Ultra-high-strength multiphase-structure gray cast iron cylinder jacket and preparation method thereof

A cylinder liner and gray cast iron technology, which is applied in the field of automobile engine cylinder liner preparation, can solve the problems of low tensile strength of gray iron and difficulty in improving the comprehensive mechanical properties of the cylinder liner, and reduce production costs, and the preparation method is simple and easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

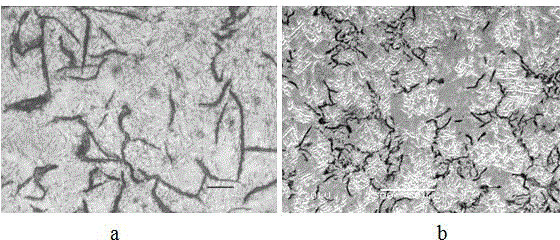

[0035] The gray cast iron cylinder liner with multiphase structure provided in this embodiment is made of gray cast iron, and its microstructure includes two phases of bainite and martensite; in terms of mass percentage, the material composition of the cylinder liner is for:

[0036] Carbon, 2.7%; Silicon, 1.85%;

[0037] Niobium, 0.4%; Copper, 0.25%;

[0038] Manganese, 0.2%; Cobalt, 0.2%;

[0039] Nitrogen, 0.15%;

[0040] Phosphorus, 0.05%; sulfur, 0.05%, the balance is iron.

[0041] The preparation method of the gray cast iron cylinder liner with multiphase structure comprises the following steps:

[0042] (1) ingredients in proportion,

[0043] (2) Melting and pouring the cylinder liner blanks, the mixed materials in step (1) are melted at 1450°C~1550°C, released at 1500°C~1550°C, centrifugally poured at 1150~1250r / min, and the pouring temperature is 1350°C~ 1450°C; the mold temperature is 350~500°C, the mold release temperature is not lower than 740°C, and the mol...

Embodiment 2

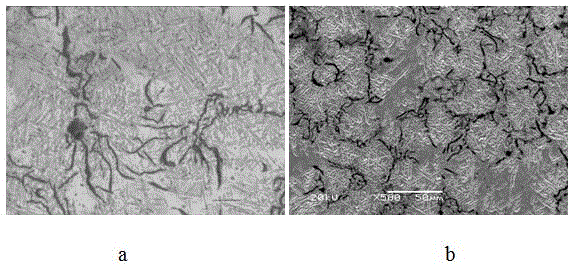

[0052] The gray cast iron cylinder liner with multiphase structure provided in this embodiment is made of gray cast iron, and its microstructure includes two phases of bainite and martensite; in terms of mass percentage, the material composition of the cylinder liner is for:

[0053] Carbon, 2.7%; Silicon, 1.85%;

[0054] Niobium, 0.8%; Copper, 0.25%;

[0055] Manganese, 0.2%; Cobalt, 0.2%;

[0056] Nitrogen, 0.15%;

[0057] Phosphorus, 0.05%; sulfur, 0.05%, the balance is iron.

[0058] The preparation method is the same as in Example 1.

[0059] The mechanical properties of the multi-phase gray cast iron cylinder liner provided in this example are tested according to relevant national standards and industry standards, and the results are: hardness = 356HB, Rm = 648MPa, E = 164GPa, and the corresponding microstructure is as follows figure 2 shown.

Embodiment 3

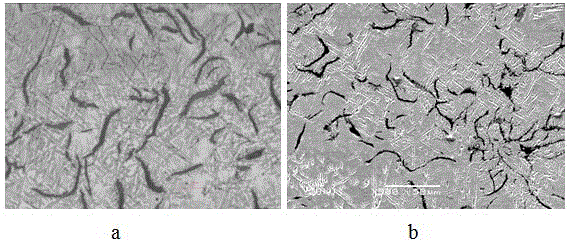

[0061] The gray cast iron cylinder liner with multiphase structure provided in this embodiment is made of gray cast iron, and its microstructure includes two phases of bainite and martensite; in terms of mass percentage, the material composition of the cylinder liner is for:

[0062] Carbon, 2.7%; Silicon, 1.85%;

[0063] Niobium, 0.4%; Copper, 0.25%;

[0064] Manganese, 0.2%; Cobalt, 0.2%;

[0065] Nitrogen, 0.15%;

[0066] Phosphorus, 0.05%; sulfur, 0.05%, the balance is iron.

[0067] (The recipe is the same as in Example 1, please check to see if it is correct)

[0068] The preparation method is the same as in Example 1, only the low temperature tempering temperature in step (5) is adjusted to 220°C.

[0069] The mechanical properties of the multi-phase gray cast iron cylinder liner provided in this example are tested according to relevant national standards and industry standards, and the results are: hardness = 335HB, Rm = 614MPa, E = 159GPa, and the corresponding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com