Patents

Literature

630 results about "Mixed waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed waste can refer to any combination of waste types with different properties. Typically commercial and municipal wastes are mixtures of plastics, metals, glass, biodegradable waste including paper and textiles along with other nondescript junk.

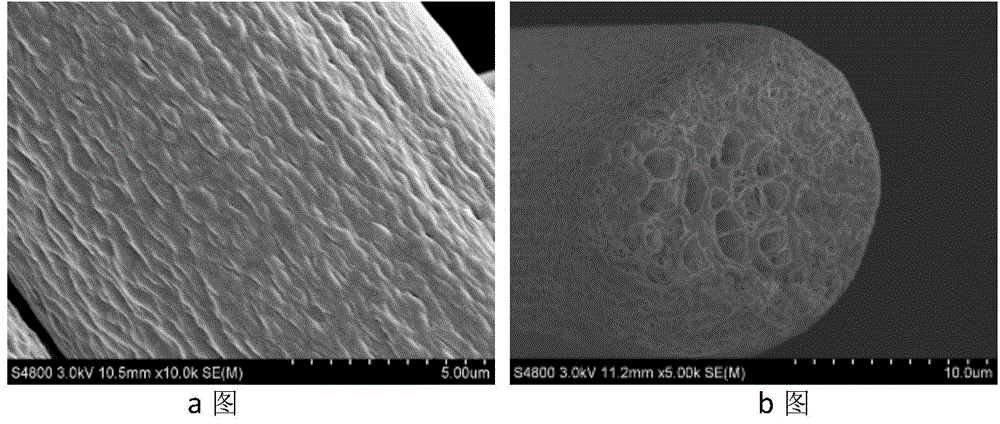

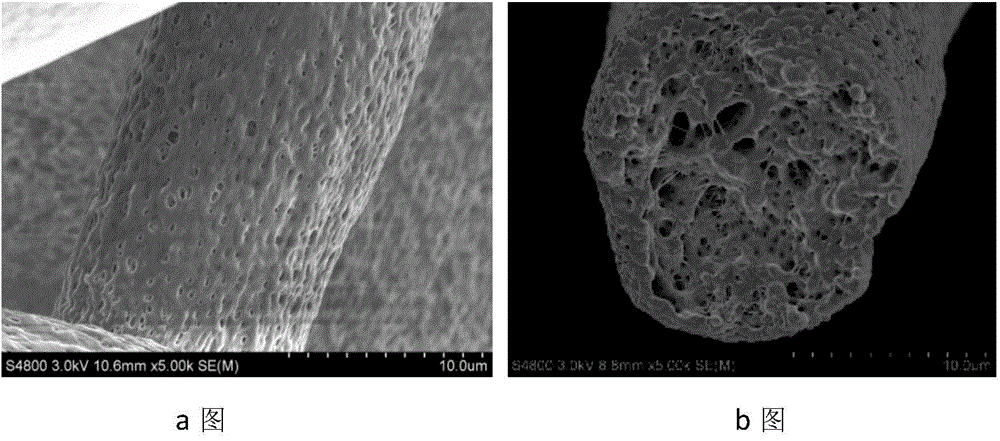

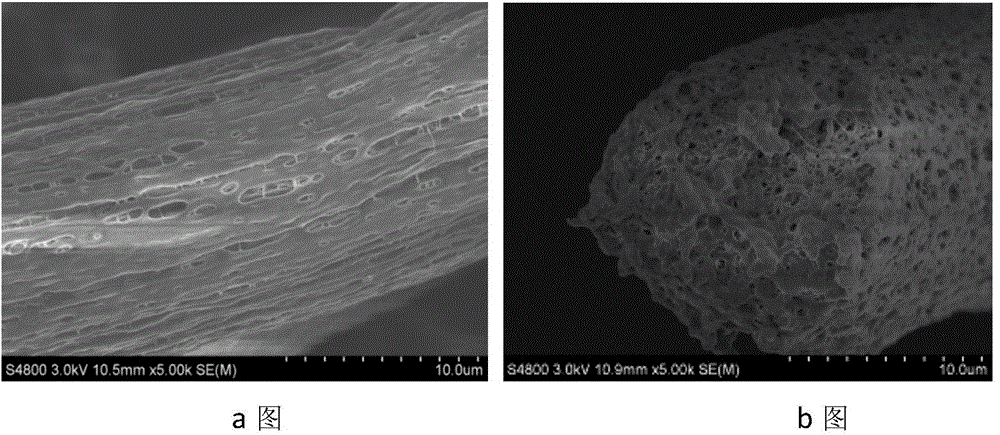

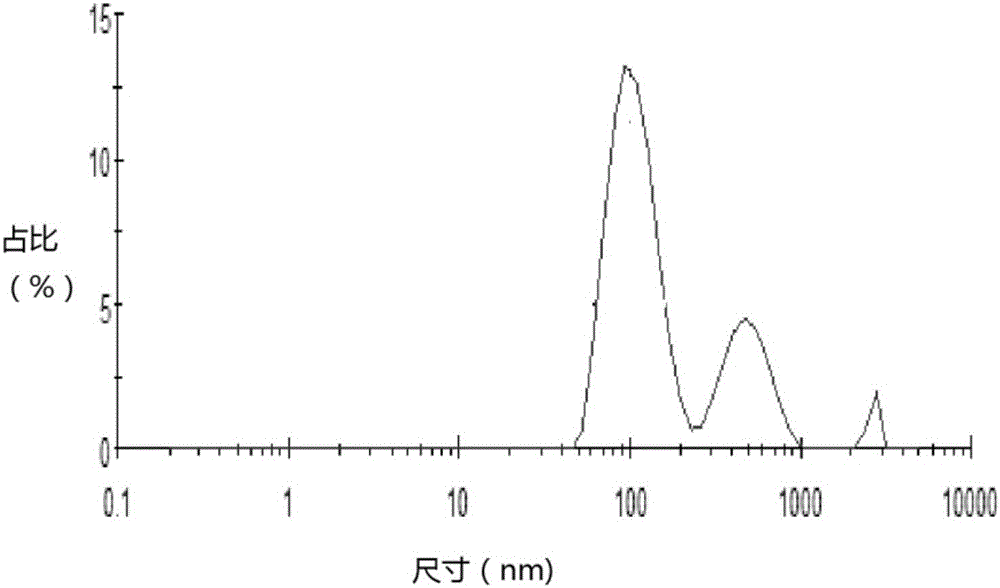

Preparation method of porous fiber non-woven fabric

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

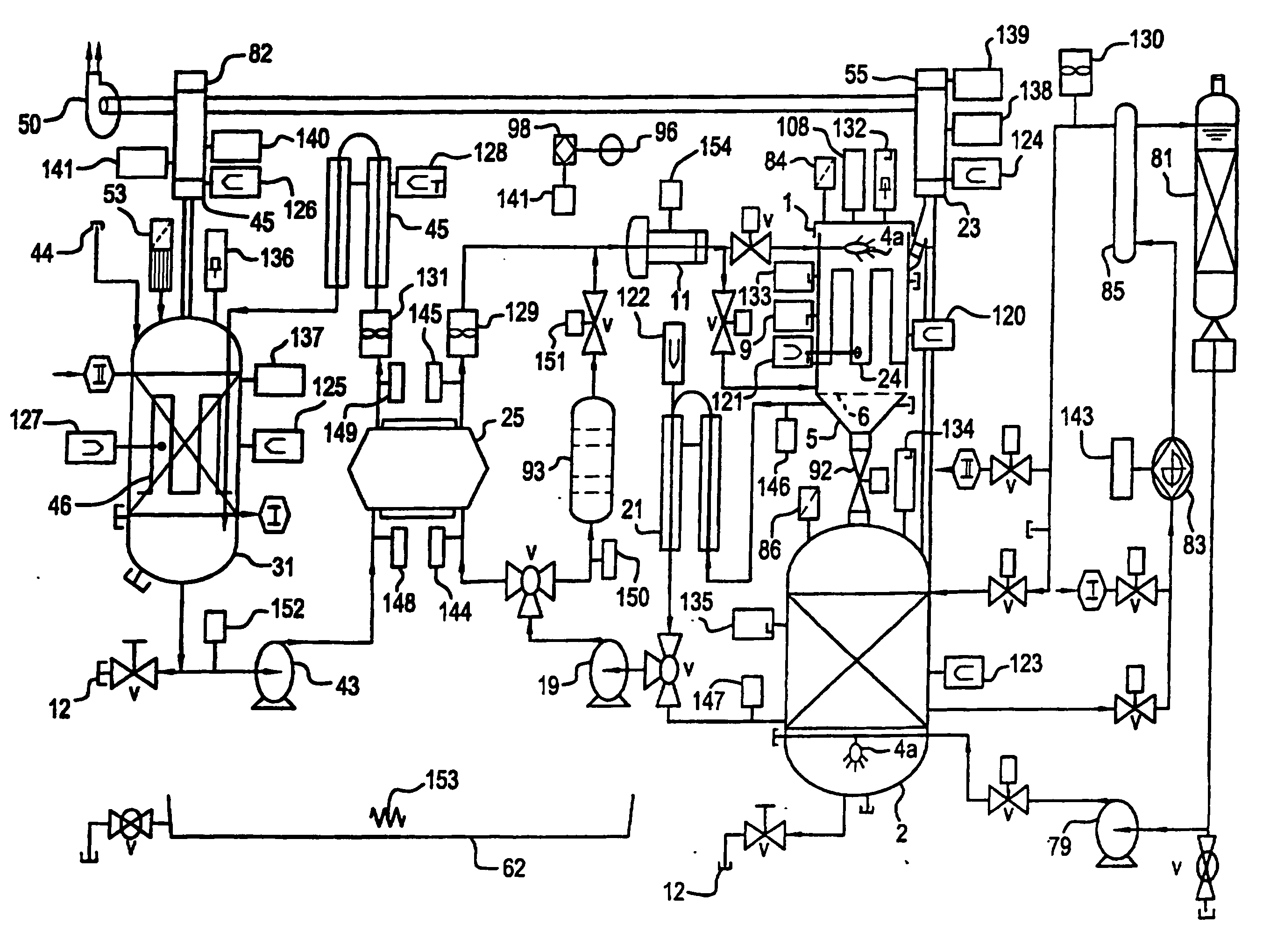

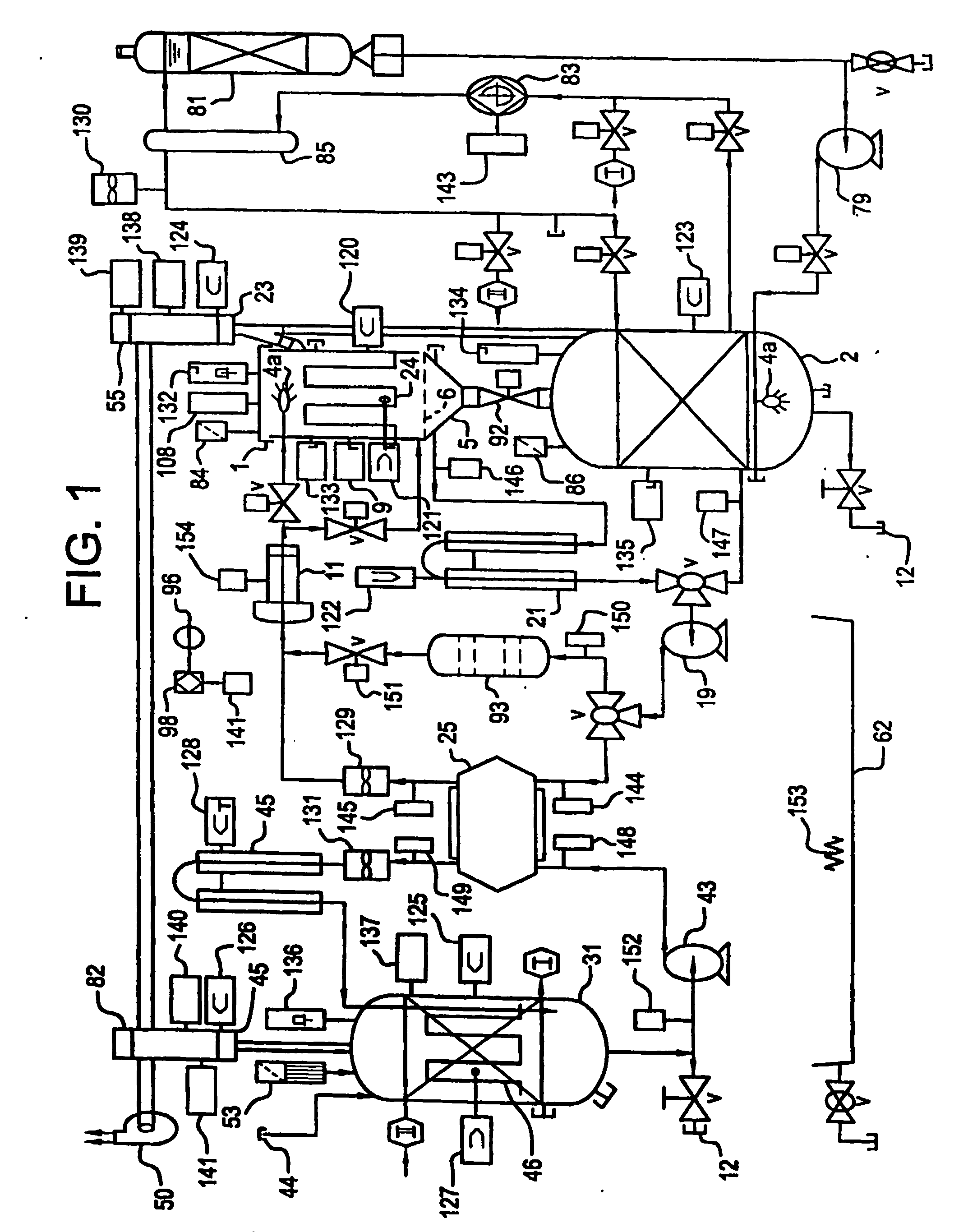

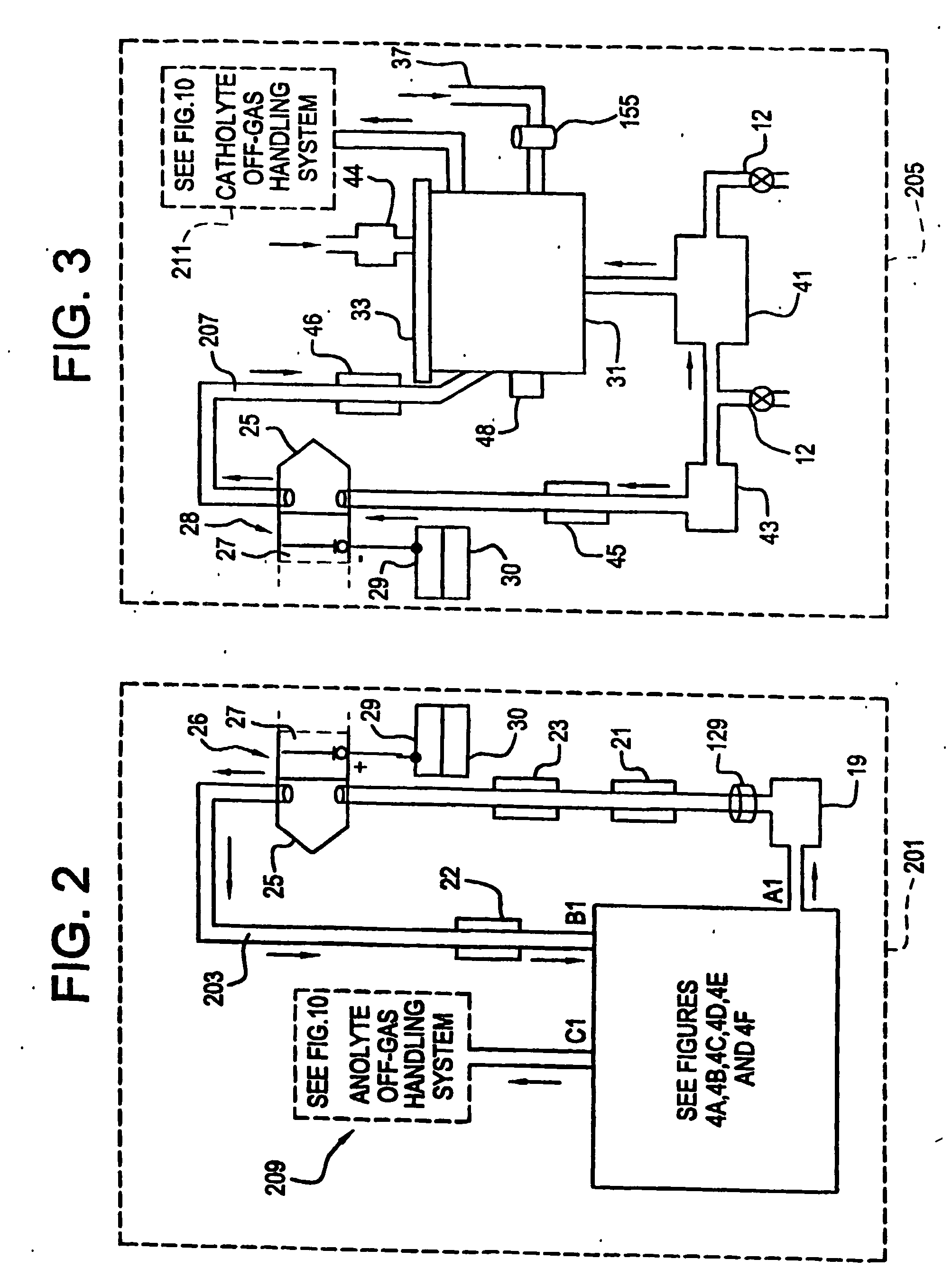

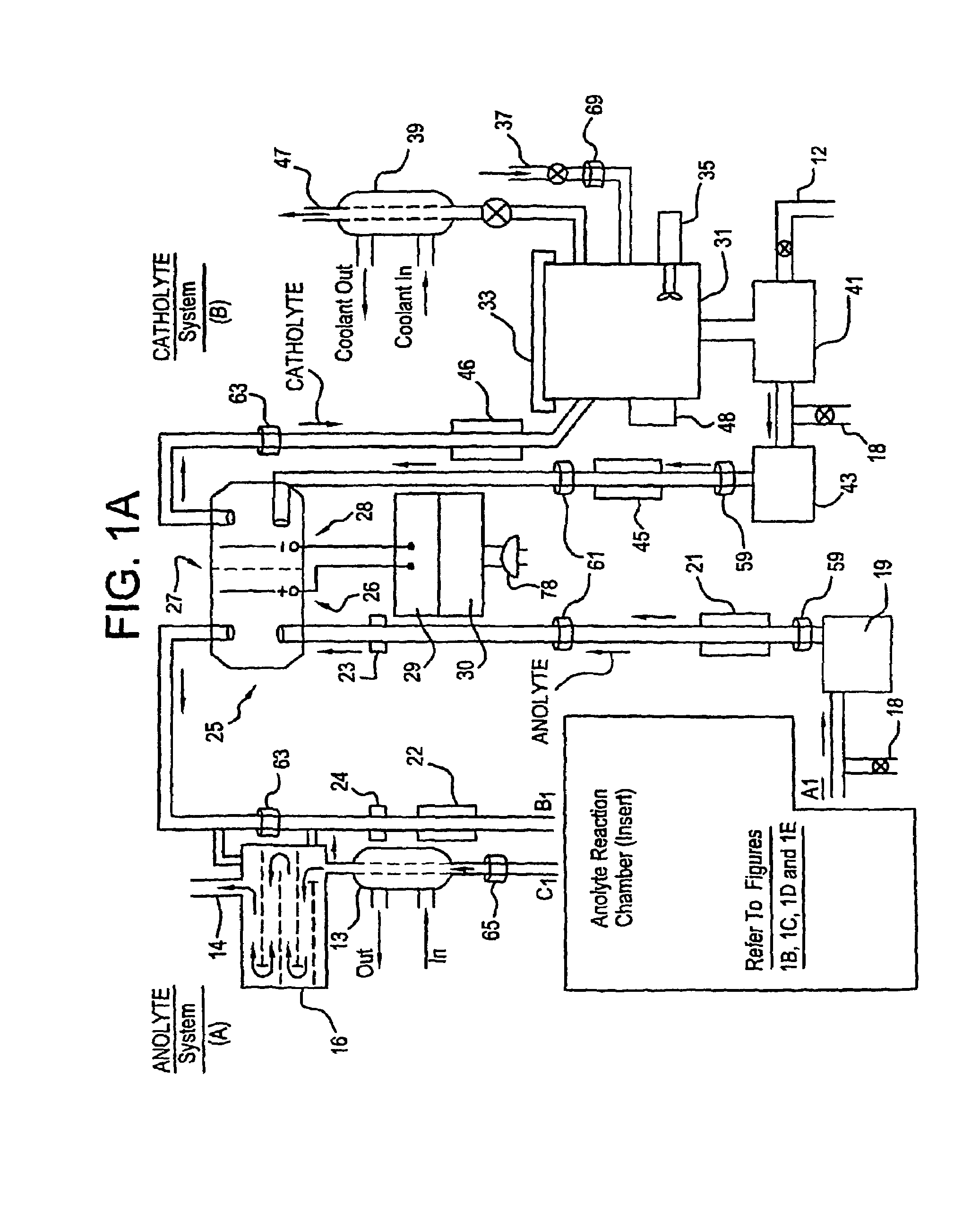

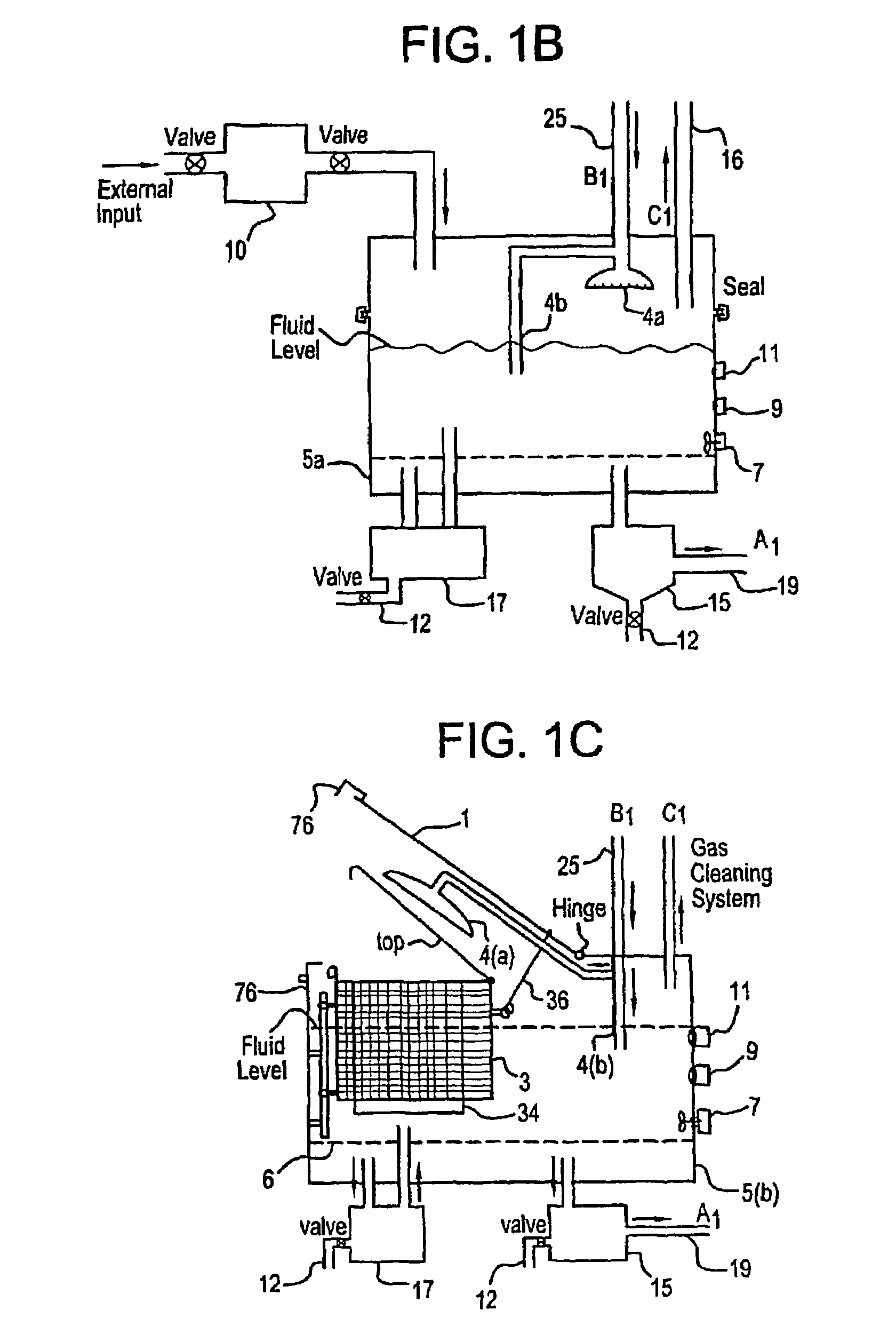

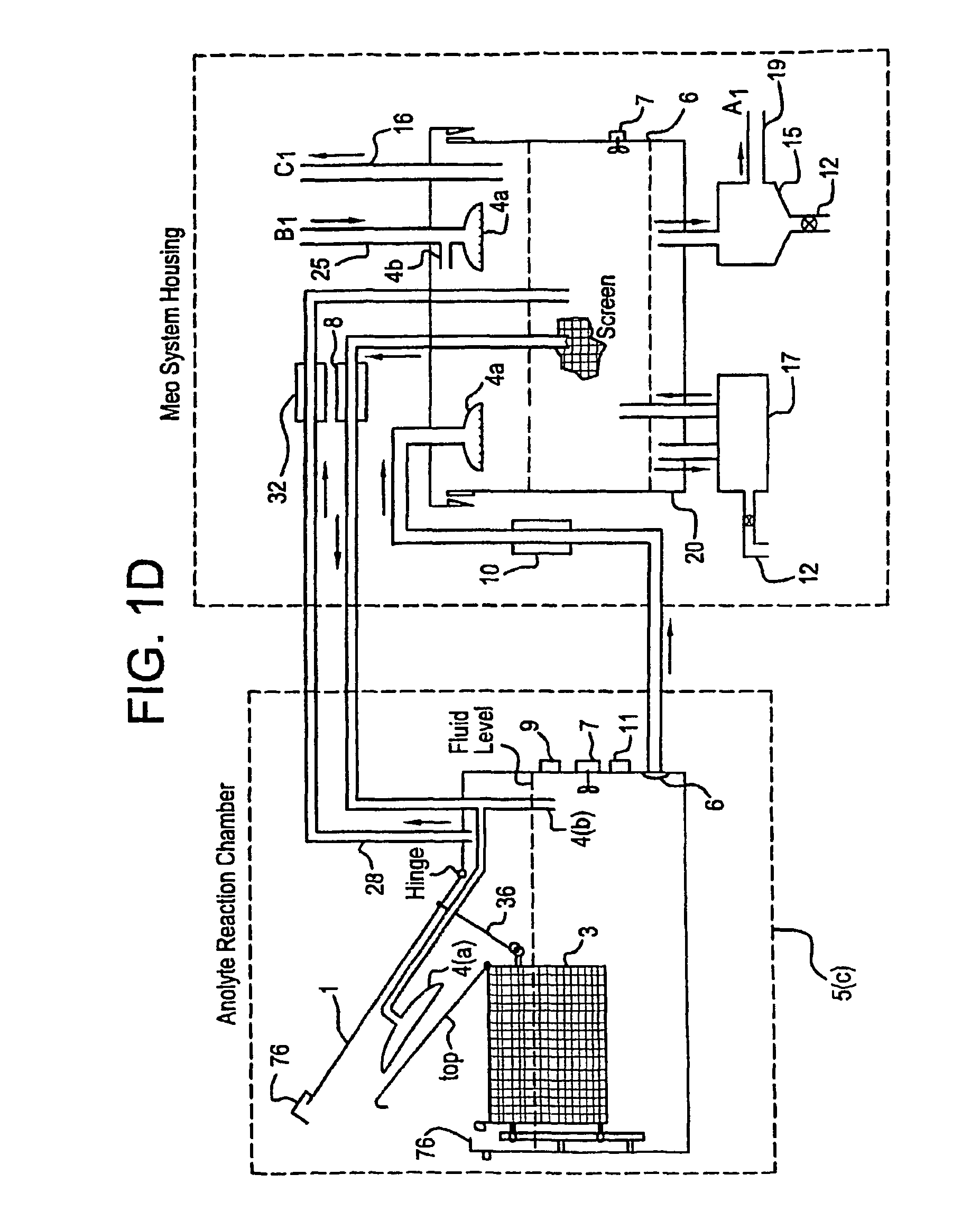

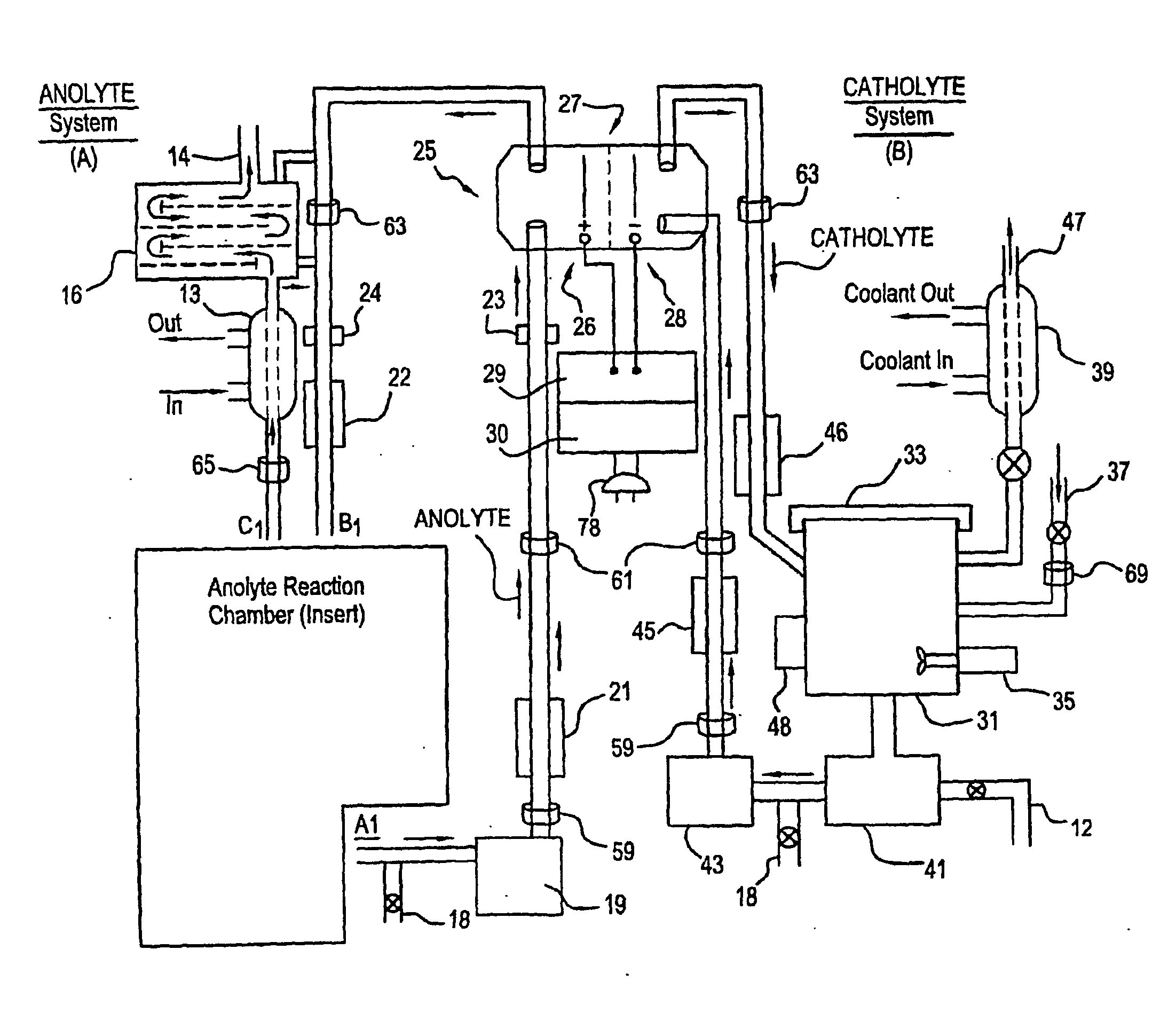

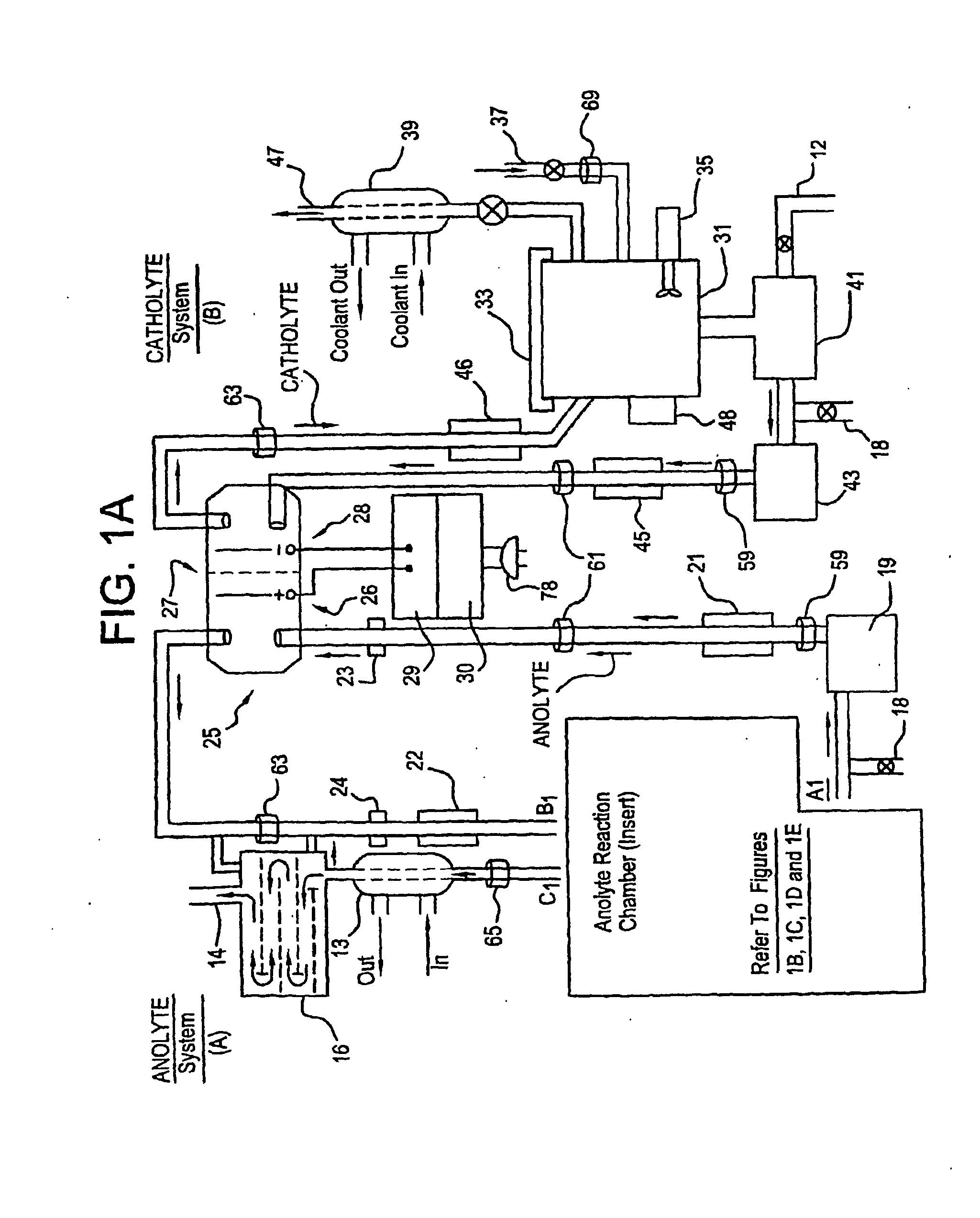

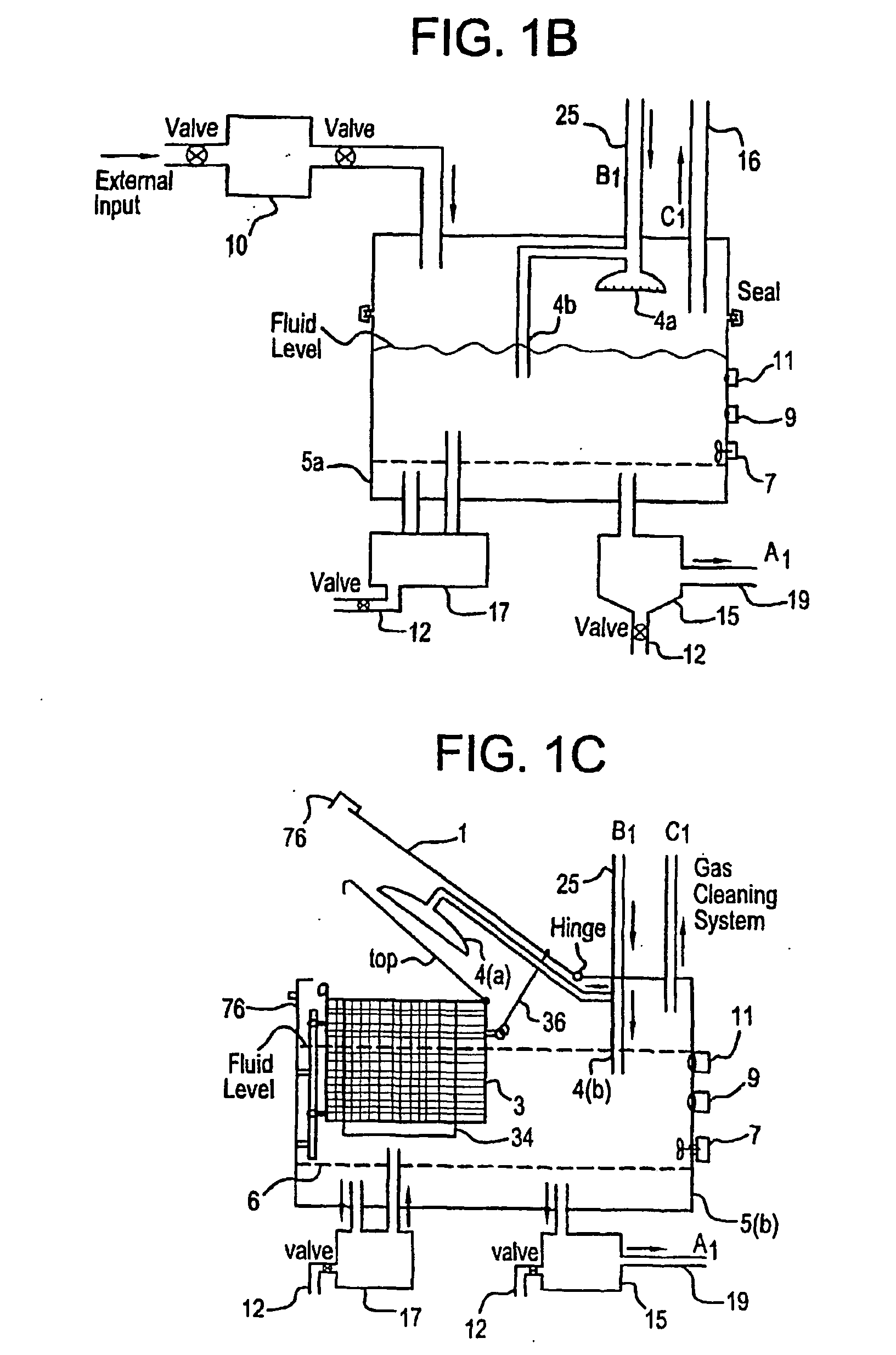

