Patents

Literature

50results about How to "Strength resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

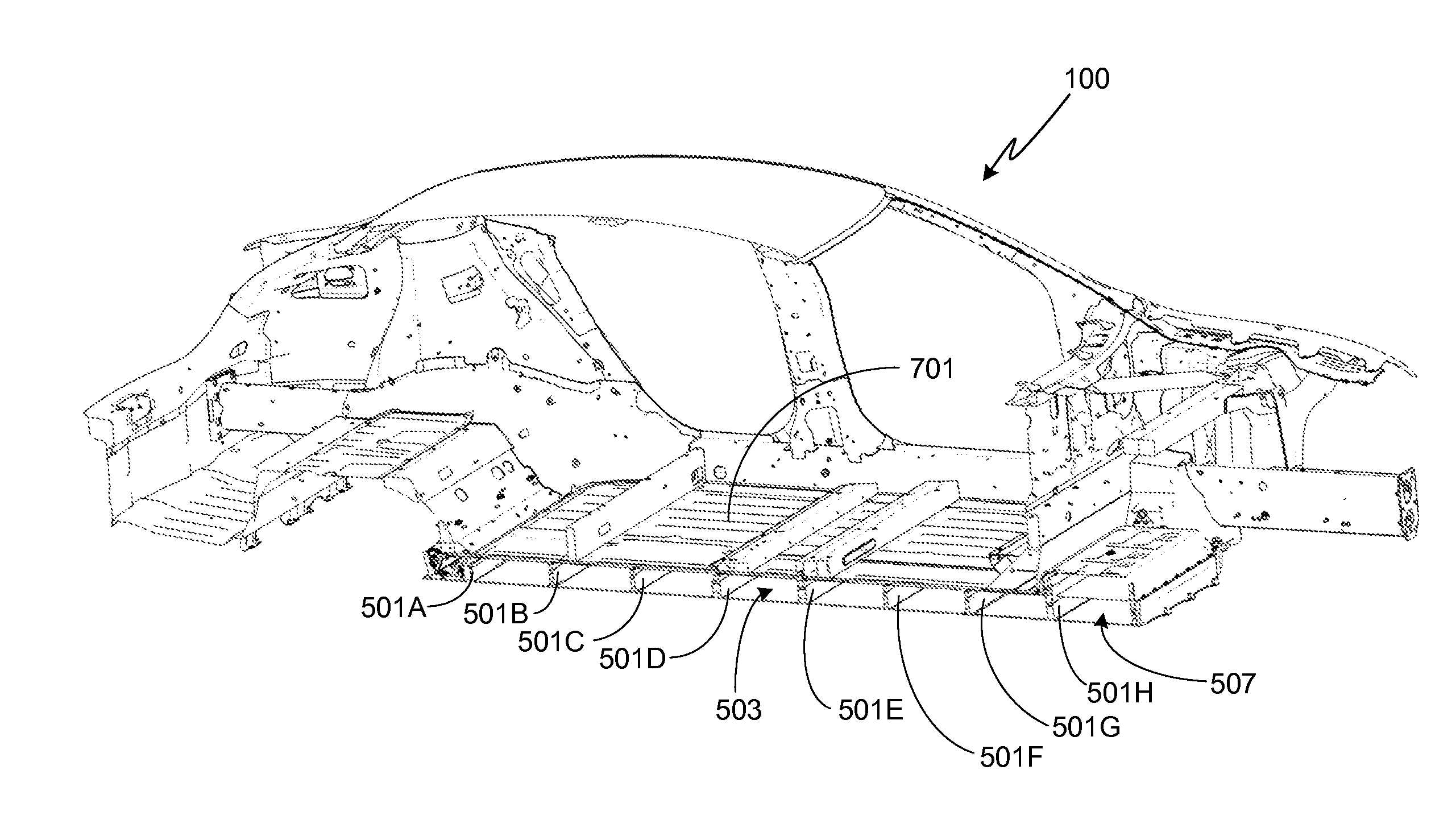

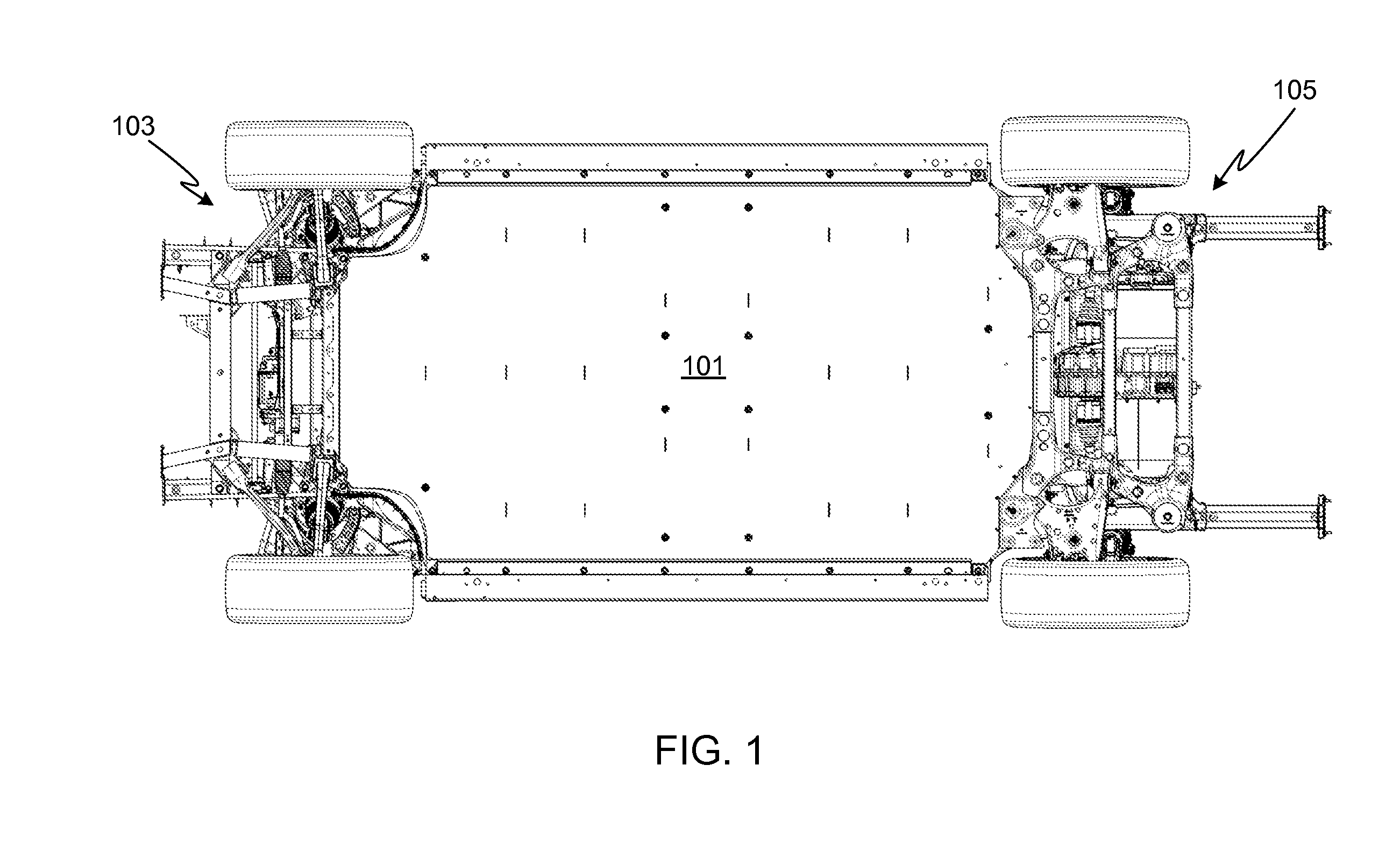

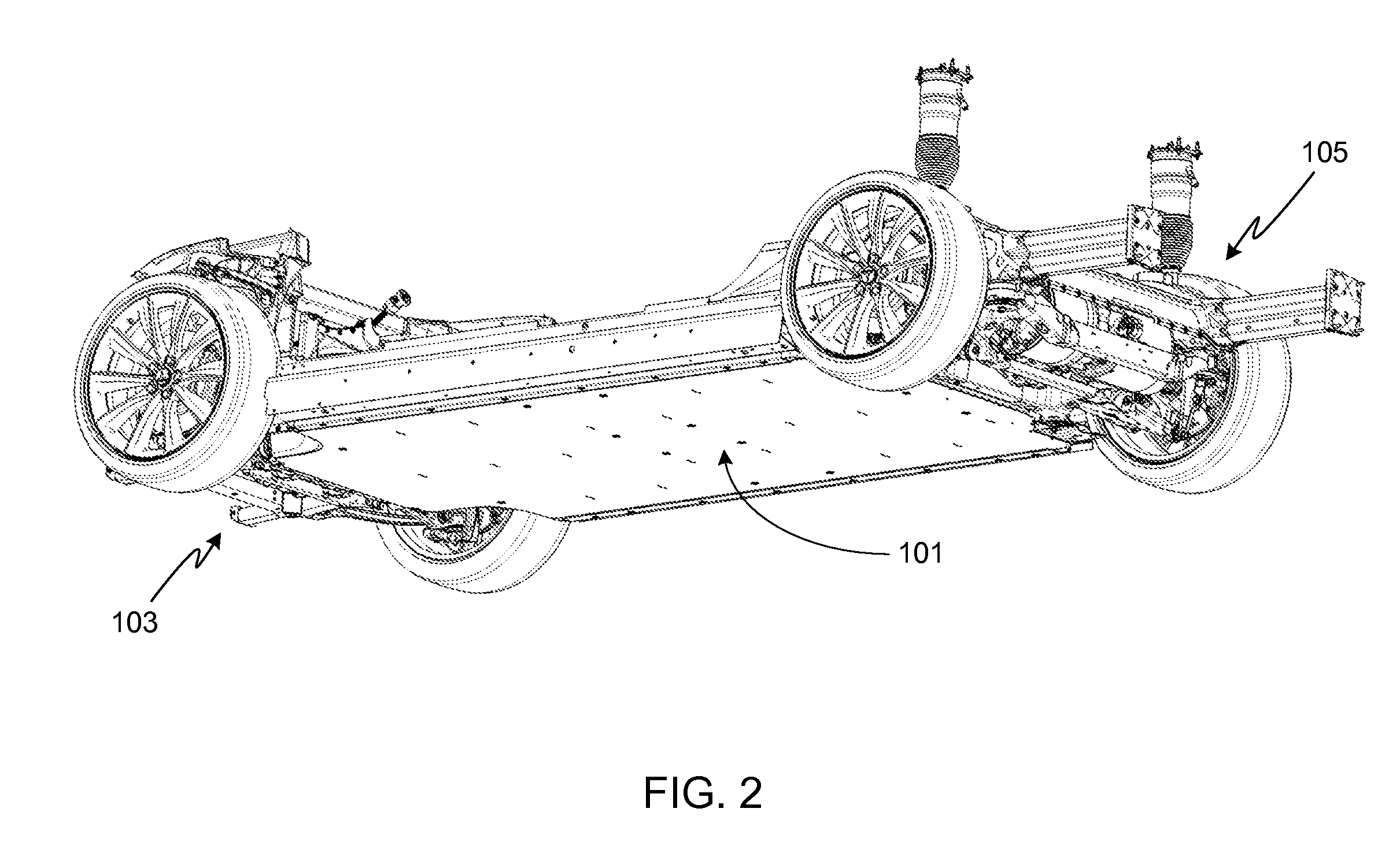

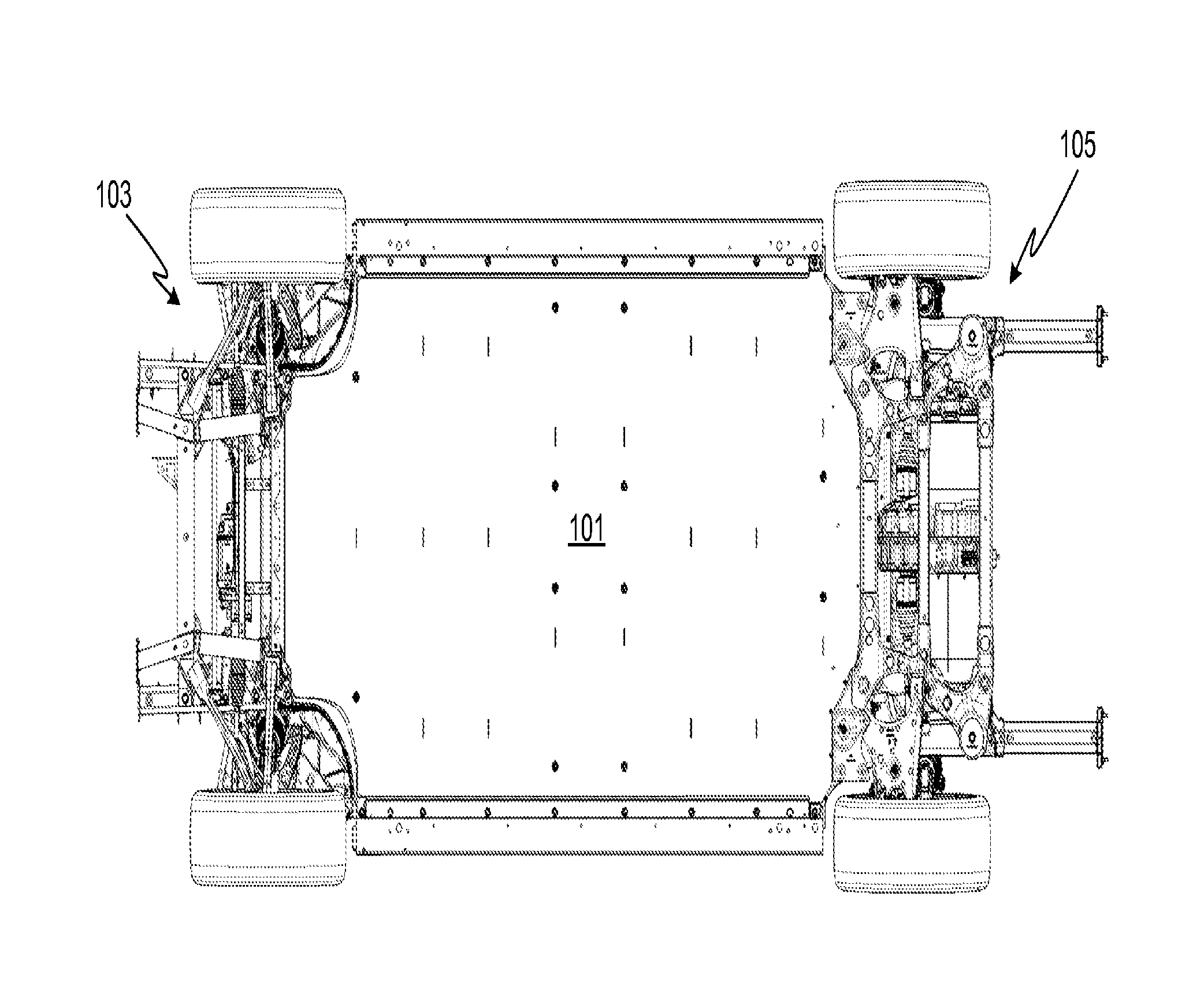

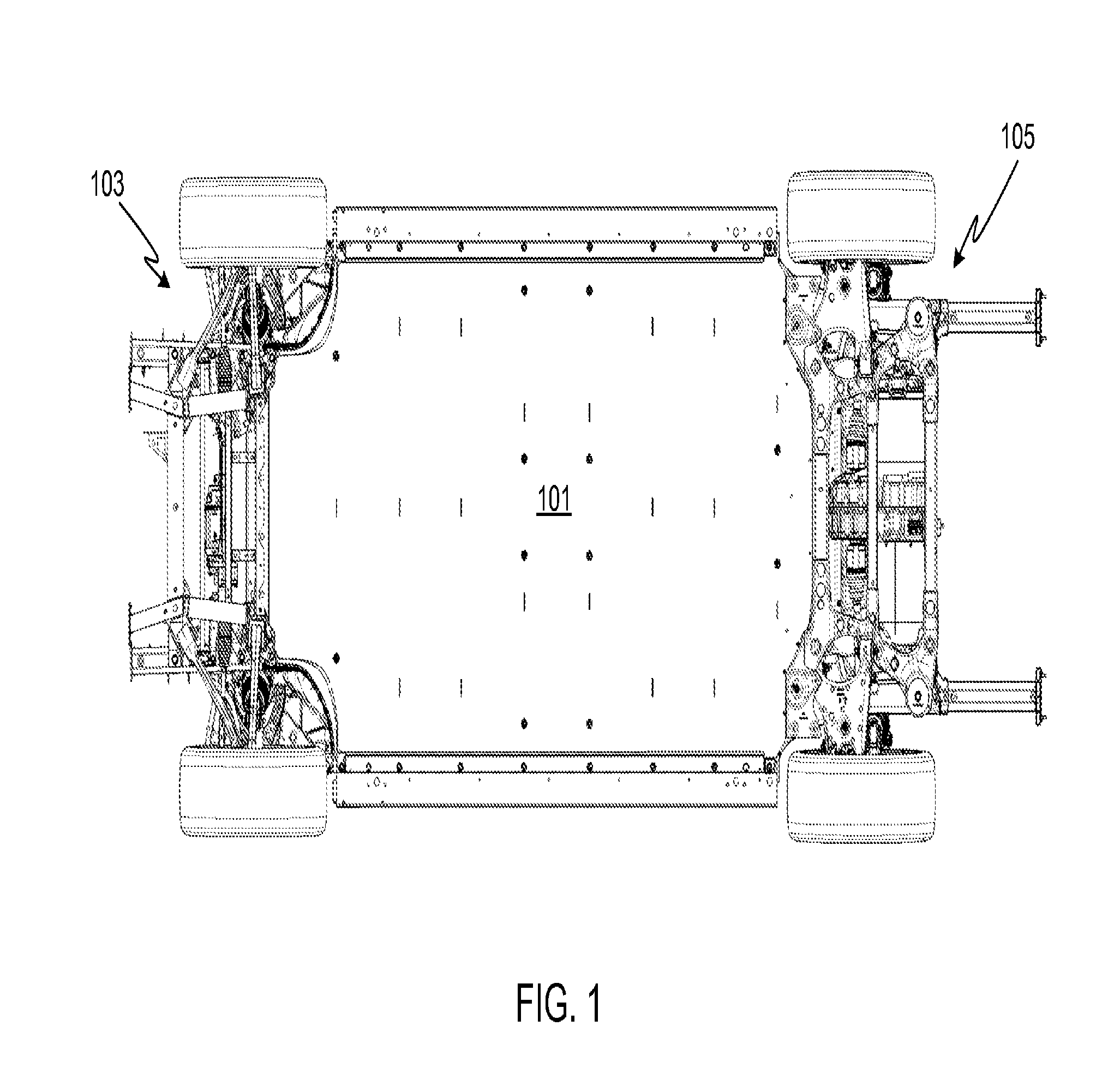

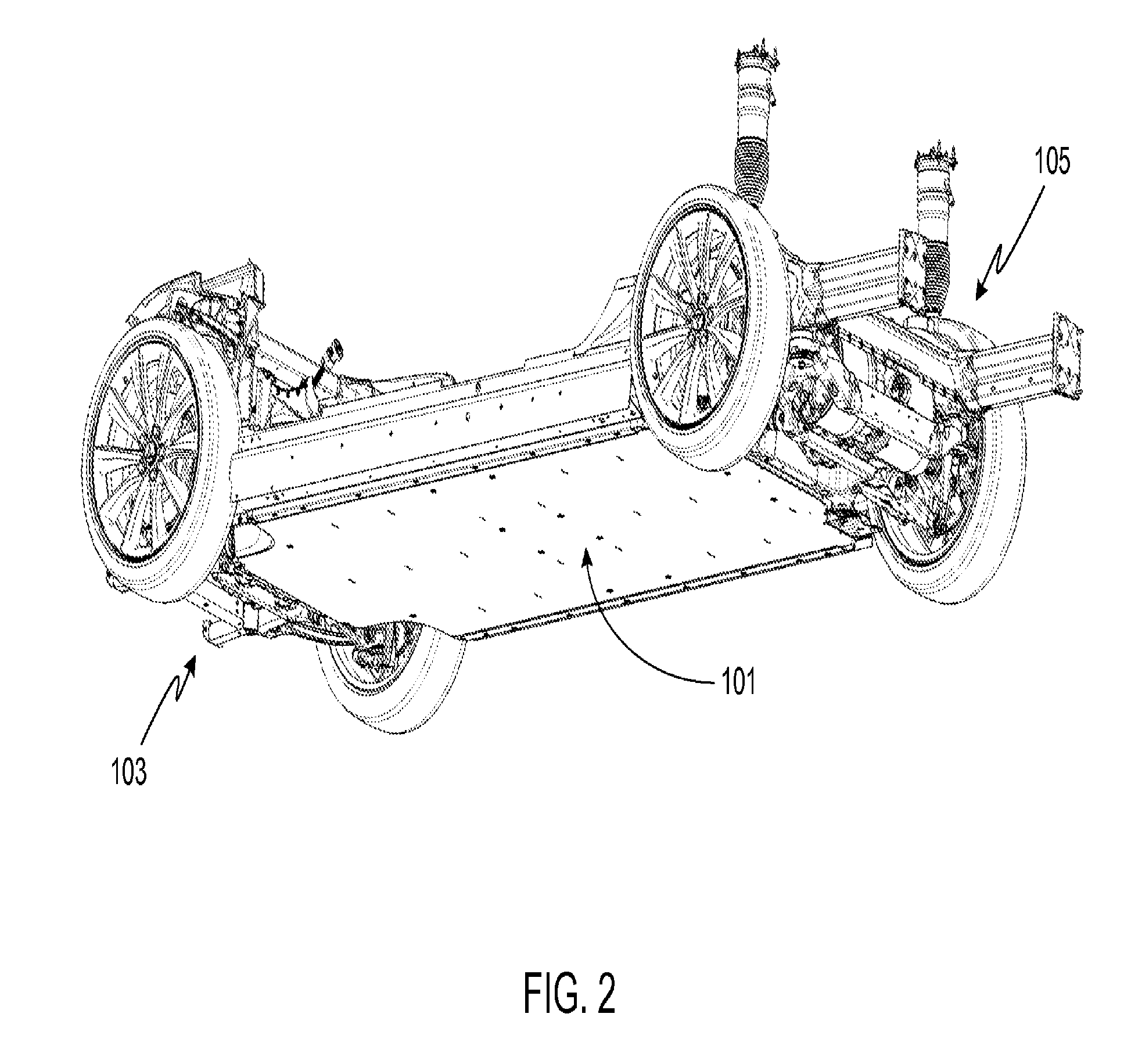

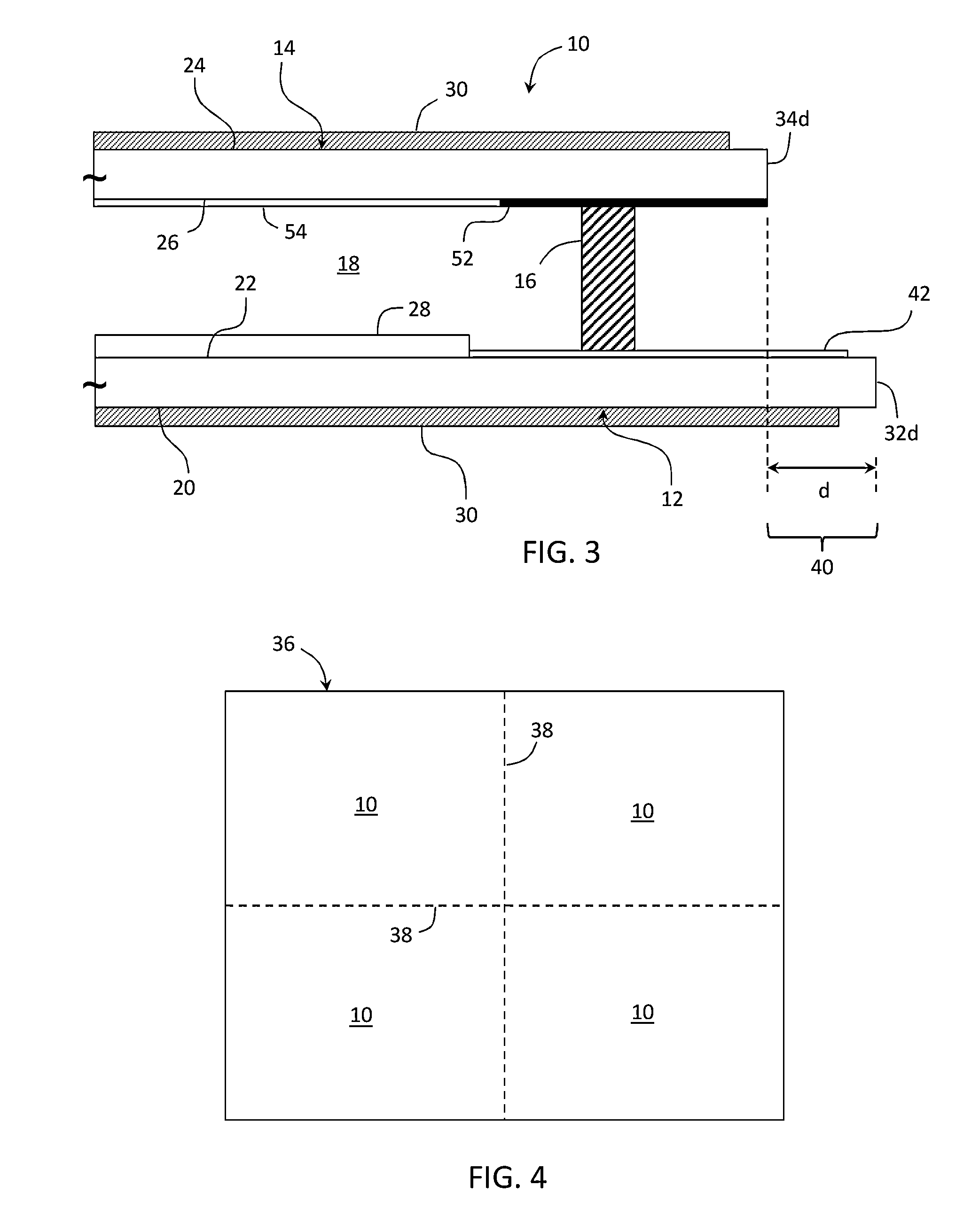

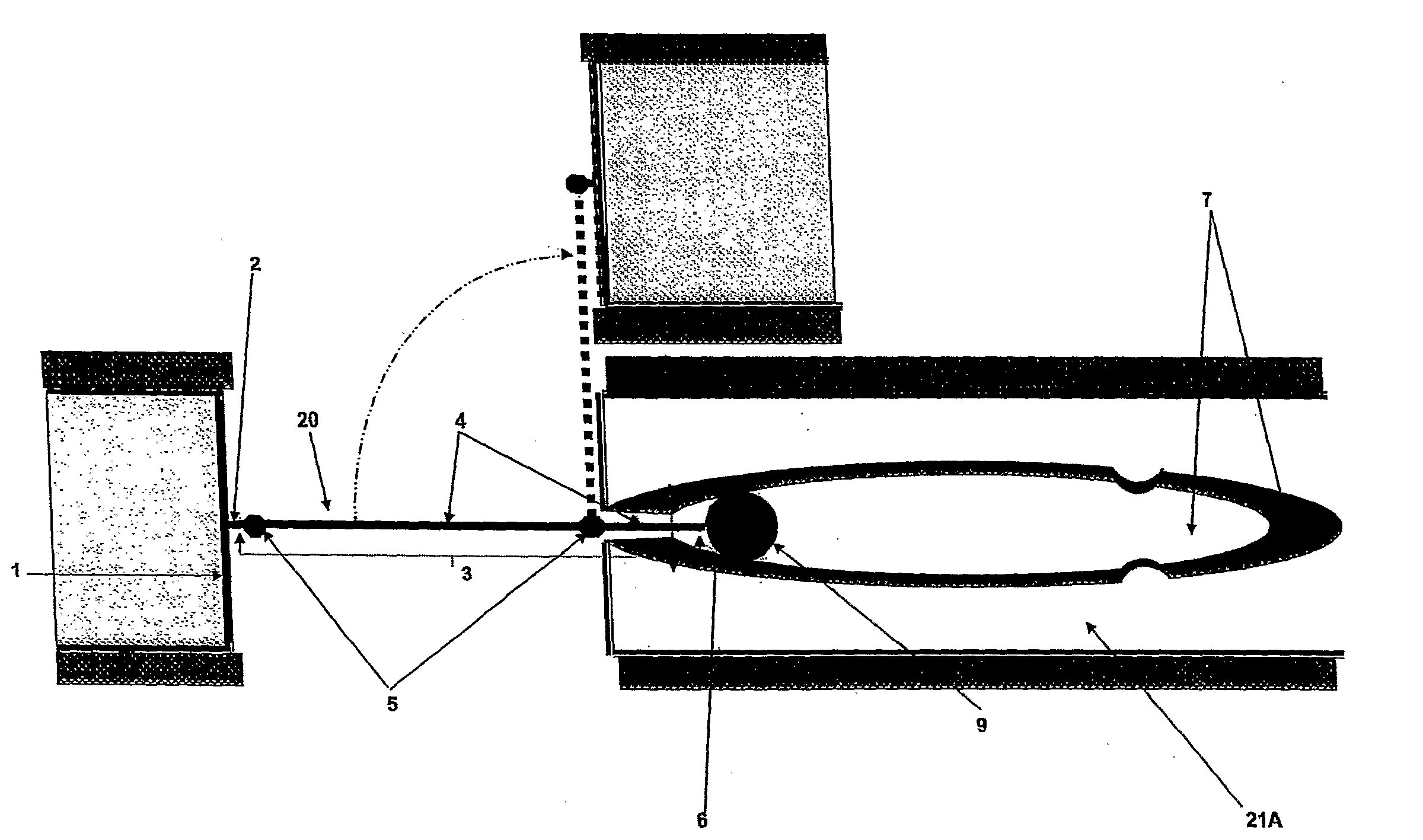

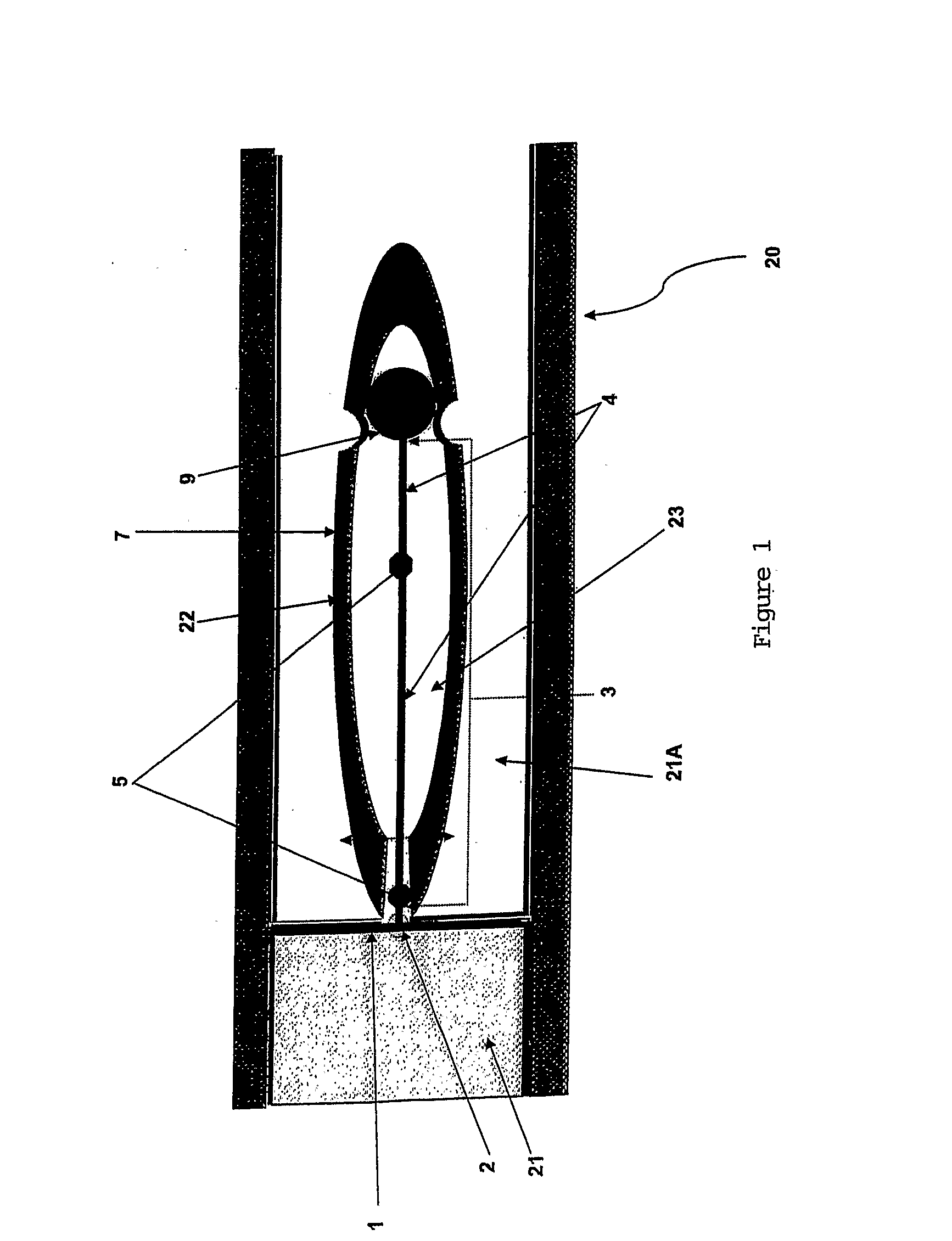

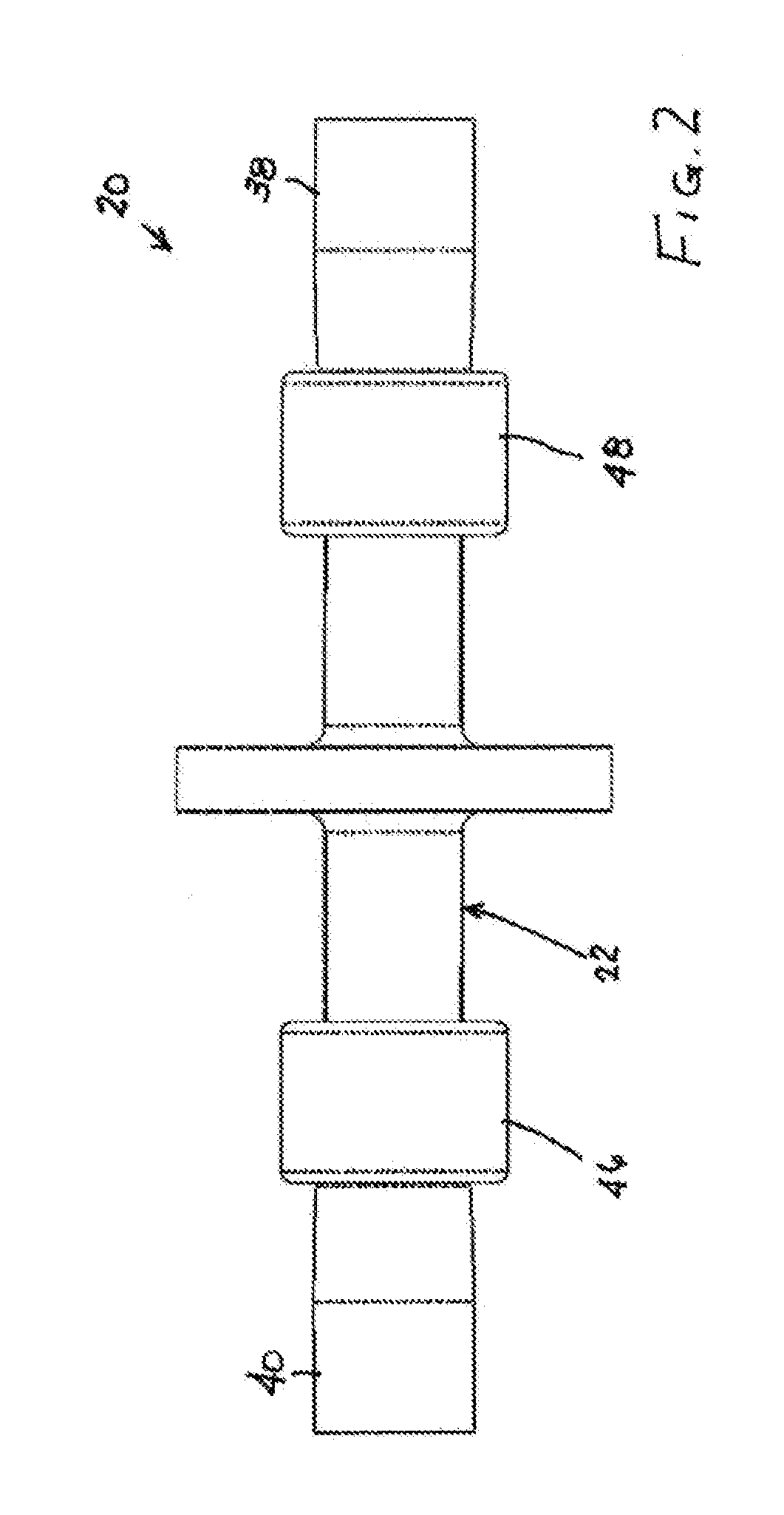

System for Absorbing and Distributing Side Impact Energy Utilizing an Integrated Battery Pack

InactiveUS20120161472A1Simplify mechanically couplingResist impactVehicle seatsElectric propulsion mountingAutomotive engineering

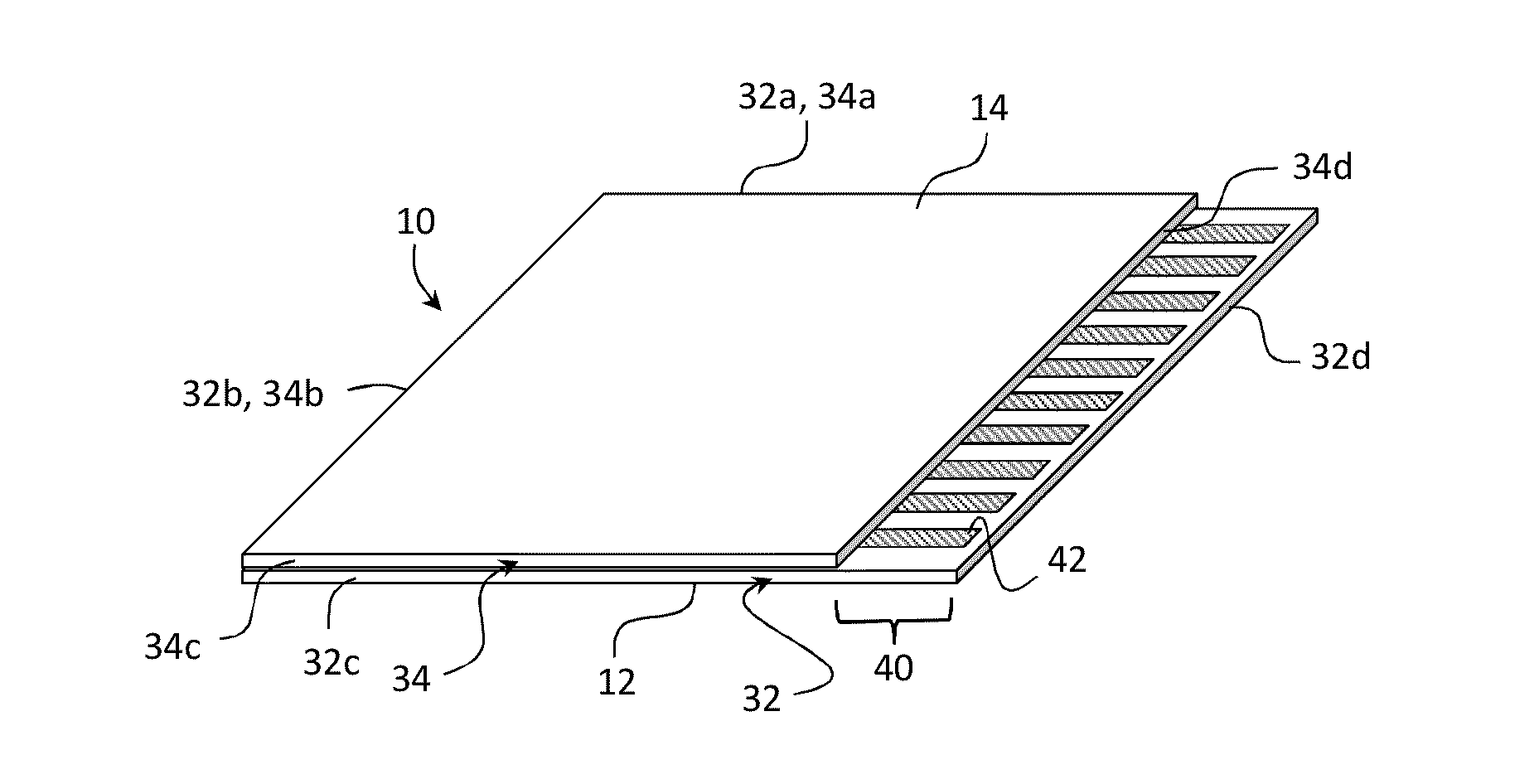

An energy absorbing and distributing side impact system for use with a vehicle is provided, the system utilizing a battery pack enclosure that includes a plurality of cross-members that transverse the battery pack enclosure and absorb and distribute at least a portion of the load received when either the first or second side of the vehicle receives a side impact. The battery pack enclosure is positioned between the front and rear vehicle suspension assemblies and mounted between, and mechanically coupled to, vehicle structural members (e.g., rocker panels) located on either side of the vehicle. In addition to providing rigidity, strength and impact resistance, the battery pack cross-members segregate the batteries contained within the battery pack enclosure into battery groups.

