Magnetic fluorescent Raman double-encoding composite microspheres and preparation method and application thereof

A Raman double-coded, composite microsphere technology, applied in the direction of microsphere preparation, Raman scattering, fluorescence/phosphorescence, etc., can solve the problems of difficult precise control, less SERS signal, etc., and achieve low cost, high luminous efficiency, light reduction Effects of low reproducibility and instability of small Raman signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

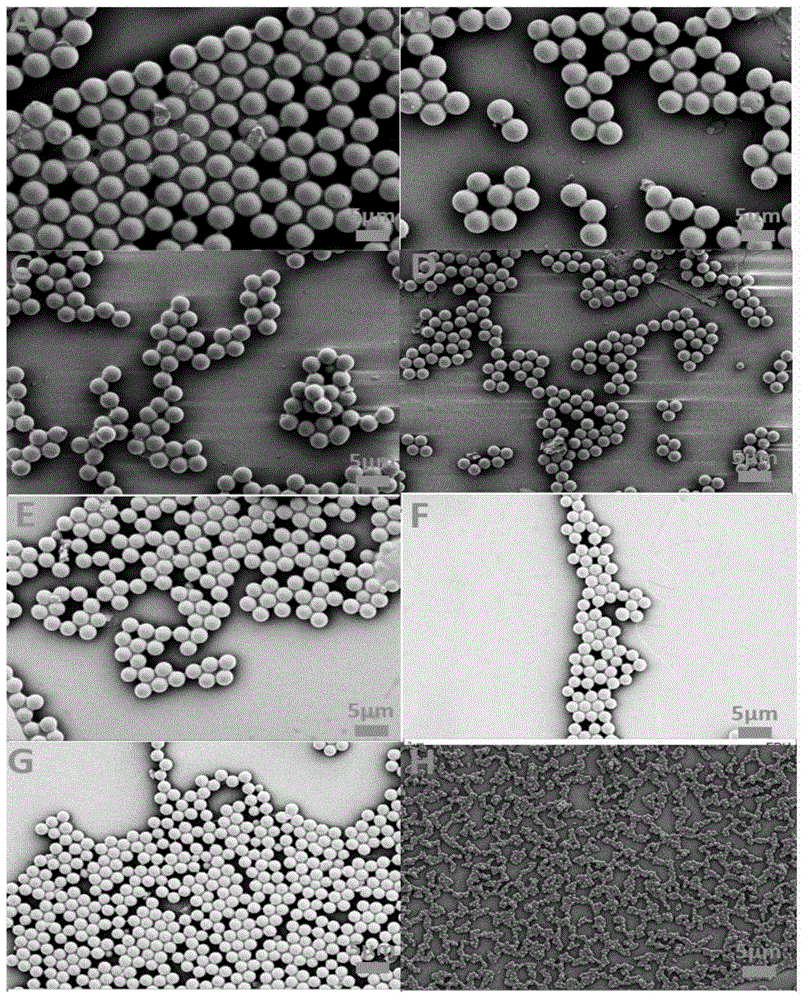

[0042] Example 1: Preparation of MF Microspheres of Different Sizes

[0043] 1. Preparation of MF balls with a particle size of 4 μm

[0044] Take 0.625g of melamine, 4.9ml of formaldehyde solution, disperse in 60ml of deionized water, pre-polymerize at 70°C for 0.5h, add 1μl of formic acid, continue mechanical stirring for 2h, let stand, remove the upper emulsion, and repeatedly wash the product with ethanol and water centrifuge , and vacuum-dried to prepare MF microspheres with a particle size of 4 μm.

[0045] 2. Preparation of MF balls with a particle size of 0.4 μm

[0046] The content of formic acid in the above reaction conditions was changed to 50 μl to obtain MF microspheres with a particle size of 0.4 μm.

Embodiment 2

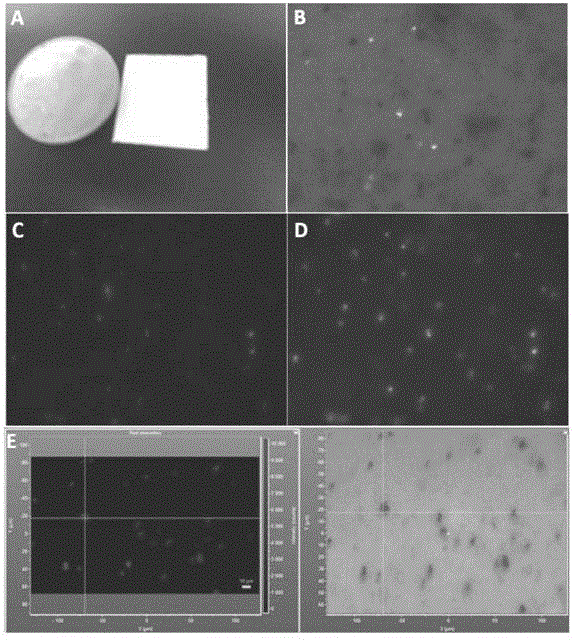

[0047] Example 2: Mixed adsorption of FMF microspheres and ferrofluid with different feeding ratios

[0048] Mix FMF microspheres and ferrofluid mass ratios in 9:1, 6:1, 3:1, 1:1, 1:3 and 1:6 in 20ml of ethanol, and incubate in a shaker at 30°C and 180rpm 3h, the obtained product was first centrifuged and washed to separate the unadsorbed magnetic fluid, and then magnetically separated to remove the FMF microspheres that did not absorb enough magnetic fluid. It was found that the magnetic enrichment rate of 3:1 feed ratio was faster (about 40s), and the magnetic enrichment rate did not increase significantly with the increase of feed ratio, and the excessive magnetic fluid adsorbed on the surface would hinder the subsequent deposition of silver nanoparticles.

Embodiment 3

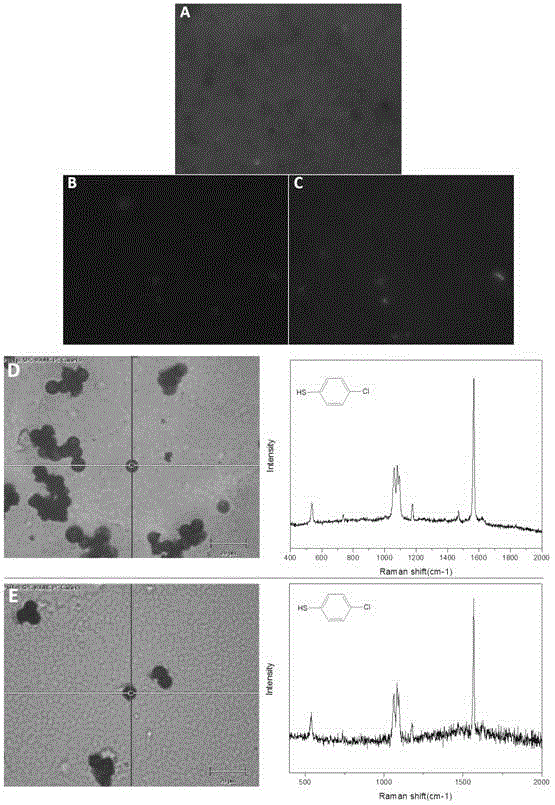

[0049] Example 3: Detection of different concentrations of 4-ABT by double-coded composite microspheres

[0050] The obtained composite microspheres were dried, and 10 mg microspheres were mixed with 15 ml different concentrations (10 -11 -10 -3 g / L) of 4-ABT ethanol solution was added to the centrifuge tube, and incubated in a shaker for 2 hours. Afterwards, the SERS signal of the sample was detected by a Raman spectrometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com