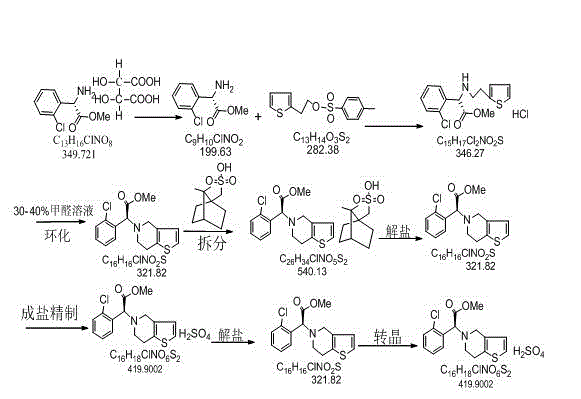

Production technique of clopidogrel hydrogen sulfate

A technology of clopidogrel hydrogen sulfate and production process, applied in the field of production technology of clopidogrel hydrogen sulfate, can solve the problems of difficult separation of solvent, complicated process, increased drug cost, etc., and achieves improved drug safety, simple process, and reduced cost The effect of the synthetic steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

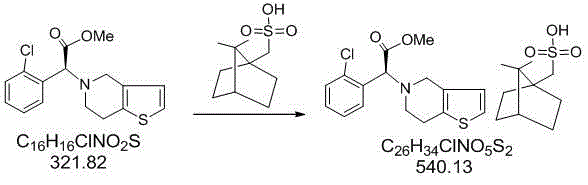

Method used

Image

Examples

Embodiment Construction

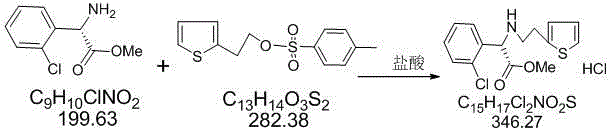

[0017] Step 1: Preparation of Amine Hydrochloride

[0018] 1.1 Preparation of o-chlorophenylglycine methyl ester

[0019] Material name Feeding amount Reagent specifications Material action 2-chlorophenylglycine methyl ester tartrate 4kg Internal Control Standards Starting material, obtain o-chlorophenylglycine methyl ester after desalination Dichloromethane 12L+4L*2=20L (26.5kg) industry Reaction solvent, dissolve o-chlorophenylglycine methyl ester ammonia 4kg industry Adjust pH value, dissolve o-chlorophenylglycine methyl ester in alkaline environment purified water 16L self made Dissolving o-chlorophenylglycine methyl ester tartrate Anhydrous Sodium Sulfate 2.7kg industry desiccant

[0020] Table 1

[0021] Table 1 is the raw material and the effect of raw material that o-chlorophenylglycine methyl ester is prepared.

[0022] Process Description:

[0023] Reaction: Add 4kg of o-chlorophenylglycine m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com