Patents

Literature

42results about How to "Fast curing at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive for compounding marble veneer with base material and preparation method thereof

ActiveCN101948667AEasy to useFast curing at room temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a bi-component modified epoxy adhesive for compounding a marble veneer with base materials such as a marble slab, a granite slab, a porcelain slab and a preparation method thereof. The adhesive comprises a component A and a component B, wherein the component A is prepared from epoxy resin, polyether, torispherical silicon micro-powder, heavy calcium carbonate and an auxiliary agent; and the component B is prepared from homemade modified amine, polyether amine, the torispherical silicon micro-powder, the heavy calcium carbonate and the auxiliary agent. The product has the characteristics of room temperature curing, high bond strength, water, heat and freeze-thaw resistance, low cost, convenient construction and the like.

Owner:HUNAN MAGPOW ADHESIVE INDS

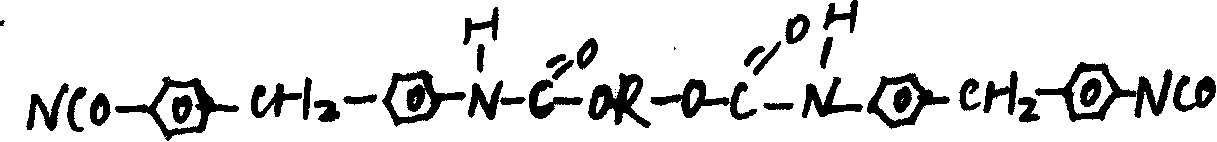

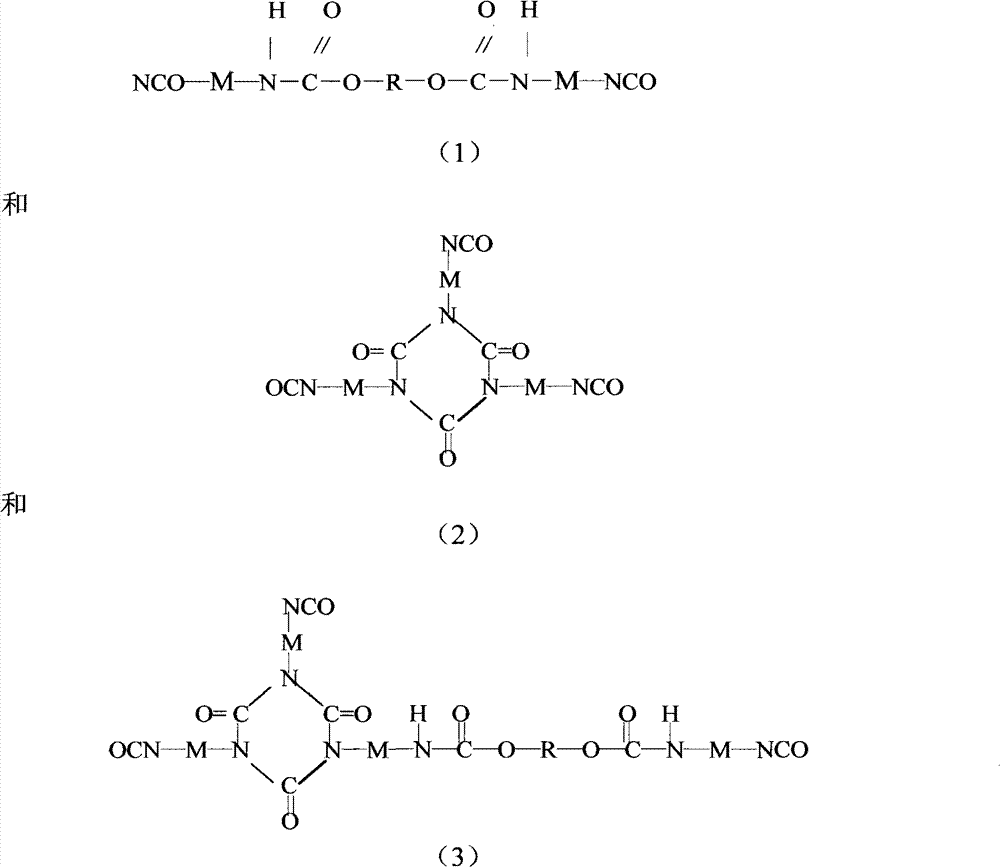

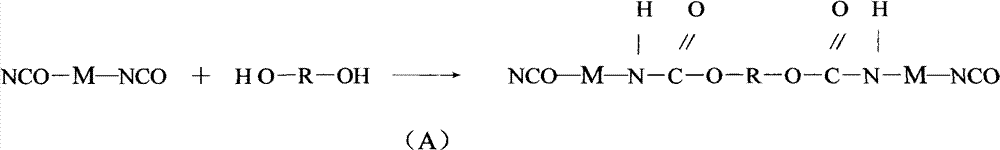

Curing agent 4,4'-biphenyl methane diisocyanate prepolymer and preparation method thereof

