Patents

Literature

716results about How to "Wide molecular weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogen and electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

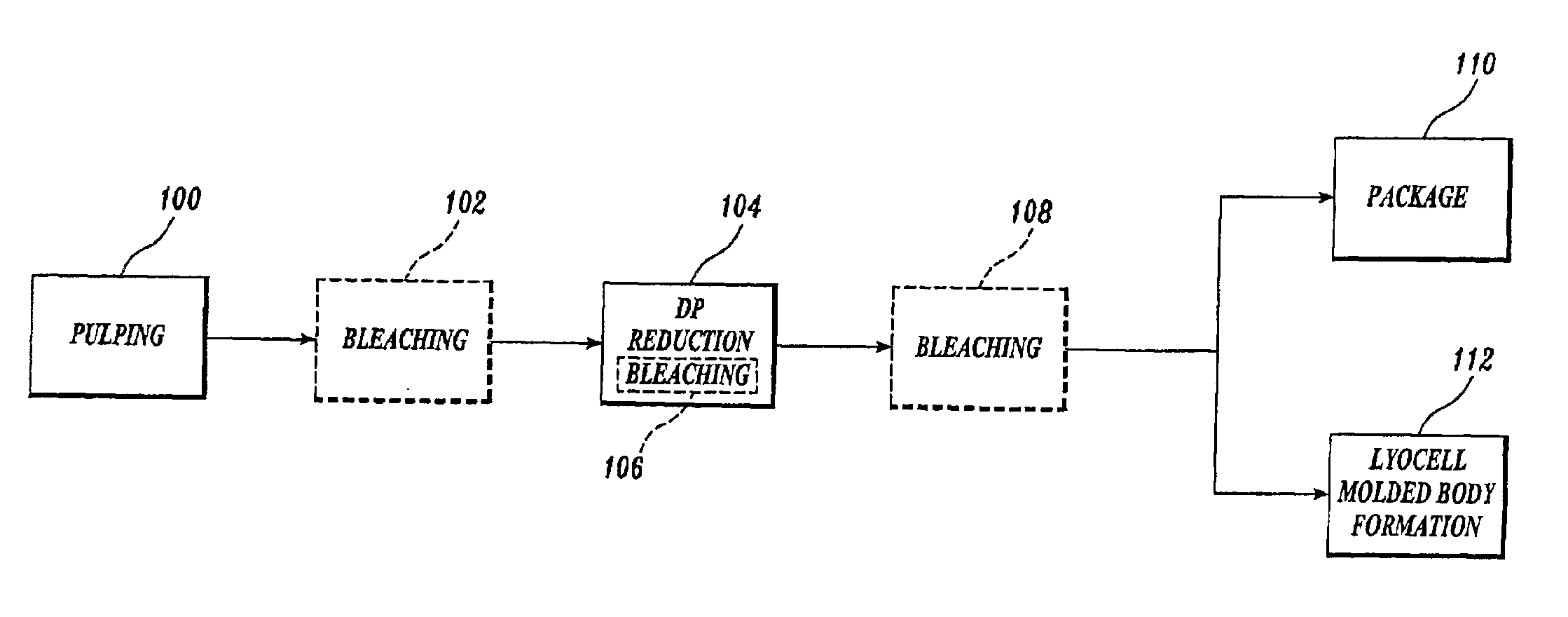

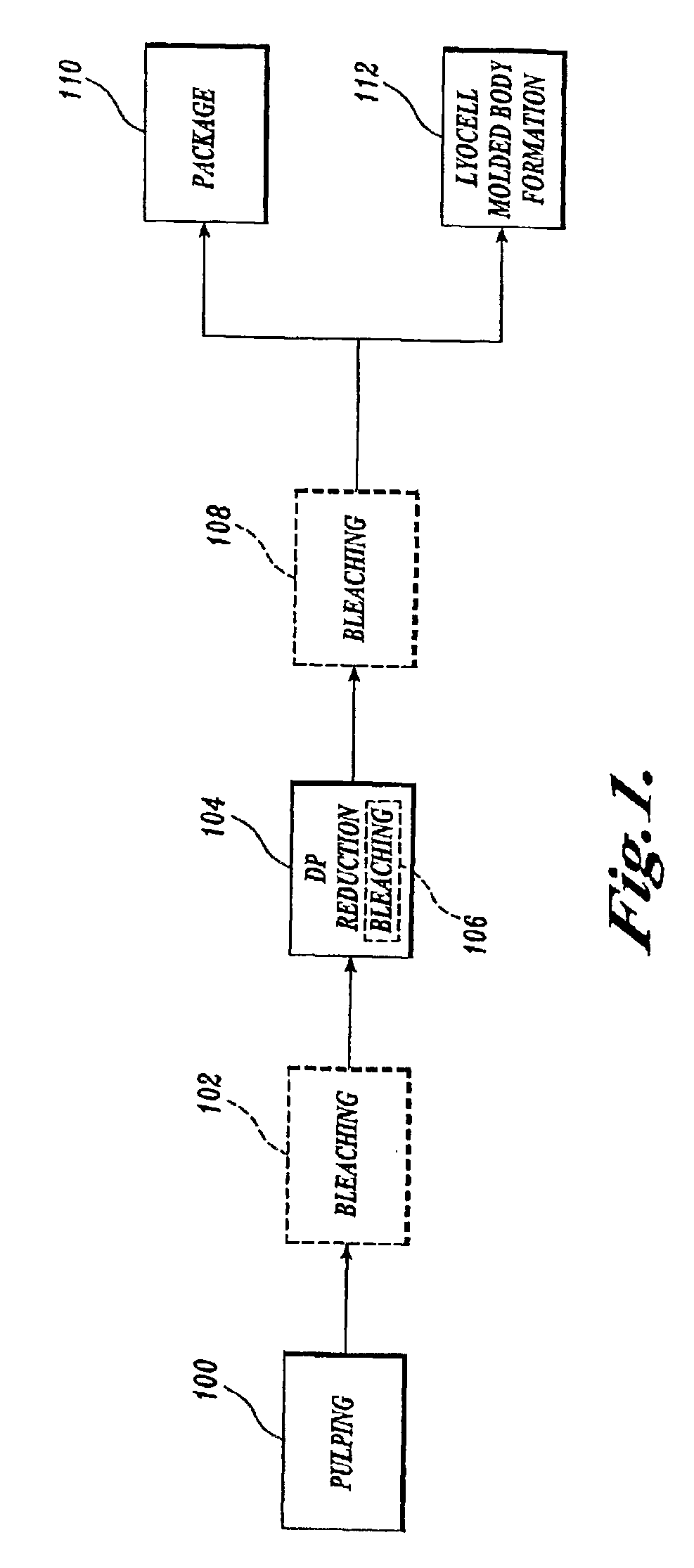

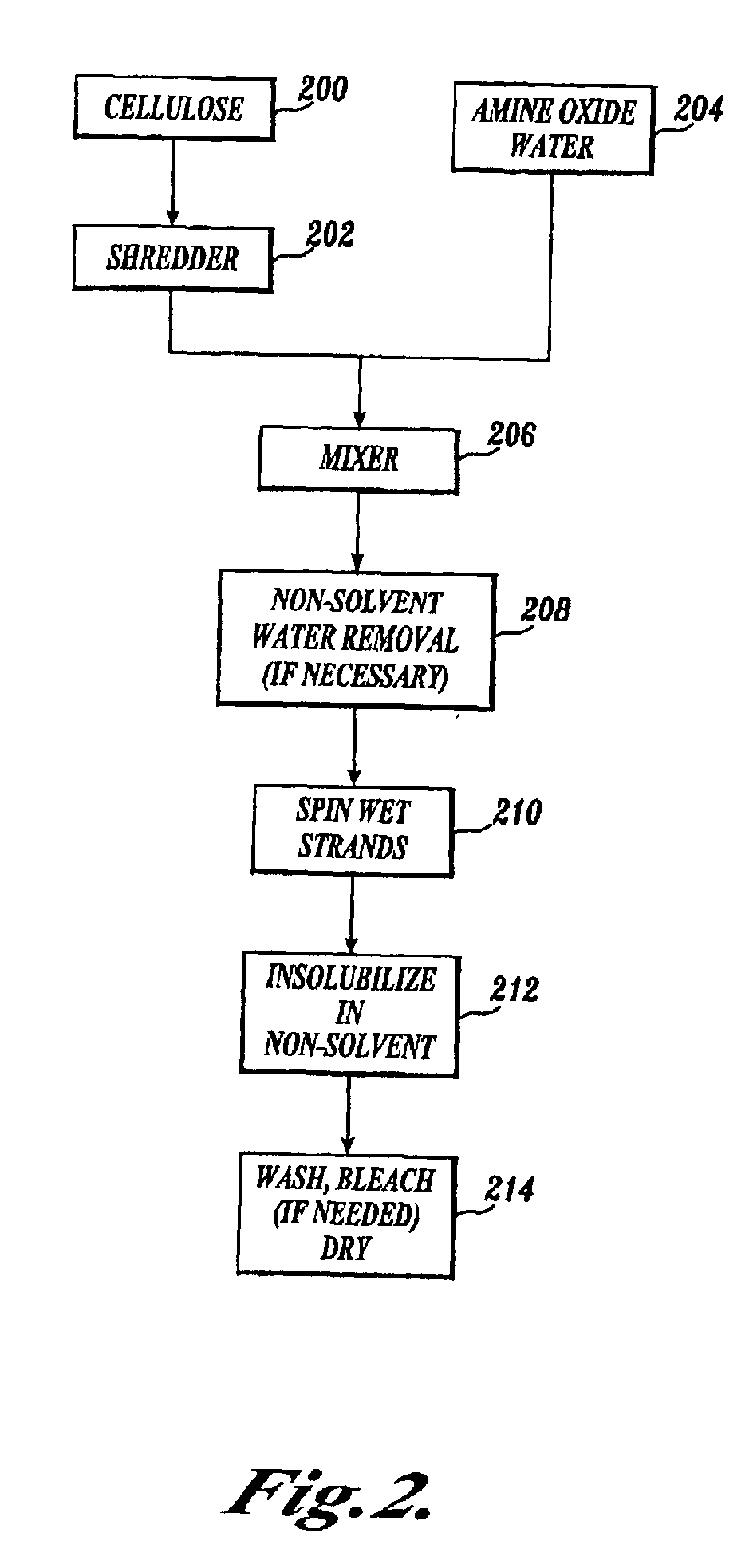

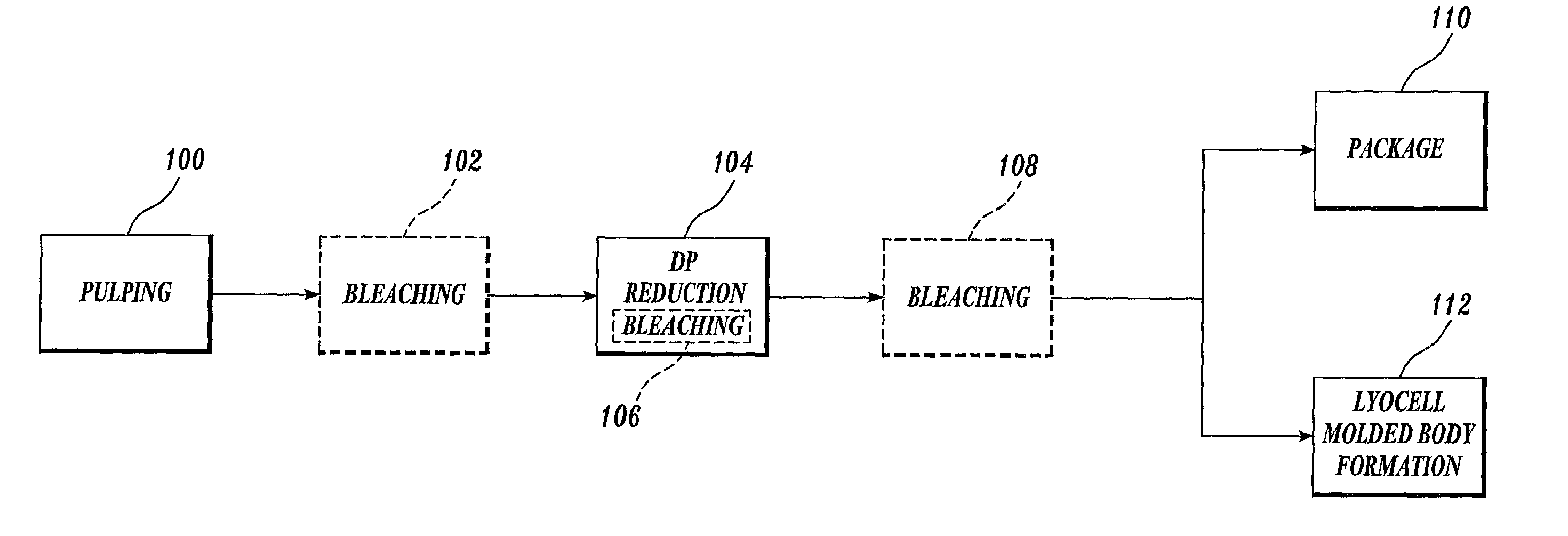

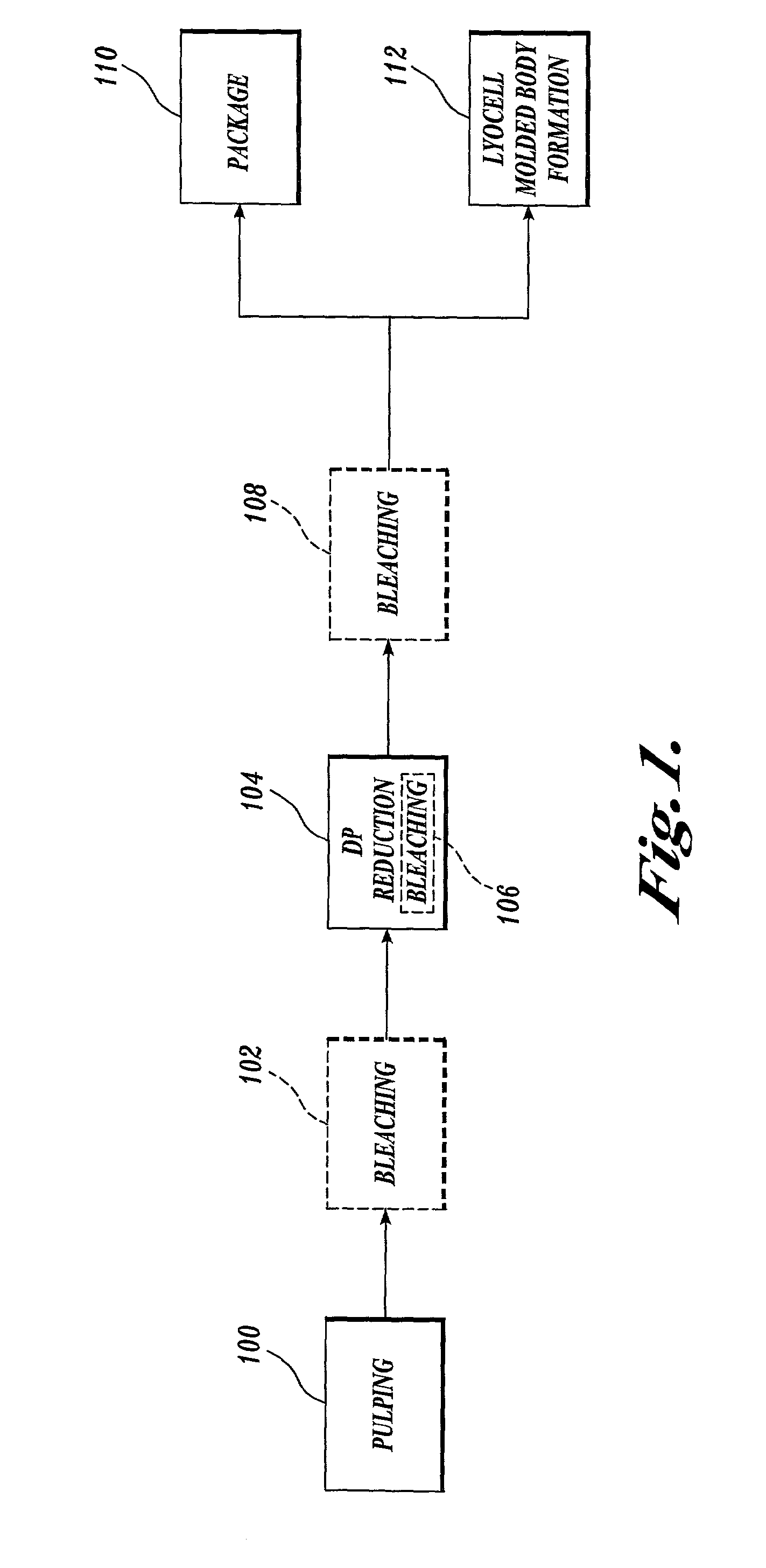

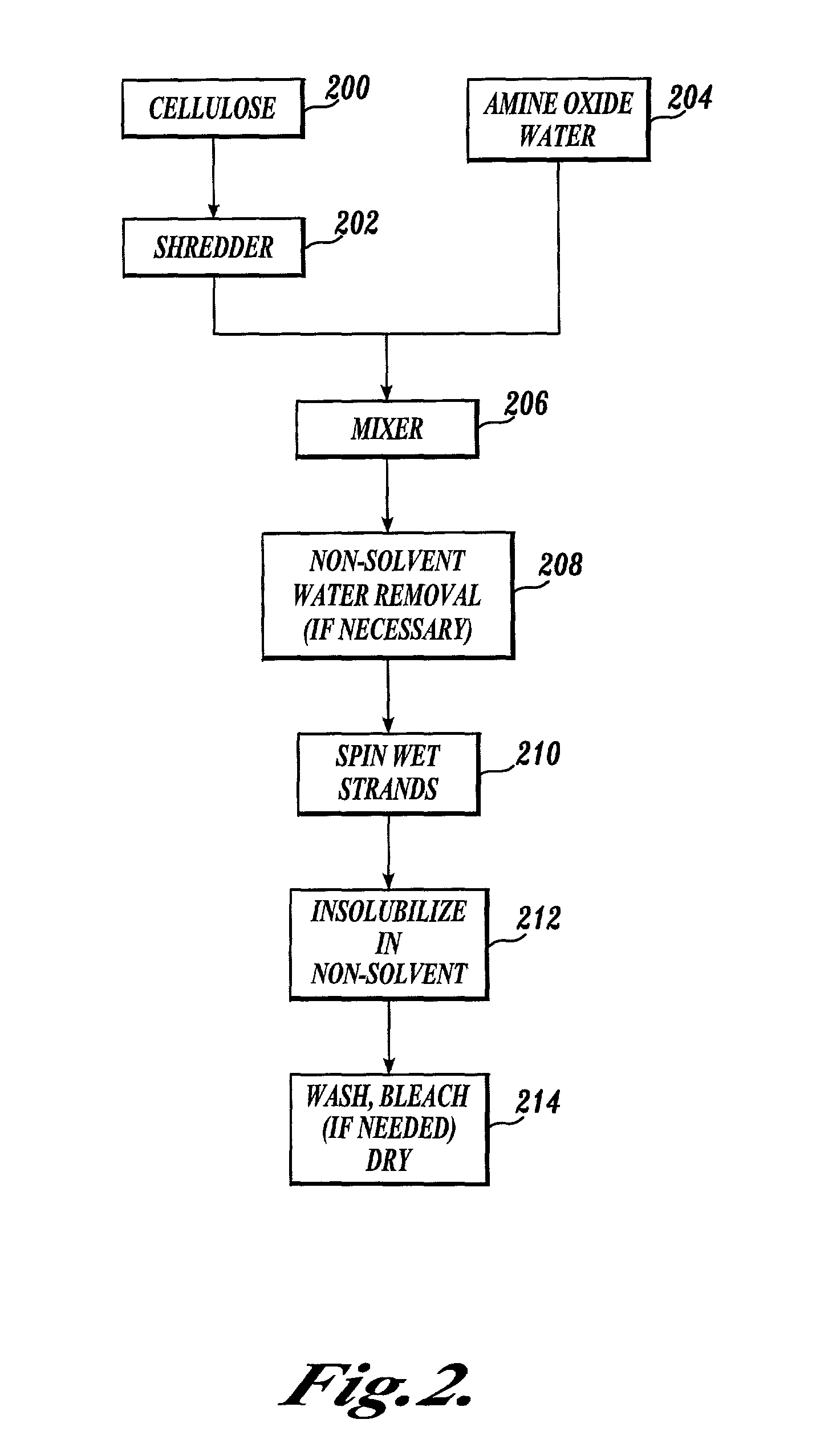

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

Gas phase olefin polymerizations using dual donor catalyst systems

InactiveUS6900281B2Wide molecular weight distributionImprove tactical performanceGas phaseElectron donor

A gas-phase olefin polymerization process in a plug flow reactor uses a catalyst system containing a magnesium halide supported titanium-containing component, an organoaluminum component, and at least one external electron donor component; in the process a first external donor component is added to the reactor at an injection point axially near an injection point for the supported transition metal containing component, and at least a second external donor component is added to the reactor axially downstream from the injection point for the first external donor component.

Owner:INEOS TECH USA

Catalyst component for olefin polymerization reaction and catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

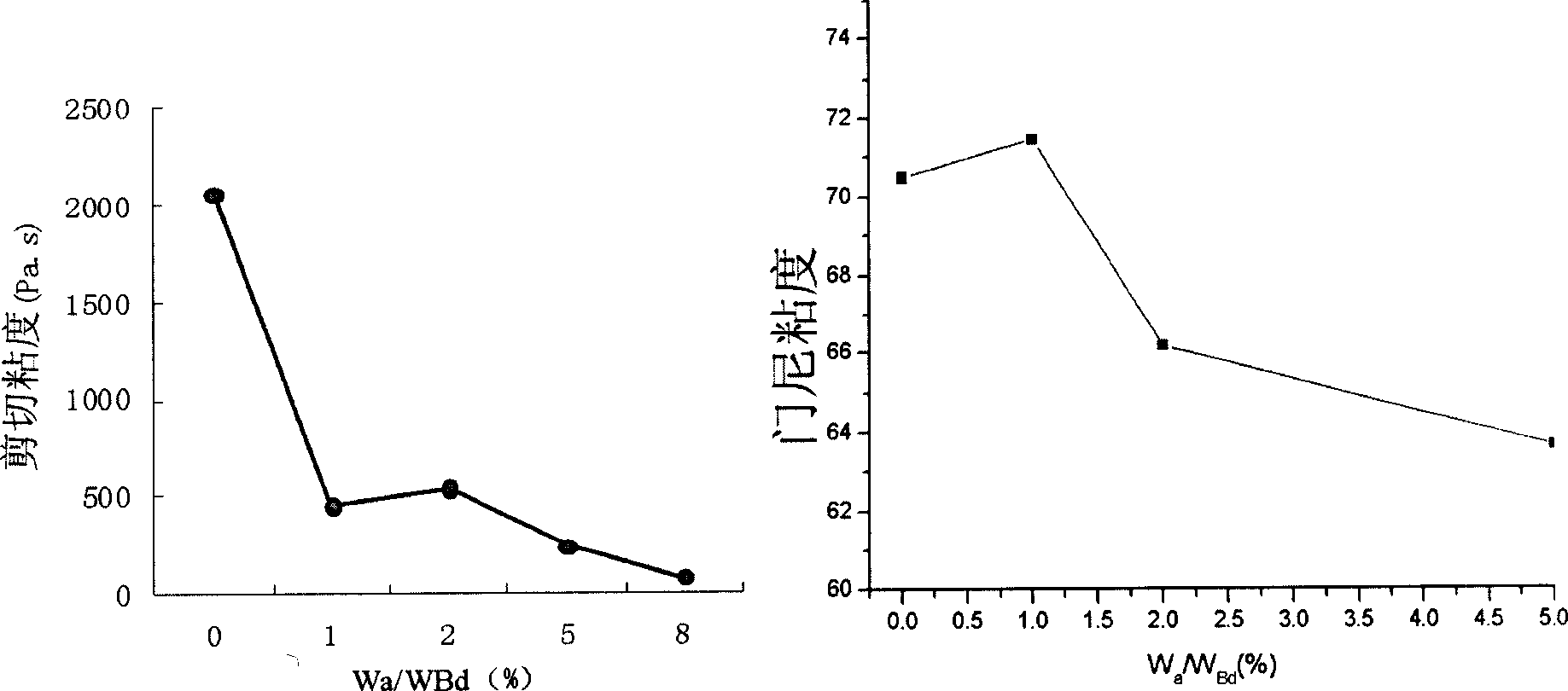

Propylene homopolymer having high melt strength and preparation method thereof

