Synthetic method of polyaniline nanofiber with helical structure

A nanofiber and helical structure technology, which is applied in the synthesis of helical polyaniline nanofibers, can solve the problems of low optical activity of polyaniline, achieve huge application potential, increase polymerization rate, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples describe the present invention in more detail.

[0018] 1. Synthesis of N,N'-bis(4'-aminobenzene)-1,4-phenylenediamine

[0019] Dissolve 0.6-0.8g of p-phenylenediamine and 1.0-1.5ml of aniline in 40ml of 1M hydrochloric acid solution containing 3-4g of sodium chloride, then cool to -5°C, stir vigorously, and dissolve 1.2-1.8g of ammonium persulfate in 10ml of 1M hydrochloric acid , add dropwise with a 10ml needle tube, stir for 1 hour after the addition, wash the product with 30-50ml of hydrochloric acid at 0°C, then wash with 10-15ml of ammonia water (10%), and finally wash with water until neutral, dry at 50°C to obtain a red solid. The solid was dissolved in ethanol, under N2 protection, hydrazine hydrate was added dropwise, and refluxed at 70-80° C. for 3-5 hours to obtain white particles.

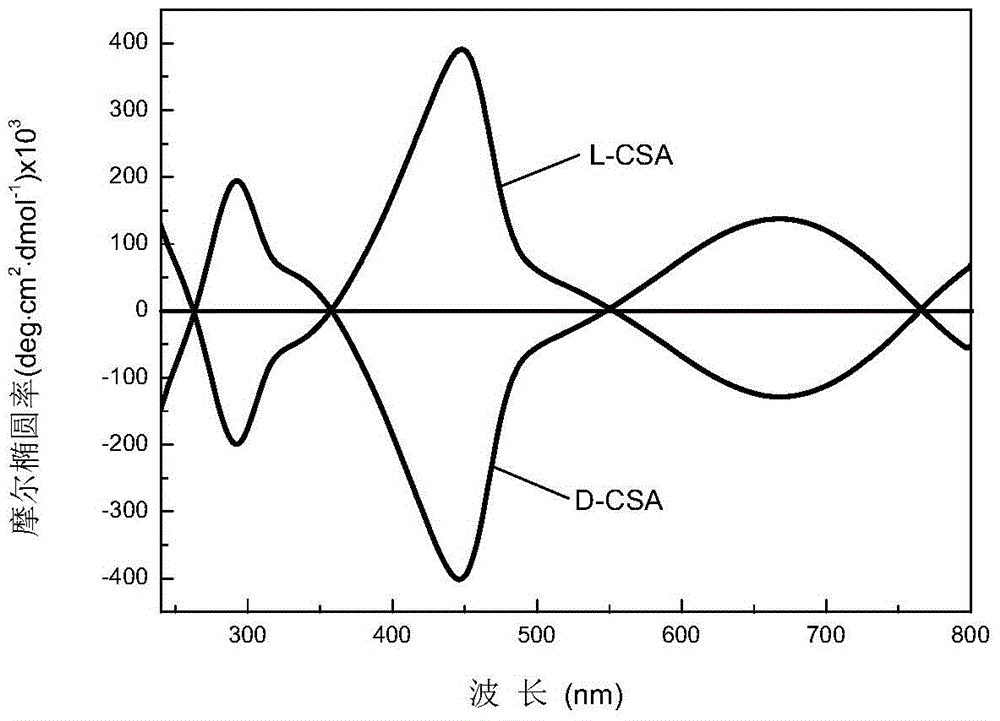

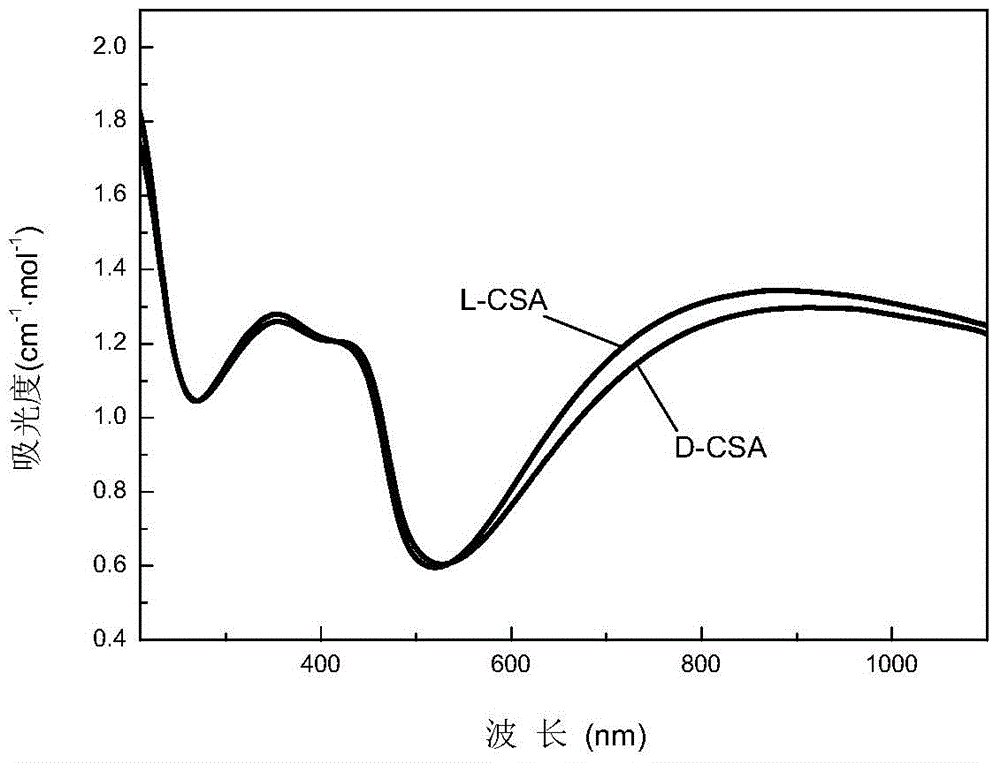

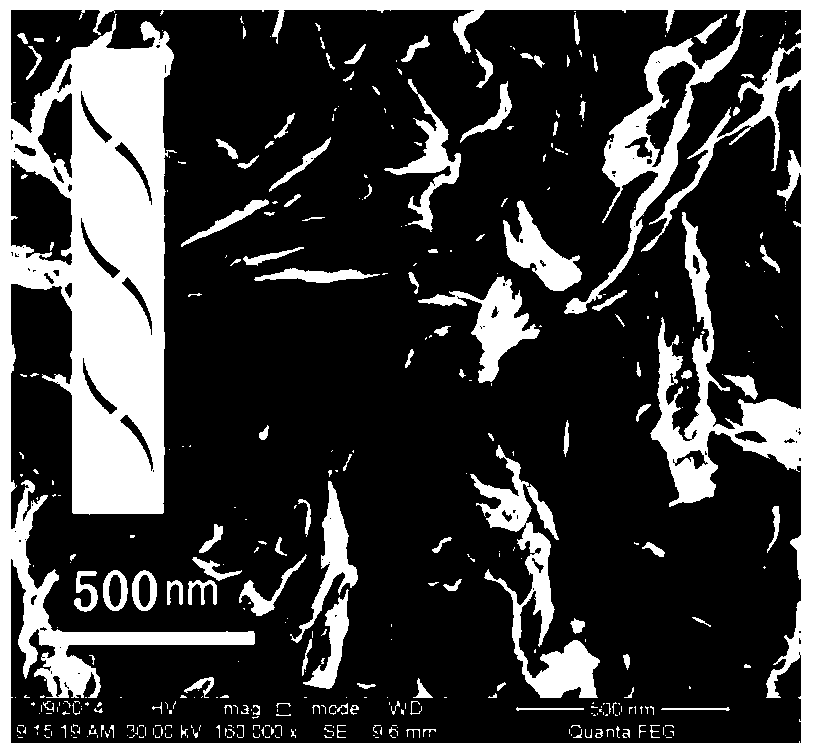

[0020] 2. Preparation of helical polyaniline nanofibers

[0021] Weigh 1.8~2.3g D-(+)-camphorsulfonic acid (CSA) or L-(-)-camphorsulfonic acid (CSA) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com