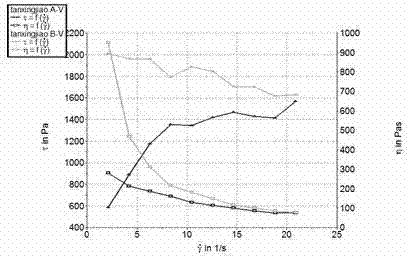

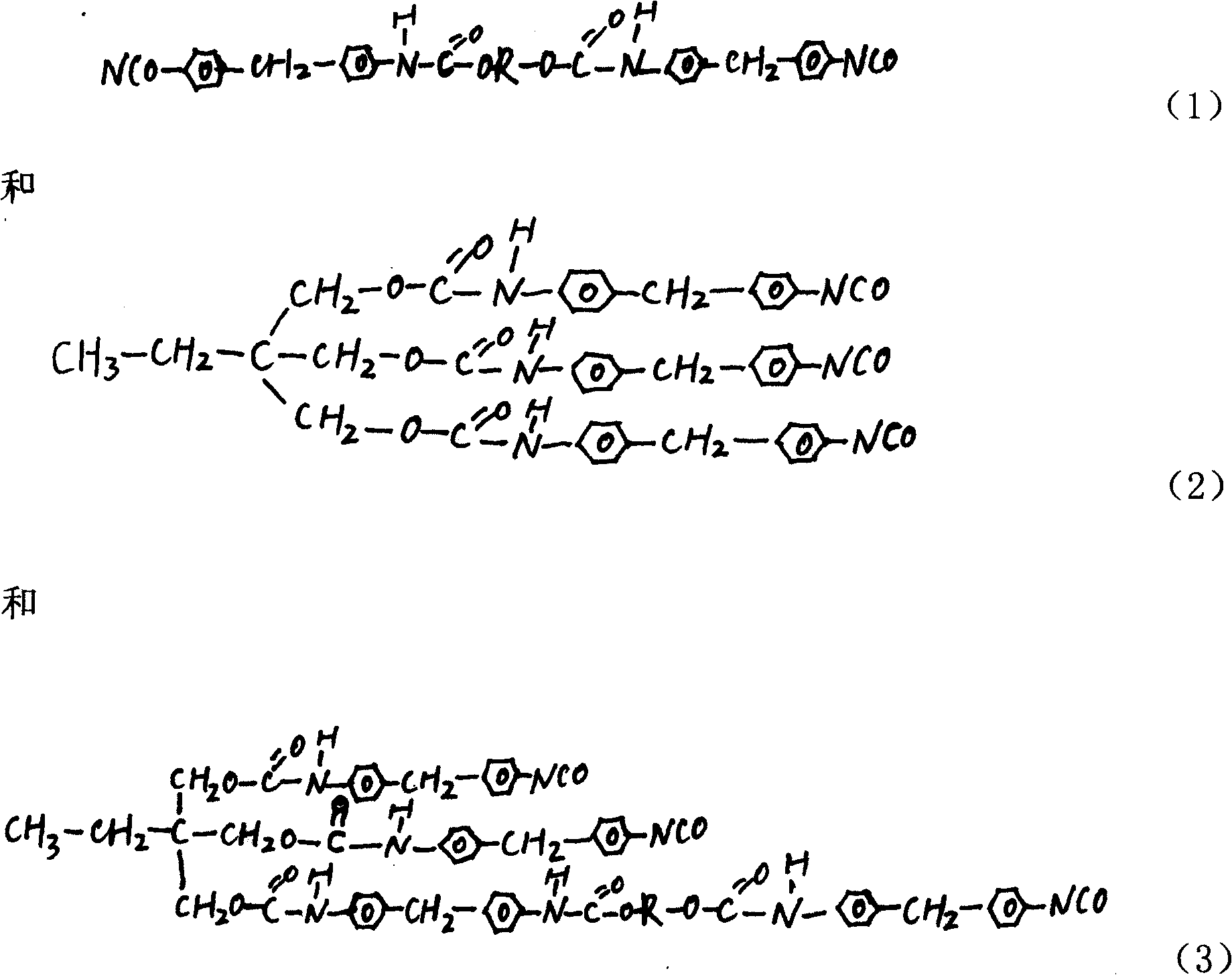

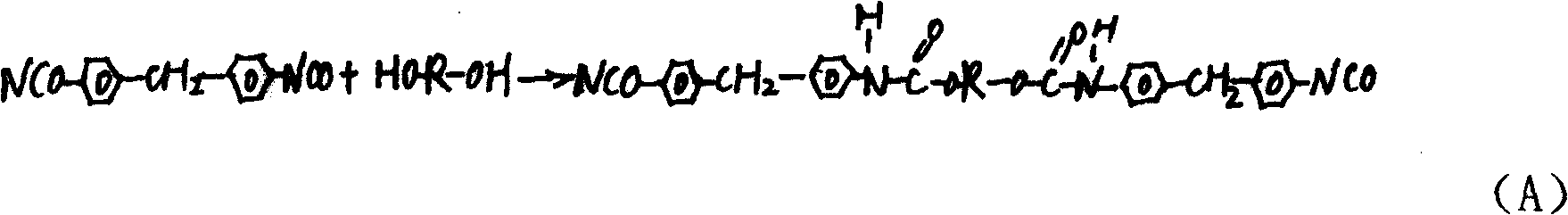

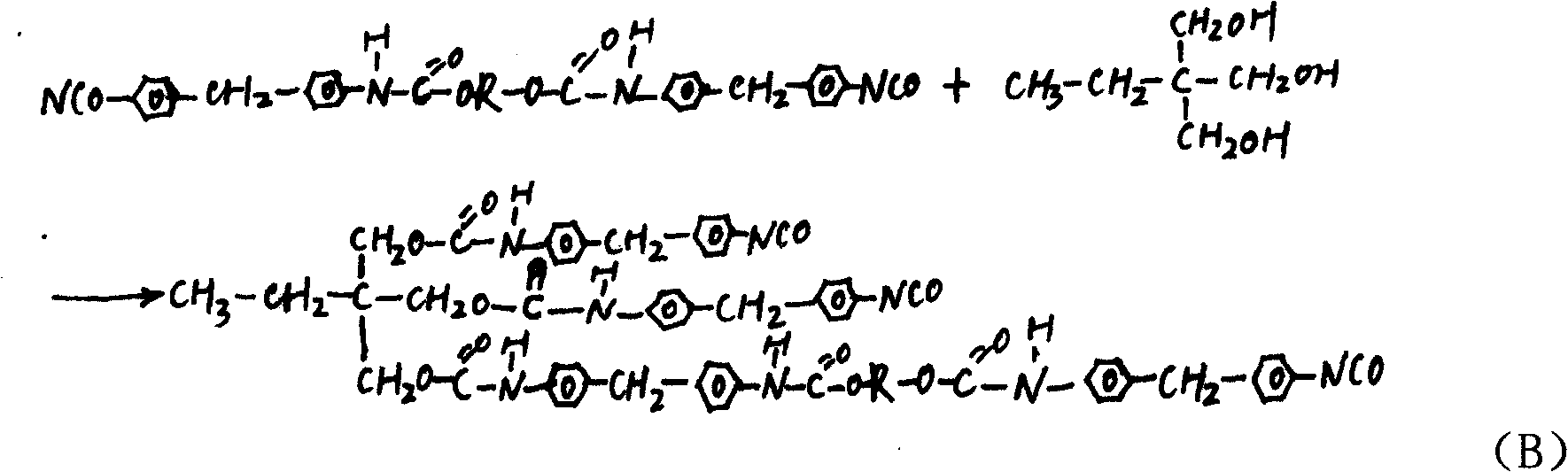

The invention relates to a curing agent, namely, 4, 4 (1)-diphenylmethane diisocyanate prepolymer and a preparation method thereof. The method comprises the steps that molten 4, 4(1)-MDI and an organic solvent are added into a reaction vessel, and stirred uniformly, the temperature is raised to 65 DEG C, polyhydric alcohol dehydrated through evacuation is added, to react for 2 to 4 hours at 60 to 100 DEG C, and then an MDI modifier is produced; when being stirred, the mixed liquor of trimethylol propane and the organic solvent is titrated into the reaction vessel for 1 to 4 hour(s), the titration temperature is 60 to 100 DEG C, heat preservation and reaction are performed for 1 to 3 hour(s), then the temperature is raised to 90 to 100 DEG C and the heat preservation and the reaction are performed again for 1 to 4 hour(s), the temperature is reduced, and the organic solvent is added for dilution to appropriate viscosity. The curing agent has the advantages that the application scope is broad, the molecular structure of the polyhydric alcohol can be adjusted according to the requirements of users to produce the prepolymer of polyurethane coating, adhesive, and the curing agent, the storage stability is good, the curing speed is quick, the toxicity is low, the price is low, products with high solid content can be obtained, etc.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

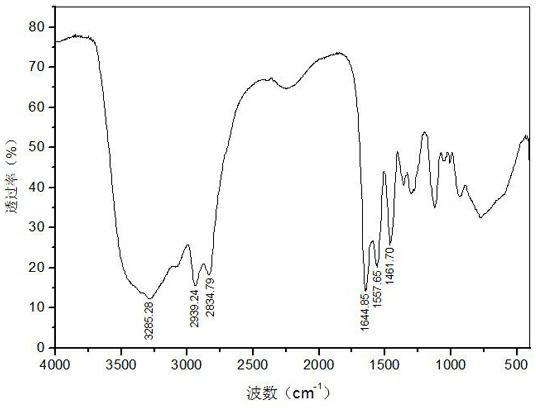

High-elasticity room temperature rapidly cured acrylic ester structure adhesive and preparation method thereof

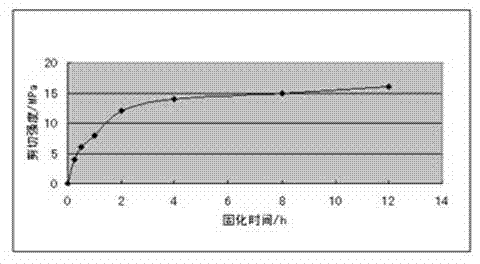

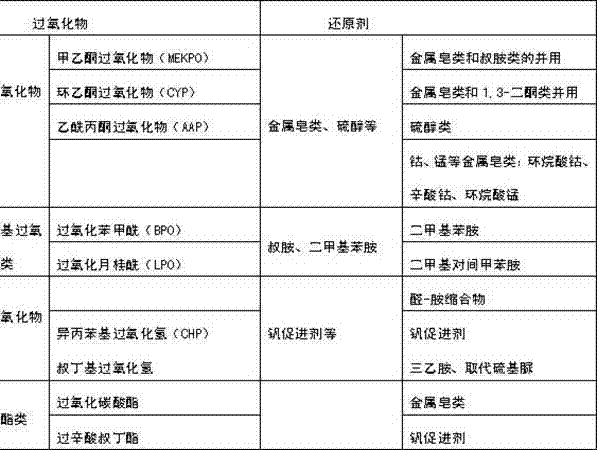

InactiveCN103571406AFast curing at room temperatureExtensive bondingNon-macromolecular adhesive additivesAcid polymer adhesivesEpoxyMethacrylate

The invention discloses a high-elasticity room temperature rapidly cured acrylic ester structure adhesive and a preparation method thereof. The acrylic ester structure adhesive consists of a component A and a component B, which comprise an oxidizing agent and a reducing agent which are polymerized through an initiating system, a (methyl) acrylic ester monomer or a (methyl) acrylic ester oligomer, (methyl) acrylic acid, (methyl) acrylic acid phosphate ester, a toughening and thickening agent, a stabilizing agent and other auxiliaries, and possibly comprise a plasticizing agent and epoxy resin. The component A and the component B are combined according to a certain ratio. The acrylic ester structure adhesive disclosed by the invention is rapid in room temperature curing speed, high in elongation rate, good in elasticity and wide in adhered base material.

Owner:TONSAN ADHESIVES INC

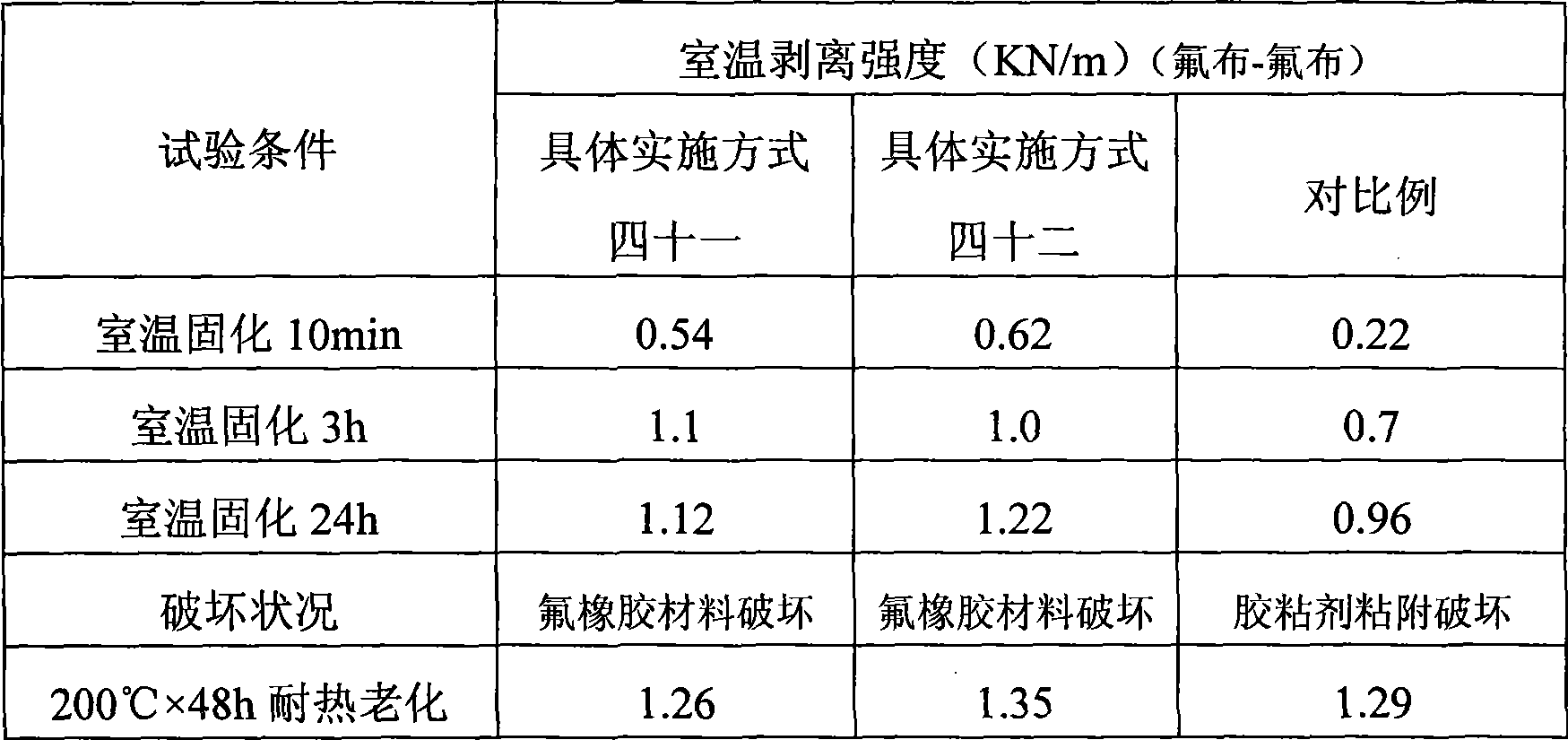

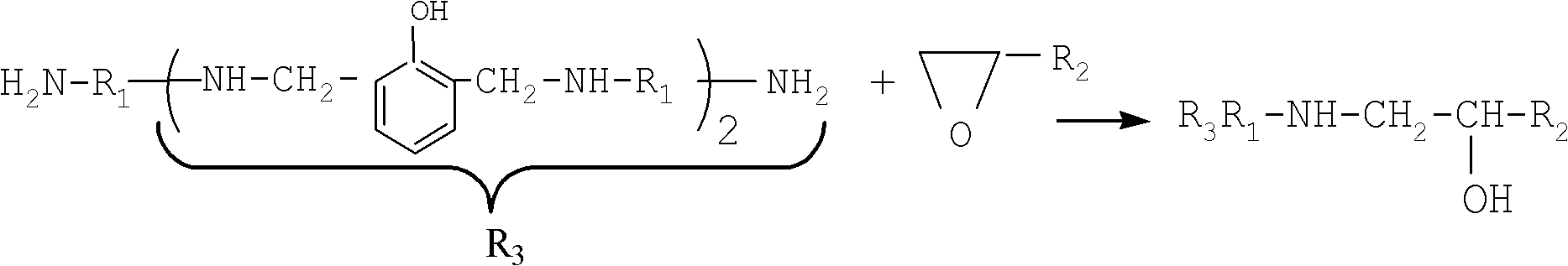

Room curing fluoro rubber adhesive and preparation method

InactiveCN101531872AImprove initial tackFast curing at room temperatureAdhesivesEpoxyOrganic solvent

The invention relates to a room curing fluoro rubber adhesive and a preparation method, solving the problems of low initial adhesive force, low curing rate and low adhesive intensity of current fluoro rubber adhesives. The adhesive of the invention comprises a component A and a component B; wherein, the component A is prepared by a fluoroelastomer compound, an epoxy resin, polyurethane emulsion and organic solvent; the component B is prepared by an organic amine curing agent, a silane coupling agent and solvent. The method is as follows: a. compounding raw fluorubber, an acid-acceptor, reinforcing fillers and a vulcanizing agent, dissolving the components in the organic solvent, adding the epoxy resin and polyurethane emulsion and evenly stirring the mixture to obtain the component A; b. evenly stirring the organic amine curing agent, silane coupling agent and organic solvent to obtain the component B. The adhesive of the invention has the advantages of high initial adhesive force, high room curing rate and adhesive intensity and can be used for adhesion of the fluorubber and metallic materials. The preparation of the adhesive is simple in technology and low in cost.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

