Preparation method of crosslinked polystyrene resin microspheres with narrow particle size distribution

A technology for cross-linked polystyrene and resin microspheres, applied in the field of preparation of cross-linked polystyrene resin microspheres, can solve problems such as high price, and achieve the effects of simple operation, easy mass industrial production and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

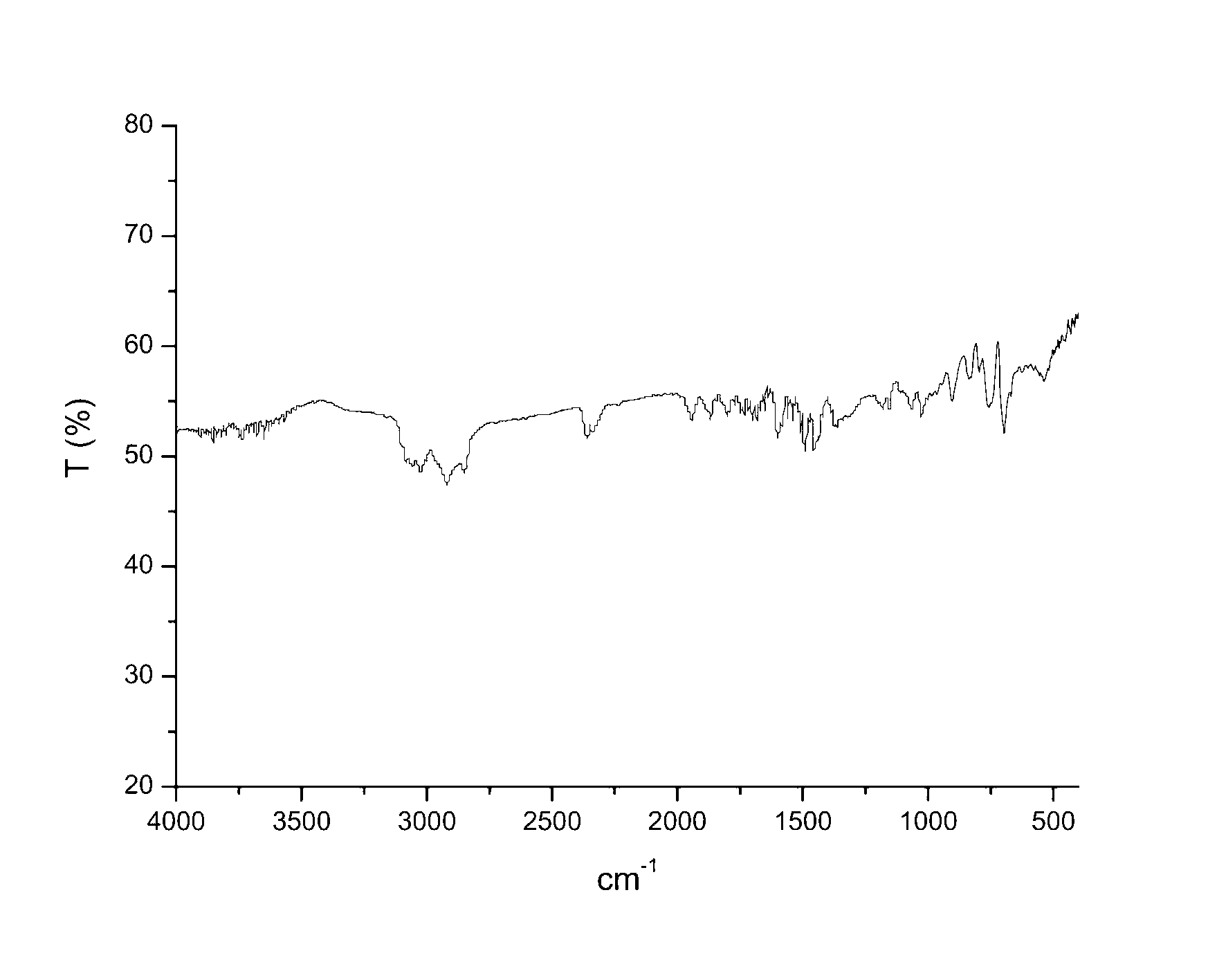

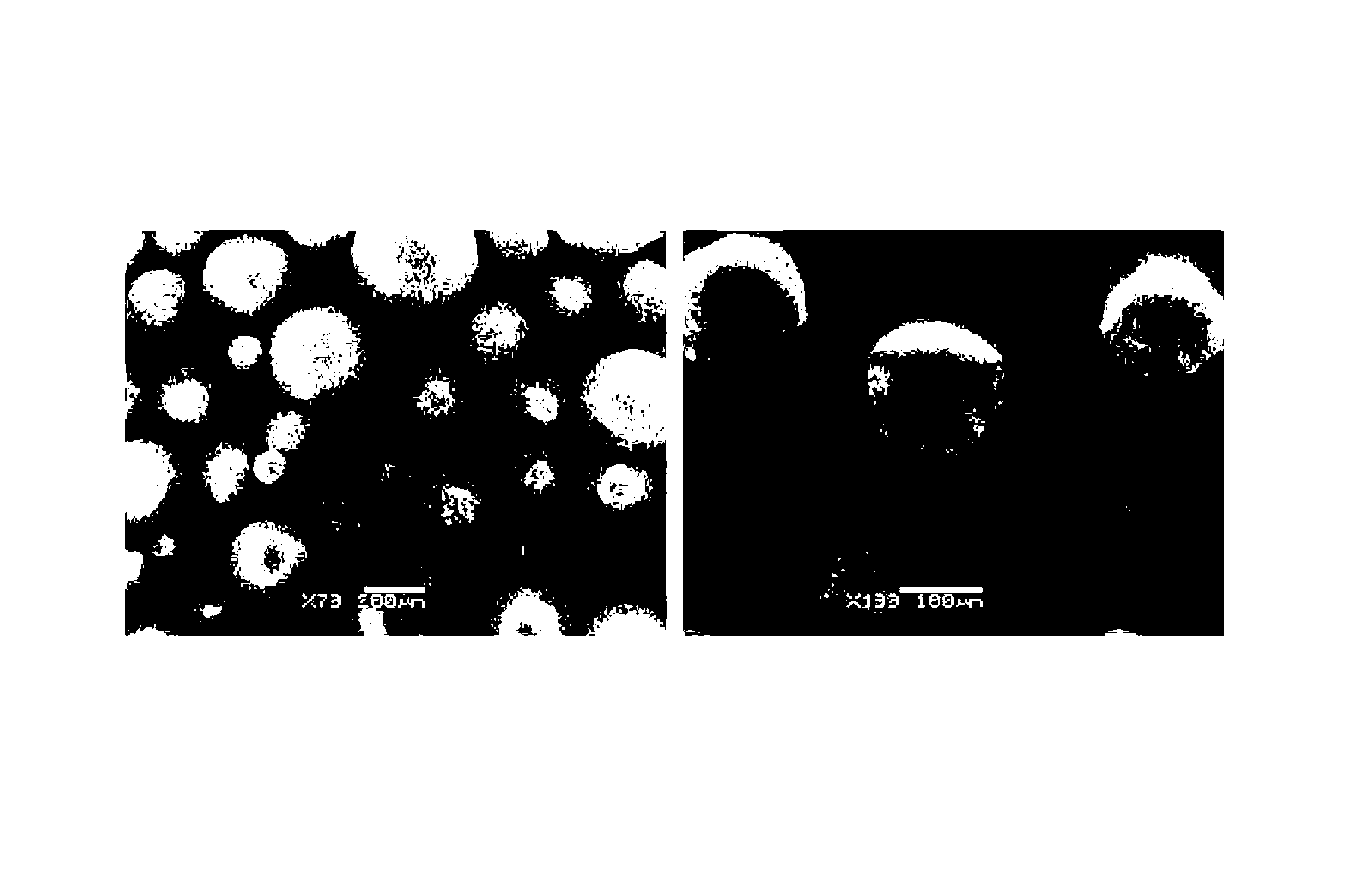

[0032] Example 1 A preparation method of cross-linked polystyrene resin microspheres with narrow particle size distribution

[0033] 1) Pretreatment: wash styrene and divinylbenzene three times with 20% NaOH aqueous solution respectively, and then wash three times with deionized water for later use;

[0034] 2) According to the weight ratio of styrene and crosslinking agent 80:20, after mixing 4g styrene, 1g crosslinking agent divinylbenzene and 2.5g porogen toluene, add 0.2g initiator azobisisobutyl Nitrile, fully dissolved to obtain liquid A;

[0035] 3) Add the dispersant gelatin and the surfactant OP-10 into water and dissolve completely to obtain liquid B. The concentration of gelatin in the liquid B is 3 g / L, and the concentration of OP-10 is 1.0 g / L;

[0036] 4) Add liquid A to liquid B to obtain a mixed liquid, then add alcohol solvent ethanol to the mixed liquid, control the volume ratio of ethanol and the mixed liquid to 10:90, stir at a speed of 900 rpm, and heat...

Embodiment 2

[0040] Example 2 A preparation method of cross-linked polystyrene resin microspheres with narrow particle size distribution

[0041] 1) Pretreatment: wash styrene and divinylbenzene three times with 20% NaOH aqueous solution respectively, and then wash three times with deionized water for later use;

[0042] 2) According to the weight ratio of styrene and crosslinking agent 80:20, after mixing 4g styrene, 1g crosslinking agent divinylbenzene and 2.5g porogen xylene, add 0.2g initiator benzyl peroxide acyl, fully dissolved to obtain liquid A;

[0043] 3) Add dispersant gelatin and surfactant AEO-9 into water and dissolve completely to obtain liquid B. The concentration of gelatin in liquid B is 3 g / L, and the concentration of AEO-9 is 1.0 g / L;

[0044] 4) Add liquid A to liquid B to obtain a mixed liquid, then add alcohol solvent n-propanol to the mixed liquid, control the volume ratio of n-propanol and mixed liquid to 10:90, stir at 900 rpm, and react During the process, t...

