Patents

Literature

167results about How to "Resist impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

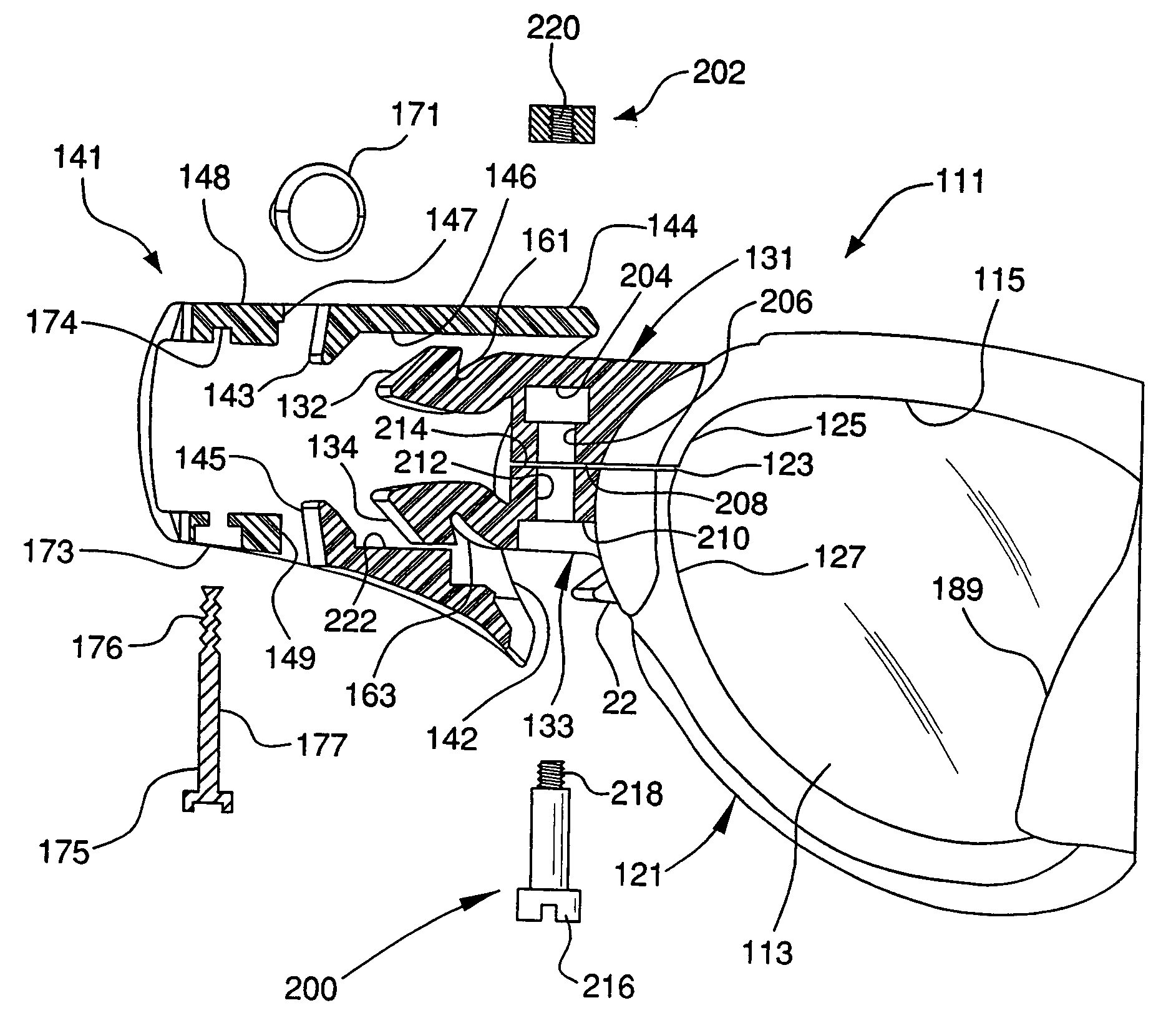

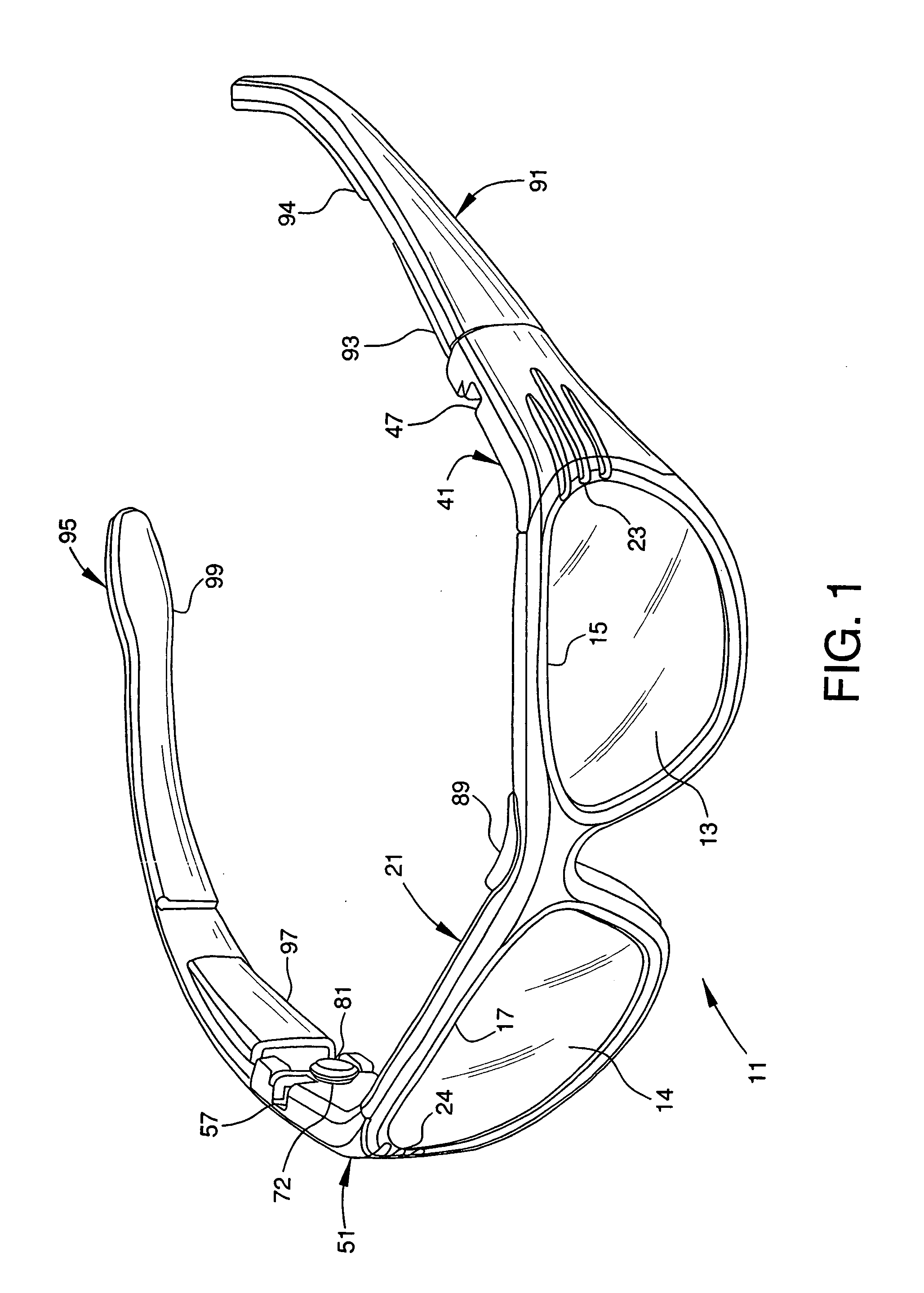

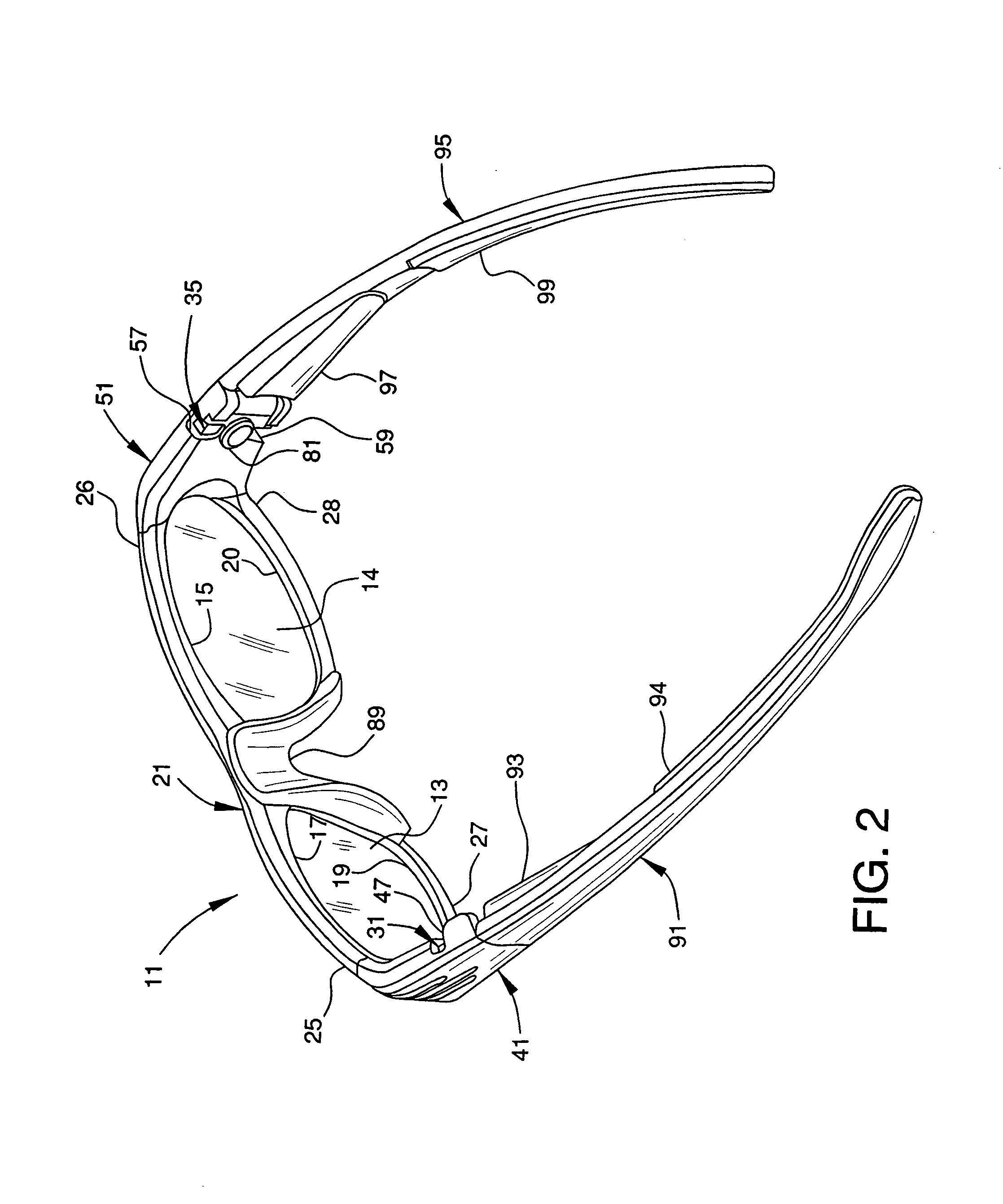

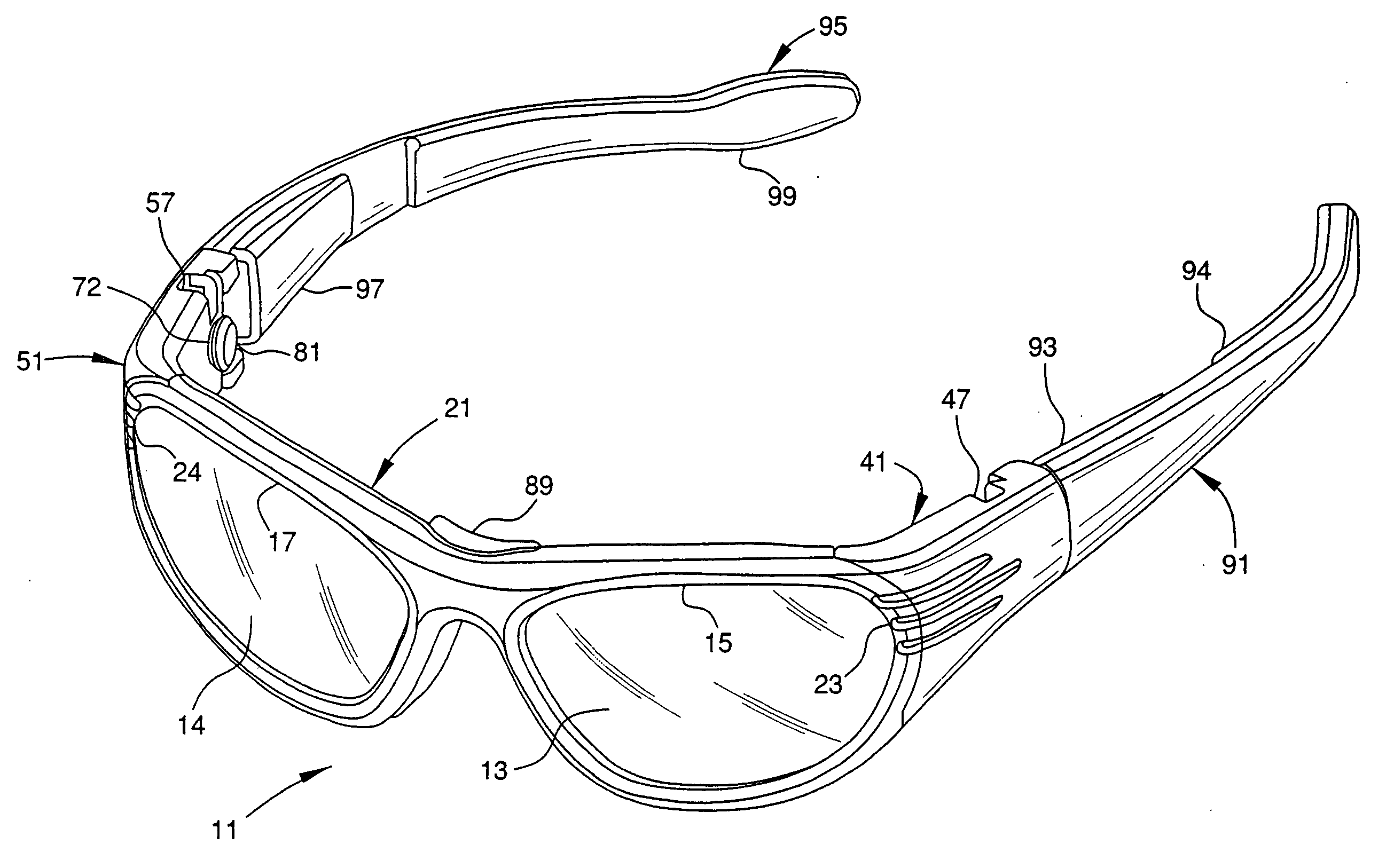

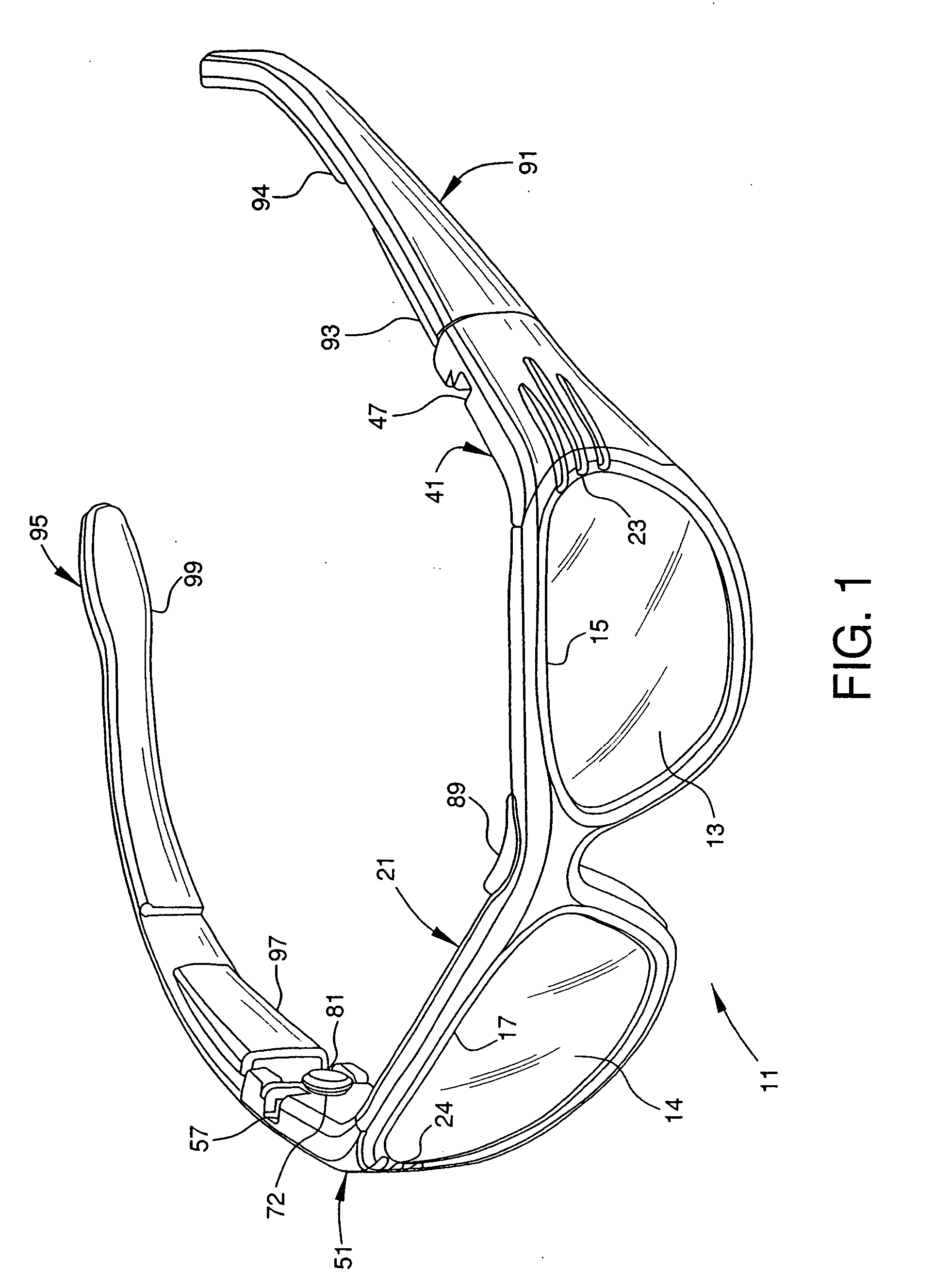

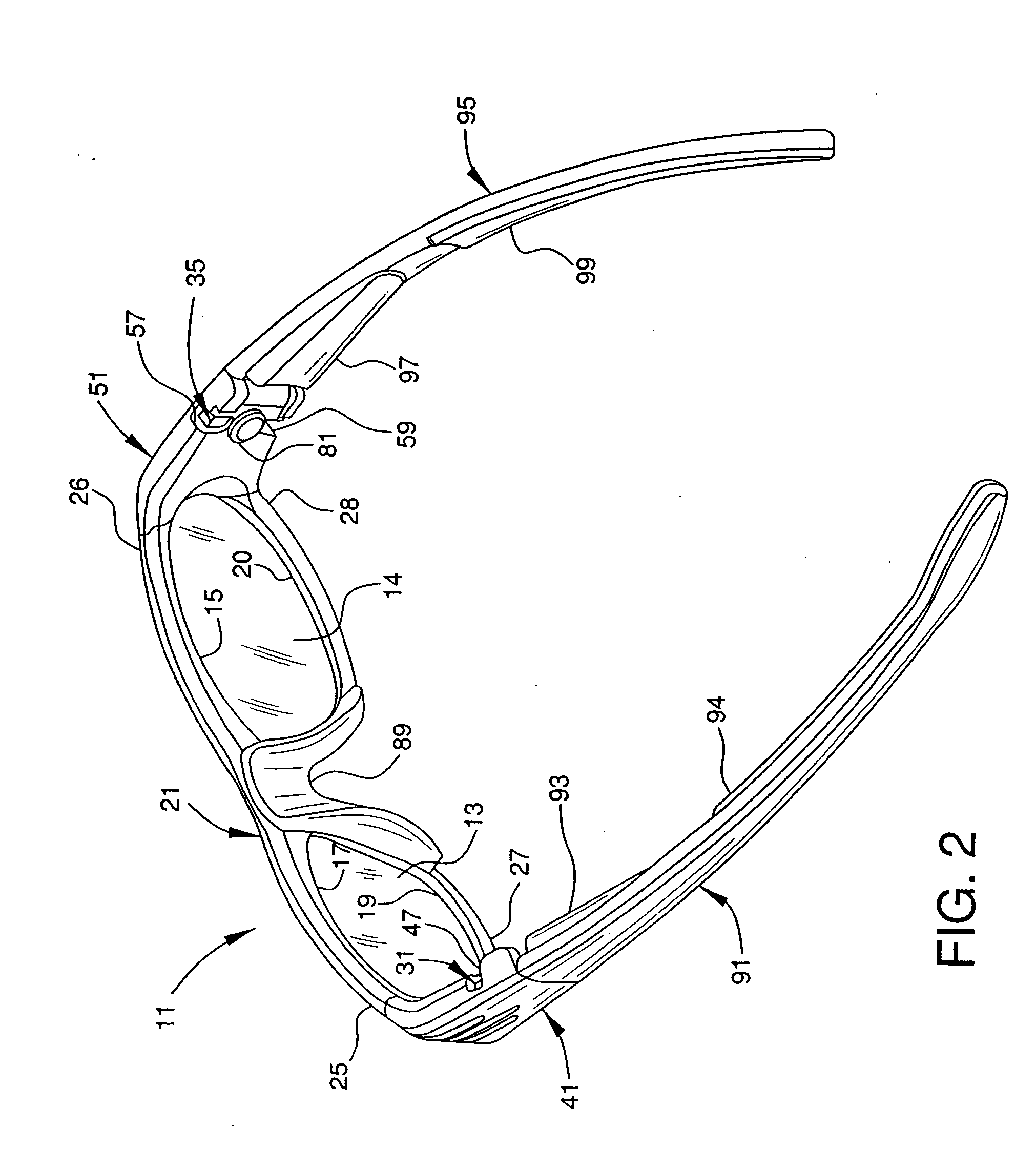

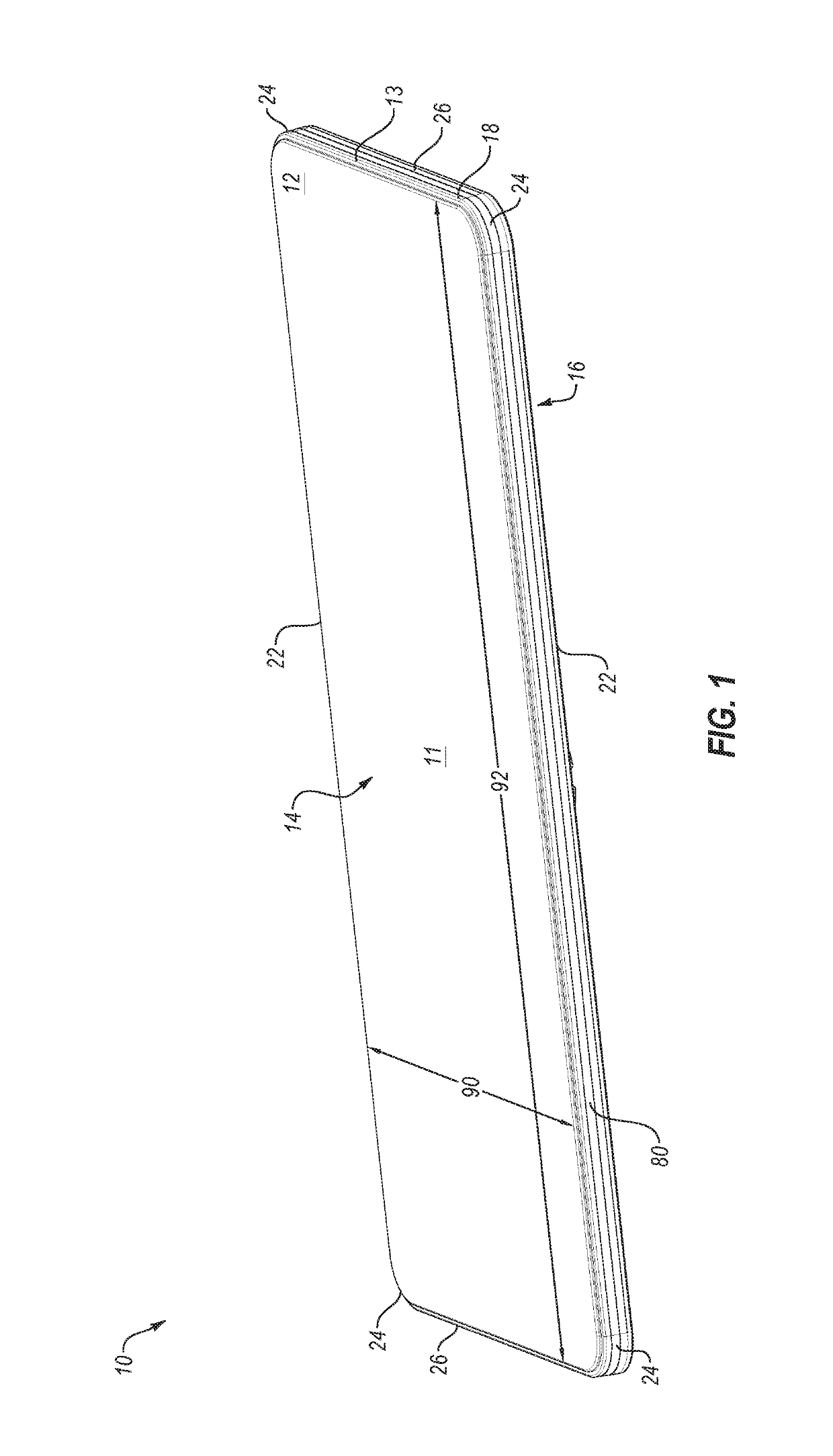

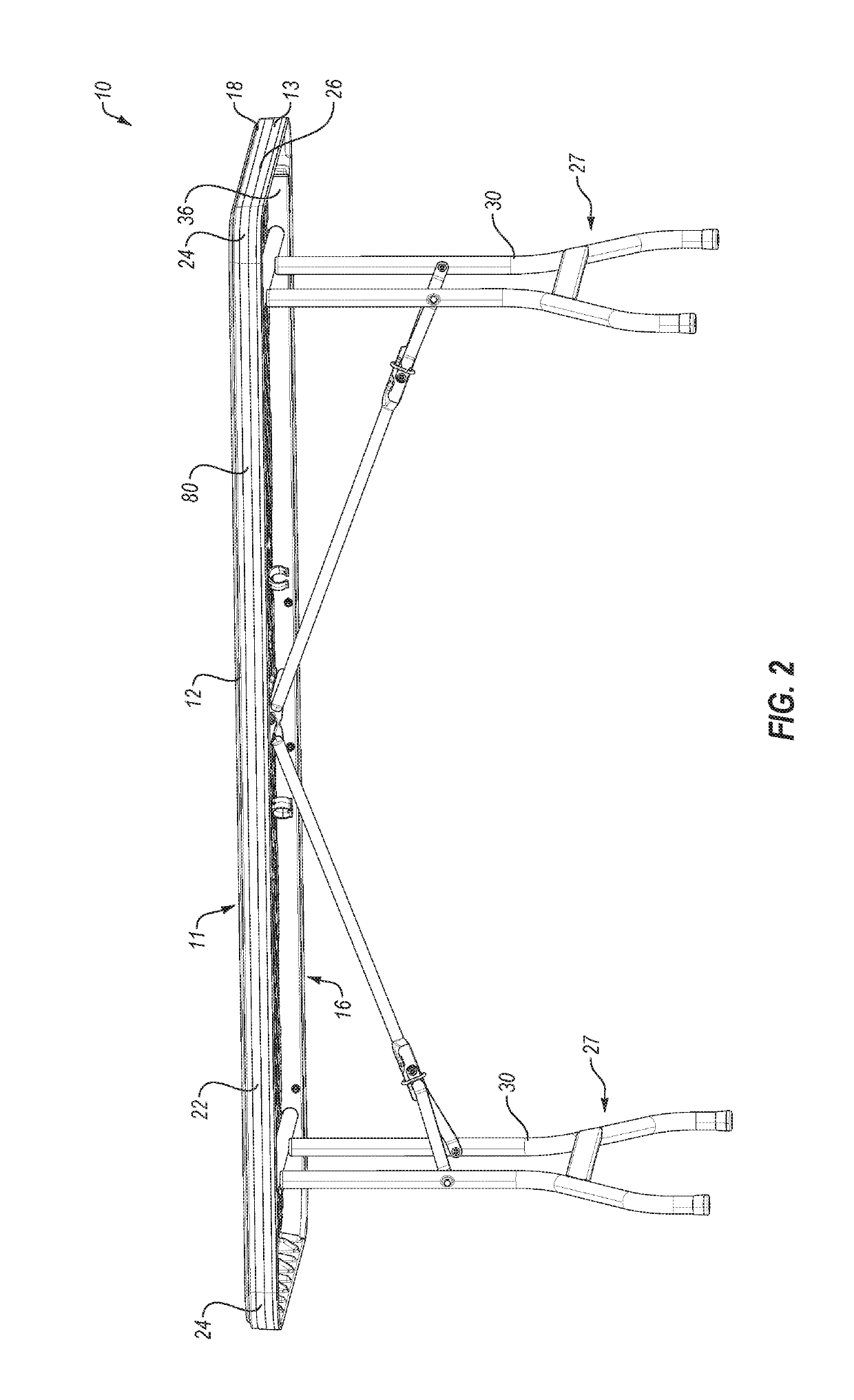

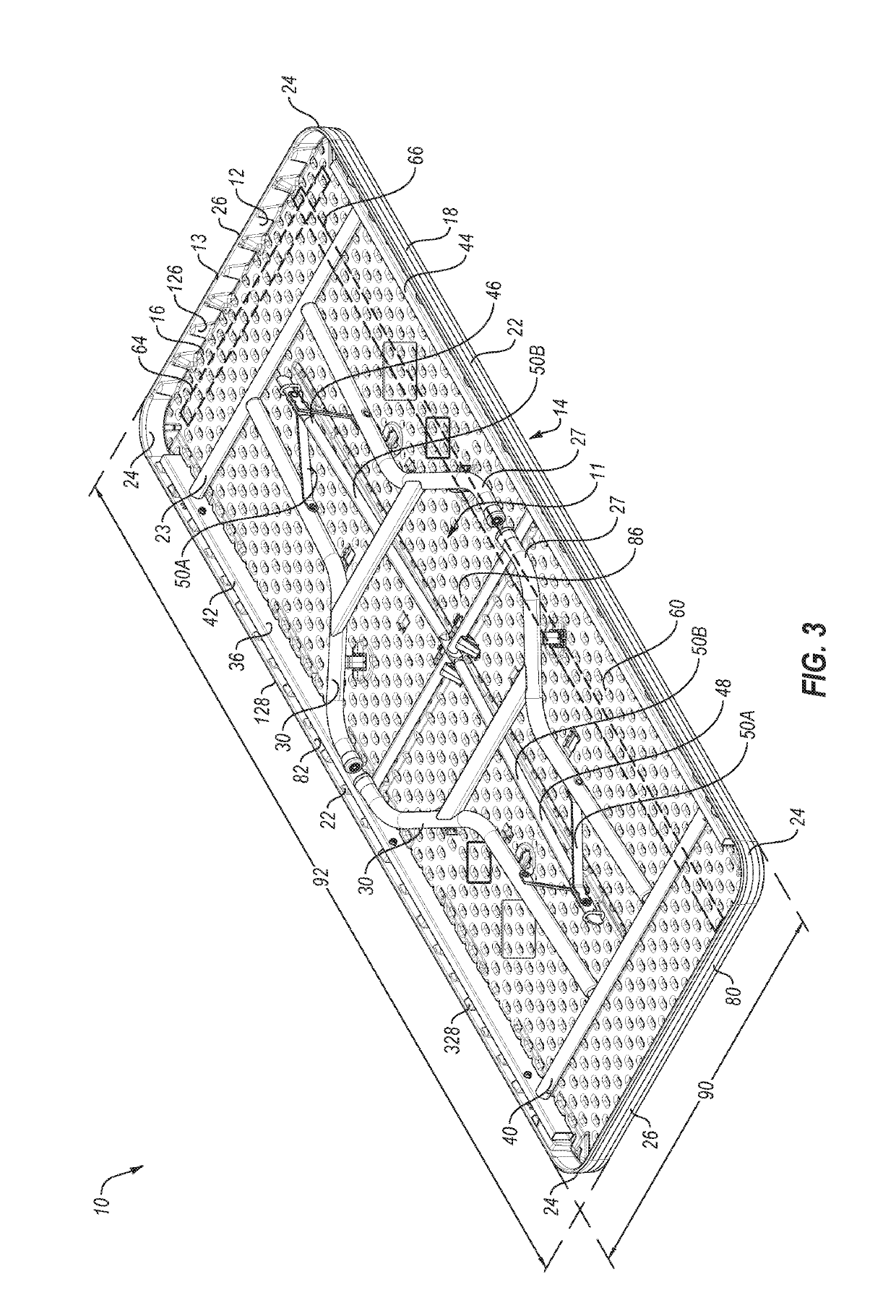

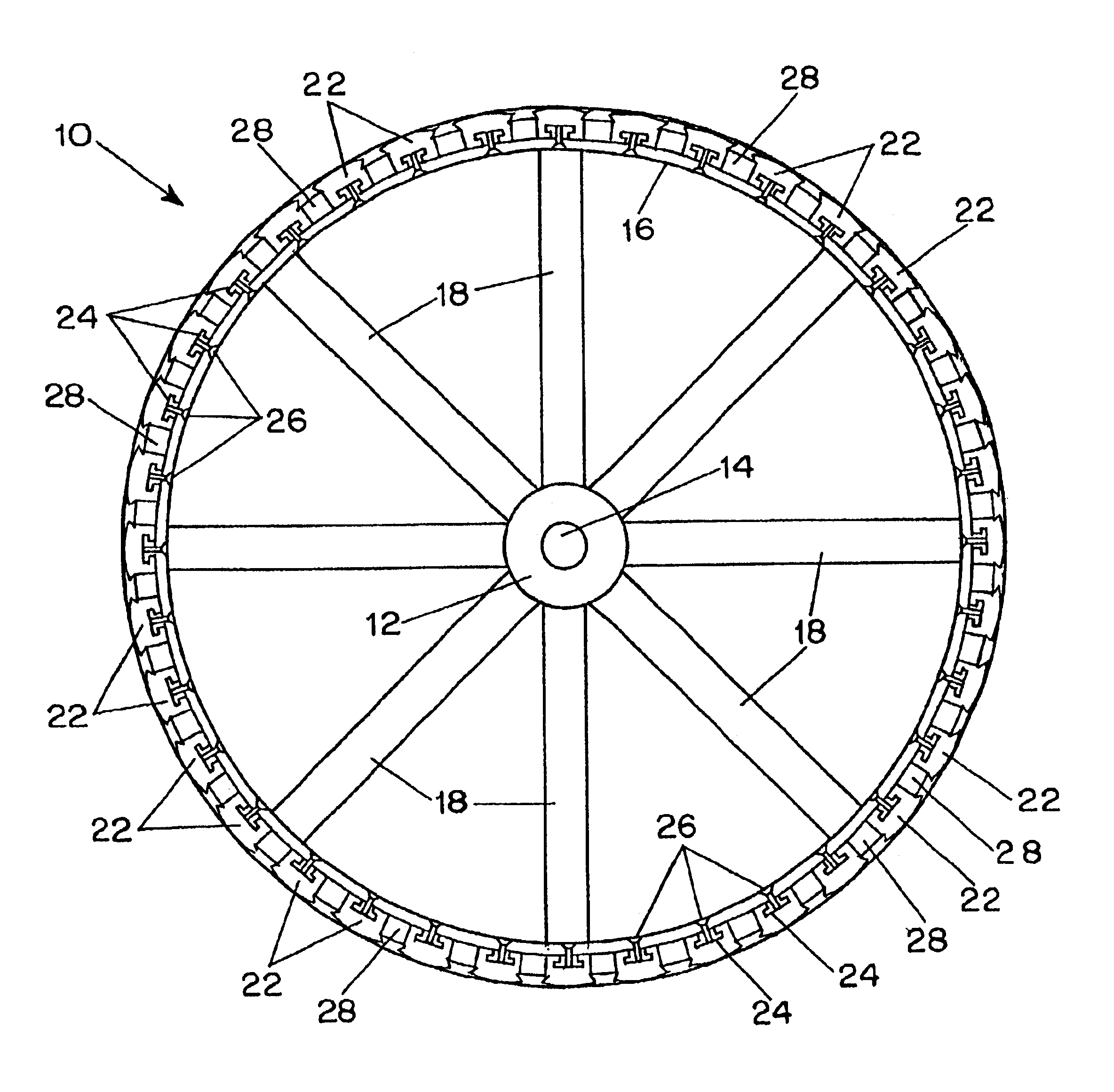

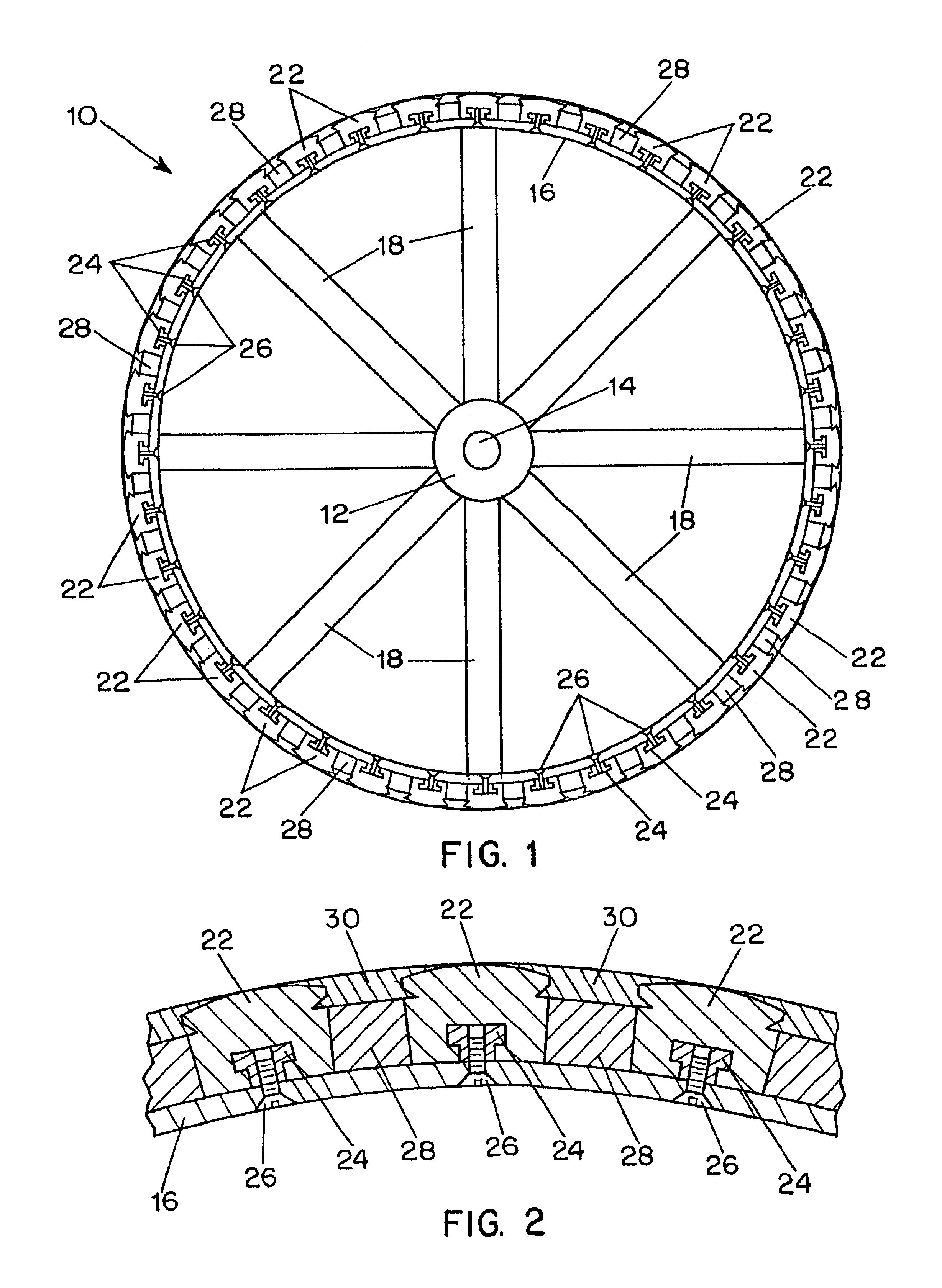

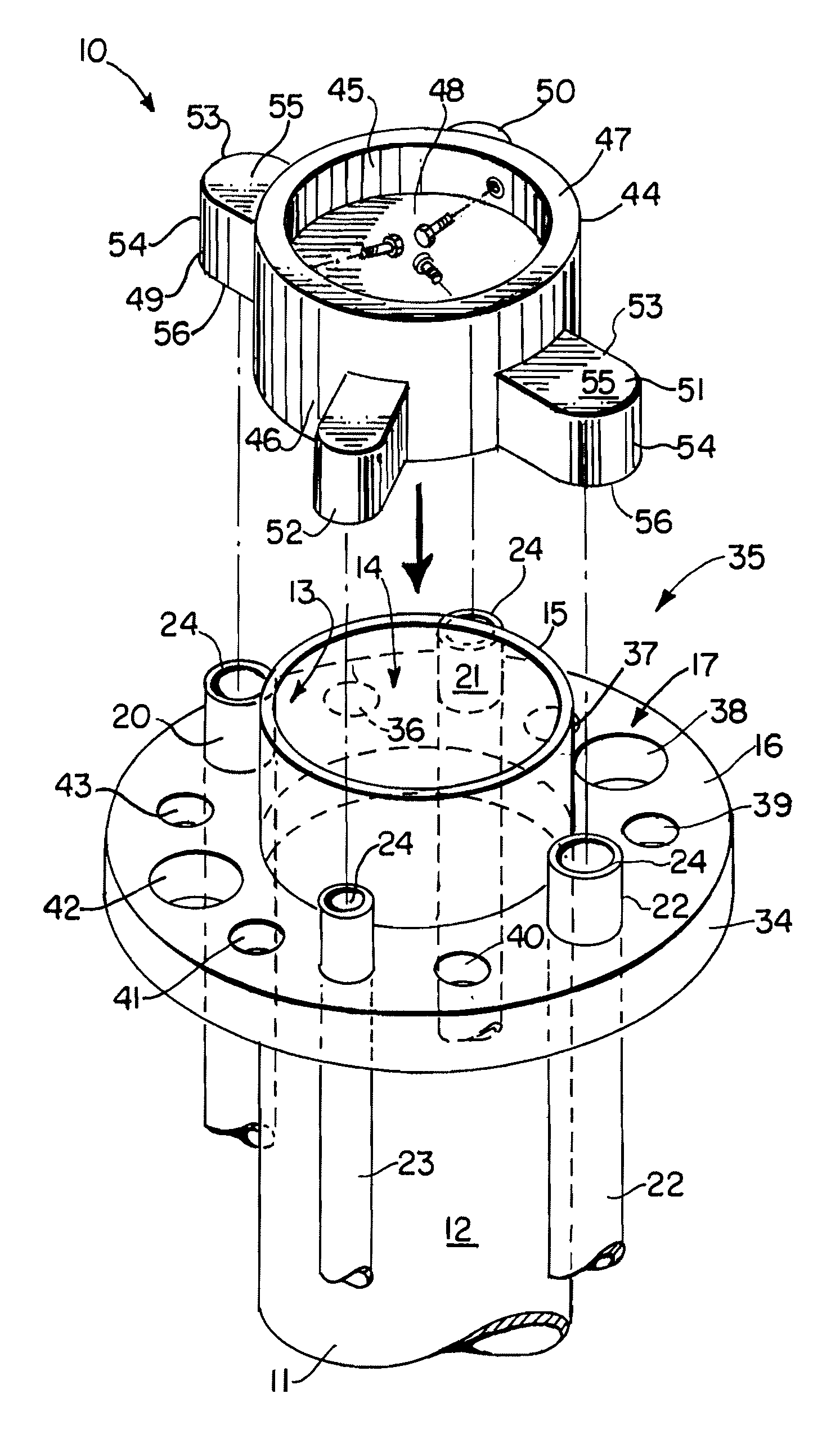

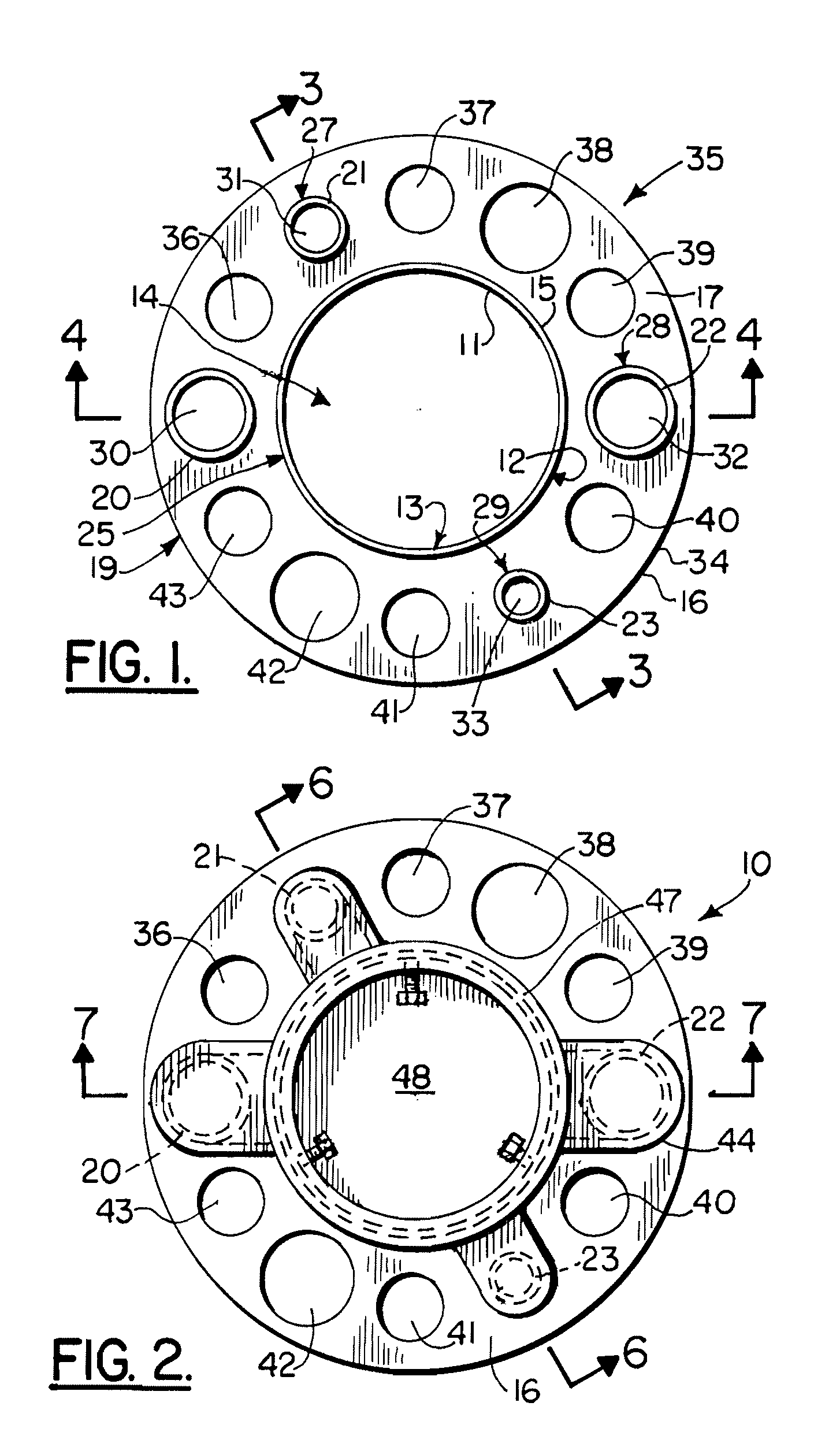

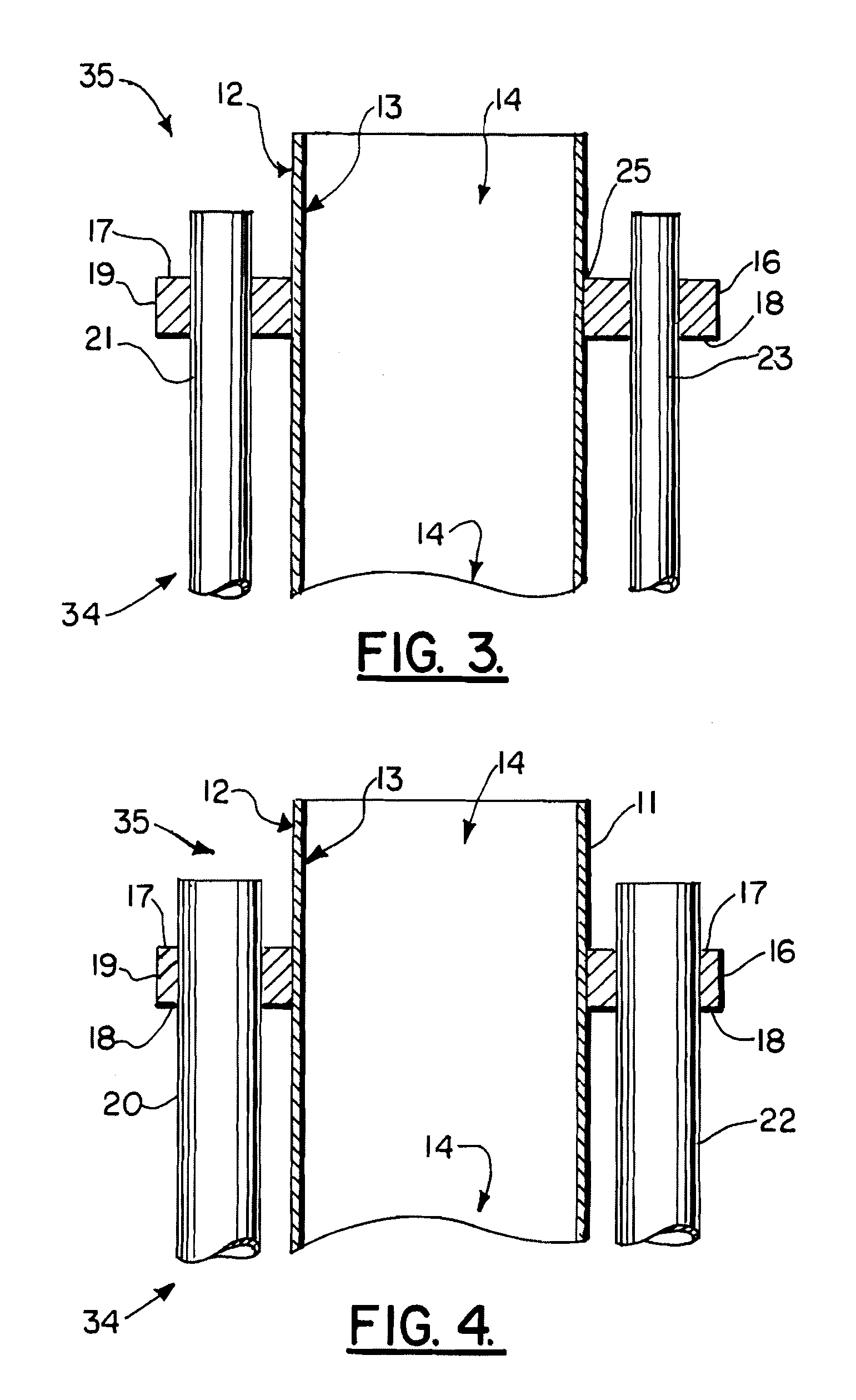

Impact resistant eyewear frame assembly having a split frame and fastener reinforcement

InactiveUS7137700B2Resist impactEasy to insertSpectales/gogglesNon-optical partsEngineeringThreaded fastener

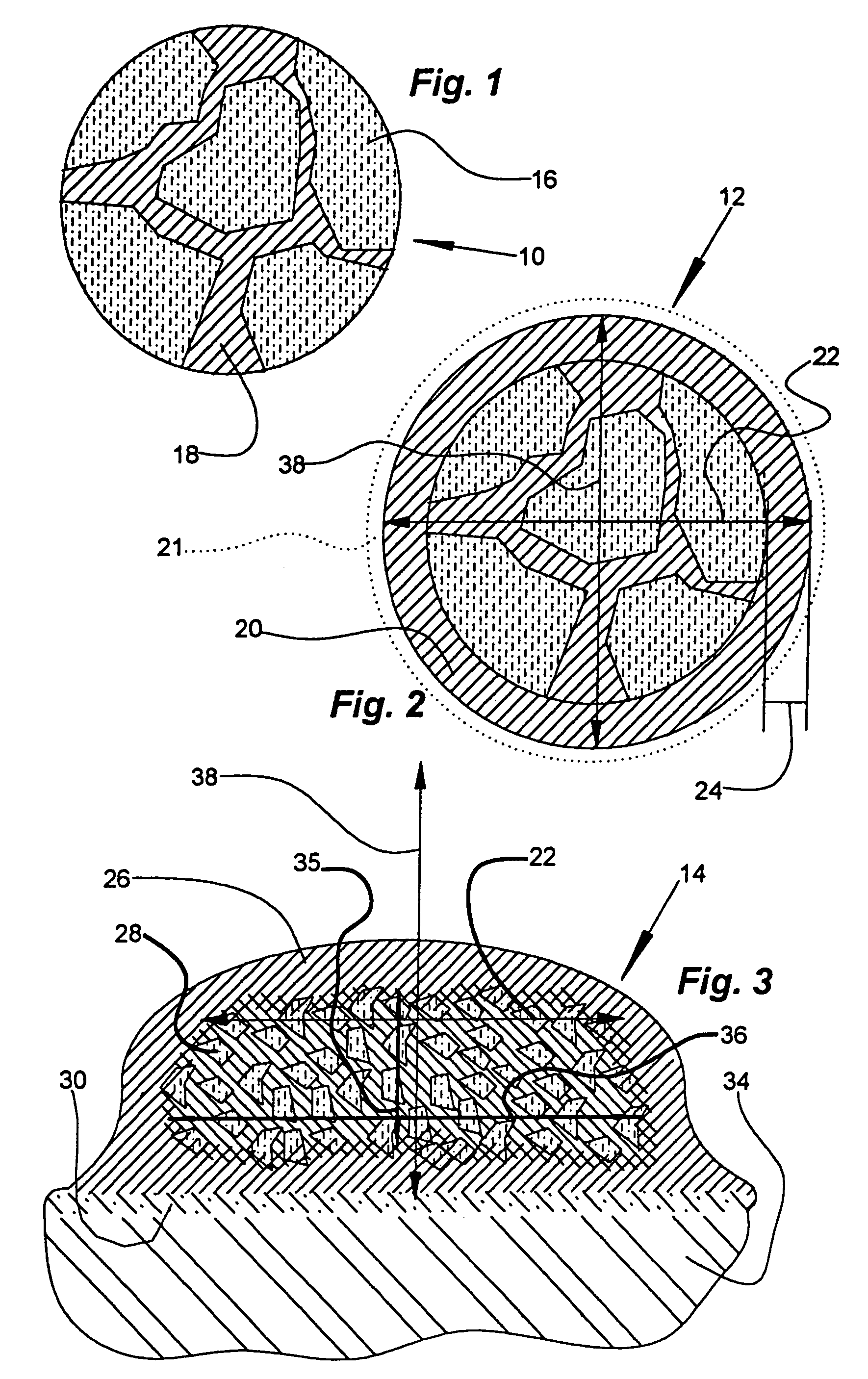

The present invention provides an eyewear frame assembly. A frame has an aperture for receiving a lens. The frame has a split to expand upper and lower portions of the frame to insert or remove the lens from the aperture. First and second projections extend outwardly from the upper and lower frame portions, respectively. The first and second projections have first and second tapered portions, respectively. A sleeve receives said first and second projections. The sleeve has first and second inwardly extending and tapered tabs adapted to receive the first and second tapered portions to secure the first and second projections within the sleeve. The upper and lower portions of the frame are prevented from expanding when the first and second projections are received within the sleeve. First and