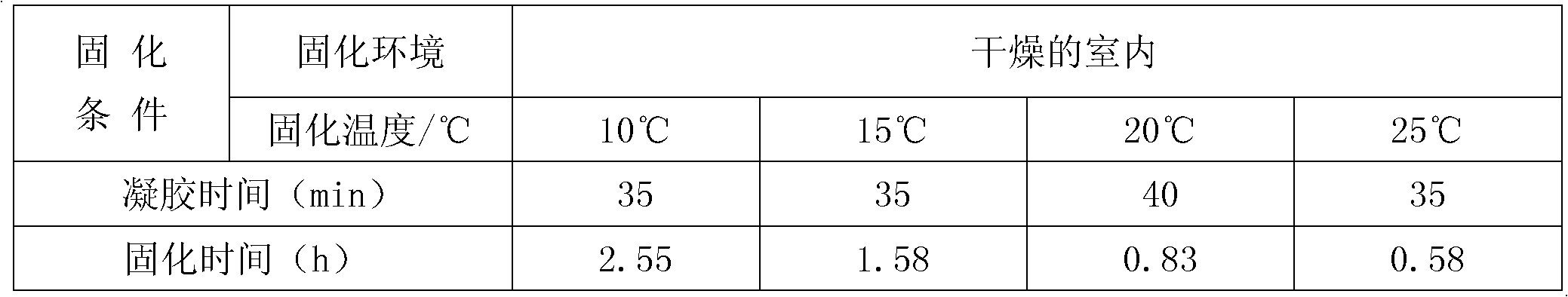

Epoxy resin injecting paste material for maintenance of road engineering and preparation method thereof

InactiveCN102061063AGood adhesionPlay the role of jointly carrying heavy loads on the road surfaceChipsealRoad engineering

The invention relates to an epoxy resin injecting paste material for the maintenance of road engineering and a preparation method thereof. The preparation method of the epoxy resin injecting paste material comprises the following steps of: (1) preparing an epoxy component A: mixing bisphenol A type epoxy resin with an activated thinner, and uniformly stirring at normal temperature so as to obtain the epoxy component A; (2) preparing a curing agent component B: mixing modified aliphatic polyamine with a curing accelerator DMP-30, and uniformly stirring at normal temperature so as to obtain the curing agent component B; (3) preparing through mixing: when in use, mixing the epoxy component A prepared from the step (1) with the curing agent component B prepared from the step (2) at normal temperature with the mixed ratio of 100:17-90, and stirring to obtain the epoxy resin injecting paste material. The invention cure fast at normal temperature and has better adhesion on a moist surface so that moist and incompact grits, gravel, and the like which are contained in a roadbed are adhered into a firm integer to a role of jointly bearing heavy loads of a road surface; and in addition, the invention has excellent mechanical property, thereby obviously enhancing the bearing capability of the repaired roadbed.

Owner:湖北省京珠高速公路管理处 +1

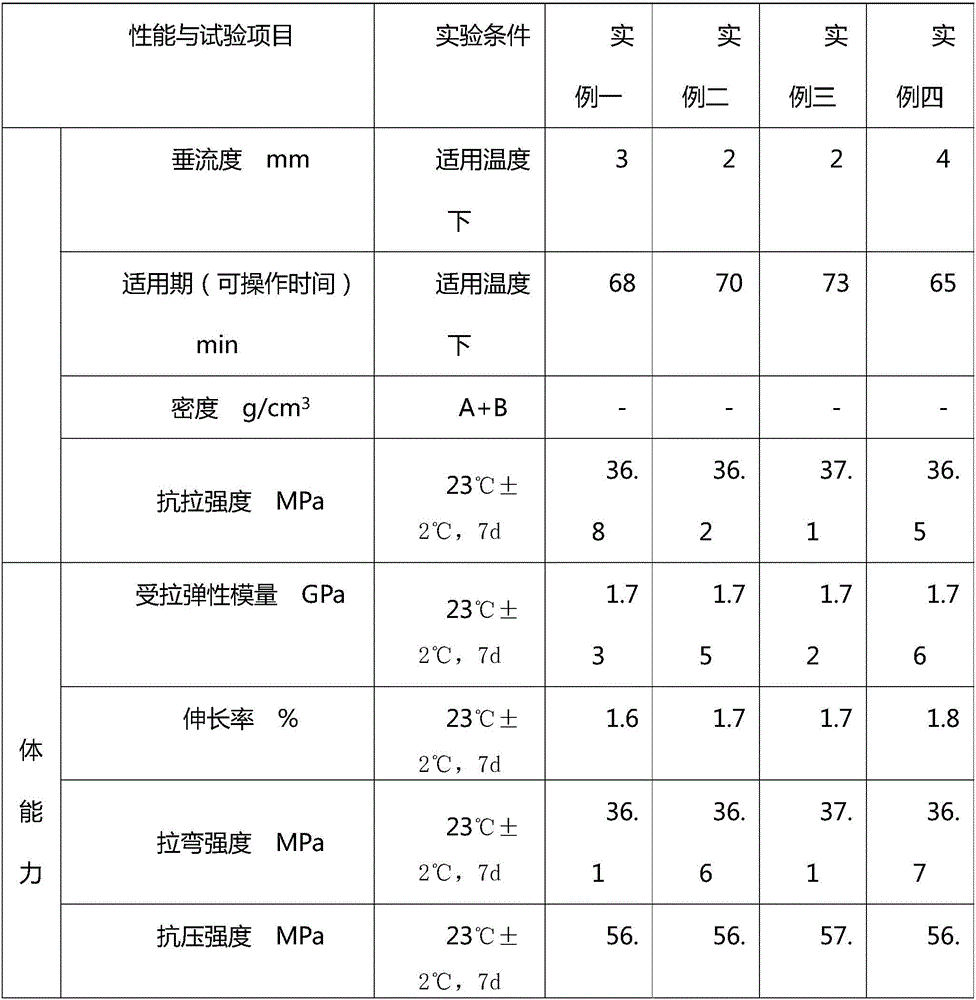

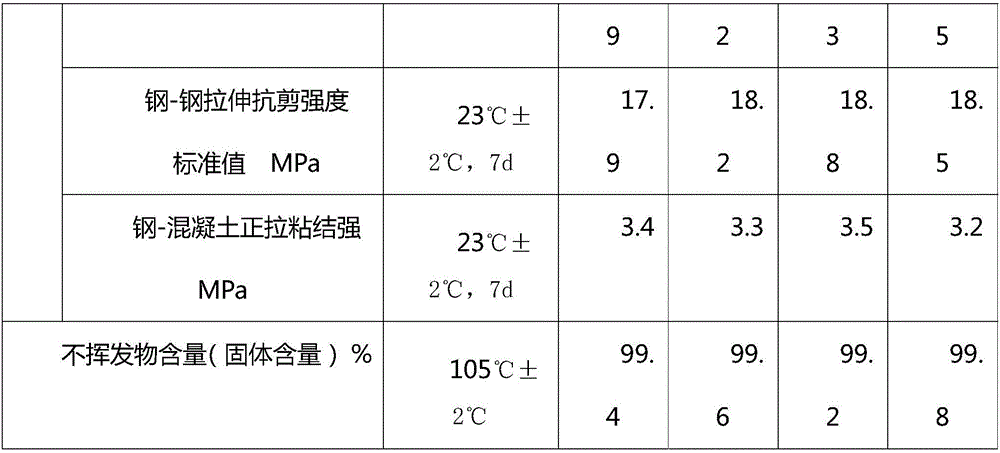

Multi-purpose modified epoxy resin adhesive

InactiveCN105925228AImprove thixotropyEasy constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesDiluentResin adhesive

The invention discloses a multi-purpose modified epoxy resin adhesive which comprises a component A and a component B, and the mass ratio of the component A to the component B is 3:1; the component A comprises the following components in parts by weight: 100 parts of bisphenol A-type epoxy resin, 10-15 parts of a toughening agent, 5-10 parts of an active diluent, 2-4 parts of a thixotropic agent and 100-150 parts of a filler; the component B comprises the following components in parts by weight: 30-55 parts of a composite curing agent, 1-3 parts of an accelerator, 1-3 parts of a coupling agent, 1-3 parts of a thixotropic agent and 30-50 parts of an active filler. The multi-purpose modified epoxy resin adhesive disclosed by the invention is excellent in thixotropic property, good in construction performance and free from flowing during construction on sunny sides, resistant to acid and alkali medium erosion, high in normal temperature curing speed, free from volatile matters contained, non-toxic and harmless, high in bonding strength and good in toughness and impact resistance.

Owner:北京中德新亚建筑技术有限公司

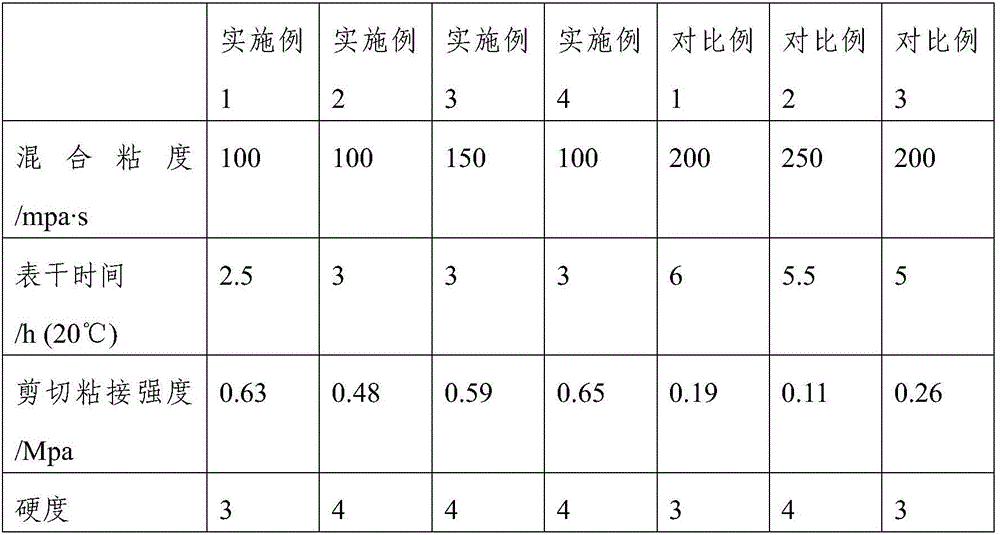

Toughened environmental-friendly back mesh glue as well as preparation method and application thereof

ActiveCN107090264AFast aggregationFast curing at room temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterToughening

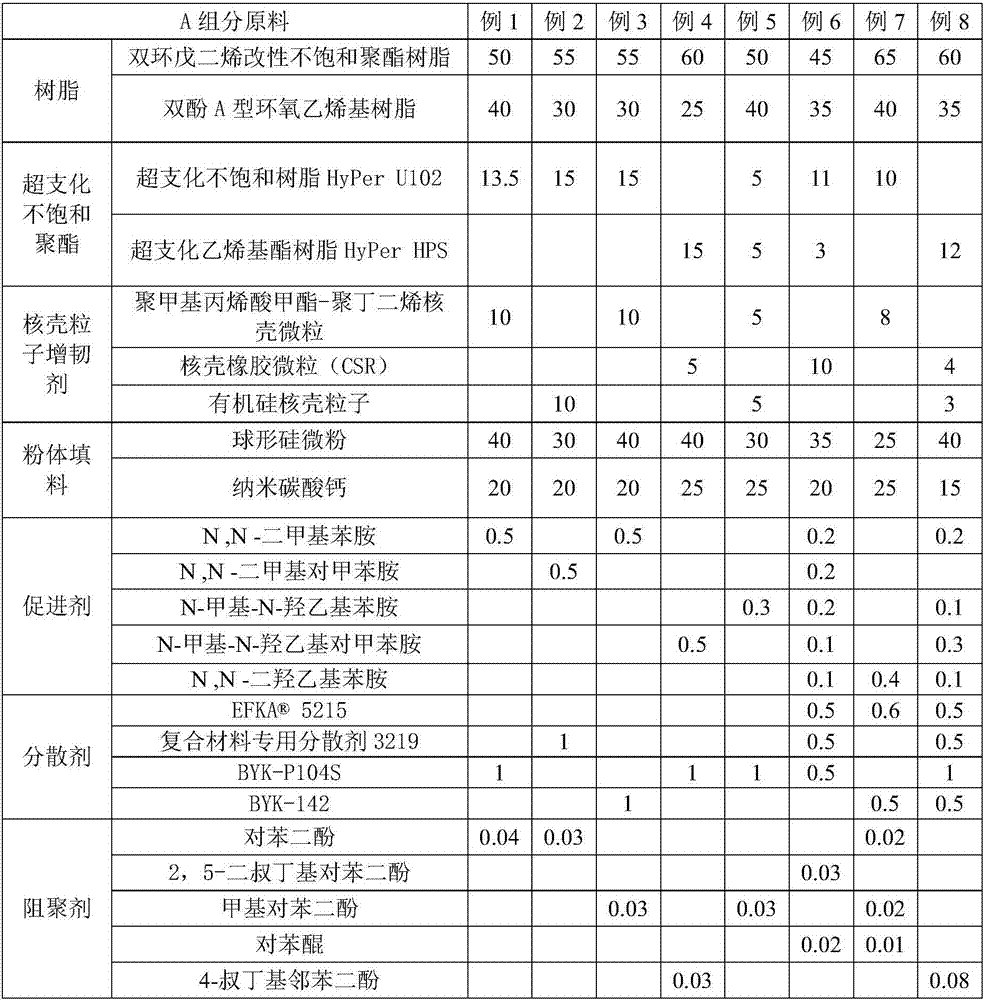

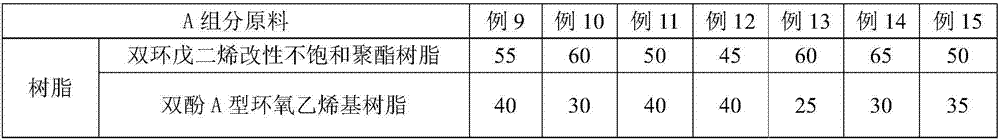

The invention discloses toughened environmental-friendly back mesh glue as well as a preparation method and application thereof. A component A is prepared from the following components in parts by weight: 45-65 parts of dicyclopentadiene modified unsaturated polyester resin, 25-40 parts of bisphenol-A epoxy vinyl ester resin, 10-15 parts of hyperbranched unsaturated polyester, 1-2.5 parts of a dispersant, 5-10 parts of a core-shell particle toughening agent, 25-40 parts of spherical fine silicon powder, 15-25 parts of nano calcium carbonate, 0.2-0.8 part of an accelerator and 0.02-0.08 part of a polymerization inhibitor. A component B is prepared from the following components in parts by weight: 10-70 parts of a solidifying agent, 30-40 parts of a blending agent, 30-50 parts of an inorganic filler and 3-10 parts of a stabilizer. After the component A and the component B are mixed, the solidifying agent accounts for 0.5-3.5 percent of the total weight of the mixture. The back mesh glue is small in viscosity, good in permeability, moderate in rheology and low in content of total volatile organic compounds (VOCs); and the mechanical strength, particularly the impact resistance, of a back mesh stone is remarkably superior to that of the existing product.

Owner:江苏大力士云石护理材料有限公司

High viscosity rapid room temperature curing sealant

InactiveCN103992764AExcellent adhesionGuaranteed mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesEpoxyAntioxidant

The invention discloses a high viscosity rapid room temperature curing sealant comprising the following raw materials by weight: 30-40 parts of chloroprene rubber, 20-30 parts of styrene butadiene rubber, 40-50 parts of terpene resin, 35-45 parts of epoxy resin, 7-12 parts of an antioxidant, 160-180 parts of an organic solvent, 16-19 parts of a thickener, 110-130 parts of light calcium carbonate, 10-13 parts of ethylene glycol, 2.5-3.5 parts of a curing accelerator and 7-11 parts of a defoaming agent. The high viscosity rapid room temperature curing sealant is high in viscosity, short in curing time at room temperature, easy to use, and wide in range of uses.

Owner:TIANCHANG YONG TAI SEALING MATERIAL

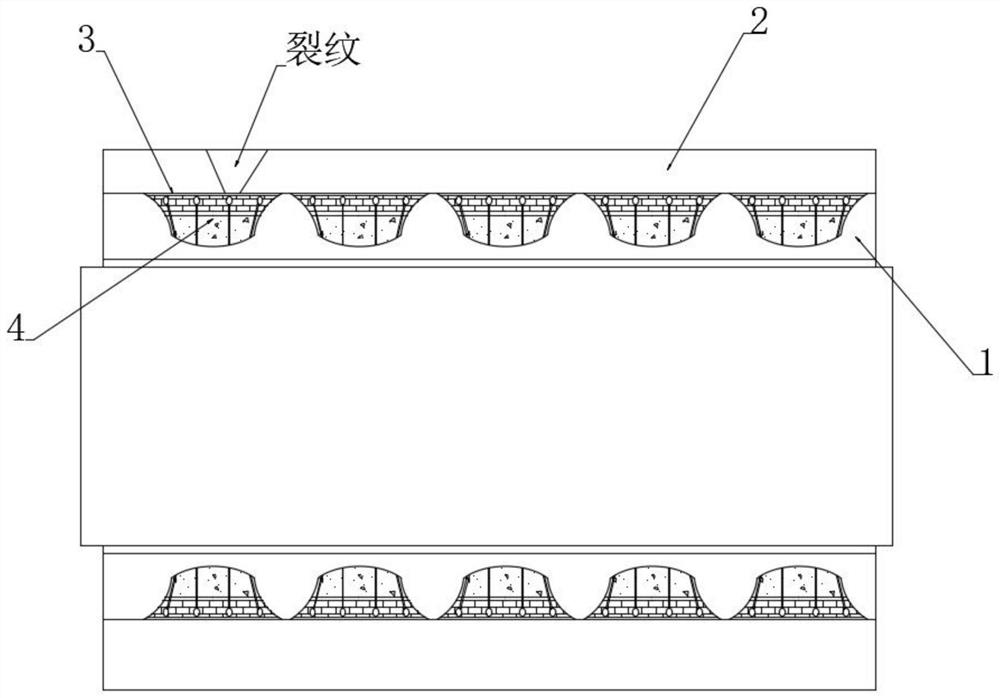

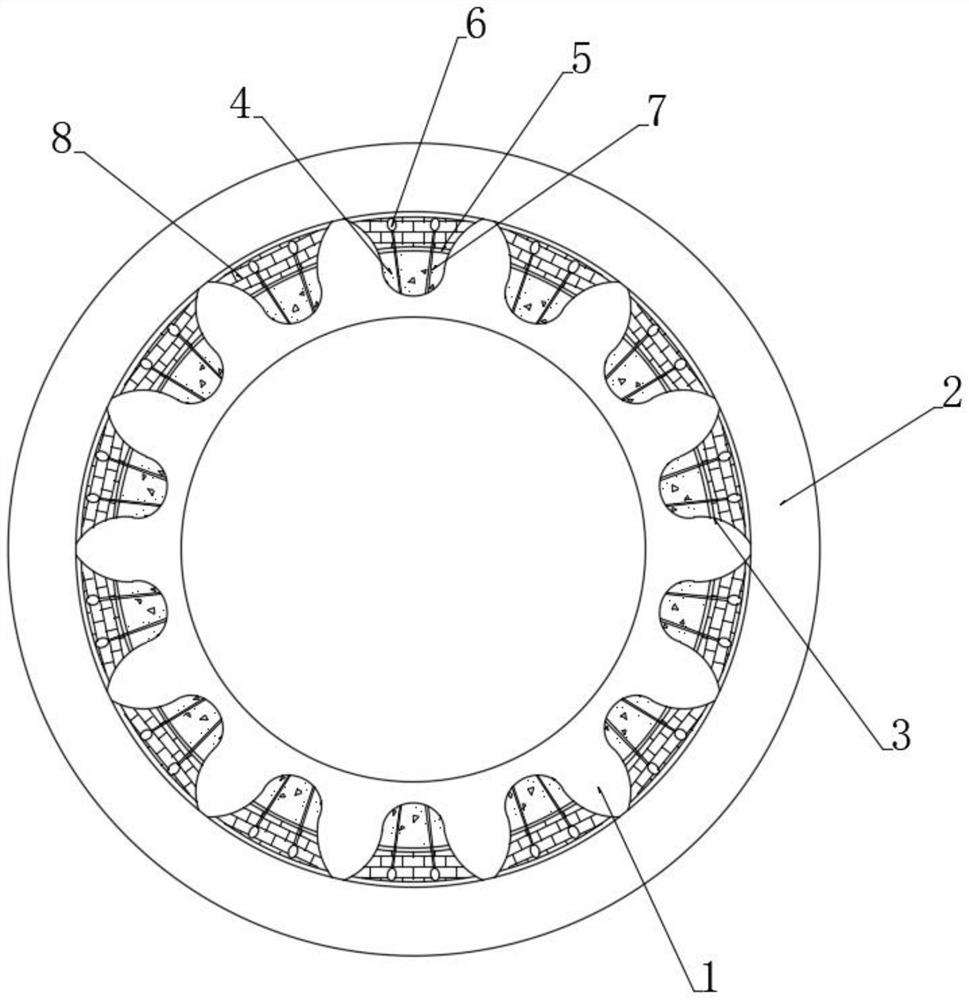

A high-pressure-resistant water-permeable porous material and a preparation method thereof

