Patents

Literature

264results about How to "Guaranteed compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength plant growing type porous concrete and preparation method thereof

InactiveCN102010155AGuaranteed compressive strengthHigh porositySolid waste managementEcological environmentCrushed stone

The invention discloses a high-strength plant growing type porous concrete and a preparation method thereof. The concrete comprises the following ingredients in proportioning by weight: water, cement, waste concrete or natural crushed stone aggregate, water reducing agents and rice straw. The preparation method comprises the steps of: firstly crushing the waste concrete or the natural crushed stone aggregate to be used as aggregate for later use; smashing the fully dried rice straw for later use; stirring the aggregate and a proper amount of water for a period of time; putting a proper amount of cement, the smashed rice straw and the water reducing agents into a stirrer for stirring; and finally, adding rest water and cement to be stirred. The high-strength plant growing type porous concrete can replace masonry flagstone with the strength of lower than M15, is applied to engineering projects such as raceways, parking lots, side slopes, riverbanks and the like and helps the growth of plants and restores the ecological environment destroyed by construction under the application condition.

Owner:孙学军 +1

Preparation method of novel alkali-free liquid accelerator

The invention discloses a preparation method of a novel alkali-free liquid accelerator. The ingredients and the proportion of the accelerator are as follows: 30-50% of aluminum sulfate, 10-20% of aluminum citrate, 2-10% of hydroxycarboxylic acid, 5-10% of ammonium hydroxide at the concentration of 20%, 0.01-0.05% of polyacrylamide and the balance of water. The preparation method comprises the following technological production steps: feeding the raw materials into a reaction kettle according to different feeding sequences, heating and uniformly mixing the raw materials at 60-80 DEG C, and cooling the mixture to obtain a colorless or light green thick liquid. The preparation method disclosed by the invention has the following advantages that due to the introduction of multi-hydroxyl functional group molecules, the coordination crosslinking of an aluminum crosslinking system and polyacrylamide molecules is promoted, a composite aluminum citrate crosslinking system with high activity is prepared, the hydration rate of cement is obviously increased, and furthermore the action effect of the accelerator is enhanced. The setting time of the cement mortar doped with the accelerator is greatly shortened, the initial setting time is shorter than 2 minutes, the final setting time is shorter than 6 minutes, the 1d (Day) compressive strength is higher than 10MPa, and the 28d compressive strength rate is higher than 140%.

Owner:BEIJING ACAD OF BUILDING ENG

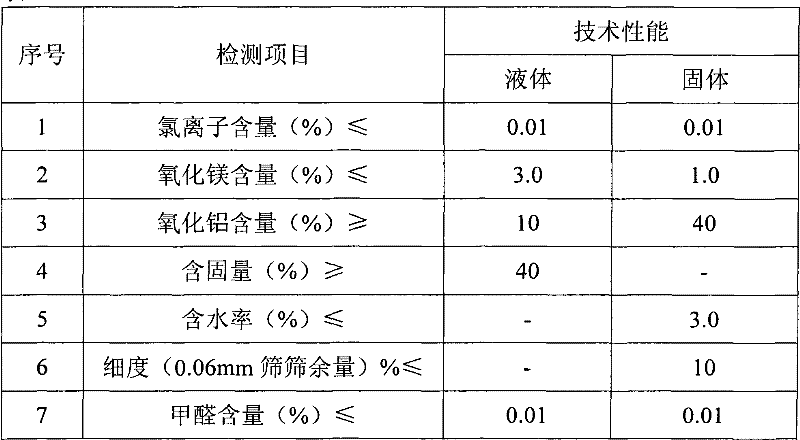

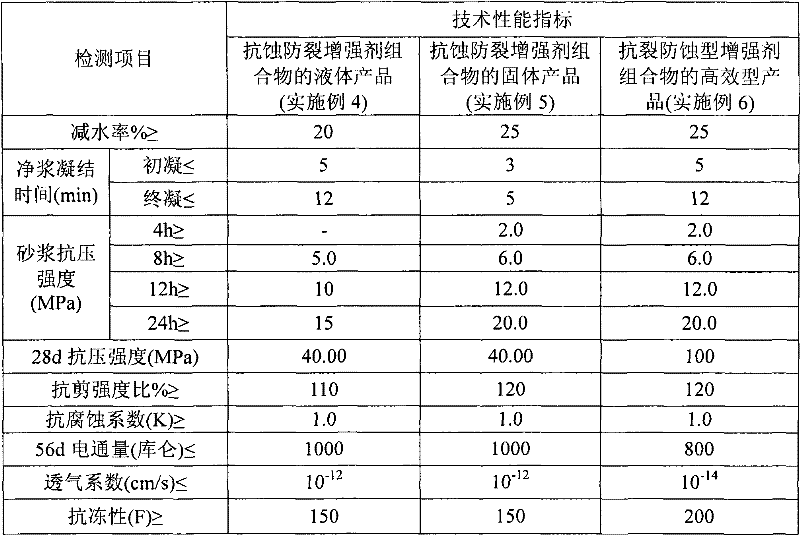

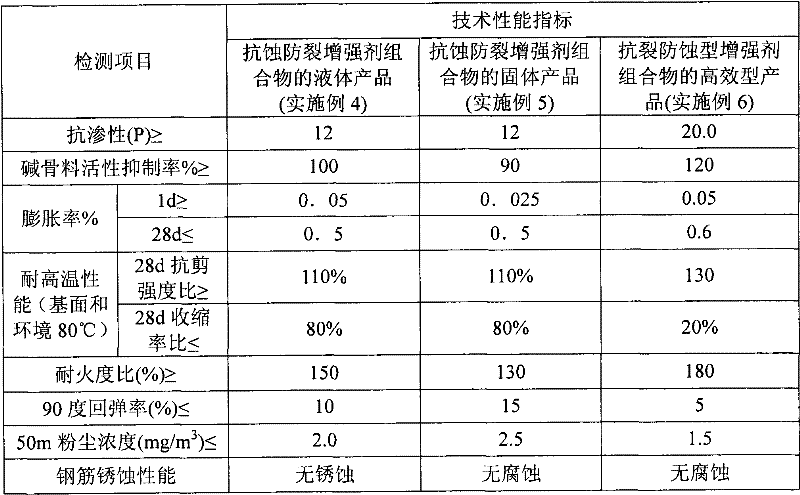

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

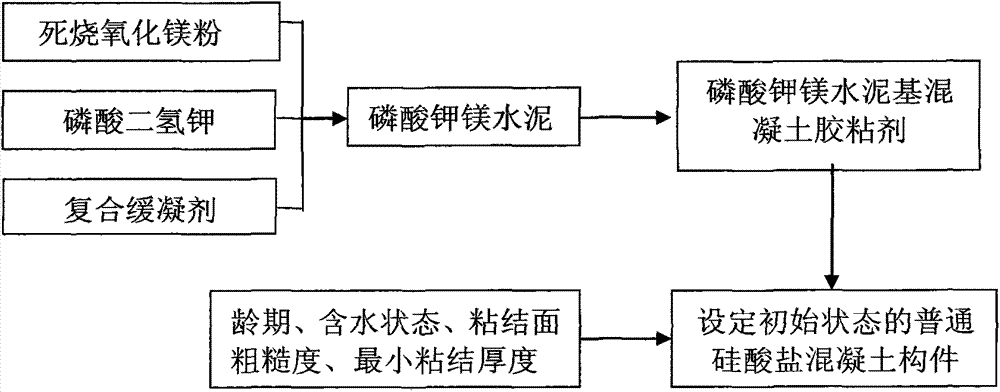

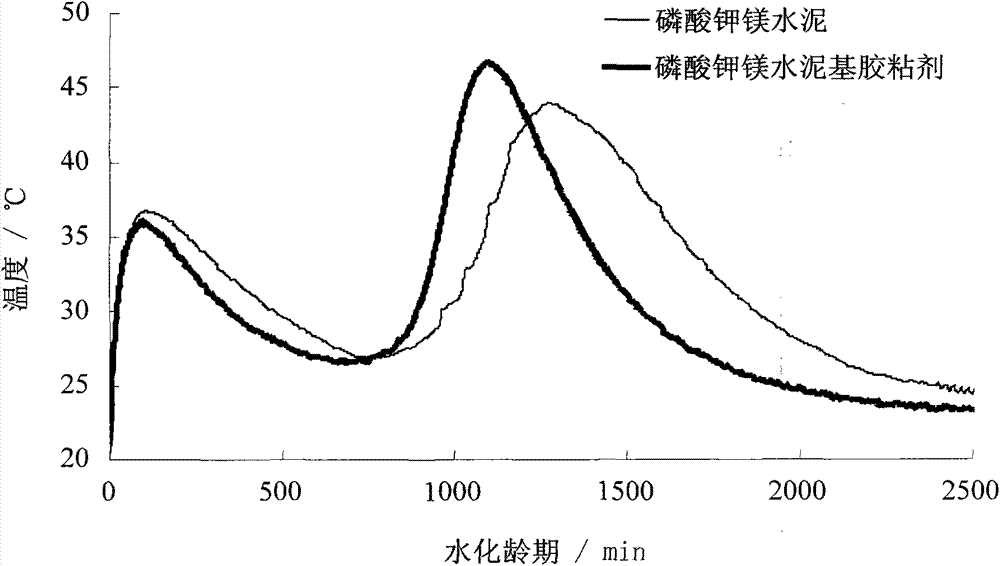

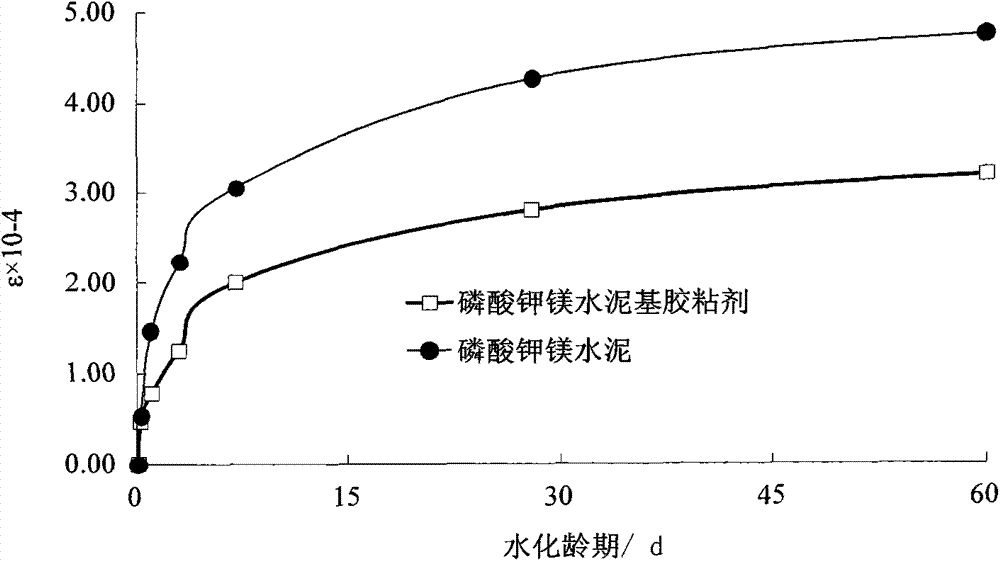

Magnesium potassium phosphate cement-based concrete adhesive and preparation method thereof

The invention discloses a magnesium potassium phosphate cement-based concrete adhesive and a preparation method thereof. The preparation method of the magnesium potassium phosphate cement-based concrete adhesive comprises the following steps: firstly, taking 50-70 parts by mass of dead-burned magnesia powder as an alkali component and 30-50 parts by mass of monopotassium phosphate as an acid component, and doping 6-10 parts by mass of complex retarder to prepare magnesium potassium phosphate cement, wherein the complex retarder is composed of sodium tetraborate, sodium phosphate dibasic dodecahydrate and inorganic chlorine salt in mass ratio of (2-4):(4-8):(2-5); secondly, preparing the magnesium potassium phosphate cement-based concrete adhesive by taking 5-15 parts by mass of limestone powder, 10-20 parts by mass of coal ash and 70-85 parts by mass of magnesium potassium phosphate cement. The complex retarder effectively delay condensation time of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement guarantees higher early strength, and the coal ash and limestone powder guarantee stable growth of strength and improve volume stability.

