Patents

Literature

193results about How to "Fully transformed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

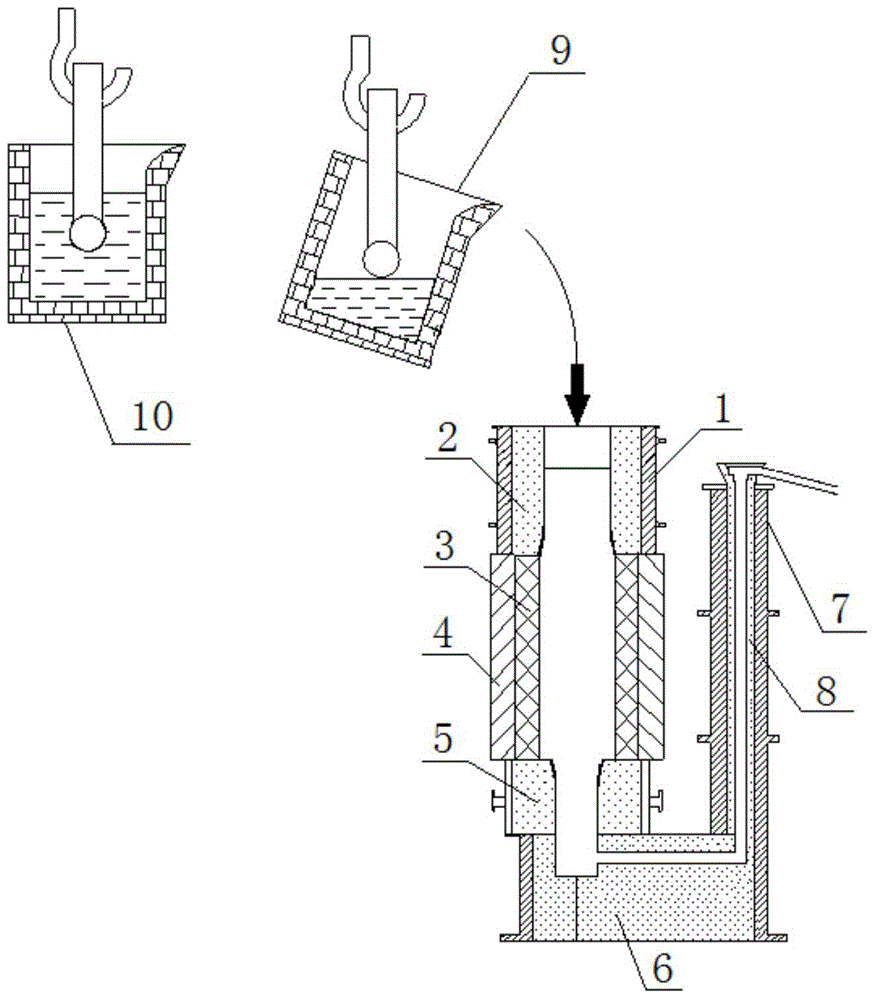

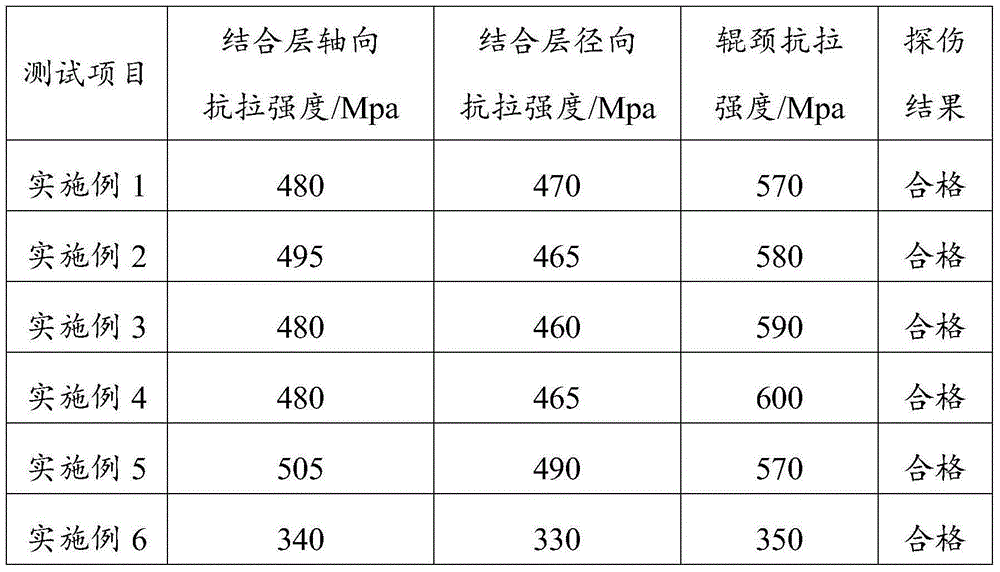

High-speed steel roller manufacturing method

ActiveCN104525889AHigh bonding strengthEnhanced resistance to peelingCarbideUltimate tensile strength

The invention discloses a high-speed steel roller manufacturing method which is suitable for small steel rolling machines and bar mills. The manufacturing method comprises the three process steps of raw material smelting, casting moulding, machining and heat treatment. On the basis that high-speed molten iron is centrifugally poured, firstly, transition layer molten iron is poured, and then the complete replacement of the transition layer molten iron is achieved by pouring core part molten iron. According to the high-speed steel roller manufacturing method, the combination strength of outer layer high-speed steel and the core part molten iron is obviously increased and increased to 500 Mpa or higher from around 350 Mpa in the past, and thus the anti-stripping performance of the combination layer of a roller body of a high-speed steel roller is greatly improved. Meanwhile, the amount of carbide forming elements generated by corrosion to the outer layer by the core part molten iron can be effectively reduced, so that the texture of a roller neck is improved, the tensile strength of the roller neck is increased, and the phenomenon of roller breakage in the using process is effectively eradicated.

Owner:邢台轧辊线棒辊有限责任公司

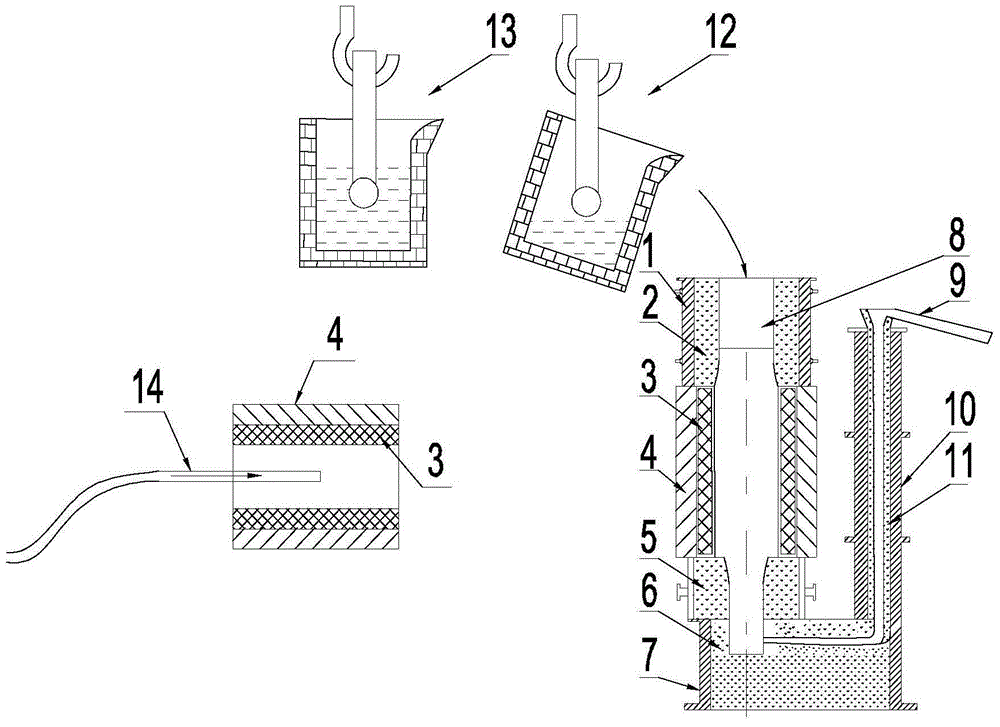

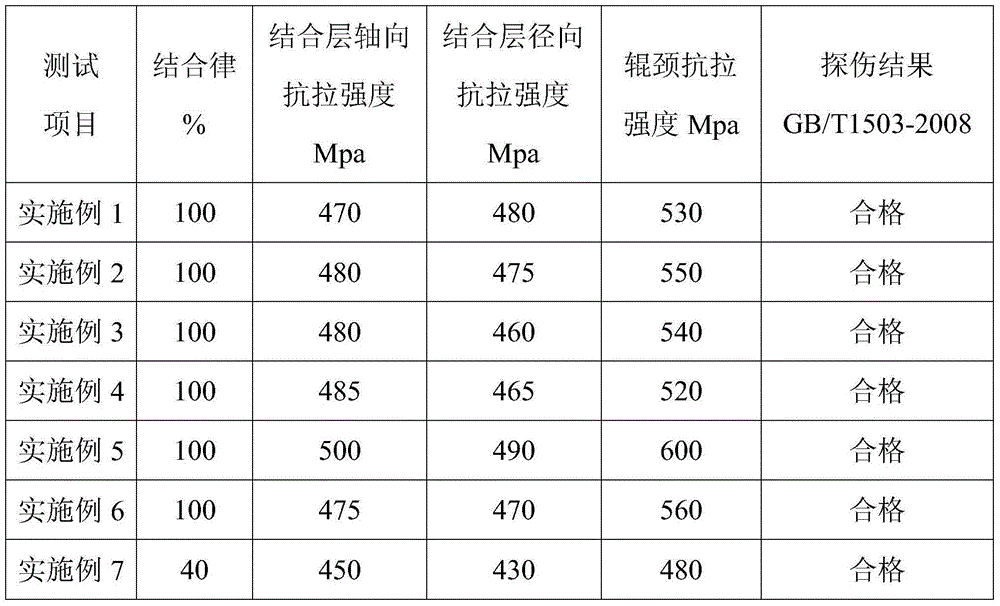

Manufacturing method for high-vanadium high-speed steel composite roll

The invention discloses a manufacturing method for a high-vanadium high-speed steel composite roll suitable for a narrow strip rolling mill. The manufacturing method comprises the steps that an outer layer of a roll body is poured by adopting a centrifugal pouring method, and after the outer layer of the roll body is poured with high-vanadium high-speed liquid steel, inert gas is continuously pumped into a cavity of the outer layer of the roll body; a centrifuge stops rotating when the outer layer temperature of high-vanadium high-speed steel reaches 1220-1280 DEG C, the inert gas is stopped being blown in, and then liquid iron in the core of the roll body is poured through mould closing. According to the manufacturing method for the high-vanadium high-speed steel composite roll, the bonding rate of the high-vanadium high-speed steel of the outer layer and the liquid iron in the core is significantly improved, the binding rate is improved from 40 percent to 100 percent, the bonding strength is improved from about 350 Mpa in the past to about 450 Mpa, and therefore the anti-stripping performance of a roll body bonding layer of the high-vanadium high-speed steel roll is greatly improved; meanwhile, the element amount formed by carbide on the corrosion outer layer of the liquid iron of the core is removed, therefore, roll neck tissues are improved, the tensile strength of the roll neck is improved, and the roll breakage phenomenon in use is effectively and completely eradicated.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