second openings in the sleeve provide access to depress the first and second projections to remove the first and second projections from the first and second sleeves. A threaded fastener and a threaded sleeve forms a reinforcement assembly for the two portions of the split frame. The sleeve engages the fastener to resist its disengagement with the bushing.

Owner:LIBERTY SPORT

Impact resistant eyewear frame assembly having a split frame and fastener reinforcement

InactiveUS20050280771A1Resist impactEasy to insertSpectales/gogglesNon-optical partsThreaded fastenerEngineering

The present invention provides an eyewear frame assembly. A frame has an aperture for receiving a lens. The frame has a split to expand upper and lower portions of the frame to insert or remove the lens from the aperture. First and second projections extend outwardly from the upper and lower frame portions, respectively. The first and second projections have first and second tapered portions, respectively. A sleeve receives said first and second projections. The sleeve has first and second inwardly extending and tapered tabs adapted to receive the first and second tapered portions to secure the first and second projections within the sleeve. The upper and lower portions of the frame are prevented from expanding when the first and second projections are received within the sleeve. First and second openings in the sleeve provide access to depress the first and second projections to remove the first and second projections from the first and second sleeves. A threaded fastener and a threaded sleeve forms a reinforcement assembly for the two portions of the split frame. The sleeve engages the fastener to resist its disengagement with the bushing.

