Patents

Literature

58results about How to "Uniform product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

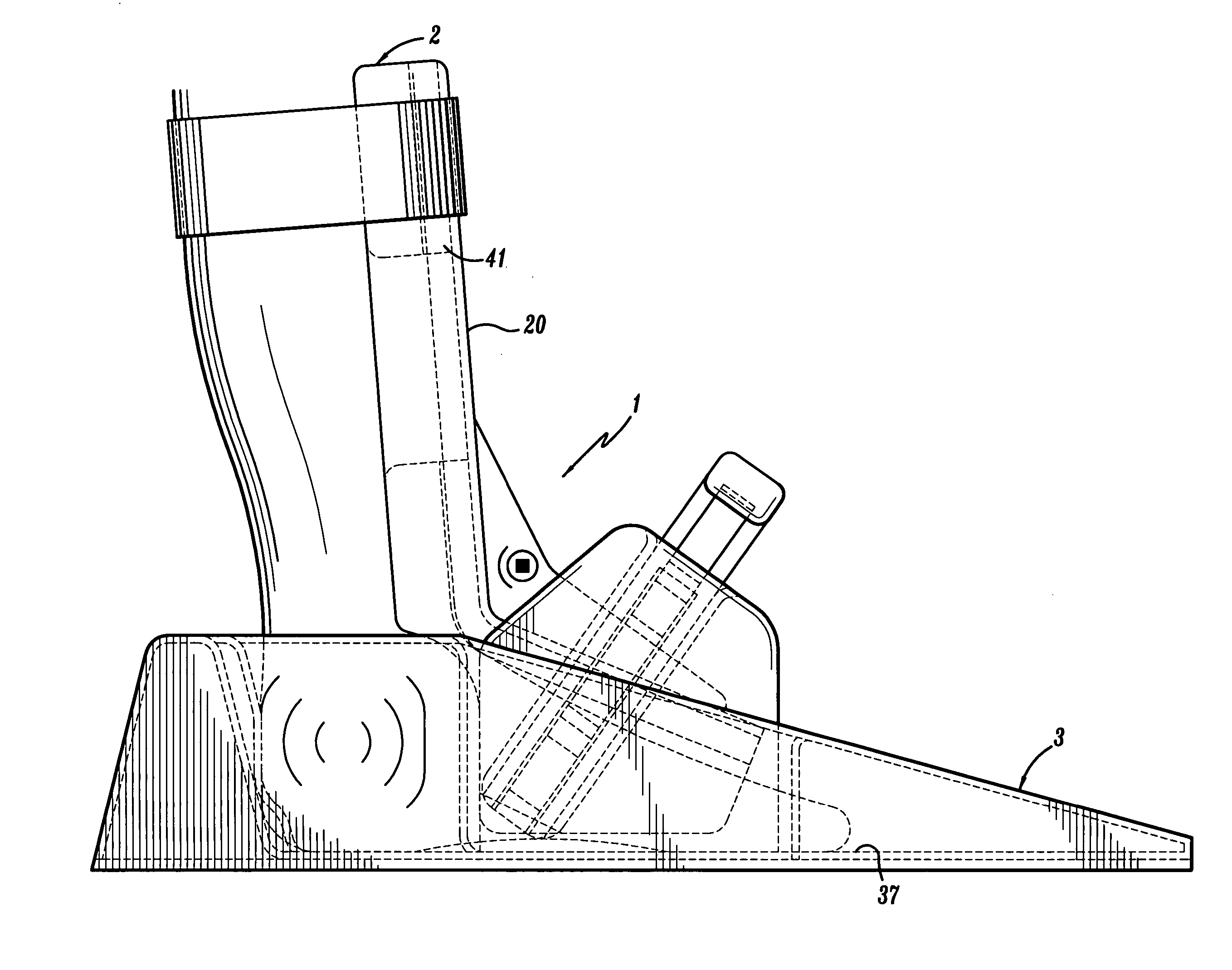

Architectural lighting

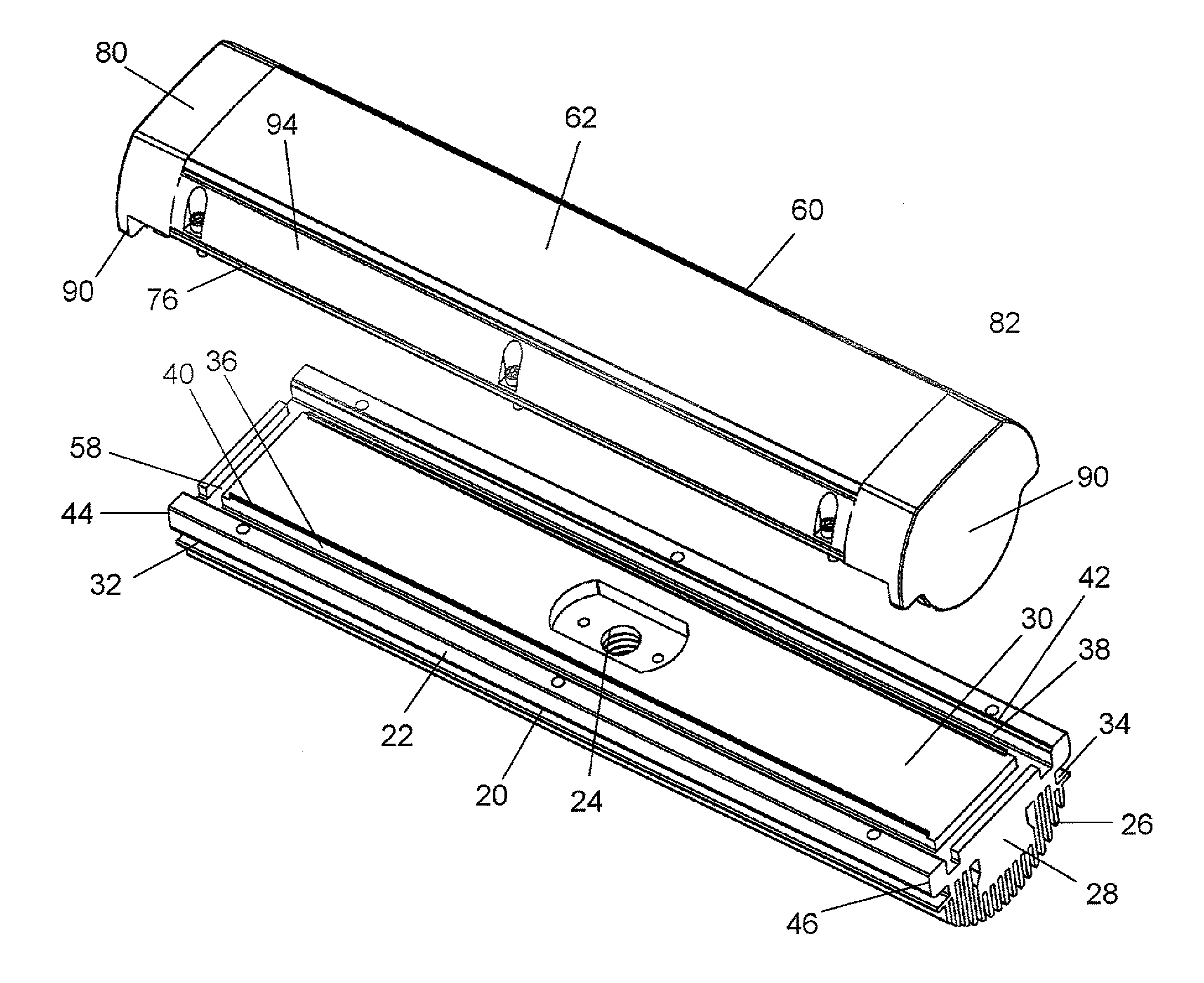

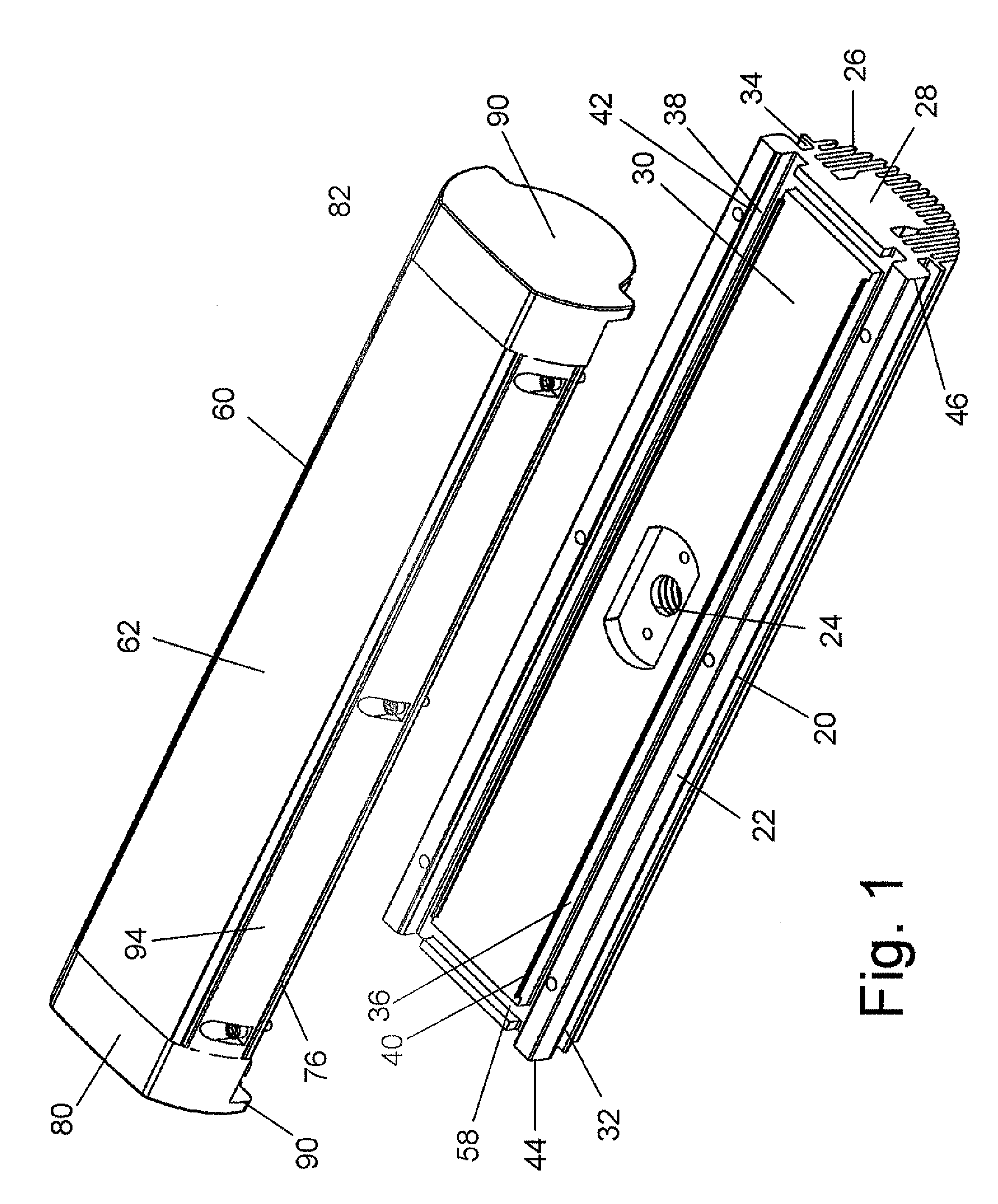

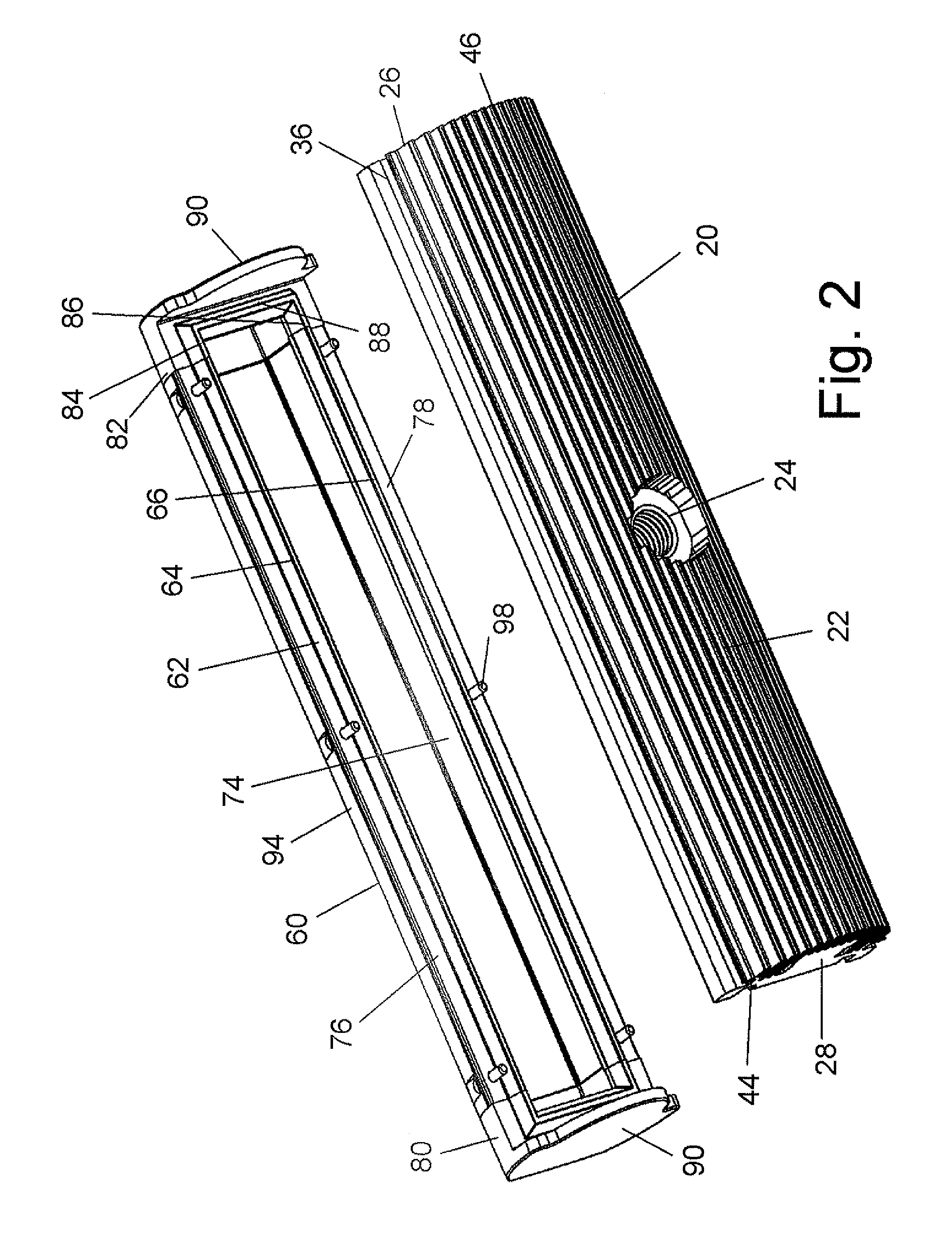

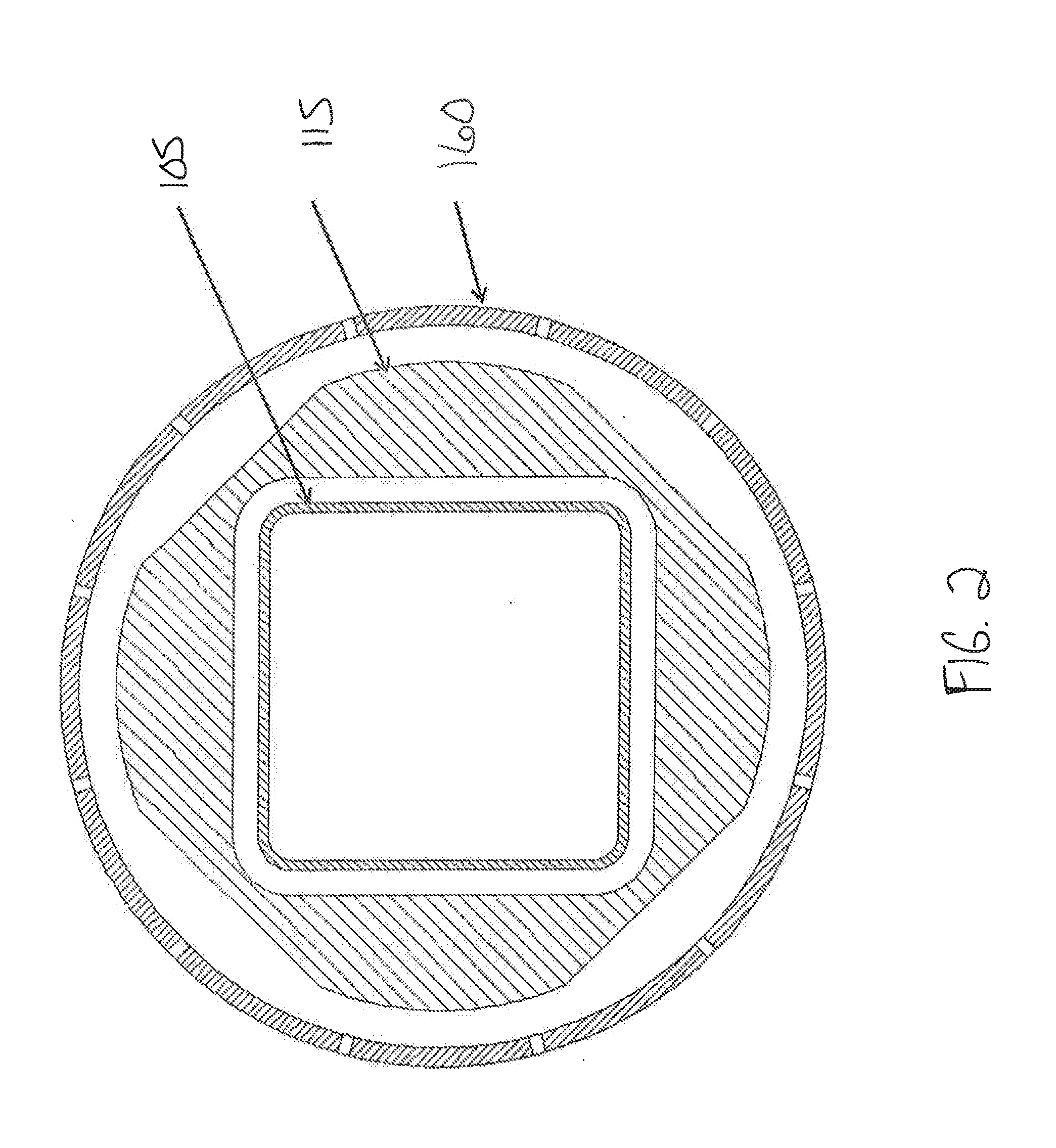

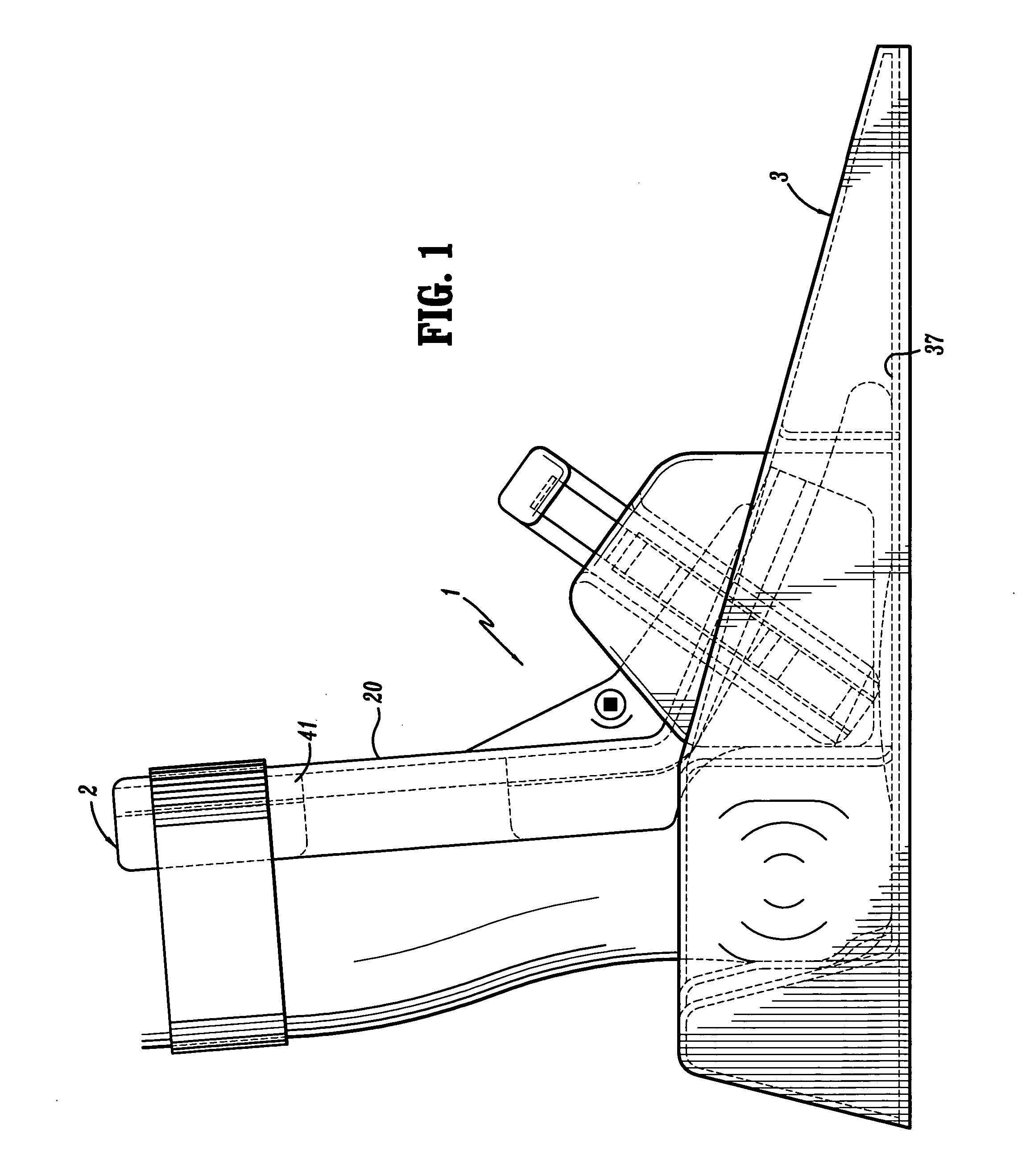

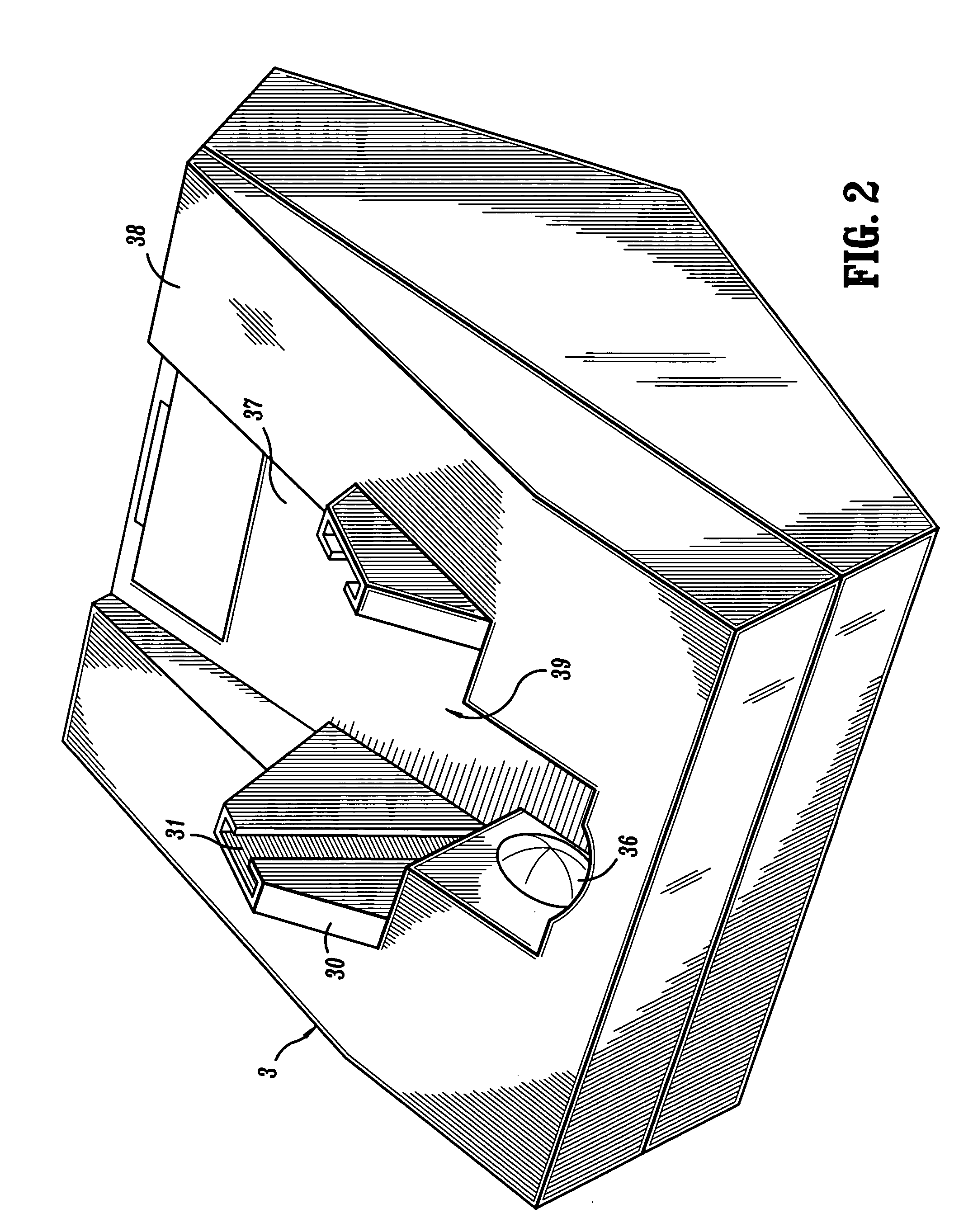

ActiveUS20110141722A1Uniform productNeed can be easilyMechanical apparatusPoint-like light sourceIn planeEffect light

An LED light fixture includes a housing, a lens and a flexible gasket there between. Each of the housing and the lens has an elongate main body and two ends sealingly fixed to the main body. The assembly of components in the housing defines a sealing channel rectangular in plan and the lens similarly defines a sealing ridge. A mounting plate with light emitting diodes distributed on the mounting plate further includes a manifold plate positioned on the mounting plate which includes holes therethrough with reflectors about the holes to receive the light emitting diodes. Mounts supporting the elongate housing define longitudinally adjustable engagements with the housing. The mounts further include tracks arranged in arcs of circles located in planes perpendicular to the extension of the elongate housing. Munting brackets engage these tracks using retainers.