Owner:YANCHENG INST OF TECH +1

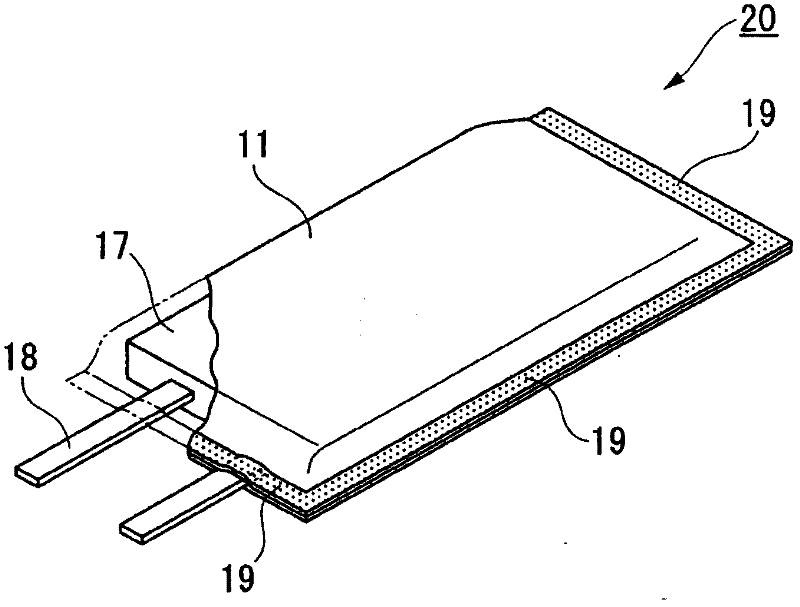

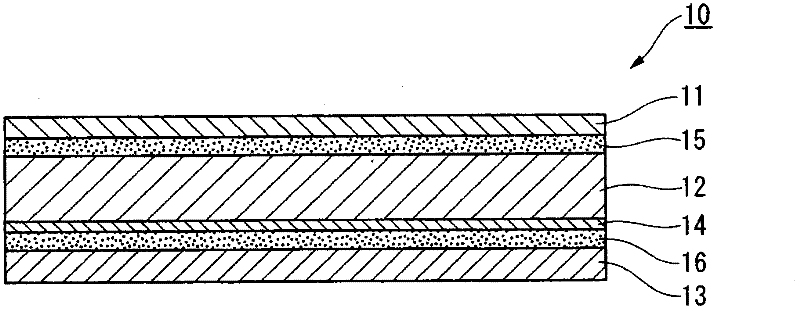

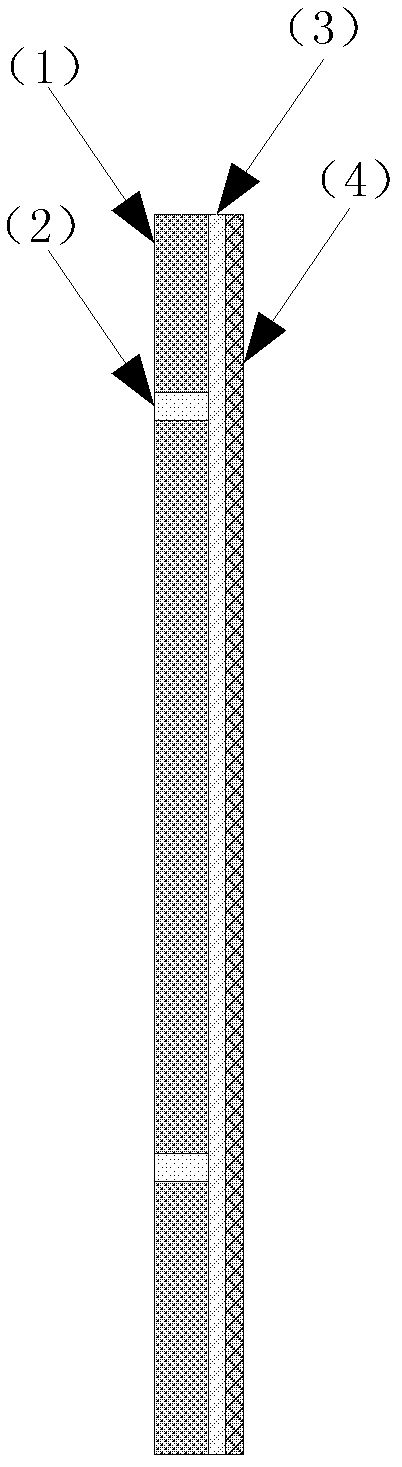

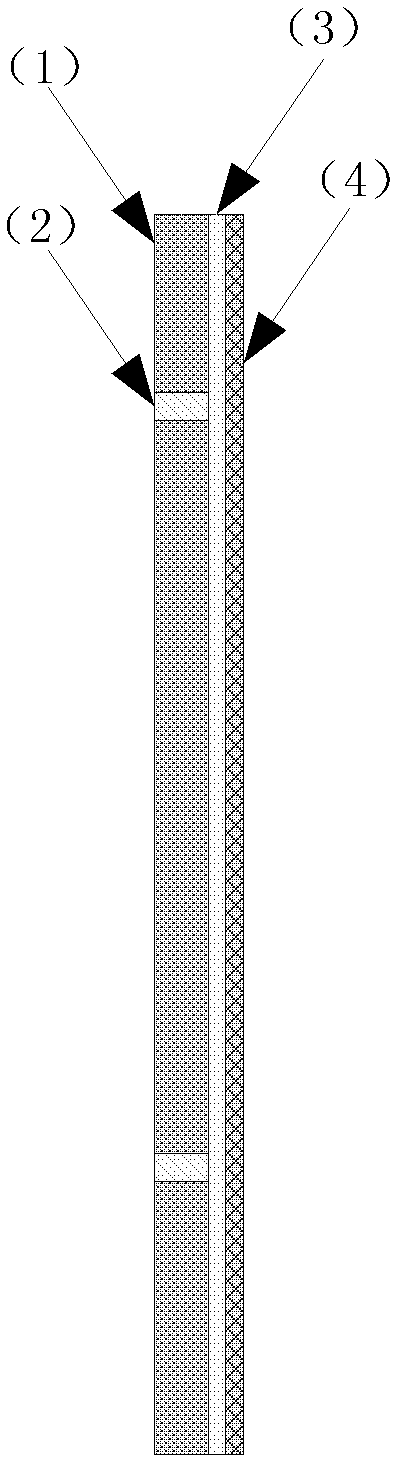

Laminating member for battery package

ActiveCN102343693AHigh bonding strengthAvoid it happening againSynthetic resin layered productsDouble layer capacitorsPolyethylene terephthalatePolyamide

Provided is a laminating member for battery packaging. The laminating member is formed by sequentially laminating an aluminum foil and a resin layer for battery packaging. The laminating member sequentially laminates a substrate layer, an aluminium foil, and an innermost layer composed of a polypropylene layer and a polyethylene layer, wherein the substrate layer is a laminating membrane formed by sequentially laminating a PET(polyethylene terephthalate) membrane layer with the thickness ranging from 3 to 11 microns and a polyamide membrane layer with the thickness ranging from 15 to 50 microns upon the outside surface side of the aluminium foil. Moreover, the innermost layer side surface of the aluminium foil is laminated by a film coating layer composed of a water soluble resin or the copolymerization resin thereof.

Owner:FUJIMORI KOGYO CO LTD

Cement-based composite material for steel box girder bridge deck, as well as preparation and pavement thereof

ActiveCN103449786AImprove toughnessLimit extensionBridge erection/assemblyBridge materialsEpoxyBridge deck

The invention relates to a cement-based composite material for pavement of a steel box girder bridge deck, as well as a preparation method and a pavement method thereof. The invention aims at providing a lightweight and high-toughness cement-based composite material which is suitable for pavement of larger-span steel box girder bridge decks, and the cement-based composite material comprises the following components in parts by weight: 849-881 parts of cement, 339-425 parts of quartz sand, 215-273 parts of pottery sand, 100-226 parts of fly ash, 30-56 parts of silica fume, 275-295 parts of water, 10-13 parts of water reducing agent, 40-80 parts of steel fiber, 6.5-13 parts of organic fiber and 20-30 parts of epoxy resin. Through material optimization, the durability of a bridge deck paving layer is improved, the overall dead weight is reduced, the cost of a project is simultaneously saved, and the cement-based composite material is suitable for pavement of the larger-span steel box girder bridge decks.

Owner:WUHAN UNIV OF TECH

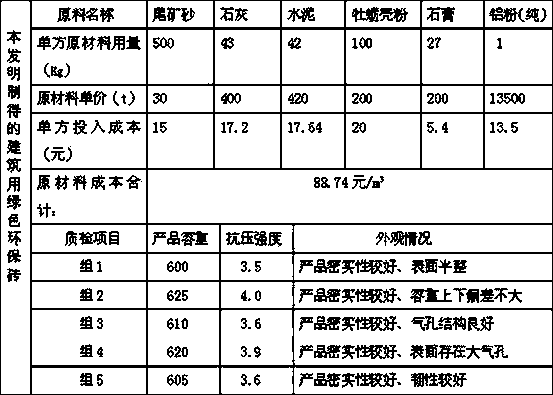

Green and environment-friendly brick for building and making technology thereof

The invention discloses a green and environment-friendly brick for building and a new technology production mode for preparation of the green and environment-friendly brick for building, and the green and environment-friendly brick for building uses calcined oyster shell powder to replace part of expensive building raw materials such as lime, cement and the like. Compressive strength and dry density and other technical parameter requirements of a product are ensured, meanwhile mixing amounts of the cement and the lime are reduced, the production cost is reduced, the oyster shell powder is mixed for mixed grinding with tailing sand to prepare good-performance mortar, so that a tailing sand early-stage processing technology requires that the fineness needs to increase from 0.08 mm-sieve screen residue weight of 30% to 60%, the tailing sand processing time and processing power consumption are reduced, the energy is saved, oyster shell produced by coastal oyster breeding is effectively used and duly processed, and the environment is improved.

Owner:东山县金石混凝土有限公司

Portland cement refractory mortar and construction technology thereof

ActiveCN102924105AImprove early strengthGood adhesionBuilding material handlingPortland cementRefractory

The invention discloses a portland cement refractory mortar and a construction technology thereof. The portland cement refractory mortar comprises the following components in percentage by weight: 12-16% of portland cement, 10-15% of powdery refractory mortar, 5% of silica powder, 20-30% of quartz sand, 30-50% of river sand and the balance of water. The refractory mortar has high early strength, can resist high calcination temperature, has high adhesive property and strength after the calcination and is used for solving the safety problem during the current construction process; and moreover, the cost is lower than that of the conventional refractory castable.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

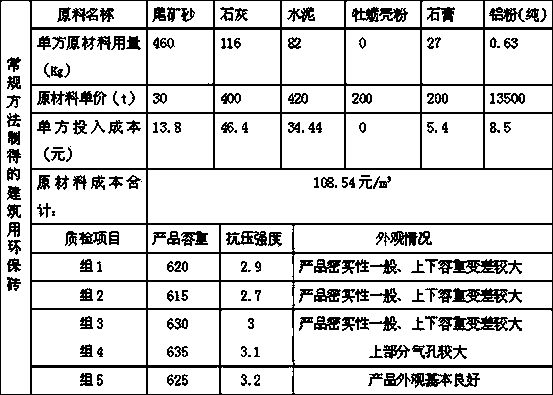

High-strength anti-cracking foam concrete and preparation method thereof

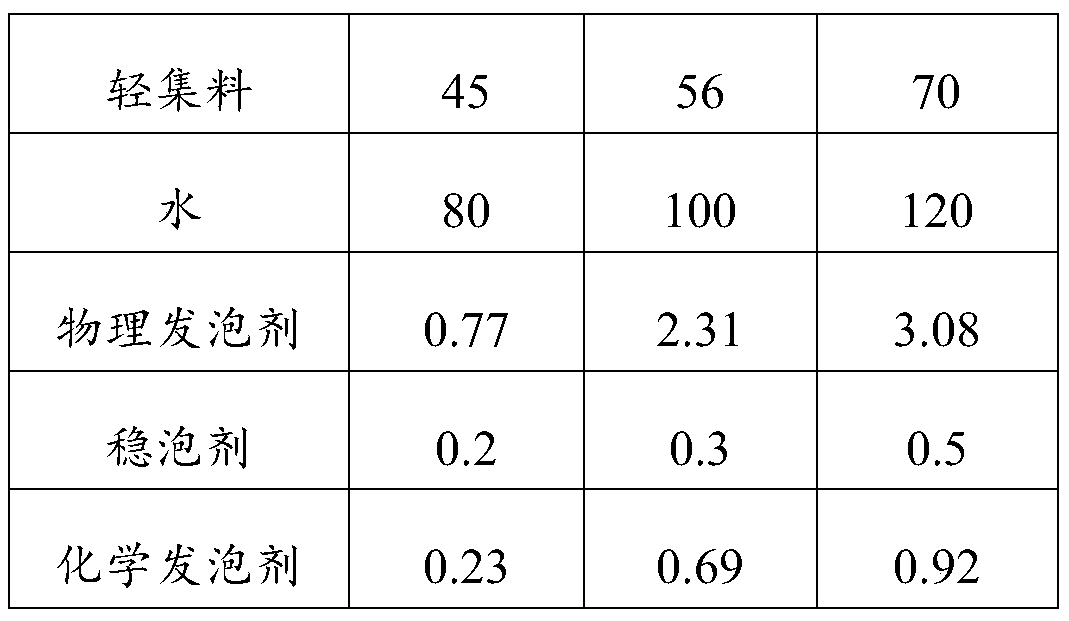

ActiveCN110105013AGuaranteed compressive strengthReduce surface tensionCeramicwareFiberFoam concrete

The invention relates to high-strength anti-cracking foam concrete and a preparation method thereof. The high-strength anti-cracking foam concrete comprises, by weight, 200-240 parts of cement, 20-45parts of slag powder, 80-120 parts of water, 1-3 parts of a waterproof agent, 1-5 parts of foaming agents, 0.2-0.5 part of a foam stabilizer, 45-70 parts of lightweight aggregate and 0.3-0.8 part of wood fiber. A double foaming method using the physical foaming agent and the chemical foaming agent is utilized, and the wood fiber is also used so that a large quantity of stable closed air holes canbe formed in the foam concrete, convection and radiation effects in the air holes can be weakened, the water absorption rate of the material is reduced, and meanwhile, the heat conductivity coefficient of the high-strength anti-cracking foam concrete is lower. Due to the double foaming method, the properties of the materials such as the cement, the slag powder and the wood fiber can be fully achieved, and the high-strength anti-cracking foam concrete with the strength and crack resistance better than those of conventional foam concrete is obtained.

