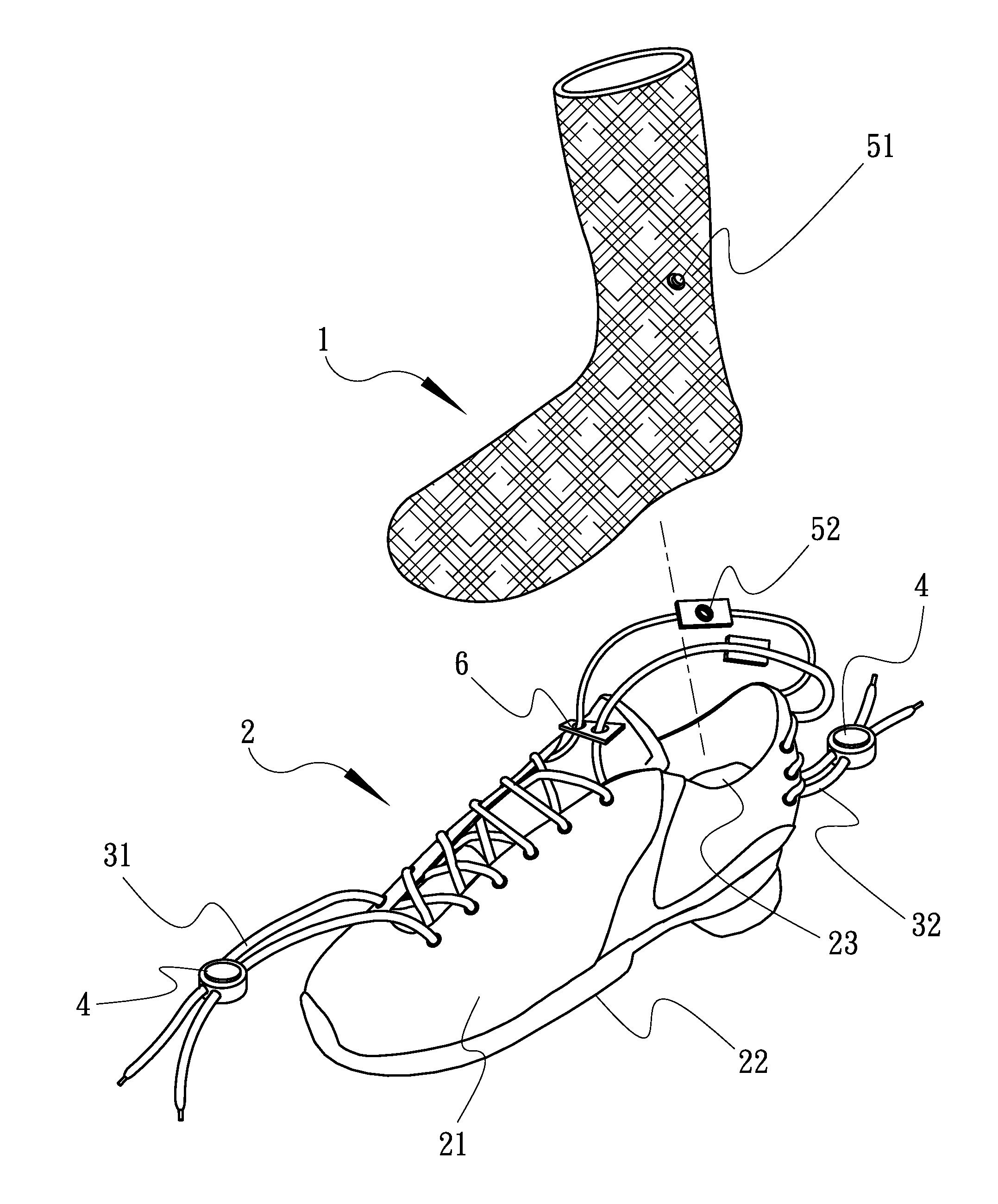

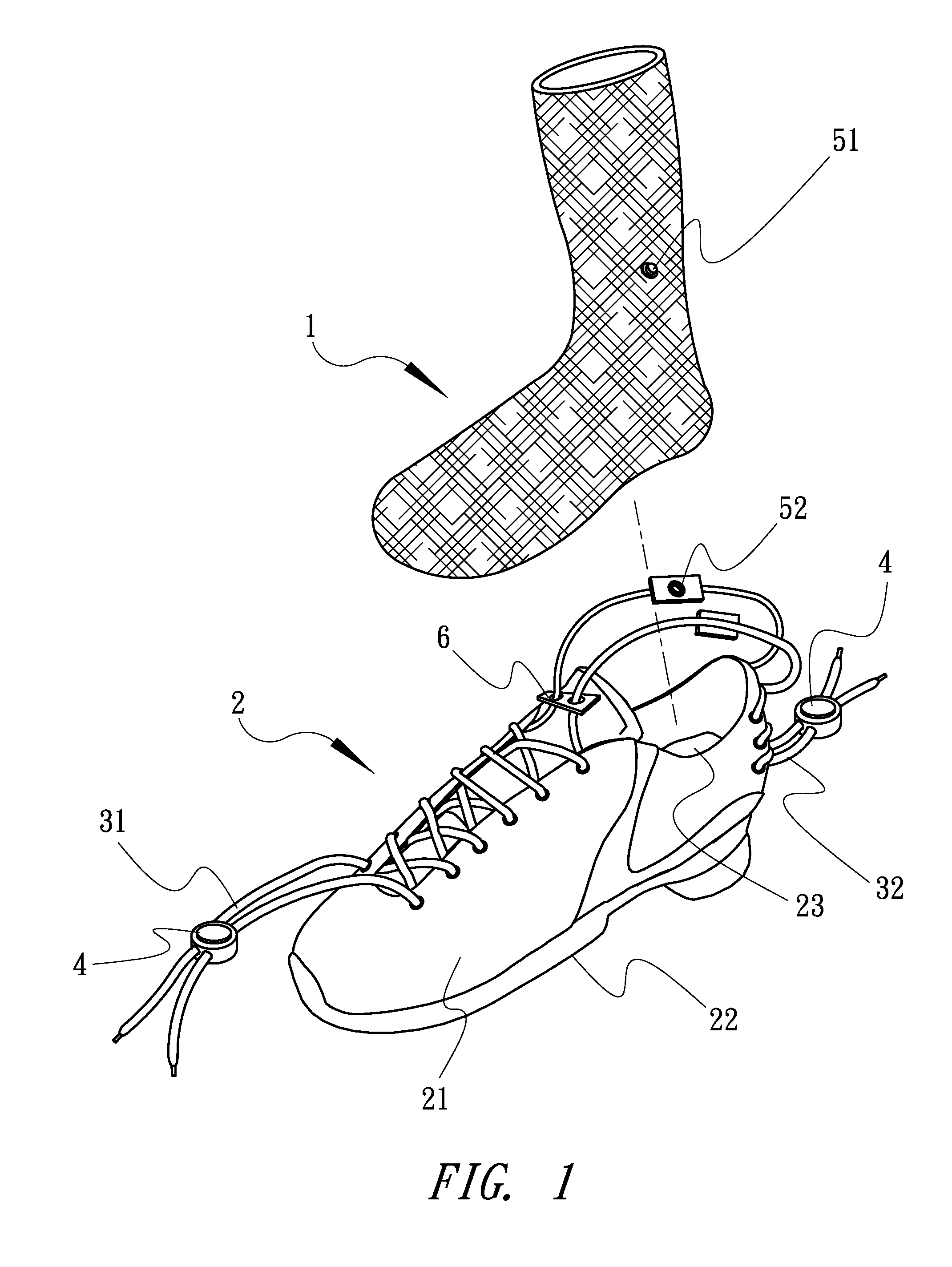

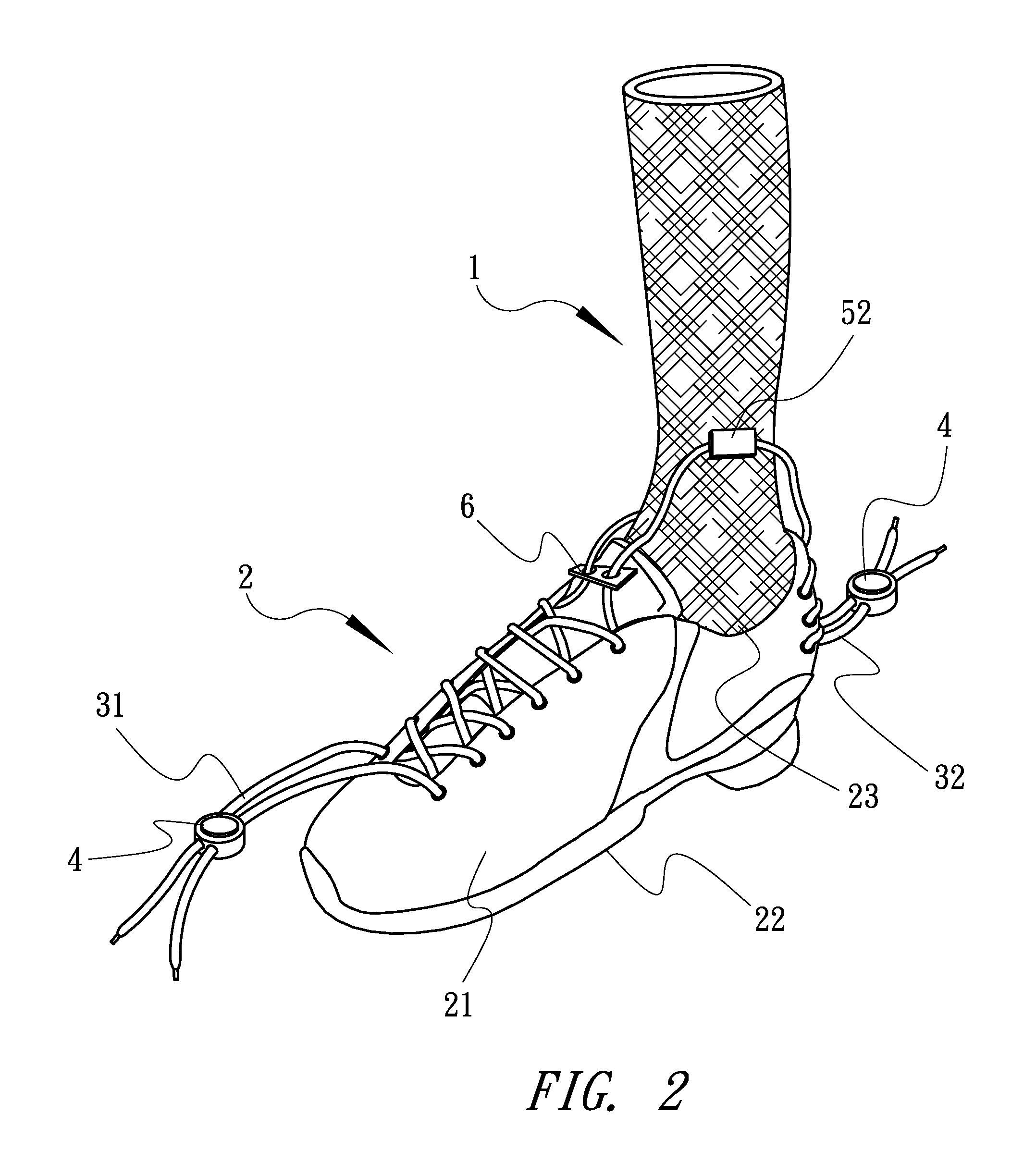

Shoes with socks which may have additional miniature stylish designs

The shoes with socks of the present invention are a combination of two shoes and two socks. The shoes with socks of the present invention can generate unique style per se; optionally, they may match with a user's clothes to provide additional stylish appearances. A front lace section is provided on the front portion of the top portion and a rear lace section is provided on the rear portion of the top portion. The rear lace section passes the opening and goes through the back wall of the top portion. In use, the rear lace section is fixedly attached to the corresponding sock through the engagement of two engagement units. In addition, a fastening unit, which is stylish, is provided on both the front lace section and the rear lace section to allow a user to adjust the tightness of either lace sections and easily and quickly.

