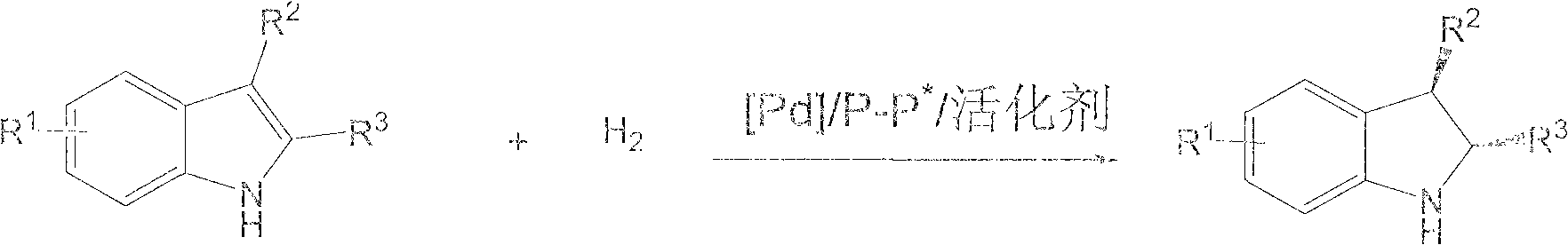

Method for synthesizing chiral indoline through palladium-catalyzed asymmetric hydrogenation

An indoline, asymmetric technology is applied in the field of catalytic hydrogenation of simple indole to synthesize chiral indoline, can solve the problem of low activity and the like, and achieve the effects of convenient separation, mild reaction conditions and complete conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

