Putty leveling integrated gypsum mortar

A technology of gypsum mortar and mortar, which is applied in the field of indoor wall leveling building mortar materials, can solve the problems of not being combined and unified into one product, and achieve the effects of improving construction feel and efficiency, reducing construction steps, and good fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

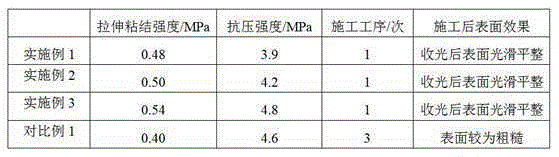

Embodiment 1

[0032] Its each material parts by weight of embodiment 1 is:

[0033] 60 parts of β-hemihydrate desulfurization gypsum, 15 parts of solo powder, 6 parts of 20-30 mesh quartz sand, 15 parts of 40 mesh quartz sand, 3 parts of vitrified microbead insulation light aggregate, 1 part of redispersible latex powder VAE, 0.3 part of hydroxyethyl methyl cellulose ether and 0.03 part of modified protein retarder are mixed and stirred evenly according to the water-material ratio of 1:2.3 to prepare the leveling putty integrated gypsum mortar of the present invention.

Embodiment 2

[0034] Its each material parts by weight of embodiment 2 is:

[0035] 65 parts of β-hemihydrate desulfurization gypsum, 10 parts of solo powder, 6 parts of 20-30 mesh quartz sand, 13 parts of 40 mesh quartz sand, 4 parts of vitrified microbead insulation light aggregate, 2 parts of redispersible latex powder VAE, 0.25 parts of hydroxyethyl methyl cellulose ether and 0.04 parts of modified protein retarder are mixed and stirred evenly according to the water-to-material ratio of 1:2.2 to prepare the leveling putty integrated gypsum mortar of the present invention.

Embodiment 3

[0036] Its each material parts by weight of embodiment 3 is:

[0037] 70 parts of β-hemihydrate desulfurization gypsum, 11 parts of solo powder, 6 parts of 20-30 mesh quartz sand, 10 parts of 40 mesh quartz sand, 2 parts of vitrified microbead insulation light aggregate, 1 part of redispersible latex powder VAE, 0.2 parts of hydroxyethyl methyl cellulose ether and 0.05 parts of modified protein retarder are mixed and stirred evenly according to the water-material ratio of 1:2.1 to prepare the leveling putty integrated gypsum mortar of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com