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirment for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechnical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

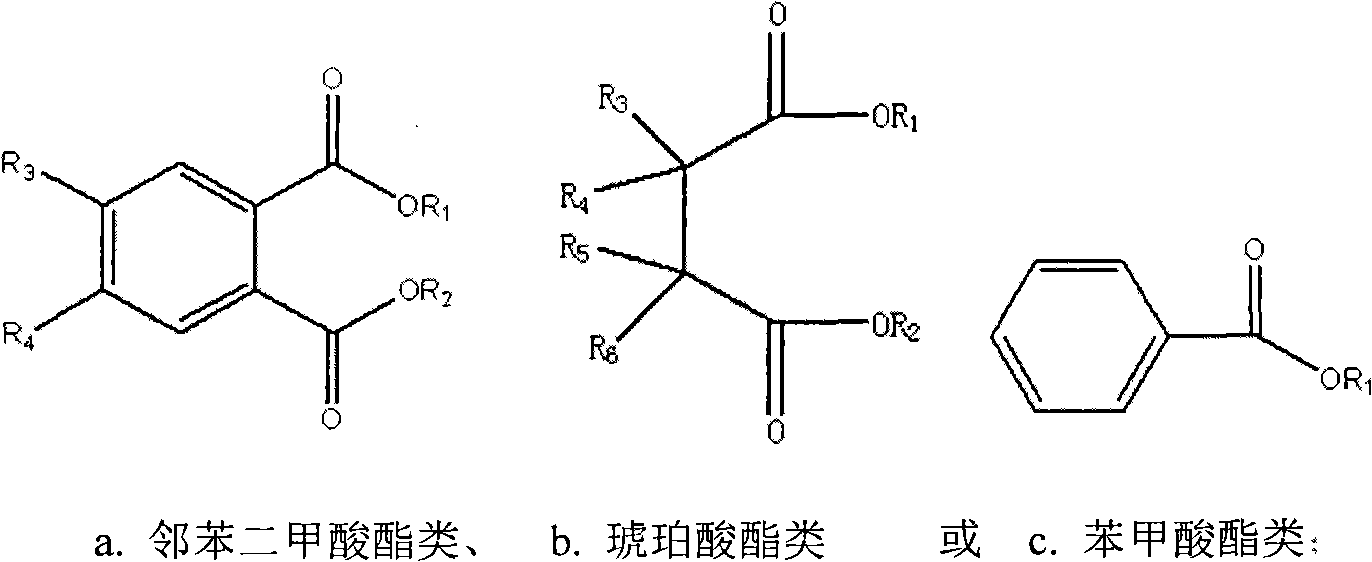

Catalyst, preparation method and application for olefin polymerization or copolymerization

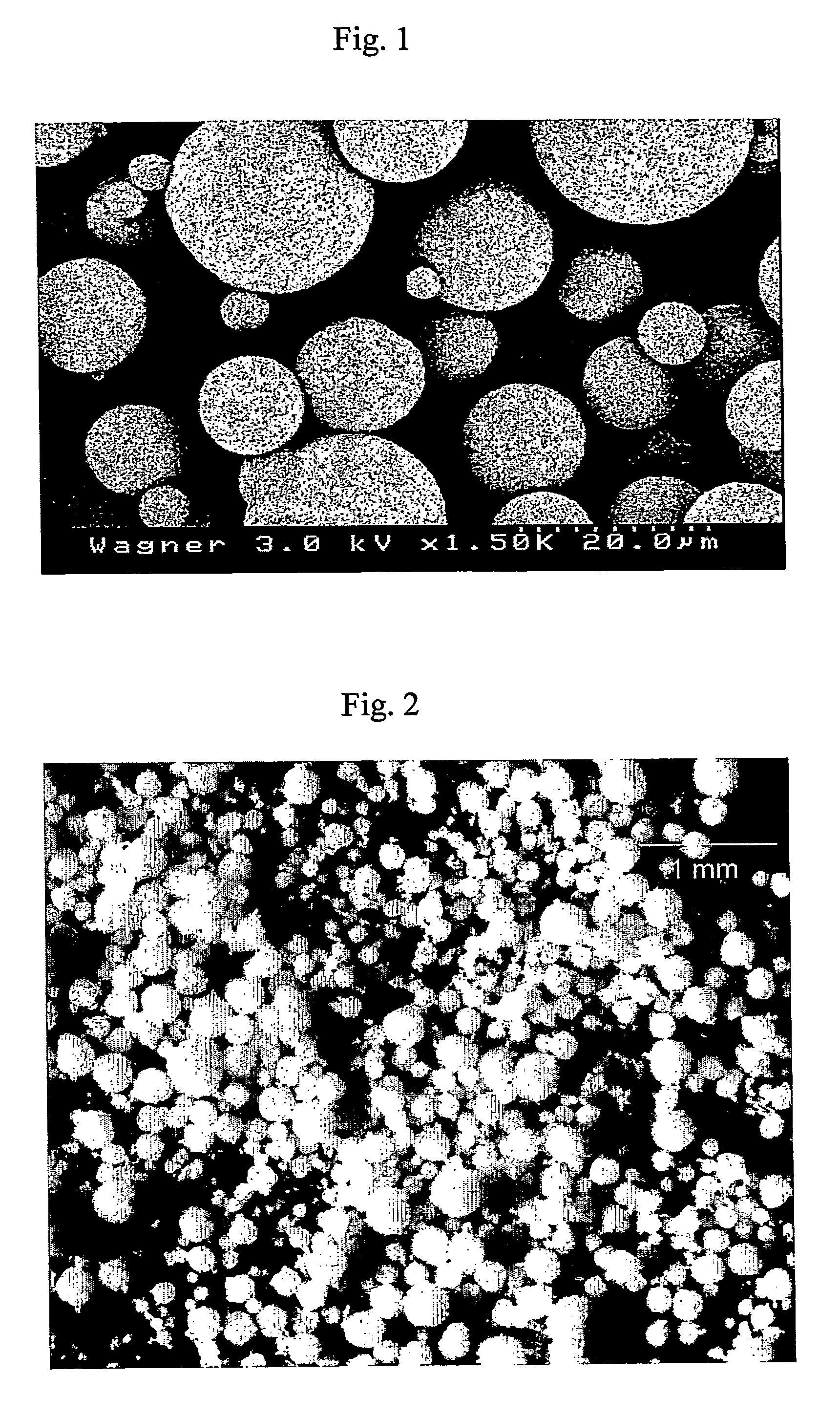

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Catalyst component for olefin polymerization and catalyst thereof

The invention provides a catalyst component for olefin polymerization. The method for preparing the catalyst component comprises the following steps of: (1) dissolving magnesium halides into a solvent system consisting of an organic epoxy compound, an organic phosphorous compound and an inert diluent to obtain a uniform solution, mixing the uniform solution and a titanium compound, precipitating solids in the presence of an auxiliary precipitation agent, and adding an organic alcoholic compound before the solids are precipitated; and (2) treating the precipitated solids by using at least one electron donor compound diatomic alcohol ester compound to make the compound attached to the solids; and treating the solids by using the titanium compound and the inert diluent. The catalyst of the invention has a simple preparation method; when the catalyst is used for the olefin polymerization, particularly propylene polymerization, the polymerization activity of the catalyst is obviously improved; and the molecular weight distribution of the polymers obtained from the catalyst is quite wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

