Patents

Literature

351 results about "Resin microsphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

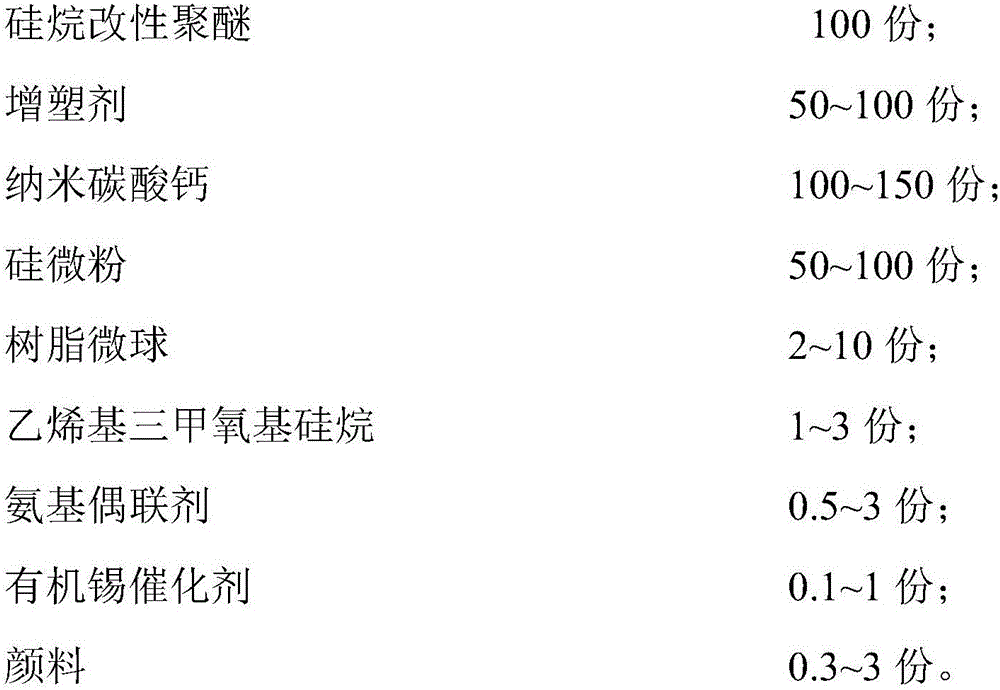

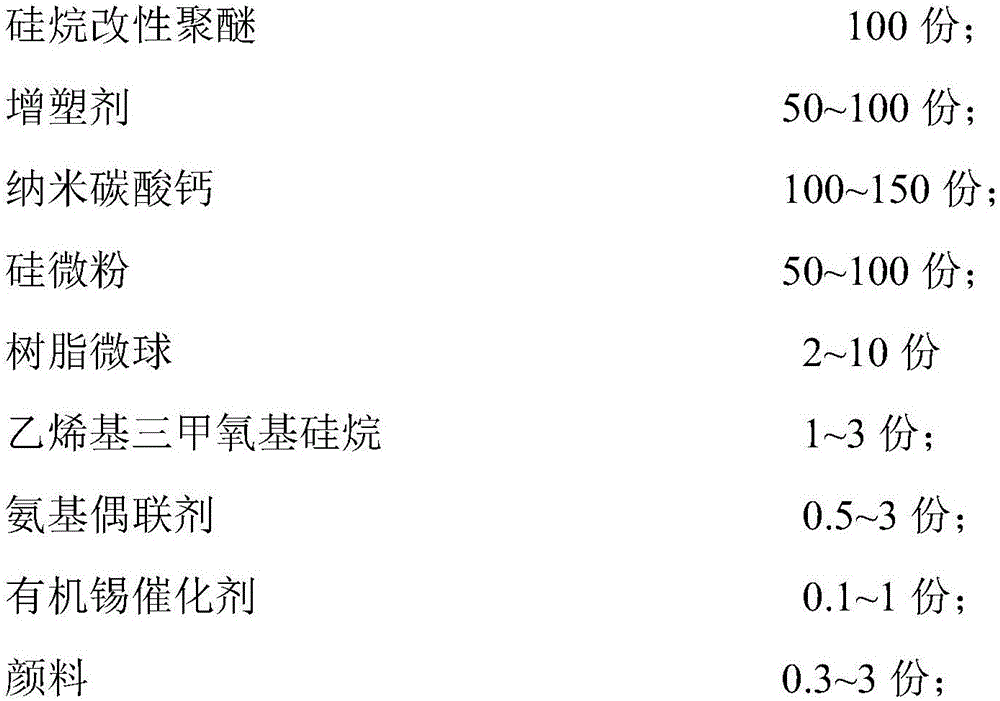

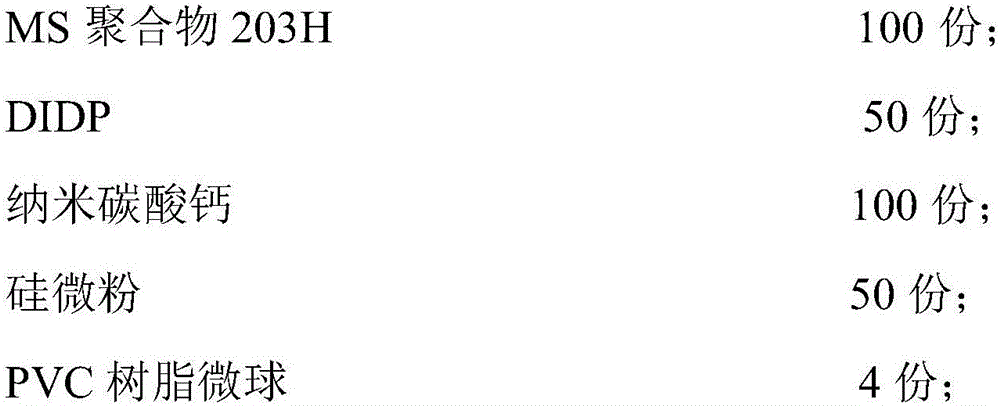

Silane modified polyether sealant with excellent water soaking bonding performance and preparation method thereof

ActiveCN106634768AImprove water resistanceHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesResin microsphereSilanes

The invention discloses a silane modified polyether sealant with excellent water soaking bonding performance and a preparation method thereof, and relates to the field of a silane modified polyether sealant. The silane modified polyether sealant is prepared from the following ingredients in parts by mass: 100 parts of silane modified polyether, 50 to 100 parts of plasticizers, 100 to 150 parts of nanometer calcium carbonate, 50 to 100 parts of silicon micro powder, 2 to 10 parts of resin microspheres, 1 to 3 parts of vinyl trimethoxy silane, 0.5 to 3 parts of amino coupling agents, 0.1 to 1 part of organic tin catalysts and 0.3 to 3 parts of pigments. The prepared silane modified polyether sealant with excellent water soaking bonding performance has the advantages that the modulus is low; the stretch intensity reaches 0.2MPa; the elongation rate is 500 percent. The water-resistant bonding performance of the silane modified polyether sealant can be improved; after the water soaking aging, according to the stretch test result, the sealant layer cohesion damage occurs, the bonding performance is not damaged after the fixed stretching for 200 percent; the silane modified polyether sealant can be widely applied to waterproof sealing in building industry.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

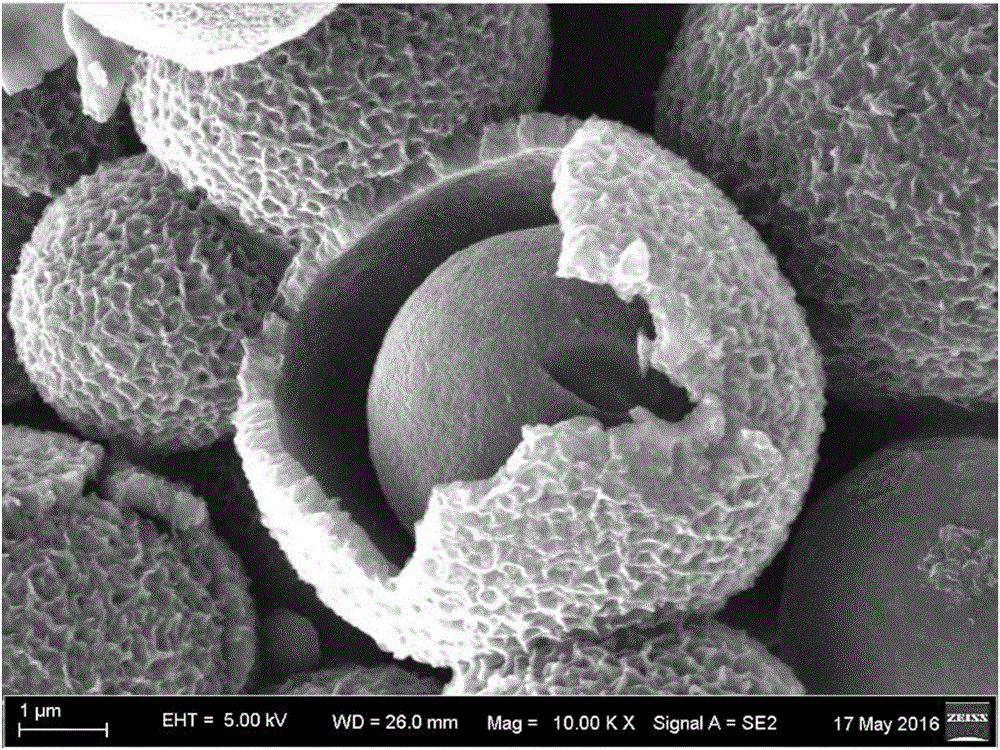

Novel carbon spheres and preparation method and application thereof

ActiveCN106654278AIncrease capacityHybrid capacitor electrodesCell electrodesSolid carbonResin microsphere

The invention belongs to the technical field of a nanomaterial, and discloses novel carbon spheres. Each carbon sphere comprises an external sphere and an internal sphere, wherein the internal sphere is a solid carbon sphere; the external sphere adopts a porous carbon shell with a mesoporous structure; and a hollow cavity is formed between the external sphere and the internal sphere. The invention also discloses a preparation method for the carbon spheres; the preparation method comprises the steps of S1, taking formaldehyde and a poly-condensation monomer as raw materials, mixing the raw materials in deionized water and preparing formaldehyde poly-condensation resin microspheres under the effect of a catalyst; S2, adding the obtained formaldehyde resin microspheres into hydrochloric acid to be cured; S3, performing pre-oxidization treatment on the cured formaldehyde resin microspheres through heating; and S4, performing carbonization on the pre-oxidized formaldehyde resin microspheres to obtain the carbon spheres. The carbon spheres are creative in structure; the internal carbon spheres and the hollow cavities can be used for storing active material particles, so that battery capacity can be greatly increased; and the carbon spheres can be applied to the fields of catalysis, adsorption, pharmaceuticals and the like and has high application prospect.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

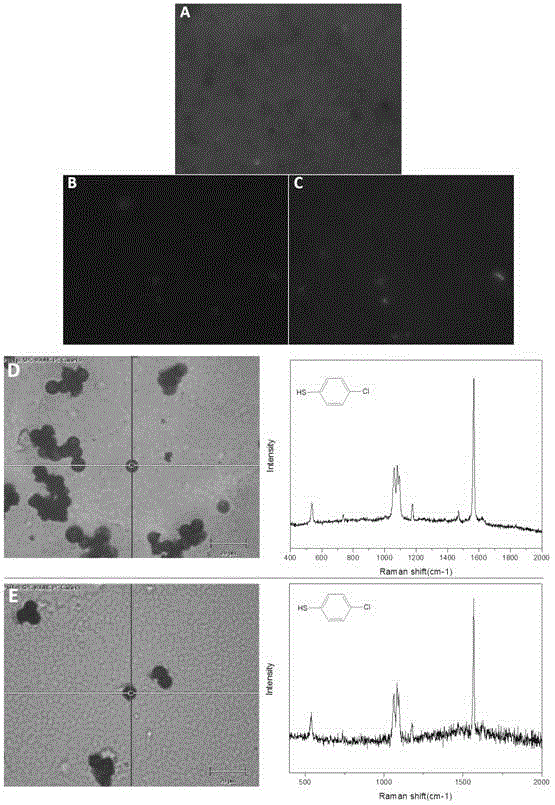

Heavy metal adsorbent for extracorporeal perfusion method and preparation method of heavy metal absorbent

InactiveCN102716719AImprove adsorption capacityLarge adsorption capacityIon-exchange process apparatusOther chemical processesResin microsphereBiocompatibility

The invention discloses an adsorbent for removing heavy metals through extracorporeal blood perfusion and a preparation method of the absorbent. Activating agents are used activating resin microsphere carriers with good biocompatibility, then sulihydryl reagents are fixed through bonding or coupling to form the heavy metal adsorbent, the surface of the heavy metal adsorbent is provided with a great quantity of sulihydryl functional groups and an adsorption effect through complexing or chelation between adsorption target liquid compositions and heavy metals and ions thereof is facilitated; the biocompatibility and the adsorption capacity are good; and the adsorbent has the characteristics of low preparation cost, simple synthesis process, strong adsorption capacity, rapid adsorption speed and the like, and can be used for extracorporeal whole-blood perfusion to remove in-vivo heavy metals and treat heavy metal poisoning.

