Patents

Literature

255 results about "Camphorsulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camphorsulfonic acid, sometimes abbreviated CSA or 10-CSA is an organosulfur compound. Like typical sulfonic acids, it is a relatively strong acid that is a colorless solid at room temperature and is soluble in water and a wide variety of organic substances.

Nanomaterial-based gas sensors

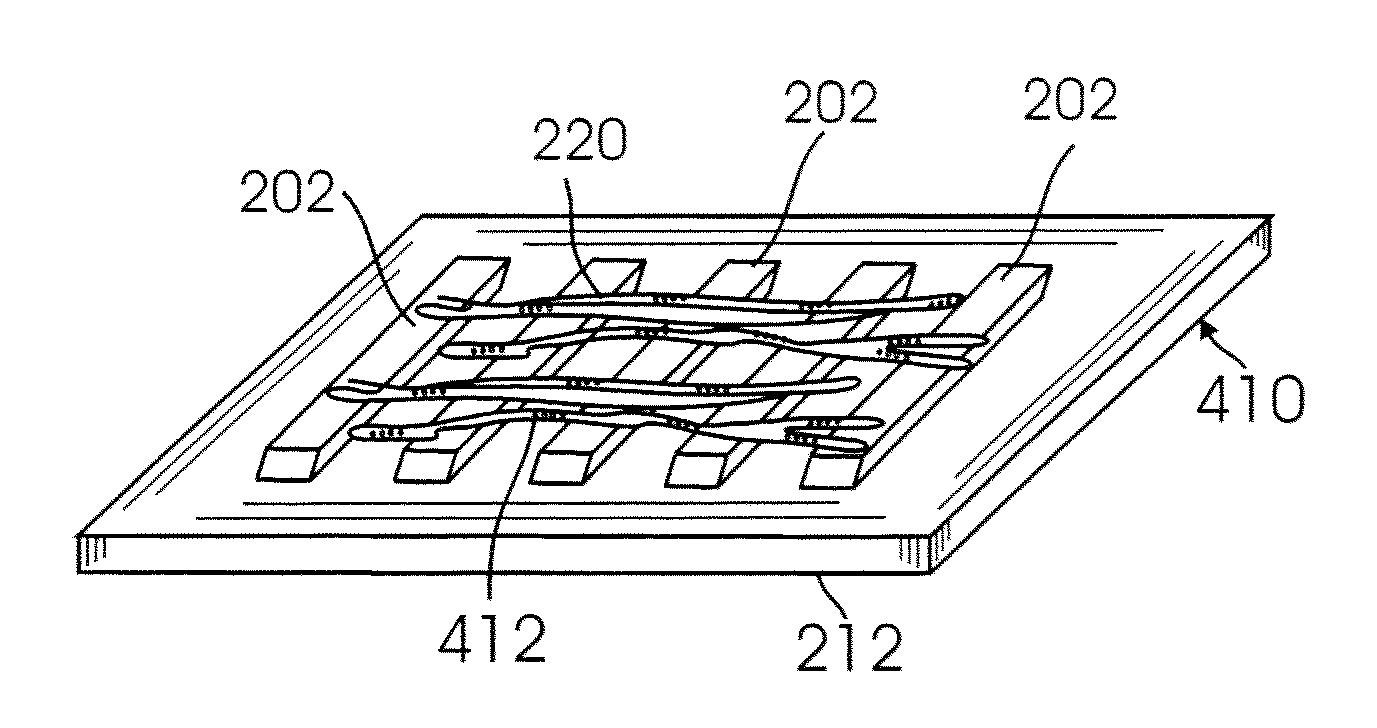

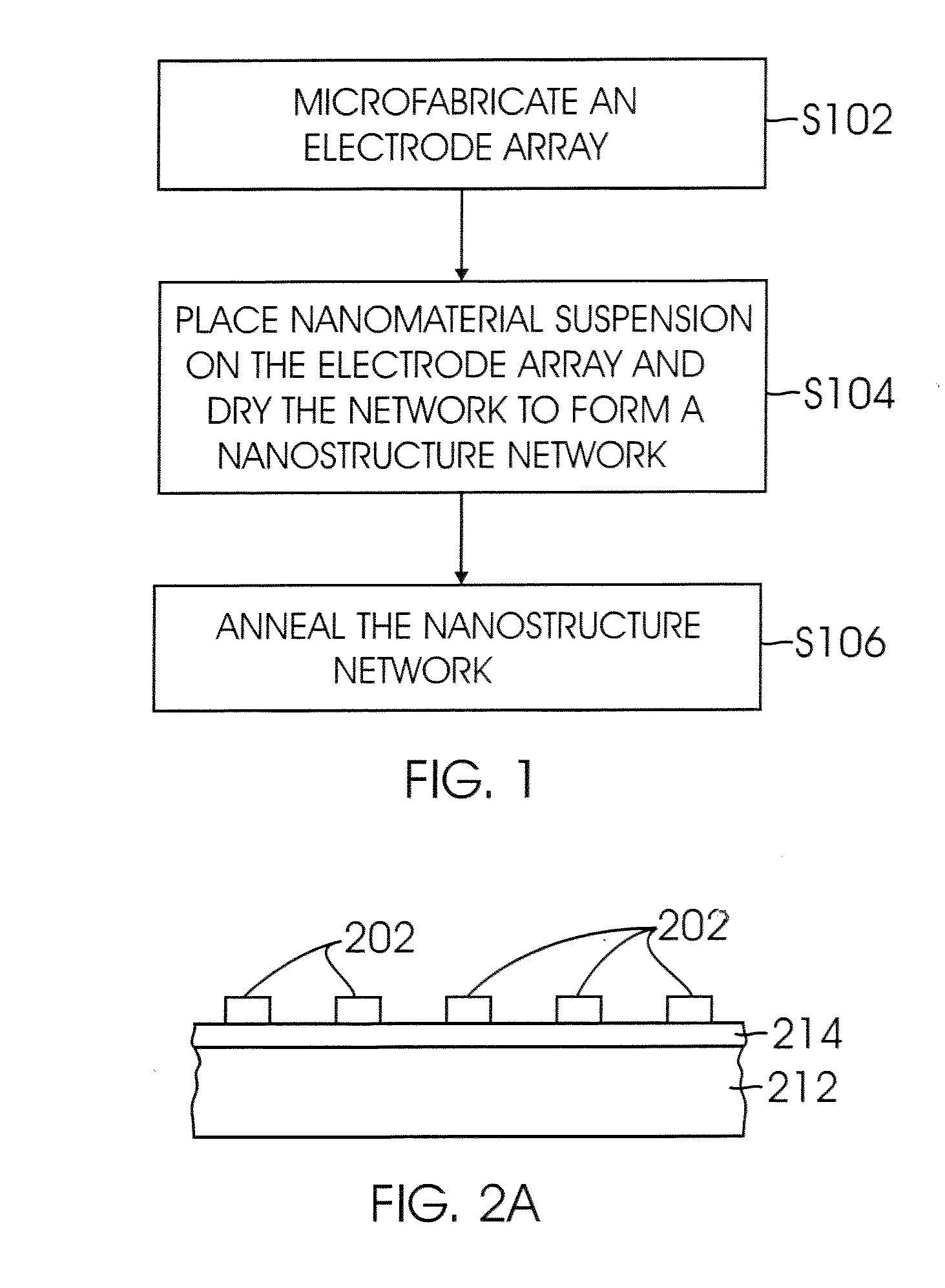

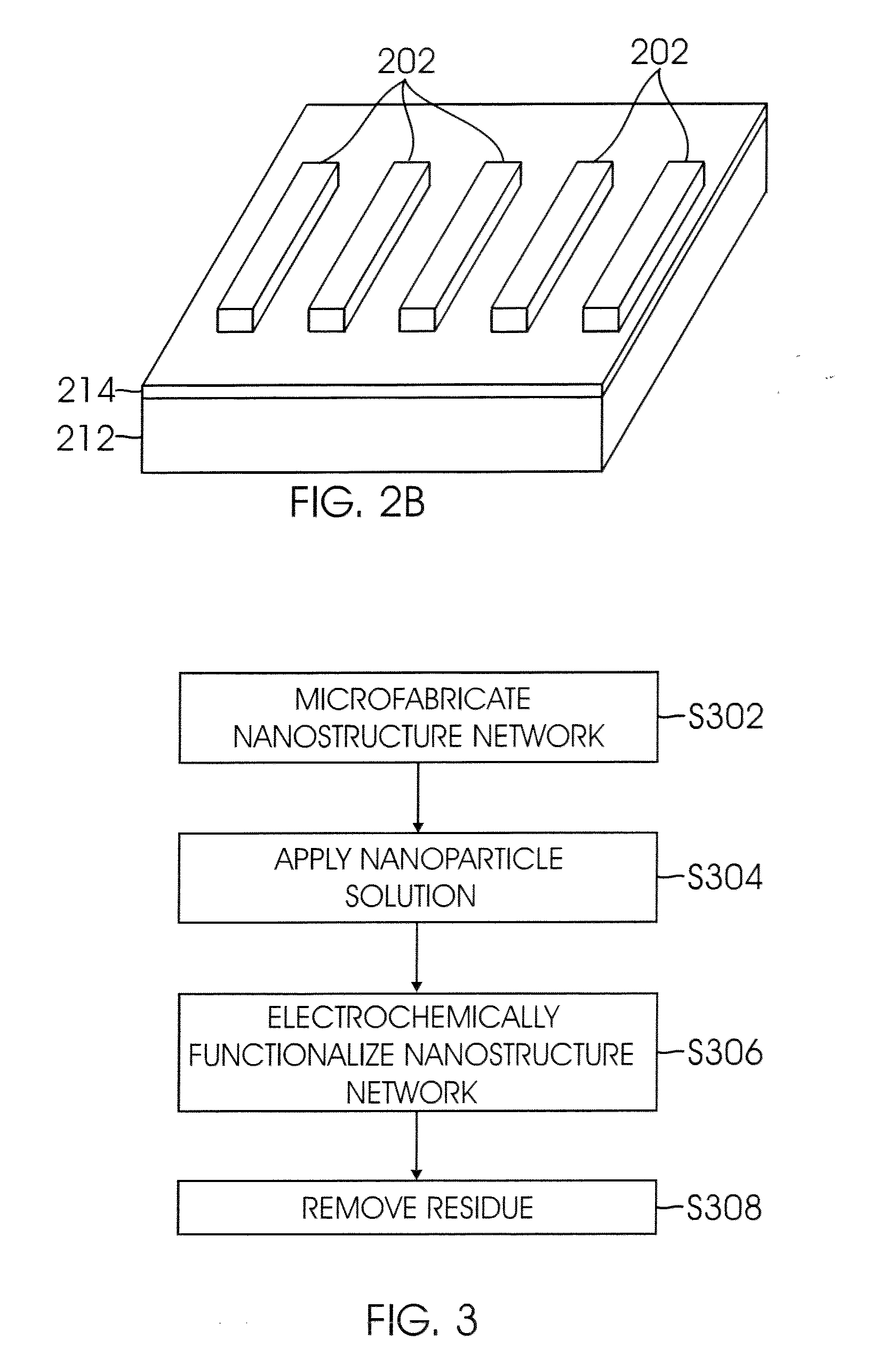

InactiveUS20100089772A1High sensitivityLow detection limitWeather/light/corrosion resistanceVolume/mass flow measurementWater vaporCarbon nanotube

A gas sensing device (nanosensor) includes a substrate with at least a pair of conductive electrodes spaced apart by a gap, and an electrochemically functionalized semiconductive nanomaterial bridging the gap between the electrodes to form a nanostructure network. The nanomaterial may be single-walled carbon nanotubes (SWNTs) functionalized by the deposition of nanoparticles selected from the group consisting of an elemental metal (e.g., gold or palladium), a doped polymer (e.g., camphor-sulfonic acid doped polyaniline), and a metal oxide (e.g. tin oxide). Depending on the nanoparticles employed in the functionalization, the nanosensor may be used to detect a selected gas, such as hydrogen, mercury vapor, hydrogen sulfide, nitrogen dioxide, methane, water vapor, and / or ammonia, in a gaseous environment.

Owner:RGT UNIV OF CALIFORNIA

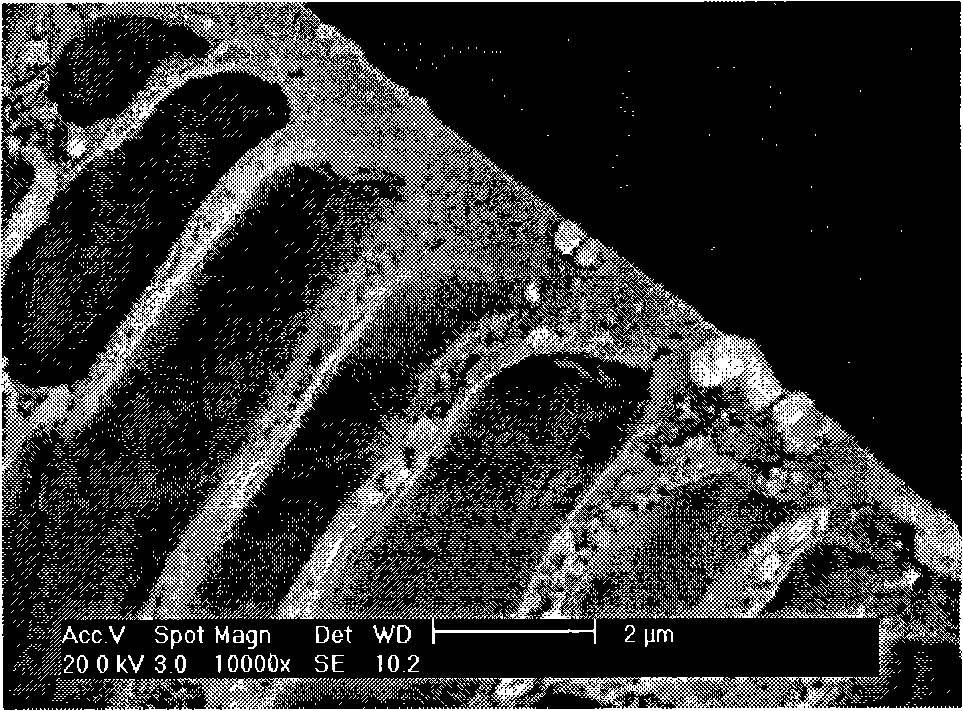

Preparation method for conduction and sustained release type nervous tissue engineering scaffold

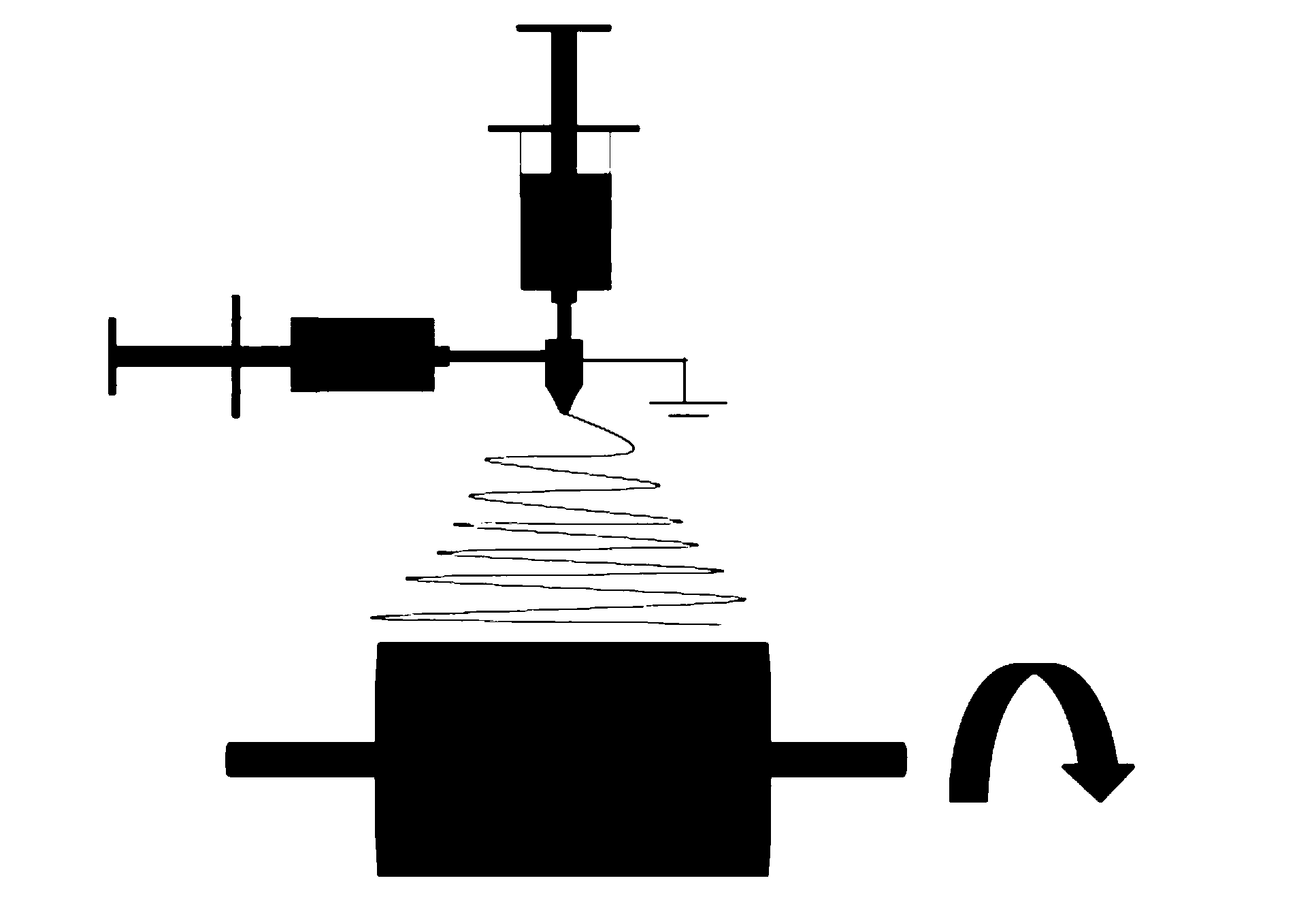

ActiveCN104225685AGood cell compatibilityExtended highFilament/thread formingNon-woven fabricsConductive polymerDefect repair

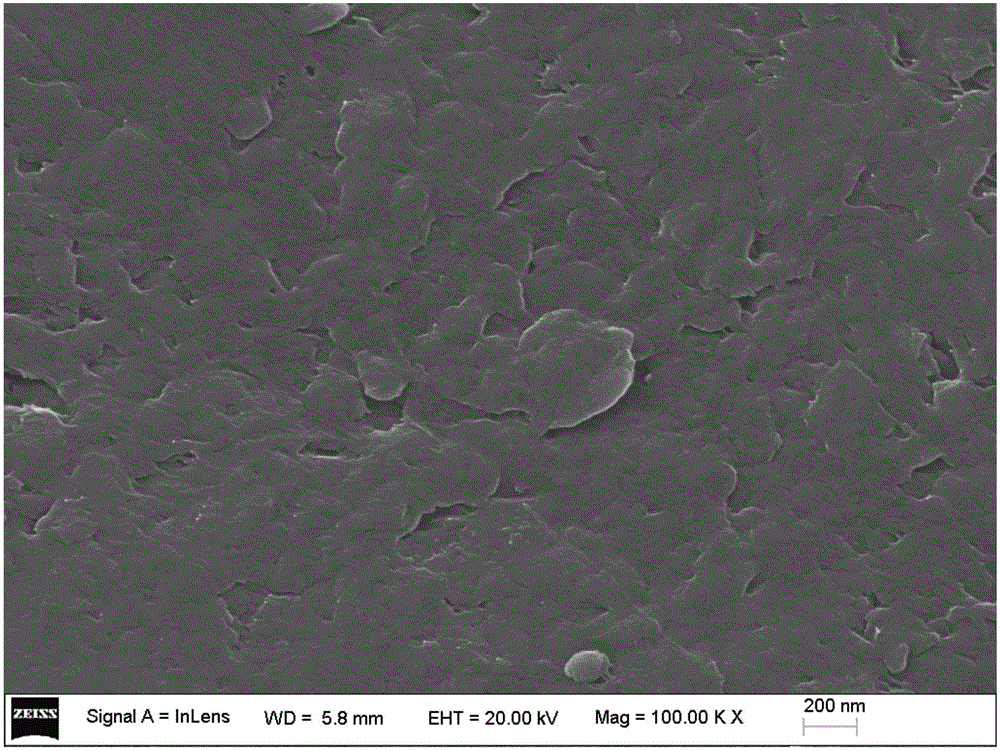

The invention relates to a preparation method for a conduction and sustained release type nervous tissue engineering scaffold. The method comprises the following steps: silk fibroin Silk and lactic acid-caprolactone copolymer are dissolved in a solvent, dissolved and stirred to obtain a solution, then polyaniline and camphorsulfonic acid are added and stirred and mixed uniformly to obtain a cortex electrospinning solution, and NGF (nerve growth factors) are dissolved in ultrapure water completely to obtain a core electrospinning solution; and the cortex electrospinning solution and the core electrospinning solution are accommodated in an injector respectively for coaxial electrospinning, and then fumigation treatment and vacuum drying are performed to obtain the conduction type nervous tissue engineering scaffold. According to the prepared nanofiber scaffold, the nerve repair speed is increased from ways including external electrical stimulation (conductive polymer), biochemistry (NGFs), a topological structure required by nerve regeneration (orientation guide) and the like. The method is simple to operate, good in repeatability and high in economic benefit, and provides novel experimental thought for nerve defect repair in clinical application.

