Patents

Literature

154results about How to "High stereoregularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon and/or silicon bridged binuclear metallocene catalyst for styrene polymerization

InactiveUS6010974AHigh catalytic activityHigh Molecular Weight DistributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylSilylene

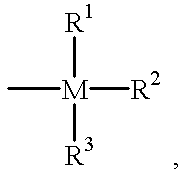

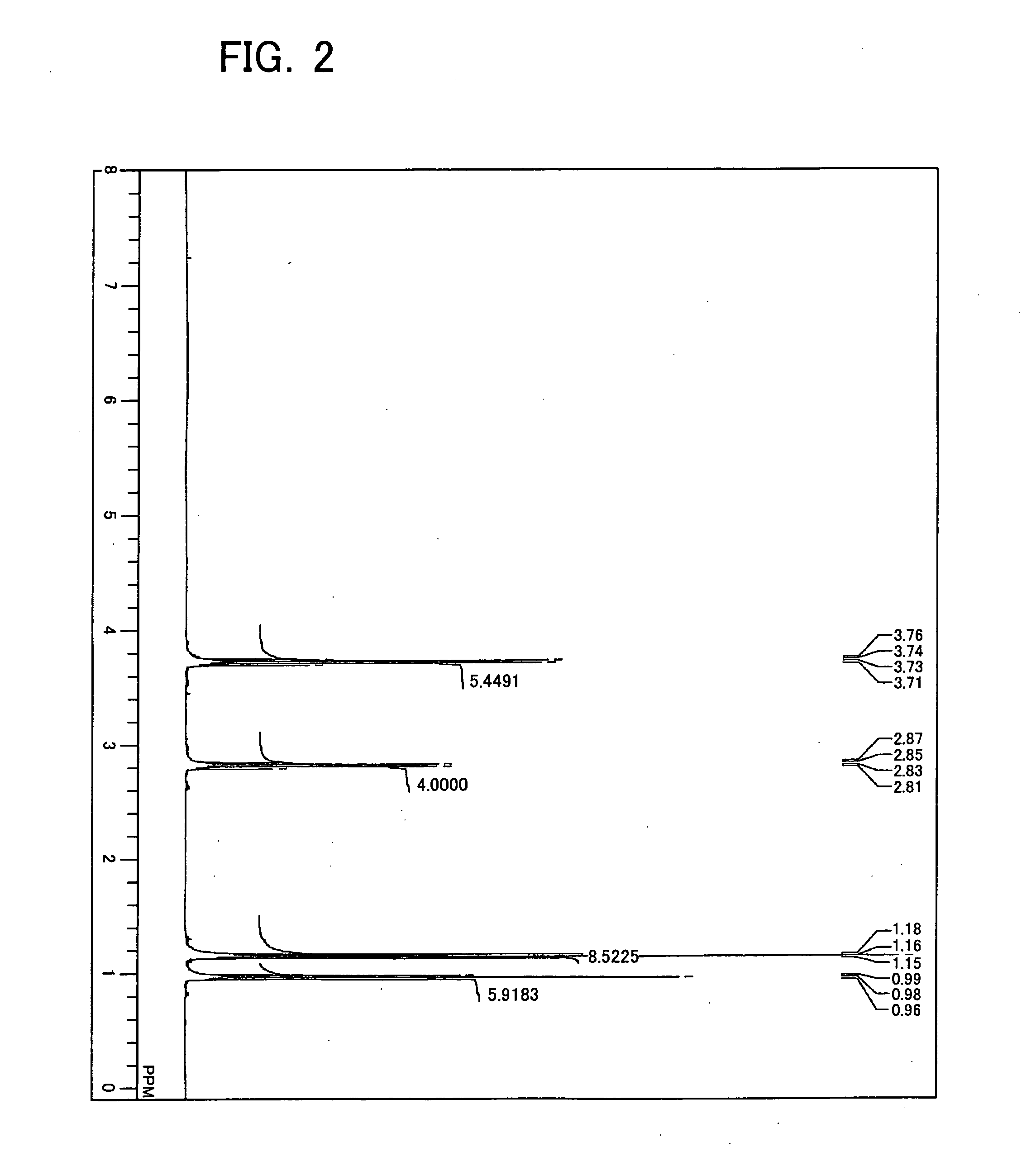

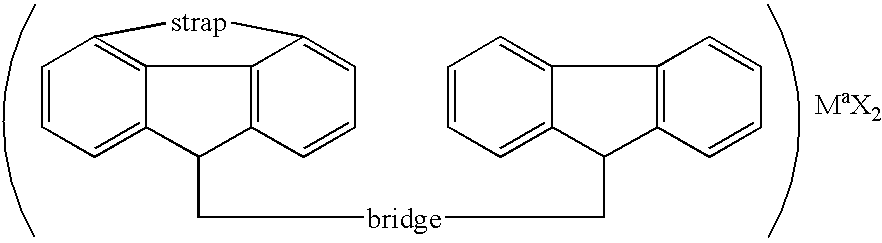

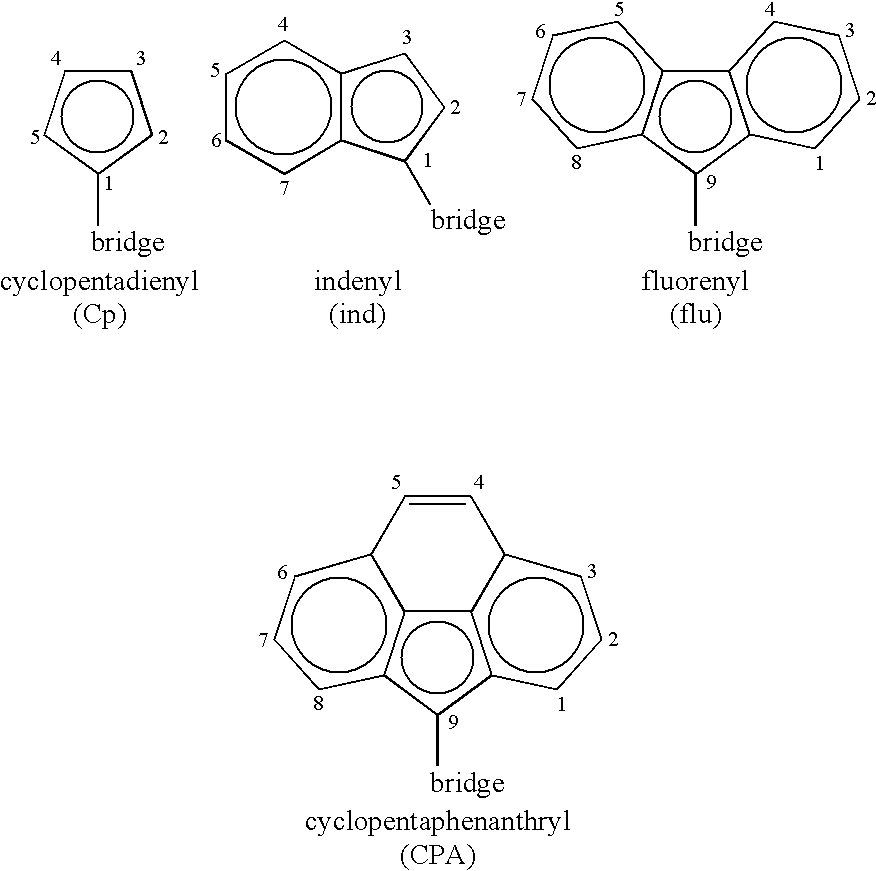

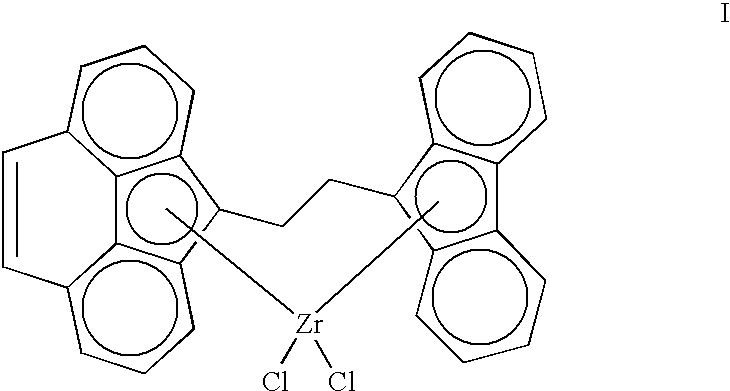

An alkylene and / or silylene bridged binuclear metallocene catalyst for styrene polymerization is represented by the following formula (I): where M1 and M2 are the same or different transition metal of Group IVb of the Periodic Table; Cp1 and Cp2 are the same or different cyclopentadienyl; alkyl, alkoxy, silyl or halogen substituted cyclopentadienyl; indenyl; alkyl, alkoxy, silyl or halogen substituted indenyl; fluorenyl; or alkyl, alkoxy, silyl or halogen substituted fluorenyl, which is capable of pi -electron, eta 5-bonding with M1 or M2; each of E1, E2 and E3, independently of one another, is a carbon atom or a silicon atom; m, p and q are integers of 0 to 15 and m+p+q> / =1; each of R1, R2, R3, R4, R5 and R6, independently of one another, is a hydrogen, an alkyl, an aryl, an alkoxy or a halogen; X is a hydrogen, an alkyl, an alkoxy or a halogen; and n is 3. M1 and M2 may also be in cardin form by mixture of (I) with a compound which abstructs an X gray from each metal atom and substitution then with non-coordinating anions.

Owner:CHEIL IND INC

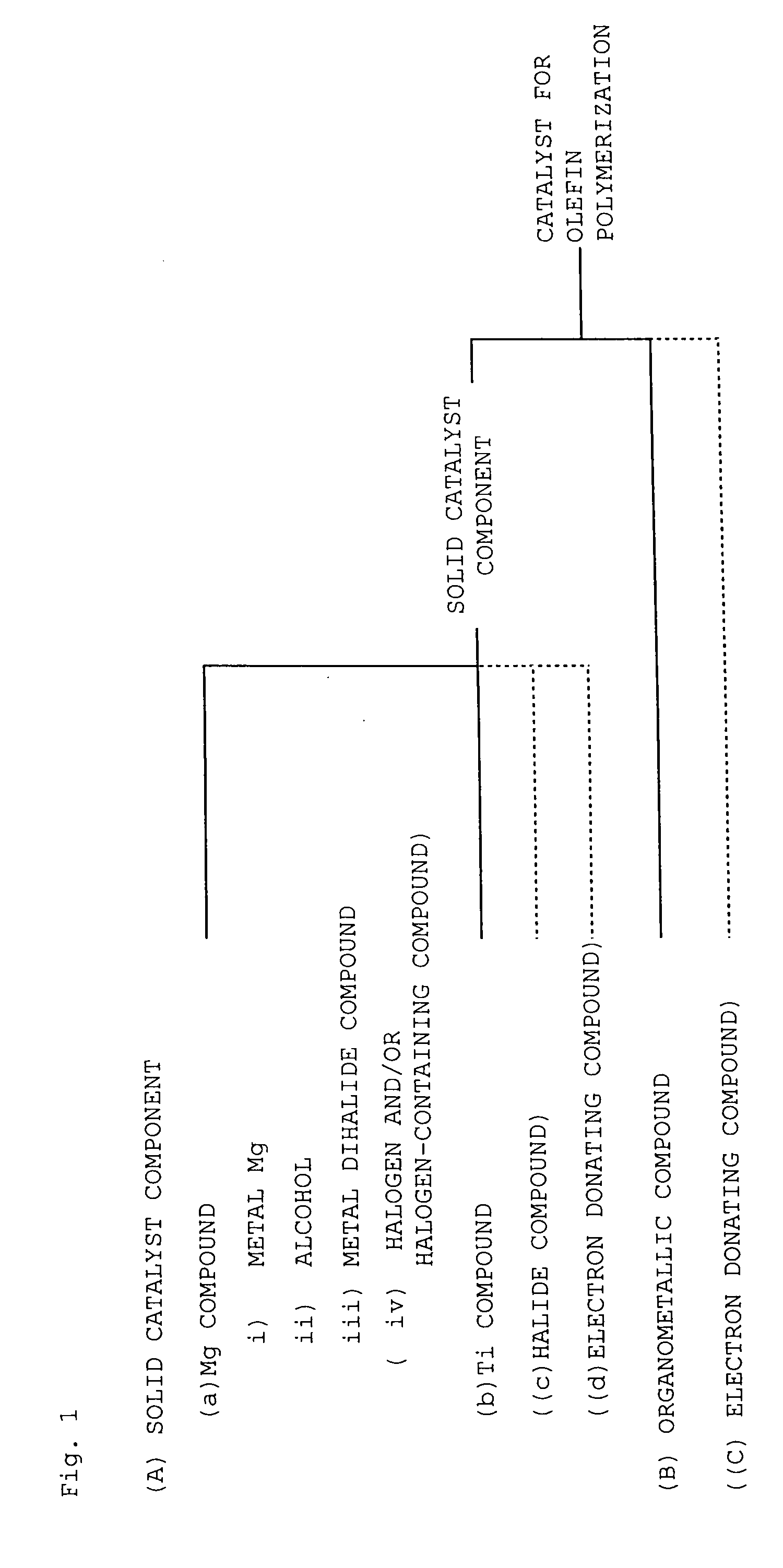

Solid catalyst component and catalyst for olefins polymerization

InactiveUS6770586B2Particles in good shapeImprove handlingOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropylene PolymersOlefin polymerization

Owner:TOHO TITANIUM CO LTD

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

InactiveUS20020006993A1High crystallinityLong mesochainLayered productsPolymer scienceHindered amine light stabilizers

Disclosed are a propylene polymer having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain (continuous propylene units wherein directions of alpha-methyl carbons are the same as each other), and a process for preparing said polymer. Also disclosed are a propylene block copolymer containing a crystalline polypropylene portion having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain, and a process for preparing said copolymer. Further disclosed is a propylene polymer composition comprising the above propylene polymer or propylene block copolymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene polymer of the invention is excellent in rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc. The propylene block polymer of the invention is well-balanced between rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance. The propylene polymer composition can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc.

