Patents

Literature

810results about How to "Improve freeze-thaw resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

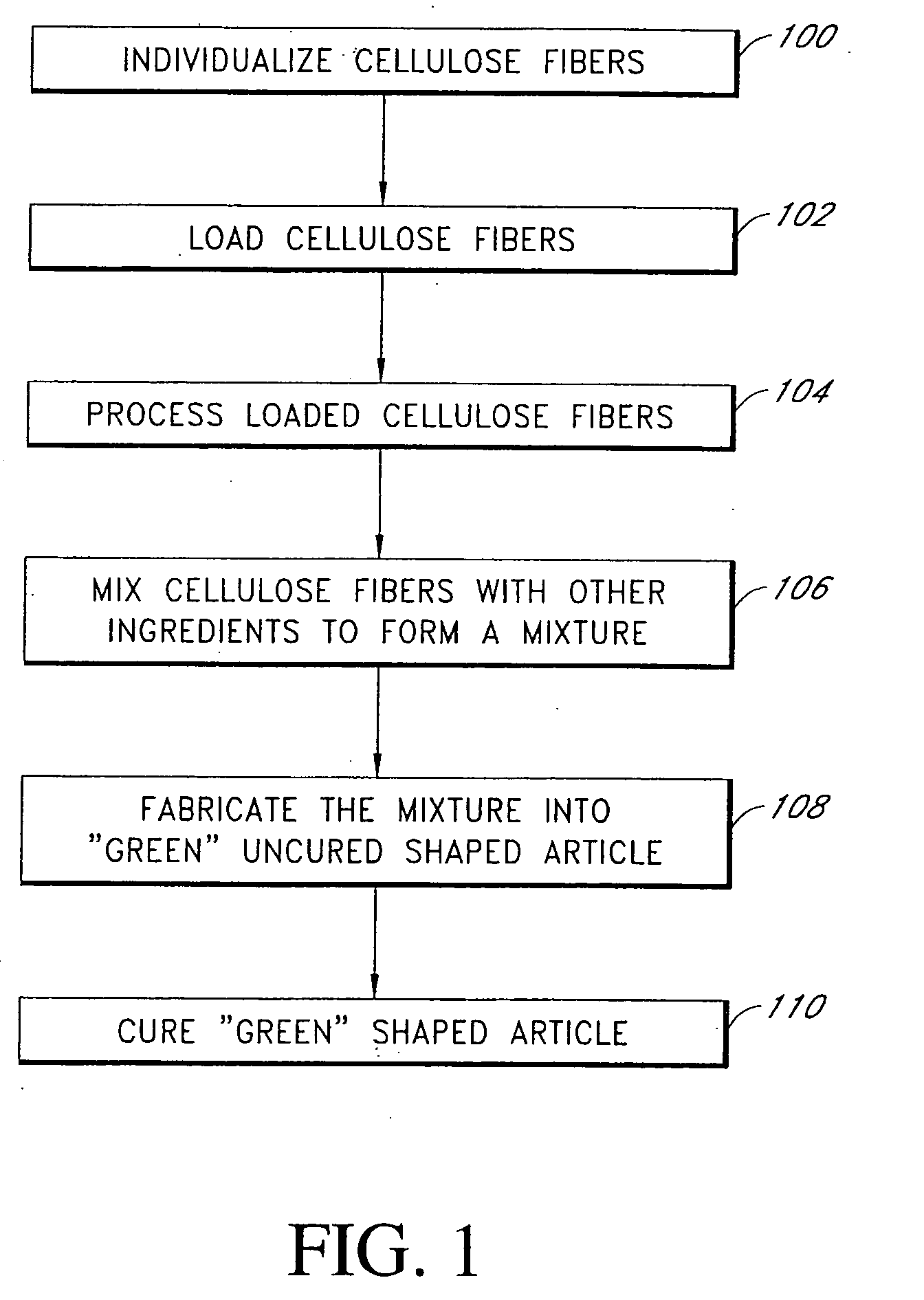

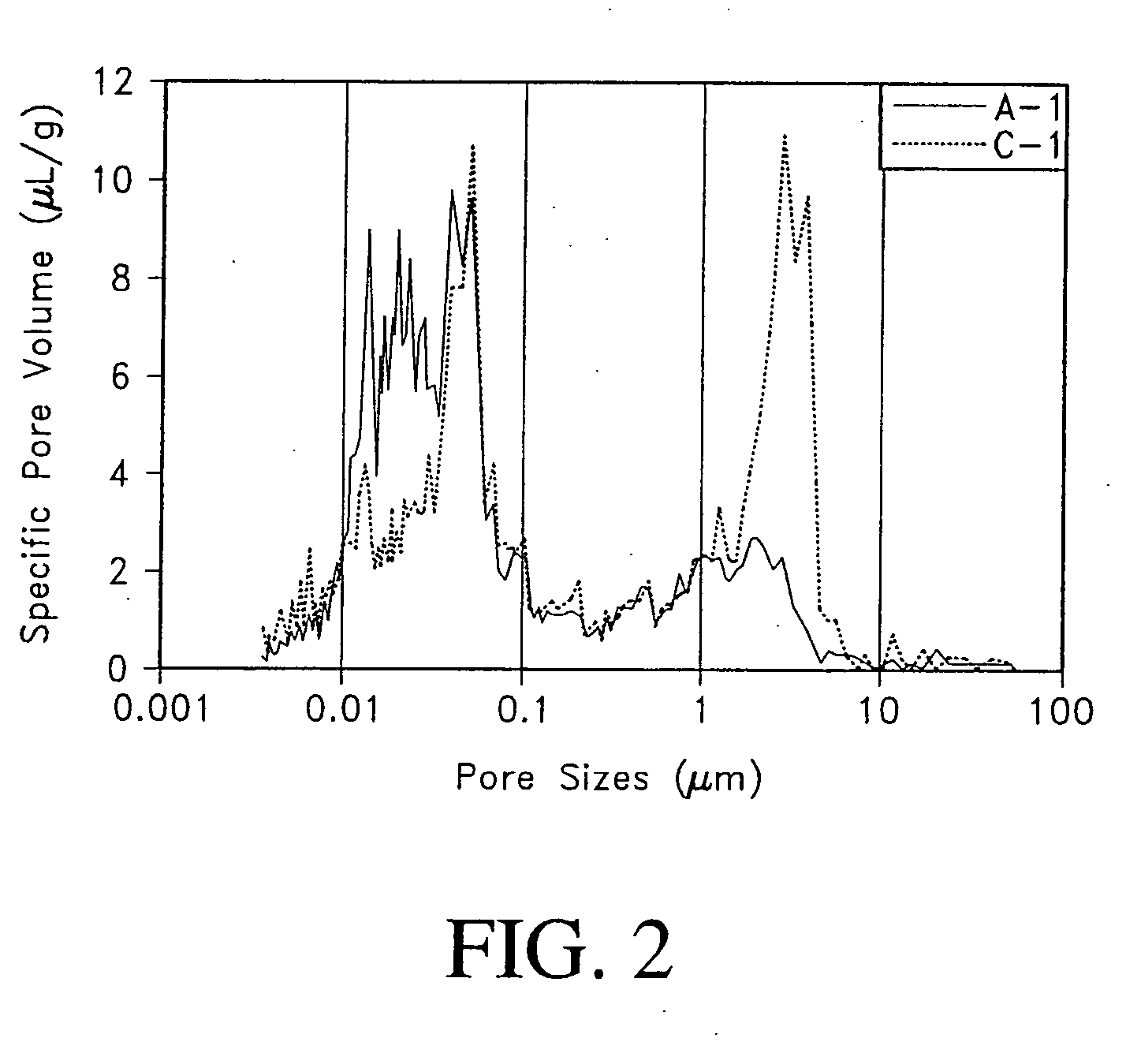

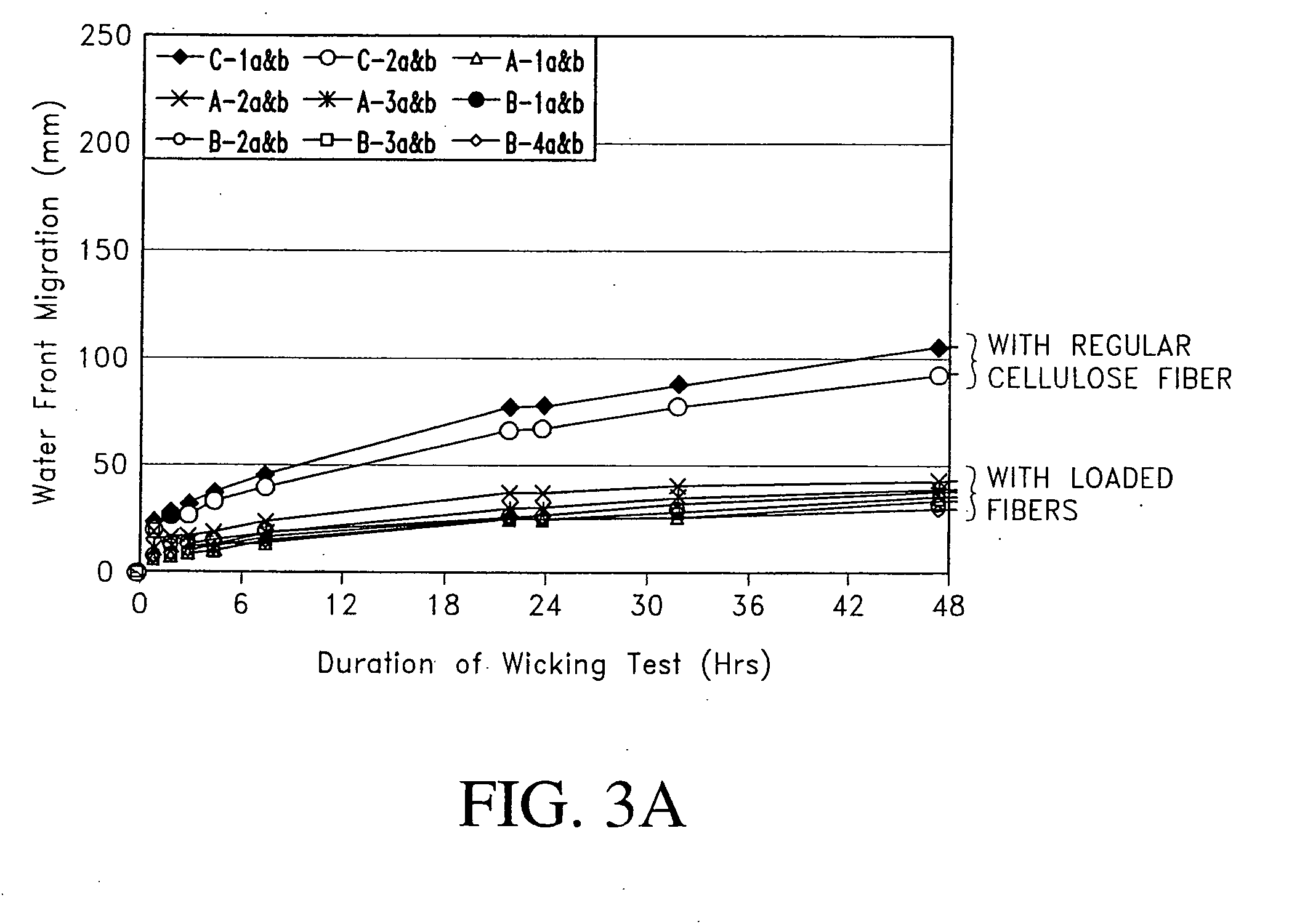

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

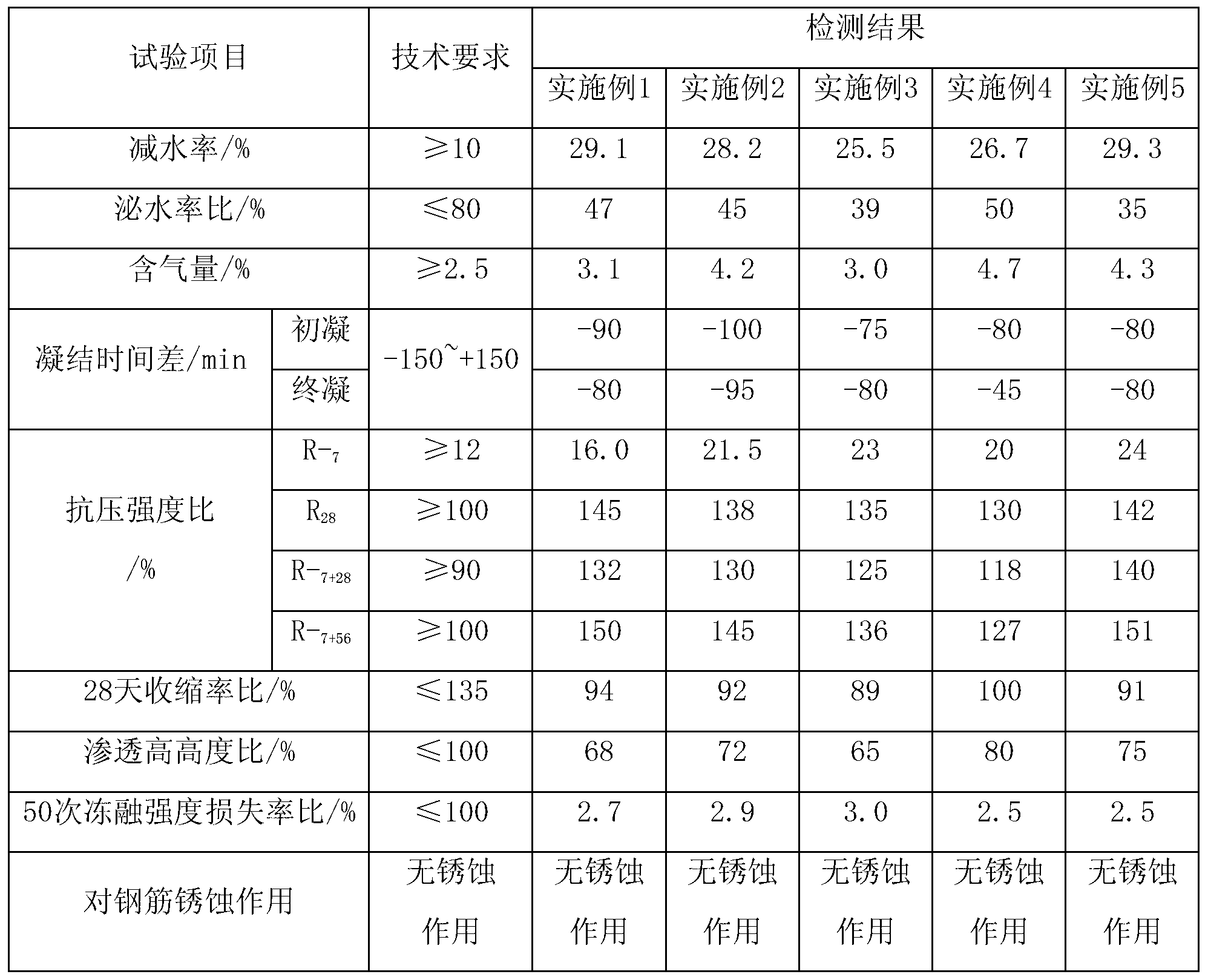

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

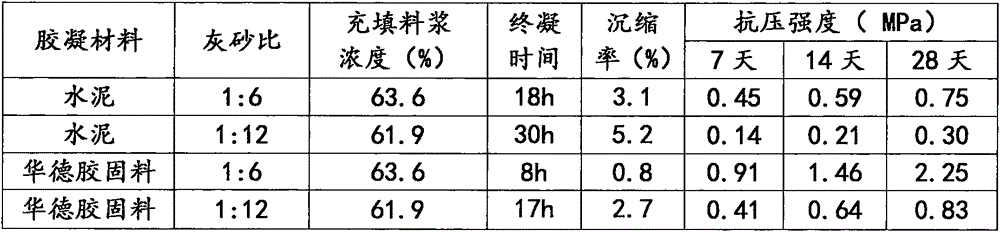

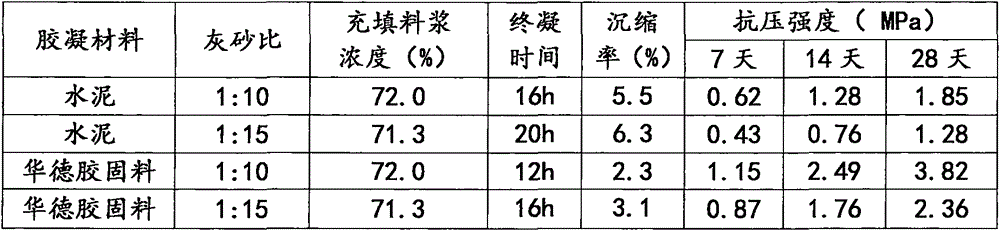

Low-shrinkage early-strength type mine filling cementing material

InactiveCN106746785AReduce surface tensionSmall shrinkageSolid waste managementCement productionGypsumSlag

The invention relates to a low-shrinkage early-strength type mine filling cementing material. The cementing material comprises the following components in percentage by weight: 50-90% of slag powder, 5-25% of cement or cement clinker, 1-30% of