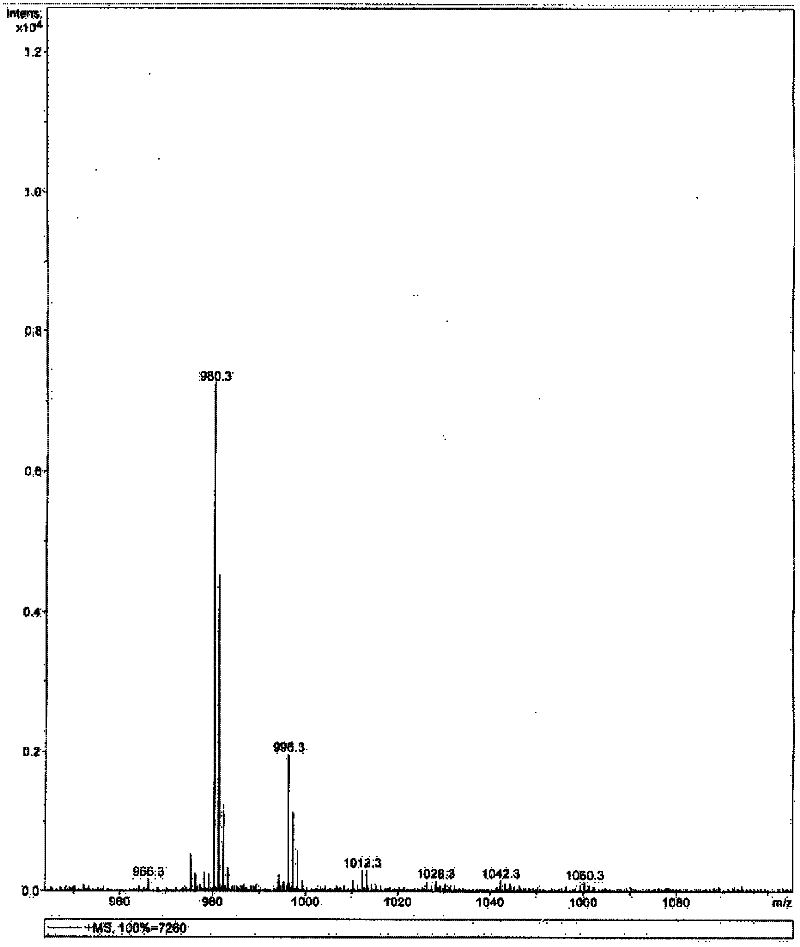

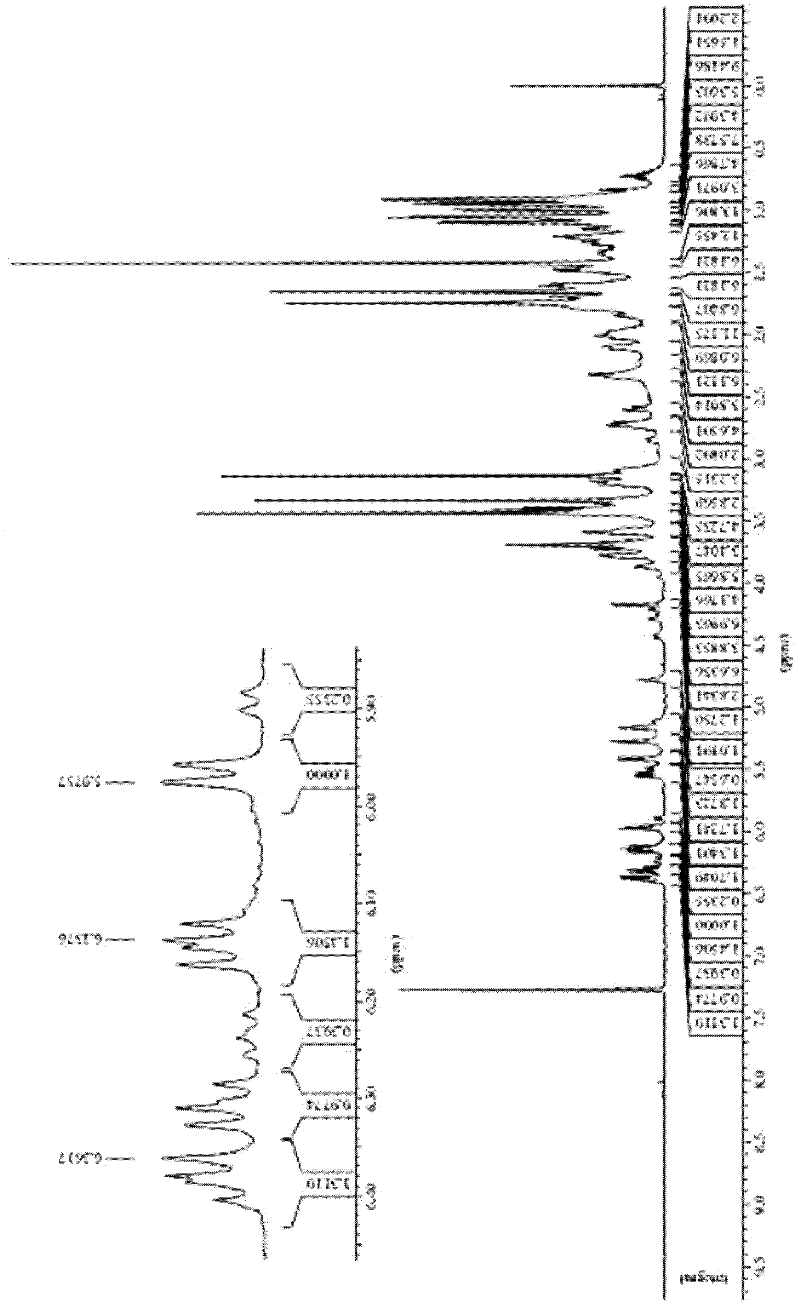

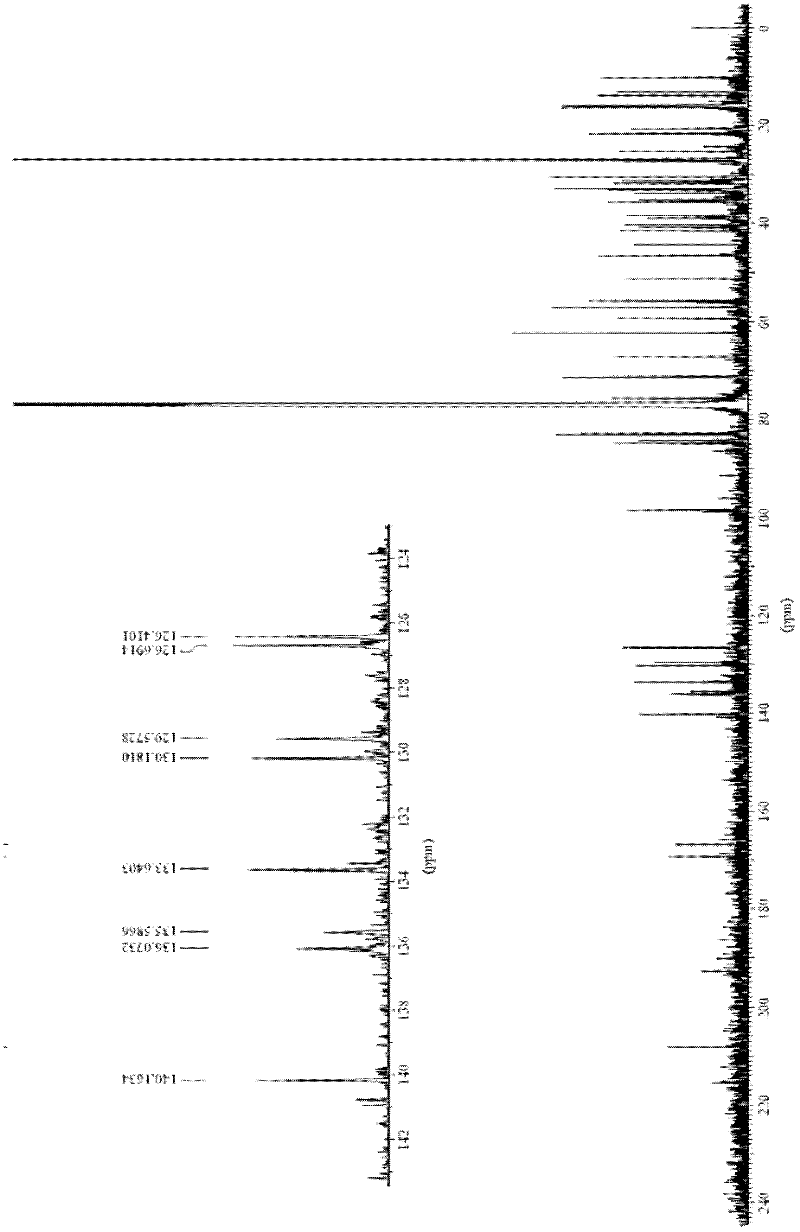

A kind of synthetic method of everolimus

ActiveCN102268015AFully convertedThorough responseOrganic chemistryTrifluoromethanesulfonic anhydrideEverolimus

The invention discloses a synthesis method of everolimus. The synthesis method of the everolimus comprises the following steps: based on rapamycin or a rapamycin derivative the 31-hydroxy of which is protected as a raw material, firstly carrying out a reaction on the raw material with triflic anhydride so as to obtain an intermediate 02; then carrying out a reaction on the intermediate 02 with mono-protected glycol so as to obtain an intermediate 03; and de-protecting the intermediate 03 so as to obtain the everolimus. In the process in the invention, the raw material can be fully converted into the intermediate 02 through reacting with triflic anhydride, and the intermediate 02 can be fully converted into the intermediate 03 through reacting with mono-protected glycol; and each step reaction can be fully carried out, and the total yield is greatly improved to above 50%.

Owner:四川摩尔生物制药有限公司

7beta-hydroxysterol dehydrogenase mutant and application of 7beta-hydroxysterol dehydrogenase mutant in ursodeoxycholic acid synthesis

ActiveCN107099516AEasy to separate and extractOvercoming the problem of inactivation processingOxidoreductasesGenetic engineeringChenodeoxycholic acidSubstrate concentration

The invention discloses a 7beta-hydroxysterol dehydrogenase mutant with increased activity and stability which is obtained through molecular evolution, recombinant expression plasmid containing the 7beta-hydroxysterol dehydrogenase mutant gene and a recombinant expression transformant and a preparation method of a recombinant mutant enzyme preparation, and the invention also provides an application of the recombinant mutant enzyme preparation in ursodeoxycholic acid synthesis. The 7beta-hydroxysterol dehydrogenase has excellent activity and heat stability, can efficiently catalyze asymmetric reduction of 7-carbonyl lithocholic acid to prepare the ursodeoxycholic acid; the 7beta-hydroxysterol dehydrogenase is subjected to immobilization and then is subjected to couple by an enzyme method with the immobilized 7beta-hydroxysterol dehydrogenase, epimerization of a substrate chenodeoxycholic acid with low cost can be directly catalyzed, ursodeoxycholic acid can be prepared through continuous conversion, and the operation is simple. Compared with the prior art reported currently, ursodeoxycholic acid prepared by hydroxysterol dehydrogenase through catalysis has the advantages of high substrate concentration, short reaction time, complete reaction, and high product purity, and has strong industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Passion fruit planting method

InactiveCN107182470ATake root fastStrong rootsBiocideCalcareous fertilisersDisease damagePassion fruit

The invention provides a passion fruit planting method, and belongs to the technical field of agriculture planting. The planting method comprises the steps of cutting seedling-raising, garden selection and land preparation treatment, passion fruit seedling transplanting, shed frame building, shaping and pruning, fertilizer and water management and pest and disease damage controlling. For cutting seedling-raising, a soilless cutting seedling-raising mode is adopted for seedling raising, and a soilless substrate is obtained by fermenting brewer's grain, pig manure, bagasse, coconut shells, potassium fulvic acid, pumpkin vines, humic acid, composite strains, banana stems, polyacrylamide and dried pine needles and then adding inorganic nutrient substances. Accordingly, by strengthening management in the seedling raising stage, the passion fruit seedlings which are high in survival rate, robust in growth and high in disease-resistant capacity are obtained, the planting cost in later period can be lowered, and the overall production cost of passion fruits is lowered.

Owner:陆川县巨丰种植园

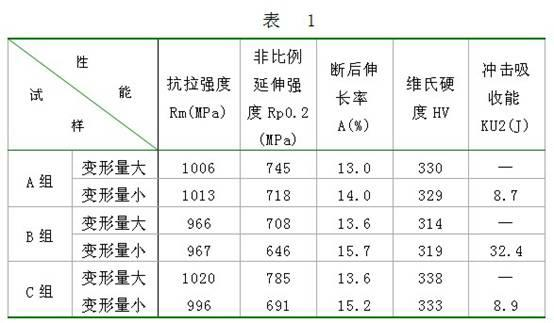

Manufacture technology for improving toughness of non-quenched and tempered steel forging

InactiveCN102586558AImprove toughness and plasticityImprove impact toughnessManufacturing technologyRoom temperature

The invenmtion relates to a manufacture technology of a forging, in particular to a manufacture technology for improving the toughness of a non-quenched and tempered steel forging, which comprises the following working procedures of: blanking-induction heating-dummying-finish forging-trimming-controlled cooling-cooling in heap in a charging box-shot blasting-magnetically inspecting-machining; the working procedure of controlled cooling comprises the following steps of: trimming workpieces, immediately arranging the workpieces on a transmission band which moves at a certain speed in a dispersing way, and under the cooling condition of compulsory aerating or water mist spraying, cooling the workpieces to some temperature within 520 DEG C-650 DEG C at the cooling speed of 2.0 DEG C / s-50.0 DEG C / s, and then cooling the workpieces in heap in the charging box; and the working procedure of cooling in heap in the charging box comprises the following step of slowly cooling the workpieces to room temperature at the cooling speed which is less than 5 DEG C / min. According to the manufacture technology, the precipitation of an eutectoid ferrite at an original austenitic crystal boundary in the form of net and the appearance of the bainite tissue can be eliminated or avoided, more intra-granular ferrite can be obtained, and the toughness and the plasticity of parts can be improved.

Owner:NANJING INST OF TECH +1

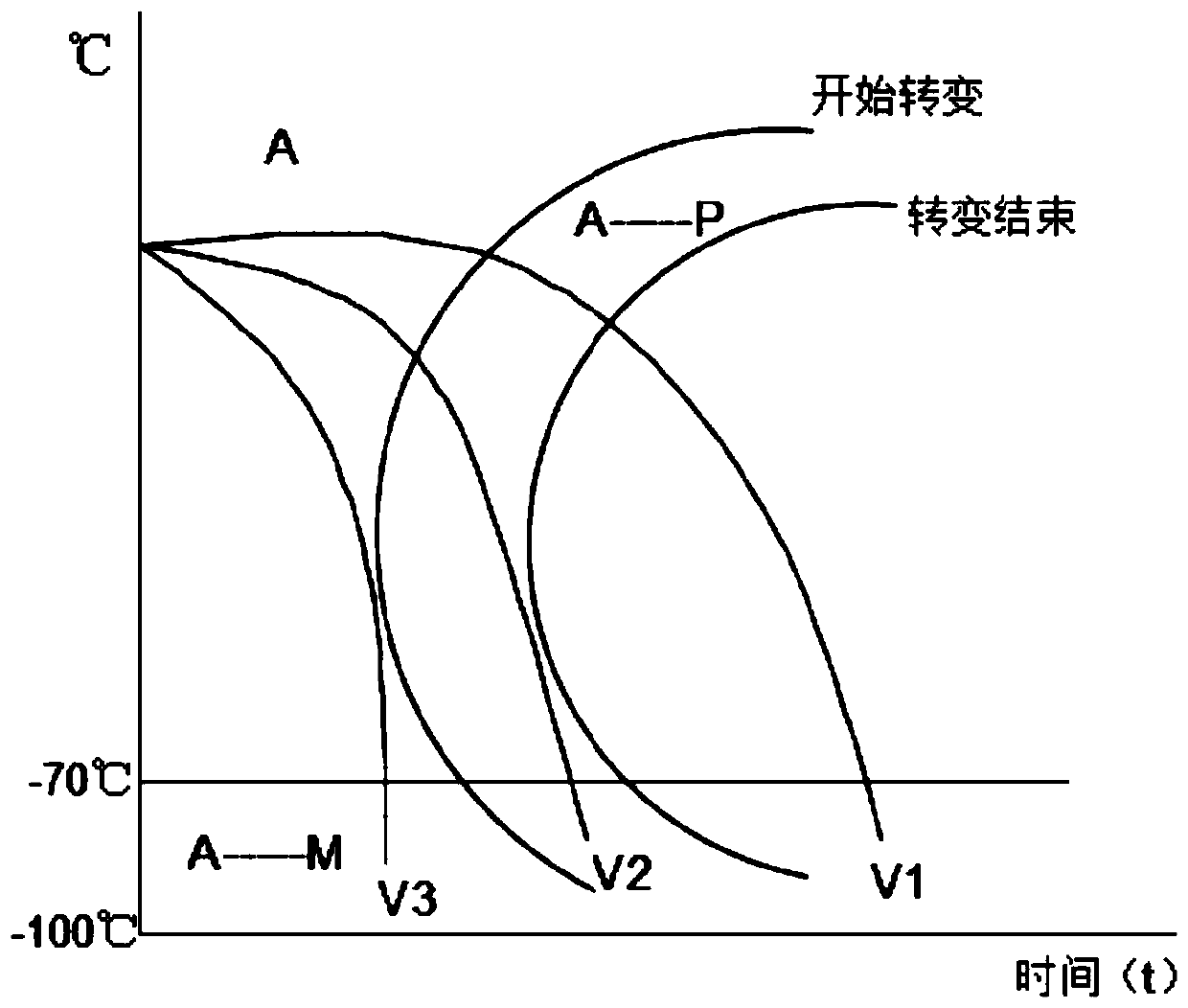

Process method for increasing surface quality and drawing property of ultra-fine high-carbon steel wire

ActiveCN103966417AQuality improvementIncrease transition timeFurnace typesHeat treatment furnacesHigh carbonSurface cleaning

The present invention relates to a process method for increasing surface quality and drawing property of an ultra-fine high-carbon steel wire. The process method comprises: carrying out rough drawing, lead bath isothermal quenching I and medium wire drawing deformation on a high-carbon steel wire rod to obtain a steel wire with a diameter of 0.7-0.95 mm, carrying out lead bath isothermal quenching II, carrying out a surface cleaning area cleaning treatment for a certain time, carrying out air cooling, adding to a brass electroplating tank, and carrying out wet drawing deformation to obtain the ultra-high strength steel wire with a diameter of 0.10-0.12 mm. According to the present invention, the process method is adopted to eliminate the lead adhered on the lead surface so as to provide the lead scraping effect; the time of conversion of austenite into perlite is prolonged, and the cooling rate is reduced, such that the conversion of the austenite is complete; the steel wire surface oxidation is eliminated so as to provide the reduction protection effect; and proeutectoid ferrite, secondary mesh cementite and other untypical untypical structures in the ultra-fine high-carbon steel wire are less, the distance between the perlite lamellas is about 70-80 nm, and the surface does not produce decarburization phenomenon.