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

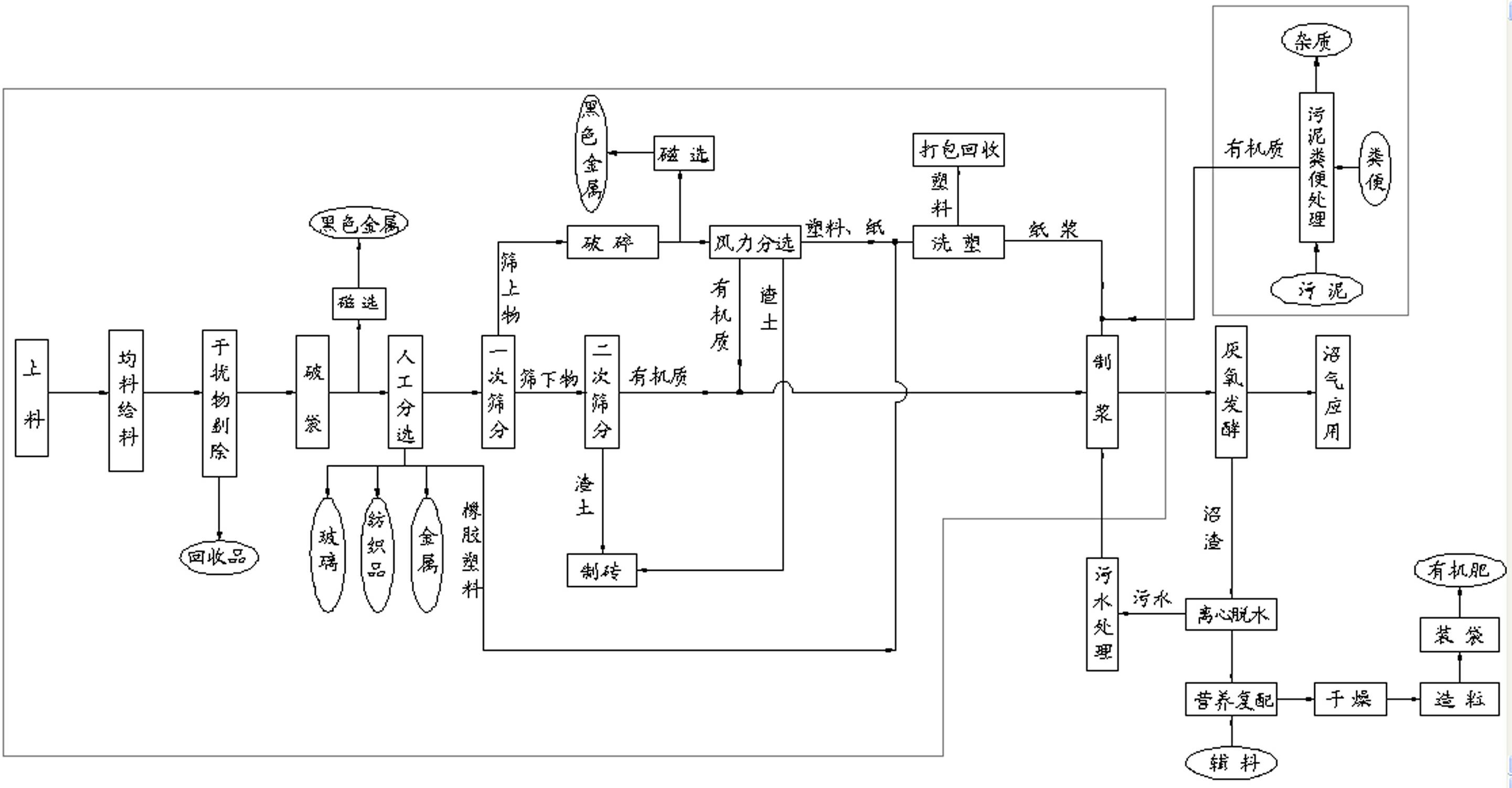

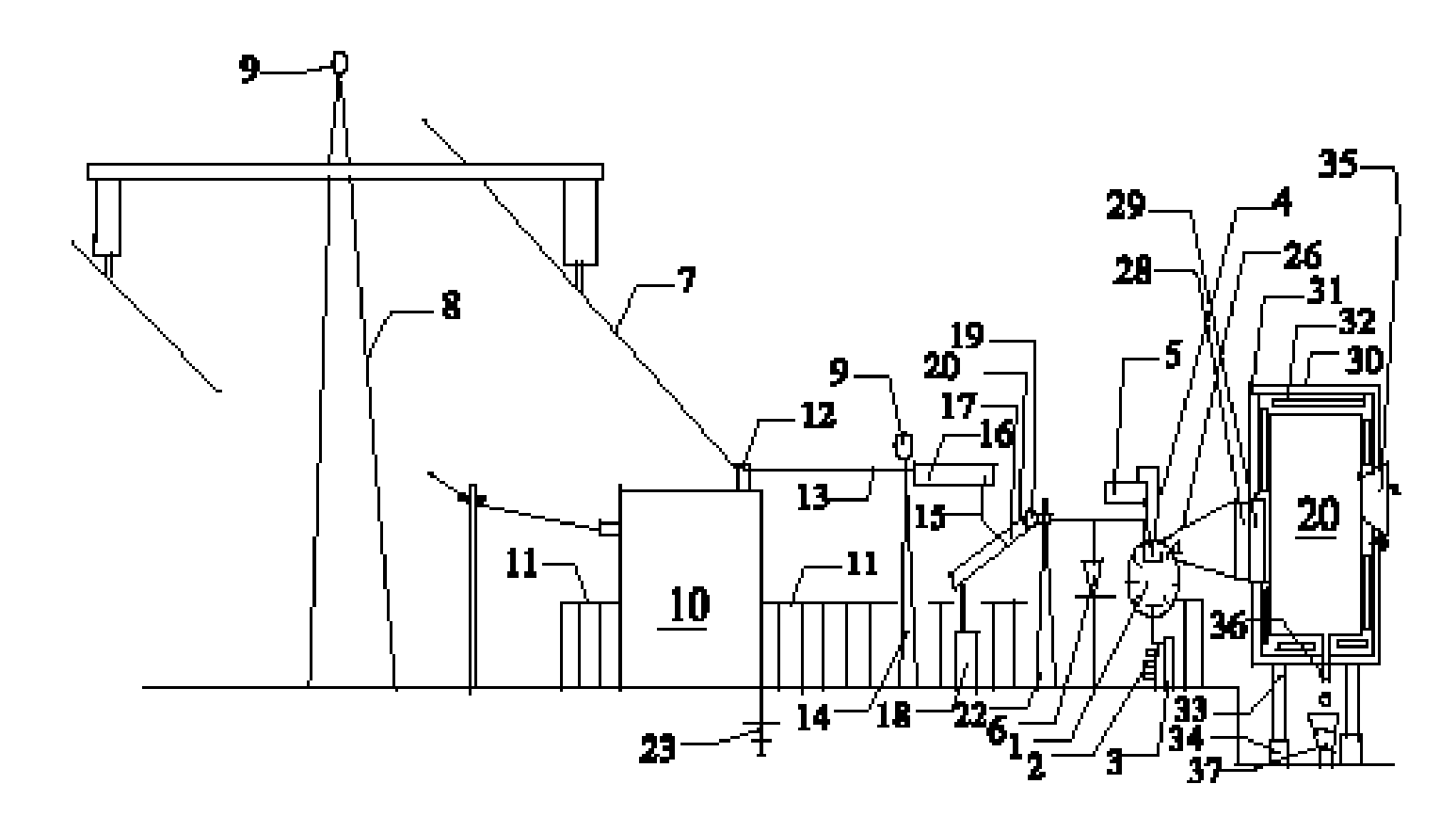

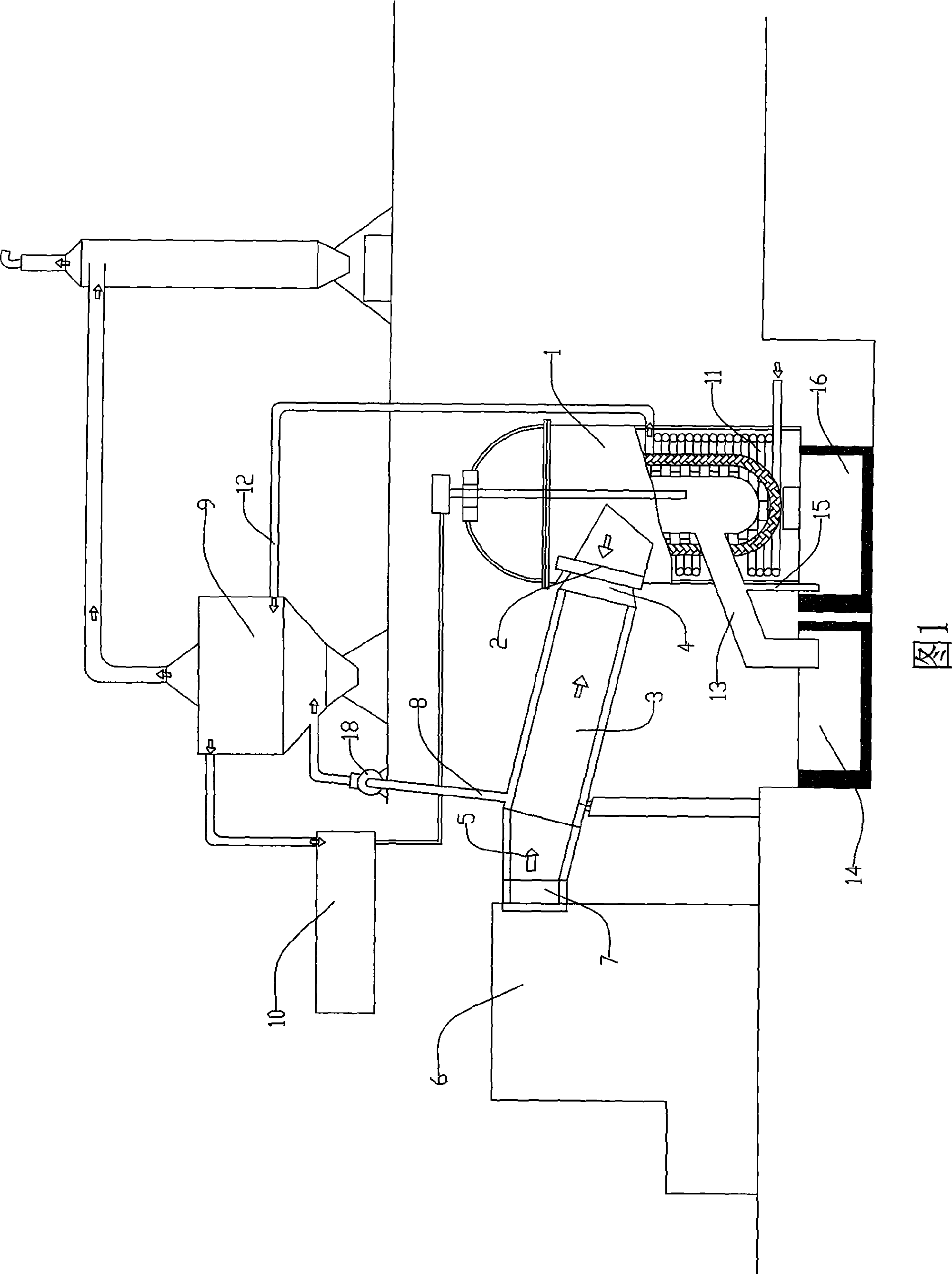

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

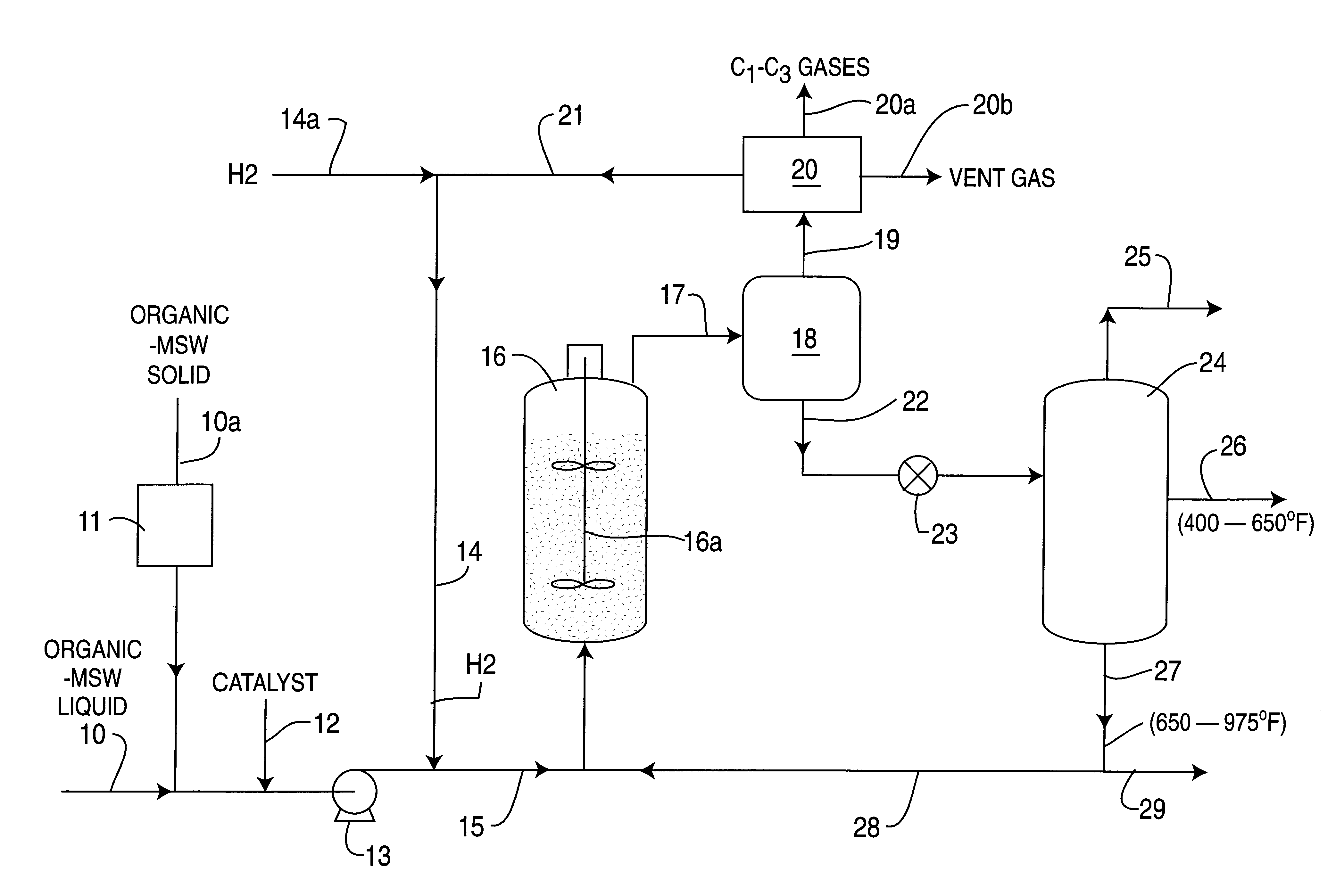

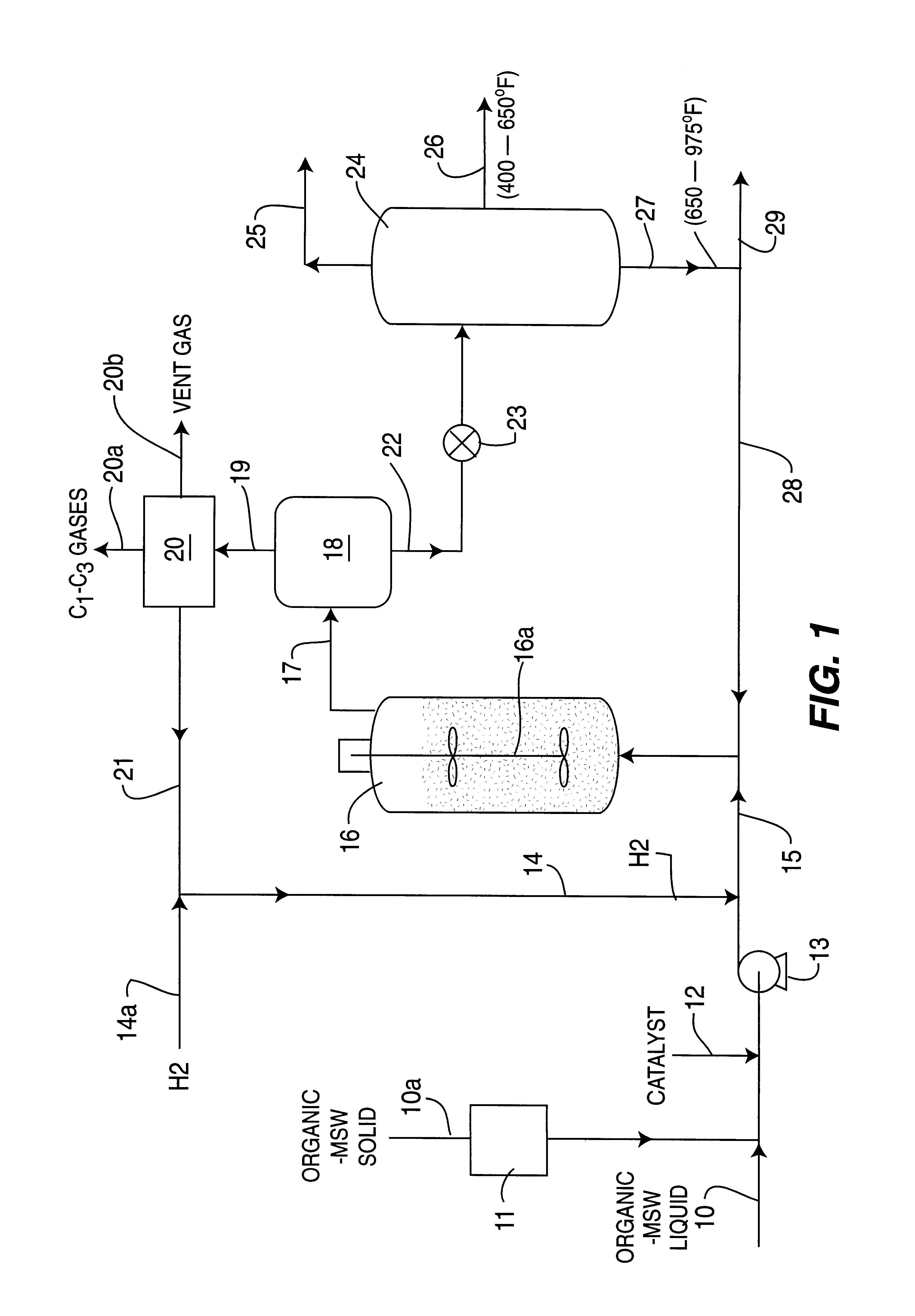

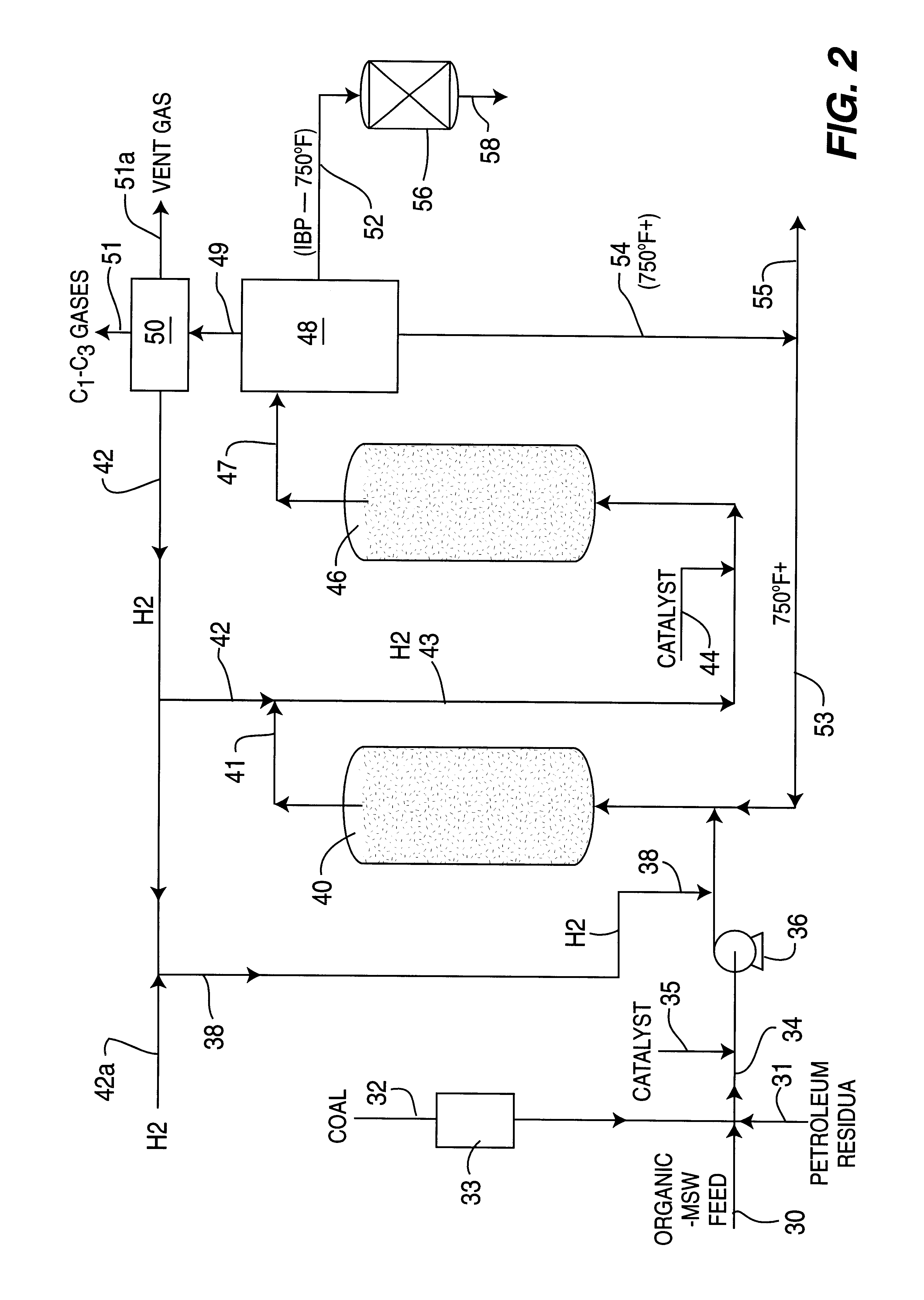

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

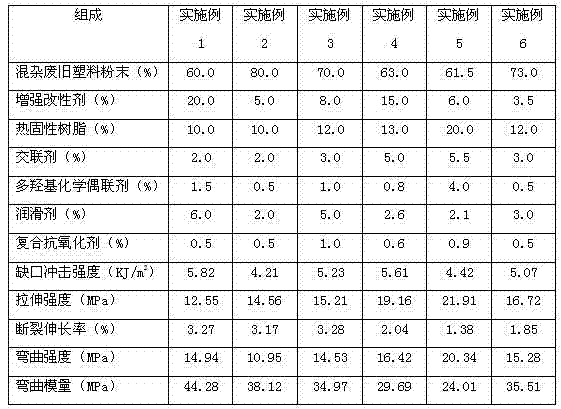

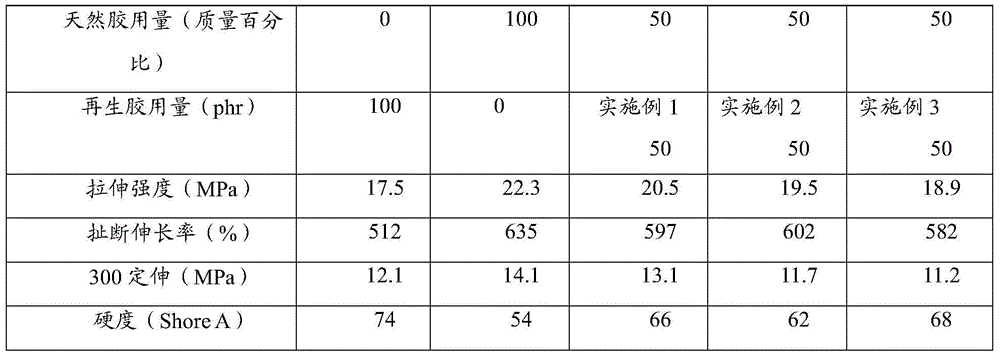

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

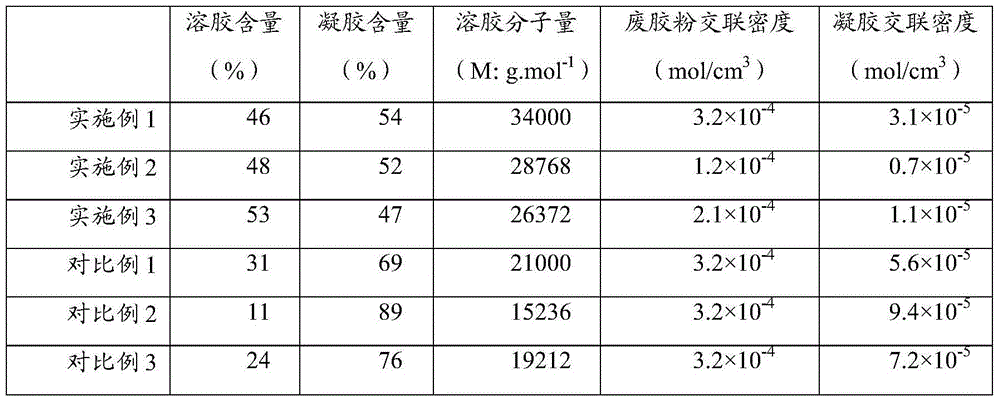

Environment-friendly method for regenerating waste rubber

ActiveCN104387611AImprove performanceFully qualitative regenerationPlastic recyclingBulk chemical productionCross-linkMicrowave

The invention discloses an environment-friendly method for regenerating waste rubber. The method comprises the following steps: 1) uniformly mixing waste rubber and an environment-friendly desulfurizing agent according to a mass ratio of 100:0.2-2; 2) guiding the mixed waste rubber into a first reaction chamber and then fully filling the first reaction chamber with supercritical CO2 fluid; 3) starting a microwave heating device of a second reaction chamber so as to desulfurize waste rubber powder; and 4) after the desulfurization is completed, cooling the waste rubber powder to be below 80 DEG C and refining into pieces after discharging. According to the method, supercritical CO2 fluid which has excellent swelling and permeating characteristics can be used for replacing a rubber softening agent so that a regenerant can permeate and disperse inside the waste rubber powder in a short time and the waste rubber can reach swelling balance; then, microwaves are utilized to selectively damage S-S and C-S cross-linked bonds of the rubber and the desulfurizing agent completely so that a main chain is protected from being damaged to the greatest extent.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