Owner:汪志友

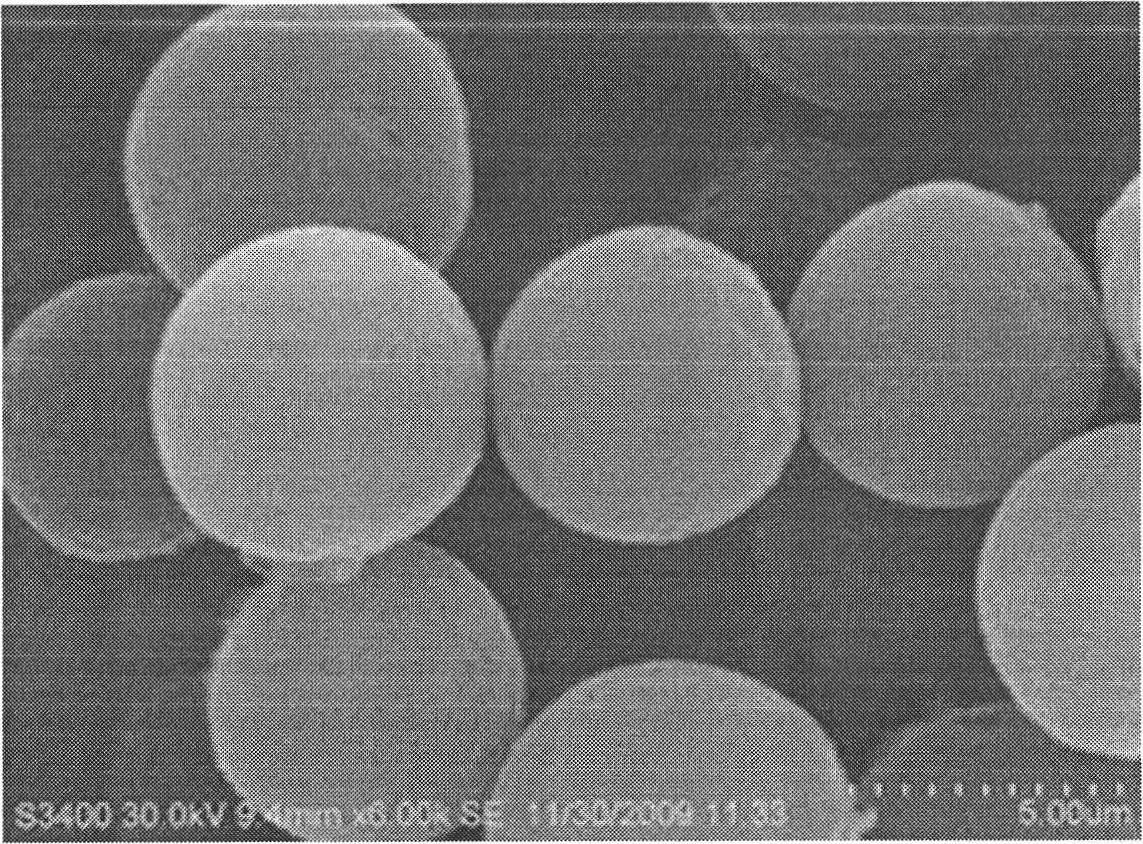

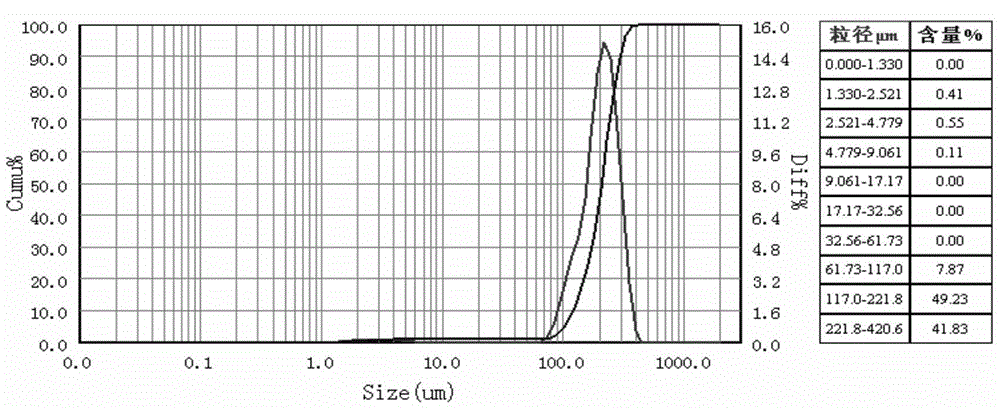

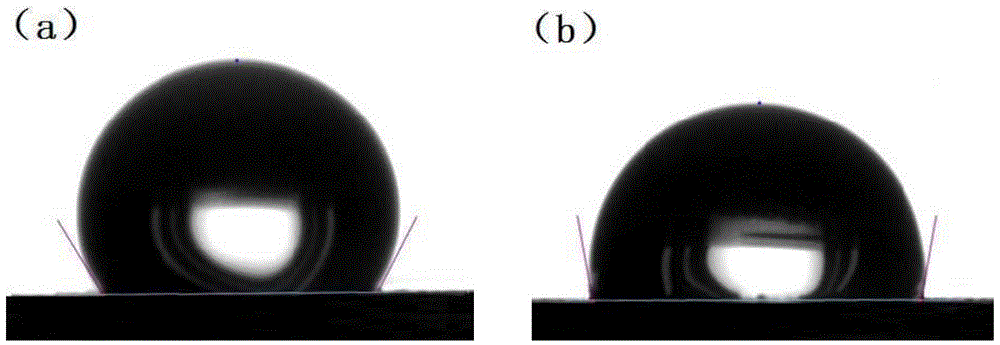

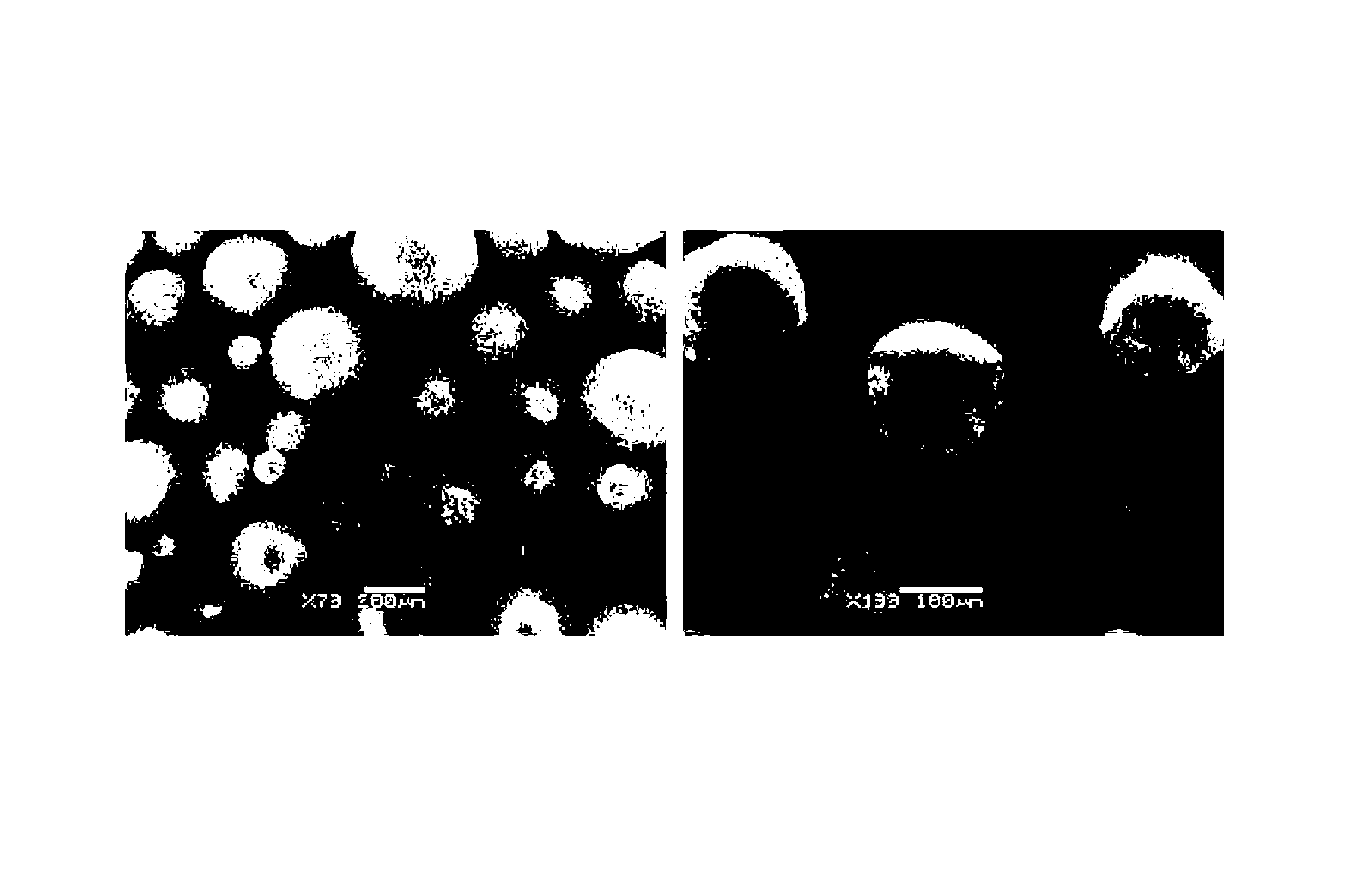

High-specific surface polymer microsphere resin with even particle size and preparation method thereof

InactiveCN101773812AReduce pollutionSimple stepsOther chemical processesAlkali metal oxides/hydroxidesResin microspherePolymer science

The invention discloses a high-specific surface polymer microsphere resin with even particle size and a preparation method thereof. In the method, a high-specific surface resin microsphere is prepared by the following steps of: dispersing vinylbenzylchloride and the like as monomers by a membrane emulsification method and polymerizing at a certain temperature and condition. The monodisperse polymer microsphere resin within the range of 1-60 Mum can be synthetized by the method, wherein the specific surface is 800-1200m2 / g. The invention has simple steps and environmental pollution reduction, easy control of process flow, strong repeatability, thereby being beneficial to scale production. The resin microsphere prepared by the method has very high specific surface, thereby being beneficial to carrying out enrichment separation and analysis on water-soluble organic pollutants in a water body and having wide application prospect.

Owner:NANJING UNIV

Method for preparing three-dimensional graphene/carbon nanotube composite material

The invention relates to a method for preparing a three-dimensional graphene / carbon nanotube composite material. The method comprises the following steps: (1) preparing graphene oxide suspension; (2) preparing carbon nanotube suspension; (3) preparing polystyrene resin microspheres; (4) preparing graphene / carbon nanotube gel; (5) preparing a three-dimensional graphene / carbon nanotube compound. The three-dimensional graphene / carbon nanotube compound prepared by using the method is rich in graded porous structure, the advantage of structural complementation of graphene and carbon nanotubes is achieved, and thus the composite material is relatively good in electric and heat conduction property. The composite material has wide application in fields such as traffic transportation, electronic industry, civil construction, buildings and chemical engineering. The method provided by the invention is low in equipment requirement, simple in process and easy in large-scale production.

Owner:JINAN JIAXING TECH

Shell-core magnetic lignin-modified phenolic microsphere adsorbent and preparation method thereof

The invention belongs to the technical field of functional materials, and mainly relates to a method for preparing a shell-core magnetic composite resin microsphere adsorbent with lignin-modified phenolic resin under an acid condition. The method includes the following steps: magnetic ferroferric oxide particles and lignin phenolic resin are first prepared, the ferroferric oxide particles and the lignin phenolic resin are uniformly mixed according to a certain proportion, a certain amount of reversed-phase solvent and surfactant is added, uniform stirring is sufficiently carried out, p-toluenesulfonic acid solution is then added, acid curing is carried out under certain temperature and stirring speed, and thereby magnetic microspheres are formed. The invention adopts an organic acid with weak acidity as acid curing agent and creatively adopts an acid low-temperature curing method to prepare the composite microspheres with uniform size by means of a reversed-phase suspension method. The microspheres have magnetism and the adsorption property of lignin, and can serve as an adsorbent to adsorb colored matters and heavy metal ions in wastewater, moreover, an additional magnet can be utilized to rapidly carry out the separation of water and the microspheres, and thereby a convenient and efficient separation method is provided for wastewater treatment.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing super absorbent resin microspheres

InactiveCN104448102ASolve the problem of poor molding and low yieldSimplify post-processingPolymer scienceResin microsphere

The invention relates to a method for preparing super absorbent resin microspheres, belongs to the technical field of high polymer materials, and solves the problems that a reversed phase suspension polymerization process for preparing super absorbent resin microspheres in the prior art is complex and is high in cost in the production process, the prepared microspheres are poor in molding and low in yield. The method adopts a reversed phase suspension technique and is simple in preparation process, the products can be used without further grinding, the after-processing process of products is simplified, the yield of products is improved, and the production cost of products is reduced.

Owner:CHENGDU JINHUI TECH

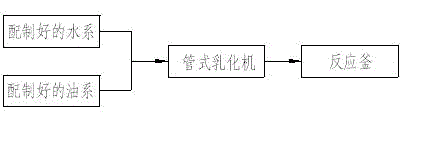

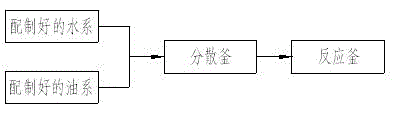

Thermal expansion resin powder with high dispersity and preparation method thereof

A casing of a thermal expansion resin microsphere is formed by thermal expansion, a foaming agent is coated inside the resin microsphere which can expand when heated, and the expansion ratio of the maximum expansion is more than 5 times. Aggregation of the microspheres is the thermal expansion resin powder provided in the invention. The preparation method includes the steps that an oily material composed of at least one monomer and the foaming agent is dispersed in a water system so as to form stable oil droplets, and when the oil droplets are heated, the monomer is subjected to a polymerization reaction to form the resin microsphere coated with the foaming agent. The synthetic thermal expansion resin powder after addition of polar-end-containing monomer into the water system has a quite good dispersity in water.

Owner:CHANGSHA YICHUAN ELECTROMECHANICAL EQUIP TECH

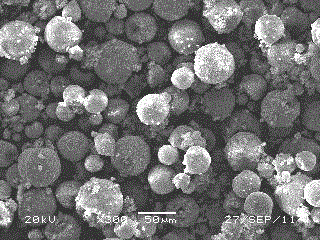

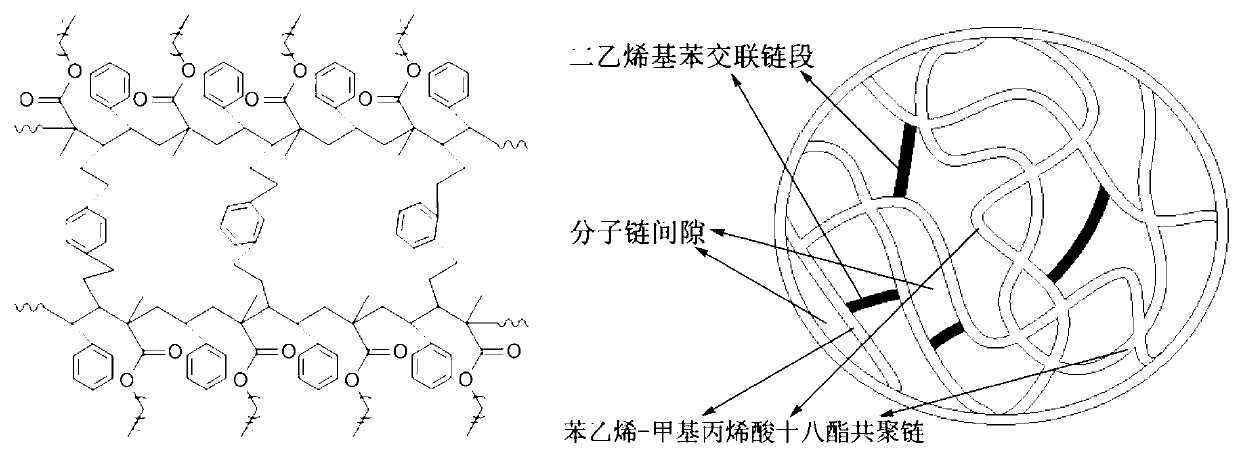

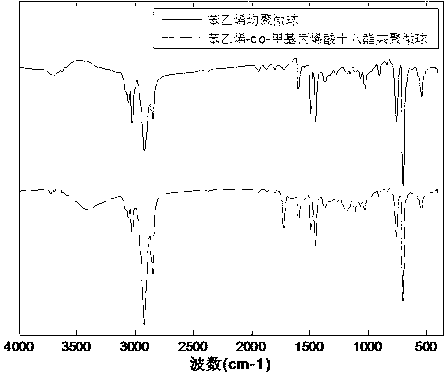

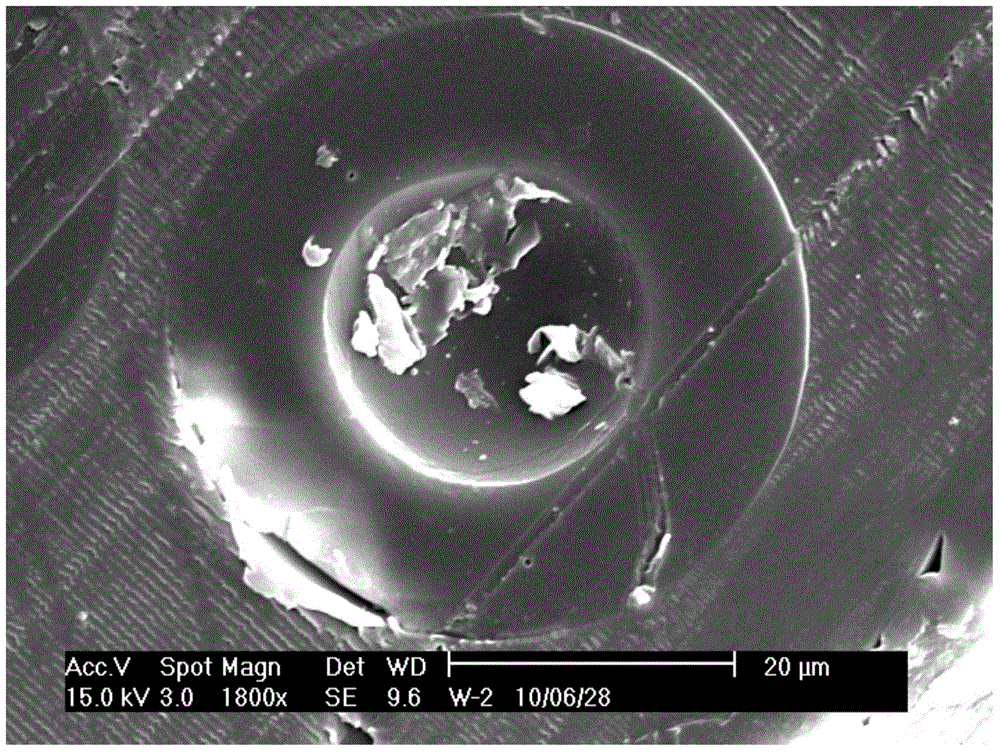

High compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere and preparation method thereof

The invention discloses a high compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere which is a crosslinking copolymer prepared by taking divinylbenzene as a cross-linking agent, taking styrene as a first monomer, taking octadecyl methacrylate as a second monomer and adding a pore-foaming agent. According to the high compressive polystyrene-co-octadecyl methacrylate copolymer resin microsphere, a long-chain flexible monomer of the octadecyl methacrylate is introduced to be copolymerized with the styrene, and therefore, the compressive strength of the resin microsphere as parents of ion exchange resin or adsorbent resin is obviously improved, the strength increase efficiency reaches more than a dozen times, and the resin microsphere cannot be crushed on account of structural defects per se in the use process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Low-density ablation-resistant polymer-based composition

The invention discloses a low-density ablation-resistant polymer-based composition. The low-density ablation-resistant polymer-based composition has density less than 1g / cm<3> and a residual weight rate more than 70% at a temperature of 900 DEG C. The low-density ablation-resistant polymer-based composition comprises, by mass, 100 parts of boron-containing phenolic resin, 10 to 45 parts of modified hollow phenolic resin microspheres, 5 to 40 parts of modified hollow ceramic microspheres, 5 to 15 parts of frit and 100 parts of anhydrous ethanol as a solvent, wherein the number of the total mass parts of the modified hollow phenolic resin microspheres and the modified hollow ceramic microspheres is less than 50. Through the synergism of the modified hollow phenolic resin microspheres and the modified hollow ceramic microspheres, material ablation-resistant integrated properties are improved. In fusion, the frit can inhibit oxidation and cracking of the phenolic resin microspheres and a polymer matrix and produce protection and reinforcement effects.