Owner:MITSUI CHEM INC

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

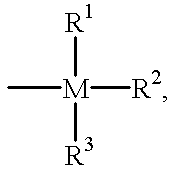

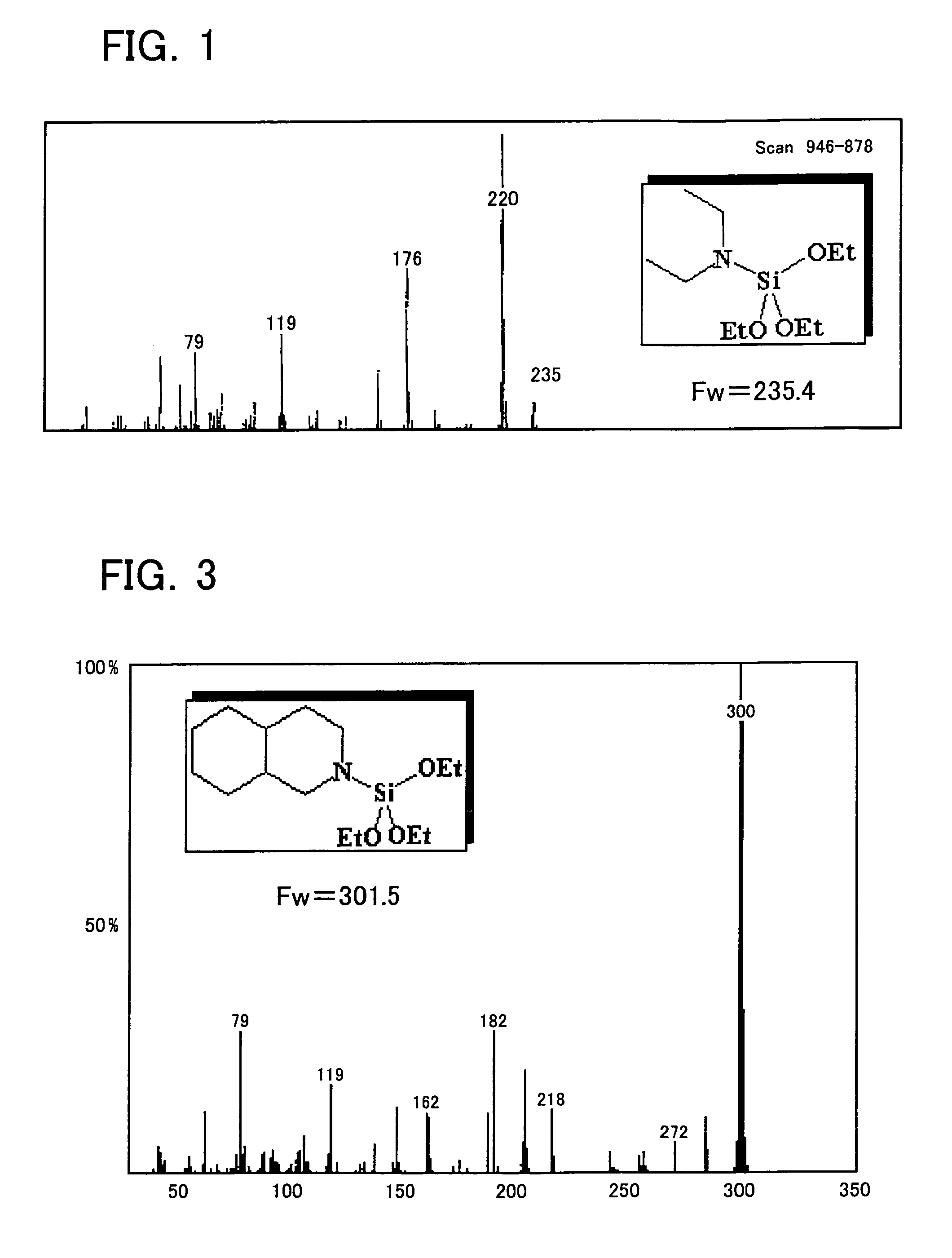

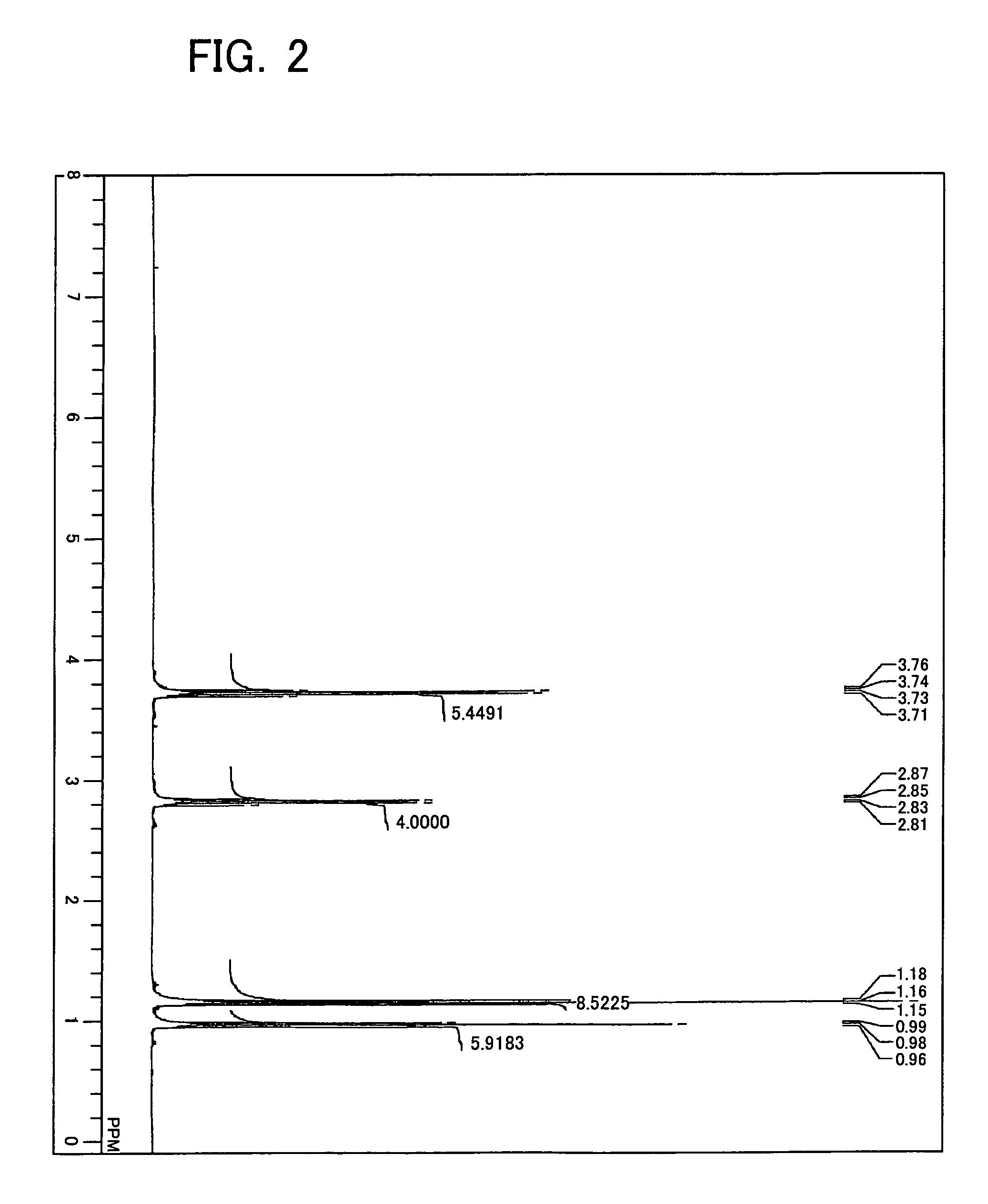

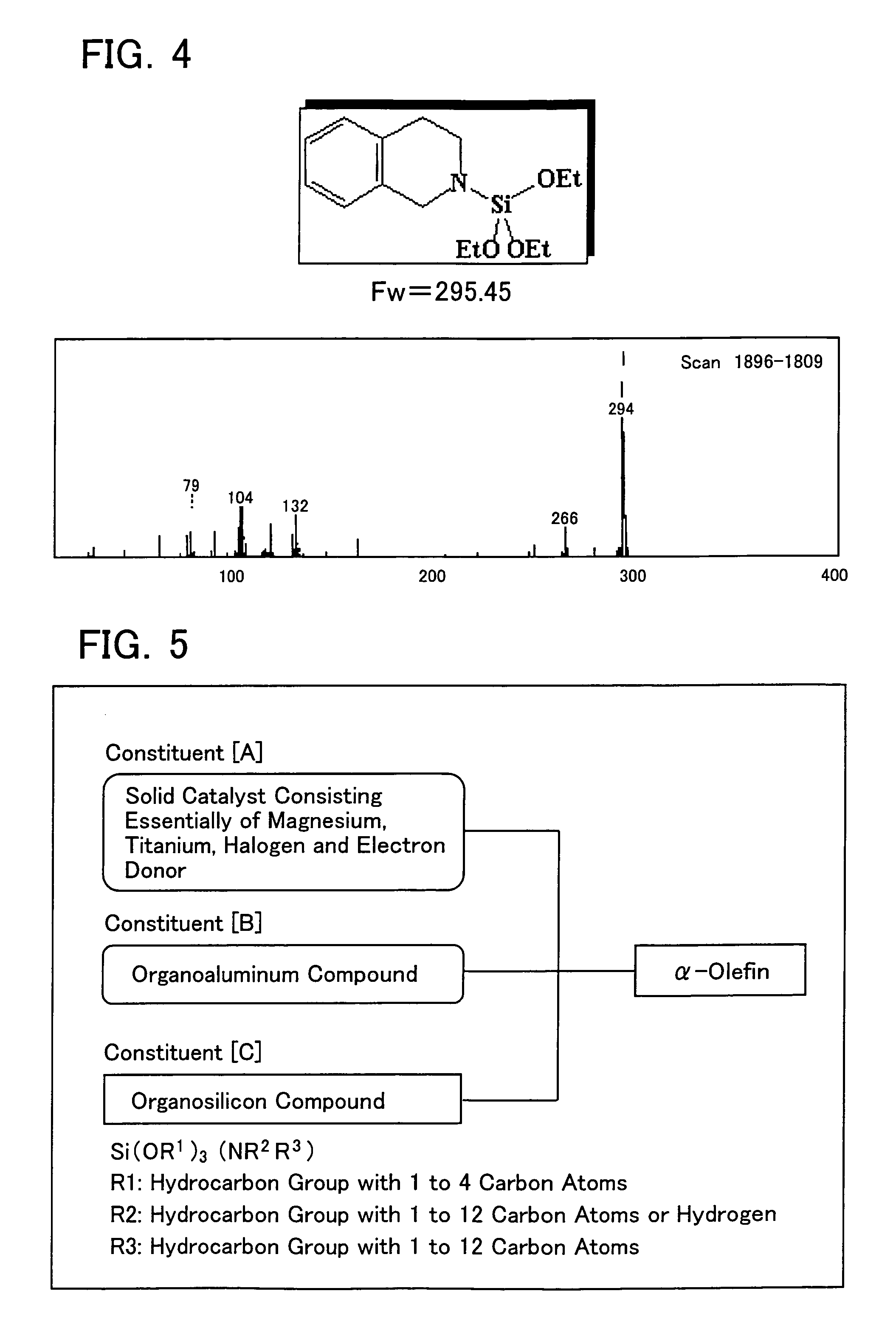

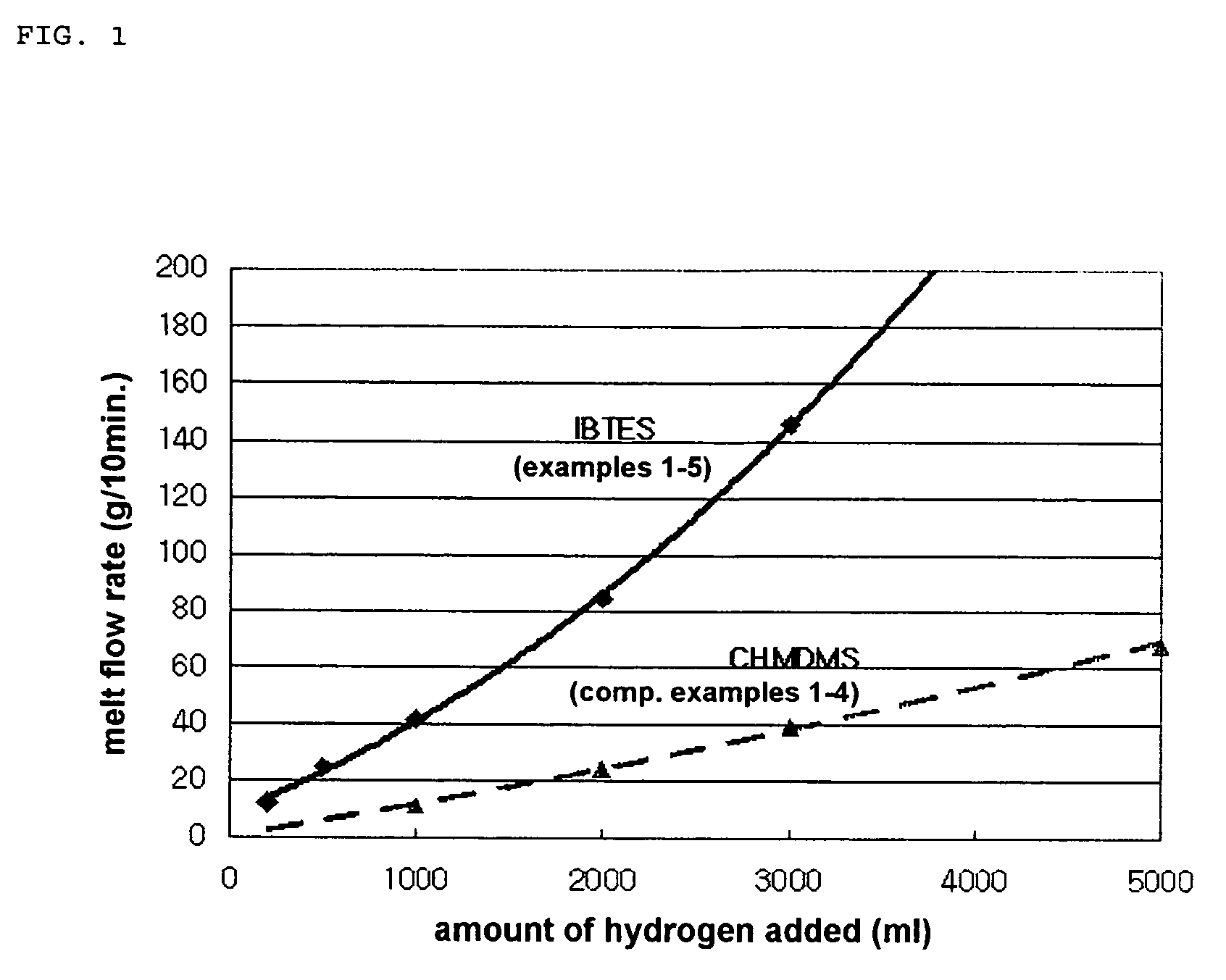

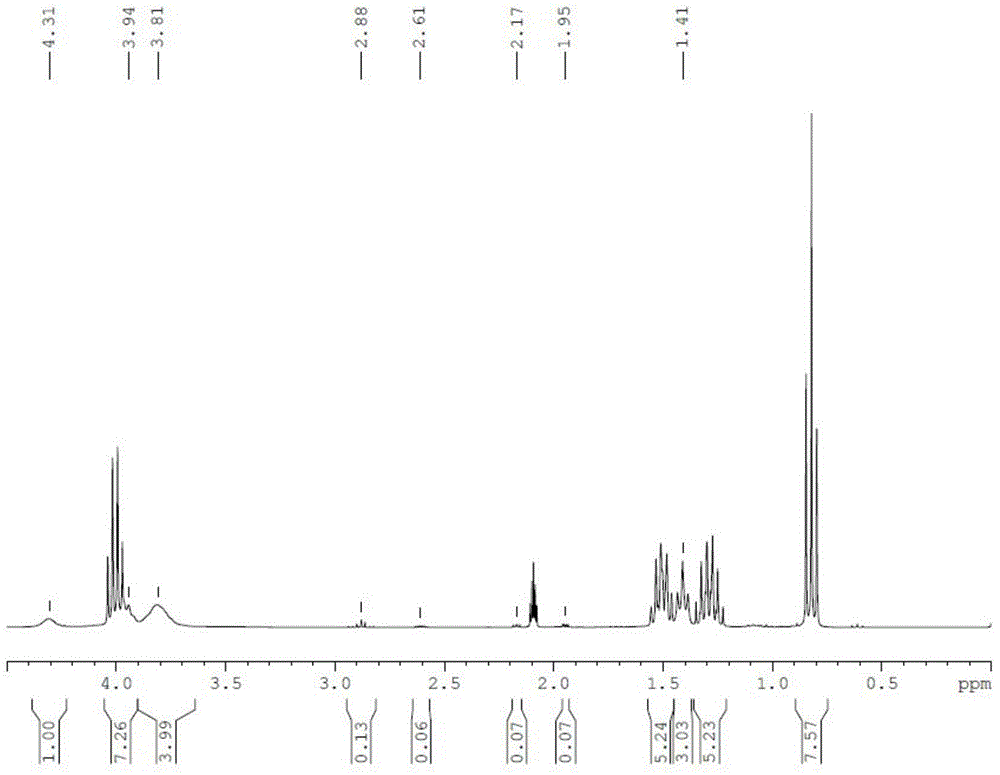

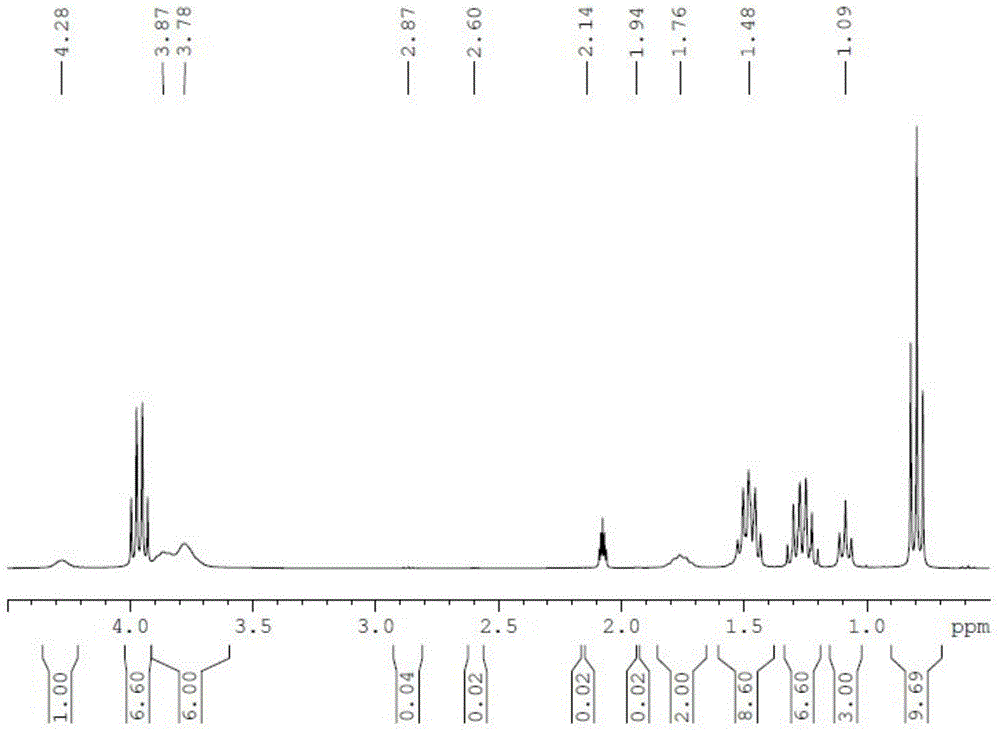

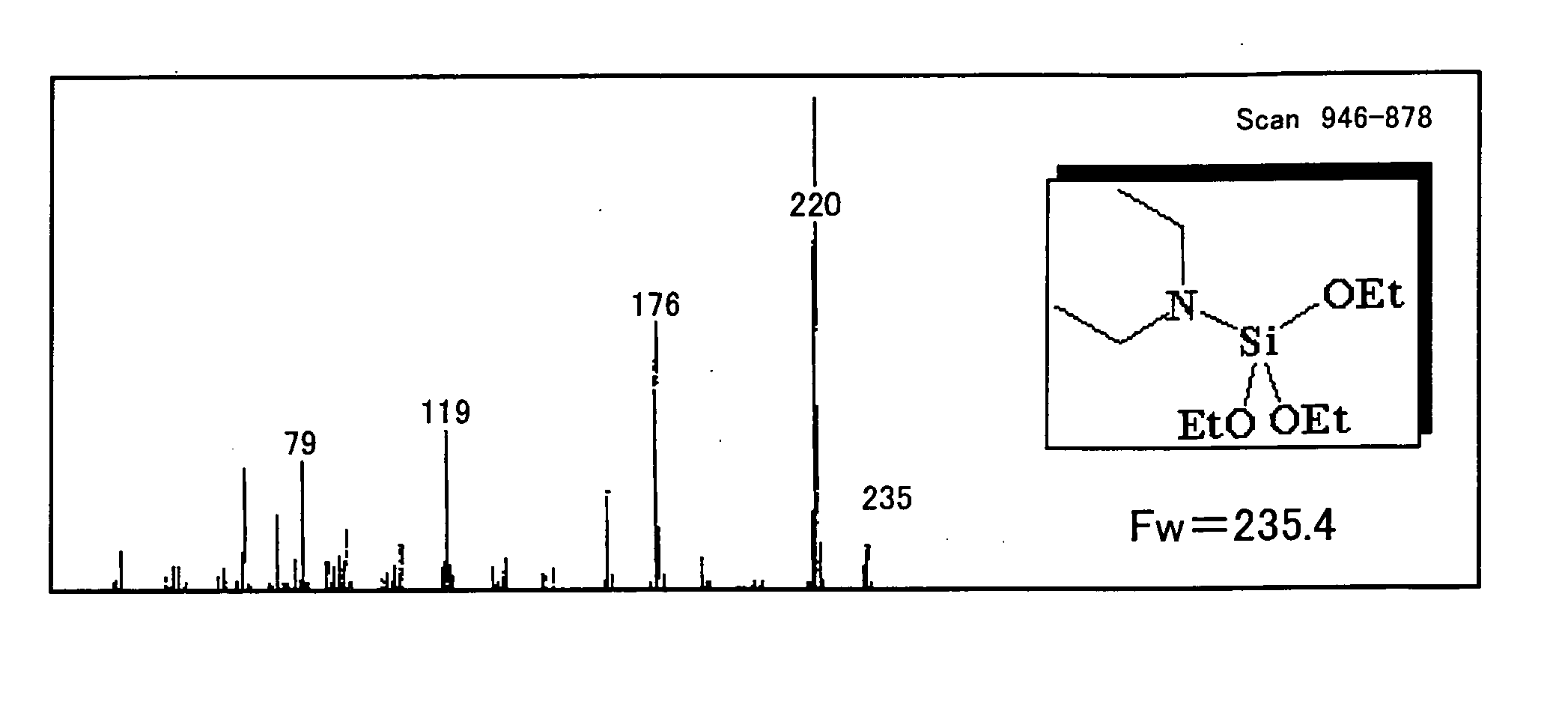

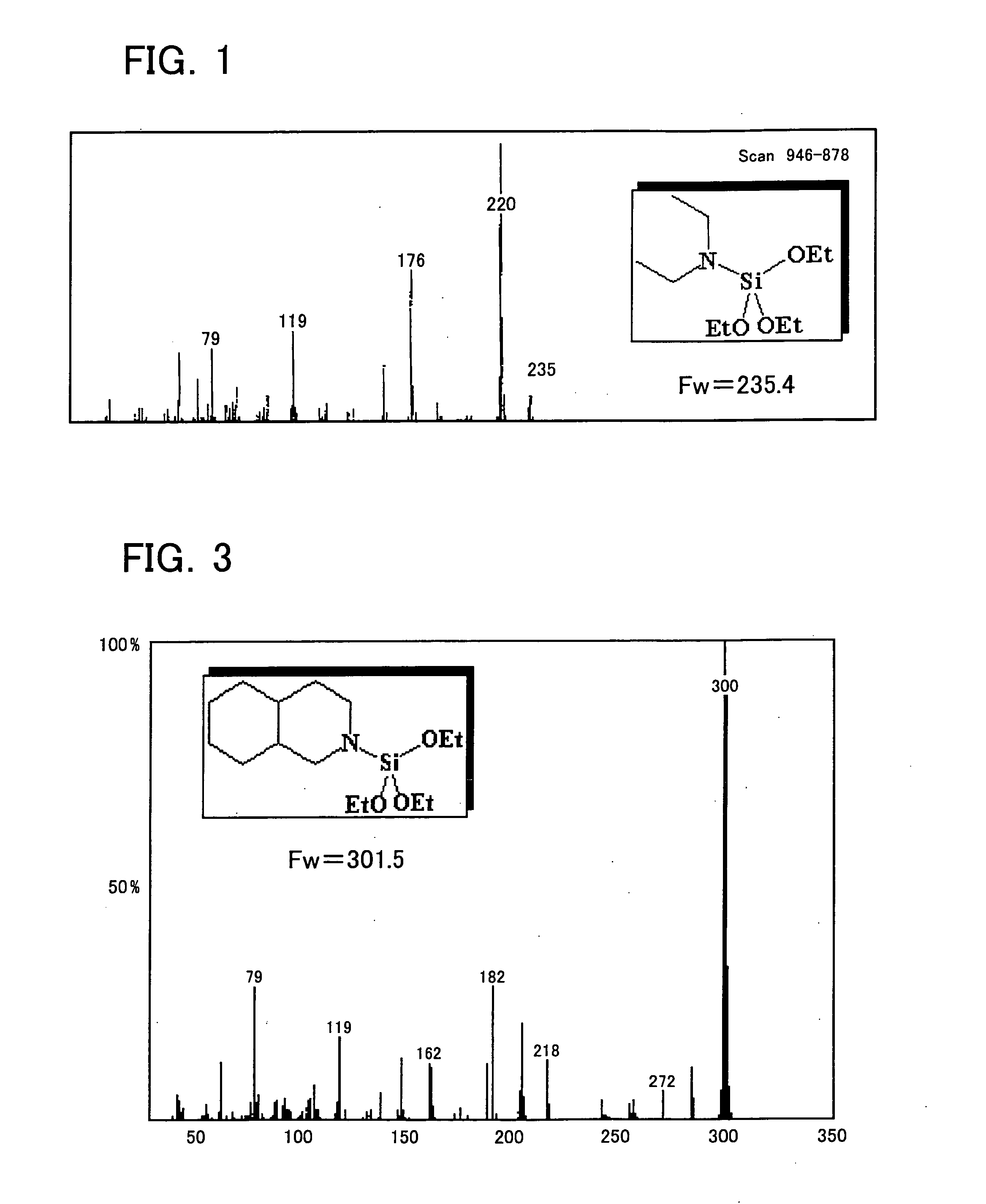

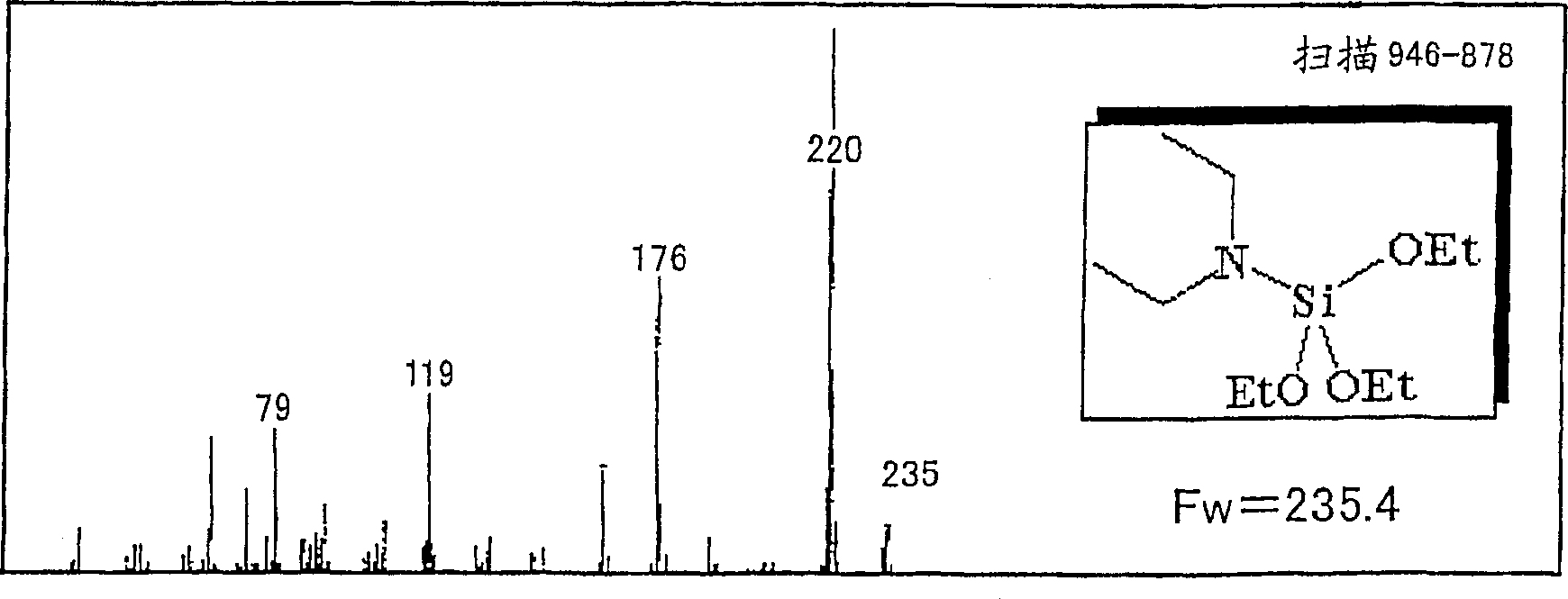

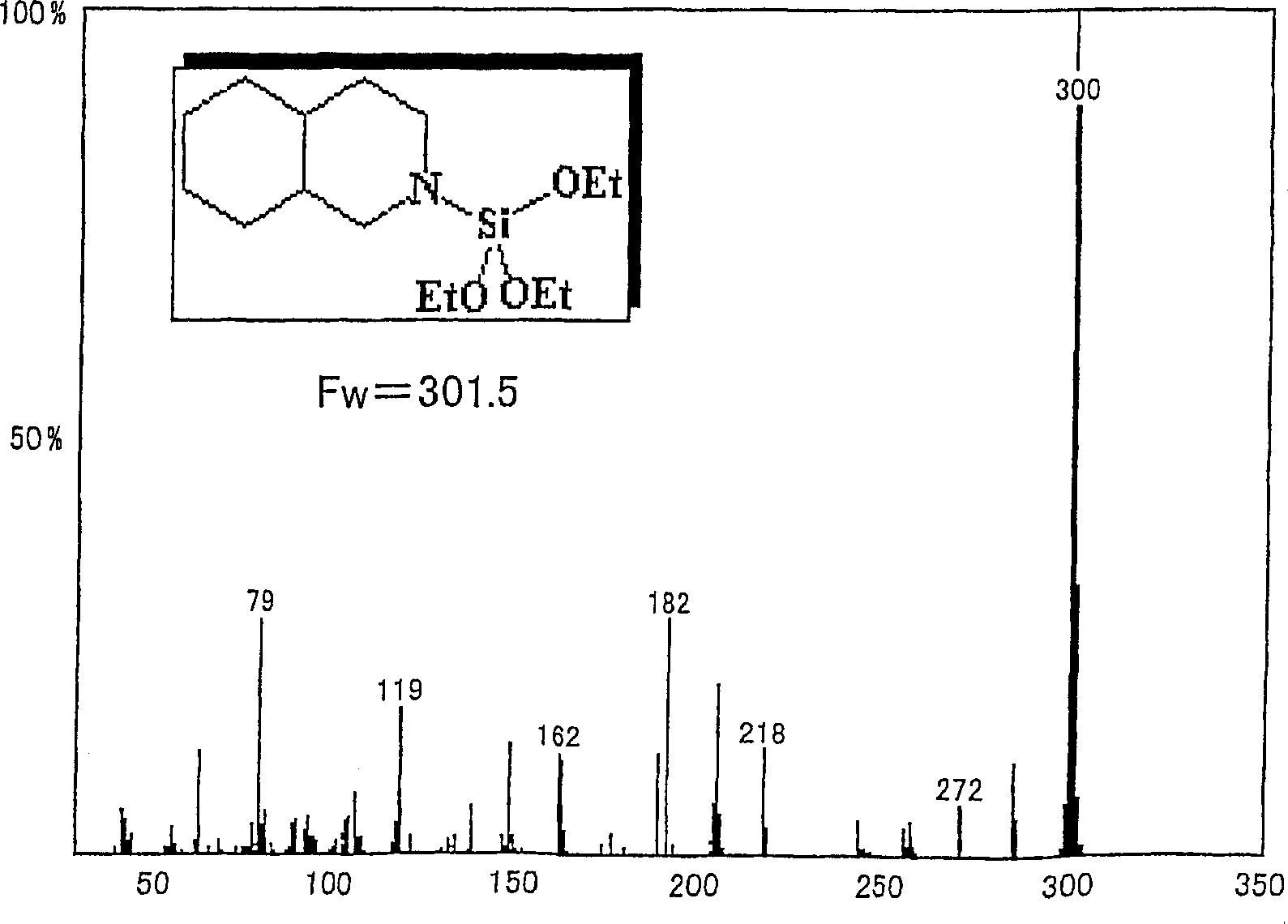

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Method for producing propylene polymer having a very high melt-flowability

ActiveUS7244794B2Ensure effective applicationHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenWeight control agent

The present invention relates to a method for producing a propylene polymer having a very high melt flowability, specifically to a method for producing an isotactic propylene polymer having