Styrene-butadiene-isoprene terpolymer integrated latex and preparation method thereof

A technology of isoprene terpolymer and integrated latex, which is applied in the field of styrene-butadiene-isoprene terpolymer integrated latex and its preparation, can solve human skin allergic reactions and affect popularization and application , Difficulty in degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Add 150 parts of water, 1.5 parts of disproportionated potassium abietate, 3.5 parts of sodium stearate, 0.06 parts of potassium hydroxide, 0.50 parts of potassium carbonate, 0.50 parts of tertiary dodecyl mercaptan, and 0.20 parts of potassium persulfate in a 20L polymerization kettle , 0.15 parts of ammonium persulfate, 20 parts of styrene, replaced with nitrogen for 3 times, then added 40 parts of isoprene, 40 parts of butadiene, started stirring, raised the temperature to 65 ° C, reacted for 11.5 hours, cooled and discharged , to end the reaction. The analysis results are as follows: the conversion rate of the monomer is 94.2%; the molecular weight of the terpolymer is 184,000, the particle size of the integrated latex of the terpolymer is 87.4nm, and the gel content is 62.38%; transition temperature T g It is -50.42°C.

Embodiment 2

[0012] The used emulsifying agent of embodiment 2 is disproportionated potassium abietate, and the consumption of disproportionated potassium abietate is 3.5 parts; Initiator is potassium persulfate, and the consumption of potassium persulfate is 0.30 part; Other monomer proportioning, reagent formula and polymerization condition are all with Example 1 is the same. The analysis results are as follows: the monomer conversion rate is 93.5%; the molecular weight of the terpolymer is 206,000, the particle size of the terpolymer integrated latex is 94.6nm, and the gel content is 64.89%; transition temperature T g It is -53.28°C.

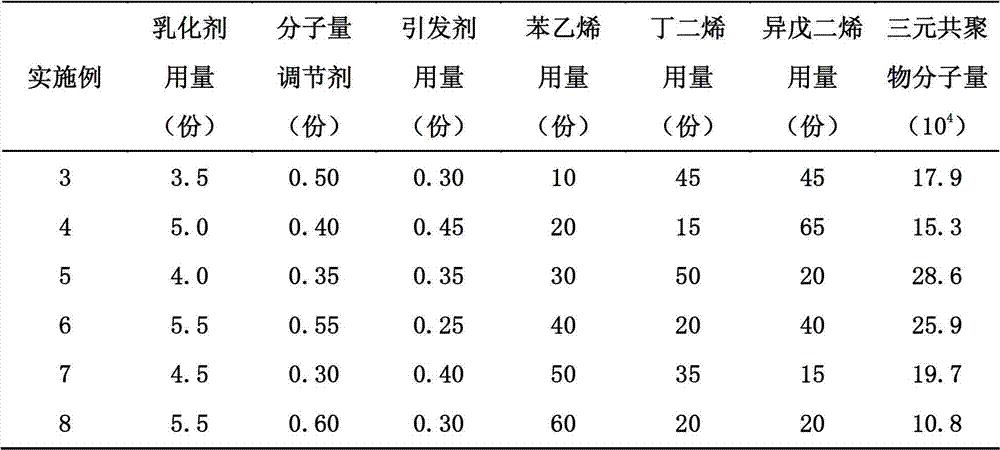

Embodiment 3-8

[0014] The monomer ratio and reagent formula of Examples 3-8 are shown in Table 2, other polymerization conditions are the same as in Example 2, the monomer conversion rate is controlled at about 95%, and the molecular weight of terpolymer integrated latex is shown in Table 2 , where the molecular weight of the terpolymer is the number average molecular weight.

[0015] Table 1. Preparation of terpolymer integrated latex under different conditions

[0016]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com