Step type normalizing technology for 25Cr2Ni4MoV forged piece

A stepped and normalizing technology, applied in the field of stepped normalizing process of 25Cr2Ni4MoV forgings, can solve the problems of uneven metallographic structure, coarse grains, coarse grains, etc. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

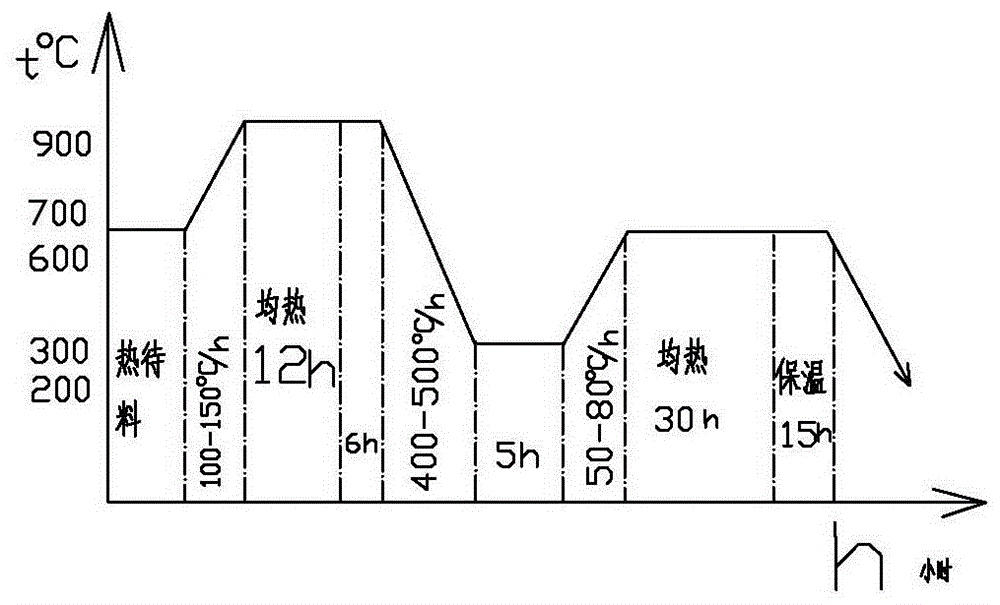

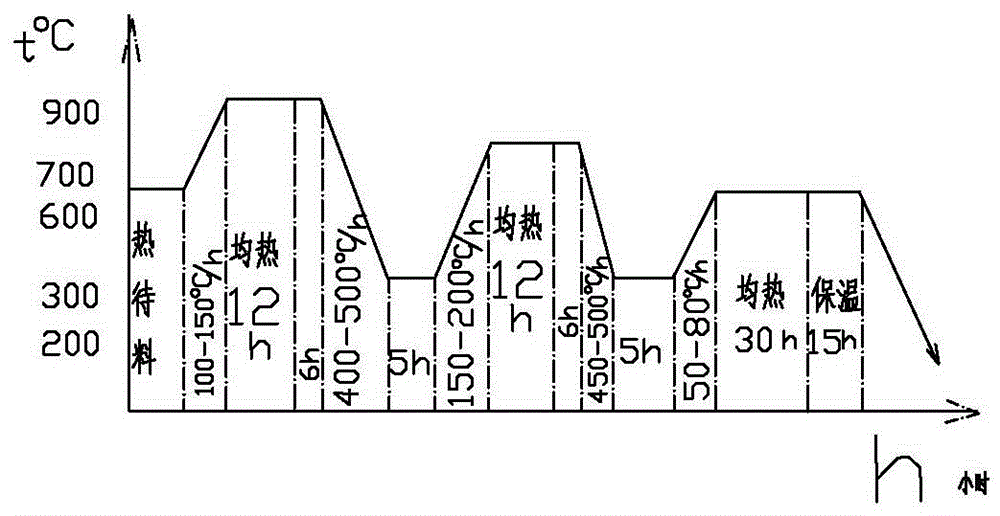

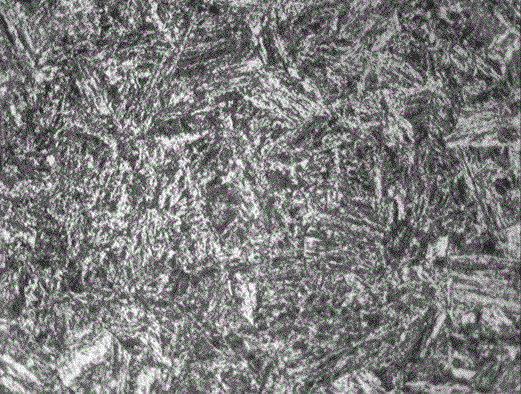

[0011] The company produces 100 pieces of 25Cr2Ni4MoV steel high-power rotors, which are forged in batches and then heat-treated in batches. After the steel ingot is forged into a forging material with a cross-sectional diameter of 900mm, the following process is performed: after forging, wait for the material to reach 630°C, then raise the temperature to a high temperature of 920°C at a rate of 130°C / h, soak for 12 hours and then hold for 6 hours to transform the structure into austenitic body, and then cooled by wind and mist at a cooling rate of 490°C / h, cooled to 310°C and then kept for 5 hours; followed by a second step of normalizing, rising to a medium temperature of 840 at a heating rate of 180°C / h, soaking for 12 hours After holding for 6 hours, the structure is fully transformed and austenitized; then the second wind and mist rapid cooling is carried out at a cooling rate of 450°C / h, and then cooled to 310°C, and held for 5h; then tempered, at 60°C Raise the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com