Owner:JOY SEWING KING & WORLD PROSPERITY

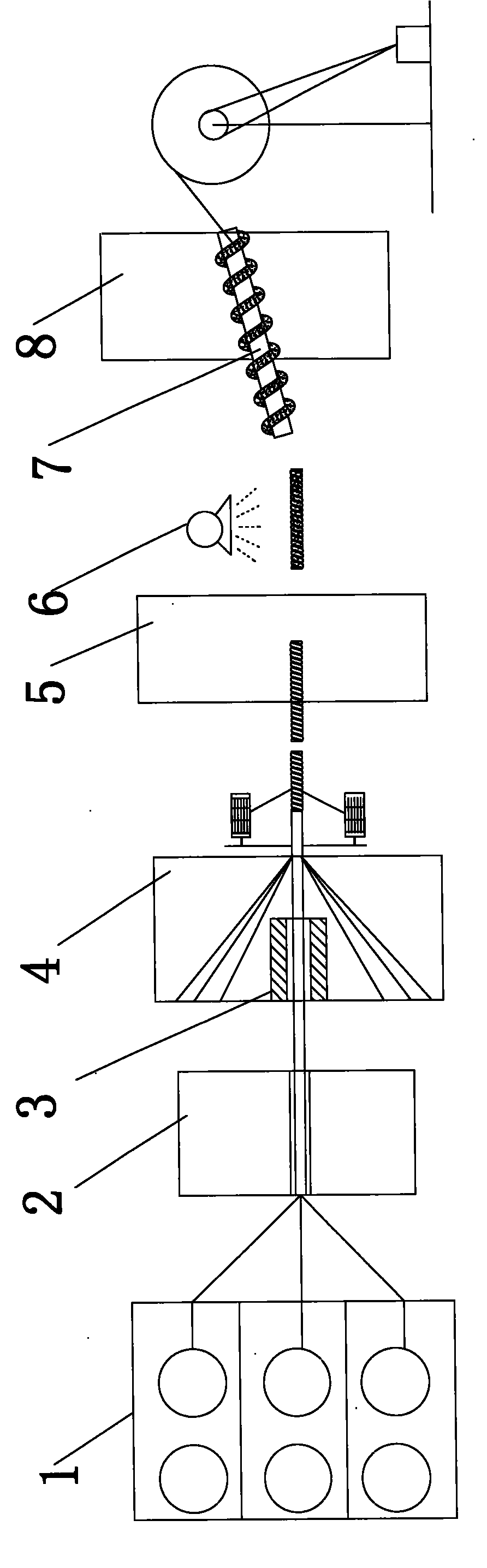

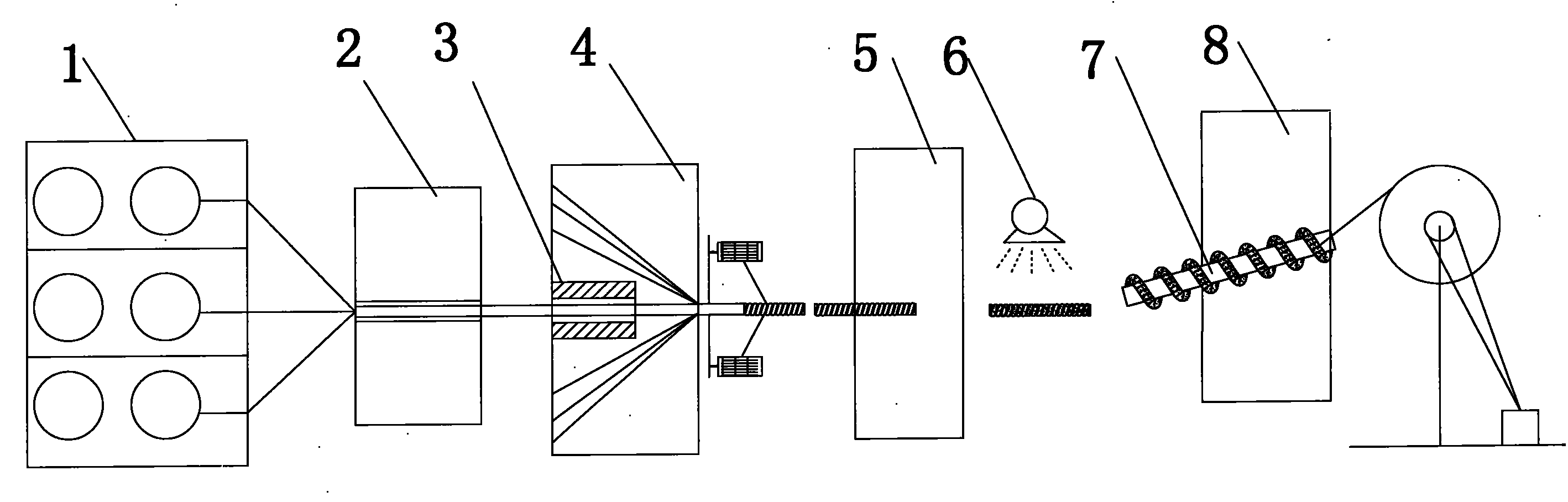

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

Epoxy modified polyurethane cryogenic adhesive

InactiveCN101298548AWater resistantWith low temperature resistancePolyureas/polyurethane adhesivesEpoxy resin adhesivesSolid componentEpoxy

