Toughened environmental-friendly back mesh glue as well as preparation method and application thereof

A back mesh adhesive, toughening type technology, applied in the direction of adhesives, modified epoxy resin adhesives, adhesive additives, etc., can solve the problems of unfavorable back mesh adhesive indoor construction, high brittleness, stone crushing and other problems, and achieve accelerated speed. The effect of room temperature curing speed, good toughness strength, excellent rigidity strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 15

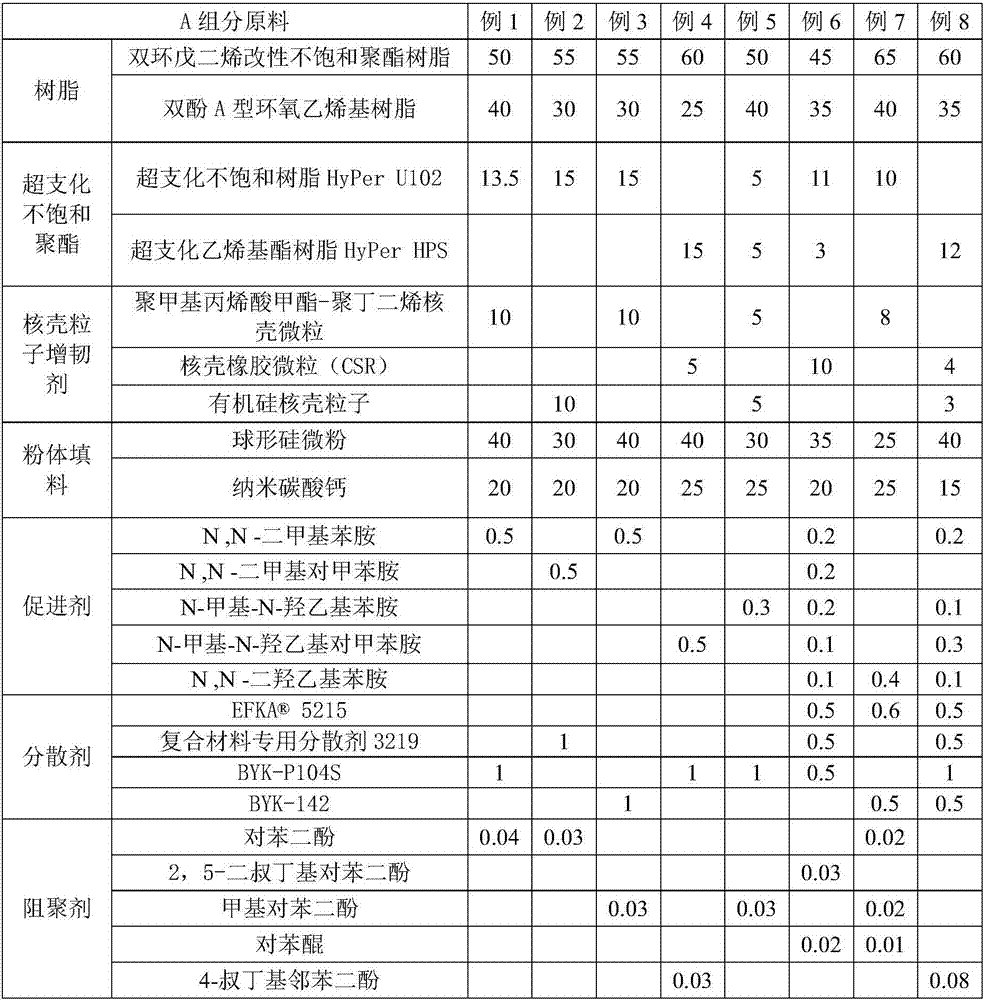

[0043] Embodiment 1-embodiment 15 (abbreviated as example 1-example 15 in the table) are all preferred embodiments of the present invention), A component composition is listed in Table 1, and B component composition is listed in Table 2 (Table 1, Table The data of each raw material in 2 is calculated according to the ratio of parts by weight):

[0044] Table 1 A component

[0045]