Owner:LIBERTY SPORT

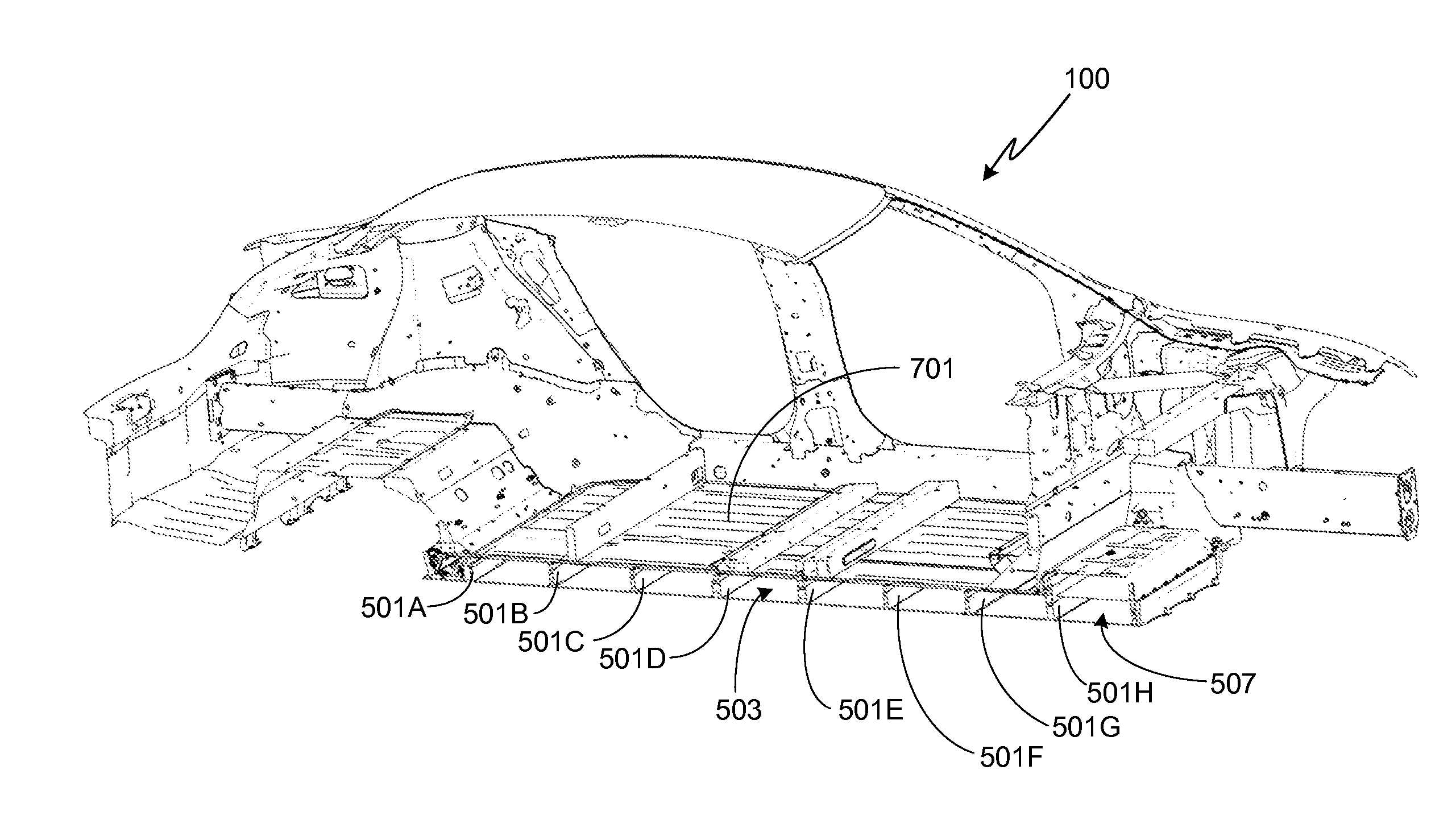

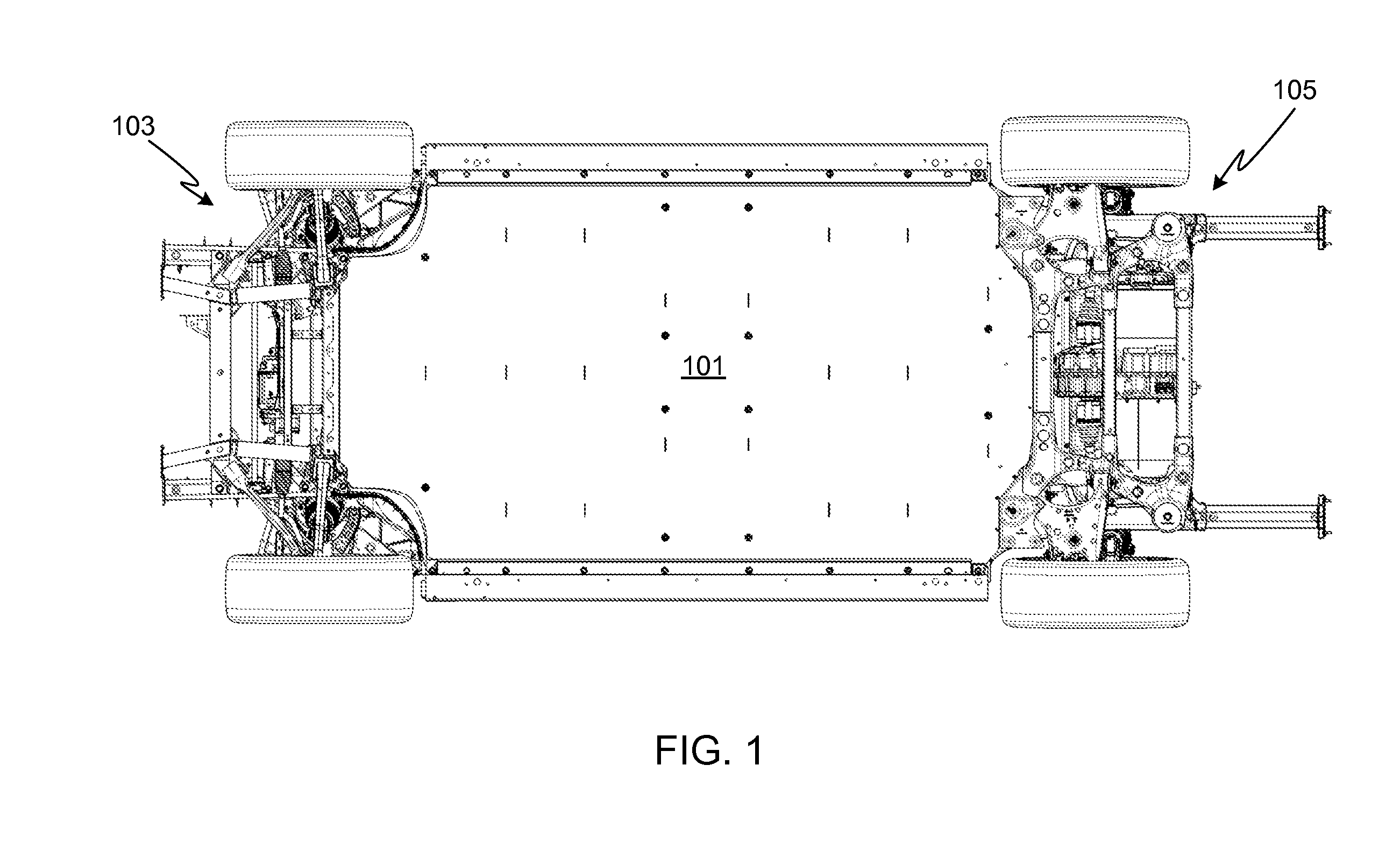

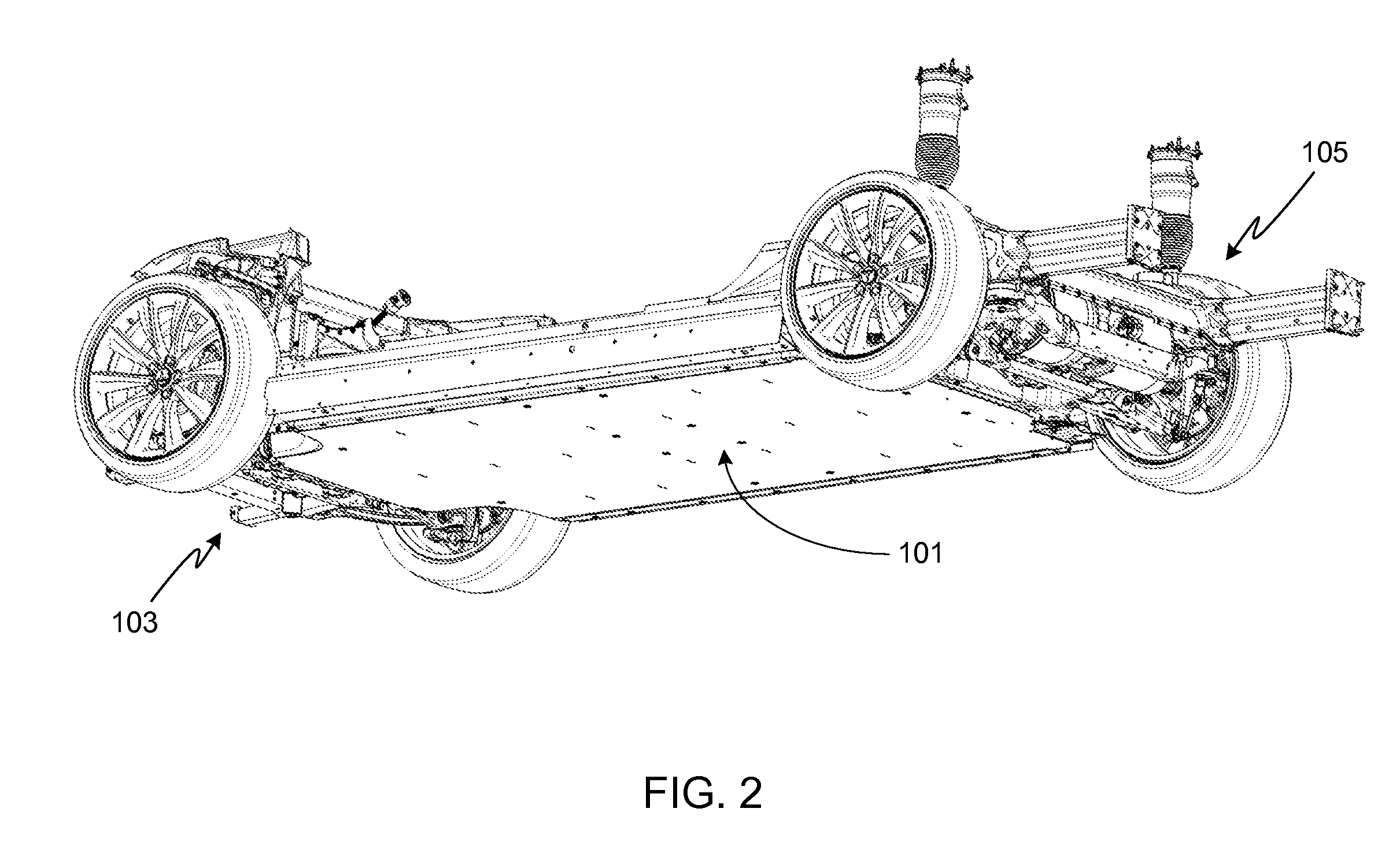

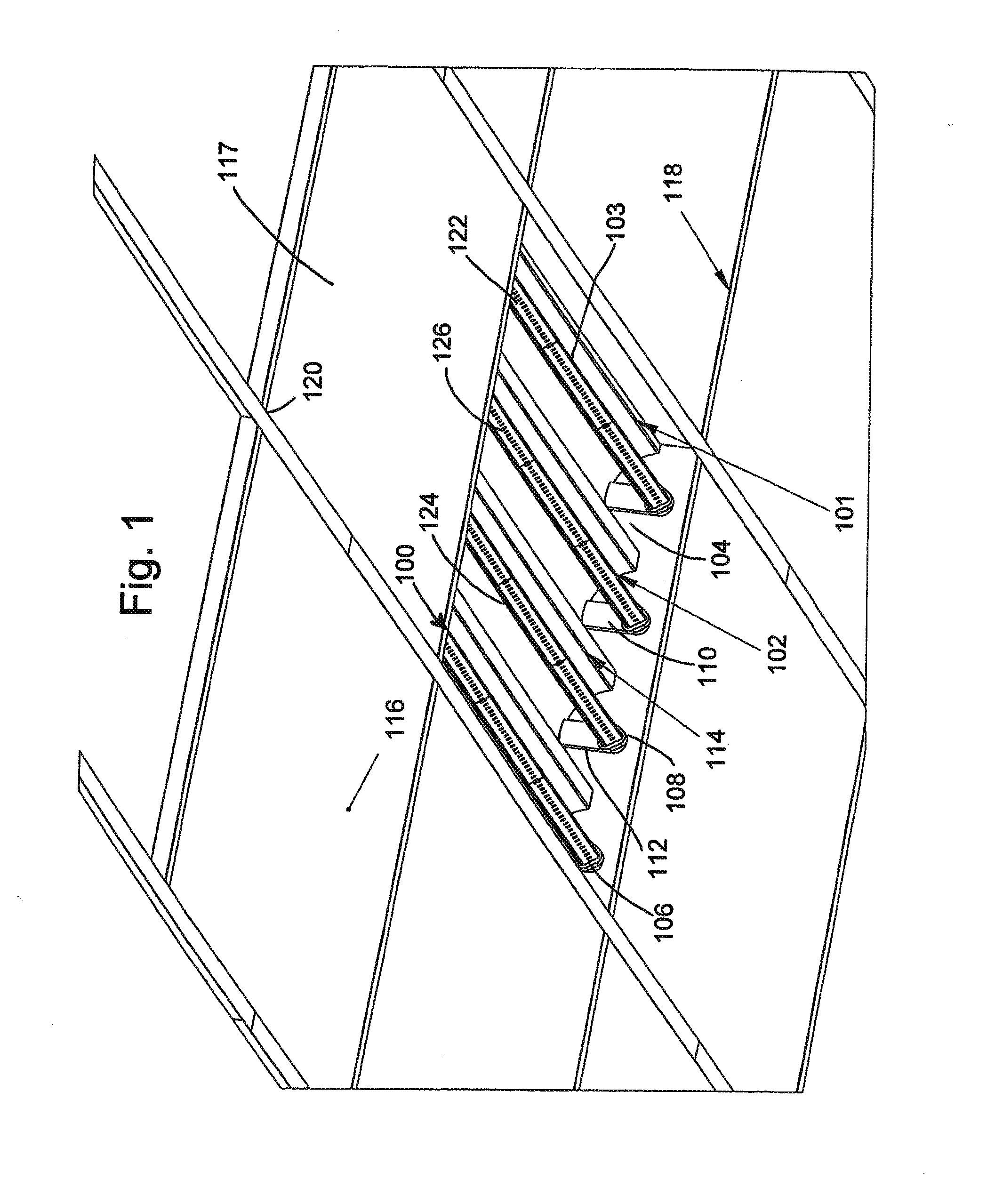

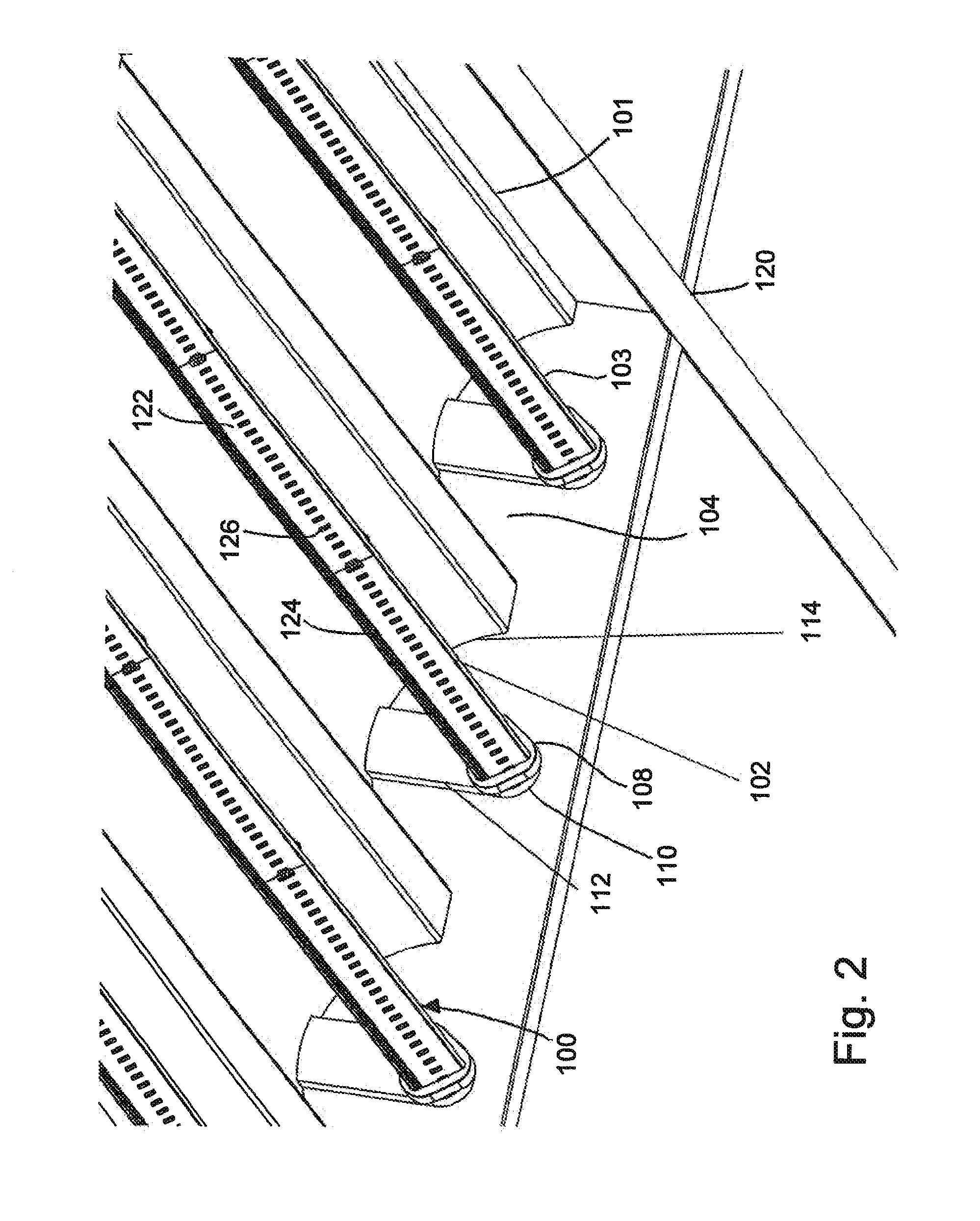

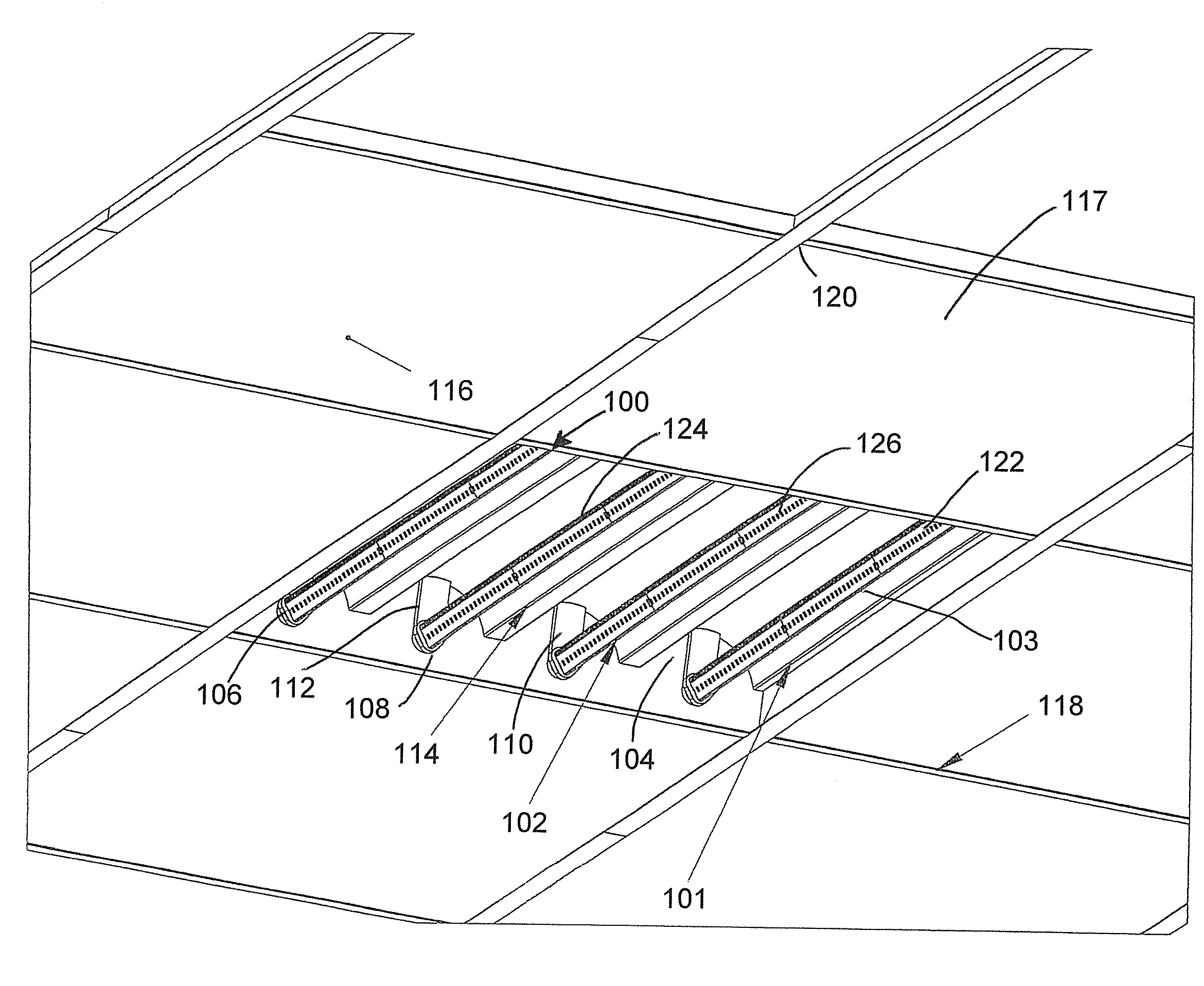

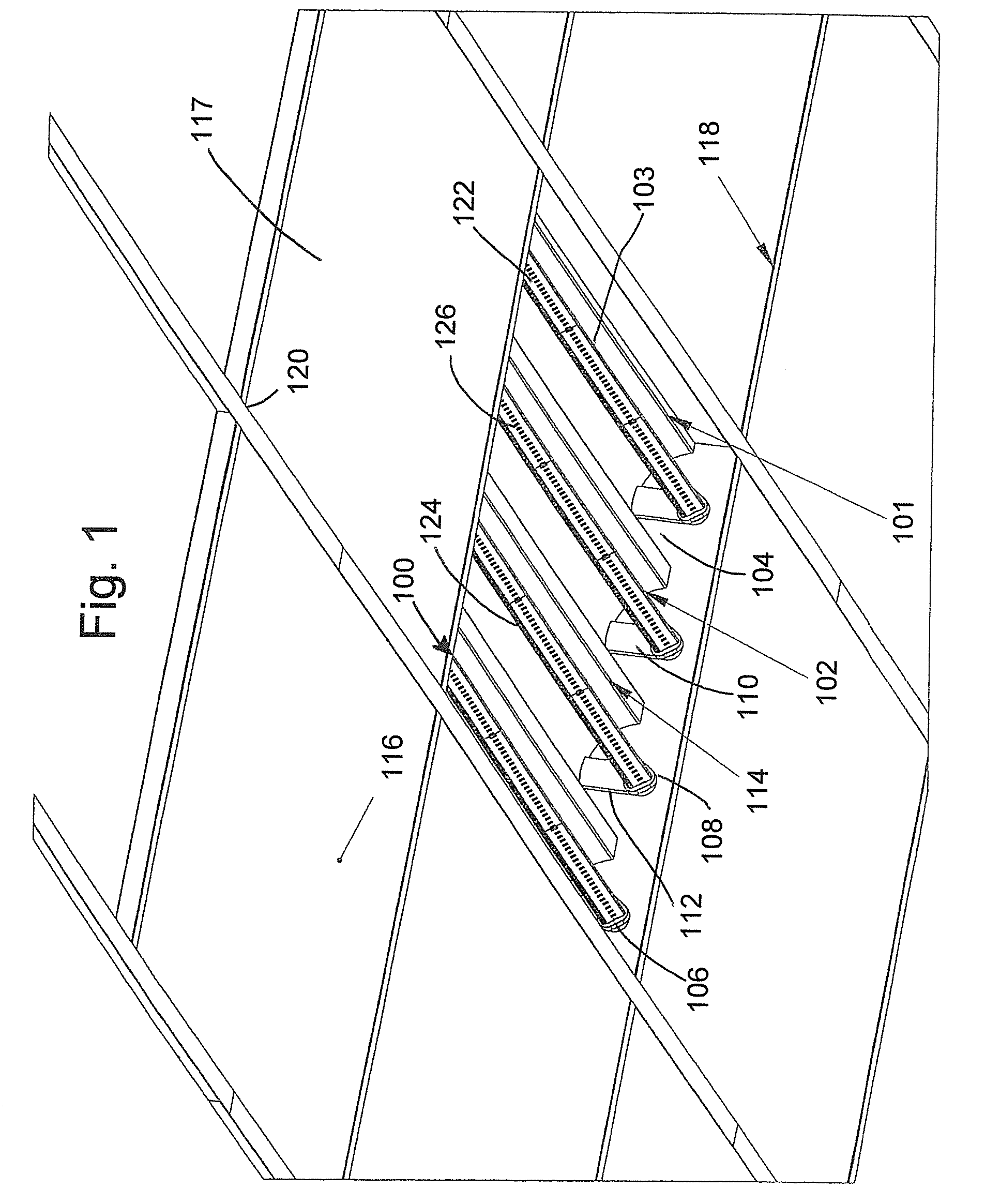

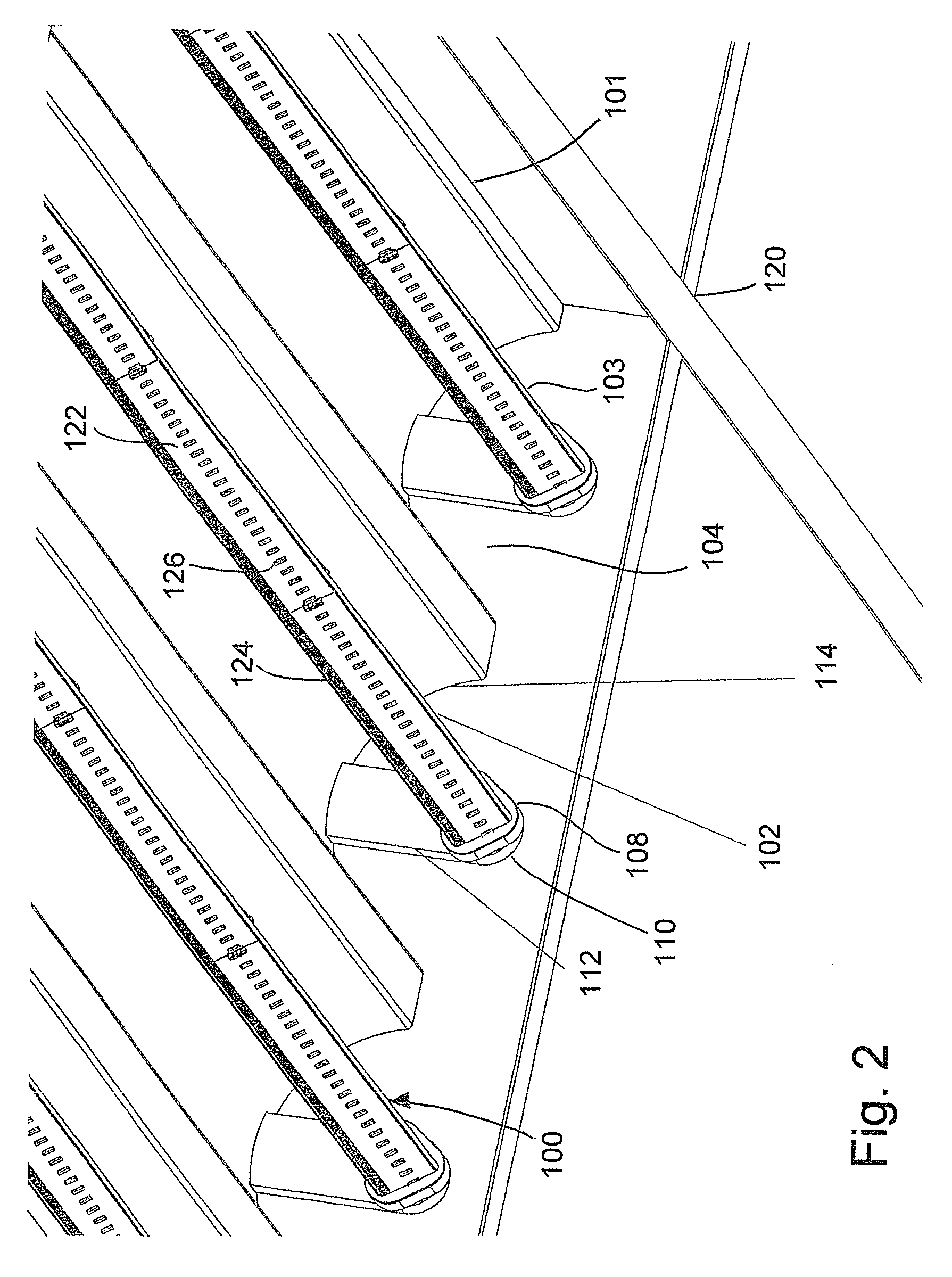

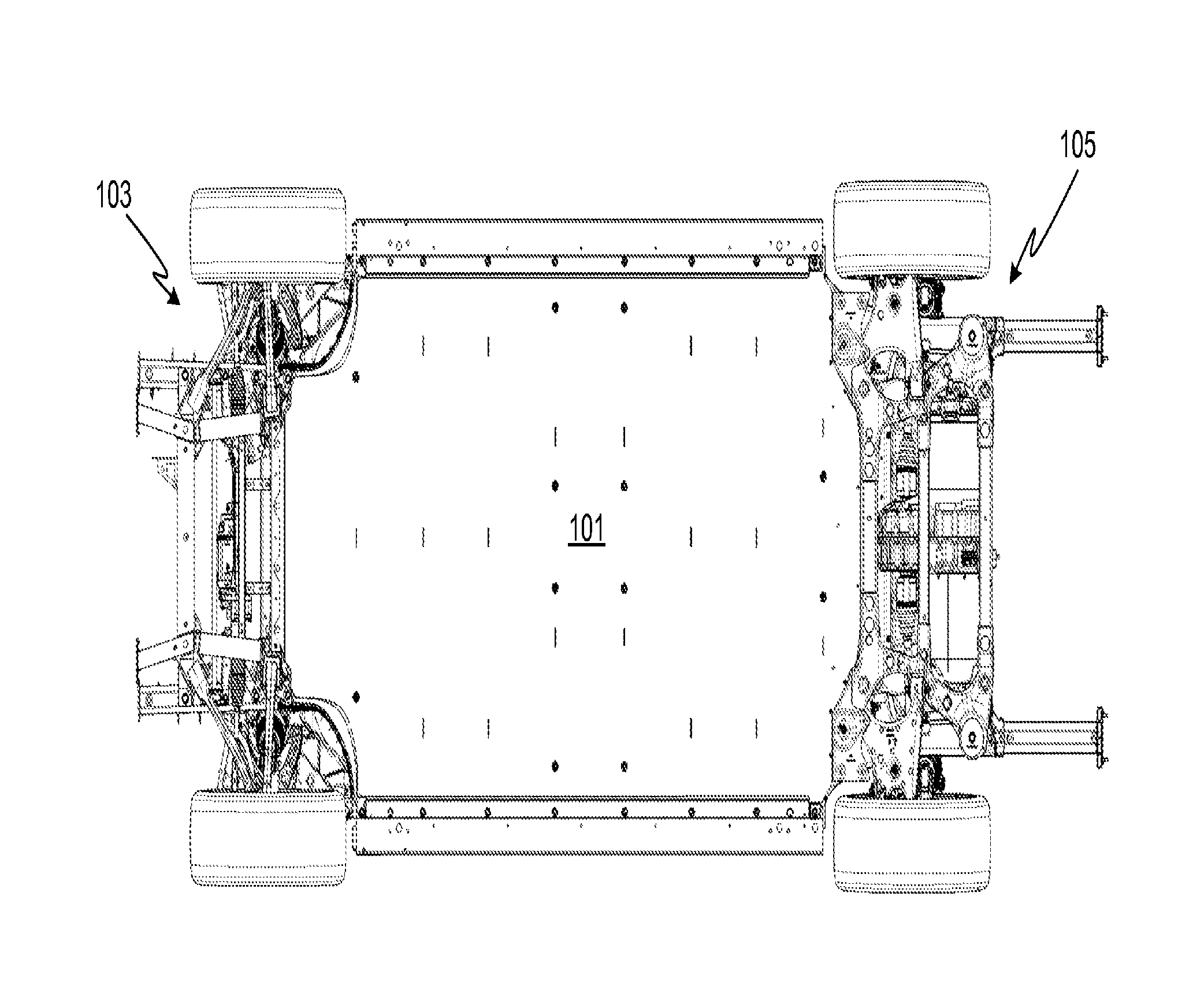

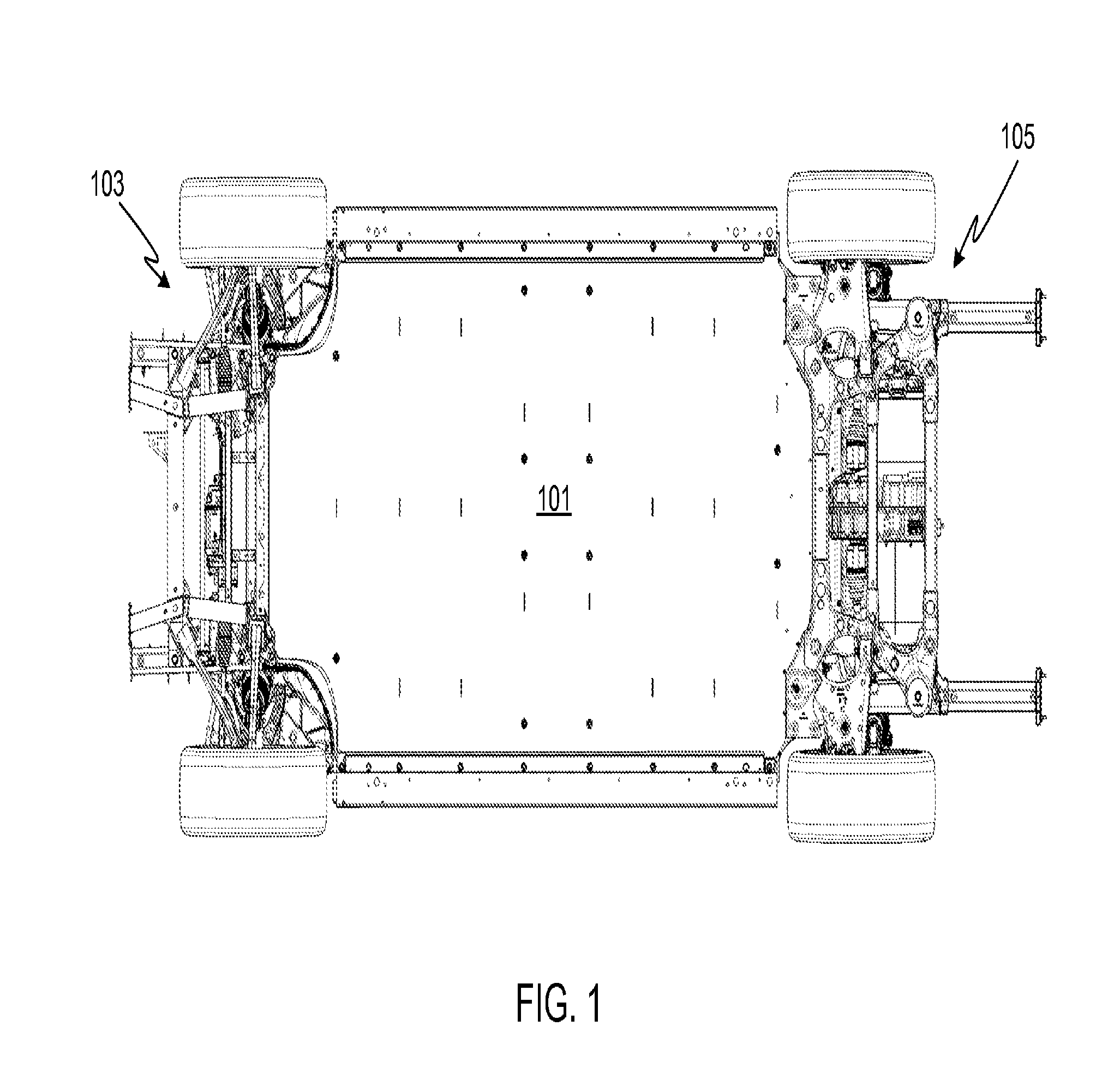

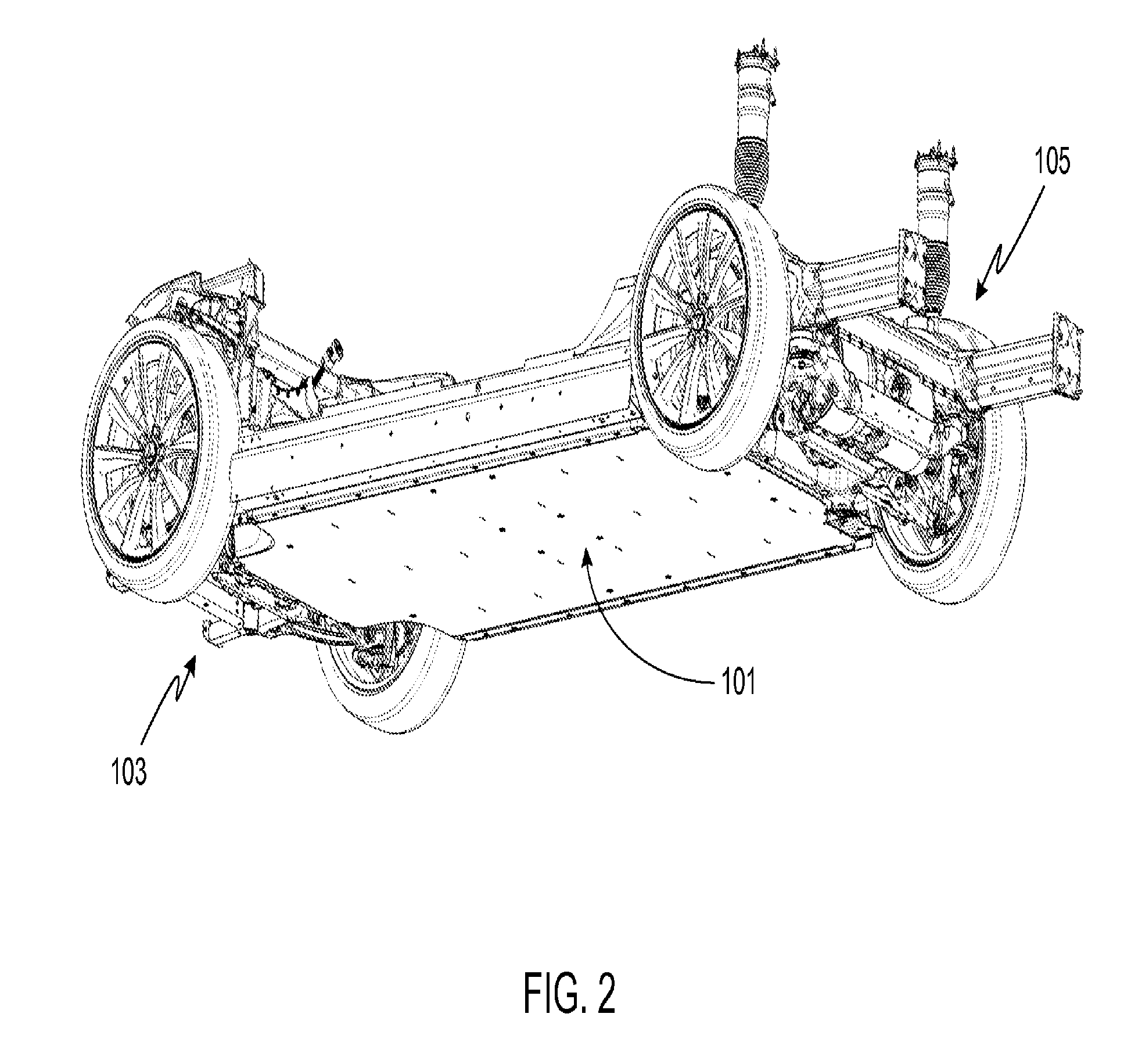

System for Absorbing and Distributing Side Impact Energy Utilizing an Integrated Battery Pack

InactiveUS20120161472A1Simplify mechanically couplingResist impactVehicle seatsElectric propulsion mountingAutomotive engineering

An energy absorbing and distributing side impact system for use with a vehicle is provided, the system utilizing a battery pack enclosure that includes a plurality of cross-members that transverse the battery pack enclosure and absorb and distribute at least a portion of the load received when either the first or second side of the vehicle receives a side impact. The battery pack enclosure is positioned between the front and rear vehicle suspension assemblies and mounted between, and mechanically coupled to, vehicle structural members (e.g., rocker panels) located on either side of the vehicle. In addition to providing rigidity, strength and impact resistance, the battery pack cross-members segregate the batteries contained within the battery pack enclosure into battery groups.

Owner:TESLA INC

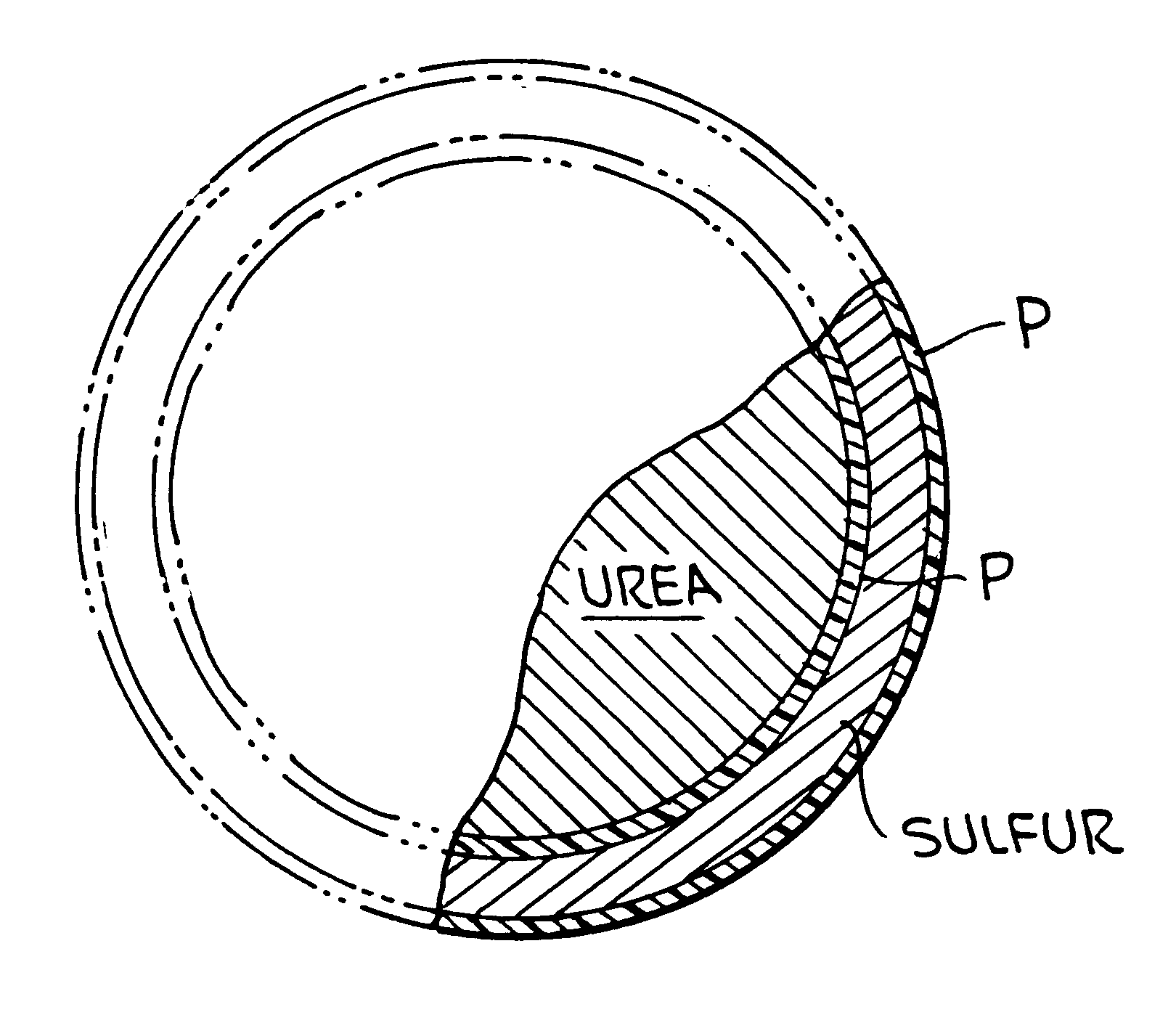

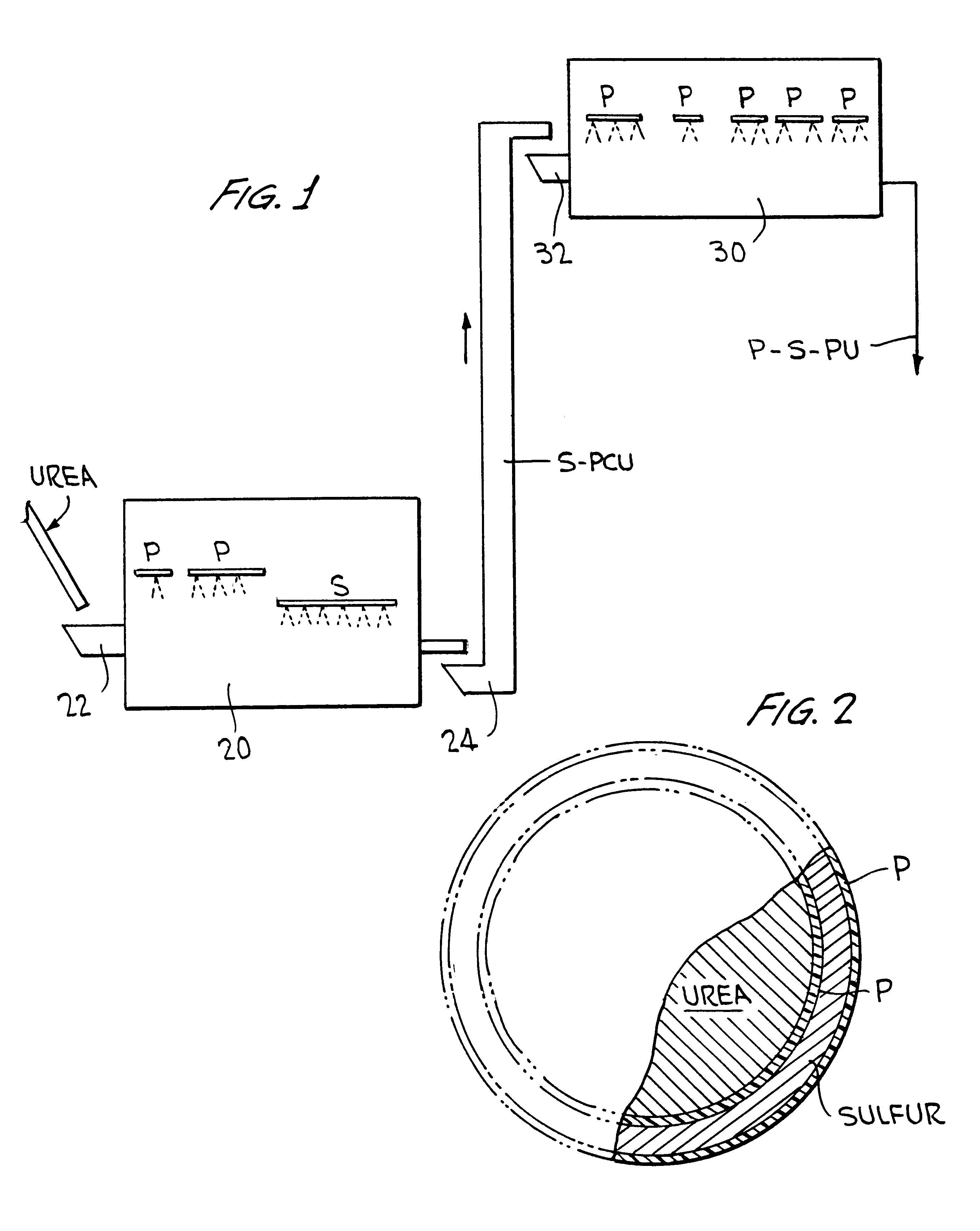

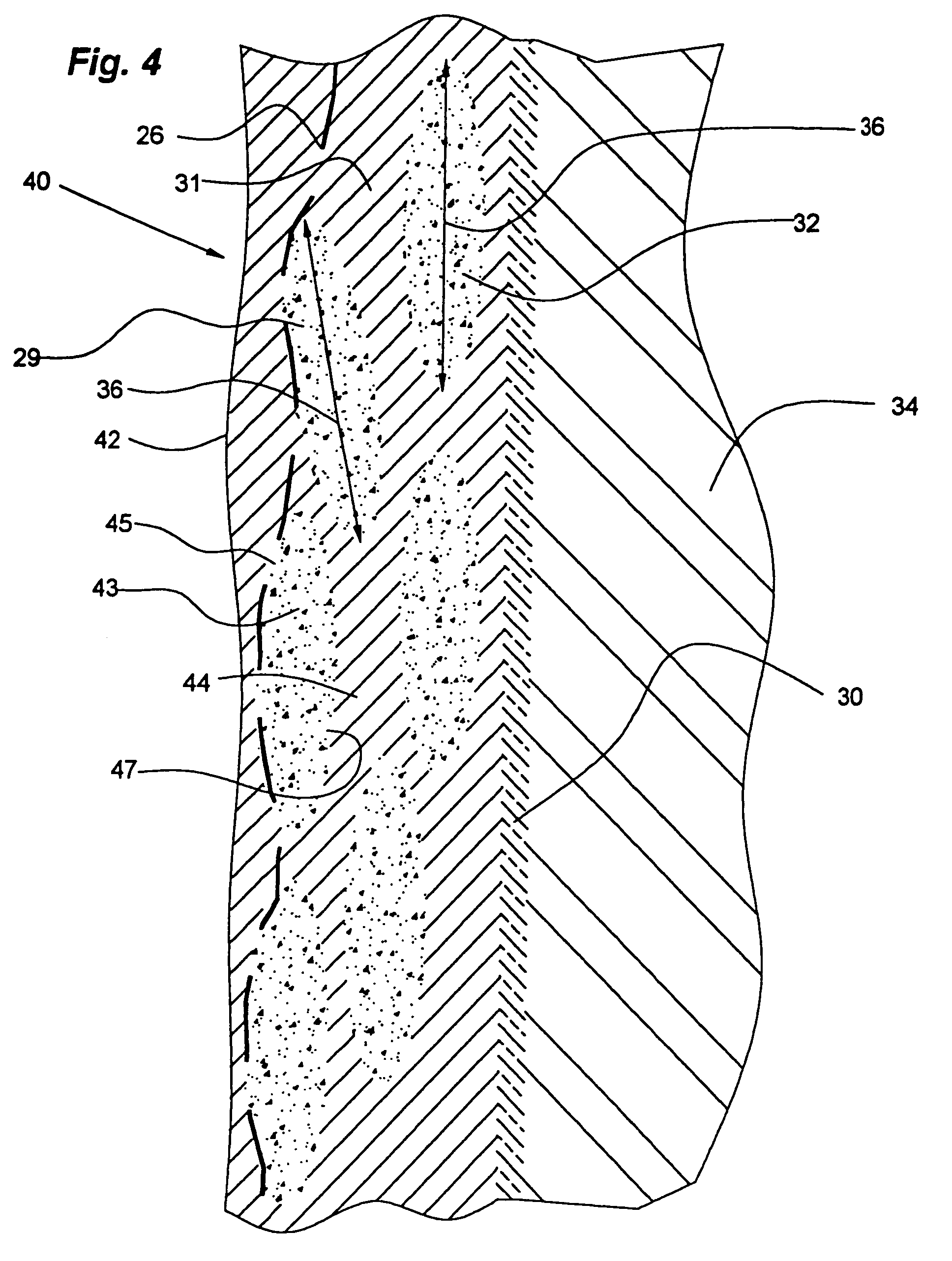

Polymer-sulfur-polymer coated fertilizers

InactiveUS6338746B1Good resistance to abrasionAvoid serious impactBiocideMaterial granulationControlled releasePositive control

The present invention described a polymer coated fertilizer, such as urea, subsequently coated with a layer of sulfur and thereafter a further coating of polymer. Preferably, the polymer coatings are formed by the direct in situ co-polymerization of the components of the polymer on the fertilizer and on the sulfur coating. The compositions provide positive controlled release characteristics, are abrasion and impact resistant and are substantially more economical to produce than polymer coated fertilizers.

