Iron tailing foam concrete and prefabricated steel-frame wall plate and construction method thereof

A foam concrete, iron tailings technology, applied in ceramic products, other household appliances, building components, etc., can solve the problems of high cost, high water absorption, short life and other problems of inorganic thermal insulation boards, and achieve good waterproof effect, high hardness, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

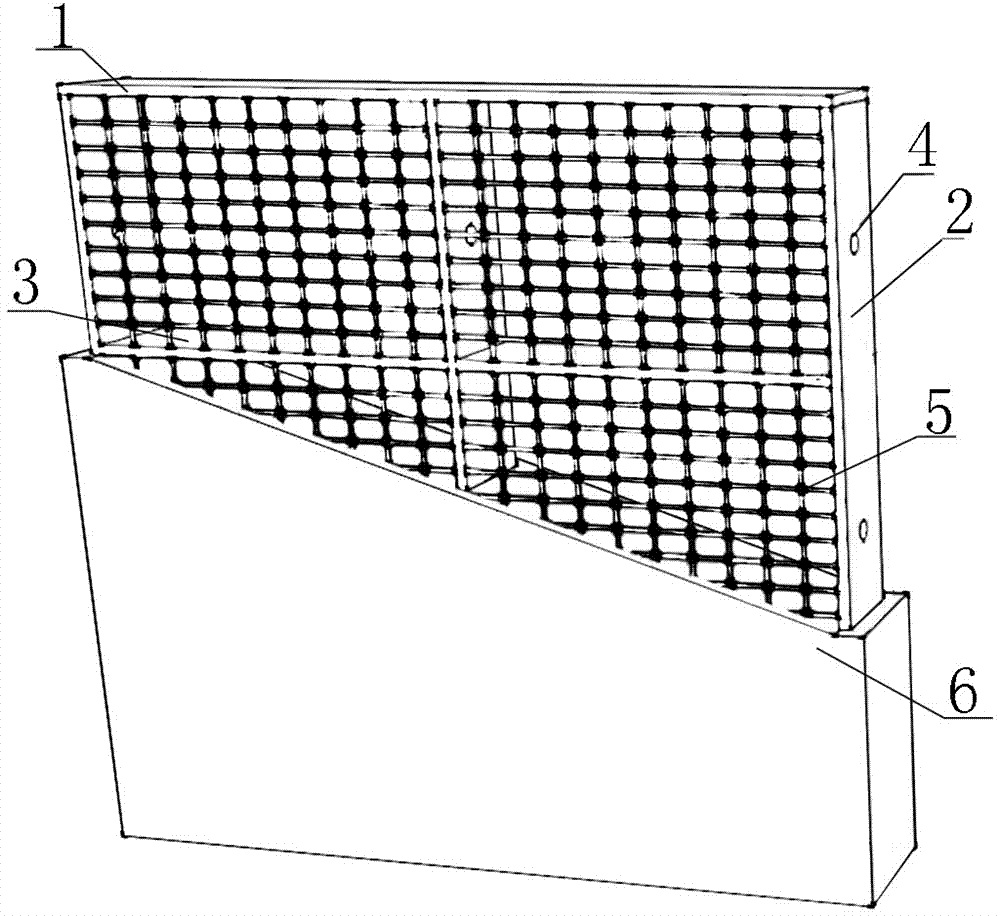

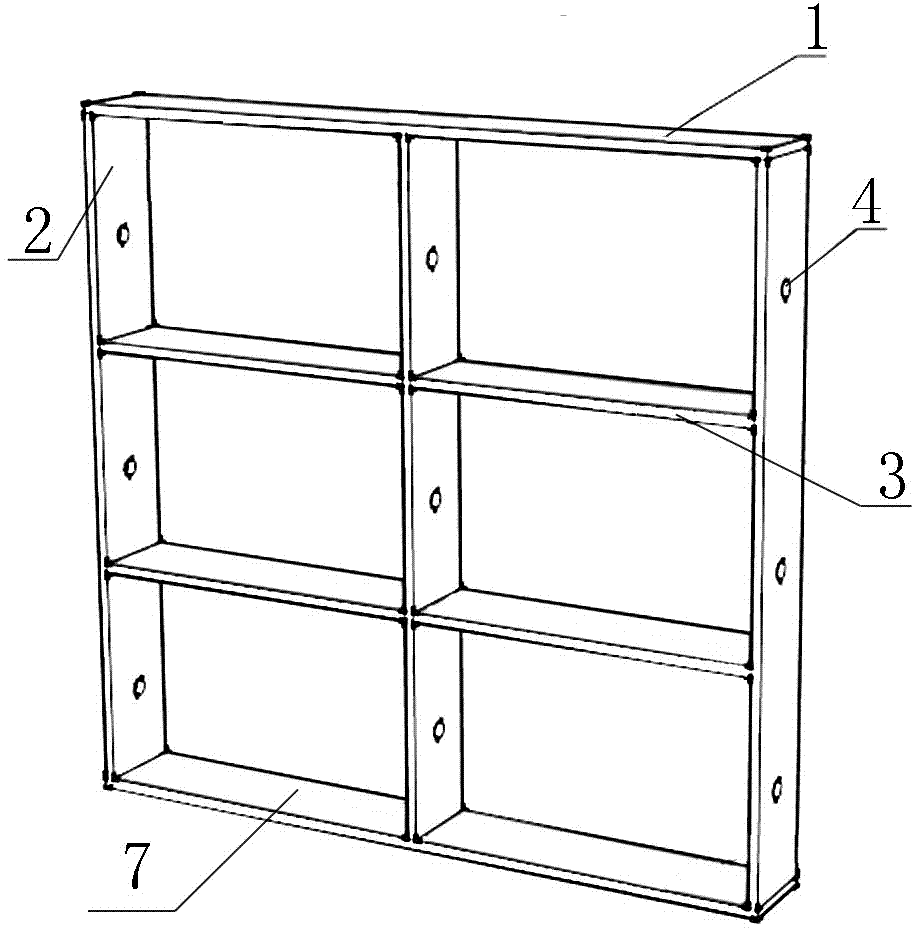

Image

Examples

Embodiment 1

[0051] This iron tailings foam concrete comprises the following components by weight:

[0052] 60 parts of cement, 25 parts of iron tailings, 15 parts of pumice powder, 8 parts of foaming agent, 1.5 parts of water-repellent agent, 1.8 parts of early strength agent, and 70 parts of water.

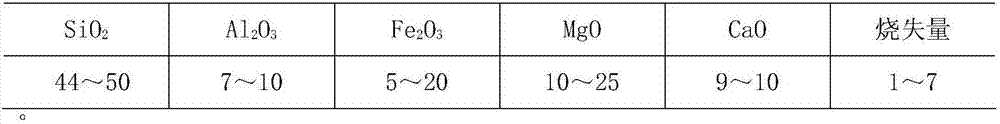

[0053] In this embodiment, the iron tailings are obtained by sieving waste discharged from the mine, and are used directly without secondary grinding, with a fineness modulus of 1.6 to 2.2; the composition and components of the iron tailings are The content is as follows:

[0054]

[0055] In this example, the cement is ordinary Portland P.O42.5 cement, and the cement surface area is greater than 300m 2 / kg.

[0056] Of course, in other embodiments, Portland P·O4 2.5 cement can also be used as cement.

[0057] In the present embodiment, the composition of described pumice powder and the content of each composition are as follows:

[0058]

[0059] In this embodiment, the foaming agen...

Embodiment 2

[0085] The iron tailings foam concrete includes the following components in parts by weight.

[0086] 55 parts of cement, 25 parts of iron tailings, 20 parts of pumice powder, 6 parts of foaming agent, 2 parts of water repellent, 1.5 parts of early strength agent, 65 parts of water.