Owner:张家港市骏马钢帘线有限公司 +1

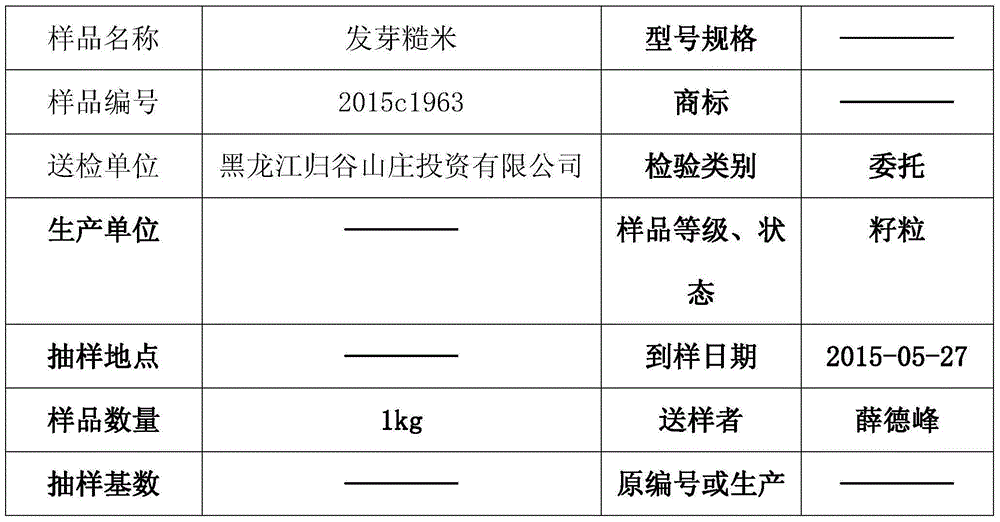

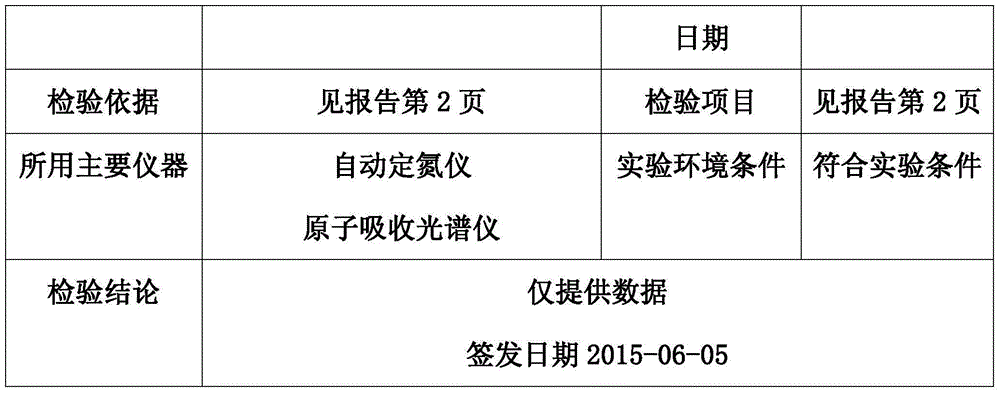

Production method for processing total-nutrient germinated brown rice and germinated milled rice

ActiveCN105080636AAffect germination rateAffect qualityGrain millingContinuous/uninterruptedWhite rice

The invention provides a production method for processing total-nutrient germinated brown rice and germinated milled rice. The production method includes the steps that new unhusked rice with the water content being below 15% is selected as raw materials and then put into an open container after being sieved and subjected to impurity removal; water is added to immerse the unhusked rice by above 10 cm; ozone with the concentration of 0.5-1.5 mg / L is introduced continuously into the water from the bottom of the container; the water is controlled to be at the constant temperature of 32+ / -1 DEG C for 36-48 hours for seed soaking and pregermination, and the water is not changed halfway; after the germinated rice with the germination length being 0.5-1 mm is obtained, the ozone supply is stopped, steam at the temperature of 80 DEG C is introduced for 4 min, and then rapid inactivation treatment is carried out; and the unhusked rice is then rapidly dried at the temperature of 50-52 DEG C until the water content is below 17%. After the unhusked rice is hulled according to a common method, the germinated brown rice is obtained. Then separation, rice milling, color sorting, polishing and grading are carried out, so that the germinated milled rice is obtained. The production method for processing the total-nutrient germinated brown rice and germinated milled rice is uniform in germination, is high in germination speed and keeps the nutrient in the unhusked rice as much as possible.

Owner:刘毅 +2

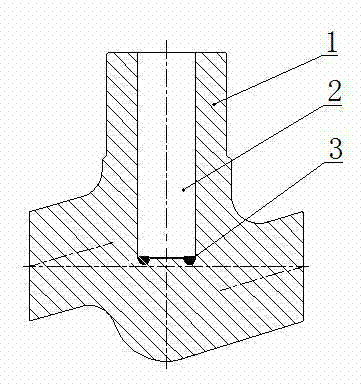

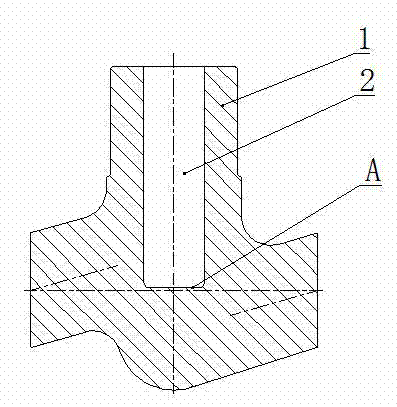

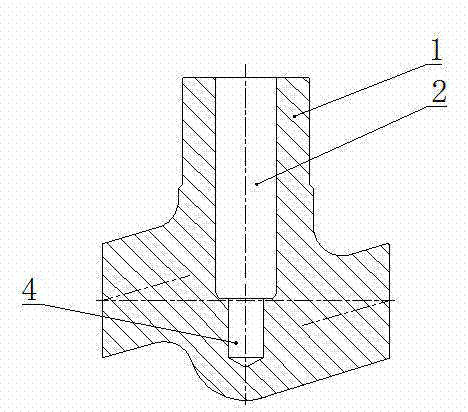

Overlay welding process for deep holes on valve body sealing surface

InactiveCN102518853AGuaranteed hardnessGuaranteed tightnessFurnace typesValve housingsEngineeringAlloy

The invention relates to an overlay welding process for deep holes on a valve body sealing surface. The innovation point of the overlay welding process is that the steps are as follows: drilling out a valve body middle hole extending to the valve body sealing surface from the position of a valve rod hole of the valve body on valve body blank; drilling out concentric process holes, diameter of which is smaller than that of the valve body middle hole, on the bottom part of the valve body middle hole of the valve body blank; carrying out overlay welding of hard alloy on a shaft shoulder surface between the process holes and the valve body middle hole; carrying out thermal treatment to the valve body blank; and finally, machining the sealing surface of the valve body blank; the bottom part of the valve body middle hole is drilled with process holes, so that the hole diameter of the process holes ensures that the welding area achieves the processing width of the overlay welding on the sealing surface; overlay welding is carried out to the annular shaft shoulder surface between the process holes and the valve body middle hole, so that compound stress is reduced to be within a safe range to avoid crackles. The inner wall of the overlay welding layer does not contact with the mother material, so that fusion phenomenon does not exist, and the hardness of the overlay welding layer is ensured, and the sealing performance is ensured. Besides, overlay welding materials on the positions of the process holes are saved, so that welding rods are saved.

Owner:NANTONG POWER STATION VALVE

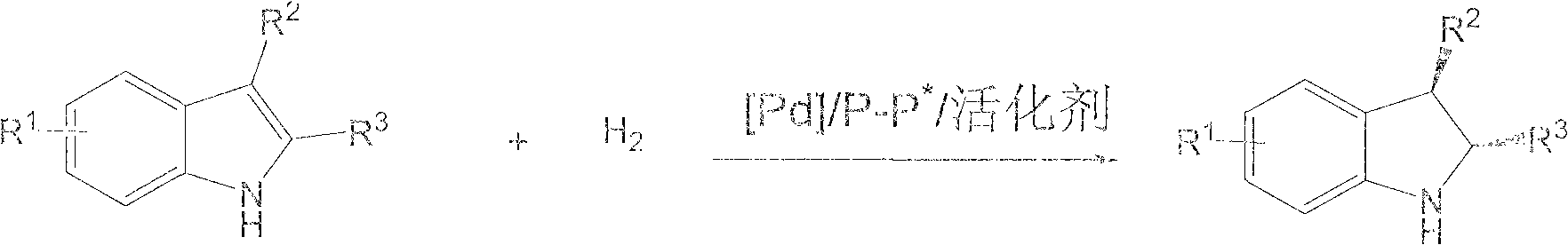

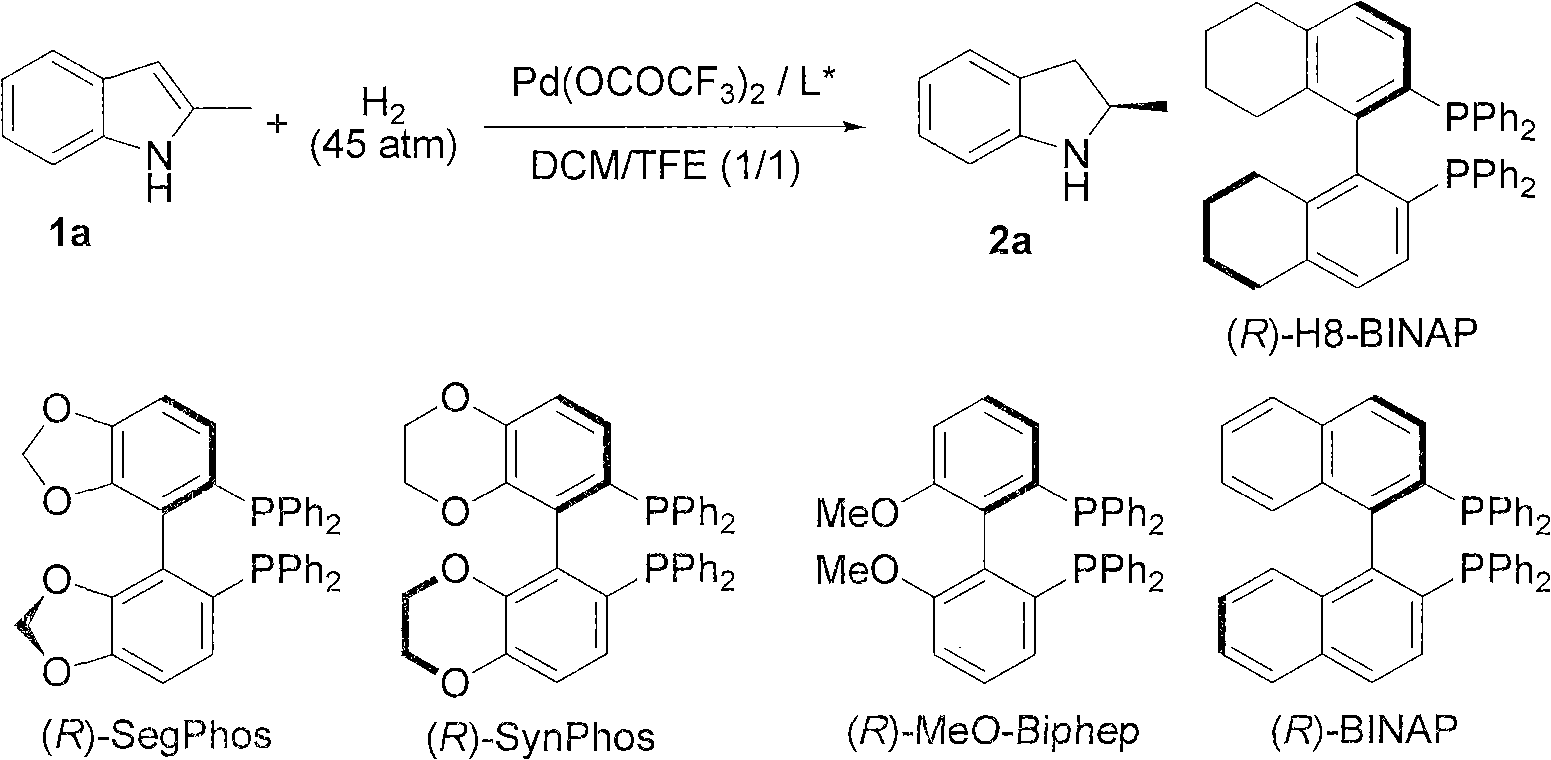

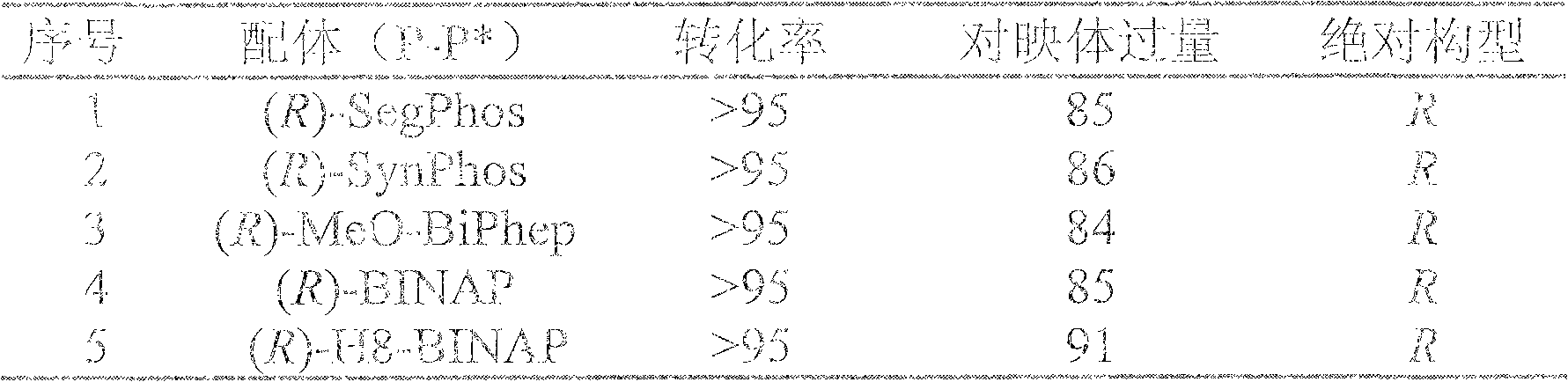

Method for synthesizing chiral indoline through palladium-catalyzed asymmetric hydrogenation

InactiveCN102336698AAsymmetric hydrogenationHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsAsymmetric synthesesHydrogen pressureReaction temperature

The invention relates to a method for synthesizing chiral indoline through palladium-catalyzed asymmetric hydrogenation, which is characterized in that Bronsted acid is used as the activator and the used catalysis system is a palladium chiral diphosphine complex. The reaction can be carried out under the following conditions: the reaction temperature is 20-50 DEG C; the solvent used in the reaction is a mixed solvent of dichloromethane and 2,2,2-trifluoroethanol (the DCM / TFE volume ratio is 1:1); the hydrogen pressure is 13-45 atmospheres; the substrate-catalyst ratio is 50 / 1; the used metal precursor is palladium trifluoroacetate (Pd(OCOCF3)2); the used chiral ligand is a chiral diphosphine ligand; the used activator is L-camphorsulfonic acid (L-CSA); and unprotected simple 2-substituted indole and 2,3-disubstituted indole can be hydrogenated to obtain the corresponding chiral indoline product, and the enantiomeric excess can be up to 96%. The method has the advantages of convenient operation process, high practicality, easy acquisition of raw materials, good enantioselectivity and high yield.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418ALess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

Ceramic tile decorated by dry lamination of colorful particles and micro powder and preparation method of ceramic tile