Owner:ABL IP HLDG

Infant formula with improved protein content

InactiveUS6863918B2Promote absorptionPrevent and reduce regurgitationVitamin food ingredientsHydrolasesHydrolysateConstipation

An improved infant formula resulting in reduced constipation, abdominal discomfort and gastrointestinal problems, comprises at least one protein component having a phosphorus content of less than 0.75 g P / 100 g protein, and at least one lipid component that can be easily digested by an infant. Preferably, it further comprises at least one prebiotic component, and at least one viscosity-improving component. The protein fraction of the formula is preferably a hydrolysate prepared by hydrolysing a protein starting material, especially a whey protein with a combination of at least one endo- and at least one exoproteinase.

Owner:NUTRICIA

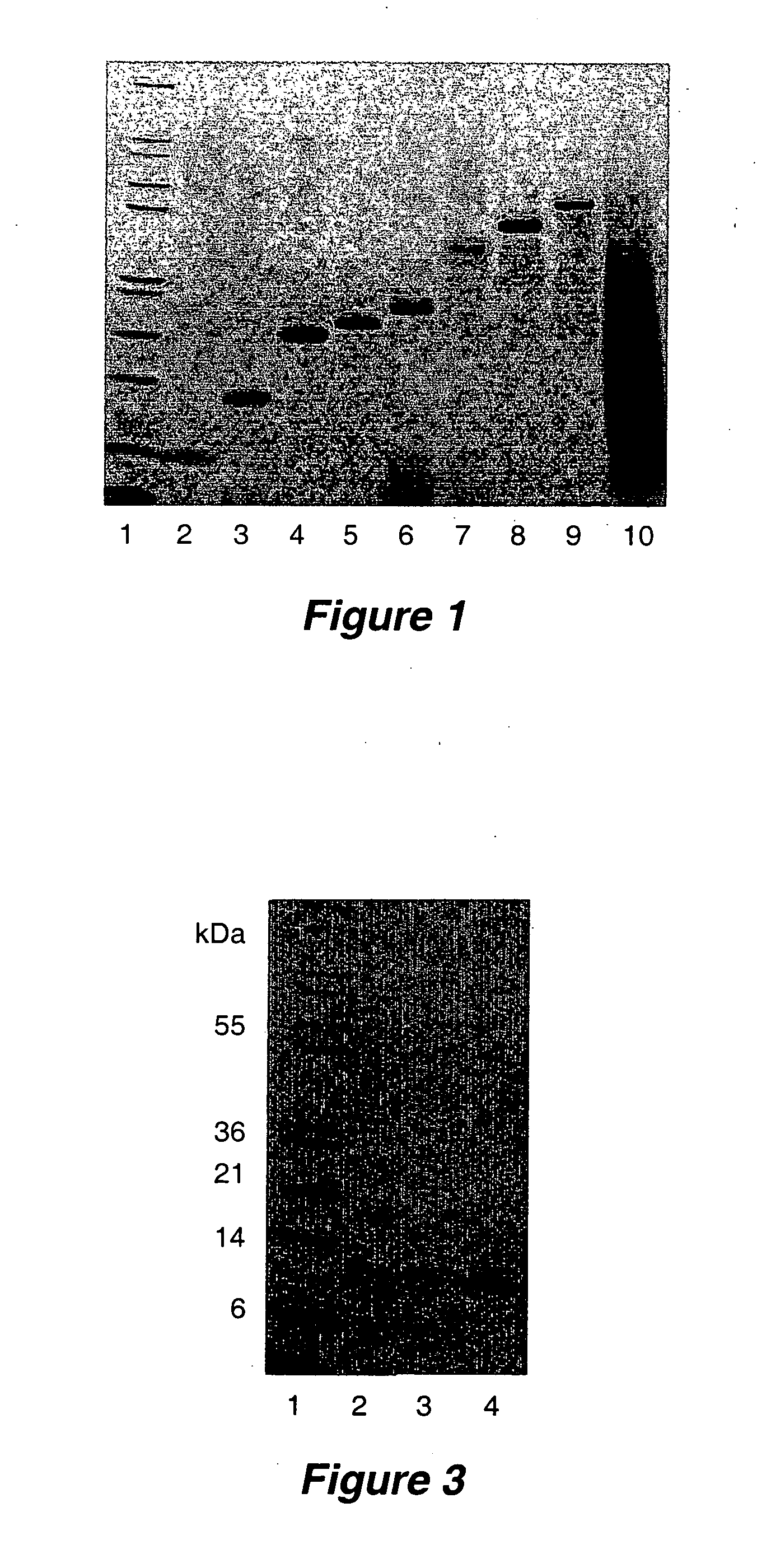

Recombinant gelatins

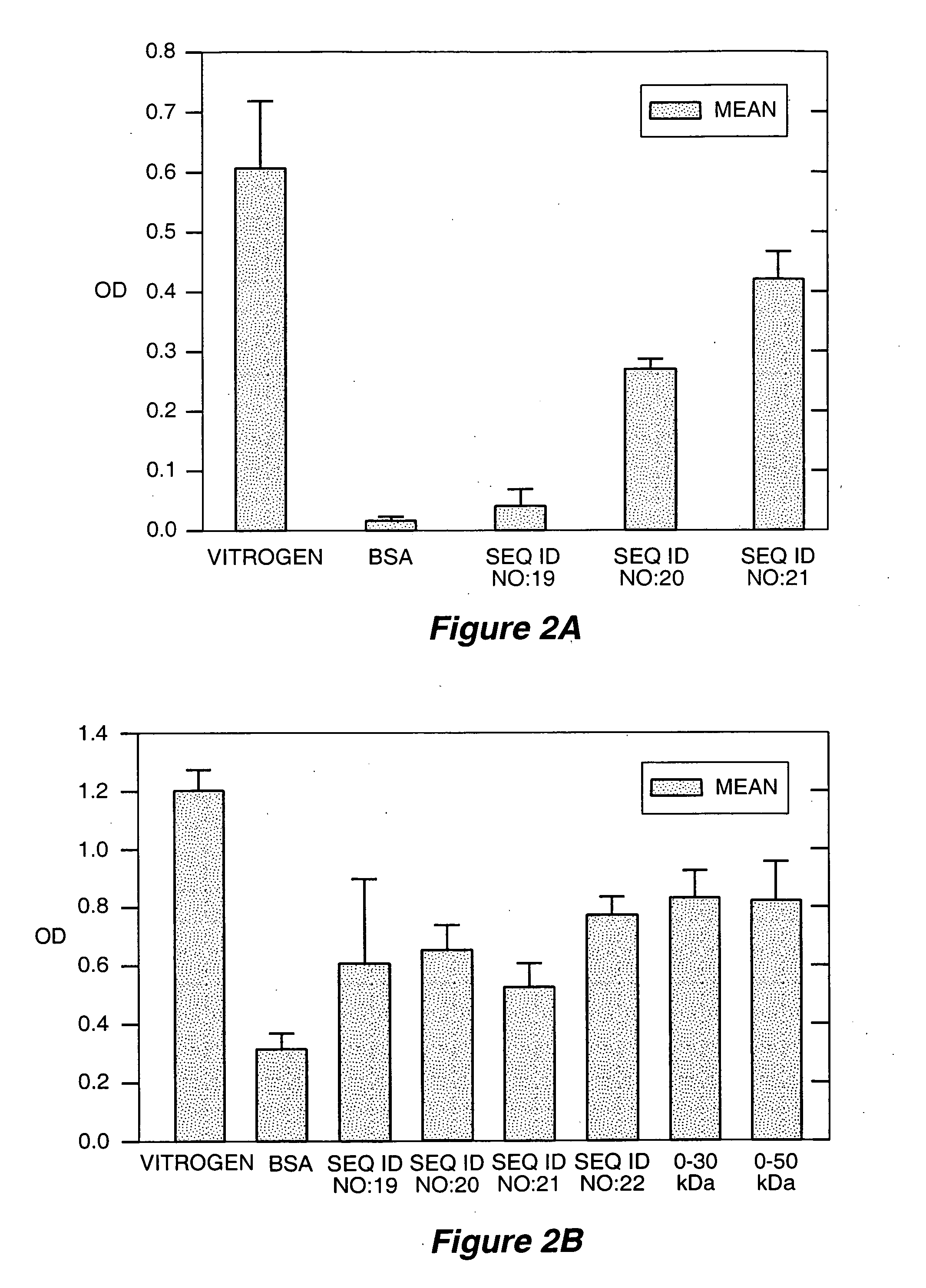

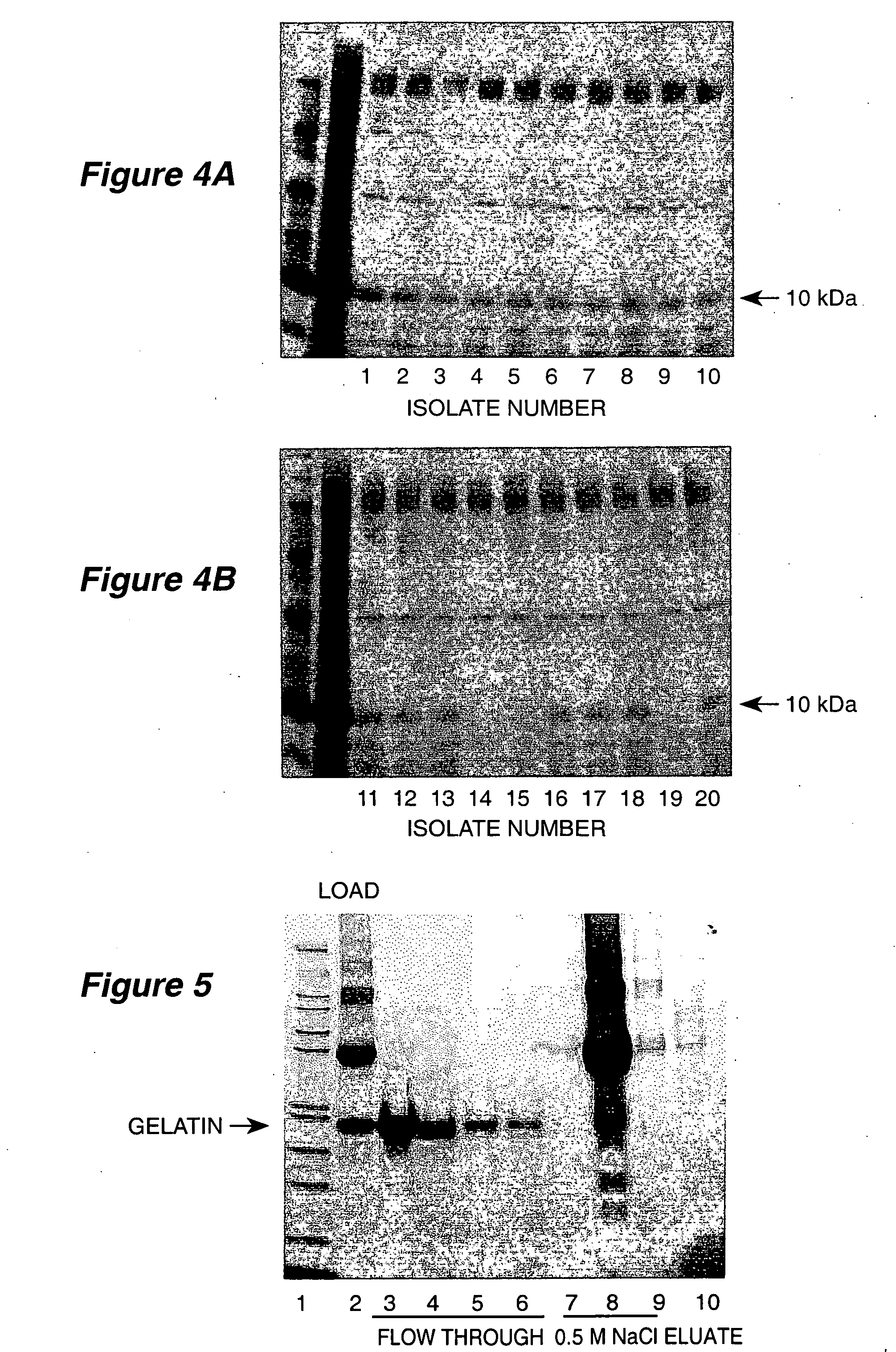

InactiveUS20050229264A1Uniform productStable quantityAntibacterial agentsPowder deliveryBiotechnologyGelatin product

Owner:FIBROGEN INC

Preparation method of super-retarding type polycarboxylate superplasticizer

The invention discloses a preparation method of a super-retarding type polycarboxylate superplasticizer. The super-retarding type polycarboxylate superplasticizer comprises a copolymer and water serving as a solvent, wherein the copolymer comprises an unsaturated polyether macromonomer, an unsaturated carboxylic acid / anhydride mini-monomer, an unsaturated sulfonic acid mini-monomer and an unsaturated phosphonic acid mini-monomer; the pH is 6-7. According to the preparation method, a phosphonate structure capable of retarding is introduced into a water reducer molecular structure; the prepared super-retarding type polycarboxylate superplasticizer can be directly applied to the concrete which needs a relatively long setting time, and thus the process of compounding a retarder can be saved, the production efficiency can be improved, the obtained product is uniform and stable, and abnormal concrete setting time can be avoided.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Alumina abrasive for chemical mechanical polishing

InactiveUS20050194358A1Reduce amountSlowing rate of settlingPigmenting treatmentOther chemical processesCompound (substance)Slurry

Methods of manufacturing alumina abrasive for use in chemical mechanical polishing are described, wherein the abrasive is in a slurry having gamma alumina formed in a low temperature fuming process, water, an acid sufficient to maintain the pH below about 7, wherein the slurry does not settle appreciably in an 8 to 24 hour period. Advantageously, the alumina is wet-milled without the use of wet-milling salt additives.

Owner:VERSUM MATERIALS US LLC +1

Polymerizable macrocyclic oligomer masterbatches containing dispersed fillers

Composites of macrocyclic oligomers and a filler material are made in a masterbatch process. The masterbatch contains at least 15% by weight of the filler material. The filler material is preferably a submicron sized material and is especially a clay or other layered material that can become at least partially exfoliated. The masterbatch can be let down into more of the macrocyclic oligomer, another polymer, another polymerizable material and subjected to polymerization conditions to form a nanocomposite material. Alternatively, the masterbatch can be polymerized to a high or intermediate molecular weight, and then blended with additional oligomer, polymer or other polymerizable material.

Owner:PAQUETTE MICHAEL STEVEN +5

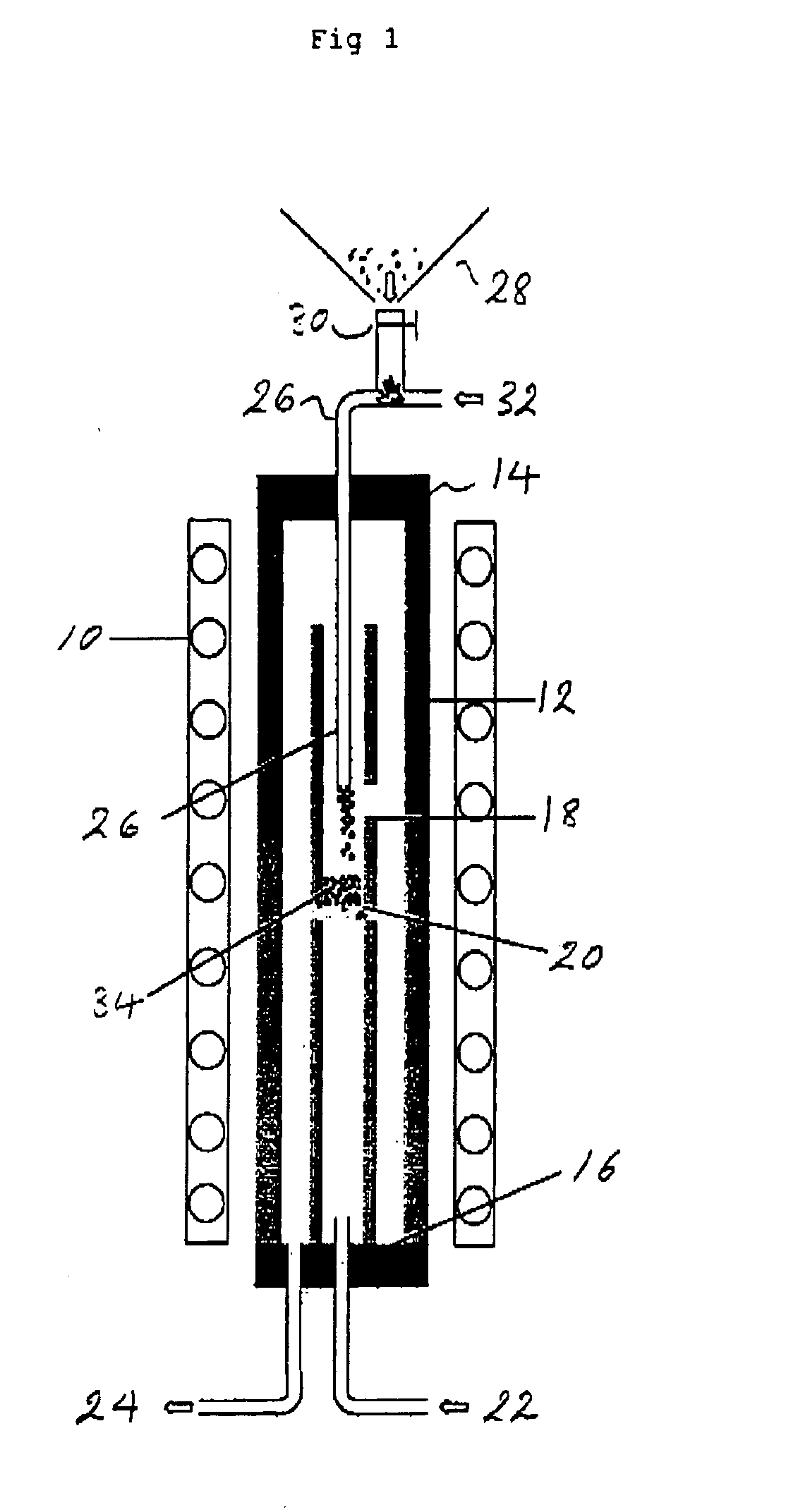

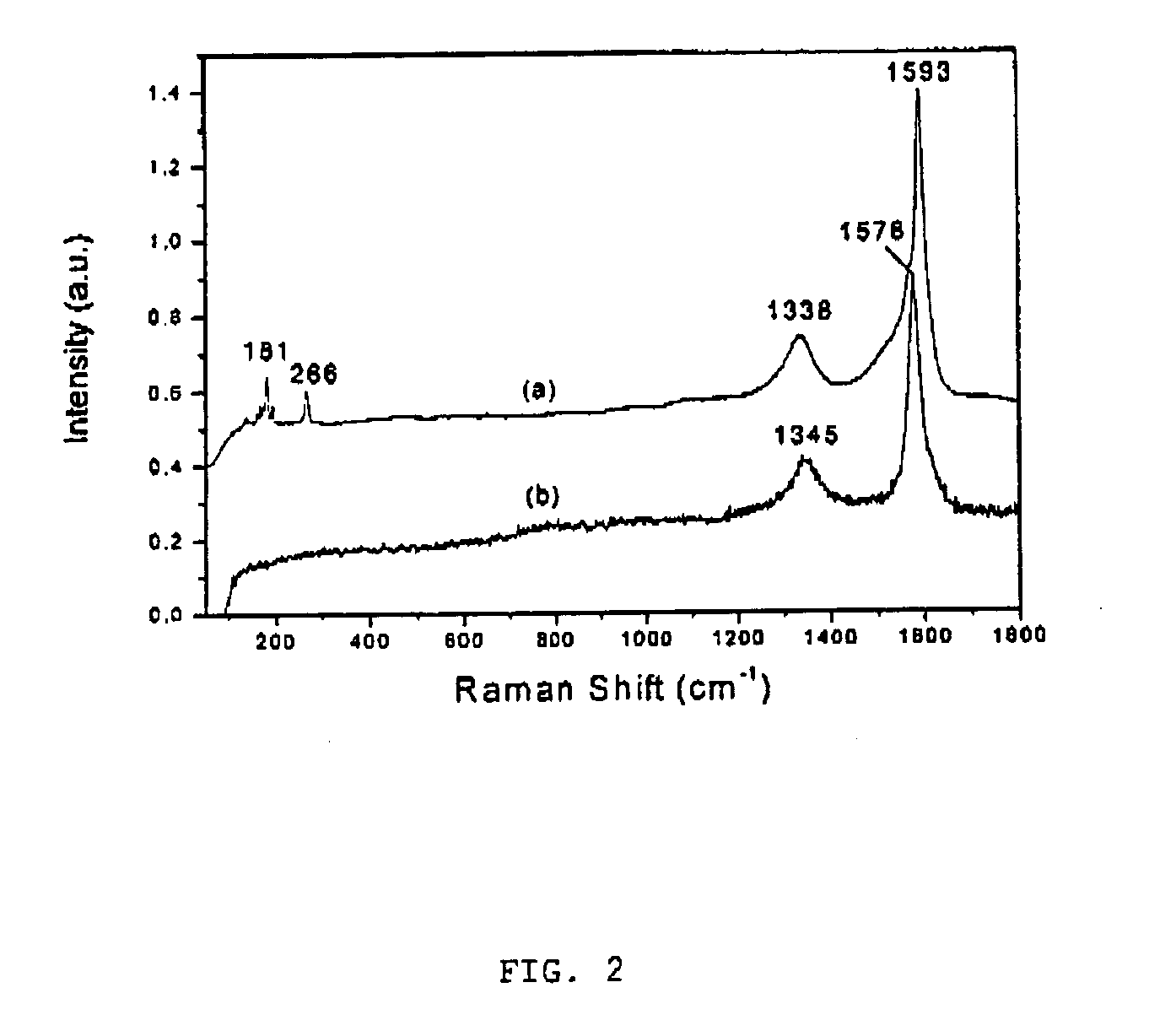

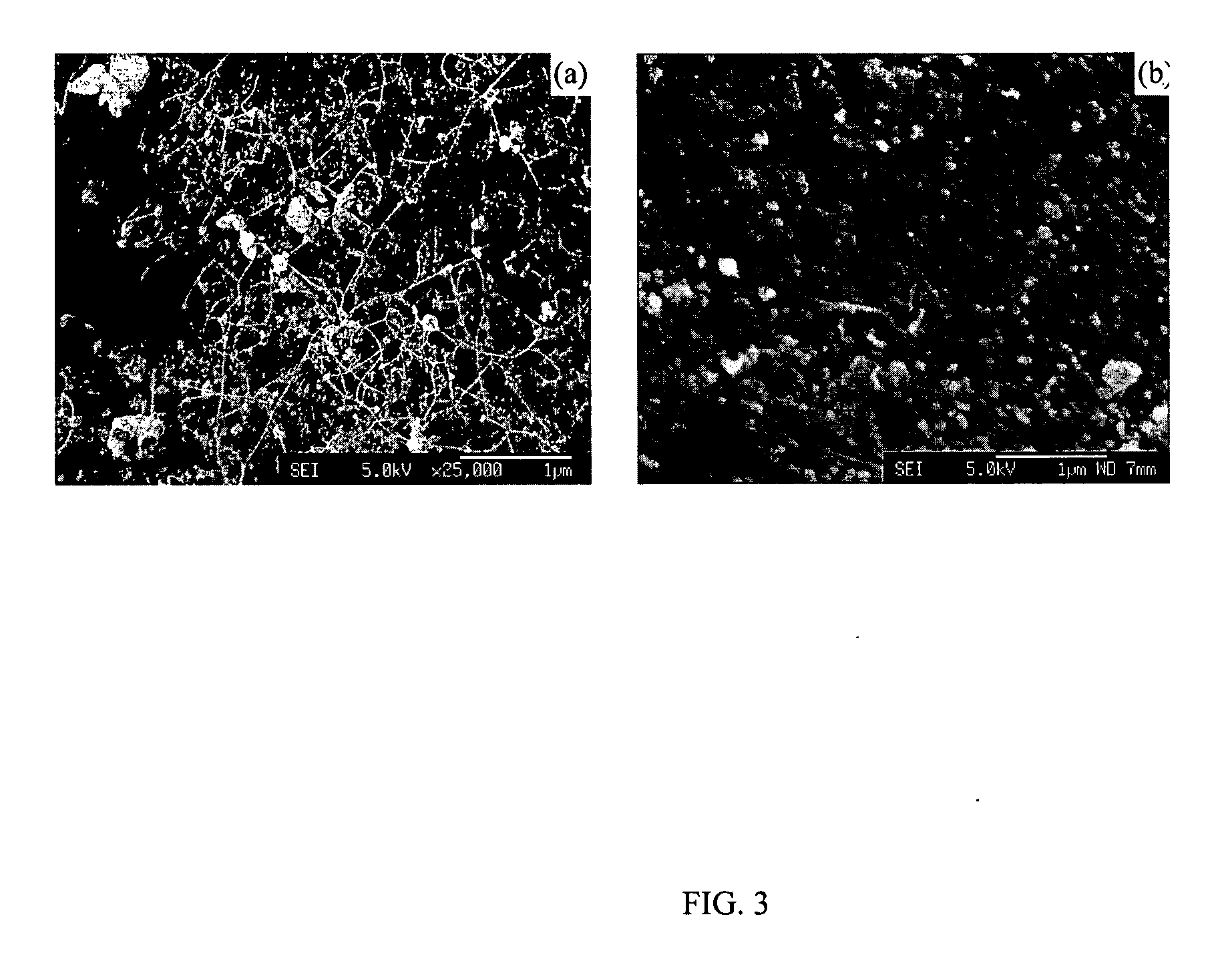

Method of producing carbon nanoparticles

InactiveUS20050063891A1Enhancing gas-solid mixingImprove reaction efficiencyMaterial nanotechnologyMulti-walled nanotubesFluidized bedCarbon Nanoparticles