Owner:CHINA FIRST METALLURGICAL GROUP

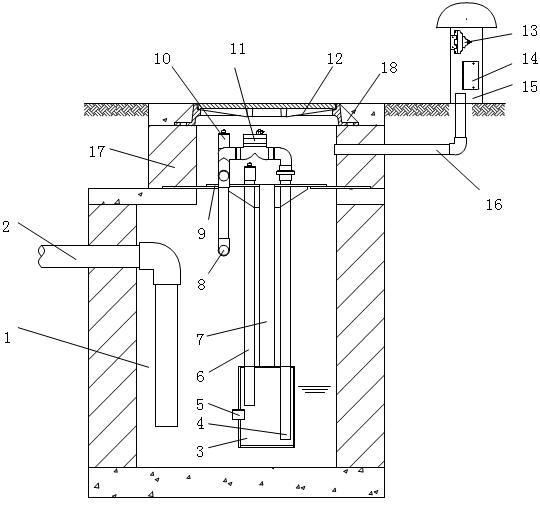

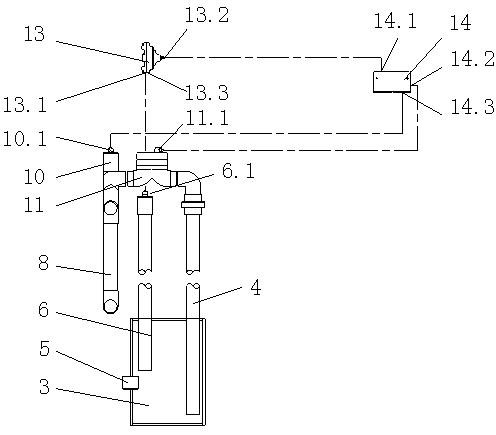

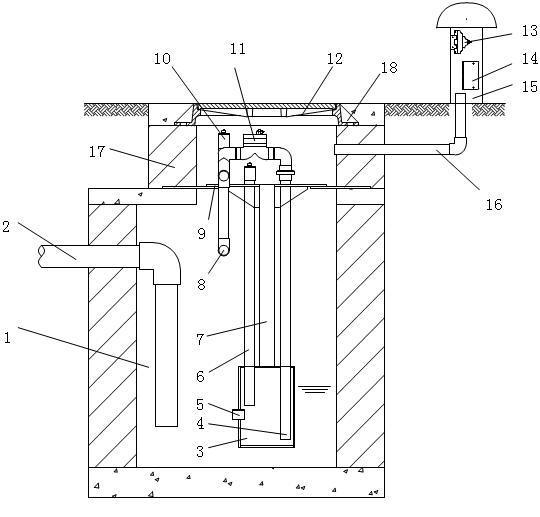

Sump well for vacuum drainage system

ActiveCN102121271ARemove balanceEliminate shockCesspoolsSewerage structuresEngineeringMultiple point

The invention relates to a sump well for a vacuum drainage system. The sump well comprises a collection well, a sewage pumping pipe, a drainage pipe, a vacuum valve, a controller for controlling connection and disconnection of the vacuum valve and a water level sensor for collecting water level information, wherein the outlet of the drainage pipe is connected into a vacuum pipeline, and the inletof the drainage pipe is connected with the outlet of the sewage pumping pipe through the vacuum valve; the inlet of the sewage pumping pipe extends into a sewage pumping level in the collection well;and a signal output end of the water level sensor is connected with a signal input end of the controller. Along with sewage collection in the well, the sump well drains automatically and intermittently to the vacuum drainage system, has a simple structure, and does not require a lift pump, so that the problems of being low in safety, easy in blockage, difficult in cleaning, high in power consumption and the like caused by assembling the lift pumps on multiple points can be avoided, and sewage collected by gravity flow can be lifted to the vacuum drainage system without extra additional power,and the sump well is convenient to check and maintain.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

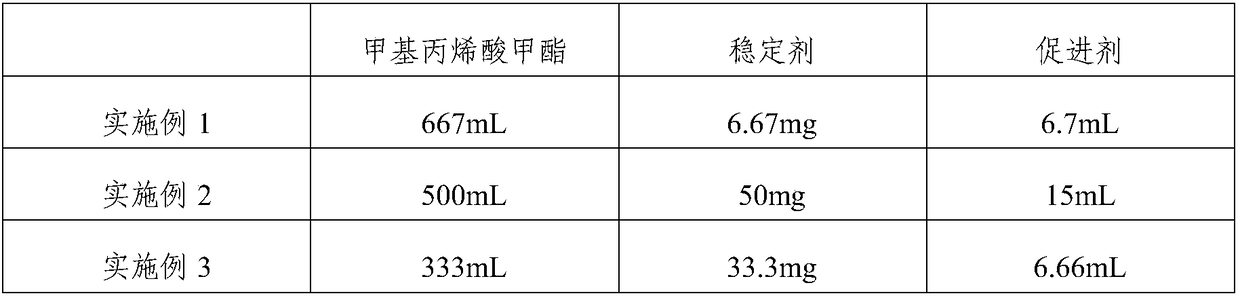

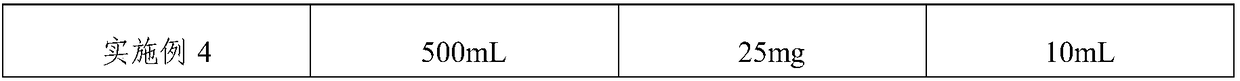

Polymethyl methacrylate bone cement and preparation method thereof

ActiveCN108096629AWon't hurtModerate viscosityTissue regenerationProsthesisSolid componentOsseointegration

The invention relates to a polymethyl methacrylate bone cement and a preparation method thereof. Concretely, the bone cement comprises a solid component and a liquid component. The solid component comprises a solid component A including polymethyl methacrylate, a methyl methacrylate-styrene segmented copolymer, a contrast agent, and an initiator; and a solid component B including mineralized collagen. The liquid component includes methyl methacrylate, a stabilizer and an accelerating agent. Through control of the molecular weight and ratio of the components, it is ensured that the obtained PMMA bone cement doesn't release a large amount of heat during application, thereby preventing damage to the surrounding bone tissue. The bone cement is suitable in viscosity and has random plasticity. Through addition of mineralized collagen which is excellent in osteogenic activity, the mechanical property and biocompatibility of bone cement are improved, and the bone cement is excellent in osseointegration capability and low in elastic modulus.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