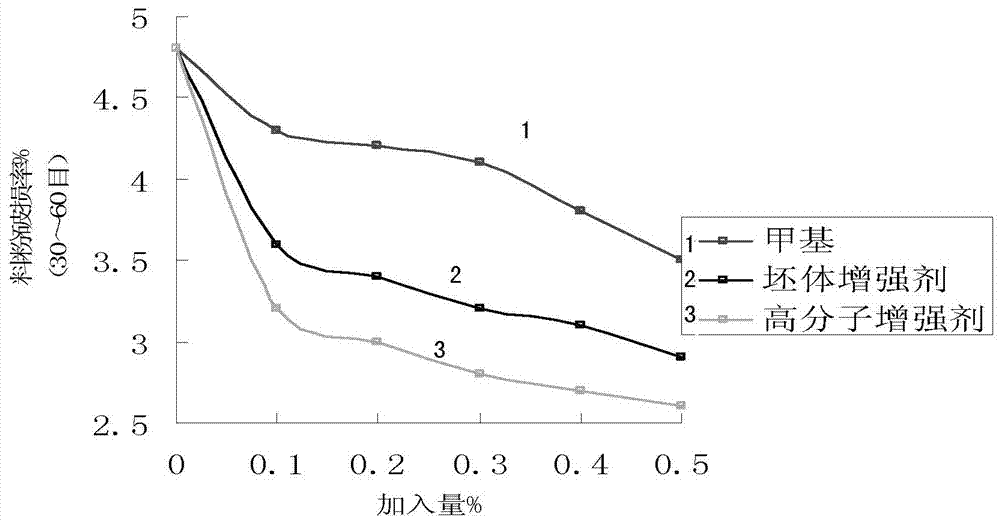

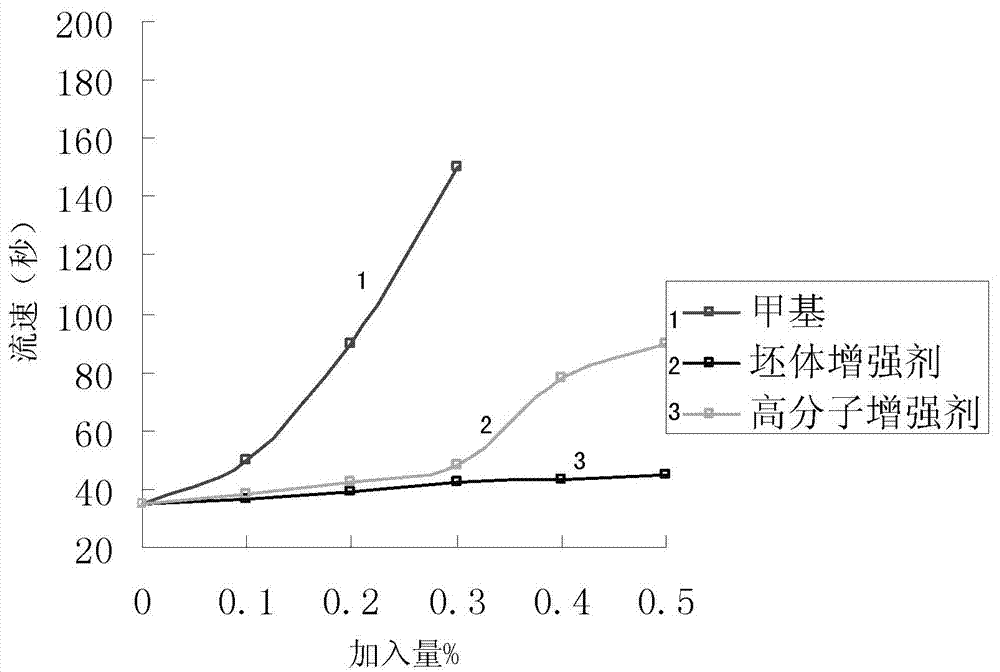

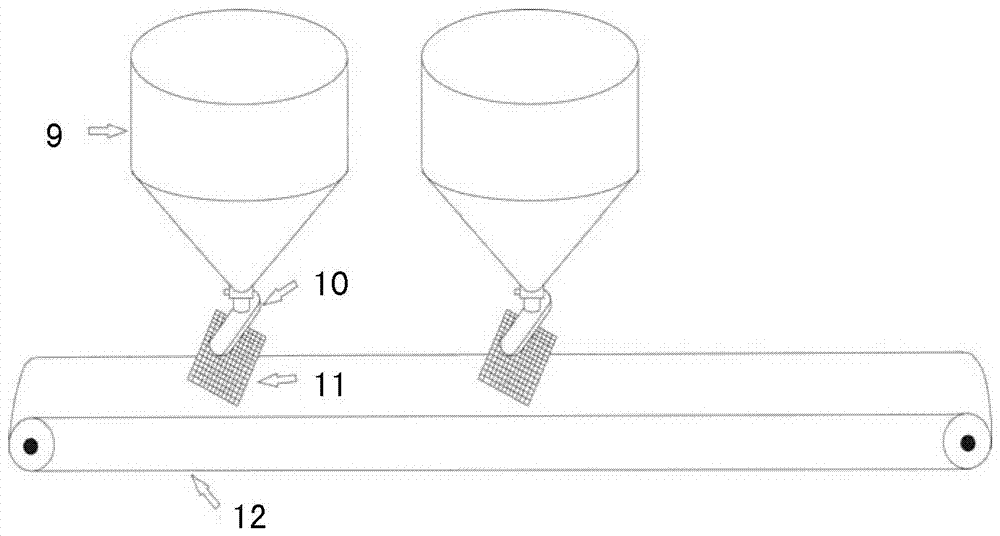

ActiveCN107116675AEasy to shapeExcellent color richnessMixing operation control apparatusCeramic shaping plantsPrillBrick

The invention provides a ceramic tile decorated by dry lamination of colorful particles and micro powder and a preparation method of the ceramic tile which are improved on floral designs, hues, and production technologies. The preparation method of the ceramic tile includes the steps that basic powder materials and colored materials are dry-mixed to prepare toner; the toner is prilled to form colored particles in different shapes; the colored particles and the toner with different colors are conveyed to and stirred in a plurality of stirrers correspondingly according to set proportions; the powder materials which are stirred in the multiple stirrers are conveyed through a plurality of feeding belts correspondingly and blanked into a vertical material loading machine according to a preset material loading procedure, and the powder materials naturally stack to form a flower shape; and the formed flower-shaped powder is conveyed to a press mold frame, pressed and formed.

Owner:广东清远蒙娜丽莎建陶有限公司 +1

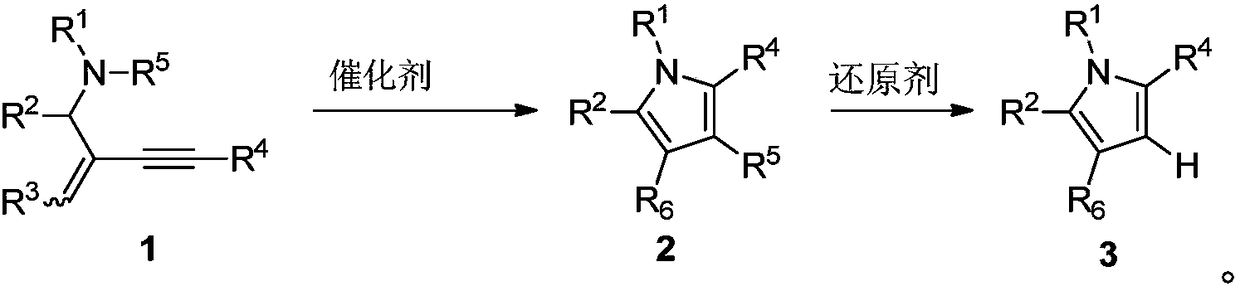

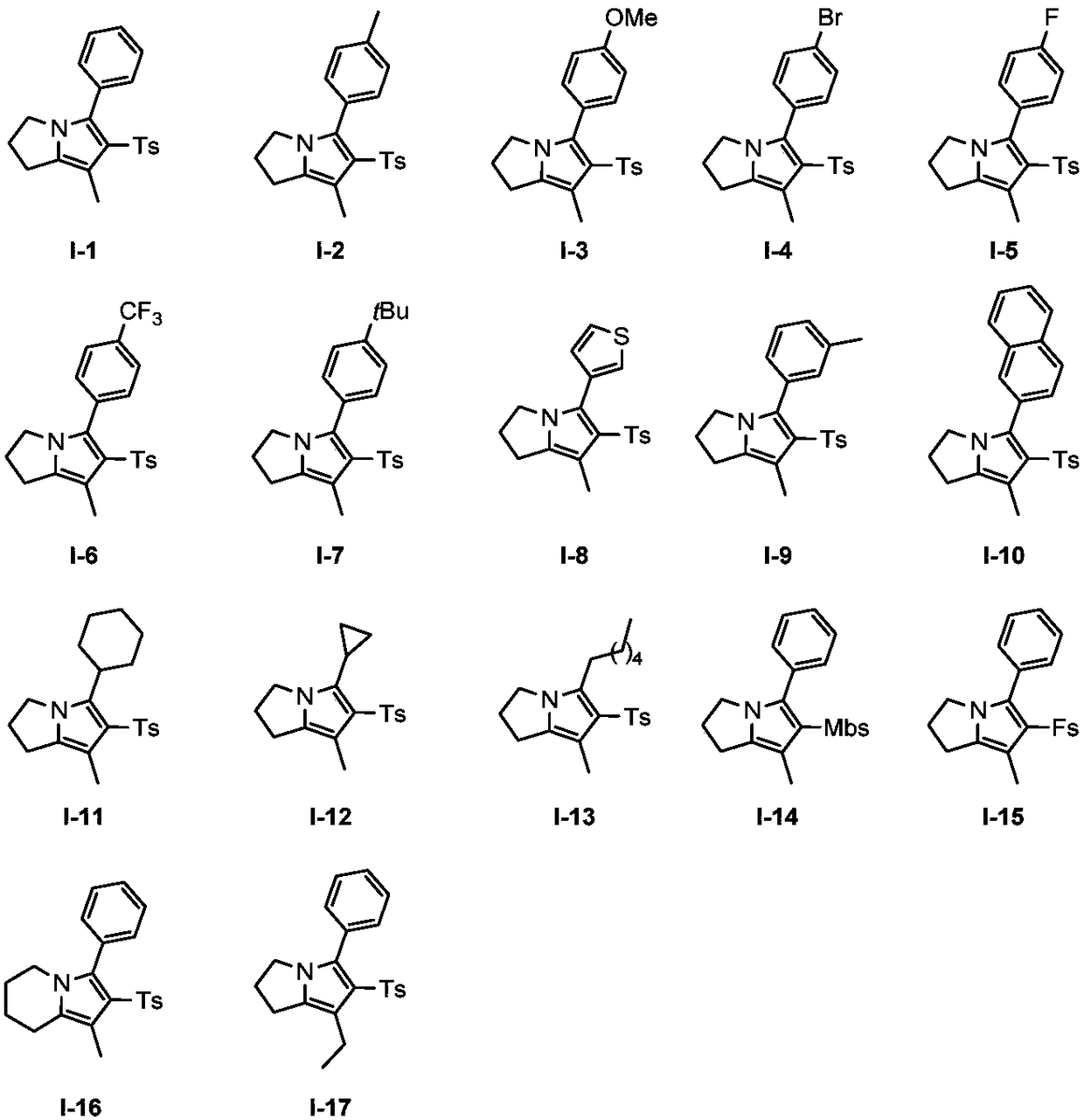

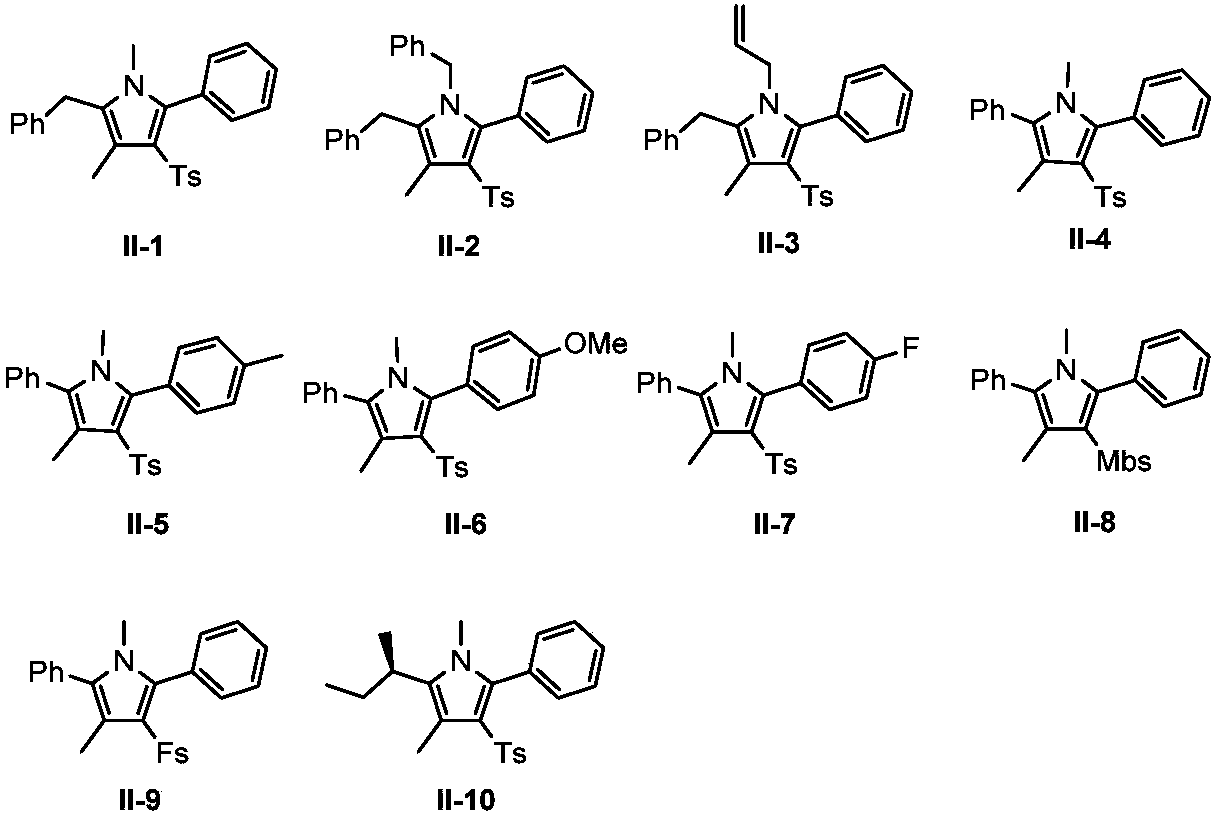

Preparation method of polysubstituted pyrrole compound

The invention discloses a preparation method of a polysubstituted pyrrole compound. The preparation method comprises steps as follows: an alkyne enamine compound is subjected to a cyclization reactionunder the catalytic action of univalent gold, a product is subjected to column chromatography or recrystallization separation, and a fully substituted pyrrole compound is obtained; substituent groupscan be removed from the pyrrole compound under the proper condition, and a tetra-substituted pyrrole compound is obtained. The chain-like alkyne enamine compound is subjected to the cyclization reaction, and the fully substituted or tetra-substituted pyrrole compound is obtained. The preparation method has the advantages that the operation is simple, steps are simple, the reaction is efficient, raw materials are cheap and easy to obtain, the pilot plant test can be amplified and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

