Preparation method of lithium titanate-graphene combination electrode material

A graphene composite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited improvement in conductivity and no increase in specific capacity, and achieve high specific capacity, good performance in large rate, and simple preparation process flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

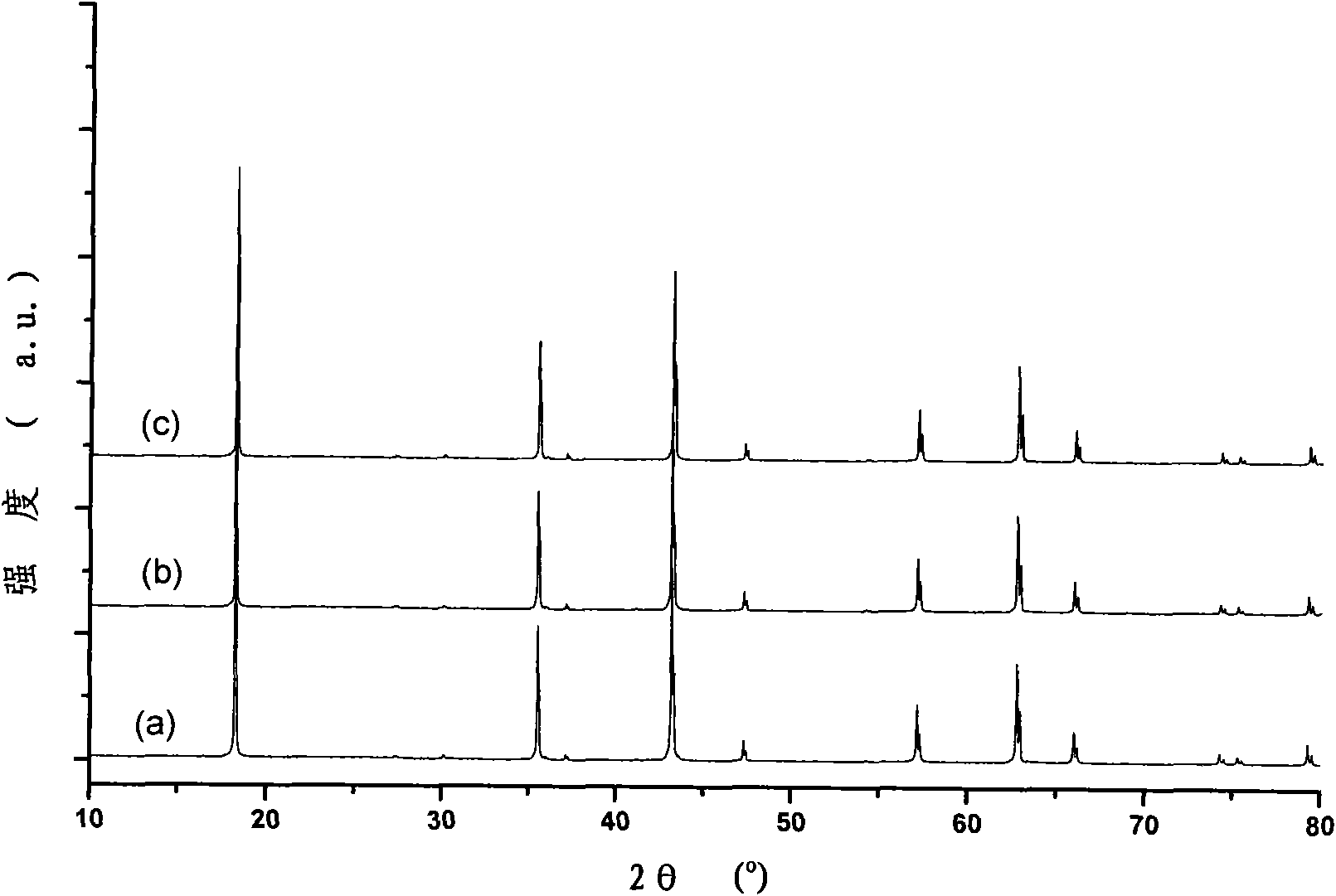

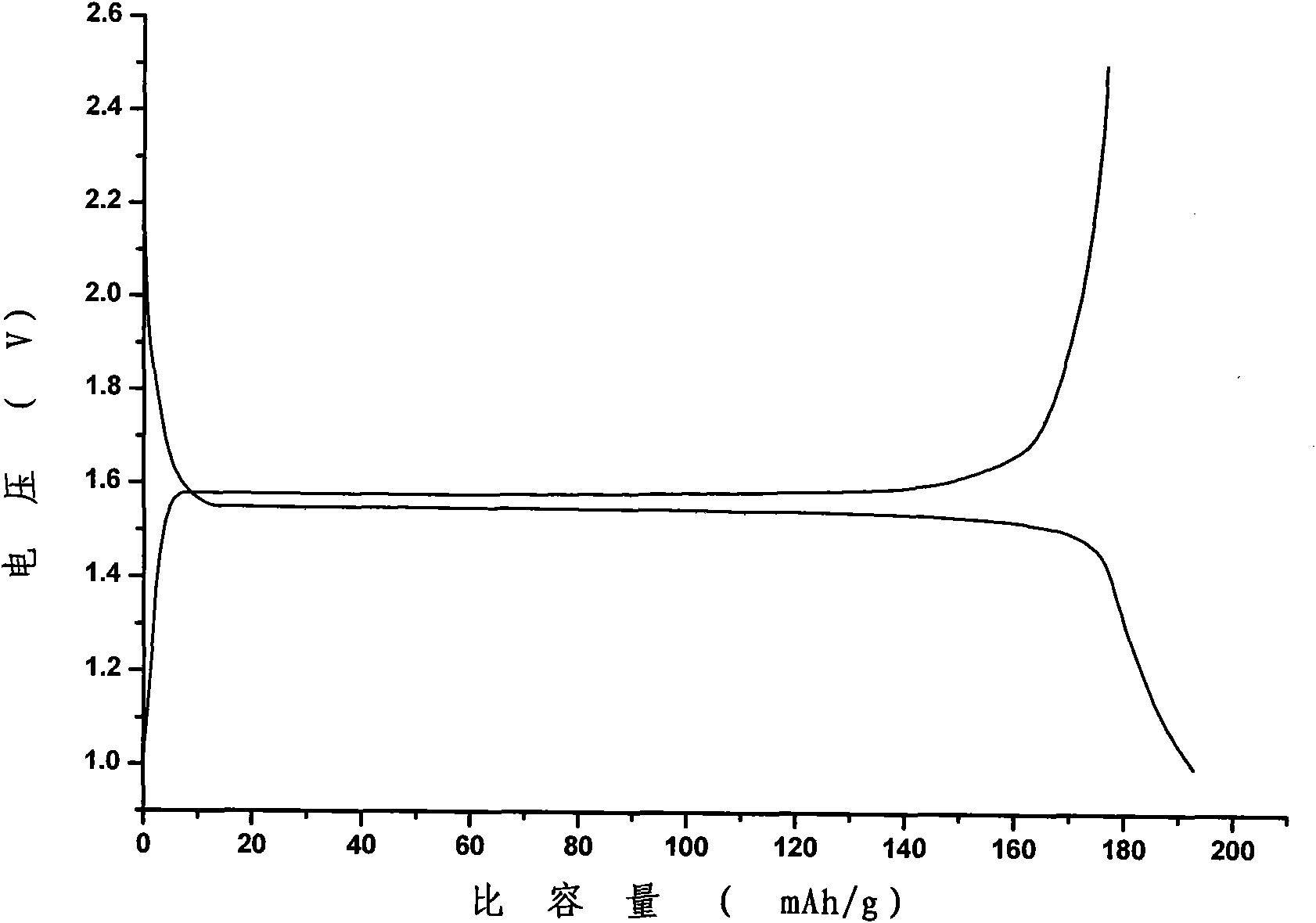

[0025] Weigh 3.9975 grams of anhydrous lithium acetate and 23.9539 grams of tetrabutyl titanate at a molar ratio of Li:Ti=0.86:1, and use ethanol as a dispersant to dissolve anhydrous lithium acetate and tetrabutyl titanate in In ethanol, mix the two solutions with stirring. 10ml of acetic acid was added dropwise. Stir at a constant temperature for 4 hours at 80°C to obtain the precursor, and dry at 120°C to obtain the precursor. The precursor was dispersed in deionized water to form a suspension, and the suspension was spray-dried to obtain a powder. The temperature of the hot air was 140°C. Raise the temperature to 800°C at 5°C / min in a muffle furnace, keep the temperature constant for 12h, cool down to room temperature naturally, grind, and pass through a 150-mesh sieve to obtain nano-lithium titanate powder. Lithium titanate with a single spinel structure after X-ray powder diffraction (XRD) test, see figure 1 (a).

[0026] Mix 2.0002g of natural flake graphite and 2.0...

