Patents

Literature

92results about How to "Good surface decoration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-Woven Fabric for Gypsum Board and Process for Producing the Same

InactiveUS20070298235A1Reduce skin irritationGood surface decorationNon-fibrous pulp additionNatural cellulose pulp/paperGypsumWoven fabric

The object of the present invention is to provide a non-woven fabric comprising a glass fiber which has a strength, flexibility and water resistance, has less skin irritancy and a good surface decoration property, and a process for producing the same, more specifically, to provide a non-woven fabric for a gypsum board which is used as a reinforcing material for a gypsum board placed on one side or both sides of the gypsum board, and a process for producing the same. A non-woven fabric for a gypsum board comprising 20 to 60% by weight of a glass fiber, 10 to 50% by weight of an organic fiber and 10 to 50% by weight of a fibrous binder, which contains the organic fiber at least on a gypsum core contact surface, is provided.

Owner:MITSUBISHI PAPER MILLS LTD

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

Aldehyde-free environment-friendly flame-retardant plywood and a preparation method thereof

InactiveCN101513744AImprove flame retardant performanceHigh strengthProtein adhesivesWood veneer joiningAntistatic agentSolid content

The invention is aldehyde-free environment-friendly flame-retardant plywood and a preparation method thereof, belonging to the processing and preparation field of plywood, in particular to environment-friendly flame-retardant plywood without the release of harmful gases, such as formaldehyde, and the preparation method thereof. The invention is characterized in that the plywood is processed and prepared by a soy-based flame-retardant antistatic biological macromolecular adhesive, wherein the adhesive comprises the following components (part by weight): 40-70 parts of soy-based lumber adhesive (solid content: 25% plus or minus 5), 5-20 parts of crosslinker, 2-10 parts of flame-retardant, 0.5-3 parts of antistatic agent, 0.5-3 parts of mothproof and mildewproof auxiliary agent and 20-40 parts of flour. The invention provides an aldehyde-free environment-friendly flame-retardant plywood which releases no harmful gases, such as formaldehyde and has excellent flame-retardant effect, high strength, good surface decoration and antistatic performance, and a preparation method thereof, thus solving the problems that the harmful gases such as formaldehyde released by the plywood products pollute the environment and the plywood products have low flame-retardant level.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

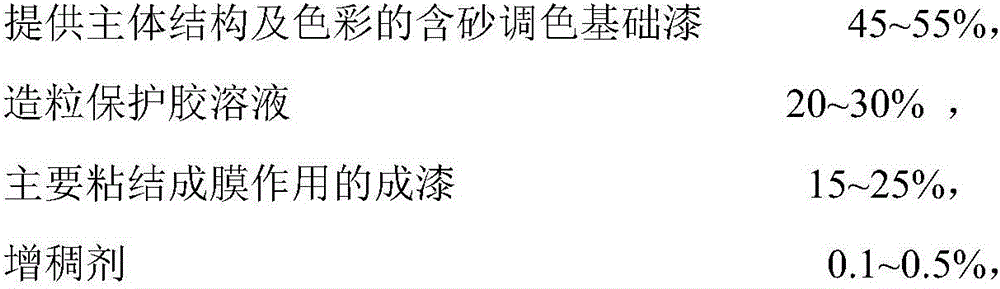

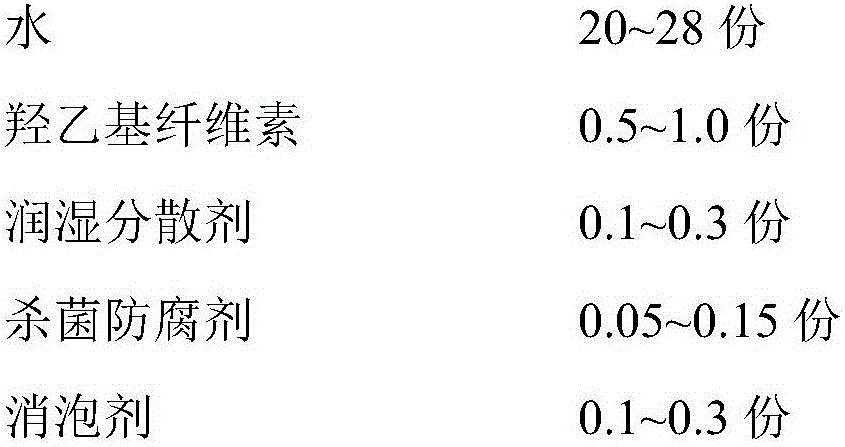

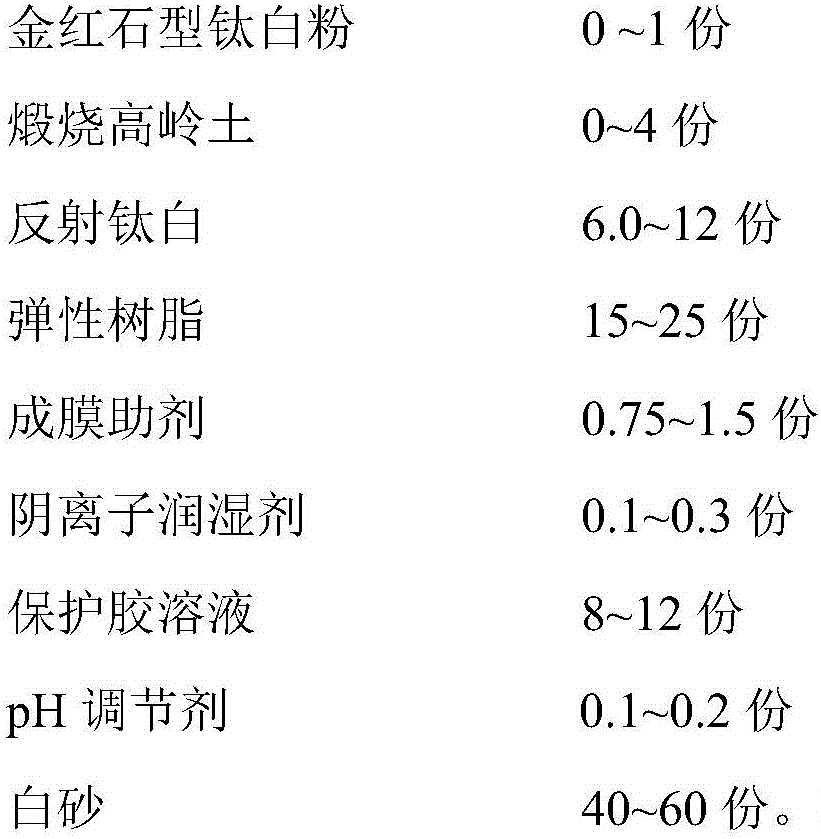

Water-based reflective insulation water pack sand bush-hammered imitation paint and its preparation method

InactiveCN106280806AGood surface decorationMeet individual needsReflecting/signal paintsWater basedMaterials science

This invention involves a kind of water-based material, especially a kind of water-based reflective insulation water pack sand bush-hammered imitation paint and its preparation method which belongs to the field of architectural coating. it is kind of water-based reflective insulation water pack sand bush-hammered imitation paint. This paint is made of the components with the following mass ratio: sand content color modulation base paint which provides the major structure and colors 45 - 55portions; grain making protection glue solution 20 - 30 portions; paint for bonding into coating15 - 25 portions; thickening agent 0.1 - 0.5 portions. The described sand content color modulation base paint providing the major structure and colors contains white sand content basic pain and reflective heat insulation mill base. The content of reflective heat insulation mill base in 0.1% - 3 % of the total weight of the sand content color modulation base pain.

Owner:浙江德尔福新型建材股份有限公司

Non-woven fabric for gypsum board and process for producing the same

InactiveUS7641764B2Reduce skin irritationGood surface decorationNon-fibrous pulp additionNatural cellulose pulp/paperGlass fiberNonwoven fabric

The object of the present invention is to provide a non-woven fabric comprising a glass fiber which has a strength, flexibility and water resistance, has less skin irritancy and a good surface decoration property, and a process for producing the same, more specifically, to provide a non-woven fabric for a gypsum board which is used as a reinforcing material for a gypsum board placed on one side or both sides of the gypsum board, and a process for producing the same. A non-woven fabric for a gypsum board comprising 20 to 60% by weight of a glass fiber, 10 to 50% by weight of an organic fiber and 10 to 50% by weight of a fibrous binder, which contains the organic fiber at least on a gypsum core contact surface, is provided.

Owner:MITSUBISHI PAPER MILLS LTD

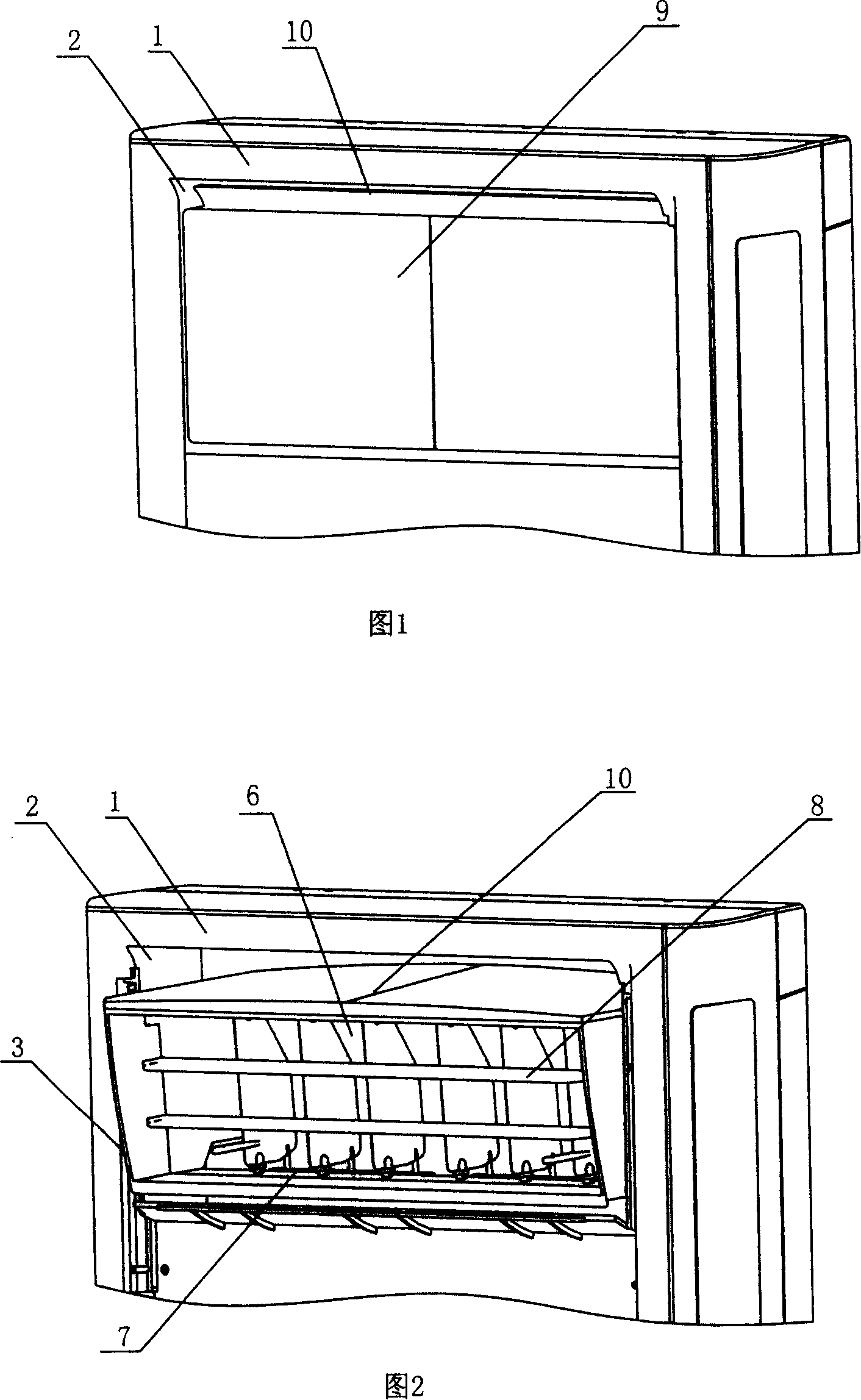

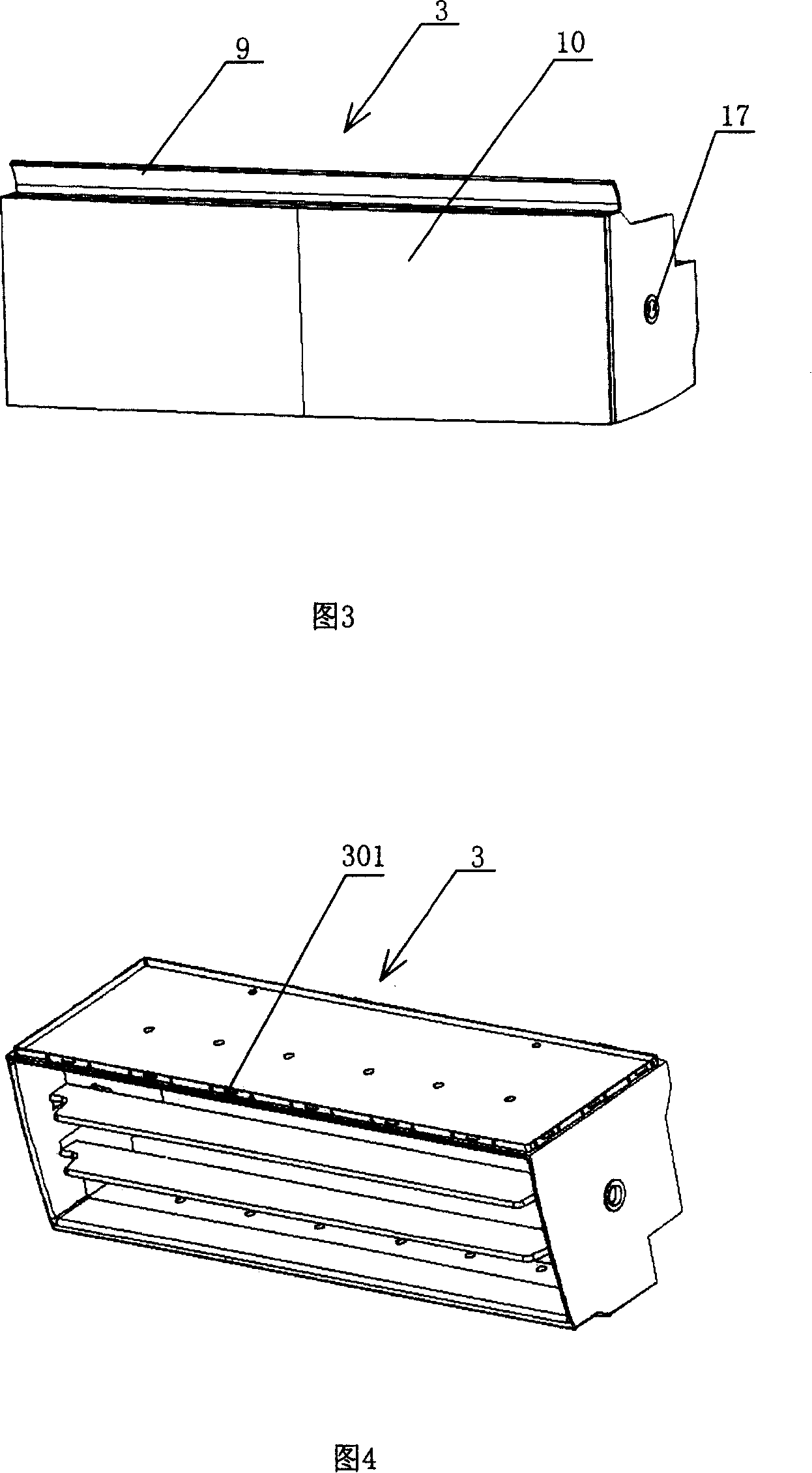

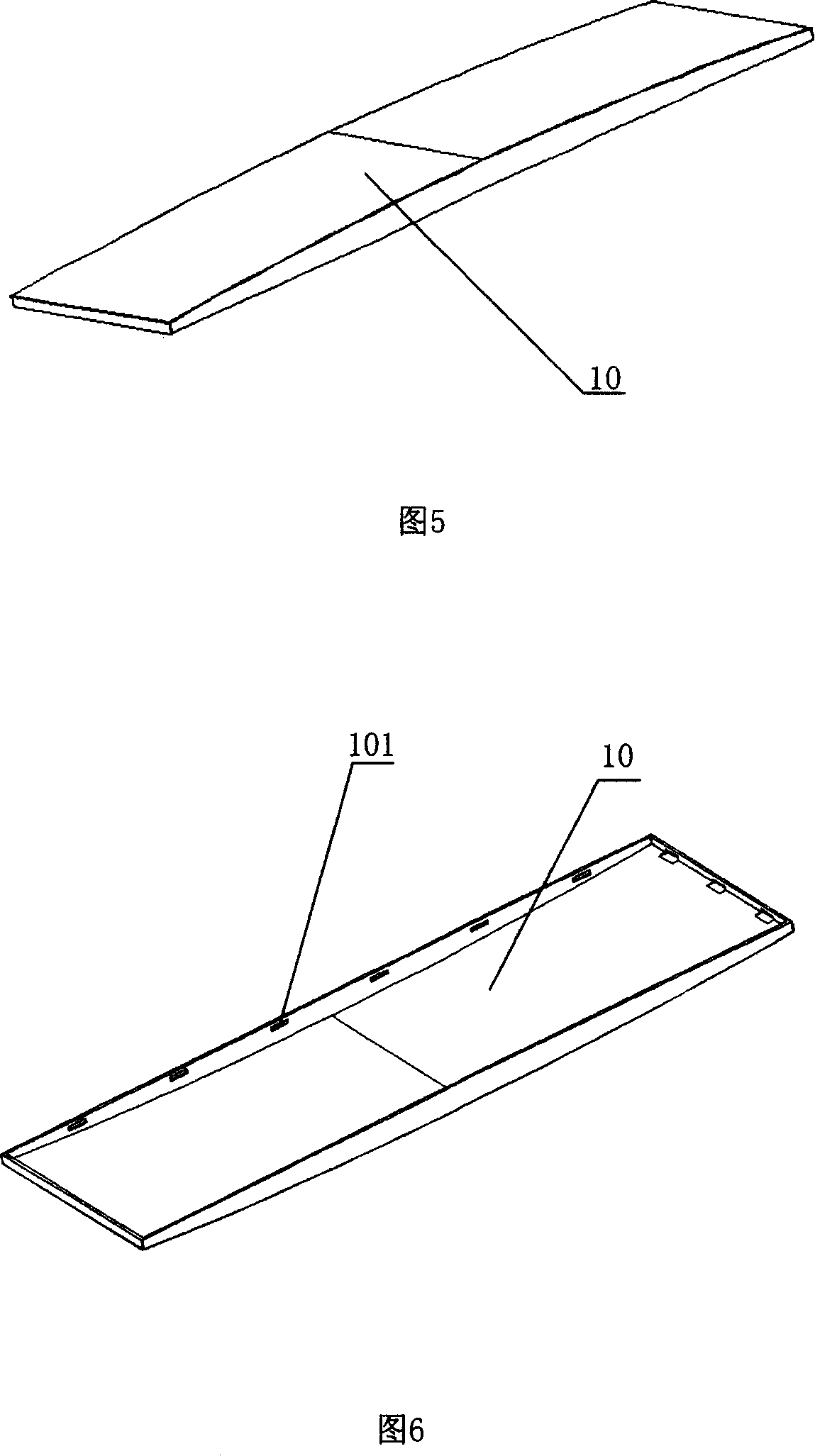

Air conditioner decorative sheet adopting novel technique of transcribing in model and its technique

ActiveCN101153737AAppearance coordinationFashionable and beautiful appearanceLighting and heating apparatusAir conditioning systemsCompression moldingWear resistant

The present invention discloses an air conditioner decorative plate adopting novel technique of transcribing in mold and the technologic method thereof, wherein, the decorative plate is arranged on an air outlet frame inside an air outlet frame of a front panel; the air outlet frame is pivoted inside the air outlet frame, can swing up and down around a shaft to supply air, and can also obstruct an air outlet to prevent dust from entering when an air conditioner is turned off. The decorative plate adopts a novel technique of transcribing in mold, and the technologic method comprises the following steps: firstly, membrane making, which comprises selection of materials for making membrane and printable materials, pattern printing in printed region and drying after making; secondly, positioning and membrane feeding, which comprise membrane feeding of a membrane feeding device, die positioning on the decorative plate and membrane fixing; thirdly, compression molding, which comprises heating for softening the membrane and molding; fourthly, injection molding, which comprises selection of castingresin corresponding to the membrane materials, corresponding to the resin temperature regulation and resin injection; fifthly, post treatment, which comprises taking-out, shearing and processing. The present invention executes silver luster treatment to the whole surface of the decorative plate; thereby the decorative plate is beautiful and stylish in exterior appearance, wear resistant and scratch resistant.