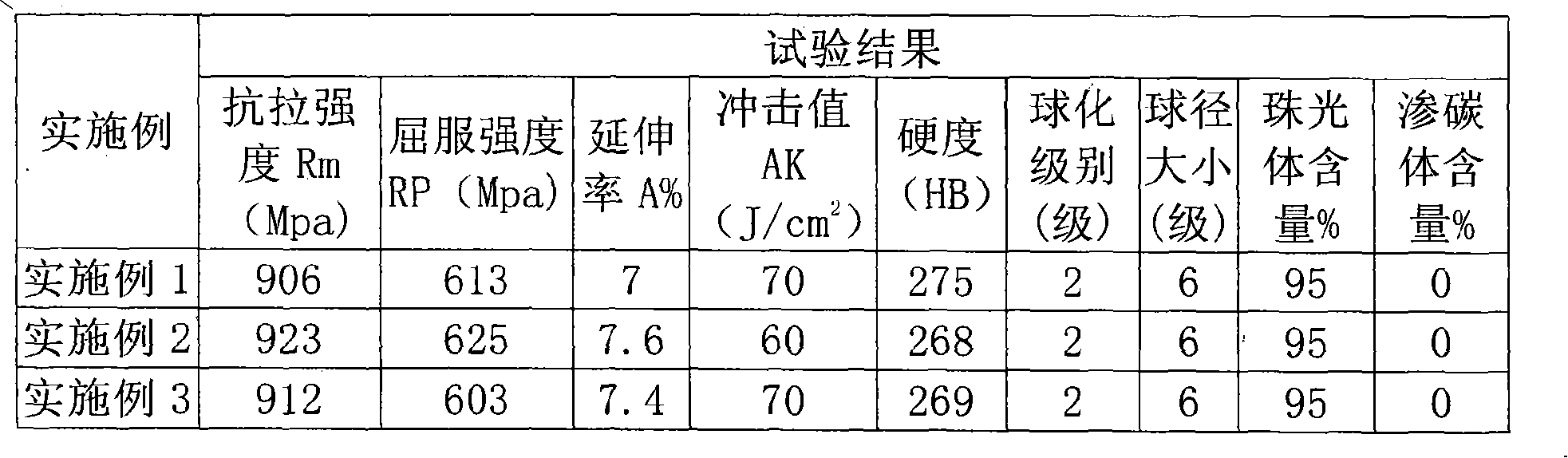

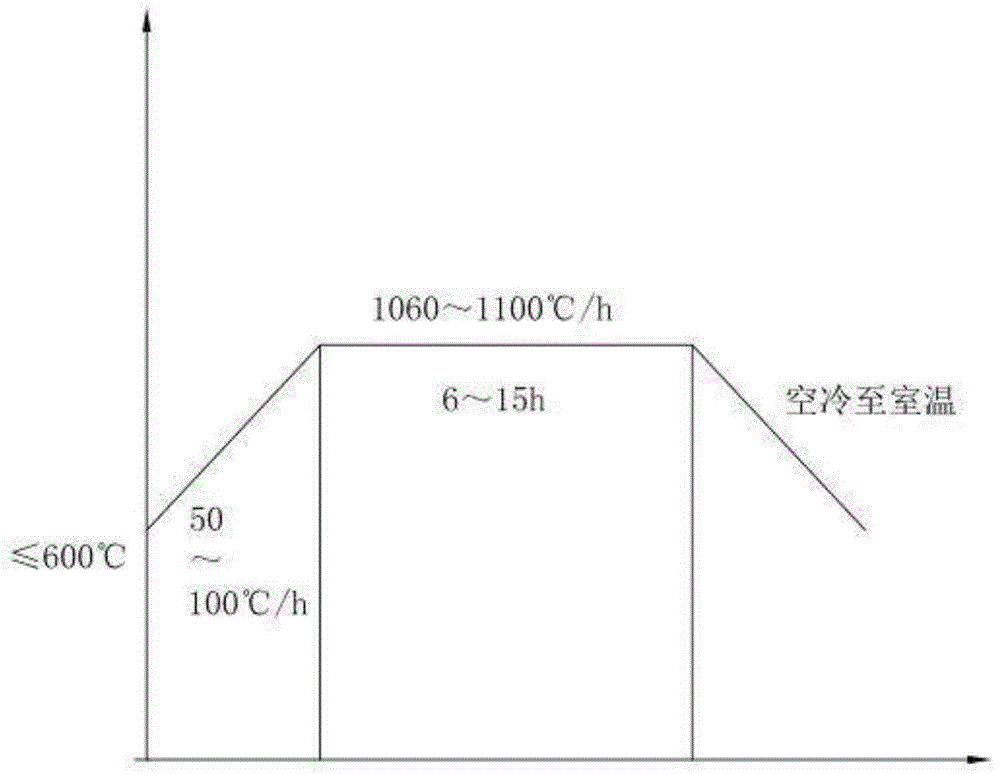

Alloy ductile iron crankshaft and heat treatment process thereof

The invention relates to an alloy ductile iron crankshaft and a heat treatment process thereof. The heat treatment process comprises the following steps: the carbon structural steel or the tool steel is taken as the raw material, carburant and ferrosilicon are added during the smelting process of an electric furnace in sequence, and the alloy ductile iron crankshaft comprises the following components (weight percentage): C accounts for 3.50-4.00, Si accounts for 1.6-2.5, Mn accounts for 0.3-0.9, P is less than 0.040, S is less than 0.03, Cr accounts for 0.03-0.07, Cu accounts for 0.2-0.5, Mg is less than 0.08, Ti is less than 0.02 and the balance is Fe. The austenization processing temperature is 840-920 DEG C, the heat preservation is carried out for 0.5-2.5 h, the three-phase region processing is performed at the temperature of 770-850 DEG C along with furnace cooling, and the time for the three-phase region processing is 1-3 h. The invention improves the nodularizing effect and the inoculation quality of the crankshaft, has low Ti content and effectively inhibits the influence of the heredity of the molten iron to the quality of the casting part; the heat treatment is added in the three-phase region processing; and the tensile strength of the alloy ductile iron crankshaft is equal to or more than 900 MPa, the yield strength is equal to or more than 500 MPa, the elongation rate is larger than or equal to 5 percent, and the alloy ductile iron crankshaft has excellent comprehensive properties and can be manufactured into high-trademark QT900-5 crankshaft.

Owner:TIANRUN IND TECH CO LTD

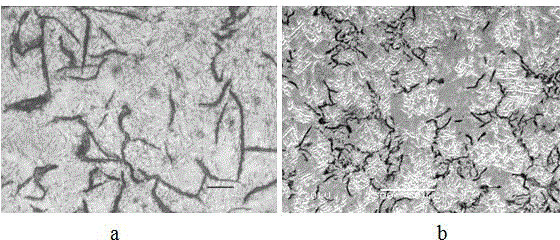

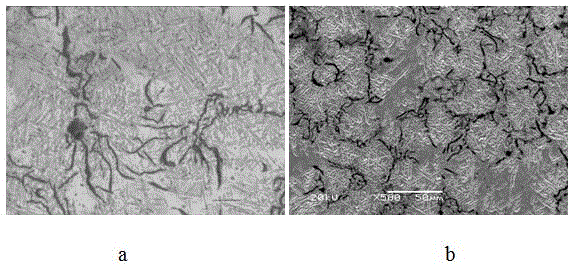

Thermal processing method improving impact resistance of 13Cr9Mo2Co1NiVNbNB forged piece

InactiveCN105063291AGood condition for liquid feedingReduce porosityQuenchingMartensitic microstructure

The invention relates to a thermal processing method improving impact resistance of a 13Cr9Mo2Co1NiVNbNB forged piece. It is guaranteed that carbonitride and elements are in sufficient solid solution through high-temperature normalizing, the elements are evenly diffused, and the evenness of the tissue of the forged piece is greatly improved. In the quenching process, a water-dissolving medium or oil is adopted, and the forged piece is effectively prevented from being cooled rapidly during quenching. After the forged piece is quenched and the medium is cooled to 250-350 DEG C, the medium is discharged for air cooling, and a martensite transformation zone is prevented from being cooled rapidly; then, air cooling is carried out on the forged piece to reach the room temperature, the tissue of the forged piece is sufficiently converted, the retained austenite of the forged piece is reduced, and the uniform austenite tissue is obtained. The first-time tempering is carried out on the forged piece to eliminate the tissue and thermal stress produced through quenching, and fine carbonitride is precipitated. During second-time tempering, the stress produced during first-time tempering can be eliminated, and the martensite newly generated through the first-time tempering is tempered. The moulding of the forged piece is improved. The carbonitride can be sufficiently precipitated, and the performance of a base body is improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Ultra-high-strength multiphase-structure gray cast iron cylinder jacket and preparation method thereof

The invention belongs to the technical field of automobile engine cylinder jacket preparation and specifically relates to an ultra-high-strength multiphase-structure (bainite & martensite) cylinder jacket and a preparation method thereof. The material of the cylinder jacket is gray cast iron, and the microstructure of the cylinder jacket comprises two structure phases of bainite and martensite; in percentage by mass, the cylinder jacket is prepared from such components as 2.6-2.8% of carbon, 1.8-2.2% of silicon, 0.4-0.8% of niobium, 0.2-0.4% of copper, 0.1-0.3% of manganese, 0.1-0.3% of cobalt, 0.08-0.3% of nitrogen, less than or equal to 0.08% of phosphorus, less than or equal to 0.08% of sulfur, and the balance of iron. The ultra-high-strength multiphase-structure gray cast iron cylinder jacket is mainly characterized in that the adopted cylinder jacket material is added with an appropriate amount of such elements as niobium, cobalt, copper and nitrogen on the basis of common gray cast iron, and noble metal elements such as nickel and molybdenum are completely avoided. The preparation method is simple and convenient, and easy to implement, and has the characteristics of high strength and high elastic modulus.

Owner:ZYNP GRP

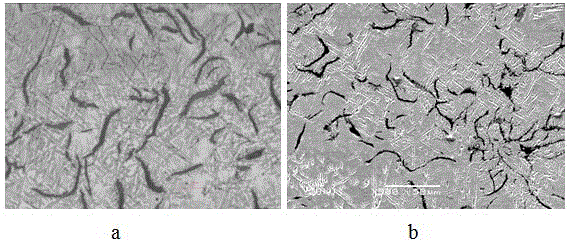

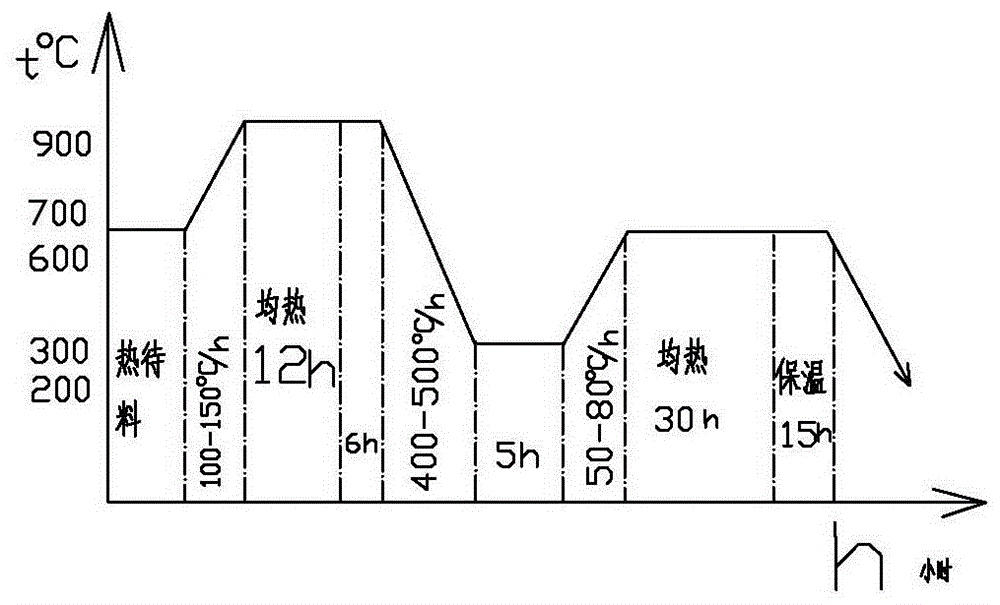

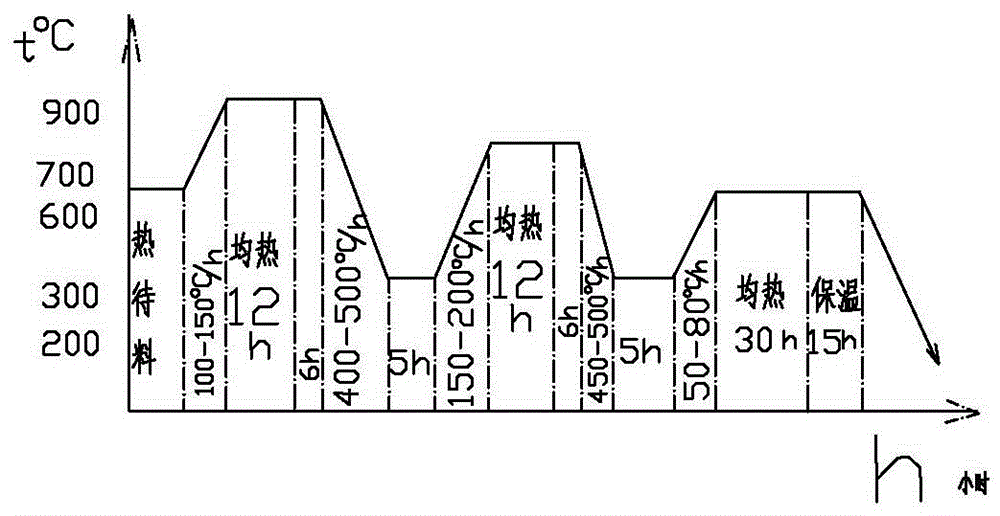

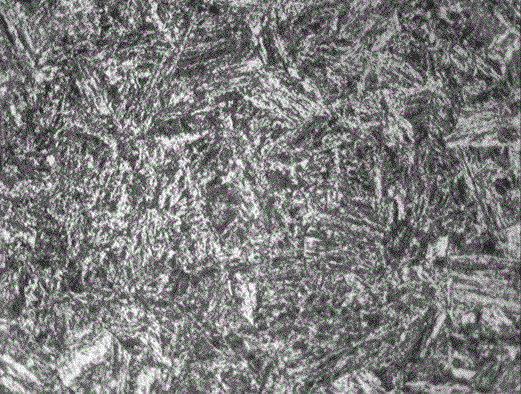

Step type normalizing technology for 25Cr2Ni4MoV forged piece

The invention discloses a stepwise normalizing process for 25Cr2Ni4MoV forgings, which includes the first step of normalizing the forging material with a cross-sectional diameter of 900mm after forging, and is characterized in that: after the first step of normalizing, the furnace is reinstalled for the second step of normalizing , at a heating rate of 150-200°C / h to a medium temperature of 840°C±10°C, soak for 12 hours and then keep warm for 6 hours, and then cool at a cooling rate of 450-500°C / h for the second time with wind and mist, and then cool down to 300 ‑320°C, hold for 5 hours; then temper, heat up to the initial temperature of the forging material at a rate of 50‑80°C / h to 650±10°C, soak for 30 hours and then hold for 15 hours; then cool with the furnace to below 200°C and leave the furnace. This step normalizing process makes the pearlite obtained by the first step normalizing austenitize again, the obtained austenite is finer and more fully transformed, the metallographic grain is finer, the structure is uniform, and the internal stress is better eliminated .

Owner:LAIWU FORGING

Wire rod for high-carbon steel cut wire shot and production method thereof

The present invention discloses a wire rod for high-carbon steel cut wire shot, and the wire rod is characterized by comprising the following components by weight: 0.70-0.86% of C, 0.50-0.90% of Mn, 0.15-0.35% of Si, no more than 0.40% of Cr, no more than 0.05% of V, no more than 0.020% of P, no more than 0.015% of S, no more than 0.20% of Cu, no more than 0.0065% of N, and the balance of Fe and unavoidable impurities. The invention also provides a production method of the wire rod for high-carbon steel cut wire shot. The wire rod for high-carbon steel cut wire shot and production method thereof can meet the technical requirements of wire product industry on new product; the wire rod for high-carbon steel cut wire shot has the characteristics of high purity, uniform composition and tissue and the good cleaning rod performance, has good social and economic benefits, and is worthy of promotion.