Owner:TESLA INC

Fire retardant and heat resistant yarns and fabrics made therefrom

InactiveUS6358608B1Improve heat resistanceIncrease abrasionNatural mineral layered productsYarnYarnEngineering

Fire retardant and heat resistant yarns, fabrics, felts and other fibrous blends which incorporate high amounts of oxidized polyacrylonitrile fibers. Such yarns, fabrics, felts and other fibrous blends have a superior LOI, TPP and continuous operating temperature compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends are also more soft and supple, and are therefore more comfortable to wear, compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends incorporate up to 99.9% oxidized polyacrylonitrile fibers, together with at least one additional fiber, such as p-aramid, in order to provide increased tensile strength and abrasion resistance of the inventive yarns, fabrics, felts and other fibrous blends. The yarns may be woven, knitted or otherwise assembled into a desired fabric.

Owner:CHAPMAN THERMAL PRODS

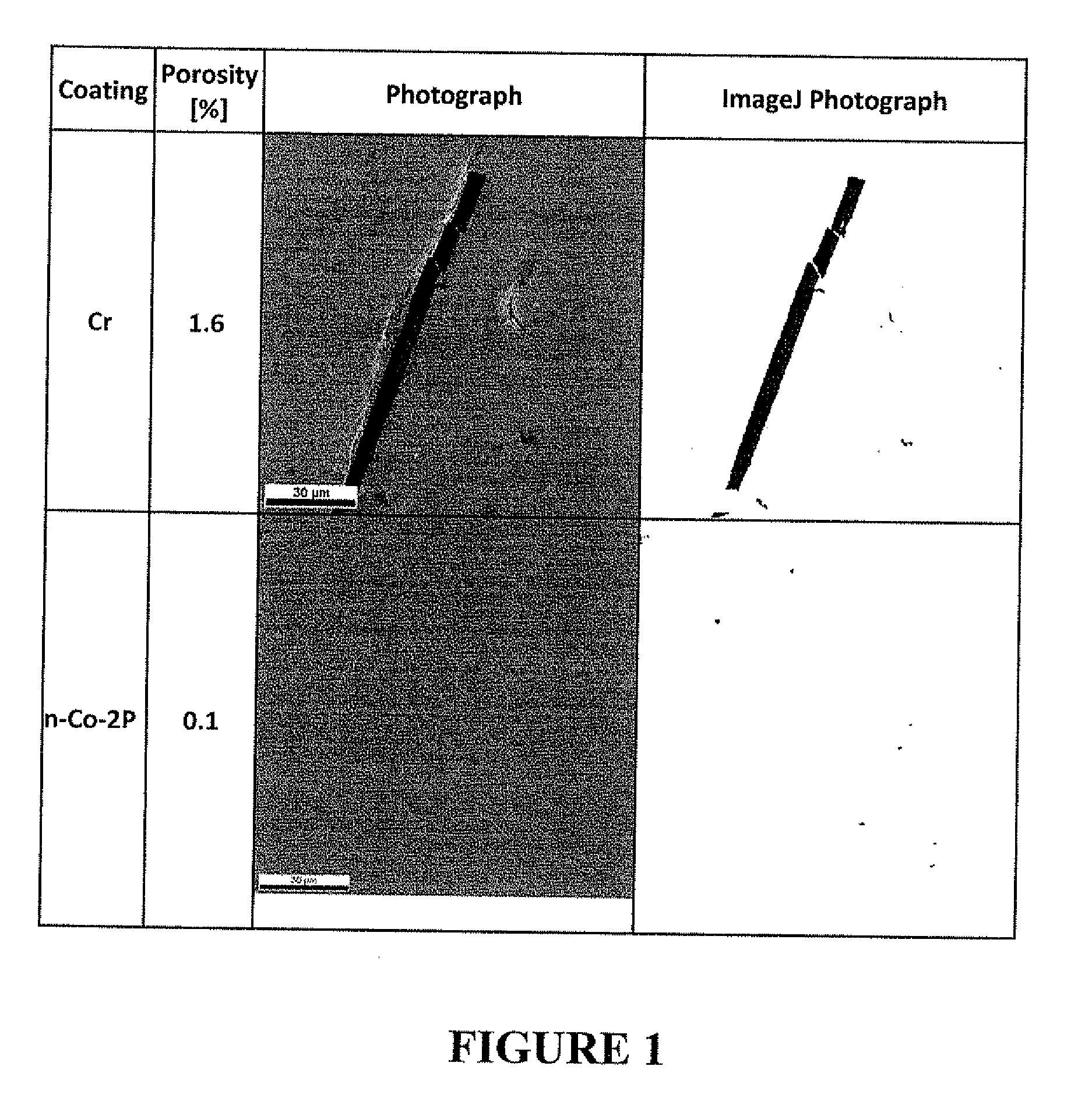

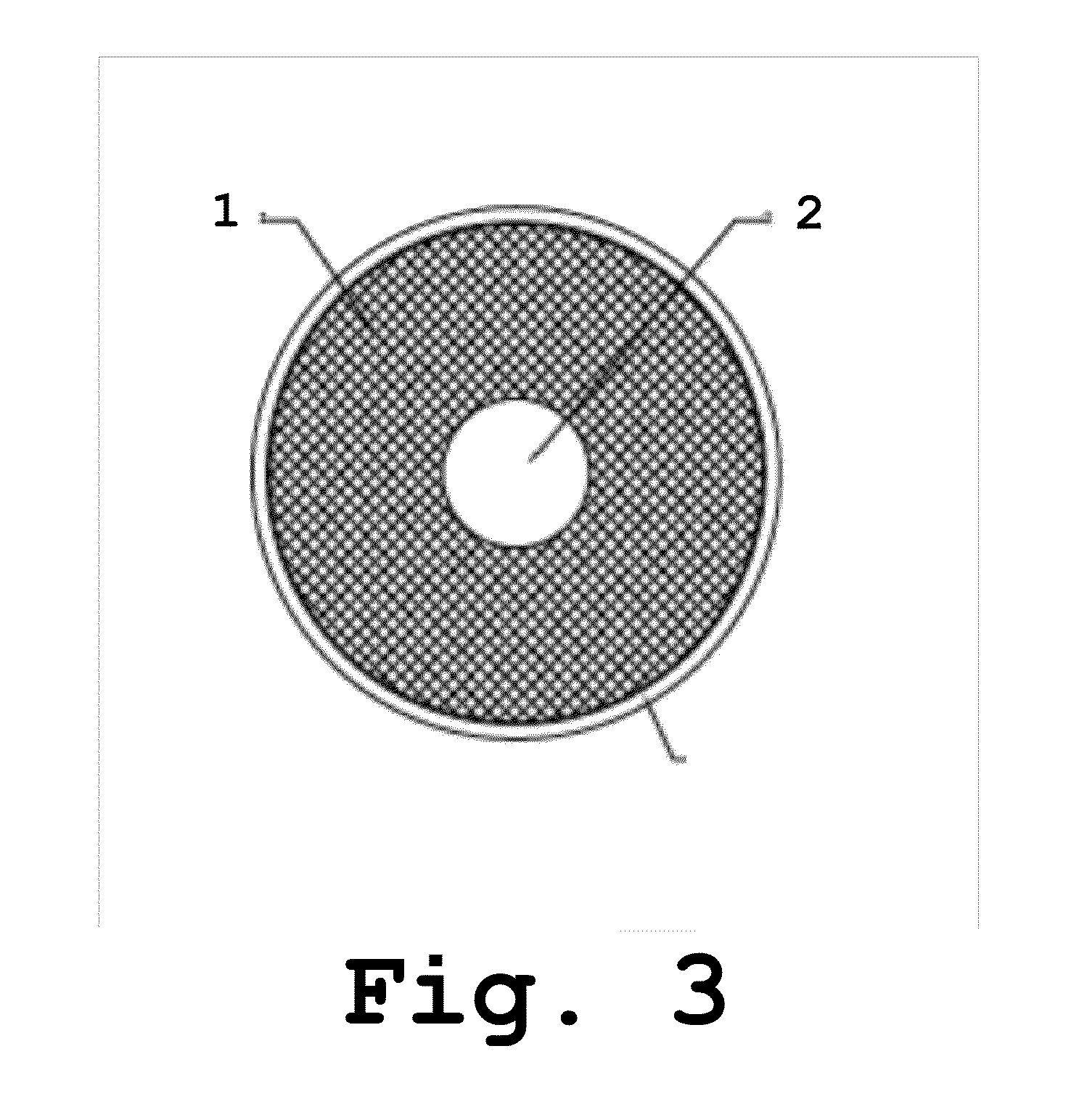

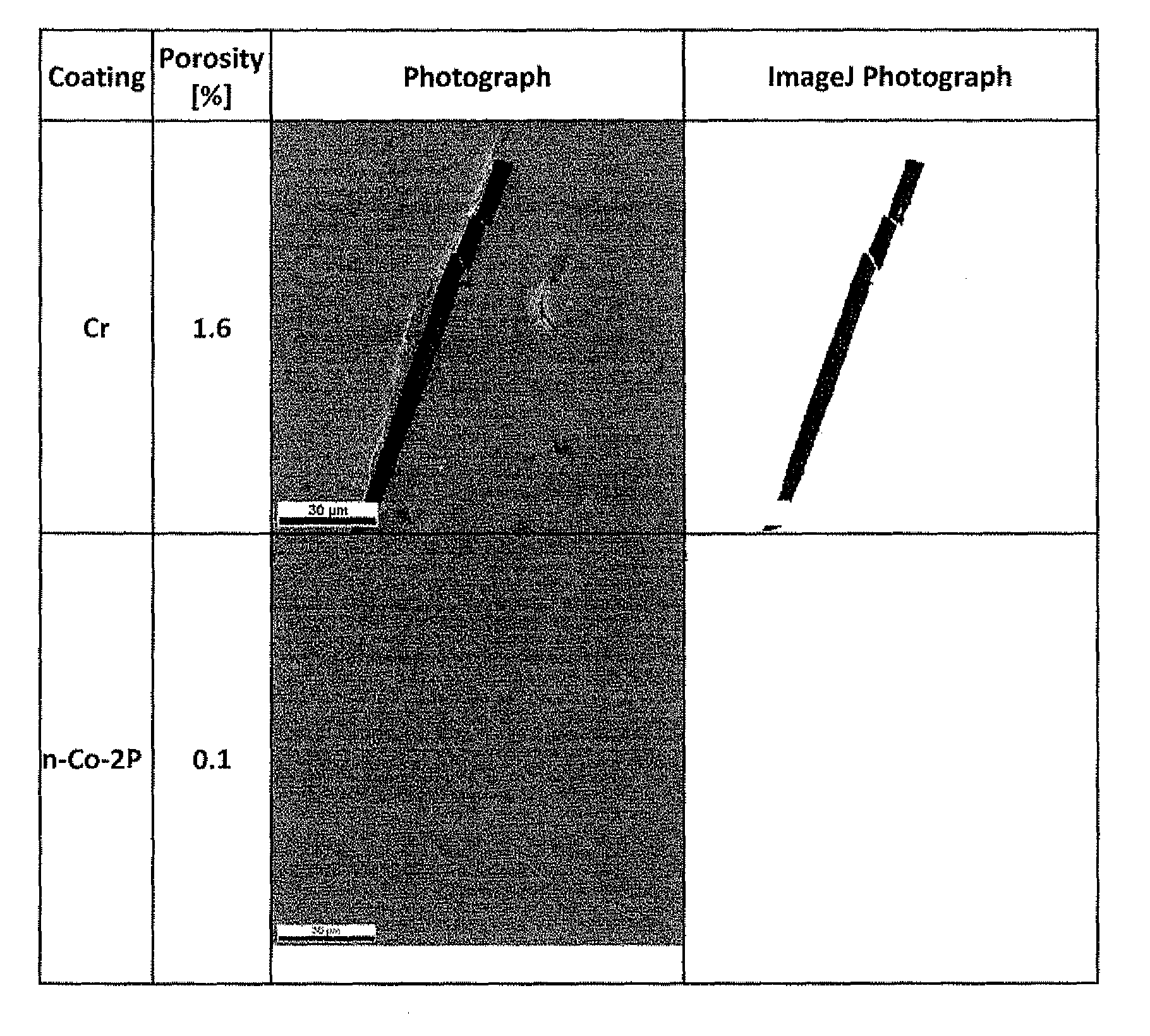

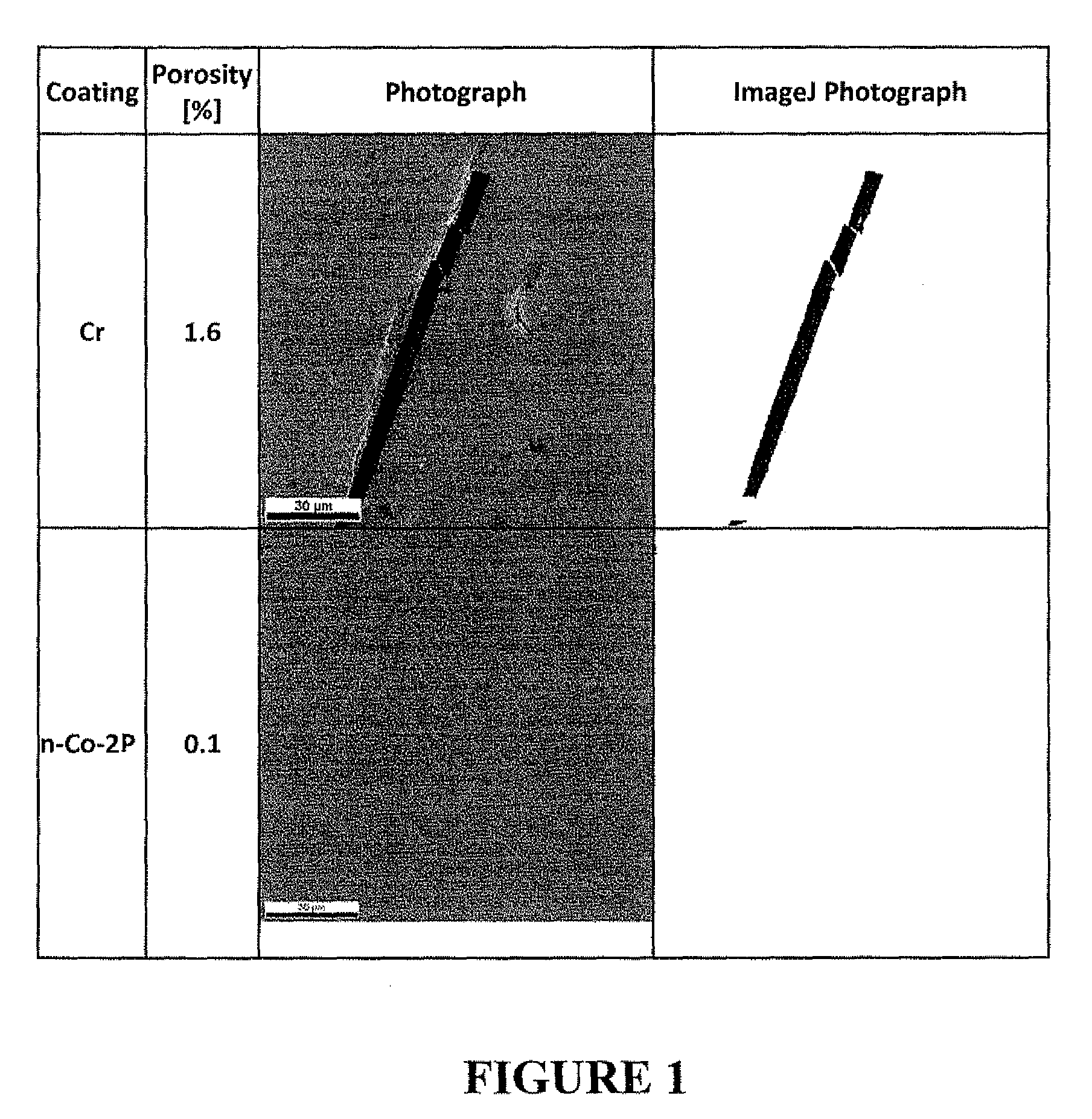

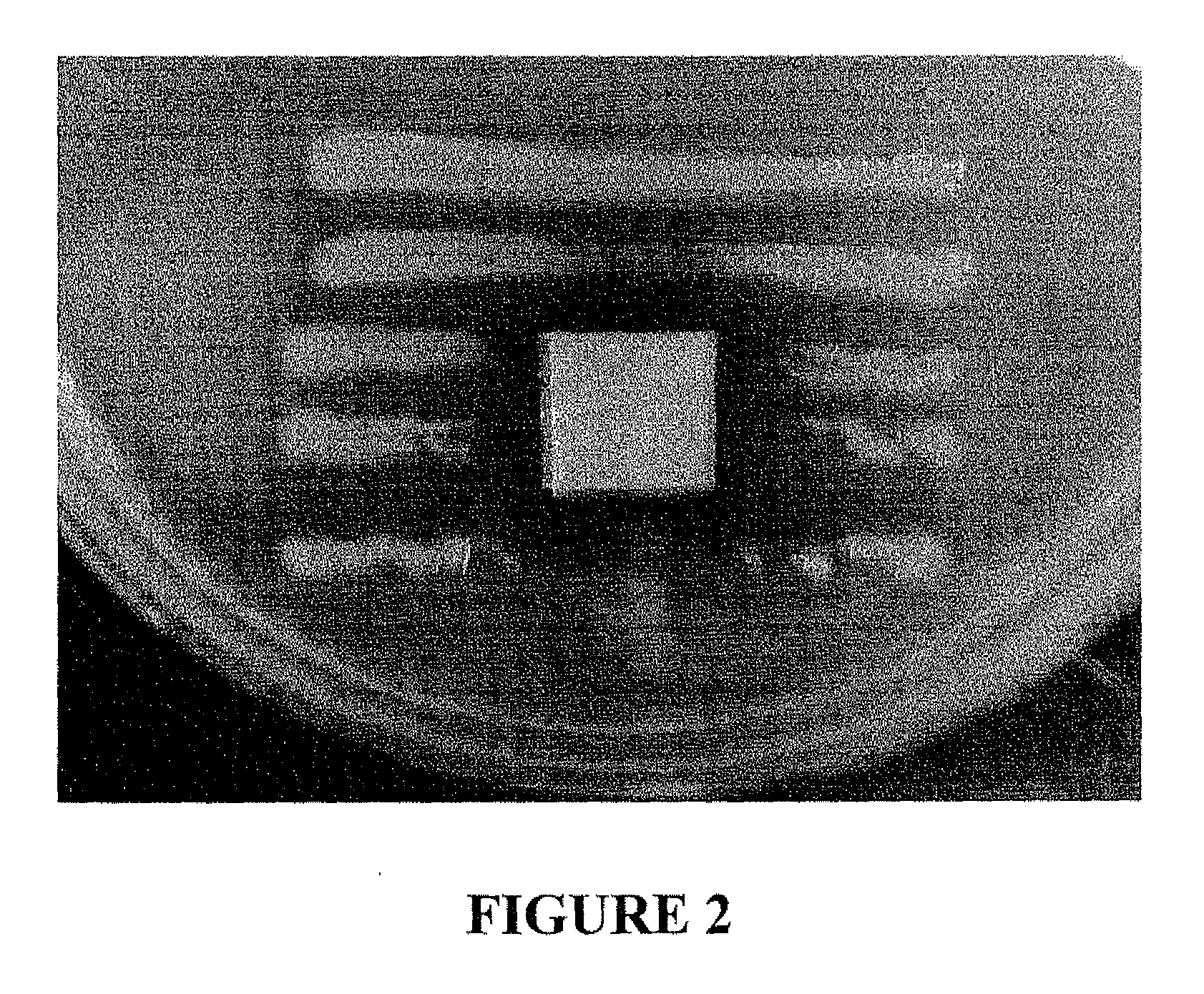

Electrodeposited metallic-materials comprising cobalt

ActiveUS20100304182A1Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageParticulatesPorosity

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

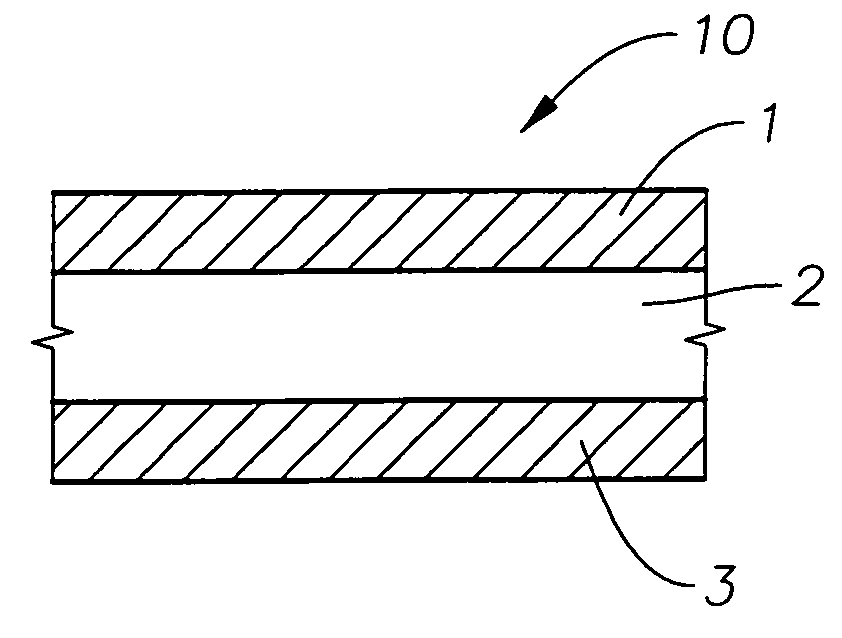

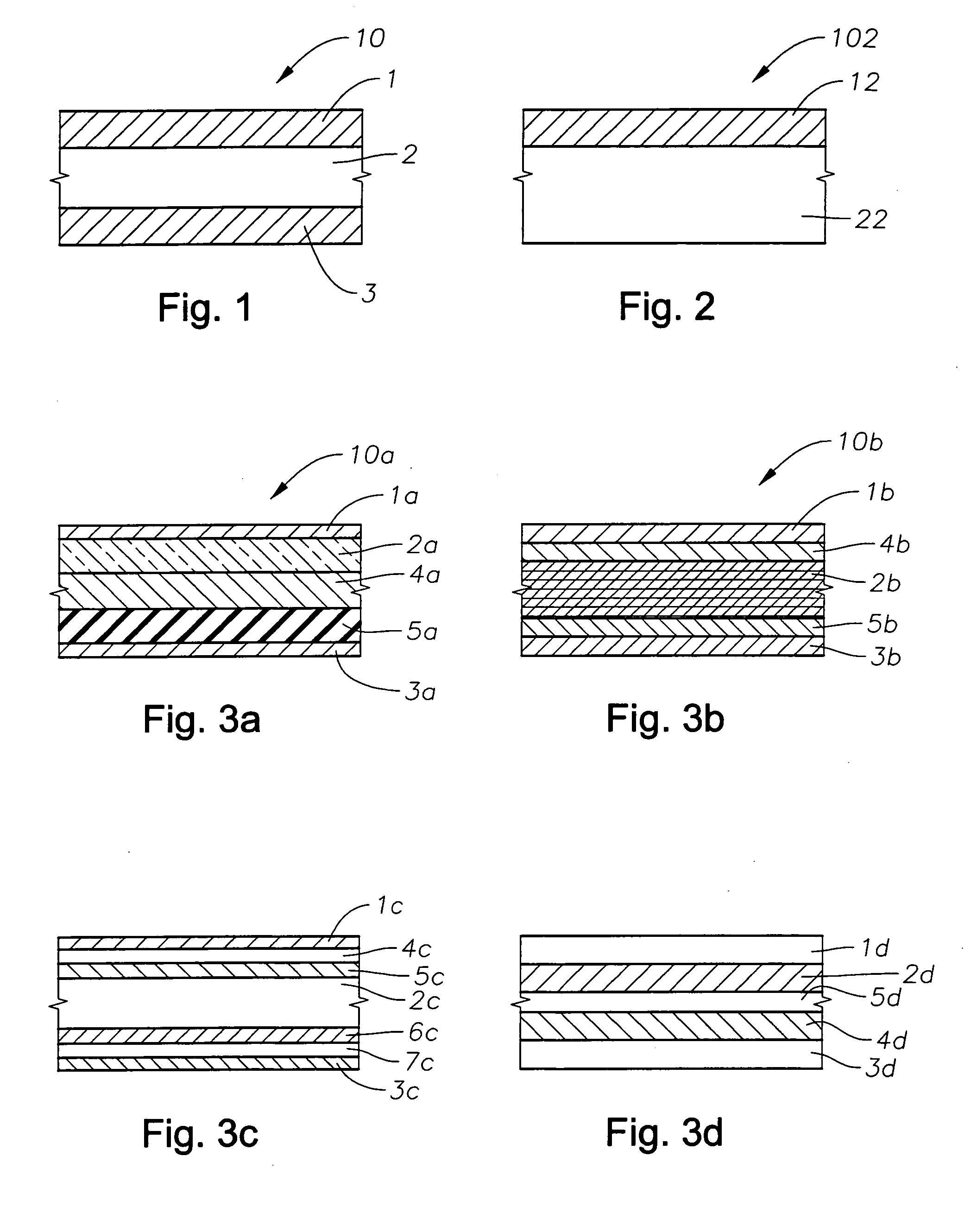

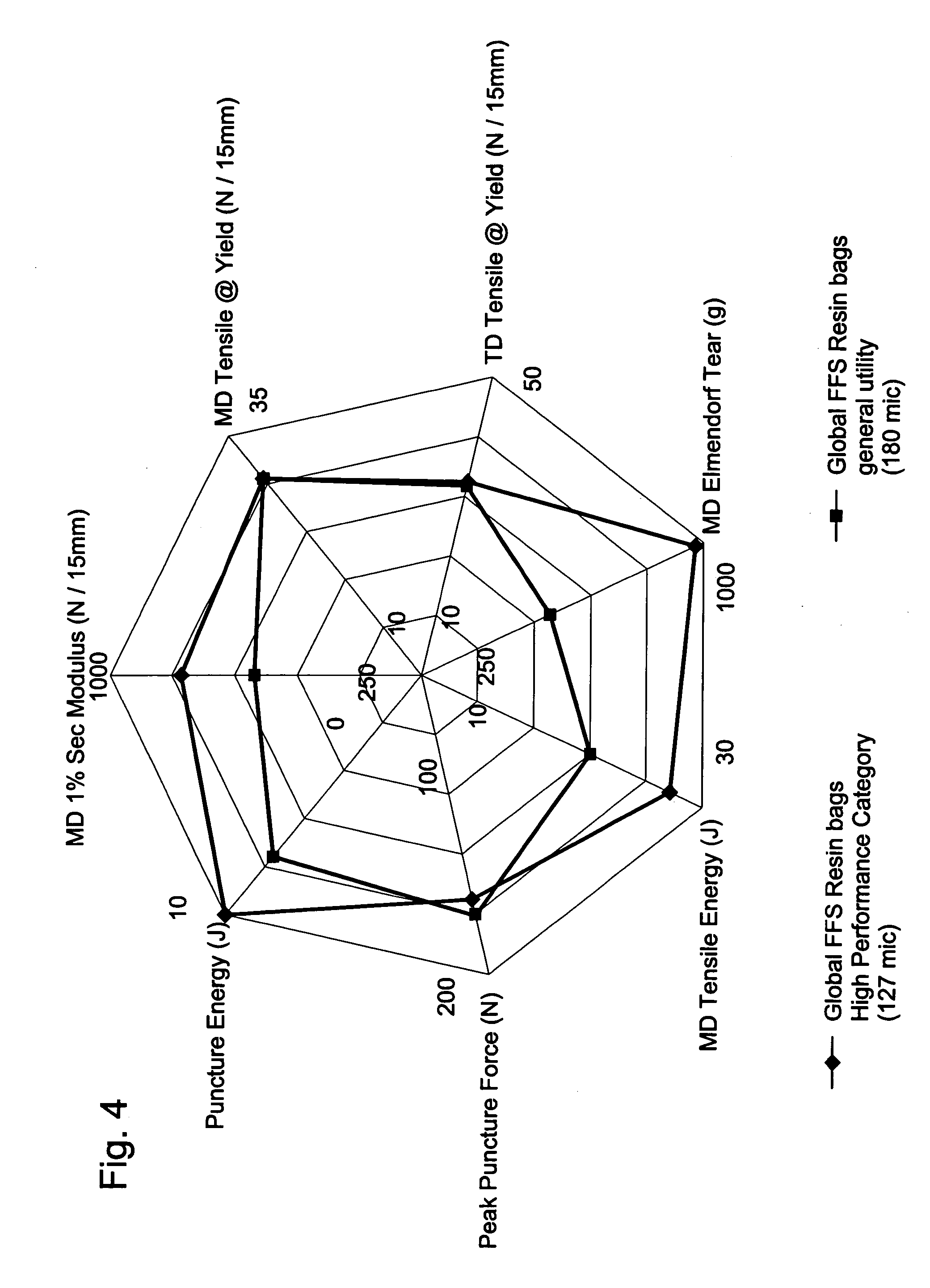

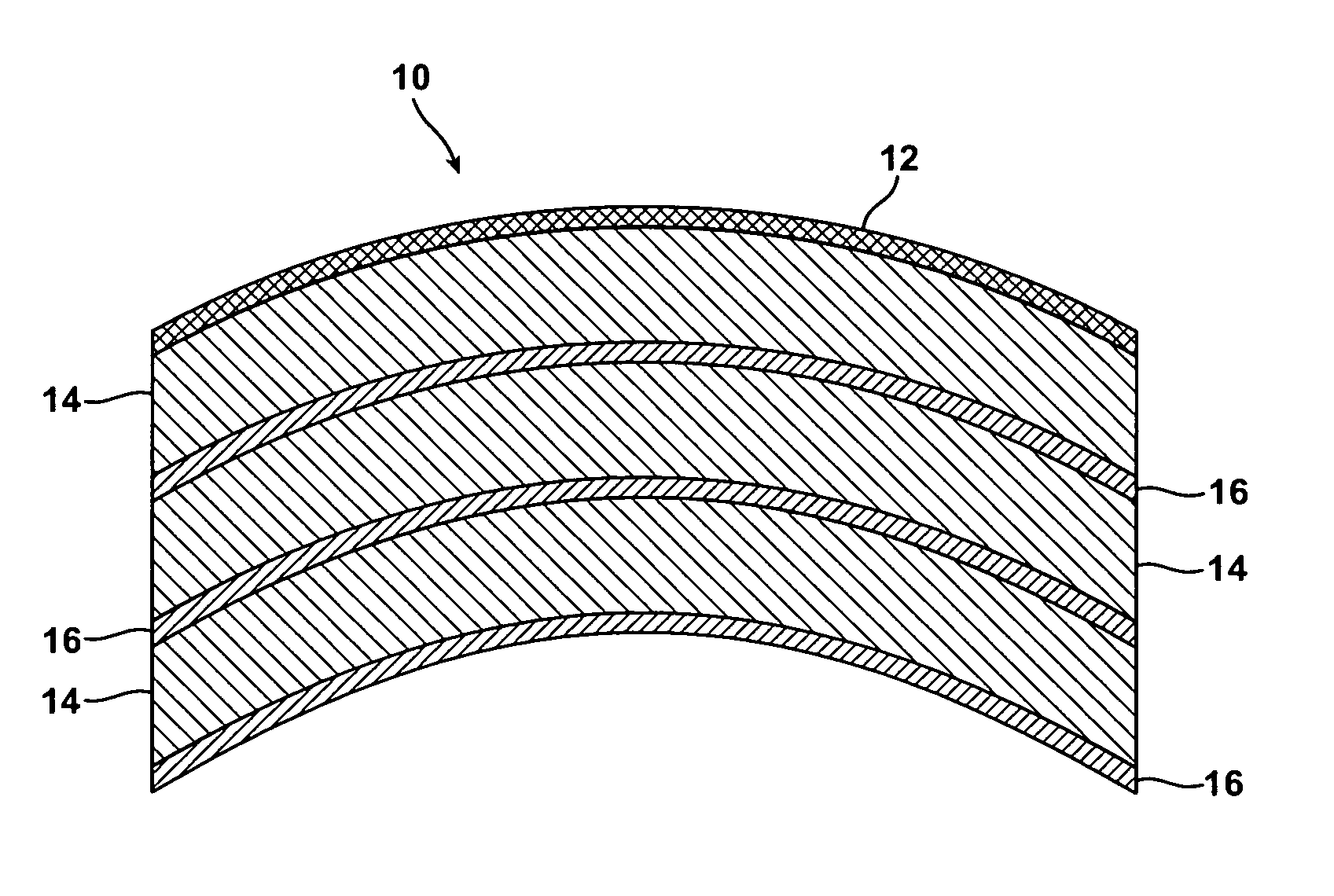

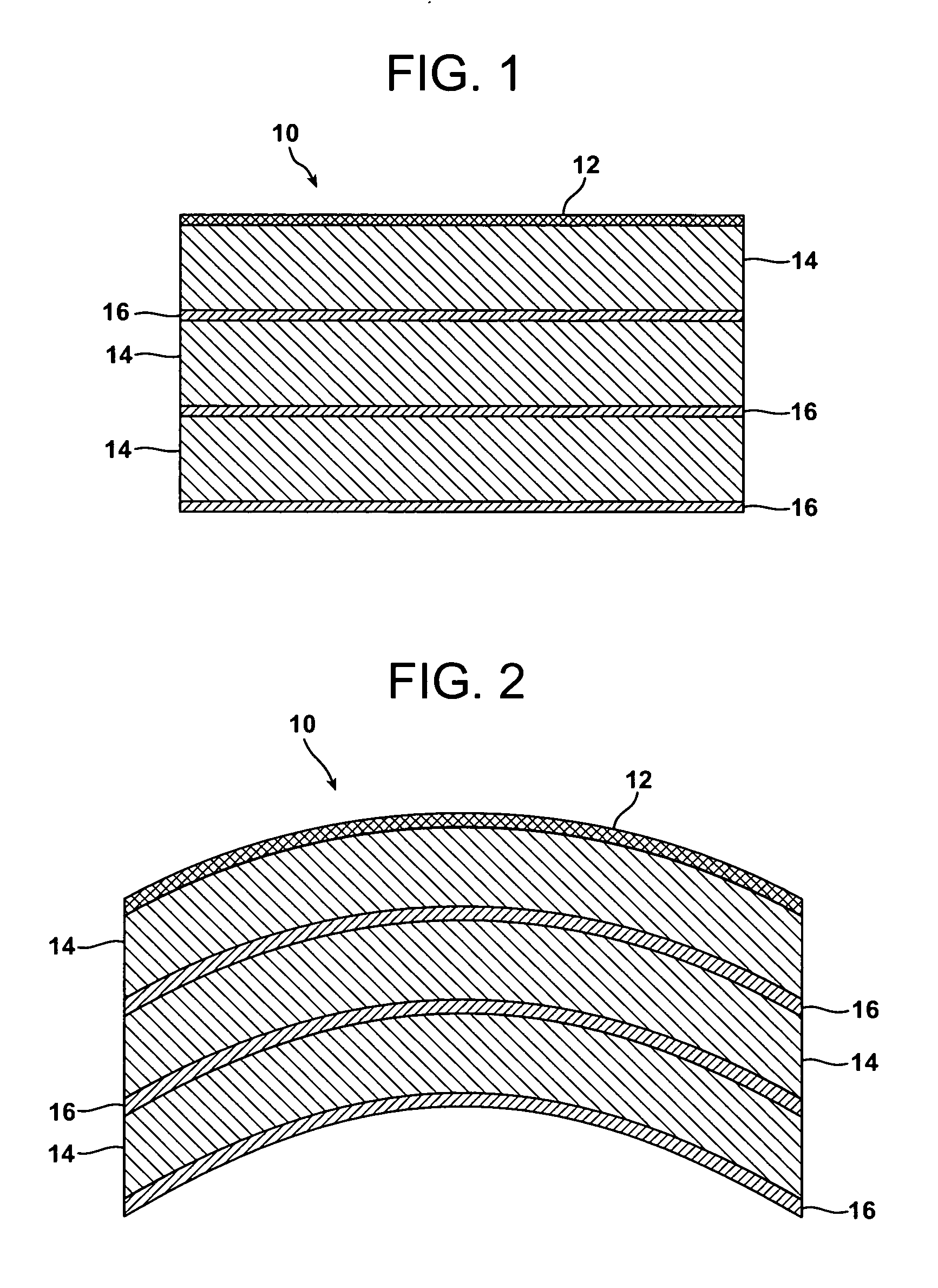

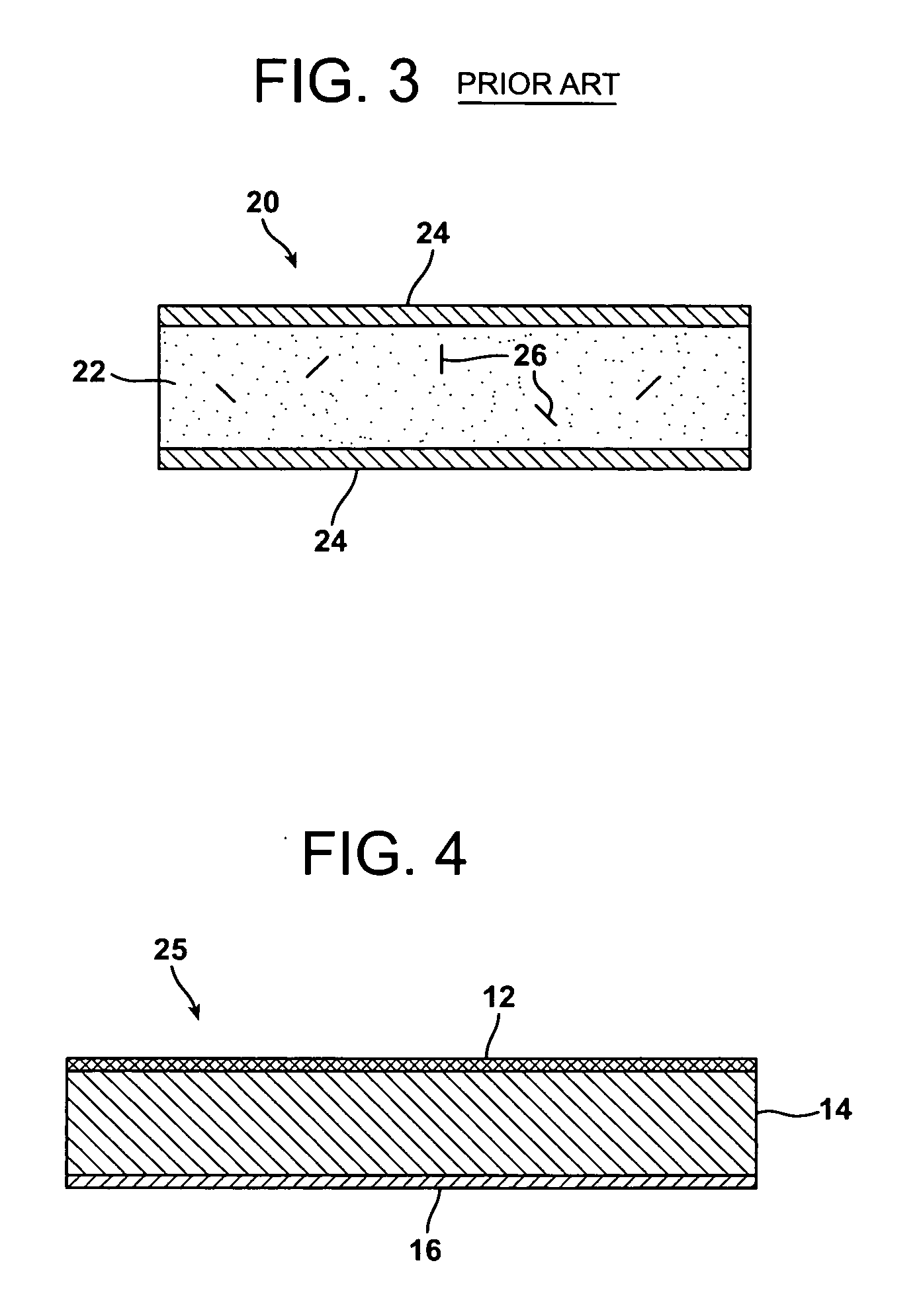

Multi-layer polyethylene films

InactiveUS20060188678A1Improve sealingResist impactSynthetic resin layered productsBagsEngineeringHeavy duty

An improved multi-layer film and packaging, including heavy duty sacks made therefrom having improved properties that permit processing on high speed bagging / Form Fill-Seal equipment are disclosed. The multi-layer films of the invention include a mLLDPE-containing skin layer and a core layer that includes both HDPE and mLLDPE.

Owner:EXXONMOBIL CHEM PAT INC

Carpet Fiber Polymeric Blend

ActiveUS20080157425A1Improve fire resistanceImprove spinnabilityFlame-proof filament manufactureCeramic shaping apparatusYarnPolymer chemistry

The invention provides carpet fibers prepared from a blend of polymeric components, said fiber exhibiting improved properties, such as improved spinnability and improved fire resistance. The carpet fibers particularly comprise a majority of polytrimethylene terephthalate (PTT) and a minority of polyethylene terephthalate (PET). The invention further provides yarns and carpets prepared from the inventive fibers, said yarns and carpets likewise exhibiting improved properties. The invention also provides methods of improving various physical properties (such as fire resistance, spinnability, and elongation) of a polymeric composition.

Owner:ALADDIN MFG CORP

Low density drywall

InactiveUS20080057318A1Good physical propertiesImprove impact resistanceLiquid surface applicatorsBuilding componentsFiberWater dispersible

A thin drywall board that includes a gel coat, at least one polymer / gypsum layer, and a wet glass fiber layer is provided. The gel coat is formed of a gel coat composition that includes a water dispersible polymer, gypsum, and optionally a crosslinking agent and / or a coupling agent. The polymer / gypsum layer is formed of a matrix composition that includes a water dispersible polymeric resin and gypsum. Components including melamine formaldehyde, a filler material, coupling agents, acetic acid, an accelerator, and / or a hardener may also be added to the matrix composition. The wet glass fiber layer is preferably a glass fiber mat. The combination of the water dispersible polymeric resin and the gypsum in the matrix composition have a synergistic effect that creates a thin drywall board that is water resistant, fire resistant, and has improved mechanical properties. A method of forming the inventive thin drywall boards is also provided.