Owner:HAIER GRP CORP +1

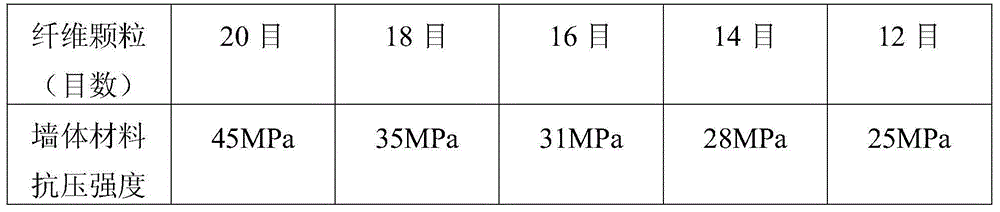

Preparation method of novel cement-based plant straw fiber particle wall material

The invention discloses a preparation method of a novel cement-based plant straw fiber particle wall material. The preparation method comprises cutting dried plant straw fibers into small pieces, immersing the small pieces in an alkali solution, carrying out air drying, sucking the air-dried plant straw fibers into a crusher from a feeing inlet for continuous 5-8min, carrying out crushing for 5-10min to obtain plant straw fiber particles, screening the plant straw fiber particles by a square hole sieve to obtain the plant straw fiber particles with appropriate particle sizes, mixing cement, fly ash, fine sand, the plant straw fiber particles and water to obtain a uniform mixture, pouring the mixture into a mold, carrying out demolding after coagulation, putting the molded test piece into a standard maintenance chamber, and carrying out maintenance to obtain the novel cement-based plant straw fiber particle wall material. The prepared wall has the bright and clean surface, is free of secondary treatment, effectively reduces wall treatment difficulty and processes, and has excellent heat insulation performances, good toughness, impact resistance and excellent sound insulation performances.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Gypsum substrate render material

The gypsum-based whitewash material consists of beta-gypsum with beta-CaSO4.1 / 2H2O as main component 99-99.9 wt% and anhydrous citric acid or its salt as coagulation regulator 0.1-1 wt%. The presentinvention has strong adhering capacity, and can inhibit the shrinkage and cracking in whitewashing. It has excellent surface decoration performance, fireproof performance and heat insulating performance. It has simple production process, low production cost and light weight.

Owner:NANJING EFFUL

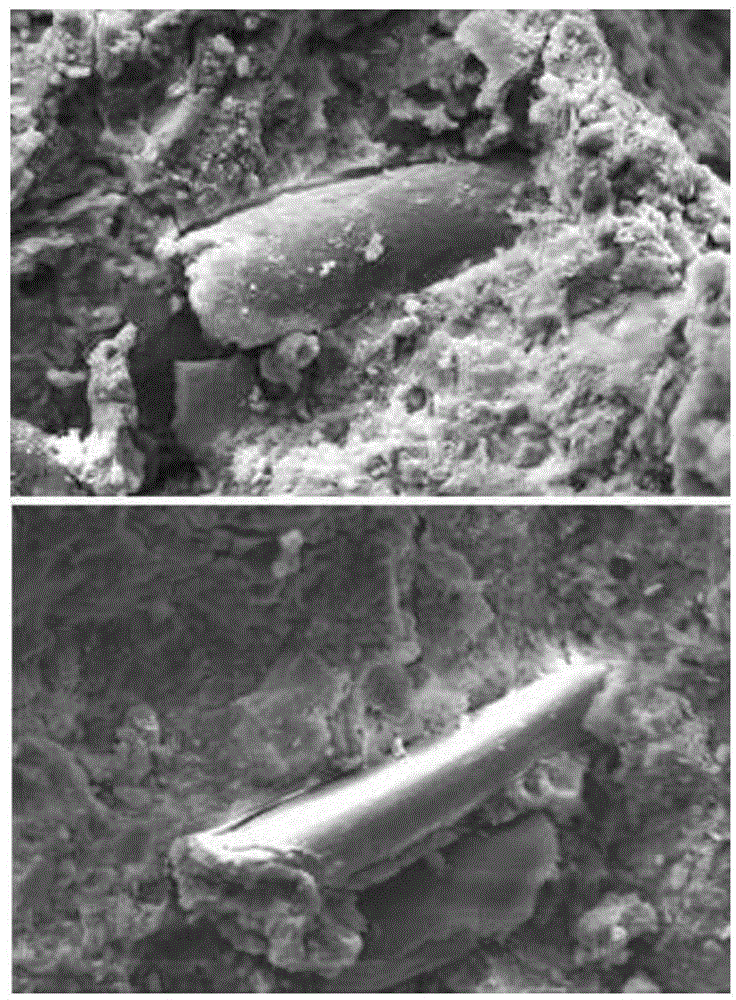

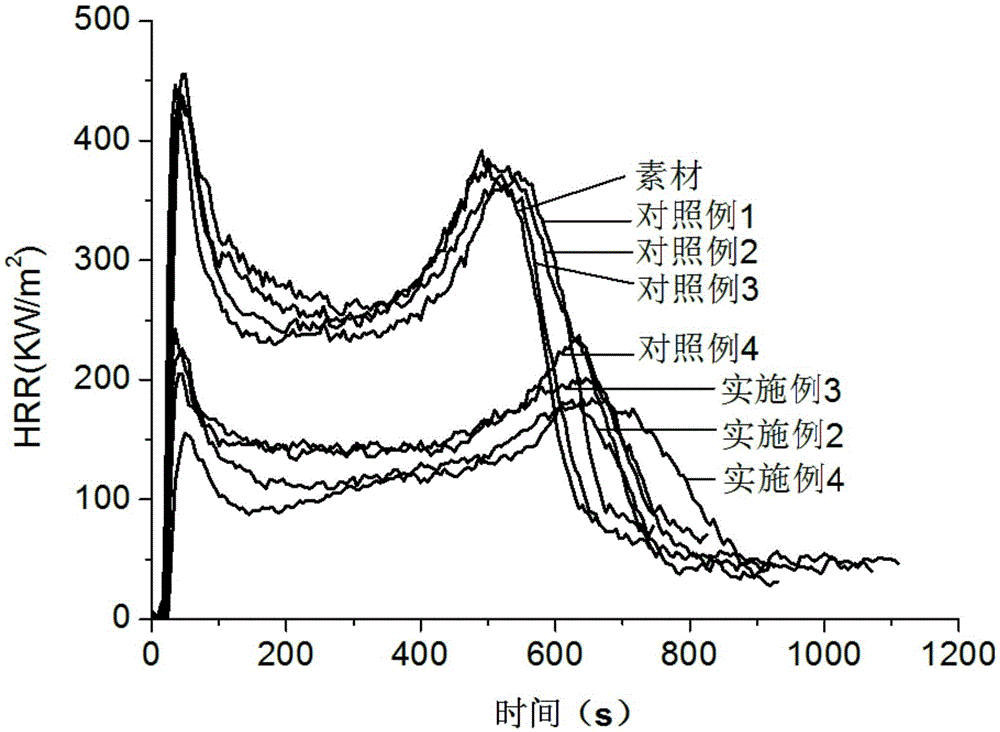

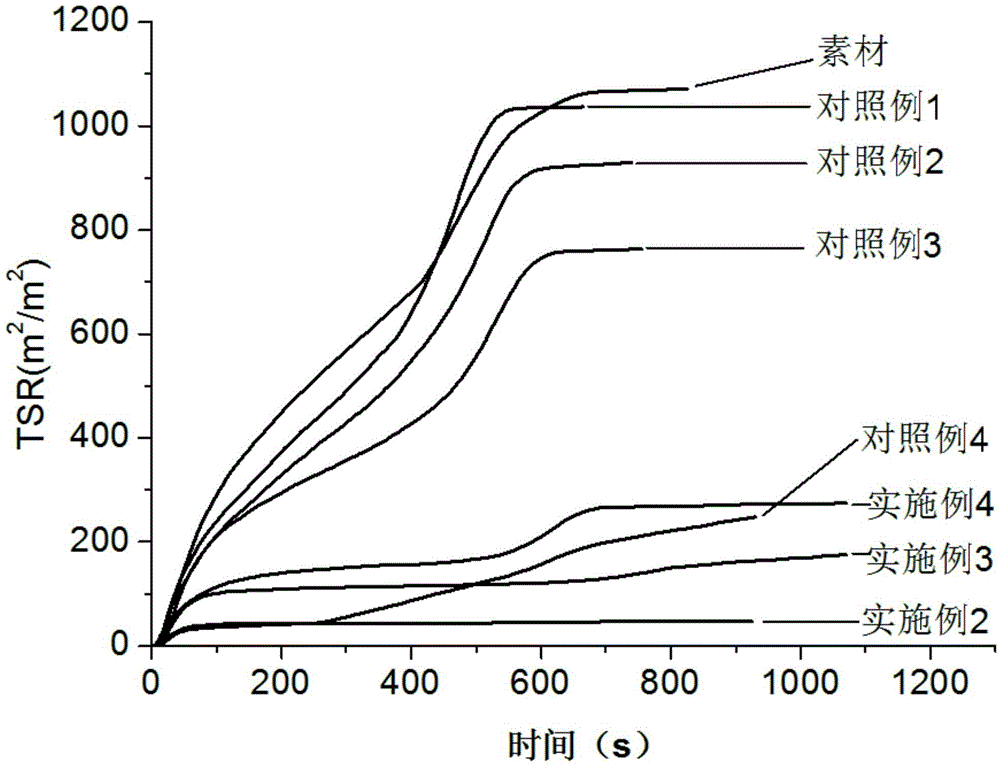

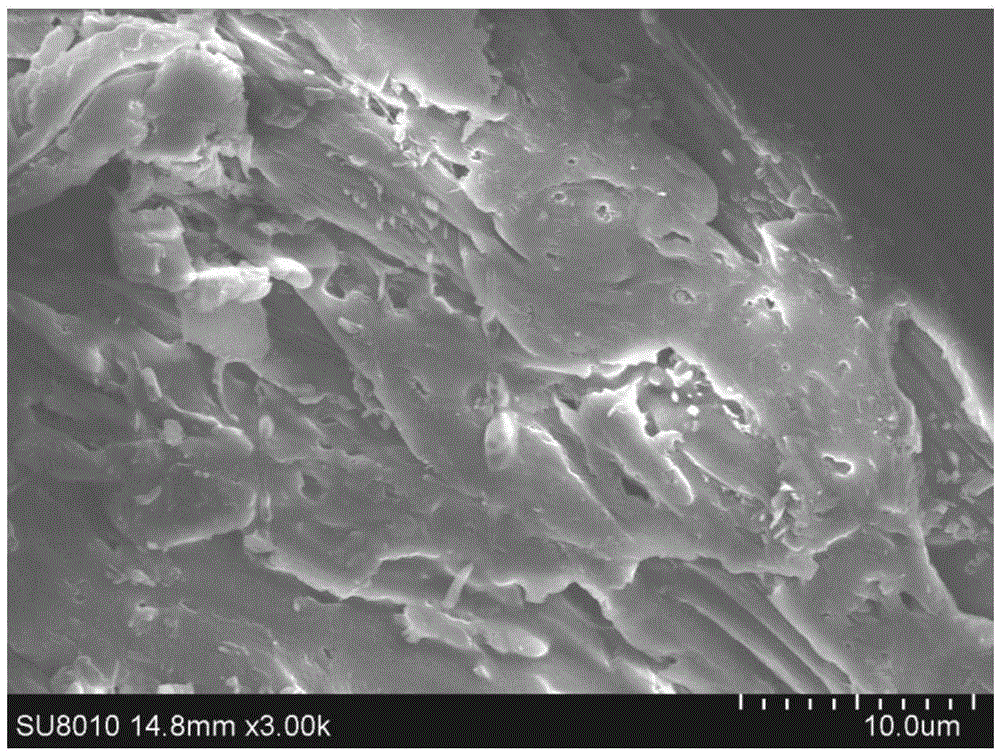

Flame-retardant thermal modification wood and preparation method thereof

ActiveCN105666612AImprove fire safetyGood surface decorationWood treatment detailsThermal wood treatmentCombustionMaterials science

The invention relates to flame-retardant thermal modification wood and a preparation method thereof. The preparation method comprises the step that after being subjected to immersion treatment, the wood is subjected to heat treatment. According to the flame-retardant thermal modification wood and the preparation method thereof, the flame-retardant thermal modification wood is prepared by combining the wood high-temperature heat treatment with the wood flame-retardant technology; the dual characteristics that the wood is subjected to high-temperature heat treatment and flame retarding are achieved at the same time; the flame-retardant thermal modification wood has the good surface decorative performance, dimensional stability and the like, and the excellent flame-retardant property is also achieved; the combustion heat release rate and smoke production are substantially decreased, and the fireproof safety of processed wood products is greatly increased.

Owner:BEIJING FORESTRY UNIVERSITY

Waste plastic recycling method

InactiveCN105315595ASimple processGood surface decorationPlastic recyclingCoatingsSimple Organic CompoundsRecovery method

The invention discloses a waste plastic recycling method. The waste plastic recycling method comprises the steps that waste plastic is subjected to the procedures of washing, drying, crushing, grinding and screening and then dissolved in acrylic ester monomers, a proper amount of packing, a reinforcing and toughening agent, Mg(OH)2 fire retardant, a small amount of an organic peroxy initiating agent, a small amount of an N,N tertiary amine organic compound and the like are added, the mixture is mixed, degassed and poured into a tempered glass die with a membrane formed on the surface in advance, a blank is subjected to exhausting and dimension deducting and then subjected to still standing at the room temperature to be solidified and formed, and finally a plastic board is obtained through high-temperature treatment, cooling, releasing and other procedures. According to the method, the waste plastic recycling technology is simple, the developed plastic board is good in surface decorating effect, free of the influences of types and colors of the waste plastic and capable of replacing a wood-plastic composite to be applied, and the application grade is increased; the plastic board can replace an acrylic face plate to lower the production cost and can replace a common plastic board to improve the decorating effect.