Owner:诺一迈尔(山东)医学科技有限公司

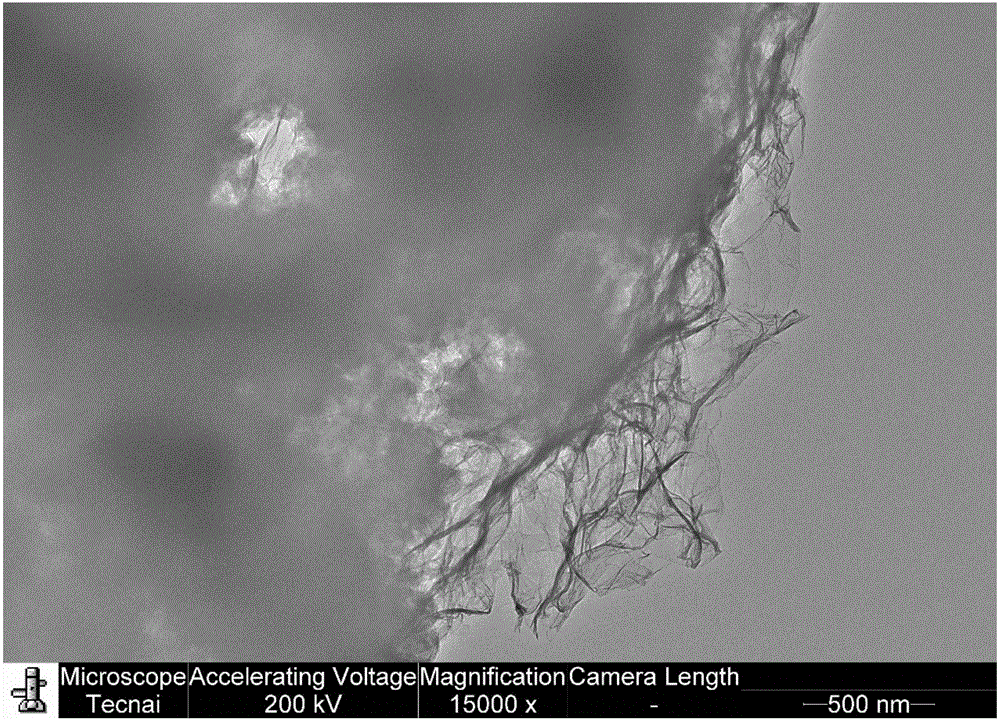

In-situ polymerization process for preparing polyaniline composite hyperfiltration membrane

InactiveCN101274221AImprove interception effectImprove hydrophilicitySemi-permeable membranesComposite filmFiltration

The invention discloses a method for preparing poly-aniline composite ultra-filtration film by in-situ polymerization, belonging to the preparation technique of ultra-filtration composite film. The method process comprises that under the temperature of 20 to 25 DEG C, citric acid, camphor sulfonic acid or hydrochloric acid is added into dodecyl benzene sulfonic acid sodium solution; after the pH value of the solution is adjusted, aniline is added into the solution; after the solution is uniformly mixed, polysulfone membrane is then added into the solution and the solution is then mixed for 4 to 6 hours under the temperature of 20 to 25 DEG C and then for 2 hours under the temperature of 0 to 5 DEG C; water solution of ammonium persulfate with a certain quantity is then added into the solution, and the solution is then mixed for a plurality of minutes under the temperature of 0 to 5 DEG C to complete the reaction. The finished poly-aniline composite ultra-filtration film is gained by a series of cleaning of the prepared poly-aniline composite ultra-filtration film. The method of the invention is simple and has easy operation; the surface of the prepared poly-aniline composite ultra-filtration film is densely and uniformly covered by nano-fibre-shaped polyaniline; the interception performance and the hydrophilicity performance of the poly-aniline composite ultra-filtration film are greatly improved compared with basic films and can be adjusted by controlling the film preparation reaction time.

Owner:TIANJIN UNIV

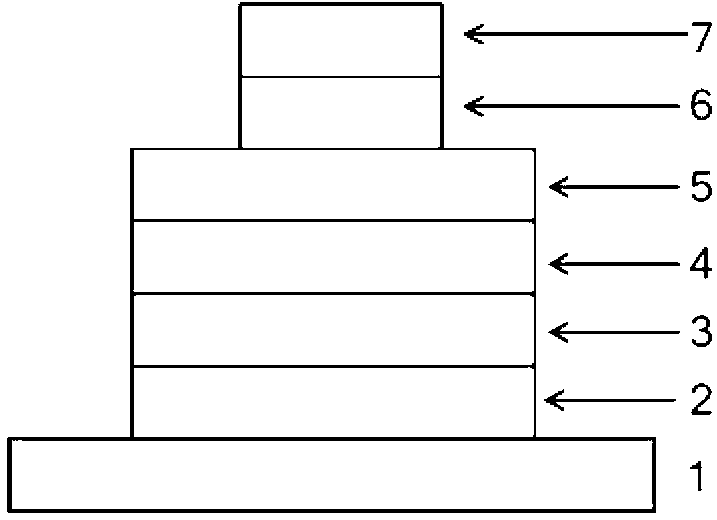

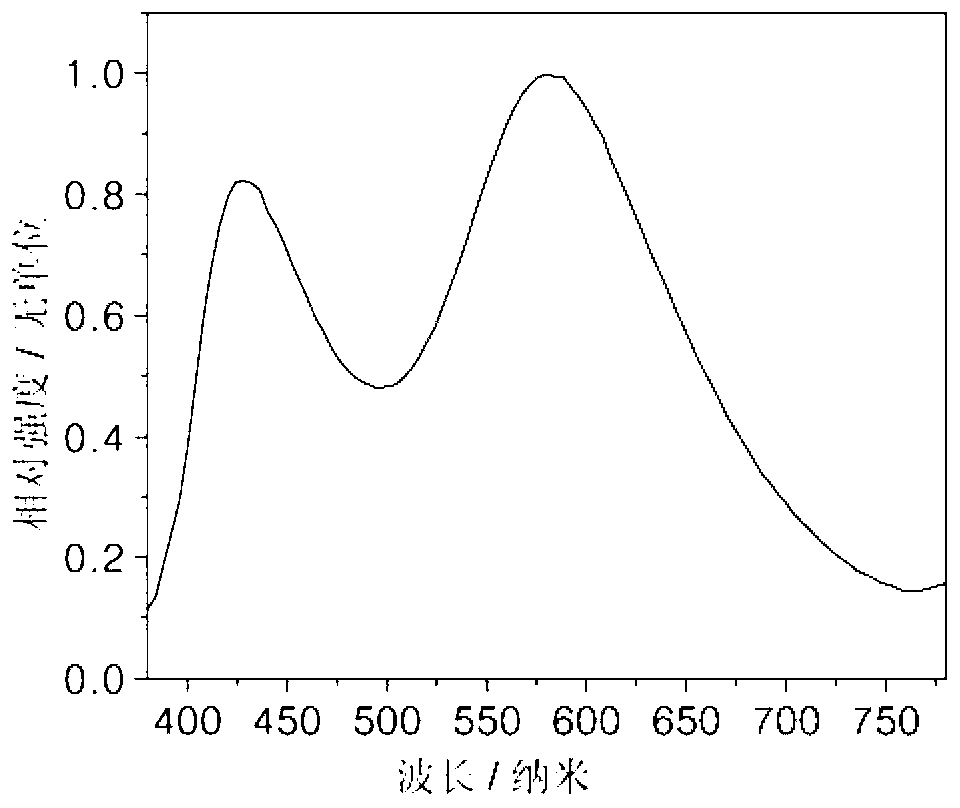

Quinazoline derivative and application thereof in organic electroluminescent device

InactiveCN103242299AEasy to manufactureLow costOrganic chemistrySolid-state devicesEvaporationOrganic electroluminescence

The invention relates to a quinazoline derivative and an application thereof in an organic electroluminescent device, belonging to the technical field of white light illumination in organic electroluminescence. By adopting the quinazoline derivative, a white light organic electroluminescent device with better CIE coordinates and better spectrum stability can be obtained by carrying out doping evaporation on the quinazoline derivative and solid acid namely camphorsulfonic acid (CSA) with strong acidity and high stability under a high-vacuum-degree condition. Although the data performance of the current device is not ideal enough, the preparation method and process are first cases, and a new idea for synthesizing a white light material and preparing devices in the future is provided.

Owner:JILIN UNIV

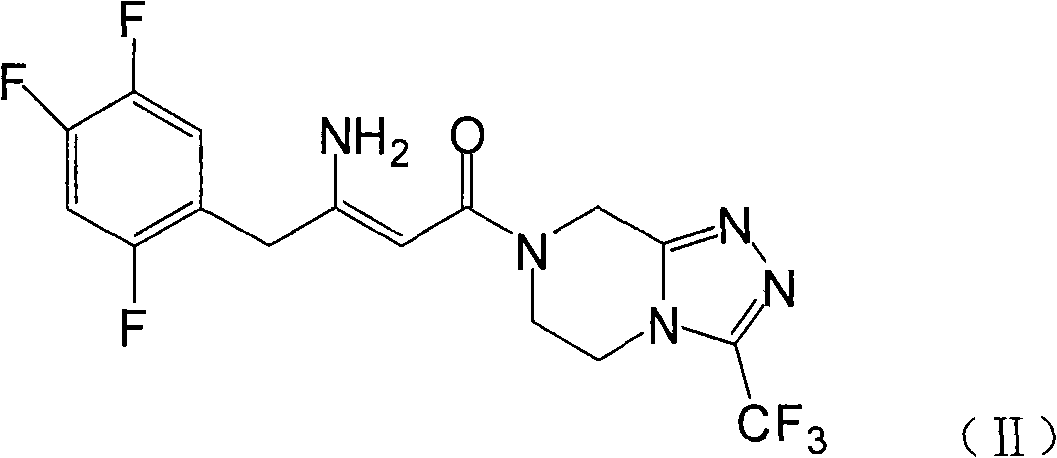

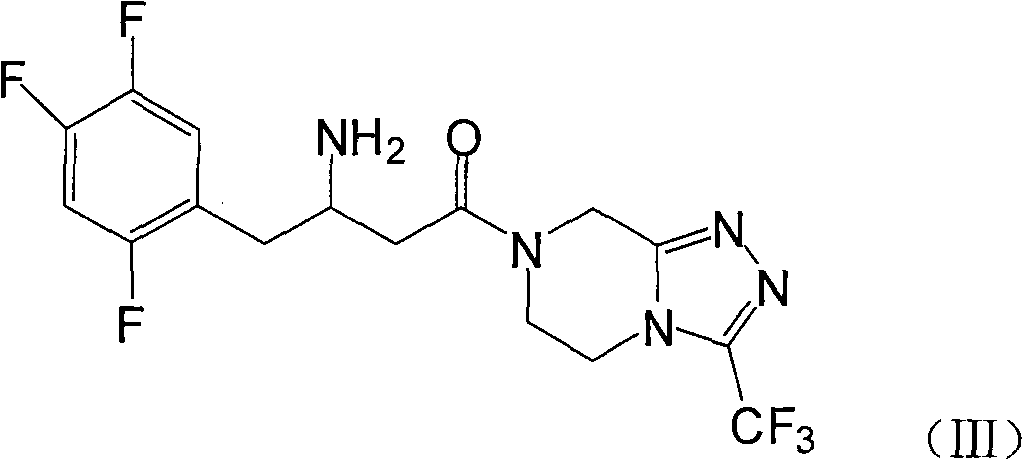

Method for preparing dipeptidyl peptidase-IV inhibitor

InactiveCN101928289AEasy to makeLow costOrganic active ingredientsDrug compositionsDipeptidyl peptidasePyrazine

The invention provides a method for preparing a dipeptidyl peptidase-IV inhibitor, and in particular relates to a method for preparing 7-[3-amino-1-oxo-4-(2,4,5-trifluorophenyl)butyl]-5,6,7,8-tetrahydro-3-trifluoromethyl-1,2,4-triazol[4,3-a]pyrazine raceme or an optically pure (R) or (S) compound thereof. The method comprises the following steps of: (1) performing hydrogenation reduction to obtain racemate; (2) reacting the racemate with camphorsulfonic acid or tartaric acid; and (3) converting a salt obtained in the step 2 into a corresponding alkali. The method has low cost and can be applied to industrial production.

Owner:BEIJING HOPE PHARMA

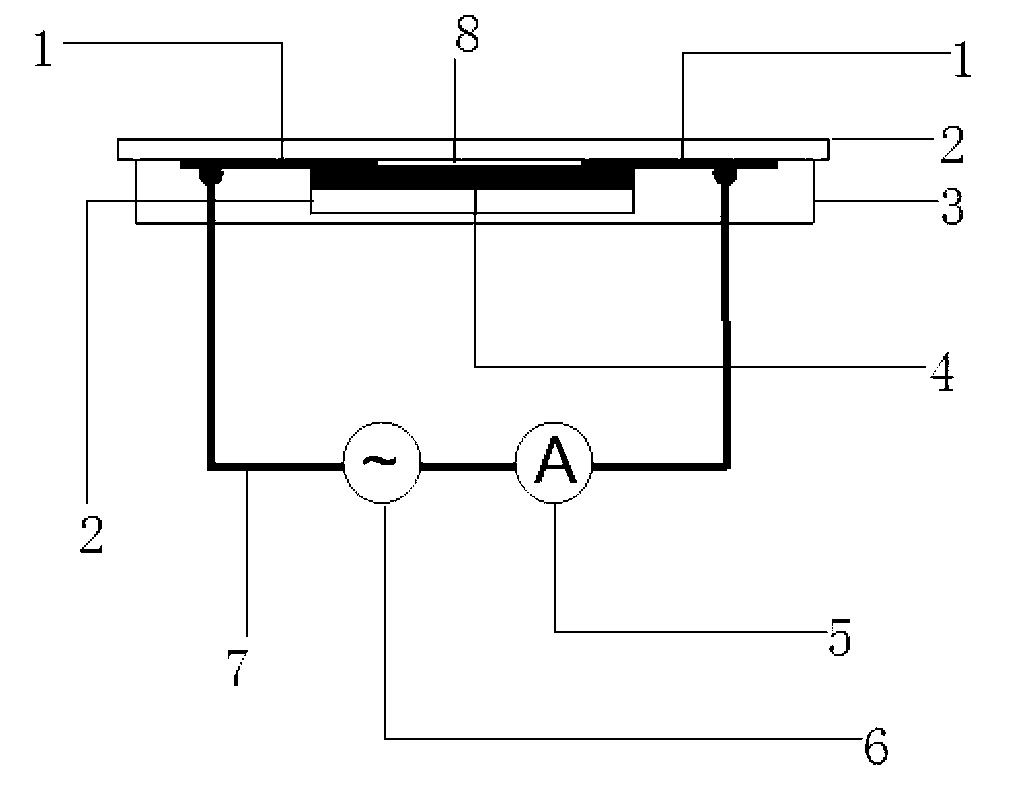

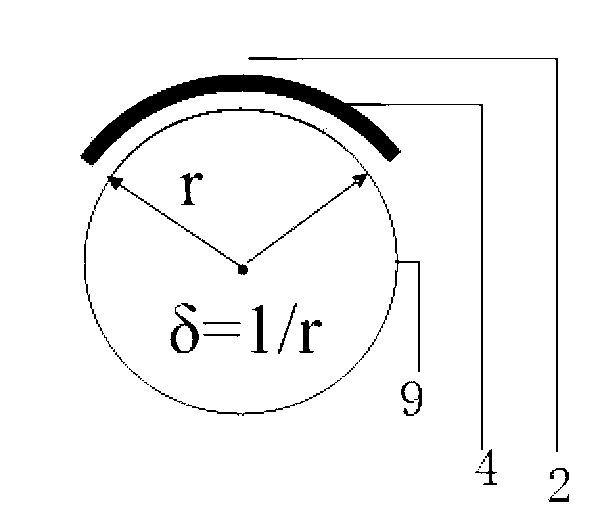

Bent flexible transparent strain sensor production method

InactiveCN103292685AImprove the finishHigh optical transmittanceNanosensorsElectrical/magnetic solid deformation measurementPolyesterAniline

The invention belongs to the technical field of strain sensor production and relates to a bent flexible transparent strain sensor production method which includes that: camphorsulfonic acid is dissolved in deionized water to form a camphorsulfonic acid water solution, aniline monomers are filled into the camphorsulfonic acid water solution and then hydrogen peroxide is filled into the camphorsulfonic acid water solution to prepare polyaniline reaction liquid; a clean polyester film substrate is vertically immersed into the polyaniline reaction liquid to be soaked and then is taken out, is soaked in meta-cresol solutions and then is taken out, is rinsed through deionized water and is blown dry to obtain a polyaniline nanometer-film sample; the polyaniline nanometer-film sample is tailored to be square, is attached to a polyester film printed with electrodes and connected into a circuit and is packaged through a polydimethylsiloxane adhesive film; and a constant voltage power supply is connected with an ampere meter, and a bent flexible transparent strain sensor can be obtained. The production method is simple and reliable in principle, the produced sensor is good in transparent flexibility, unlikely to break, high in sensitivity, low in cost and environmentally friendly.