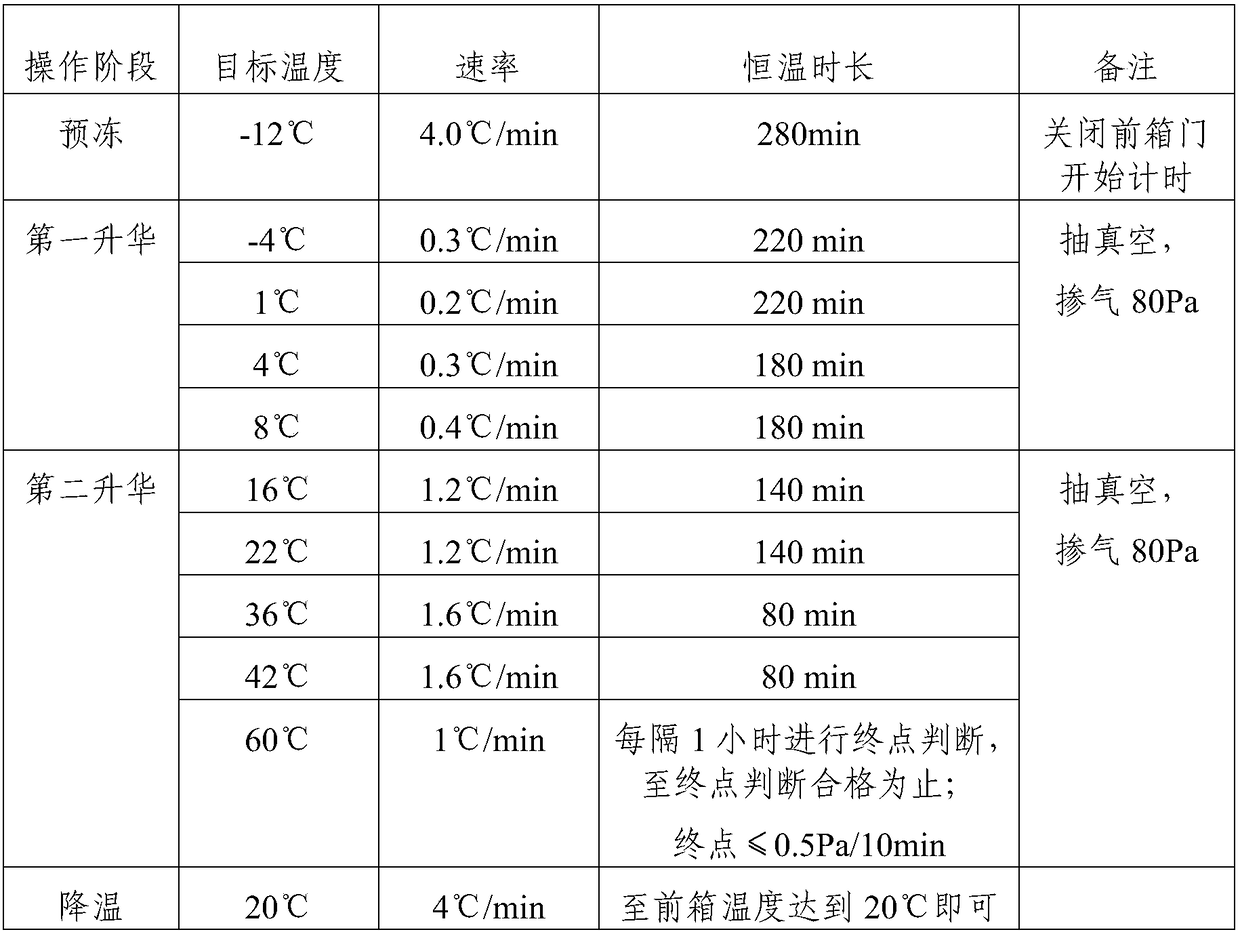

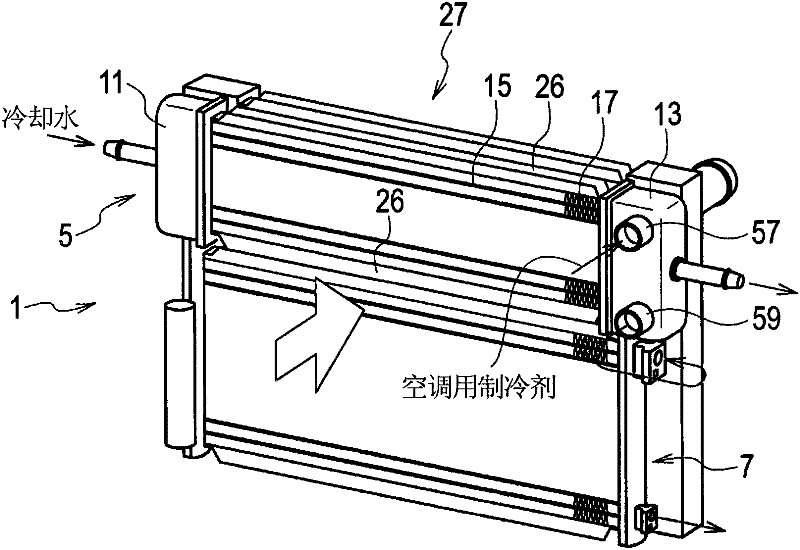

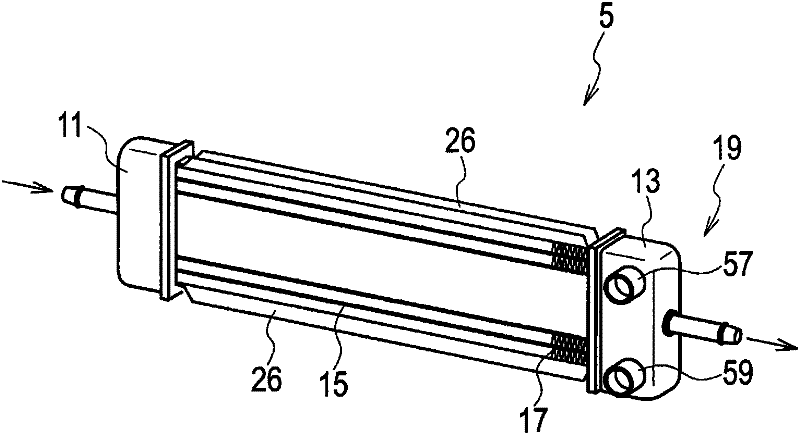

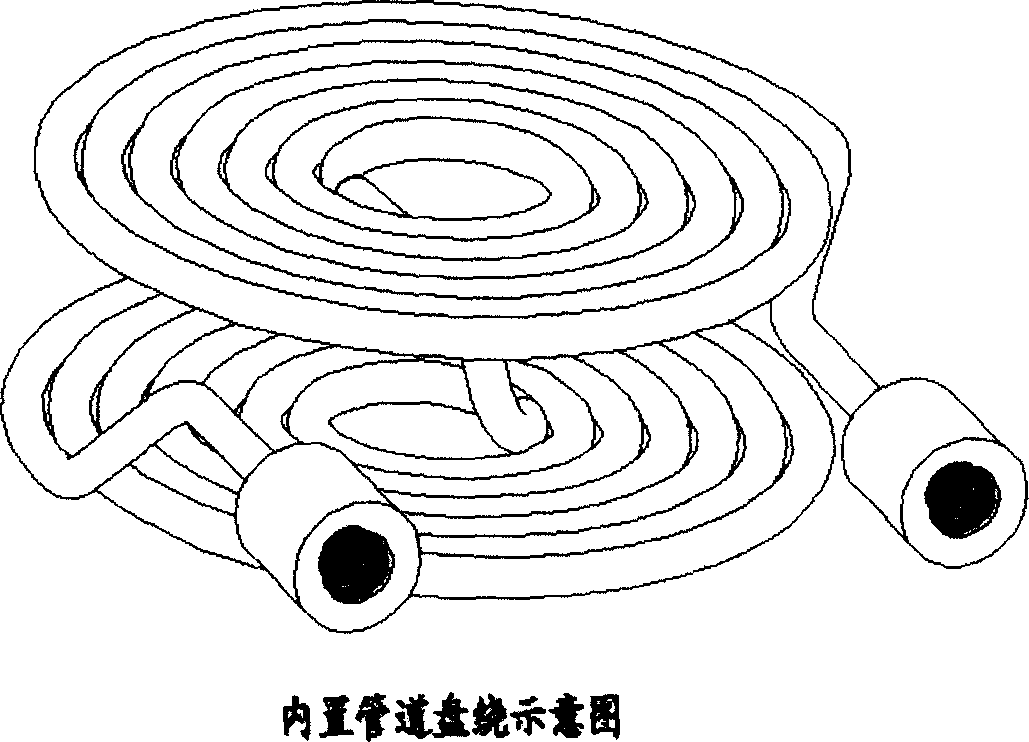

Compound heat exchange unit

InactiveCN102224391AInhibition retentionEnsure adequate lubricationStationary conduit assembliesHeat exchanger casingsCoolant flowWater flow

Disclosed is a compound heat exchange unit equipped with a first air-cooled heat exchange unit (5) that cools cooling water for the heat-generating body of an automobile other than the internal combustion engine and a second air-cooled heat exchanger unit that cools a coolant for vehicle air conditioning. The first air-cooled heat exchange unit comprises an upstream tank into which cooling water flows, a downstream tank from which coolant flows, a flow path member that connects the upstream tank to the downstream tank, radiator fins which are layered alternately with the flow path member, and a water-cooled heat exchange unit that cools the coolant. The water-cooled heat exchange unit is disposed within the downstream tank; at the upper part thereof there is an inlet port into which the coolant flows, and at the lower part thereof there is an outlet port from which the coolant flows. By means of the aforementioned heat exchange unit, it is possible to prevent accumulation of oil mixed with the coolant, heat exchange efficiency can be improved, and reduced size can be achieved.

Owner:CALSONIC KANSEI CORP

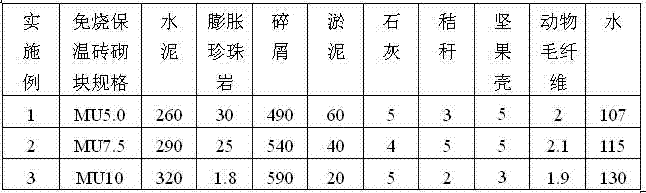

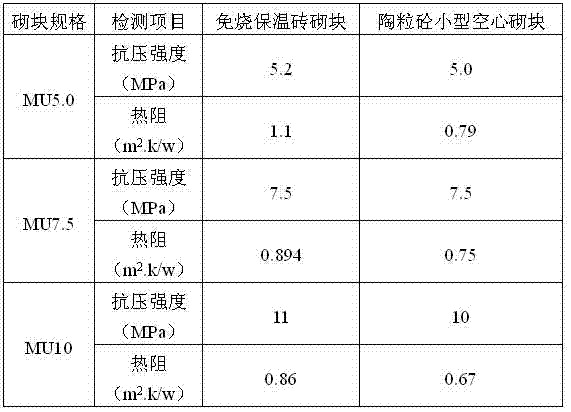

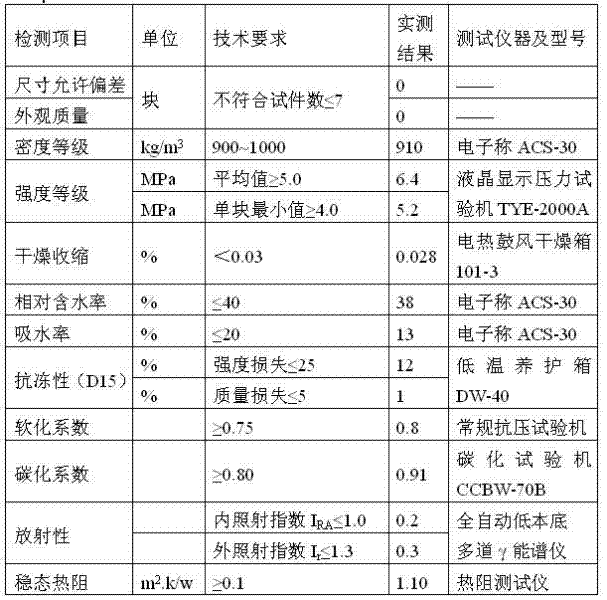

Baking-free insulating brick and production method thereof

The invention relates to a baking-free insulating brick and a production method thereof. The baking-free insulating brick provided by the invention comprises the following raw materials in parts by weight: 490-590 parts of fragment, 260-320 parts of portland cement, 20-60 parts of dried sludge, 4-5 parts of lime, 1.8-30 parts of expanded perlite, 2-5 parts of straw, 3-5 parts of nut shell, 2.1-1.9 parts of animal wool fiber and 107-130 parts of water. The baking-free insulating brick provided by the invention is prepared by the following production steps: firstly, dewatering and drying sludge; adding lime to the dry sludge to be uniformly mixed; piling; stirring; deodorizing and sterilizing; simultaneously grinding straw, nut shell and animal wool fiber into microparticles; sequentially adding all the raw materials to a stirrer to be uniformly mixed; and finally, carrying out extrusion molding and maintenance on the mixture to obtain a finished baking-free insulating brick. The baking-free insulating brick produced by the invention has good heat insulation property and compressive strength and strong freezing resistance and crack resistance, and the radiation quantity of the baking-free insulating brick is far lower than industrial specified standards.

Owner:无锡市康顺节能材料科技有限公司

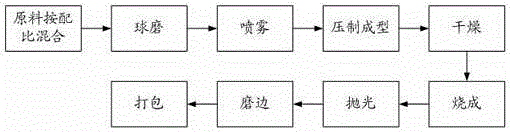

Preparation method of ardealite baked brick

InactiveCN101774797AGood effectGuaranteed compressive strengthCeramic materials productionClaywaresBrickAdhesive

The invention discloses a preparation method of an ardealite baked brick. The ardealite baked brick is prepared by the following steps of: taking ardealite, a shaping adhesive, a catalytic intensifier and a melting point depressing intensifier as raw materials, and crushing, mixing, shaping and drying and baking in a kiln according to a conventional process to obtain an ardealite baked brick, wherein the shaping adhesive is clay or shale, the catalytic intensifier is an iron-contained compound, and the melting point depressing intensifier is fluosilicate. The weight ratio of the ardealite to the shaping adhesive to the catalytic intensifier to the melting point depressing intensifier is 55-80:16-41:1-2:1-4, and the baking temperature is 700-870 DEG C. The invention not only solves the problem that sulfur dioxide generated in high-temperature sintering of the ardealite pollutes the environment but also can reduce the sintering temperature and reduce energy consumption.

Owner:TONGLING CHEM IND GRP

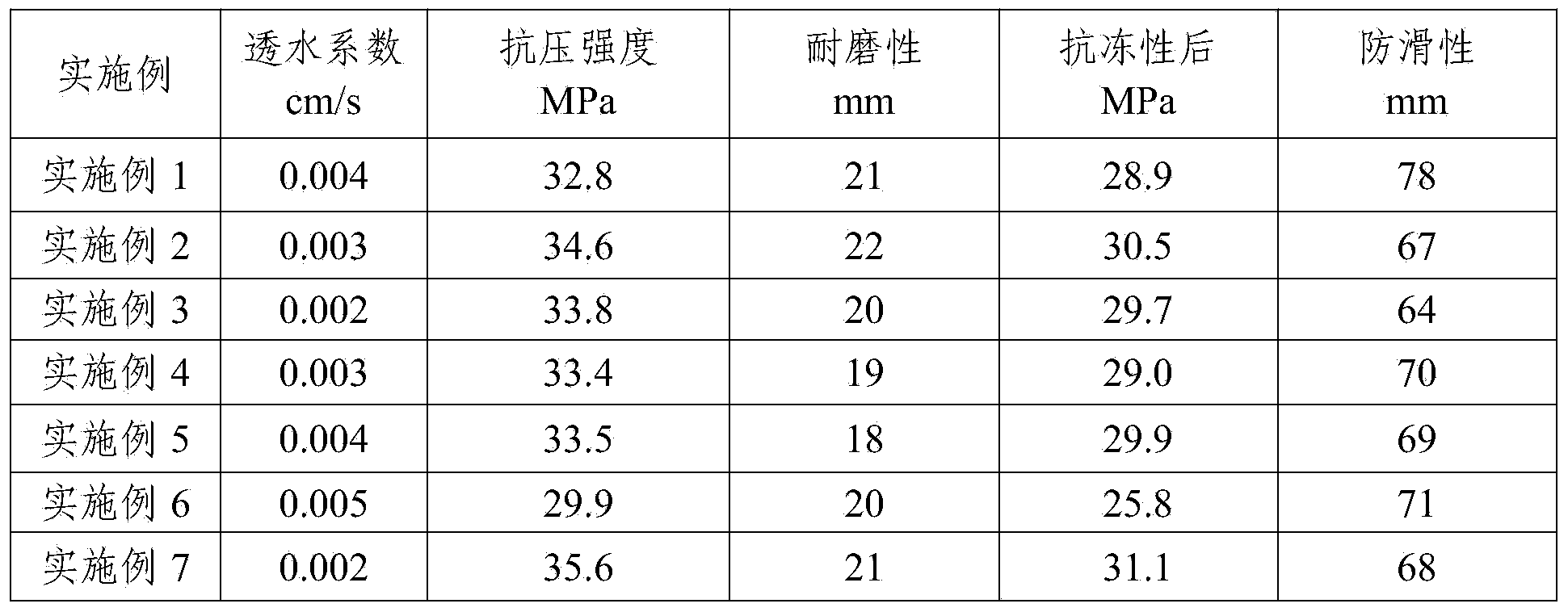

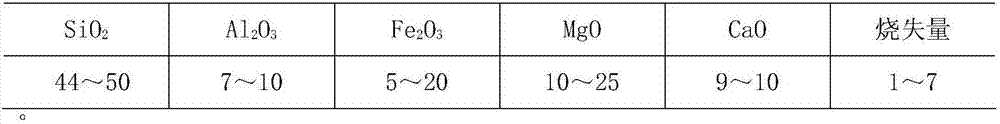

Ferro-nickel slag water permeable brick for pavements and preparation method of water permeable brick

ActiveCN104163596AEfficient resource utilizationSolve intractable problemsSolid waste managementBrickResource utilization

The invention relates to the technical field of building materials and particularly relates to a ferro-nickel slag water permeable brick for pavements and a preparation method thereof. A great deal of ferro-nickel slag is mixed into the adopted raw materials, so that the resource utilization of the ferro-nickel slag is remarkable, the treatment cost is reduced, a problem that the ferro-nickel slag is difficult to treat is effectively solved, and the environmental pollution is reduced; a modifier gypsum is introduced, so that part of a gel material can be effectively substituted by virtue of active ferro-nickel slag micro powder; by controlling the total mixing amount of the ferro-nickel slag in the water permeable brick to be over 75% and adding an activator, the breaking strength and the compressive strength as well as various indexes of the prepared ferro-nickel slag water permeable brick for pavements are guaranteed, the national comprehensive utilization industrial policy of the waste resources are fulfilled, and a great deal of the ferro-nickel slag can be treated, and thus the production cost and the energy consumption are reduced.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