Owner:KOCH AGRONOMIC SERVICES LLC

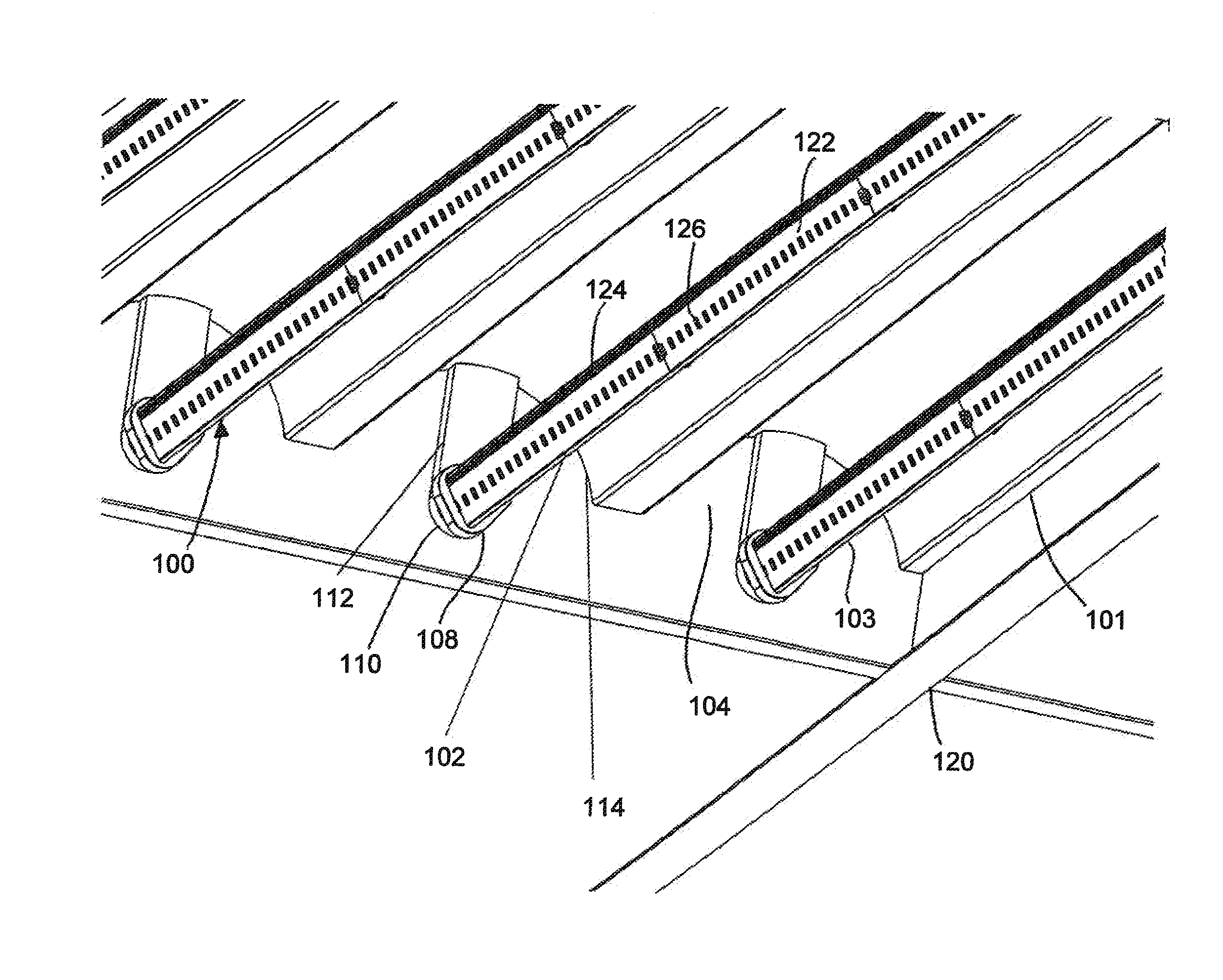

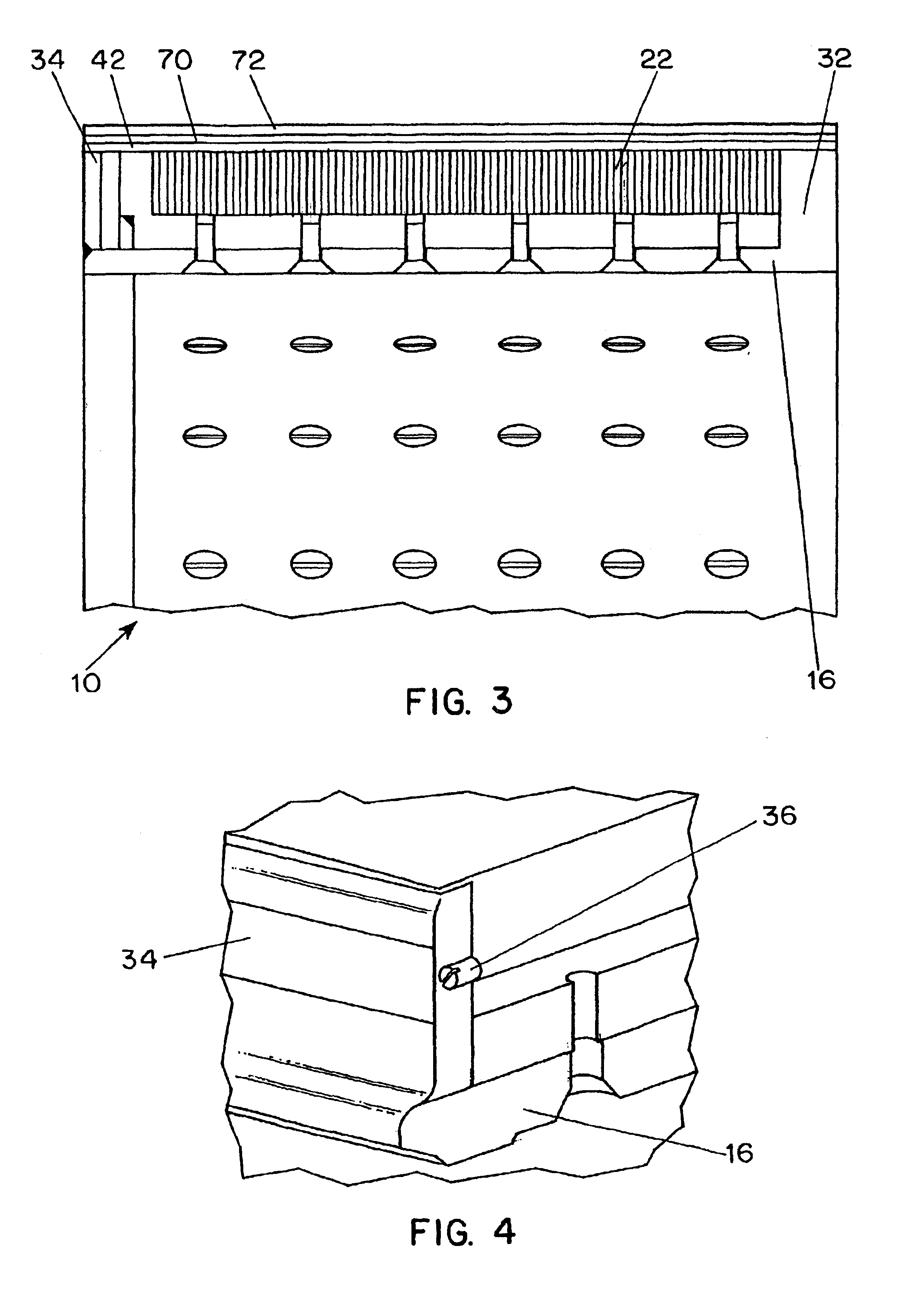

Lighting Assembly

ActiveUS20140293595A1Long life spanEnhance lightPlanar light sourcesLight source combinationsEngineeringStraight path

An elongate tubular lighting assembly having a body with a length between spaced first and second ends. The tubular lighting assembly has a source of illumination and first and second connectors respectively at the first and second body ends. The first connector has cooperating first and second parts having first and second surfaces. The first and second connector parts are configured so that the first and second surfaces are placed in confronting relationship to prevent separation of the first and second connector parts with the body in an operative state as an incident of the first connector part moving relative to the second connector part from a position fully separated from the second connector part in a substantially straight path that is transverse to the length of the body into an engaged position.

Owner:DVA HLDG LLC

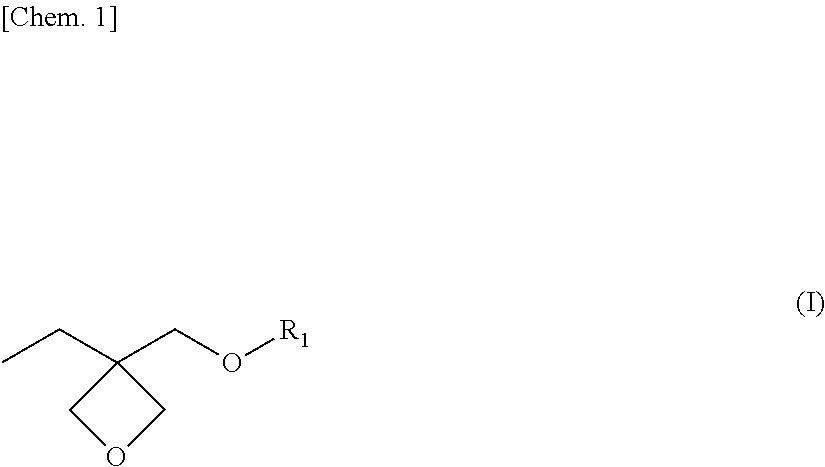

Fiber reinforced resin composition, molding material, and method for producing fiber reinforced resin composition

ActiveUS20120028047A1Improve impact resistanceImprove rigidityGroup 5/15 element organic compoundsWood working apparatusPolymer sciencePolymer chemistry

The invention provides a fiber reinforced resin composition comprising a melt-kneaded product (A) prepared by melt-kneading a first resin (A1) and a second resin (A2) that has reactive functional group as well as a third resin (B) and a fibrous filler (C), wherein, with respect to the contents of the components, the first resin (A1), the second resin with a reactive functional group (A2), and the third resin (B) account for 0.1 to 75 wt %, 0.1 to 15 wt %, and 10 to 99.8 wt %, respectively, to form a resin composition while said fibrous filler (C) accounts for 0.1 to 300 parts by weight per 100 parts by weight of said resin composition, said first resin (A1) and said third resin (B) forming a matrix resin, said second resin (A2) being dispersed as particles in said matrix resin, and said particles having a number average particle diameter of 10 to 1,000 nm. The invention relates to a fiber reinforced resin composition having rigidity and impact resistance in a good balance, a molding material, and a production method thereof.

Owner:TORAY IND INC

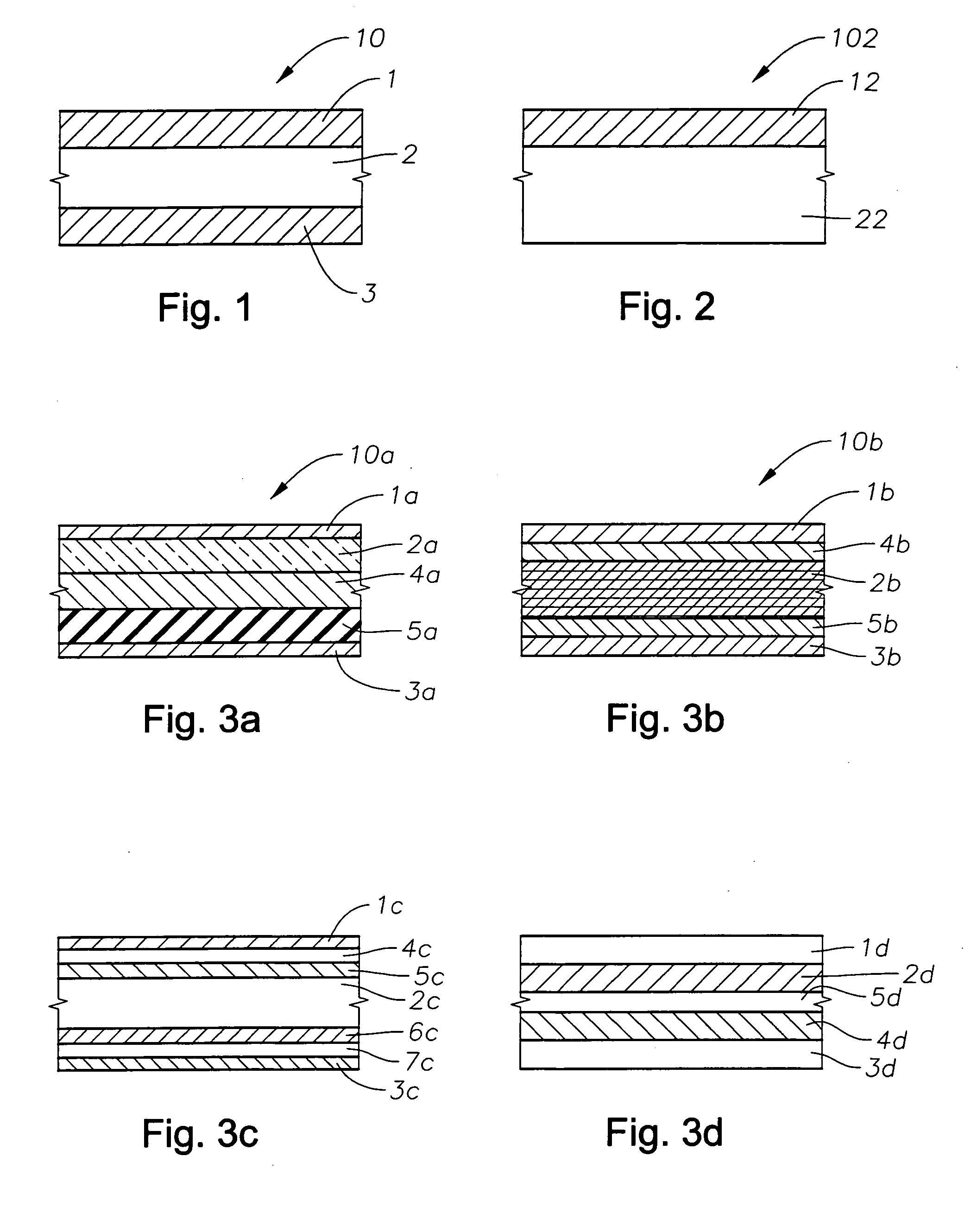

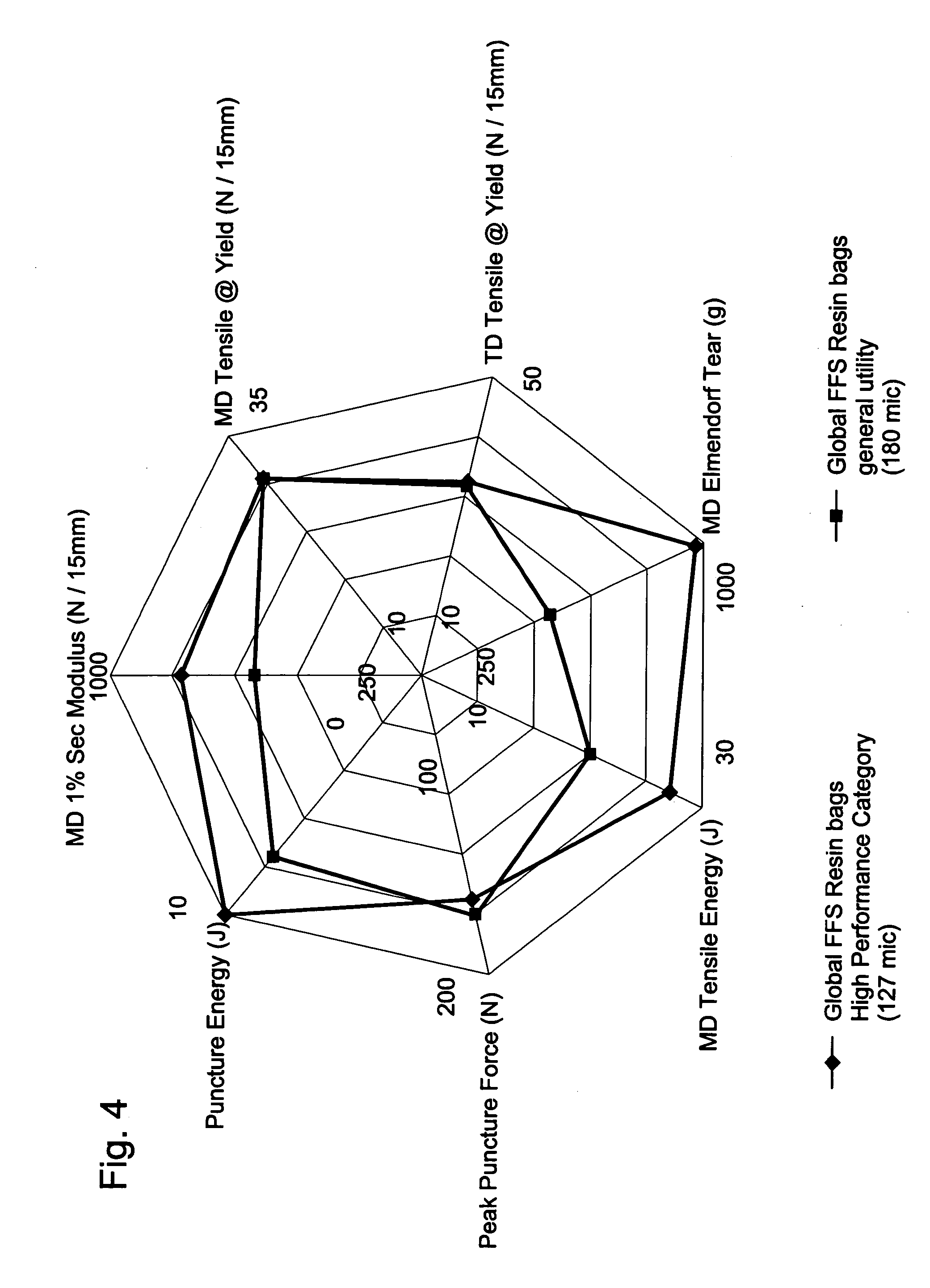

Multi-layer polyethylene films

InactiveUS20060188678A1Improve sealingResist impactSynthetic resin layered productsBagsEngineeringHeavy duty

An improved multi-layer film and packaging, including heavy duty sacks made therefrom having improved properties that permit processing on high speed bagging / Form Fill-Seal equipment are disclosed. The multi-layer films of the invention include a mLLDPE-containing skin layer and a core layer that includes both HDPE and mLLDPE.

Owner:EXXONMOBIL CHEM PAT INC

Non-curvilinear LED luminaries

ActiveUS8702265B2Easy to manufactureEasy to installLight source combinationsLighting support devicesEffect lightEngineering

An improved light emitting diode (LED) illuminating assembly is provided with a multiple sided LED lighting bar, also referred to as a multi-sided LED light bar, comprising a non-curvilinear LED luminary for enhanced LED lighting. The LED illuminating assembly can be used for overhead ceiling lighting, menu boards and other LED illuminating signs, as well as for other uses.

Owner:DVA HLDG LLC

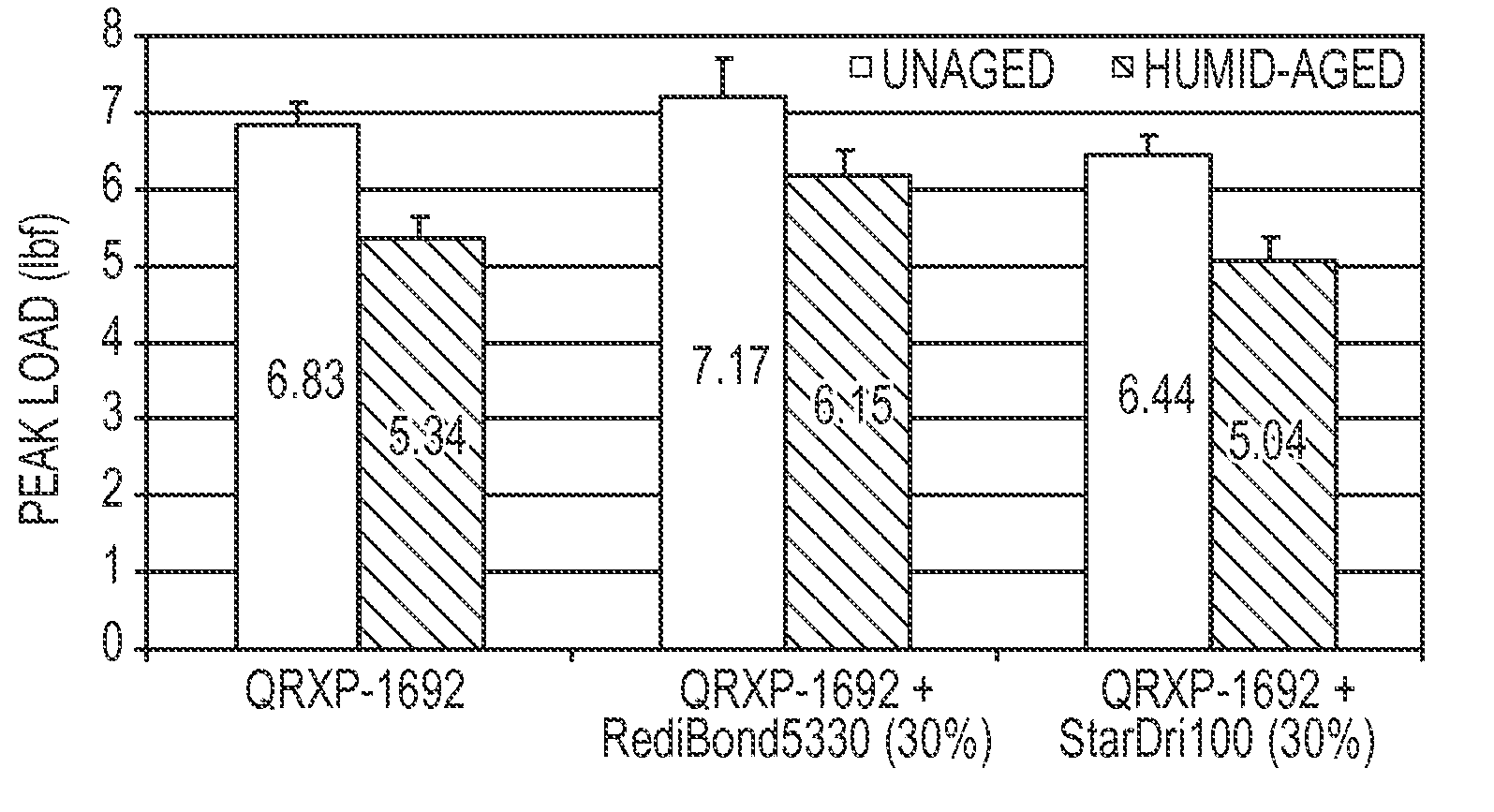

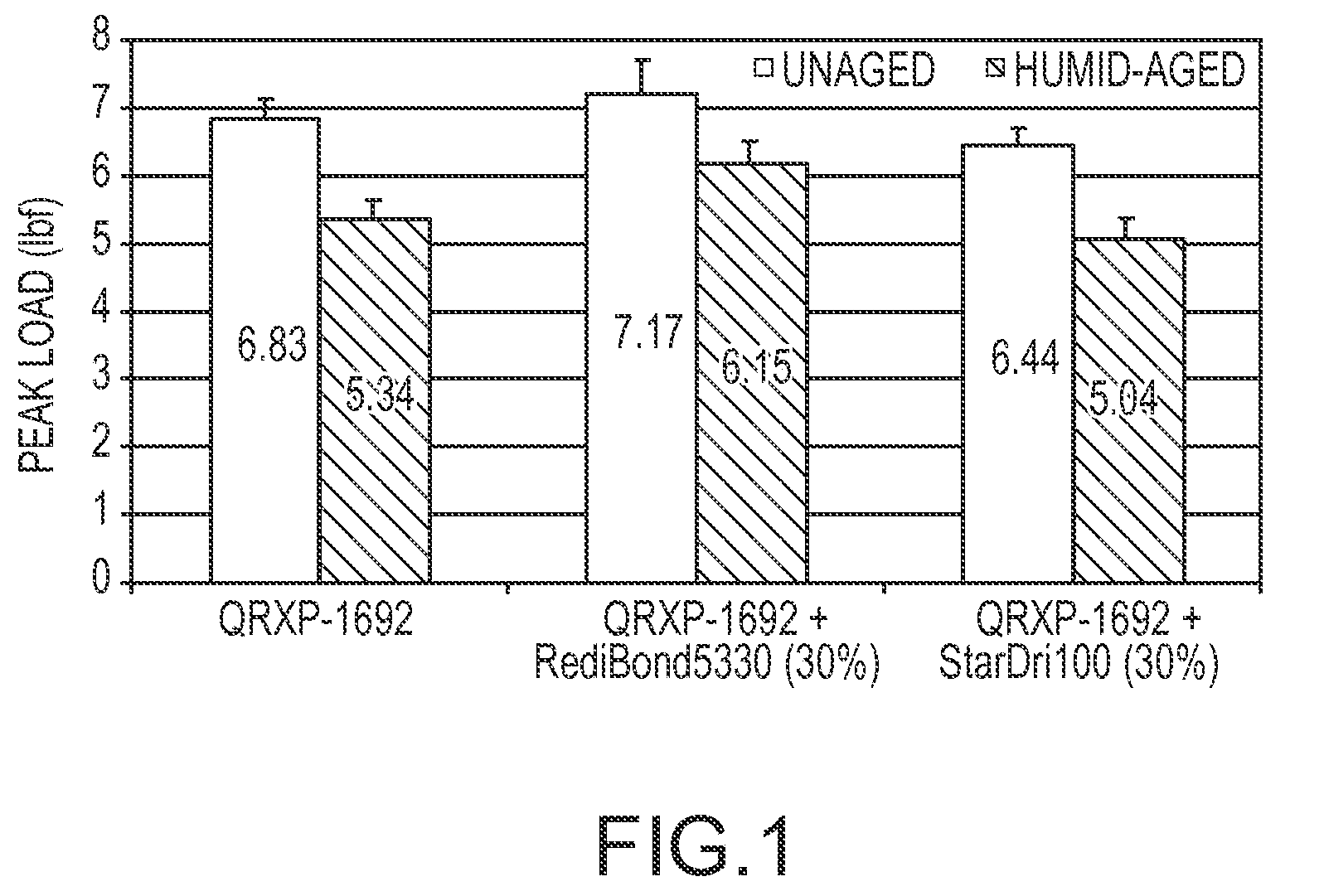

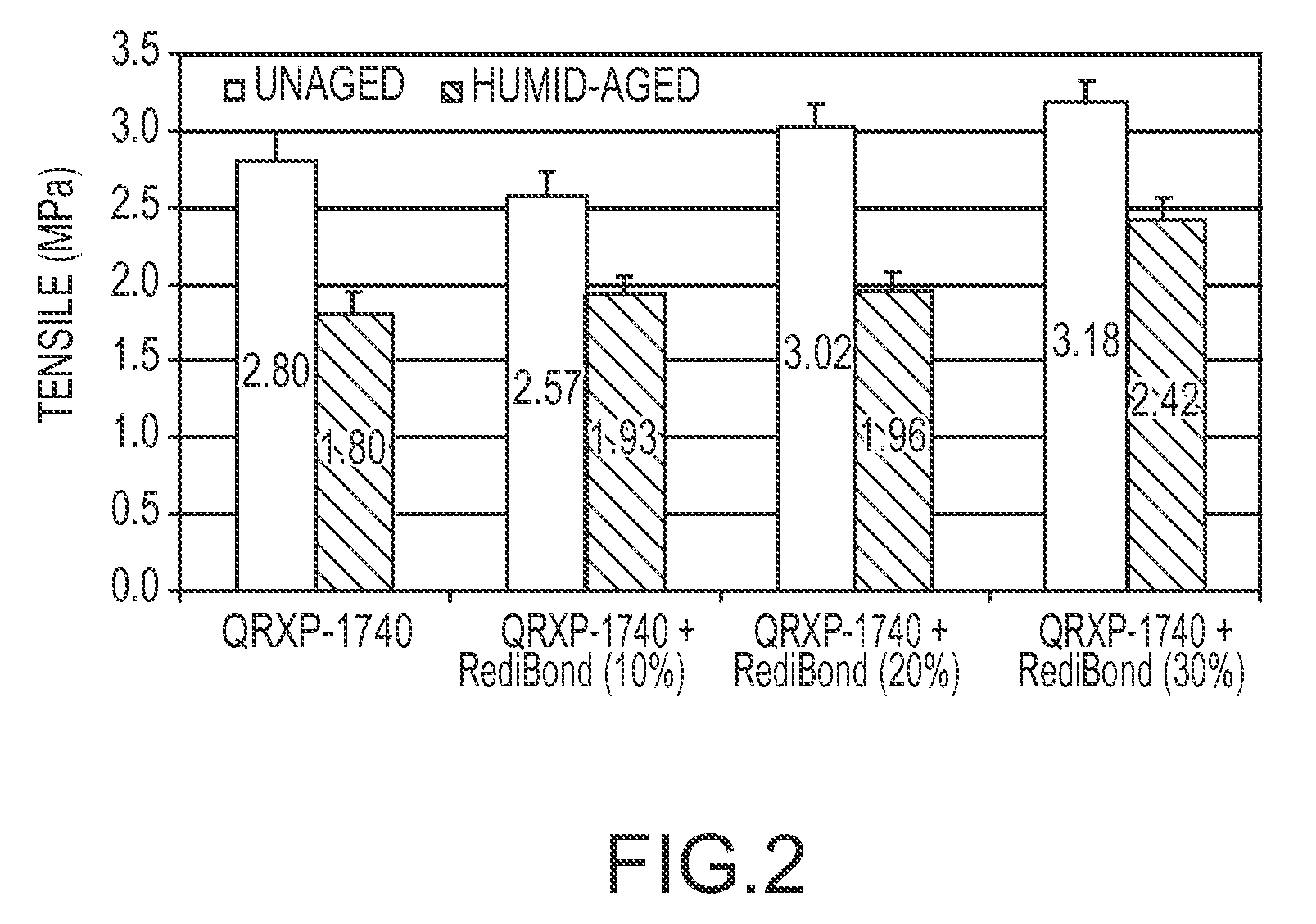

Starch containing formaldehyde-free thermoset binders for fiber products

Binder compositions are described that include a carboxyl-containing polymer, a cross-linking agent, and a starch compound having a molecular weight greater than about 10,000 g / mol. In addition, fiber products are described that include mineral or polymeric fibers and a binder prepared from an aqueous composition that includes a carboxyl-containing polymer, a cross-linking agent, and a starch having a molecular weight greater than 10,000 g / mol.

Owner:JOHNS MANVILLE CORP

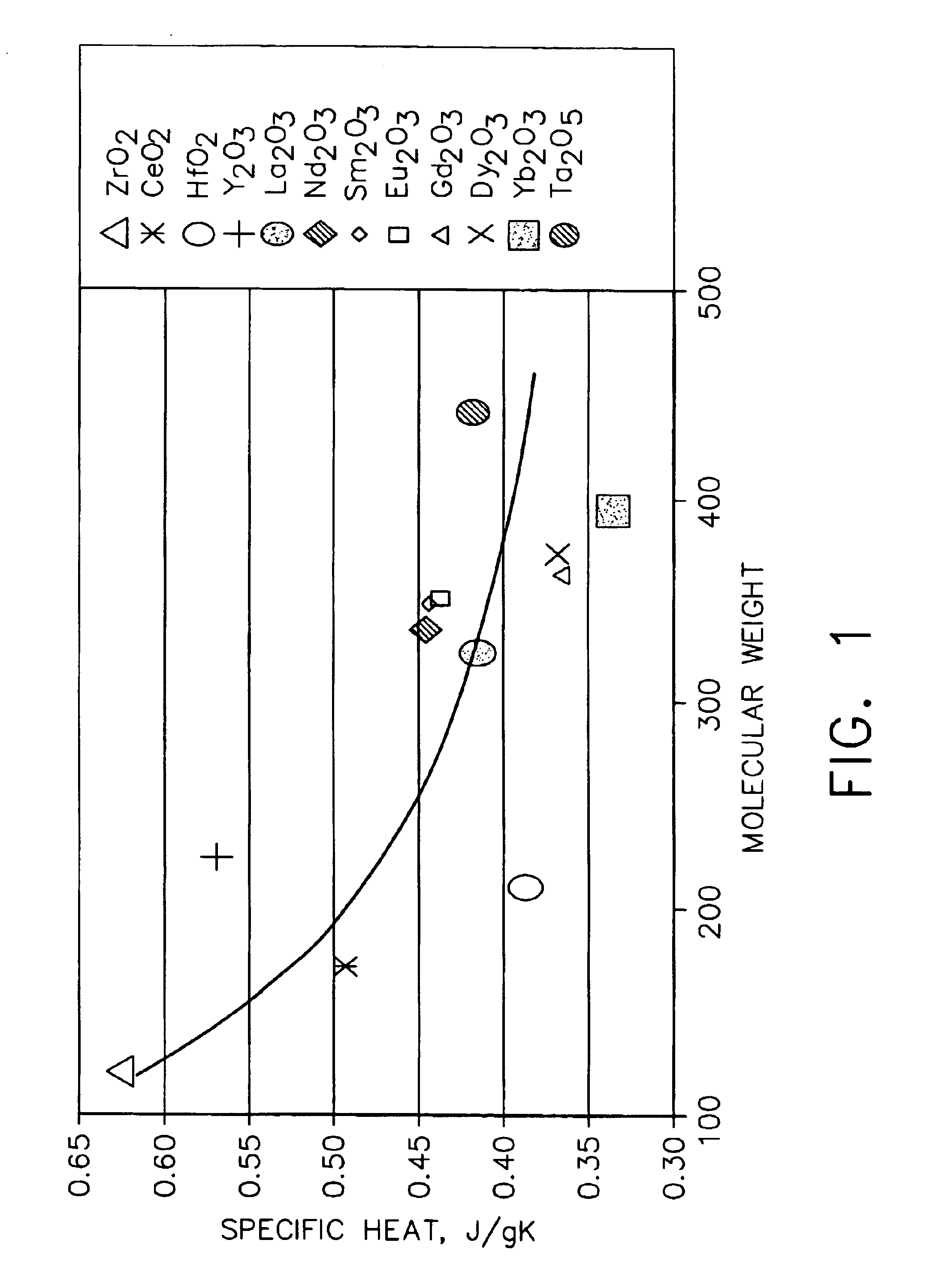

Ceramic compositions for low conductivity thermal barrier coatings

InactiveUS6858334B1Reduced and thermal conductivityGood producibilityMolten spray coatingVacuum evaporation coatingThermal barrier coatingZirconia ceramic

Zirconia-containing ceramic compositions having a c / a ratio of the zirconia lattice in the range of from about 1.005 to about 1.016. These compositions comprise a stabilizing amount up to about 10 mole % of the composition of a stabilizer component which comprises: (1) a first metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india and mixtures thereof in an amount of from about 1.5 to about 6 mole % of the composition of; (2) a second metal oxide selected from the group consisting of lanthana, neodymia and mixtures thereof in an amount of from about 0.5 to about 4 mole % of the composition; and (3) optionally ytterbia in an amount of from about 0.5 to about 4 mole % of the composition. These compositions further comprise hafnia in an amount of from about 0.5 to about 15 mole % of the composition; and optionally tantala in an amount of from about 0.5 to about 1.5 mole % of the composition. These compositions are useful in preparing thermal barrier coatings having a balance of reduced thermal conductivity with good producibility, spallation resistance and erosion / impact resistance for an underlying substrate of articles that operate at, or are exposed to, high temperatures.