The invention discloses an epoxy modified polyurethane ultra-low temperature resistant adhesive. The components and the mass percentage of the adhesive are: 30-50 percent of polyurethane modified prepolymer, 5-15 percent of epoxy resin, 10-20 percent of solvent, 1-15 percent of chain extender, and 30-50 percent of filler. First, uniformly blend all the liquid components, and then add solid components to uniformly blend, and pack after grinding on a grinding mill. The epoxy modified polyurethane ultra-low temperature resistant adhesive of the invention has the nature of ultra-low temperature resistance, the mechanical property of which can remain stabilized even being used for a long term at 200 DEG C below zero, and has the advantages of high bond strength and shear strength as well as good cohesiveness and corrosion resistance.

Owner:广东海拓创新精密设备科技有限公司

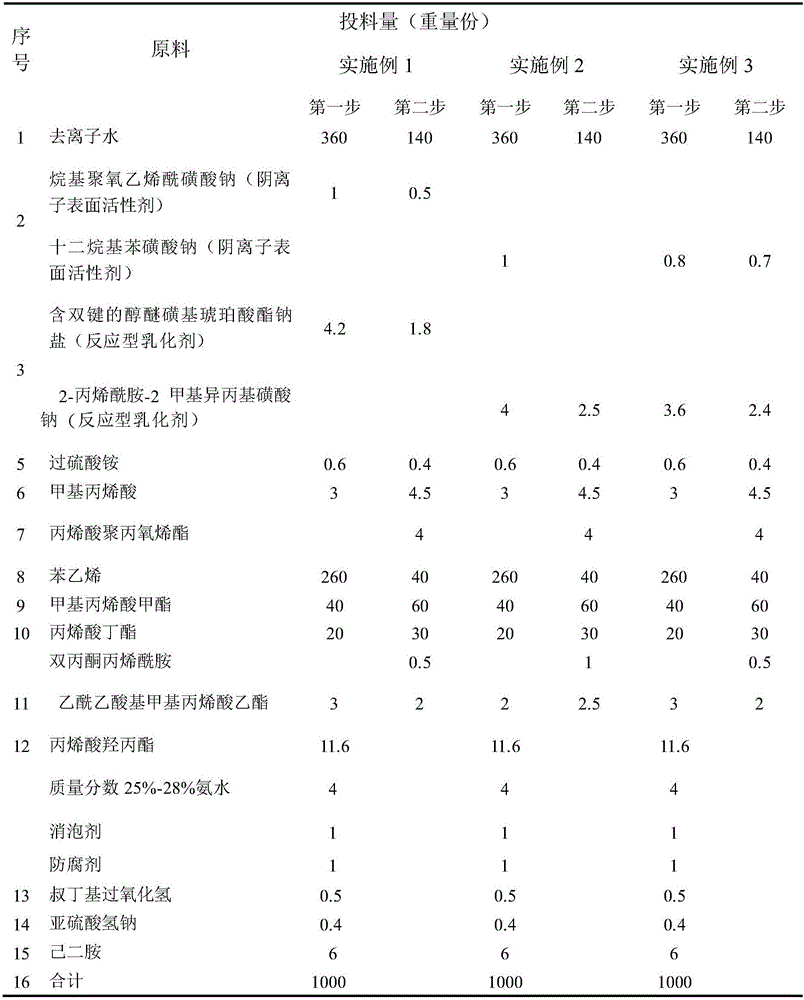

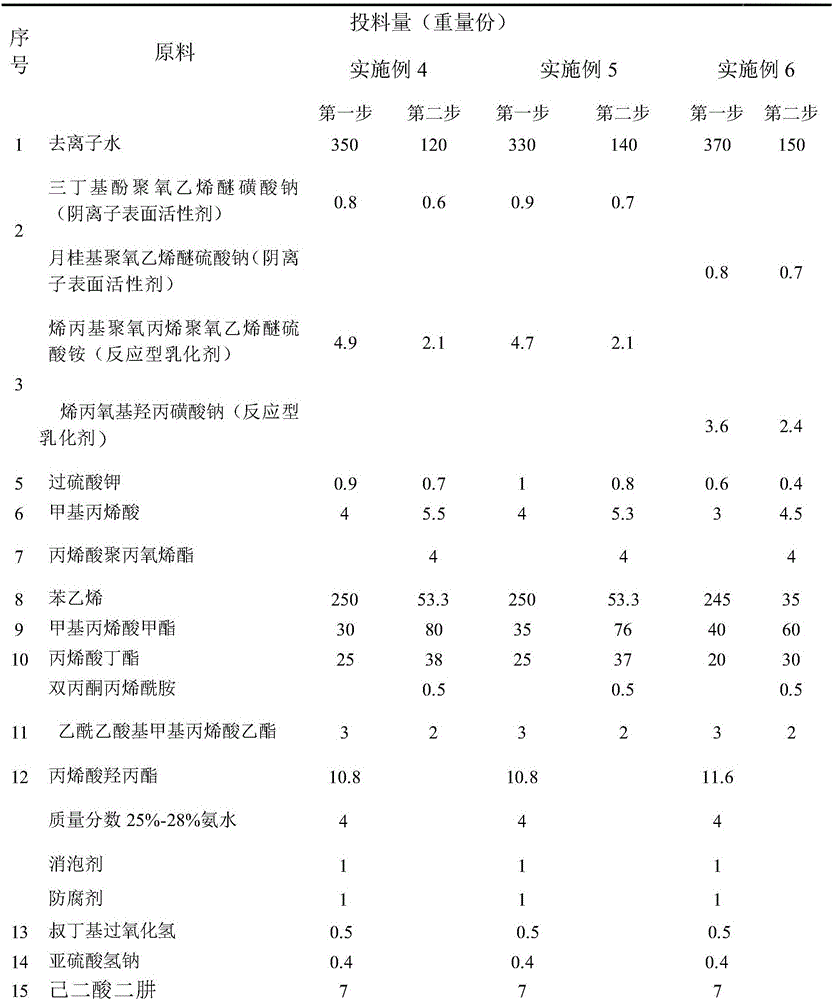

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

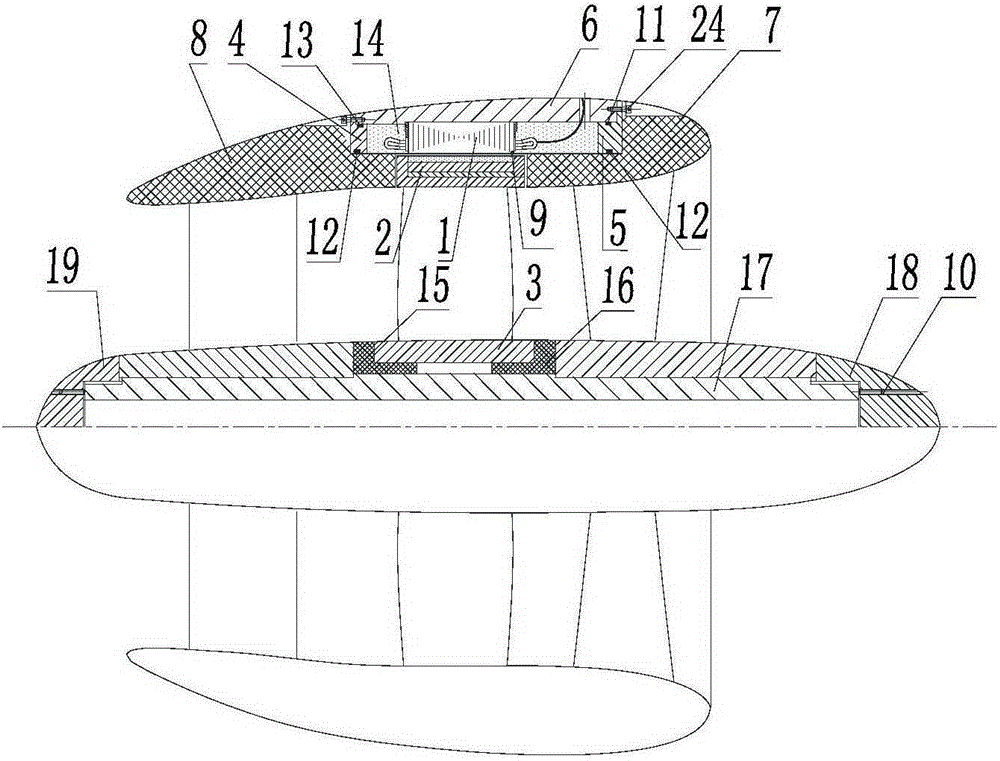

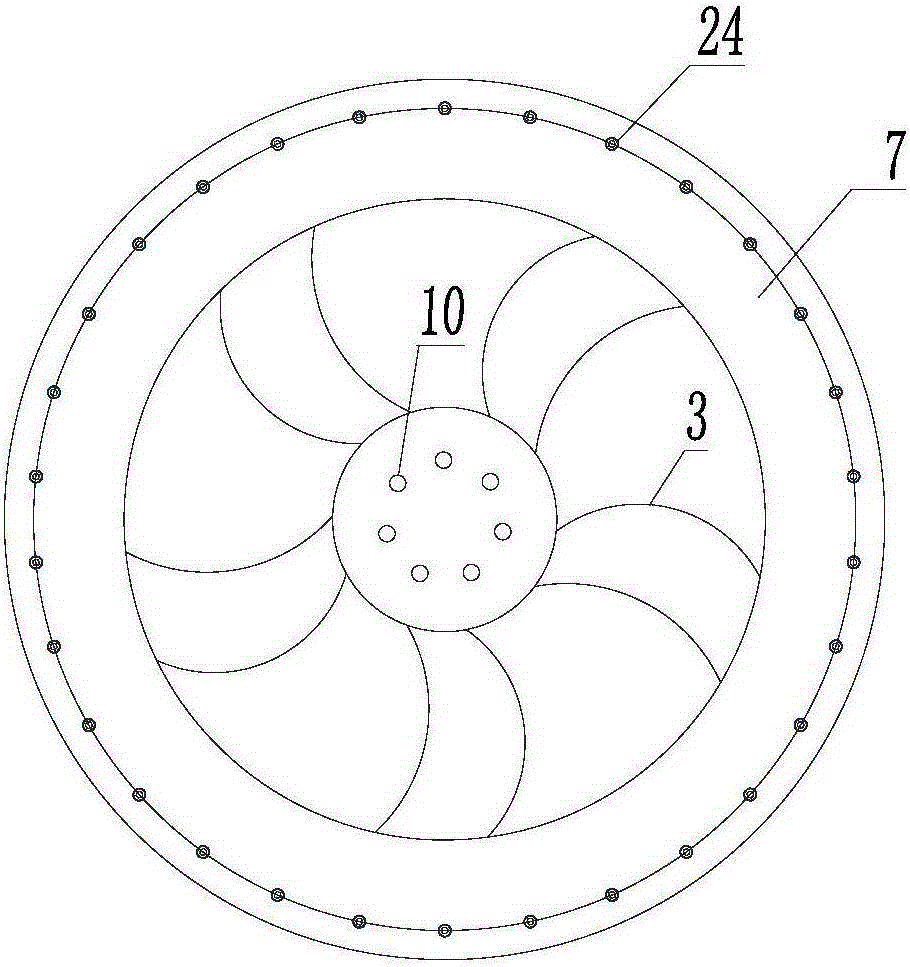

Ship flange integration propulsion device

ActiveCN105292424ASolve technical problems with access to the interior of the statorImprove sealingPropulsion power plantsPropulsive elementsFiberEngineering

The invention discloses a ship flange integration propulsion device. The ship flange integration propulsion device comprises a motor stator assembly, a motor rotor assembly, a propeller assembly, a guide tube, a rear guide cover, a front guide cover, a first water lubricated bearing, a second water lubricated bearing, an axle, a rear propeller hub cap, a front propeller hub cap, front guide cover connecting plates, rear guide cover connecting plates, a front end cover, a rear end cover and a fiber reinforced polymer sleeve, wherein the front end cover, the rear end cover and the fiber reinforced polymer sleeve are used for sealing the stator assembly, a closed space is formed among the stator assembly, the guide tube, the front end cover, the rear end cover and the fiber reinforced polymer sleeve, and the closed space is filled with epoxy resin. A static sealing structure is formed between the motor stator assembly and the guide tube, the sealing effect is good, and the technical problem that in the prior art, seawater may enter a stator can be effectively solved. In addition, due to the fact that a flange structure mode is adopted, paddles transmit hydrodynamic load at paddle tip conveniently; meanwhile, tip vortex is avoided, and the propulsive efficiency is further improved.

Owner:青岛海西电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com