A method of producing carbon nanoparticles comprises the steps of: passing a gaseous carbon source through a heated reactor; and adding catalyst supported on substrate particles or thermally decomposable catalyst precursor supported on substrate particles to the heated reactor to form a fluidised bed; such that carbon nanoparticles are formed in the heated reactor.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD

Amperometric sensors using synthetic substrates based on modeled active-site chemistry

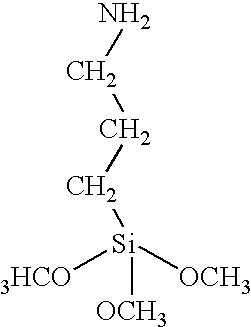

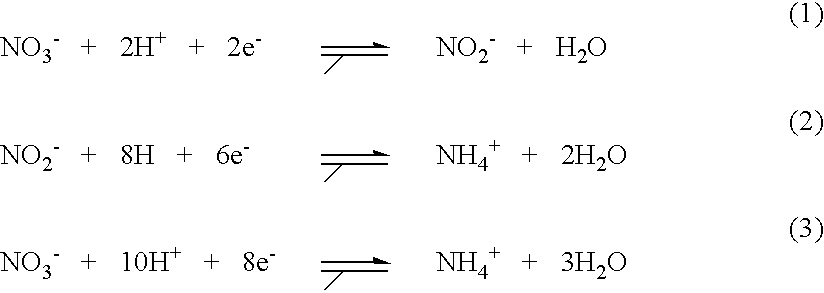

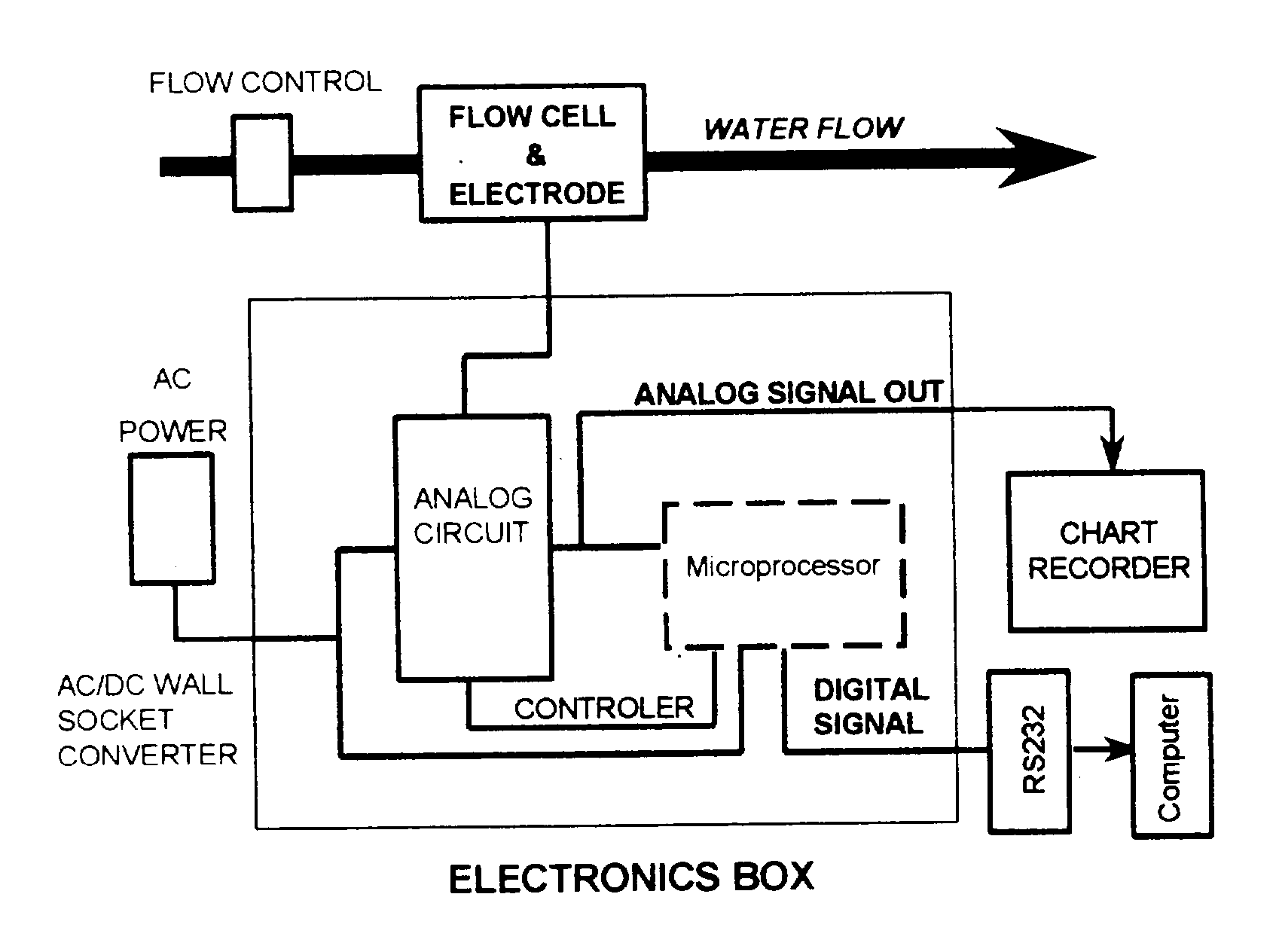

InactiveUS20030136673A1Simple and flexible formatAdvantageously ruggedImmobilised enzymesBioreactor/fermenter combinationsAnalyteReactive site

A biosensor for detecting and measuring analytes in an aqueous solution. The biosensor device has a sensor design based on modeling of the active-site chemistry of reactive molecules such as enzymes, antibodies and cellular receptors. The sensor design takes advantage of a synthetic polymer modeled after these reactive molecules to provide reversible, sensitive and reliable detection of analytes in the form of a versatile and economical device.

Owner:ARETE ASSOCIATES INC

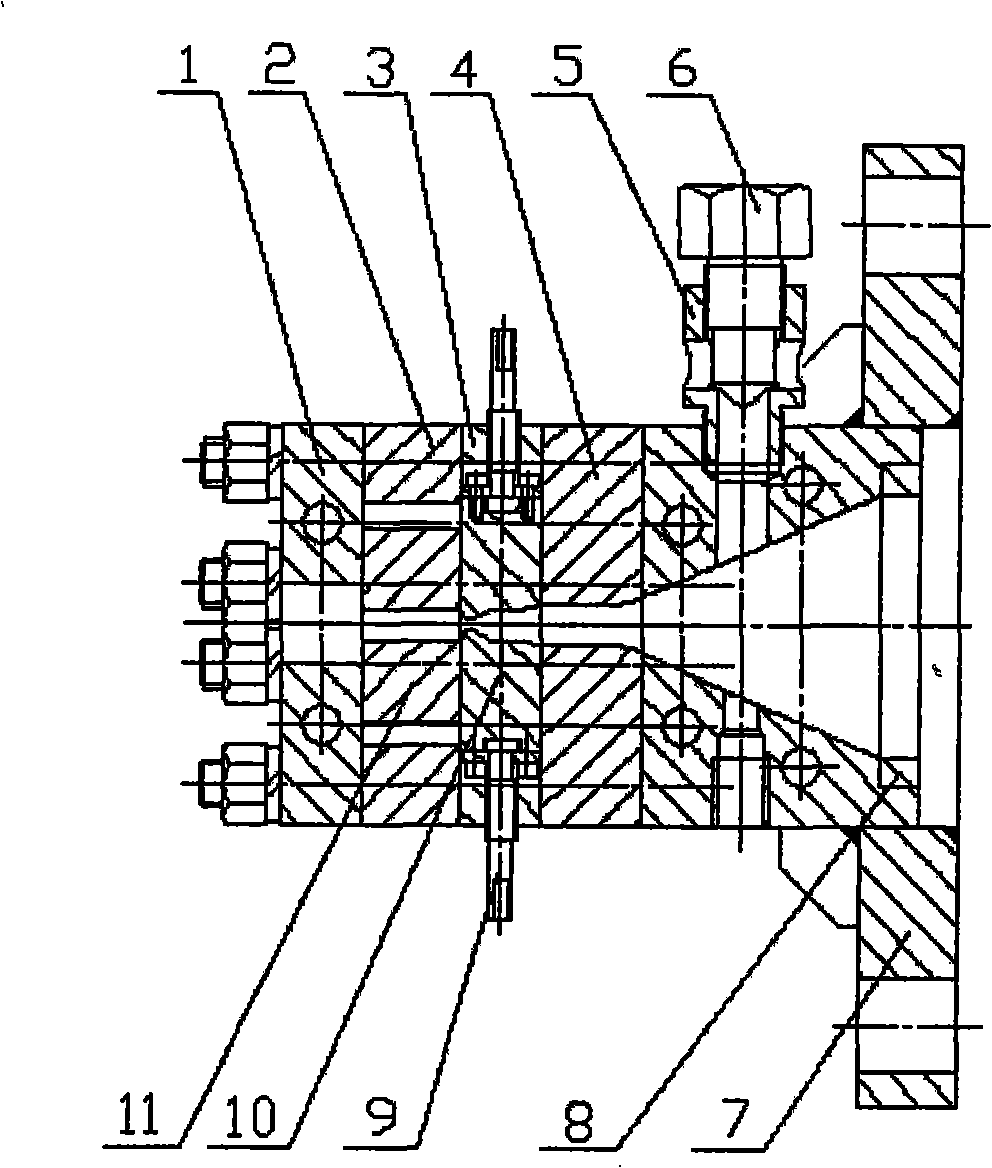

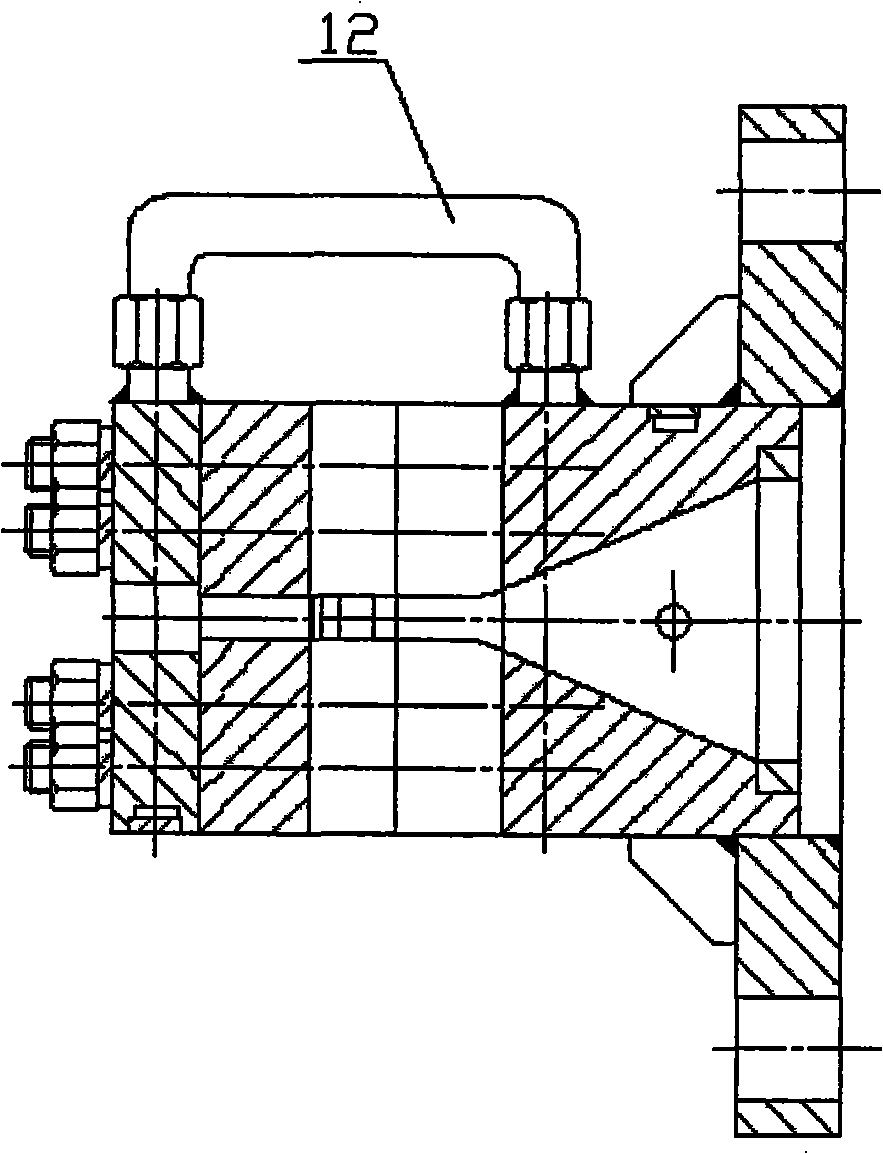

Radial extruding forming device of cut-fiber reinforcement rubber composite material

The invention relates to a radial extrusion molding device for the composite material of short fiber reinforced rubber, in particular to a device for realizing the radial direction of short fiber in rubber material. Eight threaded holes are produced on the front side of the flange of the device, eight double threaded screws and nuts are used for connecting the flange, a flow channel plate, a blocking supporting plate, a shaping plate and a machine head pressing plate into a whole in sequence, a rubber overflow valve is installed above the flange, and a threaded hole is drilled under the flange to install a pressure sensor; a pair of blocking adjusting blocks is positioned in the middle of the blocking supporting plate, one end of a blocking adjusting bolt is fixed with the blocking adjusting blocks, the other end thereof is connected with the blocking supporting plate through thread, and the blocking adjusting bolt is used for controlling the blocking gap; a pair of shaping adjusting blocks is positioned in the middle of the shaping plate to adjust the shaping gap, the shaping adjusting blocks are clamped between the blocking supporting plate and the machine head pressing plate and fixed through screws. The device has the advantages of simple structure, reliable principle, broad application range, low cost, good production efficiency, high product quality and stable performance.