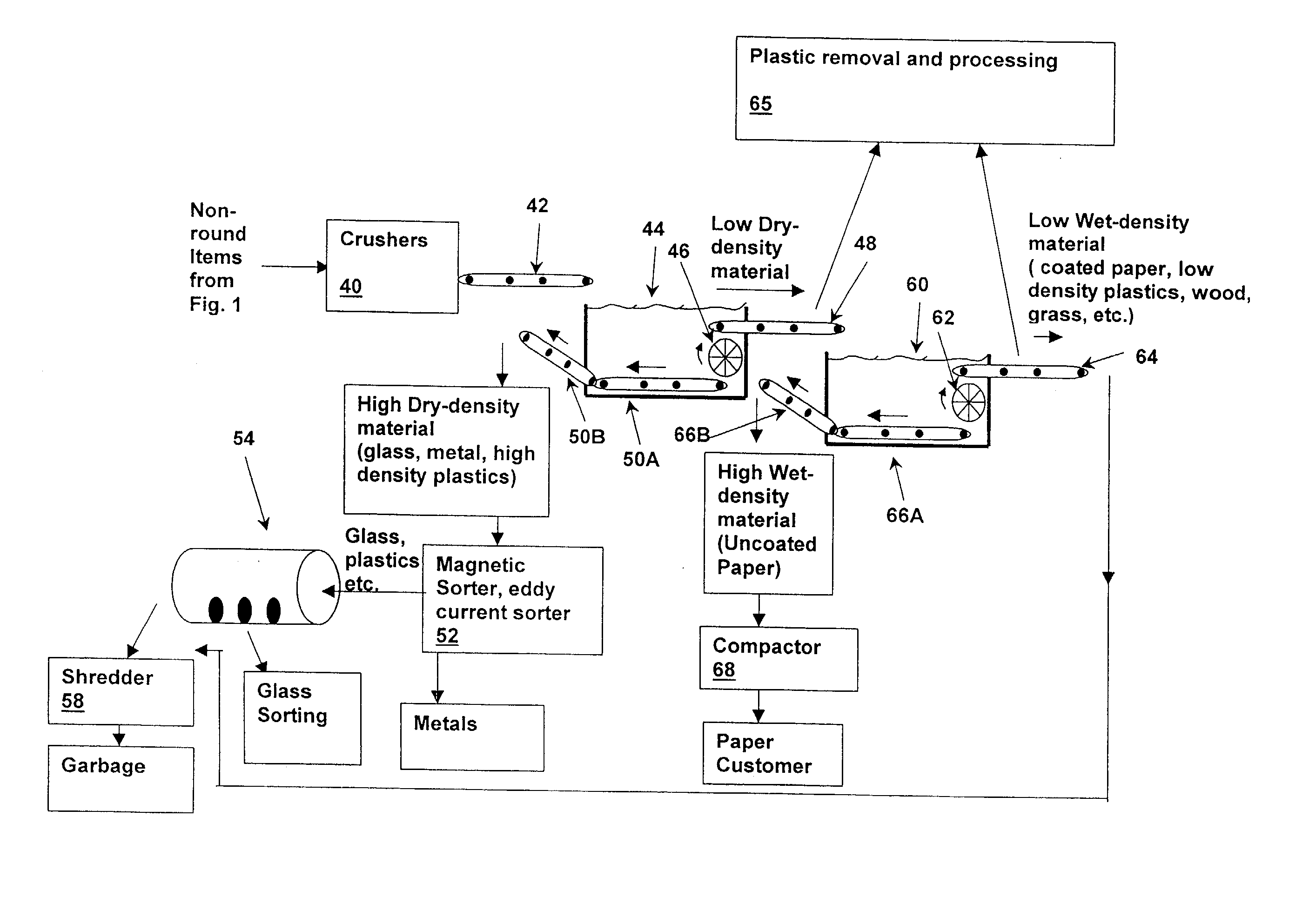

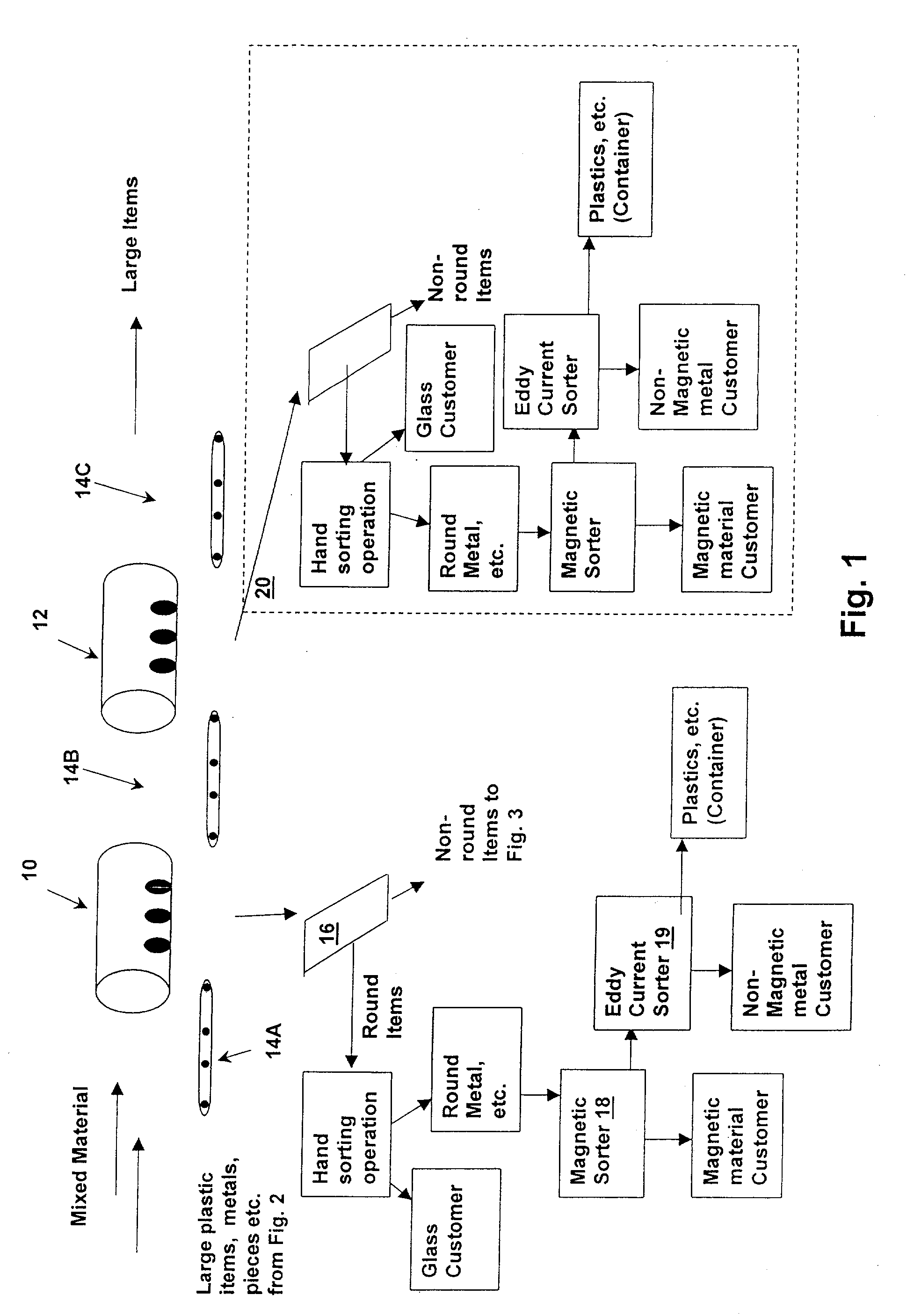

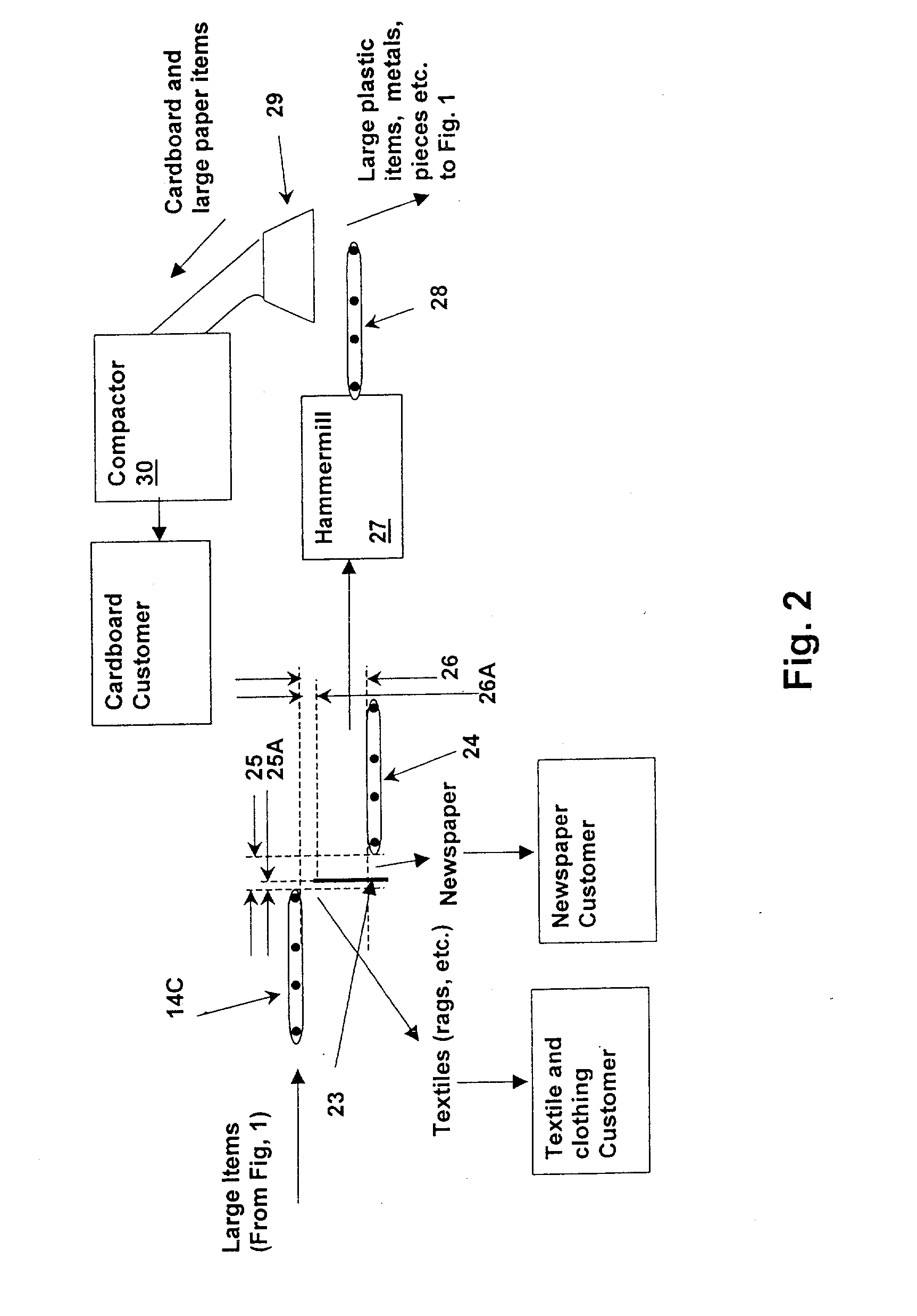

Method and system for separating and sorting recyclable materials from mixed waste streams

A method and system for separating and sorting recyclable materials from mixed waste streams provides improved separation and reduced cost in trash and recyclable material processing systems. A low surface-current bath is used within the sorting system to separate materials having a low wet-density, such as plastics and coated paper, from materials having a high wet-density, such as uncoated paper. A novel newspaper separation device using an appropriately-sized gap in a conveying system provides separation of newspaper from other large pieces of recyclable material or trash, while leaving heavier materials on the conveying system for further sorting. An improved plastics separator is included for separating plastics by melting-point range.

Owner:3R SYST L L C

Kitchen waste preprocessing technology

ActiveCN101632996ASatisfy the follow-up resource processingImprove resource conversion rateSolid waste disposalLitterPre treatment

The invention relates to a preprocessing technology for processing kitchen waste with high oil, high viscosity and high water content, comprising the following steps: (1) pouring mixed waste which mainly comprises kitchen waste into a kitchen waste receiver to realize initial solid-liquid separation in a transporting process; (2) when separated solid waste enters a bag-breaking and distributing machine, tearing and breaking bagged waste and waste in other bags; (3) transporting the bag-broken kitchen waste into a grid machine to sort, separating inorganic waste or solid and organic waste with larger grain diameters in waste, and transporting the organic waste into a full-automatic distribution bin; (4) continuously carrying out the solid-liquid separation of the waste in the full-automatic distribution bin, and completing a processing process by entering the solid waste into a lower container. The kitchen waste preprocessing technology further sorts the organic waste with even grain diameters in the kitchen waste, satisfies the following resource processing requirement of the kitchen waste and increases the resource conversion rate of the kitchen waste.

Owner:BEIJING GOLDENWAY BIO TECH

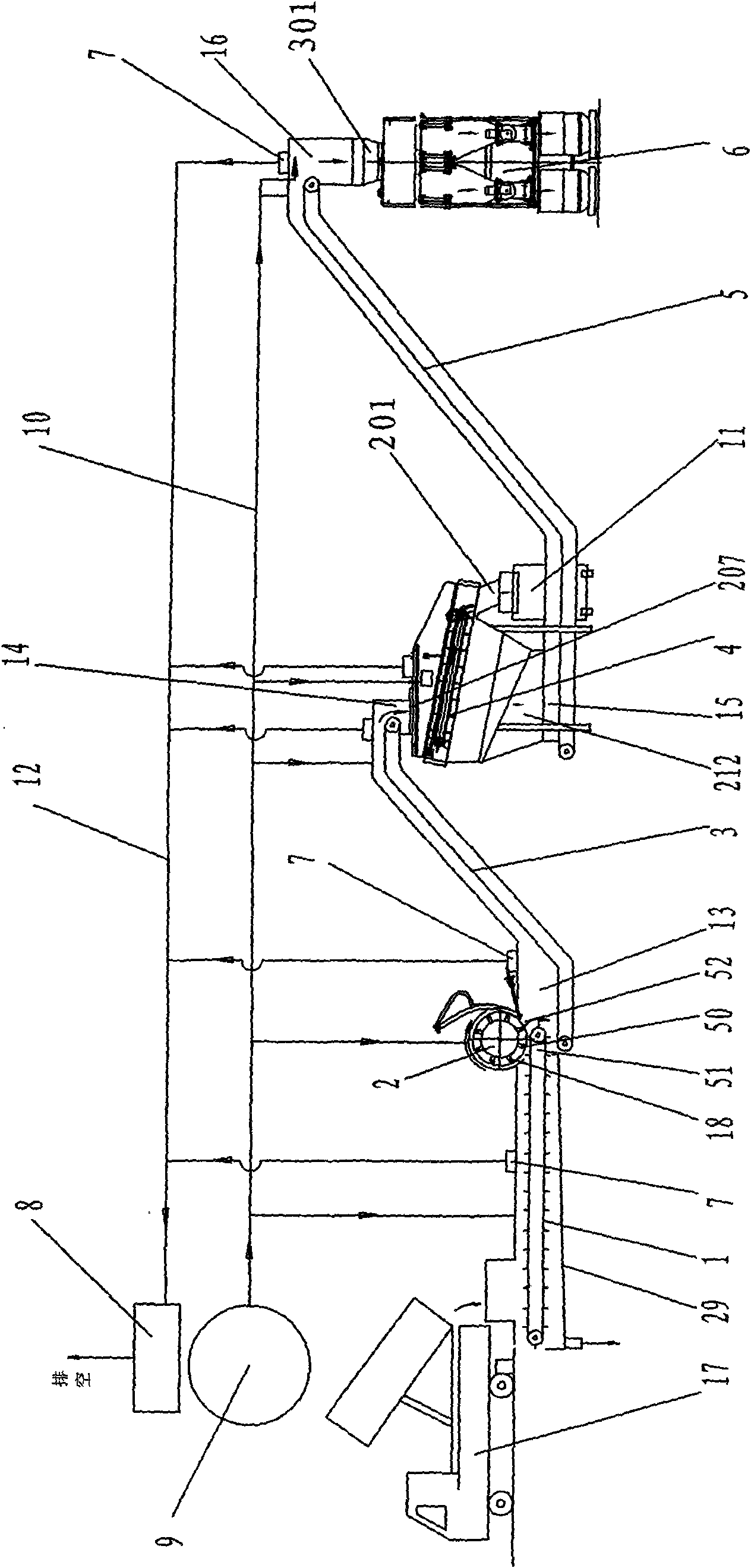

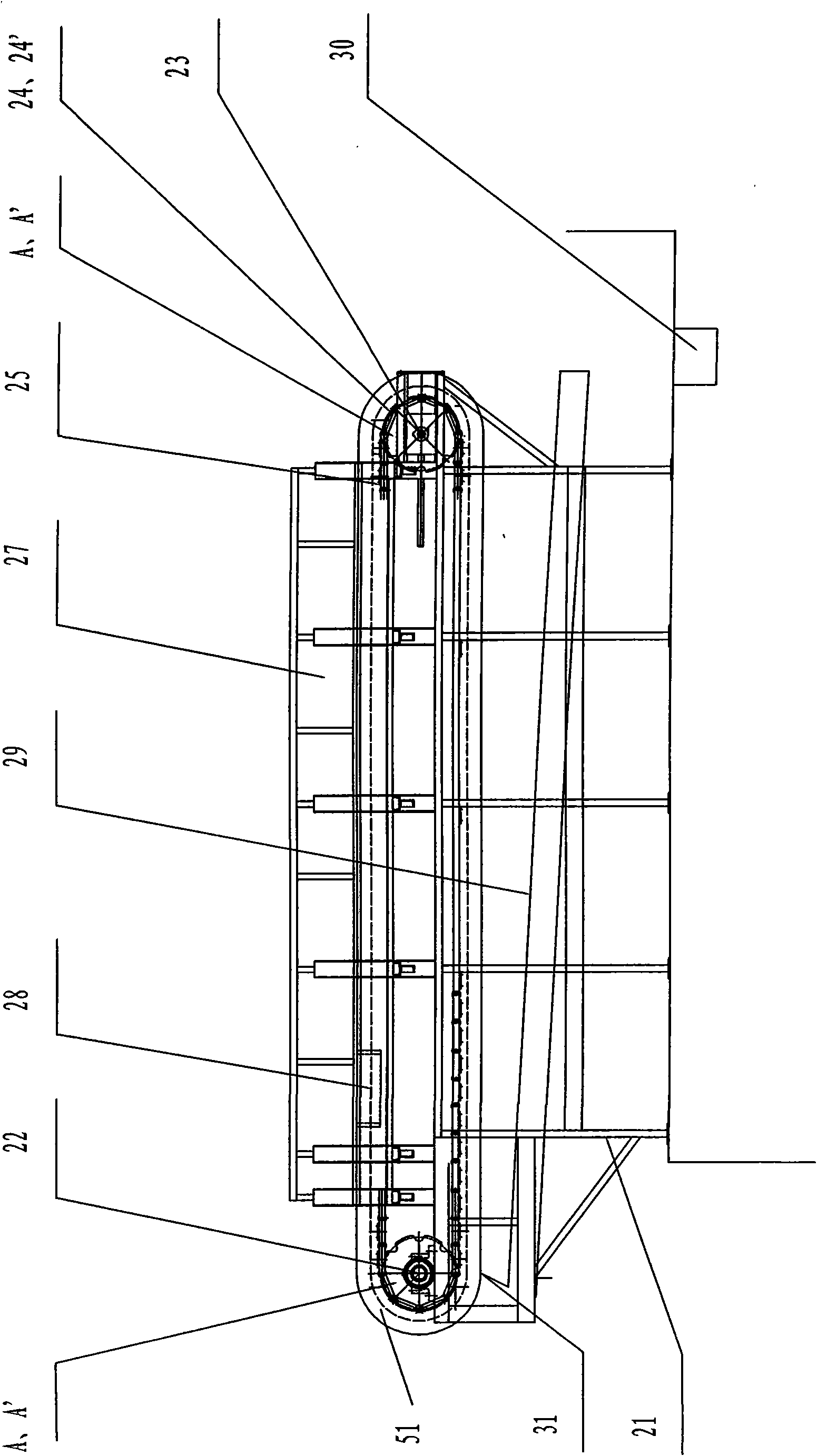

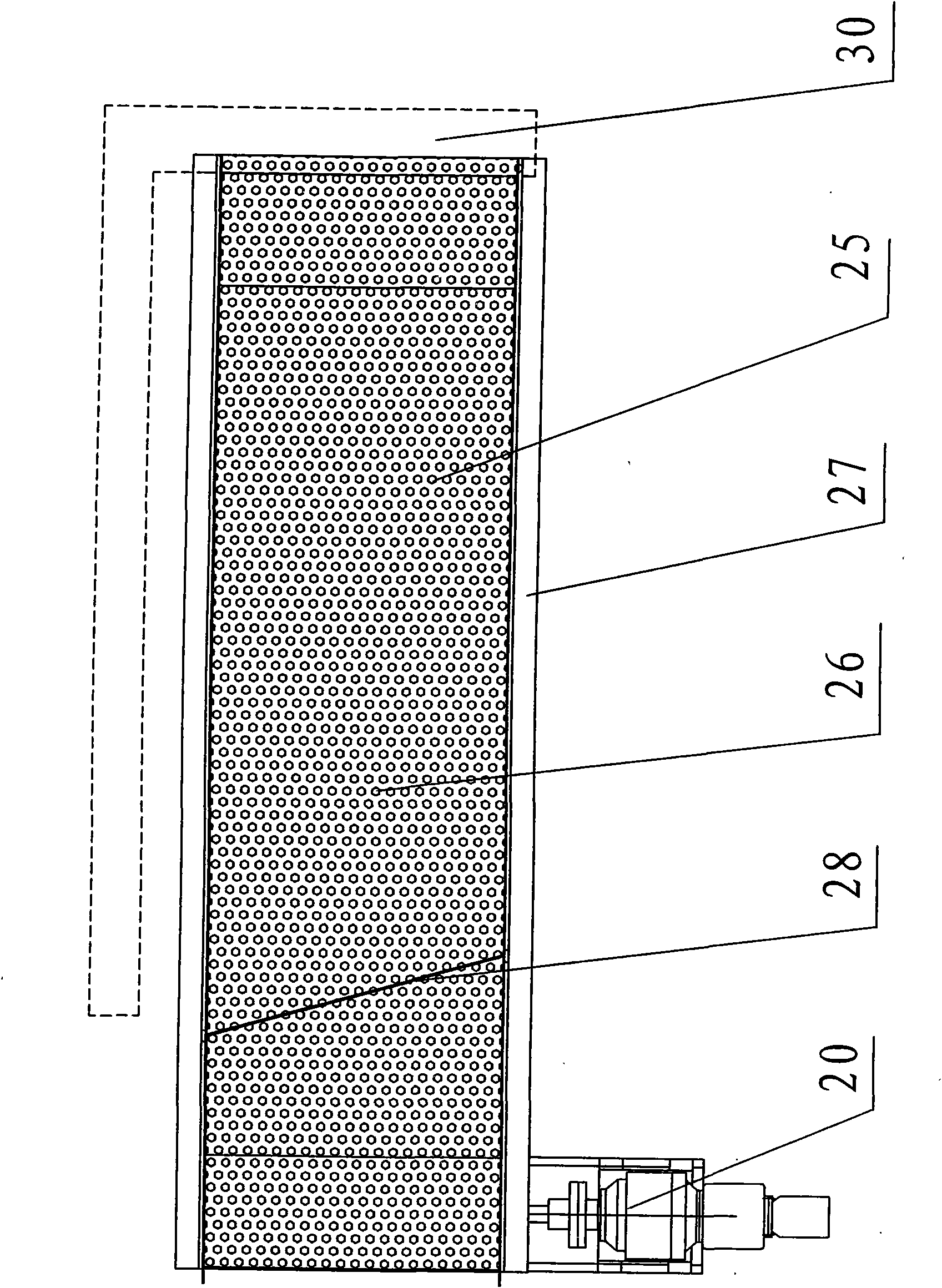

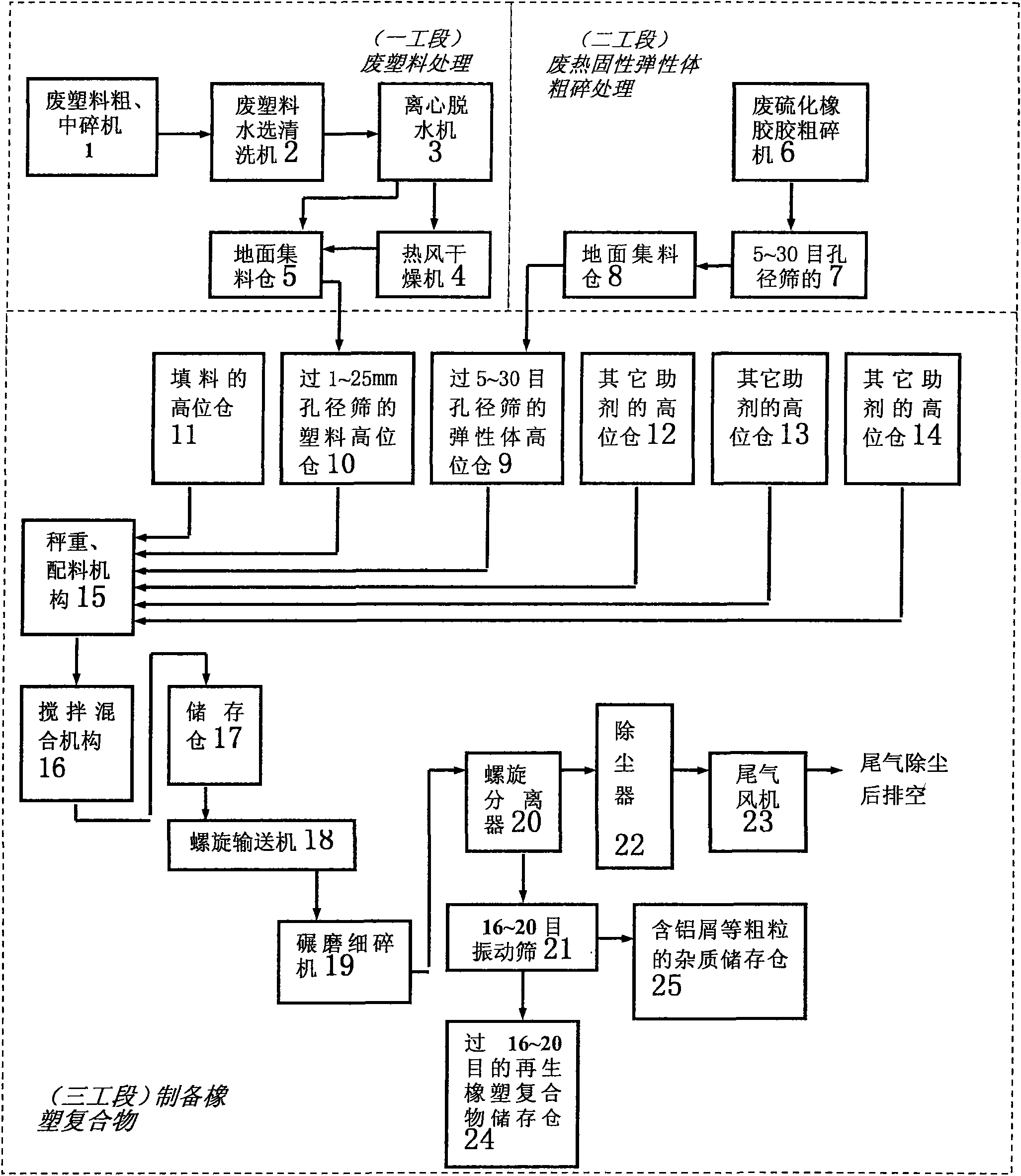

Method for preparing rubber-plastic compound

InactiveCN101665627AAvoid scorchingAvoid smokingPlastic recyclingCocoaElastomerThermoplastic elastomer

The invention provides a method for preparing a rubber-plastic compound. A composite device containing normal-temperature millstone-type elastomer fine crushing machineries is utilized to carry out crushing treatment on a mixture containing formulas of thermosetting elastomer and plastic or / and thermoplastic elastomer, and the mixture comprises the following components in weight ratio: thermosetting elastomer sieved by a sieve with the aperture of 5-40 meshes: plastic sieved by a sieve with the aperture of 1-5mm or / and thermoplastic elastomer sieved by a sieve with the aperture of 1-5 meshes:filler: other adjuvants = 40-90:60-10:0-200:0-10. The invention comprises a method, the composite device for implementing the method, and rubber-plastic compound products produced by the method, wherein a regeneration rubber-plastic compound is included. The invention not only can enable the absorb filler operation to become clean, continuous, normal-temperature and energy saving in the process of preparing new rubber-plastic composite material, but also can enable mixed waste plastic difficult to be reused by the prior art to be conveniently used for high-valued recycling.