Owner:WUHAN UNIV OF TECH

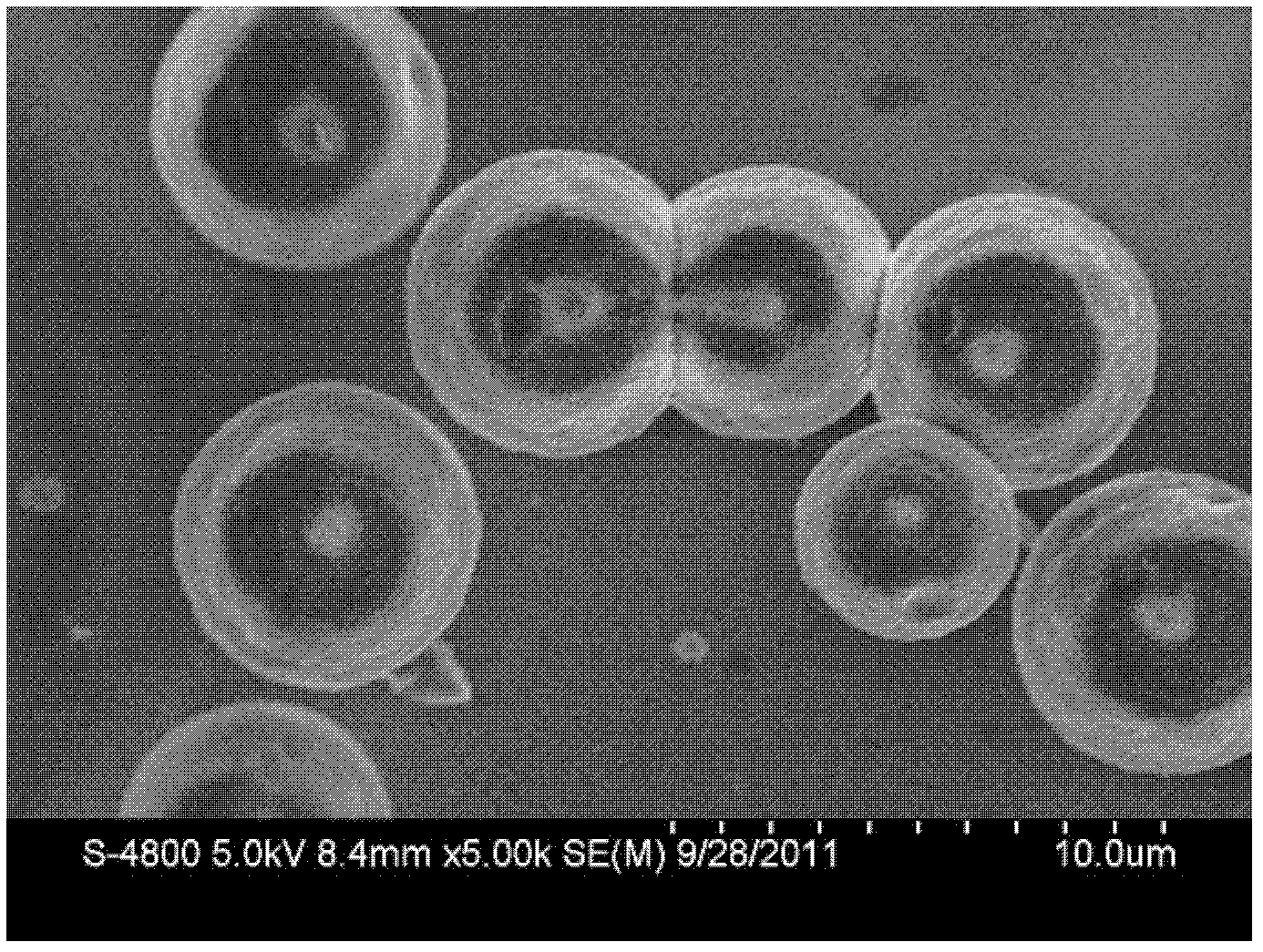

Melamine resin hollow microspheres and preparation method and application thereof

ActiveCN106140039AShort reaction timeGood hollownessDrilling compositionMicroballoon preparationPolymer scienceFoaming agent

The invention relates to melamine resin hollow microspheres and a preparation method and application thereof in the field of materials. The particle size range of the melamine resin hollow microspheres is 5-140 (mu)m, and the density is 0.21-1.20 g / cm(3). The preparation method of the melamine resin hollow microspheres comprises the following steps: adjusting the concentration of melamine resin prepolymer to be a certain value; and forming cavities in the melamine resin hollow microspheres by using spray drying equipment and under the combined action of rapid volatilization of an aqueous solution and gas produced by a foaming agent. The melamine resin hollow microspheres are prepared by the method. The method is simple and practicable, the reaction time is short, industrialization is facilitated, the cost is low, and the prepared hollow microspheres are smooth in surface and good in degree of hollowness.

Owner:CHINA PETROLEUM & CHEM CORP +1

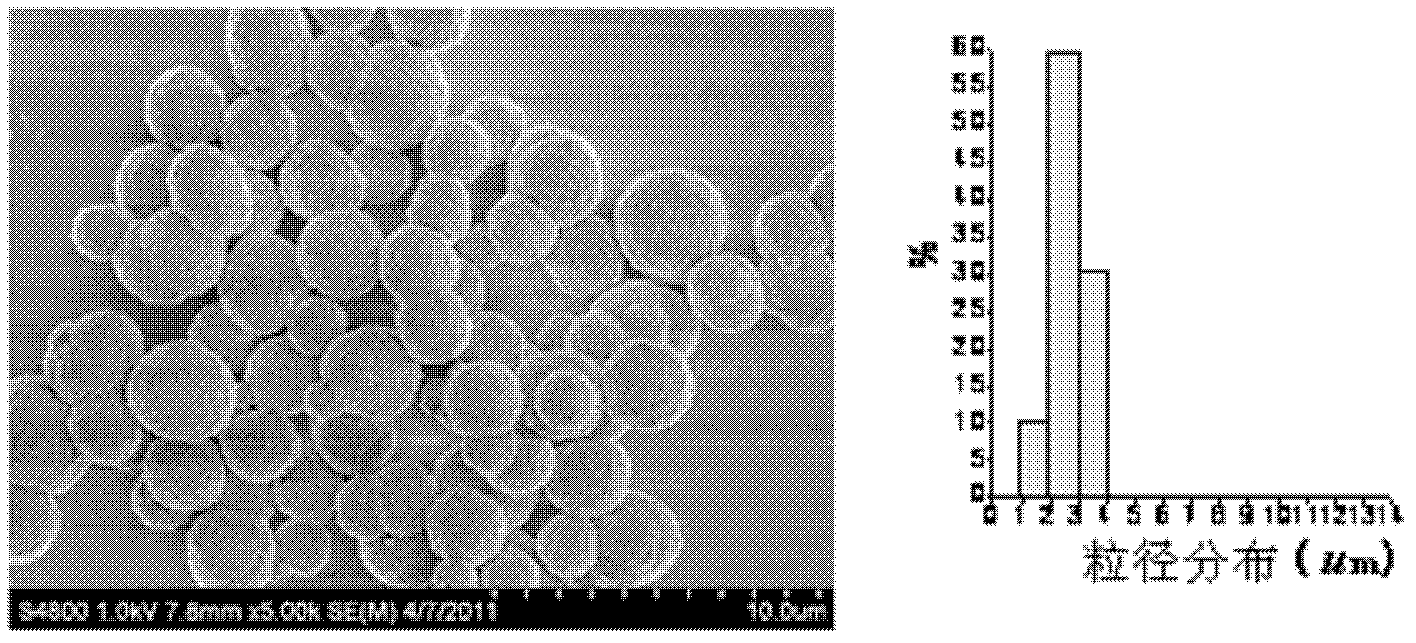

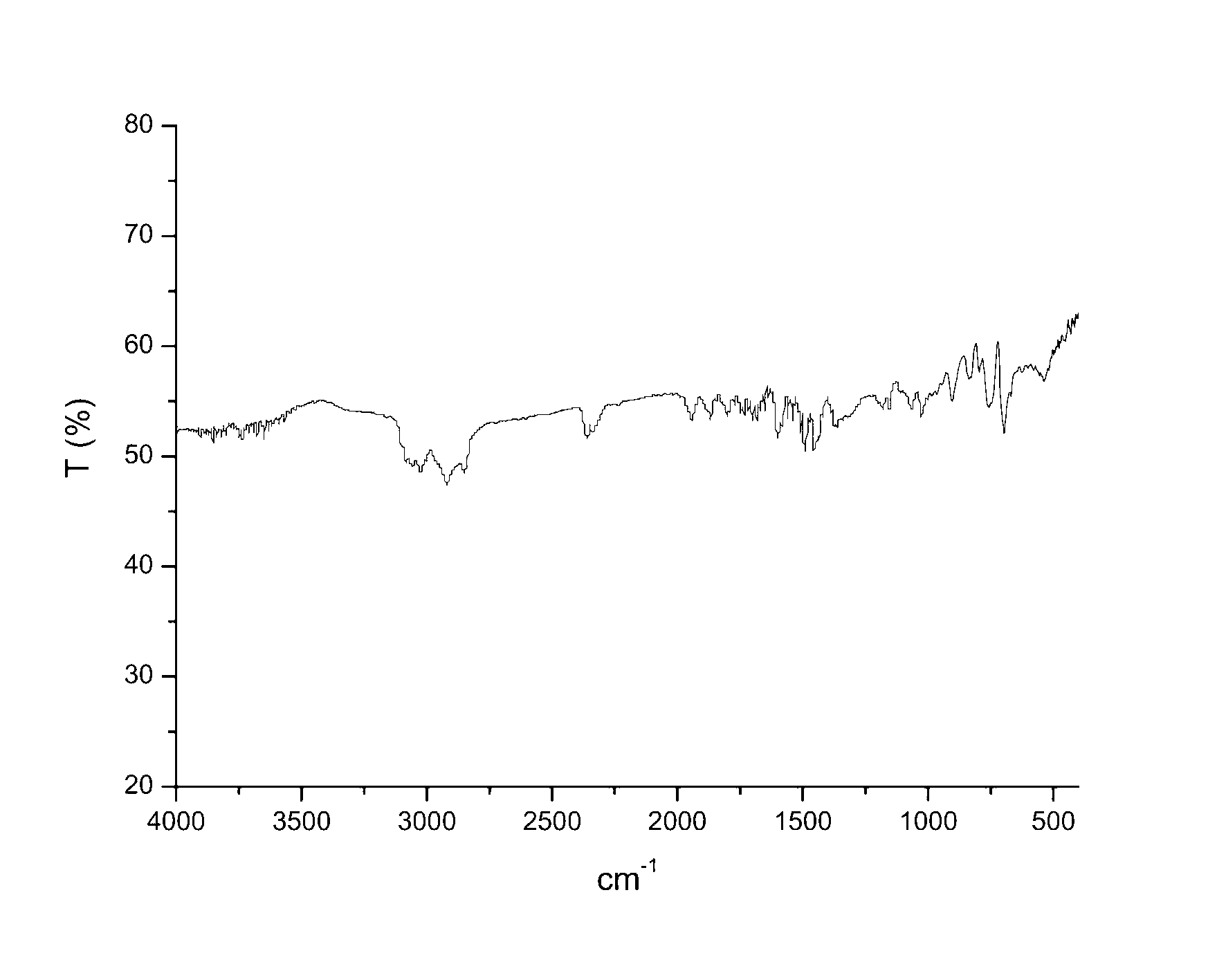

Method for synthesizing melamine urea formaldehyde resin microsphere

The invention relates to a method for synthesizing a melamine urea formaldehyde resin microsphere, and belongs to synthesis of macromolecule multifunctional microspheres. The melamine urea formaldehyde resin microsphere is prepared by utilizing melamine modified urea formaldehyde resin microsphere, the melamine urea formaldehyde resin microsphere is even in granularity, and the particle diameter of the melamine urea formaldehyde resin microsphere is distributed between 3 microns to 5 microns. The method can be used in the aspects of chromatographic packing materials, catalyst carriers, bonding agents, super-capacitor materials and absorption metal materials and the like, and is a good formwork for preparing inorganic microspheres. Melamine in different qualities is adopted to be modified and synthesized to the melamine urea formaldehyde resin microsphere which is even in distribution and monodisperse.