Owner:QINGDAO UNIV OF SCI & TECH

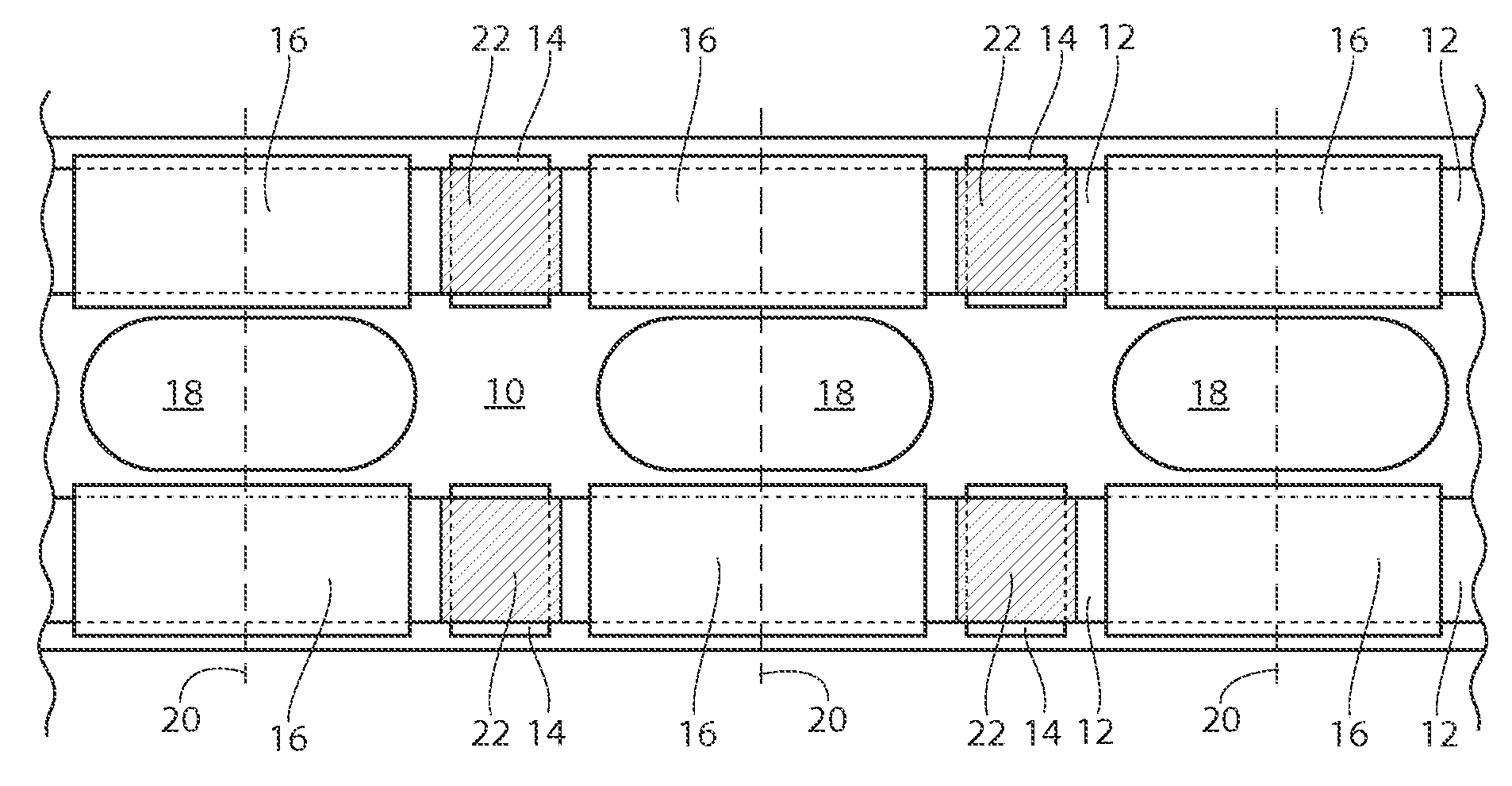

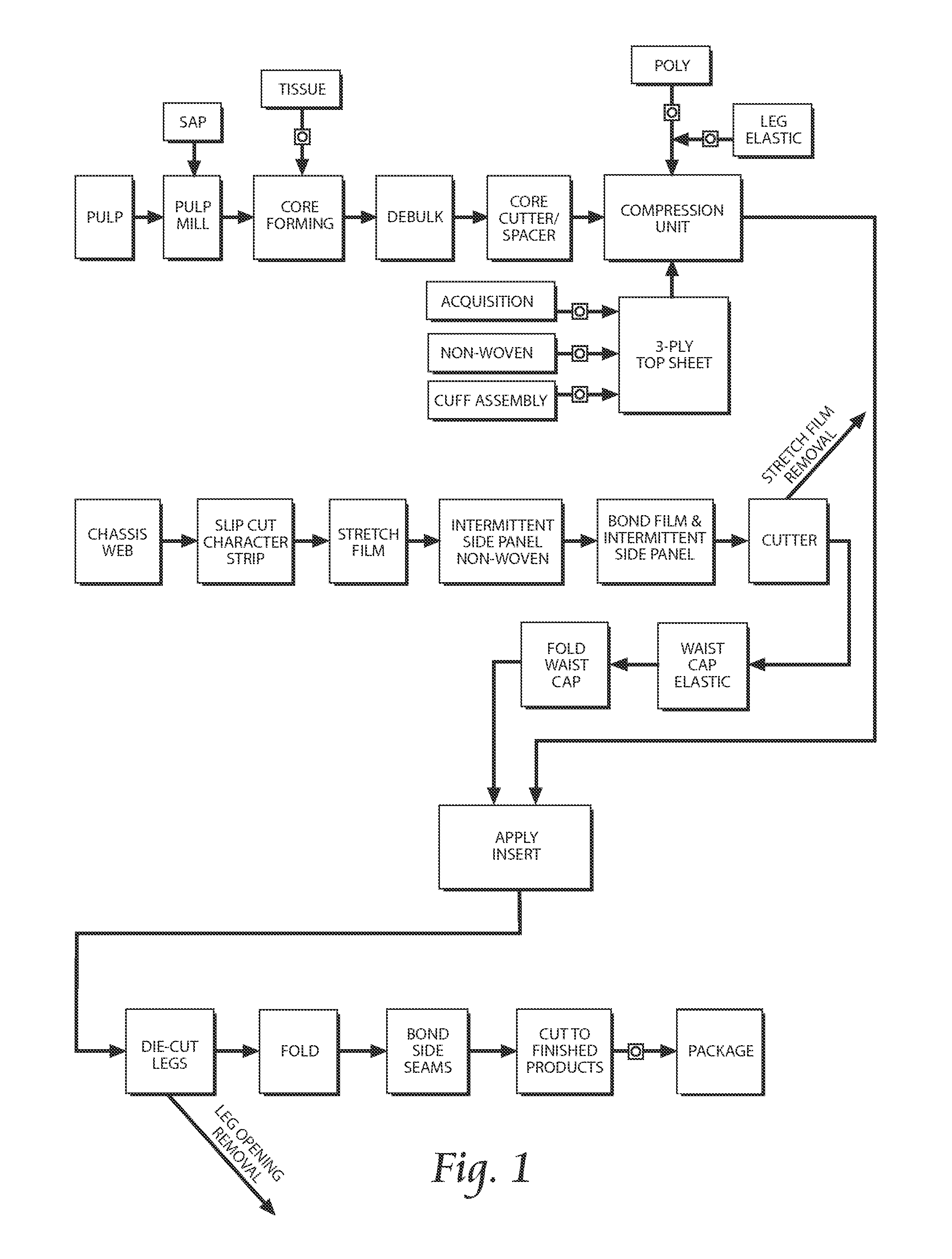

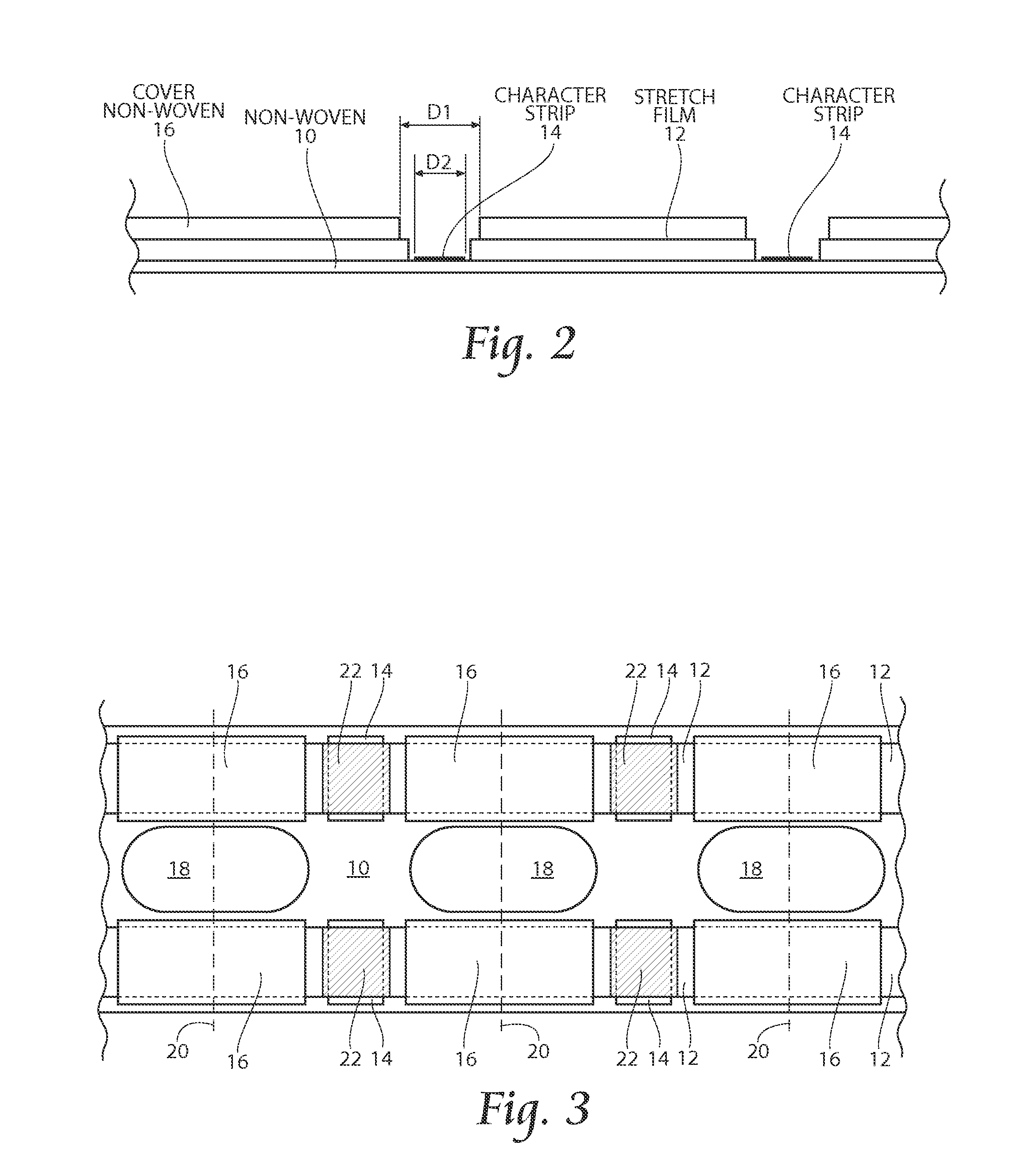

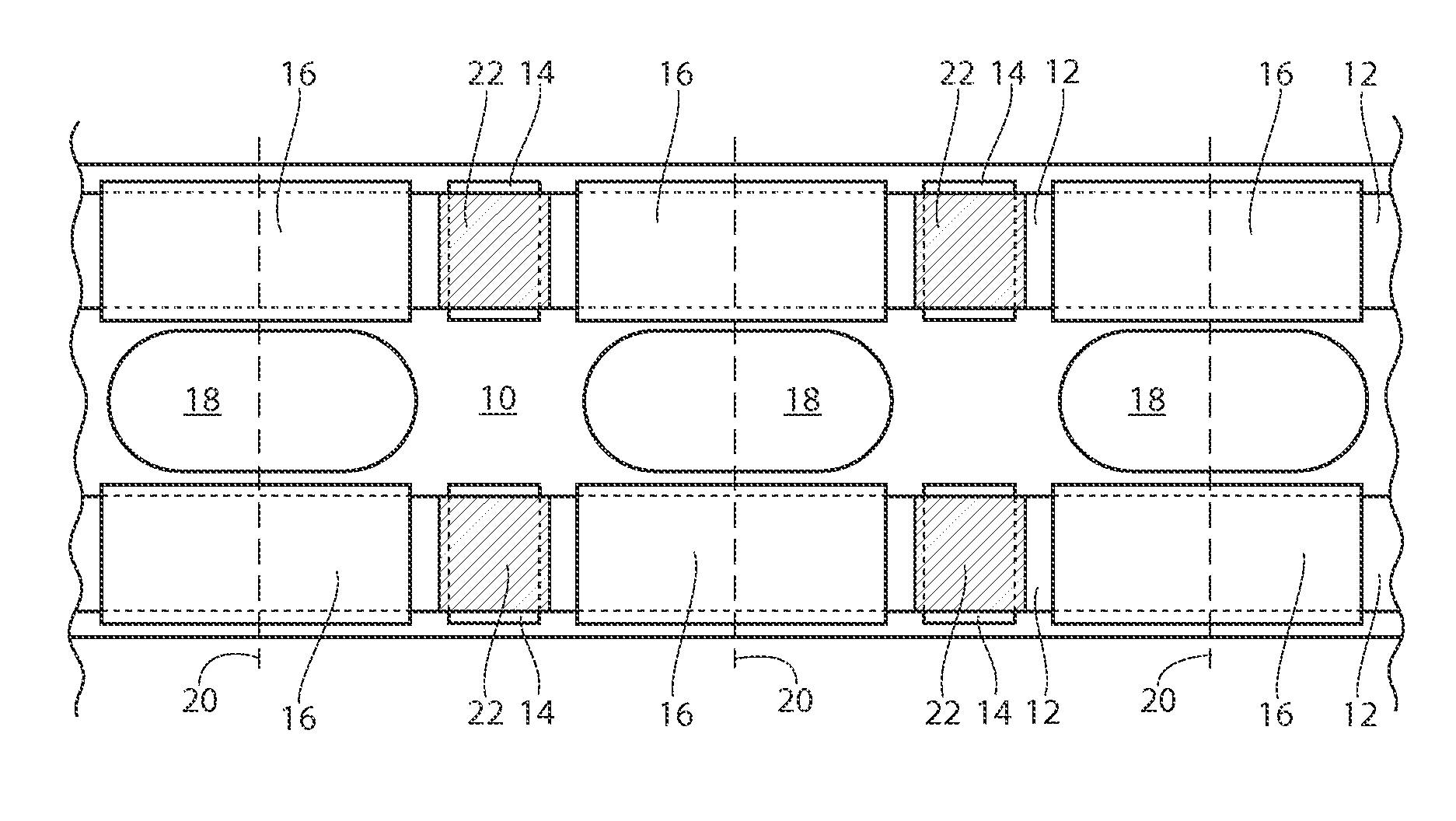

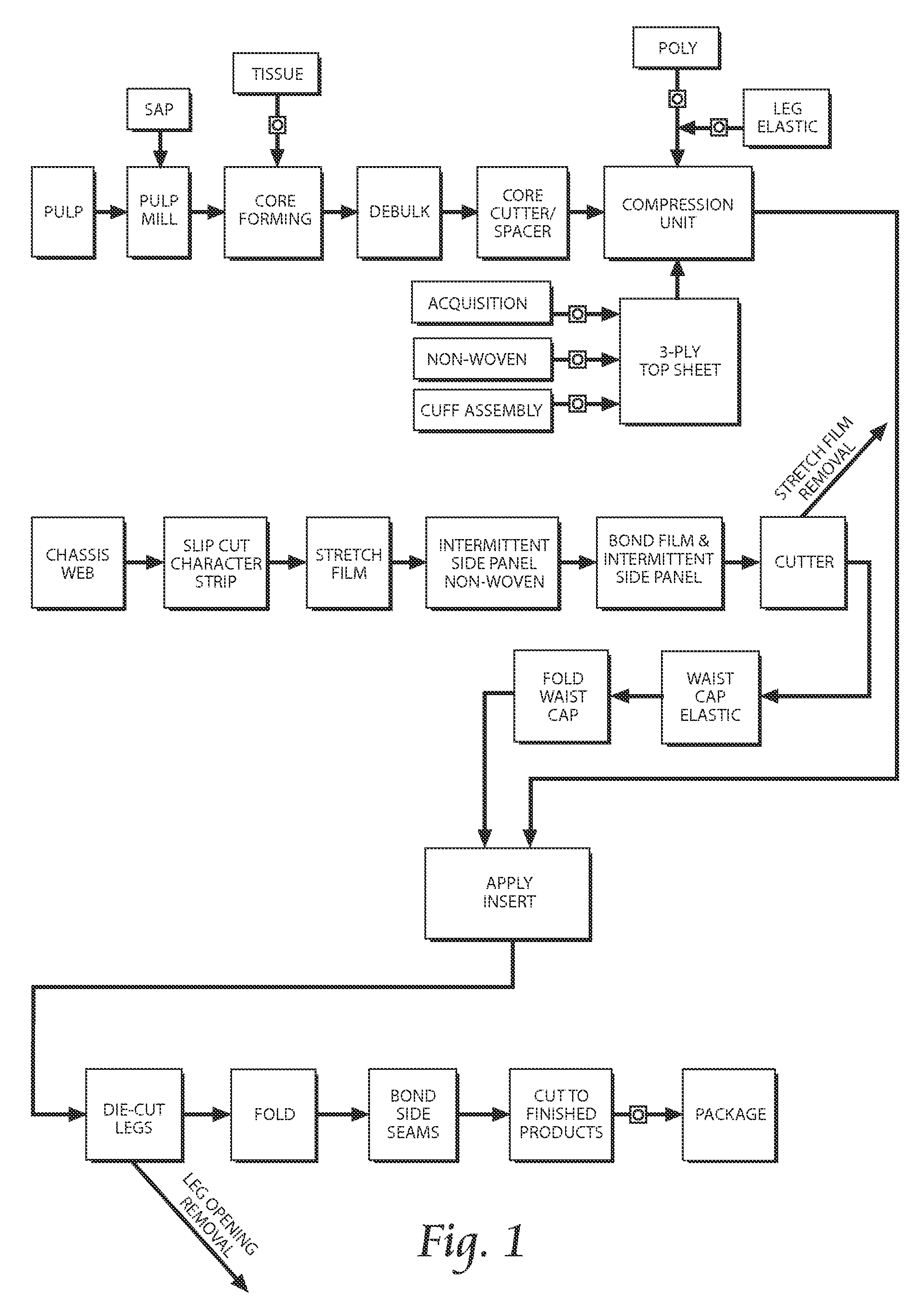

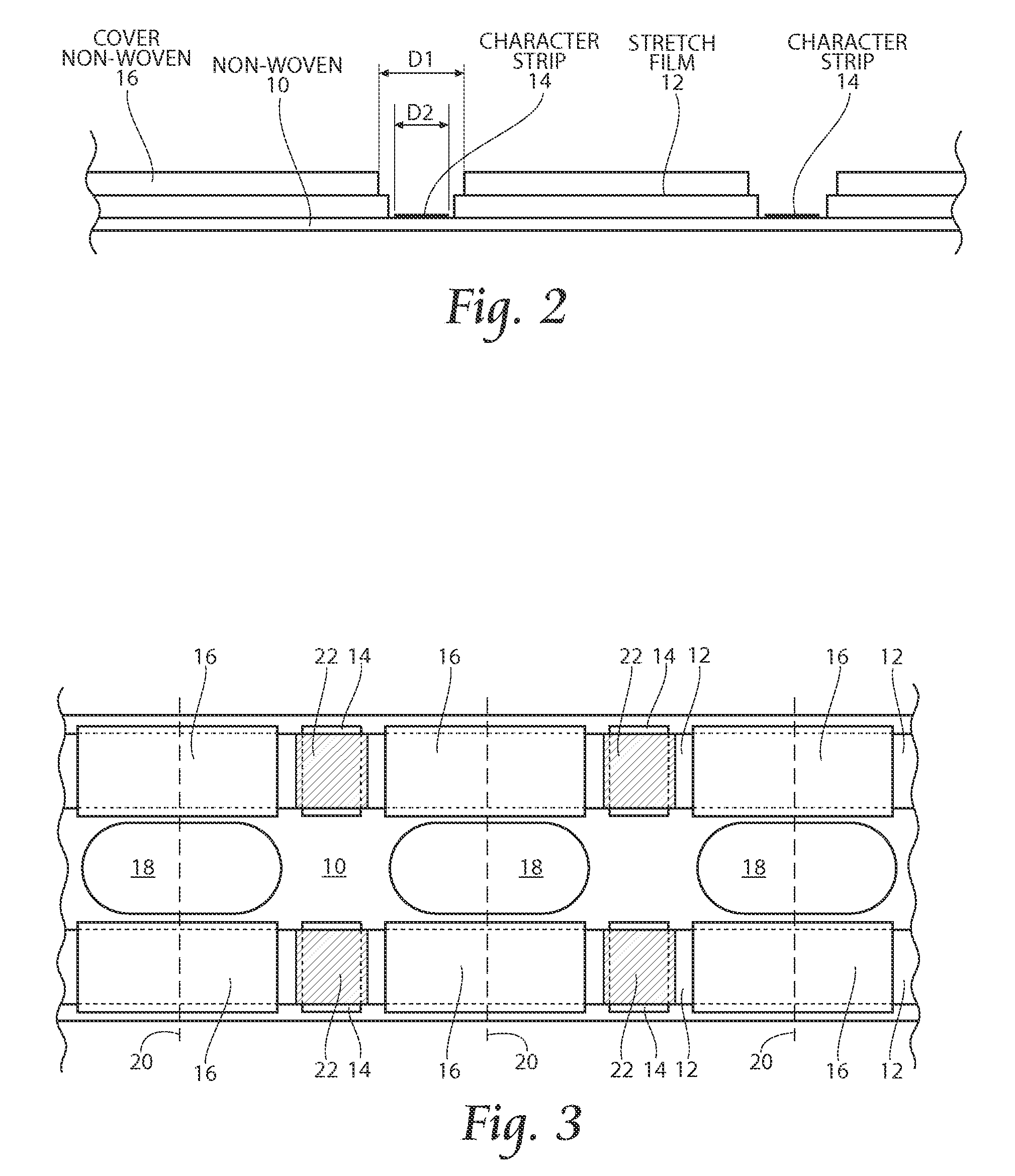

Method for producing absorbent article with stretch film side panel and application of intermittent discrete components of an absorbent article

InactiveUS8460495B2Improve bindingUniform productLamination ancillary operationsPaper/cardboard articlesEngineeringElectrical and Electronics engineering

Apparatus and methods are provided to allow for creation of a configured laminate of a non-woven material, to which a character strip is applied, the character strip exposed by either heat severing and removal of overlying materials, or intermittent application of overlying materials to leave the desired portions of the character strip exposed. A simultaneously formed core insert is applied to a preformed chassis web.

Owner:CURT G JOA

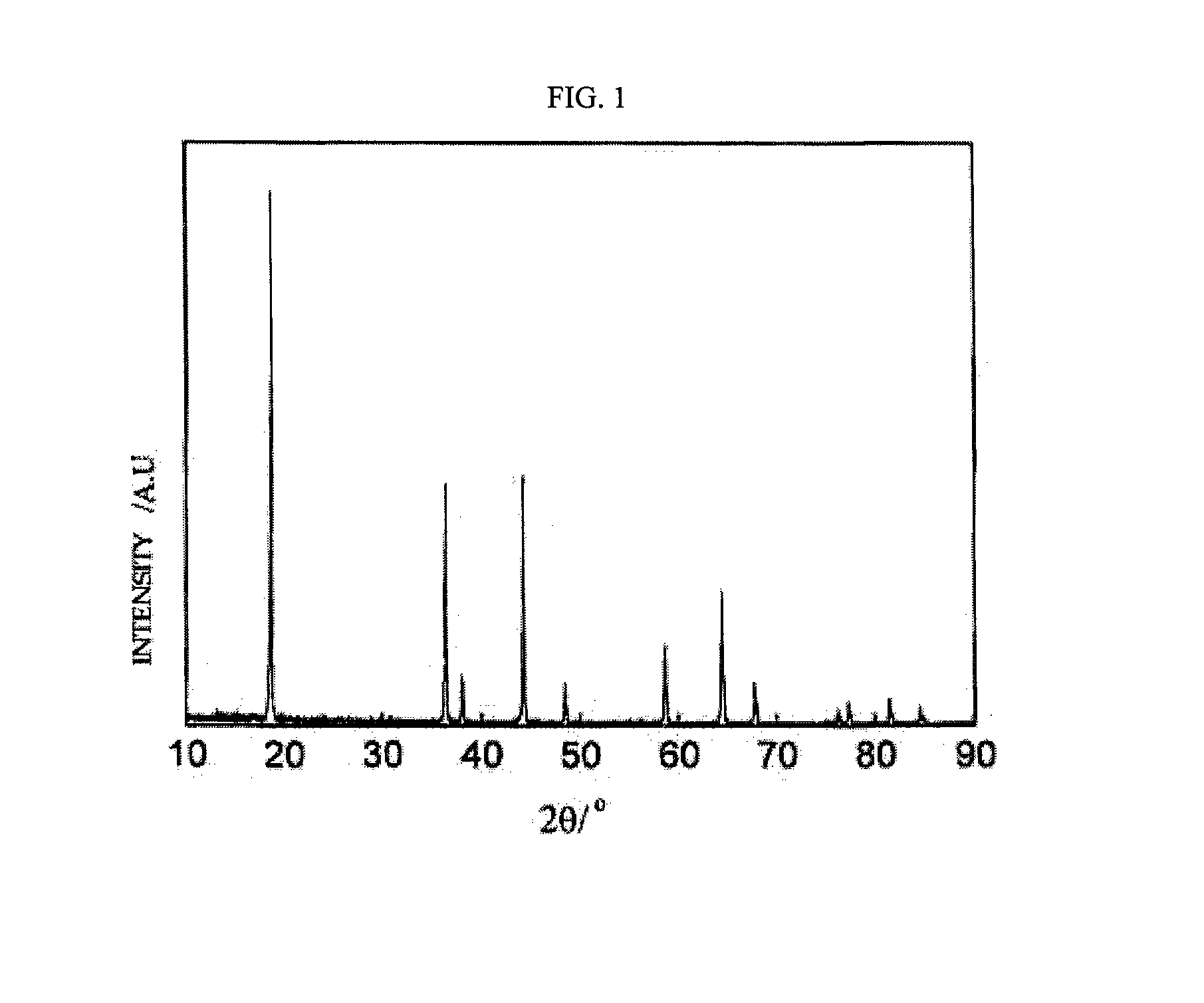

Method for reducing content of residual alkaline in nickel cobalt manganese acid lithium

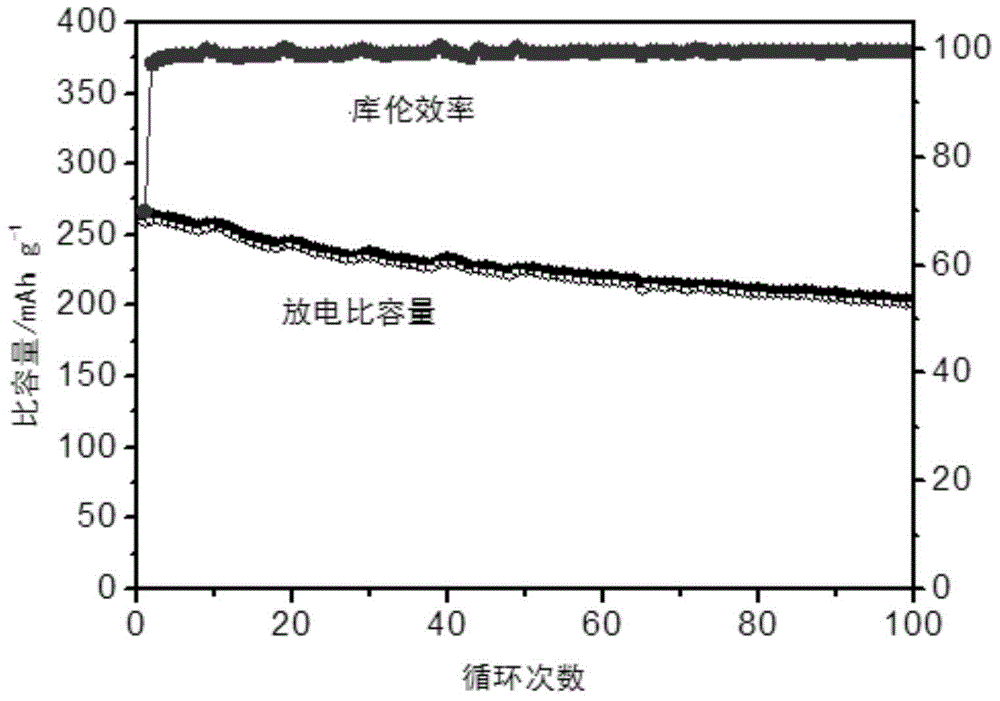

ActiveCN103700839AReduce residual alkali contentMaintain electrochemical activityCell electrodesLithiumCobalt

The invention discloses a method for reducing the content of residual alkaline in nickel cobalt manganese acid lithium. According to the method, LiH2PO4 serving as an alkaline treatment agent is used for removing alkaline components such as LiOH, Li2CO3 and LiHCO3 retained in a nickel cobalt manganese acid lithium positive electrode material, so that the structure of the positive electrode material cannot be damaged; furthermore, the circulating performance and the compaction density of the positive electrode material can be improved, and the performance of the battery can be improved; meanwhile, the method is simple and feasible and is suitable for industrial production.

Owner:北京盟固利新材料科技有限公司

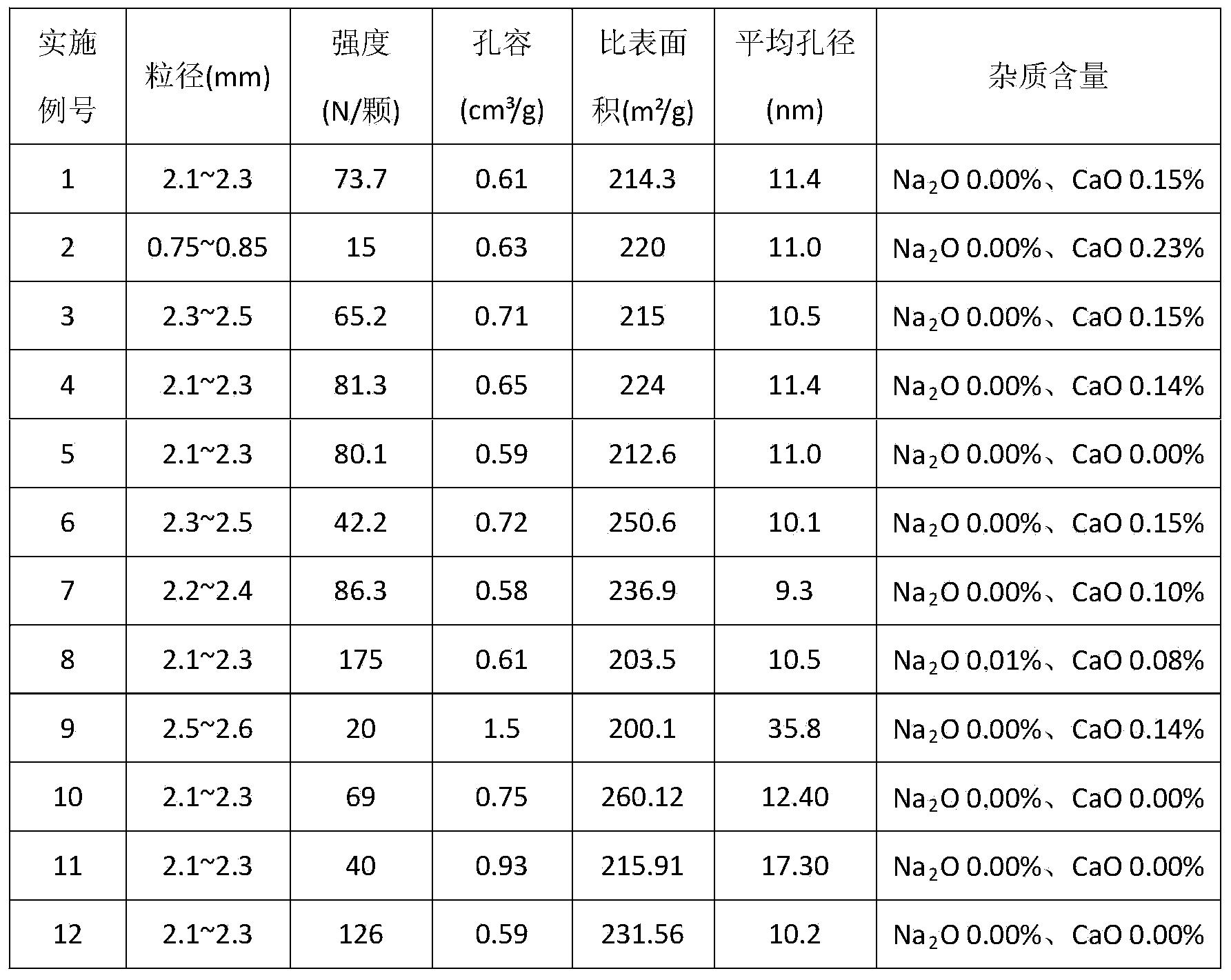

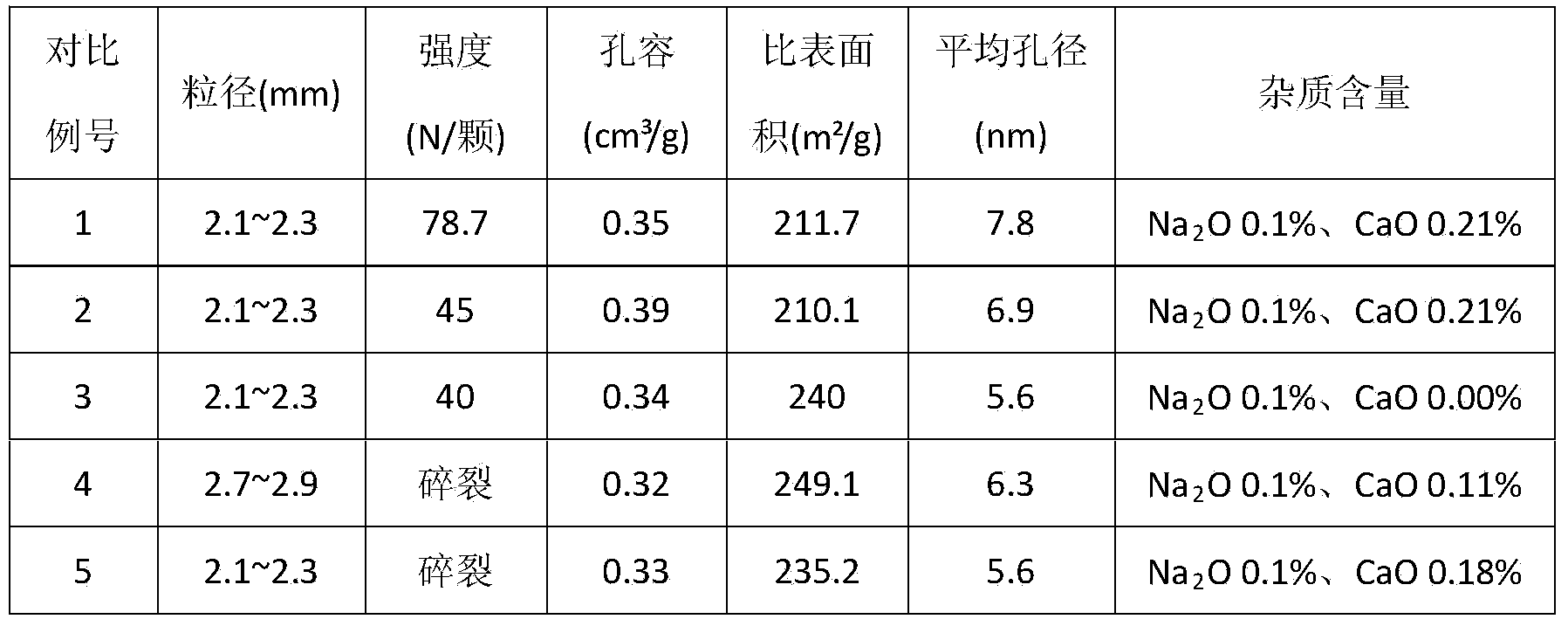

Water column forming method of spherical aluminum oxide

ActiveCN103864123AUniform productConcentrated intensity distributionAluminium oxides/hydroxidesLarge poreChemistry

