Baking-free insulating brick and production method thereof

A production method and technology of thermal insulation bricks, which are applied in the field of bricks or blocks, can solve the problems of low practicability of non-fired thermal insulation bricks, and achieve the effects of light weight, improved water resistance, and increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

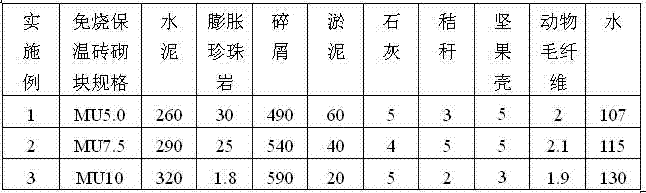

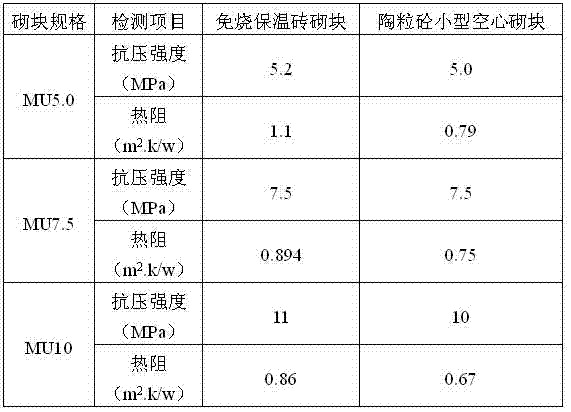

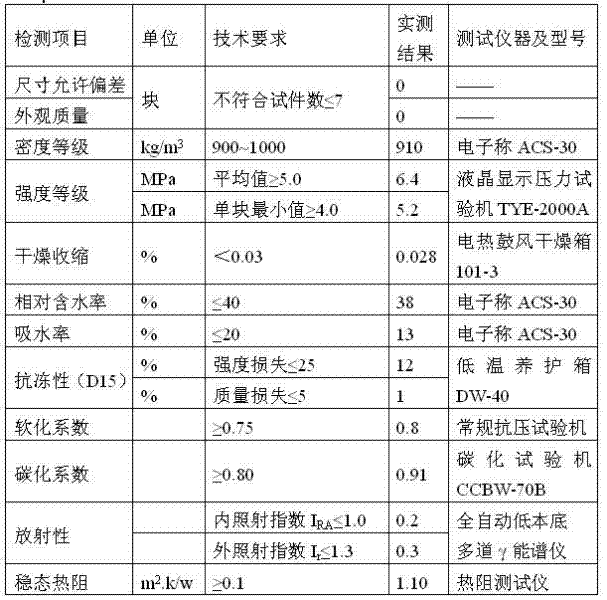

Examples

Embodiment Construction

[0025] The inventive method implements according to the following steps:

[0026] (1) Dehydrate and dry the sludge with a sludge dehydrator;

[0027] (2) Put the lime into the dry sludge and stir evenly, and the calcium hydroxide component of the lime will sterilize the sludge at the same time;

[0028] (3) Stack the mixture of silt and lime on the open space of the open shed for 3 days, stir once a day for natural deodorization;

[0029] (4) Simultaneously use a pulverizer to pulverize straw, nut shells and animal hair fibers into micro-particles with a particle size of 3-5 mm;

[0030] (5) Put all the raw materials into the mixer one by one, and stir them into a homogeneous mixture;

[0031] (6) Send the mixture in step (5) into the forming mold of the brick making machine through the material conveyor, and process it into a brick body through vibration and pressure, and the pressure of the pressure is 3MPa;

[0032] (7) Steam curing for 14 hours after the brick bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com