Owner:TONGJI UNIV

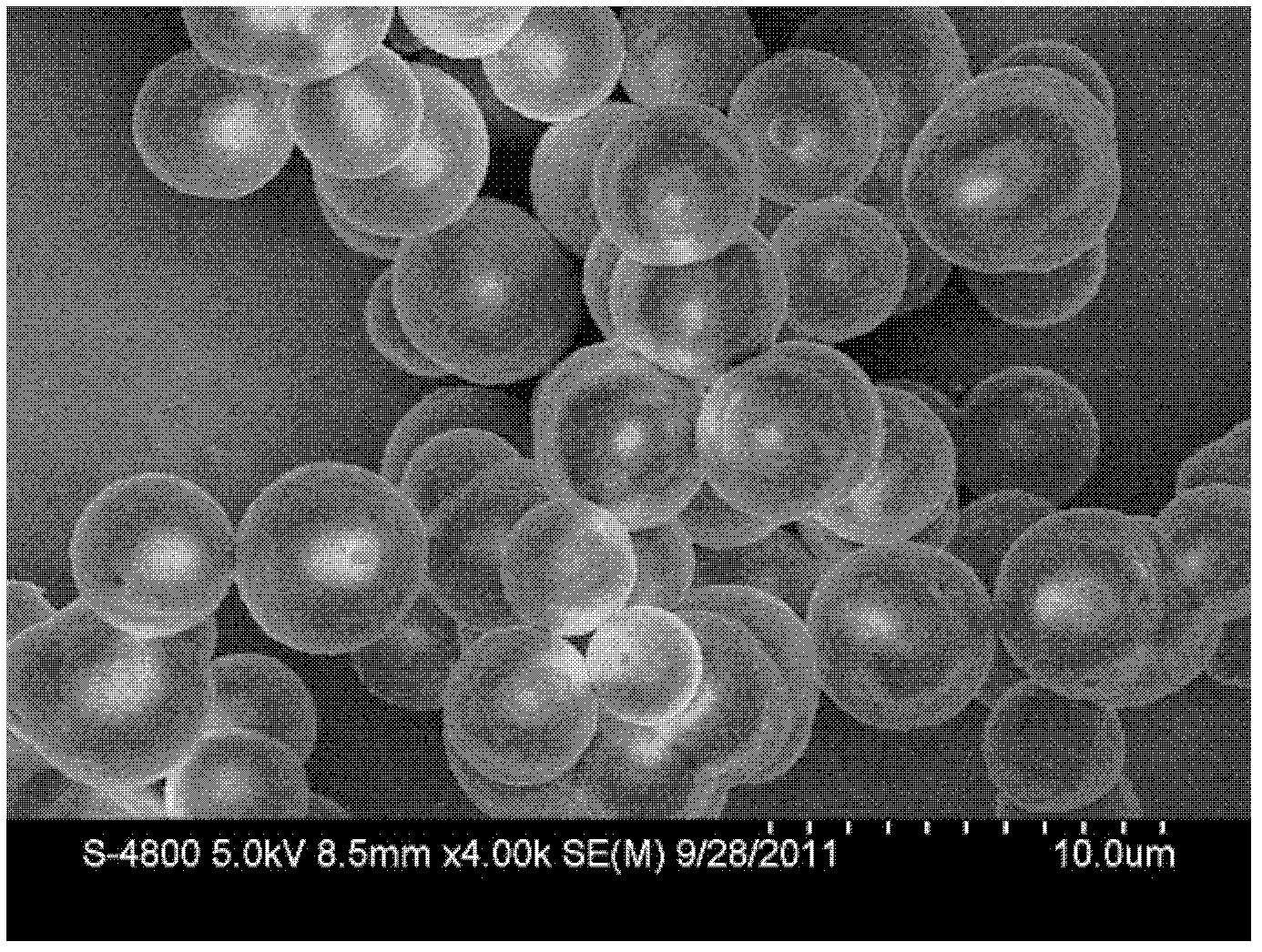

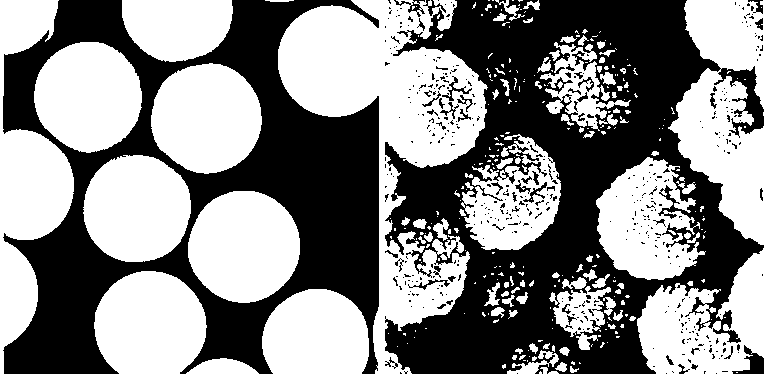

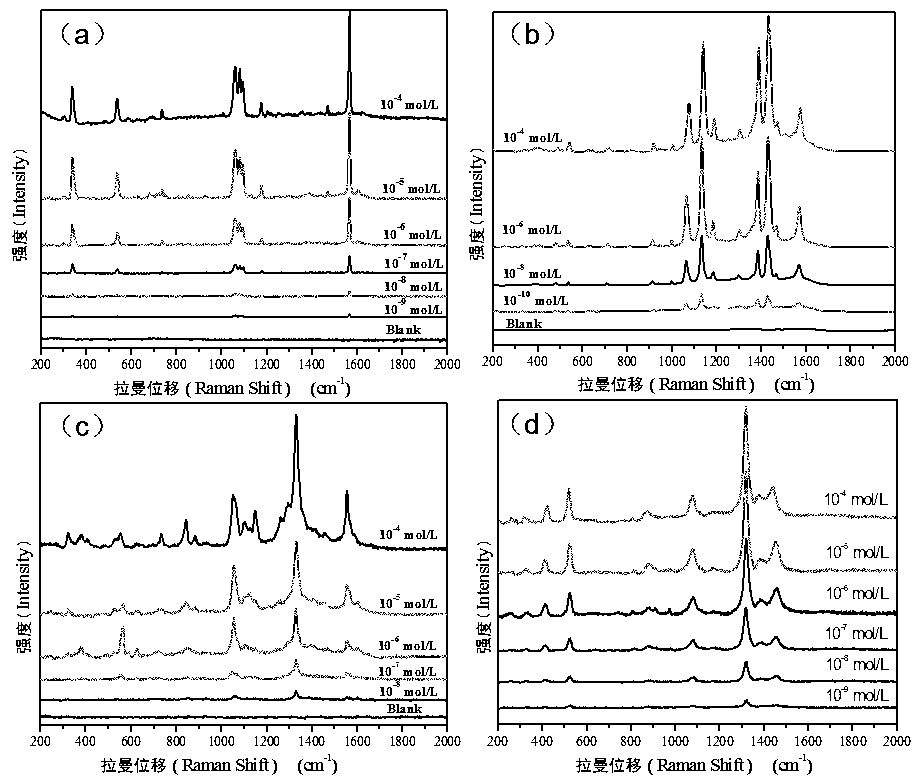

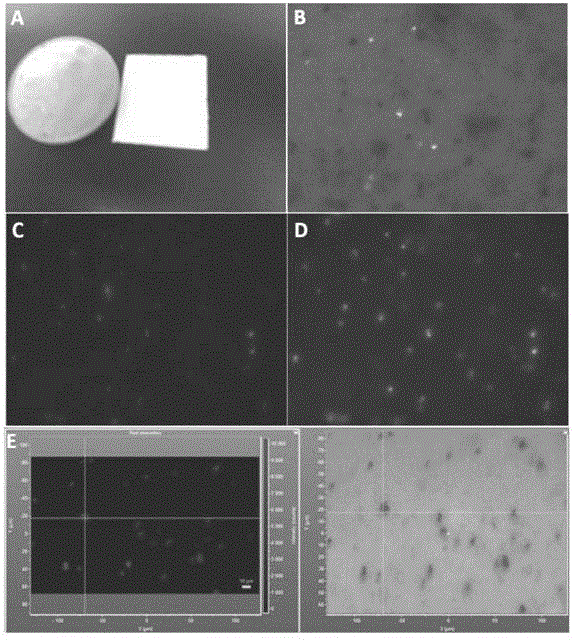

Raman strengthening active microsphere and preparation method and application thereof

InactiveCN103127890ASimple and fast operationSensitive Raman signalRaman scatteringMicroballoon preparationResin microsphereIn situ chemical reduction

The invention belongs to the technical field of function materials, and specifically relates to a Raman strengthening active microsphere and a preparation method and an application thereof. The Raman strengthening active microsphere provided by the invention has a core-shell structure, the core of the Raman strengthening active microsphere is a melamine resin microsphere, and the shell is uniform and compact silver nanometer granules. The preparation method comprises the steps of firstly preparing uniform melamine-oxymethylene microsphere through fasculation, then utilizing a reducing agent to restore silver nitrate through a normal position chemical reduction method, and uniformly and compactly depositing the generated silver nanometer granules onto the surface of the melamine resin microsphere, so as to prepare the MF / Ag-NPs composite microsphere. The raman strengthening active microsphere utilizes a single microsphere as a raman strengthening base material, and is used for detecting Raman. The single Raman strengthening active base material microsphere provided by the invention has the characteristics of high stability and high Raman strengthening property. The method provided by the invention has the advantages that the operation is simple, the process is controllable, and the prepared composite microsphere can be used for analyzing and detecting organic contaminants such as pesticide residue of a single microsphere in a Raman manner.

Owner:FUDAN UNIV

Magnetic fluorescent Raman double-encoding composite microspheres and preparation method and application thereof

InactiveCN104907019APerformance is not affectedFast and efficient enrichment and separationRaman scatteringFluorescence/phosphorescenceMicron scaleResin microsphere

The invention belongs to the technical field of functional material, and specifically relates to magnetic fluorescent Raman double-encoding composite microspheres and a preparation method and an application thereof. The composite microspheres are prepared by the steps: adding fluorescein in a condensation reaction of melamine and formaldehyde to form fluorescent melamine resin microspheres, after a magnetic fluid is physically adsorbed on the surface, depositing silver nanoparticles by a chemical deposition method to form core-shell structural microspheres with the fluorescent melamine resin microspheres as a core and the magnetic fluid and the silver nanoparticles as a shell, then fixing Raman labeled molecules and coating with an SiO2 shell layer to form the composite microspheres denoted as the FMF / Fe3O4-NPs / Ag-NPs / SiO2 composite microspheres. The composite microspheres are labeled with the fluorescein, have the micron-scale microsphere particle size, can be used as a single-microsphere Raman enhancement substrate, and are applied to Raman detection. The method is simple in operation and controllable in process, can increase the encoding capacity of the composite microspheres by labeling of different fluoresceins and adsorption of various Raman report molecules, and can be used for anti-fake marks for coatings / printing inks and the like.

Owner:FUDAN UNIV

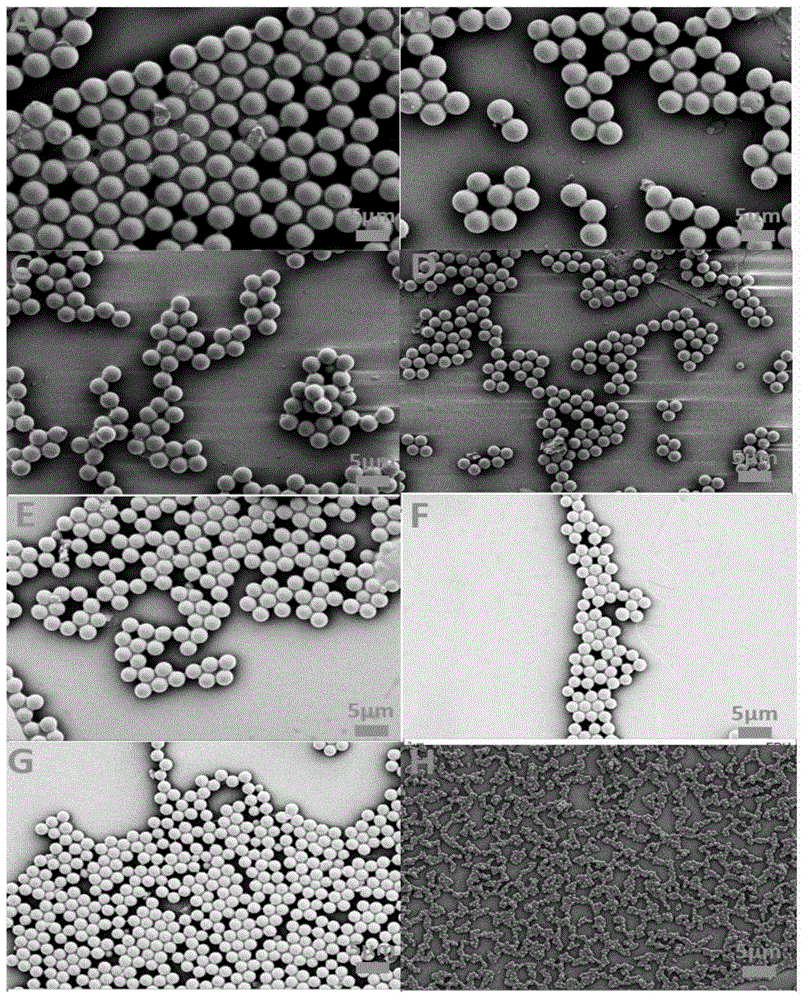

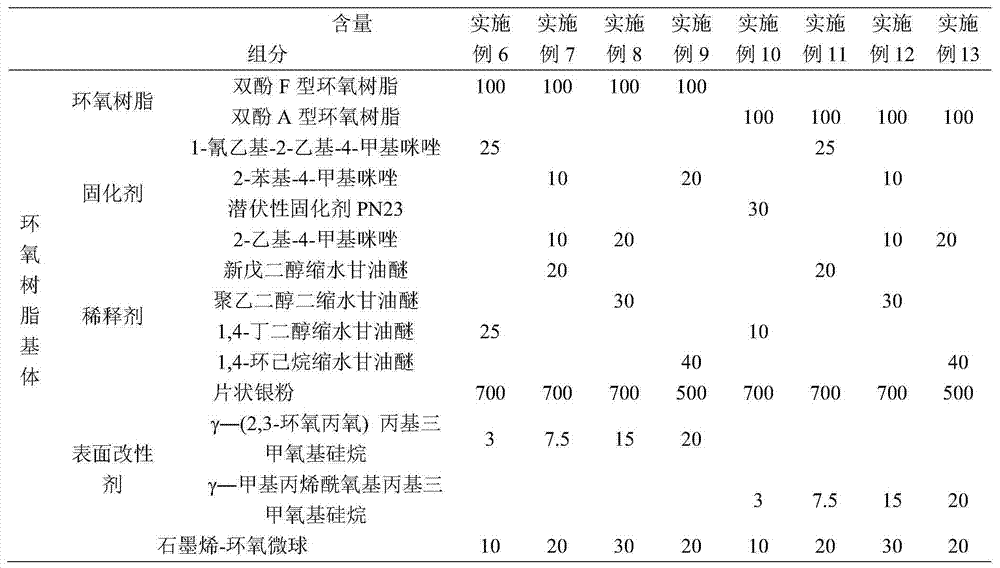

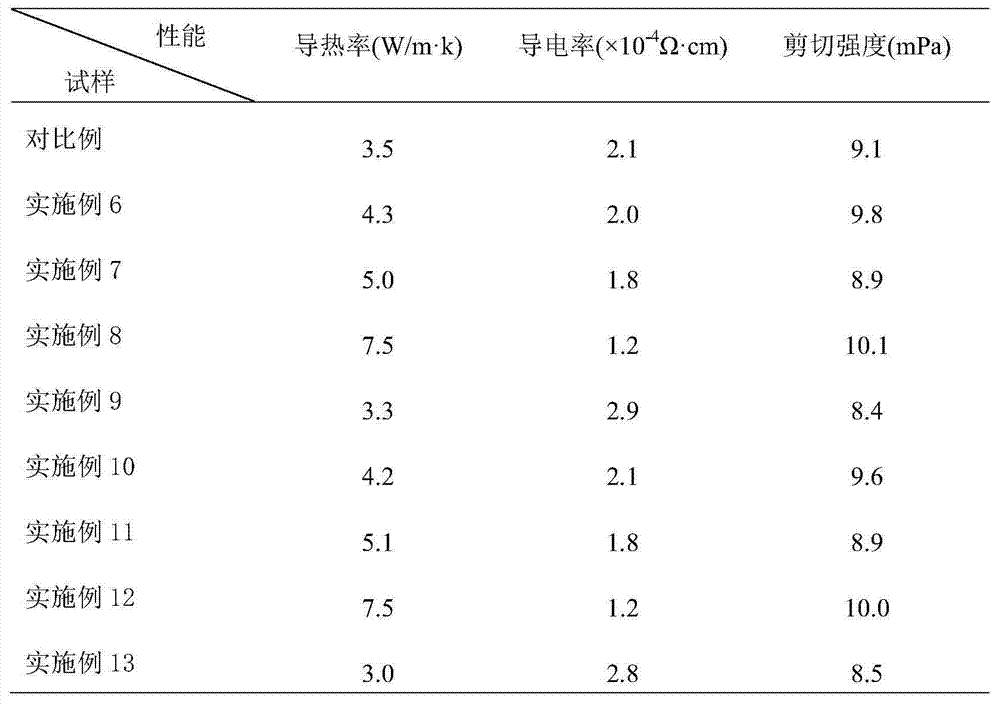

High-performance conductive silver adhesive containing graphene and preparation method thereof

ActiveCN104774573AReduce the content of organic mediaImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyResin microsphere

The invention discloses a high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene comprises the following raw materials by weight: 100 parts of epoxy resin, 10 to 50 parts of a curing agent, 10 to 40 parts of an epoxy diluent, 5 to 50 parts of a graphene-epoxy microsphere, 0.5 to 5 parts of a surface modifier and 240 to 990 parts of a silver strip, wherein the graphene-epoxy microsphere is prepared from graphene oxide and an epoxy resin microsphere in a mass ratio of 1: 4-19. The invention further discloses a preparation method for the high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene has the advantages of low cost and good conductive performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Magnetic macroporous adsorption resin microspheres, and preparation method thereof

InactiveCN103739764AImprove product qualityLow costPharmaceutical non-active ingredientsResin microspherePolyvinyl alcohol

The invention relates to magnetic macroporous adsorption resin microspheres, and a preparation method thereof. The magnetic macroporous adsorption resin microspheres comprise oil phase and water phase; the oil phase comprises following raw materials, by weight, 50 to 70 parts of 55% divinyl benzene, 5 to 10 parts of styrene, 3 to 5 parts of methyl acrylate, 30 to 50 parts of gasoline No.200, 20 to 40 parts of methylbenzene, 1 to 2 parts of dibenzoyl peroxide, and 10 to 20 parts of nano Fe3O4 particle; and the water phase comprises following raw materials, by weight, 600 to 800 parts of deionized water, 5 to 10 parts of sodium chloride, 6 to 8 parts of polyvinyl alcohol, and 2 to 6 parts of gelatin. The magnetic macroporous adsorption resin microspheres are capable of solving a problem of magnetic macroporous adsorption ion exchange resin prepared via existing technology that the magnetic macroporous adsorption ion exchange resin is not microspherical in shape, and is not suitable for applications in the field of medicine. Application range of the magnetic macroporous adsorption resin microspheres is wider, product quality is higher, and cost is relatively low.