Owner:GENERAL ELECTRIC CO

Lighting assembly

ActiveUS9228727B2Easy to manufactureEasy to installPlanar light sourcesLight source combinationsEffect lightStraight path

An elongate tubular lighting assembly having a body with a length between spaced first and second ends. The tubular lighting assembly has a source of illumination and first and second connectors respectively at the first and second body ends. The first connector has cooperating first and second parts having first and second surfaces. The first and second connector parts are configured so that the first and second surfaces are placed in confronting relationship to prevent separation of the first and second connector parts with the body in an operative state as an incident of the first connector part moving relative to the second connector part from a position fully separated from the second connector part in a substantially straight path that is transverse to the length of the body into an engaged position.

Owner:DVA HLDG LLC

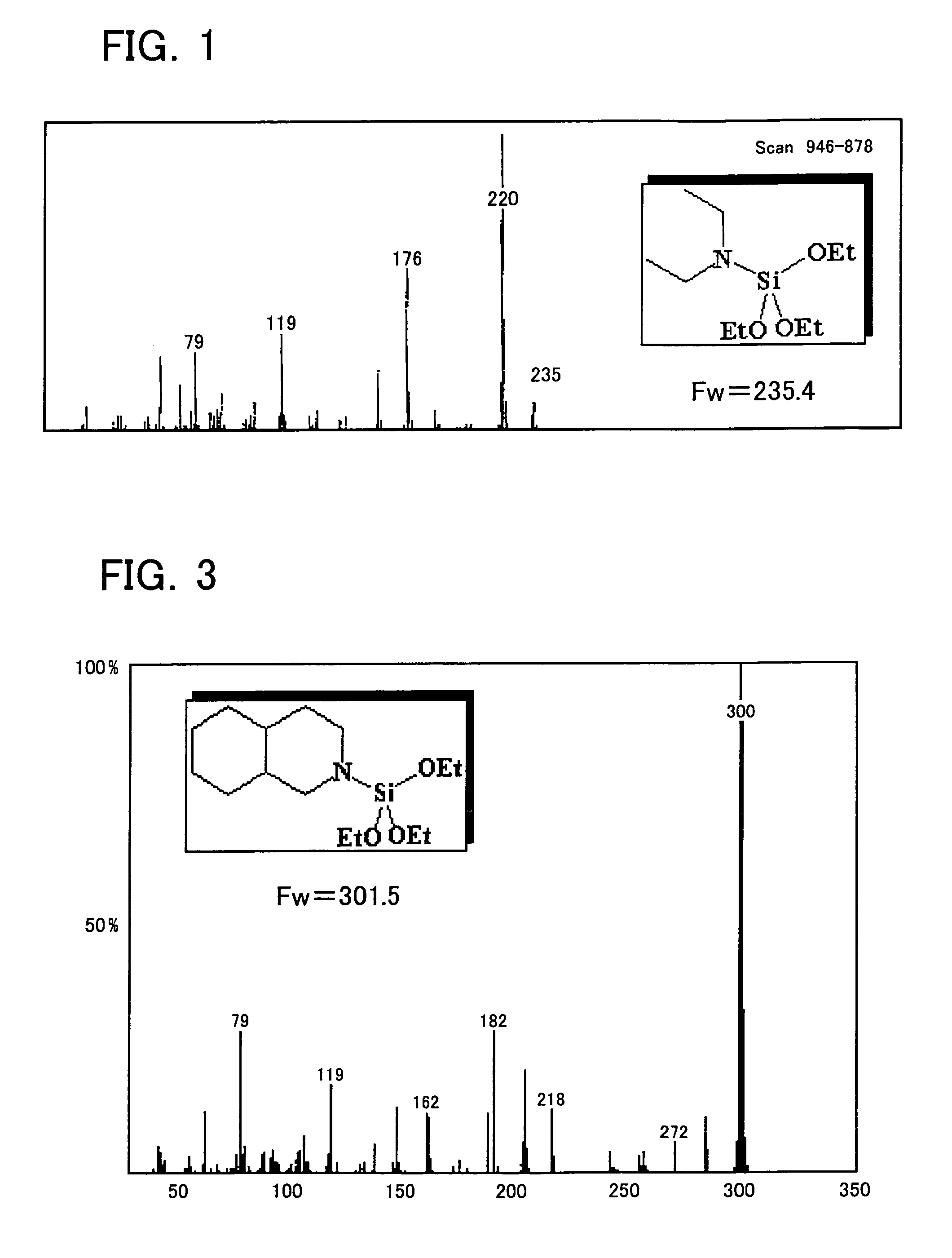

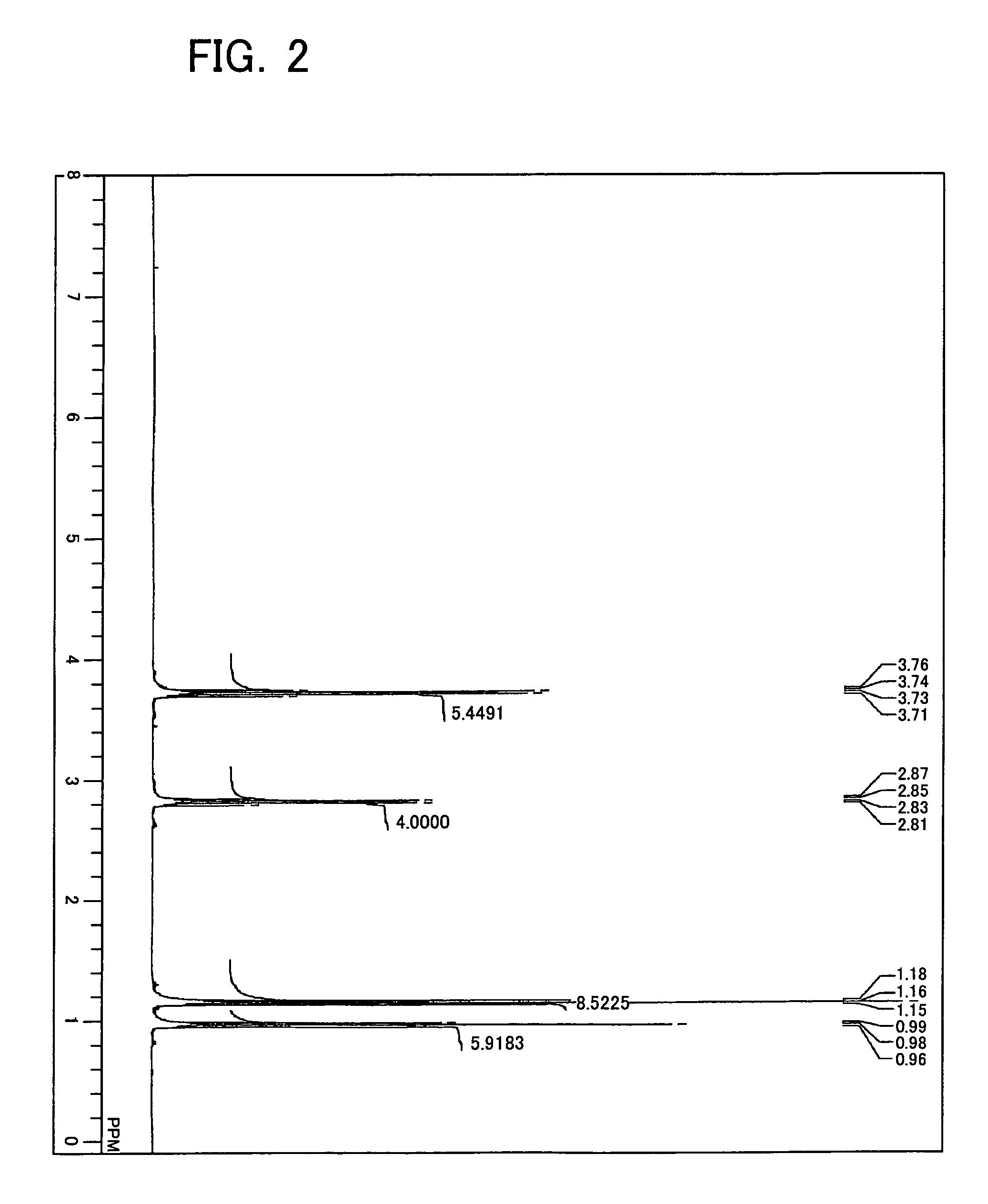

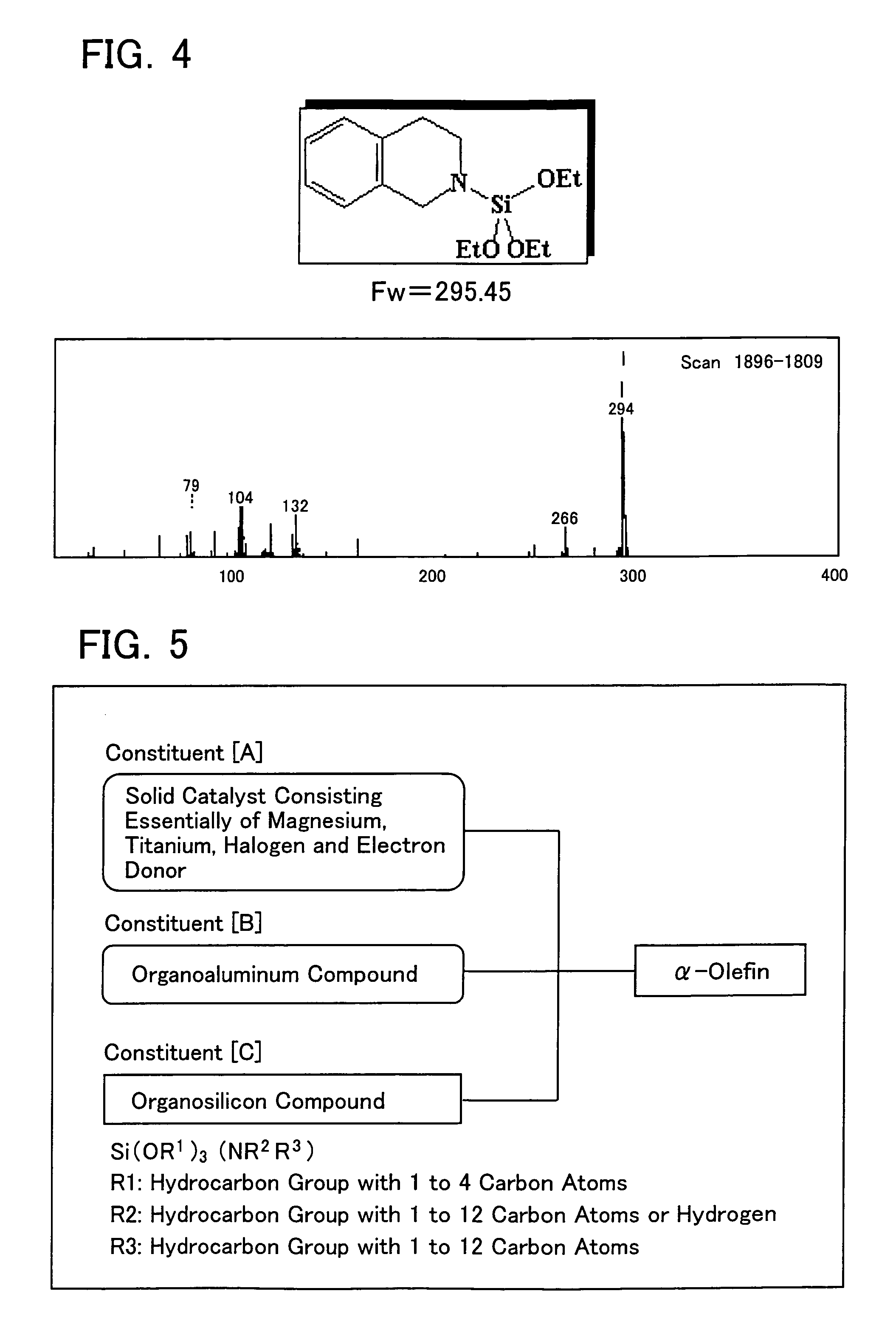

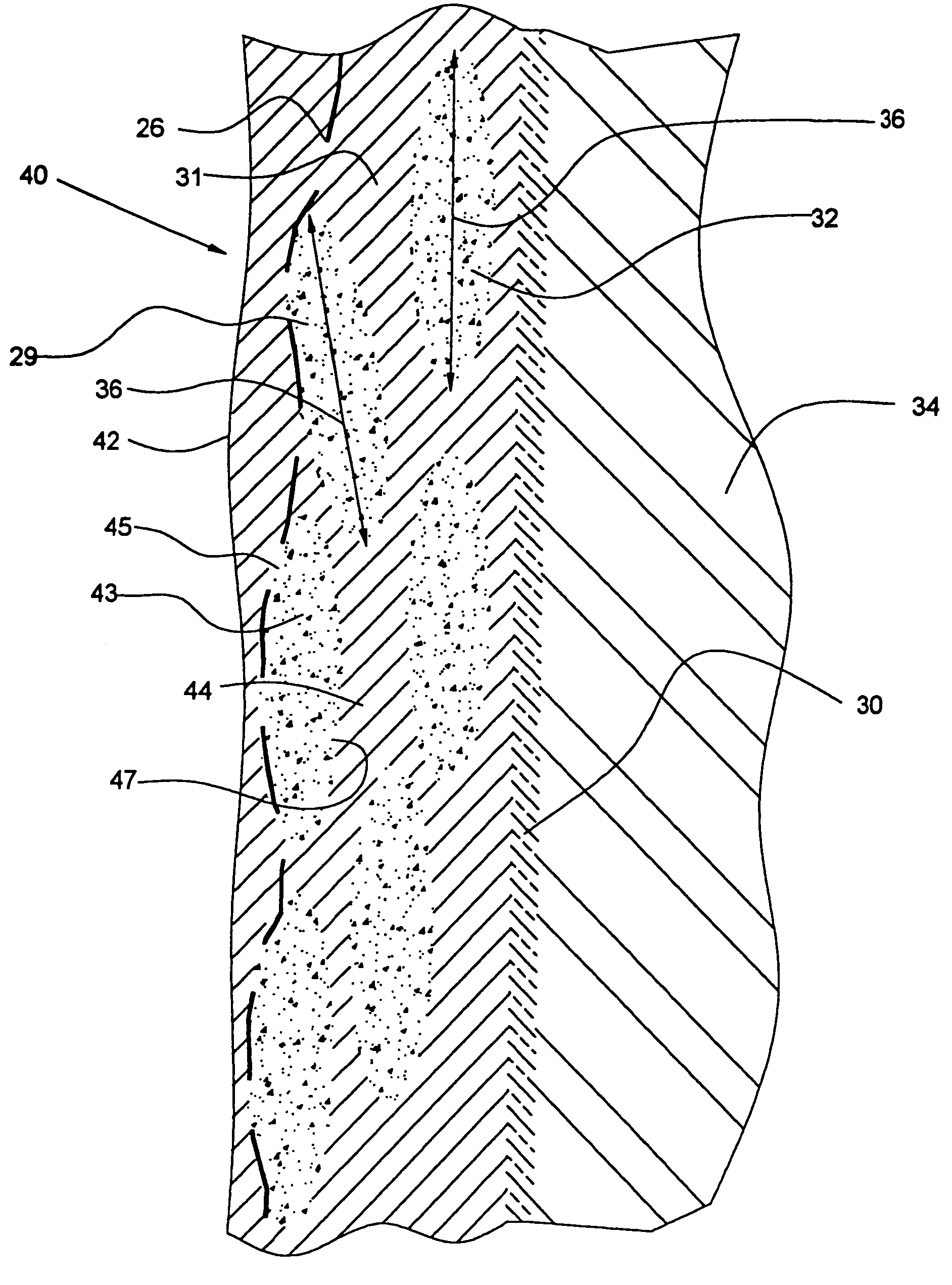

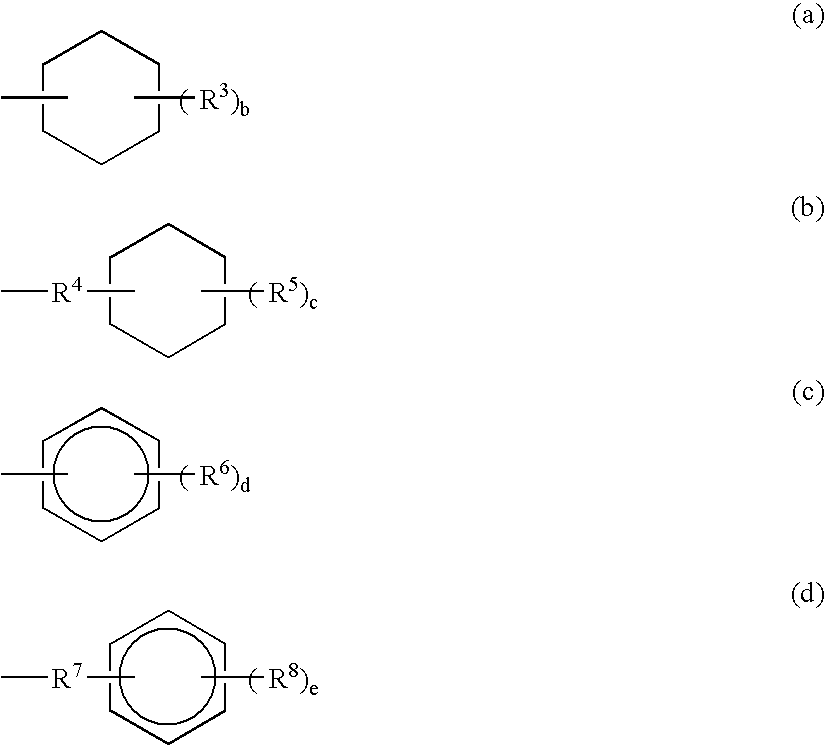

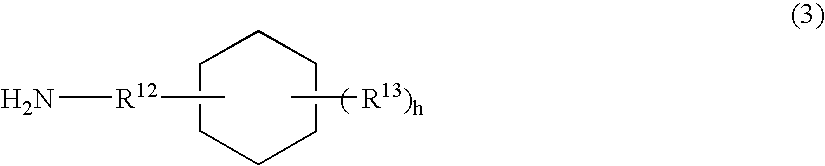

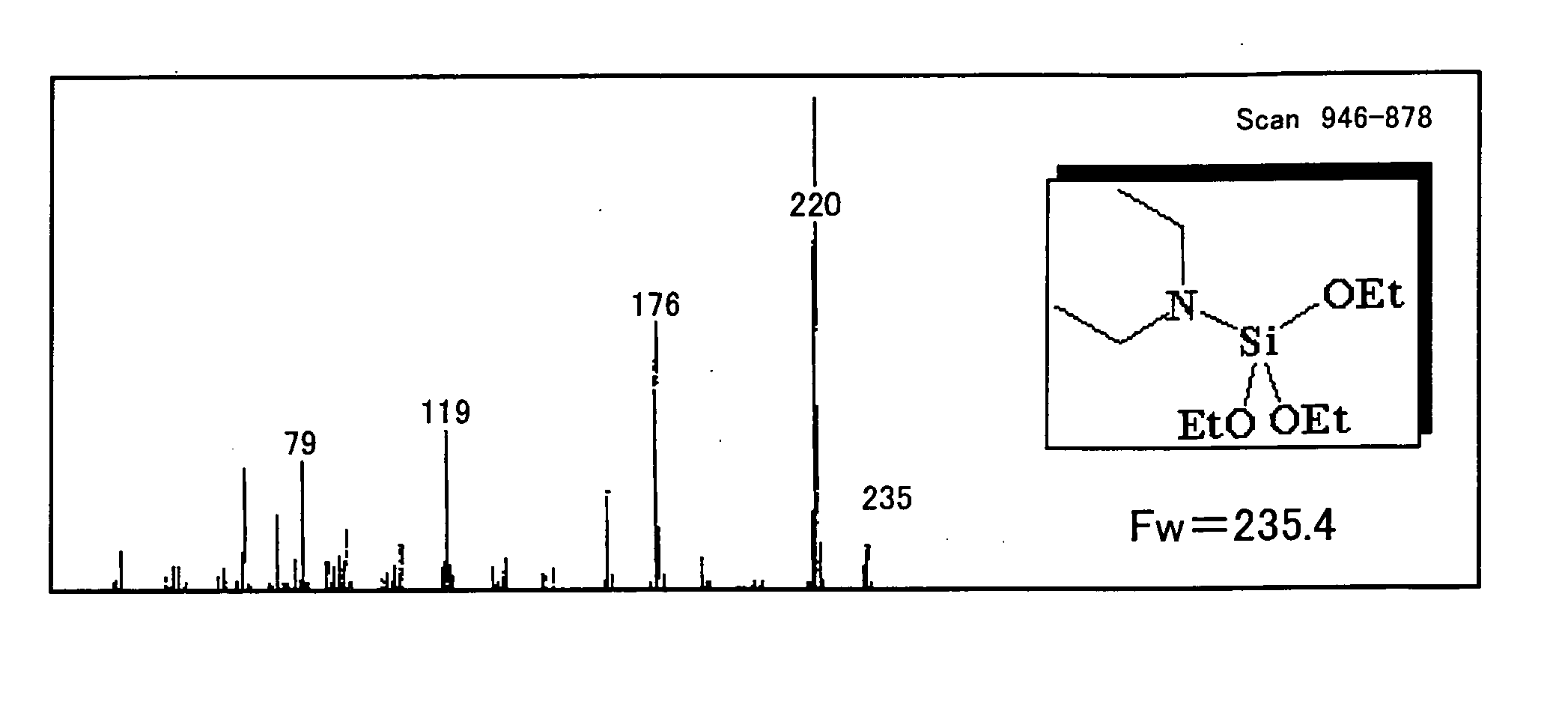

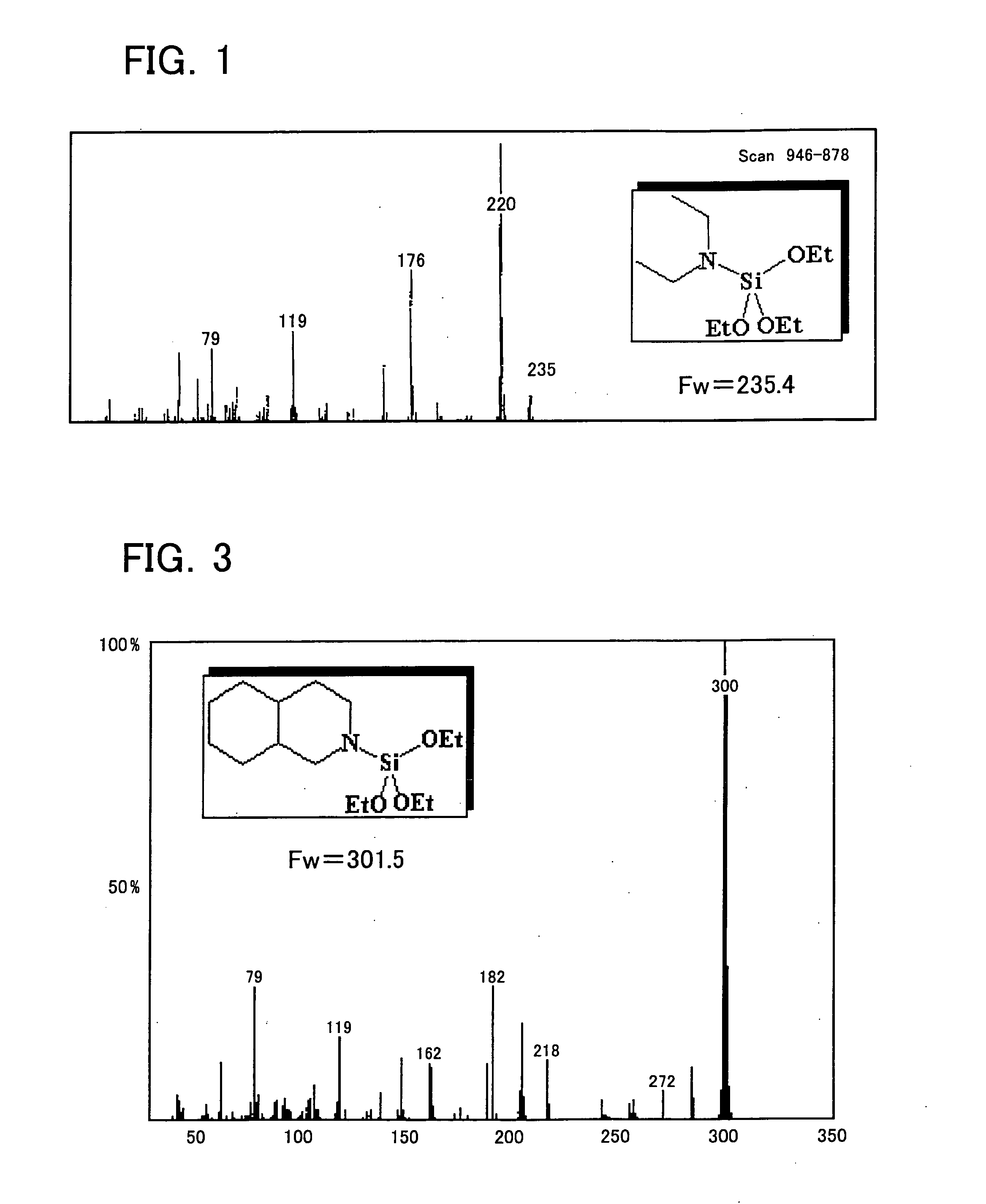

Catalysts for polymerization or copolymerization of α-olefins, catalyst components thereof, and processes for polymerization of α-olefins with the catalysts

InactiveUS7238758B2Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenReaction rate

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38:Si(OR1)3(NR2R3)Formula 37(where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms)RNSi(OR1)3Formula 38(where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

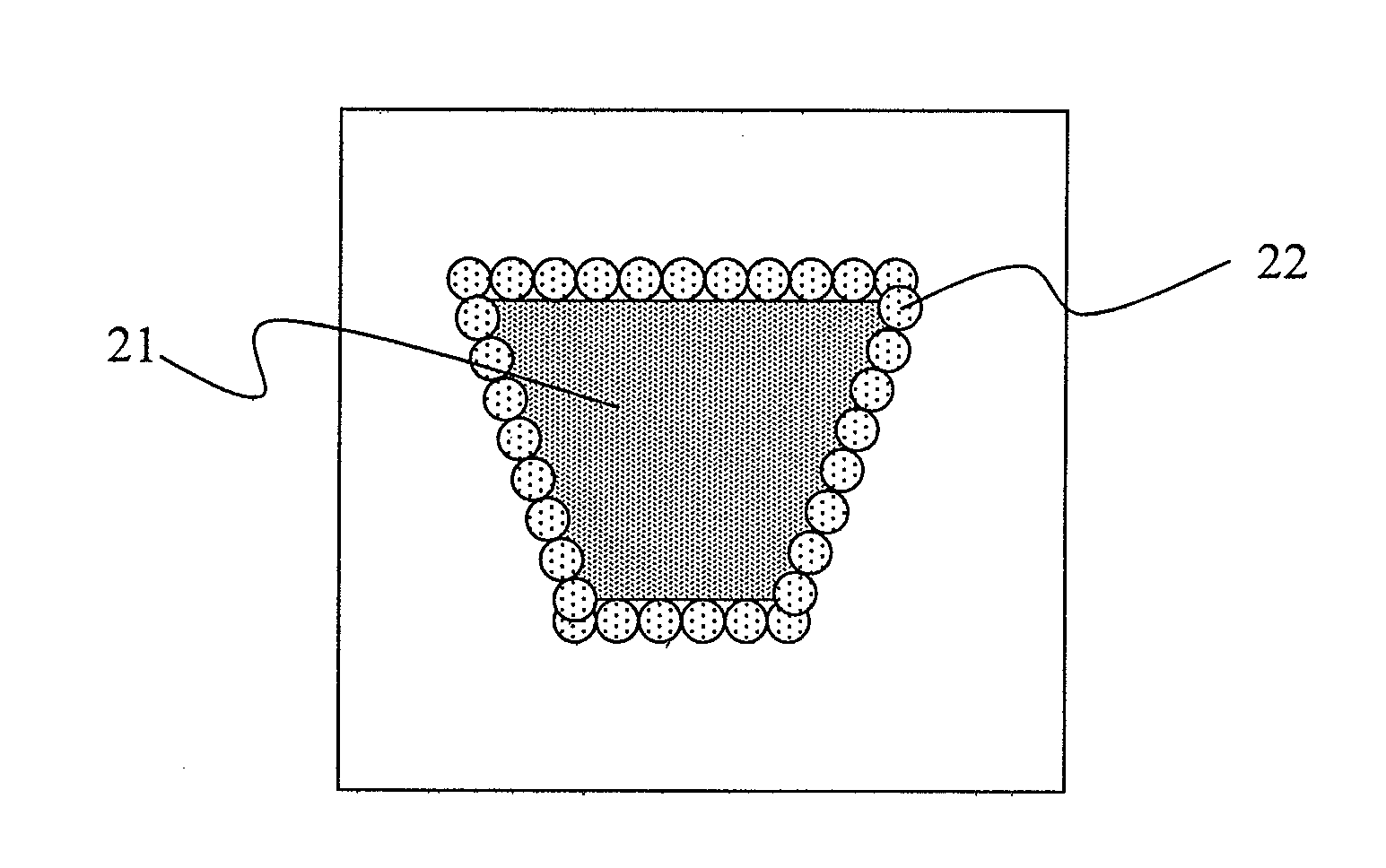

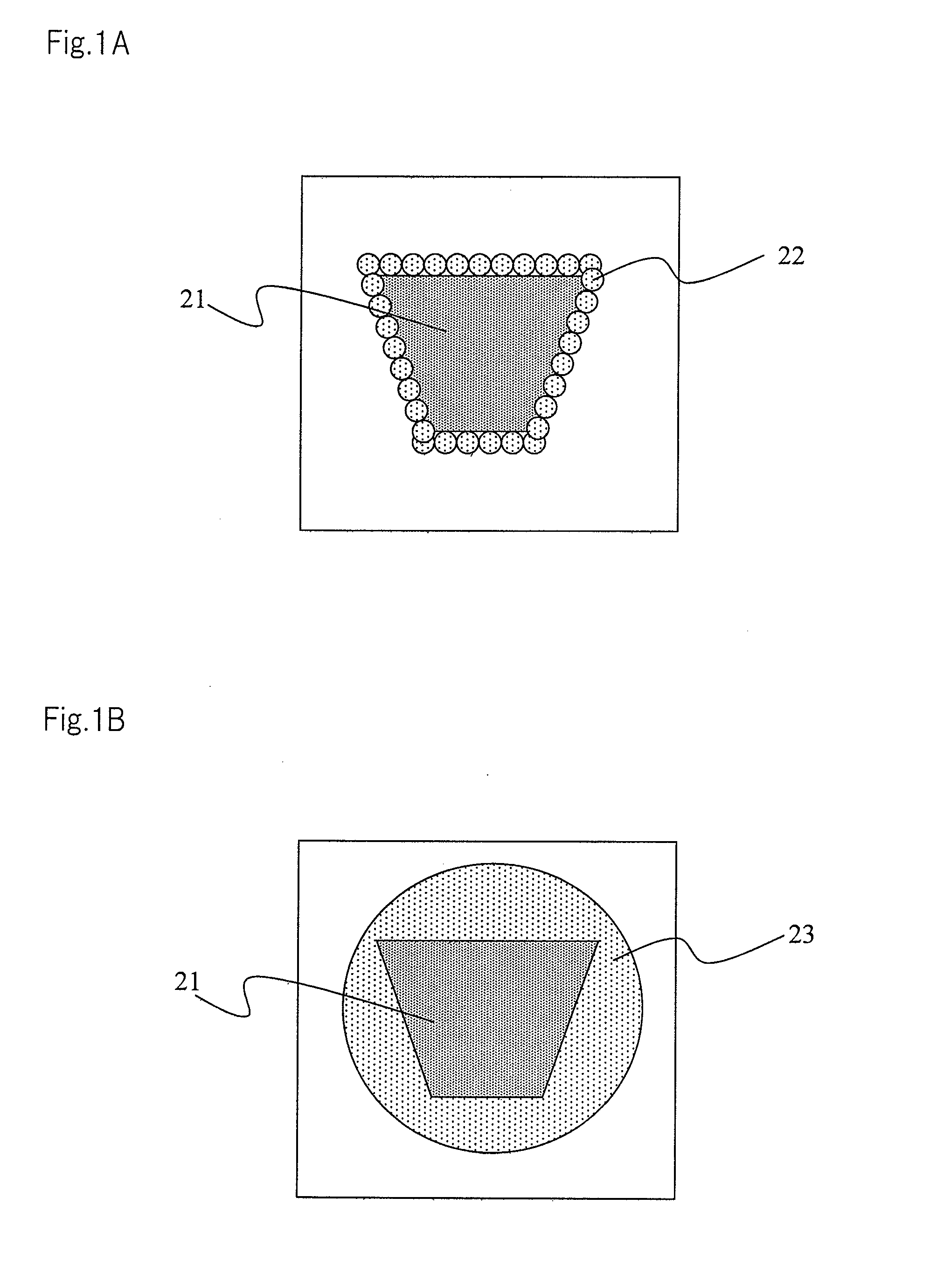

Heterogeneous composite bodies with isolated lenticular shaped cermet regions

ActiveUS7635515B1Increasing the thicknessIncrease spacingMolten spray coatingCeramic layered productsThermal sprayingSolid substrate

A heterogeneous body having ceramic rich cermet regions in a more ductile metal matrix. The heterogeneous bodies are formed by thermal spray operations on metal substrates. The thermal spray operations apply heat to a cermet powder and project it onto a solid substrate. The cermet powder is composed of complex composite particles in which a complex ceramic-metallic core particle is coated with a matrix precursor. The cermet regions are generally comprised of complex ceramic-metallic composites that correspond approximately to the core particles. The cermet regions are approximately lenticular shaped with an average width that is at least approximately twice the average thickness. The cermet regions are imbedded within the matrix phase and generally isolated from one another. They have obverse and reverse surfaces. The matrix phase is formed from the matrix precursor coating on the core particles. The amount of heat applied during the formation of the heterogeneous body is controlled so that the core particles soften but do not become so fluid that they disperse throughout the matrix phase. The force of the impact on the surface of the substrate tends to flatten them. The flattened cermet regions tend to be approximately aligned with one another in the body.