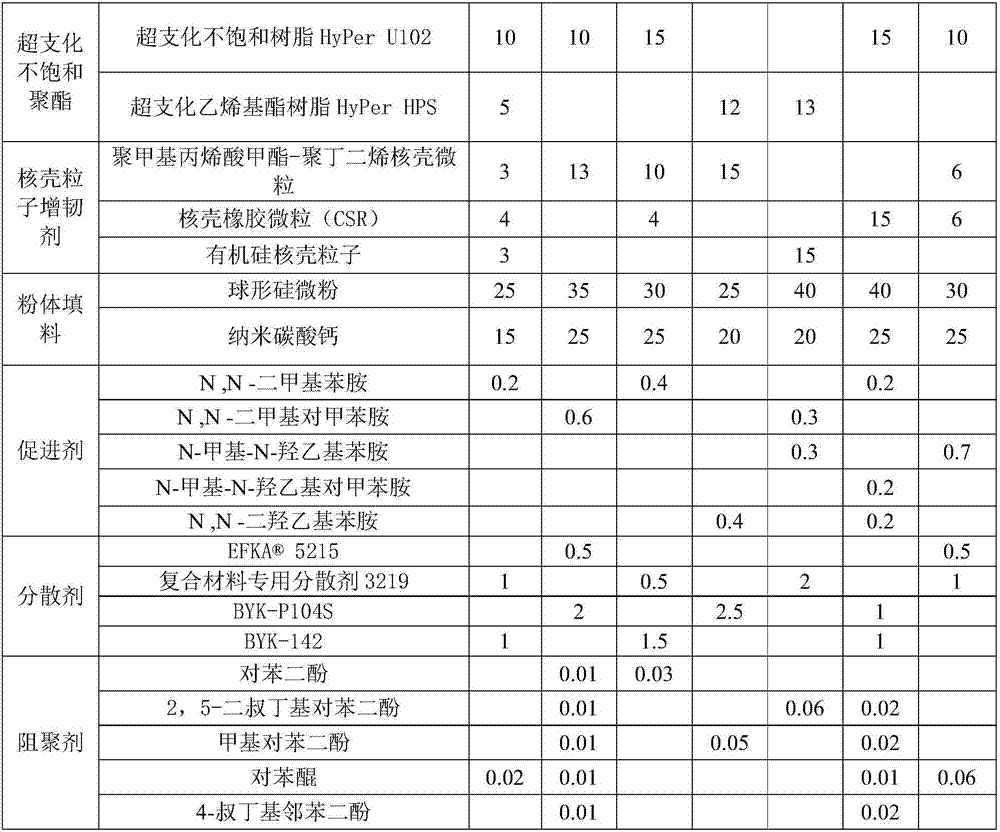

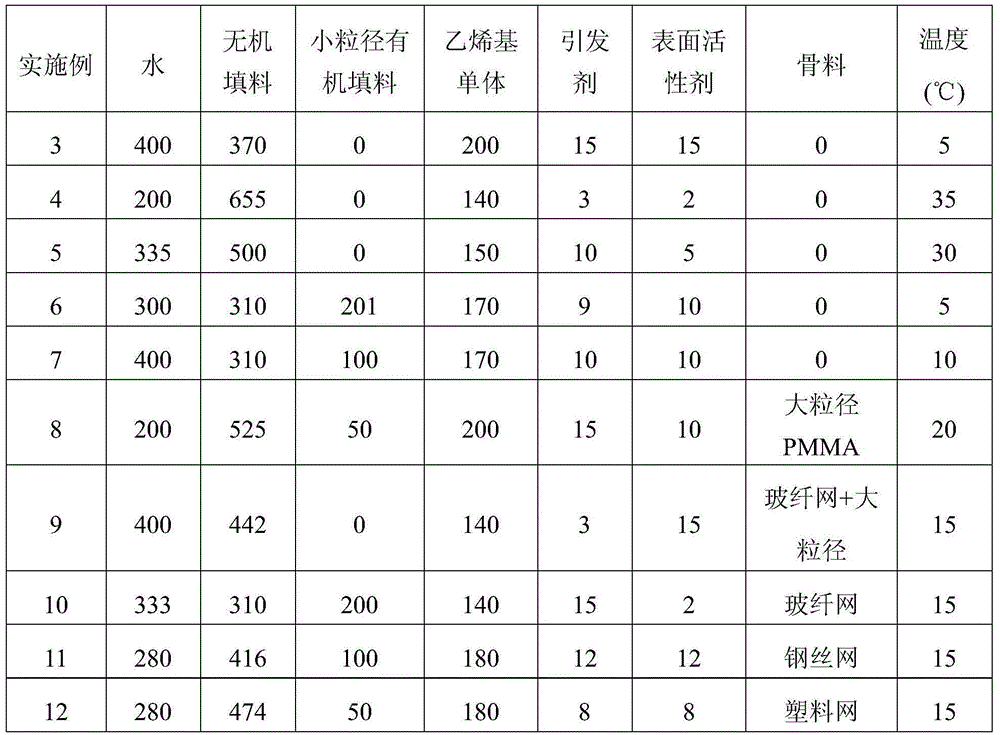

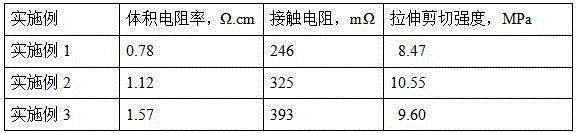

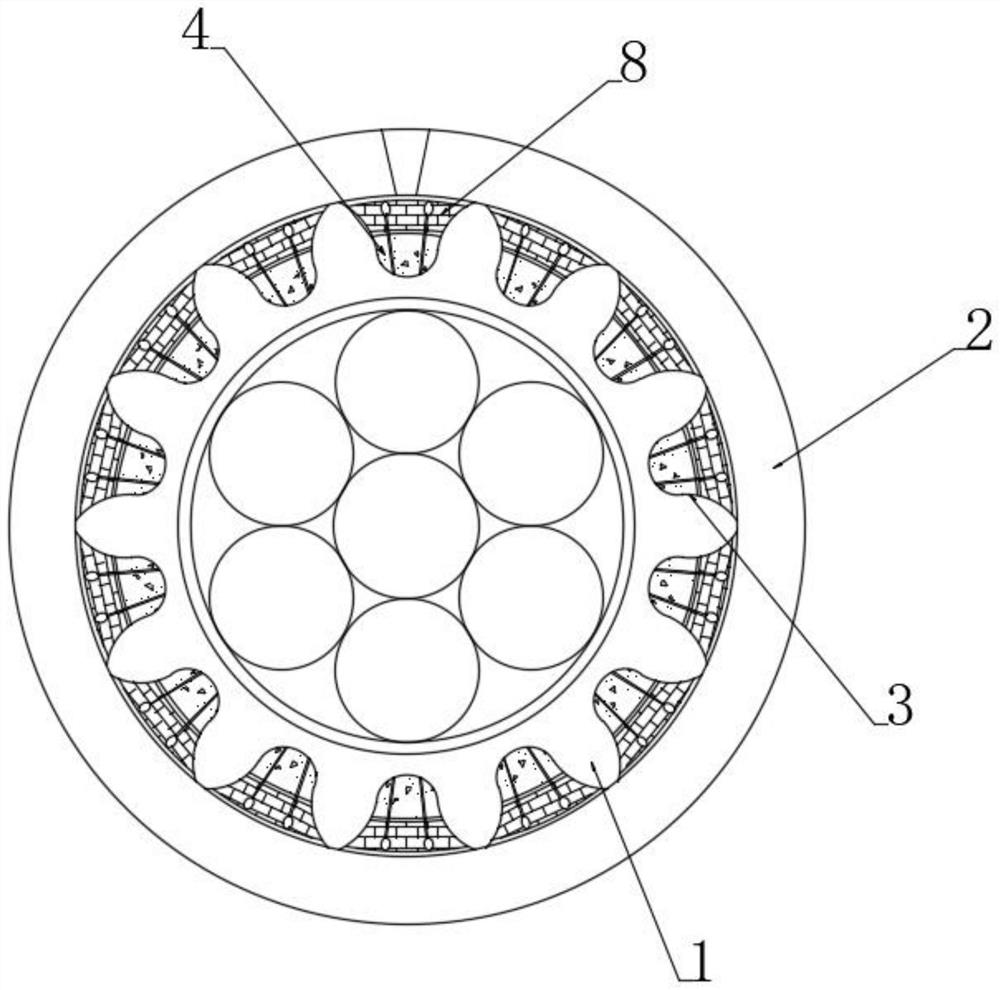

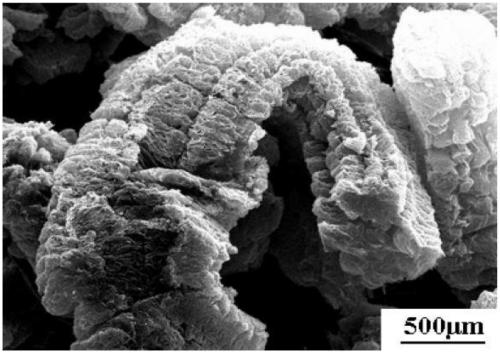

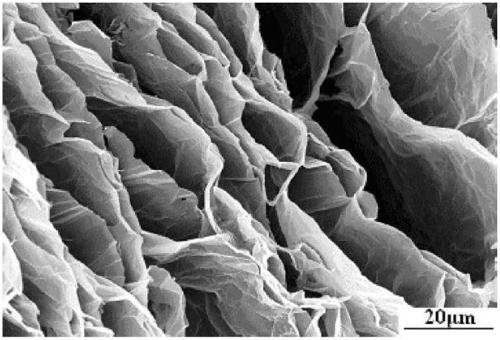

The invention belongs to the field of porous materials and discloses a high-pressure-resistant water-permeable porous material and a preparation method thereof. The porous material comprises following five components: a vinyl monomer, an oxidation-reduction initiator, a surfactant, water, and a powder filling material subjected to surface treatment with silane, or comprises the five components and aggregate. The porous material is prepared by injecting a slurry mixture formed by the five components or a uniform mixture of the slurry mixture and a large-diameter organic filling material into a mould, or injecting the slurry mixture or the mixture of the slurry mixture and the large-diameter organic filling material into a mould of a macroporous three-dimensional mesh material, curing and moulding. The cured and moulded porous material has excellent gas permeability, water permeability and high-pressure resistance. The compressive strength of the porous material is higher than 33 MPa. The bending strength of the porous material is higher than 14 MPa, and the porosity (open pores) is higher than 20%. The porous material can be repeatedly used for a plurality of times. The porous material can be used for manufacturing ceramic high-pressure slip casting moulds and used in the field of building materials and the field of water filtration and purification, and the like.

Owner:中科检测技术服务(嘉兴)有限公司

Priming coat type acrylic acid ester conductive adhesive and preparation method thereof

ActiveCN105001829AFast curing at room temperatureEasy to usePolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesive cementPolymer science

The invention discloses a priming coat type acrylic acid ester conductive adhesive and a preparation method thereof. The conductive adhesive is composed of a main agent and a primer. The main agent is composed of the following raw materials: an acrylate monomer containing at least one vinyl, a vinyl-terminated performed polymer, a conductive filling material, a stabilizing agent, a peroxide initiator, a curing accelerator and an anti-settling agent. The primer is composed of the following raw materials: a solvent and an activator. The preparation method comprises the following steps: the preparation of the main agent. The preparation method comprises the following steps : the preparation of A including 1,2,3; and the preparation of B including 1, uniformly mixing the acrylate monomer containing at least one vinyl, vinyl-terminated performed polymer and the stabilizing agent; 2, adding the conductive filling material into a resin matrix and performing uniform stirring; 3, adding the rest raw materials, removing foams, discharging and refrigerating materials for storage; the preparation of primer: including uniformly mixing the activator and the solvent in protection atmosphere, discharging materials, filling protective gas for sealing, and storing in a container with dark color at normal temperature. The priming coat type conductive adhesive has the advantages of rapid solidification at room temperature, usage convenience, good bonding strength, and good electric and heat conduction effects.