Owner:XIXIANG LINSEN BUILDING MATERIALS

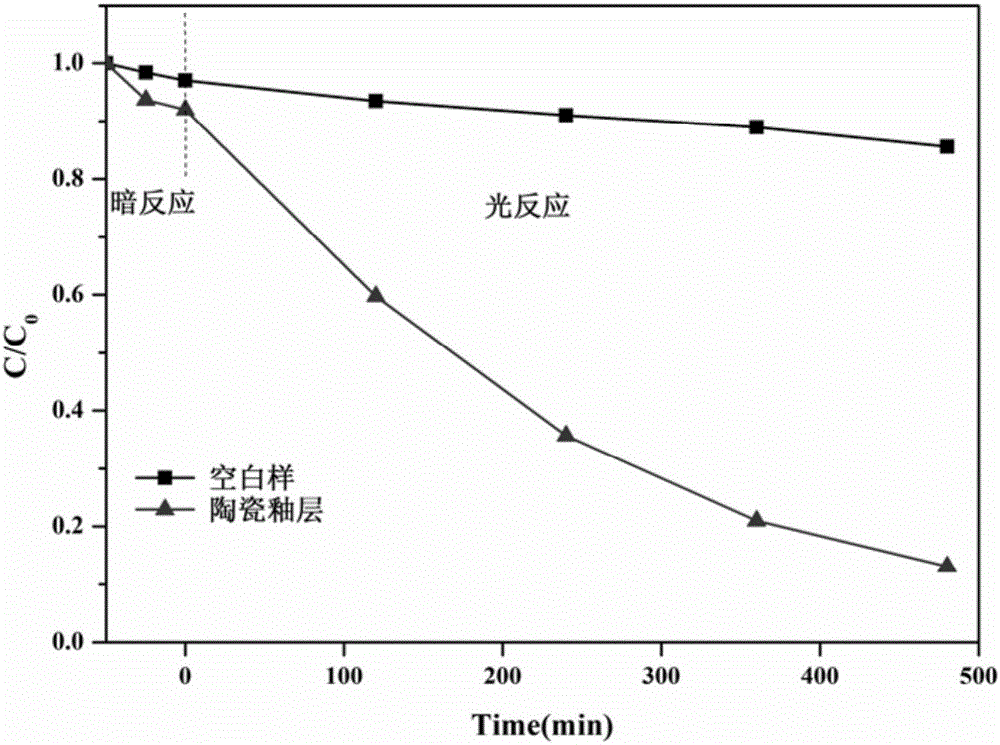

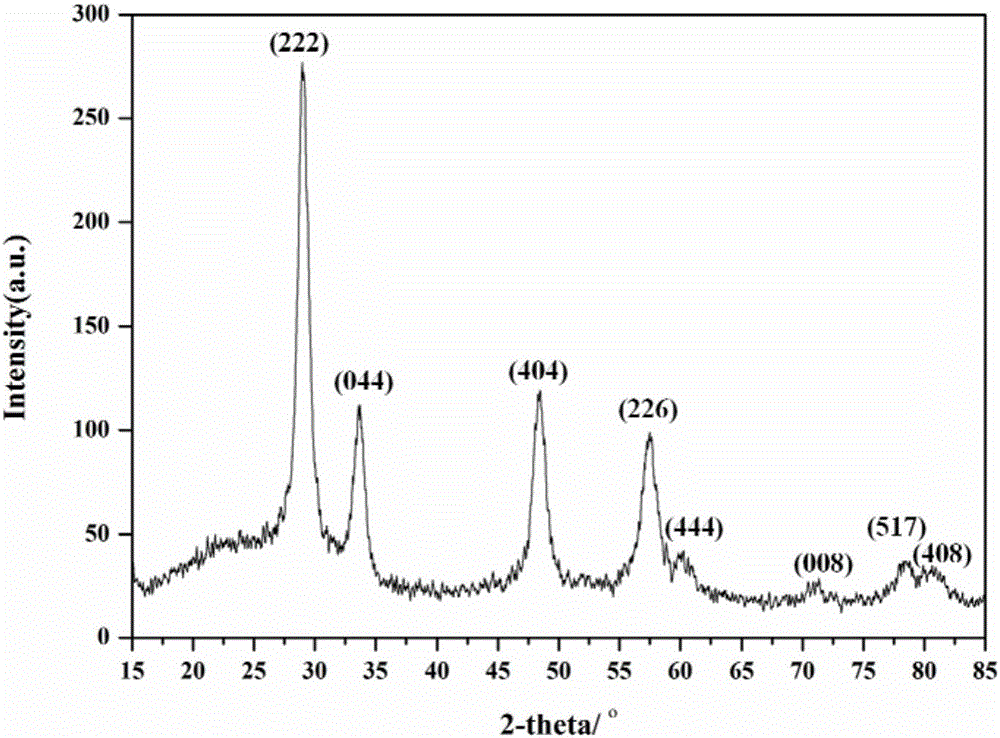

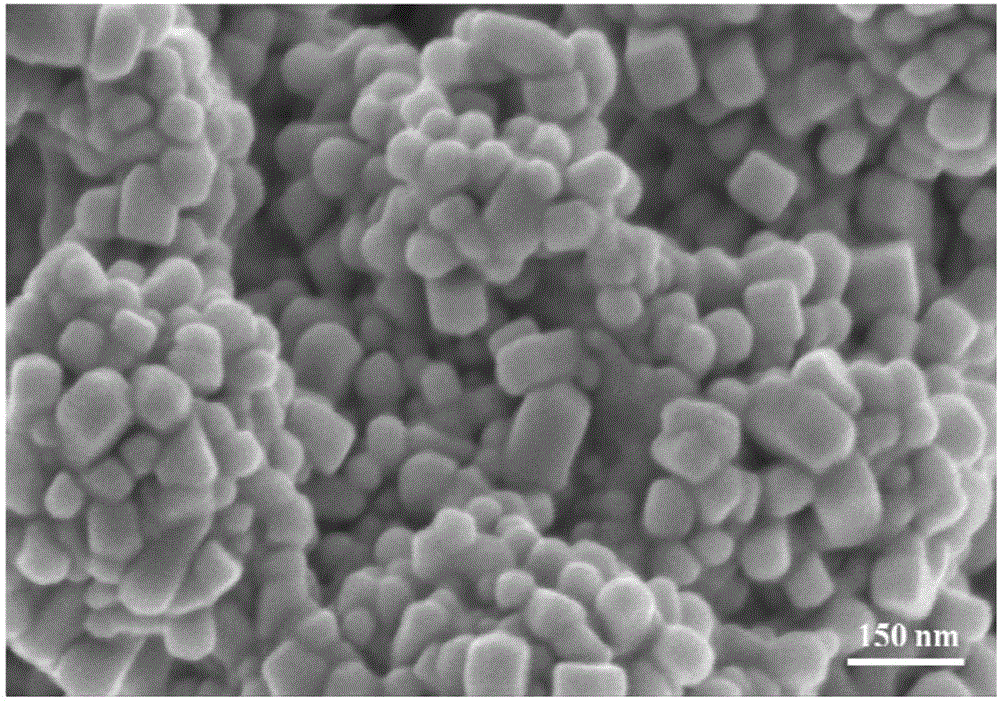

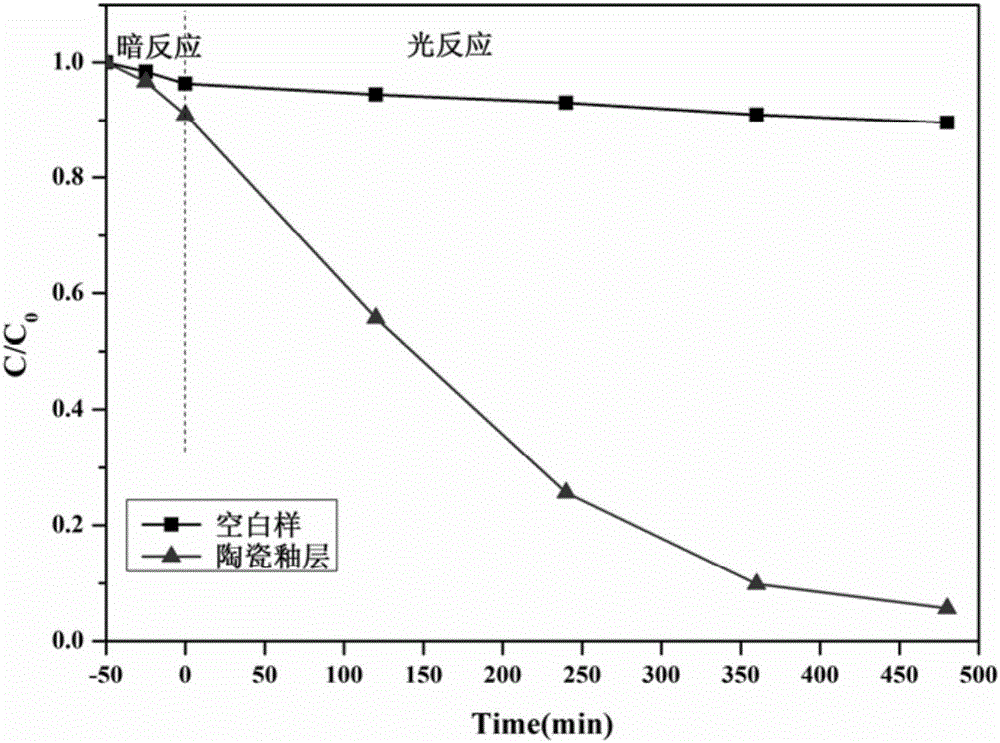

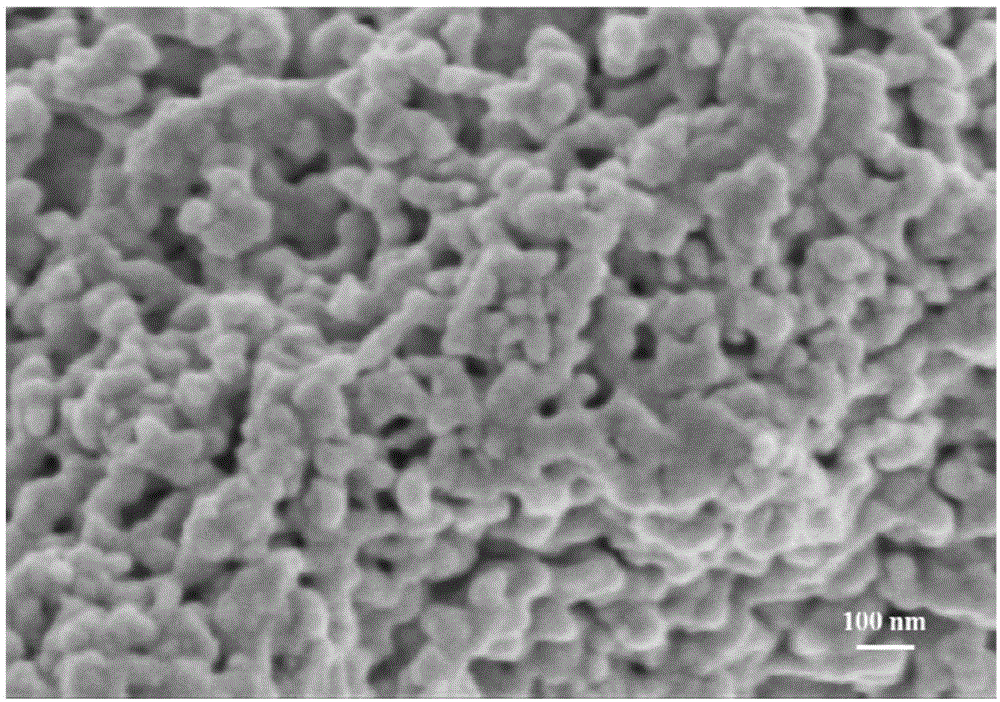

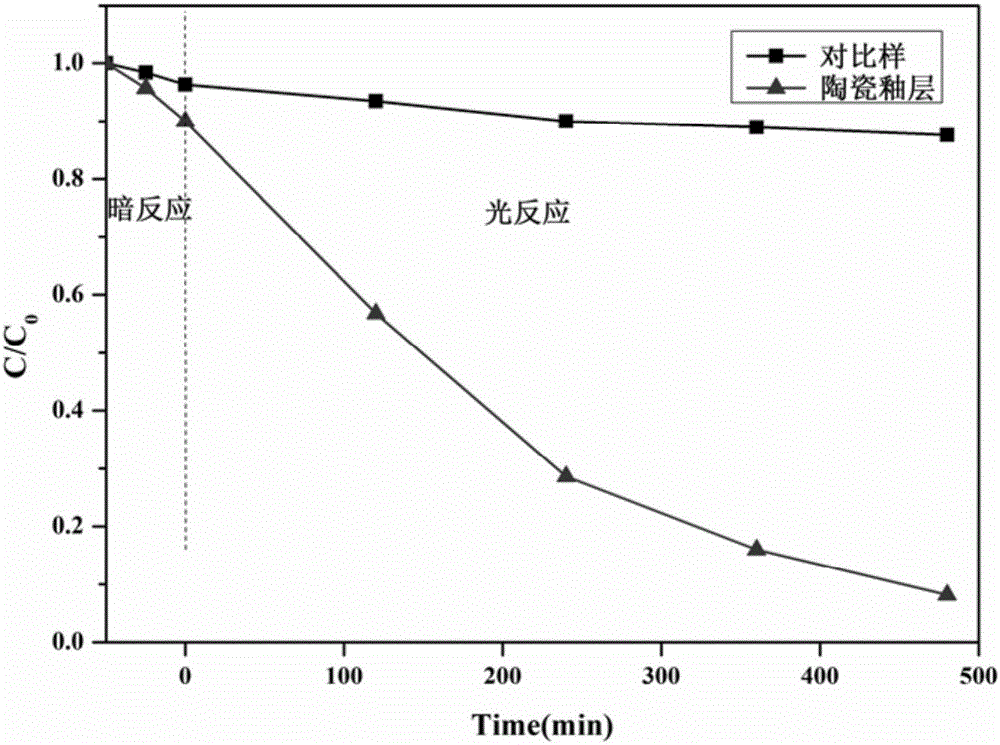

Preparation method of yttrium zirconate ceramic glaze material having photocatalytic function

The invention relates to a preparation method of a yttrium zirconate ceramic glaze material having a photocatalytic function. The preparation method comprises the following steps: preparing quartz, potash feldspar, albite, borax, Y2O3, Suzhou clay and lithium carbonate, keeping the temperature at 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water, quenching to prepare a fusion cake, and grinding the fusion cake to obtain a material A; preparing the material A, Y2O3, ZrO2 and Suzhou clay, and grinding to obtain a material B; adding the material B and dispersing agent into water, and uniformly stirring and mixing to prepare a glaze slip; and applying the glaze slip to the surface of ceramics in a glaze spray manner, and firing to obtain the yttrium zirconate ceramic glaze material having a photocatalytic function. According to the invention, the ceramic glaze is prepared through a firing process and does not need coating, so that the prepared functional ceramic glaze material can be tightly combined with a ceramic matrix; and the photocatalyst yttrium zirconate generated in the sintering process of Y2O3 and ZrO2 is uniformly distributed in the glaze material, thereby avoiding influencing the aesthetic property of the glaze material due to a rainbow effect.

Owner:广西艾陶新型材料科技有限公司

Preparation method for low-temperature curing composite resin powder coating

InactiveCN110041810AGood storage stabilityModerate molecular weightPowdery paintsEpoxy resin coatingsEpoxyHeat resistance

The invention relates to a preparation method for a low-temperature curing composite resin powder coating, and belongs to the technical field of coatings. Terminal carboxyl polyester resin and epoxy resin are taken as raw materials to prepare the low-temperature curing composite resin powder coating. Since the terminal carboxyl polyester resin and the epoxy resin are compounded, the low-temperature curing of the resin powder coating can be effectively realized, power coating application is not limited to the coating of the surface of a thermal-resistance base material, a possibility for applying the power coating to the surface coating film of a thermosensitive base material is greatly increased, the preparation method performs a great function for expanding the application range and the application field of the powder coating, the curing temperature of the low-temperature curing powder coating is low, the cost generated in a baking link in a production process is lowered, the consumption of energy is greatly reduced, resources are saved, the curing time is shortened while the mechanical property of the coating film is guaranteed, a production period is shortened, the production efficiency is improved, and economic benefits are increased.

Owner:江苏海獭新材料科技有限公司

Stainless steel acid pickling technology

InactiveCN104404551AGuaranteed passivation protection treatmentAddress macular defectsUltimate tensile strengthContamination

The invention discloses a stainless steel acid pickling technology which comprises steps as follows: (1) completely immersing a workpiece in an acid pickling tank at the temperature of 30-55 DEG C for 3-5 min; (2) washing the workpiece with clear water; (3) performing acid pickling with an HNO3 and HF mixed solution used as an acid pickling solution, wherein the content of HNO3 is in a range of 180-290 g / l, the content of HF is in a range of 26-60 g / l, the content of metal ions is in a range of 5-45 g / l, and the temperature of the acid pickling solution is in a range of 55-65 DEG C. With the adoption of the stainless steel acid pickling technology, the corrosion resistance of stainless steel is improved effectively, the fingerprint contamination resistance of the stainless steel is improved, and the surface decoration property of stainless steel products is guaranteed; the technology has the characteristics of simplicity, low production cost, low environmental pollution, easiness in operation, low labor intensity, low energy consumption and high efficiency; the defects that the stainless steel cannot be drawn to be fine and is brittle and easy to break are overcome.

Owner:QINGDAO DUANYI METAL

Metal sectional material and wood-plastic co-extrusion moulded composite plate as well as preparation method thereof

ActiveCN105484423AGuaranteed basic strengthReduce steel consumptionBuilding componentsCo extrusionPlastic materials

The application provides a metal sectional material and wood-plastic co-extrusion moulded composite plate. The metal sectional material and wood-plastic co-extrusion moulded composite plate comprises a wood-plastic frame and a metal sectional material, wherein the wood-plastic frame is provided with a first chamber; the metal sectional material is located in the first chamber; the wall surface of the first chamber is bonded with the surface of the metal sectional material; the metal sectional material is provided with a plurality of prefabricated holes; the first chamber of the wood-plastic frame is provided with projections embedding into or penetrating through the prefabricated holes; the projections are integrally moulded with the wood-plastic frame, wherein the wood-plastic frame is made from a foamed wood-plastic material, and the metal sectional material is an open metal sectional material. According to the co-extrusion moulded composite plate provided by the embodiment of the invention, the open metal sectional material is used, and a closed shape is not used, thus ensuring the basic strength of the composite plate, saving the consumption of steel, and creating conditions for realizing compressed air inner-cooling for an extrusion mould.