The invention relates to a water-column forming method of spherical aluminum oxide. The water-column forming method is characterized by comprising the following steps: (1) preparing pseudo-boehmite and a soluble alginate water solution into suspended slurry, and dropwise adding the suspended slurry into a polyvalent metal cation water solution, so as to form pseudo-boehmite-alginic acid gel beads; (2) carrying out acid treatment, heat-moisture treatment and chemical chambering treatment on the gel beads; and (3) finally drying and baking, so as to prepare the spherical aluminum oxide. The water-column forming method has the advantages that the cost is low, the operational steps are simple and feasible, the industrial production is easy to implement, and the prepared spherical aluminum oxide has the advantages of large pore volume and aperture, high strength, concentration in distribution and the like.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

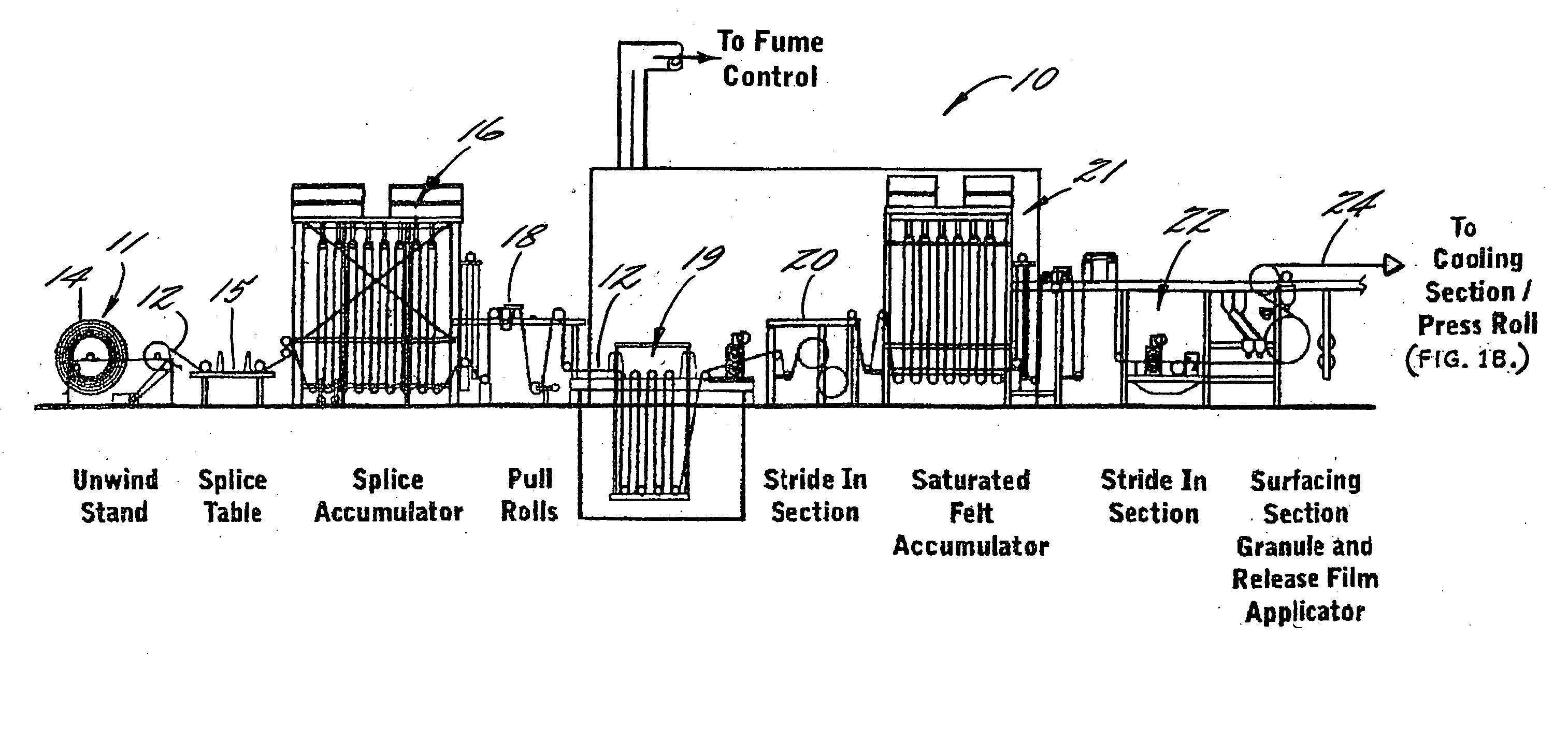

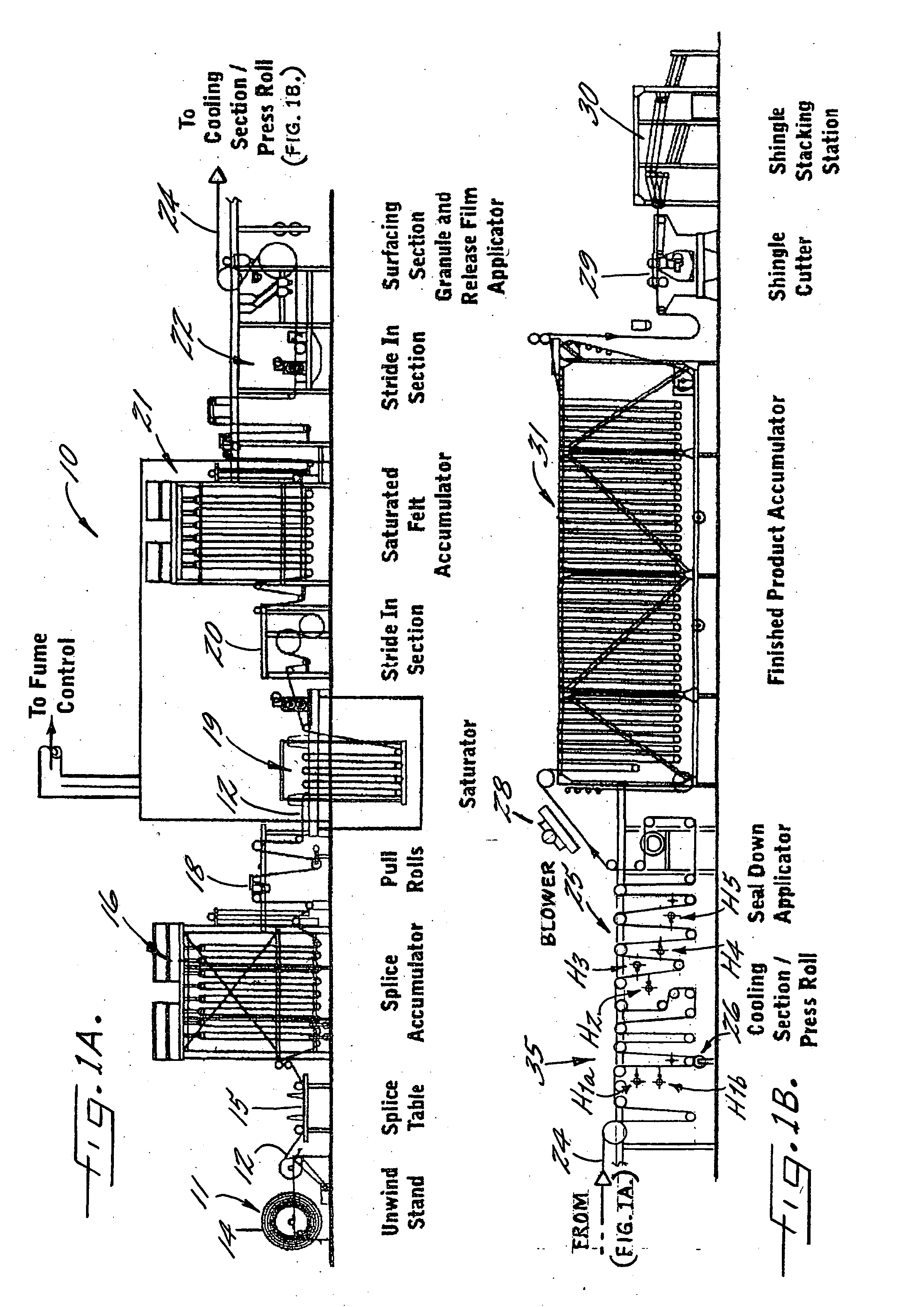

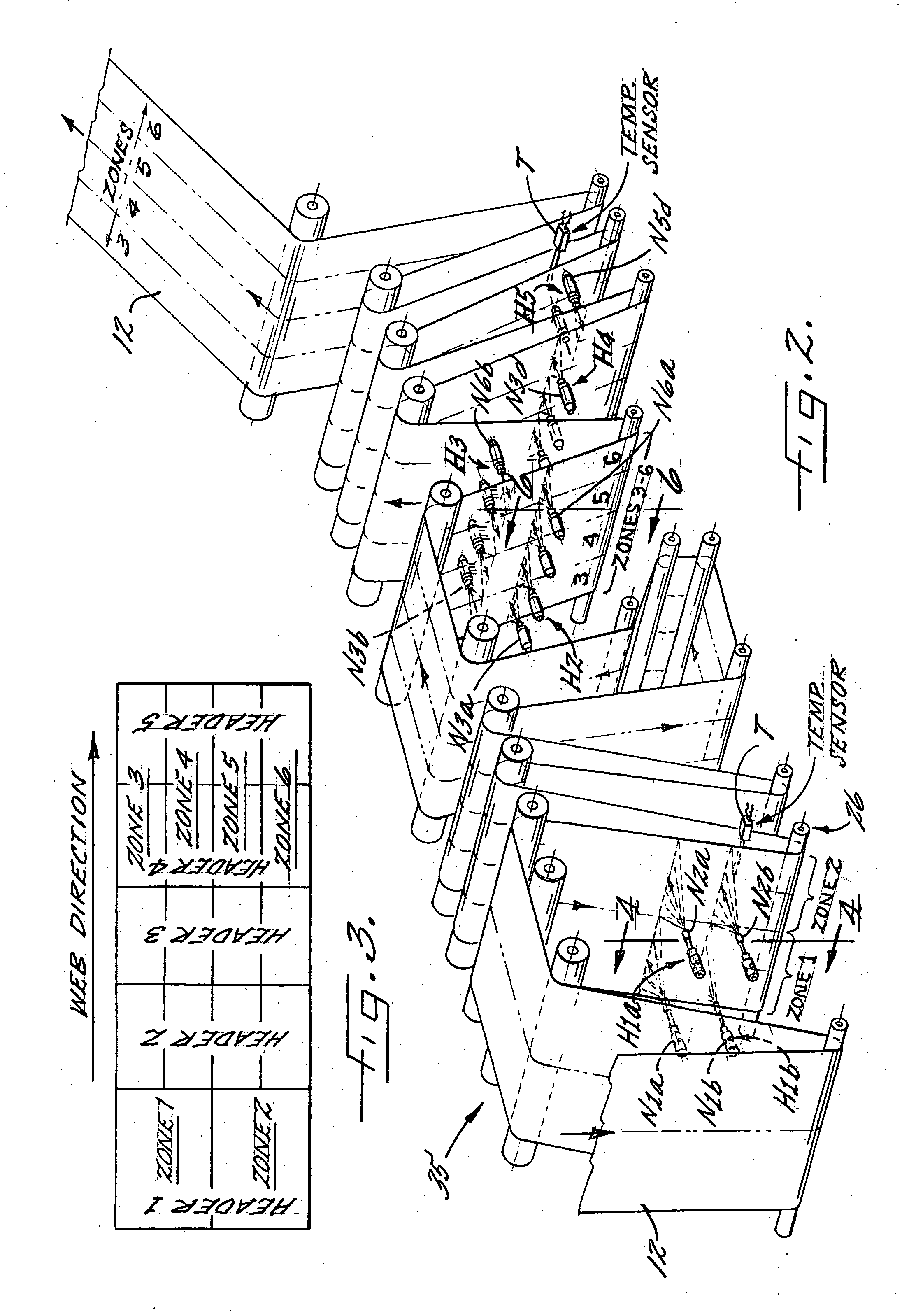

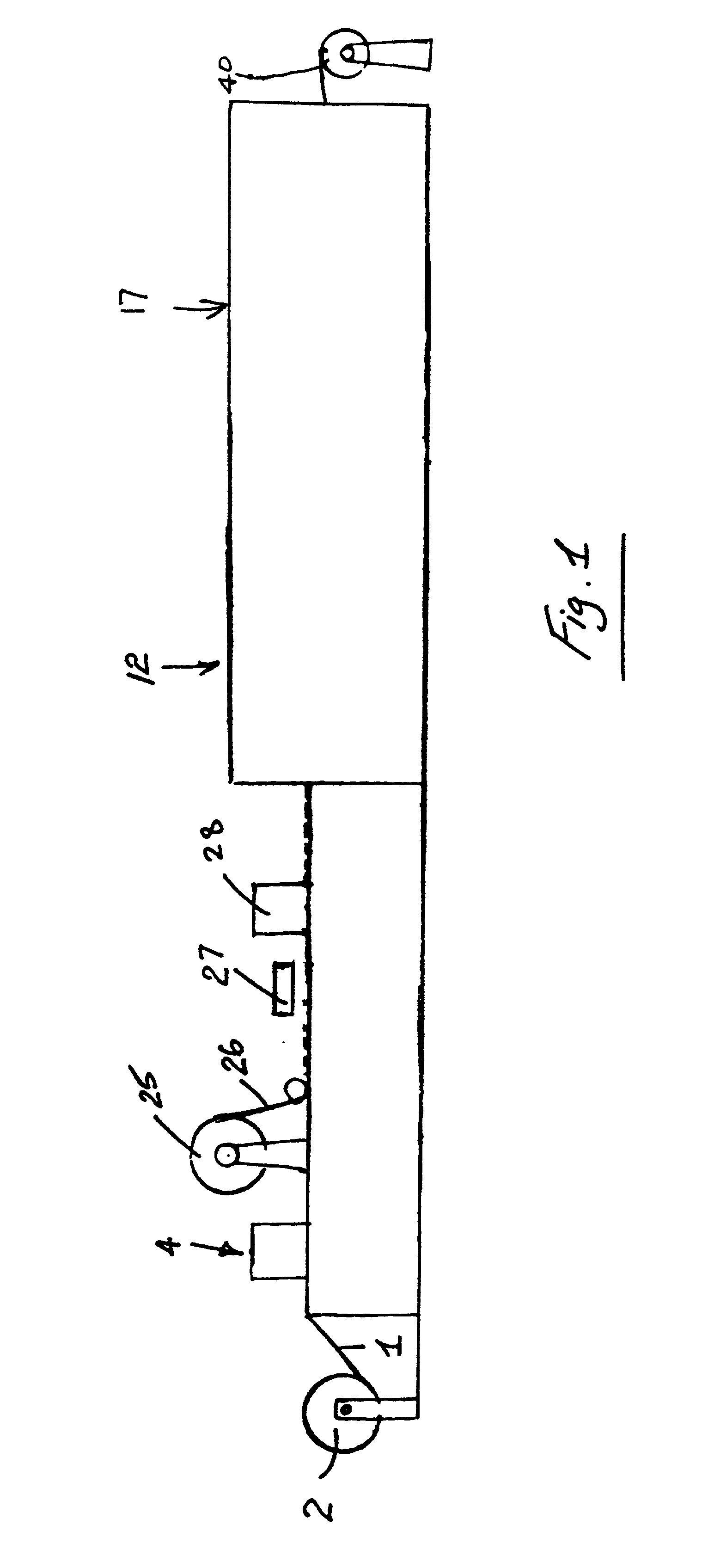

Apparatus and method for processing sheet materials

ActiveUS20060029742A1Precision coolingEfficient and uniform coolingPretreated surfacesLiquid/solution decomposition chemical coatingEngineeringCooling fluid

An apparatus and method for processing elongated sheet material through a plurality of processing stations including a cooling station for lowering the temperature of the sheet material. The cooling station includes a plurality of individually controllable cooling zones each for controlling a portion of the transverse width of the sheet material during passage through the cooling zone. The cooling zones each include a plurality of cooling fluid directing spray nozzles and a sensor for sensing the temperature of the portion of the sheet material onto which cooling fluid has been directed by the respective cooling zone. A controller responsive to the temperature sensed at each cooling zone is operable for independently controlling the flow of cooling fluid to the fluid spray nozzles of each cooling zone based upon a preset temperature setting of the controller.

Owner:SPRAYING SYST

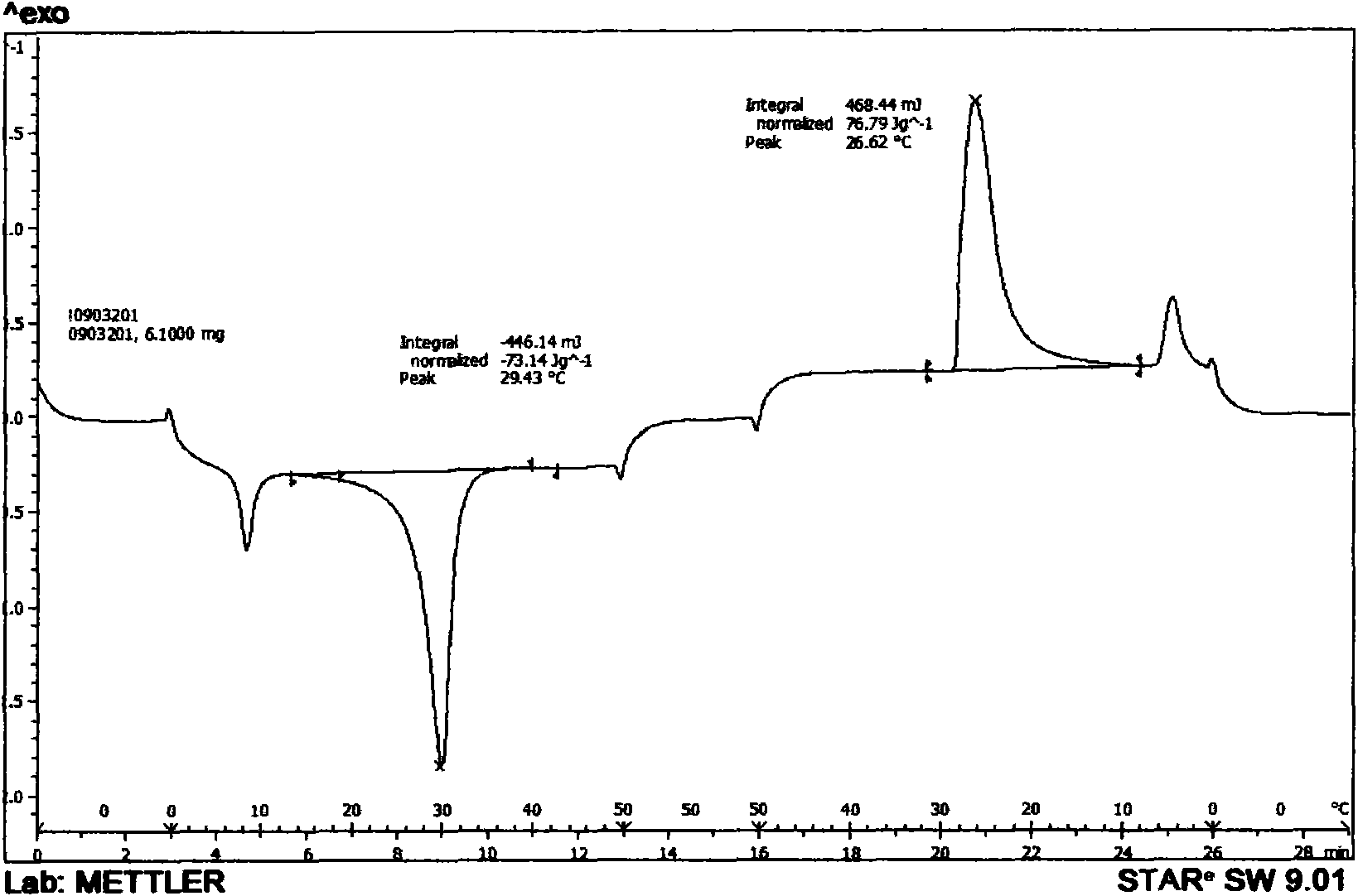

Method for quickly preparing phase change energy storage microcapsule by ultraviolet light irradiation and polymerization

InactiveCN101628218AFast polymerization rateUniform productEnergy based chemical/physical/physico-chemical processesMicroballoon preparationIonEmulsion

The invention relates to a method for quickly preparing a phase change energy storage microcapsule by ultraviolet light irradiation and polymerization, which comprises the following steps: adding 100 parts of phase change energy storage material, 5-10 parts of surface active agent, 40-80 parts of monomer material and an ultraviolet light initiating agent being 2-5 percent of the monomer material into 500-1,000 parts of deionized water; stirring the materials at a certain rotating speed for 20-40 minutes and then homogenizing and dispersing the materials for 2-5min at the rotating speed of 6,000-12,000 by a homogenizer so as to prepare the materials into an emulsion; putting the emulsion under an ultraviolet light source of 500-1,000W, irradiating the emulsion for 20-40min to initiate the monomer material to polymerize and stirring the emulsion at lower rotating speed; and after finishing initiating, filtering the emulsion to obtain solid powder and washing and drying the solid powder. Because the wavelength of the ultraviolet light is concentrated, the initiation mode of the ultraviolet light to a reactant system is easy to control, and a large quantity of the ultraviolet light initiating agent can be decomposed to generate free radicals, therefore, the reaction speed of photopolymerization is many times higher than the reaction speed of a conventional thermal initiation polymerization mode, and the improvement of the reaction speed renders possible the continuous mass production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

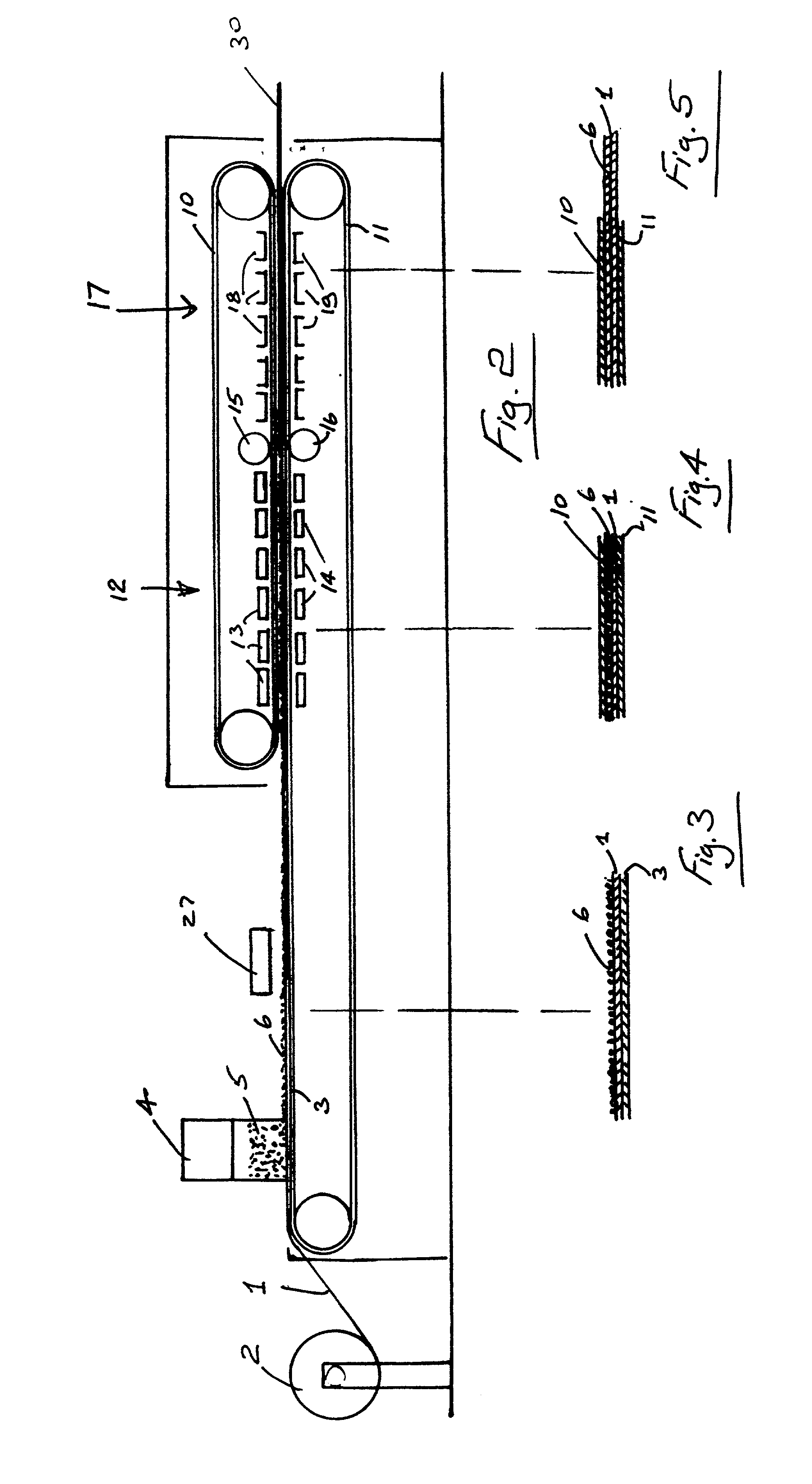

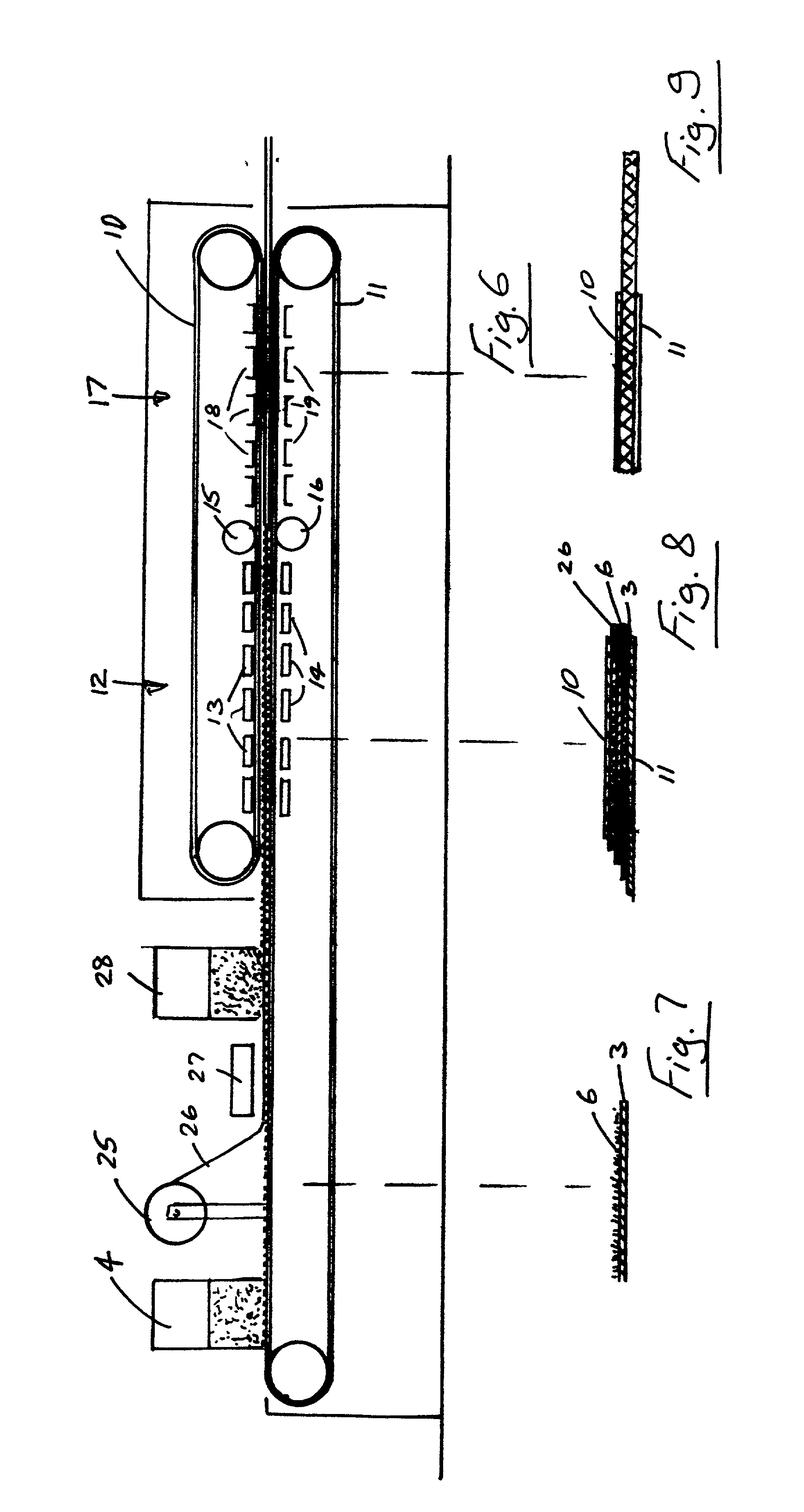

Method for manufacturing a floor covering

InactiveUS20010028127A1Easy to handleReduce usageCork mechanical workingNon-woven fabricsGlass fiberEngineering