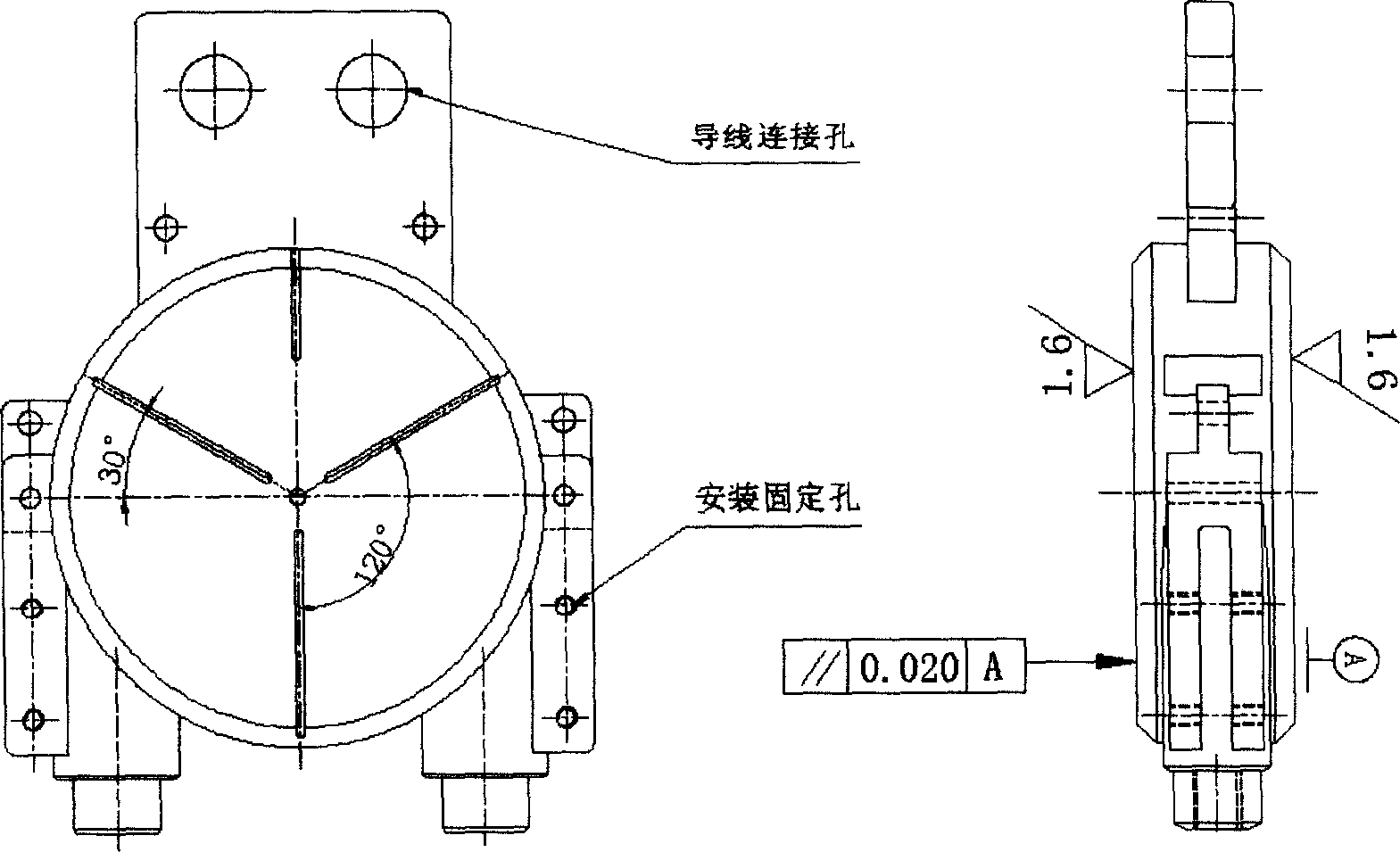

Thyratron transistor valve water-cooling radiator

ActiveCN1767183ASmall water resistance and thermal resistanceReduce maintenanceSemiconductor/solid-state device detailsSolid-state devicesWater pipeHardness

The invention relates to a thyristor valve group water cooling radiator in the field of electronic technology. It adopts plate touching conduction structure with the parallel degree of the two plates below 0.02 mm and the surface crudity degree below 1.6ª–m; The interface of the cooing water pipe is an entrance and a exit; the embed canal apprises the plate; it arranges the special wire connecting hole and fixed hole. The embed canal material uses low carbon stainless steel pipe and adds the element which can elevate the compression strength in the aluminum alloy of the plate. It adopts special embed canal surface processing craft and casing surface aluminum alloy electroplating craft.

Owner:CHINA ELECTRIC POWER RES INST

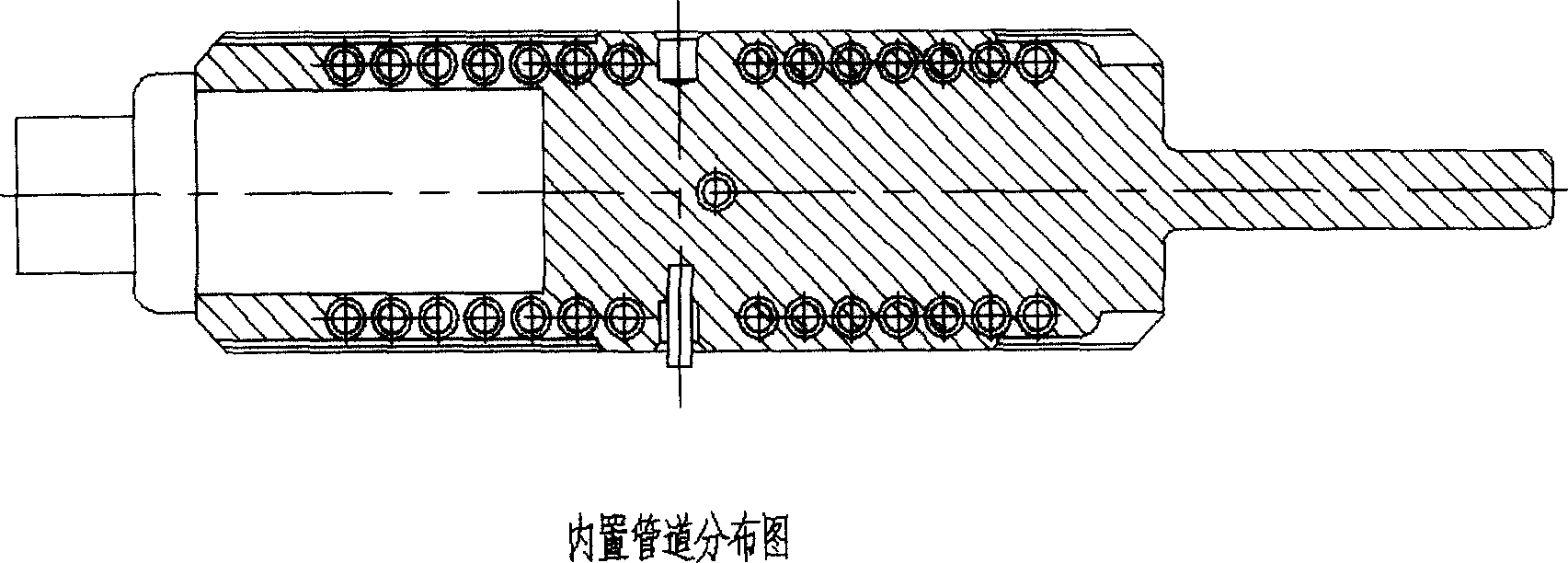

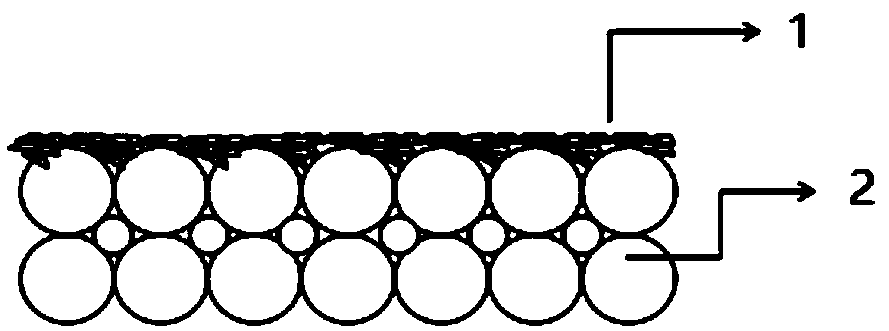

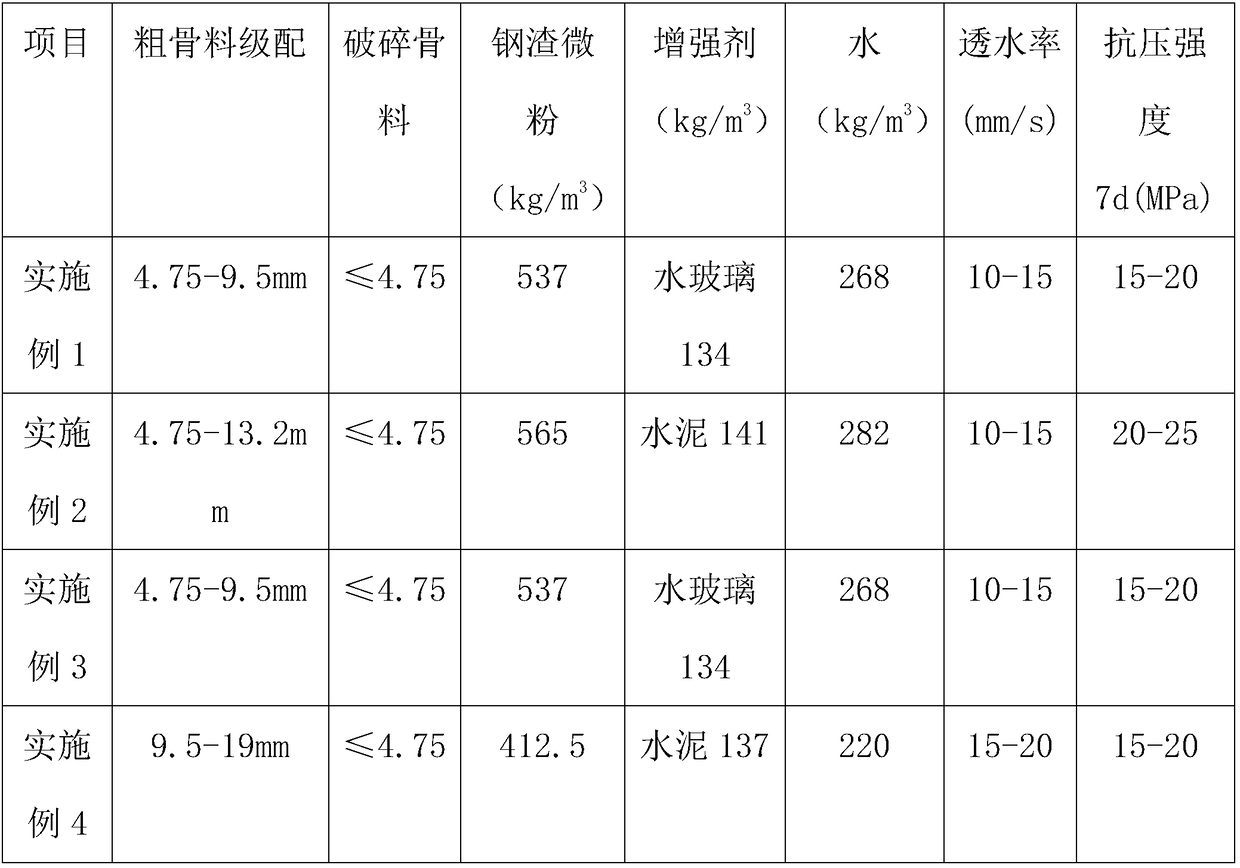

Water-permeable brick with artificial carbonized steel slag pellets as aggregates and preparation method thereof

ActiveCN108774041AUniform compositionShape controllableSolid waste managementPaving gutters/kerbsBrickSlag

The invention provides a water-permeable brick with artificial carbonized steel slag pellets as aggregates and a preparation method thereof, belonging to the technical field of green building materials. The water-permeable brick comprises a base layer and a surface layer, wherein the surface layer is located on the base layer; the base layer is made of continuously graded artificial carbonized steel slag pellet aggregates; and the surface layer is made of fine aggregates obtained by crushing and sieving carbonized steel slag bricks and formed after filling and leveling of the fine aggregates.The water-permeable brick comprises the following components by weight: 60 to 70% of artificial carbonized steel slag pellet aggregates, 5 to 10% of the fine aggregates obtained by crushing and sieving carbonized and cured steel slag bricks and having a particle size of no more than 4.75 mm, 15 to 20% of steel slag micropowder, 4 to 5% of a reinforcing agent and 4 to 5% of tap water. According tothe invention, through large addition amount of steel slag, industrial waste residues are greatly consumed; meanwhile, industrial waste gas CO2 is used as a raw material in the process of carbonization and curing, and the reaction of the CO2 with steel slag products in a carbonization kettle is an exothermic reaction, so no external heat source is need; and the advantages of waste utilization, carbon sequestration, energy conservation, emission reduction, simple preparation process, low equipment requirements, short production cycle and low cost are obtained.