mineral additive, 0-10% of gypsum, 0.5-10% of alkali activator and 0.1-10% of shrinkage-reducing and cracking-resistant material. The invention solves the problem that fillers are prone to high shrinkage, cracking, slow setting and low strength when a slag-based alkali activation material is used for full tailing filling of a mine and the concentration of filling slurry is low especially in case of improper curing. The material is used instead of cement for mine filling, has favorable adaptability for tailings of different concentrations (55-80%), and has the advantages of fast filler setting, high strength and low shrinkage.

Owner:北京华德创业环保设备有限公司

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

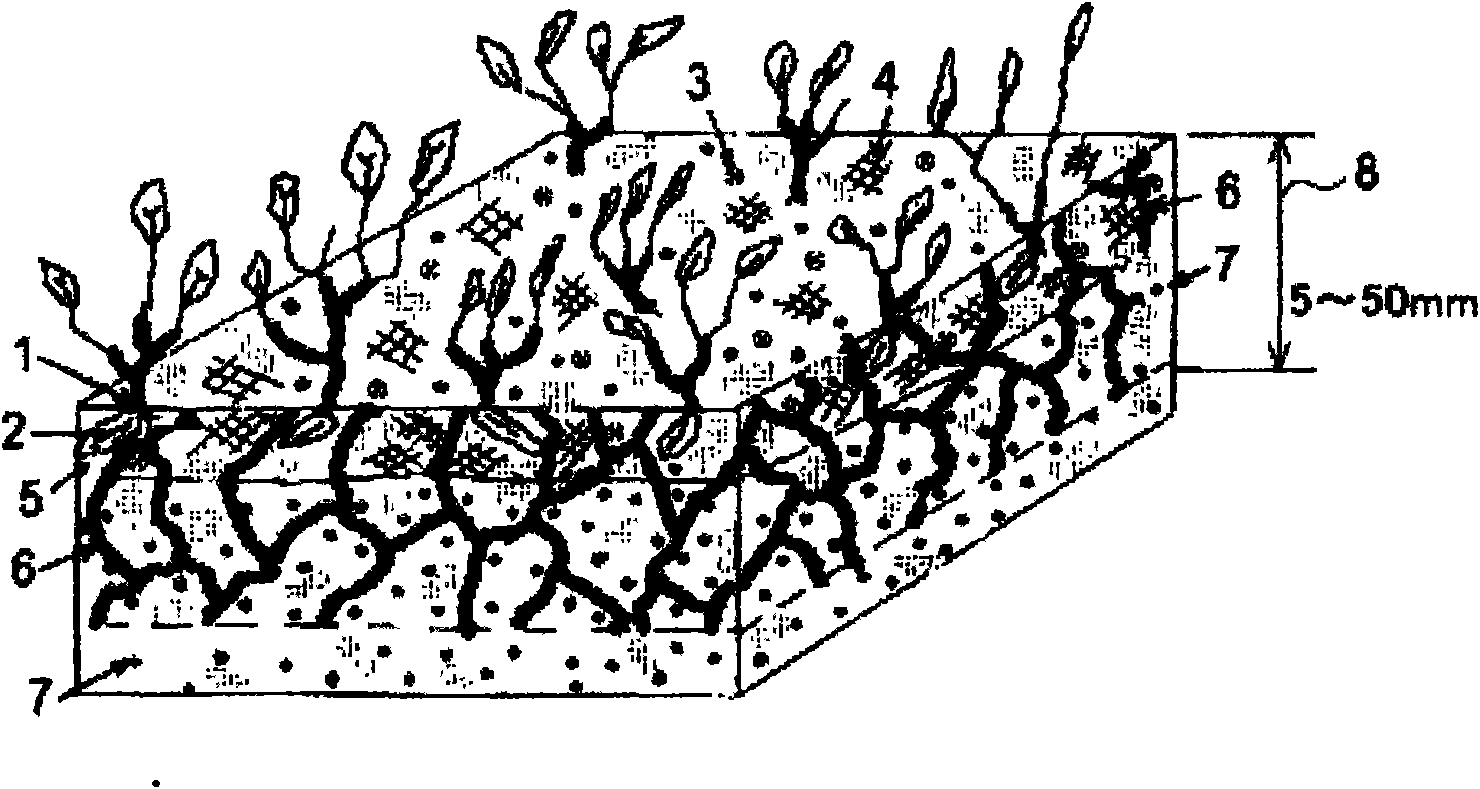

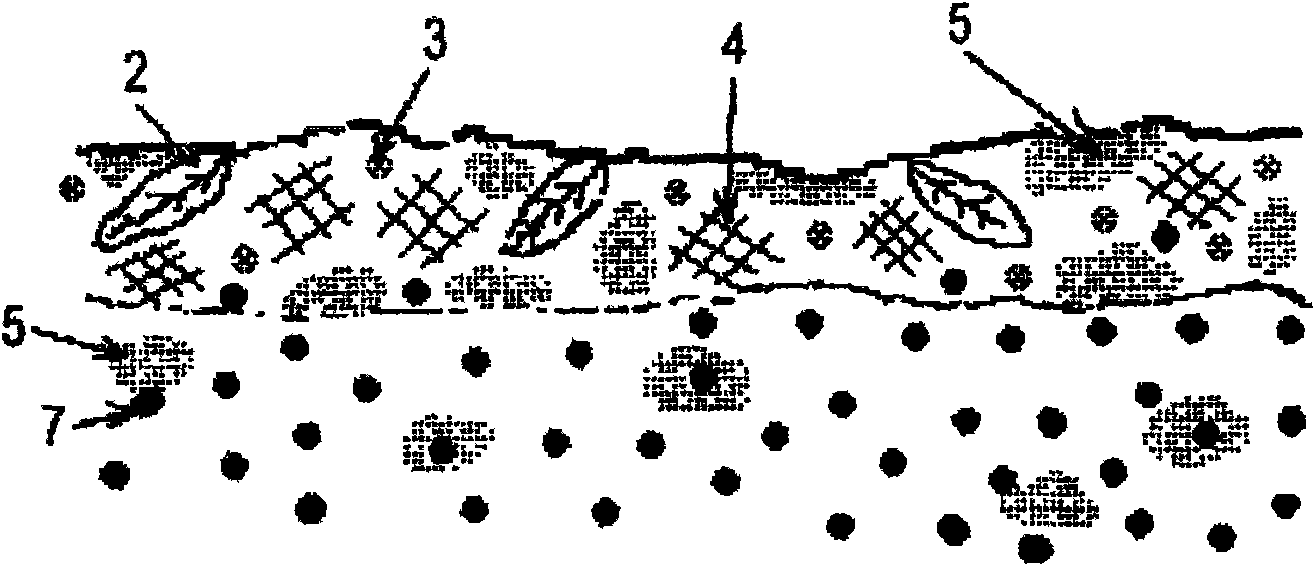

Desert control method of chemical sand-fixing greening technology based on organic composite materials