Owner:OCV INTELLECTUAL CAPITAL LLC

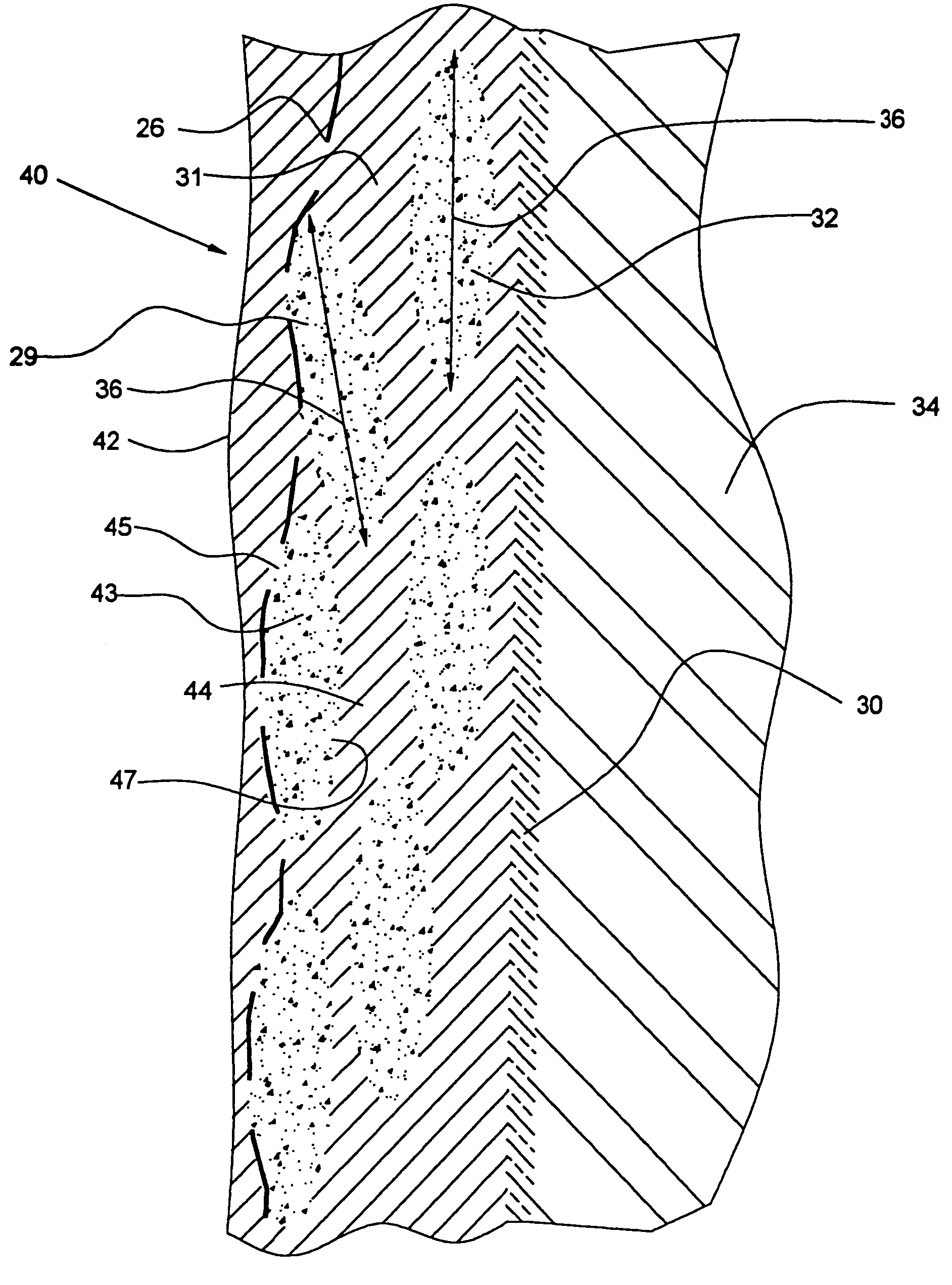

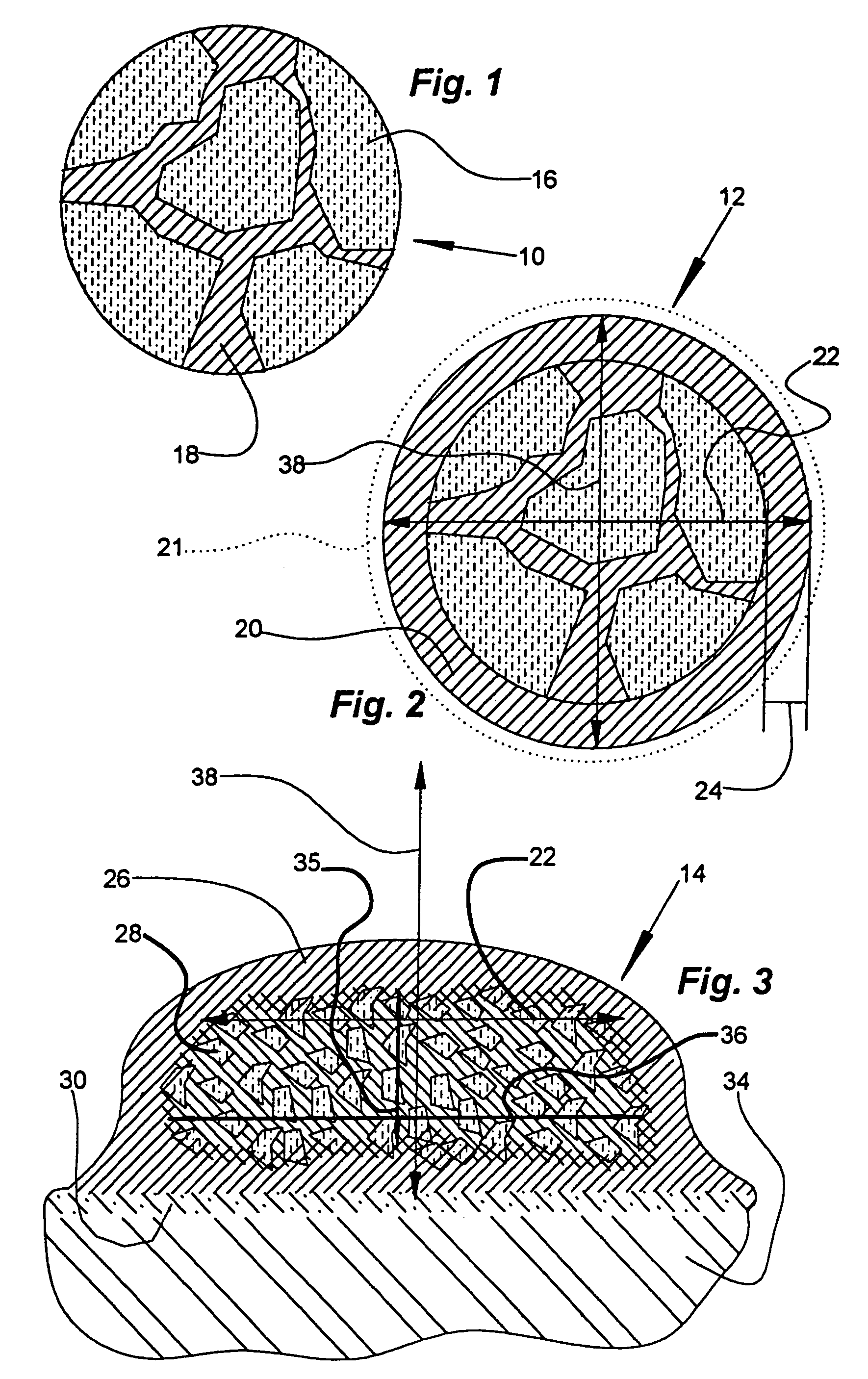

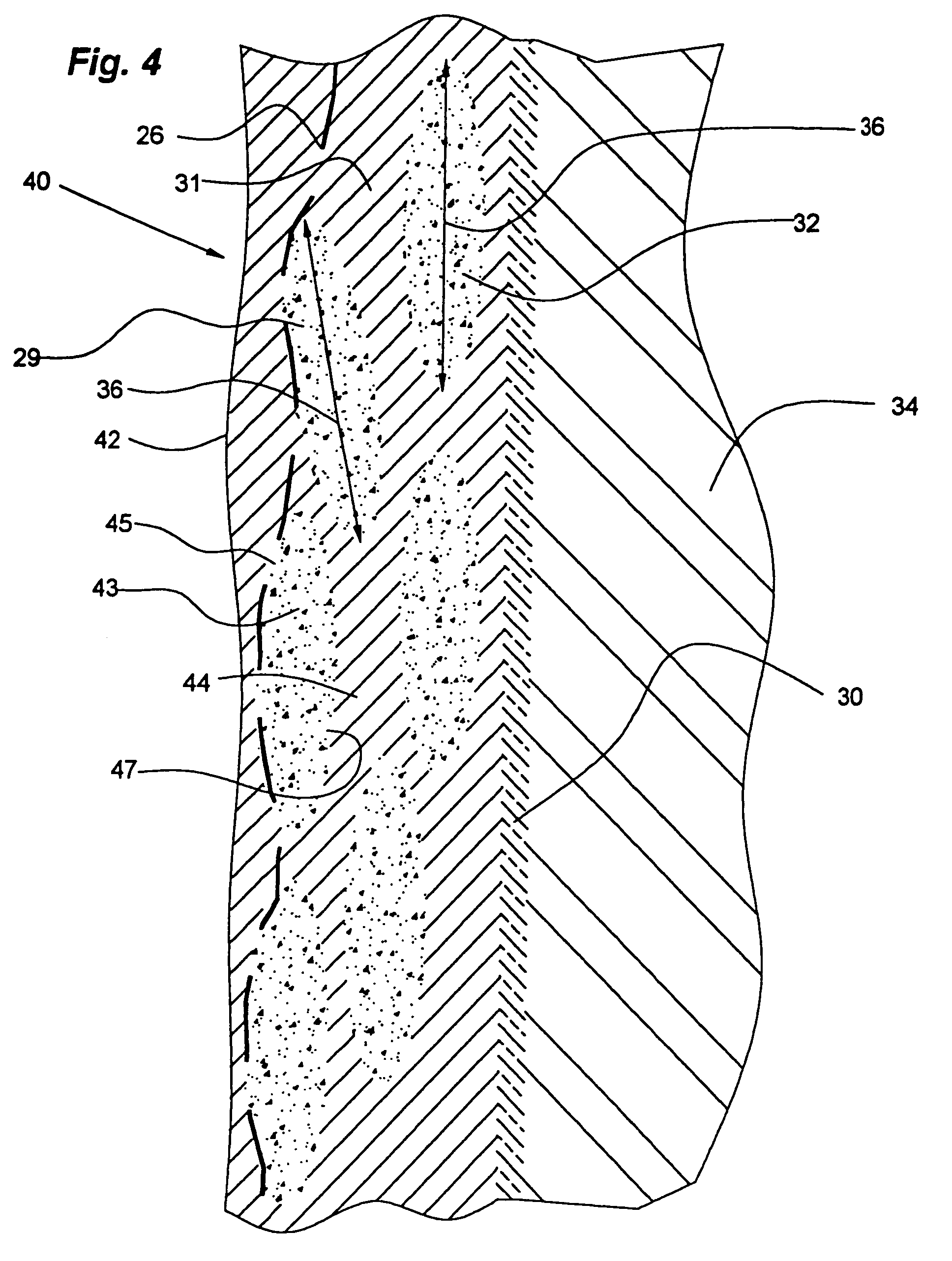

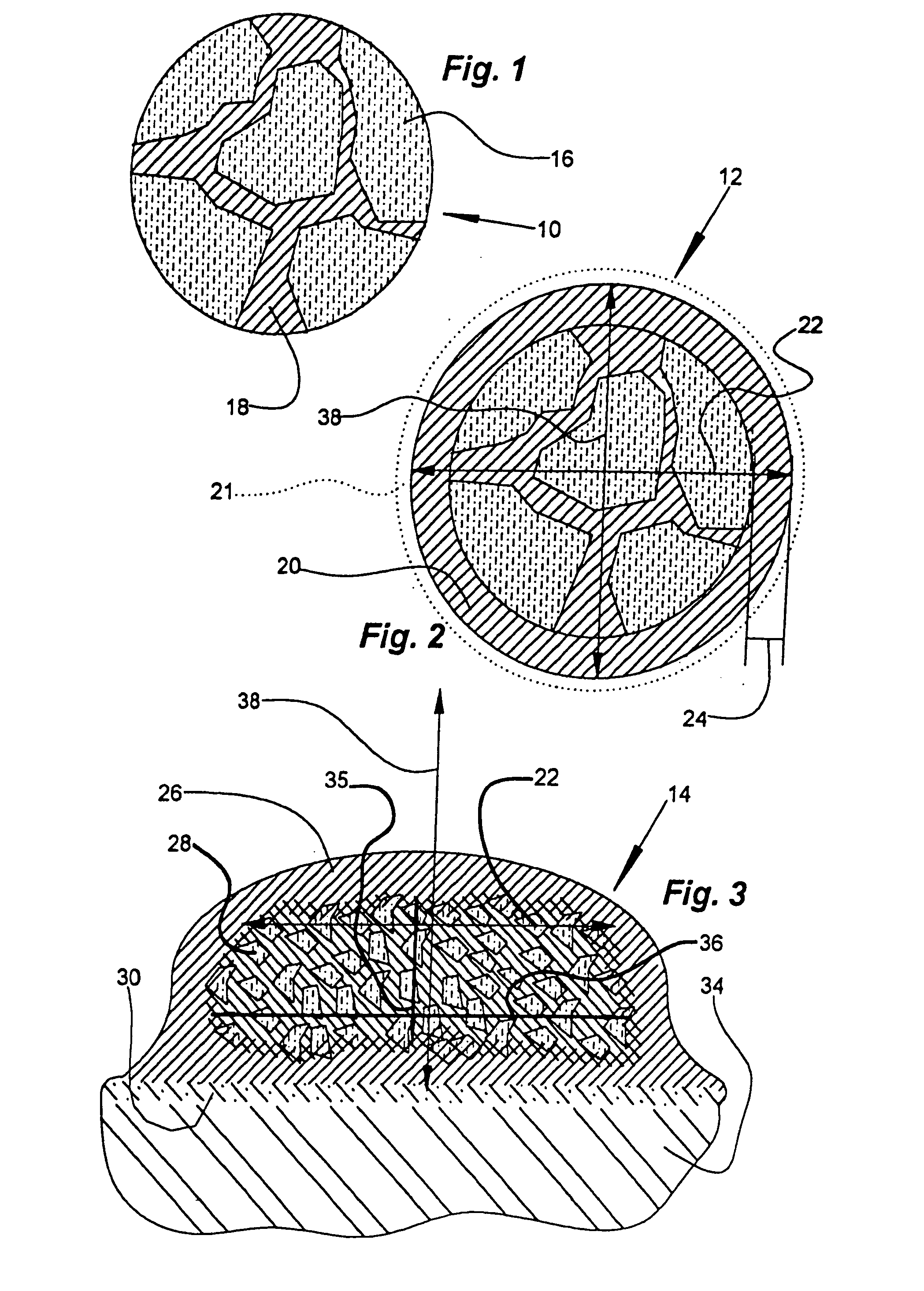

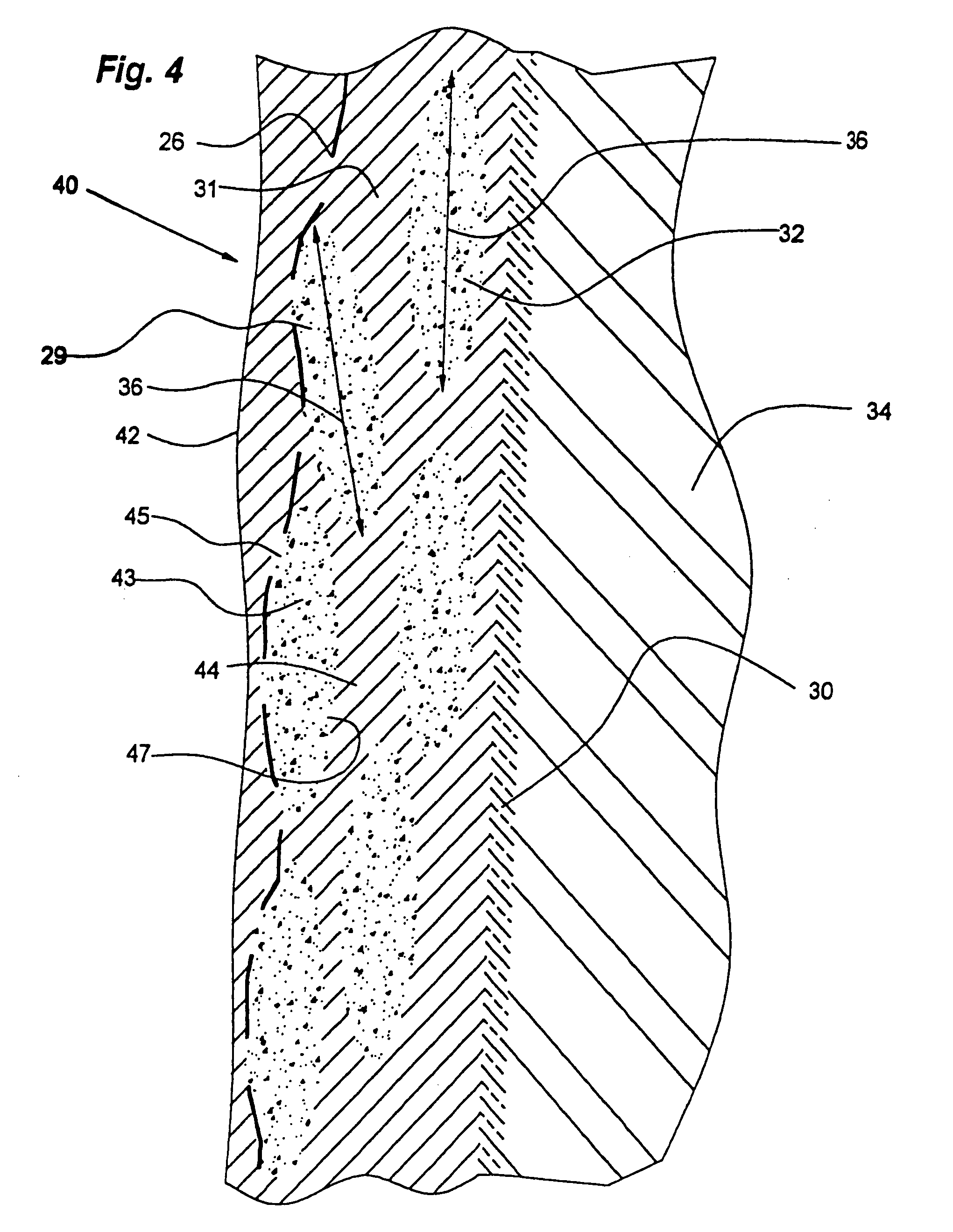

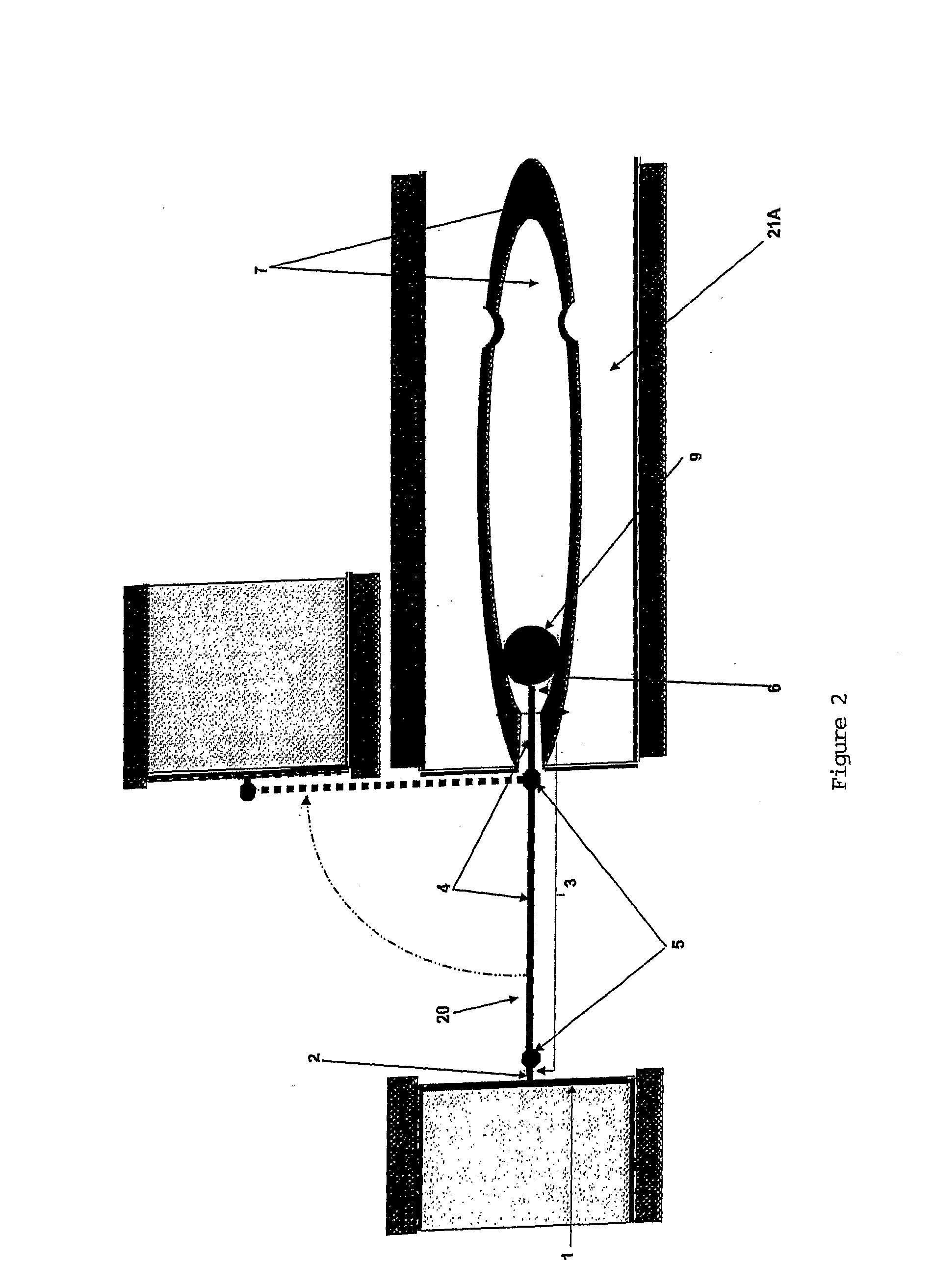

Heterogeneous composite bodies with isolated lenticular shaped cermet regions

ActiveUS7635515B1Increasing the thicknessIncrease spacingMolten spray coatingCeramic layered productsThermal sprayingSolid substrate

A heterogeneous body having ceramic rich cermet regions in a more ductile metal matrix. The heterogeneous bodies are formed by thermal spray operations on metal substrates. The thermal spray operations apply heat to a cermet powder and project it onto a solid substrate. The cermet powder is composed of complex composite particles in which a complex ceramic-metallic core particle is coated with a matrix precursor. The cermet regions are generally comprised of complex ceramic-metallic composites that correspond approximately to the core particles. The cermet regions are approximately lenticular shaped with an average width that is at least approximately twice the average thickness. The cermet regions are imbedded within the matrix phase and generally isolated from one another. They have obverse and reverse surfaces. The matrix phase is formed from the matrix precursor coating on the core particles. The amount of heat applied during the formation of the heterogeneous body is controlled so that the core particles soften but do not become so fluid that they disperse throughout the matrix phase. The force of the impact on the surface of the substrate tends to flatten them. The flattened cermet regions tend to be approximately aligned with one another in the body.

Owner:POWDERMET

System for absorbing and distributing side impact energy utilizing an integrated battery pack

ActiveUS20140182958A1Simplify mechanically couplingResist impactElectric propulsion mountingUnderstructuresElectrical batterySide impact