Owner:何小刚

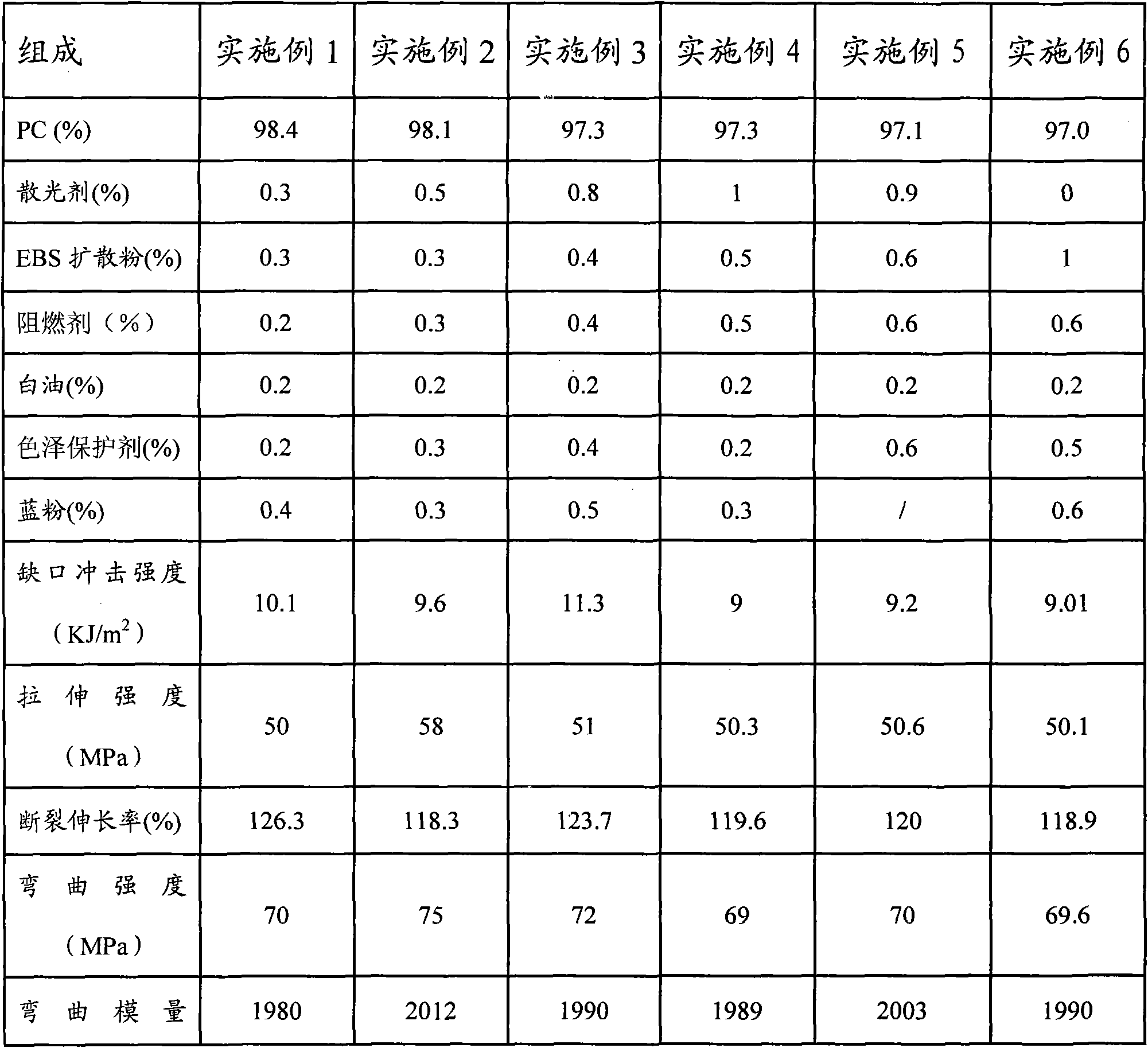

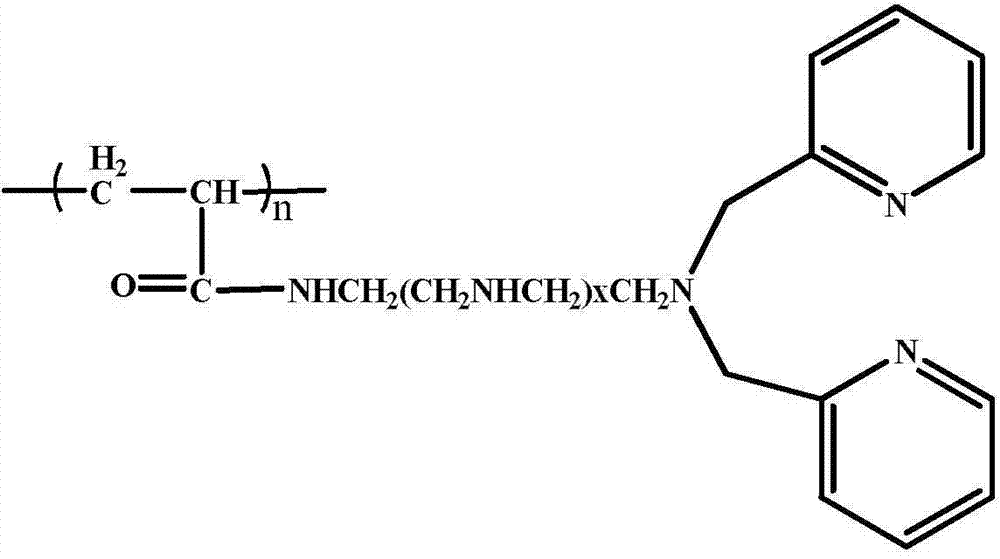

High flame resistance transparent light diffusion polycarbonate and preparation method thereof

InactiveCN102086300ADoes not affect transparencyDoes not affect hazePolymer scienceResin microsphere

The invention discloses high flame resistance transparent light diffusion polycarbonate (PC) and a preparation method thereof. The PC comprises the following components by weight percent: 97-99% of engineering plastic, 0-1% of light diffusion agent, 0.3-0.7% of dispersant, 0.2-0.6% of color protectant, 0.2-0.6% of fire retardant and 0.2-0.8% of other additives. The PC uses engineering plastic PC as main body; and the light diffusion agent of organic resin microsphere, fluoride fire retardant, color protectant and other additives are added in the main body to perform melting and blending, and extruding and granulating. The prepared high flame resistance transparent light diffusion PC can be used to prepare various transparent optical products in the optical field, the PC is environmentally friendly and has flame resistance, high safety performance and excellent physical mechanical propertics. The preparation method of the high flame resistance transparent light diffusion PC comprises the following process steps: firstly mixing the raw materials according to a certain ratio, secondly sending the mixture in a plastic extruder, and controlling the temperature to 250-300 DEG C to granulate.

Owner:SHENZHEN KEJU NEW MATERIAL

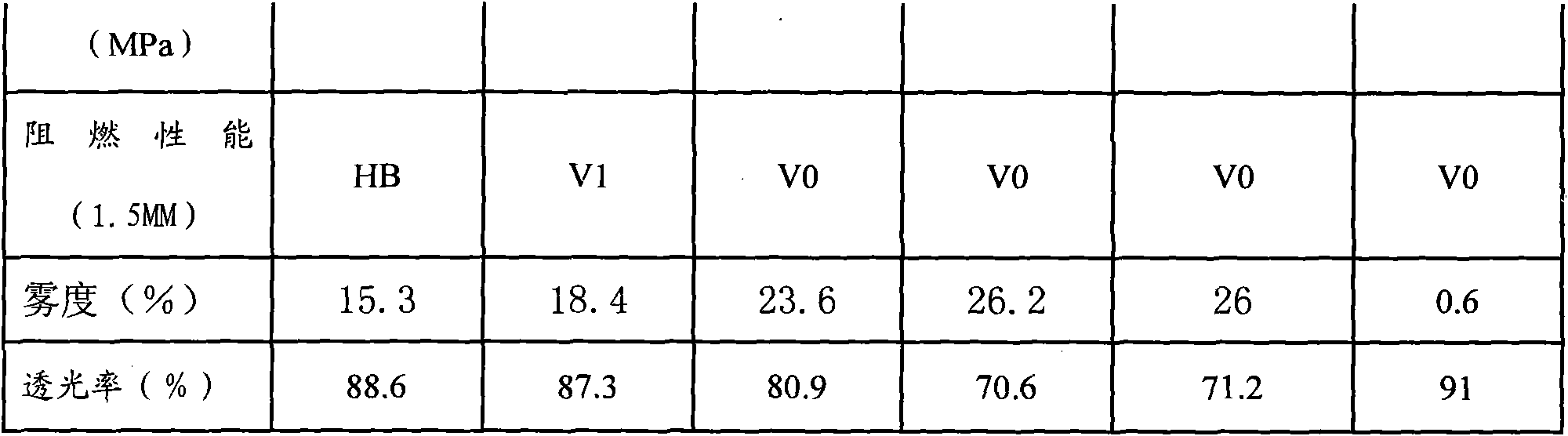

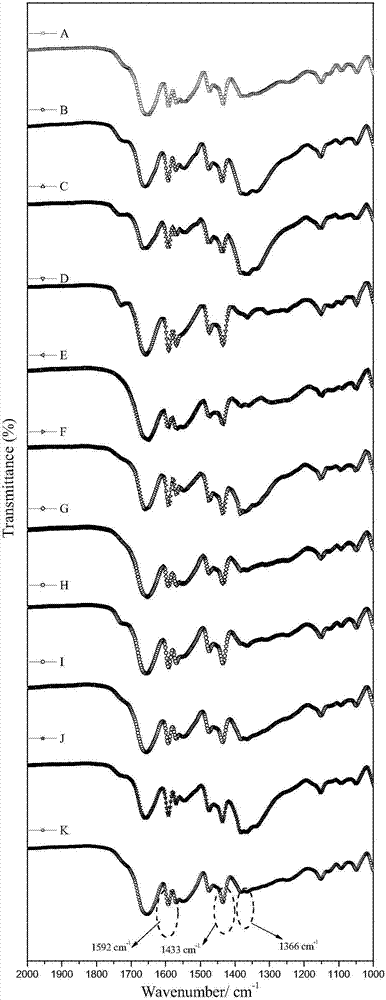

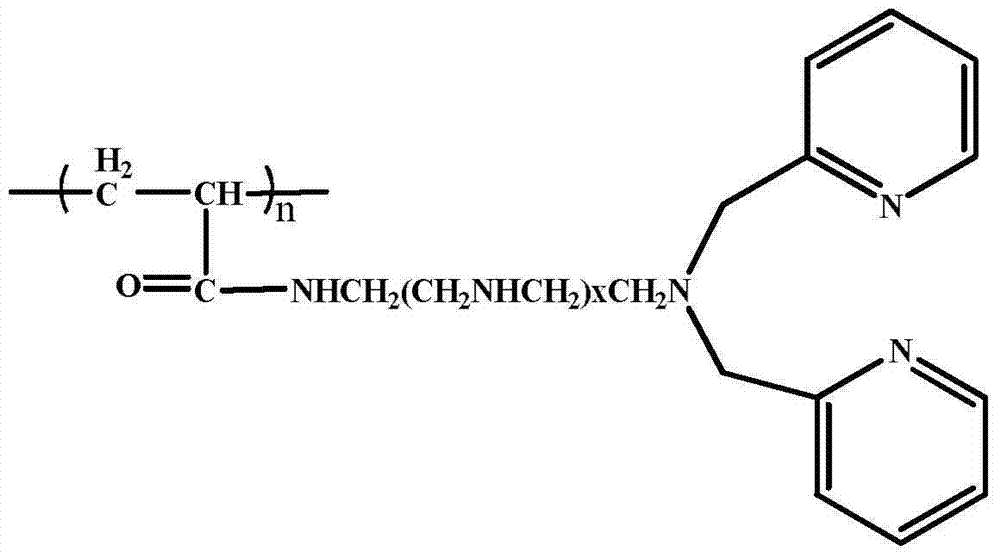

Acrylic acid pyridine chelating resin as well as preparation method and application thereof

The invention discloses an acrylic acid pyridine chelating resin as well as a preparation method and application thereof, and belongs to the field of modified resin synthesis. A basic structure unit of the resin is as shown in the specification, wherein x represents polyamines with different chain lengths; resin microspheres are faint yellow; the particle sizes are 0.15-1.20mm; and the functional group content is 1.08-3.01mmol / g. The chelating resin disclosed by the invention is wide in preparation material source, low in cost, and simple in operation step. Due to the hydrophilcity of a polyacrylic resin skeleton, the adsorption rate on heavy metal is high. In addition, due to high modification quantity of the resin functional group, the adsorption quantity on heavy metal is large. The acrylic acid pyridine chelating resin disclosed by the invention can be applied to the fields such as mining and metallurgy production, mother liquid purification, removal of heavy metal in a high-acid and high-salt complicated system and separation and pre-enrichment of the heavy metal in environment analysis; the technical problems of small adsorption amount, low adsorption rate, large in required resin amount in engineering, long operation time and the like when the heavy metal is selectively adsorbed are solved; and the economic benefits and the environment benefits are significant.