Owner:东莞优邦材料科技股份有限公司

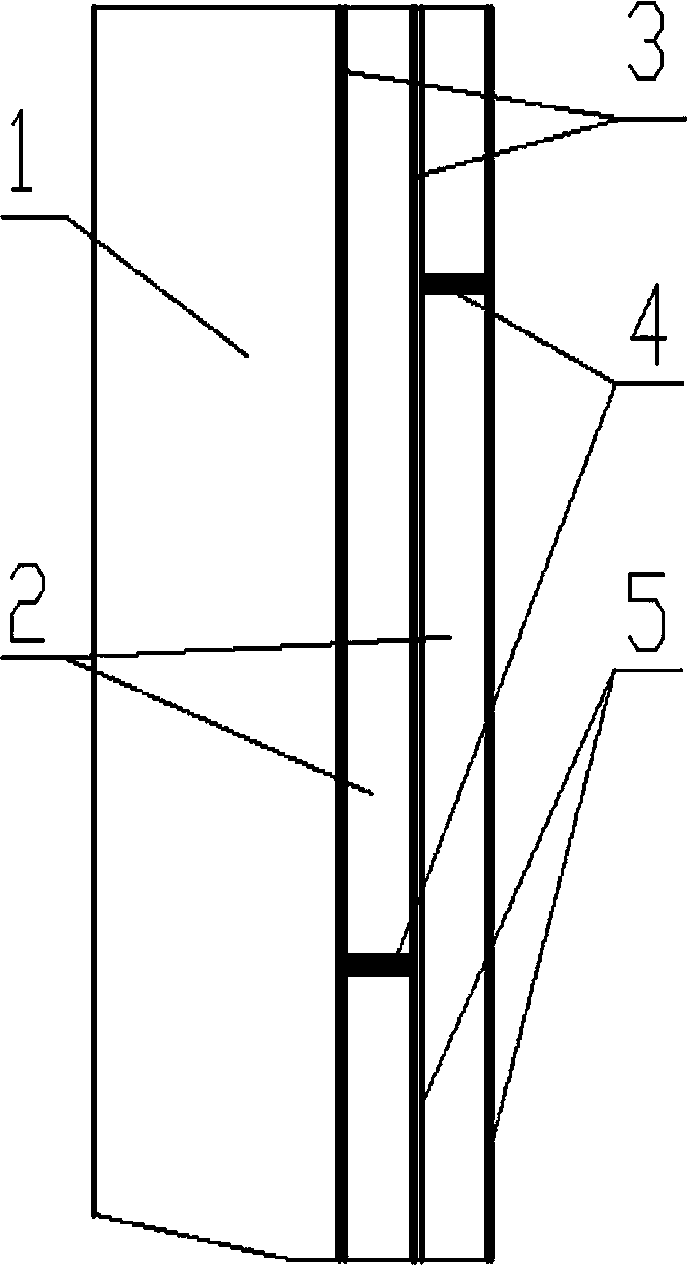

Anti-seepage self-healing underground pre-buried cable sheath

ActiveCN112582102APlay a drainage roleImprove self-healing abilityClimate change adaptationInsulated cablesThermal dilatationIron powder

The invention discloses an anti-seepage self-healing underground pre-buried cable sheath, and belongs to the technical field of cables. The anti-seepage self-healing underground pre-buried cable sheath is characterized in that an inner sheath and an outer sheath which are arranged in in-out sleeving are arranged, and a plurality of repairing embedding bodies are embedded in the inner sheath, and when cracks are generated on the outer end wall of the outer sheath, external water vapor permeates into the outer sheath, the water-soluble heat release bags on the repairing embedded bodies are dissolved in water to expose the reductive iron powder in the water-soluble heat release bags, and the reductive iron powder reacts in air to generate heat, the heat is conducted to a thermal expansion filling layer, and the thermal expansion filling layer is heated to expand to extrude the elastic discharging bags embedded in the thermal expansion filling layer. Therefore, the repair material in the elastic discharge bags is led out, the led-out repair material is used for filling and repairing the cracks of the outer sheath through a hydrolysis heat storage layer, the self-repairing of the damaged parts is completed, the self-healing capability of the outer sheath is realized, the problem of leakage of the cable sheath for a long time is effectively avoided, and the long-acting safe use of the cable is facilitated.

Owner:广西嘉意发科技有限公司

Anticorrosion method for interior of metal flue

The invention relates to an anticorrosion method for the interior of a metal flue. The method includes the steps of using flexible graphite plates as anticorrosive materials, carrying out normal-temperature curing on selected adhesive, pasting the flexible graphite plates coated with the adhesive on the inner surface of the metal flue coated with the adhesive, filling graphite paste and spraying graphite sizing agents. Through the method, the flexible graphite plates can be laid conveniently and rapidly, are easy to construct, capable of resisting 250 DEG C high temperature and resisting acid corrosion and applicable to various neutral gases or various acid gases or various fluid pipelines such as metal chimneys, petroleum pipelines and drainage pipelines, and are used for anticorrosion of the interior of the flue.

Owner:CHINA THREE GORGES UNIV

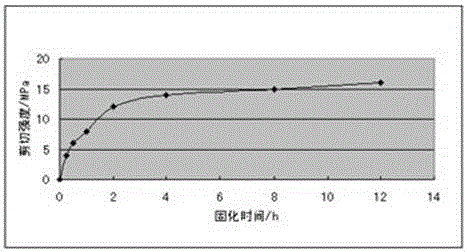

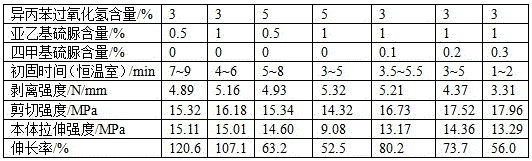

Organic one-component inserted bar glue and preparation method thereof

InactiveCN104762052AFor long-term storageLow viscosityNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer scienceAcrylic adhesive

The invention discloses an organic one-component inserted bar glue and a preparation method thereof, and belongs to the technical field of anaerobic adhesives. The organic one-component inserted bar glue is prepared from the following raw materials: methacrylic acid epoxide, triethylene-glycol dimethacrylate, acrylic acid, ethylenediamine tetraacetic acid, cumene hydroperoxide, acidified saccharin and hydracetin. By virtue of an anaerobic curing mechanism, the target of one-component inserted bar glue is reached; and the acrylic adhesive can be relatively permanently stored in a liquid state when oxygen exists, and can be cured into an insoluble and non-fusible solid at a room temperature after being isolated from air.

Owner:DALIAN UNIV OF TECH

Acrylic anaerobic adhesive

InactiveCN106811137AImprove mechanical propertiesHigh impact strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesLeveling effectAdhesive

The invention relates to the field of anaerobic adhesive, in particular to acrylic anaerobic adhesive. The acrylic anaerobic adhesive is made of raw materials including, by weight, 40-50 parts of hydroxypropyl methacrylate, 25-35 parts of bis-methacrylic acid poly-condensation glycol ester, 15-20 parts of anaerobic acrylate monomers, 8-12 parts of modified nanometer attapulgite, 10-18 parts of heat-resistant resin, 1-2 parts of initiators, 0.5-1.5 parts of accelerators, 0.5-1 part of activating accelerators and 2-4 parts of processing auxiliaries. The acrylic anaerobic adhesive has the advantages that the modified nanometer attapulgite is added into the acrylic anaerobic adhesive, accordingly, the mechanical properties of the adhesive can be enhanced, and the heat resistance and the corrosion resistance of the adhesive can be improved; the heat resistance of the acrylic anaerobic adhesive can be obviously improved by added bismaleimide resin; various raw material components are reasonably configured, accordingly, the obtained acrylic anaerobic adhesive is high in room-temperature curing speed and strength, good leveling effects can be realized by the acrylic anaerobic adhesive, and paint films on adhered surfaces are uniform and consistent and are excellent in heat resistance and corrosion resistance.

Owner:吴中区穹窿山倪源交通器材经营部

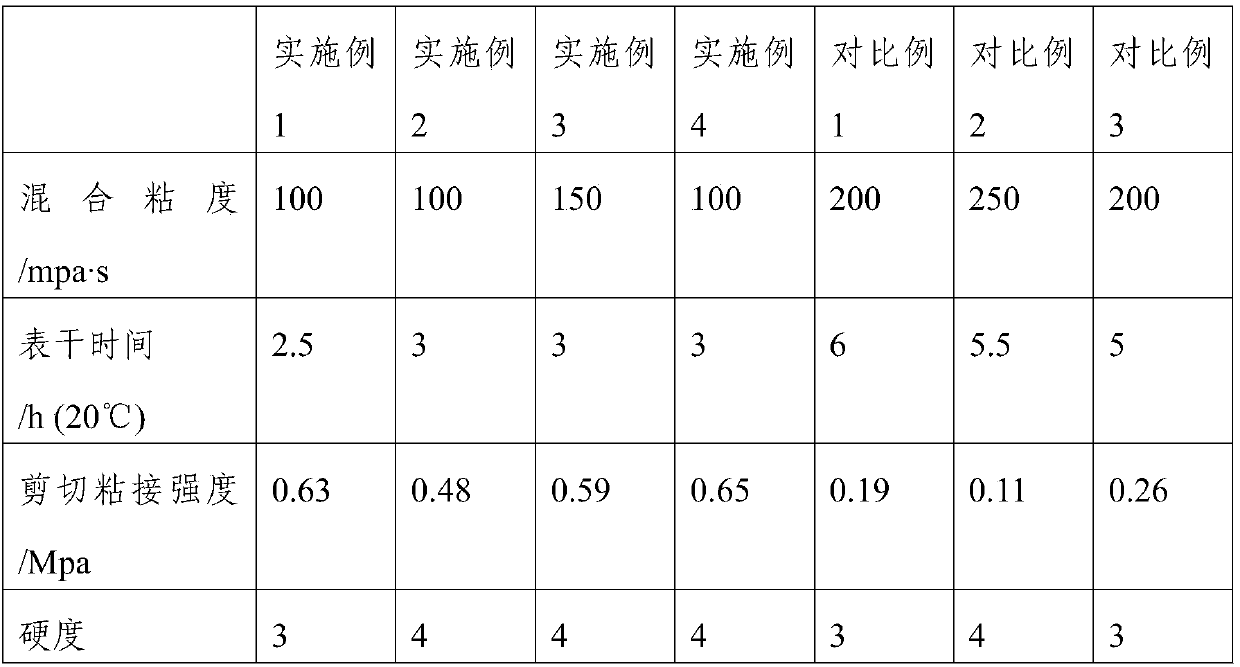

Ultralow-hardness polyurethane pouring sealant and preparation and application thereof

ActiveCN105907353AAddress process complexitySolve viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPlasticizer

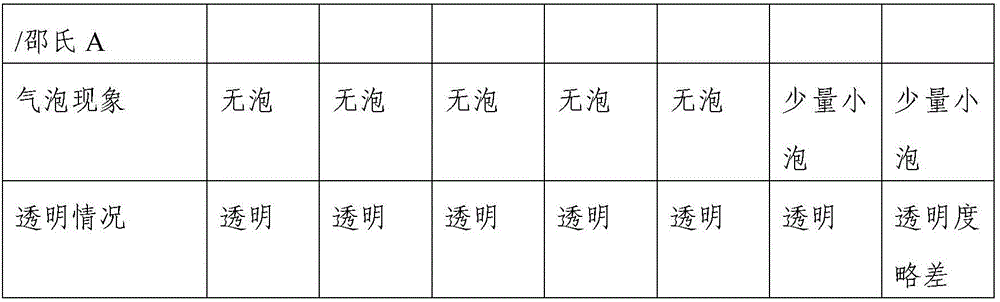

The invention relates to an ultralow-hardness polyurethane pouring sealant and a preparation method and application thereof. The polyurethane pouring sealant is composed of a component A and a component B, wherein the component A is prepared from, by weight, 90-100 parts of Polypolyol, 0.1-1 part of compound type anti-yellowing agent, 0.1-2 parts of catalyst, 0.1-1 part of defoaming agent, 0.1-5 parts of coupling agent and 0-10 parts of plasticizer, the component B is prepared from, by weight, 30-40 parts of polyisocyanate and 60-70 parts of plasticizer. The pouring sealant can be suitable for automatic pouring of handwork, is short in curing time at room temperature, and has the advantages of being transparent, few in bubble, high in insulativity, high in adhesion to metal and the like after being cured.