Owner:TESLA INC

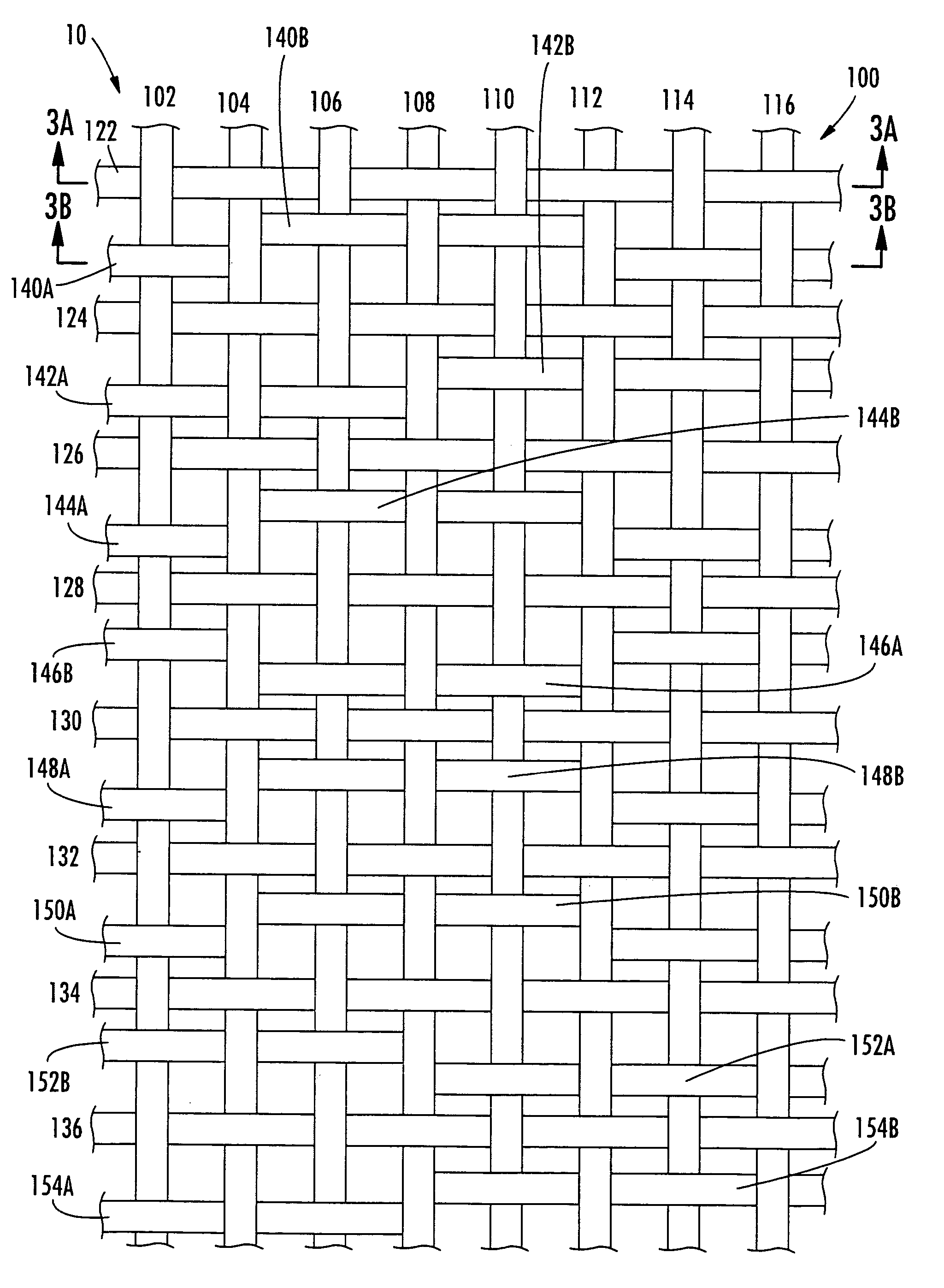

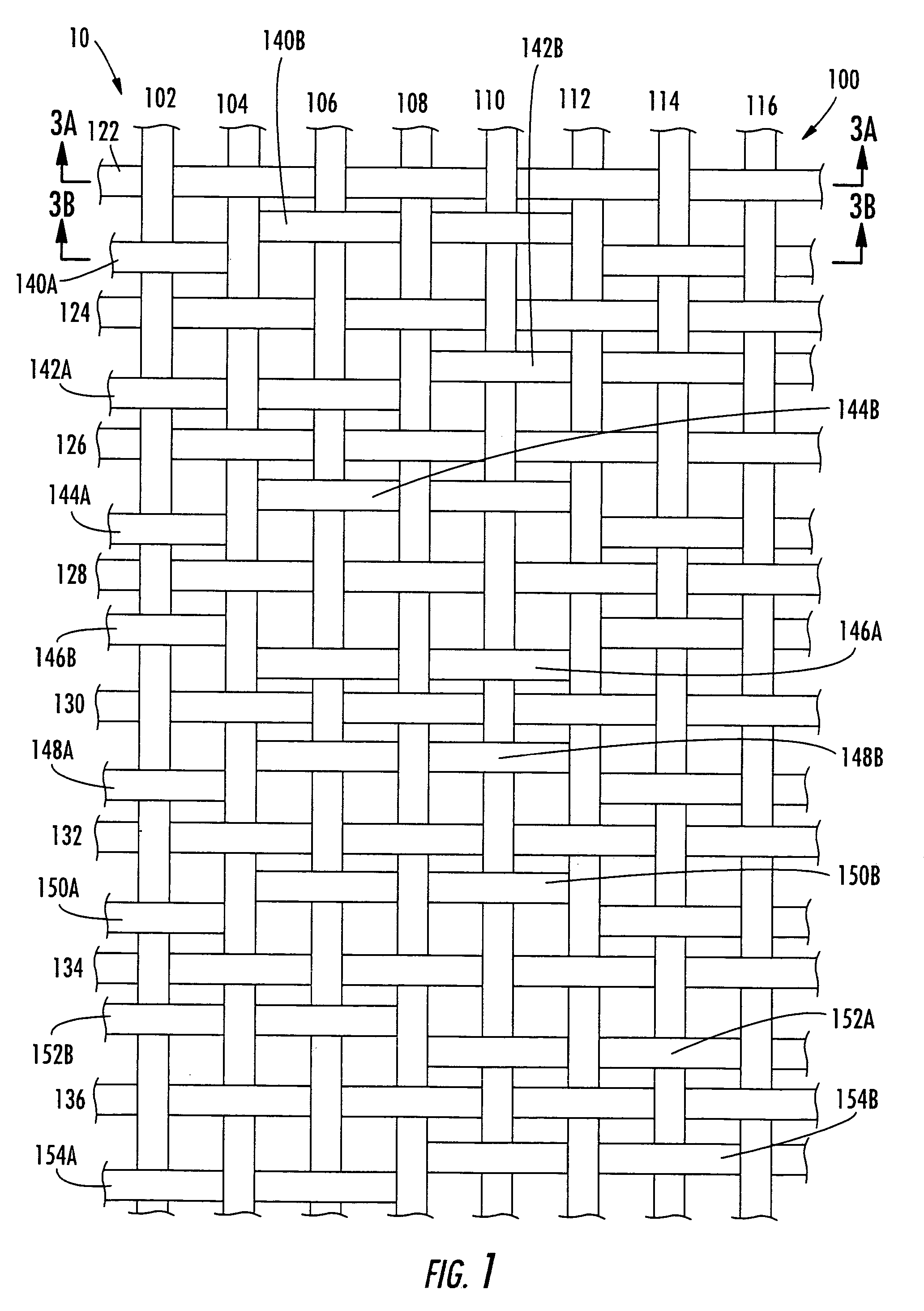

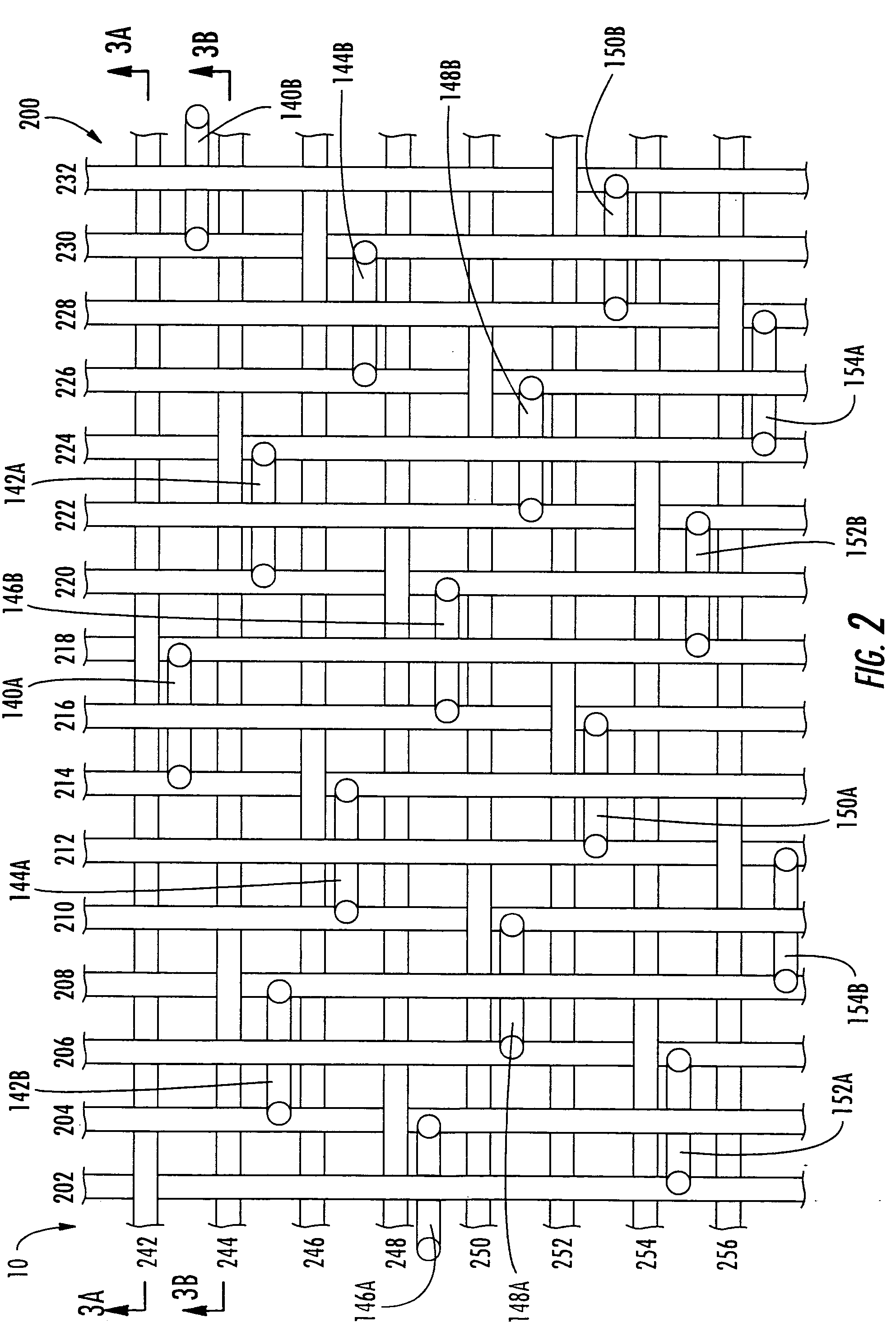

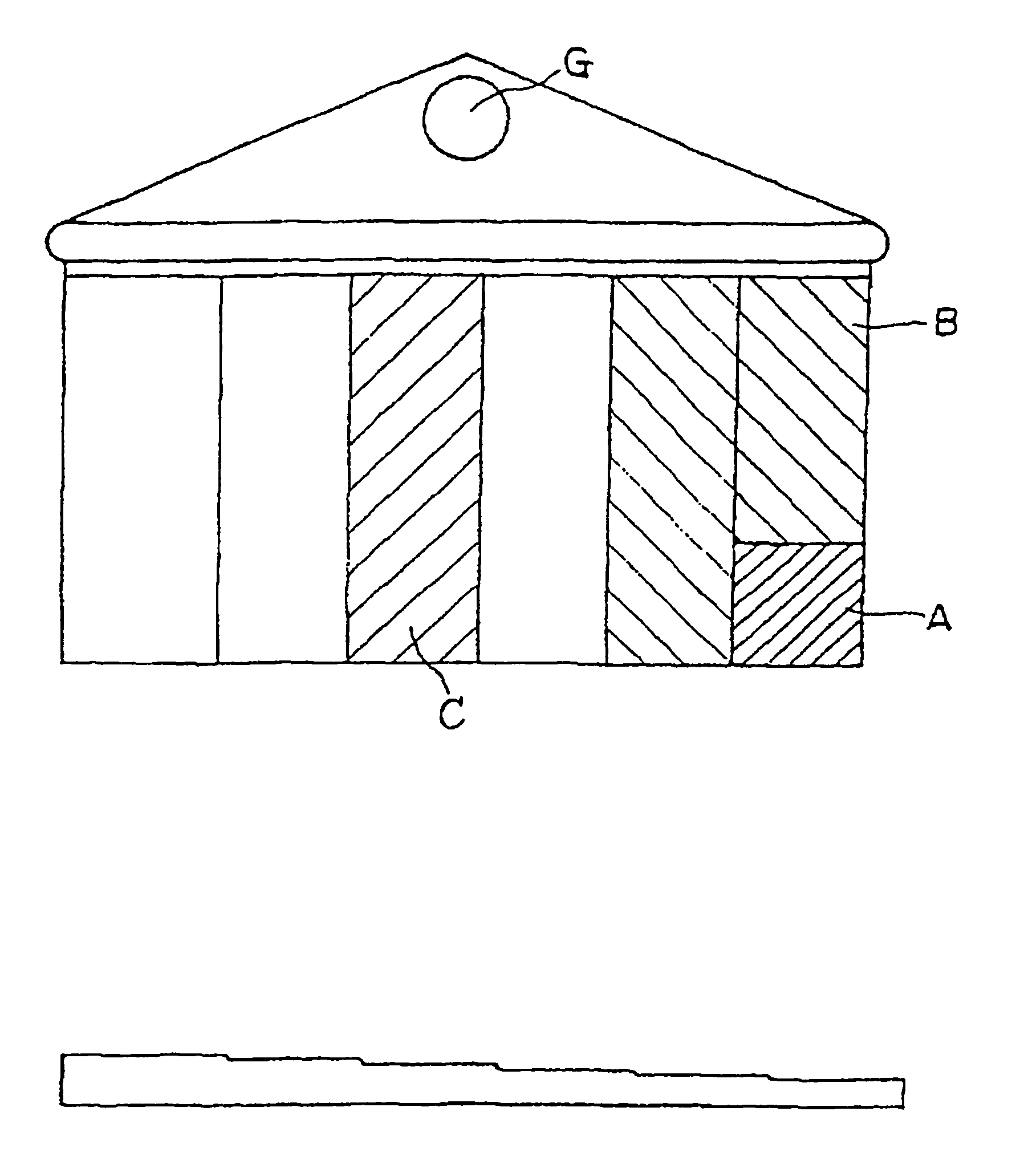

Papermaker's forming fabric with twice as many bottom MD yarns as top MD yarns

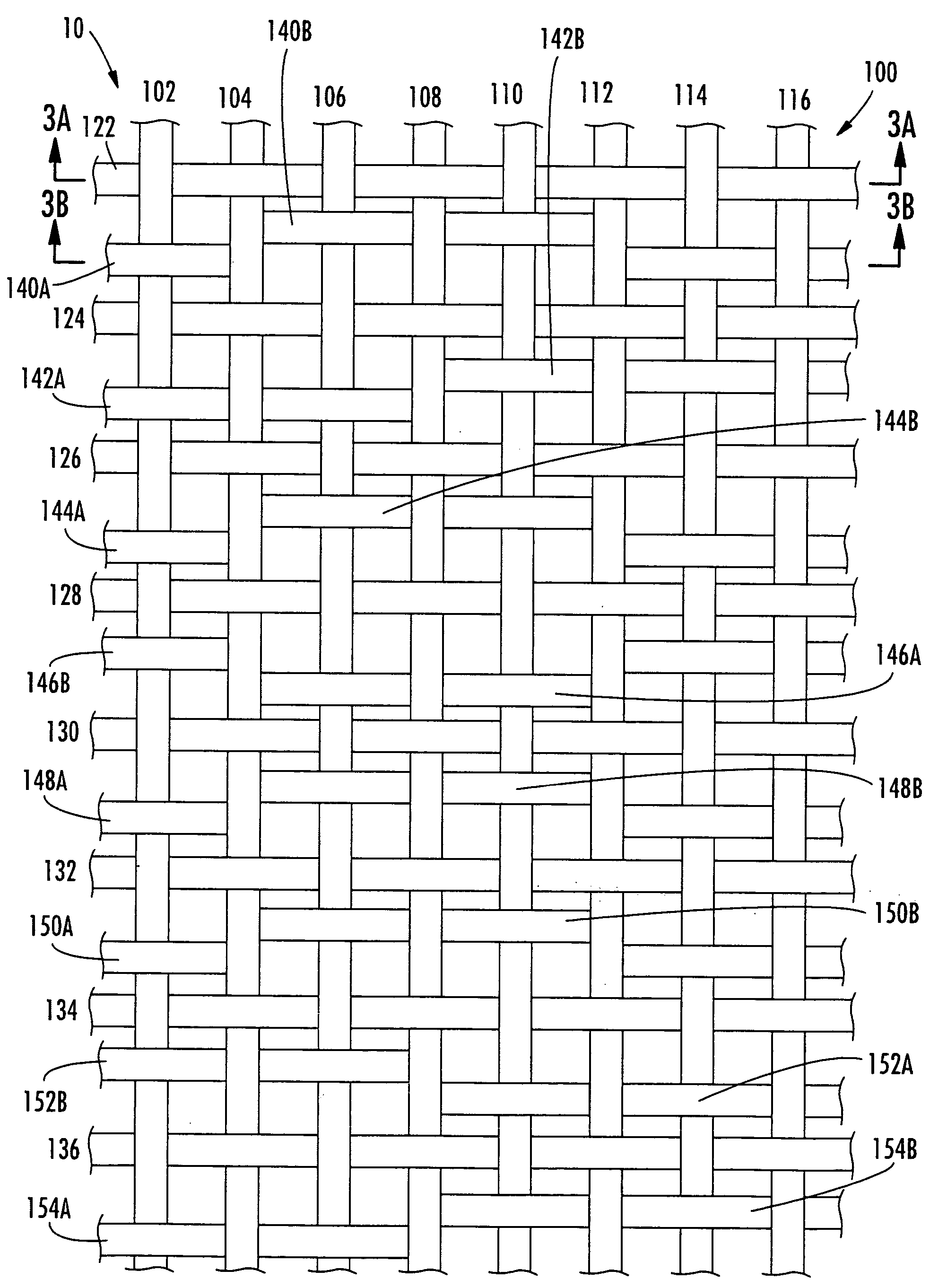

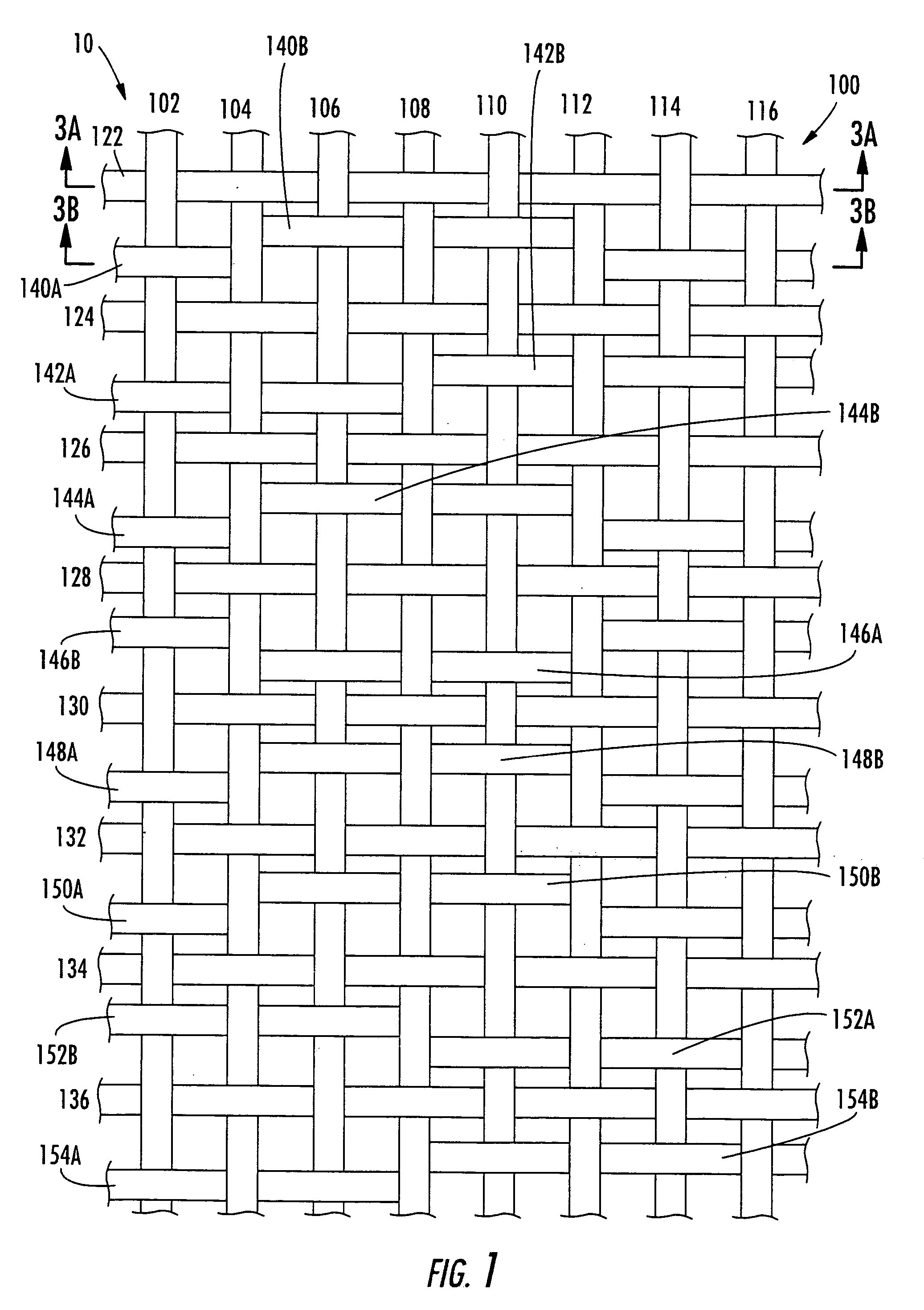

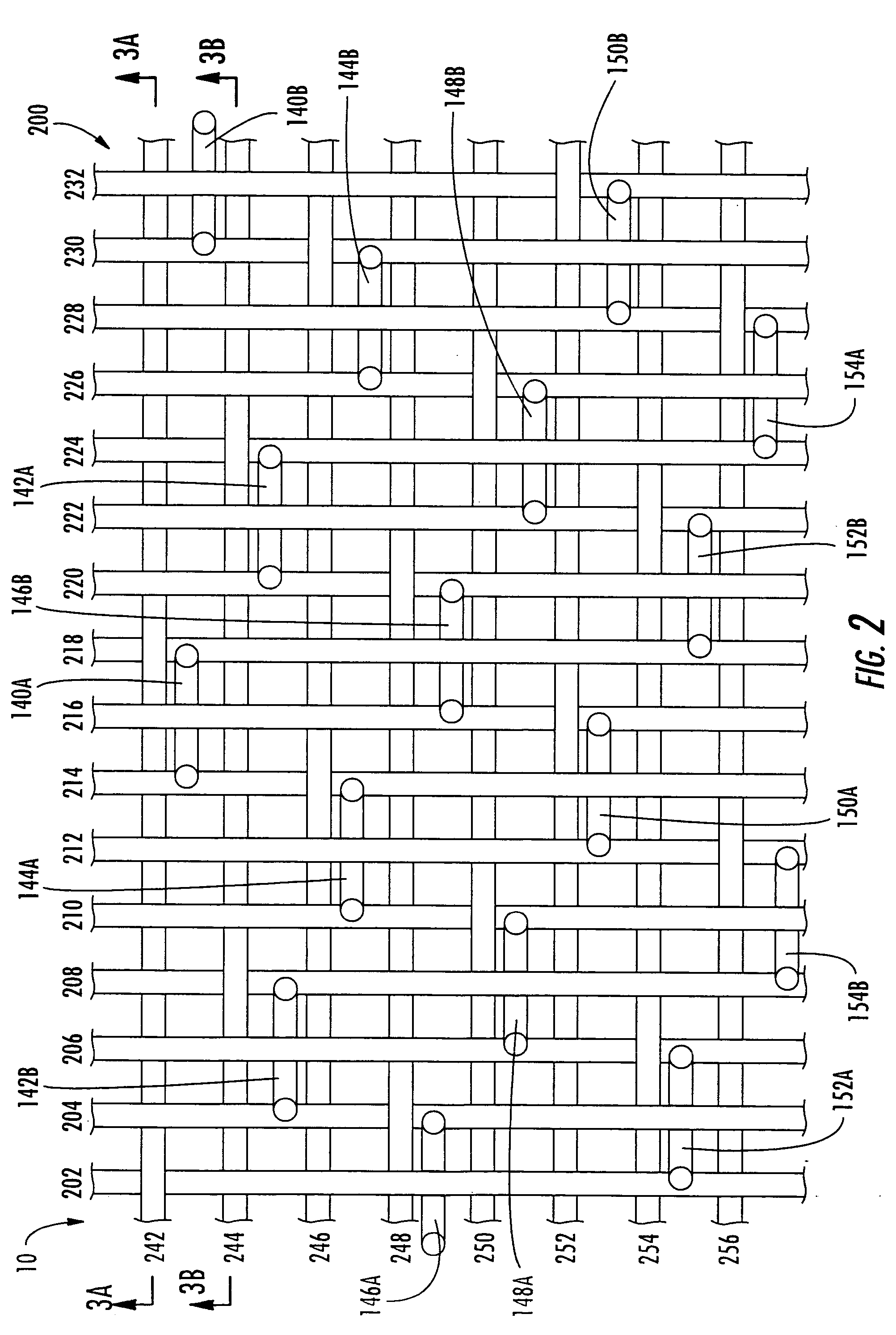

ActiveUS7243687B2Resistance in directionStrength resistanceMachine wet endPress sectionYarnEngineering

A papermaker's fabric includes a set of top machine direction yarns, a set of top cross machine direction yarns interwoven with the top machine direction yarns to form a top fabric layer, a set of bottom machine direction yarns, a set of bottom cross machine direction yarns interwoven with the bottom machine direction yarns to form a bottom fabric layer. The bottom fabric layer is stitched to the top fabric layer. The top machine direction yarns and the top cross machine direction yarns are interwoven in a series of repeat units and the bottom machine direction yarns and the bottom cross machine direction yarns are interwoven in a series of corresponding repeat units. Each repeat unit has twice the number of bottom machine direction yarns as the number of top machine direction yarns.

Owner:WEAVEXX

Barrier device with external reinforcement structure

InactiveUS20050254892A1Improve resistanceImproves Structural IntegrityTraffic restrictionsRoadway safety arrangementsEngineeringMechanical engineering

A barrier device comprises a top wall, a bottom wall, opposed end walls and opposed side walls interconnected to form a hollow interior in which a pair of spaced openings are formed which extend between the side walls. An external reinforcement structure is provided to enhance the structural integrity of the barrier device, including first and second beams each located along one of the side walls which are connected to one another by a mounting device extending through the openings in the hollow interior, or, alternatively, are mounted within a seat formed in each side wall between the opposed ends of the barrier device. The beams of one barrier device are connected end-to-end with the beams of adjacent barrier devices to form an essentially continuous wall of barriers which resist disengagement from one another and exhibit improved resistance to being broken apart upon impact by a vehicle.

Owner:TRINITY HIGHWAY PRODS

Papermaker's forming fabric with twice as many bottom MD yarns as top MD yarns

ActiveUS20050268981A1Resistance in directionTensile strength resistanceMachine wet endPress sectionYarnEngineering

A papermaker's fabric includes a set of top machine direction yarns, a set of top cross machine direction yarns interwoven with the top machine direction yarns to form a top fabric layer, a set of bottom machine direction yarns, a set of bottom cross machine direction yarns interwoven with the bottom machine direction yarns to form a bottom fabric layer. The bottom fabric layer is stitched to the top fabric layer. The top machine direction yarns and the top cross machine direction yarns are interwoven in a series of repeat units and the bottom machine direction yarns and the bottom cross machine direction yarns are interwoven in a series of corresponding repeat units. Each repeat unit has twice the number of bottom machine direction yarns as the number of top machine direction yarns.

Owner:WEAVEXX

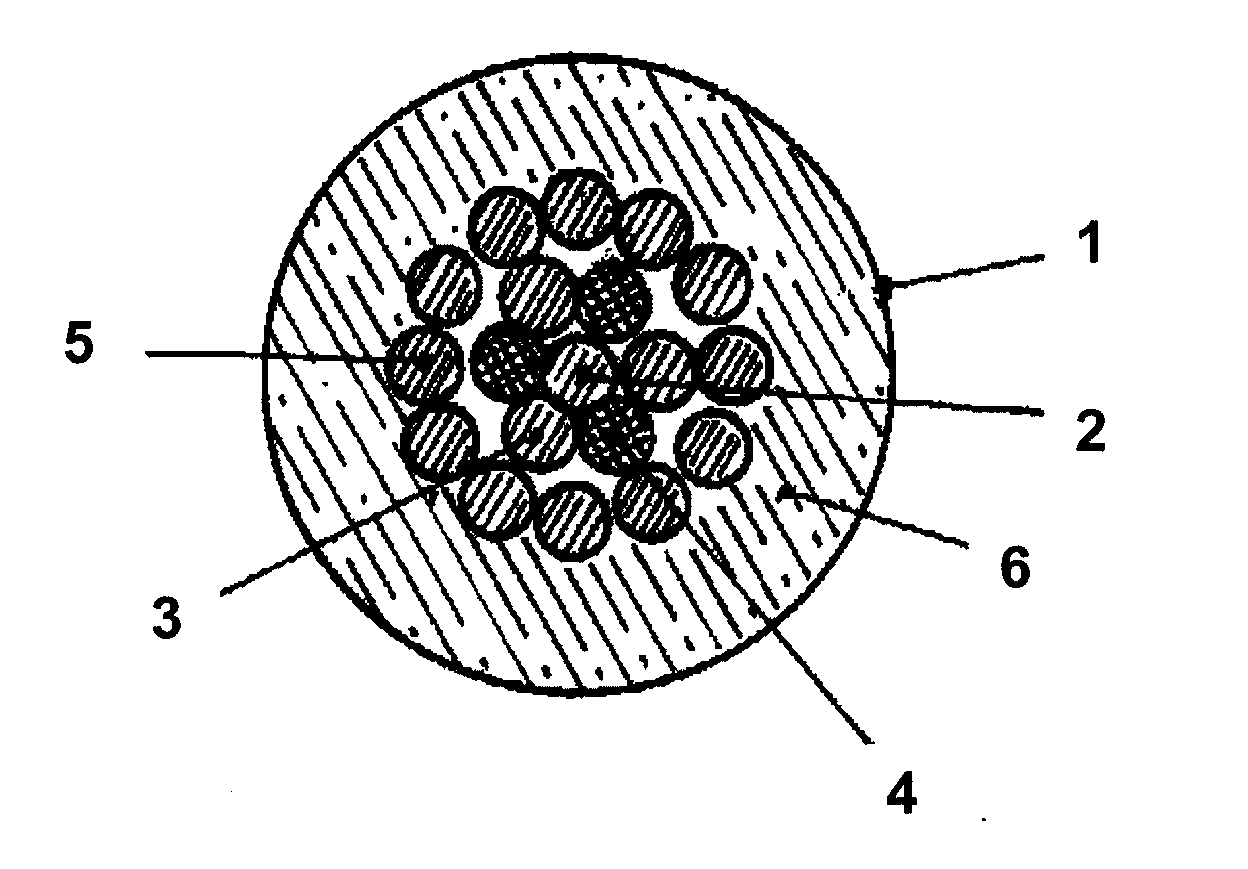

Tension-Resistant Electrical Conductor

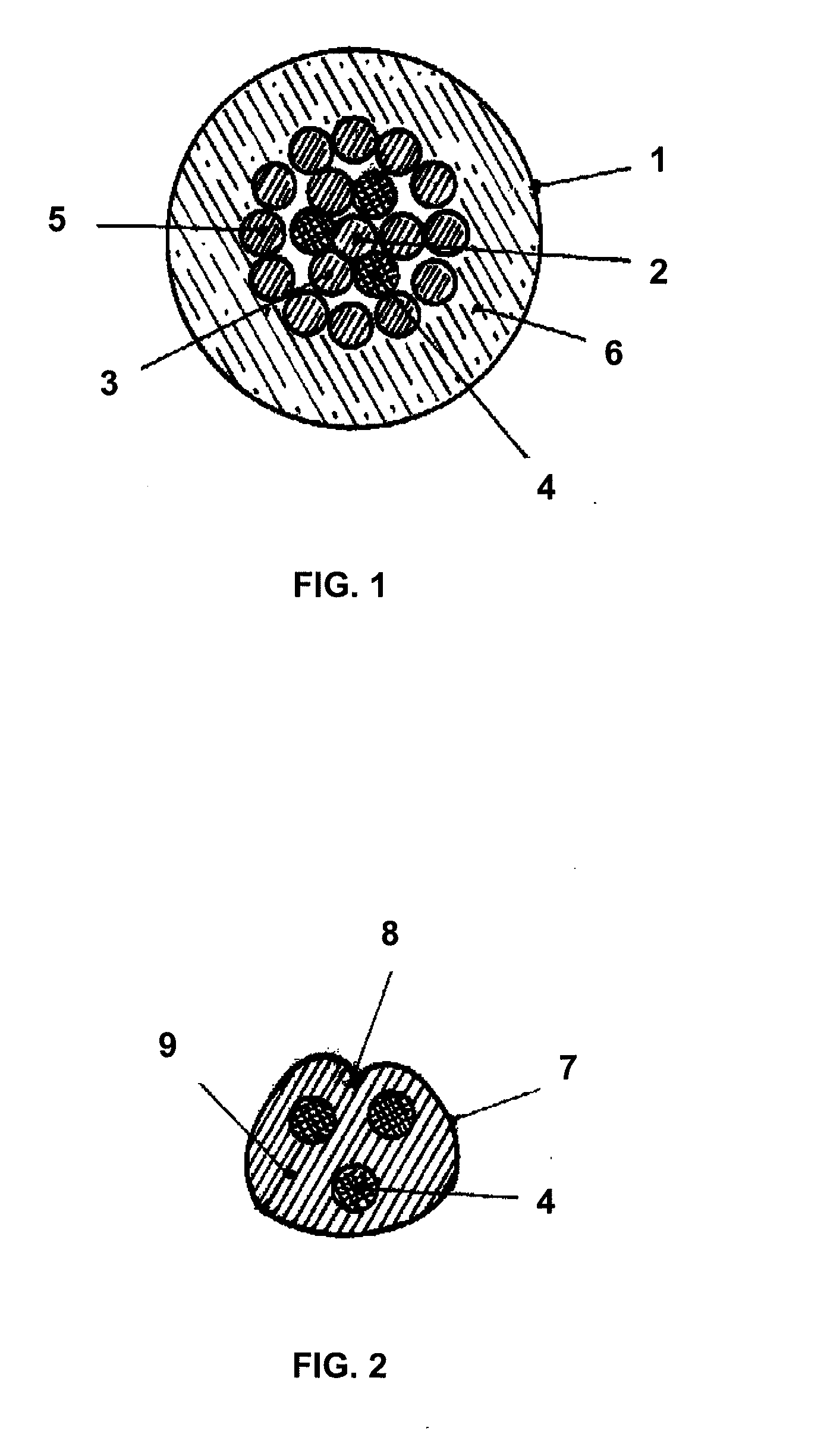

InactiveUS20110147079A1High tensile strengthGood and lasting electrical-contact connectionNon-insulated conductorsElectrically conductive connectionsElectrical conductorCopper wire

A tension-resistant electrical conductor includes a central core wire and at least a first inner wire layer and a second outer wire layer arranged over the central core wire. The central core wire is made of copper or a copper alloy. The first inner wire layer includes, in the circumferential direction, an alternating sequence of copper wires and wires having higher tensile strength, arranged over the central core wire, and the second outer wire layer, and any further outer wire layer, is composed exclusively of copper wires.

Owner:HEW KABEL

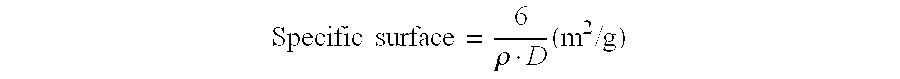

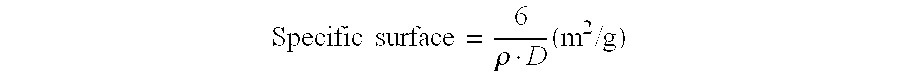

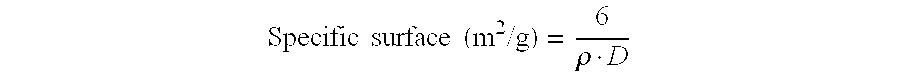

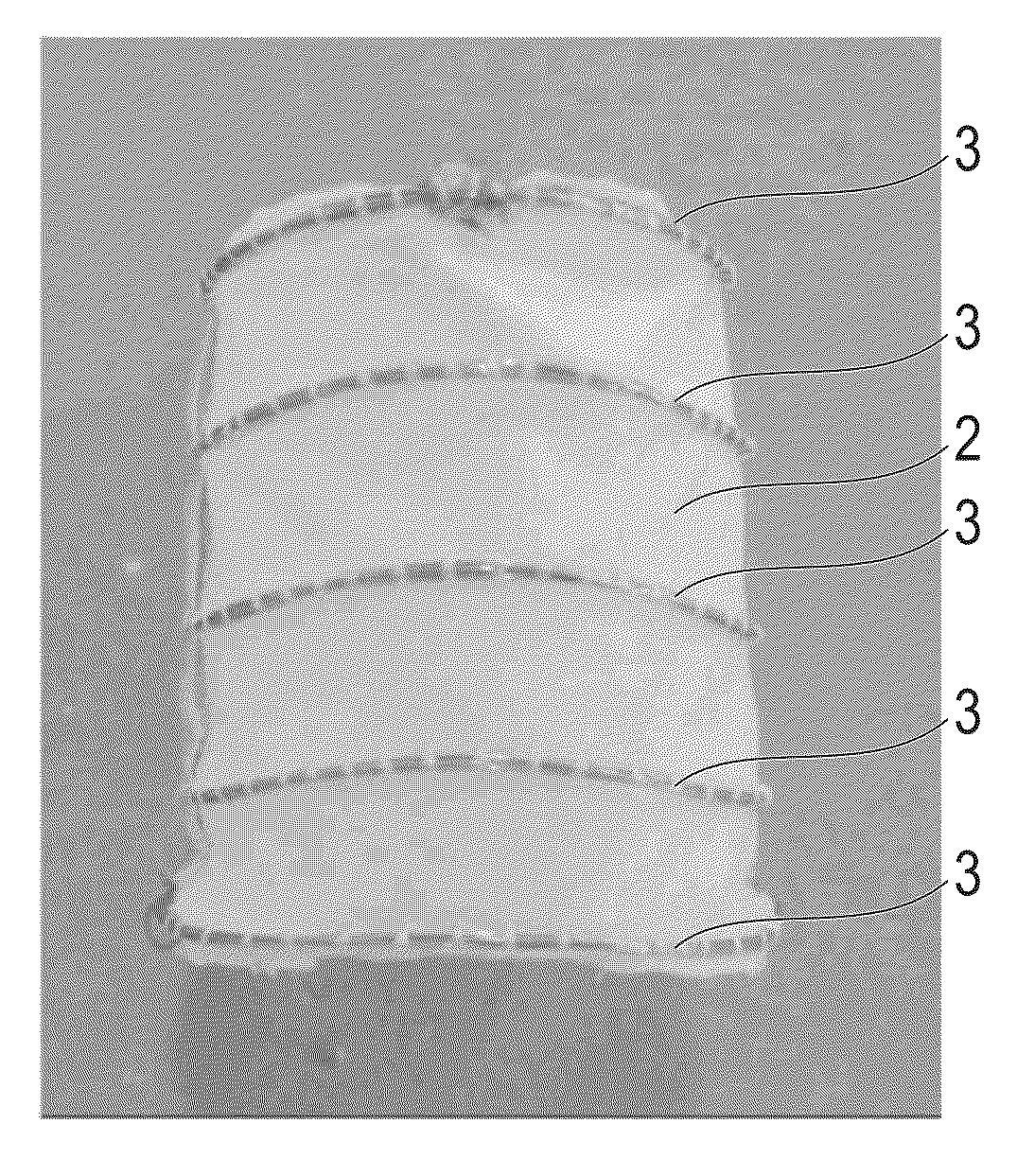

Non-woven fabric for gypsum board and process for producing the same

InactiveUS7641764B2Reduce skin irritationGood surface decorationNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberNonwoven fabric

The object of the present invention is to provide a non-woven fabric comprising a glass fiber which has a strength, flexibility and water resistance, has less skin irritancy and a good surface decoration property, and a process for producing the same, more specifically, to provide a non-woven fabric for a gypsum board which is used as a reinforcing material for a gypsum board placed on one side or both sides of the gypsum board, and a process for producing the same. A non-woven fabric for a gypsum board comprising 20 to 60% by weight of a glass fiber, 10 to 50% by weight of an organic fiber and 10 to 50% by weight of a fibrous binder, which contains the organic fiber at least on a gypsum core contact surface, is provided.

Owner:MITSUBISHI PAPER MILLS LTD

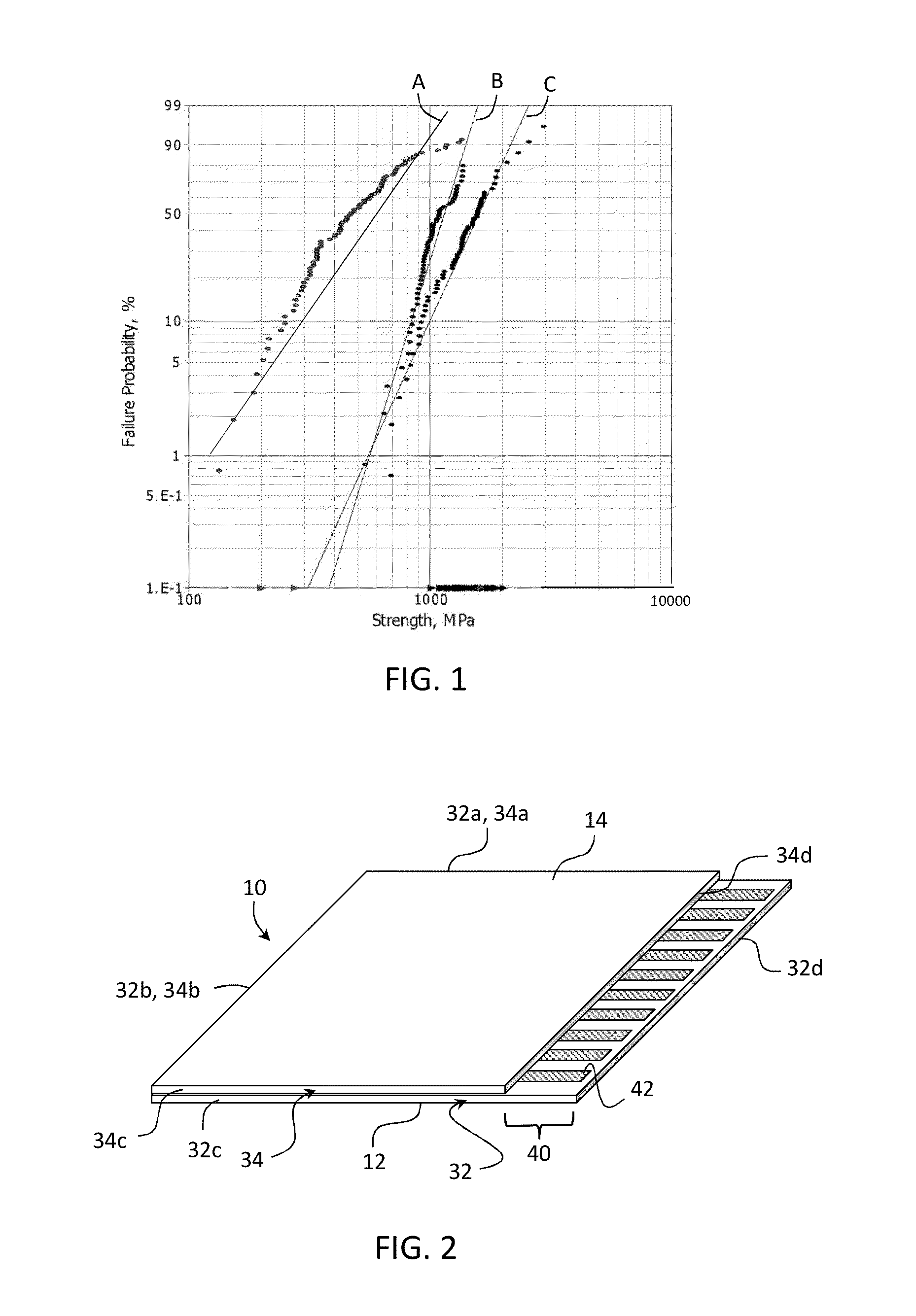

Method of strengthening an edge of a glass substrate

InactiveUS20150198838A1Reduce morbidityResist damageOptical articlesCoatingsDisplay boardEdge surface

Methods of strengthening the edge surfaces of a glass substrate, and particularly glass substrates contained within a display panel, are disclosed. The methods include exposing edges of the display panel to an acid solution for a time and at a temperature effective to remove no more than about 20 micrometers of glass from edge surfaces, rinsing the acid solution from the edge and applying a polymer protective coating the rinsed edge to maintain the post-etching strength of the edge surfaces. Electronics on the display panel that may be exposed to the acid solution are masked with a terminal mask prior to the etching. The edge etching may be combined with etching of a surface of the display panel / cover glass substrate.

Owner:CORNING INC

Heterogeneous composite bodies with isolated lenticular shapped cermet regions

ActiveUS20070141270A1Avoid insufficient heatingDetectable sizeLiquid surface applicatorsMolten spray coatingThermal sprayingSolid substrate

A heterogeneous body having ceramic rich cermet regions in a more ductile metal matrix. The heterogeneous bodies are formed by thermal spray operations on metal substrates. The thermal spray operations apply heat to a cermet powder and project it onto a solid substrate. The cermet powder is composed of complex composite particles in which a ceramic-metallic core particle is coated with a matrix precursor. The cermet regions are generally comprised of ceramic-metallic composites that correspond approximately to the core particles. The cermet regions are approximately lenticular shaped with an average width that is at least approximately twice the average thickness. The cermet regions are imbedded within the matrix and generally isolated from one another. They have obverse and reverse surfaces. The matrix is formed from the matrix precursor coating on the core particles. The amount of heat applied during the formation of the heterogeneous body is controlled so that the core particles soften but do not become so fluid that they disperse throughout the matrix phase. The force of the impact on the surface of the substrate tends to flatten them. The flattened cermet regions tend to be approximately aligned with one another in the body.