a dramatically improved melt flowability with a relatively high production yield in convenient way, by improving the reactivity of hydrogen that is served as a molecular weight controlling agent in propylene polymerization.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

Disclosed are a propylene block copolymer containing a crystalline polypropylene portion having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain, and a process for preparing said copolymer. Further disclosed is a propylene polymer composition comprising the above propylene block copolymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene block polymer of the invention is well-balanced between rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance.

Owner:MITSUI CHEM INC

Solid catalyst component for olefin polymerization and catalyst

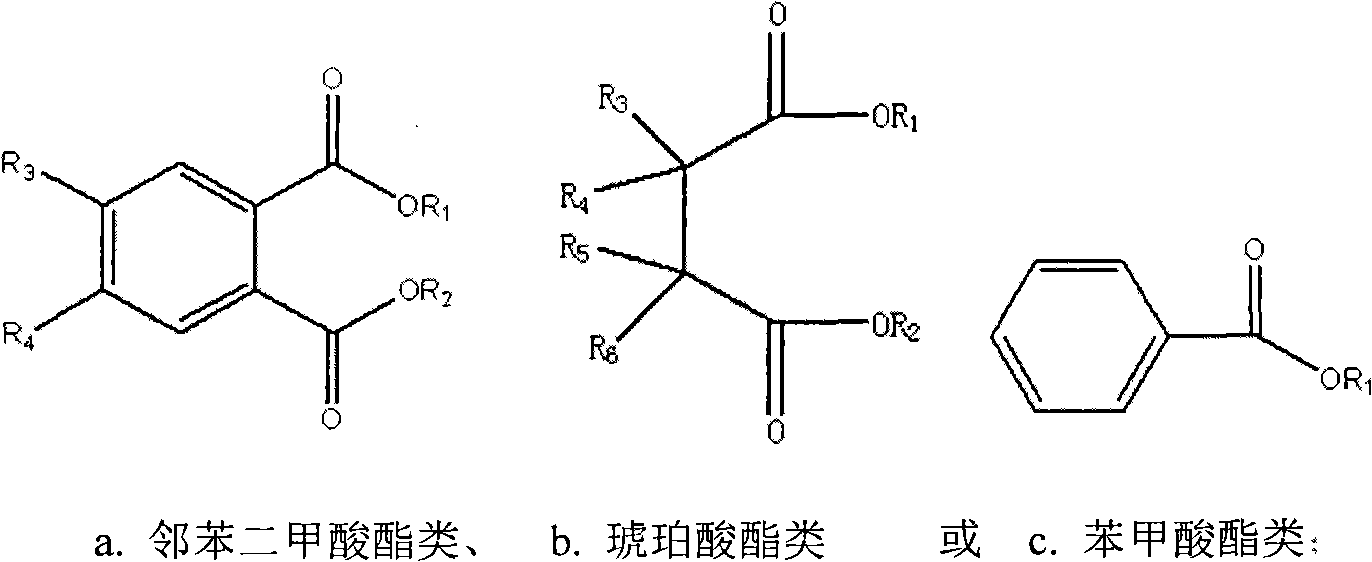

InactiveUS7208435B2Efficient processHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenElectron donor