Owner:QINGDAO UNIV

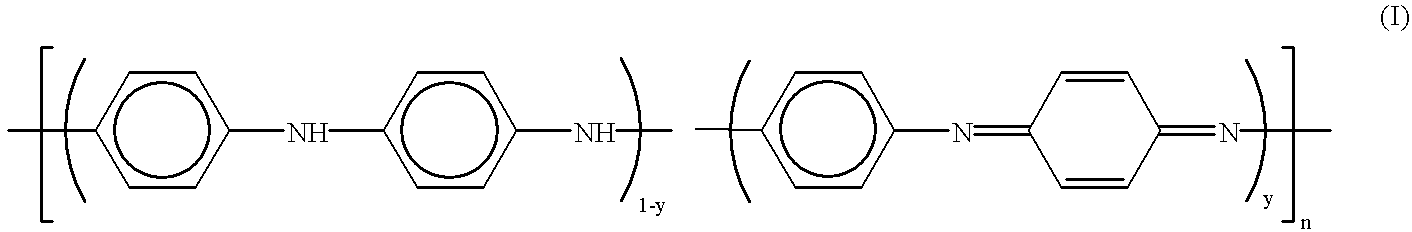

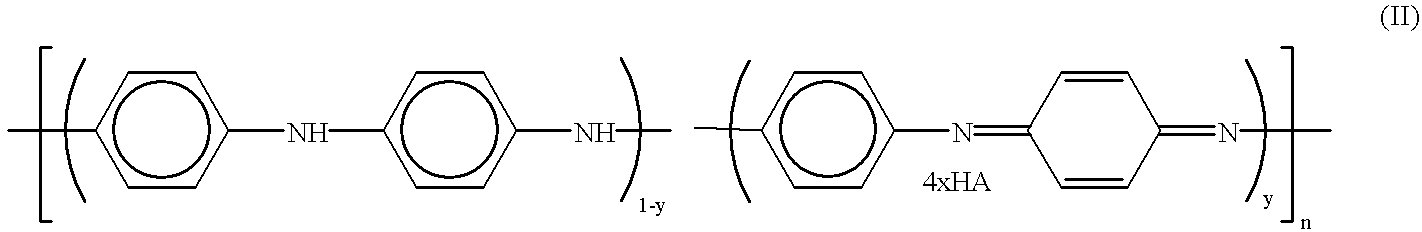

Method for making polyaniline with high molecular mass in the form of emeraldine and polyniline obtained by said method

This invention involves a process for manufacturing high molecular mass polyaniline in the form of emeraldine and polyaniline obtained by this process.The process includes the following steps:a) polymerising aniline or an aniline derivative to make pernigraniline by doing the polymerization in a homogeneous aqueous solution including the aniline or the aniline derivative, a protonic acid, a salt, an oxidizing agent and ethanol to yield pernigraniline,b) reducing the pernigraniline obtained in step a) to emeraldine by means of an aqueous reducing solution which does not contain aniline, and possibly an additional step of extraction and post-polymerisation with chloroform.The polyanilines thus protonated by (±)-10-camphor sulphonic acid are totally soluble in m-cresol and in hexafluoroisopropanol and produce flexible films with high electrical conductivity, i.e. 250-350 S / cm.

Owner:RESCOLL SOC DE RECH

Method for preparing polyaniline conductive composite film by in-situ polymerization

The invention discloses a preparation method for in situ polymerized polyaniline conductive composite membrane, belonging to the technical field of conductive membrane material. The process comprises the following steps: the citric acid, the camphor sulfonic acid or hydrochloric acid are added into the sodium dodecyl benzene sulfonate solution for regulating pH value under twenty to twenty-five DEG C, and then aniline is added into the sodium dodecyl benzene sulfonate solution, polysulfone membrane is added in the sodium dodecyl benzene sulfonate solution after uniform mixing; the solution is agitated for four to six hours under twenty to twenty-five DEG C, and then agitated for two hours under zero to five DEG C; then a plurality of ammonium persulfates are added in the solution to finish the reaction after being agitated for a plurality of minutes under zero to five DEG C; the made polyaniline conductive composite membrane is scoured off the adsorbed impurity through deionized water, then is washed through anhydrous methanol and hydrochloric acid and finally through deionized water, obtaining the finished product of polyaniline conductive composite membrane. The preparation method for in situ polymerized polyaniline conductive composite membrane has the advantages of simple method, easy operation, the conductivity range of the made polyaniline conductive composite membrane is 7.21*10<-4> S / cm to 0.286S / cm.

Owner:TIANJIN UNIV

Preparation method of graphene polyaniline aerogel thermoelectric material

ActiveCN106046401AImprove thermoelectric performanceEffective distributionThermoelectric materialsIce water

The invention relates to a preparation method of a graphene polyaniline aerogel thermoelectric material and solves the technical problems that existing methods are uncontrollable in material component content and complex and have residual metal in the prepared material, and the prepared material is poor in stability, uneven in dispersing and non-ideal in thermoelectric performance. The preparation method includes: weighing aniline monomer, dispersing in HCl solution, adding oxidizing agent ammonium persulfate, and stirring while polymerizing under ice water bath to obtain polyaniline; evenly dispersing graphene oxide and the polyaniline into aqueous solution; adding ammonia water into the aqueous solution to performing temperature rising treatment to prepare graphene polyaniline hydrogel; performing freeze drying on the graphene polyaniline hydrogel to prepare graphene polyaniline aerogel; sufficiently grinding the graphene polyaniline aerogel, dispersing the ground graphene polyaniline aerogel and camphorsulfonic acid into m-cresol solution, and using a solution pouring method to prepare a flexible thermoelectric film. The preparation method is applicable to the preparation field of thermoelectric materials.

Owner:BEIJING UNIV OF CHEM TECH

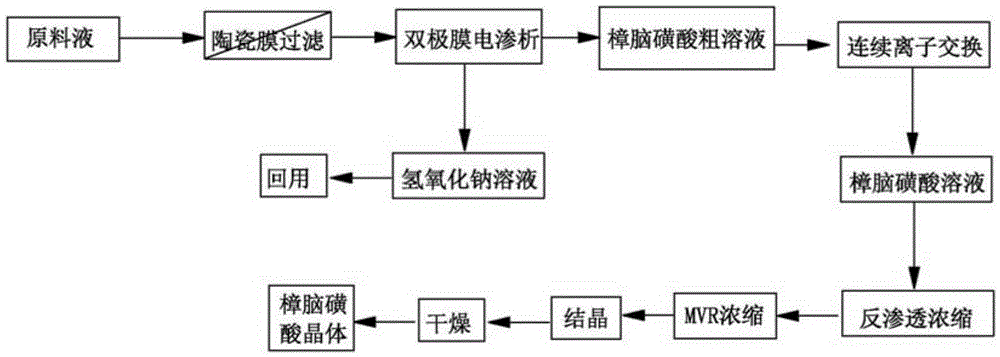

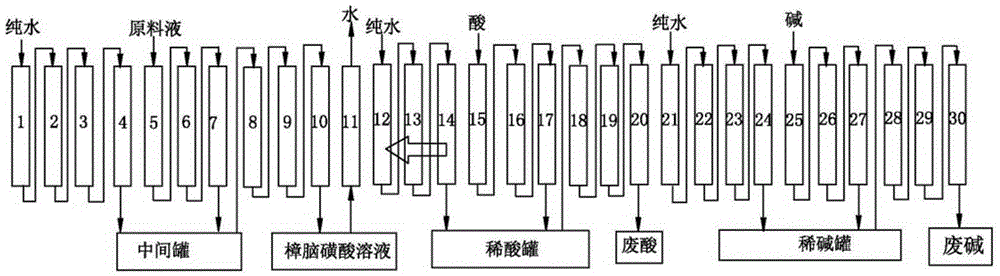

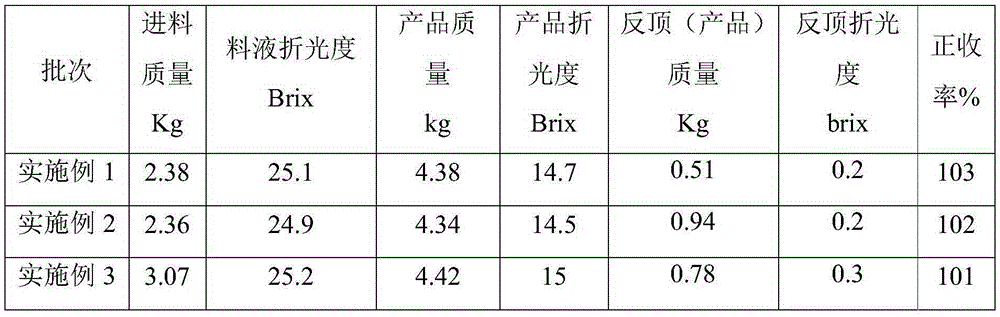

Clear production technology for converting sodium camphorsulfonate into camphorsulfonic acid

ActiveCN105418467AReduced circulation volumeReduce energy consumptionSulfonic acid preparationReverse osmosisIon exchange

The invention discloses a clear production technology for converting sodium camphorsulfonate into camphorsulfonic acid. The clear production technology comprises the following steps of step one, carrying out ceramic membrane filtration on a feed solution, and obtaining ceramic membrane dialysate; step two, enabling the ceramic membrane dialysate to enter a bipolar membrane electrodialysis system to carry out bipolar membrane electrodialysis, and obtaining a crude camphorsulfonic acid solution; step three, enabling the ceramic membrane dialysate to enter a continuous ion exchange system to carry out continuous ion exchange, and obtaining a camphorsulfonic acid solution; step four, carrying out reverse osmosis concentration on the camphorsulfonic acid solution, and obtaining a camphorsulfonic acid concentrated solution; step 5, obtaining camphorsulfonic acid crystals through crystallizing, centrifugal separation and crystal drying after carrying out mechanical vapor recompression concentration on the camphorsulfonic acid concentrated solution. According to the camphorsulfonic acid crystals produced by adopting the clear production technology disclosed by the invention, the purity can be more than 99.5 percent, and the crystals reach the pharmaceutical-grade camphorsulfonic acid level; meanwhile, a one-step recovery rate of materials can be more than 95 percent, the cycling volume is reduced, and energy consumption is reduced.

Owner:厦门欣赛科技有限公司

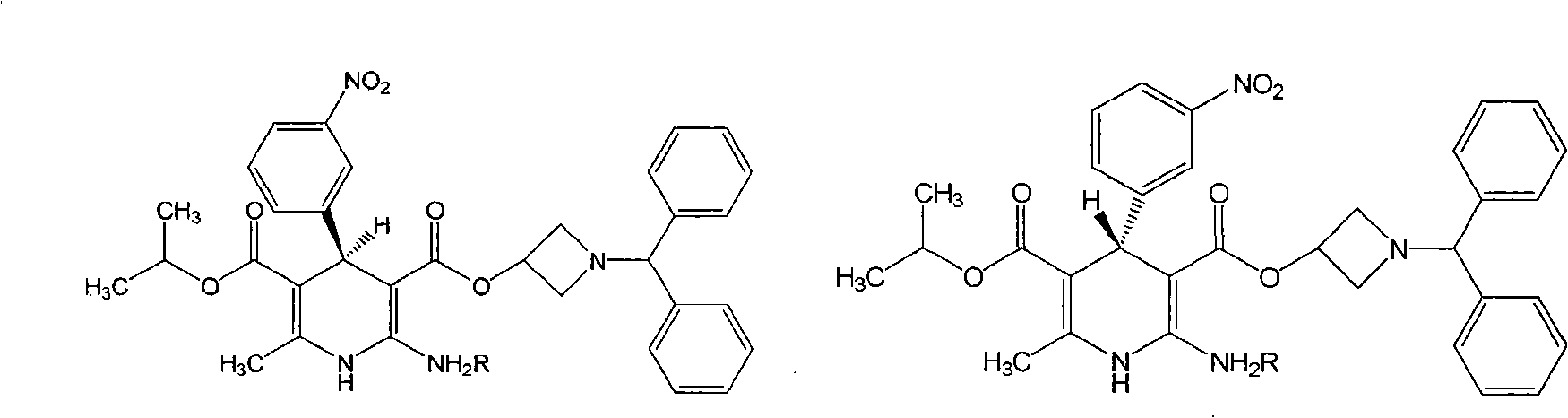

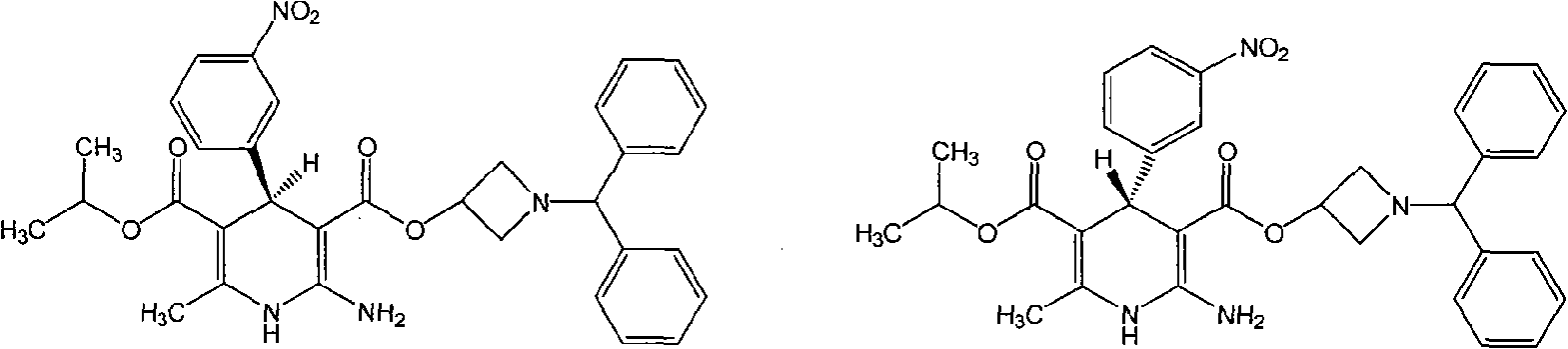

Method for preparing chiral azelnidipine and acceptable salt thereof

The invention relates to a method for preparing (S)-(+)-azelnidipine and (R)-(-)-azelnidipine as well as benzene sulfonic acid, paratoluenesulfonic acid, D-(+)-camphorsulfonic acid, L-(-)-camphorsulfonic acid, taurine and high taurine salt thereof by economically and effectively resoluting racemic azelnidipine. Compared with the prior method for preparing optically active azelnidipine and salt thereof by a high performance liquid chromatography which needs expensive instruments and equipment and has less treatment amount, the method adopts a recrystallization resolution method of the prior chiral resolution reagent and a cheap and easily-obtained solvent, has large sample treatment amount and simple operation, does not need special instruments, and is suitable for industrial production.