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

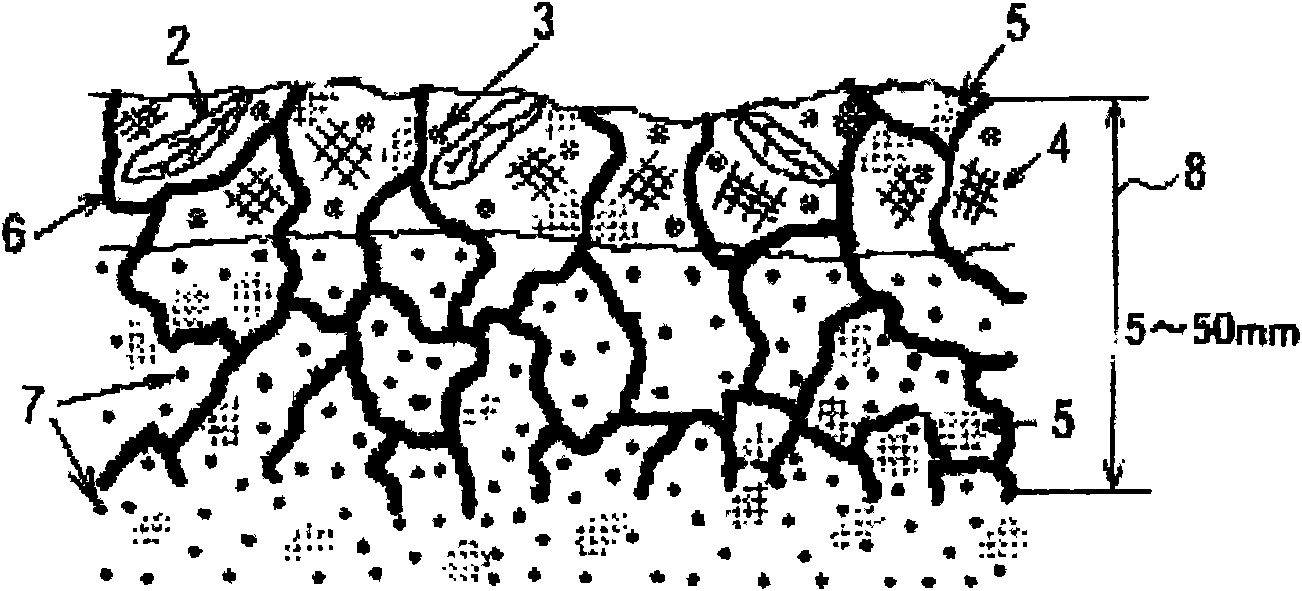

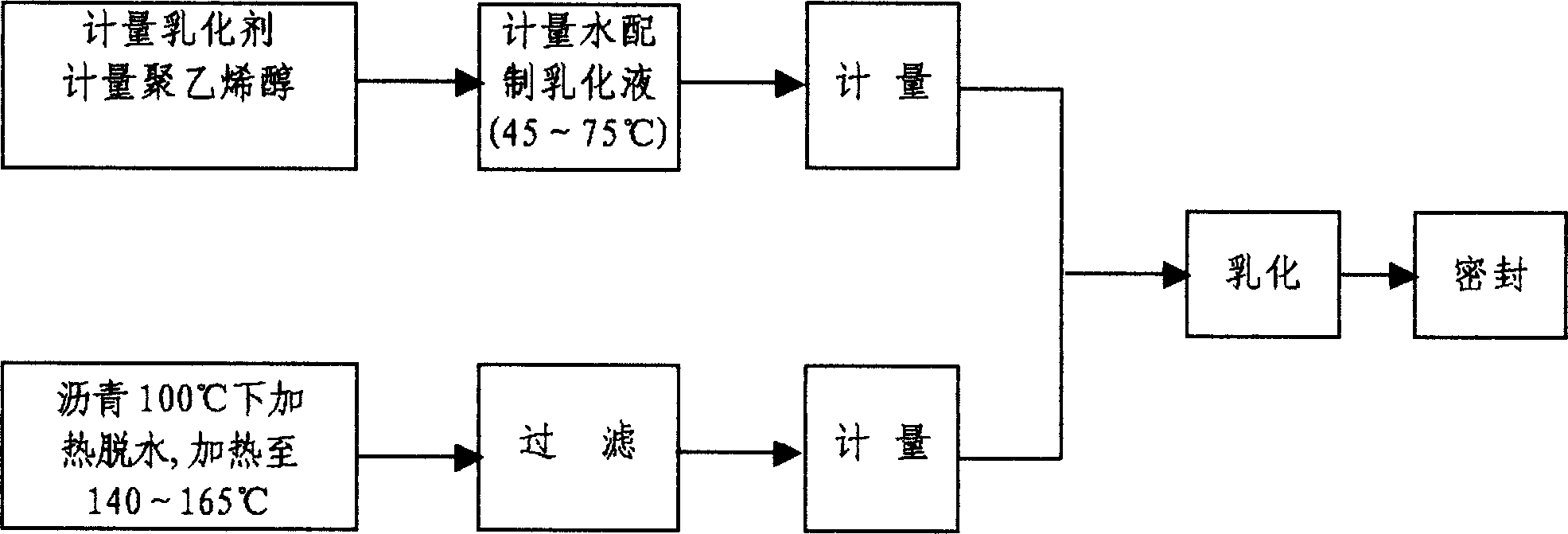

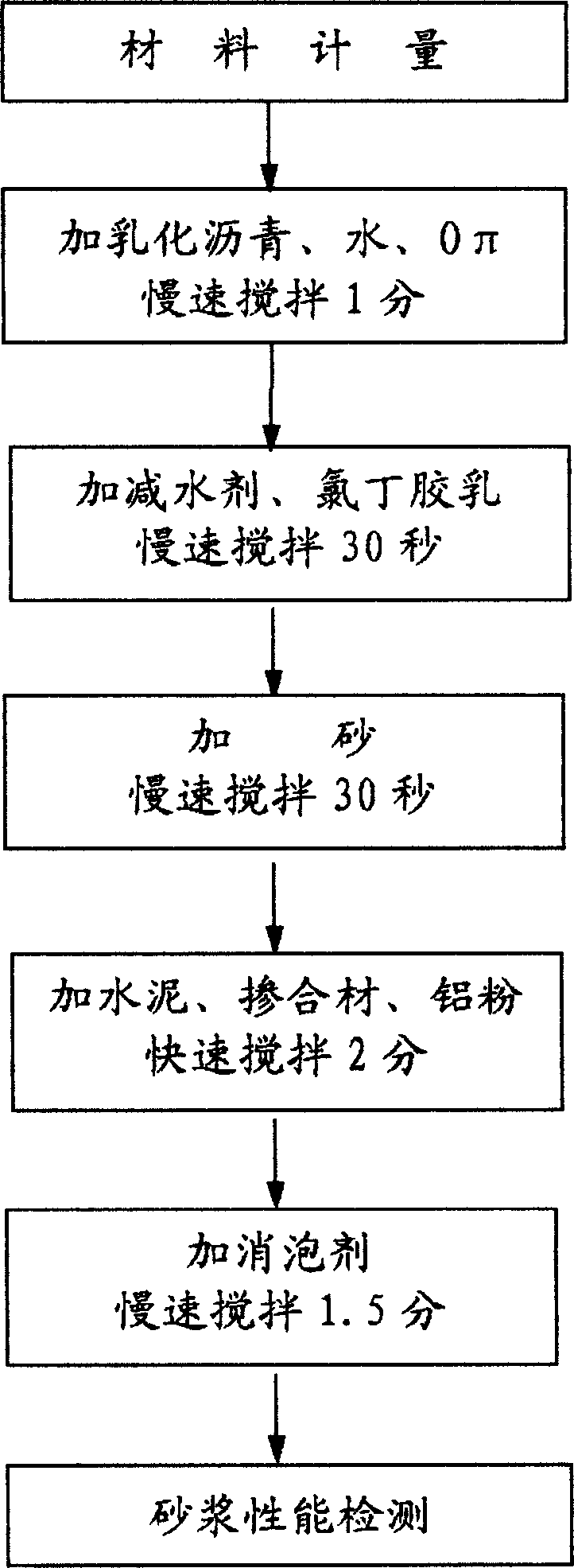

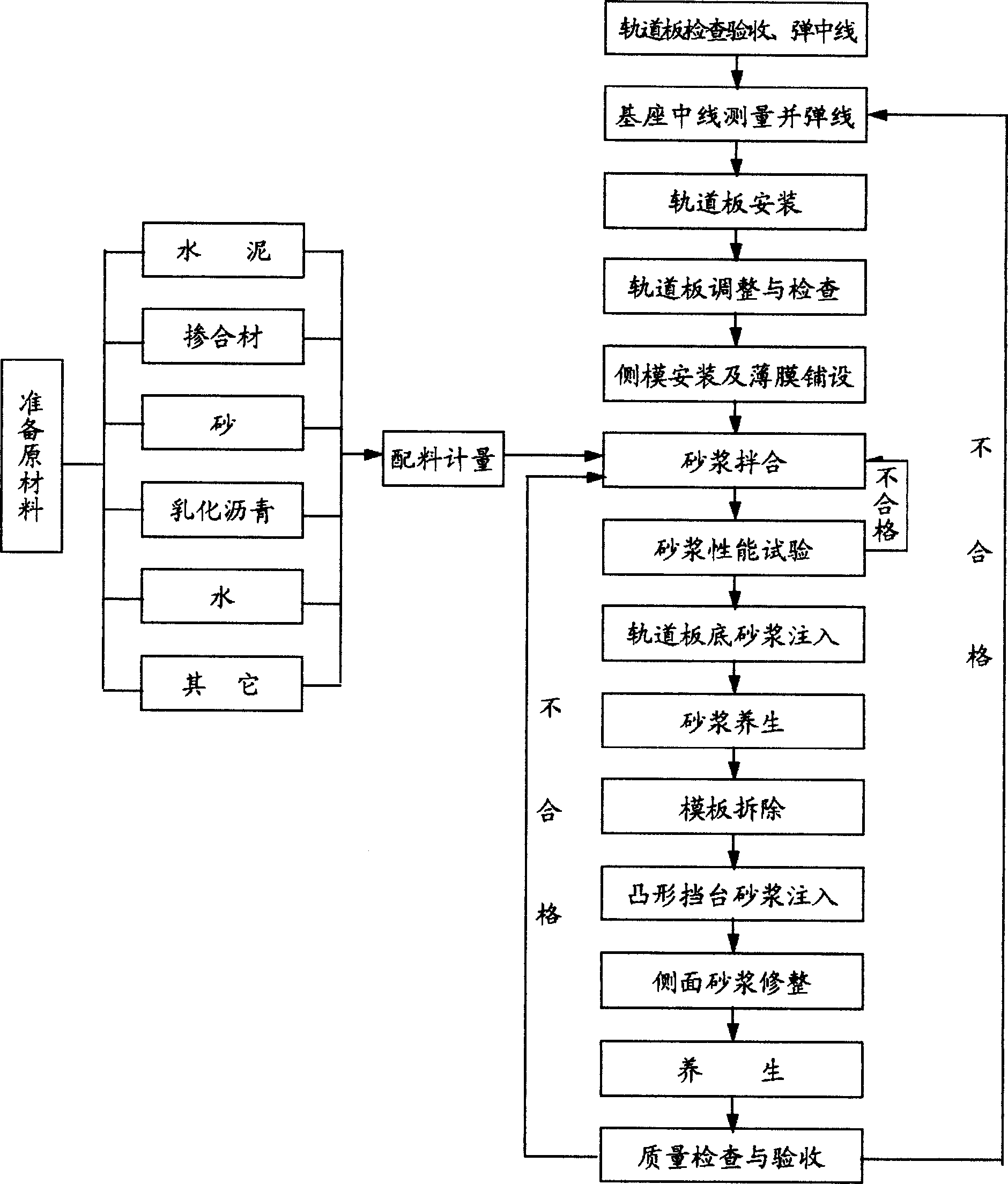

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

High-strength plant growing type porous concrete and preparation method thereof

InactiveCN102010155AGuaranteed compressive strengthHigh porositySolid waste managementEcological environmentCrushed stone

The invention discloses a high-strength plant growing type porous concrete and a preparation method thereof. The concrete comprises the following ingredients in proportioning by weight: water, cement, waste concrete or natural crushed stone aggregate, water reducing agents and rice straw. The preparation method comprises the steps of: firstly crushing the waste concrete or the natural crushed stone aggregate to be used as aggregate for later use; smashing the fully dried rice straw for later use; stirring the aggregate and a proper amount of water for a period of time; putting a proper amount of cement, the smashed rice straw and the water reducing agents into a stirrer for stirring; and finally, adding rest water and cement to be stirred. The high-strength plant growing type porous concrete can replace masonry flagstone with the strength of lower than M15, is applied to engineering projects such as raceways, parking lots, side slopes, riverbanks and the like and helps the growth of plants and restores the ecological environment destroyed by construction under the application condition.

Owner:孙学军 +1

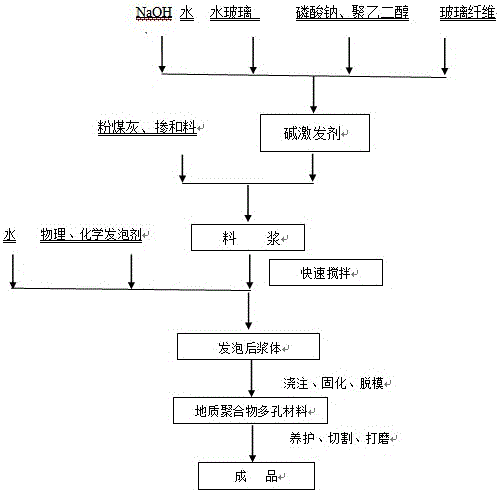

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

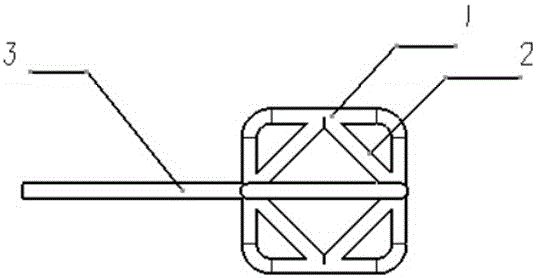

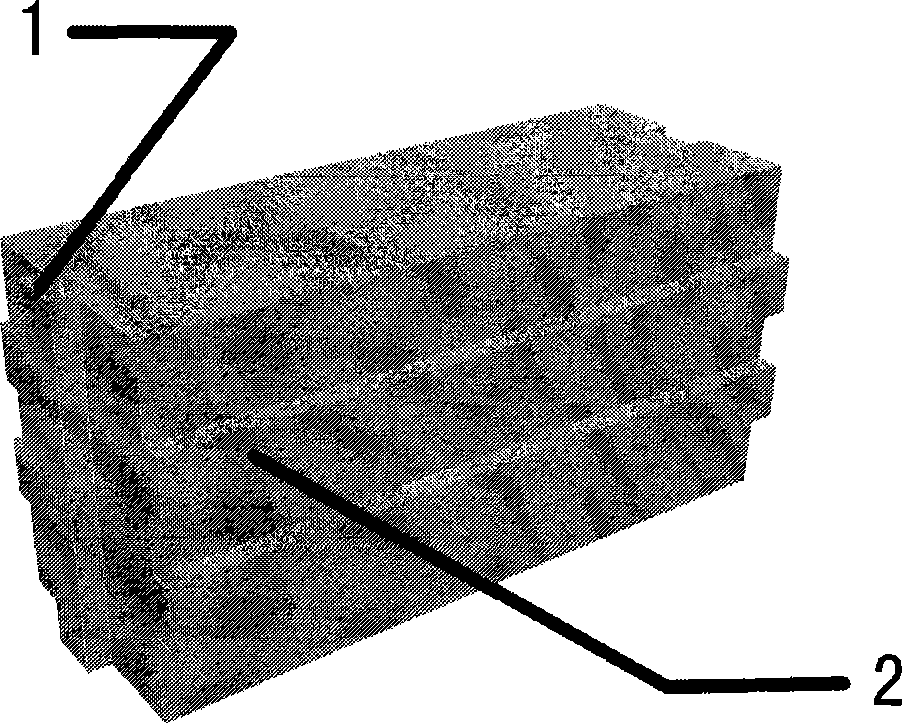

Stalk light body energy-saving heat preserving building blocks and manufacturing method thereof

InactiveCN101476365AImprove insulation effectLow water absorptionBuilding componentsPolymer scienceThermal insulation

The invention discloses a straw light-weight energy-saving insulated building block and a method for producing the same. The method comprises the following steps: using broken straw segments processed by a surface modifier, high strength low-alkali cement, fly ash, superfine active mixed materials and the like as main raw materials; adding various additives such as a waterproof impermeable agent, a preservative, a high-efficiency water reducing agent, an excitant and the like and modified materials to the main raw materials, mixing all the materials evenly, and adding water to the mixture and blending the mixture evenly; molding, demolding and maintaining the mixture to mold the building block (a reinforcing rib of which the surface is provided with a plurality of transverse lug bosses), and coating cement waterproof fluid on the outside; and making protection layers on two sides of the building block with ordinary Portland cement, sand, slag, additives and water so as to obtain the straw light-weight energy-saving insulated building block. The straw light-weight energy-saving insulated building block has the characteristics of light weight, high strength, good thermal insulation property, low water absorption rate, high freeze-melt resistance, fire prevention, water prevention, seepage prevention, insect and mouse damage prevention and the like, and saves 50 percent of energy for a single wall body material in the northern cold areas. Besides, the straw light-weight energy-saving insulated building block can be widely popularized and applied to the field of construction, in particular to the village and small town dwelling constructions in the northern cold areas.