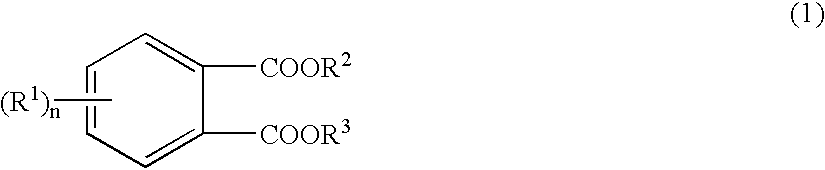

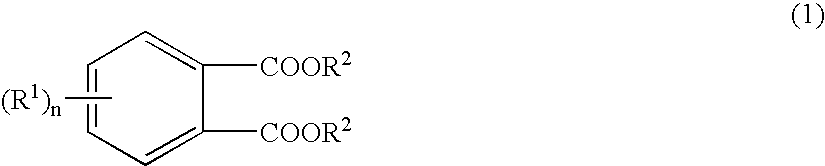

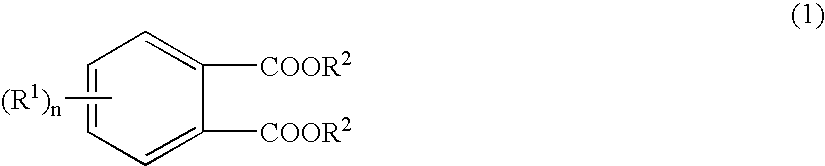

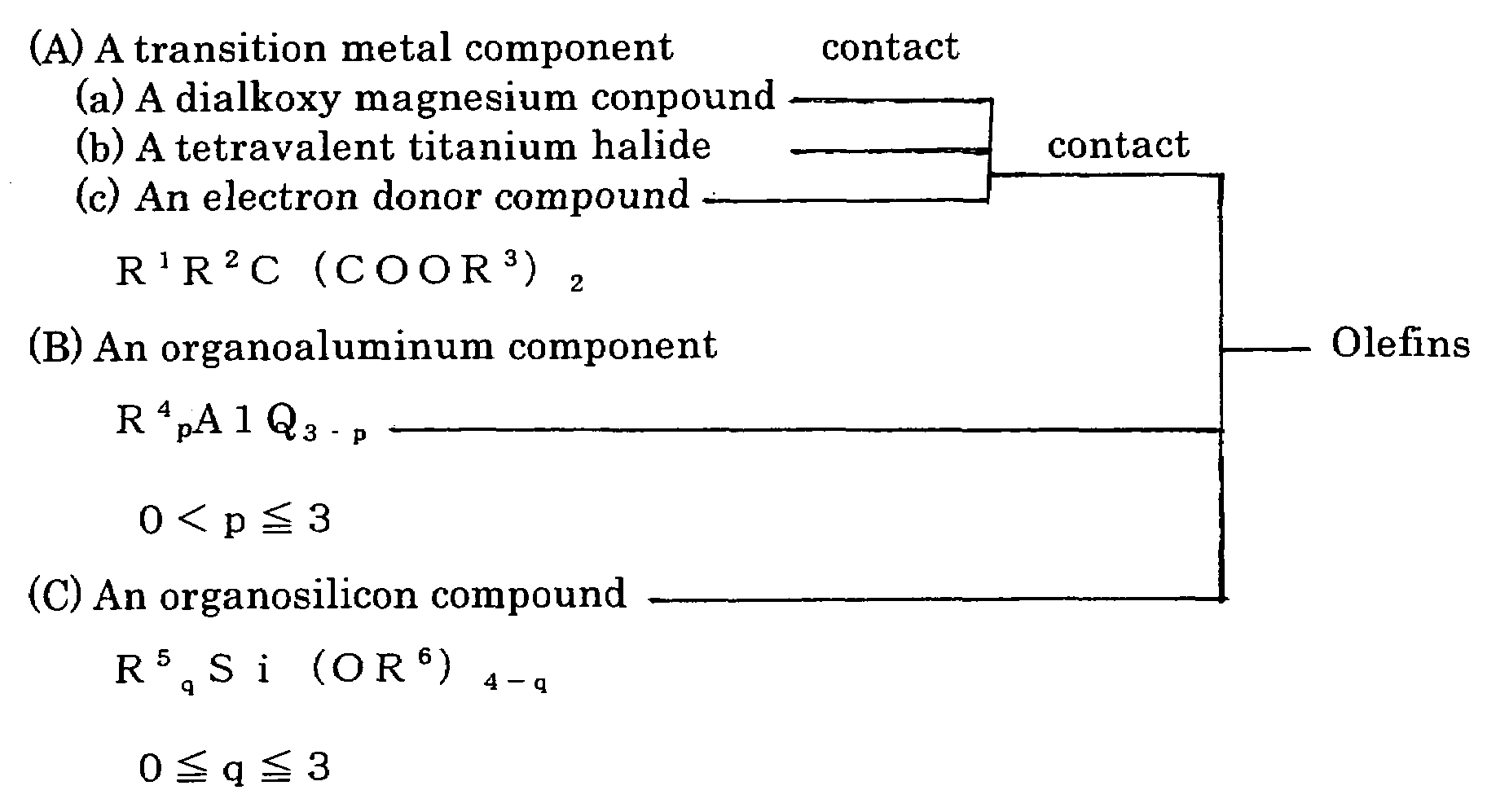

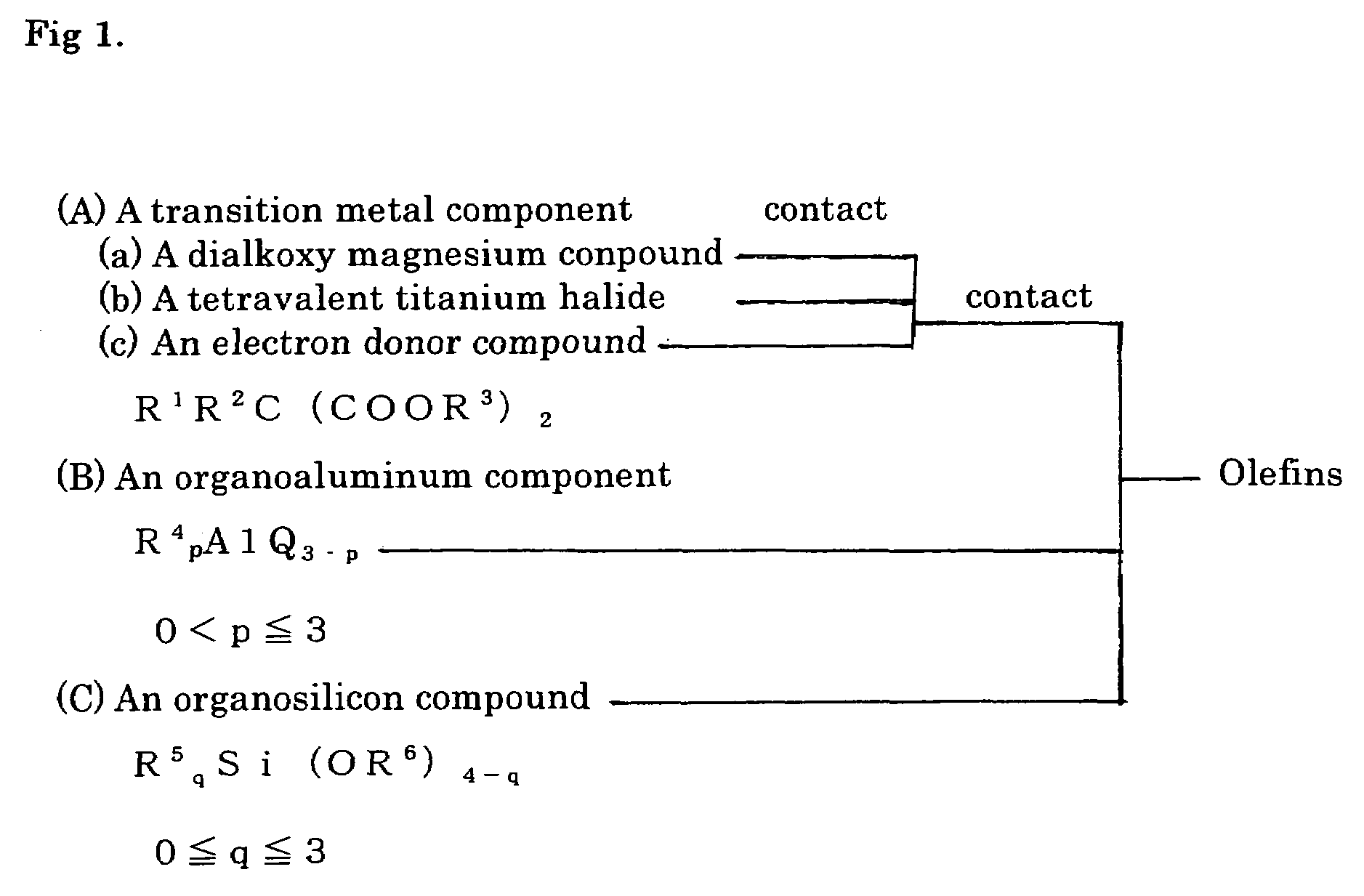

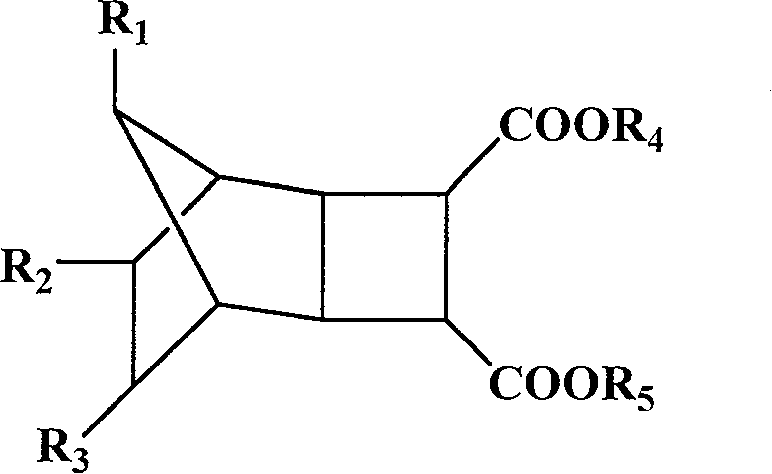

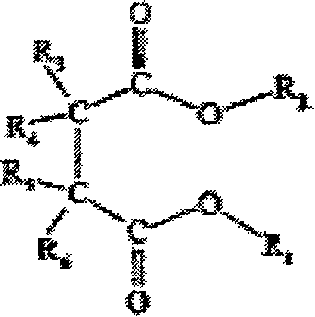

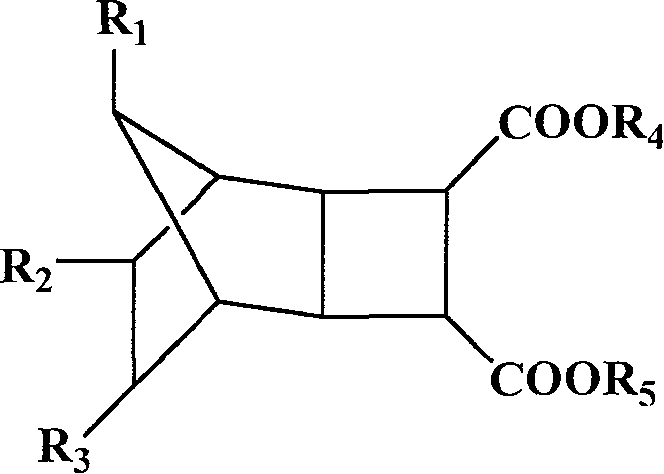

A solid catalyst component for polymerization of olefins prepared by contacting (a) a dialkoxy magnesium compound, (b) a tetra-valent titanium halide, and (c) an electron donor compound of the formula R1R2C(COOR3)2 suspended in (d) an aromatic hydrocarbon having a boiling point in the range of 50–150° C. The catalyst containing the catalyst component is excellent in the olefin polymerization catalyst activity to hydrogen and can produce a polymer with a high stereoregularity in a high yield.

Owner:TOHO TITANIUM CO LTD

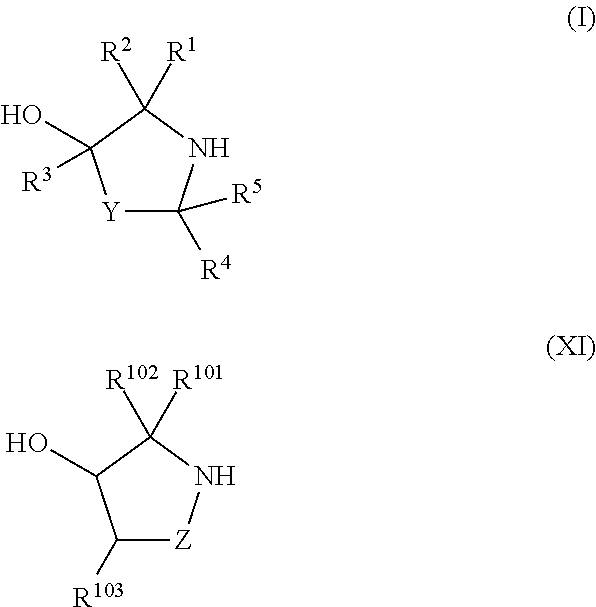

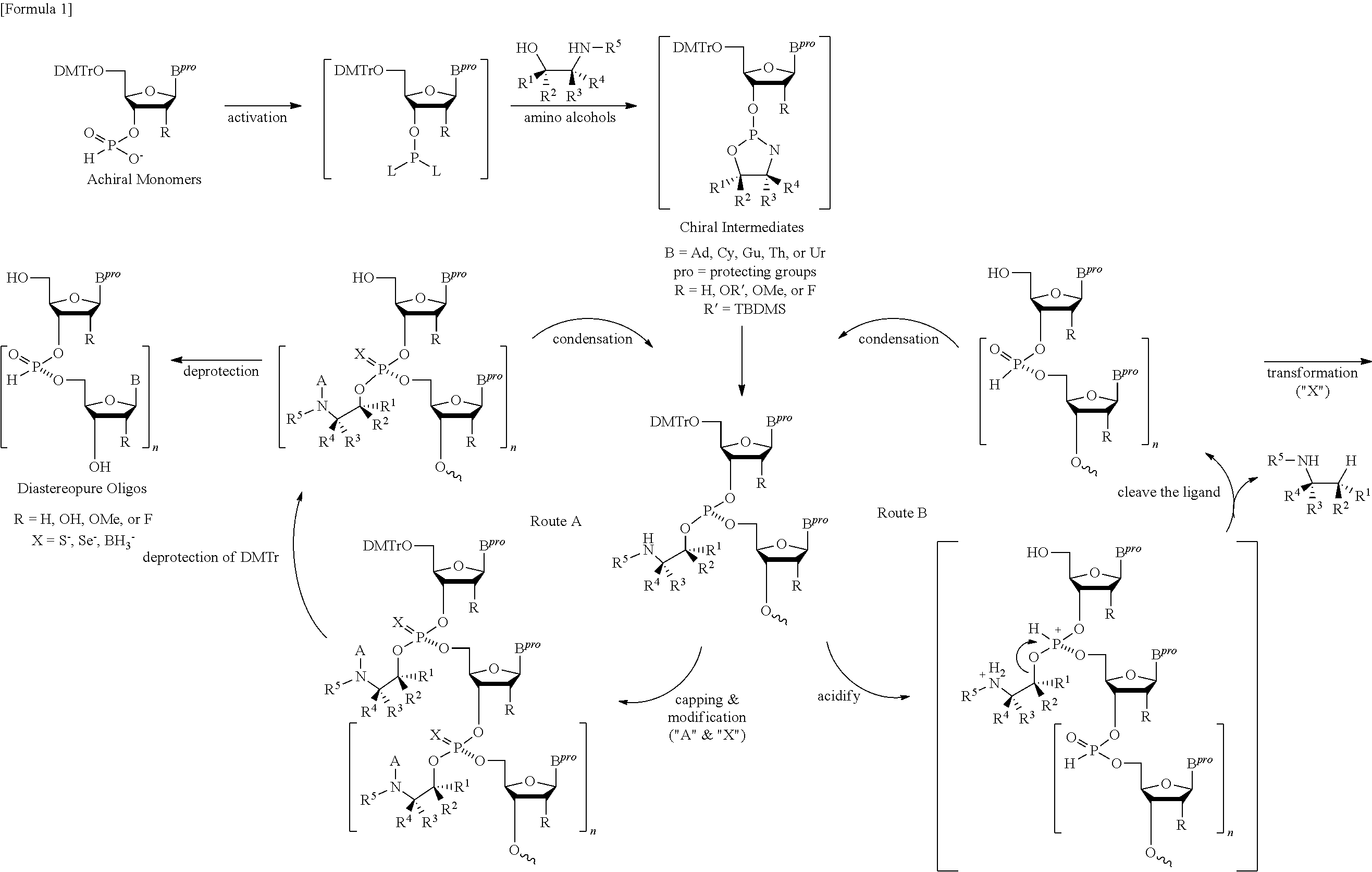

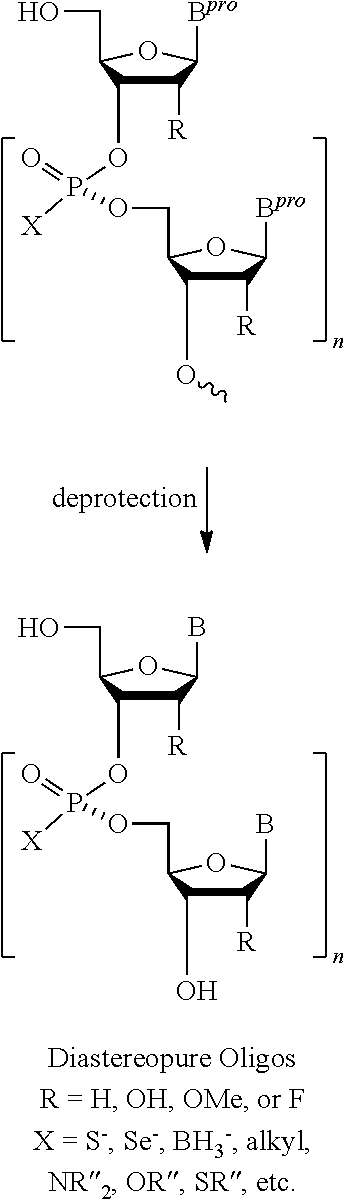

Chiral auxiliaries

ActiveUS20130178612A1High asymmetric yieldHigh stereoregularitySugar derivativesSugar derivatives preparationPhosphorus atomStereochemistry

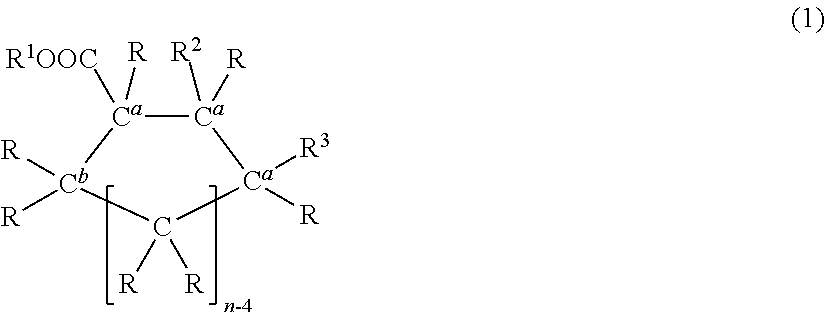

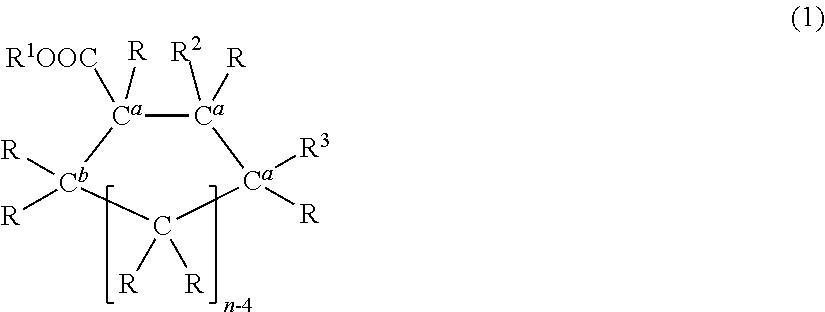

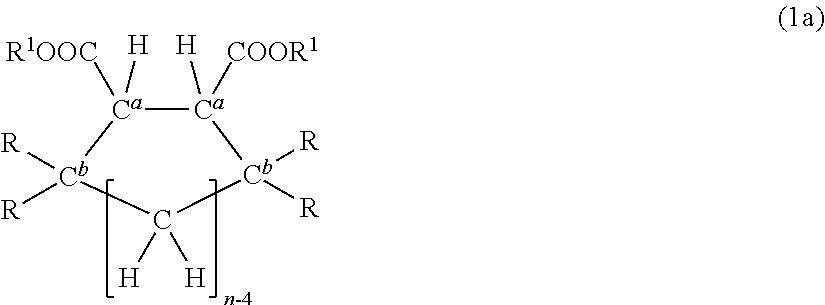

Chiral auxiliaries useful for efficiently producing a phosphorus atom-modified nucleic acid derivative with high stereoregularity, and compounds represented by the following the general formula (I) or the general formula (XI) for introducing the chiral auxiliaries.

Owner:WAVE LIFE SCI LTD

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

InactiveUS6284857B1High crystallinityLong mesochainWeather resistanceHindered amine light stabilizers

Disclosed are a propylene polymer having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain (continuous propylene units wherein directions of alpha-methyl carbons are the same as each other), and a process for preparing said polymer. Further disclosed is a propylene polymer composition comprising the above propylene polymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene polymer of the invention is excellent in rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance. The propylene polymer composition can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc.

Owner:MITSUI CHEM INC

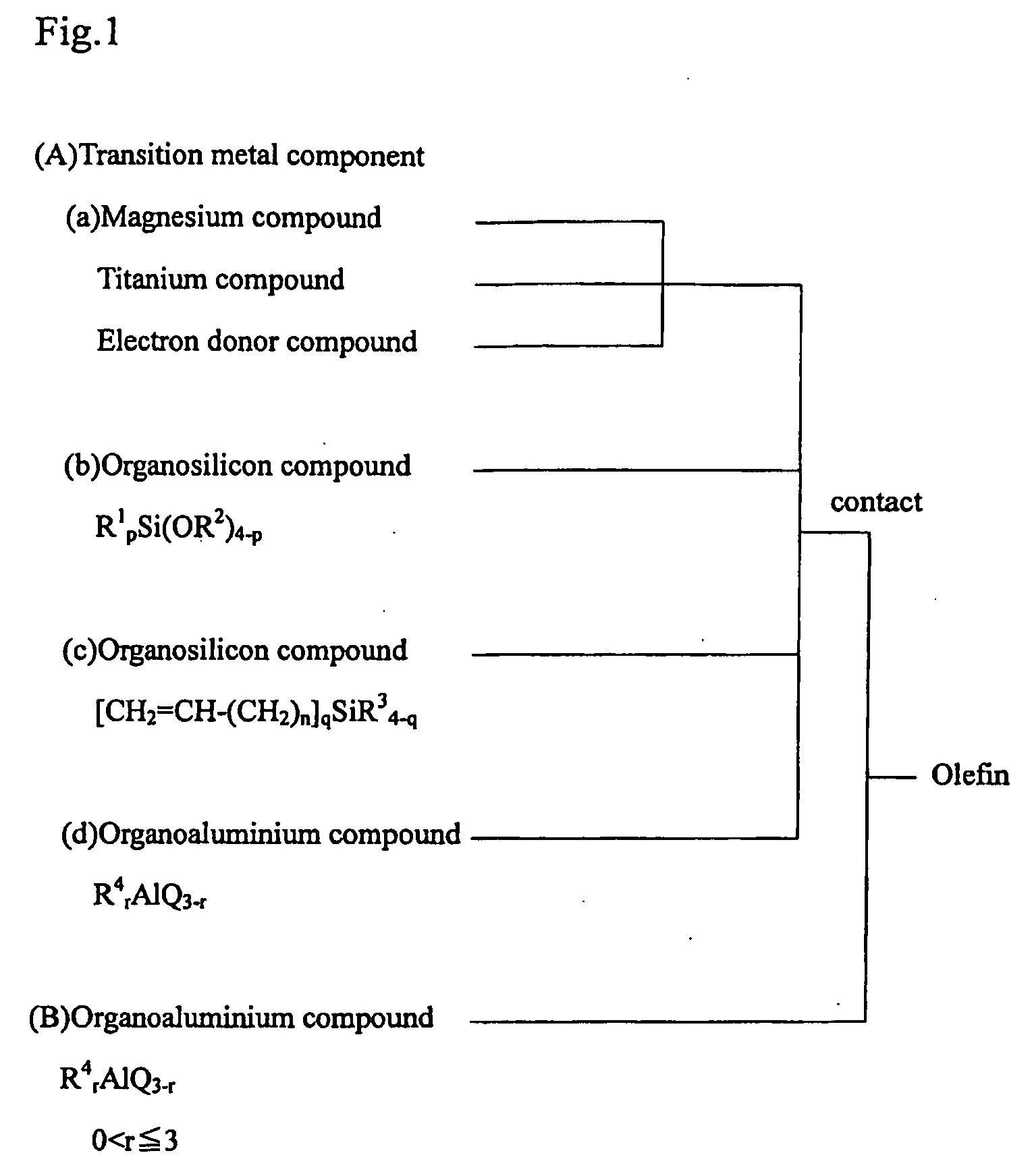

Process for polymerizing alpha-olefins

A process for polymerizing an alpha-olefin using either a catalyst formed by contacting a highly active solid titanium catalyst component, an organo-metallic compound of a metal of Group 1 to 3 of the periodic table, an organic halogen compound or a transition metal compound, and an organosilicon compound or a sterically hindered amine in an inert medium in the absence of an alpha olefin, or a catalyst prepared by preliminarily polymerizing an alpha olefin in the presence of a catalyst comprising the above four catalyst components, provided that the last one is an optional component. This process achieves the industrially advantage that the catalysts are highly active, and give a polymer having excellent stereoregularity.

Owner:MITSUI CHEM INC

Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

The invention relates to polymerization of 1-butene, in particular to a spherical catalyst of polybutylene-1. The catalyst consists of a carrier, an active component and a modifier, wherein the active component is titanium tetrachloride, the carrier is a magnesium chloride spherical carrier and the modifier is an electron donor compound; and the catalyst comprises the major components in percentage by mass of: 1.1-4.5% of Ti and 0.15-12.37% of electron donors. The spherical catalyst suitable for butane-1 polymerization solves the problems that the activity of the general catalyst is low, the normality of polymer is difficult to control, and the molecular weight of the polymer and the molecular weight distribution are difficult to control. The obtained polybutylene polymer has very high steric regularity, the normality of polybutylene is as high as 99%, the crystallinity of the polybutylene-1 polymer is greater than 60% and the fusion point is 130.5 DEG C. The invention can simplify the polymerizing process and save the production cost.

