Waste plastic recycling method

A recycling method and waste plastic technology, applied in the field of waste plastic recycling, to achieve the effect of improving decoration effect, improving application grade and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prefabricated surface film-forming tempered glass mold:

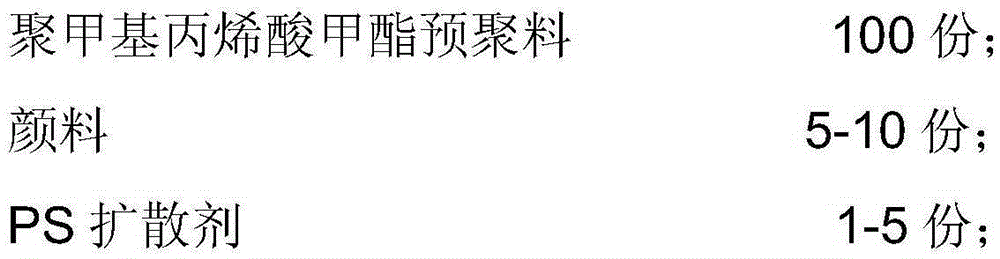

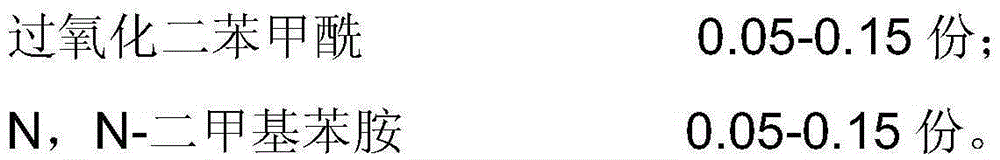

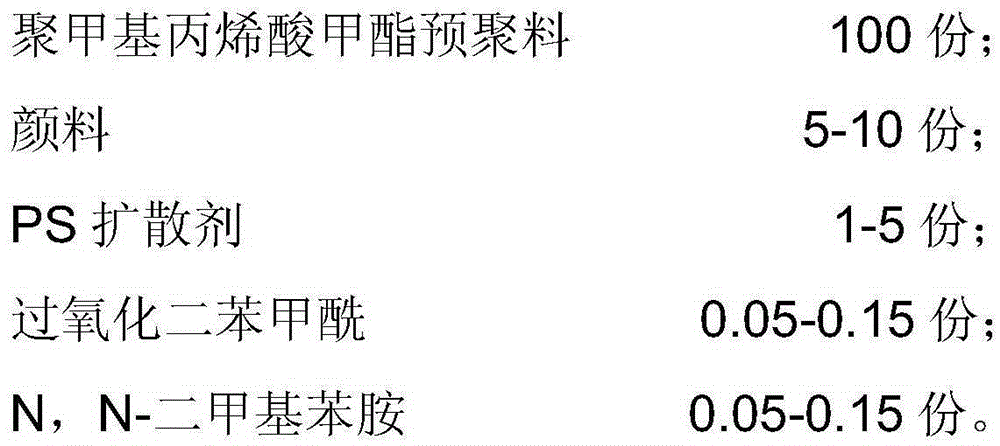

[0044] Wash the tempered glass with alkaline water and clear water for 3 times until there are no stains or traces, then dry it at 100°C for later use; use electric welding to bond PVC strips, and place it in the tempered glass to form a square cavity; add 4 parts of PS Diffusion agent and 0.08 parts of dibenzoyl peroxide are dissolved in 100 parts of polymethyl methacrylate prepolymer, then add 7 parts of pigment (common coloring pigment and near-infrared reflective pigment Black is mixed according to the ratio of 1:1) to obtain a mixed slurry by grinding, and then add 0.1 part of N, N-dimethylaniline to the mixed slurry to obtain a pre-filmed slurry; flow-coat the pre-filmed slurry to the belt In the tempered glass with square PVC adhesive strips, flow coat twice, let it stand at room temperature for 3 hours, and form a 400μm dry film; close the upper template and upper fixture, and you are done.

[0045] Rec...

Embodiment 2

[0048] Prefabricated surface film-forming tempered glass mold:

[0049]Wash the tempered glass with alkaline water and clear water for 4 times until there are no stains or traces, and dry it at 100°C for later use; use electric welding to bond PVC adhesive strips, and place it in the tempered glass to form a square cavity; add 5 parts of PS Diffusion agent and 0.05 parts of dibenzoyl peroxide are dissolved in 100 parts of polymethyl methacrylate prepolymer, and then 5 parts of pigment are added (common coloring pigment and near-infrared reflective pigment Dynamix Green 30C612 are mixed in a ratio of 1:1) After grinding to obtain a mixed slurry, add 0.05 parts of N,N-dimethylaniline to the mixed slurry to obtain a pre-filmed slurry; flow-coat the pre-filmed slurry onto tempered glass with square PVC strips Inside, flow coat once, and let it stand at room temperature for 2 hours to form a 200μm dry film; close the upper template and upper fixture, and you are done.

[0050] Rec...

Embodiment 3

[0053] Prefabricated surface film-forming tempered glass mold:

[0054] Wash the tempered glass twice with alkaline water and clear water until there are no stains or traces, and dry it at 100°C for later use; use electric welding to bond PVC strips, and place it in the tempered glass to form a square cavity; add 1 part of PS Diffusion agent and 0.15 parts of dibenzoyl peroxide are dissolved in 100 parts of polymethyl methacrylate prepolymer, then add 10 parts of pigments (common coloring pigments and near-infrared reflective pigments Black is mixed according to the ratio of 1:1) to obtain a mixed slurry by grinding, and then add 0.15 parts of N, N-dimethylaniline to the mixed slurry to obtain a pre-film-forming slurry; flow-coat the pre-film-forming slurry to the In the tempered glass with square PVC adhesive strips, flow coat it twice, and let it stand at room temperature for 4 hours to form a 500μm dry film; close the upper template and upper fixture, and you are done.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com