Owner:BEIJING NEW BUILDING MATERIAL

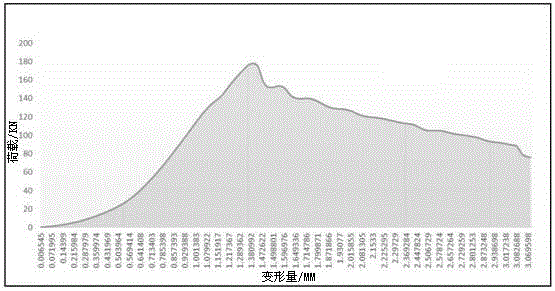

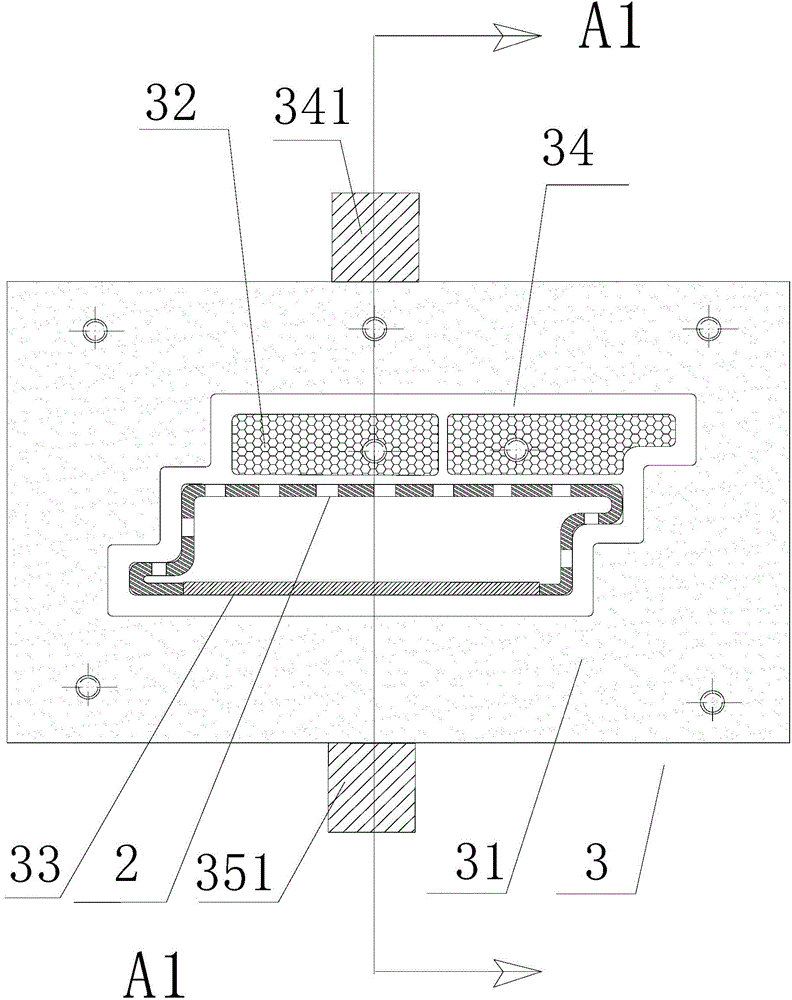

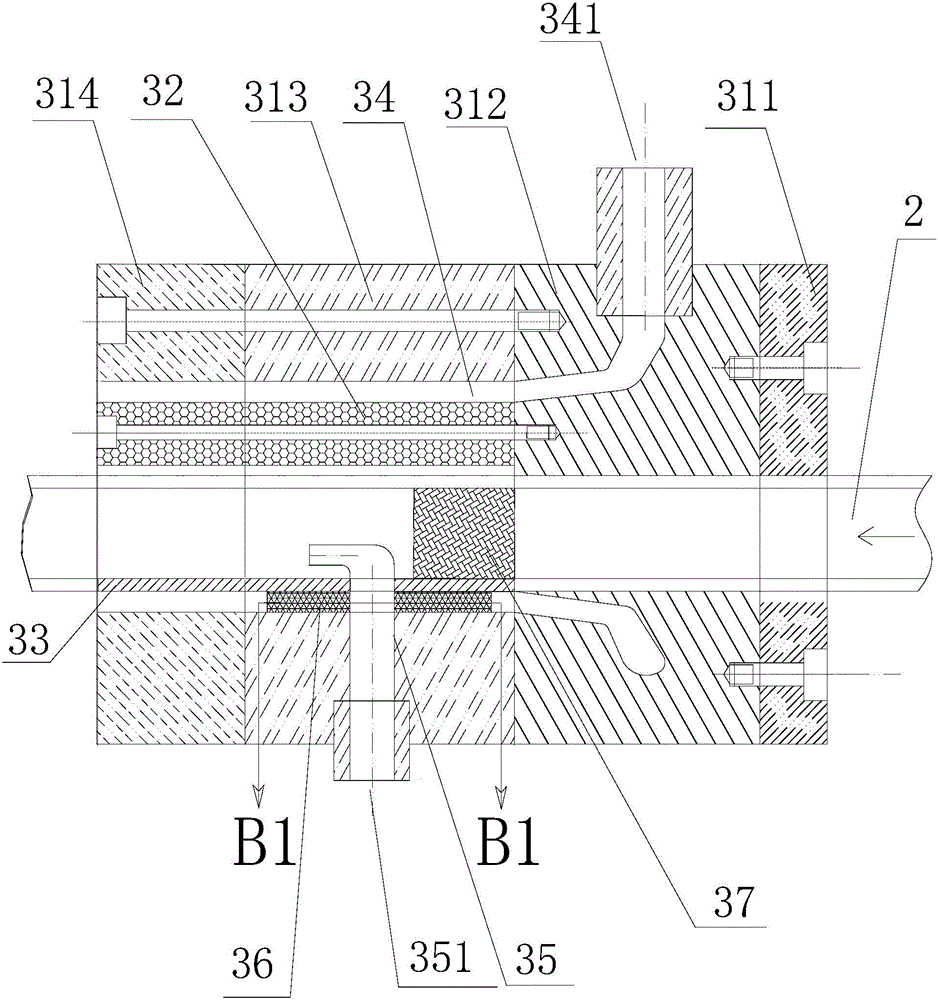

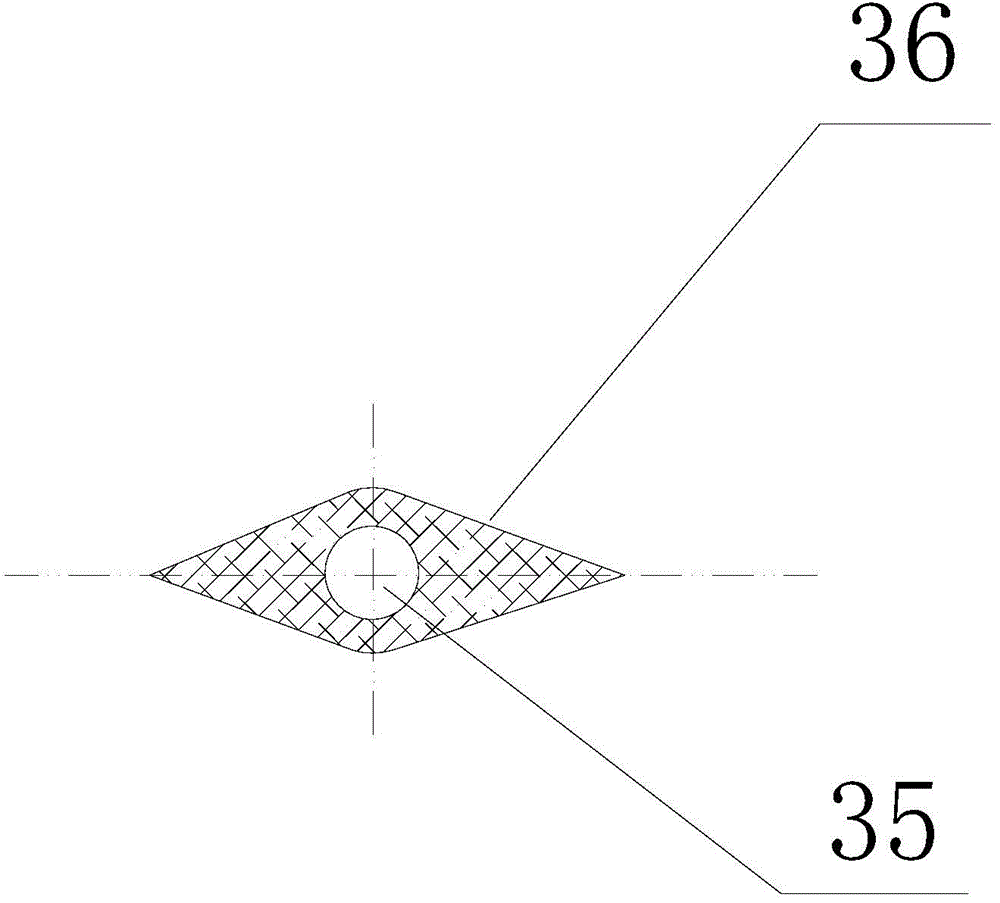

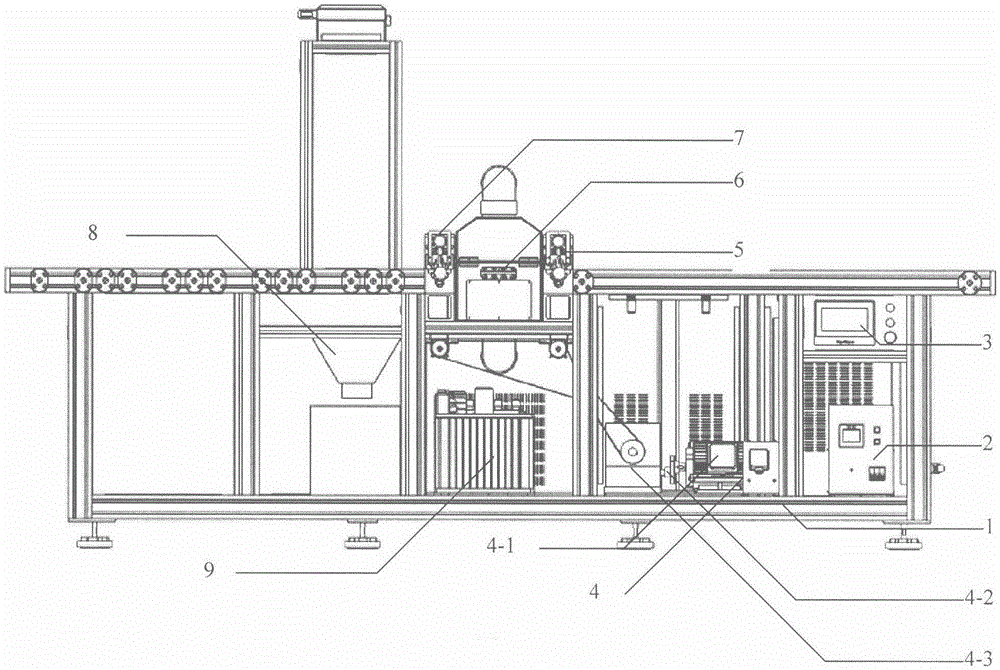

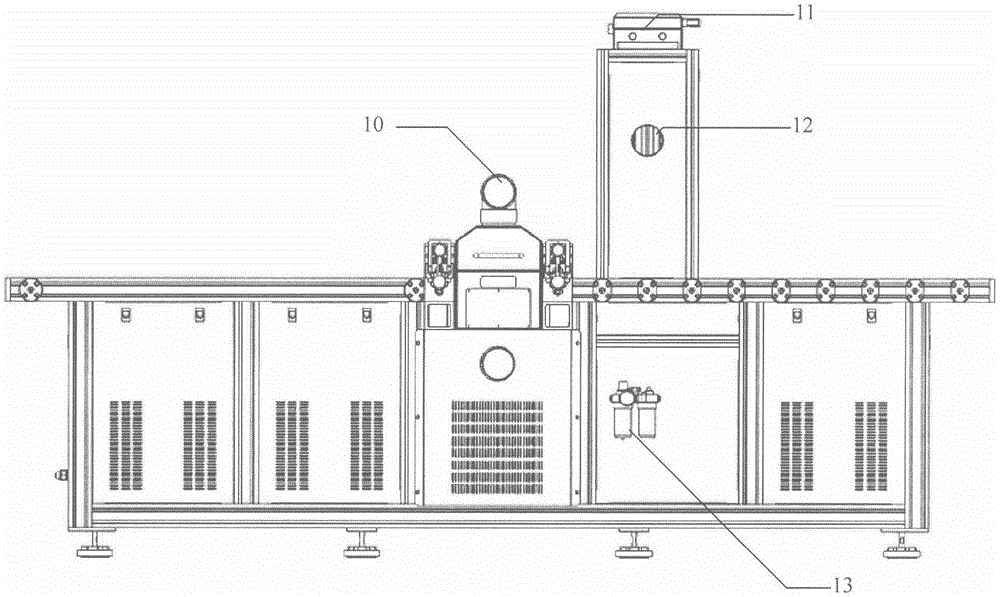

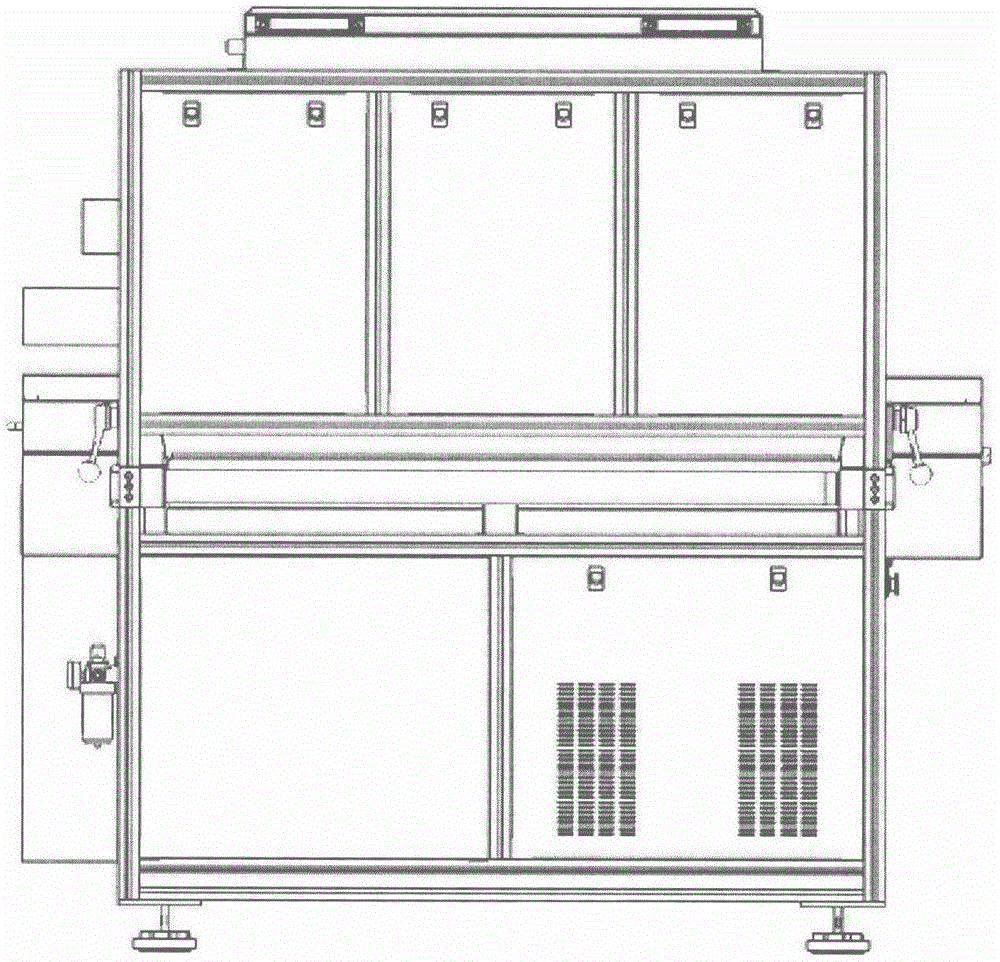

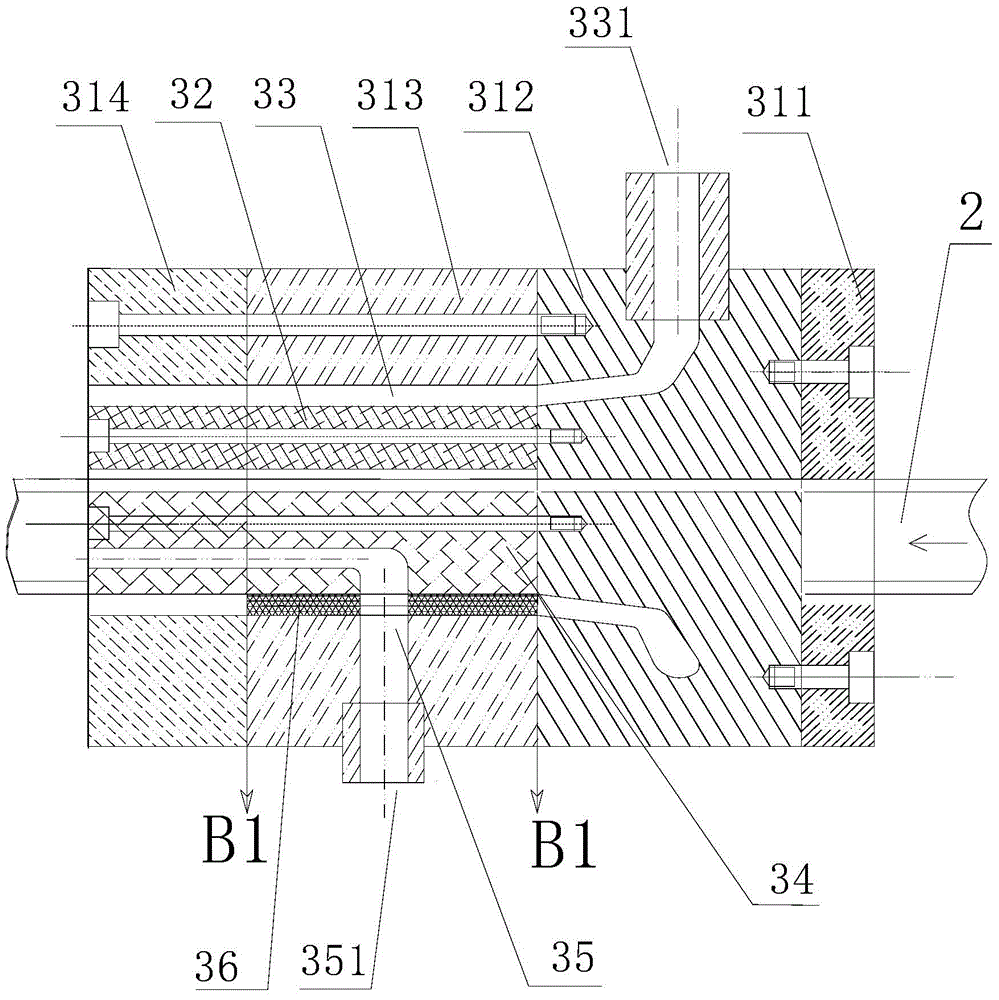

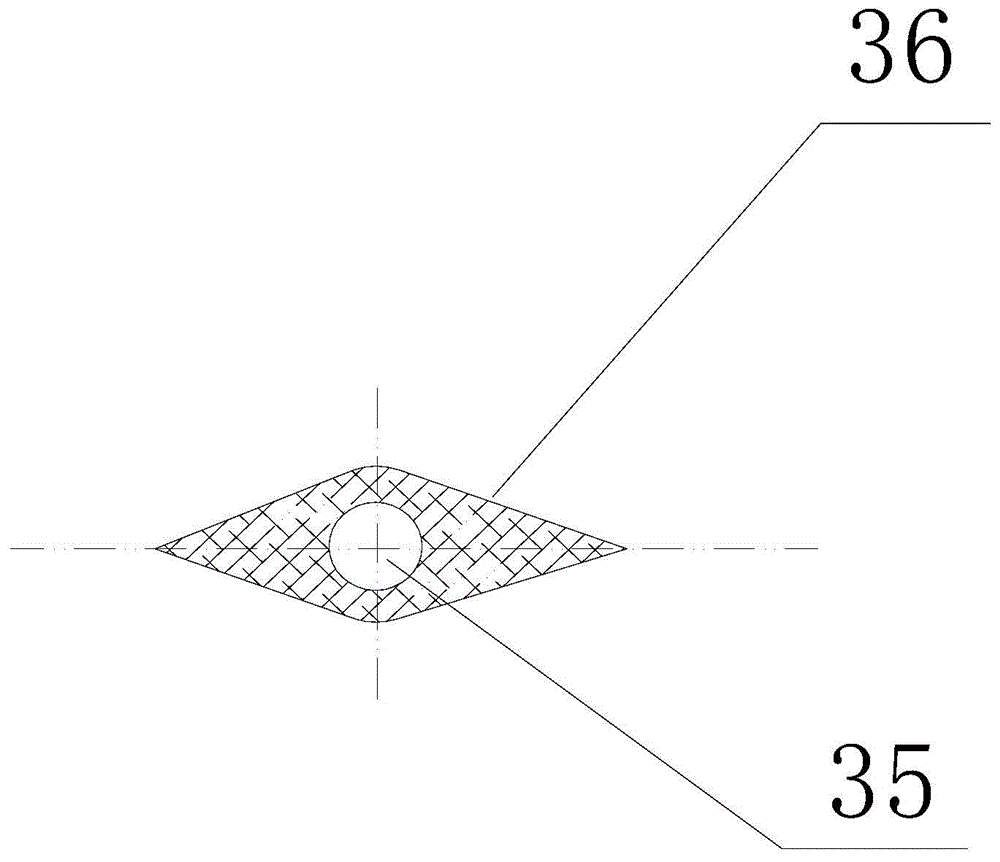

Low-temperature plasma modifying and microscale sizing integrated device for wood thin plates

The invention provides a low-temperature plasma modifying and microscale sizing integrated device for wood thin plates, which ensures that the use level of adhesive for veneer artificial board products is reduced by 30 to 70 percent compared with that in the traditional sizing mode. The device comprises an equipment framework, a wood thin plate conveying component, a power component, a low-temperature plasma processing component, an ultrasonic cyclone glue spraying component and a controller component, wherein the low-temperature plasma processing component comprises at least one pair of dielectric barrier discharge electrodes, a low-temperature plasma generator, a low-temperature plasma power supply and a cooling ozone removal device; the paired electrodes are parallel with a feeding press roll and are fixed on the equipment framework; the ultrasonic cyclone glue spraying component comprises ultrasonic cyclone synergistic nozzles, a nozzle supporting bracket, a glue amount control valve, a pipeline cleaning valve, an adhesive storage device, an adhesive collecting device and a glue sprayed smell removal device; the nozzle supporting bracket is fixed on the equipment framework and is positioned between a discharging press roll and a discharging conveying roll group; the nozzles are adjustably, parallelly and symmetrically arranged on the nozzle supporting bracket.