Owner:BEIJING POLYSTAR HITECH CO LTD

Curing agent 4,4'-biphenyl methane diisocyanate prepolymer and preparation method thereof

The invention relates to a curing agent, namely, 4, 4 (1)-diphenylmethane diisocyanate prepolymer and a preparation method thereof. The method comprises the steps that molten 4, 4(1)-MDI and an organic solvent are added into a reaction vessel, and stirred uniformly, the temperature is raised to 65 DEG C, polyhydric alcohol dehydrated through evacuation is added, to react for 2 to 4 hours at 60 to100 DEG C, and then an MDI modifier is produced; when being stirred, the mixed liquor of trimethylol propane and the organic solvent is titrated into the reaction vessel for 1 to 4 hour(s), the titration temperature is 60 to 100 DEG C, heat preservation and reaction are performed for 1 to 3 hour(s), then the temperature is raised to 90 to 100 DEG C and the heat preservation and the reaction are performed again for 1 to 4 hour(s), the temperature is reduced, and the organic solvent is added for dilution to appropriate viscosity. The curing agent has the advantages that the application scope is broad, the molecular structure of the polyhydric alcohol can be adjusted according to the requirements of users to produce the prepolymer of polyurethane coating, adhesive, and the curing agent, thestorage stability is good, the curing speed is quick, the toxicity is low, the price is low, products with high solid content can be obtained, etc.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

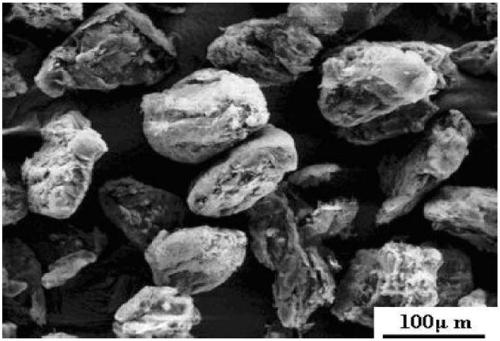

Methacrylate polymer-inorganic compound through hole material as well as preparation method and application thereof

ActiveCN104558438AEnvironmental protection and energy savingIncrease water permeability and breathabilityInorganic compoundRoom temperature

The invention discloses a methacrylate polymer-inorganic compound through hole material as well as a preparation method and an application thereof. The preparation method comprises the following steps: pouring 70-50 wt% of inorganic fillers-coated methacrylate polymer-aqueous suspension liquor into 30-50 wt% of methacrylate polymer-vinyl monomer-reactive emulsifier-initiation system premixed liquor at 10-30 DEG C, stirring for 0.5-3 minutes to obtain uniformly mixed pouring liquor, finishing pouring of the pouring liquor within 3 minutes, and curing in an environment with the room temperature of 10-30 DEG C for 1-6 hours to obtain the methacrylate polymer-inorganic compound through hole material. The methacrylate polymer-inorganic compound through hole material has the characteristics of low cost, good pouring flowability, quick curing and forming at the room temperature, opening structure, uniformly distributed tiny pores, excellent air and water permeability, relatively high strength, environmental protection and energy conservation, thereby having a wide application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

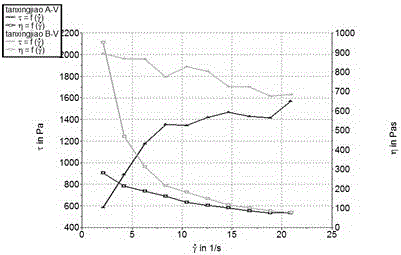

Double-component room-temperature curing adhesive and preparation method thereof

InactiveCN109504331AFast curing at room temperatureImprove stabilityNon-macromolecular adhesive additivesModified epoxy resin adhesivesChemistryVinyl ester

The invention provides a double-component room-temperature curing adhesive and a preparation method thereof. The double-component room-temperature curing adhesive is prepared from a component A and acomponent B, wherein the component A is prepared from the following raw materials in parts by weight: 40 to 50 parts of novolac vinyl ester resin and 30 to 40 parts of bisphenol A type epoxy vinyl resin; the component B comprises a peroxide initiator; the weight ratio of the component A to the component B meets the following conditions: after the component A and the component B are mixed, the peroxide initiator accounts for 0.5 to 3.5 percent of the total weight of the mixture of component A and component B. According to the double-component room-temperature curing adhesive, the novolac vinylester resin and the bisphenol A type epoxy vinyl resin are selected as main body resin of the component A, and the peroxide initiator is selected as an effective component of the component B, so thatthe room-temperature curing speed of the adhesive is extremely increased and the adhesive shows more excellent stability when being used for bonding electronic products.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

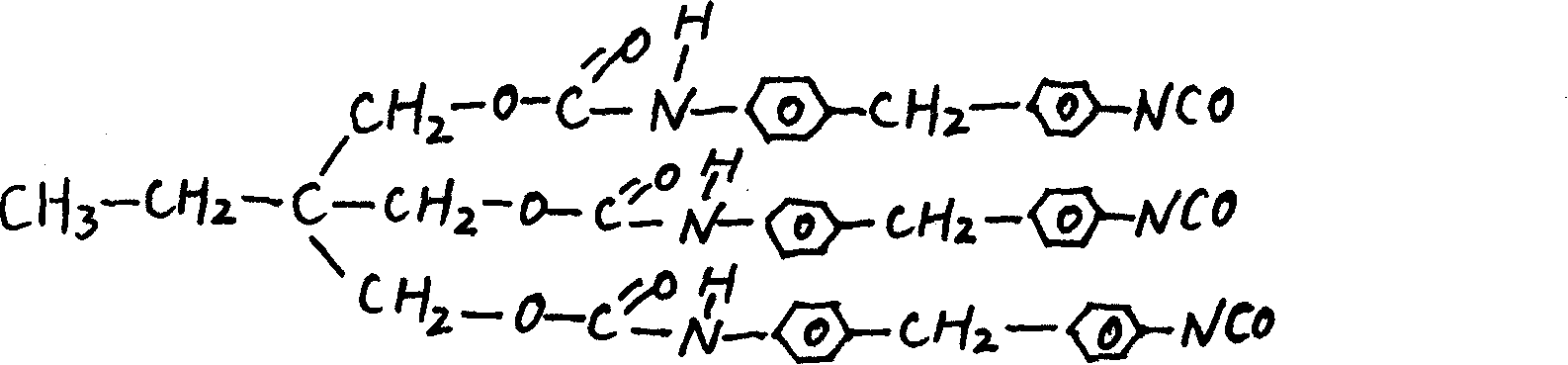

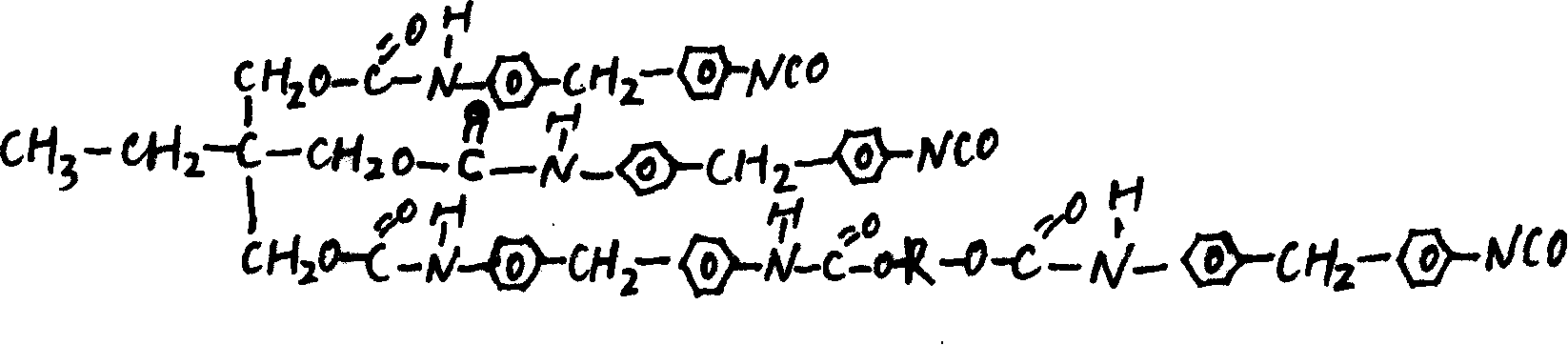

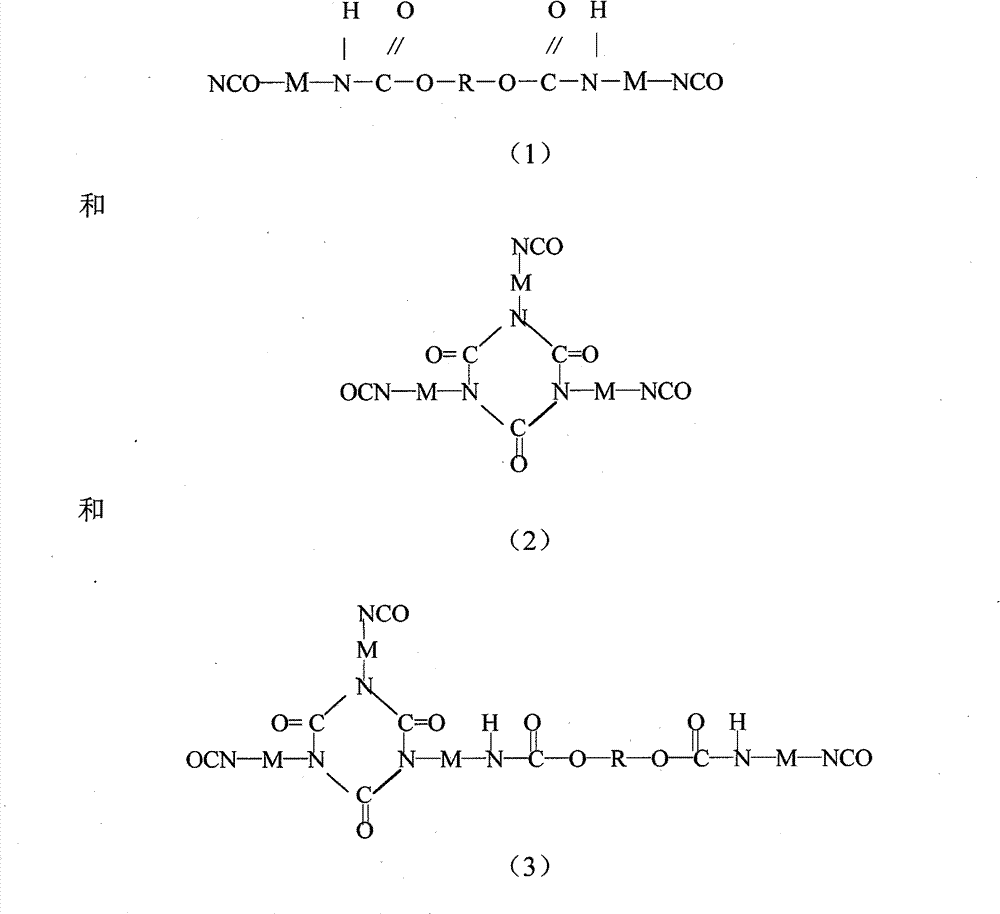

Curing agent methylene diphenyl diisocyanate tripolymer and method for preparing same

ActiveCN102212182BSolve the problem that can not be three polyEasy to manufacturePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsOrganic solventAdhesive

The invention discloses a curing agent, namely a methylene diphenyl diisocyanate (MDI) tripolymer and a method for preparing the same. The method comprises the following steps of: adding the MDI and an organic solvent into a reaction kettle, raising the temperature, dissolving the MDI, stirring uniformly, adding dehydrated polyol, and reacting for 1 to 6 hours at the temperature of between 40 and90 DEG C to obtain modified MDI; reducing the temperature to 40 DEG C, dripping mixed solution of a trimerization catalyst and an organic solvent, reacting at the temperature of between 30 and 80 DEGC, and adding a polymerization inhibitor when the percentage of isocyanate group (NCO) reaches a preset value; and reducing the temperature to obtain the MDI tripolymer curing agent. The invention provides the method for preparing the tripolymer curing agent by using the MDI. The process is simple, the requirements of equipment are low, the content of the tripolymer is high, and the curing agent is well soluble in resins and can substitute a tolylene diisocyanate (TDI) tripolymer with similar performance. The curing agent is mainly used for being matched with two-component polyurethane coatings and main agents of adhesives, and can also be used for other fields.

