Tilmicosin phosphate enteric granules and preparation method thereof

A technology of tilmicosin phosphate and granules, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problem of being unable to cover up the therapeutic effect of tilmicosin phosphate and affect the therapeutic effect , reduce the treatment effect of tilmicosin phosphate and other problems, achieve the effect of uniform drug effect, improve the treatment effect, and avoid the effect of gastric acid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

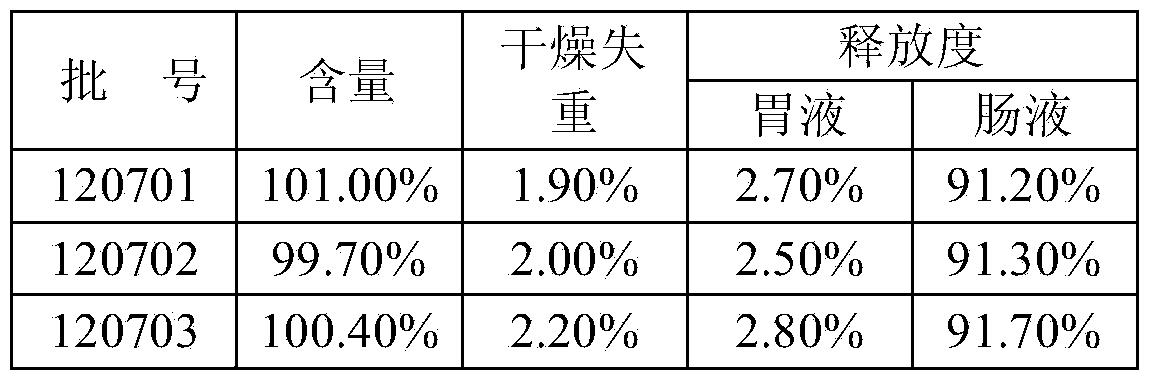

Examples

Embodiment 1

[0022] 1. Preparation of prime granules

[0023] 1) The mass percentages of preparative granule raw materials are as follows: 5% tilmicosin phosphate, 55% microcrystalline cellulose, 5% sodium carboxymethyl starch, 30% starch, 1% sodium lauryl sulfate and hydroxypropyl Methyl cellulose 4%, after above-mentioned each component crosses 100 mesh sieves to sieve respectively, according to the mass percent of preparative granule raw material, take by weighing particle diameter and be each component of 100 mesh;

[0024] 2) After mixing the components, add enough water and stir evenly to obtain a soft material. The soft material is granulated with a double-spherical extruder with a diameter of 0.6mm orifice. A 400r / min spheronizer is used for spheronizing for 10 minutes. After spheronization, the wet pellets are taken out and dried, and the dried pellets are sieved to obtain granules with a particle size of 30 meshes.

[0025] 2. Preparation of coating solution

[0026] 1) Weigh 7...

Embodiment 2

[0032] 1. Preparation of prime granules

[0033] 1) The mass percentages of preparative granule raw materials are as follows: 40% tilmicosin phosphate, 30% microcrystalline cellulose, 1% sodium carboxymethyl starch, 26.9% starch, 0.1% sodium lauryl sulfate and hydroxypropyl Methylcellulose 2%. After each of the above-mentioned components is sieved through a 60-mesh sieve, each component whose particle size is 60-mesh is weighed according to the mass percentage of the raw material of Suparin Granules;

[0034] 2) After mixing the components, add enough water and stir evenly to obtain a soft material. The soft material is granulated with a double-spherical extruder with a diameter of 0.6mm orifice. The spheronizer at 1000r / min was used for spheronizing for 5 minutes, and after spheronization, the wet pellets were taken out and dried, and the dried pellets were sieved, and the pellets with a particle size of 60 meshes were obtained to obtain plain pellets.

[0035] 2. Preparati...

Embodiment 3

[0042] 1. Preparation of prime granules

[0043] 1) The mass percentages of the raw materials of preparative granules are as follows: 30% tilmicosin phosphate, 34% microcrystalline cellulose, 5% sodium carboxymethyl starch, 27% starch, 1% sodium lauryl sulfate and hydroxypropyl Methyl cellulose 3%, after above-mentioned each component crosses 200 mesh sieves to sieve respectively, take by weighing the particle diameter and be each component of 200 mesh by the mass percentage of preparative granule raw material;

[0044] 2) After mixing the components, add enough water and stir evenly to obtain a soft material. The soft material is granulated with a double-spherical extruder with a diameter of 0.6mm orifice. The 600r / min spheronizer is used for spheronizing for 8 minutes. After spheronization, the wet spheroids are taken out and dried, and the dried spheroids are sieved, and the particles with a particle size of 50 meshes are obtained as plain granules.

[0045] 2. Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com