Owner:NANJING FORESTRY UNIV +1

High-pressure decorative door sheet comprising wood base materials and preparation method of door sheet

PendingCN107379683AReduce pollutionIncrease productivityFireproof doorsSynthetic resin layered productsPolypropyleneMolding (decorative)

The invention discloses a high-pressure decorative door sheet comprising wood base materials and a preparation method of the door sheet. The door sheet comprises base plate layers, buffer layers, decorative layers and wear-resistant protective layers which are sequentially arranged from bottom to top, wherein the base plate layer comprises at least two wood base material layers and impregnated surface paper layers for bonding are arranged between the wood base material layers. The plate layers are sequentially stacked in an intermittent hot press in the order of one wear-resistant protection layer, one decorative layer, one buffer layer, one impregnated surface paper layer for bonding, one base plate layer, a polypropylene isolating membrane, the other base plate layer, the other impregnated surface paper layer for bonding, the other buffer layer, the other decorative layer and the other wear-resistant protection layer and then subjected to high-temperature and high-pressure one-time hot press molding. The high-pressure decorative door sheet comprising the wood base materials is flame-retardant, fireproof, wear-resistant, scratch-resistant, waterproof, damp-proof, impact-resistant, fouling-resistant and scrape-resistant, the decorative layers and the base materials are subjected to one-time hot press molding and can be used without pasting, decorative surface layers cannot peel off and mildew, the surface is easy to clean, the formaldehyde release amount and TVOC release amount are low, and no heavy metals are contained.

Owner:HENAN YONGWEI SECURITY

Technique for mfg. base for supporting sun umbrella

InactiveCN1861351ASimple methodEasy way ingredientsCeramic shaping apparatusEngineeringMechanical engineering

A technology for manufacturing the supporting stand of sunshade includes such steps as preparing a prototype of needed stand, making needed decorative pattern, coating resin or silica rubber to obtain a female mould, filling concrete into the female mould, solidifying and demoulding.

Owner:黄耀宁

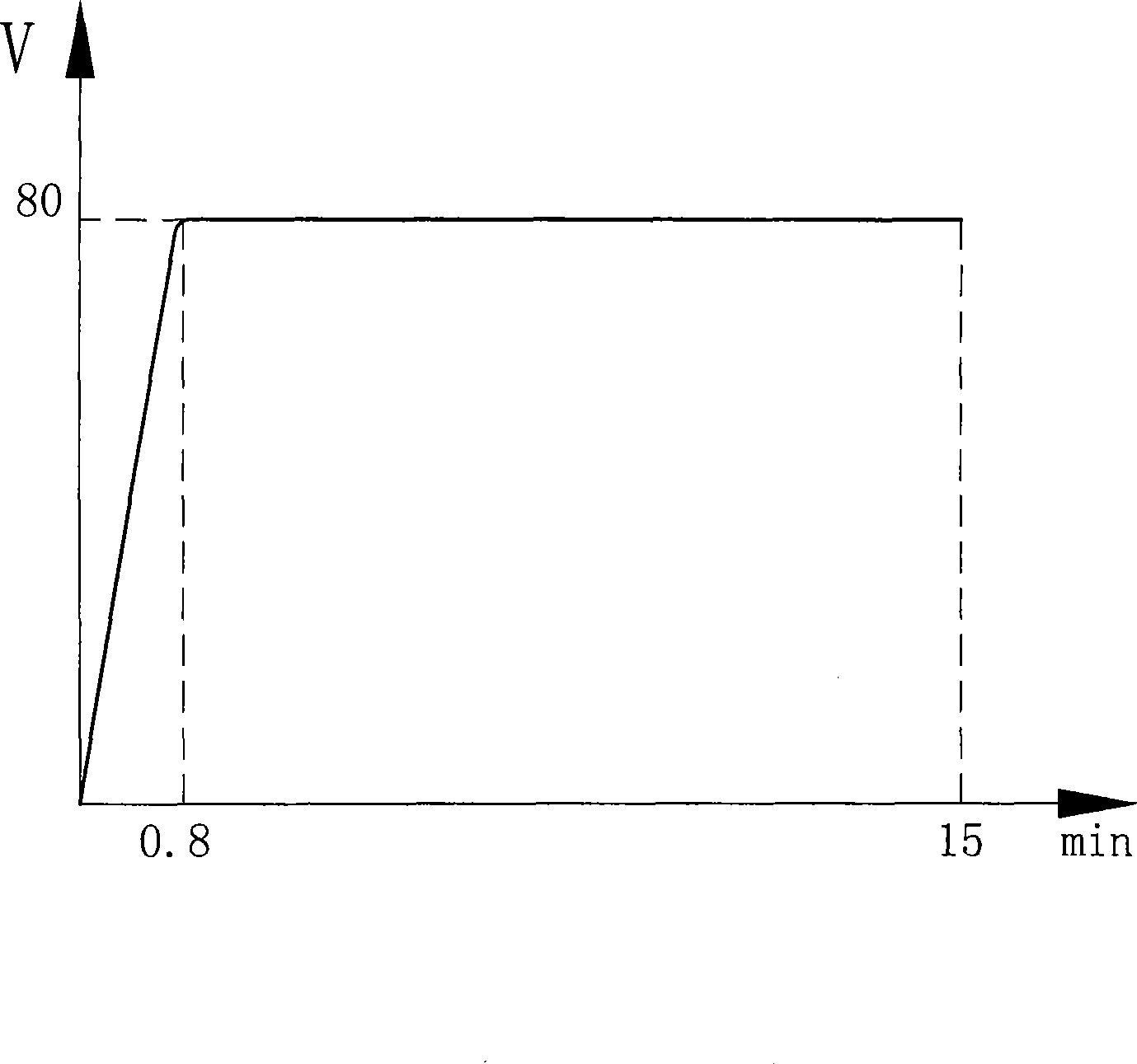

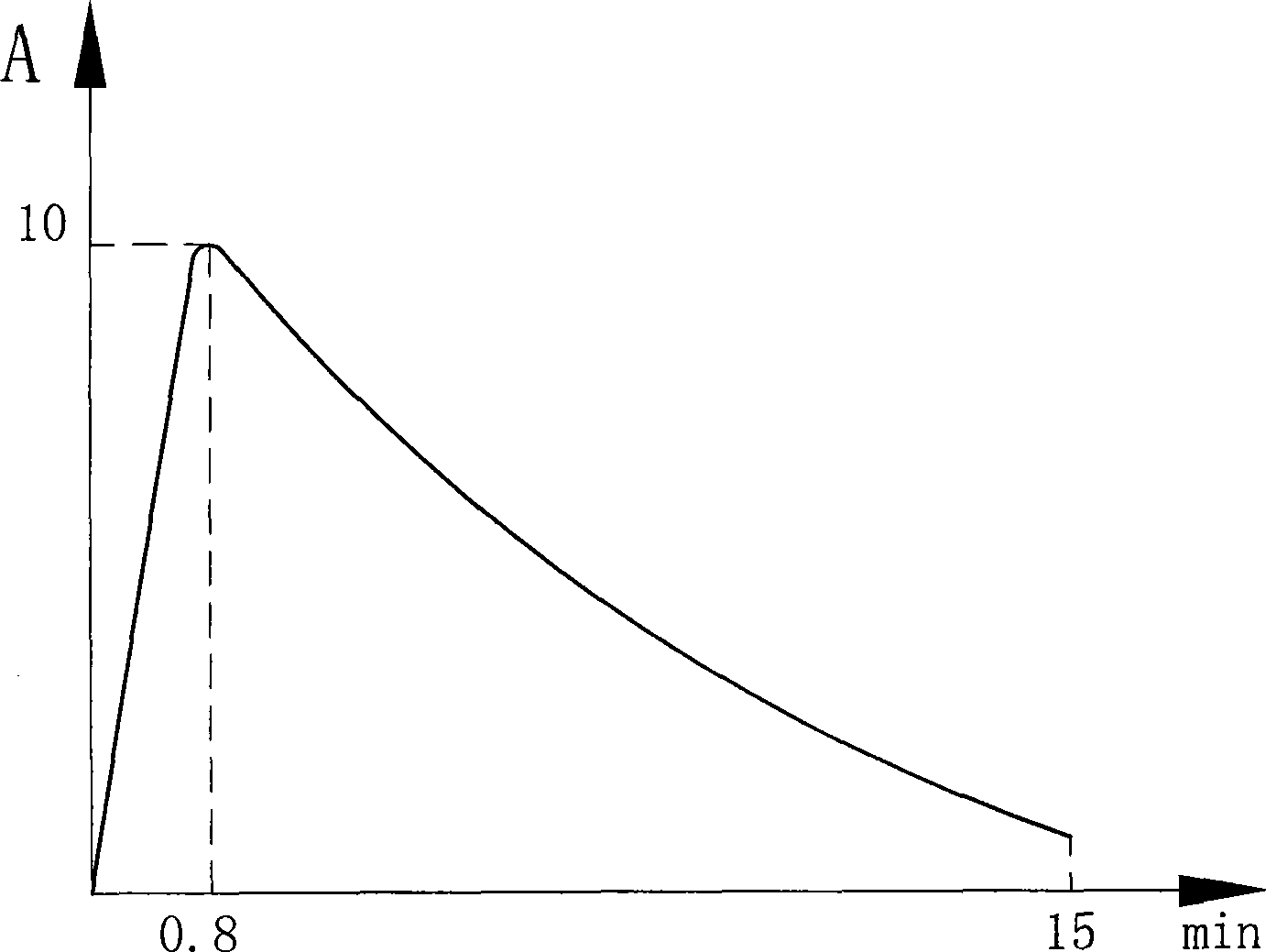

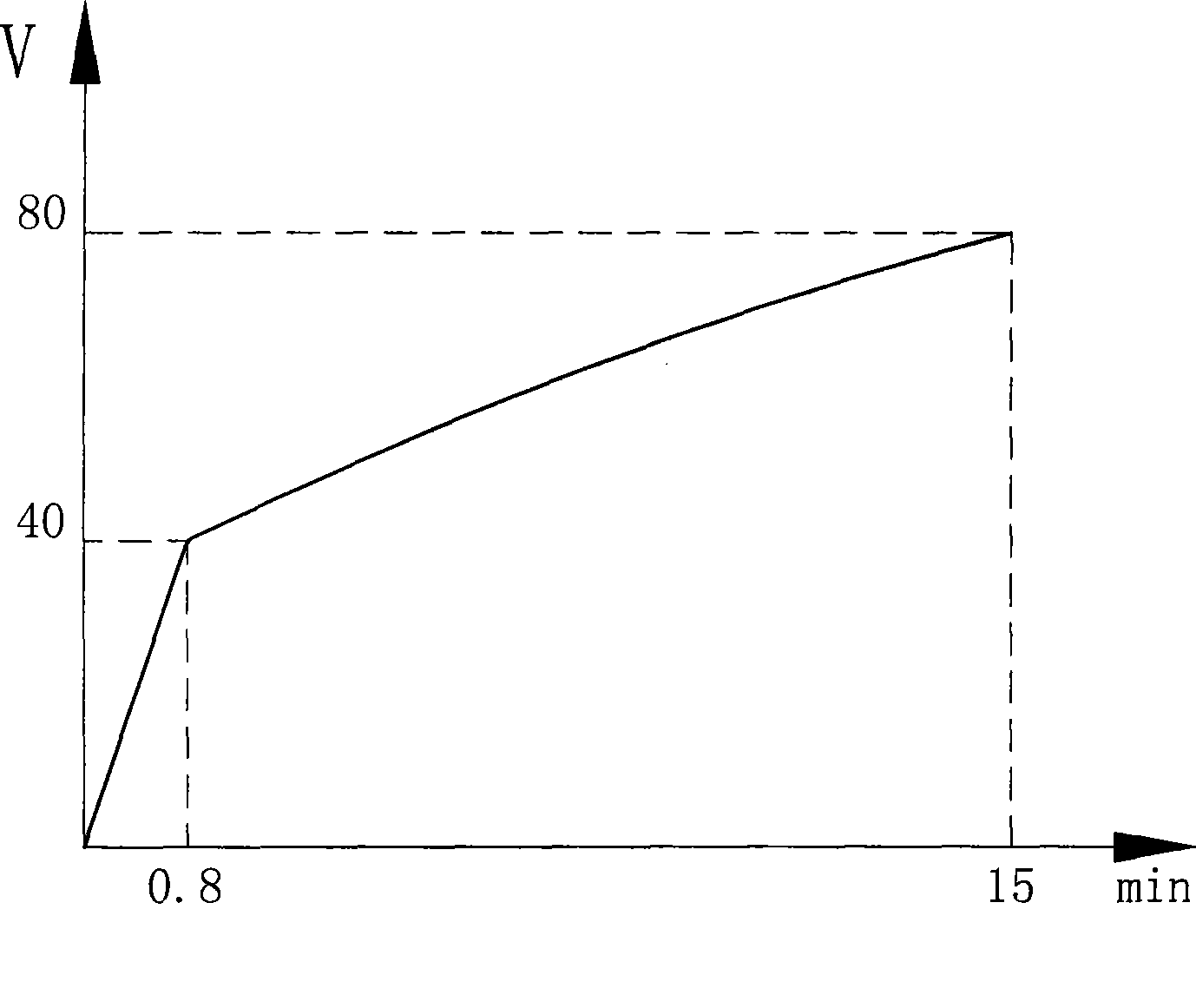

Constant current anode oxidation treatment method for surfaces of aluminum and aluminum alloy materials

ActiveCN101445950ASuitable for large-scale industrial productionLess investmentAnodisationComposite electrolyteOxidative treatment

The invention discloses a constant current anode oxidation treatment method for surfaces of an aluminum and aluminum alloy material. The method comprises the following steps: the aluminum and the aluminum alloy material are taken as anodes and placed into a composite electrolyte; current density is controlled to rise from 0A / dm<3> to 1-5A / dm<3> that is the required current density within 20-120s and kept constant; anode oxidation voltage increases along with the increase of the current in 20-120s; the voltage slowly increases after reaching 20-60V, and reaches 70-120V in 600-1200s until a film is formed completely. The method is suitable for large-scale industrial production and has the advantages of low apparatus and equipment investment, low requirement, no need of special temperature control in the whole process flow, higher hardness of the produced anode oxide film, and better wear resistance, corrosion resistance, high temperature impact resistance and electrical insulation properties.

Owner:ZHEJIANG SUPOR CO LTD

Non-machine millstone floor

The invention discloses a non-machine millstone floor, and relates to the field of terrazzo floors. The non-machine millstone floor is mainly prepared in parts by mass: 5 parts of magnesium oxide, 2 parts of magnesium chloride, 50 parts of aggregates and 6 parts of water, and thus the functions of seamless surface, stain resistance, and easy cleaning and maintenance are achieved.