Owner:NANJING UNIV

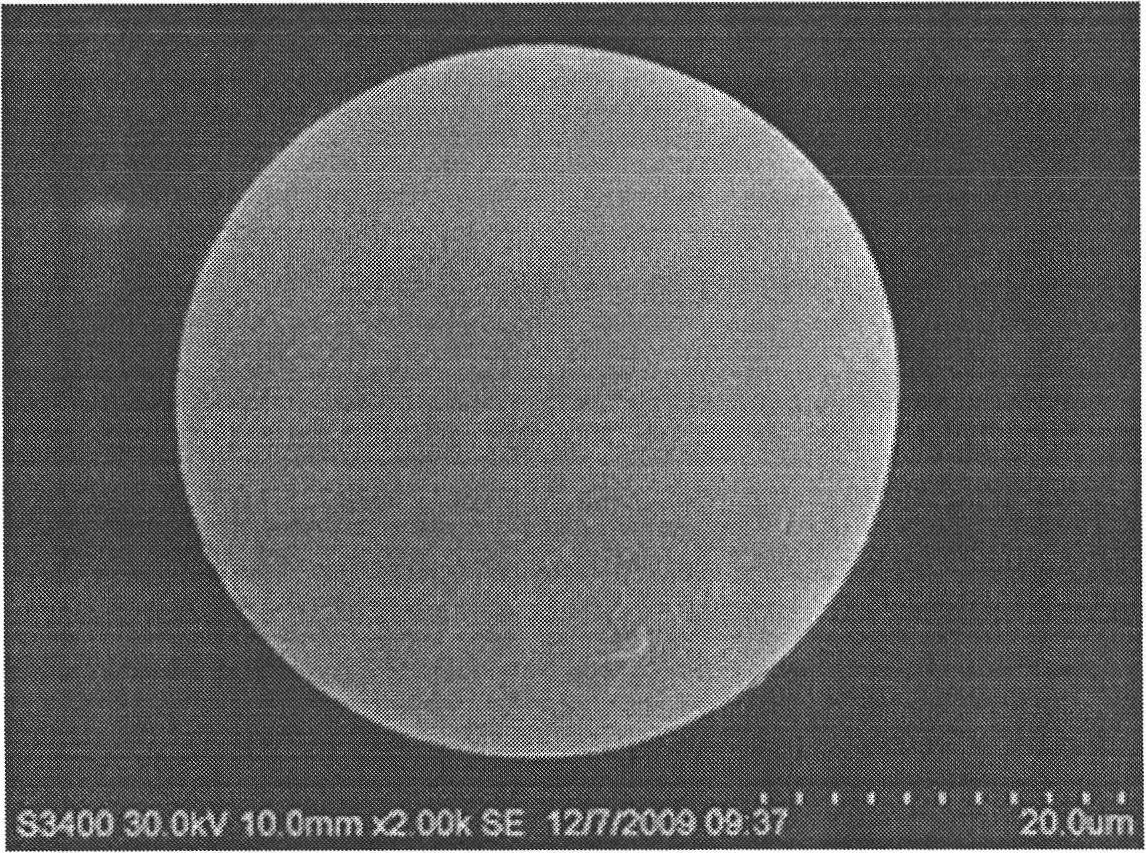

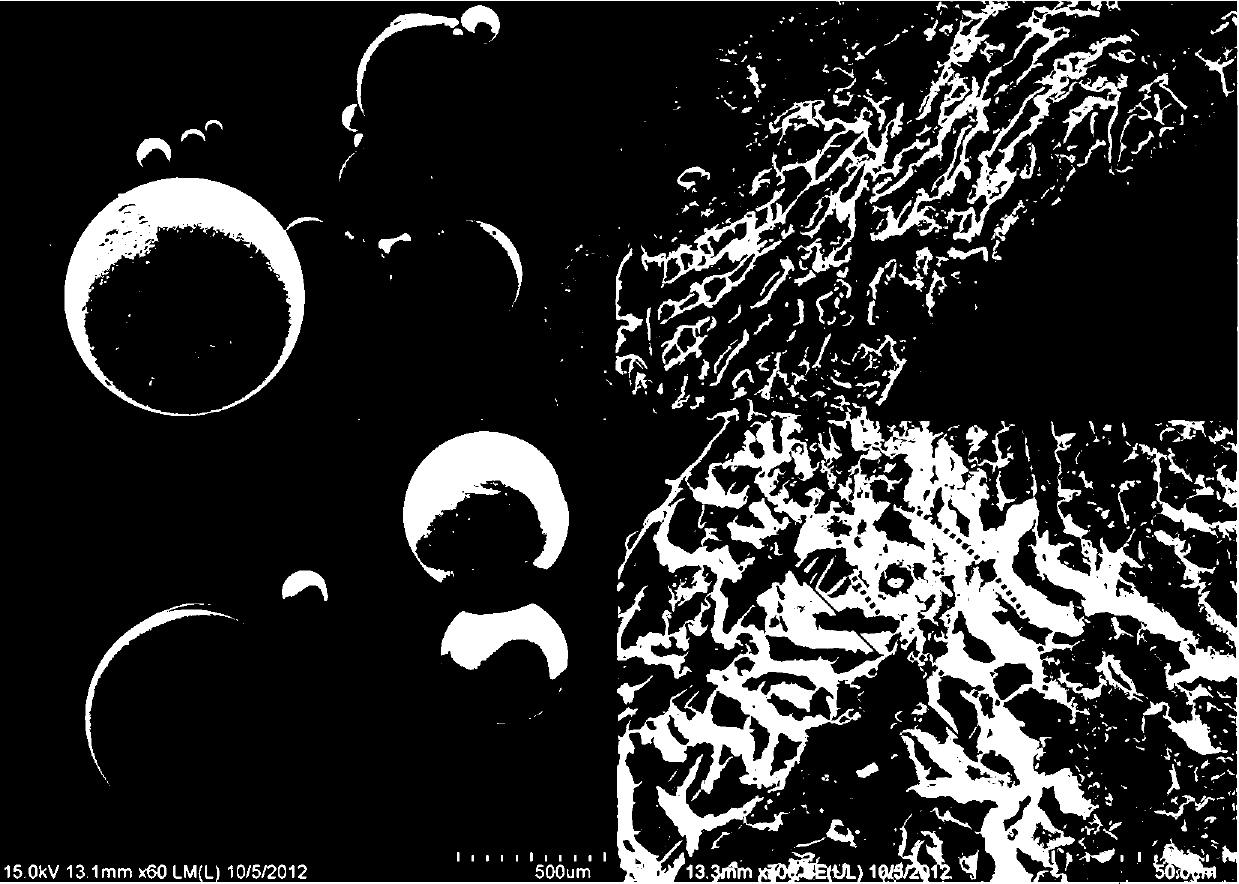

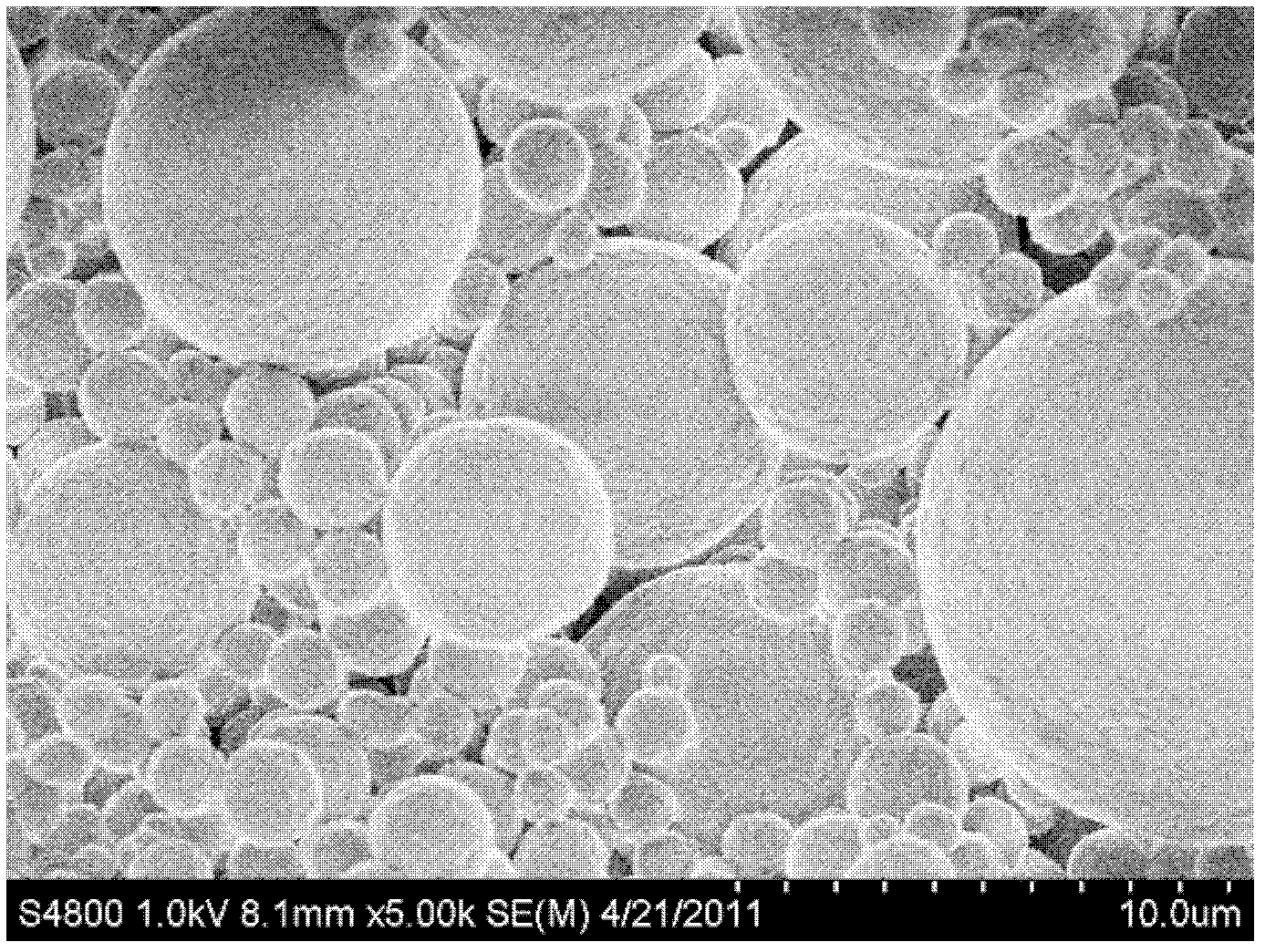

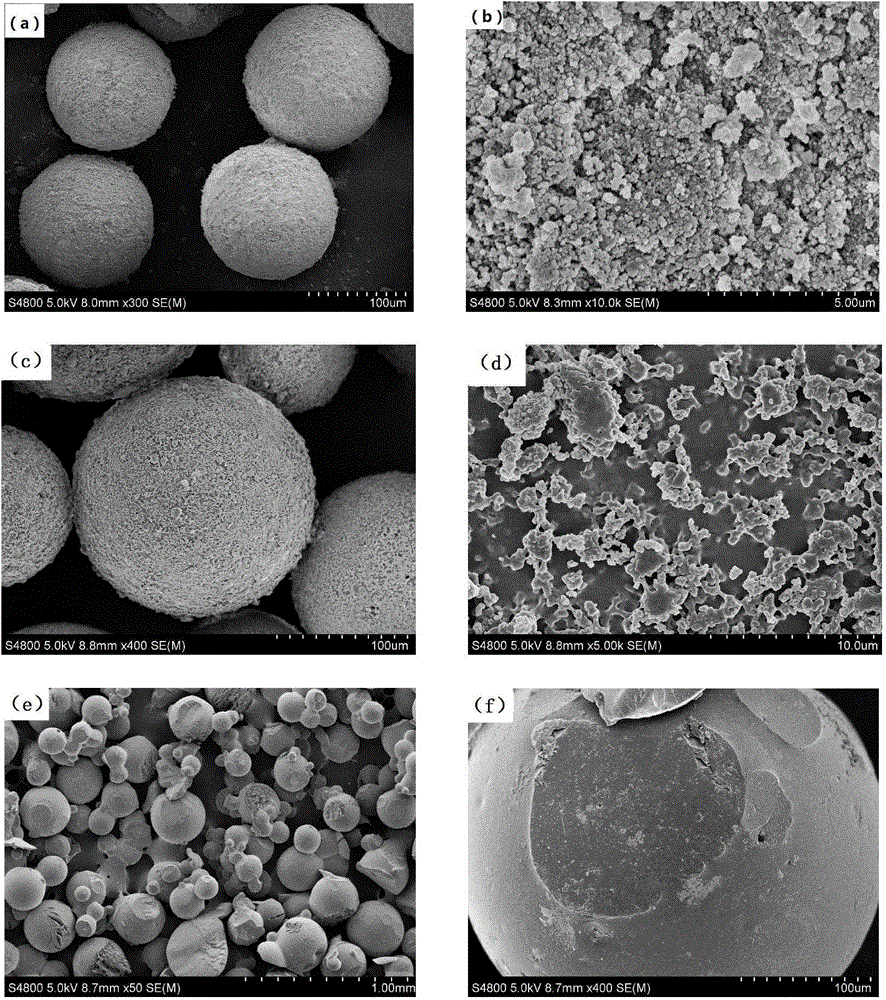

Core-shell structure oil-absorptive resin microsphere suitable for oil well cement as well as preparation method and application of core-shell structure oil-absorptive resin microsphere

The invention discloses a core-shell structure oil-absorptive resin microsphere suitable for oil well cement as well as a preparation method and an application of the core-shell structure oil-absorptive resin microsphere. The preparation method comprises the following steps: with modified nano particles as a dispersing agent and a shell material, a hard component monomer and a soft component monomer in an acrylic compound as binary monomers, adding a crosslinking agent, an initiator and a pore-foaming agent, and preparing the oil-absorptive resin microsphere with the core-shell structure by a suspension polymerization method. The core-shell structure oil-absorptive resin microsphere is stable in synthesis process; the stability and no coalescence of oil-phase droplets can be kept in the suspension polymerization process; the synthesized oil-absorptive resin microsphere is uniform in particle size and good in sphericity, and has good dispersity in an alkaline high-temperature environment of the oil well cement; the structure and the oil absorptiveness of the oil-absorptive resin microsphere can be kept stable; the oil absorption is not affected; and when a downhole cement ring of an oil well is damaged to generate a microcrack, the oil-absorptive resin microsphere can absorb oil to swell when running into oil flow through the micro-crack, and a physical packer is formed in the damaged part of the cement ring.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for producing bead-stringed PAN (polyacrylonitrile)-based carbon fiber electrode materials by electrostatic spinning

InactiveCN102560889ALarge specific surface areaIncrease the strength of the felt bodyElectrolytic capacitorsHeating/cooling textile fabricsCapacitanceResin microsphere

A method for producing controllable fibre diameter and sphere diameter bead-stringed PAN (polyacrylonitrile)-based carbon fiber electrode materials by electrostatic spinning relates to a method for producing PAN-based carbon fiber electrode materials. The method is to solve the problem in traditional carbon fiber preparation method process, the feature controllable carbon fiber electrode material is not easy to be obtained. By electrostatic spinning, phenolic resin microspheres are added into spinning dope to produce bead-stringed PAN-based carbon fiber felt electrode materials. The electrode materials have the advantages that the production method is simple and continuous, the diameter of fibers and sphere diameter ratio of bead strings are controllable, and the materials are high in specific capacitance, high in felt strength, large in specific surface area and the like.

Owner:HEILONGJIANG UNIV

Magnetic resin microspheres and preparation method thereof

The invention relates to magnetic resin microspheres and a preparation method thereof, belonging to the technical field of high molecular materials. The magnetic resin microspheres comprise the following raw materials by weight parts: 5-10 parts of acrylonitrile, 10-20 parts of styrene, 50-70 parts of divinyl benzene, 20-30 parts of triallyl isocyanurate, 10-19 parts of methyl acrylate, 50-60 parts of gasoline, 40-50 parts of methylbenzene, 1-2 parts of dibenzoyl peroxide, 10-20 parts of nano Fe3O4, 400-600 parts of de-ionized water, 50-60 parts of calcium oxide, 20-30 parts of sodium chloride and 1-2 parts of polyvinyl alcohol. According to the preparation method, a suspension polymerization process is adopted, polymerization monomers are selected from styrene, acrylonitrile and the like, a cross-linking agent is selected from divinyl benzene and triallyl isocyanurate, and magnetic particles are nano Fe3O4 particles, so that the magnetic property is improved, separation is facilitated, and no residues are generated; the magnetic resin microspheres are rich in function and suitable for various fields.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Method for preparing thermosetting amino resin microspheres

The invention relates to a method for preparing thermosetting amino resin microspheres. The invention aims to provide the method which can prepare amino resin microspheres with wide range of grain size and higher water resistance. The technical scheme I adopted by the invention is that the method for preparing the thermosetting amino resin microspheres comprises the following steps of: (A), adding an amino compound and an aldehyde compound into an aqueous solution of silica sol with an alkaline catalyst to obtain a prepolymer of water soluble amino resin, wherein the weight ratio of the amino compound to the aqueous solution of silica sol is 100: 0.5-100; (B), adding an acidic curing agent into the prepolymer of the water soluble amino resin to obtain amino resin microspheres; and (C), aging the microspheres, filtering, drying and grinding the microspheres to obtain a finished product. The amino compound may be one or more of tripolycyanamide, urea, thiourea, cyanuric acid and phenylated tripolycyanamide, and the aldehyde compound may be one or more of formaldehyde, paraformaldehyde, acetaldehyde, benzaldehyde and furfuraldehyde.

Owner:杭州精彩化工有限公司

Preparation method of epoxy resin hollow microsphere

InactiveCN102850521AHeat resistantSolvent resistantMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