Owner:HEBEI UNIV OF TECH

Catalyst for olefin polymerization and process for olefin polymerization

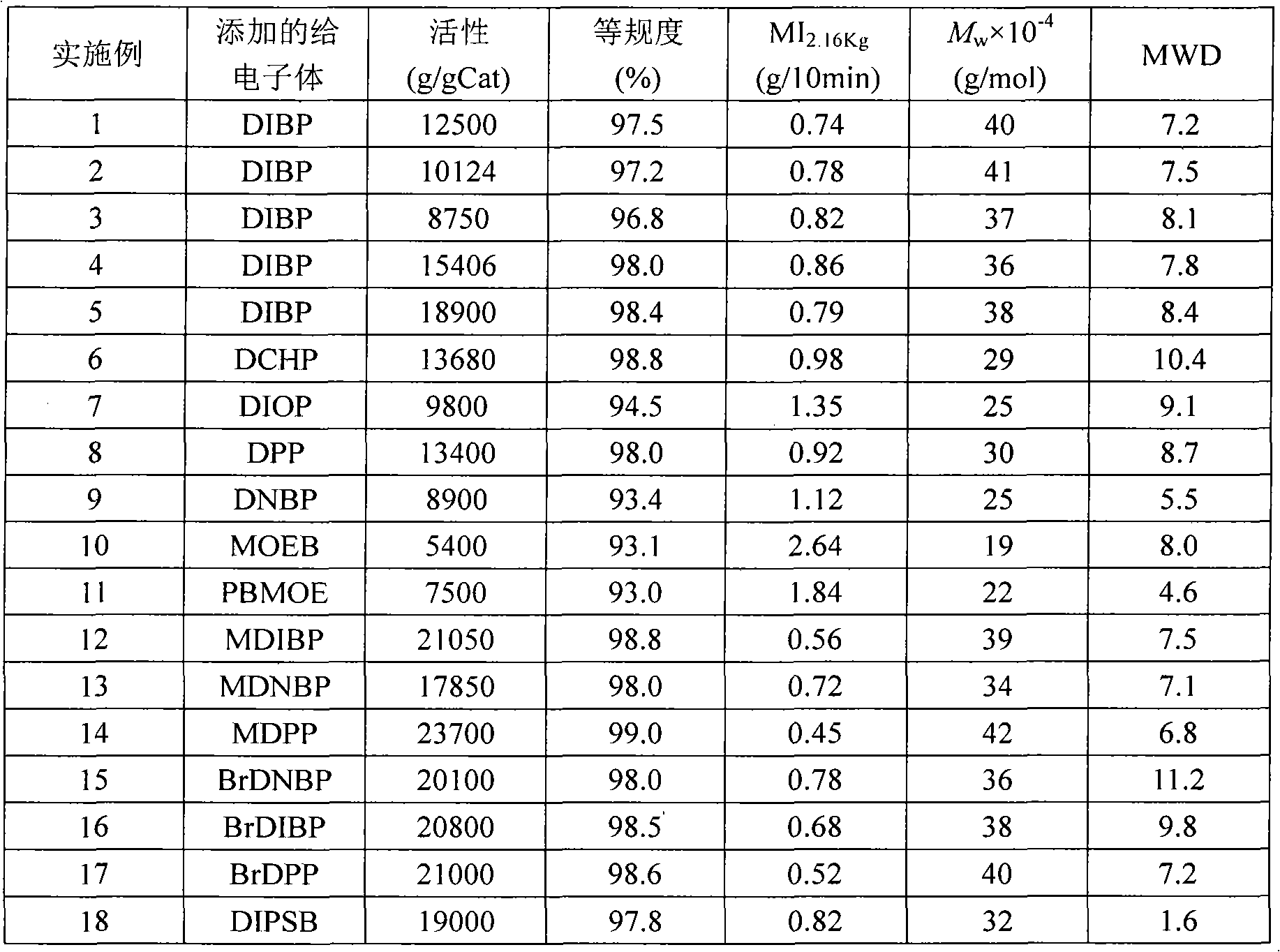

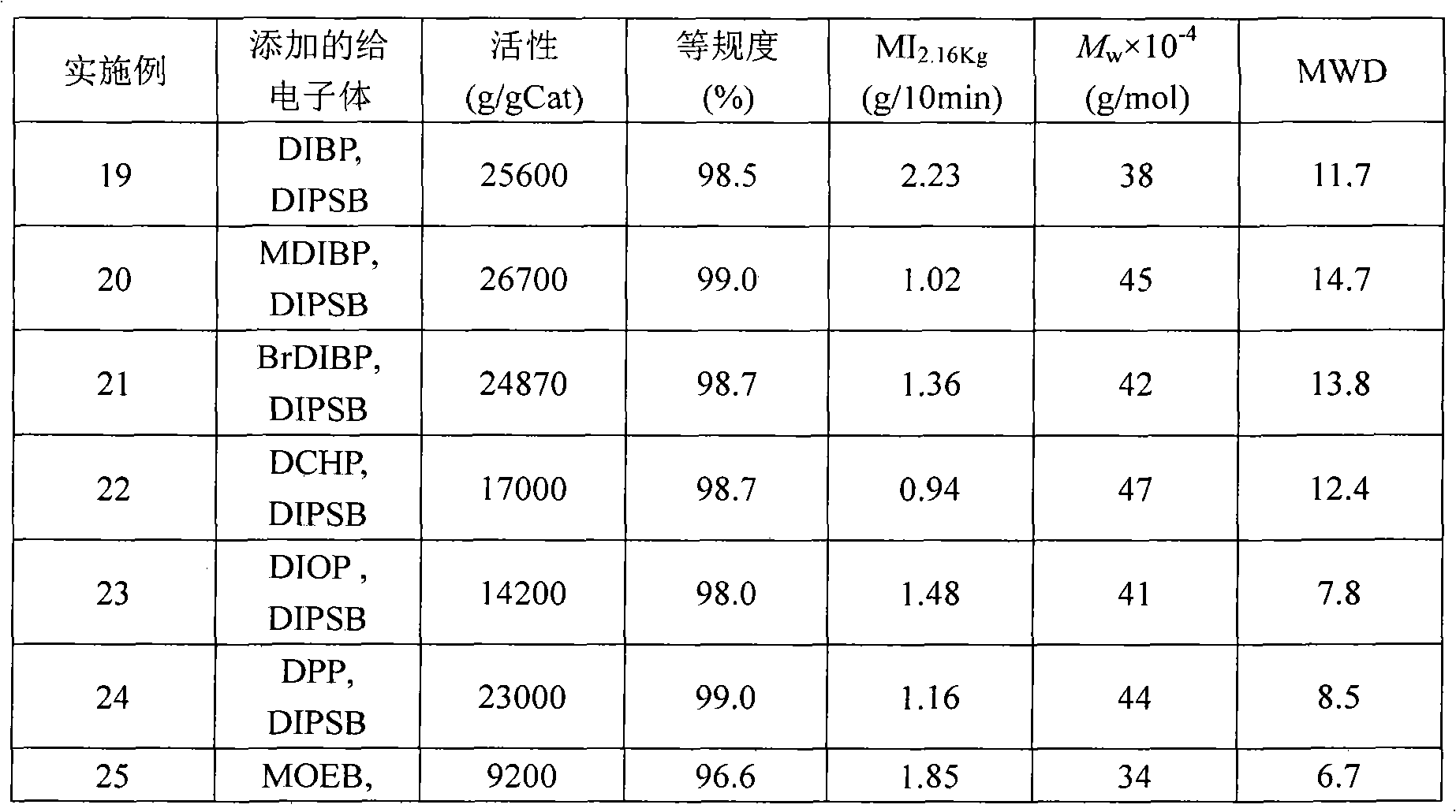

ActiveUS7888438B2High stereoregularityWide molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationDouble bondPolymer

Owner:MITSUI CHEM INC

Method of homo- or co-polymerization of alpha-olefin

InactiveUS6559250B2High stereoregularityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorSilanes

The present invention relates to a method of homo- or co-polymerization of alpha-olefin by means of using a catalyst system which comprises the following components: (1) a solid complex titanium catalyst produced by means of a production method comprising the following steps: (a) preparing a magnesium compound solution by dissolving a magnesium halide compound and a compound of Group IIIA of the Periodical Table in a solvent of mixture of cyclic ester, one or more types of alcohol, a phosphorus compound, and an organic silane; (b) precipitating the solid particles by reacting said magnesium compound solution with a transitional metal compound, a silicon compound, a tin compound, or the mixture thereof; and (c) reacting said precipitated solid particles with a titanium compound and electron donors; (2) an organometallic compound of metal of Group IIIA of the Periodical Table; and (3) external electron donors comprising three or more types of organo-silicon compounds, wherein the melt flow rates of the homopolymers obtained from polymerization by individually using said organo-silicon compounds under the same polymerization conditions are 5 or less, 5~20, and 20 or higher, respectively. According to the present invention, it has an advantage of obtaining polymers of broad molecular weight distribution with high hydrogen reactivity and melt flow rates while maintaining high stereoregularity and yields for olefin homo- or co-polymers during homo- or co-polymerization of alpha-olefin having three or more carbon atoms.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

Catalyst component used for olefin polymerization and preparation method thereof as well as catalyst used for olefin polymerization and application

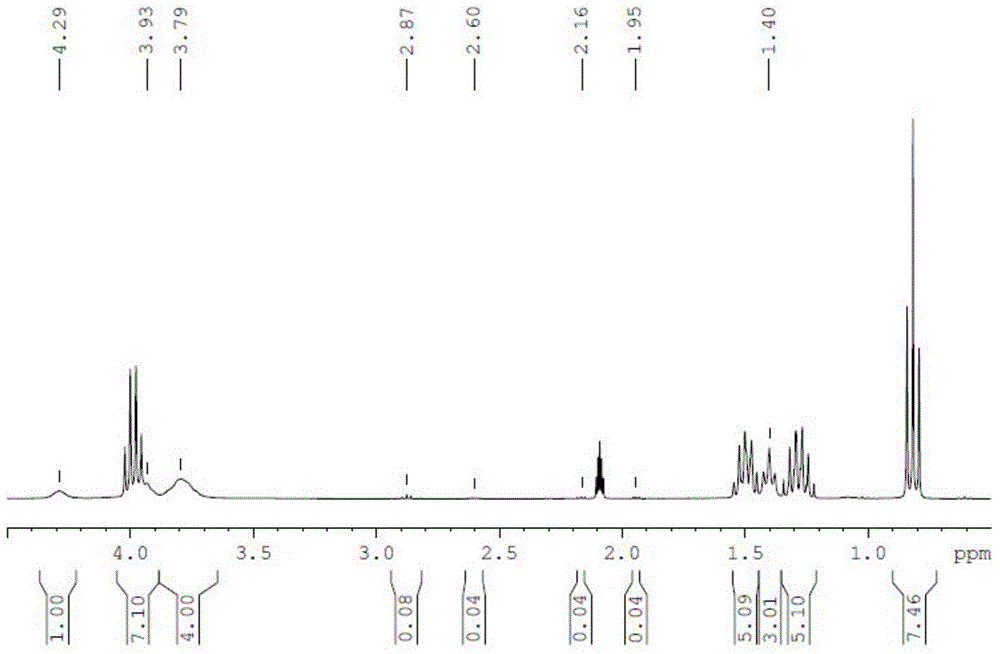

The invention relates to a catalyst component used for olefin polymerization and a preparation method thereof as well as a catalyst used for olefin polymerization and application. The catalyst component comprises reaction products of the following components: (1) a solid component and (2) at least one titanium compound, wherein the solid component comprises a magnesium compound shown in Formula (1) (shown in the description) and epoxy alkanes compounds shown in Formula (2) (shown in the description); R1 is linear alkyls or branched alkyls with C1-C12; R2 is the same as or different from R3; R2 and R3 are hydrogen, or linear alkyls or branched alkyls with C1-C5 independently; hydrogen on alkyls is optionally replaced by halogen; X is halogen, m ranges from 0.1 to 1.9, n ranges from 0.1 to 1.9, and m plus n is equal to 2. By adopting the catalyst component in the process of olefin polymerization, relatively high polymerization activity and relatively high stereotactic capability can be acquired.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveUS20050202958A1Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38: Si(OR1)3(NR2R3) Formula 37 (where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms) RNSi(OR1)3 Formula 38 (where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Elastic polypropylenes and catalysts for their manufacture

InactiveUS6429274B1Lower glass transition temperatureEasy extrusionSilicon organic compoundsOrganic solventPolypropylene

A propylene polymeric composition with elastic character that is soluble in at least one nonpolar organic solvent selected from the group consisting of toluene, xylene, heptane, and hexane, comprises greater than 3 weight percent and up to 45 weight percent homotactic sequences each having only r or m diads, all of which homotactic sequences have a helical length in the range of 20 to 150Å, and in the range of 55 to 97 weight percent of the sum of homotactic sequences of less than 20Å in helical length, each homotactic sequence having only r or m diads and having fewer than 10 repeat units with mmmm pentads being present in the range of 0 to 35 weight percent of the total composition, and heterotactic sequences having r and m diads of unequal number, the polymer having a molecular weight (Mw) of at least 70,000.

Owner:3M INNOVATIVE PROPERTIES CO

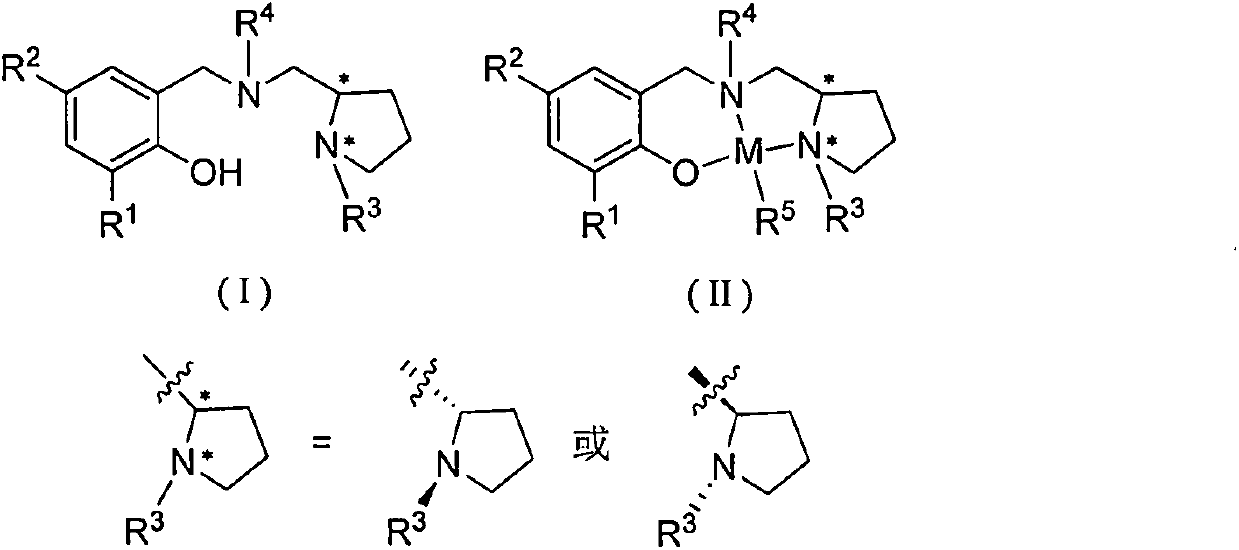

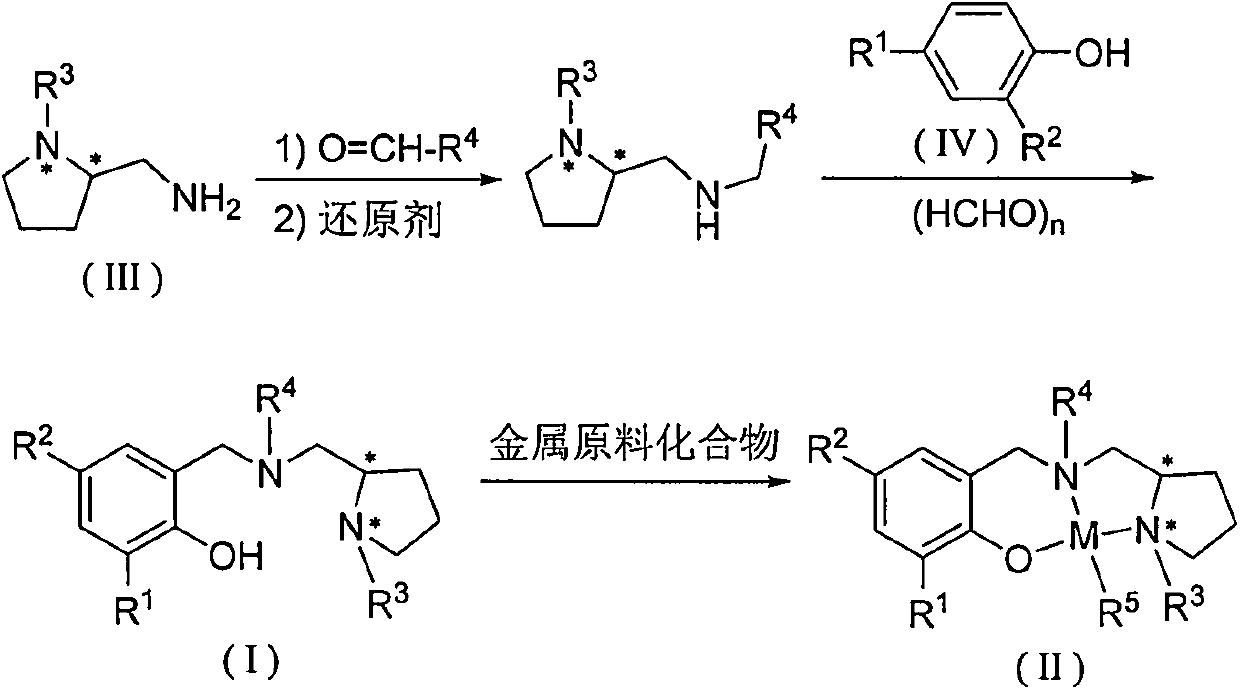

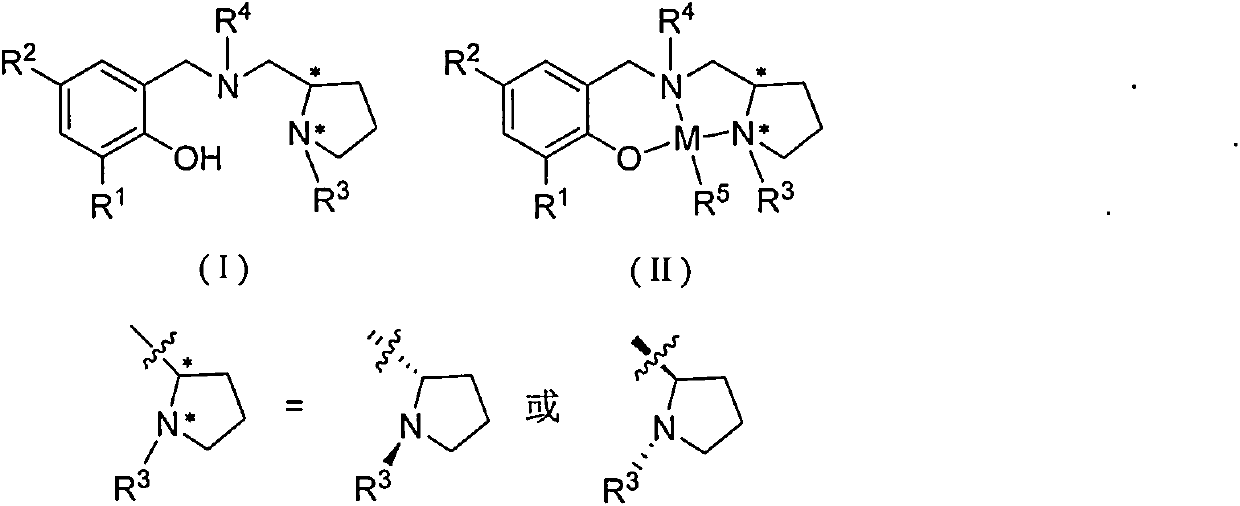

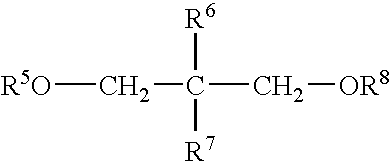

Chiral amino phenoxyl zinc and magnesium compound, and preparation method and application thereof

InactiveCN103787943ALigand raw materials are readily availableLigand raw materials are convenientGroup 4/14 element organic compoundsGroup 2/12 organic compounds without C-metal linkagesPolyesterLactide

The invention discloses a chiral amino phenoxyl zinc and magnesium compound, a preparation method of the chiral amino phenoxyl zinc and magnesium compound, and application of the chiral amino phenoxyl zinc and magnesium compound in ring opening polymerization of catalytic lactone with high activity and high selectivity. The preparation method comprises the following steps: directly reacting a neutral ligand with a metal raw material compound in an organic medium; performing filtration, concentration and re-crystallization to obtain a target compound. The chiral amino phenoxyl zinc and magnesium compound is an efficient lactone ring opening polymerization and can be applied to polymerization reaction of catalytic lactide and the like; particularly, high-isotacticity or high-heterotacticity polylactic acid can be obtained for racemization lactide. The chiral amino phenoxyl zinc and magnesium compound has the obvious advantages that raw materials are easily obtained; a synthetic route is simple; high product yield, high catalytic activity and high stereo selectivity are realized; a high-regularity and high-molecular-weight polymer material can be obtained; requirements of industrial departments can be met. A structural formula is shown as (img file='DSA00000897420700011.TIF' wi='860'he='608' / ).