Owner:上海橡源驰晨环保科技发展有限公司

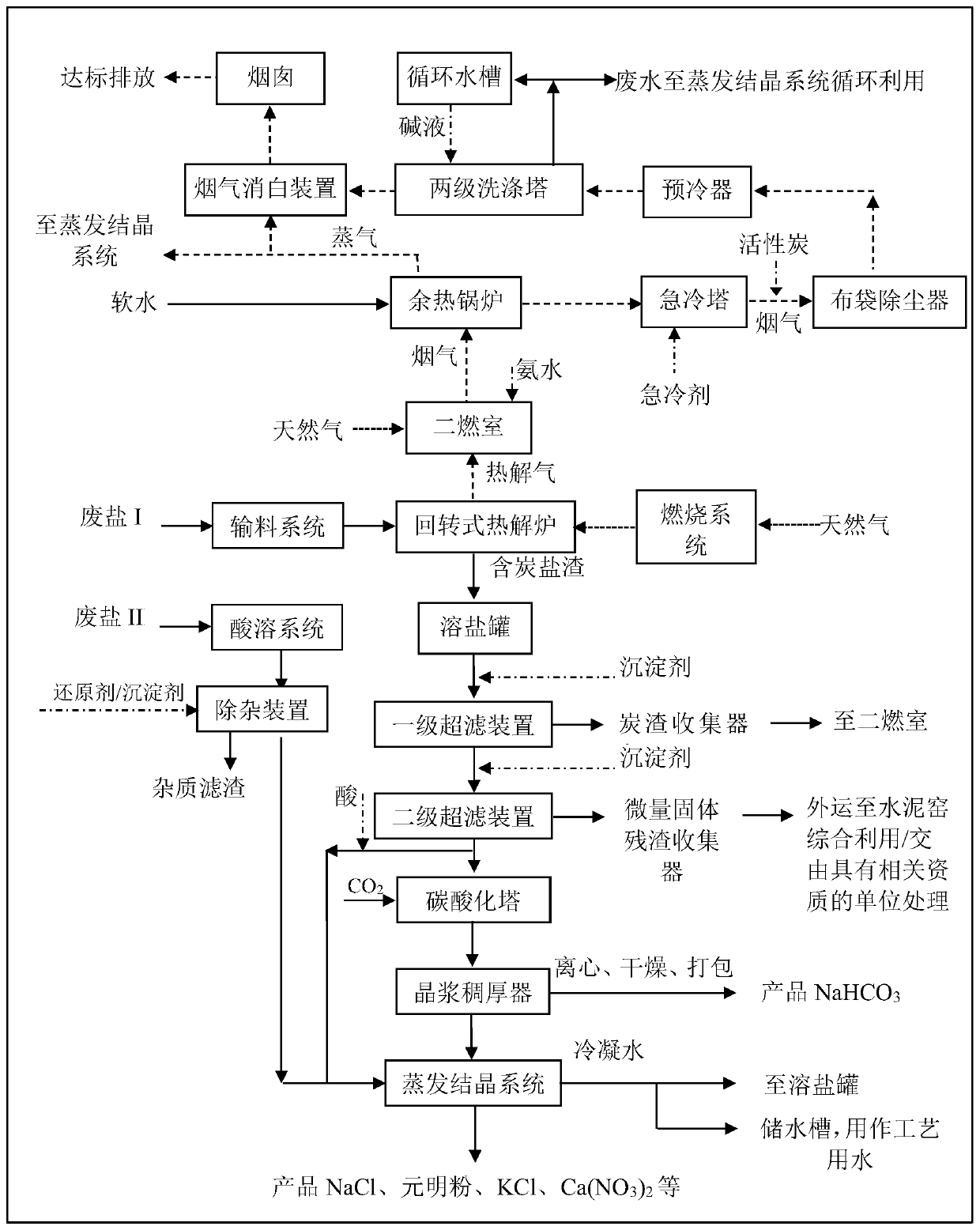

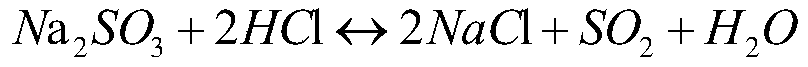

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

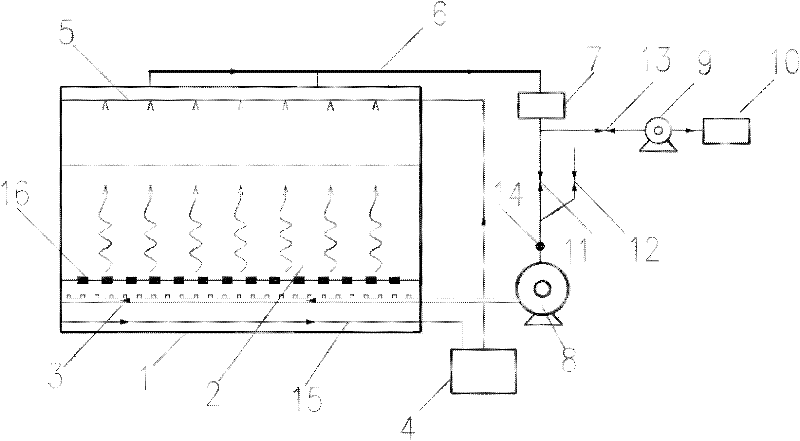

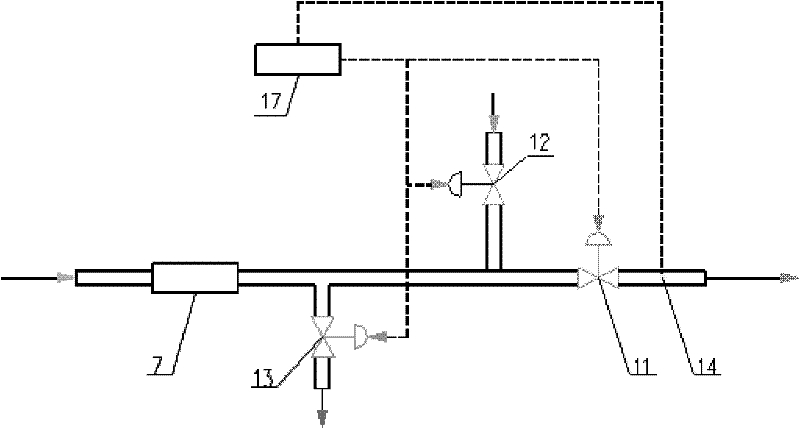

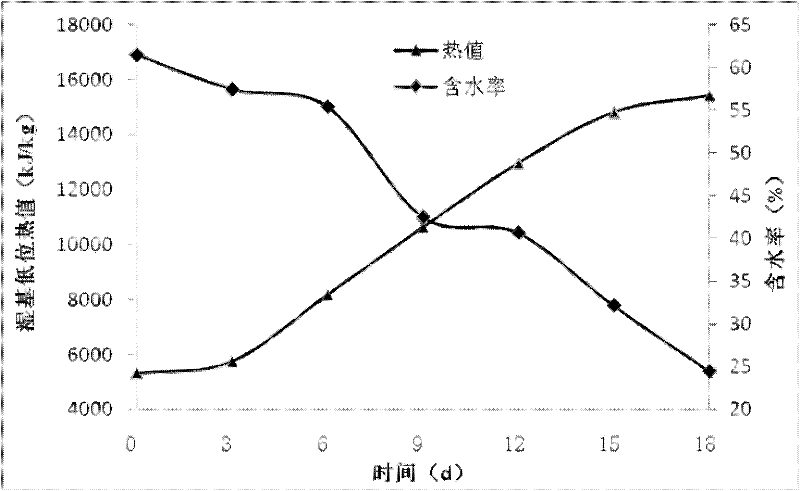

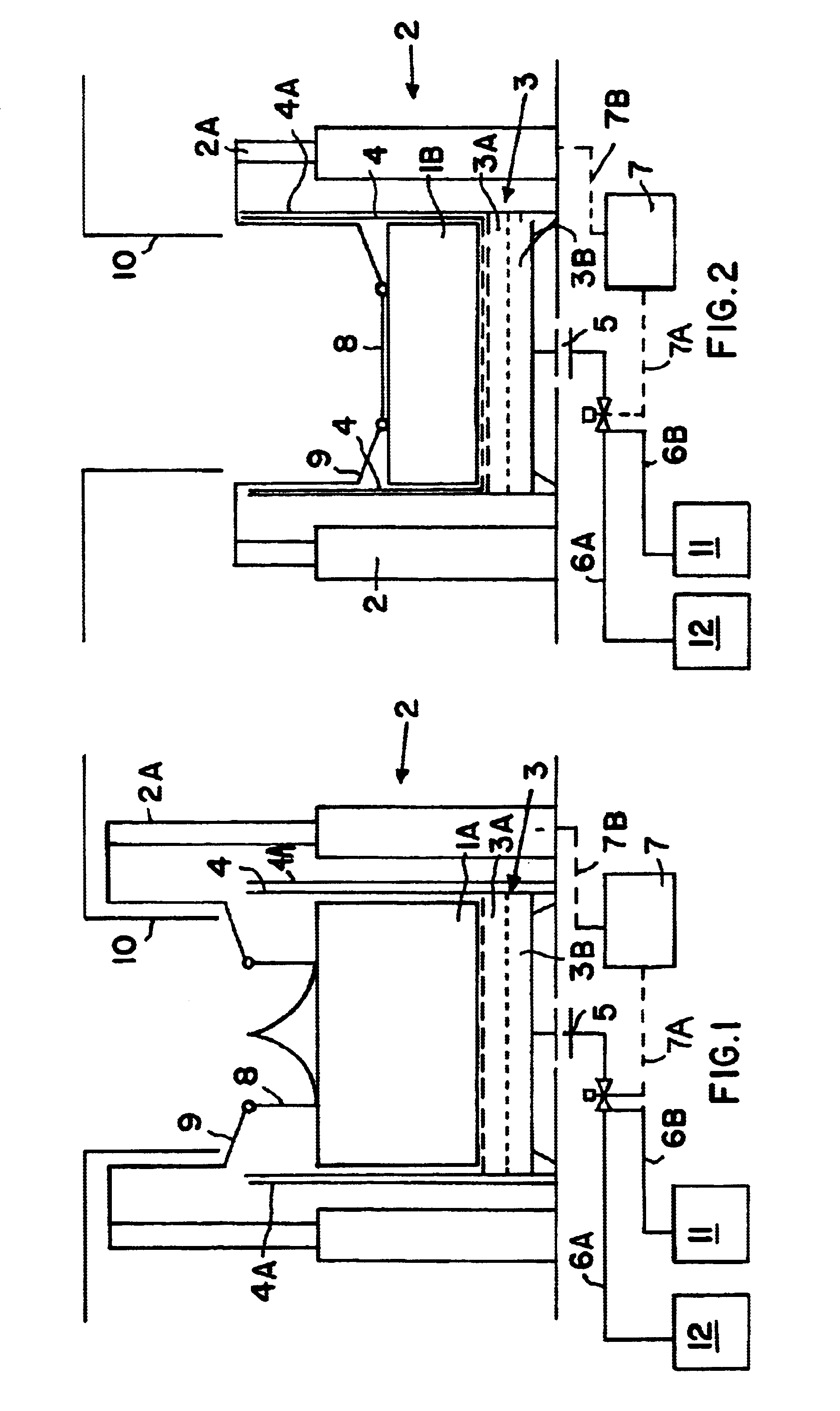

Method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste

The invention relates to a method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste. The method comprises the following steps: (1) simple pretreatment; (2) stacking; (3) biodrying of waste; (4) back spraying of leachate; (5) drying, reflux and concentrated treatment of tail gas. The apparatus comprises a sealed reactor, a leachate collector, a ventilating system and a tail gas treating device, wherein, the leachate collector is respectively connected with a leachate collecting pipe and a spray pipe in the reactor through pipelines, the tail gas treating device comprises a tail gas recovering pipe, a drying box, a tail gas treating fan and a purifying means, the tail gas recovering pipe is connected with the drying box, the drying box is respectively connected with a ventilating fan and the tail gas treating fan, and the tail gas treating fan is connected with the purifying means through a pipeline. According to the invention, the leachate does not need to be treated individually; tail gas is collected in a totally enclosed environment, and the amount of tail gas to be treated is small; a low heating value of obtained dried waste is increased by 100%; the invention is widely applicable to mixed waste with high water content and enables resource values of burning and sorting of domestic waste to be improved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

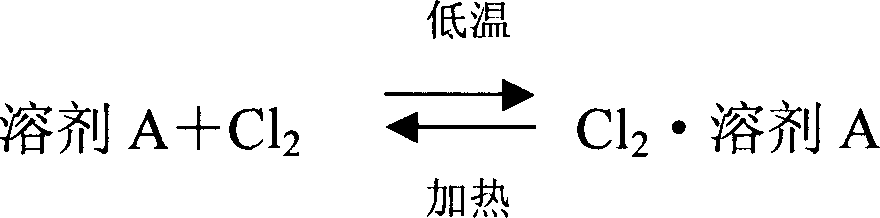

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

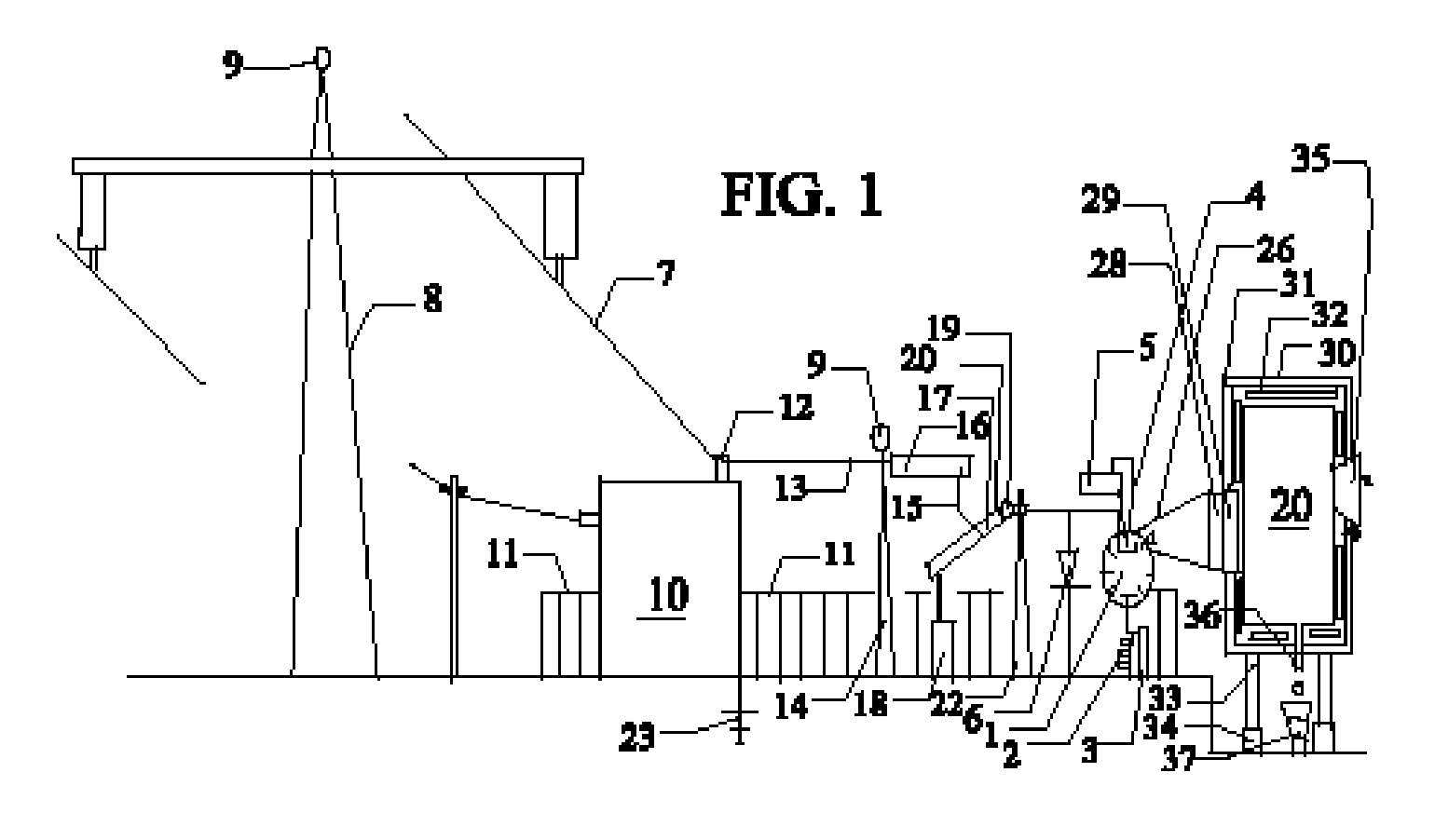

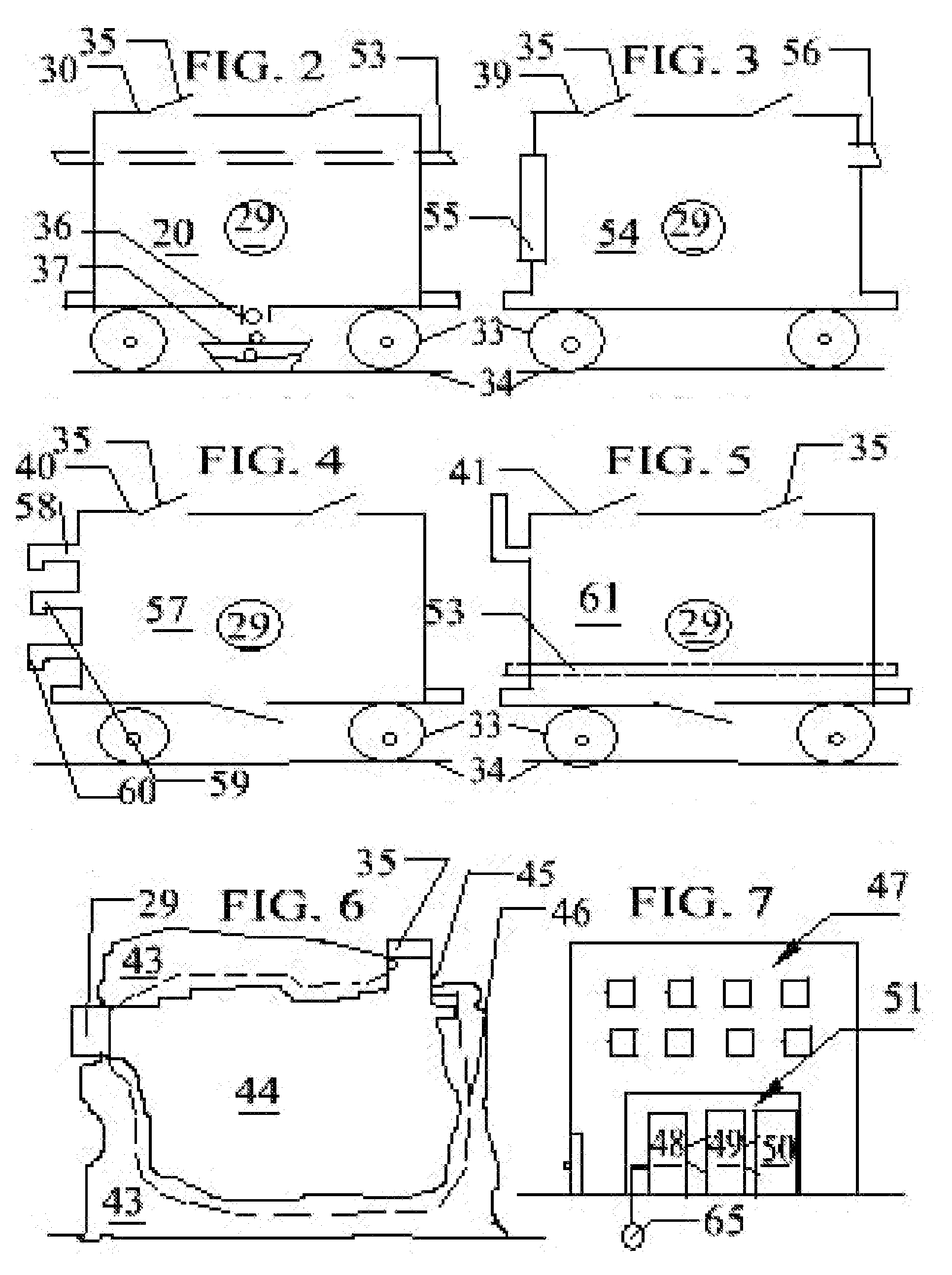

High power microwave waste management

InactiveUS20090121798A1High chemistryElectrotherapyOscillations generatorsThermal energyBuilding design

A variable capacitor power supply for a high-power, industrial magnetron is powered directly from a conventional, public-service, 4,160 volt and higher power line. The magnetron's output is removably attached to a tractor trailers or train boxcar fabricated as a microwave work chambers. Microwave work chambers are configured to dry waste, burn dried waste, enhance chemical processes, fix free nitrogen, burn waste metal, reclaim component metals from mixed waste metal, and for gasification, pyrolysis, and plasma waste disposal. Alternately, the microwave power supply is removably connected to an underground cave, configured as a microwave oven chamber, to microwave waste therein. The microwave power supply is located in the basement of a high rise building designed to convert the high rise building waste into heat and electricity.