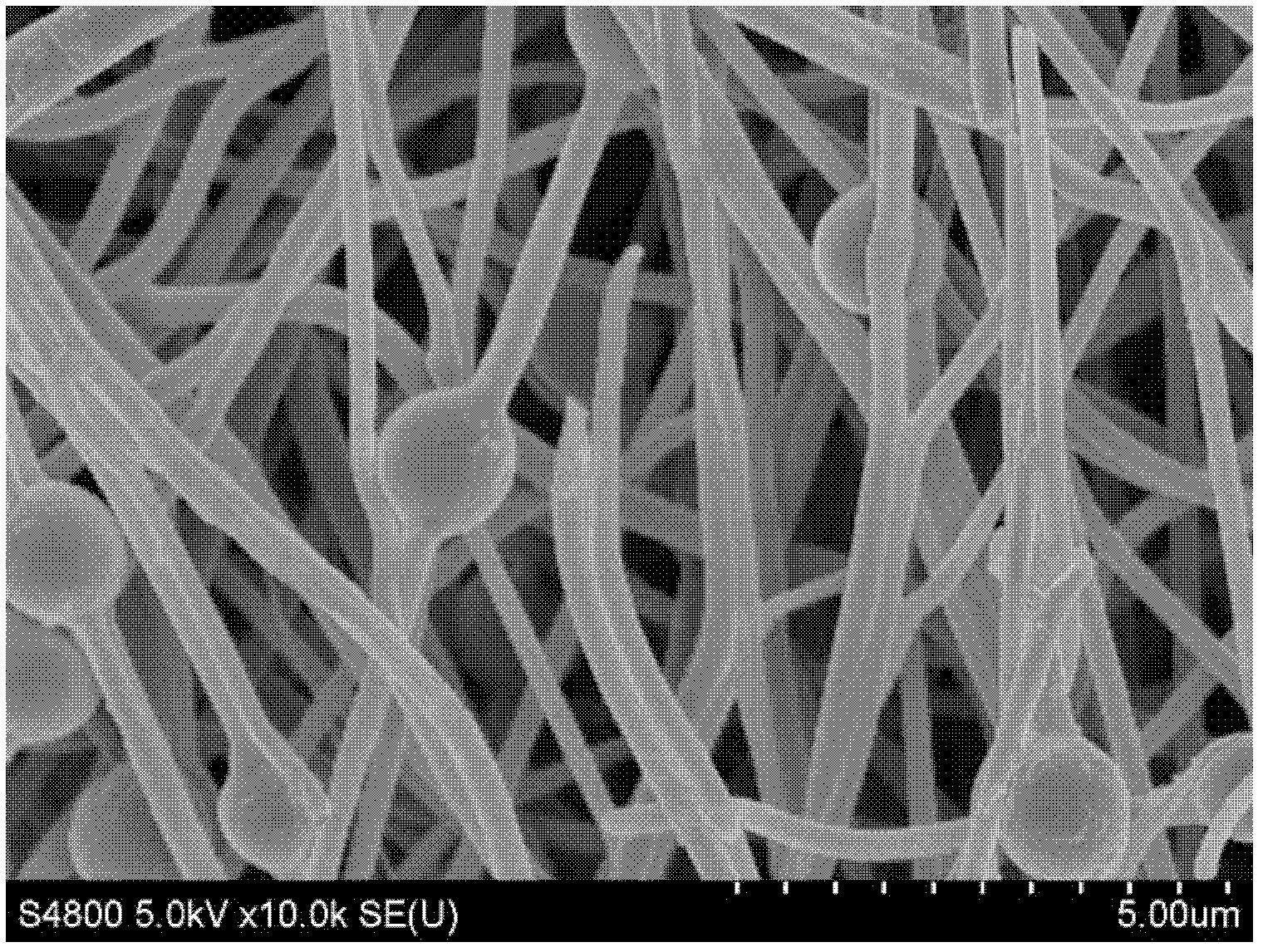

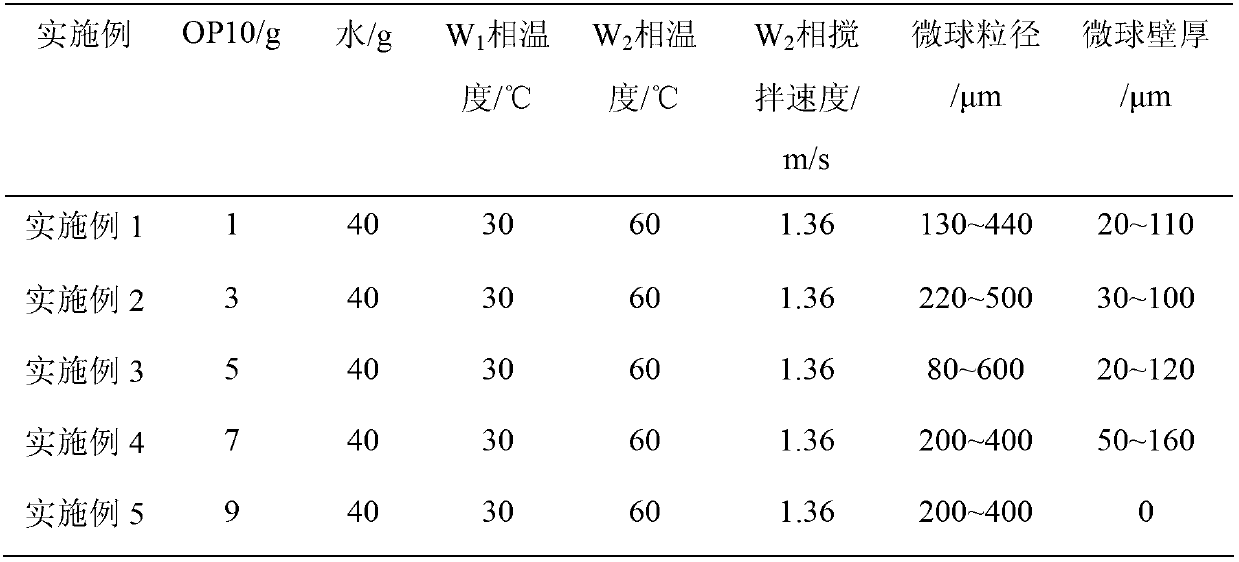

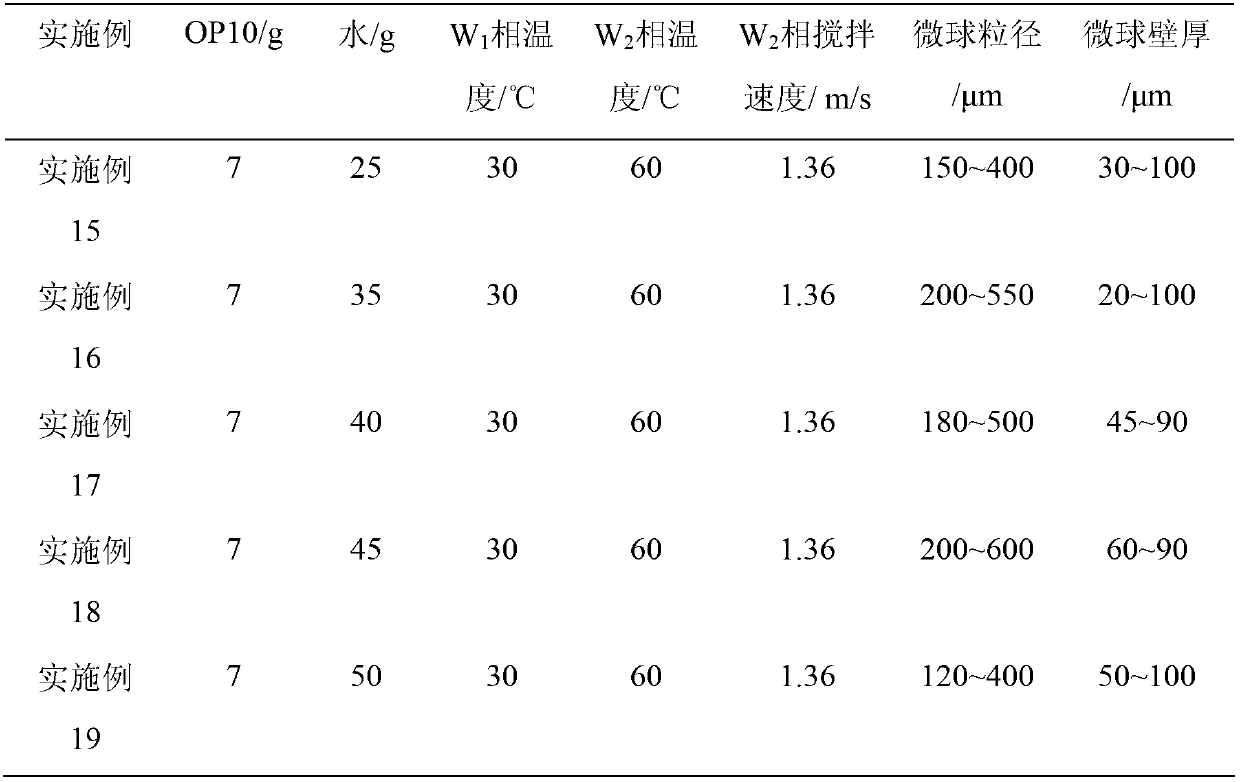

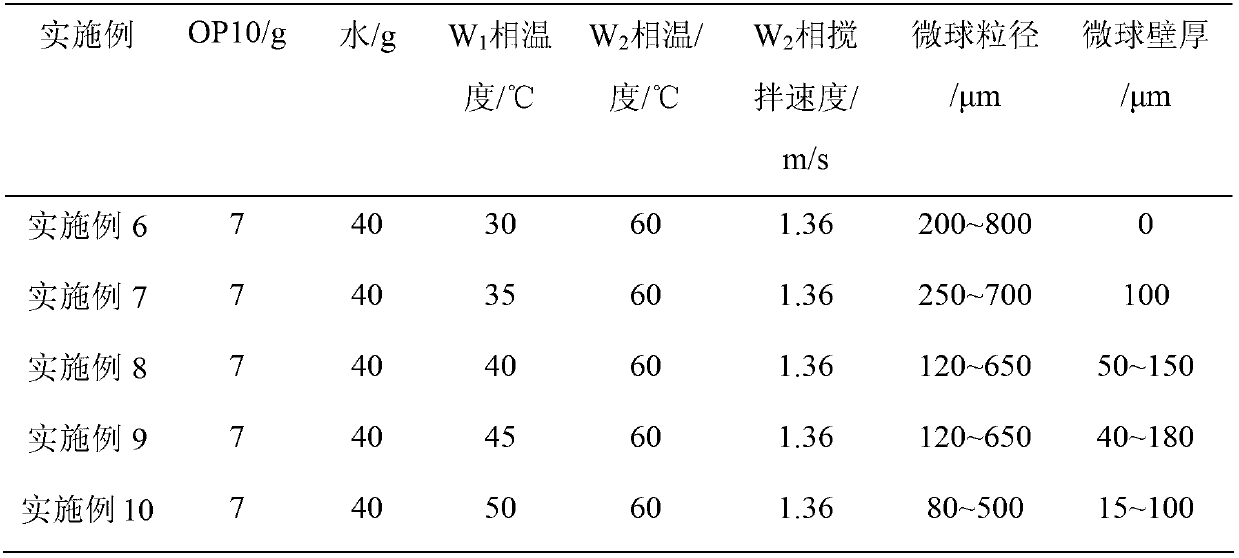

A preparation method of epoxy resin hollow microspheres belongs to the field of polymer material. The preparation method provided by the invention comprises the following steps: (a) preparation of water / epoxy emulsion: mixing epoxy resin monomers, triethylene tetramine, an emulsifier OP10 at 30-50 DEG C, and stirring while adding deionized water, so as to obtain a water / epoxy emulsion, wherein a mass ratio of epoxy resin monomer to triethylene tetramine to OP10 to deionized water equals to A: B: C: D, and A equals to 100, and B equals to 12.9, and C equals to 1-9, and D equals to 25-40; (b) dropwise adding the water / epoxy emulsion prepared in the step (a) at a stirring speed of 0.68-1.70 m / s into ethylene glycol of 30-70 DEG C; (c) heating the water / epoxy / ethylene glycol emulsion prepared in the step ( b ) to 100 DEG C for reaction for 1h; and (d) drying the water-containing epoxy resin microspheres prepared in the step (c) in vacuum. The epoxy resin microsphere prepared by the invention has high heat resistance, solvent resistance and mechanical strength.

Owner:SOUTHWEAT UNIV OF SCI & TECH

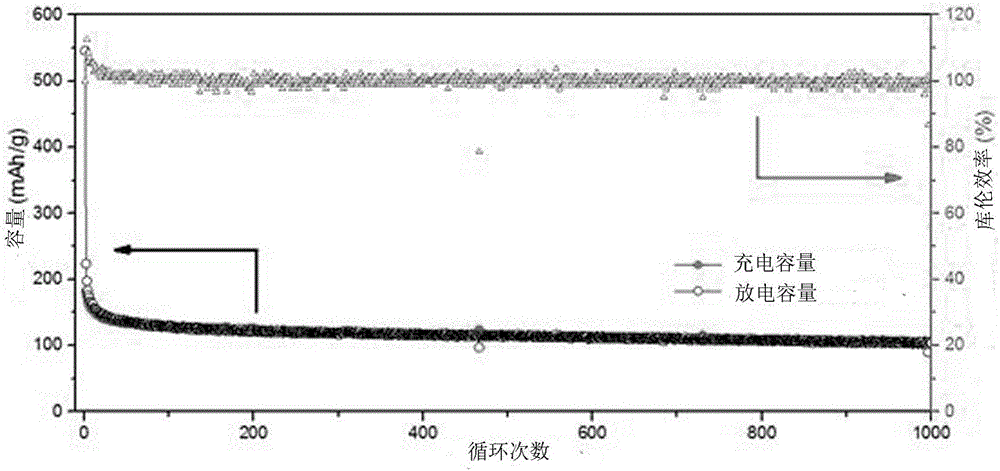

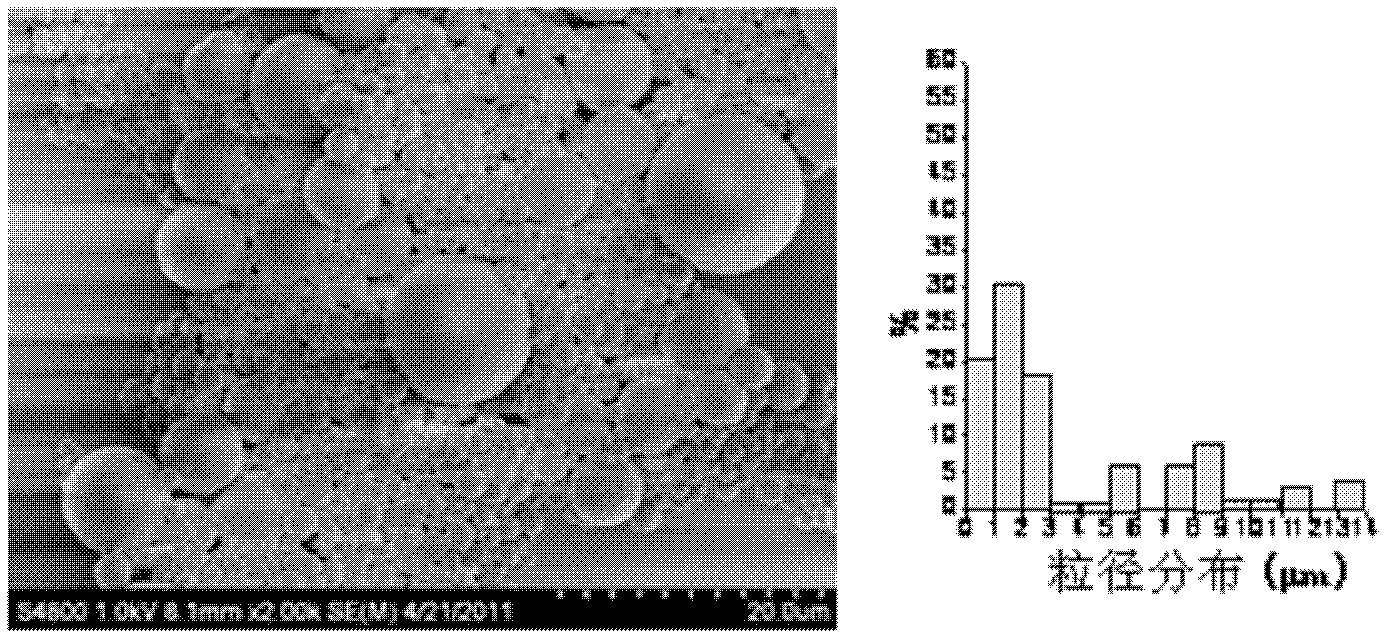

Phenol formaldehyde resin carbon micro-sphere preparation method and application of phenol formaldehyde resin carbon micro-sphere in lithium ion battery electrode

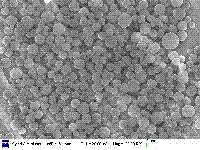

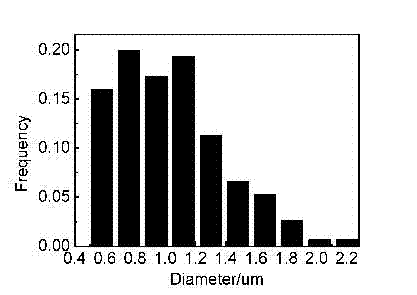

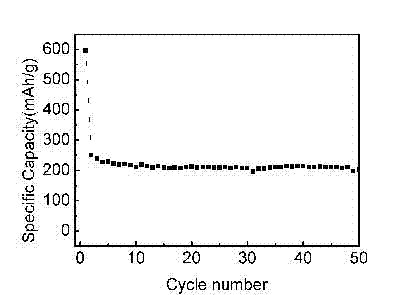

The invention provides a phenol formaldehyde resin carbon micro-sphere preparation method. The phenol formaldehyde resin carbon micro-sphere preparation method comprises the following steps: firstly preparing phenol formaldehyde resin micro-spheres under an emulsion polymerization condition, then carrying out carbonization treatment to obtain the phenol formaldehyde resin carbon micro-spheres with the average particle size diameter being 1-6 micrometers, which have good morphology and small particle sizes and are uniform in particle size distribution. When serving as lithium ion battery negative electrode materials, the phenol formaldehyde resin carbon micro-spheres with the small particle sizes, which are synthesized by using the method, show high reversible capacity and rate capability; the specific discharge capacity of the phenol formaldehyde resin carbon micro-spheres is 350mAh / g-190mAh / g at 50mA / g-1A / g.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing polyacrylic acid high-water-absorptivity resin microspheres by reversed phase suspension polymerization

The invention discloses a method for preparing polyacrylic acid high-water-absorptivity resin microspheres by reversed phase suspension polymerization. According to the method, a comonomer, a dispersant, a crosslinking agent and an initiator used as main reactants are subjected to reversed phase suspension polymerization by using cyclohexane as a solvent to obtain the polyacrylic acid high-water-absorptivity resin microspheres, wherein the dispersant is selected from two or three of Span 80, Span 60, Span 40, hexadecyl phosphate and octadecyl phosphate. The method obviously enhances the stability of the reaction system, can implement one-step mass continuous preparation of the polyacrylic acid high-water-absorptivity resin microspheres, has the advantages of simple technique, no environmental pollution, low production cost and wide application range, and completely satisfies the industrialization requirements.

Owner:CNOOC ENERGY TECH & SERVICES +1

Quantum dot/epoxy resin microspheres and preparation method thereof as well as color conversion film

InactiveCN104945855AReduce reunionNo reunionPhotosensitive materials for photomechanical apparatusEpoxyResin microsphere

The invention discloses a quantum dot / epoxy resin microspheres and a preparation method thereof as well as a color conversion film. The quantum dot / epoxy resin microspheres are prepared by encapsulating quantum dots in epoxy resin microsphere cavities. By encapsulating the quantum dots in the epoxy resin microsphere cavities, the probability of causing agglomeration due to interaction of the quantum dots is effectively reduced, and the probabilities that the quantum dots are in contact with a photoresist external environment and are interfered and damaged during photoetching of a photoresist are reduced. Meanwhile, due to the interaction between the epoxy resin microspheres and a photoresist resin matrix, the quantum dots can be dispersed into the photoresist more easily, and are dispersed uniformly without agglomeration. Therefore, the photoluminescence properties of the quantum dots are beneficially ensured. A sub-pixel unit with R / G / B colors corresponding to the prepared color conversion film is purer in color and higher in saturation degree, and the backlight source energy utilization efficiency and the luminous efficiency are also improved obviously.