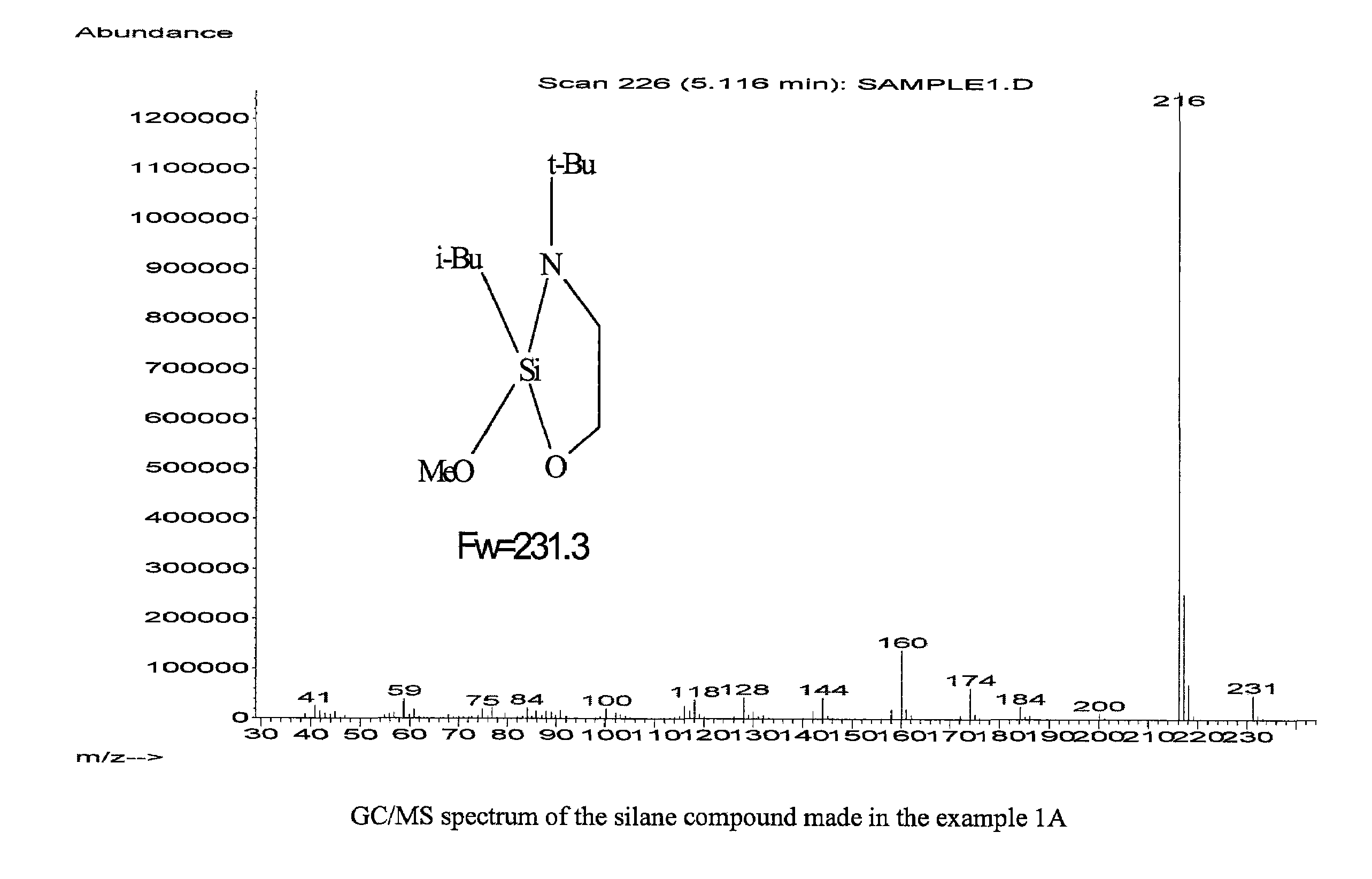

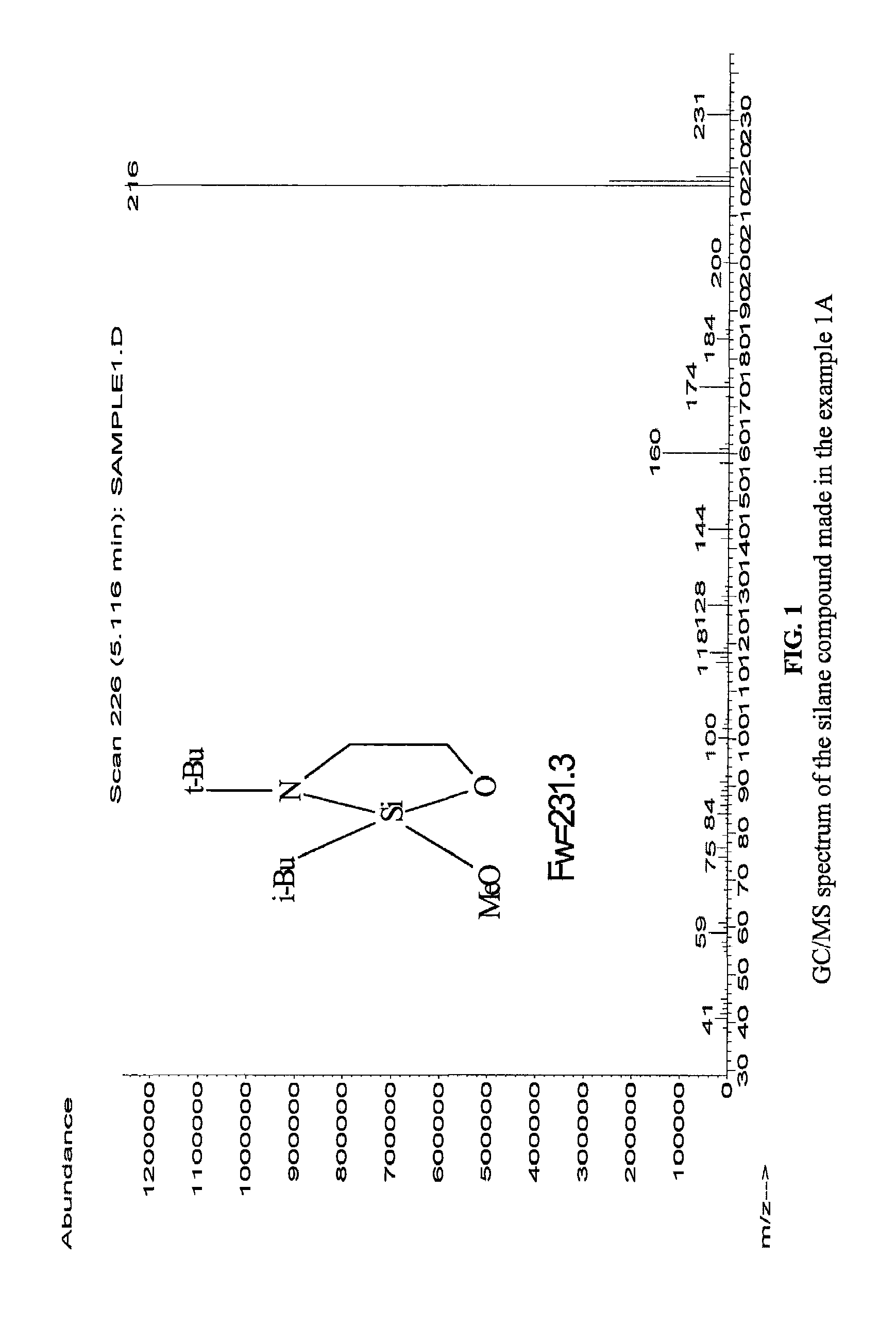

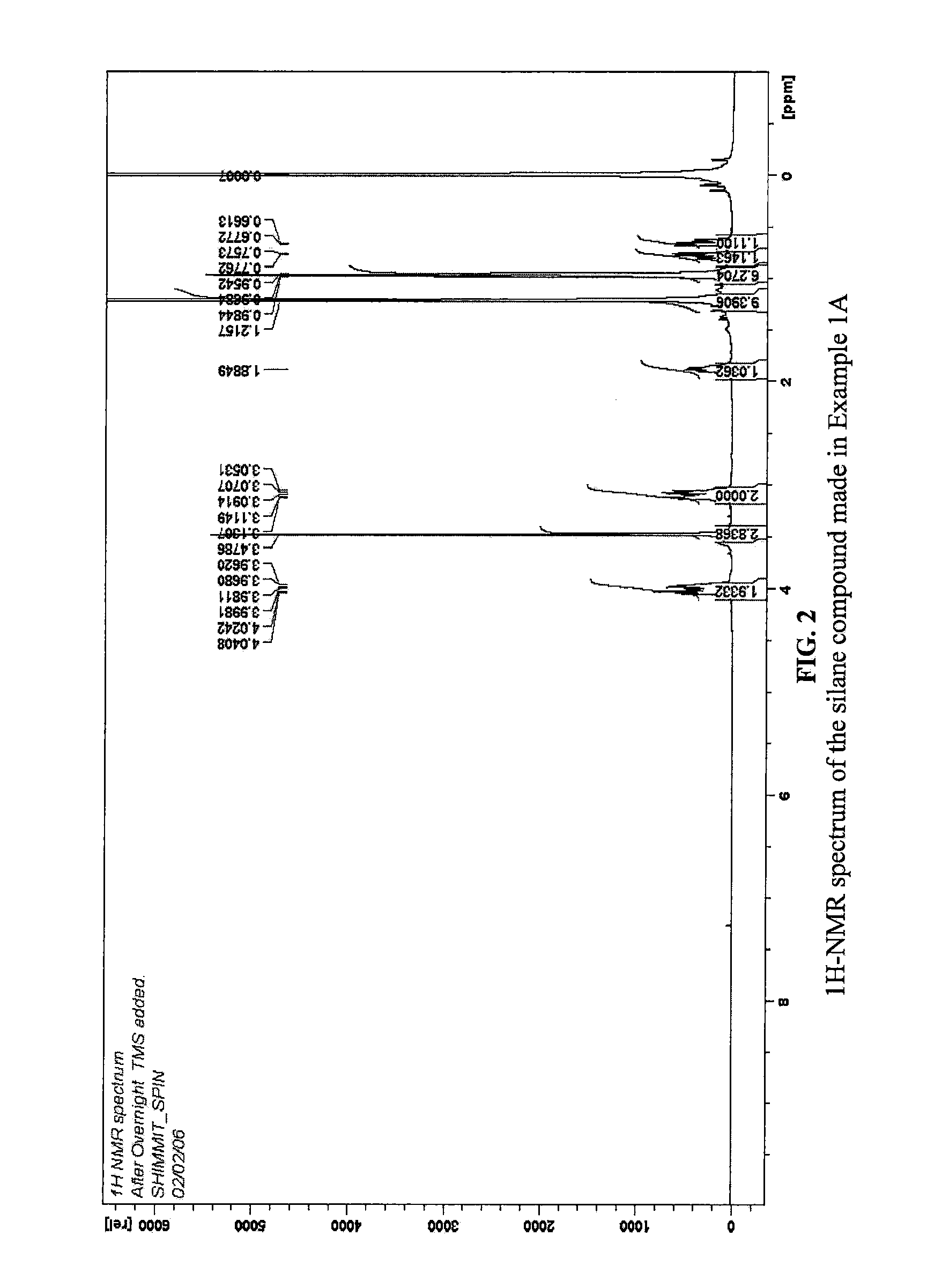

Cyclic organosilicon compounds as electron donors for polyolefin catalysts

ActiveUS7619049B1Wide molecular weight distributionEasy to adaptOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinElectron donor

Cyclic organosilicon compounds that may be employed as an electron donor for polymerization catalyst systems, polymerization catalyst systems employing the cyclic organosilicon compounds as an electron donor, methods of making the polymerization catalyst systems, and polymerization processes to produce polyolefin are disclosed. The organosilicon compounds, which are useful as electron donors in polymerization catalyst systems for the production of polyolefins, are represented by the following formula:wherein Q1 and Q2 may be identical or different and are each hetero-atoms selected from the group consisting of N, O, S, Si, B, and P, with the proviso that Q1 and Q2 cannot both be N or both be O. R1 and R2 may be identical or different and are each hydrocarbon-based substituents to Q1 and Q2, respectively. The subscripts m and n are independently 0 to 3. R3 is an aliphatic, alicyclic or aromatic group. R4 is a hydrocarbon group with 1 to 6 carbon atoms. R5 is a bridging group with a backbone chain length between the two hetero-atoms Q1 and Q2 being 1-8 atoms. The bridging group is selected from the group consisting of aliphatic, alicyclic, and aromatic bivalent radicals.

Owner:FORMOSA PLASTICCS CORP

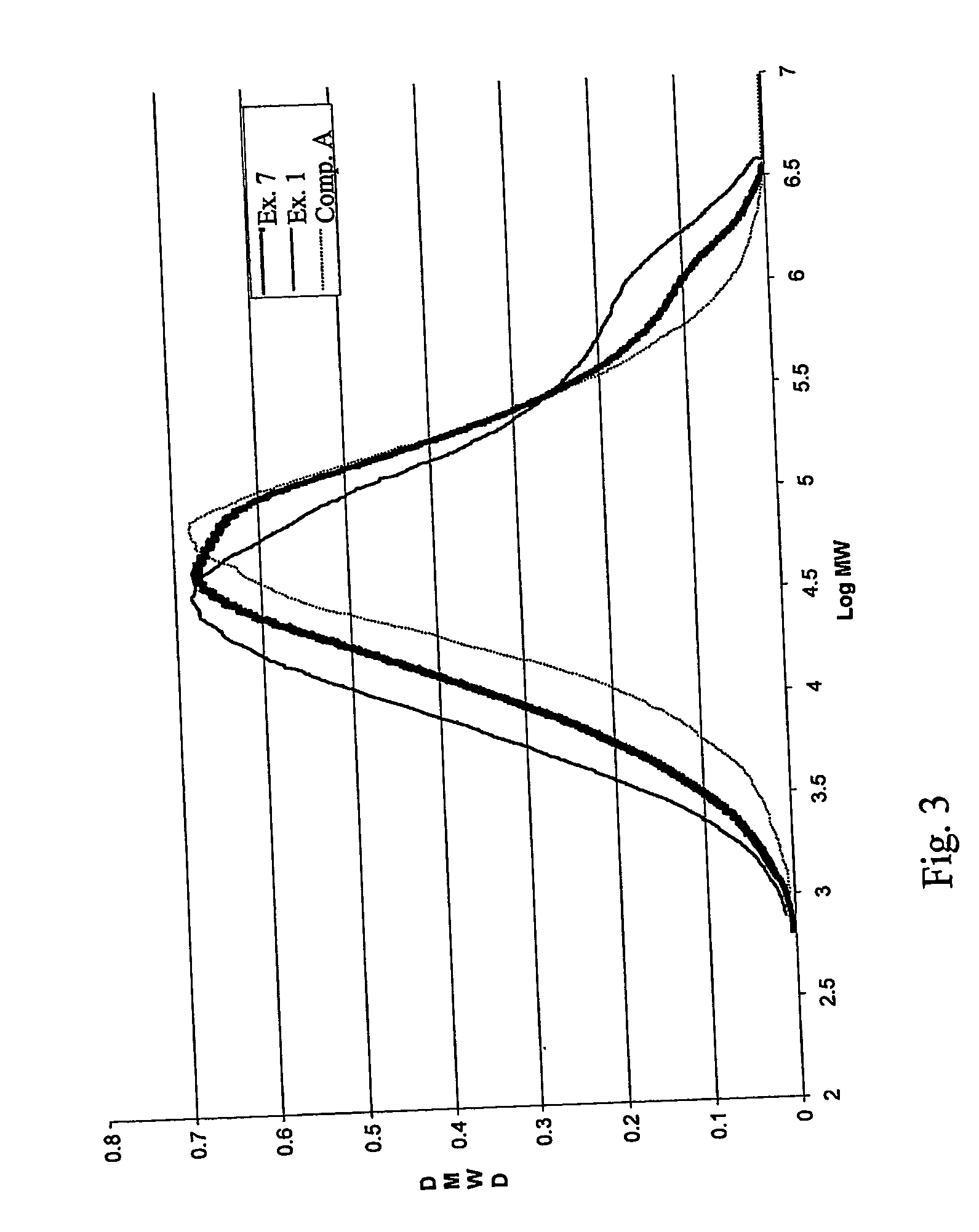

Process for preparing supported transition metal catalyst systems and catalyst systems prepared thereby

InactiveUS6943224B2Good dispersionImprove accessibilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSilicon dioxideEthylene bis

A process for forming a coordination catalyst system comprising sequentially or substantially simultaneously contacting: (I) pre-catalyst reactants comprising (a) at least one first ligand-containing reactant; and (b) at least one first transition metal reactant suitable to form at least one metallocene or constrained geometry pre-catalyst compound (e.g., rac-ethylene bis(indenyl)zirconiUm dichloride); an optionally (c) at least one second ligand-containing reactant and (d) at least one second transition metal reactant suitable to form at least one non-metallocene, non-constrained geometry, bidentate or tridentate transition metal compound (e.g., tridentate 2,6-diacetylpyridine-bis(2,4,6-trimethylanaline)FeCl2) and (II) further contacting, jointly or individually, the pre-catalyst compound(s) and optional bidentate or tridentate compound(s) with at least one support-activator agglomerate (e.g., spray dried silica / clay agglomerate). When individually contacted, the supported catalyst components can be mixed or blended. The resulting transition metal catalyst systems are suitable for addition polymerization of unsaturated monomers, e.g., ethylene and propylene.