Owner:J&H XIANGYANG CHEM

Porcelain imitated adhesive

InactiveCN102676103AFast curing at room temperatureHigh bonding strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses a porcelain imitated adhesive, which comprises the following main components in part by mass: 80 to 100 parts of E-44 epoxy resin, 3 to 10 parts of filler, 5 to 20 parts of packing, 1 to 5 parts of flexibilizer, 1 to 5 parts of coupling agent and 15 to 20 parts of curing agent. The prepared porcelain imitated adhesive is mainly used for repairing enamel and ceramic products, and has the characteristics of quick curing at room temperature, high bonding strength, acid and alkaline corrosion resistance and the like.

Owner:杨青松

Instrument signal line insulation coating and preparation method thereof

InactiveCN105969060AExtended service lifeImprove adhesionFireproof paintsEpoxy resin coatingsEpoxyInsulation layer

The invention discloses an instrument signal line insulation coating and a preparation method thereof, and relates to the technical field of signal line materials. The instrument signal line insulation coating is prepared from, by weight, 35-40 parts of epoxy resin, 10-15 parts of C9 petroleum resin, 10-15 parts of chlorosulfonated polyethylene, 6-10 parts of cinerite, 5-8 parts of petroleum coke, 5-8 parts of rubber powder, 4-6 parts of carnauba wax, 4-6 parts of plastification additive, 3-5 parts of asbestos powder, 3-5 parts of molecular sieve raw powder, 2-3 parts of cetyl alcohol, 2-3 parts of chlorinated paraffin, 1-2 pars of wool fat, 1-2 parts of aluminum-magnesium silicate and 0.1-0.2 part of nano lanthanum oxide. The insulation coating has excellent moisture resistance, fire resistance and insulation performance, the service life of an insulation layer is effectively prolonged, and therefore a signal line is protected better. By means of the added plastification additive, the flexibility of a coating can be enhanced, the adhesive force of the coating on the insulation layer can be fully improved, and the phenomenon that a coating is pulverized and falls off after the signal line is used for a long time is avoided.

Owner:马逸晗

Formaldehyde-free glue for automotive trims and preparation method of formaldehyde-free glue

InactiveCN107513356ANon-irritatingNon-toxic and non-irritatingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl acetateToxic material

The invention provides formaldehyde-free glue synthesized from chemical materials for automotive trims and a preparation method of the formaldehyde-free glue. The formaldehyde-free glue is prepared from polyvinyl acetate, ethylene glycol monoethyl ether, dibutyl acetate, a water retention agent, a food defoamer, a flame retardant, a food preservative, a thickener and water in a certain proportion. The preparation method comprises the steps of controlling the temperature of a solution reaction system at 30-40 DEG C, and uniformly stirring by virtue of a stirring machine. According to the formaldehyde-free glue, the problem that common glue contains toxic substances such as formaldehyde is solved; and the formaldehyde-free glue has the excellent characteristics of environment friendliness, safety in operation, relatively high curing speed, low processing cost and the like.

Owner:LIUZHOU YAXIANG TECH CO LTD

A kind of ultra-low hardness polyurethane potting glue and its preparation and application

ActiveCN105907353BHigh mixing viscosityLow mixing viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPlasticizer

Owner:BEIJING POLYSTAR HITECH CO LTD

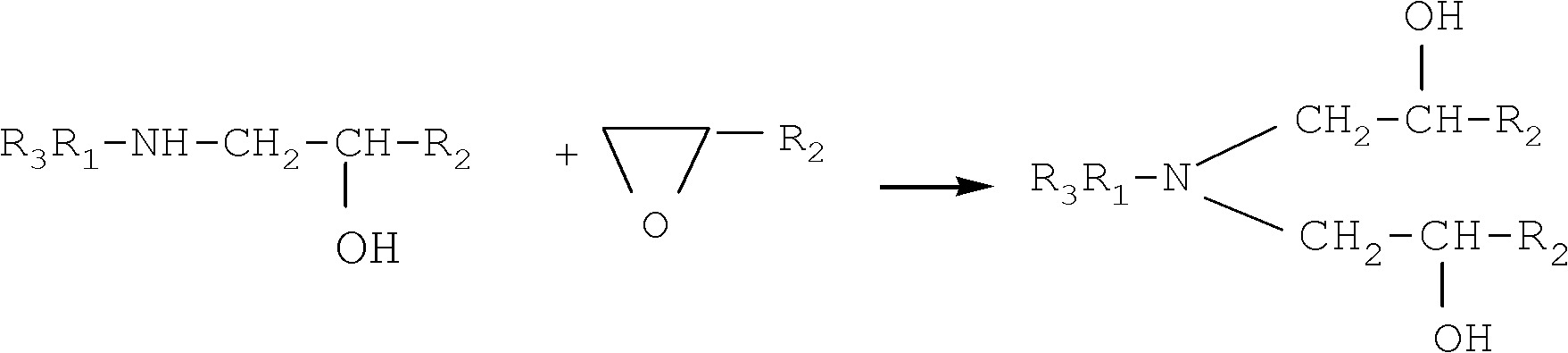

Method for synthesizing low-viscosity epoxy resin curing agent

The invention relates to a method for synthesizing a low-viscosity epoxy resin curing agent, which comprises the steps of: using adipic acid and polyamine as raw materials; weighing the adipic acid and the polyamine according to a mol ratio of 1 to (1.2-4); adding all the polyamine into a stirring reactor for one time, while adding the same mass of adipic acid into the stirring reactor in batch at intervals of 5-30 min, reacting under the condition of 155-180 DEG C for 1-2.5 h; preserving heat and obtaining a polyamide resin which is served as the low-viscosity epoxy resin curing agent. The method disclosed by the invention does not need saponification and acidification, and is more energy-saving and more environment-friendly; the polyamide curing agent prepared by the method is free from generation of pungent smell, rapid in curing at a room temperature, wide in application range when being used together with epoxy resin, low in viscosity, and also, when being used together with the low-viscosity epoxy resin, is convenient in operation even under the condition of low temperature; in addition, the polyamide curing agent is convenient in construction during use, excellent in quality, and suitable for large scale production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

AB glue based on methyl methacrylate

PendingCN114262571AHigh bonding strengthFast curing at room temperatureNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceNitrile rubber

The invention provides AB glue based on methyl methacrylate. The AB glue is prepared from the following components in parts by mass: 100 to 160 parts of methyl methacrylate, 0.1 to 0.6 part of stabilizer, 0.1 to 0.9 part of pigment, 50 to 65 parts of hydroxyethyl methylacrylate, 10 to 18 parts of reinforcing monomer and 30 to 40 parts of nitrile rubber buna. After the scheme is adopted, the bonding strength is improved, the room-temperature curing speed is accelerated, and the comprehensive performance is excellent.

Owner:湖南浩森胶业有限公司

High elasticity room temperature rapid curing acrylate structural adhesive and preparation method thereof

InactiveCN103571406BFast curing at room temperatureExtensive bondingNon-macromolecular adhesive additivesAcid polymer adhesivesEpoxyPolymer science

The present invention is a high-elastic room-temperature fast-curing acrylate structural adhesive and its preparation method. The acrylate structural adhesive consists of two components, A and B, including: an oxidizing agent and a reducing agent for initiating system polymerization, and (meth)acrylate Monomers or (meth)acrylate oligomers, (meth)acrylic acid, (meth)acrylate phosphate, toughening and tackifiers, stabilizers and other additives, may also contain plasticizers and cyclic oxygen resin. The A and B components are combined in a certain proportion. The acrylate structural adhesive of the invention has fast curing speed at room temperature, high elongation and good elasticity, and can be bonded to a wide range of substrates.

Owner:TONSAN ADHESIVES INC

Pellet glue and preparation method thereof

InactiveCN105131884AImprove water resistanceGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesElastomerCITRATE ESTER

The invention relates to the field of auxiliary materials for photoelectric element processing, in particular to pellet glue and a preparation method thereof. The pellet glue is prepared from a first component and a second component. The weight ratio of the first component to the second component is 2.5-3.5:1. The first component comprises epoxy resin, elastomers, heating expandable microspheres, citrate, filler and a thixotropic agent. The second component comprises a ketimine oxygen curing agent, a fatty amine oxygen curing agent, an arylamine oxygen curing agent, a silane coupling agent, an epoxy curing catalyst, heating expandable microspheres, filler and a thixotropic agent. When the glue is used for bonding diamond pellets and a diamond milling and grinding wheel to form a solid abrasive grinding tool, water resistance is good, bonding force is high, and room temperature curing is quick; temperature is not high in the heating and glue removing process, and residual glue is easy to remove.

Owner:云南光电辅料有限公司

Non-formaldehyde glue for automotive interiors

InactiveCN107488422ANon-irritatingNon-toxic and non-irritatingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl acetatePreservative

The invention provides non-formaldehyde glue for synthesizing automotive interiors by utilizing chemical materials. The non-formaldehyde glue is prepared from polyvinyl acetate, ethoxyethanol acetate, sec-butyl acetate, a water-retaining agent, an edible defoaming agent, a flame retardant, an edible preservative, a thickening agent and water according to a certain proportion. A preparation method for the non-formaldehyde glue comprises the steps of controlling the temperature of a solution reaction system to 30-40 DEG C, and stirring uniformly by using a stirring machine. The non-formaldehyde glue provided by the invention solves the problem of toxic substances such as formaldehyde contained in common glue and has the excellent characteristics of environment friendliness, safety in operation, higher curing speed, low processing cost and the like.

Owner:LIUZHOU YAXIANG TECH CO LTD

A strong double-sided tape

ActiveCN107353839BHigh activityImprove adhesionFilm/foil adhesivesPolyureas/polyurethane adhesivesDispersityAdhesive

The invention discloses a powerful double-sided adhesive tape and relates to the field of double-sided adhesive tapes. The powerful double-sided adhesive tape is prepared through uniformly coating both sides of a plastic film base layer with an adhesive, wherein the adhesive is prepared through mixing a nano-montmorillonite suspension, rhizoma dioscoreae surface slime and carbobenzoxy chloride, which are in the mass ratio of (10 to 12): (1 to 2): (0.1 to 0.3), and then, carrying out high-speed dispersion on a polyurethane prepolymer. The powerful double-sided adhesive tape disclosed by the invention has good water resistance and can be used in a long term in wet or water-including environments without adhesion property lowering; and the powerful double-sided adhesive tape is good in stability and dispersity, is pollution-free and odor-free and is free of influence on human health.

Owner:广东硕成科技股份有限公司

Two-component room-temperature-vulcanized silicone rubber and its individual packaging method

InactiveCN1702117AImproved adhesive bonding abilityIncreased shear strengthContainers with multiple articlesPolymer scienceVulcanization

The invention discloses a bi-component room-temperature silicon sulfide rubber and its packing method. Existing bi-component room-temperature silicon sulfide rubber is added with water-solubility macromolecular solution or emulsion containing hydroxyl group as cross linker, so it can achieve sticking effect without handling surface of object. Meanwhile, the product possesses intrinsic properties such as fast curingprocess rate and deep consolidation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com