Owner:TCL CORPORATION

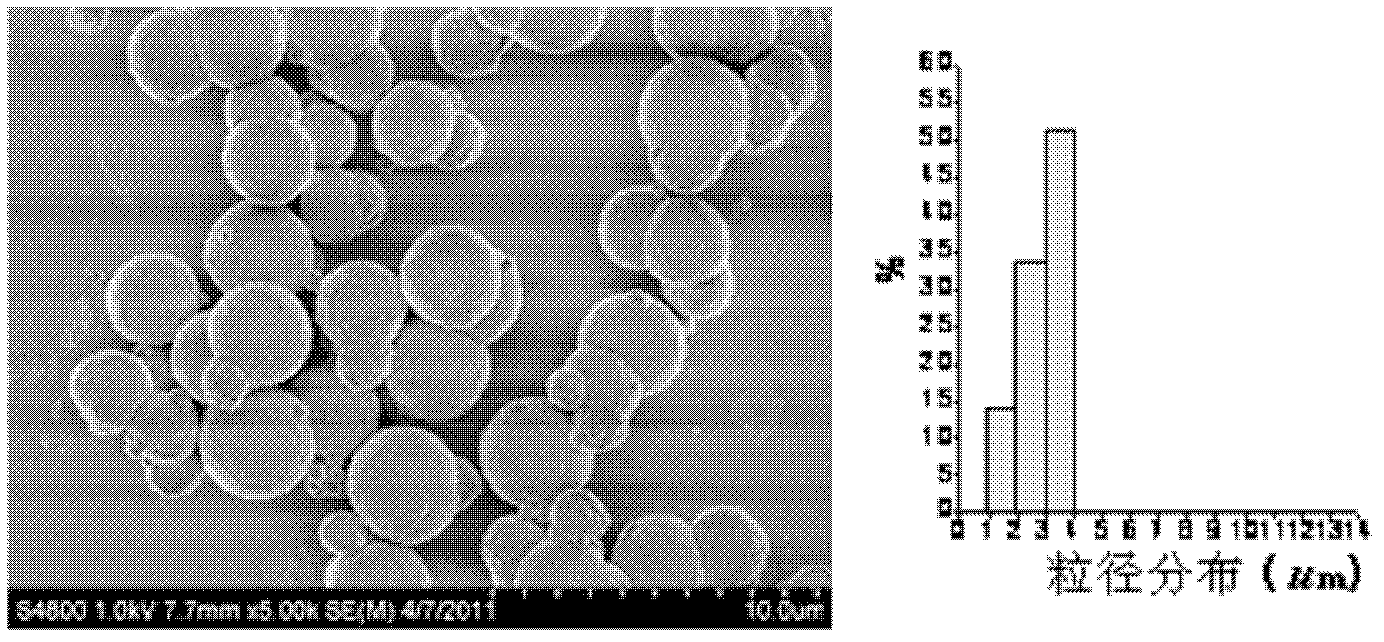

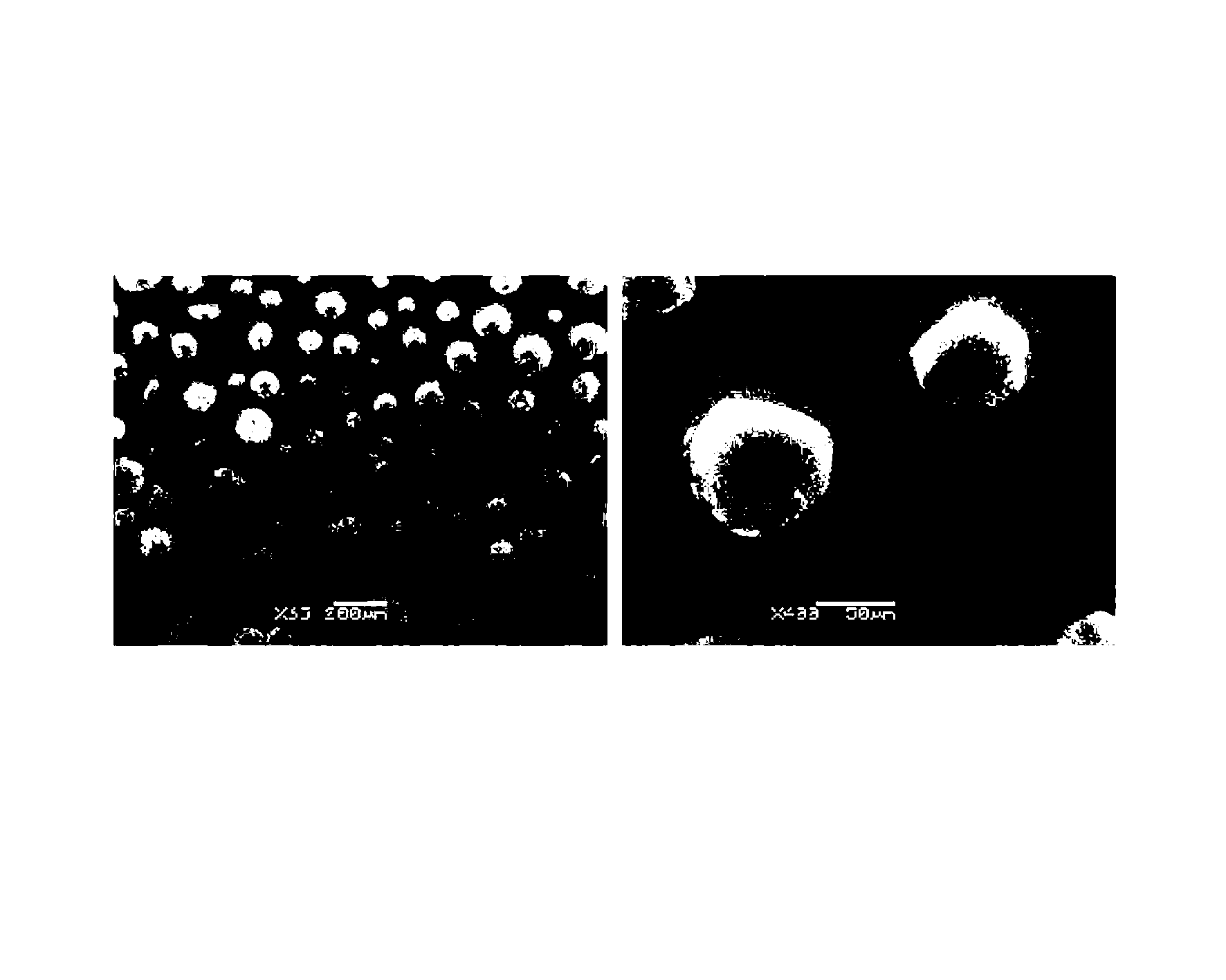

Method for synthesizing urea-formaldehyde resin microspheres with uniform particle size distribution

The invention relates to a method for synthesizing urea-formaldehyde resin microspheres with uniform particle size distribution. According to the invention, a surfactant, urea, and formaldehyde are added into distilled water; urea-formaldehyde resin deposition is prepared; and pump-filtration and washing are carried out, such that urea-formaldehyde resin microspheres are obtained. Compared with prior arts, according to the invention, urea-formaldehyde resin microspheres are modified by using the surfactant, such that urea-formaldehyde resin microspheres with uniform particle size are prepared. The microspheres can be used in respects such as chromatographic filling materials, catalyst carriers, adhesives, super capacitor materials, and environmental pollution treatments.

Owner:TONGJI UNIV

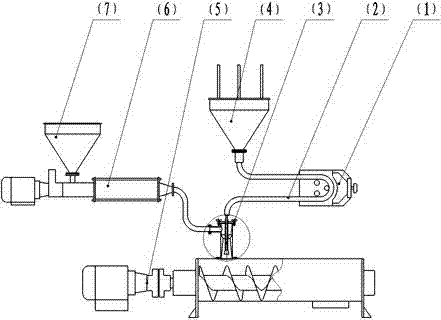

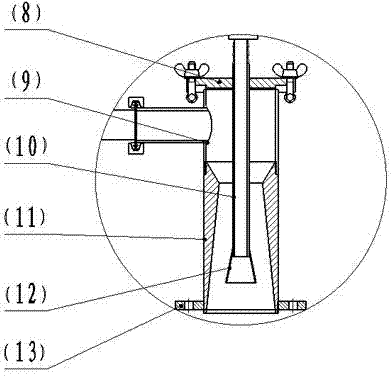

Mixing device of latex and expandable resin microspheres

ActiveCN103193557AWell mixedGood explosive performanceExplosive working-up apparatusPeristaltic pumpInjection pressure

The invention relates to a mixing device of latex and expandable resin microspheres. The device comprises a peristaltic pump, a hose, a mixing nozzle, a microsphere chamber, a mixing stirrer, a screw pump, and a latex chamber. The mixing nozzle is mainly composed of an upper connection flange, a latex injection pressure chamber, a latex injection pipe, a micro-powder delivery pipe, a flow-guide cover, and a lower connection flange. According to the invention, latex is added into the latex chamber; with the screw pump as a dynamic and metering device, the latex is delivered into the mixing nozzle; through the latex injection pressure chamber, the latex is delivered to the latex injection pipe, and enters the mixing stirrer; the resin microspheres are sucked from a resin microsphere bag through the microsphere chamber; with the peristaltic pump as a dynamic and metering device, the microspheres are delivered into the mixing nozzle through the hose; with the micro-powder delivery pipe and the flow-guide cover, the expandable resin microspheres are delivered to the middle of the latex at the latex injection pipe, and enters the mixing stirrer with the latex; and with the mixing stirrer, the latex and the expendable resin microspheres are uniformly mixed, such that explosive explosion performance and product quality are improved. The device provided by the invention has the advantages of simple structure and smooth material flow. The expendable resin microspheres are delivered in the device, such that dust is substantially prevented. Metering is carried out by using the peristaltic pump, the screw pump, and the mixing stirrer, such that the two materials can be outputted with any ratio, and material uniform mixing can be realized.

Owner:雅化集团雅安实业有限公司

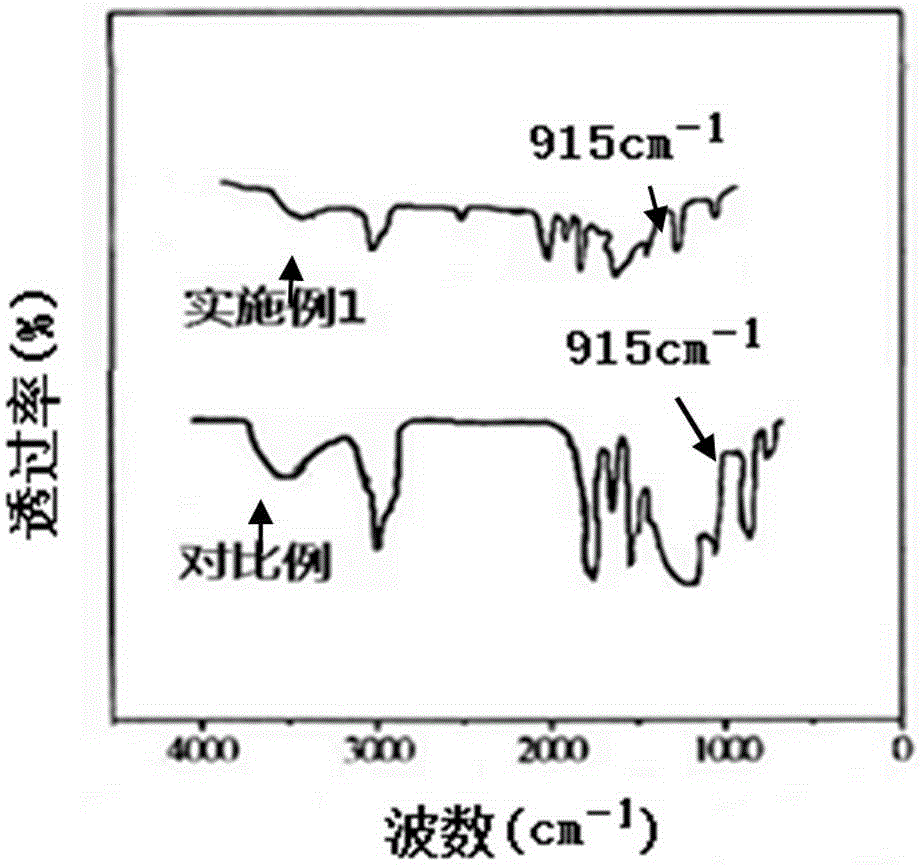

Epoxy resin microsphere and preparation method thereof

The invention discloses an epoxy resin microsphere and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 120-150 parts by weight of dispersed emulsifier polyether dibasic alcohol and 100 parts by weight of bisphenol A epoxy resin with the softening point of lower than 30 DEG C, adding ethylenediamine and other epoxy resin curing agents, curing, and naturally cooling to obtain an epoxy resin microsphere white emulsion; and cleaning the white emulsion, filtering and drying to obtain the epoxy resin microsphere. The particle size of the epoxy microsphere can be adjusted within the range of 800nm to 5 mu m according to different proportions of raw materials, and the obtained product has uniform particle size. Since no organic solvent is used and the raw materials and waste in the preparation process can be recovered and reutilized, the epoxy resin microsphere is green and environment-friendly. Meanwhile, the preparation method has the advantages of simple preparation technique, high yield, wide raw material sources and low cost, and is suitable for large-scale industrial production.

Owner:SUZHOU UNIV

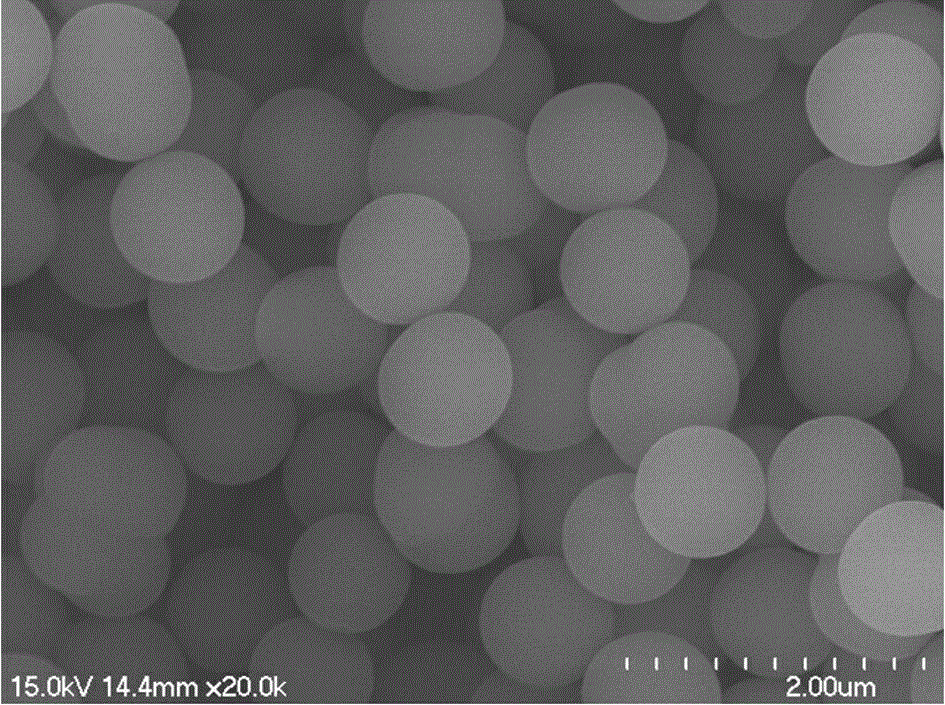

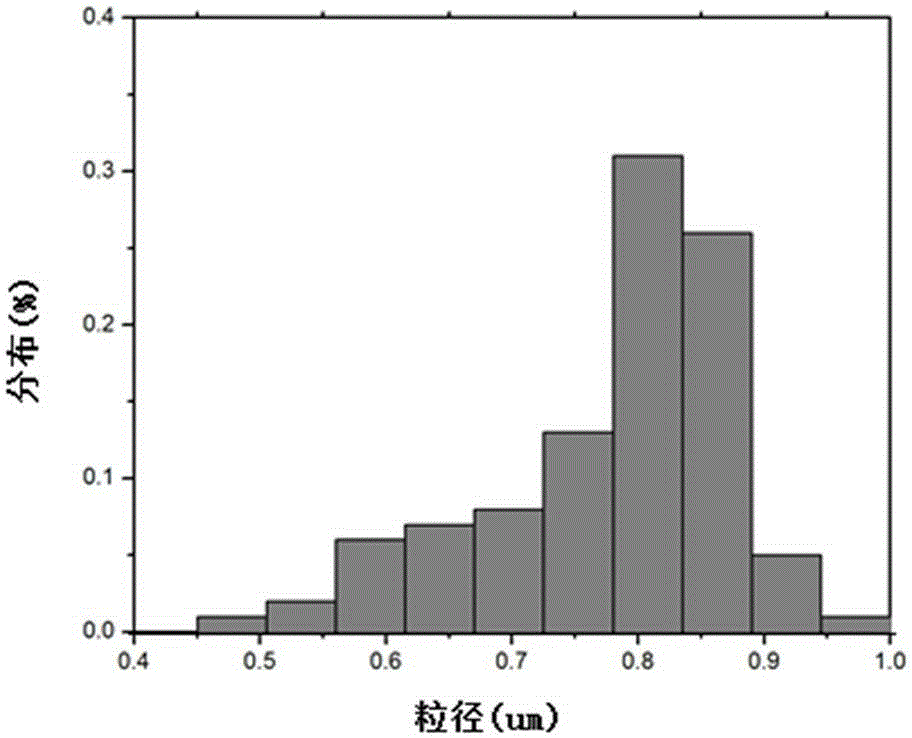

Preparation method of crosslinked polystyrene resin microspheres with narrow particle size distribution

The invention relates to a preparation method of crosslinked polystyrene resin microspheres with narrow particle size distribution. The technical scheme is as follows: the preparation method comprises the following steps: evenly mixing styrene, crosslinking agent, pore-forming agent and initiator to obtain a solution A; dissolving dispersant and surfactant in water to obtain a solution B; adding the solution A into the solution B to obtain a mixed solution, adding an alcohol solvent, and mixing the alcohol solvent and the mixed solution in a volume ratio of (10-30):(90-70) at 800-1200rpm to react for 4-5 hours at 75-85 DEG C (the temperature is raised in the reaction process), thereby obtaining a reaction solution containing the crosslinked polystyrene resin microspheres; and removing the supernatant by pouring, collecting the resin microspheres, washing with water, and eluting with ethyl acetate to obtain the finished product. The particle sizes of the crosslinked polystyrene resin microspheres are adjustable within the range of 53-350 micrometers; the sphericity is higher than 95%; and the preparation method is simple, and can easily implement industrialized mass production.

Owner:日照金慧科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com