Owner:DALIAN UNIV OF TECH

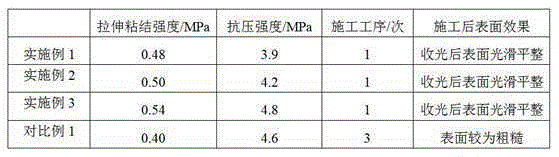

Putty leveling integrated gypsum mortar

The invention discloses putty leveling integrated gypsum mortar. The mortar is formed by mixing and stirring, by weight, 60-70 parts of desulfurized gypsum, 10-15 parts of 250-mesh heavy calcium carbonate, 6-10 parts of quartz sand of 20-30 meshes, 10-15 parts of 40-mesh quartz sand, 2-5 parts of glass bead heat preservation lightweight aggregate, 1-2 parts of redispersible emulsion powder VAE, 0.2-0.5 part of hydroxyethyl methylcellulose ether and 0.03-0.05 part of modified protein retarder. By means of the putty leveling integrated gypsum mortar, the traditional indoor leveling construction is greatly simplified, multiple construction procedures such as existing adhesion agents, leveling mortar and putty are replaced, forming can be completed at a time, the maintenance period is short, the construction period is greatly shortened, and the construction efficiency is improved.

Owner:上海曹杨建筑粘合剂厂

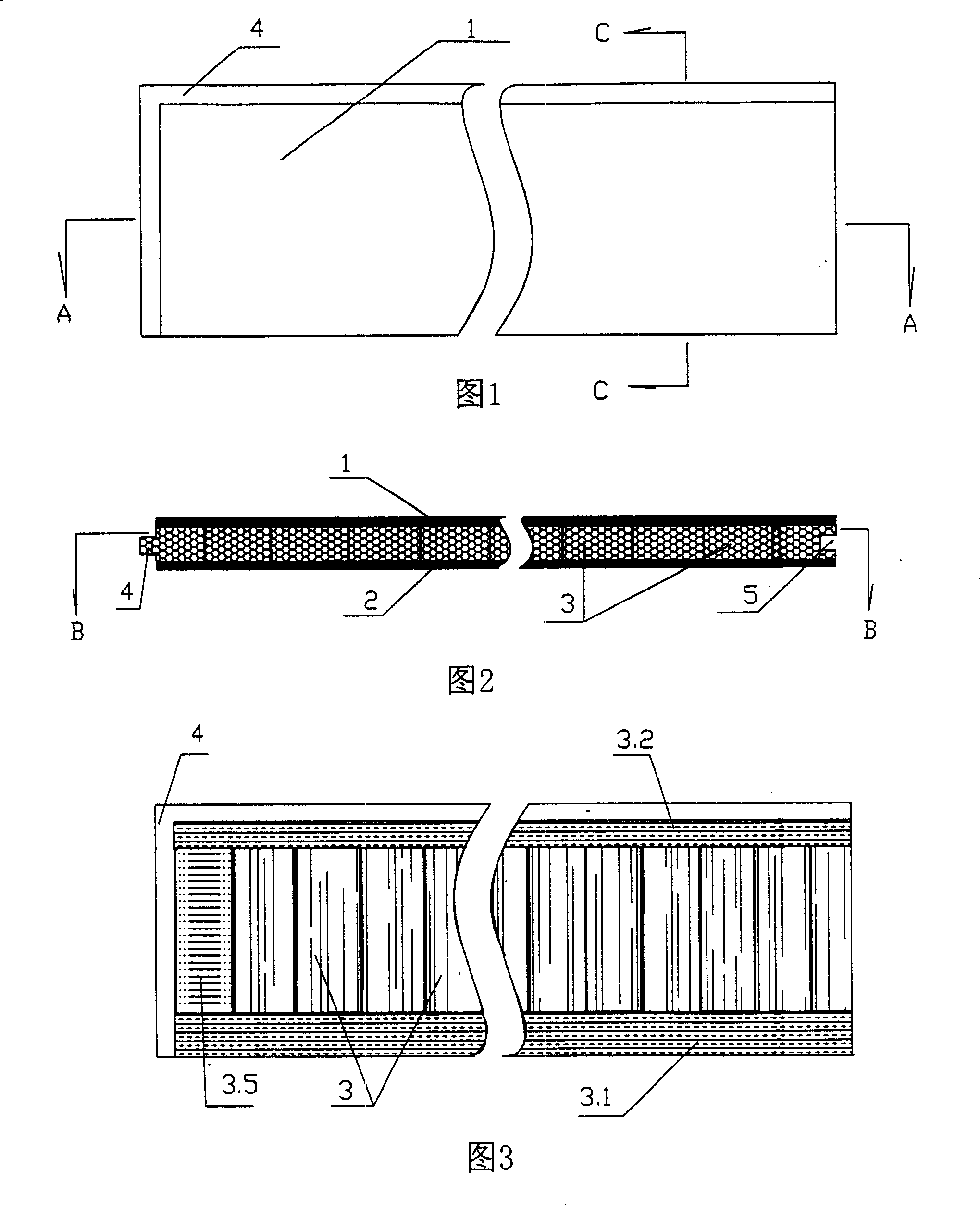

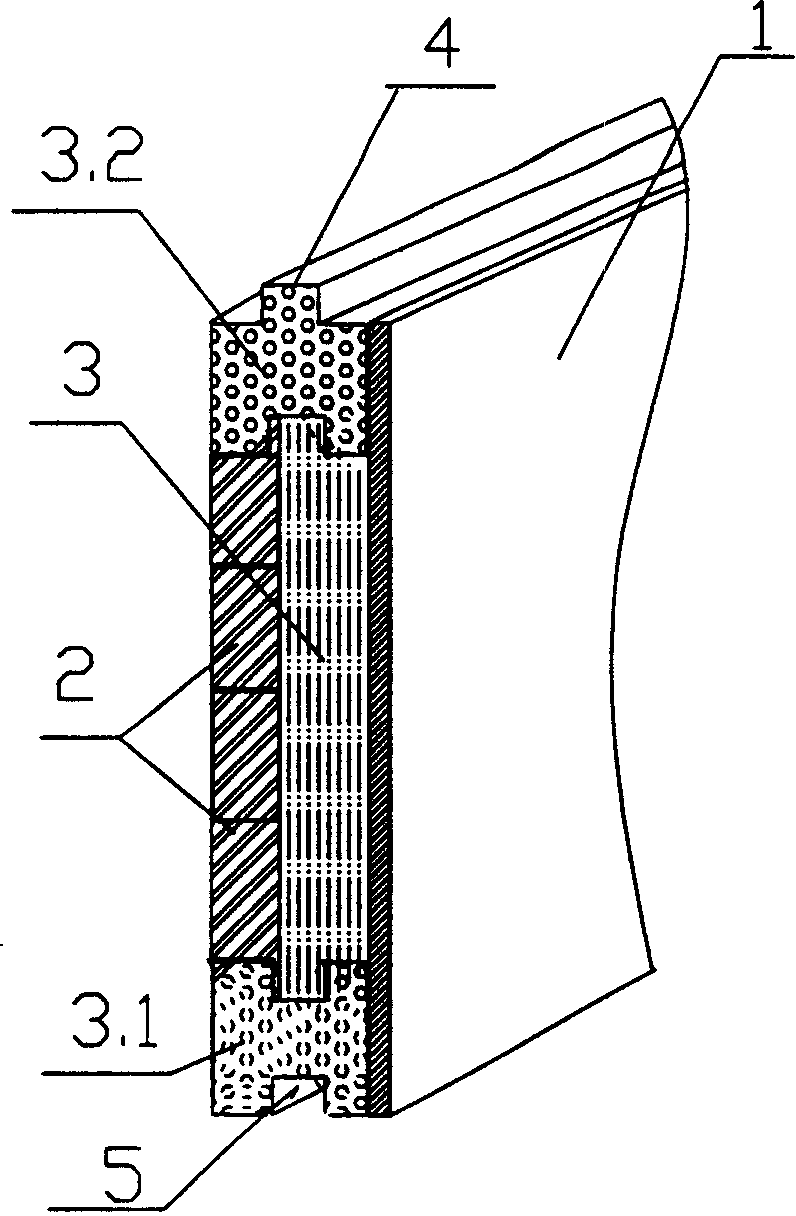

Frame type wooden floor

The invention provides a frame-type solid wood floor, which comprises a floor body, a tenon tongue and tenon slot which are around the floor body, wherein the floor body comprises a surface layer, a substrate slab, wherein the surface layer takes a longitudinal direction, the substrate slab is composed of a central filled slab, a bottom layer and filler rods which are arranged on two sides, and the tenon tongue and the tenon slot which are arranged on two sides are arranged outside the filler rods which are arranged on two sides. The central filled slab is tenon-jointed or finger jointed with the filler rods which are arranged on two sides. The central filled slab is composed of a plurality sections of short slabs on the length direction, the wood grains direction of the short slabs is arranged in a cross mode with the wood grain direction of the surface layer, the bottom layer which covers a plurality sections of central filled slabs and the filler rods which are arranged on two sides is arranged on the lower portion, the central filled slabs are combined with the bottom layer into integrity and tenon-jointed or finger jointed with the filler rods which are arranged on two sides. The wood grains of a section of short slab which are located on one end of the tenon tongue are in horizontal direction with the wood grain direction of the surface layer. The central filled slab is laminated by one or three layers on the thickness direction, the wood grain direction of each layer is arranged in the cross mode. The thickness of the surface layer is 0.6-6mm. The width of the filler rods which are arranged on two sides is 15-30mm. The bottom layer can be laminated by a plurality of strips on the transverse direction.

Owner:王仁忠 +2

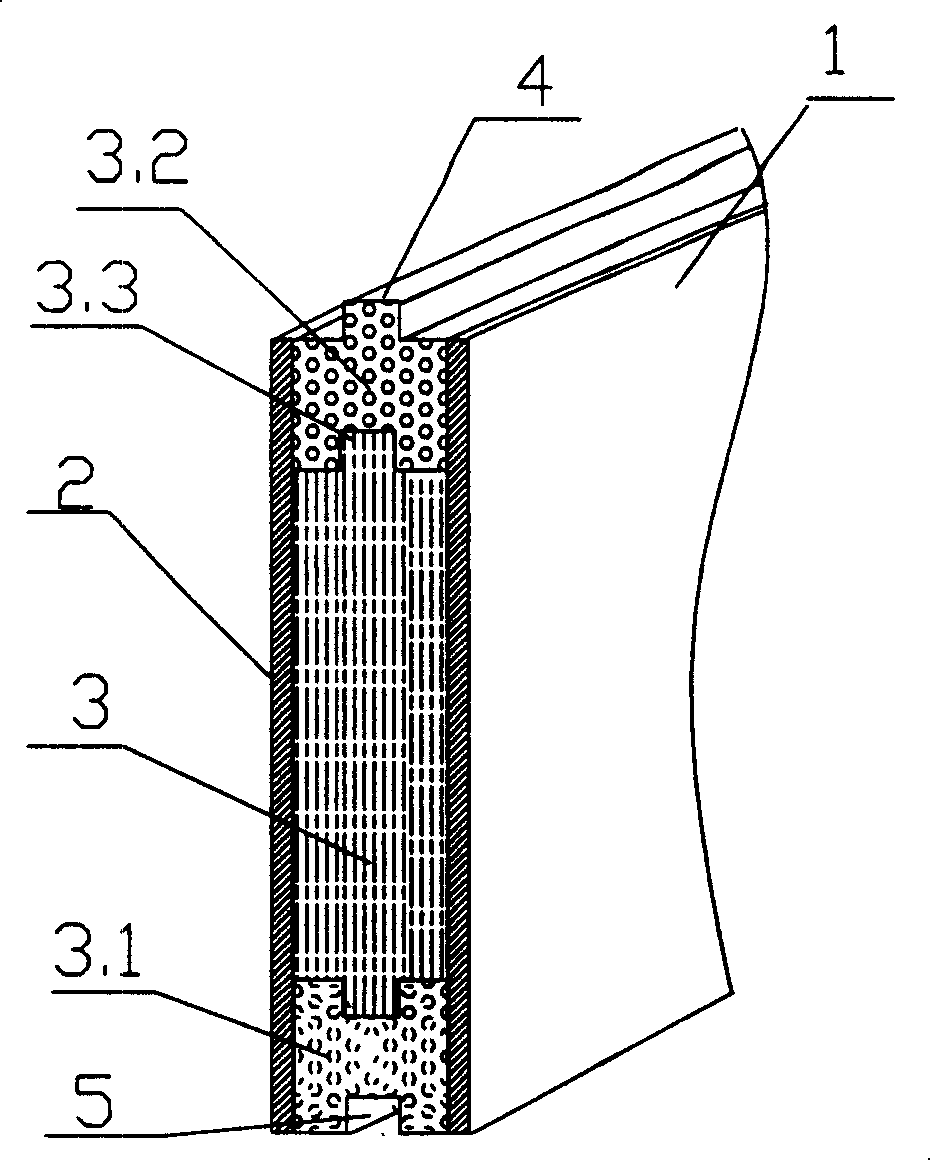

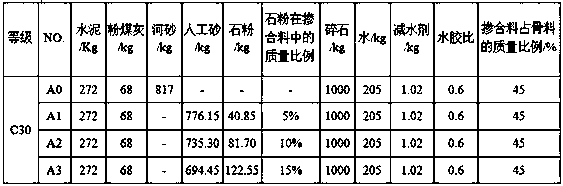

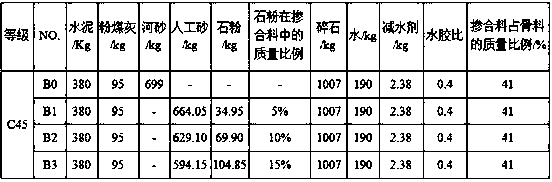

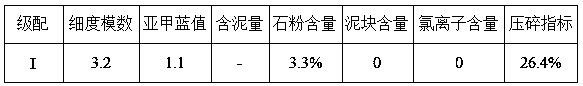

Concrete prepared from artificial sand and stone powder

The invention discloses concrete prepared from artificial sand and stone powder. The concrete is prepared from the following raw materials in parts by mass: 340 to 480 parts of gel materials, 690 to 820 parts of mixed materials, 990 to 1100 parts of coarse aggregates,190 to 210 pats of water and 1 to 3 parts of water reducing agents, wherein the gel materials are prepared from cement and fly ash;the mixed materials are prepared from artificial sand and stone powder. The artificial sand and the stone powder are used as concrete mixed materials; the consumption of natural river sand is reduced;the cost of a building prefabricated element can be reduced; the environment influence due to excessive exploitation of natural sand can be reduced; meanwhile, by selecting the consumption of the artificial sand and the stone powder, the concrete is enabled to have relatively good work performance and pressure-resistant intensity; the pressure-resistant intensity and the cracking pulling resistant intensity are a little higher than the concrete prepared from natural river sand; in addition, the artificial sand and the stone powder are used as the mixed materials; the concrete shrinkage is reduced; the concrete carbonization resistant and chloride ion seepage resistant performance is improved.