Owner:北京华禧联合科技发展有限公司

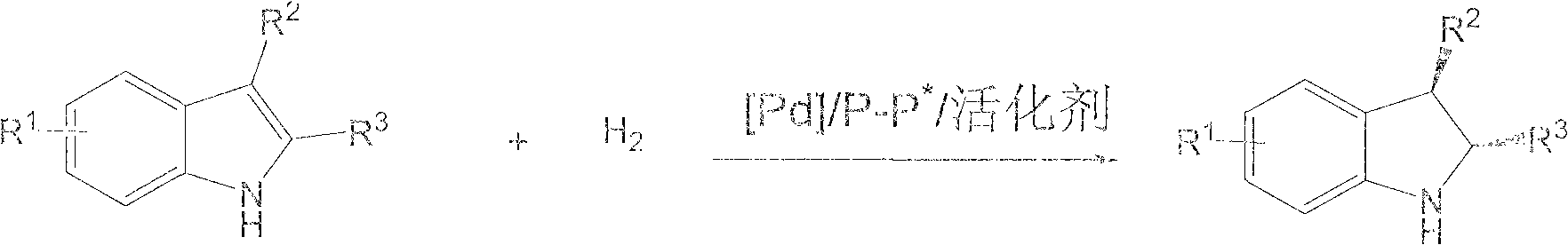

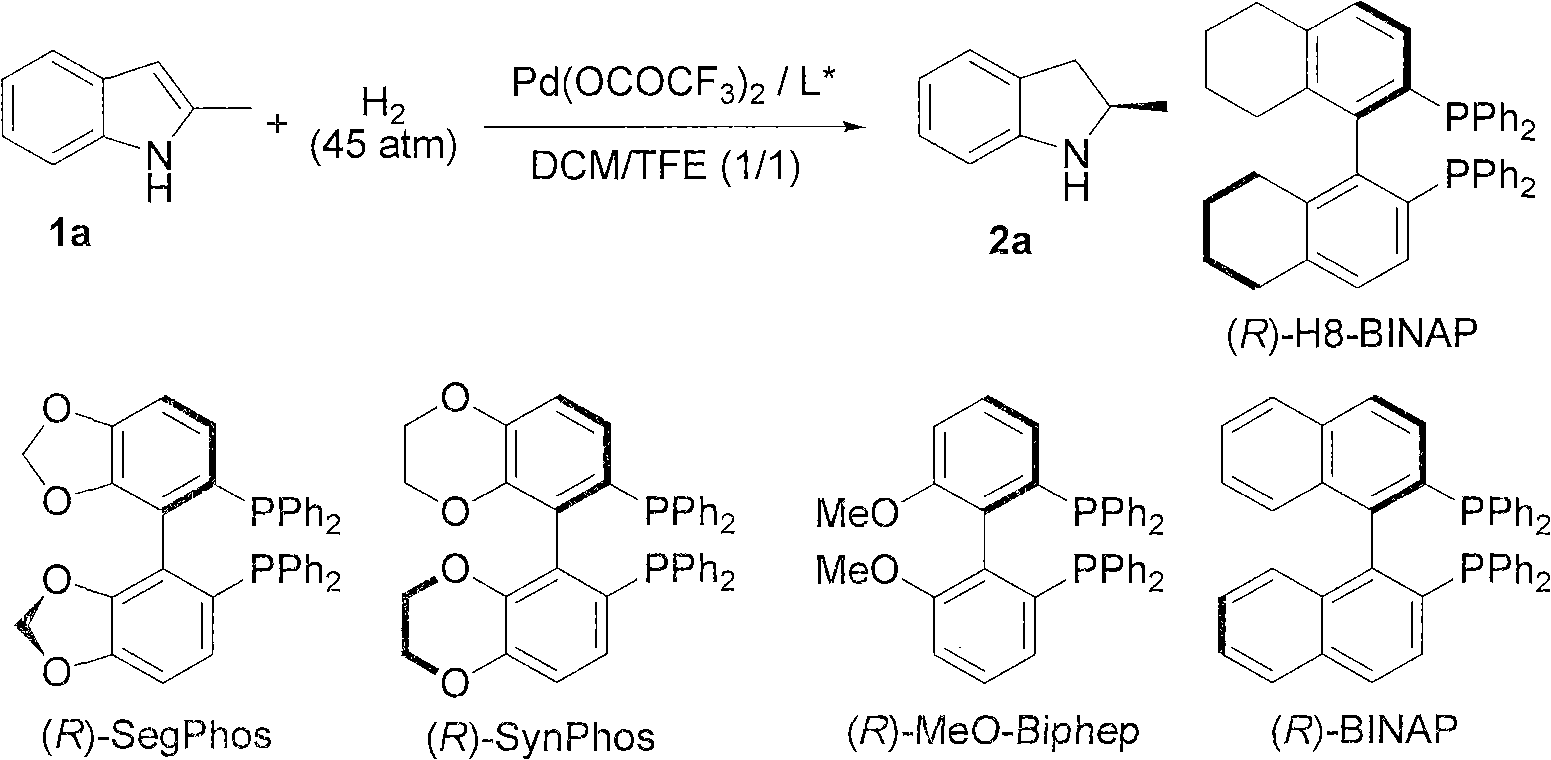

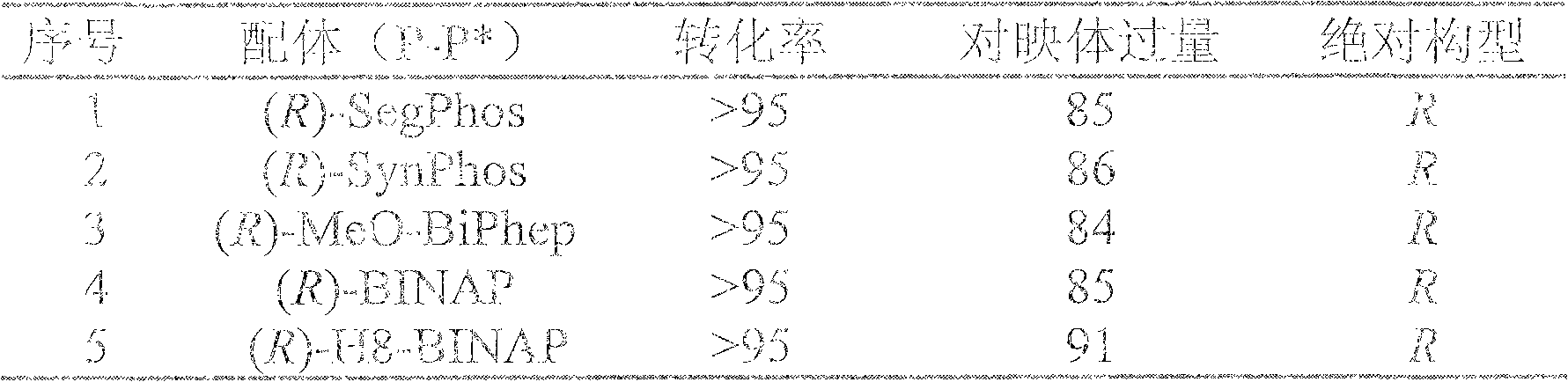

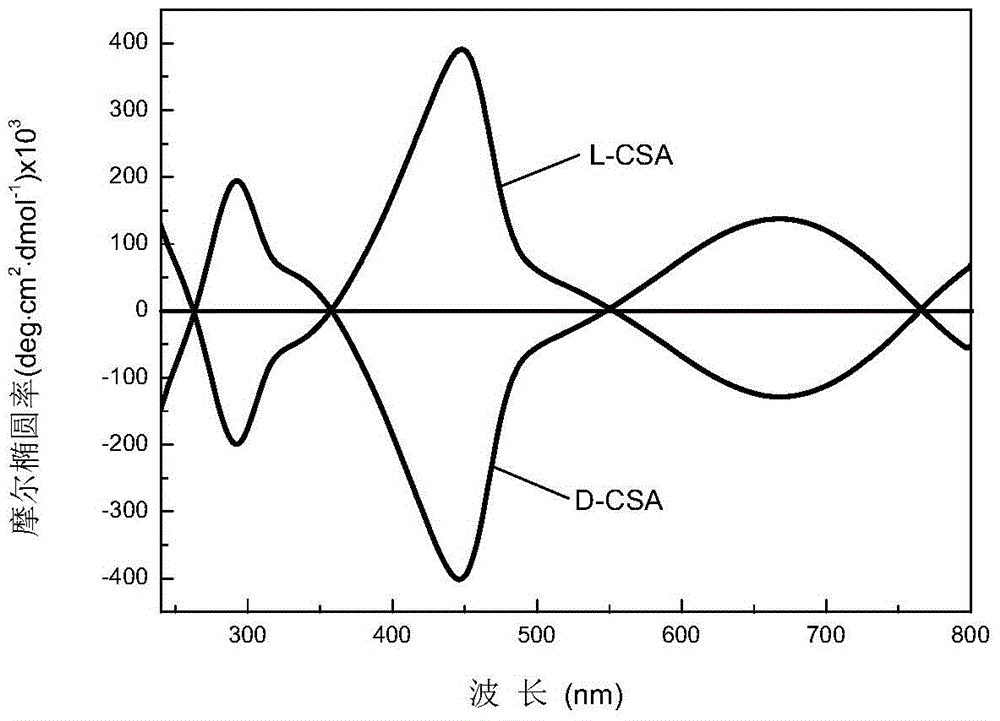

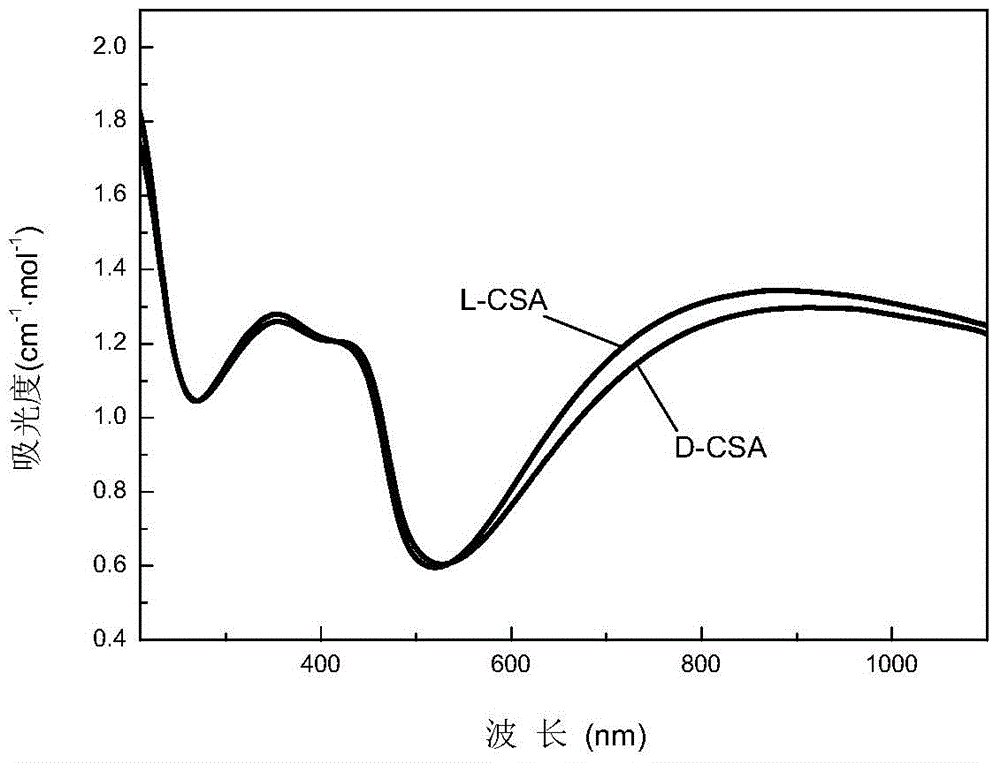

Method for synthesizing chiral indoline through palladium-catalyzed asymmetric hydrogenation

InactiveCN102336698AAsymmetric hydrogenationHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesHydrogen pressureReaction temperature

The invention relates to a method for synthesizing chiral indoline through palladium-catalyzed asymmetric hydrogenation, which is characterized in that Bronsted acid is used as the activator and the used catalysis system is a palladium chiral diphosphine complex. The reaction can be carried out under the following conditions: the reaction temperature is 20-50 DEG C; the solvent used in the reaction is a mixed solvent of dichloromethane and 2,2,2-trifluoroethanol (the DCM / TFE volume ratio is 1:1); the hydrogen pressure is 13-45 atmospheres; the substrate-catalyst ratio is 50 / 1; the used metal precursor is palladium trifluoroacetate (Pd(OCOCF3)2); the used chiral ligand is a chiral diphosphine ligand; the used activator is L-camphorsulfonic acid (L-CSA); and unprotected simple 2-substituted indole and 2,3-disubstituted indole can be hydrogenated to obtain the corresponding chiral indoline product, and the enantiomeric excess can be up to 96%. The method has the advantages of convenient operation process, high practicality, easy acquisition of raw materials, good enantioselectivity and high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