Owner:深圳市鼎顺鑫装饰工程有限公司重庆分公司

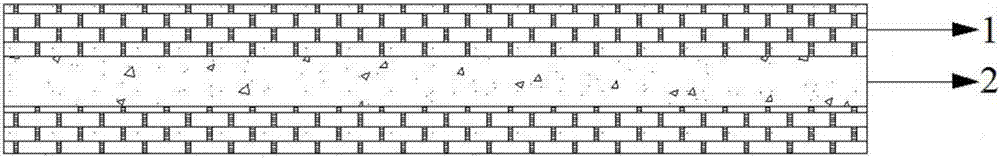

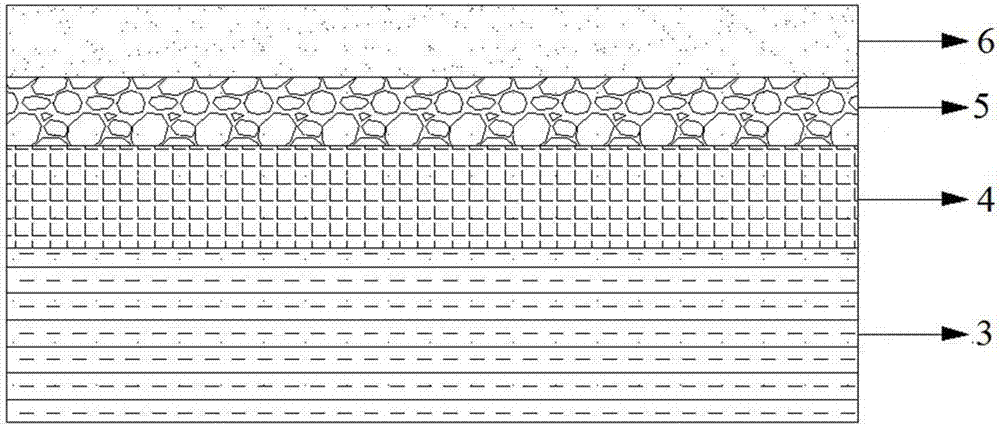

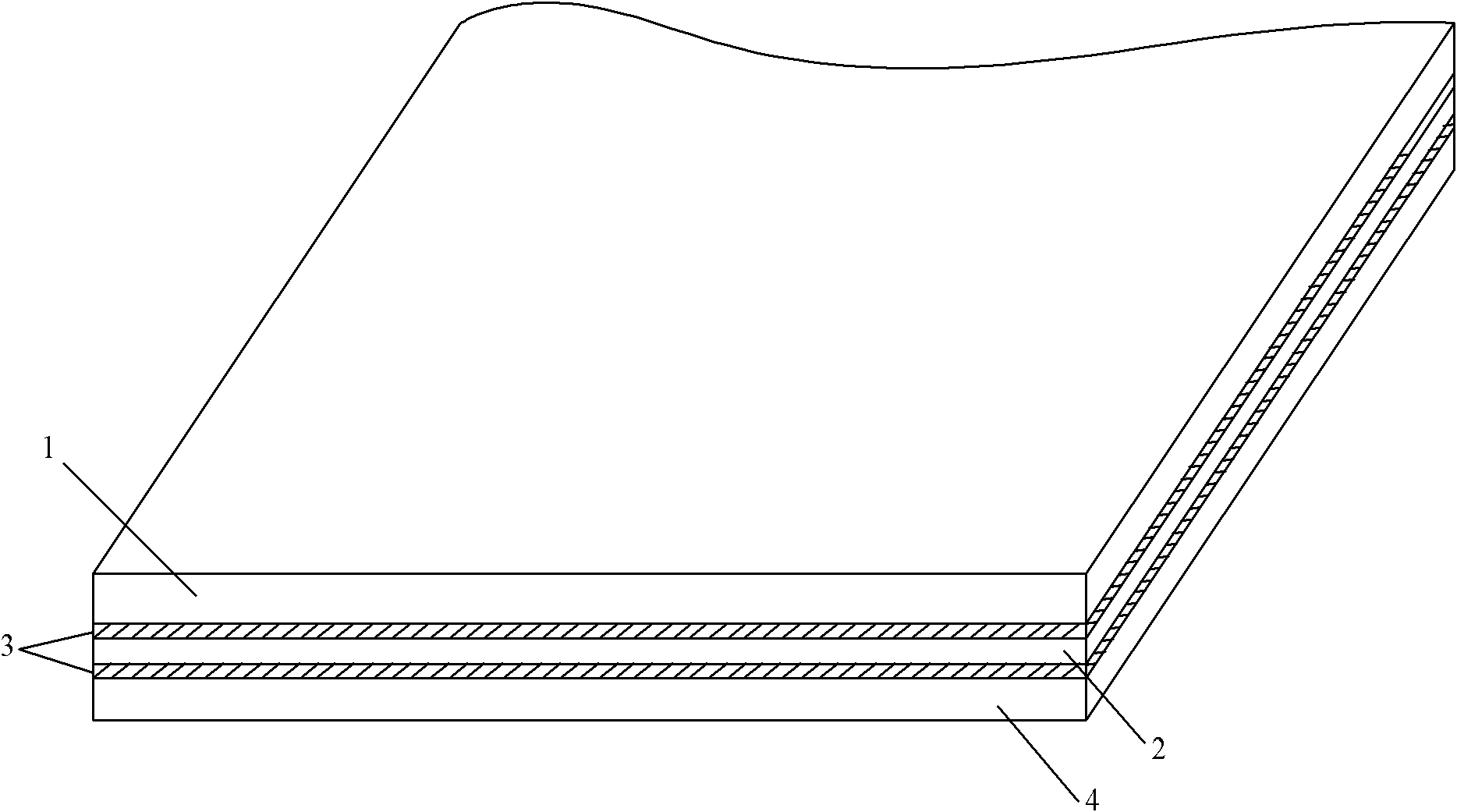

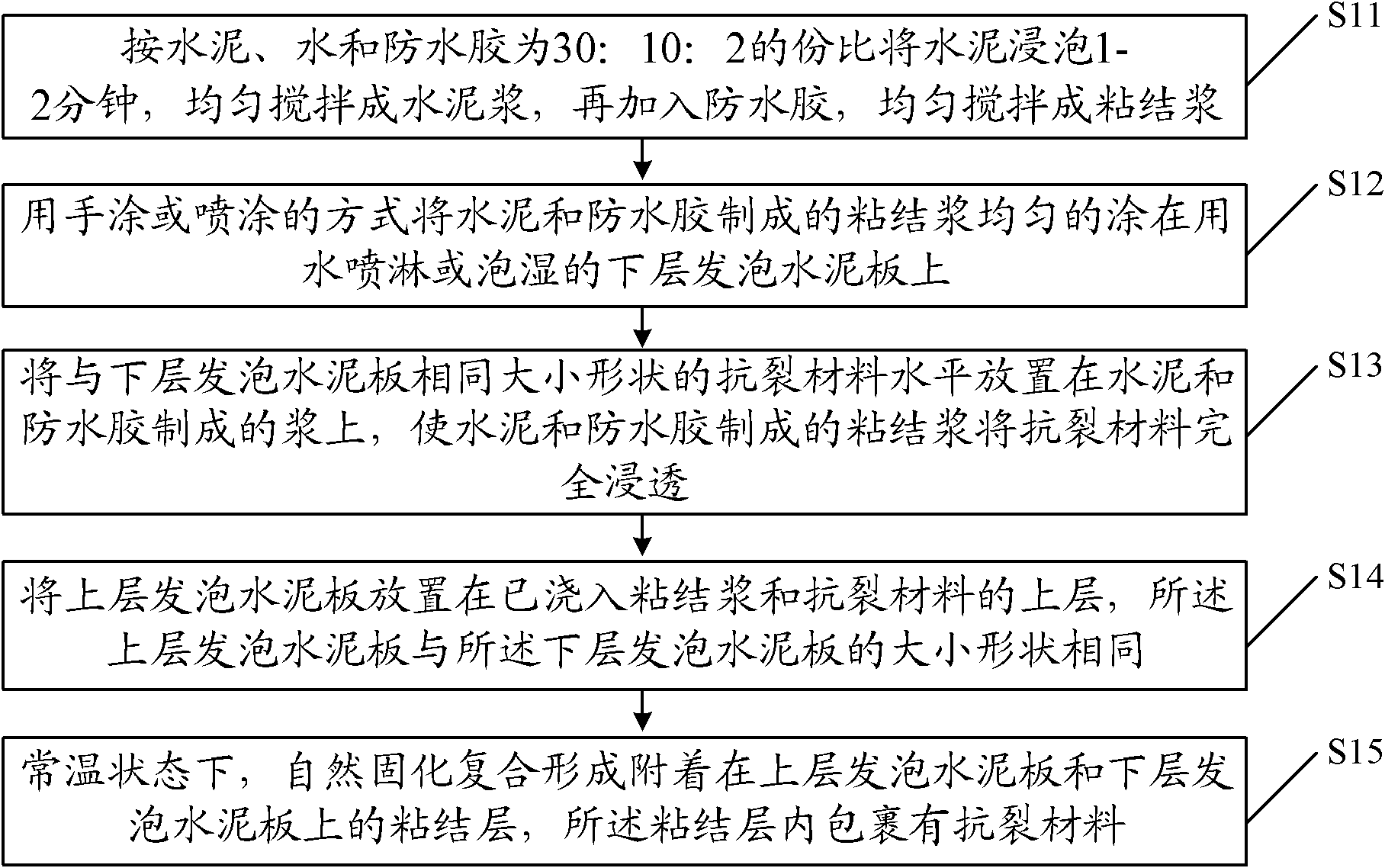

Interlayer composite foaming cement plate and manufacturing method thereof

InactiveCN103132617AHigh strengthGood toughnessCeramic shaping apparatusHeat proofingCementUltimate tensile strength

The invention discloses an interlayer composite foaming cement plate and a manufacturing method thereof, and relates to the technical field of foaming cement plates. The strength of the foaming cement plate is strengthened, toughness is good, and breaking is not easy. The interlayer composite foaming cement plate comprises an upper layer foaming cement plate, a bonding layer which is wrapped with breaking-resistant materials, and a lower layer foaming cement plate. The bonding layer is bound with the upper layer foaming cement plate and the lower layer foaming cement plate. The manufacturing method is used for the foaming cement plate.

Owner:李楚荣

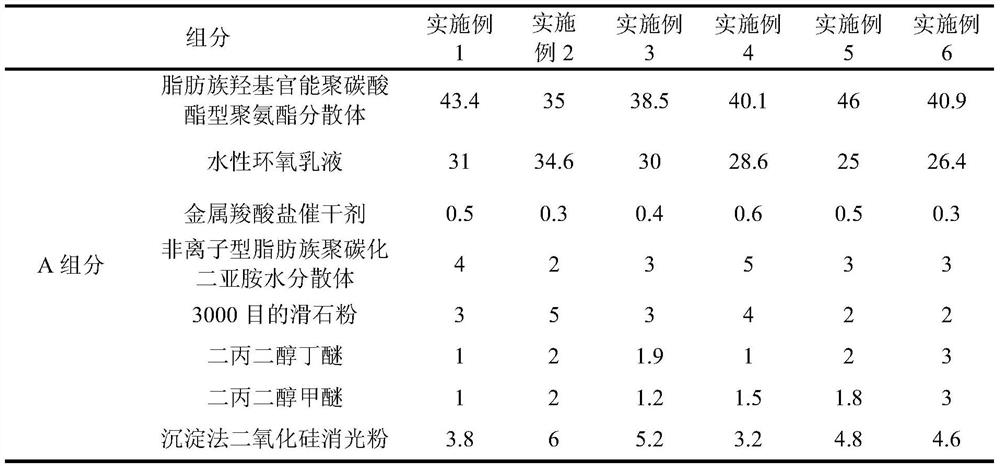

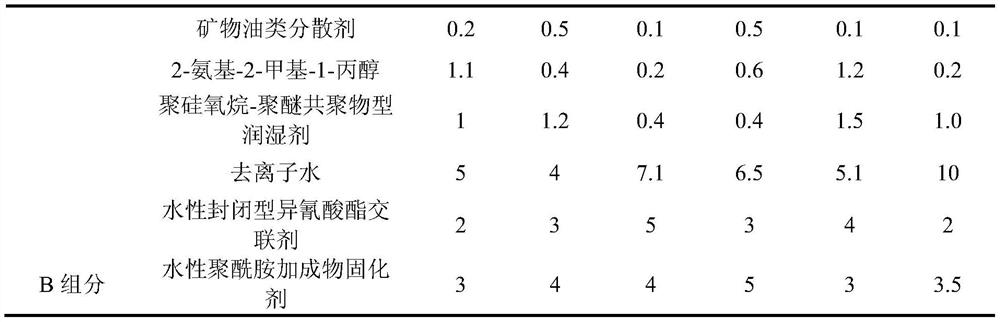

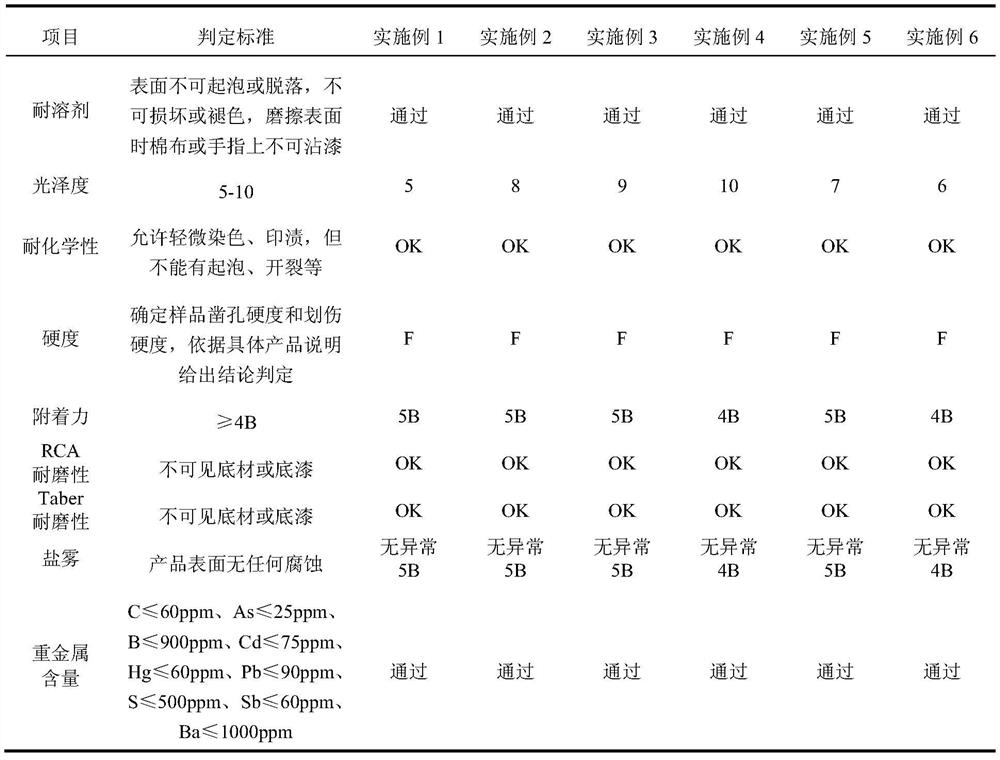

Dual-curing water-based coating as well as preparation method and construction process thereof

ActiveCN111849326AGood chemical resistanceHigh transparencyPretreated surfacesPolyurea/polyurethane coatingsDual curePolymer science

The invention discloses a dual-curing water-based coating as well as a preparation method and a construction process thereof. The coating is used for simultaneously coating a metal and plastic composite base material. The coating comprises a component A and a component B, wherein the component A comprises 30%-50% of waterborne polyurethane resin, 20%-40% of a waterborne epoxy emulsion, 0.3%-0.6% of a waterborne drier, 2%-5% of a waterborne polycarbodiimide cross-linking agent, 2%-5% of a waterborne pigment filler, 2%-6% of a hydrophilic solvent, 3%-6% of silicon dioxide, 2%-10% of a water-based blocked isocyanate cross-linking agent, 5%-10% of deionized water and 0.7%-3.4% of a water-based auxiliary agent; the component B comprises a curing agent; the mass ratio of the component A to the component B is 100:(3-6). According to the dual-curing water-based coating, the water-based polyurethane resin and the water-based epoxy emulsion serve as main film-forming resin, a coating layer capable of meeting the requirements of a plastic base material and a metal base material at the same time is formed by utilizing different reaction degrees of the water-based blocked isocyanate cross-linking agent and the curing agent to the temperature, and the dual-curing water-based coating has good adhesion performance and chemical resistance.

Owner:HUNAN SOKAN NEW MATERIAL

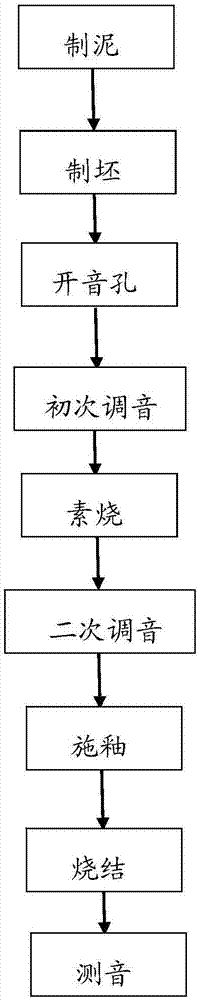

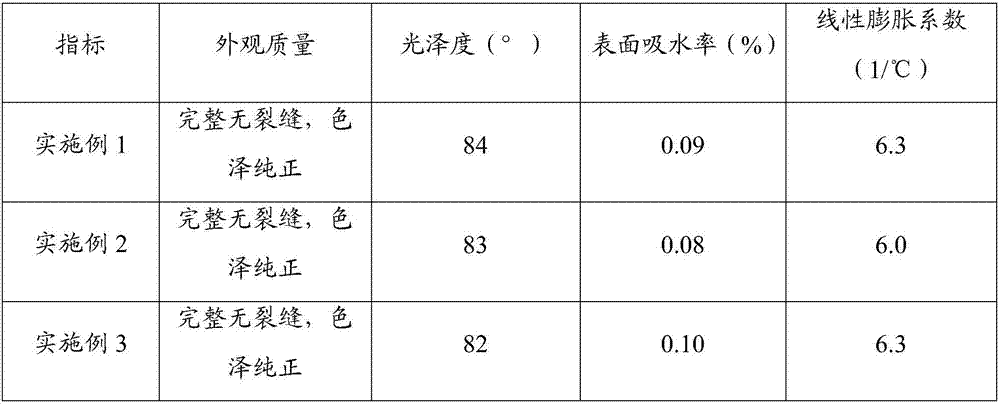

Manufacturing and firing method of jun porcelain ancient egg-shaped and holed wind instrument

The invention discloses a manufacturing and firing method of jun porcelain ancient egg-shaped and holed wind instrument. The method comprises the following steps: preparing clay, preparing a blank, biscuit firing, glazing, sintering, and detecting sound. Raw materials for preparing the clay consist of the following components in parts by weight: 40 to 50 parts of kaolin, 5 to 10 parts of alkaline stone, 10 to 15 parts of knot clay, 5 to 10 parts of quartz sand, 0.5 to 1 part of vermiculite, 1 to 2 parts of plant ash, 1 to 2 parts of sodium alginate, and 0.5 to 1 part of phenolic resin powder. A gradually heating multi-sectional heating way is adopted both in the biscuit firing process and the sintering process, so that the blank is slowly heated, the heating non-uniformity and stress change caused by the sudden change of the temperature can be avoided, so that cracks and crease on the surface of the jun porcelain ancient egg-shaped and holed wind instrument can be avoided, and the artistic ornamental value of the jun porcelain ancient egg-shaped and holed wind instrument can be improved; and moreover, the jun porcelain ancient egg-shaped and holed wind instrument fired by the invention is rigid in structure and unlikely to crack, the sound produced by the instrument is strong and ebb and flow, steady and dense and has penetration powder, and the playing requirement of the porcelain jun ancient egg-shaped and holed wind instrument can be met.

Owner:PINGDINGSHAN UNIVERSITY

Preparation method of bismuth zirconate microcrystal ceramic glaze with photocatalytic function

ActiveCN106630621ATightly boundAffect aestheticsMetal/metal-oxides/metal-hydroxide catalystsZirconatePotassium

The invention relates to a preparation method of bismuth zirconate microcrystal ceramic glaze with a photocatalytic function. The preparation method includes: blending quartz, potassium feldspar, albite, borax, Bi2O3, Suzhou kaolin and lithium carbonate according to the mass ratio, performing heat preservation at 1270-1290 DEG C for 20-40 minutes, taking out, pouring into water for quenching, and grinding to obtain a material A; blending the material A, the Bi2O3, ZrO2 and the Suzhou kaolin according to the mass ratio to obtain a material B; adding the material B and a dispersing agent into water, and evenly stirring to prepare glaze slip; glazing the surface of ceramic with the glaze slip, and sintering to obtain the bismuth zirconate microcrystal ceramic glaze with the photocatalytic function. The preparation method has the advantages that the ceramic glaze is prepared by the sintering process, coating is not needed, the prepared functional glaze can be tightly combined with a ceramic matrix, the photocatalyst generated during the sintering of the Bi2O3 and the ZrO2 is evenly distributed in the glaze, and the 'rainbow effect' which affects glaze attractiveness is not generated.

Owner:SHAANXI UNIV OF SCI & TECH

Polyphenyl sandwich light architectural material and its production method

InactiveCN1559794ASmall sizeBig moduleConstruction materialSolid waste managementBrickHazardous substance

A polybenzene sandwich building material with light weight is prepared from magnesium oxide, plant ash, powdered coal ash, assistant (efficient water-decreasing agent NB, penetrant OS15, emulsifier OP-10 and melamine), and solution of magnesium chloride (or sulfate). Its advantages are light weight, and low cost.

Owner:谢涛

Novel anti-corrosive and antistatic treating agent for textiles

InactiveCN106192382AGood surface decorationGood water resistanceBiochemical fibre treatmentAmmonium polyphosphateSolvent

The invention discloses a novel anti-corrosive and antistatic treating agent for textiles. The novel anti-corrosive and antistatic treating agent is composed of formaldehyde, melamine, urea, sodium hydroxide, siloxanyl methacrylate copolymers, pentaerythritol, sodium alkyl benzene sulfonate, ammonium polyphosphate, poly vinyl acetate, sodium fluosilicate and essence. The novel anti-corrosive and antistatic treating agent used for protecting surfaces of the textiles with 94%-98% of luster is good in surface decoration, good in water resistance, high in washing fastness, good in wear resistance and free of color difference; spots and cavity shrinkage can be prevented, hand feeling is unaffected, flexibility is good, and antistatic property is good; time for curing and drying is 20-40 minutes, solvent resistance and air permeability are good, broad-spectrum antibacterial is achieved, and the agent has good antibacterial effect on escherichia coli, candida albicans and staphylococcus aureus; the agent is high in adhesive force, harmless to the skin, good in anti-corruption, capable of greatly improving mildew resistance to textile articles, simple and convenient in process and low in cost.