Owner:武钢集团有限公司

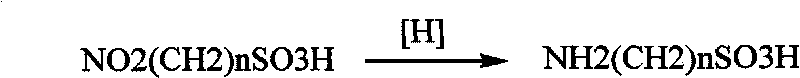

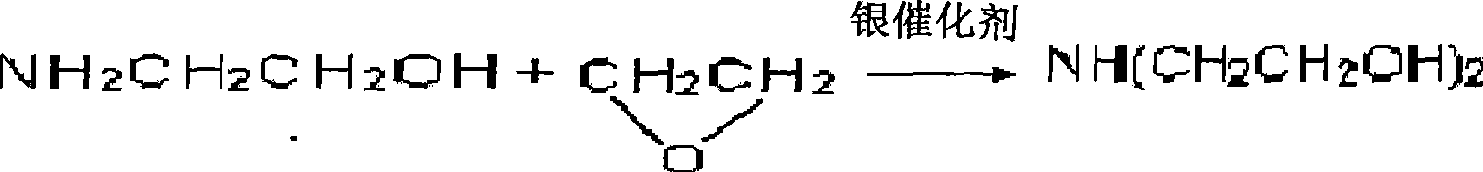

Preparation method of amino-substituted hydrocarbyl sulfonic acid

InactiveCN101759605AReduce decompositionFully transformedSulfonic acid preparationAlcoholDesalination

The invention provides a preparation method of amino-substituted hydrocarbyl sulfonic acid, which is characterized by comprising the following steps of: carrying out substitution reaction by taking esters of amino-substituted hydrocarbyl alcohol as raw materials and sulphite as a nucleophilic substitution reagent at high temperature and high pressure, concentrating and separating for desalination after reaction so that a coarse product of the amino-substituted hydrocarbyl sulfonic acid is obtained, and then purifying and crystallizing the coarse product so that the finished product of the amino-substituted hydrocarbyl sulfonic acid is obtained. The preparation method of the amino-substituted hydrocarbyl sulfonic acid is used for carrying out the substitution reaction at high temperature and high pressure by using the esters of the amino-substituted hydrocarbyl alcohol as raw materials and the sulphite as the nucleophilic substitution reagent so as to have the advantages of short reaction time and energy saving; the preparation method also has the advantage of less side reaction, simple postprocessing operation, high yield and favorable quality of the finished product; and the preparation method has no generation of SO2 gas in the production process so as to greatly improve the production environment and have safety.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

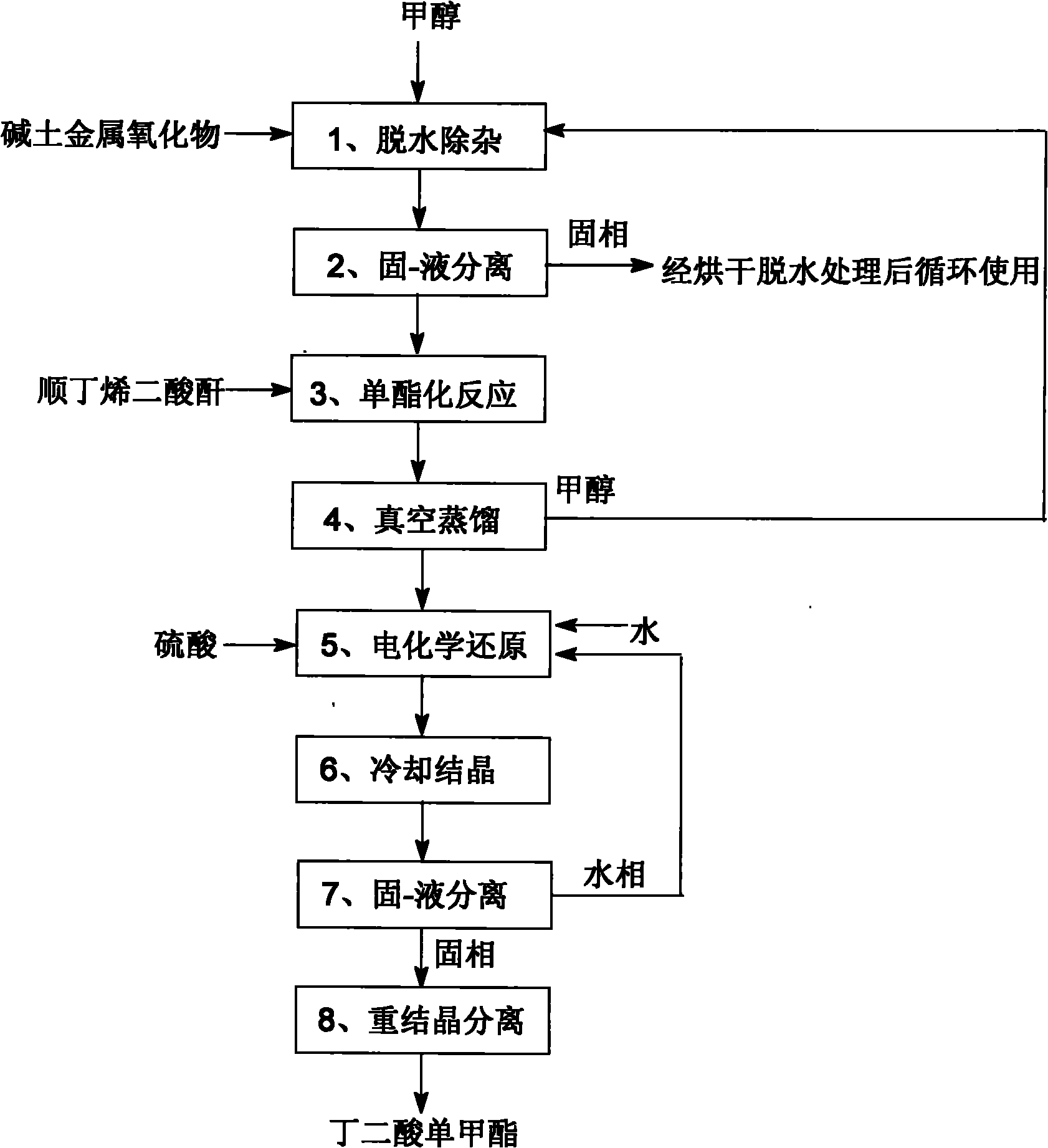

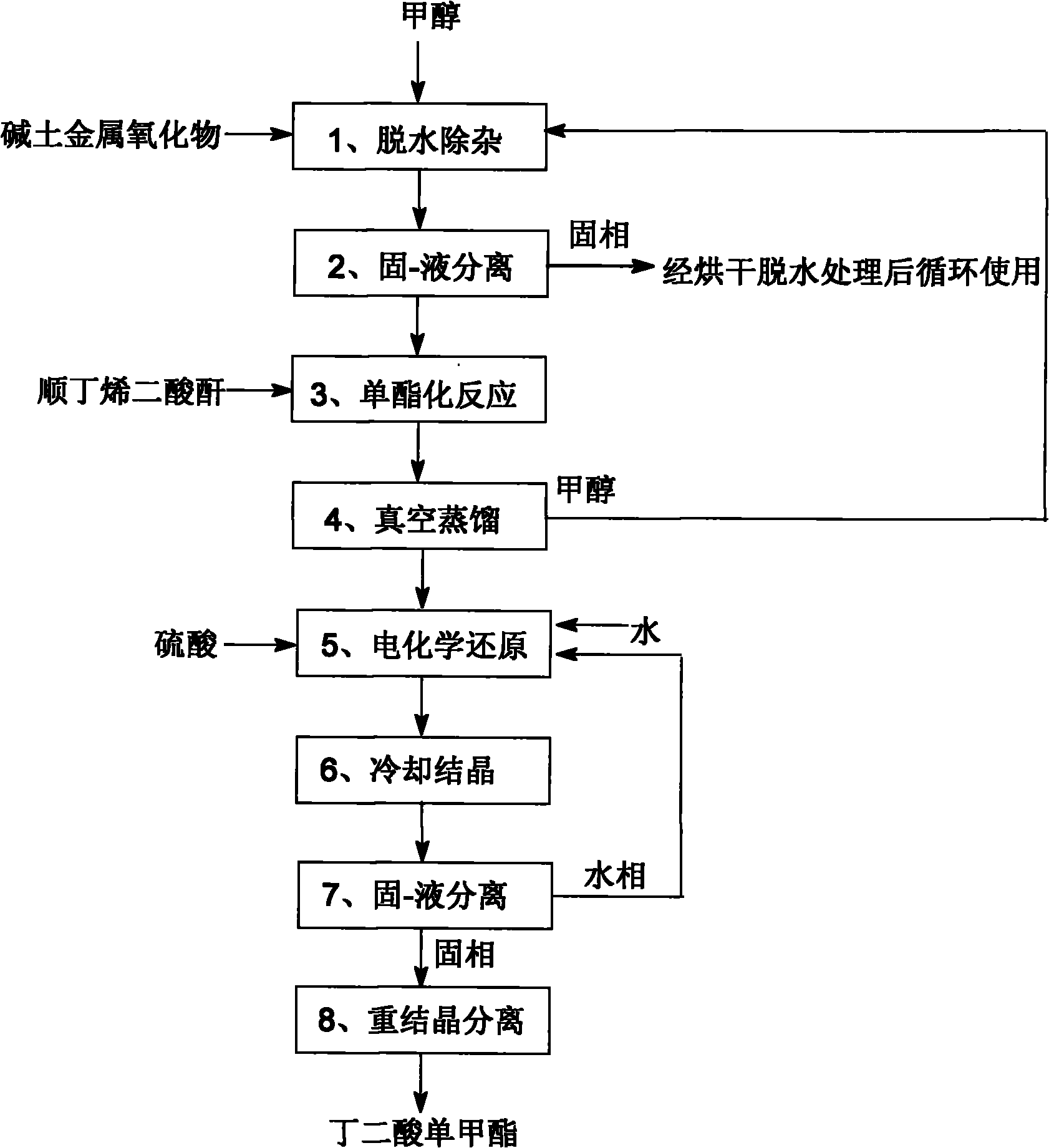

Method for preparing monomethyl succinate

InactiveCN101831662AStrong equipment applicabilityFlexible operationElectrolysis componentsElectrolytic organic productionSolid phasesMaleic anhydride

The invention relates to a method for preparing monomethyl succinate. The monomethyl succinate is prepared by using maleic anhydride and methyl alcohol as raw materials. The method comprises the steps of: 1, dehydrating and removing impurities: adding the methyl alcohol into a dehydrating and impurity-removing device, adding alkali-earth oxides for dehydrating and removing impurities; 2, carrying out solid-liquid separation: ensuring that liquid-phase materials enter the next step; 3, carrying out hemisuccination: adding the maleic anhydride into the liquid phase materials obtained by the step 2; 4, carrying out vacuum distillation: ensuring that the materials subjected to the methyl alcohol removal enter the next step; 5, carrying out electrochemistry reduction: carrying out electrochemistry hydrogenation reduction reaction on a monomethyl cis-butenedioic acid product, water and sulfuric acid; 6, cooling and crystallizing; 7, carrying out solid-liquid separation: ensuring that solid phase materials enter the next step; and 8, carrying out recrystallization separation to obtain the product of the monomethyl succinate. The invention has simple preparation method, reasonable process, low preparation cost, high product purity, good product quality, high yield and convenient implementation for mass industrialization.

Owner:淮安苏瑞精细化工有限公司

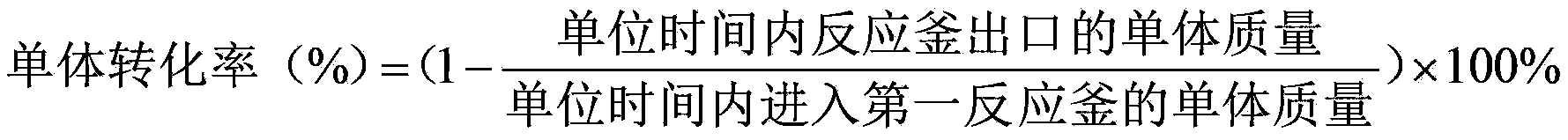

Polybutadiene rubber and preparation method thereof

ActiveCN104098726AWide molecular weight distributionGel controllableWeight distributionStructural unit

The invention discloses polybutadiene rubber and a preparation method thereof. The polybutadiene rubber comprises 5-15wt% of a structural unit obtained by 1,2-polymerization of 1,3-butadiene and 85-95wt% of a structural unit obtained by 1,4-polymerization of 1,3-butadiene. The polybutadiene rubber has cis-1,4-structural unit content of 30-45wt%, a number-average molecular weight of 40000-500000 and molecular weight distribution of 2.0-3.0. The polybutadiene rubber obtained by the preparation method has wide molecular weight distribution, guarantees complete monomer conversion in reasonable staying time and has gelling controllability in the reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method for D-calcium pantothenate

ActiveCN108440325AWell mixedFully transformedOrganic compound preparationOrganic chemistry methodsPantoyl lactoneSynthesis methods

The invention relates to the technical field of chemical production, in particular to a synthesis method for D-calcium pantothenate. The synthesis method comprises the following steps: (1) dissolvingD-pantoyl lactone with absolute methanol to obtain a D-pantoyl lactone methanol solution; (2) reacting beta-alanine and calcium oxide in absolute methanol to obtain a beta-calcium alanine methanol solution; and (3) leading the D-pantoyl lactone methanol solution and the beta-calcium alanine methanol solution into a micro channel flow reactor to mix, and reacting a mixed solution at a temperature being 50-120 DEG C for 5-30 minutes to obtain D-calcium pantothenate. The synthesis method provided by the invention has the advantages of being short in time consumption and high in yield.

Owner:安徽省恒锐新技术开发有限责任公司

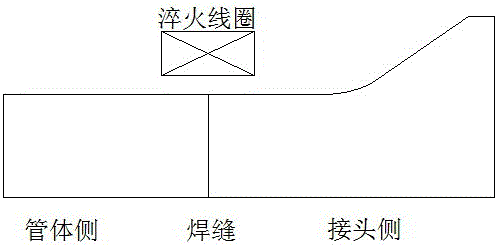

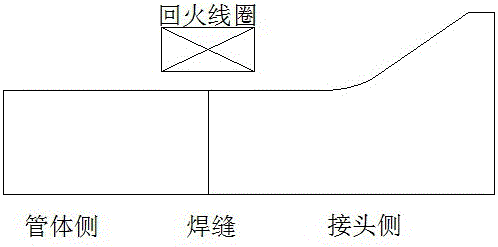

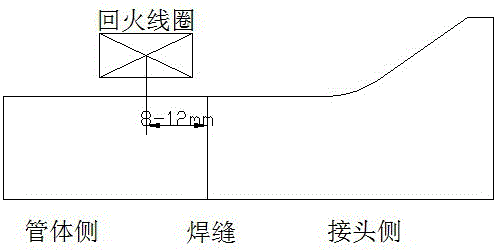

165-steel-grade drill rod weld joint heat treatment method

ActiveCN105803162AFully transformedBreak down evenlyFurnace typesHeat treatment furnacesFriction weldingHardness

The invention discloses a 165-steel-grade drill rod weld joint heat treatment method. A drill rod weld joint is formed by conducting friction welding on a drill rod connector and a drill rod pipe body, the steel grade of the drill rod connector is 135 ksi, and the steel grade of the drill rod pipe body is 165 ksi. The 165-steel-grade drill rod weld joint heat treatment method comprises the steps of 1 quenching, 2 first-time tempering and 3 second-time tempering, wherein during the second-time tempering of the step 3, the center of a tempering coil is aligned to the position, deviating from one side of the pipe body, of the weld joint for 8-12 mm. The 165-steel-grade drill rod weld joint heat treatment method reduces the side hardness of the weld joint pipe body and makes the structure of a whole welding area more uniform, better comprehensive mechanical properties are obtained, and the service life is prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

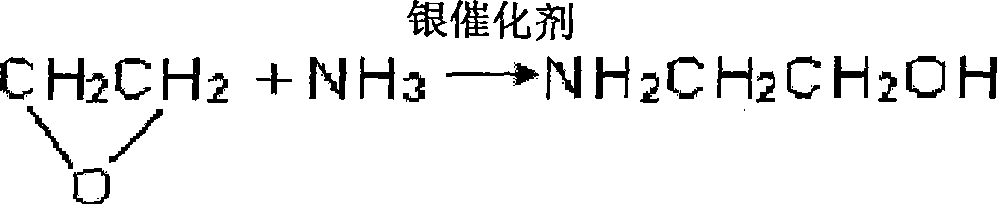

Method for synthesizing monoethanolamine

ActiveCN101434551AFully transformedHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsChemical synthesisHydrogen

The invention discloses a synthesis method of monoethanolamine, pertaining to the technical field of organic chemical synthesis. Hydroxyacetonitrile is adopted for carrying out reaction with hydrogen under the presence of a catalyst to obtain the monoethanolamine. Compared with the prior art, the technical proposal has the advantages of full transformation (more than 81 percent) and high yield (more than 70 percent).