Owner:HYBRID MATERIALS LLC

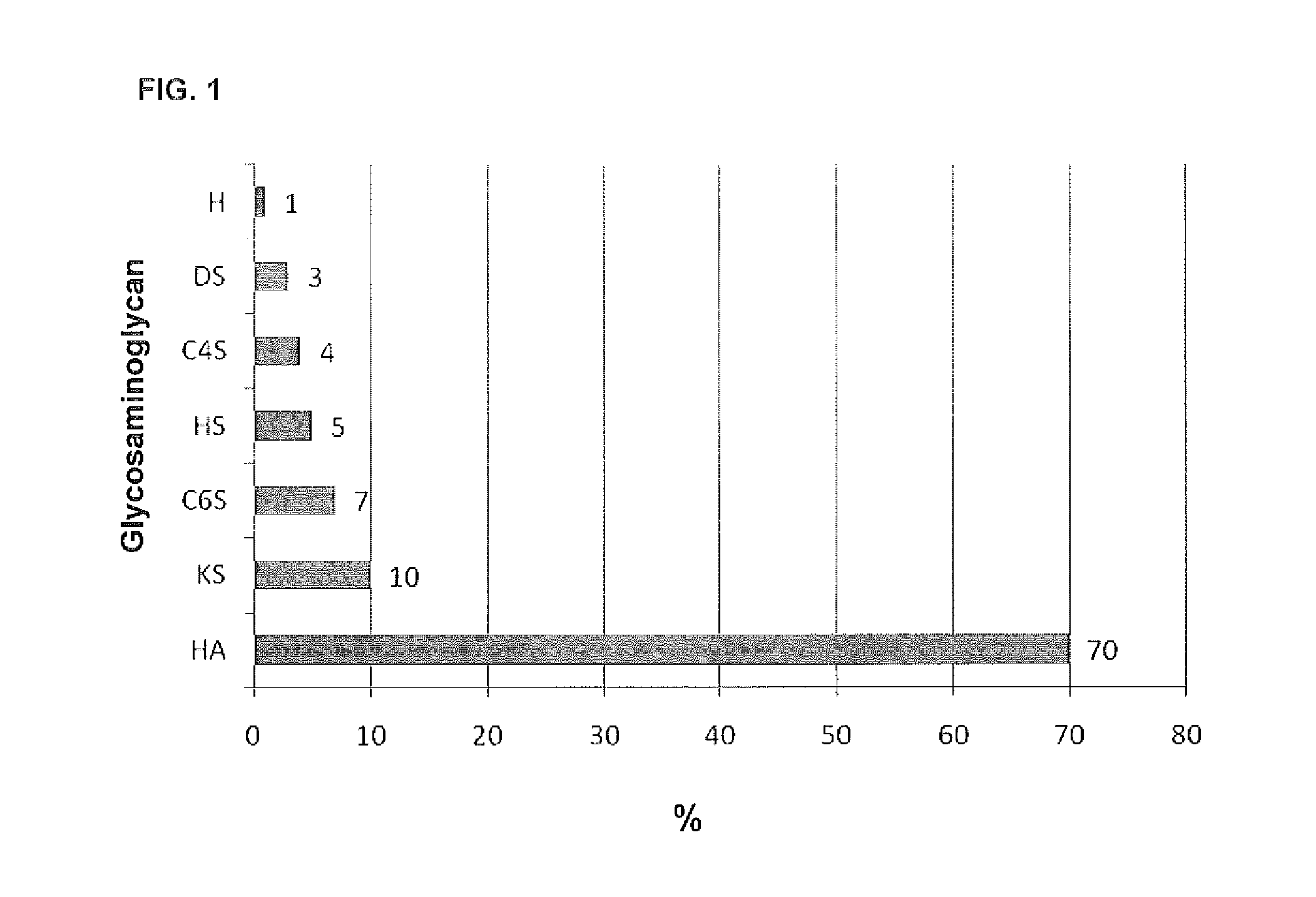

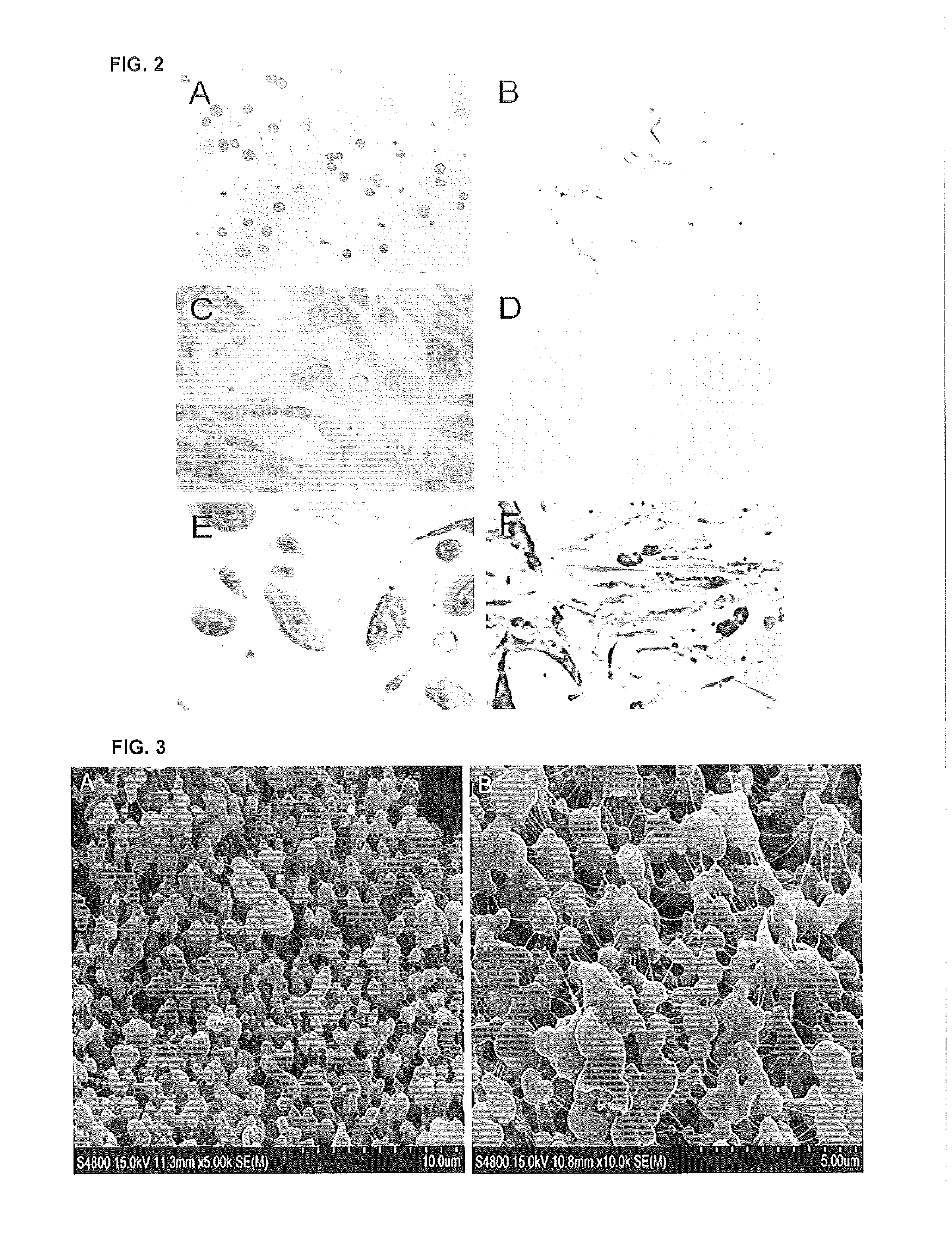

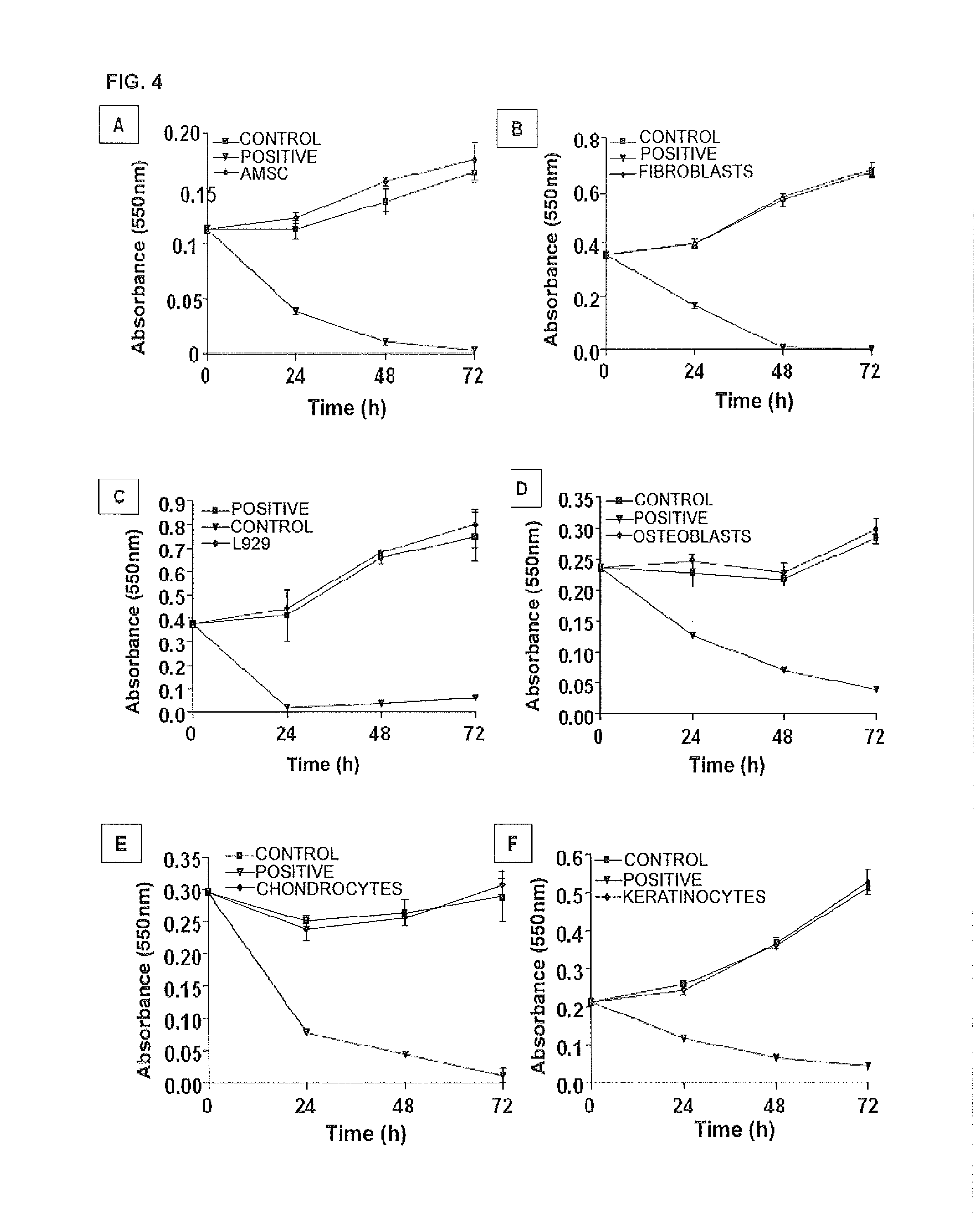

Biomaterial from wharton's jelly umbilical cord

ActiveUS20130095143A1Wide versatilityElasticity resistanceCosmetic preparationsBiocideWharton's jellyCell-Extracellular Matrix

The present invention relates to a biomaterial, specifically a hydrogel, based on the extracellular matrix of the umbilical cord for its application in regenerative medicine. The invention particularly relates to a biomaterial made up of glycosaminoglycans present exclusively in the Wharton's jelly of the umbilical cord (which can optionally be combined with cells as a combination therapy), and also to the methods for the production and use thereof.

Owner:HISTOCELL

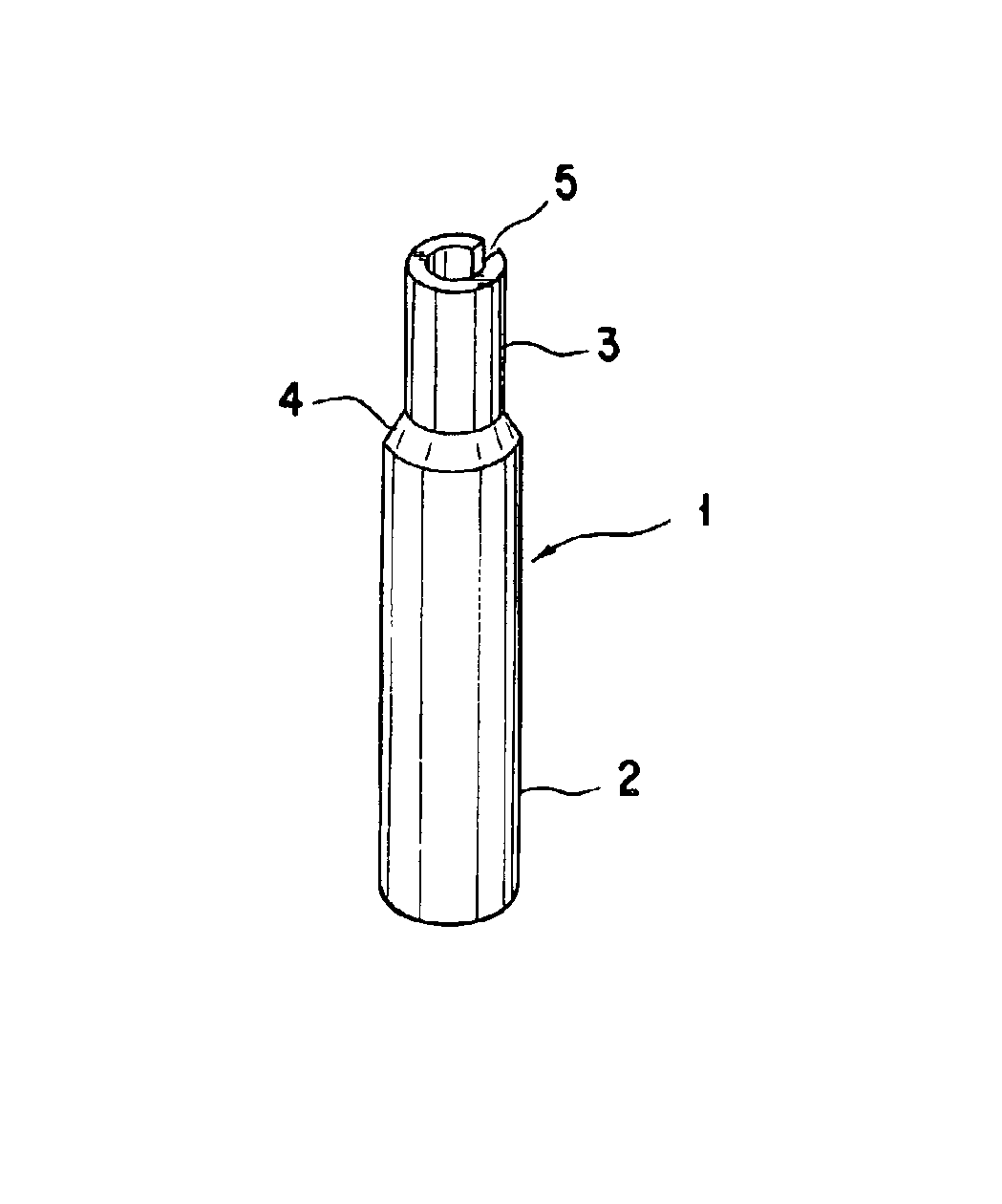

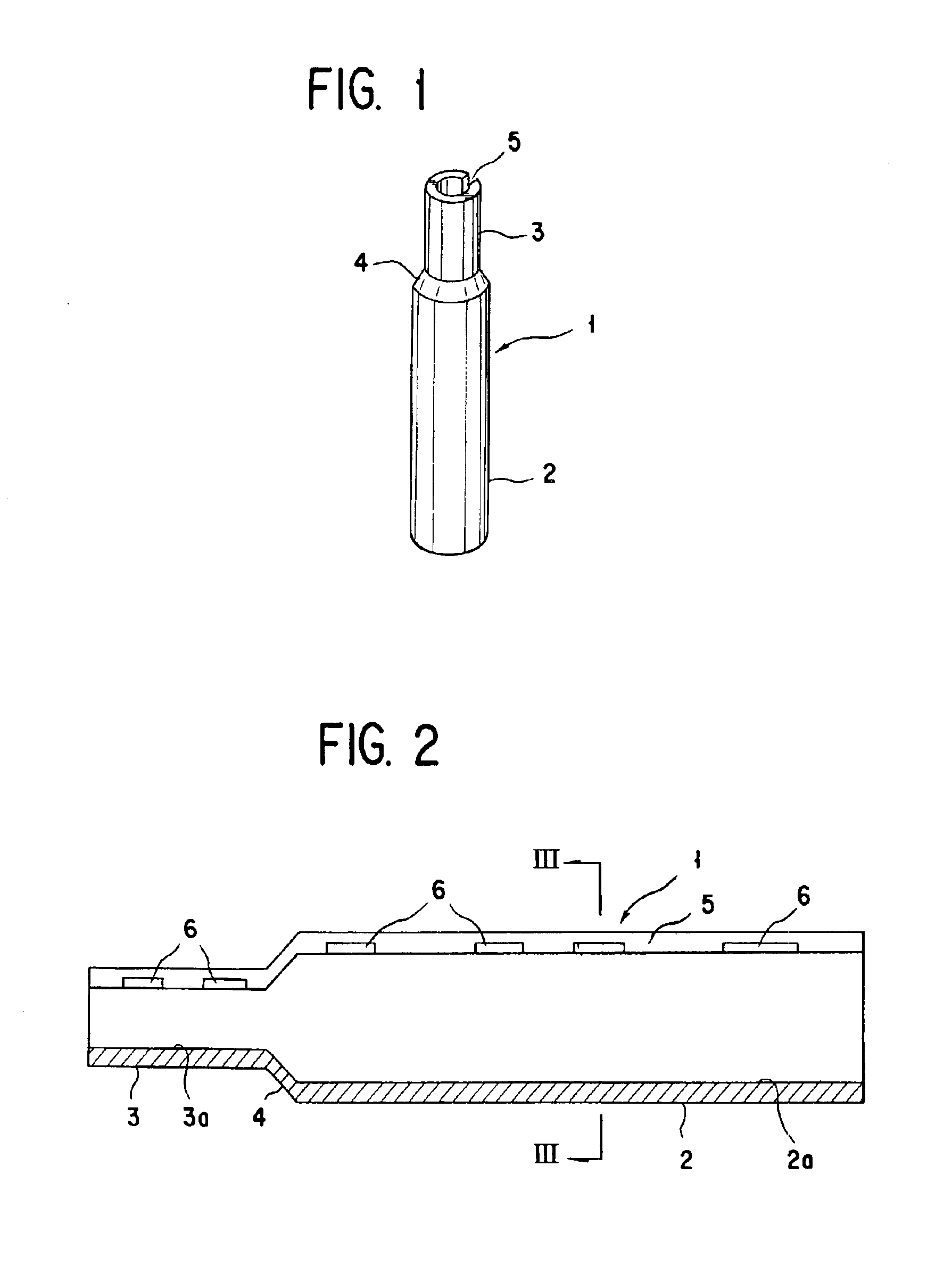

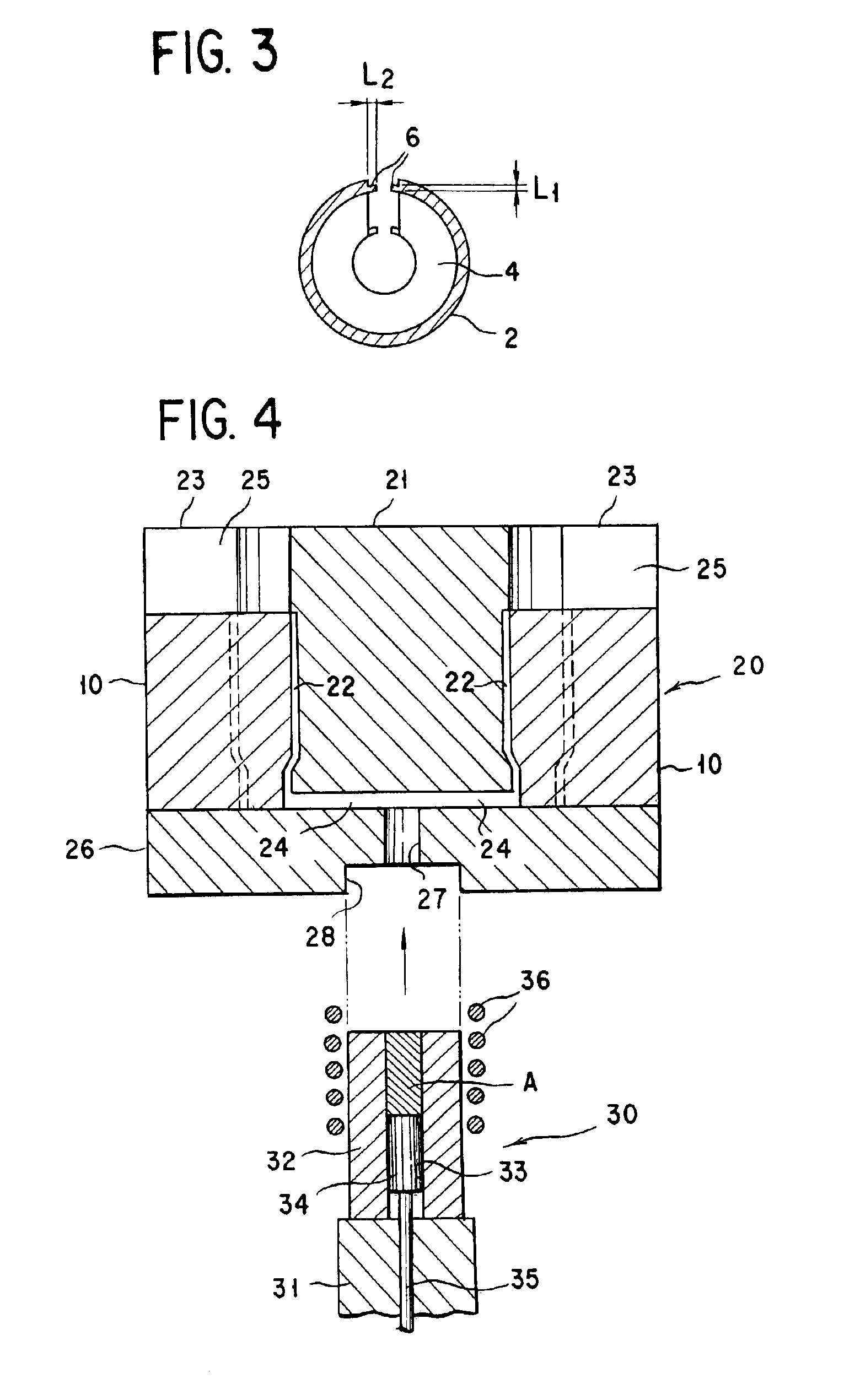

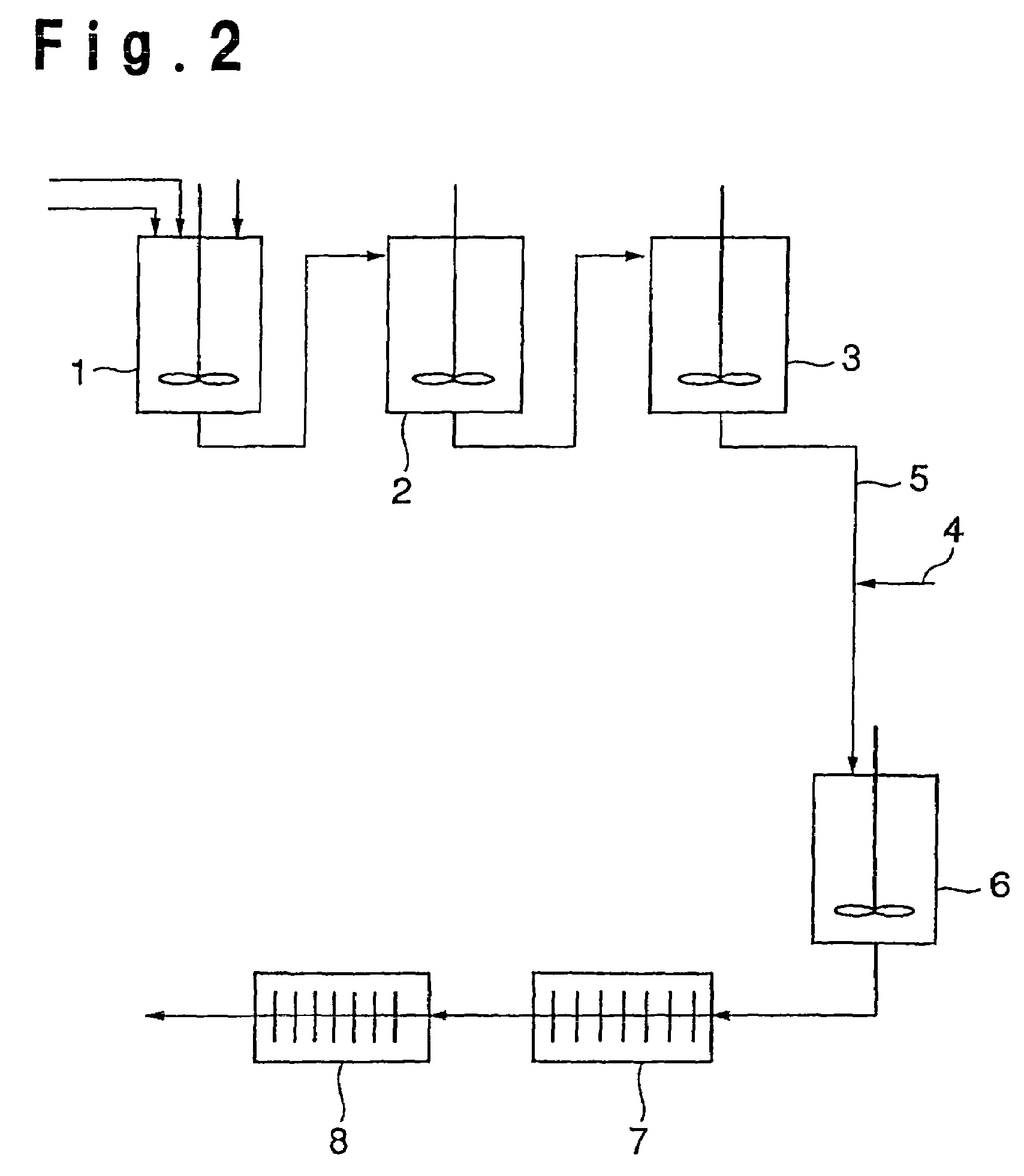

Hollow cast article with slit, method and apparatus for production thereof

InactiveUS6896417B2Improve productivityEasy to ejectFoundry mouldsOptical articlesMaterials scienceRidge

In the production of a hollow cast article having a slit, the release of a hollow cast product from a mold is carried out while opening the hollow cast product. In one embodiment, a core provided with recessed parts (or projected parts) formed in a slit forming part (or an outer peripheral part) is used and the drawing out of the core from the hollow cast product is carried out while opening the hollow cast product by means of the recessed parts (or projected parts) mentioned above. By such a method, a hollow cast article having a slit and projected parts (or recessed parts) formed in a slit part or / and an inner peripheral part thereof is obtained. In the case of the use of a core having a slit forming part of a taper-shaped ridge of which width gradually decreasing from a large width at one end to a small width at the other end, the core is drawn out from the hollow cast product in the direction to the other end of small width to open the hollow cast product by means of the slit forming part of the taper-shaped ridge.

Owner:YKK CORP

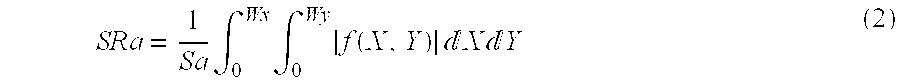

Polyolefin-based antistatic fiber, being a single component or a conjugate type fiber, and nonwoven fabric including the same

InactiveUS20130323996A1Improve antistatic performanceThin and strongElectroconductive/antistatic filament manufactureLayered productsPolymer sciencePolyolefin

A polyolefin-based antistatic fiber, wherein a polyethylene resin composition containing polyethylene resin (A) obtained using a metallocene catalyst and high molecular antistatic agent (B) forms a fiber surface, and the total amount (at 90° C. for 30 minutes) of volatile organic compounds having up to 20 carbon atoms is 10 ug / g or less. The polyolefin-based antistatic fiber may be in the form of a sheath-core type conjugate fiber in which the polyolefin resin composition forms the sheath. A nonwoven fabric formed from the polyolefin-based antistatic fiber, preferably having a defined surface resistance value, as well as a composite nonwoven fabric and formed body obtained using the nonwoven fabric are further disclosed.

Owner:JNC CORP +1

Polyester resin, molded product made thereof and process for production of polyester resin

InactiveUS7048995B2Strength resistanceTaste resistanceSynthetic resin layered productsAnimal housingShell moldingCarboxylic acid

A polyester resin produced by polycondensing a dicarboxylic acid component containing an aromatic dicarboxylic acid or its ester-forming derivative as the main component and a diol component containing ethylene glycol as the main component in the presence of at least an antimony compound and a phosphorus compound, via an esterification reaction or an ester exchange reaction, which is characterized in that the amount of antimony eluted when immersed in hot water of 95° C. for 60 minutes in the form of particles having a number average particle weight of 24 mg, is not more than 1 μg per 1 g of the polyester resin, as antimony atoms (Sb).

Owner:MITSUBISHI CHEM CORP

Drum skin for volume-reduced or electronic drums

InactiveUS20130312585A1Extended service lifeIncrease elasticityPercussion musical instrumentsPretreated surfacesPolyesterDrumhead

The invention relates to a drumhead for volume-reduced and electronic drums, comprising an elastic mesh, fixed on a drumframe and elastic colloidal coatings integrally formed on the upper and lower surfaces of the elastic mesh. The colloidal coating covers at least a part of the surfaces of the elastic mesh. The elastic mesh uses one of polyester mesh, nylon mesh, cotton-fiber and mesh. Said elastic colloidal coating is round and located at the center of the drum, and has an area of 5%-100% of the entire drumhead surface. By injecting the colloid on the mesh according to the invention, the strength, elasticity and wear resistance of the elastic mesh body can be improved, and the lifetime of the drumhead can be extended up to five times. The invention reduces the sound of the drumstick by 20 dB.

Owner:TIANJIN JINBAO MUSICAL INSTR

Electrodeposited metallic-materials comprising cobalt on iron-alloy substrates with enhanced fatigue performance

ActiveUS8367217B2Reduce resistanceEliminate security concernsEnvelopes/bags making machineryRecord information storageAlloy substrateMetallic materials

Free standing articles or articles at least partially coated with substantially porosity free, fine-grained and / or amorphous Co-bearing metallic materials optionally containing solid particulates dispersed therein, are disclosed. The electrodeposited metallic layers and / or patches comprising Co provide, enhance or restore strength, wear and / or lubricity of substrates without reducing the fatigue performance compared to either uncoated or equivalent thickness chromium coated substrate. The fine-grained and / or amorphous metallic coatings comprising Co are particularly suited for articles exposed to thermal cycling, fatigue and other stresses and / or in applications requiring anti-microbial properties.