Owner:吴国强

Co-extrusion molding composite board and preparation method thereof

The present invention provides a co-extrusion molding composite board. The co-extrusion molding composite board comprises a wood plastic frame, a foaming layer and a metal profile; the wood plastic frame is provided with a first cavity; the metal profile has an opening; the metal profile is positioned in the first cavity; the wall surface of the first cavity is bonded to the surface of the metal profile; the foaming layer is put in a space enclosed by the first cavity and the metal profile; the foaming layer is bonded to the wall surface of the first cavity and the surface of the metal profile; and the foaming layer is prepared by foaming materials. According to the composite board, the internal metal profile effectively provides mechanical strength, the metal profile, the foaming layer and the wood plastic frame are composited and integrated, so that the requirement for strength of the wood plastic part is reduced, the foaming technology can be adopted for materials of the wood plastic frame, wood plastic materials are saved, and heat and sound insulation performance of the composite board applied as a wall board is largely improved.

Owner:BEIJING NEW BUILDING MATERIAL

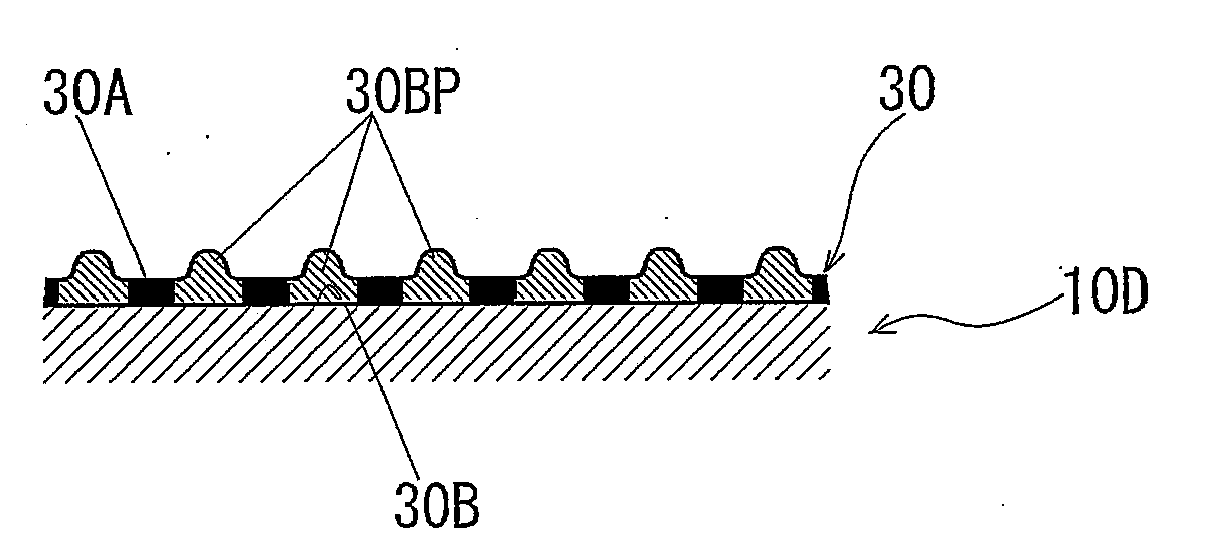

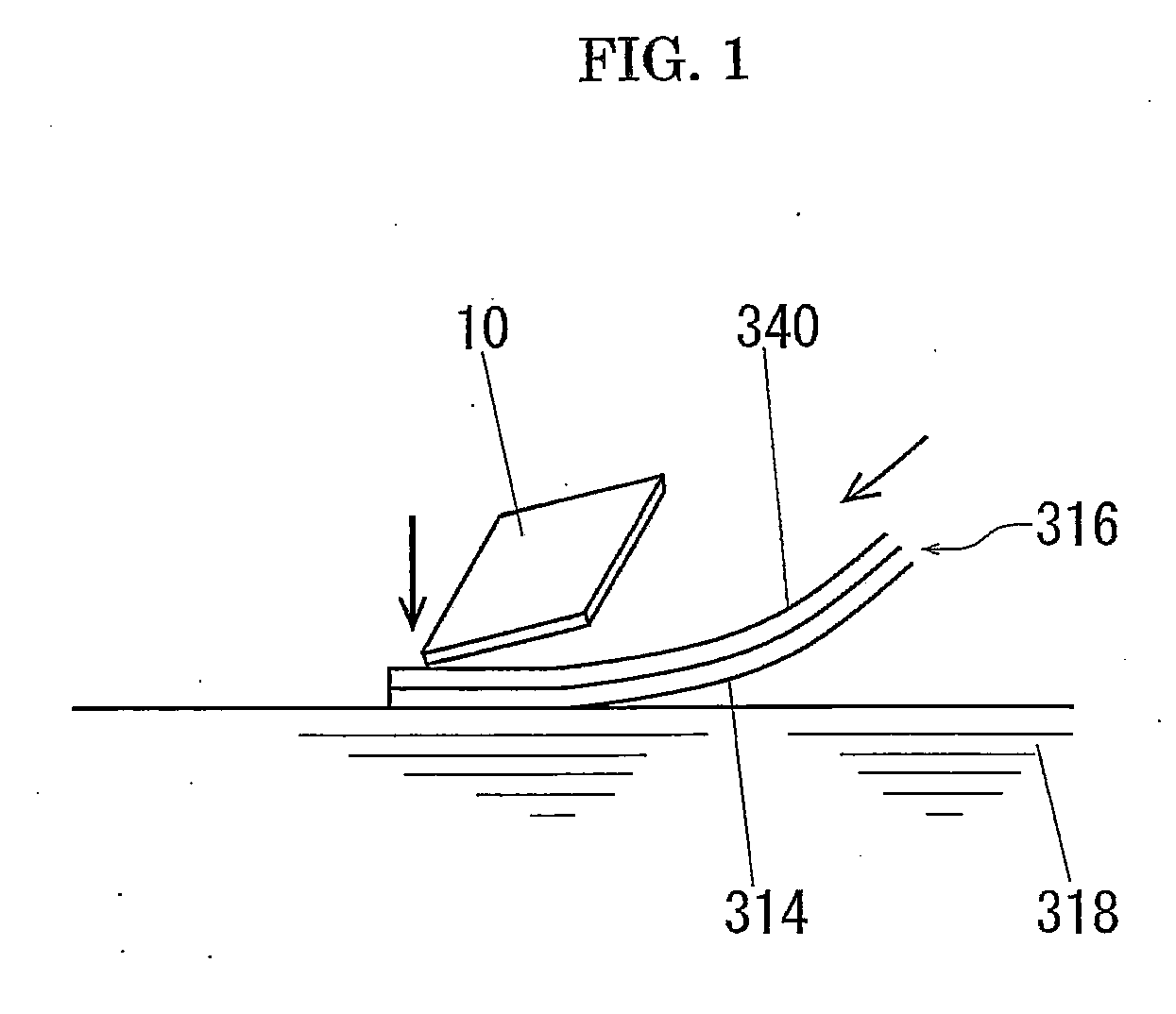

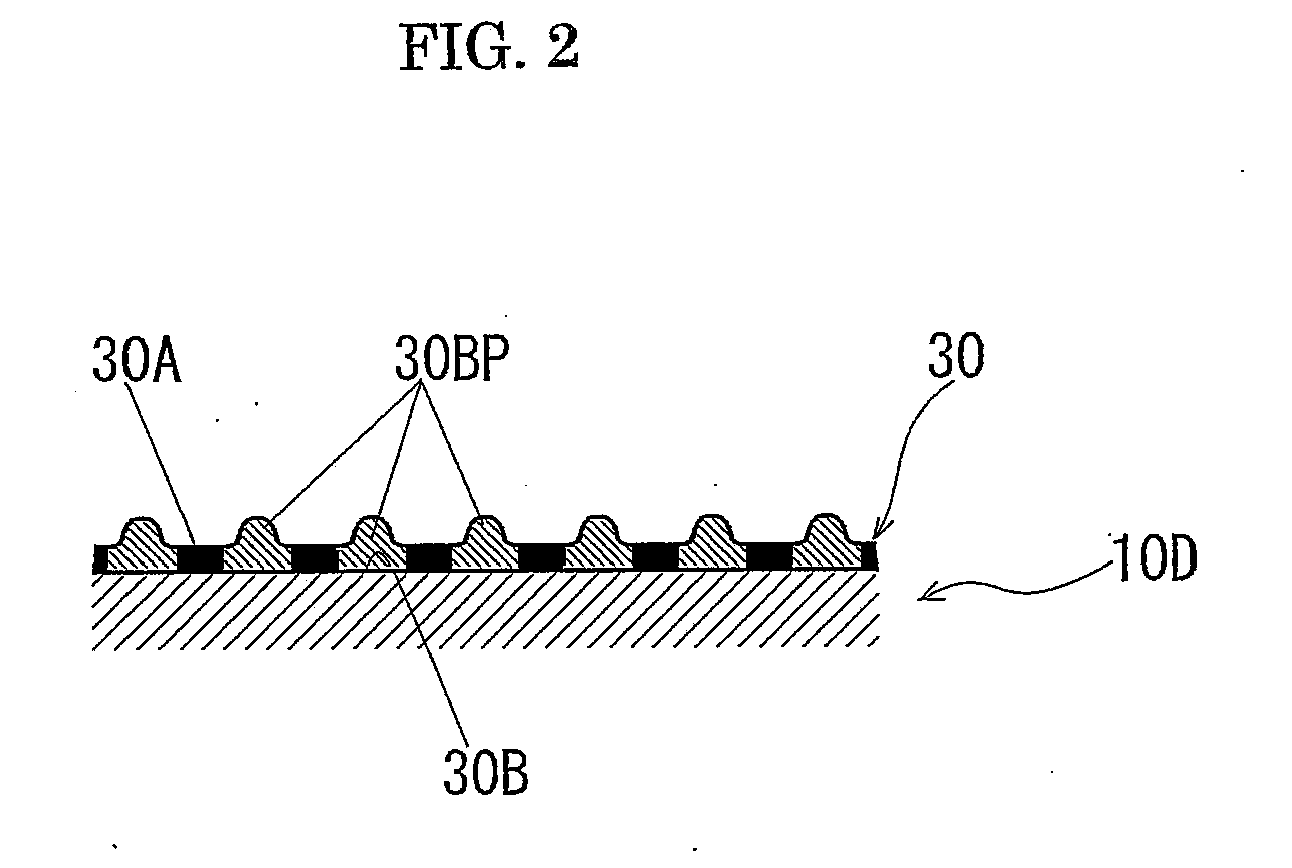

Water pressure transfer method, a transfer film for water pressure transfer and a water pressure transfer article

InactiveUS20100229745A1Good surface decorationUnevenness in propertyCylinder pressesPlaten pressesEngineeringWater pressure

A transfer film 316 which has a print pattern 340 comprising a first area 312A having an ink layer and a second area 312B having no ink layer and has no whole surface fixture layer formed thereon is prepared, an activating agent is applied onto the surface of the transfer film 316 to collect a surplus portion of the activating agent in a convex form in the second area by a repelling operation of the ink player 312I in the first area 312A and a collecting power of the activating agent 320, the convex collection portions 320C of the activating agent in the second area 312B have a concave-convex reversal made on the surface of the article 10 when the water pressure transfer is performed, and the convex collection portions of the activating agent are shrunk and protruded when the print layer is hardened whereby a three-dimensional unevenness is imparted onto the surface of the article.

Owner:TAICA

Preparation method of bismuth zirconate microcrystalline ceramic glaze with photocatalysis function

ActiveCN106630632AWith photocatalytic functionHigh glossMetal/metal-oxides/metal-hydroxide catalystsPotassiumZirconate

The invention discloses a preparation method of bismuth zirconate microcrystalline ceramic glaze with a photocatalysis function. The preparation method comprises the following steps: blending quartz, potassium feldspar, albite, borax, Bi2O3, Suzhou soil and lithium carbonate; preserving heat at 1,270-1,290 DEG C for 20-40min; taking out and pouring into water for quenching to obtain a frit; grinding the frit to obtain a material A; blending the material A with Bi2O3, ZrO2 and Suzhou soil to obtain a material B; adding the material B and a dispersing agent into water, stirring and uniformly mixing to obtain glaze slip; glazing the ceramic surface with the glaze slip; and firing to obtain a bismuth zirconate ceramic glaze with a photocatalysis function. The glaze prepared According to the invention has good gloss and stable chemical property. According to the invention, the ceramic glaze is prepared by adopting a firing technology, coating is not needed, and thus the prepared functional ceramic glaze is tightly combined with a ceramic base and does not fall off easily; and moreover, crystal flowers of special morphology can be quickly formed on the glaze surface, and the surface decoration effect is good.

