Method for quickly preparing phase change energy storage microcapsule by ultraviolet light irradiation and polymerization

A technology of phase change energy storage and phase change energy storage material, which is applied in the field of ultraviolet light-induced polymerization to rapidly prepare phase change energy storage microcapsules, can solve the problems of complex preparation process, slow reaction rate, long preparation time, etc., and achieve uniform product. , the effect of fast polymerization rate and increased reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 15g octadecane, 0.25g photoinitiator 2959, 8g methyl methacrylate, 0.4g Span80, 0.5g Tween80 to 100g deionized water, stir magnetically at 700rpm for 25min at a temperature of 40°C, and then use a homogenizer The machine was homogenized for 3 minutes at a speed of 7000 rpm to obtain an emulsion with certain stability.

[0021] Put the emulsion into a 250ml quartz beaker, change to magnetic stirring at 300rpm, and irradiate the emulsion with a 1000W UV lamp at a distance of 30cm for 30min; then turn off the UV lamp and filter; add the filter cake to a hot deionization machine at 60°C In water, keep warm, stir, wash for 30 minutes, and filter again; the filter cake is repeatedly washed three times under the above conditions, and the product is placed in an oven and dried at 45°C for 5 hours to obtain the product as an odorless, loose white powder.

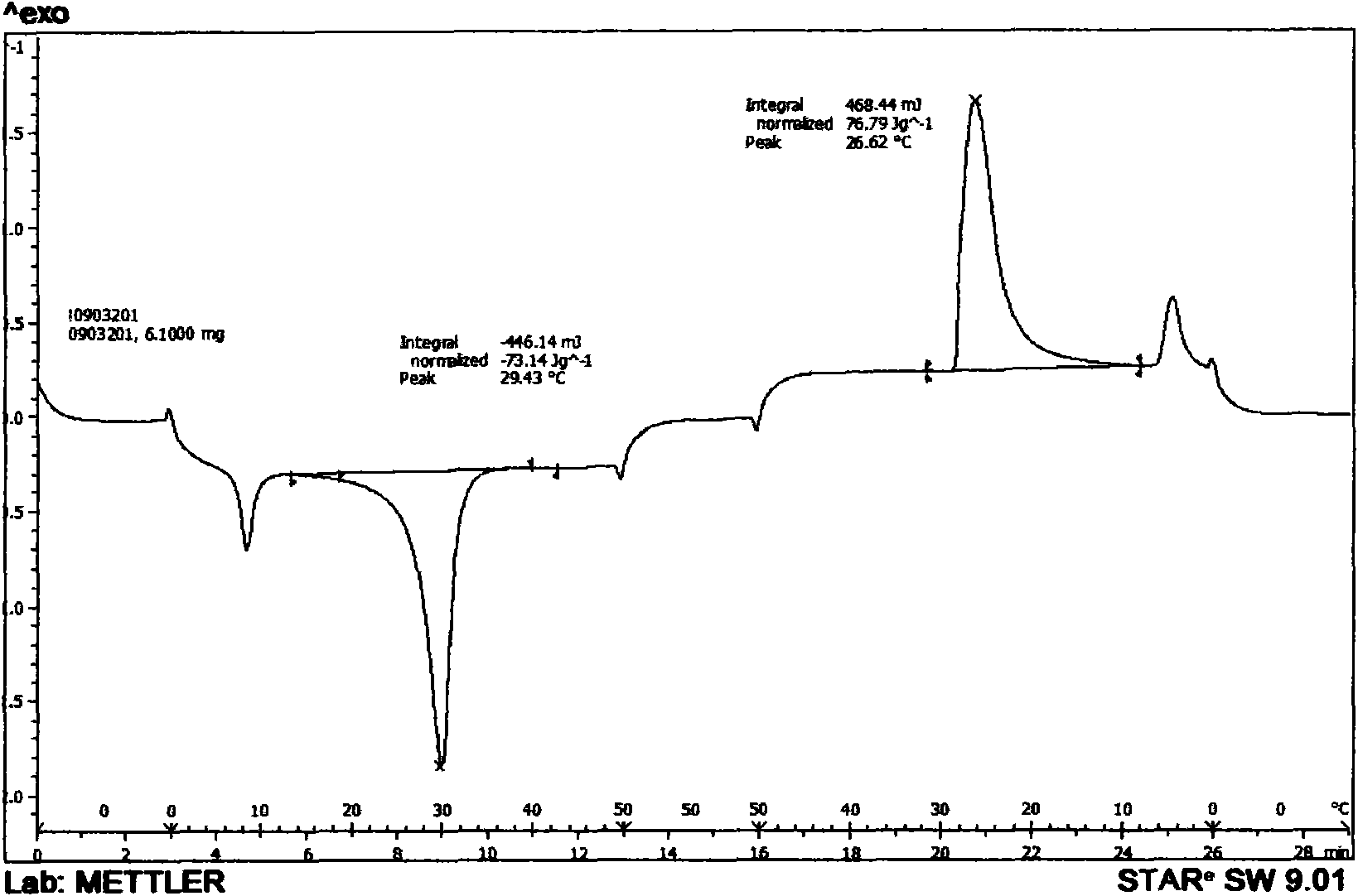

[0022] The appearance photograph of the PCM microcapsule prepared by embodiment 1 is shown in figure 1 . It can be see...

Embodiment 2

[0026] In 100g deionized water, add 15g No. 30 phase-change paraffin, 0.3g photoinitiator BTC, 10g butyl methacrylate, 0.23g Pingpingjia, 0.96g sodium dodecylbenzenesulfonate, at a temperature of 45°C, to Stir magnetically at 600rpm for 30min, then homogenize with a homogenizer at 9000rpm for 3min to obtain an emulsion with certain stability.

[0027] Add the emulsion into a 250ml quartz beaker, change to 400rpm magnetic stirring, and irradiate the emulsion with a 500W UV lamp at a distance of 20cm from the light source for 35min; then turn off the UV lamp and filter; add the filter cake to hot deionized water at 60°C , keep warm, stir, wash for 30 minutes, and filter again; the filter cake is repeatedly washed three times under the above conditions, and the product is put into an oven and dried at 45°C for 5 hours to obtain the product, which is an odorless, loose white powder.

Embodiment 3

[0029] Add 15g of dodecyl alcohol, 0.25g of photoinitiator ABP, 8g of methacrylic acid, 0.46g of emulsifier OP10, 0.790g of sodium lauryl sulfate into 100g of deionized water, and stir magnetically at 700rpm for 30min at a temperature of 30°C , and then use a homogenizer to homogenize for 3 minutes at a speed of 7000 rpm to obtain an emulsion with certain stability.

[0030] Put the emulsion into a 250ml quartz beaker, change to 300rpm magnetic stirring, and irradiate the emulsion with a 500W UV lamp at a distance of 20cm from the light source for 40min; then turn off the UV lamp and filter; add the filter cake to 60°C heat to remove In deionized water, keep warm, stir, wash for 30 minutes, and filter again; the filter cake is repeatedly washed three times under the above conditions, and the product is placed in an oven and dried at 45°C for 5 hours to obtain the product, which is an odorless, loose white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com