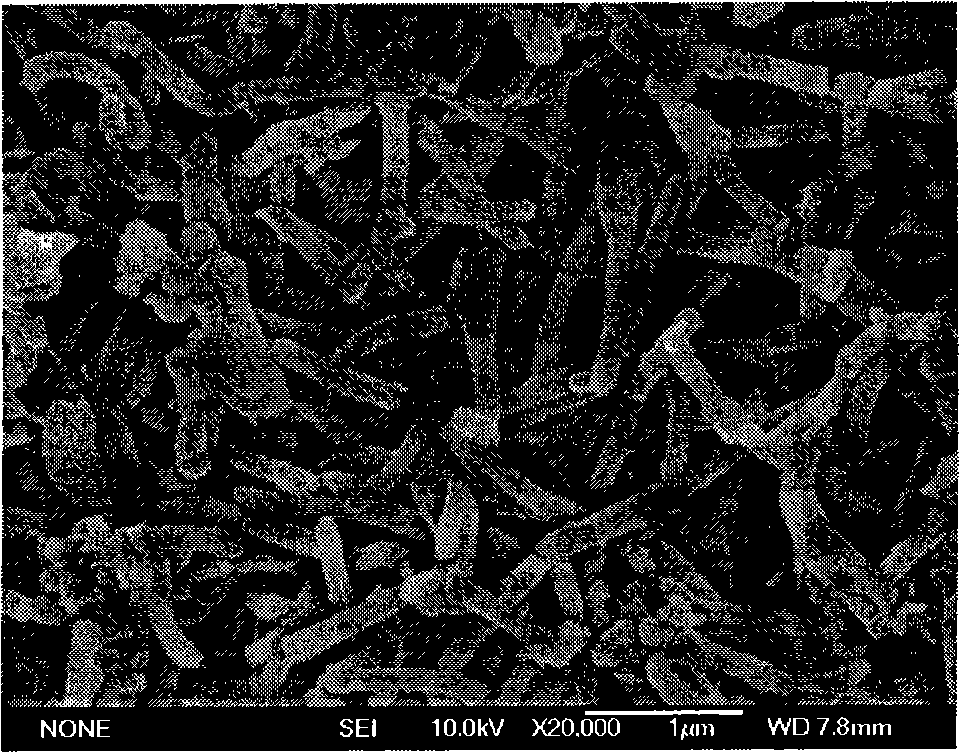

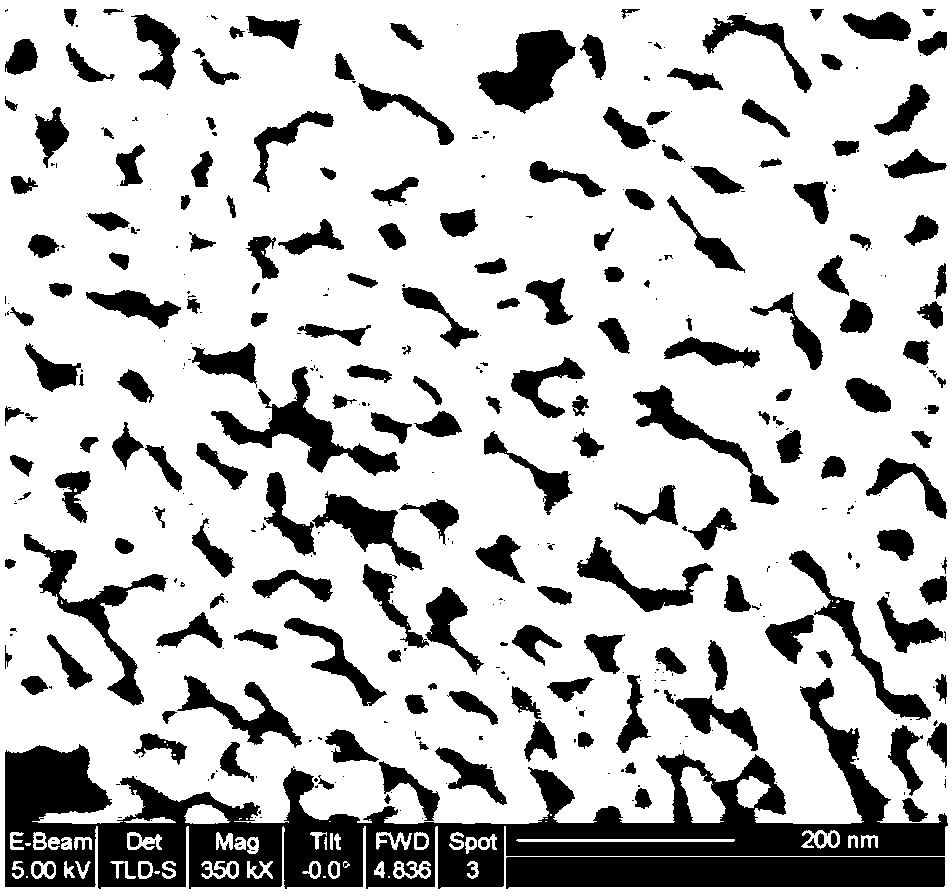

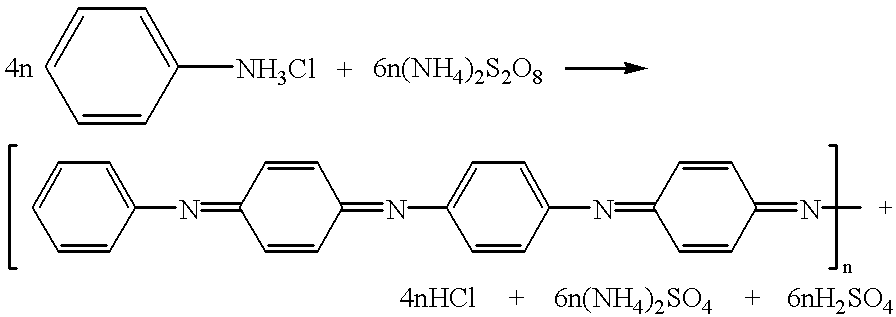

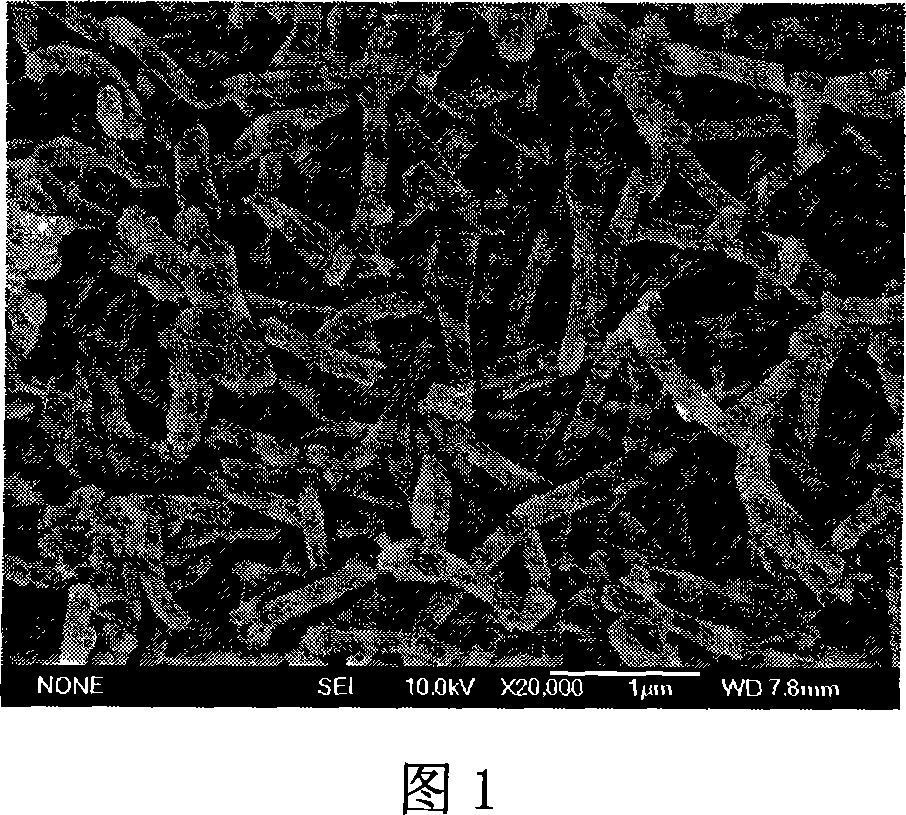

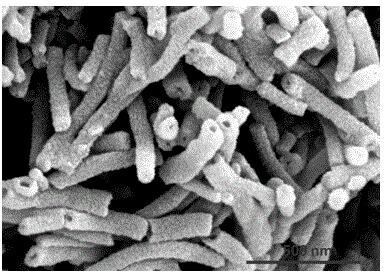

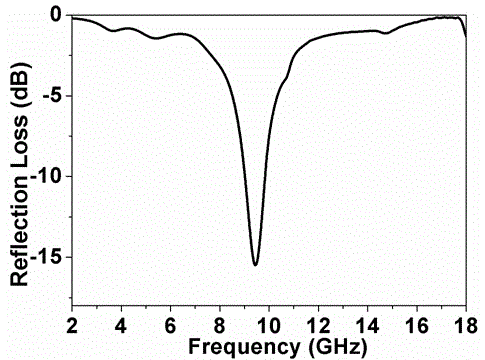

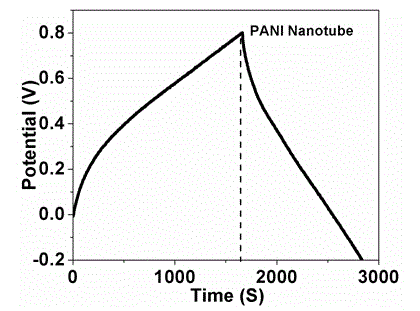

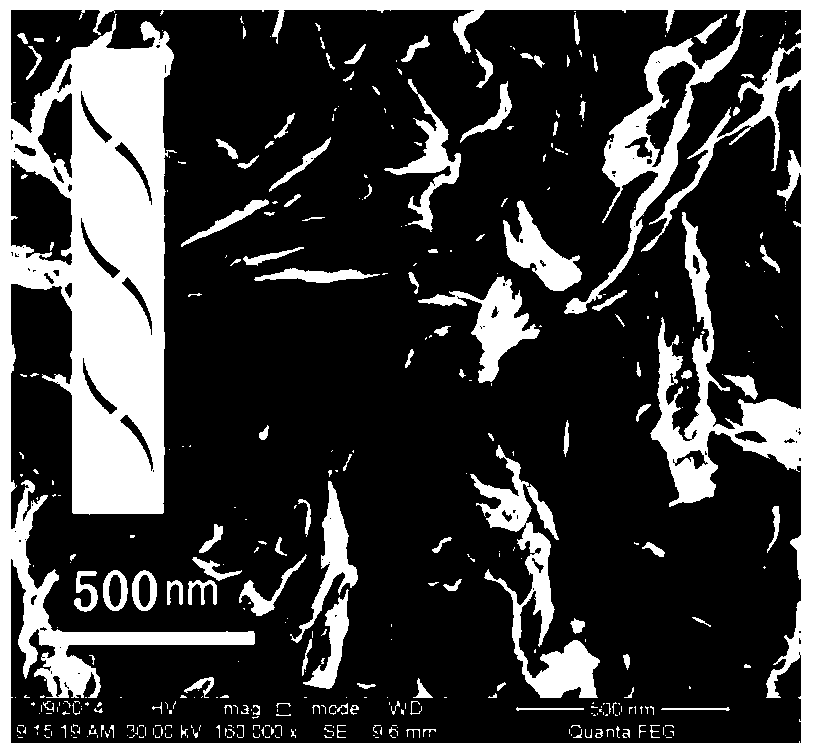

Method for synthesizing polyaniline nanotubes

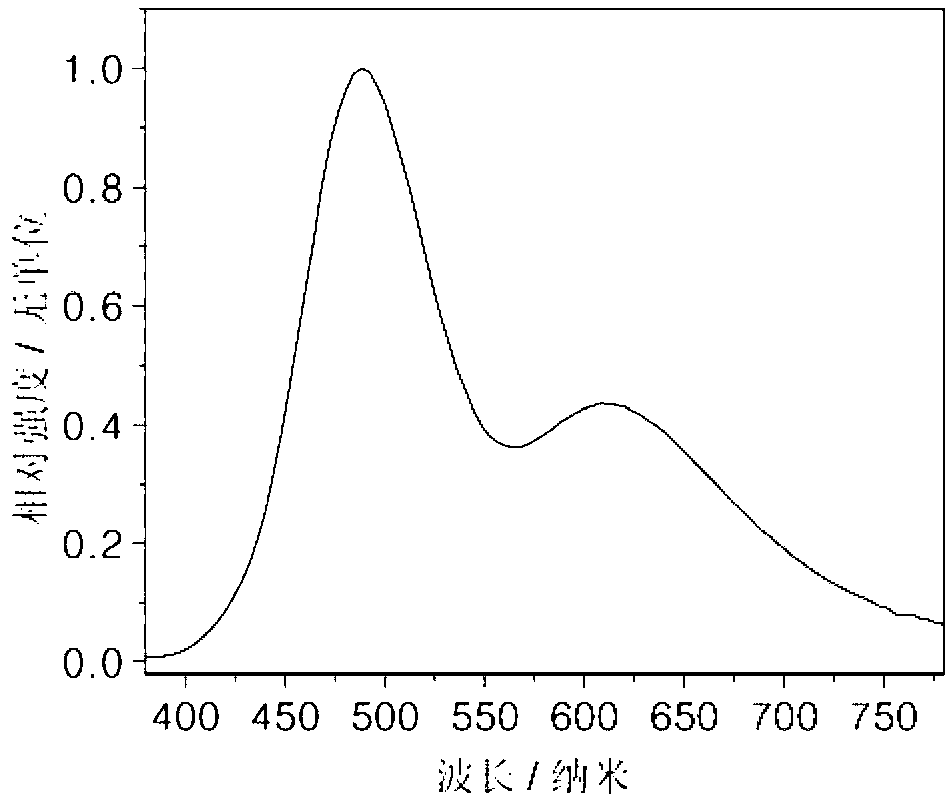

The invention discloses a novel preparation method of polyaniline nanotubes, which comprises the following steps: by using camphorsulfonic acid as a doping acid, uniformly dispersing an aniline monomer in a camphorsulfonic acid water solution, standing to react in a stable magnetostatic field (0.5-10 tesla) for 24 hours by using ammonium persulfate as an initiator, and carrying out in-situ polymerization to obtain the polyaniline nanotube material (disclosed as Figure 1). The average tube length of the novel polyaniline nanotube material is 0.3-0.5 mu m, the external diameter is 120-130nm, and the internal diameter is 50-60nm. The polyaniline nanotube material has high specific capacitance and high electromagnetic wave absorption performance, and can be widely used in the fields of supercapacitors and electromagnetic shielding.

Owner:ANHUI UNIVERSITY

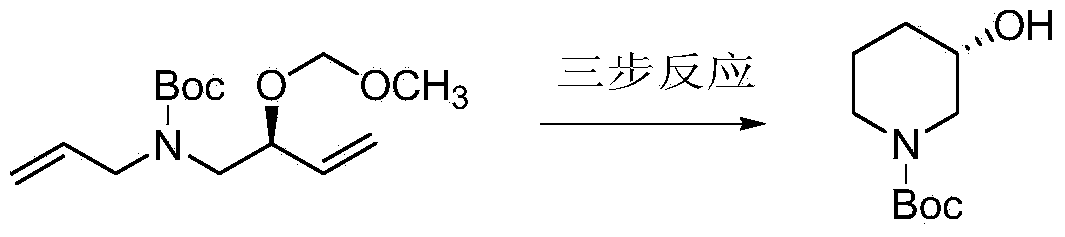

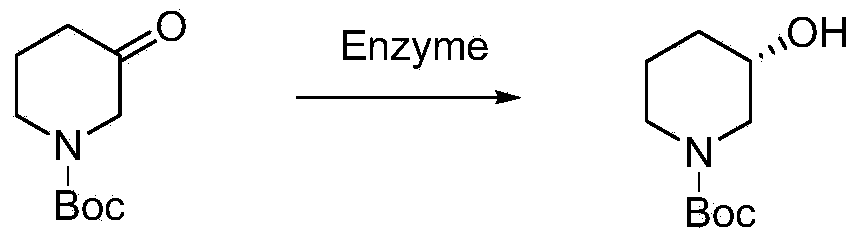

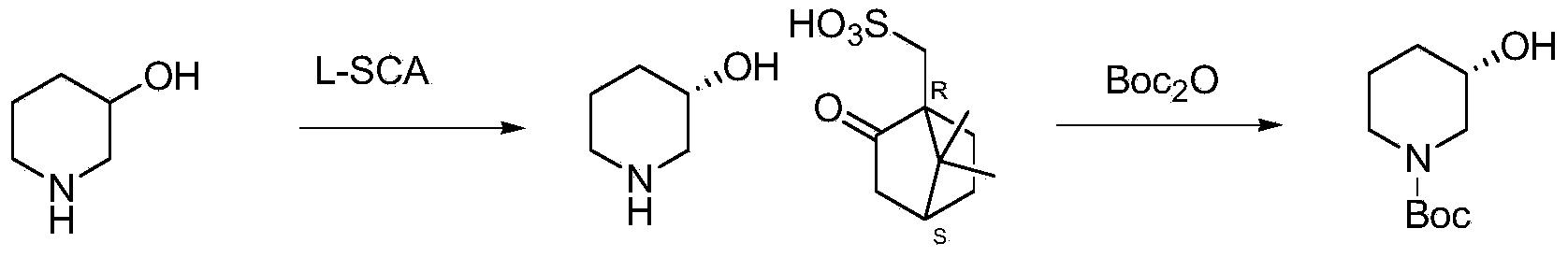

Preparation of chirality-1-t-butyloxycarboryl-3-hydroxy piperidine and method for chirality turning

ActiveCN103864673AReduce total usageSolve the problem that it is not easy to purify and obtain, and it is difficult to industrializeAsymmetric synthesesSulfonyl chlorideTert-Butyloxycarbonyl protecting group

The invention relates to preparation of chirality-1-t-butyloxycarboryl-3-hydroxy piperidine and a method for chirality turning. The preparation mainly comprises the following steps: resolving N-benzyl-3-hydroxy piperidine as a raw material to obtain a (S) or (R)-1-benzyl-3-hydroxy piperidine camphorsulfonic acid salt, performing alkali freedom to obtain (S) or (R)-1-benzyl-3-hydroxy piperidine, performing palladium carbon hydrogenation debenzylation / t-butyloxycarboryl protection to obtain (S) or (R)-1-t-butyloxycarboryl-3-hydroxy piperidine, acylating substituting sulfonyl chloride of (R) or (S)-1-substituting-3-hydroxy piperidine as a raw material to obtain (R) or (S)-1-substituting-3-hydroxy piperidine sulfonate, substituting by using substituting carboxylate to obtain (S) or (R)-1-substituting-3-hydroxy piperidine carboxylic ester, and performing alkaline hydrolysis to obtain (S) or (R)-1-substituting-3-hydroxy piperidine. The synthesis route is gentle in reaction condition, and is applicable to industrial large-scale production.

Owner:ABA CHEM CORP

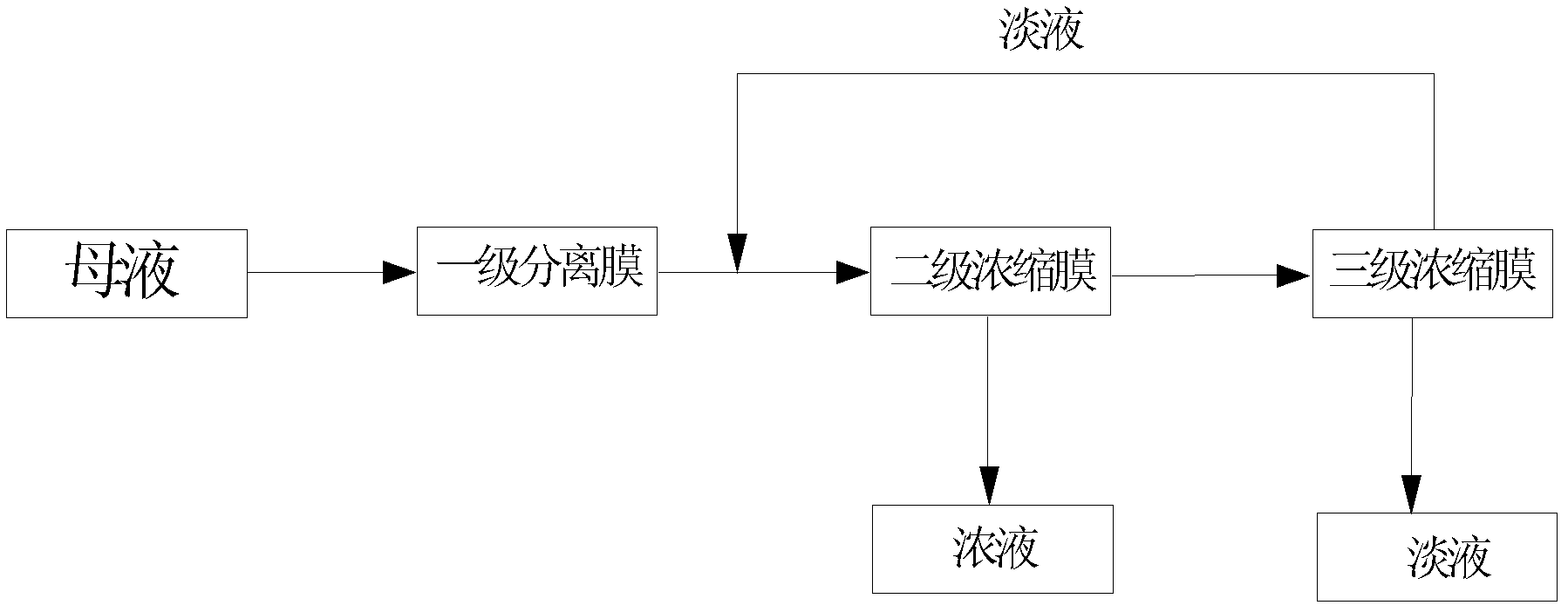

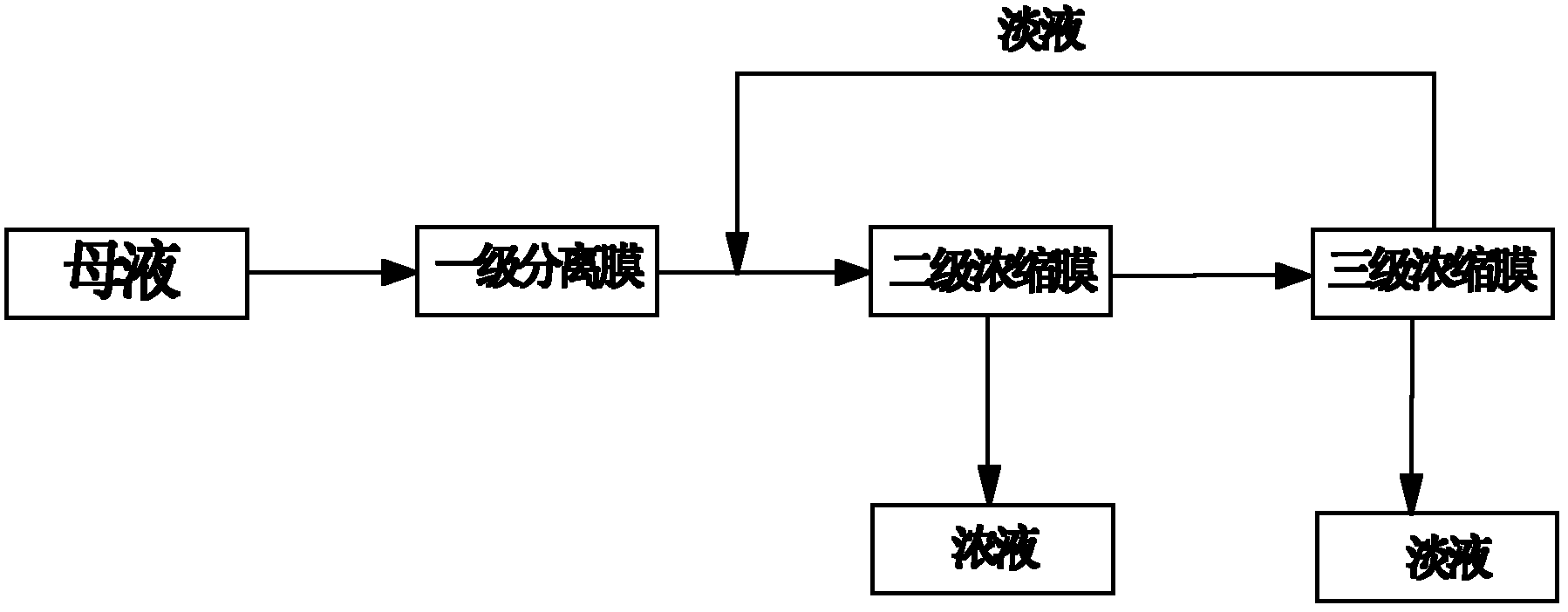

Membrane separation system and purification method for purifying camphorsulfonic acid solution

ActiveCN102423637ANo pollution in the processReduce energy consumptionSemi-permeable membranesOrganic chemistryPurification methodsEvaporation

The invention relates to a membrane separation system and a purification method for purifying camphorsulfonic acid solution. At present, an evaporation process is generally used for purifying the camphorsulfonic acid solution, which removes redundant water in a boiled state; and thus, the processing cost is relatively high, and the material is easily deteriorated and lost after staying in high-temperature state for a long time. In the invention, large particle impurities in a mother solution are filtered by a first-level separation membrane; a thin solution and a thick solution are separated by a second-level concentration membrane; the thin solution separated by the second-level concentration membrane enters a third-level concentration membrane and is recycled; the thick solution separated by the third-level concentration membrane is returned to the second-level concentration membrane again; the thick solution discharged by the second-level concentration membrane is the finished product; and the thin solution separated by the third-level concentration membrane is directly discharged out of the membrane separation system. The invention provides a physical separation process without phase change and with low energy consumption. Through the invention, the energy consumption is low, the operation cost is reduced, and atmospheric pollution is prevented as the entire membrane separation system operates in a closed pipeline.

Owner:ZHEJIANG YUNTAO BIOTECH

Phenol formaldehyde foam by using aromatic hydrocarbon polyester polyol as toughener and preparation method thereof

The invention discloses a toughening-modified phenol formaldehyde foam which is mainly prepared from the following raw materials in parts by mass: 40-80 parts of toughening-modified phenol formaldehyde resin, 2-4 parts of surfactant water-based silicon oil, 3-6 parts of composite foaming agent and 4-8 parts of acid mixture curing agent. The sulfuric acid, phosphoric acid, boric acid, methylsulfonic acid, dodecylbenzene sulfonic acid, camphorsulfonic acid and the like are proportionally mixed to obtain the inorganic-organic acid mixture used as the curing agent, the curing rate and foaming rate are proper, and the system is heated gradually, thereby ensuring the reaction uniformity; and the prepared phenol formaldehyde foam has the advantages of uniform and fine foam pores and light color.

Owner:LIAOCHENG UNIV

Process for improved water flux through a tfc membrane

ActiveUS20170197182A1Preserve TFC membrane performance propertyWater flux performanceGeneral water supply conservationSeawater treatmentBrackish waterThin-film composite membrane

Provided is a process for preparation of a highly permeable thin film composite membranes for nanofiltration, reverse osmosis, and forward osmosis, particularly for reverse osmosis of brackish water. The process includes treating a prepared TFC membrane containing a discrimination layer on a frontside, a support layer, and a felt layer on the backside by contacting the backside of TFC membrane with a solution containing a pore protection agent that includes a tertiary amine salt of camphorsulfonic acid prior to or at the same time as contacting the frontside of the membrane with a solution containing a coating agent and drying the membrane. Also provided are reverse osmosis membranes prepared in accord with the method, and modules containing the highly permeable thin film composite membranes.

