Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

A technology for butene polymerization and catalyst is applied in the field of spherical catalyst and its preparation to achieve the effects of improving processability, improving performance and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

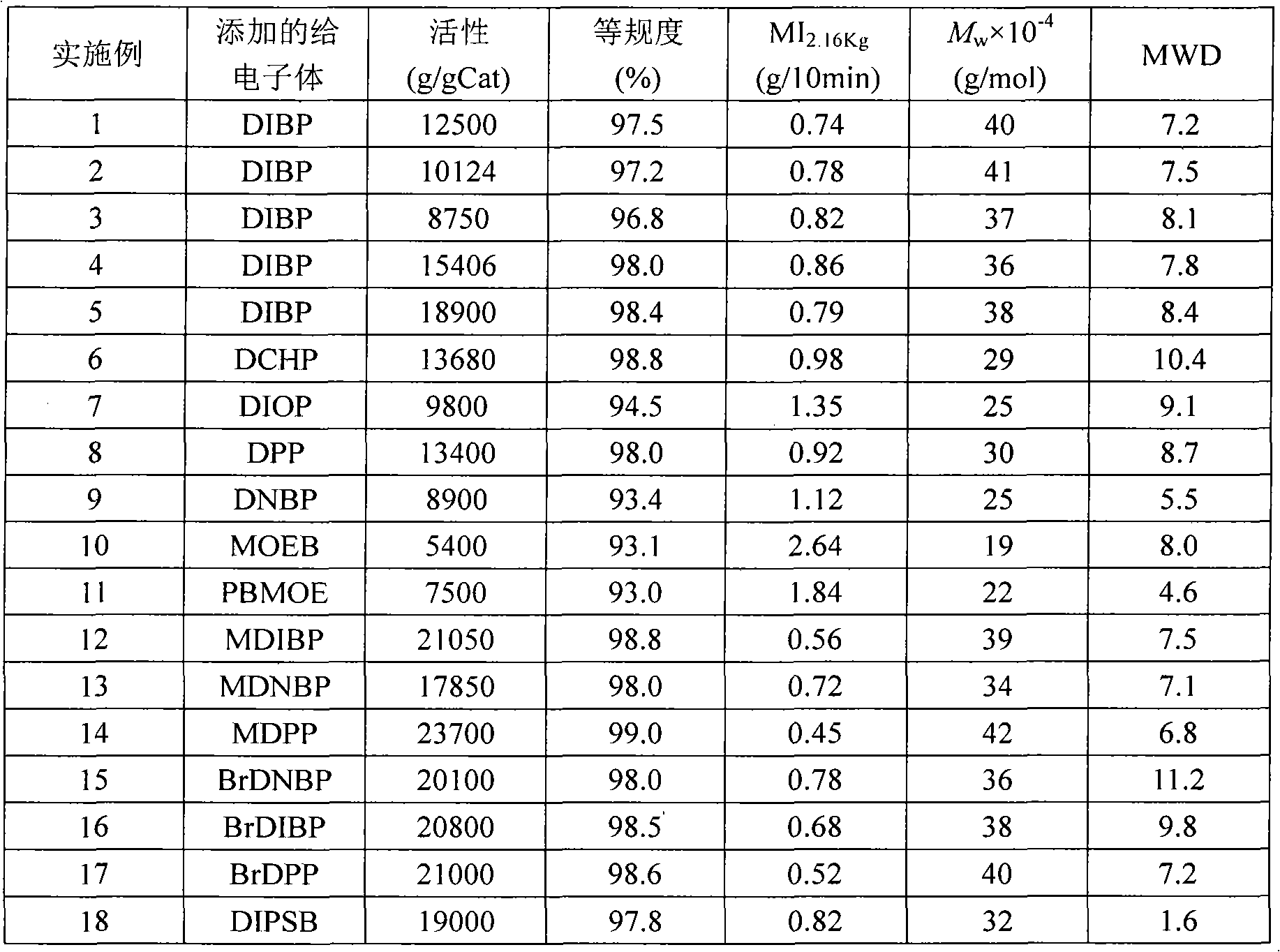

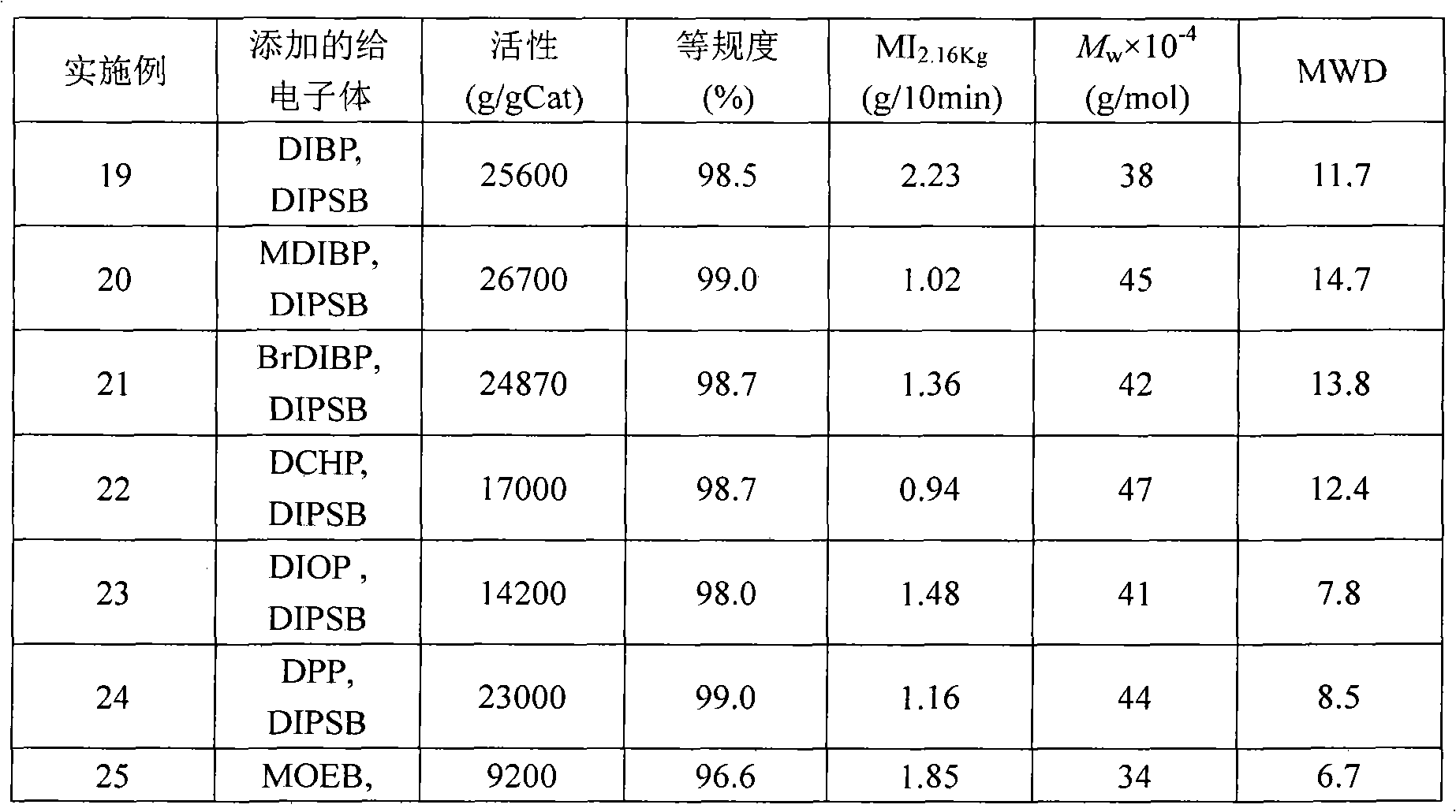

Examples

Embodiment 1

[0054] (1) Preparation of magnesium chloride spherical carrier

[0055] In a 250ml glass reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer, and fully replaced by high-purity argon, add 18.3ml of dehydrated alcohol, 10.6g of anhydrous magnesium chloride (molar ratio dehydrated alcohol: anhydrous magnesium chloride =2.8:1, heat up under stirring, add 60ml of inert solvent (a mixture of methyl silicone oil and liquid paraffin in a volume ratio of 1:1) after the magnesium chloride is completely dissolved, stir to disperse and emulsify it for 15min (pre-dispersion), and the stirring speed is 600rpm, and maintain the temperature at 120°C. In another reactor with a mechanical stirrer with a volume of 250ml, first add 60ml of inert solvent (identical to the composition of the above inert solvent), preheat to 120°C, and prepare the above-mentioned The mixture was quickly transferred to the second reactor, maintained at a temperature of 120°C, and stirred ...

Embodiment 2 and Embodiment 3

[0061] Change the molar ratio of absolute ethanol to magnesium chloride in the preparation of magnesium chloride alcoholate in Example 1 to 3.5:1 and 6:1, and other conditions and methods are the same as in Example 1. The composition of the magnesium chloride alcoholate carrier is MgCl 2 2.56C 2 h 5 OH and MgCl 2 2.67C 2 h 5 OH, the percentages of titanium and ester in the catalyst are respectively Ti=2.21%, ester=3.72% and Ti=2.87%, ester=4.23%, and the specific surface area is 256m 2 / g and 224m 2 / g. Liquid-phase butene-1 bulk polymerization is the same as in Example 1, and the results are listed in Table 1.

Embodiment 4

[0063] Change the final dispersion speed in the preparation of magnesium chloride alcoholate in embodiment 1 to 1000rpm, and other conditions and methods are all the same as in embodiment 1. The composition of the magnesium chloride alcoholate carrier is MgCl 2 2.32C 2 h 5 OH, Ti in the catalyst = 1.91%, ester 4.50%, specific surface area 249m 2 / g. Liquid-phase butene-1 bulk polymerization is the same as in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com