Owner:肖力光

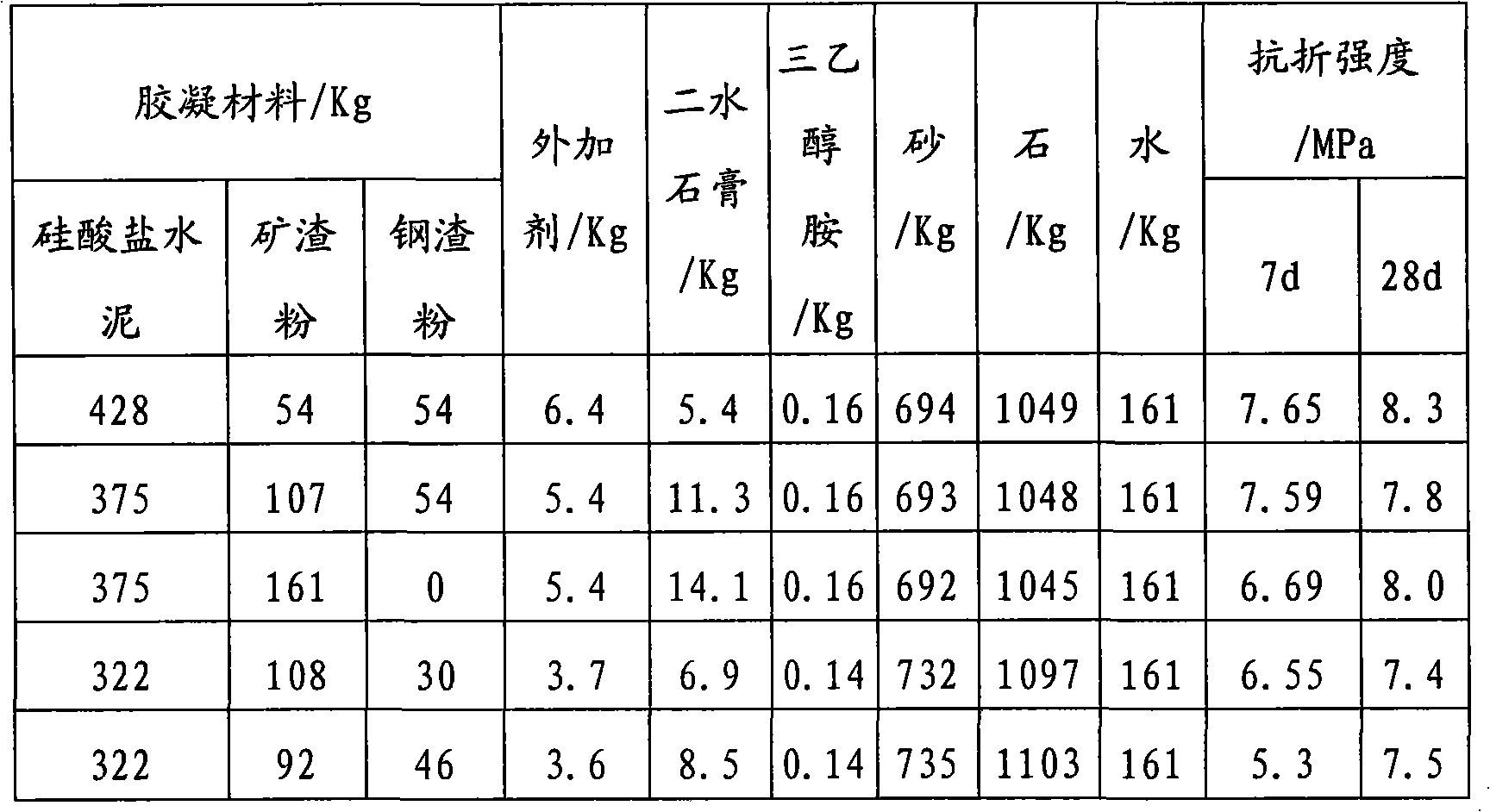

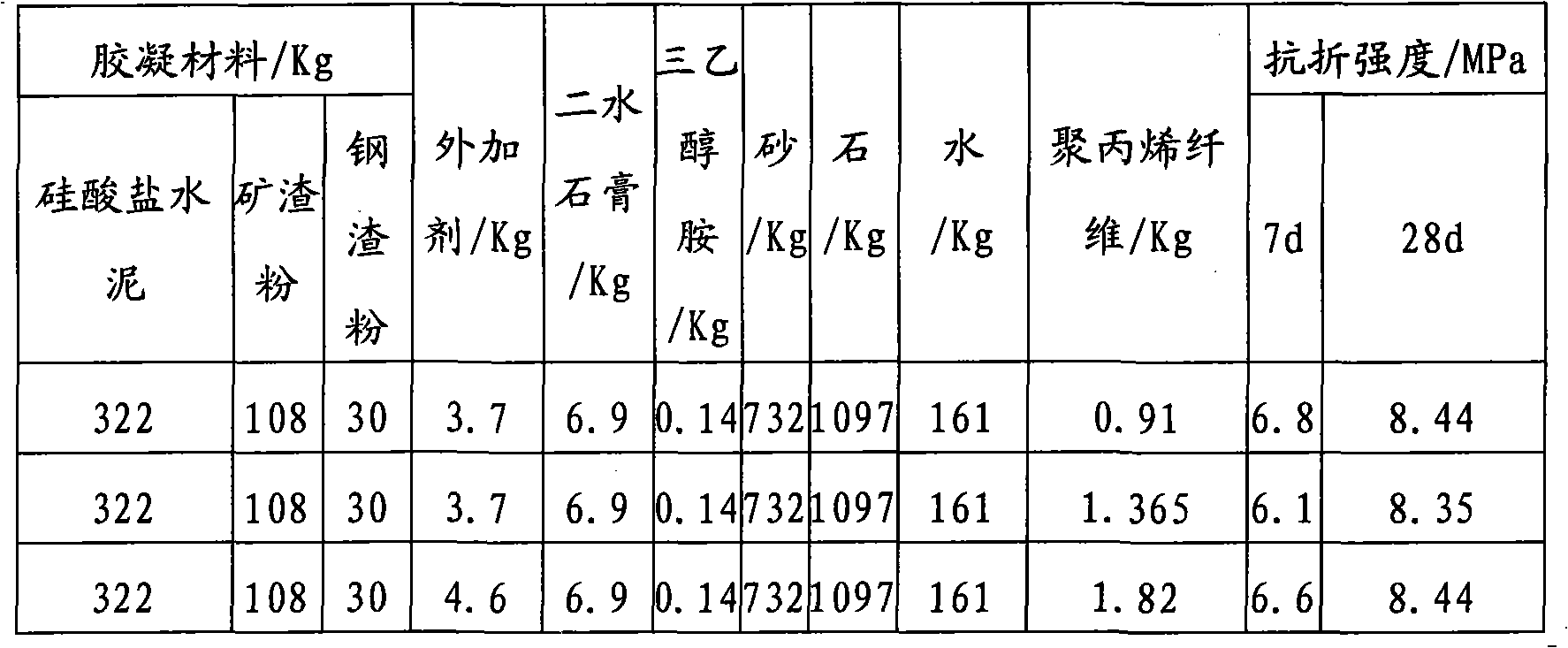

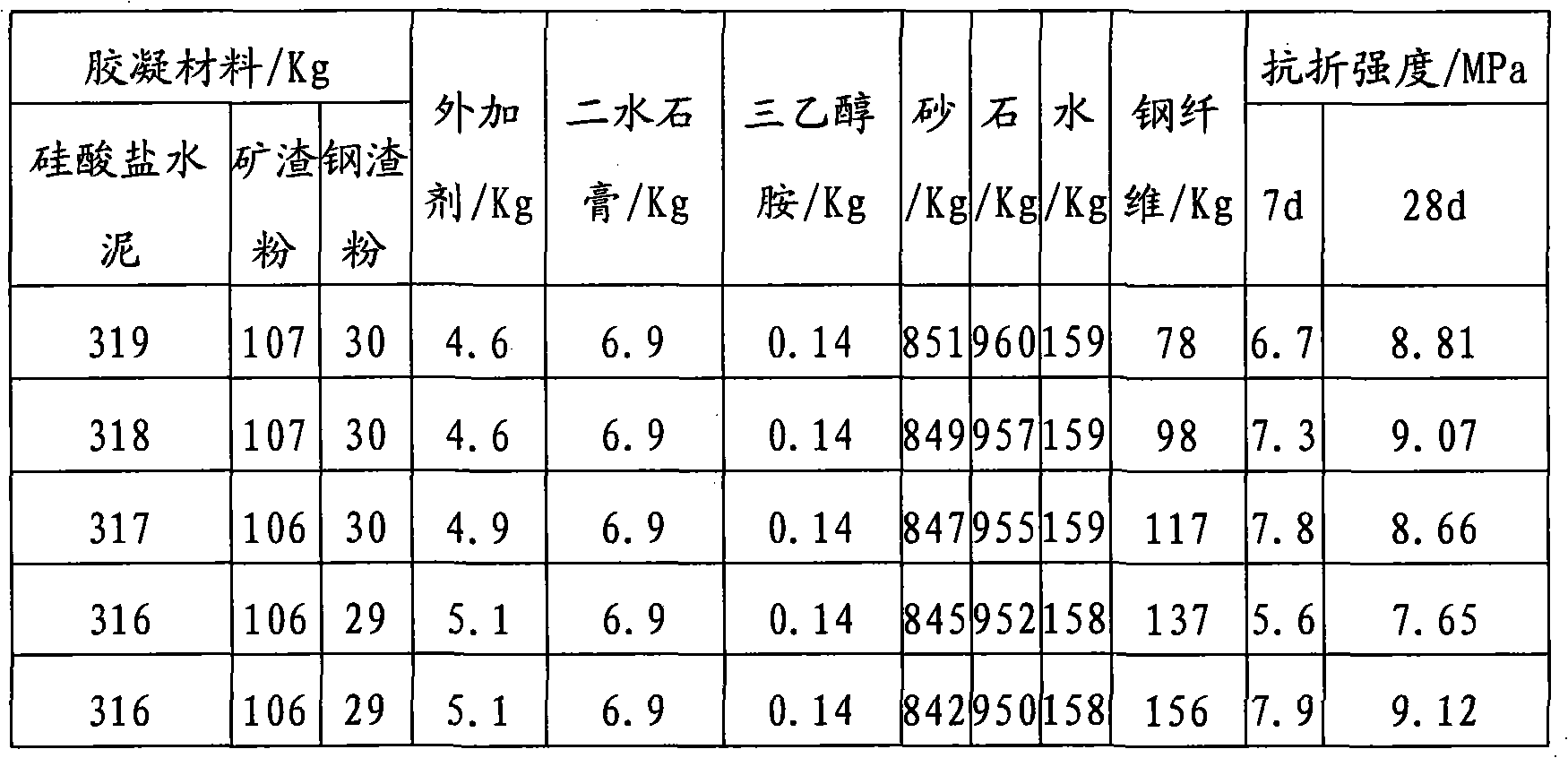

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

Lightweight high-strength ceramsite concrete and concrete pole

The invention relates to the technical field of concrete and more concretely relates to lightweight high-strength ceramsite concrete and a concrete pole. The lightweight high-strength ceramsite concrete is prepared from raw materials including the following ingredients in parts by mass: 380-420 parts of silicate cement, 45-53 parts of silica fume, 75-85 parts of slag powder, 560-620 parts of stone powder sand with the grain diameter of 0.16-4.75mm, 650-715 parts of shale ceramsite with the grain diameter of 5-20mm, 2.8-3.4 parts of efficient water reducing agent with the water reducing ratio higher than 30%, 115-126 parts of water and 0.4-0.6 part of polypropylene fiber. The concrete pole is formed through uniformly distributing the lightweight high-strength ceramsite concrete on a reinforcing steel bar net. According to the lightweight high-strength annular ceramsite concrete pole, the material source is wide, and a large amount of mineral waste is doped; and the weight is light, the carbonization resistance is good, the freeze-thaw resistance is good, the compressive strength is high, and the crack resistant strength is good.