Owner:LG NANOH2O +1

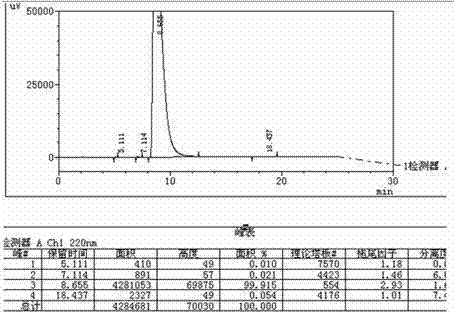

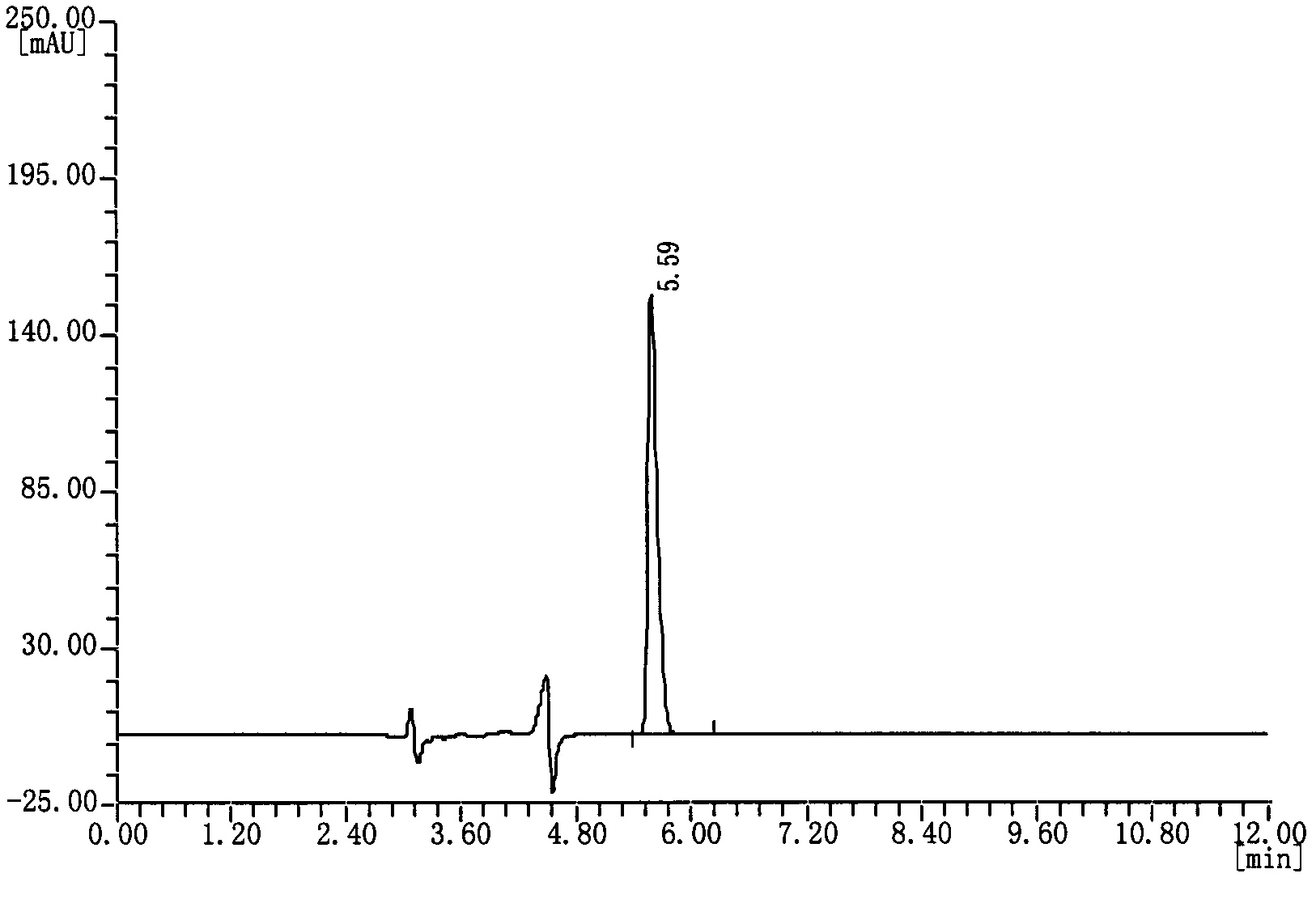

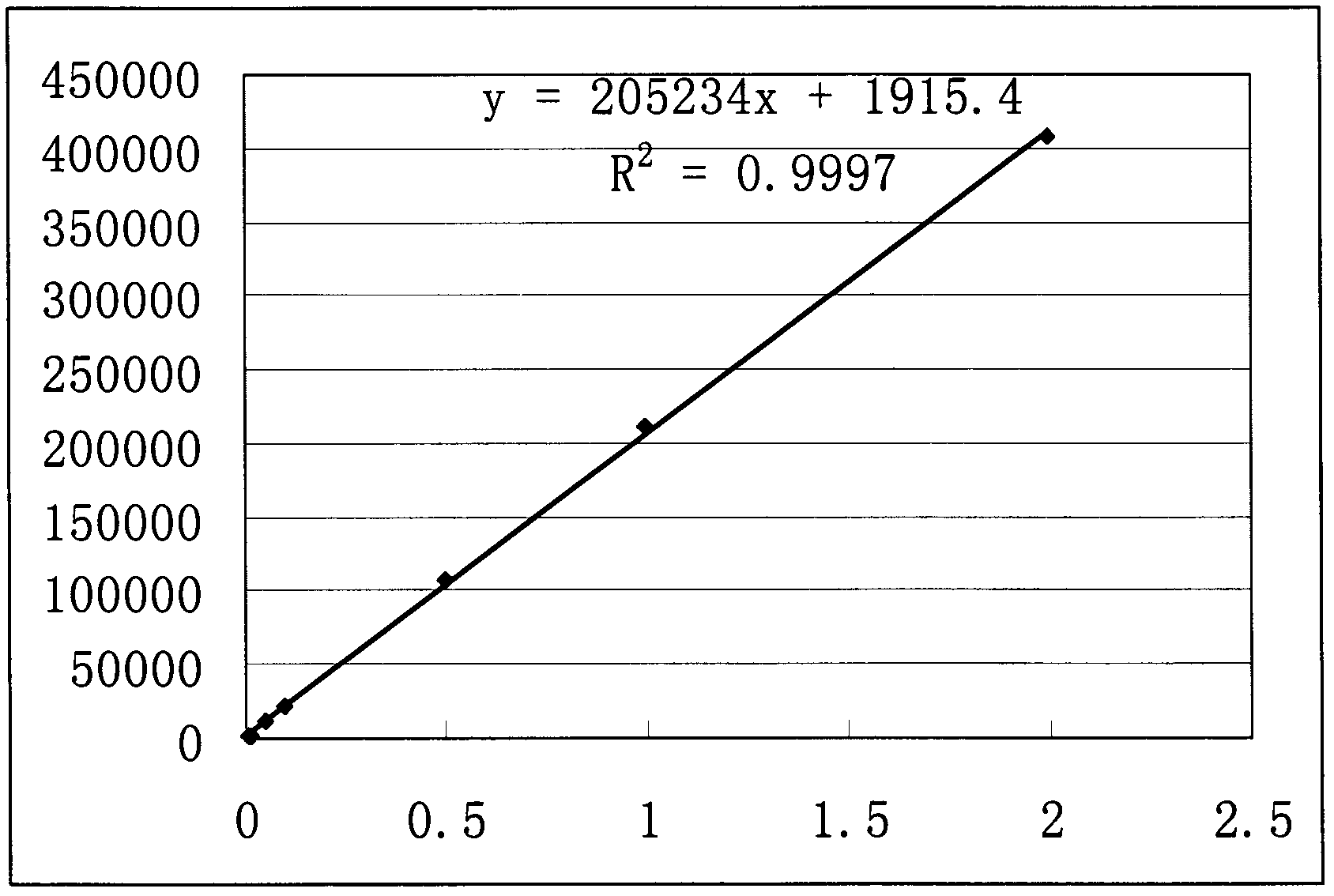

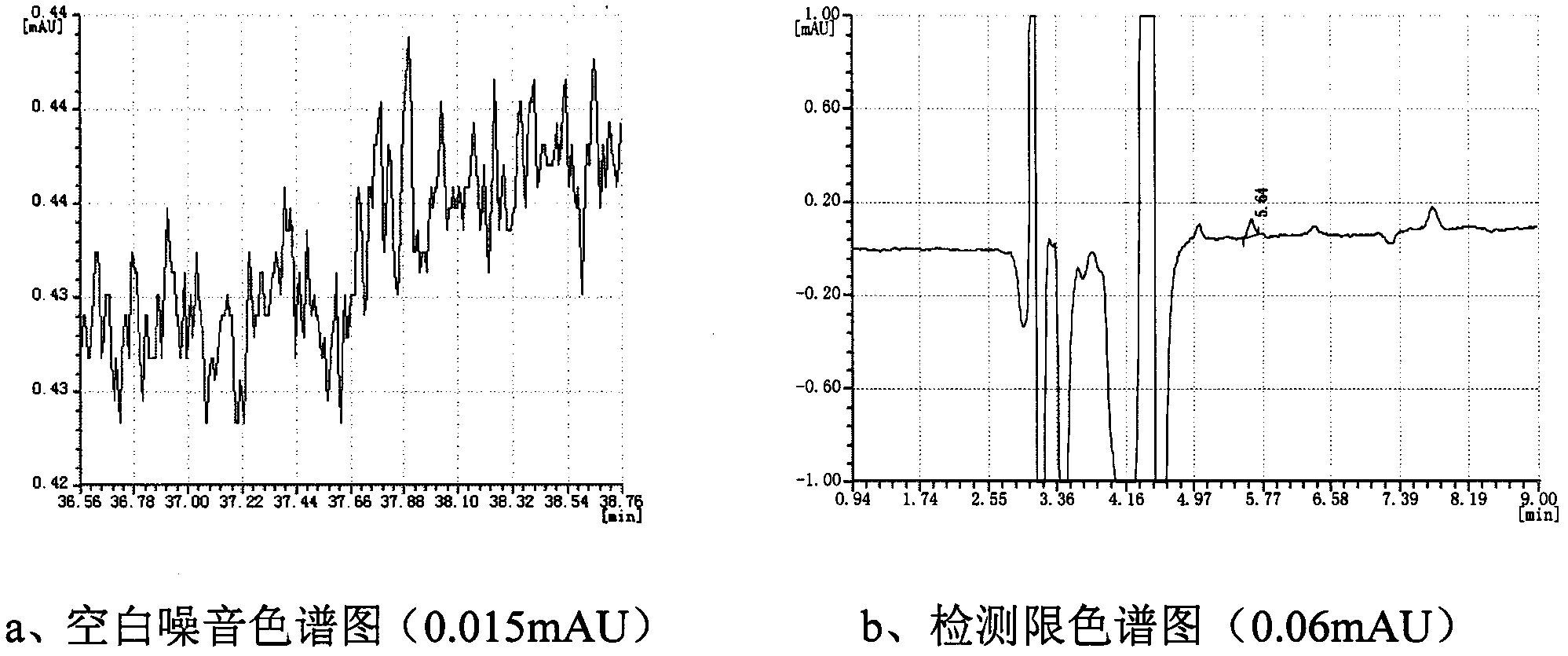

Mass control method for clopidogrel splitting agent

ActiveCN103185750AImprove stabilityWide linear rangeComponent separationUltraviolet detectorsAcetonitrile

The invention provides a mass control method for a clopidogrel splitting agent of camphorsulfonic acid or camphorsulfonic acid salt. The method is characterized in that a C18 chromatographic column high performance liquid chromatography is used to separate the camphorsulfonic acid or the camphorsulfonic acid salt, then an ultraviolet detector is used for quantitative detection, the mobile phase of the C18 chromatographic column high performance liquid chromatography is acetonitrile-phosphate aqueous solution, the pH value of the mobile phase is 2.0-6.0, and the detection wavelength of the detector is 200-210 nm. The method provided by the invention has the advantages of wider linear range, higher sensitivity, good accuracy, strong repeatability, low detection cost and simplicity and convenience in operation, and is applicable to accurate quantification of the low-concentration camphorsulfonic acid or camphorsulfonic acid salt.

Owner:HUIZHOU XINLITAI PHARMA +1

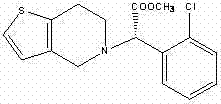

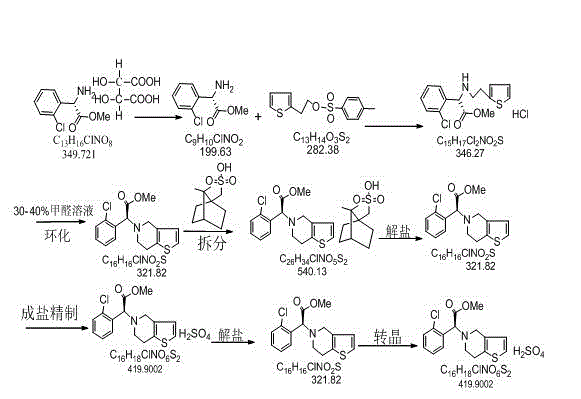

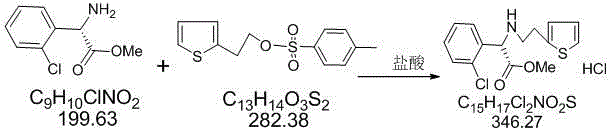

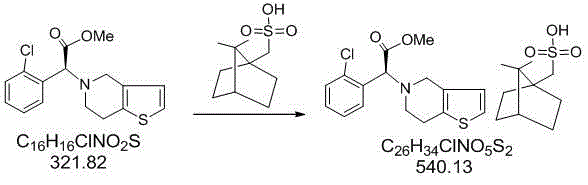

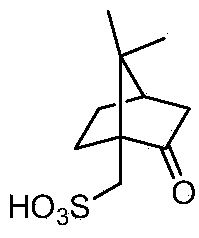

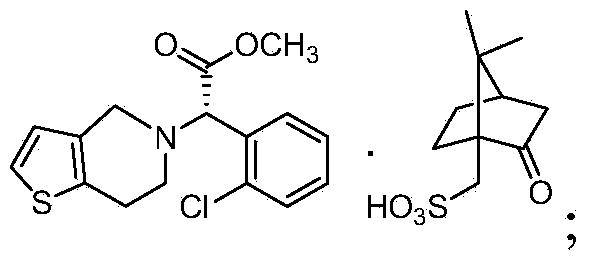

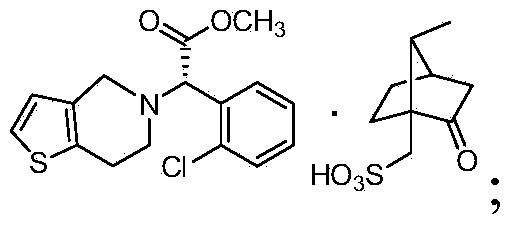

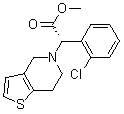

Preparation method of type I clopidogrel hydrogen sulfate

The invention relates to a preparation method of type I clopidogrel hydrogen sulfate. The preparation method comprises the following steps of: generating (S) clopidogrel free alkali from the raw material (S)-alpha-[(2-thiophene)ethylamino]-alpha-(2-chlorphenyl) methyl acetate hydrochloride; reacting L-camphorsulfonic acid with the (S)-clopidogrel free alkali, and removing impurities to obtain (S)-alpha-(2-chlorphenyl)-6,7-dichlorothieno-[3,2-c] pyridine-5(4H)-methyl acetate-(L)-camphosulfonate; performing refining and impurity removal on the (S)-alpha-(2-chlorphenyl)-6,7-dichlorothieno-[3,2-c] pyridine-5(4H)-methyl acetate-(L)-camphosulfonate by using acetone-petroleum ether to obtain (S)-clopidogrel-(L)-camphosulfonate; removing L-camphorsulfonic acid from the (S)-clopidogrel-(L)-camphosulfonate and dropwise adding concentrated sulfuric acid to the type I clopidogrel hydrogen sulfate. The preparation method provided by the invention is capable of obtaining high-purity type I clopidogrel hydrogen sulfate.

Owner:SICHUAN EMEISHAN PHARMA

Synthetic method of polyaniline nanofiber with helical structure

The invention provides a synthetic method of polyaniline nanofiber with a helical structure. The method comprises the following steps: firstly synthesizing N, N'-2(4-phenylene diamine)-1 and 4-phenylene diamine; secondly taking N, N'-2(4-phenylene diamine)-1 and 4-phenylene diamine as a polymerization reaction catalyst, chiral camphor sulfonic acid as an inducer and a doping agent, and ammonium persulfate as an oxidizing agent; finally synthesizing the polyaniline nanofiber with the helical structure through adopting the chemical oxidative polymerization. According to the synthetic method, the chiral camphor sulfonic acid is adopted as the doping agent to be interacted with the polyaniline main chain and to induce the polyaniline main chain to form the helical structure, and meanwhile, N, N'-2(4- phenylene diamine)-1 and 4-phenylene diamine with the oxidation potential lower than that of monomer aniline is further added to serve as a 'seed' and catalyze the polymerization reaction, so that the polymerization rate is greatly increased with the addition of phenylene diamine, and besides, heterogeneous nucleation is under restriction in the polymerization process, giving rise to the predominance of homogeneous nucleation, so that secondary growth is inhibited, the formation of the polyaniline helical structure is facilitated, and the optical activity of polyaniline is greatly improved.