Owner:WR GRACE & CO CONN

Catalyst component for alkene polyreaction and its catalyst

The present invention provides one kind of catalyst for polymerization of olefin and the catalyst includes Mg, Ti, halogen and electron donor. The electron donor is at least one kind of dialcohol ester compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

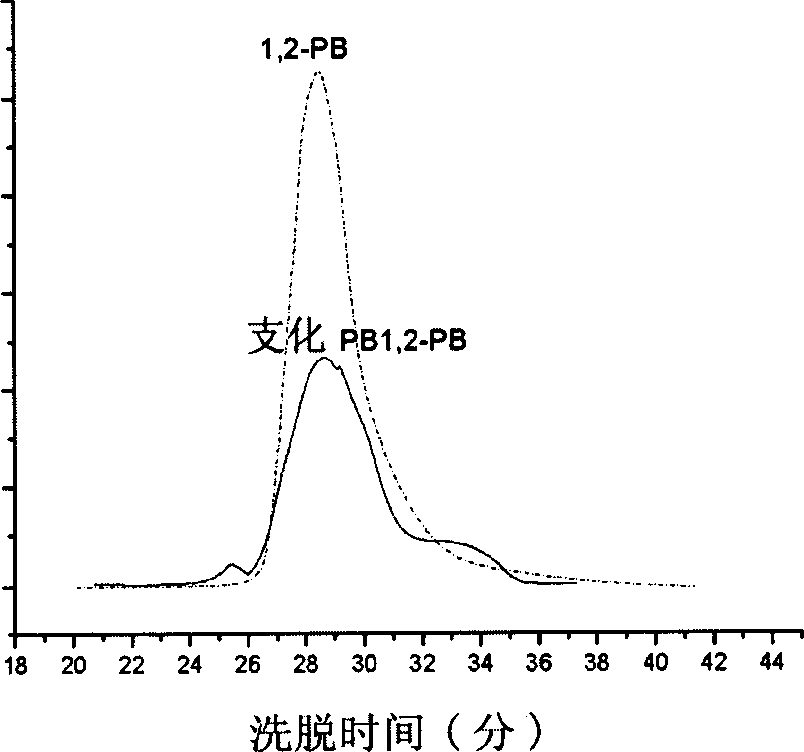

Method for preparing branched high vinyl polybutadiene rubber using molybdenum series catalysis

The invention relates to a method for preparing branched high ethenyl butadiene rubber with molybdenum catalyst, recombining macromolecular monomer prepared through polymerization of molybdenum catalyst butadiene atom free radical or butadiene anion initiated by organic lithium, naphthalene sodium, with coordinate polymerization of butadiene or original position polymerization, to prepare said product with controllable construction. The method is characterized by simple process, special construction of polymer, proper molecular weight and molecular distribution, more than 80% of ethenyl content, controllable property, length, distribution and degree of branching of branch chain in a certain range, good processing behavior and physical mechanics property and low production cost.

Owner:QINGDAO UNIV OF SCI & TECH

Spray-dried, mixed metal ziegler catalyst compositions

ActiveUS20070060725A1Improve productivityImproved catalyst homogeneityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsZiegler–Natta catalystTitanium

A Ziegler-Natta catalyst composition comprising a solid mixture formed by halogenation of: Al) a spray-dried catalyst precursor comprising the reaction product of a magnesium compound, a non-metallocene titanium compound, and at least one non-metallocene compound of a transition metal other than titanium, with A2) an organoaluminium halide halogenating agent, a method of preparing, precursors for use therein, and olefin polymerization processes using the same.

Owner:UNION CARBIDE CORP

Process for making composition for conversion to lyocell fiber from sawdust

InactiveUS7090744B2Reduce the degree of polymerizationReduce contentPulp properties modificationMonocomponent cellulose artificial filamentCopperHemicellulose

A process for making a composition for conversion to lyocell fiber where the process comprises pulping a raw material in a digester to provide an alkaline pulp, wherein the raw material comprises sawdust in an amount greater than 0 % up to 100 %; and contacting the alkaline pulp comprising cellulose and at least about 7 % hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to within the range of from about 200 to about 1100, without substantially reducing the hemicellulose content of the pulp or substantially increasing the copper number.

Owner:INT PAPER CO

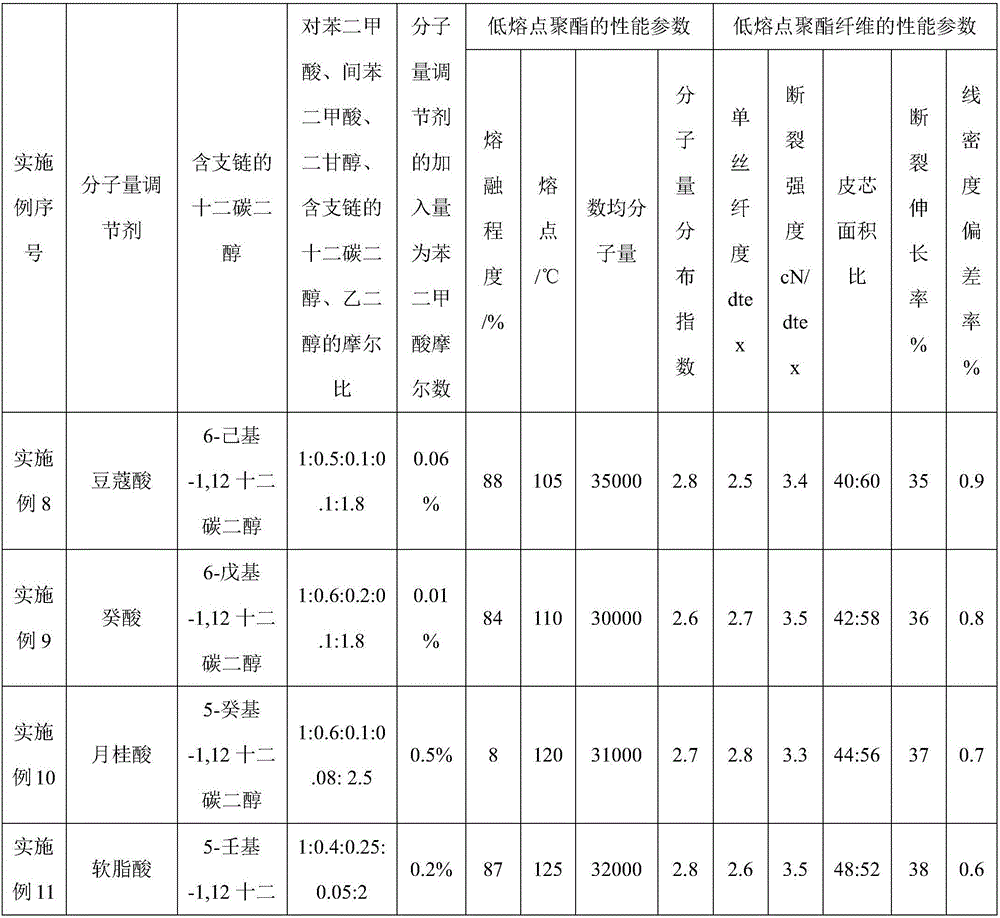

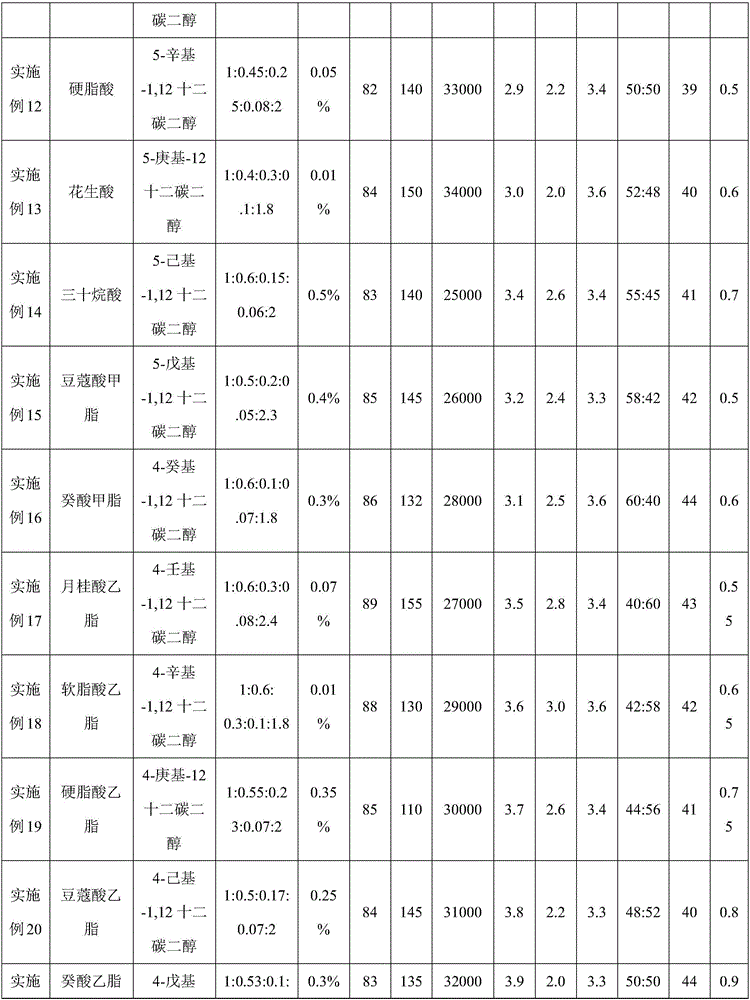

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

Catalyst component for olefin polymerization reaction and catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

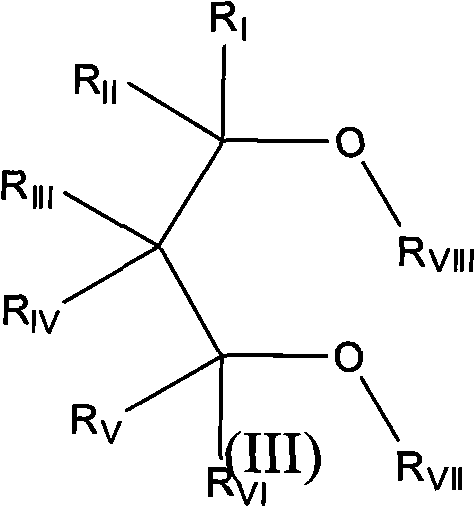

Catalyst component for olefin polymerization and catalyst

The invention relates to a catalyst component for olefin polymerization, a catalyst and application of the catalyst in olefin homopolymerization and polymerization. By using a composite internal electronic donor compound which contains an alpha-cyanosuccinate compound A and a single-functional group or double-functional group compound B which is selected from ester, ether, ketone and ketal exceptfor the compound A as the catalyst of internal electronic donor synthesis, the catalyst has the characteristics of high catalytic activity, high hydrogen adjusting sensitivity, high isotactic index of polymerized products, wide molecular weight distribution and high weight-average molecular weight when being used for propylene polymerization. The favorable performance of the catalyst is beneficial to the preparation of polypropylene and the brand development of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

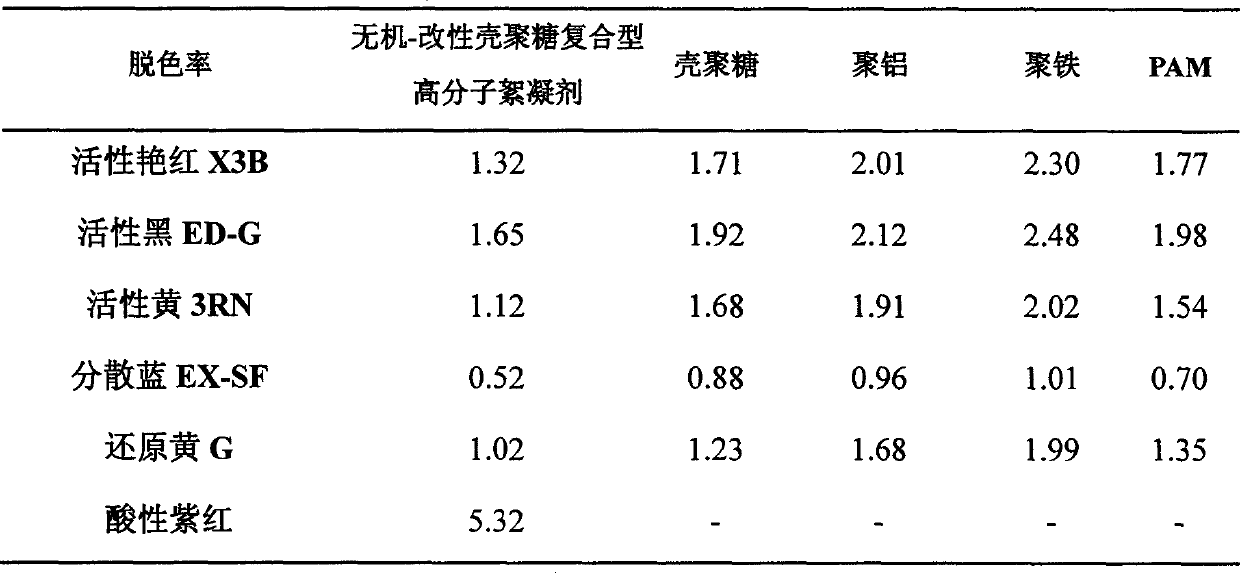

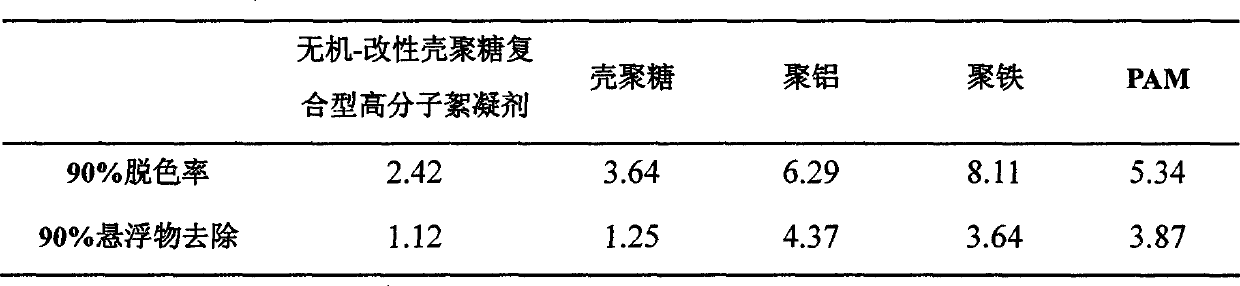

Inorganic-modified chitosan composite type polymeric flocculant

InactiveCN103121742ASimple structureRich sourcesWater/sewage treatment by flocculation/precipitationAluminium chlorideMeth-

The invention relates to an inorganic-modified chitosan composite type polymeric flocculant. The inorganic-modified chitosan composite type polymeric flocculant is characterized in that a method for preparing the composite type polymeric flocculant comprises the following steps of: taking polyacrylamide-modified chitosan as a raw material and methacryloyloxyethyl trimethyl ammonium chloride, maleic acid and ceric ammonium nitrate as initiators, synthesizing a modified chitosan copolymer under a faintly acidic condition and blending the modified chitosan copolymer with polymerized ferric chloride and polymerized aluminium chloride to obtain the inorganic-modified chitosan composite type polymeric flocculant. According to the steps, the mass ratio of modified starch to the chitosan is (1-2): 1, the reaction temperature is 50-60 DEG C, the reaction time is 2-3 hours, and the use amount of the initiators accounts for 0.02 part of the total mass of the system. The inorganic-modified chitosan composite type polymeric flocculant prepared by using the method has the characteristics of high efficiency, low cost and low secondary pollution to environment; and aiming at different sludges, compared with a conventional flocculant, the inorganic-modified chitosan composite type polymeric flocculant disclosed by the invention has the advantages that the wastewater decoloring rate and the wastewater deturbidity rate can reach more than 99 percent under the condition of low use amount.