Owner:LEVINSON MELVIN LEROY

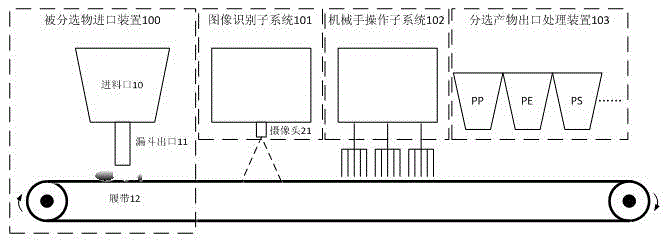

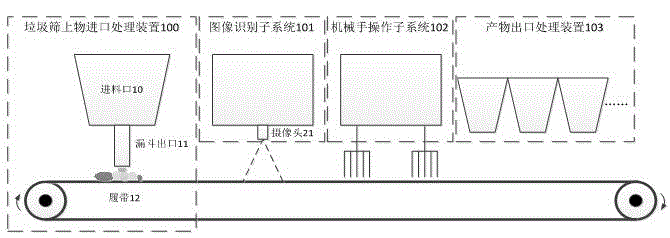

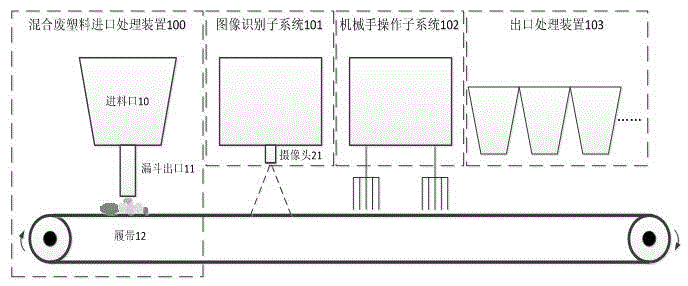

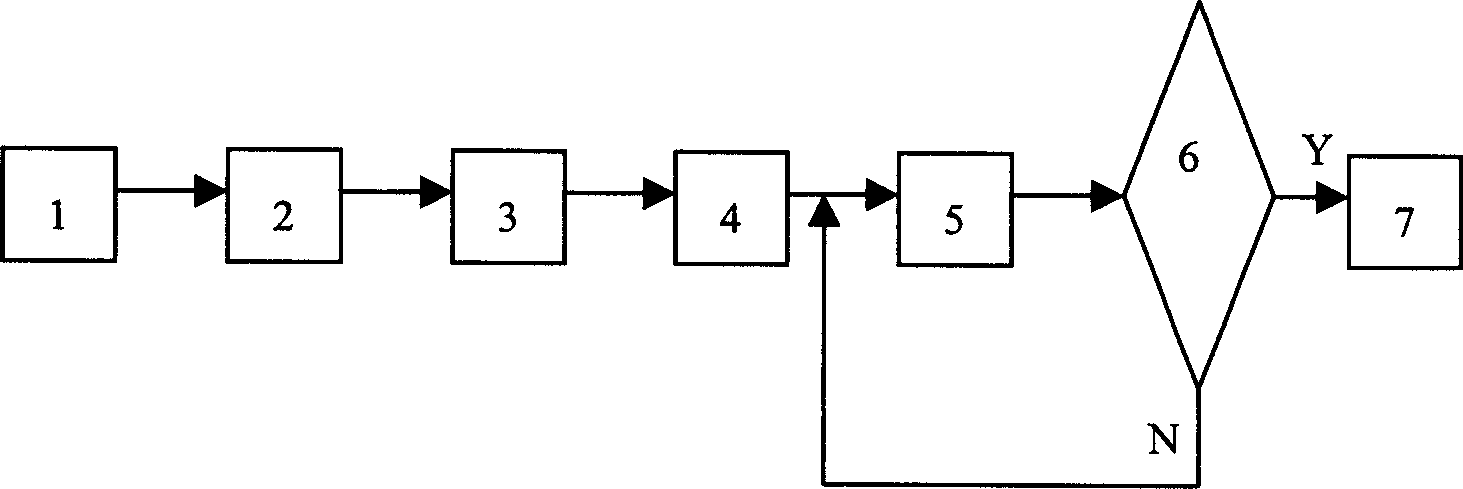

Waste plastic separating method and system based on image recognition

The invention relates to a waste plastic separating method and system based on image recognition. A current object needing to be separated is judged based on the surface texture and the reflected light spectrum distribution, and the method and the system are applied to the production process of sorting plastics from garbage oversize products and used for removing impurity components from the waste plastics and sorting different kinds of waste plastics out of the mixed waste plastics. The system comprises an inlet device of a sorted object, a sorting system and a sorted product outlet device, wherein the sorting system is composed of an image recognition subsystem and a mechanical arm operation subsystem. According to the system, the purposes of sorting the waste plastics from the garbage oversize products in which various waste is mixed and separating sundries from the waste plastics are achieved; or the purpose of separating single waste plastics from the mixed waste plastics is achieved, and the sorting efficiency of the waste plastics reaches 90 percent.

Owner:TONGJI UNIV

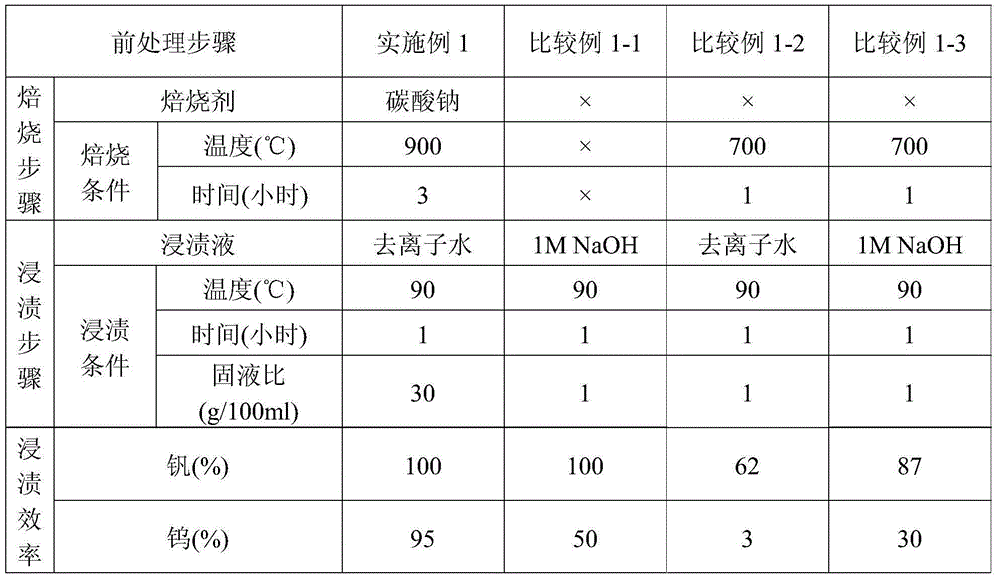

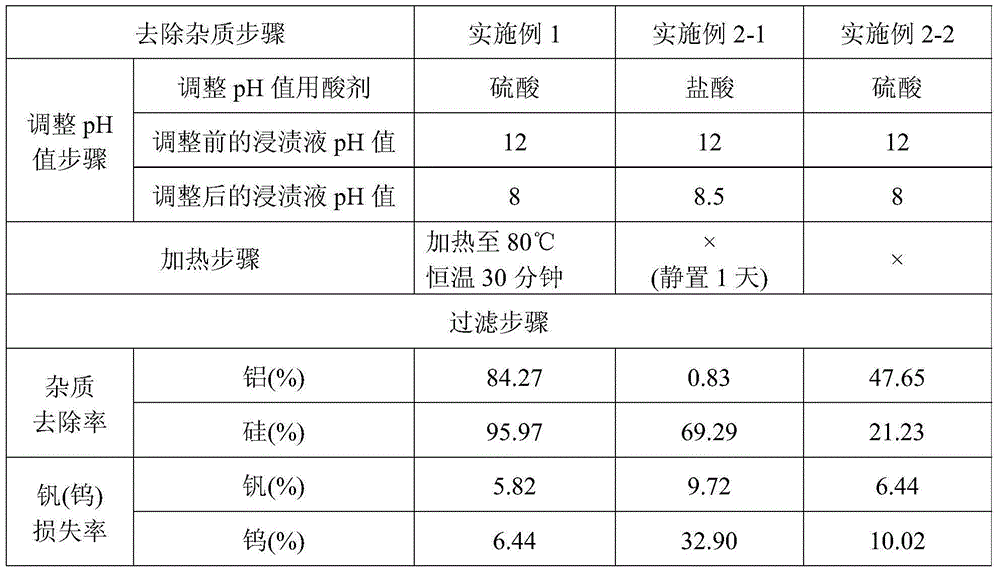

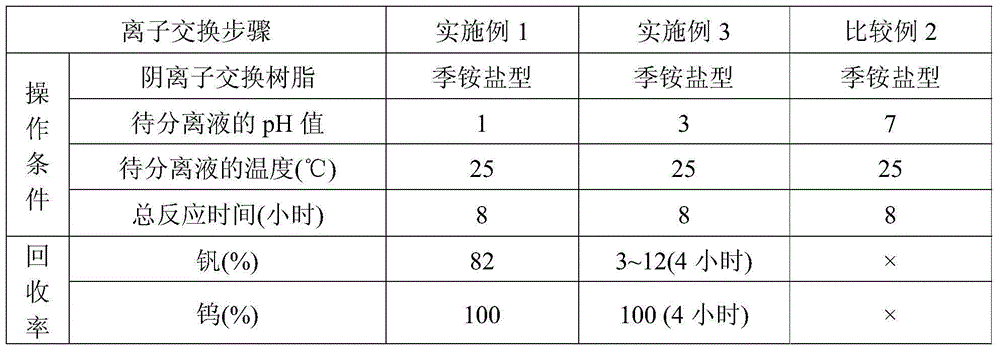

Vanadium and tungsten recovered from scrap selective catalytic reduction catalyst

InactiveCN104561554AHigh recovery rateProcess efficiency improvementPhysical chemistryIon-exchange resin

The present invention relates to a method for recovery of vanadium and tungsten catalysts from waste selective catalytic reduction. After the source of vanadium and tungsten including mixed waste source SCR catalyst calcination agent and firing process, the vanadium source and the source of tungsten and tungsten, vanadium salts are formed salt: A recovery from waste SCR catalyst vanadium and tungsten, comprising further impregnating liquid impregnated comprising the step of forming salts and vanadium salts of tungsten, then purified by impregnating solution, and adjusting the pH of the impregnating solution purified range of 1 to 3 to remove impurities formed by the step of removing the immersion liquid impurities liquid to be separated, and finally to an anion exchange resin to be separated liquid separation vanadium salts and tungsten salt, vanadium-containing solution, and tungsten-containing anion exchange resin. The method of the present invention can achieve very excellent recovery of vanadium and tungsten recoveries, without causing environmental pollution.

Owner:CHINA STEEL

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

Mediated electrochemical oxidation for decontamination

InactiveUS7531708B2Improve efficiencyElectrolysis componentsPhotography auxillary processesLow-level wasteContaminated equipment

A mixed waste mediated electrochemical oxidation process (MEO) process and apparatus for the dissolution of transuranic elements, and / or compounds thereof in transuranic waste, low level waste (LLW), low level mixed waste, special case waste, and greater than class C LLWS, and also the destruction of the non-fluorocarbon organic component in the waste. The MEO process and apparatus operates in three different modes: dissolution, destruction, and decontamination. In the first mode, dissolution, the process runs until the transuranics such as a mixed oxide or carbide, and / or mixture of oxides or carbides of uranium and plutonium are totally dissolved into solution. The second mode, destruction, the process is operated such that the mixed waste materials are reduced to CO2, water and small amounts of inorganic salts. The third mode, decontamination, involves contaminated equipment. In the decontamination mode the MEO process destroys the mixed wastes that have contaminated the equipment.

Owner:SCIMIST LNC

Mediated electrochemical oxidation used for the destruction of organics contaminated with radioactive materials, dissoulution of atransuranics, and the decontamination of equipment contaminated with mixed waste

InactiveUS20060016689A1Improve efficiencyPhotography auxillary processesElectrolysis componentsRadioactive agentLow-level waste

A mixed waste mediated electrochemical oxidation process (MEO) process and apparatus for the dissolution of transuranic elements, and / or compounds thereof in transuranic waste, low level waste (LLW), low level mixed waste, special case waste, and greater than class C LLWS, and also the destruction of the non-fluorocarbon organic component in the waste. The MEO process and apparatus operates in three different modes: dissolution, destruction, and decontamination. In the first mode, dissolution, the process runs until the transuranics such as a mixed oxide or carbide, and / or mixture of oxides or carbides of uranium and plutonium are totally dissolved into solution. The second mode, destruction, the process is operated such that the mixed waste materials are reduced to CO2, water and small amounts of inorganic salts. The third mode, decontamination, involves contaminated equipment. In the decontamination mode the MEO process destroys the mixed wastes that have contaminated the equipment.

Owner:SCIMIST LNC

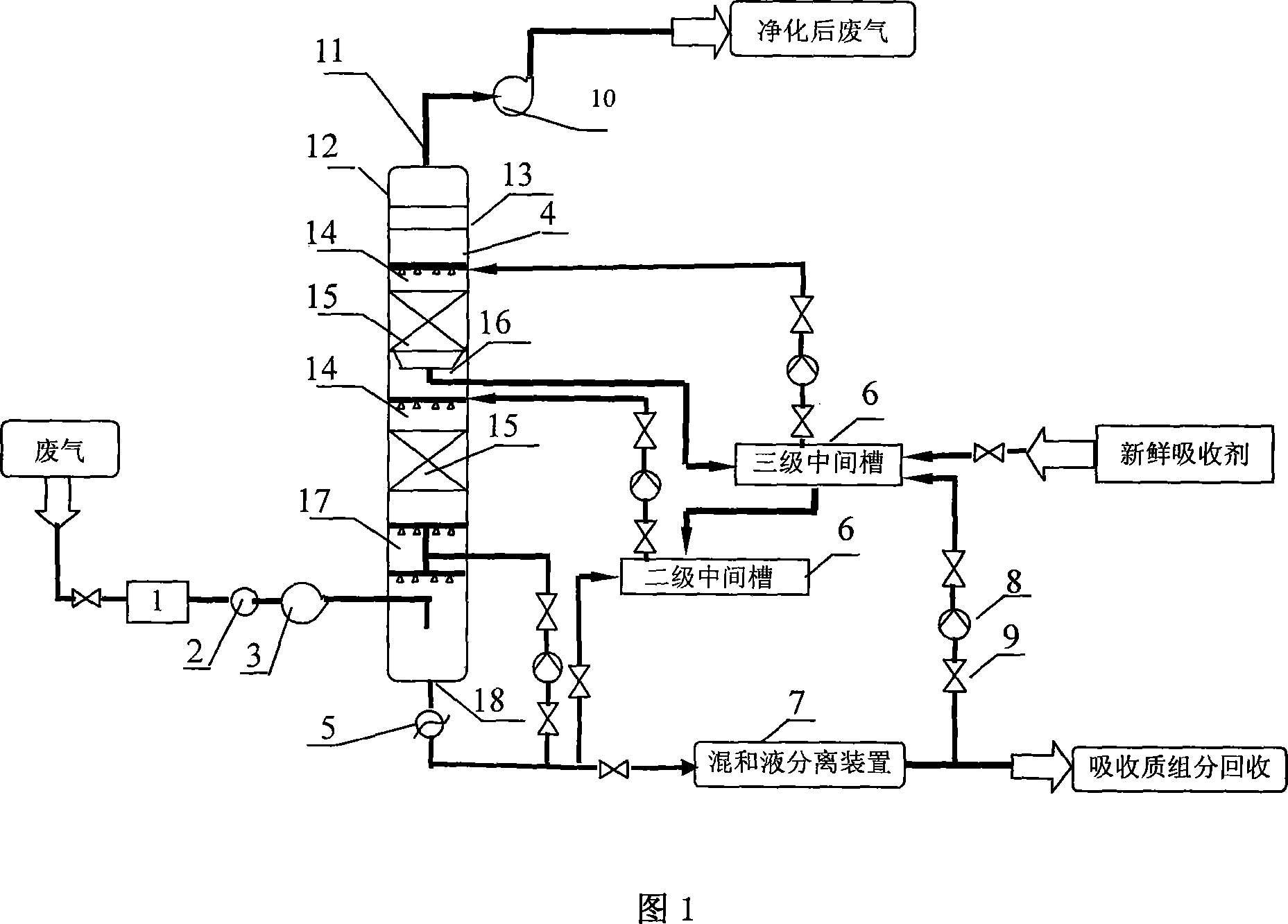

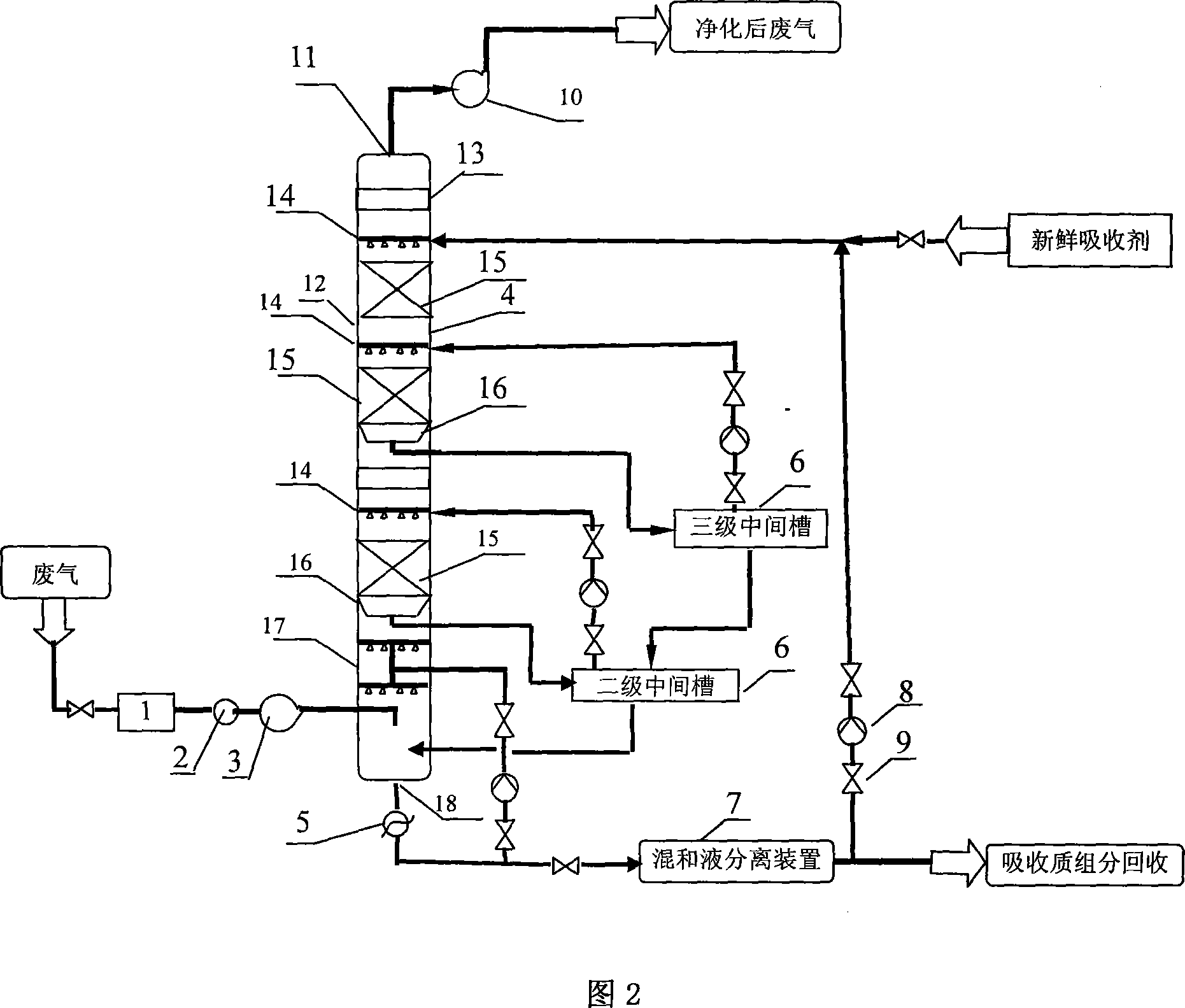

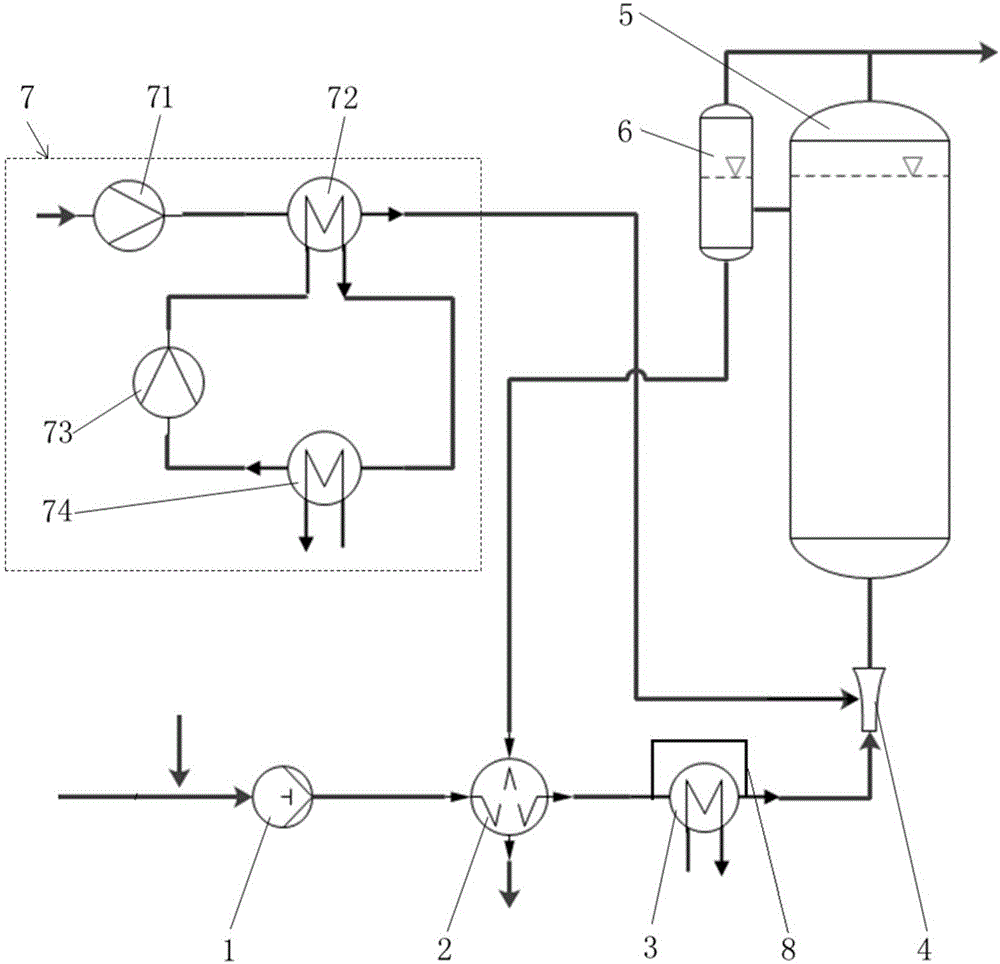

Process method of purifying and recycling mixed organic waste gas

InactiveCN101108296APromote absorptionHigh flash pointDispersed particle separationChemical industryOrganic solvent

The invention belongs to chemical industry and waste gas process field, in particular providing a process method which mixes organic waste gas purifying and resource recovery. The specific procedure is that: make the mixed waste gas pass through a filter to be filtered, and then enters into a single-seat multilevel absorption tower and contacts with a packing layer and a liquid distribution device; when the series of the single-seat tower is 3, the second-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising the mixing liquid which is pumped in after cooled by a heat interchanger at the bottom of the adsorption tower and the mixing liquid which generates in the middle groove of the third-grade; the third-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising fresh absorbent, the regenerating liquid recycled by a mixing liquid separation device and the collecting liquid collected by a collecting hopper of third-grade; when the series of the single-seat tower is N and is larger than 3, all grades of absorbent from the second grade to the N minus 2 is a mixing liquid comprising a mixing liquid generated in the middle groove of the next grade and a collecting liquid collected by the collecting hopper on the same grade, the absorbent of the N minus grade is the colleting liquid collected by the collecting hopper of the N minus 1 grade, the absorbent of the N grade is a mixing liquid comprising of pumped fresh absorbent and the regenerating liquid recycled by the mixing liquid separation device. The fresh absorbent is an environment-protected organic solvent with high boiling point, strong lipophilicity and low volatility. The invention can recycle a plurality of organic infectant in waste gas, the technics procedure is simple, practical, and the operation cost is low.