Owner:HARBIN ENG UNIV

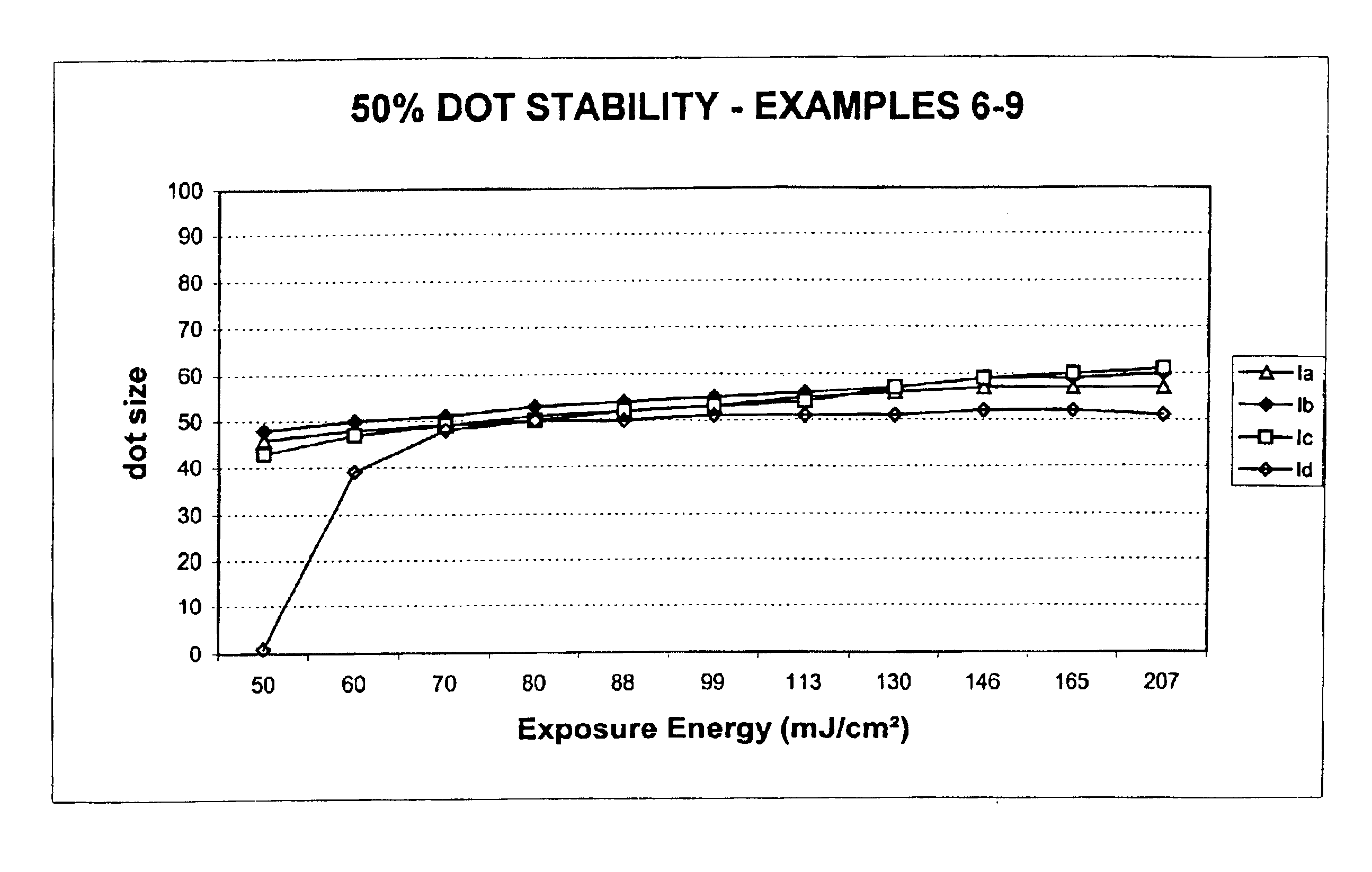

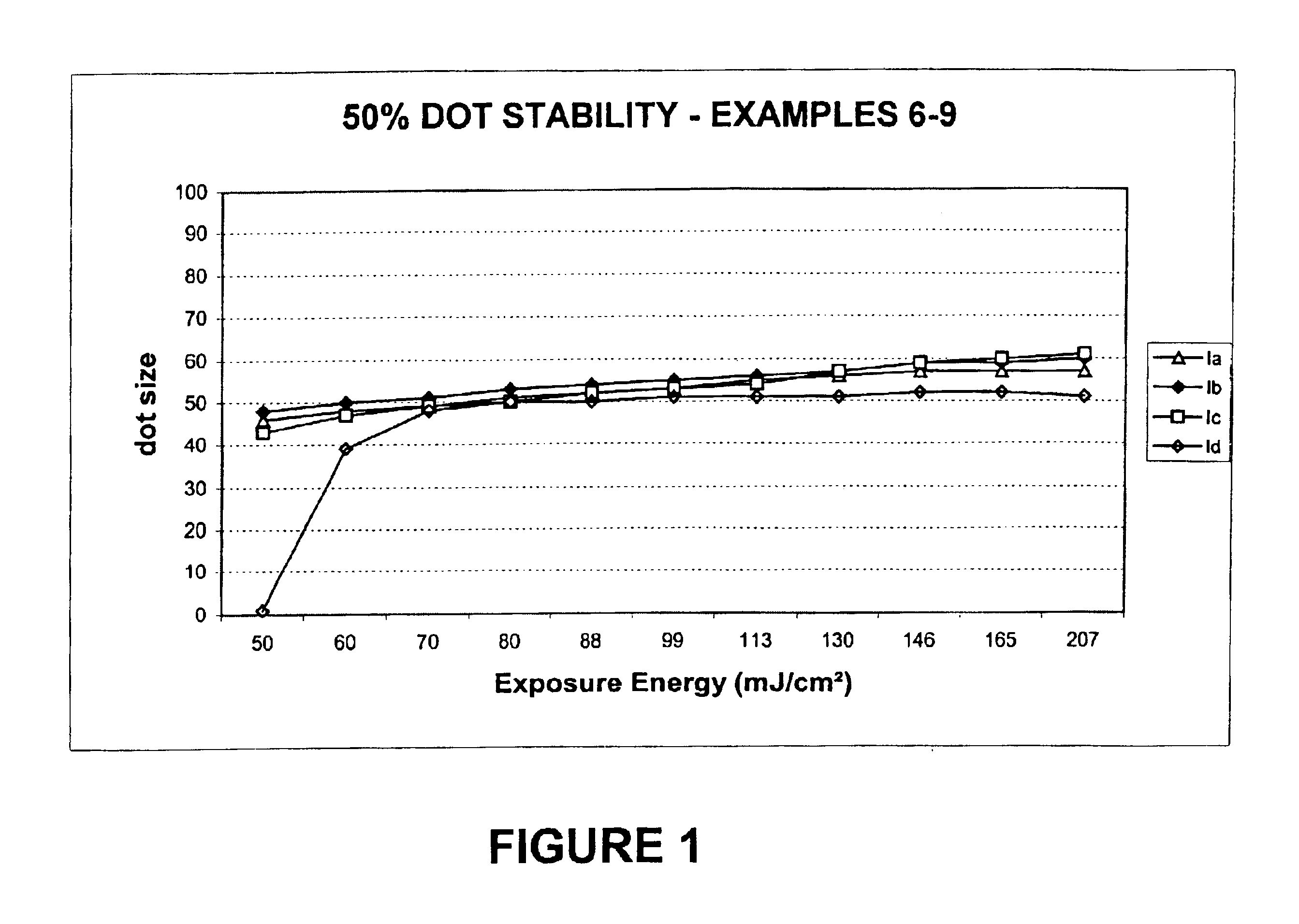

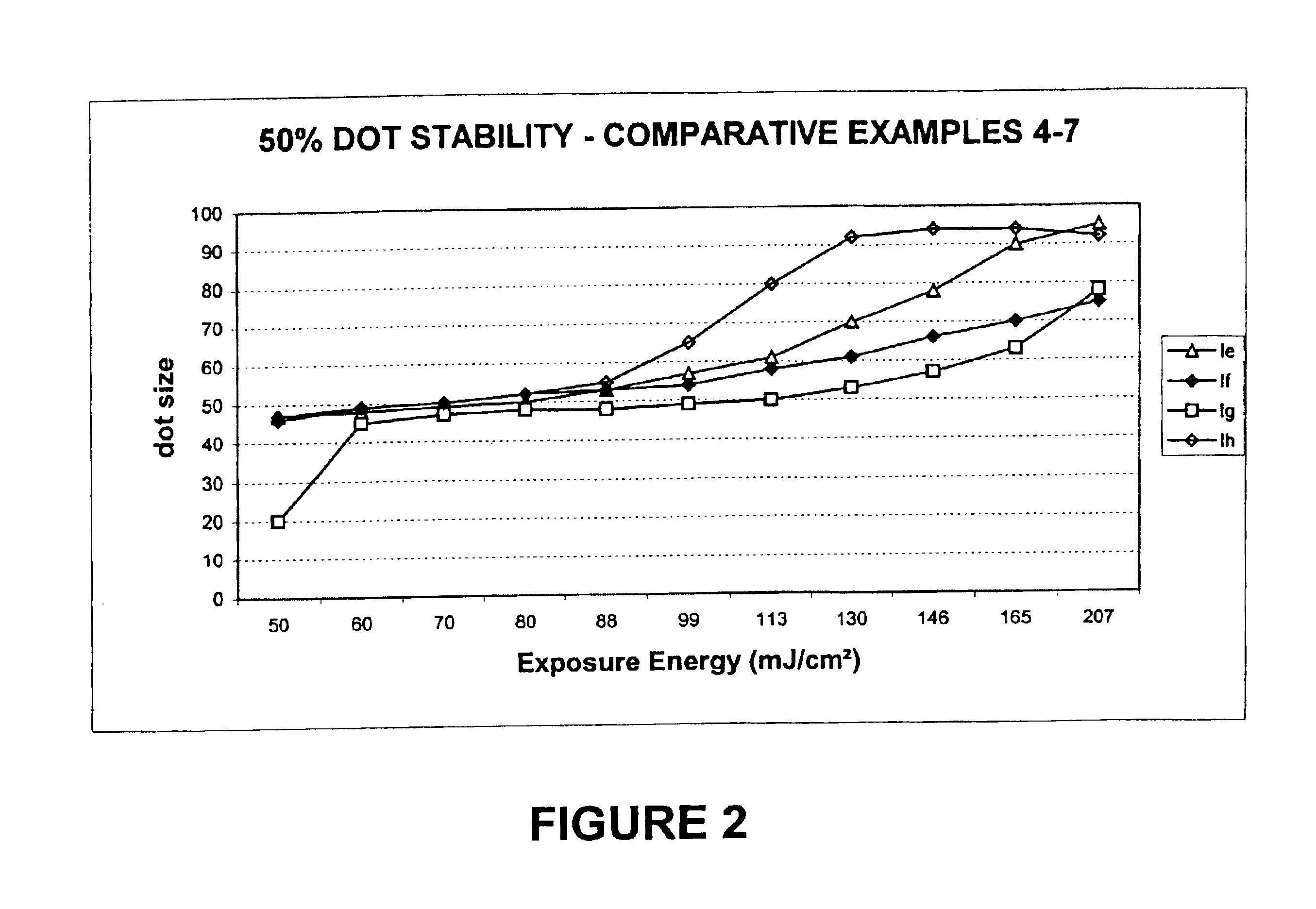

Infrared absorbing compounds and their use in photoimageable elements

InactiveUS6902861B2Improved dot stabilityLess variation of dot size with exposureMethine/polymethine dyesOrganic chemistry10-camphorsulfonic acidPhotochemistry

Infrared absorbing compounds in which the anion is selected from the group consisting of 5-isatinsulfonate, 10-camphorsulfonate, and 4,5-dihydroxy-1,3-benzenedisulfonate are disclosed. Negative-working imageable elements containing these compounds have improved dot stability.

Owner:KODAK POLYCHROME GRAPHICS

Method for synthesizing optically active laevogyrate and dexiotropous camphor sulfonic acid

InactiveCN101092379AReduce pollutionSimple processOrganic chemistryOrganic compound preparationAcetic acidAcetic anhydride

This invention relates to a method for preparing optically active L-camphor sulfonic acid and D-camphor sulfonic acid. The method comprises: preparing acetic anhydride 100 parts, acetic acid 8-20 parts, racemic camphor 60-80 parts, and fuming sulphuric acid 40-60 parts, synthesizing racemic camphor sulfonic, resolving, and puridying to obtain the products. The method has such advantages as little waste discharge, little pollution; simple process and can separate L-camphor sulfonic acid and D-camphor sulfonic acid by using one resolution agent. The products have high optical activity and high resolution yield (near 100%).

Owner:上海康福赛尔医药科技有限公司

Chemical prepn process of nanometer polyethylene thienyl dioxide

The present invention discloses chemical preparation process of nanometer polyethylene thienyl dioxide, and belongs to the field of conducting material preparing technology. The preparation process includes the following steps: compounding 0.5-1.2 mol / L concentration mixed solution of camphor sulfonic acid and ethylene thienyl dioxide, compounding 0.47-2.80 mol / L concentration solution of ferric trichloride, mixing them to initiate polymerization reaction at 0-5 deg.c; centrifugally separating and washing the product with deionized water to neutral, vacuum drying at 50-80 deg.c for 6-24 hr to obtain the navy blue polyethylene thienyl dioxide powder as the product. The preparation process is simple and environment friendly, and the prepared nanometer polyethylene thienyl dioxide has high conductivity, high crystallization degree and other physical characteristics, and possesses latent application in photoelectronic device field.

Owner:TIANJIN UNIV

Recycling method of levorotation camphorsulfonic acid serving as clopidogrel resolving agent

InactiveCN102093263ASolving Recycling ProblemsOvercome the high proportion of the costOrganic chemistryOrganic compound preparationFiltrationStrong acids

The invention discloses a recycling method of levorotation camphorsulfonic acid serving as a clopidogrel resolving agent, which belongs to the technical field of fine chemistry industry. The method comprises the following steps of: 1) adding clopidogrel camphorsulfonate into a certain amount of ethyl acetate and water mixed solution, mixing fully and uniformly, and performing alkaline treatment with saturated inorganic salt solution; 2) acidifying a water layer with strong acid, concentrating and evaporating to dryness to obtain a solid, adding an organic solvent, heating until concentrated solution is dissolved, and filtering to remote inorganic salt; and 3) cooling and crystallizing filtrate for 5 to 12 hours and performing suction filtration to obtain the levorotation camphorsulfonic acid. The method has a simple recycling process and short time. Further resolution indicates that an obtained product has high optical purity, recovery ratio of over 89 percent, low production cost and a good economic benefit, is easy to operate, is nontoxic and environmentally-friendly, and is suitable for mass industrial production.