A method for manufacturing a floor covering involves leading a glass fiber matt 1 from a supply reel 2 onto a conveyor belt 3. At a first scattering station 4, a saturation material is scattered onto the matt 1 to form a scattered layer. The matt 1 is then led between upper and lower heated belts 10, 11 to gel the scattered layer. The belts are then passed between a pair of smoothing / nipping rollers to form a layer of uniform thickness. The belts are then cooled and the matt 1 with saturation layer applied is wound for further processing. In an alternative arrangement a saturation material is scattered directly onto a substrate belt at the first scattering station 4, a glass fiber matt 26, is applied over the scattered material and, at a second scattering station 28, an amount of the saturation material or a different material is scattered onto the matt 26.

Owner:HINDS TERENCE MARTIN +2

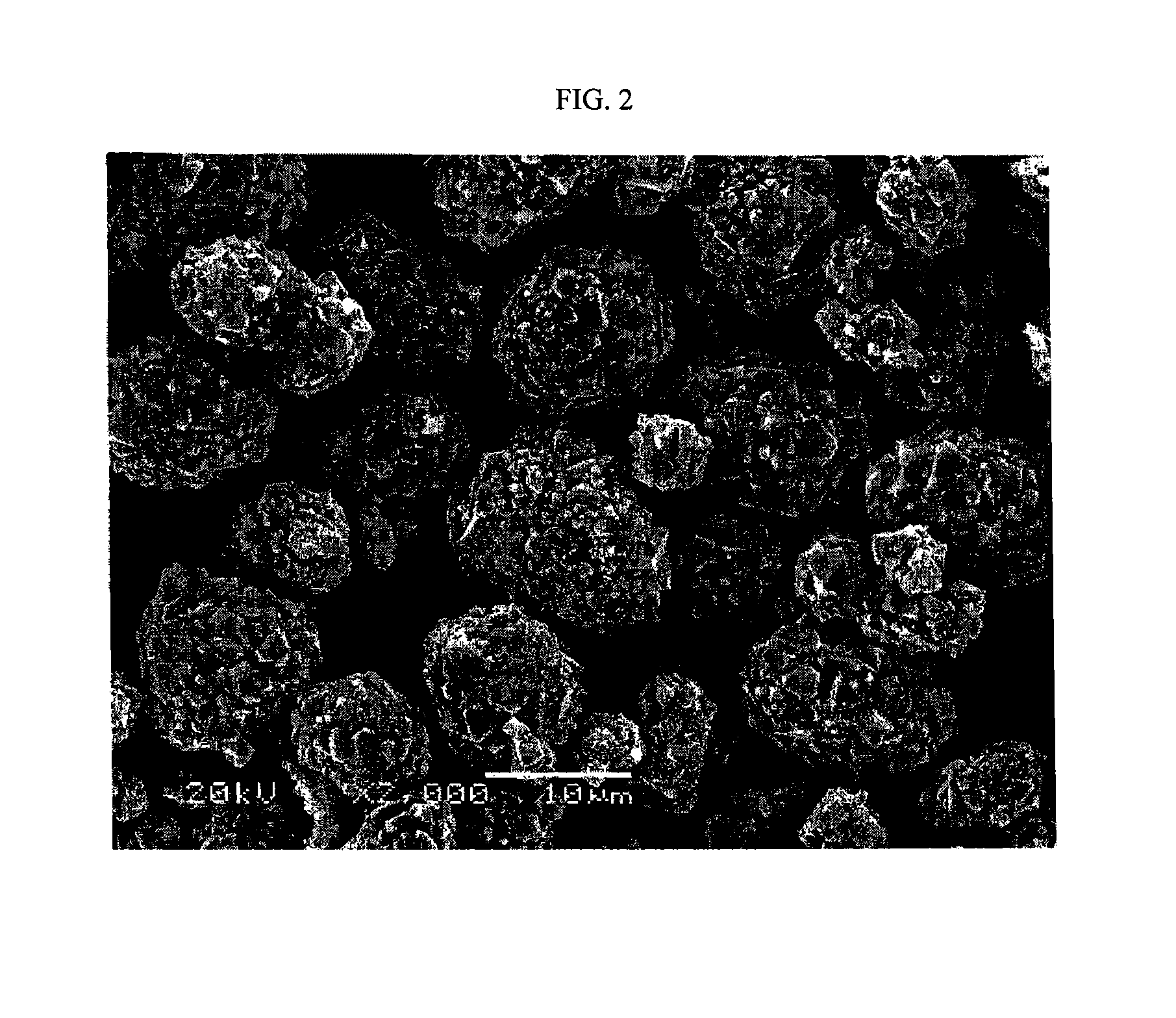

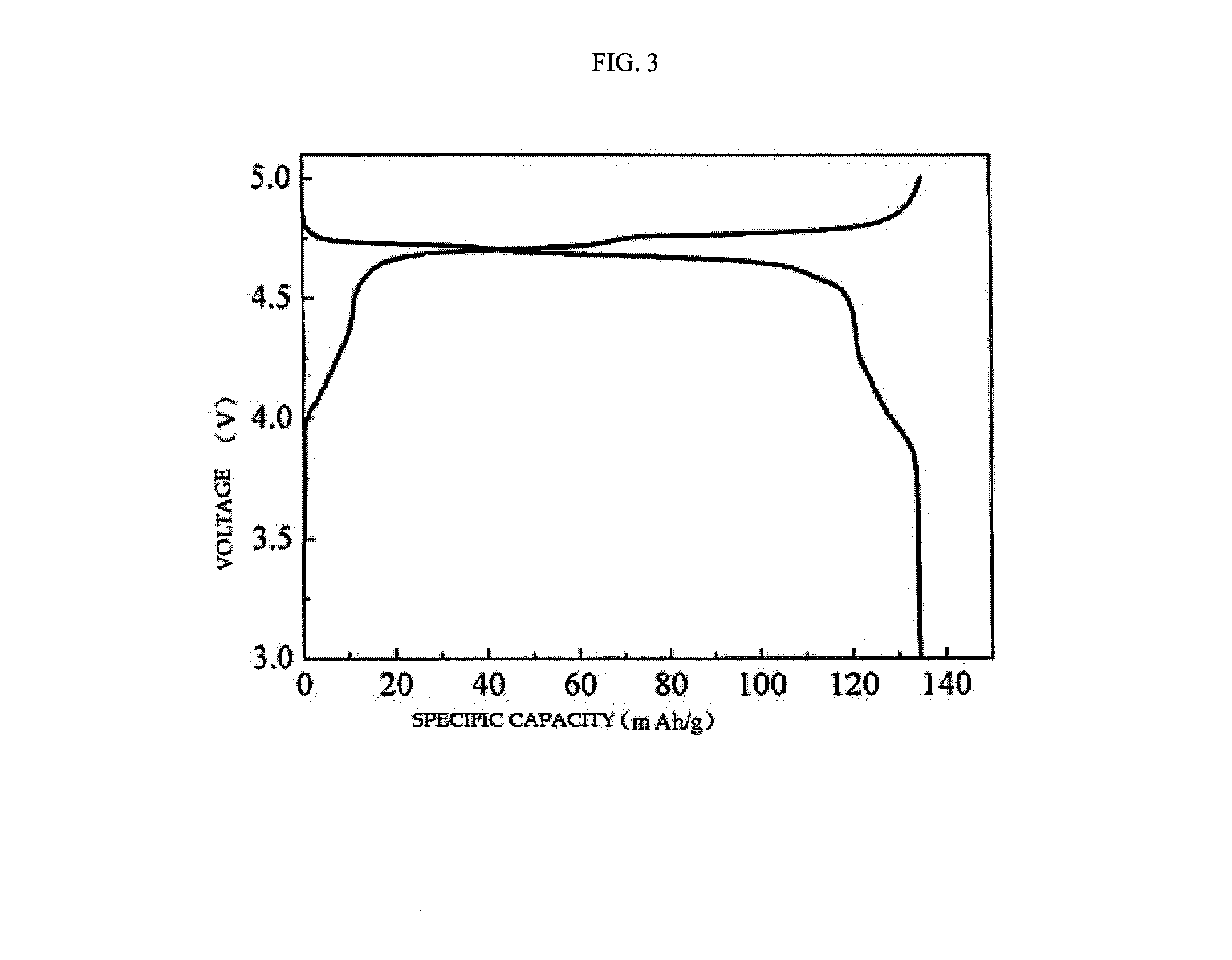

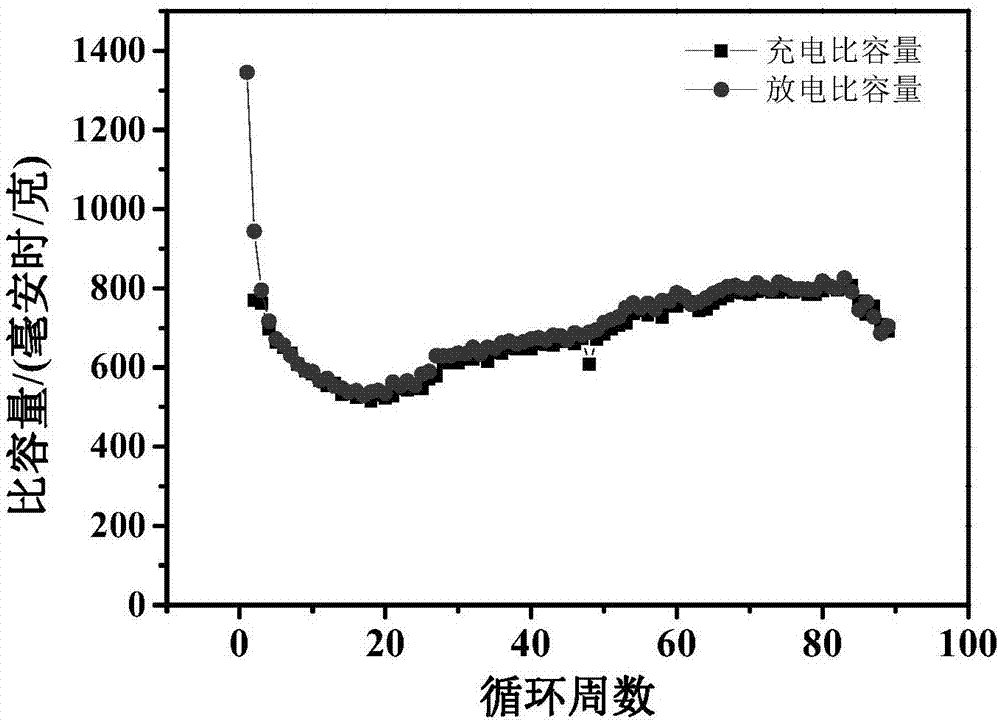

High-voltage lithium battery cathode material

InactiveUS20130126802A1Stable crystal structureImprove conductivityCell electrodesConductive materialCyclic processDecomposition

The present invention advantageously provides a high-voltage lithium battery cathode material and its general formula for the composition of the high-voltage lithium battery cathode material presented in this invention:LiMn1.5Ni0.5-XMXO4 Of which: 0<X≦0.2, M represents one or several elements comprised by copper, zinc, magnesium, aluminum, cadmium, zirconium, and titanium.The present invention relates to a high-voltage lithium battery cathode material, which utilizes the liquid-phase co-precipitation method to dope transition metal elements, so that all elements could be mixed at the atomic level and obtain a relatively uniform product, stabilizing the crystal structure, avoiding the capacity attenuation caused by structure collapse in the material cyclic process; in addition, this invention has also increased the conductivity, improved the capacity of 5 V platform, thereby avoiding the substantial damage to the battery system resulted from the decomposition of the electrolyte. Thus, a newly high-voltage lithium battery cathode material featured with good electrochemical properties and cycle performance has been proposed in the present invention; moreover, the utilization of liquid-phase co-precipitation has the advantages of simple synthesis method, convenient operation process, easier to control, high yield coefficient, low energy consumption, and easy-to-industrial production.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

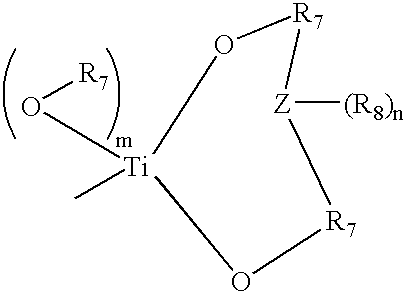

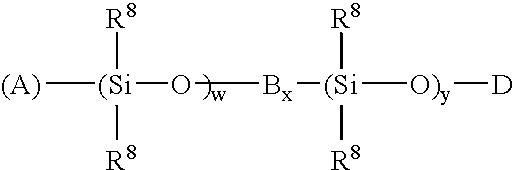

High temperature ziegler-natta solution catalysts

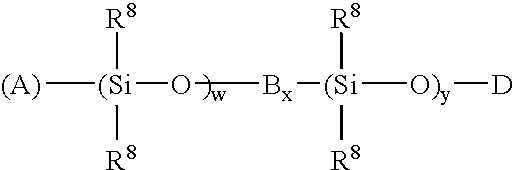

InactiveUS6878658B2Easy to controlUniform productOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationZiegler–Natta catalystEmulsion polymerization

The present invention provides a Ziegler-Natta catalyst useful in solution processes for the polymerization of olefins having a low amount of aluminum and magnesium. The catalysts of the present invention contain an alkyl silanol and have a molar ratio of Si:Ti from 0.25:1 to 4:1. The catalysts are effective for the solution polymerization of olefins at high temperatures.

Owner:NOVA CHEM (INT) SA

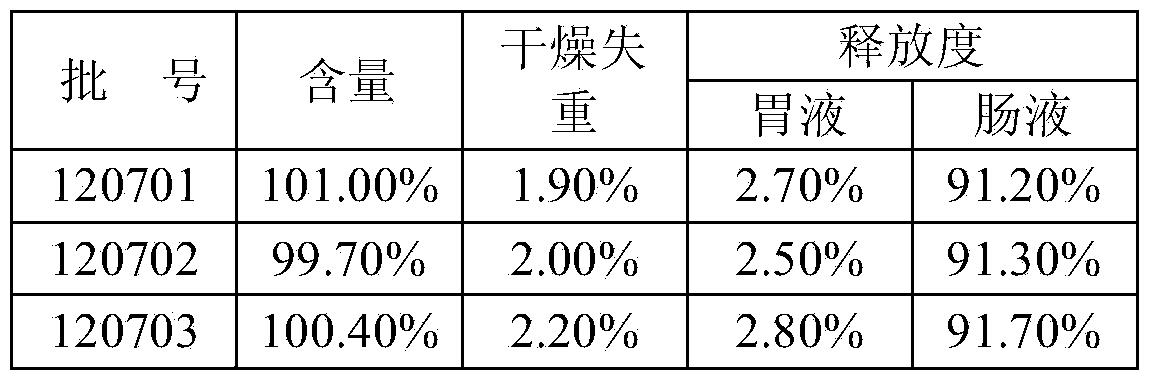

Tilmicosin phosphate enteric granules and preparation method thereof

InactiveCN103622919AAvoid destructionProlong the action timeAntibacterial agentsOrganic active ingredientsEmulsionAdhesive

The invention discloses tilmicosin phosphate enteric granules and a preparation method thereof. The enteric granules comprise 70-80 wt% of elemental granule and 20-30 wt% of coating, wherein the elemental granules are at least prepared from the following components in percentage by mass: 5-40% of tilmicosin phosphate, 30-55% of microcrystalline cellulose, 1-5% of sodium carboxymethyl starch, 26.9-30% of starch, 0.1-1% of surfactant and 2-4% of adhesive; and the coatings are at least prepared from the following components in percentage by mass: 78.9-90.9% of I acrylic resin emulsion, 2.3-7.9% of triethyl citrate and 6.8-13.2% of talcum powder. The coatings are coated outside the tilmicosin phosphate elemental granules, so that the tilmicosin phosphate enteric granules are basically not released in the livestock or fowl stomach, but are gradually and completely released in the livestock or fowl intestinal tract, thereby obviously enhancing the treatment effect of the tilmicosin phosphate.

Owner:HUBEI LONGXIANG PHARMA TECH CO LTD

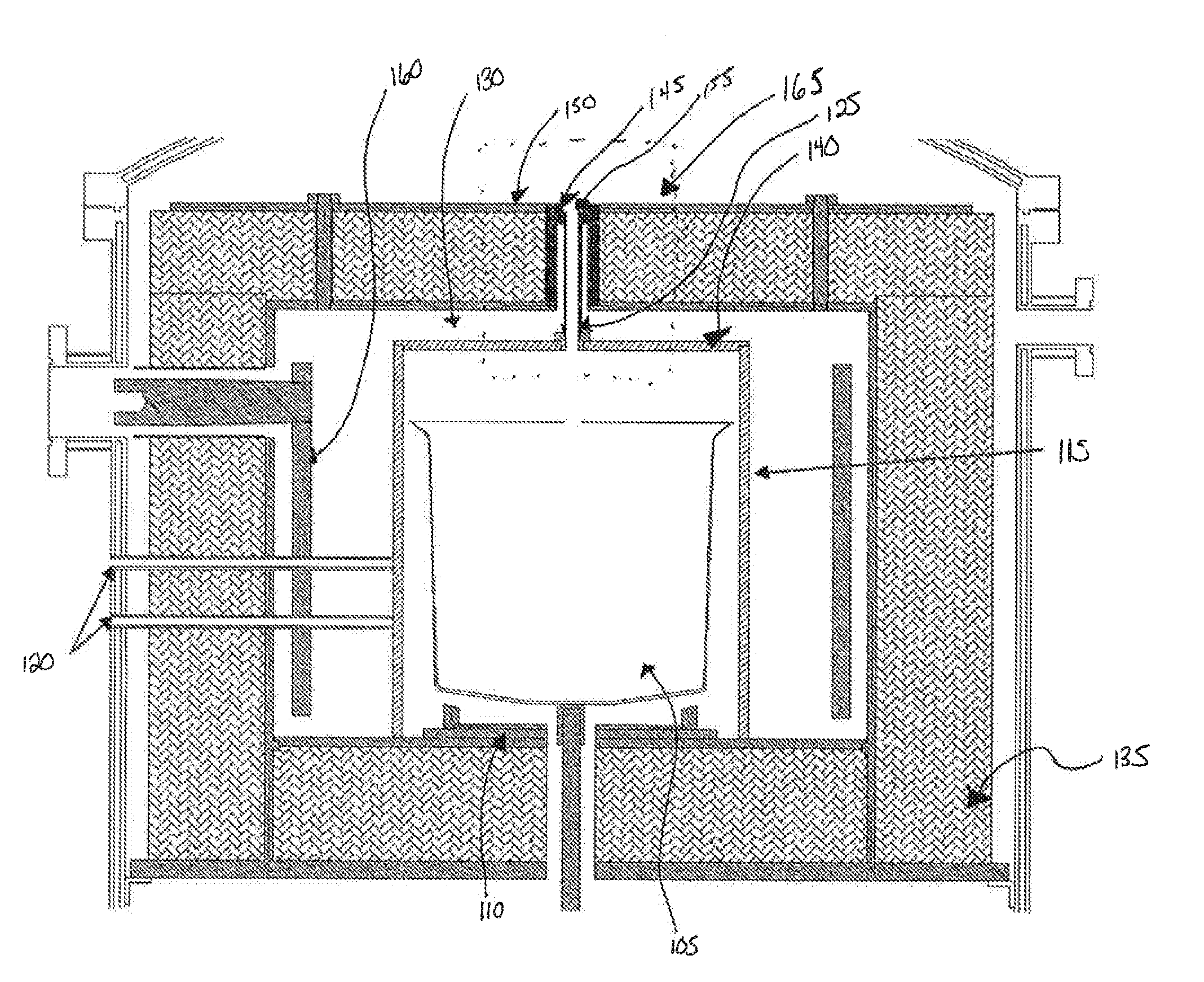

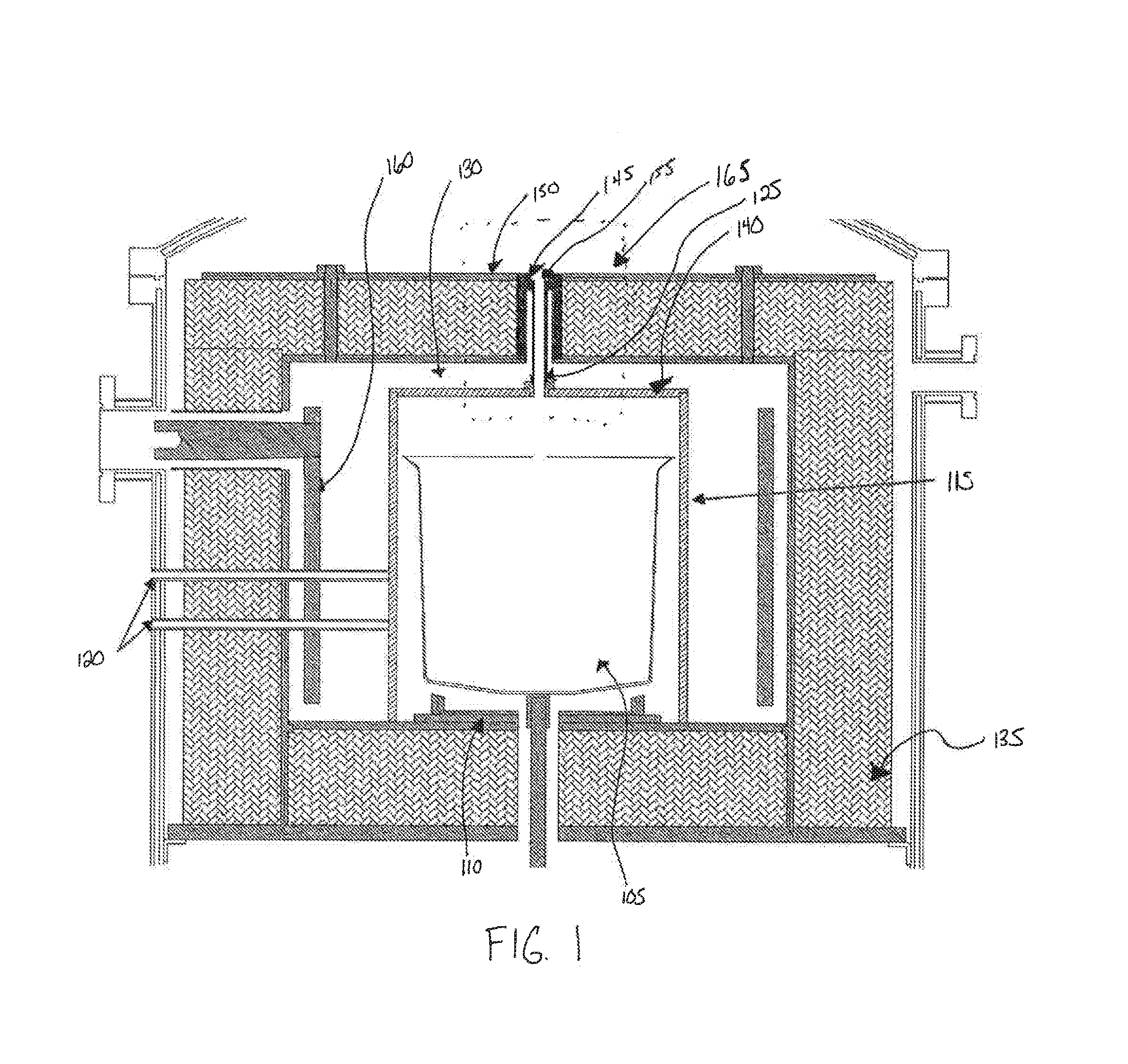

Technique for controlling temperature uniformity in crystal growth apparatus

ActiveUS20150090179A1Uniform productPolycrystalline material growthFrom melt solutionsCrucibleCrystalline materials

A sapphire crystal growth apparatus is provided that includes a chamber, a hot zone and a muffle. More specifically, the hot zone is disposed within the chamber and includes at least one heating system, at least one heat removal system, and a crucible containing feedstock. Additionally, a muffle that surrounds at least two sides of the crucible is also provided to ensure uniform temperature distribution through the feedstock during crystal growth to allow the crystalline material to be grown with a square or rectangular shaped cross section.