Owner:WUHAN SLOAN ELECTRIC

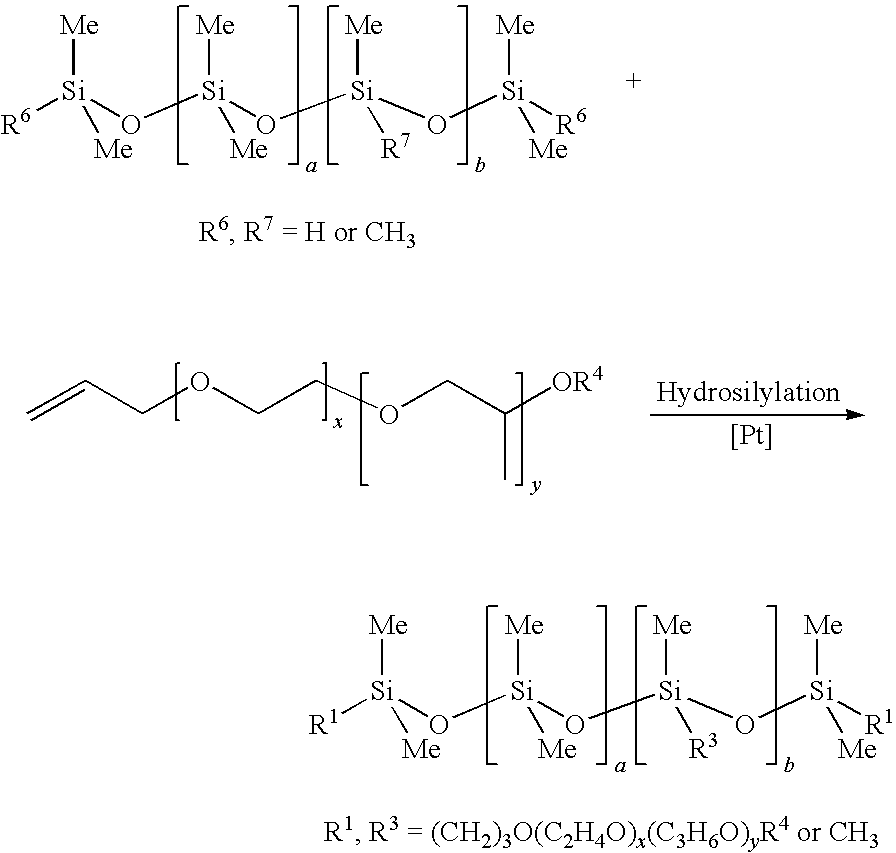

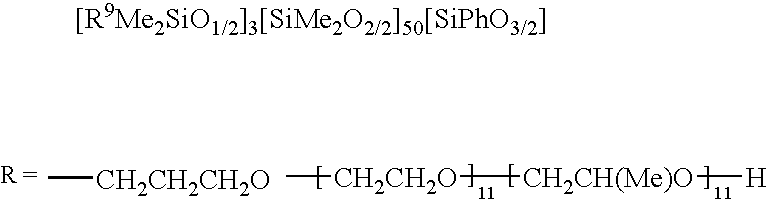

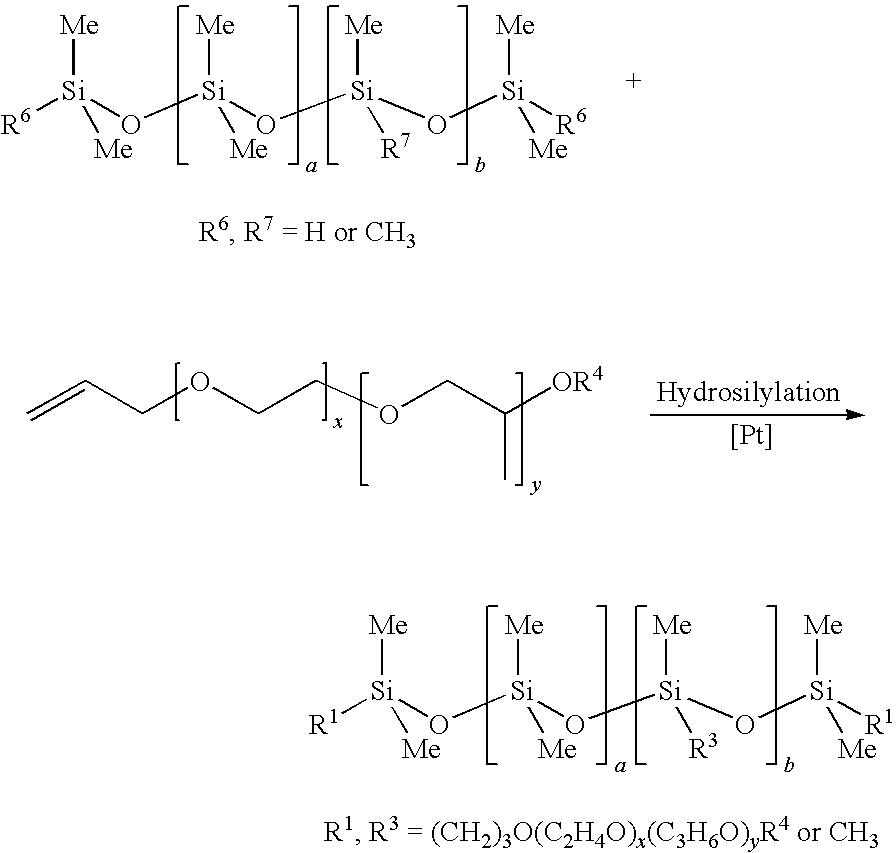

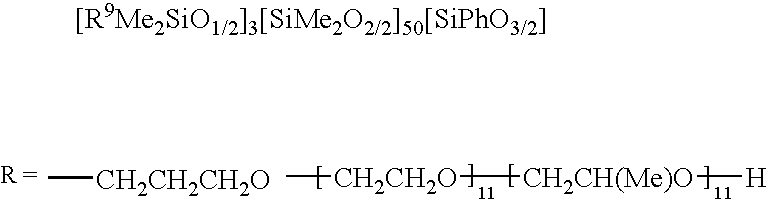

Emulsifier systems for cosmetic and pharmaceutical oil-in-water emulsions

ActiveUS8211972B2Improve stabilityImprove skinSilicon organic compoundsCosmetic preparationsPolymer chemistryCosmetics

Owner:EVONIK DEGUSSA GMBH

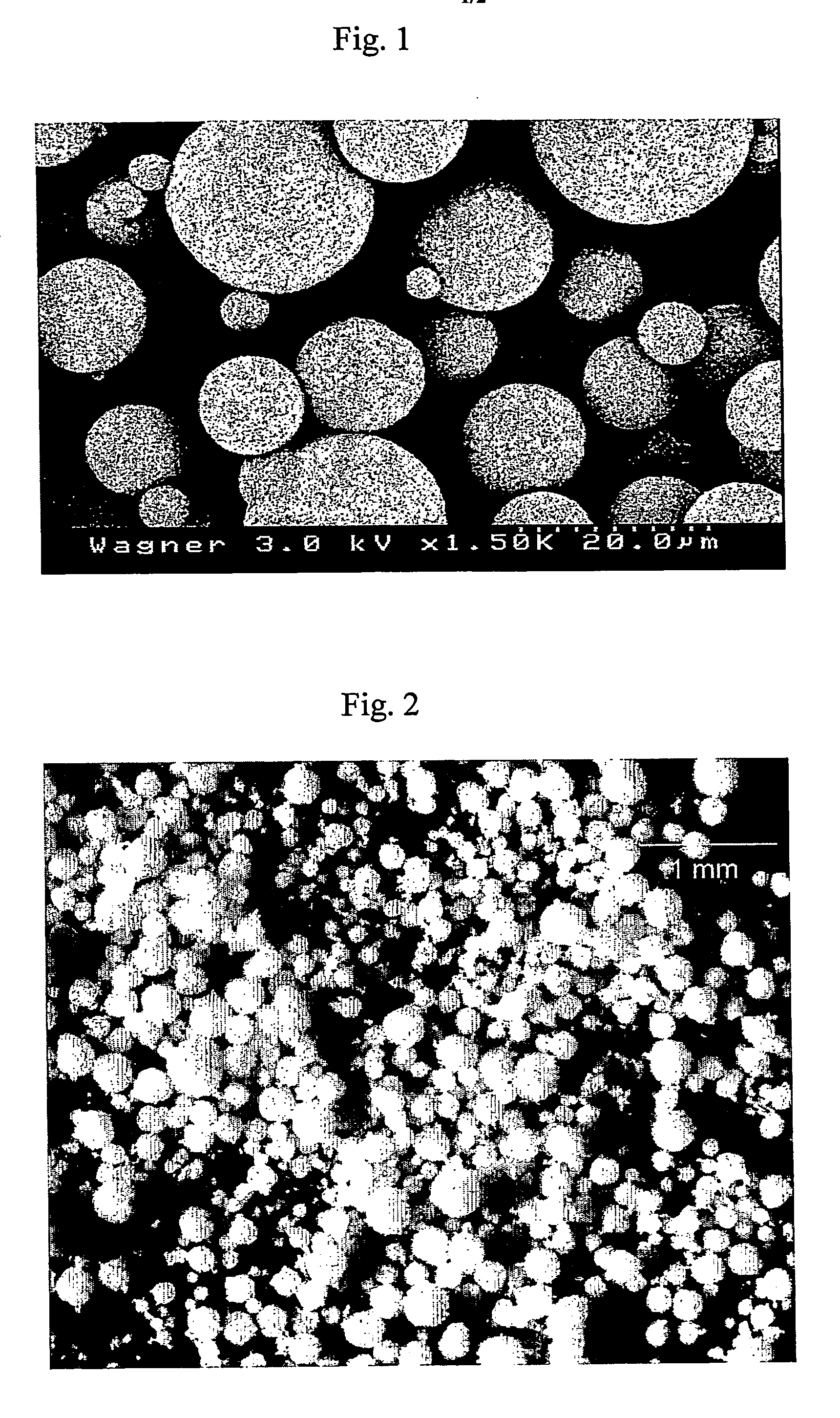

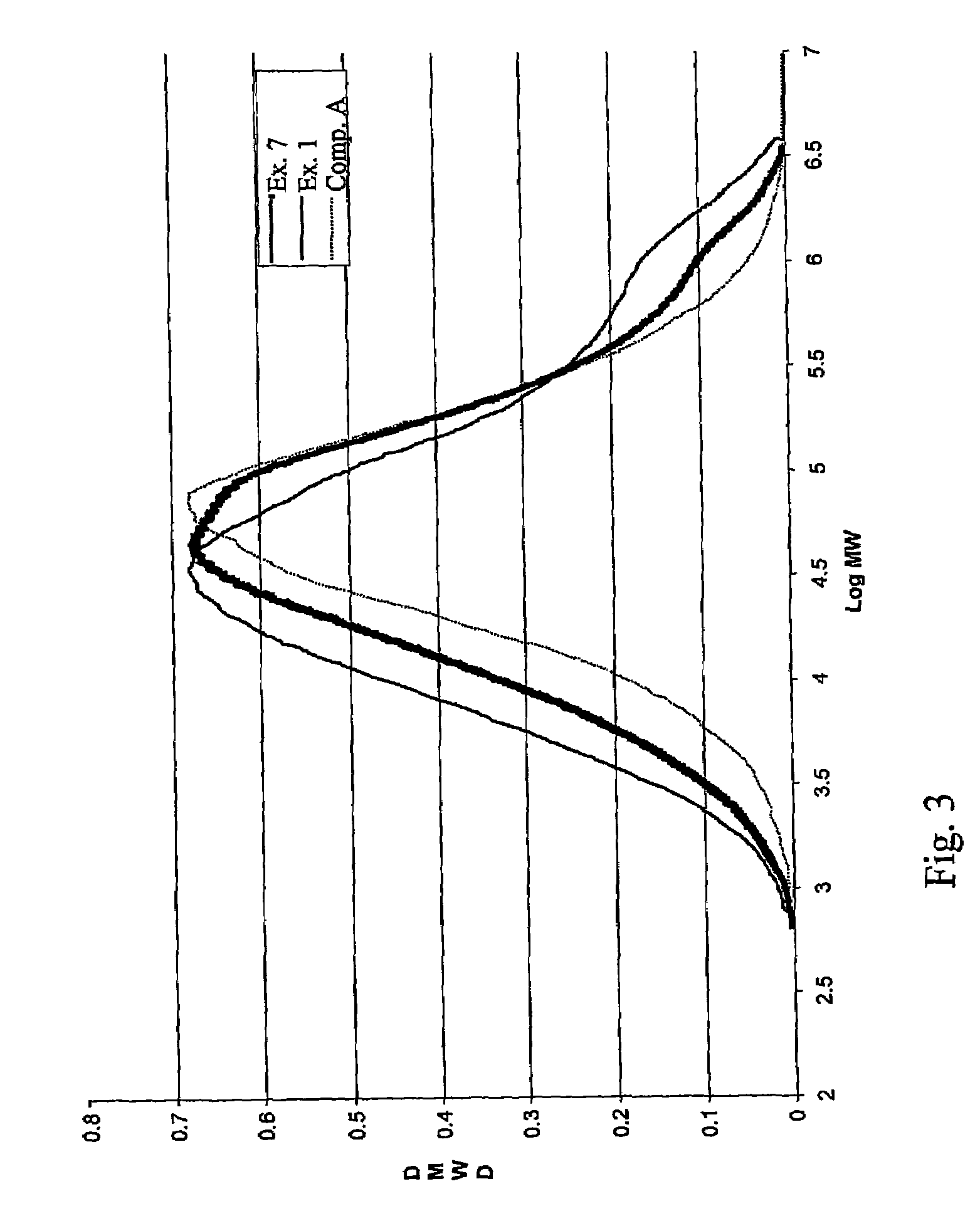

Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

The invention relates to polymerization of 1-butene, in particular to a spherical catalyst of polybutylene-1. The catalyst consists of a carrier, an active component and a modifier, wherein the active component is titanium tetrachloride, the carrier is a magnesium chloride spherical carrier and the modifier is an electron donor compound; and the catalyst comprises the major components in percentage by mass of: 1.1-4.5% of Ti and 0.15-12.37% of electron donors. The spherical catalyst suitable for butane-1 polymerization solves the problems that the activity of the general catalyst is low, the normality of polymer is difficult to control, and the molecular weight of the polymer and the molecular weight distribution are difficult to control. The obtained polybutylene polymer has very high steric regularity, the normality of polybutylene is as high as 99%, the crystallinity of the polybutylene-1 polymer is greater than 60% and the fusion point is 130.5 DEG C. The invention can simplify the polymerizing process and save the production cost.