[0087] In this embodiment, the iron tailings are obtained by sieving waste discharged from the mine, and are used directly without secondary grinding, with a fineness modulus of 1.6 to 2.2; the composition and components of the iron tailings are The content is as follows:

[0088]

[0089] In this example, the cement is ordinary Portland P.O42.5 cement, and the cement surface area is greater than 300m 2 / kg.

[0090] Of course, in other embodiments, Portland P·O4 2.5 cement can also be used as cement.

[0091] In the present embodiment, the composition of described pumice powder and the content of each composition are as follows:

[0092]

[0093] In this embodiment, the foaming agent a...

Embodiment 3

[0115] The iron tailings foam concrete includes the following components in parts by weight.

[0116] 65 parts of cement, 20 parts of iron tailings, 15 parts of pumice powder, 10 parts of foaming agent, 1 part of water repellent, 2 parts of early strength agent, 75 parts of water.

[0117] In this embodiment, the iron tailings are obtained by sieving waste discharged from the mine, and are used directly without secondary grinding, with a fineness modulus of 1.6 to 2.2; the composition and components of the iron tailings are The content is as follows:

[0118]

[0119] In this example, the cement is ordinary Portland P.O42.5 cement, and the cement surface area is greater than 300m 2 / kg.

[0120] Of course, in other embodiments, Portland P·O4 2.5 cement can also be used as cement.

[0121] In the present embodiment, the composition of described pumice powder and the content of each composition are as follows:

[0122]

[0123] In this embodiment, the foaming agent adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com