Heat treatment furnace for metal chunk, method for repairing heat treatment furnace for metal chunk, and method for producing infill for hearth used for heat treatment furnace for metal chunk

A technology for heat treatment furnaces and manufacturing methods, applied to furnaces, lining repairs, furnace components, etc., can solve problems such as low strength and corrosion resistance, and reduced heat insulation, so as to prevent the decline of fire resistance or heat insulation, and suppress fire resistance or the effect of a decrease in thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

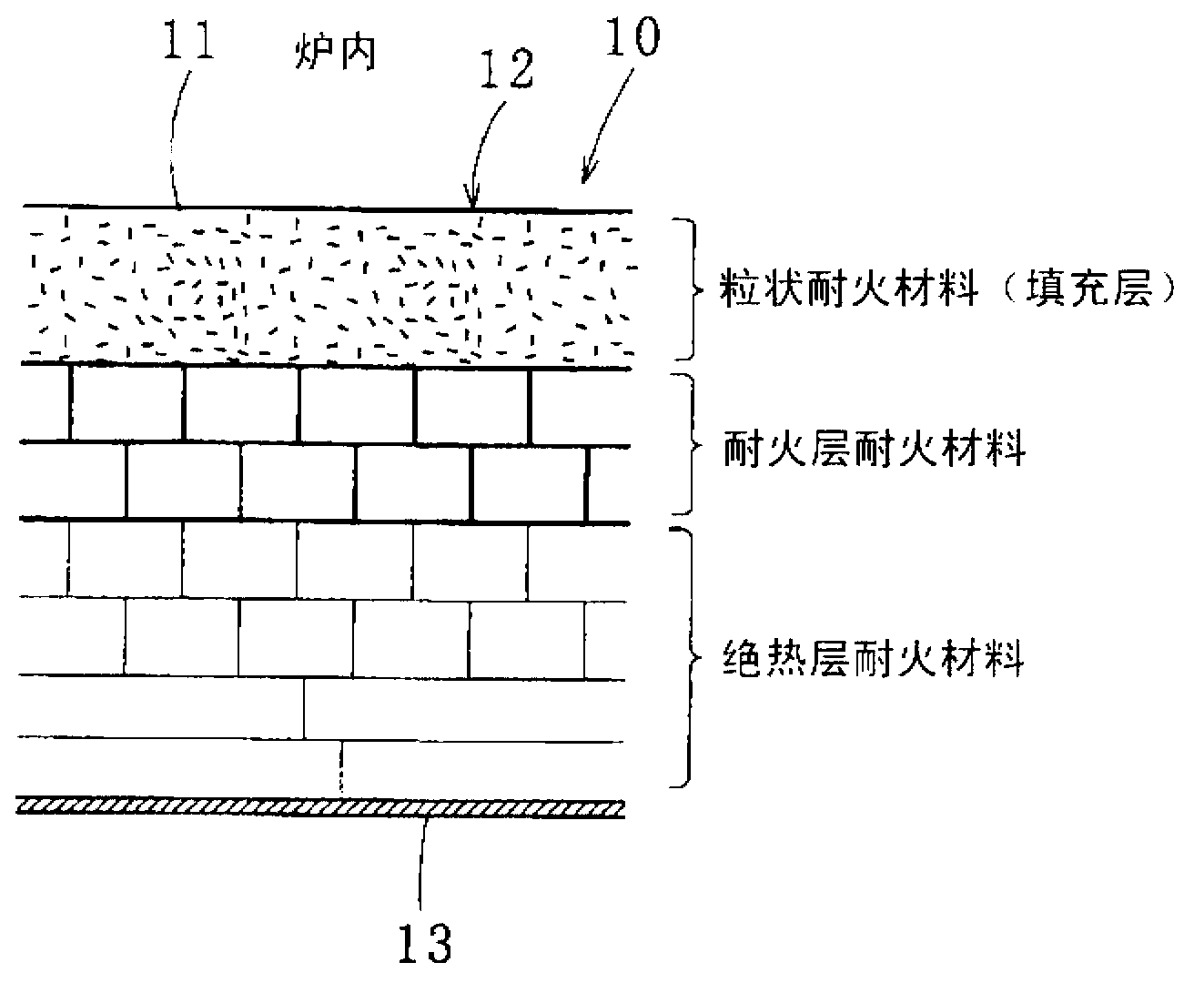

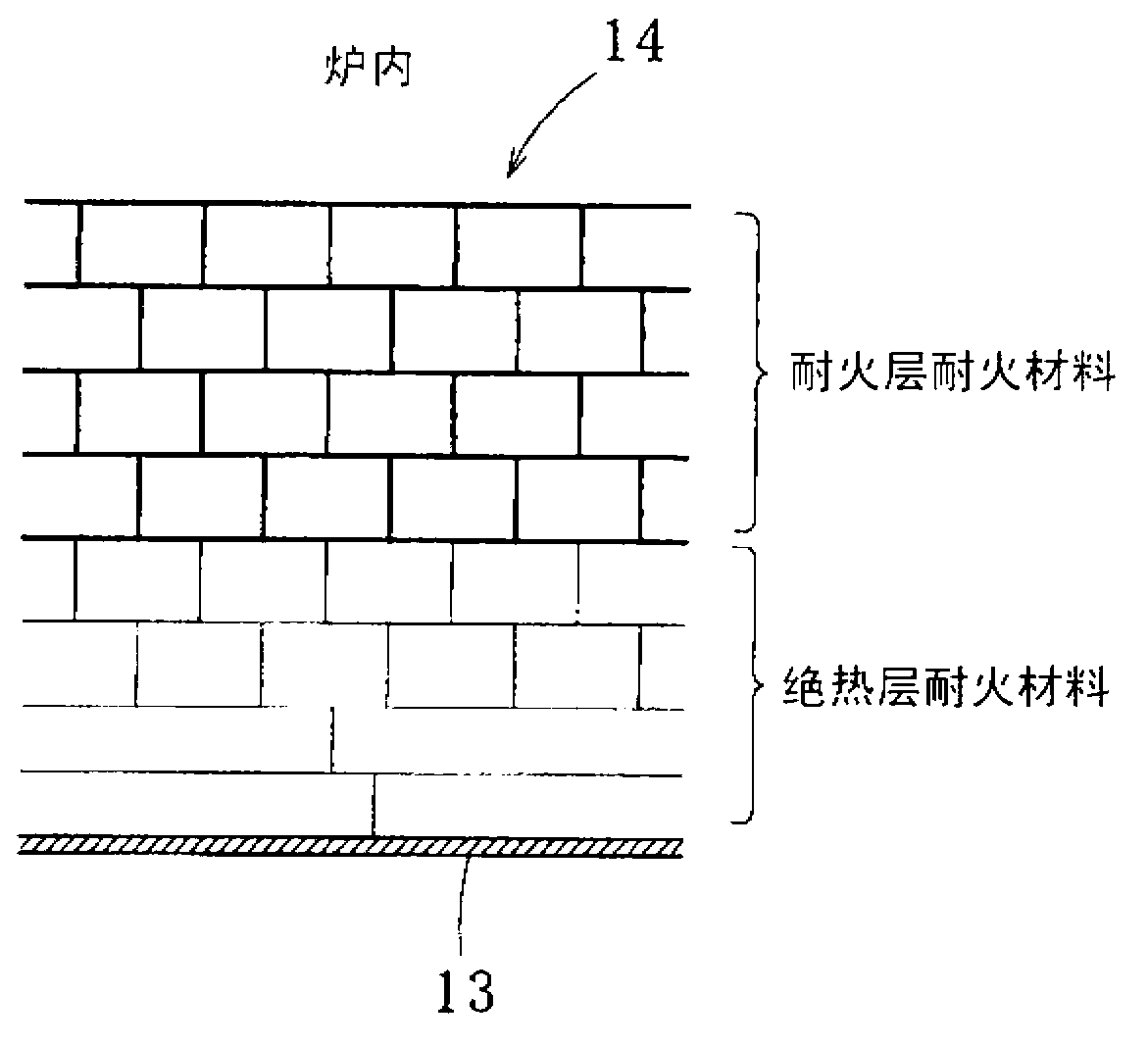

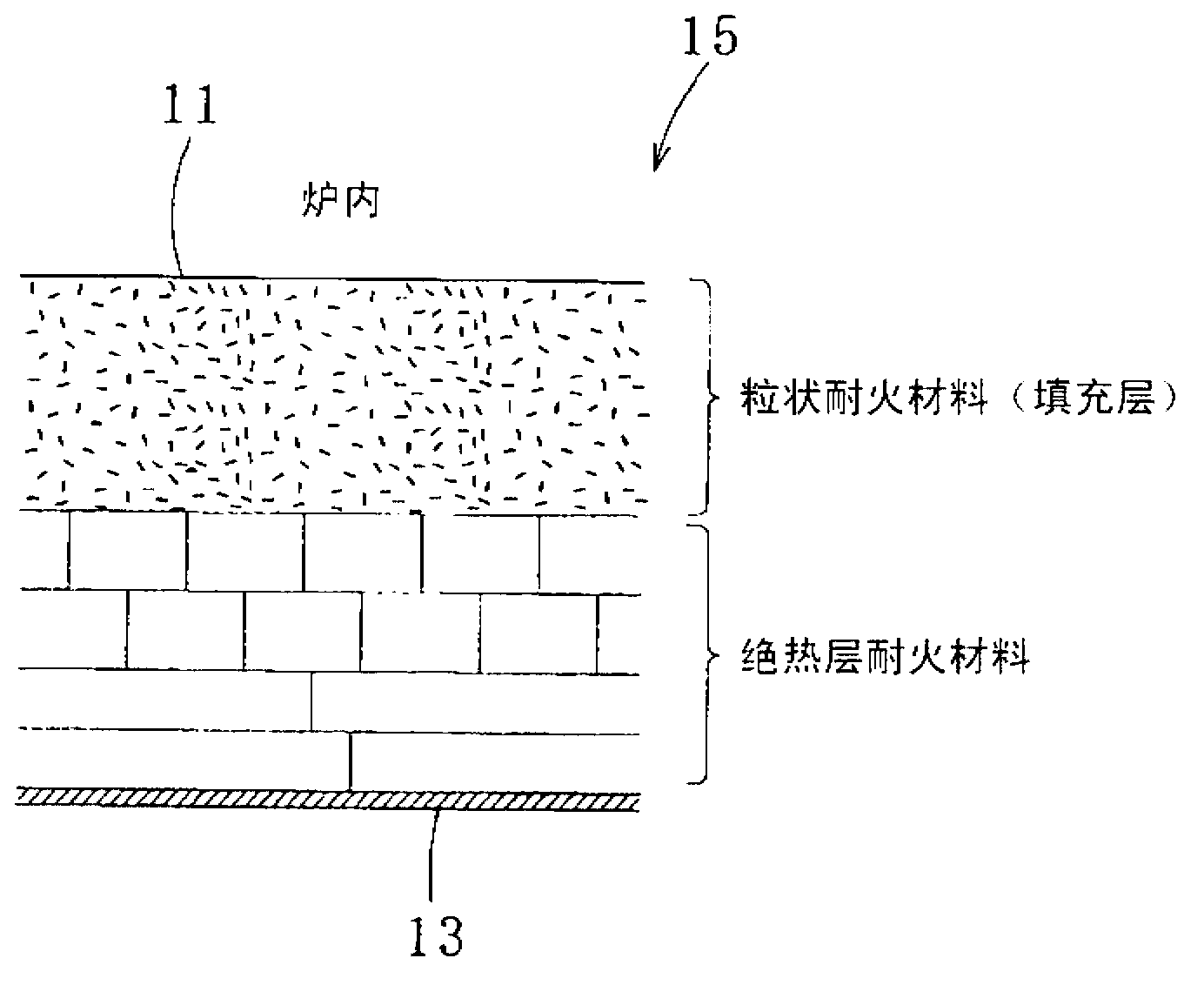

[0152] Next, examples for confirming the effects of the heat treatment furnace for metal ingots and the repairing method thereof according to the present invention will be described. First, the used refractory castable material (alumina-magnesia-based castable refractory material) used in the ladle of the steelmaking process is used, and the substrate attached to the used refractory castable material is chiseled. Metal and slag removal. Then, crush it with a jaw crusher so that the maximum particle size of the granular refractory material reaches 50mm. This crushing is carried out by throwing a block of the used refractory castable material between the paired tooth plates of the jaw crusher, so that a compressive force is mainly applied to the used refractory castable material. In addition, the so-called maximum particle size of the granular refractory material is 50 mm, which means that after the granular refractory material is screened once with a sieve with a nominal mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com