Double-component room-temperature curing adhesive and preparation method thereof

A room temperature curing and adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of short storage time of adhesives, inability to form conductive circuits, long curing time, etc., to speed up room temperature curing Speed, prolonged anti-settling effect, excellent anti-settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

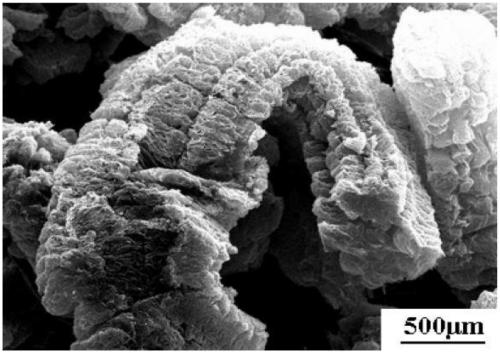

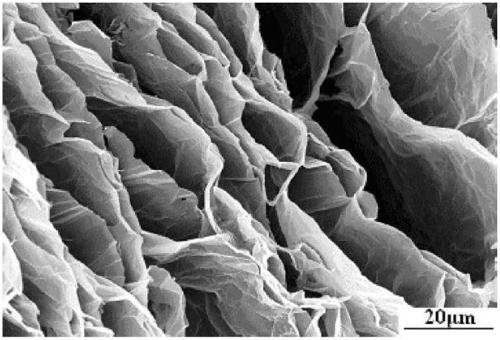

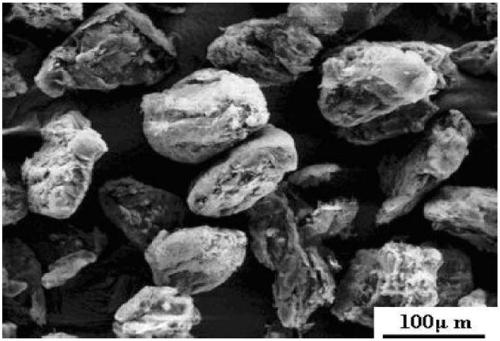

[0048] The preparation method of the modified graphite powder that the embodiment of the present invention uses is:

[0049] In an empty tank equipped with ultrasonic treatment, vacuuming and feeding devices, inject expandable graphite and inject general-purpose o-phthalic unsaturated polyester premixed with 0.5-1.2% cobalt salt accelerator and 1-2% methyl ethyl ketone peroxide resin so that it just submerges the top of the expandable graphite. After sealing, evacuate to -0.1Mpa, and ultrasonically disperse for 2-3 hours, then take out the expandable graphite and place it in an oven at 60-80°C for thermal curing for 5-12 hours. Take out the solidified material, remove the corners, top and bottom materials, cut the material into small pieces and put it into a dry ball mill to grind to get a semi-finished product, then transfer it to a fine grinder and grind it to 800 mesh to 1250 mesh, and pass through the screen three times Finally, modified graphite powder is obtained.

[0...

Embodiment 1

[0052] This embodiment provides a two-component room temperature curing adhesive. The raw materials in the A component of the two-component room temperature curing adhesive include: 50 parts of phenolic vinyl ester resin, bisphenol A type epoxy ethylene 30 parts of base resin, 12 parts of conductive carbon black, 1.5 parts of BYK-142, 0.04 parts of hydroquinone, 0.5 parts of N,N-dimethylaniline, and 5 parts of modified graphite powder.

[0053] The raw materials of the B component include: 60 parts of benzoyl peroxide, 30 parts of dibutyl phthalate, and 30 parts of flake graphite powder in parts by weight.

[0054] When used, A component and B component are mixed in a weight ratio of 100:4.

[0055] Among them, the preparation method of component A includes: putting novolac vinyl ester resin, bisphenol A type epoxy vinyl resin into a planetary stirring tank equipped with feeding device, temperature control equipment, high-speed shear dispersion disc and vacuum equipment. Resi...

Embodiment 2

[0058] The preparation method of component A and component B in the two-component room temperature curing adhesive provided in Examples 2-15 is the same, the difference is that the selection of each raw material and the proportion of each substance in component A and component B are different, wherein , in each embodiment, the raw materials of component A are shown in Table 1, and the raw materials of component B are shown in Table 2. Wherein, in Example 2, A component and B component are mixed in a weight ratio of 100:4, and in Examples 3-15, A component and B component are mixed in a weight ratio of 100:3.

[0059] A component table in table 1 embodiment 1~15 (example 1~15)

[0060]

[0061]

[0062] In table 1 embodiment 1~15 (example 1~15) A component composition list (continued)

[0063]

[0064] B component composition list in table 2 embodiment 1~15 (example 1~15)

[0065]

[0066]

[0067] B component composition list (continued) in table 2 embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com