Owner:EAST CHINA UNIV OF SCI & TECH

Solid catalyst component for alpha-olefin polymerization, process for producing catalyst therefor, and process for producing alpha-olefin polymer

InactiveUS20050267272A1Excellent ability to controlHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationHalogen

A solid catalyst component for α-olefin polymerization, which comprises a titanium atom, a magnesium atom, a halogen atom, a phthalic acid ester compound, and a 1,3-diether compound, wherein an amount of the 1,3-diether compound contained in the solid catalyst component is 0.1 to 3 mol per one mol of the phthalic acid ester compound contained therein; a process for producing a catalyst for α-olefin polymerization, which comprises the step of contacting at least the above solid catalyst component, an organoaluminum compound, and an external electron donor compound with one another; and a process for producing an α-olefin polymer, which comprises the step of homopolymerizing or copolymerizing an α-olefin in the presence of a catalyst produced by the above process.

Owner:SUMITOMO CHEM CO LTD

Polymerization process for preparing syndiotactic polystyrenes through microfluidization

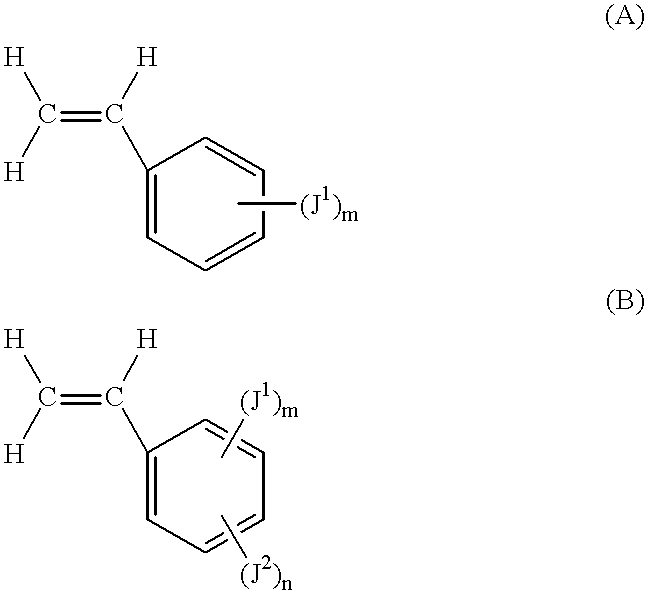

InactiveUS6245865B1Accurate particle sizeHigh Molecular Weight DistributionFluidised-bed furnacesChemical/physical processesOrganic solventPolystyrene

The present invention relates to a polymerization process for preparing syndiotactic polystyrenes, which comprises a step of microfluidizing in a microfluidization apparatus both a catalyst mixture consisting of a styrene monomer, a metallocene catalyst and an inert organic solvent and a cocatalyst mixture consisting of a styrene monomer, a cocatalyst and an inert organic solvent, and a step of reacting the microfluidized mixture with a catalyst and a cocatalyst in a reactor. The metallocene catalyst has a bridged structure of a complex of Group IV transition metals such as Ti, Zr, Hf etc. in the Periodic Table and a ligand having one or two cycloalkane dienyl groups such as cyclopentadienyl group, indenyl groups, fluorenyl group, and derivatives thereof. The reactor is a well stirred reactor equipped with agitating blades therein to mix the reactants well. In this invention, the plural number of reactors can be employed in series for more effective polymerization, and the plural number of microfluidization apparatuses can be employed in parallel.

Owner:SAMSUNG ATOFINA CO LTD

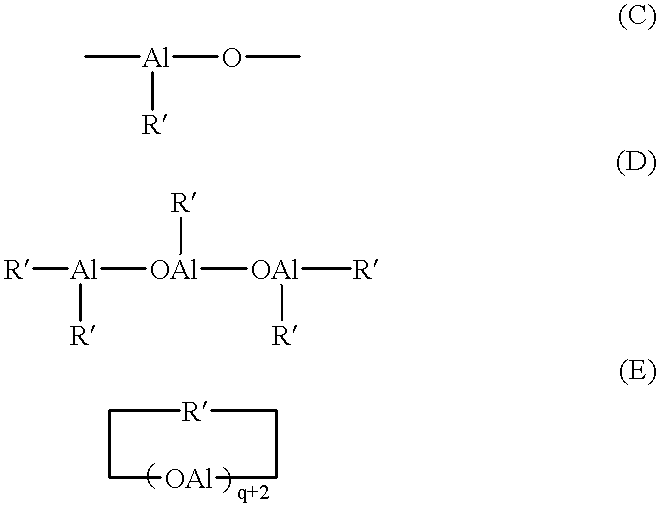

Olefin polymerization catalyst

ActiveUS6984600B2High activityHigh stereoregularityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceTitanium

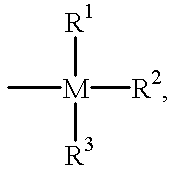

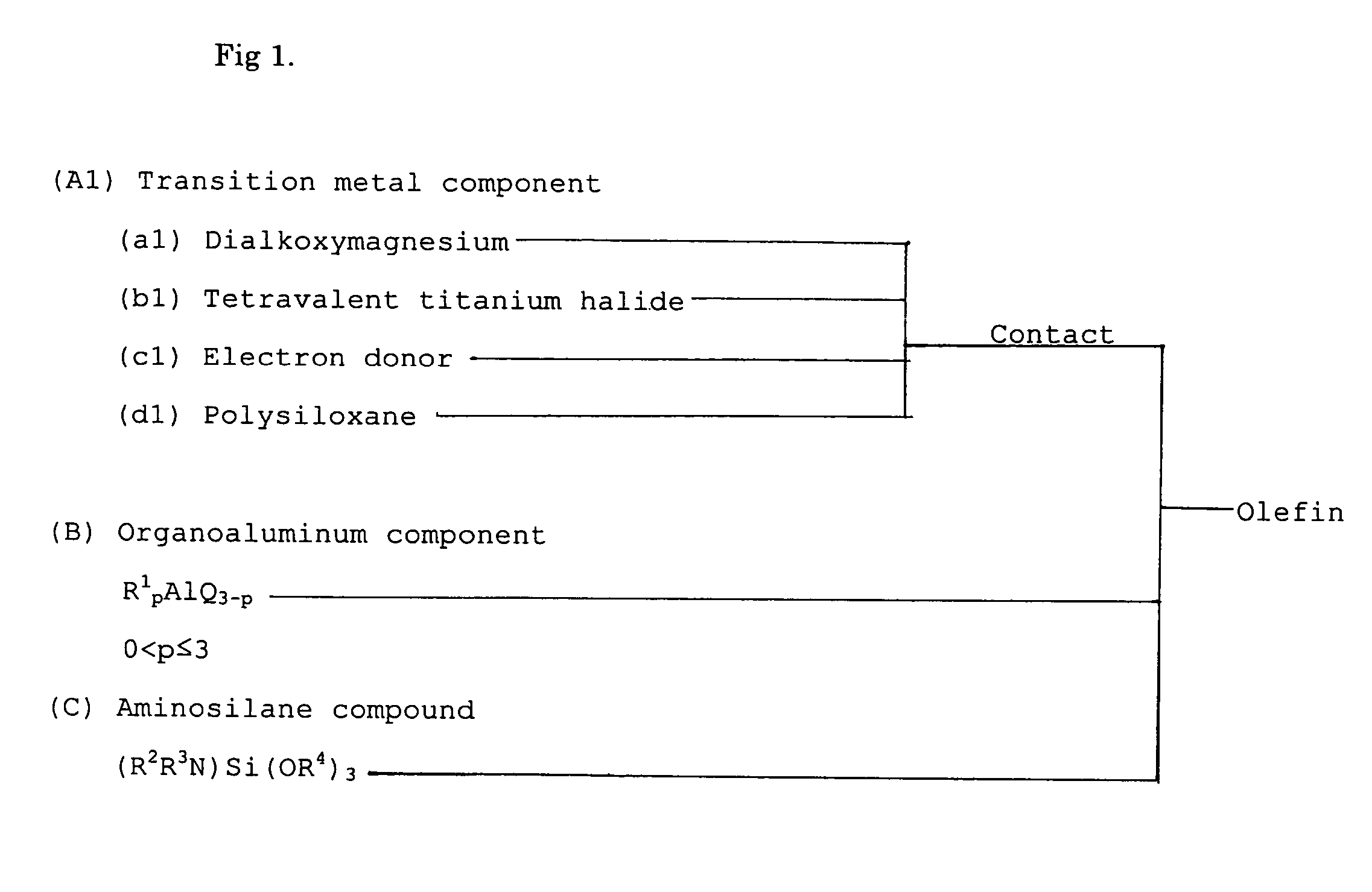

An olefin polymerization catalyst comprising: (A1) a solid catalyst component prepared by contacting (a1) a dialkoxymagnesium, (b1) a tetravalent titanium halide, (c1) an electron compound, and (d1) a polysiloxane, (B) an organoaluminum compound of the formula R1pAlQ3-p, and (C) an aminosilane compound of the formula (R2R3N)Si(OR4)3 has a high activity to hydrogen as compared with conventional catalysts and maintains the capability of producing polymers with a high stereoregularity at a high yield.

Owner:TOHO TITANIUM CO LTD

Load type catalyst for olefinic polymerization and method for producing the same

ActiveCN101195666AHigh stereoregularityIncrease space volumeBulk chemical productionElectron donorPolypropylene

The invention relates to a supported catalyst of olefin polymer, which uses 1, 4-dialkyl compound with two cyclic structures in molecular skeleton as internal electron donor compound, to obtain large spatial volume, while the inventive supported catalyst has high catalytic activity for catalyzing propone polymerization. While assisted with promoter and external electron donor, and the product polypropylene has high stereoregularity. The invention further discloses a preparation method of supported catalyst.

Owner:PETROCHINA CO LTD

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveCN1675255AGood hydrogen responseHigh polymerization activitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention has an object to provide a catalyst for polymerizing or copolymerizing an alpha -olefin, catalyst constituent thereof, and method of polymerizing alpha -olefins with the catalyst, for production of alpha -olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an alpha -olefin, represented by Formula 37 or 38: Formula 37 Si(OR<1>)3(NR<2>R<3>) (where in Formula 37, R<1> is a hydrocarbon group with 1 to 6 carbon atoms; R<2> is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R<3> is a hydrocarbon group with 1 to 12 carbon atoms) Formula 38 RNSi(OR<1>)3 (where in Formula 38, R<1> is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Method of homo- or co-polymerization of alpha-olefin

InactiveUS20020120079A1High stereoregularityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePolyolefin

The present invention relates to a method of homo- or co-polymerization of alpha-olefin by means of using a catalyst system which comprises the following components: (1) a solid complex titanium catalyst produced by means of a production method comprising the following steps: (a) preparing a magnesium compound solution by dissolving a magnesium halide compound and a compound of Group IIIA of the Periodical Table in a solvent of mixture of cyclic ester, one or more types of alcohol, a phosphorus compound, and an organic silane; (b) precipitating the solid particles by reacting said magnesium compound solution with a transitional metal compound, a silicon compound, a tin compound, or the mixture thereof, and (c) reacting said precipitated solid particles with a titanium compound and electron donors; (2) an organometallic compound of metal of Group IIIA of the Periodical Table; and (3) external electron donors comprising three or more types of organo-silicon compounds, wherein the melt flow rates of the homopolymers obtained from polymerization by individually using said organo-silicon compounds under the same polymerization conditions are 5 or less. 5~20, and 20 or higher, respectively. According to the present invention, it has an advantage of obtaining polymers of broad molecular weight distribution with high hydrogen reactivity and melt flow rates while maintaining high stereoregularity and yields for olefin homo- or co-polymers during homo- or co-polymerization of alpha olefin having three or more carbon atoms.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

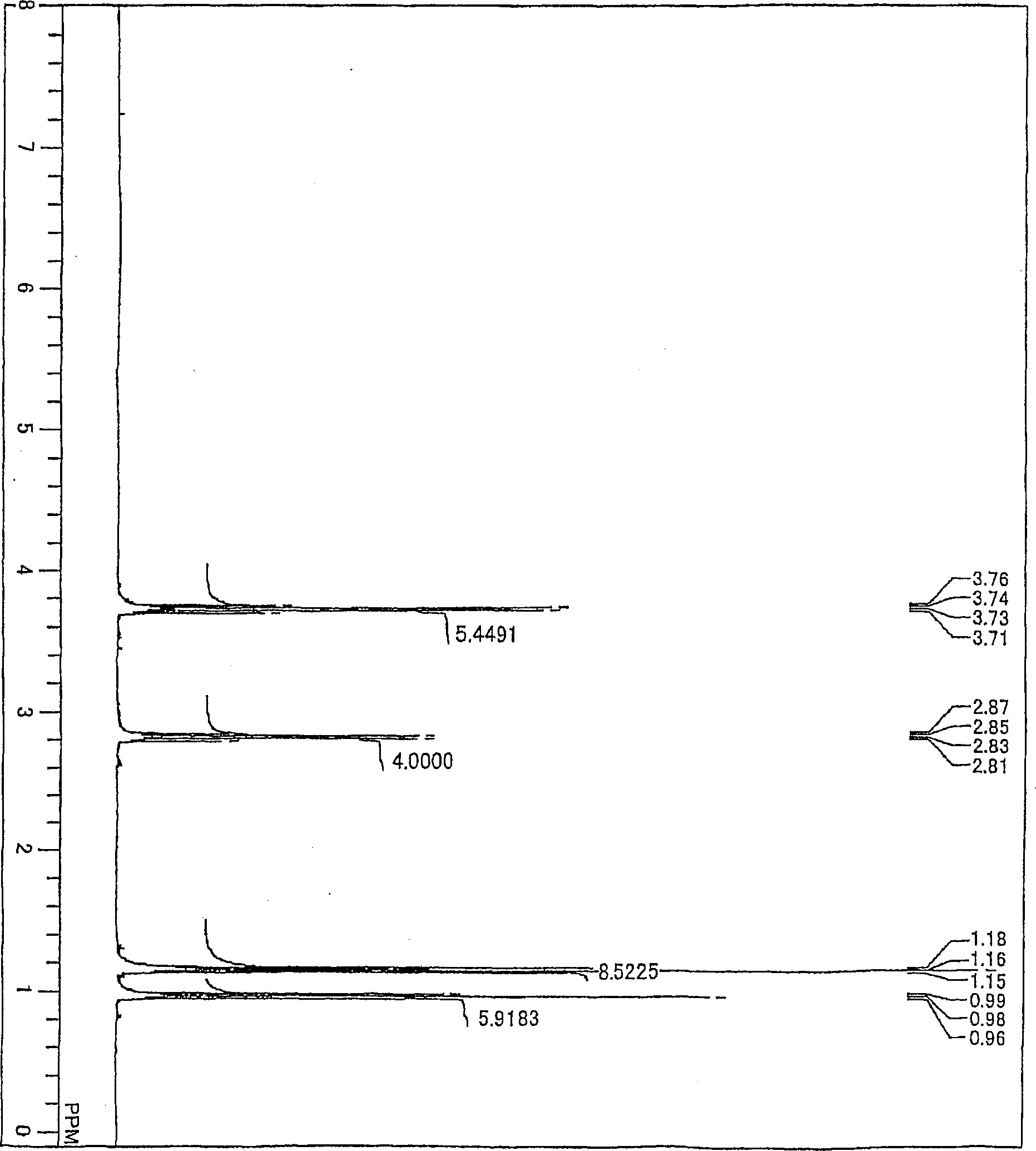

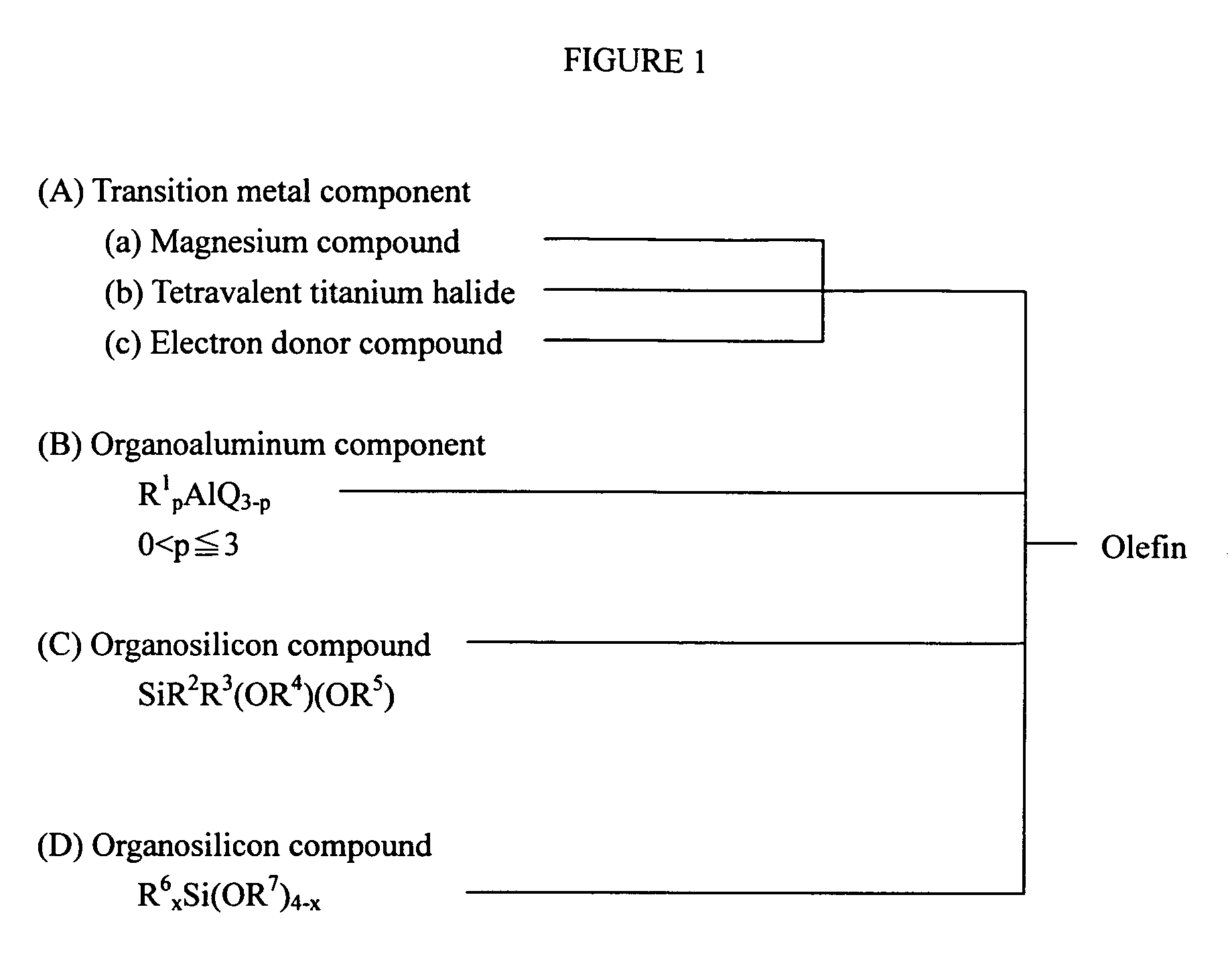

Catalyst for olefin polymerization and process for polymerizing olefins

ActiveUS7141634B2High stereoregularityWide molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenElectron donor

A catalyst for olefin polymerization comprising (A) a solid catalyst component which is prepared by causing (a) a magnesium compound, (b) a tetravalent titanium halide compound, and (c) an electron donor compound to come in contact with each other, (B) an organoaluminum compound of the formula R1pAlQ3-p, and (C) an organosilicon compound of the formula SiR2R3(OR4)(OR5), and (D) an organosilicon compound of the formula R6xSi(OR7)4-x exhibits a higher hydrogen activity than conventional catalysts.