Owner:佛冈龙清电力器材有限公司

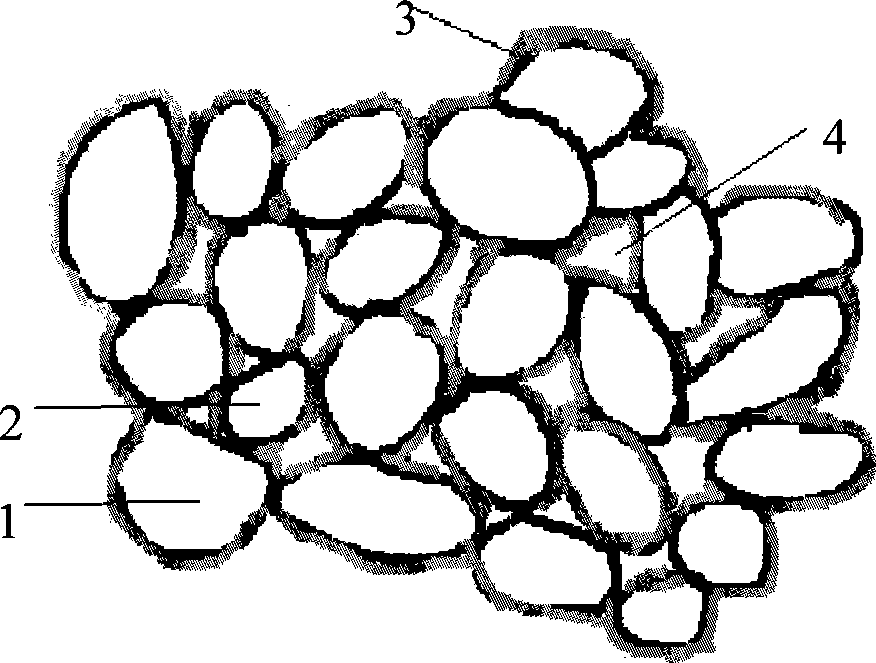

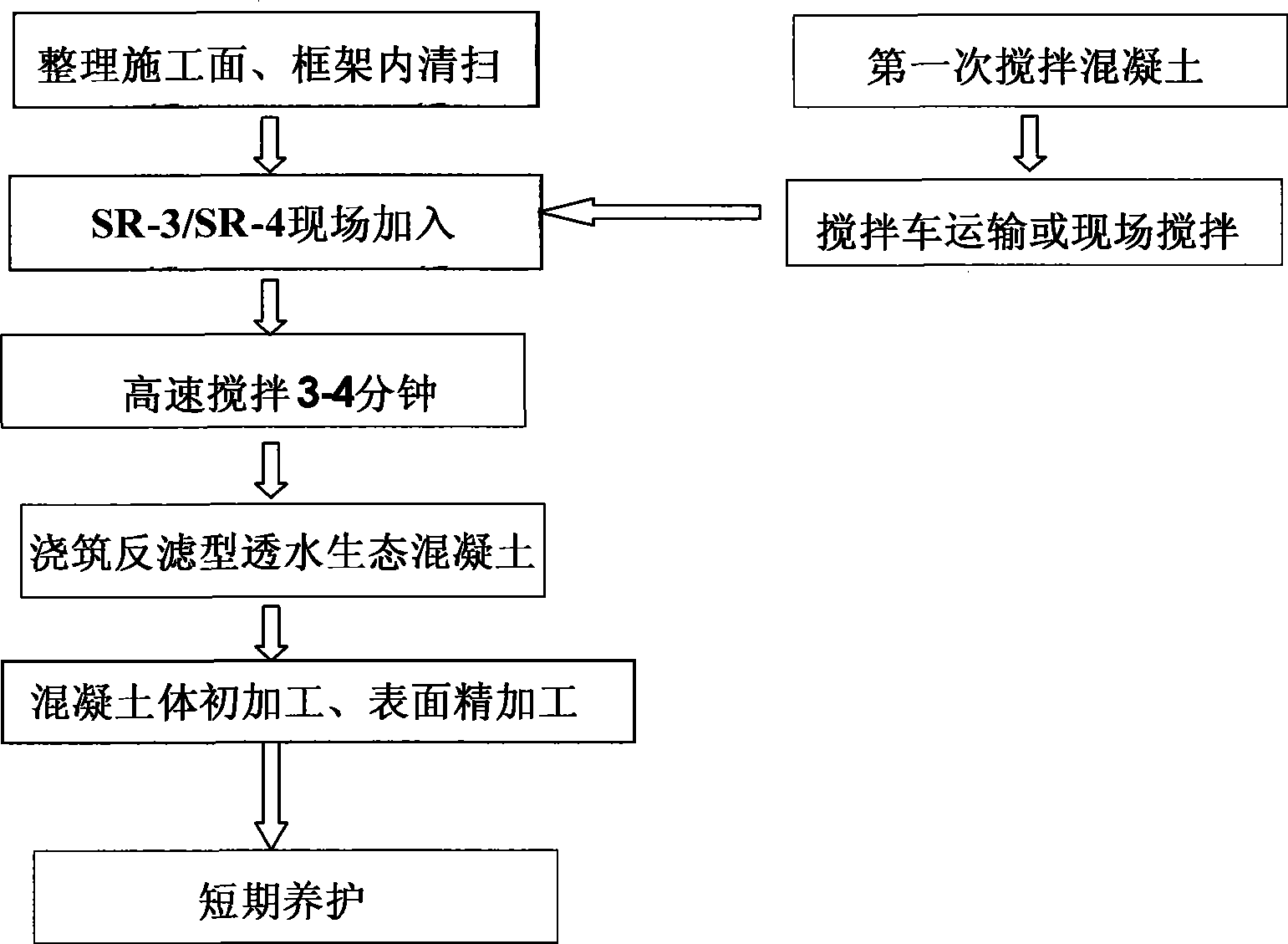

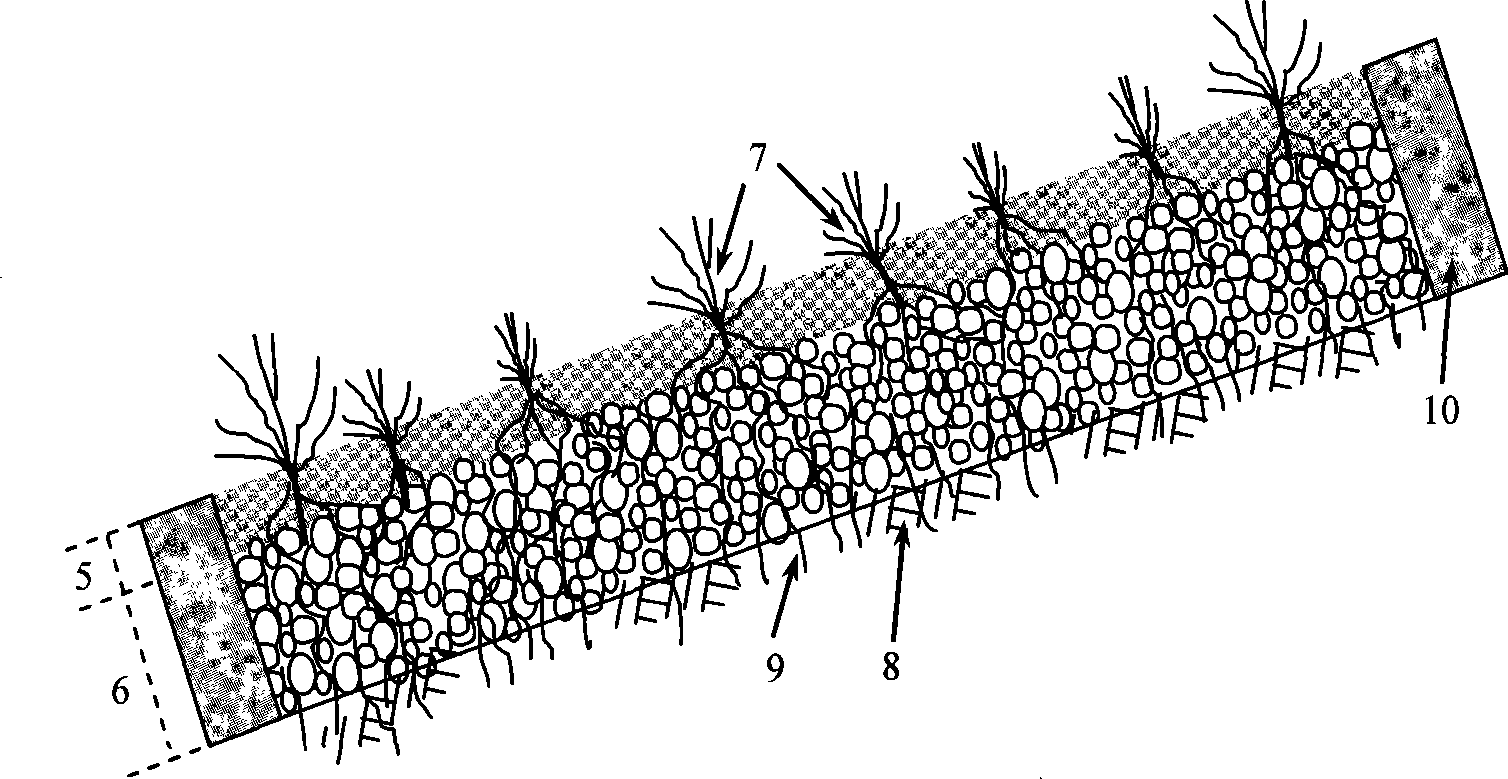

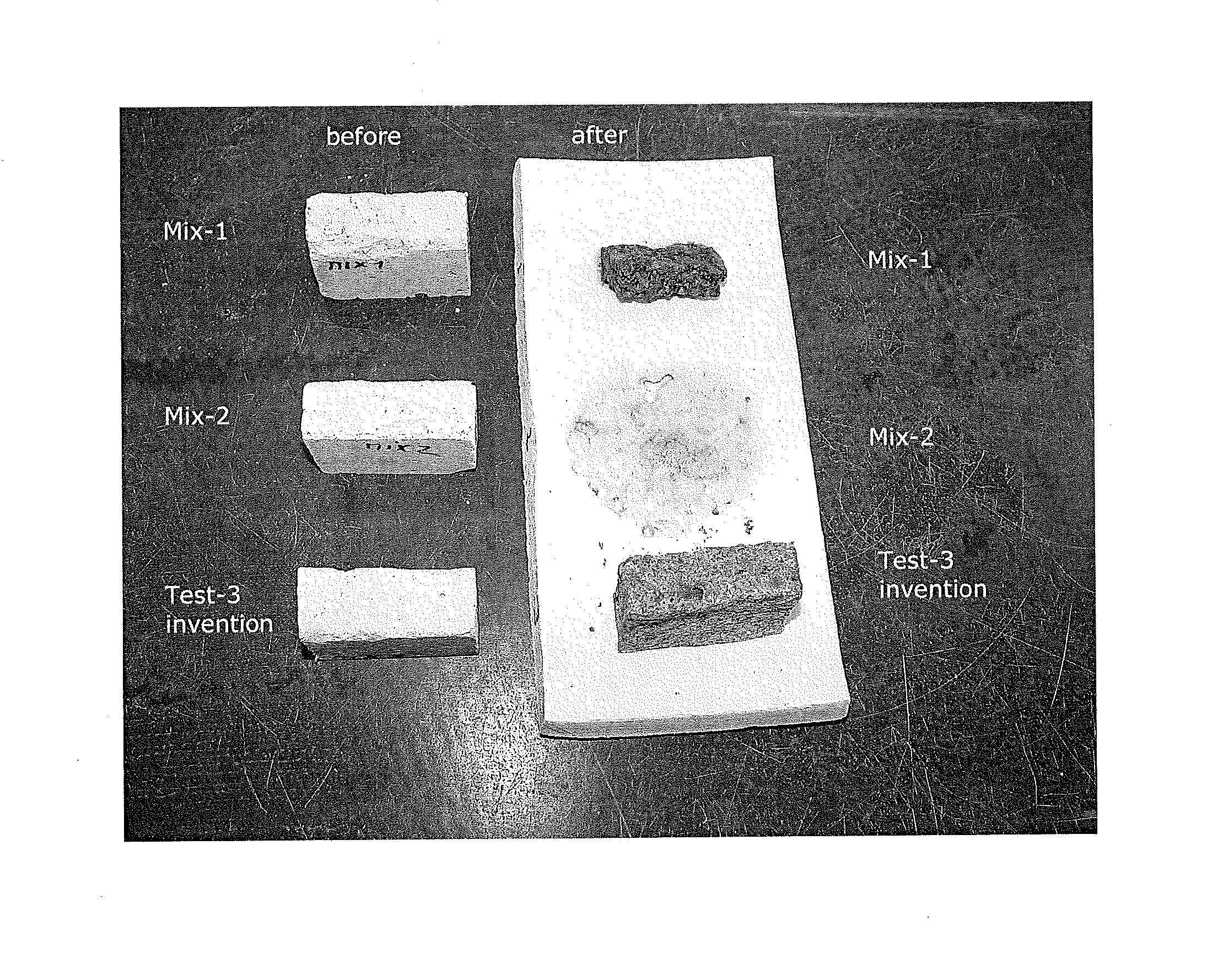

Cast-in-situ invert filter type pervious ecological concrete and method for constructing slope protection thereof

The invention discloses cast-in-situ reversed filtering type non-watertight eco-concrete and a construction method for a revetment thereof. The eco-concrete is the composition of grain aggregates and a cement hydrate; the grain aggregates comprise coarse aggregates and thin aggregates, which account for 70 to 85 percent of the total weight of the composition; the cement hydrate is the mixture of Portland cement, water and additive; the doping amount of the cement and the water accounts for 14.5 to 29.5 percent of the total weight of the composition; the additive comprises calcium salt, silicon powder, functional inorganic salt as well as lignosulphonate question mark hydroxycarboxylic acid; and the doping amount of the additive accounts for 0.1 to 0.5 percent of the total weight of the composition. The eco-concrete of the invention can realize cast-in-situ construct, and has higher anti-pressing intensity; moreover, the poriness size and the aperture distribution range can be designed and the controllability is good; the cast-in-situ reversed filtering type non-watertight eco-concrete applied to the fields of revetment protecting and controlling can improve the anti-pressing intensity, the permeable performance and the reversed filtering performance of the concrete revetment and simultaneously has the function of greening vegetation.