Owner:HEBEI UNIV OF TECH

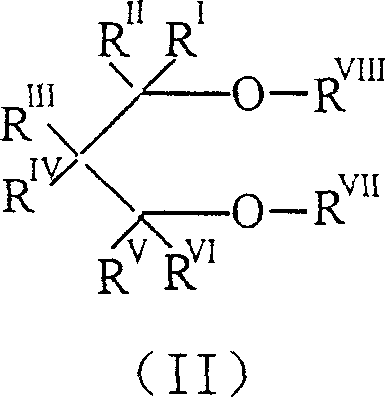

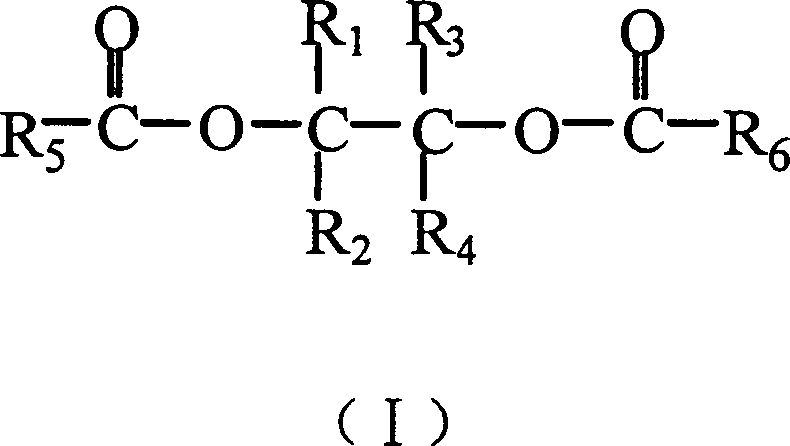

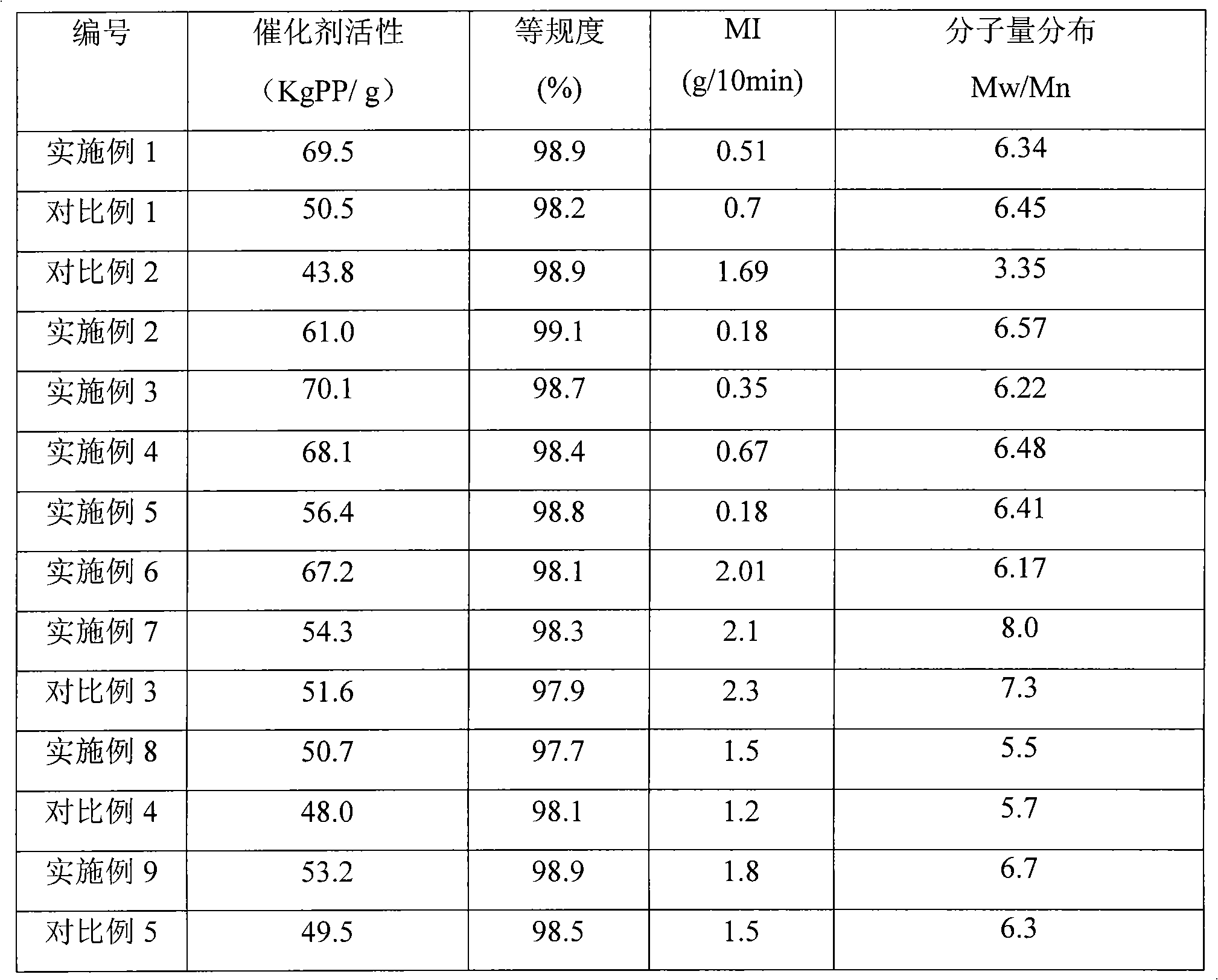

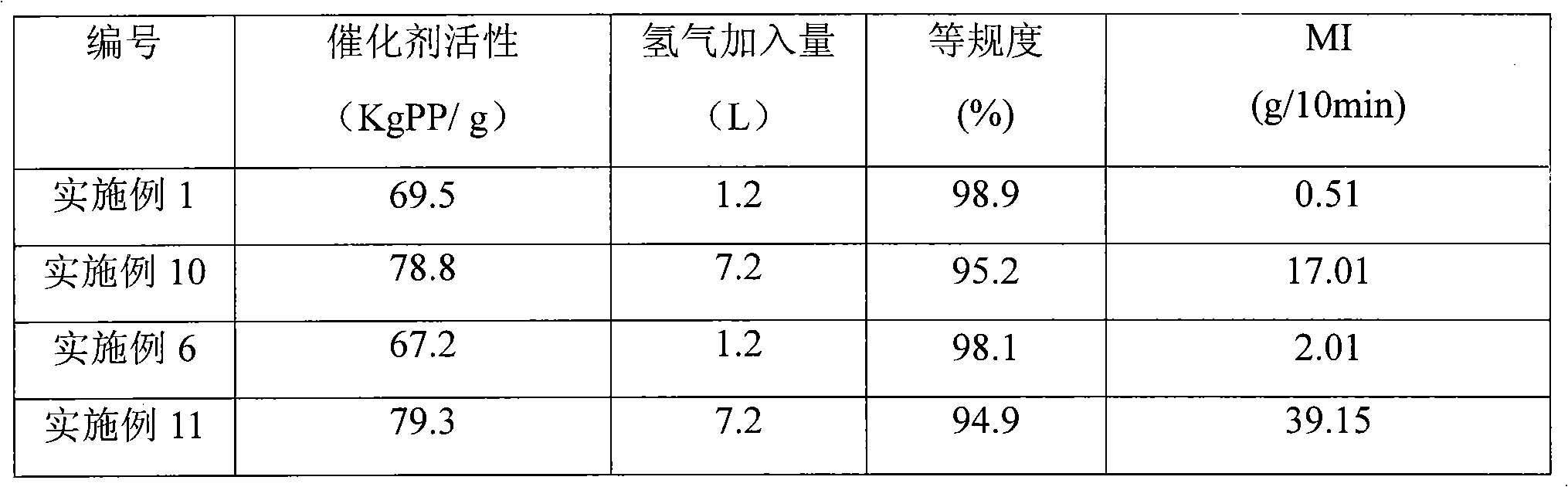

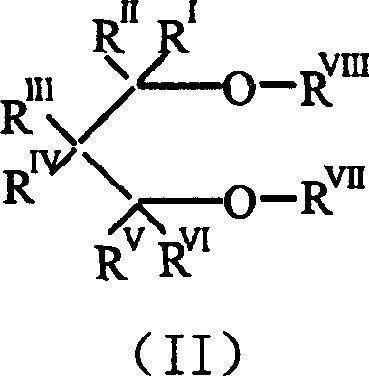

Catalyst components for olefin polymerization reaction, and catalyst thereof

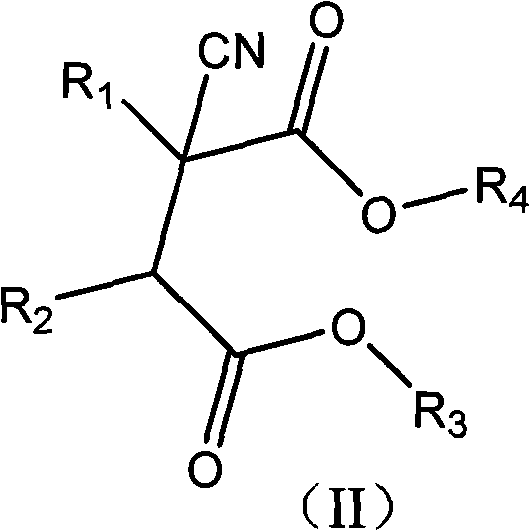

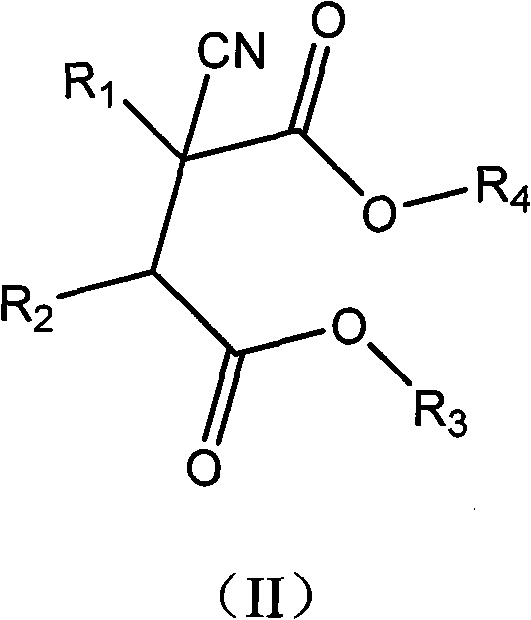

ActiveCN102234337AGood hydrogen sensitivityWide molecular weight distributionPolymer sciencePtru catalyst

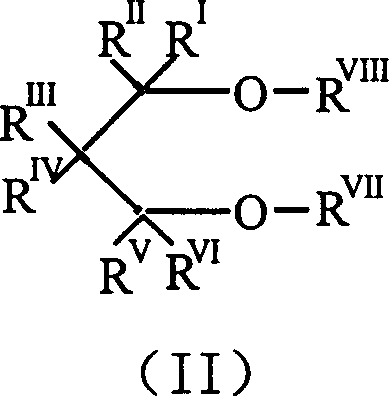

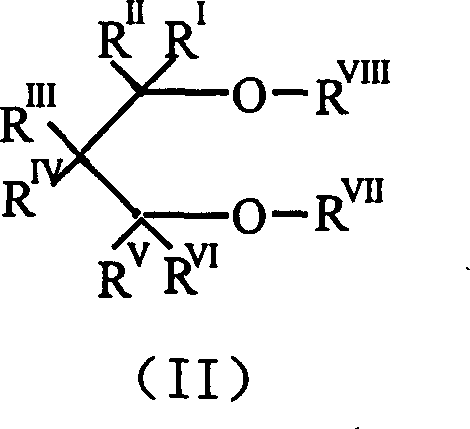

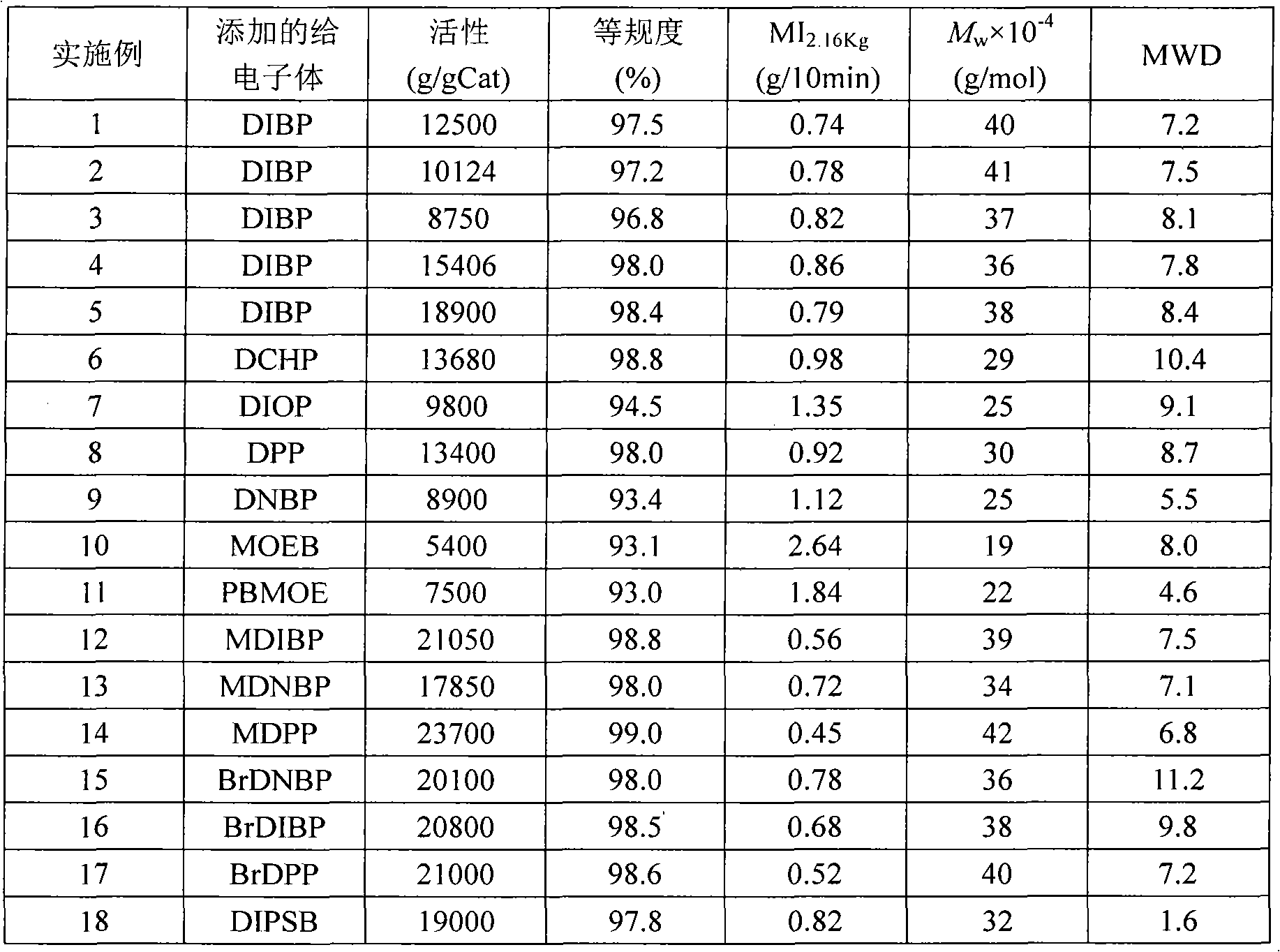

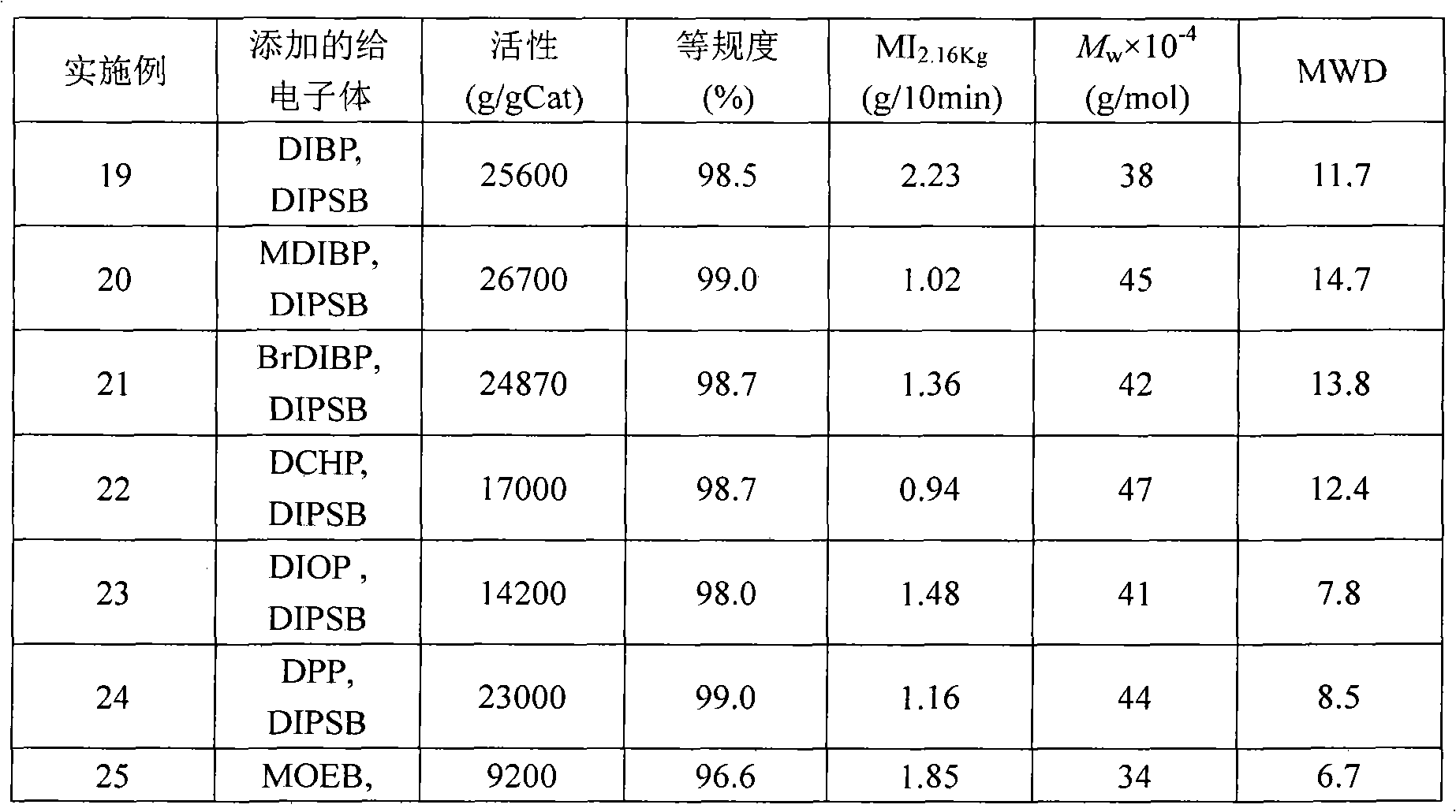

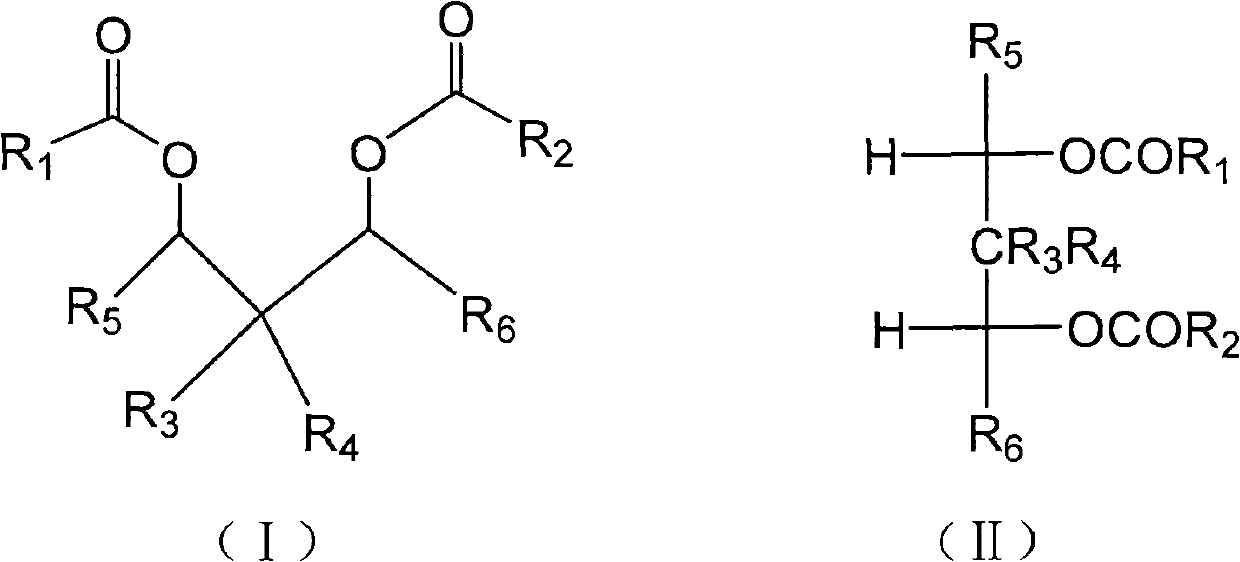

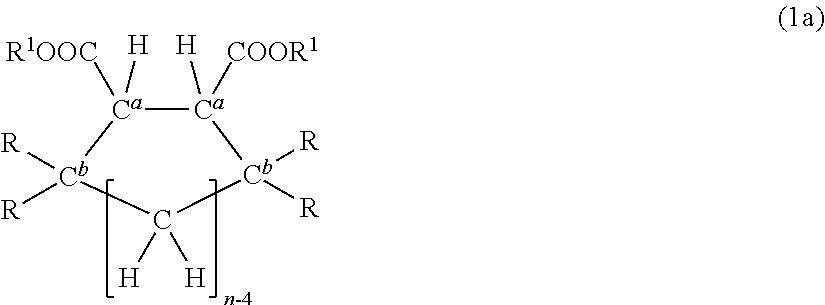

The invention provides catalyst components for an olefin polymerization reaction, and a catalyst thereof. The catalyst components comprise magnesium, titanium, halogen and electron donor, wherein the electron donor comprises at least one selected from diol ester compounds. When the diol ester compound comprises a certain amount of an isomer having a fischer projection represented by (II), activity and stereospecificity of the catalyst are improved substantially, in particular, when a polymer with the high fusion index is produced, a isotactic index of the produced polymer is raised substantially.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component for olefin (Co)polymerization, preparation thereof, a catalyst comprising the same and use thereof

ActiveUS20070155616A1High catalytic activityParticles in good shapeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHalogenAlkoxy group

The invention relates to a catalyst component for olefin (co)polymerization, to preparation thereof, to a catalyst comprising the same, and to use thereof in olefin (co)polymerization. The catalyst component of the invention comprises magnesium, titanium, halogen, inner electron donor compound, and alkoxy group derived from a surface modifier, wherein the content of the alkoxy group derived from the surface modifier is in a range of from 0.01 to 3 percent by weight, based on the weight of the catalyst component.