Owner:GTAT CORPORATION

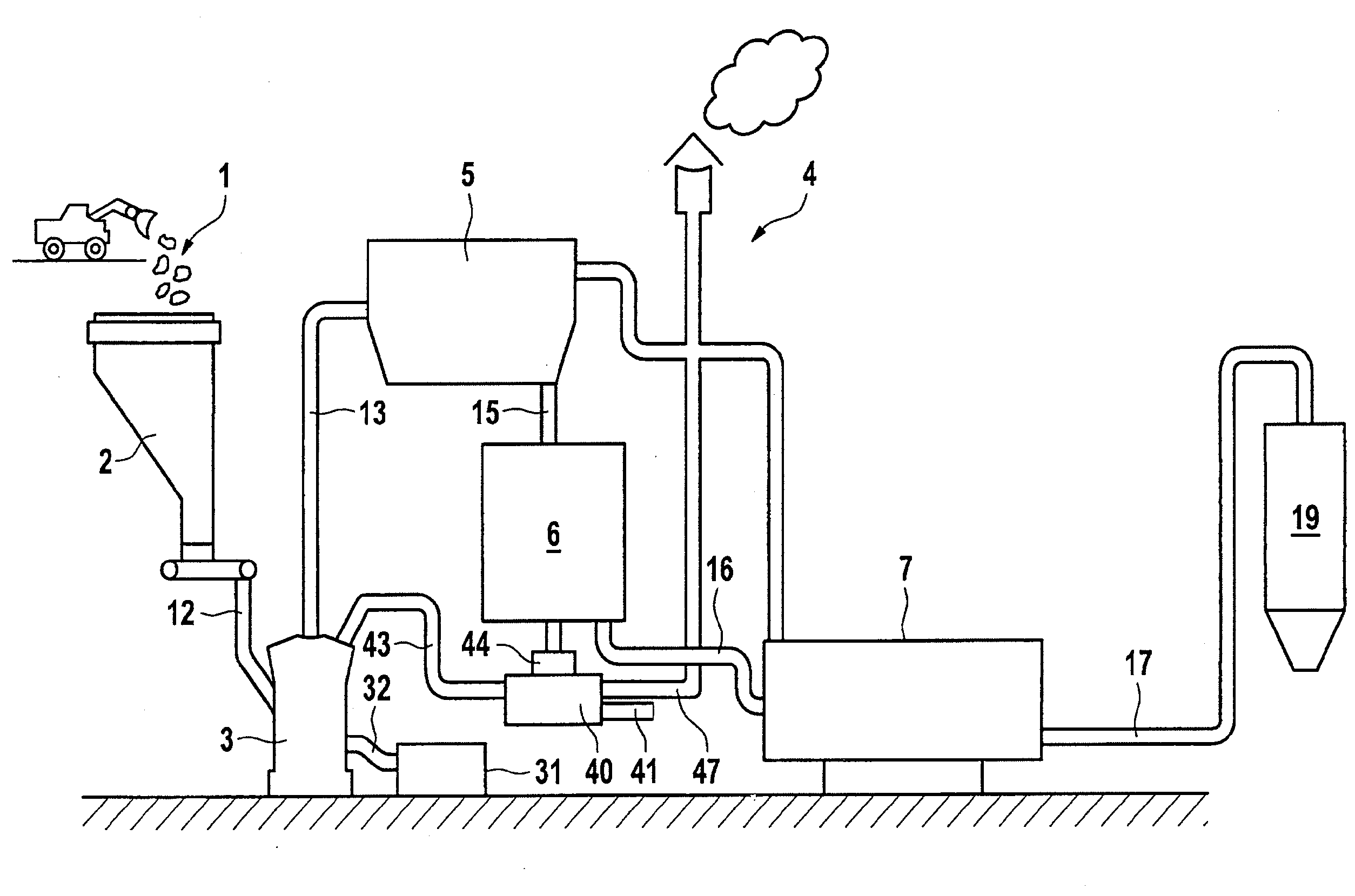

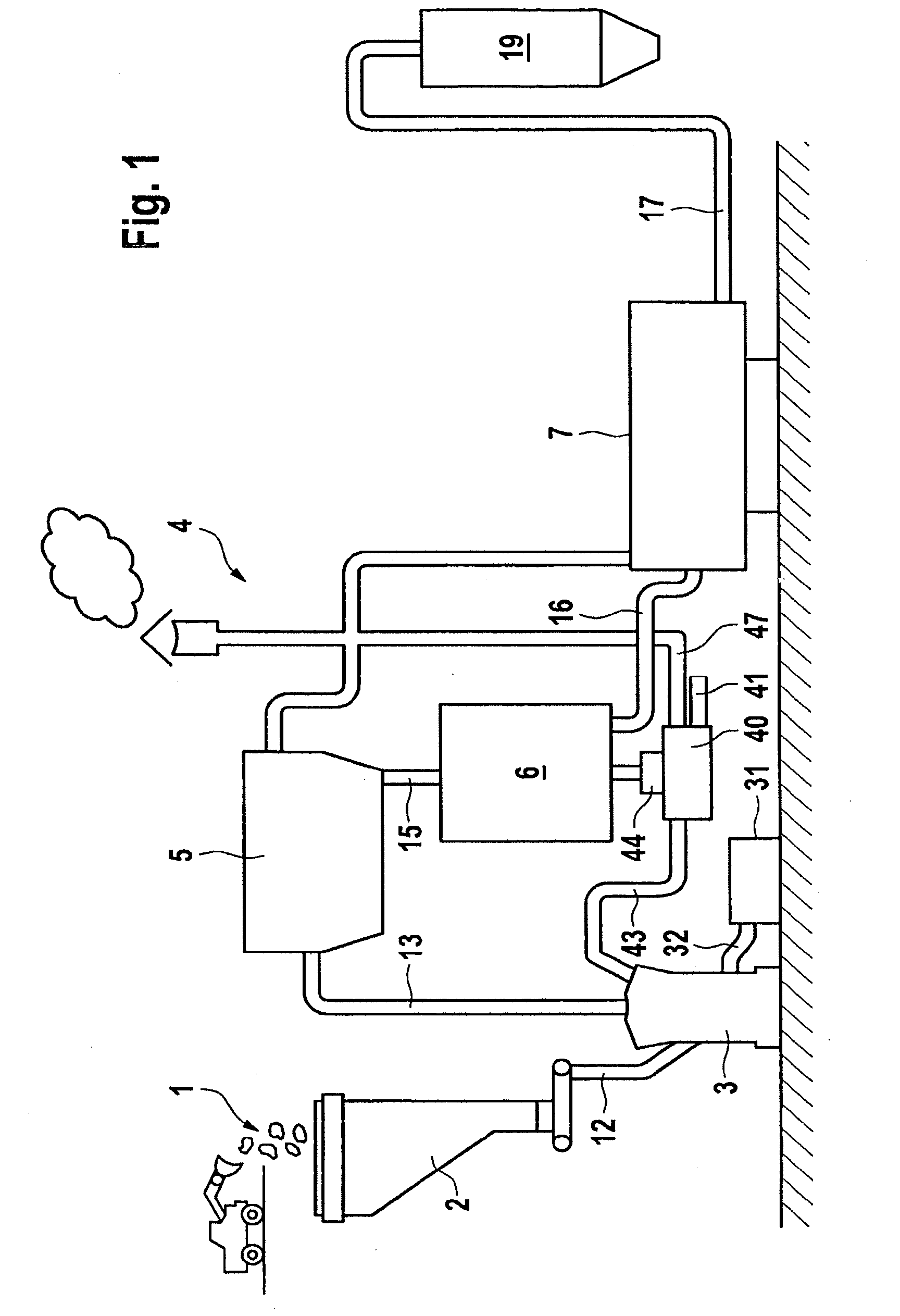

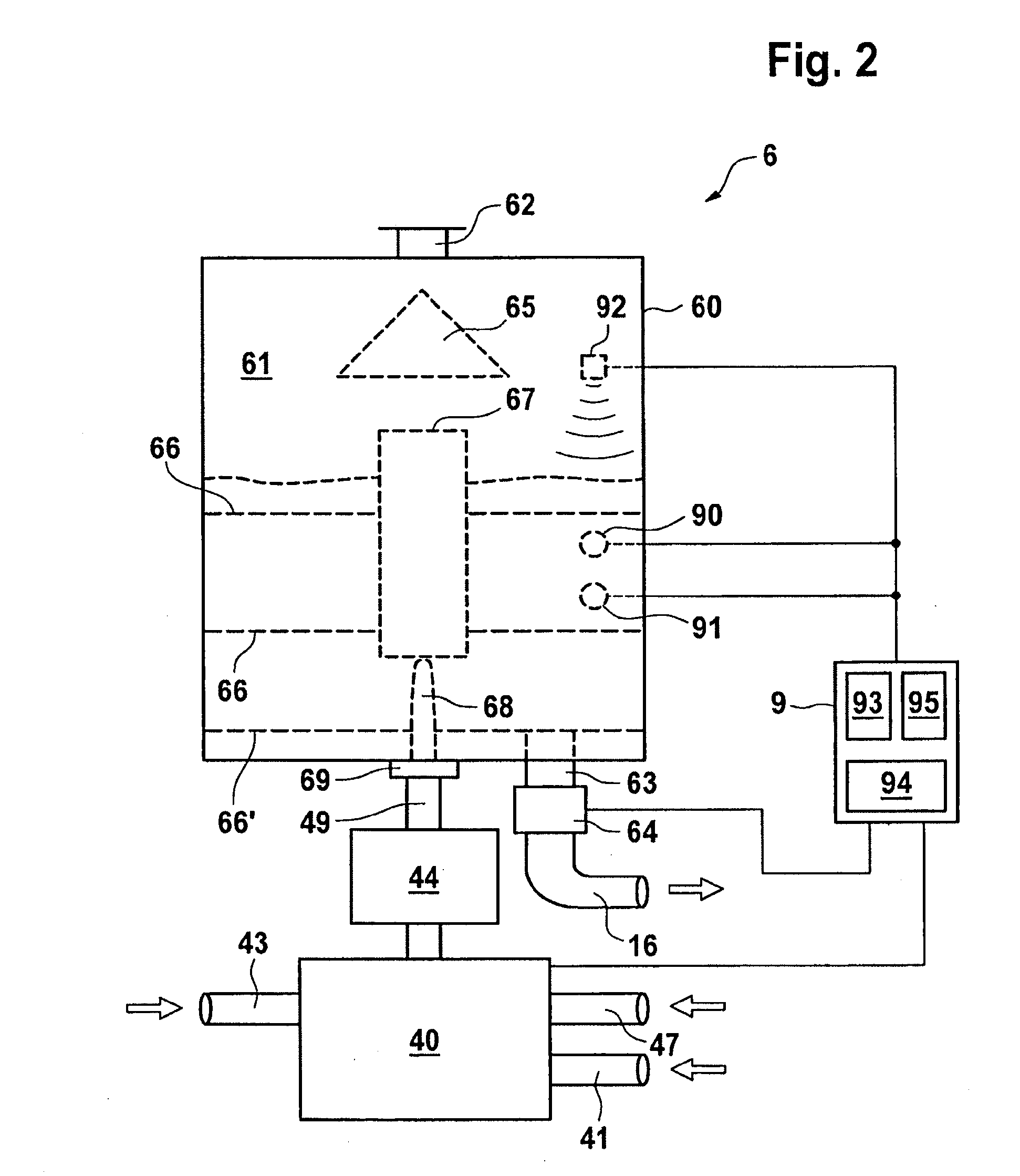

Calcination method and system

InactiveUS20110150750A1Save energyImprove product qualityGaseous chemical processesCalcium/strontium/barium sulfatesCalcinationGypsum

A method for the calcination of powdery or fine-particled plaster includes steps in which the plaster is subjected to a flash-calcination in a calcinator and then post-calcinated in a reaction vessel. The post-calcination is carried out in the reaction vessel by adding humid gas, the reaction vessel not being heated. This post-calcination takes place over a long period of time, that is at least 10 times, preferably 50-100 times longer than, the amount of time taken for flash calcination. Complete calcination can take place without expending additional energy, and the remaining dihydrate produced during the flash calcination is also transformed into semi-hydrate and undesired anhydrite fractions are reduced. The method ensures consistency in the product quality and also increases product quality. The temperature in the upstream calcinator can be lowered to save energy. The method can also be used to accelerate the ageing of calcined plaster.

Owner:CLAUDIUS PETERS PROJECTS

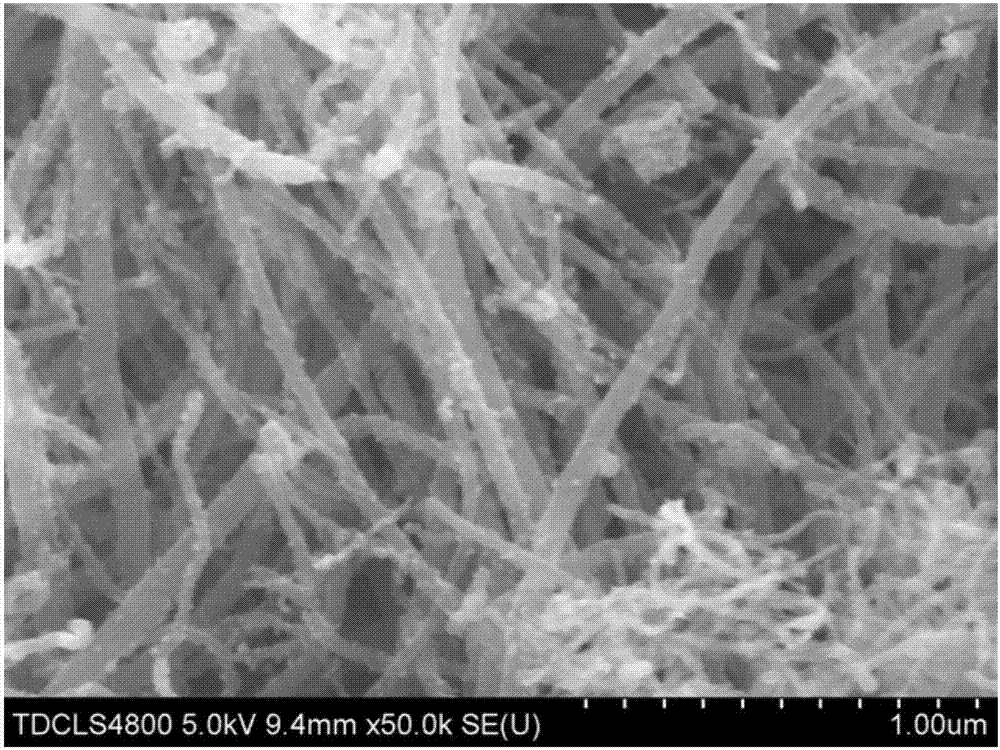

Transition metal oxide carbon nanotube composite material and its preparation method and application

InactiveCN107256954AThe synthesis process is simple and feasibleUniform productMaterial nanotechnologyCell electrodesMaterial cycleCarbon nanotube

The invention discloses a transition metal oxide carbon nanotube composite material and its preparation method and application. The preparation method includes steps of (1), dispersing carbon nanotube, transition metal nitrate, glucose, alkali environment promoter and surface active agent in mixed solution of ethanol and water respectively, performing ultrasound dispersion for 20-60 min; (2), transferring the system prepared in step (1) to a hydrothermal kettle to perform hydro-thermal synthesis reaction, wherein the reaction temperature is 160-190 DEG C, and the reaction time is 12h-24h; (3), staying and washing the system acquired in reaction of step (2) until neutral; drying for 12-24 hours under the air condition of 60-100 DEG C; finally, acquiring the transition metal oxide carbon nanotube composite material. The transition metal oxide carbon nanotube composite material has the beneficial effect of improving the material cycle performance and stabilization performance.

Owner:TIANJIN UNIV

Ultrasonic bone testing with copolymer transducers

InactiveUS20050101862A1Big economyEfficient executionOrgan movement/changes detectionInfrasonic diagnosticsElectricityUltrasonic sensor

Ultrasonic bone testing apparatus including a pair of spaced piezoelectric copolymer transducers for transmitting and receiving ultrasonic energy through a bone-containing portion of a human or other animal disposed between the transducers, and circuitry for detecting an electrical signal generated by the receiving transducer in response to reception of ultrasonic energy. The transducers are disks of the copolymer supported by rigid rings spaced inwardly of their peripheries. A method of determining a characteristic of bone in a bone-containing portion of an animal includes positioning a pair of piezoelectric copolymer ultrasonic transducers respectively on opposite sides of, and ultrasonically coupling both transducers to, the animal portion, and transmitting ultrasonic energy through the animal portion including the bone to be tested from one transducer to the other. The animal portion may be a human heel.

Owner:WILSON KEVIN +7

Production process of Tie Guanyin honey tea

The invention relates to a production method of tea leaves, in particular to a production process of Tie Guanyin honey tea. Tie Guanyin and honey are mixed in a porcelain pot with ratio of 1:1 for soaking and fermentation, the mixture is stirred uniformly regularly, and is baked at 40-50 DEG C after being soaked and fermented for two months. Compared with the existing honey tea, the Tie Guanyin honey tea is uniform, has mellow taste, special flavor, and thick and stable mouthfeel, and can be stored for more than 20 years in a sealing manner.

Owner:ANXI COUNTY GANDE QIYANG TEA CO LTD

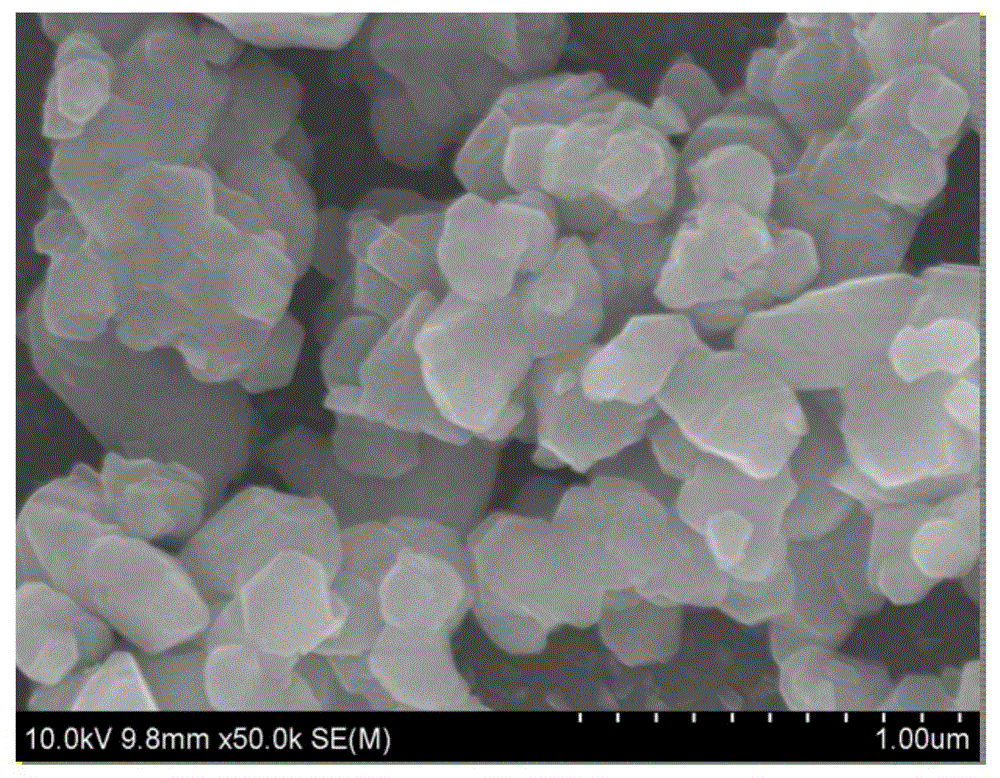

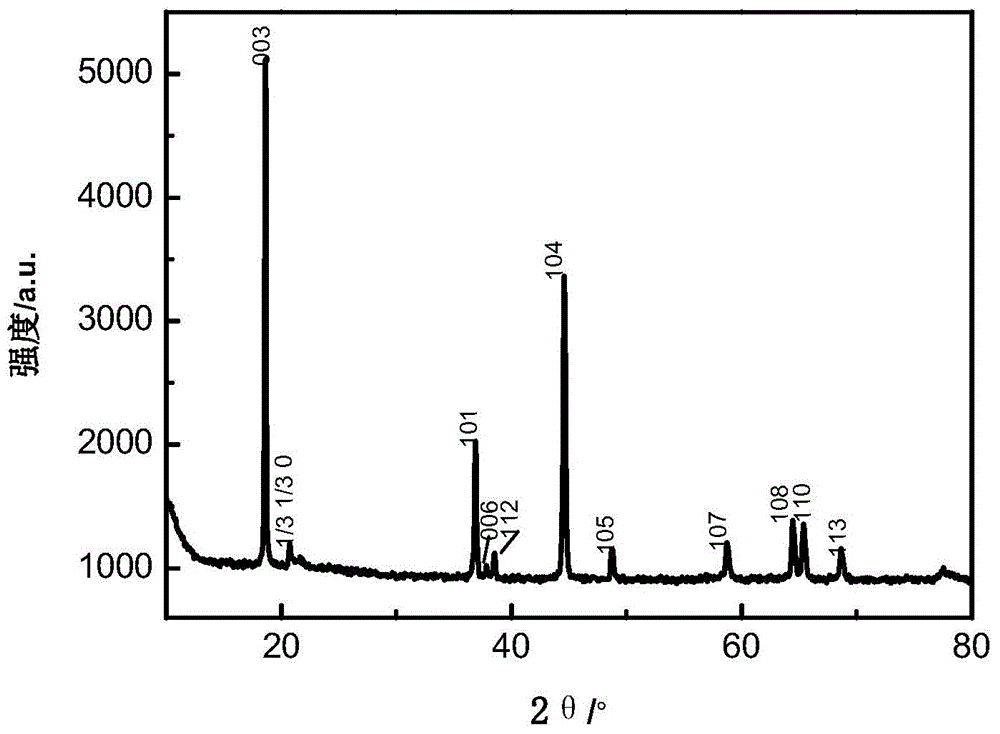

Preparation method of trace Mo-doped lamellar lithium-enriched ternary positive electrode material

InactiveCN104900857AHigh crystallinityExcellent electrochemical performanceCell electrodesTube furnaceNickel salt

The invention relates to a preparation method of a trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The molecular formula of the prepared ternary positive electrode material is Li1.2(Mn0.54Ni0.13Co0.13)(1-x)MoxO2 (x is more than 0 and smaller than 1). The adopted preparation method is an organic co-precipitation method and comprises the steps of stirring an organic precipitator in a water bath with constant temperature, and dissolving the organic precipitator into an organic solvent so as to obtain a solution A; then dissolving soluble cobalt salt, nickel salt, manganese salt, molybdenum salt and lithium salt into deionized water to obtain a solution B; after thorough dissolution, dropwise adding the solution B into the solution A at a constant speed, reacting and drying, increasing the temperature of the obtained solid powder in a high-temperature tube furnace system, and calcining so as to obtain the trace Mo-doped lamellar lithium-enriched ternary positive electrode material. The material has uniform particles and regular polygonal morphology feature, and has relatively good electrochemical performance, the preparation process is relatively simple, and the ternary positive electrode material is suitable for industrialized scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