Owner:POWDERMET

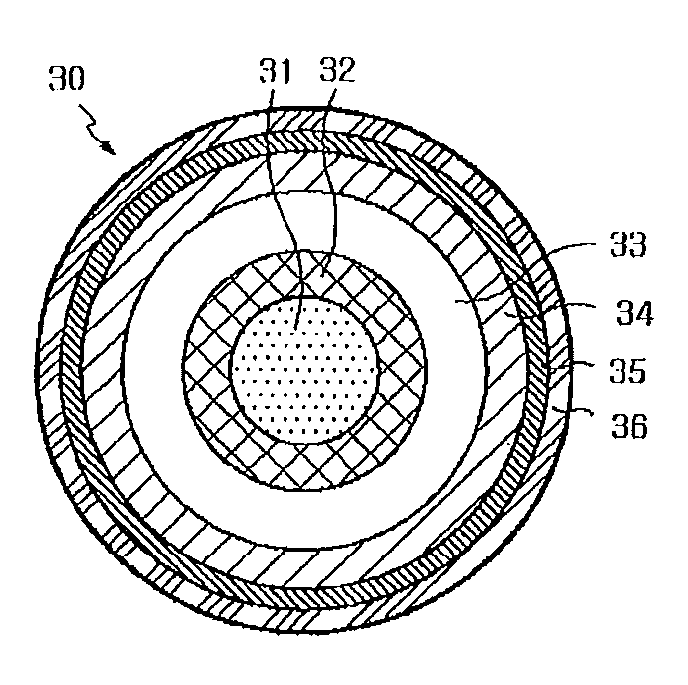

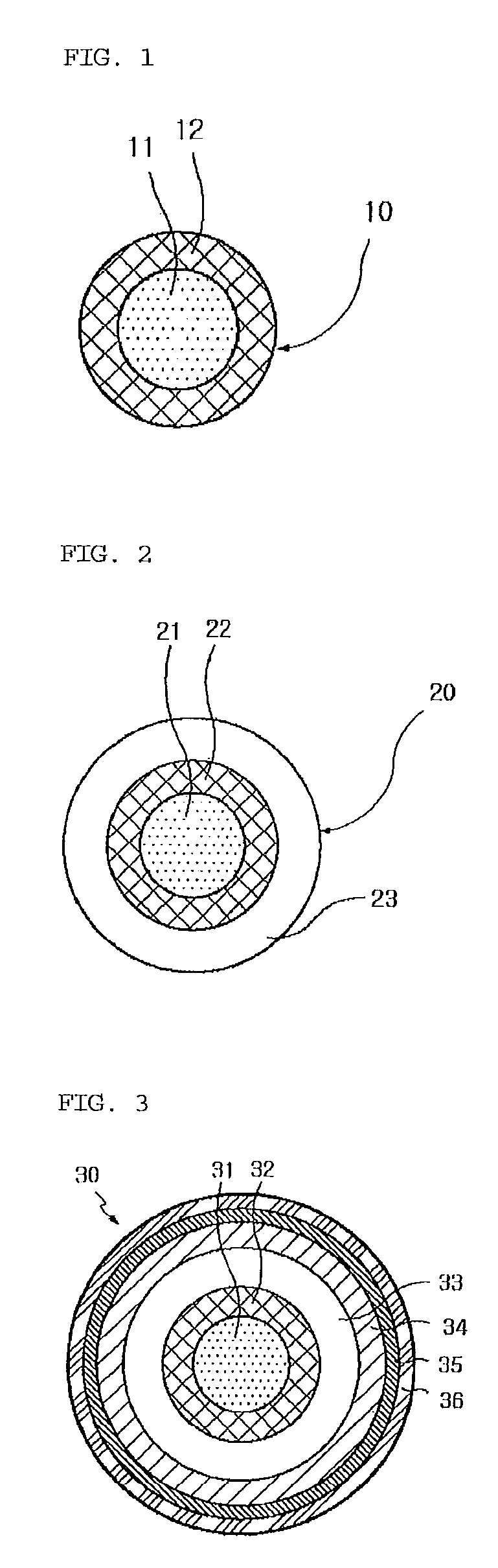

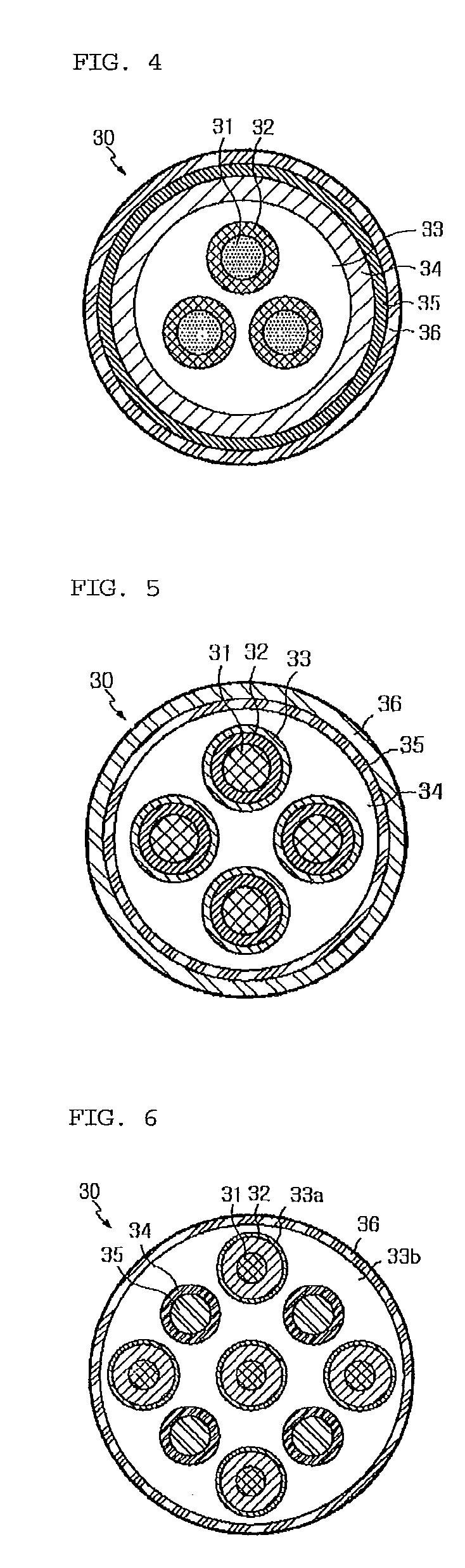

Anode for cable-type secondary battery and cable-type secondary battery including the anode

ActiveUS20120295144A1Reduce internal stressRelieve pressureFinal product manufactureElectrode carriers/collectorsLithiumElectrical battery

Disclosed is an anode for a lithium secondary battery. The anode includes a current collector in the form of a wire and a porous anode active material layer coated to surround the surface of the current collector. The three-dimensional porous structure of the active material layer increases the surface area of the anode. Accordingly, the mobility of lithium ions through the anode is improved, achieving superior battery performance. In addition, the porous structure allows the anode to relieve internal stress and pressure, such as swelling, occurring during charge and discharge of a battery, ensuring high stability of the battery while preventing deformation of the battery. These advantages make the anode suitable for use in a cable-type secondary battery. Further disclosed is a lithium secondary battery including the anode.

Owner:LG ENERGY SOLUTION LTD

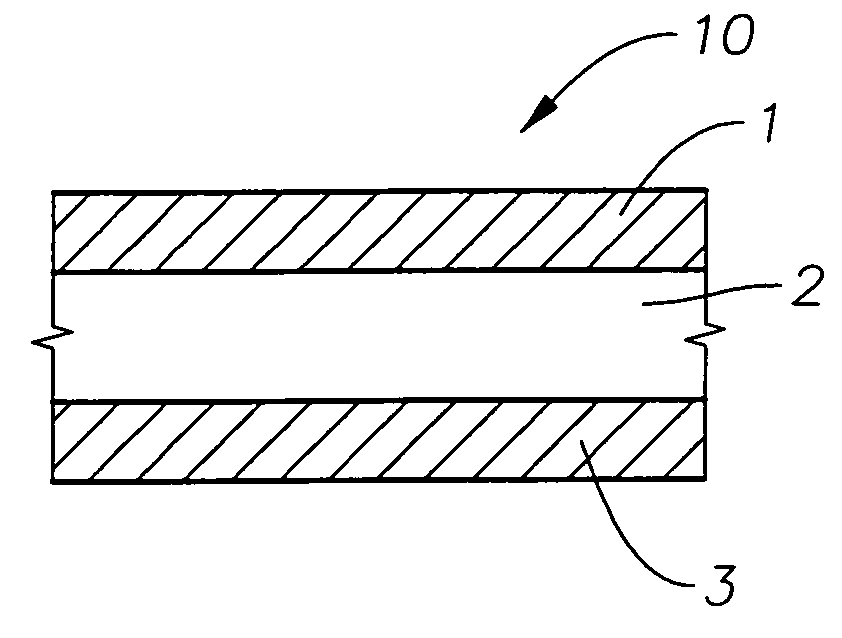

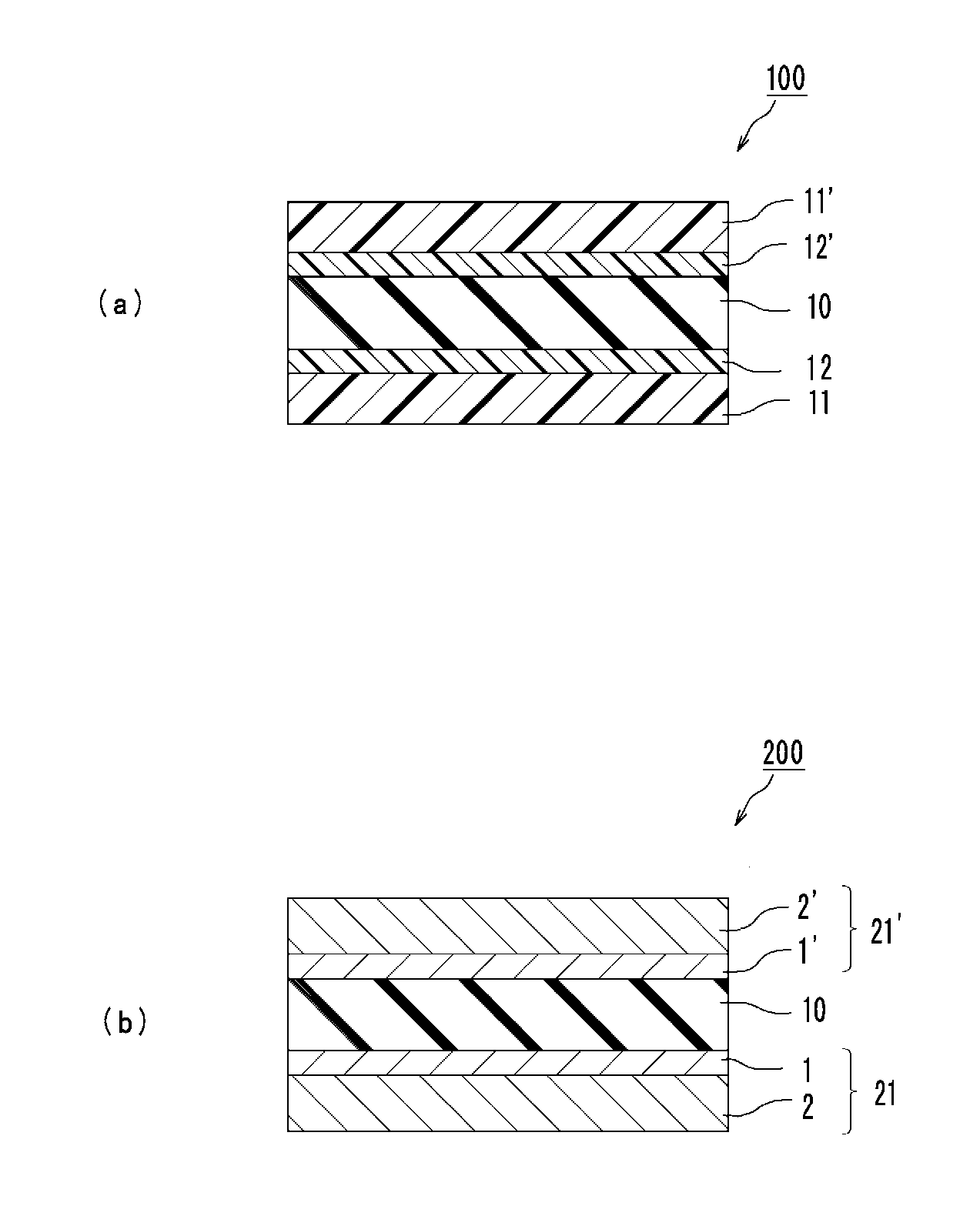

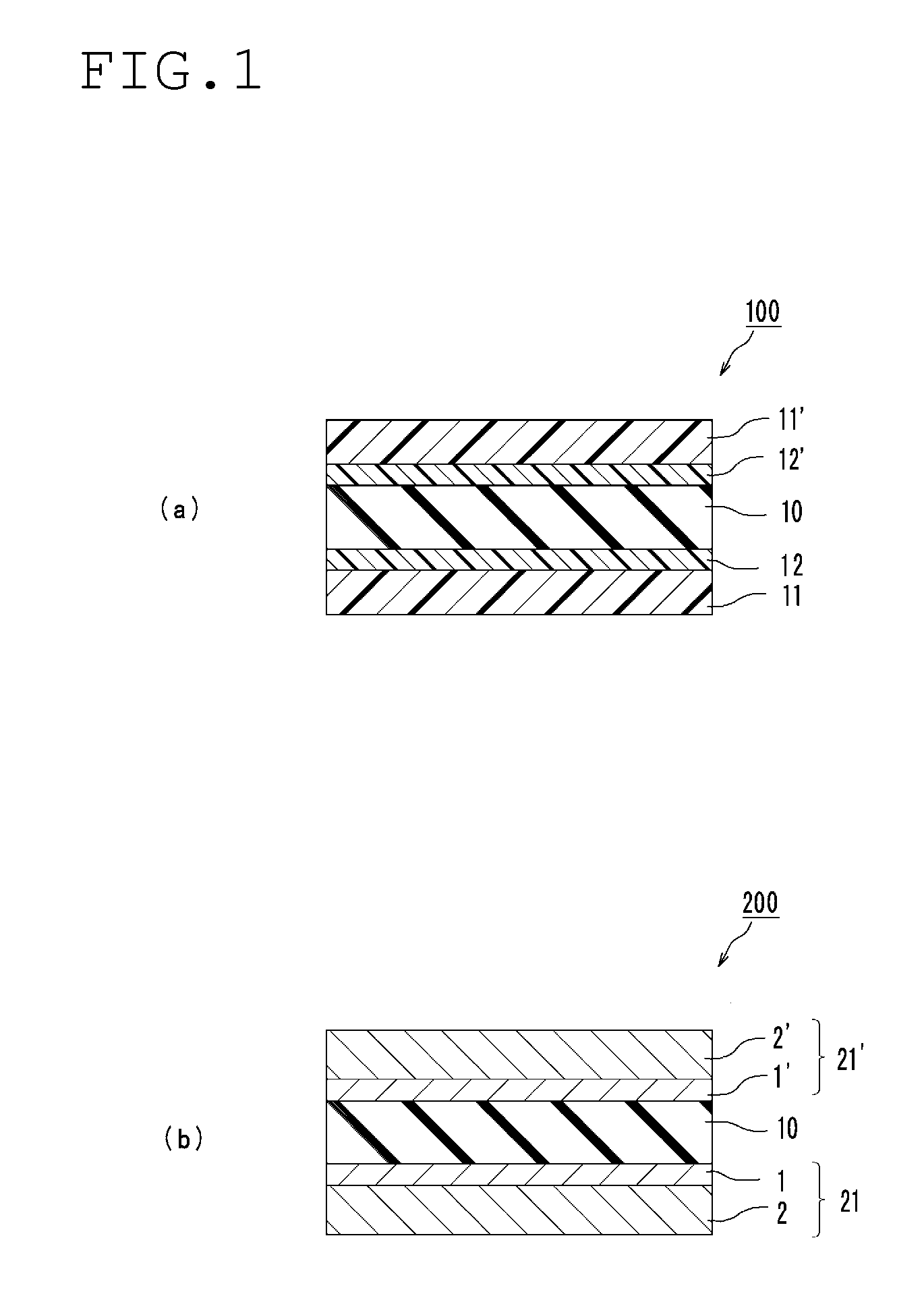

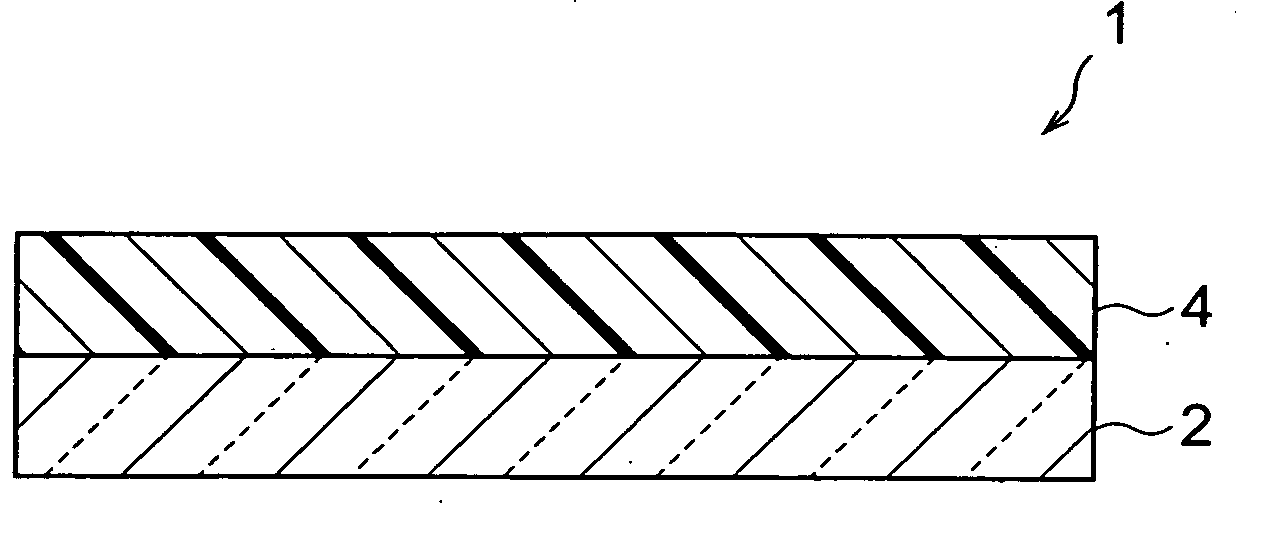

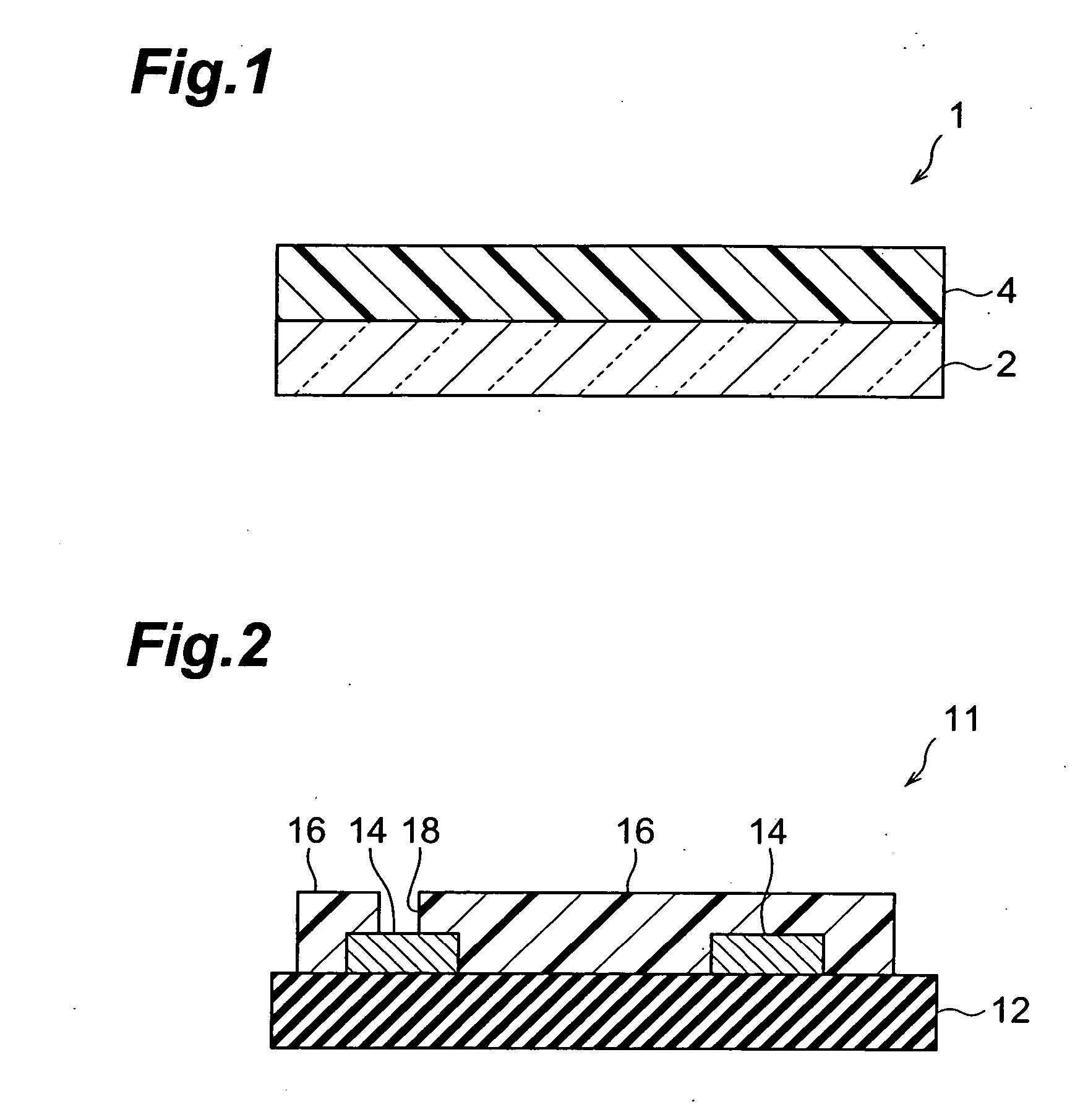

Transparent substrate and method for production thereof

InactiveUS20110244225A1Reduce thicknessImprove adhesionFilm/foil adhesivesSynthetic resin layered productsHigh humidityCoupling

There is provided a transparent substrate which can be reduced in thickness, which is excellent in adhesiveness between an inorganic glass and a resin layer under a high-temperature and high-humidity environment, bending property, flexibility, and impact resistance, and which significantly prevents the progress of a crack in a glass.A transparent substrate according to an embodiment of the present invention includes: an inorganic glass; and a resin layer, which is obtained by applying a solution of a thermoplastic resin onto one side or both sides of the inorganic glass, wherein: the solution comprises a first thermoplastic resin having a hydroxy group at a terminal; the inorganic glass and the resin layer comprise an epoxy group-terminated coupling agent layer therebetween; the coupling agent layer is directly formed on the inorganic glass; and the resin layer is directly formed on the coupling agent layer.

Owner:NITTO DENKO CORP

Lactic acid polymer composition and molded object thereof

InactiveUS20050001349A1Crystallinity impairedHeat resistance impairedArtifical filament manufacturePolymer sciencePlasticizer

Disclosed herein are a lactic acid-based polymer composition comprising: (i) an amide compound represented by General Formula (1): R1—(CONHR2)a (1) wherein R1 represents a C2-30 saturated or unsaturated aliphatic polycarboxylic acid residue, a C4-28 saturated or unsaturated alicyclic polycarboxylic acid residue, or a C6-28 aromatic polycarboxylic acid residue, and R2 represents C1-18 alkyl, C2-18 alkenyl, C3-12 cycloalkyl or cycloalkenyl or the like, (ii) an ester plasticizer, and (iii) a lactic acid-based polymer; a transparent, crystalline (heat resistant) molded article molded from such a lactic acid-based polymer composition; and a method for producing such a molded article.

Owner:NEW JAPAN CHEM CO

System for absorbing and distributing side impact energy utilizing an integrated battery pack

ActiveUS20140182958A1Simplify mechanically couplingResist impactElectric propulsion mountingUnderstructuresElectrical batterySide impact

Owner:TESLA INC

Molded plastic structures

A plastic molded lip structure may extend along a perimeter of a planar element and may include an outer wall, an inner wall, structural portions, and protruded features. The outer wall may extend in a normal direction from the planar element. The inner wall may be disposed in an inward direction relative to the outer wall. The structural portions may be disposed along structural sections of the perimeter and may include first portions of the inner wall and of the outer wall. The first portions may be disposed parallel to the inner wall and separated from the first portions by a first distance along the structural sections. The protruded features may be interposed between two structural portions and an inner wall may be separated from second portions of the outer wall by a second distance that is greater than the first distance.