Owner:JINAN UNIVERSITY

Full-light high-strength concrete for fabricated prefabricated part and preparation method thereof

The invention relates to full-light high-strength concrete for a fabricated prefabricated part. The full-light high-strength concrete comprises the following components in parts by weight: 45-55 partsof cement, 45-55 parts of ceramsite, 38-55 parts of pottery sand, 15.5-17.5 parts of fly ash, 9-35 parts of steel fibers, 22-44 parts of high-performance fibers and 1.0-1.5 parts of a water reducingagent. Compared with the prior art, the prepared concrete is uniform in distribution; the weight is light, the strength is high, and the self-heat-preservation performance is good; the concrete has good tensile deformation resistance and light specific gravity, so that the full-light concrete has toughness, various properties of the concrete are effectively improved, the volume weight of the concrete is greatly reduced, the compressive strength is ensured, the full-light high-strength concrete is simple in preparation process, environment-friendly and easy to construct, and the concrete has good popularization value.

Owner:汝州市东江建筑工业科技有限公司

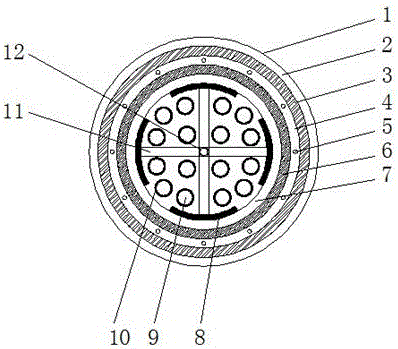

Compression-resistant cable with fast heat radiating function

InactiveCN106298011AHeat dissipation fastGuaranteed compressive strengthInsulated cablesInsulated conductorsCompressive strengthUltimate tensile strength

The invention discloses a compression-resistant cable with a fast heat radiating function. The compression-resistant cable comprises a medical cable body, an armored layer, a foamed rubber layer, an arc-shaped support plate and a power line, wherein a fluoroplastic insulating layer is arranged in the medical cable body, a cross-shaped bracket is fixed equidistantly in the fluoroplastic insulating layer, the center of the cross-shaped bracket is provided with a through hole, an arc-shaped support is fixed on each of four branches of the cross-shaped bracket, a metal shielding layer is wrapped outside the fluoroplastic insulating layer, a buffer layer is coated outside the metal shielding layer, foamed rubber rods are arranged in the buffer layer, a sheath layer is wrapped outside the buffer layer, and the armored layer is wrapped outside the sheath layer. According to the invention, the compression strength of the cable is ensured, the service life of the cable is prolonged, meanwhile, the heat radiating area of the cable is increased, the heat radiating property of the cable is improved, and fast heat radiation of the cable can be realized.

Owner:LEIYANG XINGYU WIRE & CABLE CO LTD

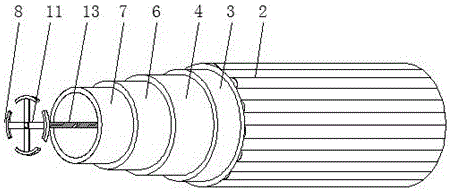

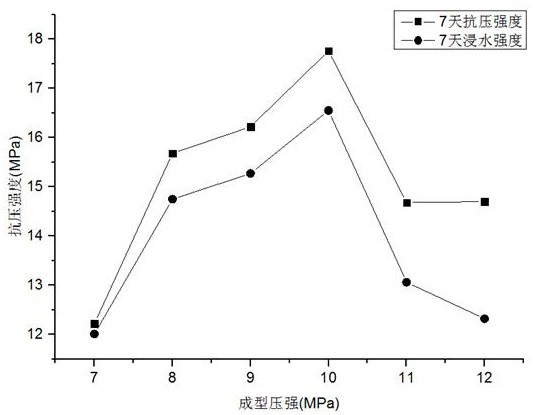

Residue soil baking-free brick and preparation method thereof

PendingCN112521096AGuaranteed compressive strengthIncrease the proportionCompressive resistanceBrick

The invention discloses a residue soil baking-free brick and a preparation method thereof, and relates to the technical field of baking-free bricks. The baking-free brick is formed by pressing 40-60%of muck, 10-20% of fly ash, 10-20% of cement, 10-20% of brick-concrete construction waste and 0.5-2% of lime as raw materials, a soil curing agent does not need to be doped any more, the specific gravity of solid waste in the raw material components reaches 78% or above, particularly, the 7-day strength of the baking-free brick is larger than 15 MPa, and the softening coefficient is larger than 0.8. The problems of high production cost, poor water stability and small specific gravity of solid wastes of the muck baking-free brick in the prior art are solved, the doping amount of the solid wastes such as muck, fly ash and construction wastes is increased on the premise of ensuring the compressive strength of the baking-free brick, the production cost is reduced, and the method is more economical and environment-friendly.

Owner:西安市政道桥建设集团有限公司

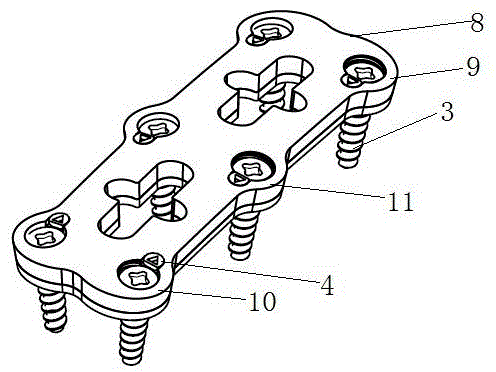

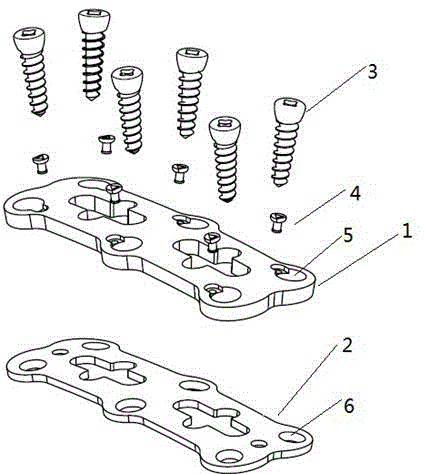

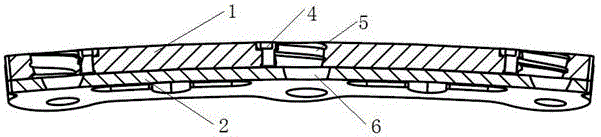

Spinal fixation device

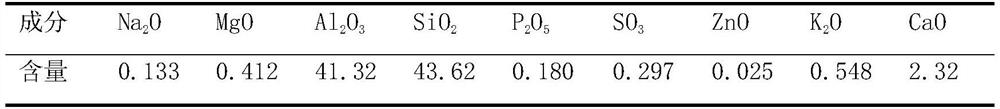

ActiveCN104856748AGuaranteed compressive strengthGood dispersionInternal osteosythesisBone platesSpinal columnBone healing

The invention provides a spinal fixation device, and belongs to orthopaedic implants. The spinal fixation device comprises a bone lamella and screws, lamella holes are formed in the upper surface and the lower surface of the bone lamella in a penetrating mode, and the screws can be matched with the lamella holes. When the spinal fixation device is used, the screws penetrate through the lamella holes to fix the bone lamella on the bone, operation is easy, fixing is firm, and bone healing is facilitated.

Owner:BEIJING NATON TECH GRP CO LTD +2

Impermeable structure applied to concrete pressure container

InactiveCN102518214AGuaranteed structural strengthAvoid water seepageBuilding insulationsGlass fiberPre stress

The invention relates to an impermeable structure applied to a concrete pressure container, which belongs to the technical field of solid engine test, and comprises a concrete wall, steel embedded parts, a steel plate and a glass fiber reinforced plastic coating, wherein the concrete wall is arranged on the outermost layer of the impermeable structure, the steel embedded parts are arranged in the concrete wall, the steel embedded parts are connected with a prestressed steel bar in concrete, the steel plate is adjacent to the concrete wall and is closely attached to the concrete wall after being welded with the steel embedded parts, and the glass fiber reinforced plastic coating is uniformly coated on the outer layer of the steel plate. The impermeable structure is simple in construction process, easy to realize, applicable to the concrete pressure container under the pressure lower than 0.4MPa, and water in the concrete pressure container can be prevented from permeating outwards via the wall.