Owner:SHAANXI UNIV OF SCI & TECH

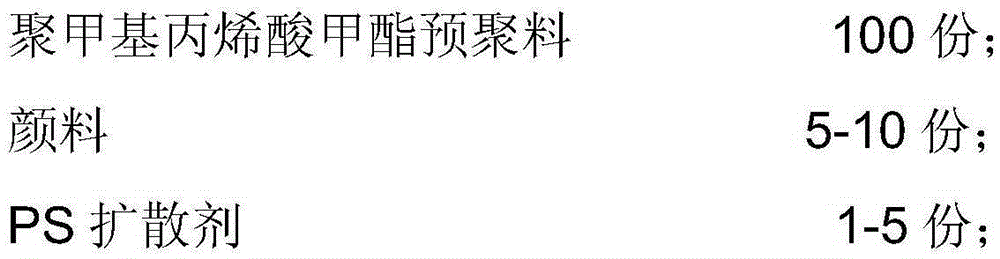

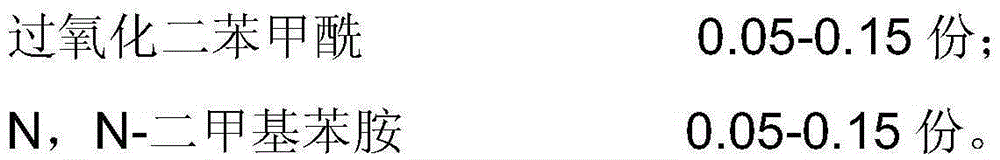

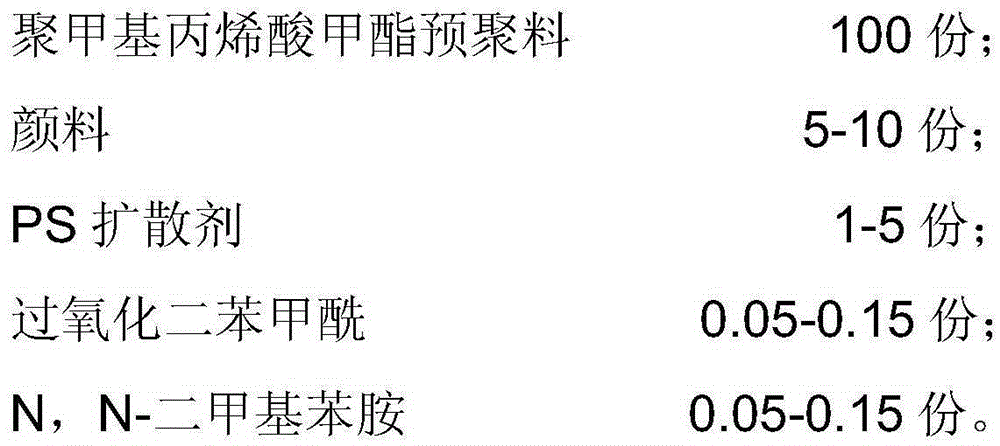

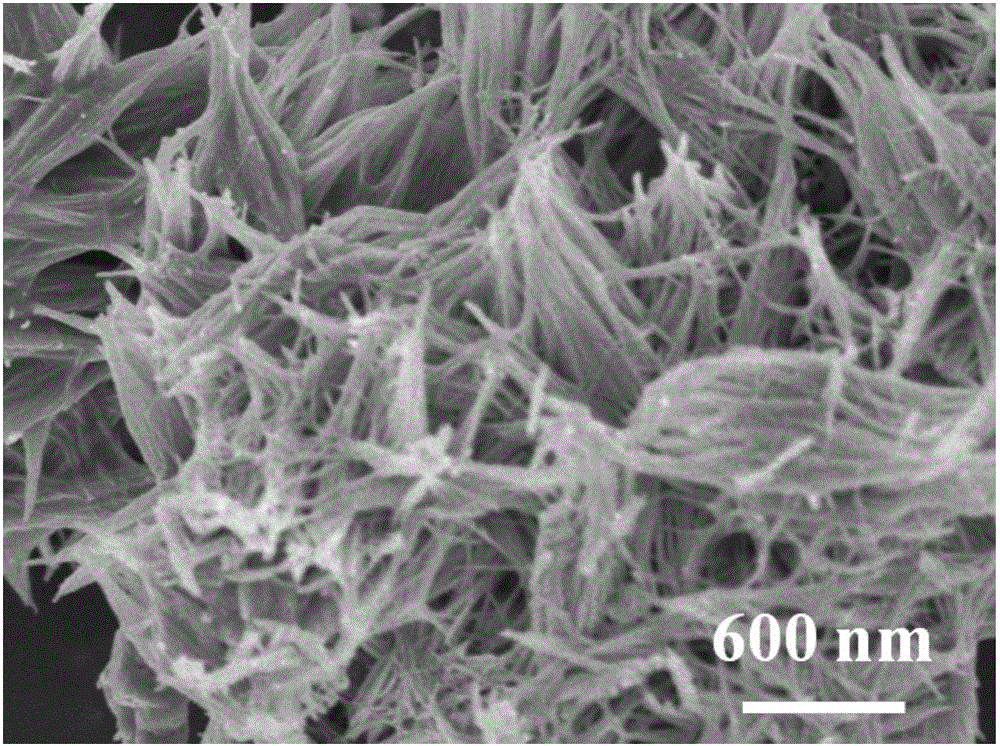

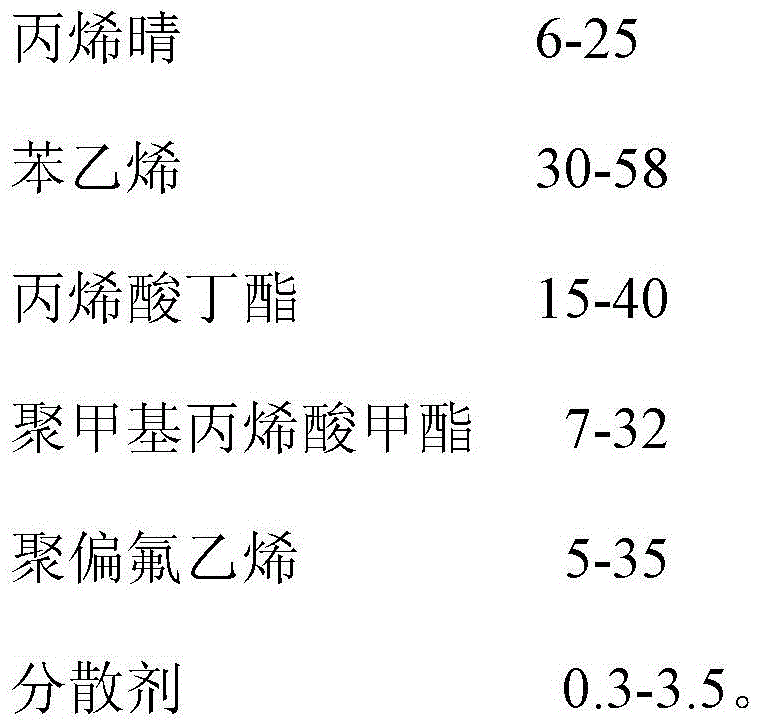

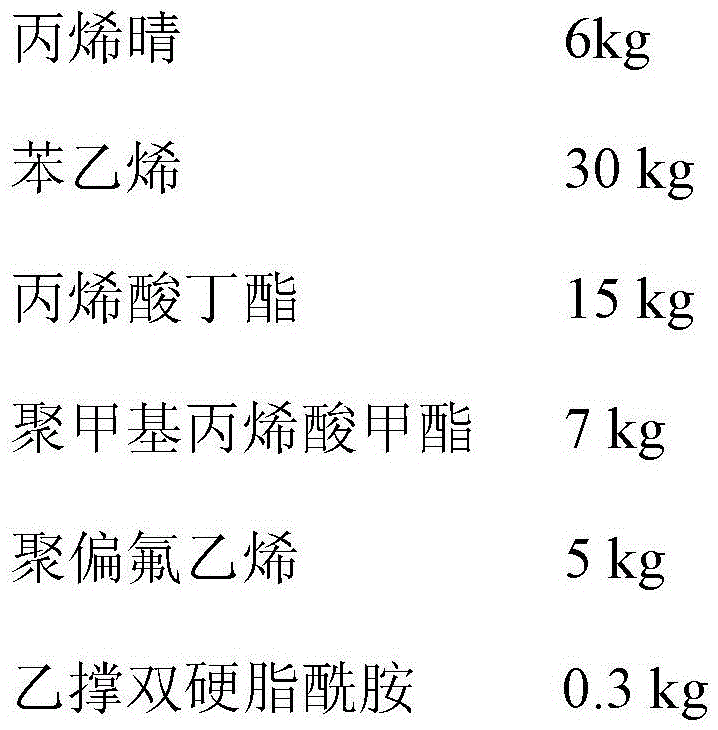

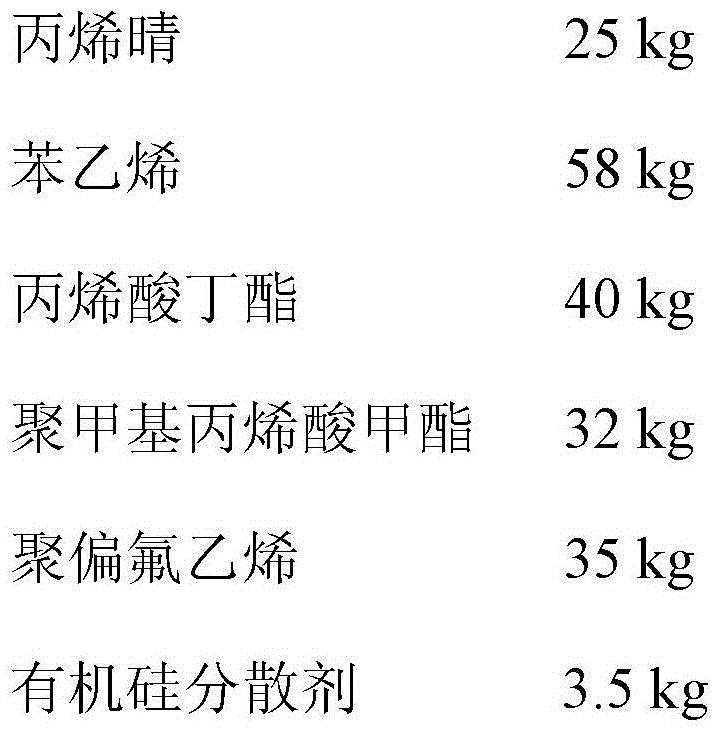

Outdoor decorative film composition for plastic door window and preparation method of outdoor decorative film

Provided are an outdoor decorative film composition for a plastic door window and a preparation method of the outdoor decorative film. The composition is prepared from 6-25 parts of acrylonitrile, 30-58 parts of styrene, 15-40 parts of butyl acrylate, 7-32 parts of polymethyl methacrylate, 5-35 parts of polyvinylidene fluoride and 1-8 parts of a dispersing agent. The outdoor decorative film composition for the plastic door window and the preparation method of the outdoor decorative film have the advantages that the outdoor decorative film is a single-layer film, the cost is far lower than that of an imported PVC multilayer composite film, and therefore application and promotion are facilitate; meanwhile, the stripping problem between two layers of the films can be avoided. The glass transition temperature of butyl acrylate is minus 55 degrees, and therefore the outdoor decorative film can still keep the good flexibility even in the cold winter. Polymethyl methacrylate is higher in weather resistance than that of ASA and high in hardness, and therefore the surface scratch resistance is good.

Owner:TIANJIN TRANSPARENT WALL TECH CO LTD

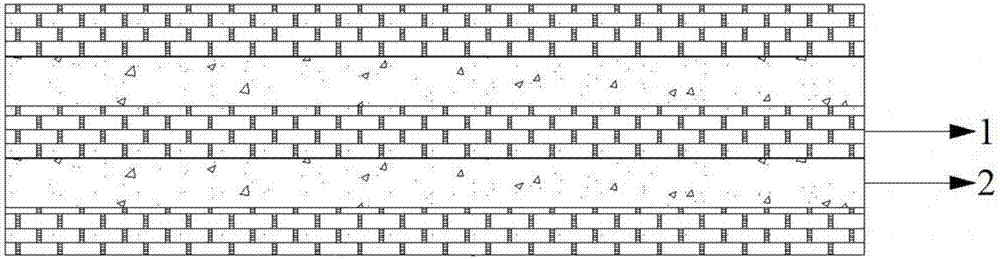

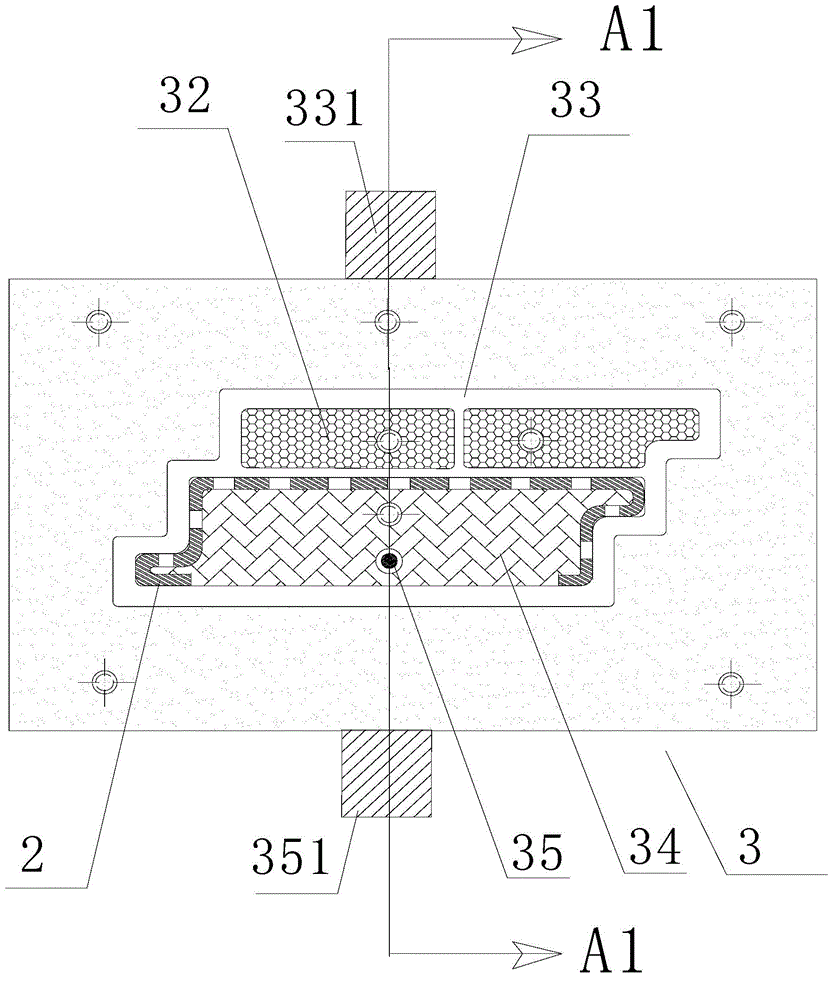

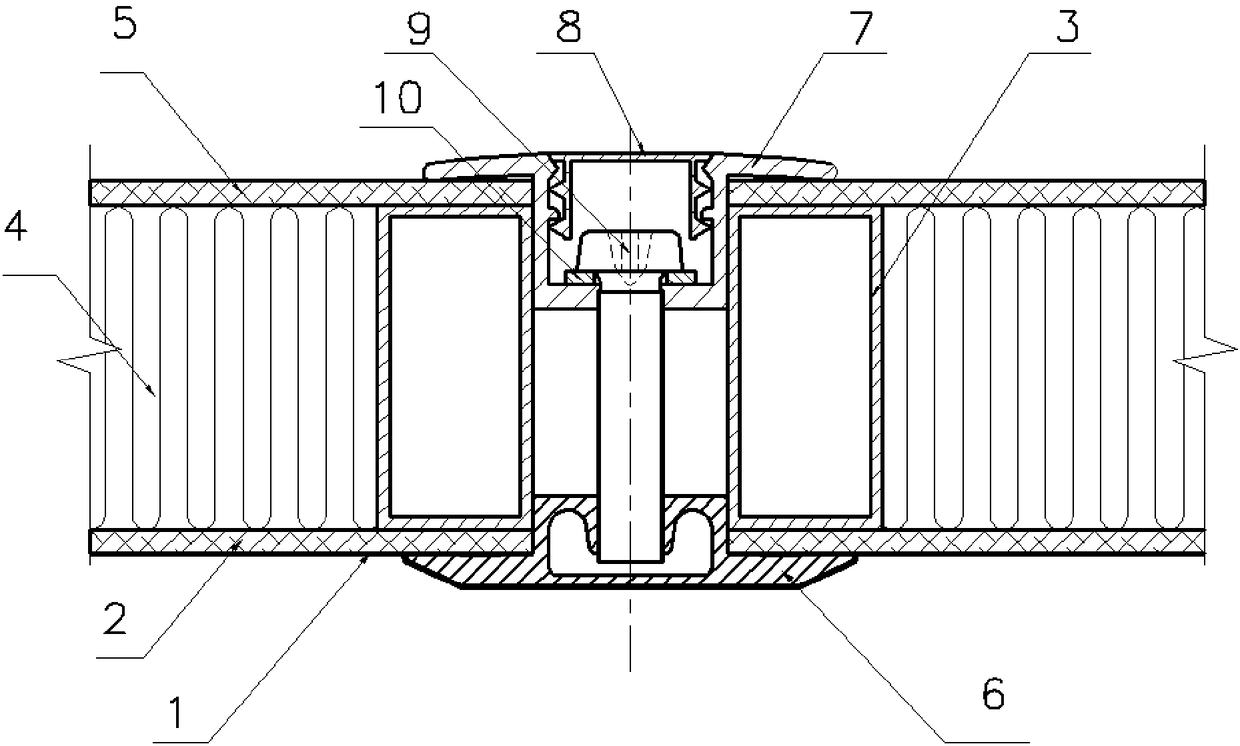

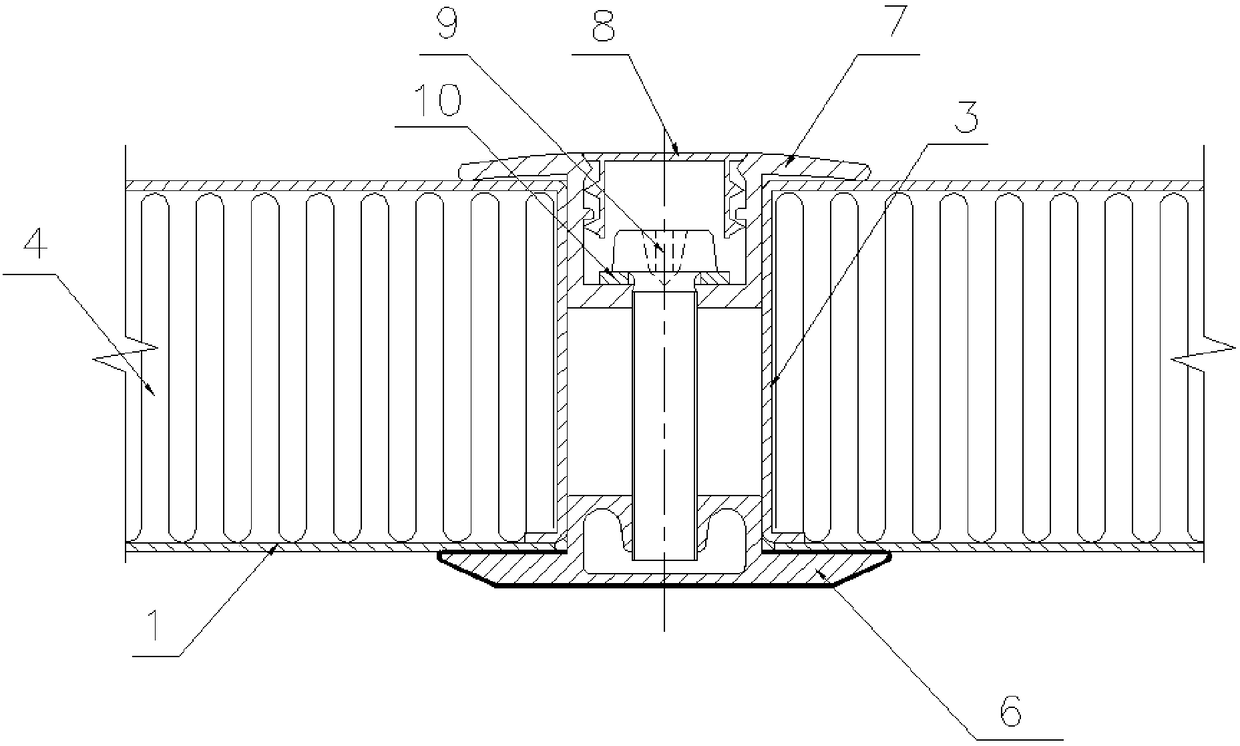

High-performance multifunctional all-in-one board for electromagnetic shielding chamber

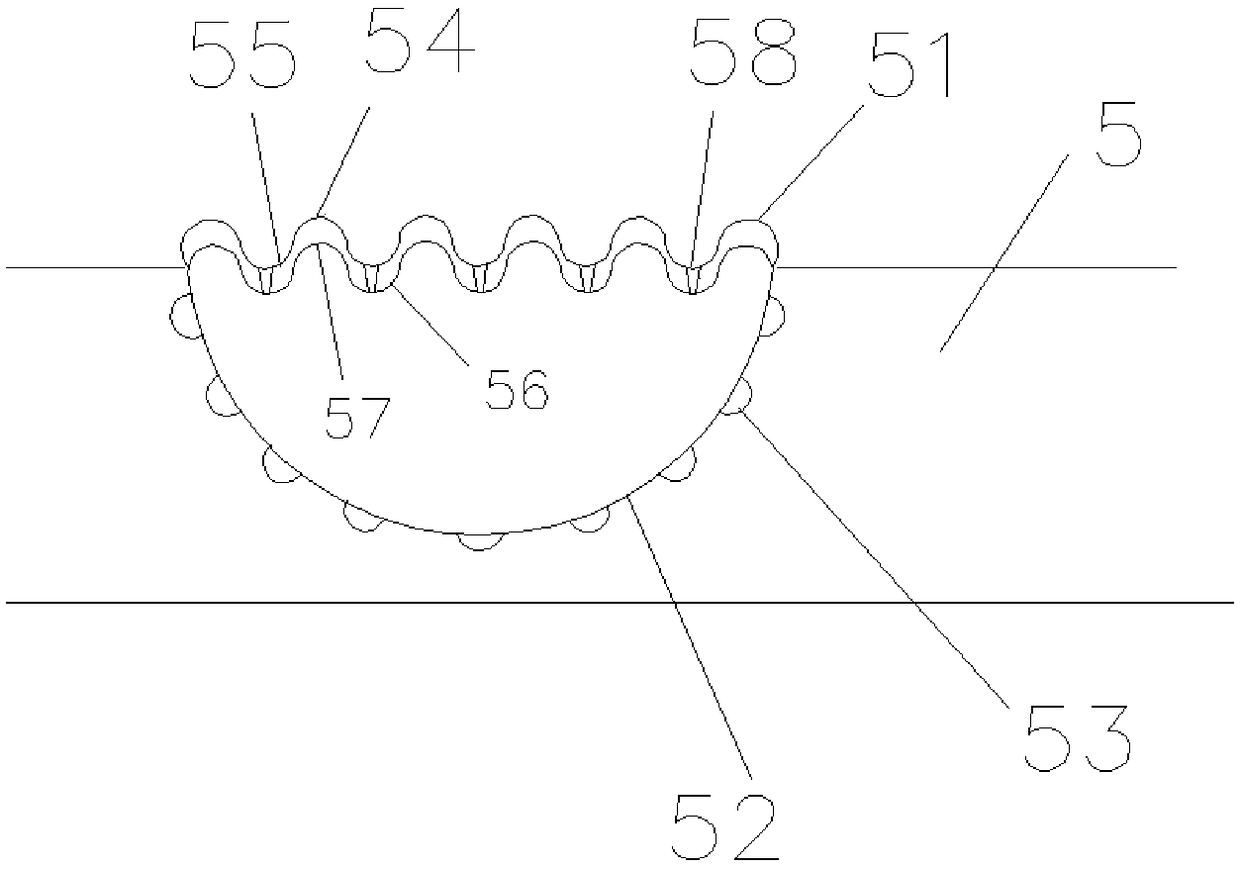

PendingCN108265925AMeet different needsHigh surface valueScreening rooms/chambersCovering/liningsUltrasound attenuationElectromagnetic shielding

A high-performance multifunctional all-in-one board for an electromagnetic shielding chamber is characterized in that the high-performance multifunctional all-in-one board comprises a shielding board(1) and a decorative board (5), and the shielding board (1) and the decorative board (5) are connected and fixed through a shielding keel (3). The high-performance multifunctional all-in-one board aims to solve shortcomings existing in the prior art. Through multiple application of a graphene technology, the electromagnetic shielding effect is greatly improved, meanwhile, electromagnetic wave shielding self-sufficiency can be further achieved, and the mute effect of sound attenuation and noise reduction is achieved.

Owner:李志珍 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com