Owner:LIFETIME PRODUCTS

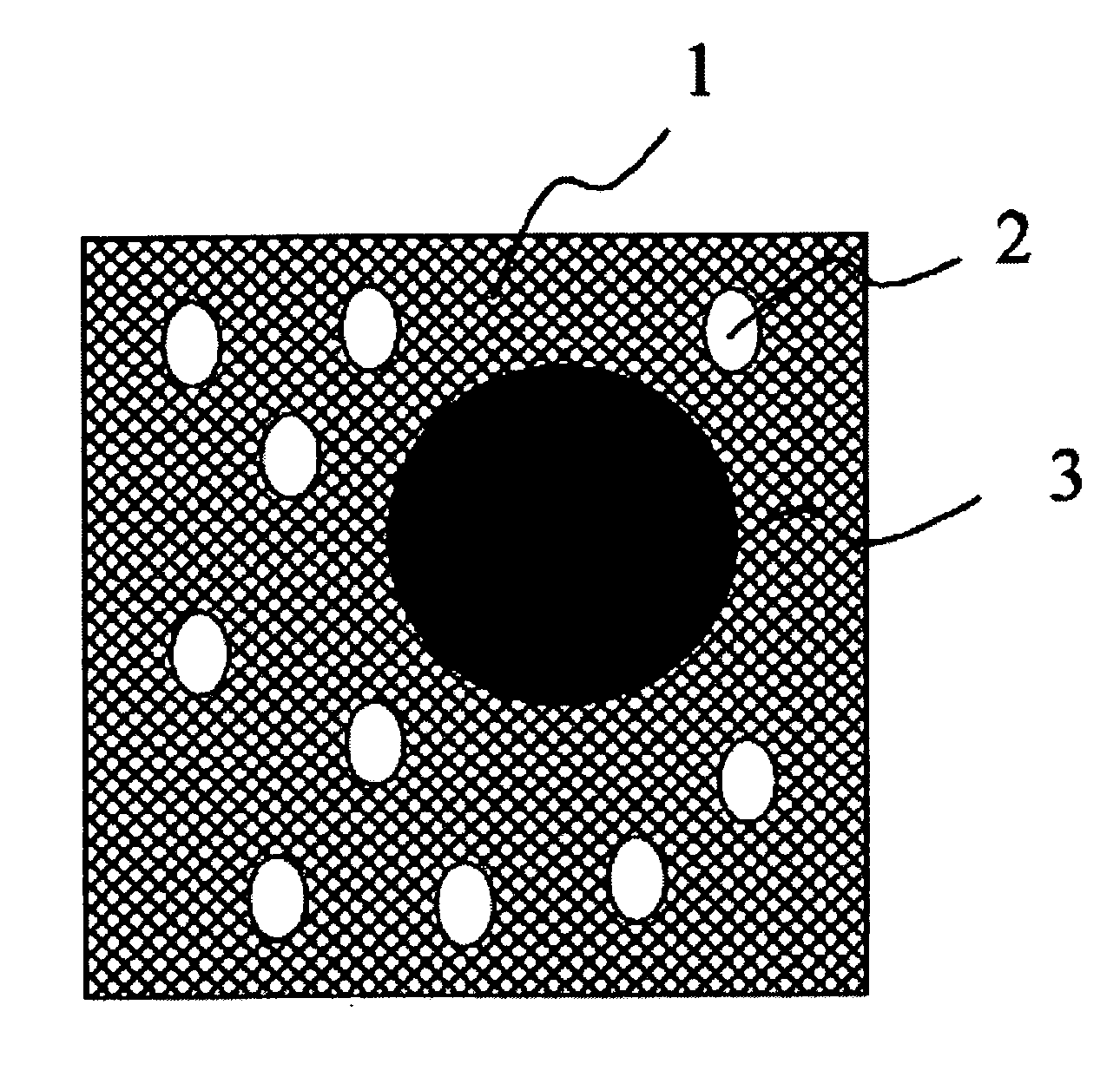

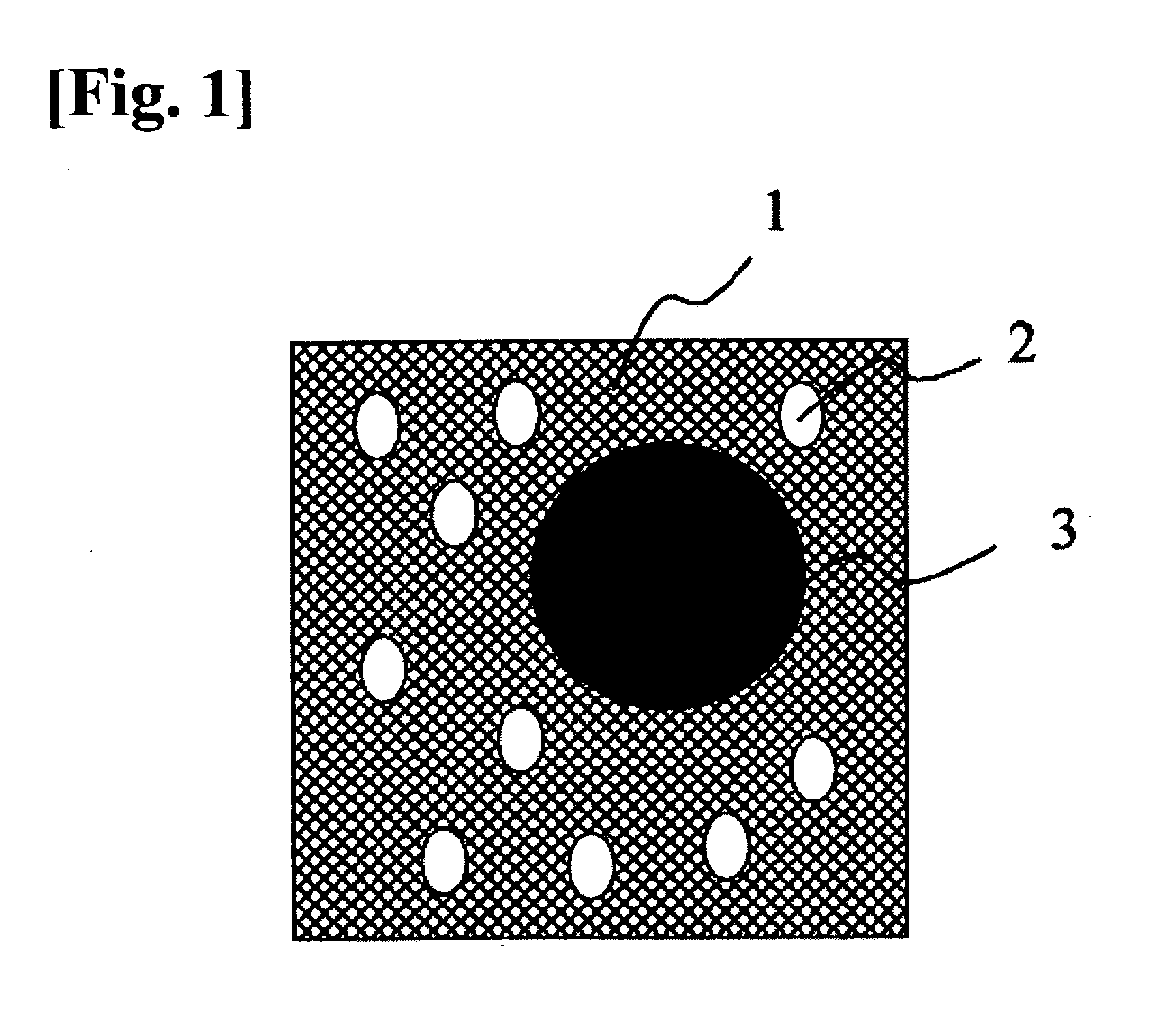

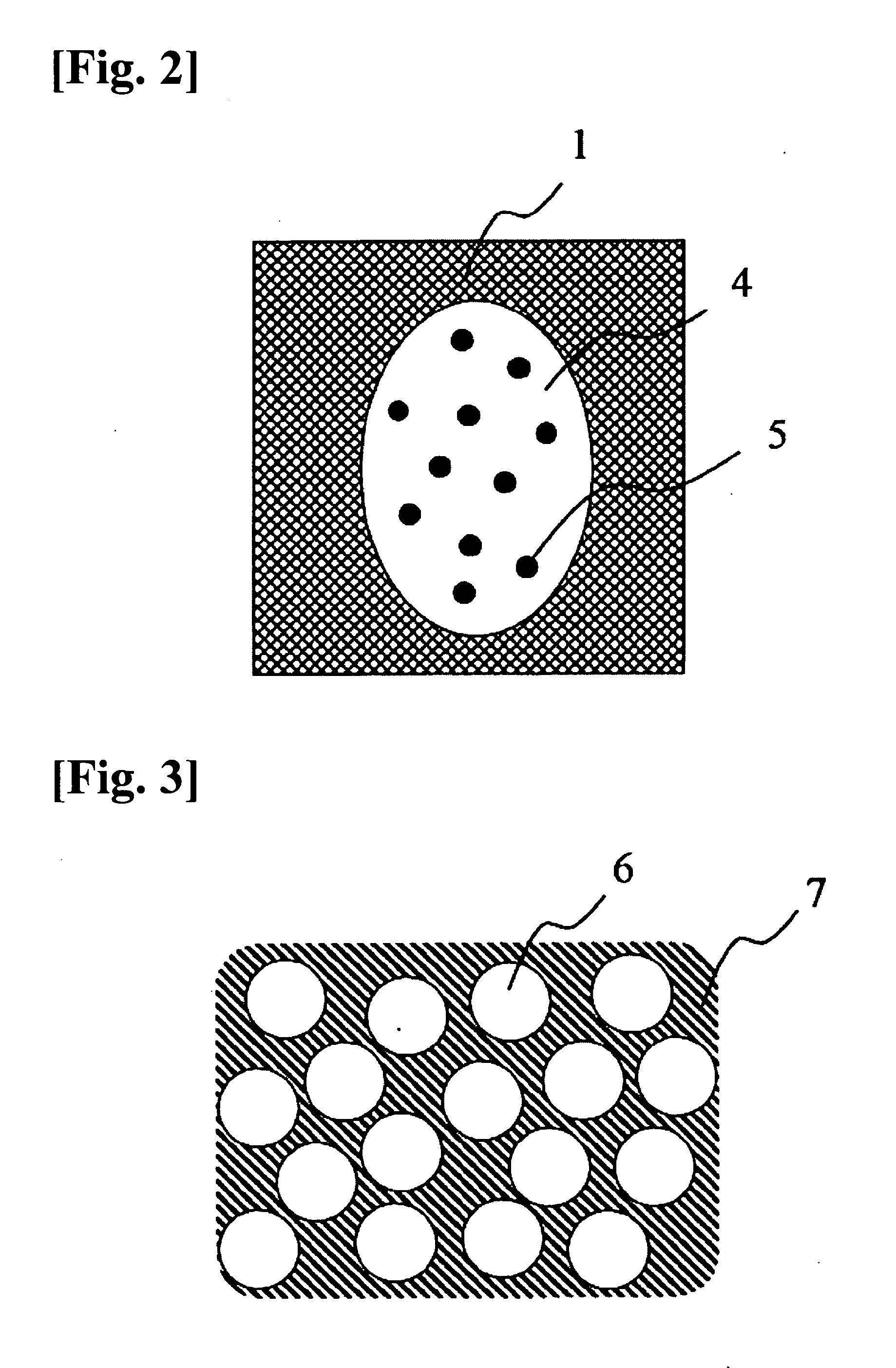

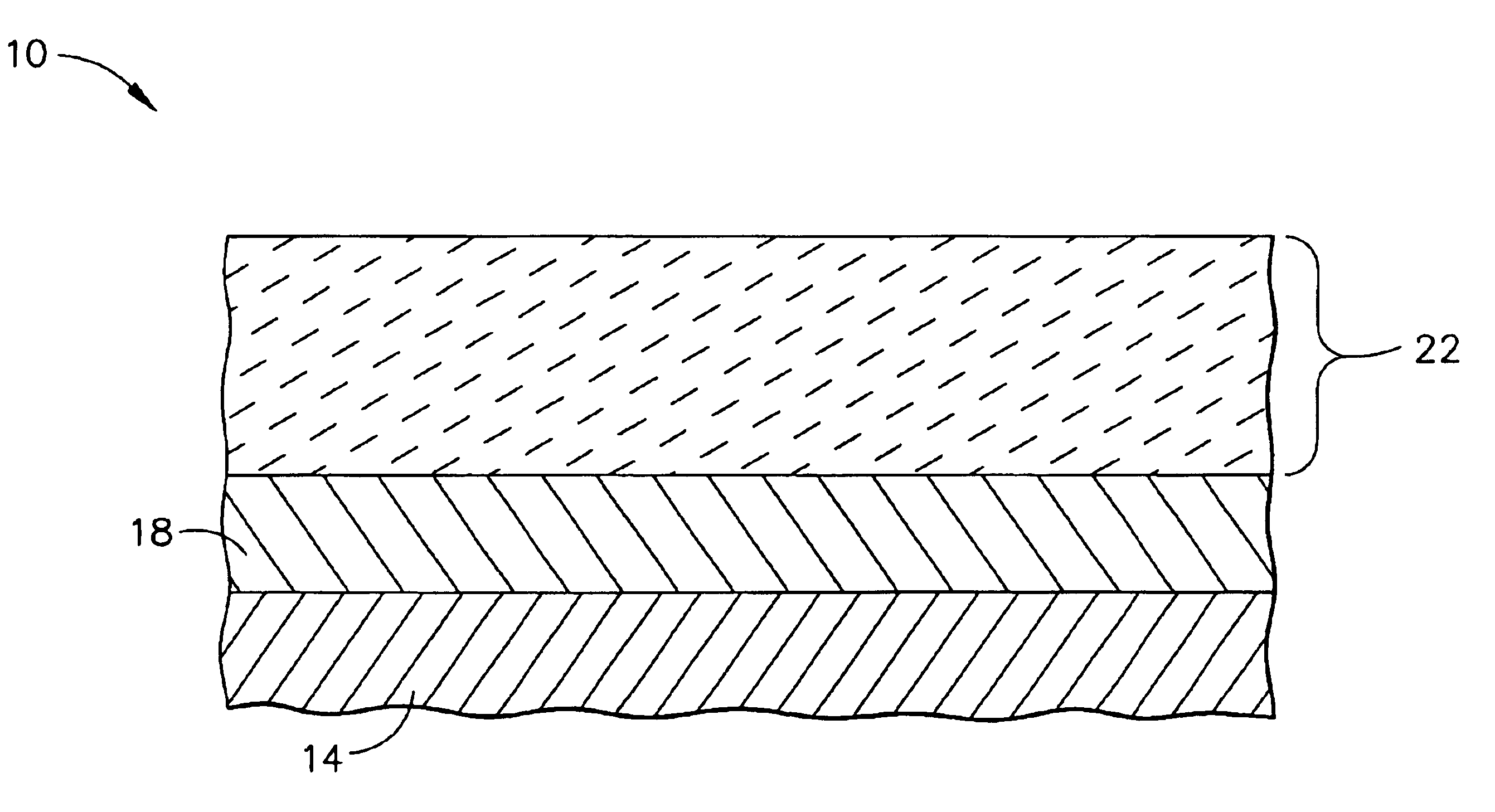

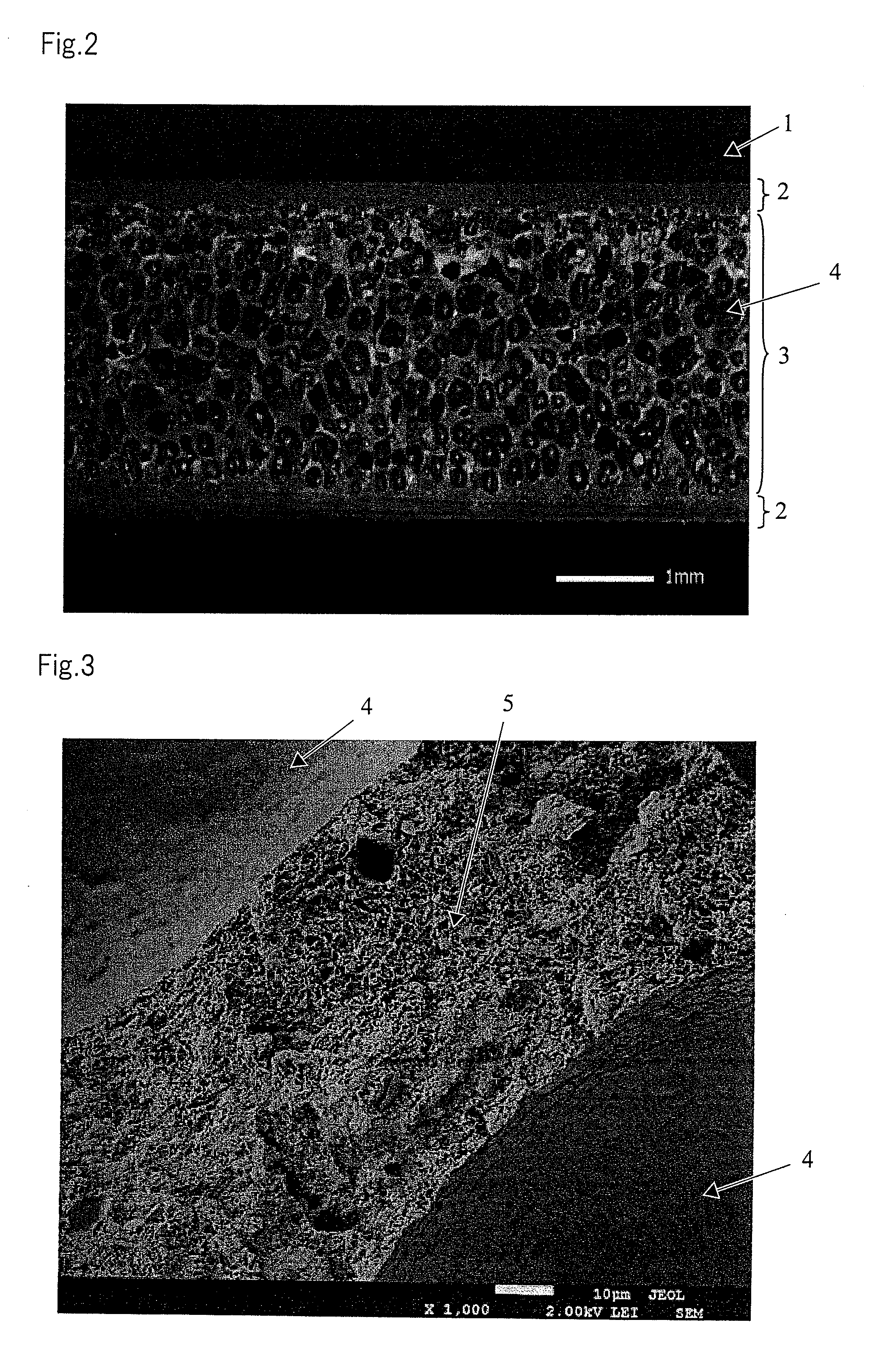

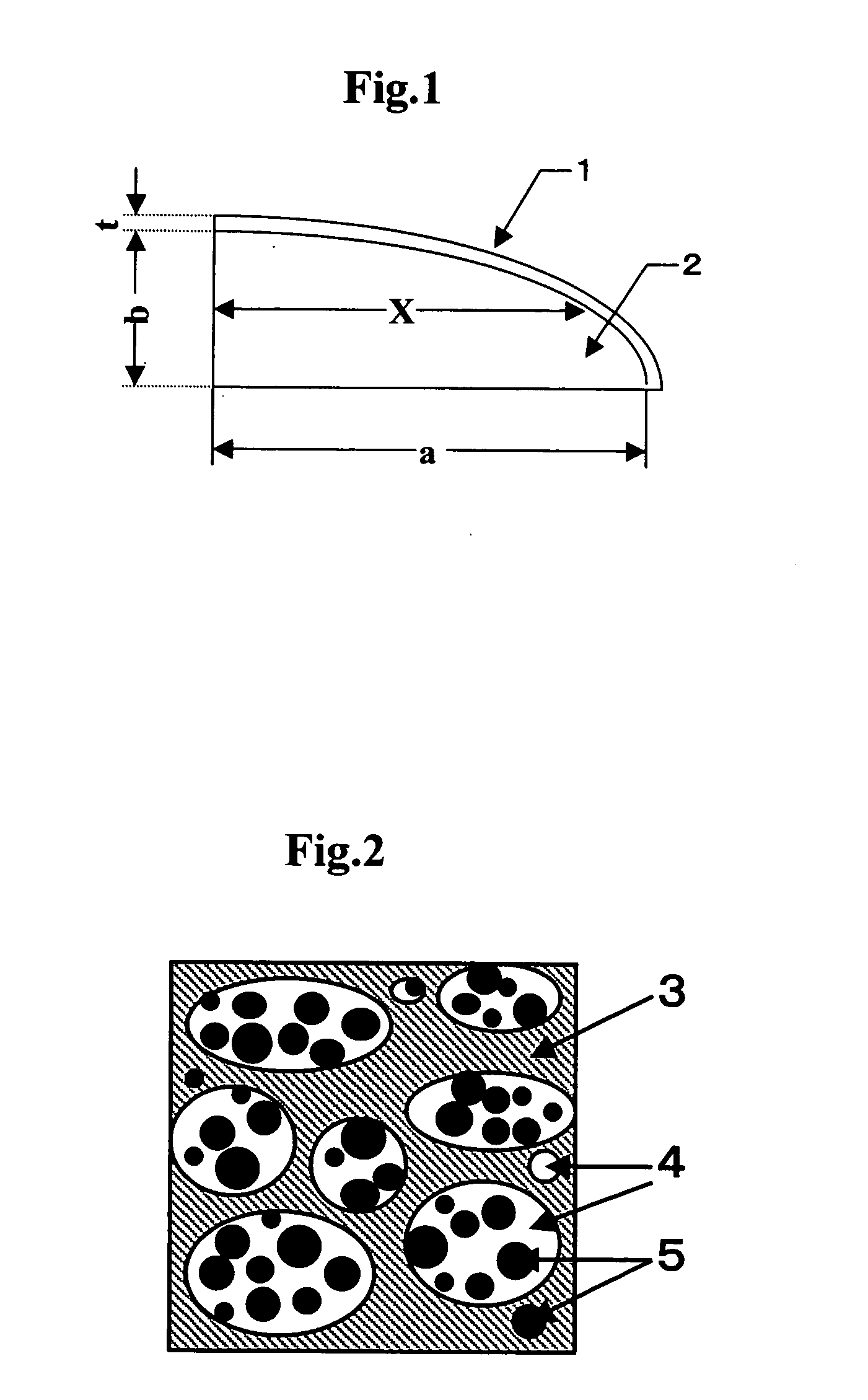

Foamed resin molded article

InactiveUS20140044954A1Resist impactResistance to rigidityLayered productsThin material handlingEngineering

There is provided a foamed resin molded article having many microscopic foamed cells formed therein. The foamed resin molded article (1) of the present invention has its surface formed of a skin layer (2) and has its interior formed of a foamed layer (3). The foamed layer (3) has a plurality of first foamed cells (4) and a plurality of second foamed cells (5) formed therein, the plurality of second foamed cells (5) being formed between the first foamed cells (4) and being smaller than the first foamed cells (4).

Owner:HAYASHI GIJUTSU KENKYUSHO KK

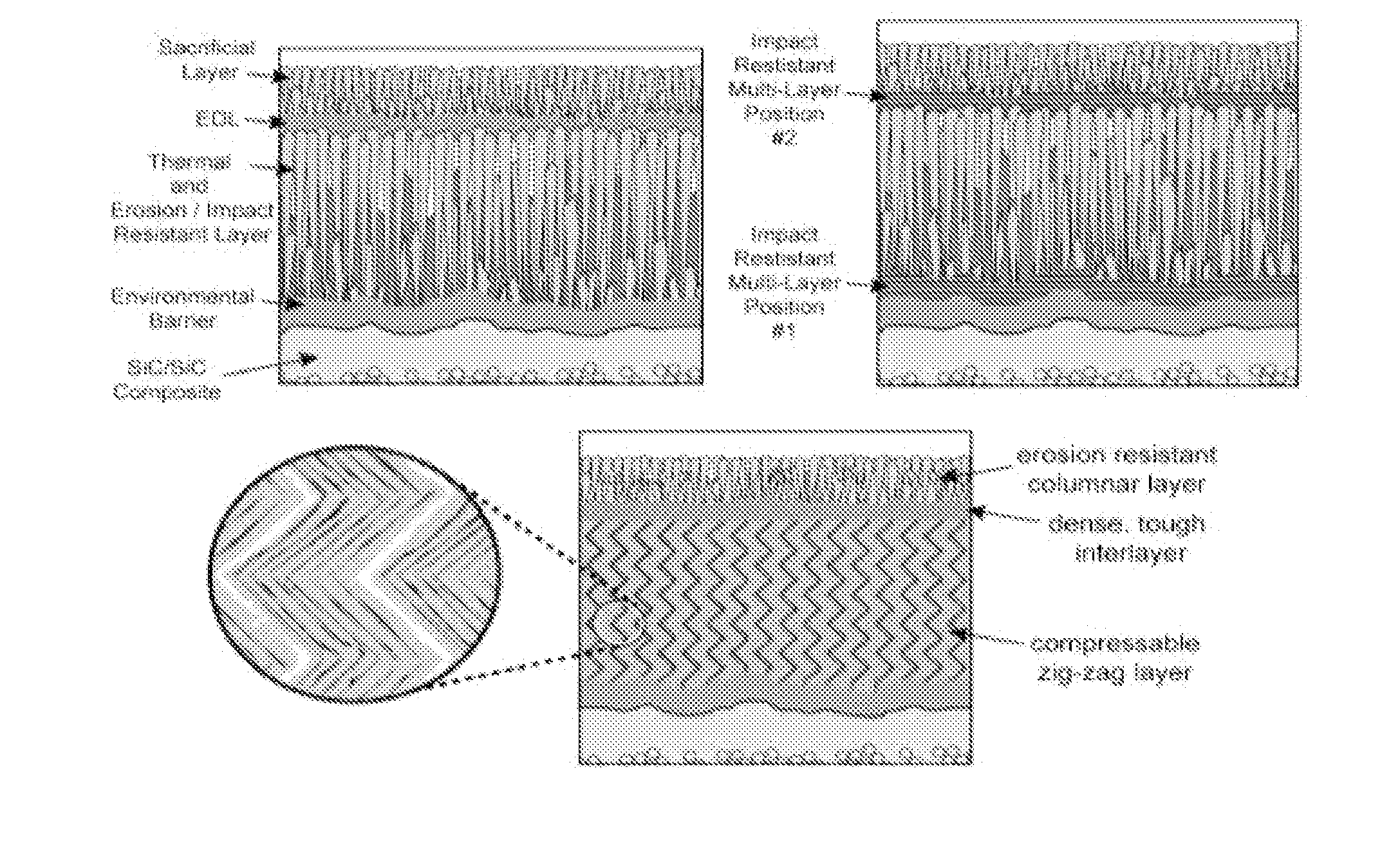

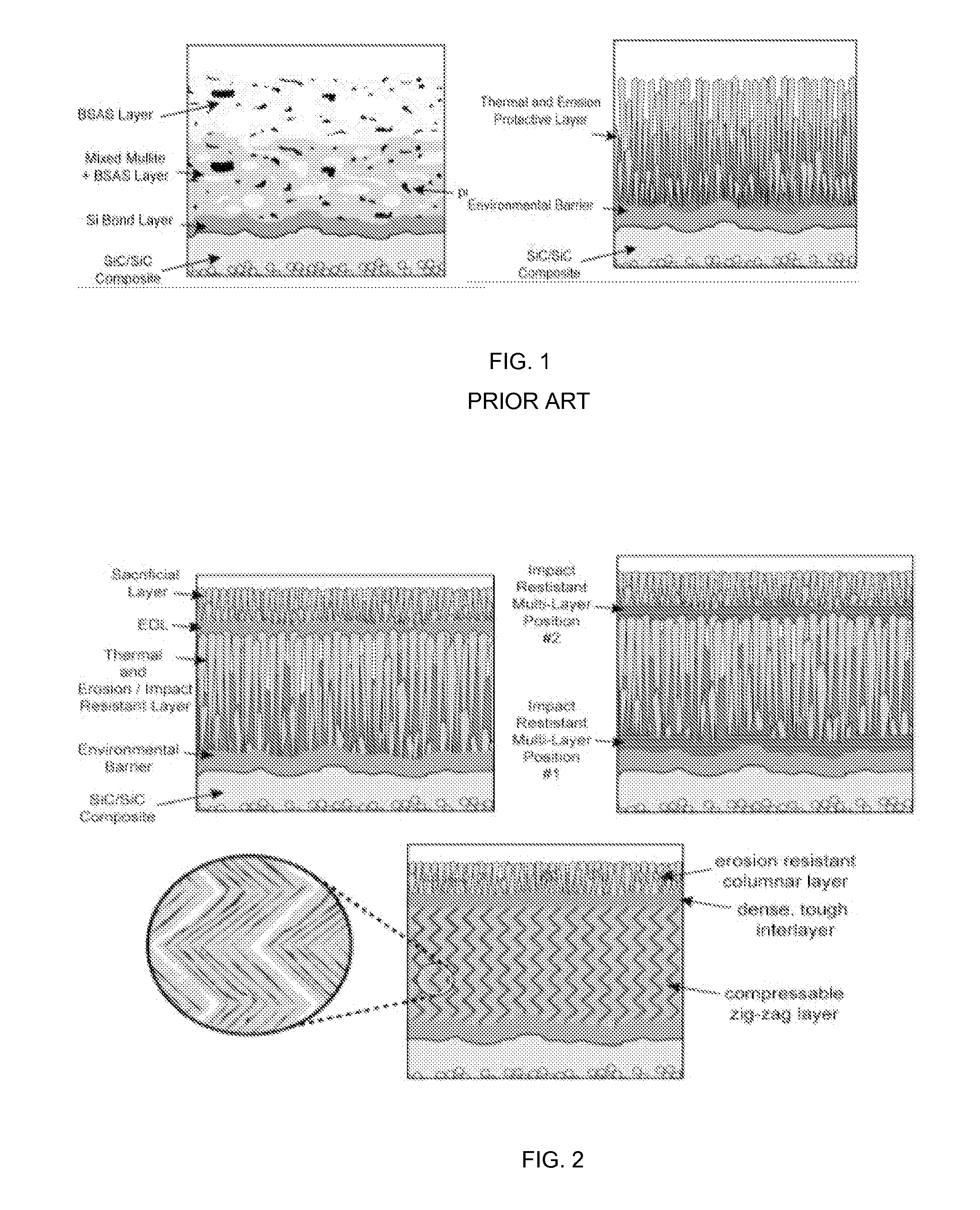

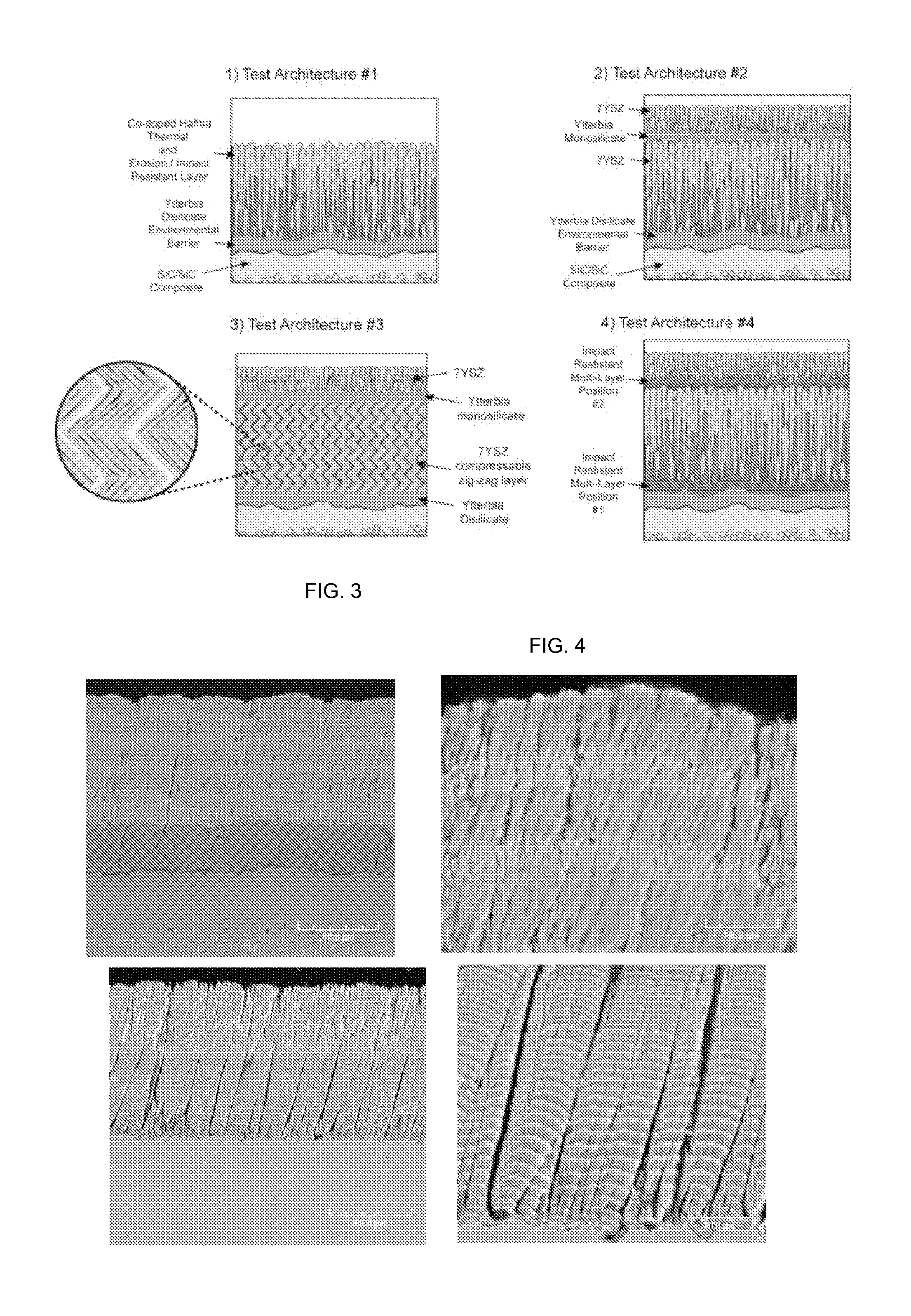

Impact and erosion resistant thermal and environmental barrier coatings

InactiveUS20130095256A1Resistant to erosion damageResistant to impact damageElectric discharge heatingBlade accessoriesCoating systemPlasma activation

The present invention provides a process for the application of high temperature coating that provide enhanced impact resistance and erosion damage for the coatings. For high temperature coating systems that provide environmental protection to silicon based ceramics, the process provides the deposition of a silicon-based bond coat on the substrate using the directed vapor deposition with plasma activation and at least one supersonic gas jet nozzle. The process provides the deposition of an EBC layer using the directed vapor deposition with the gas jet nozzle. In one embodiment, the thermal barrier layer may also contain one or more dense embedded layers which further promote impact resistance. Within the process, the particular layers, silicon bond coat, EBC layer and / or TBC layer may be deposited together or specific novel layers applied in combination with other layers deposited using prior known deposition techniques.