Owner:JIANGSU YUANYANG PHARMA

Heating treatment technology for aluminum alloy castings

InactiveCN107620017ASufficient hardenabilityHigh mechanical strengthMechanical propertyMaterials science

The invention discloses a heating treatment technology for aluminum alloy castings, and relates to the technical field of metal casting. The heating treatment technology comprises the following stepsthat (1) vacuum homogenization preheating is carried out; (2) first-time normalizing is carried out; (3) second-time normalizing is carried out; (4) high-temperature tempering is carried out; (5) vacuum hardening is carried out; and (6) annealing is carried out. According to the heating treatment technology for the aluminum alloy castings, the heating temperature is appropriately improved for prolonging the soaking time, and therefore structural transformation of the aluminum alloy castings can be sufficient, the mechanical property and the impact toughness are effectively improved, and the heating treatment technology is suitable for application and popularization.

Owner:和县华顺铸造有限公司

Heat treatment technology for engine shield

ActiveCN107190130AHigh hardnessUniform grain refinementFurnace typesHeat treatment furnacesRoom temperatureWater cooling

The invention discloses a heat treatment technology for an engine shield. The heat treatment technology comprises the steps of 1) carrying out normalizing, specifically, carrying out secondary normalizing treatment on the cast-formed engine shield; 2) carrying out high-temperature tempering, specifically, carrying out heat preservation on the normalized shield in a furnace at 340-380 DEG C for 6-8 hours, carrying out high-temperature tempering to increase the temperature to 670-730 DEG C, carrying out heat preservation for 8-10 hours, gradually cooling the shield until the temperature is lower than 120 DEG C, and discharging the shield from the furnace; 3) carrying out quenching, specifically, raising the temperature of the shield to 680-720 DEG C, carrying out heat preservation for 2-3 hours, increasing the temperature to the quenching temperature of 820-880 DEG C, carrying out heat preservation for 4-5 hours, and then carrying out water cooling to the room temperature; and 4) carrying out annealing, specifically, the shield is finally heated to 380-420 DEG c, carrying out heat preservation for 8-10 hours, increasing the temperature to the annealing temperature of 660-720 DEG C, carrying out heat preservation for 10-12 hours, and carrying out air cooling to the room temperature. According to the heat treatment technology, the heating temperature is properly increased and the heat preservation time is prolonged, and therefore the structure of alloy steel of the engine shield can be fully converted, the mechanical property and the impact toughness of the engine shield can be effectively improved, and the good comprehensive mechanical property requirements of the automobile engine shield can be met.

Owner:SHANDONG ZHONGTUO NEW ENERGY CO LTD

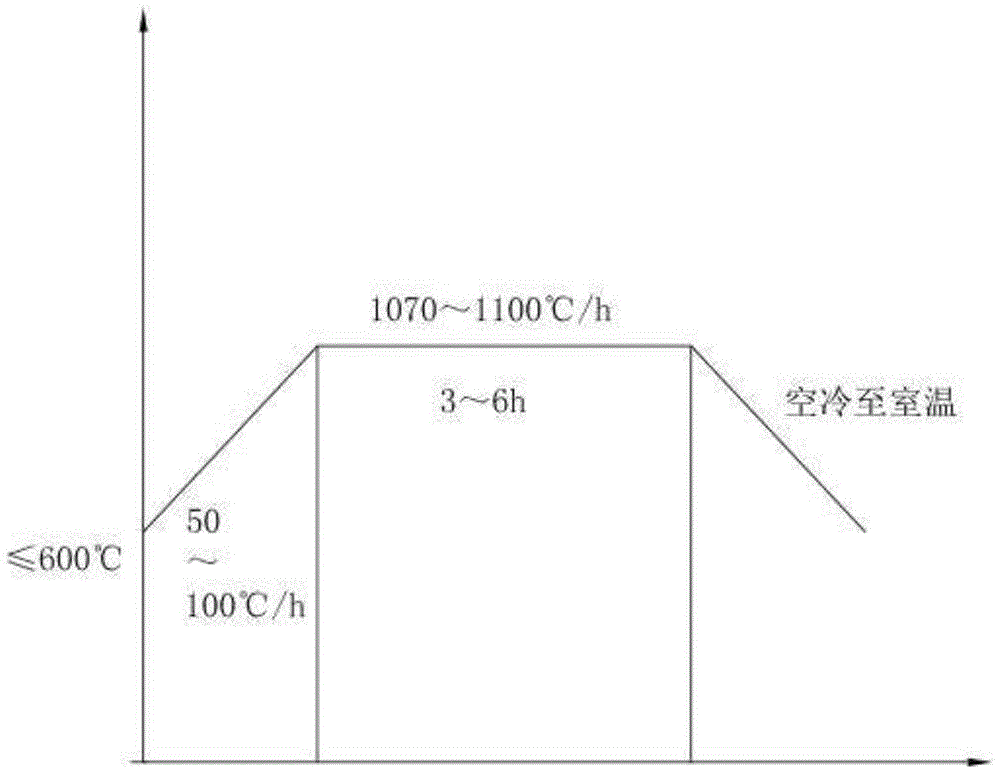

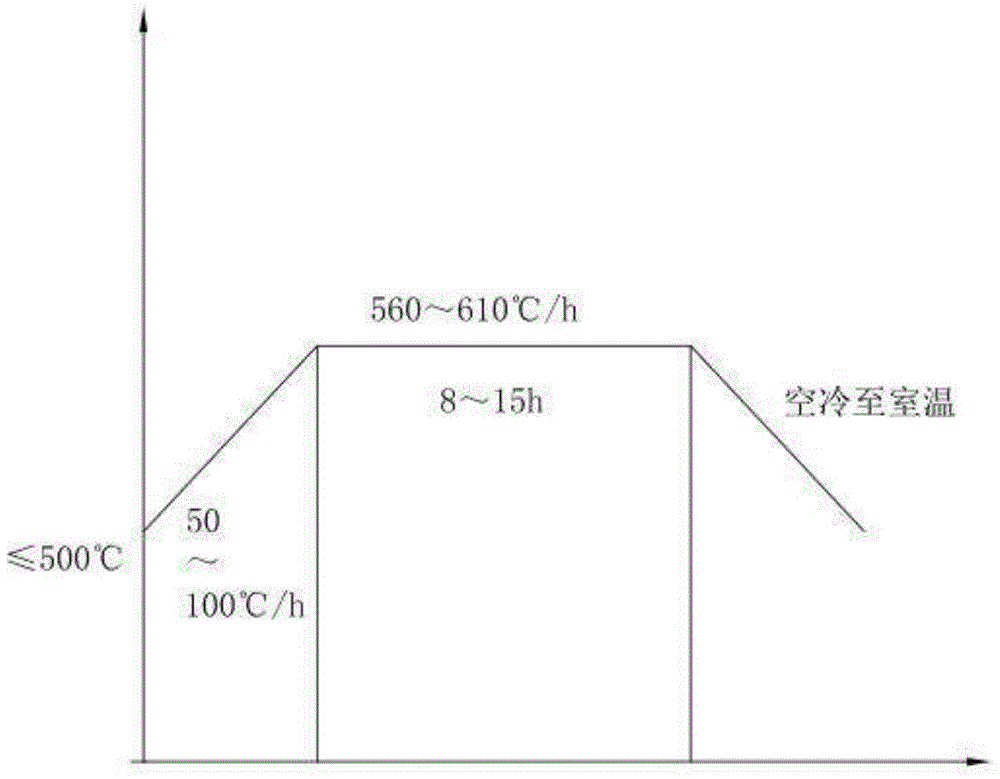

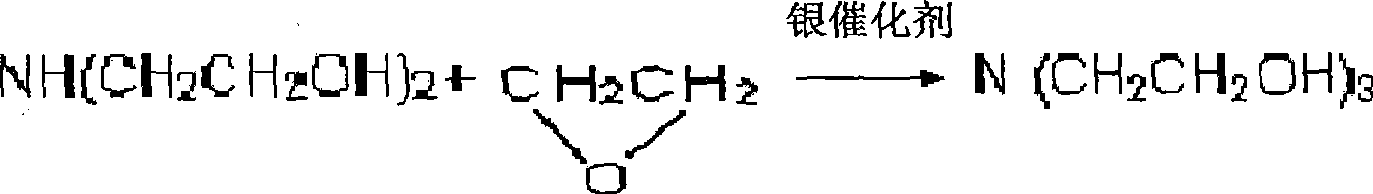

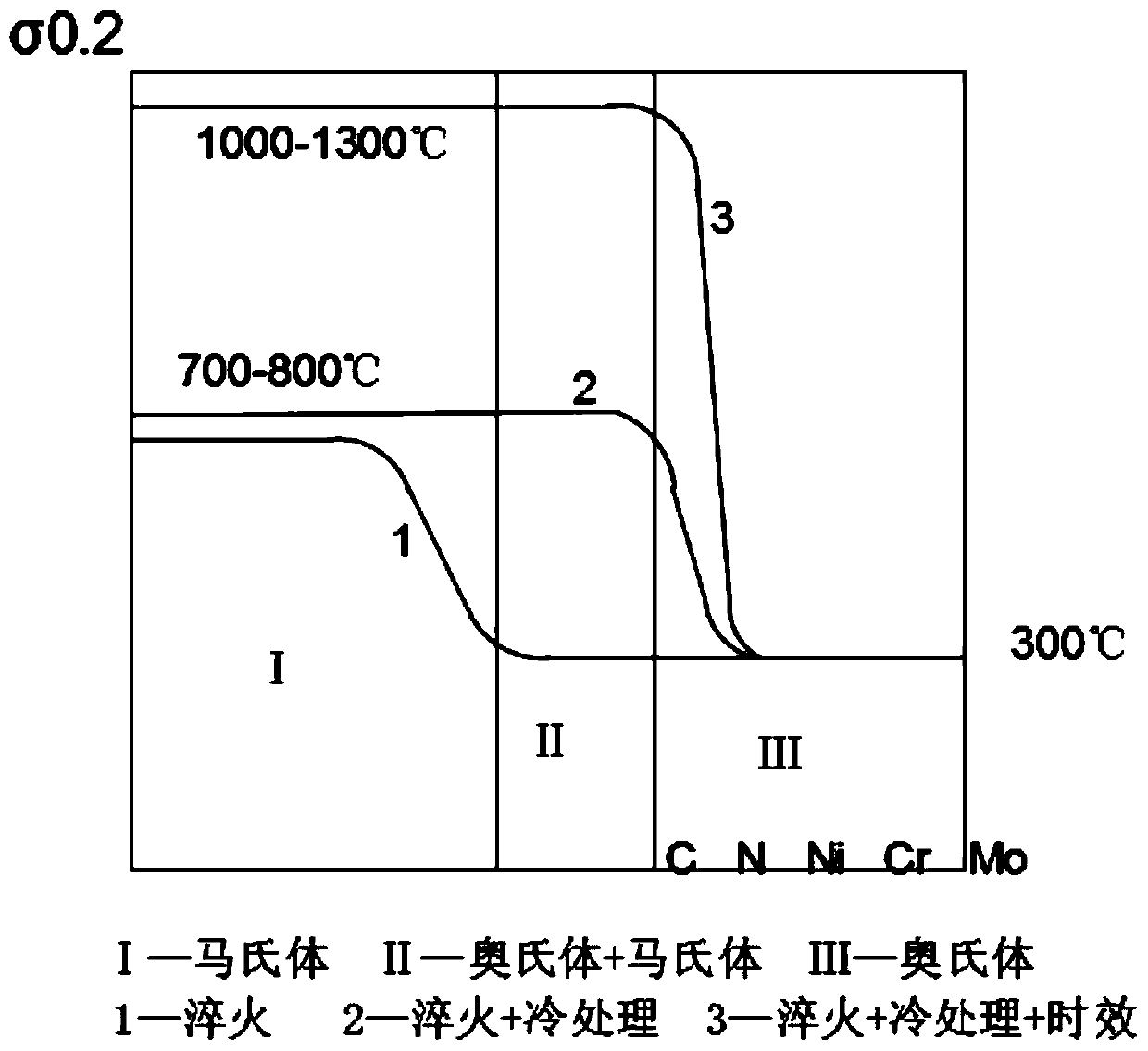

Welding process of ultrahigh-strength precipitated hardened stainless steel

ActiveCN110293287AWelding process goes wellStable welding qualityFurnace typesWelding/cutting media/materialsWeld seamPrecipitation

The invention discloses a welding process of ultrahigh-strength precipitated hardened stainless steel, and belongs to the field of chemical machinery. Aiming at the problems that the strength of stainless steel is low and the welding quality is poor in the prior art, the welding process of the ultrahigh-strength precipitation hardened stainless steel is provided. The welding process comprises thefollowing steps that index analysis is carried out on a welded stainless steel base material, and a welding method is selected; a joint groove is designed; preweld cleaning and preparation work is carried out; a welding material is selected according to whether the performance of the welding seam is required to be matched with the performance of the base material or not; solid solution treatment is carried out on the stainless steel base material, and welding is carried out when the stainless steel base material in a solid solution state; and heat treatment is carried out on the stainless steel base material after welding. According to the welding process of ultrahigh-strength precipitated hardened stainless steel, the stainless steel is subjected to the solid solution treatment, and the stainless steel is welded in the solid solution state, so that the welding process is smooth, the welding quality is stable, and welding hot cracks are reduced; and the heat treatment is carried out after welding is completed, so that the tensile strength of the stainless steel is improved to 1100 MPa or above, and the stainless steel has relatively high strength, toughness and plasticity.