Owner:BEIJING POWER MACHINERY INST

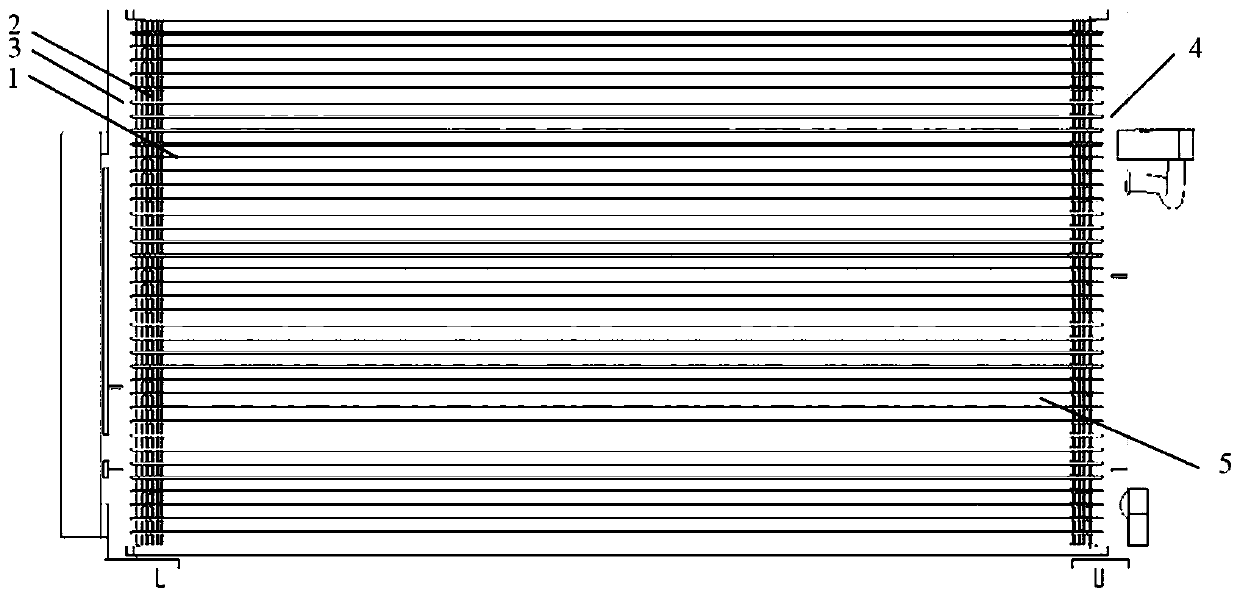

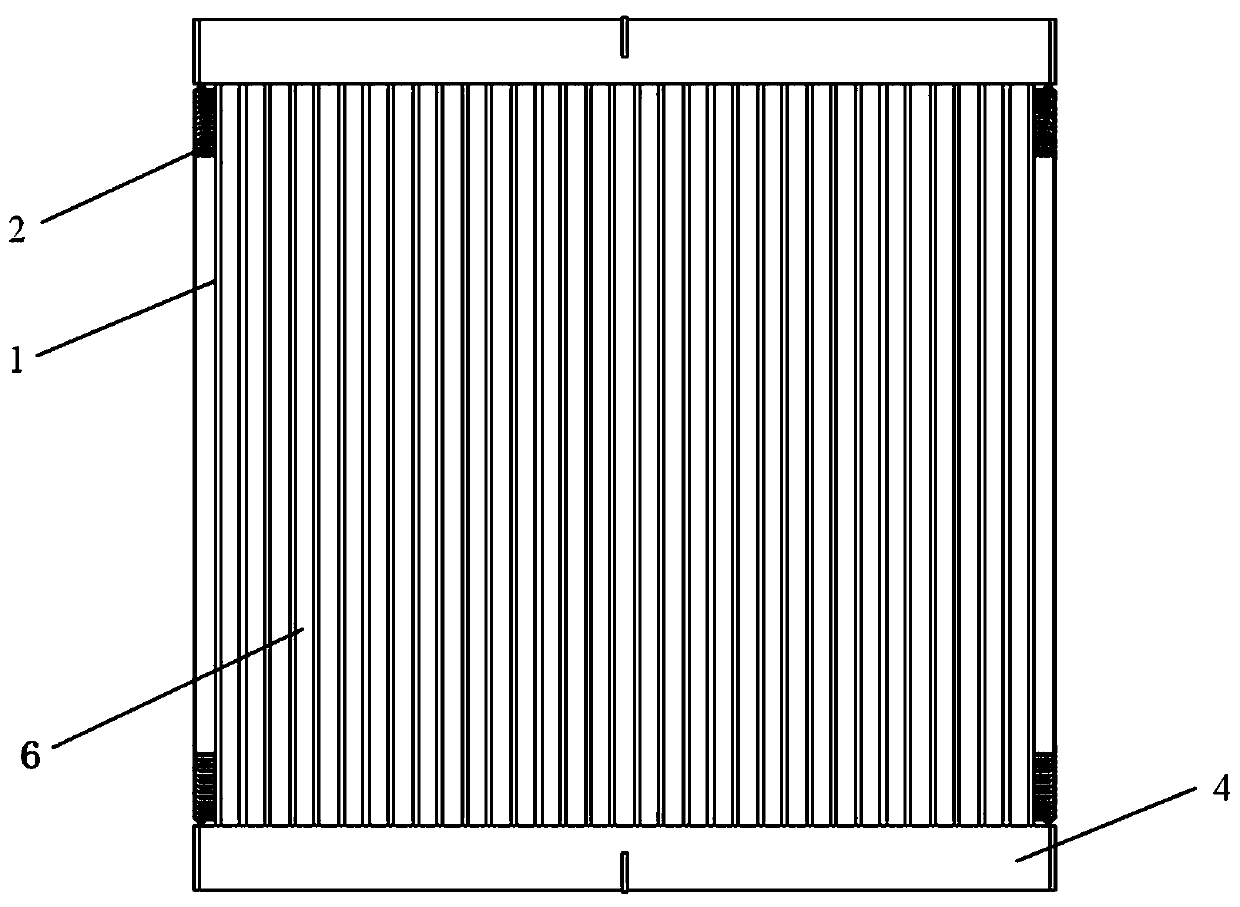

Air conditioner heat exchanger flat pipe and heat exchanger applying flat pipe

The invention belongs to the technical field of automobile air conditioners, and discloses an air conditioner heat exchanger flat pipe. The air conditioner heat exchanger flat pipe comprises a flat pipe body and inner fins. The inner fins are of a corrugated structure and are fixed in the flat pipe body. A plurality of heat exchange medium channels are formed by the inner fins and the inner wall of the flat pipe body. The invention further discloses an air conditioner heat exchanger applying the flat pipe. Due to the new flat pipe design, the heat exchange performance can be effectively improved, the refrigerant side resistance is reduced, the flat pipe weight can be better reduced, and integral performance enhancing and lightweight of the heat exchanger product are achieved; and the flatpipe forming and manufacturing difficulty is lowered, and the manufacturability and design application flexibility are improved.

Owner:SONGZ AUTOMOBILE AIR CONDITIONING

Light insulating brick

ActiveCN105175007AImprove plasticityGuaranteed compressive strengthCeramicwareSpecific gravityPotassium feldspar

The present invention discloses a light insulating brick. The light insulating brick is prepared from the following main raw materials: 50% to 76% of industrial cinder, 6% to 20% of mud, 4% to 20% of potassium feldspar, 4% to 20% of albite, 4% to 20% of quartz and 0 to 15% of polished residues. According to the light insulating brick, the industrial cinder is taken as a main formula body, and the addition is more than 50%; and moreover, the whole sintering time of the light insulating brick is controlled within 4-7 hours. The prepared light insulating brick is rigid in texture, low in specific gravity and high in porosity, and the refractory temperature is over 1000 DEG C, so that conventional fire can be resisted easily; and the light insulating brick is low in heat conductivity and high in compressive strength, and is very suitable for heat insulation of outer walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

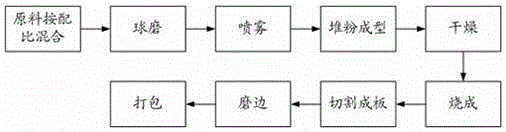

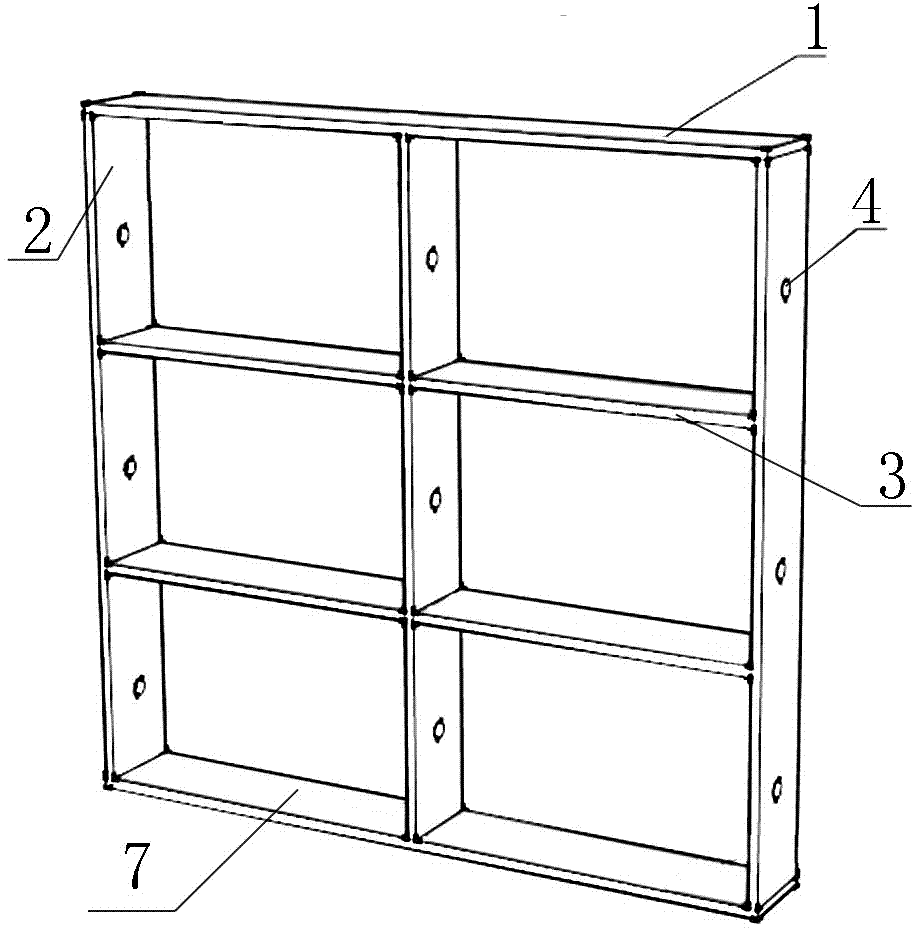

Iron tailing foam concrete and prefabricated steel-frame wall plate and construction method thereof

InactiveCN106892624AAvoid accumulationIncrease the use of added valueConstruction materialCeramicwareFoam concreteThermal insulation

Iron tailing foam concrete and a prefabricated steel-frame wall plate and a construction method thereof are provided, wherein the prefabricated steel-frame wall plate comprises a steel mesh frame, a plurality of wire meshes and a tier of iron tailing foam concrete cast outside the steel mesh frame and the wire meshes; the steel mesh frame is of rectangular mesh structure and comprises an upper guide beam, a lower guide beam, vertical supports and transverse supports; the upper guide beam is arranged horizontally at the top end of the steel mesh frame, and the lower guide beam is arranged horizontally at the bottom end of the steel mesh frame; the vertical supports in a group are connected between the upper guide beam and the lower guide beam transversely and parallelly at intervals; each vertical support is provided with a group of holes along its along axis at equal intervals; the wire meshes are connected within rectangular cells of the steel mesh frame respectively. The technical problem that accumulation of existing iron tailings affects the environment is solved, the prefabricated steel-frame wall plate with good thermal insulation property is produced with the iron tailing foam concrete, and a novel wall is provided for buildings.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

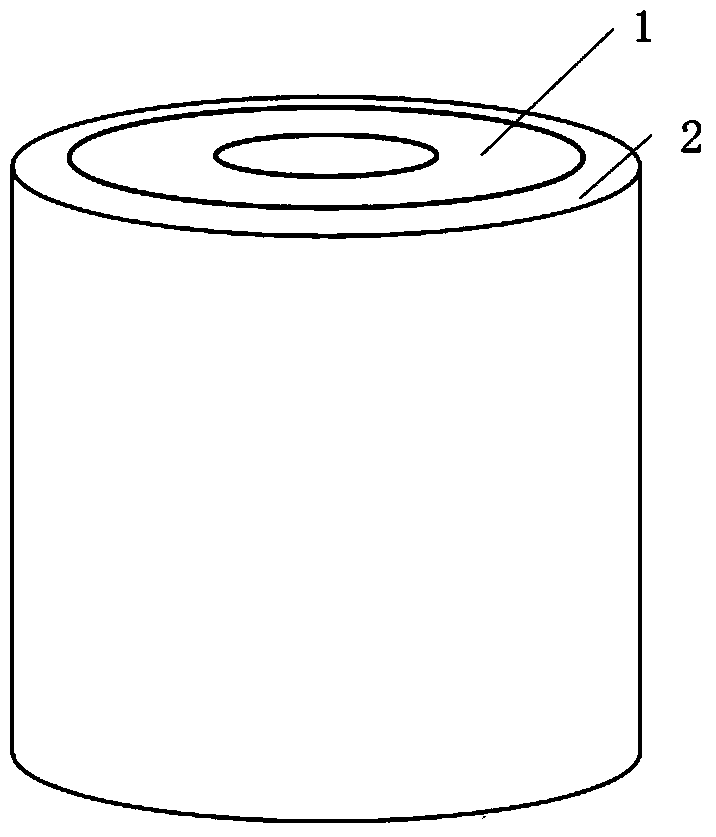

Method for treating foundation throughthrough sintered water-permeable pile

ActiveCN103643691AAvoid enteringGood water permeabilityCeramicwareBulkheads/pilesCrushed stoneBuilding construction

The invention discloses a method for treating a foundation through a sintered water-permeable pile. The method comprises the following steps: (1) sintering water-permeable piles; (2) firing each sintered water-permeable pile into multiple sections which are connected, arranging a water-permeable pile cap at the top of each pile, and inserting a drainage pipe into the hollow position of each pile and leading the drainage pipe to the outside of a construction region; (3) setting the pile distance between pile bodies arranged in the sintered water-permeable pile composite foundation as 3 to 5 times of that of the pile diameter; (4) arranging the pile bodies of the sintered water-permeable pile composite foundation in a square or triangular manner; (5) pressing each pile body into the foundation through a pile inserting machine and placing the pile caps, laying a gravel pad layer on the surface of the foundation, laying medium-coarse sand, a double-way geogrid, medium-coarse sand and gravel on the surface of the gravel pad layer sequentially from the bottom to top, and tamping; (6) externally connecting the drainage pipes in all the pile bodies to a water pump. In the construction period of the structure, pore water passes through the pile walls under the action of additional stress and enters the pile bodies, and water stagnated in the pile bodies is discharged through the water pump.

Owner:SHANDONG UNIV

Ferronickel slag self-cleaning water permeable brick and manufacturing method thereof

InactiveCN105418140AAnti-bending guaranteeGuaranteed compressive strengthCeramic materials productionCeramicwareBrickDecomposition

The invention discloses a ferronickel slag self-cleaning water permeable brick. A manufacturing method comprises the steps that corn husks are ground at indoor temperature after being carbonized, photocatalytic material nanometer titania is adsorbed to pore surfaces, hydroxyl radical, super-oxygen ion free radical and H2O free radical which are generated through light irradiation have the strong oxidation and decomposition capability, and various kinds of organic matter are directly oxidized into CO2, H2O and other inorganic micromolecules to be applied to the water permeable brick, so that automobile exhaust and the like in atmosphere can be degraded, and the adsorbability is high; modified sugar filter mud is used as a pore-forming agent, raw clay, ferronickel slag and mordenite are used as aggregate, and the fracture resistance, compressive strength and other indexes of the water permeable brick prepared after high-temperature sintering are ensured, the ferronickel slag self-cleaning water permeable brick accords with national waste resource comprehensive utilization industrial policy, a large amount of ferronickel slag can be effectively consumed, the production cost is reduced, and energy consumption is lowered.

Owner:合肥李诺新材料贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com