Application of nickel sulfide/carbon nanotube flexible composite film material in negative electrode of lithium ion battery

A carbon nanotube thin film and lithium-ion battery technology, which is applied in the direction of carbon nanotubes, battery electrodes, nano-carbon, etc., can solve the problems that cannot meet the requirements of large-scale industrialization of flexible devices, achieve low preparation costs, and improve volume change , the effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

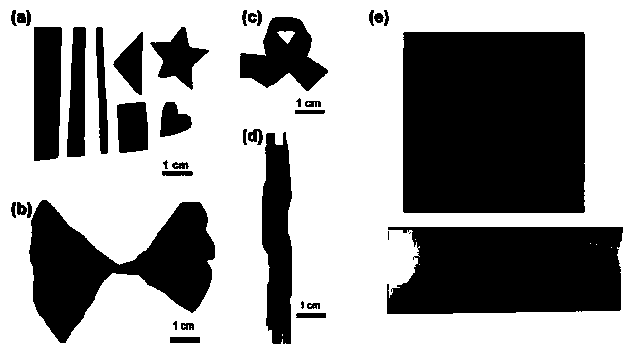

Image

Examples

Embodiment 1

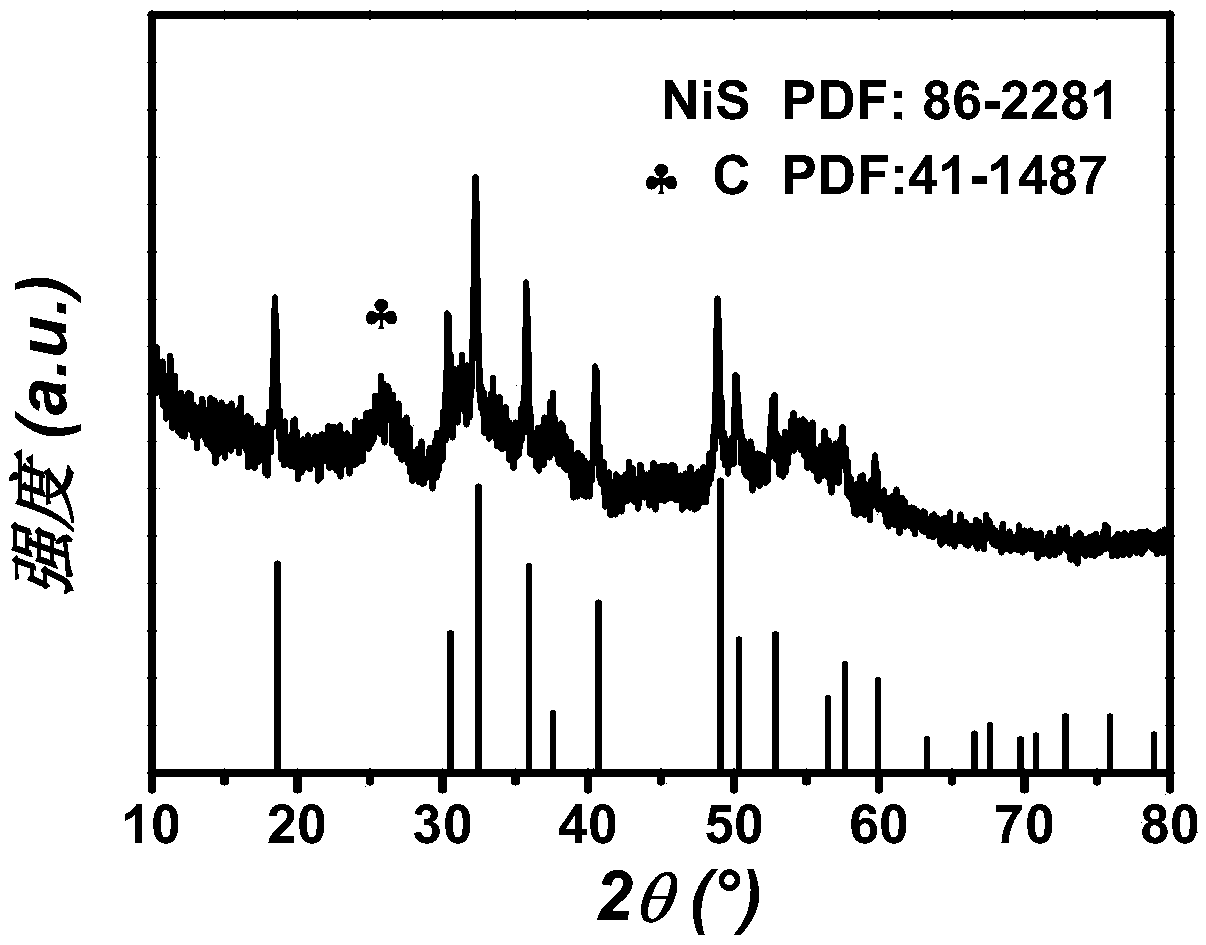

[0040] Embodiment 1: prepare NiS / CNTs-2, wherein sulfur source Na 2 The concentration of S was 2.1 mg / mL.

[0041] (1) Gas phase pyrolysis method prepares silicon oxide / carbon nanotube composite film material: 1) weigh 24.03g ethanol, 0.432g ferrocene, 0.22g thiophene, wherein, ethanol is as the carbon source of this reaction, ferrocene As a catalyst, thiophene is used as a promoter, and the above-mentioned tetraethyl orthosilicate (TEOS) with a total mass fraction of 4% (~1.028g) is weighed as a silicon source for the reaction, and the above solution is continuously ultrasonically dispersed at 50°C for 60 minutes. After obtaining a relatively uniform dispersion, transfer it to a syringe as a precursor solution; 2) Completely seal the vertical CVD furnace, continuously feed 100 sccm of Ar, completely remove the residual air in the furnace, and raise the temperature of the vertical CVD furnace to 1150°C , keep warm for 5h; 3) After steps 1) and 2) are completed, turn off the A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com