Nanomaterial-based gas sensors

a nanomaterial and gas sensor technology, applied in the field of gas sensors, can solve the problems of low selectivity, less-than-ideal sensitivity, and low sensitivity of bare nanomaterial-based sensors to certain gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

,” one will understand how the features of the various embodiments disclosed herein provide a number of advantages over the current state of the art. These advantages include, without limitation, simplified and more efficient methods of fabricating functionalized nanomaterial-based gas sensors having outstanding sensing properties, including high sensitivity, low detection limits, fast response and recovery times, good reproducibility, good selectivity in the detection of gases, and long term stability within a wide temperature range.

[0015]Another advantage of the presently-disclosed gas sensors is the elimination of the relative humidity effect on CNT sensors and functionalized CNT sensors, thereby eliminating (or at least minimizing) the need to compensate for the RH effect under varying RH conditions.

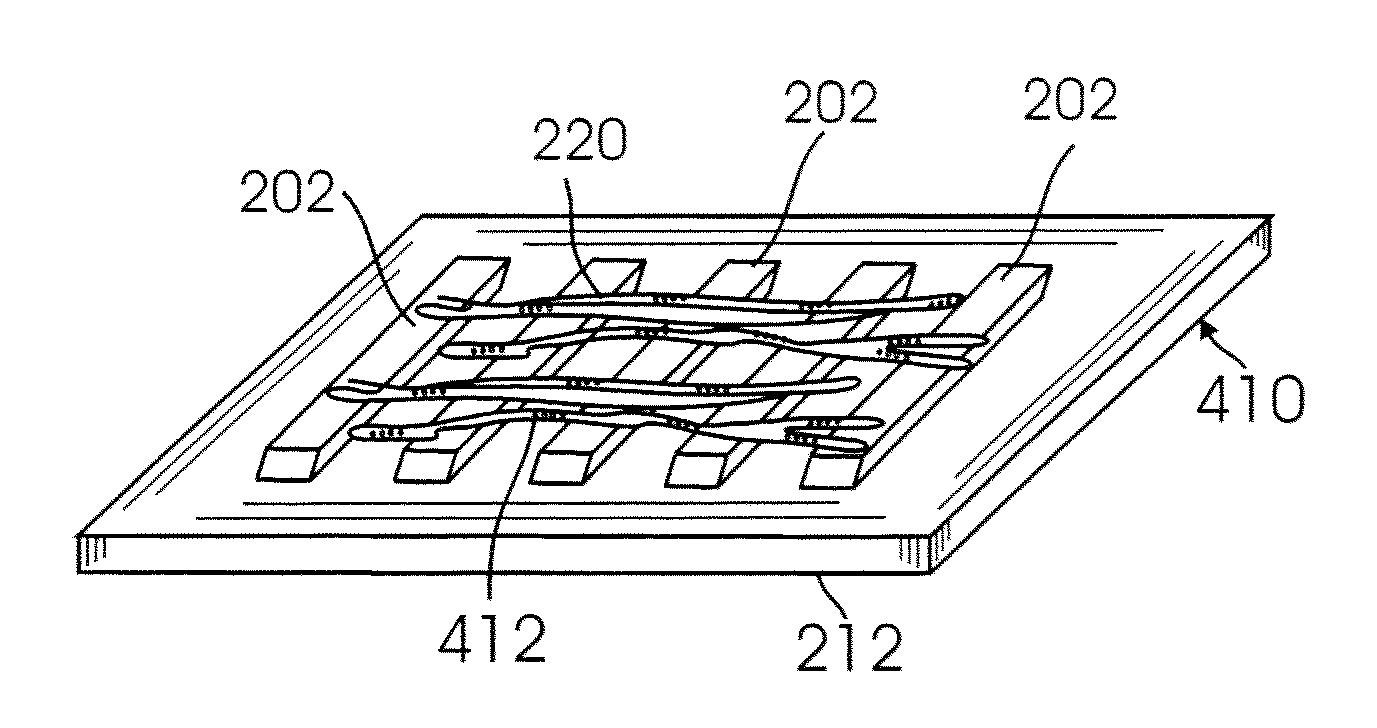

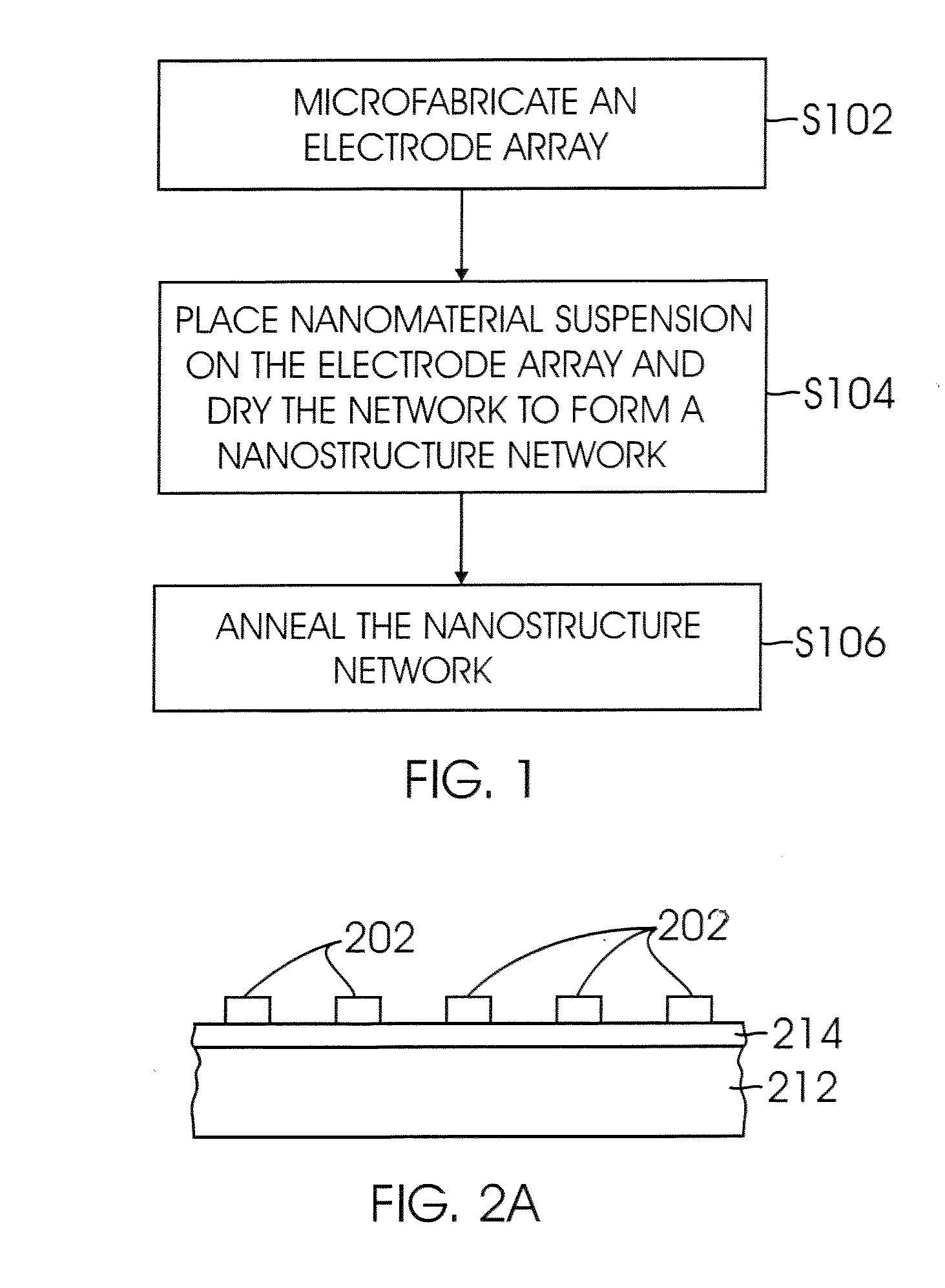

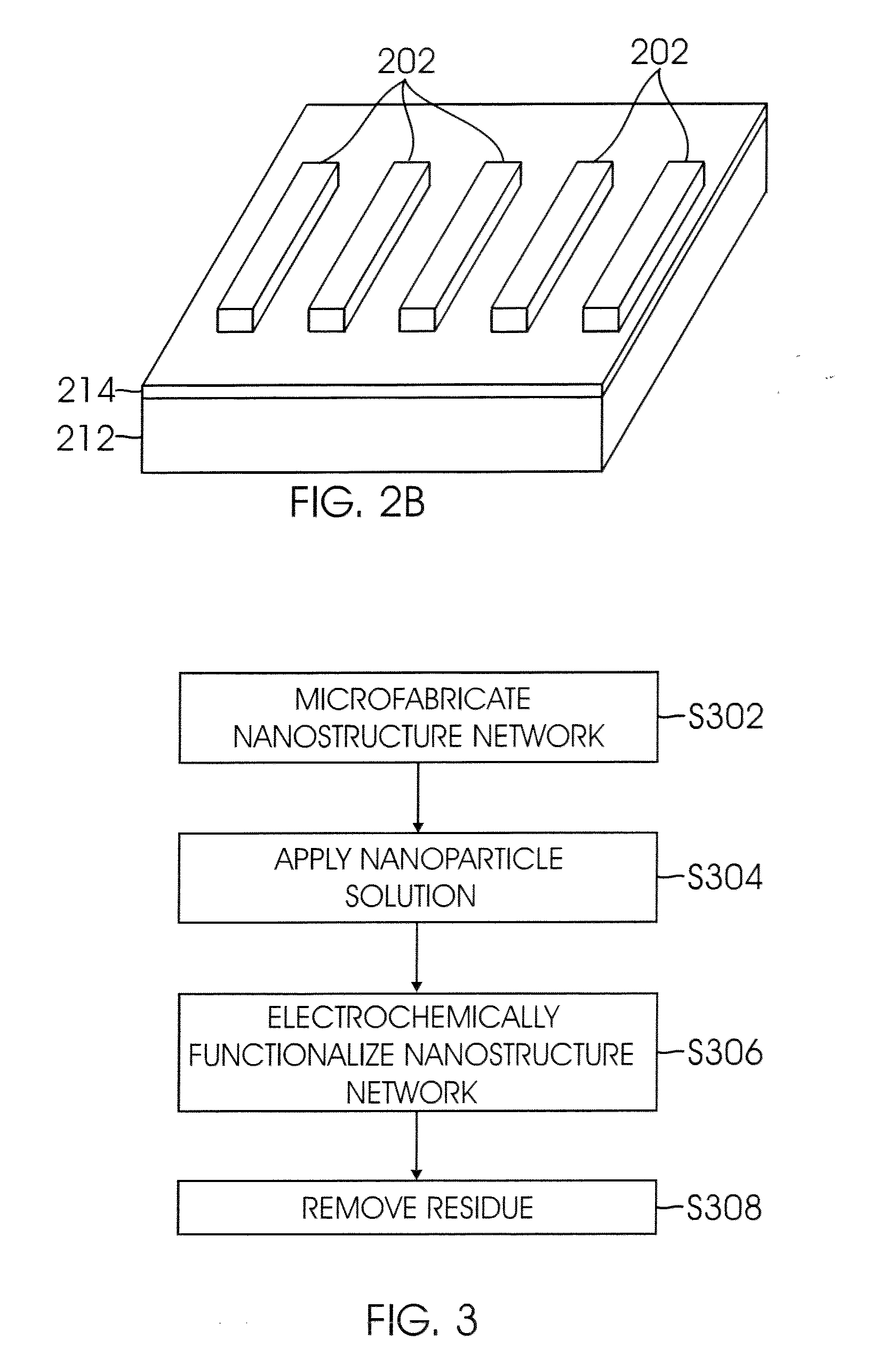

[0016]Broadly, this disclosure, in one aspect, relates to a gas sensing device comprising a substrate layer having at least a pair of conductive (e.g., metallic) electrodes formed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com