Owner:TOHO TITANIUM CO LTD

Preparation Method Of Solid Titanium Catalyst For Olefin Polymerization

InactiveUS20070298964A1Production yield be raiseHigh production yieldMechanical apparatusLighting and heating apparatusOlefin polymerizationMagnesium

The present invention relates to a preparation method of solid titanium catalyst for olefin polymerization comprising the steps of: 1) preparing a magnesium compound solution by dissolving a magnesium halide compound into a mixed solvent of a cyclic ether and one or more of alcohol; (2) preparing a carrier by, adding a mixture of titanium compound and halogenated hydrocarbon to the magnesium compound solution at low temperature and then elevating the temperature of the resulted solution for reaction; and (3) preparing a solid titanium catalyst by reacting the carrier with a titanium compound and an electron donor.

Owner:SAMSUNG TOTAL PETROCHEMICALS CO LTD

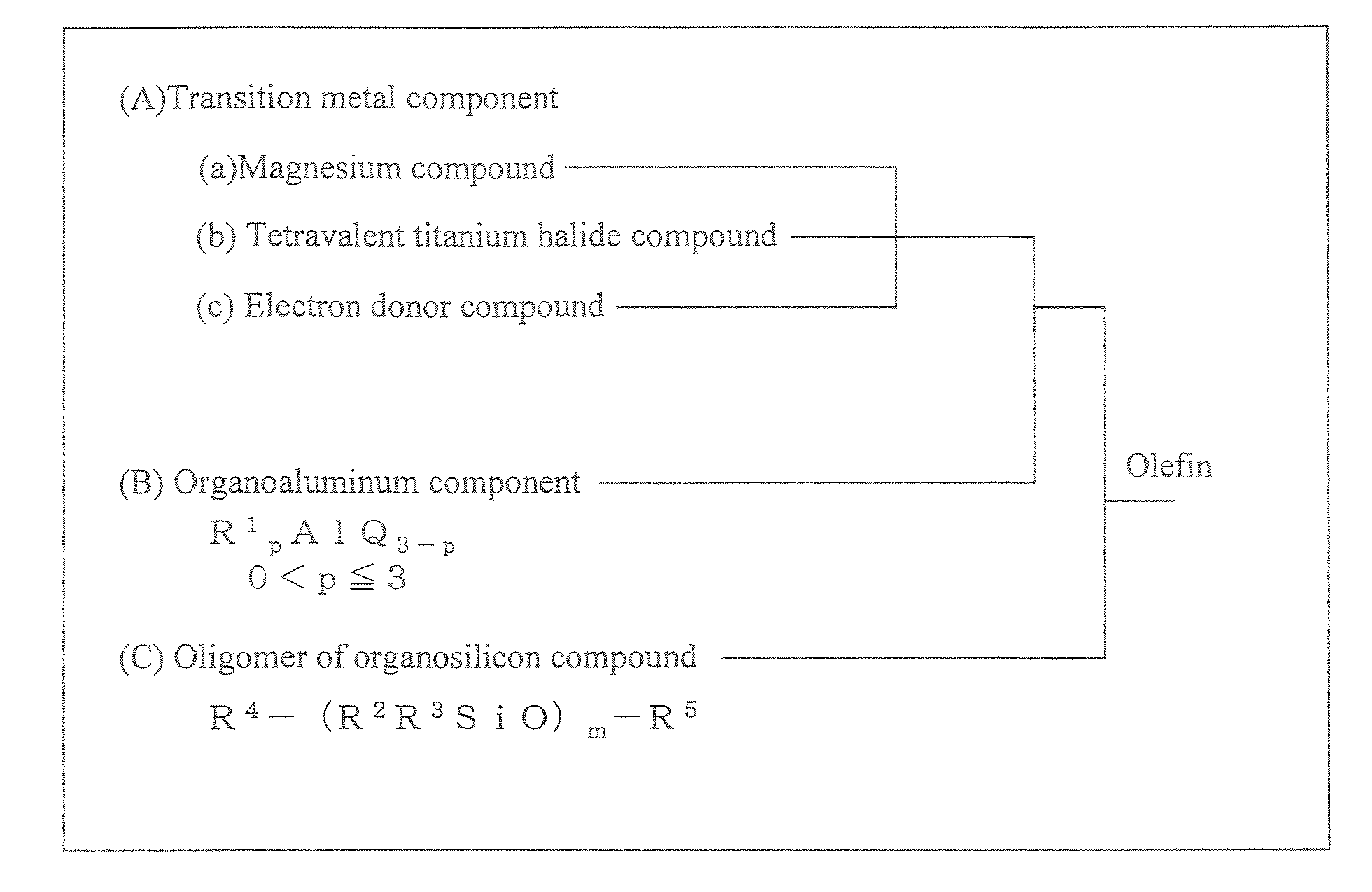

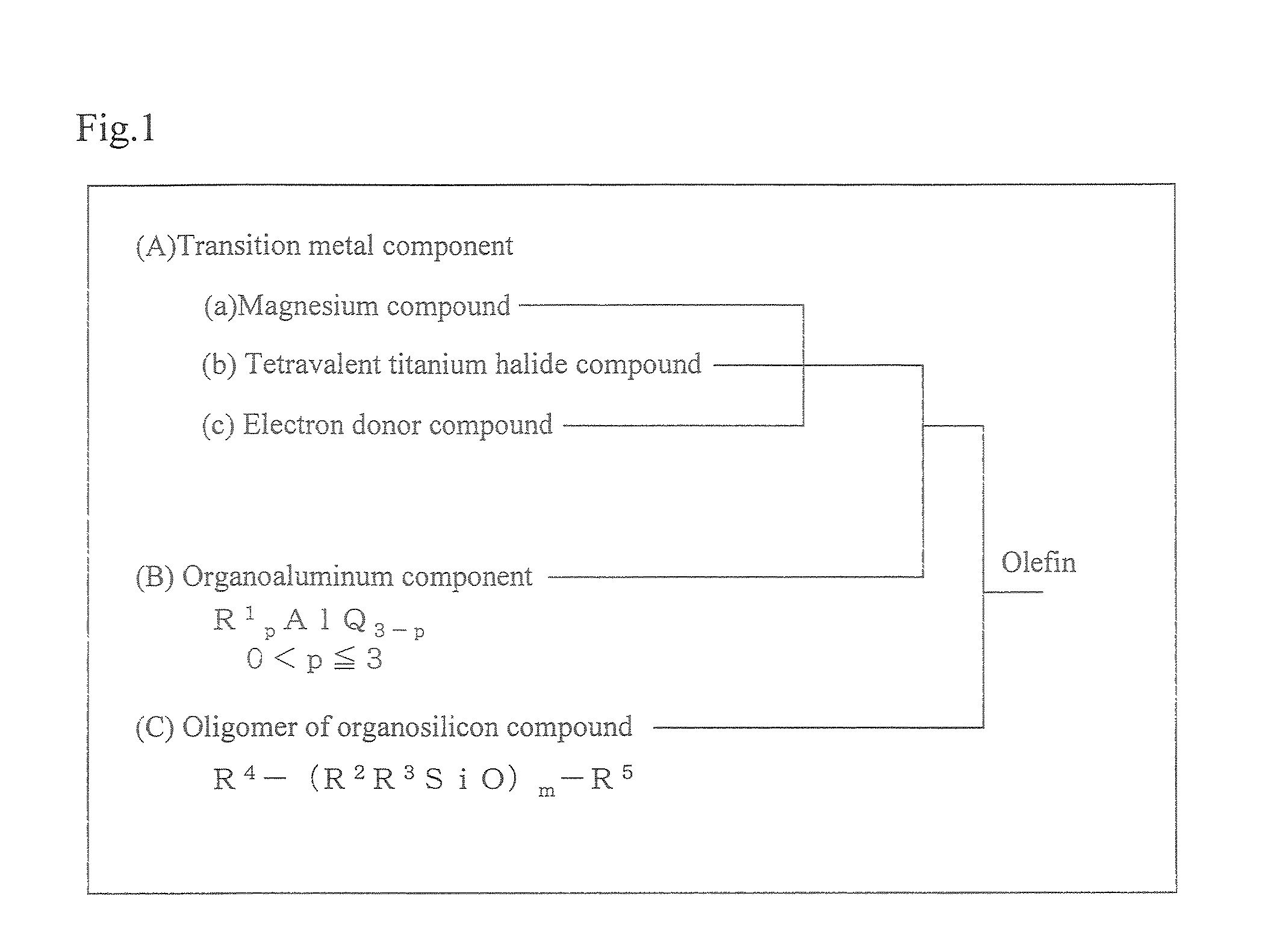

Catalyst for polymerization of olefins and method for polymerization of olefins

ActiveUS7704910B2High stereoregularityWide molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOligomerElectron donor

A catalyst for olefin polymerization comprising (A) a solid catalyst component prepared by causing (a) a magnesium compound, (b) a tetravalent titanium halide compound, and (c) an electron donor compound to come in contact with each other, (B) an organoaluminum compound of the general formula R1pAlQ3-p, and (C) an oligomer of an organosilicon compound of the following chemical formula; R4—(R2R3SiO)m—R5 can produce olefin polymers having higher stereoregularity and a broader molecular weight distribution in a higher yield than conventional catalysts.