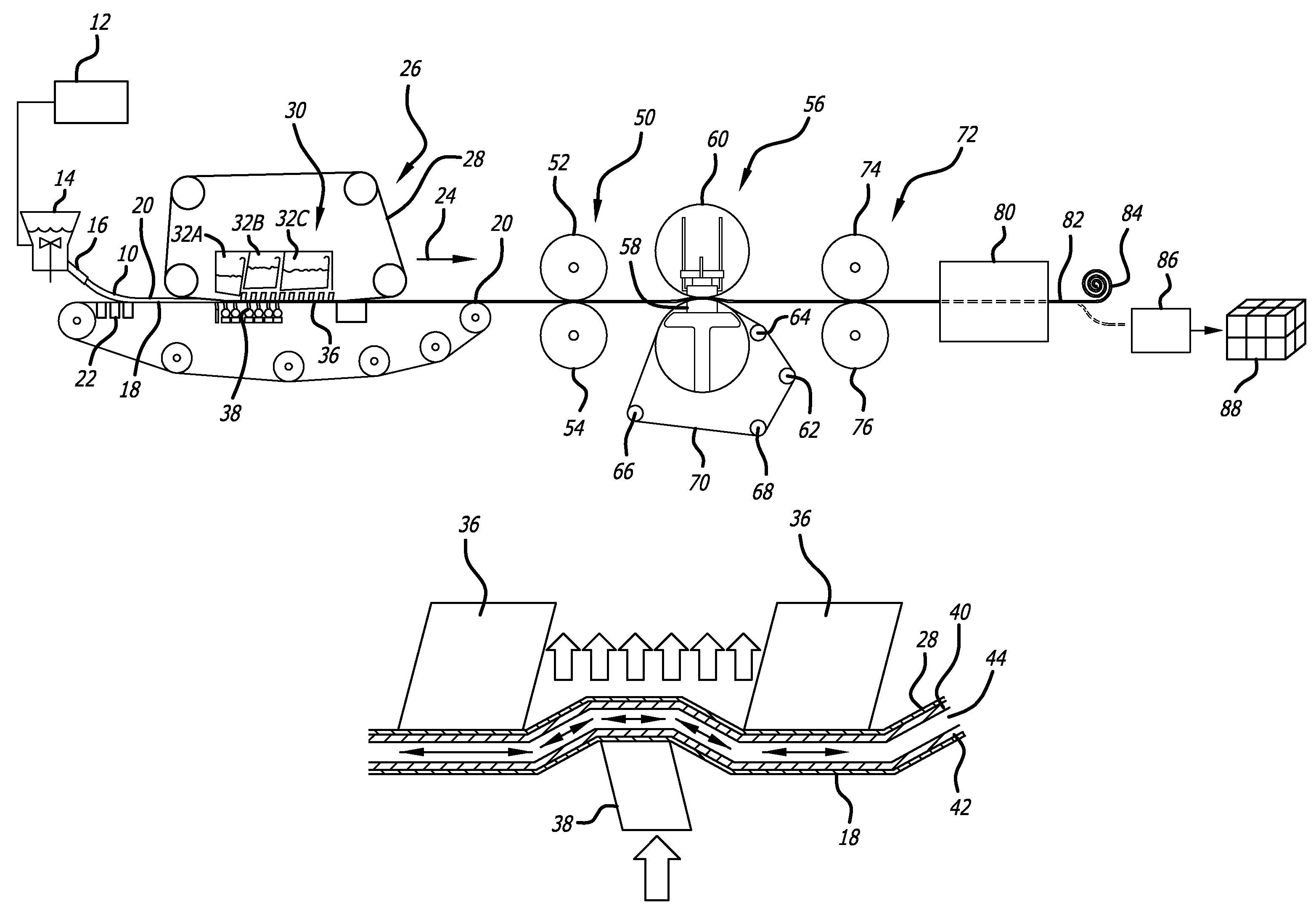

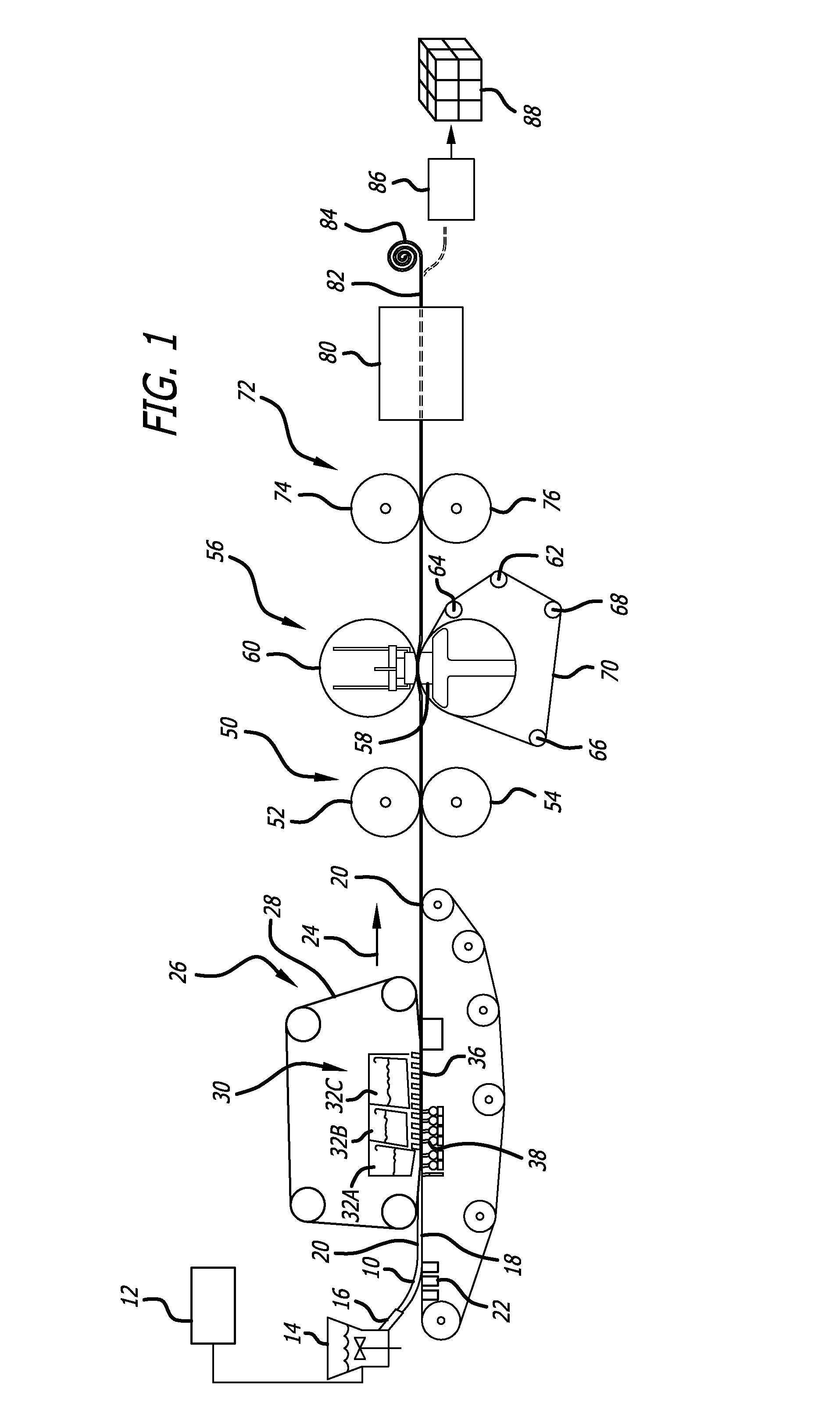

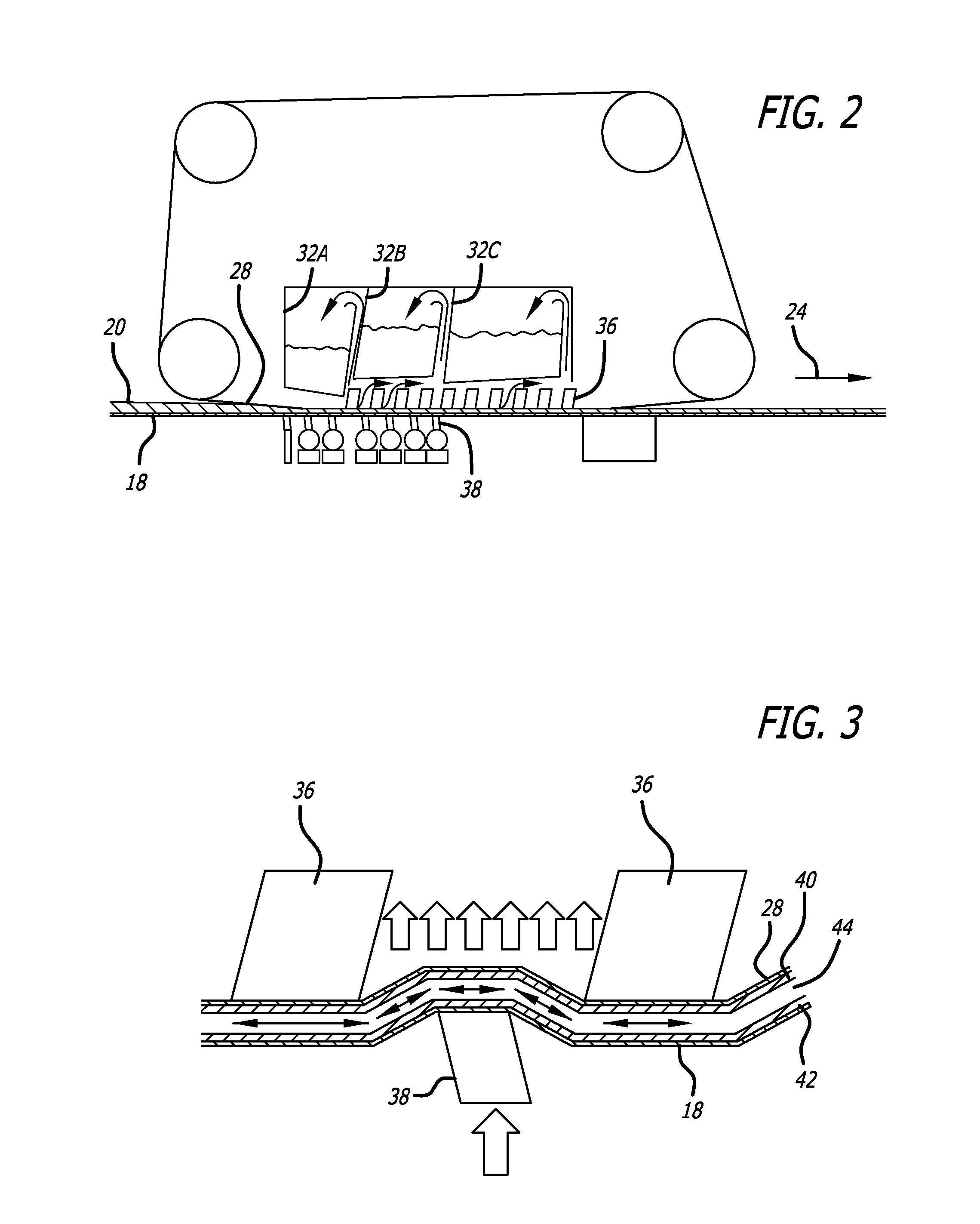

Methods and apparatus for forming fluff pulp sheets

ActiveUS8871059B2Reduce in quantityLower average energyFibreboardPulp properties modificationFiber bundleFluff pulp

Processes for making fluff pulp sheets mechanically eliminate many unwanted fiber-to-fiber bonding (fiber bundles) in the sheet. Pulp slurry is deposited on a moving bottom forming wire to form a stock web. Pulp slurry is brought into contact with a moving top forming wire. The stock web is subjected to up and down dewatering creating separately formed layers to reduce fiber-to-fiber bonding. The stock web can be subjected to strong pulsating shear forces as it is being advanced along the bottom forming wire to break fiber bundles. The pulp slurry can be deposited on the bottom forming wire utilizing a headbox with dilution control to selectively adjust the concentration of the pulp slurry. Shoe presses can be used to dewater the web after it is subjected to the pulsating shear forces.

Owner:INT PAPER CO

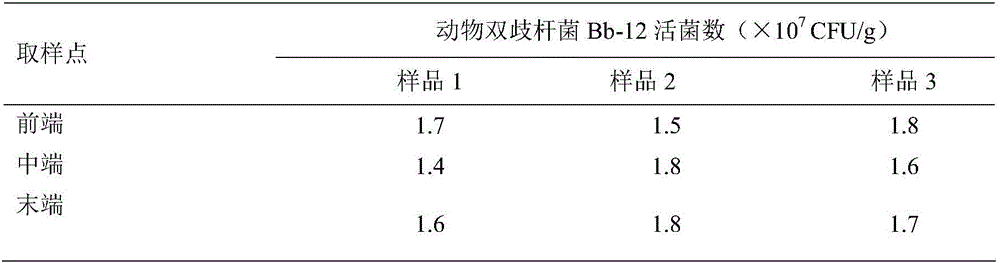

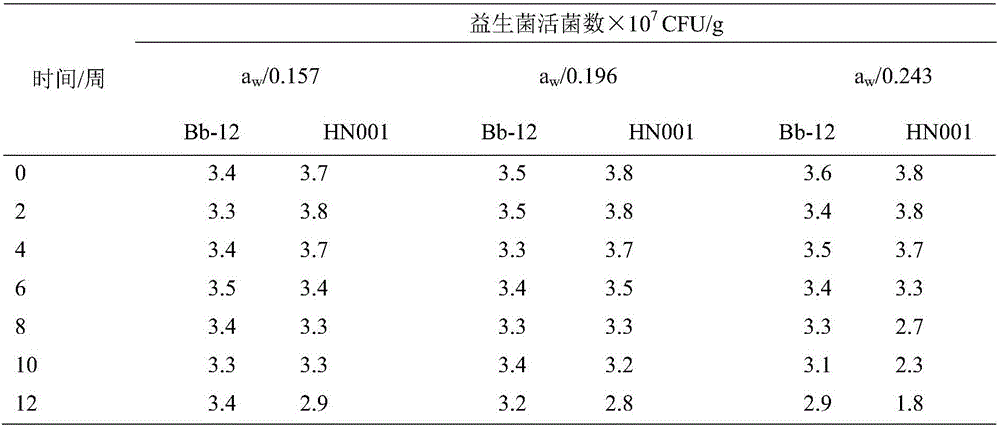

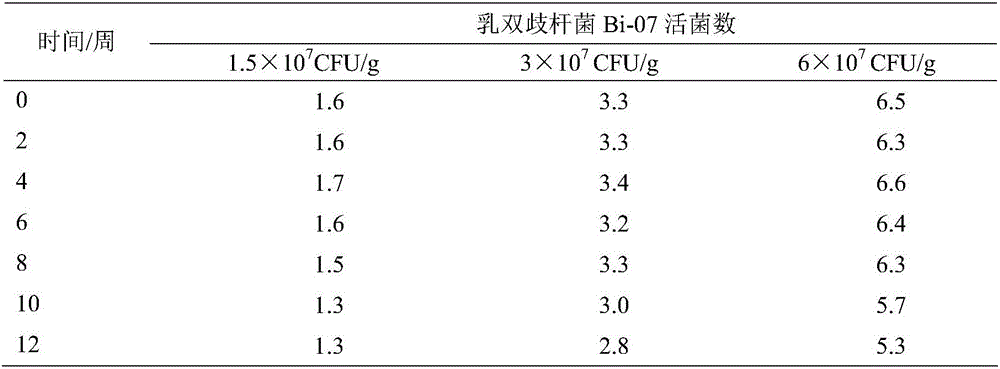

Newborn formula milk powder containing probiotics and preparation method thereof

The invention discloses newborn formula milk powder containing probiotics. The newborn formula milk powder comprises the raw materials: raw milk, milk sugar, mixed vegetable oil and activated probiotics lyophilized powder. The invention also discloses a method for preparing the milk powder. The method comprises the following steps of (1) mixing the raw materials to obtain feed liquid A; (2) homogenizing, sterilizing, concentrating and spray drying the feed liquid A to obtain a material B; (3) uniformly mixing the material B, a bioactive substance, unsaturated fatty acid and activated probiotics in a dry-mixing workshop to obtain the milk powder. The newborn formula milk powder containing the probiotics provided by the invention has the advantages that the newborn formula milk powder containing the probiotics is developed for newborns (0-28 days) according to nutritional ingredients and active substance characteristics of breast milk (colostrum and transitional milk). Meanwhile, according to the preparation method of the newborn formula milk powder containing the probiotics provided by the invention, the product uniformity of the milk powder can be ensured, the shelf life of the milk powder is stable, and the probiotics can be survived in the milk powder for a long time.

Owner:BRIGHT DAIRY & FOOD

Alumina abrasive for chemical mechanical polishing

InactiveUS7344988B2Small sizeReduce sizePigmenting treatmentOther chemical processesCompound (substance)Slurry

Methods of manufacturing alumina abrasive for use in chemical mechanical polishing are described, wherein the abrasive is in a slurry having gamma alumina formed in a low temperature fuming process, water, an acid sufficient to maintain the pH below about 7, wherein the slurry does not settle appreciably in an 8 to 24 hour period. Advantageously, the alumina is wet-milled without the use of wet-milling salt additives.

Owner:VERSUM MATERIALS US LLC +1

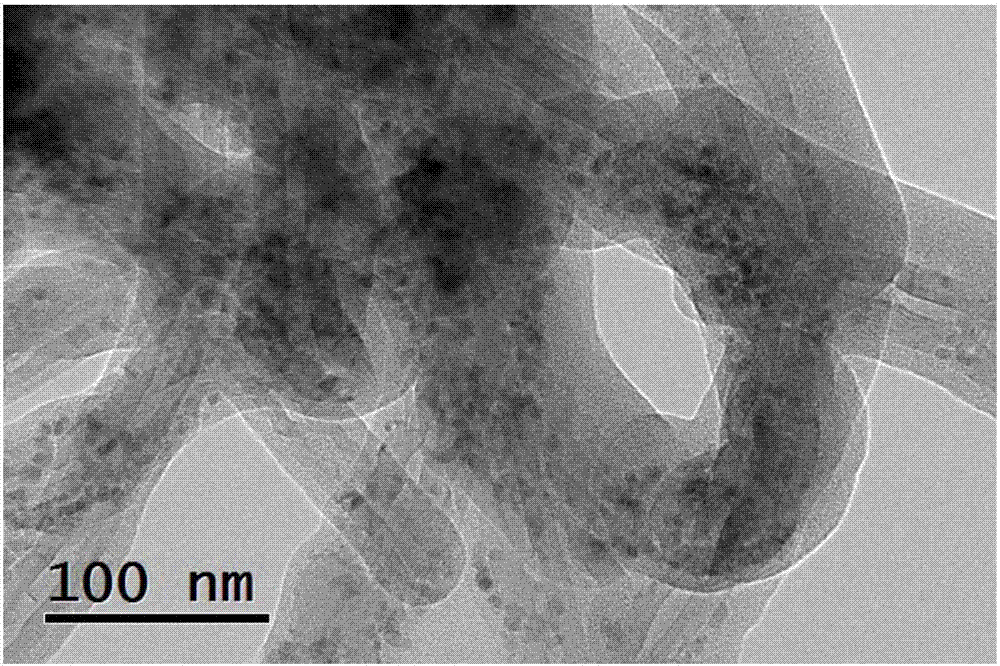

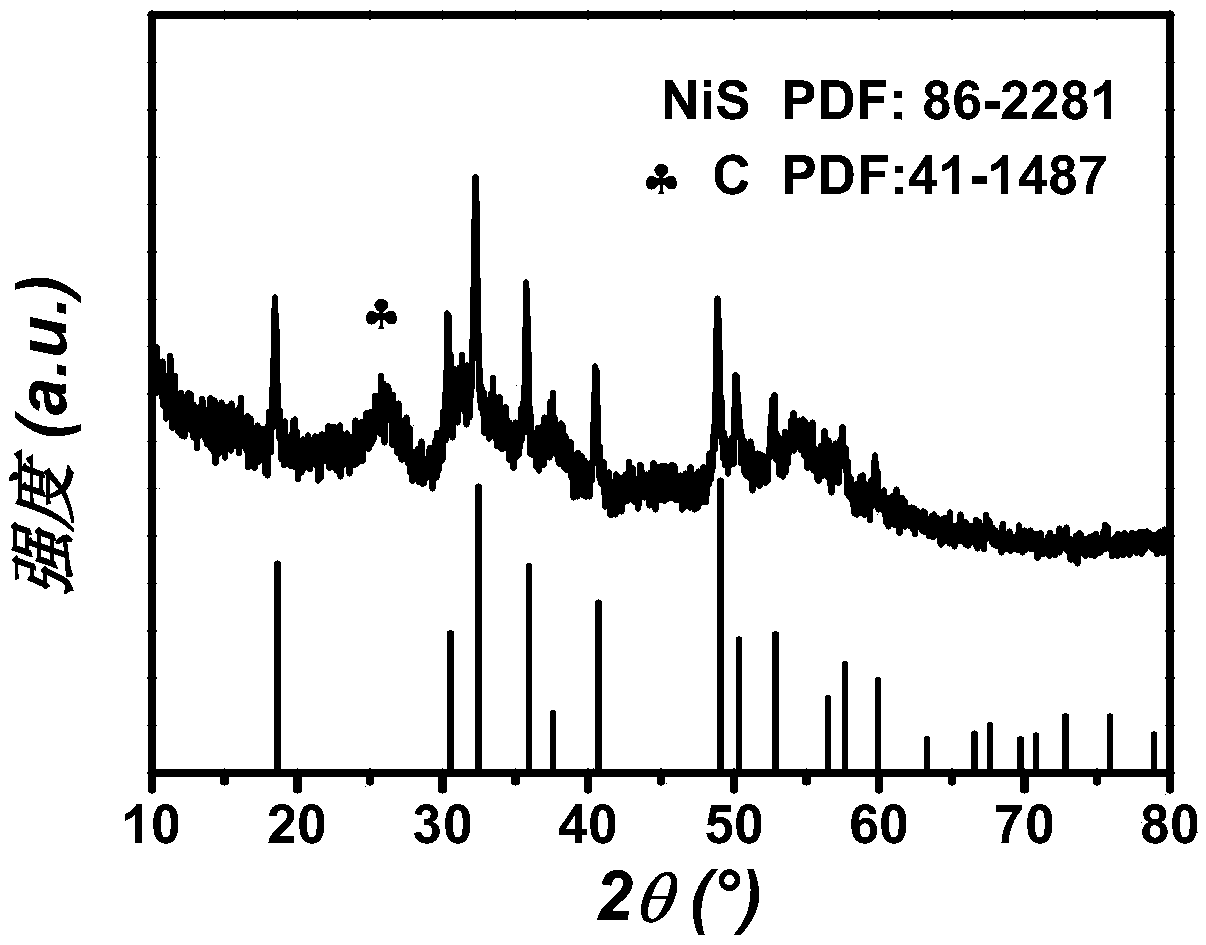

Application of nickel sulfide/carbon nanotube flexible composite film material in negative electrode of lithium ion battery

The invention discloses the application of a nickel sulfide / carbon nanotube flexible composite film material in the electrode of a lithium ion battery. The preparation method of the composite film material comprises the steps that urea and nickel nitrate are added to an aqueous solution of ethanol, and then a silicon oxide / carbon nanotube film is added, immersed and removed at room temperature, placed in an oven at 100 DEG C to 110 DEG C for 10 to 15h, cooled naturally at room temperature, washed and dried to acquire a silicate / carbon nanotube film for standby; deionized water is mixed with ethanol, and Na2S is added as a sulfur source to prepare a solution with a concentration of 1 to 2.5mg / mL; the silicate / carbon nanotube film is immersed in the solution, reacts at 150 to 200 DEG C for 10 to 15h; and natural cooling, washing and drying are carried out to acquire the nickel sulfide / carbon nanotube flexible composite film material. The nickel sulfide / carbon nanotube flexible compositefilm material can be directly used as the negative electrode material of the lithium ion battery.

Owner:TIANJIN UNIV

Method for producing absorbent article with stretch film side panel and application of intermittent discrete components of an absorbent article

InactiveUS9089453B2Improve bindingUniform productLaminationLamination apparatusEngineeringElectrical and Electronics engineering

Apparatus and methods are provided to allow for creation of a configured laminate of a non-woven material, to which a character strip is applied, the character strip exposed by either heat severing and removal of overlying materials, or intermittent application of overlying materials to leave the desired portions of the character strip exposed. A simultaneously formed core insert is applied to a preformed chassis web.

Owner:CURT G JOA

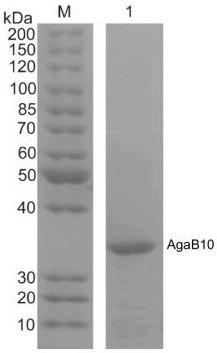

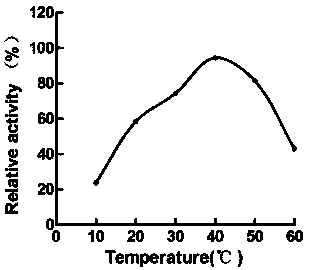

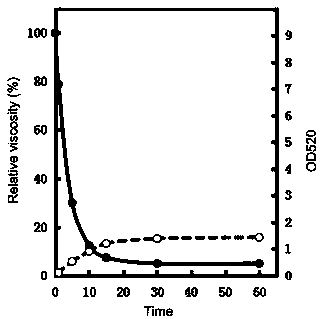

Endo-type beta-agarase with main degradation product being neoagarobiose as well as application thereof

InactiveCN109022397AEnzymes are stableUniform productGenetic engineeringFermentationChemistryAmino acid

The invention relates to endo-type beta-agarase with a main degradation product being neoagarobiose as well as an application thereof. The beta-agarase is a novel beta-agarase AgaB10, and an amino acid sequence isas shown byas SEQ ID NO. 1. The beta-agarase is an artificially-designed novel beta-agarase and comprises 350 amino acids. The similarity of the beta-agarase provided inby the invention to the existing beta-agarase sequence is only 67 percent. The degradation way of the beta-agarase AgaB10 is an endo-incision way and has the characteristic that the product is homogenous, and the ratioof the neoagarobiose in the degradation product reaches 86.2 percent. In addition, the beta-agarase AgaB10 ofprovided by the invention is stable in performance, high in yield, and great in industrialized application potential.

Owner:吴中宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com