Embodiment 2

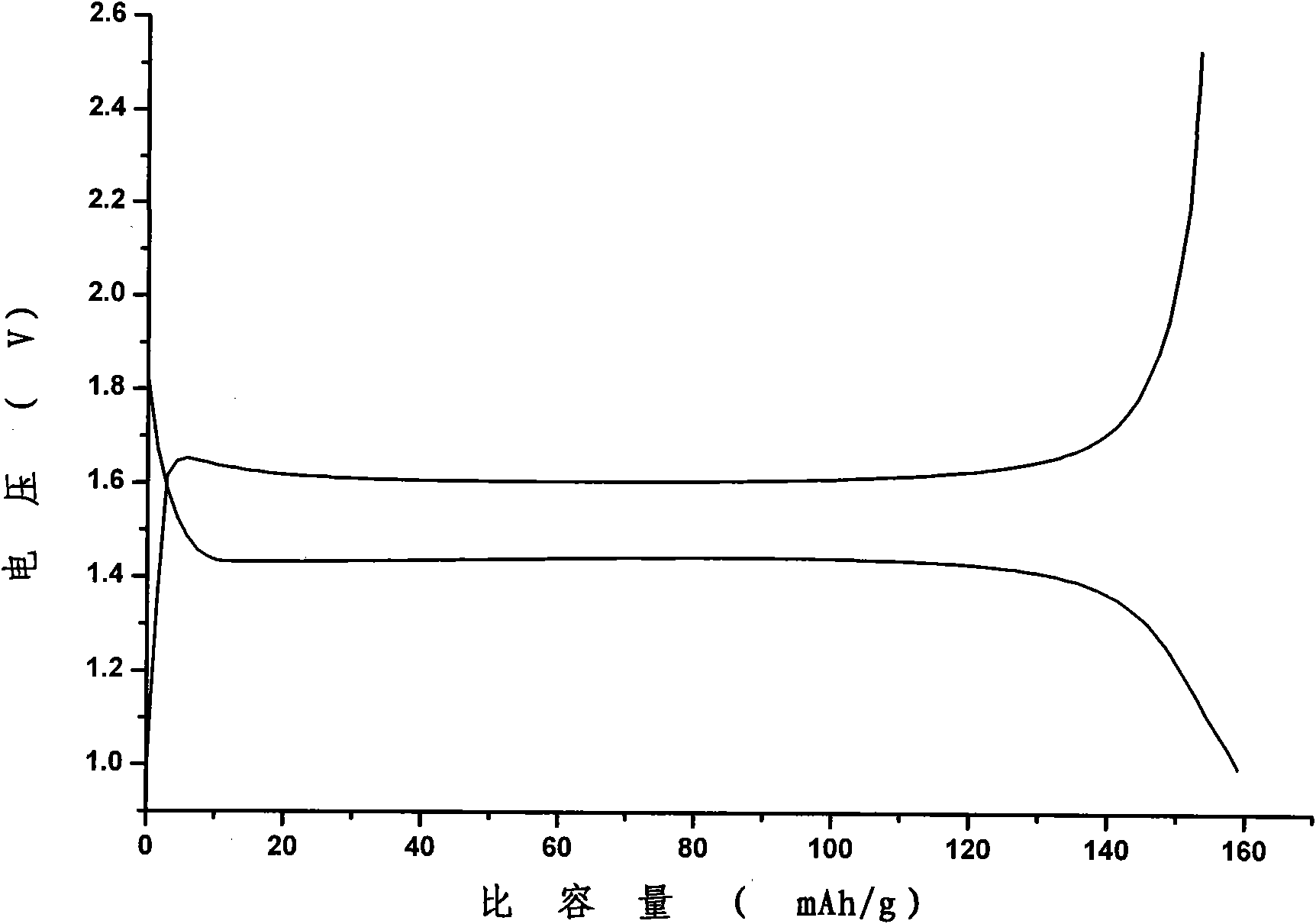

[0031] Weigh 4.3015 grams of anhydrous lithium acetate and 27.2309 grams of tetrabutyl titanate at a molar ratio of Li:Ti=0.81:1, and use ethanol as a dispersant to dissolve anhydrous lithium acetate and tetrabutyl titanate in In ethanol, mix the two solutions with stirring. 10ml of acetic acid was added dropwise. Stir at a constant temperature for 10 hours at 40°C to obtain a precursor, and dry at 80°C to obtain a precursor. The precursor was dispersed in deionized water to form a suspension, and the suspension was spray-dried to obtain a powder. The temperature of the hot air was 140°C. Raise the temperature to 1000°C at a rate of 5°C / min in a muffle furnace, keep the temperature constant for 6 hours, cool down to room temperature naturally, grind, and pass through a 150-mesh sieve to obtain nano-lithium titanate powder.

[0032] Mix 2.0006g of natural flake graphite and 2.0021g of sodium nitrate, add 120ml of concentrated sulfuric acid solution, stir in an ice-water bath ...

Embodiment 3

[0036] Weigh 6.2043 grams of anhydrous lithium acetate and 40.0000 grams of tetrabutyl titanate at a molar ratio of 0.8:1, and use ethanol as a dispersant to dissolve the anhydrous lithium acetate and tetrabutyl titanate in ethanol respectively, and stir Mix the two solutions. 10ml of acetic acid was added dropwise. Stir at a constant temperature for 8 hours at 60°C to obtain a precursor, and dry at 100°C to obtain a precursor. The precursor was dispersed in deionized water to form a suspension, and the suspension was spray-dried to obtain a powder. The temperature of the hot air was 140°C. Raise the temperature to 700°C at 5°C / min in a muffle furnace, keep the temperature constant for 18h, cool down to room temperature naturally, grind, and pass through a 150-mesh sieve to obtain nano lithium titanate powder.

[0037] Mix 1.9998g of natural flake graphite and 2.0007g of sodium nitrate, add 100ml of concentrated sulfuric acid solution, stir in an ice-water bath for 20 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com