Owner:TOHO TITANIUM CO LTD

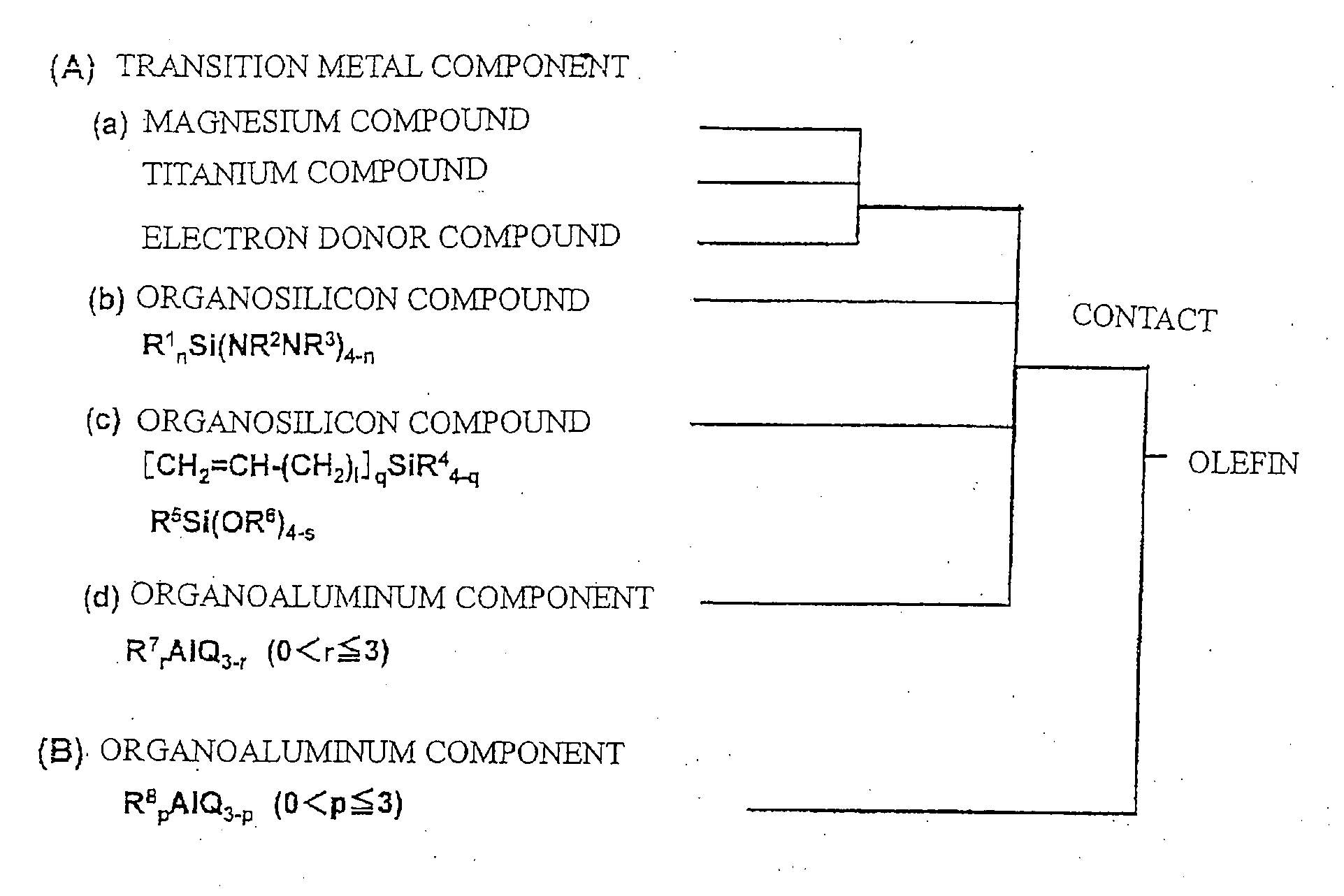

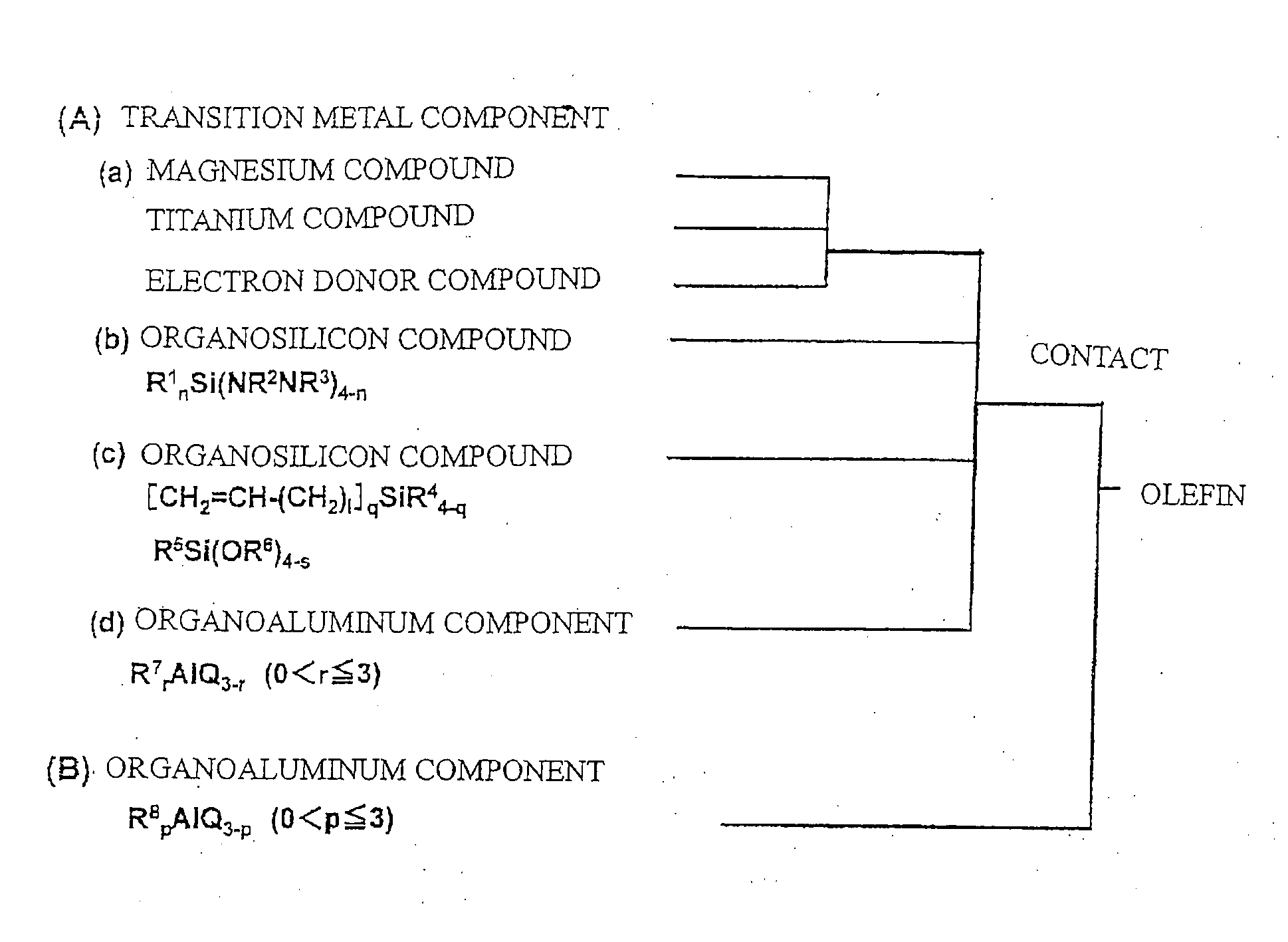

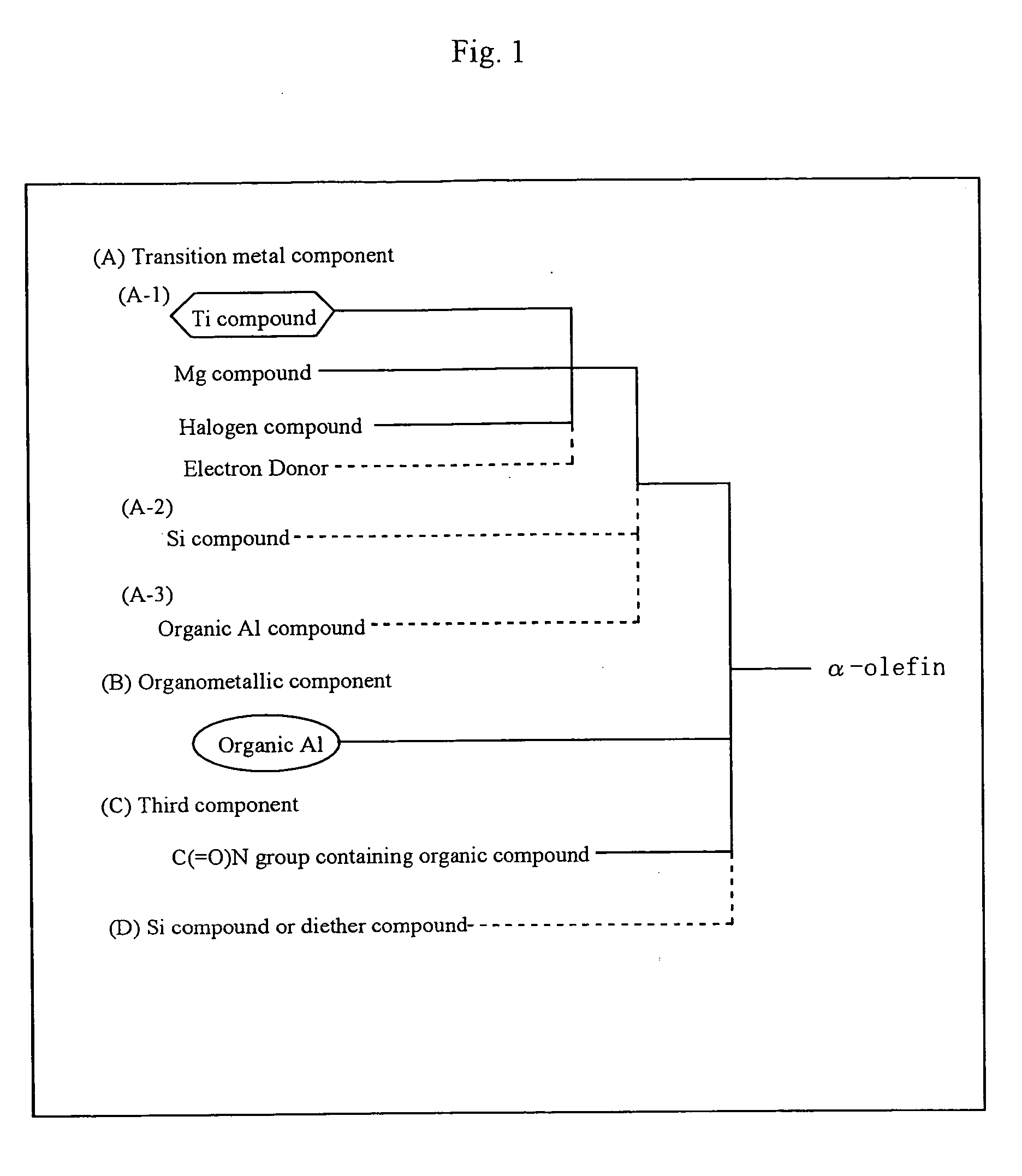

Solid catalyst component and catalyst for polymerization of olefins, and process for production of olefin polymers using same

InactiveUS20120004378A1High stereoregularityReduce the amount requiredOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSolid componentPolymer science

A solid catalyst component for olefin polymerization is produced by causing (a) a solid component that includes magnesium, titanium, a halogen, and an electron donor, (b) an aminosilane compound shown by the following general formula (1), and (c) at least one organosilicon compound selected from an organosilicon compound shown by the following general formula (2-A) and an organosilicon compound shown by the following general formula (2-B) to come in contact with each other. A polymer having high stereoregularity is produced in high yield while achieving a high melt flow rate due to hydrogen by polymerizing an olefin in the presence of a catalyst that includes the solid catalyst component.R1nSi(NR2R3)4-n (1)[CH2═CH—(CH2)1]qSiR44-q (2-A)R5Si(OR6)4-s (2-B)

Owner:TOHO TITANIUM CO LTD

Solid catalyst component and catalyst for polymerization of olefin, and method for producing polymer or copolymer of olefin using the same

InactiveUS20090253873A1Great melt flow rate effectReduce the amount requiredOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSolid componentElectron donor

A catalyst for polymerization of olefins and a process for producing an olefin polymer or copolymer are disclosed. The catalyst comprises (a) a solid catalyst component obtained by causing an organosilicon compound (b) represented by the formula, [CH2═CH—(CH2)n]qSiR34-q, and an organoaluminum compound to come in contact with a solid component comprising magnesium, titanium, halogen, and an electron donor compound, or a solid catalyst component obtained by causing a magnesium compound, two types of titanium compounds, an electron donor compound, and an organosilicon compound to come in contact with each other, and (B) an organoaluminum compound. The process for producing an olefin polymer or copolymer comprises polymerizing olefins in the presence of the catalyst. The catalyst has a high catalytic activity, exhibits excellent hydrogen response, and can produce polymers with high stereoregularity and a broad molecular weight distribution at a high yield.

Owner:TOHO TITANIUM CO LTD

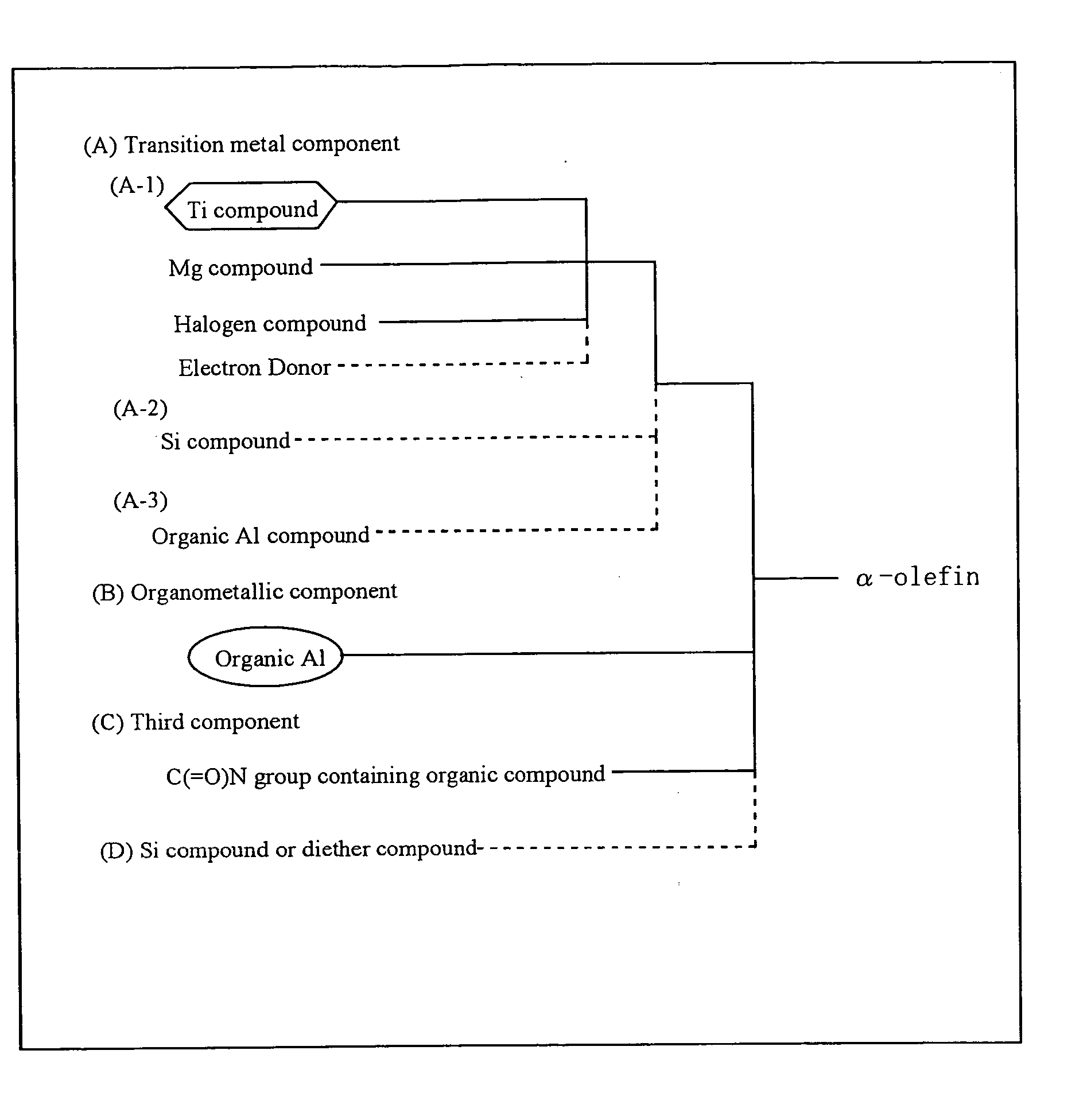

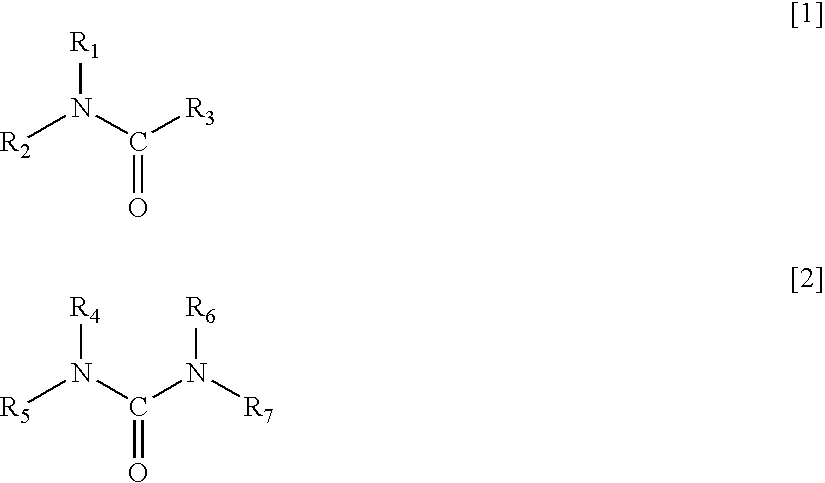

Plymerization catalyst for a-olefins and process for production of alpha-olefin polymers therewith

ActiveUS20060068984A1Improved stereoregularityLow component requirementsOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorAlpha-olefin

A catalyst having a high catalyst activity, which enables the production of an α-olefin polymer improved in stereoregularity by decreasing an amorphous component, and a production method for the α-olefin polymer, are developed. Described are a catalyst for polymerizing α-olefin comprising a combination of (A) a solid catalyst component containing magnesium, titanium and a halogen as an essential component, which may contain if necessary, a silicon compound, an organoaluminum compound, and an electron donor; (B) an organoaluminum compound; and (C) a compound containing a C(═O)N bond such as an amide or an urea; which may further contain if necessary, (D) a silicon compound or a diether compound; and a production method for an α-olefin polymer using the same.

Owner:JAPAN POLYPROPYLENE CORP

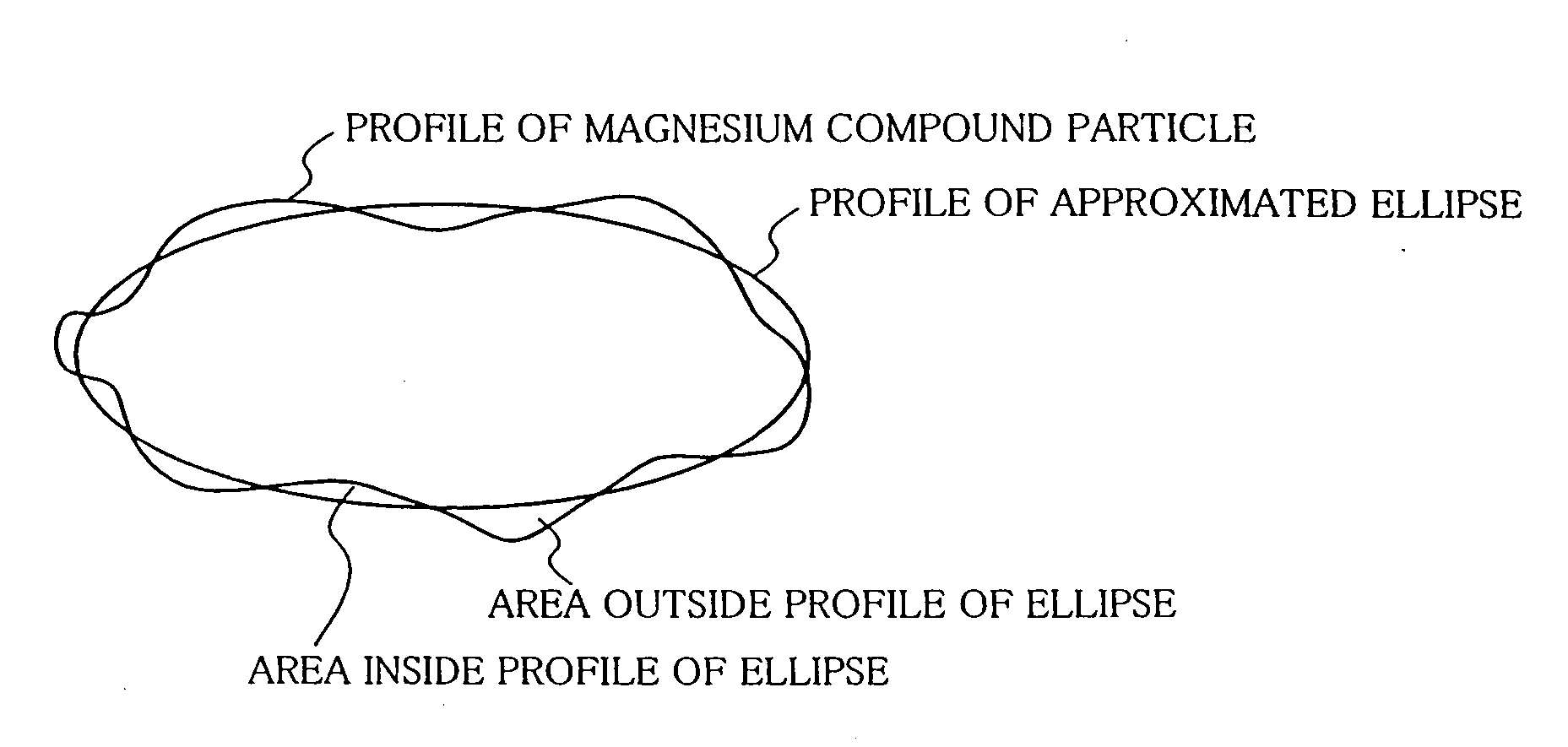

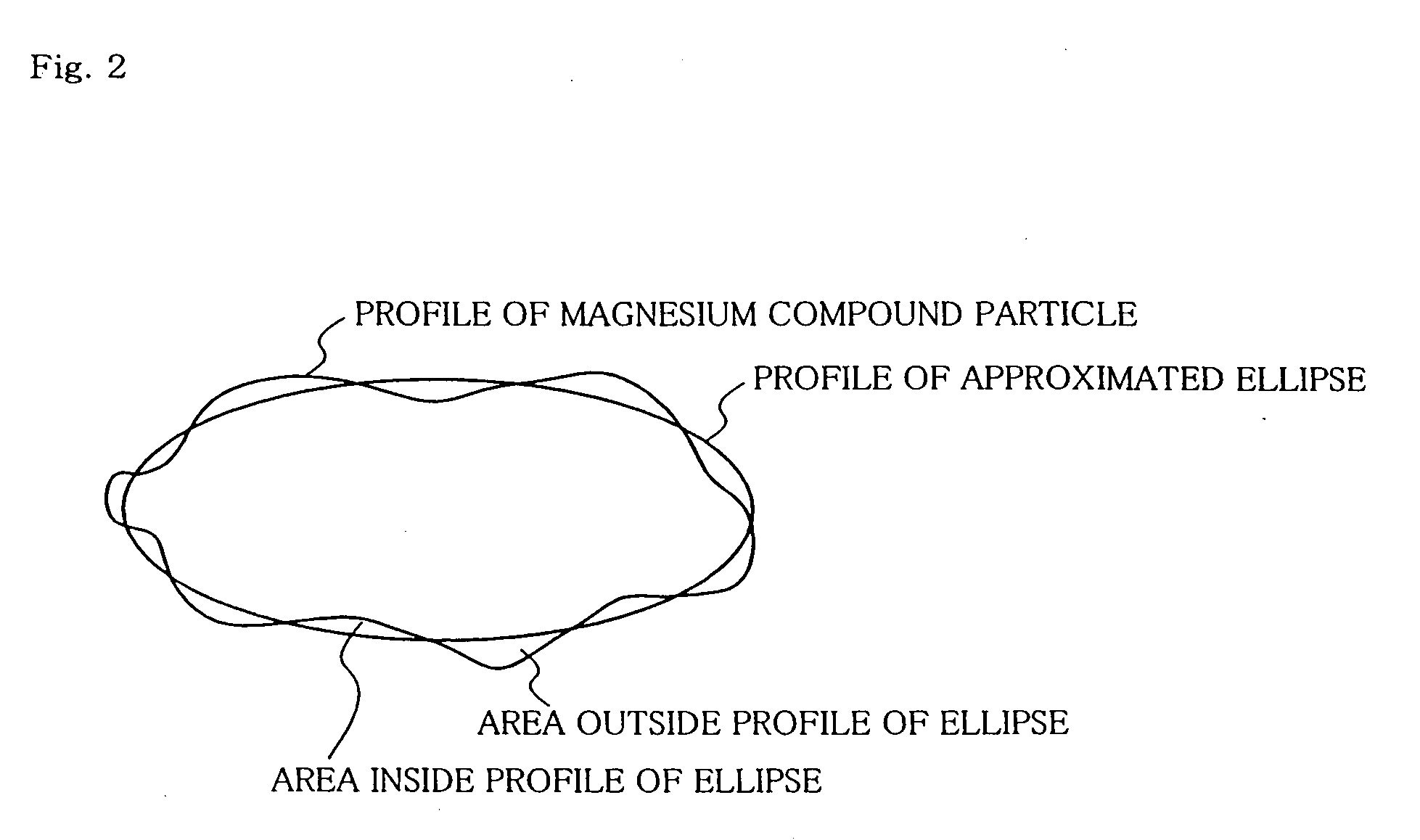

Magnesium compound, solid catalyst component, olefin polymerization catalyst, and method for producing olefin polymer

InactiveUS20090181845A1Easy to shapeHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHalogenAlcohol

A method of producing a magnesium compound by reacting the following components (i), (ii) and (iii):(i) metal magnesium(ii) an alcohol(iii) a metal dihalide compound represented by the general formula (I) containing at least 0.001 mole of M relative to one mole of magnesium of the metal magnesium (i)MX2 (I)where X is a halogen atom and M is Mn, Fe, Co or Zn.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com