Owner:JCK +1

Fire protection mortar

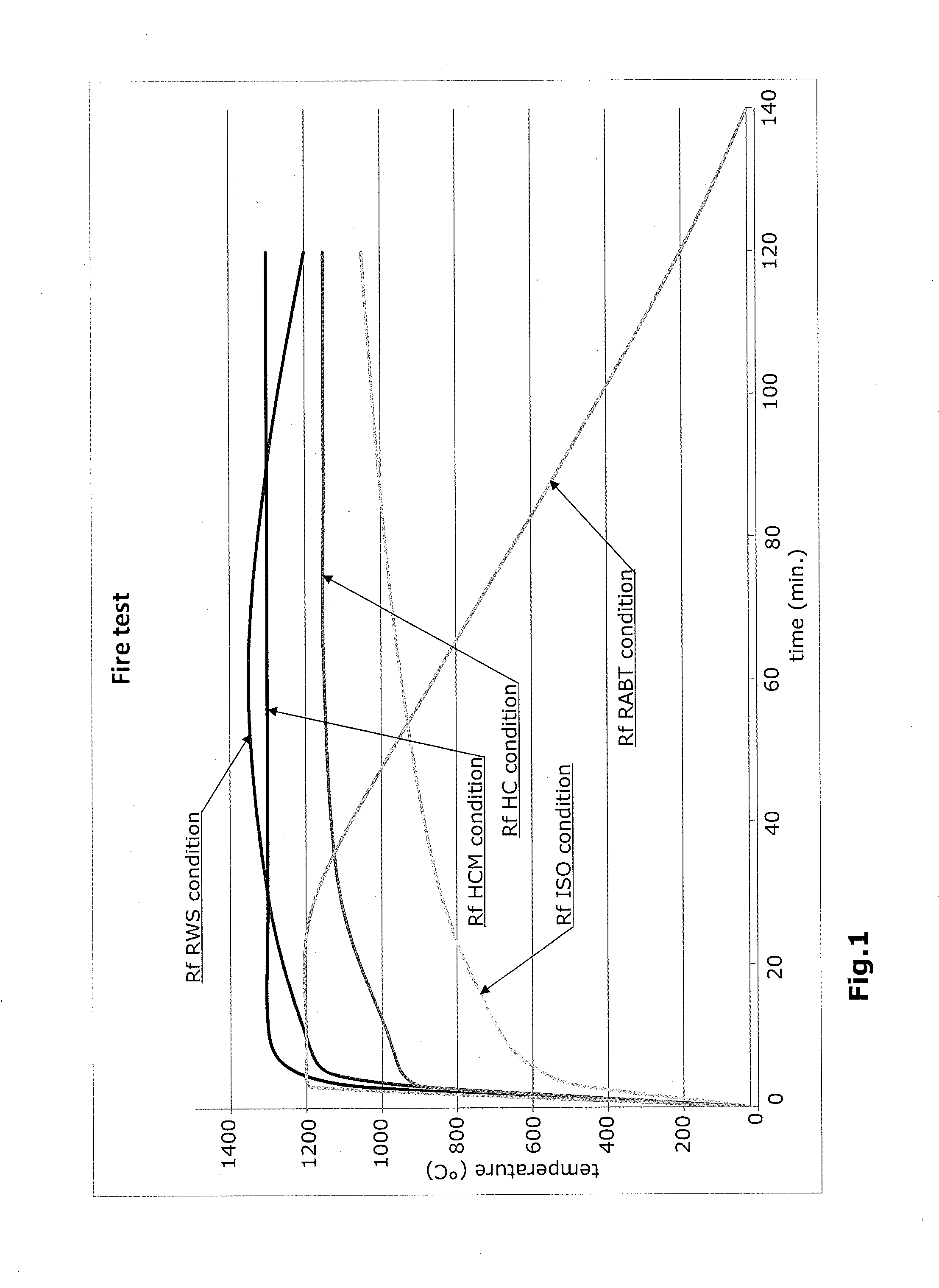

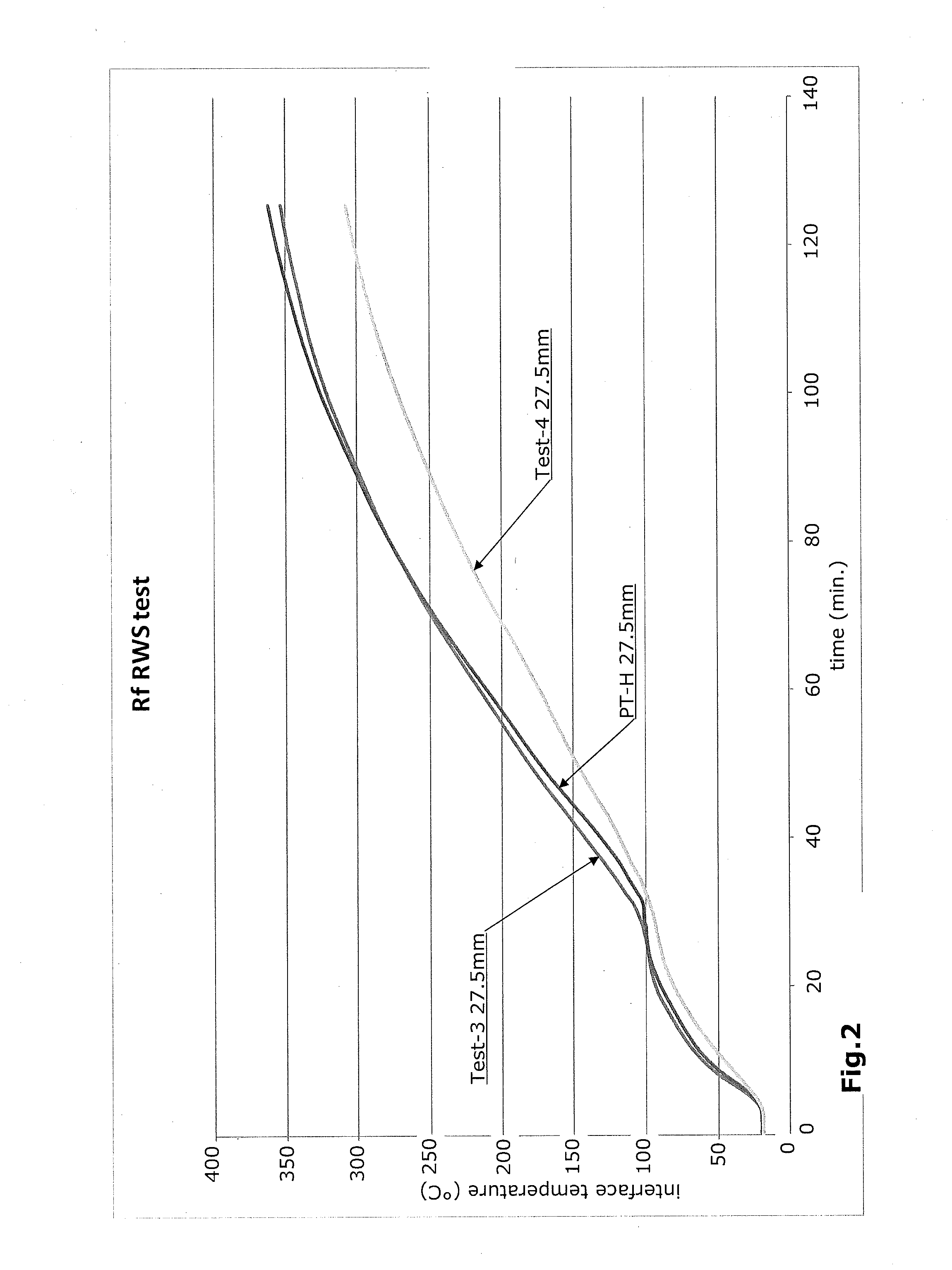

ActiveUS20140216653A1Improve freeze-thaw resistanceFireproof paintsLiquid surface applicatorsFire protectionFoaming agent

A composition for the preparation of a fire protection mortar comprising45 to 70% by weight of cement binder,8 to 20% by weight calcite,8 to 20% by weight mica,0 to 5% by weight of xonotlite,0.1 to 20% by weight of expanded perlite,0.1 to 10% by weight of fibers,0.01 to 2% by weight of air entrainer and foaming agent,0.01 to 2% by weight of processing aids.

Owner:PROMAT RES & TECH CENT

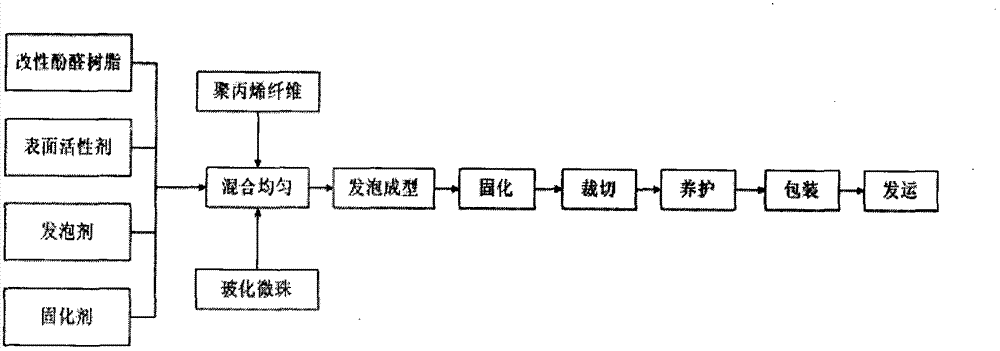

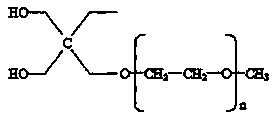

Fire-proof and thermal-insulation board and manufacturing method thereof

InactiveCN102787670AHigh bonding strengthNon-combustibleHeat proofingSound proofingFiberAdhesive cement

The invention relates to a fire-proof and thermal-insulation board and a manufacturing method thereof, and belongs to the technical field of constructional materials. According to the manufacturing method of the fire-proof and thermal-insulation board, modified phenolic resin, reinforcing fibers and inorganic micro bead thermal insulation fillings with the weight ratio of 1:(0-0.05):(0.3-1) are prepared; and after the steps of preparing adhesive, preparing a mixture, foaming, forming and solidifying to form are finished, a foam board is subjected to thermal insulation to be formed, so that the fire-proof and thermal-insulation board in a closed cell foamed structure is obtained. According to manufacturing method, organic materials and inorganic materials are organically combined, so that a novel fire-proof and thermal-insulation material with the fire-proof property of the inorganic thermal insulation materials and the thermal-insulation property of the organic thermal insulation materials is manufactured; and the fire-proof and thermal-insulation board is simple in forming technology, and can practically satisfy the energy saving and safety requirements of wall construction.

Owner:万国骅

Active powder concrete for railroad bridge cover plate

The invention discloses an active powder concrete for a railroad bridge cover plate, which is prepared by evenly mixing cement, silica powder, quartz sand, admixture, steel fiber, additive and water according to the weight ratio of 650-700:170-200:1,150-1,200:160-250:140-150:30-40:135-160, wherein the admixture is fly ash or slag, and the additive is a non-air-entraining type high-efficiency water reducing agent. The active powder concrete has the advantages of superior lasting quality, high-grade compression strength and rupture strength and simple preparation process, and a footway cover plate processed from the active powder concrete can completely satisfy the design requirement on special lines for passenger trains in China and has small workloads of later-period maintenance.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Tunnel fire retardant coating and preparation process and construction process thereof

InactiveCN101880145ASimple processImprove water retentionSolid waste managementPortland cementAluminum silicate

The invention provides a powdery mixture of a multi-component tunnel fire retardant coating, which is prepared from 582 resin, Portland cement, sepiolite, ammonium dichromate, light calcium carbonate, aluminum silicate, fly ash hollow floating beads, wollastonite powder, argil, cellulose ether, a concrete expanding agent, tin oxide and polypropylene fiber. The powdery mixture is prepared by throwing the fire retardant coating into a V-shaped forced mixer according to the proportion of the components; stirring the mixture for 10 to 15 minutes to prepare the powdery mixture; stirring water and the fire retardant coating powder in a weight ratio of 0.8-0.85 into thick paste; and spraying a tunnel from the waist to the top with spray painting equipment to reach the predetermined thickness.

Owner:成都威邦科技有限公司

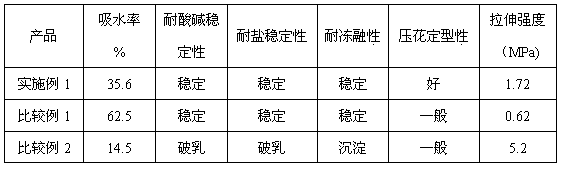

Preparation method of non-ionic waterborne polyurethane-polyacrylate composite emulsion for leather finishing

ActiveCN103724574AImprove mechanical propertiesGood embossing and settingFibre treatmentPolyurea/polyurethane coatingsPolymer scienceOligomer

The invention relates to a preparation method of non-ionic waterborne polyurethane-polyacrylate composite emulsion for leather finishing. The preparation method comprises the following steps: after low polymer dihydric alcohol, diisocyanate and a hydrophilia chain extender are stirred for reaction, cooling to indoor temperature and adding an acrylate monomer and a certain amount of a solvent for reducing viscosity; adding water for emulsification under the high-speed dispersion; then adding a micromolecule polyamine chain extender to conduct chain extension in water to obtain an acrylate monomer-polyurethane waterborne dispersing emulsion; then introducing nitrogen, heating, dropwise adding a water solution containing an initiator to trigger seeding emulsion polymerization, and continuously keeping warm to obtain the composite emulsion. The composite emulsion prepared by the invention has the advantages of low viscosity, good permeability, emulsion stability, freeze-thaw resistance, hydrolytic resistance, and excellent electrolyte resistance and acid-base resistance property, can be used for compounding with anion resin and further with cationic resin, has an excellent knurling setting property, and is particularly suitable for being used as a leather finishing agent.

Owner:SICHUAN DOWELL SCI & TECH INC

Autoclaving-free prestressed high-strength tube pile concrete and tube pile manufacturing method

The invention relates to autoclaving-free prestressed high-strength tube pile concrete and a tube pile manufacturing method. The concrete is prepared from the following components in parts by mass: 300-420 parts of PI or PII 52.5 cement, 5-80 parts of mineral powder, 5-100 parts of lithium slag powder, 5-40 parts of glass microbead powder, 680-720 parts of sand, 1125-1170 parts of broken stones, 125-135 parts of water, 4-5 parts of a polyocarboxy acid water reducing agent and 2-5 parts of an exciting agent. After stirring and shaping are performed, only constant-pressure steaming is performed for 6-8 hours, the strength requirement of C80 can be met, the energy consumption is reduced, and besides, the lithium slag powder which is industrial waste is utilized for the autoclaving-free concrete tube pile, so that the problem of resource wasting and the problem of environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

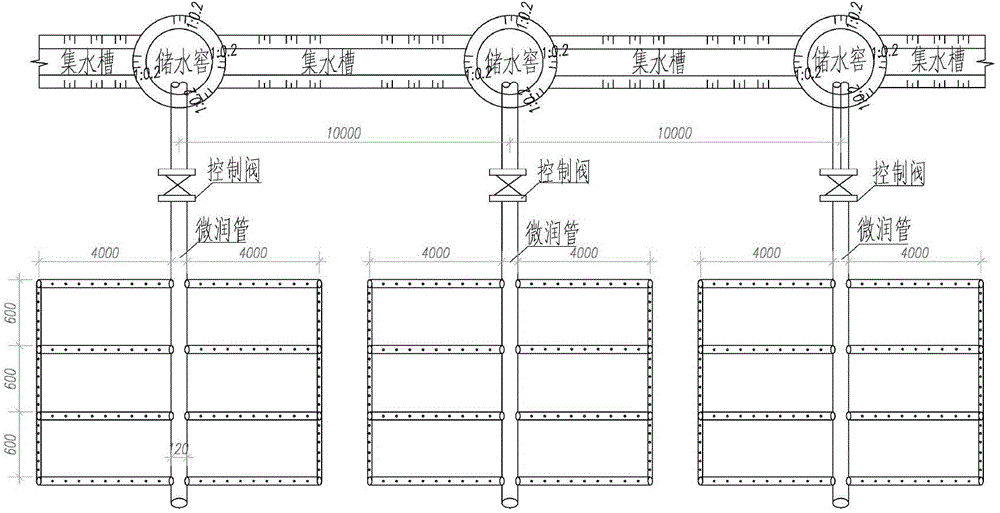

Flexible slope protection method for soft sandstone natural side slope

InactiveCN104805845AReduce penetrationImprove survival rateExcavationsHorticultureFreeze thawingVegetation

The invention provides a flexible slope protection method for a soft sandstone natural side slope. The method comprises the following steps of (1) slope surface early-stage cleaning; (2) net hanging; (3) micro lubricating system building; (4) spray coating; (5) plant planting and greening; (6) operation and maintenance. The method has the advantages that through a series of measures of the flexible slope protection method, a processed side slope surface layer soft sandstone composite body has the comprehensive performance such as excellent mechanical performance, ultraviolet degradation resistance performance, wind etching resistance performance, water etching resistance performance, gravity etching resistant performance, freeze thawing resistance, water preservation, heat insulation and fertilizer preservation, the soft sandstone can be fixed, meanwhile, the method is combined with plant-growing methods such as a seed spraying method, the vegetation recovery is promoted, and the water and soil maintaining effect is effectively improved. The flexible slope protection method is suitable for ecological control and restoration engineering of the soft sandstone natural side slope and is particularly suitable for soft sandstone regions with the serious water and soil loss.