Owner:CHINA PETROCHEMICAL CORP +1

Room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and preparation method and application thereof

InactiveCN104004477AReduce surface tensionSolve the \"chicken paw print\"StampsNon-macromolecular adhesive additivesFunctional monomerKetone

The invention belongs to the field of room temperature self-crosslinking materials, and discloses a room temperature self-crosslinking polyacrylate pressure-sensitive adhesive and a preparation method and application thereof. The method comprises the steps of preparing a pre-emulsion from 85-95 parts of acrylate soft monomer, 5-15 parts of hard monomer, 2-5 parts of functional monomer, 1.3-4 parts of emulgator and 30-55 parts of deionized water by mass fraction; then heating up the pre-emulsion, the deionized water, an initiator, the emulgator and a PH buffer agent for reaction; dripping a chain transfer agent, the pre-emulsion and an initiator solution when the emulsion shows blue light; adding ketone-containing carbonyl monomer, heating up together and reacting; then cooling down and regulating pH value to be 6.5-7.0; and adding hydrazide monomer, stirring and mixing uniformly, so as to obtain the room temperature self-crosslinking polyacrylate pressure-sensitive adhesive. The room temperature self-crosslinking polyacrylate pressure-sensitive adhesive prepared by the method has excellent indexes like excellent initial adhesive force, excellent persistent viscosity force and excellent peel strength, and can be used for preparing labels with good bond performance.

Owner:SOUTH CHINA UNIV OF TECH

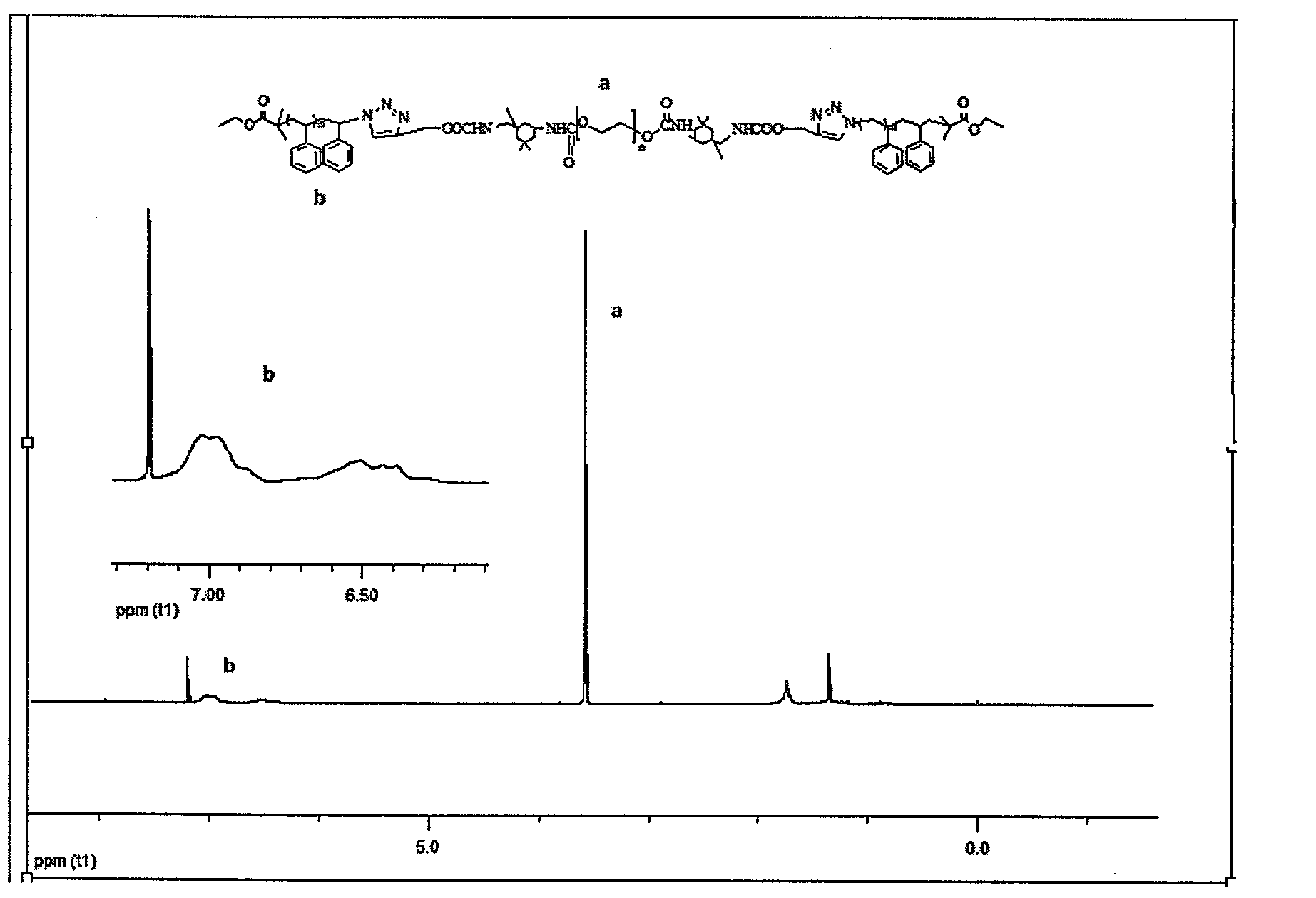

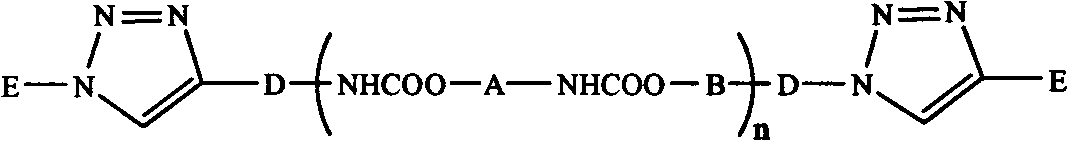

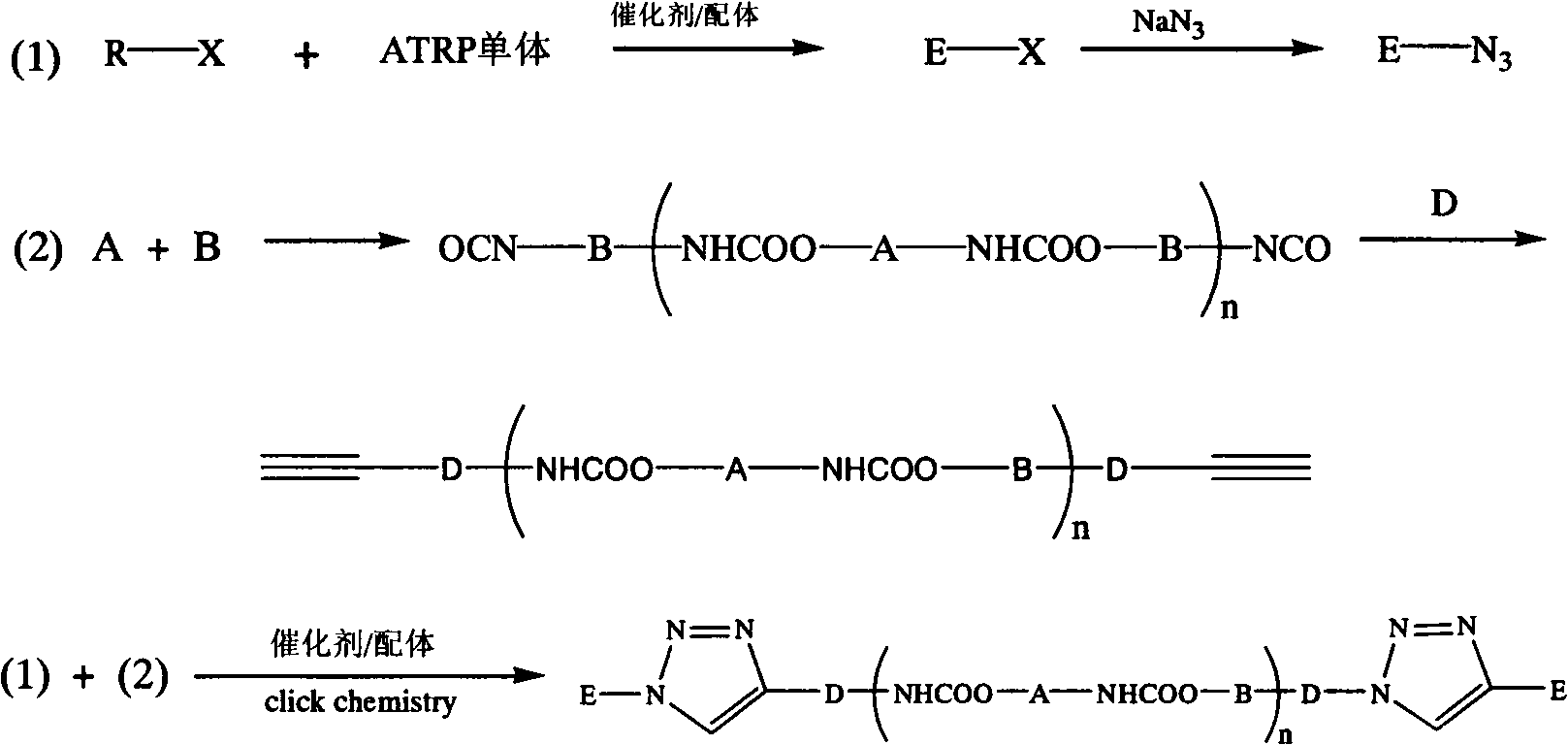

Synthetic method of triblock polymer

InactiveCN102702536ABroaden the way to achievePerfect structural designPolymer scienceSynthesis methods

The invention belongs to the technical field of synthesis and preparation of polymer materials, and discloses a synthetic method of triblock polymer, wherein stepwise polymerization (SGB), atom transfer radical polymerization (ATRP) and click chemistry method are combined at first; and 1, 3-dipolar cycloaddition reaction is performed to polymer with azido terminal group and polyurethane prepolymer with alkynyl terminal group to successfully synthesize triblock polymer containing triazole ring. The synthesis method provided by the invention overcomes the defects in traditional block polymer synthesis that reaction conditions are strict, molecular weight distribution is controlled difficultly, and selectable classes of monomers are less, and has the advantages of high conversion rate, mild reaction conditions, narrow molecular weight distribution and strong controllability. The triblock polymer provided by the invention has potential application in ways of medicine slow release, solubilizers and surfactants.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for olefin polymerization and process for olefin polymerization

ActiveUS7888438B2High stereoregularityWide molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationDouble bondPolymer

Owner:MITSUI CHEM INC

Preparation method of mud-resistant type polycarboxylate superplasticizer

The invention relates to a preparation method of a mud-resistant type polycarboxylate superplasticizer. First, polyethylene glycol monomethyl ether and acrylic acid are used as raw materials and synthetized into polyethylene glycol monomethyl ether methyl acrylate. Then, the prepared polyethylene glycol monomethyl ether methyl acrylate is copolymerized with mixed liquid which is made from the acrylic acid and diacrylamide sodium dimethallyl sulphonate and mixed liquid which is made from ammonium persulfate and mercaptoethanol, alkaline compounds are added to regulate a pH value to 7-8 after reaction, and the mud-resistant type polycarboxylate superplasticizer is obtained. In the preparation method, technical parameters and conditions, such as raw material ratio, the used amount of chain transfer agents and initiators, copolymerization temperature, time and the like are determined. The reaction conditions are mild, the adopted equipment is simple, the equipment investment is small, the technology is reasonable, and the operation is simple and favorable for industrial production.

Owner:江苏汇迪建材有限公司

Emulsifier systems for cosmetic and pharmaceutical oil-in-water emulsions

ActiveUS20100081763A1Improve emulsion stabilityImprove stabilitySilicon organic compoundsCosmetic preparationsPolymer chemistryCosmetics

Owner:EVONIK DEGUSSA GMBH

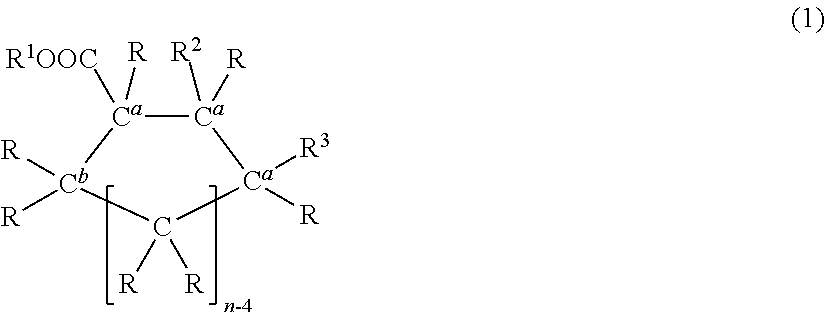

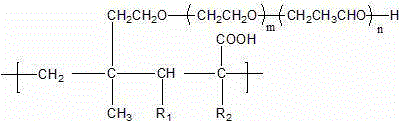

Concrete polycarboxylate water reducing agent and preparing method thereof

The invention provides a concrete polycarboxylate water reducing agent and a preparing method thereof. The concrete polycarboxylate water reducing agent is a polymer copolymerized by a monomer A and a monomer B, wherein the weight-average molecular weight of the polymer ranges from 5,000 to 30,000. The chemical structural formula is shown in the specification, wherein m is an integer ranging from 14 to 66, n is an integer ranging from 0 to 40, R1 is H or COOH, and R2 is H or CH3. The performance is stable, the water-reducing rate is high, and cement adaptation is high; the concrete polycarboxylate water reducing agent has the excellent water reducing performance and the excellent slump retaining performance, and has the advantages that the preparing process is simple in technology, time is short, reaction energy consumption is low, operability is high, and pollution to the environment is avoided.