Owner:上海同济华康环境科技有限公司

Catalyst for catalytic cracking mixed waste plastic and preparation method thereof

InactiveCN101284235AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic pyrolysisCatalytic reforming

The invention discloses a catalyst for manufacturing fuel oil through catalytic pyrolysis of mixed-waste plastics, and a preparation method thereof, and relates to catalytic thermal cracking for manufacturing the fuel oil through waste plastic cracking and a second stage catalyst in thermal cracking catalytic reforming. A first stage catalyst comprises a metallic oxide of 2.0wt percent to 30.0wt percent and carclazyte or montmorillonite of 70.0wt percent to 98.0wt percent; the first stage catalyst is innoxious and cheap, increases the reaction velocity of plastic cracking, reduces the temperature in the scission reaction, improves the selectivity of decomposition products, and is dechlorinated and transformed into innocuous substances. The second stage catalyst is composed of ferric oxide, molybdenum oxide, zinc oxide, cerium oxide, lanthana, nickel oxide or copper oxide, and ZSM-5, MCM-22, USY, REY, Beta or MOR molecular sieves; the second stage catalyst performs the second catalytic pyrolysis and isomerization and the aromatization reversion reactions on pyrolysis gas in the first stage, to increase the distillate rate of pyrolysis gasoline and gas oil. The catalyst and the preparation method thereof have good selectivity, and the raw material does not need classification, washing and drying; the operation is flexible, and the running cost is low; the method is particularly applied to the fuel oil manufacture through the cracking of the mixed-waste plastics in the urban and rural domestic refuse, the composition is complicated; the oil yield of the qualified fuel oil can reach up to more than 70 percent calculated on the basis of the waste plastic.

Owner:TONGJI UNIV

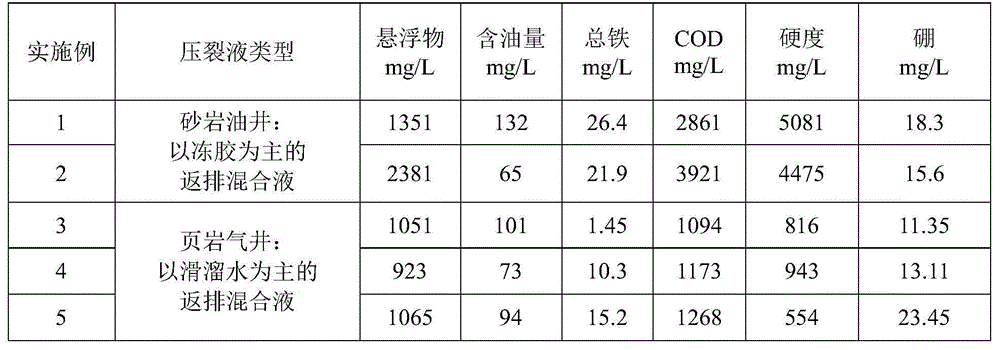

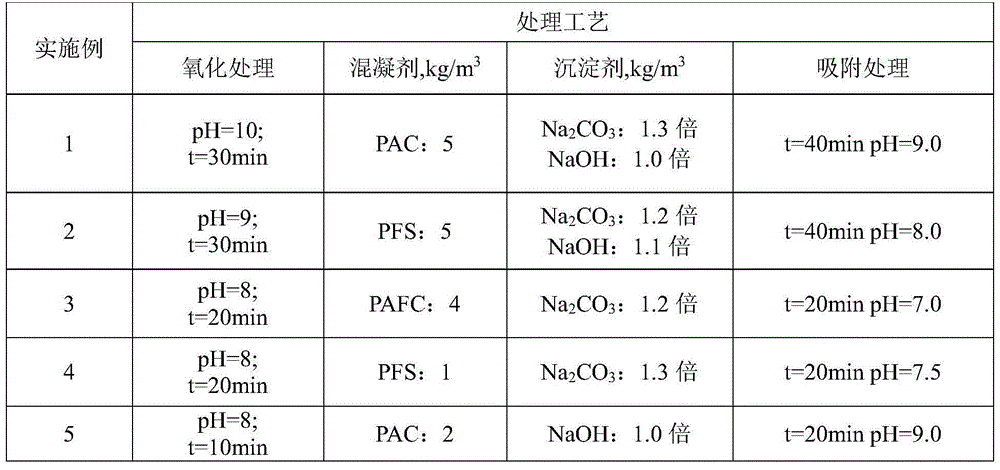

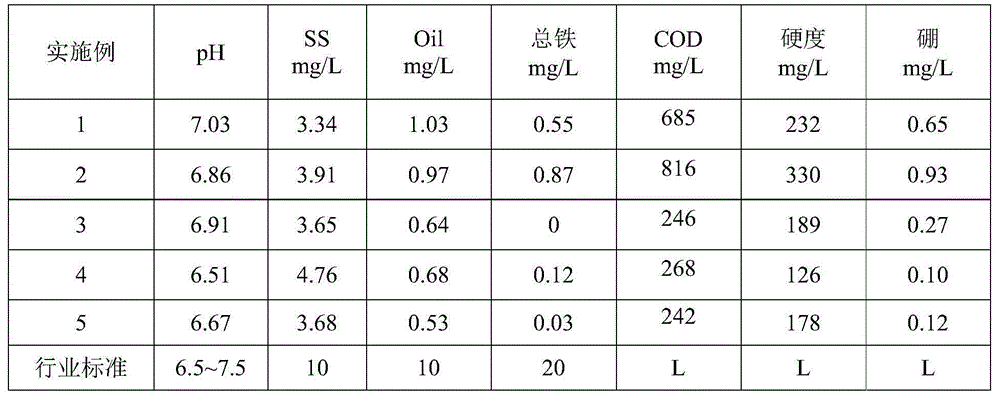

Reutilization method of water-base fracturing flowback fluid

InactiveCN104310628AReduce interventionHigh recovery rateMultistage water/sewage treatmentDrilling compositionLiquid wasteWater based

The invention relates to a reutilization method of a water-base fracturing flowback fluid, and belongs to the field of cyclic utilization technologies for water-base fracturing flowback fluids generated in non-routine oil and gas reservoir resource exploitation, especially wastewater reuse processing technologies of oil and gas fields. A mixed waste liquid of the water-base fracturing flowback fluid is subjected to ozone oxidation, flocculation precipitation processing and filter adsorption processing for removing harmful compositions in the wastewater, and the discharged water can be used to prepare slick water normally used in unconventional oil and gas wells, linear glue and gelling fracturing fluids. The method is simple in technology, continuous in operation, rapid and efficient, and helps to realize repeated reuse of fracturing flowback fluids and save water resource.

Owner:CHINA PETROCHEMICAL CORP +1

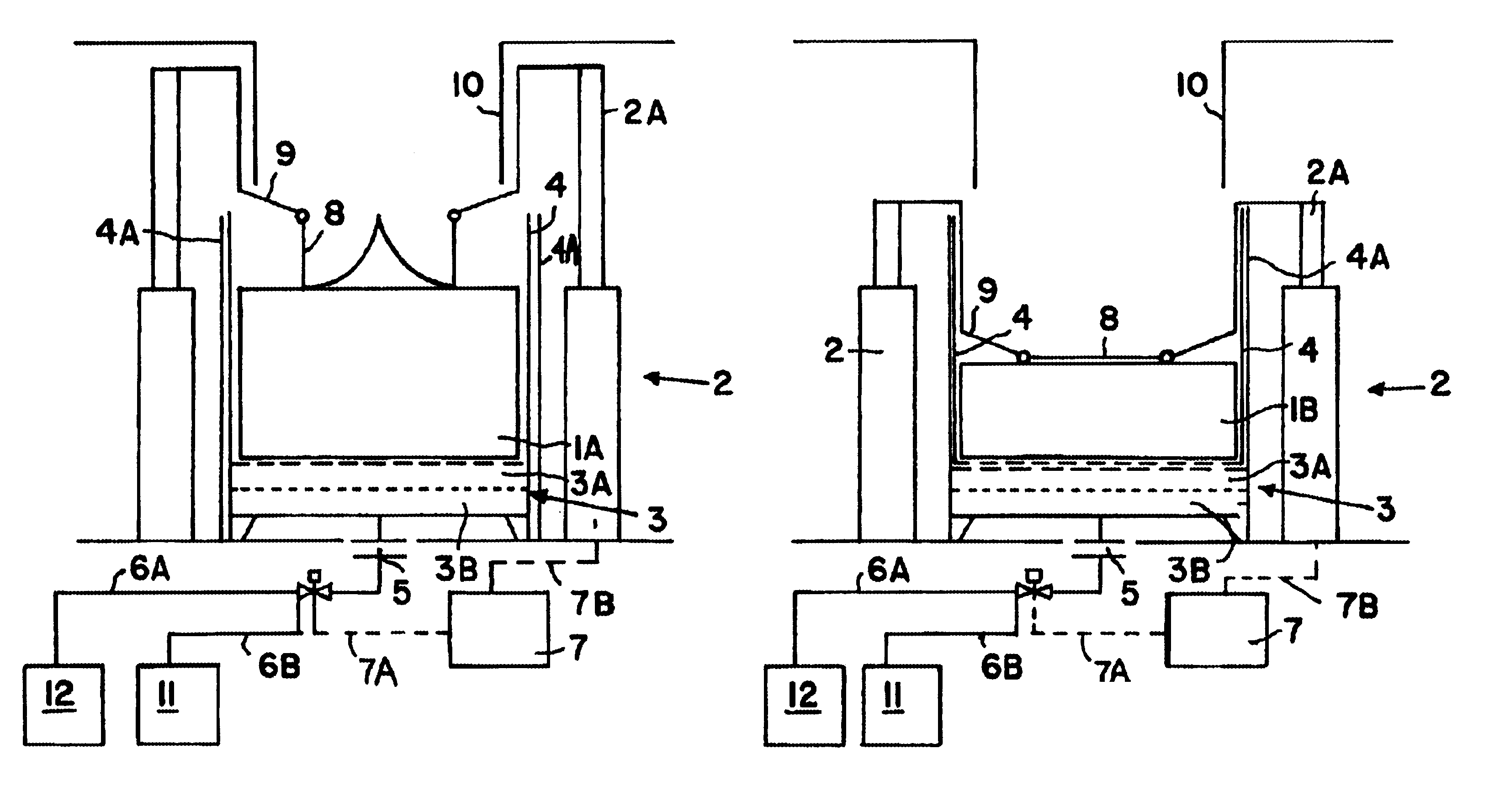

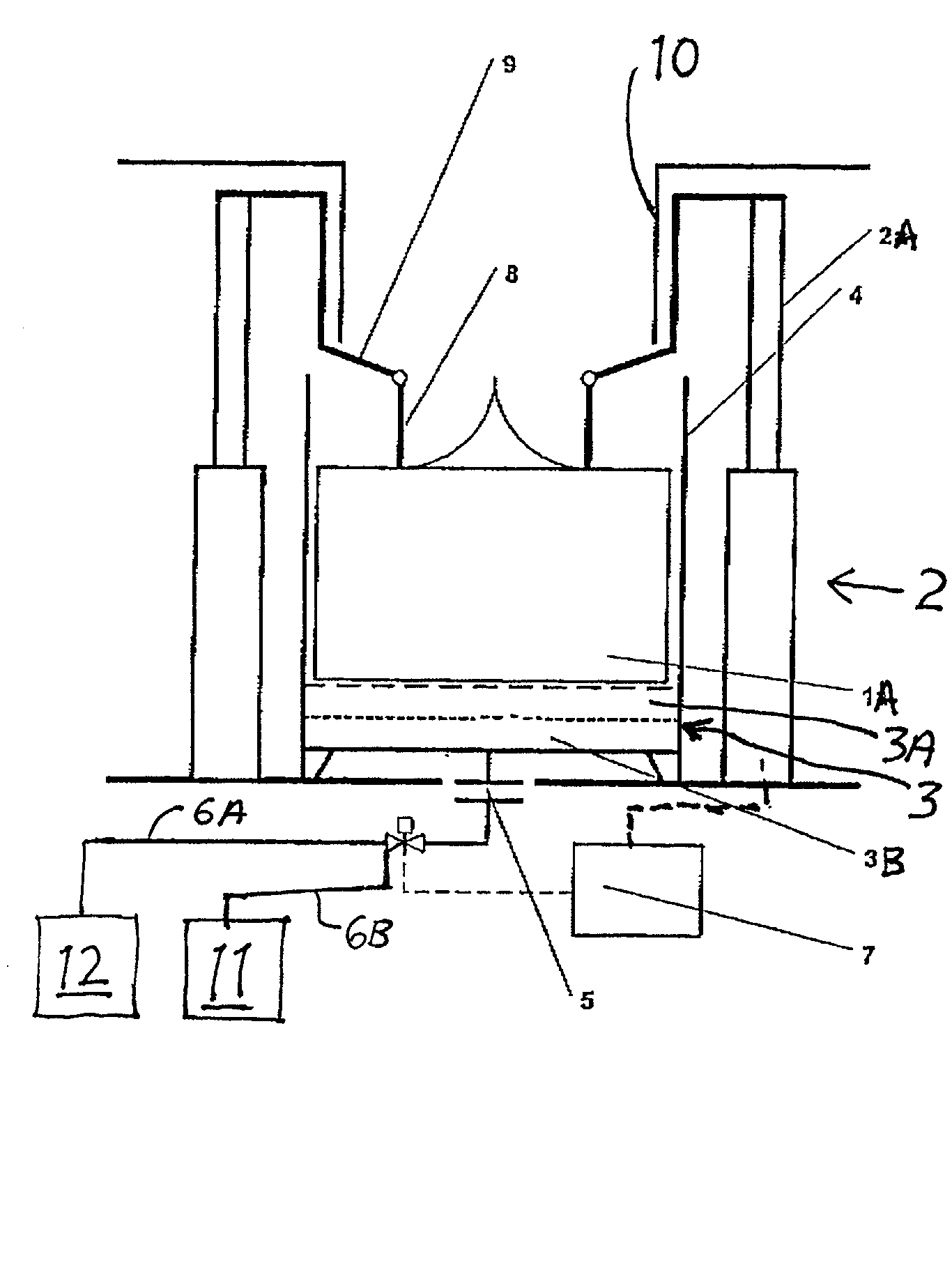

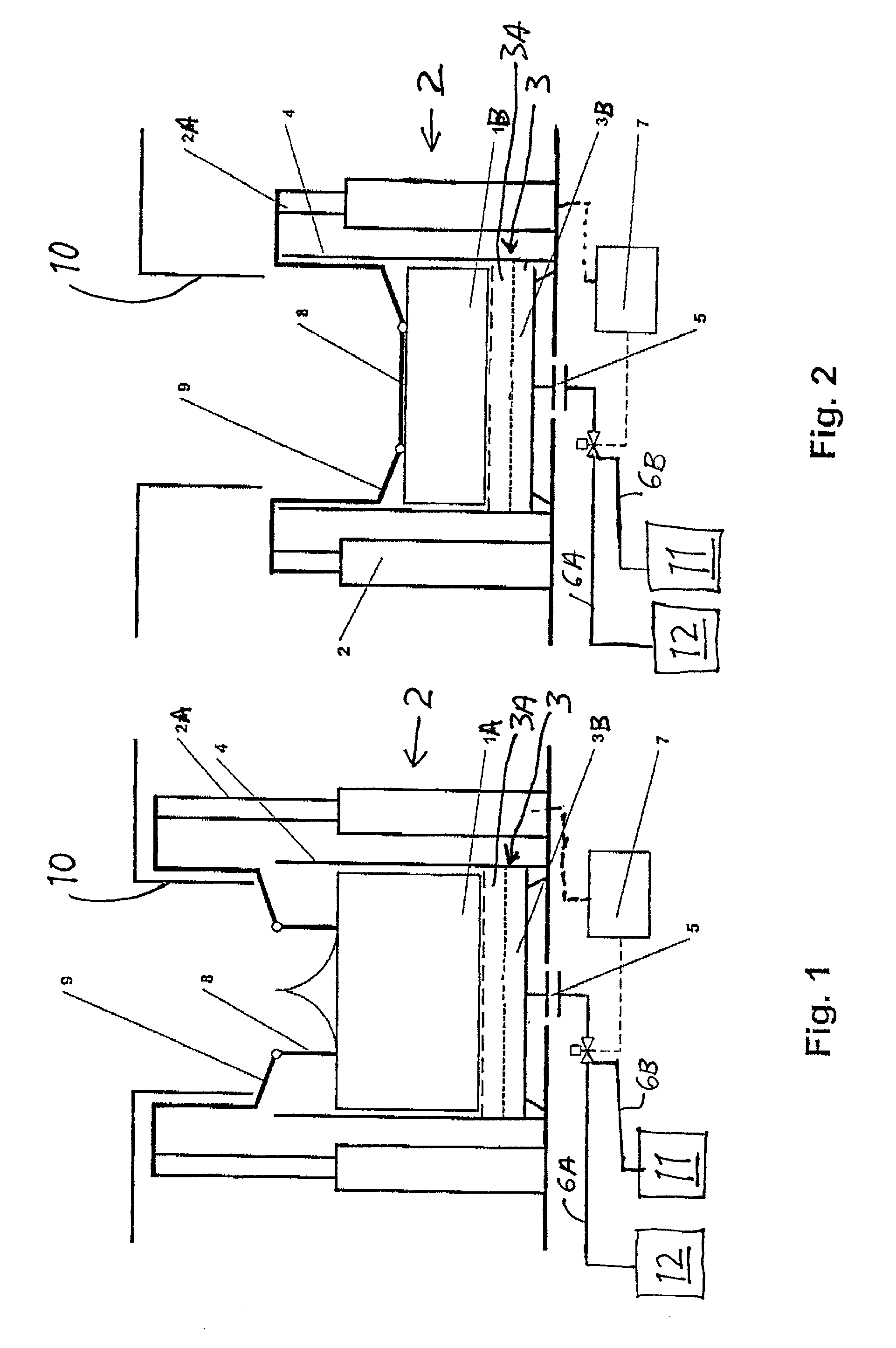

Apparatus for compacting and draining mixed waste in passenger transport vehicles

Catering in a transport vehicle like an aircraft involves collecting mixed waste including solids (e.g. left-over food portions, food wastes, napkins, disposable cutlery) and liquids (e.g. beverage rests), without separation. These wastes are disposed of into an apparatus including a receiving container with a filter and separating element at the bottom, a waste shaft leading into the container, a press arrangement with flap doors, pressure pistons which press the press arrangement and flap doors onto the waste in the container to compact the waste, and a drain and coupling system at the bottom of the container. As the waste is compacted, liquids drain down through the filter, oils and fats are removed by the separating element, and non-oily liquids are removed through the coupling system to the vacuum disposal system or the gray water drain line of the vehicle. A control unit controls the overall operation.