Owner:INTEGRAN TECH

Hot-Dip Cast Aluminum Alloy Containing Al-Zn-Si-Mg-RE-Ti-Ni and Preparation Method Thereof

ActiveUS20110293467A1Reduce resistanceGood coating effectHot-dipping/immersion processesImpurityCorrosion

The invention relates to hot-dip cast aluminum alloy for anticorrosion treatment on engineering parts resistant to marine climate and a preparation method thereof, wherein said cast aluminum alloy contains Al, Zn, Si, Mg, RE, Ti, Ni and nanometer oxide particle reinforcing agent, said nanometer oxide particle reinforcing agent is selected from one or two of TiO2 and CeO2, the mass percentage of the components is as follows: Zn: 35-58%, Si: 0.3-4.0%, Mg: 0.1-5.0%, RE: 0.02-1.0%, Ti: 0.01-0.5%, Ni: 0.1-3.0%, and the total content of the nanometer oxide particle reinforcing agent: 0.01-1.0%; and the balance consists of Al and unavoidable impurities. The coating using cast aluminum alloy prepared by the invention has sufficient corrosion resistance and scour resistance in marine climate

Owner:JIANGSU LINLONG NEW MATERIALS

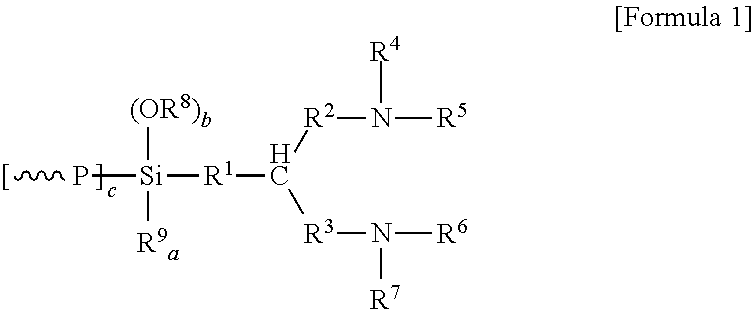

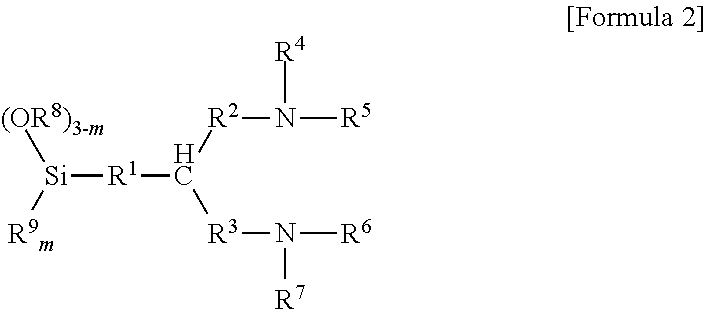

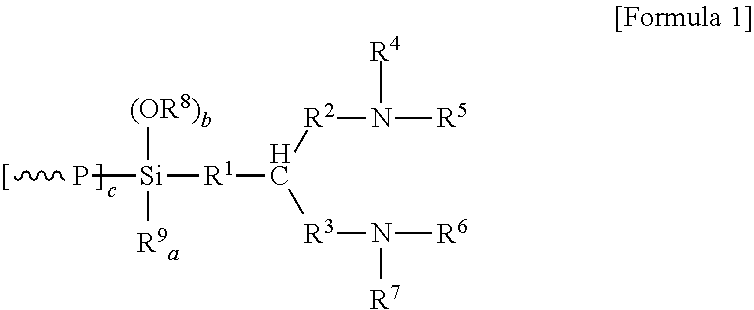

Modified conjugated diene polymer, method for preparing the same and rubber composition comprising the same

ActiveUS9422417B1Improve compatibilityReduce fuel consumptionGroup 4/14 element organic compoundsSpecial tyresPolymer scienceUltimate tensile strength

Disclosed is a modified conjugated diene polymer represented by Formula 1. Advantageously, provided are a modified conjugated diene polymer which exhibits superior compatibility with a reinforcing filler, heat generation, tensile strength and abrasion resistance, low fuel consumption and excellent wet skid resistance, a method for preparing the same and a rubber composition comprising the same.

Owner:LG CHEM LTD

Improved natural rubber compositions

There is herein described improved natural rubber compositions having nanocarbon and carbon black as reinforcing agents wherein the nanocarbon is uniformly pre-dispersed within the rubber component. In particular there is described rubber compositions comprising a mixture of natural rubber, nanocarbon and carbon black wherein the relative amount in parts per hundred rubber (pphr) of nanocarbon to carbon black is in the range of about 1:40 to about 1:2 and the relative amount in parts per hundred rubber (pphr) of nanocarbon to natural rubber is in the range of about 1:100 to about 10:100 and wherein the nanocarbon component is pre-dispersed within the natural rubber component.

Owner:AMRIL

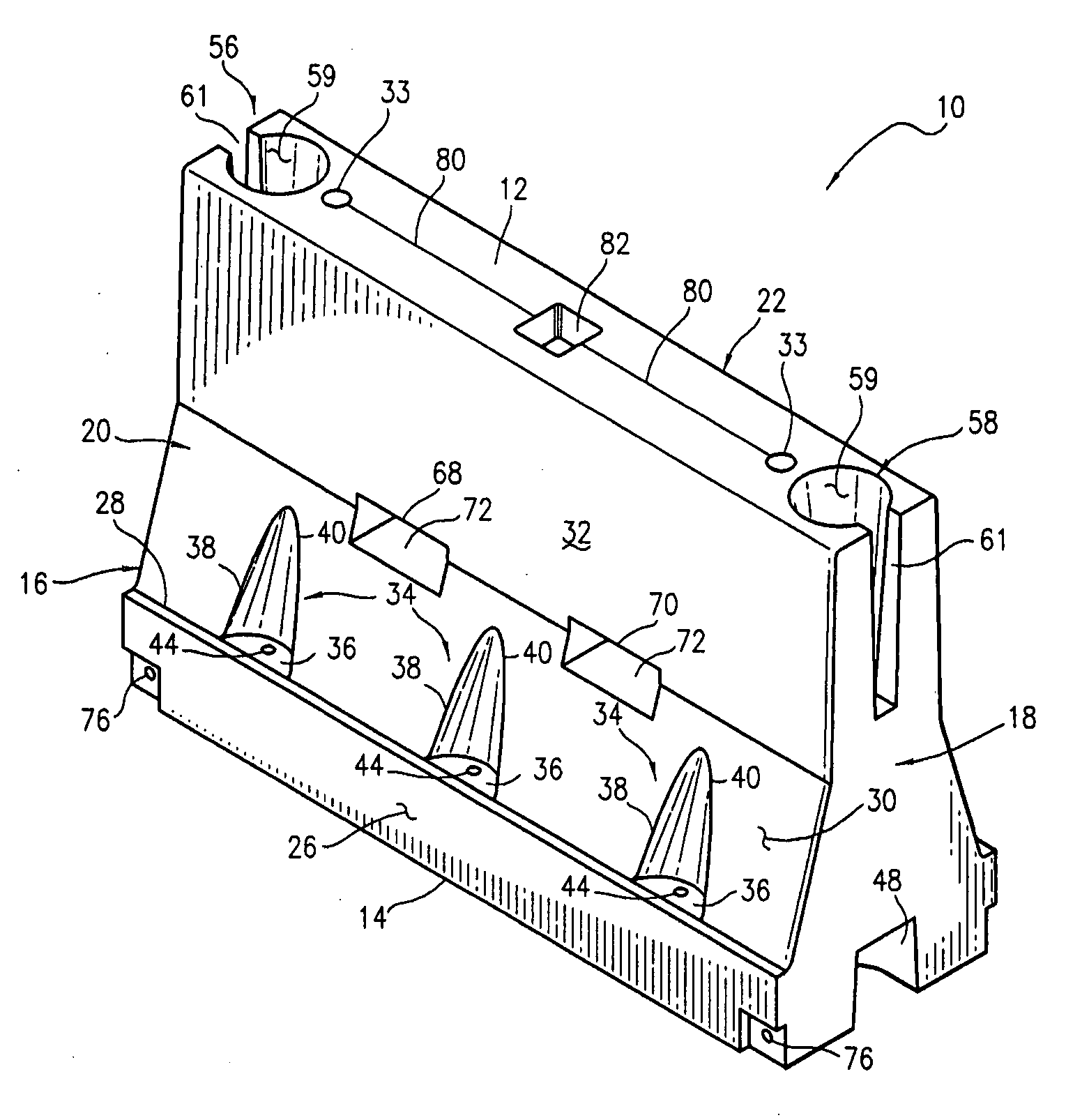

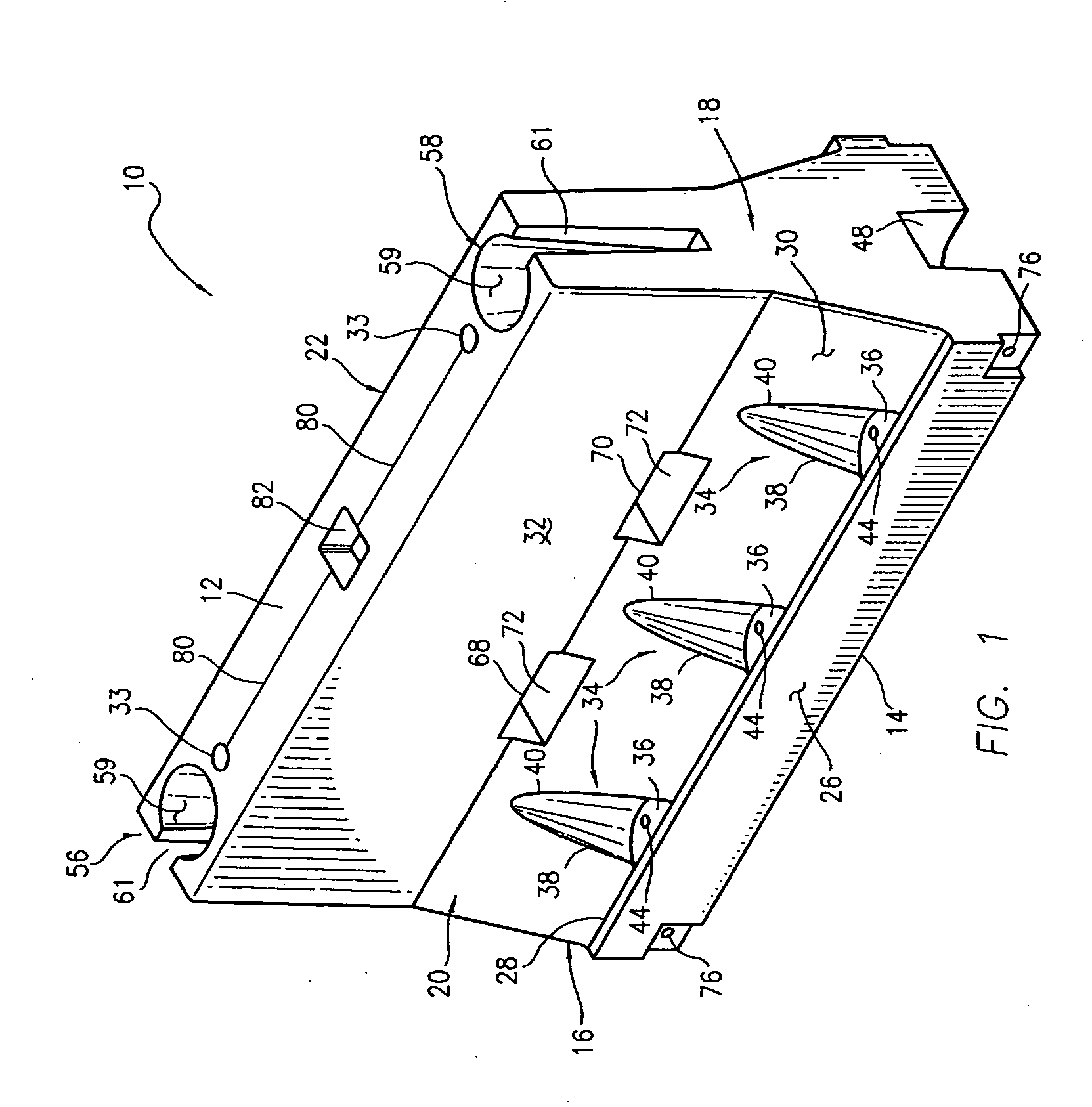

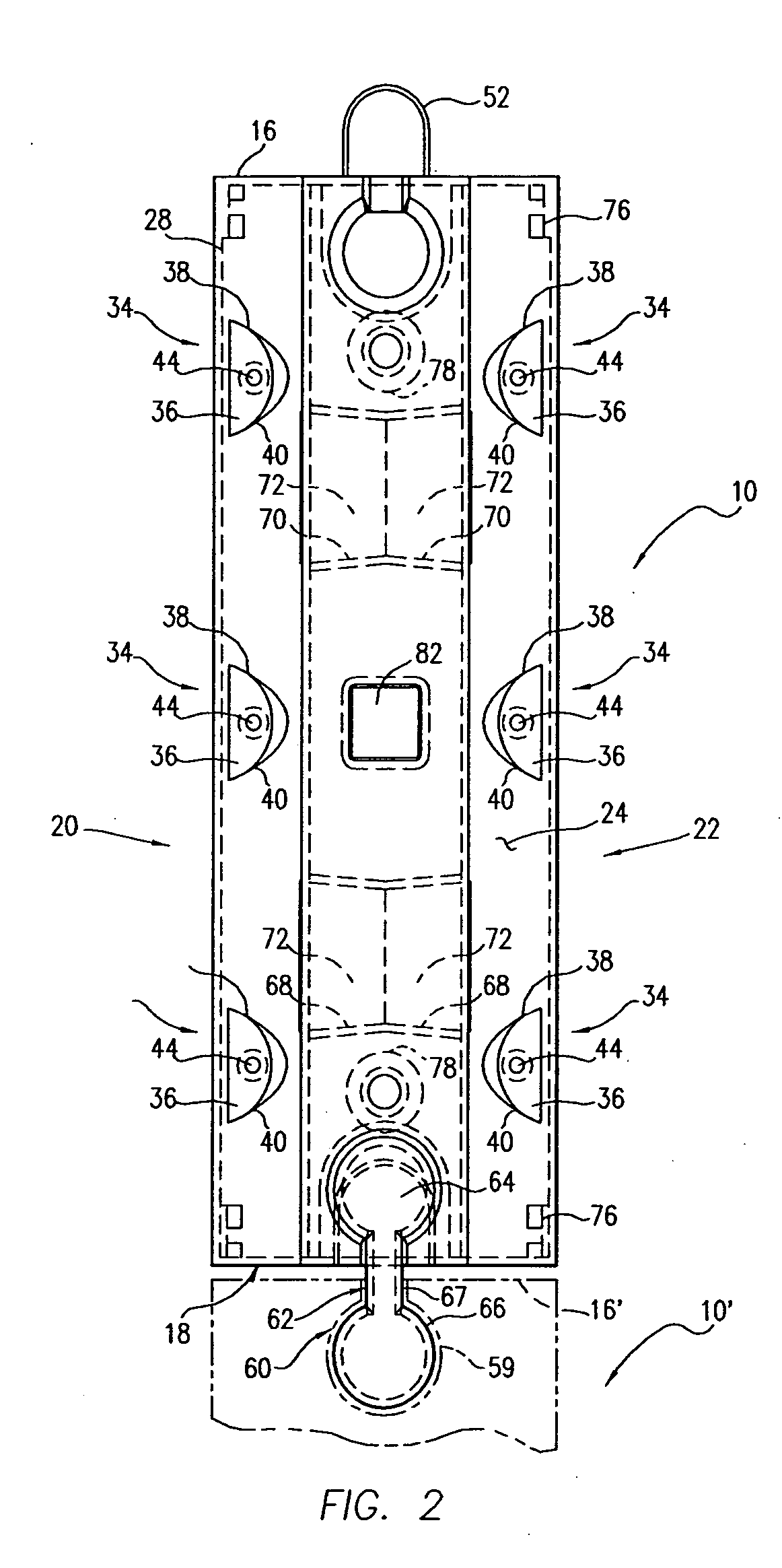

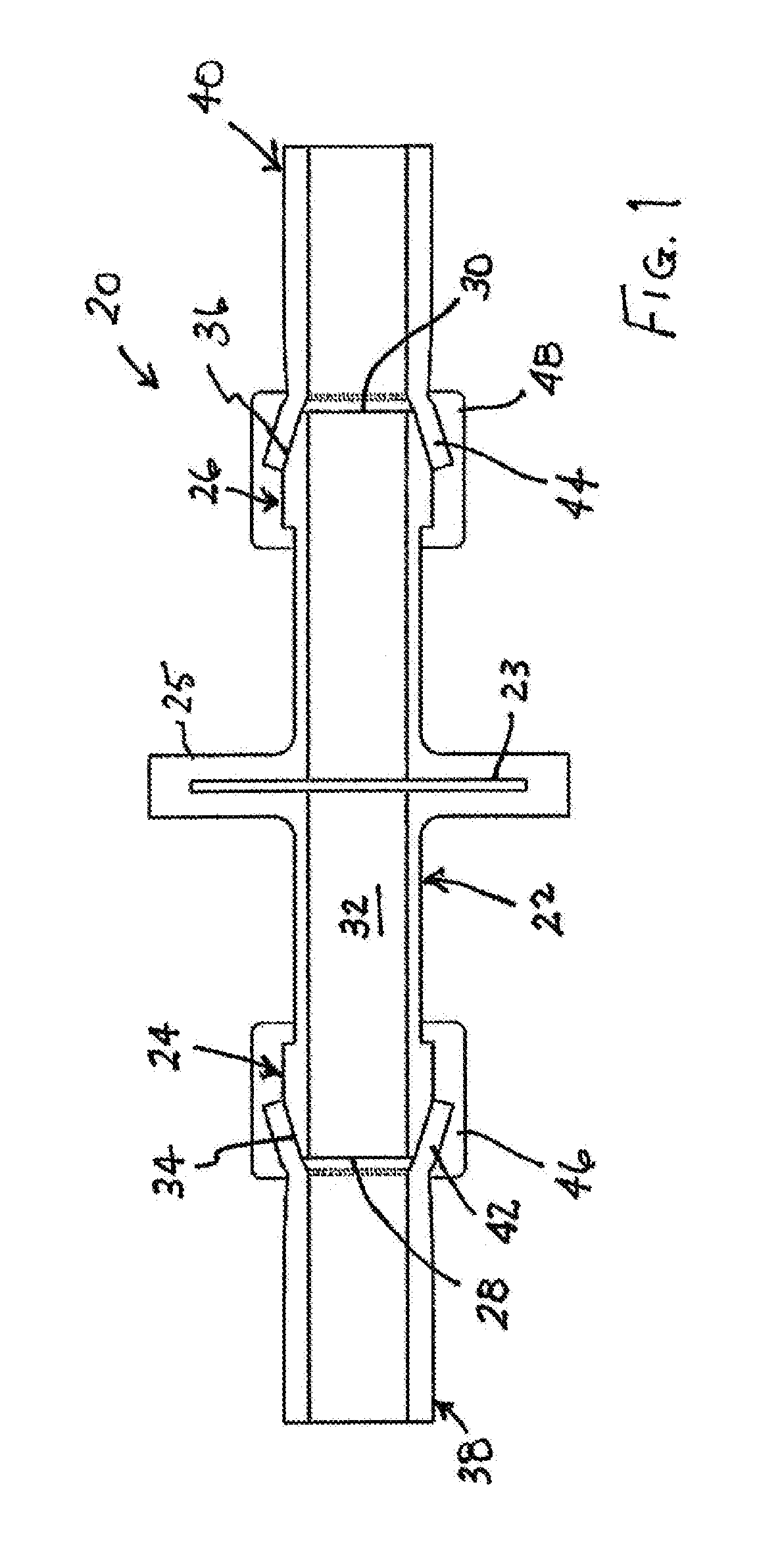

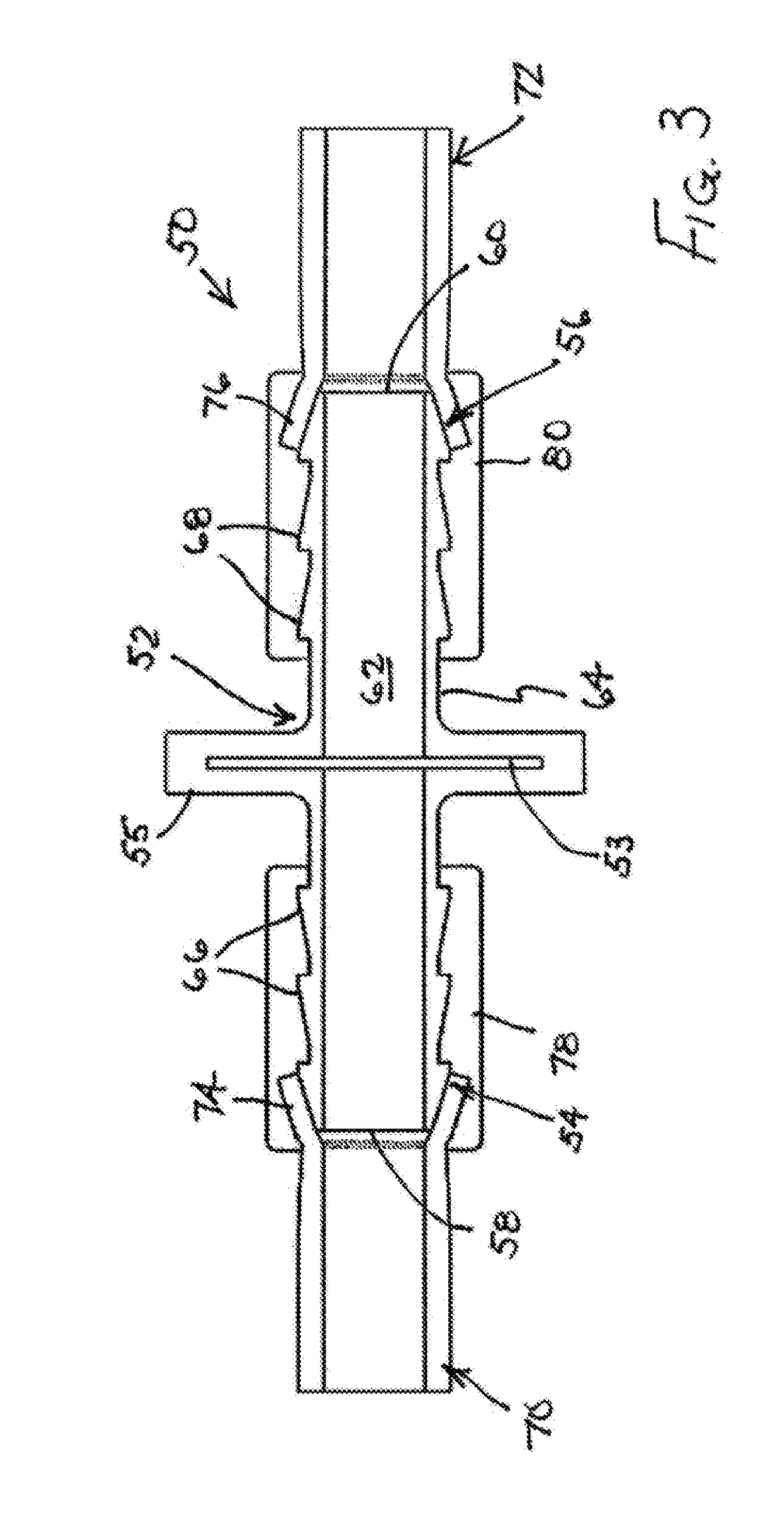

Coupling

InactiveUS20080235909A1Resist impactStrength resistancePin hingesWing suspension devicesCouplingEngineering

Disclosed is a coupling, comprising a coupling arm, the coupling arm having an attachment portion adapted to be affixed with a first article, and an anchor portion. The coupling further comprises a receptacle adapted to be affixed with a second article, the receptacle comprising one or more walls defining an interior cavity, adapted to retain at least the anchor portion of the coupling arm. The receptacle further includes an opening adapted to allow the coupling arm to extend therethrough, wherein the attachment portion of the coupling arm is moveable with respect to the opening.

Owner:ACIN 1

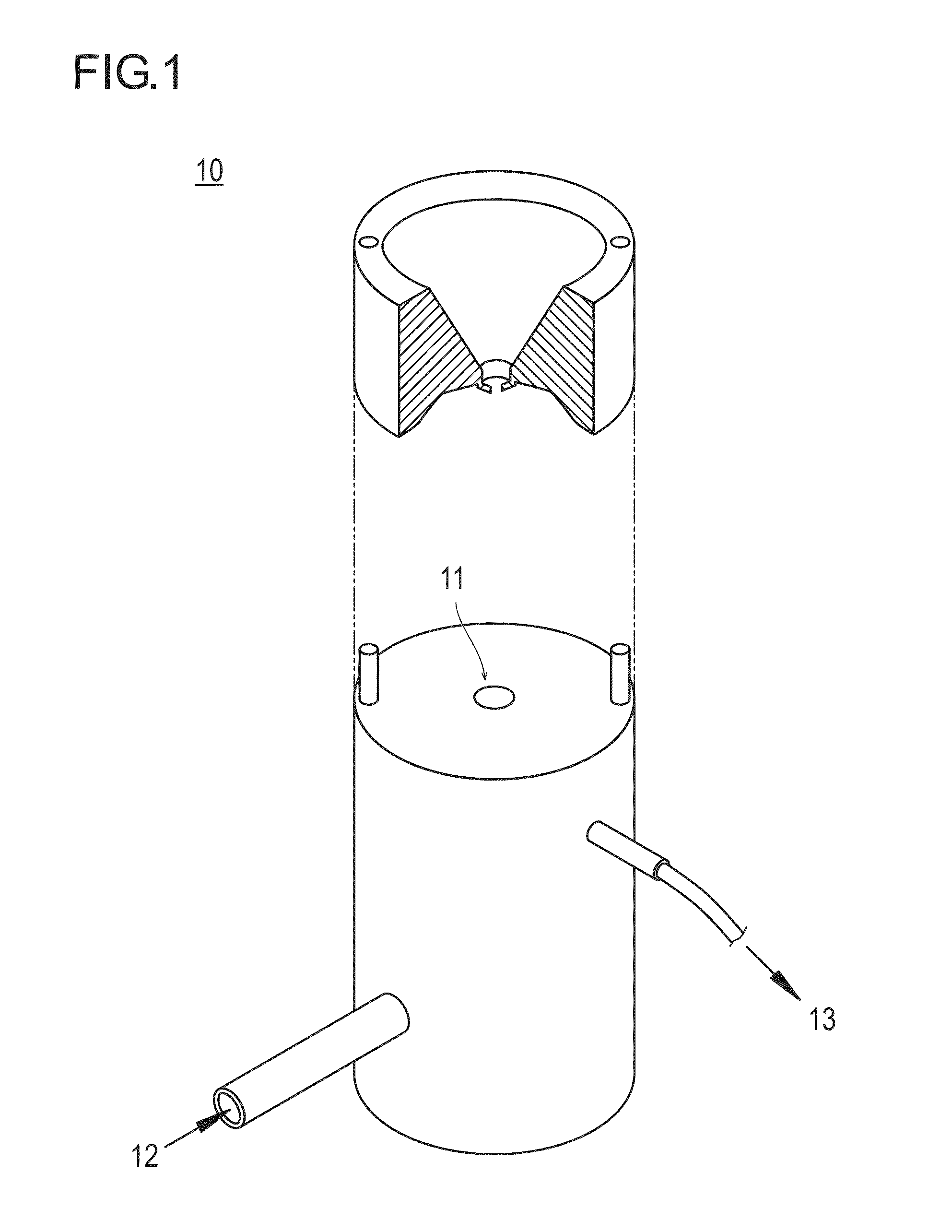

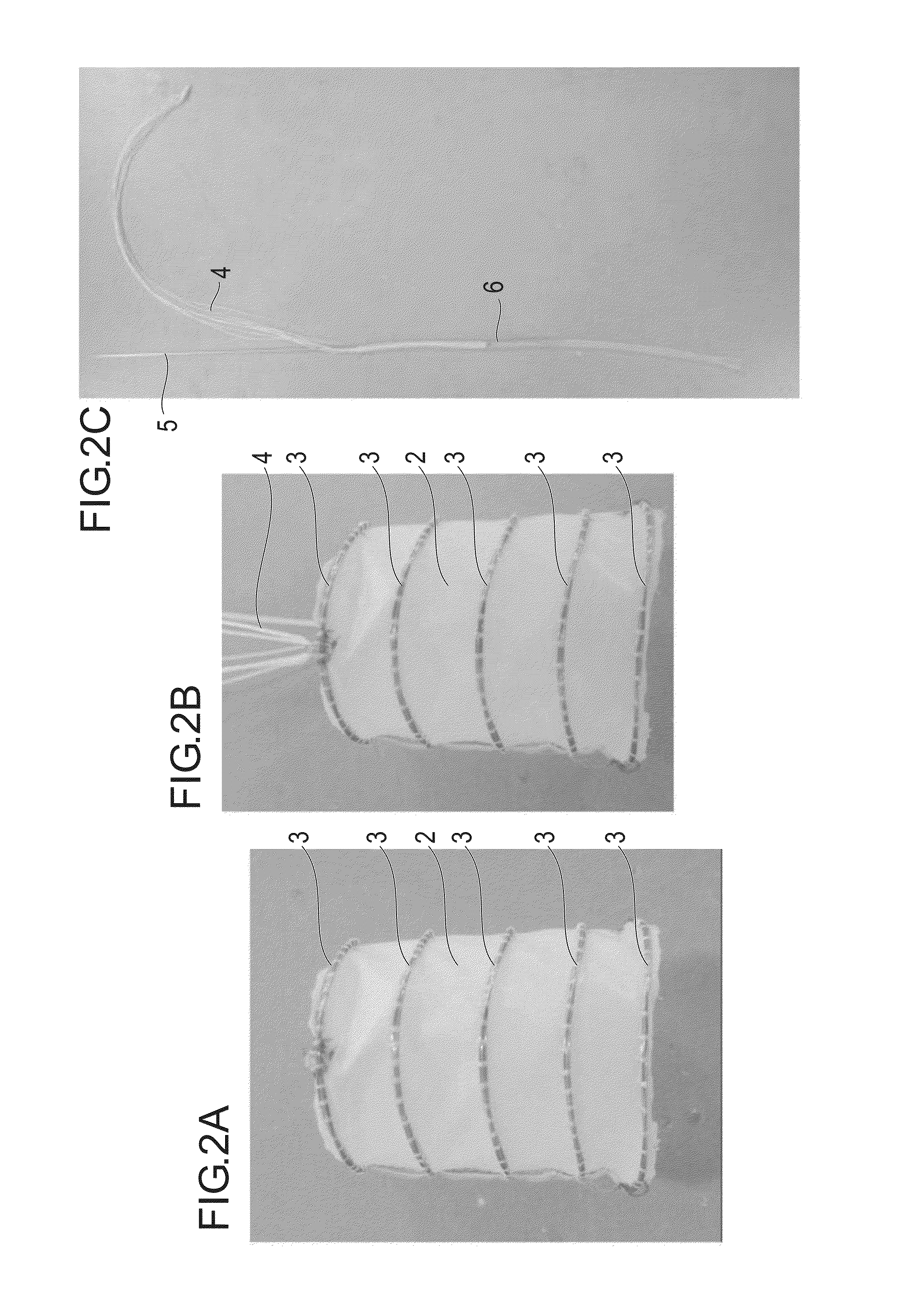

Body lumen graft base, production method of body lumen graft base, and body lumen graft using the same

InactiveUS20160135944A1Sufficient flexibilityReduce penetrationStentsSurgerySingle fiberTreatment use

The present invention provides a body lumen graft base that is a thin film, has adequate flexibility and low permeability, and can be inserted in a catheter with a small diameter. The body lumen graft base of the present invention is obtained by subjecting at least one surface of a woven fabric comprising a fiber having a total fineness of 1 to 80 decitex and a single fiber fineness of less than 0.1 decitex to press treatment using a calender machine.