Owner:国能辽宁环保产业集团有限公司材料分公司

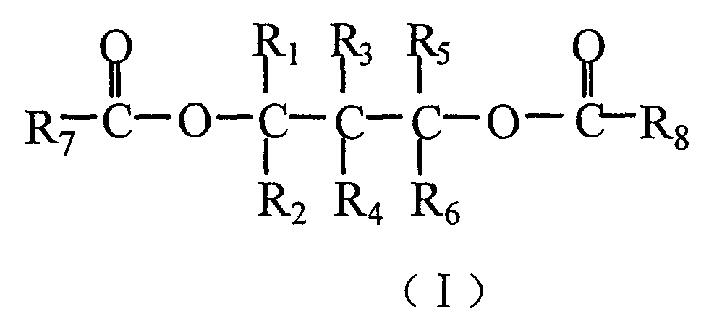

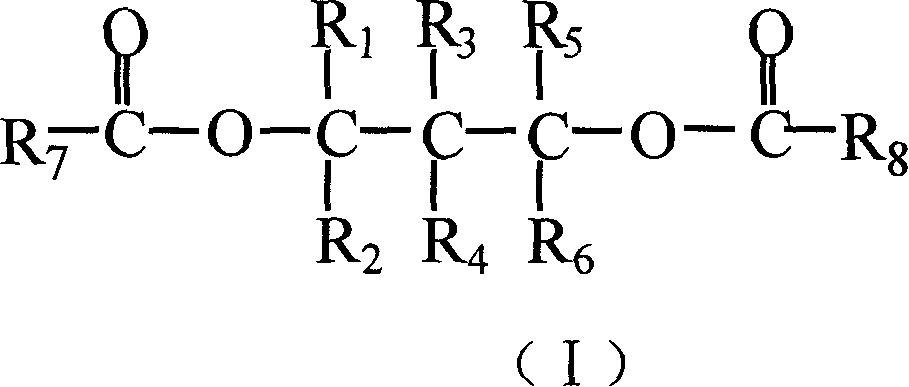

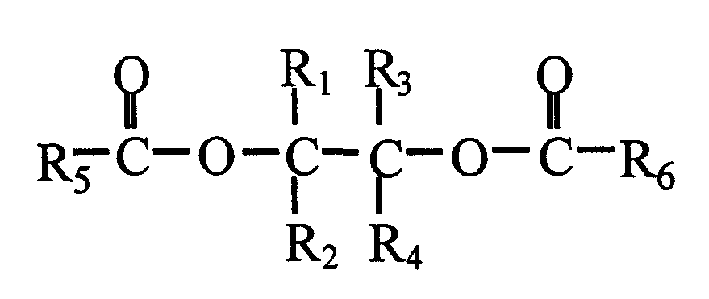

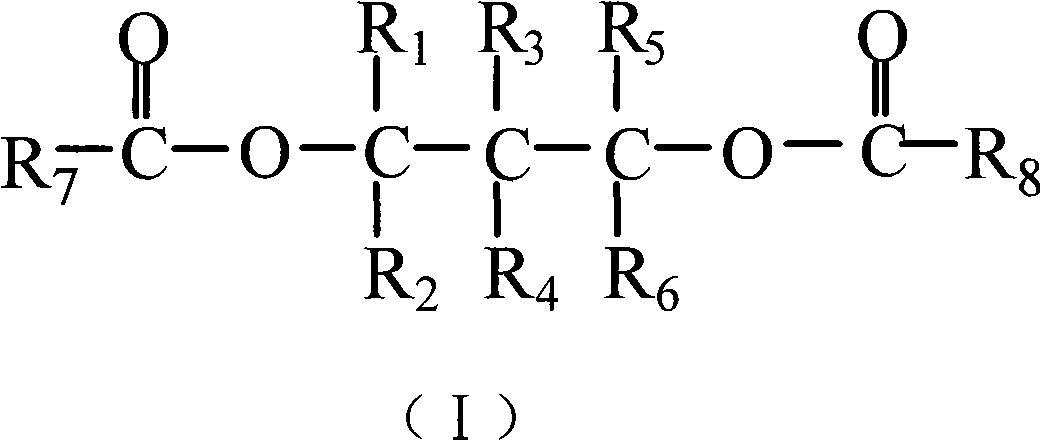

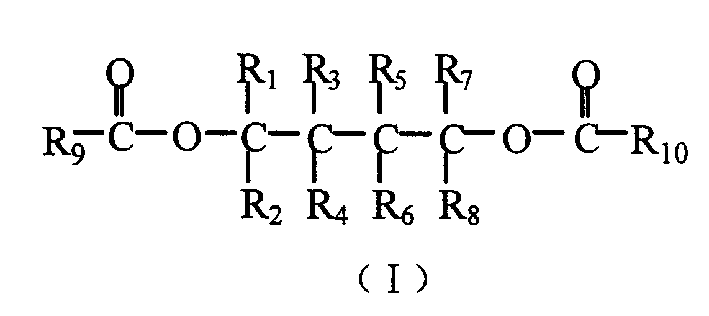

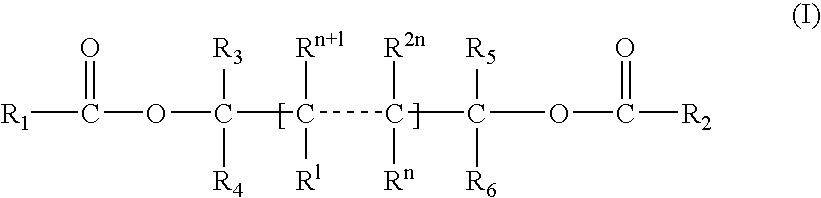

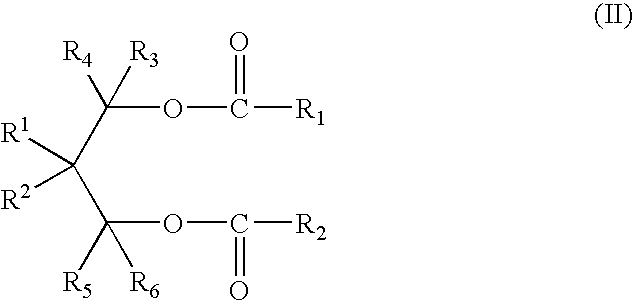

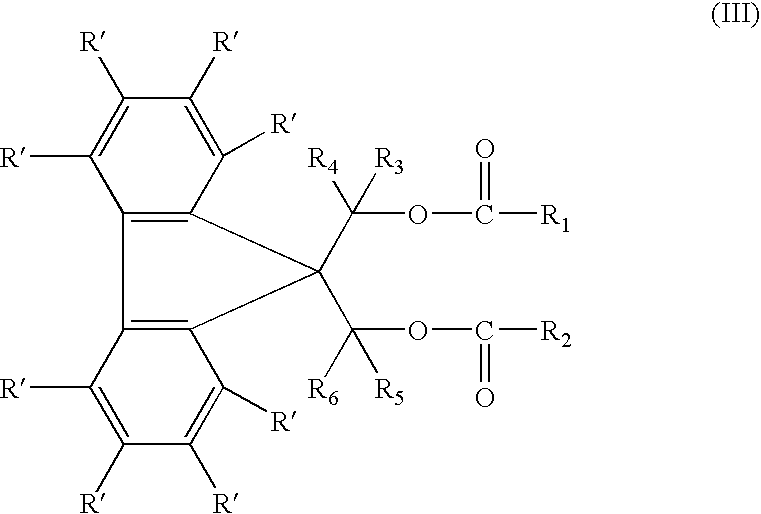

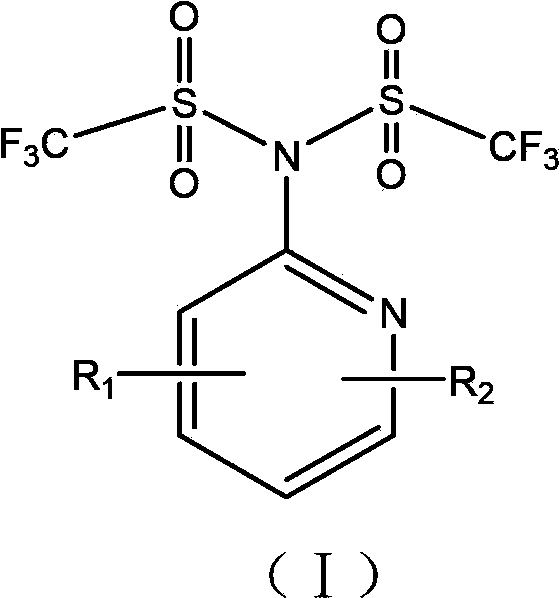

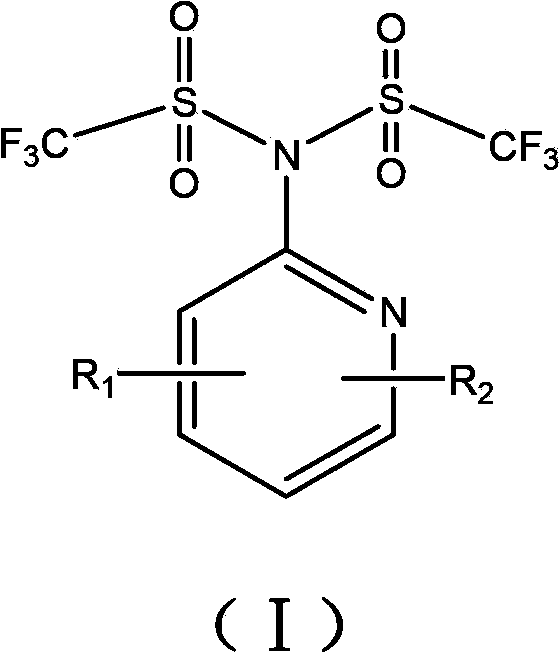

Components of catalyst used for olefin polymerization and preparation method thereof

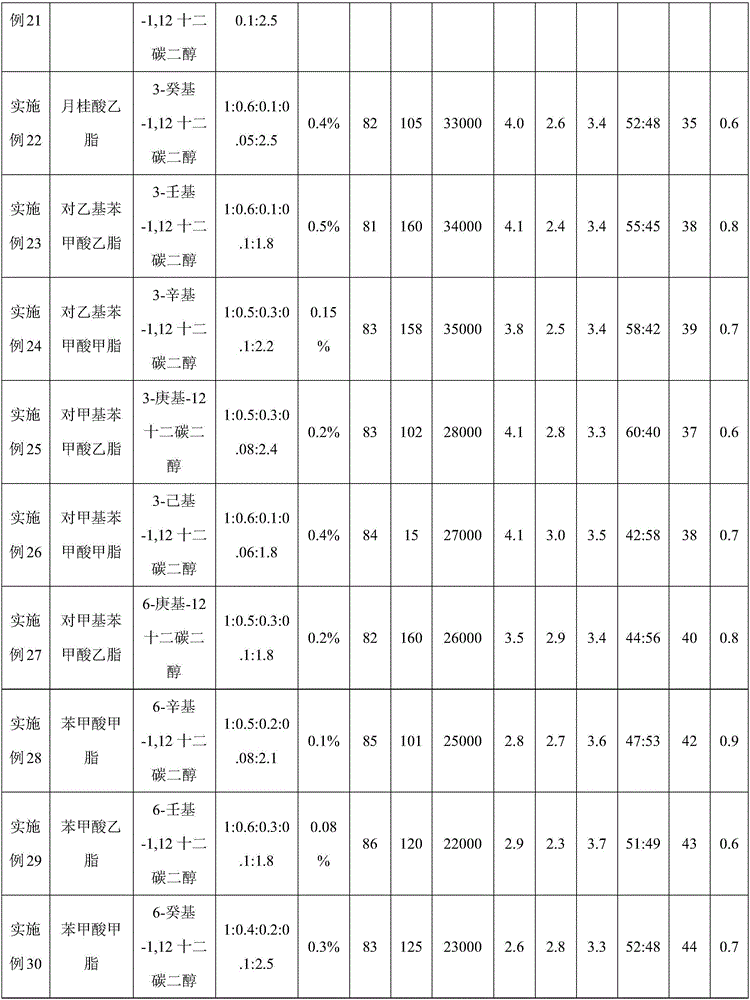

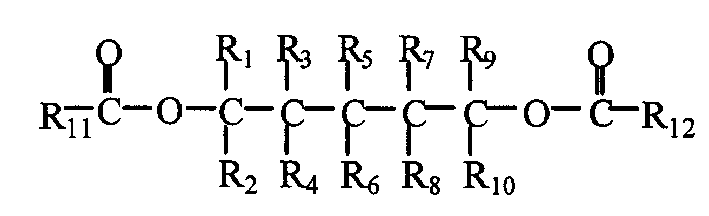

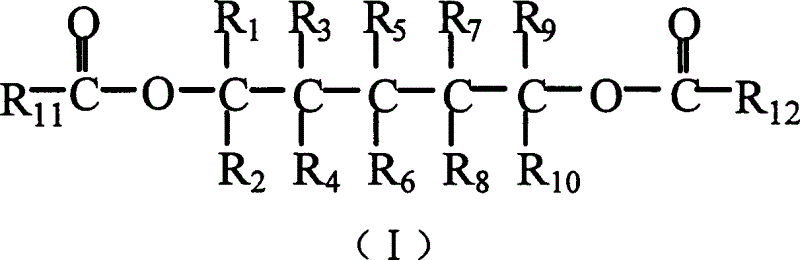

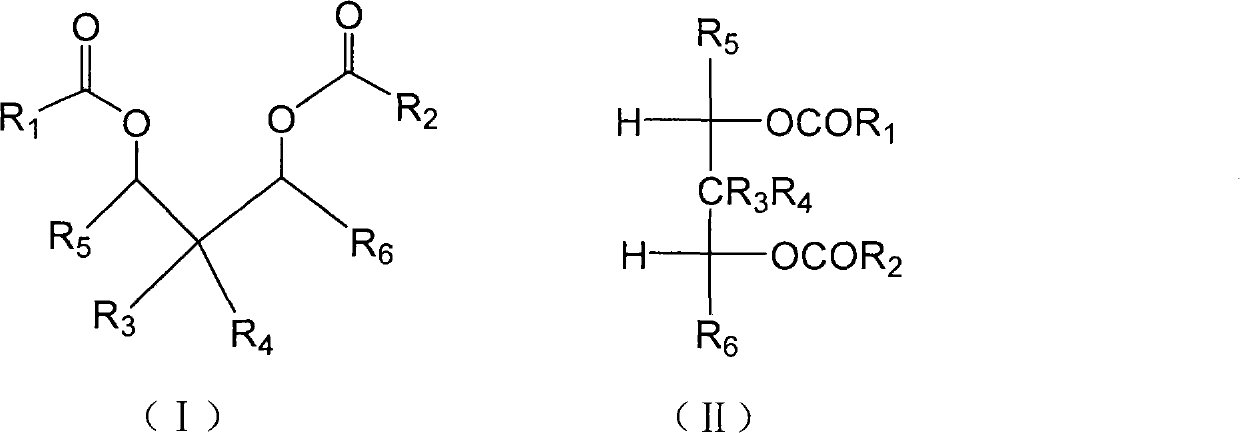

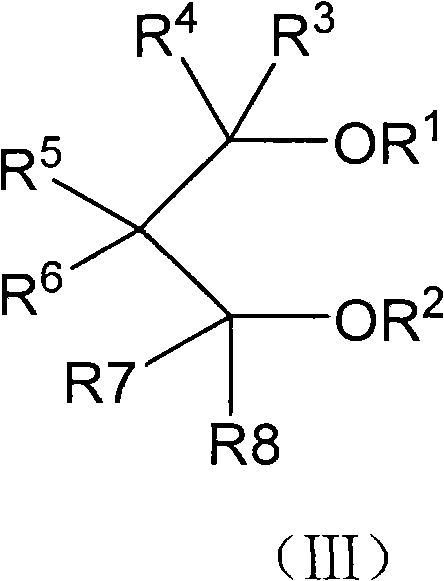

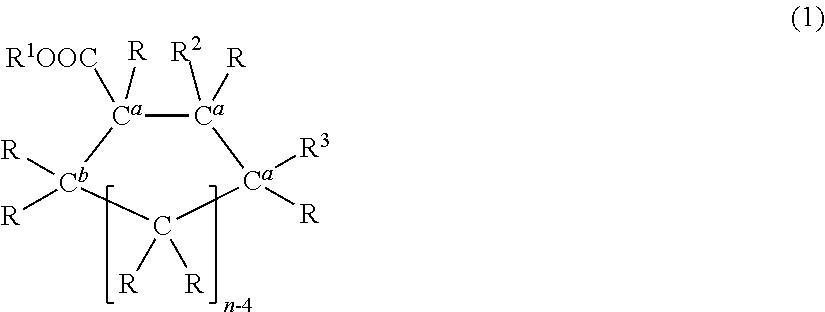

The invention provides components of a catalyst used for CH2=CHR olefin polymerization, wherein R is hydrogen or a C1-C12 alkyl or aryl group. The components of the catalyst include magnesium, titanium, halogen and an electron donor. The electron donor is at least one compound selected from groups represented by a general formula (I); and in the general formula (I), R1 and R2 may be same or different and are respectively selected from the group consisting of a straight-chain or branched-chain C1-C10 alkyl or cycloalkyl group, a C6-C20 aryl or aralkyl group, hydrogen, halogen, an acyl group, an ester group, an amido group and an amino group.

Owner:CHINA PETROLEUM & CHEM CORP +1

Spray-dried, mixed metal ziegler catalyst compositions

ActiveUS7348383B2Improve productivityImprove homogeneityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsZiegler–Natta catalystTitanium

A Ziegler-Natta catalyst composition comprising a solid mixture formed by halogenation of: Al) a spray-dried catalyst precursor comprising the reaction product of a magnesium compound, a non-metallocene titanium compound, and at least one non-metallocene compound of a transition metal other than titanium, with A2) an organoaluminium halide halogenating agent, a method of preparing, precursors for use therein, and olefin polymerization processes using the same.

Owner:UNION CARBIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com