Owner:ANHUI AGRICULTURAL UNIVERSITY

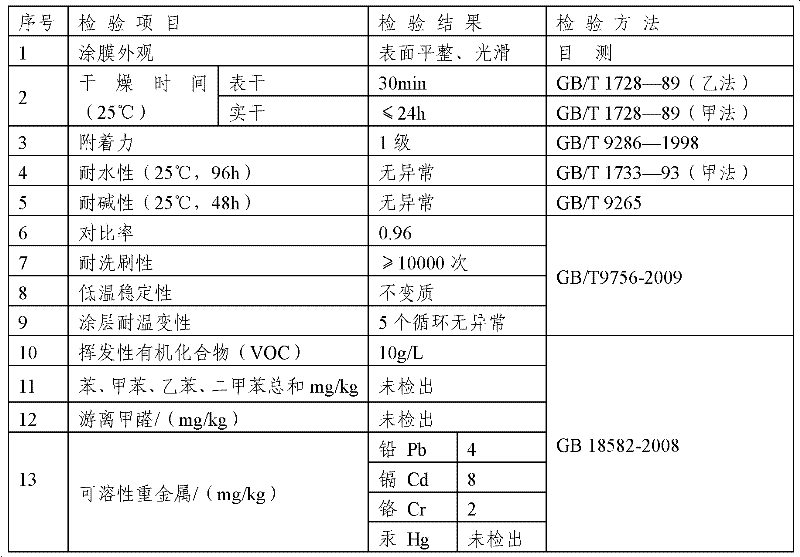

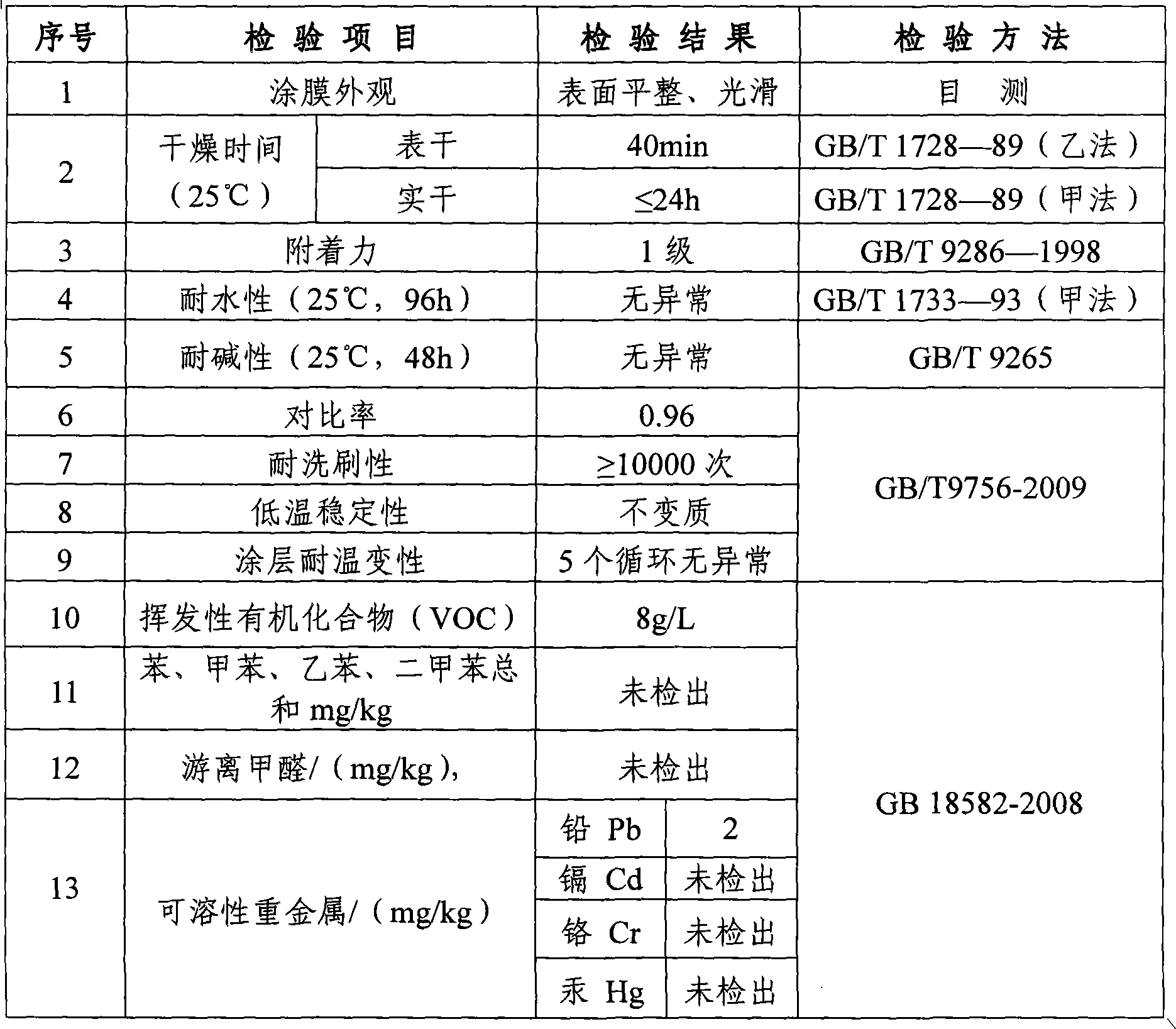

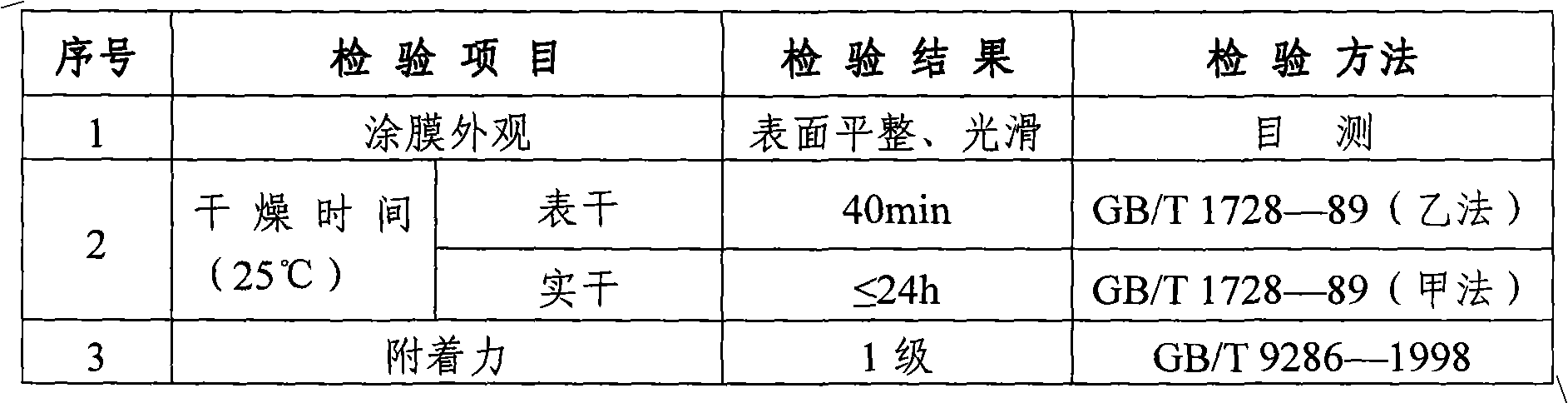

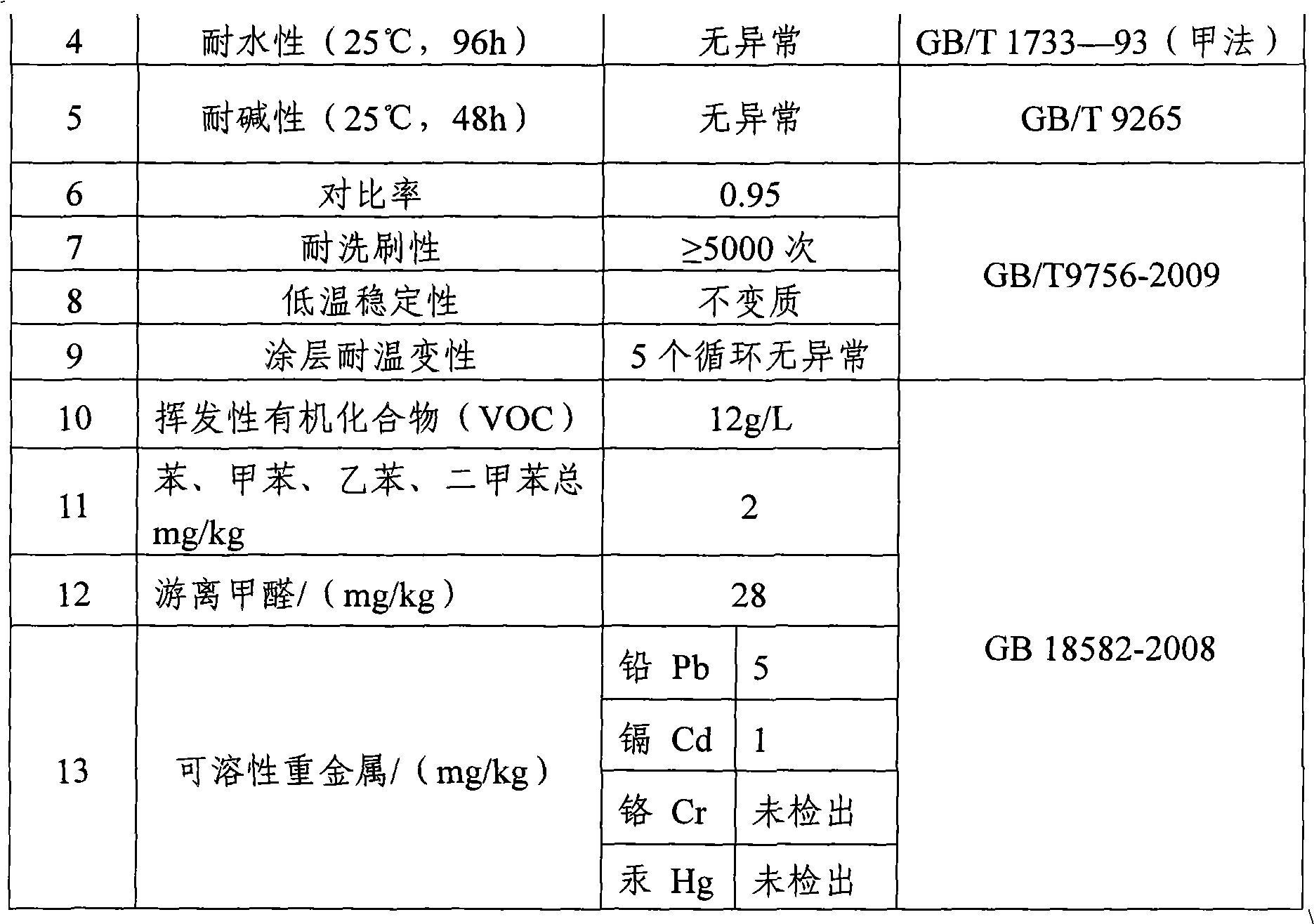

Antibacterial latex paint containing natural jade powder and preparation method for same

ActiveCN102643562AGood freeze-thaw resistanceLess free monomerAntifouling/underwater paintsPaints with biocidesVolatile organic compoundNanometre

The invention relates to an antibacterial latex paint containing natural jade powder and a preparation method for the same. The antibacterial latex paint contains the following ingredients in parts by weight: 50-150 parts of natural jade powder, and 5-15 parts of nanometre inorganic anionic auxiliary, wherein the grain diameter of the natural jade powder is 3000-6000 meshes. The latex paint provided by the invention can be coated on a wall surface or wood, and the paint film has the advantages of being weak in smell, low in VOC (volatile organic compound), good in covering power, good in adhesion power, resistant to scrub and the like, and can effectively kill the harmful bacteria contacted with the painted wall surface in a room simultaneously; and moreover, the latex paint is low in cost, good in construction performance and great in environmental protection performance, and is mainly applied to decoration and protection for the surfaces of wall body, wood, etc.

Owner:濮阳展辰新材料有限公司

Diversification premixing method modified starch and producing method thereof

InactiveCN101195692AImprove freeze-thaw resistanceImprove gel performanceEnergy consumptionChemistry

The invention discloses a diversification premixing modified starch and a relative production method, which premixes etherified-crosslink-esterified starch, esterified-esterified starch and esterified-crosslink starch which are produced independently in a certain ratio, to obtain the starch with good freeze stability, gel property, and water retention. The product supplies a new processing property for modified starch product, which can be applied for food, particularly for low-temperature meat product, to adhere, stuff and improve water retention. The invention has short production period, low energy consumption, simple operation and high product stability.

Owner:广西农垦明阳生化有限公司

Ecological slag permeable bricks and preparation method thereof

ActiveCN102061652AHydraulically gelatinousGood water absorption and permeabilitySingle unit pavingsBrickSlag

The invention discloses ecological slag permeable bricks and a preparation method thereof. Each ecological slag permeable brick comprises a basic strength permeable layer and a perceptive permeable layer which is formed by graded distribution and vibrating extrusion molding and is adhered to the upper surface of the basic strength permeable layer. The preparation method for the ecological slag permeable bricks comprises the following steps of: uniformly stirring 70 to 80 parts of ecological slag, 16 to 20 parts of cement, 2 to 5 parts of siliceous dust, 1 to 3 parts of melamine and 5.6 to 8.0 parts of water to prepare the basic strength permeable layer; and uniformly stirring 17 to 22 parts of cement, 65 to 75 parts of quartz sand, 3 to 4 parts of pigment, 2 to 7 parts of waterborne resin and 3.4 to 6.6 parts of water to prepare the perceptive permeable layer. The ecological slag permeable bricks and the preparation method thereof can overcome the defects of poor soiling resistance, poor water permeability and the like in the prior art, and have the advantages of high pollutant resistance, high water permeability, low cost, high environmental friendliness, and attractive appearance.

Owner:承德德厦新型建材有限公司

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

Paper-plastic lamination adhesive and method for preparing same

InactiveCN1632029AImprove freeze-thaw resistanceReduce charge densitySurface covering paperEster polymer adhesivesPolymer scienceAdhesive

Disclosed are a paper-plastic glue and its preparing method,comprising of high polymer latex 70-90%,resin 5-15%,inorganic powder filler 3-15%,dispersant 0.5-0.8%,thickener 0.2-0.5% and deformer 0.1-0.3%. Its preparing method is:1.pre the deformer with high polymer latex; 2. disperse; 3. add into inorganic filler and disperse;4.add into resin and disperse;5. add into thickener for adjusting the viscosity to be the construction one,the output and package the material.