Owner:ZHEJIANG LANGHUA PHARMA

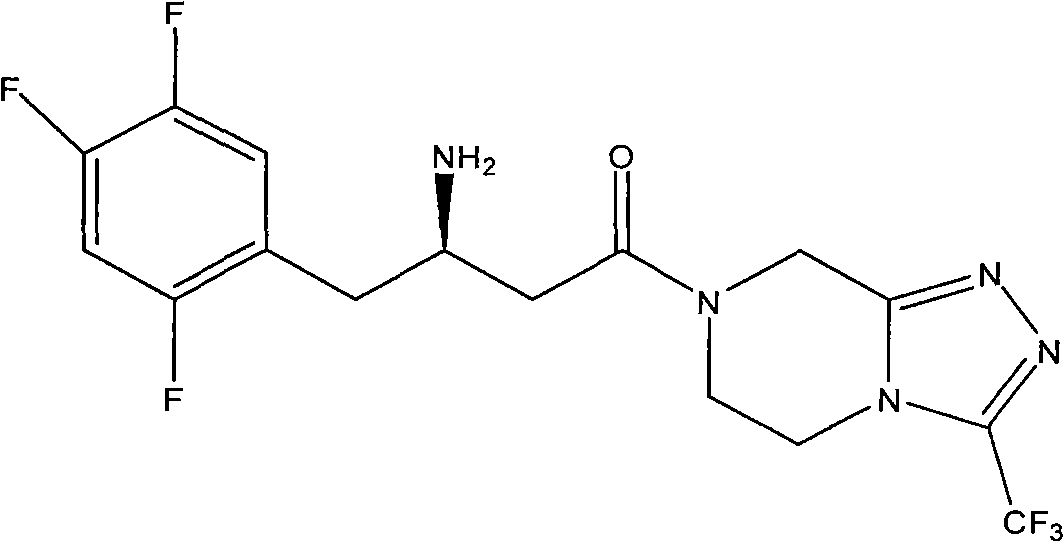

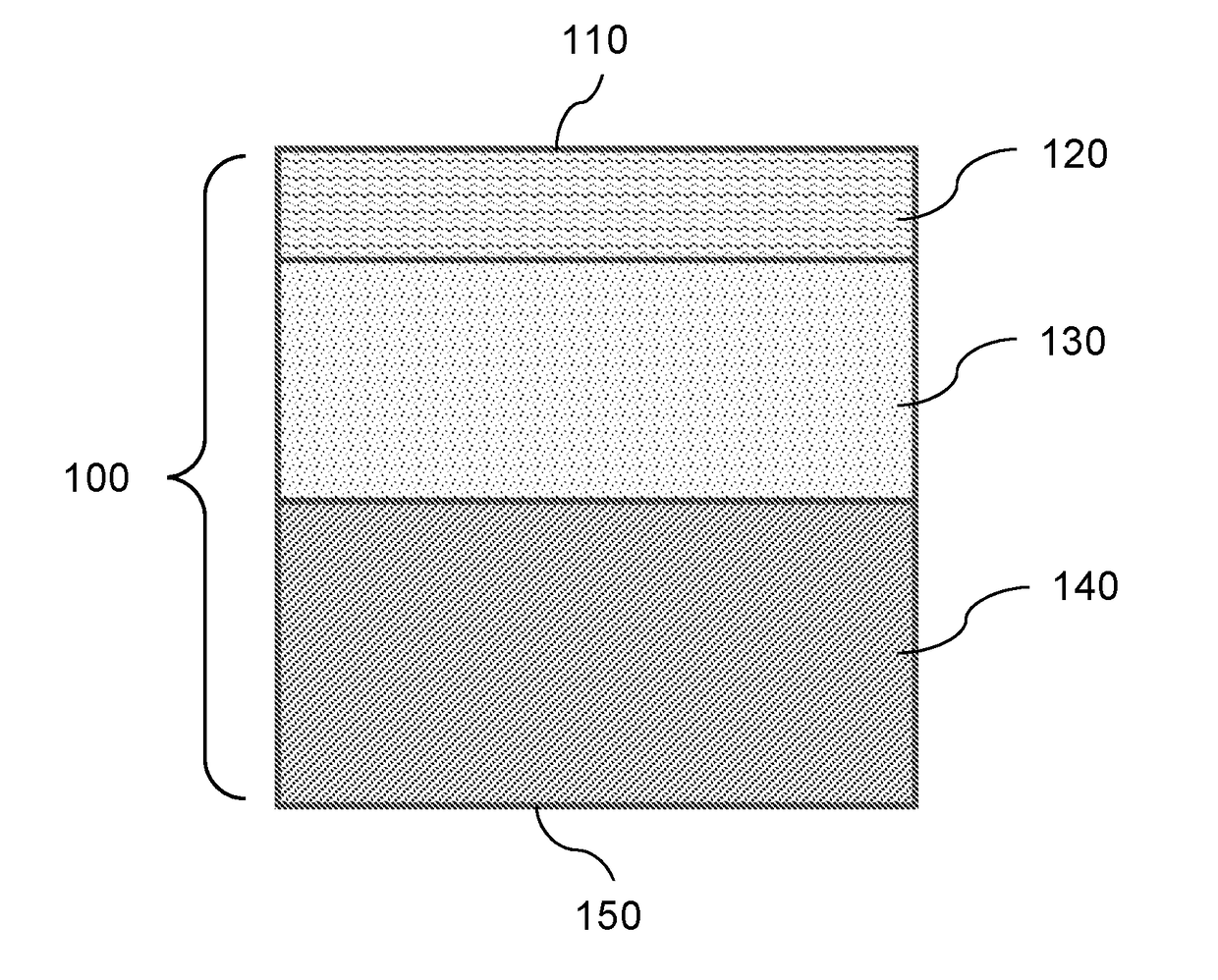

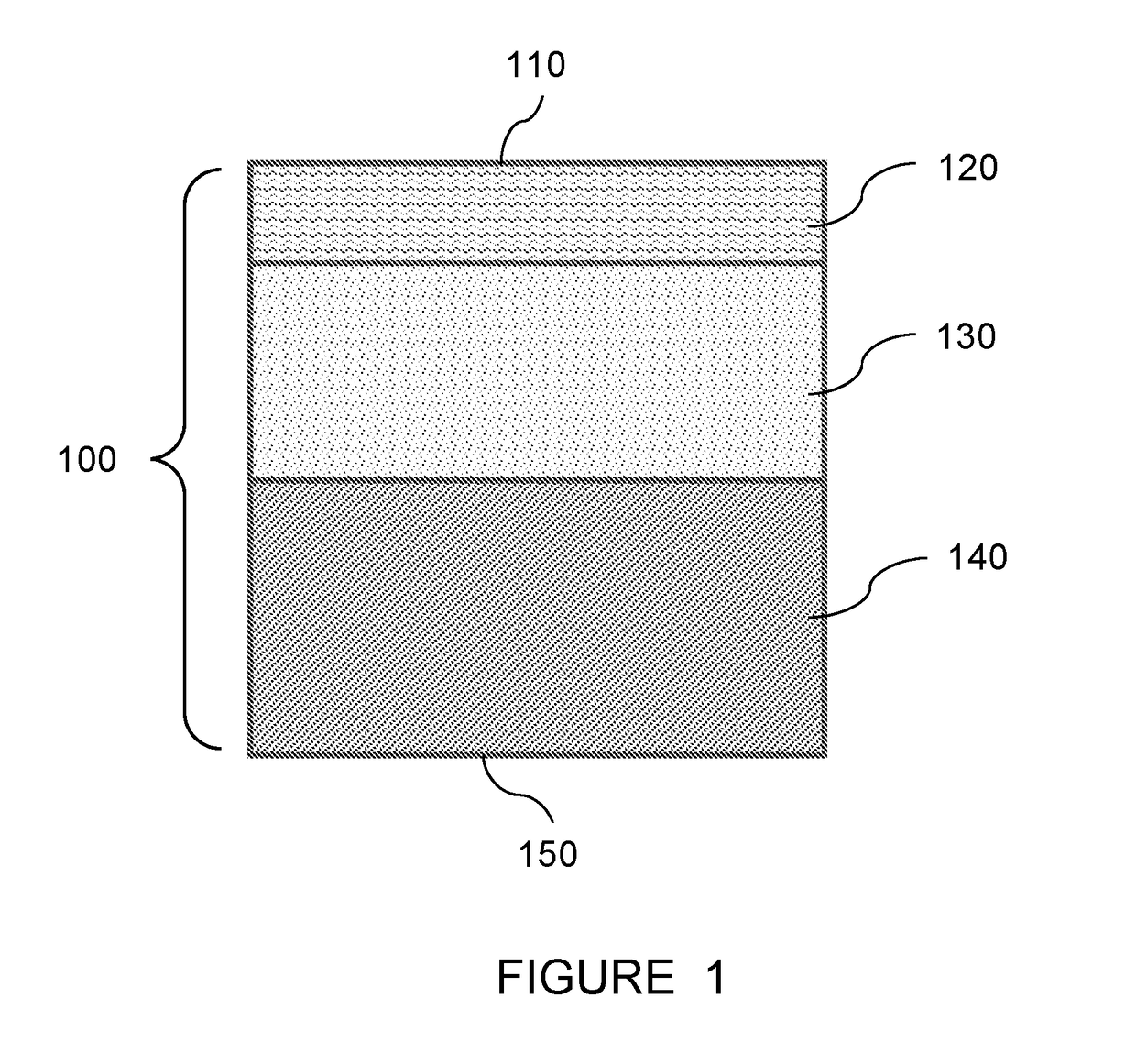

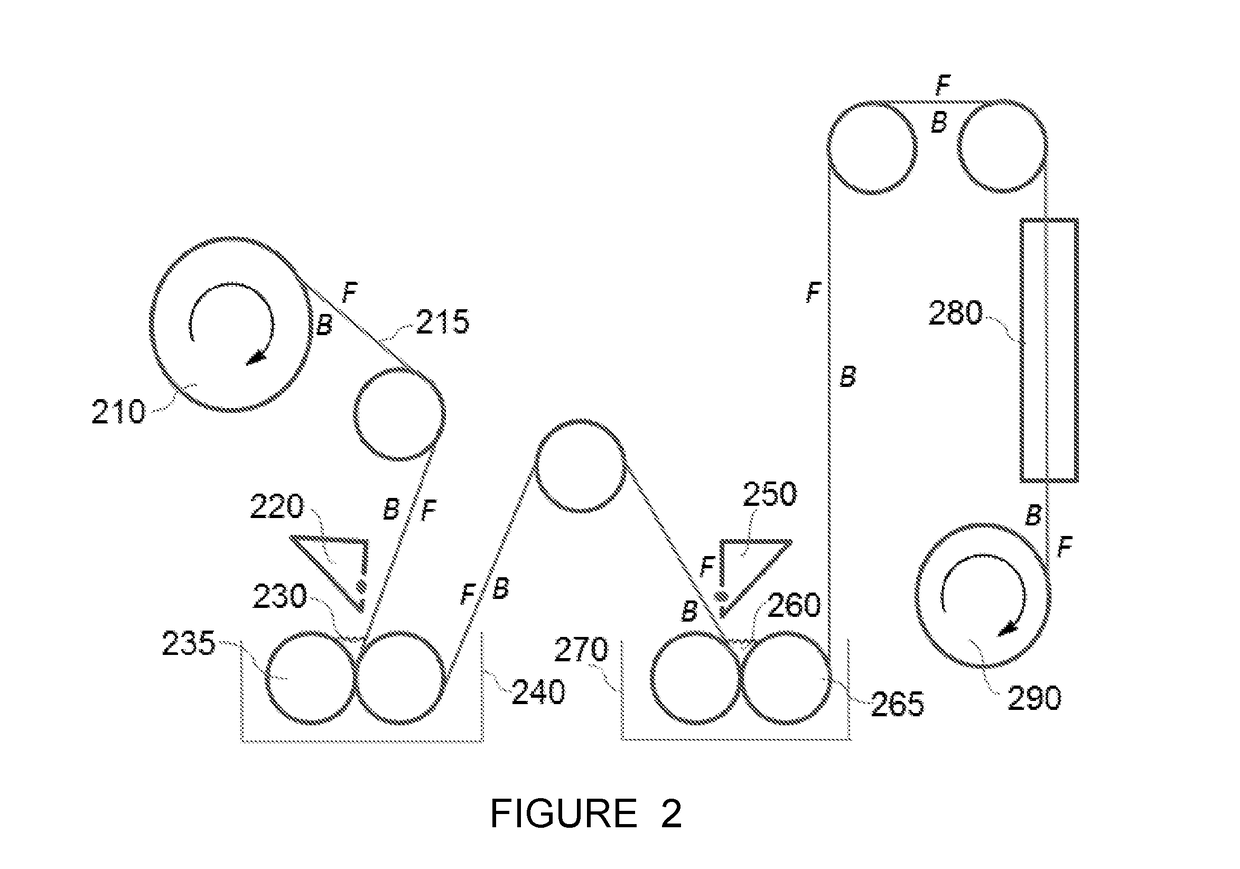

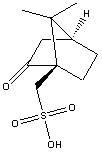

Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes

ActiveCN103420896APromote safe productionEasy to operateOrganic chemistryTert-Butyloxycarbonyl protecting groupKetone

The invention discloses a preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptane. The method comprises the following steps: reacting benzoylamide acetoacetate as a raw material with 1,2-dichloroethane to obtain 3-cyclopropyl benzoylamide acetoacetate, brominating 3-cyclopropyl benzoylamide acetoacetate by NBS (n-bromosuccinimide) to obtain 1-bromo-3-cyclopropyl benzoylamide acetoacetate, cyclizing under alkaline conditions to obtain 5-benzyl-5-aza-spiro[2,4]heptane-4,7-diketone, further reacting with hydroxylamine hydrochloride to form an oxime compound-4-oxo-5-benzyl-7-oximido-5-aza-spiro[2,4]heptane, reducing by NaBH4 and boron trifluoride diethyl etherate to obtain 5-benzyl-7-amino-5-aza-spiro[2,4]heptane, performing chiral resolution by a resolving agent-L-camphorsulfonic acid to obtain 5-benzyl-7(S)-amino-5-aza-spiro[2,4]heptane, and reacting with di-tert-butyl dicarbonate ester to obtain 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptane. According to the method, an intermediate body-carbonyl does not need protection, raw materials are easy to get, a process route is simple, and the method is suitable for industrial production.

Owner:苏州楚凯药业有限公司

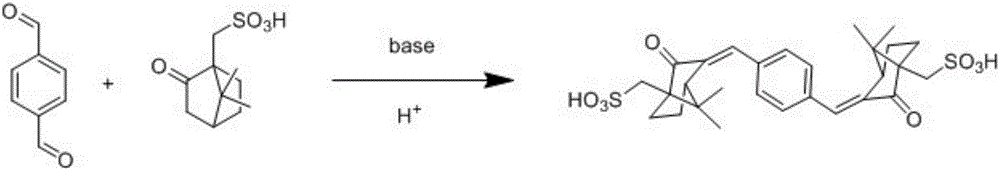

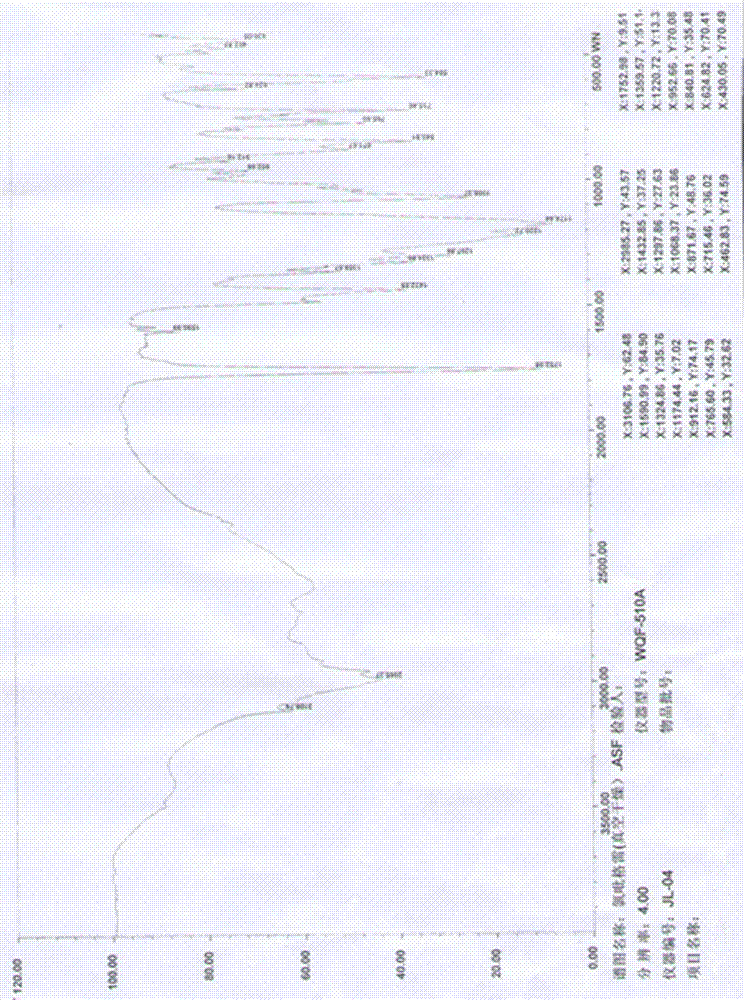

Preparation method of terephthalylidene dicamphor sulfonic acid sun-screening agent

The invention belongs to the field of producing fine chemicals and discloses a preparation method of a terephthalylidene dicamphor sulfonic acid sun-screening agent. The preparation method comprises the following steps: stirring camphor sulfonic acid, a methanol solution of sodium methylate and cyclohexane by using a water segregator at the temperature being 65-75 DEG C to carry out reaction for 20-120min, and recovering methanol; dropwise adding a cyclohexane-methanol mixed solution of terephthalic aldehyde, continuously stirring by using the water segregator at the temperature being 65-75 DEG C to carry out reaction for 30-120min, and recovering methanol; and then adding water, carrying out acidification with acid, carrying out layering by rising temperature, and carrying out crystallization and pumping filtration on a water layer to obtain a product with the HPLC purity being larger than 99 percent. The technology greatly simplifies operation and flow and is simple to operate.

Owner:广州星业科技股份有限公司

Medetomidine industrial splitting method

The invention discloses a medetomidine industrial splitting method which takes L-(-) camphorsulfonic acid as a chiral reagent and C1-C5 alcohol as a chiral auxiliary. According to the method disclosed by the invention, the splitting yield reaches up to over 40% and the splitting optical purity reaches over 99.5%. The method is simple in industrialized operation and can be used for industrialized and commercialized production.

Owner:安庆生命科技园发展有限公司

Synthesis method of high-purity I-type (+)-(S)-clopidogrel hydrogen sulfate

The invention discloses a synthesis method of high-purity I-type (+)-(S)-clopidogrel hydrogen sulfate, which comprises the following steps: 1) mixing an acetone solution of L(-)-camphorsulfonic acid and an acetone solution of (+)-(S)-clopidogrel crude product to carry out salification reaction for 6-10, filtering after the reaction finishes, and treating the filter cake to obtain (+)-(S)-clopidogrel L(-)-camphorsulfonate; 2) dissolving the product obtained in the step 1) in a mixture of dichloromethane or ethyl acetate and water, regulating the pH value to 7-8, stirring for 10-60 minutes, standing to stratify, and treating the organic layer to obtain a (+)-(S)-clopidogrel pure product; and 3) dissolving the product obtained in the step 2) in an organic solvent, adding a crystal seed, stirring, adding an organic solvent solution of sulfuric acid, heating to 50-60 DEG C, stirring for 1-3 hours, cooling to room temperature, filtering, and treating the filter cake to obtain the high-purity I-type (+)-(S)-clopidogrel hydrogen sulfate. The method has the advantages of simple technique, high product yield and high product purity, and is suitable for industrial production.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

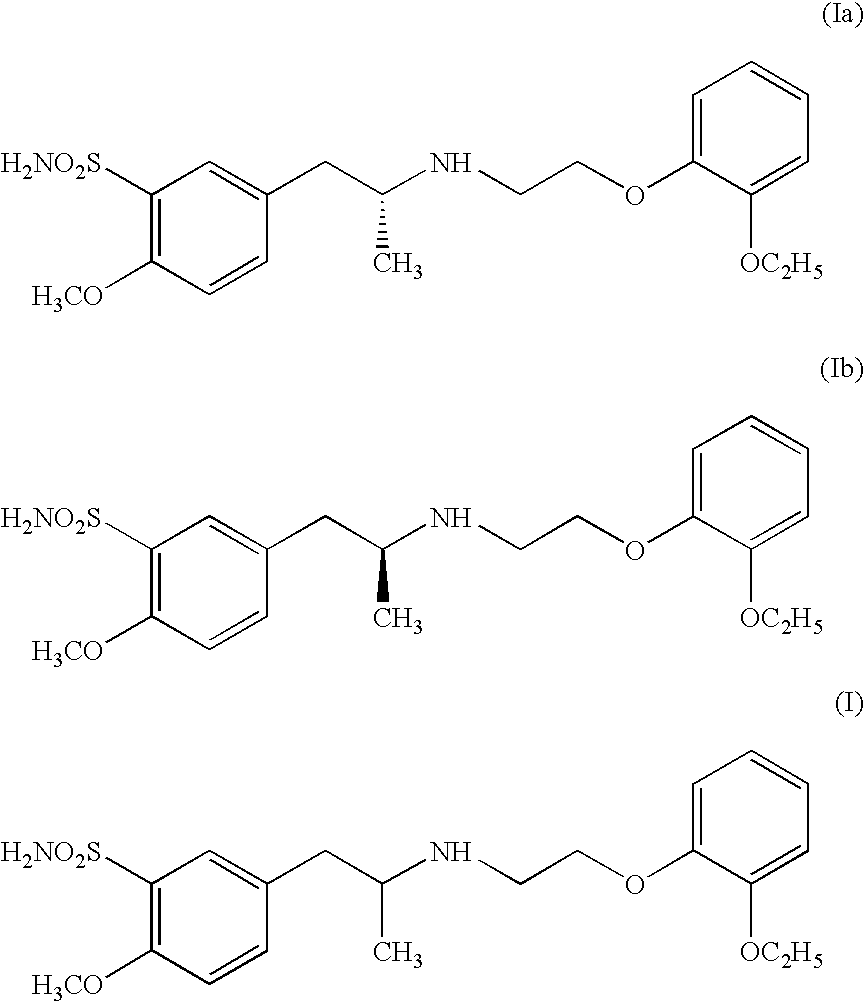

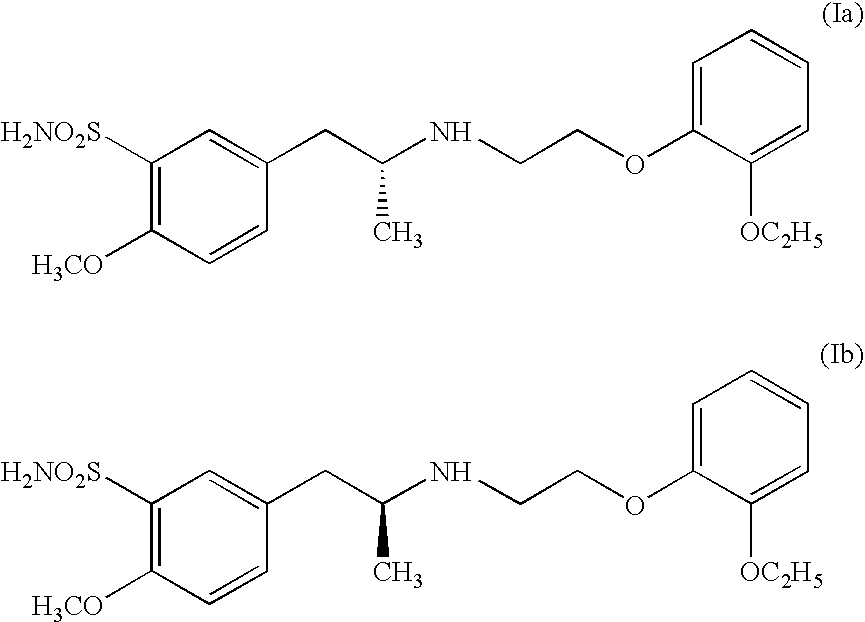

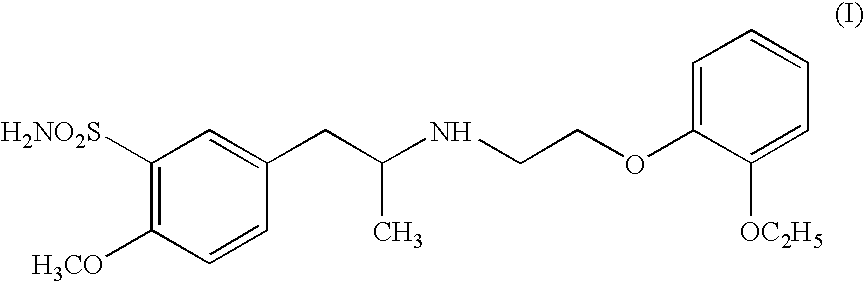

Process for preparing R- and S-isomers of (R)-5-(2-( (2-(2-ethoxyphenoxy) ethyl) amino) propyl) -2-methoxybenzenesulfonamide

InactiveUS20050079589A1Organic compound preparationOrganic chemistry methodsOrganic solventEnantiomer

A process for preparing optically pure enantiomers of R-(−)tamsulosin of formula Ia and S-(+)tamsulosin of formula Ib by resolving racemic tamsulosin of formula I by means of (1R)-(−)-camphor-10-sulfonic acid and (1S)-(+)-camphor-10-sulfonic acid, resp., in an environment of organic solvents, water or mixtures thereof.

Owner:FARMAK

Production technique of clopidogrel hydrogen sulfate

The invention relates to a production technique of clopidogrel hydrogen sulfate, which comprises the following steps: (1) preparation of amide hydrochloride, (2) preparation of levo-camphorsulfonate, (3) preparation of clopidogrel hydrogen sulfate crude product and (4) preparation of I-type clopidogrel hydrogen sulfate. The technique is simple, reduces the synthesis steps, lowers the consumption of toxic solvents, enhances the drug safety, facilitates the recovery and treatment of the waste liquid and lowers the production cost. The purity of the clopidogrel hydrogen sulfate obtained by the method is high, and the yield is 6.5% higher than other methods.

Owner:ANHUI YOUCARE KAIYUE PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes](https://images-eureka.patsnap.com/patent_img/c4e5bc10-490b-4118-8859-0b9646c67500/BSA0000093282790000011.png)

![Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes](https://images-eureka.patsnap.com/patent_img/c4e5bc10-490b-4118-8859-0b9646c67500/BSA0000093282790000021.png)

![Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes Preparation method for 5-benzyl-7(S)-t-butyloxycarborylamino-5-aza-spiro[2,4]heptanes](https://images-eureka.patsnap.com/patent_img/c4e5bc10-490b-4118-8859-0b9646c67500/BSA0000093282790000031.png)