Owner:AIRBUS OPERATIONS GMBH

Method for flue gas denitrification by organic waste gas

ActiveCN103055694ALess investmentLow construction costDispersed particle separationEnergy recoveryOxygen

The invention discloses a method for flue gas denitrification by an organic waste gas. The method comprises: introducing an organic waste gas and an oxygen-containing gas into an NOx flue gas to obtain a mixed waste gas, heating the mixed waste gas to a temperature of 100-500DEG C, then making the mixed waste gas enter a waste gas purification reactor, under the action of a flue gas denitrification catalyst, reducing the NOx in the flue gas into N2 by organic hydrocarbon in the waste gas, and simultaneously oxidizing hydrocarbon into CO2 and H2O, subjecting the denitrified flue gas to energy recovery and discharging it completely. The method disclosed in the invention utilizes the organic waste gas as a reducing agent for catalytic reduction of the NOx in the flue gas, and integrates flue gas denitrification and odor pollution control. With the characteristics of safe operation and less one-time investment, the method is especially suitable for enterprises having organic waste gas sources and NOx-containing flue gas at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plasma incineration waste treatment equipment

ActiveCN101457934AReduce power consumptionReduce volumeSteam engine plantsIncinerator apparatusElectricityCombustion chamber

The invention discloses plasma incineration waste disposal equipment. The waste feed inlet of a plasma waste incinerator is connected with a waste pre-heating device; the feed entrance of the pre-heating disposal device is connected with a waste crushing device; the waste pre-heating device is provided with an exhaust pipeline for mixed waste gas which is communicated with the combustion chamber of a steam boiler; the steam pipeline of the steam boiler is communicated with steam generating equipment and transmits steam to the steam generating equipment for generating power. Before entering the plasma waste incinerator, the waste is not only crushed into small pieces, but also is preheated for evaporating bulk of the moisture, so the waste entering the incinerator has small volume and less moisture, the possibility for rapidly generating excessive mixed gas and thus resulting in explosion under instant high temperature as the waste contains much water can not be generated, and the security performance is good. Meanwhile, the waste can produce a large amount of combustible mixed gas such as CO and the like in preheating, the mixed gas is conducted into the steam boiler for being incinerated and generating steam by heating, and the hot steam is transmitted into the steam generating equipment for doing work and generating electric energy which can be used for providing the electric energy that is needed by the plasma waste incinerator when in work, so the electricity consumption of the plasma incineration waste disposal equipment is also reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

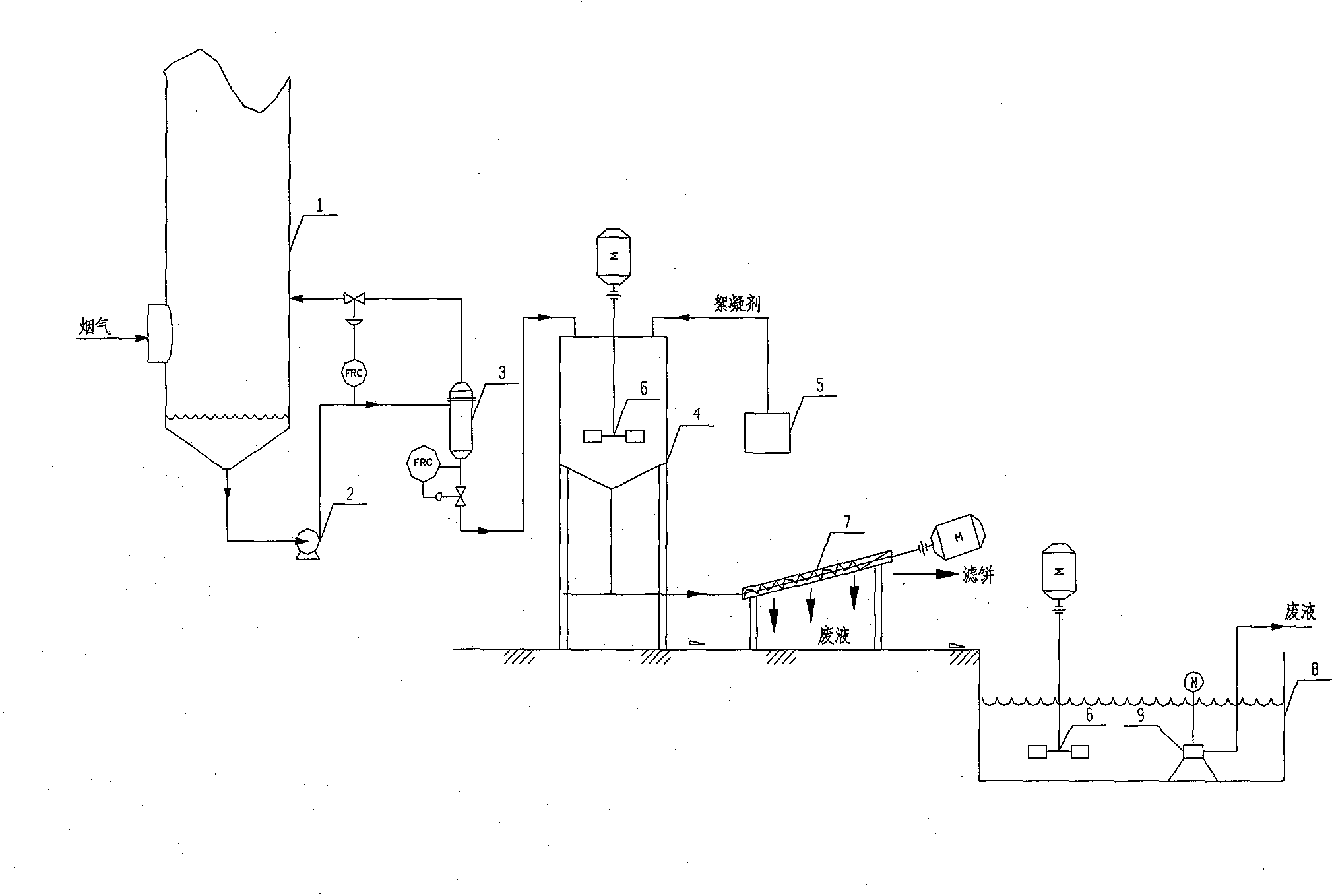

Flue gas desulfurization wastewater waste catalyst separation process

ActiveCN104341060AReduce waste volumeSmall footprintMultistage water/sewage treatmentLiquid wasteWastewater

The invention discloses a separation process of a waste catalyst in flue gas desulfurization wastewater. The method comprises the following steps: (1) waste liquid from a flue gas desulfurization part and comprising waste catalyst particles is concentrated in a hydro-cyclone separator; concentrated waste liquid rich in catalyst particles is delivered into a flocculating agent addition tank; (2) a flocculating agent is added into the waste liquid added into the flocculating agent addition tank from the step (1) and rich in catalyst particles under stirring; the waste liquid and the flocculating agent are well mixed; the mixed waste liquid is delivered into a dehydrator; and (3) in the dehydrator, the waste liquid is concentrated and dehydrated; dehydrated filter cake is directly transported, and the obtained filtrate is delivered into a sewage field for further treatments such as aeration. With the method, waste liquid discharge amount can be greatly reduced, equipment land occupation can be reduced, equipment investment can be saved, and waste catalyst transportation amount can be reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

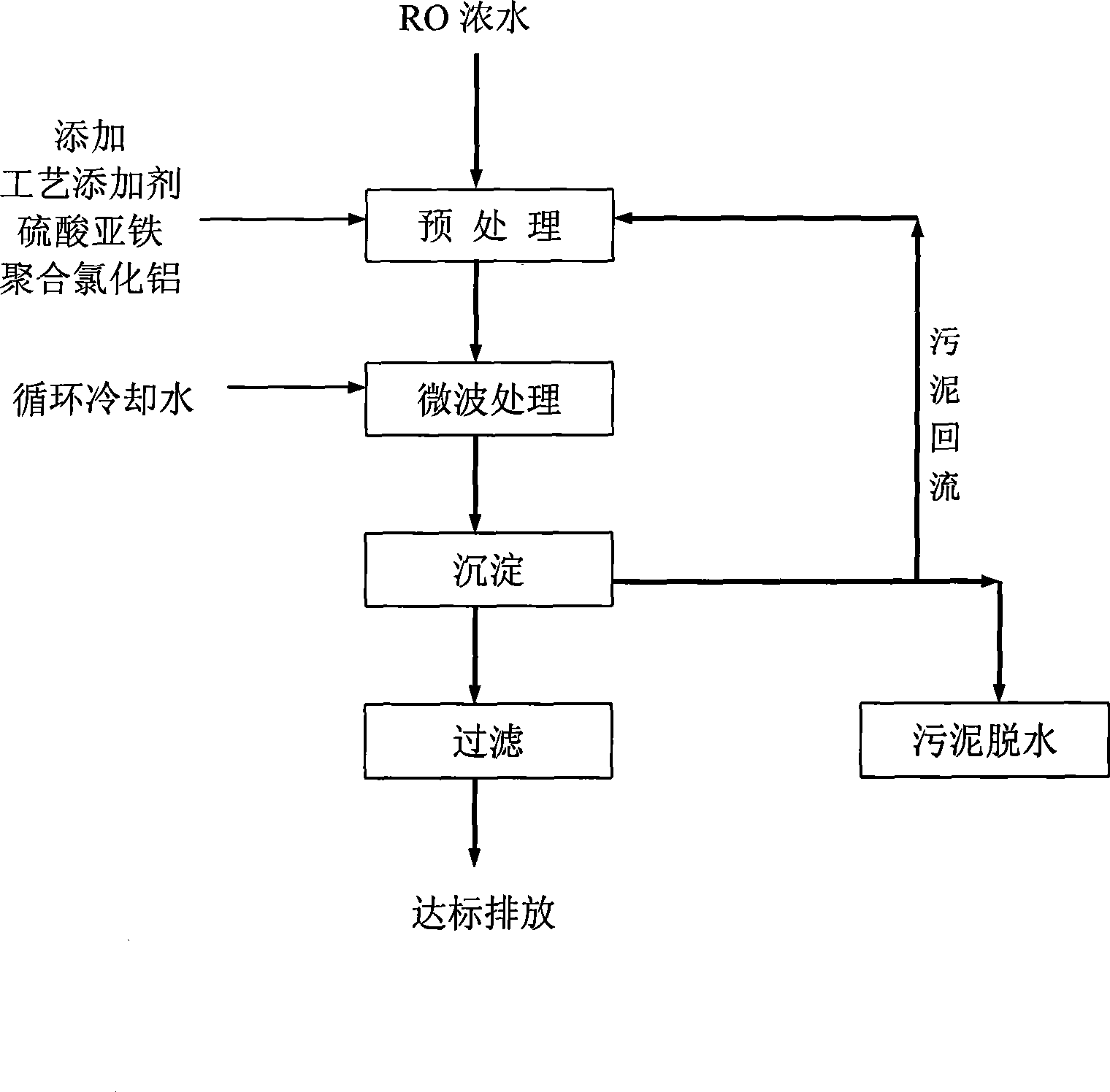

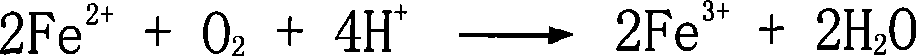

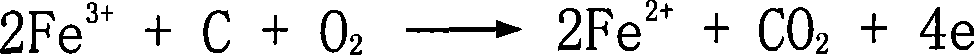

Microwave method for processing reverse osmosis concentrated water

InactiveCN101381120AStrong targetingGood processing effectSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationMicrowave methodChemical reaction

The invention relates to a method for reverse osmosis enriched water by microwave treatment. The method comprises the following steps: adding a process additive, ferrous sulfate and polyaluminium chloride into the reverse osmosis enriched water to perform the pretreatment; putting the pretreated enriched water into a microwave processor from the lower part of the microwave processor and taking out the pretreated enriched water from the middle and upper part of the microwave processor so as to ensure that the process additive, the ferrous sulfate and the polyaluminium chloride perform adequate physical and chemical reactions with the enriched water; guaranteeing that the yielding water of the microwave processor flows into a precipitation filtering unit automatically to realize stable drainage reaching the standards; and branching sludge to cause part of the precipitated sludge to be pumped back to the pretreatment reaction for recycling, and dehydrating the ineffective or residual sludge into dry sludge. The method is applicable to processing various organic waste water or mixed waste water which takes COD and heavy metal as the main pollutant and is hard to biodegrade; the method has the advantages of simple technical processes, convenient control, low treatment cost and less occupied space; in addition, the method fills in the domestic gap of the method for processing the new reverse osmosis enriched water generated in the recycling process of reclaimed water, and has good popularization value.

Owner:深圳市弘玮环境技术有限公司

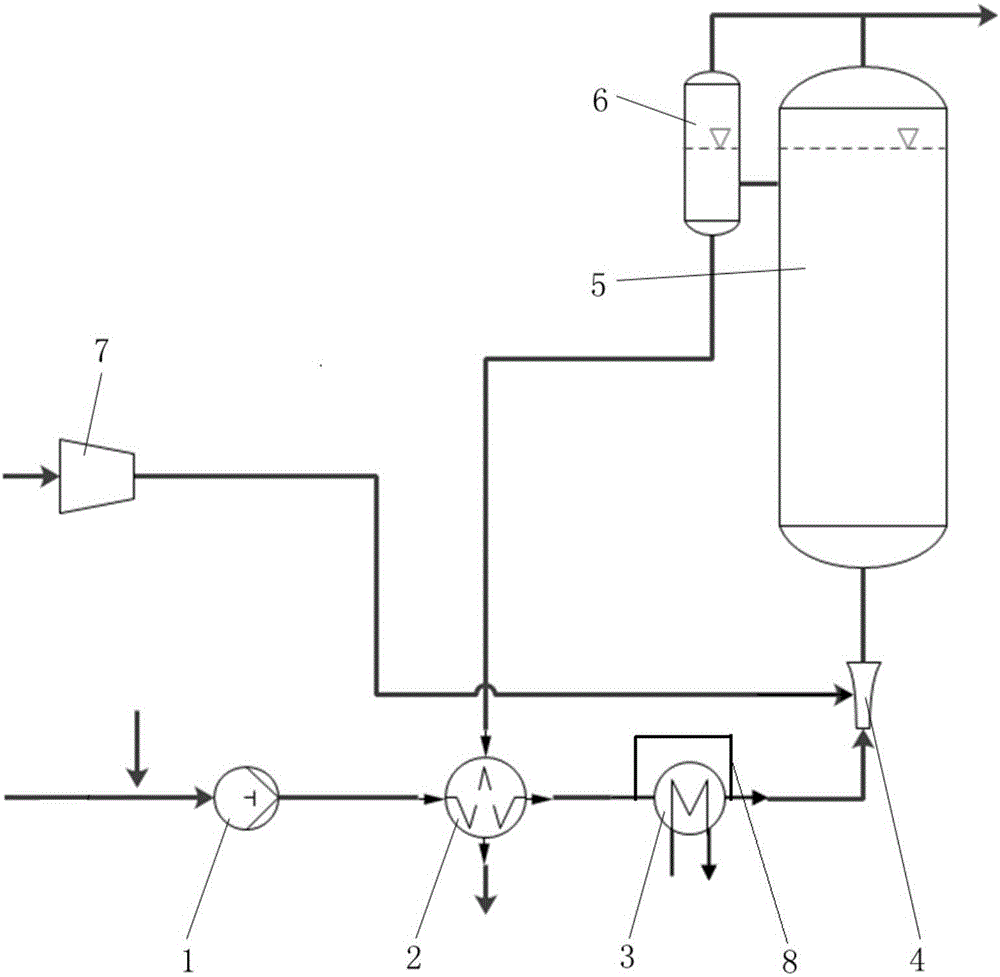

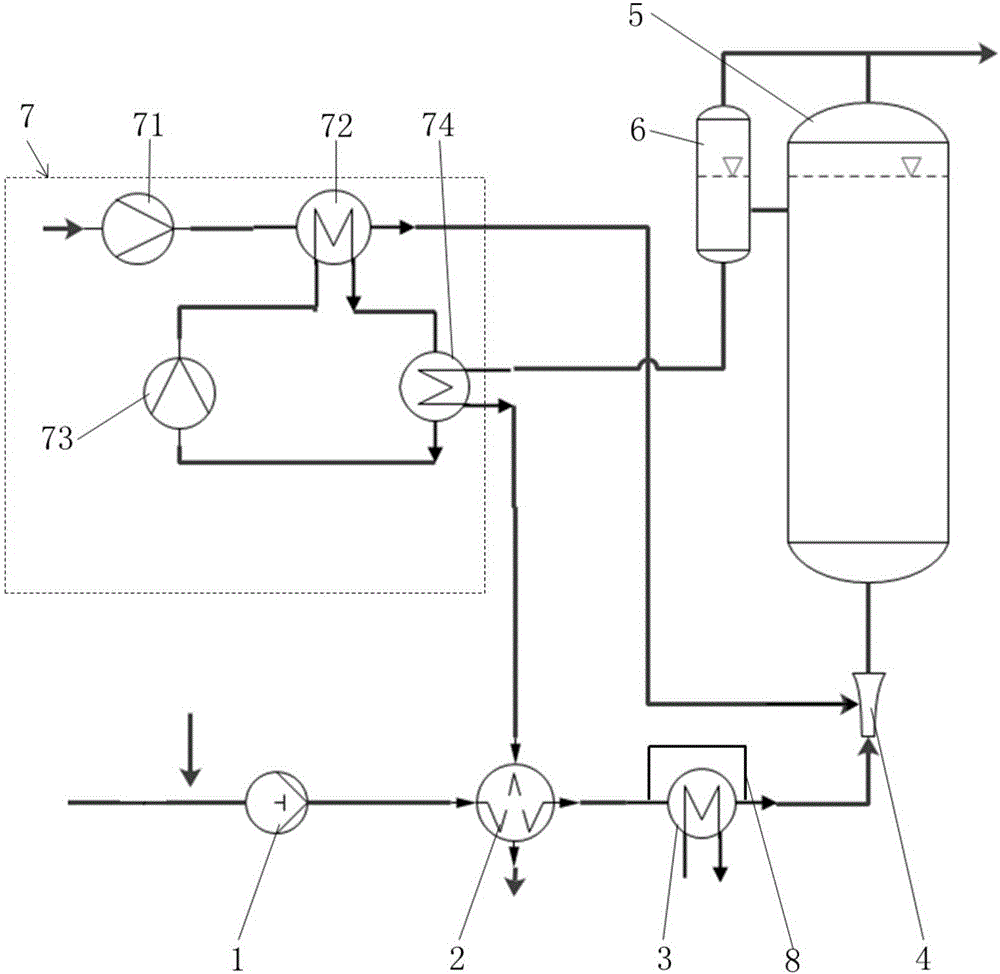

Continuous wet oxidation process for degrading high concentration organic waste water and equipment thereof

PendingCN106348421AEasy to handleSave spaceSpecific water treatment objectivesWater contaminantsHigh concentrationEnergy consumption

The invention discloses a continuous wet oxidation process for degrading high concentration organic waste water, belonging to the field of water treatment. The continuous wet oxidation process for degrading high concentration organic waste water comprises the procedures: a waste water pressurizing procedure: pressurizing waste water to be treated; a waste water heat exchange procedure: carrying out direct and / or indirect heat exchange on the pressurized waste water and treated waste water so the temperature of the pressurized waste water rises; an oxidizer pressurizing procedure: pressurizing an oxidizer; a mixing procedure: thoroughly mixing the pressurized and heated waste water with the pressurized oxidizer; a reaction procedure: causing the mixed waste water and the oxidizer to generate oxidation reaction, obtaining the treated waste water and generating gas; and a separation procedure: continuously separating the treated waste water from gas. The continuous wet oxidation process for degrading high concentration organic waste water has the advantages of high efficiency, less energy consumption, stability of operation and the like.

Owner:羿太环保科技(上海)有限公司

Parifying and regenerating process for high and medium viscosity waste oils

The present invention relates to the utilization of waste resource, and especially the regeneration and utilization of mixed waste oil of high and medium viscosity. The purification and regeneration process of waste oil of high and medium viscosity includes the following steps: natural deposition and rough filtration; heating for flocculation and deposition; three stages of pre-treatment including the secondary filtering; low temperature and high vacuum dewatering and fine filtering; inspection, etc. Through the purification and regeneration process, the produced oil product may reach the standard of new oil product.

Owner:上海宝钢废旧油处理有限公司

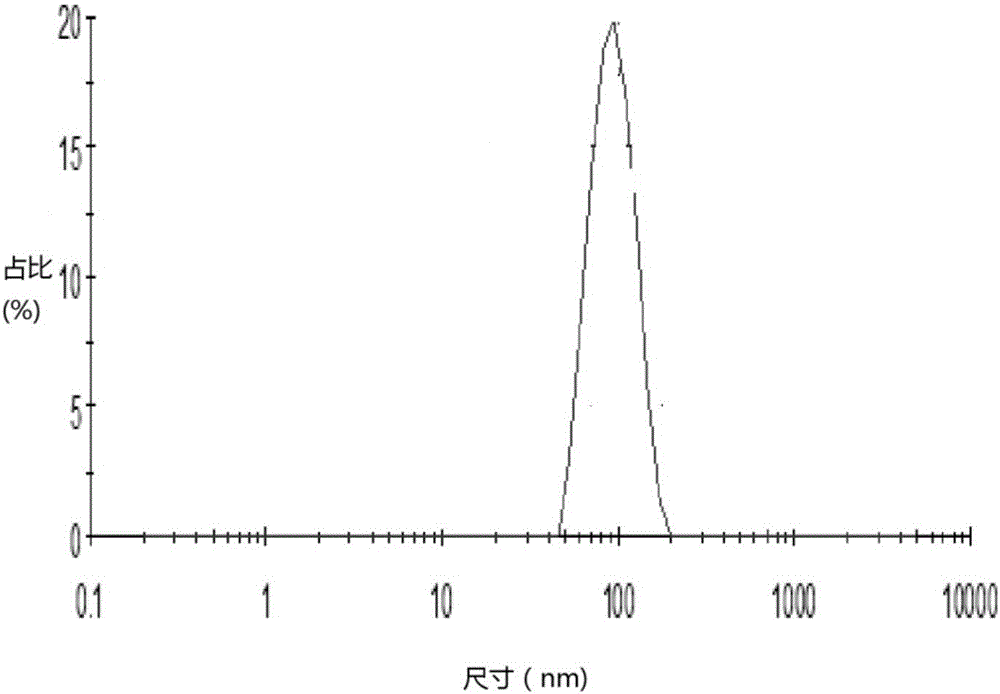

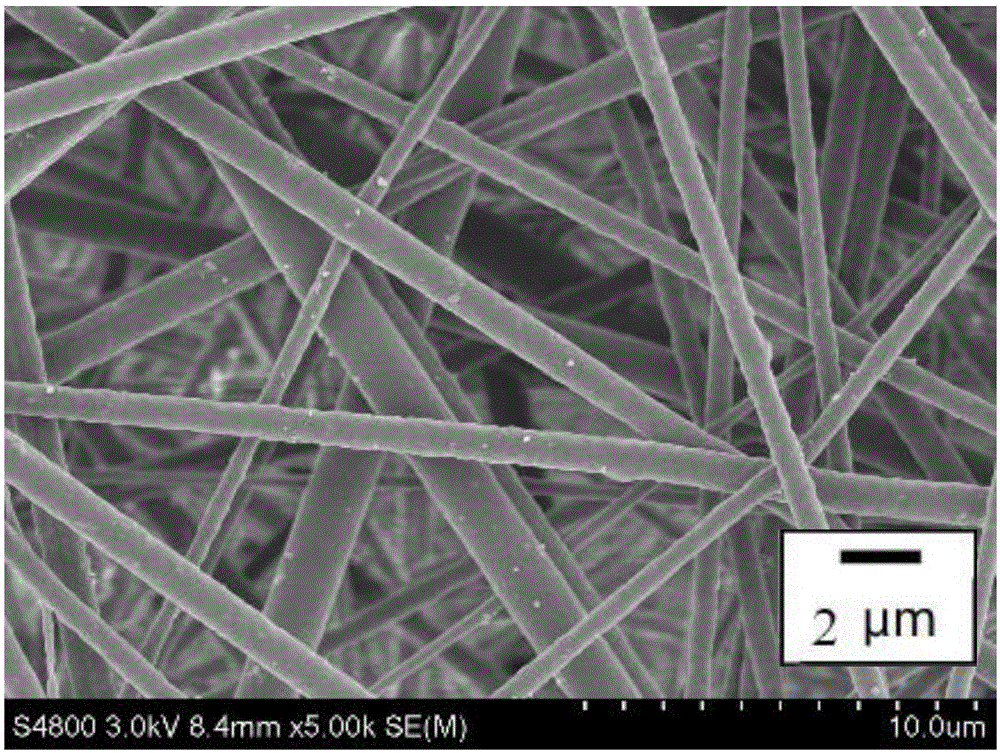

Oil-water separation fiber membrane

InactiveCN105908364AImprove oil absorption capacityGood dispersionElectro-spinningMonocomponent synthetic polymer artificial filamentFiberSilicon dioxide

The invention relates to an oil-water separation fiber membrane. The oil-water separation fiber membrane is prepared through the following steps that nanosilicon dioxide powder is added into an organic solvent to be smashed so as to obtain silicon dioxide dispersion liquid; polymer particles resistant to acid and base are added into the silicon dioxide dispersion liquid, and stirring is carried out to obtain a spinning solution; the spinning solution is injected into an electrostatic spinning machine for electrostatic spinning, and therefore the oil-water separation fiber membrane is obtained. The oil-water separation fiber membrane has good acid and base resistance, can be used for efficient static oil-water separation, has the ultrahigh specific area and good oil-wet hydrophobicity, has the good oil absorbing effect and the oil-water separation effect, and can be applied to treating oil-water mixed waste water with high acidity and alkalinity.

Owner:NANTONG LOVER APPL

Apparatus for compacting and draining mixed waste in passenger transport vehicles

Catering in a transport vehicle like an aircraft involves collecting mixed waste including solids (e.g. left-over food portions, food wastes, napkins, disposable cutlery) and liquids (e.g. beverage rests), without separation. These wastes are disposed of into an apparatus including a receiving container with a filter and separating element at the bottom, a waste shaft leading into the container, a press arrangement with flap doors, pressure pistons which press the press arrangement and flap doors onto the waste in the container to compact the waste, and a drain and coupling system at the bottom of the container. As the waste is compacted, liquids drain down through the filter, oils and fats are removed by the separating element, and non-oily liquids are removed through the coupling system to the vacuum disposal system or the gray water drain line of the vehicle. A control unit controls the overall operation.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com