Owner:DIRECTED VAPOR TECH INT

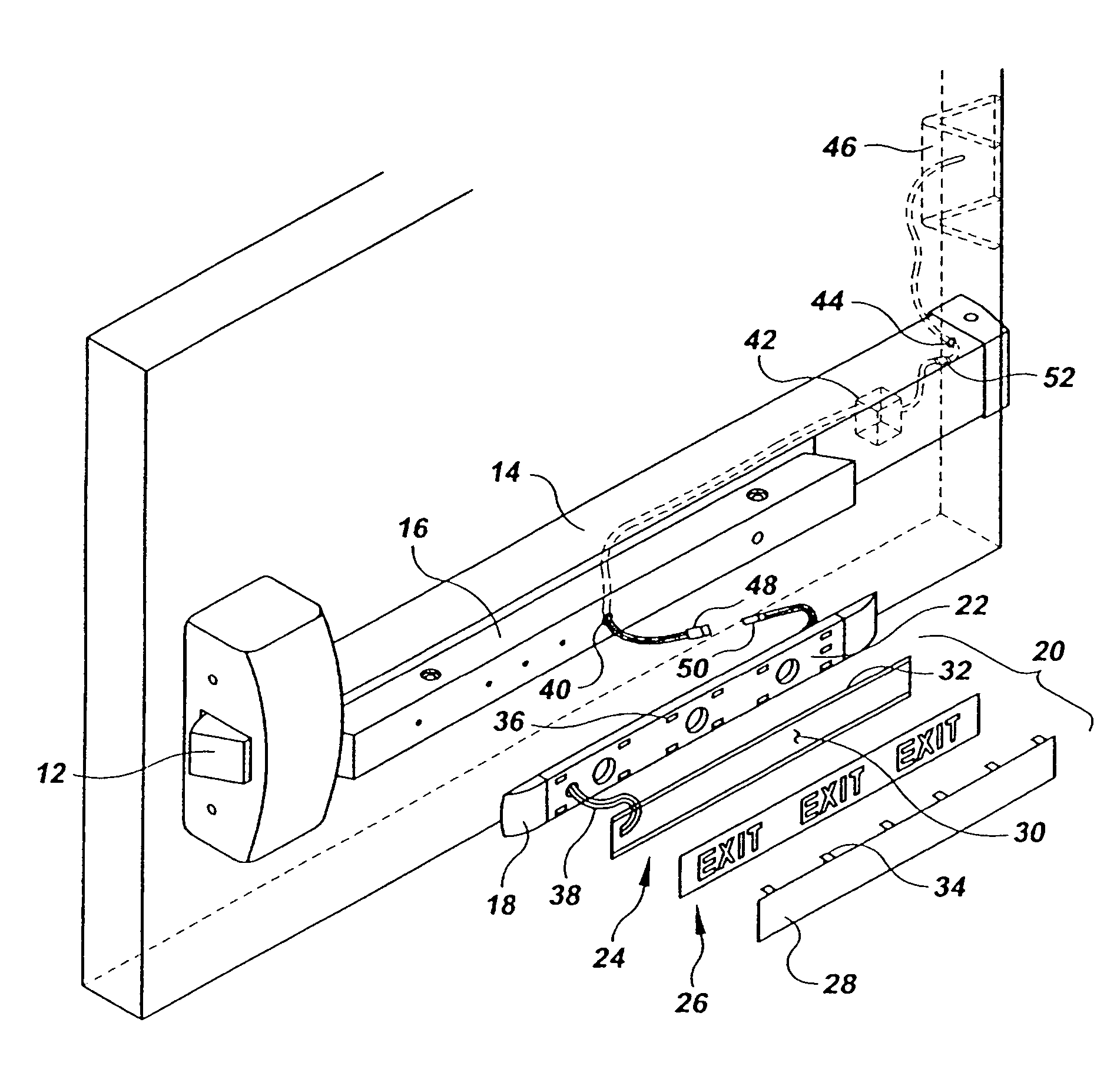

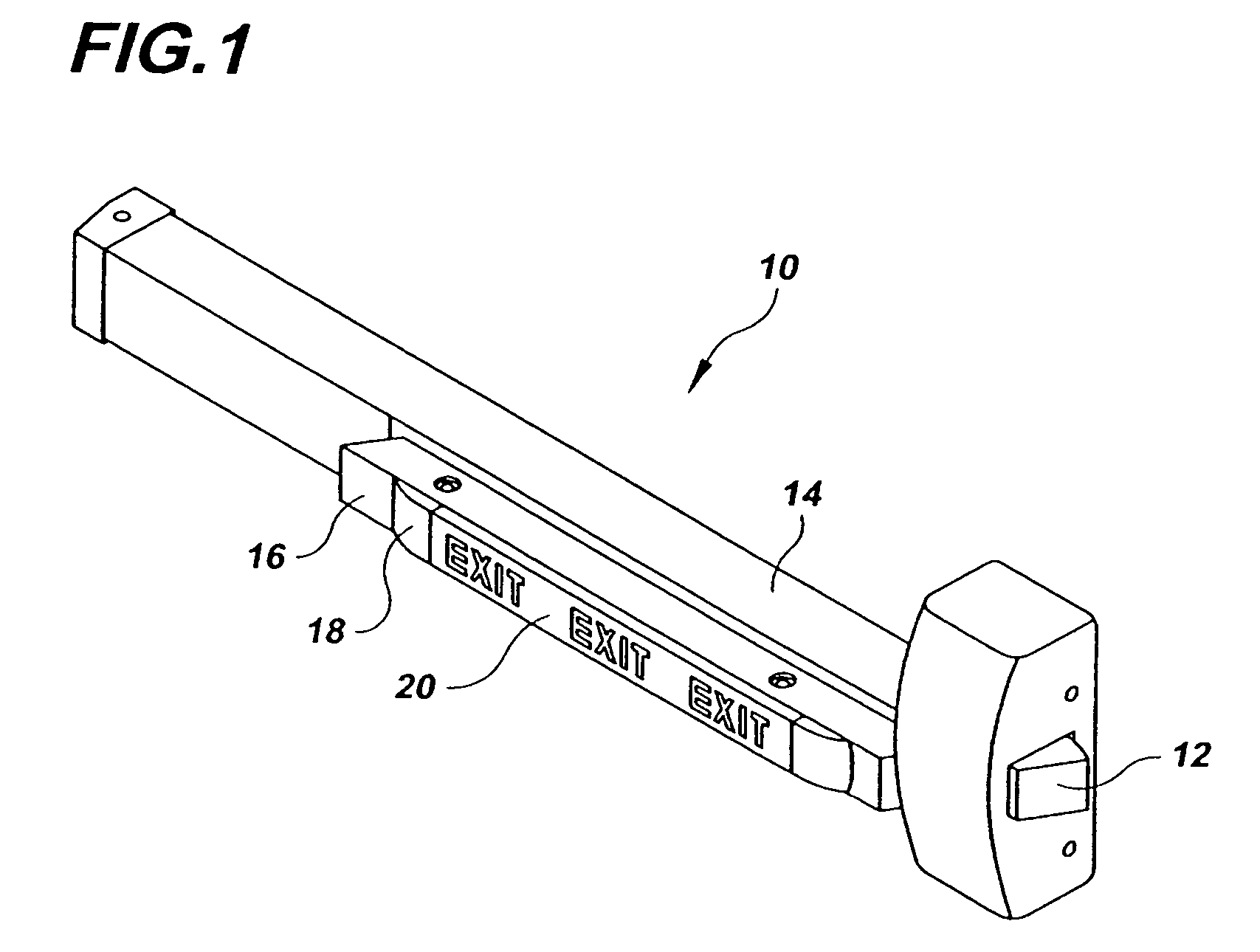

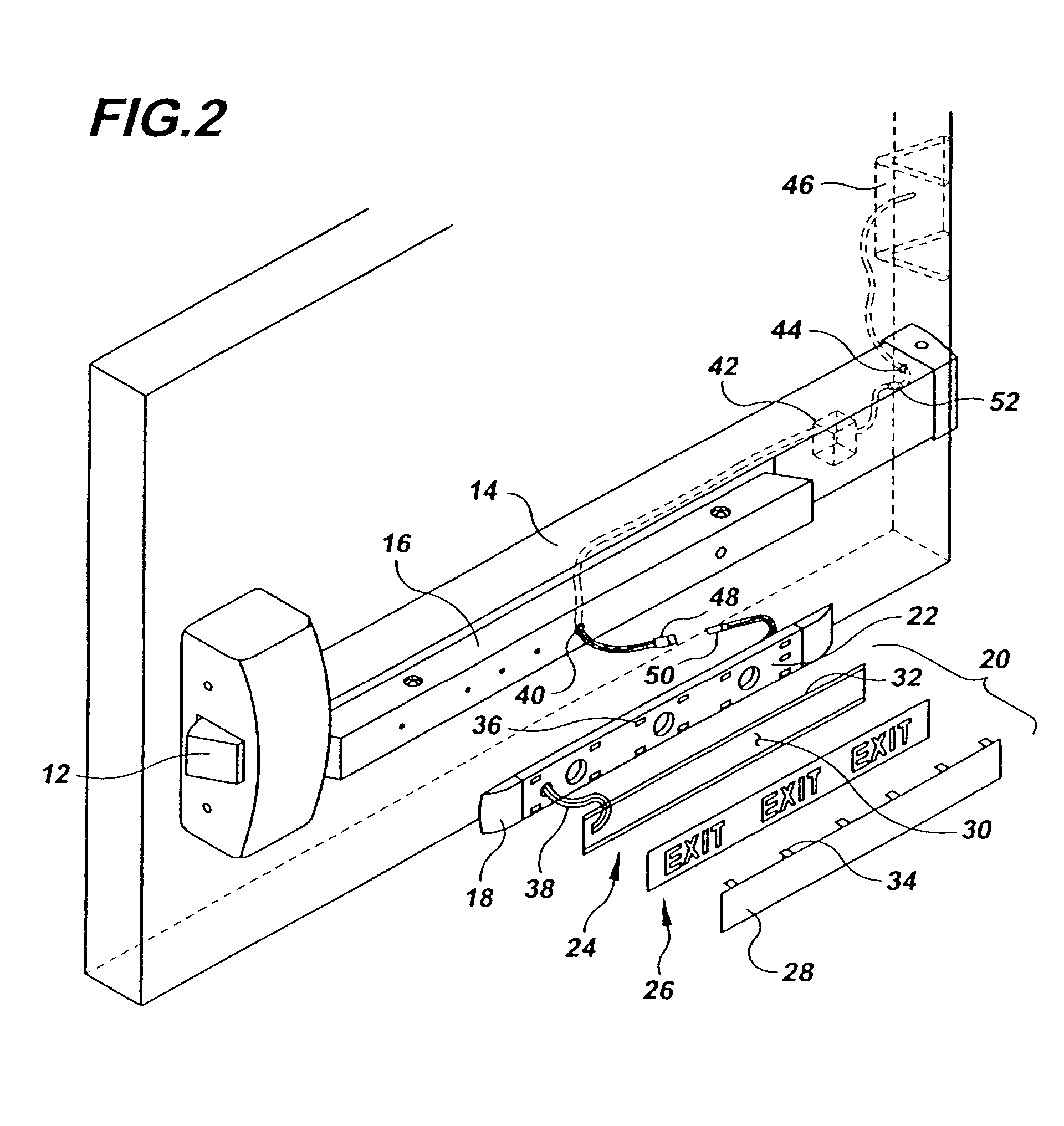

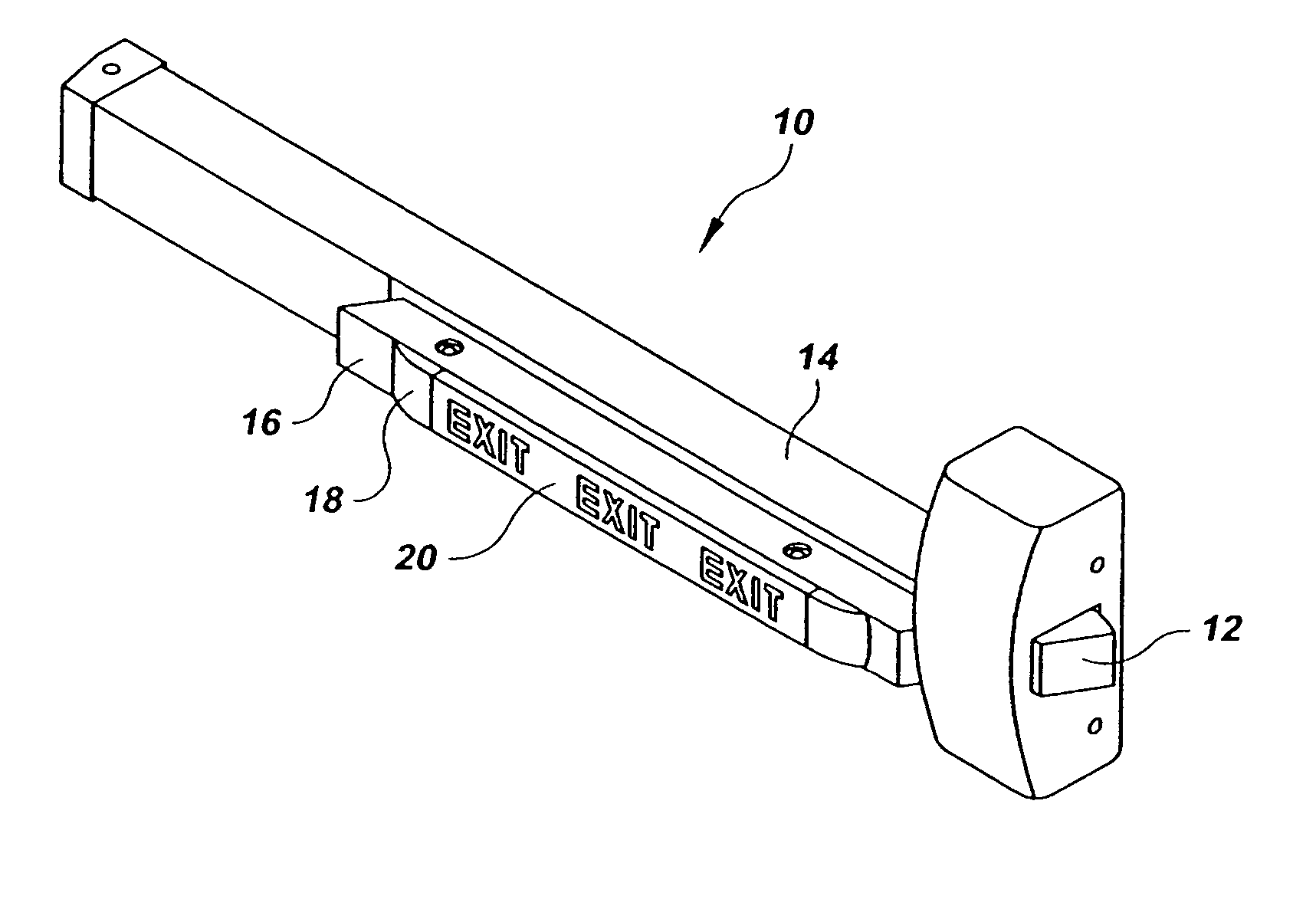

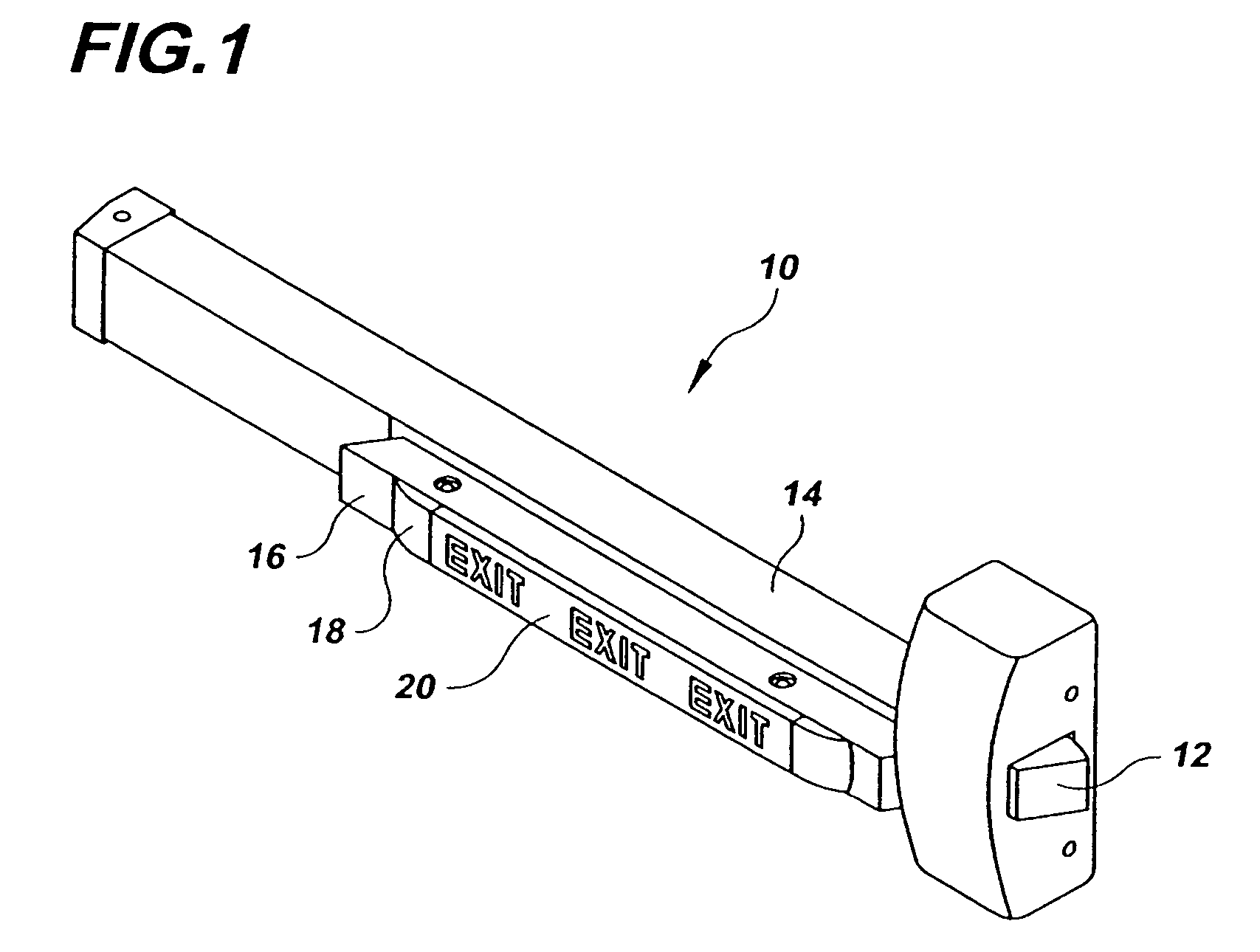

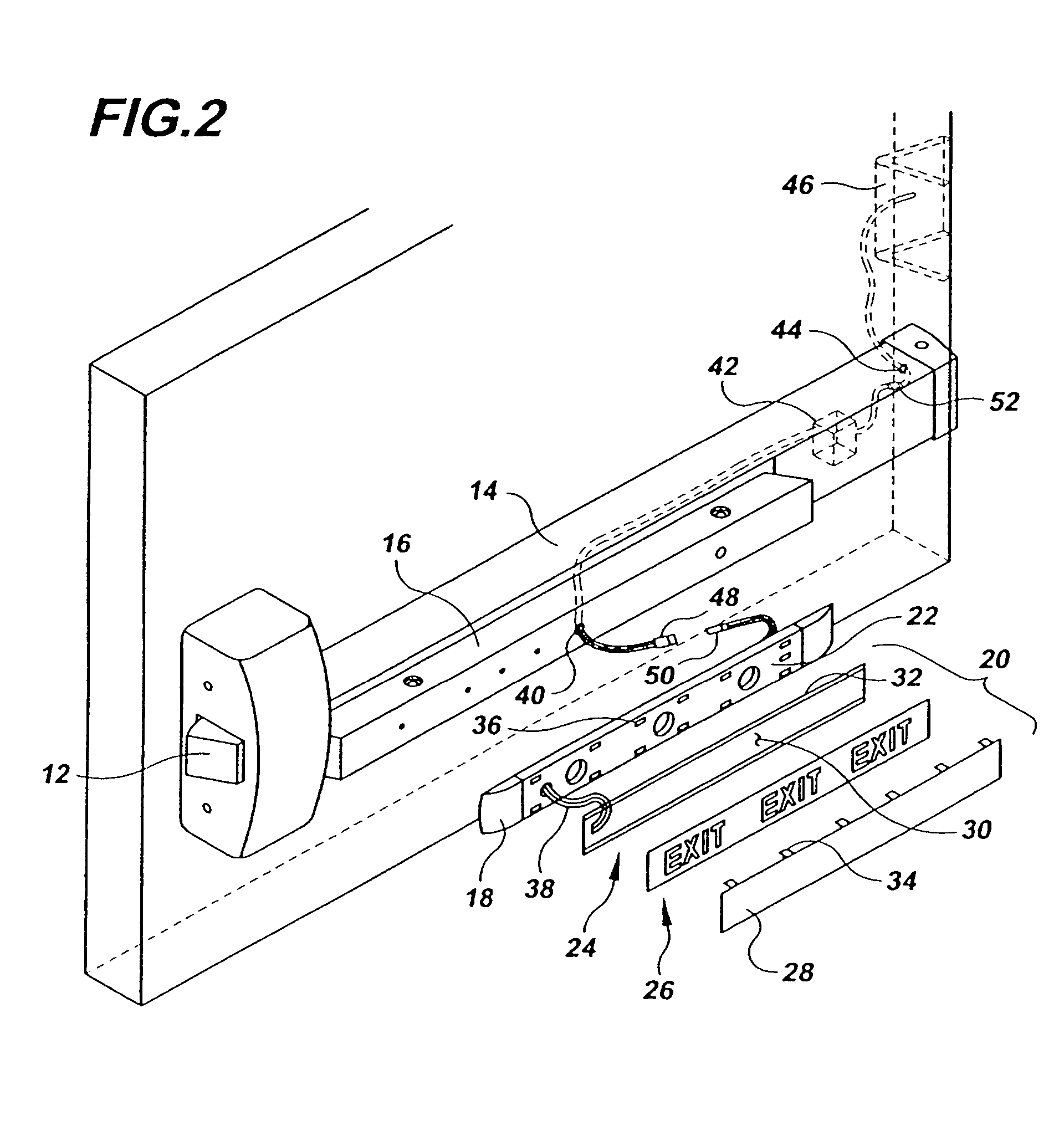

Exit device with lighted touchpad

InactiveUS7204050B2Resist impactSimplify removal and repair and replacementBuilding locksRoute devices for controlling vehiclesElectricityTouchpad

An exit device includes an electroluminescent exit sign assembly, preferably mounted on a push rail actuator of the exit device. An electroluminescent illuminator, an opaque material and a transparent protective cover form the electroluminescent sign assembly. The push rail actuator operates a latch mechanism and opens an associated exit door when pressure is applied. An inverter may be located within the exit device to power the electroluminescent illuminator with an AC or voltage. The electroluminescent sign assembly is preferably removable for repair or replacement without removing the exit device from the exit door and is located within a surface cavity in an electrically insulating touchpad on the exit device actuator. Additional transparent nonconductive material surrounds the electroluminescent material to provide further electrical insulation.

Owner:SARGENT MANUFACTURING CO INC

Encapsulated permanent magnet motor rotor

InactiveUS6847145B2Resist impactResist erosionMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorPermanent magnet motor

Encapsulation of a permanent magnet rotor is achieved by applying a glass roving material to spaces in the rotor structure, applying a veil cloth around the outer surface of the rotor, mounting a vacuum bag with vacuum ports around the outer surface of the rotor, removing vent plugs from the end walls of the rotor and screws from an inner ring of the rotor and replacing them with vacuum ports and applying a vacuum to the vacuum ports. After air has been removed from the rotor, an encapsulating resin is applied to some of the ports to introduce resin into the interior of the rotor. After curing of the resin the vacuum bag is removed and the outer surface of the rotor is machined to the desired outer dimension of the rotor.

Owner:ELECTRIC BOAT CORP

Exit device with lighted touchpad

InactiveUS20050144822A1Easy to removeSimple repairBuilding locksRoute devices for controlling vehiclesElectricityTouchpad

Owner:SARGENT MANUFACTURING CO INC

Riser protector

A piping riser protector for protectively covering the end portion of a riser assembly that includes a larger diameter central pipe and a plurality of smaller diameter peripheral pipes connected by a flange includes a polymeric body that protectively covers inner and outer surfaces of an end portion of the larger diameter pipe and provides enclosures that cover the exposed end portion of the smaller diameter pipe sections in between the end of each smaller diameter pipe section and the flange.

Owner:TAQUINO WELDON

Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

InactiveUS20050202958A1Improve responseIncrease the rate of polymerizationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenOlefin polymerization

The invention has an object to provide a catalyst for polymerizing or copolymerizing an α-olefin, catalyst constituent thereof, and method of polymerizing α-olefins with the catalyst, for production of α-olefin polymers or copolymers with high hydrogen response, high polymarization reaction rate, high stereoregularity and excellent melt fluidity. The invention discloses a catalyst constituent of the catalyst for polymerizing or copolymerizing an α-olefin, represented by Formula 37 or 38: Si(OR1)3(NR2R3) Formula 37 (where in Formula 37, R1 is a hydrocarbon group with 1 to 6 carbon atoms; R2 is a hydrocarbon group with 1 to 12 carbon atoms or hydrogen; and R3 is a hydrocarbon group with 1 to 12 carbon atoms) RNSi(OR1)3 Formula 38 (where in Formula 38, R1 is a hydrocarbon group with 1 to 6 carbon atoms; and RN is a cyclicl amino group).

Owner:TOHO TITANIUM CO LTD

Rubber-reinforced thermoplastic resin and rubber-reinforced thermoplastic resin composition

Rubber-reinforced thermoplastic resins containing a copolymer resin (A1) obtained by polymerizing a vinyl monomer (b1) in the presence of an acrylic rubber-like polymer (a), or a mixture of copolymer resin (A1) and a (co)polymer (A2) of a vinyl monomer (b2).Acrylic rubber-like polymer (a) contains 50 to 98% by weight of acrylic rubber-like polymer particles (a1) which have a particle size of less than 350 nm and 2 to 50% by weight of acrylic rubber-like polymer particles (a2) which have a particle size of not less than 350 nm.The amount of the acrylic rubber-like polymer (a) is 5 to 80% by weight based on the rubber-reinforced thermoplastic resin.

Owner:TECHNO POLYMER CO LTD

Molding resins using renewable resource component

ActiveUS20080154002A1Enhances translation of propertyResist impactOrganic chemistryPolyesterTG - Triglyceride

Unsaturated polyester compositions are disclosed that are obtainable by reacting: (i) plant and animal oil triglycerides, an alkyl ester of a saturated or unsaturated fatty acid or mixtures thereof; (ii) a difunctional, or polyfunctional glycol or mixtures thereof; (iii) a difunctional or polyfunctional acid, their anhydrides or alkyl esters and mixtures thereof; (iv) a strained cycloolefin; (v) a component(s) that function as a compound capable of initiating polymerization at high temperature and which is stable at room temperature; and (vi) low profile additives, fillers and reinforcements.Also disclosed are methods for the preparation of the polyesters and the use of the polyesters in closed and open mold compositions such as sheet molding compounding (SMC), bulk molding compounding (BMC), resin transfer molding (RTM), pultrusion, infusion, filament winding, and spray up.

Owner:REICHHOLD LLC 2

Thermoplastic Resin Composition

The present invention is a thermoplastic resin composition which is obtained by adding a specific modified vinyl copolymer having a specific intrinsic viscosity to a composition comprising a styrene-based resin and a polyamide resin. The thermoplastic resin composition has excellent flowability and has a far better surface appearance than conventional ones while satisfactorily retaining rigidity, heat resistance, chemical resistance, and impact resistance at room and low temperatures.

Owner:TORAY IND INC

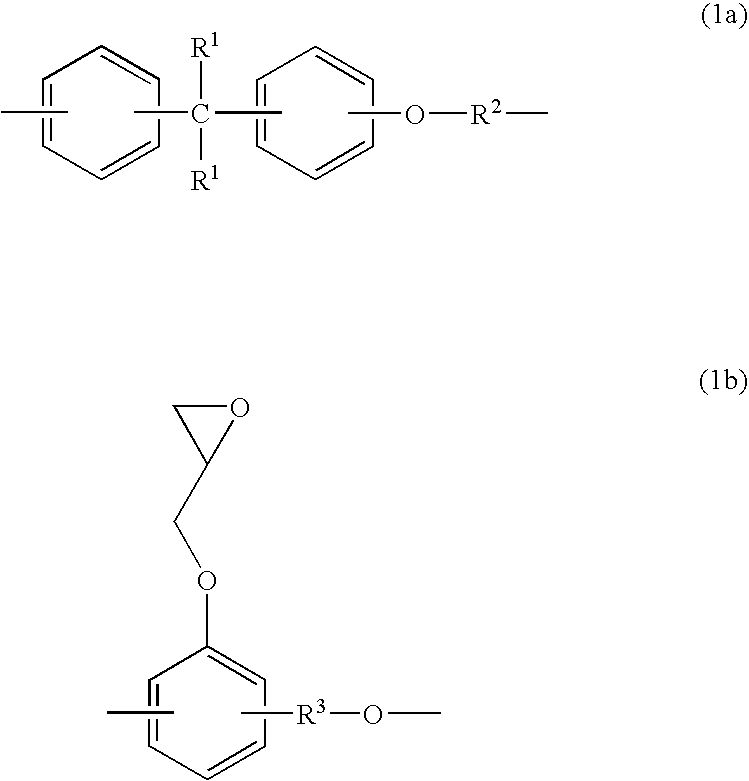

Photosensitive resin composition, and photosensitive element, method for forming resist pattern and printed wiring board using the composition

InactiveUS20060141381A1High resolutionImprove adhesionPhotomechanical apparatusPhotosensitive material auxillary/base layersPolymer scienceBackbone chain

A photosensitive resin composition, characterized in comprising: (A) a polymer having a carbon hydrocarbon double bond and carboxyl group, formed by the reaction of an acid anhydride with the reaction product of an epoxy compound having a structure wherein a glycidyloxy group is bonded to a main chain comprising an aromatic ring, an alkylene group and an oxygen atom, with an unsaturated carboxyl compound having a carbon-carbon double bond and a carboxyl group, (B) a photopolymerizable monomer, (C) a radical photopolymerization initiator, and (D) a curing agent having reactivity with the functional groups of the polymer and / or the photopolymerizable monomer. Using this photosensitive resin composition, a solder resist having excellent resolution, adhesion, PCT resistance, electrical corrosion resistance, heat resistance and thermal impact resistance can be formed.

Owner:HITACHI CHEM CO LTD

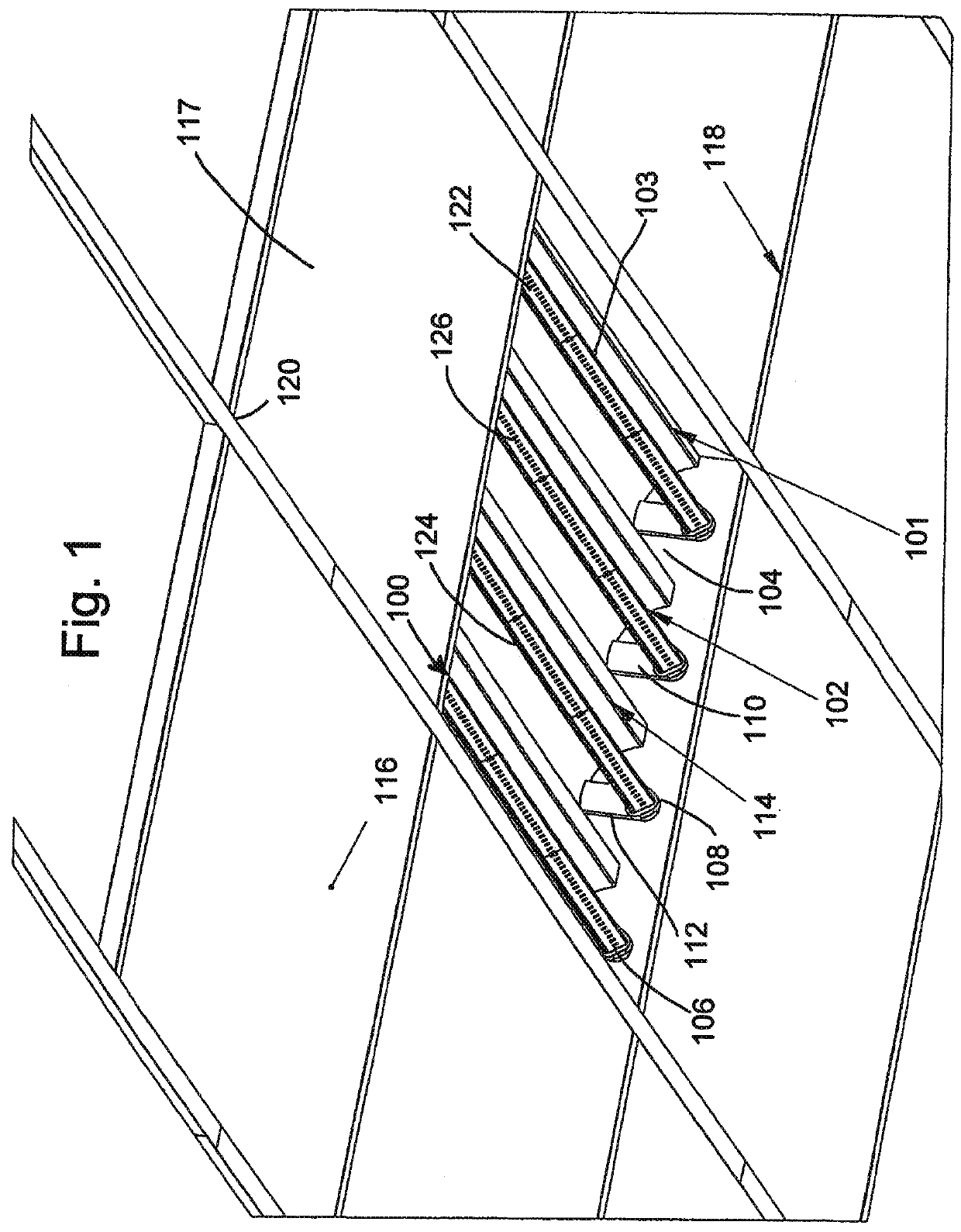

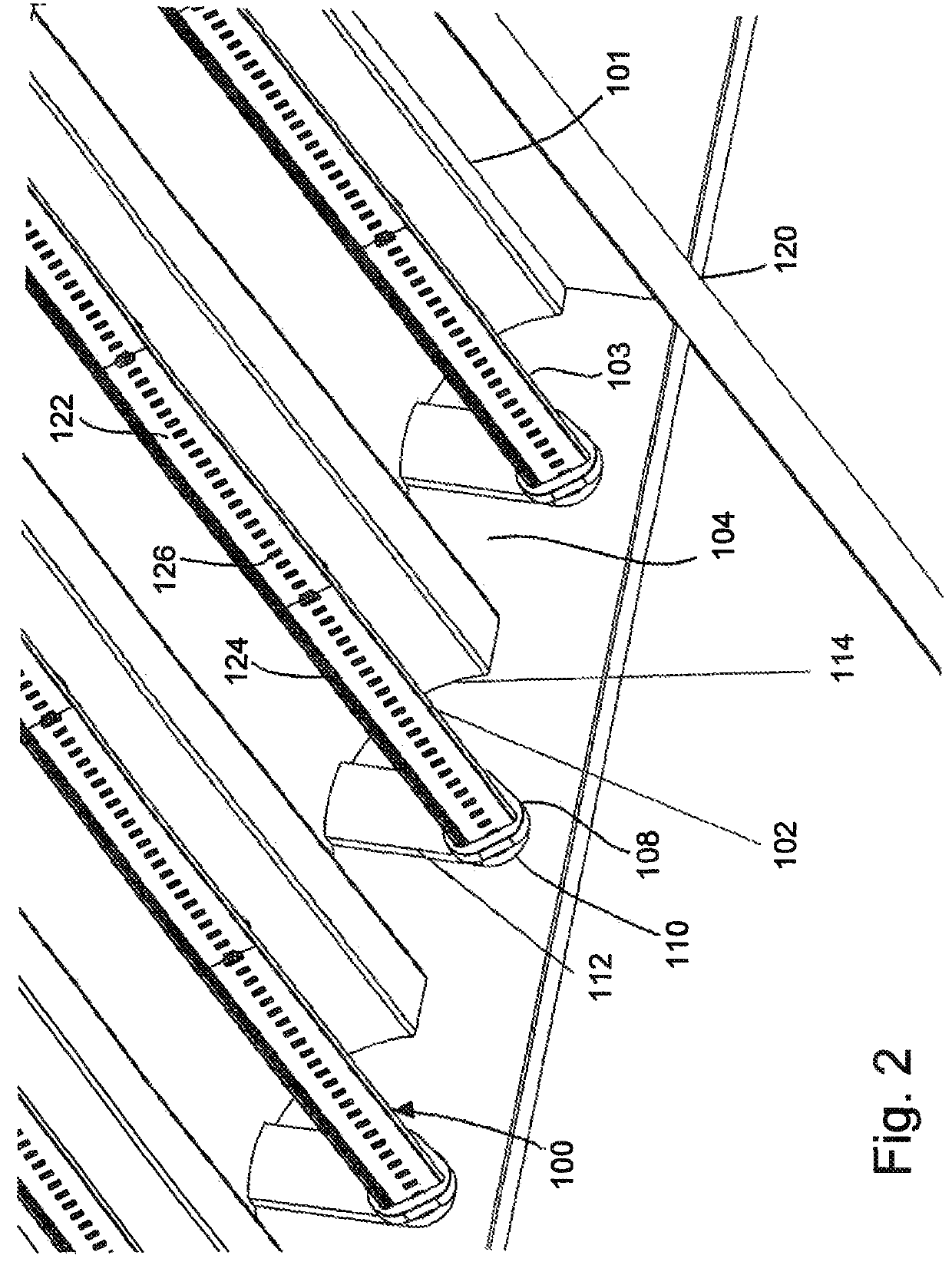

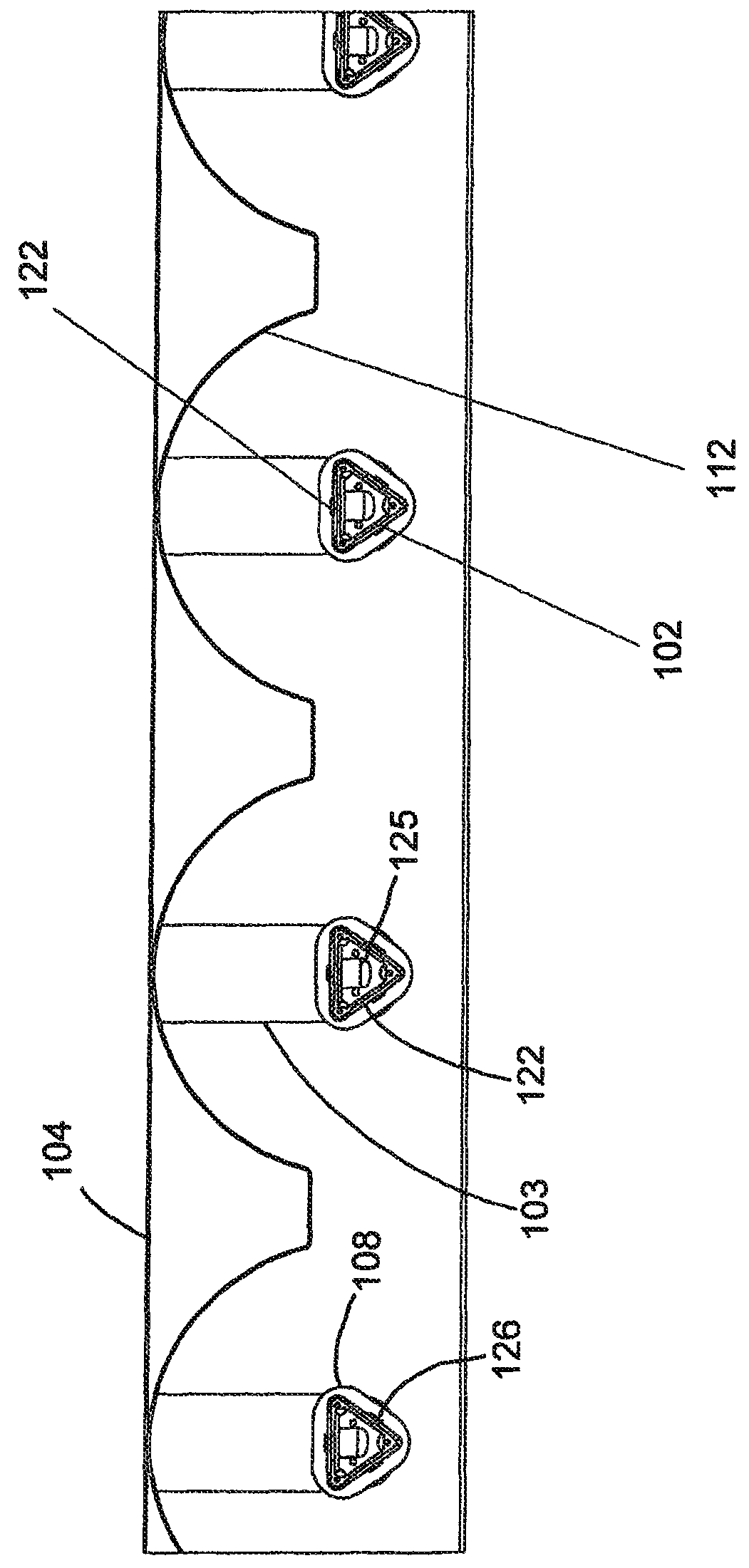

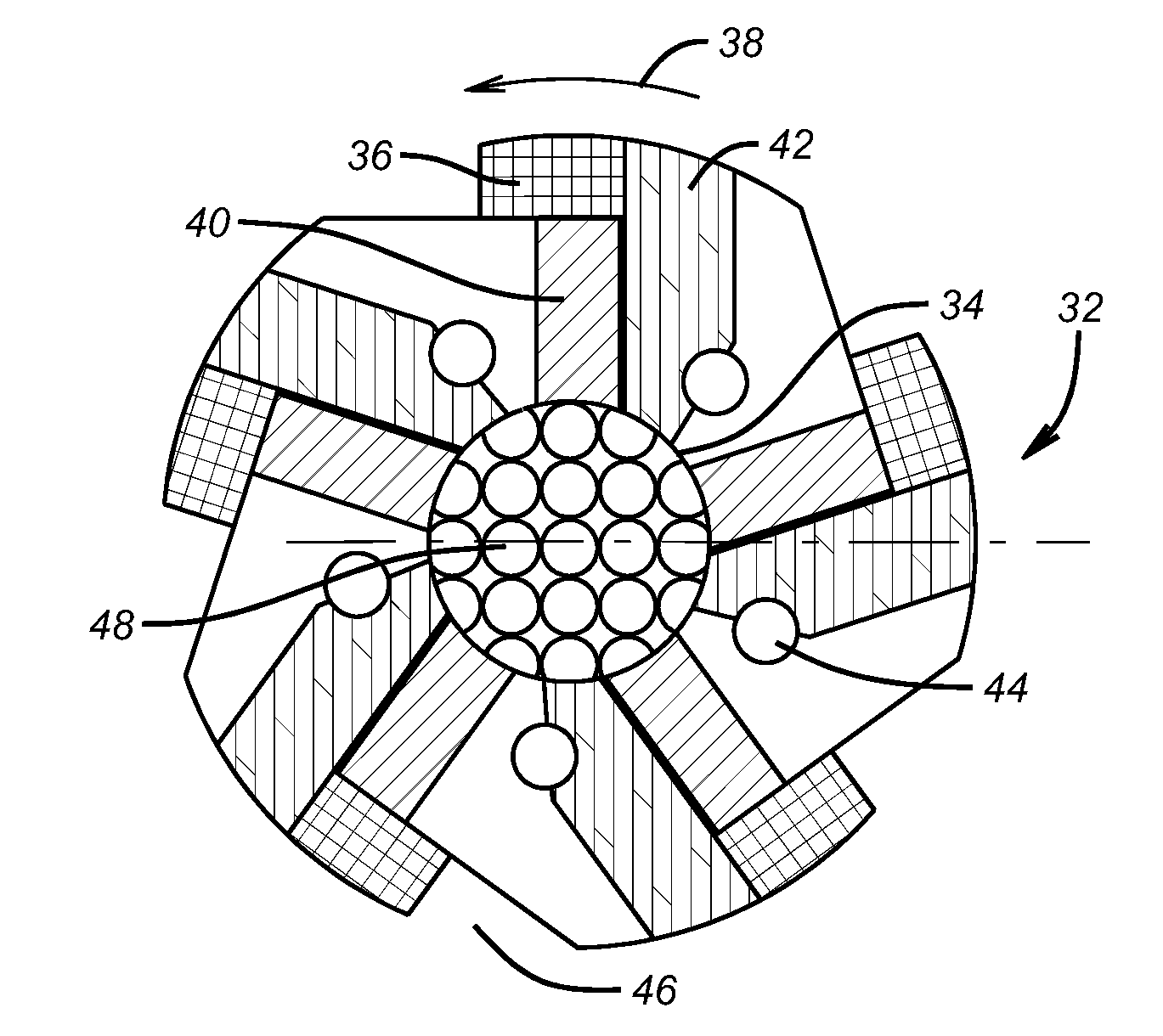

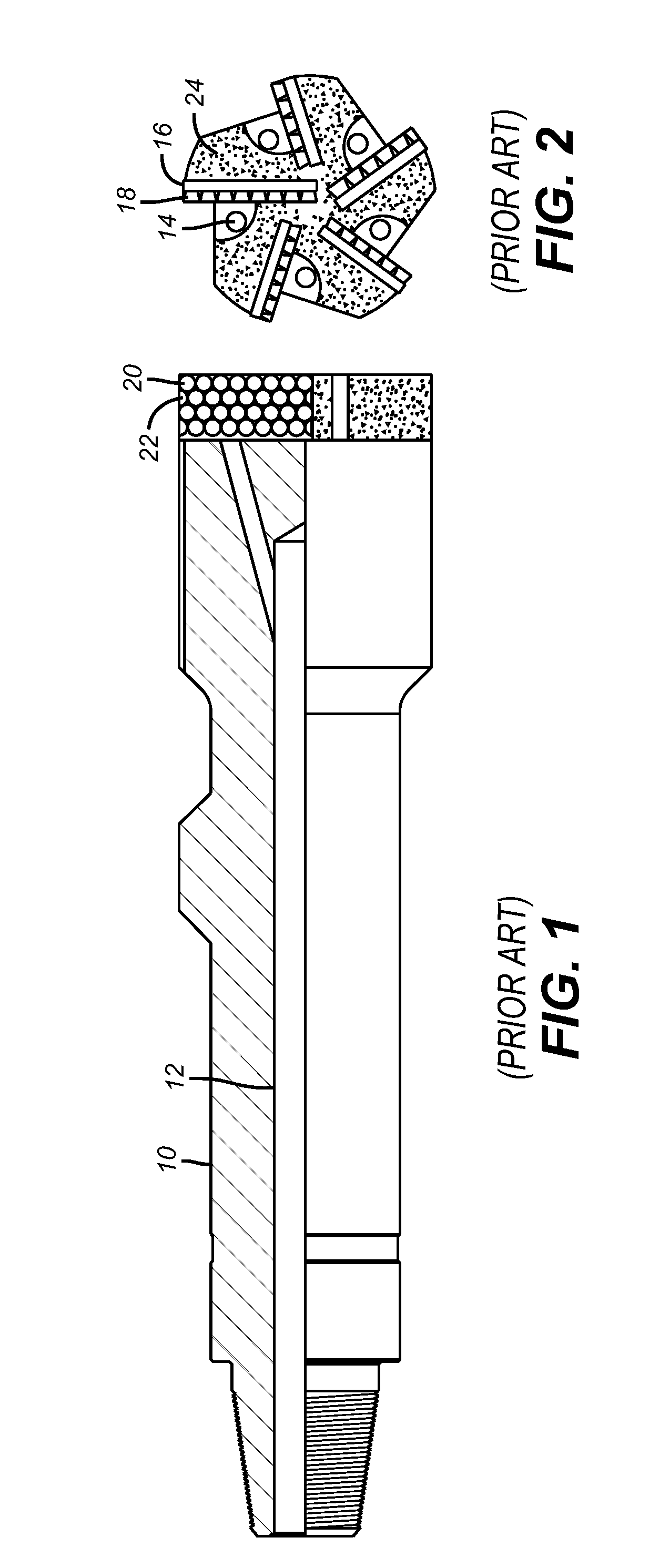

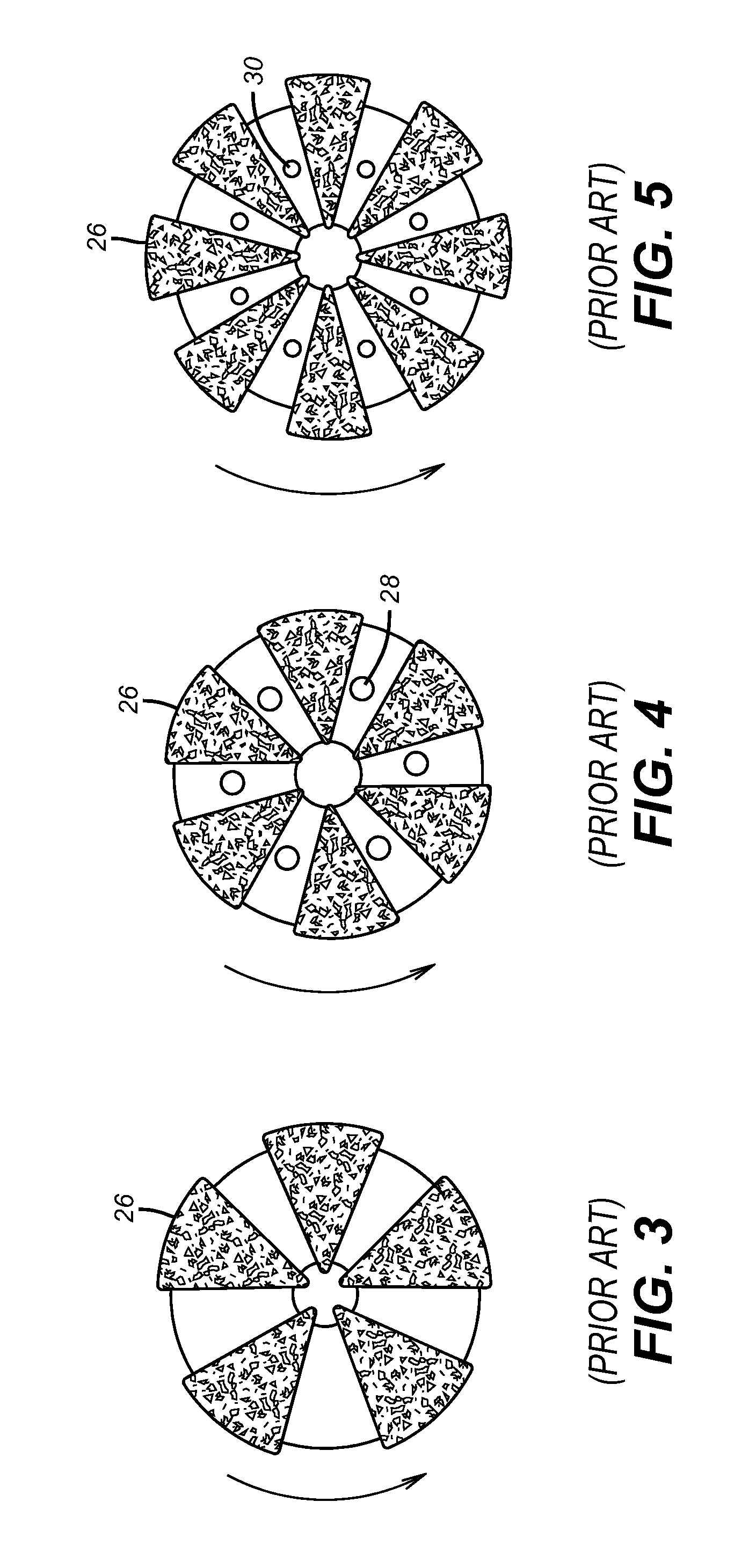

Subterranean Cutting Tool Structure Tailored to Intended Use

ActiveUS20120073880A1Improve wear resistanceGood temperature bond strengthDrill bitsConstructionsWear patternWear resistant

A mill cutting structure is differently configured in three zones. Those zones are the center, the outer edge and in between. At the center has highly wear resistant material that has good temperature bond strength and high impact resistance. The outer periphery can have a material that is highly resistant to wear and impact. In between can be inserts such as used in the Metal Muncher® mills using sintered carbide shapes that resist tracking and create a chipping rather than a grinding action. The shapes should have high edge retention capability and shapes such as a double sided pyramid can be used. The wear patterns of prior designs are addressed to allow longer and faster milling of the fish.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com