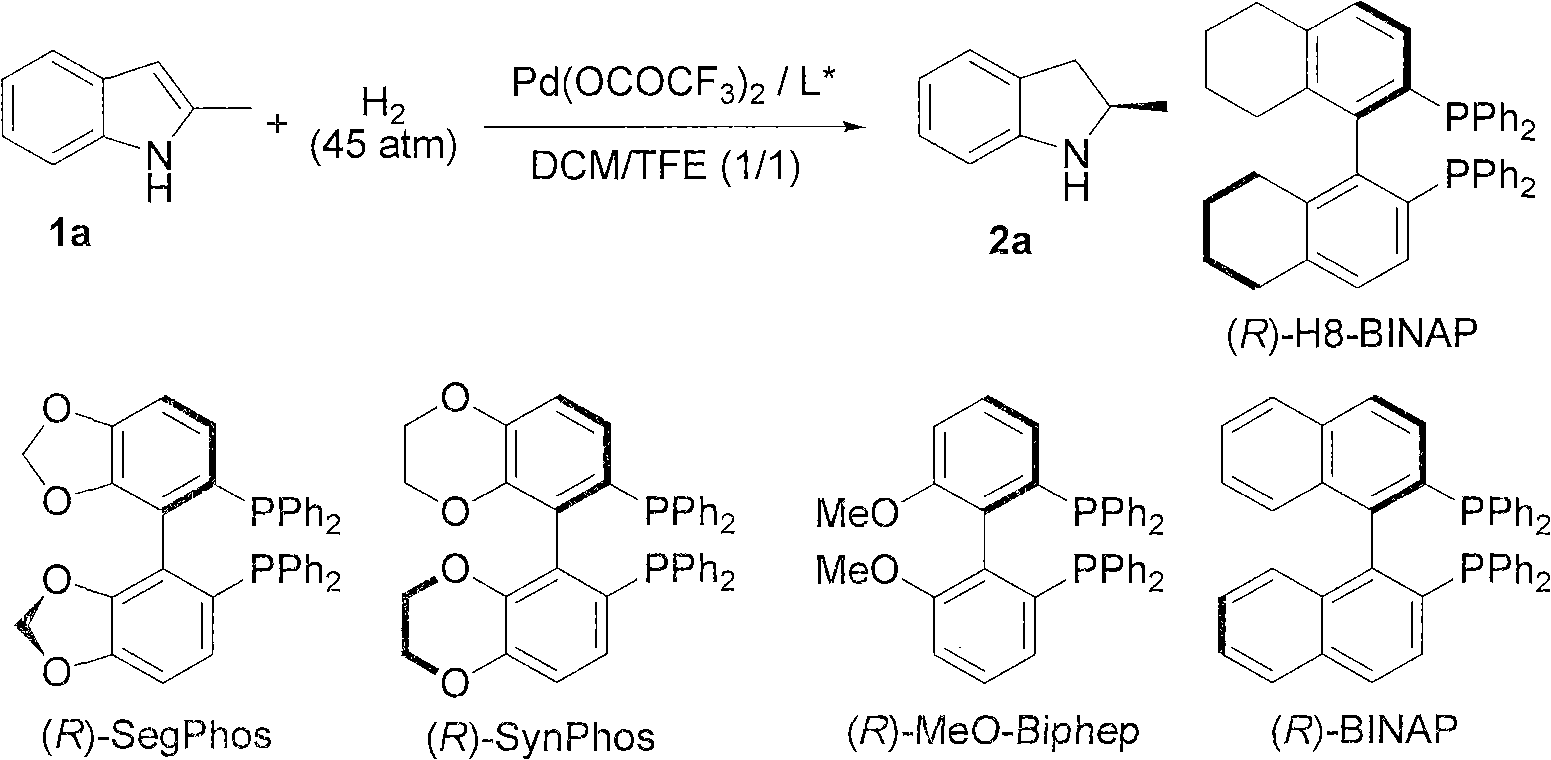

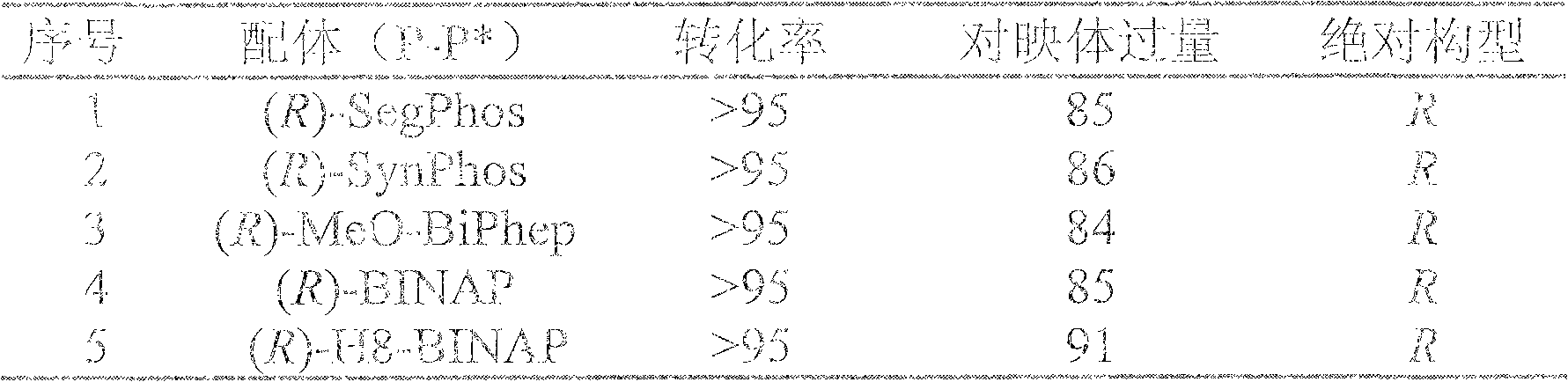

[0028] Embodiment 1: optimization of conditions

[0029] Put palladium precursor into the reaction flask; palladium trifluoroacetate (0.005 mmol) and chiral ligand: bisphosphine ligand (0.006 mmol), add 1 ml of acetone after nitrogen replacement, stir at room temperature for 1 hour and then concentrate in vacuo to remove Acetone gets the catalyst. Add 1 ml of solvent (dichloromethane and trifluoroethanol (volume ratio 1 / 1)), stirred for 5 minutes, then dissolved the previously prepared catalyst with 2 milliliters of solvent and transferred it to the reaction flask, then put it into the autoclave, fed hydrogen (45 atmospheric pressure), and reacted at 25 ° C for 24 hours. Slowly release the hydrogen gas, stir with 5 ml of saturated sodium bicarbonate at room temperature for 10 minutes to make it alkaline, remove the activator acid, extract with dichloromethane (3×5 ml), combine the organic phases, dry over anhydrous sodium sulfate, filter and spin The solvent is removed by e...

Embodiment 2

[0035] Example 2: Synthesis of various chiral indolines by palladium-catalyzed asymmetric hydrogenation 2

[0036] Put palladium trifluoroacetate (0.005 mmol) and (R)-H8-BINAP (0.006 mmol) into the reaction bottle, add 1 ml of acetone after nitrogen replacement, stir at room temperature for 1 hour and then concentrate in vacuo to remove acetone to obtain a catalyst. In the glove box, add 1 ml of solvent (dichloromethane and trifluoroethanol (1 / 1)) to the reaction bottle previously placed with substrate (0.25 mmol) and L-camphorsulfonic acid (58 mg, 0.25 mmol) , stirred for 5 minutes, then the previously prepared catalyst was dissolved in 2 milliliters of solvent and transferred to the reaction flask, then put into the autoclave, fed with hydrogen (45 atmospheric pressure), and reacted at room temperature for 24 hours. Slowly release the hydrogen gas, stir with 5 ml of saturated sodium bicarbonate at room temperature for 10 minutes to make it alkaline, remove the activator acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com