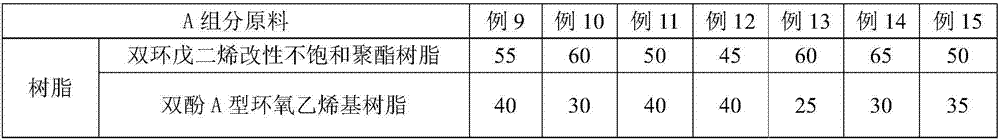

[0046] Table 1 A component (continued)

[0047]

[0048]

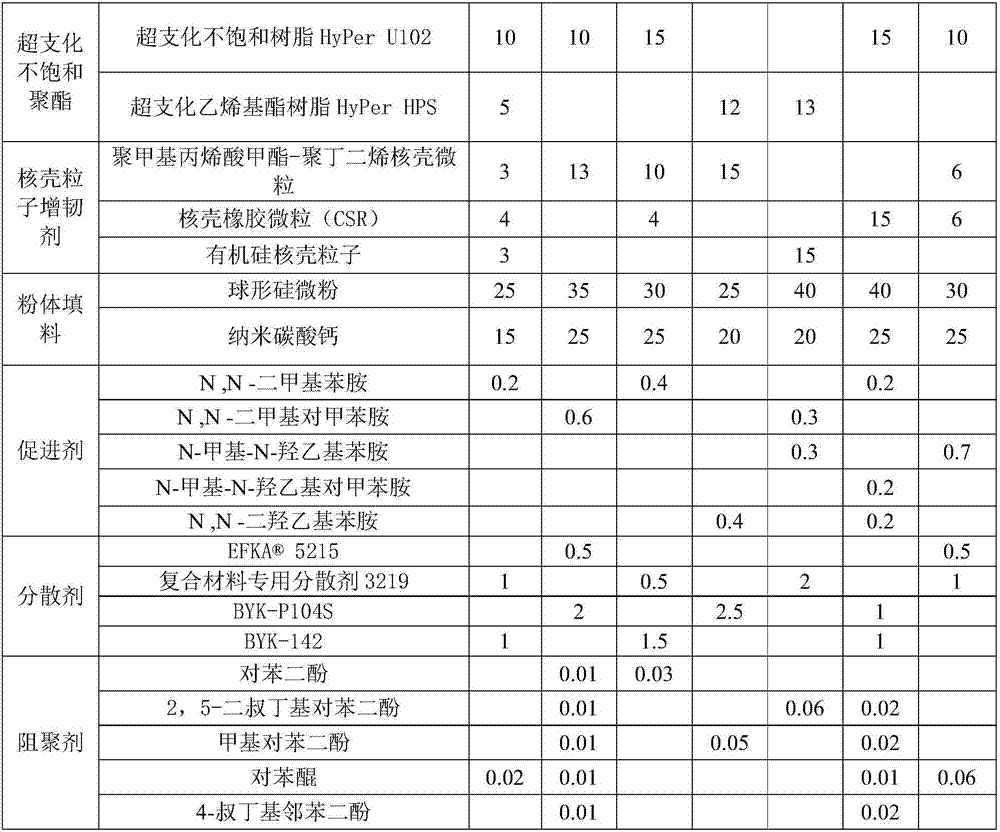

[0049] Table 2 B component

[0050]

[0051]

[0052] Table 2 B component (continued)

[0053]

[0054] Prepare the backing adhesive according to the proportions in Table 1 and Table 2 above. The component B is stirred in a kneading tank for 1-2 hours. When used, it can be mixed completely in a weight ratio of 100:5-10, and the curing agent accounts for 0.5%-3.5% of the total weight of the mixture of A component and B component.

[0055] With reference to the People's Republic of China Building Materials Industry Stand...

Embodiment 1

[0065] Embodiment 1: preferred embodiment embodiment 1 of the present invention;

Embodiment 2

[0080] Embodiment 2 of the present invention: 55 parts of dicyclopentadiene modified unsaturated polyester resin, 30 parts of bisphenol A type epoxy vinyl resin, 15 parts of hyperbranched unsaturated polyester;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com