Owner:TERUMO KK +1

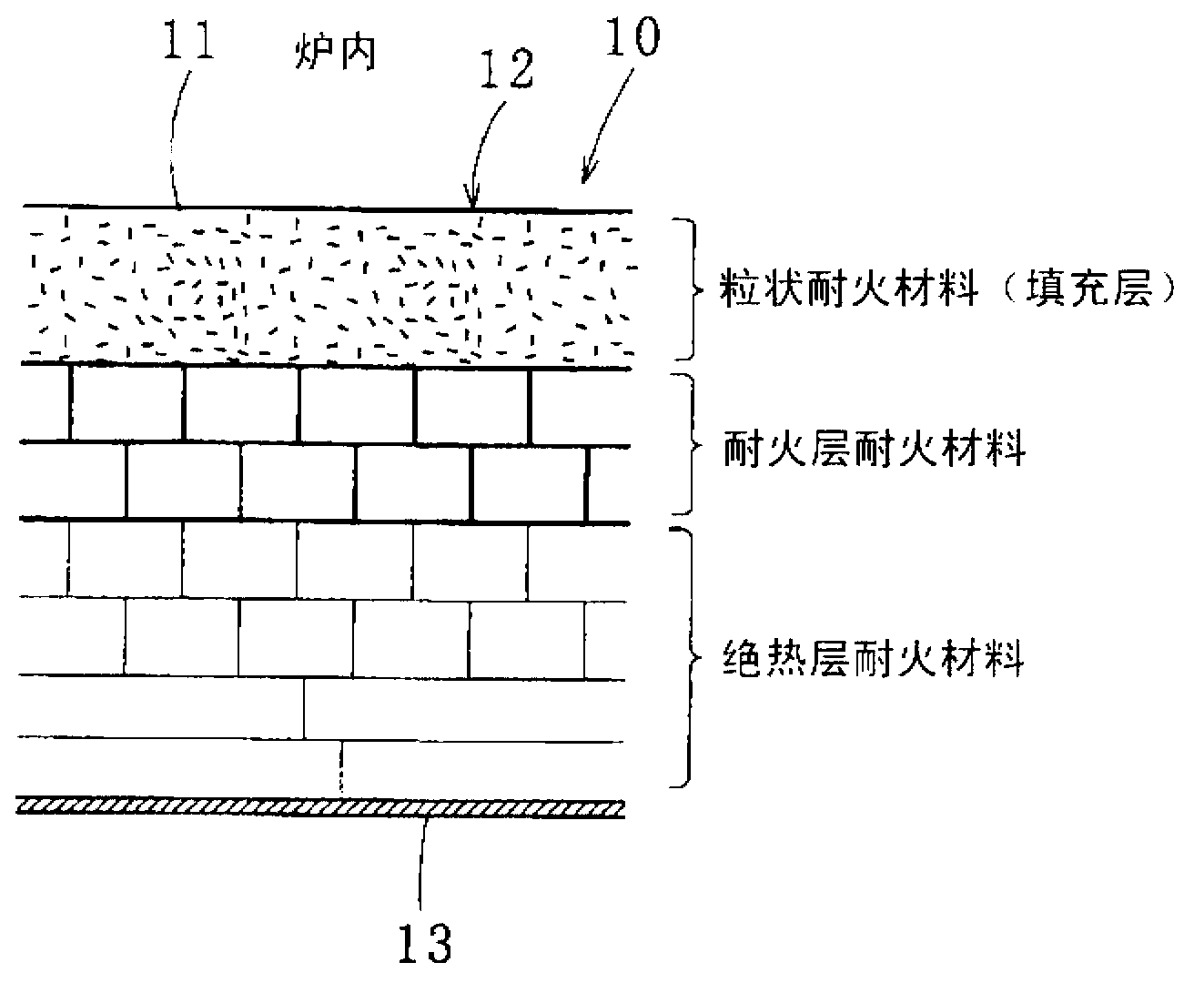

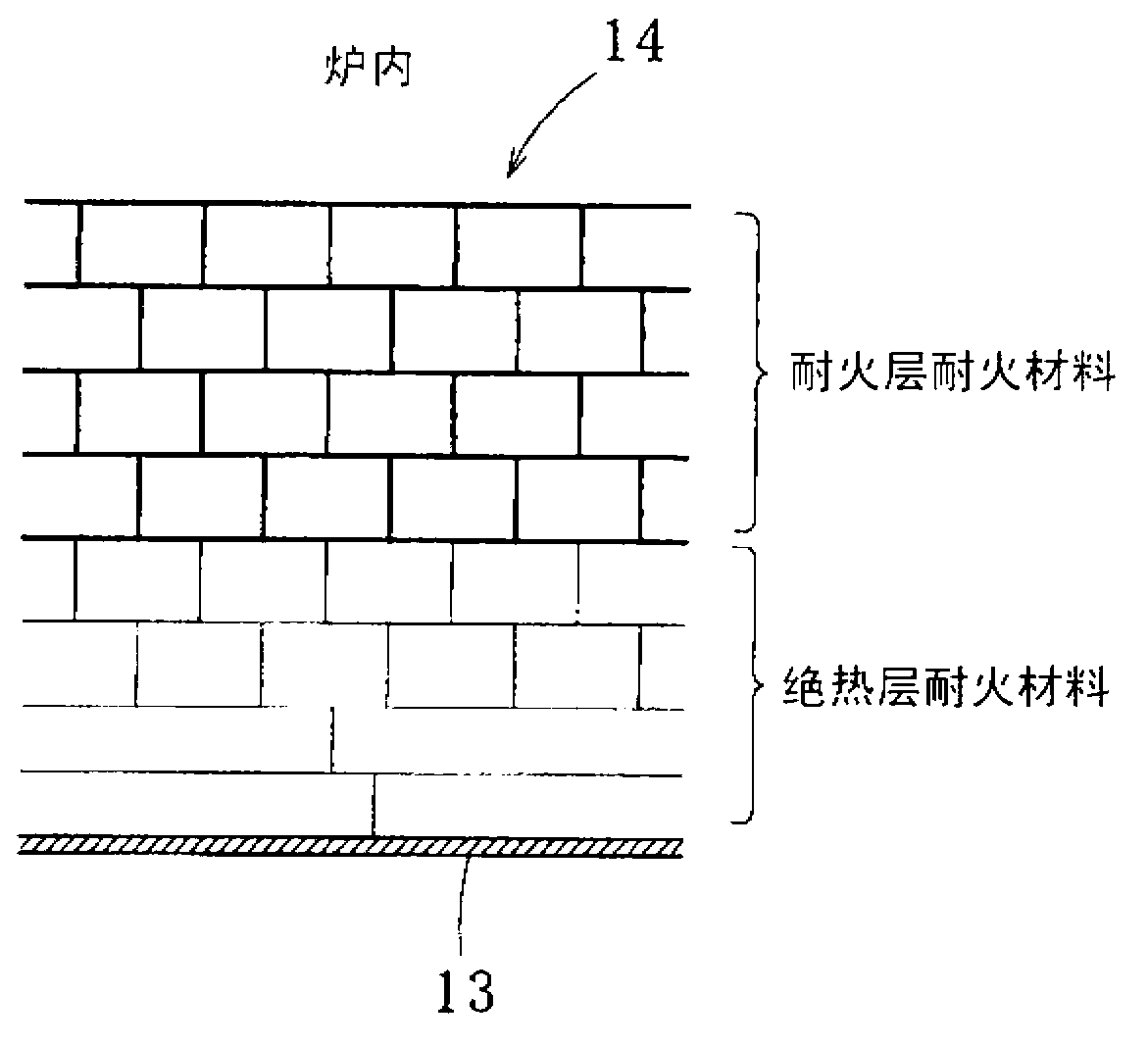

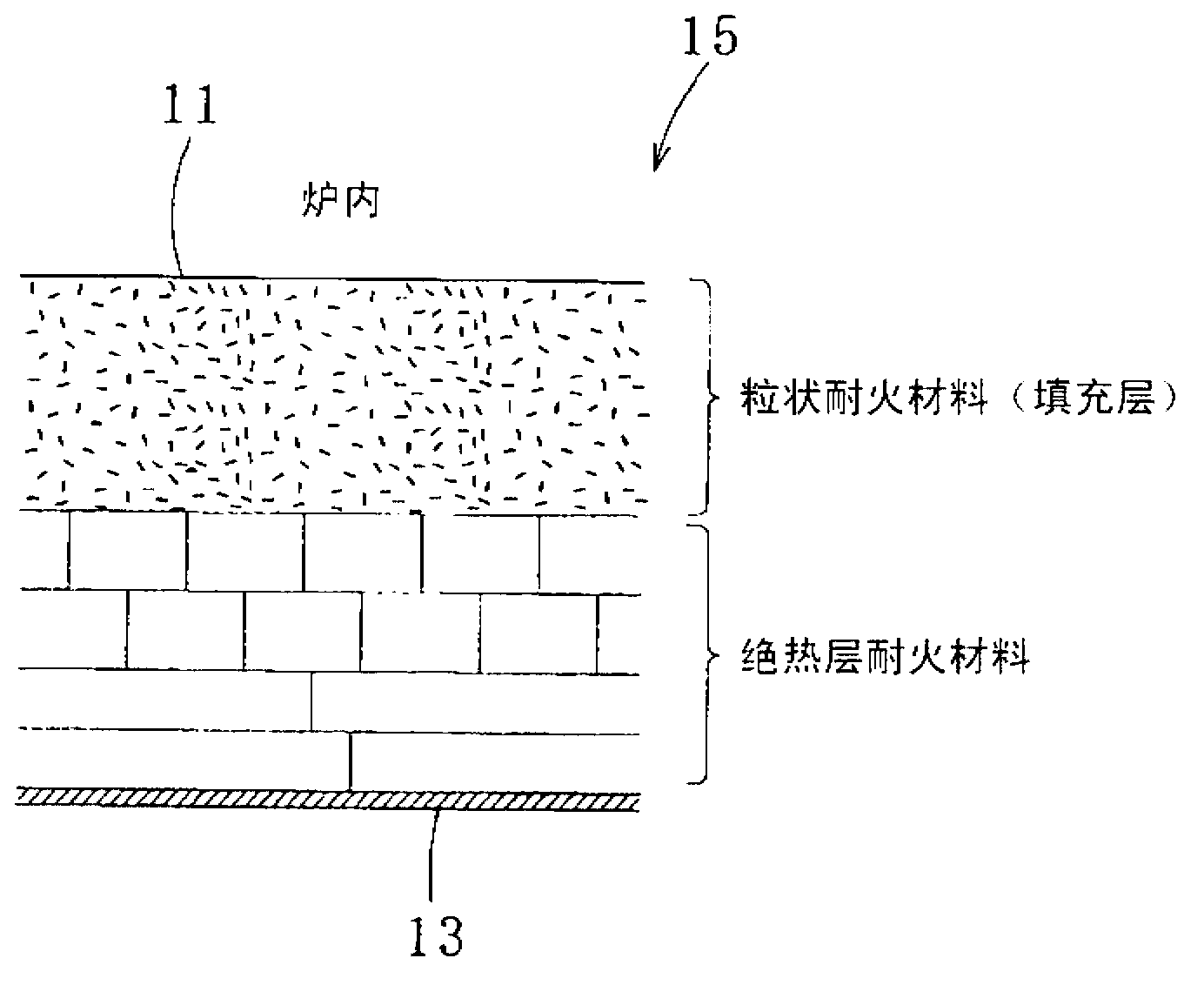

Heat treatment furnace for metal chunk, method for repairing heat treatment furnace for metal chunk, and method for producing infill for hearth used for heat treatment furnace for metal chunk

ActiveCN103109149ASuppresses decline in fire resistance or thermal insulationPrevents degradation of fire resistance or thermal insulationLinings repairMetalFilling rate

Provided is a heat treatment furnace for a metal chunk, provided with a hearth structure having a filling layer of granular refractory on the furnace operation surface side, wherein the filling rate of the granular refractory is 65-100 volume %, and the thickness of the filling layer is more than twice the maximum gain size of the granular refractory.

Owner:NIPPON STEEL CORP

Connector and tubing assembly and method of molding connector and tubing assembly

ActiveUS20190009479A1Smoother transitionConnection securityDispersed particle filtrationMedical devicesBiomedical engineering

An overmolding method for forming joints in a fluid-flow apparatus utilizes a connector or fitting as a component for mold forming. The connector or fitting is not removed after the overmolding and thus forms part of the joint assembly.

Owner:SANI TECH WEST INC

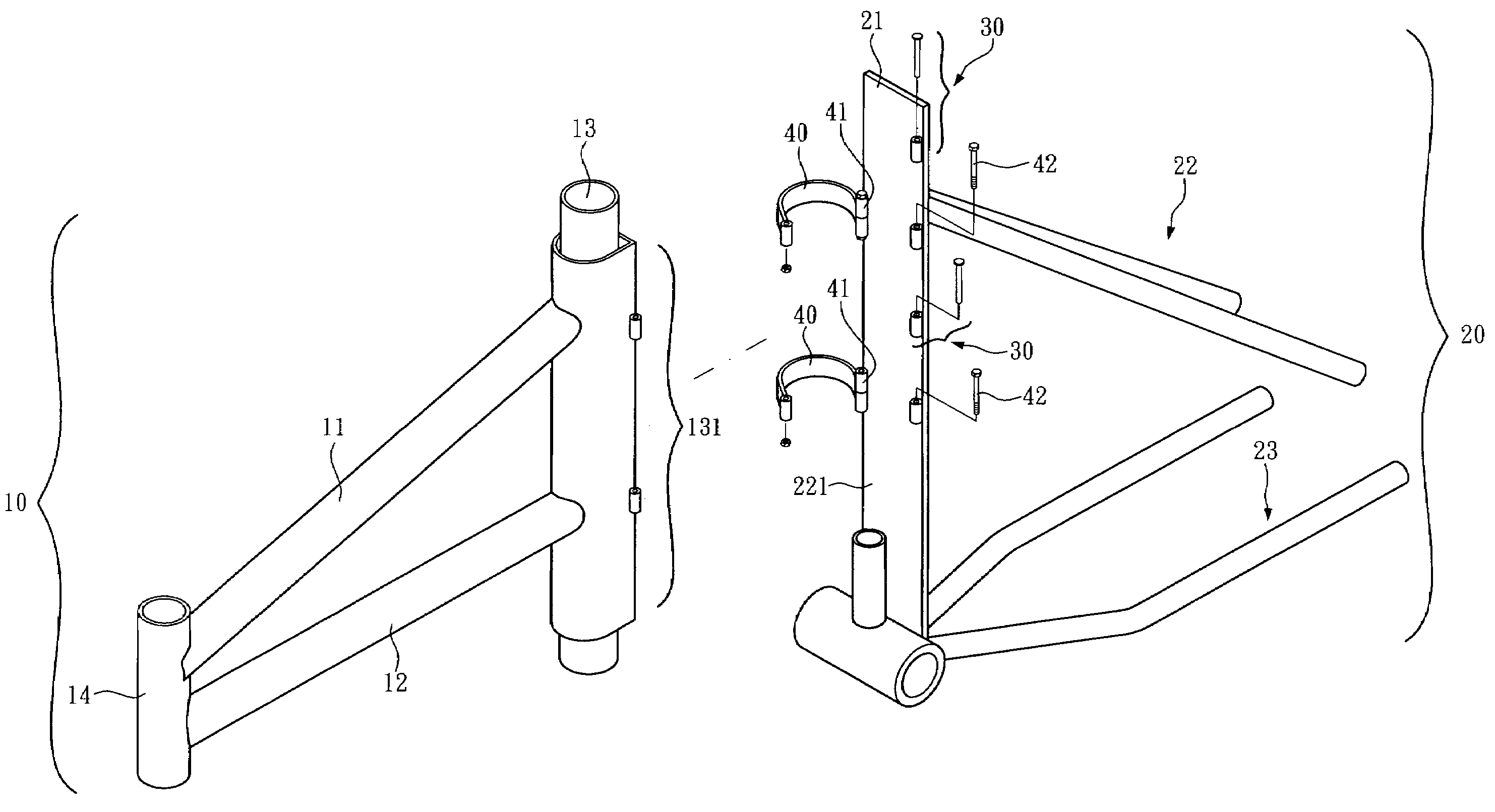

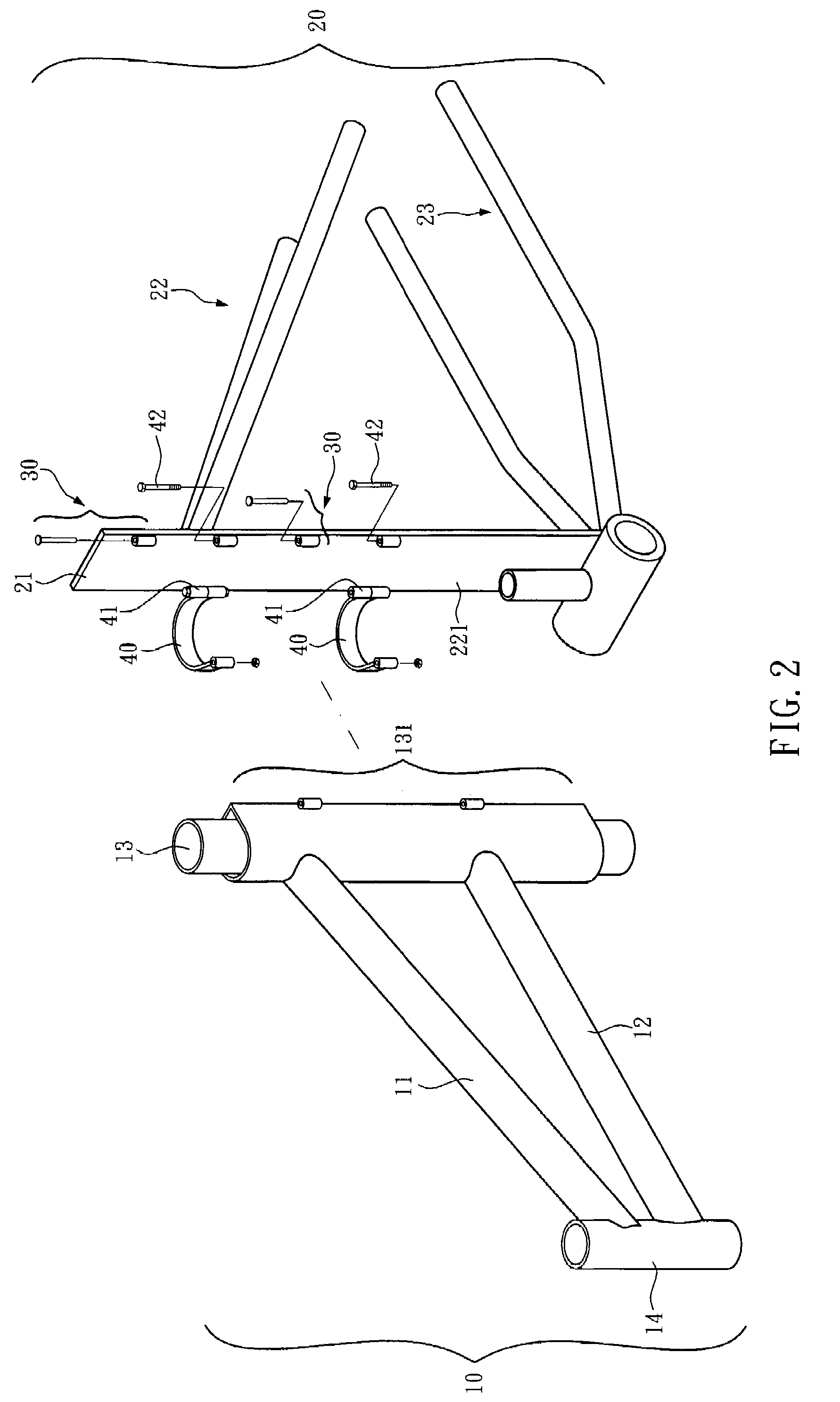

Folding mechanism

ActiveUS7669872B2Bicycle be folded or expandedStrength resistancePassenger cyclesWheel based transmissionEngineeringMechanical engineering

Owner:CYCLING & HEALTH TECH IND R & D CENT

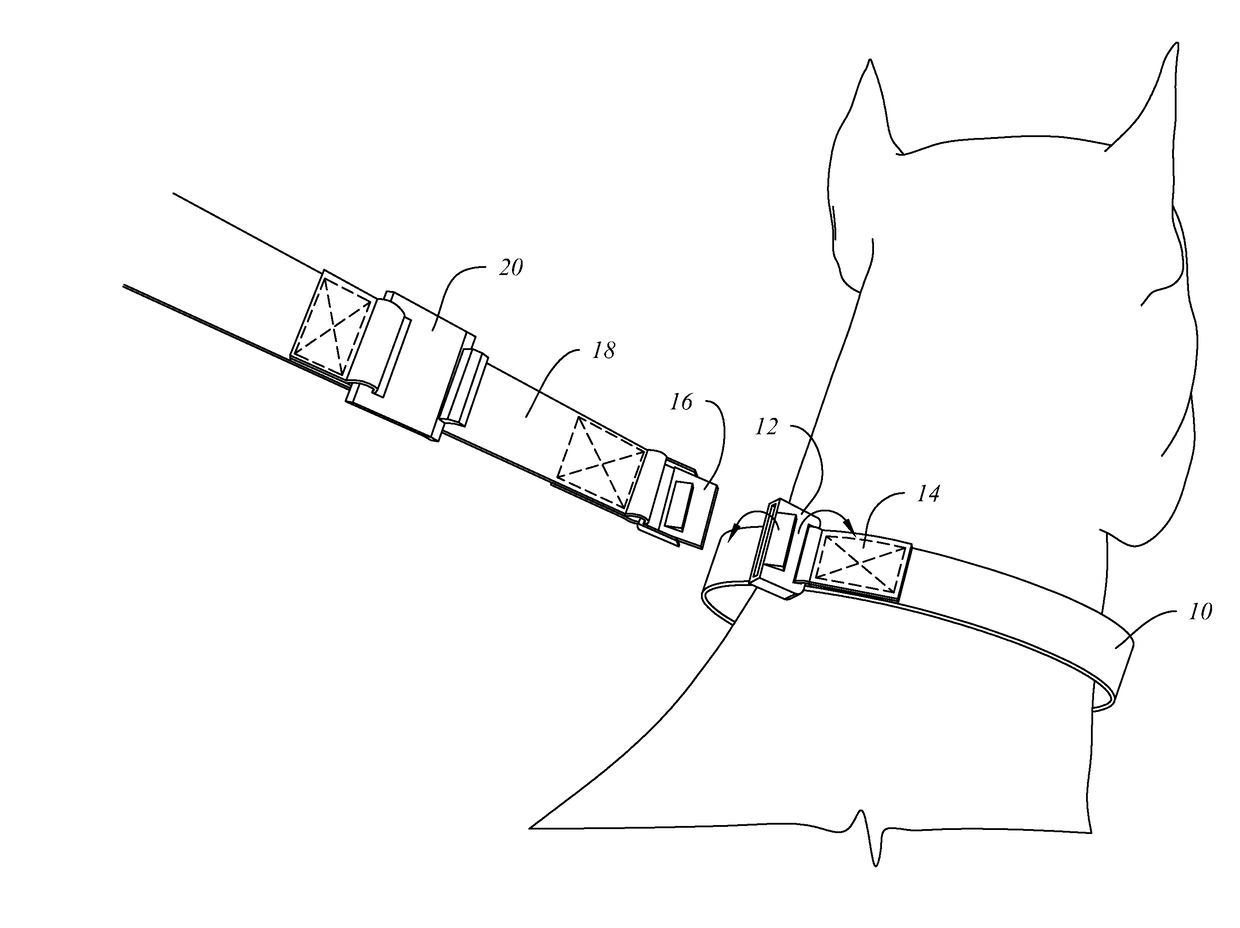

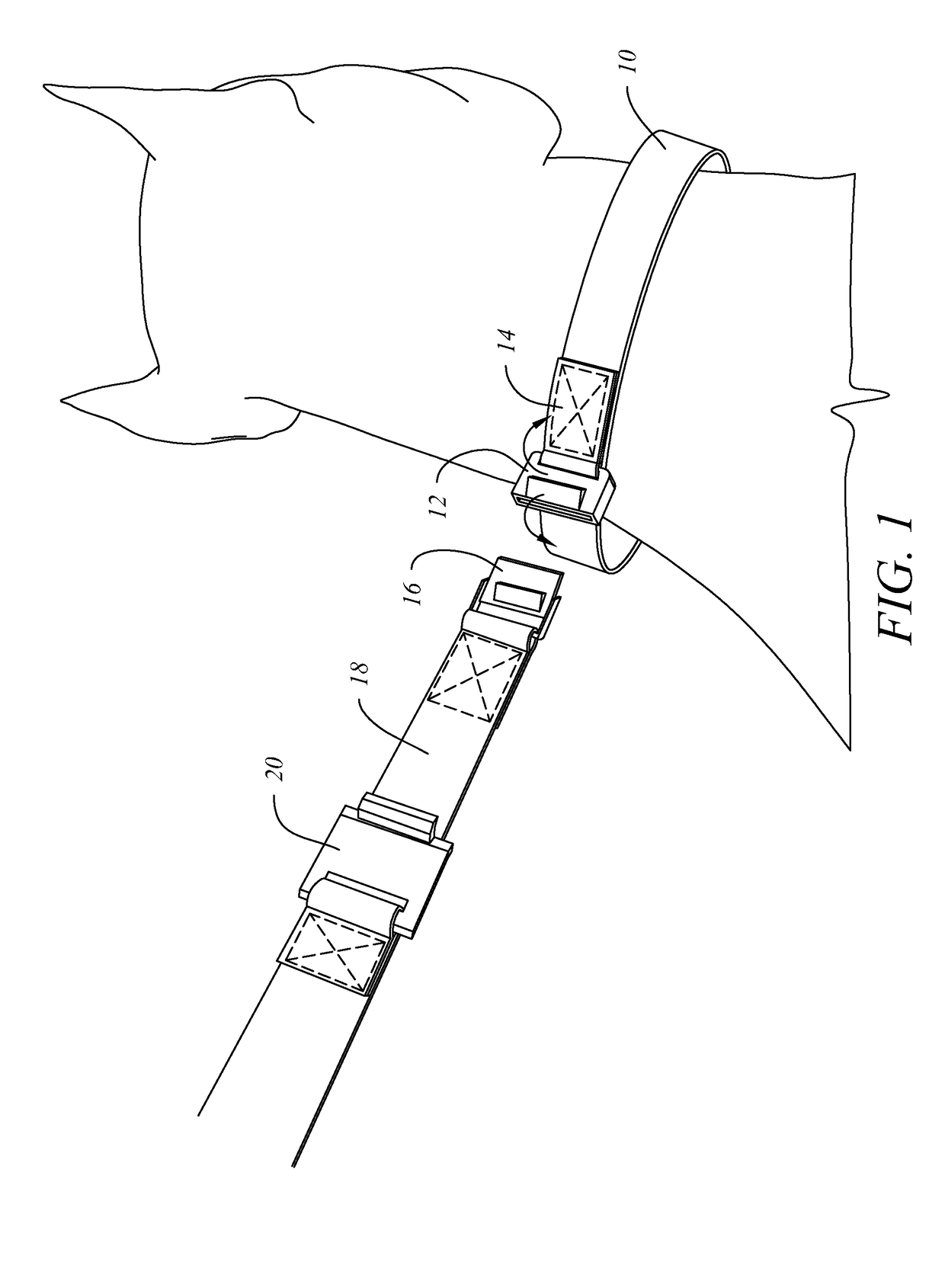

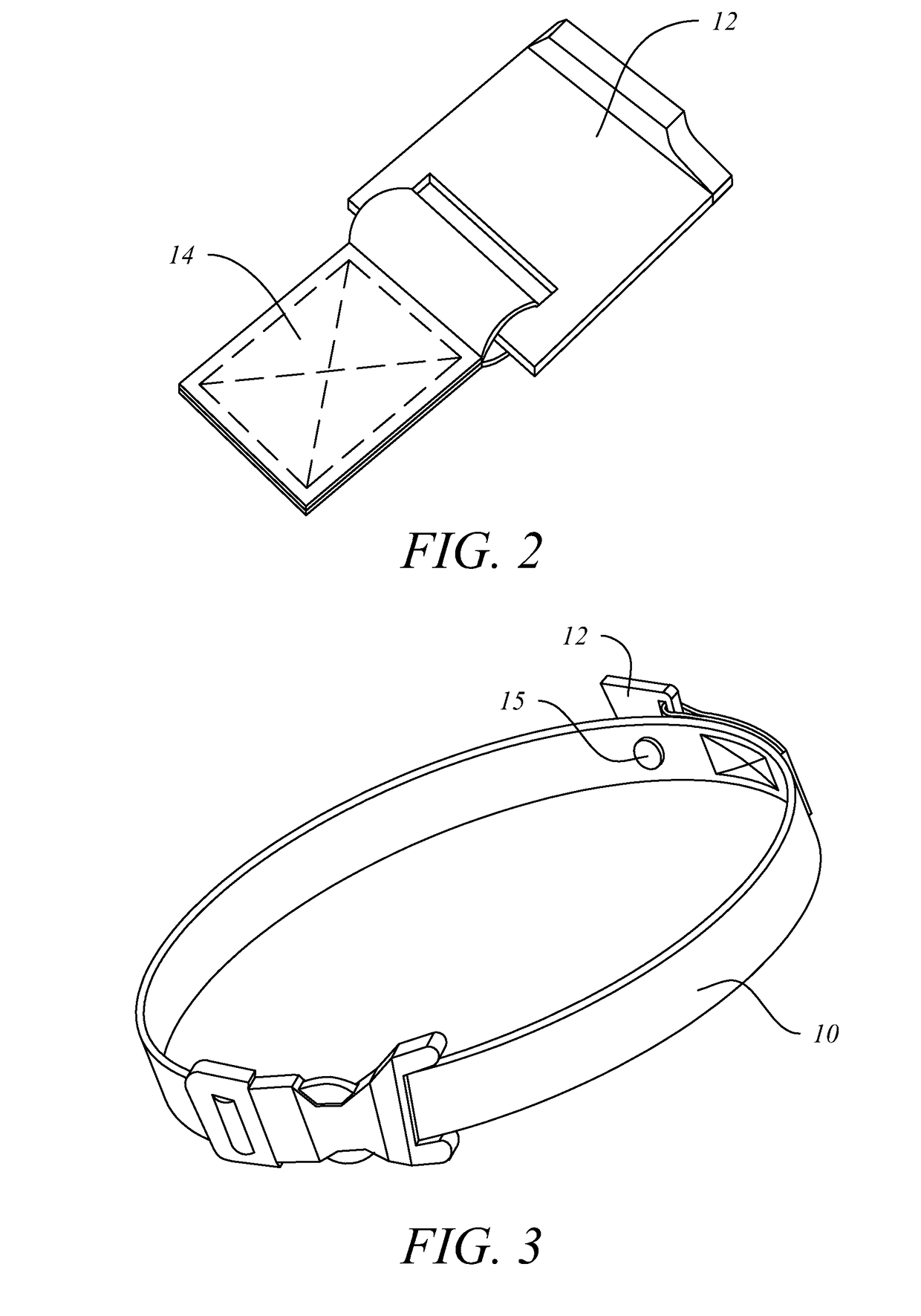

Leash Attachment System for Dog Collar or Harness

ActiveUS20180249682A1Resistance to separationStrength resistanceTaming and training devicesEngineeringMagnet

A dog leash attachment system for selectively and releasably attaching a dog leash to a dog collar or harness, wherein the dog leash and the dog collar or dog harness each comprises a portion of a fastener device further comprising at least one magnetic attachment component and at least one mechanical attachment component. One portion of the fastener device is attached in fixed relation to the dog leash at a position proximal to the distal end of the dog leash. Another magnet is disclosed for use in maintaining a portion of the fastener device proximally to the collar or harness when the leash is not in use.

Owner:MAGDOG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com