Owner:SOUTH CHINA UNIV OF TECH

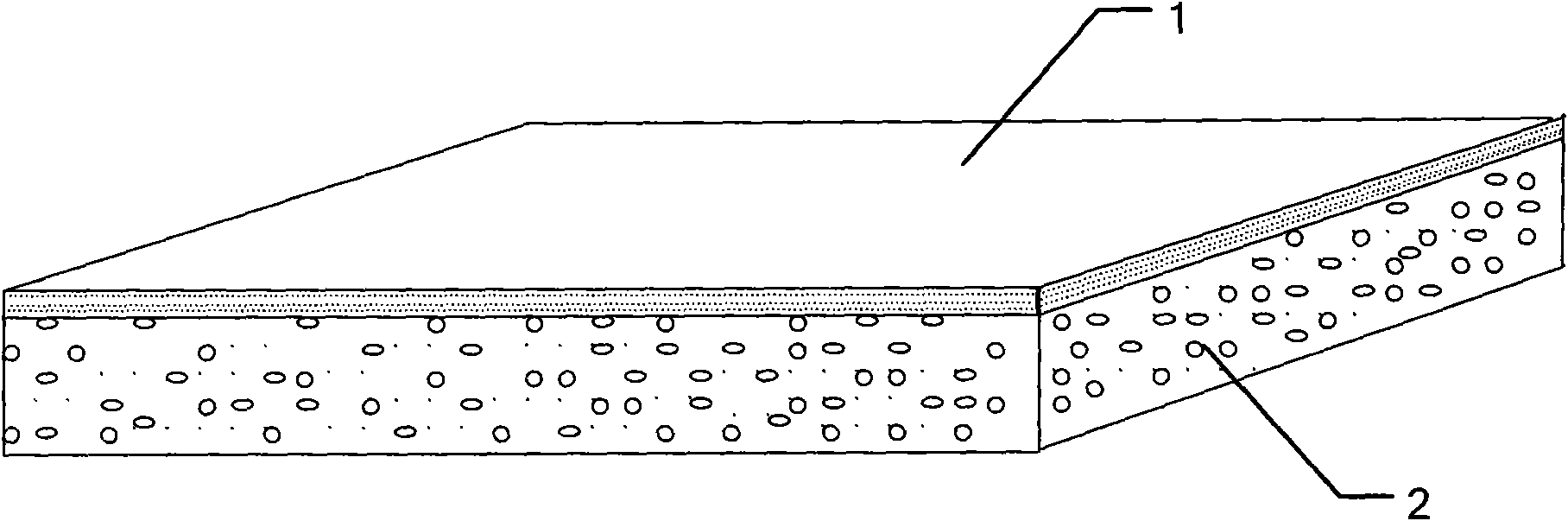

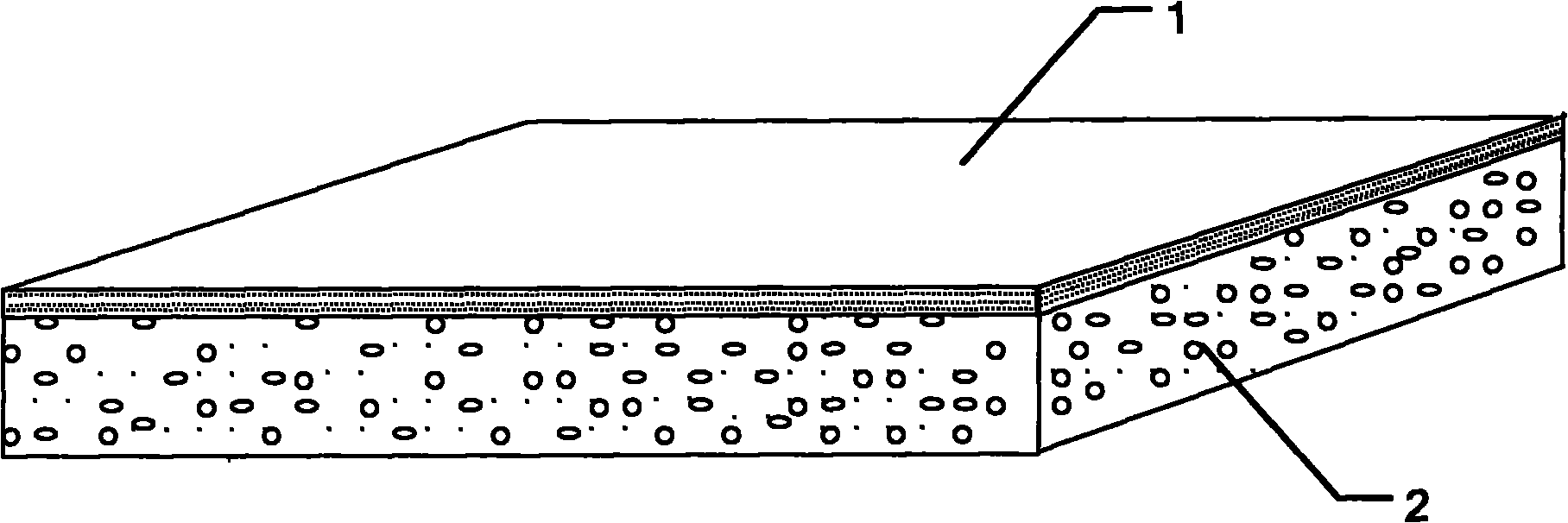

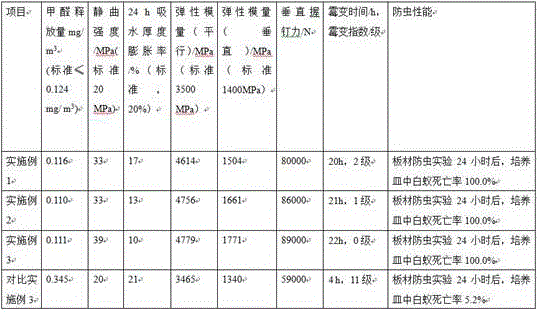

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

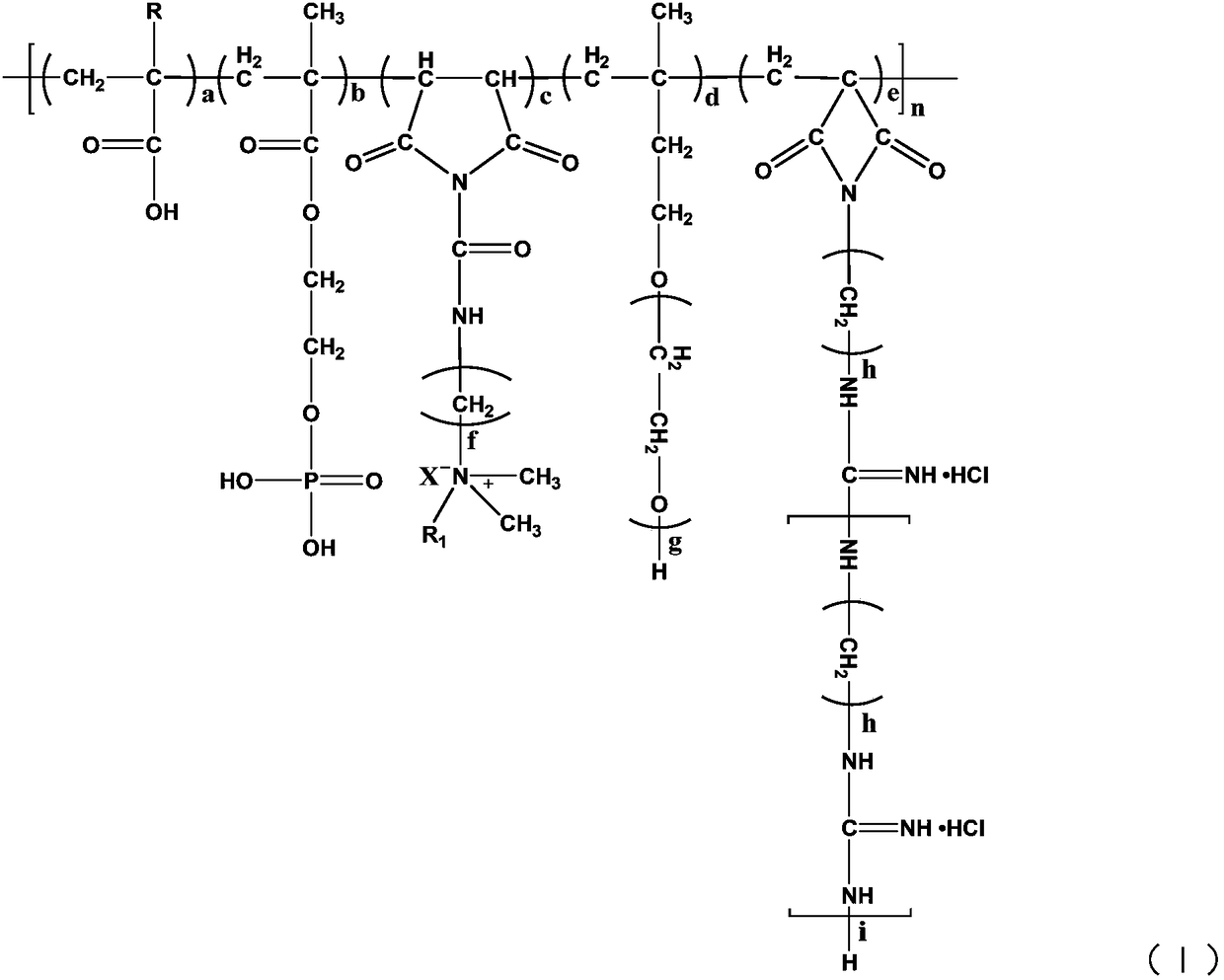

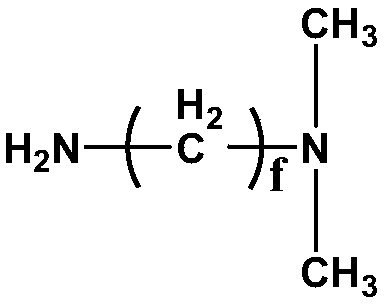

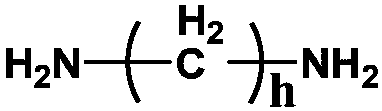

Amphoteric polycarboxylate-type efficient water reducing agent with viscosity reduction and antibiotic properties and preparation method thereof

InactiveCN109400819AIncreased carbon-carbon double bond activityImprove mildew resistancePhosphateSuperplasticizer

The invention provides an amphoteric polycarboxylate-type efficient water reducing agent with viscosity reduction and antibiotic properties, and belongs to the technical field of concrete admixtures.The general formula of the efficient water reducing agent is shown in the description, wherein R is selected from H or CH3; R1 is selected from alkyl of four to ten carbon atoms; X is selected from Cl, Br, I halogen elements; a, b, c, d, e, f, g, h, i, n are all integers, and a, b, c, d, e are selected from 1-30; f is selected from 2-6, and g is selected from 25-80; and h is selected from 2-8, andi is selected from 10-20. The efficient water reducing agent is prepared through polymerization of raw materials including TPEG, unsaturated carboxylic acid, unsaturated phosphate, a cationic monomerand an antibiotic monomer through free radicals under the effects of an initiator and a chain transfer agent. The invention further provides a preparation method of the efficient water reducing agent. The polycarboxylate water reducing agent has the capabilities of reducing the concrete viscosity and improvethe antimildew and anti-rancid properties of a finished compound polycarboxylate water reducing agent product.

Owner:中建西部建设西南有限公司 +2

Conductive concrete compositions and methods of manufacturing same

InactiveUS20050194576A1Improve freeze-thaw resistanceImprove water resistanceSolid waste managementConductive materialFiberLong chain fatty acid

Modified compositions for carbonaceous concrete conductive sheathing materials for ground electrodes are described, for use in protecting installations from electrical currents. By the incorporation of discrete fibers, superior freeze-thaw resistance is imparted. The water resistance of carbonaceous concretes according to the invention is improved by the addition of a soluble soap of long chain fatty acids. A method of precasting carbonaceous cements according to the invention allows uniform and consistent development of properties for use either in shallow trench or deep well applications.

Owner:SIROLA D BRIEN +1

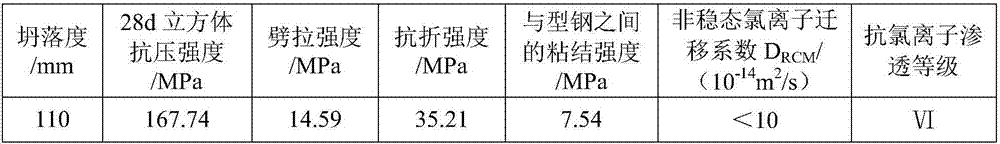

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Curb produced by using waste ceramic slag and waste road concrete and manufacturing method

InactiveCN103058613AImprove performanceEnhance and improve performanceSolid waste managementBrickCalcium formate

The invention relates to a curb produced by using waste ceramic slag and waste road concrete and a manufacturing method. The curb is characterized in that the waste ceramic slag, the waste road concrete, waste incineration residue, waste granite slag, silicate cement, calcium oxide powder, calcium sulfate powder, polycarboxylate efficient water reducing agent, calcium formate, sodium sulfate and water are used as raw materials; and the raw materials are stirred to be moist through a stirrer, extruded by using a hydraulic machine and manufactured into the waste ceramic slag and waste road concrete curb under the pressure of 25 to 30MPa, and the curb is naturally dried and cured for 28 days at normal temperature by using a water spraying method. The raw materials can be manufactured into top wall bricks, plaza bricks and sidewalk bricks with different sizes; and the curb has the advantages of light weight, high strength, pollution prevention, low cost and high benefits. The invention meets the requirements for national energy conservation and emission reduction development and low-carbon economy.

Owner:清远绿由环保科技有限公司 +1

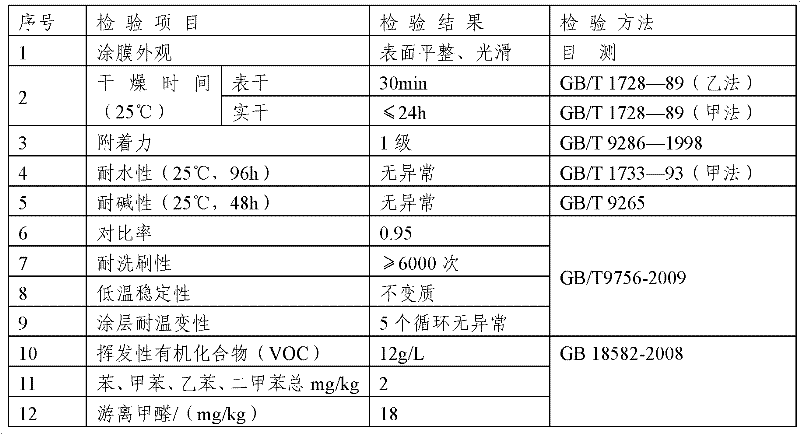

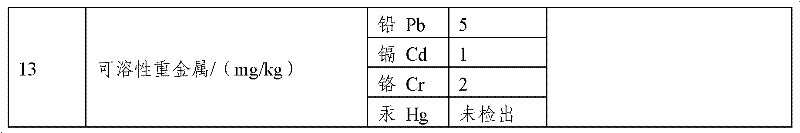

Bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint and preparation method thereof

ActiveCN102086325AReduce harmImprove freeze-thaw resistanceEmulsion paintsHazardous substanceMicrosphere

The invention provides a bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint. The emulsion paint comprises the following components in parts by weight: 100-400 parts of waterborne resin, 1-5 parts of defoaming agent, 1-5 parts of preservative, 1-10 parts of dispersant, 100-300 parts of pigment, 100-400 parts of filler, 1-10 parts of nanometer thickener, 1-10 parts of flatting agent, 5-20 parts of nanometer inorganic anionic formaldehyde-removing additive, 40-100 parts of nanometer polymer hollow microspheres, 10-20 parts of bamboo vinegar and 0-350 parts of water. The bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint can be coated on the wall and wood; the paint film is characterized by light odor, low volatile organic compound (VOC), good hiding power and adhesion, washing and wiping resistance and the like; the harmful substances such as formaldehyde and benzene can be removed; the cost is low, the construction property is good, the environmental friend is good; and the emulsion paint is a product which combines decorative function, functionality and environmental friend together perfectly.

Owner:濮阳展辰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com