Owner:ANHUI MASTEEL ENG & TECH GRP

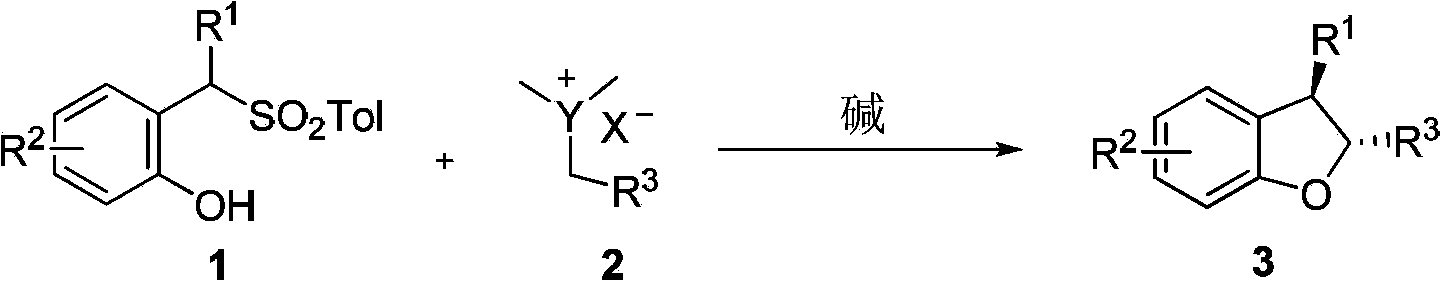

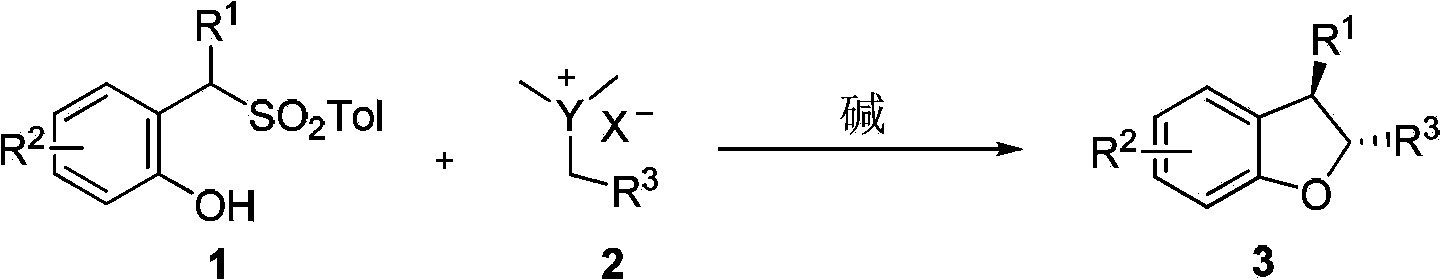

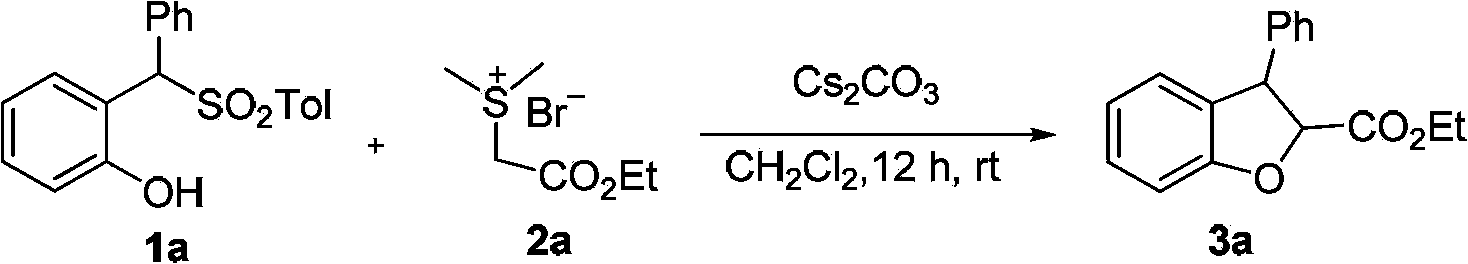

Method for synthetizing 2,3-disubstituted dihydrobenzofuran

The invention discloses a method for synthetizing 2,3-disubstituted dihydrobenzofuran. Kinds of substituted 2,3-disubstituted dihydrobenzofurans can be obtained from simple ylide and substituted phenol by reactions under an alkali catalytic condition. The method disclosed by the invention is simple and practical in operation, available in raw materials, high in yield, and good in diastereoselectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

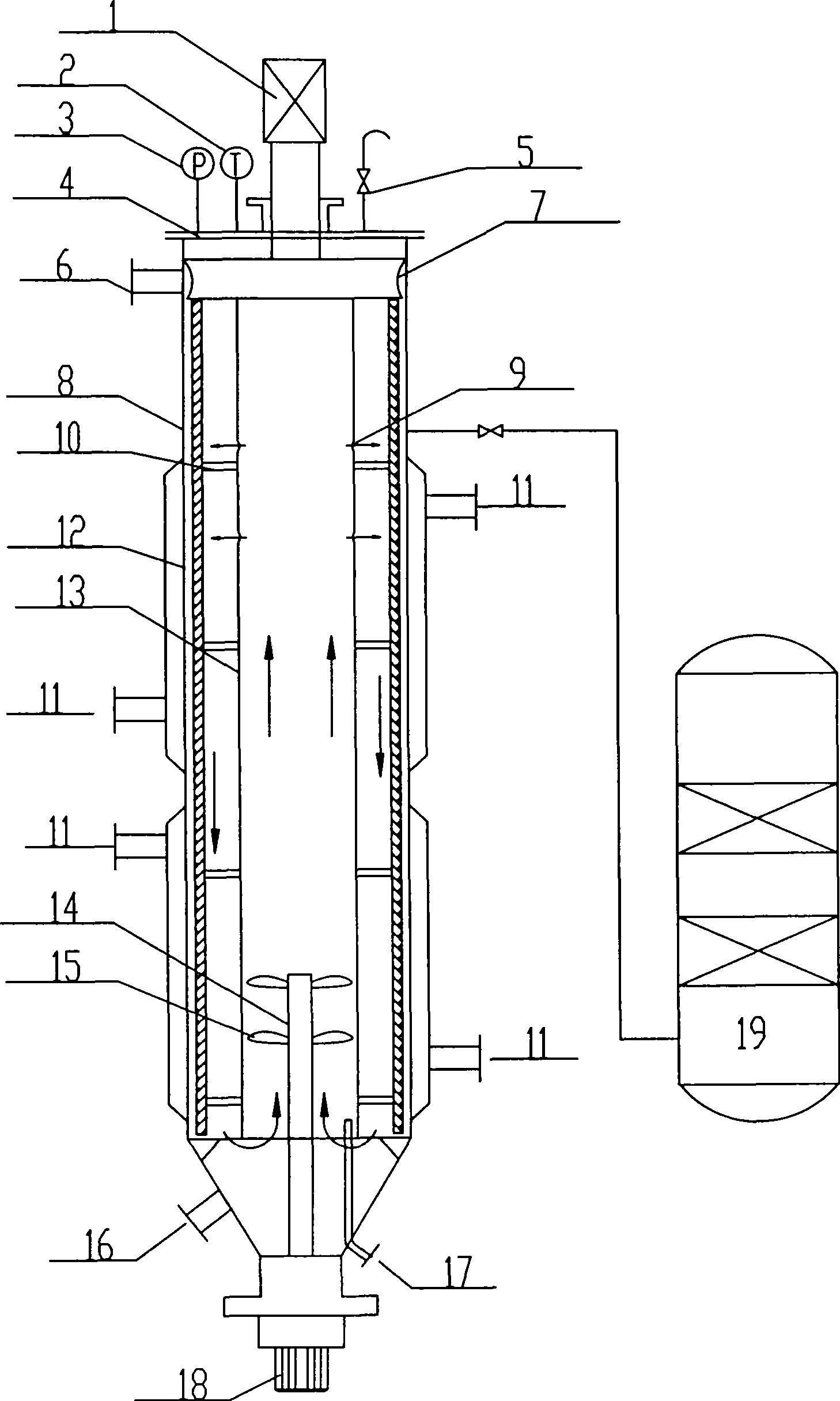

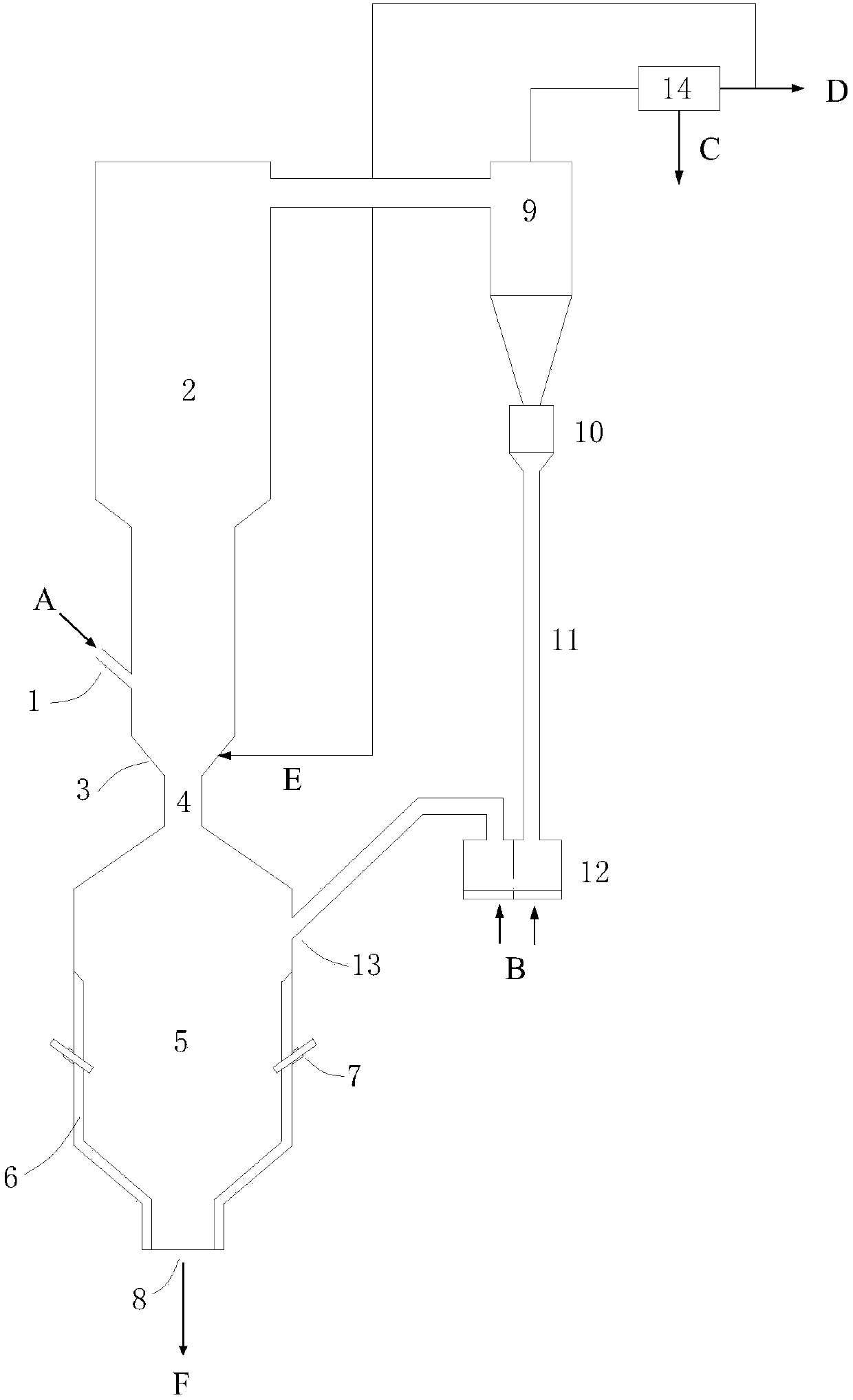

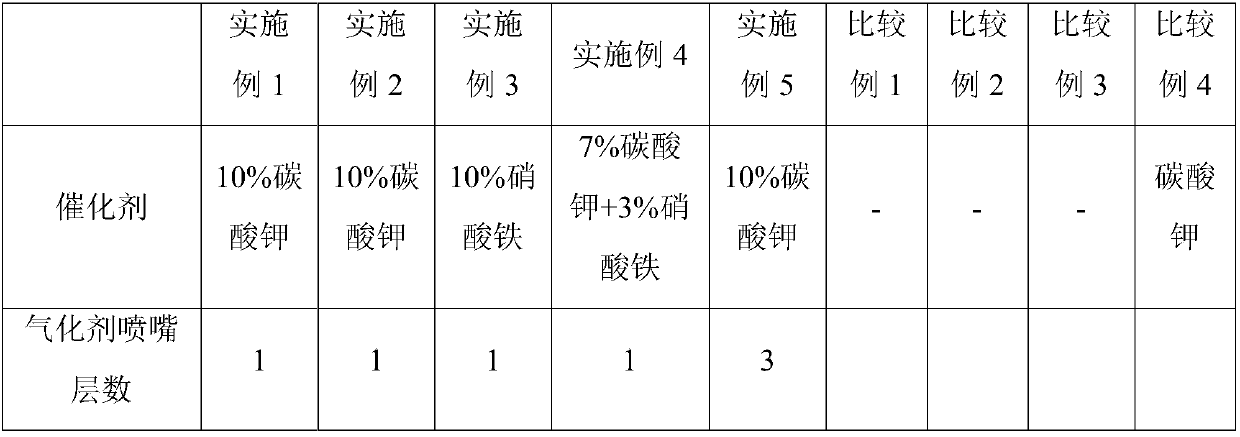

Fluidized bed and molten bed combination type coal catalytic gasification reaction apparatus and fluidized bed and molten bed combination type coal catalytic gasification reaction method

InactiveCN107760379AAchieve couplingSolve the problem of smooth slag dischargeCombustible gas productionSyngasCombustion

The invention relates to a fluidized bed and molten bed combination type catalytic gasification apparatus and a fluidized bed and molten bed combination type catalytic gasification method. A purpose of the present invention is to solve the problems of low carbon conversion rate, low gasification intensity, low methane yield, and poor operation stability and poor reliability of the gasification furnace in the prior art. The technical scheme of the present invention comprises that the fluidized bed and molten bed combination type catalytic gasification apparatus comprises a fluidized bed gasification section on the upper portion and a molten bed gasification section on the lower portion, the two gasification sections are connected by using a throat, a raw material inlet and a gas distributorfor introducing circulation synthesis gas are arranged on the lower portion of the fluidized bed gasification section, the inner-upper portion of the molten bed gasification section is provided witha return material inlet, and the side surface is provided with gasification agent spraying nozzles. The fluidized bed and molten bed combination type catalytic gasification method mainly comprises that a carbon-containing raw material, circulation synthesis gas and high-temperature mixed gas are subjected to pyrolysis, gasification and methanation in the fluidized bed gasification section, the incompletely-reacted semi-coke is separated and enters the molten bed gasification section, and a combustion gasification reaction is performed. With the technical scheme of the present invention, the problem in the prior art is well solved. The apparatus and the method of the present invention can be used in the coal-to-synthesis gas field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for efficient hydrodechlorination purification of trichlorobenzene

InactiveCN110204418ASimple processHigh selectivityHalogenated hydrocarbon preparationIsomerizationDistillation

The invention belongs to the technical field of petrochemical engineering, and relates to the technical field of organic compound purification in the field of fine chemical engineering, in particularto a method for purifying 1,2,4-trichlorobenzene. The method for purifying 1,2,4-trichlorobenzene solves the technical problems that in the prior art, a high purity product of refined 1,2,4-trichlorobenzene is not obtained easily, and isomerization impurities are hard to control. The method has the advantages of being simple and efficient, easy to implement, good in atom economy, high in product purity and the like, isomerization in 1,2,4-trichlorobenzene is removed, and therefore the purity of 1,2,4-trichlorobenzene is improved. According to the technical scheme of the method for efficient hydrodechlorination purification of trichlorobenzene, the isomerization in 1,2,4-trichlorobenzene is converted into low-aryl chloride with the low boiling point, and 1,2,4-trichlorobenzene with the purity larger than 99.9% is obtained through distillation separation.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com