Embodiment 3

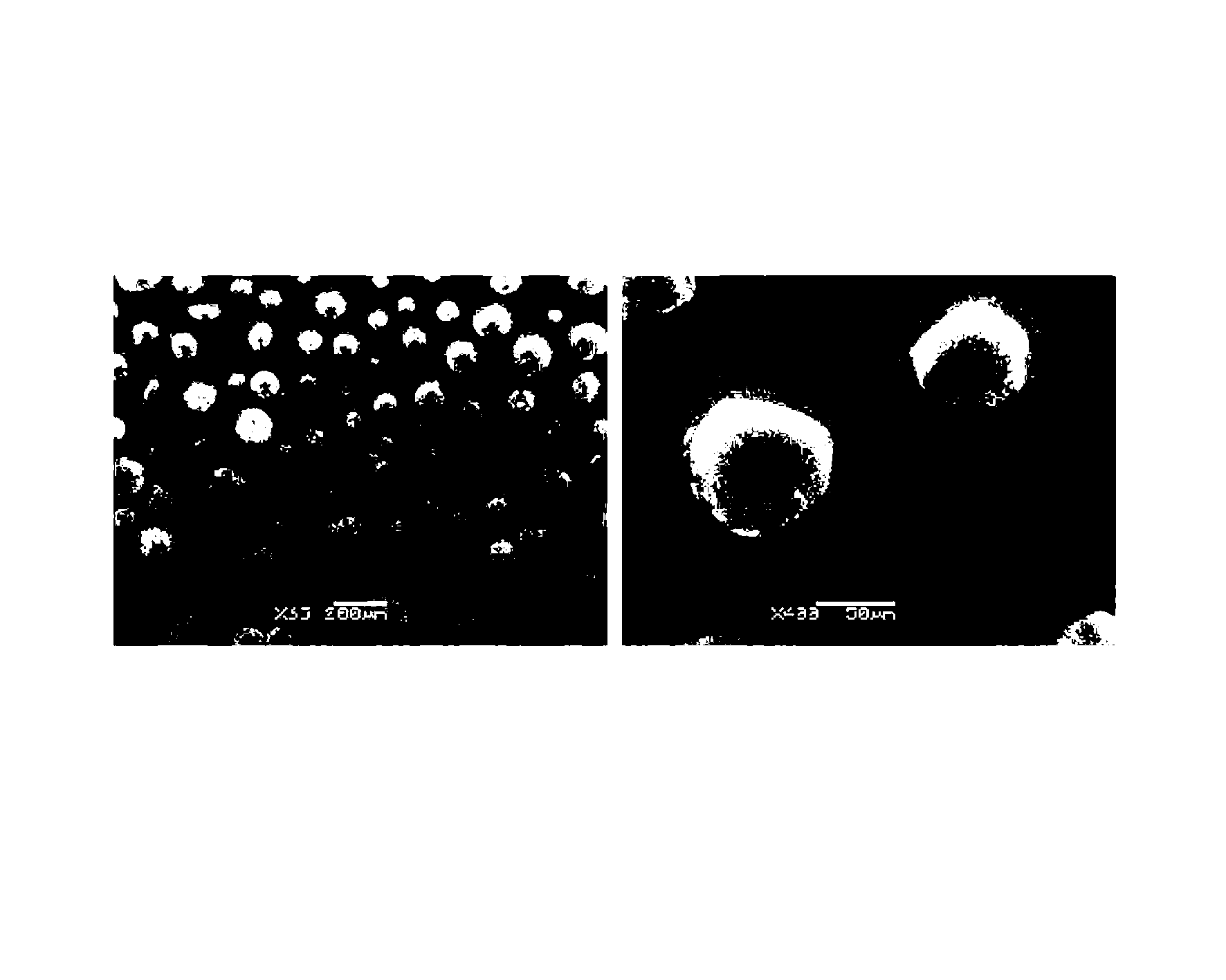

[0047] Example 3 A preparation method of cross-linked polystyrene resin microspheres with narrow particle size distribution

[0048] 1) Pretreatment: wash styrene and divinylbenzene three times with 20% NaOH aqueous solution respectively, and then wash three times with deionized water for later use;

[0049] 2) According to the weight ratio of styrene and crosslinking agent 90:10, after mixing 9g styrene, 1g crosslinking agent divinylbenzene and 2.0 g porogen toluene, add 0.3 g initiator azobisisobutyl Nitrile, fully dissolved to obtain liquid A;

[0050] 3) Add the dispersant gelatin and the surfactant OP-10 into water and dissolve completely to obtain liquid B. The concentration of gelatin in the liquid B is 4 g / L, and the concentration of OP-10 is 1.0 g / L;

[0051] 4) Add liquid A to liquid B to obtain a mixed liquid, then add alcohol solvent ethanol to the mixed liquid, control the volume ratio of ethanol and the mixed liquid to 30:70, stir at a speed of 900 rpm, and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com